MV electrical network management

Easergy range

T200 P

MV substation control unit

User’s manual

Easergy T200 P Contents

T200 P ................................................................................................................................................................... 1

1 GENERAL DESCRIPTION......................................................................................................................... 3

1.1 FUNCTIONAL DESCRIPTION ........................................................................................................................... 3

1.2 DESCRIPTION OF EQUIPMENT ........................................................................................................................ 5

1.3 T200 P BLOCK DIAGRAM .............................................................................................................................. 6

2 CONNECTION TO THE T200 .................................................................................................................... 8

2.1 STEP 1 - INSTALLING JAVA RUNTIME ENVIRONMENT 5.0 ................................................................................. 9

2.2 STEP 2 - INSTALLING THE USB DRIVER ....................................................................................................... 10

2.3 STEP 3 – CREATION OF THE PSTN OR GSM REMOTE NETWORK CONNECTION .............................................. 11

2.4 STEP 4 – STARTING CONNECTION WITH THE T200 ....................................................................................... 12

2.5 OVERVIEW OF THE EMBEDDED WEB SERVER OF THE T200 ........................................................................... 16

3 T200 SETTINGS ....................................................................................................................................... 22

3.1 COMMENT AREA : ....................................................................................................................................... 23

3.2 CONFIGURATION OF SYNCHRONIZATION BY GPS ......................................................................................... 24

3.3 CONFIGURATION OF SNTP SERVICE ........................................................................................................... 27

3.4 CONFIGURATION OF ETHERNET INTERFACES ............................................................................................... 28

3.5 SAVE/RESTORE CONFIGURATION PARAMETERS ........................................................................................... 29

3.6 DUMMY CONTROL OPTION .......................................................................................................................... 30

3.7 PARAMETERS FOR COMMUNICATION WITH THE SUPERVISOR ......................................................................... 31

3.8 SWITCH CONTROL PARAMETERS ................................................................................................................. 47

3.9 PARAMETERS OF THE VARIOUS OPTIONS ..................................................................................................... 50

3.10 AUTOMATION PARAMETERS .................................................................................................................... 52

3.11 PARAMETERS OF THE FAULT DETECTION MODULE .................................................................................... 55

3.12 CUSTOMIZATION OF T200 VARIABLES ..................................................................................................... 60

3.13 CUSTOMIZATION OF T200 CLASSES ........................................................................................................ 73

3.14 TESTS AT COMMISSIONING ..................................................................................................................... 74

4 OPERATION ............................................................................................................................................ 75

4.1 OPERATING MODE ...................................................................................................................................... 75

4.2 TESTING OF INDICATOR LAMPS AND FAULT DETECTION ................................................................................. 76

5 MAINTENANCE ....................................................................................................................................... 77

5.1 DIAGNOSTICS VIA THE FRONT PANEL INDICATOR LAMPS AND LOGS ................................................................ 78

5.2 POWER SUPPLIES ...................................................................................................................................... 81

5.3 CARD REPLACEMENT .................................................................................................................................. 82

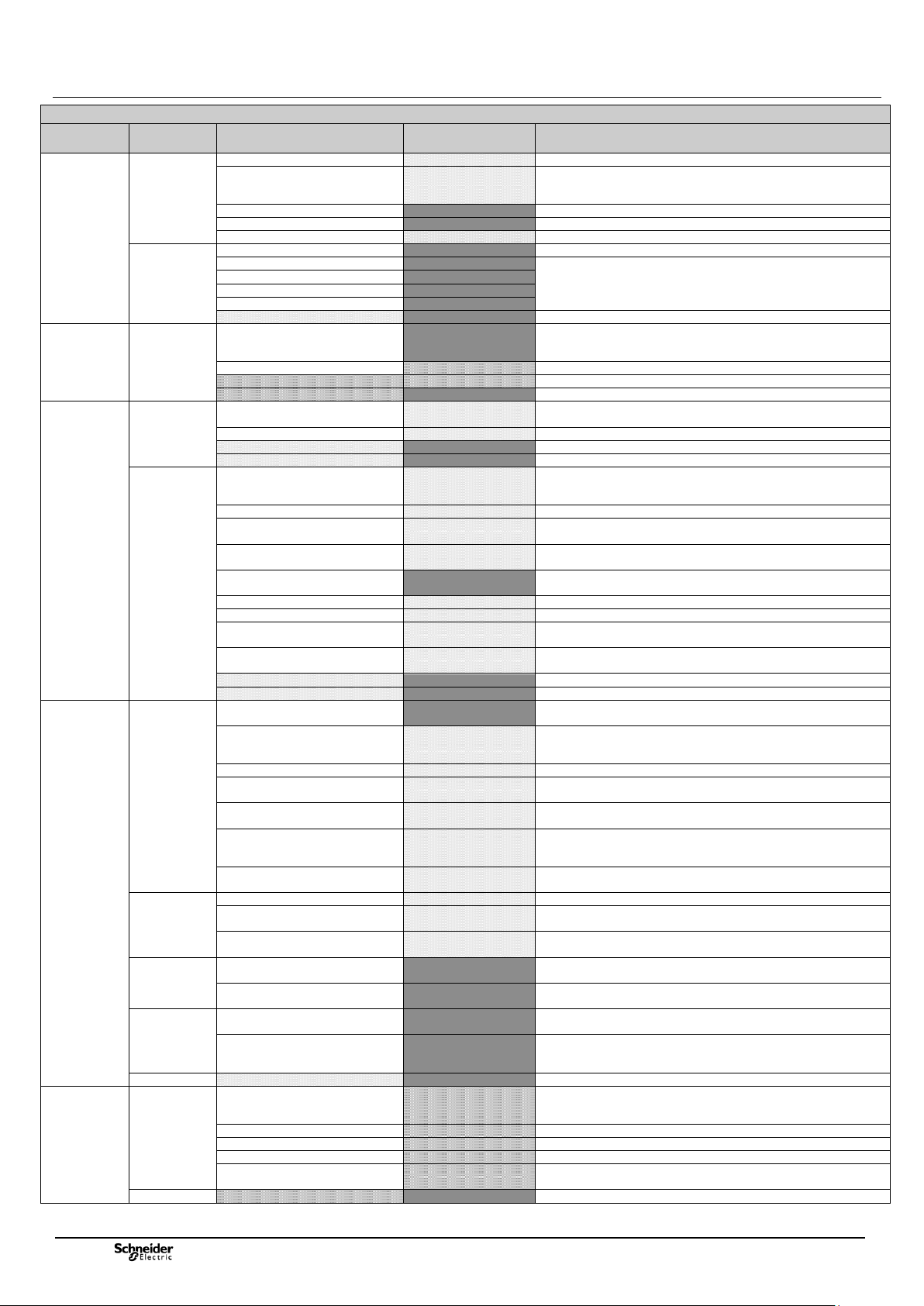

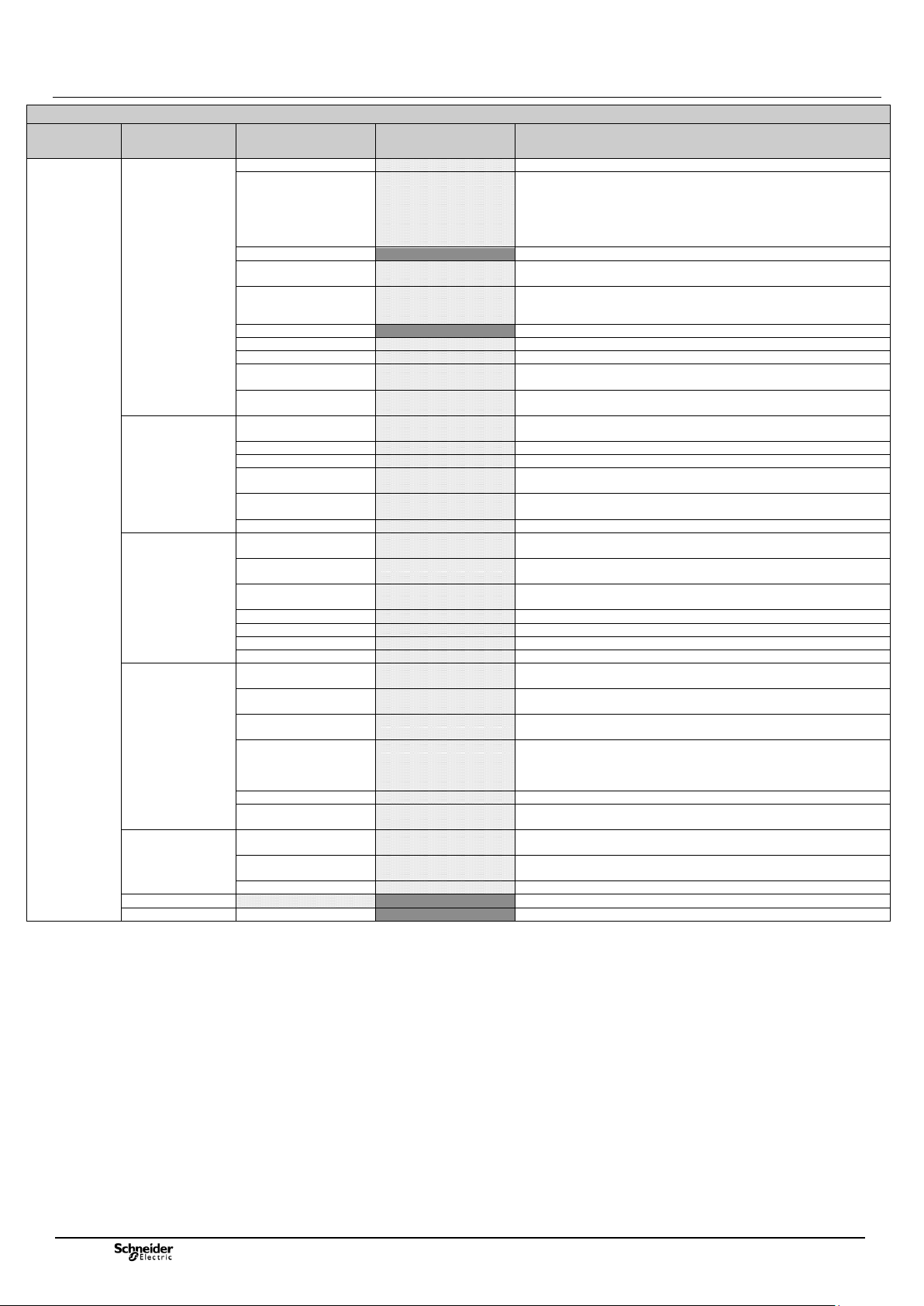

6 APPENDIX A – CONFIGURABLE PARAMETERS ................................................................................ 83

7 APPENDIX B - GENERAL CHARACTERISTICS ................................................................................... 92

2

NT00113-EN-05

Overview General description

1 General description

1.1 Functional description

Easergy T200 P is designed to be installed with overhead switches remote controlled

by the MV network. It contains all the functions required to monitor and control one or

two MV/LV switchgear devices.

Management of MV switch opening/closing electric control unit

The control is triggered by actuation from the control station, by local operator control,

or by internal automatic controls.

Measurement acquisition and processing

The T200 P can incorporate the following measurements and processing functions:

For each channel:

Current measurement on each phase;

Calculation of the average load current;

Homopolar current measurement;

Single-phase or three-phase voltage measurement;

Measurement of the phase deviation between the upstream/downstream voltages

for management of opening points;

Calculation of active and RMS power (option);

Calculation of active energy (option);

Calculation of the power factor (option);

Frequency measurement.

Monitoring, for the purposes of remote indication and/or local display,

of MV substation and Easergy T200 P information:

Open/closed position of MV switch;

“Locked” state of MV switch;

Phase-to-phase or phase-to-earth fault current detection;

Voltage present;

Automatic control ON/OFF position;

Door open;

Local/remote operating mode;

Immediate alternating supply voltage failure;

Time-delayed alternating supply voltage failure;

Charger fault;

Battery fault;

External 12 V power supply failure;

Motorization supply voltage failure.

Logs

Time-stamped chronological logging of events and measurements.

This information can be transmitted to the control centre and archived in logs for

consultation and local downloading (in file form), by connection of a microcomputer.

Predefined automations

SEC (Sectionalizer): Automatic control for opening the MV switch following

detection of a number of fault currents in the source substation reset cycle.

ATS (Automatic Transfer of Source): Automatic source changeover upon voltage

loss detected on one of the channels.

VT (Voltage Time): The detection of voltage loss (switch closed) causes channel

opening and then reclosing when the voltage returns.

Backup power supply

For all the control unit components, the transmission equipment and the switch

motorization with a battery life of several hours in the event of an AC supply outage.

Local communication or communication with the remote control centre

One or two communication ports (option) are available for remote communication

with the control centre to manage two transmission channels. These ports can be

used redundantly (normal/backup), for repeater or maintenance applications. The

ports use either modems integrated in the COM card or external equipment

managed by the rack serial link.

A choice of modem for each port allowing any type of mounting:

Radio (600/1200 baud FSK or 1200/2400 FFSK);

PSTN isolated at 8 kV (300 to 14400 bits/s -V32 bis);

GSM / GPRS (quad-band version 900/1800/850/1900 MHz), SIM card accessible

on the front panel

GSM / 3G - UMTS & HSPA+ (3,75G), EDGE, GRPS & GSM. Quad-band modem

in GSM (900/1800/850/1900 MHz) and five band in 3G (800/850/AWS/1900/2100

MHz), SIM card accessible on the front panel

LL isolated at 8 kV (1200 baud FSK);

RS232 or RS485 isolated at 2 kV (19200 baud).

Note: In an RS232 link, port 1 is replaced by the RS232 port integral with the COM

card and accessible via the RJ45 connector on the right of the rack.

NT00113-EN-05

3

Overview General description

A catalogue of communication protocols for communication with the control centre,

changing constantly:

♦ IEC 870-5-101

♦ IEC 870-5-104

♦ DNP3, DNP3 / IP

♦ Modbus, Modbus / IP

♦ Other proprietary protocols (PID1, PUR2.2, PUR2.4, EDP, etc.).

An Ethernet communication port is available for communication with the control

centre or for access from the local PC for consultation/configuration (Modbus IP

protocol, IEC 870-5-104, DNP3 IP). This port is accessible on the front of the COM

card.

A USB communication port is available for communication with the local PC for

consultation/configuration. This port is accessible on the front of the COM card.

Communication with local equipment (option)

A Modbus RS485 communication port (2 wires - isolated at 2 kV) is available (on

option) for dialogue with equipment communicating with the T200 (e.g. Sepam, etc.).

Time synchronization of the equipment

Time setting for event dating can be performed:

by the laptop PC for consultation/configuration of the T200 (manually or

automatically via the PC time);

by the control centre (if the protocol permits);

by GPS sync (option). The minimum precision of time setting is in this case

approximately 50 ms;

by SNTP sync (option) from an Ethernet network. The precision of time setting is

in this case approximately one second.

IEC 61131-3 programmable logic controller

On option, the T200 can include an IEC 61131-3 embedded virtual programmable logic

controller.

A development platform (the RTU Control software supplied in appendix on the

Easergy CD) makes it possible to design, simulate and test on a target programs

written in the following PLC languages:

• SFC – Sequential Function Chart

• FBD – Function Block Diagram

• LD – Ladder Diagram

• ST – Structured Text

• Il – Instruction List

These PLC programs allow specific customized applications or additional functions to

be implemented on the T200 by combining or actuating existing T200 variables or

virtual variables to be created specifically for the PLC application.

Inter-equipment communication

The IEC 61131-3 programmable automatic control option also includes an interequipment communication function, allowing Modbus exchange, via a TCP/IP link,

between T200 devices connected to the same MV circuit. This communication allows

exchange of a data table between these T200 devices, in order to contribute, for

example (without any other PLC than the T200's), to an automatic control function

allowing detection and clearing of a current fault on an MV circuit.

(For more details regarding these three functions, refer to the specific "RTU Control &

Formulae" manual – ref. NT00320-xx).

Calculation formulae

The calculation formulae are a standard feature of the T200.

They can be used in the T200 to create new customized functions or applications not

requiring writing of a program in PLC language.

The functions that can be used in the formulae are:

- Mathematical functions;

- Statistical functions;

- Logical functions;

- Time/date functions;

- etc.

These formulae make it possible, more easily than with a PLC program, to create logic

equations based on combinations of variables. The types of variables that can be

used are the same as for PLC programs (existing T200 variables or virtual variables

created specifically). This inter-equipment communication is typically used in

applications of the self-healing network type.

4

NT00113-EN-05

Overview General description

1.2 Description of equipment

The enclosure

The equipment is housed in a 316L stainless steel enclosure ensuring:

Resistance to mechanical stresses;

Resistance to environmental stresses;

Compliance with EMC standards.

The enclosure is fitted with a key locking system.

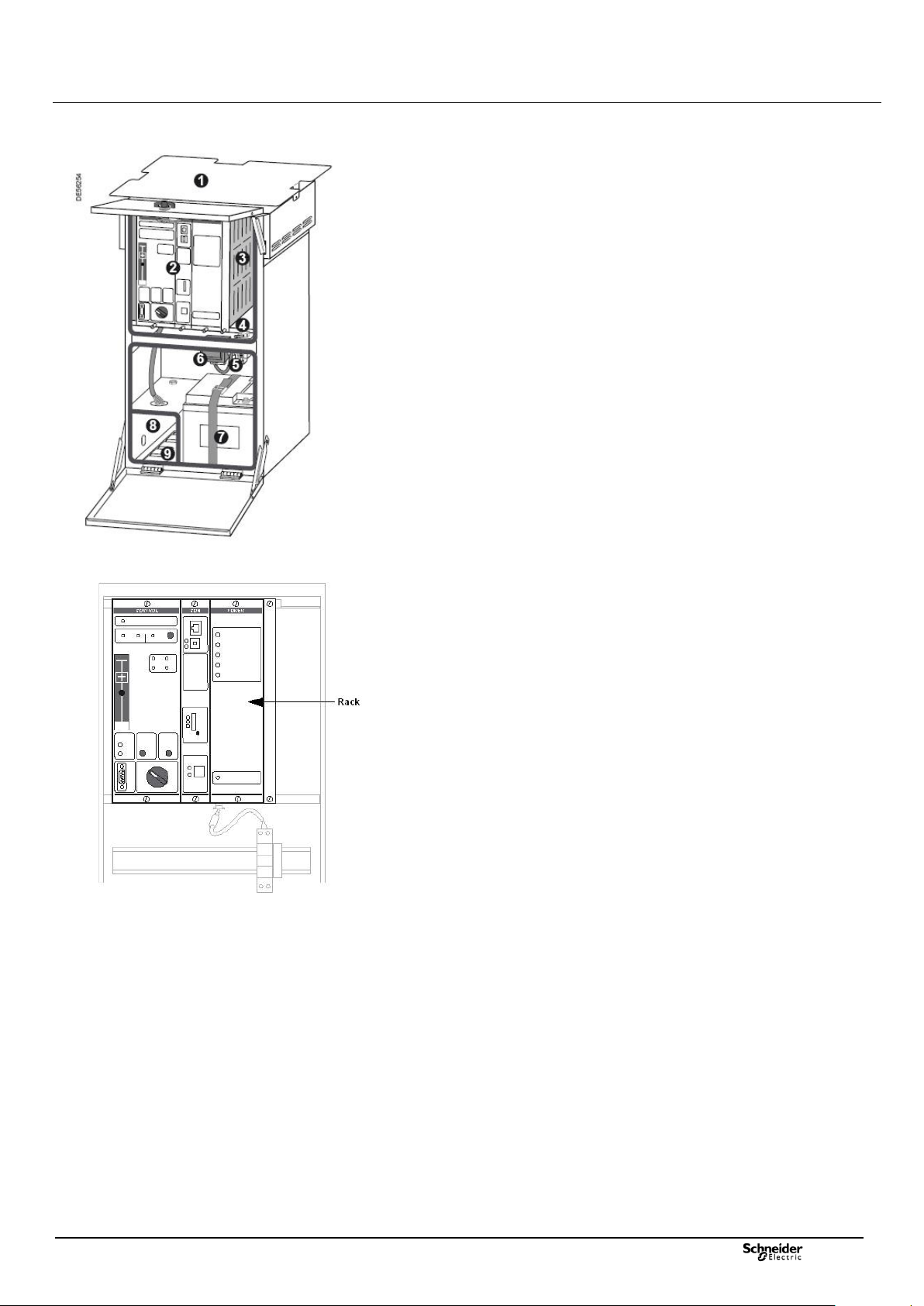

Its main constituent parts are:

1) A sun screen to restrict the influence of high external temperatures

2) A 6-unit rack containing all the electronic modules

3) Transmission equipment (radio, external modem, etc.)

4) A door switch

5) A lever type fuse holder for the AC power supply

6) A transformer for voltage measurement acquisition

7) A battery providing a backup power supply when the enclosure is no longer powered

by the AC supply

8) A “connection” part for connection to the motorization units and the toroid sensors

9) An anti-intrusion guard plate under the enclosure providing protection against any

malevolent attempt at disconnection of the “connection” part cords.

The rack

The rack contains three functional modules:

The Control module (marked CONTROL)

The control module controls the overall operation of the T200 P and the exchange of

information with the Power Supply and Communication modules.

This module implements several functions:

Interfacing with and monitoring and control of the MV switchgear;

Automatic control management;

Detection of fault currents on the MV line;

Detection of voltage loss;

Calculation of power (P, S, Q), energy, power factor, frequency;

Local operation.

The Communication module (marked COM)

The communication card serves as an interface between the cards of the “control

module”, the local equipment communicating via Modbus and the control centre.

It centralizes, processes and archives information and transmits it in accordance with

the communication protocol adopted.

The Power Supply module (marked POWER)

It supplies power to the enclosure, the battery charger and the associated selfmonitoring equipment.

NT00113-EN-05

5

Overview General description

2A

1A

PC

supply

2A

Voltage

transformer

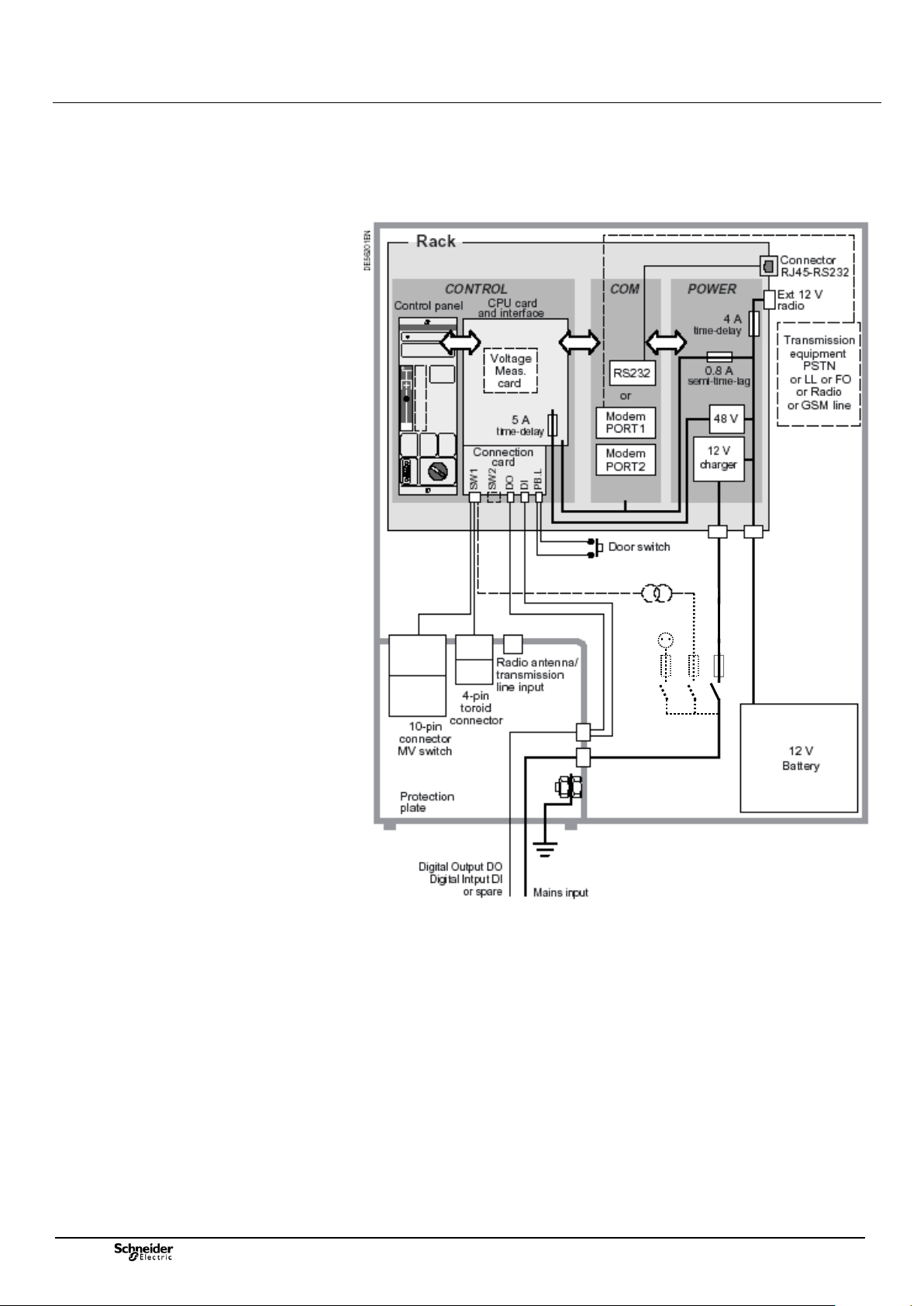

1.3 T200 P block diagram

Note: The various modules are connected via a “rack backplane card” not shown in this

diagram.

6

NT00113-EN-05

Installation Installing the enclosure

Refer to the T200P installation manual supplied with the equipment to obtain

information concerning installation of the T200P enclosure: "NT00030-FR-EN-ES-

xx".

NT00113-EN-05

7

Connection to the T200 Initialization of connection

Type B connector Type A connector

USB cable

“Cross-over” or “straight-through” Ethernet cable

depending on type of link access

2 Connection to the T200

Easergy T200 I must be configured from a configuration PC. This is

performed from the COM card (single access). It allows configuration of:

The parameters of the CPU card (date, fault detection, etc.).

The parameters of the Communication card (com. parameters, alarms,

etc.).

The system parameters (variable management, class management,

etc.).

Equipment required for T200 connection

For testing-maintenance configuration, the T200 requires:

A microcomputer operating under Windows 2000 or XP or Seven and

including Internet Explorer (version 5.5 or 6.0, 7, 8 or 9).

An USB port on this PC to perform connection with the T200.

An Ethernet port (RJ45) is available on the COM card for remote access to

the T200 from an Ethernet network.

This port can also be used for direct connection of the T200 with the PC.

The Ethernet cable required for Ethernet network-T200 connection or PCEthernet network connection is of the “straight-through” type.

The Ethernet cable required for PC-T200 connection is of the “cross-over”

type.

The USB cable required for PC-T200 connection is of the USB-A type at one

end and USB-B at the other.

A CD-ROM is supplied to the user for:

Installation of the USB driver for connection with the T200.

Installation of Java Runtime Environment 5.0 needed for port trace

operation (Supervisor-T200 frame analysis).

NB: TCP/IP ports 1168, 1169 and 1170 must be accessible on the PC

for trace operation. Contact the network administrator if it is necessary to

alter the PC or network configuration to deactivate the firewall on these ports.

Configuration of the T200 is performed directly from Internet Explorer.

No other additional software is needed to access the T200 testingmaintenance configuration operations (apart from Java Runtime 1.5).

Principle of the T200 embedded server

The T200 includes an embedded server which is initialized automatically as

soon as connection is established with the T200.

The data displayed by the T200 through this embedded server appears in the

form of HTML pages.

Various pages and sub-pages can be accessed by the user depending on

the rights available to him. The HTML pages displaying the information

managed by the T200 are refreshed in real time so as to update the latest

states.

Access and connection are secured by a Login and password. Several levels

of access to the HTML pages can be configured, provided one have the

required rights.

From the embedded server, it is possible to:

Configure the fault detector, communications and automatic control

parameters or system parameters (management of variables, classes,

rights, etc.);

View the states managed by the T200 (TSS, TSD, routine faults,

telemeasurements, etc.);

Save or load the T200 parameter configuration from files already

backed up on the PC;

Send remote control orders to the T200;

Transfer diagnostic logs in the form of Excel-compatible files;

Load a new software version of the T200 application.

The embedded server can be accessed both by the USB port and by the

Ethernet port. There is no difference in operation according to the type of port

used.

Initialization of connection to the T200

The T200 incorporates by default IP addresses necessary for local

connection from a PC. It is important to know these addresses in advance in

order to start a connection (these addresses are indicated on the Com card):

USB port: default address on the T200 = 212.1.1.10

Ethernet port: default address on the T200 = 172.16.0.5

Note: The USB address cannot be modified by the user. The Ethernet

address, on the other hand, can be modified (if the rights so permit) so as to

correspond to the local area network, which does not necessarily use the

same network addresses and masks.

For the T200 link via Ethernet, steps 2 and 3 are not necessary. In that case,

go directly to step 4.

8

NT00113-EN-05

Connection to the T200 Initialization of connection

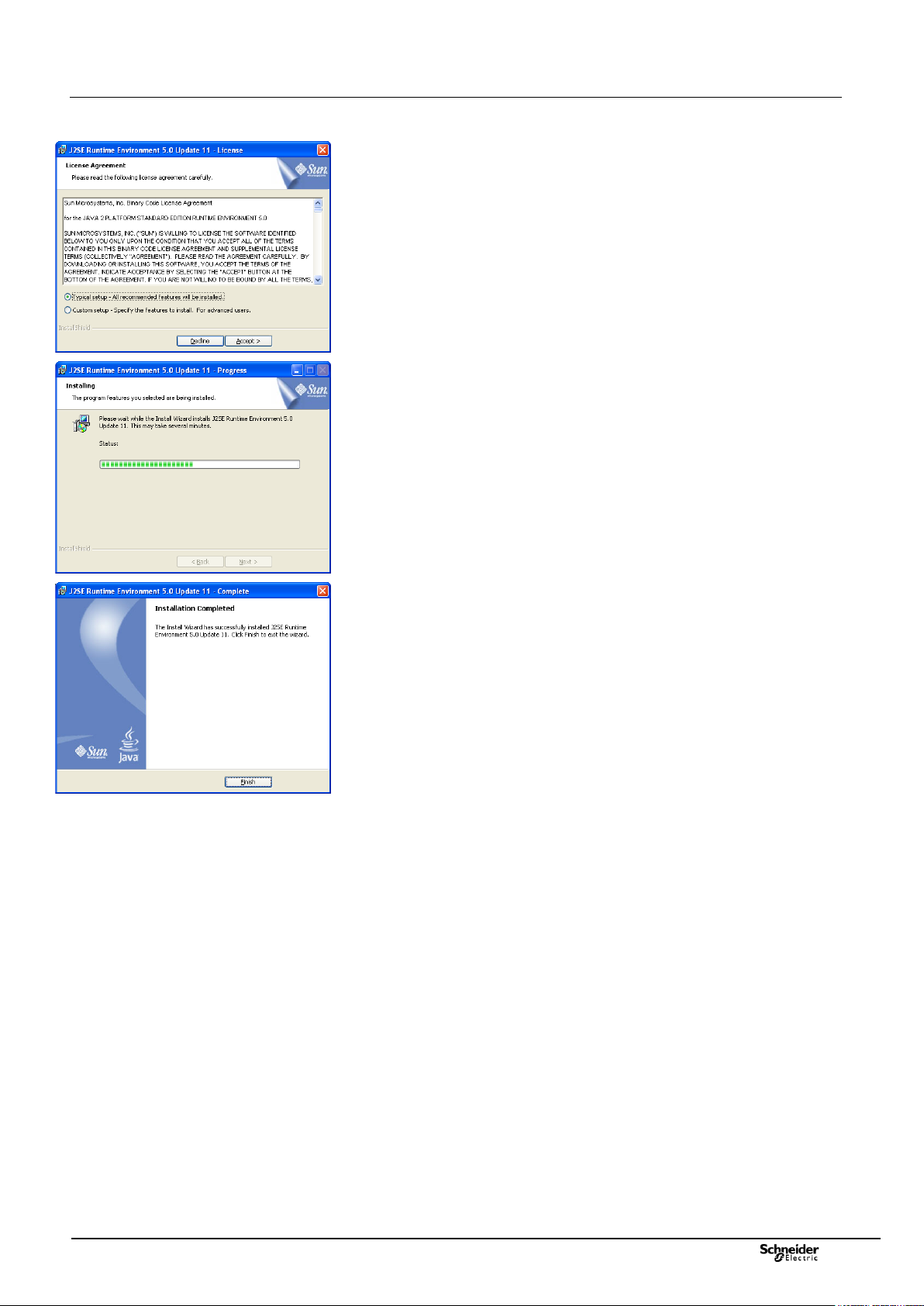

2.1 Step 1 - Installing Java Runtime

Environment 5.0

Insert the CD-ROM supplied with the T200 into the PC drive, then

double-click on the “jre-1_5_0_11-windows-i586-p-s.exe” installation file

on the CD-ROM (in folder : "D:\Tools\Java").

Software installation begins; click on the “Standard installation…" option

and then on “Accept”.

If new screen including Google options installation, deselect the two

proposed options "Google Toolbar" and "Google Desktop", then click on

"Next".

Wait until installation is completed, then click on “Terminate”.

NT00113-EN-05

9

Connection to the T200 Initialization of connection

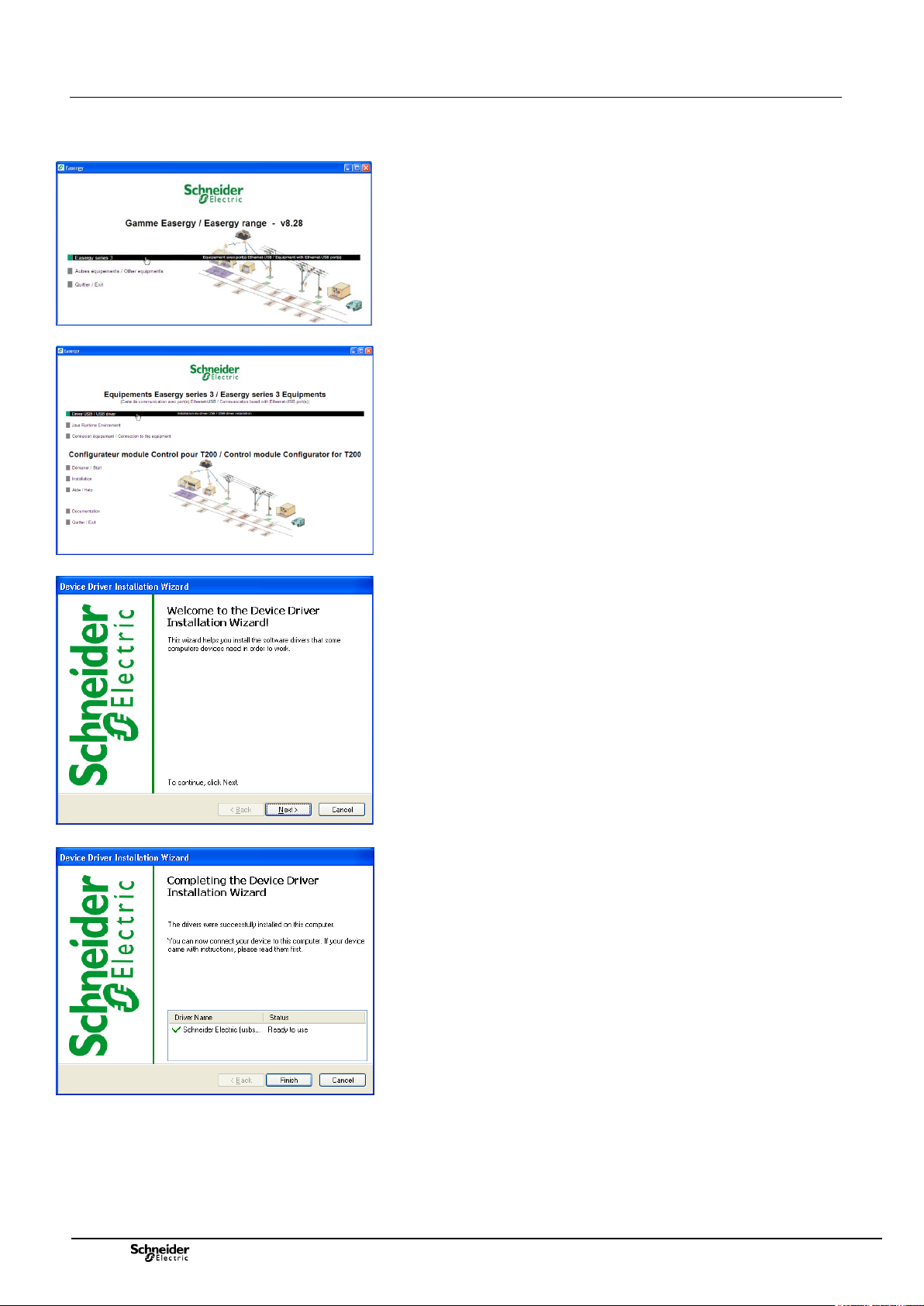

2.2 Step 2 - Installing the USB driver

Carry out the following operations to install the USB driver:

Insert the Easergy CD-Rom supplied with the unit.

Insert the Easergy CD-ROM supplied with the equipment into the PC

drive.

A "Gamme Easergy / Easergy range – Vx.xx" window should

automatically appear on screen. If this is not the case, double-click on

the "Autorun.hta" file located in the CD root directory.

Click on the "Easergy series 3" link.

In the "Equipements Easergy series 3 / Easergy series 3 Equipment"

window which appears on screen, click on the "USB Driver" link.

Choose the setup language, then click on "ok".

Click on "Next" to start the "InstallShield Wizard" module.

Choose the installation directory (the directory proposed by default can

be kept), then click on "Next".

Then click on "Install" to start installation.

A driver setup window appears on screen; click on "Next".

Installation of the Easergy USB driver starts automatically.

At the end of installation, when the window showing that the driver has

been correctly installed appears on screen, click on the "Finish" button.

The Easergy USB driver is installed.

An "Easergy USB connection" start-up shortcut is also created

automatically on the PC desktop (see step 4).

Important note: Unlike the previous USB driver, this driver is installed for all

the USB ports of the PC. This driver needs therefore be installed only once,

irrespective of the USB port used. If a different USB port is used for a future

connection, Windows will automatically detect and install the Easergy USB

driver for this other USB port.

Note: Step 2 is therefore necessary only for the first connection to equipment

with the PC. For a future connection, go directly to step 4.

10

NT00113-EN-05

Connection to the T200 Initialization of connection

2.3 Step 3 – Creation of the PSTN or

GSM remote network connection

This step is to be taken into account only if the T200 includes a GSM or

PSTN (telephone) internal modem installed on the COM card.

This connection may possibly operate with an external PSTN or GSM

modem, but that depends on the modem used.

Note: It is not necessary to create this type of connection for the GPRS/3G

link.

With Windows 2000

Click on the Windows “Start” button.

Click on “Settings”.

Click on “Network connection and remote access”.

Click on “Establish a new connection”.

Click on "Connection to a private network".

From the list of peripherals displayed, select that corresponding to the

modem to be used for connection, by checking it.

Enter the phone number of the T200 to be contacted (this number may

be changed later, at each connection attempt).

Select the option “For all users”.

Give a name to the telephone connection to the T200 (e.g. “T200

remote connection”).

When the connection window is displayed on screen, there is no need to

give a user name and login password, and if necessary change the

phone number of the T200 to be contacted.

Click on the “Dial” option.

The PSTN or GSM remote network connection between the PC and the

T200 is initialized between the two devices, then a modem connection

status icon is inserted in the Windows toolbar.

With Windows XP

Click on the Windows “Start” button.

Click on “Control Panel”.

Click on “Network connections”.

Click on “Create a new connection”.

Select the option “Connect to the network at my workplace”.

Select the option “Dial-up connection”.

From the list of peripherals displayed, select that corresponding to the

modem to be used for telephone connection to the T200, by checking it.

Give a name to the telephone connection created (e.g. “T200 remote

connection”).

Enter the phone number of the T200 to be contacted (this number may

be changed later, at each connection attempt).

Select the option “Do not use my smart card”.

Select the option “All users”.

Check the option “Add a shortcut to this connection to my desktop”, then

on “Terminate”.

When the connection window is displayed on screen, there is no need to

give a user name and login password, and if necessary change the

phone number of the T200 to be contacted.

Click on the option “Dial number”.

The PSTN or GSM remote network connection between the PC and the

T200 is initialized between the two devices, then a modem connection

status icon is inserted in the Windows toolbar.

Note: Step 3 is no longer necessary after the first connection performed with

the T200. In that case, go directly to step 4.

NT00113-EN-05

11

Connection to the T200 Initialization of connection

2.4 Step 4 – Starting connection with

the T200

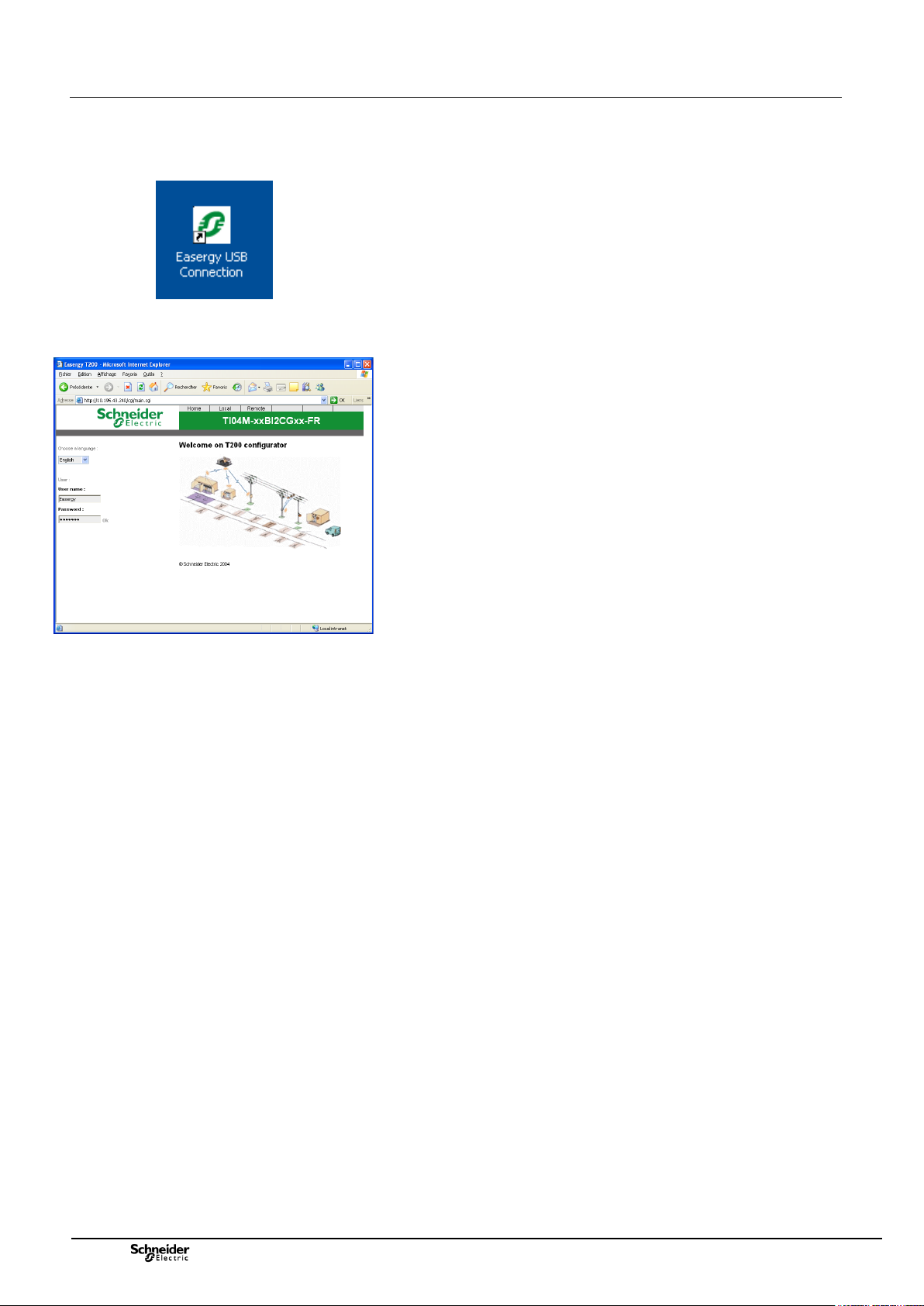

2.4.1 Local access via the USB port of the T200

The T200 being powered up without a “Fault” indicator lamp lit on the

COM card, connect the USB on one the USB port of the computer and

to the COM card of the unit.

Click on the "Easergy USB connection" shortcut already installed on the

desktop of the PC to start the USB connection.

Define the language to be used.

After few seconds, Internet explorer starts automatically and is

connected to the default USB IP address "212.1.1.10".

The connection to the unit is established automatically and the home

page of the Web server appears on screen.

Enter a “User name” and a “Password”, then click on “Ok”.

Access to the HTML pages is activated according to the rights related to

this user.

IMPORTANT NOTE: After powering up or a Reset of the T200, it is important

to wait for completion of initialization of the COM card before connecting the

USB cable, otherwise the connection is likely not to work.

When the T200 is powered up, the red “Fault” indicator lamp should flash for

approximately 10 s and then stay lit steadily for 3 s before going out.

Only then is connection of the USB cable possible.

Note: contrary to the old USB driver, to stop the USB connection, you just

have to disconnect the USB cable. Windows will stop automatically the

current USB connection.

12

NT00113-EN-05

Connection to the T200 Initialization of connection

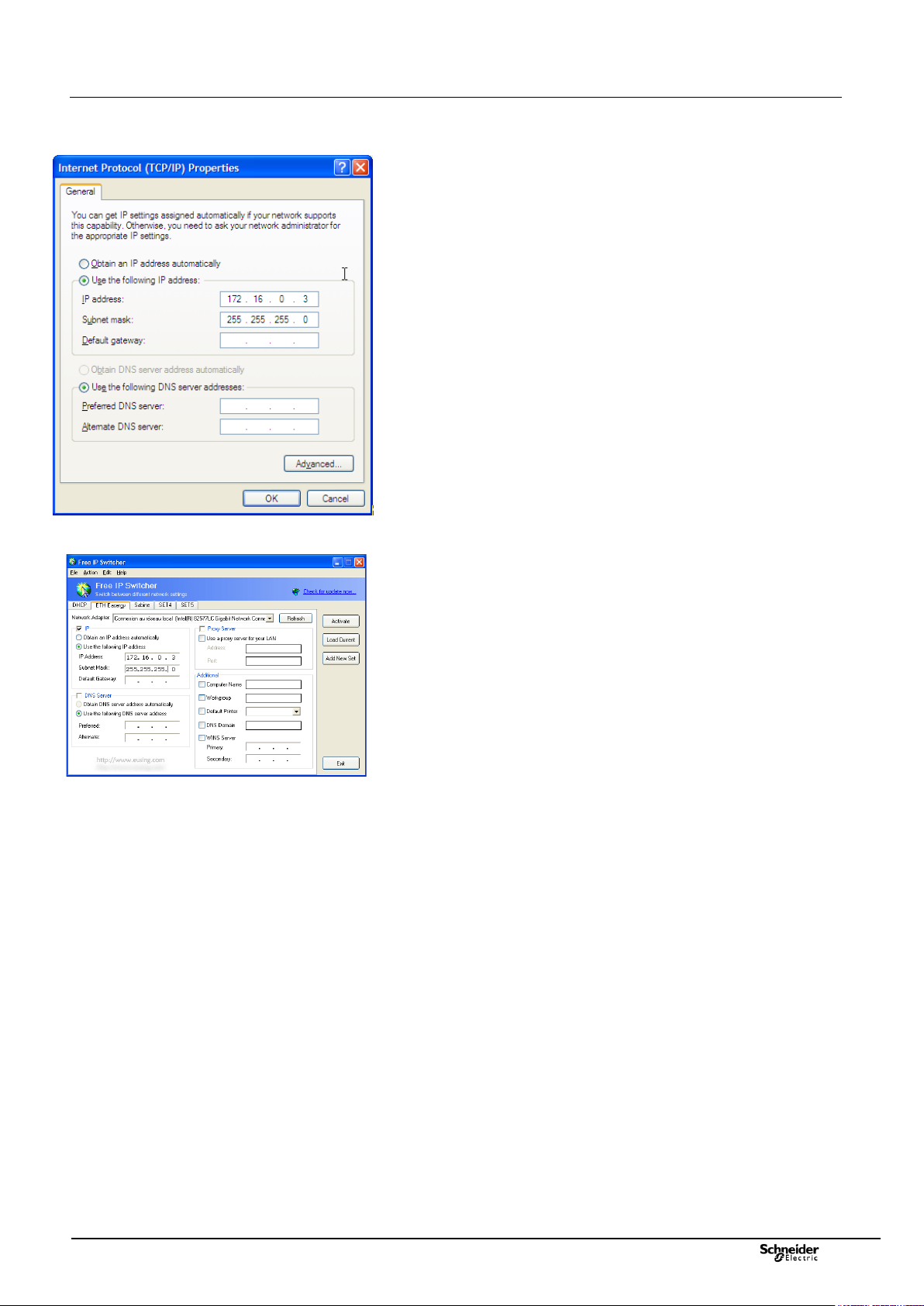

2.4.2 Local access via Ethernet port of T200

In the Windows Control Panel, click with the right mouse button on

"Connection to local area network" to be found in the "Network

Connections" directory.

Click on the "Internet Protocol (TCP/IP)" item, then on the "Properties"

button.

Then check the "Use the following IP address" option and then manually

enter the following items:

IP address = "172.16.0.3"

Subnet mask = " 255.255.255.0".

Click on the "Ok" button to accept the settings.

Start Internet Explorer.

Enter the IP address (172.16.0.5) in the “Address” field, then click on

“Ok”.

The home page of the embedded server appears on screen.

Define the language to be used.

Enter a “User name” and a “Password”, then click on “Ok”.

Access to the HTML pages is activated according to the rights related to

this user.

IMPORTANT NOTE: Once connection with the T200 is completed, you

should restore the original IP address configuration settings of the PC.

Note: there are useful utilities that can change automatically the TCP/IP

address of the PC. We recommend the software "Free IP Switcher" that can

be downloaded as a freeware on internet.

NT00113-EN-05

13

Connection to the T200 Initialization of connection

2.4.3 Remote access via a local Ethernet

network (LAN) or a GPRS or 3G network

With the T200 powered up, connect the PC and the T200 to the local

Ethernet network (LAN) using appropriate cables (straight Ethernet

cables).

Start Internet Explorer.

Enter the IP address of the T200 corresponding to the Ethernet or

GPRS/3G access in the “Address” field, then click on “Ok”.

The home page of the embedded server appears on screen.

Define the language to be used.

Enter a “User name” and a “Password”, then click on “Ok”.

Access to the HTML pages is then activated according to the rights

related to this user.

Note: Generally the default IP address of the T200 cannot be used on the

Ethernet ,3G or GPRS network employed, and it must therefore be replaced,

in the T200's specific IP address configuration page, with an address

acceptable for the network (see section on IP address configuration). In that

case, the only way to access the T200's IP address configuration page is to

use the USB local connection.

Note 2: Unlike Ethernet access, the connection speed on a GPRS or 3G link

is relatively slow (max. theoretical connection speed for GPRS = 50Kbis/s,

3G = 2Mbits/s).

Accordingly, so that the display of data on screen may be slowed as little as

possible, following a GPRS or 3G connection the T200 automatically displays

the pages of the Web server in simplified mode (Web server configuration in

"Remote" mode).

However, it is possible to return to a standard display by clicking on "Local"

configuration, at the top of the Web server home page.

14

NT00113-EN-05

Connection to the T200 Initialization of connection

2.4.4 Remote access via telephone or GSM link

This access operates only when the T200 includes a GSM or PSTN (telephone)

internal modem installed on the COM card.

When an external modem is used, it is possible that this access may operate, but

that depends on the modem used.

Start the GSM-PSTN remote network connection created previously (=> step

3).

Click on “Dial number” to start remote network connection.

Once connection is established, start Internet Explorer.

In the address field of Internet Explorer, enter one of the following IP

addresses, depending on the port No. on which the RTC or GSM modem is

installed on the T200:

- For port 1: 212.1.0.1

- For port 2: 212.1.0.3

The home page of the embedded server then appears on screen.

Define the language to be used.

Enter a “User name” and a “Password”, then click on “Ok”.

Access to the HTML pages is activated according to the rights related to this

user.

Note: Unlike a standard USB or Ethernet access, the connection speed on a

telephone or GSM link is rather slow (9600 baud).

Accordingly, so that the display of data on screen may be slowed as little as

possible, following a PSTN or GSM connection the T200 automatically displays the

pages of the Web server in simplified mode (Web server configuration in "Remote"

mode).

However, it is possible to return to a standard display by clicking on "Local"

configuration, at the top of the Web server home page.

NT00113-EN-05

15

Connection to the T200 Overview of the Web server

Home Page

Monitoring Page

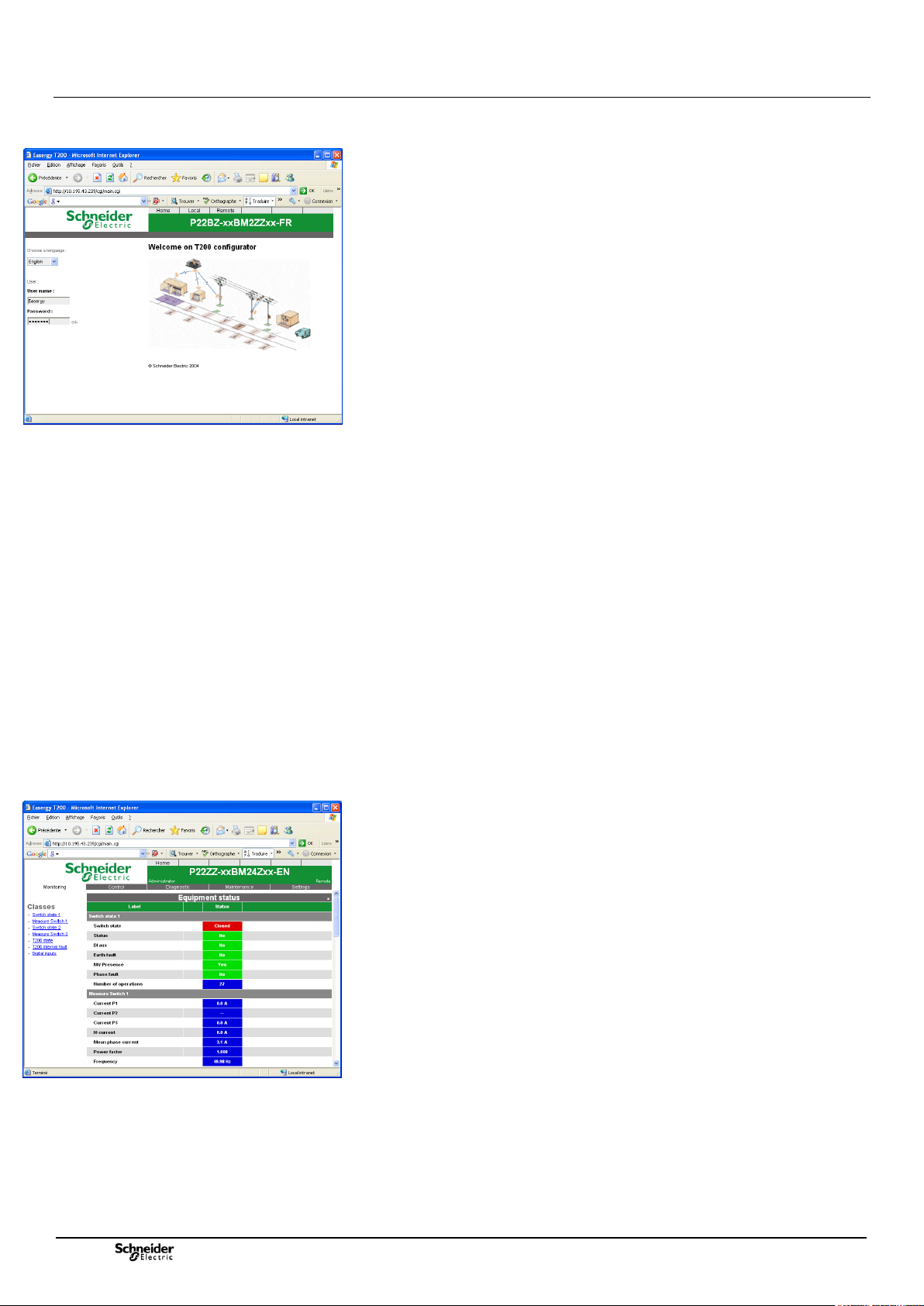

2.5 Overview of the embedded Web server of the T200

Once access to the embedded server has been identified by user name and password,

all the HTML pages can be consulted by simply clicking on the tabs or the associated

drop-down lists when they are available:

Details of the settings for each page are given in Appendix A.

Home Page:

This page is displayed at connection to the T200. It enables definition of the

language to be used for displaying the pages. It also allows definition of user access

rights by user name and password.

The users and passwords that can be accessed depend on the configuration defined

in the Maintenance page and the Users sub-menu.

By default, the “Easergy” user and “Easergy” password allow access as

“Administrator” to the embedded server.

Note: To protect your information, it is necessary to choose and use strong

passwords. Therefore, we recommend:

• Systematically change the default passwords as soon as possible the first time

you connect to the product.

• Renew your passwords with a reasonable frequency.

• Do not store passwords in a file on a computer station that is particularly

exposed to risk.

• Configure the software, including your web browser, so that it does not

"remember" the chosen passwords.

We recommend a simple rule: passwords should be at least 8 characters long and of

different types (upper case, lower case, numbers, special characters).

A click on the "Remote" option at the top of the page makes it possible to log on to

the T200 Web server with a simplified display of information (without images or

logos) so as to optimize data transfer times. This mode is used automatically for slow

remote network connections (PSTN or GSM at 9.6 Kbits/s).

A click on the "Local" button at the top of the page makes it possible to log on to the

T200 Web server with a normal display (all logos and images are transferred and

displayed). This mode is used automatically for high-speed local area connections:

USB (115.2 Kbits/s) or Ethernet (100 Mbits/s).

Monitoring Page:

This page can be used to consult the T200 states:

TSS: State of digital inputs, T200 internal faults, voltage presences, current faults,

etc.

TSD: open or closed state of switch, automatic control, digital outputs

TM: measurements of currents, voltages, frequency, etc.

Counters: number of operations or energy.

Note: Some displayed data is calculated and deduced by the T200:

Active, reactive, apparent power.

Phase difference between channels (deduced from the phase 1 voltages of each

channel).

Power factor or Cos φ.

Active power.

Neutral and average current (neutral current deduced in the case of a type A

arrangement - 3 phase toroids).

Phase-to-phase or phase-to-ground voltage (3-wire arrangement: phase-to-phase

voltages measured and phase-to-ground voltages deduced. 4-wire arrangement:

phase-to-ground voltages measured and phase-to-phase voltages deduced).

The page is displayed by class (e.g. State of channels, System, Automatic Control,

etc.).

Each class covers a category of information so as to facilitate viewing on screen.

The states of the indications or measurements are refreshed every 3 seconds

automatically.

The presentation, quantity of data displayed and content of this page may vary from

one application to another.

16

NT00113-EN-05

Connection to the T200 Overview of the Web server

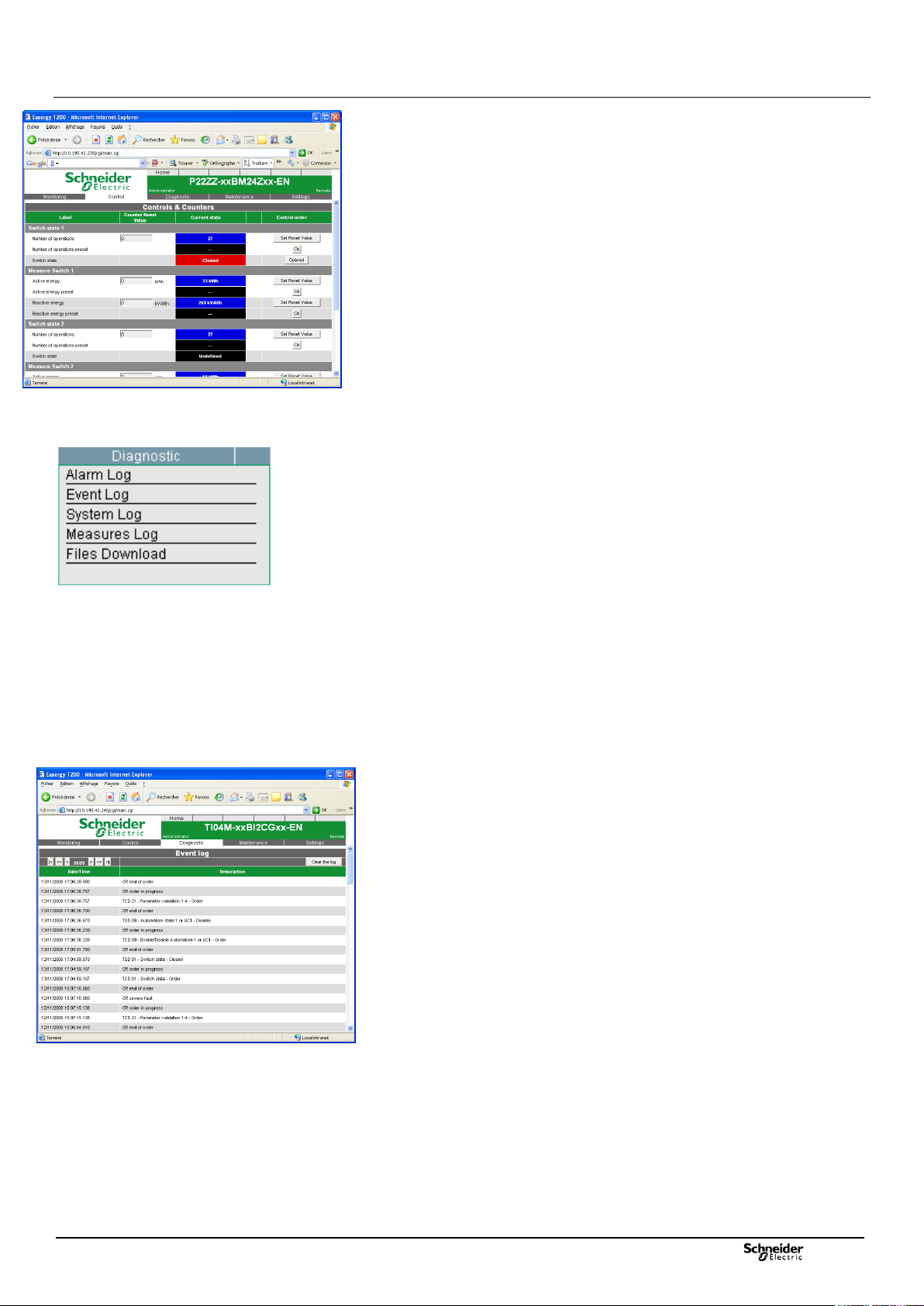

Control Page

Drop-down list – Diagnostic page

Event log - Diagnostic page

Control Page

This page allows local control orders to be sent from the PC to:

The switches (change of position by CO/CF);

The operation and energy counters (counter initialization);

The automatic controls (switching ON/OFF);

The digital outputs (forced setting open or closed);

The fault detector (fault memory resetting).

The T200 must be in "Remote" mode to be able to send control orders.

The control orders on the TSDs make it possible to go to the state complementing

that displayed by the T200.

The control orders on the counters enable them to be initialized at a value predefined

by the user.

For safety reasons, each control order must be confirmed by the user.

The state of a control order in progress is displayed in orange (default colour).

The state of the control order is refreshed on screen automatically as soon as it is

completed.

Note: The colours of the states displayed can be modified by configuration.

Diagnostic Pages:

These pages allow consultation of the logs recorded in real time by the T200. The

event time stamping is 1 ms.

Each log allows consultation of the history of states occurring on the T200 with a

description of the states.

All the information present in the logs is time-and-date stamped by the T200's

internal clock.

The logs are as follows:

• Alarm log: (storage capacity: 2000)

Alarms can be generated and transmitted spontaneously to the control centre

after an information change of state, provided that this state has been configured

as alarmed.

A box associated with each alarm is checked when the control centre has

acknowledged this alarm.

Note: Information configured as alarmed automatically implies the generation of

an associated event (in the event log or measures log depending on type).

• Event log: (storage capacity: 10000)

Every change of state generates an event, provided that the use of events for this

state has been configured.

• System log: (storage capacity: 6000)

The equipment also incorporates a function for recording additional information to

facilitate operation and maintenance.

- Storage of transmission events (to determine the origin of a recurring

communication fault);

- Indication of transmission errors (CRC error, collisions, PSTN line out of order,

switchover to redundancy, etc.);

- Indication of system events (T200 start-up, T200 reset, change of

configuration, etc.).

• Measures log: (storage capacity: 30000)

The measurements managed by the T200 (phase current or mains voltage) can

be saved in a log, provided that their use has been configured.

The measurements can be recorded in several ways:

- Periodically (sampled or averaged value with configurable period);

- Upon exceeding a threshold (configurable high or low threshold);

- Upon variation or “dead band” (configurable variation %);

- Upon periodic recording of Min. and Max. values (configurable values and

period).

For all the logs, when the storage capacity is reached, the most recent event

occurring erases the oldest event on the list.

NT00113-EN-05

17

Connection to the T200 Overview of the Web server

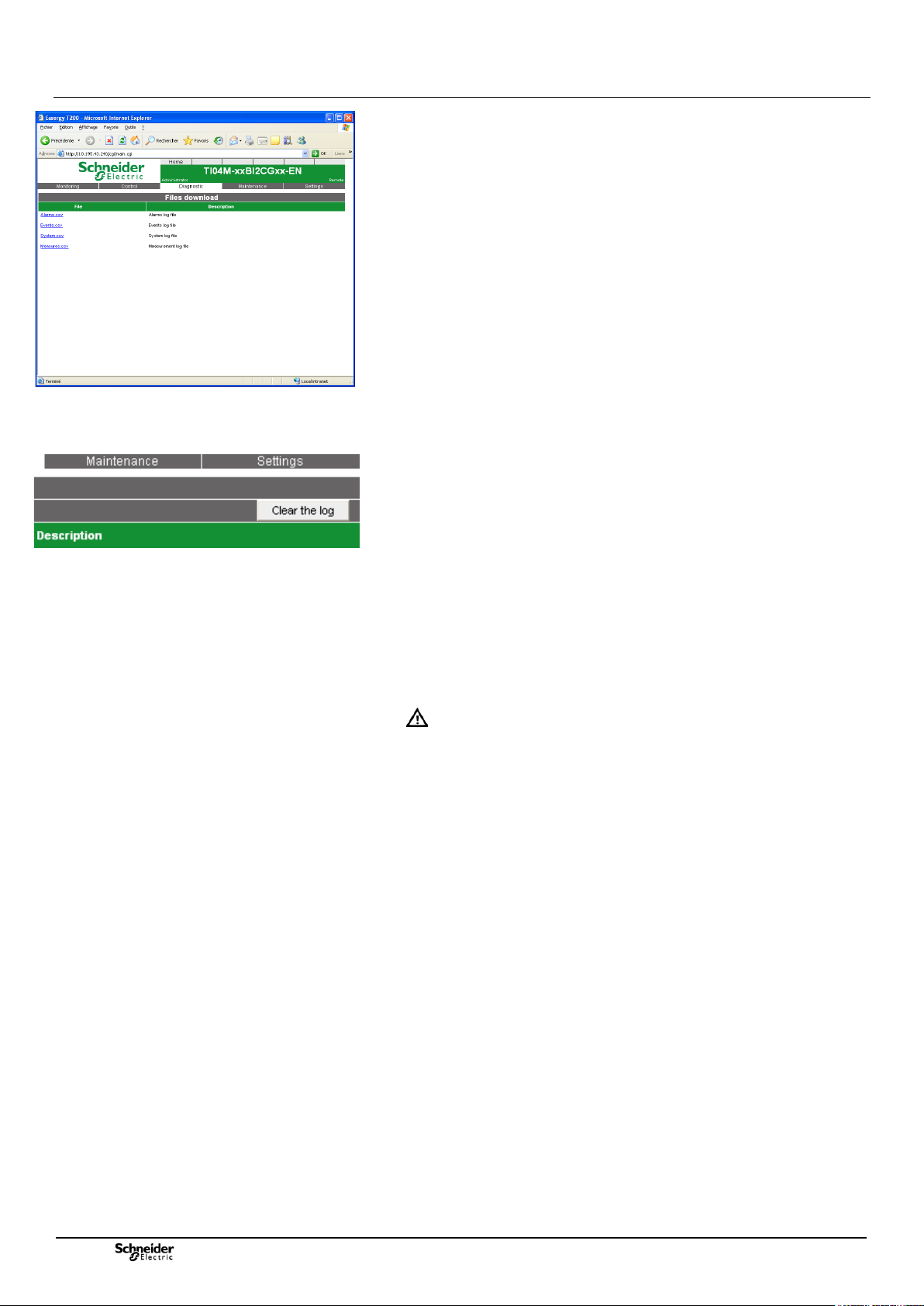

Files download – Diagnostic page

• A Files download sub-menu allows these logs to be saved to the PC in the form of

Excel-compatible files (*.csv files).

These files can be consulted or transferred, to enable the establishment of statistics

or reviews.

A "Clear the log" button in each log can be used to empty their content, i.e. to erase

all the information saved previously.

Principle of saving to logs:

To increase the life of the flash memory, saving to the logs is performed every 5

min.

Accordingly, when a reset is performed on the T200, it is possible that the most

recent events that have occurred since the last backup may not be saved in the

logs. The only exception is when imminent cut-out occurs on the enclosure. In that

case, even if the time elapsed is less than 5 min., the T200 saves the events to the

logs before cutting off the power supply.

ATTENTION : After a change of configuration, it is important to wait for

about fifteen seconds (the time needed for the equipment to store the

parameters in memory) before performing a reset on the equipment.

Otherwise, the equipment is likely to lose its configuration permanently.

18

NT00113-EN-05

Connection to the T200 Overview of the Web server

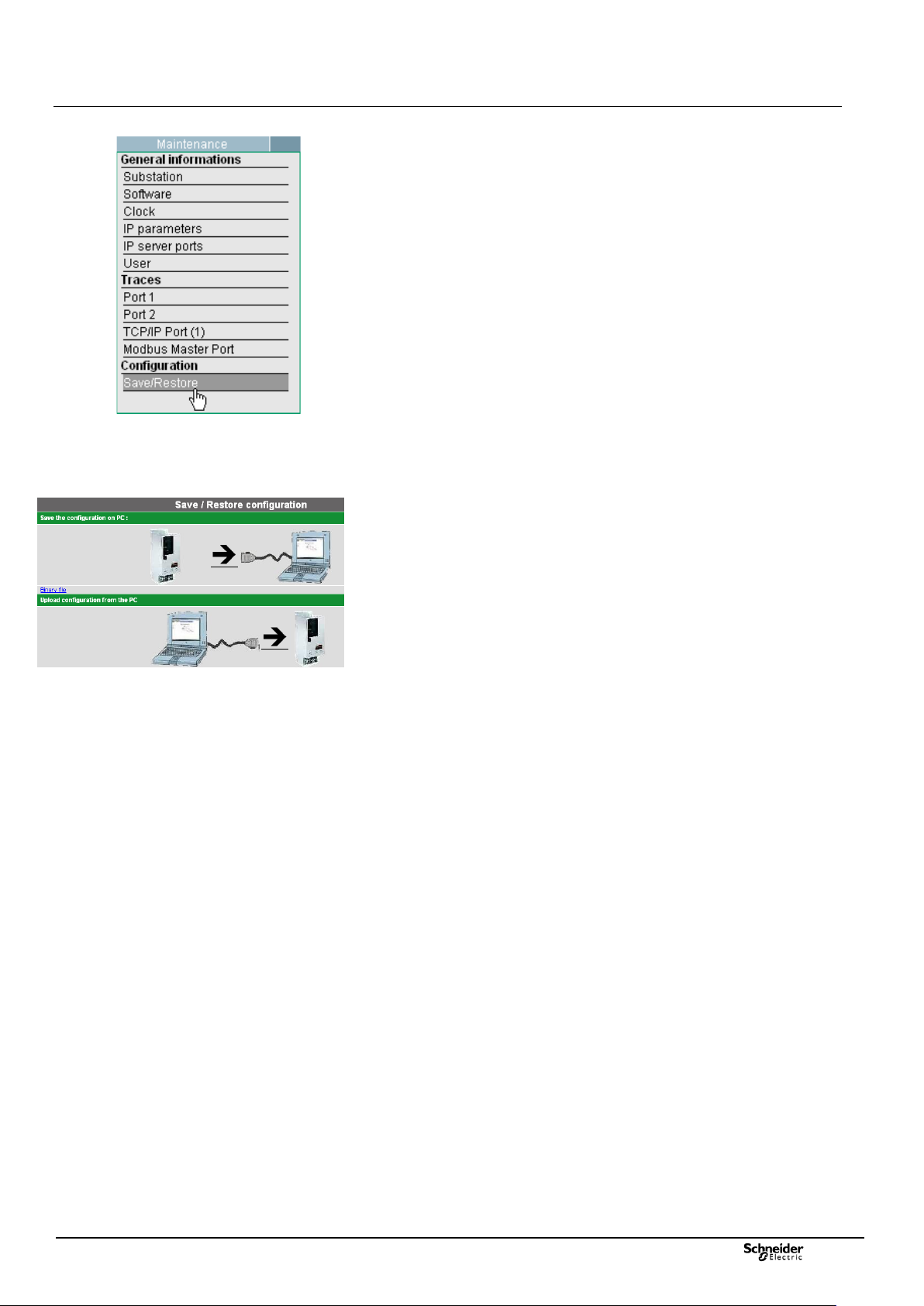

Drop-down list – Maintenance page

Substation information – Maintenance page

Port trace – Maintenance page

Saving/backup – Maintenance page

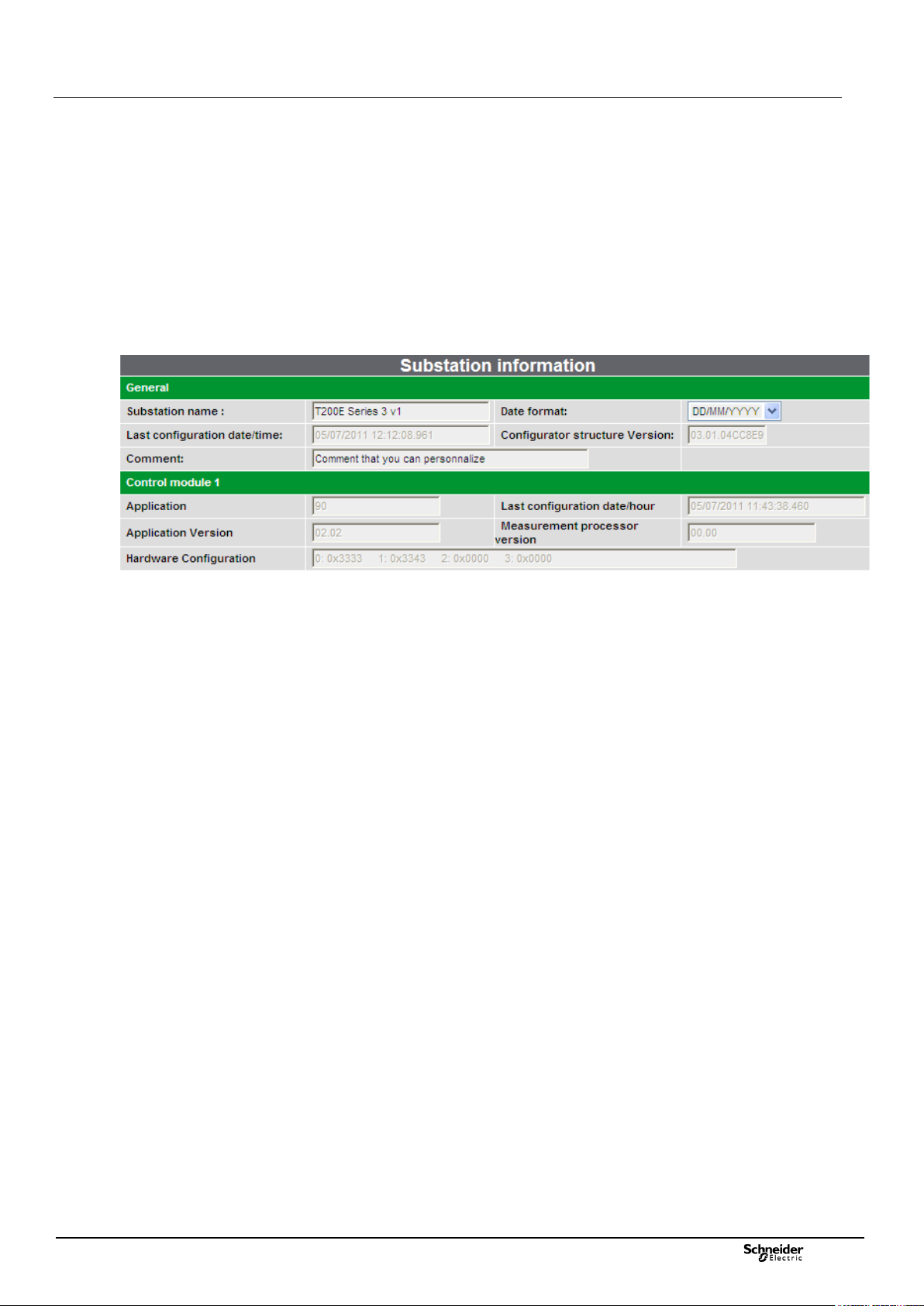

Maintenance Pages:

Several pages can facilitate maintenance of the T200, by giving information or

allowing configuration of the T200 application:

1. General information: Specific sub-pages provide information concerning the

T200 application, namely:

- Substation page: information concerning the current application (version No.

of the application and fault detector, date and time of last configuration, name

of substation, etc.).

- Software page: information concerning the software used by the T200

(version, date and time of compilation, size and CRC32).

The T200 is capable of storing two different software versions in memory. It

is possible to switch from one software version to another simply by selection

(if two versions are available).

It is also possible to load a new software version from a file available on the

PC or from a floppy disk or CD-ROM.

ATTENTION : The loading process manages only the file format with .zip

extension. The software must therefore not be unzipped before loading it on

the T200 (file with .mem extension not managed).

Note: When loading a software on the T200, one in fact loads the protocol

used for remote transmission but also all the equipment operating options,

including some that are managed and displayed by the Web server if

configured and/or detected physically on the COM card, namely:

- The Modbus master function

- The function of synchronization by GPS

- The digital input counting function.

- Clock page: Allows the T200 date and time to be configured manually or

automatically from the time on the PC.

A click on the "Update" button causes the manual change of date and time to

be accepted.

A click on the "Synchronization" button allows the PC date and time to be

taken into account automatically for configuration on the T200.

Comment: This configuration is possible only if synchronization by SNTP

server or by GPS module is not installed in the T200.

- IP parameters page: Allows consultation or where applicable configuration

of the Ethernet and USB interface parameters (IP addresses, sub-network

masks, etc.).

When a GPRS or 3G modem is installed on the COM card, this page also

allows consultation of the IP addresses assigned automatically by the

GPRS/3G server.

NB: It is dangerous to modify the Ethernet IP parameters, with a risk of no

longer being able to access the T200. Call on competent authorities to

modify these parameters.

- IP server ports page: allows redefinition of the port numbers used by the

T200 for COM card access, in the event that the transmission network does

not accept the default numbers (e.g. restriction on certain GPRS/3G

operators).

By default, the following port Nos. are configured on the T200:

HTTP server port = 80

Telnet server port = 23

Port 1,2 and TCP/IP trace server port = 1168, 1169 and 1170

TCP/IP port trace server port = 1170

This page is optional depending on the embedded software in the T200 (e.g.

present page for software including GPRS transmission).

NB: If the HTTP port number is changed in this page, to be able to log

on to the T200 Web server again, it is essential to add the port number

at the end of the T200's IP address preceded by a colon

(e.g. 10.207.154.239:1500 for a T200 access on port 1500).

- User page: Allows creation, modification or deletion of users and

management of rights (login, password, access rights).

2. Port 1 & 2 & TCP/IP & Modbus Master traces: The "Port 1, 2 and TCP/IP

traces" pages allow viewing, for each available port, of communication

exchanges between the control centre and the T200.

The "Modbus Master trace" page allows viewing of exchanges between the

T200 and the Modbus slaves of the substation (see additional manual

NT00121-xx).

This trace is displayed on screen in decoded form to facilitate reading of the

frame's content:

Column 1: frame time-and-date stamping (in

hour:minute:second.thousandth of second format).

Column 2: direction of dialogue, RTU -> PC or PC -> RTU, with

associated address Nos of the PC and RTU.

Column 3: hexadecimal frame + brief description of the content of the

frame.

NT00113-EN-05

19

Connection to the T200 Overview of the Web server

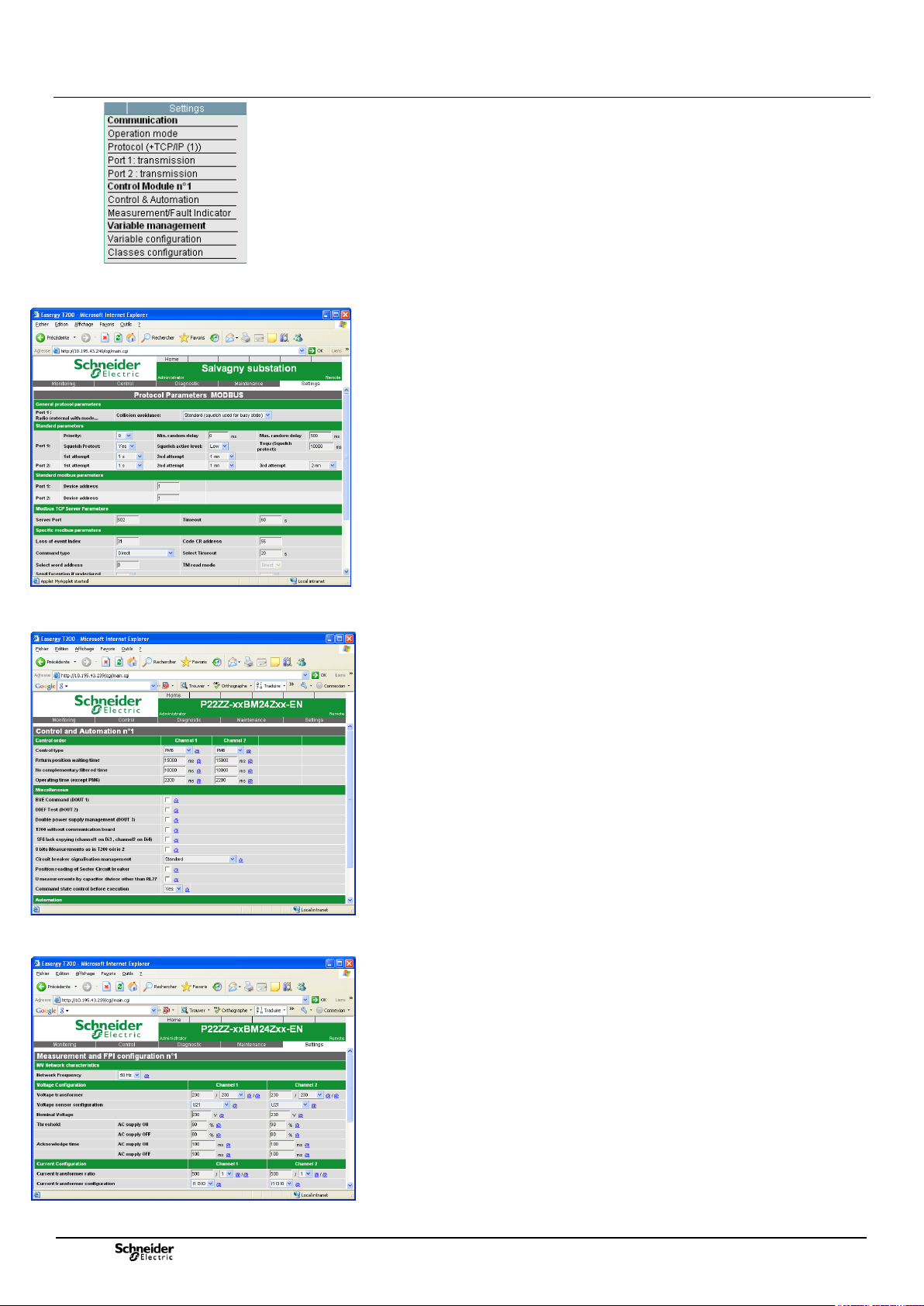

Drop-down list – Settings page

Protocol parameters – Settings page

Control and automation – Settings page

Measurements and fault detection – Settings page

3. Configuration:

- Save/Restore page: Allows all the current T200 configuration parameters to

be saved to a file.

It is also possible to load from a file available on your PC or from a floppy disk

or CD-ROM the T200 configuration parameters coming from a preceding

backup or coming from another substation.

This file can be used to configure one or more other substations in the same

way without being obliged to reconfigure all the parameters one by one.

Note: During loading from a file, the data integrity is verified automatically so as

to ensure the compatibility of application versions.

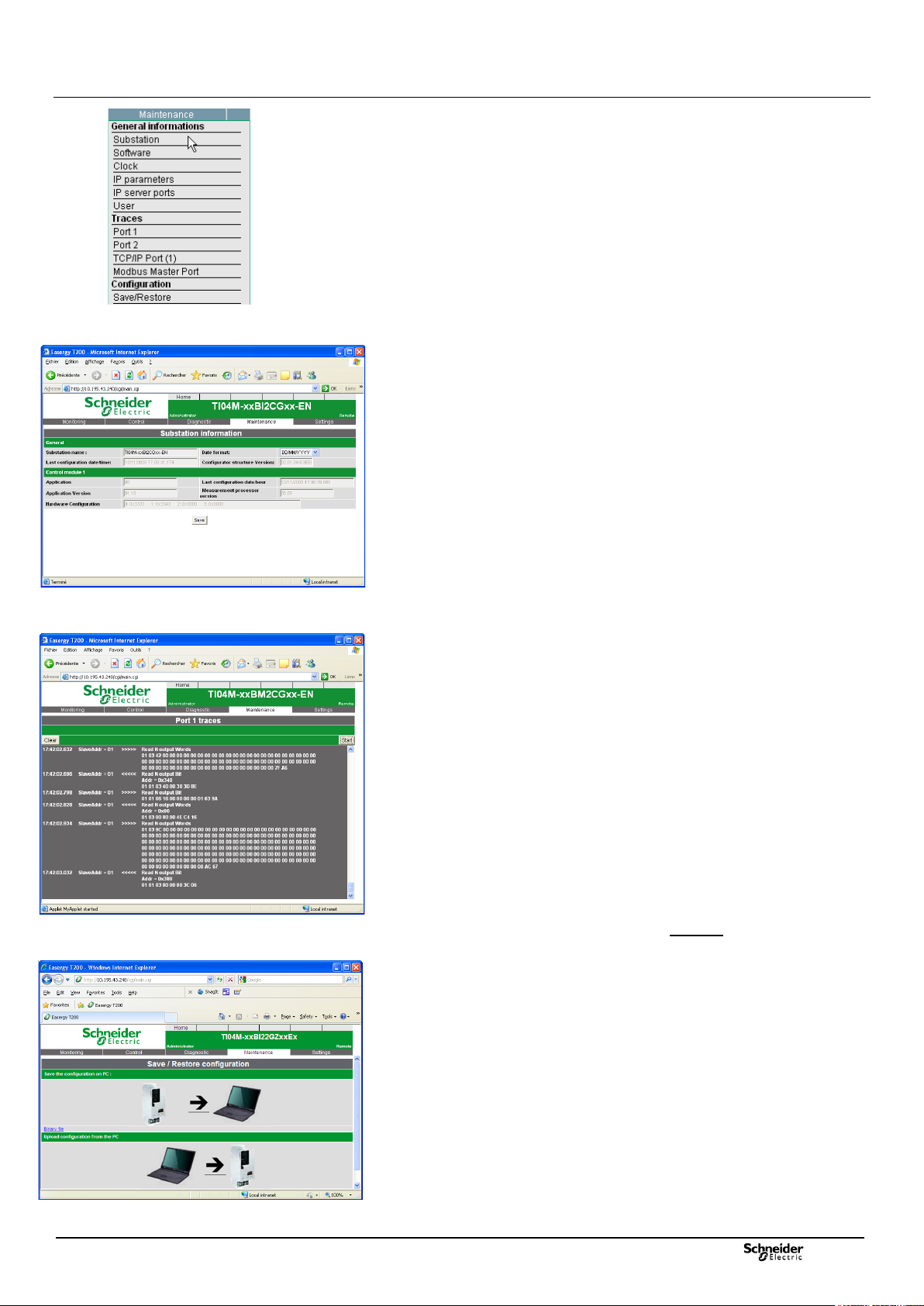

Settings Pages

Configuration of the T200 is performed from pages grouped together in several

different categories:

1. Communication: Several pages allow you to configure the specific

communication parameters of the T200:

- Operation Mode page: For each communication port available on the T200,

it is possible to determine:

The protocol available;

The type of transmission medium to be used (Radio, PSTN, GSM, etc.);

The way in which the ports will be managed according to one of the

available modes:

Not used

Normal

Balanced – Normal/Backup

Main – Normal/Backup

Backup – Normal/Backup

Store & forward

- Protocol + TCP/IP Protocol pages: These pages are used to configure the

parameters specific to the protocol used:

Max. number of send operations

Collision avoidance system;

Configuration of link addresses;

Frame size;

etc.

Note: Each type of protocol has its specific configuration page. For more

details, refer to the specific user manual for the protocol installed on the

T200.

- Ports 1 & 2 transmission page: This page is used to configure the

parameters of the communication port (modem):

Baud rate (e.g. 19200 baud);

Parity, stop bit, etc.;

Time-out management (e.g. RTS-CTS, CTS-message, etc.);

etc.

Note: The parameters displayed in this page depend on the type of

transmission medium configured in the Operating modes page.

- Modbus Master Port and Slave Configuration page:

These 2 menus can be used to configure communication with Modbus

slaves. The parameters setup for communication with Modbus slaves is

covered by additional documentation (NT00121-xx).

2. Control Module No. x: Some parameters of the T200 are managed for each

Control module of the T200.

Two pages allow this configuration:

- Control and Automation page: This page can be used to configure the

parameters related to electrical control of the switch and automation

management:

Type of switch (Standard, PM6, CI2 or other);

Change-of-position waiting time;

Type of automatic control;

Etc.

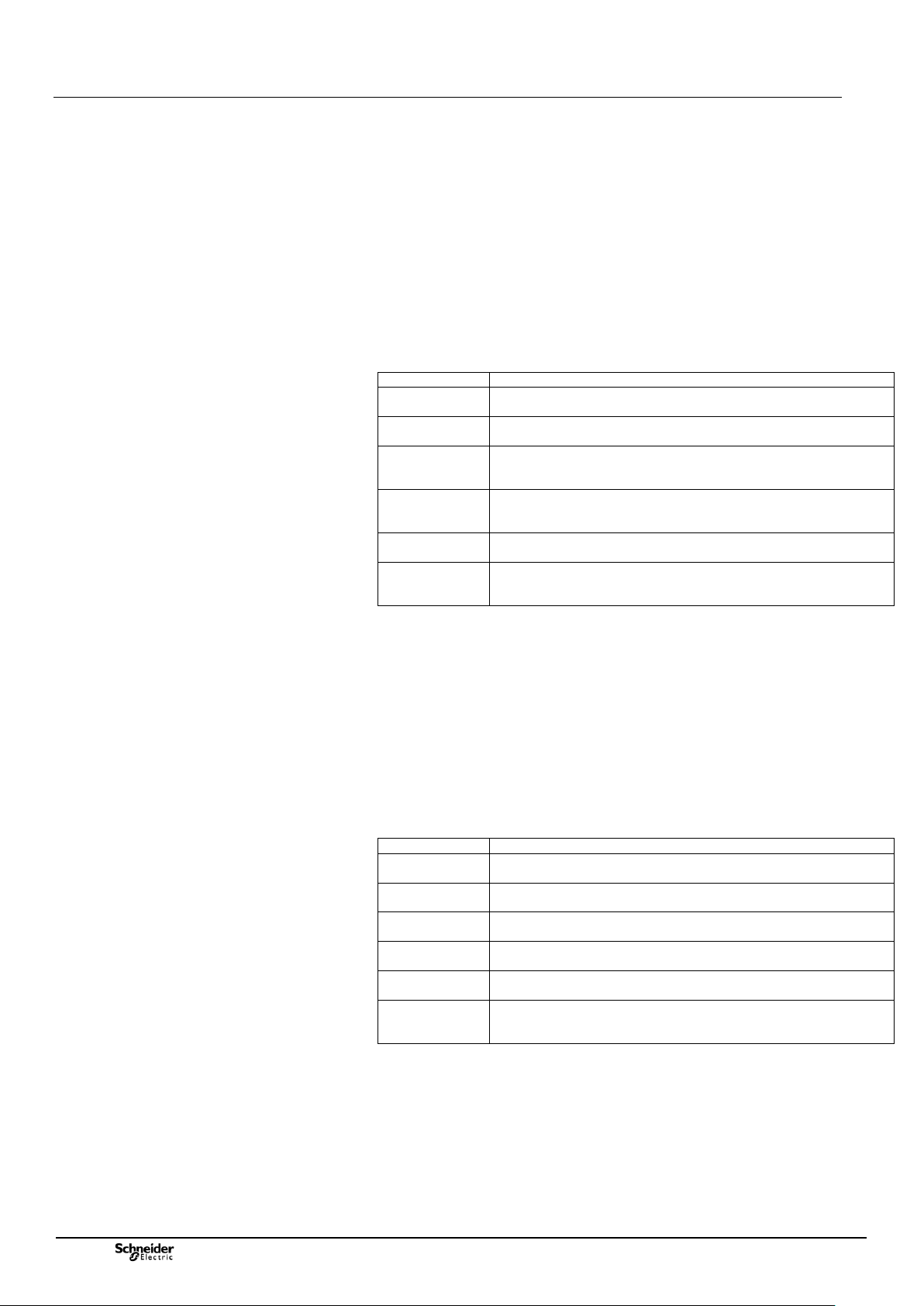

- Measurements/Fault Detector Page: This page allows configuration of all

the T200 analogue information, namely:

Mains frequency;

Current and voltage measurement parameters;

Fault detection parameters;

Etc.

20

NT00113-EN-05

Connection to the T200 Overview of the Web server

Variable Configuration – Settings page

Classes Configuration – Settings page

Example of variables associated to a class

Excerpted from the page: "Monitoring"

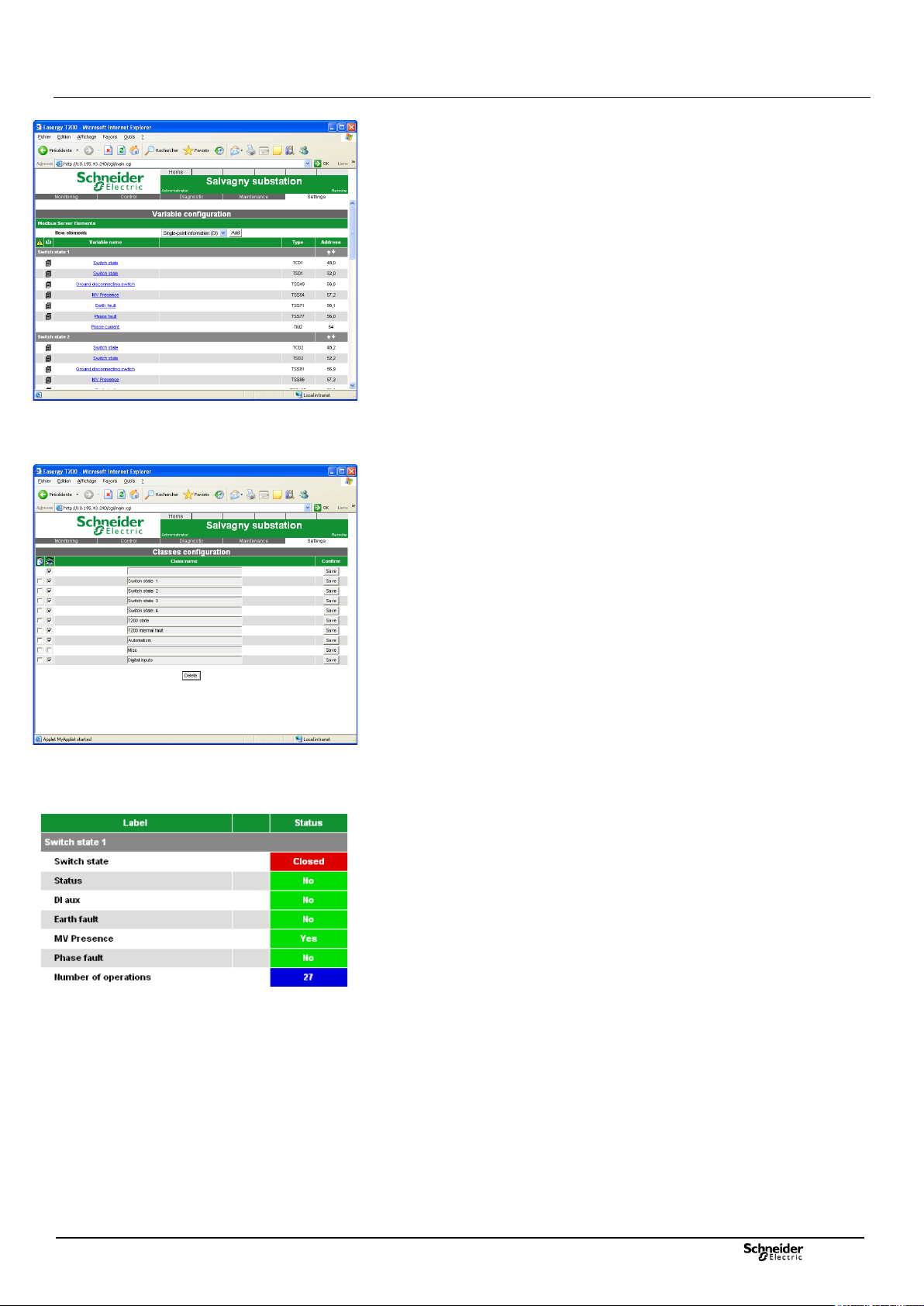

3. Variable management: All the information managed by the T200 must be

configured separately to define its operation and how it will be managed by the

embedded server:

- Variable configuration page: The complete list of information (variables)

managed by the T200 is displayed in this page, under various categories.

Depending on the type of variable, the configuration page and the

parameters displayed may be different. There is a specific type of page for:

Digital control orders (e.g. TCD)

Double indications (e.g. TSD)

Single indications (e.g. TSS)

Analogue measurements (e.g. TM).

Counter (e.g. CNT).

The parameters to be configured for each variable are (for example):

Variable name

Type of access (operator session, administrator session, etc.);

Assignment class;

Logical, remote and internal addresses;

Measurement, event and alarm management;

Type of recording for measurements (periodic, upon exceeding

high or low threshold, upon % variation or indication of min. and

max. values per period);

etc.

Note: The parameters to be configured depend on the type of page

displayed.

- Classes Configuration page: The variables created can be grouped

together by classes, so as to facilitate the management and display of

variables. Each variable can be assigned to one of these classes by

configuration. This page can be used to create, modify or delete the

classes managed by the embedded server and determine those that will

be visible in the Monitoring page.

- Modbus master communication and Slaves configuration pages:

consult the user's manual NT00121-xx.

- Embedded PLC and Formulas and Peer to Peer pages: consult the

user's manual NT00320-xx.

NT00113-EN-05

21

Commissioning T200 settings

3 T200 settings

This chapter aims to provide the user with all the information needed to be able to

perform configuration of the T200 data.

Certain complex functions of the T200, in particular, require some detailed

explanations (fault detection, automatic control, etc.) for a better understanding of

how to configure the T200.

The functions discussed in this chapter are as follows:

Comment area

Configuration of synchronization by GPS

Configuration of SNTP service

Configuration of Ethernet interfaces

Backup/Restoral of configuration parameters

Configuration of communication with the Supervisor

Configuration of switch controls

Configuration of the various options

Automatic control configuration

Configuration of the fault detection module

T200 variable configuration

Class configuration

22

NT00113-EN-05

Commissioning GPS synchronization setting

3.1 Comment area :

Access: "Maintenance/Substation" page.

The user can fill in an additional free 50-character comments area,

in the "Maintenance/Substation" page of the T200's embedded

Web server.

No special processing is performed on these comments. It is

simply a text to give the user explanations on the equipment or the

associated MV/LV substation.

NT00113-EN-05

23

Commissioning GPS synchronization setting

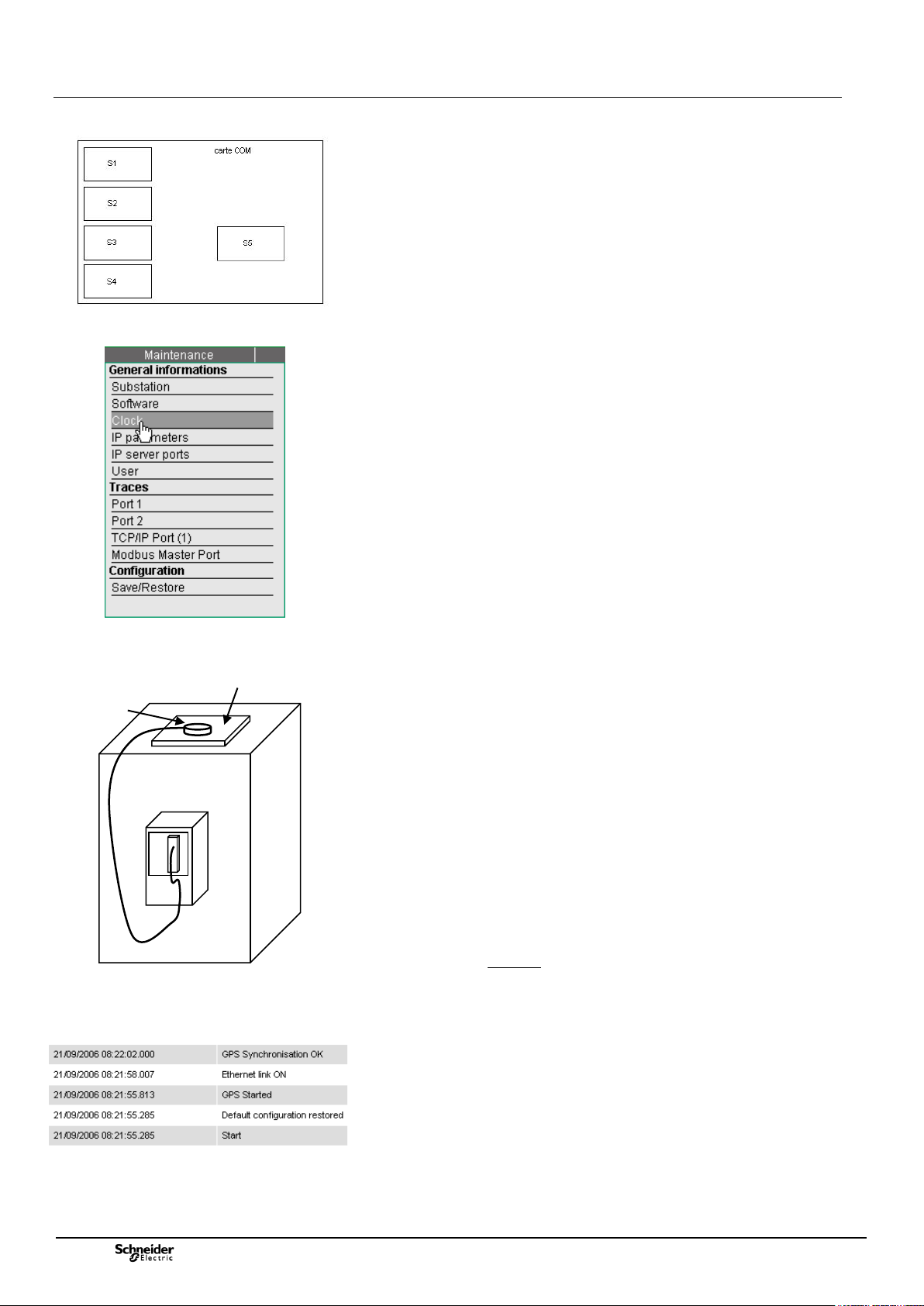

T200

MV/LV substation

Metal plate support

GPS antenna

Installation of the GPS antenna

Example of events generated by the GPS function in

the "System" log

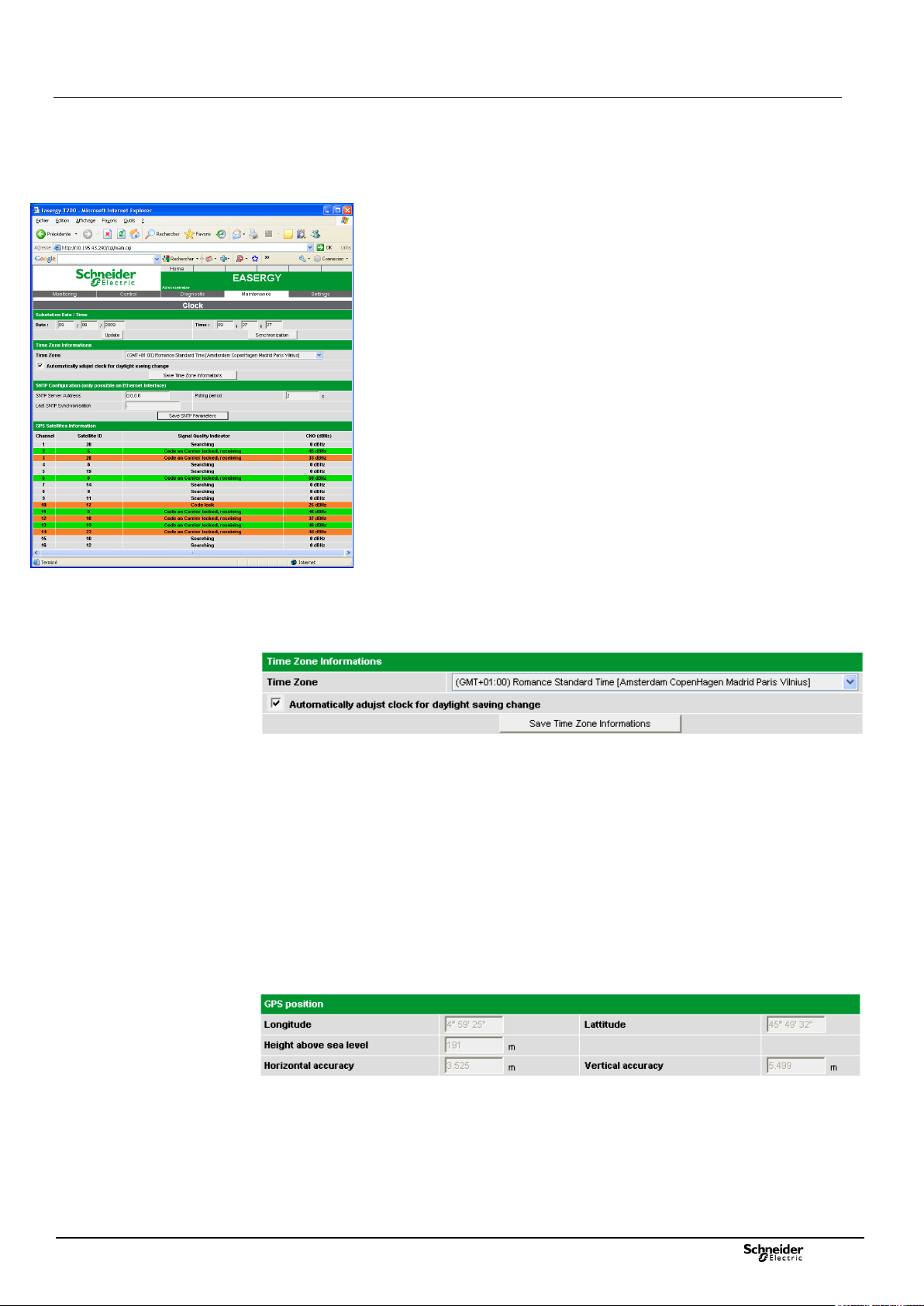

3.2 Configuration of synchronization by GPS

Access: "Maintenance/Clock" page.

In standard configuration, the T200's time can be set manually by the user or by

synchronization from a PC connected to the T200.

On option, the T200 can also be synchronized via a GPS module.

This module allows the equipment to time stamp events precisely, without internal

clock time drift.

The supply for this kit includes a GPS card, installed in factory on the COM card of

the T200 (slot S5) and a GPS antenna with a cable 5m long.

On option, an antenna extension cable 10m long is available.

Operating principle

The T200 is synchronized every second automatically from the GPS network,

provided that the satellite signal reception levels are adequate.

The T200 can receive information from at most 14 satellites at the same time.

The larger the number of satellites, the more precise will be the measurements

based on the GPS signals.

Upon initialization of the COM card, the minimum time for satisfactory reception of

the GPS satellite signals ranges between 5 min. and 15 min. (it depends on the

quality of the signals received).

The average precision of time setting is approximately 1 ms (discrimination between

two events: 10 ms).

Events specific to the GPS function are generated by the COM card (in the

"System" log) so as to provide information concerning the operating status of the

GPS module:

- "GPS started"

- "GPS synchronization OK"

- "GPS synchronization lost"

Comment: When the GPS option is present, it takes priority over SNTP time

synchronization or manual time synchronization.

Antenna mounting:

On request for this option, the T200 is supplied with a GPS signal acquisition card.

This card is installed in factory on slot "S5" of the COM card.

Note: The synchronization by GPS option can be installed only on a "full" type COM

card.

For the GPS option to operate, it is necessary to install the GPS antenna outside

the enclosure, on a horizontal metal mounting (the antenna being magnetized), in a

location where the GPS signals may not be disturbed by nearby obstacles that

could act as a screen (wall, building, etc.).

The GPS sensor should be installed so as to have a free field around it, so as to

receive the satellite signals correctly. (e.g. roof of the substation where the T200 is

located: see drawing opposite).

The GPS antenna can withstand a temperature range of: -40°C / +85°C.

24

NT00113-EN-05

Commissioning GPS synchronization setting

Information relating to the GPS function:

When the GPS card is installed on the COM card, the T200 automatically tries to

connect to the GPS network.

When the GPS signals are detected at a sufficient level, the "Clock synchronized by

GPS" display appears in the Maintenance/Clock page of the embedded Web server

of the T200 and the configuration/monitoring parameters related to this option are

displayed (see image below).

When the GPS signals are detected at a sufficient level, it is then no longer possible

to configure the PC time and date manually. The GPS card automatically takes

control of time setting for the device and also overrides time setting by SNTP (if the

latter is present).

For correct operation, the GPS option requires configuration of the following

parameters:

Information concerning the time zone:

The time provided by the GPS satellites is GMT universal time.

It is therefore necessary to configure the time zone corresponding to the country in

which the T200 is located so that the time on the T200 matches the local time in the

country. To do so, perform the following configuration:

- Time zone: In the proposed drop-down list choose the zone corresponding to

the local time zone (closest city having the same time zone).

- Adjust the clock for automatic observation of summer time: Check the

box "Adjust clock for automatic summer time adjustment" if the T200 is to

perform automatic time setting of the clock for changes related to the transition

to summer time and winter time.

- Save Time Zone information: Click on this button to accept changes in the

configuration.

GPS position:

This section gives information concerning the information delivered by the GPS

satellites, namely:

- Longitude and latitude

- Height above sea level

- Precision of horizontal measurement (longitude and latitude)

- Precision of vertical measurement (altitude)

Comment: The GPS position data appear in the page only when time

synchronization is performed with the satellites.

NT00113-EN-05

25

Commissioning GPS synchronization setting

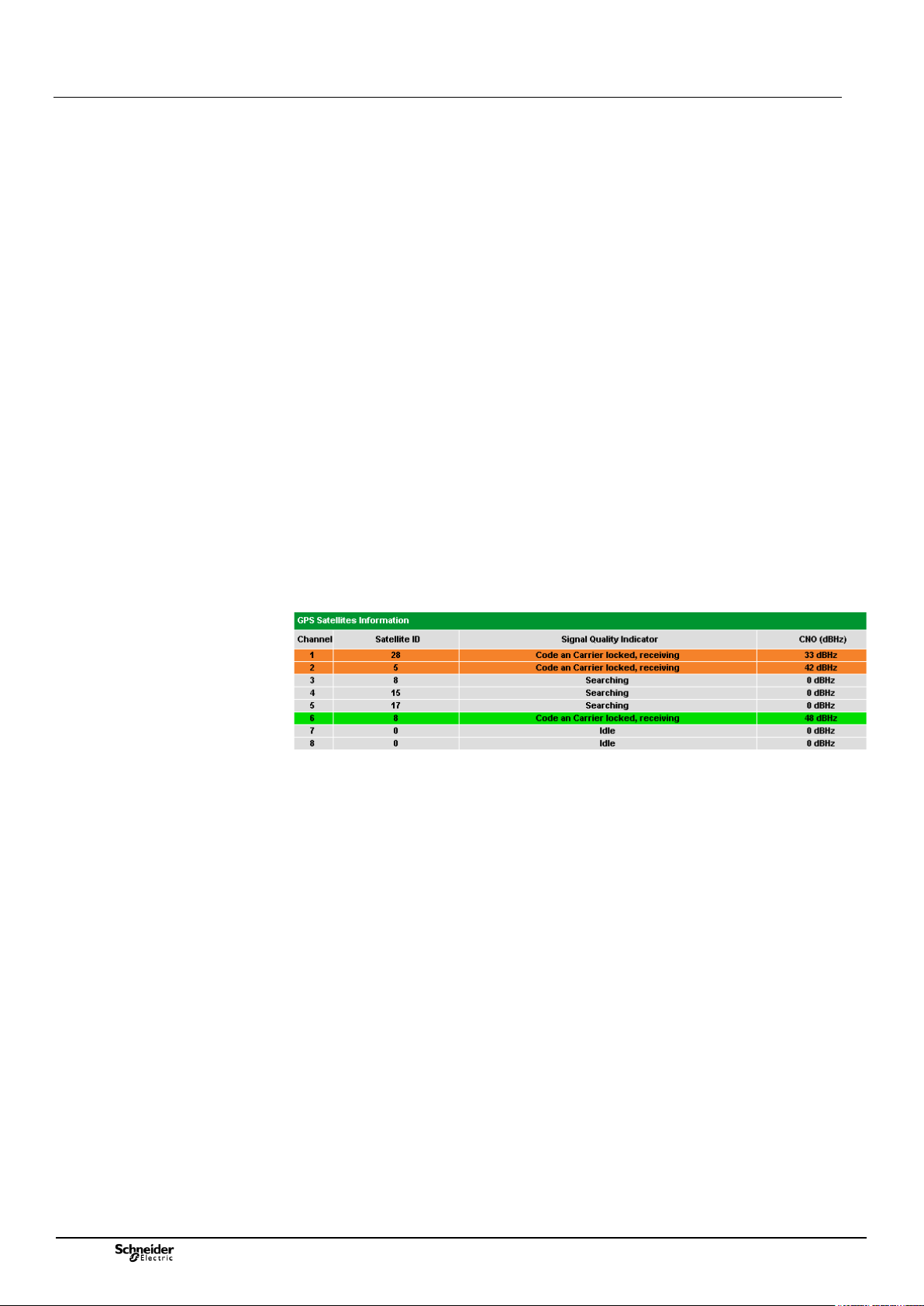

GPS satellite data:

This section gives information concerning the quantity and quality of the GPS

signals received from the satellites:

- Channels 1 to 14: The T200 assigns a channel number for each satellite

detected.

- Satellite identification: GPS identification No. of the satellite detected.

- Signal status: Provides knowledge of the connection status of the satellites. 6

statuses can be displayed:

Not connected: displayed in grey colour

Search in progress: displayed in grey colour

Signal detected, but unusable: displayed in red colour

Signal captured: displayed in green colour if signal quality ≥ 45, otherwise in

orange colour

Signal and carrier wave captured: displayed in green colour if signal quality

≥ 45, otherwise in orange colour

Signal and carrier wave captured, reception: displayed in green colour if

signal quality ≥ 45, otherwise in orange colour

Comment: The colour of display of each line makes it possible to know the state of

the GPS connection:

Grey colour: no connection or connection in progress

Orange colour: connection performed but not finalized or with mediocre

reception level but sufficient for synchronization.

Green colour: Connection performed with very good reception level.

Red colour: Reception level too weak, no connection possible.

- Signal quality: Value displayed in dBHz allowing assessment of the quality of the

signal level received for each satellite.

Level ≥ 45 dBHz: Very good reception level

Functioning of GPS synchronization:

At least two satellites in reception are required (with reception level ≥ 45 dB) for

time synchronization and position locating (longitude and latitude) to be operational

on the T200.

The larger the number of satellites, the more precise will be the measurements

based on the GPS signals.

26

NT00113-EN-05

Commissioning Ethernet interface setting

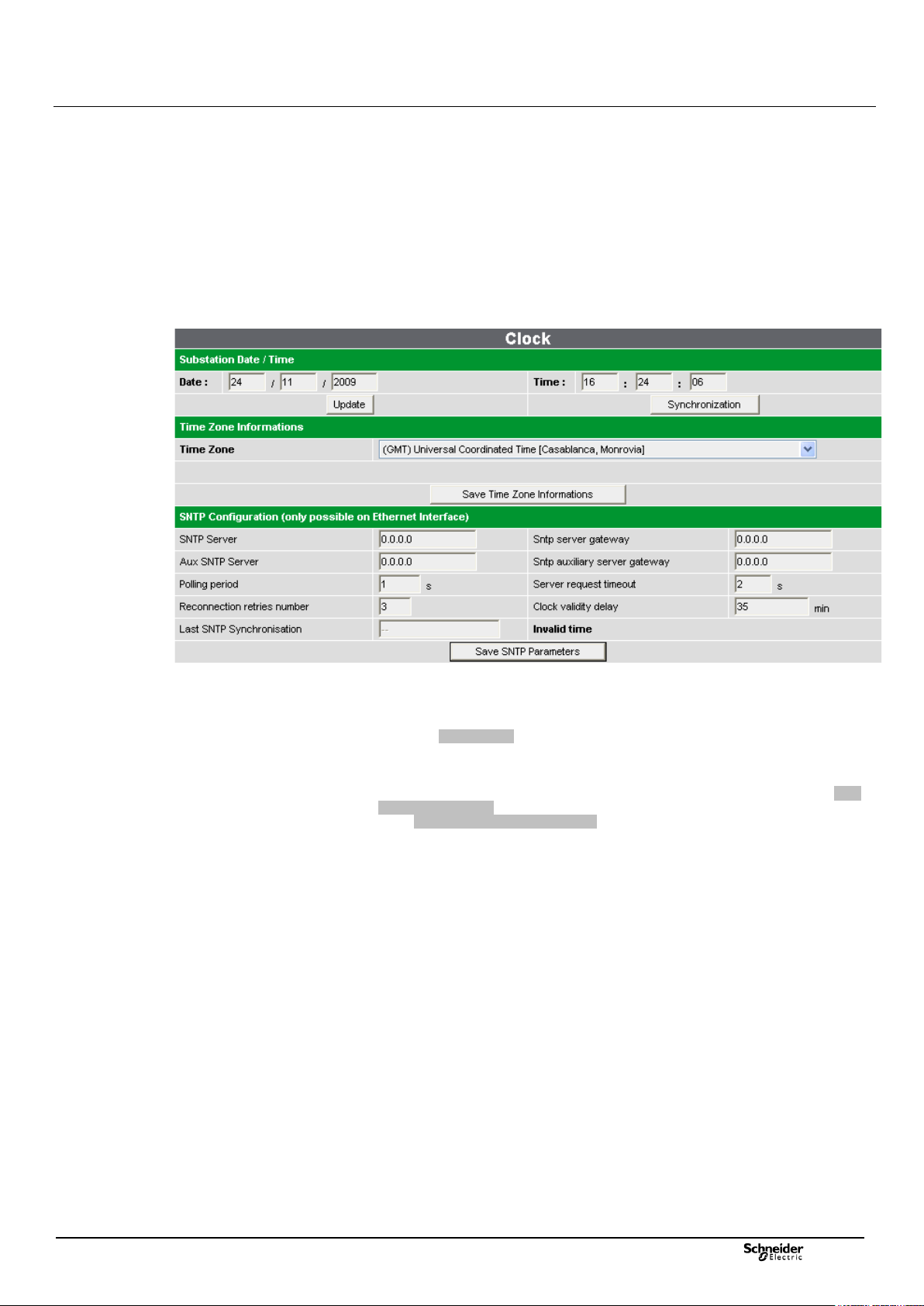

3.3 Configuration of SNTP service

Access: "Maintenance/Clock" page.

The T200 incorporates an SNTP client. It allows the time on the internal clock of the T200

to be set automatically from a network synchronization server, when T200 is connected to

this network.

Comment: When the SNTP option is configured, it overrides manual synchronization of

the T200 time and date. It is then no longer possible to configure the PC time and date

manually.

Operating principle

The T200 includes the capability for defining 2 different SNTP servers, one main server

and one auxiliary server, each being on different networks.

When the "Polling period" time delay configured has expired, the T200 sends a request to

the main SNTP server.

If the T200 receives a synchronization from the main SNTP server, the time on the latter is

set and the synchronization cycle is completed.

If the T200 obtains no response from the main SNTP server after the end of delay "Max.

server response time" has elapsed, the T200 attempts a new connection again.

If the "Number of reconnection attempts" is reached, the T200 tries to become

synchronized with the auxiliary SNTP server.

The cycle ends once the T200U has been synchronized with the second server or when it

reaches the "Number of reconnection attempts".

Configuration parameters:

• SNTP server and auxiliary SNTP server: IP address of the main and auxiliary

SNTP servers.

Note: When the address is set to "0.0.0.0", the synchronization by SNTP function is

deactivated on the server.

• Synchronization period: Allows the time synchronization period to be defined via

the SNTP server. Configurable from 1 to 300 seconds.

• Number of reconnection attempts: Upon failure of synchronization with the server,

max. number of attempts to be made.

• Last SNTP synchronization: Indication of the time and date of the last SNTP

synchronization performed (consultation exclusively).

• SNTP server gateway and auxiliary SNTP gateway: Address of the gateway for

access to the main and auxiliary SNTP servers.

• Max. server response time: Maximum time waiting for the reply from the SNTP

server before making a further attempt at synchronization.

• Period of validity of the clock: Time after which the T200 must be resynchronized

with the SNTP server.

NT00113-EN-05

27

Commissioning SNTP service setting

T200

Supervisor 1

Supervisor 2

ADSL

GPRS

1 Ethernet interface

2 virtual IP address

10.x.x.x

10.a.a.a

10.y.y.y

10.b.b.b

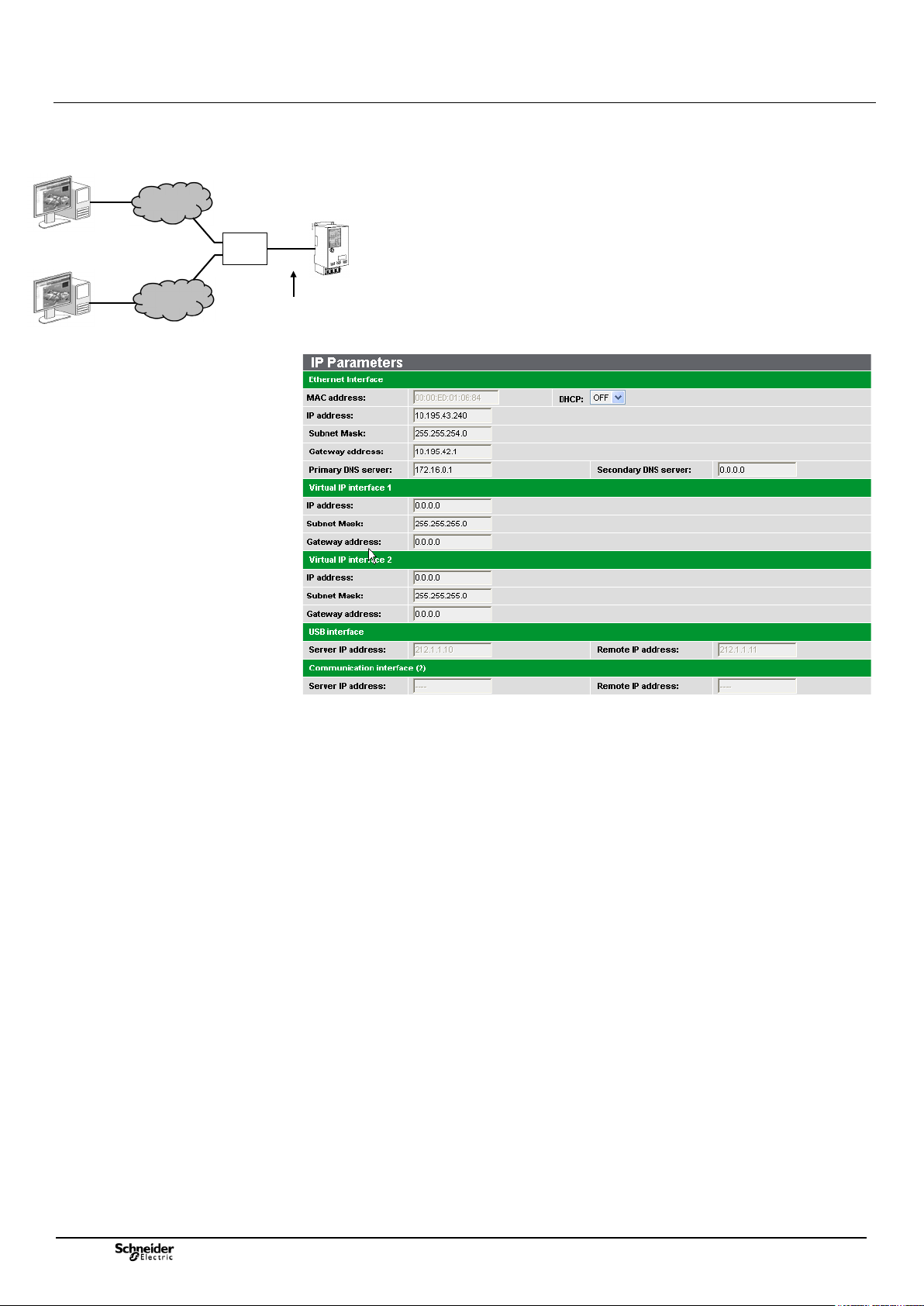

3.4 Configuration of Ethernet interfaces

Access: "Maintenance/IP Parameters" page.

This page can be used to configure the Ethernet connection parameters of the T200.

The T200 can include three IP addresses specific to the device, to allow simultaneous

connection from several TCPI/IP network access points including specific address (e.g.

Router

several Supervisors who wants to access T200 from different TCP/IP network – see

example).

The three IP addresses use the same network physical interface (single Ethernet port on

the COM card). For this reason, the two additional IP addresses added to that included as

standard in the "Ethernet Interface" part are called virtual Ethernet interfaces 1 and 2.

Note : The GPRS or 3G port is not is not affected by these virtual addresses.

Interface Ethernet :

• MAC address: Unique identification address for each T200, set in factory.

(Consultation exclusively)

• DHCP: Defines whether the router of the Ethernet local area network can allocate a

new IP address to the T200 automatically upon a new connection. It is recommended

not to activate this function or else you could no longer be able to log on to the T200

if the modified address is not known.

• IP address: Base IP address of the T200 (as standard: 172.16.0.5).

• Sub-network mask: The mask defines the possibility of configuration of the IP

address on the Ethernet network. For each IP address field, (0) means authorization

of 255 values and (255) means fixed value for this field.

(As standard: 255.255.255.0)

• Gateway addresses: IP address of the server's Ethernet gateway. The gateway

centralizes all the network IP accesses (as standard: 172.16.0.1).

• Primary DNS server: IP address of the primary DNS server (Domain Name Server).

The DNS enables the IP addresses to be associated with the website names (as

standard: 172.16.0.1).

• Secondary DNS server: IP address of the secondary DNS server (Domain Name

Server). Backup DNS server (as standard: 0.0.0.0).

Ethernet virtual interface 1 and 2:

• IP address: IP address for the virtual interface. If set to "0.0.0.0", the virtual interface

is deactivated.

• Sub-network mask: Sub-network mask of the virtual interface (same functioning as

the Ethernet interface).

• Gateway addresses: IP address of the Ethernet gateway of the virtual interface

(same functioning as the Ethernet interface).

USB interface:

• Server IP address: IP address of the T200's embedded Web server for USB access.

Unmodifiable (as standard: 212.1.1.10).

• Client IP address: IP address assigned to the PC connected via USB to the

embedded Web server. Unmodifiable. (As standard: 212.1.1.11).

28

NT00113-EN-05

Commissioning Ethernet interface setting

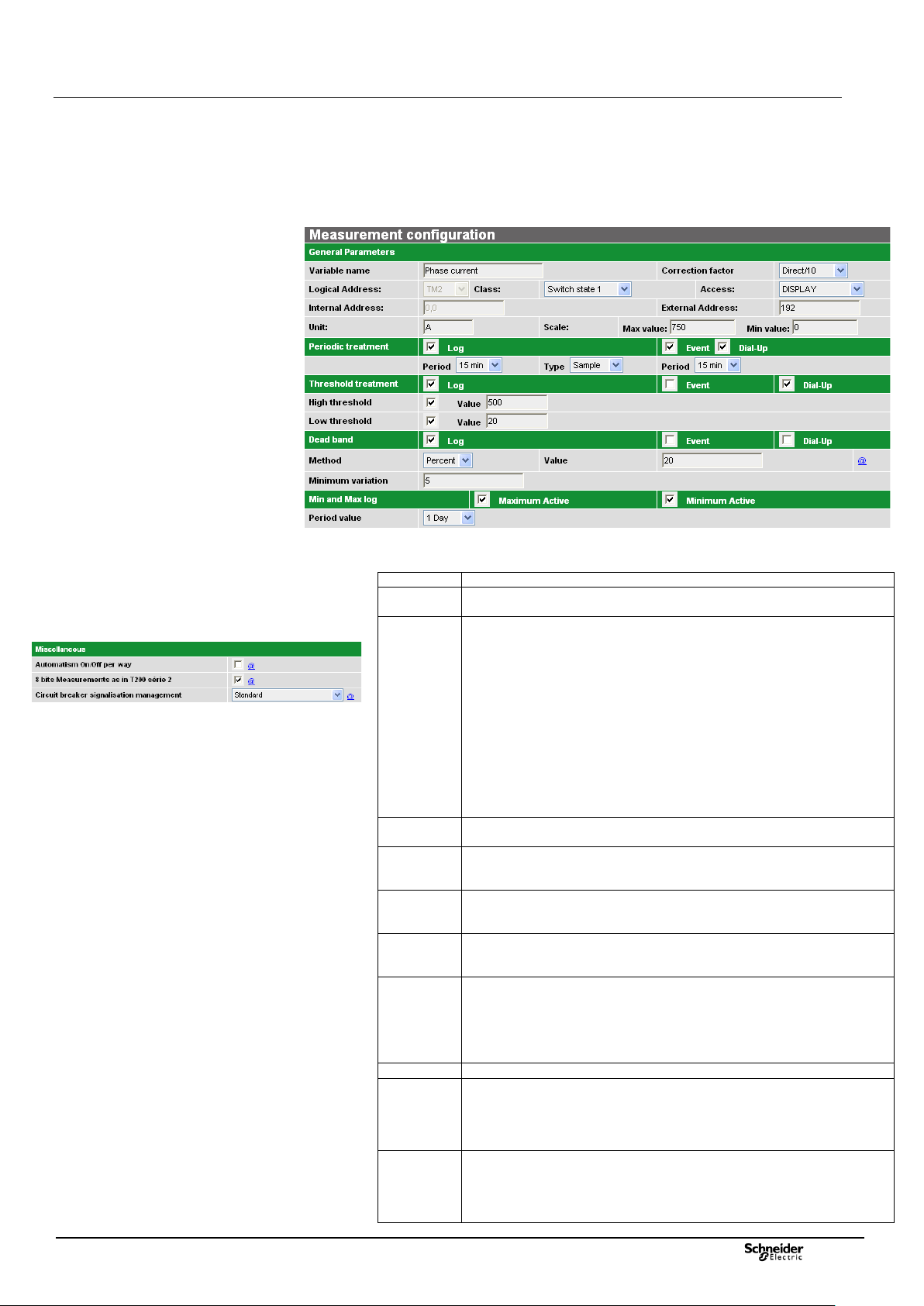

Backup/Restore page

3.5 Save/Restore configuration parameters

Access: "Maintenance/Save-Restore" page.

The T200 can save in file form all the configurable parameters of the equipment

(except the parameters of the "IP parameters" page which remain specific to each

equipment item).

This file can then be used for downloading to other equipment of the same type,

thus enabling the T200 to be configured automatically without needing to redo the

entire configuration manually, which would be rather onerous.

However, the parameters specific to each T200 must then be personalized (e.g.

protocol address, fault detection thresholds, etc.).

The "Maintenance/Backup-Restoral" page provides access to backup/restoral

resources.

Saving the configuration on PC:

This section describes saving of the T200 configuration in file form (T200 PC

direction).

There are two possible backup file formats:

- Zipped text file: Click once on the arrow (T200 PC) and the T200 automatically

creates a compressed text file (file with *.zip extension) containing the T200

parameters.

- Binary file: Click once on the "Binary file" link and the T200 automatically creates

a binary file (file without extension) containing the T200 parameters.

Note: There is in theory no need to use the binary format for backup, except if you

want to generate a backup compatible with an old software version of the T200 (see

chapter below: "Backup file compatibility").

Downloading the configuration from the PC:

This section describes downloading to the T200 the parameters contained in a

backup file (PC -> T200 direction).

In this mode there is only a single button for downloading.

The T200 automatically detects the type of file downloaded and manages the

reading of information accordingly.

It is possible to download three types of files:

Text file (extension: *.txt)

Binary file (without extension)

Compressed text file (*.zip extension).

Backup file compatibility:

In the first T200 software versions (versions below V2.50 or V3.50), backup and

restoral was possible only in a single type of file format (binary file).

To be able to load these old backup files on a recent T200, it is essential that the

T200 include a V2.5x or V3.5x version. A V4.0x or upper version will not allow this

type of file to be loaded for reasons of incompatibility.

You should therefore proceed in two stages to load a configuration file coming from

an old software version on a T200 containing a recent software version of the V4.xx

or upper type:

1. Load the old configuration file on equipment incorporating an equivalent

software version (e.g. V2.5x for V2.yx versions and V3.5x for V3.yx versions,

with y is lower than 5).

2. Save the configuration in file form (choice of format: without extension or *.zip).

3. Load software version V4.xx or upper on this equipment.

4. Load the configuration file saved previously.

5. Save the configuration.

6. The file obtained will then be compatible with recent software (V4.xx or upper,

V2.5x or V3.5x).

Note: The file obtained will no longer be compatible with the old software

(versions below V2.50 or V3.50). If the software version has not been updated

on all the T200's, it is therefore wise to keep both types of backup (old and

new).

NT00113-EN-05

29

Commissioning Communication configuration

Display of the position of the fictitious "Dummy

Control" device in the "Monitoring" page of the Web

server.

3.6 Dummy Control option

Access: "Monitoring" page.

This option allows remote simulation, from the Supervisor, of an opening or closing

remote control action on the T200.

The aim is to verify protocol exchanges between the T200 and the Supervisor by

sending a double telecontrol, but without risk of really actuating a switch, because

the command is executed only on a fictitious device installed on the COM card

("Dummy Control" module).

This option requires addition of the "Dummy Control" module on the COM card on

the port 1 slot used for transmission to the Supervisor.

No specific parameters setup is necessary to use this option. The COM card

automatically detects the presence of this module on port 1.

Configuration of the T200 must nevertheless be provided for to use the Dummy

Control option. This option can be activated (on port 1 of the COM card) by the

"OFF line" configuration (available on the Easergy CD supplied with the T200 folder

"Tools\OFF-Line Configurator"), by generating a configuration file and loading it on

the T200.

Note: When the "Dummy Control" module is installed on port 1, it is no longer

possible to communicate on this port except in RS232 mode, and this only from the

DB9 port on the right-hand side of the rack..

30

NT00113-EN-05

Commissioning Communication configuration

Excerpted from the page: "Settings/Operating mode"

3.7 Parameters for communication with the supervisor

The COM card of the T200 is designed to detect automatically the type of modem

that is installed on the communication ports used for transmission to the SCADA

system (ports 1 and 2).

The configuration software automatically proposes a choice of media on these ports

which will correspond to the type of modem installed.

The parameters present in the configuration pages for ports 1 and 2 take into

account the type of medium that has been selected, because each type of medium

has specific configuration parameters.

The configuration page for protocol parameters may take also into account certain

parameters related to the type of medium selected.

Comment: The protocol parameters related to the type of medium will be described

in this chapter. The other parameters related to the protocol will not be described in

detail, however. For more information concerning the latter, refer to the User's

Manual for the protocol.

3.7.1 "Operating Mode" page

Access: "Settings/Operating Mode" menu

Objective of this page: Activate the transmission ports and select the type of modem

to be used and how it will be managed (up to two communication ports available).

The parameters for this page can be consulted and/or modified depending on the user profile.

Configuration for each port used (Port 1 or Port 2):

Mode: Allows choice (or merely gives an indication depending on the protocol)

of the transmission mode used for dialogue with the SCADA system.

Depending on the protocol used, there is a choice between one of the two

modes mentioned below. Some protocols are fixed from the transmission

mode viewpoint and do not allow this choice.

In that case, the T200 proposes merely an indication, with no possibility of

modification:

- Master/Slave: communicates exclusively in the Scada -> T200 direction.

No remote alarm function used in this mode.

Depending on the protocol, the exact title displayed may be:

"Unbalanced" (e.g. IEC protocol);

"Master/Slave" (e.g. PUR protocol);

"No report by exception" (e.g. Modbus protocol);

"No unsolicited response" (DNP3 protocol).

- Master/Master: communicates in both directions, Scada -> T200 and

T200 -> Scada.

The remote alarm function will be used in this mode if one of the modes

mentioned below corresponding to the Master/Master mode is configured.

On the other hand, the remote alarm function will not be used if the

Master/Slave mode mentioned above is configured.

Depending on the protocol, the exact title displayed may be:

"Balanced " (e.g. IEC protocol);

"Master/Master" (e.g. PUR protocol);

"Report by exception" (e.g. Modbus protocol);

"Unsolicited response" (e.g. DNP3 protocol).

Comment: The "Report by exception" mode is not really a Master/Master

mode. It is in fact a Master/Slave mode with the possibility of alarm sending

to the SCADA system by means of the "Report by exception" function,

which from the functional viewpoint resembles a Master/Master mode.

NT00113-EN-05

31

Commissioning Communication configuration

From the page: "Settings/Operating mode"

Link: Allows definition of the way in which the ports will be managed according

to one of the following modes:

Off: No transmission over this channel.

Normal: Main transmission channel to the SCADA system. Two

"Normal" channels with the same protocol but with different

characteristics (e.g. type of transmission) can be used if there are two

remote control systems (main and maintenance). The T200 cannot

manage simultaneous remote controls coming from the two systems.

Balanced – Normal/Standby: Two channels are necessary in this

mode. The operation of the channels is symmetric. In the event of a

fault on the channel in service, switchover to the other channel takes

place automatically.

Main – Normal/ Standby: Requires another channel as " Standby –

Normal/Standby". Same operation as "Balanced" but with priority use

of the main channel.

Standby – Normal/ Standby: Requires another channel as "Main –

Normal/Standby". Same operation as "Balanced" but with use of the

backup channel if failure of the Main channel. A configurable option

can be used to define a priority return to the main channel if the latter

becomes available again.

Store & Forward: Function used only in radio mode. In addition to the

normal channel function of transmission to the SCADA system, this

channel is also used for relaying to an auxiliary T200 located within

reach of transmission and which is not accessible by any other means.

Test: (in radio mode only). Allows a fixed frequency to be generated on

the radio network to allow antenna installation adjustment operations or

level measurements on fields received on another T200 within reach of

the first.

For further information on the "Normal/Standby" and "Store & Forward"

modes, see the corresponding chapters.

Note: Depending on the protocol, all the operating modes of the ports

mentioned above are not necessarily available.

Medium: Allows definition of the type of transmission medium to be used for

the link to the SCADA system, for each port. The choice proposed below

depends on the type of modem detected on the COM card port, namely:

RS232 modem not isolated installed on the port:

♦ Direct RS232 (internal interface)

♦ Radio (external with modem)

♦ PSTN (external modem, Hayes command)

♦ GSM (external modem, Hayes command)

♦ PSTN (UMPC and external modem)

RS232/RS485 modem isolated 2,5 KV installed on the port :

♦ Direct RS232 (internal interface)

♦ Radio (external with modem)

♦ PSTN (external modem, Hayes command)

♦ GSM (external modem, Hayes command)

♦ PSTN (UMPC and external modem)

♦ Direct RS485 (internal interface)

Radio modem installed on the port:

♦ 1200/2400 baud FFSK radio (internal modem)

♦ 600/1200 baud FSK radio (internal modem)

♦ 600/1200 baud LL radio (internal modem)

GSM/GPRS modem installed on the port:

♦ GSM (internal modem)

♦ GPRS (internal modem)

GSM/3G modem installed on the port:

♦ GSM (internal modem)

♦ 3G (internal modem)

PSTN modem installed on the port:

♦ PSTN (internal modem)

etc.

Configure the port according to the type of transmission medium wanted

based on the proposed choice.

Important note: A medium not configured or incorrectly configured

generates a fault on the COM card (red fault indicator lamp lit on the front

of the card).

32

NT00113-EN-05

Commissioning Communication configuration

Excerpted from the page: "Configuration/Operating

modes"

3.7.1.1 Configuration of Normal/Standby mode

The Normal/Standby mode allows the two communication ports to the Supervisor to

be used in communication redundancy management.

When the "Normal/Standby" mode is configured as link type on ports 1 and 2, the

"Quality of transmission parameters" section becomes accessible in the "Operating

modes" page and the corresponding parameters can be configured.

This mode requires the use of two communication channels (ports 1 and 2) to

operate.

Two operating modes are possible:

- Balanced mode: No criterion of priority of one channel over the other in this

mode. So long as communication functions on the channel in service, it stays on

that channel. Upon detecting loss of communication on the channel in service, it is

switched over to the other channel. Both channels must be declared as "Balanced".

- Main/Backup mode: In this mode, priority is given to one of the two

communication channels (channel declared as "main"). So long as communication

functions satisfactorily on this channel, it stays on this channel in priority. The

channel declared as "Backup" is used only in the event of operating failure on the

main channel. Return to the main channel can be enabled or inhibited by