Toshiba MMU-AP0182H2UL, MMU-AP0152H2UL, MMU-AP0122H2UL, MMU-AP0212H2UL, MMU-AP0242H2UL Service Manual

...

R410A

4-Way Cassette Type

Compact 4-Way Cassette Type

Ceiling Type

High Wall Type

SERVICE MANUAL

AIR-CONDITIONER

MULTI TYPE

INDOOR UNIT

4-Way Cassette Type

MMU-AP0072H2UL-1

MMU-AP0072H2UL, MMU-AP0092H2UL,

MMU-AP0122H2UL, MMU-AP0152H2UL,

MMU-AP0182H2UL, MMU-AP0212H2UL,

MMU-AP0242H2UL, MMU-AP0302H2UL,

MMU-AP0362H2UL, MMU-AP0422H2UL

Compact 4-Way Cassette Type

MMU-AP0071MH2UL, MMU-AP0091MH2UL,

MMU-AP0121MH2UL, MMU-AP0151MH2UL,

MMU-AP0181MH2UL

Ceiling Type

MMC-AP0181H2UL, MMC-AP0241H2UL,

MMC-AP0361H2UL, MMC-AP0421H2UL

High Wall Type

MMK-AP0073H2UL, MMK-AP0093H2UL,

MMK-AP0123H2UL, MMK-AP0153H2UL,

MMK-AP0183H2UL, MMK-AP0243H2UL

PRINTED IN JAPAN, Mar., 2011 ToMo

FILE NO. A10-019

Revision 1 : Feb., 2013

Revision 2 : Sep., 2014

Revision 3 : Oct., 2014

Revision 4 : Jun., 2015

Revision 5 : Apr., 2016

Revision 6 : Jun., 2017

2

CONTENTS

SAFETY CAUTION .............................................................................3

1. SPECIFICATIONS ....................................................................... 8

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS) .......................11

3. WIRING DIAGRAM ................................................................... 23

4. PARTS RATING......................................................................... 27

5. REFRIGERATIN GCYCLE DIAGRAM ...................................... 29

6. CONTROL OUTLINE ................................................................ 30

7. APPLIED CONTROL AND FUNCTION .................................... 46

8. TROUBLESHOOTING............................................................... 77

9. DETACHMENTS........................................................................ 99

10. P.C. BOARD EXCHANGE PROCEDURES ............................. 138

11. EXPLODED VIEWS AND PARTS LIST ................................... 148

3

SAFETY CAUTION

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them. The manufacturer shall not assume any liability for the damage

caused by not observing the description of this manual.

[Explanation of indications]

∗ Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

[Explanation of illustrated marks]

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

(Refer to the Parts disassembly diagram (Outdoor unit).)

If removing the label during parts replace, stick it as the original.

Indication

DANGER

WARNING

CAUTION

Explanation

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage (∗) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (Including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

Turn off breaker.

Execute discharge

between terminals.

Prohibition

Turn “OFF” the breaker before removing the front panel and cabinet, otherwise an electric

shock is caused by high voltage resulted in a death or injury.

During operation, a high voltage with 400V or higher of circuit (∗) at secondary circuit of the

high-voltage transformer is applied.

If touching a high voltage with the naked hands or body, an electric shock is caused even if using an

electric insulator.

∗ :# For details, refer to the electric wiring diagram.

When removing the front panel or cabinet, execute short-circuit and discharge between

high-voltage capacitor terminals.

If discharge is not executed, an electric shock is caused by high voltage resulted in a death or injury.

After turning off the breaker, high voltage also keeps to apply to the high-voltage capacitor.

Do not turn on the breaker under condition that the front panel and cabinet are removed.

An electric shock is caused by high voltage resulted in a death or injury.

DANGER

4

Check ground wires.

Prohibition of modification.

Use specified parts.

Do not bring a child

close to the equipment.

Insulating measures

No fire

Refrigerant

Assembly/Cabling

Before troubleshooting or repair work, check the ground wire is connected to the ground

terminals of the main unit, otherwise an electric shock is caused when a leak occurs.

If the ground wire is not correctly connected, contact an electric engineer for rework.

Do not modify the products.

Do not also disassemble or modify the parts. It may cause a fire, electric shock or injury.

For spare parts, use those specified (

∗∗

∗∗

∗).

If unspecified parts are used, a fire or electric shock may be caused.

∗: For details, refer to the parts list.

Before troubleshooting or repair work, do not bring a third party (a child, etc.) except

the repair engineers close to the equipment.

It causes an injury with tools or disassembled parts.

Please inform the users so that the third party (a child, etc.) does not approach the equipment.

Connect the cut-off lead wires with crimp contact, etc, put the closed end side upward

and then apply a water-cut method, otherwise a leak or production of fire is caused at

the users’ side.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle. When using a gas stove, etc, be sure to put out fire

before work; otherwise the oil mixed with refrigerant gas may catch fire.

2) Do not use a welder in the closed room.

When using it without ventilation, carbon monoxide poisoning may be caused.

3) Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may

catch the inflammables.

Check the used refrigerant name and use tools and materials of the parts which match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a position

on the outdoor unit where is easy to see. To prevent miss-charging, the route of the service

port is changed from one of the former R22.

Do not useany refrigerant different from the onespecified for complement or replacement.

Otherwise, abnormally high pressuremay be generated in the refrigeration cycle, which may

result in a failure or explosion of the product or an injury to your body.

For an air conditioner which uses R410A, never use other refrigerant than R410A.

For an air conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the

refrigerating cycle and an injury due to breakage may be caused.

Do not charge refrigerant additionally.

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in

the refrigerating cycle changes resulted in change of air conditioner characteristics or

refrigerant over the specified standard amount is charged and an abnormal high pressure is

applied to the inside of the refrigerating cycle resulted in cause of breakage or injury. Therefore

if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute vacuuming,

and then newly recharge the specified amount of liquid refrigerant.

In this time, never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant or

air other than R410A into the specified refrigerant.

If air or others is mixed with the refrigerant, abnormal high pressure generates in the

refrigerating cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak.

If the refrigerant gas leaks in the room, poisonous gas generates when gas touches to fire

such as fan heater, stove or cocking stove though the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit.

When the equipment is moved or repaired, be sure to recover the refrigerant with recovering

device. The refrigerant cannot be recovered in the outdoor unit; otherwise a serious accident

such as breakage or injury is caused.

After repair work, surely assemble the disassembled parts, and connect and lead the

removed wires as before. Perform the work so that the cabinet or panel does not catch

the inner wires.

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire is

caused at user’s side.

WARNING

5

After the work has finished, be sure to use an insulation tester set (500V Megger) to

check the resistance is 2MΩ or more between the charge section and the non-charge

metal section (Ground position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s

side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates.

A case of leakage of the refrigerant and the closed room full with gas is dangerous because

a shortage of oxygen occurs. Be sure to execute ventilation.

When checking the circuit inevitably under condition of the power-ON, use rubber

gloves and others not to touch to the charging section.

If touching to the charging section, an electric shock may be caused.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down

and tighten the service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking

stove though the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant

such as a multi air conditioner in a sub-room, it is necessary that the density does

not the limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is

caused.

For the installation/moving/reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric

shock or fire is caused.

After repair work has finished, check there is no trouble.

If check is not executed, a fire, electric shock or injury may be caused.

For a check, turn off the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test

run to check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused.

Before test run, install the front panel and cabinet.

Check the following items after reinstallation.

1) The ground wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

Insulator check

Ventilation

Be attentive to

electric shock

Compulsion

Check after repair

Check after reinstallation

WARNING

Put on gloves

Cooling check

Be sure to put on the gloves (∗) and a long sleeved shirt:

otherwise an injury may be caused with the parts, etc.

(∗) Heavy gloves such as work gloves

When the power was turned on, start to work after the equipment has been

sufficiently cooled.

As temperature of the compressor pipes and others became high due to cooling/heating

operation, a burn may be caused.

CAUTION

6

• New Refrigerant (R410A)

This air conditioner adopts a new HFC type refrigerant (R410A) which does not deplete the ozone layer.

1. Safety Caution Concerned to New Refrigerant

The pressure of R410A is high 1.6 times of that of the former refrigerant (R22).

Accompanied with change of refrigerant, the refrigerating oil has been also changed.

Therefore, be sure that water, dust, the former refrigerant or the former refrigerating oil is not mixed into the

refrigerating cycle of the air conditioner with new refrigerant during installation work or service work.

If an incorrect work or incorrect service is performed, there is a possibility to cause a serious accident.

Use the tools and materials exclusive to R410A to purpose a safe work.

2. Cautions on Installation/Service

1) Do not mix the other refrigerant or refrigerating oil.

For the tools exclusive to R410A, shapes of all the joints including the service port differ from those of

the former refrigerant in order to prevent mixture of them.

2) As the use pressure of the new refrigerant is high, use material thickness of the pipe and tools which are

specified for R410A.

3) In the installation time, use clean pipe materials and work with great attention so that water and others

do not mix in because pipes are affected by impurities such as water, oxide scales, oil, etc.

Use the clean pipes.

Be sure to brazing with flowing nitrogen gas. (Never use gas other than nitrogen gas.)

4) For the ground protection, use a vacuum pump for air purge.

5) R410A refrigerant is azeotropic mixture type refrigerant.

Therefore use liquid type to charge the refrigerant. (If using gas for charging, composition of the

refrigerant changes and then characteristics of the air conditioner change.)

3. Pipe Materials

For the refrigerant pipes, copper pipe and joints are mainly used.

It is necessary to select the most appropriate pipes to conform to the standard.

Use clean material in which impurities adhere inside of pipe or joint to a minimum.

1) Copper pipe

<Piping>

The pipe thickness, flare finishing size, flare nut and others differ according to a refrigerant type.

When using a long copper pipe for R410A, it is recommended to select “Copper or copper-base pipe

without seam” and one with bonded oil amount 0.0001 lbs / 32’ 10” (40mg / 10m) or less.

Also do not use crushed, deformed, discolored (especially inside) pipes.

(Impurities cause clogging of expansion valves and capillary tubes.)

<Flare nut>

Use the flare nuts which are attached to the air conditioner unit.

2) Joint

The flare joint and socket joint are used for joints of the copper pipe.

The joints are rarely used for installation of the air conditioner. However clear impurities when using them.

7

4. Tools

1. Required Tools for R410A

Mixing of different types of oil may cause a trouble such as generation of sludge, clogging of capillary,

etc. Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

(Note) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

1) Vacuum pump. Use vacuum pump by

attaching vacuum pump adapter. 7) Screwdriver (+, –)

2) Torque wrench 8) Spanner or Monkey wrench

3) Pipe cutter 9) Hole core drill

4) Reamer 10) Hexagon wrench (Opposite side 4mm)

5) Pipe bender 11) Tape measure

6) Level vial 12) Metal saw

Also prepare the following equipments for other installation method and run check.

1) Clamp meter 3) Insulation resistance tester (Megger)

2) Thermometer 4) Electroscope

No.

c

d

e

f

g

h

i

j

k

Used tool

Flare tool

Copper pipe gauge for

adjusting projection margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Usage

Pipe flaring

Flaring by conventional

flare tool

Tightening of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

R410A

air conditioner installation

Existence of Whether conven-

new equipment tional equipment

for R410A can be used

Yes *(Note)

Yes *(Note)

Ye s N o

Ye s N o

Ye s N o

Ye s Ye s

Ye s N o

Ye s N o

Conventional air

conditioner installation

Whether conventional

equipment can be used

Ye s

*(Note)

No

No

Ye s

Ye s

No

Ye s

8

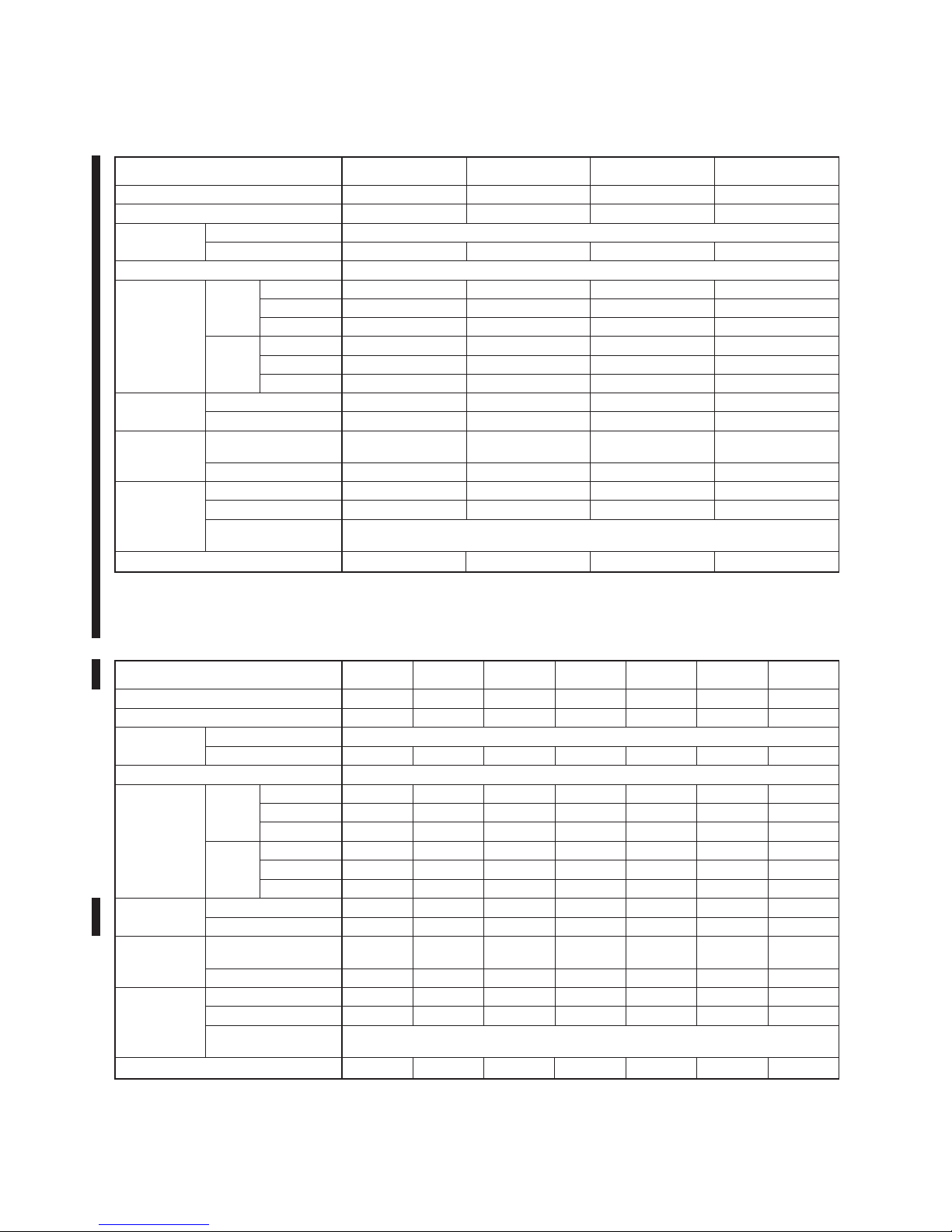

1. SPECIFICATIONS

1-1. 4-Way Cassette Type

Model name MMU-

Cooling Capacity kBtu/h

Heating Capacity kBtu/h

Electrical

Power supply

characteristics

Power consumption kW

Appearance (Celling panel)* Model

Height In

Unit Width In

Dimension

Depth In

(Celling panel)*

Height In

Packing Width In

Depth In

Total Weight

Unit Ibs

(Celling panel)*

Packed unit Ibs

Standard air flow

cfm

Fan unit (High/Mid/Low)

Motor output W

Gas side In

Connection Liquid side In

pipe

drain port

In

(nominal dia.)

Sound pressure level (High/Mid/Low) (*1)

AP0212H2ULAP0182H2ULAP0152H2UL AP0242H2UL AP0302H2UL AP0362H2UL AP0422H2UL

18 21 24 30 36 42

20 24 27 34 40 47.5

230 V (208/230V) 1 phase 60Hz

0.026 0.036 0.036 0.043 0.088 0.112

RBC-U31PG(W)-UL*

10.1 (1.2)* 10.1 (1.2)* 10.1 (1.2)* 10.1 (1.2)* 12.6 (1.2)* 12.6 (1.2)*

33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)*

33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)* 33.1 (37.4)*

11.3 (3.9)* 11.3 (3.9)* 11.3 (3.9)* 13.8 (3.9)* 13.8 (3.9)* 13.8 (3.9)*

36.0 (39.8)* 36.0 (39.8)* 36.0 (39.8)* 36.0 (39.8)* 36.0 (39.8)* 36.0 (39.8)*

37.2 (39.8)* 37.2 (39.8)* 37.2 (39.8)* 37.2 (39.8)* 37.2 (39.8)* 37.2 (39.8)*

46 (10)* 48 (10)* 48 (10)* 48 (10)* 59 (10)* 59 (10)*

55 (15.5)* 57 (15.5)* 57 (15.5)* 57 (15.5)* 69 (15.5)* 69 (15.5)*

550/480/440 670/540/490 670/540/490 730/630/510

1,160/840/630 1,250/840/670

60 60 60 60 150 150

1/2” 5/8” 5/8” 5/8” 5/8” 5/8”

1/4” 3/8” 3/8” 3/8” 3/8” 3/8”

VP25 (Polyvinyl chloride tube : Extermal Dia. 1-1/4 Internal Dia.1)

35/33/31

15.4

17

0.026

10.1 (1.2)*

33.1 (37.4)*

33.1 (37.4)*

11.3 (3.9)*

36.0 (39.8)*

37.2 (39.8)*

46 (10)*

55 (15.5)*

550/480/440

60

1/2”

1/4”

35/33/31 38/33/31 38/33/31 41/36.5/34 46/40.5/36.5

48.5/40.5/37.5

* Figuresin parentheses are for ceiling panels.

(*1) The actual values in an external opeating environment are generally higher than the indicated values due to

the contribution from ambient noise.

* Figuresin parentheses are for ceiling panels.

(*1) The actual values in an external opeating environment are generally higher than the indicated values due to

the contribution from ambient noise.

• About the connection of MMU-AP0072H2UL-1, please refer to DATA BOOK of SMMS-e UL

Model name MMU-

Cooling Capacity kBtu/h

Heating Capacity kBtu/h

Electrical

Power supply

characteristics

Power consumption kW

Appearance (Celling panel)* Model

Height In

Unit Width In

Dimension

Depth In

(Celling panel)*

Height In

Packing Width In

Depth In

Total Weight

Unit Ibs

(Celling panel)*

Packed unit Ibs

Standard air flow

cfm

Fan unit (High/Mid/Low)

Motor output W

Gas side In

Connection Liquid side In

pipe

Drain port

In

(nominal dia.)

Sound pressure level (High/Mid/Low) (*1)

AP0122H2ULAP0092H2ULAP0072H2UL

9.5 12.0

10.5 13.5

230 V (208/230V) 1 phase 60Hz

0.021 0.023

RBC-U31PG(W)-UL*

10.1 (1.2)*

33.1 (37.4)*

33.1 (37.4)*

11.3 (3.9)*

36.0 (39.8)*

37.2 (39.8)*

42 (10)*

51 (15.5)*

10.1 (1.2)*

33.1 (37.4)*

33.1 (37.4)*

11.3 (3.9)*

36.0 (39.8)*

37.2 (39.8)*

42 (10)*

51 (15.5)*

470/430/400 550/490/460

60

3/8"

1/4"

60

3/8"

1/4"

VP25 (Polyvinyl chloride tube : Extermal Dia. 1-1/4 Internal Dia.1)

32.5/30.5/29

7.5

8.5

0.021

10.1 (1.2)*

33.1 (37.4)*

33.1 (37.4)*

11.3 (3.9)*

36.0 (39.8)*

37.2 (39.8)*

42 (10)*

51 (15.5)*

470/430/400

60

3/8"

1/4"

32.5/30.5/29

AP0072H2UL-1

7.5

8.5

0.023

10.1 (1.2)*

33.1 (37.4)*

33.1 (37.4)*

11.3 (3.9)*

36.0 (39.8)*

37.2 (39.8)*

42 (10)*

51 (15.5)*

550/490/460

60

3/8"

1/4"

34/31.5/29.5 34/31.5/29.5

9

1-3. Ceiling Type

(*1) The actual values in an external opeating environment are generally higher than the indicated values due to

the contribution from ambient noise.

Model name MMC-

Cooling Capacity kBtu/h

Heating Capacity kBtu/h

Electrical

Power supply

characteristics

Power consumption kW

Height In

Unit Width In

Dimension

Depth In

Height In

Packing Width In

Depth In

Total Weight

Unit Ibs

Packed unit Ibs

Standard air flow

cfm

Fan unit (High/Mid/Low)

Motor output W

Gas side In

Connection Liquid side In

pipe

Drain port

In

(nominal dia.)

Sound pressure level

dB (A)

(High/Mid/Low) (*1)

AP0181H2UL AP0241H2UL AP0361H2UL AP0421H2UL

18 24 36 42

20 27 40 47.5

230 V (208/230V) 1 phase 60Hz

0.038 0.05 0.091 0.11

8.3 8.3 8.3 8.3

35.8 46.5 62.8 62.8

26.8 26.8 26.8 26.8

12.4 12.4 12.4 12.4

39.1 50.0 66.1 66.1

32.0 32.0 32.0 32.0

46 57 75 75

62 75 97 97

410/360/320 590/530/470 880/770/680 950/820/730

60 60 120 120

1/2” 5/8” 5/8” 5/8”

1/4” 3/8” 3/8” 3/8”

VP20 (Polyvinyl chloride tube : Exter mal Dia. 1 Internal Dia.0.79)

38.5/35/32.5 40.5/38/35 44/41/37 46/42.5/39.5

* Figuresin parentheses are for ceiling panels.

(*1) The actual values in an external opeating environment are generally higher than the indicated values due to

the contribution from ambient noise.

1-2. Compact 4-Way Cassette Type

Model name MMU-

Cooling Capacity kBtu/h

Heating Capacity kBtu/h

Electrical

Power supply

characteristics

Power consumption kW

Appearance (Celling panel)* Model

Height In

Unit Width In

Dimension

Depth In

(Celling panel)*

Height In

Packing Width In

Depth In

Total Weight

Unit Ibs

(Celling panel)*

Packed unit Ibs

Standard air flow

cfm

Fan unit (High/Mid/Low)

Motor output W

Gas side In

Connection Liquid side In

pipe

Drain port

In

(nominal dia.)

Sound pressure level

dB (A)

(High/Mid/Low) (*1)

AP0071MH2UL AP0091MH2UL AP0121MH2UL AP0151MH2UL AP0181MH2UL

7.5 9.5 12 15.4 18

8.5 10.5 13.5 17 20

230 V (208/230V) 1 phase 60Hz

0.034 0.036 0.038 0.041 0.052

RBC-UM11PG(W)-UL*

10.6 (1.1)* 10.6 (1.1)* 10.6 (1.1)* 10.6 (1.1)* 10.6 (1.1)*

22.6 (27.6)* 22.6 (27.6)* 22.6 (27.6)* 22.6 (27.6)* 22.6 (27.6)*

22.6 (27.6)* 22.6 (27.6)* 22.6 (27.6)* 22.6 (27.6)* 22.6 (27.6)*

12.6 (3.9)* 12.6 (3.9)* 12.6 (3.9)* 12.6 (3.9)* 12.6 (3.9)*

25.2 (30.7)* 25.2 (30.7)* 25.2 (30.7)* 25.2 (30.7)* 25.2 (30.7)*

25.2 (30.7)* 25.2 (30.7)* 25.2 (30.7)* 25.2 (30.7)* 25.2 (30.7)*

35 (6.6)* 35 (6.6)* 35 (6.6)* 35 (6.6)* 35 (6.6)*

42 (13.2)* 42 (13.2)* 42 (13.2)* 42 (13.2)* 42 (13.2)*

320/270/220 330/280/220 330/300/240 390/330/280 450/380/310

60 60 60 60 60

3/8” 3/8” 3/8” 1/2” 1/2”

1/4” 1/4” 1/4” 1/4” 1/4”

VP25 (Polyvinyl chloride tube : Extermal Dia. 1-1/4 Internal Dia.1)

38.5/35/31 40/35.5/31 40/36/32 42.5/37.5/33 46.5/41.5/36

10

1-4. High Wall Type

Model name MMK-

Cooling Capacity kBtu/h

Heating Capacity kBtu/h

Electrical

Power supply

characteristics

Power consumption kW

Height In

Unit Width In

Dimension

Depth In

Height In

Packing Width In

Depth In

Total Weight

Unit Ibs

Packed unit Ibs

Standard air flow

cfm

Fan unit (High/Mid/Low)

Motor output W

Gas side In

Connection Liquid side In

pipe

drain port

In

(nominal dia.)

Sound pressure level

dB (A)

(High/Mid/Low) (*1)

AP0073H2UL AP0093H2UL AP0123H2UL AP0153H2UL AP0183H2UL AP0243H2UL

7.5 9.5 12 15.4 18 24

8.5 10.5 13.5 17 20 27

230 V (208/230V) 1 phase 60Hz

0.018 0.021 0.021 0.043 0.043 0.05

12.6 12.6 12.6 12.6 12.6 12.6

41.3 41.3 41.3 41.3 41.3 41.3

9.0 9.0 9.0 9.0 9.0 9.0

15.7 15.7 15.7 15.7 15.7 15.7

43.9 43.9 43.9 43.9 43.9 43.9

11.9 11.9 11.9 11.9 11.9 11.9

33 33 33 33 33 33

42 42 42 42 42 42

340/270/230 350/280/230 350/280/230 490/390/320 490/390/320 600/440/340

30 30 30 30 30 30

3/8” 3/8” 3/8” 1/2” 1/2” 5/8”

1/4” 1/4” 1/4” 1/4” 1/4” 3/8”

VP16 (Polyvinyl chloride tube : Extermal Dia.0.87 Internal Dia.0.63)

36/32.5/30 39/34/30 39/34/30 43/38/34.5 43/38/34.5 47.5/40.5/35

(*1) The actual values in an external opeating environment are generally higher than the indicated values due to

the contribution from ambient noise.

11

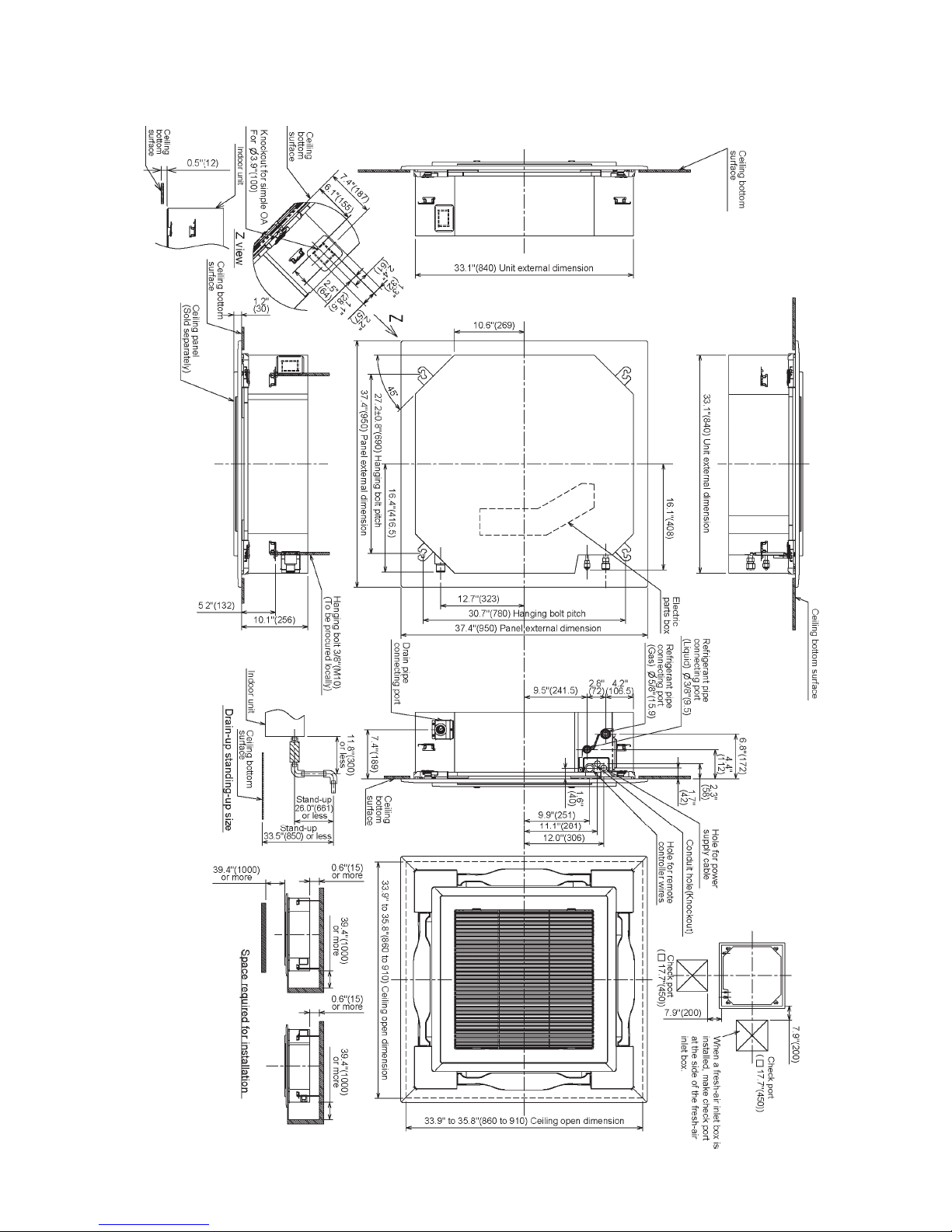

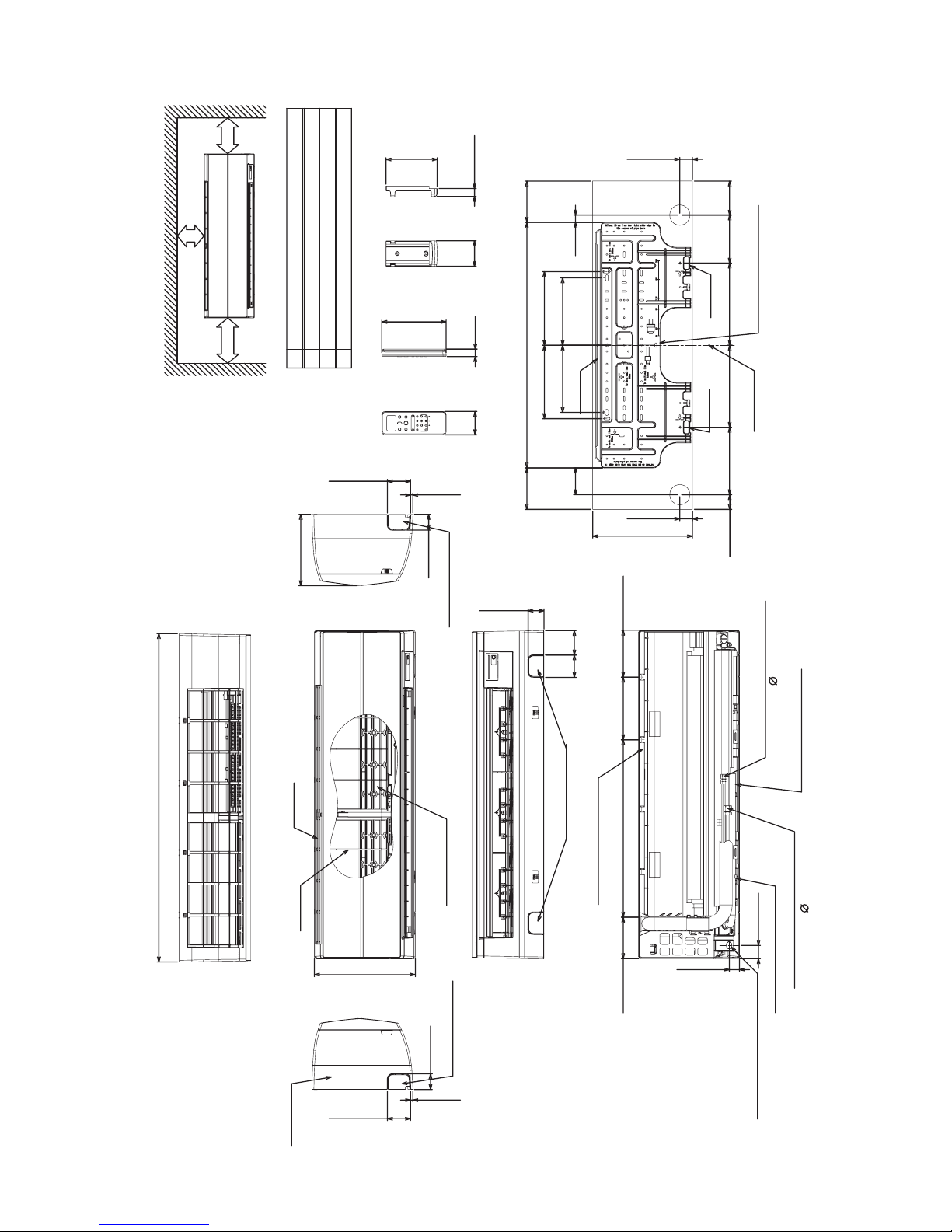

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

2-1. 4-Way Cassette Type

MMU-AP0072H2UL-1, AP0072H2UL, AP0092H2UL, AP0122H2UL

Unit: in (mm)

12

MMU-AP0152H2UL, AP0182H2UL

Unit: in (mm)

13

MMU-AP0212H2UL, MMU-AP0242H2UL, MMU-AP0302H2UL

Unit: in (mm)

14

MMU-AP0362H2UL, MMU-AP0422H2UL

Unit: in (mm)

15

2-2. Compact 4-Way Cassette Type

MMU-AP0071MH2UL, MMU-AP0091MH2UL, MMU-AP0121MH2UL

Unit: in (mm)

16

MMU-AP0151MH2UL, MMU-AP0181MH2UL

Unit: in (mm)

17

2-3. Ceiling Type

MMC-AP0181H2UL

Unit: in (mm)

Wireless sensor mounting section

35.8"(910)

Hanging bolt

Ceiling

Unit

surface

Within

2.0"(50)

3.0"

(75)

3.8"

(97)

5.7"

(146)

connecting port 1/4"(6.4)

(Liquid side)

Left drain size

(Hanging position)

3.3"

(84)

6.7"(170)12.6"(320)

33.7"(855)

(Hanging position)

Drain pipe

Connecting port

Upper pipe draw-out port(Knockout)

Hole for remote control wires(Knockout)

4.3"

(110)

3.0"

(76)

8.5"(216)

2.8"

(70)

2.1"

(53)

1.5"

(39)

2.0"

(52)

5.1"

(130)

2.0"

(50)

(Hole for power supply cable, knockout)

Conduit hole

Pipe draw-out port(Knockout)

8.5"(216)(Gas pipe)

4.1"

(105)

6.6"(167)

8.3"(210)

26.8"(680)

5.6"

(141)

4.5"(114)

7.9"(200)(Liquid pipe)

(Front side to be positioned horizontally.)

9.8"(250) or more 9.8"(250) or more

19.7"(500)

or more

Space required for installation and servicing

Knockout hole 3.6"(92)

Piping hole on the wall( 3.9"(100) hole)

Hole for remote control wires

Conduit hole(Hole for power supply cable)

Conduit hole(Knockout)

5.7"(145)

5.3"(135)

7.8"(197)

10.3"(262)

12.4"(316)

3.5"

(90)

1.3"

(32)

3.6"

(92)

Left drain pipe

draw-out port(Knockout)

6.7"(171)

3.3"

(84)

connecting port

(Gas side)

Refrigerant pipe

1/2"(12.7)

Refrigerant pipe

1.2"

Drain port VP20

(Inner dia. 1.0"(26), hose supplied)

18

Wireless sensor mounting section

46.5"(1180)

Hanging bolt

Unit

Left drain size

Upper pipe draw-out port(Knockout)

Hole for remote control wires(Knockout)

2.8"

(70)

2.1"

(53)

(Hole for power supply cable, knockout)

Conduit hole

Drain pipe

Connecting port

(Liquid side)

(Gas side)

44.3"(1125)

(Front side to be positioned horizontally.)

9.8"(250) or more 9.8"(250) or more

Left drain pipe

draw-out port(Knockout)

6.7"(171)

Knockout hole 3.6"(92)

Space required for installation and servicing

Conduit hole(Hole for power supply cable)

Conduit hole(Knockout)

5.7"(145)

5.3"(135)

10.3"(262)

12.4"(316)

1.3"

(32)

Hole for remote control wires

Drain port VP20

(Inner dia. 1.0"(26), hose supplied)

Pipe draw-out port(Knockout)

8.5"(216)(Gas pipe)

8.3"(210)

26.8"(680)

5.6"

(141)

4.5"(114)

19.7"(500)

or more

3.3"

(84)

6.7"(170)

7.8"(197)

Within

2.0"(50)

7.9"(200)(Liquid pipe)

1.5"

(39)

3.0"

(75)

3.8"

(94)

5.7"

(146)

2.0"

(52)

5.1"

(130)

2.0"(50)

4.3"

(110)

3.0"

(76)

8.5"(216)

4.1"

(105)

6.6"(167)

Ceilpng

surfce

(Hanging postion)

12.6"(320)

Refrigerant pipe connecting port 3/8"(9.5)

Refrigerant pipe connecting port 3/8"(9.5)

(Hanging position)

1.2"

(30)

3.3"

(84)

3.6"

(92)

Piping hole on wall ( 3.9"(100) hole)

3.5"

(90)

MMC-AP0241H2UL

Unit: in (mm)

19

Drain port VP20

(Inner dia. 1.0"(26), hose supplied)

Drain pipe

Wireless sensor mounting section

Upper pipe draw-out port(Knockout)

Hole for remote control wires(Knockout)

Refrigerant pipe connecting port 5/8"(15.9)

Refrigerant pipe connecting port 3/8"(9.5)

Left drain size

Hanging bolt

Ceiling

Unit

(Hanging position)

Left drain pipe

Space required for installation and servicing

Conduit hole(Hole for power supply cable)

Conduit hole(Knockout)

Pipe draw-out port(Knockout)

surface

(Liquid side)

(Gas side)

draw-out port(Knockout)

Connecting port

8.5"(216)(Gas pipe)

(Hanging position)

3.3"

(84)

6.7"(170)12.6"(320)

3.0"

(76)

8.5"(216)

2.8"

(70)

2.1"

(53)

2.0"

(50)

60.6"(1540)

Within

2.0"(50)

3.8"

(97)

62.8"(1595)

4.1"

(105)

6.6"(167)

8.3"(210)

26.8"(680)

5.6"

(141)

4.5"(114)

7.9"(200)(Liquid pipe)

9.8"(250) or more 9.8"(250) or more

5.7"(145)

5.3"(135)

3.5"

(90)

1.3"

(32)

3.6"

(92)

6.7"(171)

(Hole for power supply cable, knockout)

Conduit hole

19.7"(500)

or more

Hole for remote control wires

1.2"

(Front side to be positioned horizontally.)

2.5"

(52)

4.3"

(110)

1.5"

(39)

5.1"

(130)

3.0"

(75)

12.4"(316)

10.3"(262)

7.8"(197)

Knockout hole 3.6"(92)

Piping hole on the wall( 3.9"(100) hole)

3.3"

(84)

5.7"

(146)

MMC-AP0361H2UL, MMC-AP0421H2UL

Unit: in (mm)

20

2.9"(73.5)

0.3"(7)

2.0"(50)

Front panel

41.3"(1050)

12.6"(320)

Air filter

Air inlet

Heat exchanger

9.0"(228)

2.9"(73.5)

0.3"(7)

2.0"(50)

2.0"(50)

2.8"

(72)

3.1"

(78)

5.2"(132) 22.4"(568) 7.9"(200) 5.9"(150)

Installation plate hanger

Installation plate hanger

Conne cting pipe 13.4"(0.34m)

Drain hose 19.7"(0.5m)

C onnec ting pipe 12. 3"(0 . 49 m)

3/8"(9.52mm)

1/4"(6.35mm)

Wireless remote control

2.2"

(56)

0.9"

(24)

6.2"(157)

3.2"

(82)

0.9"(26)

6.4"(163)

Remote control holder

3.3"

(85)

8.5"(215) 8.5"(215)

9.3"(235) 9.3"(235)

0.9"

(23)

5.2"(132)30.9"(786)5.2"(132)

1.6"(40)

12.6"(316)

1.6"(40)

1.9"(47)

8.5"(215.5) 10.3"(262.5) 10.3"(262.5)

6.0"

(153.5)

4.3"

(109)

Hanger

Hanger

Hanger

C enter line

Instrallation plate outline

S pac e required for ins ta lla tion a nd s ervicing

B C

A

C

6.7"(170) or more

33.5"(850) or more

B

For exchange of cross flow fan

2.0"(50) or more

A

Distance Comments

Knock out system

Knock out system

Knock out system

1.6"(40)

1.0"(32)

Hole for power s upply cable

CAUTION

C onnecting pipe ca nnot be conne cted to

the right side of the indoor unit when

conduit pipe is used.

When connecting pipe is connected on

the le ft or bo ttom of the indoor unit,

connect the conduit pipe on other side.

2-4. High Wall Type

MMK-AP0073H2UL, MMK-AP0093H2UL, MMK-AP0123H2UL

Unit: in (mm)

21

2.9"(73.5)

0.3"(7)

2.0"(50)

Front panel

41.3"(1050)

12.6"(320)

Air filter

Air inlet

Heat exchanger

9.0"(228)

2.9"(73.5)

0.3"(7)

2.0"(50)

2.0"(50)

2.8"

(72)

3.1"

(78)

5.2"(132) 22.4"(568) 7.9"(200) 5.9"(150)

Ins tallation plate ha nger

Ins tallation pla te hanger

Conne cting pipe 13.4"(0.34m)

Drain hose 19.7"(0.5m)

C onne cting pipe 1 2. 3"(0 .49m)

1/2"(12.7mm)

1/4"(6.35mm)

Wireless remote control

2.2"

(56)

0.9"

(24)

6.2"(157)

3.2"

(82)

0.9"(26)

6.4"(163)

Remote control holder

3.3"

(85)

8.5"(215) 8.5"(215)

9.3"(235) 9.3"(235)

0.9"

(23)

5.2"(132)30.9"(786)5.2"(132)

1.6"(40)

12.6"(316)

1.6"(40)

1.9"(47)

8.5"(215.5) 10.3"(262.5) 10.3"(262.5)

6.0"

(153.5)

4.3"

(109)

Hanger

Hanger

Hanger

C enter line

Ins trallation pla te outline

S pac e require d for ins talla tion a nd s erv ic ing

B C

A

C

6.7"(170) or more

33.5"(850) or more

B

For exchange of cross flow fan

2.0"(50) or more

A

Distance Comments

K nock out s ys tem

K nock out s ys tem

K nock out s ys tem

1.6"(40)

1.0"(32)

Hole for power s upply cable

CAUTION

C onnec ting pipe ca nnot be connected to

the right s ide of the indoor unit whe n

conduit pipe is use d.

When connecting pipe is connected on

the le ft or bottom of the indoor unit,

conne ct the conduit pipe on other side.

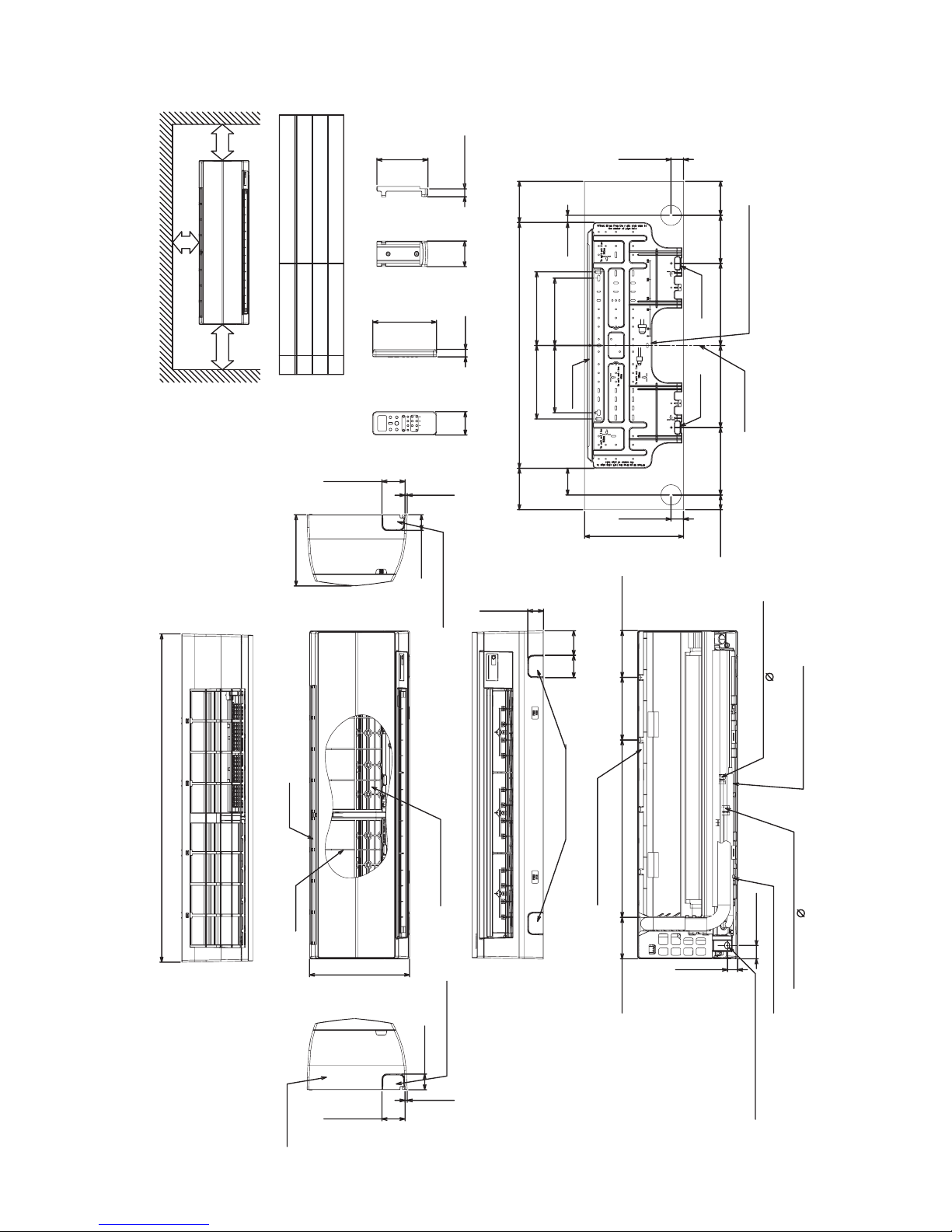

MMK-AP0153H2UL, MMK-AP0183H2UL

Unit: in (mm)

22

MMK-AP0243H2UL

2.9"(73.5)

0.3"(7)

2.0"(50)

Front panel

41.3"(1050)

12.6"(320)

Air filter

Air inlet

Heat exchanger

9.0"(228)

2.9"(73.5)

0.3"(7)

2.0"(50)

2.0"(50)

2.8"

(72)

3.1"

(78)

5.2"(132) 22.4"(568) 7.9"(200) 5.9"(150)

Insta llation plate hanger

Insta llation plate hanger

Connecting pipe 13.4"(0.34m)

Drain hose 19.7"(0.5m)

C onnecting pipe 1 2. 3 "( 0. 4 9m)

5/8"(15 .9mm)

3/8"(9.52mm)

Wireless remote control

2.2"

(56)

0.9"

(24)

6.2"(157)

3.2"

(82)

0.9"(26)

6.4"(163)

Remote control holder

3.3"

(85)

8.5"(215) 8.5"(215)

9.3"(235) 9.3"(235)

0.9"

(23)

5.2"(132)30.9"(786)5.2"(132)

1.6"(40)

12.6"(316)

1.6"(40)

1.9"(47) 8.5"(215.5) 10.3"(262.5) 10.3"(262.5)

6.0"

(153.5)

4.3"

(109)

Hanger

Hanger

Hanger

C e nte r line

Instrallation plate outline

S pac e require d for ins talla tion a nd s ervicing

B C

A

C

6.7"(170) or more

33.5"(850) or more

B

For exchange of cross flow fan

2.0"(50) or more

A

Distance C omments

K nock out s ys tem

Knock out system

Knock out system

Hole for powe r s upply ca ble

CAUTION

C onnecting pipe ca nnot be conne cted to

the r ig ht s ide o f th e indoo r u n it wh e n

conduit pipe is use d.

When connecting pipe is connected on

the left or bottom of the indoor unit,

con ne ct the con duit pipe o n o th e r s ide .

1.0"(32)

1.6"(40)

Unit: in (mm)

23

(EXCT)

(High Wall Setting)

Fan Moter

Louver Motor

Temp sensor

Float Switch

Ground Screw

Ground Screw

Indoor unit

Flow Selector

Parts Name

Indoor temp sensor

Pulse Motor Valve

Drain Pump Motor

RED:RED

WHI:WHITE

YEL:YELLOW

BLU:BLUE

BLK:BLACK

GRY:GRAY

PNK:PINK

ORN:ORANGE

GRN:GREEN

BRW:BROWN

COLOR

IDENTIFICATION

FS

unit

PMV

Symbol

LM1,2,3,4

TC1,TC2,TCJ

DM

TA

FM

(CHK)

CN71

CN60CN20

CN309

CN41

CN40

Power supply

Adapter for

or Indoor unit

Wireless Remote

Wired Remote

Control

Control

May be Outdoor unit

U1 U2

A B

U1

208/230-1-60

BLU

U2 A

BLU

B

21

21

(WHI)

CN001

BLKWHI

BLKBLK

(BLU)

(BLU)

211

2

11

32

3

3

3

1

1

(YEL)

1

(YEL)

CN61

T10

2 31

(WHI)

(OPTION)

(FANDRIVE)

(BLU)

5432

(GRL)

123

CN32

(WHI)

1

2

645

(RED)(WHI)

(WHI)

1456 4 52 3

(FILTER)

21 21

CN50

CN70 CN73

CN72

(DISP)

3

Motor

drive

circuit

3

FM

3162152341

(BLK)

CN81

(BLK)

L2L1

1

CN662(WHI)

BLK

P01

1

RED

1

3

WHI

3

CN67

31 2 54 1

(BLU)

CN82

2345

CN334

(WHI)

216 3 1

Flow Selector unit (Opt ion)

6

6

2134

2

314

PMV

5

5

21

20

181913 1514 161211109 1747651 325

CN333

8

CN510

(WHI)

(MCC-1570)

Control P.C.Board

for Indoor Unit

DC20V

Power

supply

circuit

DC12V

DC7V

DC15V

(WHI)

5 132 87645 9 121110

1 2

SW501

ON

171613 1514 201819

CN504

(WHI)

1 2

4

4

(WHI)(BLU)

4

1

2

3 5 3

2

1

LM1

1 2345

LM3

1 2 3

5

(BLK)

2

3

51

(RED)

5

4 42

31

DM

LM2

35 12 4 5

LM4

2 3145

(GRN)

321

(PNL)

4

CN508

(RED)

CN80

2

1

CN519

(WHI)

1

3

2

1 3

TCJ

TC2

TC1

11

(BRW)

CN100

33

2

(BLK)

CN101

22

11

TA

22

CN104

(YEL)

CN102

(RED)

11

22

CN34

(RED)

123

11

FS

Fuse

250V

T3.15A

Fuse

250V

F01

T6.3A

F02

1. indicates the terminal block.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate the

wiring at site.

3. indicates the control P.C.board.

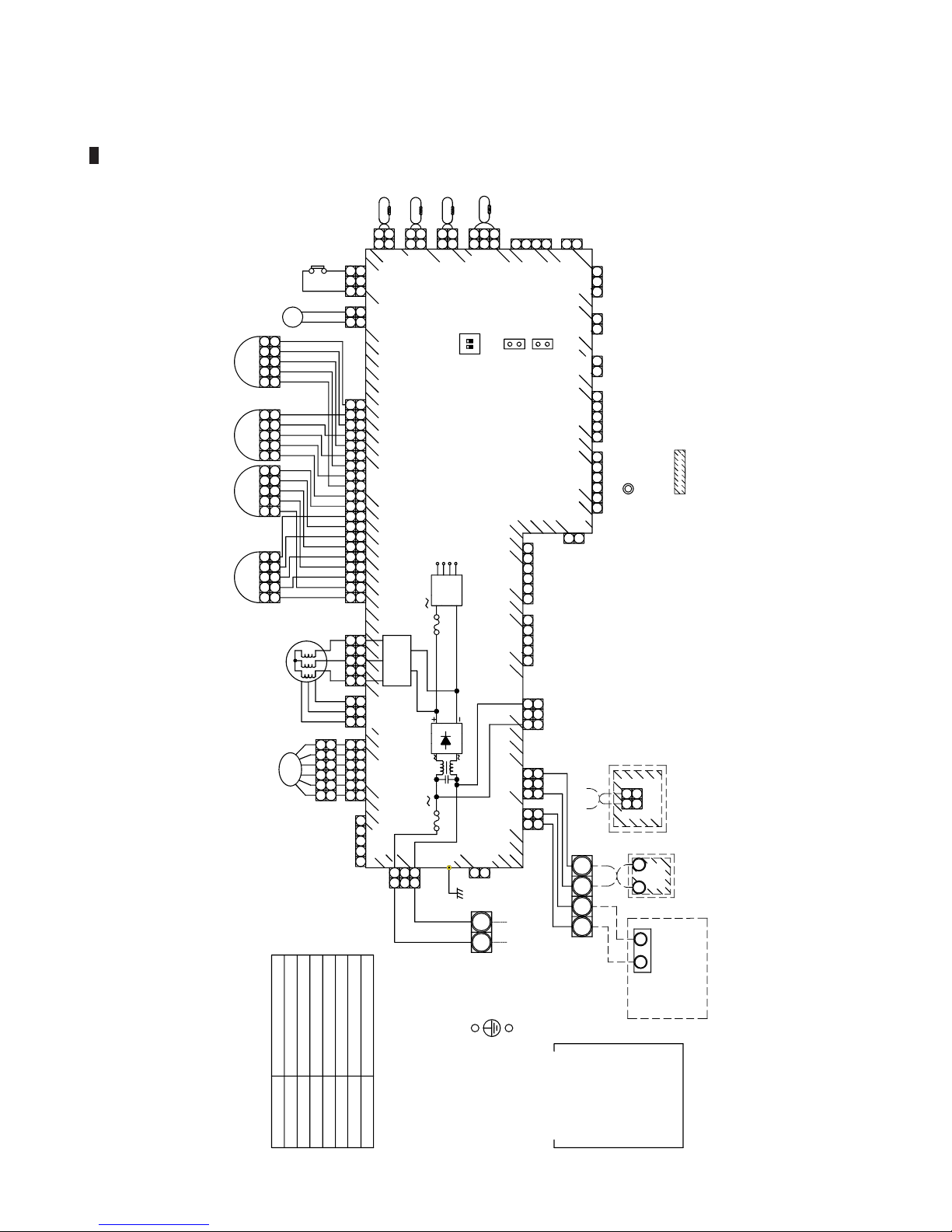

3. WIRING DIAGRAM

3-1. 4-Way Cassette Type

MMU-AP0072H2UL-1, AP0072H2UL, AP0092H2UL, AP0122H2UL, AP0152H2UL, AP0182H2UL,

AP0212H2UL, AP0242H2UL, AP0302H2UL, AP0362H2UL, AP0422H2UL

24

3-2. Compact 4-Way Cassette Type

MMU-AP0071MH2UL, AP0091MH2UL, AP0121MH2UL, AP0151MH2UL, AP0181MH2UL

䰞䰥303

䰞䰥302

Fuse

䰠6.3䰍

BLK

䰜䰻䱃䰱䰾 䰟䱁䰼䰼䰸䱅

208/230V-1-60

Ground Screw

䰜

䰐P

Control P.C. Board

(FANDRIVE)

䰠10

Motor

drive

MCC-1402

䰛䰜䰠䰕䰛䰚

Fuse

T3.15䰍䎏

Power

supply

䰒䰙

PMV

䰠䰏1

F䰟

Symbol

䰞䰥302

䰘䰙1,LM2

1.䫹䫹indicates䫹the䫹terminal䫹block letter.

Letter䫹at䫹inside䫹indicates䫹the terminal

number.

2.䫹A䫹dotted䫹line䫹and䫹broken䫹line indicate

the䫹wiring䫹at䫹site.

3. indicates䫹the䫹control䫹P.C䫹board.

U

May be Outdoor

unit or Indoor

䰘䰙1

35

4

䰘䰙2

unit

35

4

U

䰑䰤䰏䰠

2

1

䰒䰕䰘䰠䰑䰞

GRL

䰜䰚䰘

2

1

䯴䰣䰔䰕䯵

Adapter䫹for䫹

Wireless䫹Remote

BLK

䰏䰚001

WH

UU

BLK

BLU

BLU

䰠䰏2

䰠䰏䰖

䰠䰍

BLK

Louver䫹Motor

Float䫹Switch

Pulse䫹Motor䫹Valve

Drain䫹Pump䫹Motor

Drain䫹Control䫹Relay

䰜䰙䰢

䰒䰟

䰐P

Parts䫹Name

Temp䫹sensor

Temp䫹sensor

Temp䫹sensor

䰒䰭䰺䫹䰙䰻䱀o䰾

䰕䰺䰰䰻䰻䰾䫹temp䫹sensor

䰠䰍

䰠䰏䰖

䰠䰏䯾

䰠䰏䯽

䰒䰙

RED:RED

WHI:WHITE

YEL:YELLOW

BLU:BLUE

BLK:BLACK

GRY:GRAY

PNK:PINK

ORN:ORANGE

GRN:GREEN

BRW:BROWN

Wired Remote

Control

A

A

B

B

1

11

11

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11

1

Indoor

Unit

Ground

Screw

COLOR

IDENTIFICATION

1

212

2

2

2

2

2

2

1

2

1

2

2

2

2

2

2

2

2

1

1

2

2

1

1

2

2

2

2

2

2

2

2

2

3

3

3

1

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

44

5

51

2

3

4

5

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

5

5

5

5

5

6

1

2

3

4

5

6

6

6

6

6

5

5

5

5

CN68

(BLU)

CN333

(WHI)

CN334

(WHI)

CN82

(BLU)

CN100

(BRW)

CN34

(RED)

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN41

(BLU)

CN40

(BLU)

CN80

(GRN)

CN73

(RED)

CN33

(WHI)

CN70

(WHI)

CN20

(BLU)

CN32

(WHI)

CN50

(WHI)

CN67

(BLK)

CN66

(WHI)

CN44

(BRW)

DC20V

DC15V

DC12V

DC 7V

Flow Selector

Unit

250V ~

250V ~

L1

L2

RED

WHI

CN304

(GRY)

CN81

(BLK)

CN60

(WHI)

CN61

(YEL)

CN309

(YEL)

25

3-3. Ceiling Type

MMC-AP0181H2UL, AP0241H2UL, AP0361H2UL, AP0421H2UL

Adapter䫹for䫹

Wireless䫹Remote

RED

Power Supply

208/230-1-60

Indoor Unit

Ground Screw

L2L1

unit

Wired

Remote

Control

1

unit or Indoor

May be Outdoor

U

U

1

2

Closed-end

Connector

WHI

U

A

2

U

B

Ground Screw

Flow Selector Unit

Drain䫹Pump䫹Motor

Pulse䫹Motor䫹Valve

Drain䫹Control䫹Relay

PMV

TCJ

TC2

DP

LM

RY302

FS

Temp䫹sensor

Louver䫹Motor

Temp䫹sensor

Float䫹Switch

䰕䰺䰰䰻䰻䰾䫹temp䫹sensor

Symbol

TA

TC1

FM

Temp䫹sensor

Parts䫹Name

FanޓMotor

㨀㧭

㨀㧯㧶

㨀㧯㧞

㨀㧯㧝

㧲㧵㧸㨀㧱㧾

1

1

CN50

㧔WHI㧕

Letter䫹at䫹inside䫹indicates䫹the䫹terminal䫹number.

1.䫹䫹indicates䫹the䫹terminal䫹block䫹letter.

3.䫹䫹䫹䫹䫹indicates䫹the䫹control䫹P.C䫹board.

2.䫹A䫹dotted䫹lime䫹and䫹broken䫹line䫹indicate䫹the䫹wiring䫹at䫹site.

BLK

(WHI)

WHI

2

2

1

1

CN001

㧔BLU㧕

CN40

CN41

㧔BLU㧕

33

BLK

BLK

BLU

BLU

1 2

2

11

1

2

31

31

231

CN309

㧔YEL㧕

WHI

RED

RY302

㧰P

RY303

Fuse

P301

CN66

㧔WHI㧕

33

2

1

BLK

(GRY)

CN304

CN67

(BLK)

33

3

1

11

㧔WHI㧕

CN334

CN68

(BLU)

11

32

45

4

5

1

1

Control P.C. Board

for Indoor Unit

6

MCC-1402

㧔WHI㧕

2

1

45

653

㨀㧝㧜

4

㧔YEL㧕

CN61

1

2

1

FANDRIVE

435

2

OPTION

CN32

㧔WHI㧕

CN60

2

CN20

㧔BLU㧕

㧔RED㧕

3

2

1

5

1

4

CN81

㧔BLK㧕

CN70

2

453

GRL

2

1

㧱㨄㧯㨀

1

CN73

㧔WHI㧕

Power

supply

circuit

motor

䰰rive

Fuse

T3.15A

6

㧔WHI㧕

5

5

3

3

6

1

1

CN333

FM

25143

㧔BLU㧕

21 543

5

6

4

5

6

4

23

23

CN82

PMV

22

CN104

CN102

㧔BLK㧕

CN100

㧔BRW㧕

CN101

㧔GRN㧕

㧔RED㧕

DC15V

DC12V

DC7V

DC20V

1

1

2

1

3

2

3

CN80

㧼㧺㧸

3

2

1

2

1

2

1

2

1

1

1

㧔YEL㧕

34

2

5

1

34

2

1

34

2342

1

1

CN33

5

5

5

㧔WHI㧕

䰘䰙

㧲㧿

1

CN34

㧔RED㧕

3

3

2

1

RED:RED

WHI:WHITE

YEL:YELLOW

BLU:BLUE

BLK:BLACK

GRY:GRAY

PNK:PINK

ORN:ORANGE

GRN:GREEN

BRW:BROWN

A B

COLOR

IDENTIFICATION

Sold

Separately

26

㧔㧮㧸㨁㧕

㧯㧺㧝㧜㧜

㧔㧮㧾㨃㧕

㧔㧮㧸㨁㧕

㧯㧺㧝㧜㧝

㧔㧳㧾㧺㧕

㧯㧺㧝㧜㧟

㧔㨅㧱㧸㧕

㧔㨃㧴㧵㧕

㧯㧺㧝㧜㧠

㧯㧺㧝㧜㧞

㧼㧺㧸㧱㧹㧳

㧮㧾㨃

㧔㨃㧴㧵㧕

㧔㨃㧴㧵㧕

㧔㧮㧸㨁㧕

㧮㧸㨁

㧠

㧠

㧤

㧤

㧵㧺㧲㧾㧭㧾㧱㧰ޓ㧾㧭㨅㧿ޓ㧾㧱㧯㧱㧵㨂㧱

㧭㧺㧰ޓ㧵㧺㧰㧵㧯㧭㨀㧵㧻㧺ޓ㧼㧭㧾㨀㧿

㧔㧹㧯㧯㧙㧡㧜㧠㧠㧕

㧳㧾㧺㧒

FLOW SELECTOR UNIT

(Sold sepalat㪼ly)

Power Supply

㧟㧝㧞

㨅㧱㧸

㧥

㧠㧡

㧯㧺㧟㧜㧥

㧔㨅㧱㧸㧕

㧔㧮㧸㧷㧕

㧯㧺㧢㧣

HEAT EXCHANGER

㧡

㧟㧟

㧝㧝

㨃㧴㧵

㧾㧱㧰

㧯㧺㧤㧝㧔㧮㧸㧷㧕

㧟

㧟

㨅㧱㧸

㧮㧾㨃

㨃㧴㧵

㧞㧝

㧞㧝

㧝㧟

㧮㧸㨁

㧮㧸㨁

㧟

㧟

㧝㧞

㧞

㧼㧺㧷

㧳㧾㨅

㧠㧡

㧡㧠

㨀㧟㧚㧝㧡㧭ޓ㧞㧡㧜㨂㨪

㧲㧟㧜㧝ޓ㧲㨁㧿㧱

㧔㧹㧯㧯㧙㧝㧡㧝㧜㧕

Control P.C board for indoor unit

㧔㨃㧴㧵㧕

㧲㧭㧺㧰㧾㧵㨂㧱

㧝㧞

㧞

㧞

㧝

㧣㧠㧡㧢

㧢㧡㧠㧣

㧟

㧟

㧯㧺㧟㧞

㧔㧳㧾㧺㧕

㧔㨃㧴㧵㧕

㧔㨅㧱㧸㧕

㧻㧼㨀㧵㧻㧺

㧞

㧢

㧞㧠㧟㧝

㧟㧠㧞㧝 㧡

㧴㧭

㧠㧟㧞㧝 㧡㧢

㧝

㧝㧞㧟

㧠㧟 㧡㧢

㧯㧺㧢㧝

㧯㧺㧤㧜

㧯㧺㧢㧜

㧮㧸㨁

㧮㧸㨁

㧮㧸㨁

㧡㧤㧣㧢

㧣㧤

㨃㧴㧵

㧯㧺㧞㧝㧟㧔㨃㧴㧵㧕

㧼㧻㨃㧱㧾

㧯㧵㧾㧯㨁㧵㨀

㧿㨁㧼㧼㧸㨅

㧰㧯㧣㨂

㧰㧯ޓ㧜㨂

㧰㧯㧝㧞㨂

㧰㧯㧝㧡㨂

$.-

5

㧳㧾㧺㧒㨅㧱㧸

㧼㧺㧷ޓ㧦ޓ㧼㧵㧺㧷

㧳㧾㧺ޓ㧦ޓ㧳㧾㧱㧱㧺

㧻㧾㧺ޓ㧦ޓ㧻㧾㧭㧺㧳㧱

㧳㧾㧺㧒㨅㧱㧸ޓ㧦ޓ㧳㧾㧱㧱㧺ޓ㧒

㧯㧺㧞㧞

㨅㧱㧸㧸㧻㨃

㨅㧱㧸ޓ㧦ޓ㨅㧱㧸㧸㧻㨃

㧳㧾㨅ޓ㧦ޓ㧳㧾㧭㨅

㧮㧸㧷ޓ㧦ޓ㧮㧸㧭㧯㧷

㧮㧸㨁ޓ㧦ޓ㧮㧸㨁㧱

㧮㧾㨃ޓ㧦ޓ㧮㧾㧻㨃㧺

㨃㧴㧵ޓ㧦ޓ㨃㧴㧵㨀㧱

㧾㧱㧰ޓ㧦ޓ㧾㧱㧰

㧯㧻㧸㧻㧾ޓ㧵㧰㧱㧺㨀㧵㧲㧵㧯㧭㨀㧵㧻㧺

(#0

/1614

㧯㧺㧞㧝㧜

㧢

㧢

㧮㧸㨁

(

㧔㨃㧴㧵㧕

㧡

㧴㧮㧿

㧯㧺㧡㧜

㧟㧞 㧠㧝

㧝㧞

㧝㧞

㨃㧴㧵

㨅㧱㧸

㧡㧢 㧠

㧢㧡

㧠

㧻㧾㧺

㧮㧸㨁

㧮㧾㨃

㧾㧱㧰

㧯㧺㧤㧞

㧟

㧟

㨂㧭㧸㨂㧱

㧹㧻㨀㧻㧾

㧼㨁㧸㧿㧱

㧢

㧢

㨅㧱㧸

㧡 㧠㧟

㧡㧟㧠

㧝

㧝

㨅㧱㧸

㨃㧴㧵

㧮㧸㧷

㧾㧱㧰

㧯㧺㧠㧠

㧝㧞

㧯㧺㧟㧟

㧠

㧠

㧡

㧡

㧞

㧟㧞㧟

㨅㧱㧸

㨅㧱㧸

㨅㧱㧸

㨃㧴㧵

㧝

㧡

㧹㧻㨀㧻㧾

㧸㧻㨁㨂㧱㧾

㧝㧞㧠㧟

U2

㧔㧮㧸㨁㧕

U2

㧞

(Sold Separately)

㧿㧱㧺㧿㧻㧾

㧔㨀㧭㧕

㧮㧸㧷

㧮㧸㧷

㧮㧸㧷

㧝㧝

㧞

㧞

㧞㧞

㧝㧝

㧮㧸㧷

㨀㧴㧱㧾㧹㧻

㧔㨀㧯㧶㧕

㧿㧱㧺㧿㧻㧾

㧱㨄㧯㧴㧭㧺㧳㧱㧾

㧴㧱㧭㨀

䰏䰚䯽䎋䎺䎫䎬䎌

䎃

CONTROL

WIRED REMOTE

䎥䎯䎮

䎺䎫䎬

㧮㧸㧷

㧔㨀㧯㧝㧕

㧟㧟

㨀㧲

㧮㧸㧷

㧝

㧝

㧞

㧝

㧞

㧮㧸㧷

㧿㧱㧺㧿㧻㧾

㧔㨀㧯㧞㧕

㧴㧱㧭㨀

㧱㨄㧯㧴㧭㧺㧳㧱㧾

㧮㧸㧷

㨃㧴㧵

㧯㧺㧠㧝

㧝㧝

㧞

㧝

㧝

㧞

㧮㧸㧷

㧟㧟

㧿㧱㧺㧿㧻㧾

㧴㧱㧭㨀

㧱㨄㧯㧴㧭㧺㧳㧱㧾

A

B

㧮㧸㨁

㧮㧸㨁

㧯㧺㧠㧜

㧞㧞

㧝㧝

U1 U1

or Indoor unit

May be Outdoor unit

㧝㧚٧KPFKECVGUVJGVGTOKPCNDNQEM

.GVVGTCVKPUKFGKPFKECVGUVJGVGTOKPCNPWODGT

㧞㧚#FQVVGFNKPGCPFDTQMGPNKPGKPFKECVGVJGYKTKPICVUKVG

㧟㧚KPFKECVGUVJGEQPVTQN2%DQCTF

KPFKECVGUVJGEQPVTQN2%DQCTF

L1

L2

3-4. High Wall Type

MMK-AP0073H2UL, AP0093H2UL, AP0123H2UL, AP0153H2UL, AP0183H2UL, AP0243H2UL

27

4. PARTS RATING

4-1. 4-Way Cassette Type

4-2. Compact 4-Way Cassette Type

Model MMU-AP

Fan motor

Moter for horizontal grille

Pulse motor

Pulse motor valve

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

Float switch

Drain pump motor

0071MH2UL 0091MH2UL 0121MH2UL 0151MH2UL 0181MH2UL

SWF-340U60-1

MP24ZN3N

EFM-MD12TF-1

EDM-B25YGTF-3 EDM-B40YGTF-3

Lead wire length : 6.1 in (155 mm) Vinyl tube

Ø4 size lead wire length : 55.12 in (1400 mm) Vinyl tube (Blue) (Blue)

Ø6 size lead wire length : 55.12in (1400 mm) Vinyl tube (Black)

Ø6 size lead wire length : 55.12 in (1400 mm) Vinyl tube (Red)

FS-0218-103

APD-1406

Model MMU-

Fan motor

Moter for horizontal grille

Pulse motor

Pulse motor valve

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

Float switch

Drain pump motor

SWF-340U60-2

ICF-340

U150-1

MP24ZN3N

EFM-MD12TF-1

EDM-B40YGTF-2

EDM-B60

YGTF-1

Lead wire length : 12.2 in (310 mm) Vinyl tube

Ø4 size lead wire length : 47.24 in (1200 mm) Vinyl tube (Blue)

Ø6 size lead wire length : 39.37 in (1000 mm) Vinyl tube (Black)

Ø6 size lead wire length : 39.37 in (1000 mm) Vinyl tube (Red)

FS-0218-102

MDP-1401

AP042AP036AP030AP024AP021AP018AP015AP012AP009AP007

28

4-3. Ceiling Type

4-4. High Wall Type

Model MMC-

Fan motor

Driving motor for horizontal grille

Pulse motor

Pulse motor valve

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

AP0181H2UL AP0241H2UL AP0361H2UL AP0421H2UL

SWF-340U60-1A SWF-340U60-2A SWF-340U120-2A

MP24Z2

EFM-MD12TF-1

EBM-B40YGTF- 3 EDM-B60YGTF-1

Lead wire length : 6.1 in (155 mm) Vinyl tube

Ø4 size lead wire length : 47.24 in (1200 mm) Vinyl tube (Blue)

Ø6 size lead wire length : 47.24 in (1200 mm) Vinyl tube (Black)

Ø6 size lead wire length : 47.24 in (1200 mm) Vinyl tube (Red)

No.

1

2

3

4

5

6

7

Model MMK-AP

Fan motor (for indoor)

Grille motor

Thermo. sensor (TA sensor)

Heat exchanger sensor (TC1 sensor)

Heat exchanger sensor (TC2 sensor)

Heat exchanger sensor (TCJ sensor)

PMV motor

ICF-340U30-1: Output (Rated) 30W, 280-340V DC

MP24Z3T: Output (Rated) 1W, 16 poles DC

12.5 in (318 mm): 10 kΩ at 77°F (25°C)

Ø0.24, 23.62 in (Ø4,600 mm):

10 kΩ at 77°F (25°C)

Ø0.24, 31.5 in (Ø4,800 mm):

10 kΩ at 77°F (25°C)

Ø0.16, 31.5 in (Ø4,800 mm):

10 kΩ at 77°F (25°C)

EDM-MD12TF: 12 V DC

0073H2UL 0093H2UL 0123H2UL 0153H2UL 0183H2UL 0243H2UL

29

Air heat exchanger

at indoor side

Fan

M

Fan motor

Sensor

(TA)

Sensor

(TC1)

Gas sideLiquid side

Strainer

Capillary tube

Pulse Motor

Valve (PMV)

Strainer

Sensor

(TCJ)

Sensor

(TC2)

5. REFRIGERATING CYCLE DIAGRAM

Functional part name

Pulse Motor Valve PMV

Temp. sensor 1. TA

2. TC1

3. TC2

4. TCJ

Functional outline

(Connector CN082 (6P): Blue)

1) Controls super heat in cooling operation

2) Controls under cool in heating operation

3) Recovers refrigerant oil in cooling operation

4) Recovers refrigerant oil in heating operation

(Connector CN104 (2P): MMU, MMC: Yellow, MMK: White)

1) Detects indoor suction temperature

(Connector CN100 (3P): Brown)

1) Controls PMV super heat in cooling operation

(Connector CN101 (2P): MMU, MMC: Black, MMK: Blue)

1) Controls PMV under cool in heating operation

(Connector CN102 (2P): MMU, MMC: Red, MMK: Yellow)

1) Controls PMV super heat in cooling operation

30

No.

1

2

3

Item

When power

supply is reset

Operation

mode selection

Room temp.

control

Outline of specifications

1) Distinction of outdoor unit

When the power supply is reset, the outdoors are

distinguished and the control is selected according to the

distinguished result.

2) Setting of indoor fan speed and existence of air direction

adjustment

Based on EEPROM data, select setting of the indoor fan

speed and the existence of air direction adjustment.

3) If resetting the power supply during occurrence of a

trouble, the check code is once cleared. After ON/OFF

button of the remote control was pushed and the operation

was resumed, if the abnormal status continues, the check

code is again displayed on the remote control.

1) Based on the operation mode selecting command from the

remote control, the operation mode is selected.

1) Adjustment range: Remote control setup temperature (°F [°C] )

Remarks

Air speed (rpm)/

Air direction adjustment

Wired type

Wireless type

COOL/DRY

64°F [18°C] to 84°F [29°C]

63°F [17°C] to 86°F [30°C]

HEAT

64°F [18°C] to 84°F [29°C]

63°F [17°C] to 86°F [30°C]

6. CONTROL OUTLINE

6-1. 4-Way Cassette Type, Compact 4-Way Type, Ceiling Type

2) Using the Item code 06, the setup temperature in heating

operation can be corrected.

Setting at shipment

Shift of suction

temperature in heating

operation

Except while sensor of

the remote control is

controlled

(Code No. [32], “0001”)

Setup data 2

Setup data

Setup temp.

Correction

0246

+0°F +3.6°F +7.2°F +10.8°F

[+0°C] [+2°C] [+4°C] [+6°C]

Remote control

command

STOP

FAN

COOL

DRY

HEAT

Control outline

Air conditioner stops.

Fan operation

Cooling operation

Dry operation

Heating operation

Loading...

Loading...