Siemens Mammomat 3000 Nova Service Program

MAMMOMAT 1000/3000/3000 Nova

SP

Service

Service Program

from SW 4.0

© Siemens AG 2003

|

The reproduction, transmission or |

|

|

use of this document or its contents |

|

|

is not permitted without express |

|

|

written authority. Offenders will be |

|

|

liable for damages. |

All rights, |

|

including rights created by patent |

|

|

grant or registration of a utility |

|

|

model _or_ design,_are_ reserved. |

|

Register 5 |

English |

|

Print No.: SPB7-230.114.03.05.02 |

Doc. Gen. Date: |

02.03 |

Replaces: SPB7-230.114.03.04.02 |

66 30 896 |

|

0 - 2 |

|

|

Revision |

|

|

|

|

Chapter |

Page |

Revision |

|

|

|

|

|

All |

All |

04 |

|

|

|

|

|

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or one of its affiliates before attempting installation or service procedures.

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 2 of 4 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Contents |

0 - 3 |

|

Page |

1 _______Working with the service PC _____________________________________ 1 - 1

Description of the syntax used in these instructions |

. . . . . . . . . |

. . . . . . . . |

. 1 - 1 |

Connecting the service PC . . . . . . . . . . . . . |

. . . . . . . . . |

. . . . . . . . |

. 1 - 2 |

Configuration of the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 Configuration of computer BIOS. . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Configuration of Windows® |

. . . |

. . . . . . . . . . . . . . |

. . . |

. . . |

. . . . . |

. 1 - 3 |

Troubleshooting . . . . . . . . |

. . . |

. . . . . . . . . . . . . . |

. . . |

. . . |

. . . . . |

. 1 - 5 |

2 _______Adjustment and Service PC Programs _____________________________ 2 - 1

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1 System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1 Anode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2 Show configuration file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3 Save configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4 AEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 14 Filament . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 24 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 25 Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 26 Compression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 27 Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 32 Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 34 Grid speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 39 Beam limiting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 40

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 41 View error buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 41 Copy error buffer to file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 42

Delete error buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 |

- 43 |

|

Display error message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

- 44 |

Show exposure counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

- 45 |

Reset exposure counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 |

- 46 |

|

Offset compensation test |

. . . . . . . . . . . . |

. . . . . . . . . . . . . . |

. |

. |

. |

2 |

- 47 |

Panel test . . . . . . . . |

. . . . . . . . . . . . |

. . . . . . . . . . . . . . |

. |

. |

. |

2 |

- 48 |

Stand test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 49 Show/Save exposure info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 52 Normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 54 Generator data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 54 Stand data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 55 AEC data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 56

DLF data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

- 58 |

|

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

- 59 |

|

Test DUEP Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 |

- 60 |

||

Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

- 61 |

Backup procedure in Windows® 2000 Pro . . . . . . . . . . . . . . . . . . . . . |

2 |

|

- 62 |

Quit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

- 63 |

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 3 of 4 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

0 - 4 |

Contents |

|

Page |

3 ______ Dose Calculation Program (from SW 4.4 only!) ______________________3 - 1

Enable/Disable Dose Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1 Configure Tube Specific Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2 HVL values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2 Dose Exchange factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3 Factory defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4 Quit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

4 ______ Error messages ________________________________________________4 - 1

Error messages of the master Er 0XX . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1 Error messages of the panel Er 1XX . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5 Error messages of the filament Er 3XX. . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6 Error messages of the AEC Er 4XX . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7 Error messages of the power pack Er 6XX . . . . . . . . . . . . . . . . . . . . . . .4 - 13 Error messages of the stand Er 8XX . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 17

5 ______ Changes to previous version _____________________________________5 - 1

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 4 of 4 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Working with the service PC |

1 - 1 |

|||

Description of the syntax used in these instructions |

|

|||

<.....> |

|

The indication of which function keys to press is given between |

||

|

|

|

these characters, for example <ENTER>, <ESC> etc. |

|

CAPITALS |

Capital letters indicate data which must be entered unchanged, |

|||

|

|

|

for example the name of a register, files etc. |

|

Italics |

Italics represent data in which a value should be entered, e.g. for |

|||

|

|

|

user name, the name of the technician should be entered. |

|

[.....] |

|

Square brackets enclose additions to commands which may be |

||

|

|

|

optionally entered. |

|

Bold |

Data relating to formats, user entries etc., which is important for |

|||

|

|

|

the following entry, is shown in bold as it appears on the monitor |

|

|

|

|

screen. |

|

|

|

|

This character indicates that at this point the space key must be |

|

|

|

|

||

|

|

|

pressed. |

|

xx yy zz |

Data can be entered in place of "x, y, z" |

|

||

|

|

|

(e.g. day´s date). |

|

{...} |

|

Curved brackets indicate that out of several terms listed one be- |

||

|

|

|

low the other, one must be selected. |

|

|

|

|

Important remarks are indicated with this box. |

|

* * * * * |

|

When the password is entered, only these characters are shown. |

||

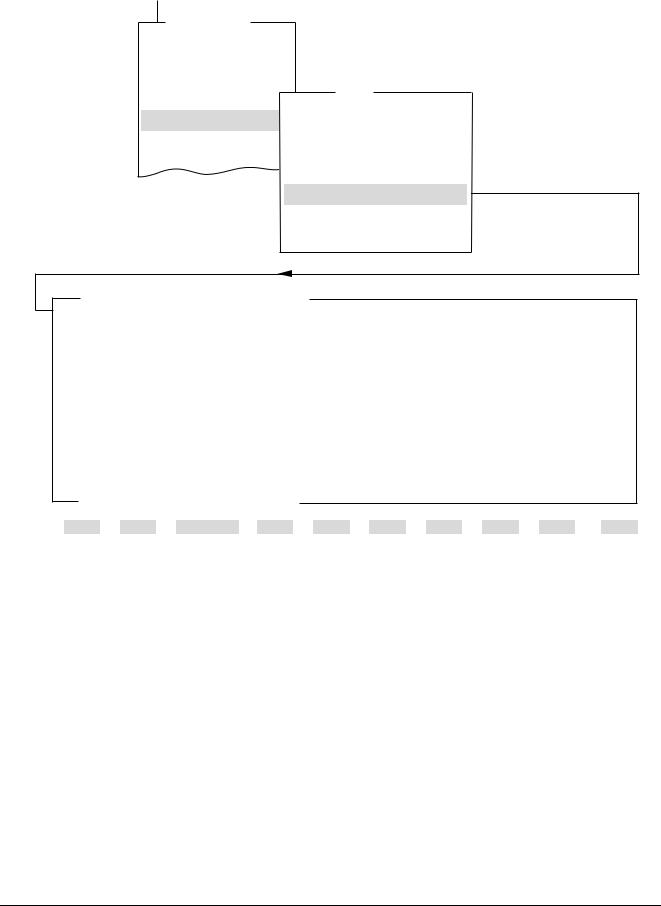

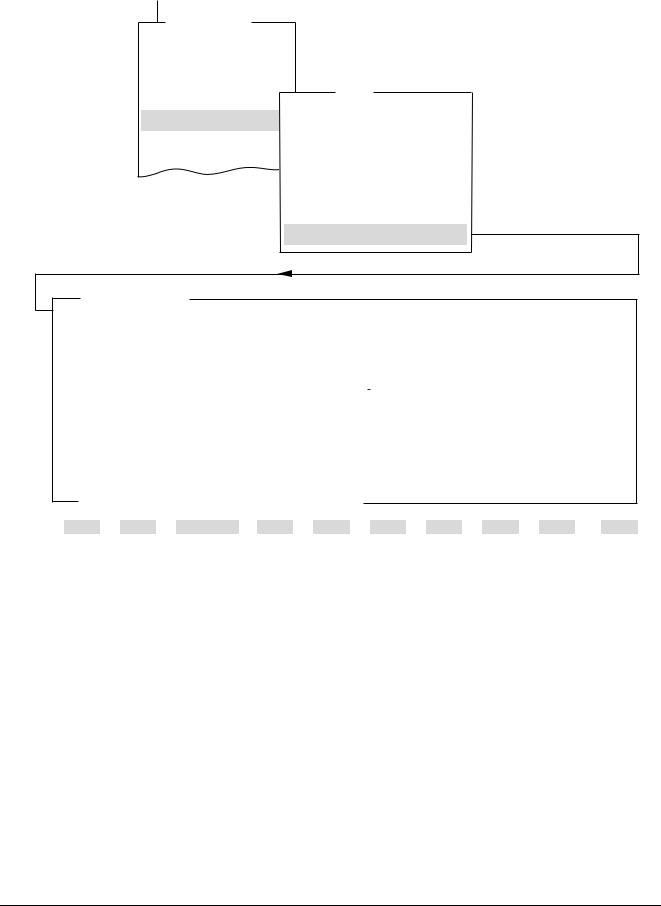

Menu Selection: |

When several menus, programs, files etc. are presented for selec- |

|||

|

|

|

tion, they are shown in a box (program window). |

|

|

|

|

Selection is made with the <↓ > and <↑ > keys. |

|

|

|

|

The module selected is highligthed in the display. |

|

<ENTER> |

Every entry must be confirmed with the <ENTER> key. |

|

||

<ESC> |

ESC allows paging back through the program. |

|

||

<xx> + <y> |

Some functions are selected by pressing two keys |

|

||

|

|

|

simultaneously. Procedure: Press, for example, the <Shift> key |

|

|

|

|

and keep it depressed, press the <*> key and then release both |

|

|

|

|

keys. |

|

<F1> |

Key <F1> calls up a selective help text. |

|

||

<F10> |

Key <F10> exits the program. |

|

||

PLD |

Programmable Logic Device on the AEC board (D701). |

|

||

Flash |

Memory device on the AEC board (D701). |

|

||

OS |

Operating System, e.g. "Microsoft® Windows®" |

|

||

BIOS |

Basic Input and Output System, a program stored in the computer |

|||

|

|

|

hardware which launches start-up functions upon computer |

|

|

|

|

power-up. |

|

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 1 of 6 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

1 - 2 |

Working with the service PC |

XXX - - XXX - - This shows where a particular subroutine can be found. |

|

XXX - - XXX |

For example: |

Main menu –

Configuration –

AEC–

Sensitivity correction-

Connecting the service PC

The service PC used must meet the following requirements:

•RAM minimum 4 MByte

•Type minimum 386SX/25MHz

•HD minimum 2.5 MByte free memory

The service PC must be connected with connecting cable part no. 99 00 440 RE999 to the PC board in the generator. (Do not insert the diskette in the drive yet).

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 2 of 6 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Working with the service PC |

1 - 3 |

Configuration of the service PC

All Service Programs use the RS232 port in order to communicate with the MAMMOMAT. This port is usually handled as COM1 by the OS of the service PC. Modern PC’s can be equipped with new types of communication hardware, e.g. infrared port and built-in modem, which may act as COM1 or share resources with COM1. This could cause malfunction of the Service Programs for the MAMMOMAT, which requires the OS and computer BIOS to be re-configured.

The following procedures are designed to ensure general compatibility with the OS’s Windows® 95, Windows® 98 and Windows® 2000 Pro on modern PC’s. If the settings are saved, this procedure has to be done only once.

Configuration of computer BIOS

1.Enter the BIOS setup, usually done by pressing e.g. <F2> during the boot sequence of the BIOS.

2.Find the configuration of the IrDA (Infrared device) port and disable it.

3.Find the configuration of a built-in modem and make sure it is configured as COM3.

4.Find the configuration of COM1 and make sure it uses the interrupt IRQ 4 and the memory address range 03F8 - 03FF.

5.Save the BIOS settings and restart the PC.

Configuration of Windows®

(This example is for Windows® 2000 Pro. Windows® 95 and Windows® 98 have a similar approach, consult the OS documentation for details.)

1.Choose Settings from the Start Menu.

2.Choose Control Panel.

3.Choose System.

4.Choose the tab Hardware.

5.Press the button Device Manager.

If the IrDA-port was disabled in the computer BIOS, it should not be present in the list of available hardware. If the IrDA is present anyway and its icon is not marked with a red cross:

6.Double-click on the device row.

7.Choose the tab General In the appearing dialog box.

8.In the section Device Usage, change the status to "Disabled in the current hardware profile".

9.Exit the dialog by pressing the OK-button.

Having performed the described configurations above, the Service Program should be able to run without difficulties.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 3 of 6 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

1 - 4 |

Working with the service PC |

Starting up and using the service PC - Service program

1.Switch on generator and service PC.

After initialization, the service PC shows: C:\>

2.Now insert the diskette with the service program.

{A:}

3. Select the appropriate drive {B:} and then press <ENTER>. The screen shows:

A:\> or B:\>

4. Start the service program by typing "SERVICE" (extension -c if you have a color display), then press <ENTER>.

The program asks for the user’s name: Your name, please

Type the name of the technician, for example NN, and then press <ENTER>.

5. The program asks for the password: Password, please Type the password (********) and then press <ENTER>.

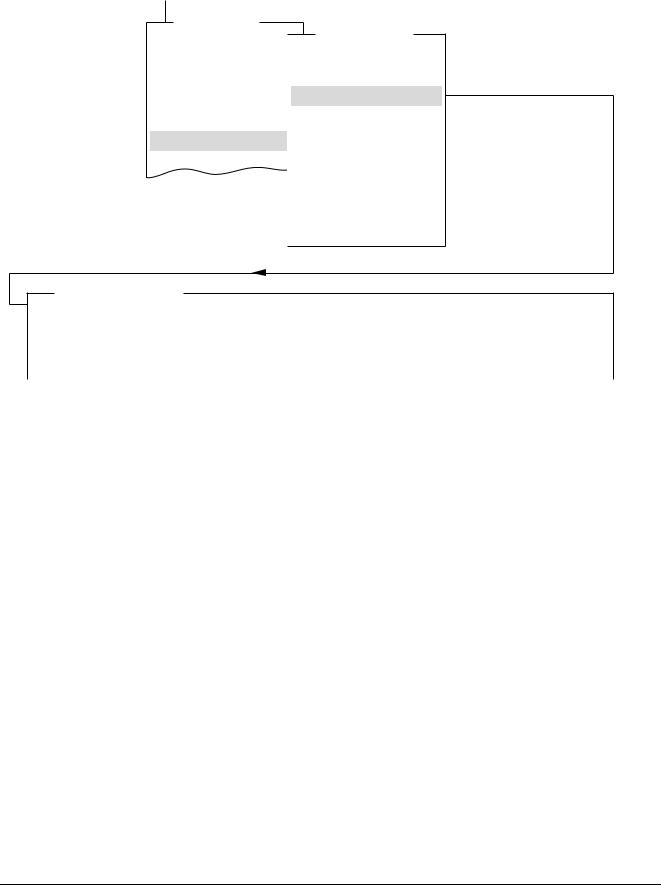

6. The display window shows: PROGRAM-MODE; Mode: Normal If Mode: Normal is the correct choice then press <ENTER> or

if Mode: Stand-alone is wanted press the <SPACE> key once and then press <ENTER>.

The display window shows: Main menu

7. Select the program part to be used with keys <↑> and/or <↓> , then press <ENTER>.

The program part selected is shown with a background: Configuration

If necessary, additional subroutines can be similarly selected here.

8. Make the necessary entries in the appropriate part of the program. Save the entered data with <F2>. Page back in the program with <ESC>. The appropriate instructions are shown on the monitor.

End the procedure with the service PC with <F10>.

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 4 of 6 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Working with the service PC |

1 - 5 |

Starting up and using the service PC - Dose Calculation program (Dose calculation applies if SW 4.4 or higher)

1.Switch on generator and service PC.

After initialization, the service PC shows: C:\>

2.Now insert the diskette with the dose calculating program.

{A:}

3. Select the appropriate drive {B:} and then press <ENTER>. The screen shows:

A:\> or B:\>

4. Start the service program by typing "DOSE_CFG", then press <ENTER>. The program asks for the user’s name: Your name, please

Type the name of the technician, for example NN, and then press <ENTER>.

5. The program asks for the password: Password, please

Type the password (********) and then press <ENTER>. This is the same password that is used for the regular service program.

6. The display window shows: PROGRAM-MODE; Mode: Normal If Mode: Normal is the correct choice then press <ENTER> or

if Mode: Stand-alone is wanted press the <SPACE> key once and then press <ENTER>.

The display window shows: Main menu

7. Select the program part to be used with keys <↑> and/or <↓> , then press <ENTER>.

8. Make the necessary entries in the appropriate part of the program. Save the entered data with <F2>. Page back in the program with <ESC>. The appropriate instructions are shown on the monitor.

End the procedure with the service PC with <F10>.

Troubleshooting

If communication with the MAMMOMAT still cannot be established, follow the instructions in this section. The following procedure will disable the buffering of the RS232 port. (This example is for Windows® 2000 Pro. Windows® 95 and Windows® 98 have a similar approach, consult the OS documentation for details.)

1.Choose Settings from the Start Menu.

2.Choose Control Panel.

3.Choose System.

4.Choose the tab Hardware.

5.Press the button Device Manager.

6.Expand the row Ports.

7.Double-click on the COM1 row.

8.Choose the tab Port Settings.

9.Press the button Advanced.

10.Uncheck the check box Use FIFO Buffers.

11.Exit the dialog by pressing the OK-button.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 5 of 6 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

1 - 6 |

Working with the service PC |

This page intentionally left blank.

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 6 of 6 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 1 |

Configuration

System type

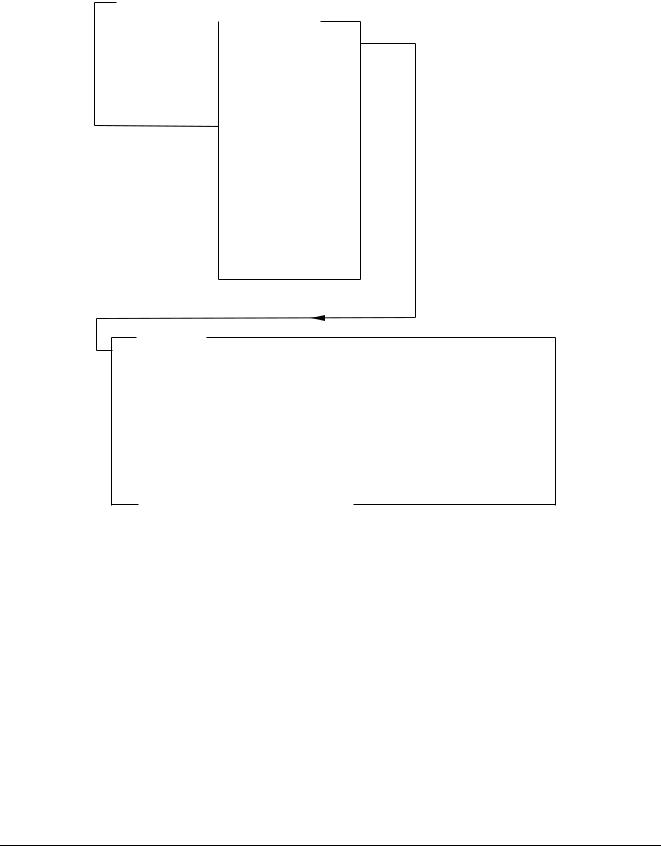

Main menu |

|

|

|

|

Configuration |

|

|

|

|

||

|

|

|

|

|

|

Configuration |

|

|

|||

|

|

|

|||

Service |

|

|

|

||

|

System type |

||||

Normal mode |

|

Anode |

|||

Test DUEP Communic Show configuration file

Backup |

Save configuration file |

Quit |

AEC |

|

Miscellaneous |

|

Filament |

|

Power |

|

Clock |

|

Compression |

|

Lift |

|

Rotation |

|

Grid speed |

|

Beam limiting device |

System type

System type |

M3000 |

Collimator |

Automatic |

NOTE: If changing system type, always check the power setting and, when changing from M1000 to M3000, also the anode selection. Collimator choice is valid only for M1000.

Changes in the 'System type' and 'Collimator' above become active after next power up of the system.

<ESC> to exit, <space> to toggle entry

1 |

Help |

2 |

Save |

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

Quit |

MAM00536

Fig. 1

System type indicates type of stand, generator and control panel. Collimator indicates type of collimator in the stand. Collimator choice (Automatic or Manual) is valid only for MAMMOMAT 1000.

When MAMMOMAT 1000 is selected, the tungsten anode is automatically deselected, and furthermore, the Anode menu cannot be selected.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 1 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 2 |

Adjustment and Service PC Programs |

Anode

|

|

Main menu |

|

|

Configuration |

|

|

|

|

||

|

|

|

|

||

|

Configuration |

|

|

||

|

Service |

|

System type |

||

|

Normal mode |

Anode |

|||

|

|

|

|||

Test DUEP Communic Show configuration file |

||

Backup |

Save configuration file |

|

Quit |

AEC |

|

|

|

Miscellaneous |

|

|

|

|

Filament |

|

Anode

Tungsten anode |

Enable |

NOTE: When changing the anode selection, always check the power setting.

<ESC> to exit, <space to toggle entry>

1 |

Help |

2 |

Save |

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

Quit |

Fig. 2

Activation and deactivation of the tungsten anode. When deactivated, it will not be possible to select the W/Rh alternative on the control panel.

MAM00585

NOTE |

|

This menu is not selectable when the system type is set to M1000. |

|

|

|

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 2 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 3 |

Show configuration file |

|

|

|

Main menu |

|

|

Configuration |

|

|

|

|

||

|

|

|

|

||

|

Configuration |

|

|

||

|

Service |

|

System type |

||

|

Normal mode |

Anode |

|||

Test DUEP Communic Show configuration file

Backup |

Save configuration file |

|

Quit |

AEC |

|

|

|

Miscellaneous |

|

|

|

|

Filament |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Show file mammo.cfg |

|

|

|

|

|

|

ENABLED Collimator AUTOMATIC |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

System M3000 |

Tungsten Anode |

|||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Molly large focus 3.75 kW |

Tungsten large focus 4.70 kW |

|

|

|||||||||||||||||

|

|

|

|

|

|

Molly small focus 0.70 kW |

Tungsten small focus 0.85 kW |

|

|

|||||||||||||||||

|

|

|

|

|

|

Filament current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

Molly large focus 6500 mA |

Tungsten large focus 6500 mA |

|

|

|||||||||||||||||

|

|

|

|

|

|

Molly small focus 6500 mA |

Tungsten small focus 6500 mA |

|

|

|||||||||||||||||

|

|

|

|

|

|

Power supply |

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Sensitivity correction (H/D) |

0 |

0 |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

Sensitivity |

|

|

|

|

Mo/Mo |

|

|

Mo/Rh |

|

|

W/Rh |

|

|

|||||||

|

|

|

|

|

|

Grid 18x24 (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||||

|

|

|

|

|

|

Grid 24x30 (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||||

|

|

|

|

|

|

No Grid 18x24 (H/D) |

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||||||

|

|

|

|

|

|

No Grid 24x30 (H/D) |

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||||||

|

|

|

|

|

|

Mag 1.5 (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||||

|

|

|

|

|

|

Mag 1.8 (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||||

|

|

|

|

|

|

Stereo (H/D) |

|

|

|

|

0/0 |

|

|

|

0/0 |

|

0/0 |

|

|

|||||||

|

|

|

|

|

|

Auto limits |

P1 |

30mm |

P2 |

45mm |

|

|

P3 |

60mm |

|

|

||||||||||

|

|

|

|

|

|

Optimized compression |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

OPCOMP 18*24, 24*30 / mag 15, 18 |

|

|

OFF |

/ |

OFF |

|

|

|||||||||||||

|

|

|

|

Any key to continue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

1 |

|

|

|

2 |

|

3 |

|

|

4 |

|

|

5 |

|

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

||

Help |

|

|

|

|

|

|

|

|

|

|

|

Quit |

||||||||||||||

MAM00771

Fig. 3

This menu displays the system configuration as stored in the “mammo.cfg” file.

The file must be stored before it is possible to show it, see "Save configuration file" on Page 2 - 4.

NOTE |

|

All data are examples and may vary for the unit in question. |

|

|

|

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 3 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 4 |

Adjustment and Service PC Programs |

|

Save configuration file |

|

|

Main menu |

|

|

Configuration |

|

|

|

|

||

|

|

|

|

||

|

Configuration |

|

|

||

|

Service |

System type |

|||

|

Normal mode |

Anode |

|||

Test DUEP Communic Show configuration file

Backup |

Save configuration file |

|

Quit |

AEC |

|

|

|

Miscellaneous |

|

|

|

|

Filament |

|

|

|

|

|

Save configuration -> mammo.cfg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Collimator AUTOMATIC |

|

|

|

|||||||||||||||||

|

|

|

|

|

System M3000 |

Tungsten Anode |

ENABLED |

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Molly large focus 3.75 kW |

|

Tungsten large focus 4.70 kW |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

Molly small focus 0.70 kW |

|

Tungsten small focus 0.85 kW |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

Filament current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

Molly large focus 6500 mA |

|

Tungsten large focus 6500 mA |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

Molly small focus 6500 mA |

|

Tungsten small focus 6500 mA |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

Power supply |

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Sensitivity (H/D) |

|

|

0 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

Sensitivity correction |

|

Mo/Mo |

|

|

|

Mo/Rh |

|

|

|

W/Rh |

|

|

|

||||||||||||||

|

|

|

|

|

|

Grid 18x24 (H/D) |

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

Grid 24x30 (H/D) |

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

No Grid 18x24 (H/D) |

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

No Grid 24x30 (H/D) |

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

Mag 1.5 (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||

|

|

|

|

|

|

Mag 1.8 (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||

|

|

|

|

|

|

Stereo (H/D) |

|

|

0/0 |

|

|

|

0/0 |

|

|

|

0/0 |

|

|

|

|

|||||||||||

|

|

|

|

|

Auto limits |

P1 30mm |

P2 |

45mm |

|

|

P3 |

|

60mm |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

Optimized compression |

|

|

|

|

|

|

|

|

|

|

/ |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

OPCOMP 18*24, 24*30 / mag 15, 18 |

OFF |

|

OFF |

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

<ESC> to exit, <F2> save list in file mammo.cfg |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

1 |

|

|

|

2 |

|

3 |

|

|

|

4 |

|

|

5 |

|

|

6 |

|

7 |

|

|

|

8 |

|

9 |

|

|

10 |

|

|

|||

Help |

Save |

|

|

|

|

|

|

|

|

|

|

|

|

|

Quit |

|

||||||||||||||||

Fig. 4

MAM00772

This menu is used for storing information about the system configuration in the “mammo.cfg” file. Press <F2> to save the file.

If the service program was started from a floppy disk, the file will be stored on floppy. If the service program was started from the hard disk, the file will be stored on hard disk.

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 4 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 5 |

AEC

AEC -> Reset installation parameters

|

|

Main menu |

|

|

Configuration |

|

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

System type |

|

||

|

Normal mode |

|

Anode |

|

||

|

Test DUEP Communic Show configuration file |

AEC |

||||

|

Backup |

Save configuration file |

||||

|

|

|||||

|

Reset installation parameters |

|||||

|

Quit |

AEC |

||||

|

|

|||||

|

|

Detector normalization |

|

|

|

||

Miscellaneous |

|||

AEC Correction tables |

|||

Filament |

|||

|

|||

|

|

Sensitivity correction |

|

|

|

Copy H to D |

|

|

|

Copy D to H |

|

|

|

Sensitivity |

|

AEC - Reset installation parameters

By pressing <F2> You will reset the AEC installation parameters.

All existing sensitivity settings and results

from performed detector normalization, including installed correction tables, will be lost.

<ESC> to exit, <F2> to reset installation parameters

1 |

4 |

5 |

6 |

7 |

8 |

9 |

10 Quit |

Help 2 Save 3 |

MAM00540

This menu is used for setting AEC installation parameters to default values and for erasure of installed AEC Correction tables in the MAMMOMAT.

NOTE |

|

It is not necessary to use this procedure with exchange of |

|

|

detector. It must be used with exchange of D701 if AEC backup is |

|

|

|

|

|

not available. |

|

|

|

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 5 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 6 |

Adjustment and Service PC Programs |

|

AEC -> Detector normalization |

|

|

Main menu |

|

|

Configuration |

|

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

System type |

|

||

|

Normal mode |

|

Anode |

|

||

|

Test DUEP Communic Show configuration file |

AEC |

||||

|

Backup |

Save configuration file |

||||

|

Reset installation parameters |

|||||

|

Quit |

AEC |

||||

|

|

|||||

|

|

Detector normalization |

|

|

|

||

Miscellaneous |

|||

AEC Correction tables |

|||

Filament |

|||

|

|||

|

|

Sensitivity correction |

|

Copy H to D

Copy D to H

Sensitivity

Detector normalization |

|

|

|

|

Wing 1 |

|

|

|

|

|

|

Wing 2 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

Exp. |

|

Dose rate |

|

|

Exp. |

|

|

Dose rate |

|

|

|

||||||||

|

|

1 |

|

430.6 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

--------- |

|

|

|

|

|

||||||||||

2 |

|

|

--------- |

|

|

|

2 |

|

|

|

|

--------- |

|

|

|

|

|

||||||

3 |

|

|

--------- |

|

|

|

3 |

|

|

|

|

--------- |

|

|

|

|

|

||||||

|

|

|

|

Average dose rate --------- |

|

|

Average dose rate |

--------- |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

Normalization factor W1: --------- |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Normalization factor W2: --------- |

|

|

|

|

|

|

|

|

|||||||

|

|

<ESC> to exit, <F2> to save, <F3> to measure dose rate |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

1 |

|

|

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

|

7 |

|

8 |

|

9 |

|

10 |

|

|

Help |

Save |

Exp support |

|

|

|

|

|

|

Quit |

||||||||||||||

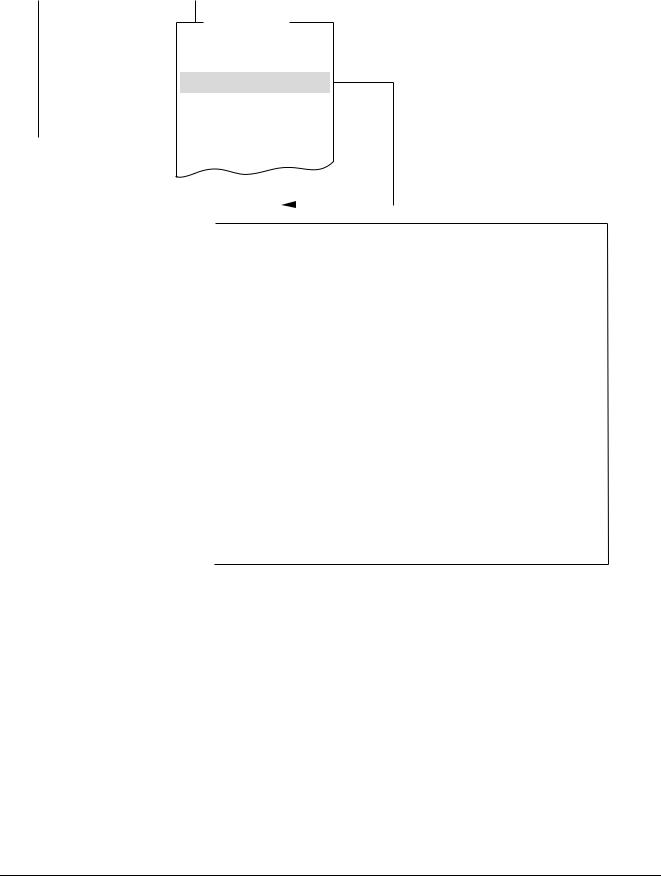

Fig. 5

MAM00775

This menu is used for normalization of the AEC detector in available wing. Values for Normalization factors are calculated and stored in the AEC.

Exposure results are stored in the result file “detnorm.txt” on the backup floppy.

NOTE |

|

All data are examples and may vary for the unit in question. |

|

|

|

NOTE |

|

Wing 1 is not selectable when the system type is set to M1000. |

|

|

|

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 6 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 7 |

Perform detector normalization:

•after replacement of an AEC detector for that wing.

•after replacement of D701 and restoring from backup of AEC and correction tables. If two wing system, normalize both detectors.

•after AEC reset installation parameters. In a two wing M3000 normalize both detectors. When performing detector normalizations:

•The detector is to be in chestwall position.

MAM00616

•The AEC calibration plexi (part no. 65 61 240) must extend at least 10 mm beyond the chestwall edge of the table and be centered.

The following exposures are to be made:

•with no cassette or film

•with the very same AEC calibration plexi and object table.

It is strongly suggested that you use a Grid 18x24 object table (Bucky).

1.Make sure a backup floppy is inserted.

2.In <Mainmenu> select <Configuration>, <AEC> and <Detector normalization>.

|

|

|

|

|

Wing 1 |

|

|

|

|

|

|

|

|

|

Wing 2 |

|

|

|

|

|

|

||||

|

|

|

|

|

Exp. |

Dose rate |

|

|

|

|

|

|

Exp. |

Dose rate |

|

||||||||||

|

|

1 |

|

--------- |

|

|

|

|

|

|

|

|

1 |

|

|

|

--------- |

|

|

|

|

|

|||

2 |

|

--------- |

|

|

|

|

|

|

|

|

2 |

|

|

|

--------- |

|

|

|

|

|

|||||

3 |

|

--------- |

|

|

|

|

|

|

|

|

3 |

|

|

|

--------- |

|

|

|

|

|

|||||

|

Average dose rate: --------- |

|

|

|

Average dose rate: |

--------- |

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

Normalization factor W1: |

--------- |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

Normalisation factor W2: |

--------- |

|

|

|

|

|

|

|

|

|

|

|

MAM00767 |

|||||

<ESC> to exit, <F2> to save, <F3> to measure dose rate |

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

|

8 |

|

|

9 |

|

10 |

|

|

|

||

Help |

Save |

Exp support |

|

|

|

|

|

|

|

Quit |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

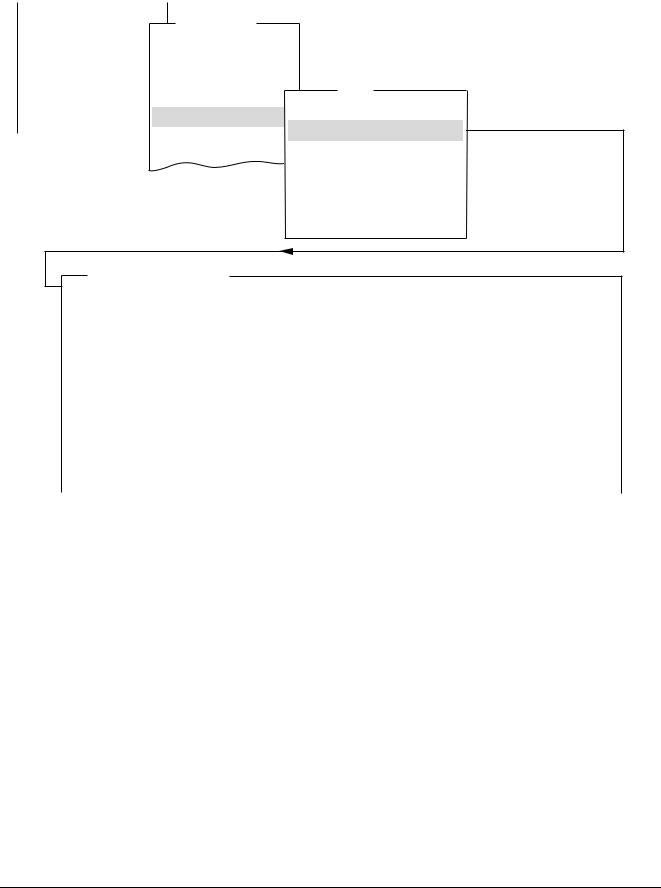

Fig. 6 Average dose rate: Out of the three obtained values, the one that differs the most is ignored. The average dose rate is then calculated based on the remaining two values. Normalization factor: The value of the normalization factor should be between 512 and 2048. If not, ensure that the correct object table and AEC calibration plexi have been

3.Bring the detector to be normalized into the x-ray field.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 7 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 8 |

Adjustment and Service PC Programs |

4.Place the cursor by one of the exposures of the wing in use and press <F3> to

start the exposure procedure.

Please put x cm of Plexi on the object table. Perform an exposure and

press <ENTER> when ready or <ESC> to cancel.

<ENTER> - ok / <ESC> - cancel

MAM00728

5.Follow the instructions in the message box.

6.After pressing <ENTER> the dialog Calibration exposure appears. The Dose rate should now have a value. Save the value with <F2>.

Calibration exposure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

Mo/Rh, wing 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Exp. |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Dose rate |

--------- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

<ESC> to exit, <F2> to save, <F3> to perform exposure |

|

|

|

|

|

|

|

|

MAM00769 |

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

|

|

Help |

Save |

Exp support |

|

|

|

|

|

|

Quit |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. Repeat steps 4 to 6 for the other two exposures, for the wing in question.

|

|

|

Wing 1 |

|

|

|

|

|

|

|

|

|

|

Wing 2 |

|

|

|

|

|

|

|

|||||

|

|

|

Exp. |

Dose rate |

|

|

|

|

|

|

|

Exp. |

Dose rate |

|

||||||||||||

1 |

|

|

213,18 |

|

|

|

|

|

|

|

|

1 |

|

|

|

204.99 |

|

|

|

|

||||||

2 |

|

|

213,92 |

|

|

|

|

|

|

|

|

2 |

|

|

|

205.72 |

|

|

|

|

||||||

3 |

|

|

215,04 |

|

|

|

|

|

|

|

|

3 |

|

|

|

204.85 |

|

|

|

|

||||||

|

Average dose rate: |

213,55 |

|

|

|

|

|

Average dose rate: |

204,92 |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

Normalization factor W1: |

1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

Normalization factor W2: |

997 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

<ESC> to exit, <F2> to save, <F3> to measure dose rate |

|

|

|

|

|

|

|

|

|

|

MAM00768 |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

|

7 |

|

|

8 |

|

|

9 |

|

|

10 |

|

|

|

|

Help |

Save |

Exp support |

|

|

|

|

|

|

|

|

Quit |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 7 Example of the final result of a wing calibration

8.If only one detector is to be normalized, save the values by pressing <F2>. Otherwise proceed to steps number 9 and 10.

9.Bring the other wing into the x-ray field. Use the same object table.

10.Repeat steps 4 to 6 for the other three exposures. Save the values on floppy by pressing <F2>.

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 8 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 9 |

||||||||||

|

|

|

AEC -> Correction tables |

|

|

|

|

||||

|

|

|

Main menu |

|

|

|

Configuration |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

Configuration |

|

|

|

|

|

|

|

||

|

|

Service |

|

|

|

System type |

|

|

|

|

|

|

|

Normal mode |

|

|

|

Anode |

|

|

|

|

|

|

|

Test DUEP Communic Show configuration file |

|

AEC |

|

|

|||||

|

|

Backup |

|

Save configuration file |

|

|

|

||||

|

|

|

|

Reset installation parameters |

|

|

|||||

|

|

Quit |

|

|

|

|

|

|

|

||

|

|

|

AEC |

|

|

|

|||||

|

|

|

|

Detector normalization |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Miscellaneous |

|

|

||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Filament |

AEC Correction tables |

|

|

|||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

Sensitivity correction |

|

|

|

|

|

|

|

|

|

|

|

Copy H to D |

|

|

|

|

|

|

|

|

|

|

|

Copy D to H |

|

|

|

|

|

|

|

|

|

|

|

Sensitivity |

|

|

|

AEC correction tables |

Existing tables in the AEC:

|

|

|

|

|

Anode/Filter |

Speed |

ID |

Calibrated |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mag |

Grid |

|

|

No grid |

Stereo |

|||||

|

|

|

|

|

Mo/Mo |

H |

1001 |

No |

Yes |

|

|

No |

No |

|||||||||||

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

Mo/Mo |

D |

---- |

--- |

|

--- |

|

|

--- |

|

--- |

|

|

|||||||

|

|

|

|

|

Mo/Rh |

H |

1002 |

No |

No |

|

|

No |

No |

|||||||||||

|

|

|

|

|

Mo/Rh |

D |

---- |

--- |

|

--- |

|

|

--- |

|

--- |

|

|

|||||||

|

|

|

|

|

W/Rh |

H |

1003 |

No |

No |

|

|

No |

No |

|||||||||||

|

|

|

|

|

W/Rh |

D |

---- |

--- |

|

--- |

|

|

--- |

|

--- |

|

|

|||||||

|

|

<ESC> to exit, <F2> to install new table, <F3> to calibrate existing |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||

1 |

|

|

|

2 |

|

3 |

|

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

||

Help |

Save |

Cal |

|

|

|

|

|

|

|

Quit |

||||||||||||||

MAM00542

Fig. 8

This menu is used for:

•Installation of correction tables (F2).

•Calibration of correction tables (F3), including rough setting of sensitivity correction.

The AEC uses one correction table for each Anode/Filter/Speed combination. Each correction table has separate corrections for each object table group (Magnification, Grid, No grid and Stereo). When pressing <F2> a dialog box will appear, in which the ID of the correction table to be installed (from floppy disk) should be entered. When the transaction of the correction table to the AEC is finished, the program will automatically go on to the calibration process.

To enter the calibration process without having installed new correction tables, press <F3>. When pressing <F3> correction tables previously installed will be loaded from the AEC. See “Installation and Start-Up Instructions” for further information.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 9 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 10 |

Adjustment and Service PC Programs |

During the calibration process of a correction table calibration reference data is fetched from a calibration file (“calxxxx.txt”, in which the four x:es represent the ID number). The ID of this file is the same as for the correction table in use and is located on the floppy containing the AEC correction tables (original AEC correction tables shall normally be copied from the floppy "AEC correction tables" to a backup floppy). The backup floppy must be inserted during the entire calibration.

When pressing <F2> exposure data from the calibration process is stored in a result file, e.g. “mrgh.txt”, on this floppy. In “mrgh.txt” the first letter represents type of anode (“m” for molly or “w” for wolfram/tungsten), the second represents type of filter (“m” for molly or “r” for rhodium), the third represents the kind of object table (“g” for grid, “n” for no grid, “s” for stereo or “m” for magnification) and the fourth represents the speed (“h” for high or “d” for detailed).

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 10 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 11 |

AEC -> Sensitivity correction

|

|

Main menu |

|

|

Configuration |

|

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

System type |

|

||

|

Normal mode |

|

Anode |

|

||

|

Test DUEP Communic Show configuration file |

AEC |

||||

|

Backup |

Save configuration file |

||||

|

Reset installation parameters |

|||||

|

Quit |

AEC |

||||

|

|

|||||

|

|

Detector normalization |

|

|

|

||

Miscellaneous |

|||

AEC Correction tables |

|||

Filament |

|||

|

|||

|

|

Sensitivity correction |

|

|

|

|

|

Copy H to D

Copy D to H

Sensitivity

Sensitivity correction |

|

|

|

H |

|

|

D |

|

|

Mo/Mo Mo/Rh |

W/Rh |

Mo/Mo Mo/Rh W/Rh |

||||

Grid 18x24 |

|

|

0 |

0 |

0 |

0 |

0 |

0 |

|||||||

Grid 24x30 |

0 |

0 |

0 |

0 |

0 |

0 |

|

No grid 18x24 |

0 |

0 |

0 |

0 |

0 |

0 |

|

No grid 24x30 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Magnification 1.5 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Magnification 1.8 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Stereo |

0 |

0 |

0 |

0 |

0 |

0 |

|

Valid entries from -120 to 120 in 1/8 E.P. (+/-15 E.P.)

<ESC> to exit, <TAB> move to next entry field, <F2> to save, <F3> exp support

1 |

Help |

2 |

Save |

3 |

Exp support |

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

Quit |

Fig. 9

MAM00537

This menu is used for setting the sensitivity correction of the AEC channel for all object table types, combinations of anode/filter and for speed H and D respectively.

By pressing <F3> the correct exposure parameters will be set for the generator and a message box appears, showing which Plexiglas thickness should be used during exposure. A floppy containing the AEC correction tables must be inserted since access to the calibration file (“calxxxx.txt”) is necessary when using the function <F3> exp support.

Values from -120 to 120 can be entered in 1/8 exposure points.

Also see “Installation and Start-Up Instructions”.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 11 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 12 |

Adjustment and Service PC Programs |

AEC -> Copy H to D

|

|

Main menu |

|

|

Configuration |

|

|

|

|

||

|

|

|

|

||

|

Configuration |

|

|

||

|

Service |

|

|

System type |

|

|

Normal mode |

|

|

Anode |

|

|

Test DUEP Communic Show configuration file |

||||

|

Backup |

Save configuration file |

|||

|

Quit |

AEC |

|||

|

|

|

|

|

Miscellaneous |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filament |

||

AEC

Reset installation parameters Detector normalization

AEC Correction tables Sensitivity correction Copy H to D

Copy D to H

Sensitivity

AEC - Copy settings between speeds

By pressing <F2> You will copy all settings for speed H to speed D.

All existing settings for speed D will be overwritten.

<ESC> to exit, <F2> to copy H -> D

1 |

4 |

5 |

6 |

7 |

8 |

9 |

10 Quit |

Help 2 Copy 3 |

This menu is used for copying AEC data from speed H to speed D.

MAM00651

NOTE |

|

Alternative Copy D to H works similarly to Copy H to D. |

|

|

|

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 12 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 13 |

AEC -> Sensitivity

|

|

Main menu |

|

|

Configuration |

|

|

|

|

||

|

|

|

|

||

|

Configuration |

|

|

||

|

Service |

|

|

System type |

|

|

Normal mode |

|

|

Anode |

|

|

Test DUEP Communic Show configuration file |

||||

|

Backup |

Save configuration file |

|||

|

Quit |

AEC |

|||

|

|

|

|

|

Miscellaneous |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filament |

||

AEC

Reset installation parameters Detector normalization

AEC Correction tables Sensitivity correction Copy H to D

Copy D to H

Sensitivity

AEC - Sensitivity |

|

H |

D |

Sensitivity |

|

0 |

0 |

valid entries from -64 to 64 in 1/8 E.P. (+ / - 8 E.P.)

<ESC> to exit, <TAB> move to next entry field

1 |

4 |

5 |

6 |

7 |

8 |

9 |

10 Quit |

Help 2 Save 3 |

This dialog indicates the sensitivity of the AEC for speed H and speed D respectively.

Values from -64 to 64 can be entered in 1/8 exposure points.

MAM00652

NOTE |

|

If only one type of film-screen-combination is used, set both val- |

|

|

ues for H and D to the same level. |

|

|

|

|

|

|

Also see “Installation and Start-Up Instructions”.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 13 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 14 |

Adjustment and Service PC Programs |

Miscellaneous

Miscellaneous -> DLF switch

|

|

Main menu |

|

|

|

Configuration |

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

|

|

System type |

|

|

Normal mode |

|

|

|

Anode |

|

|

|

|

|

|

|

|

|

Test DUEP Communic Show configuration file |

|||||

|

Backup |

|

Save configuration file |

|||

|

Quit |

|

AEC |

|||

|

|

|

|

Miscellaneous |

||

|

|

|

|

|||

|

|

|

|

Filament |

||

|

|

|

|

|

|

|

Miscellaneous

DLF switch Reduction of power Printer

Power supply Potentiometer check Panel programming Auto limits

Cassette loaded check Illumination time Software version info

Dynamic learn filament |

|

|

|

|

|

|

Switch is |

|

ON |

|

|

|

|

|

|

|

|

|

|

|||

|

|

<ESC> to exit, <space> to toggle entry |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

1 |

|

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

|

Help |

Save |

|

|

|

|

|

|

|

Quit |

|

|||||||||||

Fig. 10

MAM00543

Activation and deactivation of the filament current adaptation. When activated, the adaptation takes place after a total of ten exposures has been made with the actual focus, if the deviation of the average value from the nominal value is not within -15% to + 5%.

NOTE |

|

Without any exceptional reason, the DLF-switch shall be “ON”. |

|

|

|

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 14 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 15 |

Miscellaneous -> Reduction of power

|

|

Main menu |

|

|

|

Configuration |

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

|

System type |

||

|

Normal mode |

|

Anode |

|||

|

Test DUEP Communic Show configuration file |

|||||

|

Backup |

|

Save configuration file |

|||

|

Quit |

|

AEC |

|||

|

|

|

|

Miscellaneous |

||

|

|

|

|

|||

|

|

|

|

Filament |

||

|

|

|

|

|

|

|

Miscellaneous

DLF switch Reduction of power Printer

Power supply Potentiometer check Panel programming Auto limits

Cassette loaded check Illumination time Software version info

Reduction of power depending on line quality

Tube is P40MoW

Select nominal line voltage

240 V <-- with cursor keys and <Enter> Type in line impedance

Power is 4.70 kW TUNGSTEN 3.75 kW MOLLY

<ESC> to exit

1 |

Help |

2 |

Save |

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

Quit |

Fig. 11

MAM00544

Calculates the maximum power allowed with regard to nominal voltage and line impedance.

Select the line voltage and type in the line impedance you have measured. The processor will calculate the power and will indicate when the power must be reduced because of the line impedance.

Finally press <F2> to save.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 15 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 16 |

Adjustment and Service PC Programs |

|

Miscellaneous -> Printer |

|

|

Main menu |

|

|

|

Configuration |

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

|

System type |

||

|

Normal mode |

|

|

Anode |

||

|

Test DUEP Communic Show configuration file |

|||||

|

Backup |

|

Save configuration file |

|||

|

Quit |

|

AEC |

|||

|

|

|

|

Miscellaneous |

||

|

|

|

|

|||

|

|

|

|

Filament |

||

|

|

|

|

|

|

|

Miscellaneous

DLF switch Reduction of power Printer

Power supply Potentiometer check Panel programming Auto limits

Cassette loaded check Illumination time Software version info

Printer type selection |

|

|

|

|

Actual setting |

|

no print |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

<ESC> to exit, <space> to toggle entry |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

1 |

|

|

2 |

|

3 |

|

4 |

|

5 |

|

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

|

Help |

Save |

|

|

|

|

|

|

|

Quit |

|

||||||||||||

Fig. 12

MAM00546

Select no print, RS 232C or PC print.

RS 232C is used when the printer is connected directly to the generator.

PC print is used when the printer is connected to the system via a PC that is connected to the generator.

M1000/3000/3000 Nova |

Register 5 |

SPB7-230.114.03 |

Page 16 of 64 |

Siemens-Elema AB |

Service Program |

|

Rev. 05 02.03 |

SPS-UD |

Solna, Sweden |

Adjustment and Service PC Programs |

2 - 17 |

Miscellaneous -> Power supply |

|

|

|

Main menu |

|

|

|

Configuration |

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

|

System type |

||

|

Normal mode |

|

|

Anode |

||

|

Test DUEP Communic Show configuration file |

|||||

|

Backup |

|

Save configuration file |

|||

|

Quit |

|

AEC |

|||

|

|

|

|

Miscellaneous |

||

|

|

|

|

|||

|

|

|

|

Filament |

||

|

|

|

|

|

|

|

Miscellaneous

DLF switch Reduction of power Printer

Power supply Potentiometer check Panel programming Auto limits

Cassette loaded check Illumination time Software version info

Power supply |

Switch OFF

<ESC> to exit,

1 |

Help |

2 |

Save |

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

Quit |

Fig. 13

MAM00547

Indicates whether the MAMMOMAT is powered by an external power supply (e.g. Power Aid) or not.

Siemens-Elema AB |

Register 5 |

SPB7-230.114.03 |

Page 17 of 64 |

M1000/3000/3000 Nova |

Solna, Sweden |

|

Rev. 05 02.03 |

SPS-UD |

Service Program |

2 - 18 |

Adjustment and Service PC Programs |

|

Miscellaneous -> Potentiometer check |

|

|

Main menu |

|

|

|

Configuration |

|

|

|

|

|

||

|

|

|

|

|

||

|

Configuration |

|

|

|

||

|

Service |

|

|

|

System type |

|

|

Normal mode |

|

|

|

Anode |

|

|

|

|

|

|

|

|

|

Test DUEP Communic Show configuration file |

|||||

|

Backup |

|

Save configuration file |

|||

|

Quit |

|

AEC |

|||

|

|

|

|

Miscellaneous |

||

|

|

|

|

|||

|

|

|

|

Filament |

||

|

|

|

|

|

|

|

Miscellaneous

DLF switch Reduction of power Printer

Power supply Potentiometer check Panel programming Auto limits

Cassette loaded check Illumination time Software version info

Potentiometer check |

|

|

|

|

A/D value |

032A |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

<ESC> to exit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1 |

|

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|