SHARP VCA411VCH811, VC-A411M, VC-H811M Service Manual

VC-A411M

VC-H811M

SERVICE MANUAL

S40A1VC-A411M

VIDEO CASSETTE RECORDER

VIDEO CASSETTE RECORDER

VC-A411M

MODELS VC-H811M

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified be used.

|

CONTENTS |

|

|

|

Page |

1. |

GENERAL INFORMATION............................................................................................................ |

4 |

2. |

DISASSEMBLY AND REASSEMBLY ............................................................................................ |

6 |

3. |

FUNCTION OF MAJOR MECHANICAL PARTS ........................................................................... |

9 |

4. |

ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS ........................ |

11 |

5. |

ELECTRICAL ADJUSTMENT...................................................................................................... |

30 |

6. |

MECHANISM OPERATION FLOWCHART AND TROUBLESHOOTING GUIDE ...................... |

32 |

7. |

TROUBLESHOOTING ................................................................................................................. |

38 |

8. |

BLOCK DIAGRAM ....................................................................................................................... |

49 |

9. |

SCHEMATIC DIAGRAM AND PWB FOIL PATTERN .................................................................. |

57 |

10. |

REPLACEMENT PARTS LIST .................................................................................................... |

71 |

11. |

EXPLODED VIEW OF MECHANICAL PARTS ............................................................................ |

78 |

12. |

PACKING OF THE SET .............................................................................................................. |

82 |

SHARP CORPORATION

1

VC-A411M

VC-H811M

IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CASSETTE RECORDER

Before returning the video cassette recorder to the user, perform the following safety checks.

1.Inspect all lead dress to make certain that leads are not pinched or that hardware is not lodged between the chassis and other metal parts in the video cassette recorder.

2.Inspect all protective devices such as non-metallic control knobs, insulation materials, cabinet backs, adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3.To be sure that no shock hazard exists, check for current in the following manner.

●Plug the AC line cord directly into a 120 volt AC outlet (Do not use an isolation transformer for this test).

●Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15μF capacitor in series with all exposed metal cabinet parts and a known earth ground, such as a water pipe or conduit.

●Use an SSVM or VOM with 1000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor (See Diagram).

●Move the resistor connection to earth exposed metal part having a return path to the chassis (antenna, metal cabinet, screw heads, knobs and control shafts,

etc.) and measure the AC voltage drop across the resistor. Reverse the AC plug on the set and repeat AC voltage measurements for each exposed part. Any reading of 0.45V rms (this corresponds to 0.3mA rms AC.) or more is excessive and indicates a potential shock hazard which must be corrected before returning the video cassette recorder to the owner.

SSVM |

AC SCALE |

1.5k ohms. |

10W |

0.15 F

TEST PROBE

TO EXPOSED |

CONNECT TO |

|

KNOWN EARTH |

||

METAL PARTS |

||

GROUND |

||

|

WARNING :TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK. DO NOT REMOVE COVER. NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This symbol warns the user of uninsulated voltage within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are important operating and maintenance instructions in the literature accompanying this unit.

CAUTION:

This symbol mark means fast operating fuse.

For continued protection against risk of fire, replace

only with same type fuse F901 (3.0A, 125V).

3.0A 125V

2

VC-A411M

VC-H811M

PRECAUTIONS IN PART REPLACEMENT

When servicing the unit with power on, be careful to the section marked white all over. This is the primary power circuit which is live.

When checking the soldering side in the tape travel mode, make sure first that the tape has been loaded and then turn over the PWB with due care to the primary power circuit.

Make readjustment, if needed after replacement of part, with the mechanism and its PWB in position in the main frame.

(1) Start and end sensors: Q701 and Q702

Insert the sensor’s projection deep into the upper hole of the holder. Referring to the PWB, fix the sensors tight enough.

(2) Photocoupler: IC901

Refer to the symbol on the PWB and the anode marking of the part.

(3) Cam switches A and B: D708 and D709.

Adjust the notch of the part to the white marker of the symbol on the PWB. Do not allow any looseness.

(4) Take-up and supply sensors: D707 and D706.

Be careful not to confuse the setting direction of the parts in reference to the symbols on the PWB. Do not allow any looseness.

3

VC-A411M

VC-H811M

1. GENERAL INFORMATION

1-1 FEATURES

Only for VC-H811M

•

Hi-Fi Stereo Sound

Hi-Fi Stereo Sound

•Built-in MTS (Multi-channel TV Sound) Decoder

Common Features

•EZ Set Up

•S-VHS Quasi Playback

•Double-Azimuth 4-Heads

•19μ Clear Picture System (in EP mode)

•HQ System for Better Resolution and Color Reproduction

•Multi-Language (English/Spanish/French) OSD (On Screen Display) with Menu Screen Guidance

•181-channel PLL Quartz Synthesized Random Access Tuner with Automatic Channel Setting

•Quick Start with Full Loading Mechanism

•1-Year, 8 Event Programmable Timer

•Simple Recording Timer

•Unified Remote Control

•Sharp Super Picture

•1minute Timer Backup

•Field-Still/Variable Slow/Frame Advance

•Real-Time Counter (On Screen Display)

•Automatic Daylight Saving-Time (D.S.T.) Adjustment

•Blue Screen Noise Elimination

•Auto Tracking Control System

•Digital Program Search System (DPSS)

•Skip Search

•Instant Replay

•Auto Zero Back

•Recorded Section Auto Repeat

•Full Automatic Playback

•Tamper Proof

•Up to 8 Hours of Recording and Playback (with T-160 cassette)

1-2 SPECIFICATIONS

Format: VHS NTSC Standard

Video Recording System: Rotary, Slant Azimuth Two-Head Helical Scan System Number of Video Heads: 4

Video Signal Standard: NTSC Color System

Audio Recording System: 1 Stationary Head for Linear Audio

2 Rotary Heads for Hi-Fi stereo (Only Hi-Fi model) Tape Width: 12.7 mm (1/2 inch)

Tape Speed: (SP) 33.35 mm/sec. (1.31 i.p.s.)

(LP) 16.67 mm/sec. (0.66 i.p.s.) (playback only) (EP) 11.12 mm/sec. (0.44 i.p.s.)

Maximum Recording Time: (SP) 160 min. (T-160) (EP) 480 min. (T-160)

Channel Coverage: VHF 2-13 UHF 14-69 CATV 1-125

Antenna Input: 75 Ohm

Video Input: 0.5 to 2.0 Vp-p, 75 Ohm unbalanced Video Output: 1.0 Vp-p, 75 Ohm unbalanced

Audio Input: –8 dBs, 47 kOhm unbalanced (0 dBs = 0.775 Vrms) Audio Output: –8 dBs, 1 kOhm unbalanced (0 dBs = 0.775 Vrms)

Hi-Fi Audio (Only for Hi-Fi model):

Dynamic Range: 90 dB Frequency Response: 20 Hz-20 kHz

Memory Backup: 1 min.

Operating Temperature: 5°C to 40°C (41°F to 104°F) Storage temperature: –20°C to 60°C (–4°F to 140°F)

Power Source: 120 V AC, 60 Hz Power Consumption: 18 W

Weight: 2.8 kg (6.2 lbs)

Dimensions (approx.): 360 (W) x 92.5 (H) x 255 (D) mm (14-3/16" x 3-41/64" x 10-3/64")

Accessories included: 75 ohm coaxial cable, Operation manual, Infrared remote control, Battery (2 pcs.)

Note: Specifications are subject to change without notice.

4

Cassette compartment (see Playback/Recording)

POWER button |

Basic function controls |

(When pressed to turn on the VCR, POWER LED indicator |

(see Playback/Recording) |

will light up. When the power is turned off. POWER LED |

|

indicator wil turn off.) |

|

LED Indicator (explained throughout the operation Instruction)

|

|

|

|

|

|

|

|

|

|

|

|

TAMPER |

|

|

|

|

POWER |

TIMER |

VCR |

REC |

|

PROOF |

REMOTE SENSOR |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

1 |

2 |

|

3 |

4 |

|

|

5 |

|

6 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

POWER LED indicator |

|

|

|

|

|

4 |

REC LED indicator |

|

|

|||||

|

This indicator lights up whenever the VCR is turned on. |

|

|

|

|

|

This indicator lights up on during recording. This indicator |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

flashes during REC-Pause. |

|||

2 |

TIMER LED indicator |

|

|

|

|

|

5 |

TAMPER PROOF ( |

) LED indicator |

||||||

|

This indicator lights up when the VCR is set for timer |

|

|

|

|

|

This indicator lights up when the set mode is locked. |

||||||||

|

recording, Simple Recording Timer and Recording with |

|

|

|

|

|

|

|

|

|

|||||

|

the Timer. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

VCR LED indicator |

|

|

|

|

|

|

|

|

|

6 |

Remote Sensor |

|

|

|

|

This indicator lights up when selecting "VCR" by using |

|

|

|

|

|

Point Remote Control at this window. |

||||||||

|

the TV/VCR button. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTROL AND COMPONENTS MAJOR OF LOCATION 3-1

A411M-VC H811M-VC

VC-A411M

VC-H811M

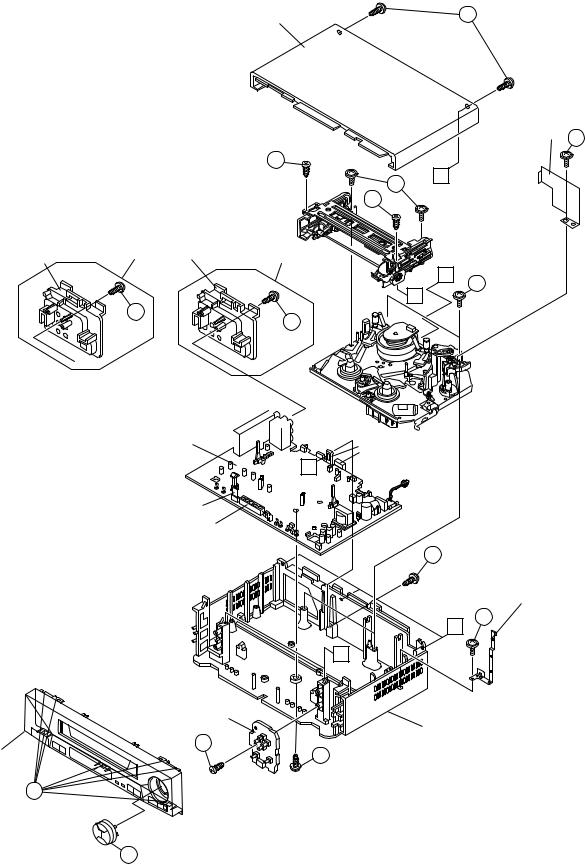

2. DISASSEMBLY AND REASSEMBLY

2-1 DISASSEMBLY OF MAJOR BLOCKS |

TOP CABINET |

1 |

||||

|

|

|

||||

TOP CABINET : Remove 2 screws 1. |

|

|

|

|

||

FRONT PANEL : Remove button 2. |

|

|

|

|

||

|

Remove 2 screws 3 and 7 clips 4. |

|

|

|||

OPERATION |

: Remove 1 screw 5. |

|

|

|

|

|

PWB |

|

|

|

|

|

|

SHIELD ANGLE : Remove 1 screw 6with shield angle. |

|

|

||||

MECHANISM/ : Remove 1 screw 7, 1 screw 8, 2 |

|

|

||||

MAIN PWB |

screws 9, 2 screws 0. Remove 1 |

3 |

|

|||

|

screw qwith antenna terminal cover. |

|

C |

|||

|

Remove 1 screw w with top cabinet |

|

10 |

|||

|

|

3 |

||||

|

fix angle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

ANTENNA |

|

ANTENNA |

|

|

|

|

TERMINAL |

VC-H811M |

TERMINAL |

|

|

|

|

COVER |

COVER |

|

VC-A411M |

|

|

|

|

|

|

|||

|

|

|

|

|

|

A |

|

|

|

|

|

|

9 |

|

|

|

|

|

|

B |

|

|

11 |

|

|

11 |

|

|

|

|

|

|

|

|

MECHANISM/

MAIN PWB

MAIN PWB

ASSEMBLY

ASSEMBLY

H/A SHIELD

H/A SHIELD

(Bottom)

A

LED PWB

LED HOLDER

SHIELD

ANGLE

6

7

12

C

B

OPERATION PWB

MAIN FRAME

5

FRONT PANEL |

8 |

4 |

TOP CABINET FIX ANGLE

2

6

VC-A411M

VC-H811M

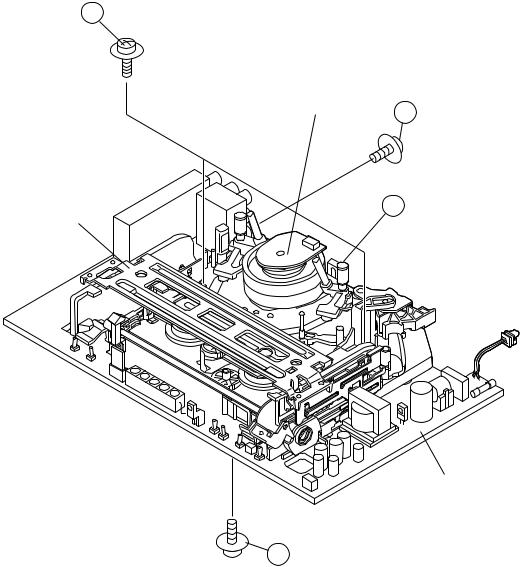

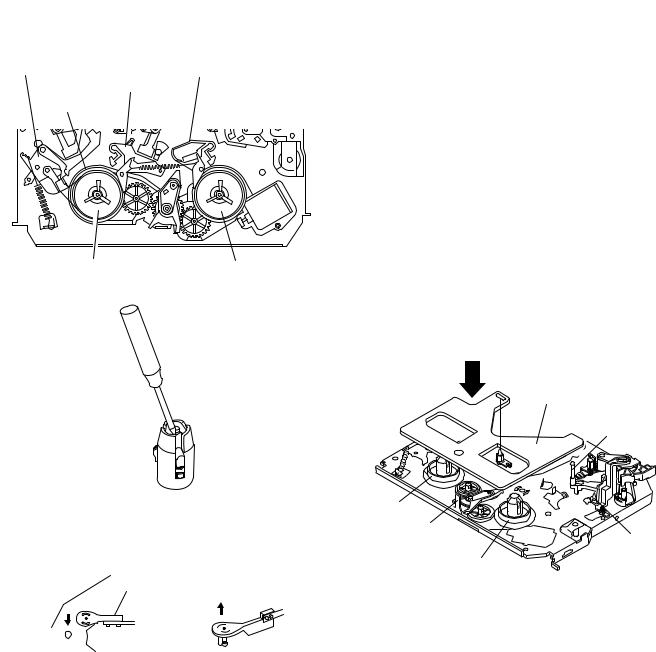

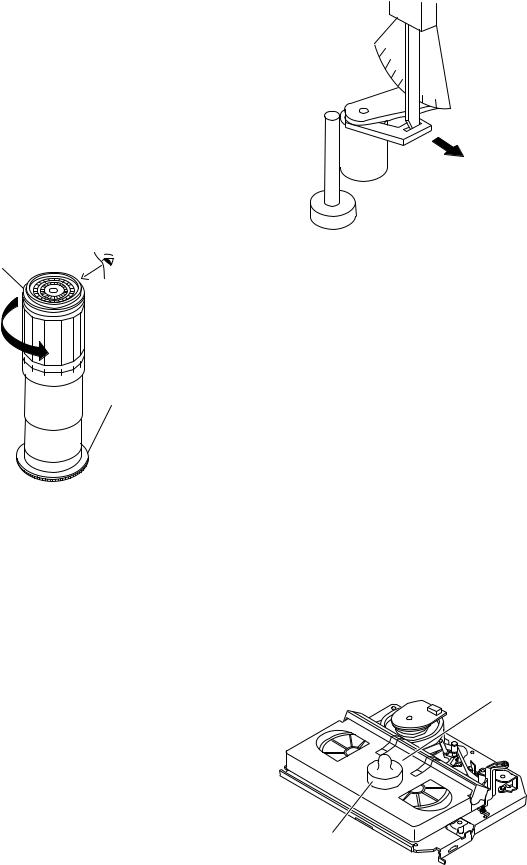

2-2 DISASSEMBLING THE MECHANISM/MAIN PWB ASSEMBLY

1.When removing the mechanism from the main PWB, remove the antenna cover 1 screw 1, and remove the

antenna terminal cover.

Remove the PWB bottom plate 1 screw 2.

Remove the FFC cable (AA, AD, AH) 3which connecting the PWB and the mechanism.

Take out vertically the mechanism so that it does not damage the adjacent parts.

2.Removing the mechanism and cassette housing. Remove 2 screws 4fixing the cassette housing to the mechanism, and remove the cassette housing.

4

MECHANISM CHASSIS 1

CASSETTE |

3 |

HOUSING |

|

MAIN PWB

2

7

VC-A411M

VC-H811M

2-3 CARES WHEN REASSEMBLING

INSTALLING THE CASSETTE HOUSING

When the cassette housing is installed on the mechanism, the initial setting is essential condition.

There are two initial setting methods, namely electrical and mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute the Step 1 of Installation of cassette housing. After ascertaining the return to the initial setting position (*1) install the

cassette housing. (Conditions: When mechanism and PWB have been installed)

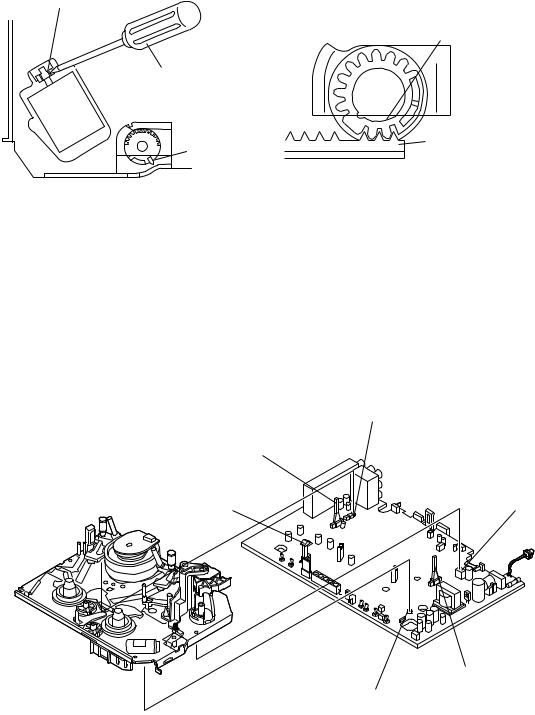

2. Mechanical initial setting

Feed the pulley feed gear of loading motor with screw driver. After ascertaining the return to the initial set position (*1) install the cassette housing in the specified position. (This method is applied only for the mechanism.)

Pulley feed gear

Casecon drive gear

Screwdriver

|

Drive angle of |

Tilt mark (*1) |

cassette housing |

INSTALLING THE MECHANISM ON PWB

Lower vertically the mechanism, paying attention to the mechanism edge, and install the mechanism with due care so that the parts are not damaged. So as to fix the mechanism to the main PWB install two housings. (Fit the antenna cover to one of them. For other, fix the vicinity of loading motor and solder joint side of main PWB.) Connect again the FFC cable (AA-MH, AD-ME, AH-MH) between the mechanism and the main PWB.

PARTS WHICH NEED PARTICULAR CARE

When installing the mechanism chassis on the PWB unit, take care so as to prevent deformation due to contact of mechanism chassis with REC TIP SW.

AE CONNECTOR

END SENSOR

REC TIP SW |

AC CONNECTOR |

START SENSOR

AL CONNECTOR

8

VC-A411M

VC-H811M

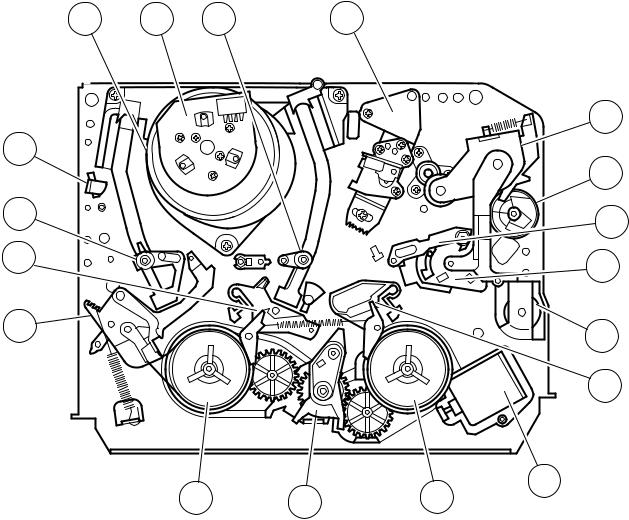

3. FUNCTION OF MAJOR MECHANICAL PARTS (TOP VIEW)

15 |

17 |

18 |

10 |

|

14 |

1 |

|

|

9 |

2 |

11 |

|

|

7 |

5 |

|

|

3 |

12 |

|

|

|

8 |

16

6 |

4 |

13 |

No. |

Function |

No. |

Function |

|

|

|

|

1 |

Full erase head |

8 |

Take-up main brake |

2 |

Supply pole base ass’y |

9 |

Pinch drive cam |

3 |

Tension arm |

10 |

A/C head ass’y |

4 |

Idler wheel ass’y |

11 |

Reverse guide lever ass’y |

5 |

Pinch drive lever ass’y |

12 |

Casecon drive gear |

6 |

Supply reel disk |

13 |

Take-up reel disk |

7 |

Supply main brake |

14 |

Pinch roller lever ass’y |

|

|

|

|

9

VC-A411M

VC-H811M

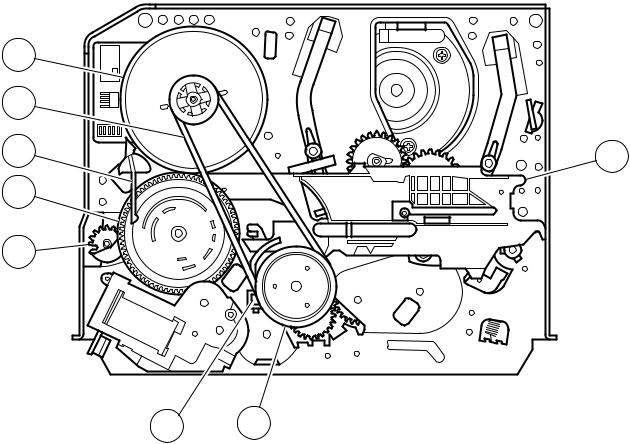

FUNCTION OF MAJOR MECHANICAL PARTS (BOTTOM VIEW)

21 |

|

22 |

|

19 |

26 |

20 |

|

12 |

|

23 24

No. |

Function |

No. |

Function |

|

|

|

|

15 |

Drum ass’y |

22 |

Reel belt |

16 |

Loading motor |

23 |

Clutch lever |

17 |

Drum drive motor |

24 |

Limiter pulley ass’y |

18 |

Take-up pole base ass’y |

26 |

Shifter |

19 |

Slow brake lever |

|

|

20 |

Master cam |

|

|

21 |

Capstan D.D. motor |

|

|

|

|

|

|

10

VC-A411M

VC-H811M

4. ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS

The explanation given below relates to the on-site general service (field service) but it does not relates to the adjustment and replacement which need high-grade equipment, jigs and skill. For example, the drum assembling, replacement and adjustment service must be performed by the person who have finished the technical courses.

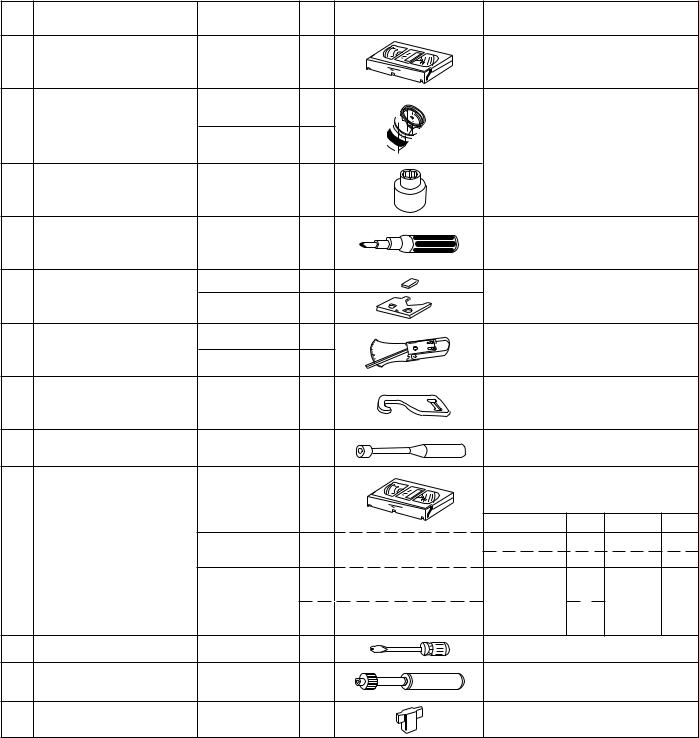

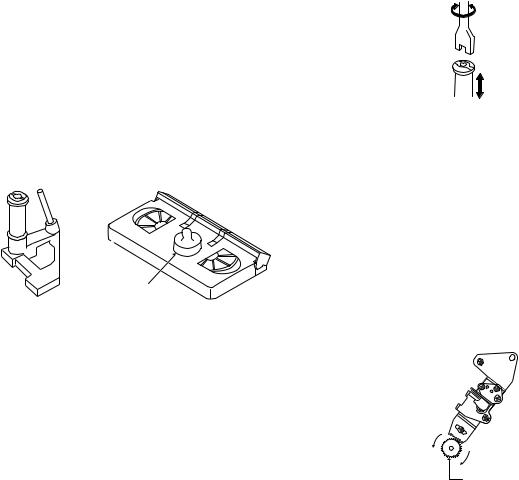

4-1 MECHANISM CONFIRMATION ADJUSTMENT JIG

So as to perform completely the mechanism adjustment prepare the following special jigs. So as to maintain the initial performance of the machine the maintenance and check are necessary. Utmost care must be taken so that the tape is not damaged. If adjustment needs any jig, be sure to use the required jig.

No. |

Jig ltem |

Part No. |

Code |

Configuration |

Remarks |

|

||

1. |

Torque Cassette Meter |

JiGVHT-063 |

CZ |

This cassette torque meter is used for check- |

||||

ing and adjusting the torque of take-up for |

||||||||

|

|

|

|

measuring tape back tension. |

|

|||

|

|

JiGTG0090 |

CM |

|

|

|

|

|

2. |

Torque Gauge |

|

|

These Jigs are used for checking |

||||

|

|

JiGTG1200 |

CN |

|||||

|

|

and adjusting the torque of take-up |

||||||

|

|

|

|

|||||

|

|

|

|

and supply reel disks. |

|

|||

3. |

Torque Gauge Head |

JiGTH0006 |

AW |

|

|

|

|

|

4. |

Torque Driver |

JiGTD1200 |

CB |

When fixing any part to the threaded |

||||

hole using resin with screw, use the |

||||||||

|

|

|

|

jig. (Specified torque 5 kg) |

|

|||

|

Master Plane Jig and |

JiGRH0002 |

BR |

These Jigs are used for checking |

||||

5. |

Reel Disk Height |

|

|

|||||

JiGMP0001 |

BY |

and adjusting the reel disk height. |

||||||

|

Adjusting Jig |

|||||||

|

|

|

|

|

||||

|

Tension Gauge |

JiGSG2000 |

BS |

There are two gauges used for the |

||||

6. |

JiGSG0300 |

BF |

tension measurements, 300 g and |

|||||

|

|

2.0 kg. |

|

|

|

|||

|

Pinch pressing force |

|

|

This Jig is used with the tension |

||||

7. |

JiGADP003 |

BK |

gauge. Rotary transformer clearance |

|||||

measuring jig |

||||||||

|

|

|

adjusting jig. |

|

|

|

||

|

|

|

|

|

|

|

||

8. |

Reverse guide height |

JiGDRiVER11055 |

AR |

This Jig is used for height adjustment of the |

||||

adjustment box driver |

reverse guide (for reverse guide height ad- |

|||||||

|

|

|

justment). |

|

|

|

||

|

|

|

|

These tapes are especially used for |

||||

|

|

|

|

electrical fine adjustment. |

|

|||

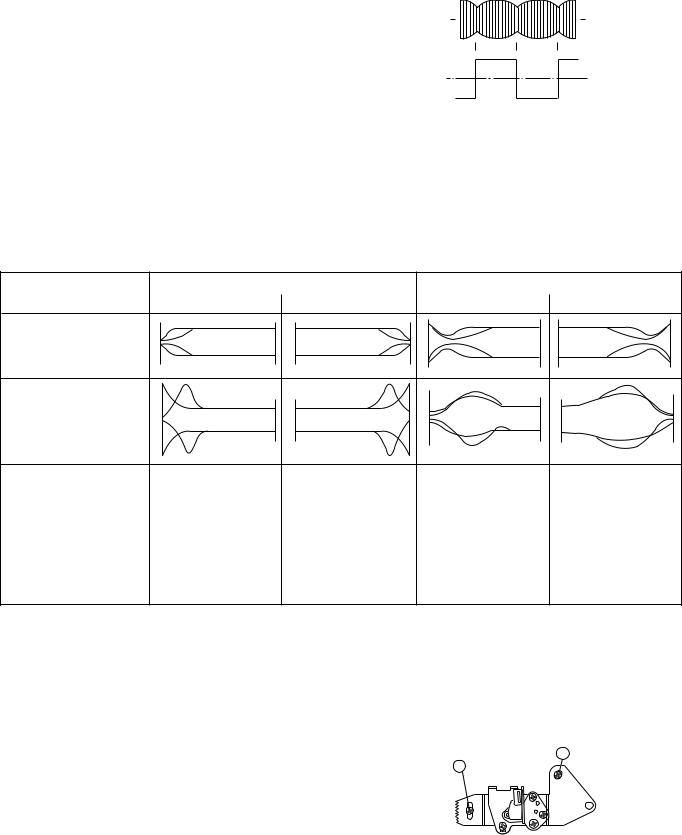

|

|

|

|

Video |

Audio |

HiFi Audio |

Track |

|

9. |

Alignment Tape |

VROATSV |

CD |

525 Monoscope |

7k |

— |

58μm |

|

NTSC Color Bar |

1k |

— |

58μm |

|||||

|

|

|

|

|||||

|

|

VROEFZCS |

BG |

Black Level |

1k |

|

|

|

|

|

OR |

|

|

— |

19μm |

||

|

|

|

(only SYNC) signal |

|

||||

|

|

VROEFZHS |

BH |

|

2.3k |

|

|

|

10. |

Guide roller height |

JiGDRiVERH-4 |

AP |

This screwdriver is used for adjusting the |

||||

adjustment driver |

guide roller height. |

|

|

|||||

11. |

X value adjustment |

JiGDRiVER-6 |

BM |

For X value adjustment |

|

|||

gear driver |

|

|||||||

|

|

|

|

|||||

12. |

Reverse Guide Height |

JiGRVGH-F18 |

BU |

This Jig is used for height |

|

|||

|

Adjusting Jig |

|

|

adjustment of the reverse guide. |

||||

|

|

|

|

11 |

|

|

|

|

VC-A411M

VC-H811M

4-2 MAINTENANCE CHECK ITEMS AND EXECUTION TIME

Perform the maintenance with the regular intervals as follows so as to maintain the quality of machine.

|

Maintained |

500 |

1000 |

1500 |

2000 |

Possible symptom |

Remarks |

Parts |

|

hrs. |

hrs. |

hrs. |

hrs. |

encountered |

|

|

|

||||||

|

|

|

|

|

|

|

|

Guide roller ass’y |

|

|

|

|

|

Abnormal rotation or significant |

|

|

|

|

|

|

vibration requires replacement. |

||

|

|

|

|

|

|

|

|

Sup guide shaft |

|

|

|

|

Lateral noises Head |

|

|

|

|

|

|

|

|

|

|

Reverse guide |

|

|

|

|

occasionally blocked |

Clean tape contact part with the |

|

|

|

|

|

|

specified cleaning liquid. |

||

|

|

|

|

|

|

|

|

Slant pole on pole base |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full erase head |

|

|

|

|

Colour and beating |

|

|

|

|

|

|

|

|

|

|

A/C head |

|

|

|

|

|

Small sound or sound |

|

|

|

|

|

|

distortion |

|

|

|

|

|

|

|

|

Clean tape contact area with the |

|

|

|

|

|

|

|

Poor S/N ratio, no colour |

|

Upper and lower drum ass’y |

|

|

|

|

Poor flatness of the |

specified cleaning liquid. |

|

|

|

|

|

envelope with alignment |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tape |

|

|

|

|

|

|

|

|

|

Capstan D.D. motor |

|

|

|

|

No tape running, |

|

|

|

|

|

|

uneven colour |

|

||

|

|

|

|

|

|

|

|

Pinch roller |

|

|

|

|

|

No tape running, tape |

|

|

|

|

|

|

slack |

Clean rubber and rubber contact |

|

|

|

|

|

|

|

||

Reel belt |

|

|

|

|

|

No tape running, tape |

area with the specified cleaning |

|

|

|

|

|

slack, no fast forward/ |

liquid. |

|

|

|

|

|

|

|

rewind motion |

|

Tension band ass’y |

|

|

|

|

Screen swaying |

|

|

|

|

|

|

|

|

|

|

Loading motor |

|

|

|

|

Cassette not loaded or |

|

|

|

|

|

|

unloaded |

|

||

|

|

|

|

|

|

|

|

Idler ass’y |

|

|

|

|

|

No tape running, tape |

|

|

|

|

|

|

|

|

|

Limiter pulley |

|

|

|

|

slack |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Supply/take-up main brake levers |

|

|

|

|

Tape slack |

|

|

|

|

|

|

|

|

|

|

NOTE |

: Part replacement. |

: Cleaning |

: Apply grease |

|

|||

<Specified> Cleaning liquid Industrial ethyl alcohol

*This mechanism does not need electric adjustment with variable resistor. Check parts. If any deviation is found, clean or replace parts.

Video head cleaning procedure

1.Apply one drop of cleaning liquid to the cleaning paper with the baby oiler.

2.Gently press the cleaning paper against the video head to fix your finger, and move the upper drum so that each head is passed to and fro 5 times (do not move the cleaning paper).

3. Wipe with the dry cleaning paper.

Notes :

•Use the commercially available ethanol of Class 1 as cleaning liquid.

•Since the video head may be damaged, do not move up and down the cleaning paper.

•Whenever the video head is cleaned, replace the cleaning paper.

•Do not apply this procedure for the parts other than the video head.

Rotate the upper drum with one hand.

Rotate the upper drum with one hand.

Gently press the cleaning paper to fix with your finger, and rotate the

upper drum to clean.

Move to and fro 5 times for each head. (Do not move the cleaning paper.)

Parts Code |

Description |

Code |

ZPAPRA56-001E |

Cleaning Paper |

AW |

ZOiLR-02-24TE |

Babe Oiler (Spoit) |

AH |

12

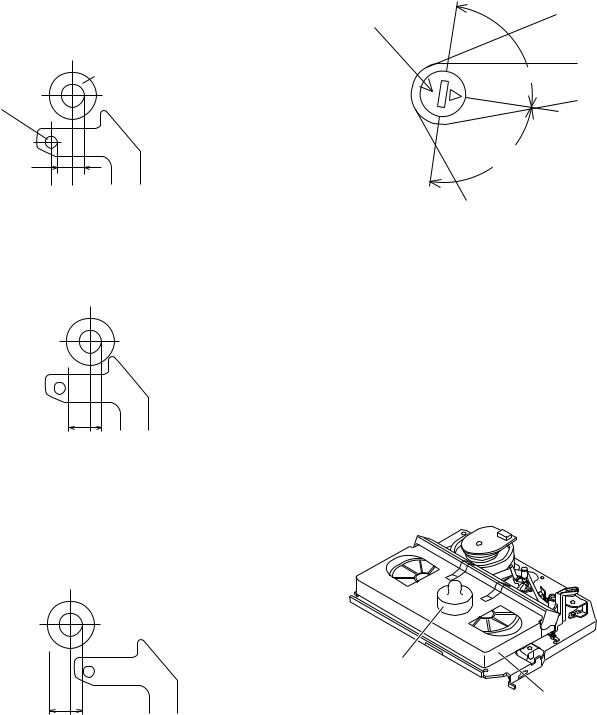

4-3 REMOVING AND INSTALLING THE CASSETTE HOUSING

• Removal

1.In the cassette removing mode, remove the cassette.

2.Unplug the power cord.

3.Remove in the following numerical order.

a)Remove two screws 1.

b)Slide and pull up the cassette housing control.

1

VC-A411M

VC-H811M

Notes:

1.When fitting the S/E sensor holder to the cassette controller frame L/R, take care.

2.Misengagement of teeth of casecon drive gear and drive angle gear causes malfunction. (The cassette cannot be set, load and ejection are repeated).

3.In the case when you use the magnet screw driver, never approach the magnet driver to the A/C head, FE head, and drum.

4.When installing or removing, take care so that the cassette housing control and tool do not contact the guide pin or drum.

5.After installing the cassette housing control once perform cassette loading operation.

4-4 TO RUN A TAPE WITHOUT THE CASSETTE HOUSING CONTROL ASSEMBLY

1.Remove the full-surface panel.

2.Short-circuit between TP803 and TP802.

3.Plug in the power cord.

4.Turn off the power switch.

(The pole bases move into U.L.position.)

5.Open the lid of a cassette tape by hand.

6.Hold the lid with two pieces of vinyl tape.

7.Set the cassette tape in the mechanism chassis.

8.Stabilize the cassette tape with a weight (500g) to prevent floating.

9.Turn on the power switch.

10.Perform running test.

Figure 4-1.

• Reassembly

1.Before installing the cassette housing control, shortcircuit between TP803 and TP802 provided at operation PWB, press the eject button. The casecon drive gear turns and stops when the positioning mark appears. Engage two teeth of casecon drive gear with the three teeth of casecon drive angle gear, and set on the mechanism chassis as shown below.

Casecon

drive gear

Casecon drive angle gear

Figure 4-2.

2. Install in the reverse order of removal.

500g

Weight to prevent

Mechanism chassis

float (500g)

Figure 4-3.

Note:

The weight should not be more than 500g.

To take out the cassette tape.

1.Turn off the power switch.

2.Take out the cassette tape.

13

VC-A411M

VC-H811M

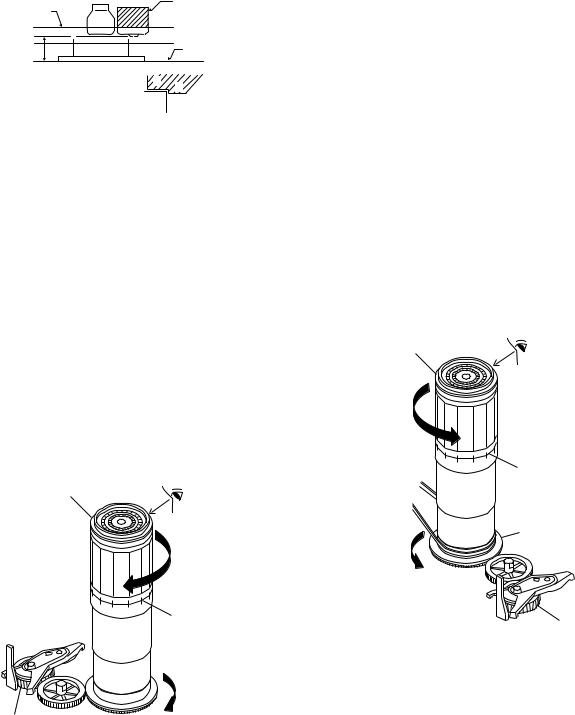

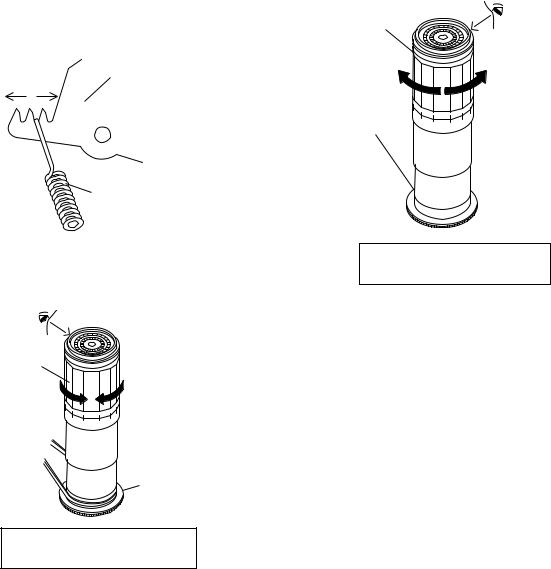

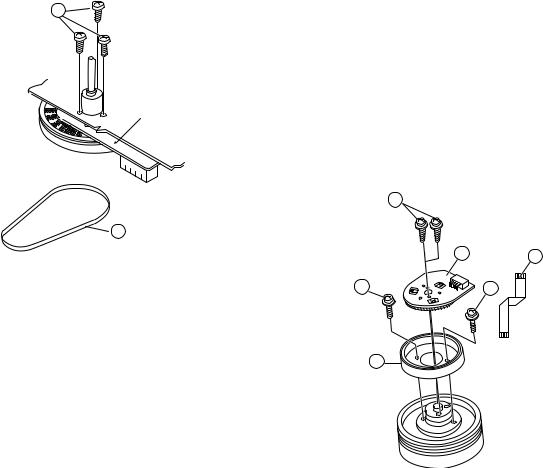

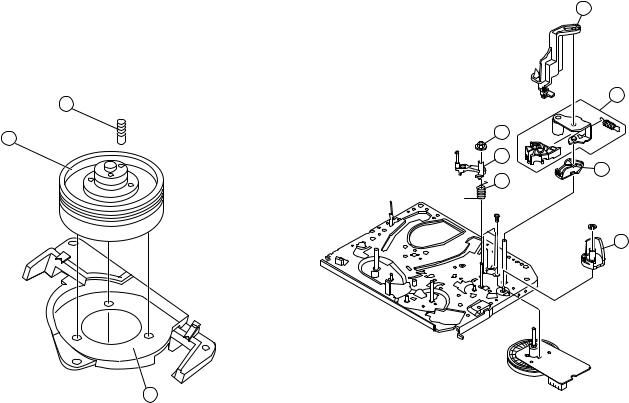

4-5 REEL DISK REPLACEMENT AND HEIGHT CHECK

• Removal

1.Remove the cassette housing control assembly.

2.Pull the tension band out of the tension arm ass'y.

3.Remove the Supply/Take-up main brake ass'y.

4.Open the hook at the top of the reel disk, and remove the

reel disk.

Note:

Take care so that the tension band ass'y and main brake ass'y (especially soft brake) ar e

e not deformed.

not deformed.

Tension arm ass'y |

Take-up main brake ass'y |

|

|

Supply main brake ass'y |

|

Tension band ass'y |

|

Supply reel disk |

Take-up reel disk |

4. Assemble the Supply main brake ass'y.

Notes:

1.When installing the reel disk, take due care so that the tension band ass'y is not deformed and grease does no adhere.

2.Do not damage the Supply main brake ass'y. Be careful so that grease does not adhere to the brake surface.

• Reassembly (Take-up reel disk)

1.Clean the reel disk shaft and apply grease (SC-141) to it.

2.Align the phase of the reel disk to that of the reel relay gear and to install a new take-up reel disk onto the shaft.

3.Check the reel disk height and reassemble the take-up

main brake ass'y.

Note:

1.Take care so that the Take-up main brake ass'y is not damaged. Take care so that grease does not adhere the brake surface.

2.After reassembly, check the video search rewind back tension (see 4-10), and check the brake torque (see 4- 14).

• Height checking and adjustment Note:

1.Set the master plane with due care so that it does not contact the drum.

2.When putting the master plane, shift the reverse guide a little in the loading direction. Care must be taken since excessive shift results in damage.

Figure 4-4.

Note:

When the tension band ass'y is pressed in the direction of the arrow for removal, the catch is hard to be deformed.

Figure 4-5.

• Reassembly (Supply reel disk)

1.Clean the reel disk shaft and apply grease (SC-141) to it.

2.Match the phases of reel disk and reel relay gear, and set the new reel disk.

3.After checking the reel disk height, wind the tension band ass'y around the reel disk, and insert into the hole of tension arm ass'y.

Master plane

Reverse guide

Supply reel disk

Cassette lock

release shaft Position pin

Take-up reel disk

Figure 4-6.

Note:

•Check that the reel disk is lower than part A but higher than part B. If the height is not correct, readjust the reel disk height by changing the poly-slider washer under the reel disk.

14

Note:

Whenever replacing the reel disk, perform the height checking and adjustment.

Master plane |

|

Reel disk height |

|

adjusting jig |

|

|

|

|

10 ± 0.2mm |

Reel disk |

Mechanism chassis |

|

A

B

Reel disk

Figure 4-7.

4-6 CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN FAST FORWARD MODE

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

1.Set a torque gauge to zero on the scale. Place it on the take-up reel disk.

2.Press the FF button.

3.To calculate the remaining capacity of the play back mode, slowly rotate the supply reel disk, and then shift it into the forward mode.

• Checking

1.Turn the torque gauge slowly (one rotation every 2 to 3 seconds) by hand in the CW direction.

2.Make sure that the indication of torque gauge is not less than 30mN·m (306gf·cm).

Torque gauge

CW

30mN·m (306gf·cm) or more

The gauge is held at its maximum value. (Red mark)

Idler ass'y

Figure 4-8.

• Adjustment

1.If the FF winding-up torque is less than the specified value, clean the capstan D.D. motor pulley, drive belt, and limiter pulley with cleaning liquid, and check again.

2.If the torque is less than the set value, replace the reel belt.

VC-A411M

VC-H811M

Notes:

1.Hold the torque gauge by hand so that it is not moved.

2.Do not keep the reel disk in lock state. Do not allow longtime measurement.

4-7 CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN REWIND MODE

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

1.Set a torque gauge to zero on the scale. Place it on the supply reel disk.

2.Press the rewind button.

3.To calculate the remaining capacity, slowly rotate the take-up reel disk, and then shift it into the rewind mode.

• Checking

1.Turn the torque gauge slowly (one rotation every 2 to 3 seconds) by hand in the CCW direction.

2.Make sure that the indication of torque gauge is not less than 30mN·m (306gf·cm).

Torque gauge

30mN·m (306gf·cm) or more

CCW

The gauge is held at its maximum value.

(Red mark)

Supply reel disk

Idler ass'y

Figure 4-9.

• Adjustment

1.If the rewind winding-up torque is less than the specified value, clean the capstan D.D. motor pulley, drive belt, and limiter pulley with cleaning liquid, rewind again, and check the winding-up torque.

2.If the winding-up torque is still out of range, replace the drive belt.

15

VC-A411M

VC-H811M

Notes:

1.Hold the torque gauge by hand so that it is not moved.

2.Do not keep the reel disk in lock state. Do not allow longtime measurement.

4-8 CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN RECORD/PLAYBACK MODE

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Turn off the power switch.

•Open the cassette torque meter lid, and fix it with tape.

•Load the cassette torque meter into the unit.

•Put the weight (500g) on the cassette torque meter.

•Turn on the power switch.

•Press the picture record button, and set EP picture record mode (x3).

Set value EP6.9 ± 2.5mN×m (70 ± 25gf×cm)

500g

Cassette torque meter

Figure 4-10.

• Checking

1.Make sure that value is within the setting 6.9 ± 2.5mN·m (70 ± 25gf·cm).

2.The winding-up torque fluctuates due to variation of rotation torque of limiter pulley ass'y. Read the center value of fluctuation as setting.

3.Set the EP record mode (x3) and make sure that the winding-up torque is within setting.

• Adjustment

If the playback winding-up torque is not within the setting, replace the limiter pulley assembly.

Note:

When the torque cassette is set, put a weight (500g) to prevent rise.

When the cassette torque meter is taken out. Turn off the power switch.

4-9 CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN VIDEO SEARCH REWIND MODE

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

Press the playback button and rewind button to set the video search rewinding mode.

• Checking

Place the torque gauge on the supply reel disk, and turn it counterclockwise very slowly (one rotation every 1 to 2 seconds) and check that the torque is within the set value 14.0 ± 3.9mN×m. (144 ± 40gf×cm)

Torque gauge

CCW

Supply reel disk

Figure 4-11.

Note:

Surely put the torque gauge on the reel disk to measure. If the torque gauge is raised, accurate measurement is impossible.

• Adjustment

If the rewinding playback winding-up torque is not within the setting, replace the limiter pulley assembly.

Note:

The winding-up torque fluctuates due to variation of rotation torque of supply reel disk. Read the center value of fluctuation as setting.

16

4-10 CHECKING THE VIDEO SEARCH REWIND BACK TENSION

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Checking

1.After pressing the play button, press the rewind button, and set the video search rewind mode.

2.Place the torque gauge on the take-up reel disk, and turn it counterclockwise very slowly (one rotation every 2 to

3 seconds) and check that the torque is within the set value 3.4 ± 1.5mN×m (35 ± 15gf×cm).

VC-A411M

VC-H811M

Pinch roller |

Tension gauge |

|

900 - 1,200gf |

||

|

Capstan shaft

Tension gauge adapter

Torque gauge

CCW

Take-up reel disk

Figure 4-13.

1.Detach the pinch roller from the capstan shaft.

Do not separate excessively. Or the pinch lever and pinch double action lever may disengage.

2.Engage the tension gauge adapter with the pinch roller shaft, and pull in the arrow direction.

3.Gradually return the pinch roller, and measure the pulling force when the pinch roller contacts the capstan shaft.

4.Make sure that the measured value is within setting 9.0 N to 11.8 N (900 to 1,200gf).

Figure 4-12.

Notes:

Set the torque gauge securely on the take-up reel disk. If it is not secure, the measurement will be incorrect.

4-11 CHECKING THE PINCH ROLLER PRESSURE

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Checking

Press the play button to set the playback mode.

4-12 CHECKING AND ADJUSTMENT OF TENSION POLE POSITION

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

1.Turn off the power switch.

2.Open the cassette tape (T-120), and fix with tape.

3.Set the cassette tape in loading state.

4.Put the weight (500g) on the cassette tape.

5.Turn on the power switch.

6.Make the adjustment with the beginning of a T-120 tape.

(T-120)

500g

Weight to prevent float (500g)

Figure 4-14.

• Checking

1.Set a cassette tape, push the REC button to place the unit in the SP record mode. Now check the tension pole position.

17

VC-A411M

VC-H811M

2.Visually check to see if the right edge of the tension pole is within the 2.3 ± 0.25 from the right edge of the Sup guide shaft.

Sup guide shaft

Tension pole

2.3 ± 0.25

Make the adjustment with the beginning of a T-120 tape.

Figure 4-15.

At left side from the center line

Tension pole adjuster adjusting range

Tension pole adjuster

90°

90°

Figure 4-18.

Adjust so that the delta mark of tension pole adjuster is within 90° range (left, right).

2.3 ± 0.25

Figure 4-16.

Insert the slotted screwdriver in the tension pole adjuster, and rotate counterclockwise.

At right side from the center line

4-13 CHECKING AND ADJUSTMENT OF RECORD/PLAYBACK BACK TENSION

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

1.Turn off the power switch.

2.Open the torque cassette meter and fix with tape.

3.Set the cassette tape in loading state.

4.Put the weight (500g) on the cassette torque meter.

5.Turn on the power switch.

2.3 ± 0.25

Figure 4-17.

Insert the slotted screwdriver in the tension pole adjuster, and rotate clockwise.

500g

Weight to prevent float (500g)

Cassette torque meter

Figure 4-19.

• Checking

1.Push the REC button to place the unit in the SP record mode.

2.At this time ascertain that the back tension is within the setting (36.5 to 52g·cm) by seeing the indication of torque cassette meter.

18

• Adjustment

1.If the indication of torque cassette meter is lower than the setting, shift the tension spring engagement to the part A.

2.If the indication of torque cassette meter is higher than the setting, shift the tension spring engagement to the part B.

Tension arm

A B

Tension spring

VC-A411M

VC-H811M

• Checking the brake torque at the take-up side

Torque gauge

CW |

CCW |

Take-up reel disk

Figure 4-20.

4-14 CHECKING THE BRAKE TORQUE

• Checking the brake torque at the supply side

Torque gauge

CCW |

CW |

Supply reel disk

CCW: 2.9~9.8mN×m (30~100gf×cm)

CW: 4.9~13.7mN×m (50~140gf×cm)

Figure 4-21.

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

1.Set a torque gauge to zero on the scale. Place it on the supply reel disk.

2.Switch from the FF mode to the STOP mode.

3.Disconnect the power cord.

• Checking

Turn the torque gauge at a rate of about one turn/2 sec in the CW direction/CCW direction with respect to the supply reel disk so that the reel disk and torque gauge pointer rotate at equal speed, and make sure that the value is within the setting (CW direction: 4.9 to 13.7mN·m (50 to 140gf·cm); CCW direction: 2.9 to 9.8mN·m (30 to 100gf·cm).

CCW: 4.9~13.7mN×m (50~140gf×cm)

CW: 3.9~10.8mN×m (40~110gf×cm)

Figure 4-22.

•Remove the cassette housing control assembly.

•After short-circuiting between TP803 and TP802 provided at operation PWB, plug in the power cord.

•Setting

1.Switch from the FF mode to the STOP mode.

2.Disconnect the power cord.

3.Set a torque gauge to zero on the scale. Place it on the take-up reel disk.

• Checking

1.Turn the torque gauge at a rate of about one turn/2 sec in the CCW direction/CW direction so that the reel disk and torque gauge pointer rotates at equal speed and make sure that the value is within the setting (CCW direction: 4.9 to 13.7mN·m (50 to 140gf·cm), CW direction: 3.9 to 10.8 mN·m (40 to 110gf·cm).

2.Adjustment of the brake torque at the supply side and the take-up side

•Unless the supply side brake torque or take-up side brake torque is within the setting, clean the felt surface of reel disk (supply, take-up) brake lever, check again the brake torque.

•If value cannot be set within the setting yet, replace the main brake ass'y or main brake spring.

19

VC-A411M

VC-H811M

4-15 REPLACEMENT OF A/C (AUDIO/CONTROL) HEAD

1.Remove the cassette housing control assembly.

2.In unloading state unplug the power cord.

• Removal

1.Remove the screws 123, Azimuth screw, Tilt screw.

2.Unsolder the PWB fitted to the A/C head.

Notes:

1.When replacing, never touch the head. If you touched, clean with the cleaning liquid.

2.When removing the screw 3, take care so that the spring may out.

3 Tilt screw

Azimuth screw

Height screw

Spring |

1 |

|

|

2 |

|

Figure 4-23.

• Replacement

1.Solder the removed PWB to the new head assembly.

2.Adjust the height from the A/C head arm (lower surface) to the A/C head plate to 10.8mm with slide calipers. (3 places of azimuth screw section, tilt screw section and A/

Solder

New A/C head ass'y

A/C head PWB

Never touch the head

A/C head plate

10.8mm |

10.8mm |

Figure 4-24.

C head front section) (See the figure below.)

3.Align the left end of gear of A/C head arm with the

punched mark of chassis, tentatively tighten the screws 1 and 2 so as to ensure smooth motion of A/C head arm. Tentative tightening torque must be 0.15 to 0.20

N·m (1.5 to 2.0kgf·cm).

1

|

3 |

|

Height screw |

|

Left end of A/C head arm gear |

2 |

Punched line mark on chassis |

Figure 4-25.

Note:

1.If the screws 1and 2are tighten tentatively too loose, the azimuth and height of A/C head may change when they are finally tightened. Therefore care must be taken.

2.After completion of A/C head be sure to adjust tape running. (Execute the running adjustment by the method described in 4-18.)

20

VC-A411M

VC-H811M

4-16 A/C HEAD HEIGHT ROUGH ADJUSTMENT 4-17 HEIGHT ADJUSTMENT OF REVERSE GUIDE

• Setting

Azimuth screw

Height screw |

Tilt screw |

Cassette tape

|

500g |

Weight to prevent |

Mechanism chassis |

float (500g) |

|

Figure 4-26.

1.Adjust the height from the mechanism chassis to the reverse guide lower flange to 13.38 mm, using the reverse guide height adjustment jig, in tape loading state. (Refer to Figure 4-28 (a) (b).)

Reverse guide |

Reverse guide height |

|

Reverse guide height |

adjusting jig |

|

adjusting jig |

|

|

Mechanism |

13.38mm |

|

chassis |

|

|

(a) |

(b) |

|

Figure 4-28.

2.Rotate counterclockwise the reverse guide height adjustment nut 1/10 turn. (For height adjustment use the reverse guide height adjustment box driver (JiGDRiVER 11055)).

Box driver

1.Set the cassette tape in the unit.

2.Press the PLAY button to put the unit in the playback mode.

3.Roughly adjust the height of the A/C head by turning the height screw until the tape is in the position shown below.

A/C head

Tape

0.3mm

CCW

Height adjusting nut

Figure 4-29.

Figure 4-27.

• Adjustment

Adjust the height screw visually so that the control head is visible 0.3mm below the bottom of the tape.

3.Set the tape, and check for tape crease near the reverse guide in the playback mode.

If crease is found, turn the reverse guide adjustment nut to remove crease. (As for crease check refer to Figure 4-

30.)

|

A |

Capstan |

|

|

|

motor shaft |

|

500g |

|

Fixing guide |

|

Weight to |

Mechanism |

|

|

prevent float (500g) |

|

||

chassis |

An example of |

||

|

|||

|

|

||

|

Reverse guide |

crease near the |

|

|

reverse guide |

||

|

|

* Check for crease from the A direction.

Figure 4-30.

21

VC-A411M

VC-H811M

4-18 ADJUSTMENT OF TAPE DRIVE TRAIN

1.Tape run rough adjustment

1 Remove the cassette housing control assembly.

2 After shortcircuiting between TP803 and TP802 pro-

vided at operation PWB, plug in the power cord. 3 Check and adjust the position of the tension pole.

(See 4-12.)

4 Check and adjust the video search rewind back

tension. (See 4-10.)

5 Connect the oscilloscope to the test point for PB CHROMA envelope output (TP201). Set the synchronism of the oscilloscope to EXT. The PB CHROMA signal is to be triggered by the head switching pulse (TP202).

6 Set the alignment tape (VROATSV) to play. (Put a 500g weight on the cassette tape to prevent lift of cassette tape.)

Guide roller

Cassette Tape

500g

Weight of 500g

Figure 4-31.

7Press the tracking button (+), (–) and change the envelope waveform from max to min and from min to max. At this time make sure that the envelope waveform changes nearly parallel.

8Unless the envelope waveform changes nearly parallel, adjust the height of supply side and take-up side guide roller so that the envelope waveform changes nearly parallel. (For envelop adjustment procedure refer to Figure 4-35.)

9Turn the tilt screw to remove the tape crease at the fixing guide flange.

Playback the tape and check for tape crease at the fixing guide flange.

(1)If there is no tape crease

Turn the tilt screw clockwise so that tape crease appears once at the flange, and then return the tilt screw so that the crease disappears.

(2)If there is tape crease

Turn counterclockwise the tilt screw so that the tape crease disappears.

(Reference) If the tilt screw is turned clockwise crease appears at the lower flange.

Notes:

1.Previously set the tracking control in the center position, and adjust the envelop waveform to maximum with X value adjustment nut. Thereby the tape run rough adjustment is facilitated.

2.Especially the outlet side envelope waveform must have higher flatness.

Figure 4-32.

2.Adjustment of A/C head height and azimuth

1 Perform the initial setting of A/C head position by the method stated in "4-15 Replacement 3".

2Connect the oscilloscope to the audio output terminal.

3Using the alignment tape in which 1 kHz linear audio signal has been recorded, adjust the height screw so as to get max audio output.

4Using the alignment tape in which 7 kHz linear audio signal has been recorded, adjust the azimuth screw so as to get max audio output.

5The adjustment of 3 and 4 twice or three times repeat, and finally adjust 4.

For X value adjustment

Adjust the X value, turning the geartype screwdriver.

Figure 4-33.

3.Tape run adjustment

1 Connect the oscilloscope to PB CHROMA envelope output test point, set oscilloscope sync to EXT, trigger-input the PB CHROMA signal (head switching pulse).

2Rough adjustment of X value

Tentatively fix A/C head arm screws 1and 2by the method described in 4-15 "Replacement 3". Playback the alignment tape (VROATSV) and shortcircuit between TP801 and TP802. As a result the auto-tracking is automatically cancelled, so that the X value adjustment mode is set.

Move the A/C head with the X value adjustment gear driver (JiGDRiVER-6) by the method shown in Figure 4-33, and adjust the A/C head so as to get the maximum envelope waveform. (Note: When the A/ C head is adjusted, adjust so that the maximum envelop waveform is obtained nearest the position of initial setting made in 4-15.)

22

3Next, press the tracking button (+), (–) and change the envelope waveform from max to min and from min to max. At this time adjust the height of supply and take-up side guide roller with the adjustment driver (JiGDRiVERH-4) so that the envelope waveform changes nearly parallel.

4If the tape is lifted or sunk from the helical lead surface, the PB CHROMA envelope waveform appears as shown in Figure 4-35.

5Press the tracking button (+), (–) and make sure that the envelope waveform changes nearly parallel.

6Finally check tape crease near the reverse guide. If tape crease is found, remove it as stated in 4-17 "HEIGHT ADJUSTMENT OF REVERSE GUIDE" item 3.

VC-A411M

VC-H811M

PB CHROMA

Envelope

CH-1 CH-2

Head switching pulse

Figure 4-34.

4.A/C head X value adjustment

1 Tentatively fix A/C head arm screws 1and 2by the method described in 4-15 "Replacement 3".

2Playback the alignment tape (VROATSV), and shortcircuit between TP801 and TP802. As a result the auto-tracking is automatically cancelled, so that the X value adjustment mode is set.

When the tape is above the helical lead. |

When the tape is below the helical lead. |

||

Supply side |

Take-up side |

Supply side |

Take-up side |

|

Supply side guide roller |

Take-up side guide roller |

Supply side guide roller |

Take-up side guide roller |

|

rotated in clockwise |

rotated in clockwise |

rotated in counterclock- |

rotated in counterclock- |

|

direction (lowers guide |

direction (lowers guide |

wise direction (raises |

wise direction (raises |

|

roller) to flatten |

roller) to flatten |

guide roller) to make the |

guide roller) to make the |

Adjustment |

envelope. |

envelope. |

tape float above the helical |

tape float above the |

|

|

|

lead. The supply |

helical lead. The take-up |

|

|

|

side guide roller is then |

side guide roller is then |

|

|

|

rotated in the clockwise |

rotated in the clockwise |

|

|

|

direction to flatten the |

direction to flatten the |

|

|

|

envelope. |

envelope. |

Figure 4-35.

3Move the A/C head with the X value adjustment gear driver by the method shown in Figure 4-33, and adjust the A/C head so as to get the maximum envelope waveform. (Note: At this time adjust so as to get the maximum envelope waveform nearest the

A/C head position which has been set in case of X value rough adjustment as stated in 4-18, 3- 2.)

4Tighten finally the screws 1 and 2. Be sure to tighten at first the screw 1and then the screw 2. Final tightening torque is 0.6N·m (If the screw 2 is

tightened first, the X value may deviate.)

5Adjust the playback switching point (Refer to the electric adjustment method.)

6Playback the self-picture-recorded tape, and check the flatness of envelope waveform and sound.

Notes:

When the A/C head X value adjustment is performed, be sure to perform at first X value rough adjustment (refer to 4- 18, 3-2).

1 |

2

Figure 4-36.

23

VC-A411M

VC-H811M

4-19 REPLACEMENT OF THE CAPSTAN D.D. (DIRECT DRIVE) MOTOR

•Remove the mechanism from the main PWB (refer to 2- 2 item 1 When removing the mechanism from the main PWB ).

•Removal (Follow the order of indicated numbers.)

1.Remove the reel belt 1.

2.Remove the SLOW BRAKE LEVER 2.

3.Remove the three screws 3.

3

Capstan D.D. motor

control PWB

Capstan D.D. motor

motor

1 Reel belt

Figure 4-37.

• Reassembly

1.Taking care so that the capstan shaft does not contact the mechanism chassis, set its position on the mechanism chassis, and then install with the three screws.

2.Install the reel belt.

Notes:

1.After installing the capstan D.D. motor, be sure to rotate the capstan D.D. motor and check the movement.

2.Set the tape, and check for the tape crease near the reverse guide in the playback mode. Adjust the A/C head and azimuth as stated in 4-18 item 2. If crease is found, adjust as stated in 4-17 "HEIGHT ADJUSTMENT OF REVERSE GUIDE".

4-20 REPLACEMENT OF DRUM D.D. MOTOR

1.Set the ejection mode.

2.Withdraw the main power plug from the socket.

• Removal (Perform in numerical order.)

1.Disconnect the FFC cable 1.

2.Unscrew the D.D. stator assembly fixing screws 2.

3.Take out the D.D. stator assembly 3.

4.Unscrew the D.D. rotor assembly fixing screws 4.

5.Take out the D.D. rotor assembly 5.

Notes:

1.In removing the D.D. stator assembly, part of the drum earth spring pops out of the pre-load collar.

Be careful not to lose it.

2.Install, so that the D.D. rotor ass'y and upper drum ass'y mounting direction check holes align.

(Align the upper drum dent with the rotor hole.)

3.Be careful not to damage the upper drum or the video head.

4.Protect the hole elements from shock due to contact with D.D. stator or D.D. rotor ass'y.

5.After installation adjust the playback switching point for adjustment of servo circuit.

2

D.D. stator ass'y

3 |

1 |

FFC

4 |

4 |

5

D.D. rotor ass'y

Upper drum

Upper drum

Figure 4-38.

24

4-21 REPLACING THE UPPER AND LOWER DRUM ASSEMBLY

• Replacement (Perform in the numerical order)

1Remove the motor as stated in 4-20 D.D. motor replacement.

2Remove the drum earth brush ass’y 2.

3Remove the drum base 3 from the upper and lower drum assembly 1.

[Cares when replacing the drum]

1.Be careful so that the drum earth brush is not lost.

2.Do not touch directly the drum surface.

3.Fit gently the screwdriver to the screws.

4.Since the drum assembly is an extremely precise assembly, it must be handled with utmost care.

5.Make sure that the drum surface is free from dust, dirt and foreign substances.

6.After replacing the drum be sure to perform the tape running adjustment.

After that, perform also the electrical adjustment.

•Playback switching point adjustment

•X-position adjustment and check

•Standard and x-3 slow tracking adjustment

7.After replacing the drum clean the drum.

2

1

3

Figure 4-39.

VC-A411M

VC-H811M

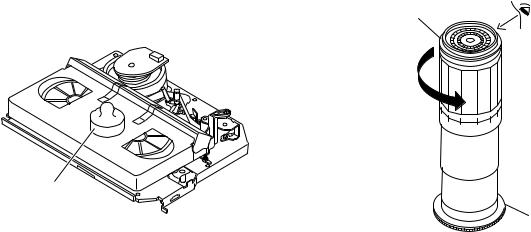

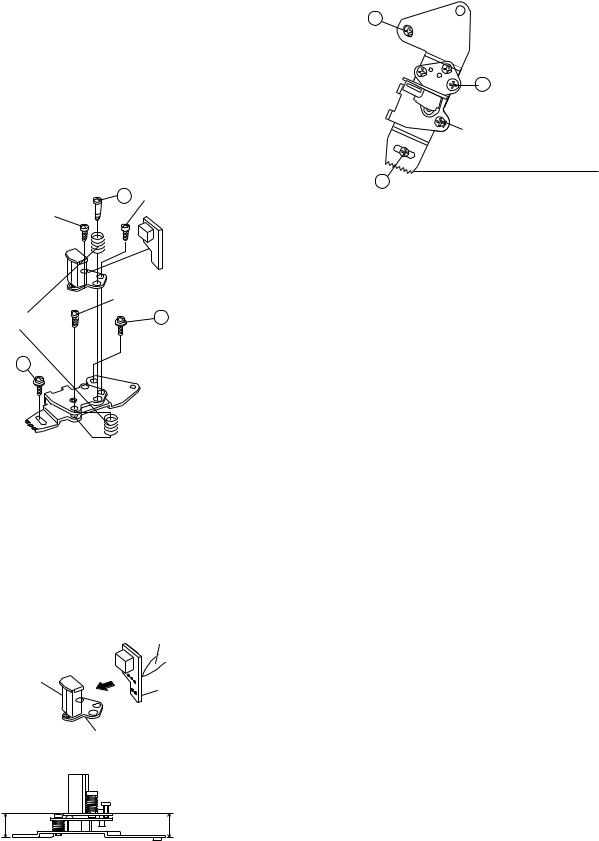

4-22 ASSEMBLING OF PHASE MATCHING MECHANISM COMPONENTS

• Assemble the phase matching mechanism components in the following order.

1.Assemble the pinch roller assembly and pinch drive cam.

2.Mounting the shifter (on the back of the mechanism chassis).

3.Mounting the master cam (on the back of the mechanism chassis).

4.Assemble the connection gear, slow brake and loading motor parts.

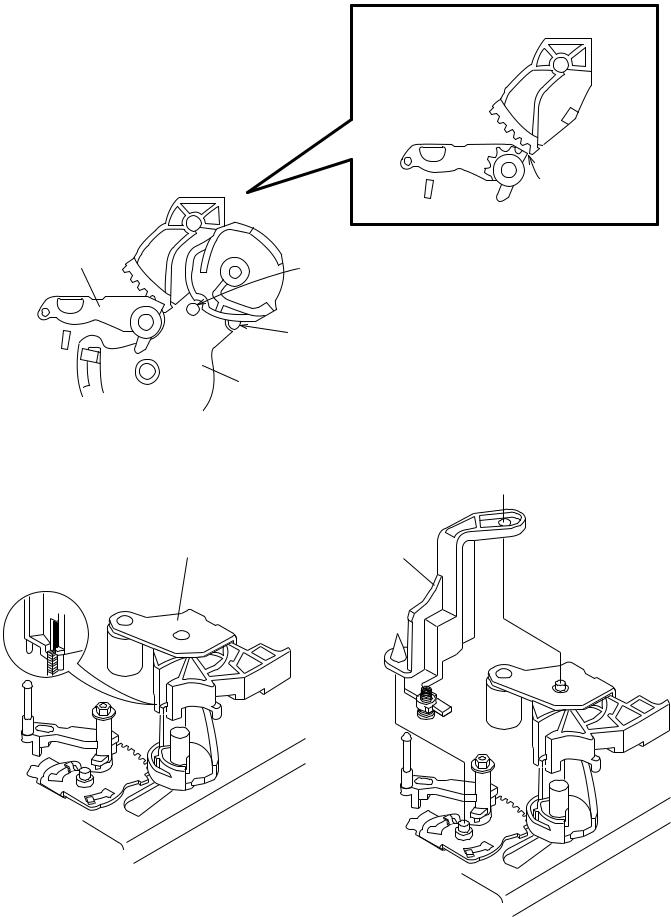

• PINCH DRIVE CAM AND PINCH ROLLER ASSEMBLING METHOD.

(Place the following parts in position in numerical order.)

(1)Reverse drive lever 1 (2)Reverse guide spring 2 (3)Reverse guide lever ass’y 3

(4)Reverse guide height adjusting nut 4 (5)Pinch drive cam 5

(6)Pinch roller ass’y 6

7

(7)Open lever 7

6

4

3

1

2

5

Figure 4-40.

25

VC-A411M

VC-H811M

1Insert Reverse Guide Lever Ass’y

Insert reverse guide lever ass'y

2Insert pinch drive cam |

Align here. |

|

Turn the reverse guide lever assembly counterclockwise to the stopper.

Fit the pinch drive cam so that the notch of pinch drive cam aligns with the dent of pinch drive lever assembly.

Fit the pinch drive cam so that the notch of pinch drive lever assembly aligns with the half-round notch of chassis.

Pinch drive lever ass'y

Figure 4-41-1. |

|

2Insert Pinch Roller/Pinch Double Action Lever Ass’y. |

3Insert Open Lever. |

Pinch Roller Double |

Open lever |

Action Lever Ass'y |

|

Phase Matching Point 2 |

|

Figure 4-41-2. |

Figure 4-41-3. |

|

26

Loading...

Loading...