Siemens Mammomat Balance Troubleshooting Guide

MAMMOMAT Balance

SP

Troubleshooting Guide

Service Instructions (incl)

Print No.: SPB7-115.840.01.02.02

Replaces: SPB7-115.840.01.01.02

© Siemens AG 2004

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will be liable for damages. All rights, including rights created by patent grant or registration of a utility model or_ design, _are_ reserved.

English

Doc. Gen. Date: 10.04

Revision

Chapter |

Page |

Revision |

|

|

|

all |

all |

02 |

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or one of its affiliates before attempting installation or service procedures.

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 2 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

|

Contents |

LIST OF FUSES.......................................................................................................................................... |

5 |

DIP SWITCHES.......................................................................................................................................... |

6 |

CONTROL LEDS....................................................................................................................................... |

7 |

SUBASSEMBLIES AND PCB REPLACEMENT....................................................................................... |

9 |

COLLIMATOR LAMP REPLACEMENT ............................................................................................... |

10 |

SWITCH ON CIRCUIT AND SEQUENCE.............................................................................................. |

11 |

TABLE DETECTION AND GRID TEST ................................................................................................. |

12 |

TABLE DRIVER......................................................................................................................................... |

12 |

TABLE DETECTION................................................................................................................................... |

12 |

GRID MOVEMENT TEST ............................................................................................................................. |

12 |

TROUBLESHOOTING ............................................................................................................................ |

13 |

1) OPERATING ERRORS ON DISPLAY.......................................................................................................... |

13 |

2) TECHNICAL MENU................................................................................................................................ |

18 |

3) TECHNICAL ERRORS IN LOG FILE ......................................................................................................... |

20 |

MEMORY STRING..................................................................................................................................... |

21 |

LIST OF ERROR CODES.............................................................................................................................. |

22 |

ROTATING ANODE STARTER.............................................................................................................. |

23 |

CALIBRATION OF PROTECTION CIRCUIT ..................................................................................................... |

23 |

FUNCTION CONFIGURATION...................................................................................................................... |

25 |

DEFAULT JUMPER SETTING....................................................................................................................... |

25 |

BRAKE DISABLE FOR HEAVY USE .............................................................................................................. |

25 |

FILAMENT............................................................................................................................................... |

26 |

FILAMENT POWER SUPPLY........................................................................................................................ |

26 |

ANODE CURRENT CALIBRATION................................................................................................................ |

28 |

CALIBRATION OF FILAMENT CURRENT PROTECTION ................................................................................... |

31 |

CALIBRATION OF FILAMENT VOLTAGE PROTECTION................................................................................... |

31 |

ANODE CURRENT CHECK BY EXTERNAL DEVICE......................................................................................... |

32 |

HIGH VOLTAGE GENERATOR............................................................................................................. |

33 |

DESCRIPTION........................................................................................................................................... |

33 |

NON INVASIVE KV CHECK ........................................................................................................................ |

34 |

KV CHECK AT TP1/TP2 PCB 94-132......................................................................................................... |

34 |

TEST POINTS AND ADJUSTMENT ................................................................................................................ |

35 |

AEC CALIBRATION ............................................................................................................................... |

37 |

DOSE CALCULATOR ............................................................................................................................. |

38 |

INTRODUCTION........................................................................................................................................ |

38 |

ACCESSING THE PROGRAM ....................................................................................................................... |

38 |

SYSTEM CONFIGURATION FOR CALIBRATION ............................................................................................. |

42 |

RADIATION TABLE ................................................................................................................................... |

42 |

DOSEMETER CONFIGURATION................................................................................................................... |

45 |

DOSEMETER DATA ................................................................................................................................... |

47 |

COMMUNICATIONS WITH M AMMO UNIT..................................................................................................... |

50 |

OPTIONS ................................................................................................................................................. |

51 |

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 3 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

|

Contents |

COMPRESSION SYSTEM ....................................................................................................................... |

52 |

INTRODUCTION........................................................................................................................................ |

52 |

CONFIGURATION OF MAXIMUM COMPRESSION FORCE................................................................................ |

52 |

CALIBRATION OF MAXIMUM COMPRESSION FORCE .................................................................................... |

52 |

MOTOR CURRENT DETECTOR.................................................................................................................... |

52 |

MOTOR OR CLUTCH REPLACEMENT........................................................................................................... |

52 |

C-ARM ROTATION BRAKE................................................................................................................... |

53 |

BRAKE FORCE ADJUSTMENT ..................................................................................................................... |

53 |

X-RAY / LIGHT FIELD ALIGNMENT PROCEDURE ........................................................................... |

54 |

ASSEMBLY / DISASSEMBLY OF ORIGINAL TUBE .......................................................................................... |

54 |

X-RAY BEAM COLLIMATION ................................................................................................................... |

54 |

LIGHT / BEAM ALIGNMENT....................................................................................................................... |

56 |

GAS SPRING REPLACEMENT............................................................................................................... |

58 |

MAMMOMAT BALANCE / EASY LABEL COMMUNICATION PROTOCOL .................................... |

60 |

CHANGES TO PREVIOUS VERSION..................................................................................................... |

62 |

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 4 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

List of Fuses

List of Fuses

FUSE HOLDERS

F1 |

|

10 x 38 |

gG 20A |

|

|

F2 |

|

10 x 38 |

gG 20A |

|

|

F3 |

6 |

x 30 |

CT 3.15A |

|

|

F4 |

6 |

x 30 |

CT 3.15A |

|

|

F5 |

6 |

x 30 |

CT 500mA |

|

|

F6 |

|

10 x 38 |

gG 10A |

|

|

F7 |

5 |

x 20 |

CT 40mA |

|

|

F8 |

6 |

x 30 |

CT 100mA |

|

|

F9 |

|

10 x 38 |

gG 10A |

|

|

F10 |

6 |

x 30 |

CT 10A |

|

|

F11 |

6 |

x 30 |

CT 4A |

|

|

F12 |

6 |

x 30 |

CT 100mA |

|

|

PCB 03-186 |

|

|

|

|

|

|

|

|

|

|

|

F1 |

|

5 x 20 |

CT 500mA |

|

|

F2 |

|

5 x 20 |

CT 500mA |

|

|

PCB 03-188 |

|

|

|

|

|

|

|

|

|

|

|

F1 |

5 |

x 20 |

ET 1.6A |

|

|

F2 |

5 |

x 20 |

ET 1A |

|

|

F3 |

5 |

x 20 |

CT 0.5A |

|

|

F4 |

|

6.3x 32 |

GT 2A |

|

|

F11 |

5 |

x 20 |

ET 3.15A |

|

|

PCB 92-073 |

|

|

|

|

|

|

|

|

|

|

|

F1 |

|

6.3x 32 |

GT 1.6A |

|

|

F2 |

|

6.3x 32 |

GT 1.6A |

|

|

PCB 92-074 |

|

|

|

|

|

|

|

|

|

|

|

F1 |

6 |

x 30 |

CT 10A |

|

|

F2 |

6 |

x 30 |

CT 4A |

|

|

F3 |

5 |

x 20 |

CT 40mA |

|

|

INVERTER PCB 94-132 |

|

|

|||

|

|

|

|

|

|

F2 |

|

5 x 20 |

CT 1A |

|

|

F3 |

|

BUSSMANN |

B1000 20FC 20A 660V |

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 5 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

DIP switches

DIP switches

PCB 01-170 Main CPU

SW1 |

|

|

|

DIP1 |

= |

ON |

Anode current calibration mAH |

DIP2 |

= |

ON |

Anode current calibration mAL |

DIP3 |

= |

ON |

DEMO mode without x-ray |

DIP4 |

= |

ON |

Pulsed radiation disabile with grid table |

DIP5 |

= |

ON |

AEC frozen to single Film/Screen |

DIP6 |

= |

OFF |

Not in use, must remain OFF |

DIP7 |

= |

ON |

Compression force calibration |

DIP8 |

= |

ON |

Mo/Rh filter enabled |

|

|

|

|

SW2 |

|

|

|

DIP1 |

= |

ON |

C-arm Brake, disabled for service |

DIP2 |

= |

ON |

Inverter Vdc input sense disabled |

DIP3 |

= |

ON |

Max compression force 200N |

DIP4 |

= |

ON |

Exposure start on left to right grid movement |

DIP5 |

= |

OFF |

Future expansion |

PCB 92-083 Keyboard

Language |

DIP1 |

DIP2 |

DIP3 |

DIP4 |

Italian |

OFF |

OFF |

OFF |

OFF |

French |

ON |

OFF |

OFF |

OFF |

English |

OFF |

ON |

OFF |

OFF |

German |

ON |

ON |

OFF |

OFF |

Spanish |

OFF |

OFF |

ON |

OFF |

Polish |

ON |

OFF |

ON |

OFF |

Turkish |

OFF |

ON |

ON |

OFF |

Portuguese |

ON |

ON |

ON |

OFF |

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 6 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Control LEDs

Control LEDs

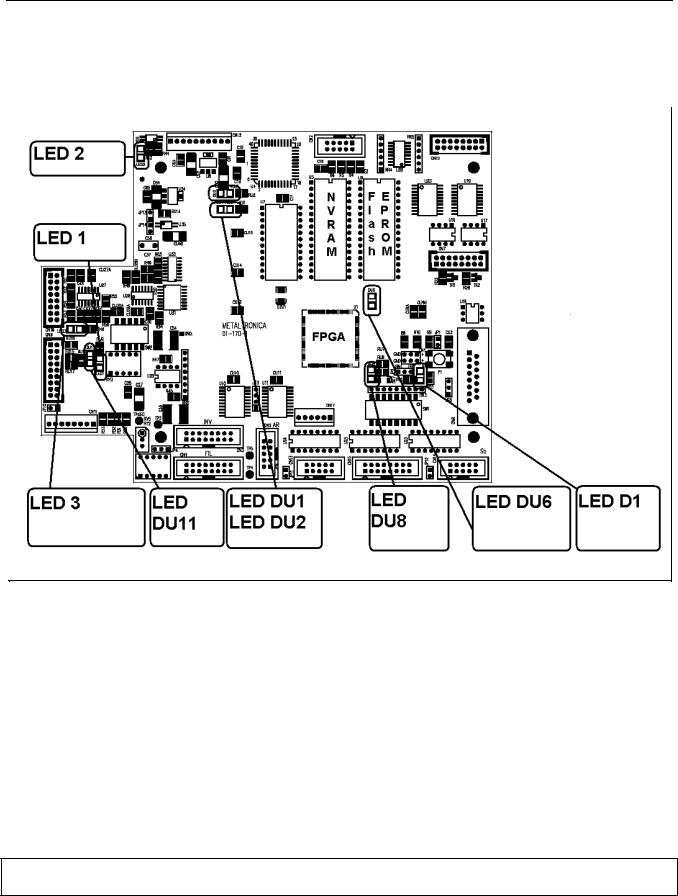

CPU 01-170

_________________________________________________________________________________

|

Color |

Function |

LED1 |

YELLOW |

Don’t care |

LED2 |

YELLOW |

blinking during x-ray |

LED3 |

YELLOW |

bright during x-ray ( mAs meter pulses) |

LED D1 |

RED |

IRQ activity monitor, blinks in normal condition; if bright fix CPU |

|

|

hanged UP |

LED DU1 |

YELLOW |

internal +2,5Vdc |

LED DU2 |

YELLOW |

internal +3,3Vdc |

LED DU6 |

RED |

ON at start UP during FPGA initialization |

LED DU8 |

RED |

ON during CPU initial reset |

LED DU11 |

YELLOW |

+5Vdc |

CPU Reset sequence

At power ON, LED DU6 and LED DU8 are bright, LED DU8 goes OFF, LED DU6 goes OFF, LED D1becomes bright fix and after blinks to indicate that CPU is running.

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 7 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Control LEDs

Motherboard 03-188

|

Color |

Function |

DL1 |

GREEN |

-15Vdc |

DL2 |

GREEN |

+15Vdc |

DL3 |

GREEN |

+24Vdc |

DL4 |

GREEN |

+5Vdc |

DL5 |

RED |

bright with x-ray pushbutton pressed |

DL6 |

GREEN |

-15Vdc delayed at power ON |

DL7 |

GREEN |

+5Vdc |

DL8 |

RED |

CPU / Table driver communication monitor, blinks in normal |

|

|

condition, bright fix during grid movement. |

Anode starter 92-074 |

|

|

|

Color |

Function |

LED1 |

YELLOW |

Bright during tube running |

LED2 |

YELLOW |

Bright during brake or alarm |

LED3 |

YELLOW |

Bright during brake |

LED5 |

GREEN |

Bright in Stand by or rotation |

LED6 |

GREEN |

Bright during rotation |

Filament power supply PCB 92-073 |

||

|

Color |

|

Function |

LED1 |

GREEN |

|

Bright fix in normal condition |

LED2 |

RED |

|

don’t care |

LED3 |

RED |

|

Bright when Small focal spot is selected |

LED4 |

GREEN |

|

Bright with filament ON |

LED5 |

YELLOW |

|

bright during exposure. Brightness is directly proportional to anode |

|

|

|

current |

Inverter control board 94-132 |

|

||

|

|

|

|

|

Color |

|

Function |

DL1 |

GREEN |

|

+15Vdc |

DL2 |

YELLOW |

|

bright or blinking during exposure depending on continuous |

|

|

|

or pulsed mode |

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 8 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Subassemblies and PCB replacement

Subassemblies and PCB replacement

When replacing subassemblies and/or PCB, take care of calibration or Firmware version according the following table :

SIEM.code |

MTL code |

Part description |

Calibration |

Firmware |

|

|

|

|

|

08883402 |

DS/INVC132 |

Display SP14N003 power supply |

NO |

NO |

|

|

|

|

|

08883410 |

DS/LMG7401 |

SP14N003 DISPLAY |

NO |

NO |

|

|

|

|

|

08883436 |

KTFLA0206 |

INVERTER module |

Note (1) |

NO |

|

|

|

|

|

08883444 |

KTFLI0009 |

H.V. Transformer |

Note (1) |

NO |

|

|

|

|

|

08883451 |

PCB/01-170-X |

CPU Board |

NO |

YES |

|

|

|

|

|

08883469 |

PCB/02-171-0 |

TUBE Temperature sensor |

NO |

NO |

|

|

|

|

|

08883477 |

PCB/02-179-X |

C-ARM Service board |

NO |

YES |

|

|

|

|

|

08883485 |

PCB/03-181-X |

CPU Keyboard |

NO |

YES |

|

|

|

|

|

08883493 |

PCB/03-186-X |

Service board |

NO |

YES |

|

|

|

|

|

08883501 |

PCB/03-187-X |

Serial port connectors board |

NO |

NO |

|

|

|

|

|

08883519 |

PCB/03-188-X |

CPU Mother board |

YES |

YES |

|

|

|

|

|

08883527 |

PCB/92-073-X |

Filament power supply |

YES |

NO |

|

|

|

|

|

08883535 |

PCB/92-074-X |

Anode starter |

YES |

YES |

|

|

|

|

|

08883543 |

PCB/92-083-X |

Keyboard |

NO |

NO |

|

|

|

|

|

08883550 |

PHTM9000 |

AEC Detector |

YES |

NO |

|

|

|

|

|

Note (1)

kV check and eventual adjustment is necessary.

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 9 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Collimator lamp replacement

Collimator lamp replacement

1)Remove attachment of Face shield protection by means of four fixing screws

2)Open collimator assembly by removing the four fixing screws

3)replace lamp only with original spare part having the same filament orientation.

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 10 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

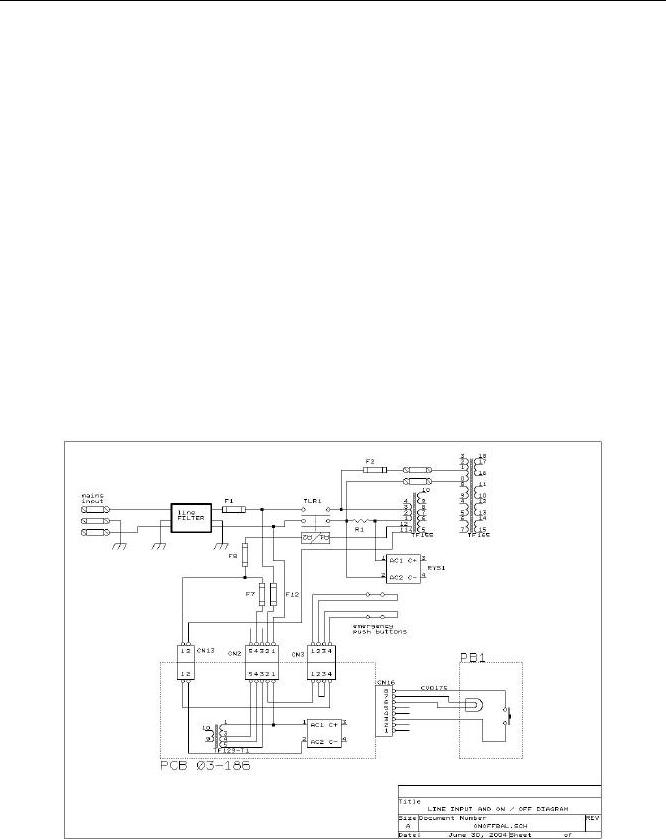

Switch ON circuit

Switch on circuit and sequence

Unit is switched ON by means of main contactor TLR1 and solid state relay RYS1. Drive and timing circuit is on board of PCB 03-186, powered by TF129.

Switch On sequence

Main contactor TLR1 switches ON at first and dumping resistor R1 smooths inrush current of TF155, TF165 and capacitors C1,C2,C3,C4.

After few seconds RYS1, with zero cross drive, shorts R1 and full power is available for H.V. generator and other high power services.

Display and Keyboard initialization

Keyboard (PCB 92-083+03-181) has its own dedicated CPU.

At power ON, empty frame is drawn by keyboard CPU on the display.

When main CPU of PCB 01-170 starts, display frame is filled with icons.

Grid position initialization

At power ON grid is moved to search home position and noise from the table is normal. Grid home position is at left side from patient position.

Emergency shutdown

Emergency push buttons located on both sides of MAMMOMAT Balance.

Operating Emergency push button will switch OFF immediately main contactor TLR1 and the whole unit is switched OFF.

ON/OFF pushbutton and control lamp

Connected to CN16 of PCB 03-186 has control lamp inside.

Control lamp is bright when unit is OFF, after switch OFF, lamp blinks for a short time during which further switch ON is disabled to allow high power circuit to reset.

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 11 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Table detection and grid test

Table detection and grid test

Table driver

Table driver is onboard of PCB 03-188 motherboard, it contains both cassette sensing + leds for all tables and stepper motor driver for grid tables.

Table driver is connected by serial port to main CPU.

Table detection

The following tables are detected by the CPU in order to guarantee the appropriate functionality.

Model |

Part number |

18x24 gridless |

83.83.189 |

18x24 grid |

83.83.171 |

24x30 gridless |

83.83.239 |

24x30 grid |

83.83.221 |

18x24 gridless 1,8 X magnification device |

83.83.353 |

Cassette detection functions are the same for all the tables.

Green LED is bright fix when unexposed cassette is in. Unit could not be ready for exposure depending on Door Open and/or no collimation plate.

Green LED is blinking for all other conditions.

If cassette notch sensing switch is enabled ( Table internal jumper removed ) and cassette has no notch, green Led is blinking even if cassette is properly inserted.

Grid tables.

If grid table is recognized, x-ray beam is pulsed. Both large and small focus can be selected from the control panel.

Gridless tables.

If gridless table, any kind, is recognized, x-ray beam is continuous, small focus is selec ted automatically and deselected when gridless table is removed.

Grid movement test

If grid table is inserted, by means of pushbuttons Bell + Compression [-] grid can be moved without exposure for functionality check.

Grid must oscillate back and forth.

Grid speed is different during the first 7 runs for strokes First right / left, speed for movement must be regular

Grid movement has time-out of 20” to protect stepper motor.

When Grid movement is activated by main CPU, DL8 of PCB 03-188 becomes bright fix and .LED2 PCB 01-170 blinks following x-ray interruption at grid direction change.

Grid home position is at left side from patient position.

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 12 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Troubleshooting

Troubleshooting

o If unit doesn’t switch ON refer to dedicated section of this manual.

oIf unit can be switched ON but: no Frame and no Icons appear on the screen and CPU reset sequence is wrong , check voltages on CPU motherboard 03-188

oIf unit can be switched ON but: Frame and no Icons appear on the screen and CPU reset sequence is wrong , check CPU 01-170.

oIf unit can be switched ON but: no Frame and no Icons appear on the screen and CPU reset sequence is correct check keyboard 92-083, KEYBOARD CPU 03-181, cable CV0155 and supply voltages onboard of KEYBOARD 92-083

If the unit is operative fault finding and troubleshooting is based on the followings:

1)Operating or technical errors on display

2)Technical menu

3)Technical errors in Log file

1)Operating errors on Display

Operating errors on Display are described in the Operator’s manual SPB7-115.620.01…. For the technical aspects related to such alarms:

|

ALARM |

|

|

GAS SPRING DEFECTIVE ! |

|

|

|

Code |

|

|

Gs |

|

|

|

When |

Any time when unit is ON |

|

|

||

|

|

|

|

|

|

|

|

Why |

Gas spring has loosed it’s capacity to balance c-arm suspended masses |

|

|

||

|

|

|

|

|

|

|

|

Action |

For Gas Spring replacement refer to “Gas spring replacement” section in this document |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

For safety reasons unit can’t be operate d if Gas Spring is defective. |

|

|

|

WARNING |

|

|

|

||

|

|

Alarm can’t be cleared |

|

|

||

|

|

|

|

|

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 13 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

|

|

Troubleshooting |

|

|

|

|

ALARM |

CHECK ARM PUSH BUTTON |

|

|

CHECK BRAKE PUSH BUTTONS |

|

|

CHECK FOOT PEDAL SWITCH |

|

Code |

Pa |

|

|

Pb |

|

|

Pc |

|

When |

during operating of compression or c-arm rotation or c-arm vertical movement or anytime |

|

|

for eventual malfunction of pushbuttons or foot pedal switches |

|

|

. |

|

Why |

pushbutton or foot pedal switch of mentioned functions remains activated for more than |

|

|

20” |

|

|

|

|

Action |

Check pushbuttons or foot pedal switches and eventually disconnect them from the |

|

|

boards for easier investigation. |

|

|

|

|

Note |

Alarm goes OFF by itself if normal condition is restored releasing pushbutton or foot pedal |

|

|

switch. |

|

|

|

ALARM |

CHECK CASSETTE |

Code |

Ci |

When |

At power ON |

|

|

Why |

Cassette was inside the table and could be exposed. |

|

|

Action |

Remove cassette check it and reinsert. |

|

If alarm comes out without cassette inside check cassette sensing microswitches. |

|

|

Note |

Alarm goes OFF by itself if normal condition is restored removing cassette |

|

|

ALARM |

DOOR OPEN |

Code |

Do |

When |

Starting exposure |

|

|

Why |

Door of Examination room was open when operator pressed x-ray push button |

|

|

Action |

Close door or check door contact and / or wiring to PCB 03-186. |

|

|

Note |

Alarm goes OFF by itself if normal condition is restored closing the door. |

|

Exposure is not interrupted if door is open after that exposure sequence started. |

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 14 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

|

|

Troubleshooting |

|

|

|

|

ALARM |

ABSENCE OF COLLIMATOR CONE |

|

Code |

C0 |

|

|

|

|

When |

Starting exposure |

|

|

|

|

Why |

Collimation plate is missing |

|

|

|

|

Action |

Insert collimation plate or check sensing microswitch and / or PCB 02-179 and |

|

|

connection cable to main CPU CV0158 |

|

|

|

|

Note |

Alarm goes OFF by itself if collimation plate is inserted |

|

|

|

ALARM |

CASSETTE NOT INSERTED |

|

CASSETTE ALREADY EXPOSED |

Code |

Nc |

|

Ce |

When |

Starting exposure |

|

|

Why |

Cassette is not inserted or already exposed or cassette sensing switches are defective |

|

|

Action |

Insert or replace cassette or check cassette sensing switches |

|

|

Note |

Alarm goes OFF by itself if cassette is inserted or removed. |

|

|

ALARM |

MIRROR POSITION ERROR |

Code |

Me |

When |

Starting exposure |

|

|

Why |

Mirror is not out of field |

|

|

Action |

Check if mirror doesn’t move totally or partially for mechanical or electrical problems. |

|

Mirror drive motor has position sensing switch inside that must switch ( audible click ) |

|

when is at 60 degrees with respect to the base plate. |

|

Mirror driver is onboard of PCB 02179 connected to the main CPU by CV0158. |

|

|

ALARM |

|

FILTER POSITION ERROR |

|

|

|

Code |

|

|

Fi |

|

|

When |

Filter changes from Mo to Rh or vice-versa |

|

|

||

|

|

|

|

||

Why |

Position sensing switch is not closed |

|

|

||

|

|

|

|||

Action |

Select manual mode, select filters several time to investigate if it’s mechanical or electric |

||||

|

problem. |

|

|

|

|

|

Filter is driven by PCB 02-179. |

|

|

|

|

|

|

|

|

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 15 of 62 |

Siemens AG |

||

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

||

|

|

Troubleshooting |

|

|

|

|

ALARM |

NOT ACTIVE |

|

Code |

T0 |

|

When |

Starting exposure in automatic mode |

|

|

|

|

Why |

Film Screen or technique STD, EXT, LD, HC selected on the control panel is not |

|

|

programmed. |

|

|

|

|

Action |

Select programmed Film Screen and technique STD, EXT, LD, HC. |

|

|

If only one is programmed, freeze it by means of DIP5 SW1 PCB 01-170. |

|

|

If problem persist it’s probably due to memory corruption, transfer again AEC calibration |

|

|

curve to CPU memory |

|

|

|

|

|

|

|

ALARM |

EARLY PUSHBUTTON RELEASE |

|

Code |

Rp |

|

When |

During exposure |

|

|

|

|

Why |

Pushbutton has been released before the end of exposure |

|

|

Pushbutton is defective |

|

Action |

Inspect pushbutton at sight, select high mAs value and during exposure force: cable, |

|

|

connector and pushbutton to locate possible false contact. |

|

|

Replace pushbutton. |

|

|

|

|

Note |

Display shows exposure mAs and kV |

|

|

|

|

|

|

|

ALARM |

LOW ANODE CURRENT |

|

Code |

Bt |

|

When |

After exposure in MANUAL mode |

|

|

|

|

Why |

Anode current was below lower limit or zero. |

|

|

Exposure has been terminated by Back Up Timer. |

|

|

|

|

Action |

Check anode current calibration according to specific section of this manual. |

|

|

Also check kV value according to specific section of this manual. |

|

|

Alarm can also depend on malfunction of V/F converter onboard of PCB 92-073, event |

|

|

counter on board of PCB 01-170 and cable CV0173. |

|

|

To investigate mAs integrator, check LED5 PCB 92-073 and LED3 PCB 01-170 |

|

|

For further investigation, external Dose meter or radiographic cassette with film can be |

|

|

used to detect if x-ray are generated or not. |

|

|

LOW ANODE CURRENT could also be due to H.V. generator defect or failure, check it as |

|

|

described in dedicated section of this manual. |

|

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 16 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

|

|

Troubleshooting |

|

|

|

|

ALARM |

AEC DETECTOR OVER EXPOSED |

|

Code |

A1 |

|

When |

After pre exposure |

|

|

|

|

Why |

Breast and / or detector position is/ are wrong, part of detector was exposed to direct x- |

|

|

ray beam. |

|

|

Breast or phantom density was too low. |

|

|

|

|

Action |

Check for proper breast / detector positioning or thin phantom. |

|

|

|

|

Note |

Film must be replaced. |

|

|

Delivered mAs are less than 1 mAs |

|

|

|

ALARM |

BREAST TOO DENSE |

Code |

A0 |

When |

After pre exposure |

|

|

Why |

Breast density is too high and [p] value lower than limit selected during AEC calibration |

|

Breast could have silicone prosthesis. |

|

Refer to AEC calibration procedure for [p] lower limit calibration. |

|

|

Action |

Reduce breast density and check for AEC calibration with reference phantom. |

|

|

Note |

Film must be replaced. |

|

Delivered mAs are less than 1 mAs |

|

|

ALARM |

LOW mAs SELECTION WITH AEC |

Code |

Mi |

When |

After exposure |

|

|

Why |

Could happen with magnification and small focus if grid table is used and breast is large or |

|

very dense. |

|

Can also happen for calibration problems or system malfunction. |

|

|

Action |

Evaluate operating conditions and eventually use One point mode with higher kV. |

|

|

Note |

Quite impossible with large focus, if happens check very carefully mA, kV, [r] and [o] |

|

calibrations. |

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 17 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

|

|

Troubleshooting |

|

|

|

|

ALARM |

TUBE THERMAL LIMIT REACHED |

|

Code |

HU |

|

When |

Starting exposure |

|

|

|

|

Why |

X-ray tube assembly has reached maximum operating temperature. |

|

|

|

|

Action |

Wait for tube cooling. |

|

|

Evaluate operating conditions from last 1300 exposure memory. |

|

|

Check tube temperature sensor PCB 02-171. |

|

|

Disable tube rotation brake. |

|

|

|

ALARM |

TECHNICAL ERROR |

Code |

Refer to list |

When |

Any time. |

|

|

Why |

Internal error having no meaning for the operator. |

|

|

Action |

Check Log File to find out what it is. |

|

Date and time of error / fault can be helpful to locate it quickly |

|

|

2) Technical menu

When |

Any time. |

|

|

|

|

|

|

|

|

||

Why |

Broken Fuse or defective block has been located by CPU diagnostic functions |

||||

|

|

|

|

||

Action |

Check Log File to find out when it occurred |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIEMENS AG |

|

|

|

|

CPU 01-170 |

F2=OK |

F4=OK |

|

|

|

SW1 00000000 |

SW2 0000 |

|

|

|

|

INVERTER Vdc (in) = 545 V |

LV= OK |

|

|

|

|

Filament |

92-073 |

>> PASS << |

|

|

|

Rotating Anode |

92-074 |

>> PASS << |

|

|

|

FIRMWARE REV |

BAL__ XX TUBE |

|

|

|

|

Tube Housing kJ |

25°C |

|

|

|

|

n. .............. |

../../.. .................. |

|

|

|

|

|

|

|

|

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 18 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Troubleshooting

Fault

CPU fuses F2 or F4

Action Replace fuse

Fault |

Filament 92-073 >> FAIL << |

|

|

Action 1) check LED status of PCB 92-073

2)if problem persists after having switched the Unit off and on again, verify the integrity of fuses F1 F2 PCB 92-073 and of filaments by an ohmmeter.

3)if Alarm Code is T2 it was generated during preparation, check for eventual corruption of filament calibration values

Check also calibration of Over-current and Over-voltage protection circuits.

4)if Alarm Code is R2 it was generated during exposure check calibration of Over-current and Over-voltage protection circuits.

5)if in doubt that filament board safety circuits are not recognized by CPU, they can be simulated by means of jumpers on the flat cable CV0173.

Fault |

Rotating anode 92-074 >> FAIL << |

|

|

Action 1) check LED status of PCB 92-074

2)if problem occurs when the unit is in stand by check that flat cable CV174 connecting PCB 92-074 and PCB 01-170 has been correctly seated. Also check fuses F1 and F3 of PCB 92-074

3)if problem occurs in preparation error code is T1 check for line voltage, protection circuit calibration of PCB 92-074, voltage across shift capacitors C5 and C6 that typically is about 120 Vac ( 50hz) during anode running. If voltage is lower shift capacitor is probably defective. For capacitor voltage check, protection circuit has to be disabled.

4)if problem occurs during exposure, error code is R1 check the same as above point 3

5)alarm can also occur due to tube overheating when internal thermo switch opens.

6)if in doubt that starter board safety circuits are not recognized by CPU, they can be simulated by means of jumpers on CN5 PCB 01-170 or flat cable CV0174.

CN5

MAMMOMAT Balance |

SPB7-115.840.01 |

Page 19 of 62 |

Siemens AG |

Troubleshooting Guide |

Rev.02 |

10.04 |

Medical Solutions |

Loading...

Loading...