Siemens Mammomat 3000 User manual

MAMMOMAT 1000/3000

SP

Service Instructions

New AEC

|

|

|

|

© S ie men s AG 2 00 0 |

|

|

The reproduction, transmission or |

|

|

use of this document or its contents |

|

|

is not permitted without express |

|

|

written authority. Offenders will be |

|

|

liable for damages. |

All rights, |

|

including rights created by patent |

|

|

grant or registration of a utility |

|

|

model _or_ design,_are_ reserved. |

|

Register 5 |

English |

|

Print No.: SPB7-230.898.01.01.02 |

Doc. Gen. Date: |

04.00 |

Replaces: n.a.

0 - 2 |

|

|

Revision |

|

|

|

|

Chapter |

Page |

Revision |

|

|

|

|

|

1 |

all |

01 |

|

|

|

|

|

2 |

all |

01 |

|

|

|

|

|

3 |

all |

01 |

|

|

|

|

|

4 |

all |

01 |

|

|

|

|

|

5 |

all |

01 |

|

|

|

|

|

6 |

all |

01 |

|

|

|

|

|

MAMMOMAT 1000/3000 |

Register 5 |

SPB7-230.898.01 |

Page 2 of 4 |

Siemens AG |

|

|

Rev. 01 04.00 |

TD SD 24 |

Medical Engineering |

Contents |

0 - 3 |

|

Page |

1 _______Functional description __________________________________________ 1 - 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 Main function of the MAMMOMAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Object Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Film and Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 Measured Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 Dose Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 Dose Rate Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4 Time Dependency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4 Two Wings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

User Choices . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 |

- 4 |

|||||

Exposure control . . . . . . |

. . . . . . |

. . . . . . |

. . . . . . . . . . . |

. . . . . |

. |

. 1 |

- 4 |

Control of One Exposure |

. . . . . . |

. . . . . . |

. . . . . . . . . . . |

. . . . . |

. |

. 1 |

- 5 |

Initial Dose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5 Dose Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5 Entire Set of Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7 Correction Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7 Sensitivity Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8 Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

2_______Error messages ________________________________________________ 2 - 1

3_______Parts replacement ______________________________________________ 3 - 1

Action list for MAMMOMAT 1000/ 3000 with new AEC . . . . . . . . . . . . . . . . . 3 - 1

4 _______Description of LED’s and measuring points _________________________ 4 - 1

Measuring points on AEC board D701 . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1 Switches on AEC board D701. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1 Jumpers on AEC board D701 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1 LEDs on AEC board D701 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

5 _______Tests _________________________________________________________ 5 - 1

Check the AEC according to "Installation and start-up instructions"

for MAMMOMAT 1000/ 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Siemens AG |

Register 5 |

SPB7-230.898.01 |

Page 3 of 4 |

MAMMOMAT 1000/3000 |

Medical Engineering |

|

Rev. 01 04.00 |

TD SD 24 |

|

0 - 4 |

Contents |

|

Page |

6 ______ Problems during Installation/ Service ______________________________ 6 - 1

AEC Correction tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Measured dose rate exceeds + 30% . . . . . . . . . . . . . . . . . . . . . . . . |

6 - 1 |

|

Error during backup from disc/ floppy . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

- 2 |

Error during reset of installation parameters . . . . . . . . . . . . . . . . . . . . . . |

6 |

- 3 |

Errors during offset compensation test . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

- 4 |

Detector Normalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6 |

||

Normalization factor out of range . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

- 6 |

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

- 7 |

Communication Errors with Service PC . . . . . . . . . . . . . . . . . . . . . . |

6 - 7 |

|

MAMMOMAT 1000/3000 |

Register 5 |

SPB7-230.898.01 |

Page 4 of 4 |

Siemens AG |

|

|

Rev. 01 04.00 |

TD SD 24 |

Medical Engineering |

Functional description |

1 - 1 |

Overview

This document describes the control model of the AEC unit for M1000/3000. A view of the function of the Mammomat is given together with a summary of possible exposure settings, their effects and characteristics of Mammomat performance. The function of dose control is described together with an explanation of measurements done during the exposure, on which it is based.

Main function of the MAMMOMAT

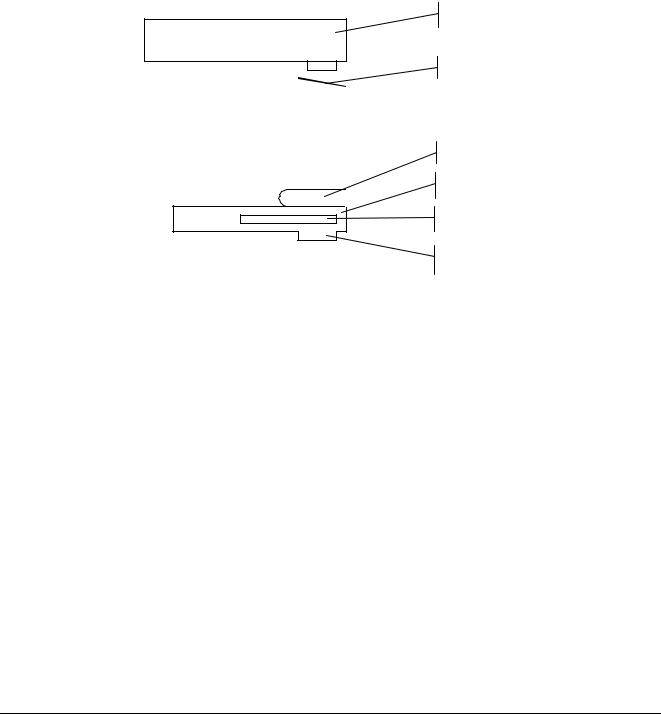

Picture below gives a schematic view of the exposure system.

X-ray Tube

Filter

Target - Breast

Object Table

Screen and Film

Detector

Schematic view of the Mammomat

The generator supplies a voltage across the x-ray tube. The resulting radiation is filtered before it reaches the target. Then it passes through an object table and reaches the fluorescent screen, which emits visible light giving the desired picture on the film. The part of the radiation, which is not attenuated in the screen, reaches finally the detector and results in a signal measured by the AEC unit. The main purpose of the AEC unit is to stop the exposure so that the resulting picture is given the desired average optical density based on current exposure settings and the measured signal from the detector.

Tube

When a voltage is applied across the x-ray tube, the electrons, hitting the anode, initiate radiation. The tube contains two different anode materials - molybdenum and tungsten - giving different kind of x-ray spectra. There are actually two different anodes for each mentioned material, used to give large and small focus for the x-ray beam. Small focus is used together with magnifying object tables. Large focus is used for all other object tables.

Siemens AG |

Register 5 |

SPB7-230.898.01 |

Page 1 of 8 |

MAMMOMAT 1000/3000 |

Medical Engineering |

|

Rev. 01 04.00 |

TD SD 24 |

|

1 - 2 |

Functional description |

The operator is allowed to choose a desired tube voltage from a range between 23 and 35 kV with 1 kV resolution. The voltage influences the energy spectrum and gives the operator a control of how hard x-rays are used during the exposure. The current through the tube, which is directly proportional to the overall intensity of the beam, is a function of the chosen voltage, the maximum power setting and the maximum current limit.

Neither the energy spectrum of the beam nor it's intensity are constant during the exposure, due to raising and falling times for the voltage and the tube current. The voltage has typical raising times of app. 50 ms and the tube current 5 ms.

Filter

Different filtering is used to give the beam desired energy spectrum. For the molybdenum anode, two filter selections are possible: molybdenum and rhodium. For the tungsten anode, only rhodium is used as the filter material. This gives three possible anode/filter combinations - Mo/Mo, Mo/Rh and W/Rh - resulting in three main kinds of x-ray beam. Within each, a fine adjustment of the energy spectrum, i.e. the hardness of the beam, is possible by adjusting the voltage.

Object Table

There are totally 7 different kinds of object tables that can be used described in the table below.

Name |

Type |

Used beam focus |

Size |

Magnification |

|

|

|

|

|

Grid 18 x 24 |

Grid |

Large |

18 x 24 cm |

- |

|

|

|

|

|

Grid 24 x 30 |

Grid |

Large |

24 x 30 cm |

- |

|

|

|

|

|

NoGrid 18 x 24 |

Grid-less |

Large |

18 x 24 cm |

- |

|

|

|

|

|

NoGrid 24 x 30 |

Grid-less |

Large |

24 x 30 cm |

- |

|

|

|

|

|

Mag 1.5 |

Magnification |

Small |

- |

1.5 |

|

|

|

|

|

Mag 1.8 |

Magnification |

Small |

- |

1.8 |

|

|

|

|

|

Biopsy |

Grid-less with |

Large |

- |

- |

table |

biopsy unit |

|

|

|

|

|

|

||

|

|

|

|

|

According to their x-ray characteristics and use, the object tables are ordered into four groups: grid, grid-less, magnification and biopsy:

Grid tables are used to take ordinary pictures and are equipped with a moving grid that reduces the amount of secondary radiation, i.e. scattered radiation from the target object.

The grid-less tables are not equipped with a grid.

The Magnification tables have enlarged distance between the object and the film, giving together with small focus of the radiation the desired magnification in the picture.

The biopsy table, also called stereotactic table, is very similar to the grid-less tables. It is equipped with a biopsy unit that together with stereotactics is used to identify the 3D-position of the biopsy target within the breast and perform the biopsy. The pictures are smaller and can be taken from a direction not perpendicular to the object table. Angles of + 10° are used.

MAMMOMAT 1000/3000 |

Register 5 |

SPB7-230.898.01 |

Page 2 of 8 |

Siemens AG |

|

|

Rev. 01 04.00 |

TD SD 24 |

Medical Engineering |

Functional description |

1 - 3 |

Film and Screen

A considerable part of the radiation, which passes the target and possibly the grid of the object table, is attenuated in the fluorescent screen. The energy is than emitted as visible light and gives the desired picture on the film. The film is also sensitive to the x-rays, however the x-rays do not contribute to the picture significantly, compared to the visible light emitted by the screen.

Detector

After passing the filter, the breast, the object table with screen and film, the radiation finally reaches the detector. It is a semiconductor device that acts as a current source supporting a current proportional to the overall intensity of the attenuated radiation. The attenuation of the detector varies of course with the energy of the radiation, which makes the generated current dependent on the energy spectrum of the beam. The generated current is amplified and converted to a voltage level, which is the signal received from the detector by the AEC unit.

Measured Signal

The signal from the detector is amplified on the AEC board and than converted to pulses with a frequency proportional to the voltage level of the signal. The AEC unit contains a PLD (Programmable Logic Device), programmed to register the detector signal by counting the pulses that the signal is converted to.

Gain

Before every exposure, there is a possibility to alter the gain applied to the detector signal by the AEC board. Higher gain gives stronger signal to the V/F-converter, i.e. more pulses and better precision in the counters of the PLD. There is however an upper bound for the voltage level of the amplified signal - the V/F-converter functions for signals up to 10 V and all voltages above this limit does not contribute to larger frequency of out-coming pulses.

Dose Measuring

The dose is measured by counting the pulses from the V/F-converter during a time of interest. This dose measure is not comparable to any conventional dose units because it gives varying responses depending strongly on the energy spectrum of the radiation registered by the detector. However, for the same anode, filter, tube voltage, object table, screen and object, this dose measure is directly proportional to the dose received by the screen.

A logarithmic scale for the dose is also used. It is based on the usual definition of relative exposure and the unit exposure points (EP).

EP 10 ΕlogDose1 logDose0 Φ |

10 log |

Dose1 |

|

||

Dose0 |

The used logarithmic scale is however absolute in the sense that 0 EP is defined to be equal to 100 counts:

|

|

DoseEP |

|

|

|

Dosecounts |

|

Dose |

100 10 10 i.e. |

Dose |

10 log |

||||

|

|||||||

counts |

|

|

|

EP |

100 |

||

|

|

|

|

|

|||

Siemens AG |

Register 5 |

SPB7-230.898.01 |

Page 3 of 8 |

MAMMOMAT 1000/3000 |

Medical Engineering |

|

Rev. 01 04.00 |

TD SD 24 |

|

1 - 4 |

Functional description |

Dose Rate Measuring

In order to measure the dose rate, the pulses are counted during a period of time and the resulting dose is then divided by the length of the time period. The resulting dose rate is an average over the chosen time interval.

Time Dependency

Due to the raising and falling times of the tube voltage and current, the detector signal is also time dependent and has typical raising times of 50 ms.

Two Wings

The Mammomat can have one or two wings using separate detectors.

User Choices

The following table summarises possible user choices affecting the exposure:

User choice |

Range |

Change consequence |

|

|

|

Anode/ filter |

Mo/Mo, Mo/Rh, W/Rh |

Rough change of spectral properties of the |

|

|

beam, possibly affecting power settings and |

|

|

automatic choice of tube current. |

|

|

|

Tube voltage |

23 - 35 kV |

Fine change of spectral properties of the |

|

|

beam, possibly affecting power settings and |

|

|

automatic choice of tube current. |

|

|

|

Speed |

H or D |

Choice between two sets of parameters for |

|

|

two different film/ screen-combinations. |

|

|

|

Density correction |

-24/8 to + 24/8 EP |

Relative adjustment of exposure length, |

|

|

0 = nominal AEC exposure. |

|

|

|

Object table |

One of 7 |

See section Object Table |

|

|

|

Wing |

1 or 2 |

Different detectors in both wings. |

|

|

|

Exposure control

The control model for the AEC-unit is typically subdivided into two parts. First part handles the control of a single exposure with one set of exposure settings such as kV, anode/filter etc. It is based on the knowledge of these parameters before the start and measurements done during the exposure. Second part puts the control model for one exposure into a systematic approach to all possible exposure settings for the Mammomat. It explains how the entire set of control parameters for the AEC-unit is build up in order to cover all possible combinations of kV, object tables, anode/filter choices and up to 2 film/screen combinations.

MAMMOMAT 1000/3000 |

Register 5 |

SPB7-230.898.01 |

Page 4 of 8 |

Siemens AG |

|

|

Rev. 01 04.00 |

TD SD 24 |

Medical Engineering |

Functional description |

1 - 5 |

Control of One Exposure

Before start of exposure, the AEC-unit is only aware of exposure settings chosen by the operator and has no knowledge of thickness or density of the actual breast. This implies a two step approach to control of the entire exposure. First step is done before the exposure start and contains calculation of an initial dose that will be executed before the AEC will decide what to do next. During the execution of the initial dose, the unit measures the dose rate and uses it to calculate a correction dose that has to be executed before the exposure stops. When the AEC-unit has registered a total dose being equal to the sum of the initial dose and the correction dose, it will stop the exposure.

Initial Dose

The initial dose is chosen in EP. It consists of an estimated dose, a sensitivity, a sensitivity correction and a density correction:

Doseinitial EP Ζ Doseestimated EP Η S EP Η Sc EP Η Dc EP

where:

Doseestimated,EP - the estimated dose, a value specifically chosen for the used film/screen combination, anode/filter combination, object table group and tube voltage.

S,EP - the sensitivity, a value controlling an overall level of target optical density for all AEC-exposures.

SC,EP - the sensitivity correction, chosen as a part of the calibration of specific equipment (Mammomat, object tables).

DC,EP - the density correction, a value that is chosen by the operator for each exposure.

The estimated dose is usually chosen, so it will give an OD = 1,5 for a 5 mm thick PMMAphantom.

Dose Correction

In order to measure the dose rate with the detector, the following procedure is used. The initial dose is subdivided into a 60%-part and a 40%-part. Both parts are handled in the AEC-unit by two separate counters, implemented in the PLD. At the exposure start, the 60% counter starts counting down at the rate of pulses from the V/F-converter that handles the amplified signal from the detector. During counting down the 60% of the initial dose, time is measured by a time monitor. When the 60% counter has reached 0, the time is read and used together with the actual value of 60 % of the initial dose as an average dose rate:

Dr60% |

0,6 Doseinitial counts |

||

Time Ε0,6 |

Doseinitial counts Φ |

||

|

|||

where

TimeΕ0,6 Doseinitial counts Φ - time as a function of 60 % of initial dose in counts.

Siemens AG |

Register 5 |

SPB7-230.898.01 |

Page 5 of 8 |

MAMMOMAT 1000/3000 |

Medical Engineering |

|

Rev. 01 04.00 |

TD SD 24 |

|

Loading...

Loading...