Toshiba MJ-1101 User Manual

TOSHIBA

MJ-1101 Service Manual Addendum

Supplement to the Tr oubleshooting Section

TOSHIBA

Index

Er r or Code |

P age |

EA20 |

1,2,3,4,13,14 |

EA40 |

5,13,14 |

EA60/CC30 |

6,7,8,9 |

EA70 /CC41 |

6,7,8,9,13,14 |

EAEO |

10 |

CB31 |

11,12 |

*Recommended Lubr icant |

Molykote EM-30L - 6LE36904000 |

i

Error code |

Phenomenon |

Possible cause |

Items to confirm / Countermeasures |

Precautions / Remarks |

||

|

|

|

|

|

|

|

EA20 |

- Paper jams at the |

1. Improper installation height |

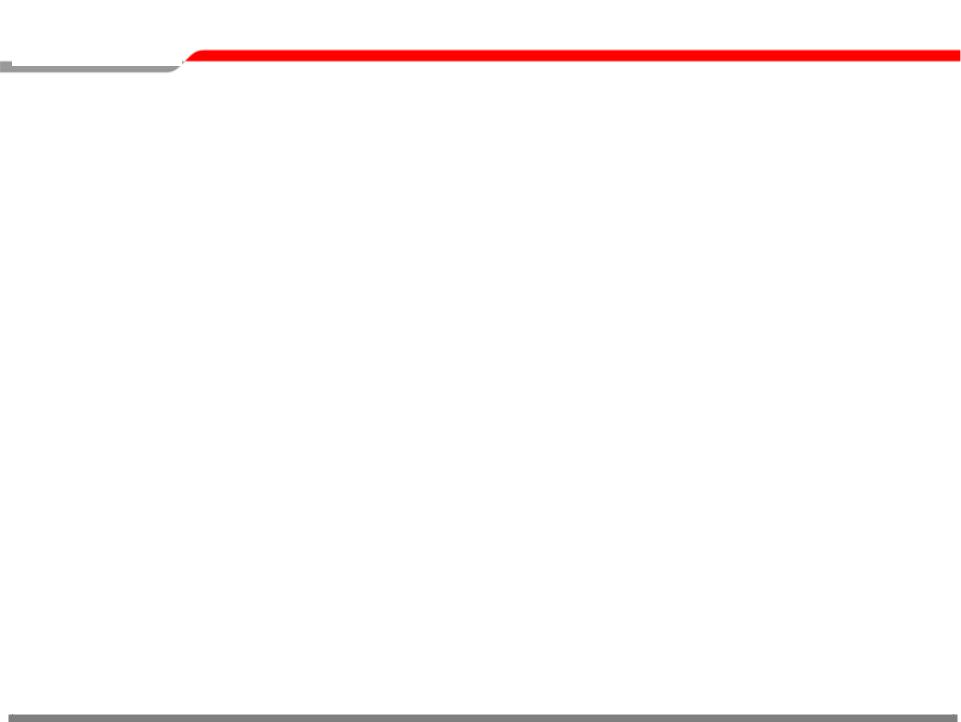

A. Confirm that the Finisher is installed horizontally (the height of its front side and that of its rear side are the |

- Note that the height should be different between the cases when the Finisher |

||

|

entrance section of |

|

same). |

is installed in e-STUDIO281c/351c/451c and when installed in e- |

||

|

the Finisher (or the |

(Paper is not properly transported |

|

|

|

STUDIO352/452 or e-STUDIO2500c/3500c/3510c. |

|

Hole Punch Unit) |

from the equipment to the |

|

The length of the arrows should be the same. |

|

- Confirm the height every time you move the equipment. |

|

|

Finisher if each height is |

|

|

|

|

|

- Folded paper edge |

|

|

|

|

|

|

|

|

|

|

||

|

improper.) |

|

|

|

|

|

-Paper jams C2in the buffer tray section

-C2Paper exit problems on the finishing tray

B. To keep the installation height of the Finisher stable, it is preferable that the casters are faced to the equipment side.

Caster

quipment side

C. When installing the Finisher in the equipment, make sure that the height of the Finisher is proper. If it is not, the

Bridge Unit exit Mylar may be deformed, and thus the deformed Mylar may obstruct the paper transport path.

Improper |

|

case |

Installation height |

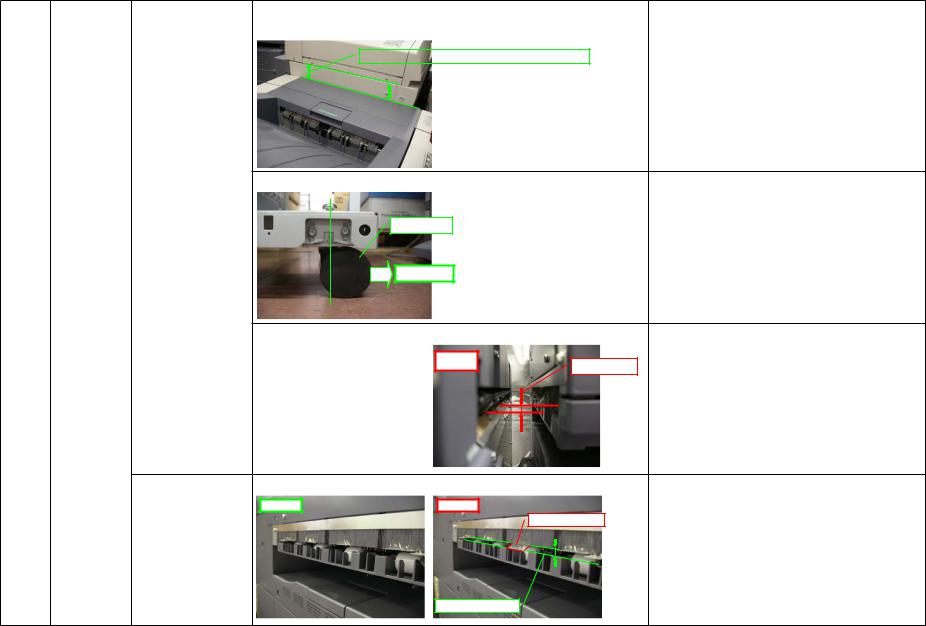

2. Bridge Unit exit Mylar deformed Check if the Mylar attached to the exit of the Bridge Unit is deformed and obstructing the paper transport path. Correct it if deformed.

Normal |

Abnormal |

Deformed Mylar

Note that the height should be different between the cases when the Finisher is installed in e-STUDIO281c/351c/451c and when installed in e- STUDIO352/452 or e-STUDIO2500c/3500c/3510c.

Paper transport path

Error code Phenomenon |

Possible cause |

Items to confirm / Countermeasures |

Precautions / Remarks |

|

|

|

|

EA20 |

- Paper jams at the |

3. Improper connection between |

When the Hole Punch Unit is installed, check if the connection point is shifted forward or backward. |

|

|

entrance section of |

the equipment and the Hole |

|

|

|

the Finisher (or the |

Punch Unit |

Normal |

Abnormal |

|

Hole Punch Unit) |

|

||

|

|

|

|

|

(Paper is not properly transported - Folded paper edge from the equipment to the Hole

Punch Unit if they are not

-Paper jams C2in the connected correctly.) buffer tray section

-C2Paper exit

problems on the finishing tray

|

|

|

Hole Punch Unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

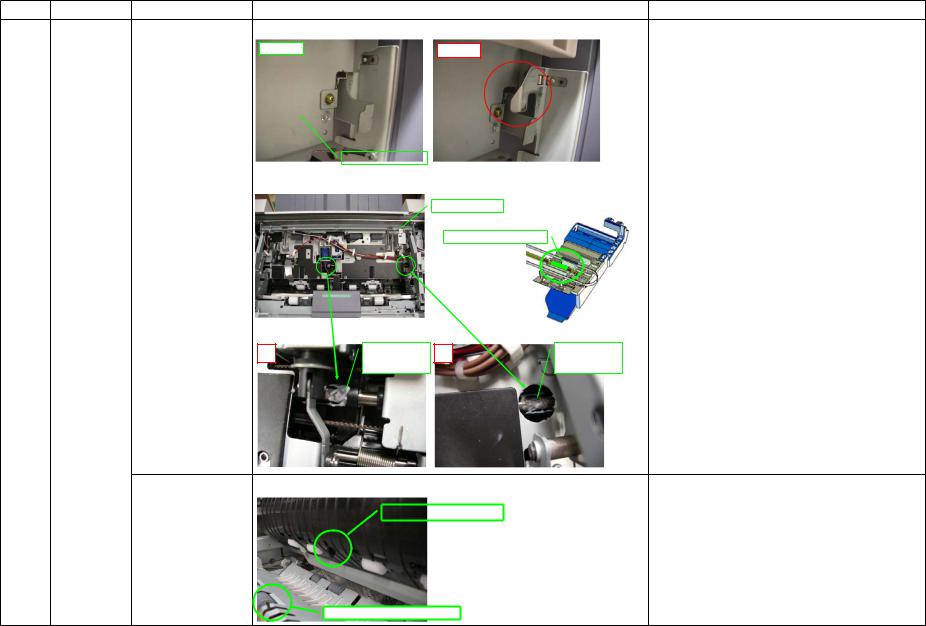

4. False operation of the buffer |

Remove the stationary tray and apply grease "Molykote EM-30L" (the size of 5 grains of rice) to the buffer guide |

||||||||

guide |

shaft. |

||||||||

(Paper jams may occur if the load |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Buffer roller |

|

|

|

|

|

|

|

|

|

|

|

|

|

is applied to the buffer guide |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

during its opening or closing |

|

|

|

|

|

|

|

|

|

movement.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Buffer guide shaft |

|

||

|

|

|

|

|

|

|

|

||

|

Molykote EM-30L |

|

Molykote EM-30L |

a: Slide the buffer guide to the center and lubricate between the shafts of the |

|

front buffer guide. |

|||||

(the size of 5 |

(the size of 5 |

||||

|

|

||||

|

|

b: Slide the buffer guide forward or backward and lubricate between the shafts |

|||

|

grains of rice) |

|

grains of rice) |

||

|

|

of the rear buffer guide. |

|||

|

|

|

|

||

|

|

|

|

* Be sure to lift up the buffer roller before sliding the guide. |

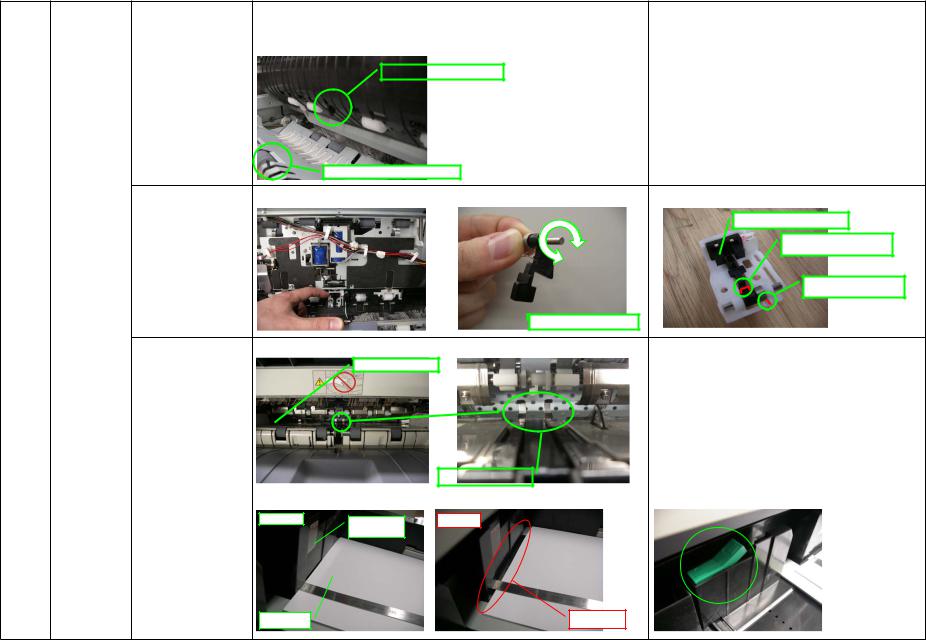

5. False operation of the entrance |

A. Check if the wires of the entrance sensor or the transport sensor are being caught or short circuited, or any of |

|

||

sensor or the transport sensor |

their connectors is disconnected. |

|

||

(An error may occur when the |

|

|

|

If the entrance sensor does not retract quickly, replace the spring |

|

Transport sensor actuator |

|

||

entrance sensor or the transport |

|

|

||

|

|

|

with a new one P/N 6LB09015000 SPG-FEED-SNSR-1. |

|

sensor does not perform proper |

|

|

|

|

|

|

|

|

|

detection.) |

|

|

|

|

Entrance sensor actuator

Error code |

Phenomenon |

Possible cause |

Items to confirm / Countermeasures |

Precautions / Remarks |

||

|

|

|

|

|

|

|

EA20 |

- Paper jams at the |

5. False operation of the entrance |

B. Check if the actuators of the entrance sensor and the transport sensor are operating smoothly. If they are not, |

|

||

|

entrance section of |

sensor or the transport sensor |

remove the actuator and check if there is any paper dust or foreign matter between the shaft and the hole. Clean if |

|

||

|

the Finisher (or the |

|

there is. |

|

||

|

Hole Punch Unit) |

(An error may occur when the |

|

|

|

|

|

|

entrance sensor or the transport |

|

|

|

|

|

|

|

Transport sensor actuator |

|

|

|

|

- Folded paper edge |

sensor does not perform proper |

|

|

|

|

|

|

detection.) |

|

|

|

|

|

|

|

|

|

|

|

-Paper jams C2in the buffer tray section

-C2Paper exit problems on the finishing tray

Entrance sensor actuator

Operation check of the transport sensor actuator: Rotate the shaft slowly. If the actuator is not rotated together, its operation is normal.

Transport sensor actuator

Hook this to the actuator.

Hook this onto the bracket.

Transport sensor actuator

6. False operation of the paper Replace SPG-SFFD-SUPT-SF (6LB090140) if the paper exit guide is not operating properly. exit guide

Finishing tray

(An error may occur when the paper exit guide is not operating properly because paper may remain on the finishing tray or not exit properly during sort or stapling exit.)

|

Paper exit guide |

|

|

|

|

|

|

|

7. Paper not placed properly in |

|

Be sure to lock the side wall. |

the drawer |

|

|

(Paper may be skewed if there is |

Normal |

Abnormal |

extra gap between the paper and |

|

Side wall |

|

|

|

the side wall in the drawer and |

|

|

thus may cause a jam on the |

|

|

Finisher transport path.) |

|

|

Paper |

Gap |

Error code |

Phenomenon |

Possible cause |

Items to confirm / Countermeasures |

|

Precautions / Remarks |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

EA20 |

- Paper jams at the |

8. Drive not transmitted from the |

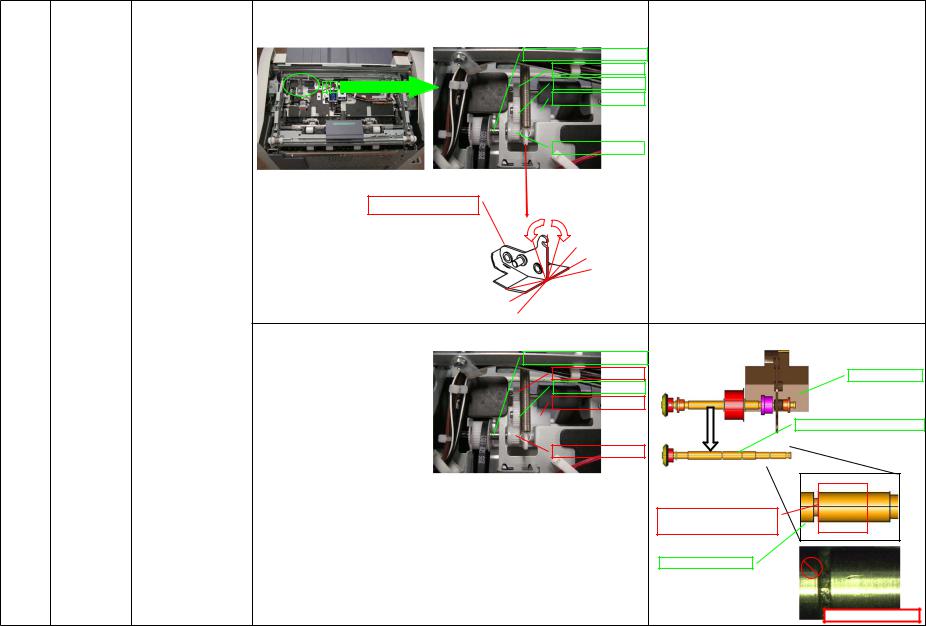

A. Check if there is any rattling on ASYS-LVR-E-RLR-BUF. If there is, replace ASYB-SFT-EXT-RLR-DRV-BUF, |

|

|

|||||||

|

entrance section of |

gear in the paper transport |

ASYS-LVR-E-RLR-BUF, GEAR-IDLER-EXT-BUF, GEAR1-EXT-RLR-BUF and GEAR2-EXT-RLR-BUF. |

|

|

|||||||

|

the Finisher (or the |

section |

|

|

|

|

|

|

|

|

|

|

|

Hole Punch Unit) |

|

|

|

|

|

|

|

ASYB-SFT-EXT-RLR-DRV-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Folded paper edge |

|

|

|

|

|

|

|

|

GEAR1-EXT-RLR-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Paper jams C2in the |

|

|

|

|

|

|

|

|

GEAR-IDLER-EXT-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASYS-LVR-E-RLR-BUF |

|

|

|

|

buffer tray section |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- C2Paper exit |

|

|

|

|

|

|

|

|

|

|

|

|

problems on the |

|

|

|

|

|

|

|

|

|

|

|

|

finishing tray |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GEAR2-EXT-RLR-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Check that there is no rattling. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

B. Check if the gear teeth of GEAR-IDLER-EXT-BUF, GEAR1-EXT-RLR-BUF and GEAR2-EXT-RLR-BUF mesh |

|

When replacing, be sure not to scratch the shaft (ASYB-SFT-EXT-RLR-DRV- |

|

||||||

correctly. If any of them does not mesh correctly, replace ASYB-SFT-EXT-RLR-DRV-BUF, ASYS-LVR-E-RLR- |

|

BUF). |

|

||||||

BUF, GEAR-IDLER-EXT-BUF, GEAR1-EXT-RLR-BUF or GEAR2-EXT-RLR-BUF. |

|

|

|

|

|

|

|

||

|

ASYB-SFT-EXT-RLR-DRV-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GEAR1-EXT-RLR-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LVR-E-RLR-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GEAR-IDLER-EXT-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASYS-LVR-E-RLR-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASYB-SFT-EXT-RLR-DRV-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GEAR2-EXT-RLR-BUF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Do not scratch this area.

SFT-EXT-RLR-DRV-BUF

Scratch on the shaft

Loading...

Loading...