MasterPactMTZ2/MTZ3

DOCA0101EN-04 07/2020

MasterPact MTZ2/MTZ3

IEC Circuit Breakers and Switch-Disconnectors

from 800 to 6300 A

User Guide

07/2020

DOCA0101EN-04

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 DOCA0101EN-04 07/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 MasterPact MTZ2/MTZ3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MasterPact MTZ2/MTZ3 Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawout Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MicroLogic X Control Unit: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Go2SE Landing Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 MasterPact MTZ2/MTZ3 Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1 Device Operating Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engaging the ERMS Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Drawout Device Racking Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawout MasterPact MTZ2/MTZ3 Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disconnecting the Drawout Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Drawout Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Drawout Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Drawout Device in the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Device Locking Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking the Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking the Device in Open Position with Padlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking the Device in Open Position with Keylocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chassis Locking in Disconnected Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chassis Locking in Any Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking the Safety Shutters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Device Interlocking Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mismatch Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VPEC Door Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VPOC Open-door Racking Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IPA Cable-type Door Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Interlocking for Transfer Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAE Automatic Spring-Discharge Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IBPO Racking Interlock Between Racking Handle and Opening Pushbutton . . . . . . . . . . . .

Chapter 3 MasterPact MTZ Critical Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Finding the Cause of a Trip or an Alarm in Critical Cases. . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the Circuit Breaker After a Trip Due to an Electrical Fault . . . . . . . . . . . . . . . . . .

Resetting the Circuit Breaker After a Trip Due to an Incident Detected by the MicroLogic X

Self-tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosing Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosing Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

12

16

23

26

29

31

34

35

39

44

47

50

51

53

60

61

65

68

71

74

77

78

80

82

84

88

90

93

94

96

99

102

103

105

105

108

111

114

116

124

DOCA0101EN-04 07/2020 3

Chapter 4 MasterPact MTZ Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Introduction to Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and MicroLogic X Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Checks and Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MasterPact MTZ Test Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

128

130

132

135

136

137

Chapter 5 MasterPact MTZ Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Introduction to Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Chassis Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Unexpected Tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Mechanical Control Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Electrical Control Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Control Operations from EcoStruxure Power Device App . . . . . . . . . . . . .

Troubleshooting: Control Operations from IO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Control Operations from EcoStruxure Power Commission Software . . . . .

Troubleshooting: Control Operations from IFE/EIFE Webpages . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Control Operations from Communication Network. . . . . . . . . . . . . . . . . . .

Troubleshooting: Control Operations from FDM128 Display . . . . . . . . . . . . . . . . . . . . . . . . .

142

144

145

146

147

149

151

152

154

156

158

Chapter 6 Schneider Electric Green Premium™ Ecolabel . . . . . . . . . . . . . . . . . . . . . . 159

Schneider Electric Green Premium™ Ecolabel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

159

4 DOCA0101EN-04 07/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

DOCA0101EN-04 07/2020 5

SAFETY NOTICE

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See

NFPA 70E, CSA Z462, NOM 029-STPS or local equivalent.

This equipment must only be installed and serviced by qualified electrical personnel.

Turn off all power supplying this equipment before working on or inside this equipment.

Always use a properly rated voltage sensing device to confirm power is off.

Replace all devices, doors, and covers before turning on power to this equipment.

Beware of potential hazards, and carefully inspect the work area for tools and objects that may have

been left inside the equipment.

Failure to follow these instructions will result in death or serious injury.

CYBERSECURITY SAFETY NOTICE

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND CONFIDENTIALITY

Change default passwords at first use to help prevent unauthorized access to device settings,

controls, and information.

Disable unused ports/services and default accounts to help minimize pathways for malicious

attackers.

Place networked devices behind multiple layers of cyber defenses (such as firewalls, network

segmentation, and network intrusion detection and protection).

Use cybersecurity best practices (for example, least privilege, separation of duties) to help prevent

unauthorized exposure, loss, modification of data and logs, or interruption of services.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

WARNING

6 DOCA0101EN-04 07/2020

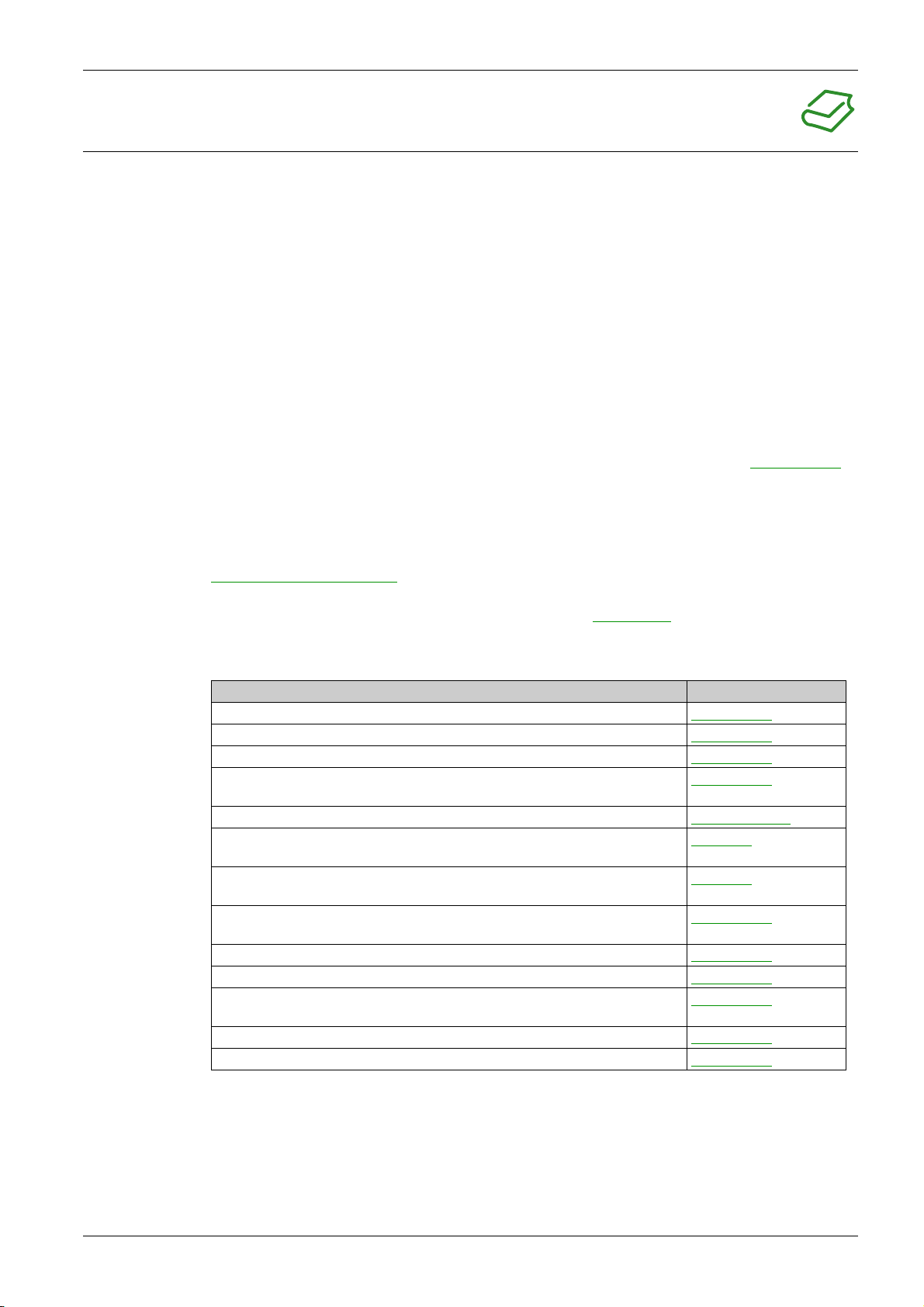

At a Glance

Document Scope

Validity Note

Online Information

About the Book

The aim of this guide is to provide users, installers, and maintenance personnel with technical information

needed to operate MasterPact™ MTZ2/MTZ3 circuit breakers and switch-disconnectors, in compliance

with the IEC standards.

This guide applies to MasterPact MTZ2/MTZ3 circuit breakers and switch-disconnectors.

This guide applies to MicroLogic™ X control units:

With firmware version 004.000.000 or greater

With hardware version 001.000.000 or greater

NOTE: This guide also applies to MicroLogic™ Xi control units. A MicroLogic Xi control unit is a

MicroLogic X control unit without Bluetooth low energy (BLE) communication.

The specific features of the MicroLogic Xi control units are described in the appendix in

MasterPact MTZ - MicroLogic X Control Unit - User Guide

.

DOCA0102EN

The information contained in this guide is likely to be updated at any time. Schneider Electric strongly

recommends that you have the most recent and up-to-date version available on

www.se.com/ww/en/download

.

The technical characteristics of the devices described in this guide also appear online. To access the

information online, go to the Schneider Electric home page at

www.se.com

.

Related Documents

Title of Documentation Reference Number

MasterPact MTZ - MicroLogic X Control Unit - User Guide DOCA0102EN

MasterPact MTZ - Modbus Communication Guide DOCA0105EN

MasterPact MTZ - IEC 61850 Communication Guide DOCA0162EN

MasterPact MTZ - IEC Circuit Breakers and Switch-Disconnectors - Maintenance

Guide

MasterPact MTZ Catalogue LVPED216026EN

MasterPact MTZ2/MTZ3 - Fixed IEC Circuit Breaker or Switch-Disconnector Instruction Sheet

MasterPact MTZ2/MTZ3 - Drawout IEC Circuit Breaker or Switch-Disconnector Instruction Sheet

Enerlin'X IO - Input/Output Application Module for One IEC Circuit Breaker - User

Guide

Enerlin'X IFE - Ethernet Switchboard Server - User Guide DOCA0084EN

Enerlin'X IFE - Ethernet Interface for One IEC Circuit Breaker - User Guide DOCA0142EN

Enerlin'X EIFE - Embedded Ethernet Interface for One MasterPact MTZ Drawout

Circuit Breaker - User Guide

Enerlin’X FDM128 - Ethernet Display for Eight Devices - User Guide DOCA0037EN

ULP System for MasterPact and ComPact (IEC Standard) - User Guide DOCA0093EN

DOCA0099EN

NVE35469

NVE35470

DOCA0055EN

DOCA0106EN

You can download these technical publications and other technical information from our website at

https://www.se.com/ww/en/download/ .

Trademark Notice

All trademarks are owned by Schneider Electric Industries SAS or its affiliated companies.

DOCA0101EN-04 07/2020 7

8 DOCA0101EN-04 07/2020

MasterPact MTZ2/MTZ3

MasterPact MTZ2/MTZ3 Description

DOCA0101EN-04 07/2020

MasterPactMTZ2/MTZ3 Description

Chapter 1

MasterPact MTZ2/MTZ3 Description

What Is in This Chapter?

This chapter contains the following topics:

MasterPact MTZ2/MTZ3 Range 10

Fixed Device 12

Drawout Device 16

Device Identification 23

MicroLogic X Control Unit: Description 26

Go2SE Landing Page 29

Operating Conditions 31

Topic Page

DOCA0101EN-04 07/2020 9

MasterPact MTZ2/MTZ3 Description

MasterPact MTZ2/MTZ3 Range

Description

The MasterPact MTZ2/MTZ3 range of circuit breakers and switch-disconnectors offers current ratings from

800 A to 6,300 A, for AC power systems up to 1,150 Vac.

The MasterPact MTZ2/MTZ3 range is available in the following frame sizes:

MasterPact MTZ2 for current ratings from 800 A to 4,000 A

MasterPact MTZ3 for current ratings from 4,000 A to 6,300 A

Each frame size is available in the following power systems:

3-pole (3P)

4-pole (4P)

Devices are available in the following installation types:

Fixed-mounted devices

Drawout devices

Convention

In this guide, the term

Circuit Breakers

The following performance levels are available:

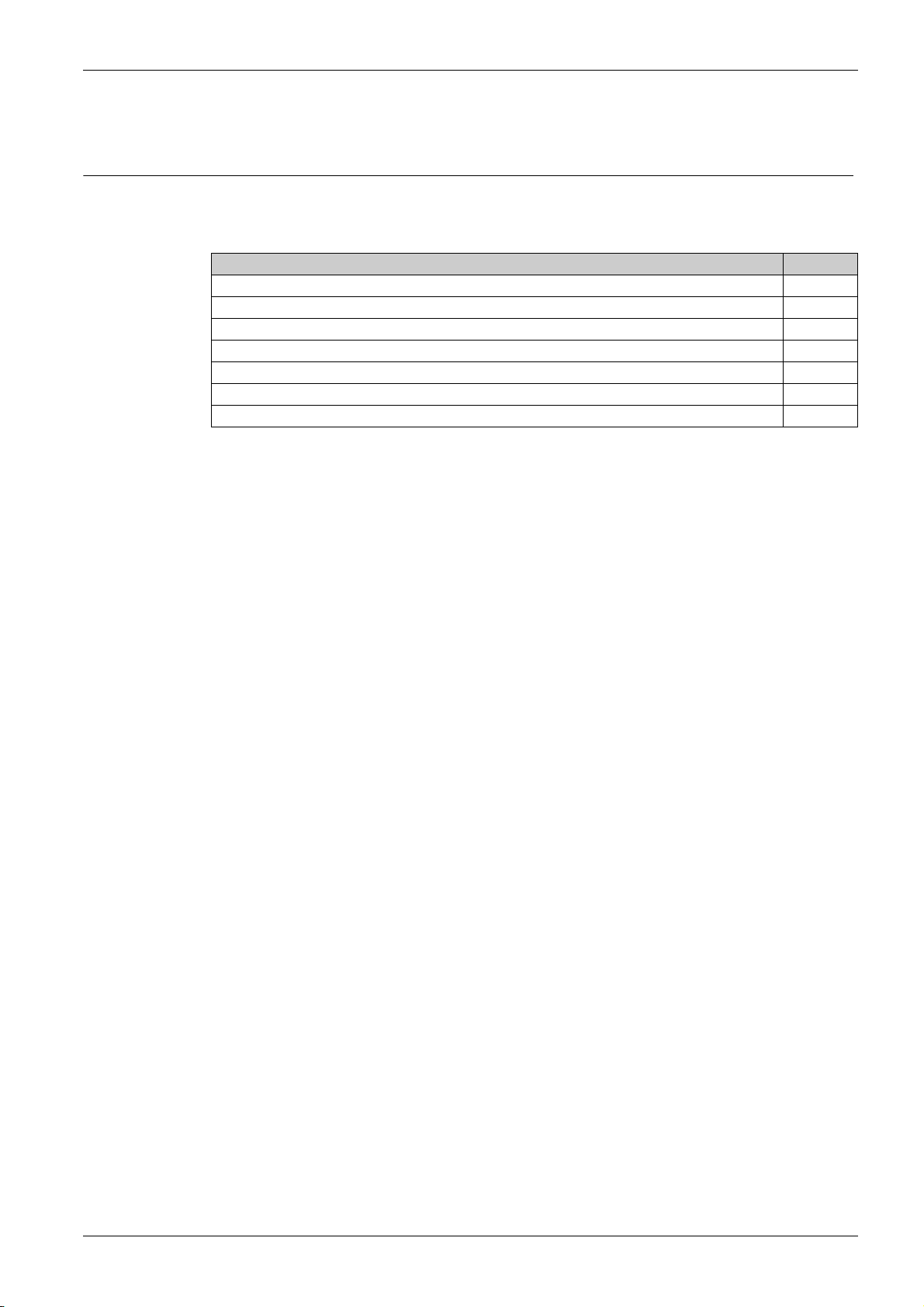

N1: standard short-circuit level (42 kA) with total selectivity

H1: high short-circuit level (66 kA) with total selectivity

H2: very high short-circuit level (100 kA) with very high selectivity (85 kA)

H2V: very high short-circuit level (100 kA) with very high selectivity (100 kA) (Rated operational voltage

Ue limited to 440 Vac)

H3: extremely high short-circuit level (150 kA) with high selectivity (66 kA)

L1: extremely high short-circuit level (150 kA) with strong current limitation and significant selectivity

(30 kA)

NOTE: The values above correspond to a 440 Vac network, for higher voltage levels the values can be

different. Refer to

MasterPact MTZ device

covers circuit breakers and switch-disconnectors.

LVPED216026EN MasterPact MTZ Catalogue

.

Switch-Disconnectors

10

Circuit breakers are fitted with a MicroLogic X control unit.

For full information about available circuit breaker models, frame sizes, interrupting ratings, sensor ratings,

and control units, refer to

LVPED216026EN MasterPact MTZ Catalogue

.

The following performance levels are available:

NA: Icw = 42 kA/1s

HA: Icw = 66 kA/1s

HF: Icw = 85 kA/1s

HH: Icw = 100 kA/1s

For information about available switch-disconnector models and frame sizes, refer to

MasterPact MTZ Catalogue

.

LVPED216026EN

DOCA0101EN-04 07/2020

Neutral Position on 4P Devices

On 4P circuit breakers:

For MasterPact MTZ2 N1, H3, L1, H10, the neutral position is on the left side as standard.

For MasterPact MTZ2 H1, H2, and H2V, the neutral position is on the left side as standard. A version

with neutral position on the right side is available when ordering.

For MasterPact MTZ3 H1, H2, the neutral position is on the left side as standard. A version with neutral

position on the right side is available when ordering.

On 4P switch-disconnectors:

For MasterPact MTZ2 NA, HA, HF, the neutral position can be switched from the left side to the right

side using the label provided.

For MasterPact MTZ2 HH, the neutral position is on the left side as standard. A version with neutral

position on the right side is available when ordering.

For MasterPact MTZ3 HA, the neutral position is on the left side as standard.

MasterPact MTZ2/MTZ3 Description

DOCA0101EN-04 07/2020 11

MasterPact MTZ2/MTZ3 Description

Fixed Device

Fixed Device Description

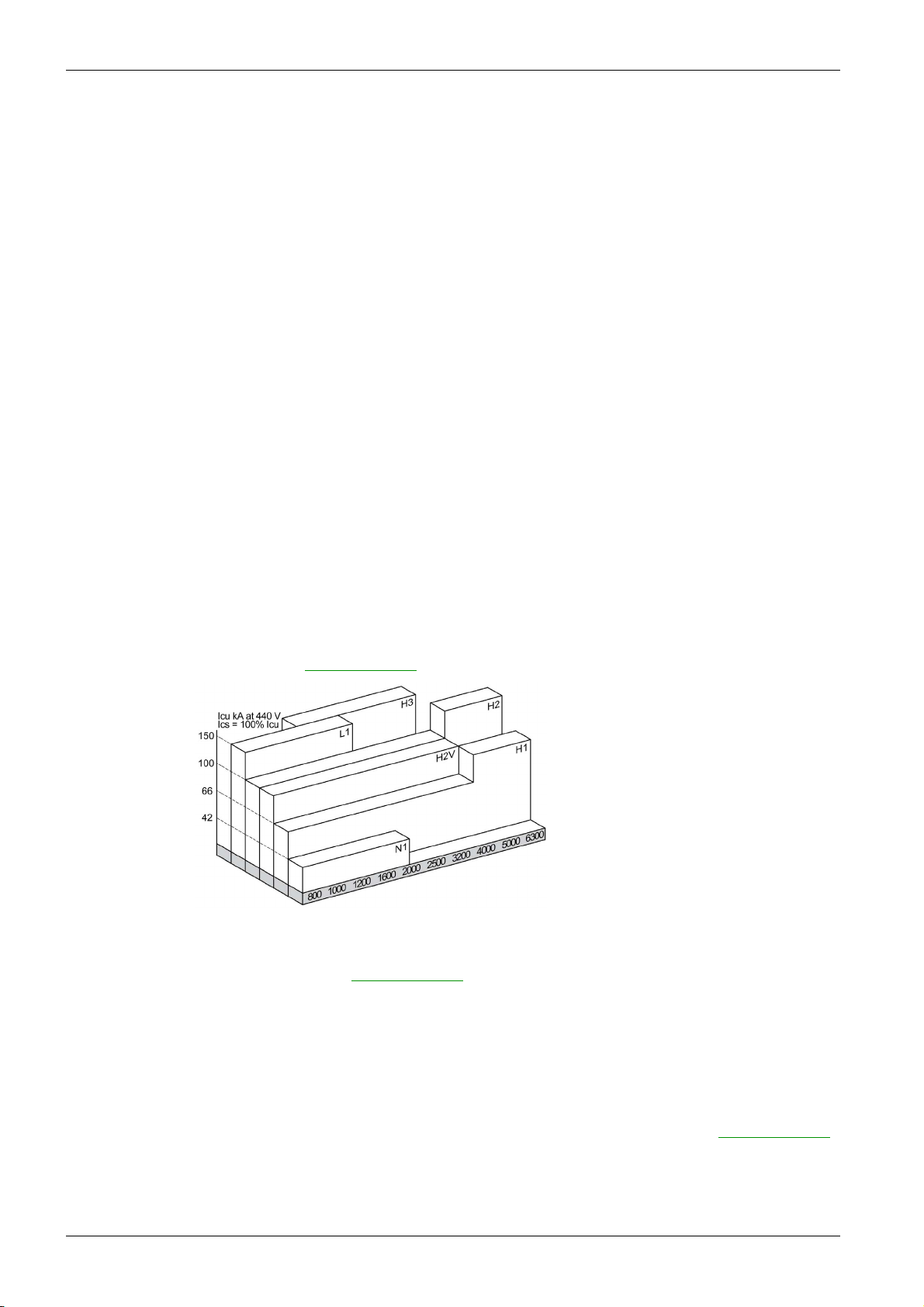

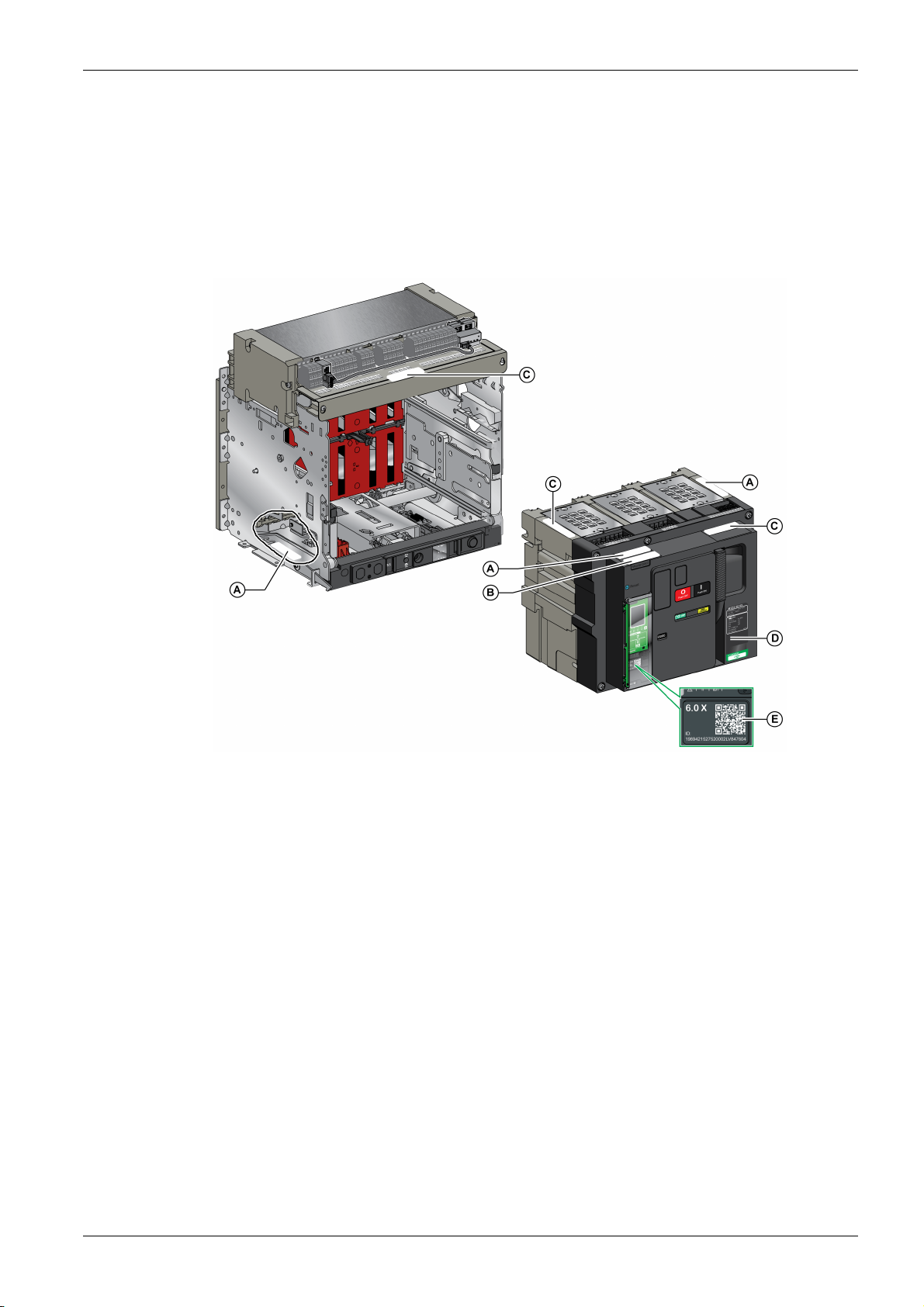

The following image shows the standard version of the fixed device (no optional accessories).

A Mounting side plate

B Carrying grip

C Arc chute

D Blue fault-trip reset button

E Opening pushbutton

F Closing pushbutton

G Spring charging handle

H Terminal blocks for standard accessories

I Front cover

J VBP pushbutton locking cover (optional)

K Rating plate

L Spring charged and ready-to-close indicator

M Main-contact position indicator

N Window to read the (optional) CDM mechanical

operation counter

O Control unit

P Control unit transparent cover

Fixed Device Accessories Description

The following image shows the accessories available for the fixed device.

A Additional support brackets for mounting on a

backplate

B ULP port module

C Terminal blocks for optional accessories

D Four OF indication contacts (optional)

E Four OF indication contacts (delivered as

standard)

F KMT grounding kit

G MCH gear motor

H CDM mechanical operation counter

Z1, Z2 See following images

12

DOCA0101EN-04 07/2020

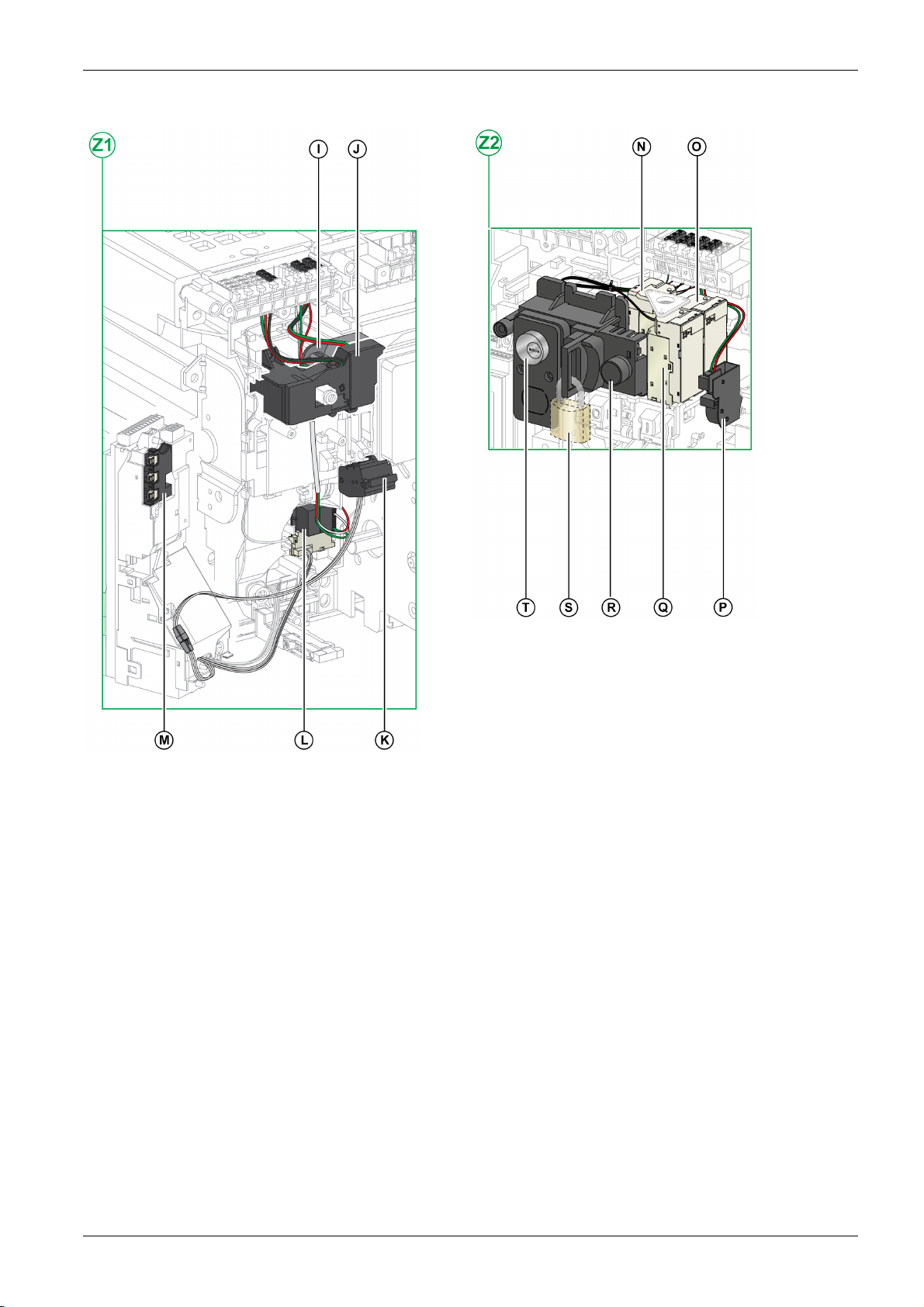

The following images zoom in on the accessories for the fixed device:

MasterPact MTZ2/MTZ3 Description

I Standard SDE1 fault-trip indication contact

J Optional SDE2 fault-trip indication contact or RES electrical

remote reset

K Microswitch

L M2C programmable contacts or ESM ERMS switch module

M Isolation module

N MN undervoltage release or MX2 opening voltage release

O MX1 opening voltage release

P PF ready-to-close contact

Q XF closing voltage release

R BPFE electrical closing pushbutton

S VCPO OFF-position locking by padlocks

T VSPO OFF-position locking by keylocks

DOCA0101EN-04 07/2020 13

MasterPact MTZ2/MTZ3 Description

Fixed Device Terminal Block Description

Terminal block supplied as standard on the circuit breaker

Terminal block for optional accessories on the circuit breaker

14

DOCA0101EN-04 07/2020

Assignment of Terminal Blocks

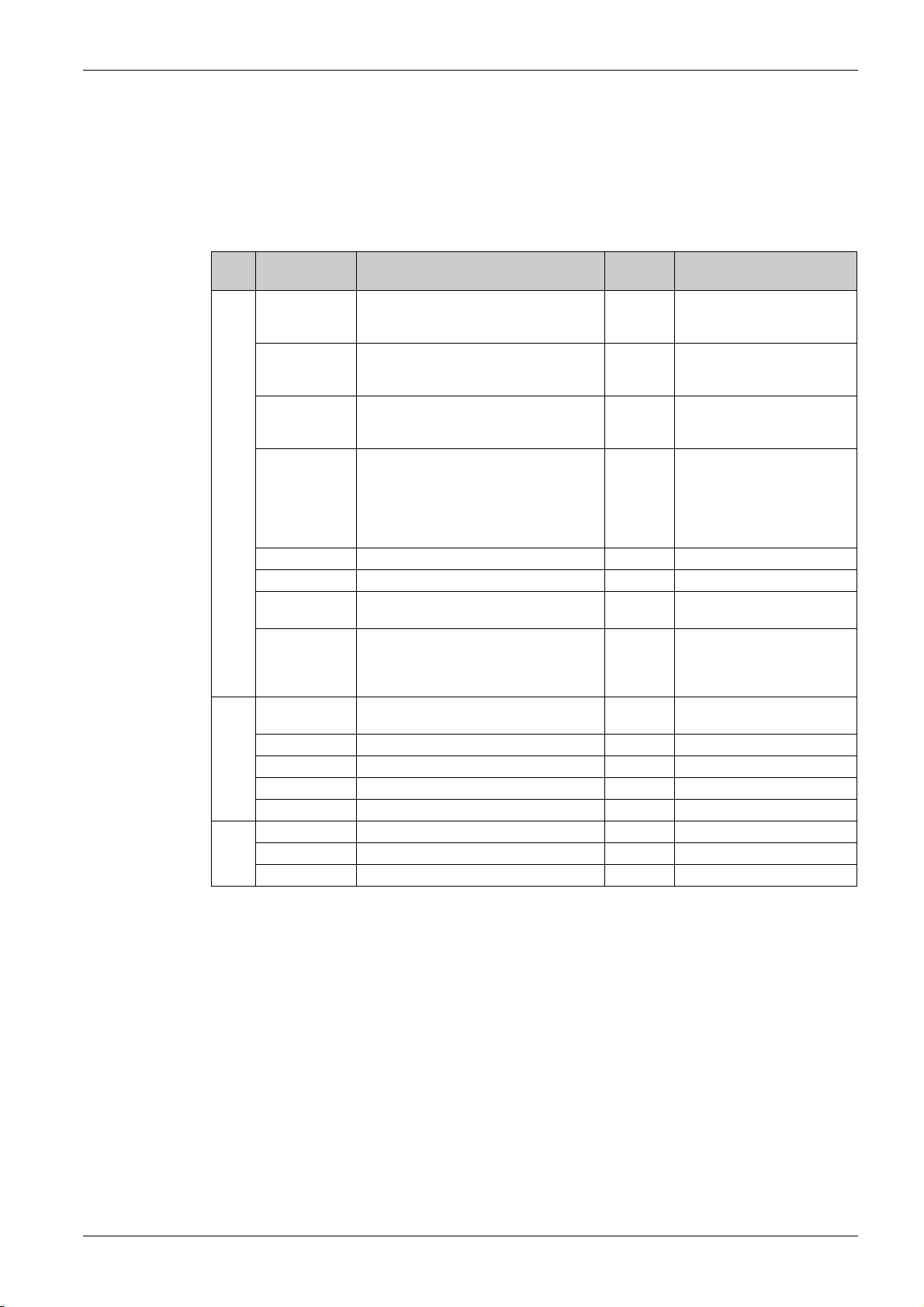

The following table describes the assignment and the availability of the terminal blocks for circuit breakers

and switch-disconnectors for fixed devices:

Standard terminal blocks and the associated accessories are delivered with the device.

Optional terminal blocks are delivered with the device only if the associated optional accessories are

installed in the device.

N/A indicates that the terminal blocks and the associated optional accessories are not compatible with

the device.

MasterPact MTZ2/MTZ3 Description

Block Marking Description Circuit

breaker

A COM Terminal block for the external power supply

of the MicroLogic X control unit

or ULP port module

UC1 Zone selective interlocking (ZSI),

rectangular sensor for earth-leakage

protection, or MDGF module input

UC2 Neutral external sensor, rectangular sensor

for earth-leakage protection, or MDGF

module input

SDE2/RES SDE2 additional fault-trip indication contact

or RES electrical remote reset

UC4 External voltage connector Optional N/A

UC3 External voltage connector Optional N/A

M2C/ESM M2C programmable contacts or ESM ERMS

switch module

SDE1 SDE1 fault-trip indication contact Standard N/A on MasterPact MTZ NA,

B MN/MX2 MN undervoltage release

or MX2 opening voltage release

MX1 MX1 opening voltage release Optional Optional

XF XF closing voltage release Optional Optional

PF PF ready-to-close contact Optional Optional

MCH MCH gear motor Optional Optional

C OF21–OF24 4 OF indication contacts Optional Optional

OF11–OF14 4 OF indication contacts Optional Optional

OF1–OF4 4 OF indication contacts Standard Standard

Standard

Optional

Standard N/A

Standard N/A

Optional N/A on MasterPact MTZ NA,

Optional N/A

Optional Optional

Switch-disconnector

N/A

N/A

HA, HA10

Optional on MasterPact MTZ2

HF, HH

N/A

HA, HA10

Standard on MasterPact MTZ2

HF, HH

DOCA0101EN-04 07/2020 15

MasterPact MTZ2/MTZ3 Description

Drawout Device

Definition

A drawout device is composed of the moving part (also called the device) and the fixed part (or chassis).

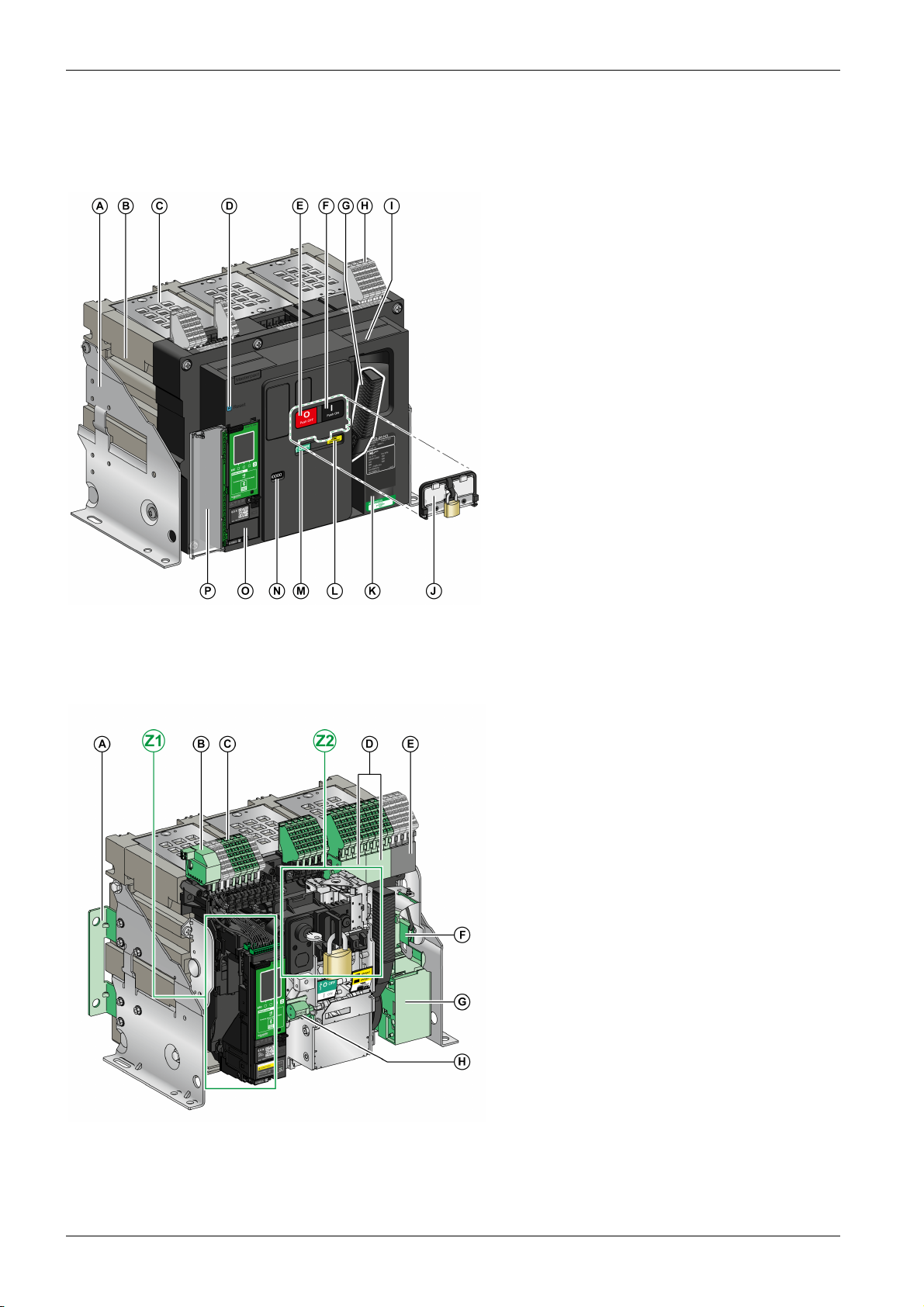

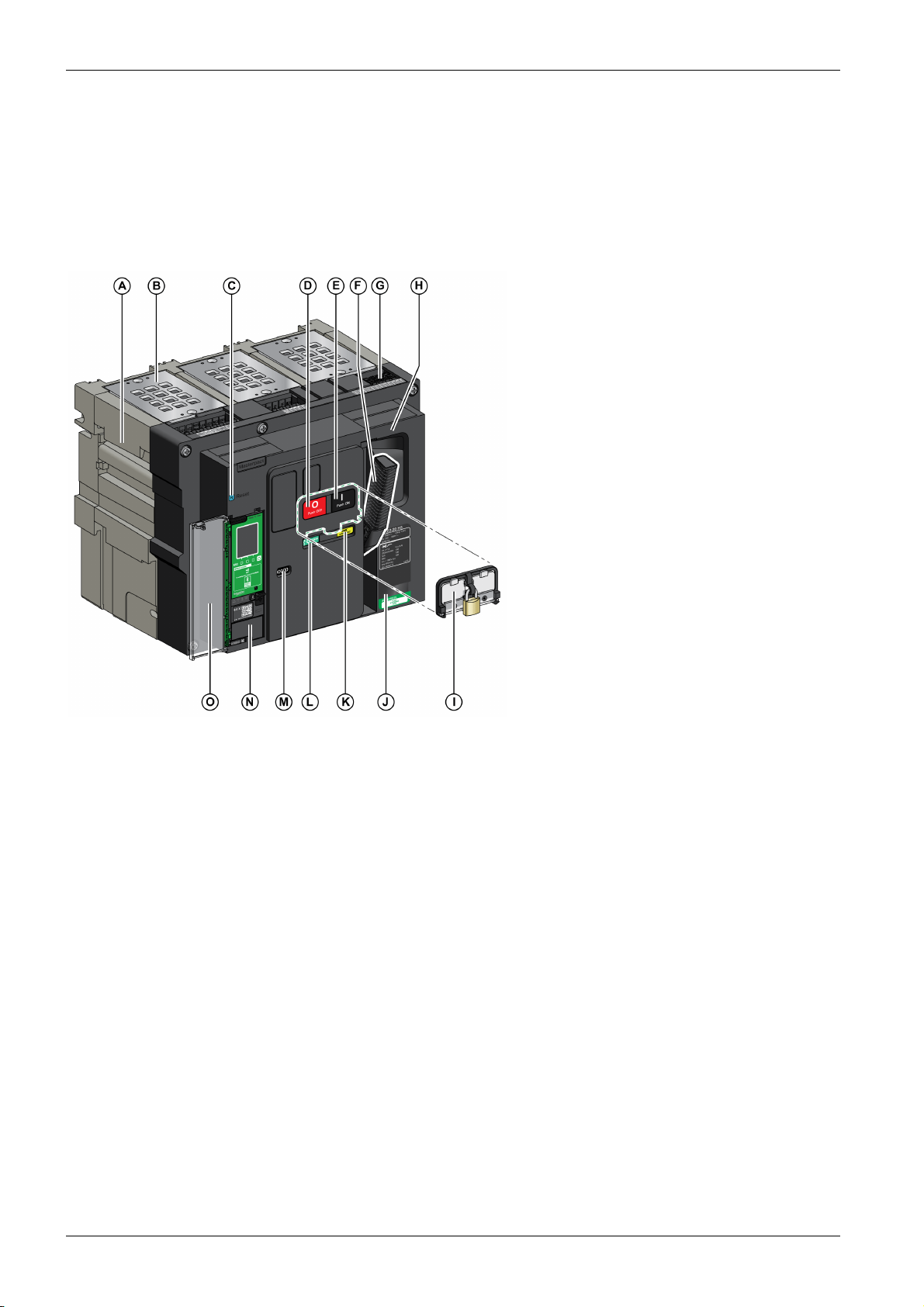

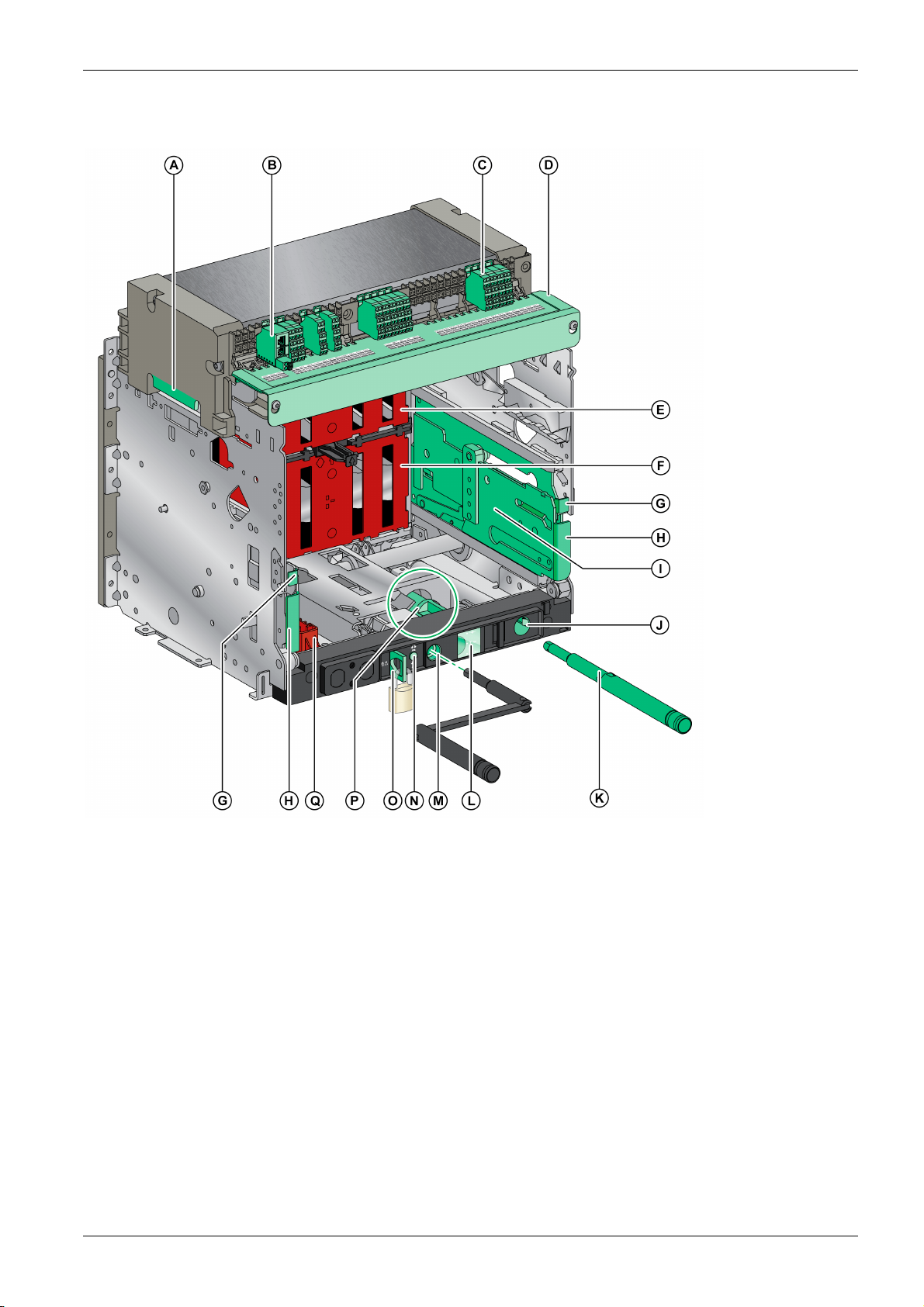

Drawout Device Moving Part Description

The following image shows the standard version of the moving part of a drawout device (no optional

accessories).

A Carrying grip

B Arc chute

C Blue fault-trip reset button

D Opening pushbutton

E Closing pushbutton

F Spring charging handle

G Terminal block connectors

H Front cover

I VBP pushbutton locking cover (optional)

J Rating plate

K Spring charged and ready-to-close indicator

L Main-contact position indicator

M Window to consult the (optional) CDM

mechanical operation counter

N Control unit

O Control unit transparent cover

16

DOCA0101EN-04 07/2020

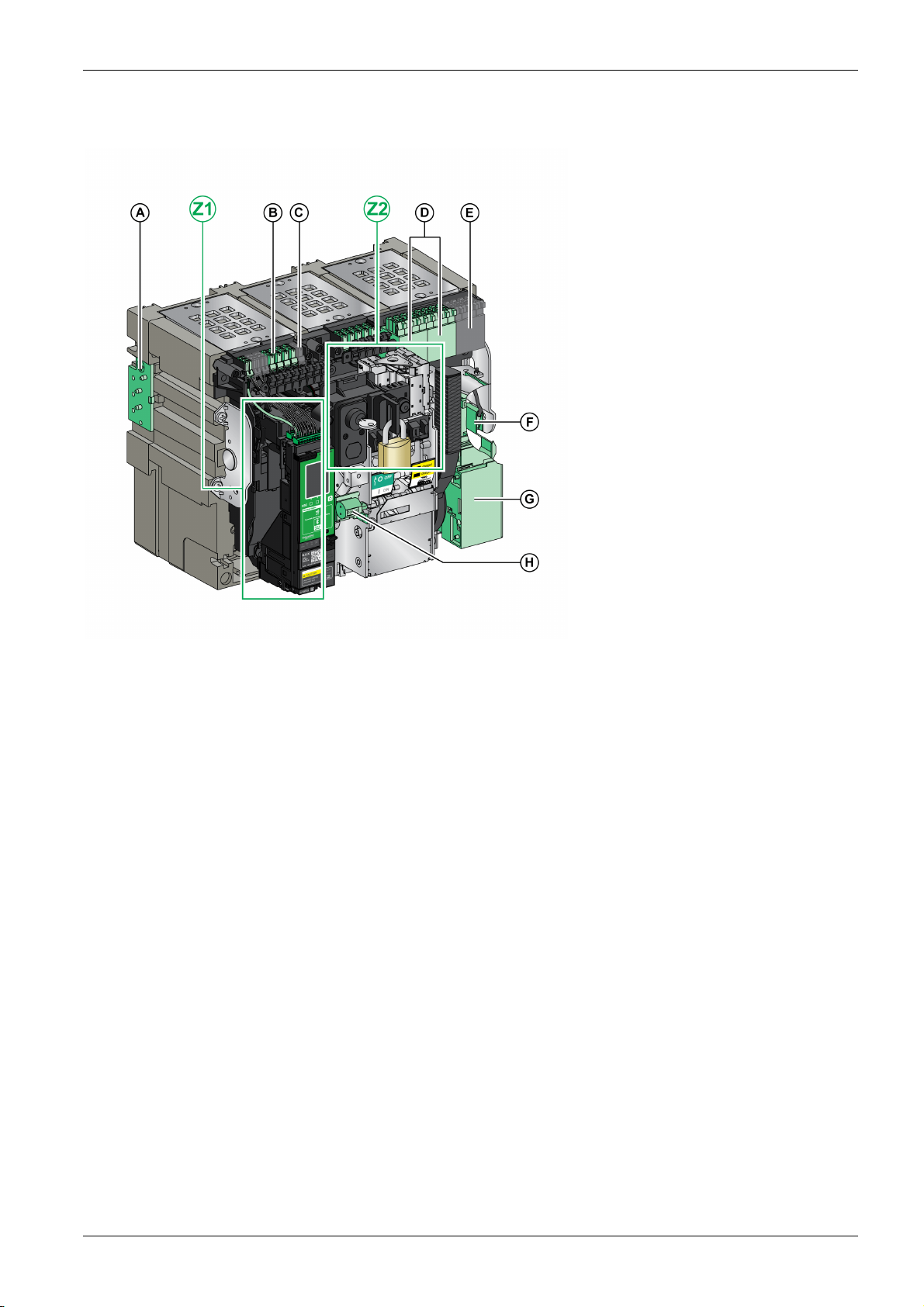

Drawout Device Accessories Description

The following image shows the accessories available for the moving part of a drawout device.

MasterPact MTZ2/MTZ3 Description

A VDC mismatch protection

B Terminal block connectors for optional

accessories

C Terminal block connectors for standard

accessories

D Optional block of four OF indication contacts

or EF combined connected/closed contacts

E Four OF indication contacts (delivered as

standard)

F KMT grounding kit

G MCH gear motor

H CDM mechanical operation counter

Z1, Z2 See following images

DOCA0101EN-04 07/2020 17

MasterPact MTZ2/MTZ3 Description

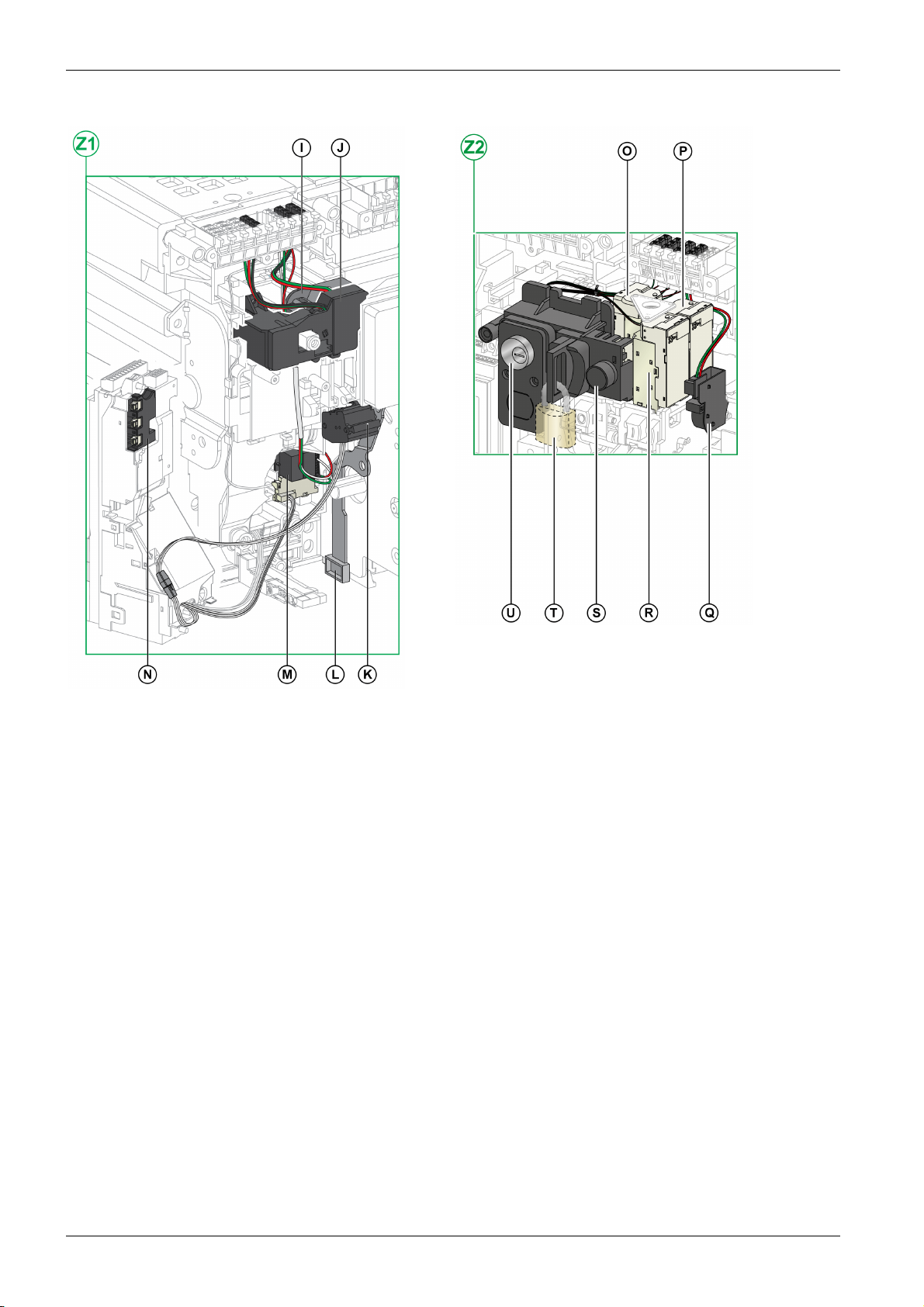

The following images zoom in on the accessories for the moving part of a drawout device.

I Standard SDE1 fault-trip indication contact

J Optional SDE2 fault-trip indication contact or RES electrical

remote reset

K Microswitch

L IBPO interlock between racking handle and opening pushbutton

M M2C programmable contacts or ESM ERMS switch module

N Isolation module

O MN undervoltage release or MX2 opening voltage release

P MX1 opening voltage release

Q PF ready-to-close contact

R XF closing voltage release

S BPFE electrical closing pushbutton

T VCPO OFF-position locking by padlocks

U VSPO OFF-position locking by keylocks

18

DOCA0101EN-04 07/2020

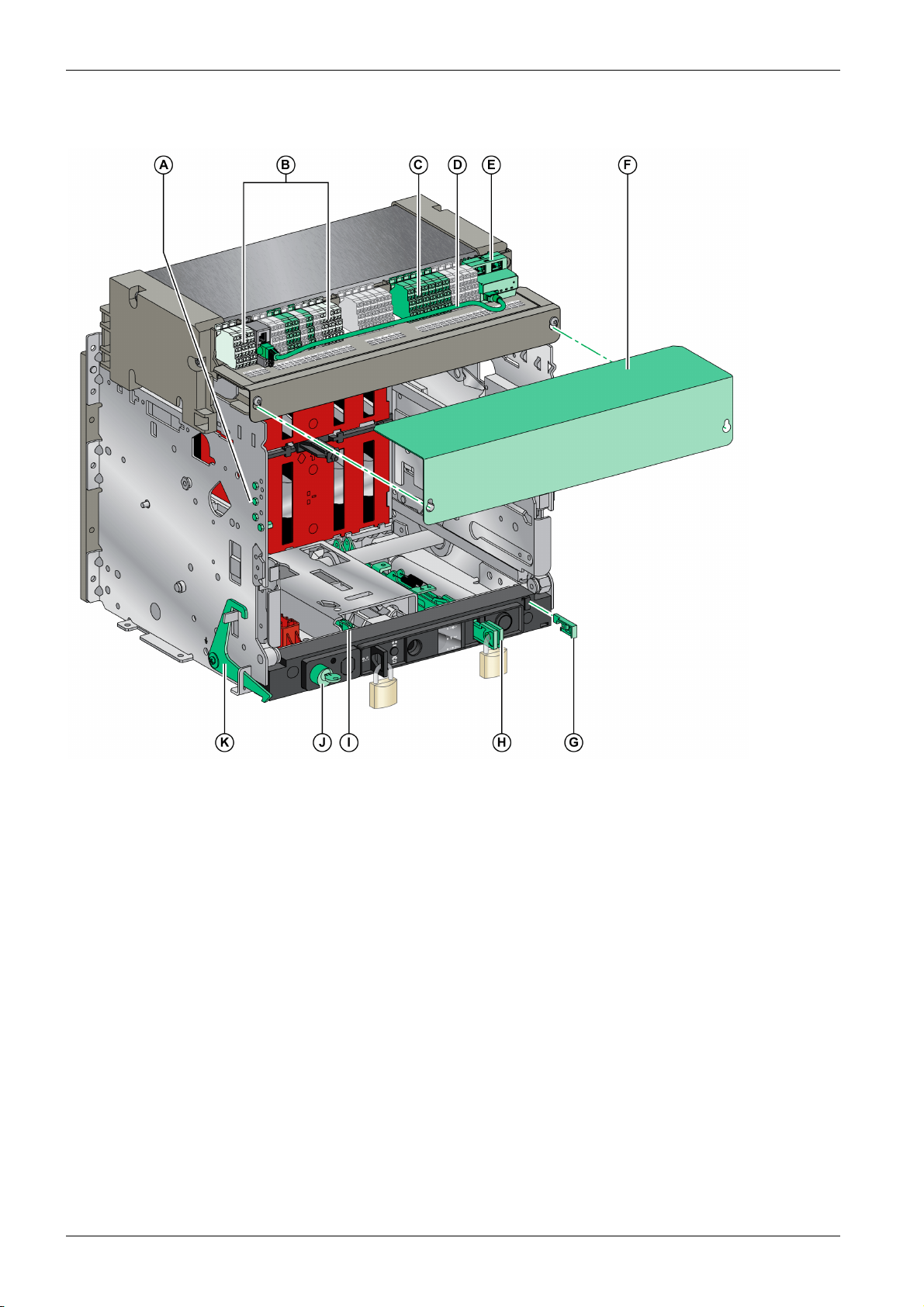

Chassis Description

MasterPact MTZ2/MTZ3 Description

The following image shows the standard version of the chassis (no optional accessories).

A Carrying grip

B ULP port module

C Terminal blocks supplied as standard

D Terminal block identification plate

E Top safety shutter

F Bottom safety shutter

G Rail release tab

H Drawout grip

I Extension rail

J Racking handle storage space

DOCA0101EN-04 07/2020 19

K Racking handle

L Moving part position indicator

M Racking handle socket

N Position release button

O Chassis locking by padlocks

P Latch for switching chassis locking from disconnected position to

any position (connected, test, disconnected)

Q Shutter locking block

MasterPact MTZ2/MTZ3 Description

Chassis Accessories Description

The following image shows the accessories available for the chassis.

A VDC mismatch protection

B Drawout device position contacts

C Optional terminal block

D Cord between ULP port module and EIFE interface

E EIFE embedded Ethernet interface

F Circuit breaker auxiliary terminal shield

G VPOC open-door racking interlock

H VIVC shutter position indication and locking

I IBPO interlock between racking handle and opening pushbutton

J VSPD chassis locking by keylocks

K VPEC door interlock

20

DOCA0101EN-04 07/2020

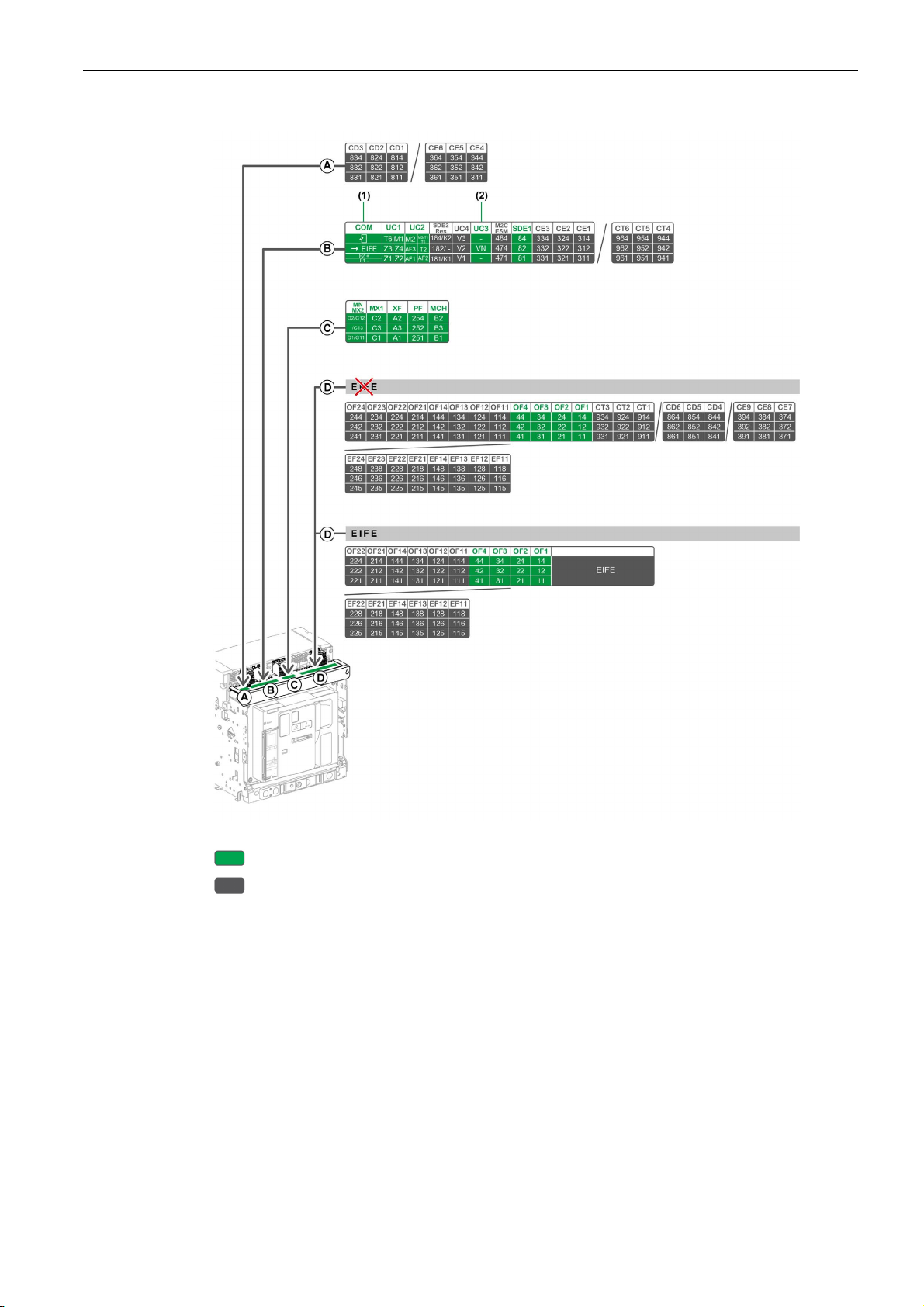

Chassis Terminal Block Description

MasterPact MTZ2/MTZ3 Description

Terminal block supplied as standard on the chassis

Optional terminal block on the chassis

(1) Supplied as standard with chassis for MasterPact MTZ2/MTZ3 circuit breakers only

(2) Supplied as standard with 3P chassis only

DOCA0101EN-04 07/2020 21

MasterPact MTZ2/MTZ3 Description

Assignment of Terminal Blocks

The following table describes the assignment and the availability of the terminal blocks for circuit breakers

and switch-disconnectors for drawout devices:

Standard terminal blocks are delivered on the chassis, even if the associated optional accessories are

not installed in the device.

Optional terminal blocks are delivered on the chassis only if the associated optional accessories are

installed in the device.

N/A indicates that the terminal blocks and the associated optional accessories are not compatible with

the device.

Block Marking Description Circuit breaker Switch-disconnector

A CD1–CD3

CE4–CE6

B COM ULP port module Standard N/A

UC1 Zone selective interlocking (ZSI), rectangular

UC2 Neutral external sensor, rectangular sensor

SDE2/RES SDE2 additional fault-trip indication contact

UC4 External voltage connector Optional N/A

UC3 External voltage connector Standard on

3 CD disconnected position contacts

or 3 CE connected position contacts

sensor for earth-leakage protection, or

MDGF module input

for earth-leakage protection, or MDGF

module input

or RES electrical remote reset

Optional Optional

Standard Standard

Standard Standard

Optional N/A on MasterPact MTZ

NA, HA, HA10

Optional on

MasterPact MTZ2 HF, HH

N/A

Standard on 3P switch-

3P circuit

disconnectors

breakers

Optional on 4P

circuit

breakers

M2C/ESM M2C programmable contacts

Optional N/A

or ESM ERMS switch module

SDE1 SDE1 fault-trip indication contact Standard Standard

CE1–CE3

CT4–CT6

C MN/MX2 MN undervoltage release

3 CE connected position contacts

or 3 CT test position contacts

Optional Optional

Standard Standard

or MX2 opening voltage release

MX1 MX1 opening voltage release Standard Standard

XF XF closing voltage release Standard Standard

PF PF ready-to-close contact Standard Standard

MCH MCH gear motor Standard Standard

(1)

D

OF11–OF24

EF11–EF24

8 OF indication contacts

or 8 EF combined connected/closed position

Optional Optional

auxiliary contacts

OF1–OF4 4 OF indication contacts Standard Standard

Optional Optional

Optional N/A

(2)

D

CT1–CT3

CD4–CD6

CE7–CE9

OF11–OF22

EF11–EF22

3 CT test position contacts

or 3 CD disconnected position contacts

or 3 CE connected position contacts

6 OF indication contacts

or 6 EF combined connected/closed position

auxiliary contacts

OF1–OF4 4 OF indication contacts Standard Standard

EIFE EIFE embedded Ethernet interface Optional N/A

(1) Without EIFE interface

(2) With EIFE interface

N/A on 4P switchdisconnectors

22

DOCA0101EN-04 07/2020

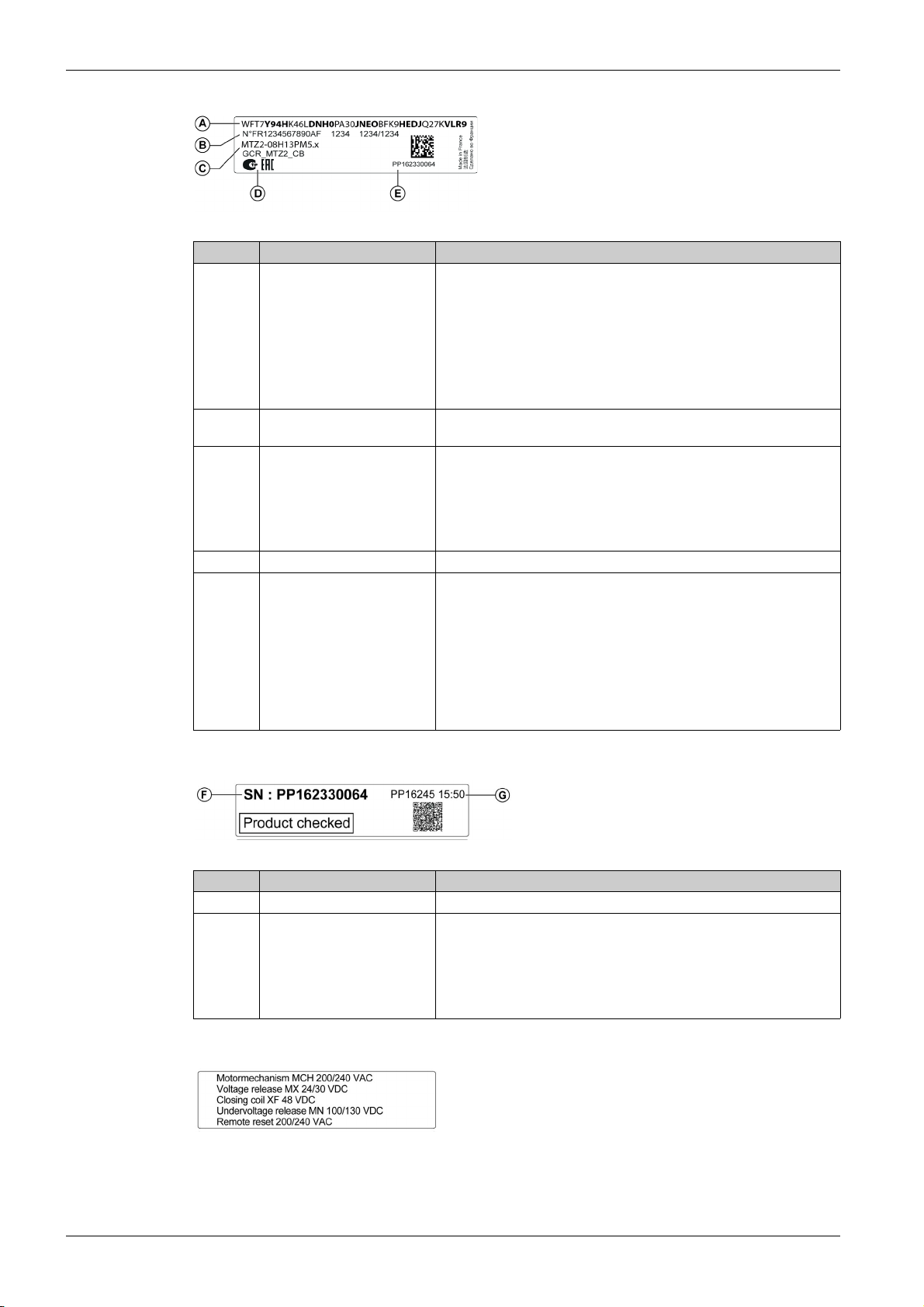

Device Identification

Identification

The MasterPact MTZ2/MTZ3 device can be identified in the following ways:

Rating plate on device

QR code located:

Identification labels on the device and on the chassis

MasterPact MTZ2/MTZ3 Description

On the front face of the control unit of the circuit breaker

On the front face of the switch-disconnector

A Product identification label

B Product checked label

C Accessory voltages label

D Rating plate

E QR code to access product information

DOCA0101EN-04 07/2020 23

MasterPact MTZ2/MTZ3 Description

Product Identification Label

Legend Description Explanation

A Product code The product code is a line of code representing the complete

B Schneider Electric internal

C Description of device The description of the device, specifies the following characteristics:

D Certification logos The logos of the mandatory certifications of the device.

E Device serial number The device serial number is coded PPYYWWDXXXX, where:

configuration of a MasterPact circuit breaker or switch-disconnector. It is

automatically generated for each MasterPact device after completing the

configuration using the Product Selector configuration tool.

The product code appears on the invoice and on the delivery documents

as well as on the MasterPact device and packaging labels.

The product code can be entered in the Product Selector configuration

tool, which generates the complete configuration of the MasterPact

device.

–

identification numbers

Range

Rating

Performance level

Number of poles

Control unit type

PP: Plant code

YY: Year of manufacture

WW: Week of manufacture

D: Day of the week of manufacture (Monday = 1)

XXXX: The production number of the product on the day. Ranges from

0001 to 9999

For example, PP162330064 is the sixty fourth device manufactured at

plant PP on Wednesday, June 8, 2016.

Product Checked Label

Legend Description Explanation

F Device serial number See explanation in preceding table.

G Device test date code The device test date code is coded PPYYWWD HH:MM, where:

Accessory Voltages Label

The accessory voltages label gives the voltage of the accessories which are installed in the device and

which need to be connected to a power supply.

PP: plant code

YY: year of test

WW: week of test

D: day of the week of test (Monday = 1)

HH:MM: the time of test in hours and minutes

24

DOCA0101EN-04 07/2020

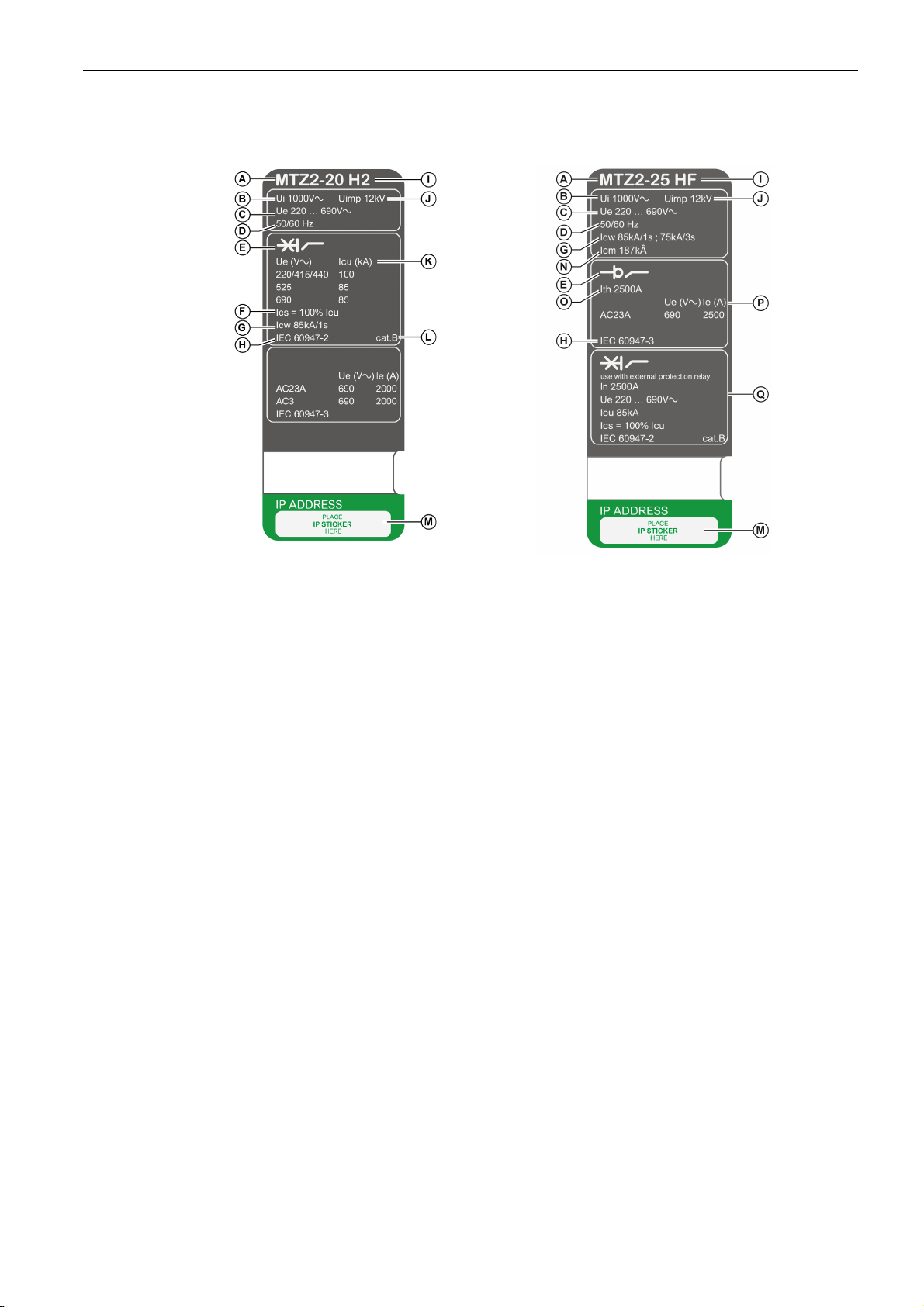

Rating Plate

MasterPact MTZ2/MTZ3 Description

The rating plate with the device information is located on the front cover of the device.

Circuit breaker rating plate Switch-disconnector rating plate

QR Code

A Device size and rated current x 100 A

B Ui: rated insulation voltage

C Ue: rated operational voltage

D Frequency

E Type of device: circuit breaker or switch-disconnector,

suitable for insulation

F Ics: rated service short-circuit breaking capacity

G Icw: rated short-time withstand current

H Standards

I Performance level

J Uimp: rated impulse withstand voltage

K Icu: rated ultimate short-circuit breaking capacity

L Selectivity category as per IEC 60947-2

M Place for sticker with IP address of the optional EIFE

interface

N Icm: rated short-circuit making capacity

O Ith: conventional free air thermal current

P Ie: rated operational current

Q Information related to switch-disconnectors used as

unprotected circuit breakers

When the QR code on the front face of a MasterPact MTZ device is scanned with a smartphone running a

QR code reader and connected to the Internet, the Go2SE landing page is displayed

(see page 29)

. The

landing page displays some information about the device and a list of menus.

DOCA0101EN-04 07/2020 25

MasterPact MTZ2/MTZ3 Description

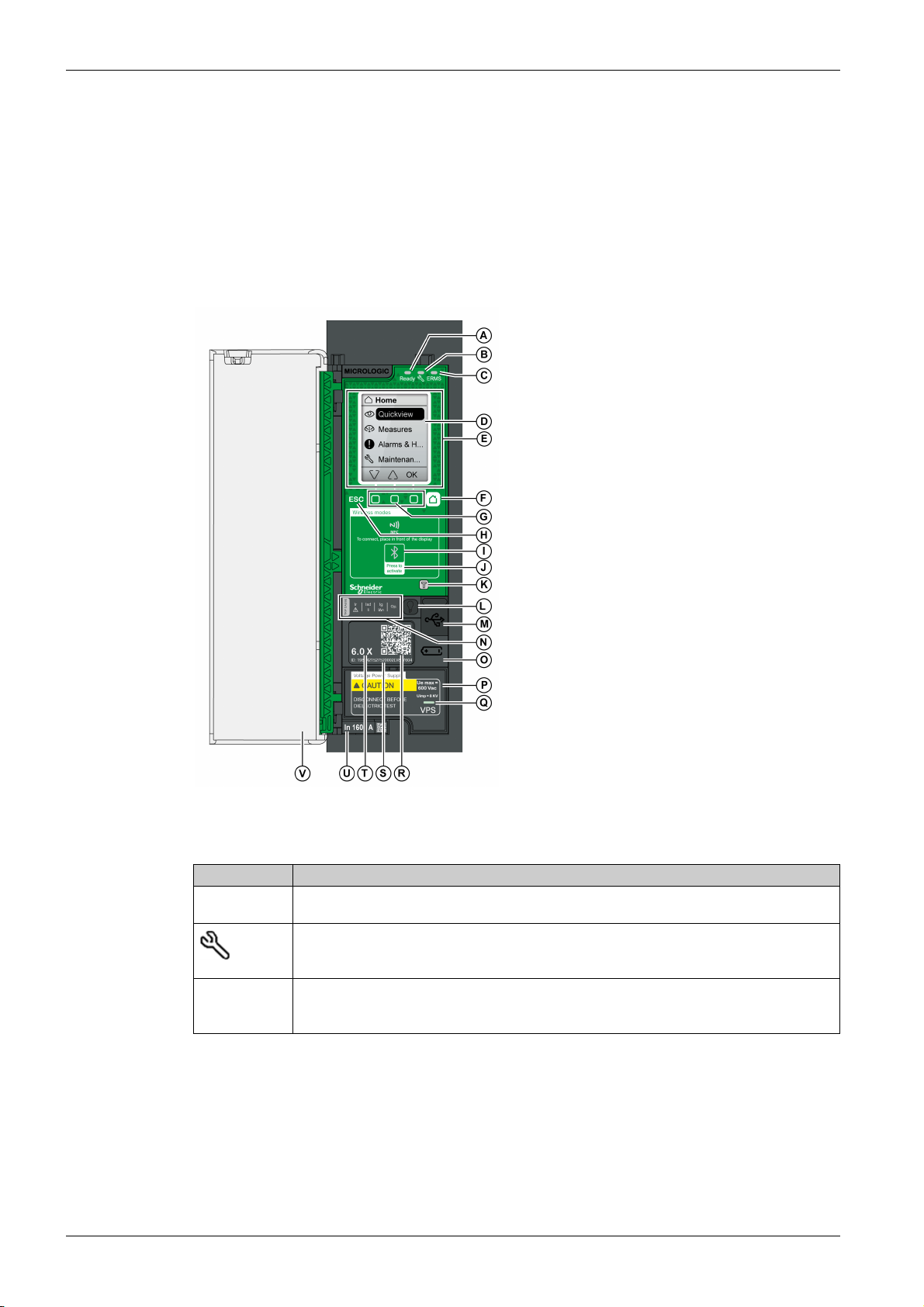

MicroLogic X Control Unit: Description

Introduction

The MicroLogic X control unit includes:

LEDs to monitor the status of the circuit breaker

A local Human Machine Interface comprising a graphic display with colored backlight, contextual

buttons, and dedicated buttons

LEDs to monitor the cause of trips and alarms

Control Unit Description

A Ready LED

B Service LED

C ERMS LED

D Graphic display screen

E NFC wireless communication zone

F Home button

G Three contextual buttons

H Escape button ESC

I Bluetooth LED

J Bluetooth activation button

K Test button for ground-fault and earth-leakage

protection (MicroLogic 6.0 X and 7.0 X)

L Test/Reset button for trip cause LEDs and alarms

M Mini USB port under rubber cover

N Overload and trip cause LEDs

O Cover for internal battery

P VPS voltage power supply module (optional)

Q VPS LED to indicate that the VPS module is

supplying the control unit

R QR code to access product information

S Control unit identification number

T Control unit type

U Sensor plug with the rated current of the circuit

breaker

V Plastic cover

Status LEDs

LED Description

Ready The Ready LED blinks slowly when the standard protection functions of the control unit are

operational.

The service LED alerts the user to the health state of the circuit breaker.

Orange LED: medium severity detected alarm that requires non-urgent maintenance action.

Red LED: high severity detected alarm that requires immediate maintenance action.

ERMS The ERMS (Energy Reduction Maintenance Setting) LED has the following statuses:

Blue LED: ERMS engaged

Off LED: ERMS disengaged

Display Screen with Contextual Buttons and Dedicated Buttons

The local HMI screen and buttons are used to:

Navigate the menu structure.

Display monitored values.

Access and edit configuration settings.

26

DOCA0101EN-04 07/2020

NFC Communication Zone

The NFC communication zone is used to establish an NFC connection between a smartphone running the

EcoStruxure Power Device app and the MicroLogic X control unit. When the connection is established, the

circuit breaker operating data is automatically uploaded to the smartphone.

Bluetooth Activation Button and LED

The Bluetooth activation button is used to establish a Bluetooth low energy connection between a

smartphone running the EcoStruxure Power Device app and the MicroLogic X control unit. When the

connection is established, the circuit breaker can be monitored and controlled from the smartphone.

When the Bluetooth LED is blinking, it indicates that the MicroLogic X control unit is in communication with

a Bluetooth device.

Test Button

The test button is used to test the ground-fault protection for MicroLogic 6.0 X and the earth-leakage

protection for MicroLogic 7.0 X.

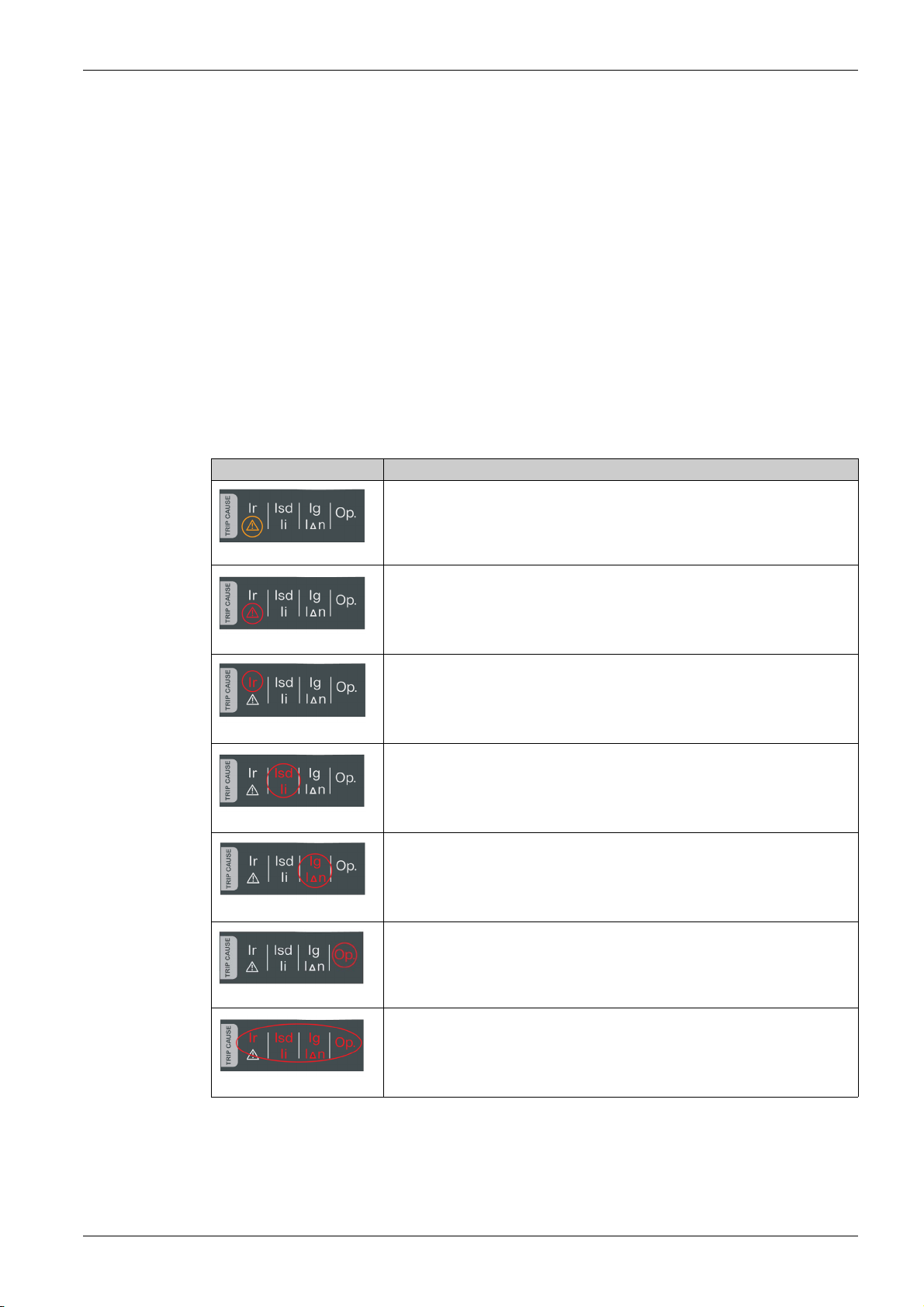

Overload and Trip Cause LEDs

The indications of the four trip cause LEDs depend on the type of MicroLogic X control unit.

LEDs Description

MasterPact MTZ2/MTZ3 Description

MicroLogic 2.0 X, 5.0 X, 6.0 X, 7.0 X: Overload pre-alarm, the load exceeds 90%

and is lower than 105% of the Ir setting of the long-time protection.

o

MicroLogic 2.0 X, 5.0 X, 6.0 X, 7.0 X: Overload alarm, the load exceeds 105% of

the Ir setting of the long-time protection.

MicroLogic 2.0 X, 5.0 X, 6.0 X, 7.0 X: Trip due to long-time protection.

MicroLogic 2.0 X: Trip due to instantaneous protection.

MicroLogic 5.0 X, 6.0 X, 7.0 X: Trip due to short-time protection or instantaneous

protection.

MicroLogic 2.0 X, 5.0 X: Not applicable.

MicroLogic 6.0 X: Trip due to ground-fault protection.

MicroLogic 7.0 X: Trip due to earth-leakage protection.

MicroLogic 2.0 X, 5.0 X, 6.0 X, 7.0 X: Trip due to optional protections.

MicroLogic 2.0 X, 5.0 X, 6.0 X, 7.0 X: MicroLogic control unit invalid result detected

during self test.

NOTE: If the MicroLogic X control unit is not powered, the trip cause LEDs go off after 4 hours. After this

period, press the Test/Reset button to light them again.

DOCA0101EN-04 07/2020 27

MasterPact MTZ2/MTZ3 Description

Test/Reset Button

The Test/Reset button performs the following functions:

Test of the internal battery or check LED functionality: press and hold the Test/Reset button for less than

3 seconds, the four trip cause LEDs switch off for one second. One of the following results:

The four trip cause LEDs switch on for two seconds: the battery is OK.

The four trip cause LEDs flash sequentially for two seconds: the battery is near the end of its life.

Replace the battery.

The four trip cause LEDs do not light: replace the battery.

NOTE: This test must be carried out immediately after the replacement of the internal battery to check

the correct functioning of the new battery. It can then be carried out at any time in the life of the internal

battery.

Reset of the latched events: press and hold the Test/Reset button for more than 3 seconds to reset the

latched events. The trip cause LEDs and the service LED switch off.

Mini USB Port

Remove the rubber cover of the mini USB port to connect the following devices:

A Mobile Power Pack to supply power to the MicroLogic X control unit.

A smartphone running the EcoStruxure Power Device app through USB OTG connection.

A PC running EcoStruxure Power Commission software.

NOTE: The MicroLogic X control unit does not support USB keys. Even if a USB key is connected using

an adapter, data is not transferred.

QR Code

When the QR code on the front face of a MicroLogic X control unit is scanned with a smartphone running

a QR code reader and connected to the Internet, the Go2SE landing page is displayed

landing page displays some information about the device and a list of menus.

Control Unit Identification Number

The identification number is made up as follows:

The serial number of the MicroLogic X control unit in the format FFFFFFYYWWDLXXXX

The commercial reference of the control unit in the format LV8•••••

Use the identification number to register your MicroLogic X control unit through mySchneider app, the

customer care mobile application.

Registering your MicroLogic X control unit enables you to keep your records up to date and enables

traceability.

Control Unit Type

This code indicates the type of MicroLogic control unit:

The number (for example, 6.0) defines the types of protection provided by the control unit.

The letter (X) identifies the range of the control unit.

Internal Battery

The internal battery powers the trip cause LEDs and the main diagnostic functions in the absence of any

other power supply.

(seepage29)

. The

VPS Voltage Power Supply Module

The VPS module provides an internal voltage supply to the MicroLogic X control unit.

The VPS module is optional for MicroLogic 2.0 X, 5.0 X, and 6.0 X. It is installed as standard on

MicroLogic 7.0 X.

Sensor Plug

The protection ranges depend on the rated current In, defined by the sensor plug present below the

MicroLogic X control unit.

28

DOCA0101EN-04 07/2020

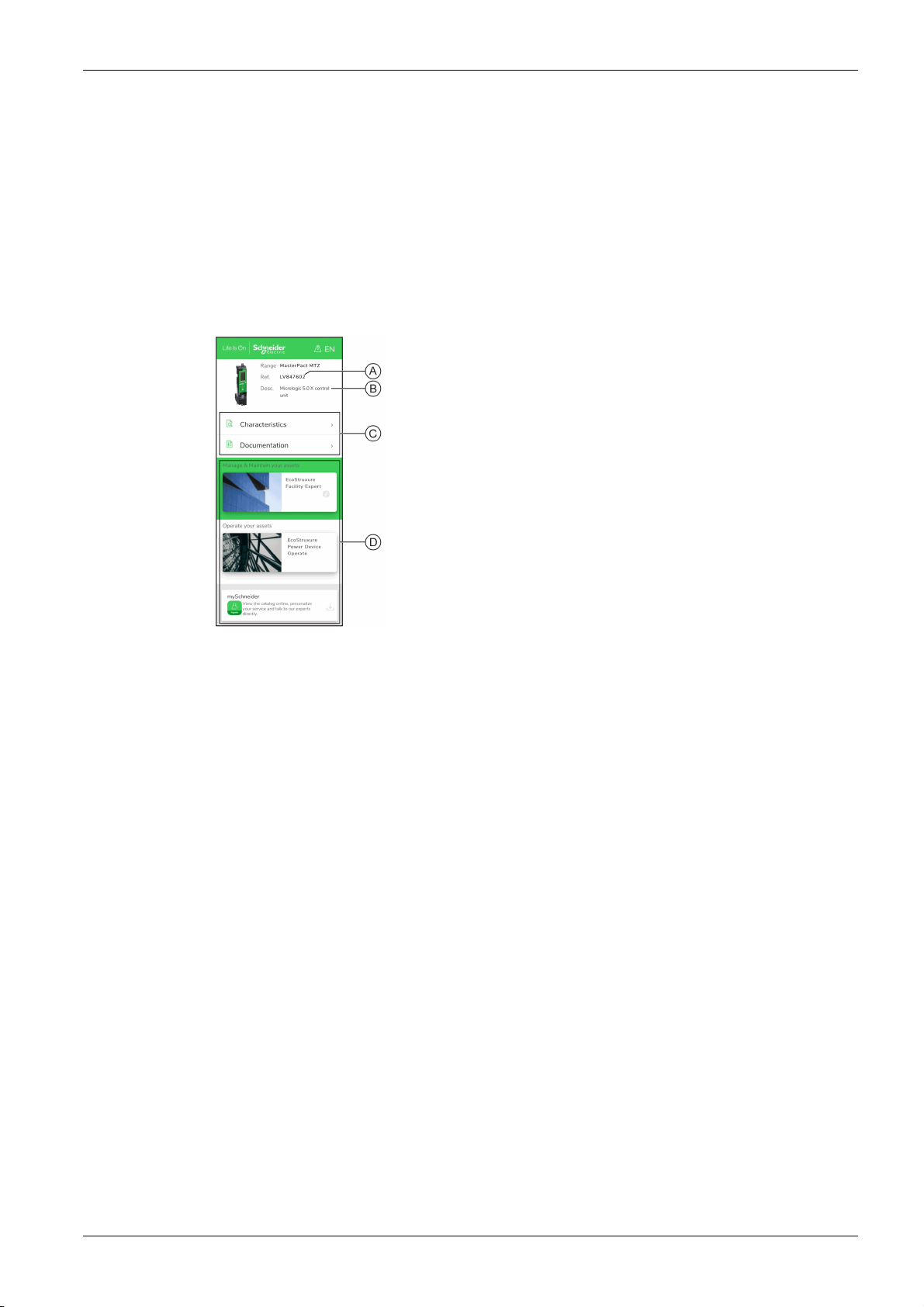

Go2SE Landing Page

Presentation

When the QR code on the front face of a MasterPact MTZ device is scanned with a smartphone running a

QR code reader and connected to the Internet, the Go2SE landing page is displayed.

The landing page displays information about the device and a list of menus.

Landing Page Description

The landing page is accessible from Android and iOS smartphones. It displays the same list of menus with

slight differences in presentation.

The following example shows the landing page displayed on an Android smartphone:

MasterPact MTZ2/MTZ3 Description

A Commercial reference of MicroLogic X control unit

B Type of MicroLogic X control unit

C Landing page menus. See the following menu descriptions

for details.

D Downloadable applications

Characteristics

Documentation

Selecting this menu gives access to a product datasheet with detailed information about the MicroLogic X

control unit.

Selecting this menu gives access to a sub-menu with the following options:

Asset Life Cycle Documents: gives access to Safe Repository.

Safe Repository is a web service allowing documentation linked to assets to be consulted, stored, and

shared in a Schneider Electric environment. Access to Safe Repository is restricted to authorized users.

Safe Repository gives access to the bill of materials of the MasterPact MTZ circuit breaker.

Technical Guidance at Glance: gives access to the MasterPact MTZ technical publications, including:

MasterPact MTZ - MicroLogic X Control Unit - User Guide

MasterPact MTZ1 - Circuit Breakers and Switch-Disconnectors - User Guide

MasterPact MTZ2/MTZ3 - Circuit Breakers and Switch-Disconnectors - User Guide

All the instruction sheets for MasterPact MTZ devices and MicroLogic X control units

Product Documentation: gives access to the MicroLogic X technical publications

DOCA0101EN-04 07/2020 29

MasterPact MTZ2/MTZ3 Description

EcoStruxure Facility Expert App

Selecting this application gives access to the EcoStruxure Facility Expert mobile application that can be

downloaded on Android and iOS smartphones. For smartphone compatibility, check on your application

store.

EcoStruxure Facility Expert optimizes operations and maintenance, helping to ensure business continuity,

and provides insights to service providers or facility managers.

EcoStruxure Facility Expert is a real-time collaborative technology available on mobile devices and PCs

that enables managers and maintenance personnel to be connected with facilities and equipment.

Information exchange between users is simple and fast.

The QR code on MasterPact MTZ devices enables managers and maintenance personnel to access the

following automatic downloads:

MasterPact MTZ device identifier.

Technical documentation.

The maintenance plan for the MasterPact MTZ device.

EcoStruxure Facility Expert enables managers and maintenance personnel to access the maintenance

plan for MasterPact MTZ devices.

EcoStruxure Facility Expert helps maintenance personnel to diagnose issues remotely and manage

maintenance efficiently by:

Providing relevant information on critical assets.

Sending immediate state of the equipment and detailed information helping for diagnostics.

EcoStruxure Power Device App

Selecting this application gives access to the EcoStruxure Power Device app that can be downloaded and

installed on Android and iOS smartphones. For smartphone compatibility, check on your application store.

mySchneider App

Selecting this application gives access to the Schneider Electric customer care mobile application

mySchneider app that can be downloaded on Android and iOS smartphones. For smartphone

compatibility, check on your application store. The customer care application offers self-service

instructions and easy access to expert support and information.

30

DOCA0101EN-04 07/2020

Operating Conditions

Introduction

MasterPact MTZ devices are designed and tested for operation in industrial atmospheres. It is

recommended that equipment is cooled or heated to the proper operating temperature and kept free of

excessive vibration and dust.

Ambient Temperature

MasterPact MTZ devices can operate under the following temperature conditions:

Electrical and mechanical characteristics specified for an ambient temperature of -25 °C to +70 °C .

Circuit-breaker closing specified down to -35 °C by manual operation with closing pushbutton.

Storage conditions are as follows:

-40 °C to +85 °C for the device without the control unit.

-25 °C to +85 °C for the control unit.

Extreme Atmospheric Conditions

MasterPact MTZ devices have successfully passed tests for extreme atmospheric conditions, defined by

the following standards:

Standard Title

IEC 60068-2-1 Dry cold, at -40 °C

IEC 60068-2-2 Dry heat, at +85 °C

IEC 60068-2-30 Damp heat (temperature +55 °C, relative humidity 95%)

IEC 60068-2-52 level 2 Salt mist

MasterPact MTZ2/MTZ3 Description

Industrial Environments

MasterPact MTZ devices can operate in the industrial environments defined by IEC 60947 (pollution

degree up to 3).

It is advisable to check that devices are installed in suitably cooled switchboards without excessive dust.

Conditions Standard

Corrosive industrial atmospheres Category 3C3 compliant with IEC 60721-3-3

Sea salts 0.8 to 8 mg/m² day average over the year Compliant with IEC 60721-2-5

Mechanically active substances Category 3S3 compliant with IEC 60721-3-3

Beyond these conditions, MasterPact MTZ devices must be installed inside switchboards with an IP rating

equal to or greater than IP54.

Vibration

MasterPact MTZ devices have successfully passed tests for the following vibration levels, in compliance

with IEC 60068-2-6 and IEC 60068-2-27:

2 Hz to 13.2 Hz: amplitude +/- 1 mm.

13.2 Hz to 100 Hz: constant acceleration of 0.7 g.

Vibration testing to these levels is required by merchant marine inspection organizations (for example,

Veritas, Lloyd’s).

MasterPact MTZ devices have also been successfully tested according to:

Annex Q - IEC 60947-1: Special tests – damp heat, salt mist, vibration and shock

IEC 60947-1 - Category D: Environment subject to temperature, humidity and vibration

DOCA0101EN-04 07/2020 31

MasterPact MTZ2/MTZ3 Description

Altitude

MasterPact MTZ devices are designed and tested to operate at altitudes below 2,000 m.

At altitudes above 2,000 m, the characteristics of the ambient air (electrical resistance, cooling capacity)

lower product characteristics as follows:

Characteristics Altitude

Impulse withstand voltage Uimp (kV) 12 11 10 8

Rated insulation voltage (Ui) (V) 1,000 900 780 700

Maximum rated operational

voltage 50/60 Hz Ue (V)

Rated current (A) at 40 °C 1 x In 0.99 x In 0.96 x In 0.94 x In

NOTE: Intermediate values can be obtained by interpolation.

Electromagnetic Disturbances

MasterPact MTZ devices have protection against:

Overvoltages caused by devices that generate electromagnetic disturbance.

Overvoltages caused by atmospheric disturbance or by a distribution-system outage (for example, a

lighting system failure).

Devices emitting radio waves (for example, radio transmitters, walkie-talkies, or radar).

Electrostatic discharge produced by users.

MasterPact MTZ devices have successfully passed the electromagnetic-compatibility tests (EMC) defined

by the following international standards:

IEC 60947-2, appendix F.

IEC 60947-2, appendix B (control units with earth-leakage function).

The devices have passed the above tests and therefore:

No nuisance tripping occurs.

Tripping times are respected.

2,000 m 3,000 m 4,000 m 5,000 m

MasterPact MTZ2/MTZ3

except H10

MasterPact MTZ2/MTZ3 H10 1,000 890 795 700

690 690 630 560

32

DOCA0101EN-04 07/2020

MasterPact MTZ2/MTZ3

MasterPactMTZ2/MTZ3 Normal Operation

DOCA0101EN-04 07/2020

MasterPactMTZ2/MTZ3 Normal Operation

Chapter 2

MasterPact MTZ2/MTZ3 Normal Operation

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

2.1 Device Operating Actions 34

2.2 Drawout Device Racking Actions 60

2.3 Device Locking Actions 77

2.4 Device Interlocking Actions 93

DOCA0101EN-04 07/2020 33

MasterPact MTZ2/MTZ3 Normal Operation

Device Operating Actions

Section 2.1

Device Operating Actions

What Is in This Section?

This section contains the following topics:

Operating the Device 35

Control Modes 39

Opening the Device 44

Closing the Device 47

Resetting the Circuit Breaker 50

Engaging the ERMS Function 51

Operating Accessories 53

Topic Page

34

DOCA0101EN-04 07/2020

Operating the Device

Device Status

The indicators on the front of the device show the following information:

Reset button:

In: the device is closed or open voluntarily (not tripped)

Out: the device has tripped

Position indicator of main contacts: ON or OFF.

Closing spring and ready-to-close indicator. The state can be one of the following:

Discharged (no energy to close the circuit breaker)

Charged not ready-to-close

Charged ready-to-close

MasterPact MTZ2/MTZ3 Normal Operation

A Reset button

B Position indicator of main contacts

C Closing spring and ready-to-close indicator

The combination of both indicators gives the device status:

Position indicator of main

contacts

Closing spring and readyto-close indicator

Device status description

Device is off (main contacts are open) and closing spring is

discharged.

Device is off (main contacts are open) and closing spring is

charged. The device is not ready-to-close because at least

one of the following conditions is true:

The device has tripped and must be reset.

The MX opening voltage release is energized.

The MN undervoltage release is not energized.

The device is mechanically locked in the open position

by using padlock or keylock or by using an interlocking

system.

Device is off (main contacts are open) and closing spring is

charged.

The device is ready-to-close.

Device is on (main contacts are closed) and closing spring

is discharged.

Device is on (main contacts are closed) and closing spring

is charged.

The device is not ready-to-close because it is already

closed.

DOCA0101EN-04 07/2020 35

MasterPact MTZ2/MTZ3 Normal Operation

Device Indication Contacts

The position of the device main contacts is indicated by OF indication contacts.

Anti-Pumping Function

MasterPact MTZ devices provide a mechanical anti-pumping function. In the event of simultaneous

maintained opening and closing orders, the standard mechanism blocks the main contacts in the open

position. After a trip due to an electrical fault or intentional opening using the manual or electrical controls,

the closing order must first be discontinued, then reactivated to close the circuit breaker. This prevents a

cycle of closing and opening.

When remote operation features are used, allow at least four seconds for the MCH gear motor to charge

the device closing spring completely before the XF closing voltage release is actuated.

To prevent the device from closing prematurely, the PF ready-to-close contact can be series connected

with the XF closing voltage release.

Name Contact

number

Device status – ON OFF Tripped (by

Position indicator of

main contacts

Main contact position – Closed Open Open

Reset button position – IN IN OUT

OF indication contact

position

SDE indication contact

position

–

1–2 Open Closed Closed

1–4 Closed Open Open

1–2 Closed Closed Open

1–4 Open Open Closed

Position of indicators and contacts

MicroLogic X control

unit)

Charging the Closing Spring

The closing spring must be charged with sufficient energy to close the MasterPact MTZ:

Manual charge: Charge the mechanism by pulling the spring charging handle down seven times.

Automatic charge: If the optional MCH gear motor is installed, the spring is automatically charged after

closing.

NOTE: For drawout devices fitted with the optional DAE automatic spring-discharge before device removal

(see page 105)

withdrawn position.

, the closing spring is discharged when the device is moved from disconnected to

36

DOCA0101EN-04 07/2020

Manual Operation Cycle with the Spring Charging Handle

The following image shows an Open/Close/Open (OCO) cycle for manually charged devices without MCH

gear motor:

MasterPact MTZ2/MTZ3 Normal Operation

DOCA0101EN-04 07/2020 37

MasterPact MTZ2/MTZ3 Normal Operation

Electrical Operation Cycle with an MCH Gear Motor

The following image shows an Open/Close/Open (OCO) cycle for electrically charged devices using an

MCH gear motor:

38

DOCA0101EN-04 07/2020

Control Modes

Presentation

MasterPact MTZ2/MTZ3 Normal Operation

The circuit breaker control mode is a MicroLogic X setting which defines the means to control the opening

and closing functions of the circuit breaker.

Two control modes are available: Manual and Auto.

Manual control mode only accepts orders made using one of the following:

The mechanical buttons on the front of the circuit breaker.

The external pushbutton connected to the MN/MX/XF voltage releases.

The BPFE electrical closing pushbutton.

Auto control mode has two settings: Local or Remote. All orders accepted in Manual control mode are

accepted in Auto control mode, as well as orders from local or remote communication as follows:

Auto Local: the operator needs to be close to the circuit breaker to establish communication and only

orders sent from a local source through communication are accepted:

EcoStruxure Power Commission software through USB connection

EcoStruxure Power Device app with MasterPact Operation Assistant Digital Module through

Bluetooth or USB OTG connection

Auto Remote: the operator does not need to be next to the circuit breaker to establish communication

and orders are accepted only when sent from a remote source through the communication network.

NOTE: EcoStruxure Power Commission software connected through the communication network can be

used to send control orders to the circuit breaker.

The control mode factory setting is Auto Remote.

NOTE: The switch-disconnector control mode corresponds to the Manual control mode of circuit breakers.

To operate a switch-disconnector through communication, it is possible to use an IO module. Refer to

DOCA0055EN Enerlin'X IO - Input/Output Application Module for One IEC Circuit Breaker - User Guide

.

Operation According to Control Mode Configured

The following table summarizes the opening and closing operations available, depending on the control

mode configured:

Control mode Type of order and delivery method

Mechanical Electrical Through communication

Pushbutton BPFE Point to

point

(voltage

release)

Manual ✔ ✔ ✔ – – – – –

Auto: Local ✔ ✔ ✔

Auto: Remote ✔ ✔ ✔

(1) Through USB

(2) Through Bluetooth or USB OTG

(3) According to IO input mode setting

IO

module

(3)

✔

(3)

✔

EcoStruxure Power

Commission software

✔✔––

––✔✔

EcoStruxure Power

(1)

Device app +

MasterPact

Operation Assistant

Digital Module

Communication

network

(2)

IFE/EIFE

Webpages

DOCA0101EN-04 07/2020 39

MasterPact MTZ2/MTZ3 Normal Operation

Operation in Manual Control Mode

A MicroLogic X control unit

B ULP port module

C EIFE embedded Ethernet interface

D Circuit breaker mechanism

Opening and closing operations available in Manual control mode:

0: mechanical opening pushbutton

1: mechanical closing pushbutton

BPFE: electrical closing pushbutton

External pushbuttons wired by customer, and connected to:

XF: standard or communicating and diagnostic closing voltage release

MX: standard or communicating and diagnostic opening voltage release

MN: standard or diagnostic undervoltage release

40

DOCA0101EN-04 07/2020

Operation in Auto: Local Mode

A MicroLogic X control unit

B ULP port module

C EIFE embedded Ethernet interface

D Circuit breaker mechanism

E IO input/output application module

MasterPact MTZ2/MTZ3 Normal Operation

Opening and closing operations available in Auto: Local mode:

0: mechanical opening pushbutton

1: mechanical closing pushbutton

BPFE: electrical closing pushbutton

External pushbuttons wired by customer, and connected to:

XF: communicating and diagnostic closing voltage release

MX: communicating and diagnostic opening voltage release

MN: standard or diagnostic undervoltage release

IO: with the Breaker Operation predefined application of the IO module set to local control mode

EcoStruxure Power Commission software: command sent through USB connection

EcoStruxure Power Device app with MasterPact Operation Assistant Digital Module:

Through Bluetooth low energy wireless communication

Through USB OTG connection

DOCA0101EN-04 07/2020 41

MasterPact MTZ2/MTZ3 Normal Operation

Operation in Auto: Remote Mode

A MicroLogic X control unit

B ULP port module

C EIFE embedded Ethernet interface

D Circuit breaker mechanism

E IO input/output application module

Opening and closing operations available in Auto: Remote mode:

0: mechanical opening pushbutton

1: mechanical closing pushbutton

BPFE: electrical closing pushbutton

External pushbuttons wired by customer, and connected to:

IO: with the Breaker Operation predefined application of the IO module set to remote control mode

Communication: remote command through IFE, EIFE, or IFM interface.

Setting the Control Mode

The Auto or Manual control mode can be set as follows:

On the MicroLogic X display screen, at Home → Configuration → Communication → Control Mode →

With the EcoStruxure Power Device app through Bluetooth or USB OTG connection.

The Local or Remote mode can be set as follows:

When the IO module is used with the Breaker Operation predefined application, the local or remote

When the IO module is not used with the Breaker Operation predefined application, the local or remote

NOTE:

The Local or Remote mode cannot be set on the MicroLogic X display screen.

When Auto control mode is set, the control mode is Auto Local or Auto Remote, depending on the last

XF: communicating and diagnostic closing voltage release

MX: communicating and diagnostic opening voltage release

MN: standard or diagnostic undervoltage release

Mode.

mode is defined only by the control mode selector switch wired on the digital input I1 of the IO module.

mode can be set as follows:

With EcoStruxure Power Commission software through USB connection

With the EcoStruxure Power Device app through Bluetooth or USB OTG connection.

setting.

42

DOCA0101EN-04 07/2020

Displaying the Control Mode

The control mode (Manual, Auto Local, or Auto Remote) is displayed as follows:

On the MicroLogic X display screen, at Home → Configuration → Communication → Control Mode →

Mode

With EcoStruxure Power Commission software through USB connection

With the EcoStruxure Power Device app through Bluetooth or USB OTG connection

On the IFE/EIFE webpages

By a remote controller using the communication network.

Predefined Events

Changing the control mode settings generates the following events:

Code Event History Severity

0x1002 (4098) Manual mode enabled Operation Low

0x1004 (4100) Local mode enabled Operation Low

0x0D0D (3341) Config. error IO and CU - Local/Remote mode Configuration Medium

Recommended Actions

Code Event Recommended actions

0x0D0D (3341) Config. error IO and CU - Local/Remote mode Correct the configuration error with EcoStruxure

MasterPact MTZ2/MTZ3 Normal Operation

Power Commission:

If you want the L/R mode to be controlled by

the IO module, connect an IO module with

L/R mode assignment.

If you do not want the L/R mode to be

controlled by the IO module, connect an IO

module without L/R mode assignment.

DOCA0101EN-04 07/2020 43

MasterPact MTZ2/MTZ3 Normal Operation

Opening the Device

Opening Conditions

To open the device, the device must be closed (I).

NOTE: An opening order always takes priority over a closing order.

Opening the Device

The following tables present the different ways to open the device in the different control modes available.

The device can be opened in the following ways in all control modes:

Opening type Control

mode

Mechanical Manual,

Auto:

Local, or

Auto:

Remote

Automatic Manual,

By external

pushbutton

Auto:

Local, or

Auto:

Remote

Manual,

Auto:

Local, or

Auto:

Remote

Accessories Opening action

– Press the opening

pushbutton on the front

of the device.

This opening action is

possible at any time.

MN undervoltage

release, with or without

MN delay unit

External pushbutton

wired by customer

One of the following

accessories:

MX standard or

communicating

opening voltage

release

MN undervoltage

release, with or

without MN delay

unit

The MN undervoltage release opens the device

automatically in the case of voltage drop.

Press the external pushbutton which is connected to the MX

opening voltage release or to the MN undervoltage release

via the customer terminal block.

When the MN undervoltage release is connected to the MN

delay unit, the device opens with the corresponding time

delay.

44

DOCA0101EN-04 07/2020

MasterPact MTZ2/MTZ3 Normal Operation

In addition, the circuit breaker can be opened in the following ways when Auto control mode is configured.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not operate the circuit breaker without confirming that doing so will not create a hazardous

situation.

Do not allow any person to work on the electrical network without physically validating the successful

execution of the local or remote software actions for opening the circuit breaker or switching off the

electrical circuit.

Failure to follow these instructions will result in death or serious injury.

Opening type Control mode Accessories Opening action

Through IO module Auto: Local or

Auto: Remote

Through EcoStruxure

Auto: Local

Power Commission

software

Through EcoStruxure

Auto: Local

Power Device app

Through Modbus

Auto: Remote

communication

MX communicating

opening voltage release

Isolation module

ULP port module

IO module

MX communicating

opening voltage release

Isolation module

MX communicating

opening voltage release

Isolation module

MasterPact Operation

Assistant Digital Module

MX communicating

opening voltage release

Isolation module

ULP port module

IFE, EIFE, or IFM interface,

or IFE server

Open the circuit breaker by using the

predefined application 2 Breaker

Operation of the IO module.

When the circuit breaker is set to

local control mode by the IO

module, the command to open is

issued from local pushbuttons

wired on digital inputs.

When the circuit breaker is set to

remote control mode by the IO

module, the command to open is

issued from remote PLC outputs

wired on digital inputs.

Refer to

DOCA0055EN Enerlin'X IO -

Input/Output Application Module for

One IEC Circuit Breaker - User

Guide

.

Send a command to open the circuit

breaker from EcoStruxure Power

Commission software running on a

PC connected locally to the device

through the mini USB port on the

MicroLogic X control unit.

This opening action is passwordprotected.

Refer to

Commission Online Help

EcoStruxure Power

.

Send a command to open the circuit

breaker from the EcoStruxure Power

Device app with MasterPact

Operation Assistant Digital Module,

through Bluetooth wireless

communication or USB OTG

connection. The opening action is

password-protected.

Send a command to open the circuit

breaker through the Modbus

communication network.

This opening action is passwordprotected.

Refer to

DOCA0105EN

MasterPact MTZ - Modbus

Communication Guide

.

NOTE: EcoStruxure Power

Commission software running on a

PC connected to the device through

the communication network can be

used to send commands to open.

DOCA0101EN-04 07/2020 45

MasterPact MTZ2/MTZ3 Normal Operation

Opening type Control mode Accessories Opening action

Through IEC 61850

communication

Through IFE/EIFE

webpages

Auto: Remote MX communicating

opening voltage release

Isolation module

ULP port module

IFE or EIFE interface

IEC 61850 for MasterPact

MTZ Digital Module

Auto: Remote

MX communicating

opening voltage release

Isolation module

ULP port module

IFE or EIFE interface, or

IFE server

Send a command to open the circuit

breaker through the IEC 61850

communication network.

This opening action is passwordprotected.

Refer to

DOCA0162EN MasterPact

MTZ - IEC 61850 Communication

Guide

.

Send a command to open the circuit

breaker from the IFE/EIFE control

webpage.

This opening action is passwordprotected.

Refer to the relevant document:

DOCA0084EN Enerlin'X IFE -

Ethernet Switchboard Server User Guide

DOCA0142EN Enerlin'X IFE -

Ethernet Interface for One IEC

Circuit Breaker - User Guide

DOCA0106EN Enerlin'X EIFE -

Embedded Ethernet Interface for

One MasterPact MTZ Drawout

Circuit Breaker - User Guide

If the device does not open, refer to the troubleshooting chapter

(see page 142)

.

46

DOCA0101EN-04 07/2020

Closing the Device

Closing Conditions

To close the device, the following conditions must be met:

Device is open (O).

Closing spring is charged.

The device is ready to close, OK is displayed.

NOTE: An opening order always takes priority over a closing order. The device cannot be closed while an

opening order is being received. If OK is crossed-out on the ready-to-close indicator, an order to open is

being received (either electrically or mechanically) and must be ended before OK can be displayed.

Closing the Device

The following tables present the different ways to close the device in the different control modes available.

The device can be closed in the following ways in all control modes:

MasterPact MTZ2/MTZ3 Normal Operation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not re-close the device on an electrical fault.

First inspect and, if necessary, repair the downstream equipment.

Failure to follow these instructions will result in death or serious injury.

Closing type Control

mode

Mechanical Manual,

Electrical with

BPFE

External

pushbutton

Auto: Local,

or Auto:

Remote

Manual,

Auto: Local,

or Auto:

Remote

Manual,

Auto: Local,

or Auto:

Remote

Accessories Closing action

– Press the closing

BPFE electrical

closing pushbutton

XF communicating

closing voltage

release

Isolation module

External pushbutton

wired by customer

XF standard or

communicating

closing voltage

release

Isolation module

MCH gear motor

pushbutton on the front of

the device.

The closing action is

possible when the closing

conditions are met.

Press the BPFE electrical

closing pushbutton,

mounted on the front cover.

The closing action takes

into account internal closing

conditions of the device and

the external conditions that

are part of the control and

monitoring system of the

installation.

Press the external pushbutton, which is connected to the XF

closing voltage release through the customer terminal block.

DOCA0101EN-04 07/2020 47

MasterPact MTZ2/MTZ3 Normal Operation

In addition, the circuit breaker can be closed in the following ways when Auto control mode is configured.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not operate the circuit breaker without confirming that doing so will not create a hazardous

situation.

Do not allow any person to work on the electrical network without physically validating the successful

execution of the local or remote software actions for closing the circuit breaker or switching on the

electrical circuit.

Failure to follow these instructions will result in death or serious injury.

DANGER

Closing type Control

mode

Through IO module Auto: Local

or Auto:

Remote

Through

Auto: Local

EcoStruxure Power

Commission

software

Through

Auto: Local

EcoStruxure Power

Device app

Through Modbus

communication

Auto:

Remote

Accessories Closing action

XF communicating

closing voltage

release

Isolation module

MCH gear motor

ULP port module

IO module

Close the circuit breaker by using the predefined

application 2 Breaker Operation of the IO module:

When the circuit breaker is set to local control mode by

the IO module, the command to close is issued from

local pushbuttons wired on digital inputs.

When the circuit breaker is set to remote control mode

by the IO module, the command to close is issued

from remote PLC outputs wired on digital inputs.

DOCA0055EN Enerlin'X IO - Input/Output

Refer to

Application Module for One IEC Circuit Breaker - User

Guide

.

XF communicating

closing voltage

release

Isolation module

MCH gear motor

XF communicating

closing voltage

release

Isolation module

MCH gear motor

MasterPact

Send a command to close the circuit breaker from

EcoStruxure Power Commission software running on a

PC connected locally to the circuit breaker through the

mini USB port on the MicroLogic X control unit.

The closing action is password-protected.

Refer to

EcoStruxure Power Commission Online Help

Send a command to close the circuit breaker from the

EcoStruxure Power Device app with MasterPact

Operation Assistant Digital Module, through Bluetooth

wireless communication or USB OTG connection.

The closing action is password-protected.

Operation Assistant

Digital Module

XF communicating

closing voltage

release

Isolation module

MCH gear motor

ULP port module

IFE, EIFE, or IFM

interface, or IFE

server

Send a command to close the circuit breaker through the

Modbus communication network.

The closing action is password-protected.

Refer to

DOCA0105EN MasterPact MTZ - Modbus

Communication Guide

NOTE: EcoStruxure Power Commission software

running on a PC connected to the circuit breaker through

the communication network can be used to send

commands to close.

.

.

48

DOCA0101EN-04 07/2020

MasterPact MTZ2/MTZ3 Normal Operation

Closing type Control

mode

Through

IEC 61850

communication

Through IFE/EIFE

webpages

Auto:

Remote

Auto:

Remote

Accessories Closing action

XF communicating

closing voltage

release

Isolation module

MCH gear motor

ULP port module

IFE or EIFE

interface

IEC 61850 for

MasterPact MTZ

Digital Module

XF communicating

closing voltage

release

Isolation module

MCH gear motor

ULP port module

IFE or EIFE

interface, or IFE

server

Send a command to close the circuit breaker through the

IEC 61850 communication network.

This closing action is password-protected.

Refer to

DOCA0162EN MasterPact MTZ - IEC 61850

Communication Guide

Send a command to close the circuit breaker from the

IFE/EIFE control webpage.

The closing action is password-protected.

Refer to the relevant document: