Toshiba MMU-AP0074YH-TR, MMU-AP0094YH-TR, MMU-AP0124YH-TR, MMU-AP0154SH-TR, MMU-AP0184SH-TR SERVICE MANUAL

...

FILE No. A10-033

AIR CONDITIONER (MULTI TYPE)

SERVICE MANUAL

This service manual provides relevant explanations about new indoor unit (4 series). Please refer to the following service manuals for each indoor units.

Indoor unit

Model name:

4-way Cassette Type |

A08-004 |

(MMU-AP 2H) |

|

2-way Cassette Type (2 series) |

A10-007 |

(MMU-AP 2WH) |

|

Fresh Air Intake Indoor Unit Type |

A06-016 |

(MMD-AP 1HFE) |

|

High-wall Type (2 series) |

SVM-05052-1 |

(MMK-AP 2H) |

|

High-wall Type (3 series) |

SVM-09059 |

(MMK-AP 3H) |

|

Other indoor units (1 series) |

A03-009, A03-010, A05-006, A05-007, A06-002 |

Indoor unit

<1-way Cassette Type (YH, SH)> MMU-AP0074YH-E(-TR) MMU-AP0094YH-E(-TR) MMU-AP0124YH-E(-TR) MMU-AP0154SH-E(-TR) MMU-AP0184SH-E(-TR) MMU-AP0244SH-E(-TR)

<Concealed Duct High Static Pressure Type> MMD-AP0184H-E(-TR) MMD-AP0244H-E(-TR) MMD-AP0274H-E(-TR) MMD-AP0364H-E(-TR) MMD-AP0484H-E(-TR) MMD-AP0724H-E(-TR) MMD-AP0964H-E(-TR)

<Floor Standing Concealed Type> MML-AP0074BH-E(-TR) MML-AP0094BH-E(-TR) MML-AP0124BH-E(-TR) MML-AP0154BH-E(-TR) MML-AP0184BH-E(-TR) MML-AP0244BH-E(-TR)

<Compact 4-way Cassette Type> MMU-AP0074MH-E(-TR) MMU-AP0094MH-E(-TR) MMU-AP0124MH-E(-TR) MMU-AP0154MH-E(-TR) MMU-AP0184MH-E(-TR)

<Slim Duct Type> MMD-AP0074SPH-E(-TR) MMD-AP0094SPH-E(-TR) MMD-AP0124SPH-E(-TR) MMD-AP0154SPH-E(-TR) MMD-AP0184SPH-E(-TR)

<Ceiling Type> MMC-AP0154H-E(-TR) MMC-AP0184H-E(-TR) MMC-AP0244H-E(-TR) MMC-AP0274H-E(-TR) MMC-AP0364H-E(-TR) MMC-AP0484H-E(-TR)

<Floor Standing Type> MMF-AP0154H-E(-TR) MMF-AP0184H-E(-TR) MMF-AP0244H-E(-TR) MMF-AP0274H-E(-TR) MMF-AP0364H-E(-TR) MMF-AP0484H-E(-TR) MMF-AP0564H-E(-TR)

<Floor Standing Cabinet Type> MML-AP0074H-E(-TR) MML-AP0094H-E(-TR) MML-AP0124H-E(-TR) MML-AP0154H-E(-TR) MML-AP0184H-E(-TR) MML-AP0244H-E(-TR)

<Concealed Duct Standard Type>

MMD-AP0074BH-E(-TR), MMD-AP0094BH-E(-TR), MMD-AP0124BH-E(-TR), MMD-AP0154BH-E(-TR) MMD-AP0184BH-E(-TR), MMD-AP0244BH-E(-TR), MMD-AP0274BH-E(-TR), MMD-AP0304BH-E(-TR) MMD-AP0364BH-E(-TR), MMD-AP0484BH-E(-TR), MMD-AP0564BH-E(-TR)

PRINTED IN JAPAN, Apr, 2011, TDOC

Contents

Precautions for Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 1 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-1. Compact 4-way cassette type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 1-2. 1-way cassette type (compact type YH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 1-3. 1-way cassette type (SH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 1-4. Concealed duct standard type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 1-5. Concealed duct high static pressure type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 1-6. Slim duct type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 1-7. Ceiling type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 1-8. Floor standing cabinet type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 1-9. Floor standing concealed type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 1-10. Floor standing type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 Parts Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-1. Indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

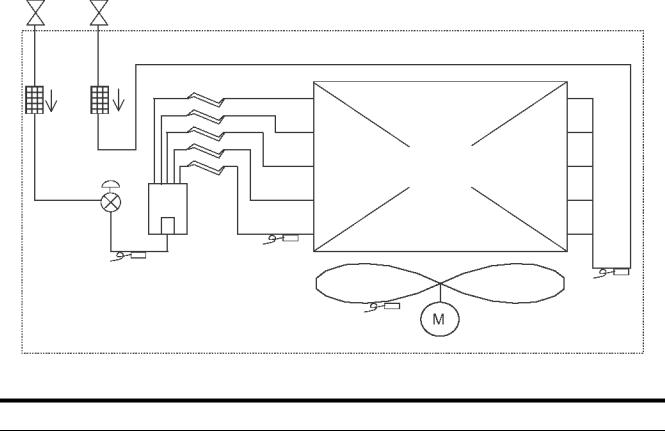

3 Refrigerant Cycle Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4 Control Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Applied Control and Functions (Including Circuit Configuration) . . . . . . . . . . . . . 37

5-1. Indoor controller block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

5-1-1. |

When main (sub) remote controller connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

5-1-2. |

When wireless remote controller kit connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

5-1-3. |

When both main (sub) remote controller and wireless remote controller kit connected. 41 |

|

5-2. Indoor printed circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

5-3. |

Optional connector specifications of indoor P.C. board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

5-4. |

Test operation of indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

5-5. |

Method to set indoor unit function DN code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

5-6. |

Applied control of indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6-1. |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

6-2. |

Troubleshooting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

6-3. Troubleshooting based on information displayed on remote controller . . . . . . . . . . . . . . . . . . . . |

74 |

|

6-4. |

Check codes displayed on remote controller and SMMS outdoor unit (7-segment display on I/F |

|

|

board) and locations to be checked. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

79 |

6-5. |

Sensor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

1

7 P.C. Board Exchange Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7-1. Replacement of indoor P.C. boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8 Detachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8-1. |

1-way cassette (SH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

105 |

8-2. |

Compact 4-way cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

114 |

8-3. |

Slim duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

8-4. |

Concealed duct standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

129 |

8-5. Concealed duct high static pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

132 |

|

8-6. |

Ceiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

133 |

8-7. |

Floor standing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

8-8. |

Floor standing cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

144 |

9 Exploded Diagram / Service Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

9-1. 1-way cassette type (YH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 9-2. 1-Way cassette type (SH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 9-3. Compact 4-way cassette type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 9-4. Slim duct type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 9-5. Concealed duct standard type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164 9-6. Concealed duct high static pressure type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178 9-7. Ceiling type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186 9-8. Floor standing type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193 9-9. Floor standing concealed type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202 9-10. Floor standing cabinet type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

2

Original instruction

Please read carefully through these instructions that contain important information which complies with the “Machinery” Directive (Directive 2006/42/EC), and ensure that you understand them.

Generic Denomination: Air Conditioner

Definition of Qualified Installer or Qualified Service Person

The air conditioner must be installed, maintained, repaired and removed by a qualified installer or qualified service person. When any of these jobs is to be done, ask a qualified installer or qualified service person to do them for you. A qualified installer or qualified service person is an agent who has the qualifications and knowledge described in the table below.

Agent |

Qualifications and knowledge which the agent must have |

|

|

|

|

|

• The qualified installer is a person who installs, maintains, relocates and removes the air conditioners |

|

|

made by Toshiba Carrier Corporation. He or she has been trained to install, maintain, relocate and |

|

|

remove the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been |

|

|

instructed in such operations by an individual or individuals who have been trained and is thus |

|

|

thoroughly acquainted with the knowledge related to these operations. |

|

|

• The qualified installer who is allowed to do the electrical work involved in installation, relocation and |

|

|

removal has the qualifications pertaining to this electrical work as stipulated by the local laws and |

|

|

regulations, and he or she is a person who has been trained in matters relating to electrical work on |

|

|

the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been |

|

|

instructed in such matters by an individual or individuals who have been trained and is thus thoroughly |

|

Qualified installer |

acquainted with the knowledge related to this work. |

|

• The qualified installer who is allowed to do the refrigerant handling and piping work involved in |

||

|

||

|

installation, relocation and removal has the qualifications pertaining to this refrigerant handling and |

|

|

piping work as stipulated by the local laws and regulations, and he or she is a person who has been |

|

|

trained in matters relating to refrigerant handling and piping work on the air conditioners made by |

|

|

Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such matters by an |

|

|

individual or individuals who have been trained and is thus thoroughly acquainted with the knowledge |

|

|

related to this work. |

|

|

• The qualified installer who is allowed to work atheights has been trained in matters relating to working |

|

|

at heights with the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she |

|

|

has been instructed in such matters by an individual or individuals who have been trained and is thus |

|

|

thoroughly acquainted with the knowledge related to this work. |

|

|

|

|

|

• The qualified service person is a person who installs, repairs, maintains, relocates and removes the |

|

|

air conditioners made by Toshiba Carrier Corporation. He or she has been trained to install, repair, |

|

|

maintain, relocate and remove the air conditioners made by Toshiba Carrier Corporation or, |

|

|

alternatively, he or she has been instructed in such operations by an individual or individuals who have |

|

|

been trained and is thus thoroughly acquainted with the knowledge related to these operations. |

|

|

• The qualified service person who is allowed to do theelectrical work involved in installation, repair, |

|

|

relocation and removal has the qualifications pertaining to this electrical work as stipulated by the local |

|

|

laws and regulations, and he or she is a person who has been trained in matters relating to electrical |

|

|

work on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been |

|

|

instructed in such matters by an individual or individuals who have been trained and is thus thoroughly |

|

Qualified service |

acquainted with the knowledge related to this work. |

|

person |

• The qualified service person who is allowed to do the refrigerant handling and piping work involved in |

|

|

installation, repair, relocation and removal has the qualifications pertaining to this refrigerant handling |

|

|

and piping work as stipulated by the local laws and regulations, and he or she is a person who has |

|

|

been trained in matters relating to refrigerant handling and piping work on the air conditioners made |

|

|

by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such matters by an |

|

|

individual or individuals who have been trained and is thus thoroughly acquainted with the knowledge |

|

|

related to this work. |

|

|

• The qualified service person who is allowed to work at heights has been trained in matters relating to |

|

|

working at heights with the air conditioners made by Toshiba Carrier Corporation or, alternatively, he |

|

|

or she has been instructed in such matters by an individual or individuals who have been trained and |

|

|

is thus thoroughly acquainted with the knowledge related to this work. |

|

|

|

3

Definition of Protective Gear

When the air conditioner is to be transported, installed, maintained, repaired or removed, wear protective gloves and ‘safety’ work clothing.

In addition to such normal protective gear, wear the protective gear described below when undertaking the special work detailed in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, burns, electric shocks and other injuries.

Work undertaken |

Protective gear worn |

|

|

|

|

All types of work |

Protective gloves |

|

‘Safety’ working clothing |

||

|

||

|

|

|

|

Gloves to provide protection for electricians and from heat |

|

Electrical-related work |

Insulating shoes |

|

|

Clothing to provide protection from electric shock |

|

|

|

|

Work done at heights |

Helmets for use in industry |

|

(50 cm or more) |

||

|

||

|

|

|

Transportation of heavy objects |

Shoes with additional protective toe cap |

|

|

|

|

Repair of outdoor unit |

Gloves to provide protection for electricians and from heat |

|

|

|

The important contents concerned to the safety are described on the product itself and on this Service Manual. Please read this Service Manual after understanding the described items thoroughly in the following contents (Indications / Illustrated marks), and keep them.

[Explanation of indications]

Indication |

Explanation |

|

|

|

|

DANGER |

Indicates contents assumed that an imminent danger causing a death or serious injury of |

|

the repair engineers and the third parties when an incorrect work has been executed. |

||

|

||

|

|

|

WARNING |

Indicates possibilities assumed that a danger causing a death or serious injury of the |

|

repair engineers, the third parties, and the users due to troubles of the product after work |

||

|

when an incorrect work has been executed. |

|

|

|

|

CAUTION |

Indicates contents assumed that an injury or property damage (*) may be caused on the |

|

repair engineers, the third parties, and the users due to troubles of the product after work |

||

|

when an incorrect work has been executed. |

|

|

|

* Property damage: Enlarged damage concerned to property, furniture, and domestic animal / pet

[Explanation of illustrated marks]

Mark |

Explanation |

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (Including danger / warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

4

Warning Indications on the Air Conditioner Unit [Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

If removing the label during parts replace, stick it as the original.

Warning indication |

Description |

|

|

|

WARNING |

|

ELECTRICAL SHOCK HAZARD |

|

Disconnect all remote electric power supplies before servicing. |

|

|

|

WARNING |

|

Moving parts. |

|

Do not operate unit with grille removed. |

|

Stop the unit before the servicing. |

|

|

|

CAUTION |

|

High temperature parts. |

|

You might get burned when removing this panel. |

|

|

|

CAUTION |

|

Do not touch the aluminium fins of the unit. |

|

Doing so may result in injury. |

|

|

|

CAUTION |

|

BURST HAZARD |

|

Open the service valves before the operation, otherwise there might be the |

|

burst. |

|

|

|

CAUTION |

|

Do not climb onto the fan guard. |

|

Doing so may result in injury. |

|

|

5

Precautions for Safety

The manufacturer shall not assume any liability for the damage caused by not observing the description of this manual.

DANGER

DANGER

|

Before carrying out the installation, maintenance, repair or removal work, be sure to set the circuit breaker for |

|

|

both the indoor and outdoor units to the OFF position. Otherwise, electric shocks may result. |

|

|

|

|

|

Before opening the intake grille of the indoor unit or service panel of the outdoor unit, set the circuit breaker to |

|

|

the OFF position. |

|

|

Failure to set the circuit breaker to the OFF position may result in electric shocks through contact with the interior |

|

|

parts. |

|

|

Only a qualified installer (*1) or qualified service person (*1) is allowed to remove the intake grille of the indoor |

|

|

unit or service panel of the outdoor unit and do the work required. |

|

|

|

|

|

Before starting to repair the outdoor unit fan or fan guard, be absolutely sure to set the circuit breaker to the |

|

|

OFF position, and place a “Work in progress” sign on the circuit breaker. |

|

Turn off |

|

|

When cleaning the filter or other parts of the indoor unit, set the circuit breaker to OFF without fail, and place a |

||

breaker. |

||

“Work in progress” sign near the circuit breaker before proceeding with the work. |

||

|

||

|

|

|

|

When you have noticed that some kind of trouble (such as when an error display has appeared, there is a smell |

|

|

of burning, abnormal sounds are heard, the air conditioner fails to cool or heat or water is leaking) has occurred |

|

|

in the air conditioner, do not touch the air conditioner yourself but set the circuit breaker to the OFF position, |

|

|

and contact a qualified service person. Take steps to ensure that the power will not be turned on (by marking |

|

|

“out of service” near the circuit breaker, for instance) until qualified service person arrives. Continuing to use the |

|

|

air conditioner in the trouble status may cause mechanical problems to escalate or result in electric shocks or |

|

|

other failure. |

|

|

|

|

|

When you access inside of the service panel to repair electric parts, wait for about five minutes after turning off |

|

|

the breaker. Do not start repairing immediately.Otherwise you may get electric shock by touching terminals of |

|

Electric shock |

high-voltage capacitors. Natural discharge of the capacitor takes about five minutes. |

|

hazard |

|

|

|

|

|

|

Place a “Work in progress” sign near the circuit breaker while the installation, maintenance, repair or removal |

|

|

work is being carried out. |

|

|

There is a danger of electric shocks if the circuit breaker is set to ON by mistake. |

|

|

|

|

|

Before operating the air conditioner after having completed the work, check that the electrical parts box cover |

|

Prohibition |

of the indoor unit and service panel of the outdoor unit are closed, and set the circuit breaker to the ON position. |

|

|

You may receive an electric shock if the power is turned on without first conducting these checks. |

|

|

|

|

|

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the electrical parts with |

|

|

the electrical parts box cover of one or more of the indoor units and the service panel of the outdoor unit |

|

|

removed in order to find out exactly where the trouble lies, wear insulated heat-resistant gloves, insulated boots |

|

Stay on |

and insulated work overalls, and take care to avoid touching any live parts. |

|

You may receive an electric shock if you fail to heed this warning. Only qualified service person (*1) is allowed |

||

protection |

to do this kind of work. |

|

|

|

6

WARNING

WARNING

|

Before starting to repair the air conditioner, read carefully through the Service Manual, and repair the air |

|

|

conditioner by following its instructions. |

|

|

|

|

|

Only qualified service person (*1) is allowed to repair the air conditioner. |

|

|

Repair of the air conditioner by unqualified person may give rise to a fire, electric shocks, injury, water leaks and |

|

|

/ or other problems. |

|

|

|

|

|

Do not use any refrigerant different from the one specified for complement or replacement. |

|

|

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may result in a failure |

|

|

or explosion of the product or an injury to your body. |

|

|

|

|

|

Only a qualified installer (*1) or qualified service person (*1) is allowed to carry out the electrical work of the air |

|

|

conditioner. |

|

|

Under no circumstances must this work be done by an unqualified individual since failure to carry out the work |

|

|

properly may result in electric shocks and / or electrical leaks. |

|

|

|

|

|

When transporting the air conditioner, wear shoes with protective toe caps, protective gloves and other |

|

|

protective clothing. |

|

|

|

|

|

When connecting the electrical wires, repairing the electrical parts or undertaking other electrical jobs, wear |

|

|

gloves to provide protection for electricians and from heat, insulating shoes and clothing to provide protection |

|

|

from electric shocks. |

|

|

Failure to wear this protective gear may result in electric shocks. |

|

|

|

|

|

Electrical wiring work shall be conducted according to law and regulation in the community and installation |

|

|

manual. Failure to do so may result in electrocution or short circuit. |

|

|

|

|

|

Only a qualified installer (*1) or qualified service person (*1) is allowed to undertake work at heights using a |

|

|

stand of 50 cm or more or to remove the intake grille of the indoor unit to undertake work. |

|

|

|

|

General |

When working at heights, use a ladder which complies with the ISO 14122 standard, and follow the procedure |

|

|

in the ladder’s instructions. |

|

|

Also wear a helmet for use in industry as protective gear to undertake the work. |

|

|

|

|

|

When working at heights, put a sign in place so that no-one will approach the work location, before proceeding |

|

|

with the work. |

|

|

Parts and other objects may fall from above, possibly injuring a person below. |

|

|

|

|

|

When executing address setting, test run, or troubleshooting through the checking window on the electric parts |

|

|

box, put on insulated gloves to provide protection from electric shock. Otherwise you may receive an electric |

|

|

shock. |

|

|

|

|

|

Do not touch the aluminum fin of the outdoor unit. |

|

|

You may injure yourself if you do so. If the fin must be touched for some reason, first put on protective gloves |

|

|

and safety work clothing, and then proceed. |

|

|

|

|

|

Do not climb onto or place objects on top of the outdoor unit. |

|

|

You may fall or the objects may fall off of the outdoor unit and result in injury. |

|

|

|

|

|

When transporting the air conditioner, wear shoes with additional protective toe caps. |

|

|

|

|

|

When transporting the air conditioner, do not take hold of the bands around the packing carton. |

|

|

You may injure yourself if the bands should break. |

|

|

|

|

|

Be sure that a heavy unit (10 kg or heavier) such as a compressor is carried by two persons. |

|

|

|

|

|

This air conditioner has passed the pressure test as specified in IEC 60335-2-40 Annex EE. |

|

|

|

|

|

Before troubleshooting or repair work, check the earth wire is connected to the earth terminals of the main unit, |

|

|

otherwise an electric shock is caused when a leak occurs.If the earth wire is not correctly connected, contact |

|

|

an electric engineer for rework. |

|

|

|

|

Check earth |

After completing the repair or relocation work, check that the ground wires are connected properly. |

|

|

||

Be sure to connect earth wire. (Grounding work) Incomplete grounding causes an electric shock. |

||

wires. |

||

|

Do not connect ground wires to gas pipes, water pipes, and lightning rods or ground wires for telephone wires. |

|

|

|

|

|

Do not modify the products.Do not also disassemble or modify the parts. |

|

Prohibition of |

It may cause a fire, electric shock or injury. |

|

|

||

modification. |

|

|

|

|

|

|

When any of the electrical parts are to be replaced, ensure that the replacement parts satisfy the specifications |

|

|

given in the Service Manual (or use the parts contained on the parts list in the Service Manual). |

|

Use specified |

Use of any parts which do not satisfy the required specifications may give rise to electric shocks, smoking and |

|

/ or a fire. |

||

parts. |

|

7

|

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the electrical parts with |

|

the electrical parts box cover of one or more of the indoor units and the service panel of the outdoor unit |

Do not bring a |

removed in order to find out exactly where the trouble lies, put a sign in place so that no-one will approach the |

child close to |

work location before proceeding with the work. Third-party individuals may enter the work site and receive |

the |

electric shocks if this warning is not heeded. |

equipment. |

|

|

|

|

Connect the cut-off lead wires with crimp contact, etc., put the closed end side upward and then apply a water- |

Insulating |

cut method, otherwise a leak or production of fire is caused at the users’ side. |

|

|

measures |

|

|

|

|

When performing repairs using a gas burner, replace the refrigerant with nitrogen gas because the oil that coats |

|

the pipes may otherwise burn. |

|

When repairing the refrigerating cycle, take the following measures. |

1)Be attentive to fire around the cycle. When using a gas stove, etc., be sure to put out fire before work; otherwise the oil mixed with refrigerant gas may catch fire.

2)Do not use a welder in the closed room. When using it without ventilation, carbon monoxide poisoning may

No fire |

be caused. |

3)Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may catch the inflammables.

|

The refrigerant used by this air conditioner is the R410A. |

|

|

Check the used refrigerant name and use tools and materials of the parts which match with it. |

|

|

For the products which use R410A refrigerant, the refrigerant name is indicated at a position on the outdoor unit |

|

|

where is easy to see. To prevent miss-charging, the route of the service port is changed from one of the former |

|

|

R22. |

|

|

|

|

|

For an air conditioner which uses R410A, never use other refrigerant than R410A. For an air conditioner which |

|

|

uses other refrigerant (R22, etc.), never use R410A. |

|

|

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating cycle and an |

|

|

injury due to breakage may be caused. |

|

|

|

|

|

When the air conditioner has been installed or relocated, follow the instructions in the Installation Manual and |

|

|

purge the air completely so that no gases other than the refrigerant will be mixed in the refrigerating cycle. |

|

|

Failure to purge the air completely may cause the air conditioner to malfunction. |

|

|

|

|

|

Do not charge refrigerant additionally. If charging refrigerant additionally when refrigerant gas leaks, the |

|

|

refrigerant composition in the refrigerating cycle changes resulted in change of air conditioner characteristics or |

|

|

refrigerant over the specified standard amount is charged and an abnormal high pressure is applied to the inside |

|

Refrigerant |

of the refrigerating cycle resulted in cause of breakage or injury. Therefore if the refrigerant gas leaks, recover |

|

the refrigerant in the air conditioner, execute vacuuming, and then newly recharge the specified amount of liquid |

||

|

||

|

refrigerant. |

|

|

In this time, never charge the refrigerant over the specified amount. |

|

|

|

|

|

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant or air other than R410A into |

|

|

the specified refrigerant. If air or others is mixed with the refrigerant, abnormal high pressure generates in the |

|

|

refrigerating cycle resulted in cause of injury due to breakage. |

|

|

|

|

|

After installation work, check the refrigerant gas does not leak. If the refrigerant gas leaks in the room, |

|

|

poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove though the |

|

|

refrigerant gas itself is innocuous. |

|

|

|

|

|

Never recover the refrigerant into the outdoor unit. When the equipment is moved or repaired, be sure to recover |

|

|

the refrigerant with recovering device. |

|

|

The refrigerant cannot be recovered in the outdoor unit; otherwise a serious accident such as breakage or injury |

|

|

is caused. |

|

|

|

|

|

After repair work, surely assemble the disassembled parts, and connect and lead the removed wires as before. |

|

|

Perform the work so that the cabinet or panel does not catch the inner wires. |

|

Assembly / |

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire is caused at user’s |

|

side. |

||

Wiring |

|

|

|

After the work has finished, be sure to use an insulation tester set (500 V Megger) to check the resistance is |

|

|

1 MΩ or more between the charge section and the non-charge metal section (Earth position). |

|

Insulator |

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s side. |

|

check |

|

|

|

|

|

|

When the refrigerant gas leaks during work, execute ventilation. |

|

|

If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of the refrigerant and the |

|

Ventilation |

closed room full with gas is dangerous because a shortage of oxygen occurs. Be sure to execute ventilation. |

|

|

8

|

When the refrigerant gas leaks, find up the leaked position and repair it surely. |

|

|

If the leaked position cannot be found up and the repair work is interrupted, pump-down and tighten the service |

|

|

valve, otherwise the refrigerant gas may leak into the room. |

|

|

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove though the |

|

|

refrigerant gas itself is innocuous. |

|

|

When installing equipment which includes a large amount of charged refrigerant such as a multi air conditioner |

|

|

in a sub-room, it is necessary that the density does not the limit even if the refrigerant leaks. |

|

|

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is caused. |

|

|

|

|

|

Tighten the flare nut with a torque wrench in the specified manner. |

|

Compulsion |

Excessive tighten of the flare nut may cause a crack in the flare nut after a long period, which may result in |

|

|

refrigerant leakage. |

|

|

|

|

|

Nitrogen gas must be used for the airtight test. |

|

|

|

|

|

The charge hose must be connected in such a way that it is not slack. |

|

|

|

|

|

For the installation / moving / reinstallation work, follow to the Installation Manual. |

|

|

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric shock or fire is caused. |

|

|

|

|

|

Once the repair work has been completed, check for refrigerant leaks, and check the insulation resistance and |

|

|

water drainage. |

|

|

Then perform a trial run to check that the air conditioner is running properly. |

|

|

|

|

|

After repair work has finished, check there is no trouble. If check is not executed, a fire, electric shock or injury |

|

|

may be caused. For a check, turn off the power breaker. |

|

|

|

|

Check after |

After repair work (installation of front panel and cabinet) has finished, execute a test run to check there is no |

|

repair |

generation of smoke or abnormal sound. |

|

|

If check is not executed, a fire or an electric shock is caused. Before test run, install the front panel and cabinet. |

|

|

|

|

|

Be sure to fix the screws back which have been removed for installation or other purposes. |

|

|

|

|

|

Check the following matters before a test run after repairing piping. |

|

|

• Connect the pipes surely and there is no leak of refrigerant. |

|

Do not |

• The valve is opened. |

|

Running the compressor under condition that the valve closes causes an abnormal high pressure resulted in |

||

operate the |

damage of the parts of the compressor and etc. and moreover if there is leak of refrigerant at connecting section |

|

unit with the |

||

of pipes, the air is sucked and causes further abnormal high pressure resulted in burst or injury. |

||

valve closed. |

||

|

|

|

|

Only a qualified installer (*1) or qualified service person (*1) is allowed to relocate the air conditioner. It is |

|

|

dangerous for the air conditioner to be relocated by an unqualified individual since a fire, electric shocks, injury, |

|

|

water leakage, noise and / or vibration may result. |

|

|

|

|

|

Check the following items after reinstallation. |

|

|

1) The earth wire is correctly connected. |

|

|

2) The power cord is not caught in the product. |

|

Check after |

3) There is no inclination or unsteadiness and the installation is stable. |

|

If check is not executed, a fire, an electric shock or an injury is caused. |

||

reinstallation |

||

|

||

|

When carrying out the pump-down work shut down the compressor before disconnecting the refrigerant pipe. |

|

|

Disconnecting the refrigerant pipe with the service valve left open and the compressor still operating will cause |

|

|

air, etc. to be sucked in, raising the pressure inside the refrigeration cycle to an abnormally high level, and |

|

|

possibly resulting in reputing, injury, etc. |

|

|

|

|

|

When the service panel of the outdoor unit is to be opened in order for the compressor or the area around this |

|

|

part to be repaired immediately after the air conditioner has been shut down, set the circuit breaker to the OFF |

|

|

position, and then wait at least 10 minutes before opening the service panel. |

|

|

If you fail to heed this warning, you will run the risk of burning yourself because the compressor pipes and other |

|

|

parts will be very hot to the touch. In addition, before proceeding with the repair work, wear the kind of insulated |

|

|

heat-resistant gloves designed to protect electricians. |

|

|

|

|

|

Take care not to get burned by compressor pipes or other parts when checking the cooling cycle while running |

|

|

the unit as they get heated while running. Be sure to put on gloves providing protection for electric shock and |

|

|

heat. |

|

Cooling check |

|

|

When the service panel of the outdoor unit is to be opened in order for the fan motor, reactor, inverter or the |

||

|

areas around these parts to be repaired immediately after the air conditioner has been shut down, set the circuit |

|

|

breaker to the OFF position, and then wait at least 10 minutes before opening the service panel. |

|

|

If you fail to heed this warning, you will run the risk of burning yourself because the fan motor, reactor, inverter |

|

|

heat sink and other parts will be very hot to the touch. |

|

|

In addition, before proceeding with the repair work, wear the kind of insulated heat-resistant gloves designed to |

|

|

protect electricians. |

|

|

|

9

Only a qualified installer (*1) or qualified service person (*1) is allowed to install the air conditioner. If the air conditioner is installed by an unqualified individual, a fire, electric shocks, injury, water leakage, noise and / or vibration may result.

Before starting to install the air conditioner, read carefully through the Installation Manual, and follow its instructions to install the air conditioner.

Be sure to use the company-specified products for the separately purchased parts. Use of non-specified products may result in fire, electric shock, water leakage or other failure. Have the installation performed by a qualified installer.

Do not supply power from the power terminal block equipped on the outdoor unit to another outdoor unit. Capacity overflow may occur on the terminal block and may result in fire.

Do not install the air conditioner in a location that may be subject to a risk of expire to a combustible gas. If a combustible gas leaks and becomes concentrated around the unit, a fire may occur.

Install the indoor unit at least 2.5 m above the floor level since otherwise the users may injure themselves or Installation receive electric shocks if they poke their fingers or other objects into the indoor unit while the air conditioner is

running.

Install a circuit breaker that meets the specifications in the installation manual and the stipulations in the local regulations and laws.

Install the circuit breaker where it can be easily accessed by the qualified service person (*1).

If you install the unit in a small room, take appropriate measures to prevent the refrigerant from exceeding the limit concentration even if it leaks. Consult the dealer from whom you purchased the air conditioner when you implement the measures. Accumulation of highly concentrated refrigerant may cause an oxygen deficiency accident.

Do not place any combustion appliance in a place where it is directly exposed to the wind of air conditioner, otherwise it may cause imperfect combustion.

Explanations given to user

If you have discovered that the fan grille is damaged, do not approach the outdoor unit but set the circuit breaker to the OFF position, and contact a qualified service person to have the repairs done.

Do not set the circuit breaker to the ON position until the repairs are completed.

Relocation

• Only a qualified installer (*1) or qualified service person (*1) is allowed to relocate the air conditioner.

It is dangerous for the air conditioner to be relocated by an unqualified individual since a fire, electric shocks, injury, water leakage, noise and / or vibration may result.

• When carrying out the pump-down work shut down thecompressor before disconnecting the refrigerant pipe. Disconnecting the refrigerant pipe with the service valve left open and the compressor still operating will cause air, etc. to be sucked in, raising the pressure inside the refrigeration cycle to an abnormally high level, and possibly resulting in reputing, injury, etc.

(*1) Refer to the “Definition of Qualified Installer or Qualified Service Person”

10

|

Declaration of Conformity |

Manufacturer: |

Toshiba Carrier Corporation |

|

336 Tadehara, Fuji-shi, Shizuoka-ken 416-8521 JAPAN |

Authorized Representative / |

Nick Ball |

TCF holder: |

Toshiba EMEA Engineering Director |

|

Toshiba Carrier UK Ltd. |

|

Porsham Close, Belliver Industrial Estate, |

|

PLYMOUTH, Devon, PL6 7DB. |

|

United Kingdom |

Hereby declares that the machinery described below:

Generic Denomination: |

Air Conditioner |

Model / type: |

Indoor unit |

|

<1-way Cassette Type (YH, SH)> |

|

MMU-AP0074YH-E(TR), MMU-AP0094YH-E(TR), MMU-AP0124YH-E(TR), |

|

MMU-AP0154SH-E(TR), MMU-AP0184SH-E(TR), MMU-AP0244SH-E(TR) |

|

<Compact 4-way Cassette Type> |

|

MMU-AP0074MH-E(TR), MMU-AP0094MH-E(TR), MMU-AP0124MH-E(TR), MMU-AP0154MH-E(TR), |

|

MMU-AP0184MH-E(TR) |

|

<Slim Duct Type> |

|

MMD-AP0074SPH-E(TR), MMD-AP0094SPH-E(TR), MMD-AP0124SPH-E(TR), MMD-AP0154SPH-E(TR), |

|

MMD-AP0184SPH-E(TR) |

|

<Concealed Duct Standard Type> |

|

MMD-AP0074BH-E(TR), MMD-AP0094BH-E(TR), MMD-AP0124BH-E(TR), MMD-AP0154BH-E(TR), |

|

MMD-AP0184BH-E(TR), MMD-AP0244BH-E(TR), MMD-AP0274BH-E(TR), MMD-AP0304BH-E(TR), |

|

MMD-AP0364BH-E(TR), MMD-AP0484BH-E(TR), MMD-AP0564BH-E(TR) |

|

<Concealed Duct High Static Pressure Type> |

|

MMD-AP0184H-E(TR), MMD-AP0244H-E(TR), MMD-AP0274H-E(TR), MMD-AP0364H-E(TR), |

|

MMD-AP0484H-E(TR), MMD-AP0724H-E(TR), MMD-AP0964H-E(TR) |

|

<Ceiling Type> |

|

MMC-AP0154H-E(TR), MMC-AP0184H-E(TR), MMC-AP0244H-E(TR), MMC-AP0274H-E(TR), |

|

MMC-AP0364H-E(TR), MMC-AP0484H-E(TR) |

|

<Floor Standing Type> |

|

MMF-AP0154H-E(TR), MMF-AP0184H-E(TR), MMF-AP0244H-E(TR), MMF-AP0274H-E(TR), |

|

MMF-AP0364H-E(TR), MMF-AP0484H-E(TR), MMF-AP0564H-E(TR) |

|

<Floor Standing Concealed Type> |

|

MML-AP0074BH-E(TR), MML-AP0094BH-E(TR), MML-AP0124BH-E(TR), MML-AP0154BH-E(TR), |

|

MML-AP0184BH-E(TR), MML-AP0244BH-E(TR) |

|

<Floor Standing Cabinet Type> |

|

MML-AP0074H-E(TR), MML-AP0094H-E(TR), MML-AP0124H-E(TR), MML-AP0154H-E(TR), |

|

MML-AP0184H-E(TR), MML-AP0244H-E(TR) |

Commercial name: |

Super Modular Multi System Air Conditioner |

|

Super Heat Recovery Multi System Air Conditioner |

|

MiNi-Super Modular Multi System Air Conditioner (MiNi-SMMS series) |

Complies with the provisions of the “Machinery” Directive (Directive 2006/42/EC) and the regulations transposing into national law

Complies with the provisions of the following harmonized standard:

EN 378-2: 2008+A1:2009

NOTE

This declaration becomes invalid if technical or operational modifications are introduced without the manufacturer’s consent.

11

Specifications

Model |

Sound power level (dBA) |

Weight (kg) |

||

Cooling |

Heating |

Main unit (Ceiling panel) |

||

|

||||

MMU-AP0074MH-E |

* |

* |

17 (3) |

|

MMU-AP0094MH-E |

* |

* |

17 (3) |

|

MMU-AP0124MH-E |

* |

* |

17 (3) |

|

MMU-AP0154MH-E |

* |

* |

17 (3) |

|

MMU-AP0184MH-E |

* |

* |

17 (3) |

|

MMU-AP0074YH-E |

* |

* |

22 (3.5) |

|

MMU-AP0094YH-E |

* |

* |

22 (3.5) |

|

MMU-AP0124YH-E |

* |

* |

22 (3.5) |

|

MMU-AP0154SH-E |

* |

* |

21 (5.5) |

|

MMU-AP0184SH-E |

* |

* |

21 (5.5) |

|

MMU-AP0244SH-E |

* |

* |

22 (5.5) |

|

MMD-AP0074BH-E |

* |

* |

28 |

|

MMD-AP0094BH-E |

* |

* |

28 |

|

MMD-AP0124BH-E |

* |

* |

28 |

|

MMD-AP0154BH-E |

* |

* |

32 |

|

MMD-AP0184BH-E |

* |

* |

32 |

|

MMD-AP0244BH-E |

* |

* |

43 |

|

MMD-AP0274BH-E |

* |

* |

43 |

|

MMD-AP0304BH-E |

* |

* |

43 |

|

MMD-AP0364BH-E |

* |

* |

55 |

|

MMD-AP0484BH-E |

* |

* |

55 |

|

MMD-AP0564BH-E |

* |

* |

55 |

|

MMD-AP0184H-E |

* |

* |

50 |

|

MMD-AP0244H-E |

* |

* |

52 |

|

MMD-AP0274H-E |

* |

* |

52 |

|

MMD-AP0364H-E |

* |

* |

56 |

|

MMD-AP0484H-E |

* |

* |

67 |

|

MMD-AP0724H-E |

* |

* |

160 |

|

MMD-AP0964H-E |

70 |

70 |

160 |

|

MMD-AP0074SPH-E |

* |

* |

22 |

|

MMD-AP0094SPH-E |

* |

* |

22 |

|

MMD-AP0124SPH-E |

* |

* |

22 |

|

MMD-AP0154SPH-E |

* |

* |

23 |

|

MMD-AP0184SPH-E |

* |

* |

23 |

|

MMC-AP0154H-E |

* |

* |

22 |

|

MMC-AP0184H-E |

* |

* |

22 |

|

MMC-AP0244H-E |

* |

* |

26 |

|

MMC-AP0274H-E |

* |

* |

26 |

|

MMC-AP0364H-E |

* |

* |

34 |

|

MMC-AP0484H-E |

* |

* |

34 |

|

MML-AP0074H-E |

* |

* |

37 |

|

MML-AP0094H-E |

* |

* |

37 |

|

MML-AP0124H-E |

* |

* |

37 |

|

MML-AP0154H-E |

* |

* |

37 |

|

MML-AP0184H-E |

* |

* |

40 |

|

MML-AP0244H-E |

* |

* |

40 |

|

MML-AP0074BH-E |

* |

* |

21 |

|

MML-AP0094BH-E |

* |

* |

21 |

|

MML-AP0124BH-E |

* |

* |

21 |

|

MML-AP0154BH-E |

* |

* |

29 |

|

MML-AP0184BH-E |

* |

* |

29 |

|

MML-AP0244BH-E |

* |

* |

29 |

|

MMF-AP0154H-E |

* |

* |

48 |

|

MMF-AP0184H-E |

* |

* |

48 |

|

MMF-AP0244H-E |

* |

* |

49 |

|

MMF-AP0274H-E |

* |

* |

49 |

|

MMF-AP0364H-E |

* |

* |

65 |

|

MMF-AP0484H-E |

72 |

72 |

65 |

|

MMF-AP0564H-E |

72 |

72 |

65 |

|

12

Model |

Sound power level (dBA) |

Weight (kg) |

||

|

|

|

||

Cooling |

Heating |

Main unit (Ceiling panel) |

||

|

||||

|

|

|

|

|

MMU-AP0074MH-TR |

* |

* |

17 (3) |

|

MMU-AP0094MH-TR |

* |

* |

17 (3) |

|

MMU-AP0124MH-TR |

* |

* |

17 (3) |

|

MMU-AP0154MH-TR |

* |

* |

17 (3) |

|

MMU-AP0184MH-TR |

* |

* |

17 (3) |

|

MMU-AP0074YH-TR |

* |

* |

22 (3.5) |

|

MMU-AP0094YH-TR |

* |

* |

22 (3.5) |

|

MMU-AP0124YH-TR |

* |

* |

22 (3.5) |

|

MMU-AP0154SH-TR |

* |

* |

21 (5.5) |

|

MMU-AP0184SH-TR |

* |

* |

21 (5.5) |

|

MMU-AP0244SH-TR |

* |

* |

22 (5.5) |

|

MMD-AP0074BH-TR |

* |

* |

28 |

|

MMD-AP0094BH-TR |

* |

* |

28 |

|

MMD-AP0124BH-TR |

* |

* |

28 |

|

MMD-AP0154BH-TR |

* |

* |

32 |

|

MMD-AP0184BH-TR |

* |

* |

32 |

|

MMD-AP0244BH-TR |

* |

* |

43 |

|

MMD-AP0274BH-TR |

* |

* |

43 |

|

MMD-AP0304BH-TR |

* |

* |

43 |

|

MMD-AP0364BH-TR |

* |

* |

55 |

|

MMD-AP0484BH-TR |

* |

* |

55 |

|

MMD-AP0564BH-TR |

* |

* |

55 |

|

MMD-AP0184H-TR |

* |

* |

50 |

|

MMD-AP0244H-TR |

* |

* |

52 |

|

MMD-AP0274H-TR |

* |

* |

52 |

|

MMD-AP0364H-TR |

* |

* |

56 |

|

MMD-AP0484H-TR |

* |

* |

67 |

|

MMD-AP0724H-TR |

* |

* |

160 |

|

MMD-AP0964H-TR |

70 |

70 |

160 |

|

MMD-AP0074SPH-TR |

* |

* |

22 |

|

MMD-AP0094SPH-TR |

* |

* |

22 |

|

MMD-AP0124SPH-TR |

* |

* |

22 |

|

MMD-AP0154SPH-TR |

* |

* |

23 |

|

MMD-AP0184SPH-TR |

* |

* |

23 |

|

MMC-AP0154H-TR |

* |

* |

22 |

|

MMC-AP0184H-TR |

* |

* |

22 |

|

MMC-AP0244H-TR |

* |

* |

26 |

|

MMC-AP0274H-TR |

* |

* |

26 |

|

MMC-AP0364H-TR |

* |

* |

34 |

|

MMC-AP0484H-TR |

* |

* |

34 |

|

MML-AP0074H-TR |

* |

* |

37 |

|

MML-AP0094H-TR |

* |

* |

37 |

|

MML-AP0124H-TR |

* |

* |

37 |

|

MML-AP0154H-TR |

* |

* |

37 |

|

MML-AP0184H-TR |

* |

* |

40 |

|

MML-AP0244H-TR |

* |

* |

40 |

|

MML-AP0074BH-TR |

* |

* |

21 |

|

MML-AP0094BH-TR |

* |

* |

21 |

|

MML-AP0124BH-TR |

* |

* |

21 |

|

MML-AP0154BH-TR |

* |

* |

29 |

|

MML-AP0184BH-TR |

* |

* |

29 |

|

MML-AP0244BH-TR |

* |

* |

29 |

|

MMF-AP0154H-TR |

* |

* |

48 |

|

MMF-AP0184H-TR |

* |

* |

48 |

|

MMF-AP0244H-TR |

* |

* |

49 |

|

MMF-AP0274H-TR |

* |

* |

49 |

|

MMF-AP0364H-TR |

* |

* |

65 |

|

MMF-AP0484H-TR |

72 |

72 |

65 |

|

MMF-AP0564H-TR |

72 |

72 |

65 |

|

13

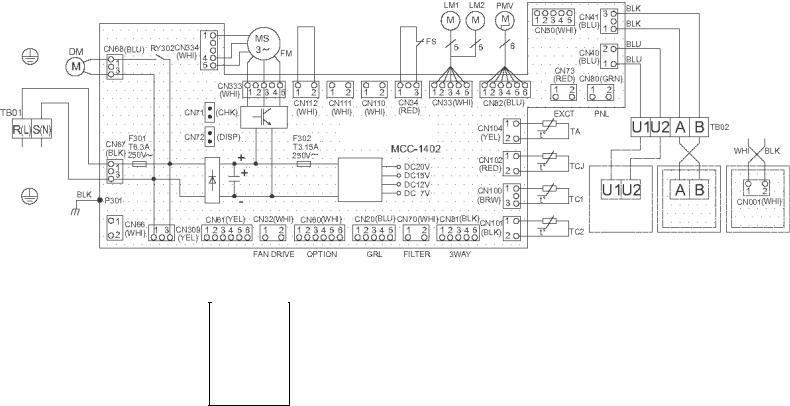

<![endif]>14

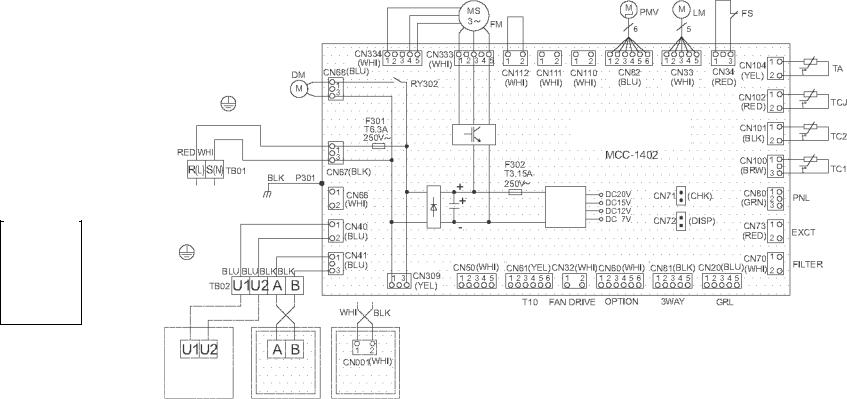

Indoor unit

Earth screw

Power supply 1~50Hz 220-240V 1~60Hz 220V

Flow selector unit

Earth screw

Symbol |

Parts Name |

CN** |

Connector |

|

|

DM |

Drain Pump Motor |

|

|

F301,302 |

Fuse |

|

|

FM |

Fan Motor |

|

|

FS |

Float Switch |

|

|

LM1,2 |

Louver Motor |

|

|

PMV |

Pulse Motor Valve |

|

|

RY302 |

Drain Control Relay |

|

|

TA |

Indoor temp sensor |

|

|

TB01,02 |

Terminal Block |

|

|

TC1,2,TCJ |

Temp sensor |

|

|

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE YEL : YELLOW BLU : BLUE BLK : BLACK GRY : GRAY PNK : PINK ORN : ORANGE BRW : BROWN GRN : GREEN

(High ceiling reshuffling)

Control P.C. Board

for Indoor Unit

Power supply circuit

Outdoor unit

Wired Remote |

Adapter for |

Controller |

Wireless |

|

Remote |

|

Controller |

1.Broken line indicate the wiring at site.

Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the control P.C. board.

indicates the connector on the control P.C. board.

3. indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

| <![if ! IE]> <![endif]>E(TR),-AP0124MH E(TR),-AP0094MH E(TR),-AP0074MH-MMU Models: E(TR)-AP0184MH |

<![if ! IE]> <![endif]>type cassette way-4 Compact .1-1 |

| <![if ! IE]> <![endif]>E(TR),-AP0154MH |

|

<![endif]>Diagrams Wiring 1

<![endif]>15

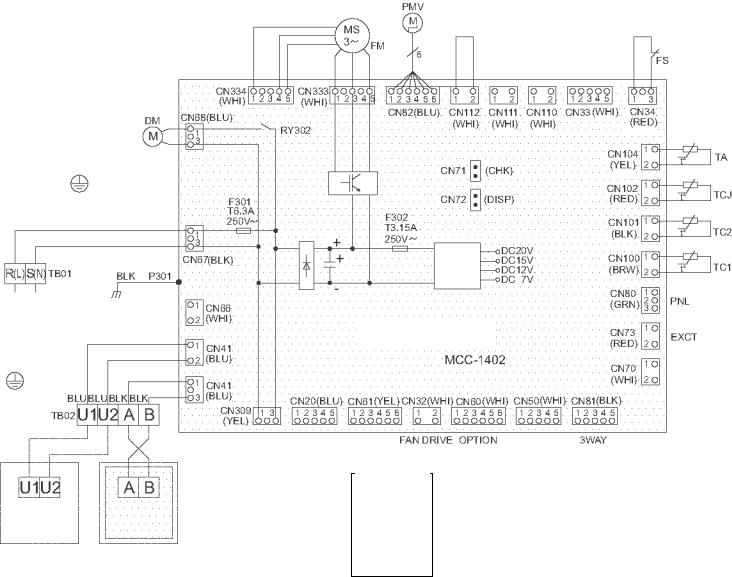

1.Broken line indicate the wiring at site.

Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the control P.C. board.

indicates the connector on the control P.C. board.

3. indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Symbol |

Parts Name |

|

|

CN** |

Connector |

|

|

DM |

Drain Pump Motor |

|

|

F301,302 |

Fuse |

|

|

FM |

Fan Motor |

|

|

FS |

Float Switch |

|

|

LM |

Louver Motor |

|

|

PMV |

Pulse Motor Valve |

|

|

RY001 |

Louver Control Relay |

|

|

RY002 |

Drain Control Relay |

|

|

RY005,006,007 |

Fan Motor Control Relay |

|

|

TA |

Indoor temp sensor |

|

|

TB01,02 |

Terminal Block |

|

|

TC,TCJ |

Temp sensor |

|

|

TR |

Transformer |

|

|

Flow selector unit

Earth screw

Power supply 1~50Hz 220-240V 1~60Hz 220V

Indoor unit

Earth screw

Line Filter

Outdoor unit

Remote Controller

Power supply circuit

Sub P.C. Board

Control P.C. Board

for Indoor Unit

| <![if ! IE]> <![endif]>E(TR)-AP0124YH E(TR),-AP0094YH E(TR),-AP0074YH-MMU Models: |

<![if ! IE]> <![endif]>YH) type (compact type cassette way-1 .2-1 |

<![endif]>16

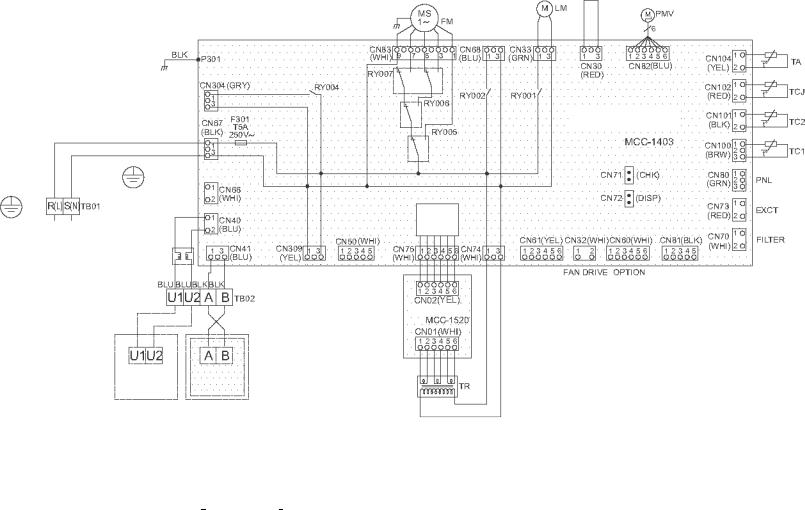

Symbol |

Parts Name |

|

CN** |

Connector |

|

|

|

|

DM |

Drain Pump Motor |

|

|

|

|

F301,302 |

Fuse |

|

|

|

|

FM |

Fan Motor |

|

|

|

|

FS |

Float Switch |

Flow selector unit |

|

|

|

LM |

Louver Motor |

Earth screw |

PMV |

Pulse Motor Valve |

|

|

|

|

RY302 |

Drain Control Relay |

|

|

|

|

TA |

Indoor temp sensor |

|

|

|

|

TB01,02 |

Terminal Block |

|

|

|

|

TC1,2,TCJ |

Temp sensor |

|

|

|

|

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE YEL : YELLOW BLU : BLUE BLK : BLACK GRY : GRAY PNK : PINK ORN : ORANGE BRW : BROWN GRN : GREEN

Power supply 1~50Hz 220-240V 1~60Hz 220V

Indoor unit

Earth screw

Outdoor unit

Wired Remote |

Adapter for |

Controller |

Wireless Remote |

|

Controller |

(High ceiling reshuffling)

Control P.C. Board

for Indoor Unit

Power supply circuit

1.Broken line indicate the wiring at site.

Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the control P.C. board.

indicates the connector on the control P.C. board.

3. indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

| <![if ! IE]> <![endif]>E(TR),-AP0184SH E(TR),-AP0154SH-MMU Models: |

<![if ! IE]> <![endif]>(SH) type cassette way-1 .3-1 |

| <![if ! IE]> <![endif]>E(TR)-AP0244SH |

|

<![endif]>17

1.Broken line indicate the wiring at site.

Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the control P.C. board.

indicates the connector on the control P.C. board.

3. indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

Flow selector unit

Earth screw

Reactor

Power supply 1~50Hz 220-240V 1~60Hz 220V

Indoor unit

Earth screw

Outdoor unit

Wired Remote |

Adapter for |

Controller |

Wireless Remote |

|

Controller |

(High ceiling reshuffling)

Control P.C. Board

for Indoor Unit

Power supply circuit

Symbol |

Parts Name |

|

|

CN** |

Connector |

|

|

DM |

Drain Pump Motor |

|

|

F301,302 |

Fuse |

|

|

FM |

Fan Motor |

|

|

FS |

Float Switch |

|

|

PMV |

Pulse Motor Valve |

|

|

RY302 |

Drain Control Relay |

|

|

TA |

Indoor temp sensor |

|

|

TB01,02 |

Terminal Block |

|

|

TC1,2,TCJ |

Temp sensor |

|

|

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE YEL : YELLOW BLU : BLUE BLK : BLACK GRY : GRAY PNK : PINK ORN : ORANGE BRW : BROWN GRN : GREEN

| <![if ! IE]> <![endif]>E(TR),-AP0154BH E(TR),-AP0124BH E(TR),-AP0094BH E(TR),-AP0074BH-MMD Models: E(TR),-AP0304BH E(TR),-AP0274BH E(TR),-AP0244BH E(TR),-AP0184BH E(TR)-AP0564BH E(TR),-AP0484BH E(TR),-AP0364BH |

<![if ! IE]> <![endif]>type standard duct Concealed .4-1 |

<![endif]>18

|

Symbol |

Parts Name |

|

|

|

|

43F1,F2 |

Fan motor Control Relay |

|

|

|

|

CN** |

Connector |

|

|

|

|

F |

Fuse |

|

|

|

|

F301 |

Fuse |

|

|

|

|

FM |

Fan Motor |

|

|

|

|

PMV |

Pulse Motor Valve |

|

|

|

|

RC |

Running Capacitor |

|

|

|

|

RY002 |

Drain Control Relay |

|

|

|

|

RY005,006,007 |

Fan Motor Control Relay |

|

|

|

|

TA |

Indoor temp sensor |

|

|

|

|

TB01,02,03 |

Terminal Block |

|

|

|

|

TC1,2,TCJ |

Temp sensor |

|

|

|

|

TR |

Transformer |

|

|

|

Sold |

DM |

Drain Pump Motor |

Separately |

FS |

Float Switch |

|

|

|

1.Broken line indicate the wiring at site. Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the

indicates the connector on the

control P.C. board.

3.  indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

5.When installing the drain pump connect the froat switch connector to CN30 connector.

6. position is connected to terminal block when change to static pressure.

position is connected to terminal block when change to static pressure.

Exchange the lead wire of arrow (  ) position after check the terminal number as figure and lead wire's color of fan motor.

) position after check the terminal number as figure and lead wire's color of fan motor.

7.Be careful when modify the static pressure, the static pressure of high tap is different by 50Hz or 60Hz.

Control P.C. Board

for Indoor Unit

Power supply circuit

Line Filter

Sub P.C. Board

Outdoor

unit

Flow selector unit

Earth screw Remote Controller

Indoor unit Earth screw

Power supply 1~50Hz 220-240V 1~60Hz 220V

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

When drain pump is installed

Terminal |

Fan motor wiring(MMD-) |

Static |

|

No. |

AP0484 |

AP0184~AP0364 |

pressure tap |

|

|

|

|

F1 |

BLU(50/60Hz) |

Low tap |

|

|

|

|

|

F2 |

ORN(50/60Hz) |

Middle tap |

|

|

|

|

|

F3 |

BLK(60Hz) |

BLK(50/60Hz) |

High tap |

|

|

|

|

F4 |

BRW(50Hz) |

— |

High tap |

|

|

|

|

(Refer tha static pressure specifications for each tap.)

Fan motor inside wiring diagram (exp.)

Motor over heating protection switch

Wired for MMD-AP0484H-E only

Brown color wire.

| <![if ! IE]> <![endif]>AP0364H E(TR),-AP0274H E(TR),-AP0244H E(TR),-AP0184H-MMD Models: E(TR)-AP0484H |

<![if ! IE]> <![endif]>type pressure static high duct Concealed .5-1 |

| <![if ! IE]> <![endif]>E(TR),- |

|

<![endif]>19

|

Symbol |

Parts Name |

|

|

|

|

43F1,F2 |

Fan motor Control Relay |

|

|

|

|

CN** |

Connector |

|

|

|

|

F1,2,3 |

Fuse for Fan Motor |

|

|

|

|

F301 |

Fuse |

|

|

|

|

FM |

Fan Motor |

|

|

|

|

PMV |

Pulse Motor Valve |

|

|

|

|

RC |

Running Capacitor |

|

|

|

|

RY002 |

Drain Control Relay |

|

|

|

|

RY005,006,007 |

Fan Motor Control Relay |

|

|

|

|

TA |

Indoor temp sensor |

|

|

|

|

TB01,02,03, |

Terminal Block |

|

04,05,06 |

|

|

|

|

|

|

|

|

TC1,2,TCJ |

Temp sensor |

|

|

|

|

TR |

Transformer |

|

|

|

Sold |

DM |

Drain Pump Motor |

Separately |

FS |

Float Switch |

|

|

|

1.Broken line indicate the wiring at site. Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the control P.C. board.

indicates the connector on the control P.C. board.

3. indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

5.When installing the drain pump connect the froat switch connector to CN30 connector.

6. position is connected to terminal block when change to static pressure.

position is connected to terminal block when change to static pressure.

Exchange the lead wire of arrow (  ) position after check the terminal number as figure and lead wire's color of fan motor.

) position after check the terminal number as figure and lead wire's color of fan motor.

7.Be careful when modify the static pressure, the static pressure of high tap is different by 50Hz or 60Hz.

Terminal |

Fan motor |

Static pressure |

Note |

|

No. |

wiring |

Pa (mmAq) |

||

|

||||

|

|

|

|

|

F1 |

YEL |

69(7) |

|

|

|

|

|

|

|

F2 |

BLU |

137(14) |

Setting from factory |

|

|

|

|

|

|

F3 |

ORN |

196(20) |

|

|

|

|

|

|

Flow selector unit

Earth screw

Indoor unit

Earth screw

Power supply 1~50Hz 220-240V 1~60Hz 220V

When drain pump is installed

Control P.C. Board

for Indoor Unit

Power supply circuit

Line Filter

Sub P.C. Board

Fan motor inside wiring diagram

Outdoor

unit

Remote

Controller

Motor over heating

protection switch

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

<![endif]>E(TR)-AP0964H E(TR),-AP0724H-MMD Models:

<![endif]>20

(High ceiling reshuffling)

Flow selector unit

Earth screw

Power supply circuit

Power supply 1~50Hz 220-240V

1~60Hz 220V

Control P.C. Board for Indoor Unit

Indoor unit

Earth screw

|

Symbol |

Parts Name |

|

|

CN** |

Connector |

|

|

|

|

|

|

DM |

Drain Pump Motor |

|

|

|

|

|

Outdoor unit |

F301,302 |

Fuse |

|

|

|

||

|

FM |

Fan Motor |

|

|

|

|

|

|

FS |

Float Switch |

|

|

|

|

|

Wired Remote |

RY302 |

Drain Control Relay |

|

Controller |

|

|

|

TA |

Indoor temp sensor |

||

|

|||

|

|

|

|

|

TB01,02 |

Terminal Block |

|

|

|

|

|

|

TC1,2,TCJ |

Temp sensor |

|

|

|

|

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE YEL : YELLOW BLU : BLUE BLK : BLACK GRY : GRAY PNK : PINK ORN : ORANGE BRW : BROWN GRN : GREEN

1.Broken line indicate the wiring at site. Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.

indicates the connection terminal.

indicates the connector on the control P.C. board.

indicates the connector on the control P.C. board.

3. indicates the protection ground.

indicates the protection ground.

4.  indicates the control P.C. board.

indicates the control P.C. board.

| <![if ! IE]> <![endif]>AP0094SPH E(TR),-AP0074SPH-MMD Models: E(TR)-AP0184SPH E(TR),-AP0154SPH |

<![if ! IE]> <![endif]>type duct Slim .6-1 |

| <![if ! IE]> <![endif]>E(TR),-AP0124SPH E(TR),- |

|

Flow selector unit

Earth screw

Indoor unit Power supply Earth screw

1~50Hz 220-240V 1~60Hz 220V

<![if ! IE]><![endif]>21

Outdoor unit |

|

|

|

|

|

Remote Controller |

|

|

|

|

|

|

Symbol |

Parts Name |

|

|

|

|

|

|

CN** |

Connector |

|

|

|

|

|

|

F301,302 |

Fuse |

|

|

|

|

|

|

FM |

Fan Motor |

|

|

|

|

|

|

LM |

Louver Motor |

|

|

|

|

|

|

PMV |

Pulse Motor Valve |

|

|

|

|

|

|

RY302 |

Drain Control Relay |

|

|

|

|

|

|

TA |

Indoor temp sensor |

|

|

|

|

|

|

TB01,02 |

Terminal Block |

|

|

|

|

|

|

TC1,2,TCJ |

Temp sensor |

|

|

|

|

|

Sold |

DM |

Drain Pump Motor |

|

Separately |

FS |

Float Switch |

|

|

|

|

|

Adapter for Wireless

Remote Controller

COLOR

IDENTIFICATION

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

When drain (High ceiling pump is installed reshuffling)

Control P.C. Board for

Indoor Unit

Power supply circuit

1.Broken line indicate the wiring at site. Long dashed short dashed line indicate the accessories.

2. indicates the terminal block.

indicates the terminal block.

indicates the connection terminal.