Schneider Electric M580 Original instructions

Modicon M580

EIO0000004111 04/2020

Modicon M580

Open Ethernet Network

System Planning Guide

Original instructions

04/2020

EIO0000004111.00

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000004111 04/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Designing an Open Ethernet Network . . . . . . . . . . . . . . 13

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Design Principles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility and Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Open Ethernet Network Configuration . . . . . . . . . . . . . . 23

Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Industrial Ethernet Managed Switches Configuration . . . . . . . . . . . . .

Chapter 3 System Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 System Commissioning and Diagnostics . . . . . . . . . . . . 33

System Commissioning and Diagnostics . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

16

21

24

25

29

33

35

EIO0000004111 04/2020 3

4 EIO0000004111 04/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000004111 04/2020 5

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

BEFORE YOU BEGIN

Do not use this product on machinery lacking effective point-of-operation guarding. Lack of

effective point-of-operation guarding on a machine can result in serious injury to the operator of

that machine.

UNGUARDED EQUIPMENT

Do not use this software and related automation equipment on equipment which does not have

point-of-operation protection.

Do not reach into machinery during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

This automation equipment and related software is used to control a variety of industrial processes.

The type or model of automation equipment suitable for each application will vary depending on

factors such as the control function required, degree of protection required, production methods,

unusual conditions, government regulations, etc. In some applications, more than one processor

may be required, as when backup redundancy is needed.

Only you, the user, machine builder or system integrator can be aware of all the conditions and

factors present during setup, operation, and maintenance of the machine and, therefore, can

determine the automation equipment and the related safeties and interlocks which can be properly

used. When selecting automation and control equipment and related software for a particular

application, you should refer to the applicable local and national standards and regulations. The

National Safety Council's Accident Prevention Manual (nationally recognized in the United States

of America) also provides much useful information.

In some applications, such as packaging machinery, additional operator protection such as pointof-operation guarding must be provided. This is necessary if the operator's hands and other parts

of the body are free to enter the pinch points or other hazardous areas and serious injury can occur.

Software products alone cannot protect an operator from injury. For this reason the software

cannot be substituted for or take the place of point-of-operation protection.

Ensure that appropriate safeties and mechanical/electrical interlocks related to point-of-operation

protection have been installed and are operational before placing the equipment into service. All

interlocks and safeties related to point-of-operation protection must be coordinated with the related

automation equipment and software programming.

WARNING

6 EIO0000004111 04/2020

NOTE: Coordination of safeties and mechanical/electrical interlocks for point-of-operation

protection is outside the scope of the Function Block Library, System User Guide, or other

implementation referenced in this documentation.

START-UP AND TEST

Before using electrical control and automation equipment for regular operation after installation,

the system should be given a start-up test by qualified personnel to verify correct operation of the

equipment. It is important that arrangements for such a check be made and that enough time is

allowed to perform complete and satisfactory testing.

EQUIPMENT OPERATION HAZARD

Verify that all installation and set up procedures have been completed.

Before operational tests are performed, remove all blocks or other temporary holding means

used for shipment from all component devices.

Remove tools, meters, and debris from equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Follow all start-up tests recommended in the equipment documentation. Store all equipment

documentation for future references.

Software testing must be done in both simulated and real environments.

Verify that the completed system is free from all short circuits and temporary grounds that are not

installed according to local regulations (according to the National Electrical Code in the U.S.A, for

instance). If high-potential voltage testing is necessary, follow recommendations in equipment

documentation to prevent accidental equipment damage.

Before energizing equipment:

Remove tools, meters, and debris from equipment.

Close the equipment enclosure door.

Remove all temporary grounds from incoming power lines.

Perform all start-up tests recommended by the manufacturer.

WARNING

EIO0000004111 04/2020 7

OPERATION AND ADJUSTMENTS

The following precautions are from the NEMA Standards Publication ICS 7.1-1995 (English

version prevails):

Regardless of the care exercised in the design and manufacture of equipment or in the selection

and ratings of components, there are hazards that can be encountered if such equipment is

improperly operated.

It is sometimes possible to misadjust the equipment and thus produce unsatisfactory or unsafe

operation. Always use the manufacturer’s instructions as a guide for functional adjustments.

Personnel who have access to these adjustments should be familiar with the equipment

manufacturer’s instructions and the machinery used with the electrical equipment.

Only those operational adjustments actually required by the operator should be accessible to

the operator. Access to other controls should be restricted to prevent unauthorized changes in

operating characteristics.

8 EIO0000004111 04/2020

About the Book

At a Glance

Document Scope

EcoStruxure Plant is Schneider Electric IIoT platform (Industrial Internet of Things) designed to

address the key challenges of many different types of users, including plant managers, operations

managers, engineers, maintenance teams, and operators, by delivering a system that is scalable,

flexible, integrated, and collaborative.

This document presents usage of industrial Ethernet managed switches with the Modicon M580

offer. A switch centric architecture provides flexibility and openess on system network design.

This guide provides detailed information about planning such M580 open architecture, including

the following:

topology rules and recommendations for designing an open network architecture

implementation of industrial managed Ethernet Switches

system commissioning and maintenance

system performance and limitations

system diagnostics

Validity Note

This documentation is valid for Standalone Modicon M580 and M580 safety systems.

The technical characteristics of the devices described in the present document also appear online.

To access the information online:

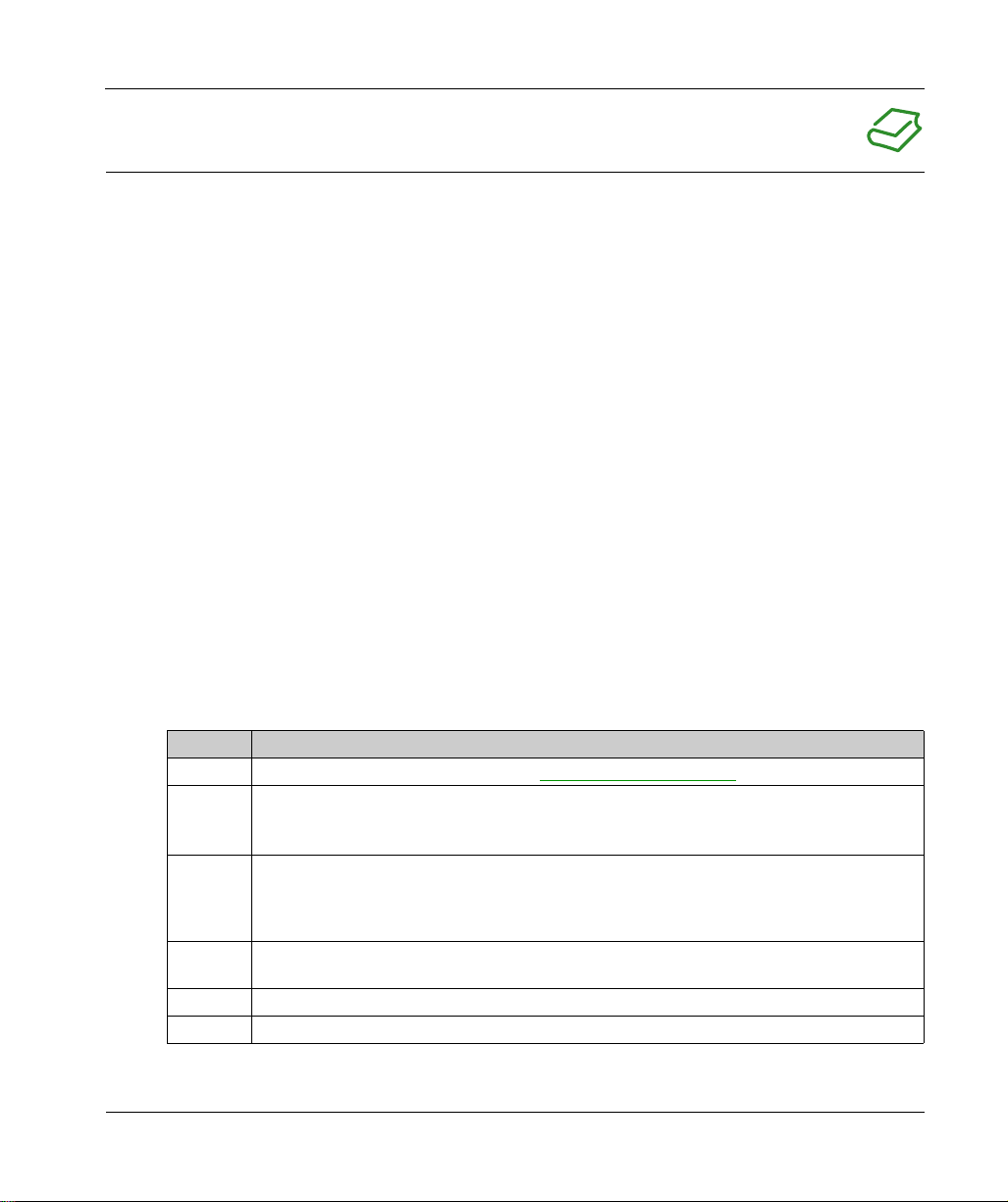

Step Action

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

3 If you entered a reference, go to the Product Datasheets search results and click on the

reference that interests you.

If you entered the name of a product range, go to the Product Ranges search results and click

on the product range that interests you.

4 If more than one reference appears in the Products search results, click on the reference that

interests you.

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

EIO0000004111 04/2020 9

www.schneider-electric.com

*

.

).

The characteristics that are described in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

Related Documents

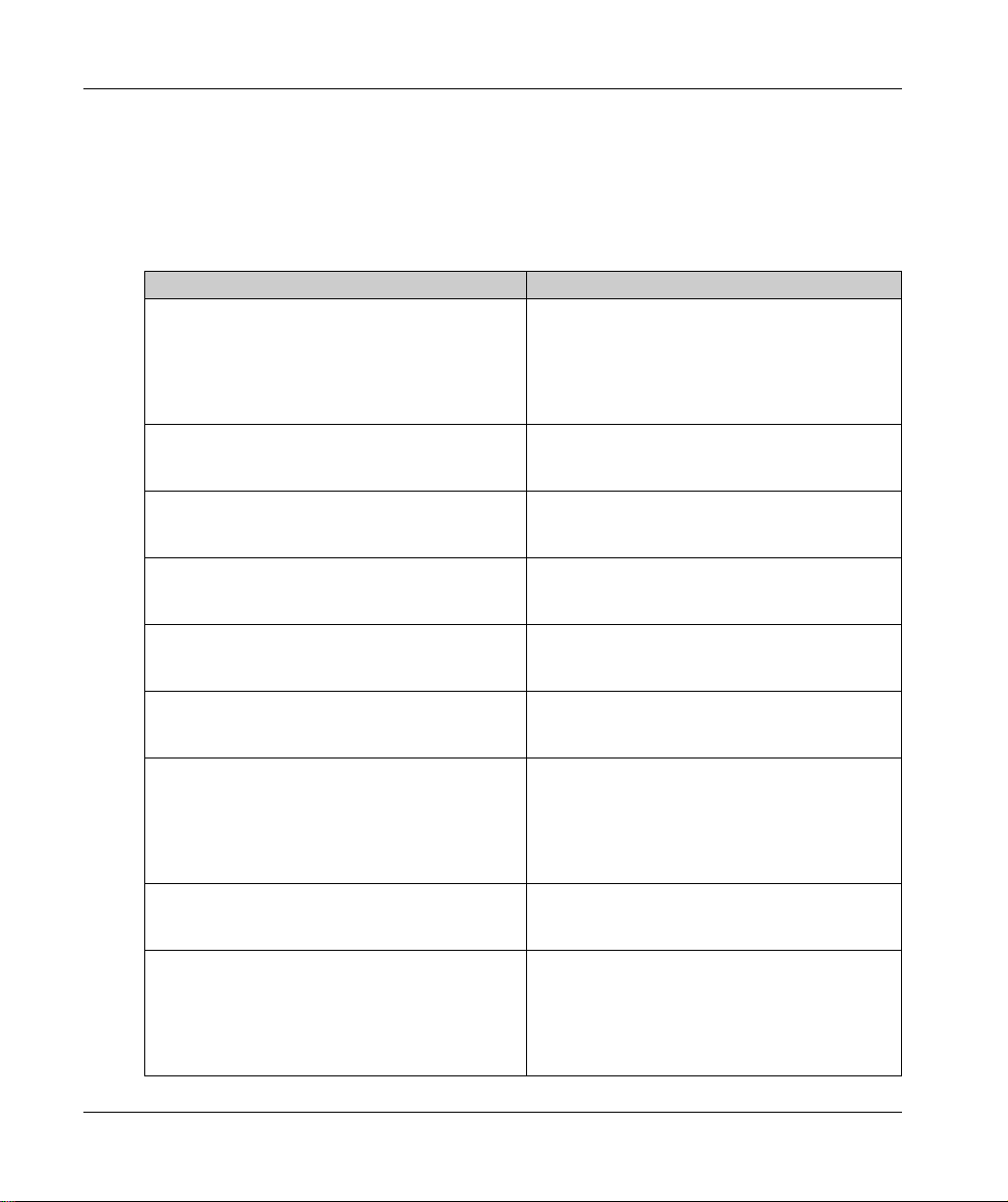

Title of documentation Reference number

Modicon M580, Hardware, Reference Manual EIO0000001578 (English),

Modicon M580 BMENOC0301/11, Ethernet

Communication Module, Installation and

Configuration Guide

Modicon M580 BMENOC0321, Control Network

Module, Installation and Configuration Guide

M580 BMENOS0300, Network Option Switch,

Installation and Configuration Guide

Modicon M580 Standalone, System Planning Guide

for Frequently Used Architectures

Modicon M580, System Planning Guide for Complex

Topologies

Modicon M580, RIO Modules, Installation and

Configuration Guide

Modicon M580, Safety System Planning Guide QGH60283 (English), QGH60284 (French),

EcoStruxure™ Control Expert, System Bits and

Words, Reference Manual

EIO0000001579 (French),

EIO0000001580 (German),

EIO0000001582 (Italian),

EIO0000001581 (Spanish),

EIO0000001583 (Chinese)

HRB62665 (English), HRB65311 (French),

HRB65313 (German), HRB65314 (Italian),

HRB65315 (Spanish), HRB65316 (Chinese)

NVE24232 (English), NVE24233 (French),

NVE24237 (German), NVE24240 (Italian),

NVE24239 (Spanish), NVE24242 (Chinese)

NHA89117 (English), NHA89119 (French),

NHA89120 (German), NHA89121 (Italian),

NHA89122 (Spanish), NHA89123 (Chinese)

HRB62666 (English), HRB65318 (French),

HRB65319 (German), HRB65320 (Italian),

HRB65321 (Spanish), HRB65322 (Chinese)

NHA58892 (English), NHA58893 (French),

NHA58894 (German), NHA58895 (Italian),

NHA58896 (Spanish), NHA58897 (Chjnese)

EIO0000001584 (English),

EIO0000001585 (French),

EIO0000001586 (German),

EIO0000001587 (Italian),

EIO0000001588 (Spanish),

EIO0000001589 (Chinese),

QGH60285 (German), QGH60286 (Spanish),

QGH60287 (Italian), QGH60288 (Chinese)

EIO0000002135 (English),

EIO0000002136 (French),

EIO0000002137 (German),

EIO0000002138 (Italian),

EIO0000002139 (Spanish),

EIO0000002140 (Chinese)

10 EIO0000004111 04/2020

You can download these technical publications and other technical information from our website

at

www.schneider-electric.com/en/download

.

EIO0000004111 04/2020 11

Loading...

Loading...