Page 1

Installation & Operation Manual

304P_D

Switching Relay 304P

Zoning

12/18

Replaces: 11/16

Introduction

The Switching Relay

heating system. Zone 1 has optional priority over zones 2 through 4 and can be used to provide heat to an indirect

domestic hot water tank. The 304P includes optional exercising to prevent circulator seizure when not in use, and optional

post purge operation of the last operating zone to maximize energy savings. The 304P provides a RoomResponseTM

signal to modulating-condensing boilers to optimize comfort while improving boiler efficiency.

304

P connects up to four thermostats and operates circulators to provide heating to a zoned hydronic

Features

• RoomResponseTM signal

• Compatible with all low voltage thermostats

• Unlimited zone expansion

• Zone priority

• Priority override

• Pump exercising

• Post purge

•

LED for each zone, priority, end switch and RoomResponse

• Away signal shared between tekmar thermostats

• Four ground screws

• Top, bottom and back conduit knockouts

• Fuses protect transformers and pumps

• Two spare fuses included

• CSA approved

TM

Switching Relay 304P

Four Zones with Priority

Power

Priority

RoomResponse

TM

Zone 1 Zone 2 Zone 3 Zone 4

H3020A

© 2018 tekmar 304P_D - 12/18

Page 2

Table of Contents

Important Safety Information .............................................2

Installation .........................................................................3

Preparation .................................................................... 3

Location ......................................................................... 3

Installing the Enclosure ................................................. 3

Application 304P–1 ........................................................ 4

Application 304P–2 ....................................................... 5

Application 304P–3 ....................................................... 6

User Interface ....................................................................7

Indicator LED ................................................................. 7

Sequence of Operation .....................................................7

Technical Data ..................................................................12

Limited Warranty and Product Return Procedure ............12

Important Safety Information

It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards. tekmar is

not responsible for damages resulting from improper installation and/or maintenance.

This is a safety-alert symbol. The safety alert symbol is shown alone or used with a signal word (DANGER,

WARNING, or CAUTION), a pictorial and/or a safety message to identify hazards. When you see this symbol

alone or with a signal word on your equipment or in this manual, be alert to the potential for death or serious

personal injury.

This pictorial alerts you to electricity, electrocution, and shock hazards.

This symbol identifies hazards which, if not avoided, could result in death or serious injury.

This symbol identifies hazards which, if not avoided, could result in minor or moderate injury.

This symbol identifies practices, actions, or failure to act which could result in property damage or damage to

the equipment.

Read manual and all product labels BEFORE using the equipment. Do not use unless you know

the safe and proper operation of this equipment. Keep this manual available for easy access by all

users. Replacement manuals are available at tekmarControls.com

•

It is the installer’s responsibility to ensure that this control is safely installed according to all applicable codes and

standards.

•

Improper installation and operation of this control could result in damage to the equipment and possibly even personal

injury or death.

• This control is not intended for use as a primary limit control. Other controls that are intended and certified as safety limits

must be placed into the control circuit.

The control includes fuses and transformer that are serviceable. Do not attempt to service any other parts on the control.

Attempting to service the control voids the warranty.

• Strip all wiring to a length of 3/8 in. or 10 mm for all terminals.

• A circuit breaker or power disconnect that provides power to the control should be located nearby and clearly labeled.

• Refer to the current and voltage ratings at the back of this manual before connecting devices to this control.

© 2018 tekmar 304P_D - 12/18

2 of 12

Page 3

-----------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------

------------------------------------------------------------------------------------

Radio Frequency Interference

The installer must ensure that this control and its wiring are

isolated and/or shielded from strong sources of electromagnetic

noise. Conversely, this Class B digital apparatus complies

with Part 15 of the FCC Rules and meets all requirements of

the Canadian Interference-Causing Equipment Regulations.

However, if this control does cause harmful interference to

radio or television reception, which is determined by turning

Installation

Preparation

Tools R equir ed

• tekmar or jeweler screwdriver

• Phillips head screwdriver

Materials Required

• 18 AWG LVT solid wire (low-voltage connections)

• 14 AWG solid wire (line-voltage connections)

Packaging Contents

• 1 Switching Relay 304P

• 2 Spare fuses (located in cover)

-----------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------

------------------------------------------------------------------------------------

the control off and on, the user is encouraged to try to correct

the interference by re-orientating or relocating the receiving

antenna, relocating the receiver with respect to this control,

and/or connecting the control to a different circuit from that

to which the receiver is connected.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

• Needle-nose pliers

• Wire stripper

• Four 1/8" - 1" wood screws

• 1 Installation and Operation Manual 304P_D

Location

• Keep the control dry. Avoid potential leakage onto the control.

• Maintain relative humidity less than 90% in a non-condensing environment.

• Avoid exposure to extreme temperatures beyond 32-122°F (0-50°C).

• Install away from equipment, appliances, or other sources of electrical interference.

• Install to allow easy access for wiring, viewing, and adjusting the display screen.

• Install approximately 5 feet (1.5 m) off the finished floor.

• Locate the control near pumps if possible.

• Provide a solid backing which the enclosure can be mounted to. Example: plywood or wall studs.

• Use the conduit knockouts provided on the upper, lower, and back of the enclosure for wiring.

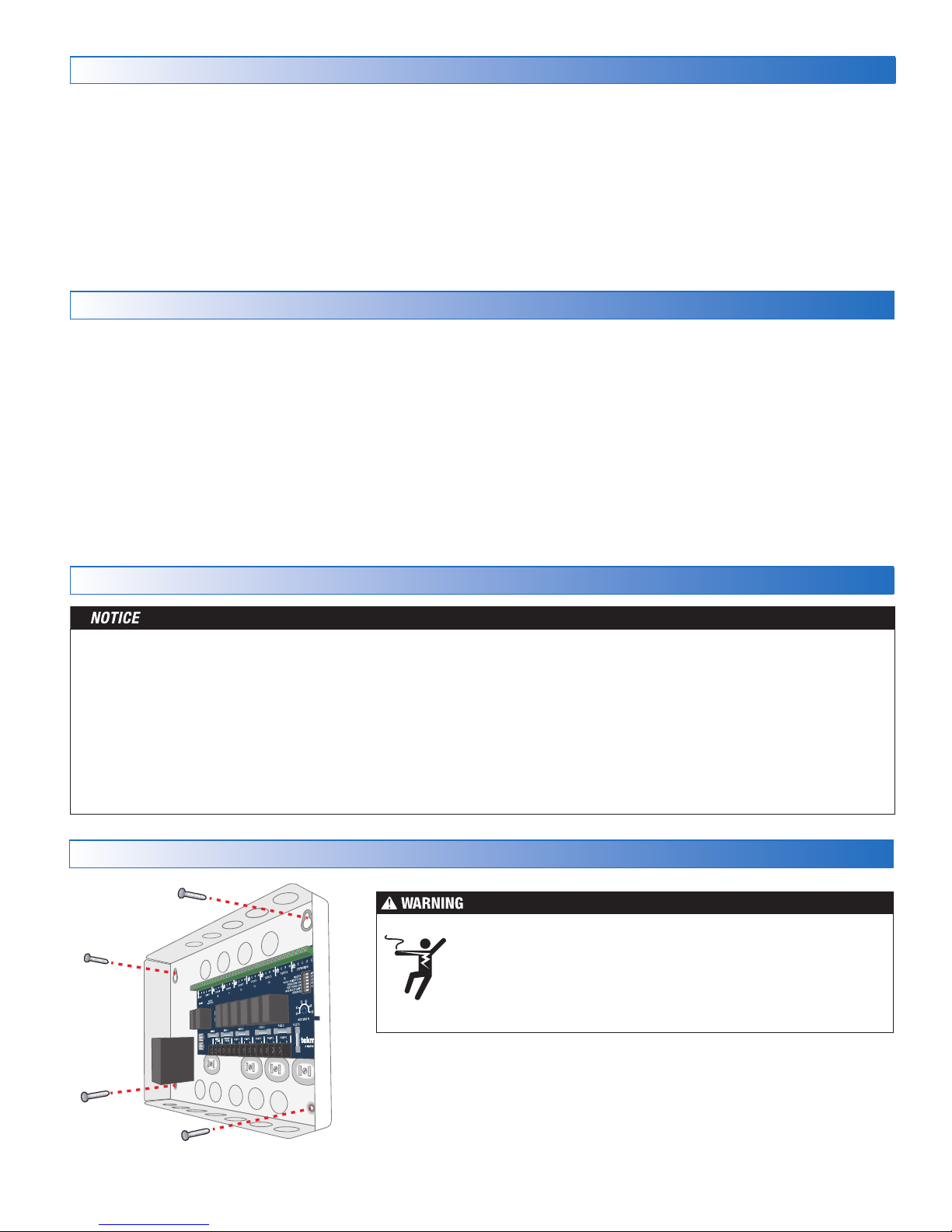

Installing the Enclosure

To prevent the risk of personal injury and/or death, make sure power

is not applied to the control until it is fully installed and ready for final

testing. All work must be done with power to the circuit being worked

on turned off.

Please be aware local codes may require this control to be installed

or connected by an electrician.

3 of 12

© 2018 tekmar 304P_D - 12/18

Page 4

Application 304P–1

---------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------

The Switching Relay 304P operates the circulators for four heating zones when the corresponding thermostat calls for heat.

The boiler is fired whenever a zone calls for heat.

Mechanical

---------------------------------------------------------------------------------------------

Legend

B1 = Boiler

P1 to P4 = Zone 1 through 4 Pumps

T1 = WiFi Thermostat 561 or 562

T2 = Thermostat 518 or 519

T3 = Generic Digital Power-Stealing Thermostat

T4 = Generic Bi-Metallic Strip Thermostat

B1

304P

P1

P2 P3 P4

Electrical

B1

-----------------------------------------------------------------------------------------------

T1

T2 T3 T4

70

Away C R Rh W Away C R Rh W

R W R W

DIP Switches

Master

T-stat 1 Priority Off

Exercising On

Post Purge On

Mod Boiler - not applicable

-

+

XX

MOD

POWER ROOM

A

DHW C R W

tN4

BOILER T-STAT 1 T-STAT 2 T-STAT 3

RESPONSE

FUSE 1

120 VAC

POWER

L

A

tN4

T1 T2 T3 T4 T5 T6

FUSE 7

FUSE 8

FUSE 2

PRIORITY

PUMP 1

NLNLNL N LNL NLN

A

CRW

tN4

FUSE 3 FUSE 4 FUSE 5

PUMP 2 PUMP 3 PUMP 4 PUMP 5 PUMP 6

CRW

A

tN4

T-STAT 4

CRW

A

tN4

T-STAT 5

CRW

A

CRW

tN4

T-STAT 6 EXPANSION

A

BCDE

tN4

MASTER MEMBER

T-STAT 1 PRIORITY : 0N

EXERCISING : ON

POST PURGE : ON

MOD BOILER : 0-10V

RESERVED

50 100

MOD MAX %

FUSE 6

70 80

OFF

OFF

OFF

4-20 mA

9060

LN

© 2018 tekmar 304P_D - 12/18

P1 P2 P3 P4

4 of 12

Page 5

Application 304P–2

-----------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

The Switching Relay 304P operates four heating zone circulators when the corresponding thermostat calls for heat. Zone 1

heats a domestic hot water tank. When priority is selected, zones 2 through 4 shut off when zone 1 is heating. The boiler is

fired when there is a call for heat.

Mechanical

---------------------------------------------------------------------------------------------

Legend

A1 = DHW Tank Aquastat

B1 = Modulating Condensing Boiler

BP = Boiler Pump

P1 = Zone 1 DHW Tank Pump

P2 to P4 = Zone 2 through 4 Pump

T1 = WiFi Thermostat 561 or 562

T2 = Thermostat 518 or 519

T3 = Generic Bi-Metallic Strip Thermostat

B1

BP

P1

A1

304P

P2

P3

P4

Electrical

DHW

B1

-----------------------------------------------------------------------------------------------

T1

A1

T2 T3

70

DIP Switches

Master

T-stat 1 Priority On

Exercising On

Away C R Rh W Away C R Rh W R W

+T-T

-

-

+

XX

MOD

POWER ROOM

A

DHW C R W

tN4

BOILER T-STAT 1 T-STAT 2 T-STAT 3

RESPONSE

FUSE 1

120 VAC

POWER

L

A

tN4

T1 T2 T3 T4 T5 T6

FUSE 7

FUSE 8

FUSE 2

PRIORITY

PUMP 1

NLNLNL N LNL NLN

A

CRW

tN4

FUSE 3 FUSE 4 FUSE 5

PUMP 2 PUMP 3 PUMP 4 PUMP 5 PUMP 6

CRW

A

tN4

T-STAT 4

CRW

A

tN4

T-STAT 5

CRW

A

CRW

tN4

T-STAT 6 EXPANSION

T-STAT 1 PRIORITY : 0N

POST PURGE : ON

MOD BOILER : 0-10V

Post Purge On

Mod Boiler - depends on boiler

A

BCDE

tN4

MASTER MEMBER

EXERCISING : ON

RESERVED

50 100

FUSE 6

70 80

MOD MAX %

OFF

OFF

OFF

4-20 mA

9060

LN

P1

P2 P3 P4

5 of 12

© 2018 tekmar 304P_D - 12/18

Page 6

Application 304P–3

---------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------

Two Switching Relay 304P's operate eight heating zone circulators. The two controls are connected together using an expansion

bus wire. The master 304P fires the boiler when any zone calls for heat. If priority is selected, zones 2 through 8 shut off when

zone 1 is calling for heat.

Mechanical

---------------------------------------------------------------------------------------------

Legend

A1 = DHW Tank Aquastat

B1 = Modulating Condensing Boiler

BP = Boiler Pump

P1 = Zone 1 DHW Tank Pump

P2 to P8 = Zone 2 through 8 Pump

B1

T1 to T3 = WiFi Thermostat 561 or 562

T4 to T5 = Thermostat 518 or 519

T6 = Generic Digital Power-Stealing Thermostat

T7 = Generic Bi-Metallic Strip Thermostat

304P 304P

A1

P1

P2 P3 P4

BP

Expansion

P5 P6

P7

P8

Electrical

-----------------------------------------------------------------------------------------------

A1

+TT

-

A

DHW C R W

XX

tN4

BOILER T-STAT 1 T-STAT 2 T-STAT 3

T1 T2 T3 T4 T5 T6

RESPONSE

FUSE 7

FUSE 8

FUSE 1

120 VAC

POWER

L

B1

-

+

MOD

POWER ROOM

LLN

DIP Switches

Master

T-stat 1 Priority On

Post Purge On

Mod Boiler - depends on boiler

Exercising On

© 2018 tekmar 304P_D - 12/18

T1

T2 T3

T4 T5

70 70 70

Away

C R Rh W

Away

C R Rh W

Away

C R Rh W

A

A

A

A

A

CRW

CRW

CRW

tN4

tN4

tN4

FUSE 2

PRIORITY

PUMP 1

NLNLNL NL NLNL N

P1 P7

FUSE 3 FUSE 4 FUSE 5

PUMP 2 PUMP 3 PUMP 4 PUMP 5 PUMP 6

P2 P8P3 P4 P5 P6

T-STAT 4

tN4

T-STAT 5

CRW

A

CRW

tN4

BCDE

tN4

T-STAT 6 EXPANSION

MASTER MEMBER

T-STAT 1 PRIORITY : 0N

EXERCISING : ON

POST PURGE : ON

MOD BOILER : 0-10V

RESERVED

50 100

MOD MAX %

FUSE 6

70 80

9060

OFF

OFF

OFF

4-20 mA

-

+

DHW C R W

XX

BOILER T-STAT 1 T-STAT 2 T-STAT 3

MOD

POWER ROOM

RESPONSE

FUSE 1

Away

C R Rh W

Away

C R Rh W R W R W

A

A

tN4

120 VAC

POWER

L

CRW

tN4

T1 T2 T3 T4 T5 T6

FUSE 7

FUSE 8

FUSE 2

PRIORITY

PUMP 2 PUMP 3 PUMP 4 PUMP 5 PUMP 6

PUMP 1

NLNLNL NL NLNL N

N

DIP Switches

Member

T-stat 1 Priority Off

Exercising On

6 of 12

T6 T7

A

A

A

CRW

tN4

CRW

tN4

T-STAT 4

FUSE 3 FUSE 4 FUSE 5

tN4

T-STAT 5

CRW

A

tN4

Post Purge On

Mod Boiler - not applicable

A

CRW

BCDE

tN4

T-STAT 6 EXPANSION

MASTER MEMBER

T-STAT 1 PRIORITY : 0N

EXERCISING : ON

POST PURGE : ON

MOD BOILER : 0-10V

RESERVED

70 80

50 100

MOD MAX %

FUSE 6

9060

OFF

OFF

OFF

4-20 mA

Page 7

User Interface - Indicator LED

Power

• On when 115 V (ac) is applied.

Off when power disconnected or transformer fuse is blown.

•

Priority

• On when zone 1 has priority over zones 2 to 4.

RoomResponse

• On when modulating condensing boiler is operating below

maximum setting.

TM

Sequence of Operation

Zone Operation

When a thermostat calls for heat by closing the R and W

terminals:

• 115 V (ac) is applied to the corresponding circulator pump.

• The corresponding zone indicator LED is turned on.

Boiler Operation

When a thermostat calls for heat by closing the R and W

terminals:

• The boiler end switch XX is closed to fire the boiler.

The RoomResponseTM 0-10 V (dc) or 4-20 mA signal is sent

•

to a modulating-condensing boiler.

DHW Operation

Many modulating-condensing boilers have multiple temperature

call inputs. Wire the DHW end switch to input recommended

in the boiler's manual.

When a zone 1 calls for heat by closing the R and W terminals:

• The DHW end switch is closed to fire the boiler at the DHW

temperature.

• The Mod Boiler output is changed to 10 V (dc) or 20 mA.

Master / Member DIP Switch

•

Allows for unlimited expansion using additional Switching

Relays and/or Zone Valve Controls.

The Master Switching Relay is wired and operates the boiler.

•

• If using a single Switching Relay set to Master.

When using multiple Switching Relays and/or Zone Valve

•

Controls, set one control to Master and set all other controls to Member.

T-Stat 1 Priority DIP Switch

When T-Stat 1 is calling for heat by closing the R and W

terminals:

• 115 V (ac) is applied to the zone 1 circulator pump.

• Zone 1 indicator LED is turned on.

• Priority indicator LED is turned on.

• Zones 2 to 6 circulator pumps and LEDs are turned off.

• Expansion Member controls shut off their zones.

•

After 60 minutes of continuous zone 1 call for DHW heating,

zones 2 to 6 and all Expansion Member control zones are

able to turn back on. This prevents building freeze up if the

DHW tank aquastat fails in the closed position.

Exercising DIP Switch

ON: Each circulator pump is energized for 30 seconds every

72 hours.

OFF: Circulator pump exercising disabled.

Zone 1

• On when thermostat 1 calls for heat.

Zones 2 to 4

• On when the corresponding thermostat calls for heat.

• Off during priority operation.

• Off when corresponding thermostat stops calling for heat.

Post Purge DIP Switch

ON: After the last thermostat stops calling for heat, the last

circulator pump remains on for 2 minutes to purge heat from

the boiler to the zone.

OFF: Post purge disabled.

Mod Boiler DIP Switch

Select either 0-10 V (dc) or 4-20 mA signal to the modulating

condensing boiler. Consult the boiler manual to determine

the signal type. The DIP switch position does not matter if

the modulating boiler output is not used.

Fuses

• All fuses are T5A 250V slow blow.

• Fuses 1 to 4 correspond to the zone 1 to 4 circulator pump

output. If a fuse is blown, first check that the pump is not

seized and the wiring is not shorted. Then replace the fuse.

•

Fuse 7 and 8 correspond to the 24 V (ac) transformer power

supply. If a fuse is blown, first check that the thermostat

wiring is not shorted. Then replace the fuse.

Expansion Terminals

Connect the five wires of the expansion bus from the master

to the member controls.

Ter min al

A/tN4 Away signal connecting tekmar thermostats

BRoomResponse

CPower common

D

E Priority signal. 0 Vdc = priority. 2 Vdc = no priority

Description

TM

signal from member controls

Demand signal. 0 Vdc = demand. 2 Vdc = no demand

7 of 12

© 2018 tekmar 304P_D - 12/18

Page 8

RoomResponseTM Signal

The RoomResponseTM signal adjusts the temperature of a

modulating condensing boiler that accepts a 0-10 V(dc) or

4-20 mA input. It works by continually adjusting boiler water

temperatures to the lowest possible value to meet comfort

without wasting energy. This is done by monitoring each

thermostat's on and off time pattern and determines the ideal

water temperature for each zone. The control then chooses the

highest water temperature requirement of all the thermostats

and provides a 0-10 V (dc) or 4-20 mA signal proportional to

the boiler operating temperature. The RoomResponse

is a DOE compliant method of controlling boiler temperature

to building load. The RoomResponse

to on/off boilers.

Benefits of the RoomResponse

• Increase in boiler efficiency

• Reduction in room temperature swing

• Reduction in expansion noises from heating pipes

TM

signal is not available

TM

signal include:

TM

signal

Mod Max % Dial

The upper limit of the 0-10 V (dc) or 4 -20 mA signal to the

modulating condensing boiler can be set using the Mod Max

% Dial.

This sets the upper temperature limit for the boiler.

70 80

9060

50 100

MOD MAX %

Mod Max % dial set to 100% in the illustration.

The dial is only applicable to controls set as the Master.

Mod Max % Max Voltage Max mA

50 5 12

60 6 13.6

70 7 15.2

80 8 16.8

90 9 18.4

100 10 20

Setting the Max Mod % Dial

Required Adapter

Boiler Make/Model

Aerco AM series Not required 0-10 V 50% 65% 80% 100%

Bosch Greenstar ICM Module 0-10 V 55% 70% 80% 100%

Buderus GB142, GB162 EM10 Module 0-10 V 50% 60% 75% 90%

Burnham

Camus

HTP Elite Not required 0-10 V 50% 65% 80% 90%

IBC VFC and SL series

Laars

Laars

Lochinvar

Lochinvar

NTI Trinity Fire Tube and LX Not required 4-20 mA 55% 65% 75% 90%

Peerless PureFire PFA-1 Adapter 0-10 V 55% 65% 75% 90%

Raypak Xfyre, Xtherm, MVB, XPakFT Not required 0-10 V 55% 65% 80% 90%

Riverside HeatStation

Viessmann 100-W, WB1B

Viessmann 200-W, B2HB and 300 CU3A Not required 0-10 V 50% 60% 70% 80%

Weil-McLain

* Requires changes to boiler's settings

®

®

Modulating Micoflame

®

Mascot LX Not required 0-10 V 55% 70% 85% 100%

®

Mascot FT Not required 0-10 V 50% 65% 80% 100%

®

®

Alpine

Knight

FTXL*

®

Evergreen*

™

*

®

*

™

*

(Supplied by boiler

manufacturer)

Not required 4-20 mA 50% 70% 85% 100%

Not required 0-10 V 50% 60% 70% 85%

Not required 0-10 V 65% 75% 85% 100%

Not required 0-10 V 55% 70% 85% 100%

Not required 0-10 V 55% 70% 85% 100%

Not requi red 0 -10 V 50% 6 5% 85% 100%

OpenTherm

Module

Not requi red 0 -10 V 50% 70% 85% 100%

0-10 V (dc) /

4-20 mA

DIP Switch

0-10 V 55% 70% 85% 100%

Mod Max % Dial for Boiler Design Temperature

120°F 140°F 160°F 180°F

© 2018 tekmar 304P_D - 12/18

8 of 12

Page 9

Aerco AM Series

--------------------------------

-------------------------------

----------------------

---------------------------------

------------------

---------------------

--------------------------

--------------------------------

--------------------------------

Camus Modulating MicoFlame

------------------

–

304P

+

22+23

–

Aerco AM

• No changes to the boiler are required.

Bosch Greenstar

–

-------------------------------

+

304P

9+10

–

Bosch ICM

• Install the Bosch ICM as per the directions.

•

Set ICM jumper to the left position to enable system supply

water temperature (VT) mode.

Buderus GB142 and GB162

----------------------

–

304P

+

5+6

–

Camus

Micoflame

• Change control to mode 6 in the control parameters.

Heat Transfer Products Elite

–

+

304P

---------------------

16–17

+

HTP

Elite

• Move jumper on connection board from A to B.

• Set function 17 to temperature.

IBC VFC and SL Series

--------------------------

2

–

304P

+

EM10 Module

1

Buderus

• Install the Buderus EM10 module as per the directions.

• Do NOT install the jumper between U terminals 1 and 3 on

the EM10 module.

Burnham Alpine

–

---------------------------------

T

+

T

+

304P

X

X

12910

Burnham

Alpine

–

• Change Parameter 9 Remote 4-20 mA to Setpoint Source.

Change "Energy Management" setting "Central Heat

•

Modulation Source" to 4-20 mA.

Change "Energy Management" setting "Central Heat 4-20

•

mA Setup, 4 mA Water Temperature" to 80°F (26.5°C).

T

+

T

–

X

+

X

304P

12910

IBC V10

Control

–

On the V10 controller:

• Set Load 1 to External Control

• Change "Max Control @ 9.5 Vdc" to 190°F (88°C)

• Change "Min Control @ 2.1 Vdc" to 32°F (0°C)

Laars Mascot LX

–

•

Change Installer Parameter 25 "0-10V to Power" to Disabled.

--------------------------------

T

+

T

+

304P

X

X

561112

Mascot LX

–

Laars

• Change Installer Parameter 26 "0-10V to outlet setpoint" to

Disabled.

9 of 12

© 2018 tekmar 304P_D - 12/18

Page 10

Laars Mascot FT

--------------------------------

--------------------------------

---------------------------------

------------------------------------

------------------------------

---------

---------------------------

--------------------------------

NTI Trinity FireTube

------------------------------

–

304P

+

16–17

+

Laars

Mascot FT

• No changes to the boiler are required.

Lochinvar Knight

–

+

304P

•

Set BMS Type to Setpoint. This is the factory default setting.

Lochinvar FTXL

--------------------------------

R

+

W

X

X

---------------------------------

19 20 33 3 4

Lochinvar

–

Knight

–

X

+

X

304P

R

35 45

24Vac I/O

NTI Trinity Fire Tube

CH1

+

–

Sensor I/O

• Enter boiler password.

• Set Parameter "Setpoint source" to 4-20mA

Peerless Pinnacle PF-200, 210, 300, 399

–

+

304P J5 J8 J18

15+16

–

Peerless

Pinnacle

Terminal Strip

2–8+12 12

Peerless

PFA-1 Interface

Adapter

---------

Peerless

Pinnacle

Control Board

• Install the Peerless PFA-1 Interface Adapter

On the boiler display, change Central Heating Mode to 4 for

•

0-10 VDC Input to Modulate Setpoint

R

+

W

–

X

+

X

304P

21 22 35 3 6

Lochinvar

–

FTXL

• Set BMS parameter to ACTIVE.

• Set BMS Type to SETPOINT.

NTI Trinity LX

------------------------------------

R

–

–

X

+

X

304P

CH1

351112

NTI Trinity LX

• Enter boiler password.

• Set Parameter "Setpoint source" to 4-20mA

Riverside HeatStation

+–

304P

---------------------------

+

–

EMS

9

8

Riverside

HeatStation

• Set boiler PIM DIP switch 2 to Off.

• Set boiler PIM DIP switch 5 to On.

• Set boiler PIM DIP switch 6 to Off.

+

• Set APP parameter to EMS

• Set SIGNAL parameter to 0-10Vdc

• Set SETP LO to 70°F

• Set SETP HI to 180°F

© 2018 tekmar 304P_D - 12/18

10 of 12

Page 11

--------------

--------------------------

Raypak MVB and XTherm

-----------------------

----------------------

---------------------------

-----------------------

Weil-McLain Evergreen

--------------------------

+

–

X

+

X

304P

–

13 1 4 17 18

Raypak MVB or

XTherm

• Set boiler PIM DIP switch 2 to Down.

• Set boiler PIM DIP switch 5 to Up.

Raypak XFyre and XPakFT

+– XX

304P

----------------------

+

–

89 910

J2 J1

Raypak XFyre or

XPakFT

• Set boiler PIM DIP switch 2 to Down.

• Set boiler PIM DIP switch 5 to Up.

–

304P

+

5+6

–

Weil-McLain

Evergreen P15

• Use Local Priority 1 for DHW tank heating.

TM

• Use Local Priority 2 for the RoomResponse

signal.

• Set Local Priority 2 Supply Min to 60°F.

• Set Local Priority 2 Supply Max to 180°F.

• Set Local Priority 2 Volts For Min to 2 V.

• Set Local Priority 2 Volts For Max to 10 V.

T

T

Viessmann Vitodens 100-W, WB1B

–

+

304P

Install the OpenTherm Module as per the boiler manufac-

•

OpenTherm Module

--------------

1–4

+

Viessmann

turer's instructions.

Viessmann Vitodens 200-W, B2HP and

Vitocrossal 300 CU3A

–

+

304P

---------------------------

1–2

+

Viessmann

Extension Module EA1

Plug 0-10V

•

Connect to the Viessmann Extension Module EA1 Plug 0-10V.

11 of 12

© 2018 tekmar 304P_D - 12/18

Page 12

Technical Data

Switching Relay 304P Four Zones with Priority

Literature 304P_C, 304P_D, 304_J

Control Microprocessor control. This is not a safety (limit) control.

Packaged weight 5.0 lb. (2250 g)

Dimensions 8-3/16" H x 10-12/18" W x 2-3/8" D (208 x 271 x 60 mm)

Enclosure Cover: ABS plastic, Base: galvanized steel, NEMA type 1

Approvals

Ambient conditions 32 to 122°F (0 to 50°C), ≤ 90% RH non-condensing

Power supply 115 V (ac) ±10%, 60 Hz, 17.3 A

Transformer 40 VA at 24 V (ac), expandable to 80 VA with additional transformer M3069 (sold separately)

Control load 7 VA at 24 V (ac)

Fuses T5A 250 V slow blow, two spare fuses included

Pump relays 115V (ac), 5 A, 1/3 hp, 17.3 A combined

Boiler XX end switch 24 V (ac), 5 A

DHW end switch 24 V (ac), 5 A

Mod boiler output 0-10 V (dc) 500 min impedance / 4-20 mA 1 k max impedance

CSA C US

Limited Warranty and Product Return Procedure

Limite d Warranty The liability of tekmar under this warranty is limited. The

Purchaser, by taking rec eipt of any tekm ar product (“Product”), acknowledges the terms of the Limited Warranty in effect at the time of such Product

sale and acknowledges that it has re ad and understands same.

The tekmar Limited Warranty to the Purchaser on the Products sold hereunder

is a manufacturer’s pass-through warranty which the Purchaser is authorized to

pass through to its customers. Under the Limited Warranty, each tekmar Product is warranted against defects in workmanship and materials if the Product

is installed and used in compliance with tekmar’s instructions, ordinary wear

and tear excepted. The pass-through warranty period is for a period of twenty-four (24) months from the production date if the Product is not installed during

that period, or twelve (12) months from the documented date of installation if

installed within twenty-four (24) months from the production date.

The liability of tekmar under the Limited Warranty shall be limited to, at tekmar’s

sole discretion: the cost of parts and labor provided by tekmar to repair defects in

materials and / or workmanship of the defective product; or to the exchange of the

defective product for a warranty replacement product; or to the granting of credit

limited to the original cost of the defective product, and such repair, exchange or

credit shall be the sole remedy available from tekmar, and, without limiting the

foregoing in any way, tekmar is not responsible, in contract, tort or strict product liability, for any other losses, c osts, expenses, inconveniences, or damages,

whether direct, indirect, special, secondary, incidental or consequential, arising

from ownership or use of the product, or from defects in workmanship or materials,

including any liabilit y for fundamental breach of contract.

The pass-through Limited Warrant y applies only to those defective Products

returned to tekmar during the warranty p eriod. This Limited Warranty does not

cover the cost of the parts or labor to remove or transport the defective Product, or

to reinstall the repaired or replacement Product, all such costs and expenses being

subjec t to Purchaser’s agreement and warranty with its customers.

Any representations or warranties about the Products made by Purchaser to its customers which are different from or in excess of the tek mar Limited Warranty are the

Purchaser’s sole responsibility and obligation. Purchaser shall indemnify and hold

tekmar harmless from and against any and all claims, liabilities and damages of any

kind or nature which arise out of or are related to any such representations or warranties by Purchaser to its customers.

The pass-through Limited Warrant y does not apply if the returned Product has been

damaged by negligence by persons other than tekmar, accident, fire, Act of God,

abuse or misuse; or has been damaged by modifications, alterations or attachments

made subsequent to purchase which have not been authorized by tekmar; or if the

Product was not installed in complianc e with tekmar’s instructions and / or the local

codes and ordinances; or if due to defective installation of the Product; or if the Product was not used in c ompliance with tekmar’s instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, WHICH THE GOVERNING LAW ALLOWS PARTIES TO CONTRACTUALLY EXCLUDE, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, DURABILITY OR DESCRIPTION OF THE PRODUCT, ITS NON-INFRINGEMENT OF

ANY RELEVANT PATENTS OR TRADEMARKS, AND ITS COMPLIANCE WITH

OR NON-VIOLATION OF ANY APPLICABLE ENVIRONMENTAL, HEALTH OR

SAFETY LEGISLATION; THE TERM OF ANY OTHER WARRANTY NOT HEREBY

CONTRACTUALLY EXCLUDED IS LIMITED SUCH THAT IT SHALL NOT EXTEND

BEYOND TWENTY-FOUR (24) MONTHS FROM THE PRODUCTION DATE, TO

THE EXTENT THAT SUCH LIMITATION IS ALLOWED BY THE GOVERNING LAW.

Product Warranty Return Procedure All Products that are believed to have

defects in workmanship or materials must be returned, together with a written

description of the defect, to the tekmar Representative assigned to the territory in

which such Product is located. If tekmar receives an inquiry from someone other

than a tekmar Representative, including an inquiry from Purchaser (if not a tekmar

Representative) or Purchaser’s customers, regarding a potential warranty claim,

tekmar’s sole obligation shall be to provide the address and other contact information regarding the appropriate Representative.

WARNING: This product contains chemicals known to the State of

California to cause cancer and birth defects or other reproductive harm.

For more information: Watts.com/prop65

304P_D - 12/18 12 of 12 © 2018 tekmar

All speci cations are subject to change without notice

Tel: (250) 545-7749 • Fax: (250) 984-0815

tekmarControls.com

Loading...

Loading...