Schneider Electric TAC I/A Series Operation Manual

TAC I/A Series MicroNet BACnet

Smoke-Control Systems Manual

TAC I/A Series MicroNet BACnet

Smoke-Control Systems Manual

Printed in U.S.A. 9-10 F-27419-2

On October 1st, 2009, TAC became the Buildings Business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric,

howev

er there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corporate brand changes.

All brand names, trademarks and registered trademarks are the property of their respective owners. Information contained within this document is subject to change

without notice.

Schneider Electric

F-27419-2 September 2010 ptm

© 2010 Schneider Electric. All rights reserved.

Table of Contents

Preface

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Abbreviations Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Manual Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Chapter 1 Introduction

What is the UL 864 UUKL/UUKL7 Listing? . . . . . . . . . . . . . . . . . . . . .1-1

What Was Required to Gain the UL 864 UUKL/UUKL7 Listing? . . . . . 1-2

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What are Your UL 864 UUKL/UUKL7 Responsibilities? . . . . . . . . . . . . 1-3

Explanation of Smoke-Control Systems . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Building Pressurization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Dedicated and Nondedicated Systems . . . . . . . . . . . . . . . . . . . . . .1-4

Basic System Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Shaft Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

HVAC Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Smoke-Control System Activation . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Firefighter’s Smoke Control Station . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Control Sequence for Stair Pressurization Systems . . . . . . . . . . . .1-9

Control Sequence for Zoned Smoke-Control Systems . . . . . . . . . .1-9

Automatic Response To Multiple Signals . . . . . . . . . . . . . . . . . . . .1-10

Maintaining System Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Smoke-Control System Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

I/A Series MicroNet BACnet Smoke Control Manual iii

Table of Contents

Chapter 2 High-rise Smoke Control

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Normal HVAC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Smoke Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Smoke-Control System Configuration Schedule . . . . . . . . . . . . . . . . 2-20

Firefighter’s Smoke Control Station (FSCS) . . . . . . . . . . . . . . . . . . . 2-22

Location and Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Physical Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Audible Annunciation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Control Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Additional Control Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

System Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

MNB-1000 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Ethernet/IP Infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Central System Interface and Overlay Devices . . . . . . . . . . . . 2-26

MNB-Vx Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

MS/TP Bus Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

MNB-1000 Interface to FSCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Fire Alarm Panel Interface and Remaining System Topology . . . 2-32

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Chapter 3 Warehouse Smoke Control

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Normal HVAC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Smoke Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Smoke-Control System Configuration Schedule . . . . . . . . . . . . . . . . 3-39

Firefighter’s Smoke Control Station (FSCS) . . . . . . . . . . . . . . . . . . . 3-40

System Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Warehouse Building Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Ethernet/IP Infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Central System Interface and Overlay Devices . . . . . . . . . . . . 3-41

MNB-1000 Interface to FSCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Fire Alarm Panel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Chapter 4 Campus Smoke Control

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Normal HVAC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Smoke Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

iv I/A Series MicroNet BACnet Smoke Control Manual

Smoke-Control System Configuration Schedule . . . . . . . . . . . . . . . .4-53

Firefighter’s Smoke Control Station (FSCS) . . . . . . . . . . . . . . . . . . . .4-55

System Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Campus Topology with MNB-1000 Controllers . . . . . . . . . . . . . . . 4-55

Ethernet/IP Infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

Central System Interface and Overlay Devices . . . . . . . . . . . . . . .4-56

MNB-V2 Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

MS/TP Bus Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-59

MNB-1000 Interface to FSCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

Fire Alarm Panel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

Chapter 5 Restrictions and General Comments

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-65

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65

Software Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-65

System Overrides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

Approved Fire Alarm Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

Approved Firefighter’s Smoke Control Stations . . . . . . . . . . . . . . .5-67

Approved IP/Ethernet Infrastructure Devices . . . . . . . . . . . . . . . . . 5-71

Approved MS/TP Repeaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Use of MNB-1000 IP Switch Feature . . . . . . . . . . . . . . . . . . . . . . . 5-74

Dedicated Supply Air Dampers . . . . . . . . . . . . . . . . . . . . . . . . . . .5-74

Class 2 Powered Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

EIA-485 Termination and Bias Resistors . . . . . . . . . . . . . . . . . . . .5-75

System Self-Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-75

Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-76

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-77

Hardware and Firmware Upgrade Process Requirements . . . . . . .5-78

UL-1459 (Abnormal Overvoltage) Compliance . . . . . . . . . . . . . . .5-78

General Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-78

FSCS Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-78

MNB-1000 Using ADI ModBus Interface . . . . . . . . . . . . . . . . . . . .5-78

Job Estimating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-78

Spare I/O Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-80

Lost Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-80

Use of BACnet Priority Structures . . . . . . . . . . . . . . . . . . . . . . . . .5-83

Use of Transient Suppressor on MNB-300 DO . . . . . . . . . . . . . . .5-84

Multiple MNB-V1/-V2 Controllers for Pressure Summation . . . . . .5-85

VAV Zone Pressure or Position Indication . . . . . . . . . . . . . . . . . . .5-85

I/A Series BACnet Applications . . . . . . . . . . . . . . . . . . . . . . . . . . .5-85

Table of Contents

I/A Series MicroNet BACnet Smoke Control Manual v

Table of Contents

Appendix A Additional Information

MicroNet BACnet Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Common Controller Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

MNB-300 Unitary Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

MNB-V1, MNB-V2 VAV Controllers . . . . . . . . . . . . . . . . . . . . . . . . A-4

MNB-1000 Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Input and Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Universal Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Universal Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Digital Outputs, Triac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

20 Vdc Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Inputs from MN-Sx MicroNet Sensor . . . . . . . . . . . . . . . . . . . . A-12

Velocity Pressure Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Communication Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Intermixing of Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Sensor Link (S-Link) Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

MicroNet MS/TP Network Wiring . . . . . . . . . . . . . . . . . . . . . . . A-15

ADI Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Ethernet Network Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

MicroNet MS/TP Network Wiring . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Approved Cable Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Signaling Line Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

ADI Wiring Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Intermixing of Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Universal Inputs (UI), Universal Outputs (UO), and Digital Inputs (DI)

A-19

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

Appendix B Approved Part Numbers

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Final Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Third Party UUKL Listed Products . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Appendix C Applicable Documentation

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

vi I/A Series MicroNet BACnet Smoke Control Manual

Table of Contents

Appendix D

References

Other Reference Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

I/A Series MicroNet BACnet Smoke Control Manual vii

Table of Contents

viii I/A Series MicroNet BACnet Smoke Control Manual

Preface

Preface

Purpose of this Manual

This manual is intended for use by qualified, authorized engineers and

technicians who are responsible for meeting a UL 864 UUKL/UUKL7 project

specification. The specification, created by the smoke-control system designer,

should have already considered the selected mechanical equipment design.

Proper duct sizing and layout, motor/blower selection, and damper selection must

be completed by the smoke-control system designer to provide the planned

smoke-control pressurization under all possible expected environmental (wind,

weather, etc.) and building (door, elevator hoistway, leakage, system response,

stairwell, occupied mode, etc.) conditions.

Note:

• UUKL7, which is referred to throughout this manual, is the Category Code

Number (CCN) for smoke-control system equipment certified for use in

Canada.

• Throughout this manual, all references to UUKL are intended to refer to

UUKL7 also (i.e. UUKL/UUKL7).

• Throughout this manual, all references to the MNB-V1 equally apply to the

MNB-V1-2 and all references to the MNB-V2 equally apply to the MNB-V2-2.

This manual’s purpose is to provide the fundamentals for the controls engineer

and technicians to meet a properly designed smoke-control specification. General

topologies, specific requirements, and exceptions to our published literature that

are required by Underwriters Laboratories, Inc. for UL 864 UUKL/UUKL7 are

provided. This manual does not provide guidelines for mechanical system

selection and design. Recognized smoke pressurization program models are

available for this purpose.This manual also does not cover all installation and

wiring requirements for TAC I/A Series

be used along with the I/A Series MicroNet BACnet Wiring, Networking, and Best

Practices Guide, F-27360, and applicable I/A Series BACnet controller installation

instructions.

®

MicroNet™ BACnet™ controllers. It must

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual ix

Abbreviations Used in this Manual

ADA Americans for Disabilities Act

ADI Automation Displays, Inc.

AHJ Authority Having Jurisdiction

AHU Air Handling Unit

AI Analog Input

CCN Category Code Number (UL)

CFM Cubic Feet per Minute

DI Digital Input

DO Digital Output

EOL End of Line (Termination)

EOL JPR End-of-Line Jumper (EOL resistor and/or bias

resistor engaged through on-board jumper)

FAP Fire Alarm Panel

FSCS Firefighter’s Smoke Control Station

HVAC Heating-Ventilating-Air Conditioning

I/O Input/Output

IP Internet Protocol

ITE Information Technology Equipment

JPR Jumper

LAN Local Area Network

LED Light Emitting Diode

NEC National Electrical Code

NFPA National Fire Protection Association

N.O. Normally Open

NW Network

O.A. Outside Air

UI Universal Input

UL Underwriters Laboratories, Inc.

VAV Variable Air Volume

WP Tech WorkPlace Tech Tool

x TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

Definitions BACnet

The following are definitions of terms related to BACnet.

Instance A device’s instance number, also known as its

Smoke Control

The following definitions of terms related to smoke control are found in

NFPA 92A, Recommended Practice for Smoke-Control Systems.

Area of Refuge An area of the building separated from other

Preface

BACnet Device Object Identifier.

spaces by fire-rated smoke barriers in which a

tenable environment is maintained for the

period of time that such areas may need to be

occupied at time of fire.

Authority Having

Jurisdiction

End Process Verification A method that provides positive confirmation

Firefighter’s Smoke

Control Station

Positive/Negative

Pressurization

Smoke Barrier A continuous membrane, either vertical or

The organization, office, or individual

responsible for approving equipment,

materials, an installation, or a procedure.

that the desired result (i.e.airflow, damper

position, etc.) has been achieved when a

controlled device has been activated, such as

during smoke control, testing, or manual

override operations, where failure or cessation

of such positive confirmation results in an

off-normal indication.

A system that provides graphical monitoring

and manual overriding capability over

smoke-control systems and equipment at

designated location(s) within the building for

the use of the fire department.

The desired pressure difference between the

protected space and an adjacent space

measured at the boundary of the protected

space under a specified set of conditions with

the smoke-control system operating.

horizontal, such as a wall, floor, or ceiling

assembly, that is designed and constructed to

restrict the movement of smoke.

Smoke Control Mode A predefined operational configuration of a

system or device for the purpose of smoke

control.

Smoke-Control System An engineered system that uses mechanical

fans to produce pressure differences across

smoke barriers to inhibit smoke movement.

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual xi

Smoke Control Zone A space within a building enclosed by smoke

barriers, including the top and bottom, that is

part of a zoned smoke-control system.

Smoke Exhaust System A mechanical or gravity system intended to

move smoke from the smoke zone to the

exterior of the building, including smoke

removal, purging, and venting systems, as

well as the function of exhaust fans utilized to

reduce the pressure in a smoke zone.

Smoke Zone The smoke-control zone in which the fire is

located.

Applicable Standards

Stairwell Pressurization

System

Tenable Environment An environment in which smoke and heat is

Zoned Smoke-Control

System

This manual should be used in conjunction with the following standards

which apply to the Schneider Electric UL 864, 9th ed. Listing.

Underwriters Laboratories (UL) Standards

A type of smoke-control system in which stair

shafts are mechanically pressurizaed, with

respect to the fire area, with outdoor air to

keep smoke from contaminating them during a

fire event.

limited or otherwise restricted to maintain the

impact on occupants to a level that is not life

threatening.

A smoke-control system that includes smoke

exhaust for the smoke zone and

pressurization for all contiguous

smoke-control zones.

• UL 864, 9th ed. (2003) Control Units for Fire Protective Signaling

Systems

• UUKL Smoke-Control System Equipment (Category under UL 864)

• CAN/ULC-S527-99 Standard For Control Units For Fire Alarm Systems

• ULC/ORD-C100-92 Smoke Control System Equipment

• UUKL7 Category for Smoke-Control System Equipment Certified for

Use in Canada

National Fire Protection Association (NFPA) Standards

• NFPA 70 National Electrical Code

• NFPA 72 National Fire Alarm Code, 2007 Edition

This standard covers the application, installation, performance, and

maintenance of protective signaling systems and their components.

• NFPA 92A Standard for Smoke-Control Systems Utilizing Barriers and

Pressure Differences, 2009 Edition

This standard covers the design, installation, testing, operation, and

maintenance of new and retrofitted mechanical air conditioning and ven-

xii TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

Preface

tilation systems for the purpose of controlling smoke.

• NFPA 92B Standard for Smoke Management Systems in Malls, Atria,

and Large Areas, 2005 Edition

This standard provides technical data relevant to the design, installation,

testing, operation, and maintenance of new and retrofitted smoke management systems. It is intended for buildings having large volume

spaces, for the management of smoke within the space where the fire

exists, or between spaces not separated by smoke barriers.

Other Standards

• Canadian Electrical Code, Part 1

Conventions Used in this Manual

The following conventions apply to this printed manual:

• Menu commands appear in bold.

Example — On the Special menu, point to Security, then click Log On.

• Italics is used for emphasis in a statement, such as:

If maximum closed switch voltage is not more than 1.0 V and minimum

open switch voltage is at least 4.5 V, then solid state switches may be

used for a UI or a DI.

It is also used when referring to a document, such as:

Refer to the WorkPlace Tech Tool 5.x Engineering Guide Supplement,

F-27356.

Acrobat (PDF) Conventions

If you are reading this manual online in Adobe

numerous hypertext links exist, both in normal black text and in blue text.

®

Acrobat® (.PDF file format),

• Hypertext links in this document include all entries in the Table of

Contents, as well as cross-references within the body text. For ease of recognition, cross-reference links within the body text appear in blue type, for example Manual Summary. A link is indicated whenever the mouse pointer changes to a hand with a pointing finger.

• When viewing this guide with Adobe Acrobat, you can display various

“bookmark” links on the left side of your screen by choosing “Bookmarks

and Page” from the “View” menu. As with the links described above,

these “bookmark” links will also cause the mouse pointer to change to a

hand with a pointing finger.

Manual Summary This manual contains five chapters and two appendices.

Chapter 1 - Introduction

This chapter explains the UL 864 UUKL/UUKL7 Listing and defines various

terms related to Smoke-Control Systems.

Chapter 2 - High-rise Smoke Control

This chapter provides application guidelines for using I/A Series MicroNet

BACnet controllers in a five-floor, high-rise office building that requires the

UL 864 UUKL/UUKL7 Listing for Smoke-Control Systems.

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual xiii

Chapter 3- Warehouse Smoke Control

This chapter provides application guidelines for using I/A Series MicroNet

BACnet controllers in a single-story warehouse building that requires the

UL 864 UUKL/UUKL7 Listing for Smoke-Control Systems.

Chapter 4 - Campus Smoke Control

This chapter provides application guidelines for using I/A Series MicroNet

BACnet controllers in a large campus with multiple buildings that require the

UL 864 UUKL/UUKL7 Listing for Smoke-Control Systems.

Chapter 5 - Restrictions and General Comments

This chapter lists any restrictions associated with the application of

I/A Series MicroNet BACnet controllers to UL 864 UUKL/UUKL7

Smoke-Control Systems. This chapter also includes general comments that

may provide additional insight or flexibility during the engineering process.

Appendix A - Additional Information

Appendix A presents additional information related to the wiring of an

I/A Series MicroNet BACnet Smoke-Control System.

Appendix B - Approved Part Numbers

Appendix B lists the part numbers of all I/A Series MicroNet BACnet

equipment that have been UL 864 UUKL/UUKL7 listed.

Appendix C - Applicable Documentation

Appendix C lists, by F-number, applicable documentation that is required to

install, apply, engineer, operate, and troubleshoot I/A Series MicroNet

BACnet and related equipment.

Appendix D - References

Appendix D lists additional reference documents that are relevant to the

design of Smoke-Control Systems.

xiv TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

Chapter 1

Introduction

Schneider Electric has worked with Underwriters Laboratories, Inc. to gain

the UL 864 UUKL/UUKL7 listing. This UL listing involves testing both

hardware and software for reliability by Underwriters Laboratories, Inc. as it

pertains to this standard and sub-category.

What is the UL 864 UUKL/UUKL7 Listing?

According to Underwriters Laboratories, the UL 864 UUKL/UUKL7 is a

category that has been established for Smoke-Control System Equipment.

“The products covered by this category are intended to be installed in

conjunction with heating-ventilating-air conditioning (HVAC) equipment to

form a system for controlling the flow of smoke in a building during a fire

condition in accordance with Smoke-Control Systems, NFPA 92A or 92B.”

Additionally, according to Underwriters Laboratories (UL), smoke-control

equipment is assigned one or more of the following attributes:

Note: Schneider Electric is listed for all of the following UUKL attributes.

1

1. Operation

Manual—Activation of the smoke-control system occurs as a result of

the intervention of an authorized person.

Automatic—Activation of the smoke-control system occurs as a result of

an alarm condition from a fire detection device, such as a smoke detector or heat detector, or fire alarm control unit.

2. Type

Nondedicated—A system which provides the building HVAC function

under normal conditions and provides a smoke-control objective during

a fire alarm condition.

Dedicated—A system which is normally inactive and is used exclusively

for the purpose of smoke control.

3. Use

Stairwell—Configuration of equipment which provides pressurizing of

stairwells for the purpose of maintaining a tenable environment for building egress.

1. Underwriters Laboratories, Heating, Cooling, Ventilating, Cooking and Food Safety

Equipment Directory 2006.

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 1

Chapter 1

Zoned Smoke Control—A configuration which provides the exhausting of the

smoke area and pressurizing all of the other contiguous areas of the build-

2

ing.”

The design of an overall smoke-control system is a complete system engineered

to the particular installation. The interconnection of the smoke-control equipment

to the HVAC equipment, and to other system equipment, is intended to be in

accordance with a specific installation diagram that is generated by either the

smoke-control equipment listee or by another responsible party.

In practice, Schneider Electric, as a UL Smoke Control Equipment Listee, and its

associated field offices do not design the smoke-control system. Rather, the

Schneider Electric field office works closely with the smoke-control system

designer to develop the interface between the controls and equipment supplied by

Schneider Electric and the mechanical equipment that provides smoke-control

pressurization. The Schneider Electric field office then generates the control

system installation diagrams based on the total smoke-control system design.

What Was Required to Gain the UL 864 UUKL/UUKL7 Listing?

UL 864 UUKL/UUKL7 testing has two basic elements: hardware and software.

Each element was reviewed and tested to meet the UL 864 UUKL/UUKL7

acceptance criteria.

Hardware The hardware has been designed to meet UL 864 transient testing requirements

on all communications and input/output points. This includes EIA-485 (formerly

RS-485) ports, Ethernet ports, power, and all I/O points. The result of these

modifications has been to protect the I/A Series BACnet products against high

level transients and further reduce the susceptibility of the I/A Series BACnet

controllers to static electricity and lightning. This does not mean that lightning

protection is not required. In fact, lightning protection is still required whenever

communication lines enter or leave a building.

Software A systems level application was created, documented, and tested to prove

I/A Series BACnet controllers could perform a smoke-control sequence within the

guidelines of UL 864 UUKL/UUKL7 and NFPA 92A. This systems level application

used a representative selection of I/A Series BACnet hardware. Three additional

systems applications were created to provide a guideline for applying I/A Series

BACnet controllers to generic smoke-control situations. These applications are

briefly explained here and detailed in Chapters 2 through 4.

• High-rise Smoke Control Using MNB-300, MNB-Vx, and MNB-1000

Controllers

Detailed in Chapter 2, this application provides guidelines for using I/A Series

BACnet controllers in a five-floor, high-rise office building that requires the

UL 864 UUKL/UUKL7 listing for Smoke-Control Systems. This application

performs the smoke-control sequences by controlling stairwell pressurization

2. Underwriters Laboratories, Heating, Cooling, Ventilating, Cooking and Food Safety

Equipment Directory 2006.

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

2

Introduction

systems, terminal boxes, dedicated smoke-control dampers, and central air

handling unit (AHU) systems. The normally open (N.O.) relay contacts of a

UOJZ fire alarm panel are monitored for smoke/fire alarm signals which initiate automatic activation of the smoke-control sequences. The UUKL listed

Firefighter’s Smoke Control Station (FSCS) is monitored for manual activation

and overrides. Control of the FSCS visual and audible status indicators is also

provided.

• Warehouse Smoke Control Using MNB-300 and MNB-1000 Controllers

Detailed in Chapter 3, this application provides guidelines for using I/A Series

BACnet controllers in a single-story warehouse building that requires the

UL 864 UUKL/UUKL7 listing for Smoke-Control Systems. This application

performs the smoke-control sequences by controlling several zoned AHU systems. The N.O. relay contacts of a UOJZ fire alarm panel are monitored for

smoke/fire alarm signals which initiate automatic activation of the smoke-control sequences. The UUKL listed Firefighter’s Smoke Control Station (FSCS)

is monitored for manual activation and overrides. Control of the FSCS visual

and audible status indicators is also provided.

• Campus Smoke Control Using MNB-300, MNB-Vx, and MNB-1000

Controllers

Detailed in Chapter 4, this application provides guidelines for using I/A Series

BACnet controllers in a large campus with multiple buildings that require the

UL 864 UUKL/UUKL7 listing for Smoke-Control Systems. This application

performs the smoke-control sequences by controlling terminal boxes, dedicated smoke-control dampers, and several AHU systems. The N.O. relay

contacts of a UOJZ fire alarm panel are monitored for smoke/fire alarm signals which initiate automatic activation of the smoke-control sequences. The

UUKL listed Firefighter’s Smoke Control Station (FSCS) is monitored for manual activation and overrides. Control of the FSCS visual and audible status

indicators is also provided. Multiple Fire Alarm Panels and FSCSs are used.

What are Your UL 864 UUKL/UUKL7 Responsibilities?

Schneider Electric field offices can now contract for smoke-control systems that

require the UL 864 UUKL/UUKL7 listing for a BACnet system. The I/A Series

BACnet system, however, is not the system that initiates or annunciates the

smoke/fire alarm. That is the responsibility of the primary system, a dedicated fire

alarm system that is listed for the UOJZ category of the UL 864 standard. The

primary system provides the means for detecting, indicating, and annunciating the

smoke/fire alarm. I/A Series BACnet controllers interface to the primary fire alarm

system to monitor the smoke/fire alarm panel output contacts and subsequently

control the HVAC equipment, as required, in the event of a fire/smoke condition.

In addition, the automation system may redundantly (as a secondary system)

annunciate fire/smoke alarms.

The applications produced and the guidelines provided by Schneider Electric in

the I/A Series Micronet BACnet Smoke-Control Systems Manual are intended as

a reference. They must be reviewed and revised to fit the individual installation

and the project’s specifications. It is the individual field office’s responsibility to

ensure that the I/A Series BACnet system meets the requirements of the project’s

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 3

Chapter 1

specifications, but not necessarily to perform the system’s mechanical design

function. The smoke-control system designer should have already completed the

mechanical system design, and validated the design’s concept using a proven

smoke-control system program model.

Proper duct sizing and layout, motor/blower selection, and damper selection must

be completed by the smoke-control system designer to provide the planned

smoke-control pressurization under all possible expected environmental (wind,

weather, etc.) and building (door, elevator hoistway, leakage, system response,

stairwell, occupied mode, etc.) conditions. Adjacent corridors and zones should

have been considered by the smoke-control system designer because they have

a direct impact on pressurization.

The smoke-control system designer should also specify the required controls

sequence, and realizing that there are reaction and confirmation times for HVAC

controls, specify any critical response times that are necessary to meet the

requirements of the smoke-control system design.

Each field office is responsible for the implementation of the smoke-control

sequence as specified by the smoke-control system designer. Additionally, it is the

responsibility of the field office to work with the smoke-control system designer

and gain the smoke-control system approval from the Authority Having

Jurisdiction (AHJ) — and there could be several. I/A Series BACnet equipment

installation must be in strict adherence to the appropriate UL, NFPA, and local

authority requirements. The field office is responsible for following the installation

standards and guidelines set forth by Schneider Electric in this document and as

approved by UL.

Explanation of Smoke-Control Systems

This documentation is intended to be used in conjunction with the NFPA 92A and

UL 864 UUKL/UUKL7 standards. The explanation of smoke-control systems here

consists of highlights from these standards.

Building Pressurization

Dedicated and Nondedicated Systems

The primary means of controlling smoke movement is by creating air pressure

differences between smoke-control zones. The basic concept of building

pressurization is to establish a higher pressure in adjacent spaces than in the

smoke zone. In this way, air moves into the smoke zone from the adjacent areas

and smoke is prevented from dispersing throughout the building.

Smoke control systems are either dedicated or nondedicated. A dedicated

smoke-control system is intended for smoke-control purposes only. It is a

separate system of air moving and distribution equipment that does not function

under normal building operating conditions. When activated, this type of system

performs a specific smoke-control function.

smoke-control systems are stairwell pressurization fans and exhaust dampers

that operate only when in a smoke-control situation.

3. National Fire Protection Association, Inc., NFPA 92A, Standard for Smoke-Control

Systems Utilizing Barriers and Pressure Differences, 2009 ed., chap. 1, para. 1.2.1.

4. NFPA 92A, 2009 ed., chap 3, para. 3.3.11.1, 3.3.11.2..

4

Examples of dedicated

3

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

4

Introduction

Nondedicated smoke-control systems are systems that share components with

some other systems such as the building automation (HVAC) system. When

activated, the system changes its mode of operation to achieve the smoke-control

objectives.

building that supplies several smoke-control zones. Under normal HVAC

operation, the central air handler modulates the outdoor, exhaust, and return air

dampers to maintain a desired discharge temperature. When a smoke-control

sequence is initiated, the control objective changes from maintaining a desired

discharge temperature to a smoke-control sequence that drives the outdoor and

exhaust air dampers fully open and the return air damper fully closed to provide

the maximum amount of outdoor air.

5

An example of this type of system is the central air handler for a

Basic System Types

Building smoke-control systems can generally be divided into two basic types:

shaft protection and floor protection. Shaft protection consists of stairwell

pressurization systems and elevator hoistway systems. Floor protection involves

several variations of zoned smoke control. Use of a particular system or

combination of systems is dependent on building and fire code requirements, as

well as specific occupancy and life safety requirements of the situation being

considered.

Note: Recent trends have indicated areas of refuge are being designed into

many buildings as dictated by the Americans for Disabilities Act (ADA).

Specifications may refer to these areas of refuge which are typically located

adjacent to stairwells or elevator hoistways. These refuge zones may require

special pressure compensated systems in order to maintain a tenable

environment. The requirements for these systems must be dictated by the

building’s smoke-control system designer based on the smoke-control system

design and its associated sequence of operation. When these types of zones are

encountered, additional time and resources may be required to establish and

verify compliance to the specification. These areas of refuge are not part of the

UUKL listing requirements.

Shaft Protection

Stairwell Pressurization Systems

The goal of pressurized stairwells is to maintain “a tenable environment within exit

stairwells for the time necessary to allow occupants to exit the building.”

6

A

tenable environment is defined as “An environment in which the products of

combustion, including toxic gases, particulates, and heat, are limited or otherwise

restricted to maintain the impact on occupants to a level that is not life

threatening.”

staging area for firefighters.

pressurized, with respect to the fire area, with outdoor air to keep smoke from

contaminating them during a fire incident.”

5. NFPA 92A, 2009 ed., chap 3, para. 3.3.11.2.

6. NFPA 92A, 2009 ed., chap. 4, para. 4.1.2 (2), annex A, para. A.8.1.

7. NFPA 92A, 2009 ed., chap. 4, para 4.1.2 (2).

8. NFPA 92A, 2009 ed., annex A, para A.4.1.2 (1).

9. NFPA 92A, 2009 ed., chap 3, para 3.3.6..

7

A secondary objective of stairwell pressurization is to provide a

8

This is achieved when “stair shafts are mechanically

9

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 5

Chapter 1

There are two types of stairwell systems: noncompensated and compensated. In

a noncompensated system, supply air is provided to the stairwell by starting a fan.

This provides two or more positive pressure differentials: one differential with all of

the doors closed, a second differential with one door open, and so on.

10

In a

compensated system, supply air is also provided to the stairwell by starting a fan,

but the fan system adjusts the positive differential pressure based on the various

combinations of opened and closed doors. This adjustment may be accomplished

by either modulating supply airflows or by relieving excess pressure from the

stairwell.

motor-operated dampers, an automatically opening stairwell door to the outside at

ground level, or an exhaust fan.

11

Typically, over-pressure relief may utilize barometric dampers,

12

Elevator Smoke Control

“Historically, elevator hoistways have proved to be a readily available conduit for

the movement of smoke throughout buildings.”

13

Although several methods for

correcting this problem have been proposed and investigated, there are no firm

recommendations regarding elevator smoke control. Refer to the NFPA 92A and

UL 864 UUKL/UUKL7 standards for additional information. Remember, the local

AHJ and project specifications may require control beyond that specified in the

above standards.

Floor Protection

Zoned Smoke Control

Pressurized stairwells, discussed above, “are intended to control smoke to the

extent that they inhibit smoke infiltration into the stairwell. However, in a building

with just a pressurized stairwell, smoke can flow through cracks in floors and

partitions and through other shafts to threaten life or damage property at locations

remote from the fire. The concept of zoned smoke control …is intended to limit

this type of smoke movement within a building.”

With zoned smoke control, smoke movement is inhibited by dividing the building

“into smoke-control zones, with each zone separated from the others by smoke

barriers.”

closed. When a fire occurs in one of these smoke-control zones, it is called a

smoke zone.

by mechanical fans and operating dampers can be used to limit the smoke to the

zone in which the fire originated.

15

These smoke barriers can be partitions, floors, or doors that can be

16

In the event of a fire, pressure differences and airflows produced

17

When a fire/smoke condition occurs, all of the

nonsmoke zones that are contiguous to the smoke zone are positively

pressurized and the smoke zone is negatively pressurized. Optionally, all of the

remaining smoke-control zones in the building may also be positively

pressurized.

18

With the smoke contained to the smoke zone, it can then be

14

10.NFPA 92A, 2009 ed., annex B, para. B.1.

11.NFPA 92A, 2009 ed., annex B, para. B.2.

12.NFPA 92A, 2009 ed., annex B, para. B.4.

13.NFPA 92A, 2009 ed., annex A, para. A.5.4.

14.NFPA 92A, 2009 ed., annex A, para. A.5.5, annex A, para. A.8.1.

15.NFPA 92A, 2009 ed., chap. 5, para. 5.5.1.1.

16.NFPA 92A, 2009 ed., chap. 3 para. 3.3.15.

17.NFPA 92A, 2009 ed., annex A, para. A.5.5.

18.NFPA 92A, 2009 ed., annex A, para. A.5.5.1.1.1.

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

6

Introduction

exhausted. Typically, the fire/smoke signals from a protective signaling

system (UOJZ, a UL 864 Listed Fire Alarm Control Unit; i.e. fire alarm panel)

are used to activate the zoned smoke-control sequence.

19

HVAC Equipment HVAC equipment normally provides a means of supplying, returning and

exhausting air to, or from, a space. Most HVAC equipment “can be adapted

to provide the necessary logic and control sequences to configure HVAC

systems for smoke control.”

ducts are interconnected as part of the normal HVAC operation, smoke

dampers are needed to separate the supply and exhaust air during a

smoke-control sequence (return air damper).

use centralized HVAC equipment in main mechanical areas to serve multiple

floors or zones. These central systems may require fire and smoke shaft

dampering to provide exhaust of the fire floor and pressurization of the

adjacent floors with outdoor air. Due to their capacity, central systems should

include a means to prohibit excessive pressures within the duct system and

prevent rupture, collapse, or other damage.

Typically, fan coil units and water source heat pump units can be excluded

from performing smoke-control sequences. However, if these units have the

ability to supply outdoor air, any of the units that are within the smoke zone

should be shut down so that the zone can be negatively pressurized.

induction-type air handling unit is used within a smoke zone, it should be

shut down or have its primary air supply closed off.

20

However, when the supply and return air

21

Additionally, some buildings

22

24

23

If an

Smoke-Control System Activation

Some VAV systems bypass supply air to the return air inlet of the fan. In

these cases, the bypasses must be closed when the unit is in the

smoke-control mode. Additionally, the VAV system fan and terminal unit

controls should be configured to supply the maximum amount of outdoor air

to pressurize the nonsmoke zones.

supplying the smoke zone, the terminal fan should be turned off. “Terminal

units serving zones adjacent to the smoke zone can continue to operate.”

25

If a fan-powered terminal unit is

26

“Operating controls of the HVAC system shall be designed or modified to

provide the smoke-control mode with the highest priority over all other

control modes.”

27

Normally the smoke-control sequences are activated

automatically, but in some cases, manual activation may be more

appropriate. In either case, “the smoke-control system shall be capable of

being manually overridden and manually deactivated.”

28

The automatic

smoke-control system “shall be automatically activated in response to

signals received from a specific fire detection device or a combination of fire

detection devices.”

19.NFPA 92A, 2009 ed., chap. 6, para. 6.4.5.1.1.

20.NFPA 92A, 2009 ed., annex A, para. A.6.4.2.

21.NFPA 92A, 2009 ed., chap. 6, para. 6.2.3.

22.NFPA 92A, 2009 ed., annex C, para. C.3.

23.NFPA 92A, 2009 ed., annex C, para. C.4.

24.NFPA 92A, 2009 ed., annex C, para. C.5.

25.NFPA 92A, 2009 ed., annex C, para. C.7.

26.NFPA 92A, 2009 ed., annex C, para. C.8.

27.NFPA 92A, 2009 ed., chap. 6, para. 6.4.2.

28.NFPA 92A, 2009 ed., chap. 6, para. 6.4.3.3.

29.NFPA 92A, 2009 ed., chap. 6, para. 6.4.3.4.

29

Fire detection devices “include automatic devices such

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 7

Chapter 1

as smoke detectors, waterflow switches, and heat detectors.”30 Manual fire

alarm pull stations should generally not be used to activate automatic

smoke-control systems, other than stairwell pressurization systems,

because of the likelihood of a person signaling an alarm from a station

outside the smoke zone of origin.

31

Response Time Smoke control system activation should be started immediately after

receiving an activation command. A maximum of 10 seconds transmission

time is allowed, from the initiation of an activation signal (i.e. fire alarm

input), to the time it reaches the MicroNet BACnet smoke control system

(i.e. binary input of a MicroNet controller). The smoke-control sequence

should activate individual components in the sequence necessary to prevent

physical damage to fans, ducts, dampers, and other equipment. The total

response time of the individual component starts from the moment the

smoke-control command is issued (whether automatic or manual) to the final

action. This time is 60 seconds for fan operation at the desired state and

75 seconds for the completion of the damper travel.

component fail, the time lapse from the moment the component should have

reached its final state and the moment its associated trouble signal

annunciates, should not exceed 10 seconds.

33

annunciation of the trouble signal for a fan must occur within 70 seconds of

the automatic or manual activation command. The annunciation of the

damper trouble signal must occur within 85 seconds of the automatic or

manual activation command.

32

Should an individual

This means that the

Firefighter’s Smoke

Control Station

The Firefighter's Smoke Control Station (FSCS) “shall provide status

indication, fault condition indication, and manual control of all smoke-control

system components.”

over all smoke-control systems and equipment. “

take precedence over fire suppression, electrical protection, or personnel

protection devices.”

34

“The FSCS shall have the highest priority control

36

For more information, refer to the NFPA 92A and

35

“FSCS control shall not

UL 864 UUKL/UUKL7 standards.

The FSCS should contain a building diagram that clearly indicates the type

and location of all smoke control equipment, such as fans and dampers.

37

The areas of the building that are affected by the equipment and the actual

status of all of the smoke control equipment should be clearly indicated at

the FSCS. Status indication should be provided for each fan showing

whether it is ON or OFF. Status indication of the full-closed and full-open

positions of each smoke control damper should also be shown on the

38

FSCS.

30.NFPA 92A, 2009 ed., annex 6, para. A.6.4.3.4.

31.NFPA 92A, 2009 ed., chap. 6, para’s 6.4.3.5.2 and 6.4.3.5.3, and annex A,

32.Underwriters Laboratories Inc., UL 864, Control Units and Accessories for Fire

33.UL 864, 9th ed., para. 49.2.b

34.NFPA 92A, 2009 ed., chap. 6, para. 6.4.3.7.3.

35.NFPA 92A, 2009 ed., chap. 6, para. 6.4.3.7.11.

36.NFPA 92A, 2009 ed., chap. 6, para. 6.4.3.7.14, and UL 864, 9th ed., para. 48.3.

37.NFPA 92A, 2009 ed., chap. 6, para 6.4.3.7.10 and annex D, para D.1 (2).

Proof of air flow should be used to determine the fan status. Proof

para’s A.6.4.3.5.2 and A.6.4.3.5.3.

Alarm Systems, 9th ed. (2003), para. 49.2.c.

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

8

Introduction

of damper positions should be done using end process verification. This may

be done through the use of damper degree-of-opening switches, flow

stations, etc.

Whenever the communications fails between any of the I/A Series MicroNet

BACnet controllers that are integral to the smoke-control equipment or

sequences, including instances when a controller loses power, a system

trouble visual indicator (i.e. LED) at the FSCS should illuminate and an

audible signal must sound.

also be generated if any of the smoke-control equipment proof sensors fail

to operate within a specified period of time during the smoke-control

sequence or when under control of the FSCS.

indicators must annunciate an audible sound. In addition to the status

indication that is required for all of the smoke-control equipment, each

dedicated piece of smoke-control equipment must also provide a visual

trouble indicator specifically for that device.

39

The visual and audible trouble indicators must

40

In general, all visual trouble

41

Control Sequence for Stair Pressurization Systems

Control Sequence for Zoned Smoke-Control Systems

Any time a smoke/fire detector trips (refer to NFPA 92A and

UL 864 UUKL/UUKL7 for acceptable signaling device types), initiating an

automatic smoke-control sequence, all stairwell pressurization fans shall be

energized

determines that operation of all stairwell pressurization fans is not required

to achieve the design objective, only the stairwell pressurizaiton fans

identified during the analysis shall be required to be activated.”

detector should be provided in the air supply to each fan that stops the

respective pressurization fan when smoke is detected.

switch for each fan should be provided at the FSCS that allows the stairwell

fans to restart after they have been shutdown due to the supply air smoke

detectors,

entering the fan than smoke migrating into the stairwell. When a stairwell

pressurization sequence is used in conjunction with zoned smoke control,

care must be taken to prevent the interrelation of the two sequences from

adversely affecting each other.

“Automatic activation of systems and equipment for zoned smoke control

should have the highest priority over all other sources of automatic control

within the building.”

used for normal building control such as HVAC systems, the equipment

control should be pre-empted as required by the smoke-control sequence.

“The following controls should not be automatically overridden:

42

, with one exception. “Where an engineering analysis

43

A smoke

44

A manual override

45

should it be determined that a lessor hazard exists from smoke

46

47

For example, when the smoke-control equipment is

• Static pressure high limits.

38.NFPA 92A, 2009 ed., chap 6, para’s 6.4.3.7.3 through 6.4.3.7.10, and annex D,

para D.1 (5).

39.UL 864, 9th ed., para’s 48.5, 49.4, 49.6, and 49.7.

40.UL 864, 9th ed., para’s 48.5 and 49.6.

41.NFPA 92A, 2009 ed., chap 6, para’s 6.4.3.7.3 and UL 864, 9th ed., para 49.6.

42.NFPA 92A, 2009 ed., chap 6, para 6.4.4.1.

43.NFPA 92A, 2009 ed., chap 6, para 6.4.4.1.1.

44.NFPA 92A, 2009 ed., chap 6, para’s 6.4.4.2.1 and 6.4.4.2.2.

45.NFPA 92A, 2009 ed., chap 6, para 6.4.4.4.

46.NFPA 92A, 2009 ed., annex A, para. A.5.7.

47.NFPA 92A, 2009 ed., chap. 6, para. 6.4.5.2.1.

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 9

Chapter 1

• Duct smoke detectors on supply air systems.”

Manual activation or deactivation of zoned smoke-control systems and equipment

(at the FSCS) should take priority over automatic activation, as well as take

priority over all other sources of automatic control within the building.

controls provided specifically for this purpose should be clearly marked as to the

zone and function served (typically part of the FSCS).

Any time a smoke/fire detector trips initiating an automatic smoke-control

sequence, all stairwell pressurization sequences should operate as stated

previously.

several smoke-control zones, the supply and return fan for the AHUs are

commanded ON. The outdoor and exhaust air dampers for each AHU drive to the

full-open position and the return air damper drives to the full-closed position. All

exhaust air dampers in the smoke zone drive to the full-open position and the

supply air dampers drive to the full-closed position. All smoke-control zones

contiguous to the smoke zone (and optionally all remaining smoke-control

zones

their exhaust air dampers driven to the full-closed position. Pressurization of the

non-contiguous (optional) smoke-control zones is dependent upon the

smoke-control system design and its associated specification. Regardless of

whether or not non contiguous zones are positively pressurized, sufficient

differential pressure must be achieved to limit the smoke spread to the zone in

which the fire originated.

This smoke-control sequence provides the maximum amount of outdoor air to the

nonsmoke zones causing them to be positively pressurized. Since the exhaust air

dampers are fully open in the smoke zone and no supply air is being provided, the

AHU begins exhausting the smoke from the smoke zone. With the nonsmoke

zones being positively pressurized in this manner, smoke is inhibited from

migrating outside of the smoke zone.

51

For applications where each central air handling unit (AHU) supplies

52

) should have their supply air dampers driven to the full-open position and

48

50

49

Manual

Automatic Response To Multiple Signals

Maintaining System Integrity

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

10

Once an automatic activation has occurred, subsequent alarm signals that would

normally result in the automatic actuation of a smoke-control sequence should be

annunciated only. No fans or dampers should be actuated in response to any

subsequent automatic alarm signal in order to avoid the possibility of defeating

any smoke-control sequence which is in process.

A prime concern with any emergency signaling system is maintaining system

integrity. This is typically accomplished by electrical supervision of wiring,

however, since the proper operation of the fans and dampers associated with a

smoke-control system may involve mechanically and pneumatically operated

devices, as well as electrically operated devices, end-process verification is

considered an acceptable alternative.

Smoke control system equipment is required to verify that a fan or damper has

achieved its required end function. This end function verification consists of

monitoring fans by differential pressure switches, flow stations, and etc., and

48.NFPA 92A, 2009 ed., chap. 6, para. 6.4.5.2.1.2.

49.NFPA 92A, 2009 ed., chap. 6, para. 6.4.5.2.2.

50.NFPA 92A, 2009 ed., chap. 6, para. 6.4.5.2.4.1.

51.NFPA 92A, 2009 ed., chap 6, para’s 6.4.4.1 and 6.4.4.1.1.

52.NFPA 92A, 2009 ed., annex A, para. A.5.5.1.1.1.

Introduction

monitoring dampers by degree-of-opening switches, differential pressure

switches, and etc. These verification devices should be connected back to

the smoke-control system equipment (I/A Series BACnet, for example) and

the system programmed to expect the appropriate signal within the specified

amount of time.

Any change in a smoke-control signal input (i.e. FAP, FSCS, etc) must be

received into the smoke-control system in 10 seconds or less. Fans and

dampers have 60 and 75 seconds, respectively, from the time the signal

input is received, to successfully respond to smoke-control sequence

commands. If a fan or damper fails to achieve its desired state within the

times referenced above, the failures have to be annunciated within an

additional 10 seconds. Other trouble signals, such as communication

failures (supervised through software), have up to 200 seconds to

annunciate their failures.

Annunciation of the end function sensor is not required if the proof sensor

operates as intended, but if the proof sensor fails to operate, an audible and

visual trouble signal must be generated at the FSCS. This would be typical

of the operation of the smoke-control system during an emergency

condition.

For operation during a nonemergency condition, the means for verifying

system integrity varies based on whether the smoke-control system is a

dedicated or nondedicated system. Nondedicated smoke-control systems

and equipment consist of HVAC components within a building which are

operated regularly. Therefore, the normal “comfort” level associated with the

operability or inoperability of the equipment is considered an acceptable

means of maintaining system integrity.

53

54

55

Smoke-Control System Schedule

Dedicated smoke-control systems and equipment are used solely for the

purpose of smoke-control and are not operated in a nonemergency

condition. Dedicated system equipment is therefore required to incorporate

an automatic weekly self-test of each smoke-control function. The self-test

consists of the smoke-control system automatically commanding the

associated function to operate and expecting that the associated proof

sensor operates within a specified period of time (refer to response times

noted earlier). A valid proof sensor operation is not required to annunciate,

however, the lack of an expected proof sensor operation must produce an

audible trouble signal, as well as indicate the specific device that did not

operate (for example, LED at the FSCS).

Each different smoke-control system configuration/sequence should be

defined in a schedule, typically a matrix chart. The schedule should list all

dedicated and nondedicated smoke-control equipment and show the

equipment response for each sensor that activates an automatic sequence.

At a minimum, the schedule should include the following information:

• Each smoke zone in which a smoke-control system automatically

activates.

53.NFPA 92A, 2009 ed., chap. 6, para. 6.4.6. and annex A, para. A.6.4.6.

54.UL 864, 9th ed., para. 36.1.2 (c), 49.2 (b).

55.NFPA 92A, 2009 ed., chap. 2, para. 2.1.2. and 2.1.5., and UL 864, 9th ed.,

para’s 49.7.

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 11

Chapter 1

• The type of alarm signal that activates the smoke-control system (smoke

detector, sprinkler water flow, and etc.)

• The smoke zones where maximum mechanical exhaust to the outside is

implemented and no supply air is provided.

• The positively pressurized smoke-control zones where maximum supply air is

implemented and no exhaust to the outside is provided.

• The fans that are ON as required to implement the smoke-control system.

Multiple-speed fans should be further noted as FAST or MAX VOLUME to

ensure that the intended control configuration is achieved.

• The fans that are OFF as required to implement the smoke-control system.

• The dampers that are Open where maximum air flow must be achieved.

• The dampers that are Closed where no air flow should take place.

• Any additional functions that may be required to achieve the smoke-control

objective or that may be desirable in addition to smoke control. Changes or

override of normal static pressure control setpoints should also be indicated if

applicable.

• Damper position at fan failure.

56

Conclusion

When applying I/A Series BACnet controllers to smoke-control sequences, review

this introductory information along with the NFPA 92A and UL 864 UUKL/UUKL7

standards. This information should be used in conjunction with the sample

smoke-control applications (Chapters 2 through 4) and the restrictions and

general comments (Chapter 5) that are part of the total smoke-control

documentation provided by Schneider Electric.

56.NFPA 92A, 2009 ed., annex A, para 6.4.5.3 (10).

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

12

Chapter 2

High-rise Smoke Control

Purpose

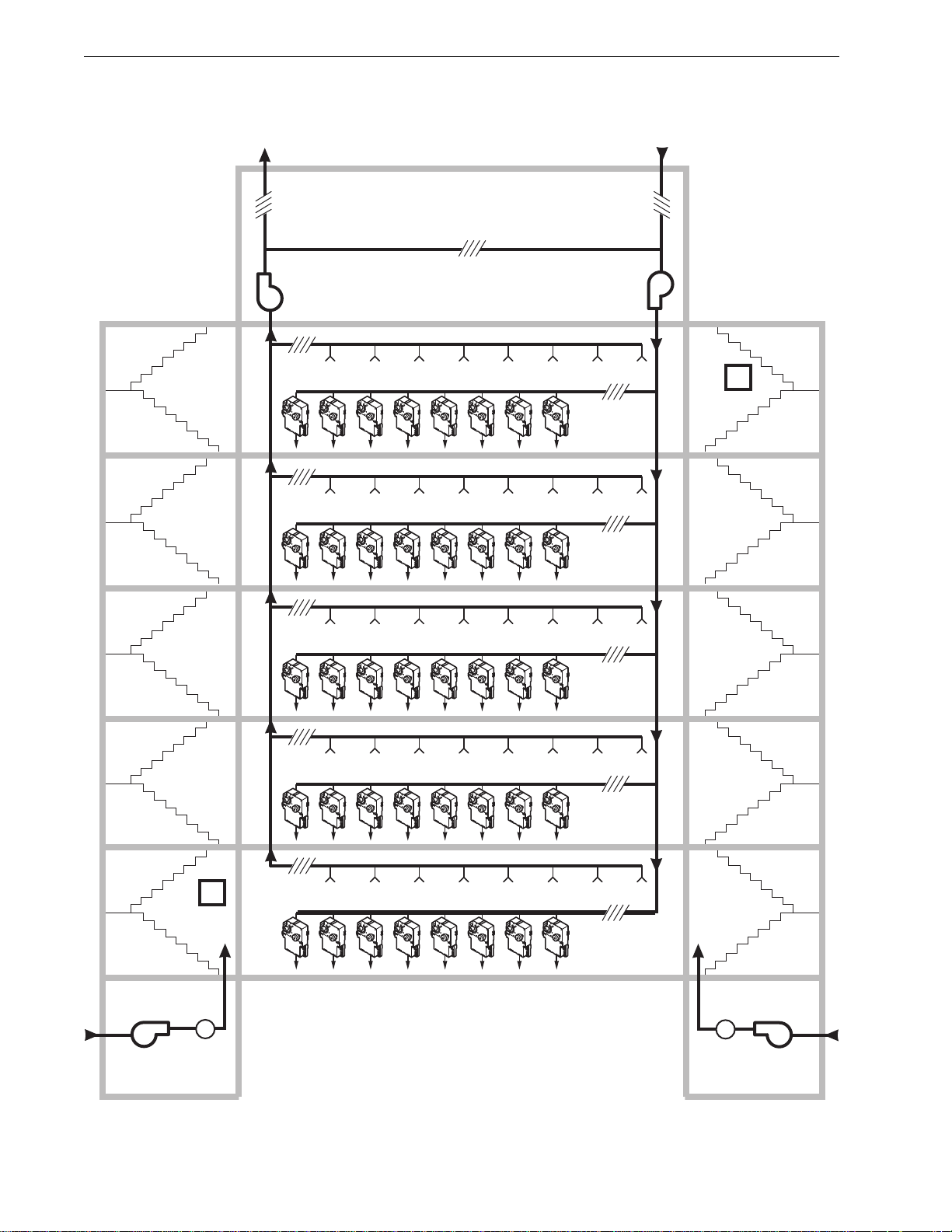

This application provides guidelines for using I/A Series MicroNet BACnet

controllers in a five-floor, high-rise office building (Figure–2.1) that requires

the UL 864 UUKL/UUKL7 listing for Smoke-Control Systems. This

application uses MNB-300, MNB-Vx, and MNB-1000 controllers that perform

HVAC functions when in the normal control mode. When in the

smoke-control mode, they perform the required smoke-control sequences

by controlling the stairwell pressurization fans, the individual terminal boxes,

the dedicated smoke-control dampers, and the central air handling unit

(AHU) fans. Additionally, they control all supply, exhaust, and return air

dampers, and provide the feedback of all end-process verification required.

The I/A Series BACnet controllers monitor N.O. relay contacts of a UOJZ

listed fire alarm panel for automatic activation of the smoke-control

sequences and monitor a UL 864 UUKL/UUKL7 Listed Firefighter’s Smoke

Control Station (FSCS) for manual activation commands and overrides. In

this example, an ADI FSCS is used, which supports the ADI ModBus

interface to the MNB-1000. This interface provides control over all the FSCS

visual and audible status indicators, as well as receipt of the FSCS override

commands, thus eliminating the need to allocate additional controllers to

interface to the FSCS through individual I/O points.

Sequence of Operation

Normal HVAC Control

F-27419-2 TAC I/A Series MicroNet BACnet Smoke Control Systems Manual 13

Under normal conditions, the central AHU follows an occupied schedule that

determines when the AHU operates. During the unoccupied mode, the

outdoor and exhaust air dampers are in the full-closed position. The return

air damper is in the full-open position. The supply and return fans are

commanded OFF. During the occupied mode, the supply and return fans are

commanded ON. The outdoor, exhaust, and return air dampers modulate as

required to maintain a mixed air temperature setpoint. The central AHU can

have a wide variety of additional control sequences that determine its

operation and establish its operating priorities (for example, low limit stats

and minimum outdoor air).

Chapter 2

Figure–2.1 High-rise Building Layout.

Central Air Handling Unit

Exhaust Air Damper

Return Air Damper

Return Air Supply Fan

Exhaust

Air

Damper

Exhaust

Air

Damper

Exhaust

Air

Damper

Eight MNB-Vx Controllers

Eight MNB-Vx Controllers

Eight MNB-Vx Controllers

Outdoor Air Damper

Supply Air

Damper

5th Floor

Supply Air

Damper

4th Floor

Supply Air

Damper

Stairwell #2Stairwell #1

Pull

Station

Pull

Station

Pressurization

Fan - Stair 1

Duct Smoke

Detector

SD

3rd Floor

Exhaust

Air

Damper

Exhaust

Air

Damper

Note: All references to the MNB-V1 equally apply to the

MNB-V1-2 and all references to the MNB-V2 equally

apply to the MNB-V2-2.

Eight MNB-Vx Controllers

2nd Floor

Eight MNB-Vx Controllers

1st Floor

Supply Air

Damper

Supply Air

Damper

Pressurization

Fan - Stair 1

SD

Duct Smoke

Detector

TAC I/A Series MicroNet BACnet Smoke Control Systems Manual F-27419-2

14

Loading...

Loading...