Samsung AM200xXV Series, AM120xXV Series, AM220xXV Series, AM100xXV Series, AM160xXV Series Service Manual

...

AIR CONDITIONER CONTENTS

SYSTEM AIR CONDITIONER

OUTDOOR UNIT

AM080/100/120/140/160/180/200/220/240/2606XV666

AM080/100/120/200FXWA666

AM080/100/120/140/160/180/200/220JXVA66

AM140/160/180/200/220/240/260/280/300KXV666

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram and Parts List

6. Wiring Diagram

7. Cycle Diagram

8. Key Options

9. Test Operation

Section 0

Samsung Electronics 1

Contents

1. Precautions .......................................................................................................... 1-1

1-1 Precautions for the Service ......................................................................................................................................1-1

1-2 Precautions for the Static Electricity and PL .....................................................................................................1-1

1-3 Precautions for the Safety ........................................................................................................................................1-1

1-4 Precautions for Handling Refrigerant for Air Conditioner ..........................................................................1-2

1-5 Precautions for Welding the Air Conditioner Pipe .........................................................................................1-2

1-6 Precautions for Additional Supplement of Air Conditioner Refrigerant ...............................................1-2

1-7 Other Precautions ........................................................................................................................................................1-2

2. Product Specifications ....................................................................................... 2-1

2-1 The Feature of Product ..............................................................................................................................................2-1

2-1-1 Feature ...............................................................................................................................................................2-1

2-1-2 Changes in comparison to basic mode ................................................................................................2-3

2-1-3 Structure of product(Heat Pump) ...........................................................................................................2-9

2-1-4 Structure of product(Heat Recovery) ................................................................................................. 2-10

2-1-5 Structure of product(Power supply for 460V, 60Hz, 3Φ) ............................................................ 2-11

2-1-6 Structure of product (DVM S WATER) .................................................................................................2-12

2-1-7 Structure of product (Heat Pump AM666KX6 Series)............................................................. 2-13

2-2 Product Specifications ........................................................................................................................................... 2-14

2-2-1 Outdoor Unit ................................................................................................................................................2-14

2-3 Accessory and Option Specifications ............................................................................................................... 2-43

2-3-1 Accessories ....................................................................................................................................................2-43

3. Disassembly and Reassembly ........................................................................... 3-1

3-1 Necessary Tools .............................................................................................................................................................3-1

3-2 Disassembly and Reassembly .................................................................................................................................3-2

3-2-1 AM080/100/120JXV666 ...........................................................................................................................3-2

3-2-2 AM140FXVAGH, AM140JXV6GH .........................................................................................................3-12

3-2-3 AM160/180/200/220/240/2606XV666, AM140JXVA6H ........................................................ 3-22

3-2-4 AM080/100/120FXWA66 ....................................................................................................................... 3-33

3-2-5 AM200FXWA66 .........................................................................................................................................3-41

3-2-6 AM140/160KXVG66, AM140/160/180KXVA66...........................................................................3-48

3-2-7 AM180/200/220KXVG66, AM200/220KXVA66...........................................................................3-55

3-2-8 AM240/260/280/300KXV666, AM080KXVS66 .......................................................................... 3-63

3-3 Caution at compressor exchange ...................................................................................................................... 3-72

3-4 MCU ................................................................................................................................................................................ 3-77

3-5 EEV KIT ........................................................................................................................................................................... 3-78

4. Troubleshooting .................................................................................................. 4-1

4-1 Check-up Window Description ..............................................................................................................................4-1

4-2 Service Operation ........................................................................................................................................................4-2

4-2-1 Special Operation ..........................................................................................................................................4-2

4-2-2 DVM S Models EEPROM Code Table ...................................................................................................4-12

4-2-3 Number Display Method ........................................................................................................................ 4-13

4-3 Appropriate Measures for Different Symptom ............................................................................................. 4-18

4-3-1 Outdoor Unit Operation Flow ............................................................................................................... 4-17

4-3-2 Main PCB has no power phenomenon ............................................................................................. 4-21

4-3-3 Communication Error between Indoor and Outdoor Units during Tracking.................... 4-22

4-3-4 Communication Error between Indoor and Outdoor Units after Tracking ........................ 4-24

4-3-5 Communication error between main and sub Unit of outdoor unit or

between outdoor units ............................................................................................................................ 4-25

4-3-6 Internal Communication error of the Outdoor Unit C-Box ....................................................... 4-26

4-3-7 Internal PCB Communication error of the Outdoor Unit C-Box..............................................4-27

4-3-8 MCU branch part setup error-inconsecutive connection with the use

of 2 branch Parts .........................................................................................................................................4-29

Section 0

2 Samsung Electronics

Contents

4-3-9 MCU branch part setup error-Repeated setup for the same address over 3 times ........ 4-30

4-3-10 MCU branch part setup error-non-installed address setup ................................................... 4-31

4-3-11 Setup Error for MCU Branch part-Setup Error for MCU Quantity Used ............................. 4-32

4-3-12 MCU branch part setup error-Overlapping Indoor unit Address setup ...........................4-33

4-3-13 MCU branch part setup error_Set as being used without connection

to an Indoor unit ...................................................................................................................................... 4-34

4-3-14 MCU branch part setup error-Connect an Indoor unit to a branch part

not being used ..........................................................................................................................................4-35

4-3-15 MCU branch part setup error-Connect more Indoor units than what is

actually set up in MCU ........................................................................................................................... 4-36

4-3-16 MCU/MCU subcooler entrance/exit sensor error (Open/Short) ........................................... 4-37

4-3-17 Outdoor Temperature Sensor Error .................................................................................................. 4-38

4-3-18 Cond Out Temperature Sensor Error (Open/Short) ...................................................................4-39

4-3-19 Outdoor Cond Out sensor breakway error ................................................................................... 4-40

4-3-20 Compressor Discharge or TOP 1/2 Temperature sensor error ............................................... 4-42

4-3-21 Compressor Discharge or TOP temperature sensor breakway error ..................................4-43

4-3-22 E269 : Suction Temperature sensor breakway error .................................................................4-44

4-3-23 High Pressure sensor error (Open/Short) .......................................................................................4-45

4-3-24 Low Pressure sensor error (Open/Short) ........................................................................................ 4-46

4-3-25 Suction Temperature sensor error (Open/Short) ........................................................................ 4-47

4-3-26 Liquid Pipe Temperature sensor error (Open/Short) ................................................................. 4-48

4-3-27 EVI In Temperature sensor error (Open/Short) ............................................................................ 4-49

4-3-28 EVI Out Temperature sensor error (Open/Short) ........................................................................ 4-50

4-3-29 Suction-2 Temperature Sensor Error (Open/Short) ...................................................................4-51

4-3-30 Measures of other outdoor unit error ............................................................................................. 4-52

4-3-31 E407 : Comp. Down due to High Pressure Protection Control .............................................4-53

4-3-32 E410 : Comp. Down due to Low Pressure Protection Control ...............................................4-55

4-3-33 E416 : Suspension of starting due to Compressure discharge

temperature sensor/Top temperature sensor .................................................................4-57

4-3-34 3-phase Input Wiring error ...................................................................................................................4-58

4-3-35 E428 : Suspension of starting by abnormal compression ratio ........................................... 4-59

4-3-36 EVI EEV Open error ..................................................................................................................................4-60

4-3-37 Refrigerant leakage error ...................................................................................................................... 4-61

4-3-38 Prevention of heating/cooling operation due to outdoor temperature ..........................4-62

4-3-39 Prevention of heating refrigerant charge due to outdoor temperature ..........................4-63

4-3-40 CH wire breaking error........................................................................................................................... 4-64

4-3-41 Fan starting error ......................................................................................................................................4-66

4-3-42 Fan lock error ............................................................................................................................................. 4-67

4-3-43 Momentary Blackout error .........................................................................................................................4-69

4-3-44 Outdoor Fan Motor overheating ....................................................................................................... 4-70

4-3-45 Fan IPM Overheat error .......................................................................................................................... 4-71

4-3-46 Compressor starting error ....................................................................................................................4-72

4-3-47 COMP Overcurrent error ....................................................................................................................... 4-74

4-3-48 Overvoltage/Low voltage error ..........................................................................................................4-78

4-3-49 DC Link voltage sensor error ............................................................................................................... 4-79

4-3-50 Fan Motor Overcurrent error ...............................................................................................................4-80

4-3-51 Input/Output Current sensor error ................................................................................................... 4-82

4-3-52 Outdoor Fan PCB Overvoltage/Low voltage error .....................................................................4-83

4-3-53 Hall IC(Fan) error ....................................................................................................................................... 4-84

4-3-54 Inverter Overheat error .......................................................................................................................... 4-85

4-3-55 Option setting error of outdoor unit ............................................................................................... 4-86

4-3-57 Error due to using single type outdoor unit in a module installation ............................... 4-87

4-3-57 Indoor unit and MCU address duplication error ......................................................................... 4-88

Section 0

Samsung Electronics 3

Contents

5. PCB Diagram and Parts List ............................................................................... 5-1

5-1 ASS'Y PCB MAIN ...........................................................................................................................................................5-1

5-2 ASS'Y PCB MAIN-HUB ................................................................................................................................................5-4

5-3 ASS’Y PCB INVERTER ..................................................................................................................................................5-8

5-4 ASS’Y PCB FAN ........................................................................................................................................................... 5-12

5-5 ASS’Y PCB EMI .......................................................................................................................................................... 5-16

5-6 SUB-COMM ................................................................................................................................................................ 5-19

6. Wiring Diagram ................................................................................................... 6-1

6-1 AM080/100/120/140/160/180/200/220FXV666 ..........................................................................................6-1

6-2 AM080/100/120/200FXWA66 ...............................................................................................................................6-3

6-3 AM240/26066XV66 .................................................................................................................................................6-5

6-4 AM080JXVAFH ...............................................................................................................................................................6-7

6-5 AM100/120JXVAFH .....................................................................................................................................................6-9

6-6 AM140/160/180/200JXVAFH ................................................................................................................................6-11

6-7 AM080/100/120/140/160/180/200/220JXVAJH ........................................................................................... 6-13

7. Cycle Diagram ...................................................................................................................7-1

7-1 AM080/100/1206XV66H ........................................................................................................................................7-1

7-2 AM1406XV6GH ...........................................................................................................................................................7-1

7-3 AM160/180/200/2206XV66H ..............................................................................................................................7-2

7-4 AM080/100/1206XV6GR .........................................................................................................................................7-2

7-5 AM1406XV6GR............................................................................................................................................................7-3

7-6 AM160/180/200/2206XV6GR ...............................................................................................................................7-3

7-7 AM080/100/120FXWA66 ........................................................................................................................................7-4

7-8 AM200FXWA66 ...........................................................................................................................................................7-4

7-9 AM240/260HXVAGH/EU ............................................................................................................................................7-5

7-10 AM240/260/280KXVG66, AM280/300KXVA66, AM080KXVS66 ......................................................7-5

7-11 AM180/200/220KXVG66, AM200/220KXVA66 .........................................................................................7-6

7-12 AM140/160KXVG66, AM140/160/180KXVA66 .........................................................................................7-6

7-13 Cooling operation (H/R) ..........................................................................................................................................7-6

7-14 Main cooling operation (H/R) ...............................................................................................................................7-7

7-15 Heating operation (H/R) .........................................................................................................................................7-8

7-16 Main heating operation (H/R) ..............................................................................................................................7-9

7-17 Cooling operation (H/P) .......................................................................................................................................7-10

7-18 Heating operation (H/P) ......................................................................................................................................7-11

7-19 Cooling operation(H/R) - AM080/100/120/200FXWA66 .....................................................................7-12

7-20 Main cooling operation(H/R) ............................................................................................................................. 7-14

7-21 Heating operation(H/R) .......................................................................................................................................7-15

7-22 Main heating operation(H/R) ............................................................................................................................7-16

7-23 Cycle Component Function Explanation ...................................................................................................... 7-17

8. Key Options .........................................................................................................8-1

8-1 Outdoor unit option switch settings ...................................................................................................................8-1

8-2 How to set the key function of the outdoor unit ...........................................................................................8-4

8-3 How to check the view mode using a tact switch ...................................................................................... 8-12

9. Test Operation .....................................................................................................9-1

9-1 Auto Trial Operation ....................................................................................................................................................9-1

9-1-1 Auto Trial Operation Synopsis ..................................................................................................................9-1

9-1-2 Auto Trial Operation functions .................................................................................................................9-3

9-1-3 How to troubleshoot of the "Undetermined"....................................................................................9-4

9-2 Amount of refrigerant automatically checking ............................................................................................ 9-14

9-3 Model Naming ...........................................................................................................................................................9-15

Samsung Electronics 1-1

1. Precautions

1-1 Precautions for the Service

OUse the correct parts when changing the electric parts.

– Please check the labels and notices for the model name, proper voltage, and proper current for the electric parts.

OFully repair the connection for the types of harness when repairing the product after breakdown.

– A faulty connection can cause irregular noise and problems.

OWhen disassembling or assembling, make sure that the product is laid down on a work cloth.

– Doing so will prevent scratching to the exterior of the rear side of the product.

OCompletely remove dust or foreign substances on the housing, connection, and inspection parts when performing repairs.

– This can prevent fire hazards for tracking, short, etc.

OPlease tighten the service valve of the outdoor unit and the valve cap of the charging valve as securely as possible by using

a monkey spanner.

OCheck whether the parts are properly and securely assembled after performing repairs.

– These parts should be in the same condition as before the repair.

1-2 Precautions for the Static Electricity and PL

OPlease carefully handle the PCB power terminal during repair and measurement when it is turned on since it is vulnerable

to static electricity.

– Please wear insulation gloves before performing PCB repair and measurement.

OCheck if the place of installation is at least 2m away from electronic appliances such as TV, video players, and stereos.

– This can cause irregular noise or degrade the picture quality.

OPlease make sure the customer does not directly repair the product.

– Arbitrary dismantling may result in electric shock or fire.

1-3 Precautions for the Safety

ODo not pull or touch the power plug or the subsidiary power switch with wet hands.

– This may result in electric shock or fire.

OIf the power line or the power plug is damaged, then it must be changed since this is a hazard.

ODo not bend the wire too much or position it so that it can be damaged by a heavy object on top.

– This may result in electric shock or fire.

OThe use of multiple electric outlets should be prohibited.

– This may result in electric shock or fire.

OGround the connection if it is necessary.

– The connection must be grounded if there is any risk of electrical short due to water or moisture.

OUnplug the power or turn off the subsidiary power switch when changing or repairing electrical parts.

– Doing so will prevent electric shock.

OExplain to workers that the battery for the remote control needs to be separated for storage purposes when the product

will not be used for a long time.

– This can cause a problem for the remote control since battery fluid may trickle out.

1-2 Samsung Electronics

1-4 Precautions for Handling Refrigerant for Air Conditioner

Environmental Cautions: Air pollution due to gas release

OSafety Cautions

If liquid gas is released, then body parts that come into contact with it may experience frostbite/blister/numbness.

If a large amount of gas is released, then suffocation may occur due to lack of oxygen. If the released gas is heated, then noxious

gas may be produced by combustion.

OContainer Handling Cautions

Do not subject container to physical shock or overheating. (Flowage is possible while moving within the regulated pressure.)

1-5 Precautions for Welding the Air Conditioner Pipe

ODangerous or flammable objects around the pipe must be removed before the welding.

OIf the refrigerant is kept inside the product or the pipe, then remove the refrigerant prior to welding.

If the welding is carried out while the refrigerant is kept inside, the welding cannot be properly performed. This will also produce

noxious gas that is a health hazard. This leakage will also explode with the refrigerant and oil due to an increase in the refrigerant

pressure, posing a danger to workers.

OPlease remove the oxide produced inside the pipe during the welding with nitrogen gas.

Using another gas may cause harm to the product or others.

1-6 Precautions for Additional Supplement of Air Conditioner Refrigerant

OPrecisely calculate the refrigerant by using a scale and S-net, and proceed with the test operation.

Excessive supplement can cause harm to the product since it can cause an inflow of the liquid refrigerant into the compressor.

ODo not heat the refrigerant container for a forced injection.

This may cause harm to the product or others since the refrigerant container may burst.

ODo not operate the product after removing the product safety pressure switch and sensor.

If the product is blocked inside, then this may cause harm to the product or others due to the excess pressure increase of the

refrigerant gas.

1-7 Other Precautions

OThere should be no leakage of the pipes after installation. When withdrawing the refrigerant, the compressor should be

stopped before removing the connecting pipe.

If the compressor is operating while the refrigerant pipe is not correctly connected and the service valve is opened, then

air and other substances can enter the pipe. The interior of the refrigerant cycle may then build up excessive high pressure

resulting in explosion and damage.

Samsung Electronics 2-1

2. Product Specifications

2-1 The Feature of Product

2-1-1 Feature

Q Dual SSC System Technology

When load changes, capacity amendment that is soft by continuous operation of Dual Inverter is available.

Q Dual Smart Inverter System

DSC System

Digital base Inverter base

. DVI variable + DVI constant speed

. AC Motor

. 2 generation, Vapor Injection

. Dual Smart Inverter : SSC + SSC

. BLDC Inverter Motor (14~160Hz driving)

. 3 generation, Vapor Injection

(Performance maximization of low temperature heating)

DSI System

High Pressure Refrigerant Outlet

Medium Pressure

Refrigerant Injection

Low Pressure

Refrigerant Inlet

Low Pressure

Refrigerant Inlet

3 generation,

Vapor Injection

3 generation,

Vapor Injection

Low Pressure

Refrigerant Inlet

High Pressure Refrigerant Outlet High Pressure Refrigerant Outlet

Medium Pressure

Refrigerant Inlet

Capacity

Variable

Ŷ Compressor driving : When load changes, is variable by fast inverter frequency.

Ŷ Amenities elevation : ᇹ0.5°C

Step 1

ON OFF

Step 2

Step 3 Step 4

ON OFF

ON ON ON ON

Product Specications

2-2 Samsung Electronics

Feature

(cont.)

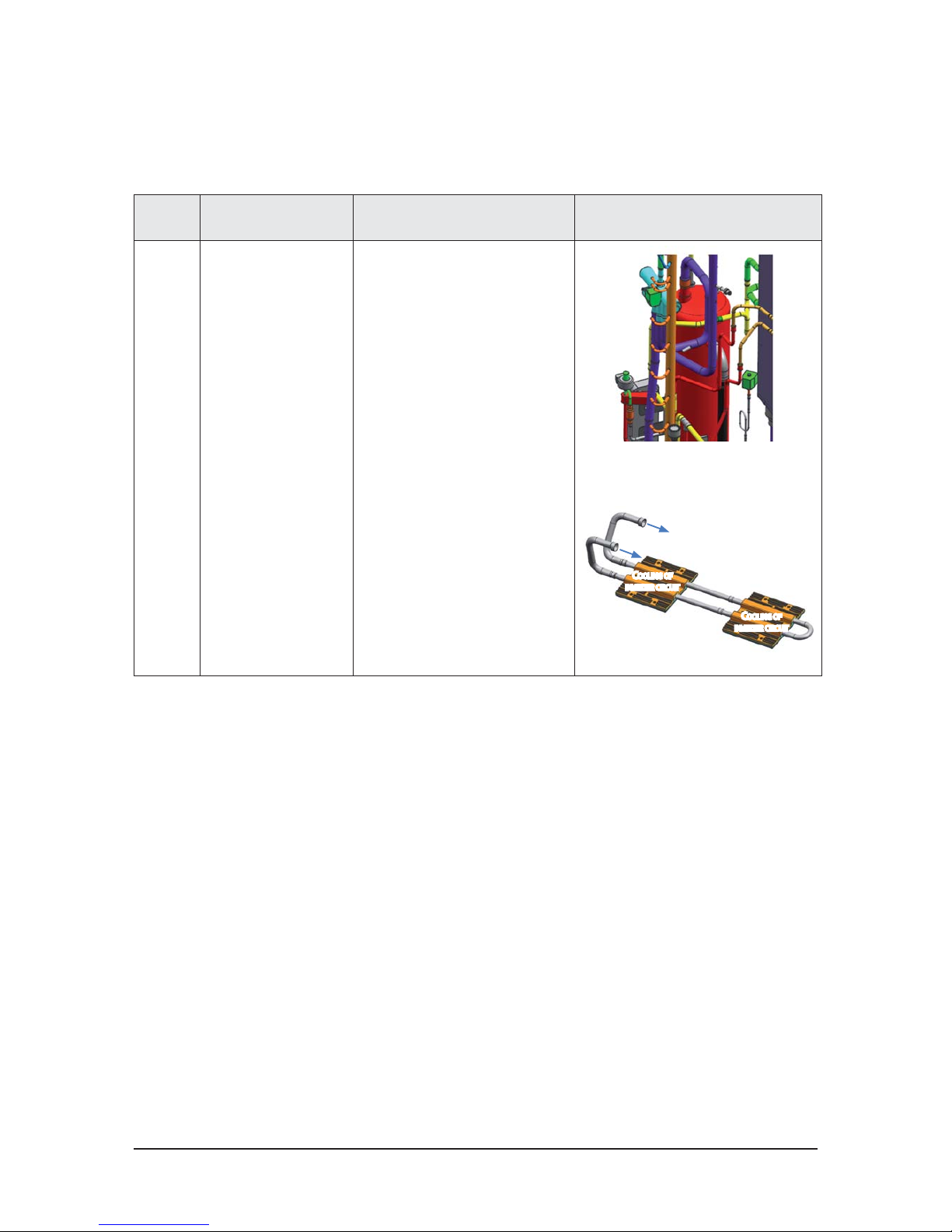

QInverter circuit refrigerant cooling technology

- Applied high eciency refrigerant cooling circuit. Secured stable Inverter PCB cooling performance.

- Air cooling method : When natural convection / electric heat performance is low and is high load, eciency is fallen.

- Refrigerant cooling system : Forced circulation / electric heat performance is high and control of (thermal conductivity is

10 times higher than air) load is available.

Cooling of

inverter circuit

Refrigerant cooling system :

It is cooling technology of inverter circuit that use

refrigerating cycle technology.

Cooling of

inverter circuit

Product Specications

Samsung Electronics 2-3

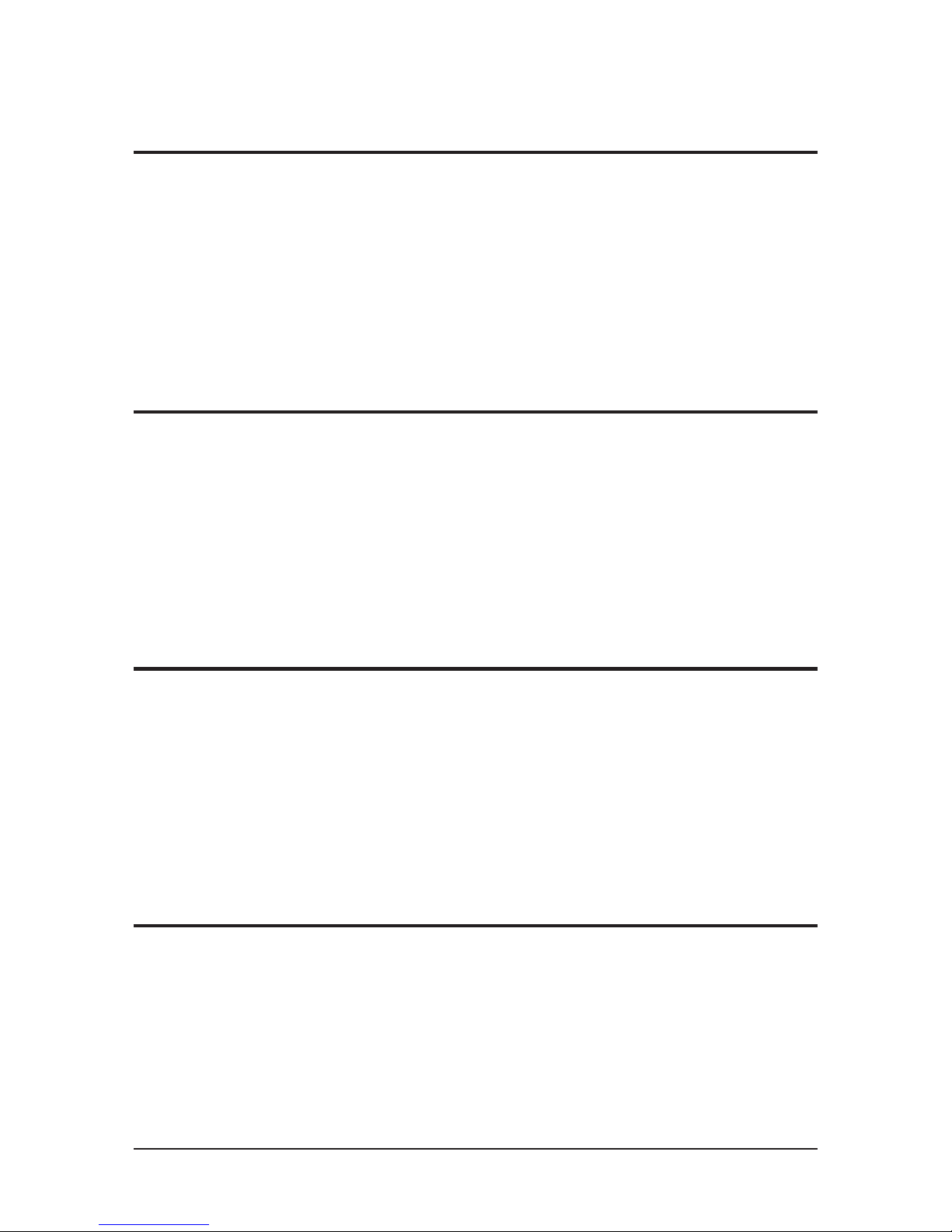

2-1-2 Changes in comparison to basic mode

Changed

part

Changed item

and feature

Basic After changed

Control Box

structure

Monolayer structure ࣖ Double

Layer Structure

- Inverter technology integration

(Inverter control circuit

composition)

- C/Box volume maximum use

Built-in type Controller embodi-

ment

- Integrated power supply

+ control unit

- Piping service easiness

Q Control Box & PCB

Changed

part

Changed item

and feature

Basic After changed

CABINET

Change the color :

TOUCH GRAY

ࣖ EARTH BROWN

Wire Harness installation part

change

LOGO change

Product Specications

2-4 Samsung Electronics

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

Main PCB

Change Main PCB

- Separation for load / control.

- Option resistance delete by model.

(standardization)

- When do PCB replace, need option

download.

Hub PCB

Hub PCB newly application

- Separation for load / control.

- Enhanced fixing of load / sensor wire.

FAN PCB

Use controller of 3 phase power

- Prevented phase unbalance.

- Temperature protection of IPM.

Inverter PCB

(Compressor

Control PCB)

Applied inverter Compressor

- Refrigerant cooling method

- Mount power relay on PCB

EMI PCB

3 phase power EMI PCB

- Fuse mount

Communication

Terminal block

- Mount communication terminal block

on PCB

Q

AM080/100/120/140/160/180/200/220JXV666

Product Specications

Samsung Electronics 2-5

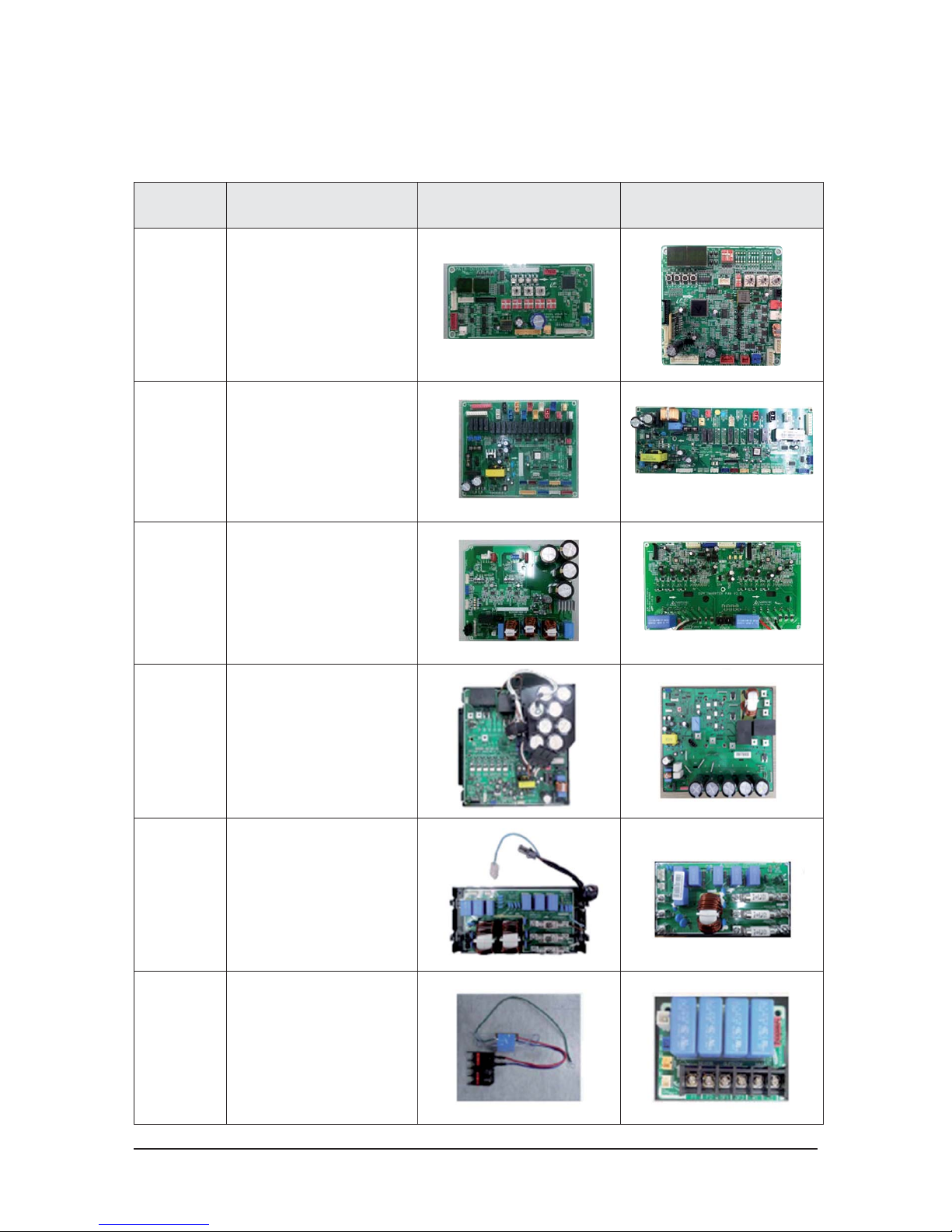

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

Main PCB

Change Main PCB

- Separation for load / control.

- Option resistance delete by model.

(standardization)

- When do PCB replace, need option

download.

←

Hub PCB

Hub PCB newly application

- Separation for load / control.

- Enhanced fixing of load / sensor wire.

←

FAN PCB

Use controller of 3 phase power

- Prevented phase unbalance.

- Temperature protection of IPM.

-

Inverter PCB

(Compressor

Control PCB)

Applied inverter Compressor

- Refrigerant cooling method

- Magnet S/W

ױ Did Power Relay mount to PCB.

←

EMI PCB

3 phase power EMI PCB

- Fuse mount

←

Communication

Terminal block

Did Communication Terminal block

mount to PCB.

←

Water Hub PCB

Water Hub PCB

- External contact for DVM S WATER

-

Q

AM080/100/120/200FXWA66

Product Specications

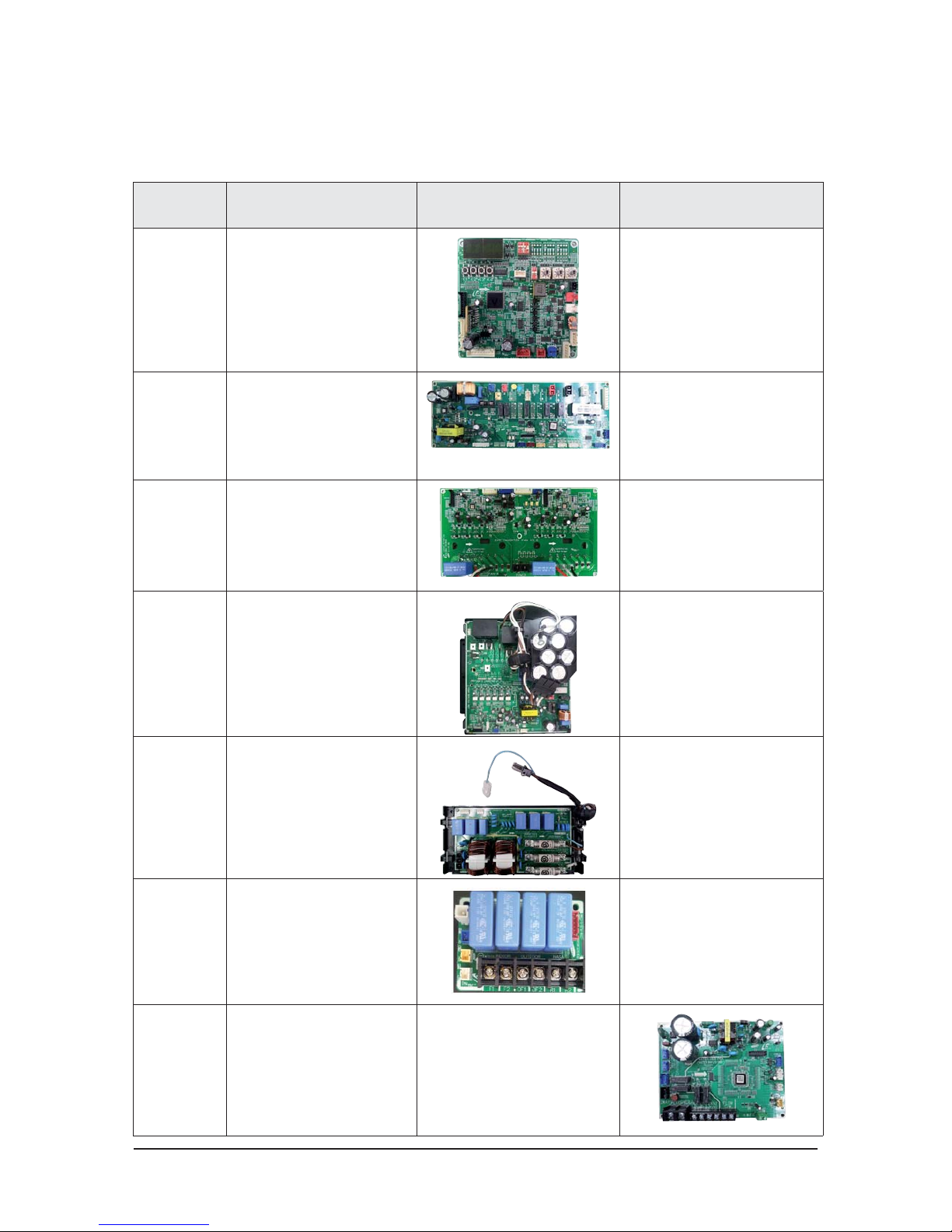

2-6 Samsung Electronics

Changed

part

Changed item

and feature

Basic After changed

Main PCB

Change Main PCB

- Increase MICOM capability

FAN PCB

Applies 600V IPM by LC

resonance buck-converter

Inverter PCB

(Compressor

Control

PCB)

- Increases current due to

high capacity compressor

- Increases capacitor's capacity

- Applies EMI coil on board

(Deletes core in wire)

EMI PCB

- Develops 50A EMI PBA

ױIncreases coil size and

fuse capacity

- Improves EMI characteristic.

REACTOR

- Increases current due to

high capacity compressor

- Improved wire connection terminal

Refrigerant

cooling

- Increases heat cooling capacity

- Increases pipe size and heat

exchange area

Changes in comparison to basic mode (cont.)

Q

AM140/160/180/200/220/240/260/280/300KXV666

Product Specications

Samsung Electronics 2-7

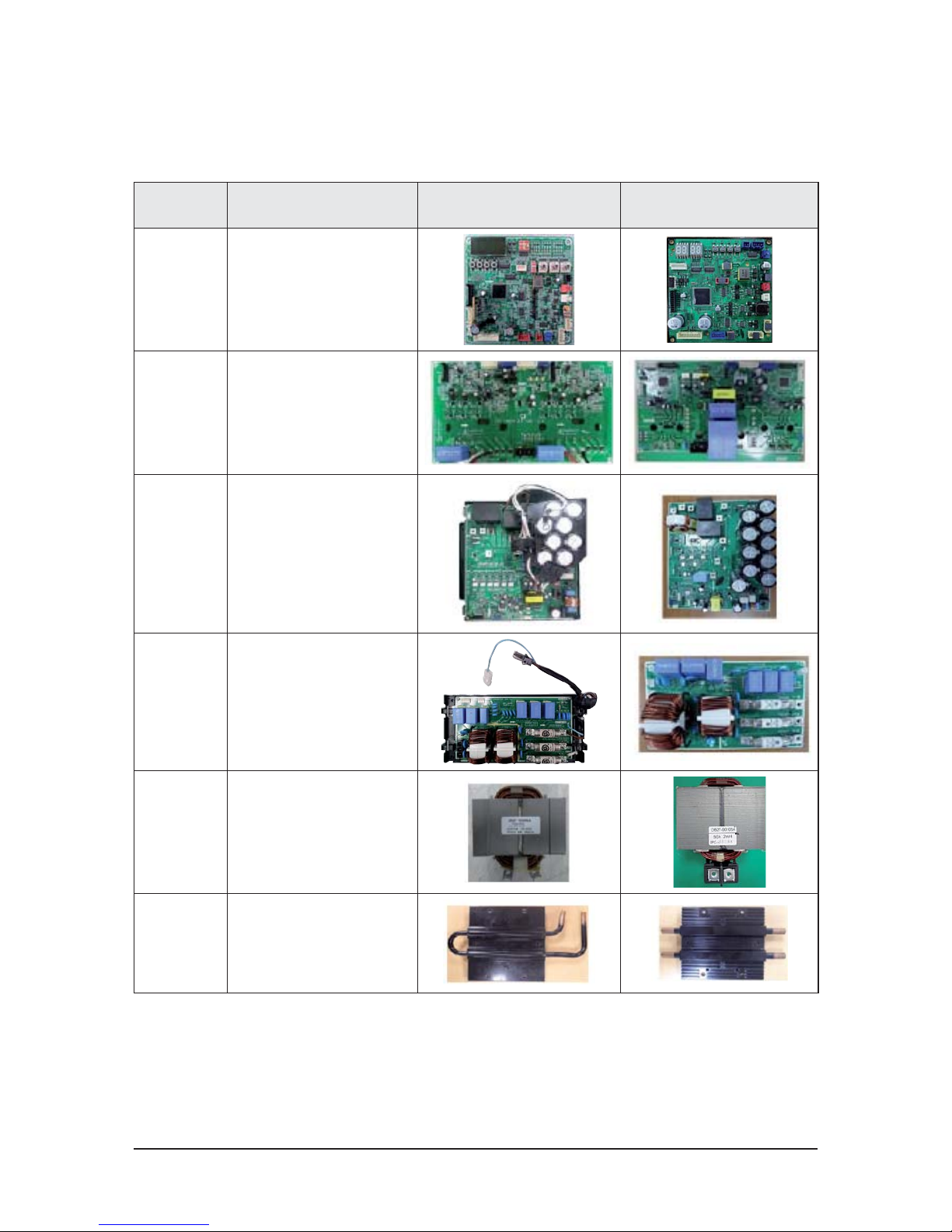

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

Pipe

Cooling

New Pipe Cooling for cooling

of inverter PCB.

Unapplied

C

OOLING OF

INVERTER CIRCUIT

REFRIGERANT COOLING SYSTEM :

I

T IS COOLING TECHNOLOGY OF INVERTER CIRCUIT THAT USE

REFRIGERATING CYCLE TECHNOLOGY.

C

OOLING OF

INVERTER CIRCUIT

Q

PIPE COOLING

2-8 Samsung Electronics

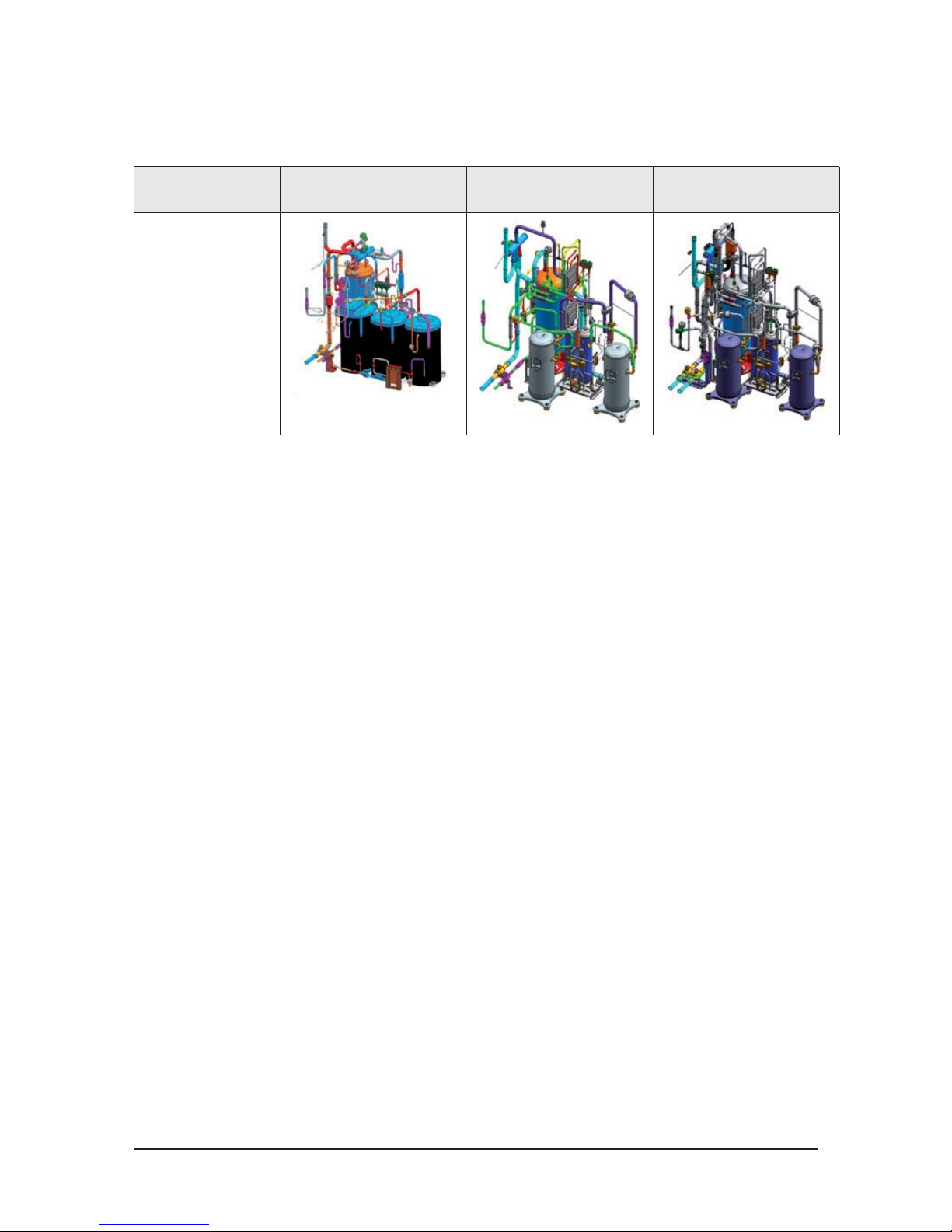

Changed

part

Changed item

and feature

Basic After changed [HP] After changed [HR]

Tube

struc-

ture

New inverter

cycle technol-

ogy application

New piping

Q

TUBE

Samsung Electronics 2-9

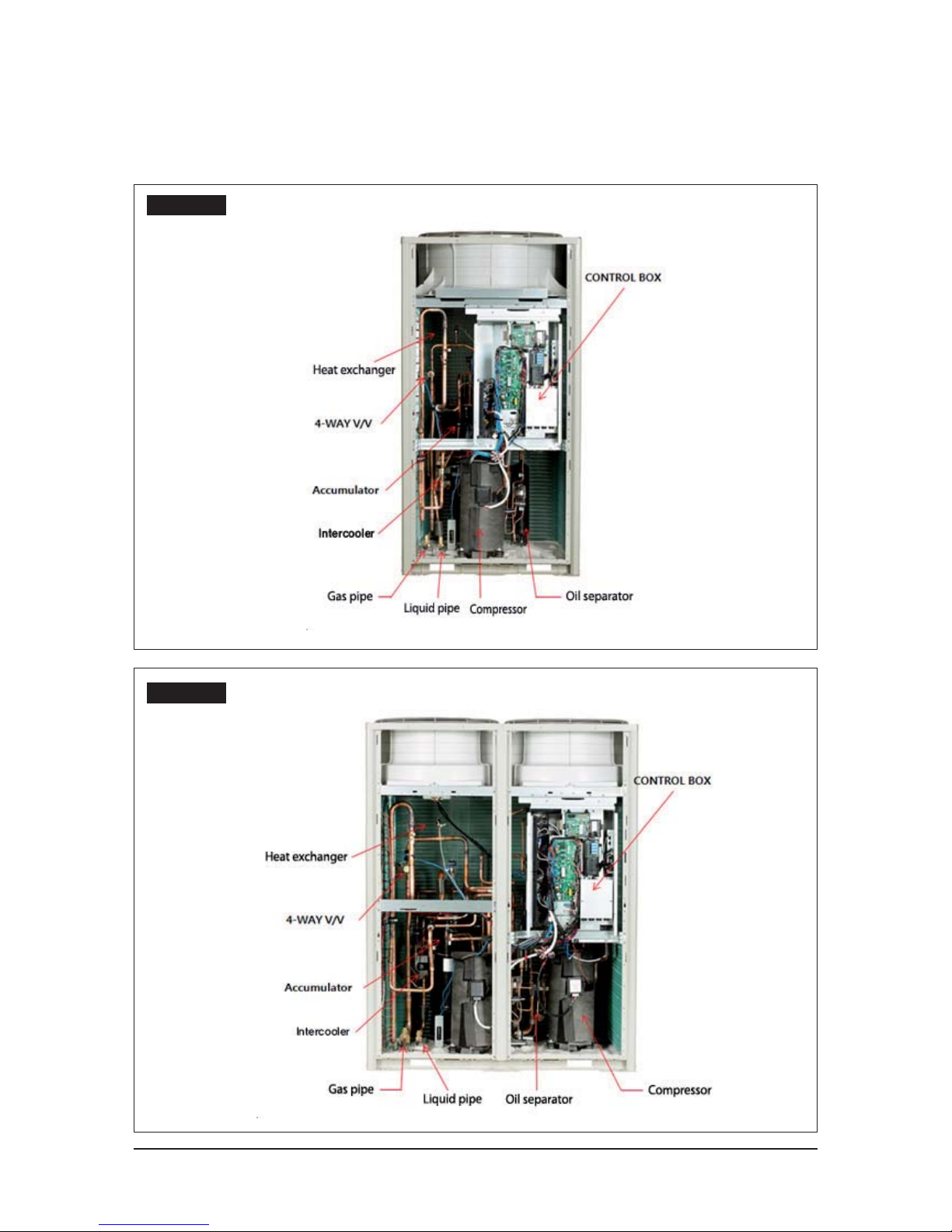

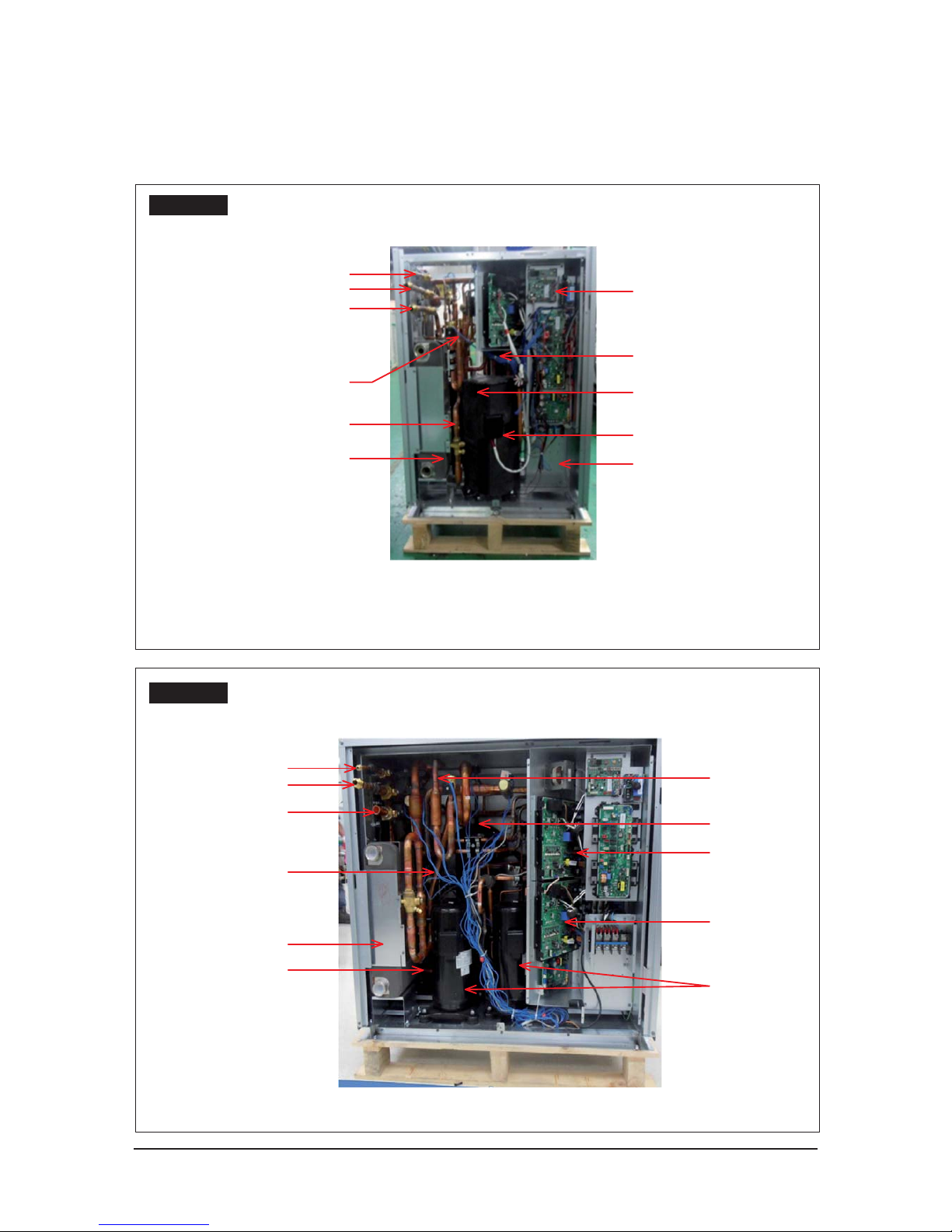

2-1-3 Structure of product ( Heat Pump: AM6666XV66H Series )

Small size

Large size

2-10 Samsung Electronics

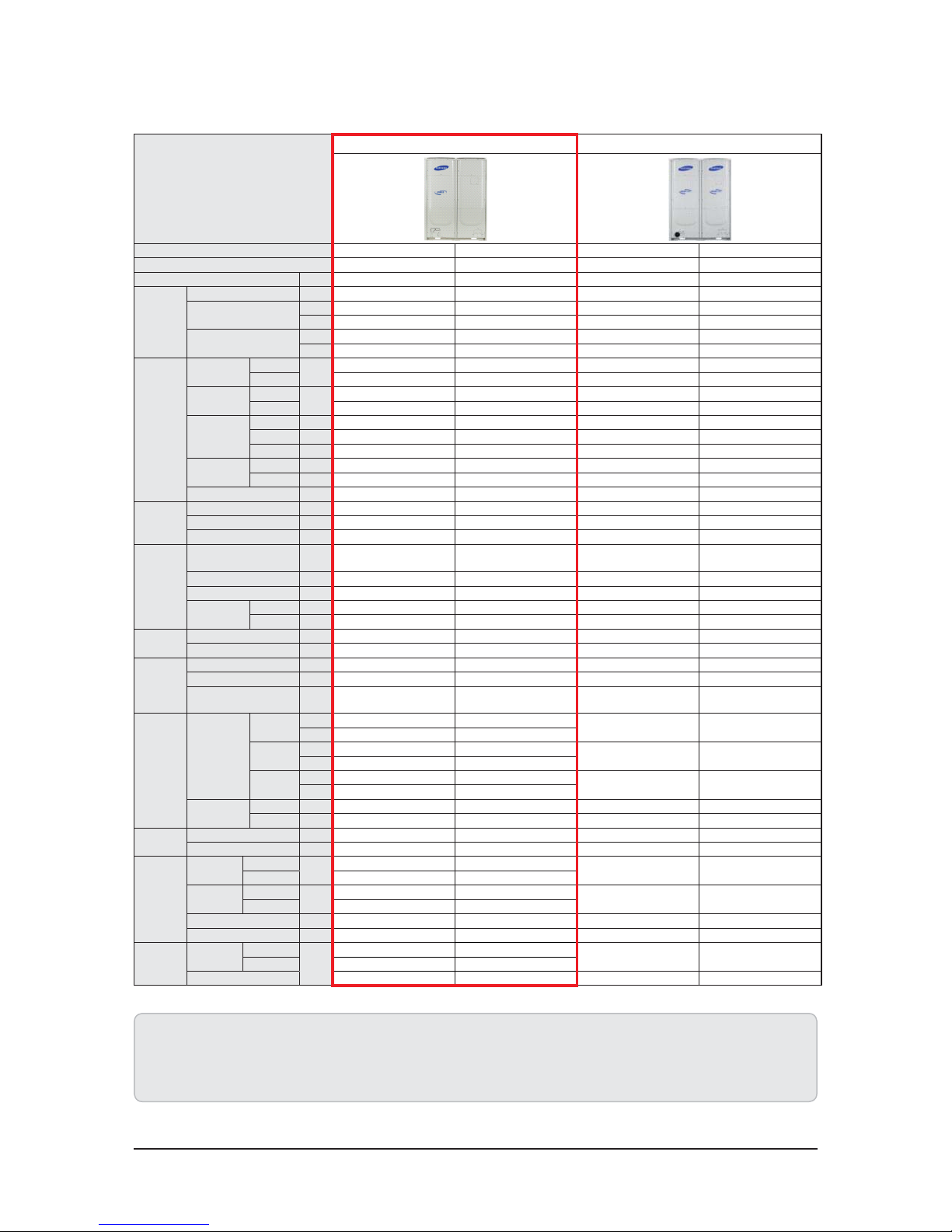

2-1-4 Structure of product (Heat Recovery: AM6666XV66R Series )

Small size

Large size

Heat exchanger

CONTROL BOX

4-WAY V/V

Intercooler

Accumulator

Low Pressure

Gas Pipe

Oil separator

Compressor

High Pressure Gas Pipe

Liquid pipe

Heat exchanger

4-WAY V/V

Accumulator

Intercooler

Low Pressure

Gas Pipe

High Pressure Gas Pipe

Liquid pipe

Compressor

Oil separator

CONTROL BOX

Samsung Electronics 2-11

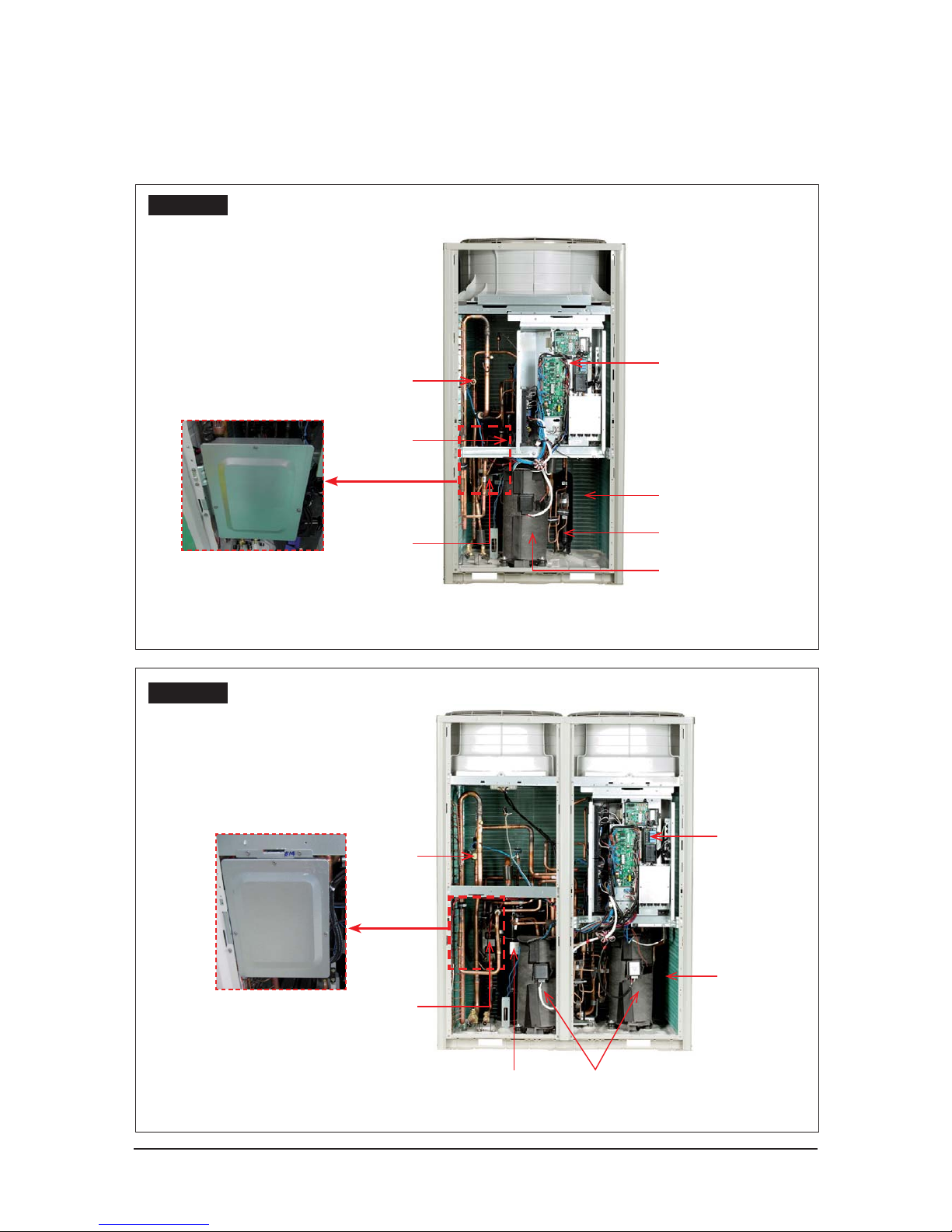

2-1-5 Structure of product (Power supply for 460V, 60Hz, 3Φ : AM6666XV66J6 Series )

Small size

Large size

CONTROL BOX

4-WAY V/V

Oil separator

Heat exchanger

Sub-Cooler

Compressor

CONTROL BOX

4-WAY V/V

Accumulator

Compressor

Oil separator

Heat exchanger

Sub-Cooler

TRANS BOX

TRANS BOX

2-12 Samsung Electronics

2-1-6 Structure of product (DVM S WATER)

Small size

Large size

Liquid Pipe

4 WAY V/V

Accumulator

CONTROL BOX

Oil separator

Compressor

High pressure Gas Pipe

Low pressure Gas Pipe

Sub Cooler

Plate Heat Exchanger

Receiver

CONTROL BOX

Liquid Pipe

High pressure Gas Pipe

Low pressure Gas Pipe

4 WAY V/V

Receiver

Plate Heat Exchanger

Accumulator

Sub Cooler

Compressor

Oil separator

Samsung Electronics 2-13

2-1-7 Structure of product (Heat Pump AM666KX6 Series)

AM140/160KXVG66, AM140/160/180KXVA66

AM180/200/220KXVG66, AM200/220KXVA66

Control Box

CompressorLiquid V/V

Gas V/V

Subcooler

Accumulator

4-WAY V/V

Heat

Exchanger

Control Box

Control Box

Liquid V/V

Gas V/V

Subcooler

Accumulator

4-WAY V/V

Heat

Exchanger

2-14 Samsung Electronics

Structure of product (Heat Pump AM666KX6 Series)

AM240/260/280KXVG66, AM240/260/280/300KXVA66, AM080KXVS66

Heat Exchanger

Compressor

CONTROL BOX

4-WAY V/V

Subcooler

Gas Pipe

Liquid Pipe

Samsung Electronics 2-15

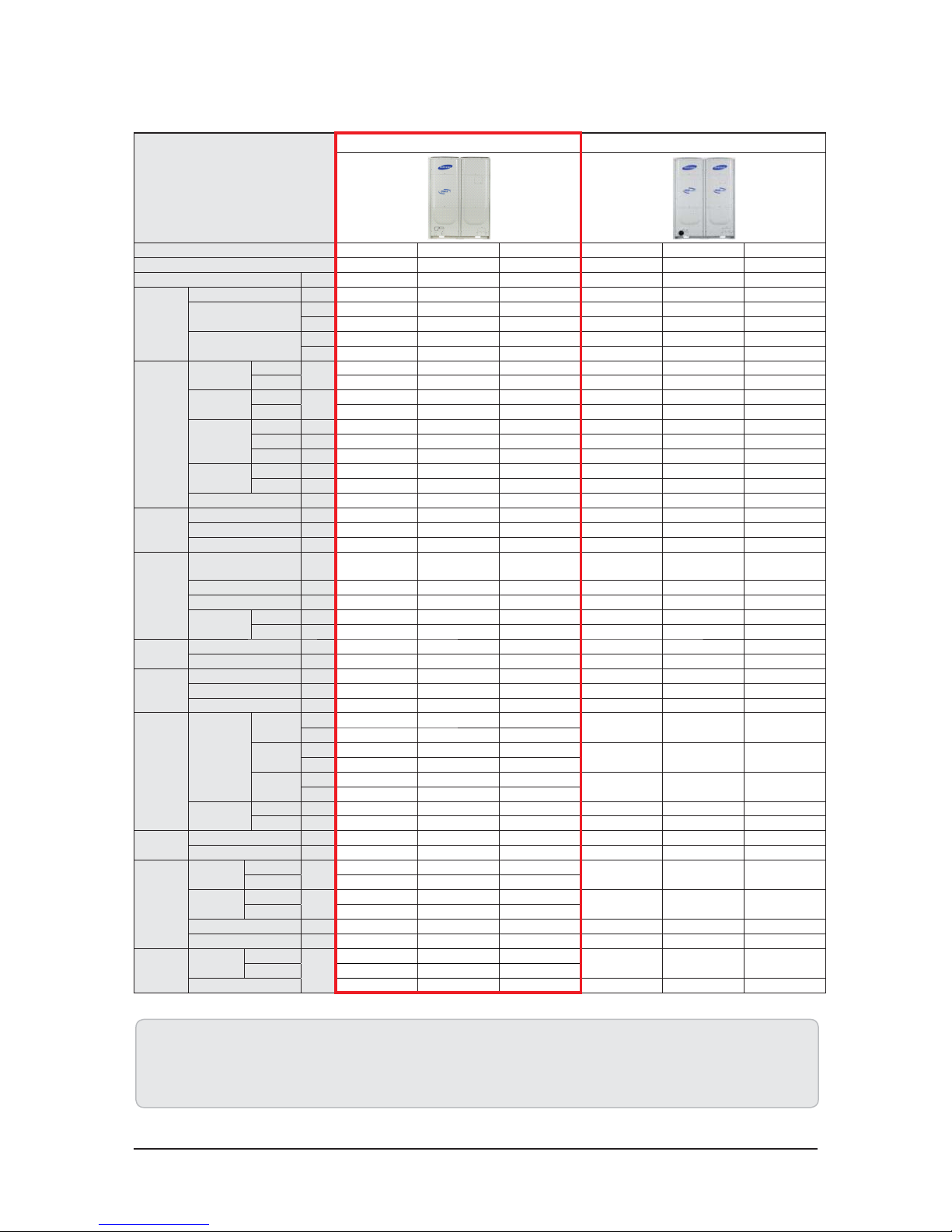

2-2 Product Specifications

2-2-1 Outdoor Unit

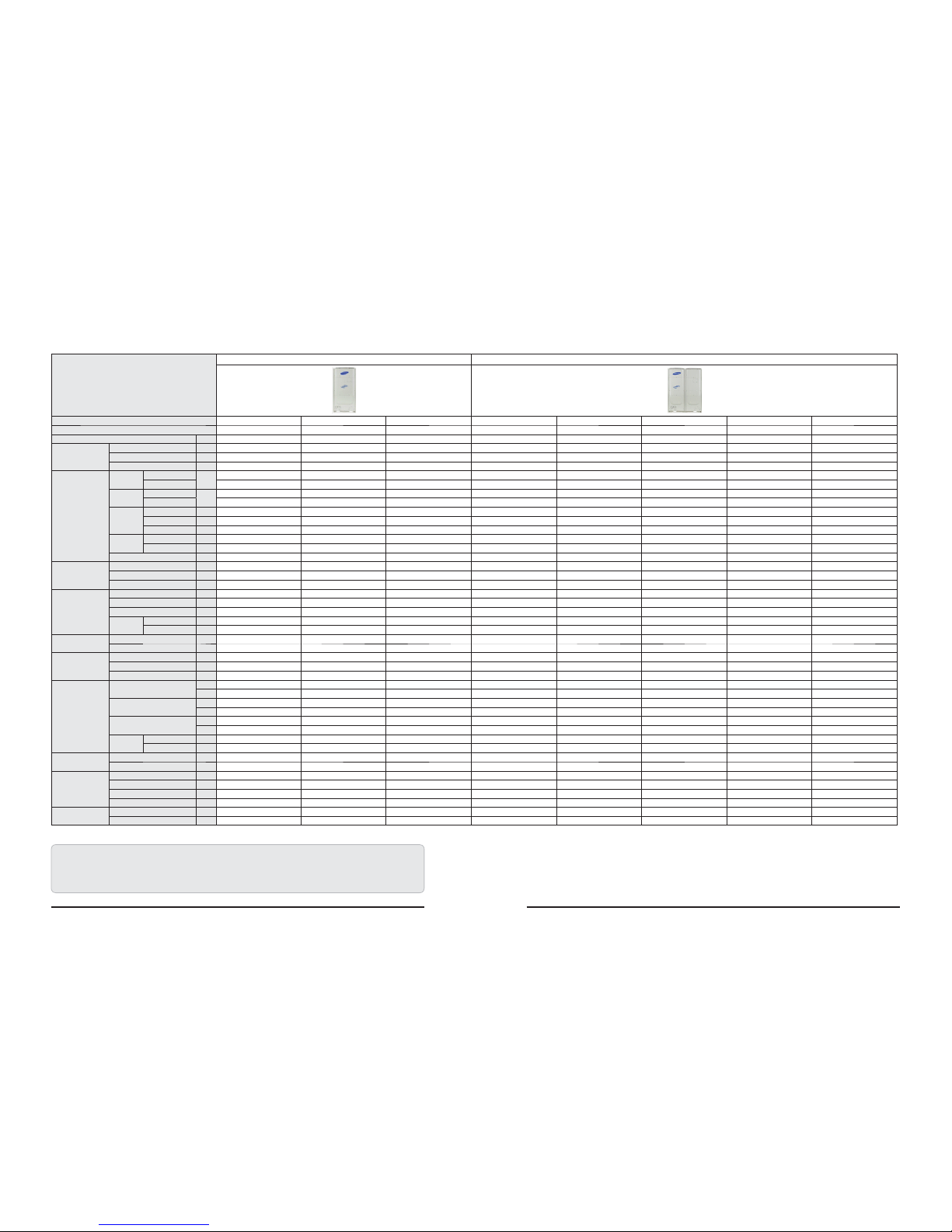

TYPE

New Model

Comparative Model

Model AM080FXVAGH AM100FXVAGH AM120FXVAGH RD080HHXG

6

RD100HHXG

6

RD120HHXG

6

Mode HP HP HP HP HP HP

Power Ø,V,Hz 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50

Capacity

Horse Power HP 8 10 12 8 10 12

Cooling

kW 22.4 28.0 33.6 22.4 28.0 33.6

btu/h 76,400 95,500 114,600 76,400 95,500 114,600

Heating

kW 25.2 31.5 37.8 25.2 31.5 37.8

btu/h 86,000 107,500 129,000 86,000 107,500 129,000

Power

Power Input

(Nominal)

Cooling 1)

kW

5.00 6.80 8.40 - - -

Heating 2) 5.10 6.70 8.70 - - -

Current Input

(Nominal)

Cooling 1)

A

8.00 10.90 13.50 - - -

Heating 2) 8.20 10.70 14.00 - - -

Running

Current

Cooling A 8.00 10.90 13.50 8.80 13.00 20.00

Heating A 8.20 10.70 14.00 11.40 12.70 18.40

Max. A 18.00 21.10 25.00 18.40 21.50 28.40

Power

Consumption

Cooling kW 5.00 6.80 8.40 5.20 7.04 9.20

Heating kW 5.10 6.70 8.70 5.46 6.89 8.50

MCA / MFA A 22.5 / 30 29.9 / 40 31.3 / 40 - - -

COP

Nominal Cooling - 4.48 4.12 4.00 - - Nominal Heating - 4.94 4.70 4.34 - - -

ESEER (HP) 7.85 7.25 7.03 - - -

Compressor

Model - DS-GB052FA**** DS-GB066FA**** DS- GB066FA****

ZPJ61KCE-TFD

ZPI61KCE-TFD

ZPJ61KCE-TFD

ZPI61KCE-TFD

ZPJ83KCE-TFD

ZPI83KCE-TFD

Type INV x1 INV x1 INV x1 DVI x1 + FVl x1 DVI x1 + FVl x1 DVI x1 + FVl x1

Output kW 4.70 5.80 5.80 4.36 + 4.36 4.36 + 4.36 5.87 + 5.87

Lubricant

Type - FVC68D FVC68D FVC68D 3MAF POE 3MAF POE 3MAF POE

Charging cc 3,900 3,900 3,900 4,370 4,370 4,370

Refrigerant

Type - R410A R410A R410A R410A R410A R410A

Factory Charging kg 5.5 5.2 5.5 5.0 5.0 5.0

FAN

Type - Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W 400 400 400 630 630 630

Airow rate

㎥

/min

173 173 210 173 173 210

Pipe

Piping

Connections

Liquid

Ø,mm 9.52 9.52 12.70

9.52 9.52 12.70

Ø,inch 3/8" 3/8" 1/2"

Gas

Ø,mm 19.05 22.22 28.58

19.05 22.22 25.40

Ø,inch 3/4" 7/8" 1 1/8"

Dis. Gas

Ø,mm 15.88 19.05 19.05

---

Ø,inch 5/8" 3/4" 3.4"

Installation

Limitation

Max.Length m 200(220) 200(220) 200(220) 200 200 200

Max.Height m 110(40) 110(40) 110(40) 50(40) 50(40) 50(40)

Cable

Main Power(Below/about20m) mm2 4.0 4.0 4.0 1.5 2.5 4.0

Communication mm2 VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VC TF 0.75~1.5(2P)

Set

Dimension

Net Weight

DVM S HP

kg

190.0 190.0 190.0

237 237 240

DVM S HR 195.0 195.0 195.0

Shipping

Weight

DVM S HP

kg

206.0 206.0 206.0

253 253 256

DVM S HR 211.0 211.0 211.0

Net Dimension(WxHxD) mm 880x1,695x765 880x1,695x765 880x1,695x765 880x1695x765 880x1695x765 880x1695x765

Gross Dimension(WxHxD) mm 948x1,657x832 948x1,657x832 948x1,657x832 948x1912x832 948x1912x832 948x1912x832

Operating

Temp Range

Cooling

DVM S HP

ఁ

-5.0~48.0 -5.0~48.0 -5.0~48.0

-5.0 ~ 48 -5.0 ~ 48.0 -5.0 ~ 48.0

DVM S HR -15.0~48.0 -15.0~48.0 -15.0~48.0

Heating

-20.0~24.0 -20.0~24.0 -20.0~24.0

-20.0 ~ 24.0 -20.0 ~ 24.0 -20.0 ~ 24.0

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

Product Specications

2-16 Samsung Electronics

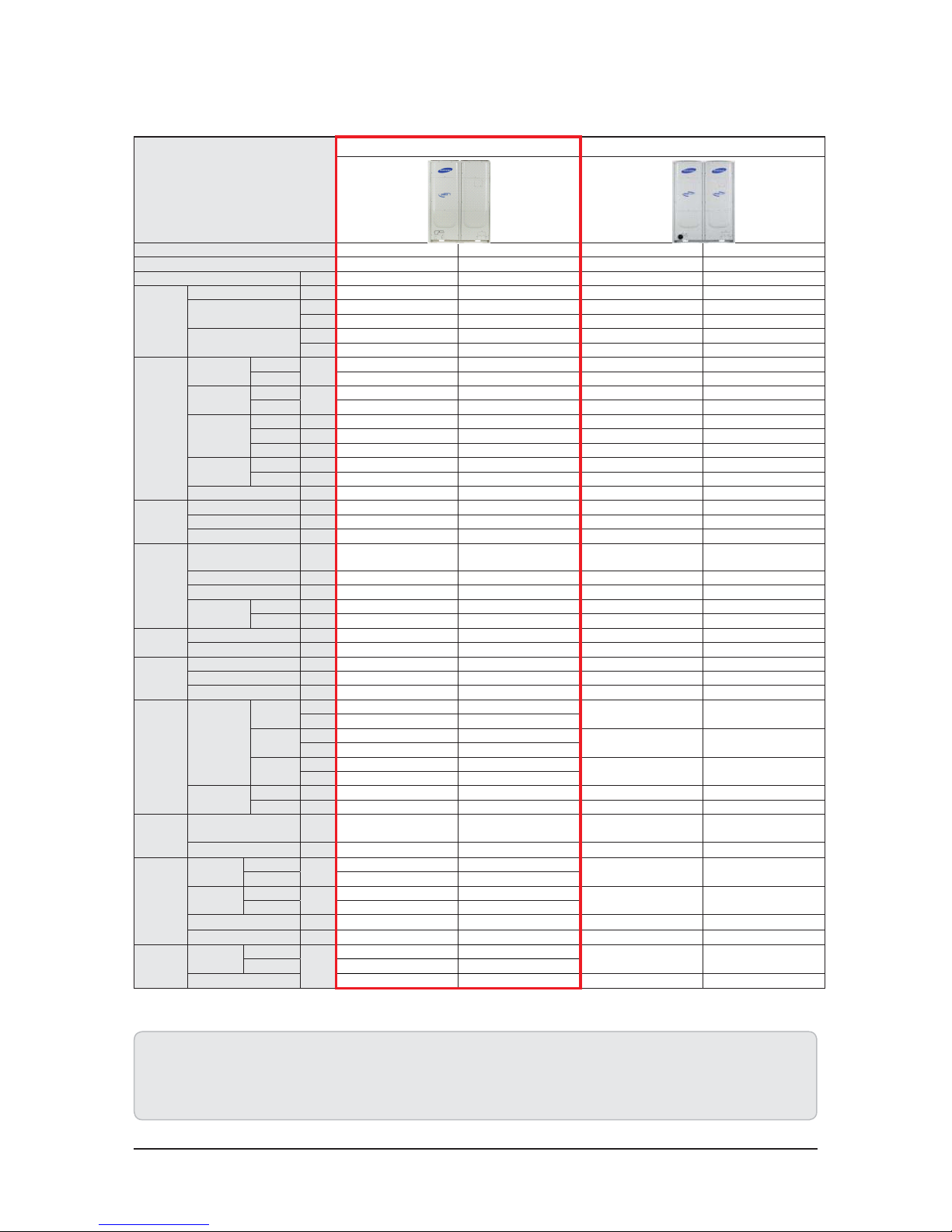

TYPE

New Model Comparative Model

Model AM140FXVAGH AM160FX VAGH RD140HHXG

6

RD160HHXG

6

Mode HP HP HP HP

Power Ø,V,Hz 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50

Capacity

Horse Power HP 14 16 14 16

Capacity

kW 40.0 45.0 39.2 44.8

btu/h 136,000 153,000 133,800 152,900

Heating

kW 45.0 50.0 44.1 50.0

btu/h 153,000 170,000 150,500 172,000

Power

Power Input

(Nominal)

Cooling 1)

kW

8.90 11.00 - -

Heating 2) 9.50 11.50 - -

Current Input

(Nominal)

Cooling 1)

A

14.30 17.60 - -

Heating 2) 15.20 18.40 - -

Running

Current

Cooling A 14.30 17.60 20.90 22.00

Heating A 15.20 18.40 19.40 27.20

Max. A 25.00 32.00 29.40 38.30

Power

Consumption

Cooling kW 8.90 11.00 10.10 12.00

Heating kW 9.50 11.50 9.65 11.30

MCA / MFA A 31.3 / 40 40 / 40 - -

COP

Nominal Cooling - 4.49 4.09 - -

Nominal Heating - 4.74 4.35 - -

ESEER (HP) 7.02 6.78 - -

Compressor

Model - DS-GB066FA**** DS-GB052FA****

ZPJ83KCE-TFD

ZPI83KCE-TFD

ZPJ72KCE-TFD

ZPI72KCE-TFD

Type INV x1 INV x2 DVI x1 + FVl x1 DVI x1 + FVl x2

Output k W 5.80 4.7 x2 5.87 + 5.87 5.16 + 5.16 x2

Lubricant

Type - FVC68D FVC68D 3MAF POE 3MAF POE

Charging cc 3,900 6,200 4,370 6,540

Refrigerant

Type - R410A R410A R410A R410A

Factory Charging kg 7.7 7.4 7.0 7.0

FAN

Type - Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W 630 x 2 630 x 2 630 x 2 630 x 2

Airflow rate

᎑

ΞΚΟ

226 250 226 250

Pipe

Piping

Connections

Liquid

Ø,mm 12.70 12.70

12.70 12.70

Ø,inch 1/2" 1/2"

Gas

Ø,mm 28.58 28.58

25.40 28.58

Ø,inch 1 1/8" 1 1/8"

Dis. Gas

Ø,mm 19.05 22.22

--

Ø,inch 3/4" 7/8"

Installation

Limitation

Max.Length m 200(220) 200(220) 200 200

Max.Height m 110(40) 110(40) 50(40) 50(40)

Cable

Main Power(Below/about20m) mm2 4.0 6.0 4.0 6.0

Communication mm2 VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P)

Set

Dimension

Net Weight

DVM S HP

kg

235.0 278.0

280 329

DVM S HR 214.0 184.0

Shipping

Weight

DVM S HP

kg

254.0 297.0

301 350

DVM S HR 260.0 303.0

Net Dimension(WxHxD) mm 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765

Gross Dimension(WxHxD) mm 1363x1857x832 1363x1857x832 1363x1912x832 1363x1912x832

Operating

Temp Range

Cooling

DVM S HP

ఁ

-5.0~48.0 -5.0~48.0

-5.0 ~ 48.0 -5.0 ~ 48.0

DVM S HR -15.0~48.0 -15.0~48.0

Heating -20.0~24.0 -20.0~24.0 -20.0 ~ 24.0 -20.0 ~ 24.0

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

Product Specications

Samsung Electronics 2-17

Outdoor Unit (cont.)

TYPE

New Model Comparative Model

Model AM180FXVAGH AM200FXVAGH AM220FXVAGH RD180HHXG

6

RD200HHXG

6

Mode HP HP HP HP HP

Power Ø,V,Hz 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50

Capacity

Horse Power HP 18 2 0 22 18 20

Cooling

kW 50.4 56.0 61.6 50.4 56.0

btu/h 171,900 191,000 210,000 171,900 191,000

Heating

kW 56.7 63.0 69.3 56.7 63.0

btu/h 193,500 215,000 236,000 193,500 215,000

Power

Power Input

(Nominal)

Cooling 1)

kW

12.80 15.19 17.35 - -

Heating 2) 11.90 13.90 16.70 - -

Current Input

(Nominal)

Cooling 1)

A

20.70 24.40 27.80 - -

Heating 2) 19.10 22.30 26.80 - -

Running

Current

Cooling A 20.70 24.40 27.80 31.30 32.80

Heating A 19.10 22.30 26.80 26.70 29.10

Max. A 39.10 42.50 44.50 42.50 44.10

Power

Consumption

Cooling kW 12.88 15.19 17.35 15.70 17.00

Heating kW 11.90 13.90 16.70 12.90 14.50

MCA / MFA A 48.9 / 50 52.5 / 75 52.5 / 75 - -

COP

Nominal Cooling - 3.91 3.69 3.55 - Nominal Heating - 4.76 4.53 4.15 - -

ESEER (HP) 6.59 6.56 6.25 - -

Compressor

Model - DS-GB066FA**** DS-GB066FA**** DS- GB066FA****

ZPJ83KCE-TFD

ZPI83KCE-TFD

ZPJ83KCE-TFD

ZPI83KCE-TFD

Type INV x2 INV x2 INV x2 DVI x1 + FVl x2 DVI x1 + FVl x2

Output kW 5.8 x2 5.8 x2 5.8 x2 5.87 + 5.87 x2 5.87 + 5.87 x2

Lubricant

Type - FVC68D FVC68D 3MAF POE 3MAF POE

Charging cc 6,200 6,200 6,200 6,540 6,540

Refrigerant

Type - R410A R410A R410A R410A R410A

Factory Charging kg 8 .7 8.4 8. 4 8 .5 8.5

FAN

Type - Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W 630 x2 630 x2 630 x2 630 x2 630 x2

Airflow rate

᎑ ΞΚΟ

270 275 280 270 275

Pipe

Piping

Connections

Liquid

Ø,mm 15.88 15.88 15.88

15.88 15.88

Ø,inch 5/8" 5/8" 5/8"

Gas

Ø,mm 28.58 28.58 28.58

28.58 28.58

Ø,inch 1 1/8" 1 1/8" 1 1/8"

Dis. Gas

Ø,mm 22.22 28.58 28.58

--

Ø,inch 7/8" 1 1/8" 1 1/8"

Installation

Limitation

Max.Length m 200(220) 200(220) 200(220) 200 200

Max.Height m 110(40) 110(40) 110(40) 50(40) 50(40)

Cable

Main Power(Below/about20m) mm2 10.0 10.0 10.0 6.0 10.0

Communication mm2 VCT F 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VC TF 0.75~1.5(2P) VCTF 0.75~1.5(2P)

Set

Dimension

Net Weight

DVM S HP

kg

300.0 300.0 300.0

340.0 349.0

DVM S HR 306.0 306.0 306.0

Shipping

Weight

DVM S HP

kg

319.0 319.0 319.0

361.0 370.0

DVM S HR 325.0 325.0 325.0

Net Dimension(WxHxD) mm 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765

Gross Dimension(WxHxD) mm 1363x1857x832 1363x1857x832 1363x1857x832 1363x1912x832 1363x1912x832

Operating

Temp Range

Cooling

DVM S HP

ఁ

-5.0 ~ 48.0 -5.0 ~ 48.0 -5.0 ~ 48.0

-5.0~ 48.0 -5.0 ~ 48.0

DVM S HR -15.0~48.0 -15.0~48.0 -15.0~48.0

Heating -20.0 ~ 24.0 -20.0 ~ 24.0 -20.0 ~ 24.0 -20.0 ~ 24.0 -20.0 ~ 24.0

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

Product Specications

2-18 Samsung Electronics

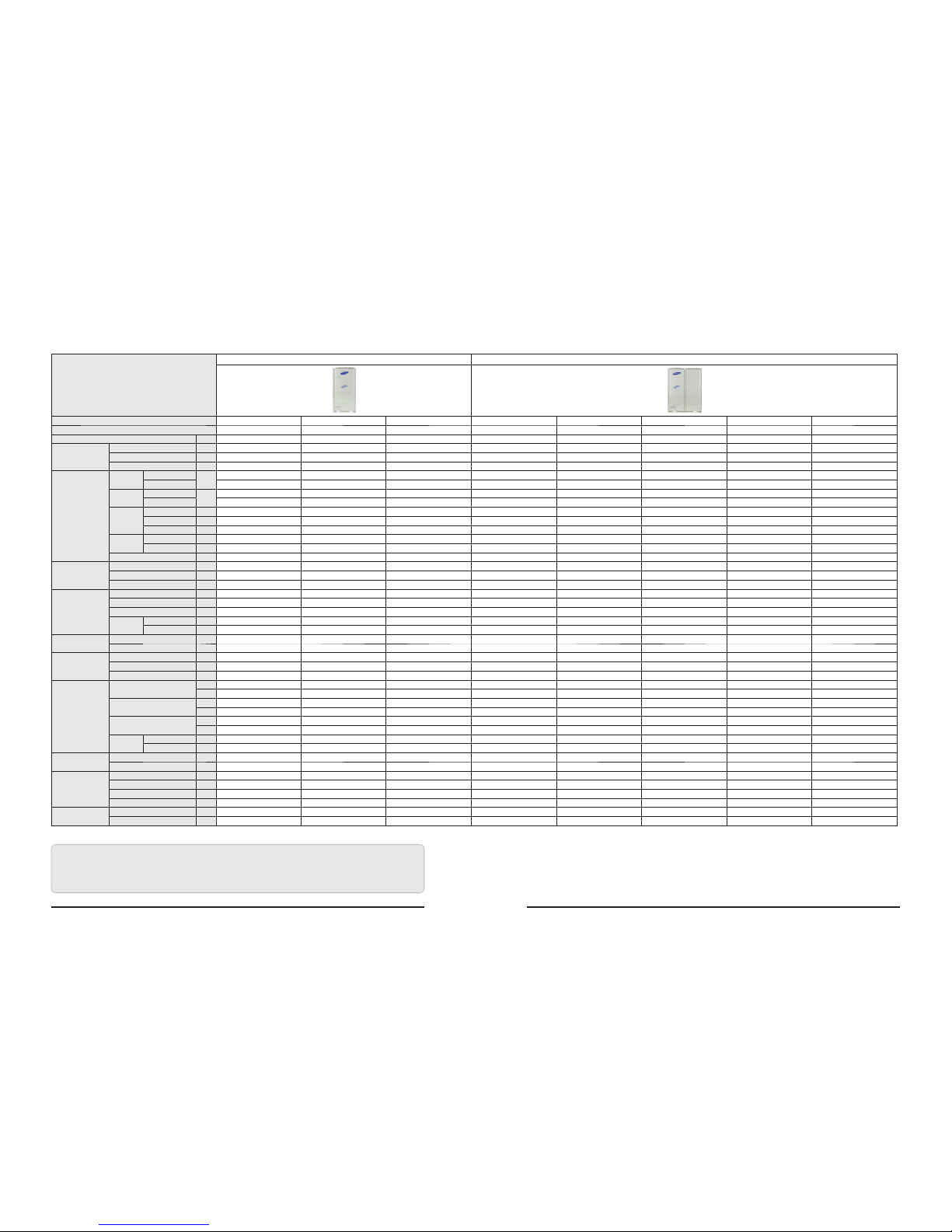

TYPE

New Model Comparative Model

Model AM080FX VAGR AM100FXVAGR AM120FXVAGR RD080HRXG

6

RD100HRXG

6

RD120HRXG

6

Mode HR HR HR HR HR HR

Power Ø,V,Hz 3/AC380~415/50 3/A C380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50

Capacity

Horse Power HP 8 10 12 8 10 12

Capacity

kW 22.4 28.0 33.6 22.4 28.0 33.6

btu/h 76,400 95,500 114,600 76,400 95,500 114,600

Heating

kW 25.2 31.5 37.8 25.2 31.5 37.8

btu/h 86,000 107,500 129,000 86,000 107,500 129,000

Power

Power Input

(Nominal)

Cooling 1)

kW

5.00 6.80 8.40 - - -

Heating 2) 5.10 6.70 8.70 - - -

Current Input

(Nominal)

Cooling 1)

A

8.00 10.90 13.50 - - -

Heating 2) 8.20 10.70 14.00 - - -

Running

Current

Cooling A 8.00 10.90 13.50 8.80 13.00 20.00

Heating A 8.20 10.70 14.00 11.40 12.70 18.40

Max. A 18.00 21.10 25.00 18.40 21.50 28.40

Power

Consumption

Cooling kW 5.00 6.80 8.40 5.20 7.04 9.20

Heating kW 5.10 6.70 8.70 5.46 6.89 8.50

MCA / MFA A 22.5 / 30 29.9 / 40 31.3 / 40 - - -

COP

Nominal Cooling - 4.48 4.12 4.00 - - Nominal Heating - 4.94 4.70 4.34 - - -

ESEER (HP) 7.85 7.25 7.03 - - -

Compressor

Model - DS-GB052FA**** DS -GB066FA**** DS-GB066FA****

ZPJ61KCE-TFD

ZPI61KCE-TFD

ZPJ61KCE-TFD

ZPI61KCE-TFD

ZPJ83KCE-TFD

ZPI83KCE-TFD

Type INV x1 INV x1 INV x1 DVI x1 + FVl x1 DVI x1 + FVl x1 DVI x1 + FVl x1

Output kW 4.70 5.80 5.80 4.36 + 4.36 4.36 + 4.36 5.87 + 5.87

Lubricant

Type - FVC68D

FVC68D FVC68D 3MAF POE 3MAF PO E 3MAF POE

Charging cc 3,900 3,900 3,900 4,370 4,370 4,370

Refrigerant

Type - R410A R410A R410A R410A R410A R410A

Factory Charging kg 5.5 5.2 5.5 5.0 5.0 5.0

FAN

Type - Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W 400 40 0 400 630 6 30 630

Airflow rate

᎑ ΞΚΟ

173 173 210 173 17 3 210

Pipe

Piping

Connections

Liquid

Ø,mm 9.52 9.52 12.70

9.52 9.52 12.70

Ø,inch 3/8" 3/8" 1/2"

Gas

Ø,mm 19.05 22.22 28.58

19.05 22.22 25.40

Ø,inch 3/4" 7/8" 1 1/8"

Dis. Gas

Ø,mm 15.88 19.05 19.05

15.88 19.05 22.22

Ø,inch 5/8" 3/4" 3.4"

Installation

Limitation

Max.Length m 200(220) 200(220) 200(220) 200 200 200

Max.Height m 110(40) 110(40) 110(40) 50(40) 50(40) 50(40)

Cable

Main Power(Below/about20m) mm2 4.0 4.0 4.0 1.5 2.5 4.0

Communication mm2 VC TF 0.75~1.5(2P) VCT F 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VC TF 0.75~1.5(2P) VCTF 0.75~1.5(2P)

Set

Dimension

Net Weight

DVM S HP

kg

190.0 190.0 190.0

243 243 243

DVM S HR 195.0 195.0 195.0

Shipping

Weight

DVM S HP

kg

206.0 206.0 206.0

259 259 259

DVM S HR 211.0 211.0 211.0

Net Dimension(WxHxD) mm 880x1,695x765 880x1,695x765 880x1,695x765 880x1695x765 880x1695x765 880x1695x765

Gross Dimension(WxHxD) mm 948x1,657x832 948x1,657x832 948x1,657x832 948x1912x832 948x1912x832 948x1912x832

Operating

Temp Range

Cooling

DVM S HP

ఁ

-5.0~48.0 -5.0~48.0 -5.0~48.0

-5.0 ~ 48.0 -5.0 ~ 48.0 -5.0 ~ 48.0

DVM S HR -15.0~48.0 -15.0~48.0 -15.0~48.0

Heating -20.0~24.0 -20.0~24.0 -20.0~24.0 -20.0 ~ 24.0 -20.0 ~ 24.0 -20 .0~ 24.0

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

Product Specications

Samsung Electronics 2-19

TYPE

New Model Comparative Model

Model AM140FXVAGR AM160FXVAGR RD140HRXG

6

RD160HRXG

6

Mode HR HR HR HR

Power Ø,V,Hz 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50

Capacity

Horse Power HP 14 16 14 16

Capacity

kW 40.0 45.0 39.2 44.8

btu/h 136,000 153,000 133,800 152,900

Heating

kW 45.0 50.0 44.1 50.0

btu/h 153,000 170,000 150,500 172,000

Power

Power Input

(Nominal)

Cooling 1)

kW

8.90 11.00 - -

Heating 2) 9.50 11.50 - -

Current Input

(Nominal)

Cooling 1)

A

14.30 17.60 - -

Heating 2) 15.20 18.40 - -

Running

Current

Cooling A 14.30 17.60 20.90 22.00

Heating A 15.20 18.40 19.40 27.20

Max. A 25.00 32.00 29.40 38.30

Power

Consumption

Cooling kW 8.90 11.00 10.10 12.00

Heating kW 9.50 11.50 9.65 11.30

MCA / MFA A 31.3 / 40 40 / 40 - -

COP

Nominal Cooling - 4.49 4.09 - Nominal Heating - 4.74 4.35 - -

ESEER (HP) 7.02 6.78 - -

Compressor

Model - DS-GB066FA**** DS-GB052FA****

ZPJ83KCE-TFD

ZPI83KCE-TFD

ZPJ72KCE-TFD

ZPI72KCE-TFD

Type INV x1 INV x2 DVI x1 + FVl x1 DVI x1 + FVl x2

Output kW 5.80 4.7 x2 5.87 + 5.87 5.16 + 5.16 x2

Lubricant

Type - FVC68D FVC68D 3MAF POE 3MAF POE

Charging cc 3,900 6,200 4,370 6,540

Refrigerant

Type - R410A R410A R410A R410A

Factory Charging kg 7.7 7.4 7.0 7.0

FAN

Type - Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W 630 x 2 630 x 2 630 x 2 630 x 2

Airflow rate

᎑ ΞΚΟ

226 250 226 250

Pipe

Piping

Connections

Liquid

Ø,mm 12.70 12.70

12.70 12.70

Ø,inch 1/2" 1/2"

Gas

Ø,mm 28.58 28.58

25.40 28.58

Ø,inch 1 1/8" 1 1/8"

Dis. Gas

Ø,mm 19.05 22.22

22.22 25.40

Ø,inch 3/4" 7/8"

Installation

Limitation

Max.Length m 200(220) 200(220) 200 200

Max.Height m 110(40) 110(40) 50(40) 50(40)

Cable

Main Power(Below/

about20m)

mm2 4.0 6.0 4.0 6.0

Communication mm2 VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P)

Set

Dimension

Net Weight

DVM S HP

kg

235.0 278.0

293 338

DVM S HR 214.0 184.0

Shipping

Weight

DVM S HP

kg

254.0 297.0

314 359

DVM S HR 260.0 303.0

Net Dimension(WxHxD) mm 1295x1695x765 1295x1695x765

1295x1695x765 1295x1695x765

Gross Dimension(WxHxD) mm 1363x1857x832 1363x1857x832

1363x1912x832 1363x1912x832

Operating

Temp Range

Cooling

DVM S HP

ఁ

-5.0~48.0 -5.0~48.0

-5 .0~ 48.0 -5.0~ 48.0

DVM S HR -15.0~48.0 -15.0~48.0

Heating -20.0~24.0 -20.0~24.0

-20.0~ 24.0 -20.0~ 24.0

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

Product Specications

2-20 Samsung Electronics

TYPE

New Model Comparative Model

Model AM180FXVAGR AM200FXVAGR AM220FX VAGR RD180HRXG

6

RD200HRXG

6

Mode HR HR HR HR HR

Power Ø,V,Hz 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50 3/AC380~415/50

Capacity

Horse Power HP 18 20 22 18 20

Capacity

kW 50.4 56.0 61.6 50.4 56.0

btu/h 171,900 191,000 210,000 171,900 191,000

Heating

kW 56.7 63.0 69.3 56.7 63.0

btu/h 193,500 215,000 236,000 193,500 215,000

Power

Power Input

(Nominal)

Cooling 1)

kW

12.80 15.19 17.35 - -

Heating 2) 11.90 13.90 16.70 - -

Current Input

(Nominal)

Cooling 1)

A

20.70 24.40 27.80 - -

Heating 2) 19.10 22.30 26.80 - -

Running

Current

Cooling A 20.70 24.40 27.80 31.30 32.80

Heating A 19.10 22.30 26.80 26.70 29.10

Max. A 39.10 42.50 44.50 42.50 44.10

Power

Consumption

Cooling kW 12.88 15.19 17.35 15.70 17.00

Heating kW 11.90 13.90 16.70 12.90 14.50

MCA / MFA A 48.9 / 50 52.5 / 75 52.5 / 75 - -

COP

Nominal Cooling - 3.91 3.69 3.55 - Nominal Heating - 4.76 4.53 4.15 - -

ESEER (HP) 6.59 6.56 6.25 - -

Compressor

Model - DS-GB066FA**** DS-GB066FA**** DS- GB066FA****

ZPJ83KCE-TFD

ZPI83KCE-TFD

ZPJ83KCE-TFD

ZPI83KCE-TFD

Type INV x2 INV x2 INV x2 DVI x1 + FVl x2 DVI x1 + FVl x2

Output kW 5.8 x2 5.8 x2 5.8 x2 5.87 + 5.87 x2 5.87 + 5.87 x2

Lubricant

Type - FVC68D FVC68D 3MAF POE 3MAF POE

Charging cc 6,200 6,200 6,200 6,540 6,540

Refrigerant

Type - R410A R410A R410A R410A R410A

Factory Charging kg 8.7 8.4 8.4 8.5 8.5

FAN

Type - Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W 630 x2 630 x2 630 x2 630 x2 630 x2

Airflow rate

᎑ ΞΚΟ

270 275 280 270 275

Pipe

Piping

Connections

Liquid

Ø,mm

15.88 15.88 15.88

15.88 15.88

Ø,inch

5/8" 5/8" 5/8"

Gas

Ø,mm

28.58 28.58 28.58

28.58 28.58

Ø,inch

1 1/8" 1 1/8" 1 1/8"

Dis. Gas

Ø,mm

22.22 28.58 28.58

28.58 28.58

Ø,inch

7/8" 1 1/8" 1 1/8"

Installation

Limitation

Max.Length m

200(220) 200(220) 200(220)

200 200

Max.Height m

110(40) 110(40) 110(40)

50(40) 50(40)

Cable

Main Power(Below/

about20m)

mm2 10.0 10.0 10.0 6.0 10.0

Communication mm2 VCTF 0.75~1.5(2P) VC TF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P) VCTF 0.75~1.5(2P)

Set

Dimension

Net Weight

DVM S HP

kg

300.0 300.0 300.0

349 355

DVM S HR 306.0 306.0 306.0

Shipping

Weight

DVM S HP

kg

319.0 319.0 319.0

369 376

DVM S HR 325.0 325.0 325.0

Net Dimension(WxHxD) mm 1295x1695x765 1295x1695x765 1295x1695x765

1295x1695x765 1295x1695x765

Gross Dimension(WxHxD) mm 1363x1857x832 1363x1857x832 1363x1857x832

1363x1912x832 1363x1912x832

Operating

Temp Range

Cooling

DVM S HP

ఁ

-5.0 ~ 48.0 -5.0 ~ 48.0 -5.0 ~ 48.0

-5.0 ~ 48.0 -5.0 ~ 48.0

DVM S HR -15.0~48.0 -15.0~48.0 -15.0~48.0

Heating -20.0 ~ 24.0 -20.0 ~ 24.0 -20.0 ~ 24.0

-20.0 ~ 24.0 -20.0~ 24.0

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

Product Specications

2-21 Samsung Electronics Samsung Electronics 2-22

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

TYPE

New Model Comparative Model

Model Name AM080FXWANR/EU AM100FXWANR/EU AM120FXWANR/EU AM200FXWANR/EU RD100DRXH1 RD200DRXH1 RD300DRXH1

Power Supply Φ, #, V, Hz 3/AC380~415/50 3/AC380~415/50

Performance

HP HP 8 10 12 20 10 20 30

Capacity

(Nominal)

Cooling

kW 23 29 34.8 58 29 58 87

kcal/h 19780 24940 29928 49880 24940 49880 74820

Heating

kW 26 32.6 39.2 65.2 32.6 65.2 97.9

kcal/h 22360 28036 33712 56072 28036 56072 84194

Power

Power Input

(Nominal)

Cooling

kW

4.18 5.58 6.69 11.15 5.8 11.6 17.4

Heating 4.33 5.62 6.76 11.24 5.69 11.8 17.8

Current Input

(Nominal)

Cooling

A

7.0 9.4 11.3 18.8 10.5 21.4 31.9

Heating 7.3 9.5 11.4 19.0 9.5 20.9 31.1

MFA - 20 20 30 40 20 40 60

COP

Nominal Cooling 1) - 5.50 5.20 5.20 5.20 - - -

Nominal Heating 2) - 6.00 5.80 5.80 5.80 - - -

Compressor

Type SSC Scroll x 1 SSC Scroll x 1 SSC Scroll x 1 SSC Scroll x 2 DVI Scrollx1 DVI Scrollx1 + FVI Scrollx1 DVI Scroll + FVI Scrollx2

Output kW 4.96 4.96 6.13 4.96 x 2 7.04 7.48 + 7.43 7.48 + (7.43 x 2)

Oil

Type - PVE PVE PVE PVE 3MAF POE 3MAF POE 3MAF POE

Initial Charge Liter 3.9 3.9 3.9 6.2 2.185 4.37 6.555

Condenser

Type -

Stainless steel

plate

Stainless steel

plate

Stainless steel

plate

Stainless steel

plate

Stainless steel

plate

Stainless steel

plate

Stainless steel

plate

Pipe Size Φ, inch(A) PT1-1/4 (32) PT1-1/4 (32) PT1-1/4 (32) PT1-1/4 (32) 1 1/4" (32A) 1 1/4" (32A) 2 (50A)

Lost Head

kPa22304354305454

Water Flow Rate

LPM 80 96 114 190 96 190 285

Max. Pressure

MPa 1.96 1.96 1.96 1.96 1.96 1.96 1.96

Piping

Connections

Liquid Pipe Φ, mm 9.52 9.52 12.7 15.88 9.52 15.88 19.05

Gas Pipe Φ, mm 19.05 22.23 25.4 28.58 22.23 28.58 31.75

Discharge Gas Pipe Φ, mm 15.88 19.05 22.23 25.4 19.05 25.4 28.58

Oil Equalizing Pipe Φ, mm -----6.35 6.35

Installation

Limitation

Airow rate

Max. Length m 170 170 170 170 150 150 150

Max. Height m 50 50 50 50 50(40) 50(40) 50(40)

Field

Wiring

Power Source Wire mm2 2.50 2.50 4.00 6.00 1.5 4.0 10.0

Transmission Cable mm2 0.75~1.25 0.75~1.25 0.75~1.25 0.75~1.25 0.75~1.5 0.75~1.5 0.75~1.5

Refrigerant

Type -

R410A R410A R410A R410A R410A R410A R410A

Factory Charging kg

5.5 5.8 6.0 9.8 5.8 9.4 12.0

External

Dimension

Net Weight

kg

160 160 160 240 160 235 320

Shipping Weight 167 167 167 250 167 242 330

Net Dimensions (WxHxD)

kg

770x1000x545 770x1000x545 770x1000x545 1100x1000x545 770 x 1,117 x 545 770 x 1,117 x 545 1,100 x 1,117 x 550

Shipping Dimensions

(WxHxD)

840x1200x620 840x1200x620 840x1200x620 1170x1200x620 840 x 1,287 x 620 840 x 1,287 x 620 1,170 x 1,170 x 620

Operating

Temp.

Range(Water)

Cooling

ఁ

10~45 10~45 10~45 10~45 10~45 10~45 10~45

Heating

ఁ

10~45 10~45 10~45 10~45 10~45 10~45 10~45

2-23 Samsung Electronics

TYPE

New Model

Model AM240HXVAGH AM260HXVAGH

Mode HP HP

Power Φ, V, Hz 3/AC380~415/50

Capacity

Horse Power HP 24 26

Cooling

kW 67.2 72.8

btu/h - -

Heating

kW 75.6 81.9

btu/h - -

Power

Power input

(Nominal)

Cooling 1)

kW

17.10 19.30

Heating 2) 19.80 21.80

Current Input

(Nominal)

Cooling 1)

A

26.83 30.28

Heating 2) 31.06 34.20

Running

Current"

Cooling A 26.83 30.28

Heating A 31.06 34.20

Max A 55 58

Power

Consumption

Cooling kW 26.83 30.28

Heating kW 31.06 34.20

MCA/MFA A 60.5/75 63.8/75

COP Nominal Cooling - 3.930 3.772

Nominal Heating - 3.818 3.757

ESEER (HP) - - -

Compressor Model - DS-GB066FA* DS-GB070FA*

Type INV x 2EA INV x 2EA

Output kW - -

Lubricant

Type - FVC68D FVC68D

Charging cc 6,200 6,200

Refrigerant Type - R410A R410A

Factory Charging kg 14.3 14.3

Fan Type - Propeller + BLDC Propeller + BLDC

Motor Output W 620 x 2 620 x 2

Airflow rate

᎑ ΞΚΟ

310 310

Piping

Connections

Liquid pipe

Φ, mm 15.88 19.05

Φ, inch 5/8" 3/4"

Gas pipe

Φ, mm 34.92 34.92

Φ, inch 1 3/8" 1 3/8"

High pressure gas pipe

Φ, mm - -

Φ, inch

Installation

Limitation

Max. Length m 200(220) 200(220)

Max. Height m 110.0(40.0) 110.0(40.0)

Cable Main Power(Below 20m) mm2 16 16

Communication mm2 VCTF 0.75 ~ 1.5(2P) VCTF 0.75 ~ 1.5(2P)

Set

Dimension

Net weight kg 360 360

Gross weight kg 370 370

Net dimension (WxHxD) mm 1,295 x 1,695 x 765 1,295 x 1,695 x 765

Gross dimension (WxHxD) mm

1,363 x 1,887 x 832 1,363 x 1,887 x 832

Operating Temp. Range

Cooling

ఁ

-5.0 ~ 48.0 -5.0 ~ 48.0

Heating

ఁ

-25.0 ~ 24.0 -25.0 ~ 24.0

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

2-24 Samsung Electronics Samsung Electronics 2-25

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

TYPE

New Model New Model

Model

AM080JXVAGH AM100JX VAGH AM120JXVAGH AM140JXVAGH AM160JXVAGH AM180JXVAGH AM200JXVAGH AM220JXVAGH

Mode

HP HP HP HP HP HP HP HP

Power Φ, V, Hz

3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50

Capacity

Horse Power HP

8 10121416182022

Cooling kW

22.4 28.0 33.6 40.0 45.0 50.4 56.0 61.6

Heating kW

25.2 31.5 37.8 45.0 50.4 56.7 63.0 69.3

Power

Power input

(Nominal)

Cooling 1)

kW

5.00 6.85 8.16 10.93 11.98 12.45 14.59 17.35

Heating 2)

5.10 6.65 8.03 10.15 11.60 11.90 13.90 16.70

Current Input

(Nominal)

Cooling 1)

A

8.00 11.00 13.10 17.50 19.20 20.00 13.90 27.80

Heating 2)

8.20 10.70 12.90 16.30 18.60 19.10 23.40 26.80

Running

Current"

Cooling A

8.00 11.00 13.10 17.50 19.20 20.00 13.90 27.80

Heating A

8.20 10.70 12.90 16.30 18.60 19.10 23.40 26.80

Max A

18.0 21.1 25.0 25.0 32.0 39.1 22.30 44.5

Power

Consumption

Cooling kW

5.00 6.85 8.16 10.93 11.98 12.45 14.59 17.35

Heating kW

5.10 6.65 8.03 10.15 11.60 11.90 13.90 16.70

MCA/MFA A

22.5/30 29.9/40 31.3/40 31.3/40 40.0/40 48.9/50 52.5/75 55.6/75

COP

Nominal Cooling -

4.480 4.090 4.120 3.660 3.760 4.050 3.840 3.550

Nominal Heating -

4.940 4.740 4.710 4.430 4.340 4.760 4.530 4.150

ESEER (HP) -

--------

Compressor

Model -

DS-GA046FA* DS-GB066FA* DS-GB066FA* DS-GB066FA* DS-GA046FA* DS-GB066FA* DS-GB066FA* DS-GB066FA*

Type

INV x 1EA INV x 1EA INV x 1EA INV x 1EA INV x 2EA INV x 2EA INV x 2EA INV x 2EA

Output kW

--------

Lubricant

Type -

FVC68D FVC68D FVC68D FVC68D FVC68D FVC68D FVC68D FVC68D

Charging cc

3700 3900 3900 3900 5800 6200 6200 6200

Refrigerant

Type -

R410A R410A R410A R410A R410A R410A R410A R410A

Factory Charging kg

5.5 5.5 6.5 7.7 7.7 8.4 8.4 8.4

Fan

Type -

Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC Propeller + BLDC

Motor Output W

830 830 830 620 x 2 620 x 2 620 x 2 620 x 2 620 x 2

Airflow rate

᎑ ΞΚΟ

170 170 220 255 255 290 290 290

Piping

Connections

Liquid pipe

Φ, mm

9.52 9.52 12.7 12.7 12.7 15.88 15.88 15.88

Φ, inch

3/8" 3/8" 1/2" 1/2" 1/2" 5/8" 5/8" 5/8"

Gas pipe

Φ, mm

19.05 22.22 28.58 28.58 28.58 28.58 28.58 28.58

Φ, inch

3/4" 7/8" 1+1/8" 1+1/8" 1+1/8" 1+1/8" 1+1/8" 1+1/8"

High pressure gas pipe

Φ, mm

--------

Φ, inch

--------

Installation

Limitation

Max. Length m

220 220 220 220 220 220 220 220

Max. Height m

50(110)/40 50(110)/40 50(110)/40 50(110)/40 50(110)/40 50(110)/40 50(110)/40 50(110)/40

Cable

Main Power(Below 20m) mm2

--------

Communication mm2

--------

Set

Dimension

Net weight kg

186 197 210 239 269 307 307 307

Gross weight kg

193 204 217 249 279 317 317 317

Net dimension (WxHxD) mm

880x1695x765 880x1695x765 880x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765

Gross dimension (WxHxD) mm 948x1887x832 948x1887x832 948x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832

Operating Temp. Range

Cooling

ఁ

-5 ~ 48 -5 ~ 48 -5 ~ 48 -5 ~ 48 -5 ~ 48 -5 ~ 48 -5 ~ 48 -5 ~ 48

Heating

ఁ

-25 ~ 24 -25 ~ 24 -25 ~ 24 -25 ~ 24 -25 ~ 24 -25 ~ 24 -25 ~ 24 -25 ~ 24

2-26 Samsung Electronics Samsung Electronics 2-27

Outdoor Unit (cont.)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 27˚C DB/19°C WB, outdoor 35˚C DB, length 7.5m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 20˚C DB, outdoor 7˚C DB, length 7.5m of piping, fall 0m standard.

2. If proper form heating capacity is outdoor temperature 7˚C standard and outdoor temperature goes down by below zero, heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 200m (Equivalent length 220m).

5. If the indoor unit is below, height length allows up to 110m (If over 50m, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 40m.

TYPE

New Model New Model

Model

AM080JXVHGH AM100JXVHGH AM120JXVHGH AM140JXVHGH AM160JXVHGH AM180JXVHGH AM200JXVHGH AM220JXVHGH

Mode

HP HP HP HP HP HP HP HP

Power Φ, V, Hz

3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50 3/AC380-415/50

Capacity

Horse Power HP

8 10121416182022

Cooling kW

22.4 28.0 33.6 40.0 45.0 50.4 56.0 61.6

Heating kW

25.2 31.5 37.8 45.0 50.4 56.7 63.0 69.3

Power

Power input

(Nominal)

Cooling 1)

kW

4.59 6.22 7.57 10.55 10.92 11.51 13.05 15.75

Heating 2)

4.59 5.89 7.56 9.72 10.75 11.62 13.10 15.86

Current Input

(Nominal)

Cooling 1)

A

7.40 10.00 12.10 16.90 17.50 18.50 20.90 25.30

Heating 2)