Page 1

TAC I/A Series MicroNet BACnet

Wiring, Networking, and

Best Practices Guide

Page 2

Page 3

TAC I/A Series MicroNet BACnet

Wiring, Networking, and

Best Practices Guide

Printed in U.S.A. 06-14 F-27360-11

Page 4

Distributed, manufactured, and sold by Schneider Electric.

I/A Series trademarks are owned by Invensys Systems, Inc. and are

used on this product under master license from Invensys. Invensys does

not manufacture this product or provide any product warran ty or support.

For service, support, and warranty information, contact

Schneider Electric.

All brand names, trademarks and registered trademarks are the property of th eir respective owners. Information contained within this document is subj ect to change

without notice.

Schneider Electric

F-27360-11 June 2014 tl

© 2014 Schneider Electric. All rights reserved.

Page 5

Table of Contents

Preface

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Applicable Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Acrobat (PDF) Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Abbreviations and Terms Used in this Manual . . . . . . . . . . . . . . .xii

Manual Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Chapter 1 I/A Series BACnet Hardware

MicroNet BACnet Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Common Controller Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

BACnet Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

MNB-300 Unitary Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MNB-V1, MNB-V2 VAV Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MNB-70 Zone Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MNB-1000 Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MNB-1000-15 Remote I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Input and Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Universal Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Universal Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Digital Outputs, Triac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

20 Vdc Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inputs from MN-Sx MicroNet Sensor . . . . . . . . . . . . . . . . . . . . . . 19

Velocity Pressure Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MicroNet Digital Wall Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Common Sensor Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Keypad Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LCD Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Intermixing of Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide iii

Page 6

Table of Contents

Chapter 2 Networking Practices

Sensor Link (S-Link) Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MicroNet MS/TP Network Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 26

ADI and Remote I/O Network Wiring . . . . . . . . . . . . . . . . . . . . . . 27

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Sensor Link (S-Link) Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

MicroNet MS/TP Network Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Approved Cable Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ADI and Remote I/O Module Network Wiring . . . . . . . . . . . . . . . . . . 31

Wiring Specifications for ADI or Remote I/O . . . . . . . . . . . . . . . . 31

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Introduction to BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

MS/TP Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Physical Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Number of Connected Devices . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Logical Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Addressing Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Limits to Number of Polled Points . . . . . . . . . . . . . . . . . . . . . . . . 43

Limits to Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connection to an MS/TP Network . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Remote I/O Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Physical Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Number of Connected Devices . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Logical Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Addressing Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Increased I/O Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

MS/TP Network Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Master and Slave Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Physical Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Required Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

MS/TP Address for BACnet Tools . . . . . . . . . . . . . . . . . . . . . . . . 47

Other Network Setup Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Port Bridging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Single Path to Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Routers and Network Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Network Setup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Physical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Set the DIP Switches on the Controllers . . . . . . . . . . . . . . . . . . . . . . 52

iv MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 7

MS/TP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Remote I/O Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Power on the MNB-xxxx Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Commission UNCs and ENCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Commission the Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 3 Checkout and Troubleshooting

Mechanical Hardware Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Communications Hardware Checkout . . . . . . . . . . . . . . . . . . . . . . . . . 55

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Field-replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

BACnet Best Practices

I/A Series MicroNet BACnet System Architecture Overview . . . . . . . . 64

MS/TP Network Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Master-Slave Token Passing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Device Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

BACnet Rules that Must be Followed . . . . . . . . . . . . . . . . . . . . . . . . . . 69

General BACnet Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

No Duplicate Device Instances . . . . . . . . . . . . . . . . . . . . . . . . . . 69

No Duplicate Object Identifiers within a Device . . . . . . . . . . . . . . 69

No Duplicate Network Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Devices on a Network Must Share a Single Network Number . . . 69

One Communication Path Only . . . . . . . . . . . . . . . . . . . . . . . . . . 69

MS/TP Network Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

No Duplicate Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Install Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Set Bias Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Use Proper Communication Cable . . . . . . . . . . . . . . . . . . . . . . . 72

Bond the Shield to a Proper Ground . . . . . . . . . . . . . . . . . . . . . . 72

BACnet Best Practice Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Selection of WP Tech Object Type for BACnet . . . . . . . . . . . . . . . . 73

MS/TP Network Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Keep Exposed Communication Conductors Short . . . . . . . . . . . . 73

Do Not Nick the Insulation When Removing the Cable Sheath . . 74

Make Low Resistance Terminations . . . . . . . . . . . . . . . . . . . . . . 74

Address Devices Consecutively . . . . . . . . . . . . . . . . . . . . . . . . . . 74

A Router’s Address Should Be 0 (Zero) . . . . . . . . . . . . . . . . . . . . 74

Few Controllers Per Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Use BACnet/IP for the MNB-1000 . . . . . . . . . . . . . . . . . . . . . . . . 74

Use Higher Baud Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Use Auto-baud to Change Baud Rate . . . . . . . . . . . . . . . . . . . . . 75

Add a Controller as MS/TP Slave After a Failed Upgrade . . . . . . 75

Power the Controllers Properly . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Repeaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Set MaxInfoFrames to Value Greater Than 1 . . . . . . . . . . . . . . . 76

Set the MaxMaster Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Tuning the MaxMaster Property . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Discussion of Joining Token Passing . . . . . . . . . . . . . . . . . . . . . 78

Table of Contents

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide v

Page 8

Table of Contents

Understanding the Transmit and Receive Data LEDs on MS/TP Net-

works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

BACnet/IP Network Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Set the gateway address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Use BBMDs When Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

BACnet/IP Through a NAT Router . . . . . . . . . . . . . . . . . . . . . . . . 81

BACnet Ethernet Network Guidelines . . . . . . . . . . . . . . . . . . . . . . . . 81

BACnet/Ethernet is Not Routed . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Do Not Leave BACnet/Ethernet Enabled if Not Used . . . . . . . . . 81

BACnet Guidelines for UNCs and ENCs . . . . . . . . . . . . . . . . . . . . . 81

Fewer Points Equals Better Performance . . . . . . . . . . . . . . . . . . 81

Use Poll On Demand for Schedules, Alarms, and Trends . . . . . . 82

Delete Unused Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Keep the UNC or ENC Routing . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Keep the Processor Idle Time Above 20% . . . . . . . . . . . . . . . . . . 83

UNC and ENC Bias Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Use COV Subscription for Slowly Changing Points . . . . . . . . . . . 83

Do Not Use COV for Priority Type Points . . . . . . . . . . . . . . . . . . . 84

Tuning Policy for ENC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

General BACnet Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Consider Network Design Carefully . . . . . . . . . . . . . . . . . . . . . . . 84

Remote Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

BBMDs–

Connecting BACnet/IP Devices on Different Subnets . . . . . . . . . . . 85

Setup of BBMD in the MNB-1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Use of VPN for Off-site Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Using a BBMD with an NAT Router . . . . . . . . . . . . . . . . . . . . . . . . . 90

WP Tech/WPCT BACnet/IP Remote Connection Setup . . . . . . . . . 91

Performance Improvements for MS/TP . . . . . . . . . . . . . . . . . . . . . . . . . 94

Implementing Performance Im pr ov em e nts . . . . . . . . . . . . . . . . . . . . 94

COV Subscription in a UNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

COV Subscription in an ENC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Using AdminTool Object to Change useCOV Value . . . . . . . . . . . . . 98

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Performing a Search and Replace . . . . . . . . . . . . . . . . . . . . . . . 100

Optimizing the covIncrement Value . . . . . . . . . . . . . . . . . . . . . . . . 101

COV Subscription Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

covIncrement Value too Small . . . . . . . . . . . . . . . . . . . . . . . . . . 101

covIncrement Value too Large . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Choose the Right covIncrement Value . . . . . . . . . . . . . . . . . . . . 102

The Type of Point Affects COV Efficiency . . . . . . . . . . . . . . . . . . . 103

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Setting Up a Remote I/O Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Installing Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configuring Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . 105

The Remote I/O Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Understanding the Transmit and Receive Data LEDs on Remote I/O

Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

vi MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 9

Table of Contents

Remote I/O Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

EOL Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Bias Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Fallback Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide vii

Page 10

Table of Contents

viii MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 11

Preface

Purpose of this Manual

This TAC I/A Series MicroNet™ BACnet™ Wiring, Networking, and Best

Practices Guide is a reference for creating a network of TAC I/A Series

MicroNet BACnet controllers. This guide provides the following discussions

and instructions for the TAC I/A Series MicroNet BACnet series:

• Best practices related to the configuration and maintenance of a T AC I/A

Se

ries MicroNet BACnet system

• TAC I/A Series MicroNet BACnet Controllers and Remote I/O Modules,

an

d their features

• Controller and module wiring terminals and wiring recommendations

• Controller and module input and output specifications

• TAC I/A Series MicroNet Digital Wall Sensors and their features

• Diagnostic functions of the TAC I/A Series MicroNet Digital Wall Sensors

• BACnet overview

• TAC I/A Series MicroNet BACnet system architecture overview

• MS/TP and Remote I/O Network configuration, including physical and

l

ogical restrictions

• How to network into an IP over an Ethernet backbone

Other literature related to the implementation of a TAC I/A Series MicroNet

BACnet system are referenced througho ut this gu ide an d ar e lis te d in

"Applicable Documentation,” on page x.

It is assumed that readers of this manual already understand basic HVAC

concepts. An understanding of BACnet networking and communications, as

well as a general understanding of Ethernet networks, is also helpful. This

manual is written for:

• Applicatio n en gin eer s.

• Users who change hardware or control logic.

• Schneider Electric technicians and field engineers.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide ix

Page 12

Applicable Documentation

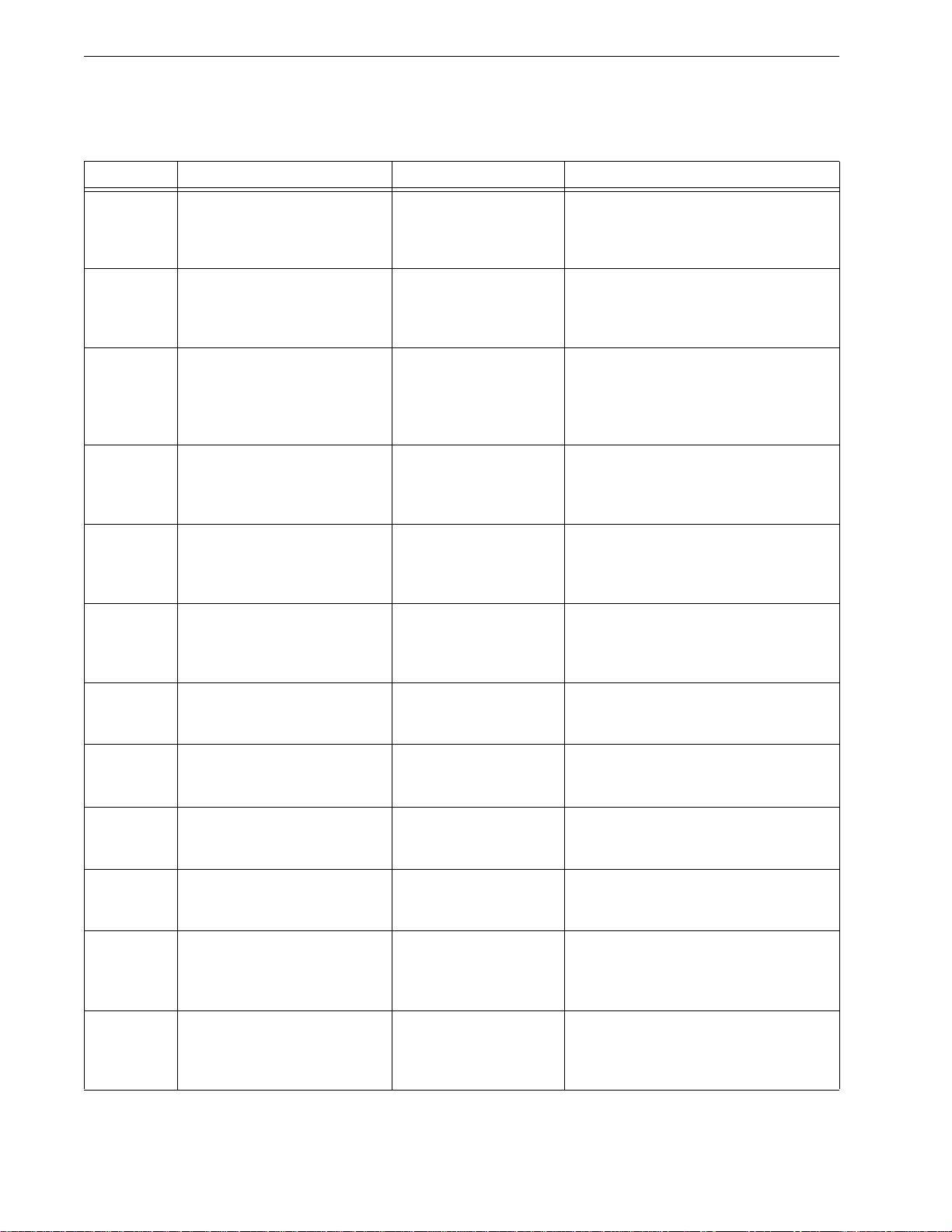

F-Number Description Audience Purpose

Provides a programming reference for

F-27254

F-27255

F-27356

TAC I/A Series WorkPlace Tech

Tool Engineering Guide.

TAC I/A Series WorkPlace Tech

Tool User’s Guide

TAC I/A Series WorkPlace Tech

Tool BACnet Engineering Guide

Supplement

– Application Engineers

– Service Personnel

– Application Engineers

– Installers

– Start-up Technicians

– Service Personnel

– Application Engineers

– Service Personnel

MicroNet controllers. Gives detailed

descriptions for each of the Control Objects

used with MicroNet controllers.

Provides step-by-step instructions for using

the WorkPlace Tech Tool, version 4.0.

Provides supplemental information for

programming MicroNet BACnet controllers.

Gives detailed descriptions for each of the

unique BACnet Control Objects used with

these controllers.

F-27419

F-27358

F-27365

F-27461

F-27462

F-27463

F-27485

T AC I/A Series MicroNet BACnet

Smoke Control Systems Manual

T AC I/A Series MicroNet BACnet

WorkPlace Commissioning Tool

and Flow Balance T ool User’s

Guide

T AC I/A Series MicroNet BACnet

MNB-70, MNB-300, MNB-V1,

and MNB-V2 Controllers BACnet

PIC Statement

T AC I/A Series MicroNet BACnet

MNB-1000 Controller BACnet

PIC Statement

TAC I/A Series UNC-520

Universal Network Controller

BACnet PIC Statement

TAC I/A Series ENC-520

Enterprise Network Controller

BACnet PIC Statement

T AC I/A Series ENS-1 Enterprise

Network Server BACnet PIC

Statement

– Application Engineers

– Installers

– Start-up Technicians

– Service Personnel

– Application Engineers

– Installers

– Start-up Technicians

– Service Personnel

– Application Engineers

– Application Engineers

– Application Engineers

– Application Engineers

– Application Engineers

Provides information for creating smoke

control systems that meet a UL 864

UUKL/UUKL7 project specification, using

MicroNet BACnet controllers.

Provides step-by-step instructions for using

the WorkPlace Commissioning Tool and

Flow Balance Tool.

Provides BACnet compliance information

on MicroNet BACnet MNB-70, MNB-300,

MNB-V1, and MNB-V2 controllers.

Provides BACnet compliance information

on the MicroNet BACnet MNB-1000

controller.

Provides BACnet compliance information

on the UNC-520 controller.

Provides BACnet compliance information

on the ENC-520 controller.

Provides BACnet compliance information

on the ENS-1 enterprise network server.

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

Provides step-by-step mounting and

installation instructions for the MicroNet

MNB-70 Controller.

Provides step-by-step mounting and

installation instructions for the MicroNet

MNB-300 Controller.

F-27456

F-27345

TAC I/A Series MicroNet BACnet

MNB-70 Zone Controller

Installation Instructions

TAC I/A Series MicroNet BACnet

MNB-300 Unitary Controller

Installation Instructions

x MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 13

F-Number Description Audience Purpose

Preface

TAC I/A Series MicroNet BACnet

F-27346

F-27347

F-27486

F-26277

MNB-V1, MNB-V2 VAV

Controllers Installation

Instructions

TAC I/A Series MicroNet BACnet

MNB-1000 Plant Controller

Installation Instructions

TAC I/A Series MicroNet BACnet

MNB-1000-15 Remote I/O

Module Installation Instructions

TAC I/A Series MicroNet

MN-SX Series Sensors

General Instructions

Related Documentation

Applies To Description Source

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

Provides step-by-step mounting and

installation instructions for the MicroNet

MNB-V1 and MNB-V2 Controllers.

Provides step-by-step mounting and

installation instructions for the MicroNet

MNB-1000 Controller.

Provides step-by-step mounting and

installation instructions for the MicroNet

MNB-1000-15 Remote I/O Module.

Provides step-by-step installation and

checkout procedures for TAC I/A Series

T AC I/A Series MicroNet MN-SX Series

Sensors. Also contains instructions for

sensor operation.

For more information, consult the following documentation:

UNC and ENC Network

Controllers

BACnet Networks

Niagara Release 2.3.4 Installation and Upgrade

Instructions

Niagara System and Power Monitoring, Engineering

Notes

Niagara Networking & Connectivity Guide

Niagara Standard Programming Reference Manual,

Release 2.3.4

BACnet Integration Reference

NiagaraAX BACnet Guide

NiagaraAX Networking and IT Guide

ANSI/ASHRAE Standard 135-2001

BACnet—A Data Communication Protocol for

Building Automation and Control Networks.

• TAC I/A Series Enterprise Server

CD

• Tech Zone at The Source

(http://source.tac.com/)

• TAC I/A Series Enterprise Network

Server CD

• ANSI/ASHRAE

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide xi

Page 14

Conventions Used in this Manual

The following conventions apply to this printed manual:

• Menu commands appear in bold.

Example — On the Special menu, point to Security, then click Log On.

• Italics is used for emphasis in a statement, such as:

If maximum closed switch voltage is not more than 1.0 V and minimum

open switch voltage is at least 4.5 V, then solid state switches may be

used for a UI or a DI.

It is also used when referring to a document, such as:

Refer to the WorkPlace Tech Tool BACnet Engineering Guide Supple-

ment, F-27356.

Acrobat (PDF) Conventions

If you are reading this manual online in Adobe® Acrobat® (.PDF file format),

numerous hypertext links exist, both in normal black text and in blue text.

• Hypertext links in this document include all entries in the Table of

Contents, as well as cross-references within the body text. For ease of recognition, cross-reference links within the body text appear in blue type, for example Manual Summary. A link is indicated whenever the mouse pointer changes to a hand with a pointing finger.

• When viewing this guide with Adobe Acrobat, you can display various

“bookmark” links on the left side of your screen by choosing “Bookmarks

and Page” from the “View” menu. As with the links described above,

these “bookmark” links will also cause the mouse pointer to change to a

hand with a pointing finger.

Abbreviations and Terms Used in this Manual

Refer to Glossary for definitions, abbre viations, and acron yms that may be

used in this document:

Manual Summary The MicroNet BACnet Wiring, Networking, and Best Practices Guide

contains three chapters.

Chapter 1, I/A Series BACnet Hardware, provides a brief overview of the

various I/A Series

sensors.

Chapter 2, Networking Practices, provides an overview of the BACnet

protocol and, more specifically, its implementation in the TAC I/A Series

MicroNet BACnet system. This chapter then explains how TAC I/A Series

MicroNet BACnet controllers and sensors are configured for an MS/TP

network. It also explains how remote I/O networks are constructed by

connecting one to eight remote I/O modules to an MNB-1000 controller.

Chapter 3, Checkout and T roubleshooting , provides steps for determini ng

the proper operation of the TAC I/A Series MicroNet BACnet system and

suggests corrective actions for any discovered faults.

Appendix A, BACnet Best Practices, provides best practices information

for creating and maintaining a network of TAC I/A Series MicroNet BACnet

controllers, remote I/O modules, and sensors, a nd pr ovides ad ditional d etail

for information contained elsewhere in this document.

®

MicroNet BACnet controllers, remote I/O modules, and

xii MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 15

Chapter 1

I/A Series BACnet Hardware

This chapter provides a brief overview of the various I/A Series MicroNet

BACnet controllers and sensors, including:

• Common Controller Features

• BACnet Compliance

• MNB-300 Unitary Controller

• MNB-V1, MNB-V2 VAV Controllers

• MNB-70 Zone Controllers

• MNB-1000 Plant Controller

• MNB-1000-15 Remote I/O Module

• MicroNet Digital Wall Sensors (MN-Sx Series)

MicroNet BACnet hardware products include controllers and compa tible

sensors.

• MicroNet BACnet controllers provide direct-digital control for packaged

rooftop, heat pump, fan coil, unit ventilator , and VAV, as well as complex

mechanical equipment such as central station air handlers, VAV air

handlers, and cooling towers. Five basic controller platforms are

available, each with a number of I/O points and supp ort for a digital roo m

temperature or humidity sensor (MicroNet sensor).

• MicroNet sensors are digital wall temperature and humidity sensors

designed specifically for use with MicroNet controllers. 12 different

models offer varying levels of sensor push-buttons and LCD screens.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 1

Page 16

Chapter 1

MicroNet BACnet Controllers

There are five hardware platforms for MicroNet BACnet controllers: the

MNB-70, the MNB-300, the MNB-V1, the MNB-V2, and the MNB-1000. In

addition, the MicroNet BACnet family includes the MNB-1000-15 remote I/O

module. Each of these platforms is described in the following sections.

Common Controller Features

BACnet Compliance

While all controller platforms differ by their physical characteristics and

numbers and types of I/O points, all controller plat forms provide the following

common features:

Note: See"MNB-1000-15 Remote I/O Module" on page 13 for features of

the remote I/O module.

• 24 V ac powered.

• Capability to function in standalone mode or as part of an I/A Series

building automation network.

• Support for a digital MicroNet sensor via a Sensor Link (S-Link) bus.

• Sequence of operation and BACnet image are fully programmable using

WorkPlace Tech Tool (WP Tech) 5.0 or greater.

• Extensive BACnet object and services support.

• DIP switch for setting the physical address.

• LED indication of MS/TP communication link and activity, and controller

status.

• Isolated EIA-485 (formerly RS-485) transceiver for MS/TP

communications.

• Firmware upgradeable over the network or directly to the controller.

Each MicroNet BACnet controller conforms to the requirement s of a BACnet

Application Specific Device (B-ASD). For a list of objects suppor ted by these

controllers, and the services provided, refer to the BACnet PIC Statements,

available on the BACnet Testing Laboratories website

(http://www.bacnetinternational.net/btl/).

2 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 17

I/A Series BACnet Hardware

MNB-300 Unitary Controller

The I/A Series MicroNet BACnet Unitary Controller, MNB-300, is an

interoperable controller with native BACnet MS/TP communications support.

The controller features Sensor Link (S-Link) support, LED status and output

indication, screw terminal blocks, as well as a panel-mou nt su b- base w ith

removable electronics module. The MNB-300 also includes one end-of-line

(EOL) termination and two bias resistors, both of which are

jumper-selectable.

When programmed using WP Tech, the MNB-300 provides a wide range of

control strategies for packaged rooftop, heat pump, fan coil, unit ventilator,

and similar applications.

Unique Features

In addition to common MicroNet BACnet controller features ("Common

Controller Features" on page 2), the MNB-300 offers the following:

• Removable electronics module that mates with panel-mounted subbase.

• Optional NEMA 1 enclosure.

• IAM button for BACnet “I am” message broadcast.

• Integral MS/TP jack for direct connection of a PC with the WP Tech.

• Removable terminals for power and communications, to facilitate

commissioning.

• LED indication of UO and TO state.

Memory Available

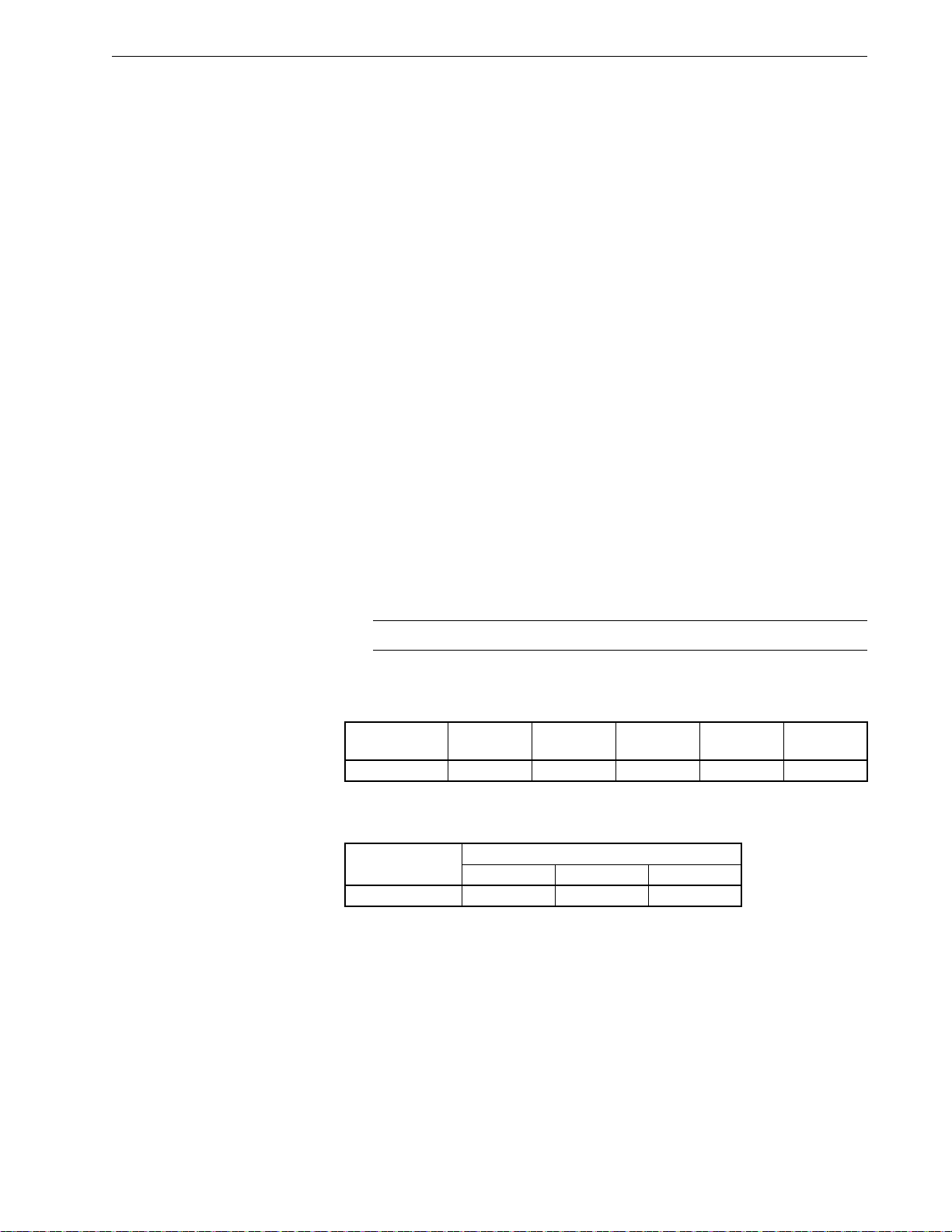

T able–1.1 MNB-300 Available Memory.

Model

Number

MNB-300 256 KB 8 KB n/a 4 KB 8 KB

Physical I/O Points

T able–1.2 MNB-300 Inputs and Output s.

Model

Number

MNB-300 636

Refer to "Input and Output Spe cifications" on page 15 for a detailed

discussion of each input or output type.

Time Clock

The

MNB-300 controller uses a software clock. This software clock defaults to

a predefined Date/Time following a reset.

Flash SRAM SDRAM EEPROM FRAM

Inputs and Outputs

UI UO DO (Triac)

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 3

Page 18

Chapter 1

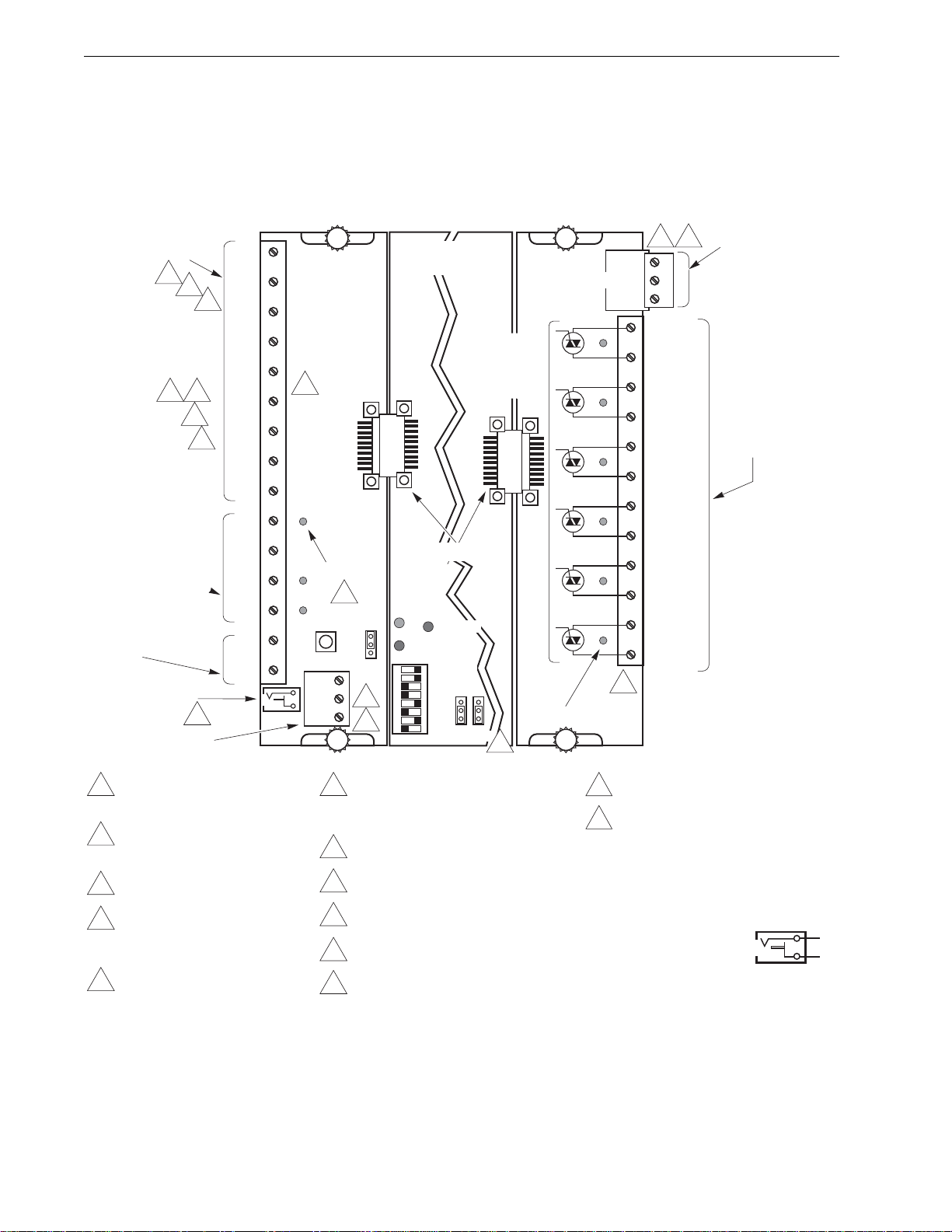

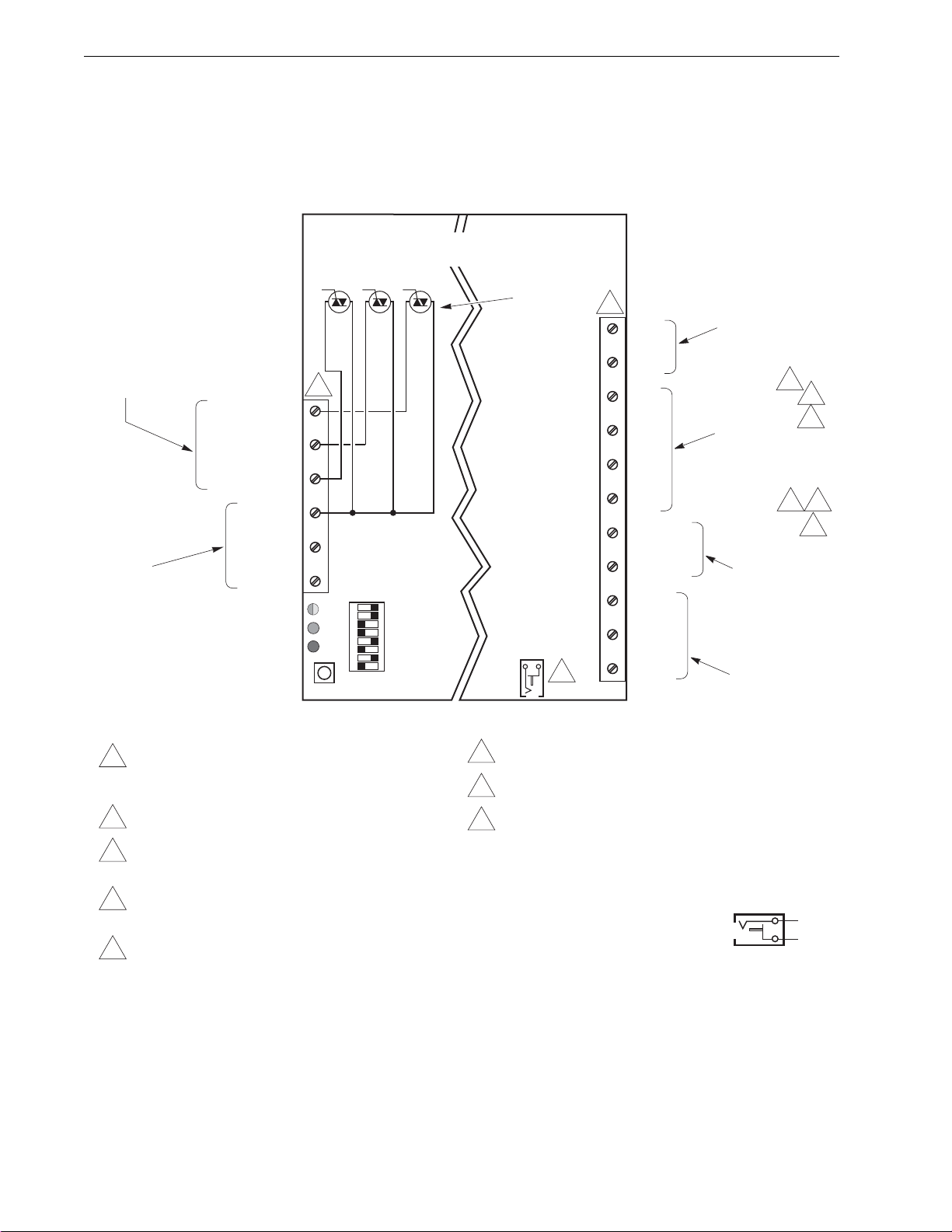

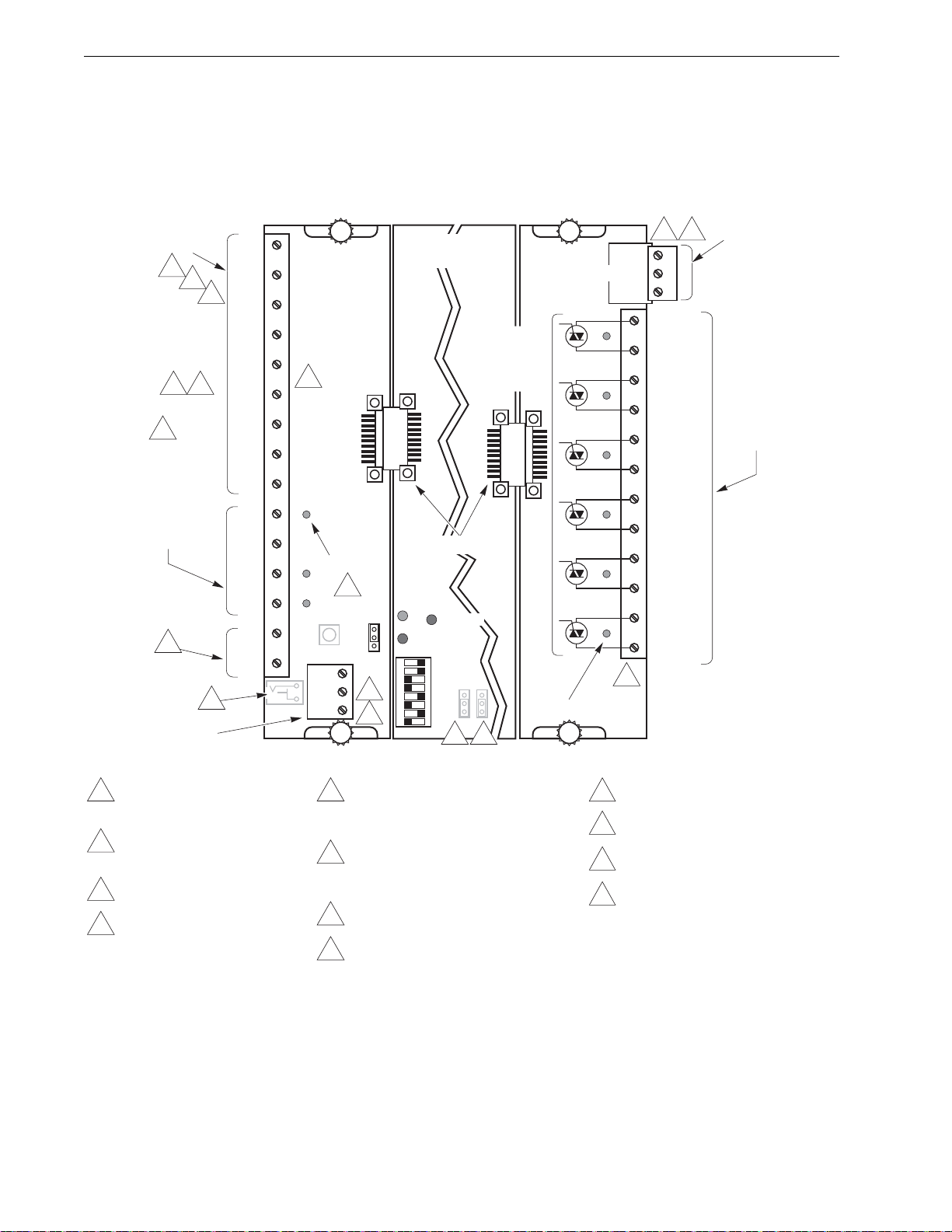

MS/TP Jack

EOL

Enable

Disable

TO1 (DO1)

C1

TO2 (DO2)

C2

TO3 (DO3)

C3

TO4 (DO4)

C4

TO5 (DO5)

C5

TO6 (DO6)

C6

UI1

COM

UI2

UI3

COM

UI4

UI5

COM

UI6

UO1

COM

UO2

UO3

COM

S-LK

IAM

MS+

MS-

SLD

MSB

LSB

MNB-300

Unitary Controller

24H

24G COM

GND

XMT

RCV

STATUS

Physical

Address

EN DIS

MS BIAS

Note: Components are

shown in their

approximate locations.

Universal Inputs

0 to 5 Vdc

0 to 20 mA

10K Thermistor

1K Balco

1K Platinum

1K Resistive

10K Resistive

Digital (dry switched

contact)

Standard Pulse

Fast Pulse (UI1)

Universal Outputs

0 to 20 mA into an

80 to 550

ohm load

S-LK

Supports one

TAC I/A Series

MN-Sxxx Sensor

BACnet Network

MS/TP Communications

AC Power

20.4 to 30 Vac

50/60 Hz

Class 2 (EN 60742)

16 VA per controller

Digital Outputs

(Triac)

12 VA at 24 Vac,

50/60 Hz. Each Triac

output individually

isolated from AC

input and other I/O.

Class 2

2

5

6

4

7 8

10

12

13

1

11

3

9

2 3

2

1 Do not exceed two AWG #24

(0.205 mm

2

) wires per MS/TP

wiring terminal.

2 Power and I/O point wiring

terminals accept up to two AWG

#14 (2.08 mm

2

) or smaller wires.

3 Power and MS/TP connectors

have removable screw terminals

.

4 Input signals of 1 to 11 Vdc must

be converted to 0.45 to 5 Vdc with

a voltage divider, part number

AD-8961-220.

5 In applications requiring universal

inputs with ranges of 0 to 20 mA,

a 250 ohm

shunt resistor kit, part

number AD-8969-202, is needed.

6 An 11 kilohm shunt resistor kit, part

number AD-8969-206, is required for a

10 kilohm Thermistor Sensor (non-850

series) universal inputs.

7 To detect a closed switch, resistance must

be less than 300

ohm

.

8 To detect an open switch, resistance must

be greater than 2.5

kilohm

.

9 External load is not required to illuminate

UO LEDs.

10 Minimum rate of 1 pulse per 4 minutes.

Maximum rate of 1 pulse per second.

11 MS/TP network bias resistors are shipped

in the disabled setting, and are located

under the controller’s cover.

12 Minimum rate of 1 pulse per 4 minutes.

Maximum rate of 10 pulses per second.

13 When making an MS/TP cable, use a

1.3 x 3.5 mm Vdc power plug with strain

relief (Vimex part number

SCP-2009A-T, TAC part number

E24-1442, or equivalent). The cable

should be no longer than 6 ft. Connect

MS+ to the center contact and MS– to

the outside contact:

Note: The MS/TP cable

described above is

available from

Schneider-Electric as

MNB-CT-CBL. Contact

Schneider-Electric for

more information.

TO (DO) LEDs (6)

UO LEDs (3)

Internal

Triac

Switches

(Isolated)

Connectors (2)

+

_

Figure–1.1 MNB-300 Terminal Connections.

Wiring Terminals

Refer to Figure-1.1 for the power and network communications wiring connections

available on the MNB-300 controller.

4 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 19

I/A Series BACnet Hardware

SW24H1

SW24H2

SW24H3

24H

24G(COM)

GND

STATUS

MSTP RCV

MSTP XMT

UO 1

COM

UI 1

COM

UI 2

UI 3

S-LK/COM

MSTP +

SHLD

MSTP -

MNB-V1, MNB-V2 VAV Controllers

The I/A Series MicroNet BACnet VAV (Variable Air Volume) Controllers,

MNB-V1 and MNB-V2, are interoperable controllers with native BACnet

MS/TP communications support. Both models incor p or at e: an inte gr a l

actuator with manual override; an integral, patented, pressure transducer;

three universal inputs; Sensor Link (S-Link) support; LED st atus indication;

and over-the-shaft damper mounting. The MNB-V1 controller is designed

specifically for cooling applications, while the MNB-V2 controller adds digital

and universal outputs that make it suitable for additional VAV applications.

When programmed using WP Tech, these controllers provide a wide range

of control strategies for pressure-dependent and pressure-independent

terminal boxes, with or without reheat capabilities.

Unique Features

In addition to common MicroNet BACnet controller features ("Common

Controller Features" on page 2), the MNB-V1 and MNB-V2 offer the

following:

• Air balancing performed using WorkPlace Flow Balance Tool (WPFBT).

• Integrated packaging with actuator, pressure transducer, and controller.

• Integral actuator features manual override and travel limit stops for easy

set up and adjustment.

• Enclosure approved for use in air plenums.

• Damper position feedback to the BACnet Building Automation System

(BAS) via integral hall effect sensor.

• Stable flow control down to 0.004 in. W.C. (0.996 Pa) differential

pressure.

Memory Available

Table–1.3 MNB-Vx Available Memory.

Model

Number

MNB-V1

MNB-V2

Flash SRAM SDRAM EEPROM FRAM

256 KB 8 KB n/a 4 KB n/a

Physical I/O Points

Table–1.4 MNB-Vx Inputs and Outputs.

Model

Number

Inputs and Outputs

UI UO DO (Triac)

MNB-V1 300

MNB-V2 313

Refer to the "Input and Output Specifications" on page 15 for a detailed

discussion of each input or output type.

Time Clock

The

MNB-V1 and MNB-V2 controllers use a software clock. This software clock

defaults to a predefined Date/Time following a reset.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 5

Page 20

Chapter 1

UO1*

COM*

UI1

COM

UI2

UI3

S-LK/COM

S-LK

MSTP +

MSTP –

SHLD

SW24H1* (DO1)

SW24H2* (DO2)

SW24H3* (DO3)

24H

24G (COM)

GND

MSTP RCV

MSTP XMT

STATUS

Physical

Address

MSB

LSB

MNB-V1 / -V2

Controllers

MS/TP Jack

6 To detect an open switch, minimum resistance must be

greater than 2.5 kilohm.

7 Minimum rate of 1 pulse per 4 minutes. Maximum rate of

1 pulse per second.

8 When making an MS/TP cable, use a 1.3 x 3.5 mm Vdc

power plug with strain relief (Vimex part number

SCP-2009A-T, Schneider-Electric part number E24-1442,

or equivalent). The cable should be no longer than 6 ft.

Connect MS+ to the center contact and MS– to the

outside contact:

Note: The MS/TP cable described above

is available from Schneider-Electric as

MNB-CT-CBL. Contact

Schneider-Electric for more information.

1 Fixed screw terminals that accept a single AWG #14

(2.08 mm

2

) wire or up to two AWG #18 (0.823 mm2) or

smaller wires. Do not exceed two AWG #24 (0.205 mm

2

)

wires per MS/TP wiring terminal.

2 Input signals of 1 to 11 Vdc must be converted to 0.45 to

5 Vdc with a voltage divider, part number AD-8961-220.

3 In applications requiring universal inputs with ranges of

0 to 20 mA, a 250 ohm shunt resistor kit,

AD-8969-202, is needed.

4 An 11 kilohm shunt resistor kit, AD-8969-206, is

required for a 10 kilohm

Thermistor Sensor (non-850

series) universal inputs.

5 To detect a closed switch, maximum resistance must

be less than 300 ohm.

AC Power

20.4 to 30 Vac,

50/60 Hz

Class 2 (EN 60742)

15 VA per controller

plus DO load

Digital Outputs

Total 24 VA (DO1+DO2),

12 VA (DO3) at 24 Vac,

50/60 Hz, Class 2.

Pilot Duty

Universal Output

0 to 20mA into an

80 to 550

ohm

load

S-LK

Supports one I/A

Series MN-Sxxx

Sensor

BACnet Network

Communications

8

1

1

2

3

4

5 6

7

Universal Inputs

0 to 5 Vdc

0 to 20 mA

10K Thermistor

1K Balco

1K Platinum

1K Resistive

10K Resistive

Digital (dry switched

contact)

Standard Pulse

Internal Triac

Switches (3)

+

_

Note: Components are shown in

their approximate locations.

Note: Asterisks (*) indicate terminals

that apply to the MNB-V2

controller but not to the MNB-V1.

Figure–1.2 MNB-Vx Terminal Connections.

Wiring Terminals

Refer to Figure-1.2 for the power and network communications wiring connections

available on the MNB-V1 and MNB-V2 controllers.

6 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 21

I/A Series BACnet Hardware

MNB-70 Zone Controllers

SW24H1

SW24H2

SW24H3

24H

24G(COM)

GND

STATUS

MSTP RCV

MSTP XMT

UO 1

COM

UI 1

COM

UI 2

UI 3

S-LK/COM

MSTP +

MSTP -

SHLD

AO

The I/A Series MicroNet BACnet Zone Controller, MNB-70, is an

interoperable controller with native BACnet MS/TP communications support.

The controller features: three universal inputs; one universal output; three

digital (Triac) outputs; Sensor Link (S-Link) support; LED status indication;

and screw terminal blocks.

When programmed using WP Tech, the MNB-70 provides a wide range of

control strategies for heat pump, fan coil, unit ventilator, mixing boxes, and

similar applications.

Unique Features

In addition to common MicroNet BACnet controller features ("Common

Controller Features" on page 2), the MNB-70 offers the following:

• I-Am button for BACnet “I-am” message broadcast.

• Integral MS/TP jack for direct connection of a PC with the WP Tech.

• Small footprint.

• Enclosure approved for use in air plenums.

Memory Available

Table–1.5 MNB-70 Available Memory.

Model

Number

MNB-70 256 KB 8 KB n/a 4 KB n/a

Flash SRAM SDRAM EEPROM FRAM

Physical I/O Points

Table–1.6 MNB-70 Inputs and Outputs.

Model

Number

Inputs and Outputs

UI UO DO (Triac)

MNB-70 313

Refer to the "Input and Output Specifications" on page 15 for a detailed

discussion of each input or output type.

Time Clock

The

MNB-70 controller uses a software clock. This software clock defaults to a

predefined Date/Time following a reset.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 7

Page 22

Chapter 1

UO1

COM

UI1

COM

UI2

UI3

S-LK/COM

S-LK

MSTP +

MSTP –

SHLD

SW24H1 (DO1)

SW24H2 (DO2)

SW24H3 (DO3)

24H

24G (COM)

GND

MSTP RCV

MSTP XMT

STATUS

Physical

Address

MSB

LSB

MNB-70

Controller

MS/TP Jack

IAM

1 Fixed screw terminals that accept a single AWG #14

(2.08 mm

2

) wire or up to two AWG #18 (0.823 mm2) or

smaller wires. Do not exceed two AWG #24 (0.205 mm

2

)

wires per MS/TP wiring terminal.

2 Input signals of 1 to 11 Vdc must be converted to 0.45 to

5 Vdc with a voltage divider, part number AD-8961-220.

3 In applications requiring universal inputs with ranges of

0 to 20 mA, a 250 ohm shunt resistor kit,

AD-8969-202, is needed.

4 An 11

kil

ohm shunt resistor kit, AD-8969-206, is

required for a 10

kilohm

Thermistor Sensor (non-850

series) universal inputs.

5 To detect a closed switch, maximum resistance must

be less than 300 ohm.

AC Power

20.4 to 30 Vac,

50/60 Hz

Class 2 (EN 60742)

15 VA per controller

plus DO load

Digital Outputs

Total 24 VA (DO1+DO2),

12 VA (DO3) at 24 Vac,

50/60 Hz, Class 2.

Pilot Duty

Universal Output

0 to 20mA into an

80 to 550

ohm

load

S-LK

Supports one I/A

Series MN-Sxxx

Sensor

BACnet Network

Communications

8

1

1

2

3

4

5 6

7

Universal Inputs

0 to 5 Vdc

0 to 20 mA

10K Thermistor

1K Balco

1K Platinum

1K Resistive

10K Resistive

Digital (dry switched

contact)

Standard Pulse

Internal Triac

Switches (3)

6 To detect an open switch, minimum resistance must be

greater than 2.5

kilo

hm.

7 Minimum rate of 1 pulse per 4 minutes. Maximum rate of

1 pulse per second.

8 When making an MS/TP cable, use a 1.3 x 3.5 mm Vdc

power plug with strain relief (Vimex part number

SCP-2009A-T, Schneider-Electric part number E24-1442,

or equivalent). The cable should be no longer than 6 ft.

Connect MS+ to the center contact and MS– to the

outside contact:

Note: The MS/TP cable described above

is available from Schneider-Electric as

MNB-CT-CBL. Contact

Schneider-Electric for more information.

+

_

Note: Components are shown in

their approximate locations.

Figure–1.3 MNB-70 Terminal Connections.

Wiring Terminals

Refer to Figure-1.3 for the power and network communications wiring connections

available on the MNB-70 controller.

8 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 23

I/A Series BACnet Hardware

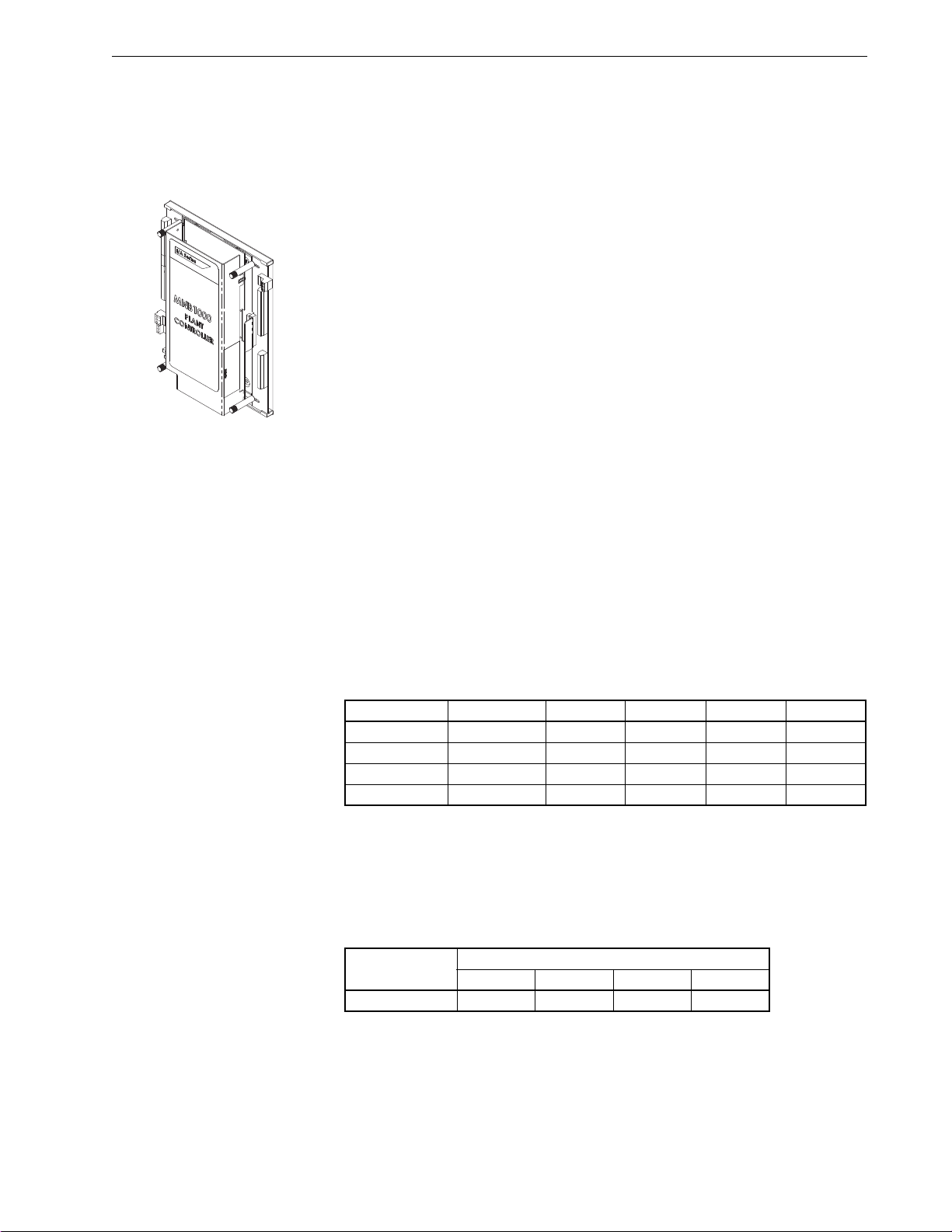

MNB-1000 Plant Controller

The I/A Series MicroNet BACnet Plant Controller, MNB-1000, is an

interoperable controller with native BACnet MS/TP communications support.

The controller features Sensor Link (S-Link) support, LED status and output

indication, two Ethernet ports, and screw terminal blocks.

The MNB-1000’s sequence of operation and BACnet image are fully

programmable using WP Tech, and can be applied to a wide range of

mechanical equipment. Typical applications include central station air

handlers, VAV air handlers, and cooling towers.

Unique Features

In addition to common MicroNet BACnet controller features ("Common

Controller Features" on page 2), the MNB-1000 offers the following:

• Optional NEMA 1 enclosure.

• IAM button for BACnet “I am” message broadcast.

• Integral MS/TP jack for direct connection of a PC with the WP Tech.

• LED indication of Ethernet communication link and activity, DO state,

UO state, and remote I/O communications.

• Application-programmable LED provides on/off indication of a

user-defined application parameter.

• BACnet router functionality.

• Support for remote I/O modules.

• Etherne t po rt bridgin g.

• 20 Vdc output

• 72 hour, battery-backed real time clock.

Memory Available

Table–1.7 MNB-1000 Available Memory.

Component Flash SRAM SDRAM EEPROM FRAM

µC 128 KB 4 KB n/a 4KB n/a

Motherboard n/a 256 KB n/a 128 KB n/a

Engine (Core) 32 or 16 MB

Engine (Boot) 2 MB n/a n/a n/a n/a

a. MNB-1000s with a date code prior to 0726 have 32 MB of core memory. Beginning with

date code 0726, core memory was changed to 16 MB. However, because the MNB-1000

has always used only the first 16 MB of memory, this change has no impact on the

controller’s operation, the size of the application allowed, or the controller’s application

compatibility.

Physical I/O Points

Table–1.8 MNB-1000 Inputs and Outputs.

Model

MNB-1000 12488

Refer to the "Input and Output Specifications" on page 15 for a detailed

discussion of each input or output type.

a

n/a 64 MB 1 Kb n/a

Inputs and Outputs

UI DI UO DO (Triac)

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 9

Page 24

Chapter 1

Note: The onboard I/O points of the MNB-1000 can be greatly expanded

with the addition of one to eight MNB-1000-15 remote I/O modules, each of

which adds 15 I/O points. Refer to "MNB-1000-15 Remote I/O Module" on

page 13.

Time Clock

The MNB-1000 features an onboard, real-time clock. A lithium battery

provides backup power for up to 72 hours in the event of a primary power

interruption. The real-time clock acts as a Date/Time server using native

BACnet services. In the absence of another Date/Time server on the

network, the MNB-1000 can provide this functionality to other nodes on the

BACnet internetwork.

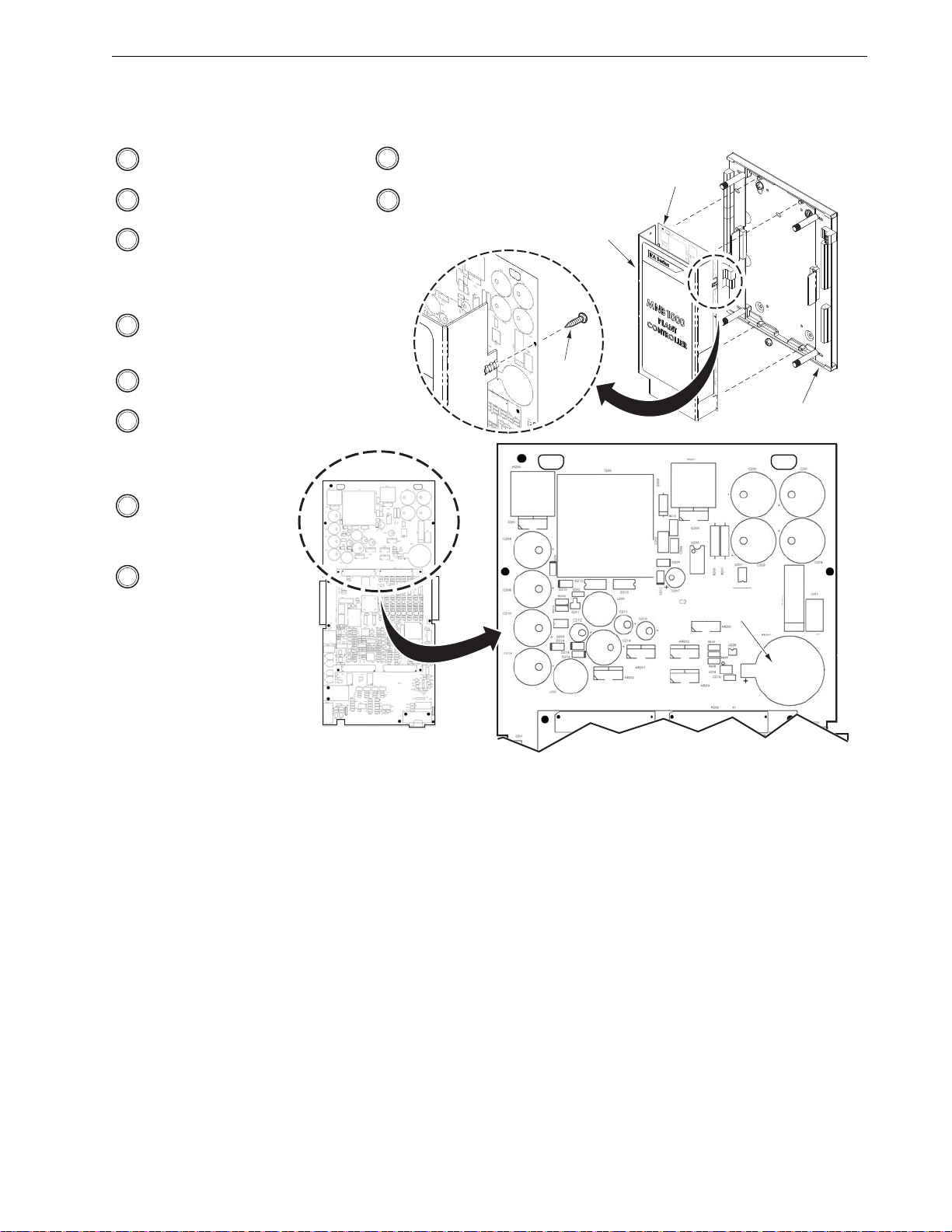

Battery Replacement

If the real-time clock’s battery becomes depleted, replace it with lithi um

battery, part number E17-137, according to the instructions in Figure-1.4.

For additional disassembly and reassembly instructions, refer to MicroNet

BACnet MNB-1000 Plant Controller Installation Instructions, F-27347

Caution: Follow static discharge precautions when hand ling the MNB-1000

and its component parts.

Note: Whenever the battery is removed from the MNB-1000, the clock

setting and volatile data will be lost. Reprogram the MNB-1000 as needed

after installing the replacement battery.

10 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 25

I/A Series BACnet Hardware

Printed Circuit Board

Cover

Base Plate

Printed Circuit

Board

Screw

(1 of 2)

Lithium Battery

E17-137

1 If the controller is mounted inside an

enclosure, open the enclosure cover.

2 Remove power from the

controller.

3 Referring to MicroNet BACnet

MNB-1000 Controller Installation

Instructions, F-27347, remove

the controller’s main assembly

from the base plate.

4 Remove two screws, and then

separate the printed circuit

board from the cover.

5 Locate the battery on the printed

circuit board.

6 Remove the depleted battery,

and then install a new lithium

battery, part number E17-137.

Make sure that the positive (+)

side faces upward.

7 Reassemble the printed

circuit board to the cover,

and secure with the two

screws removed in step 4.

8 Referring to F-27347,

reassemble the

controller’s main

assembly to the base

plate.

9 Restore power to the controller.

10 If applicable, close the enclosure

cover.

Figure–1.4 MNB-1000 Real-time Clock Battery Replacement.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 11

Page 26

Chapter 1

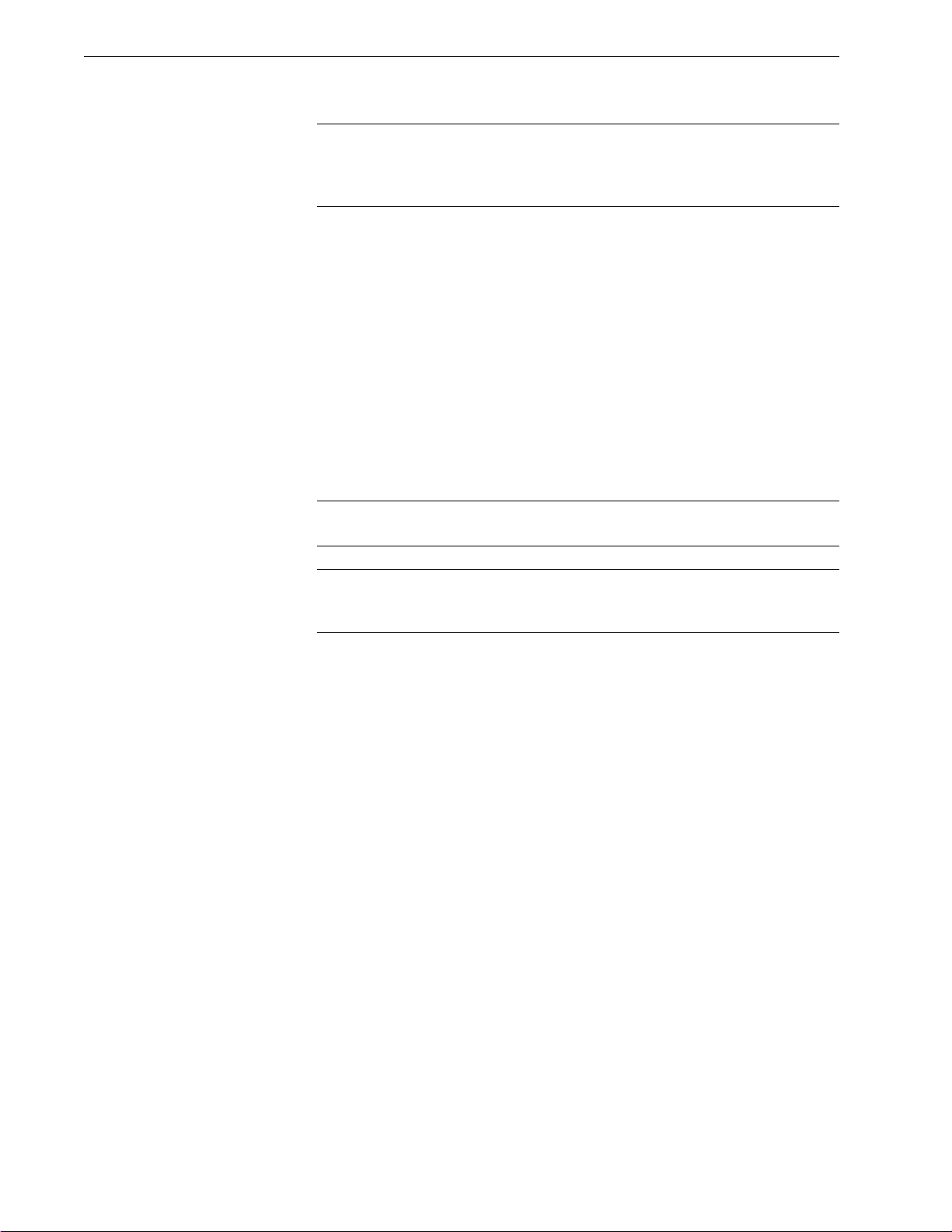

Figure–1.5 MNB-1000 Terminal Connections.

Wiring Terminals

Refer to Figure-1.5 for the wiring connections available on the MNB-1000 controller.

20 Vdc Output

±10% at

20 Vdc

100 mA

Universal Inputs

0 to 5 Vdc

0 to 20 mA

4

5

10K Thermistor

1K Balco

1K Platinum

1K Resistive

10K Resistive

Digital (dry switched

contact)

9

7

Digital Inputs

Dry Switched

Contact

Fast Pulse

12

10

7

Local Display

(for future use)

S-LK

Supports one I/A

Series MN-Sxxx

Sensor

ADI or

Remote I/O

BACnet Network

Communications

1 I/O point wiring terminals

accept a single AWG #14

(2.08 mm

2

) or up to two

AWG #18 (0.823 mm2) or

20V

UI1

COM

UI2

UI3

COM

UI4

UI5

6

COM

UI6

UI7

COM

UI8

UI9

COM

UI10

UI11

COM

UI12

DI1

COM

DI2

DI3

COM

DI4

LD

COM

S-LK

IO+

IO-

31

31

SLD

MS+

MS-

SLD

Note: Components are

1

8

Disable Enable

13

I AM

MS/TP Jack

shown in their

approximate

locations.

0 PORT

IO EOL

MS BIAS

MS EOL

MS BIAS

ACT LNK

1 PORT

Physical

Address

Plant Controller

smaller wires. Do not

exceed two AWG #24

(0.205 mm

2

) wires per

MS/TP or Remote I/O

wiring terminal.

2 Power wiring terminals accept up to two AWG #14

(2.08 mm

2

) or smaller wires.

3 Power, MS/TP, and Remote I/O connectors have

removable screw terminals.

4 Input signals of 1 to 11 Vdc must be converted to 0.45 to

5 Vdc with a voltage divider, part number AD-8961-220.

5 In applications requiring universal inputs with ranges of 0 to

20 mA, a 250

ohm

shunt resistor kit, AD8969-202, is

needed.

6 An 11 kil

for a 10 kil

ohm

shunt resistor kit, AD-8969-206, is required

ohm

thermistor Sensor (non-850 series)

universal inputs.

MNB-1000

Internal Triac

Switches (8)

(Isolated)

TO (DO)

LEDs (8)

24H

24G COM

GND

1

TO1 (DO1)

C1

TO2 (DO2)

C2

TO3 (DO3)

C3

TO4 (DO4)

C4

TO5 (DO5)

C5

TO6 (DO6)

C6

TO7 (DO7)

C7

TO8 (DO8)

C8

2 3

AC Power

20.4 to 30 Vac

50/60 Hz

Class 2 (EN 60742)

50 VA per controller

Isolated from I/O

Digital Outputs

12 VA at 24 Vac,

50/60 Hz each Triac

output individually

isolated from AC

input and other I/O.

1

Universal Outputs

0 to 20 mA into an

80 to 550 ohm

load.

7 To detect a closed

switch, maximum

resistance must be

less than 300

8 Remote I/O network

bias resistor is built-in.

minimum resistance must be

greater than 2.5 kil

ETHERNET

LSB

UO LEDs (8)

RCV

XMT

IO

MSTP

STATUS AUX

11

UO1

COM

UO2

UO3

COM

UO4

UO5

COM

UO6

UO7

COM

UO8

9 To detect an open switch,

10 To detect an open switch,

minimum resistance must

be equal to or greater than

2.5 kil

MSB

ohm

11 External load is required to

illuminate UO LEDs.

12 Minimum rate of 1 pulse per 4 minutes. Maximum rate of 10 pulses

per second. With digital inputs only.

13 When making an MS/TP cable, use a 1.3 x 3.5 mm Vdc power

plug with strain relief (Vimex part number SCP-2009A-T,

Schneider-Electric part number E24-1442, or equivalent). The

cable should be no longer than 6 ft. Connect MS+ to the center

contact and MS– to the outside contact:

–

Note: The MS/TP cable described above

is available from Schneider-Electric as

MNB-CT-CBL. Contact

+

Schneider-Electric for more information.

ohm

.

ohm

.

.

12 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 27

I/A Series BACnet Hardware

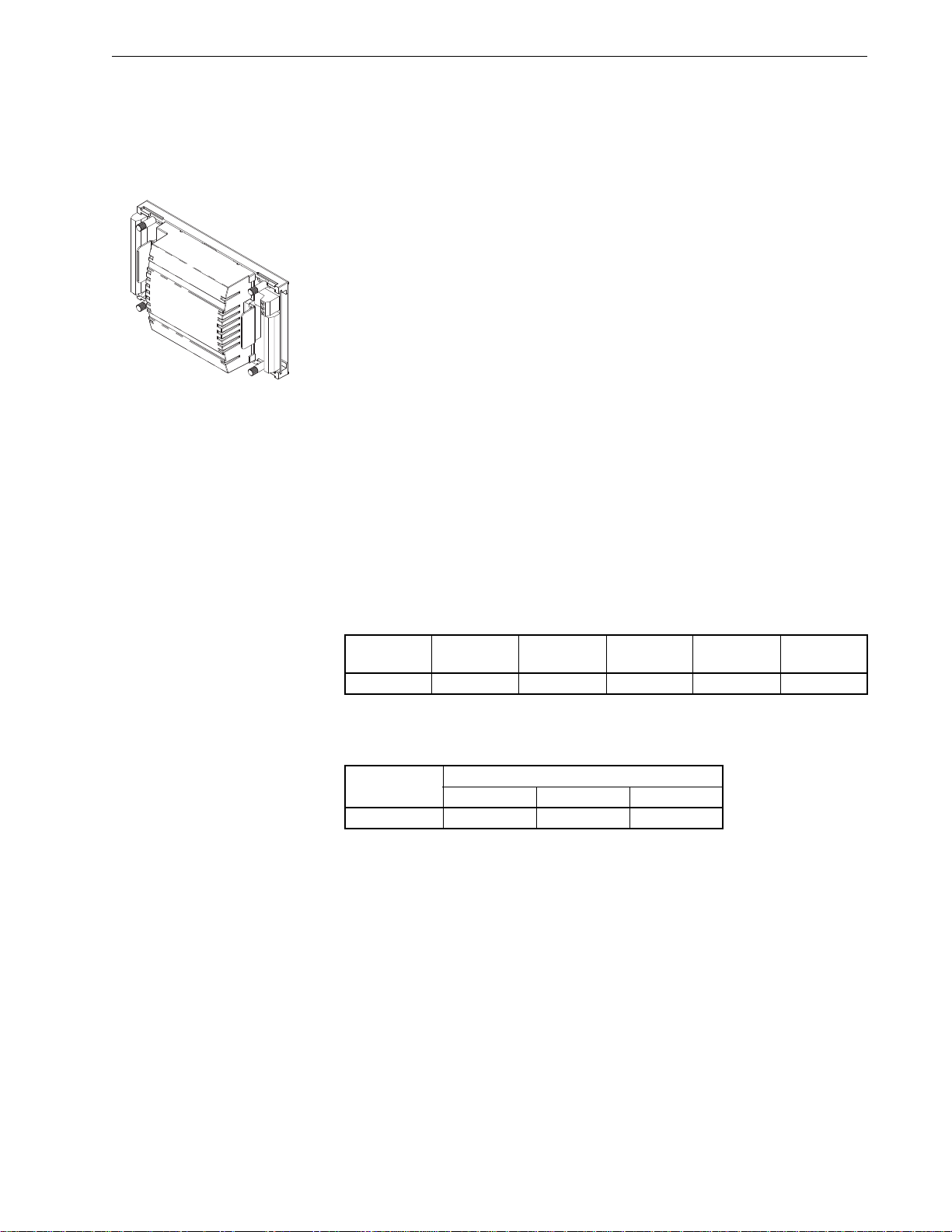

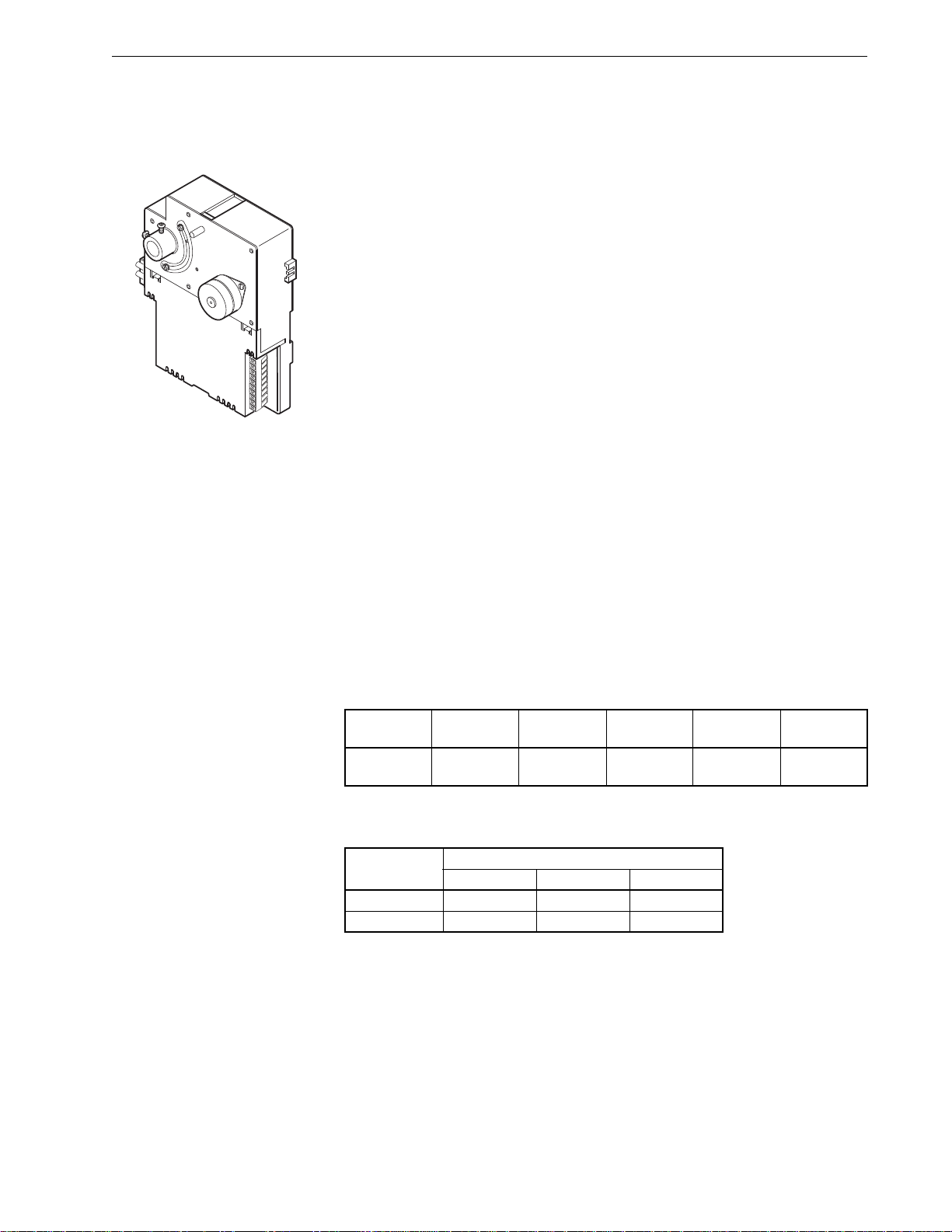

MNB-1000-15 Remote I/O Module

The I/A Series MicroNet BACnet Remote I/O Module, MNB-1000-15, is

designed to be connected to an MNB-1000 Plant Controller, so as to expand

the controller’s I/O count. When programmed using WP Tech, each module

increases the count by 15 inputs and outputs. Up to ei ght modules can be

connected to a given MNB-1000, for a potential increase of 120 I/O points,

total. In this way, the controller’s existing 32 onboard I/O can be e xpanded to

47 I/O points (with one module), up to a maximum total of 152 I/O points

(with eight modules).

Features

The MNB-1000-15 offers the following:

• 24 Vac powered.

• DIP switch for setting the physical address on the remote I/O network.

• Isolated EIA-485 (formerly RS-485) transceiver for remote I/O

communications.

• Removable electronics module that mates with panel-mounted subbase.

• Optional NEMA 1 enclosure.

• Removable terminals for power and communications, to facilitate

commissioning.

• LED indication of compatibility, UO and TO state, and communication

state (with the MNB-1000).

• Firmware upgradeable over the network.

• Fallback function, in case of loss of communication with MNB-1000.

Note: The MNB-1000-15 does not support the S-Link bus.

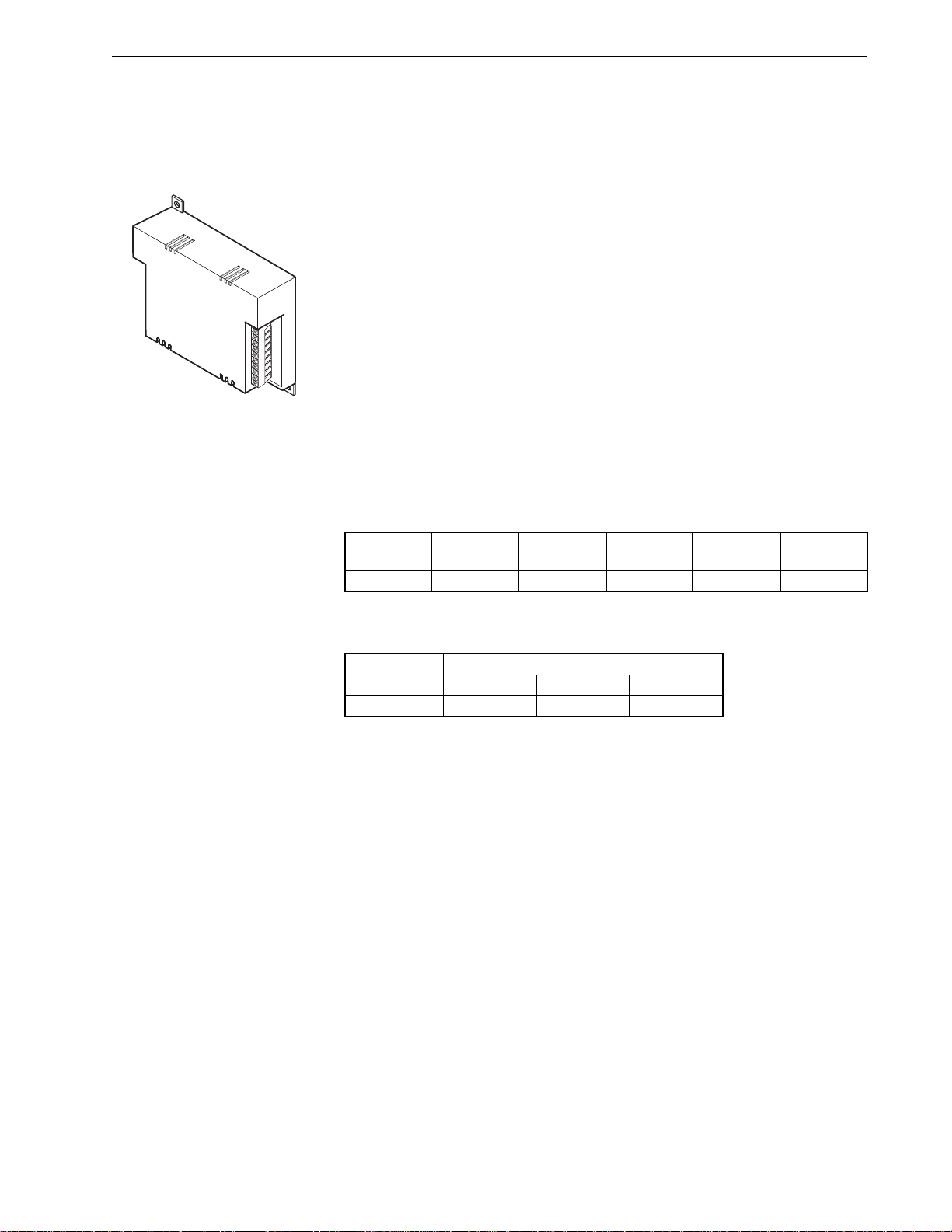

Memory Available

Table–1.9 MNB-1000-15 Available Memory.

Model

Number

MNB-1000-15 256KB 8KB n/a 4KB 8KB

Physical I/O Points

T able–1.10 MNB-1000-15 Inputs and Outputs.

Model

Number

MNB-1000-15 636

Refer to "Input and Output Spe cifications" on page 15 for a detailed

discussion of each input or output type.

Fallback Function

The MNB-1000-15 module’s outputs are driven directly by the MNB-1000

Plant Controller, in which the application resides. If communications

between the module and the MNB-1000 is lost, the module’s output s are set

to fallback values that were previously sent to the module during normal

communications. Refer to "Fallback Function" on page 107 for more

information on this function.

Flash SRAM SDRAM EEPROM FRAM

Inputs and Outputs

UI UO DO (Triac)

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 13

Page 28

Chapter 1

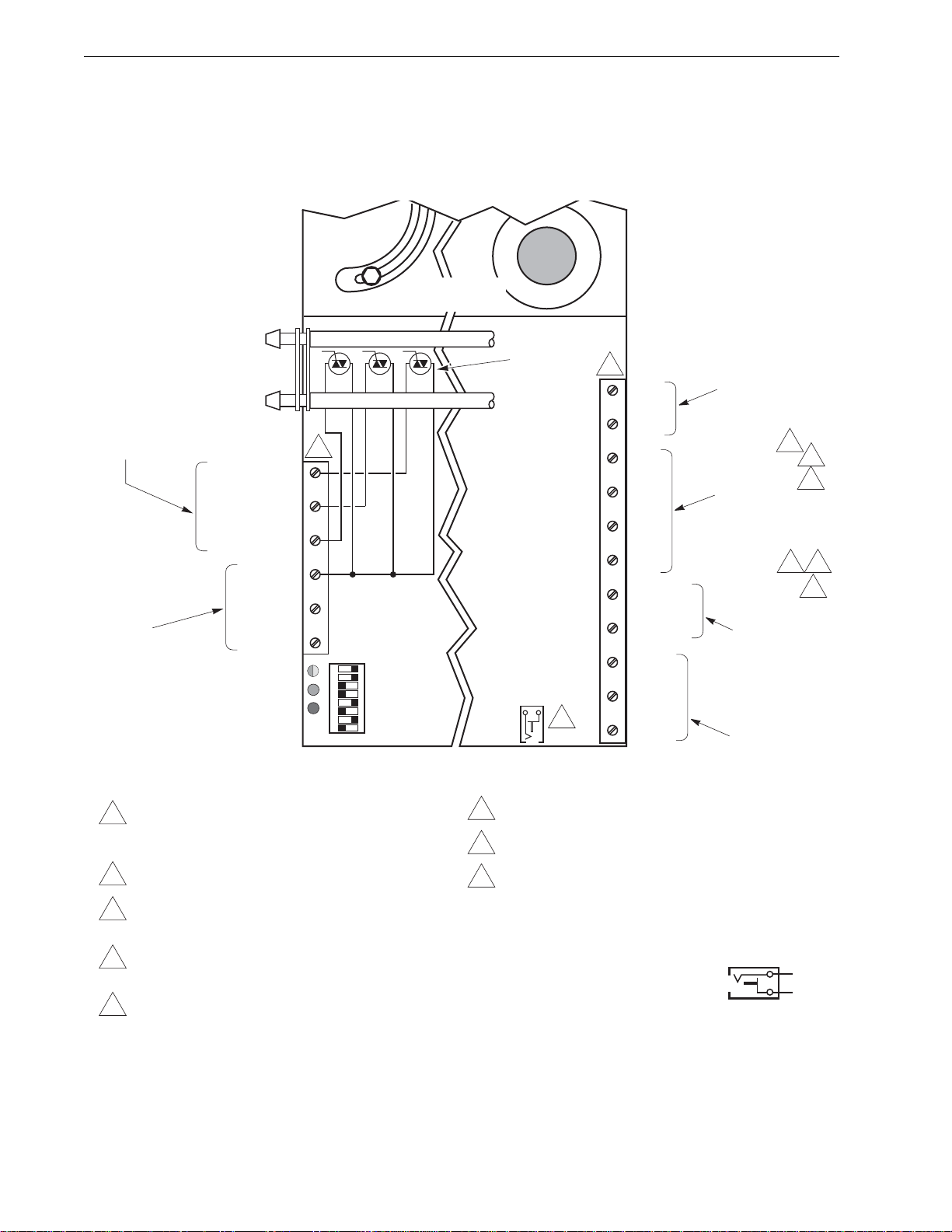

EOL

Enable

Disable

TO1 (DO1)

C1

TO2 (DO2)

C2

TO3 (DO3)

C3

TO4 (DO4)

C4

TO5 (DO5)

C5

TO6 (DO6)

C6

UI1

COM

UI2

UI3

COM

UI4

UI5

COM

UI6

UO1

COM

UO2

UO3

COM

S-LK

IO+

IO

-

SLD

MSB

LSB

MNB-1000-15

Remote I/O Module

24H

24G COM

GND

XMT

RCV

STATUS

Physical

Address

Universal Inputs

0 to 5 Vdc

0 to 20 mA

10K Thermistor

1K Balco

1K Platinum

1K Resistive

10K Resistive

Digital (dry switched

contact)

Standard Pulse

(UI1-UI6)

Universal Outputs

0 to 20 mA into an

80 to 550 ohm load

Remote I/O Network

Communications to

MNB-1000

AC Power

20.4 to 30 Vac

50/60 Hz

Class 2 (EN 60742)

16 VA per module

Digital Outputs

(Triac)

12 VA at 24 Vac,

50/60 Hz. Each Triac

output individually

isolated from AC

input and other I/O.

Class 2

2

5

6

4

7 8

10

1

3

9

2 3

2

1 Do not exceed two AWG #24

(0.205 mm

2

) wires per Remote I/O

wiring terminal.

2 Power and I/O point wiring

terminals accept up to two AWG

#14 (2.08 mm

2

) or smaller wires.

3 Power and remote I/O connectors

have removable screw terminals

.

4 Input signals of 1 to 11 Vdc must

be converted to 0.45 to 5 Vdc with

a voltage divider, part number

AD-8961-220.

5 In applications requiring universal inputs

with ranges of 0 to 20 mA, a 250 ohm

shunt resistor kit, part number

AD-8969-202, is needed.

6 An 11

kil

ohm shunt resistor kit, part

number AD-8969-206, is required for a

10

kil

ohm Thermistor Sensor (non-850

series) universal inputs.

7 To detect a closed switch, resistance must

be less than 300

ohm

.

8 To detect an open switch, resistance must

be greater than 2.5 kil

ohm

.

9 External load is not required to

illuminate UO LEDs.

10 Minimum rate of 1 pulse per 4 minutes.

Maximum rate of 1 pulse per second.

11 Items in gray, although present, are not

used in the MNB-1000-15.

12 Bias for the remote I/O network is

provided by the built-in bias resistor on

the MNB -1000 controller.

TO (DO) LEDs (6)

UO LEDs (3)

Internal

Triac

Switches

(Isolated)

Connectors (2)

11

11

11 12

Note: Components are shown

in their approximate

locations.

Figure–1.6 MNB-1000-15 Terminal Connections.

Wiring Terminals

Refer to Figure-1.6 for the power and network communications wiring

connections available on the MNB-1000-15 remote I/O module.

14 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 29

I/A Series BACnet Hardware

UI1

COM

UI2

Controller

UI1

COM

UI2

+

_

250 ohm

UI1

COM

UI2

+

_

1

10 kilohm Thermistor

(with an 11 kilohm

shunt resistor)

4 to 20 mA

Transmitter

0 to 5 Vdc

Transmitter

Controller

Inputs

Controller

Inputs

Sensor Power

Source

Sensor Power

Source

1 Resistor kit, AD-8969-202. Be

sure to install the resistor at the

controller, not at the 4 to 20 mA

device.

Figure–1.7 Universal Input Connections.

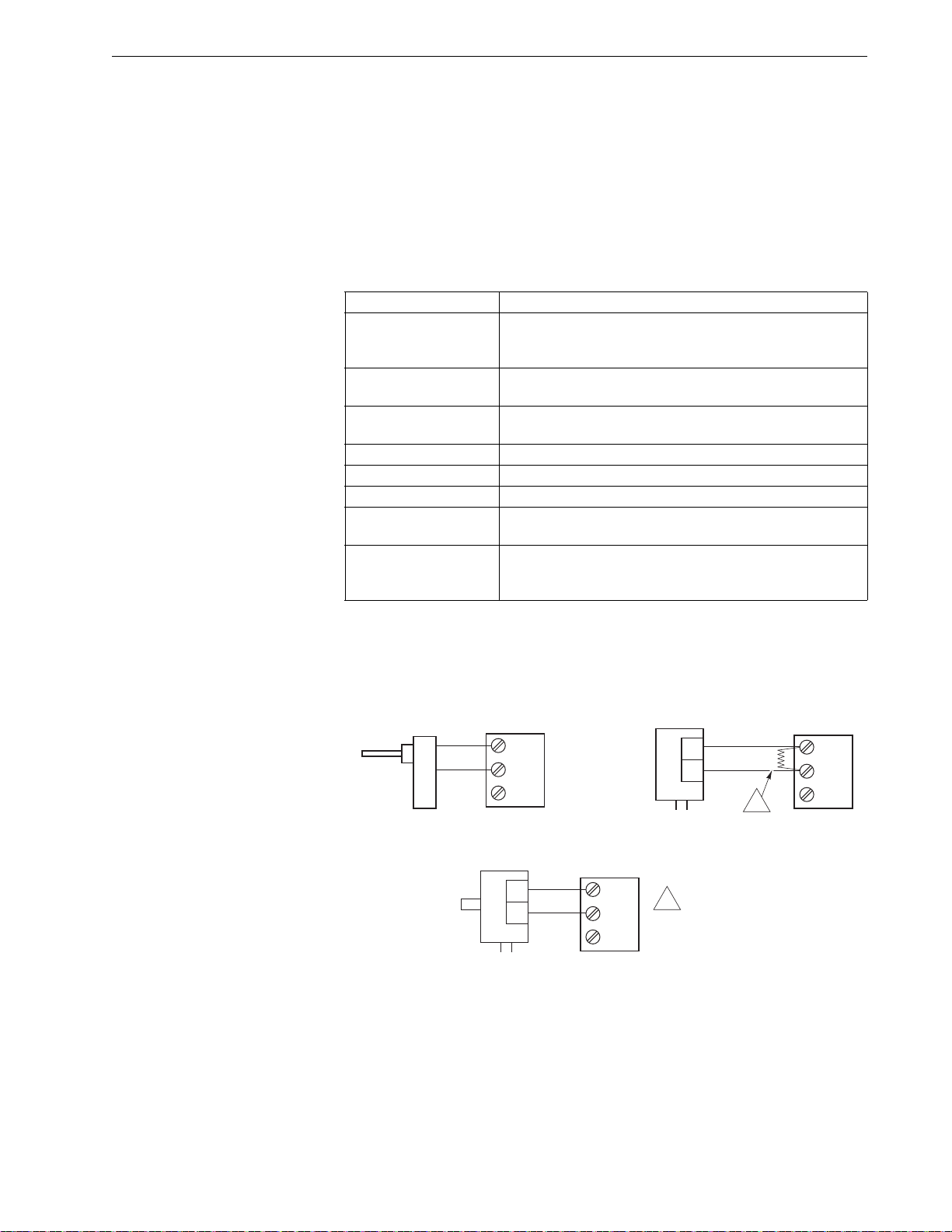

Input and Output Specifications

All MicroNet BACnet controllers use input and output types as described in

this section.

Universal Inputs

The universal input characteristics are software-configured to respond to

one of the eight input types listed in Table–1.11.

Table–1.11 Universal Inputs.

Input Characteristics

10 kilohm Thermistor

with 11 kilohm Shunt

Resistor

1kilohm Balco

1 kilohm Platinum

1 kilohm Resistive 0 to 1500 ohm.

10 kilohm Resistive 0 to 10.5 kilohm.

Analog Voltage Range 0 to 5 Vdc

Analog Current

Digital

Sensor operating range -40 to 250 °F (-40 to 121 ° C),

requires Schneider Electric model TSMN-57011-850

series, TS-5700-850 series, or equivalent.

-40 to 250 °F (-40 to 121 °C), Schneider Electric model

TSMN-81011, TS-8000 series, or equivalent.

-40 to 240 °F (-40 to 116 °C), Schneider Electric model

TSMN-58011, TS-5800 series, or equivalent.

0 to 20 mA, requires external 250 ohm shunt resistor kit,

AD-8969-202.

Dry switched contact; detection of closed switch requires

less than 300 ohm resistance; detection of open switch

requires more than 2.5 kilohm.

See Figure-1.7 for examples of connections to universal inputs.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 15

Page 30

Chapter 1

UO1

COM

UO2

+

_

500 ohm

Controller

Outputs

+

_

UO1

COM

UO2

1

2

3

1 Output accuracy degrades as input

impedance decreases.

2 Resistor kit, AM-708. Be sure to

install the resistor at the 0 to 10 Vdc

device, not at the controller.

3 Can be purchased through PS3,

part number FUN-RIBU1-C.

Controller

Outputs

4 to 20 mA

Actuator

Controller Output

Configured as

0 to 20 mA

Functional Devices

RIBU1C Relay

0 to 10 Vdc

Actuator

N/C

COM

N/O

Wht/Blu

10-30 Vdc

Wht/Yel

COM

UO1

COM

Figure–1.8 Universal Output Connections.

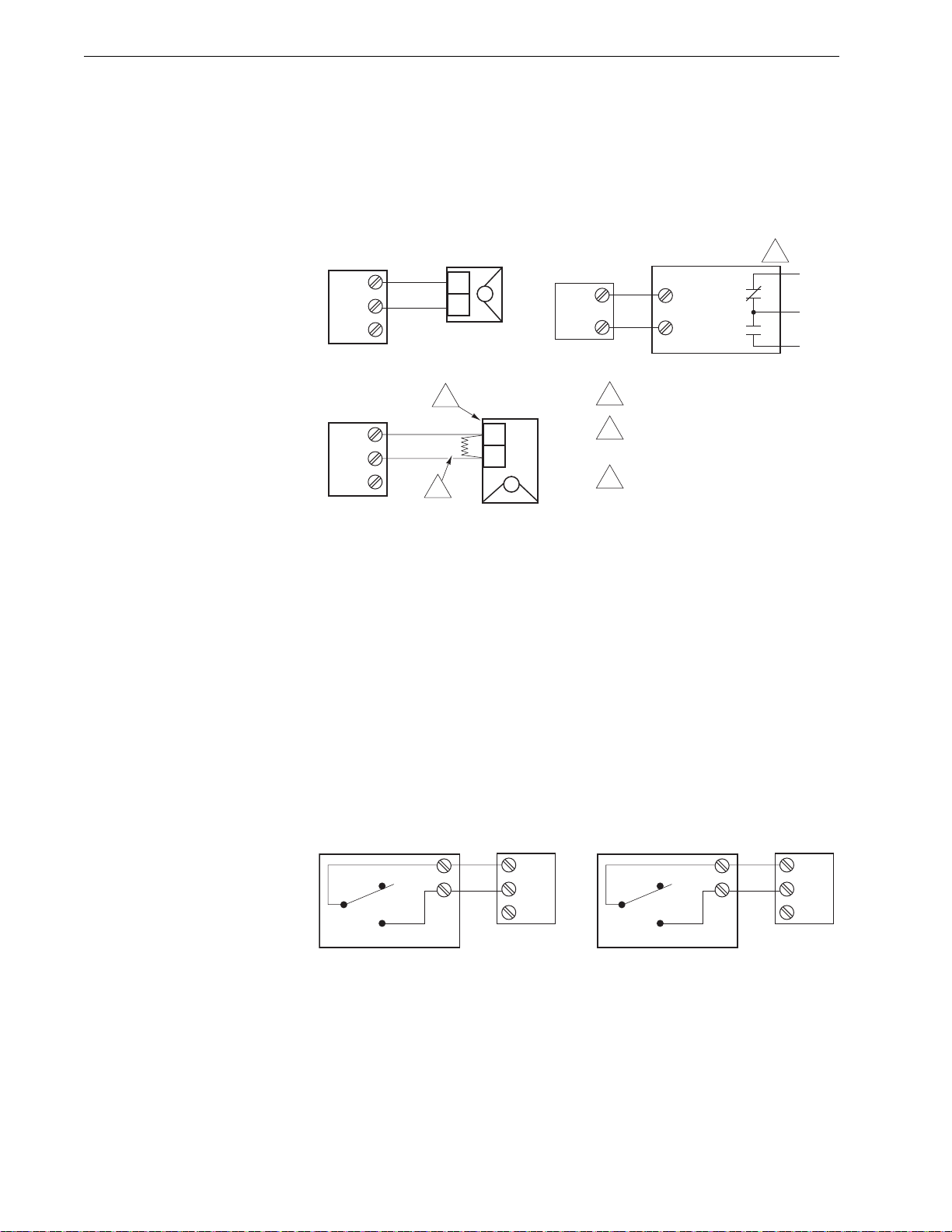

r

Figure–1.9 Fixed Digital Input Connections.

Universal Outputs

0 to 20 mA (output load from 80 to 550 ohm). See Figure-1.8 for examples of

connections to universal outputs.

Digital Inputs

Dry switched contact. Detection of a closed switch requires less than

300 ohm resistance. When connected to a controller’s digital inputs,

detection of an open switch requires more than 2.5 kilohm. When connected

to a controller’s universal inputs (used as digit al inputs), d etection of an open

switch requires more than 2.5 kilohm. See Figure-1.9 for examples of a

connection to digital inputs.

Connection to Digital Inputs Connection to Universal Inputs

DI Input

On-Off Type Device

NC

COM

NO

Controller

Inputs

DI1

COM

DI2

DI Input

On-Off Type Device

NC

COM

NO

Controlle

Inputs

UI1

COM

UI2

16 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 31

I/A Series BACnet Hardware

Figure–1.10 MNB-V2 and MNB-70 Controller Triac Output Circuit Configuration.

GND 24H24G

SW24H1

(DO1)

SW24H2

(DO2)

SW24H3

(DO3)

Class 2

Transformer

24 Vac Primary

Load1 Load2 Load3

MNB-V2

Controller

Digital Output s, Triac

MNB-V2 and MNB-70

Table–1.12 lists specifications for the Triac outputs featured on the MNB-V2

and MNB-70 controllers.

Caution: The Triac (digital) output s o n MicroNet BACnet controller s are not

protected against short circuits. Take necessary precautions to protect these

outputs against short circuits.

Table–1.12 Digital Outputs, Triac, on MNB-V2 and MNB-70.

Input Characteristics

Internally sourced, high side switching. Triac outputs

Common Terminal

share a common supply (24H) that is independently

switched to each output terminal, SW24H1, SW24H2, and

SW24H3 (DO1, DO2, and DO3).

b

Rating (DO1+DO2)

Rating (DO3)

b

24 VA total at 24 Vac, 50/60 Hz.

12 VA at 24 Vac, 50/60 Hz.

Default Output State OFF (inactive).

a. As with all Triac devices, a high-impedance meter on the output without a load will show

24 Vac, due to low level leakage through the device.

b. As labeled on the controller, SW24H1=DO1, SW24H2=DO2, and SW24H3=DO3 (see

Figure-1.2).

a

See Figure-1.10 for an example of a connection to an MNB-V2 or MNB-70

controller’s Triac outputs.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 17

Page 32

Chapter 1

Figure–1.11 MNB-300 Controller , MNB-1000 Controller, and MNB-1000-15 Remote

I/O Module Triac Output Circuit Configuration.

Note: With the MNB-V2 and MNB-70, AC voltage to Triacs is sourced from

the controller . This is different fr om the MNB-300 and MNB-1000 contr ollers,

and the MNB-1000-15 module, where AC voltage is sourced externally.

MNB-300, MNB-1000, and MNB-1000-15

Table–1.13 lists specifications for the Triac outputs featured on MNB-300

and MNB-1000 controllers, and on the MNB-1000-15 remote I/O module.

Caution: The Triac (digit al) outp ut s on Mi croNet BACnet contro llers are not

protected against short circuits. Take necessary precautions to protect these

outputs against short circuits.

Table–1.13 Digital Outputs, Triac, on MNB-300, MNB-1000, and MNB-1000-15.

Input Characteristics

Isolation Each output individually isolated from circuit common.

Common Terminal

Rating 12 VA at 24 Vac, 50/60 Hz.

Default Output State OFF (inactive).

a. As with all Triac devices, a high-impedance meter on the output without a load will show

24 Vac, due to low level leakage through the device.

Each TO has its own common terminal. This is the voltage

switched to each TO output.

a

See Figure-1.11 for an example of a connection to the Triac outputs on an

MNB-300, MNB-1000, or MNB-1000-15.

24 Vac

Load1

TO1 (DO1) C1

GND

Load2

TO2 (DO2) C2

24H24G

Class 2

Transformer

24 Vac Primary

24 Vac

TOx (DOx) Cx

24 Vac

Loadx

20 Vdc Output

20 Vdc ±10% at 100 mA for supplying power to an external device. See

Figure-1.12 for an example of a connection to a 20 Vdc output.

18 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Page 33

I/A Series BACnet Hardware

Figure–1.12 20 Vdc Output Connection.

ControllerAuxiliary Device

+

–

Humidity 4 to 20 mA

(example)

250 ohm

1

20V

UI1

COM

1 Resistor kit, AD-8969-202,

4 to 20 mA only. Not

required for Vdc.

Inputs from MN-Sx MicroNet Sensor

Table–1.14 lists specifications for the inputs from MicroNet Sensors. For an

example showing how a MicroNet Sensor may be wired to a MicroNet

BACnet controller, see Figure-1.13.

Table–1.14 Inputs from MN-Sx MicroNet Sensor.

Input Characteristics

Space Temperature 32 to 122 °F (0 to 50 °C).

Space Humidity 5 to 95% RH, non-condensing.

Local Setpoint

Override Pushbutton For standalone occupancy control.

Fan Operation and

Speed Mode

System Mode Heat, cool, off, or auto.

Emergency Heat Enable or disable.

Adjustable within limits set by application programming

tool.

On/off, speed (low/medium/high), or auto.

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 19

Page 34

Chapter 1

Wire S-Link to terminals

1 and 2 on baseplate

1 MS/TP wiring of controller to sensor screw terminals

is optional.

Note: To preserve the integrity of the network, the

MS/TP network wiring connecting a MicroNet

BACnet controller to an MN-Sx sensor must be run

to the sensor and back, in daisychain fashion. A

wire “spur” must not be used to connect the sensor

to the controller.

2 Observe consistent polarity when wiring.

3 S-Link wiring is not polarity-sensitive.

4 Tie the MS/TP shields together at the sensor.

5 MS/TP shields must be connected to the SLD (or SHLD)

terminal of all MicroNet BACnet controllers.

6 S-Link communications is not supported in the

MNB-1000-15 remote I/O module.

To Rest of the

MS/TP Network

To Rest of the

MS/TP Network

4

5

6

S-Link

MN-Sx

Sensor

MS/TP

MS/TP Jack

+

_

12

43

S-Link Jack

1

3

2

2

Shield

Controller

COM

SLK

SLD (SHLD)

MS+ (MSTP+)

MS- (MSTP-)

Wire MS/TP to terminals

3 and 4 on baseplate

Figure–1.13 Sensor Link (S-Link) Connection.

20 MicroNet BACnet Wiring, Networking, and Best Practices Guide F-27360-11

Velocity Pressure Input

MNB-V1 and MNB-V2

Table–1.15 lists specifications for the velocity pressure inputs on MNB-Vx

controllers.

Table–1.15 Velocity Pressu re Input, on MNB-V1 and MNB-V2.

Control Range 0.004 to 1.5 in. of W.C. (0.996 to 373.5 Pa)

Over Pressure

Withstand

Accuracy

Sensor Type Self-calibrating flow sensor (differential pressure).

Tu bing Connections

Tubing Length 5 ft (1.52 m) maximum, each tube.

Input Characteristics

±20 in. of W.C. (4.980 kPa)

±5% at 1.00 in. of W.C. (249.00 Pa) with laminar flow at

77 °F (25 °C) and suitable flow station.

Barb fittings for 0.170 in. I.D. (4.3 mm I.D.) FRPE

polyethylene tubing or 0.25 in. O.D./0.125 in. I.D. (6.4 mm

O.D./3.2 mm I.D.) Tygon

taps).

®

tubing (high and low pressure

Page 35

I/A Series BACnet Hardware

MicroNet Digital Wall Sensors

Each MicroNet BACnet controller supports a single MN-Sx digital wall

sensor. 12 sensor models are presently available, six sensing zone

temperature and six sensing both zone temperature and humidity. These

range from a sensor-only model to one with seven pushbuttons and an LCD

screen. Table–1.16 provides a feature summary of the MN-Sx sensors.

Note: S-Link communications is not supported in the MNB-1000-15 remote

I/O module.

T able–1.16 MicroNet Sensors.

Sensor Model Features Sensor Model Features

MN-S1

MN-S1HT

MN-S2

MN-S2HT

MN-S3

MN-S3HT

MN-S4-FCS

MN-S4HT-FCS

No buttons

• Sensor only.

Its primary function is to provide room

temperature or humidity sensing values

to the controller via the Sensor Link.

Three buttons

• MN-S2 features—Sensor; Override key

with LED indicator.

• 3-digit LCD for showing (typically) the

current temperature.

• Up and Down keys to allow adjustment

of the current setpoint.

Six buttons

• Larger LCD capable of showing up to

four possible temperature, humidity,

and function displays

• Up and Down keys for setpoint

adjustment.

• Three fan speed selection keys:

– High Fan Speed

– Medium Fan Speed

– Low Fan Speed

• Fan On / Off / Auto key.

MN-S4

MN-S4HT

MN-S5

MN-S5HT

One button

• Sensor (as in MN-S1).

• Override key with LED indicator, to

allow the timed override of unoccupied

to occupied modes of operation.

Six buttons

• MN-S3 features—Sensor; Override key

with LED indicator; LCD temperature,

humidity, and function display (larger

than in MN-S3, capable of showing up

to four possible displays); Up and

Down keys for setpoint adjustment.

• These “sub-base” functions:

– Mode key allowing two

Heat/Cool/Auto/Off modes.

– Fan key to control fan operation or

speed.

– Setpoint key to select up to four

Heat/Cool setpoints.

Seven buttons

• MN-S4 features—Sensor; Override key

with LED indicator; larger LCD capable

of showing up to four possible

temperature, humidity, and function

displays; Up and Down keys for

setpoint adjustment; Mode key, Fan

key, and Setpoint key “sub-base”

functions.

• Emergency Heat key with LED

indicator for emergency heat activation

or indication (Heat Pump applications).

F-27360-11 MicroNet BACnet Wiring, Networking, and Best Practices Guide 21

Page 36

Chapter 1

A

Figure–1.14 MN-Sx Sensor Pre-Wirable Baseplate and Electronic Assembly .

+

+

!

Common Sensor Features

An MN-Sx sensor communicates with (and is powere d by) two Sensor Link

(S-Link) terminals on a MicroNet controller — it does not consume a typical

I/O point. The S-Link connection between the sensor and the controller can

use low-cost, twisted-pair wire up to 200 ft (61 m), and is not polarity

sensitive. All MN-Sx sensor models also include an MS/TP jack for a

convenient means of connecting a network tool, such as a Work Place Tech

Tool PC, to the BACnet network.

Under each MN-Sx sensor’s detachable cover is a pre-wirable baseplate

and a removable electronic assembly (Figure–1.14). The same baseplate is

used in all MN-Sx sensor models.

Pre-wirable Sensor

Baseplate

Removable Electronic

ssembly (contains

temperature sensor)

S-Link Screw Terminals

(1 and 2)

MS/TP Jack

Note: MN-Sx sensors have no independent intelligence. This means any