Page 1

kÉï=~ë=çÑW=

T

R

Prog.

S

kV

mA

P1

NMKOMNR

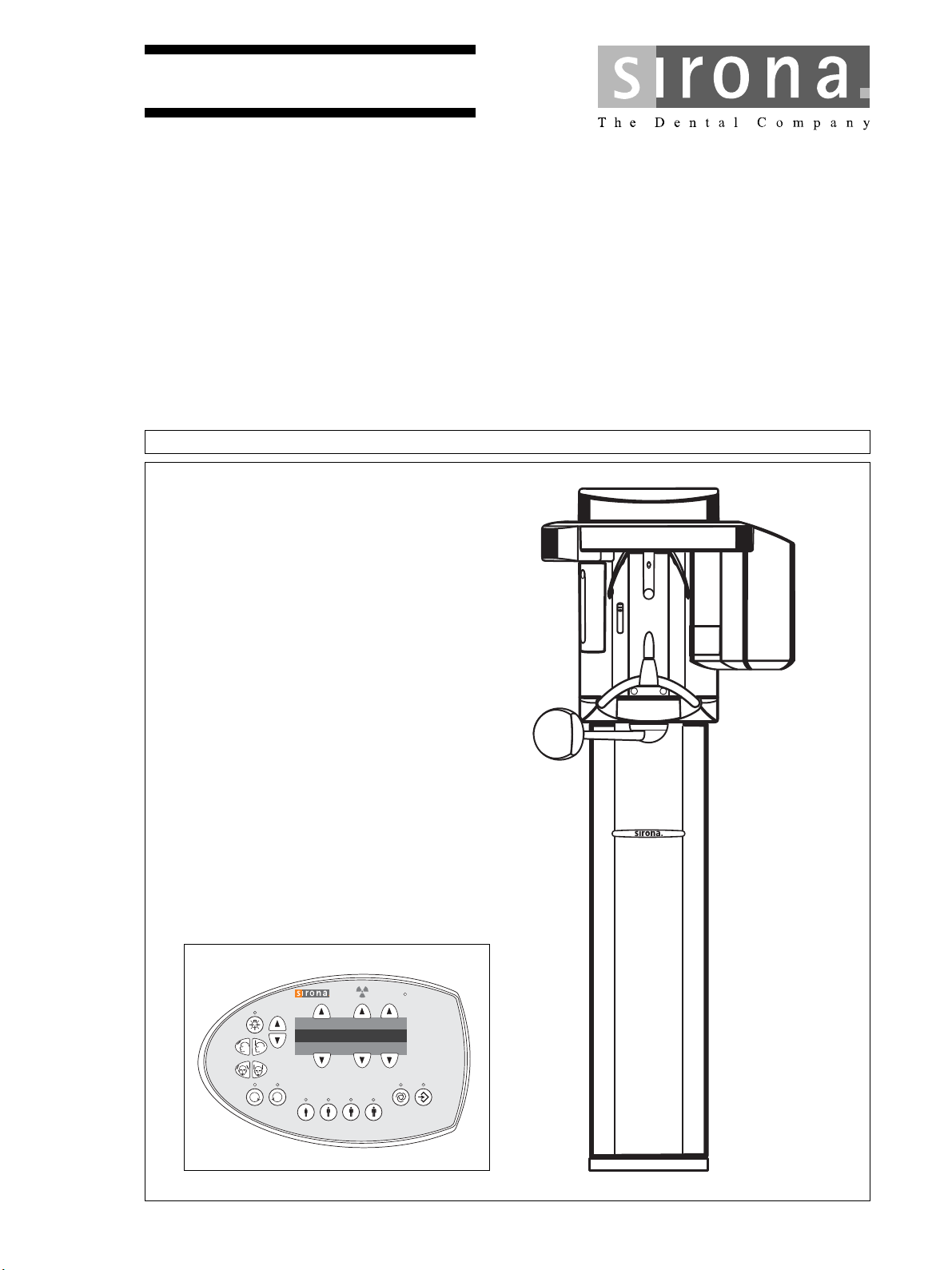

loqelmelp=ud=P=

fелн~дд~нбзе=fелнкмЕнбзел

bеЦдблЬ

Page 2

Sirona Dental Systems GmbH

Installation Instructions ORTHOPHOS XG 3

General information

About this document

This document describes the installation of the ORTHO

PHOS XG XG3 panoramic X-ray unit.

kÉï=~ë=çÑW=

NMKOMNR

For installation, please refer also to the following docu

ments:

-

• Installation drawings

• "Installation Requirements" (separate document)

• Operating Instructions

•Service Manual

• Installation Report and Warranty Passport

• SIDEXIS XG, Digital Radiography:

Installation instructions

Our Customer Service Center can provide the technical

documentation in paper form free of charge on request pro

vided that the respective order numbers are specified cor

rectly.

The latest documentation can always be downloaded from

the Sirona homepage:

www.sirona.com/HOME/Service/Technical Documentation

-

-

-

Changes since the last version 07.2013:

Chapter or section page

6.2 Checking the device leakage current .................... 63

60 51 416 D 3352

D 3352.031.03.18.02

Page 3

Sirona Dental Systems GmbH

Installation Instructions ORTHOPHOS XG 3

Contents

1 Before you begin ............................................................................................................... 5

1.1 Identification of warnings ......................................................................... 6

1.2 Safety....................................................................................................... 7

1.3 System and sensor versions.................................................................... 8

1.4 Dimensions/Space requirements............................................................. 9

1.5 Mounting options ................................................................................... 10

1.6 Installation versions ............................................................................... 11

2 Delivery and transport .................................................................................................... 13

2.1 Delivery.................................................................................................. 14

2.2 Transport to the installation site............................................................. 18

3 Installation: Panoramic X-ray unit ................................................................................. 19

3.1 Installation material................................................................................ 20

3.2 Required tools........................................................................................ 22

3.3 Wall mounting (standard/option 1)......................................................... 23

3.4 Installing the floor stand (option 2)......................................................... 30

3.5 Removing the transport safety device ................................................... 40

3.6 Installing the release button holder........................................................ 41

3.7 Attaching the covers .............................................................................. 42

English

4 Electrical connection ...................................................................................................... 45

4.1 Connecting the control cables (PAN)..................................................... 46

4.2 Connecting the line voltage ................................................................... 47

5 Installation: Remote control........................................................................................... 49

5.1 Installation material/tools ....................................................................... 50

5.2 Mechanical installation........................................................................... 51

5.3 Connecting the control cables (REMOTE)............................................. 53

5.4 Connecting the door contact switch....................................................... 56

5.5 Connecting the X-ray warning lamp....................................................... 57

5.6 Final work .............................................................................................. 58

6 Safety checks................................................................................................................... 59

6.1 Checking the protective ground wires.................................................... 60

6.2 Checking the device leakage current..................................................... 63

7 Initial startup.................................................................................................................... 65

7.1 Inserting the forehead and temple supports .......................................... 66

7.2 Inserting the sensor ............................................................................... 67

7.3 Switching the units ON .......................................................................... 68

7.4 Checking the data paths ........................................................................ 69

60 51 416 D 3352

D 3352.031.03.18.02

Page 4

Sirona Dental Systems GmbH

Installation Instructions ORTHOPHOS XG 3

8 Startup for USA/Canada only ......................................................................................... 73

8.1 Startup, measurements and controls ..................................................... 74

8.2 Power supply adequacy ......................................................................... 75

8.3 Tube Current Verification ....................................................................... 76

8.4 kV – verification / Exposure Time Verification........................................ 79

8.5 Checking the laser for USA/Canada only............................................... 81

9 Checking the system adjustment .................................................................................. 83

9.1 Test exposures....................................................................................... 84

10 Final work......................................................................................................................... 91

10.1 Attaching the profile covers.................................................................... 92

10.2 Selecting More details............................................................................ 93

10.3 Declaration of Conformity....................................................................... 94

10.4 Unit handover......................................................................................... 95

11 Appendix .......................................................................................................................... 97

11.1 Service routines (for installation)............................................................ 98

11.2 Adjusting the panoramic X-ray unit ...................................................... 109

11.3 Demo mode.......................................................................................... 136

60 51 416 D 3352

D 3352.031.03.18.02

Page 5

ORTHOPHOS XG 3

1 Before you begin

60 51 416 D 3352

D 3352.031.03.18.02

5

Page 6

1 Before you begin Sirona Dental Systems GmbH

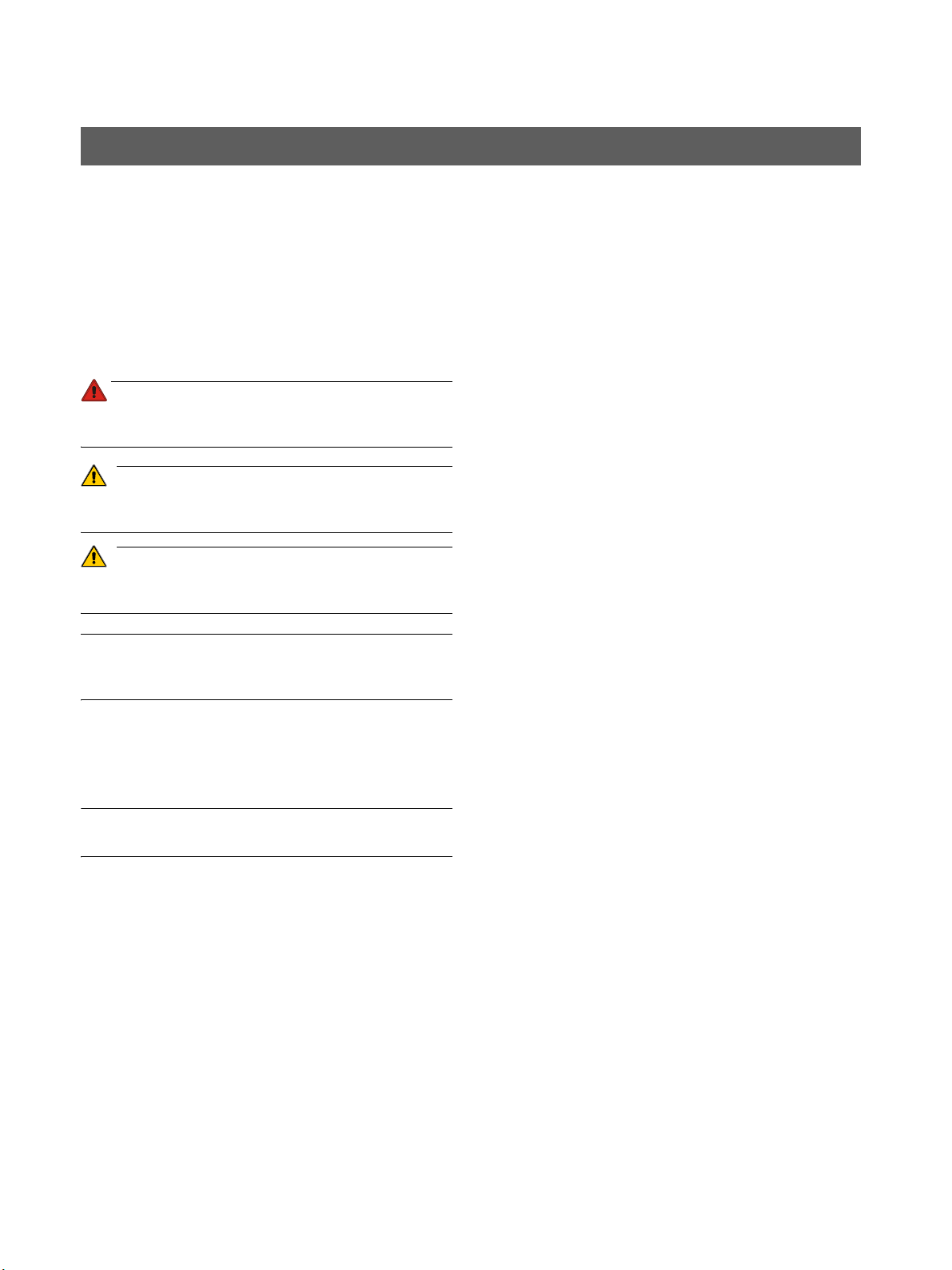

DANGER

WARNING

CAUTION

NOTICE

IMPORTANT

1.1 Identification of warnings Installation Instructions ORTHOPHOS XG 3

1.1 Identification of warnings

Warning and safety information

To prevent personal injury and material damage, please

observe the warning and safety information provided in the

present operating instructions.

The structure, appearance and use of warning and safety

information in Sirona documents are based on the ANSI

Z535 standard.

The following warnings may be used in this document:

An imminent danger that could result in serious bodily

injury or death.

A possibly dangerous situation that can result in seri

ous bodily injury or death.

A possibly dangerous situation that can result in slight bodi

ly injury.

A possibly harmful situation which can lead to damage of

the product or an object in its environment.

Instructions for use

The following application information may be used in this

document:

Application instructions and other important information.

Tip: Information on making work easier.

-

-

6 D 3352.031.03.18.02

60 51 416 D 3352

Page 7

Sirona Dental Systems GmbH 1 Before you begin

DANGER

WARNING

WARNING

WARNING

WARNING

CAUTION

NOTICE

NOTICE

NOTICE

Installation Instructions ORTHOPHOS XG 3 1.2 Safety

1.2 Safety

Fixed connection!

The installation of a power plug instead of the pre

scribed fixed (hard-wired) connection violates interna

tional medical regulations and is prohibited.

In case of a fault, you would thus endanger the life and

limb of the patient, the operator or other persons.

Installation and startup must be carried out in accor

dance with the requirements stated in our Installation

Instructions.

Installation and startup may be carried out only by per

sonnel specifically authorized by SIRONA.

Any person who assembles or modifies a medical elec

trical system complying with the standard IEC 60

601-1-1

(safety requirements for medical electrical equipment)

by combining it with other equipment is responsible for

ensuring that the requirements of this regulation are

met to their full extent for the safety of the patients, the

operators and the environment.

-

-

The unit contains class 1 lasers.

Keep a distance of at least 4" (10 cm) between eye and la

-

ser. Do not stare into the beam.

Do not use the system with any other lasers, and do not

make any changes to settings or processes that are not de

scribed in these operating instructions. This may lead to a

dangerous exposure to radiation.

Use an ESD wrist band during installation.

Connect it to the

protective ground wire.

-

When opening the unit:

Please observe the usual precautionary

measures for handling PCBs (ESD).

Touch a ground point to discharge static elec

-

tricity before handling any components.

Extreme fluctuations of temperature may cause condensa

tion inside the unit. Do not switch the unit on before it has

reached normal room temperature.

-

-

-

-

English

If any equipment not approved by SIRONA is connect

ed, it must comply with the applicable standards:

- IEC 60950-1 for information technology equipment

and

- IEC 60 601-1 for medical electrical equipment.

See also “On-site installation, dimensions, technical

data” and the “Compatibility list/Declaration of

conformity” issued by the system integrator.

In case of doubt, contact the manufacturer of the sys

tem components.

Wireless phone interference with medical electrical

equipment:

To ensure safe operation of medical electrical equip

ment, the use of mobile wireless phones in practice or

hospital environments is prohibited.

-

-

-

60 51 416 D 3352

D 3352.031.03.18.02

7

Page 8

1 Before you begin Sirona Dental Systems GmbH

1.

2.

1.3 System and sensor versions Installation Instructions ORTHOPHOS XG 3

1.3 System and sensor versions

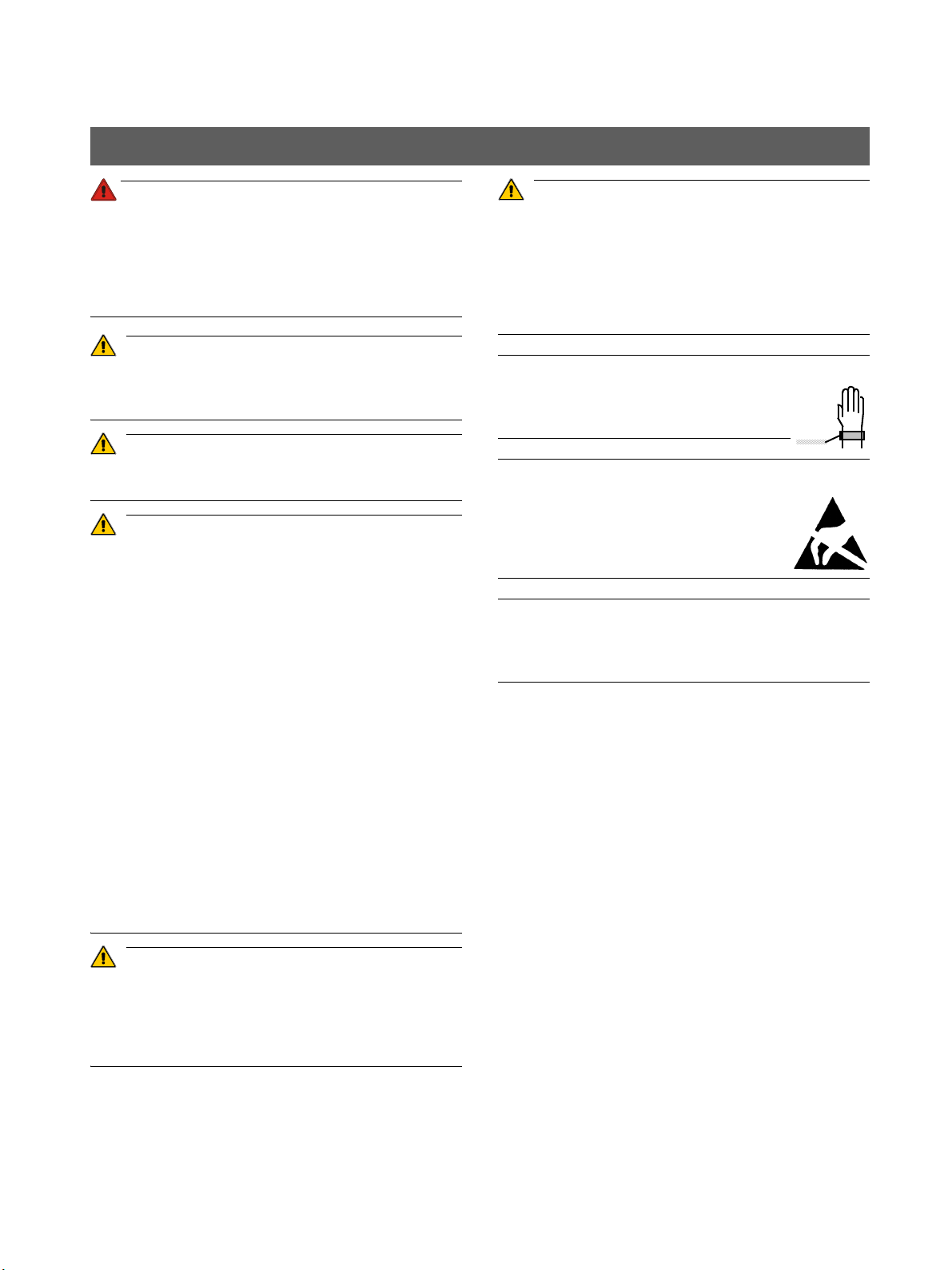

1. ORTHOPHOS XG 3

Digital unit

2. XG PAN sensor

Sensor for panoramic (PAN) X-ray

60 51 416 D 3352

8 D 3352.031.03.18.02

Page 9

Sirona Dental Systems GmbH 1 Before you begin

NOTICE

NOTICE

Installation Instructions ORTHOPHOS XG 3 1.4 Dimensions/Space requirements

1.4 Dimensions/Space requirements

English

The minimum ceiling height should be 2.10 m (82 11/16"). If

the ceiling height is lower than 2.27 m (89 3/8“) (max. travel

height of 2.25 m (88 1/2“)), the travel height of the unit must

be adjusted or limited prior to startup of the unit (see section

11.1.7). )

60 51 416 D 3352

D 3352.031.03.18.02

The dimensions specified here apply to installation of the

X-ray unit without the floor stand. Installation with the floor

stand results in an additional 30 mm (1 3/16“) increase of all

height dimensions.

9

Page 10

1 Before you begin Sirona Dental Systems GmbH

IMPORTANT

1. 3.2.

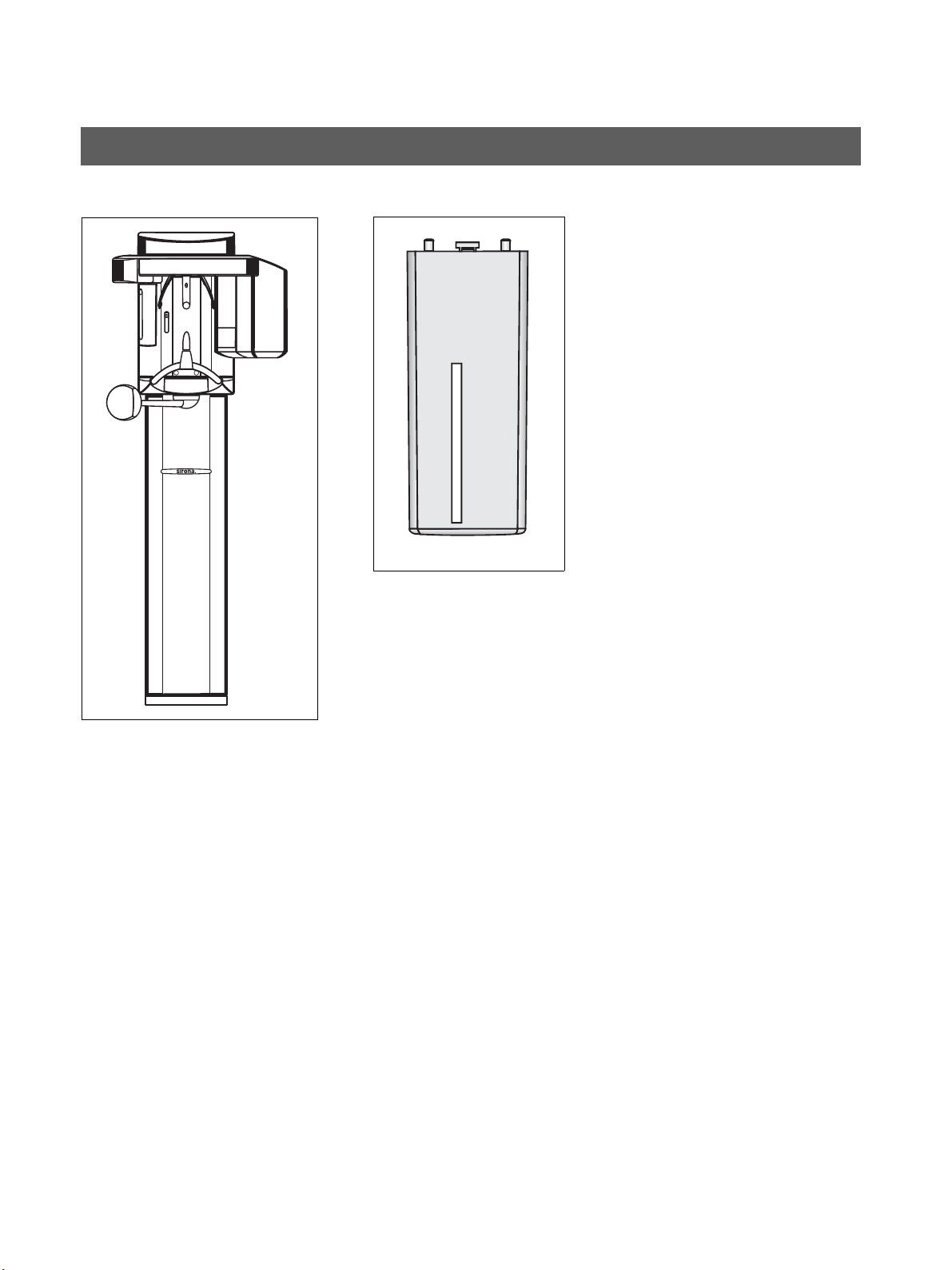

Standard version Option 1 Option 2

1.5 Mounting options Installation Instructions ORTHOPHOS XG 3

1.5 Mounting options

Standard version

(see Section 3.3)

1. Wall-mounted installation with 1 wall holder and

floor fastening if both wall and floor installation are

possible on-site.

Option 1: with second wall holder

(see Section 3.3)

2. Wall-mounted installation with 2 wall holders (and

no floor fastening) if only wall installation is possible

on-site.

Option 2: with floor stand

(see section 3.4)

3. Installation with floor stand for free installation any

where in the room or if wall-mounted installation is not

possible on-site (e.g. with lightweight walls).

If the unit is installed freely with a floor stand, the quality of

the resulting X-ray exposures may be impaired,

depending on the floor or surface conditions. Sirona there

fore recommends additional fastening of the unit with an up

per wall holder also when installing it with a floor stand.

-

-

-

10 D 3352.031.03.18.02

60 51 416 D 3352

Page 11

Sirona Dental Systems GmbH 1 Before you begin

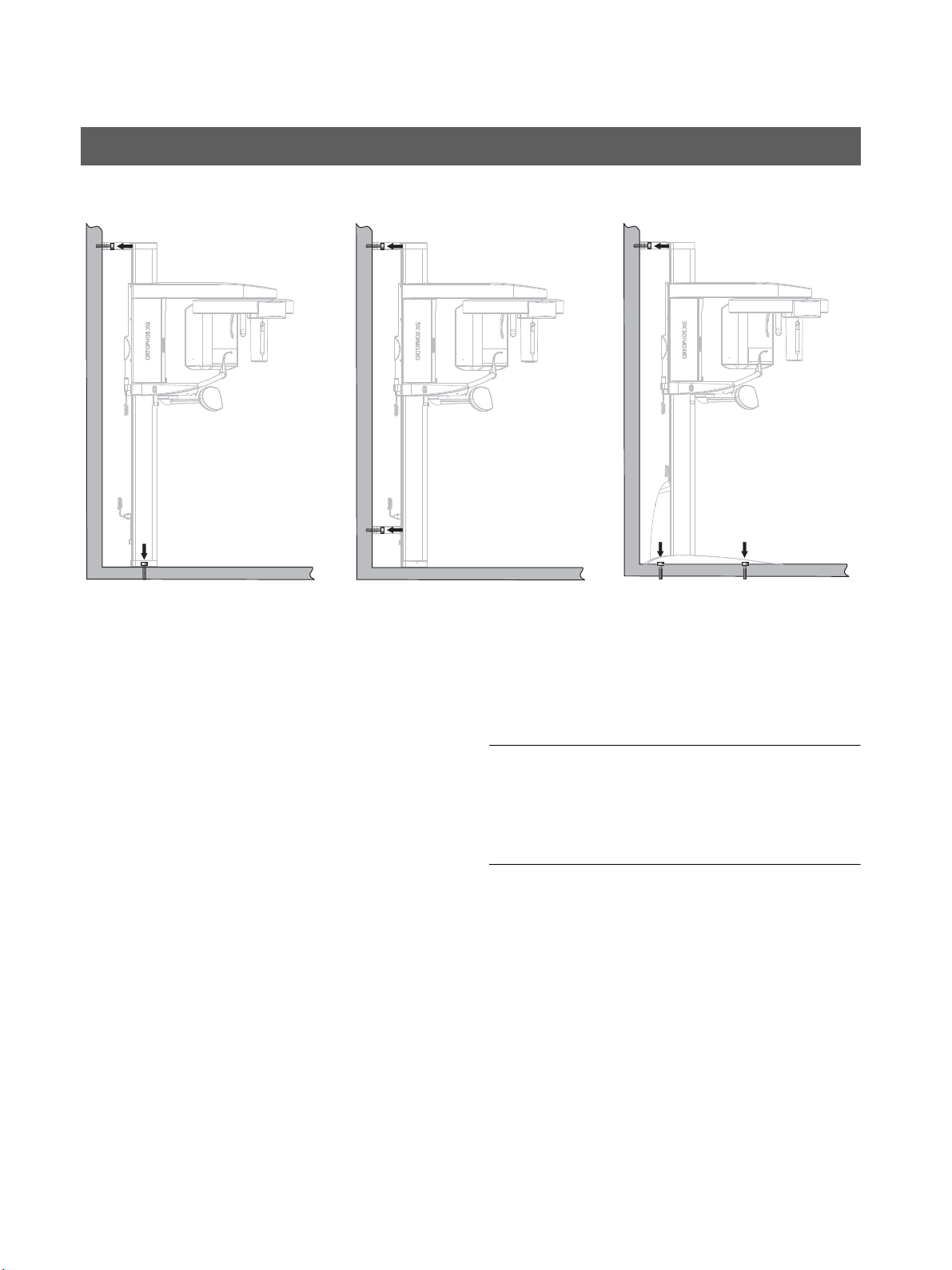

1. 2.

3.

Installation Instructions ORTHOPHOS XG 3 1.6 Installation versions

1.6 Installation versions

1. Standard installation:

ORTHOPHOS XG 3 without remote control with re

lease button on the coiled cable in the treatment

room.

2. Installation version 1 (see section 5.3.1):

-

ORTHOPHOS XG 3 with remote control outside the

X-ray room without release button on the coiled ca

ble.

English

-

60 51 416 D 3352

D 3352.031.03.18.02

3. Installation version 2 (see section 5.3.2):

ORTHOPHOS XG 3 with remote control outside the

X-ray room with release button on the coiled cable.

11

Page 12

1 Before you begin Sirona Dental Systems GmbH

1.6 Installation versions Installation Instructions ORTHOPHOS XG 3

12 D 3352.031.03.18.02

60 51 416 D 3352

Page 13

ORTHOPHOS XG 3

2 Delivery and transport

60 51 416 D 3352

D 3352.031.03.18.02

13

Page 14

2 Delivery and transport Sirona Dental Systems GmbH

NOTICE

IMPORTANT

IMPORTANT

Dimensions (cm): 199 x 69 x 122

Weight: 177 kg (390 lbs)

(inches): 78 3/8 x 30 3/4 x 28 3/4

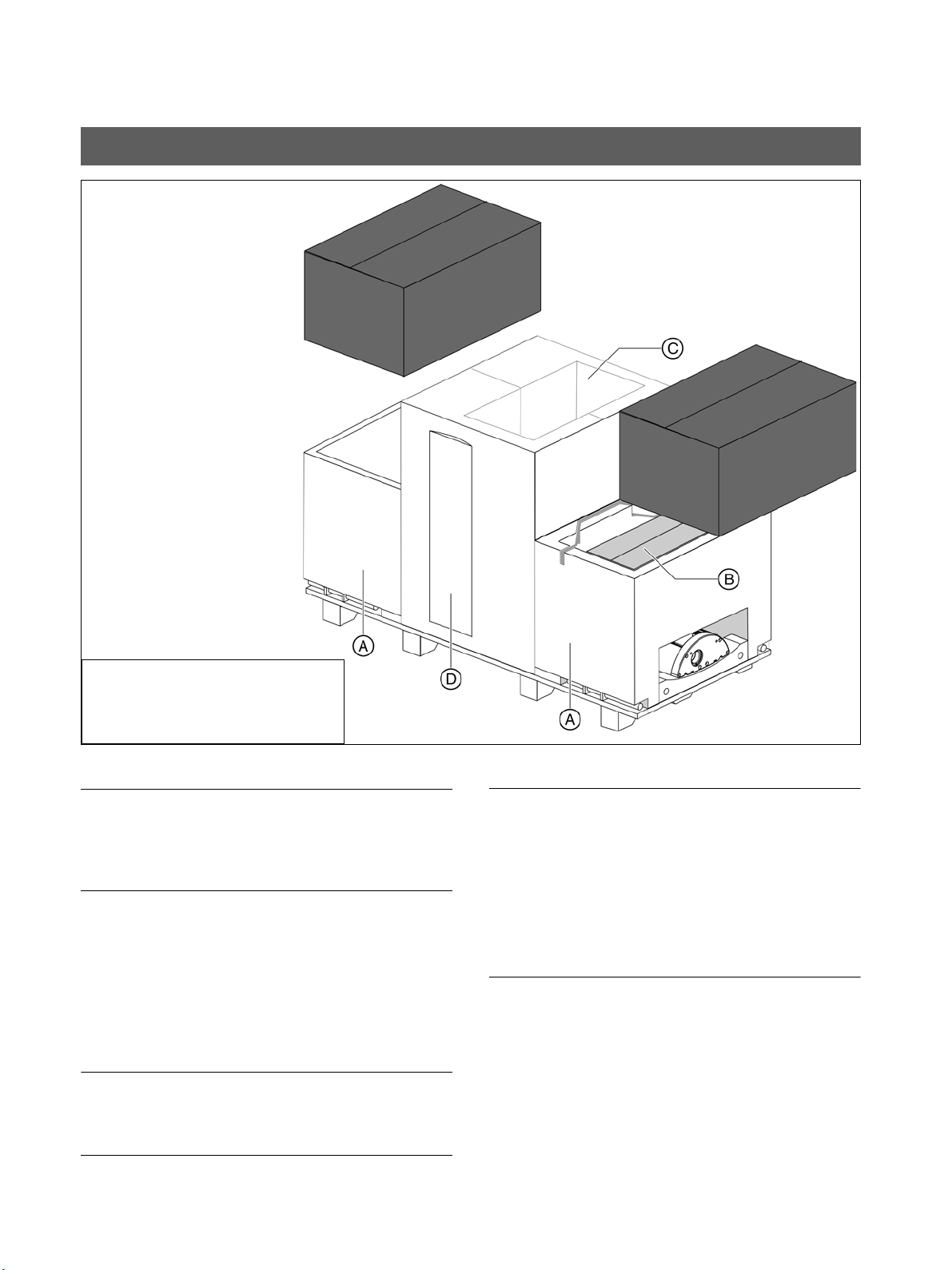

2.1 Delivery Installation Instructions ORTHOPHOS XG 3

2.1 Delivery

Possible transport damage!

If the shipment was damaged during transport, document

all damage carefully and contact the responsible carrying

agent immediately.

All SIRONA equipment is carefully checked and packed

prior to shipment. Please carry out an incoming inspection

of the equipment in order to make sure that it was not dam

aged during transport.

• Check the packaging and the equipment for visible

signs of damage.

• Check the shipment for completeness based on the at

tached “scope of supply” checklist.

Disposal: Return the packaging materials to SIRONA or

dispose of them in compliance with the legal regulations ap

plicable in your country.

14 D 3352.031.03.18.02

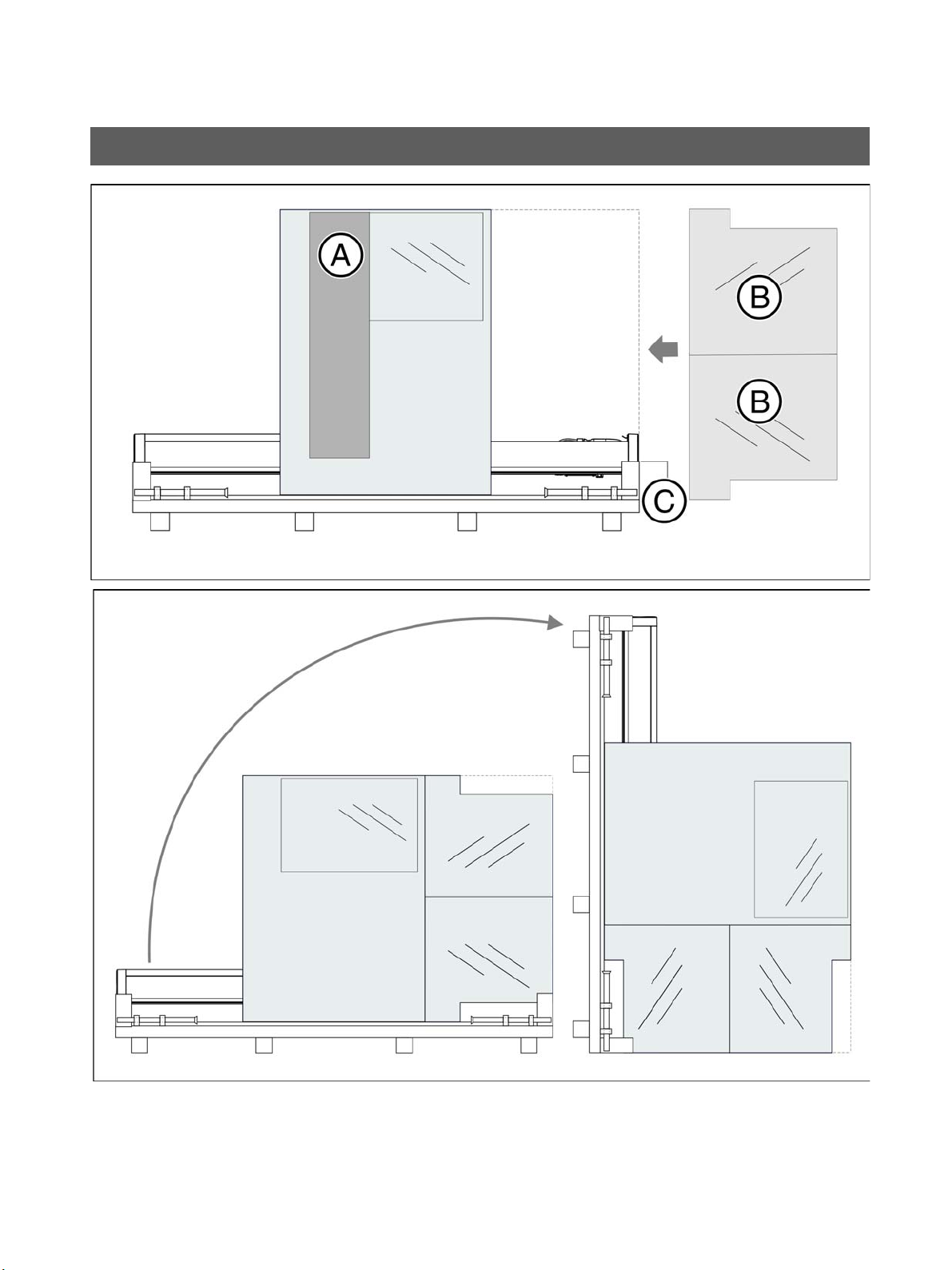

The packaging of the X-ray unit is designed both for protec

tion during transport and as an installation aid.

Therefore, please remove only the surrounding packaging

prior to installation. Please leave the styrofoam packaging

and transport pallet attached to the unit.

Save one of the lateral styrofoam packaging parts for

-

later use as an installation aid A.

Scope of supply

• Panoramic X-ray unit

-

• Profile cover (D)

•Sensor (B)

• Accessories and hygienic protective covers (see pp.

16 ff.) (B)

• Installation material (see section 3.1) (B)

-

• Safety strap (B)

• Remote control (optional) (C)

60 51 416 D 3352

-

Page 15

Sirona Dental Systems GmbH 2 Delivery and transport

A

A

B

Installation Instructions ORTHOPHOS XG 3 2.1 Delivery

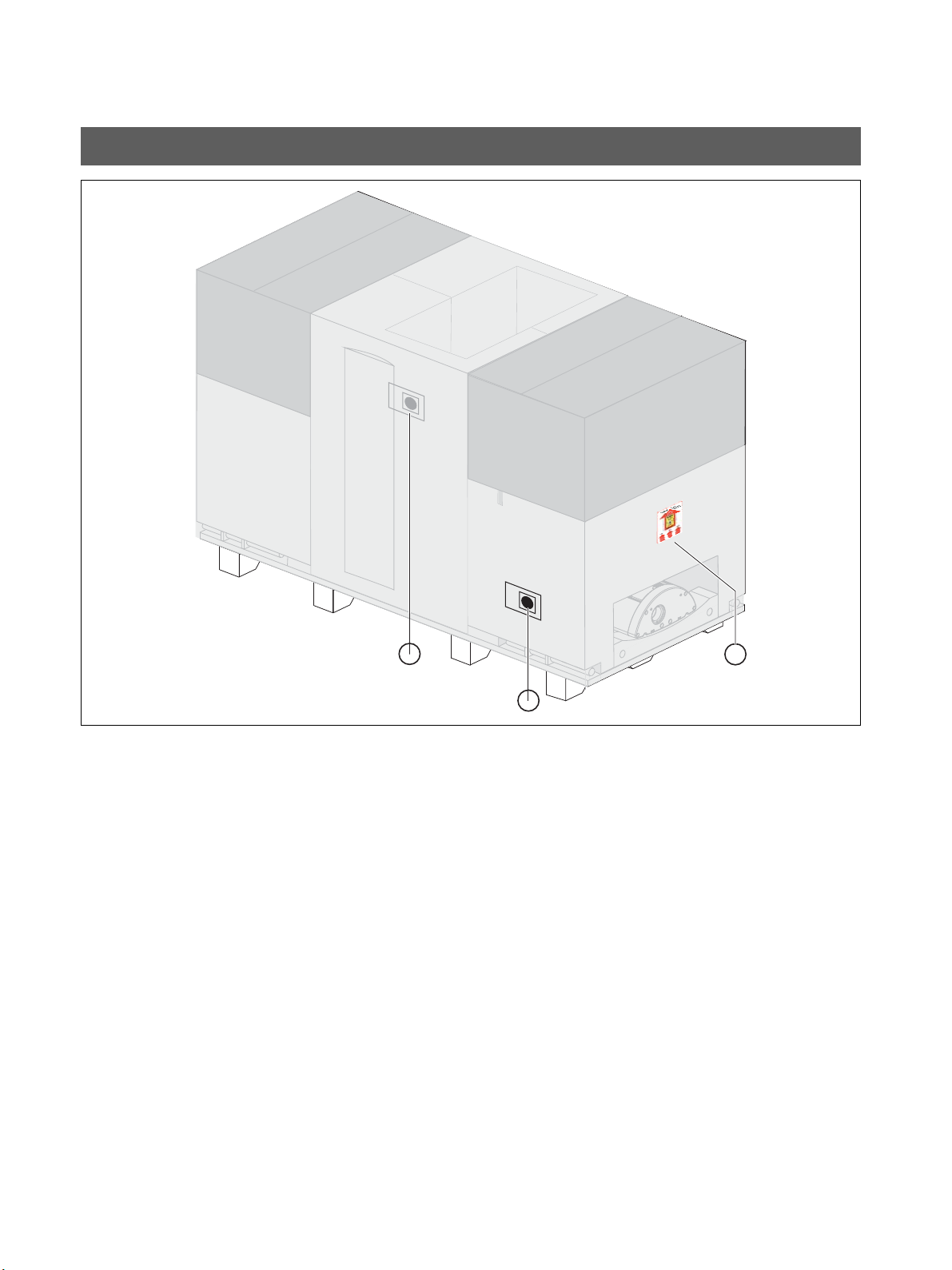

Tw o shock indicators A are attached to the side of the

packaging to indicate whether the unit was exposed to a

shock during transport.

• White indicator: No shock

• Red indicator: Shock

A tilt indicator B that enables you to recognize whether the

unit was transported improperly is also attached to the

packaging.

• Red indicator: Improper transport

The display of improper transport doesn't necessarily mean

that the unit is damaged.

Make a note on the delivery slip that the indicator is acti

-

vated. Have this confirmed on the delivery note by the driver

of the transport company.

Fax the delivery slip to the Sirona Customer Service Center

(CSC).

Enter the state of the indicators in the startup report in the

case of warranty claims.

60 51 416 D 3352

D 3352.031.03.18.02

15

Page 16

2 Delivery and transport Sirona Dental Systems GmbH

8.

12.

10.

11.

13.

7.

9.

Bar

Bite block

Bite block fixation

14.

Chin rest

Chin pad

2.1 Delivery Installation Instructions ORTHOPHOS XG 3

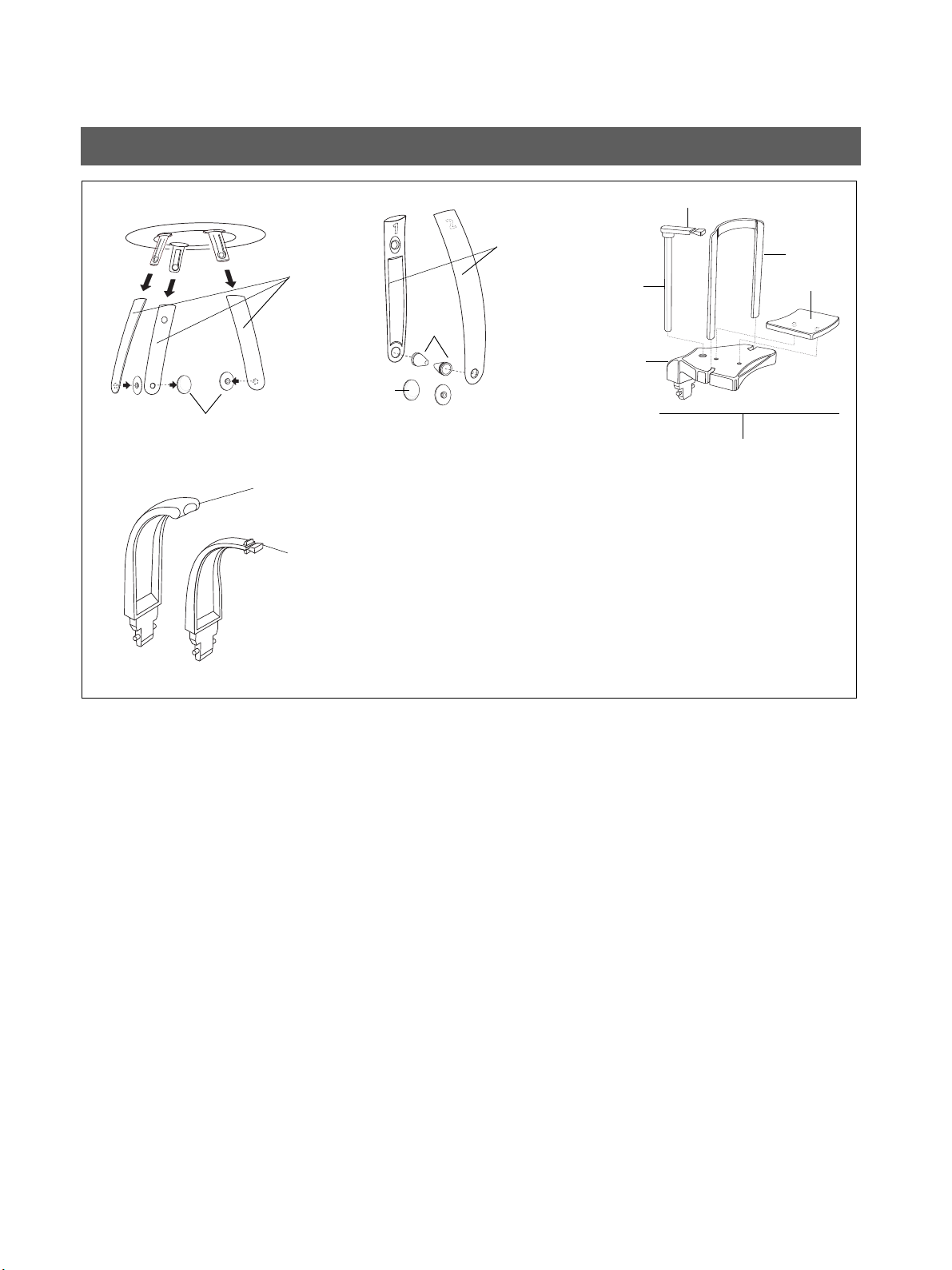

Accessories: Panoramic X-ray unit

1. Forehead (1x) and temple supports (2x)

2. Buttons (2x)

3. Temporomandibular joint supports 1 (1x) and 2 (1x)

4. Ear holders (4x)

5. Buttons TMJ (2x)

6. Chin rest accessories (1x)

– Bite block (5x)

– Bite block fixation (1x)

–Bar (1x)

– Chin pad (1x)

– Chin rest (1x)

7. Contact segment standard yellow (1x)

8. Bite block standard yellow (1x)

16 D 3352.031.03.18.02

60 51 416 D 3352

Page 17

Sirona Dental Systems GmbH 2 Delivery and transport

19.

18.

17.

20.

21.

22.

23.

Top sideBottom side

Installation Instructions ORTHOPHOS XG 3 2.1 Delivery

Hygienic protection

Hygienic protective sleeves for...

9. Forehead and temple supports (500x)

10. Bite block (500x)

11. Chin rest and bar (100x)

12. Bite blocks and contact segments (500x)

13. XG hygienic handle (100x)

Adjustment set: Panoramic X-ray unit

14. Panoramic needle phantom

15. Set of Torx offset screwdrivers

60 51 416 D 3352

D 3352.031.03.18.02

17

Page 18

2 Delivery and transport Sirona Dental Systems GmbH

NOTICE

WARNING

IMPORTANT

NOTICE

IMPORTANT

1. 2.

A

B

short

long

C

D

D

E

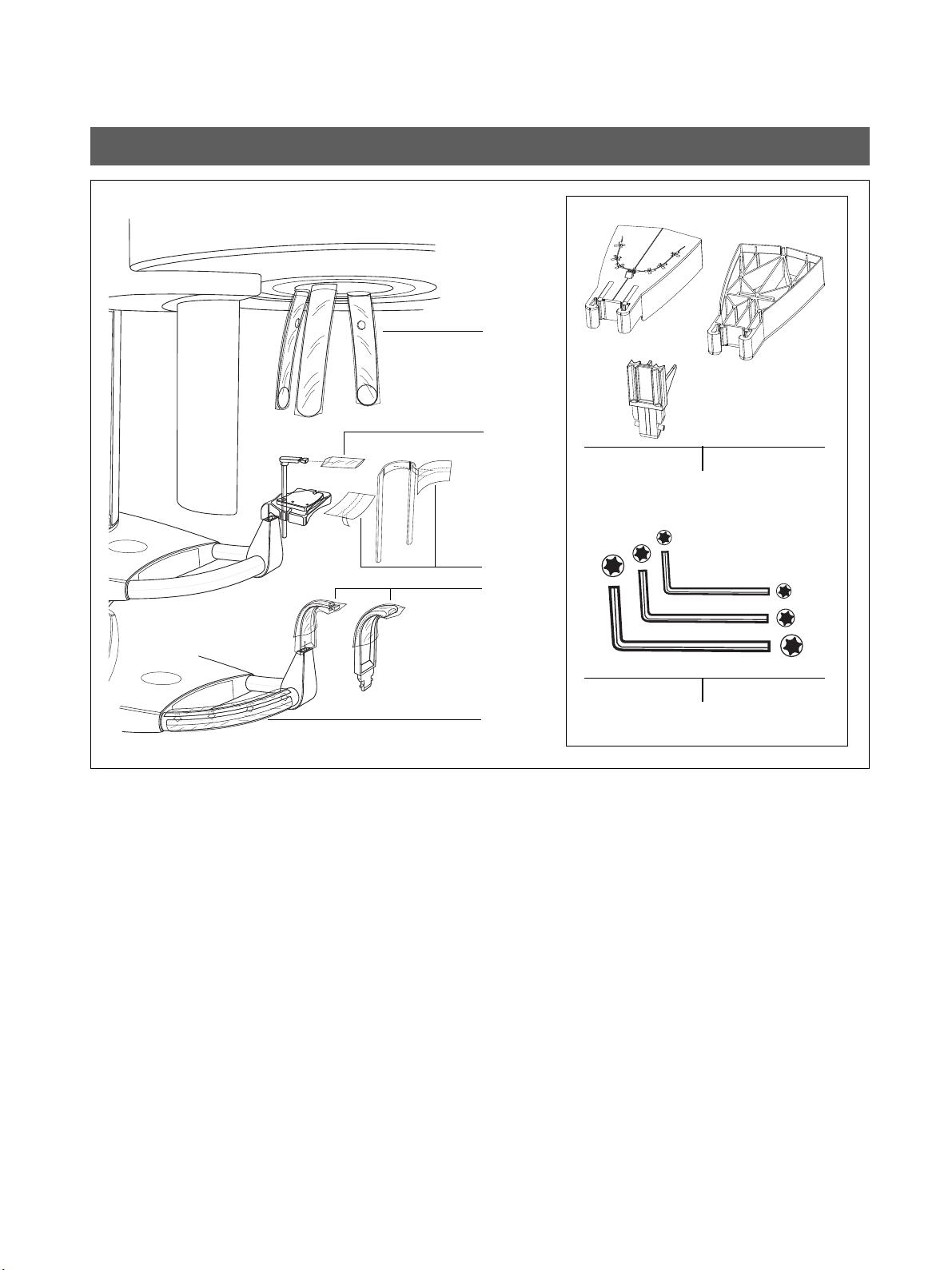

2.2 Transport to the installation site Installation Instructions ORTHOPHOS XG 3

2.2 Transport to the installation site

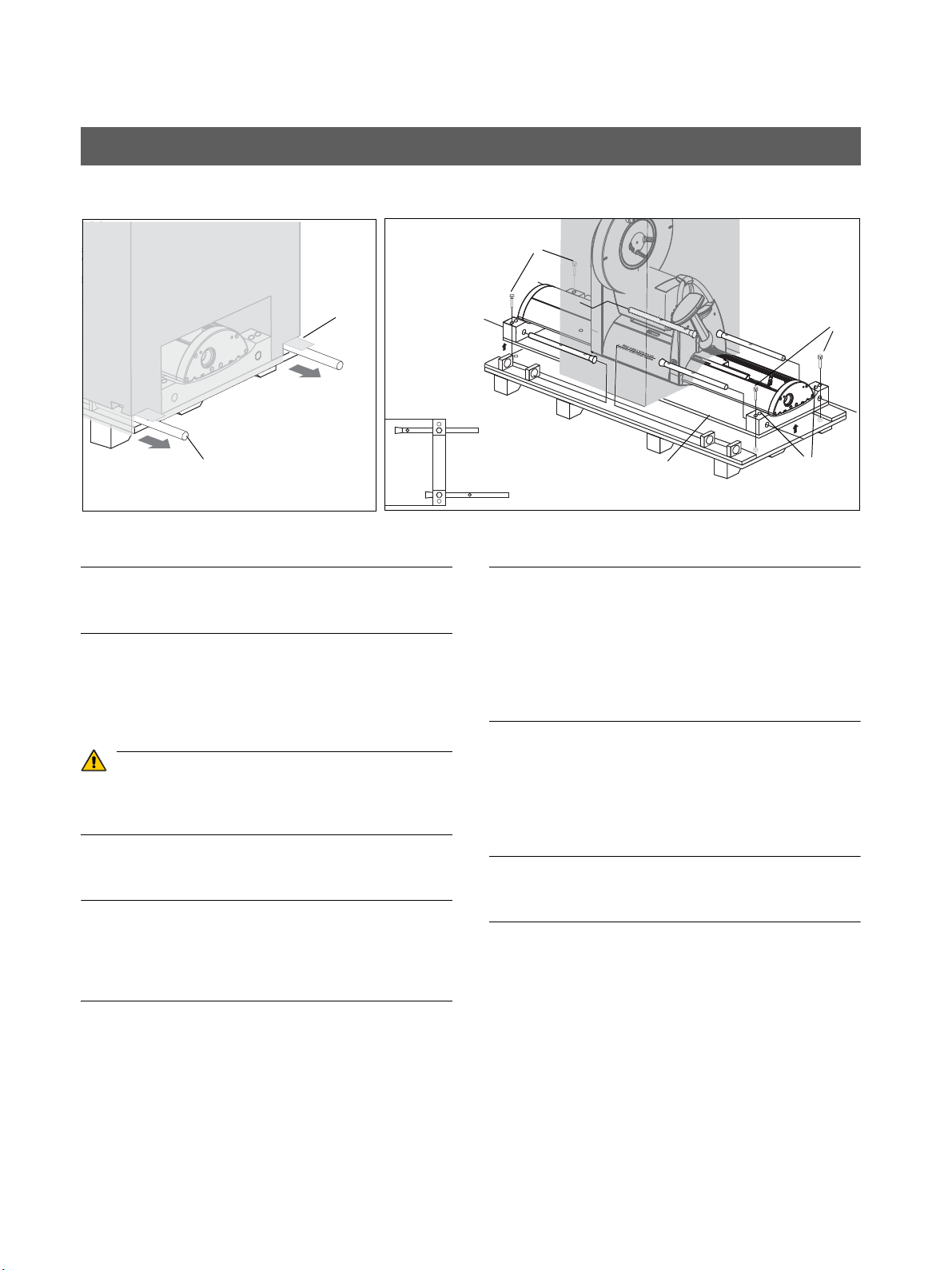

If possible leave the packaging attached to the unit during

transport in order to protect it against damage.

1. Transport with packaging attached (normal case)

– Open the surrounding packaging at the tabs pro

vided for that purpose (A), pull out the carrying

handles (B), and transport the unit to the installa

tion site.

When in transport position, the unit has a very high

center of gravity. Take care that the unit does not tip

over during transport.

2. Transport without pallet (exception)

If the pallet is too wide for transport to the installation site,

you may unscrew the pallet from wooden support C and

transport the unit by means of the wooden supports without

the pallet.

To do this, proceed as follows:

– Remove the surrounding packaging, the two card

board boxes, as well as the two lateral styrofoam

parts.

– Loosen the four screws D.

The center styrofoam part should remain attached to the

unit for protection. If this is not possible, SIRONA recom

mends securing the tube assembly in its position with the

supplied strap prior to any further transport

-

-

-

(see the label on the styrofoam packaging)!

Tighten the strap only loosely. Do not stretch!

– Pull the carrying handles B out of their holders and

insert them through the drillings of the wooden sup

port C from the back.

– Insert screws D through the drillings E into the drill

ings of the carrying handles to attach them firmly.

Long or short.

The carrying handles have rims which prevent them from

slipping out of the holes.

-

-

-

18 D 3352.031.03.18.02

60 51 416 D 3352

Page 19

3 Installation: Panoramic X-ray unit

ORTHOPHOS XG 3

60 51 416 D 3352

D 3352.031.03.18.02

19

Page 20

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

1. 2.

for installation

on wooden stud

frame

for installation

on wooden stud

frame

3.1 Installation material Installation Instructions ORTHOPHOS XG 3

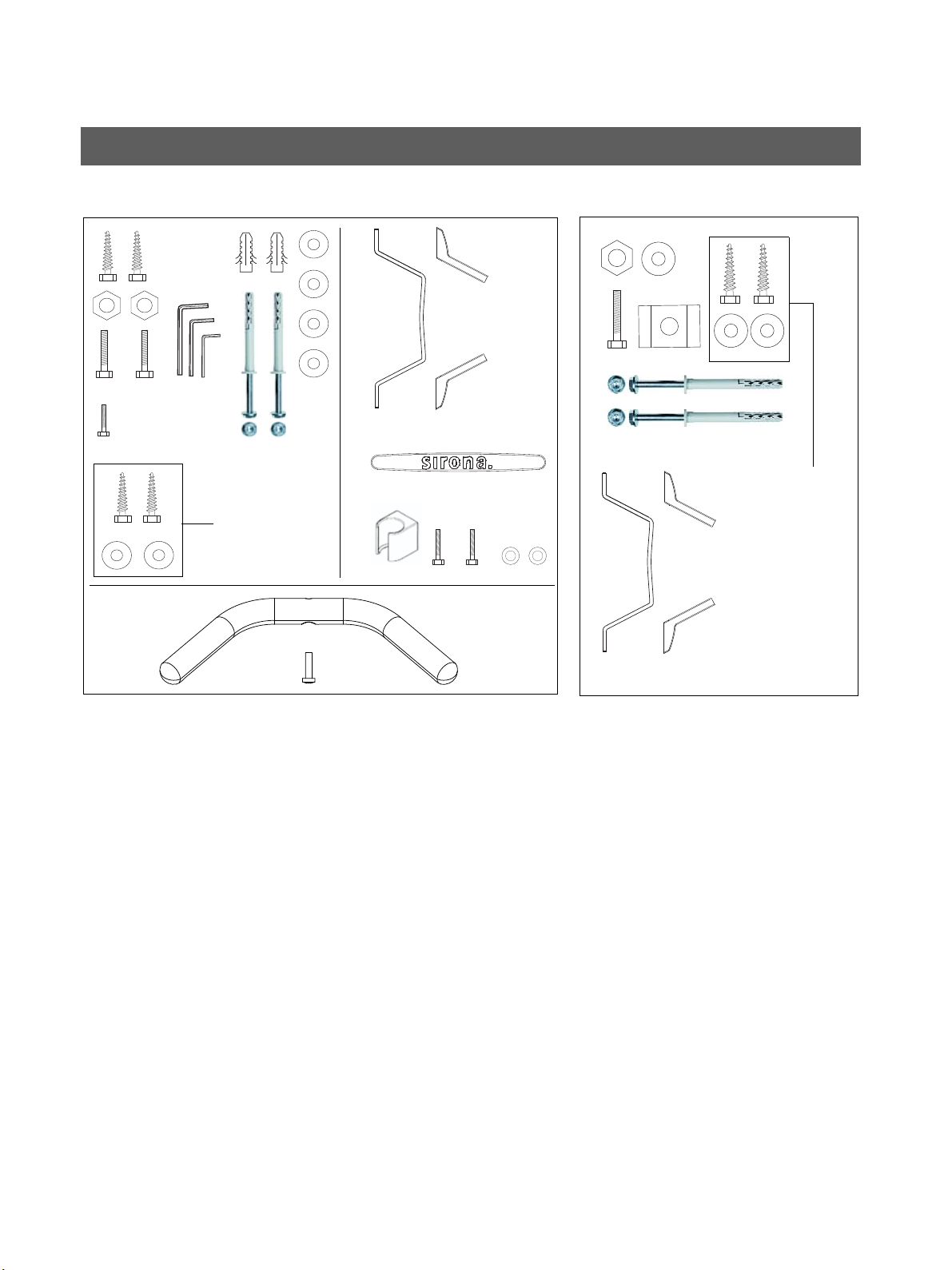

3.1 Installation material

Standard version

(see Section 3.3)

Option 1: with second wall holder

(see Section 3.3)

1. Wall/floor mounting

– Hexagon wood screws 8x80 (5/16x3"): 4 pc.

– Plastic wall plug S10: 2 pc.

– Screw M8x30: 2 pc.

–Washer δια. 8.4: 6 pc.

– Nut M8: 2 pc.

– Screw M4x10: 3 pc.

–Washer δια. 4.3: 2 pc.

– Mounting kit δια. 10 SXR: 2 pc.

– Torx offset screwdrivers TX10, TX20, TX25: resp. 1

pc.

– Offset Allen key (size 6):

1 pc.

– Wall holder: 1 pc.

– Cover for wall holder: 2 pc.

– Intermediate piece: 1 pc.

– Release button holder: 1 pc.

– Handle: 1 pc.

– Screw (for handle) M6x25: 1 pc.

2. Additional wall holder (for bottom wall mounting)

– Wall holder: 1 pc.

– Wood screws 8x80 (5/16x3"): 2 pc.

–Washer δια. 8.4: 3 pc.

– Hexagon head screw M8x50: 1 pc.

– Nut M8: 1 pc.

– Mounting kit δια. 10 SXR: 2 pc.

– Profile clamp: 1 pc.

– Cover for wall holder: 2 pc.

20 D 3352.031.03.18.02

60 51 416 D 3352

Page 21

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

3.

Option 2

Mounting hardware

Floor stand

Covers

Floor stand

Cover

Slide

Installation Instructions ORTHOPHOS XG 3 3.1 Installation material

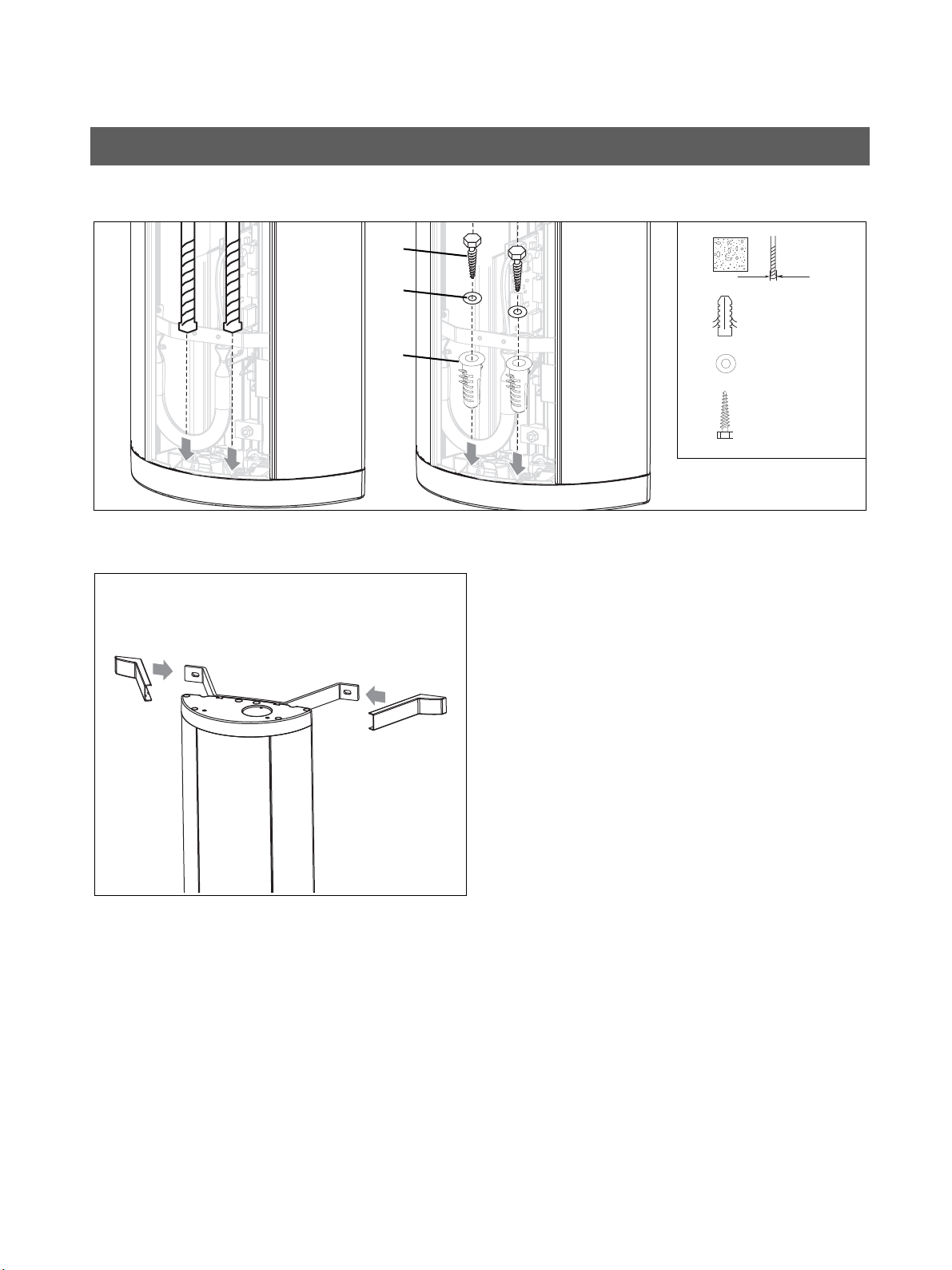

Option 2: Floor stand installation

(see Section 3.4)

3. Floor stand installation

– Floor stand

– Floor stand covers

– Wood screws 10x160 (3/8x6"): 5 pc.

– Plastic wall plug S12: 5 pc.

– Screw EM8x60: 2 pc.

– Screw M8x80: 2 pc.

– Washer δια. 8.4: 2 pc.

– Nut M8: 2 pc.

– Screw M10x50: 1 pc.

– Profile clamp: 1 pc.

– Screw M5x12: 1 pc.

– Washer δια. 10.5: 13 pc.

– Nut M10: 4 pc.

– Spring steel clamp: 8 pc.

– Screw M10x25: 4 pc.

– Wood screw M10x80 (3/8x3): 5 pc.

– Mounting kit δια. 10 SXR: 2 pc.

60 51 416 D 3352

D 3352.031.03.18.02

21

Page 22

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

1.

2.

3.

7.4.

5.

6.

8.

9.

3.2 Required tools Installation Instructions ORTHOPHOS XG 3

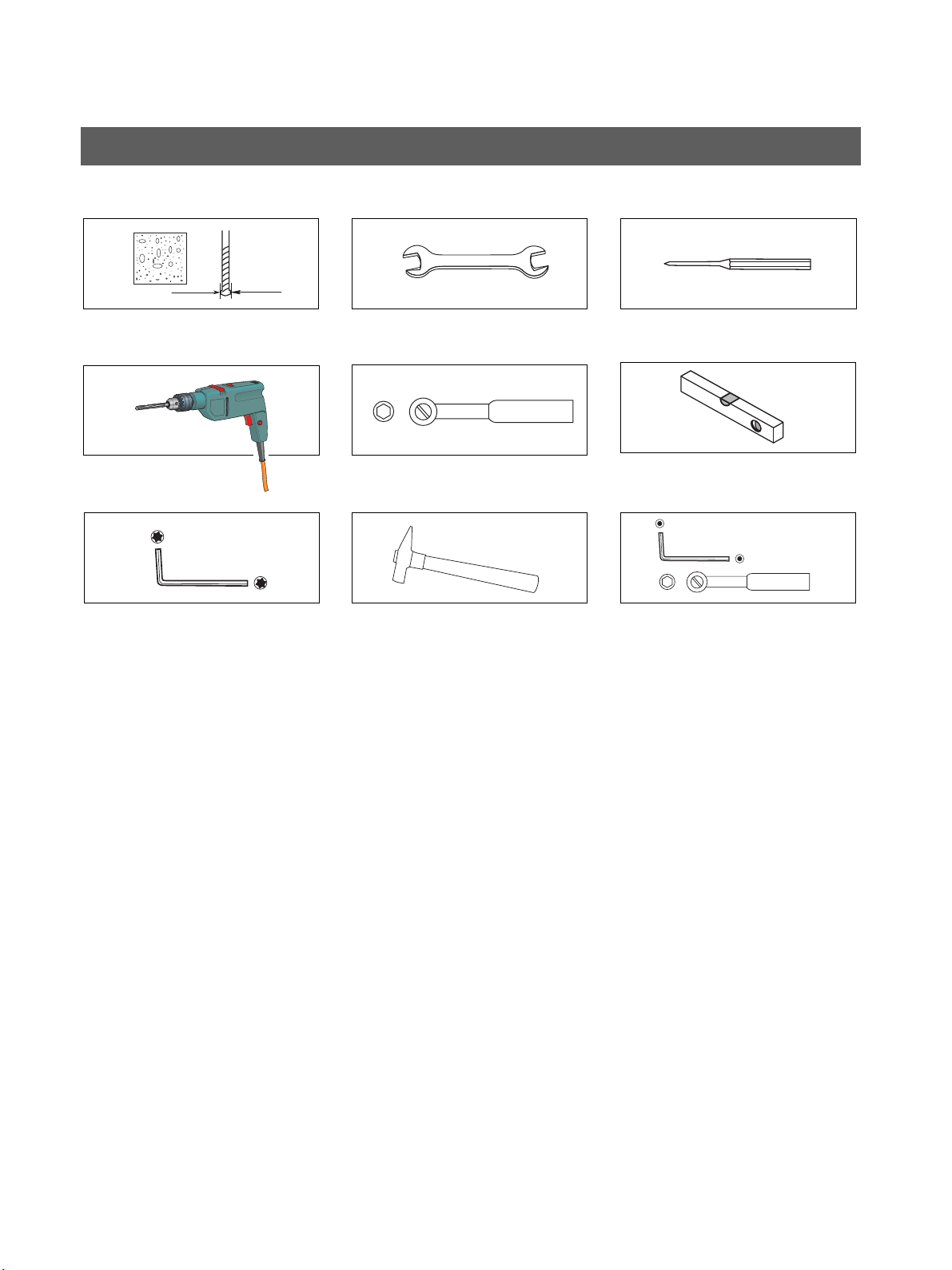

3.2 Required tools

1. Masonry drill

– Δια.10mm (3/8“)

2. Impact drill or percussion drill

3. Torx offset screwdriver *

–TX10

–TX20

–TX25

4. Open-end wrench

– 13 mm A/F

5. Socket wrench

– Wrench insert 13

6. Hammer

7. Center punch

8. Spirit level

9. Additional requirements for installation with floor stand:

– Masonry drill δια.12mm (1/2“)

– Allen key 6 mm

– Socket wrench and extension

Wrench insert 17

Required measuring instruments

• Multimeter or ammeter (battery-operated)

• Test unit for device leakage current measurement,

e.g. Bender tester or line-frequency, high-resistance

measurement voltage source (isolation transformer)

and measuring circuit (MD) that meets the require

ments of IEC 60 601-1.

• Power source for protective ground wire test

Technical data:

– No-load voltage of at least 4 V - maximally 24V

– Short-circuit current at least 0.2A

-

* included in the scope of supply

22 D 3352.031.03.18.02

60 51 416 D 3352

Page 23

1.

2.

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

Installation Instructions ORTHOPHOS XG 3 3.3 Wall mounting (standard/option 1)

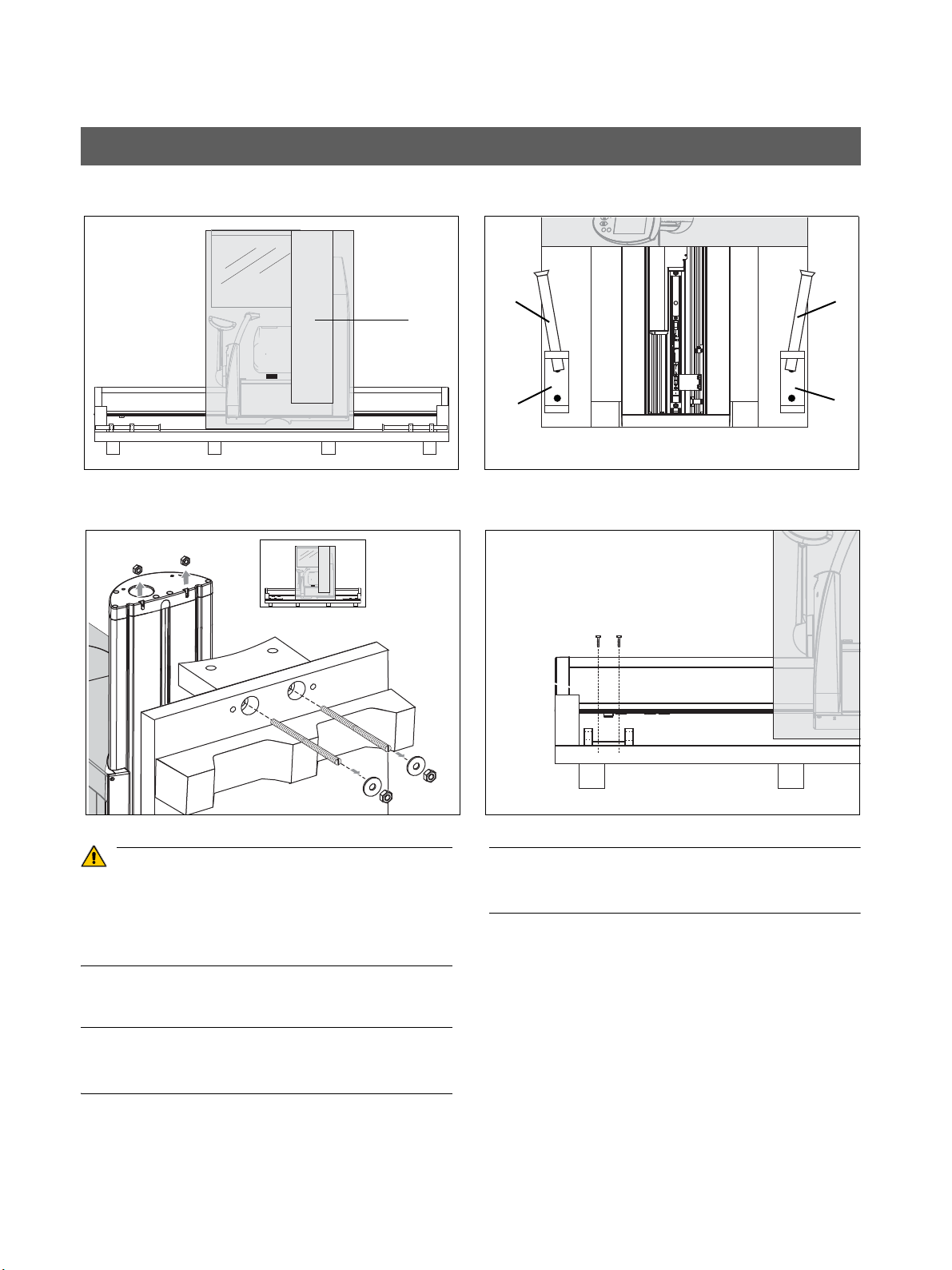

3.3 Wall mounting (standard/option 1)

60 51 416 D 3352

D 3352.031.03.18.02

23

Page 24

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

IMPORTANT

CAUTION

IMPORTANT

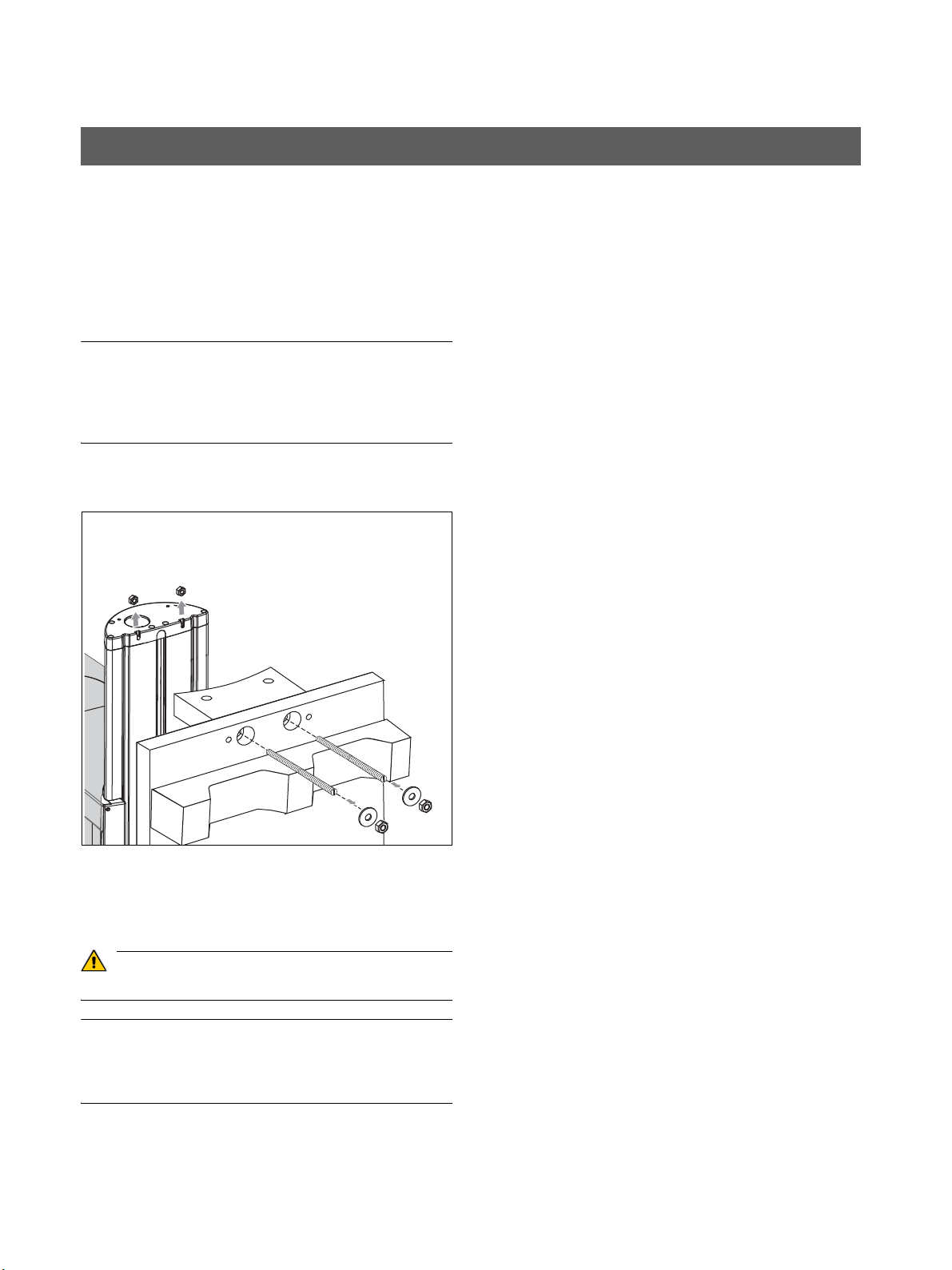

3.

B

C

D

3.3 Wall mounting (standard/option 1) Installation Instructions ORTHOPHOS XG 3

• Remove profile cover A.

1. Position the two installation aids B at the foot C of the

device and secure their position with adhesive tape.

CAUTION! The installation aids must be placed on

top of each other in such a way that their openings

lie on top of each other

2. Set up the unit. To do this, tilt the transport pallet up

right.

-

If you have transported the unit on the wooden support with

out a pallet, set the unit upright with the wooden support.

You can also use the lateral styrofoam packaging as a sup

port with this variation.

-

-

3. Loosen the nuts B (with washers) on both sides of the

Remove the lower bolts first, followed by the upper bolts.

The nuts D on the unit may remain inside the unit when the

threaded rods are removed. Remove the upper nuts. The

lower nuts may remain in the unit.

24 D 3352.031.03.18.02

pallet (or the wooden support). Take off the pallet (or

the wooden support).

Remove the threaded bolts C.

60 51 416 D 3352

Page 25

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

CAUTION

2x 8x80

2x δια. 8.4

4.

Δια. 3/8″

Δια.

10 mm

Installation Instructions ORTHOPHOS XG 3 3.3 Wall mounting (standard/option 1)

4. Mount the upper wall holder.

If the setup site for the unit is carpeted, the carpeting must

be removed.

Wall plugs! Each wall plug must withstand an extraction

force of 700 N.

The wall construction must be suitable for installation of the

unit (see "On-site installation, dimensions, technical data")

In case of mounting on weight-bearing wooden con

structions:

Use the enclosed wood screws and washers from the

mounting kit for mounting the unit on weight-bearing wood

structures.

-

60 51 416 D 3352

D 3352.031.03.18.02

25

Page 26

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

5.

Δια. 3/8″

Δια.

10 mm

3.3 Wall mounting (standard/option 1) Installation Instructions ORTHOPHOS XG 3

Only with second wall holder (option 1):

5. Mount the lower wall holder.

26 D 3352.031.03.18.02

60 51 416 D 3352

Page 27

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

NOTICE

IMPORTANT

6.

E

F

2x M 8x30

2x δια. 8.4

2x M 8

7.

1x M 8x50

1x δια. 8.4

G

H

E

F

G

H

8.

D

1x M 8

J

Profile clamp

1x

K

K

J

Installation Instructions ORTHOPHOS XG 3 3.3 Wall mounting (standard/option 1)

• Move the panoramic X-ray unit into its installation posi

tion at the wall. Hold the unit laterally at the styrofoam

packaging to do this.

SIRONA recommends leaving the styrofoam packaging on

the unit during the entire installation procedure!

If due to on-site conditions it is unavoidable to remove the

styrofoam packaging already at this point, you may move

the unit by carefully grasping the bite block bar and the

stand.

6. Fasten the panoramic X-ray unit to the upper wall hold

er.

– Insert the screws E into the groove.

– Screw the panoramic X-ray unit firmly onto the wall

holder using the washers and nuts F.

The wall holder must be flush with the upper edge of the

unit.

-

-

7. Insert screw G through washer H and then through

the wall holder and into the stand from the rear.

8. Fit profile clamp J onto screw G from the other (front)

side and screw nut K onto the screw.

Tighten nut K firmly.

60 51 416 D 3352

D 3352.031.03.18.02

27

Page 28

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

12.

➊

➋

9. 10.

L

A

3.3 Wall mounting (standard/option 1) Installation Instructions ORTHOPHOS XG 3

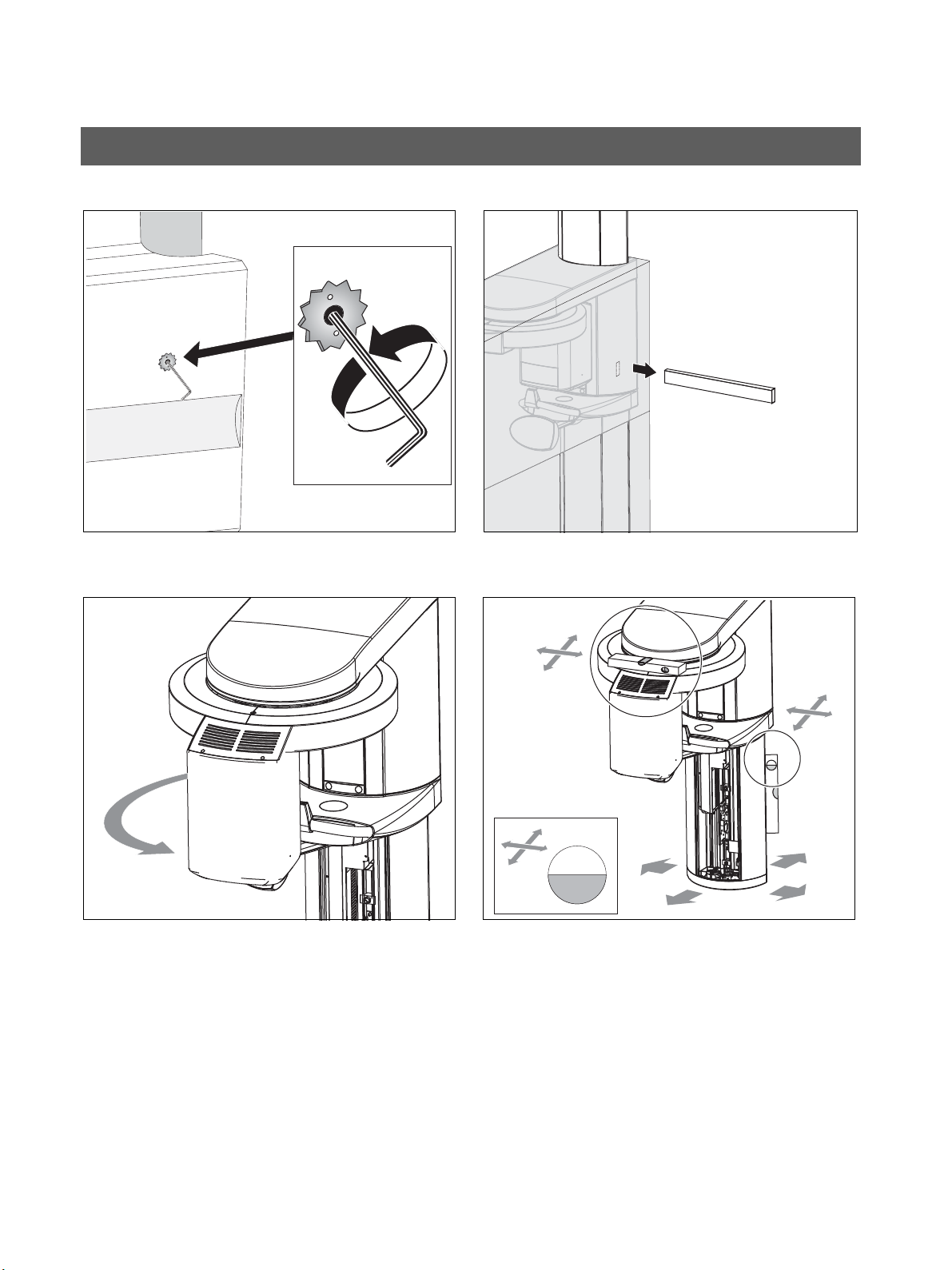

9. Remove the transport safety device (A) prior to unit

startup.

10. Pull the wooden board L out of the styrofoam packag

ing and remove all styrofoam packaging.

11. Rotate the X-ray tube assembly counterclockwise to

the front side of the unit.

12. Level the unit by moving the unit base in both directions

while measuring with the spirit level.

-

– Align the stand first by placing the spirit level

against the side and rear of the stand

– Then align the ring with the spirit level in both

directions by placing the spirit level on the ring

➊ .

➋ .

28 D 3352.031.03.18.02

60 51 416 D 3352

Page 29

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

14.

2x S 10

Δια. 10 mm

2x 8x80

2x δια. 8.4

N

M

N

O

M

O

13.

Installation Instructions ORTHOPHOS XG 3 3.3 Wall mounting (standard/option 1)

13. Drill through the recesses of the stand into the floor. In

sert wall plug M, and check again that the stand is

aligned correctly (see step 10).

Screw the stand to the floor with the two wood screws N

and the washers O.

14. Attach the covers of the wall holder(s).

-

60 51 416 D 3352

D 3352.031.03.18.02

29

Page 30

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

CAUTION

NOTICE

IMPORTANT

1.

A

B

C

C

B

C

D

2. 4.

E

G

F

Must be dis

-

mantled ly

-

ing on its

3.

E

F

F

3.4 Installing the floor stand (option 2) Installation Instructions ORTHOPHOS XG 3

3.4 Installing the floor stand (option 2)

For installation with the floor stand, the unit remains lying on

the pallet until the floor stand has been completely assem

bled. Only then may the unit be installed. For enhanced rep

resentation, some of the following drawings are shown in

the standing state.

1. Remove the surrounding packaging, the two lateral sty

rofoam parts and profile cover A.

The center styrofoam part should remain attached to the

unit for protection.

The nuts D on the unit may remain inside the unit when the

-

threaded rods are removed. Remove the nuts.

-

3. Remove the carrying handles E on the lower side of the

pallet from the holders F.

4. Loosen screws G and remove the holders F.

-

2. Loosen the nuts B (with washers) on both sides of the

30 D 3352.031.03.18.02

pallet (or the wooden support). Take off the pallet (or

the wooden support). Remove the threaded bolt C.

60 51 416 D 3352

Page 31

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

NOTICE

5.

H

6.

JJ

H

Installation Instructions ORTHOPHOS XG 3 3.4 Installing the floor stand (option 2)

5. Carefully push the unit toward the base just far enough

so that the center styrofoam part nudges lower

supporting block H.

Make absolutely sure that the interfaces do not have firm

contact with supporting block H and are not damaged when

you push the unit.

6. Remove the two screws J from the bottom of the stand.

60 51 416 D 3352

D 3352.031.03.18.02

31

Page 32

IMPORTANT

7.

J

K

M

M

2x M 8x80

2x M8

2x EM 8 x 60

L

L

2x δια. 8.4

K

M

J

8.

N

O

4x δια. 10.5

4x M 10x25

P

M

J

L

O

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

3.4 Installing the floor stand (option 2) Installation Instructions ORTHOPHOS XG 3

7. Screw adjustment plate (K) onto the stand firmly.

To do this, use screws J for the two front holes and secure

them with the corresponding nuts L and washers (from the

installation material). Use two new screws M for the rear

holes.

The recessed drill holes of the adjustment plate must point

downward.

8. Screw the support N firmly onto the base plate P using

the 4 screws O and washers.

32 D 3352.031.03.18.02

60 51 416 D 3352

Page 33

NOTICE

9.

Q

3x δια. 10.5

3x M 10

Q

Q

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

Installation Instructions ORTHOPHOS XG 3 3.4 Installing the floor stand (option 2)

9. Position the base plate with the threaded bolts (includ

ing the mounted support) on the adjustment plate and

attach the base plate loosely with the 3 adjustment

nuts Q (and washers).

-

Make sure that the cables are fed through the support cor

rectly and are not crushed.

60 51 416 D 3352

D 3352.031.03.18.02

-

33

Page 34

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

10. + 11.

U

R

1x M 10x50

1x δια. 10.5

S

S

R

U

T

1x M 10

Profile clamp

1x

T

R

S

U

T

3.4 Installing the floor stand (option 2) Installation Instructions ORTHOPHOS XG 3

10. Insert screw R through washer S and then through the

support and into the stand from behind.

11. Fit profile clamp T onto screw R from the other (front)

side and screw nut U onto screw R.

• Tighten adjusting nuts Q (see page 33) and screw R

firmly.

34 D 3352.031.03.18.02

60 51 416 D 3352

Page 35

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

IMPORTANT

12.

Installation Instructions ORTHOPHOS XG 3 3.4 Installing the floor stand (option 2)

• Set up the unit including the center styrofoam part.

Please observe the required movement range of the X-ray

unit during installation (see section 1.6).

12. Remove the styrofoam packaging and rotate the X-ray

tube assembly counterclockwise to the front side of the

unit.

60 51 416 D 3352

D 3352.031.03.18.02

35

Page 36

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

IMPORTANT

13.

Q

Q

Q

➋

➊

14.

R

3.4 Installing the floor stand (option 2) Installation Instructions ORTHOPHOS XG 3

• Loosen screw R and adjusting nuts Q again slightly.

13. Level the unit in both directions by turning adjusting

nuts Q while measuring with the spirit level.

– Align the stand first by placing the spirit level

against the side and rear of the stand ➊ .

– Then align the ring with the spirit levelin both

directions ➋ by placing the spirit level on the ring.

Be sure to tighten all adjusting nuts equally (to the same

torque) after leveling.

14. Tighten screws R again firmly.

36 D 3352.031.03.18.02

60 51 416 D 3352

Page 37

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

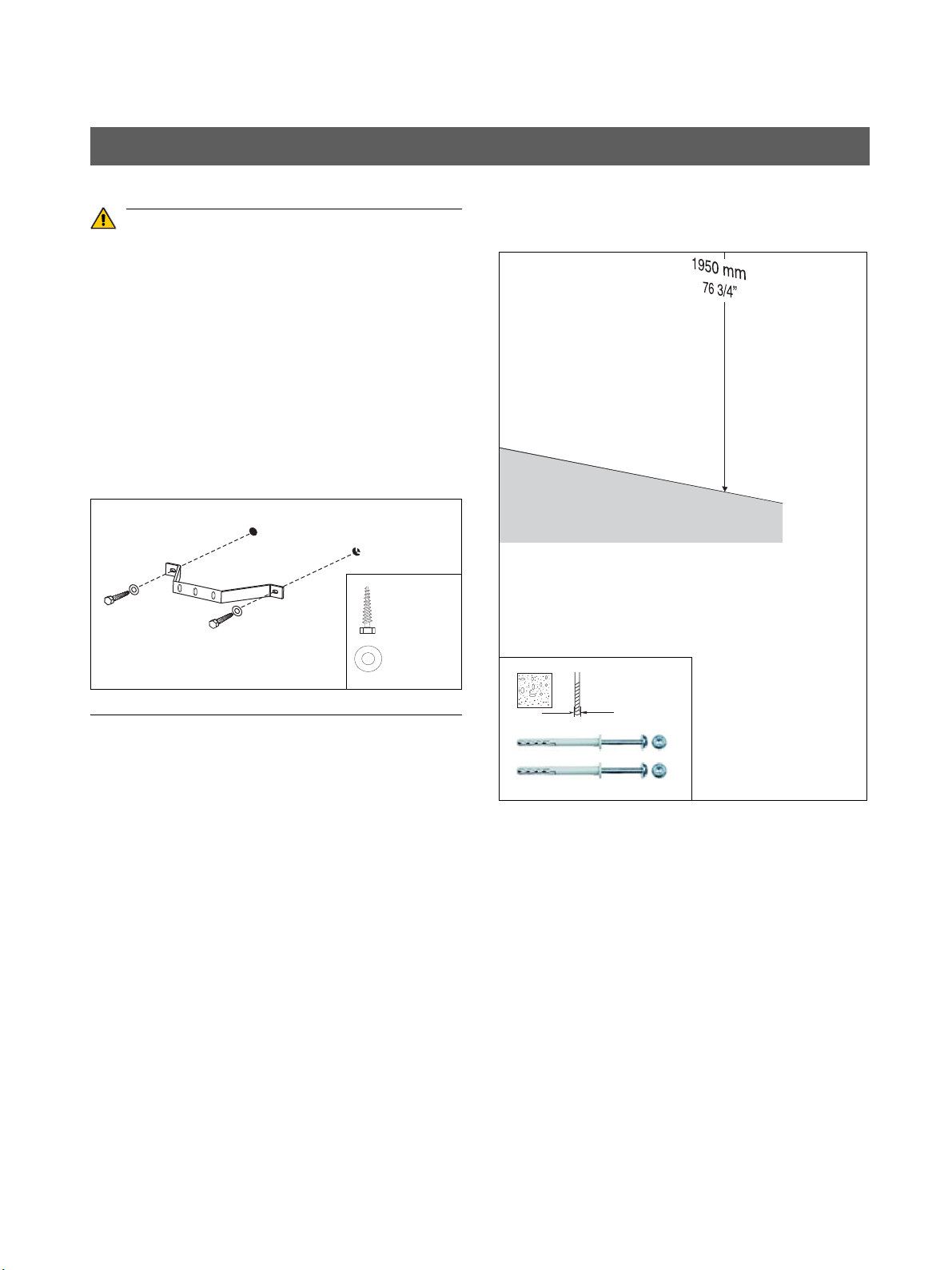

CAUTION

IMPORTANT

2x 8x80

2x δια. 8.4

15.

Δια. 3/8″

Δια.

10 mm

IMPORTANT

The floor stand version is

30 mm (1 3/16“) higher than

the standard version.

Installation Instructions ORTHOPHOS XG 3 3.4 Installing the floor stand (option 2)

15. Mount the upper wall holder.

In case of mounting on weight-bearing wood struc

tures:

Use the enclosed wood screws and washers from the

mounting kit for mounting the unit on weight-bearing wood

structures.

Even when the unit is installed using the floor stand it must

be secured with the upper wall holder.

-

60 51 416 D 3352

D 3352.031.03.18.02

37

Page 38

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

NOTICE

16.

2x M8x30

2x δια. 8.4

2x M8

V

W

V

W

3.4 Installing the floor stand (option 2) Installation Instructions ORTHOPHOS XG 3

• Slide the unit with the assembled floor stand up to the

wall.

Please observe the required movement range of the unit

during positioning (see section 1.2).

16. Mount the unit loosely on the upper wall holder.

– Insert the screws V into the groove.

– Screw the unit onto the wall holder loosely using

nuts W (and washers). Do not tighten the screws!

60 51 416 D 3352

38 D 3352.031.03.18.02

Page 39

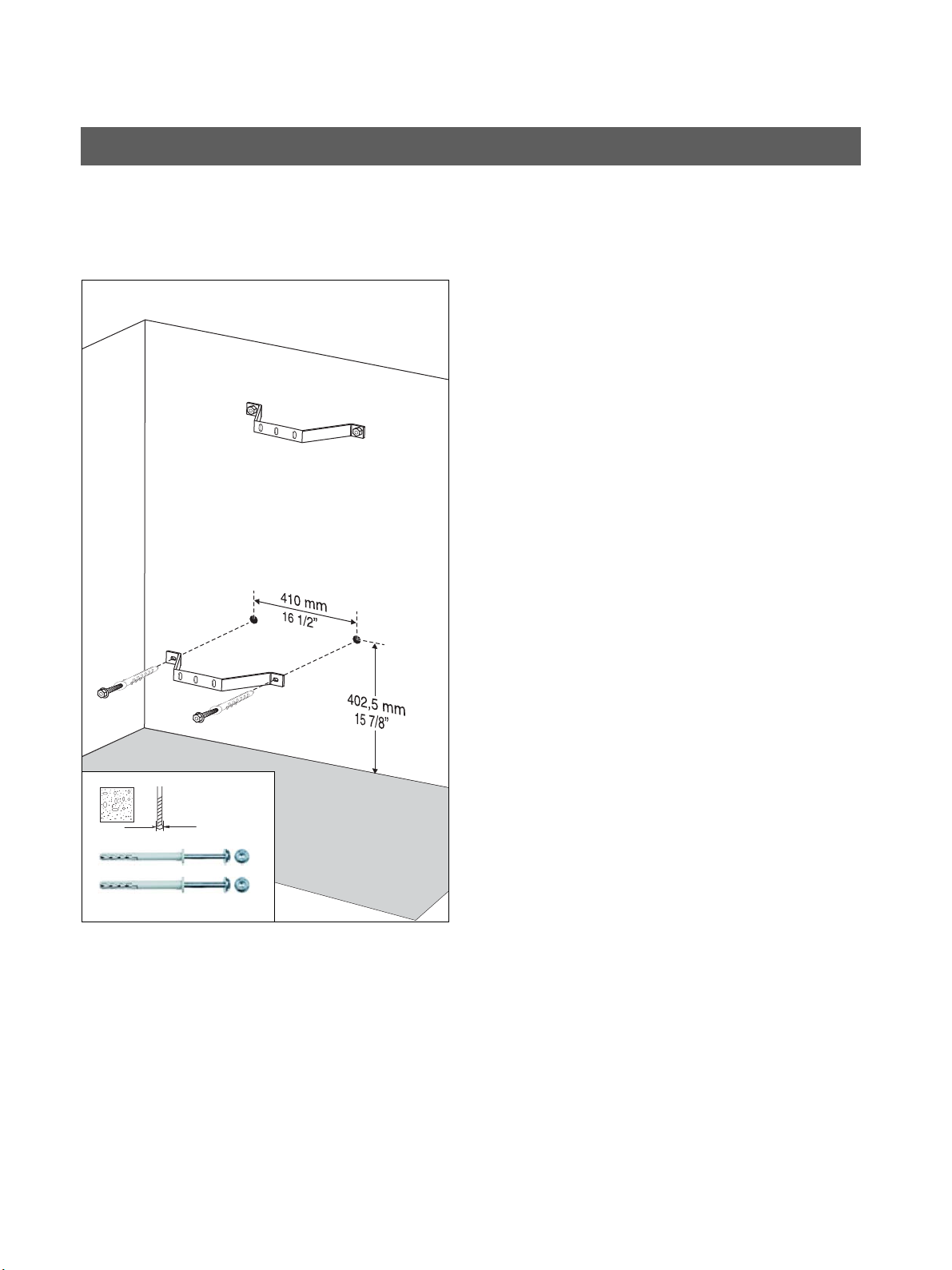

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

17.

X

Y

5x S12

5x 10 x 160

X

Y

Δια. 1/2″

Δια.

12 mm

Installation Instructions ORTHOPHOS XG 3 3.4 Installing the floor stand (option 2)

• Level the unit again in both directions with the help of

the spirit level (see step 12.) and tighten the screws on

the wall holder firmly.

17. Mount the unit onto the floor.

– Drill the fastening holes in the floor through the

holes in the base plate.

– Remove the drilling dust with a vacuum cleaner.

– Slide wall plugs (X) through the base plate and into

the drilled holes.

– Use the five screws (Y) (and washers) to screw the

base plate firmly onto the floor.

60 51 416 D 3352

D 3352.031.03.18.02

39

Page 40

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

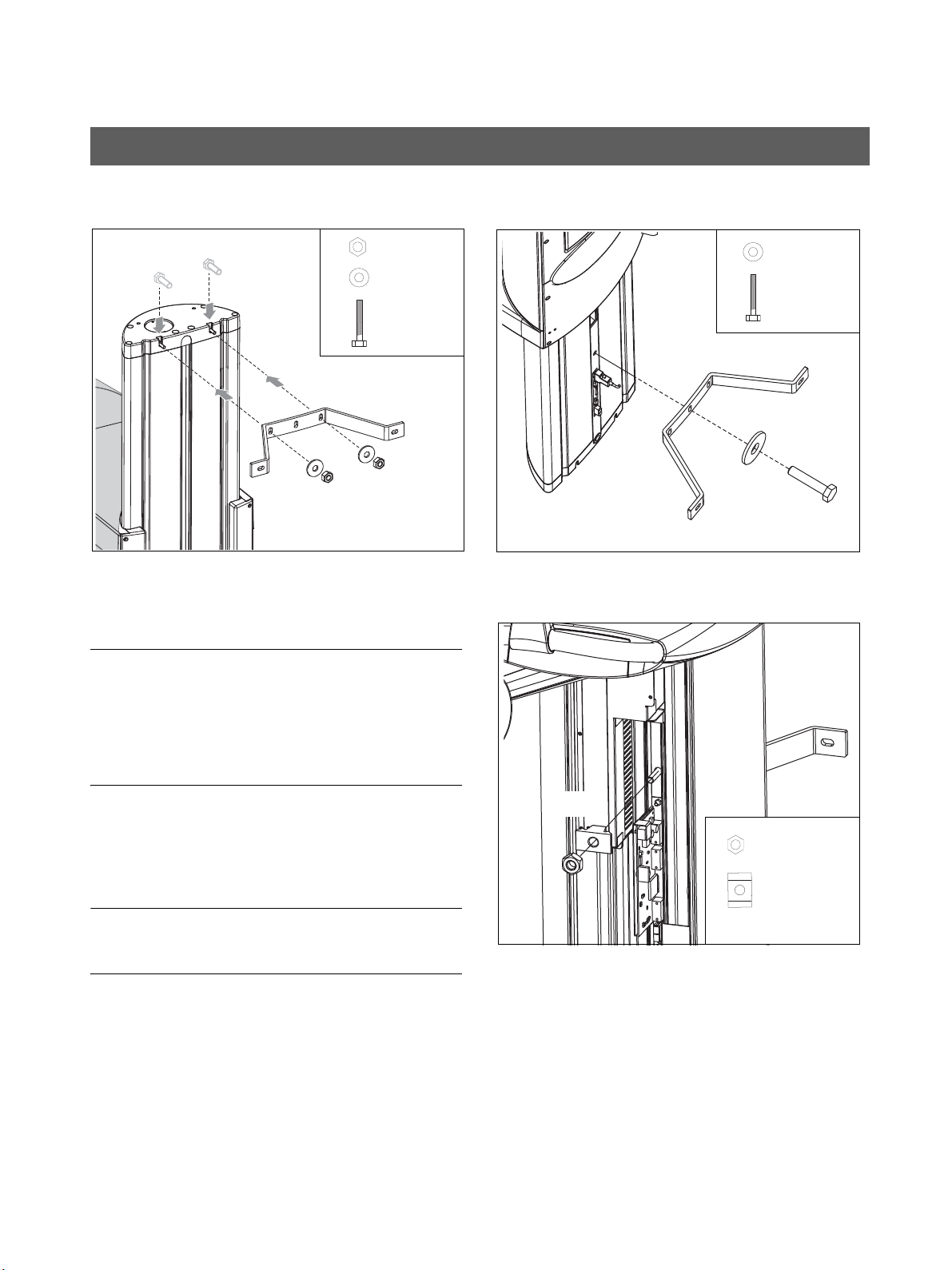

IMPORTANT

1.

3.5 Removing the transport safety device Installation Instructions ORTHOPHOS XG 3

3.5 Removing the transport safety device

1. Remove the transport safety devices B prior to unit

startup.

Keep transport safety devices B in a safe place. You will

need them should the unit be moved again.

40 D 3352.031.03.18.02

60 51 416 D 3352

Page 41

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

IMPORTANT

1.

A

B

Installation Instructions ORTHOPHOS XG 3 3.6 Installing the release button holder

3.6 Installing the release button holder

Only install the holder to the unit if you do not intend to use

a remote control! If you use a remote control in combina

tion with the release button, attach the holder to the remote

control (see page 49).

-

1. Unscrew and remove cover A.

Attach holder B and screw the cover back onto the unit.

60 51 416 D 3352

D 3352.031.03.18.02

41

Page 42

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

IMPORTANT

1.

3.

4.

2.

3x

1x

A

B

C

B

C

D

D

D

A

B

D

3.7 Attaching the covers Installation Instructions ORTHOPHOS XG 3

3.7 Attaching the covers

These covers must be attached only if the unit is installed

with the floor stand and does not stand against a wall.

1. Loosen the 4 screws A on the upper housing cover B

and remove this housing cover toward the rear.

2. Insert the cover C included in the floor stand accesso

ries in the outer cover B.

4. Use the 4 screws A to refasten the assembled housing

cover to the unit.

-

3. Fasten the cover C to the cover B with the 3 spring steel

42 D 3352.031.03.18.02

clamps D.

60 51 416 D 3352

Page 43

Sirona Dental Systems GmbH 3 Installation: Panoramic X-ray unit

IMPORTANT

5.

E

F

G

Installation Instructions ORTHOPHOS XG 3 3.7 Attaching the covers

5. Attach all remaining unit housing covers.

In order to attach the floor stand covers properly, the four

spring clamps E must be placed on the base plate in such a

way that the two covers F and G remain assembled after

they are attached (see detail drawing above).

60 51 416 D 3352

D 3352.031.03.18.02

43

Page 44

3 Installation: Panoramic X-ray unit Sirona Dental Systems GmbH

3.7 Attaching the covers Installation Instructions ORTHOPHOS XG 3

44 D 3352.031.03.18.02

60 51 416 D 3352

Page 45

ORTHOPHOS XG 3

4 Electrical connection

60 51 416 D 3352

D 3352.031.03.18.02

45

Page 46

4 Electrical connection Sirona Dental Systems GmbH

NOTICE

1.

L117

Coiled cable

Media convert

-

X108

Cat.5

RJ45

3.

2.

Switch*

L25

L25

L117

Duplex patch cable,

1:1 connection,

SC/SC 50/125 μm

X101

4.1 Connecting the control cables (PAN) Installation Instructions ORTHOPHOS XG 3

4.1 Connecting the control cables (PAN)

1. Connect the personal computer to socket SC:SC of the

• Install the media converter at a suitable location using

Do not fasten the media converter to the X-ray unit.

*) not included in the scope of supply

panoramic X-ray unit via the media converter (see the

Operating Instructions supplied with the media convert

er).

fastening screws or the Velcro strap supplied for this

purpose.

For the installation version without remote control

2. Connect the coiled cable of the release button to socket

-

X103 of the panoramic X-ray unit.

For the installation version with remote control

3. Connect the remote control to socket X103 of the pan

oramic X-ray unit with cable L117.

Secure the connector on socket X103.

-

46 D 3352.031.03.18.02

60 51 416 D 3352

Page 47

Sirona Dental Systems GmbH 4 Electrical connection

DANGER

DANGER

WARNING

CAUTION

1.

Second protective ground wire

Power cable

Power cable

Second

Protective ground wire

Second

Protective ground wire

L N PE L N PE

PE

to the ORTHOPHOS XG

Power cable

to the ORTHOPHOS XG

ORTHOPHOS XG

Installation Instructions ORTHOPHOS XG 3 4.2 Connecting the line voltage

4.2 Connecting the line voltage

Fixed connection!

The installation of a power plug instead of the pre

scribed fixed (hard-wired) connection violates interna

tional medical regulations and is prohibited.

In case of a fault, you would thus endanger the life and

limb of the patient, the operator or other persons.

Danger of electrical shock!

Be sure to switch off the line power supply before con

necting the line voltage!

-

Be sure to connect the second protective ground wire

to ground.

-

Incorrectly connected units can pose a risk to patients!

Building installation with 3x1.5 mm² or 3x2.5 mm² (16 AWG

or 14 AWG) and a 16 A/20 A overcurrent circuit breaker.

-Connect only units which do not pose any risk to patients

when the

automatic circuit breaker is triggered.

-

-Do not connect any EDP units.

-See also "Installation requirements".

ORTHOPHOS XG 3

• The unit is suitable for connection to networks of

200 - 240 V and 50 - 60 Hz, ± 10 %.

60 51 416 D 3352

D 3352.031.03.18.02

1. Check the protective ground wires and the device leak

age current according to IEC 62353: 2007 (See sec

tions "6.1 Checking the protective ground wires Page

60" and "6.2 Checking the device leakage current Page

63").

2. Record the measured values in chapter 3 of the docu

ment "Inspection, maintenance and safety-related

check".

3. Carry out the power supply connection as shown above

first.

-

-

-

47

Page 48

4 Electrical connection Sirona Dental Systems GmbH

WARNING

Second

Protective ground wire

Power cable

to the ORTHOPHOS XG

Emergency

LNPE

Shutdown btton

4.2 Connecting the line voltage Installation Instructions ORTHOPHOS XG 3

Media converter

When operating the unit at exhibitions and fairs, you

must observe the information provided in section 11.3

Demo mode!

• Plug the connector of the media converter's power sup

ply unit into the electric outlet.

EMERGENCY STOP installation

(if legally prescribed)

-

• Use the emergency shutdown button that is integrated

into the power cable to switch on the unit.

48 D 3352.031.03.18.02

60 51 416 D 3352

Page 49

ORTHOPHOS XG 3

5 Installation: Remote control

60 51 416 D 3352

D 3352.031.03.18.02

49

Page 50

5 Installation: Remote control Sirona Dental Systems GmbH

1.

2.

5.1 Installation material/tools Installation Instructions ORTHOPHOS XG 3

5.1 Installation material/tools

1. Installation material for remote control

– Wood screw 4x30 (3/16x1 1/4): 3 pc.

– Plastic wall plug S6: 3 pc.

2. Required tools

– Masonry drill δια.6 mm (1/4“)

– Impact drill or percussion drill

– Blade screwdriver (small and medium sized)

– Torx offset screwdriver TX20

– Hammer

– Center punch/awl

50 D 3352.031.03.18.02

60 51 416 D 3352

Page 51

Sirona Dental Systems GmbH 5 Installation: Remote control

IMPORTANT

1.

2.

C

3x S 6

Δια. 6mm

3x 4x30

A

B

C

Installation Instructions ORTHOPHOS XG 3 5.2 Mechanical installation

5.2 Mechanical installation

1. Carefully press the blade screwdriver in groove A from

below (do not pry!) and remove the chassis to the rear.

Hold the chassis against the wall in its mounting posi

tion and mark the positions for the three drill holes with

an awl.

Drill the holes and insert the wall plugs.

For concealed installation, the control cable is drawn into

-

the chassis from the rear. For surface installation it is drawn

in from underneath.

For concealed installation

2. Draw the control cable into the chassis from the wall

through rear opening B and fasten the chassis securely

to the wall with the three screws C.

– For concealed installation, the cable length

between the wall exit and the stripped wire ends

should be 250 mm.

60 51 416 D 3352

D 3352.031.03.18.02

51

Page 52

5 Installation: Remote control Sirona Dental Systems GmbH

3.

C

5.

3x 4x30

Concealed installation

surface installation

4.

L117

Cable shield

60 mm

23/8“

10 mm

approx.

250 mm

from wall exit

3/8“

5.2 Mechanical installation Installation Instructions ORTHOPHOS XG 3

For surface installation

3. Fasten the chassis firmly to the wall with the three

screws C.

Shortening cable L117

4. If necessary, shorten cable L117 to the required length

and prepare it for reconnection.

– Expose the cable shield (see condition on delivery).

The length of the wires should be approx. 60 mm (2

3/8“).

– Place the shortened shielding over the insulation

and wrap the shielding with 3 layers of self-adhe

sive copper foil.

Attaching the strain relief

5. Attach cable L117 at the strain relief in the chassis

-

52 D 3352.031.03.18.02

– Strip the wire ends 5 mm.

Crimp on the end sleeves.

Insert the orange, white-blue, blue

and white-orange wires

in separate end sleeves.

(concealed or surface installation).

– The cable length between the strain relief and the

stripped wire ends should be 200 mm (8“).

60 51 416 D 3352

Page 53

Sirona Dental Systems GmbH 5 Installation: Remote control

IMPORTANT

15 m

2.

L 117

DX42

X108

X 108

1.

3.

590“

A

(Shorten if necessary)

Installation Instructions ORTHOPHOS XG 3 5.3 Connecting the control cables (REMOTE)

5.3 Connecting the control cables (REMOTE)

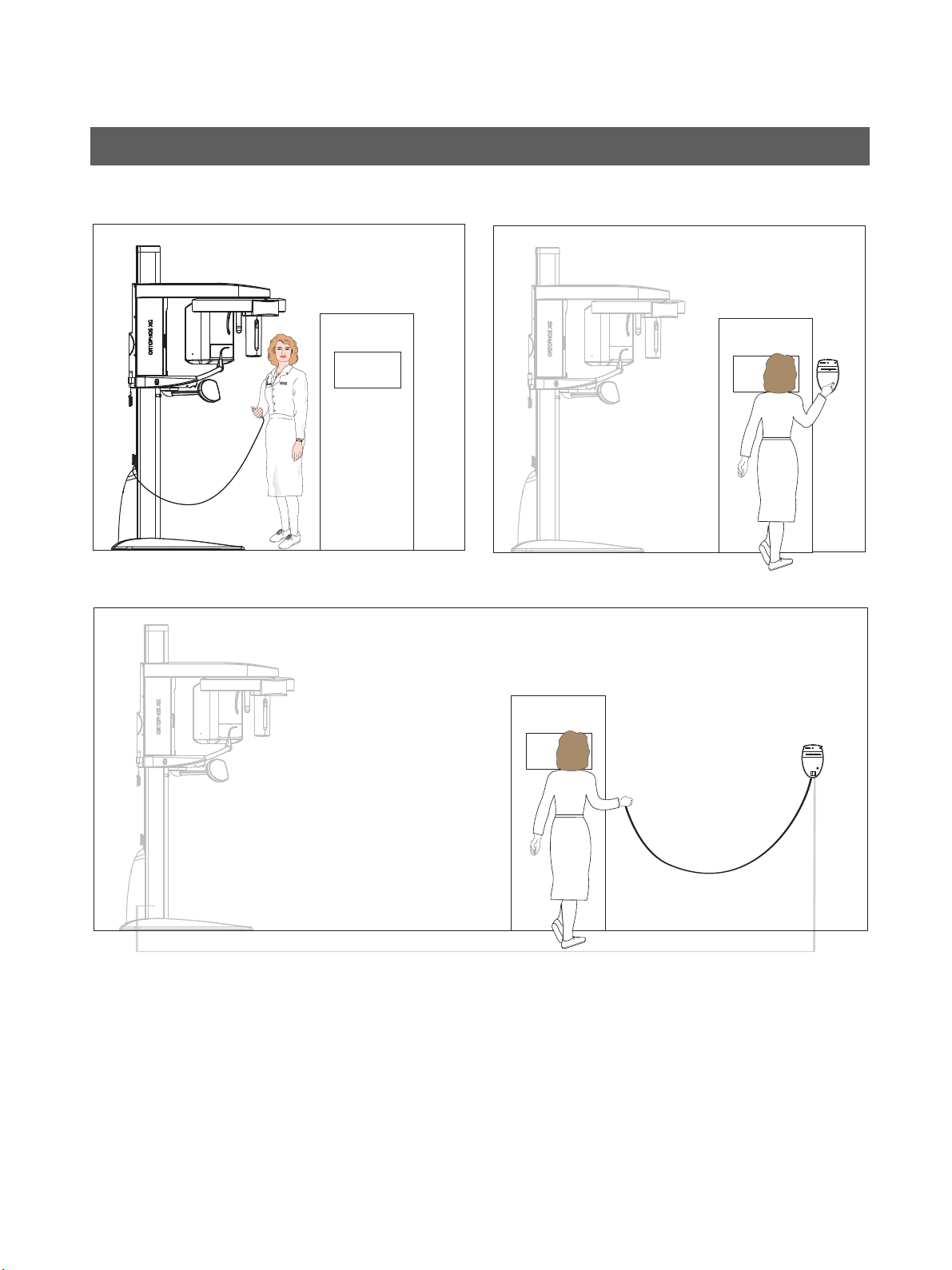

5.3.1 Installation version 1: without release button and coiled cable

1. Attach cable L117 at shield clamp A.

– Unscrew clamp A from the board.

– Place the cable in the clamp so that the turned up

cable shield is completely enclosed.

– Re-attach the clamp to the board.

2. Connect control cable L117 to terminal X108 (board

DX42) as shown in the connection diagram above.

3. Roll cable L117 into a loop and stow it away at the bot

tom edge of the chassis before closing the housing.

For information on the connection of a door contact switch,

see section 5.4.

-

60 51 416 D 3352

D 3352.031.03.18.02

53

Page 54

5 Installation: Remote control Sirona Dental Systems GmbH

NOTICE

3.

4.

X101

E

1.

2.

C

B

D

5.3 Connecting the control cables (REMOTE) Installation Instructions ORTHOPHOS XG 3

5.3.2 Installation version 2: with release button and coiled cable

2. Using the two screws D, fasten the release button hold

Operation of the remote control via the membrane keyboard

is prohibited when installing the remote control with release

button.

Installing the release button holder

er B to the keyboard.

3. Plug the connector of the coiled cable into socket X101

on board DX42 and screw the connector down tight.

4. Hang the coiled cable in strain relief E of the assembled

chassis.

-

1. Use an awl to puncture the membrane keyboard at the

prepared points C from the rear.

54 D 3352.031.03.18.02

60 51 416 D 3352

Page 55

Sirona Dental Systems GmbH 5 Installation: Remote control

Installation Instructions ORTHOPHOS XG 3 5.3 Connecting the control cables (REMOTE)

Connecting the control cable

• Connect control cable L117 as described in section 5.3

on page 53.

60 51 416 D 3352

D 3352.031.03.18.02

55

Page 56

5 Installation: Remote control Sirona Dental Systems GmbH

1.

Door contact switch

DX42

X108

X108

5.4 Connecting the door contact switch Installation Instructions ORTHOPHOS XG 3

5.4 Connecting the door contact switch

1. Connect the door contact switch between terminal

X 108 pin 1 (board DX 42) and control cable L117 pin

1 (WHGN).

56 D 3352.031.03.18.02

60 51 416 D 3352

Page 57

Sirona Dental Systems GmbH 5 Installation: Remote control

NOTICE

2.

DX42

X105

1.

3.

A

A

L117

B

Installation Instructions ORTHOPHOS XG 3 5.5 Connecting the X-ray warning lamp

5.5 Connecting the X-ray warning lamp

It is possible to activate an X-ray warning lamp via the

remote control. For connection, proceed as follows:

1. Insert cable A for connection of the X-ray warning lamp

in the chassis (concealed or surface installation) and

attach it to the unused strain relief.

Use a 3-wire cable (1.5 mm2) to connect the X-ray warning

lamp.

A maximum load of 50 W is permissible and no additional

circuit may be connected.

60 51 416 D 3352

D 3352.031.03.18.02

2. Connect the current-carrying cables and the ground

wire to terminal X105 (board DX42) as shown in the

connection diagram above. Secure the current-carrying

cables with a cable tie B to prevent them from slipping

out.

3. Run cable A parallel to control cable L117 before clos

ing the housing.

-

57

Page 58

5 Installation: Remote control Sirona Dental Systems GmbH

NOTICE

IMPORTANT

1. 2.

DHHS label

WARNING

5.6 Final work Installation Instructions ORTHOPHOS XG 3

5.6 Final work

1. Reassemble the remote control and place the release

button (if installed) in the holder.

Make sure that no cables are pulled off when you clip the

cover on.

For operation with a remote control, the unit must be config

ured accordingly. After initial startup of the unit, check the

configuration with the help of service routine S017, test

step 6 (see section 11.1.6).

2. For the USA/Canada only: Attach the DHHS and warn

ing labels.

-

-

58 D 3352.031.03.18.02

60 51 416 D 3352

Page 59

ORTHOPHOS XG 3

6 Safety checks

60 51 416 D 3352

D 3352.031.03.18.02

59

Page 60

6 Safety checks Sirona Dental Systems GmbH

DANGER

V

A

~

A

B

C

D

E

Ammeter

Power source

Measuring point

Central ground wire

Measuring points B-E

Volt m et er

Measuring setup for protective

ground wire test

6.1 Checking the protective ground wires Installation Instructions ORTHOPHOS XG 3

6.1 Checking the protective ground wires

Shock hazard! It is essential that you switch the X-ray

unit OFF before replacing any components!

If you have not done it already...

Switch OFF the line voltage at the main switch of the

building installation.

Disconnect the power cable and the second protective

ground wire from the building installation.

Remove the following cover parts:

– Profile cover

– Tube assembly cover, front

– Tube assembly cover, rear

Check whether the ground wire resistance complies

with the specifications

Protective ground wire test

between...

A and

A and

A and

A and

A power source with a current of at least 0.2 A and a

Connect the power source between the measuring

B GNYE wire 0,1Ω

C 2. Protective

ground wire

D Housing DX32 0,2Ω

E Tube assembly

housing

no-load voltage of 24 V max. and 4 V min. is required.

points specified in the table for at least 5 s and mea

sure:

– the voltage drop with the voltmeter

– the current with the ammeter and

– calculate the resistance using the formula R=U/I

0,1Ω

0,2Ω

-

60 D 3352.031.03.18.02

60 51 416 D 3352

Page 61

Sirona Dental Systems GmbH 6 Safety checks

A

Measuring point A: Central ground wire

Second protective ground wire

Power cable

PE

ORTHOPHOS XG

Power cable

Second

Protective ground wire

Second

Protective ground wire

to the ORTHOPHOS XG

Power cable

to the ORTHOPHOS XG

B

C

B

C

B

C

A

Measuring points B and C:

GNYE power connection and 2nd ground

Installation Instructions ORTHOPHOS XG 3 6.1 Checking the protective ground wires

60 51 416 D 3352

D 3352.031.03.18.02

61

Page 62

6 Safety checks Sirona Dental Systems GmbH

IMPORTANT

E

X-ray tube

assembly

D

Measuring points D and E:

Board

cage

DX32

6.1 Checking the protective ground wires Installation Instructions ORTHOPHOS XG 3

If the resistance exceeds the value specified in the table,

check whether the protective ground wire is fastened ac

cording to specifications:

–Check whether the flat washer, toothed lock washer and

cable lug are fitted on the protective ground wire in the right

order (see page 61) and whether the nuts of the ground wire

connections are tightened securely.

If the ground wire is not fastened according to specifica

tions, fasten the ground wire properly (see page 61).

Do not connect the power cable and the second ground

wire to the building installation yet, but perform a mea

surement of the device leakage current first (see sec

tion ).

-

-

-

-

62 D 3352.031.03.18.02

60 51 416 D 3352

Page 63

Sirona Dental Systems GmbH 6 Safety checks

DANGER

NOTICE

IMPORTANT

Installation Instructions ORTHOPHOS XG 3 6.2 Checking the device leakage current

6.2 Checking the device leakage current

Perilous shock hazard!

It is essential to switch the unit off and to wait at least

one more 1 minute before beginning the check!

Ensure that the unit is not unintentionally turned back

on.

Important information on building installation

The connection and disconnection of the unit (power cable)

to/from the building installation must be performed by a

qualified expert in compliance with the national regulations.

DIN VDE 0100-710 applies in Germany.

According to Note 2 below Table 2 of standard IEC 62353,

the maximum device leakage current permitted by the man

ufacturer is 2 mA for permanently connected units. Make

sure that the automatic tester is programmed for 5 mA

(not 1 mA)

6. Perform the measurements according to the operating

instructions of the tester.

7. Document the measured value of the leakage current in

the technical document "Inspection and maintenance

and safety-related checks" (REF 59 87 685) to identify

changes from the original value.

– A maximum deviation of ±20% from the original

value is permitted for the measured leakage cur

rent.

8. If a deviation from the original value is >±20%:

Perform troubleshooting according to chapter “Unit

leakage current too high” (see service manual for the

unit).

Reconnect the unit to the building installation (fixed

connection) (see the installation instructions for the

unit).

-

-

For measurements, Sirona recommends an automatic

tester (example illustration) which complies with standard

IEC 62353. If you do not use an automatic tester, please

pay attention to the specifications in the standard IEC

62353.

1. Switch the line voltage off at the main switch of the

building installation.

2. DANGER! Note the electrical safety rules without

fail.

Disconnect the power cable and the second protective

ground wire from the building installation.

3. Attach a connector compatible with the tester (see the

user’s manual for the tester) to the unit’s power cable.

4. Plug the connector of your power supply unit into the

intended socket on the tester in accordance with the

user’s manual for the tester.

5. Check whether the unit power switch is turned on.

60 51 416 D 3352

D 3352.031.03.18.02

63

Page 64

6 Safety checks Sirona Dental Systems GmbH

6.2 Checking the device leakage current Installation Instructions ORTHOPHOS XG 3

64 D 3352.031.03.18.02

60 51 416 D 3352

Page 65

ORTHOPHOS XG 3

7 Initial startup

60 51 416 D 3352

D 3352.031.03.18.02

65

Page 66

7 Initial startup Sirona Dental Systems GmbH

1.

7.1 Inserting the forehead and temple supports Installation Instructions ORTHOPHOS XG 3

7.1 Inserting the forehead and temple supports

1. Insert the forehead and temple supports until they lock

in place.

66 D 3352.031.03.18.02

60 51 416 D 3352

Page 67

Sirona Dental Systems GmbH 7 Initial startup

NOTICE

1.

A

Installation Instructions ORTHOPHOS XG 3 7.2 Inserting the sensor

7.2 Inserting the sensor

The sensor is a sensitive component, and therefore must be

handled with special care.

1. Carefully plug sensor A upward into the holder until it

audibly locks in place.

60 51 416 D 3352

D 3352.031.03.18.02

67

Page 68

7 Initial startup Sirona Dental Systems GmbH

WARNING

NOTICE

1.

? ?

2.

7.3 Switching the units ON Installation Instructions ORTHOPHOS XG 3

7.3 Switching the units ON

When performing the following test, be sure to observe

the radiation protection regulations applicable in your

country (see operating instructions).

It is prohibited for any person to be positioned in the

unit when it is switched on.

If the room height is less than 2.27 m (89 3/8“) (2.30 m (90

1/2“) with floor stand), you must limit the maximum travel

height of the unit (see section 11.1.7).

1. Switch the unit ON.

– All LEDs and the LED display on the Multipad light

up briefly.

– The green LED at the top of the Multipad

permanently as long as the unit is ON.

– The initialization status is visualized by a progress

indicator while the unit executes a self-adjustment

routine (approx. ½ min.). At the same time, the

rotating element rotates briefly clockwise and coun

terclockwise and the diaphragm is positioned. The

forehead and temple supports on the panoramic

unit open and close and then stop moving in fully

opened position.

– Once the self-adjustment routine is completed, help

message H301 prompts you to move the unit to the

starting position.

2. Press the R key to move the unit back to the starting

position.

• Switch the PC ON and start SIDEXIS XG.

➋ is lit

-

60 51 416 D 3352

68 D 3352.031.03.18.02

Page 69

Sirona Dental Systems GmbH 7 Initial startup

IMPORTANT

IMPORTANT

Installation Instructions ORTHOPHOS XG 3 7.4 Checking the data paths

7.4 Checking the data paths

7.4.1 Generating pan/ceph test images/Checking the pan/ceph/PC data path

1. In SIDEXIS XG, select the constancy test:

SIDEXIS XG must be installed and configured before you

begin checking the data paths (see "SIDEXIS - Operators

Manual").

UTILITIES

The classical SIDEXIS user interface is started. Con

stancy test is already preset.

2. Start the exposure mode:

Click

The dialog box for selecting the X-ray device opens.

If no X-ray device has been configured yet in SIDEXIS XG,

the password input window appears instead of the dialog

box for selecting the X-ray device. For creating a new X-ray

device (see documentation "SIDEXIS XG - Installation of

Stand-Alone Systems").

CONSTANCY TEST

XCXP

.

-

60 51 416 D 3352

D 3352.031.03.18.02

69

Page 70

7 Initial startup Sirona Dental Systems GmbH

IMPORTANT

IMPORTANT

5.

4.

7.4 Checking the data paths Installation Instructions ORTHOPHOS XG 3

3. Select/confirm the X-ray device:

ROOM

3

Select e.g.

The

SELECT X-RAY DEVICE

X-ray devices are installed.

The dialog box for selecting the test type appears on

the screen.

4. Select/confirm the test type:

SERVICE EXPOSURE

Click

The dialog box for selecting the service exposure ap

pears on the screen.

5. Select/confirm the service exposure:

Click

DIGITAL TEST PATTERN

– If several different X-ray components are available,

a dialog box for selecting the X-ray component

appears on the screen. In this case, select/confirm

the required component.

– If only one X-ray component is available, the expo

sure readiness dialog box appears on the screen

and shows the status of the exposure.

and click OK.

dialog appears only if several

.

During operation in the service mode, the unit switches from

the user mode to the PC service mode logged by the PC.

The service mode is indicated by the

the Multipad (see page 84).

The unit switches back to the user mode as soon as the ex

posure is completed.

-

-

SERVICE

display on

-

70 D 3352.031.03.18.02

60 51 416 D 3352

Page 71

Sirona Dental Systems GmbH 7 Initial startup

IMPORTANT

7.

6.

T

R

Prog.

S

kV

mA

G

Installation Instructions ORTHOPHOS XG 3 7.4 Checking the data paths

6. Take an exposure:

– Press the R key on the Multipad to move the unit

back to the starting position.

– Press the release button. Hold down the button

until the exposure has been completed.

A service message box indicates whether the generated

test image is correct. Acknowledge this message with OK.

The test image is displayed on the screen.

7. Test pattern for panoramic unit

Check the images according to the following criteria:

– Tile structure of the existing segments

Tip: To facilitate checking, you can adjust the image con

trast and brightness in SIDEXIS.

– Linear grayscale gradient

– Intensity steps clearly recognizable

– No image artifacts detectable

-

60 51 416 D 3352

D 3352.031.03.18.02

71

Page 72

7 Initial startup Sirona Dental Systems GmbH

7.4 Checking the data paths Installation Instructions ORTHOPHOS XG 3

72 D 3352.031.03.18.02

60 51 416 D 3352

Page 73

ORTHOPHOS XG 3

8 Startup for USA/Canada only

60 51 416 D 3352

D 3352.031.03.18.02

73

Page 74

8 Startup for USA/Canada only Sirona Dental Systems GmbH

NOTICE

NOTICE

ON

OFF

I

O

8.1 Startup, measurements and controls Installation Instructions ORTHOPHOS XG 3

8.1 Startup, measurements and controls

Required measuring instruments

1. Digital multimeter Fluke 87 III or equivalent.

Accuracy:

DC voltage ± 0.1 % of reading plus 0.02% of range

DC current ± 0.4 % of reading plus 0.1% of range.

2. A dose measurement device (e.g. Mult-O-Meter

type 510L) is required for dosimetry

Duty cycle

Between exposures maintain at least a cool-off time (auto

matic exposure blockage, see Operating Instructions man

ual).

Operating instructions

During measurements and controls it is necessary to ener

gize or de-energize the unit. For all operating steps please

refer to the Operating Instructions manual.

CAUTION with PC boards!

All PC boards are fitted with electronic components sensi

tive to electrostatic discharge (ESD). In an environment of

moving people, electrostatic charges are unavoidable due

to friction caused by clothing, carpeting etc.

To prevent damage to electronic chips, do not touch same.

Always handle circuit boards by their edges.

-

-

-

-

Radiation protection

Observe the radiation protection guidelines as outlined in

the Operating Instructions manual.

X-radiation is emitted as long as the exposure key on the

Multitimer is depressed.

The X-ray indicator must light up on the Multitimer during

radiation. An acoustic signal must also be heard.

Power supply adequacy

To assure that the ORTHOPHOS XG system performance

is in accordance with Sirona specifications, an adequate

power supply for permanent installation is essential.

The Federal Performance Standard for Diagnostic

X-ray Units, Code of Federal Regulations, Title 21 CFR,

Subchapter J, mandates an adequate power supply.

Electrical shock hazard!

Always turn unit OFF before connecting and disconnecting

the test leads to the test points.

74 D 3352.031.03.18.02

60 51 416 D 3352

Page 75

Sirona Dental Systems GmbH 8 Startup for USA/Canada only

DANGER RADIATION

IMPORTANT

3.

1.

2.

K1

300 VAC

K1

➊

➋

4. - 5.

Installation Instructions ORTHOPHOS XG 3 8.2 Power supply adequacy

8.2 Power supply adequacy

• To determine power supply adequacy, the line volt

age drop

1. Be sure power is disconnected at the central distribu

tion panel!

• Remove front cover (for details see Service Manual).

2. Select 300 VAC line voltage range on multimeter .

Connect measuring leads to terminal K1, L and N.

3. Connect power and switch unit ON

Wait 1 min. for self-adjustment of the unit.

Press key R

position.

4. Establish exposure readiness via SIDEXIS.

5. Select highest exposure level e.g. 90 kV/12 mA.

Depress the exposure key until meter reading is

obtained.

during exposure must be measured.

➊ .

➋ to return X-ray tube head into the initial

-

-

Line voltage, no-load: Max. permissible

180 – 208 V 9 V

208 – 230 V 8 V

230 – 240V 7.5 V

240 – 264V 7 V

Record reading.

• Turn unit OFF.

• Remove meter leads and refit cover.

If the voltage drop is not within the specified

range

advise the customer that an adequate power supply

must be installed. Refer to Pre-Installation Instructions.

Disconnect unit and do not release for use!

line voltage drop:

60 51 416 D 3352

D 3352.031.03.18.02

75

Page 76

8 Startup for USA/Canada only Sirona Dental Systems GmbH

WARNING

WARNING

NOTICE

1.

2.

A

B

8.3 Tube Current Verification Installation Instructions ORTHOPHOS XG 3

8.3 Tube Current Verification

The electronics of the X-ray tube assembly are always

connected to line voltage.

Always switch the X-ray unit off and wait until V203 is

no longer illuminated before contacting the test leads.

The test leads and measuring instruments used must

have a dielectric strength of at least 1000V!

Be sure to use a battery-powered measuring instru

ment with shock-hazard-protected sockets.

Use only test leads with shock protection.

The X-ray tube assembly moves during the measurement.

Therefore, be sure to use test leads of sufficient length and

place the measuring instrument in a location where it is firm

ly seated so that it doesn’t fall down.

-

1. Remove cover (for details see Service Manual).

2. Loosen the four screws A and remove cover plate B of

the electronics box.

-

76 D 3352.031.03.18.02

60 51 416 D 3352

Page 77

Sirona Dental Systems GmbH 8 Startup for USA/Canada only

WARNING

DANGER RADIATION

IMPORTANT

IMPORTANT

C

D

4.

MA–MA+

20mADC

com.

PC-board DX6

A

400 VDC

3.

➊

➋

6. - 7.

Installation Instructions ORTHOPHOS XG 3 8.3 Tube Current Verification

Be sure to switch the X-ray unit off before removing the

jumper for the mA measuring jack.

3. Remove jumper A from MA+/MA – test points on PC

board DX6. Connect digital ammeter to MA+ and MA–

and select range 20 mADC.

4. Reattach cover C and tighten screw D securely.

5. Switch unit ON ➊ .

Wait 1 min. for self-adjustment of the unit.

Press key R to return X-ray tube head into the initial

position.

6. Select 66kV/8mA. Establish exposure readiness via

SIDEXIS.

7. If P1 program and 66kV/8mA are selected .

The unit must be ready for radiation.

Measurement:

– Depress the exposure key and hold depressed until

meter reading is obtained.

The ammeter shall indicate 8mA ±1.6mA.

Record reading.

Readings: 1mA corresponds to a tube current of 1mA, per

missible tolerance +/-20%.

If specified values cannot be obtained, see Service Man

ual, chapter ”Tube Current Verification”.

-

-

60 51 416 D 3352

D 3352.031.03.18.02

77

Page 78

8.

9. 10.

8 Startup for USA/Canada only Sirona Dental Systems GmbH

8.3 Tube Current Verification Installation Instructions ORTHOPHOS XG 3

• If specified value is obtained switch unit OFF.

8. Remove upper cover and meter leads

• Replace jumper!

9. Screw the cover plate back on to the electronics box.

10. Reattach the housing covers.

78 D 3352.031.03.18.02

60 51 416 D 3352

Page 79

Sirona Dental Systems GmbH 8 Startup for USA/Canada only

T

R

Prog.

S

kV

mA

P1 14.1 64 8

C

B

A

60kV/8mA

0.5s

-

-

+

+

S2

3

AA

1.

4.

7.

Installation Instructions ORTHOPHOS XG 3 8.4 kV – verification / Exposure Time Verification

8.4 kV – verification / Exposure Time Verification

Preparing the measurement

1. Attach the Mult-O-Meter sensor in the middle of the du

al sensor.

2. Switch the unit on via the switch A (see also Operating

Instructions)

The X-Ray radiation indicator (B) lights up briefly.

After approx. 2 seconds, the green LED (C) in the

upper part of the control panel lights up. This LED

remains lit as long as the unit is on.

The start screen appears on the touchscreen of

the Easypad and the system's self-adjustment

routine starts running (for approx. 1 minute). The

rotating element rotates briefly clockwise and

counterclockwise. The diaphragm moves into

position. The forehead and temple supports on the

panoramic unit open and close and then stop

moving in fully opened position.

On completion of the self-adjustment routine, the

main menu appears on the touchscreen. Help

3. Press the R key.

message H301 prompts you to move the unit into

the starting position.

The unit moves to its starting position.

4. Call the Service menu and the Service routine S002.3

-

(see Service Manual).

5. Use the arrow keys (A) in selection field 1 to select the

kV/mA level 62kV/8mA.

6. Use the arrow keys (A) in selection field 2 to select the

radiation time 0.5 s.

Performing measurements

7. Initiate the radiation. Hold the release button pressed

until the set radiation time has expired.

CAUTION! Activating the release button triggers

X-rays

60 51 416 D 3352

D 3352.031.03.18.02

79

Page 80

8 Startup for USA/Canada only Sirona Dental Systems GmbH

8.4 kV – verification / Exposure Time Verification Installation Instructions ORTHOPHOS XG 3

kV – verification

Analyzing measurements

➢ Read the voltage values on the Mult-O-Meter.

The value for the voltage displayed on the

Mult-O-Meter must correspond to the 62 kV

selected in the service routine. The permissible

tolerance is ± 10 %..

If the measured values do not fall within the

permissible tolerance range, replace the tube

assembly (see Service Manual).

If the measured values fall within the permissible

tolerance range, finalize the measurement.

Exposure Time Verification

Analyzing measurements

➢ Read the radiation time on the Mult-O-Meter.

The value for the radiation time displayed on the

Mult-O-Meter must correspond to the radiation

time of 0.5s selected in the service routine. The

permissible tolerance is ± 10 %.

If the measured radiation time does not fall within

the permissible tolerance, replace the tube

assembly (see Service Manual).