SHARP VECG40U, VECG30U Service Manual

VE-CG30U

VE-CG40U

1

In the interests of user-safety (Required by safety regula-

tions in some countries) the set should be resrored to its

original condition and only parts identical to those specified

be used.

S72M7VL-MC500

DIGITAL STILL CAMERA

SERVICE MANUAL

SHARP CORPORATION

VE-CG30U

VE-CG40U

MODELS

Page

1. IMPORTANT SERVICE NOTES ........................................................................................................ 2

2. SPECIFICATIONS .............................................................................................................................. 4

3. PART NAMES .................................................................................................................................... 5

4. DISASSEMBLY OF THE SET ............................................................................................................ 6

5. TEST MODE FUNCTION ................................................................................................................... 9

6. TROUBLESHOOTING...................................................................................................................... 19

7. BLOCK DIAGRAMS ......................................................................................................................... 24

8. SCHEMATIC DIAGRAMS ................................................................................................................ 30

9. SEMICONDUCTOR LEAD IDENTIFICATION ................................................................................. 64

10.PRINTED WIRING BOARD ASSEMBLIES ...................................................................................... 66

11.REPLACEMENT PARTS LIST / EXPLODED VIEWS...................................................................... 72

12.PACKING OF THE SET ................................................................................................................... 82

CONTENTS

This document has been published to be used for after

sales service only.

The contents are subject to change wthout notice.

S92Q8VE-CG30U

2

VE-CG30U

VE-CG40U

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isola-

tion resistor/capacitor networks, mechanical insula-

tors etc.

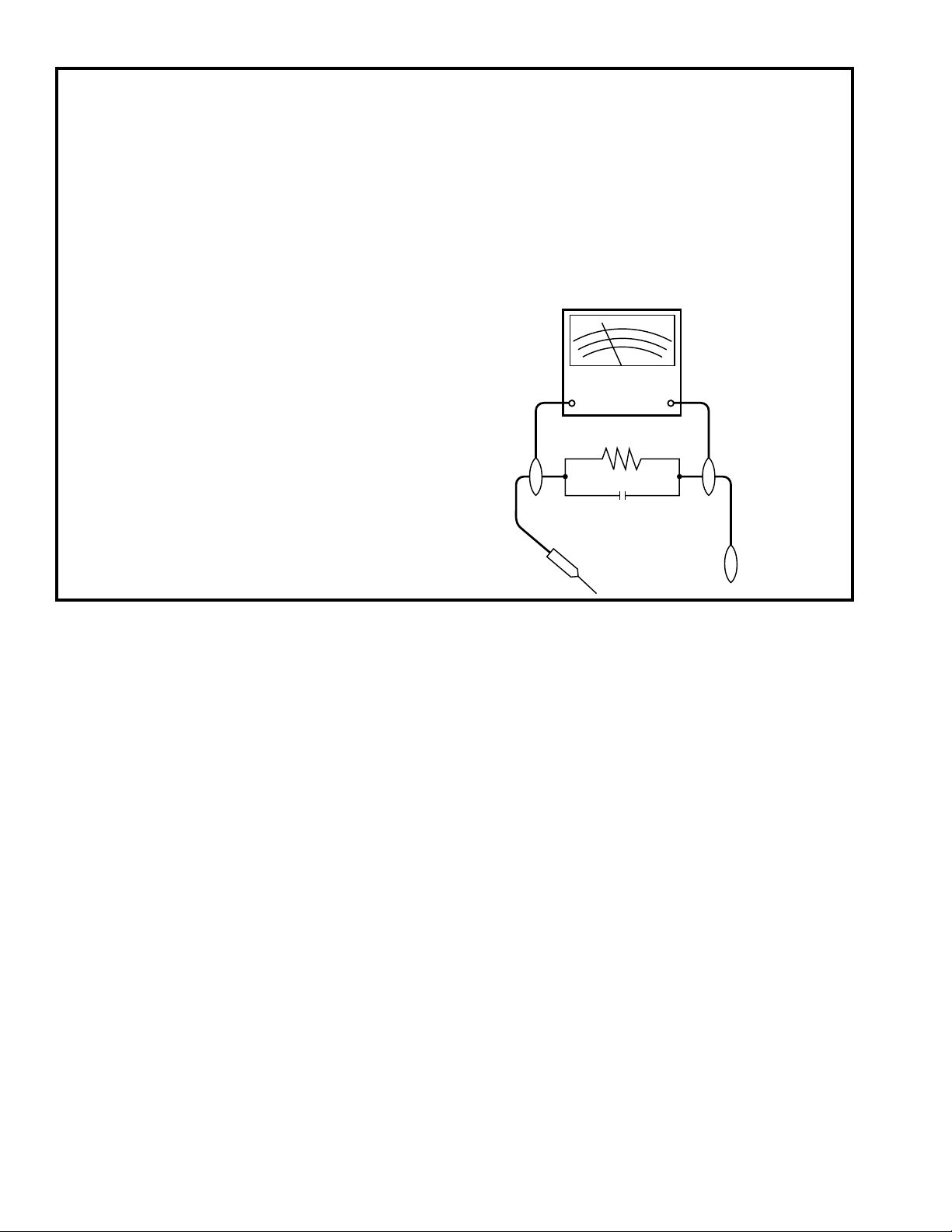

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

· Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

· Using two clip leads, connect a l.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all

exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

· Use a VTVM or VOM with 1000 ohm per volt, or higher

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

· Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each ex-

posed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

VTVM

AC SCALE

1.5k ohms

10W

CONNECT TO

KNOWN EARTH

GROUND

TO EXPOSED

METAL PARTS

0.15 µF

TEST PROBE

VE-CG30U

VE-CG40U

3

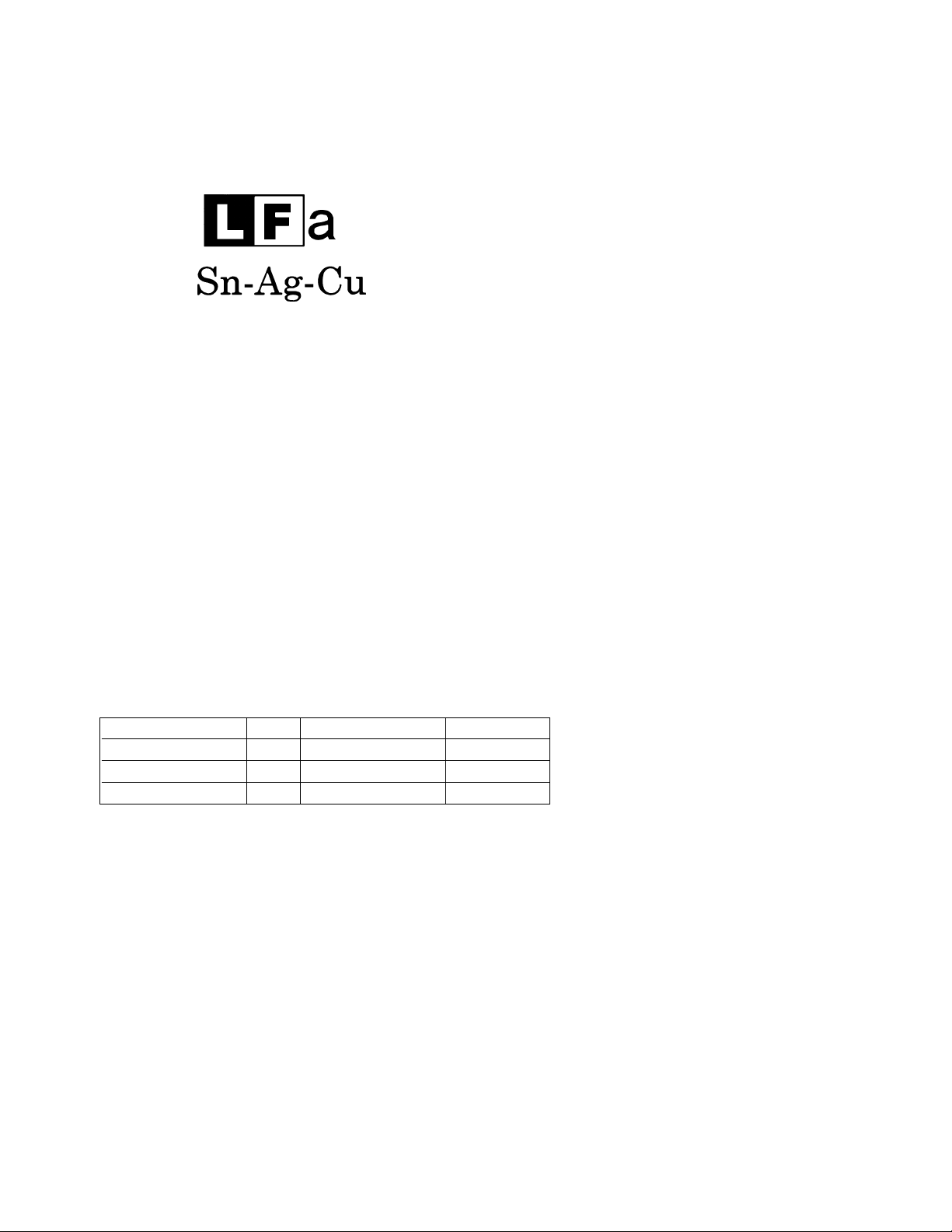

■ PRECAUTIONS FOR USING LEAD-FREE SOLDER

1) Employing lead-free solder

"Main PWB", "Camera head PWB", "Audio I/O PWB", "Card PWB", "Inverter PWB", "Operation PWB", "DC Jack

PWB", "CCD PWB" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached

on the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper

2) Using lead-free solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend you

to use a dedicated soldering bit. If you are not familiar with how to obtain lead-free solder or soldering bit, contact

our service station or service ranch in your area.

3) Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is 220°C which is higher than the conventional lead solder by

40°C, and as it has poor solderability, you may be apt to keep the soldering bit in contact with the PWB for extended

period of time. However, since the land may be peeled off or the maximum heat-resistance temperature of parts may

be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Lead-free wire solder for servicing

Part No. ★ Description Price Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

4

VE-CG30U

VE-CG40U

2. SPECIFICATIONS

Image Capturing Device 1/1.8" CCD image sensor (effective pixels: 4.04 megapixels(CG40U)

3.2megapixels(CG30U))

Lens F2.0-F2.5 f=7-21mm (35mm film equivalent: 33-99mm)

Power zoom 1-3x in optical range, 3-9x in digital range

Color Temperature Compensation Auto white balance with daylight, fluorescent or tungsten

LCD monitor 1.5" CGSilicon, 134,000pixels

Power Source AA size alkaline batteries

Ni-MH rechageble batteries

DC 6.0V with AC adapter

Power Consumption 3.2W (CG40U), 2.9W (CG30U)

Recording Format JPEG for still images

Motion JPEG for motion images (CG40U ONLY)

Recording Medium SD Memory Card

Sound Recording Format WAV (monaural) (CG40U ONLY)

Dimensions(W x H x D) 4.5" x 2.9" x 2.4" (113.5 x 74.5 x 60 mm)

Weight 0.64lbs (290 g)(CG40U)(without batteries, card, wrist strap, and lens cap)

0.63lbs (285 g)(CG30U)(without batteries, card, wrist strap, and lens cap)

Operating Temperature 32°F to 104°F (0°C to +40°C)

Storage Temperature -4°F to 140°F (-20°C to +60°C)

Operating Humidity 30% to 80%

Digital still camera

AC adapter

Power Requirement AC 100-120V, 50/60Hz

DC Output 6V

Operating Temperature 32°F to 104°F (0°C to +40°C)

Dimetions (W x H x D) 2.0" x 1.1" x 2.6" (50.0 x 27.0 x 65.5 mm)

Weight 0.24 lbs (108g)

Specifications are sbject to change without notice.

SERVICE INFOMATION (FOR THE U.S.)

For the location of the nearest Sharp Authorized Service Center, or to obtain product literature, accessories,

supplies or customer assistance, please call 1-800-BE SHARP (1-800-237-4277) or visit SHARP's website

(http://www.sharpusa.com).

VE-CG30U

VE-CG40U

5

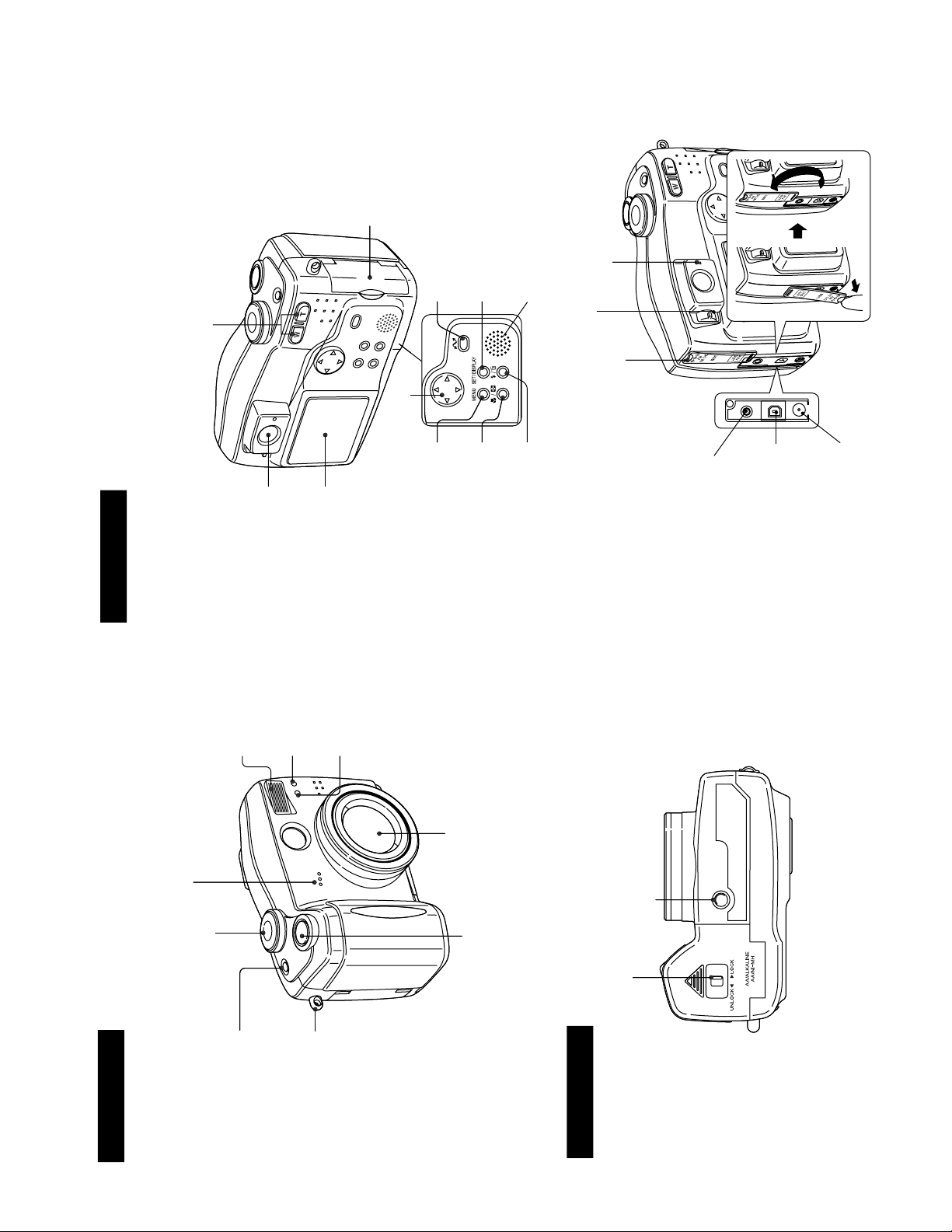

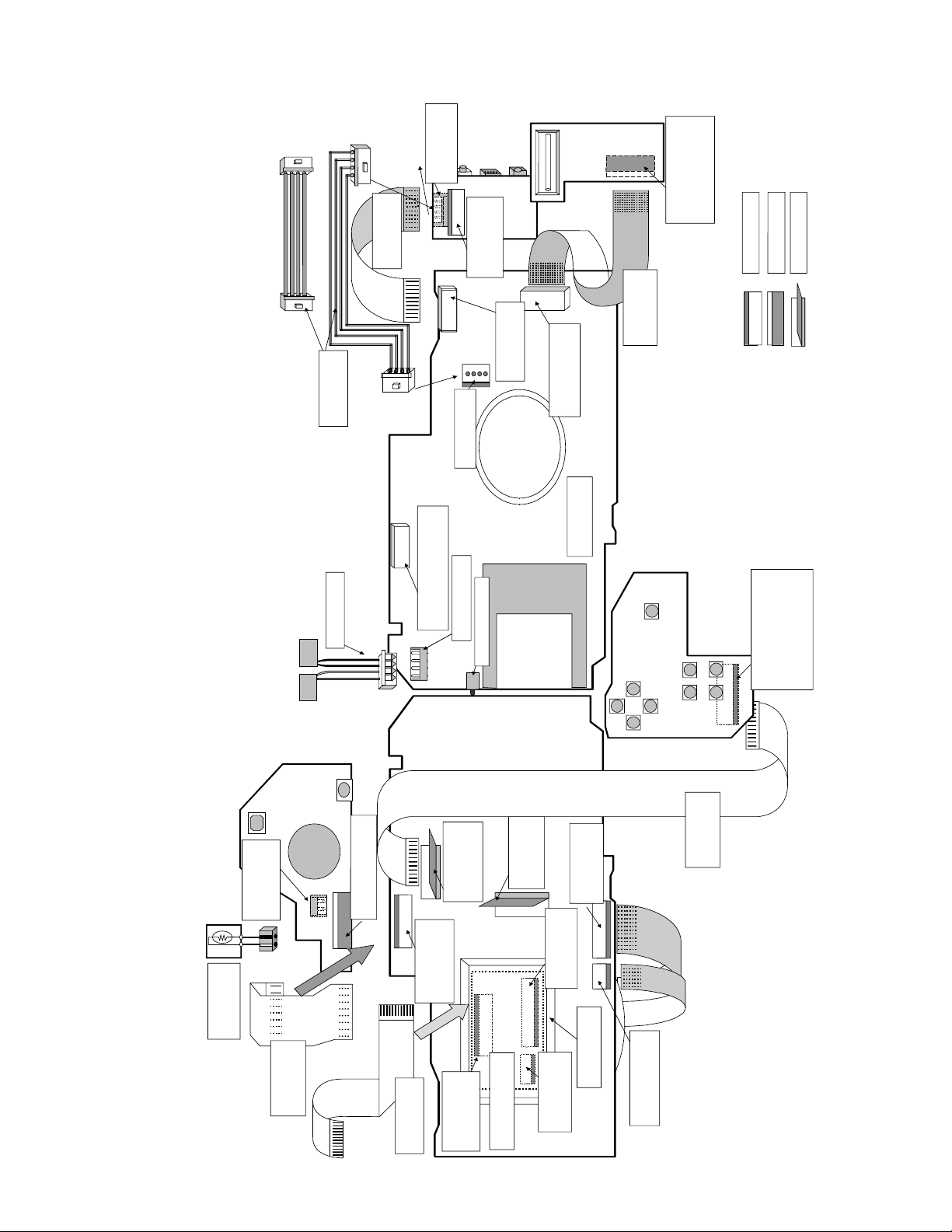

3. PART NAMES

For details on the use of each control.

Zoom lens

Microphone (CG40 ONLY)

Self timer indicator

Shutter button

Flash sensor

Flash

Wrist strap loop

Power button

Mode Dial

Battery compartment door release

Tripod socket

Front view

Bottom view

Rear view

SET/DISPLAY button

MENU button

Viewfinder

Power Zoom buttons (W: wide

angle,T: telephoto)

Speaker

Card slot cover

Macro /

Thumbnail

button

button

LCD screen

Flash /

Delete

Operation button

Data transfer button

A/V OUT jack (CG40U)

VIDEO OUT jack (CG30U)

USB terminal

DC IN jack

Jack cover

Diopter control

Status indicator

(CG40 ONLY)

6

VE-CG30U

VE-CG40U

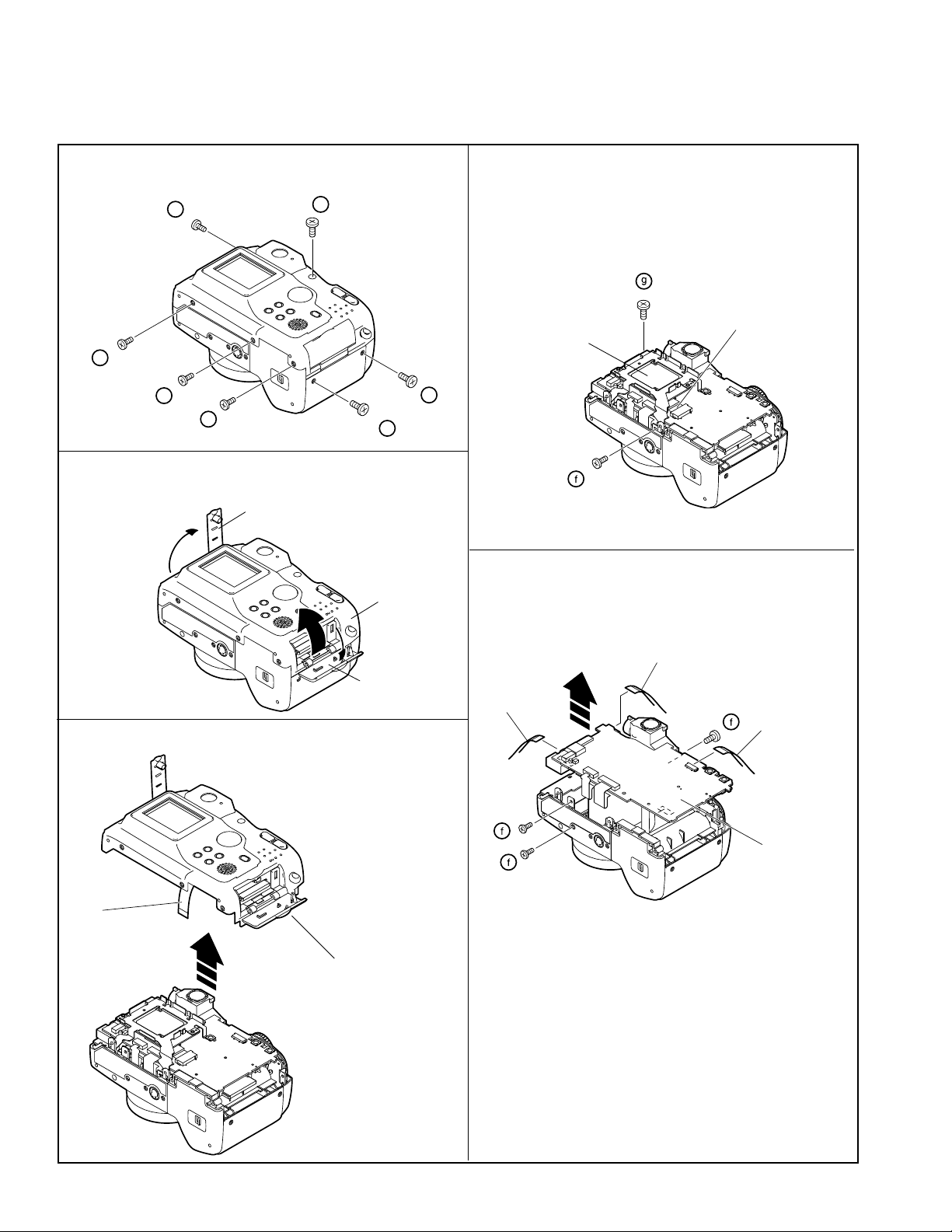

4. DISASSEMBLY OF THE SET

4-1. DISASSEMBLY OF THE SET

Note:

Before removing the cabinet, turn off the power supply, and ascertain that the battery have been removed.

5.

1.

3.

4.

2.

Remove the five screws ((a)LX-HZ0063TAFF) and

two screws ((h)XiPSF17P04000).

a

a

a

a

a

h

h

Open the media lid and jack cover, and then open the

back cabinet turning it.

Jack cover

Back cabinet

Media lid

FFC

Disconnect the connector and pull out the FFC.

LCD unit

FFC

After removing the one screw ((f)XiPSF17P03000)

and one screw ((g)XiPSN17P02000), disconnect

the connector and pull out the FFC to take out the

LCD unit.

CCD PWB

FFC

FFC

FFC

After removing the three screws ((f)XiPSF17P03000),

disconnect the connector and pull out the three

FFCs.

Pull out the CCD PWB slightly.

Be sure to keep the media

lid open when attaching

the back cabinet ass'y.

VE-CG30U

VE-CG40U

7

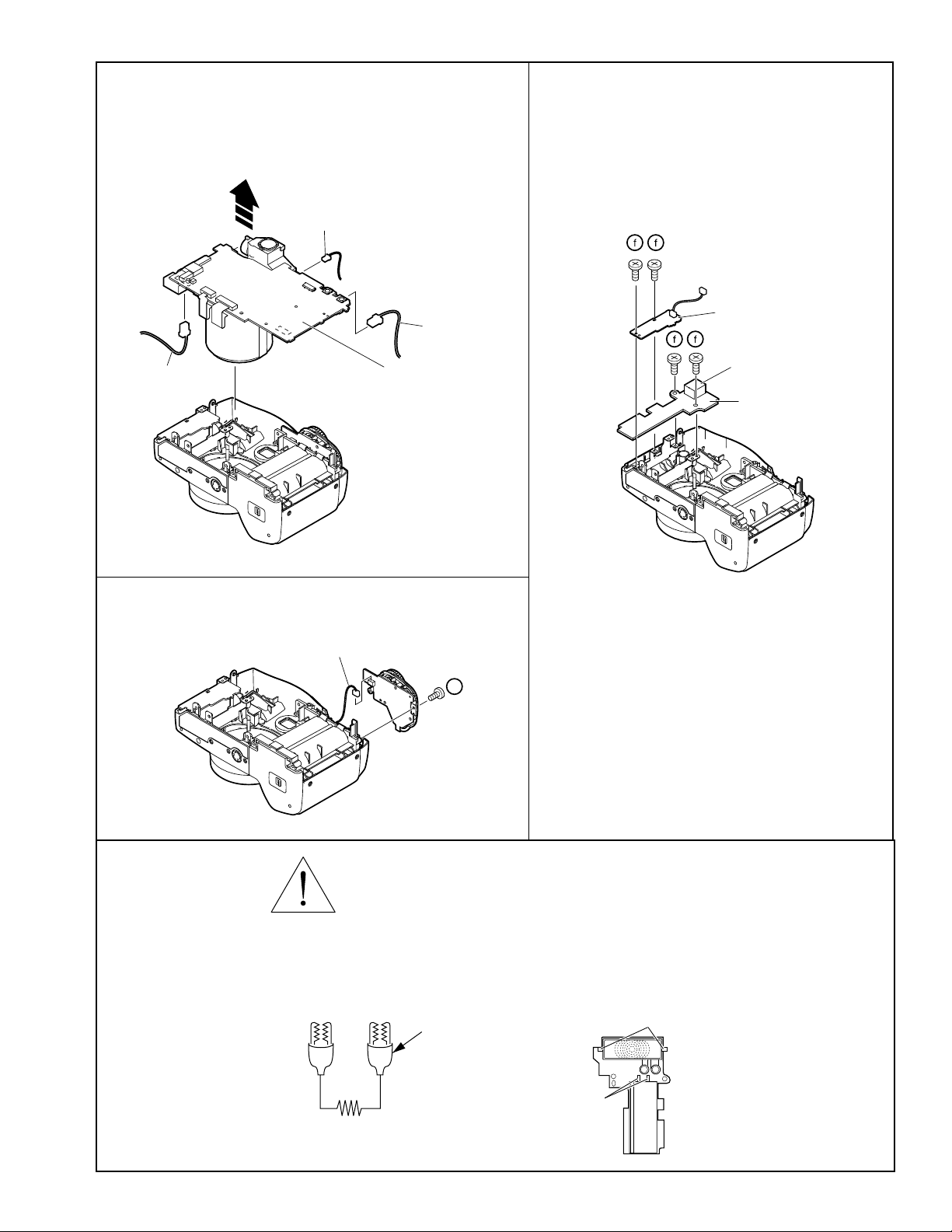

6.

7.

Disconnect the two connectors to take out the CCD

PWB.

Each connector has four wires.

(For 40U, disconnect the three connectors.)

Remove the one screw ((b)LX-HZ0050TAFF) and

disconnect the connector to take out the top cabinet.

8. Remove the four screws ((f)XiPSF17P03000)

to take out the AV jack PWB and strobe unit.

Caution:

Hold the transformer to remove the strobe unit.

CCD PWB

Connector(CG40U only)

Connector

Connector

b

Connector

AV jack PWB

Strobe unit

Transformer

Prepare approx. 5kΩ/5W.

Figure 1

Clip

+

-

High voltage section

Clip connection

Caution: Electric shock

When disassembling or repairing the set, do not touch the high voltage section of the main capacitor

since it contains high voltage. Be especially careful when removing and mounting the screws of the jack

unit (DUNTKB359PM) and strobe unit as well as when replacing the wires (QCNW-A562/564/565WJ).

After removing the strobe unit, prepare the following discharging jig (1) and connect it to the (2) position

as shown in the figure. Discharge main capacitor by leaving discharge jig attached for 60 seconds.

8

VE-CG30U

VE-CG40U

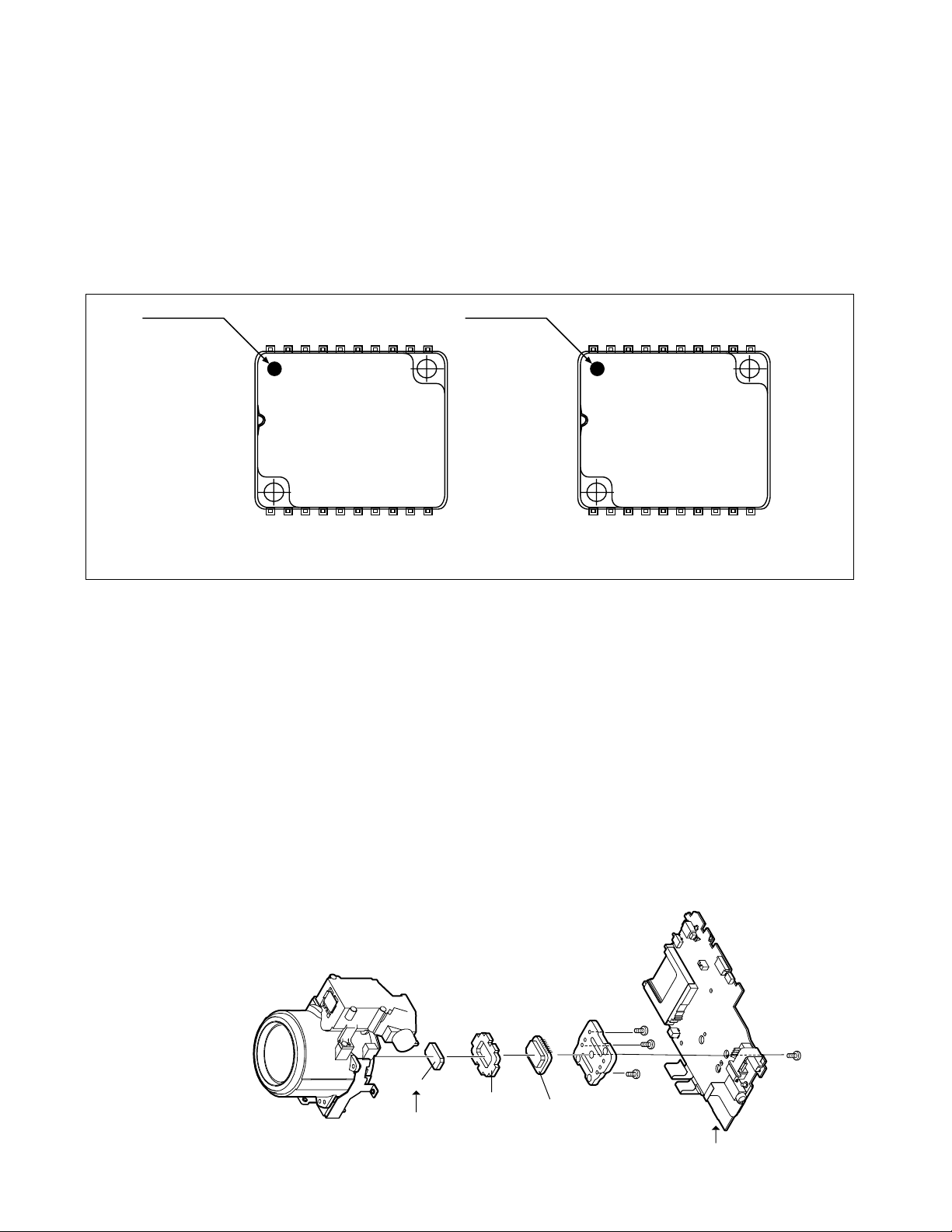

4-2. REPLACEMENT OF CCD SENSOR

4-2-1. BEFORE REPLACEMENT

1) The CCD image sensor is more sensitive to electrostatic breakage than C-MOS LSI.Therefore sufficient means

to prevent electrostatic damage must be taken when it is replaced.

• Ground the soldering iron.

• Ground also the human body, using the wrist strap(through an 1 M ohm resistor).

• Until the CCD sensor is mounted on the PWB, fit it to the conductive sponge, and short-circuit the foot lead.

2) Take utmost care so that the surface glass of CCD sensor and optical filter are not contaminated and damaged.

If any contamination is found, for example fingerprint, wipe it off with silicon paper or clean chamois skin.

3) When replacing the CCD sensor, use the static electricity prevention grounded soldering-iron, and perform

quickly soldering.

110

20 11

Index Mark

110

20 11

Index Mark

CG30 CG40

JAPAN

SHARP

RJ21P3

BA0PT

YYWWXX

JAPAN

SHARP

RJ21R3

BA0PT

YYWWXX

4-2-2. REMOVAL OF CCD

1) Unsolder the CCD sensor leads from the MAIN PWB.

2) Take out the MAIN PWB.

3) Remove the three screws (LX-HZ0013TAFF), and remove the sensor holder and CCD sensor.

4-2-3. MOUNTING OF CCD

1) Place the lens unit upright (since the CCD sensor mount ID faces upward, care must be taken so as not to

damage the front lens of unit), put the crystal filter first and then the dust protection rubber into the CCD holder

of lens unit.

Set the crystal unit with its thin side toward the lens unit.

2) Place the CCD sensor so that the its No. 1 pin is at the right lower (Positioning hole to be at right), and put the

CCD sensor into the CCD holder. For smooth and tight fitting, press the right lower part of back of CCD sensor,

and then press the left upper part.

Note: Pay attention to the direction of CCD sensor.

3) Place the sensor holder so that its two round markings be visible, and fix the sensor holder with the theree screws

(LX-HZ0013TAFF).

4) Mount the MAIN PWB so that the CCD sensor leads go thorough the PWB holes.

5) Solder the CCD sensor lead to the sensor PWB.

Note: Take care not to apply excessive heat.

*Refer to P.80

PFiLWA025WJZZ (CG40U)

PFiLWA026WJZZ (CG30U)

Crystal

DUNTKB356QA00 (CG40U)

DUNTKB357QA00 (CG30U)

Rubber

CCD

VE-CG30U

VE-CG40U

9

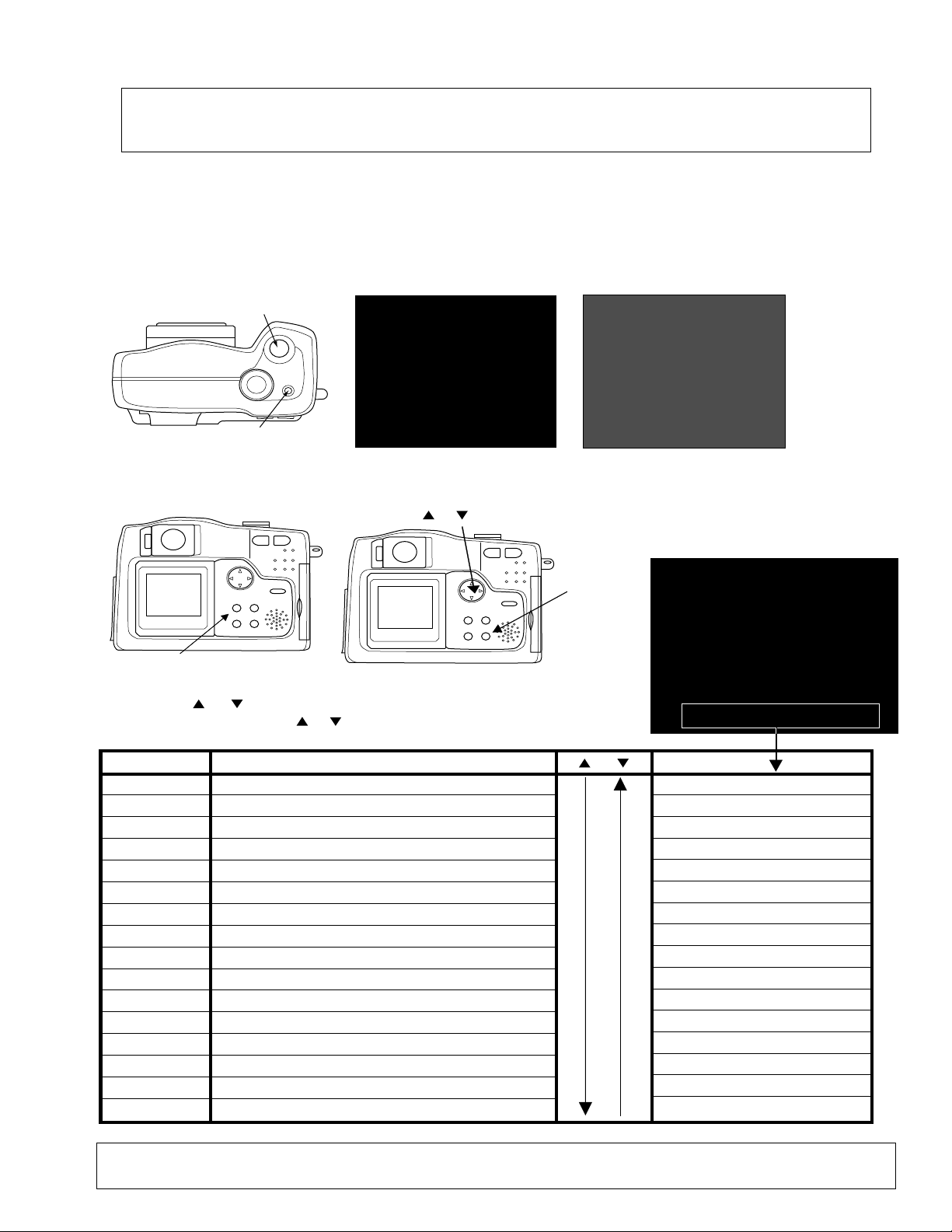

5.TEST MODE FUNCTION

[Note]: The meaning of TEST MODE FUNCTION Under this test mode, following things can be done.

1; Check and change EEPROM values, if required. 2; Apply several tests and adjustments.

3; Check the version # of firmware.

MENU Key

How to enter each test mode

1) Press the or key to select the desired test mode.

Each time you press the or key, each test item is displayed.

Test Nos. and the corresponding test items are as follows.

TEST NOS. Test item Display

TEST 0 EEPROM address change 0 CANGE E2PROM

TEST 1 LCD test pattern display 1 TEST PATERN

TEST 2 Default settings 2 SET SHIPPING

TEST 3 White balance low color temp. adjustment 3 WB LOW TEMP

TEST 4 White balance high color temp. adjustment 4 WB HIGH TEMP

TEST 5 CCD pixel defect correction 5 DEFECT WHT BLK

TEST 6 Not use in service 6 DEFECT WHT BLK

TEST 7 AF adjustment 7 FOCUS

TEST 8 Not use in service 8 CCD SENSITIVITY

TEST 9 Shutter timing adjustment (open side) 9 SHUTTER OPEN

TEST A Shutter timing adjustment (close side) A SHUTTER CLOSE

TEST B Not use in service B WB HIGH CALIB

TEST C Not use in service C LCD POSITION

TEST D Battery adjustment D BATTERY VOLTAGE

TEST E Not use in service E WB LOW CALIB

TEST F Not use in service F TEST F

3X

OPTICAL ZOOM

DIGITAL STILL

Shutter

Power Key

How to enter the test mode (TEST MODE initial screen)

Reset the user mode settings first. Download the user mode settings reset program to the SD card to create a test mode

setting card. Regarding Test Mode Setting Program("Shce0009.dat" & "Shcu0009.dat"), please refer to Service

Information. Insert this SD card for resetting the user mode settings in the camera and turn on the power while pressing

shutter. Then, "do you vertion up?; Do: Push Shutter, No: Do Not" appears on the CGS display. Next press shutter to

set the factory mode setting. (If it is not mecessary to reset the user mode setting, turn off the power and remove the

SD card.) The message changes to "vertion up start", and "version up complete" appears soon. After checking that

the power has turned on, turn it off and remove the SD card. Now restting the default settings is finished.

Version Up Complete

Do You VersionUp?

Do : Push Shutter

No : Do Not

Set the camera to the factory mode in the following procedure.

1) Turn on the power by pressing the power key with the MENU key pressed down.

2) When entering the test mode, the screen on the right(TEST MODE initial screen)

MENU Key

or key

SET key

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

0 CHANGE E2PROM

2) If the desired test item is found, press the SET key to select it.

TEST MODE initial screen

[Note]: When finishing the service works, the camera must be set USER MODE again. In order to set the camera back

to USER MODE, execute TEST 2 written as "User mode settings" on page 11.

10

VE-CG30U

VE-CG40U

5-1. Test mode specifications

5-1-1. TEST 0: EEPROM address change

[Note]: If address is selected and the data is changed during adjustment, the data of EEPROM is rewritten,

so take sufficient care for operation and never fail to take a memo of the address and the data before changing

the data.

When entering the test mode 0, the screen on the right appears.

[Operation]

1. Move the triangle mark ( ) to the digit to be changed using the or button.

Then change the address value with the or button as desired.

2. The value in the flash memory for the set address (upper line) and the initial

value (lower line) - if it has been set - are displayed under VALUE.

Example: With the initial value 0, the upper line shows FF and the lower

shows 01 at default.

3. When the address value is set, press the SET key to validate it.

( ) shifts to the value change mode.

4. As with the address value setting, change the value using the or and

or buttons.

5. When the value is set, press the SET key to validate it. ( ) shifts to the

address change mode.

6. When changing other address values, repeat from step 1.

ADDRESS

0001

VALUE

ADDRESS

0010

VALUE

ADDRESS

0100

VALUE

ADDRESS

0000

VALUE

ADDRESS

0000

VALUE

ADDRESS

0000

VALUE

ADDRESS

0000

VALUE

FF

01

0 CHANGE E2PROM

ADDRESS

0000

VALUE

FF

01

0 CHANGE E2PROM

Set the address and press

the SET key.

( ) shifts to the value

change mode.

<<When displaying the battery adjustment value>>

The battery adjustment correction value may be displayed in negative. If so, “-” is displayed in front of the value

(0000).

[Exit]

When setting is complete, perform either operation below.

• To select another test mode: Press the DELETE key to return to the TEST MODE initial screen.

• To end the test mode: Press the power key to turn off the camera.

5-1-2. TEST 1: LCD test pattern display

When entering the test mode 1, the screen below appears.

Test pattern

1: Color bar

2: BLACK

3: BLUE 10%

4: GREEN 50%

5: RED 30%

6: 50% WHITE

7: 30% WHITE

8: CROSS HATCH

9: 14 Steps Gray Scale

[Operation]

• Press the or button to switch the test

pattern. See above for available test

patterns.

• Press the DELETE key to return to the

TEST MODE initial screen.

Blue

Magenta

Cyan

White

Red Yellow

Green Gray

VE-CG30U

VE-CG40U

11

5-1-3. TEST 2: User mode settings

When finishing the service works, the camera must be set USER MODE again.

In order to set the camera back to USER MODE, execute TEST 2 as below.

Select the TEST 2 and press the SET key.

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

2 SET SHIPPING

ENTER : START

DEL : RETURN

2 SET SHIPPING

TEST MODE 2 screen After settng

[Operation]

· Press the SET key start to [User Mode settings].

· When completed, the screen below appears.

00XX

00XX

0000

0000

0000

COMPLETE

DEL RETURN

2 SET SHIPPING

· Press the power key to end the test mode.

5-1-4. TEST 3: White balance low color temp.

adjustment

Select the TEST 3 and press the SET key.

TEST 3,4,5,7,9,A and D are test modes for camera adjustment. See "5-2 Adjustment method" for detailed test

environment.

ENTER : START

DEL : RETURN

3 WB LOW TEMP

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

3 WB LOW TEMP

TEST MODE 3 screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

00XX

00XX

0000

0000

0000

COMPLETE

DEL RETURN

3 WB LOW TEMP

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

5-1-5. TEST 4: White balance high color temp.

adjustment

Select the TEST 4 and press the SET key.

ENTER : START

DEL : RETURN

4 WB HIGH TEMP

TEST MODE 4 screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

00XX

00XX

0000

0000

0000

COMPLETE

DEL RETURN

4 WB HIGH TEMP

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

4 WB HIGH TEMP

5-1-6. TEST 5: CCD pixel defect correction.

adjustment

Select the TEST 5 and press the SET key.

ENTER : START

DEL : RETURN

5 DEFECT WHT BLK

TEST MODE 5 screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

5 DEFECT WHT BLK

0XXX

0XXX

0XXX

0XXX

0XXX

COMPLETE

DEL RETURN

5 DEFECT WHT BLK

12

VE-CG30U

VE-CG40U

5-1-7. TEST 7: AF adjustment

Select the TEST 7 and press the SET key.

TEST MODE 7 screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

7 FOCUS

ENTER : START

DEL : RETURN

7 FOCUS

0XXX

0XXX

0XXX

0XXX

0XXX

COMPLETE

DEL RETURN

7 FOCUS

5-1-8. TEST 9: Shutter timing adjustment (close

side)

Select the TEST 9 and press the SET key.

TEST MODE 9 screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

9 SHUTTER CLOSE

ENTER : START

DEL : RETURN

9 SHUTTER CLOSE

0XXX

0XXX

0XXX

0XXX

0XXX

COMPLETE

DEL RETURN

9 SHUTTER CLOSE

5-1-9. TEST A: Shutter timing adjustment (open

side)

Select the TEST A and press the SET key.

TEST MODE A screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

5-1-10. TEST D: Battery adjustment (open side)

Select the TEST D and press the SET key.

TEST MODE D screen After settng

[Operation]

· Press the SET key to start adjustment.

· When completed, the screen below appears.

· To select another test mode:

Press the DELETE key to return to the TEST MODE

initial screen.

· To end the test mode:

Press the POWER key to turn off the camera.

ENTER : START

DEL : RETURN

A SHUTTER OPEN

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

A SHUTTER OPEN

0XXX

0XXX

0XXX

0XXX

0XXX

COMPLETE

DEL RETURN

A SHUTTER OPEN

TEST MODE

BOOT VER xxxxx

IPL VER xxxxx

MAIN VER xxxxx

SUB VER xxxxx

USB SNUM xxxxxxxx

D BATTERY VOLTAGE

ENTER : START

DEL : RETURN

D BATTERY VOLTAGE

00XX

00XX

0000

0000

0000

COMPLETE

DEL RETURN

D BATTRY VALTAGE

VE-CG30U

VE-CG40U

13

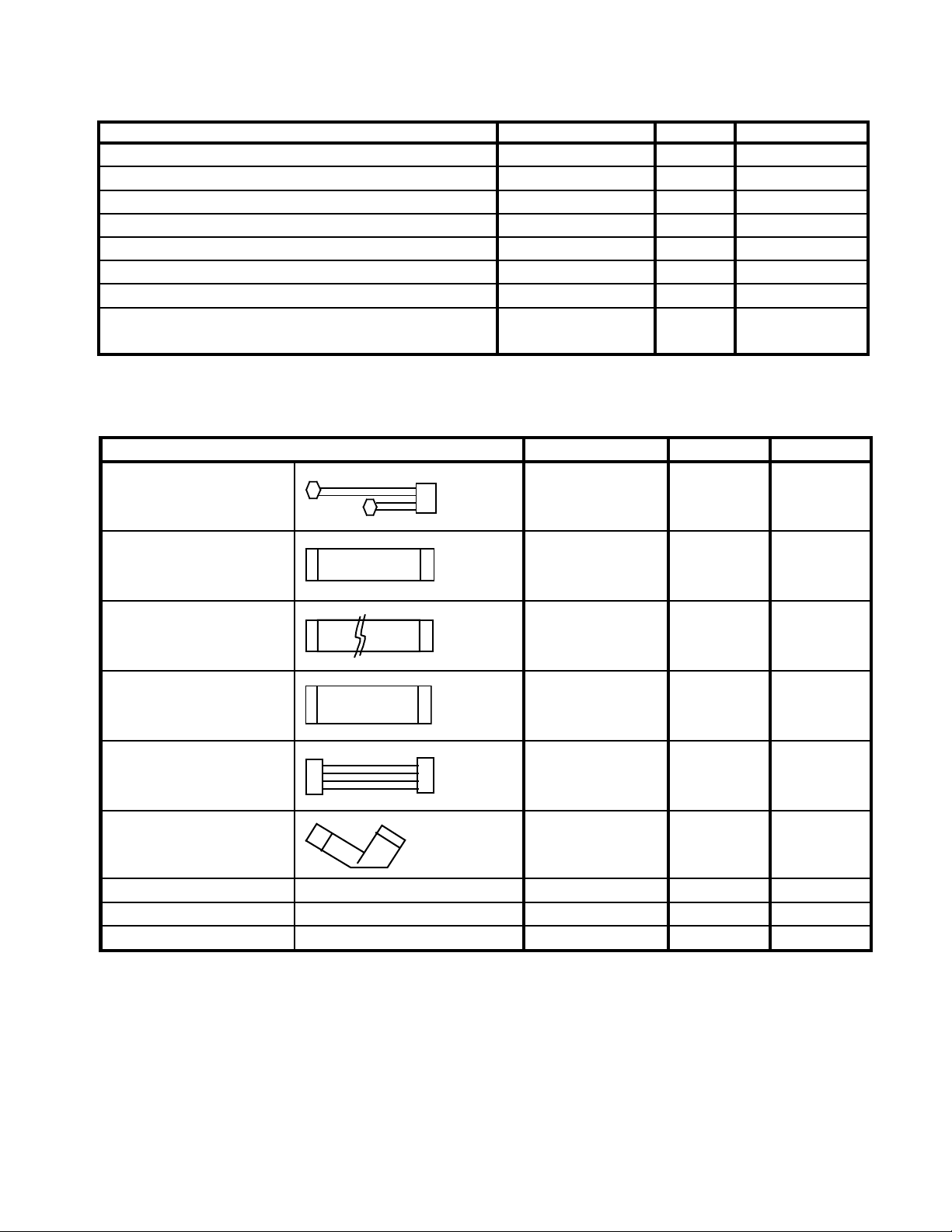

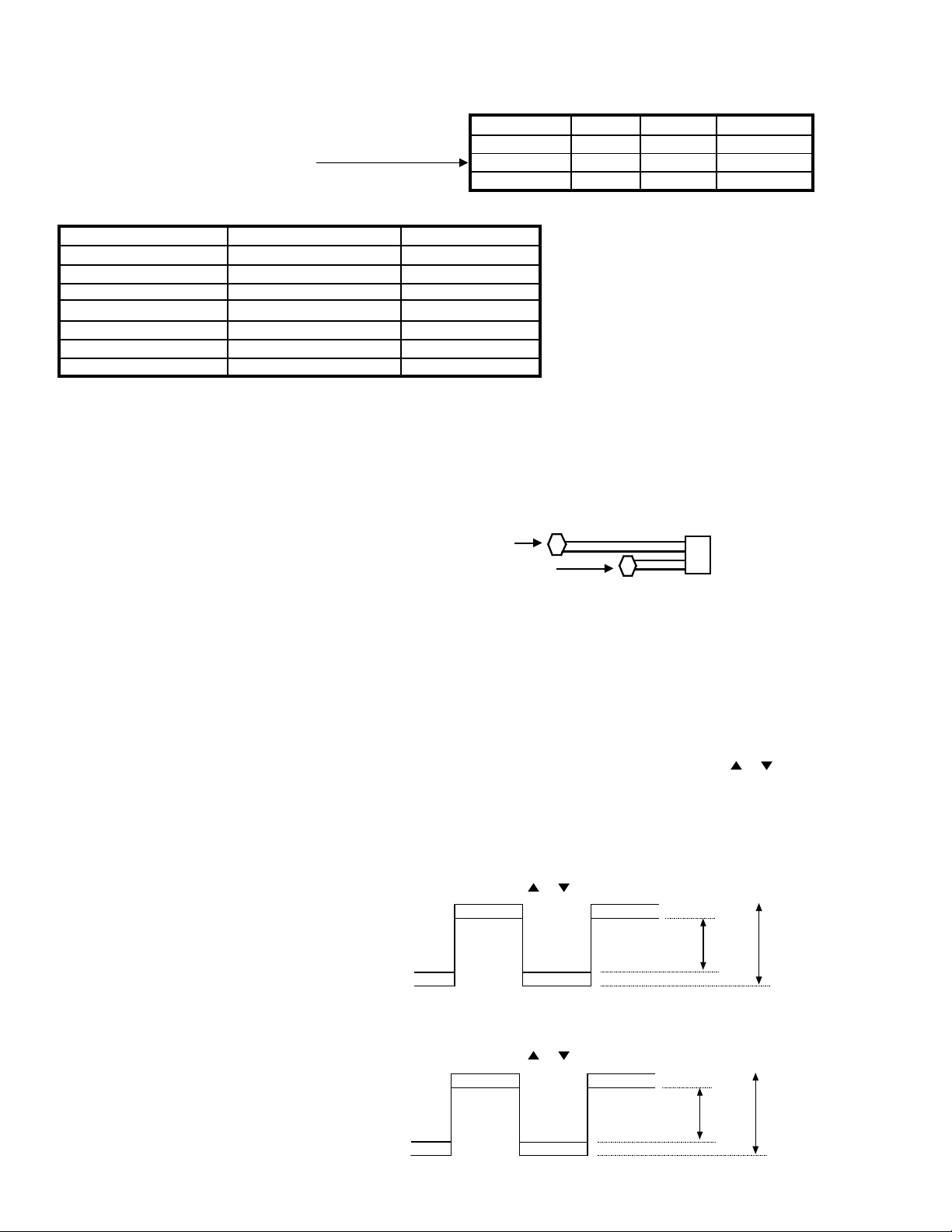

5-2. Adjustment method

<Neccesary object of shooting, measuring instrument and jigs>

Jig name Part code

Price code

Remarks

AC adapter UADP-A013WJZZ AY

2 halogen lamps Commerical item –

Gray scale chart JiGCHART-1 CP

Color Bar Chart JiGCHART-4 DA

Siemens star chart JiGCHART-11 CE

Illuminometer (0-3000 lux) JiGMETER-1 CT

Color temperature meter (1600 - 400000K) JiGMETER-3 FF

Color temperatute conversion filter (3200 - 6800K) JiGHOYA-LB165 BN

HOYA "LB-165"

<Extention Cable etc.>

Jig name Part code

Price code

Remarks

QTANZA006WJZZ AG

QCNW-A561WJZZ AB

QCNW-A563WJZZ AC

QCNW-A564WJZZ AC

QCNW-A565WJZZ AD

QCNW-A566WJZZ AC

ø3.5 A/V Cable

QCNWGA016WJZZ AH

ø3.5 Video Cable

QCNWGA017WJZZ AH

USB Cable

QCNWGA018WJPZ AL

* QCNW-A562WJZZ (P=0,5mm, FFC, 10 pin) is used for "Jack PWB - Main PWB" in production.

BATT.IN CHECK

Shutter PWB - Main PWB

P=0.5mm

FFC

8 pin

Jack PWB - Main PWB *

&

Operation PWB - Main PWB

Strobe Unit - Main PWB

Jack PWB -

Main PWB

4 pin

Wire A'ssy

LCD I/F PWB -

Main PWB

P=0.5mm

FFC

10 pin

P=0.5mm

FFC

15 pin

P=0.5mm

FFC

18 pin

14

VE-CG30U

VE-CG40U

12

Mic.

14

2

1

reverse contact

normal contact

normal contact

1

2

2 1

—

+

1: GND

2: GND

3: VCC

4: VCC

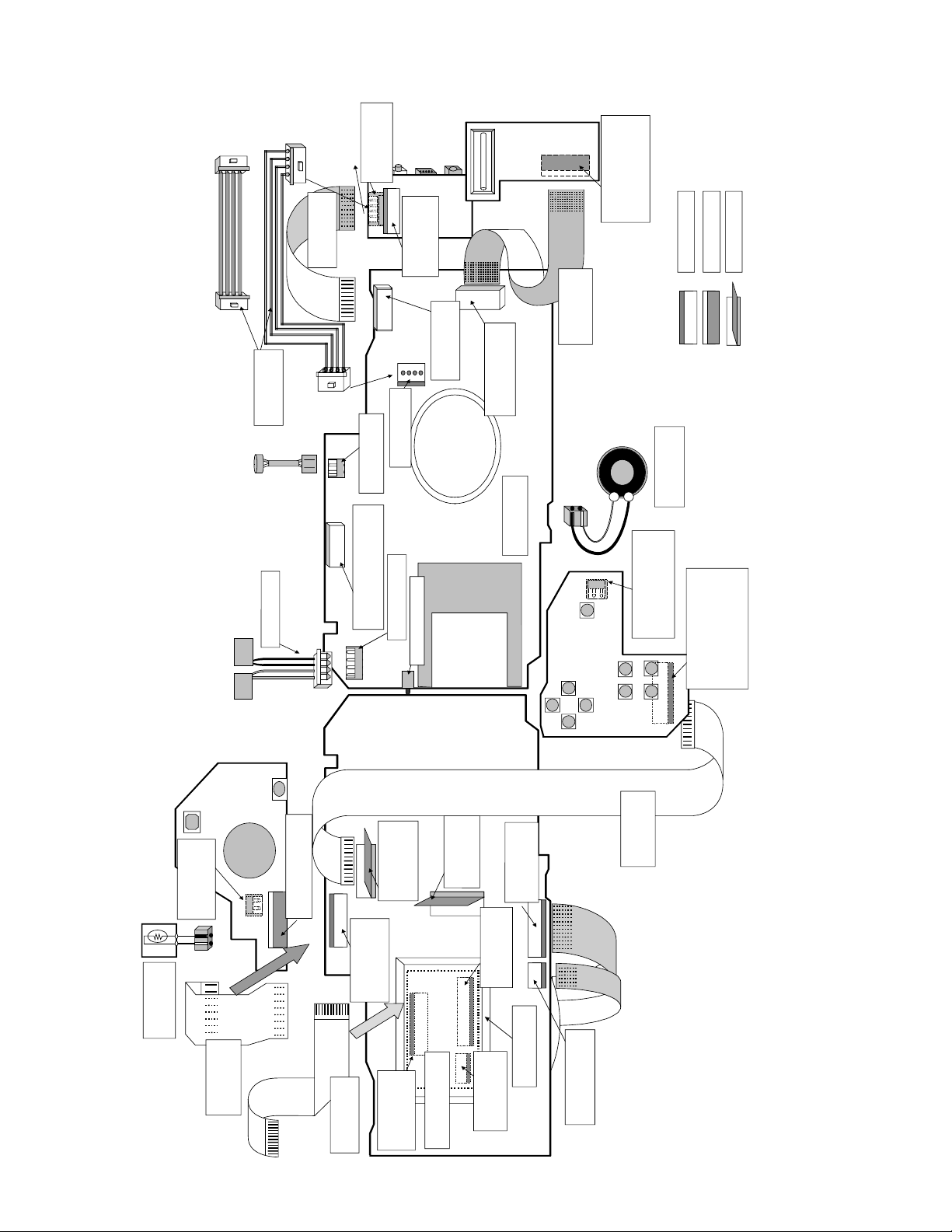

SC7201 TO:MAIN

QSOCN0871TAZZ

(normal contact)

SC702

QSOCN1098TAZZY

(normal contact)

To: Operation

SC202

QSOCN0825TAN1Y

(reverse contact)

To:TOP(Shutter)

SC702

QSOCN1898TAZZY

(normal contact)

SC1002

QSOCN0672TAZZY

(reverse contact)

CGS IF PWB

Parts are monted on the back.

SC1802

QSOCN1872TAZZY

(reverse contact)

To: MAIN

18 pin FFC

QCNW-A566WJZZ

CGS IF - MAIN

8 pin FFC

QCNW-A561WJZZ

TOP - MAIN

P7201

QPLGN0276TAZZY

1mm pitch

(mounted on the back)

SC1801

QSOCN2472TAZZY

(reverse contact)

RUNTKA028WJZZ

TEMP.DET.

SC1803

QSOCN0672TAZZY

(reverse contact)

SC1001

QSOCN1672TAZZY

(reverse contact)

SC7201

QSOCN1872TAZZ

P2902

QPLGN0463TAZZY

SC401 (JACK)

QSOCN1007REN1

NON-ZIF Type

QSW-MA001WJZZY

SC4401

QSOCN1072TAZZY

TO : MAIN

(reverse contact)

10 pin FFC

QCNW-A562WJZZ

Jack - MAIN

4 pin Wire

QCNW-A565WJZZ

Jack - MAIN

P4401

QPLGN0463TAZZY

(mounted on the back)

P1602 (MIC)

QPLGN0274TAZZY

QTANZA006WJZZ

SC701

Do not care (Factory use)

QSOCN1007REN1

NON-ZIF Type

P2901 (DC-IN)

QPLGN0458REZZY

SC1701

QSOCN1025TAN1Y

(reverse contact)

TO : MAIN

(mounted on the back)

QSOCN1571TAZZY

TO : MAIN

(normal contact)

(mounted on the back)

SC201 (SD Card)

QSOCZA035WJZZY

Speaker

VSPA016P-F18N

P1701

QPLGN0276TAZZY

1 mm pitch

(mounted on the back)

15 pin FFC

QCNW-A564WJZZ

STROBE - MAIN

SC3001 (STROBE)

QSOCN1507REN1Y

NON-ZIF Type

1: GND

2: GND

3: VCC

4: VCC

4: GND

3: GND

2: VCC

1: VCC

4: GND

3: GND

2: VCC

1: VCC

1: GND

2: GND

3: VCC

4: VCC

10 pin FFC

QCNW-A563WJZZ

OPE - MAIN

CONNECTOR LAYOUT DRAWING

VE-CG40U

VE-CG30U

VE-CG40U

15

12

14

reverse contact

normal contact

normal contact

—

+

1: GND

2: GND

3: VCC

4: VCC

SC7201 TO:MAIN

QSOCN0871TAZZ

(normal contact)

SC702

QSOCN1098TAZZY

(normal contact)

To: Operation

SC202

QSOCN0825TAN1Y

(reverse contact)

To:TOP(Shutter)

SC702

QSOCN1898TAZZY

(normal contact)

SC1002

QSOCN0672TAZZY

(reverse contact)

CGS IF PWB

Parts are monted on the back.

SC1802

QSOCN1872TAZZY

(reverse contact)

To: MAIN

18 pin FFC

QCNW-A566WJZZ

CGS IF - MAIN

8 pin FFC

QCNW-A561WJZZ

TOP - MAIN

P7201

QPLGN0276TAZZY

1mm pitch

(mounted on the back)

SC1801

QSOCN2472TAZZY

(reverse contact)

RUNTKA028WJZZ

TEMP.DET.

SC1803

QSOCN0672TAZZY

(reverse contact)

SC1001

QSOCN1672TAZZY

(reverse contact)

SC7201

QSOCN1872TAZZ

P2902

QPLGN0463TAZZY

SC401 (JACK)

QSOCN1007REN1

NON-ZIF Type

QSW-MA001WJZZY

SC4401

QSOCN1072TAZZY

TO : MAIN

(reverse contact)

10 pin FFC

QCNW-A562WJZZ

Jack - MAIN

4 pin Wire

QCNW-A565WJZZ

Jack - MAIN

P4401

QPLGN0463TAZZY

(mounted on the back)

QTANZA006WJZZ

SC701

Do not care (Factory use)

QSOCN1007REN1

NON-ZIF Type

P2901 (DC-IN)

QPLGN0458REZZY

SC1701

QSOCN1025TAN1Y

(reverse contact)

TO : MAIN

(mounted on the back)

QSOCN1571TAZZY

TO : MAIN

(normal contact)

(mounted on the back)

SC201 (SD Card)

QSOCZA035WJZZY

15 pin FFC

QCNW-A564WJZZ

STROBE - MAIN

SC3001 (STROBE)

QSOCN1507REN1Y

NON-ZIF Type

1: GND

2: GND

3: VCC

4: VCC

4: GND

3: GND

2: VCC

1: VCC

4: GND

3: GND

2: VCC

1: VCC

1: GND

2: GND

3: VCC

4: VCC

10 pin FFC

QCNW-A563WJZZ

OPE - MAIN

CONNECTOR LAYOUT DRAWING

VE-CG30U

16

VE-CG30U

VE-CG40U

5-2-1. Power circuit adjustment

Conditions

Mode dial setting: AUTO

Measuring instrument: Digital voltmeter

Adjustment jig: Dummy load is connected to

each TL.

5-2-1-1. Power line voltage check

5-2-1-2. Temperature detection function check

Connect a resistor of 680Ω between TL770 and GND and check that the power is turned off.

5-2-1-3. Battery shutoff voltage adjustment

1) Connect the BTT.IN Check jig (QTANZA006WJZZ) to the main PWB P2902.

2) Apply 3.90±0.03V between the positive (+) and negative (-) electrodes of the BATT.IN Check jig (QTANZA006WJZZ).

3) According to the procedure of 5-1, set <TEST D> and press the SET key to adjust the voltage.

Line name TL Current Resistance

LCD 12.0V TL5904 8.6mA 1.4KΩ

CAM 15.0V TL1 10.0mA 1.4KΩ

CAM -7.0V TL3 8.0mA 0.8KΩ

BATT.IN Check jig (QTANZA006WJZZ)

5-2-2. LCD circuit adjustment

Conditions

Mode: Set <TEST 0> according to the procedure of 5-1 and select the ADDRESS value which is specified in the

following adjustment items. Set E2PROM data to the value specified in the adjustment procedure. See 5-1-1.

Measuring instrument: Digital voltmeter, oscilloscope

5-2-2-1. VCO adjustment

Address: 0518 (1) Connect the digital voltmeter to TL1819.

Measuring point: TL1819 (2) Select the address 0518 and set the address. (No signal on the LCD Display)

TL1818 (GND) (3) Set the data of the DC voltage to a specified value using or key.

Adjustment specification: 1.66V±0.1V

5-2-2-2. R-W/B ADJ

Address: 0501 (1) Connect the oscilloscope to TL1837 (G-OUT)/TL1838 (R-OUT).

Measuring point: TL1837 (G-OUT) (2) Select the address 0501 and set the address. (No signal on LCD Display)

TL1838 (R-OUT) (3) Adjust the difference between peak-to-peak values of TL1837 (G-OUT)

TL1832 (GND) and TL1838 (R-OUT) using or key.

Adjustment specification: 0V±0.05V

5-2-2-3. B-W/B ADJ

Address: 0502 (1) Connect the oscilloscope to TL1837 (G-OUT)/TL1836 (B-OUT).

Measuring point: TL1837 (G-OUT) (2) Select the address 0502 and set the address. (No signal on LCD Display)

TL1836 (B-OUT) (3) Adjust the difference between peak-to-peak values of TL1837 (G-OUT)

TL1832 (GND) and TL1838 (R-OUT) using or key.

Adjustment specification: 0V±0.05V

GR

G

B

Power line name Measuring point (TL) Measured value

1.APCON 5V TL3901 5.0±0.1V

2.APCON 3.3V TL4901 3.3±0.1V

3.DPCON 3.3V TL4902 3.3±0.1V

4.DPCON 1.8V TL6901 1.8±0.1V

5.LCD 12V TP5903 12.0±0.4V

6.CAM 15V TL5901 15.0±0.5V

7.CAM -7.0V TL5902 -7.0±0.35V

Long : (-)

Short : (+)

VE-CG30U

VE-CG40U

17

5-2-2-4. Common bias DC voltage adjustment

Address: 0509 (1) Connect the digital voltmeter to TL1842.

Measuring point: TL1842 (2) Select the address 0509 and set the address.

TL1832 (GND) (Color Bar pattern appears onLCD Display)

(3) Set the data of the DC voltage to a specified value using or key.

Adjustment specification: 6.3V±0.1V

5-2-2-5. Video output level adjustment

Address: 0065 (1) Connect the oscilloscope to TL407.(Video out; 75Ω termination)

Measuring point: TL407 (2) Select the address 0065 and set the address. (No signal on LCD Display)

TL411 (GND) (3) Set the level of H-SYNC to the adjustment specified value using or key.

Adjustment specification: 0.28V±0.01Vp-p

5-2-3. Camera circuit adjustment

• Preparation before adjustment and check items

(1) Illuminate the entire pattern evenly with luminance of approx. 2000 lux(In the white chart) (2 or more light sources

are recommended). Set the color temperature to 3200K.

(2) Use a new test pattern with no soil or color degradation.

(3) If defects are found in the electric circuit, identify the defective part using the measuring instrument and repair/

replace it before adjustment.

5-2-3-1. Focus infinity adjustment

[Purpose]

Focus point in each zoom position of the lens is memorized to correct the focus tracking position when operating

the zoom lens.

[Object]

Siemens Star Chart via the collimator or an object with simple and distinct outline.

If you do not have a collimator, perform adjustment while shooting an object with distinct outline from a long

distance.

Since the lens is automatically moved from Wide to Tele during adjustment, do not put an object in front of the

camera (do not shoot an object with a distinct outline when the lens is located at Wide).

[Procedure]

• After making the settings above, set <TEST 7> according to the procedures of 5-1 and execute it.

• Auto adjustment is performed.

Each optical zoom position is set, and the focus infinity position at that time is stored in memory.

• During adjustment, <EXECUTING> and the object are displayed on the LCD monitor.

• Data is collected while changing the zoom from Wide to Tele. Do not place any obstacles in front of the camera

until the adjustment is completed.

• If <OK> appears on the LCD monitor, adjustment is completed.

5-2-3-2. Adjustment for CCD pixel defect detection

[Purpose]

To memorize and correct the CCD imager’s white balance defect in the dark and black balance defect in the

brightness.

[Object]

An evenly illuminated white object under the lighting described in “Preparation before adjustment and check

items” (a light box can be used).

[Procedure]

• After making the settings above, set <TEST 5> according to the procedures of 5-1 and execute it.

• Auto adjustment is executed.

The lens is automatically shielded from the light and white balance in the dark is corrected.

Next, the aperture of the lens is automatically opened and black balance in the brightness is corrected while

a white object is shot.

• During adjustment, <EXECUTING> and the object appear on the LCD monitor.

• If <OK> appears on the LCD monitor, adjustment is completed.

18

VE-CG30U

VE-CG40U

5-2-3-3. Mechanical shutter open aperture adjustment/CCD sensitivity adjustment

[Purpose]

• Brightness of the optical system including the CCD imager is adjusted to obtain ISO100.

• Operation time in the open state of the mechanical shutter aperture is memorized and the variation of exposing time

is removed.

[Object]

• An evenly illuminated white object under the lighting described in “Preparation before adjustment and check

items”.

[Procedures]

• After making the settings above, set <TEST 9> according to the procedures of 5-1 and execute it.

• Auto adjustment is executed.

• During adjustment, <EXECUTING> and the object are displayed on the LCD monitor.

• If <OK> appears on the LCD monitor, adjustment is completed.

• With <TEST 9>, the mechanical shutter opening adjustment and the CCD sensitivity adjustment are executed.

5-2-3-4. Mechanical shutter closed aperture adjustment

[Purpose]

• Operation time in the closed state of the mechanical shutter aperture is memorized and the variation of

exposing time is removed.

[Object]

• An evenly illuminated white object under the lighting described in “Preparation before adjustment and check

items”.

[Procedures]

• After making the settings above, set <TEST A> according to the procedures of 5-1 and execute it.

• Auto adjustment is executed.

• During adjustment, <EXECUTING> and the object are displayed on the LCD monitor.

• If <OK> appears on the LCD monitor, adjustment is completed.

5-2-3-5. WB low color temperature adjustment

[Purpose]

• The variation of CCD spectral characteristic (R, G, B) at low color temperature (3200K) is removed.

[Object]

• An evenly illuminated white object under the lighting described in “Preparation before adjustment and check

items”.

[Procedure]

• After making the settings above, set <TEST 3> according to the procedures of 5-1 and execute it.

• Auto adjustment is executed.

• During adjustment, <EXECUTING> and the object appear on the LCD monitor.

• If <OK> appears on the LCD monitor, adjustment is completed.

5-2-3-6. WB high color temperature adjustment

[Purpose]

• The variation of CCD spectral characteristic (R, G, B) at high color temperature (outside light, etc.) is removed.

[Object]

• An evenly illuminated white object under the lighting described in “Preparation before adjustment and check

items”.

• Mount the color temperature conversion filter LB165 in front of the lens.

[Procedure]

• After making the settings above, set <TEST 4> according to the procedures of 5-1 and execute it.

• Auto adjustment is executed.

• During adjustment, <EXECUTING> and the object appear on the LCD monitor.

• If <OK> appears on the LCD monitor, adjustment is completed.

VE-CG30U

VE-CG40U

19

6.TROUBLESHOOTING

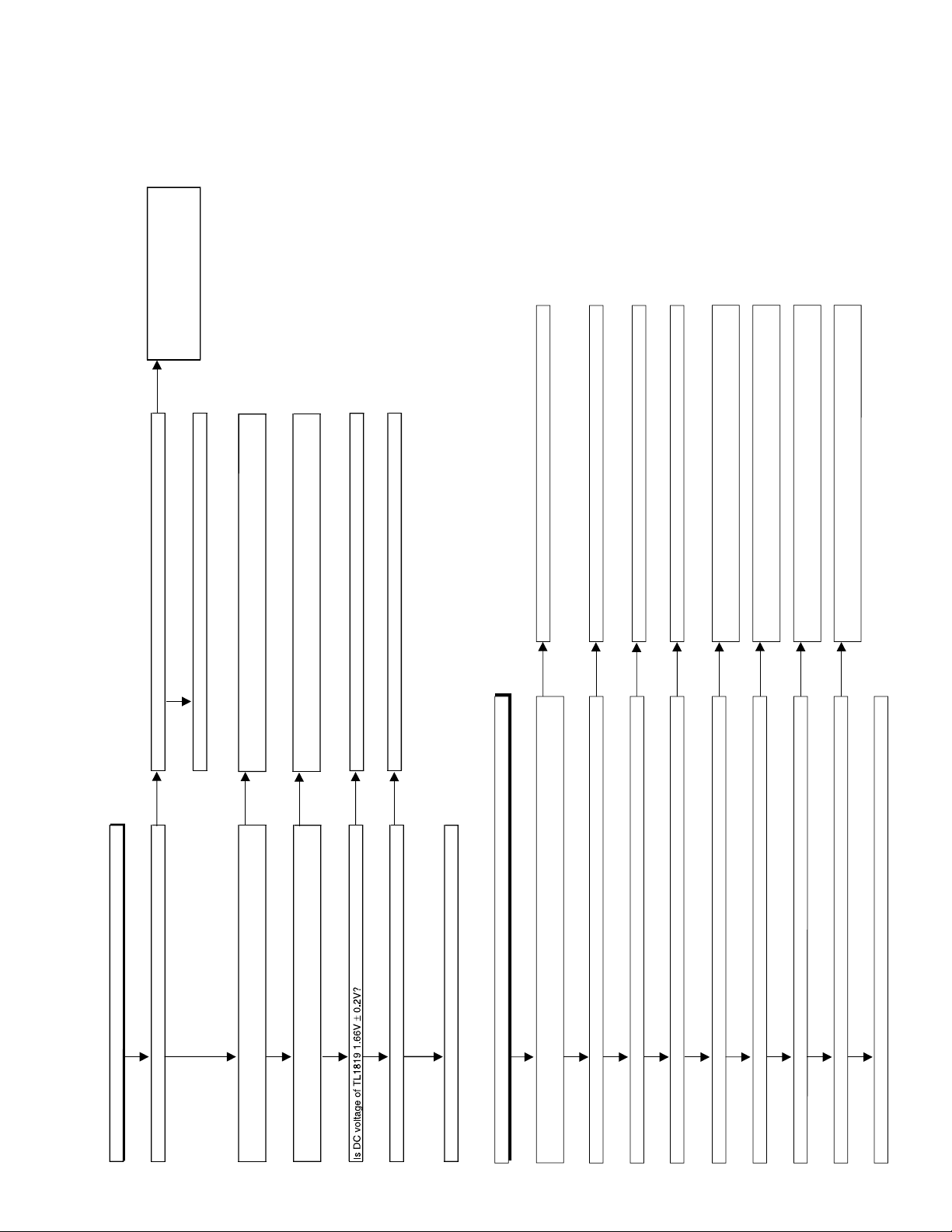

Power circuit troubleshooting

Power does not turn on.

Yes

Battery input

Check battery, battery terminals,

F2902, FB2901, FB2902, IC2901,

and R2901 - 2904.

Which is used, battery or DC input? When using DC input, does power turn on with battery?

DC input

Yes

Check AC adapter, DC jack,

FFC connection bet. JACK

PWB and MAIN (improper

insertion), F2901, and D2902.

When using battery, does power turn on with DC input?

No

No

Yes

Is P-CON-H sent to IC1901 6PIN?

Is 3.3V applied to TL7901?

Check soldering of IC702 33PIN and

IC1901 6PIN.

Check R1926.

Yes

Yes

No

Is triangular wave delivered to IC1901 7PIN even

for a moment?

Check IC1901 8PIN and

9PIN soldering, R1906, and

C1902.

No

Yes

Is pulse delivered to IC702 40PIN?

Check IC7901, C7901, and C7902.

No

Is voltage applied to D3901 cathode?

Check D3901, L3901, and

Q3901.

Yes

Yes

No

No

When Power SW is pressed, IC702 (43) pin falls

to "L".

Check IC702 40PIN and 41PIN, and

FL701.

Is 1.8V applied to TL6901 even for a moment?

Check Q6901, L6901, and

L6902.

Yes

No

No TOP PWB: Check power SW, connector and

harness.

MAIN: Check SC202 and R706.

Is 3.5V applied to both ends of C4902 even for a

moment?

Check Q4901 and L4901.

Yes

Yes

No

Check IC4902, R4904, and

and IC702 34PIN.

Is 3.3V applied to TL4902 even for a moment? Failure inside IC702.

Yes

No

Is voltage (NONREG) applied to T5901 3PIN and

4PIN?

Check Q5901 and R5901.

Yes

No

Check T5901, D5902, C5904,

D5901, C5903, L5901,

C5911, L5902, and C5907.

Is 15V applied to both ends of C5904?

Yes

Though voltage is applied to all power lines, power

does not turn on (LED and LCD are not lit).

No

Check power lines again.

Yes

FL201 or IC204(ASIC) failure.

Is voltage (3V) applied to IC702 33PIN(P-CON-H) ?

No

20

VE-CG30U

VE-CG40U

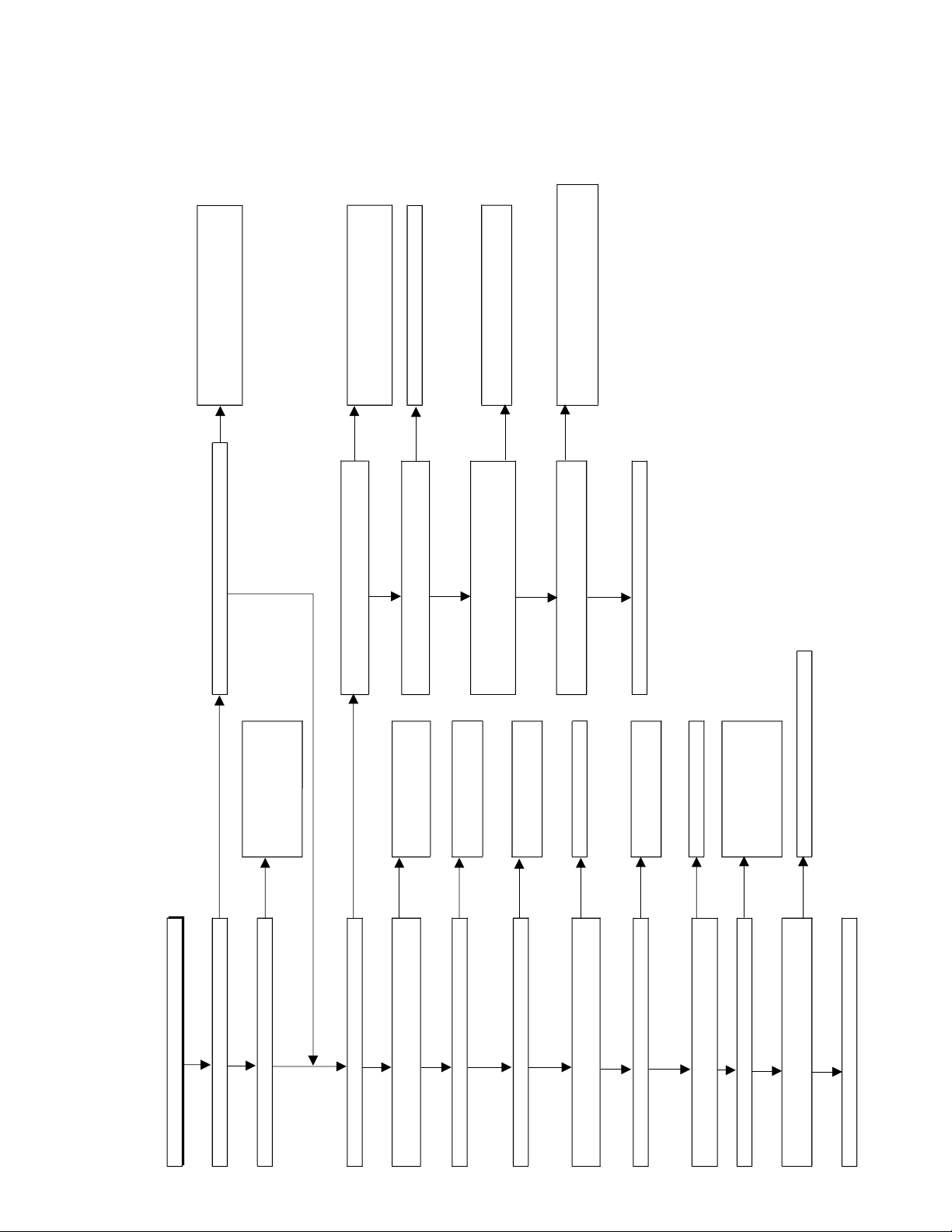

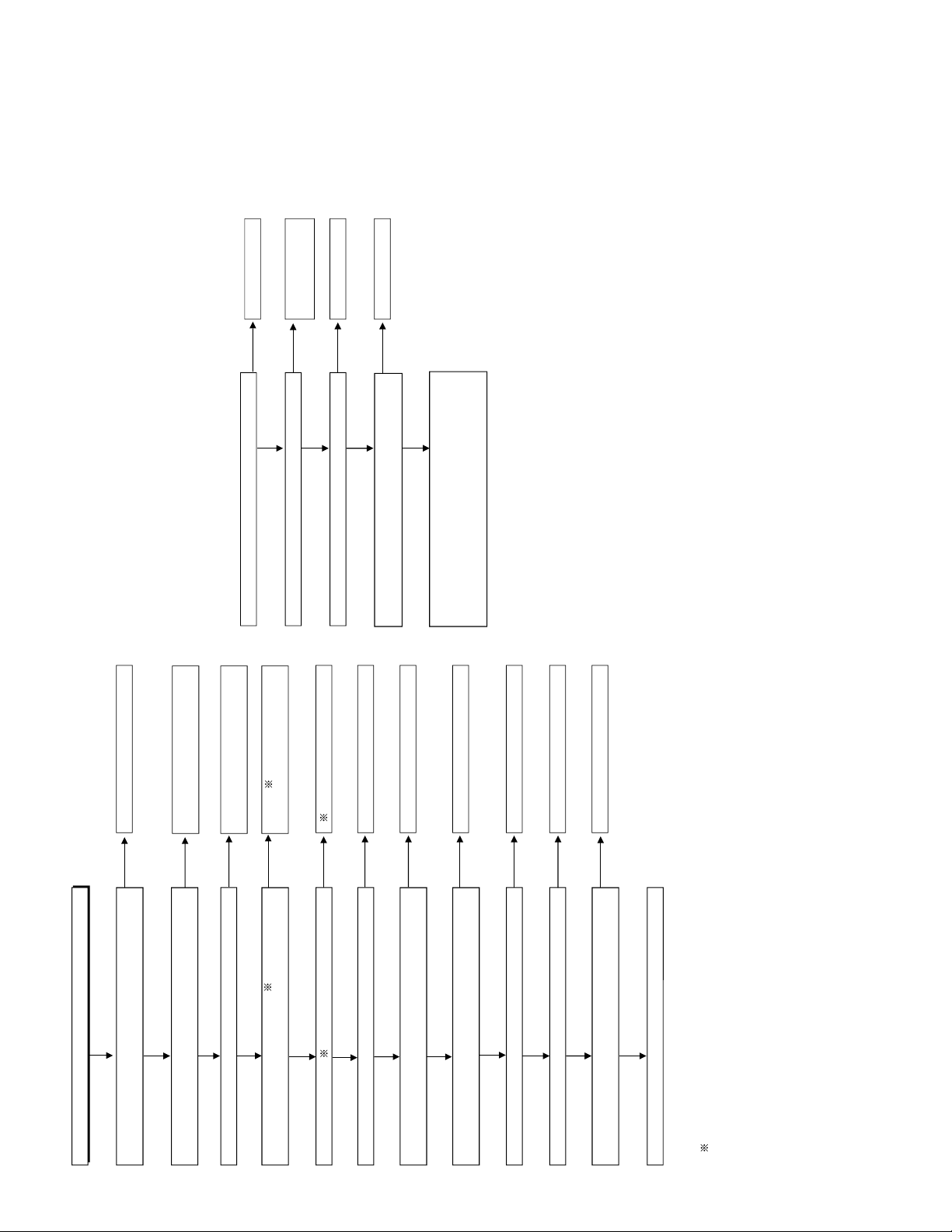

Camera troubleshooting

No

Yes

No

Check IC2 (in the checkable range since it is CSP).

Yes

No

No

Yes

Yes

No

No

Yes

Yes

No

No

Yes

Yes

No

No

Yes

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

Set mode SW to AUTO or MOV.

Is power voltage of CAM_5V, CAM_3.3V,

CAM_15V, and CAM_-7V normal?

Is LCD monitor normal?

Is OSD delivered?

Refer to LCD troubleshooting.

Refer to power troubleshooting.

Is pulse signal sent to TL4-TL13 of

IC1, 15V to TL1,

and -7V to TL3?

Check IC1 peripheral circuit

and IC2.

Is X1 oscillating?

Check IC4 and its peripheral

circuit.

Is signal delivered o

IC1 (20) pin (TL14)?

IC1 failure

Is signal sent to IC3 (30) pin?

Check Q2 and C26.

Is power [3.3V] of (13)(18)(24)(27)(33)(34)(40) of IC3

normal?

Check L4 and L5.

Is pulse signal sent to (16)(19)(20)(21)(22)(23) pins of

IC3?

Check IC2.

Is pulse signal sent to IC3 (46)(47)(48) pin?

Check IC204.

Check periphery of IC204.

Does IC204 operate normally?

Is video composite signal sent from (23) pin?

IC1 corresponds to the part 103 of the Camera Exploded View on page 82.

Are 10-bit signals (3) - (12) of IC3 sent?

IC3 failure

Check IC401 and its peripheral circuit.

L3 failure.

Is power supplied to L3[3.3V] ?

Is clock delivered from R15[CCDCLK]?

Check IC4 peripheral

circuit.

Is pulse delivered to R36[HD], R38[VD]?

Check IC204.

Is serial transfer pulse delivered to R33, R34, and

R35?

Check IC204.

Check whether pulse is delivered from each output

terminal of IC2. If there are terminals which do not

emit it, solder unwetting or IC failure.

VE-CG30U

VE-CG40U

21

LCD PWB troubleshooting

Image is not displayed on LCD normally.

No

Is backlight lit? Is 12V applied to TL1801?

Yes

Is voltage of 12V and 3.3V applied to TL1807 and TL1806, respectively?

No

Backlight of LCD unit is defective.

Yes

No

Is RGB signal sent to TL1815, TL1816 and TL1817?

Is CSYNC signal sent to TL1813?

Refer to "Power circuit troubleshooting".

Check FFC between MAIN PWB and LCD PWB.

No

No

Check peripheral circuit of L1802.

Check IC1801 27PIN to 32PIN.

Check SC801 on MAIN PWB and its peripheral circuit.

Check FFC between MAIN PWB and LCD PWB.

Check FFC between MAIN PWB

and LCD PWB.

Check IC8901 on MAIN PWB and its

peripheral circuit.

Yes

Yes

Yes

Is LCD-RGB signal sent to TL1836, TL1837 and TL1838?

Yes

LCD unit is defective. Replace

No

Sound playback system troubleshooting, when audio signal is not sent from line out (CG40 only)

Insert SD card recording sound into the set, and play back file in playback mode.

No

Is 3.3V applied to both ends of L1602, L1603 and L1605?

Is 5V applied to both ends of L1604?

Refer to "Power circuit troubleshooting".

Yes

No

Check peripheral circuit of IC1604 and FL1601.

Yes

No

Are IC1602 13PIN and 14PIN set to "H"?

Is 4.096MHz sent to R1637?

Check IC702 48PIN and 49PIN and its peripheral circuit.

Yes

Is pulse sent to IC1602 9PIN?

No

Yes

No

Is audio signal sent to IC1603 15PIN?

Check peripheral circuit of IC1602 15PIN.

Check peripheral circuit of IC1603 15PIN.

Yes

No

Is audio signal sent to IC1603 13PIN?

Check peripheral circuit of IC1603 13PIN and 14PIN.

IC1603 1PIN: "H" at audio output

Yes

No

Is audio signal sent from IC1603 12PIN?

Check peripheral circuit of IC1603 12PIN.

IC1603 1PIN: "H" at audio output

Yes

Is audio signal sent to TL4406 on JACK PWB?

Check periphery of IC1602 and peripheral circuit of IC204.

Yes

Video/Audio cable is defective.

No

Check FFC between JACK PWB and MAIN PWB.

Check peripheral circuit of J4403.

Loading...

Loading...