Welch Allyn Propaq Encore User manual

Propaq® Encore

Vital Signs Monitor

Service Manual

ii Welch Allyn Propaq Encore Vital Signs Monitor

Copyright 2006 Welch Allyn. All rights are reserved. No one is permitted to reproduce or duplicate, in any

form, this manual or any part thereof without permission from Welch Allyn.

Welch Allyn assumes no responsibility for any injury to anyone, or for any illegal or improper use of the

product, that may result from failure to use this product in accordance with the instructions, cautions,

warnings, or statement of intended use published in this manual.

Welch Allyn

of Welch Allyn. ParamSet

®

SET

a Masimo SpO

®

, Propaq®, Acuity®, FlexNet®, Smartcuf®, and Flexible Monitoring® are registered trademarks

™

is a trademark of Welch Allyn.

, LNOP®, and Masimo® are registered trademarks of Masimo Corporation. Possession or purchase of

-equipped monitor does not convey any express or implied license to use the device with

2

unauthorized sensors or cables which would, alone or in combination with this device, fall within the

scope of one or more of the patents relating to this device.

Nellcor

®

and Oximax® are registered trademarks of Nellcor Puritan Bennett.

Software in this product is Copyright 2006 Welch Allyn or its vendors. All rights are reserved. The software

is protected by United States of America copyright laws and international treaty provisions applicable

worldwide. Under such laws, the licensee is entitled to use the copy of the software incorporated with

this instrument as intended in the operation of the product in which it is embedded. The software may not

be copied, decompiled, reverse-engineered, disassembled or otherwise reduced to human-perceivable

form. This is not a sale of the software or any copy of the software; all right, title and ownership of the

software remain with Welch Allyn or its vendors.

For information about any Welch Allyn product, call the nearest Welch Allyn representative:

USA 1800 535 6663

1315 685 4560

Canada 1800 561 8797 China 86 216 327 9631

European Call Center 353 46 906 7790 France 3315 569 5849

Germany 49 747 792 7186 Japan 8133 219 0071

Latin America 1305 669 9003 Netherlands 3115 750 5000

Singapore 656 419 8100 South Africa 2711 777 7555

United Kingdom 44 133 236 3812

Australia 6129 638 3000

800 074 793

Reorder Part Number 810-1084-XX (CD)

Reorder Part Number 810-1316-XX (Printed)

Manual Part Number 810-0696-03 Rev A, 04/2006

Welch Allyn

8500 SW Creekside Place

Beaverton, Oregon 97008-7107

www.monitoring.welchallyn.com

Printed in USA

0123

Contents

1 - Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

iii

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purpose and Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Other Applicable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Technical Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended Service Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Identifying Propaq Encore Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Self Test and Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 - Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 - Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Equipment Needed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Recharger Supply Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Display Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Main Power Supply Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibrating Realtime ECG Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Non-Invasive Blood Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

EMI Null Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Invasive Blood Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

MSP Board (MCO2) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Screen Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Non-Recoverable Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Battery Capacity Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

iv Contents Welch Allyn Propaq CS Vital Signs Monitor

6 - Repair Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Propaq Encore Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Propaq Encore Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Field Replaceable Units in the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Replacing the Power Input Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Replacing the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Opening the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Closing the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Replacing the Analog Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Replacing the Digital Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replacing the EL Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Removing the Front Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Replacing the Recharger Board Fuse (F2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing Air Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Replacing PROMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Cuff Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Replacing the Recharger Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Replacing the Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Replacing the Expansion Module Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Replacing the Expansion Module Button Board and Buttons . . . . . . . . . . . . . . . 82

Replacing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Opening the SpO2 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing the SpO2 Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Replacing the MSP/SpO2 Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Replacing the Sidestream CO2 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Replacing Expansion Module Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7 - Technical Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Cabling Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Expansion Module and Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Pulse Oximetry (SpO2) Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Capnography (CO2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8 - Field Replaceable Units (FRUs) . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

A - Manufacturable Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B - Dynatech/Nevada Patient Simulator Modification . . . . . . . . . . . . 125

1

1

Warnings

Safety Summary

This Safety Summary should be read by all Propaq CS monitor users. Specific warnings

and cautions are placed throughout the documentation where they apply.

Caution: Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the

order of a licensed medical practitioner.

WARNING Place the Propaq monitor and accessories in locations where they

cannot harm the patient if they fall from their shelf or mount. Lift the monitor only

by its handle; do not lift it by any attached cables.

WARNING Do not connect more than one patient to a monitor. Do not connect

more than one monitor to a patient.

WARNING Do not use the Propaq Encore in an MRI suite or a hyperbaric

chamber.

WARNING Do not autoclave the Propaq Encore. Autoclave accessories only if

the manufacturer's instructions clearly approve it. Many accessories can be

severely damaged by autoclaving.

WARNING Inspect the power adapter cord periodically for fraying or other

damage, and replace the adapter as needed. Do not operate the apparatus from

mains power with a damaged power adapter cord or plug.

WARNING Make frequent electrical and visual checks on cables and electrode

wires.

WARNING Safe interconnection between the Propaq monitor and other devices

must comply with applicable medical systems safety standards such as IEC

60601-1-1. Within certain governmental jurisdictions, all interconnected accessory

equipment must be labeled by an approved testing laboratory. After

interconnection with accessory equipment, risk (leakage) current and grounding

requirements must be maintained.

WARNING As with all medical equipment, carefully route the patient cabling to

reduce the possibility of patient entanglement or strangulation.

WARNING Avoid electrosurgery burns at monitoring sites by ensuring proper

connection of the electrosurgery return circuit so that the return paths cannot be

made through monitoring electrodes and probes.

WARNING During defibrillation, keep the discharge paddles away from ECG and

other electrodes, as well as other conductive parts in contact with the patient.

Avoid contact with any accessories connected to the Propaq’s left side panel.

2 Safety Summary Welch Allyn Propaq Encore Vital Signs Monitor

WARNING To ensure patient safety, the conductive parts of the ECG electrodes

(including associated connectors) and other patient-applied parts should not

contact other conductive parts, including earth ground, at any time.

WARNING Do not operate this product in the presence of flammable

anesthetics or other flammable substance in combination with air, oxygenenriched environments, or nitrous oxide; explosion can result.

WARNING The pulse oximetry channel should NOT be used as an apnea

monitor.

WARNING This monitor is to be operated by qualified personnel only. The

operator of this monitor should read this entire manual, the monitor Reference

Guide or Directions For Use, and all accessory Directions For Use before

operating the monitor.

WARNING This monitor should only be repaired by qualified service personnel.

The operator should not attempt to open the monitor case or perform any

maintenance on the monitor except for procedures explicitly described in this

manual that can be performed by operators such as inspection and cleaning.

WARNING When using a power adapter with this monitor, be sure to connect

the power adapter to a three-wire, grounded, hospital-grade receptacle. Do not

under any circumstances attempt to remove the grounding conductor from the

power plug of the power adapter. Do not plug the power adapter into an

extension cord. If there is any doubt about the integrity of the protective earth

ground of the receptacle for the power adapter, do not plug in the power adapter;

operate the monitor only on battery power. Contact your biomedical engineering

department for assistance in identifying the proper power receptacle and making

appropriate power connections.

Note

WARNING To ensure conformance to risk (leakage) current requirements when

operating from an ac mains power source, use only a Welch Allyn’ 503-0054

series power adapter.

WARNING To ensure patient safety, use only accessories recommended or

supplied by Welch Allyn. For a list of those accessories, see the Welch Allyn

Products and Accessories book that accompanied this manual (PN 810-0409-XX).

Accessories must be used according to your hospital’s standards and the

manufacturer’s recommendations. Always refer to the manufacturer’s directions

for use.

WARNING A product that has been dropped or severely abused should be

checked by qualified service personnel to verify proper operation and acceptable

risk (leakage) current values.

WARNING If the monitor detects an unrecoverable problem, an error message

window appears containing an error number and a short message. Report such

errors to Welch Allyn.

WARNING The Propaq Encore should be serviced only by a Welch Allyn service

technician while under warranty.

Within certain governmental jurisdictions, all interconnected accessory

equipment must be labeled by an approved testing laboratory. After

interconnection with accessory equipment, risk (leakage) current and grounding

requirements must be maintained.

Service Manual Safety Summary 3

Definitions

Note Identifies information that may be important to the reader.

Caution Identifies conditions or practices that could result in damage to

equipment or other property.

WARNING Identifies conditions or practices that could result in personal injury.

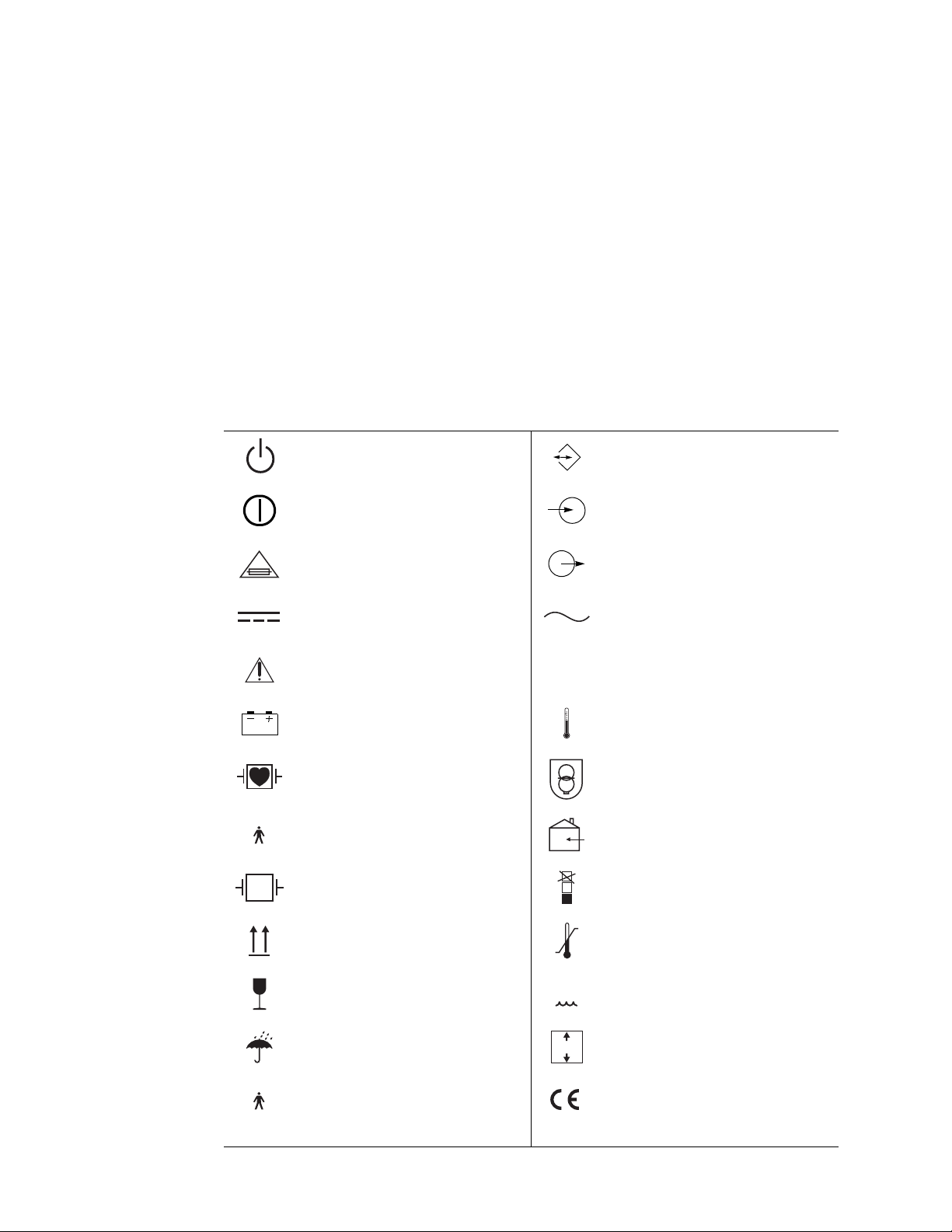

Symbols

The following symbols appear in the monitor documentation and on monitor labels. These

internationally recognized symbols are defined by the International Electrotechnical

Commission, IEC 878 and IEC 417A.

Off (Standby) Two-way communication port

On Input port to monitor

For continued fire protection, use only the

specified fuse.

Direct current Alternating current

Caution: Refer to Reference Guide and

accompanying documentation.

Battery charging when green indicator

illuminated.

All patient connections are Type CF, isolated

for direct cardiac application, and protected

against defibrillation.

All patient connections are Type BF, and

protected against defibrillation.

Protected during defibrillation Stacking limit by number

This way up Temperature limits

Fragile Humidity limit

IPX1

Signal output port from monitor

Enclosure Protection Drip proof:

Classification IPX1 per IEC Publication 529.

Temperature sensor input

Transformer meets requirements of a shortcircuit-proof safety-isolating power

transformer.

For indoor use only (on power adapter only).

n

a

n%

Keep away from rain Altitude limit

All patient connections are Type B The CE mark signifies the device has met all

n

essential requirements of European Medical

Device Directive 93/42/EEC for a Class 1

1

product.

4 Safety Summary Welch Allyn Propaq Encore Vital Signs Monitor

The CE mark and notified body registration

number signify Propaq CS Series monitors

0123

have met all essential requirements of

European medical device directives 93/42/

EEC.

The Canadian Standards Association has

NRTL/C

Evaluated to CSA 601-1

and UL2601-1

evaluated this device according to CSA 6011 and Underwriters Laboratory Standard UL

1

2601-1.

NIBP cuff sizes:

Thigh

Large adult

Adult

Small adult

Child

Infant

a. This symbol is on the Universal Power Adapter.

Single-use only (not reusable).

2

This device has been tested and certified by

the Canadian Standards Association

International to comply with applicable U.S.

and Canadian medical safety standards.

Apply the NIBP cuff as shown.

5

2

Overview

Purpose and Scope

The Propaq Encore Service Manual is intended as a reference for monitor maintenance

and repair to the field replaceable unit (FRU) level (“Field Replaceable Units (FRUs)” on

page 117). This manual provides the technically qualified service person with

troubleshooting information, repair procedures, and calibration and performance

verification instructions. A technical overview of the monitor subsystems is provided as an

introduction to the device’s circuitry and pneumatics.

Note

This manual is intended for the technically qualified service person. Service training

classes on Welch Allyn’ products are available. Contact Welch Allyn Technical Service for

information.

Configurations vary nationally. Some early versions of the Propaq Encore do not

include impedance pneumagraphy (RESP) in some countries.

Other Applicable Documents

Several other documents are available for the Encore monitor. Refer to those documents

for other than maintenance and repair information. Check the Encore Reference Guide for

information on other user’s documentation.

Title Part Number

Propaq Encore Reference Guide, English 810-0640-XX

Products & Accessories Guide 810-0409-XX

Unpacking Procedure

Use the following guidelines when unpacking the Encore monitor from its shipping

carton.

1. Before opening the Encore monitor shipping carton, check it for damage.

2. If damage is apparent, stop unpacking the carton and contact the shipping company

for further instructions. If the carton is intact, unpack the Encore monitor.

3. With the Encore monitor out of its carton, check to see that all the items listed on the

packing slip (provided with shipment) are in the shipping carton.

4. If an item is missing, first recheck the carton, then check with your receiving

department. If necessary, contact Welch Allyn at the address and phone number

shown below.

6 Overview Welch Allyn Propaq Encore Vital Signs Monitor

Note

Save the shipping carton and packing material for repacking the Encore monitor in

case it needs to be sent to a repair center or back to Welch Allyn for service.

Warranty Service

DO NOT ATTEMPT TO REPAIR the Encore monitor yourself during the warranty period.

For service and repair, contact Welch Allyn as described below.

Technical Support Services

Welch Allyn offers a wide range of technical support services including:

• 24-hour telephone support

• loaner equipment

• service contracts

• field replaceable units (FRUs)

• factory repair

For any of these services, contact Welch Allyn Technical Support at the following

numbers:

USA 1-800-535-6663 France (+33) 1-60-09-33-66 Australia (+61) 2-9638-3000

Latin America (+1) 305-669-9591 Germany (+49) 7477-927-173 Singapore (+65) 6291-0882

European Call Center (+353) 469-067-790 Canada 1-800-561-8797 Japan (+81) 3-5212-7391

United Kingdom 0-207-365-6780 South Africa (+27) 11-777-7509 China (+86) 21-6327-9631

Worldwide Internet Access

World Wide Web (WWW) URL: http://www.monitoring.welchallyn.com/service

World Wide E-mail: solutions@monitoring.welchallyn.com

Recommended Service Intervals

At the intervals listed below, check the Encore monitor for normal operation.

Interval/Condition Perform Located in this manual

Every 6 months to 2 years

(according to hospital protocols).

If battery does not retain a charge. Check battery pack capacity. “Troubleshooting”

Monitor is dropped or suspected of

damage or rough handling.

Suspected malfunction with all or

part of monitoring parameters.

Complete risk (leakage) current Safety Check

followed by a Functional Verification.

Complete Safety Check followed by Functional

Verification.

Functional Verification of suspected parameter(s). “Functional Verification”

“Functional Verification”

“Functional Verification”

Monitor does not pass Functional

Verification.

Calibration of monitoring parameter circuits, or

repair, followed by Safety Check and Functional

Verification.

“Functional Verification”

and “Calibration”

Service Manual Overview 7

WARNING If the monitor is opened for repair or calibration, a dielectric strength

test must be completed to ensure the integrity of the patient isolation barrier. The

dielectric strength test procedure is provided in “Functional Verification” on

page 11.

Identifying Propaq Encore Configurations

The following table identifies Propaq monitor configurations and how they are indicated.

The model-option number and serial number are located on the back of the housing. The

monitor indicators are located under the handle on the back.

Table 1. Monitor Configurations

Product Model Option Parameters

Propaq Encore Monitor 202-EL ECG, NIBP, Two Temps, Resp, EL Display

204-EL ECG, NIBP, Two Temps, IBP, Resp, EL Display

206-EL ECG, NIBP, Two Temps, 2 IBP, Resp, EL Display

SpO2-Only Module 210 SpO2 and one of the following:

Nellcor MP-405 (Top level assembly 007-0059-XX)

Nellcor MP-203 (Top level assembly 007-0020-XX)

Nellcor MP-507 (Top level assembly 007-0109-XX)

Masimo MS3 (Top level assembly 007-0060-XX)

Expansion Module (See next table.)

a

a. The Acuity option is available with all models.)

8 Overview Welch Allyn Propaq Encore Vital Signs Monitor

Table 2. Expansion Module Option Configurations

Option

Number

Printer Mainstream CO2Sidestream CO2SpO

2

Top Level Assembly

Number

221 Yes No No N/A 007-0046-XX

222 No No No Nellcor MP-203 007-0050-XX

223 Yes No No Nellcor MP-203 007-0047-XX

223 Yes No No Nellcor MP-203 007-0051-XX

223 Yes No No Masimo MS3 007-0069-XX

223 Yes No No Nellcor MP-405 007-0086-XX

223 Yes No No Nellcor MP-507 007-0116-XX

224 No Yes No Nellcor MP-203 007-0049-XX

224 No Yes No Masimo MS3 007-0070-XX

224 No Yes No Nellcor MP-405 007-0085-XX

224 No Yes No Nellcor MP-507 007-0115-XX

225 Yes Yes No Nellcor MP-203 007-0048-XX

225 Yes Yes No Masimo MS3 007-0071-XX

225 Yes Yes No Nellcor MP-405 007-0084-XX

225 Yes Yes No Nellcor MP-507 007-0114-XX

226 No No Yes Nellcor MP-203 007-0045-XX

226 No No Yes Masimo MS3 007-0072-XX

226 No No Yes Nellcor MP-405 007-0083-XX

226 No No Yes Nellcor MP-507 007-0113-XX

227 Yes No Yes Nellcor MP-203 007-0043-XX

227 Yes No Yes Masimo MS3 007-0073-XX

227 Yes No Yes Nellcor MP-405 007-0082-XX

227 Yes No Yes Nellcor MP-507 007-0112-XX

228 No Yes Yes Nellcor MP-203 007-0052-XX

228 No Yes Yes Masimo MS3 007-0074-XX

228 No Yes Yes Nellcor MP-405 007-0081-XX

228 No Yes Yes Nellcor MP-507 007-0111-XX

229 Yes Yes Yes Nellcor MP-203 007-0044-XX

229 Yes Yes Yes Masimo MS3 007-0075-XX

229 Yes Yes Yes Nellcor MP-405 007-0080-XX

229 Yes Yes Yes Nellcor MP-507 007-0110-XX

Service Manual Overview 9

Self Test and Service Menus

The Encore monitor includes built-in self-tests that verify the integrity of its hardware and

software each time you turn it on. If the monitor turns on and displays the Main Menu, all

self-tests were passed. If a self-test results in a failure, a message and error code are

displayed indicating the failure mode. Refer to “Troubleshooting” on page 43 and contact

Welch Allyn Technical Support for help.

The Encore monitor contains software routines that make the Functional Verification and

Calibration procedures quicker and easier. You access these routines through the Service

Menus as indicated in each of the procedures.

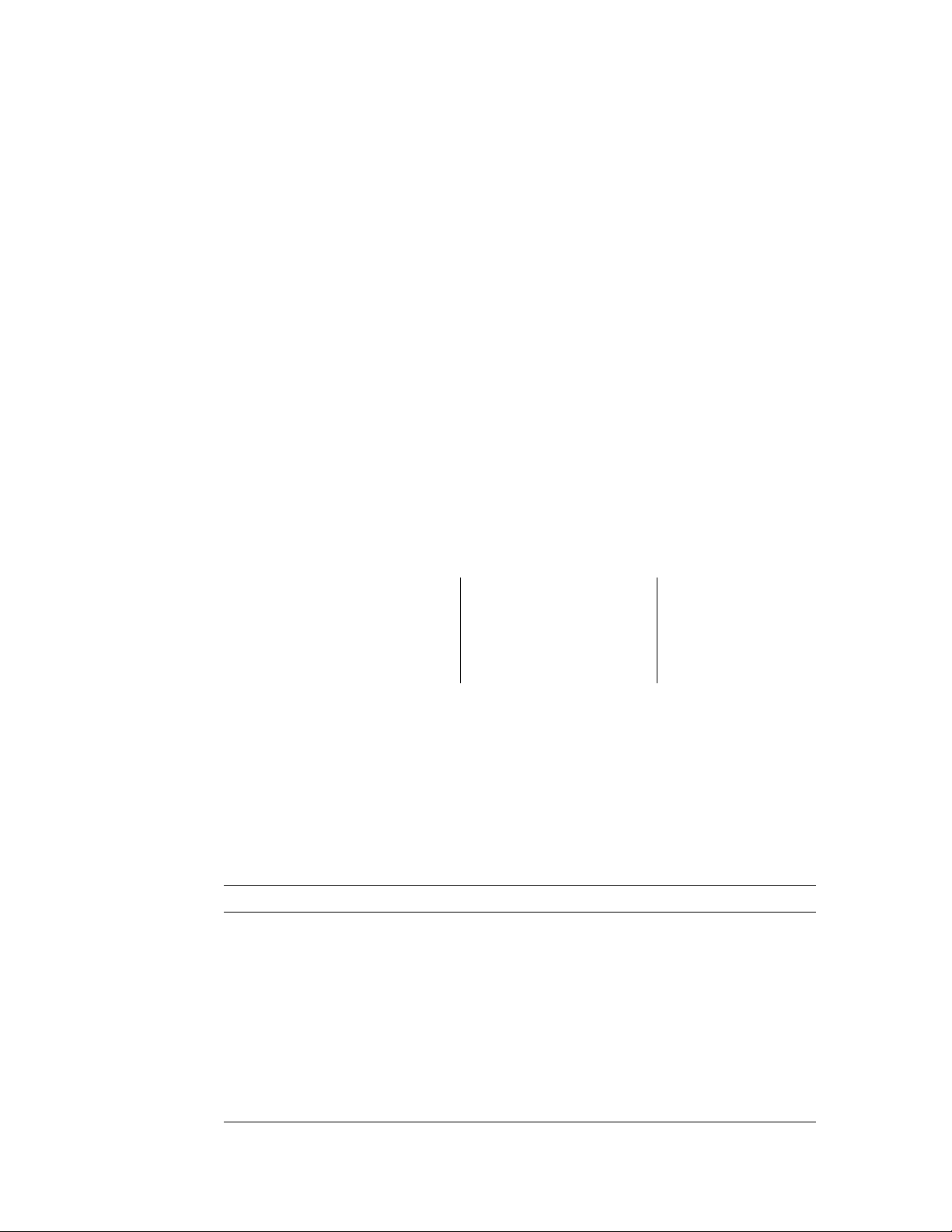

The figure below shows the hierarchy of the Service Menus once you enter the top level

Service Menu.

The procedures in this manual indicate which buttons to push by separating each button

menu name with the (>) character. For example, to access the Service Menu, the

procedures would indicate for you to press SETUP > MORE > MORE > SERVICE > YES,

which means you press the SETUP button, then the MORE button, then the MORE

button, then the SERVICE button, and finally the YES button.

Note

service menus

The figure illustrates all Service Menu functions. Some of these functions are not

available if you do not have the appropriate option.

NIBP TEST IBP TEST SpO2 TST CO2 TEST MORE

PUMP TEST AUTO PMP NIBP CAL ZERO PREV MENU

TEMP TEST PIXL TEST NET TST MORE

CYCLE CHECKER 1 CHECKER 2 BORDER PREV MENU

LOOP TEST OUT TEST PREV MENU

MAIN CAL MAIN TEST SIDE CAL SIDE TEST

PREV MENU

SETTINGS KEY TEST SYSTEM

(Software v. 2.5X only)

KEY 0 KEY 1 KEY 2 KEY 3

NEXT CHANGE ALL ALARM

MORE

PREV MENU

PREV MENU

10 Overview Welch Allyn Propaq Encore Vital Signs Monitor

11

3

Functional Verification

Introduction

The functional verification procedures ensure proper operation of the Encore monitor and

its options. These procedures should be performed following module-level repairs,

calibration, or whenever there is a question about the accuracy or safety of the patient

functions.

Use the calibration procedures (“Calibration” on page 33) to return the monitor to

operation within its performance specifications. If the monitor does not pass the

functional verification, or when it is time to do a routine calibration, see “Calibration” on

page 33.

The Encore’s service menu facilitates the functional verification. It has several features for

testing and verifying the NIBP (cuff) channel, display, invasive pressure channel, and

printer. Refer to “Over v iew ” on page 5 for information about the Service Menu.

WARNING Whenever the monitor is opened for calibration or repair, a risk

(leakage) current safety check as well as a dielectric strength integrity (hi-pot) test

must be performed as described in this section.

Self Tests

Many functions, such as alarms, waveform and scale sizing, and printer control, are

software operations. During the monitor’s power-up self-test, the integrity of all

programming is checked first. If software testing is successful, hardware tests are

initiated. If all testing is successful, the monitor is ready for use. (See “Troubleshooting”

on page 43 for information on error messages.)

12 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

Required Equipment

You will need the following equipment to verify that all functions of the Encore operate

correctly. All test equipment must be calibrated to function within parameters specified

by the manufacturer, and must be traceable to a national calibration standard.

Some equipment can be manufactured. See “Manufacturable Test Equipment” on

page 123 for information on manufacturable test equipment.

Table 3. Required Equipment

Description

Luer connector, male, for use with 1/8" I.D. tubing (Value Plastics, MTLL230-1)

Luer connector, female, for use with 1/8" I.D. tubing (Value Plastics, FTLL230-1)

Test water trap, Welch Allyn, 008-0370-00

1/8" inside diameter tubing

Flow meter, Cole Parmer E 32000-06, 200ml/min. or equivalent

0 to 300 mmHg calibrated digital pressure meter, with inflation squeeze bulb (Netech, Digamano, or equivalent)

50 MHz triggered sweep oscilloscope

Variable dc power supply, 0-28 V, 3A with voltage and current metering

Dynatech/Nevada 213A, 214A, 215A, or 217A with IBP, Temperature, and EGG Cable/Leads

Adult cuff (provided with monitor); Neonatal cuff #3; 3 cm diameter solid cylinder; solid cylindrical object about the size

of an adult’s arm

Welch Allyn cuff calibration kit, Welch Allyn PN 008-0012-XX

Power supply adapter cable, Welch Allyn PN 008-0290-00

Physio Control LifePak 5 or LifePak 6s with appropriate Welch Allyn Defib Sync adapter to use as Defib Sync Marker

pulse source

Propaq ac power adapter (provided with the Encore)

Safety analyzer, Dynatech/Nevada, 431F-1D or equivalent

Rod-L Model M100AVS5 high-voltage potential (hi-pot) tester, or equivalent

Static-free work area

Simulator, Fluke (Biotek) Index 2 XL/XLFE

SpO

2

Test gas source: dry 4% to 10% CO

concentration must be certified to ±0.01. (Convert percentage to partial pressure (mmHg) as instructed in “Partial

pressure of test gas source” on page 27.)

Two rubber test tube stoppers, with 1/8" to 1/4" holes drilled through (for CO2 tests)

a. Of the gas tolerance available, usually described as ±0.03% absolute, the container must contain at least 2,000 psi grams of gas, to

be within ±0.01% of the certified percentage of gas stated on the tag supplied by the vendor. The acutal percentage of gas in the

container may vary from lot to lot.

, balance air (with flow meter). Gas may be between 4% and 10%, but exact CO2

2

a

Safety Tests

The following two safety tests, a risk (leakage) current safety check and a dielectric

strength integrity (hi-pot) test, must be performed whenever the Encore has been opened

for calibration or repair.

Service Manual Functional Verification 13

Note

A hi-pot test is only required if the monitor has been opened.

Risk (Leakage) Current Test

A risk (leakage) current test must be performed to verify that the patient remains

electrically isolated from the power circuits of the Encore.

Check leakage currents using a Dynatech/Nevada 431F-1D safety analyzer or its

equivalent. The source current should not exceed 10μA rms. The sink current, measured

between the isolated patient connections (ECG) and the dc power input connector of the

monitor, should not exceed 20μA rms. See the analyzer's operator's manual for the

proper safety check procedure.

Note

Table 4. Electrical Connections for Patient Risk (Leakage) Current Safety Tests

Safety Test Power Adapter Monitor

Source current Plugged into analyzer

Sink current Not used Connected to ground

Because of the all-insulated construction of the monitor, an Enclosure Leakage

Current Test to ground is not necessary.

outlet

dc Input

Connected to power

adapter

connector on analyzer

Monitor

Cable

RA

LA

LL

C

RL

RA

LA

LL

C

RL

Safety

Analyzer

RA

LA

LL

C

RL

RA

LA

LL

C

RL

Dielectric Strength (Hi-Pot) Test

Because of the close spacings of the monitor's internal components and the critical

positioning of the insulation sheet within the monitor, Welch Allyn recommends that a

dielectric strength test be performed following any procedure in which the monitor is

opened.

WARNING The Hi-Pot test is extremely hazardous. Only qualified service

personnel should perform this test. Conduct the test only on an insulated table

top, away from other people and equipment.

Use a Rod-L Model M100AVS5 high-voltage potential tester, or equivalent. Refer to the

Rod-L instruction manual for operating information and safety recommendations.

1. Set the high voltage potential of the tester as specified in the table below.

14 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

Table 5. Summary of Connection Points and High-Voltage Test Potentials

Tester's high-voltage terminal

connection

All ECG leads on patient cable

connected together

2. Connect the high-voltage output lead of the tester to all ECG leads, using a dedicated

patient cable reserved for use only in such tests.

3. Connect the tester's chassis-connected return lead to the monitor's dc input

connector, using a suitable plug.

4. Apply the test voltage for one second. The tester must not indicate dielectric

breakdown.

WARNING If any dielectric breakdown occurs, do not use the monitor. All

internal sheet insulation barriers must be properly installed. Check the monitor to

determine the cause of dielectric breakdown; then repair the monitor or return

the monitor to Welch Allyn for repair.

Functional Verification

The functional verification must be done only when the monitor is fully assembled. If the

monitor has been stored for longer than one month without the monitor connected to the

ac adapter (for recharging), the battery voltage must be checked. The battery must be

replaced if it cannot hold a charge. Refer to “Battery Capacity Check” on page 45.

Tester's grounded return

connection

DC input connector; all pins connected

together

High-voltage test parameters

Output: 4000 V ac rms

Current Limit: 2.5mA

Ramp-up: 8 seconds

Dwell: 1 second

Note

Power System

The following steps check the integrity of the Encore’s power system.

1. Turn the ac power adapter’s power switch off.

2. Plug the ac power adapter into an ac mains receptacle and connect it to the Encore’s

3. Check that the green LED charging indicator on the monitor’s right side panel is off.

Some configurations of the Encore monitor do not include impedance

pneumography (RESP) and other neonatal monitoring parameters. In these

versions, RESP does not appear in menus or on the screen displays. You can

ignore RESP and other terms relating to neonatal monitoring when indicated in

the following instructions.

If you plan to use a Dynatech/Nevada model 213A, 215A, or 217A Patient

Simulator to simultaneously simulate ECG and invasive blood pressure, see

“Dynatech/Nevada Patient Simulator Modification” on page 125 for important

information.

Before starting the verification procedures, charge the battery for at least 8 hours

with the monitor turned off. (Charge for 12 hours if a Printer or SpO

module is

2

attached.)

right side panel dc power connector.

Service Manual Functional Verification 15

4. Turn on the power adapter’s power switch.

5. Check that the green LED on the power adapter turns on and that the green LED

charging indicator on the monitor’s right side panel turns on.

6. Disconnect the power adapter from the monitor. Check that the monitor’s green LED

charging indicator on the right side panel turns off.

Caution In the next steps, carefully check for the proper polarity of the

connection between the power supply and the monitor. If voltage is applied with

the wrong polarity, it will open the right side panel fuse (F1). Refer to the figure

below to verify proper polarity.

7. Set the dc power supply meter to Volts and turn the power switch on; set it for

15.0V ± 0.1V.

8. Turn off the dc power supply.

9. Using the Welch Allyn dc power supply adapter cable, refer to the figure below for

polarity and connect the dc power supply to the monitor's dc input connector on the

right side panel.

RIBBED (+) SMOOTH (-)

0696-02

10. Turn on the dc power supply.

11. Check that the green LED indicator lights up.

Note

Initial charge current for a low battery is higher than for a charged battery. As the

battery charges, the current will decrease. The current draw may slowly drop the

longer the dc supply is connected to the monitor.

12. Switch the dc power supply meter to current and check that the current draw from

the supply is less than 1.8 A.

16 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

13. Vary the power supply from 12 V to 28 V and verify that the charging LED stays on.

14. Turn off the power supply.

15. Disconnect the supply from the monitor.

System Tests

The following procedures check that the buttons operate properly, that the display works

correctly, and that the date is correctly displayed.

1. Turn on the monitor.

2. Verify that no error messages appear and the monitor correctly powers up.

3. Press SETUP > MORE > MORE > SERVICE > YES > MORE > PIXL TST to test the

display.

4. Press CYCLE three times, each time verifying that no pixels are missing.

5. Press MAIN MENU twice.

6. Press SETUP > WAVE SEL > INSERV to access the inservice features. This generates

simulated waveforms.

7. If dual stream monitor, look for CO2 Sensor Change - Switching to Mainstream, YES

or NO.

8. IBP screen indicates need to zero P1 or P2.

9. Press MAIN MENU.

10. Using the appropriate table below as a guide, press the indicated buttons in sequence

and verify that the monitor responds as indicated and that the buttons do not stick.

Sequence for Software Versions 2.5

X

Press Result

FREEZE/UNFREEZE Freezes the waveforms

FREEZE/UNFREEZE Unfreezes the waveforms

SETUP Changes the menu

ALARMS Changes the display to ALARM STATUS

4 SUSPND (on menu) 4 SUSPND changes to RESUME

ALARM SILENCE/RESUME (button) Changes RESUME to 4 SUSPND

LIMITS Changes display to HR Limits

NEXT Moves cursor block: Next block within selected parameter limits, NEXT

MAIN MENU (button) Returns to the main menu

PAGE moves to next parameter

NIBP START/STOP (button) Starts the NIBP pump

NIBP START/STOP (button) Stops the NIBP pump

Service Manual Functional Verification 17

Sequence for All Other Software Versions

Press Result

FREEZE/UNFREEZE Freezes the waveforms

FREEZE/UNFREEZE Unfreezes the waveforms

SETUP Changes the menu

ALARMS Changes the display to ALARM STATUS

SUSPEND (on menu) SUSPEND changes to RESUME

ALARM SUSPEND/RESUME (button) Changes RESUME to SUSPEND

ALL ALRM Changes display: Turn All Off, Are You Sure, Y or N

LIMITS Changes display to HR Limits

NEXT Moves cursor block: Next block within selected parameter limits, NEXT

PAGE to next parameter

MAIN MENU (button) Returns to the main menu

NIBP START/STOP (button) Starts the NIBP pump

NIBP START/STOP (button) Stops the NIBP pump

1. Press ECG/RESP > MORE. Then press CHANGE to select the four HR/PR TONE

levels. Verify that the tone volume changes and goes off when turned OFF. Set the

volume to LOW.

2. Press MAIN MENU.

3. Software versions 2.5X: Press SETUP > MORE > MORE > SERVICE > YES > MORE

> MORE > SETTINGS > ALL ALRM. Verify alarm status displays "TURNING OFF ALL

AUDIBLE VITAL SIGNS ALARMS", "ARE YOU SURE?", YES or NO. Then press MAIN

MENU.

4. All software versions: Press SETUP > MORE > MORE (> TIME/DAY for monitor

software less than version 2.0) and check that the displayed time and date are correct.

If incorrect, press NEXT and UP or DOWN to select and change the time and date,

and then set by pressing the ENTER button.

5. Turn off the monitor.

ECG/RESP Channel and Alarm Indicators

The following procedures verify the ECG channel and the alarm indicator drivers. The

setup procedure below is used for both the visual and the electrical checks that follow.

Setup

1. Turn on the monitor and verify that it powers up correctly.

2. Put the monitor into FACTORY ADULT MODE.

Software version 2.XX: SETUP > MORE > CHANGE > SETUP > USE NOW > YES

Software version 1.XX: SETUP > MORE > CHANGE > ADULT > YES > MORE >

PROGRAM > DEFAULT > YES

3. Press MAIN MENU.

18 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

4. Set the patient simulator as follows:

• ECG Waveform: normal sinus rhythm

• ECG Rate: 80 beats per minute (bpm)

• ECG Size: 1 mV amplitude

• Resp Lead: Lead I

• Resp Baseline Impedance: 1 KΩ

• Resp Rate: 40 breaths/minute (br/m)

• Resp Breath Amplitude: 1.0Ω

5. Set the monitor as follows:

• Respiration Lead: Lead I (ECG/RESP > MORE; select lead and change as

necessary)

• ECG Lead: Lead II (ECG/RESP > ECG LEAD)

• ECG Size: 1 mV (ECG/RESP > ECG SIZE)

• Resp Size: 8X (ECG/RESP > RESP SZE)

• Respiration ON (ECG/RESP > MORE; select and set RESP to ON)

• ECG Sweep: 25 mm/Sec (SETUP > MORE; select and change HR/PR sweep as

necessary)

•Alarms (software versions 2.5X): Set alarm limits to OFF for HR/PR and RR/BR

(SETUP > ALARMS > LIMITS > ON/OFF > NEXT > ON/OFF > NEXT PAGE > ON/

OFF > NEXT > ON/OFF. Press the MAIN MENU button. The ALARM(S) OFF light

will turn on, indicating one or more alarm limits have been disabled.

•Alarms (all other software versions): All alarms OFF (SETUP > ALARMS > ALL

ALRM [software version 2.XX: press YES when prompted] until all alarms are off

except for the Apnea alarm, which cannot be turned off. The ALARM(S) OFF light

will turn on, indicating that one or more alarm limits have been disabled.

• Audible vital signs alarms (software versions 2.5X): OFF (SETUP > MORE >

MORE > SERVICE > YES > MORE > MORE > SETTINGS > ALL ALRM > YES.

The ALARM light will turn on, indicating the patient alarms are suspended.

6. Connect the ECG channel to the patient simulator using all five ECG leads.

Part 1— Visual Check

1. Press MAIN MENU.

2. Press the FREEZE/UNFREEZE button to freeze the waveform.

3. Check that a normal sinus rhythm ECG waveform is displayed with a peak-to-peak

amplitude of 10 ±1 mm. There should be a soft beep tone with each QRS event.

4. Check that the monitor’s displayed respiration peak-to-peak amplitude is 12.5 ±1 mm.

5. Press FREEZE/UNFREEZE to unfreeze the display.

6. Check that the monitor's heart rate display is 80 ± 4 bpm, and the respiration rate is

40 ± 2 bpm before proceeding to the next step.

7. Disconnect the LA ECG lead wire from the simulator.

Service Manual Functional Verification 19

8. Check that an equipment alarm occurs. The EQUIPMENT ALERT / MULTIPLE

message should accurately indicate the removed lead. The ALARM(S) OFF light will

flash.

• Software version 2.5X: The ECG FAULT will flash in the upper left-hand corner of

the screen.

• All other software versions: The ECG FAULT and RESP FAULT will alternate in the

upper left-hand corner.

9. Press any button to acknowledge. Check that the ALARM(S) OFF light is on and no

longer flashing.

10. Disconnect the LL ECG lead from the simulator.

11. Check that an equipment alert occurs. The ECG FAULT and RESP FAULT will alternate

in the upper left-hand corner. The ALARM(S) OFF light will flash.

• Software version 2.5X: The EQUIPMENT ALERT - MULTIPLE message should be

displayed.

• All other software versions: The EQUIPMENT ALERT / ECG FAULT / MULTIPLE

LEAD FAIL message is displayed.

12. Press any button to acknowledge. Check that the ALARM(S) OFF light is on and no

longer flashing.

13. Reconnect the LL ECG lead, and then LA ECG lead.

14. Check that the ALARM(S) OFF light is on. Software version 2.5X: Check that the

ALARM light is on.

15. Check that the monitor's heart rate display is 80 ± 4 bpm, and the respiration rate is

40 ± 2 bpm before proceeding to the next step.

16. Software version 2.5X: Press RESUME to enable alert and alarm tones.

All other software versions: Press SETUP > ALARMS > ALL ALRM to turn all alarms

ON.

17. Press SETUP > ALARMS > STAT SET to automatically set heart and respiration rate

alarm limits. Software version 2.XX: Select YES when prompted.

18. Check that the ALARM(S) OFF light is off.

19. Check that the ALARM light is off.

20. Set the patient simulator heart rate to 180 bpm or higher.

21. Check that an alarm violation occurs, causing the tone to sound and the ALARM light

to flash.

22. Software version 2.5X: Press the 4 SUSPND button and verify that the tone turns off

and the ALARM light is on and no longer flashing.

Software version 2.XX: Press the ALARM SUSPEND/RESUME button and verify that

the tone turns off and the ALARM light is on and no longer flashing.

23. Press MAIN MENU.

24. Set the patient simulator heart rate to 80 bpm.

25. Check that the ALARM light is ON.

26. Press SETUP > ALARMS > RESUME.

20 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

27. Check that the ALARM light is OFF.

28. Press MAIN MENU.

Part 2— Electrical Check

Use the same setup for this check described in “Setup” on page 17.

1. Set the patient simulator to provide pacer signals.

2. If the pacer indicator is not on, press ECG/RESP > MORE and select and change the

pacer setting.

3. Check that a dashed vertical line is displayed on the ECG waveform each time a pacer

pulse occurs.

4. Set the oscilloscope to 0.2 second/division sweep and 0.5 Volt/division amplitude.

5. Insert a short piece of thin conductive wire into each of the ECG X1000 connector

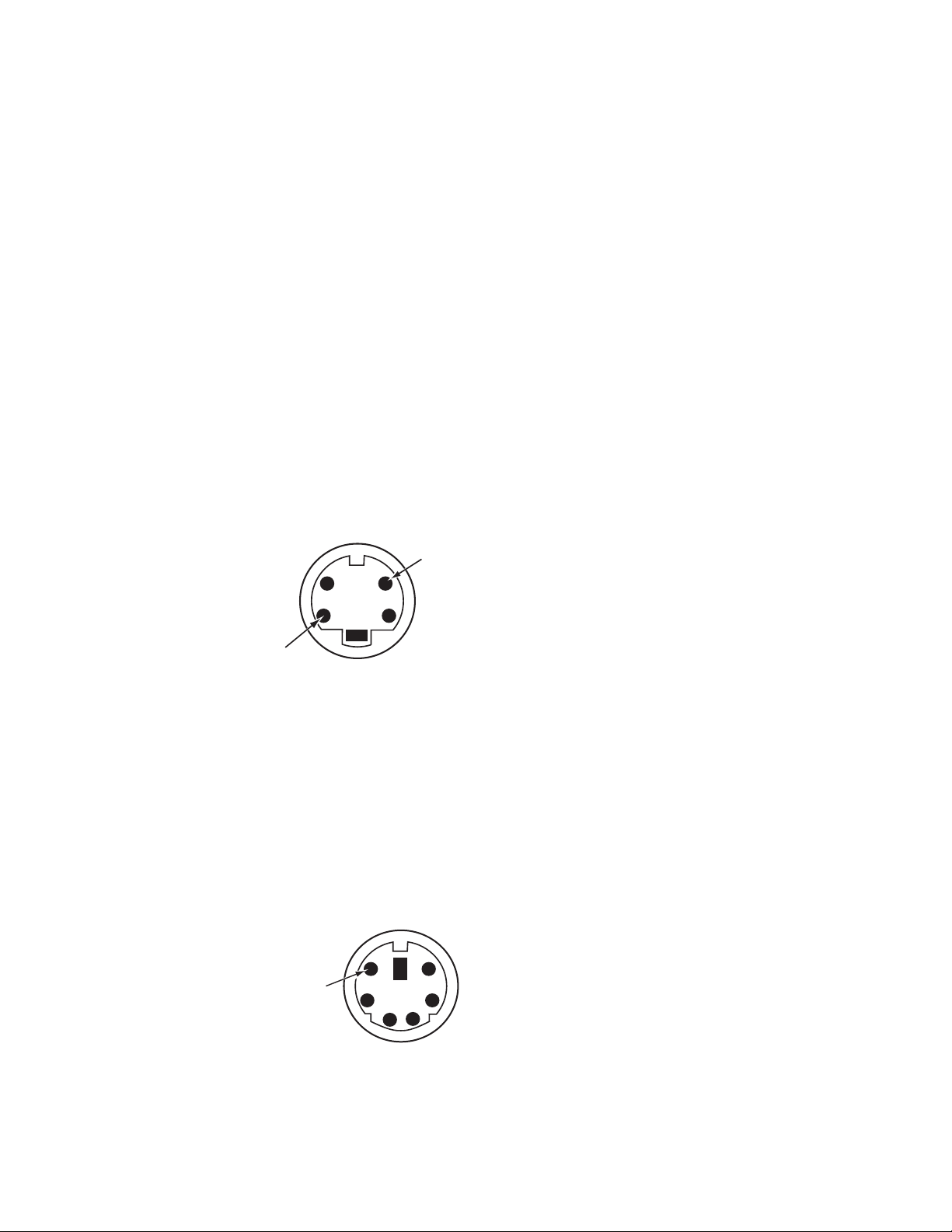

holes shown in the figure below or use real time ECG Out cable 008-0320-00.

ECG X1000

GND

(scope gnd. clip)

ECG

(scope probe)

0696-69

6. Connect the scope probe and the scope ground clip to the wires.

7. Check that the scope displays an ECG signal with an amplitude of 1 V ±100 mV

baseline to peak of R-wave.

Note

Some amount of mains noise may also be present in the signal.

8. Move the wire and scope probe from the ECG pin of the ECG X1000 connector to the

DEFIB SYNC connector pin shown in the figure below or use Defib Sunc Output

cable, 008-0237-00. Leave the scope’s ground clip where it is.

DEFIB SYNC

SYNC OUT

(scope probe)

0696-70

9. Change the vertical sensitivity of the scope to 1 Volt/division.

10. Check that the scope displays a 5 V p-p pulse with a 100 ±5 ms width.

Service Manual Functional Verification 21

11. Disconnect the scope probe and ground clip and remove the wires from the

connectors.

12. Using either a LifePak 5 or LifePak 6s and appropriate Welch Allyn adapter, set up the

monitor and defibrillator according to instructions provided in the Defib Sync User’s

Guide.

13. Check the monitor display for sync markers on the ECG waveform.

14. Disconnect the defibrillator from the monitor.

IBP

Note

15. Disconnect the ECG cable from the monitor. (Disconnecting an active channel

The following procedure verifies the operation of the invasive blood pressure channels.

Some models of the Propaq Encore have no IBP channels; skip this procedure if your

Encore does not support IBP. If your Encore has multiple IBP channels, repeat the

verification procedure for each channel.

Note

If the patient simulator does not also provide an appropriate ECG signal, the heart

rate value will be displayed as – – – and an alarm violation will occur.

initiates an equipment alarm; press any key to acknowledge the discontinuance of

ECG monitoring.)

Caution Many blood pressure simulators are not intended to be used as

calibration standards. Use only the blood pressure simulators specified in

“Required Equipment” on page 12.

If you are using the Dynatech/Nevada model 213A, 215A, or 217A patient

simulator, do not simultaneously monitor ECG and invasive blood pressure (IBP)

unless the modification to the simulator is performed as described in “Dynatech/

Nevada Patient Simulator Modification” on page 125. If you do not wish to modify

your simulator, use ECG and IBP independently.

1. Press SETUP > WAVESEL and check that the P1 and P2 waveforms are turned on.

2. Connect the IBP cable from the patient simulator to an IBP input jack on the left side

panel of the Encore.

3. Set the simulator output pressure to 0 mmHg.

Note

4. Zero P1 by pressing ZERO P1.

5. Check that ZEROED is displayed.

6. Press RESCALE.

7. Check for a noise level of ≤3 mm on the IBP waveform.

8. After allowing a few seconds for settling, check that the mean pressure reading is 0

9. Set the pressure simulator to 200 mmHg.

If an alarm tone sounds, press the SUSPEND/RESUME button.

mmHg ±1 mmHg.

22 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

10. After allowing a few seconds for settling, check that the mean pressure reading is 200

mmHg ±2 mmHg.

11. Remove the cable from the P1 input jack and verify that the message: P1 FAULT TRANSDUCER NOT DETECTED appears.

12. Press any button to acknowledge the discontinuance of IBP monitoring.

13. Press MAIN MENU.

NIBP

1. Connect the cuff, digital pressure meter, bulb, and the Encore together with the cuff

calibration kit. Using T-connectors from the kit, connect the cuff, pressure meter, and

bulb.

2. Connect this NIBP test setup to the pressure transducer at PT1 on the Analog board.

3. Wrap the adult cuff around the black tube volume or a cylindrical object about the size

of an adult’s arm.

4. Press SETUP > MORE > MORE > SERVICE > YES > NIBP TEST > NIBP CAL.

Note

The NIBP CAL mode holds pressure for 10 minutes. If performing steps 4 through

9 takes longer than 10 minutes, press NIBP CAL again.

5. Close the valve on the bulb and inflate the cuff to 250 mmHg as shown on

thepressure meter.

6. Check that the readings (PR1 and PR2) on the monitor's display are 250 ±3 mmHg

(PR1) and 250 ±15 mmHg (PR2), as show in the figure below.

19:00:25

NIBP TEST BATTERY: 8.1 VOLTS

CNTS mmHg DAC VALVE

PR1: 578 249.4 130 0

PR2: 338 259

OSC: 1600

LEAK: 10 mmHg DIAG: 0

BLEED: mmHg/min PUMP: secs

PUMP TEST

AUTO PMP NIBP CAL ZERO PREV MENU

7. Manually reduce the pressure as indicated on the pressure meter to each of the levels

shown in the following table, and check the displayed value of PR1 to be within the

tolerance listed in the following table.

Pressure (mmHg) Tolerance

(mmHg)

270 ± 4

250

± 3

Service Manual Functional Verification 23

Pressure (mmHg) Tolerance

(mmHg)

200 ± 2

100

50

20

8. Reduce the pressure to 0 mmHg and check that the displayed readings (PR1 and PR2)

are 0 ± 2 mmHg.

9. Close the bulb valve.

10. Press CANCEL. (If there is no CANCEL button at this time, go to the next step.)

11. Disconnect the adult cuff from the test setup and connect the neonatal cuff #3 that is

wrapped around a solid 3 cm diameter cylinder, the black PVC tube volume.

12. Press PUMP TEST.

13. Check that the pump inflates the cuff to approximately 280 mmHg.

14. After four minutes, check that the displayed leakage is less than 50 mmHg.

Note

15. Press MAIN MENU.

16. Disconnect the cuff and Cuff Calibration Kit.

If the leakage exceeds this specification, first check all exterior hoses and fittings

before diagnosing an internal air leak problem.

± 2

± 2

± 2

Temperature

1. Plug a 37.0° C YSI 400 series (two conductor) calibrated temperature probe simulator

into the T1 jack on the Encore’s left side panel.

2. Check that the T1 temperature is 37° ± 0.1° C.

3. Repeat Steps 1 and 2 for T2.

4. Plug a 37° C YSI 700 series (three conductor) temperature probe simulator into the T1

jack.

5. Check for 37° ± 0.1° C.

6. Repeat Steps 4 and 5 for T2.

7. Remove all connectors and turn the Encore off.

Functional Verification for Masimo SpO

This functional verification procedure helps to confirm the proper operation of the Masimo

Pulse Oximetry option installed in the Propaq monitor. This procedure supports the

requirements of routine preventive maintenance. No monitor disassembly is required to

perform this procedure.

You will need the following equipment to perform this procedure.

2

• Masimo-compatible SpO

cable.

2

24 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

• Compatible adult SpO2 sensor for finger.

• BIO-TEK Index 2 Series SpO

Simulator with optical finger for sensor connection

2

(or equivalent).

1. Turn on power to the SpO

2. Connect the SpO

3. Apply the SpO

cable to the monitor and the SpO2 sensor.

2

sensor to the SpO2 simulator optical finger.

2

simulator.

2

4. Set the simulator manufacturer type (“MAKE”) to Masimo.

5. Set the simulator output to SpO

saturation 94% and pulse rate 60 beats per minute

2

(with no motion artifact selected).

Confirm that the monitor displays SpO

moving.

Confirm that the displayed saturation is 94% ±4 counts, and the displayed pulse rate

is 60 ± 4 bpm.

6. Disconnect the sensor from the simulator and cable, and disconnect the SpO

Functional Verification for Nellcor SpO

This functional verification procedure helps to confirm the proper operation of the Nellcor

Pulse Oximetry option installed in the Propaq monitor. This procedure supports the

requirements of routine preventive maintenance. No monitor disassembly is required to

perform this procedure.

You will need the following equipment to perform this procedure.

data and the pulse amplitude indicator is

2

2

cable.

2

• Nellcor-compatible adult SpO

• BIO-TEK Index 2 Series SpO

finger sensor

2

Simulator with optical finger for sensor connection

2

(or equivalent).

1. Turn on power to the SpO

2. Connect the SpO

sensor to the monitor and apply to the SpO2 simulator optical

2

simulator.

2

finger.

3. Set the simulator manufacturer type (“MAKE”) to Nellcor.

4. Set the simulator output to SpO

saturation 94% and pulse rate 60 beats per minute

2

(with no motion artifact selected).

Confirm that the monitor displays SpO

data and the pulse amplitude indicator is

2

moving.

Confirm that the displayed saturation is 94% ±4 counts, and the displayed pulse rate

is 0 ± 4 bpm.

5. Disconnect the sensor from the simulator.

6. Check that an equipment alarm occurs.

7. Press any button to acknowledge the discontinuance of SpO

monitoring.

2

8. Press MAIN MENU.

Service Manual Functional Verification 25

Sensor Compatibility

Some sensors are not compatible with the particular Nellcor processing board installed in

the Propaq. To determine which pulse oximetry optional processing board is installed in

the Propaq, find the option number on the back label of the Propaq, then refer to the table

“Expansion Module Option Configurations” on page 8. The following table shows how to

identify compatible sensors for each Nellcor option:

Table 6. Sensor Compatibility

Sensor Description Connector Compatible With

Pins Notches Color MP-203 MP-405 MP-507

Single-ended 7 0 Varies Yes No No

Differential 7 1 Varies Yes Yes No

OxiMax 9 2 Purple Yes Yes Yes

OxiMax-Exclusive 8 2 White No No Yes

Printer Tests

The following steps check the functionality of the printer.

Note

1. Disconnect all cables from the monitor.

2. Turn the monitor OFF then ON.

3. Press SETUP > WAVE SEL > INSERV.

4. Press MAIN MENU.

5. Wait at least 8 seconds and then press the printer's SNAPSHOT button.

6. Check that the printer prints an approximately eight-inch strip of the simulated patient

7. Press the printer's START/STOP button. The printer should begin continuous printing.

8. Press the START/STOP button to stop printing.

9. Lay the Propaq Encore on its back.

10. Press the START/STOP button to start printing.

Functional verification should be performed on the monitor before beginning the

printer tests. The monitor must be functioning properly in order to perform printer

tests.

data. The paper should stop only after the entire waveform has been fed out of the

printer.

11. Completely open the paper door on the bottom of the Expansion Module.

12. Check that the printer stops printing, and that an equipment alarm and CHECK DOOR

message appear on the monitor screen.

13. Cut or tear the printer paper in the printer mechanism from the roll, leaving the strip of

paper in the printer mechanism.

14. Completely close the paper door.

26 Functional Verification Welch Allyn Propaq Encore Vital Signs Monitor

15. Press the START/STOP button.

16. After the printer runs out of paper, check that an equipment alarm and PAPER OUT

message appear on the monitor screen.

17. Open the printer door and reload the paper into the printer.

18. Close the paper door and set the monitor upright.

19. Simultaneously press the PRINT TRENDS and START/STOP buttons.

20. Check that a test printout similar to one shown in the figure below is printed.

test print

VER. 1.00.01

5B 4F B7

CO2 Verification Preparation

The mainstream and sidestream CO2 functional verification procedures require calculating

the local barometric pressure and partial pressure of the test gas (in mmHg) to compare

to Propaq Encore displayed values.

Local barometric pressure

The first step is to determine the local barometric pressure:

1. Determine local altitude above sea level.

For worldwide locations, obtain altitude from local geological maps (U.S.G.S. maps in

the United States) or other local references on the maps. Refer to the table titled:

Uncorrected Barometric Pressure as as Function of Altitude; use this table to

determine the local uncorrected pressure (LUP).

2. Determine ATIS reported pressure (inches or millimeters of Hg).

For U.S. locations, consult local telephone directories to obtain the Automated

Terminal Information Service (ATIS) number, typically listed under United States

Government Offices, Department of Transportation, Federal Aviation Administration,

and Air Traffic Control Towers.

Among various statistics reported is the “altimeter,” which is given in four integers.

The four digits represent the barometric pressure as referred to sea level, in units of

inches of mercury, with an assumed decimal point occurring between the second and

third numbers.

For worldwide locations, equivalent altimeter statistics, in millimeters of mercury,

may be obtained from local agencies.

Note

The difference in altitude between the calibration site and the ATIS site should not

be greater than 30 m or 100 ft.

3. Determine local barometric pressure using LUP and ATIS. Apply the ATIS and LUP

values to the following formula to calculate the local barometric pressure (mmHg):

Loading...

Loading...