Toshiba MMY-MAP1202FT8, MMY-MAP1002FT8, MMY-MAP0802FT DATA BOOK

Super-HRM

(2 series)

Super Heat Recovery Multi System

Engineering

Data Book

1

1

The engineering data book details all specific data, charts

and drawings to enable you to get the best performance

from the Toshiba Super Heat Recovery Multi System (2 Se-

ries) for the various different applications.

The information is aimed to assist you with greater detail of

the system and the wider applications that the system will

cover.

It is recommended the use of the data book is used in accor-

dance with the following as references.

Design manual : File No.A04-017

Installation manual : File No.A05-018

Foreword

Foreword

1

2

2

2

Foreword

Contents

1 Forward

....................................................................

1

2 Contents

.....................................................................

2

3 Introduction

.................................................................

3

4 System overview

.........................................................

7

5 Capacity compensation chart

.....................................

17

6 Piping requirements

..................................................

25

7 Refrigerant cycle diagram

..........................................

31

8 Sensible capacity table

..............................................

43

9 Part load performance

...............................................

69

10 Wiring guideline

........................................................

81

11 Wiring diagram

..........................................................

89

12 Controls

..................................................................

107

13 Fan characteristics

..................................................

129

14 Sound characteristics (NC curve)

.............................

139

15 Dimensional drawing

...............................................

155

1. Indoor units

2. Outdoor units

3. FS units

4. Branch header/Branch joint

16 Specifications

..........................................................

191

Appendix

High Wall Type (2 series)

1-Way Air Discharge Cassette Type (2 series)

Slim Duct Type

3

Introduction

3

4

5

Suction gas

Discharge gas

Liquid

3

3

Foreword

Introduction

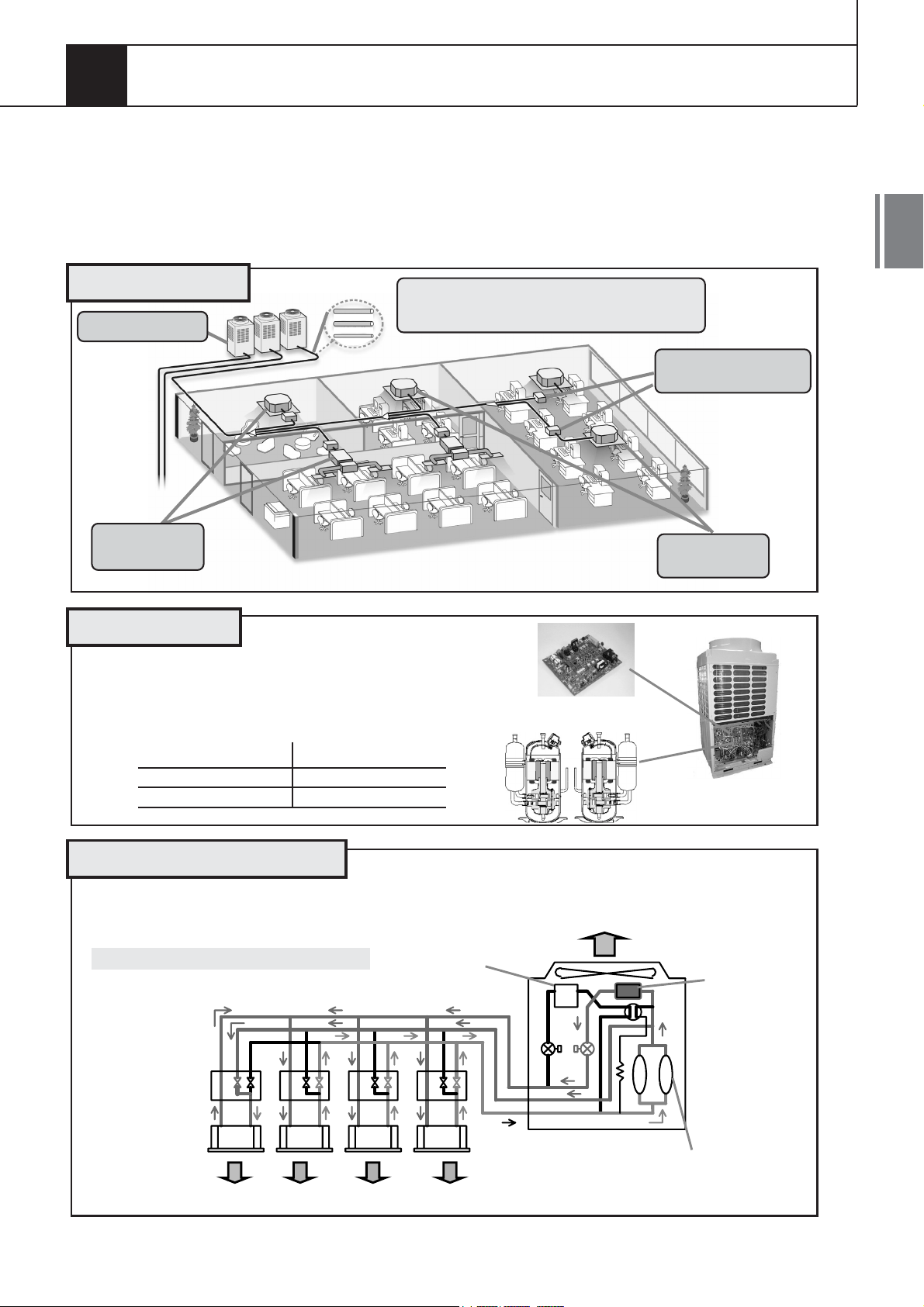

The World's Best Technology for Energy Saving, Heat Recovery VRF

Toshiba is proud to introduce the Super HRM system, 3pipe heat recovery VRF operating

on R410A. Incorporating advanced technology in all aspects of efficiency,

durability, flexibility and comfort. Super HRM will meet various different site applications.

System Outline

Energy saving

Simultaneous Operation

No.1 COP in heat recovery VRF industry.

DC twin rotary compressors are most congenial with R410A

and are used within the outdoor units. All compressors are

driven by a High-speed Calculation Vector Control Inverter.

10HP System

3.45

By control of the FS unit, Super HRM enables simultaneous operation of cooling and heating.

Super HRM also improves the energy efficiency by the recycling of exhaust heat.

Main Heat

Exchanger Sub-Heat

Exchanger

Compressor

Outdoor unit

FS unit

Indoor unit

Heating

Cooling Cooling Cooling

Outdoor unit

DC Twin Rotary

Compressor

High-speed Calculation

Vector Control Inverter

Outdoor unit

FS unit

(Flow Selector unit)

Indoor unit

(Heating)

Indoor unit

(Cooling)

3 pipe

(Discharge gas / Suction gas / Liquid)

Ex. Mainly Cooling, Partly Heating Operation

Average COP

8HP System

Super-HRM(R410A)

3.83

6

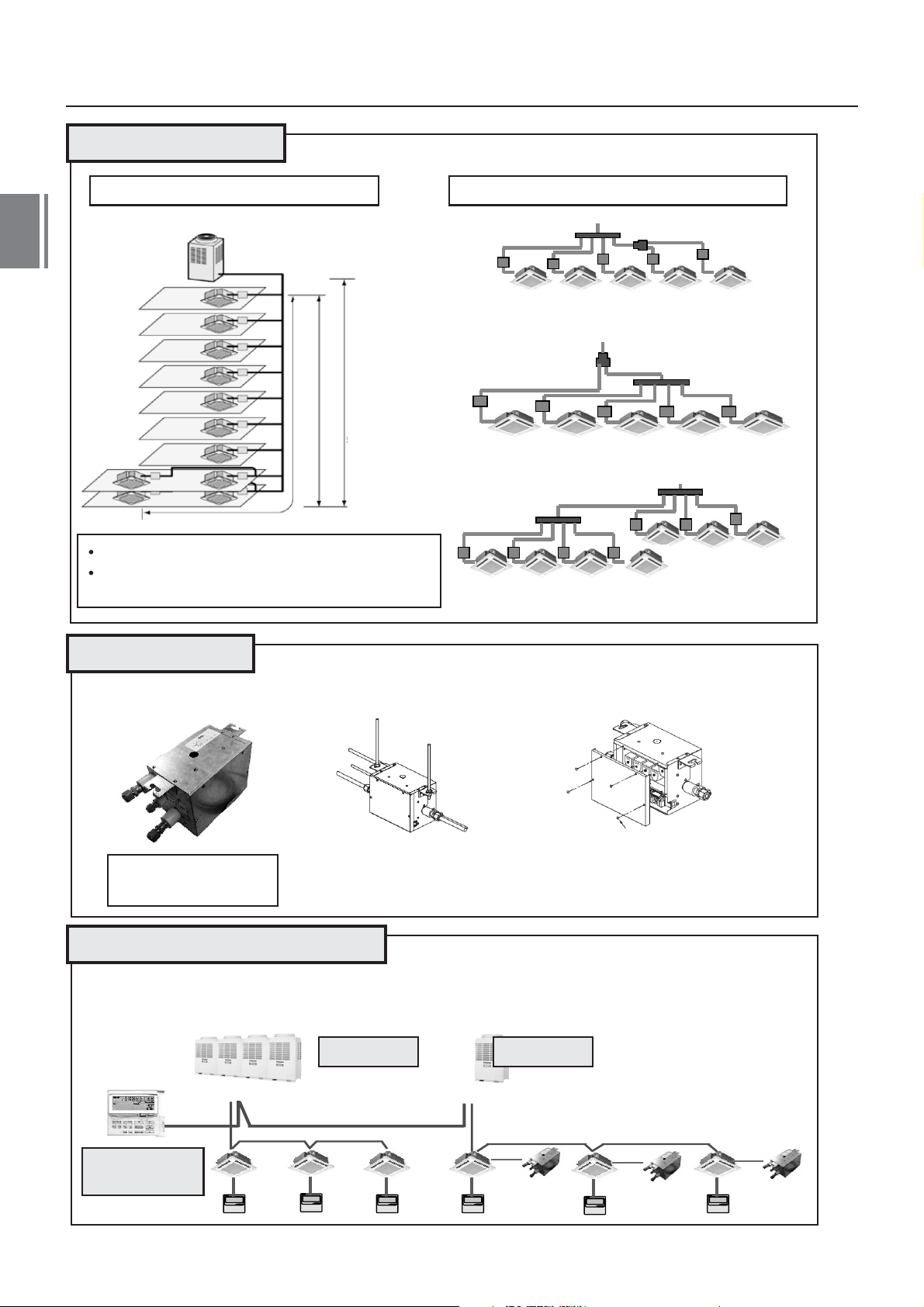

Design Flexibility

Piping flexibility

Y Branch after header branch

(Toshiba unique technology)

FS Unit Design

The compact and light weight design of the FS unit(Flow Selector Unit)allows it to be easily

installed within a limited space.

Centralized Control System

Flexibile Joint Combination

Header branch after Y joint

Header after header branch

(Toshiba unique technology)

Equivalent piping length

Up to 125m

Elevation between indoor units = 35m(No.1!)

Furthest piping length from 1st branch

= 50m(No.1!)

50m (from 1st branching)

35m (elevation between FCU)

50m (Elevation between CDU and FCU)

190H x 250W x 160D

5kg

Easy of hanging

(Only 2 hangers)

Easy maintenance

(Valve coil and P.C. board are

on the same side)

Central remote

controller

Super MMS Super HRM

By using the central control devices, individual control of indoor units is possible throughout

multiple systems. Centralized control systems with Super MMS can also be integrated with Build-

ing Management System (BMS).

3

7

4

System overview

8

9

4

4

Foreword

System overview

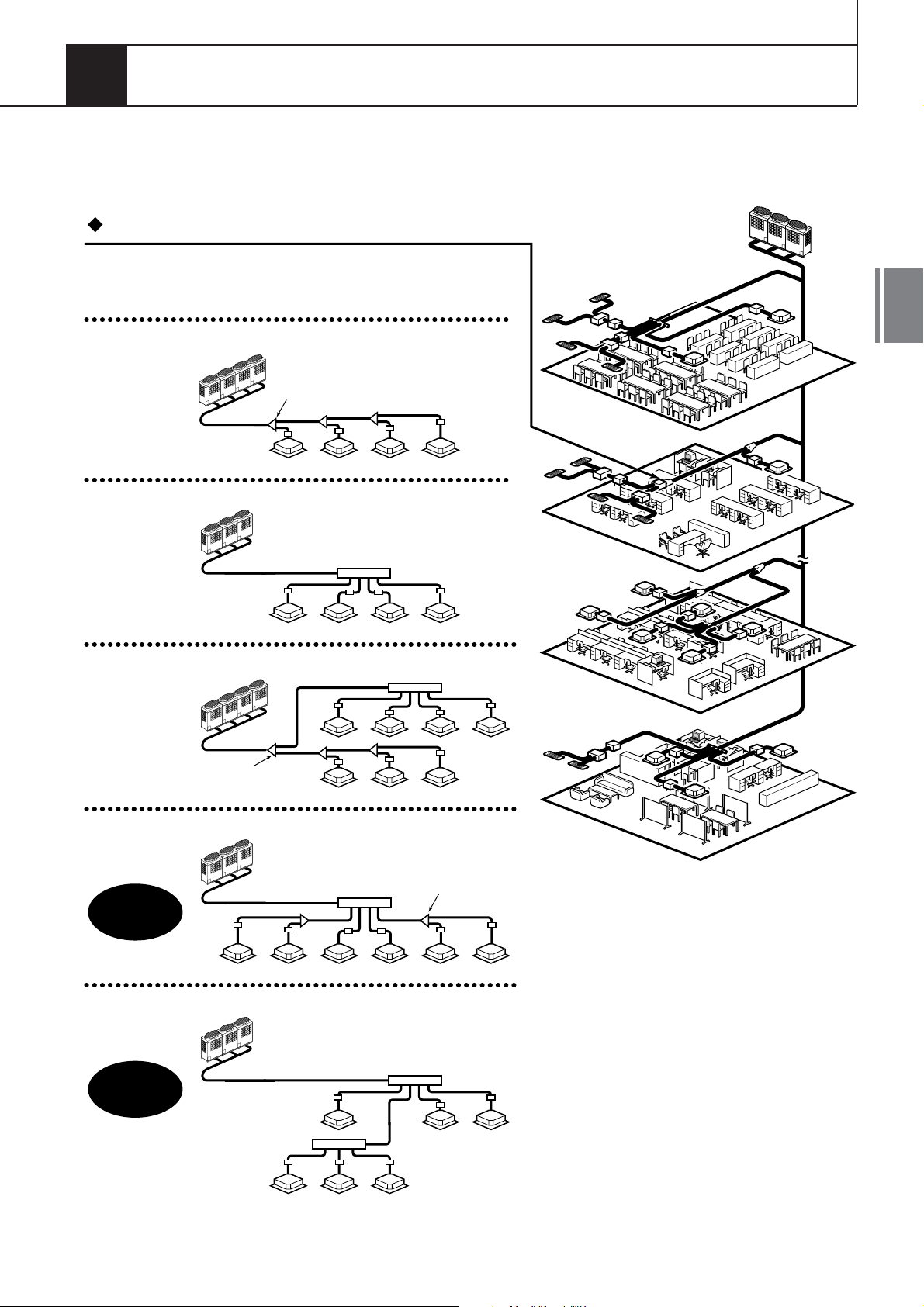

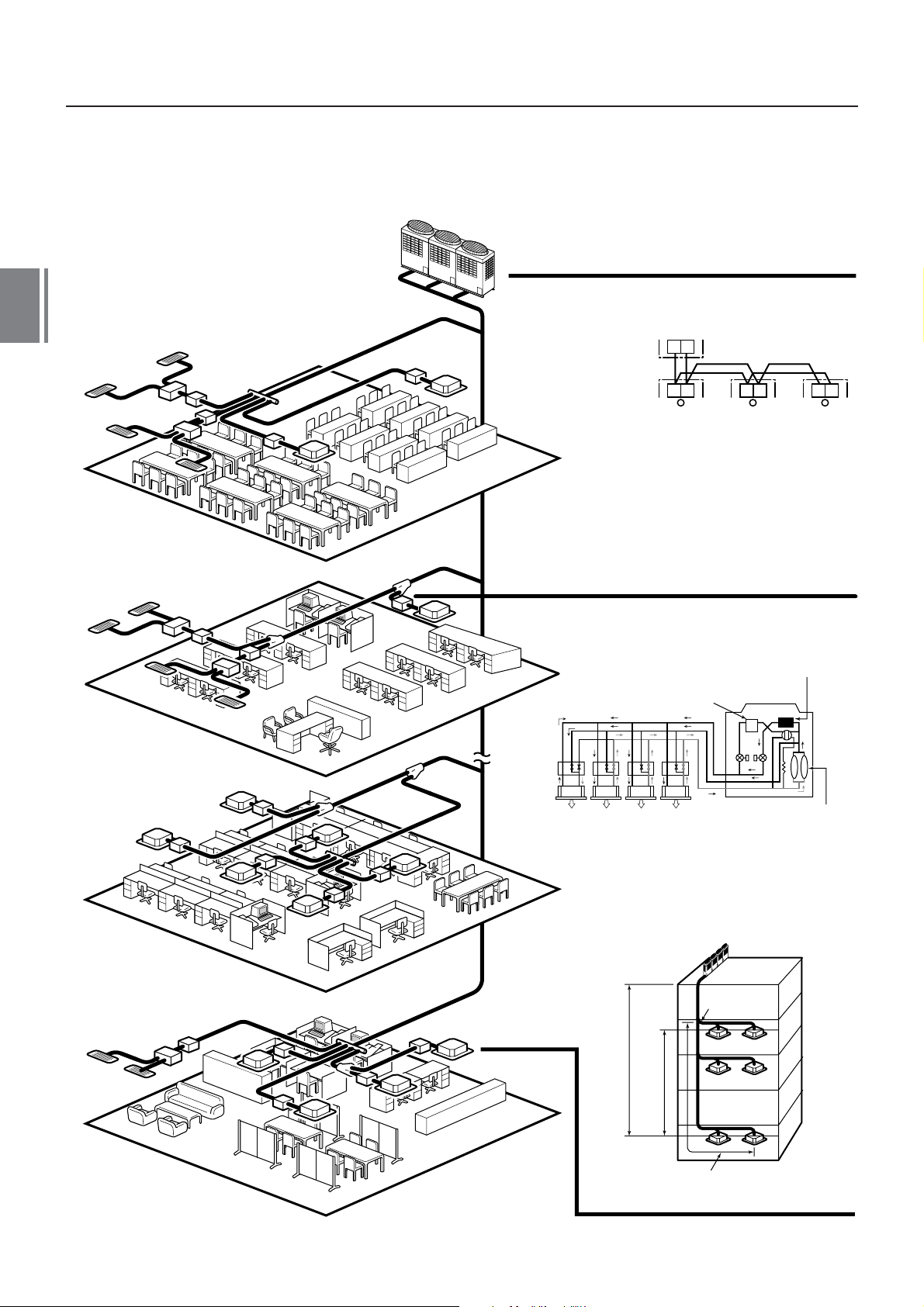

1. OUTLINE OF TOSHIBA SUPER HRM

(Super Heat Recovery Multi System)

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

Indoor

unit

Indoor unit

Indoor unit

Indoor unit

Branching joint

Branching joint

Branching joint

Branching

header

Header

Header

Header

Header

MMS Only

Super HRM

Only

Super HRM

Only

8F

7F

2F

1F

FS unit

FS unit

FS

unit

FS unit

FS unit

Shortest route design by free branching

The Combination of line and header branching is highly flexible.

This follows for the shortest design route possible, thereby saving

on installation time and cost. Line/header branching after the

header branching is only available with TOSHIBA Super HRM.

Line branching

Header branching

Line + Header branching

Header branching after header branching

Line branching after header branching

10

4

U1 U2

U1 U2 U1 U2 U1 U2

8F

7F

2F

1F

Non-polarized control wiring

between outdoor and indoor units

Outdoor unit

Indoor unit

main heat exchanger

Sub heat exchanger

FS unit

Indoor

unit

Compressor

Simultaneous operation

Heating Cooling Cooling Cooling

Allowable pipe length :

150m equivalent length

Outdoor unit

Outdoor

unit

1st branching

section

From 1st branching to the

furthest indoor unit : 50m

Height difference between indoor

unit and outdoor unit : 50m

Height difference between indoor

unit and indoor unit : 35m

11

4

Energy saving

No.1 COP in heat recovery VRF industry.Compared with the conventional chiller fan coil system,

a large energy saving can be achieved.

Advanced bus communication system

Wiring between indoor and outdoor units is a simple 2 core wire system.

Communication of addresses is also automatically configured.

A default test mode operation is available.

Self diagnostics system

Comprehensive troubleshooting codes allows for a timely identification of possible problems arising.

High lift and flexible piping design

Equivalent pipe length of 150m and vertical lift of 50m is possible with TOSHIBA Super HRM.

Vertical lift between indoor units of 35m is the highest in the industry.

Also the maximum piping length from the 1st branch is 50m.

This allows for greater flexibility within the building design of the system.

Simultaneous operation

By controlling the FS unit, Super HRM enables simultaneous operation of cooling and heating.

This operation meets the various requirements of modern buildings that are highly airtight or have

an increasing heat load due to the use of computers. Super HRM also improves energy efficiency by

recycling of the exhaust heat.

Extended outdoor temperature operating range

By use of sophisticated system control with inverter driven compressors, the operating range

in cooling has been increased from -5

to -10 .

Compact FS unit design

The compact and light weight design of the FS unit (Flow selector unit) allows it to be easily

installed with in a limited space.

Group control by one FS unit

Up to 8 indoor units can be group controlled by the use of only one FS unit, this gives greater flexibility for

various different types and sizes of rooms.

Intelligent control

TOSHIBA Super HRM intelligent controls and modulating valves deliver the required capacity

according to the load variation from 50% to 100%.

The intelligent controls and modulating valves limit or increase the cooling capacity dynamically so

humidity and temperature are kept within the comfort zone.

Conforms to building control law

IAQ (Indoor Air Quality) is also achieved by combining various accessories required by the Building

Control Law.

Wide control applications

Artificial Intelligence Network system.

Central control and monitoring system available.

Weekly schedule operation through weekly timer.

Integration with Building Management System (BMS) is available.

12

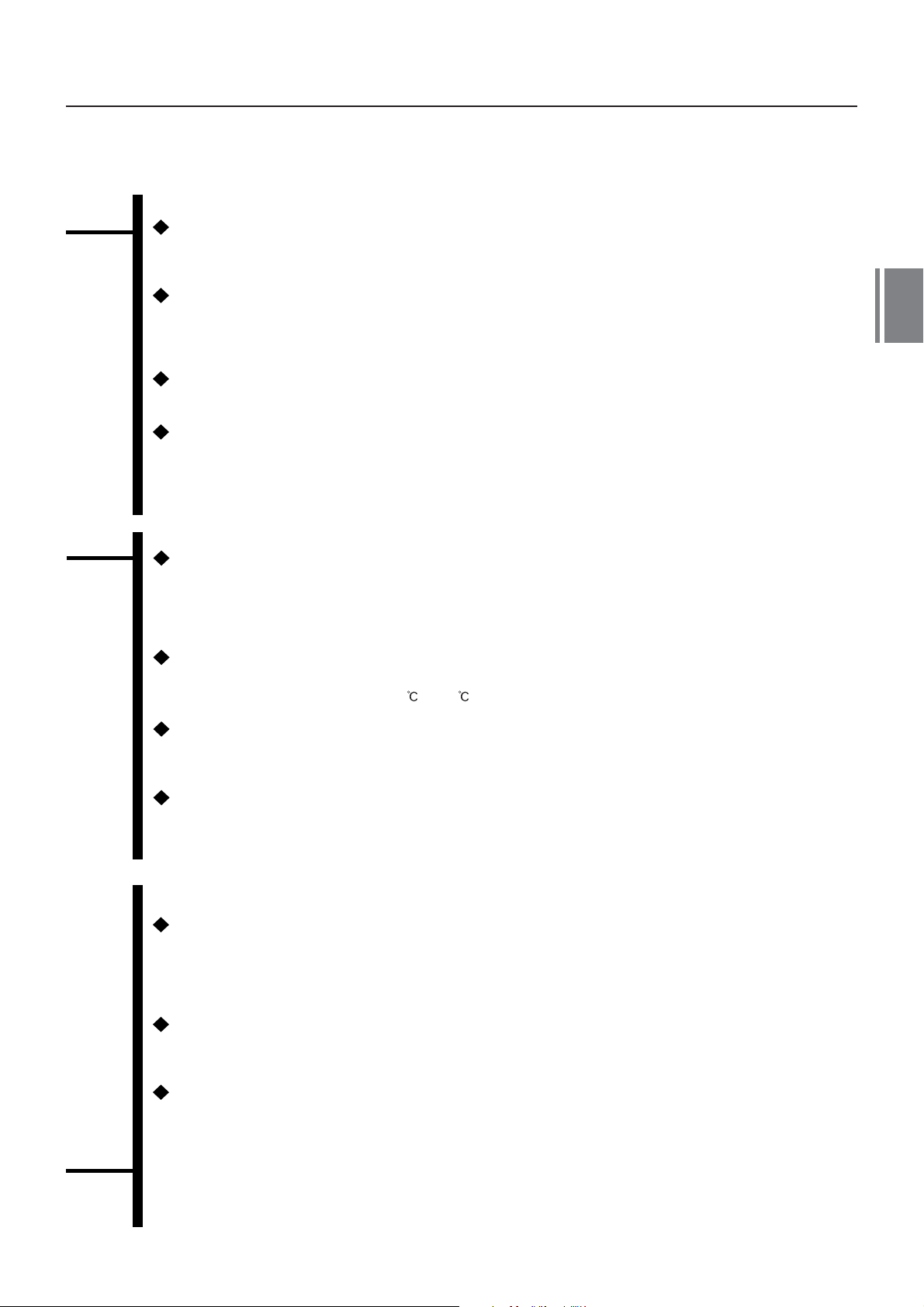

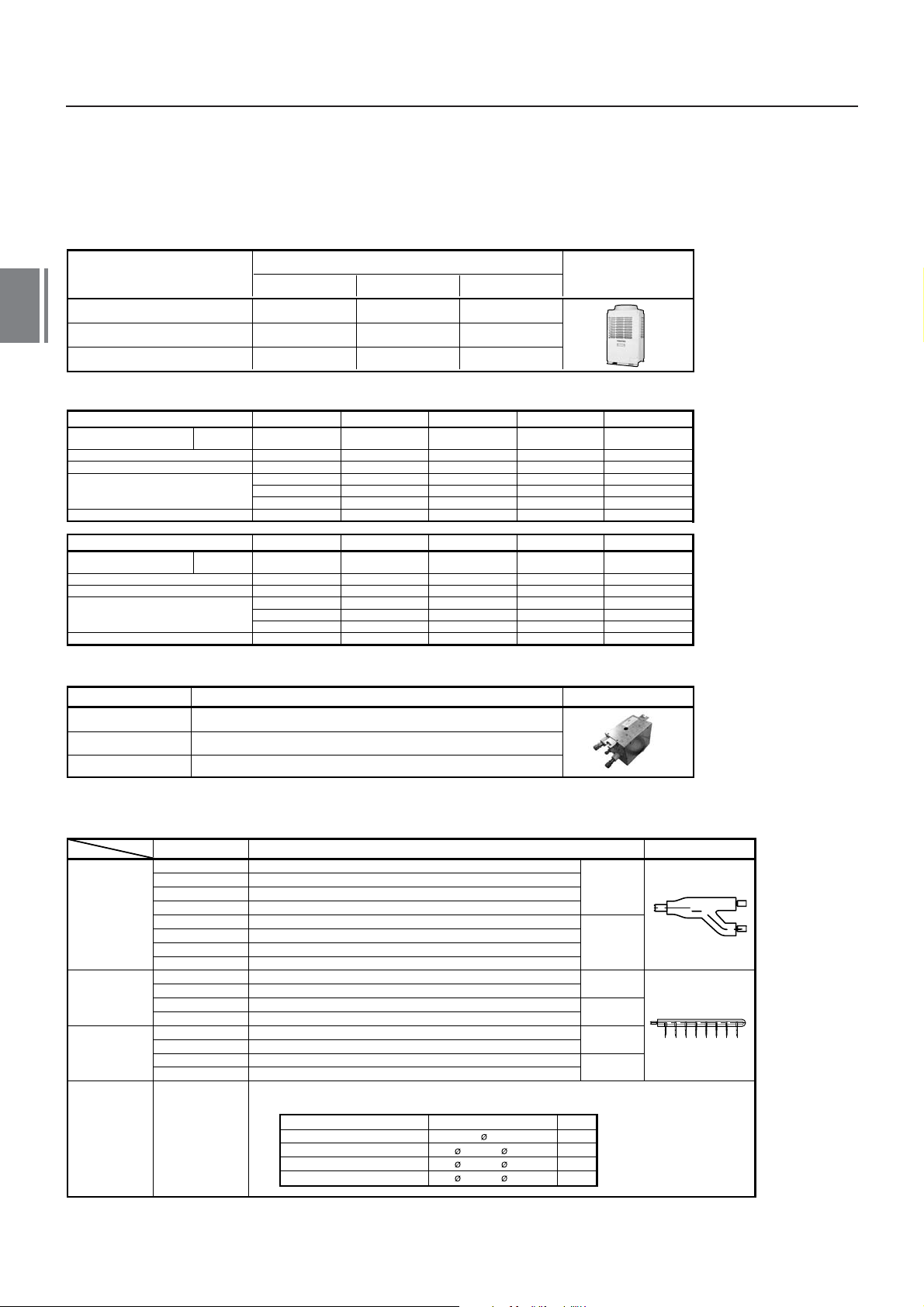

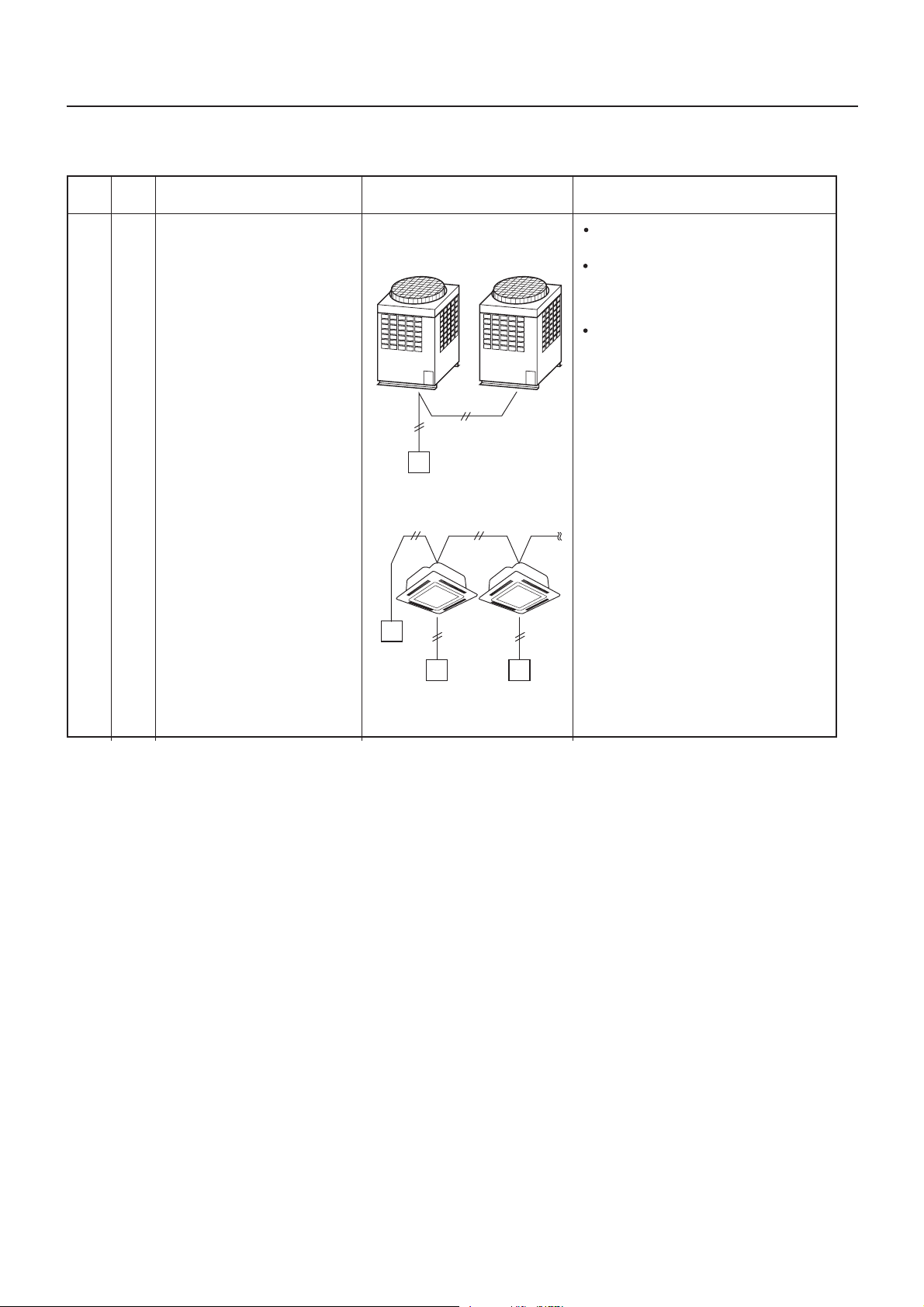

2. SUMMARY OF SYSTEM EQUIPMENTS

Equipment

2. Outdoor units (Combination of outdoor units)

3. FS units (Flow selector units)

4. Branching joints and headers

Corresponding HP

Inverter unit

Appearance

8HP

MAP0802FT8

22.4

25.0

10HP

MAP1002FT8

28.0

31.5

12HP

MAP1202FT8

33.5

35.5

Model name MMY-

Cooling capacity (kW)

Heating capacity (kW)

Corresponding HP

8HP 10HP

MAP0802FT8

22.4

25

8HP

13

Combined model

Cooling capacity (kW)

Heating capacity (kW)

Combined outdoor units

No. of connectable indoor units

MMY-

MAP1002FT8

28

31.5

10HP

16

MAP1202FT8

33.5

35.5

12HP

16

12HP

AP1602FT8

45

50

8HP

8HP

27

16HP

AP1802FT8

50.4

56.5

10HP

8HP

30

18HP

Corresponding HP

20HP 24HP

AP2002FT8

56

63

10HP

10HP

33

Combined model

Cooling capacity (kW)

Heating capacity (kW)

Combined outdoor units

No. of connectable indoor units

MMY-

68

76.5

8HP

8HP

8HP

40

AP2602FT8

73

81.5

10HP

8HP

8HP

43

26HP

AP2802FT8

78.5

88

10HP

10HP

8HP

47

28HP

AP3002FT8

84

95

10HP

10HP

10HP

48

30HP

Model name

RBM-Y1122FE

RBM-Y1802FE

RBM-Y2802FE

Total capacity for indoor unit : Below 11.2 kw

Total capacity for indoor unit : 11.2 to below 18.0 kw

Total capacity for indoor unit : 18.0 to 28.0 kw or less

Usage Appearance

Y-shape

branching

joint (*3)

4-branching

header (*4) (*5)

8-branching

header (*4) (*5)

T-shape

branching

joint (For

connection

of outdoor

units)

RBM-BY53FE

RBM-BY103FE

RBM-BY203FE

RBM-BY303FE

RBM-BY53E

RBM-BY103E

RBM-BY203E

RBM-BY303E

RBM-HY1043FE

RBM-HY2043FE

RBM-HY1043E

RBM-HY2043E

RBM-HY1083FE

RBM-HY2083FE

RBM-HY1083E

RBM-HY2083E

Indoor unit capacity code (*1) : Total below 6.4

Indoor unit capacity code (*1) : Total 6.4 or more and below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

Indoor unit capacity code (*1) : Total 25.2 or more

Indoor unit capacity code (*1) : Total below 6.4

Indoor unit capacity code (*1) : Total 6.4 or more and below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

Indoor unit capacity code (*1) : Total 25.2 or more

Indoor unit capacity code (*1) : Total below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

Indoor unit capacity code (*1) : Total below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

Indoor unit capacity code (*1) : Total below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

Indoor unit capacity code (*1) : Total below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

For 3

piping

For 2

piping (*6)

For 3

piping

For 2

piping (*6)

For 3

piping

For 2

piping (*6)

Appearance

Model name Usage

RBM-BT13FE

Connection piping

Balance pipe

Piping at liquid side

Piping at discharge gas side

Piping at suction gas side

Corresponded dia. (mm)

9.5

12.7 to 22.2

19.1 to 28.6

22.2 to 38.1

1

1

1

1

Q'ty

*1 ``Capacity code`` can be obtained from page 8. (Capacity code is not actual capacity)

*2 If total capacity code value of indoor unit exceeds that of outdoor unit, apply capacity code of outdoor unit.

*3 When using Y-shape branching joint for 1st branching, select according to the capacity code of outdoor unit.

*4 Max. capacity code of 6.0 in total can be connected.

*5 If capacity code of outdoor unit is 26 or more, it is not used for the 1st branching.

*6 This is used for branching to ``cooling only`` indoor unit.

*7 Model names for outdoor and indoor units described in this guide are shortened because of the space constraint.

*Accessory part (Sold separately): Connection cable kit (RBC-CBK15FE) up to 15m.

1. Outdoor units

1 set 4 types T-shape joint pipes as described below:

The required quantity is arranged and they are combined on site.

4

AP2402FT8

13

4

50Hz

Super Heat Recovery Multi System Outdoor Unit

HP (Capacity

code)

Model name

MMY-

No. of

combined

units

Inverter

8 HP

MMY-

Used

Qty

Inverter

10 HP

MMY-

Used

Qty

Used

Qty

Inverter

12 HP

MMY-

8HP ( 8)

10HP (10)

12HP (12)

16HP (16)

18HP (18)

20HP (20)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

MAP0802HT8

MAP1002HT8

MAP1202HT8

1

1

1

2

2

2

MAP0802FT8

MAP0802FT8

MAP0802FT8

MAP0802FT8

MAP0802FT8

MAP0802FT8

1

2

1

3

2

1

1

1

2

1

2

3

1

MAP1002FT8

MAP1002FT8

MAP1002FT8

MAP1002FT8

MAP1002FT8

MAP1002FT8

MAP1202FT8*

*

12HP unit is for stand-alone use only.

Outdoor unit combination with a 12HP unit is not available.

1. Allocation standard of model name

2. Rated conditions (Rated mode : Condition)

Cooling : Indoor air temperature 27 DB/19 WB, Outdoor air temperature 35 DB

Heating : Indoor air temperature 20

DB, Outdoor air temperature 7 DB/6 WB

3. Compatibility with 1 Series

FS unit

1 Series

RBM-Y***1E

2 Series

RBM-Y***2E

Oudoor unit MMY-

1 Series

-MAP**1FT8

OK

OK

2 Series*

-MAP**2FT8

NG

OK

* 2 series outdoor units cannot be used with 1 series outdoor units.

MMY- M AP T 8F

Power supply specifications, 3 380-415 V, 50Hz ....... 8

T : Capacity variable unit

F : Heat recovery

Development series No.

Capacity rank HP x 10

New refrigerant R410A

M : Single module unit, No mark : Combined Model name

Modular Multi

14

4

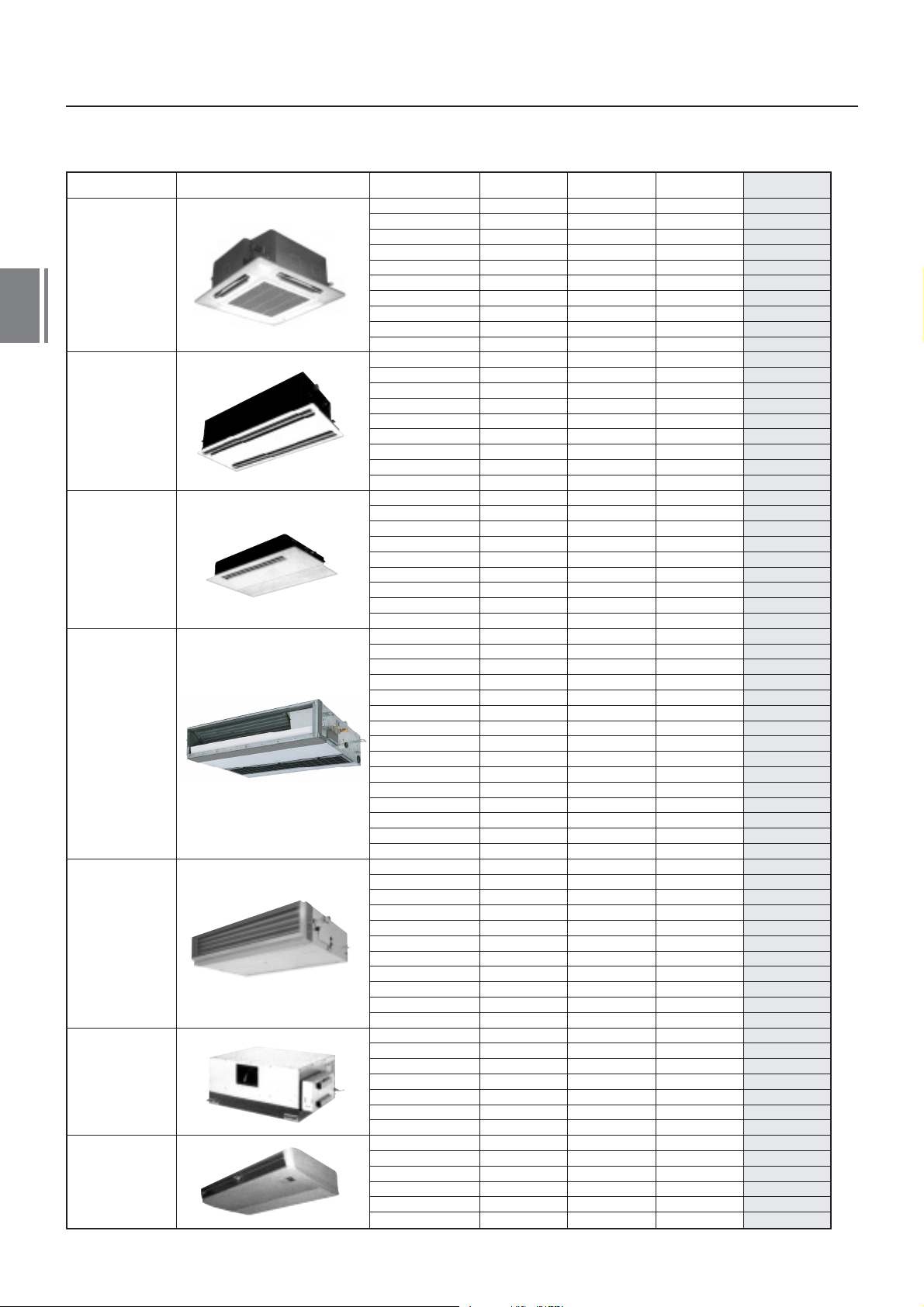

4. Indoor unit

Type Appearance Model name Capacity rank Capacity code

Cooling

capacity (kW)

Heating

capacity (kW)

4-way Air Discharge

Cassette Type

2-way Air Discharge

Cassette Type

1-way Air Discharge

Cassette Type

Slim Duct Type

Concealed Duct

Standard Type

Concealed Duct

High Static

Pressure Type

Under Ceilling Type

MMU-AP0091H

MMU-AP0121H

MMU-AP0151H

MMU-AP0181H

MMU-AP0241H

MMU-AP0271H

MMU-AP0301H

MMU-AP0361H

MMU-AP0481H

MMU-AP0561H

MMU-AP0071WH

MMU-AP0091WH

MMU-AP0121WH

MMU-AP0151WH

MMU-AP0181WH

MMU-AP0241WH

MMU-AP0271WH

MMU-AP0301WH

MMU-AP0481WH*

1)

MMU-AP0071YH

MMU-AP0091YH

MMU-AP0121YH

MMU-AP0151SH

MMU-AP0181SH

MMU-AP0241SH

MMU-AP0152SH

MMU-AP0182SH

MMU-AP0242SH

MMD-AP0071SPH

MMD-AP0091SPH

MMD-AP0121SPH

MMD-AP0151SPH

MMD-AP0181SPH

MMD-AP0071SPH(SH)-C

*

1)

MMD-AP0091SPH(SH)-C

*

1)

MMD-AP0121SPH(SH)-C

*

1)

MMD-AP0151SPH(SH)-C

*

1)

MMD-AP0181SPH(SH)-C

*

1)

MMD-AP0071SPH-K

*

3)

MMD-AP0091SPH-K

*

3)

MMD-AP0121SPH-K

*

3)

MMD-AP0151SPH-K

*

3)

MMD-AP0181SPH-K

*

3)

MMD-AP0071BH

MMD-AP0091BH

MMD-AP0121BH

MMD-AP0151BH

MMD-AP0181BH

MMD-AP0241BH

MMD-AP0271BH

MMD-AP0301BH

MMD-AP0361BH

MMD-AP0481BH

MMD-AP0561BH

MMD-AP0181H

MMD-AP0241H

MMD-AP0271H

MMD-AP0361H

MMD-AP0481H

MMD-AP0721H

MMD-AP0961H

MMC-AP0151H

MMC-AP0181H

MMC-AP0241H

MMC-AP0271H

MMC-AP0361H

MMC-AP0481H

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

056 type

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

048 type

007 type

009 type

012 type

015 type

018 type

024 type

015 type

018 type

024 type

007 type

009 type

012 type

015 type

018 type

007 type

009 type

012 type

015 type

018 type

007 type

009 type

012 type

015 type

018 type

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

056 type

018 type

024 type

027 type

036 type

048 type

072 type

096 type

015 type

018 type

024 type

027 type

036 type

048 type

1.00

1.25

1.70

2.00

2.50

3.00

3.20

4.00

5.00

6.00

0.8

1.00

1.25

1.70

2.00

2.50

3.00

3.20

5.00

0.80

1.00

1.25

1.70

2.00

2.50

1.70

2.00

2.50

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

2.50

3.00

3.20

4.00

5.00

6.00

2.00

2.50

3.00

4.00

5.00

8.00

10.00

1.70

2.00

2.50

3.00

4.00

5.00

2.8

3.6

4.5

5.6

7.1

8.0

9.0

11.2

14.0

16.0

2.2

2.8

3.6

4.5

5.6

7.1

8.0

9.0

14.0

2.2

2.8

3.6

4.5

5.6

7.1

4.5

5.6

7.1

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

7.1

8.0

9.0

11.2

14.0

16.0

5.6

7.1

8.0

11.2

14.0

22.4

28.0

4.5

5.6

7.1

8.0

11.2

14.0

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

16.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

6.3

8.0

9.0

10.0

16.0

25.0

31.5

5.0

6.3

8.0

9.0

12.5

16.0

*1) China market only *2) European market only *3) Korea market only

15

4

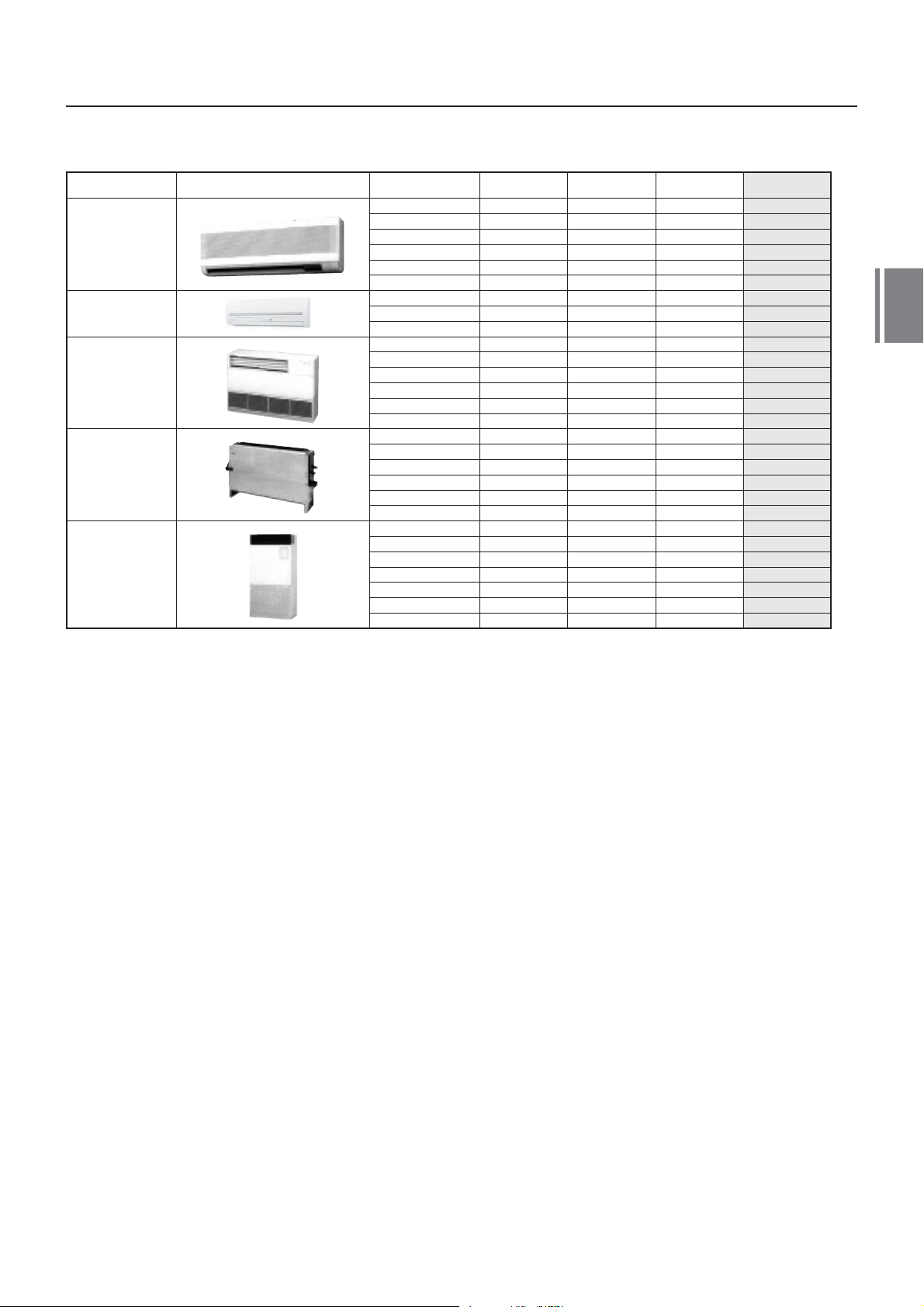

Type Appearance Model name Capacity rank Capacity code

Cooling

capacity (kW)

Heating

capacity (kW)

Floor Standing

Cabinet Type

Floor Standind

Concealed Type

Floor Standind Type

*1) China market only *2) European market only

MMK-AP0071H

MMK-AP0091H

MMK-AP0121H

MMK-AP0151H

MMK-AP0181H

MMK-AP0241H

MMK-AP0072H*

2)

MMK-AP0092H*

2)

MMK-AP0122H*

2)

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MMF-AP0151H

MMF-AP0181H

MMF-AP0241H

MMF-AP0271H

MMF-AP0361H

MMF-AP0481H

MMF-AP0561H

007 type

009 type

012 type

015 type

018 type

024 type

007 type

009 type

012 type

007 type

009 type

012 type

015 type

018 type

024 type

007 type

009 type

012 type

015 type

018 type

024 type

015 type

018 type

024 type

027 type

036 type

048 type

056 type

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

1.70

2.00

2.50

1.70

2.00

2.50

3.00

4.00

5.00

6.00

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

4.5

5.6

7.1

4.5

5.6

7.1

8.0

11.2

14.0

16.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

9.0

10.0

16.0

18.0

*3) Korea market only

High Wall Type

(2 series)

High Wall Type

(1 series)

4. Indoor unit

16

4

16-1

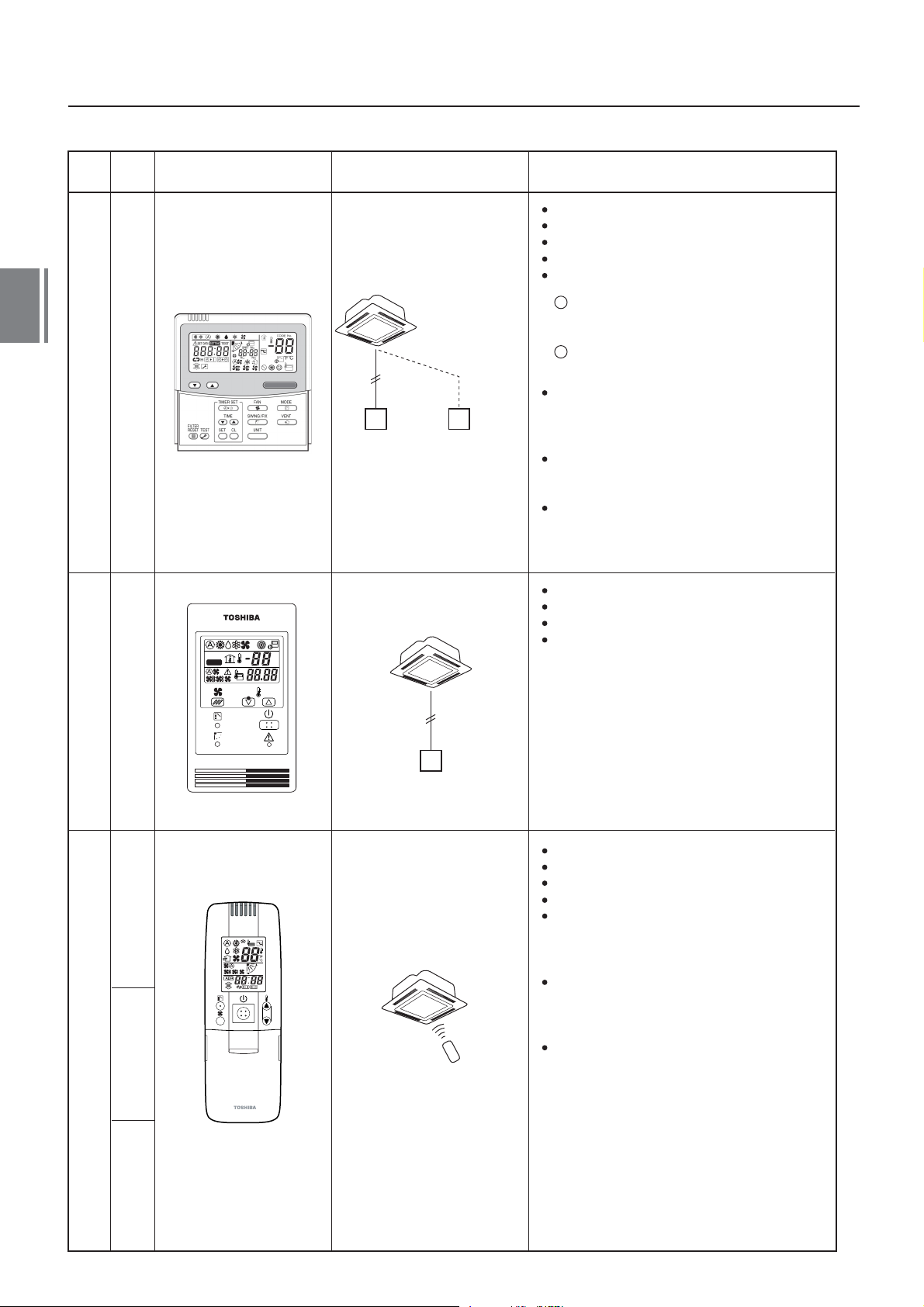

5. Remote controller

UNIT

SET

CL

SETTING

UNIT No.

CODE No.

TEST

SET DATA

R.C. No.

ûC

ûF

TEST

SETTING

Name

Model

name

Appearance Application Function

Wired remote controllerSimple wired remote controllerWireless remote controller kit

TCB-AX21E

TCB-AX21E2

RBC-AX22CE

RBC-AX22CE2

TCB-AX21U(W)-E

TCB-AX21U(W)-E2

RBC-AS21E/RBC-AS21E2 RBC-AMT21E/RBC-AMT31E

Connected to indoor unit

Connected to indoor unit

Connected to indoor unit

Simple remote controller

Wired remote

controller

Wired remote controller

(In case of control by

2 remote controllers)

Start / Stop

Mode Change

Temperature setting

Change of air flow

Timer function

Filter sign

Displays automatically maintenance time of

indoor filter.

Filter sign flashes.

Self-diagnosis function

Pressing ``CHECK`` button displays cause of

fault on the check code.

Control by 2 remote controllers is available.

Two remote controllers can be connected to

one indoor unit. The indoor unit can be

separately operated from a different location.

1

2

Start / Stop

Temperature setting

Change of air flow

Check code display

Start / Stop

Mode change

Temperature setting

Change of air flow

Timer function

On or off timer operation, setting in 30 minute

increments.

Automatic Off function.

Control by 2 remote controllers is available.

Two wireless remote controllers can operate

one indoor unit. The indoor unit can be

separately operated from a different location.

Check code display

TCB-AX21U(W)-E2

(for 4-way airdischarge cassette)

RBC-AX22CE2

(for under ceiling)

TCB-AX21-E2

(for other units except for the concealed duct

high static pressure)

On or off timer operation, setting in 30 minute

increments.

Automatic Off function.

Combined with the weekly timer, weekly

schedule operation can be operated.

17

ON

8:00 12:00 13:00 18:00 19:00 21:00

OFF ON OFF ON OFF

WEEKLY TIMER

ERROR

SuMoTuWeTh FrSa

PROGRAM1

PROGRAM2

PROGRAM3

SELECT ZONE

CL

SET

GROUP

CODE

No.

UNIT No.

No.

R.C.

TEST

ZONE

ALL

ZONE

GROUP

SETTING

1234

SET DATA

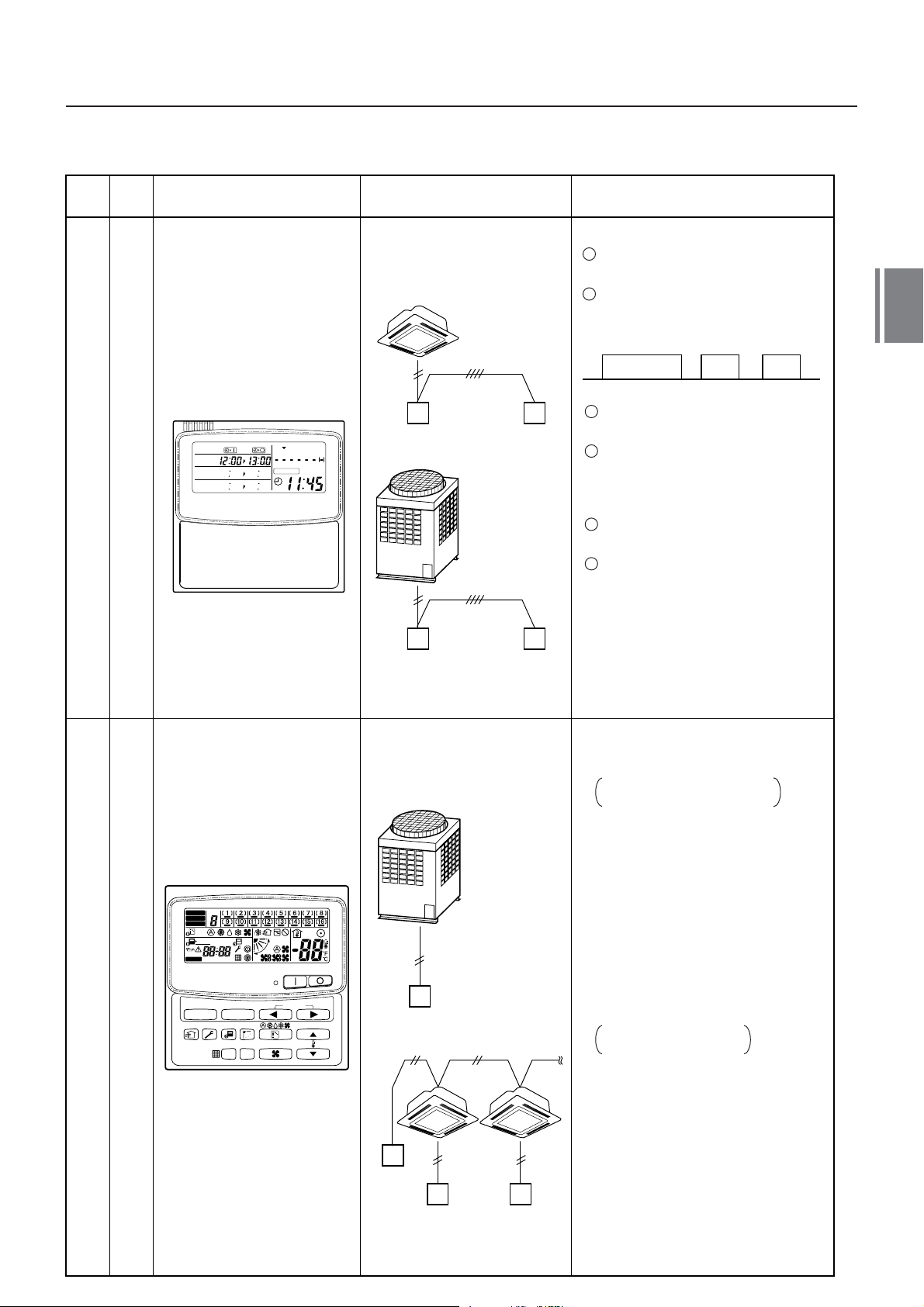

Name

Weekly timer

Model

name

Appearance Application Performance

RBC-EXW21E

RBC-EXW21E2

Central remote controller

TCB-SC642TLE

TCB-SC642TLE2

Connected to central

remote controller or

wired remote controller

Connected to outdoor unit,

indoor unit

Wired

remote controller

Weekly

timer

Outdoor unit

Central

remote controller

Weekly

timer

Outdoor

unit

Central

remote controller

Indoor

remote controller

Central

remote

controller

Weekly schedule operation

Setting different start / stop time for each

day of the week

ON / OFF can be set 3 times

a day.

1

2

3

Two different schedules for a

week can be specified.

(Summer schedule and winter

schedule, etc.)

4

5

If power supply fails, the setting

contents are stored in the memory for

100 hours.

6

Individual control up to 64 indoor units.

Individual control for max. 64 indoor

units divided into 4 zones.

Up to 16 indoor units for each

zone

Up to 16 outdoor header units are

connectable.

Four selectable central control settings to

restrict individual remote controller

operations.

Setting for one of 1 to 4 zones is

available.

Can be used with other central control

devices (Up to 10 central control

devices with in one control circuit)

Two selectable control modes

Central controller mode

Remote controller mode

Setting of simultaneous ON/OFF 3

times for each day of the week

combined with a weekly timer.

``CHECK`` ``PROGRAM`` ``DAY``

button copying of settings easy.

``CANCEL`` ``DAY`` button enables

holiday setting.

16-2

4

18

16-3

Name

Model

name

Appearance Application Performance

ON-OFF controller

TCB-CC163TLE2

Connected to outdoor unit,

indoor unit

Outdoor unit

Header

Indoor

remote controller

Follower

Outdoor unit

ON-OFF

controller

ON-OFF

controller

Setting of simultaneous ON-OFF 3

times for each day of the week when

combined with a weekly timer.

Individual control up to 16 indoor units.

Connected to 2 remote controllers is

possible.

17

5

Capacity compensation chart

18

19

15

1.2

1.1

1.0

0.9

0.8

20 24

1.1

1.0

0.9

80 90 100 110 120

-

50 5 1015202530354043

1.2

1.1

1.0

0.9

5

5

Foreword

Capacity compensation chart

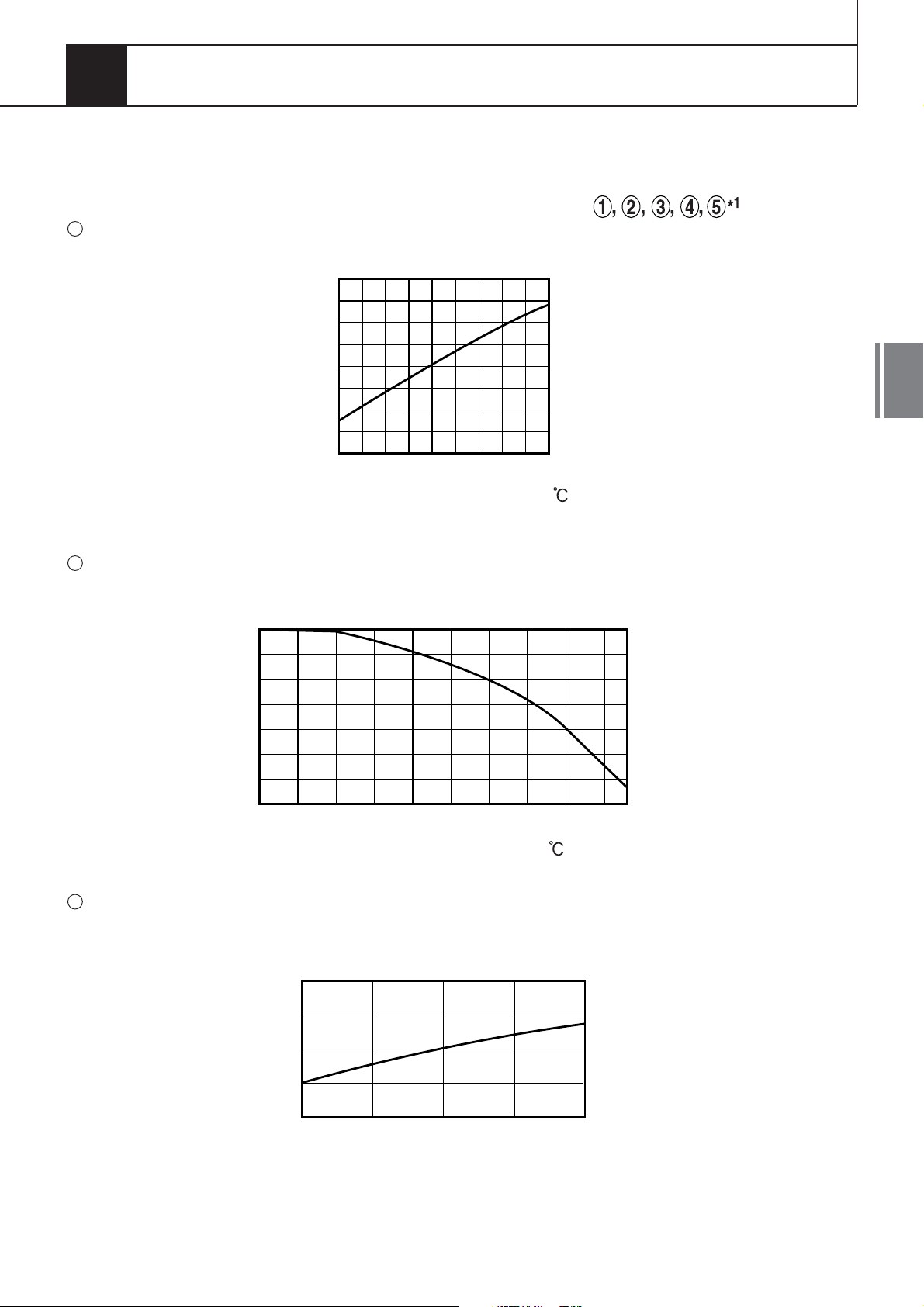

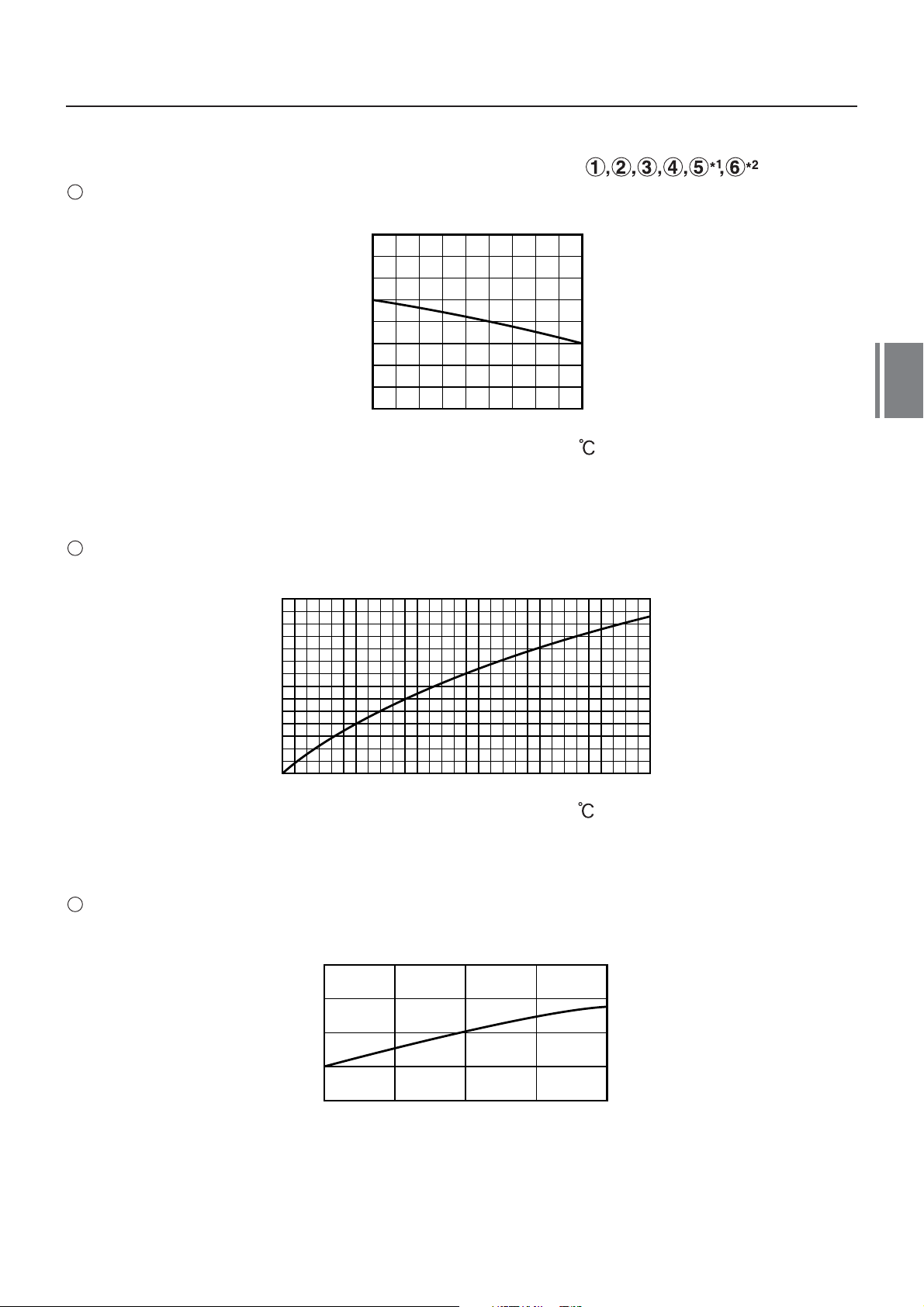

Cooling/heating capacity characteristics

1. Cooling capacity calculation method :

Required cooling capacity = Cooling capacity x Factor ( ) kW

Indoor air wet bulb temperature vs. capacity correction value

1

Outdoor air dry bulb temperature vs.capacity correction value

2

Air flow variation ratio of indoor unit vs. capacity correction (For concealed duct type only)

3

*

1: Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

the indoor units are not equal to the outdoor unit capacity.

Capacity correction value

Capacity correction value

Outdoor air dry bulb temp. ( )

Capacity correction value

Indoor air wet bulb temp. ( )

Air flow variation ratio (%)

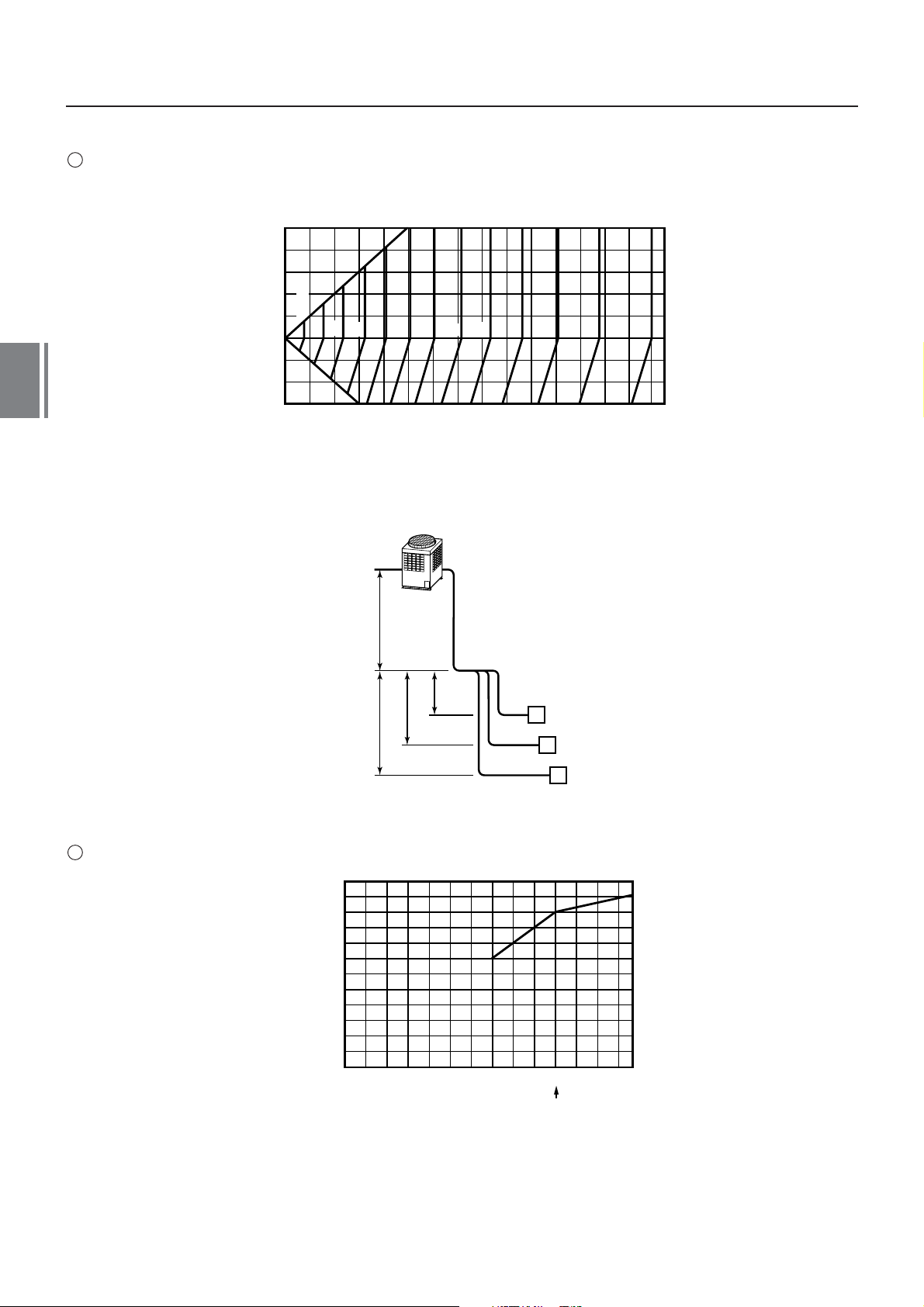

20

Outdoor unit

Indoor unit

L

,

is the longest one of

(l

,

o + l

,

a, l

,

o + l

,

b, l

,

o + l

,

c)

H = ho +

(Largest one of ha, hb, and hc)

A

ha

hb

hc

ho l

,

o

l

,

a

l

,

b

l

,

c

B

C

0

80

60

40

20

20 40 60 80 100 120 135

120

100

100

50

40

30

20

10

0

-

10

-

20

20 30 40 50 60 70 80 90

100 110 120 130 140 150

-

30

98

%100

92

90

84

88

86

82

80

78

76

96

94

5

*

1: Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

the indoor units are not equal to the outdoor unit capacity.

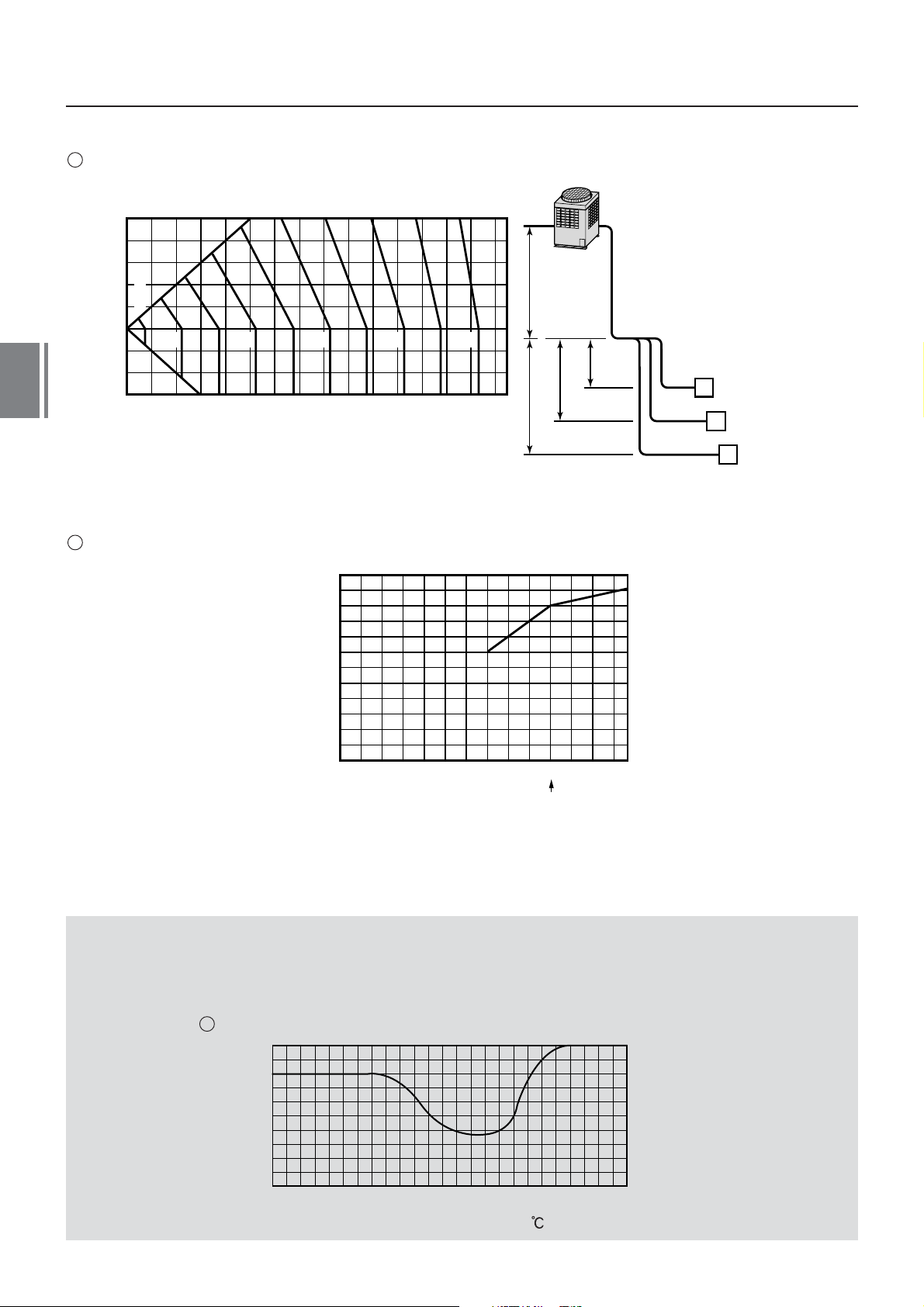

Height of outdoor unit H (m)

Pipe length (Equivalent length) L (m)

Correction (%)

Outdoor unit (8 to 30HP)

Standard capacity ratio

Indoor units total capacity ratio (%)

Correction of outdoor unit diversity

5

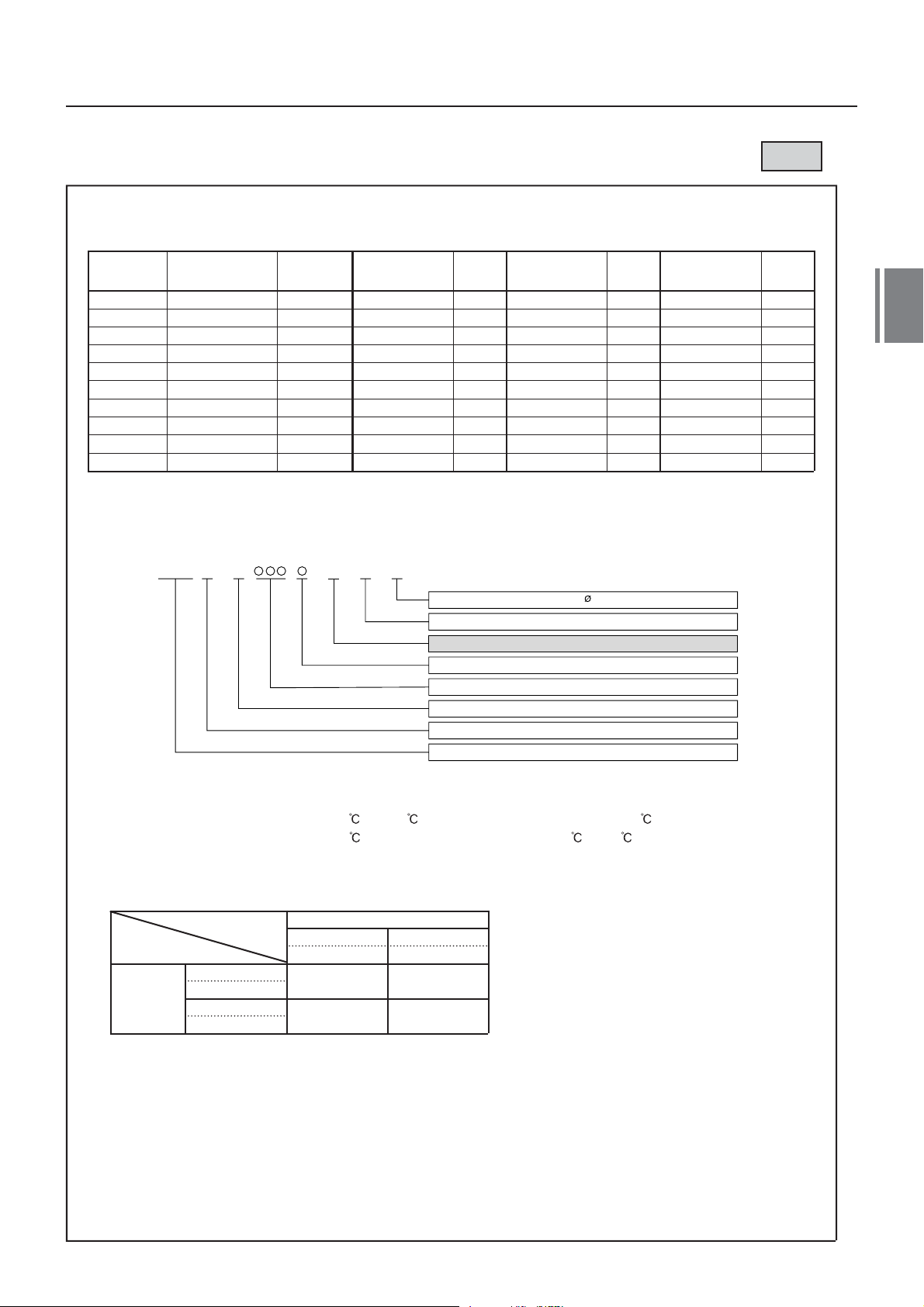

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

4

21

0.8

15 20 24

0.9

1.0

1.1

1.2

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

-

15

-

10

-

50 5 1015

0.9

1.0

1.1

80 90 100 110 120

5

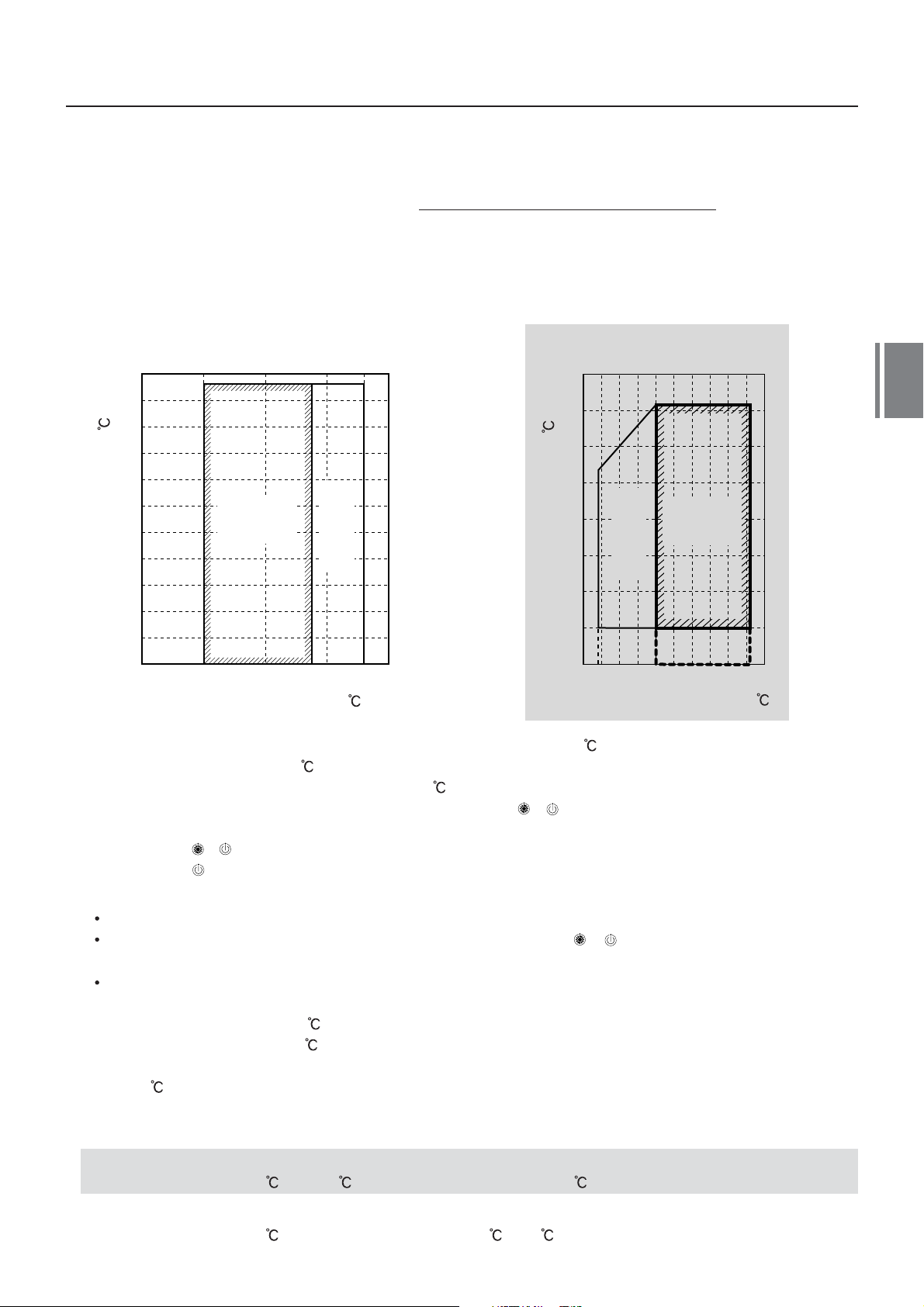

2. Heating capacity calculation method :

Required heating capacity = Heating capacity x Factor ( ) kW

Indoor air dry bulb temperature vs. capacity correction value

1

Outdoor air wet bulb temperature vs. capacity correction value

2

Air flow variation ratio of indoor unit vs. capacity correction (For concealed duct type only)

3

*

1: Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

the indoor units are not equal to the outdoor unit capacity.

*

2: Refer to item 3 on the next page.

Indoor air dry bulb temp. ( )

Outdoor air wet bulb temp. (

)

Capacity correction value

Air flow variation ratio (%)

Capacity correction value

Capacity correction value

22

0

80

60

40

20

20 40 60 80 100 120 135

120

100

Outdoor unit

Indoor unit

L

,

is the longest one of

(l

,

o + l

,

a, l

,

o + l

,

b, l

,

o + l

,

c)

H = ho +

(Largest one of ha, hb, and hc)

A

ha

hb

hc

ho l

,

o

l

,

a

l

,

b

l

,

c

B

C

100 2030405060708090

100 110 120 130 140 150

-

20

-

10

0

10

20

30

40

50

-

30

100%

92

93

94

96

97

98

99

91

95

0.8

0.9

1.0

-

15

-

10

-

50 5 10

5

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

4

Correction of outdoor unit diversity

5

*

1: Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

the indoor units are not equal to the outdoor unit capacity.

3. Capacity correction in case of frost on the outdoor heat exchanger when in heating

Correct the heating capacity when frost can be found on the outdoor heat exchanger.

Heating capacity =Capacity after correction of outdoor unit Correction value of capacity resulted from frost

(Capacity after correction of outdoor unit : Heating capacity calculated in the above item 2.)

Capacity correction in case of frost on the outdoor heat exchanger

6

Outdoor air wet bulb temp. (

)

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

Correction (%)

Pipe length (Equivalent length) L (m)

Height of outdoor unit H (m)

Outdoor unit (8 to 30HP)

23

3025 28201510

-

10

-

5

0

5

10

15

20

25

30

35

40

45

-

20

-

15

-

10

-

5

0

5

10

15

20

5 1015202530

4. Capacity calculation for each indoor unit

Capacity for each indoor unit

= Capacity after correction of outdoor unit x

Required standard capacity of indoor unit

Total value of standard indoor unit capacity

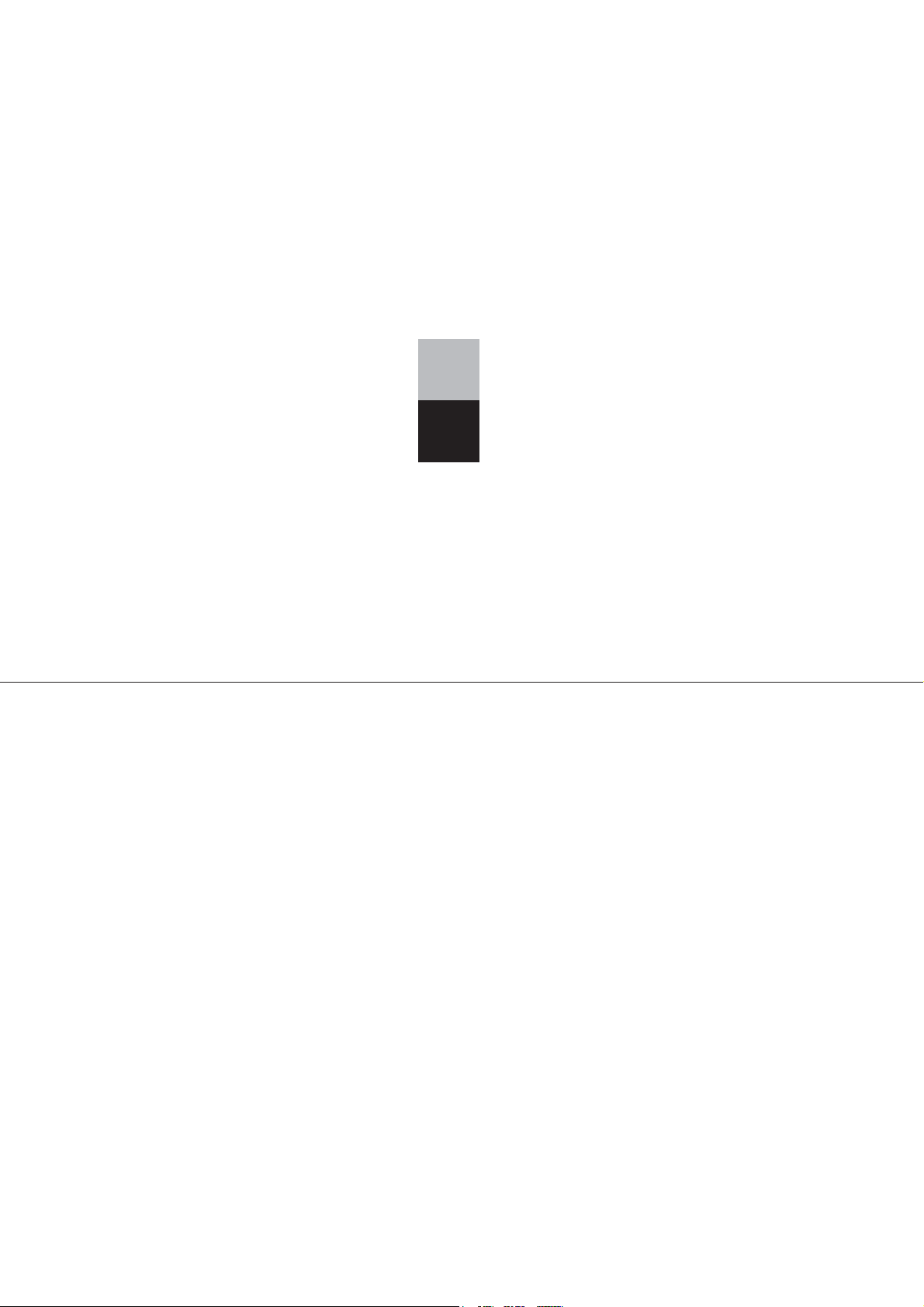

5. Operating temperature range

* The unit can be operated even if the outdoor temperature goes below -20 , however you must note that the war-

ranty only covers down to -15

this is because operation beyond this temperature is outside of specification.

* When outdoor air temperature falls to below -15

, it may shorten the lifespan of the product.

* When outdoor temperature goes out of the specified range

`` or `` mark is indicated on the remote control-

ler display and the required operation will stop.

`` & `` : When heating operation

`` `` : When cooling operation

[Notice]

This indication is not a failure.

When outdoor temperature goes back to within the specified range,

`` or `` disappear and normal operation

will start.

Operation stops because the concurrent operation can not be kept in the condition, as it is out of specification

for Super HRM.

(Outdoor temp.(DB) <-10

: Cooling,

>21

: Heating)

* Do not use ``Super HRM`` other than for personal usage where the ambient temperature may go down

below -10

. (For example, fresh air intake equipment/Electric device/Food/Animals and plants/Art object)

6. Rated conditions

Cooling :

Indoor air temperature 27

DB/19.0 WB, Outdoor air temperature 35 DB

Heating :

Indoor air temperature 20

DB, Outdoor air temperature 7 DB/6 WB

In cooling time

In heating time

Indoor air wet bulb temp. ( )

Outdoor air dry bulb temp. ( )

Outdoor air wet bulb temp. (

)

Indoor air dry bulb temp. ( )

Continuously

operable

range

Usable range

(in warming-up)

Usable range

(in pull down)

Continuously

operable

range

5

24

25

6

Piping requirements

26

27

H4 0.5 m

a

ghi j

lmn

o

pq

(q)

k

bc

Indoor unit

FS unit

H1 50m

H3 5m

L1

A

La Lb Lc

LA

C

A B C

B

L9

L3

L4 L5 L6 L7

Lh

L8

Lj

FS unit

def

H2 35m

L 150m

A B C

Li

50m

L2

LO 25m

FS unit

(Header)

300 m

LA+La+Lb+Lc+L1+L2+L3+L4+L5+L6+L7+L8+9

+a+b+c+d+e+f+g+h+i+j+k+l+m+n+o+p+q

125 m

150 m

LA+Lc+L1+L3+L4+L5+L6+L7+L8+q

85 m L1

50 m L3+L4+L5+L6+L7+L8+q

30 m a+g, b+h, c+i, d+l, e+m, f+n, j, k

15 m g, h, i, l, m, n, L7+o, L7+L8+p, L7+L8+q

25 m LA+Lc (LA+Lb)

10 m La, Lb, Lc

30 m

L7+L8+q, L7+L8+p

15 m

L7+o

50 m

-

30 m

-

35 m

-

15 m

-

5 m

-

0.5 m

-

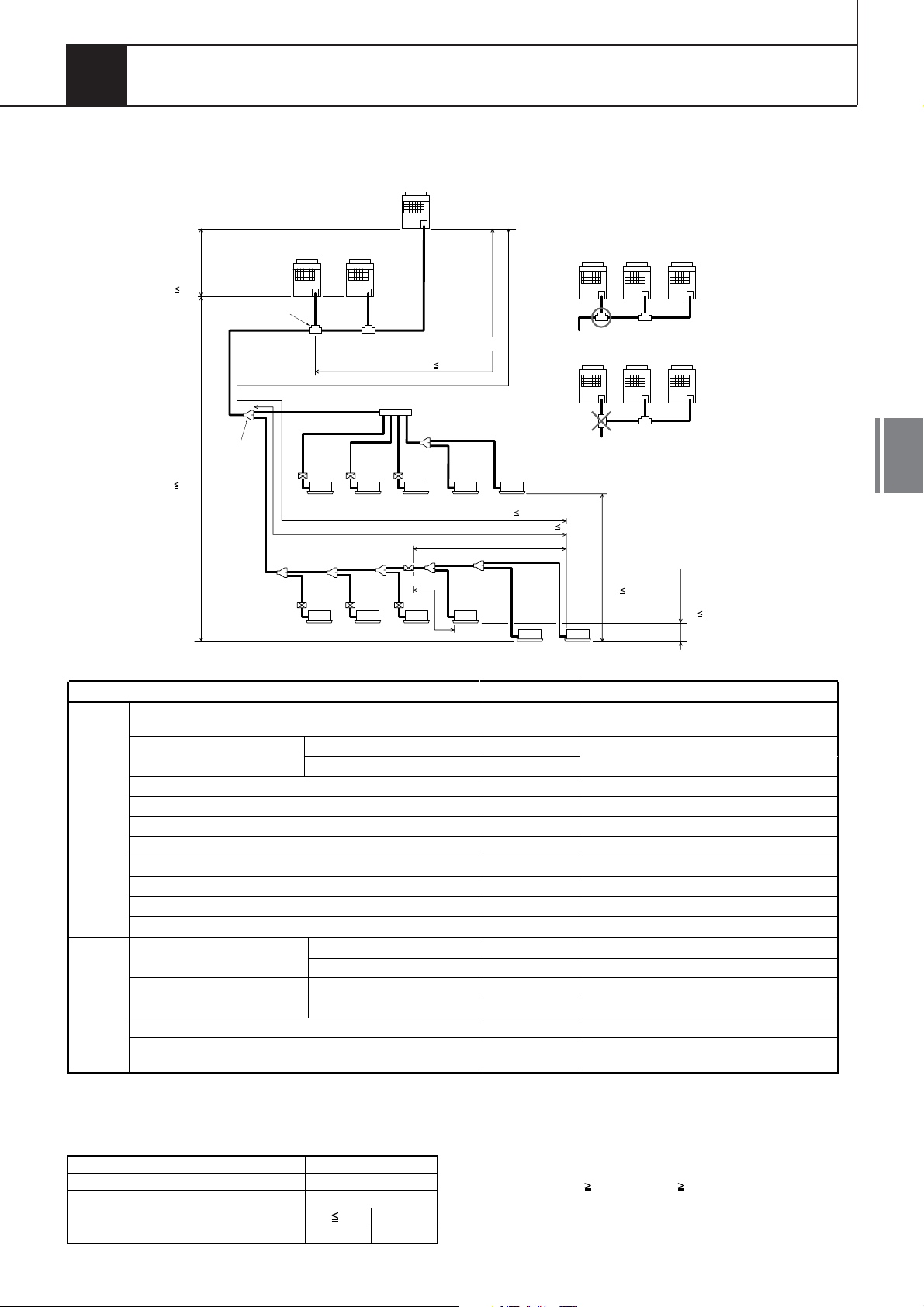

6

Foreword

Piping requirements

6

1. Allowable length/height difference of refrigerant piping

*

1 : The furthest outdoor unit from 1st branch is to be named C, and furthest indoor unit from 1st branch to be named (q).

*

2 : The supplied connection cable can be used up to 5 m in pipe length between the indoor and FS unit. When the pipe length

between the indoor and FS unit exceeds 5 m, you must use the connection cable kit (RBC-CBK15FE).

* System restrictions

3 units

84.0 kW

48 units

H2 15m

H2

>

15m

135% (*1)

105%

*

1 : MMY-MAP1201HT8 : UP to 120 %

Note 1) Combination of outdoor units : Header unit (1 unit) +

Follower unit (0 to 2 units). Header unit is outdoor unit

nearest to the connected indoor units

Note 2) Install the outdoor units in order of capacity.

(Header unit Follower unit 1 Follower unit 2)

Note 3) Refer to outdoor unit combination table in page.6.

Note 4) Piping to indoor units shall be perpendicular to piping to

the head outdoor unit as Ex.1.

Do not connect piping to indoor units in the same

direction of head outdoor unit as Ex.2.

Max. No. of combined outdoor units

Max. capacity of combined outdoor units

Max. No. of connected indoor units

Max. capacity of combined indoor units

Total extension of pipe (Liquid pipe, real length)

Farthest piping length L (*1)

Real length

Equivalent length

Max. equivalent length of main piping

Equivalent length of farthest piping from 1st branching Li (*1)

Max. real length of indoor unit connecting piping

Max. real length between FS unit and indoor unit (*2)

Max. Equivalent length of outdoor unit connecting piping LO (*1)

Max. real length of outdoor unit connecting piping

Max. equivalent length between FS unit and indoor unit Lj

Max. real length between FS unit and header indoor unit Lh (*2)

Height between outdoor units H3

Height difference between indoor units in group control by one

FS unit H4

Height between indoor

and outdoor units H1

Height between indoor units H2

Upper outdoor unit

Lower outdoor unit

Upper outdoor unit

Lower outdoor unit

Height

Difference

Pipe

Length

Piping section

* Allowable length and height difference of refrigerant piping

Allowable value

Note:

In case of connecting method Ex.2, a large

amount of refrigerant and refrigerant oil may

return to the head unit. Therefore, set the T-shape

joint so that oil does not enter directly

<Ex.1> Header UnitFollower UnitFollower Unit.

<Ex.2> Header UnitFollower UnitFollower Unit

Height difference

between

indoor

units

Height difference

between indoor units

in group control by

one FS unit

(Upper outdoor unit)

Height

difference

between

outdoor

units

Height

difference

between

outdoor

and indoor

units

Header Unit Follower Unit

Follower Unit

Outdoor Unit

T-shape

branching

Main piping

1st branching

section

Branching piping

Connecting piping of

indoor unit

Branching

header

Indoor unit

< Cooling only > < Cooling only >

Equivalent length corresponded to farthest piping

Equivalent length corresponded to farthest piping after 1st branching

Main connecting piping between outdoor units

Length corresponded to farthest piping

between outdoor units

Loading...

Loading...