Samsung AM009NN4DCH Series, AM056NN4DEH Series, AM012NN4DCH Series, AM018NN4DCH Series, AM071NN4DEH Series Service Manual

...

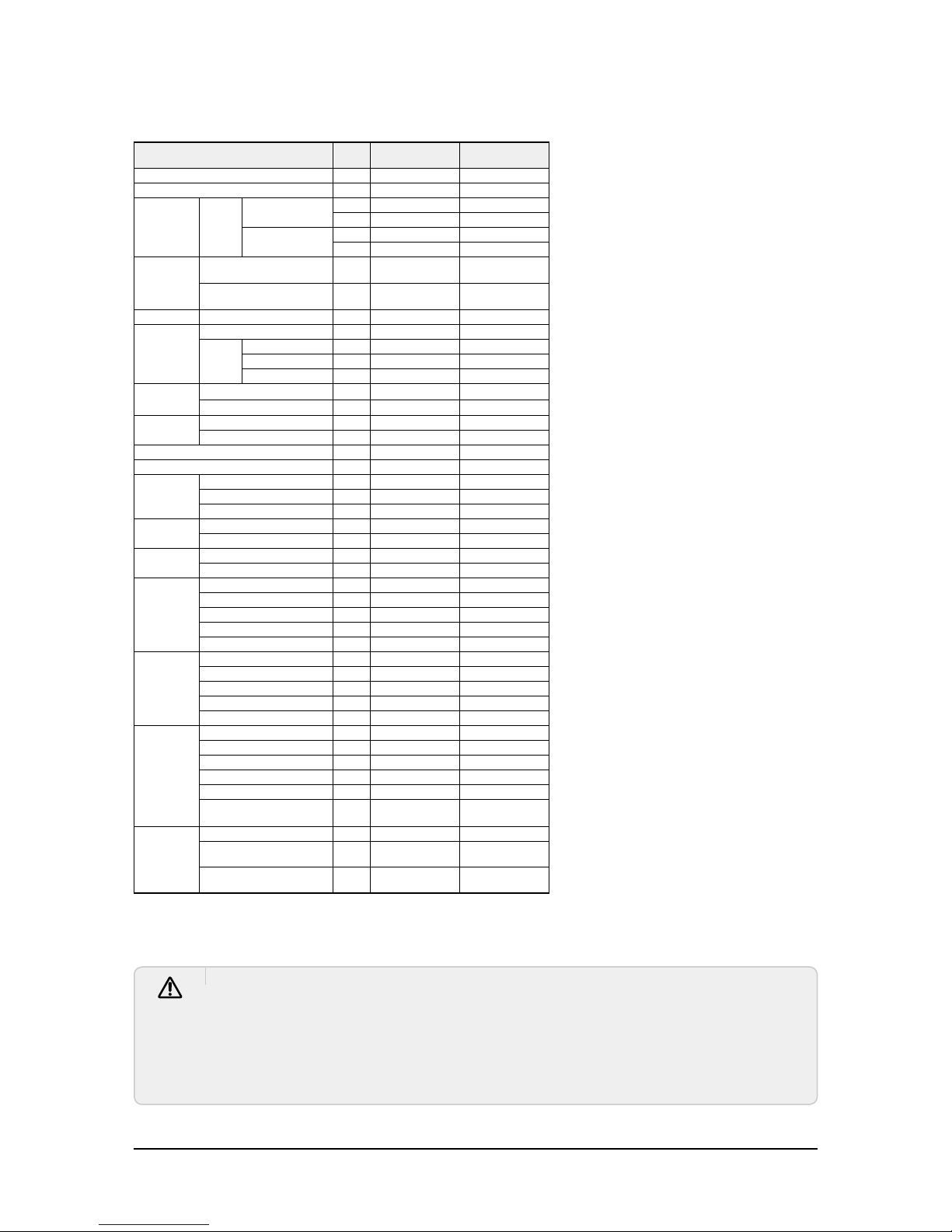

SYSTEM AIRCONDITIONER CONTENTS

SYSTEM AIRCONDITIONER

INDOOR UNIT

AM045/056/071/090/112/128/140NN4DEH/**

AM015/022/028/036/045/056/060NNNDEH/**

AM009/012/018/024/036/048NN4DCH/**

AM005/007/009/012/018/020NNNDCH/**

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram and Parts List

6. Wiring Diagram

7. Reference Sheet

Contents

1. Precautions .................................................................................................................................. 5

1-1 Precautions for the Service ........................................................................................................................ 5

1-2 Precautions for the Static Electricity and PL ............................................................................................ 5

1-3 Precautions for the Safety ......................................................................................................................... 5

1-4 Precautions for Handling Refrigerant for Air Conditioner ..................................................................... 6

1-5 Precautions for Welding the Air Conditioner Pipe .................................................................................. 6

1-6 Precautions for Additional Supplement of Air Conditioner Refrigerant ............................................. 6

1-7 Other Precautions ....................................................................................................................................... 6

2. Product Specifications ............................................................................................................... 7

2-1 Product Specifacations .............................................................................................................................. 7

2-1-1 Indoo r Uni t .................................................................................................................................................................................7

2-2 Accessory and Option Specifications ..................................................................................................... 13

2-2-1 Accessories ............................................................................................................................................................................. 13

3. Disassembly and Reassembly ................................................................................................. 16

3-1 Indoor Unit ................................................................................................................................................ 17

4. Troubleshooting ........................................................................................................................ 24

4-1 Check-up Window Description ................................................................................................................24

4-2 Service Operation .................................................................................................................................... 25

4-2-1 Special Operation ................................................................................................................................................................ 25

4-2-2 DVM S Models EEPROM Code Table............................................................................................................................ 29

4-3 Troubleshooting .......................................................................................................................................30

4-3-1 Setting Option Setup Method ......................................................................................................................................30

4-3-2 Option Items.......................................................................................................................................................................... 41

4-3-3 What to check before diagnosis ................................................................................................................................... 42

4-3-4 Number Display Method (Outdoor Unit, MCU, Cable remote control, wall-mount, etc.) .................. 44

4-4 Appropriate Measures for Different Symptom .....................................................................................50

4-4-1 Outdoor Unit Operation Flow .......................................................................................................................................50

4-4-2 Main PCB has no power phenomenon ..................................................................................................................... 51

4-4-3 Indoor Unit ROOM sensor Error (Open/Short) ...................................................................................................... 52

4-4-4 Indoor unit EVAP IN sensor Error (Open/Short) .................................................................................................... 53

4-4-5 Indoor EVAP OUT sensor Error (Open/Short) .........................................................................................................54

4-4-6 Indoor Heat Exchanger's EVAP IN sensor dislocation error.............................................................................55

4-4-7 Indoor Heat Exchanger's EVA OUT sensor dislocation error (Open/Short) .............................................. 56

4-4-8

imultaneous Indoor Heat Exchanger's EVA IN, OUT sensor dislocation error (Open/Short) ....................... 57

4-4-9 Electronic Expansion Valve opening malfunction (2nd stage) - ........................................ 58

4-4-10 Breakdown of EEV (2nd) ................................................................................................................................................ 59

4-4-11 Problem with EEV closure (2nd) ................................................................................................................................. 60

4-4-12 EEV(Electronic Expansion Valve) opening malfunction (2nd stage) ........................................................ 61

4-4-13

: EEV(Electronic Expansion Valve) closure malfunction (2nd stage) ............................62

4-4-14

: Detection of Floating Switch of Indoor Unit's Drain Pump ................................................ 63

4-4-15 The operational error of Indoor Unit's Fan Motor..............................................................................................64

4-4-16 Mixed operation Error (Only applicable to Heat Pump Model/Not to HR model) .............................. 65

4-4-17 EEPROM error .................................................................................................................................................................... 66

4-4-18 Option error of the Remote Controller for an Indoor Unit ........................................................................... 67

4-4-19 Error due to confused use of Fahrenheit and Celsius ..................................................................................... 67

4-4-20 Simultaneous opening of Cooling/heating MCU SOL Valves 1st/2nd .................................................... 68

4-4-21 Error due to incorrect Indoor Unit Power/Communication Cable Connection ....................................69

4-4-22 SPI Feedback Error ........................................................................................................................................................... 70

4-4-23 Outdoor Unit Pipe Inspection Error ......................................................................................................................... 71

4-4-24 Communication Error between Indoor and Outdoor Units during Tracking ....................................... 72

4-4-25 Communication Error between Indoor and Outdoor Units after Tracking ........................................... 73

4-4-26 Communication error between main and

sub Unit of outdoor unit or between outdoor units ........................................................................................ 74

4-4-27 Communication Error between MCU and Outdoor Unit ............................................................................... 75

4-4-28 Internal Communication error of the Outdoor Unit C-Box ............................................................................ 76

4-4-29 Internal PCB Communication error of the Outdoor Unit C-Box .................................................................. 77

4-4-30 Communication Error between MCU and Outdoor Unit after Tracking is Completed .................... 78

4-4-31 MCU branch part setup error – inconsecutive connection with the use of 2 branch parts ........... 79

4-4-32 MCU branch part setup error – Repeated setup for the same address over 3 times ........................ 80

4-4-33 MCU branch part setup error – non-installed address setup....................................................................... 81

Contents

4-4-34 Setup Error for MCU Branch part – Setup Error for MCU Quantity Used ................................................ 82

4-4-35 MCU branch part setup error – Overlapping Indoor unit Address setup ............................................... 83

4-4-36 MCU branch part setup error – Set as being used without connection to an Indoor unit ........... 84

4-4-37 MCU branch part setup error – Connect an Indoor unit to a branch part not being used ............ 85

4-4-38

MCU branch part setup error – Connect more Indoor units than what is actually set up in MCU ...........86

4-4-39 Outdoor Temperature Sensor Error ......................................................................................................................... 87

4-4-40 Outdoor Temperature dislocation error ................................................................................................................88

4-4-41 Cond Out Temperature Sensor Error (Open/Short) .......................................................................................... 89

4-4-42 Outdoor Cond Out sensor breakaway error ........................................................................................................ 90

4-4-43 Digital Compressor Discharge Temperature Sensor Error (OPEN/SHORT) ............................................ 91

4-4-44 Constant Rate Compressor Discharge Temperature Sensor Error (OPEN/SHORT) ............................ 92

4-4-45 Compressor Discharge or Top 1/2 Temperature sensor error ....................................................................93

4-4-46

: Dislocation error of Compressor SUMP Temperature (oil temperature) Sensor ......... 94

4-4-47

: Suction Temperature sensor breakaway error ...................................................................... 95

4-4-48 SUMP Temperature Sensor Error (OPEN/SHORT) ..............................................................................................96

4-4-49 High Pressure sensor error (Open/Short) .............................................................................................................. 97

4-4-50 Low Pressure sensor error (Open/Short) ............................................................................................................... 98

4-4-51 Suction Temperature sensor error (Open/Short) ............................................................................................... 99

4-4-52 Liquid Pipe Temperature sensor error (Open/Short) .....................................................................................100

4-4-53 EVI In Temperature sensor error (Open/Short) ................................................................................................. 101

4-4-54 EVI Out Temperature sensor error (Open/Short) .............................................................................................102

4-4-55 Suction-2 Temperature Sensor Error (OPEN/SHORT) ..................................................................................... 103

4-4-56

: Comp. Down due to High Pressure Protection Control ..................................................104

4-4-57

: Comp. Down due to Low Pressure Protection Control .................................................... 105

4-4-58 Sump Sensor Error Due to Protection Control .................................................................................................. 10 6

4-4-59

: Comp. Down due to Compressor Discharge Temperature sensor .............................107

4-4-60 3-phase Input Wiring error ........................................................................................................................................108

4-4-61

: Comp. Down by Compression Ratio Control ......................................................................109

4-4-62 EVI EEV Open error ........................................................................................................................................................ 110

4-4-63 Refrigerant Leakage Error ...........................................................................................................................................111

4-4-64

,

: Prohibition of the operation of Compressor due to Ooutdoor Temperature.........112

4-4-65 High Pressure Standard Not Met before Air Conditioning (Inability to Re-operate) ..................... 113

4-4-66 CCH Malfunction and Sump Sensor Miswiring Error ..................................................................................... 114

4-4-67 Fan starting error ........................................................................................................................................................... 115

4-4-68 Fan lock error ................................................................................................................................................................... 116

4-4-69 Momentary Blackout error ....................................................................................................................................... 117

4-4-70 Outdoor Fan Motor overheating ............................................................................................................................. 118

4-4-71 Outdoor Unit Fan Motor RPM Error ........................................................................................................................ 119

4-4-72 Fan IPM Overheat error ................................................................................................................................................120

4-4-73 Over-Voltage Error of an Outdoor Fan Motor .................................................................................................... 121

4-4-74 Counter-Rotation Error of an Outdoor Fan Motor ........................................................................................... 121

4-4-75

: Compressor Excess Current Error ................................................................................................12 2

4-4-76 Compressor starting error ..........................................................................................................................................123

4-4-77 Inverter Overcurrent error ..........................................................................................................................................124

4-4-78 Overvoltage / Low voltage error .............................................................................................................................12 5

4-4-79 DC Link voltage sensor error .....................................................................................................................................126

4-4-80 Liquid Compression Prevention Control .............................................................................................................127

4-4-81 Fan Motor Overcurrent error.....................................................................................................................................128

4-4-82 Input / Output Current sensor error ...................................................................................................................... 129

4-4-83 Outdoor Fan PCB Overvoltage / Low voltage error .......................................................................................13 0

4-4-84 Hall IC(Fan) error ............................................................................................................................................................. 131

4-4-85 Inverter Overheat error ...............................................................................................................................................132

4-4-86 Model mismatching of Indoor unit........................................................................................................................ 133

4-4-87 Breakdown of an EEV(1st) ...........................................................................................................................................134

4-4-87 Breakdown of an EEV closure ...................................................................................................................................135

4-4-88

Electronic expansion valve closing malfunction (2nd stage) ................................................................................. 136

4-4-89

Electronic expansion valve opening malfunction (2nd stage) ...............................................................................137

4-4-90

Hydro Unit Water In Temperature Sensor Error (Open/Short)................................................................................ 138

4-4-91

Hydro Unit Water Out Temperature Sensor Error (Open/Short) ............................................................................ 139

4-4-92

Hydro Unit Water Tank Temperature Sensor Error (Open/Short) .......................................................................... 14 0

4-4-93

Emergency Error (Check the Water Piping Equipment) .............................................................................................141

4-4-94

Error to prevention from freezing and bursting of Heat Exchanger ...................................................................142

4-4-95

Breakaway of Water Out temperature sensor ................................................................................................................ 143

Contents

4-4-96

Breakaway of Flow switch .......................................................................................................................................................14 4

4-4-97 Thermostat Wiring Error .............................................................................................................................................145

4-4-98 DC FAN Motor Feedback Error .................................................................................................................................146

4-4-99 Water Tank Sensor defective ....................................................................................................................................147

5. PCB Diagram and Parts List ................................................................................................... 148

5-1 Indoor Unit .............................................................................................................................................. 148

5-1-1 Wind-free 4way cassette type, mini 4way cassette .......................................................................................... 148

6. Wiring Diagram ....................................................................................................................... 151

6-1 Indoor ....................................................................................................................................................... 151

6-1-1 Wind-free 4way cassette type ..................................................................................................................................... 151

7. Reference Sheet ......................................................................................................................152

7-1 Index for Model Name ............................................................................................................................152

7-1-1 Ind oor Unit ............................................................................................................................................................................ 152

7-1-2 Panel ........................................................................................................................................................................................153

7-2 Pump-down Method .............................................................................................................................. 154

7-2-1 Precautions for Pump-down ........................................................................................................................................15 4

7-2-2 For Single Installation of Outdoor Unit (Only One Outdoor Unit Installed) ............................................154

7-2-3 When Two or More Outdoor Units are Installed .................................................................................................. 154

7-3 How to Put Refrigerant in Refrigerant Container ...............................................................................155

7-3-1 How to put refrigerant in container before pump-down ............................................................................... 155

Samsung Electronics

5

1. Precautions

1-1 Precautions for the Service

●

Use the correct parts when changing the electric parts.

– Please check the labels and notices for the model name, proper voltage, and proper current for the electric parts.

●

Fully repair the connection for the types of harness when repairing the product after breakdown.

– A faulty connection can cause irregular noise and problems.

●

When disassembling or assembling, make sure that the product is laid down on a work cloth.

– Doing so will prevent scratching to the exterior of the rear side of the product.

●

Completely remove dust or foreign substances on the housing, connection, and inspection parts when performing repairs.

– This can prevent fire hazards for tracking, short, etc.

●

Please tighten the service valve of the outdoor unit and the valve cap of the charging valve as securely as possible by using

a monkey spanner.

●

Check whether the parts are properly and securely assembled after performing repairs.

– These parts should be in the same condition as before the repair.

1-2 Precautions for the Static Electricity and PL

●

Please carefully handle the PCB power terminal during repair and measurement when it is turned on since it is vulnerable

to static electricity.

– Please wear insulation gloves before performing PCB repair and measurement.

●

Check if the place of installation is at least 2m away from electronic appliances such as TV, video players, and stereos.

– This can cause irregular noise or degrade the picture quality.

●

Please make sure the customer does not directly repair the product.

– Arbitrary dismantling may result in electric shock or fire.

1-3 Precautions for the Safety

●

Do not pull or touch the power plug or the subsidiary power switch with wet hands.

– This may result in electric shock or fire.

●

If the power line or the power plug is damaged, then it must be changed since this is a hazard.

●

Do not bend the wire too much or position it so that it can be damaged by a heavy object on top.

– This may result in electric shock or fire.

●

The use of multiple electric outlets should be prohibited.

– This may result in electric shock or fire.

●

Ground the connection if it is necessary.

– The connection must be grounded if there is any risk of electrical short due to water or moisture.

●

Unplug the power or turn off the subsidiary power switch when changing or repairing electrical parts.

– Doing so will prevent electric shock.

●

Explain to workers that the battery for the remote control needs to be separated for storage purposes when the product

will not be used for a long time.

– This can cause a problem for the remote control since battery fluid may trickle out.

Precautions

6

Samsung Electronics

1-4 Precautions for Handling Refrigerant for Air Conditioner

Environmental Cautions: Air pollution due to gas release

●

Safety Cautions

If liquid gas is released, then body parts that come into contact with it may experience frostbite/blister/numbness.

If a large amount of gas is released, then suffocation may occur due to lack of oxygen. If the released gas is heated, then noxious

gas may be produced by combustion.

●

Container Handling Cautions

Do not subject container to physical shock or overheating. (Flowage is possible while moving within the regulated pressure.)

1-5 Precautions for Welding the Air Conditioner Pipe

●

Dangerous or flammable objects around the pipe must be removed before the welding.

●

If the refrigerant is kept inside the product or the pipe, then remove the refrigerant prior to welding.

If the welding is carried out while the refrigerant is kept inside, the welding cannot be properly performed. This will also produce

noxious gas that is a health hazard. This leakage will also explode with the refrigerant and oil due to an increase in the refrigerant

pressure, posing a danger to workers.

●

Please remove the oxide produced inside the pipe during the welding with nitrogen gas.

Using another gas may cause harm to the product or others.

1-6 Precautions for Additional Supplement of Air Conditioner Refrigerant

●

Precisely calculate the refrigerant by using a scale and S-net, and proceed with the test operation.

Excessive supplement can cause harm to the product since it can cause an inflow of the liquid refrigerant into the compressor.

●

Do not heat the refrigerant container for a forced injection.

This may cause harm to the product or others since the refrigerant container may burst.

●

Do not operate the product after removing the product safety pressure switch and sensor.

If the product is blocked inside, then this may cause harm to the product or others due to the excess pressure increase of the

refrigerant gas.

1-7 Other Precautions

●

There should be no leakage of the pipes after installation. When withdrawing the refrigerant, the compressor should be

stopped before removing the connecting pipe.

If the compressor is operating while the refrigerant pipe is not correctly connected and the service valve is opened, then

air and other substances can enter the pipe. The interior of the refrigerant cycle may then build up excessive high pressure

resulting in explosion and damage.

Samsung Electronics

7

2. Product Specifications

2-1 Product Specifacations

2-1-1 Indoor Unit

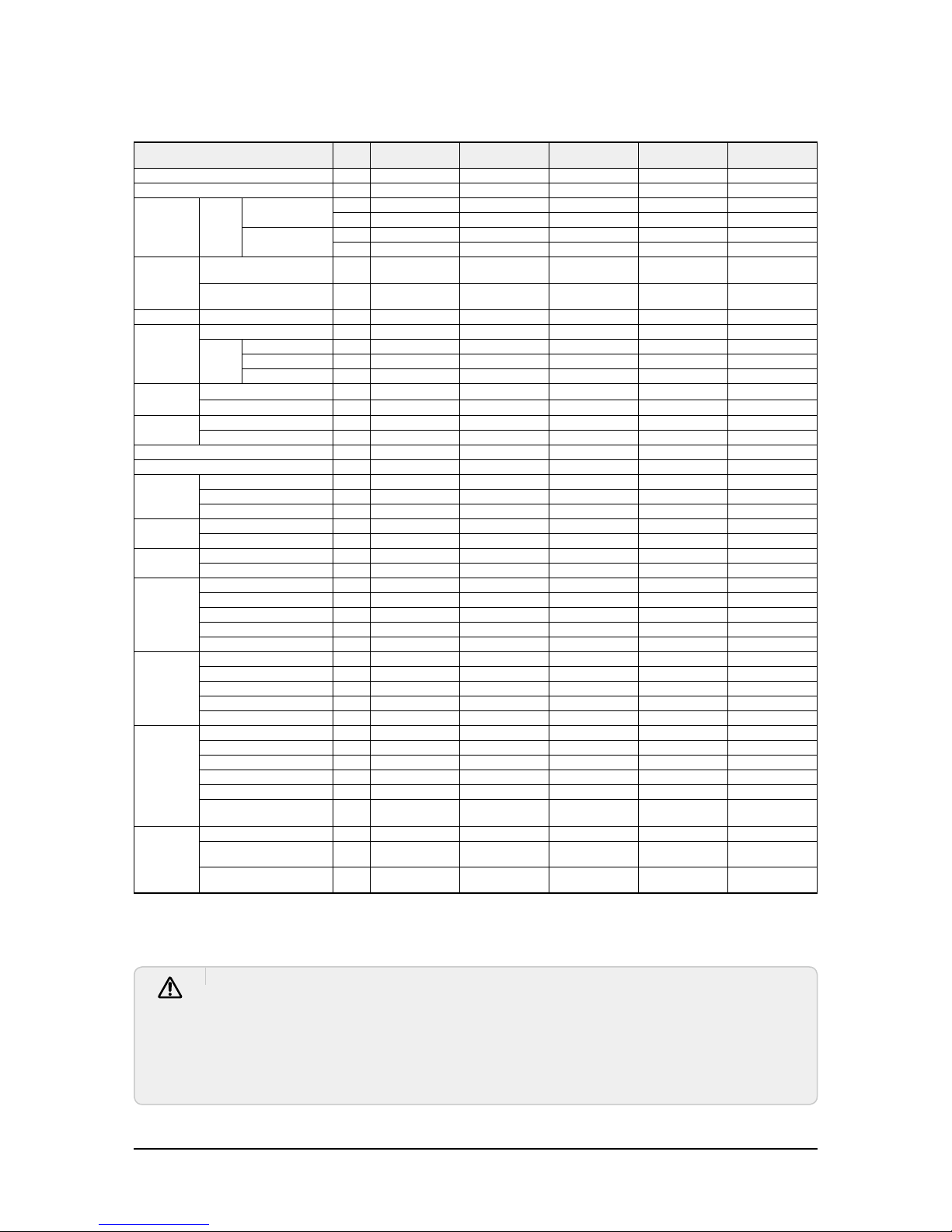

*1) Mode

- HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

- Indoor temperature : 27˚C DB, 19˚C WB

- Outdoor temperature : 35˚C DB, 24˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*3) Nominal heating capacities are based on;

- Indoor temperature : 20˚C DB, 15˚C WB

- Outdoor temperature : 7˚C DB, 6˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*4) Sound pressure was acquired in a dead room. This actual noise level may be different depending on the installation conditions.

*5) Specifications may be subject to change without prior notice for product improvement.

Model Europe

AM045NN4DEH/**

AM045NN4DEH/**

AM056NN4DEH/**

AM056NN4DEH/**

AM071NN4DEH/**

AM071NN4DEH/**

AM090NN4DEH/**

AM090NN4DEH/**

AM112NN4DEH/**

AM112NN4DEH/**

Power Supply φ,V,Hz

1,2,220-240,50 1,2,220-240,50 1,2,220-240,50 1,2,220-240,50 1,2,220-240,50

Mode*

1)

-

HP/HR HP/HR HP/HR HP/HR HP/HR

Performance Capacity

Cooling*

2)

kW

4.5 5.6 7.1 9.0 11.2

Btu/h

15,400 19,100 24,200 30,700 38,200

Heating*

3)

kW

5.0 6.3 8.0 10.0 12.5

Btu/h

17,100 21,500 27,300 34,100 42,700

Power

Input Consumption

(Cooling/Heating)

W 110% ↓

32.0 32.0 45.0 62.0 78.0

Running Current

(Cooling/Heating)

A 110% ↓

0.22 0.22 0.31 0.43 0.55

Sound Level Sound Pressure*

4)

dB(A) ↓

- - - - -

Fan

Type -

Turbo Fan Turbo Fan Turbo Fan Turbo Fan Turbo Fan

Motor

Model -

FMC6531SSH FMC6531SSH FMC6531SSH FMC6531SSH FMC6531SSF

Type -

BLDC BLDC BLDC BLDC BLDC

Output W

65

*

5)

65

*

5)

65

*

5)

65

*

5)

65

*

5)

Air Flow Rate

H/M/L (UL) CMM

14.5/13.5/12.5 15.0/14.0/13.0 17.0/15.5/14.5 19.5/18.0/16.5 26.0/24.0/22.0

l/s

242/225/208 250/233/217 283/258/242 325/300/275 433/400/367

Refrigerant

Type -

R410A R410A R410A R410A R410A

Control Method -

EEV EEV EEV EEV EEV

Temperature Control -

Micom & Thermistors Micom & Thermistors Micom & Thermistors Micom & Thermistors Micom & Thermistors

Safety Devices -

Fuse Fuse Fuse Fuse Fuse

Piping

Connections

Liquid (Flare) Φ,mm

6.35 6.35 9.52 9.52 9.52

Gas (Flare) Φ,mm

12.7 12.7 15.88 15.88 15.88

Drain Φ,mm

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

Weight

Net Weight kg

15 15 15 15 16.5

Shipping Weight kg

18.5 18.5 18.5 18.5 20.0

Dimensions

Net Dimensions (W x H x D) mm

840 x 204 x 840 840 x 204 x 840 840 x 204 x 840 840 x 204 x 840 840 x 246 x 840

Shipping Dimensions (W x H x D) mm

898 x 275 x 898 898 x 275 x 898 898 x 275 x 898 898 x 275 x 898 898 x 316 x 898

Panel Size

Model -

PC4NUFMAN PC4NUFMAN PC4NUFMAN PC4NUFMAN PC4NUFMAN

Net Weight kg

6.3 6.3 6.3 6.3 6.3

Shipping Weight kg

8.7 8.7 8.7 8.7 8.7

Net Dimensions (W x H x D) mm

950 x 64 x 950 950 x 64 x 950 950 x 64 x 950 950 x 64 x 950 950 x 64 x 950

Shipping Dimensions (W x H x D) mm

1,010 x 117 x 1,000 1,010 x 117 x 1,000 1,010 x 117 x 1,000 1,010 x 117 x 1,000 1,010 x 117 x 1,000

Functions

Auto Restart -

O O O O O

Auto Swing -

O O O O O

Group/Individual Control -

O O O O O

External Contact Control -

O O O O O

Trouble Shooting by LED -

O O O O O

Standard

Accessories

Installation Manual -

O O O O O

Operation Manual -

O O O O O

Pattern Sheet for Installation -

O O O O O

Flexible Drain Hose -

O O O O O

Filter / Safety Grille -

Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille

Drain Pump

(Pumping speed, lift)

ℓ/h,

mm

24, 750 24, 750 24, 750 24, 750 24, 750

Optional

Accessories

Wireless Remote Controller -

AR-DH00 AR-DH00 AR-DH00 AR-DH00 AR-DH00

Wired Remote

Controller

-

MWR-WE10N MWR-WE10N MWR-WE10N MWR-WE10N MWR-WE10N

External Contact

Interface Module

-

MIM-B14 MIM-B14 MIM-B14 MIM-B14 MIM-B14

Product Specifications

8

Samsung Electronics

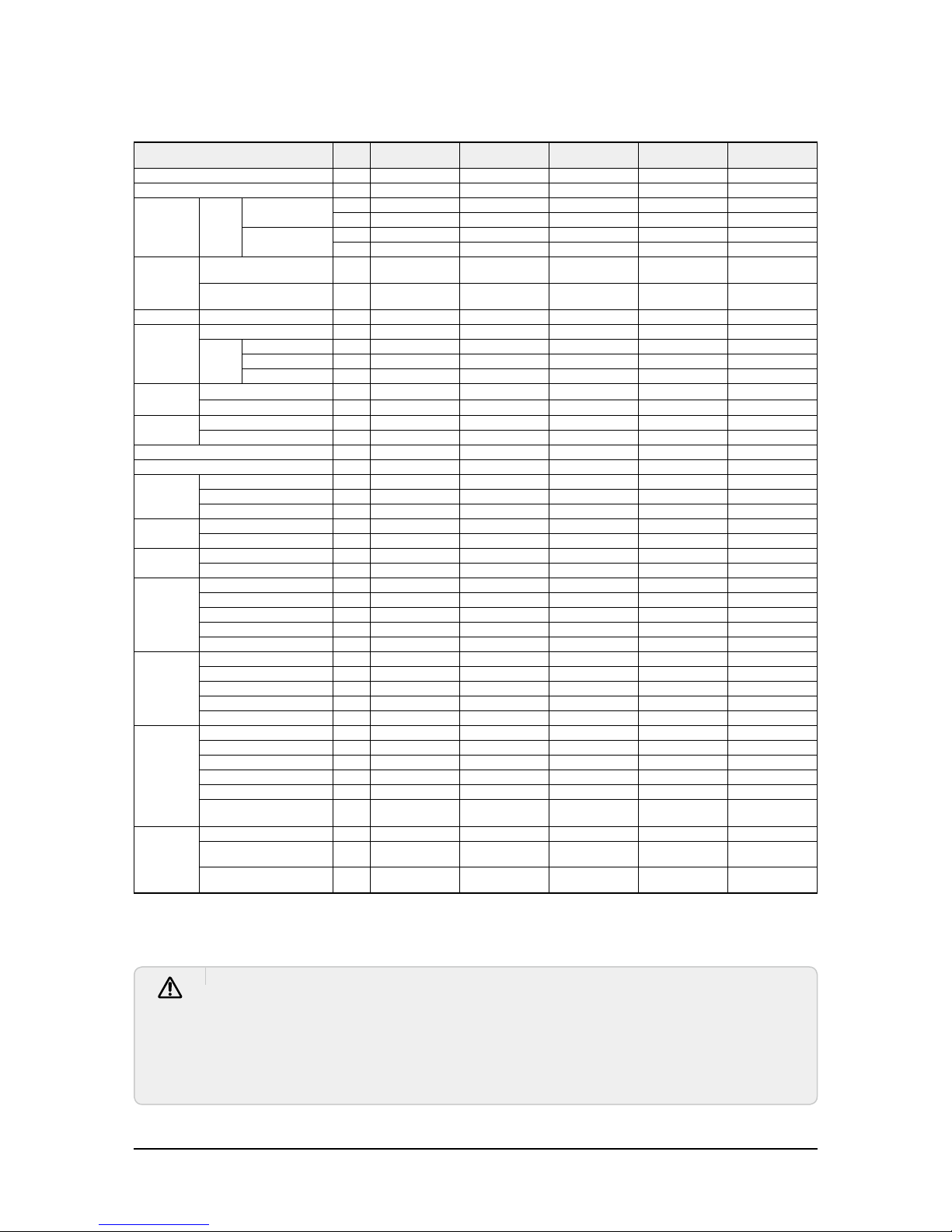

*1) Mode

- HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

- Indoor temperature : 27˚C DB, 19˚C WB

- Outdoor temperature : 35˚C DB, 24˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*3) Nominal heating capacities are based on;

- Indoor temperature : 20˚C DB, 15˚C WB

- Outdoor temperature : 7˚C DB, 6˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*4) Sound pressure was acquired in a dead room. This actual noise level may be different depending on the installation conditions.

*5) Specifications may be subject to change without prior notice for product improvement.

Indoor Unit (cont.)

Model Europe

AM128NN4DEH/**

AM128NN4DEH/**

AM140NN4DEH/**

AM140NN4DEH/**

AM009NN4DCH/**

AM012NN4DCH/** AM018NN4DCH/**

Power Supply φ,V,Hz

1,2,220-240,50 1,2,220-240,50

1,2,208-230,60 1,2,208-230,60 1,2,208-230,60

Mode*

1)

-

HP/HR HP/HR

HP/HR HP/HR HP/HR

Performance Capacity

Cooling*

2)

kW

12.8 14.0

2.64 3.52 5.28

Btu/h

43,700 47,800

9,000 12,000 18,000

Heating*

3)

kW

13.8 16.0

2.93 3.96 5.86

Btu/h

47,100 54,600

10,000 13,500 20,000

Power

Input Consumption

(Cooling/Heating)

W 110% ↓

73.0 89.0

32.00 32.00 32.00

Running Current

(Cooling/Heating)

A 110% ↓

0.51 0.62

0.25 0.25 0.25

Sound Level Sound Pressure*

4)

dB(A) ↓

- -

- - -

Fan

Type -

Turbo Fan Turbo Fan

Turbo Fan Turbo Fan Turbo Fan

Motor

Model -

FMC9731SSB FMC9731SSB

FMC6531SSH FMC6531SSH FMC6531SSH

Type -

BLDC BLDC

BLDC BLDC BLDC

Output W

97*5) 97 *5)

65 *5) 65 *5) 65 *5)

Air Flow Rate

H/M/L (UL) CMM

28.0/26.0/23.0 30.0/28.0/26.0

15.50 / 14.00 / 12.00 15.50 / 14.00 / 12.00 15.50 / 14.00 / 12.00

l/s

467/433/383 500/467/433

258/233/200 258/233/200 258/233/200

Refrigerant

Type -

R410A R410A

R410A R410A R410A

Control Method -

EEV EEV

EEV EEV EEV

Temperature Control -

Micom & Thermistors Micom & Thermistors

Micom & Thermistors Micom & Thermistors Micom & Thermistors

Safety Devices -

Fuse Fuse

Fuse Fuse Fuse

Piping

Connections

Liquid (Flare) Φ,mm

9.52 9.52

6.35 6.35 6.35

Gas (Flare) Φ,mm

15.88 15.88

12.7 12.7 12.7

Drain Φ,mm

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

Weight

Net Weight kg

18.5 18.5

15 15 15

Shipping Weight kg

22.5 22.5

18.5 18.5 18.5

Dimensions

Net Dimensions (W x H x D) mm

840 x 288 x 840 840 x 288 x 840

840 x 204 x 840 840 x 204 x 840 840 x 204 x 840

Shipping Dimensions (W x H x D) mm

898 x 357 x 898 898 x 357 x 898

898 x 275 x 898 898 x 275 x 898 898 x 275 x 898

Panel Size

Model -

PC4NUFMAN PC4NUFMAN

PC4NUFMAN PC4NUFMAN PC4NUFMAN

Net Weight kg

6.3 6.3

6.3 6.3 6.3

Shipping Weight kg

8.7 8.7

8.7 8.7 8.7

Net Dimensions (W x H x D) mm

950 x 64 x 950 950 x 64 x 950

950 x 64 x 950 950 x 64 x 950 950 x 64 x 950

Shipping Dimensions (W x H x D) mm

1,010 x 117 x 1,000 1,010 x 117 x 1,000

1,010 x 117 x 1,000 1,010 x 117 x 1,000

1,010 x 117 x 1,000

Functions

Auto Restart -

O O

O O O

Auto Swing -

O O

O O O

Group/Individual Control -

O O

O O O

External Contact Control -

O O

O O O

Trouble Shooting by LED -

O O

O O O

Standard

Accessories

Installation Manual -

O O

O O O

Operation Manual -

O O

O O O

Pattern Sheet for Installation -

O O

O O O

Flexible Drain Hose -

O O

O O O

Filter / Safety Grille -

Filter / Safety Grille Filter / Safety Grille

Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille

Drain Pump

(Pumping speed, lift)

ℓ/h,

mm

24, 750 24, 750

24, 750 24, 750 24, 750

Optional

Accessories

Wireless Remote Controller -

AR-DH00 AR-DH00

AR-EH03E AR-EH03E AR-EH03E

Wired Remote

Controller

-

MWR-WE10N MWR-WE10N

MWR-WE13N MWR-WE13N MWR-WE13N

External Contact

Interface Module

-

MIM-B14 MIM-B14

MIM-B14 MIM-B14 MIM-B14

Product Specifications

Samsung Electronics

9

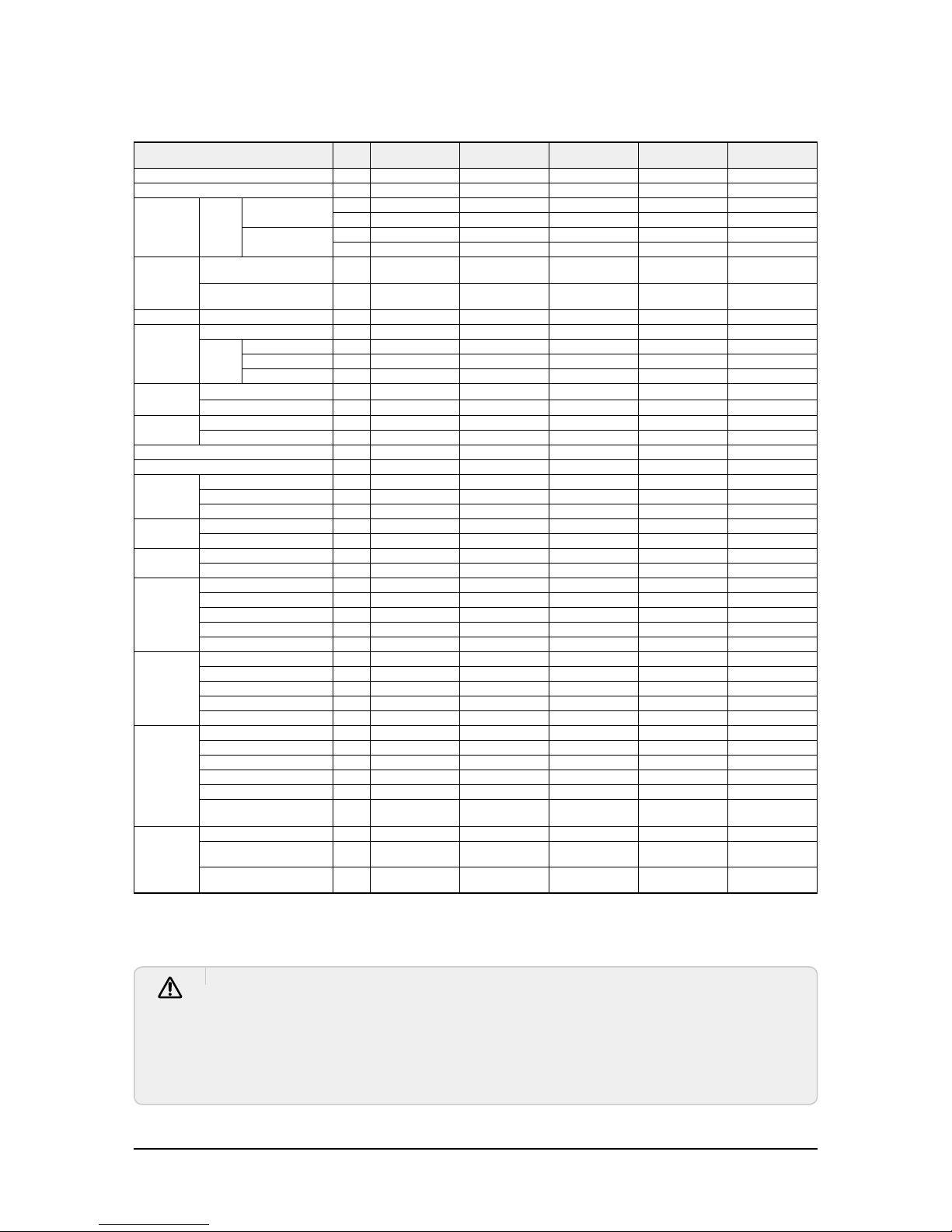

*1) Mode

- HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

- Indoor temperature : 27˚C DB, 19˚C WB

- Outdoor temperature : 35˚C DB, 24˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*3) Nominal heating capacities are based on;

- Indoor temperature : 20˚C DB, 15˚C WB

- Outdoor temperature : 7˚C DB, 6˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*4) Sound pressure was acquired in a dead room. This actual noise level may be different depending on the installation conditions.

*5) Specifications may be subject to change without prior notice for product improvement.

Indoor Unit (cont.)

Model Europe

AM024NN4DCH/** AM030NN4DCH/**

AM036NN4DCH/**

AM048NN4DCH/** AM005NNNDCH/**

Power Supply φ,V,Hz

1,2,208-230,60 1,2,208-230,60 1,2,208-230,60 1,2,208-230,60 1,2,208-230,60

Mode*

1)

-

HP/HR HP/HR HP/HR HP/HR HP/HR

Performance Capacity

Cooling*

2)

kW

7.03 8.79 10.55 14.07 1.47

Btu/h

24,000 30,000 36,000 48,000 5,000

Heating*

3)

kW

7.91 9.96 11.72 15.83 1.76

Btu/h

27,000 34,000 40,000 54,000 6,000

Power

Input Consumption

(Cooling/Heating)

W 110% ↓

40.00 65.00 75.00 95.00 18

Running Current

(Cooling/Heating)

A 110% ↓

0.30 0.50 0.56 0.75 0.19

Sound Level Sound Pressure*

4)

dB(A) ↓

- - - - -

Fan

Type -

Turbo Fan Turbo Fan Turbo Fan Turbo Fan Turbo Fan

Motor

Model -

FMC6531SSH FMC9731SSB FMC9731SSB FMC9731SSB FMC6531SSJ

Type -

BLDC BLDC BLDC BLDC BLDC

Output W

65

*

5)

97

*

5)

97

*

5)

97

*

5)

65

*

5)

Air Flow Rate

H/M/L (UL) CMM

17.50 /16.00 / 14.00 22.00 / 19.50 /17.00 24.00 /22.00 / 20.00 29.00 / 27.00 / 24.00 8.50/7.20/6.50

l/s

291/266/233 367/235/283 400/367/333 483/450/400 142/120/108

Refrigerant

Type -

R410A R410A R410A R410A R410A

Control Method -

EEV EEV EEV EEV EEV

Temperature Control -

Micom & Thermistors Micom & Thermistors Micom & Thermistors Micom & Thermistors Micom & Thermistors

Safety Devices -

Fuse Fuse Fuse Fuse Fuse

Piping

Connections

Liquid (Flare) Φ,mm

9.52 9.52 9.52 9.52 6.35

Gas (Flare) Φ,mm

15.88 15.88 15.88 15.88 12.7

Drain Φ,mm

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

Weight

Net Weight kg

15 18.5 18.5 18.5 11.7

Shipping Weight kg

18.5 23.0 23.0 23.0 13.7

Dimensions

Net Dimensions (W x H x D) mm

840 x 204 x 840 840 x 288 x 840 840 x 288 x 840 840 x 288 x 840 575 x 250 x 575

Shipping Dimensions (W x H x D) mm

898 x 275 x 898 898 x 357 x 898 898 x 357 x 898 898 x 357 x 898 623 x 298 x 653

Panel Size

Model -

PC4NUFMAN PC4NUFMAN PC4NUFMAN PC4NUFMAN PC4SUFMAN

Net Weight kg

6.3 6.3 6.3 6.3 2.7

Shipping Weight kg

8.7 8.7 8.7 8.7 3.9

Net Dimensions (W x H x D) mm

950 x 64 x 950 950 x 64 x 950 950 x 64 x 950 950 x 64 x 950 620 x 57 x 620

Shipping Dimensions (W x H x D) mm

1,010 x 117 x 1,000 1,010 x 117 x 1,000

1,010 x 117 x 1,000 1,010 x 117 x 1,000

670 x 120 x 655

Functions

Auto Restart -

O O O O O

Auto Swing -

O O O O O

Group/Individual Control -

O O O O O

External Contact Control -

O O O O O

Trouble Shooting by LED -

O O O O O

Standard

Accessories

Installation Manual -

O O O O O

Operation Manual -

O O O O O

Pattern Sheet for Installation -

O O O O O

Flexible Drain Hose -

O O O O O

Filter / Safety Grille -

Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille

Drain Pump

(Pumping speed, lift)

ℓ/h,

mm

24, 750 24, 750 24, 750 24, 750 24, 750

Optional

Accessories

Wireless Remote Controller -

AR-EH03E AR-EH03E AR-EH03E AR-EH03E AR-EH03E

Wired Remote

Controller

-

MWR-WE13N MWR-WE13N MWR-WE13N MWR-WE13N MWR-WE13N

External Contact

Interface Module

-

MIM-B14 MIM-B14 MIM-B14 MIM-B14 MIM-B14

Product Specifications

10

Samsung Electronics

*1) Mode

- HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

- Indoor temperature : 27˚C DB, 19˚C WB

- Outdoor temperature : 35˚C DB, 24˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*3) Nominal heating capacities are based on;

- Indoor temperature : 20˚C DB, 15˚C WB

- Outdoor temperature : 7˚C DB, 6˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*4) Sound pressure was acquired in a dead room. This actual noise level may be different depending on the installation conditions.

*5) Specifications may be subject to change without prior notice for product improvement.

Indoor Unit (cont.)

Model Europe

AM007NNNDCH/** AM009NNNDCH/** AM012NNNDCH/** AM018NNNDCH/** AM020NNNDCH/**

Power Supply φ,V,Hz

1,2,208-230,60 1,2,208-230,60

1,2,208-230,60 1,2,208-230,60 1,2,208-230,60

Mode*

1)

-

HP/HR HP/HR

HP/HR HP/HR HP/HR

Performance Capacity

Cooling*

2)

kW

2.20 2.78

3.52 5.28 5.86

Btu/h

7,500 9,500

12,000 18,000 20,000

Heating*

3)

kW

2.55 3.08

3.96 5.86 6.74

Btu/h

8,700 10,500

13,500 20,000 23,000

Power

Input Consumption

(Cooling/Heating)

W 110% ↓

20 20

23 28 31

Running Current

(Cooling/Heating)

A 110% ↓

0.19 0.19

0.22 0.27 0.3

Sound Level Sound Pressure*

4)

dB(A) ↓

- -

- - -

Fan

Type -

Turbo Fan Turbo Fan

Turbo Fan Turbo Fan Turbo Fan

Motor

Model -

FMC6531SSJ FMC6531SSJ

FMC6531SSJ FMC6531SSJ FMC6531SSJ

Type -

BLDC BLDC

BLDC BLDC BLDC

Output W

65

*

5)

65

*

5)

65

*

5)

65

*

5)

65

*

5)

Air Flow Rate

H/M/L (UL) CMM

9.00/7.70/6.50 10.00/8.50/7.50

10.50/9.50/8.00 13.00/11.00/9.50 13.50/12.00/10.20

l/s

150/128/108 167/142/125

175/158/133 217/183/158 225/200/170

Refrigerant

Type -

R410A R410A

R410A R410A R410A

Control Method -

EEV EEV

EEV EEV EEV

Temperature Control -

Micom & Thermistors Micom & Thermistors

Micom & Thermistors Micom & Thermistors Micom & Thermistors

Safety Devices -

Fuse Fuse

Fuse Fuse Fuse

Piping

Connections

Liquid (Flare) Φ,mm

6.35 6.35

6.35 6.35 6.35

Gas (Flare) Φ,mm

12.7 12.7

12.7 12.7 12.7

Drain Φ,mm

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

Weight

Net Weight kg

12.0 12.0 12.0 12.0 12.0

Shipping Weight kg

14.0 14.0 14.0 14.0 14.0

Dimensions

Net Dimensions (W x H x D) mm

575 x 250 x 575 575 x 250 x 575

575 x 250 x 575 575 x 250 x 575 575 x 250 x 575

Shipping Dimensions (W x H x D) mm

623 x 298 x 653 623 x 298 x 653

623 x 298 x 653 623 x 298 x 653 623 x 298 x 653

Panel Size

Model -

PC4SUFMAN PC4SUFMAN

PC4SUFMAN PC4SUFMAN PC4SUFMAN

Net Weight kg

2.7 2.7

2.7 2.7 2.7

Shipping Weight kg

3.9 3.9

3.9 3.9 3.9

Net Dimensions (W x H x D) mm

620 x 57 x 620 620 x 57 x 620

620 x 57 x 620 620 x 57 x 620 620 x 57 x 620

Shipping Dimensions (W x H x D) mm

670 x 120 x 655 670 x 120 x 655

670 x 120 x 655 670 x 120 x 655 670 x 120 x 655

Functions

Auto Restart -

O O

O O O

Auto Swing -

O O

O O O

Group/Individual Control -

O O

O O O

External Contact Control -

O O

O O O

Trouble Shooting by LED -

O O

O O O

Standard

Accessories

Installation Manual -

O O

O O O

Operation Manual -

O O

O O O

Pattern Sheet for Installation -

O O

O O O

Flexible Drain Hose -

O O

O O O

Filter / Safety Grille -

Filter / Safety Grille Filter / Safety Grille

Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille

Drain Pump

(Pumping speed, lift)

ℓ/h,

mm

24, 750 24, 750

24, 750 24, 750 24, 750

Optional

Accessories

Wireless Remote Controller -

AR-EH03E AR-EH03E

AR-EH03E AR-EH03E AR-EH03E

Wired Remote

Controller

-

MWR-WE13N MWR-WE13N

MWR-WE13N MWR-WE13N MWR-WE13N

External Contact

Interface Module

-

MIM-B14 MIM-B14

MIM-B14 MIM-B14 MIM-B14

Product Specifications

Samsung Electronics

11

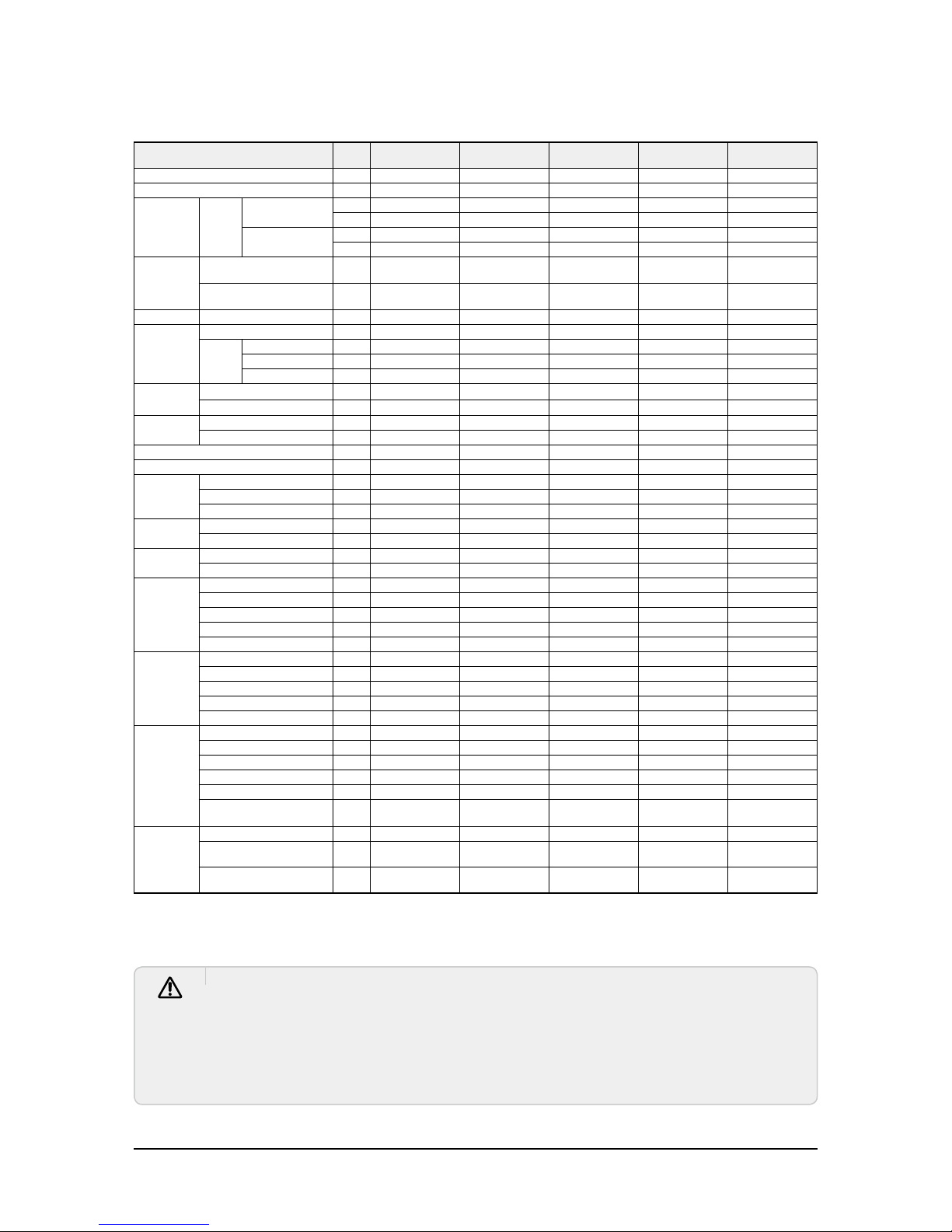

*1) Mode

- HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

- Indoor temperature : 27˚C DB, 19˚C WB

- Outdoor temperature : 35˚C DB, 24˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*3) Nominal heating capacities are based on;

- Indoor temperature : 20˚C DB, 15˚C WB

- Outdoor temperature : 7˚C DB, 6˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*4) Sound pressure was acquired in a dead room. This actual noise level may be different depending on the installation conditions.

*5) Specifications may be subject to change without prior notice for product improvement.

Indoor Unit (cont.)

Model Europe

AM015NNNDEH/**

AM015NNNDEH/**

AM022NNNDEH/**

AM022NNNDEH/**

AM028NNNDEH/**

AM028NNNDEH/**

AM036NNNDEH/**

AM036NNNDEH/**

AM045NNNDEH/**

AM045NNNDEH/**

Power Supply φ,V,Hz

1,2,220-240,50 1,2,220-240,50 1,2,220-240,50

1,2,220-240,50 1,2,220-240,50

Mode*

1)

-

HP/HR HP/HR HP/HR

HP/HR HP/HR

Performance Capacity

Cooling*

2)

kW

1.5 2.2 2.8

3.6 4.5

Btu/h

5,100 7,500 9,600

12,300 15,400

Heating*

3)

kW

1.7 2.5 3.2

4.0 5.0

Btu/h

8,500 8,500 10,900

13,600 17,100

Power

Input Consumption

(Cooling/Heating)

W 110% ↓

18.0 18.0 18.0

20.0 23.0

Running Current

(Cooling/Heating)

A 110% ↓

0.17 0.17 0.17

0.19 0.22

Sound Level Sound Pressure*

4)

dB(A) ↓

- - -

- -

Fan

Type -

Turbo Fan Turbo Fan Turbo Fan

Turbo Fan Turbo Fan

Motor

Model -

FMC6531SSJ FMC6531SSJ FMC6531SSJ

FMC6531SSJ FMC6531SSJ

Type -

BLDC BLDC BLDC

BLDC BLDC

Output W

65

*

5)

65

*

5)

65

*

5)

65

*

5)

65

*

5)

Air Flow Rate

H/M/L (UL) CMM

8.50/7.20/6.50 9.00/7.70/6.50 10.00/8.50/7.50

10.50/9.00/7.50 11.50/10.20/9.00

l/s

142/120/108 150/128/108 167/142/125

175/150/125 192/170/150

Refrigerant

Type -

R410A R410A R410A

R410A R410A

Control Method -

EEV EEV EEV

EEV EEV

Temperature Control -

Micom & Thermistors Micom & Thermistors Micom & Thermistors

Micom & Thermistors Micom & Thermistors

Safety Devices -

Fuse Fuse Fuse

Fuse Fuse

Piping

Connections

Liquid (Flare) Φ,mm

6.35 6.35 6.35

6.35 6.35

Gas (Flare) Φ,mm

12.7 12.7 12.7

12.7 12.7

Drain Φ,mm

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

Weight

Net Weight kg

11.7 12.0 12.0

12.0 12.0

Shipping Weight kg

13.7 14 14

14 14

Dimensions

Net Dimensions (W x H x D) mm

575 x 250 x 575 575 x 250 x 575 575 x 250 x 575

575 x 250 x 575 575 x 250 x 575

Shipping Dimensions (W x H x D) mm

623 x 298 x 653 623 x 298 x 653 623 x 298 x 653

623 x 298 x 653 623 x 298 x 653

Panel Size

Model -

PC4SUFMAN PC4SUFMAN PC4SUFMAN

PC4SUFMAN PC4SUFMAN

Net Weight kg

2.7 2.7 2.7

2.7 2.7

Shipping Weight kg

3.9 3.9 3.9

3.9 3.9

Net Dimensions (W x H x D) mm

620 x 57 x 620 620 x 57 x 620 620 x 57 x 620

620 x 57 x 620 620 x 57 x 620

Shipping Dimensions (W x H x D) mm

670 x 120 x 655 670 x 120 x 655 670 x 120 x 655 670 x 120 x 655 670 x 120 x 655

Functions

Auto Restart -

O O O

O O

Auto Swing -

O O O

O O

Group/Individual Control -

O O O

O O

External Contact Control -

O O O

O O

Trouble Shooting by LED -

O O O

O O

Standard

Accessories

Installation Manual -

O O O

O O

Operation Manual -

O O O

O O

Pattern Sheet for Installation -

O O O

O O

Flexible Drain Hose -

O O O

O O

Filter / Safety Grille -

Filter / Safety Grille Filter / Safety Grille Filter / Safety Grille

Filter / Safety Grille Filter / Safety Grille

Drain Pump

(Pumping speed, lift)

ℓ/h,

mm

24, 750 24, 750 24, 750

24, 750 24, 750

Optional

Accessories

Wireless Remote Controller -

AR-DH00 AR-DH00 AR-DH00

AR-DH00 AR-DH00

Wired Remote

Controller

-

MWR-WE10N MWR-WE10N MWR-WE10N

MWR-WE10N MWR-WE10N

External Contact

Interface Module

-

MIM-B14 MIM-B14 MIM-B14

MIM-B14 MIM-B14

Product Specifications

12

Samsung Electronics

*1) Mode

- HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

- Indoor temperature : 27˚C DB, 19˚C WB

- Outdoor temperature : 35˚C DB, 24˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*3) Nominal heating capacities are based on;

- Indoor temperature : 20˚C DB, 15˚C WB

- Outdoor temperature : 7˚C DB, 6˚C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*4) Sound pressure was acquired in a dead room. This actual noise level may be different depending on the installation conditions.

*5) Specifications may be subject to change without prior notice for product improvement.

Indoor Unit (cont.)

Model Europe

AM056NNNDEH/**

AM056NNNDEH/**

AM060NNNDEH/**

AM060NNNDEH/**

Power Supply φ,V,Hz

1,2,220-240,50 1,2,220-240,50

Mode*

1)

-

HP/HR HP/HR

Performance Capacity

Cooling*

2)

kW

5.6 6.0

Btu/h

19,100 20,500

Heating*

3)

kW

6.3 6.8

Btu/h

21,500 23,200

Power

Input Consumption

(Cooling/Heating)

W 110% ↓

28.0 31.0

Running Current

(Cooling/Heating)

A 110% ↓

0.27 0.30

Sound Level Sound Pressure*

4)

dB(A) ↓

- -

Fan

Type -

Turbo Fan Turbo Fan

Motor

Model -

FMC6531SSJ FMC6531SSJ

Type -

BLDC BLDC

Output W

65

*

5)

65

*

5)

Air Flow Rate

H/M/L (UL) CMM

13.00/11.00/9.50 13.50/12.00/10.20

l/s

217/183/158 225/200/170

Refrigerant

Type -

R410A R410A

Control Method -

EEV EEV

Temperature Control -

Micom & Thermistors Micom & Thermistors

Safety Devices -

Fuse Fuse

Piping

Connections

Liquid (Flare) Φ,mm

6.35 6.35

Gas (Flare) Φ,mm

12.7 12.7

Drain Φ,mm

VP25 (OD 32,ID 25) VP25 (OD 32,ID 25)

Weight

Net Weight kg

12.0 12.0

Shipping Weight kg

14 14

Dimensions

Net Dimensions (W x H x D) mm

575 x 250 x 575 575 x 250 x 575

Shipping Dimensions (W x H x D) mm

623 x 298 x 653 623 x 298 x 653

Panel Size

Model -

PC4SUFMAN PC4SUFMAN

Net Weight kg

2.7 2.7

Shipping Weight kg

3.9 3.9

Net Dimensions (W x H x D) mm

620 x 57 x 620 620 x 57 x 620

Shipping Dimensions (W x H x D) mm

670 x 120 x 655 670 x 120 x 655

Functions

Auto Restart -

O O

Auto Swing -

O O

Group/Individual Control -

O O

External Contact Control -

O O

Trouble Shooting by LED -

O O

Standard

Accessories

Installation Manual -

O O

Operation Manual -

O O

Pattern Sheet for Installation -

O O

Flexible Drain Hose -

O O

Filter / Safety Grille -

Filter / Safety Grille Filter / Safety Grille

Drain Pump

(Pumping speed, lift)

ℓ/h,

mm

24, 750 24, 750

Optional

Accessories

Wireless Remote Controller -

AR-DH00 AR-DH00

Wired Remote

Controller

-

MWR-WE10N MWR-WE10N

External Contact

Interface Module

-

MIM-B14 MIM-B14

Product Specifications

Samsung Electronics

13

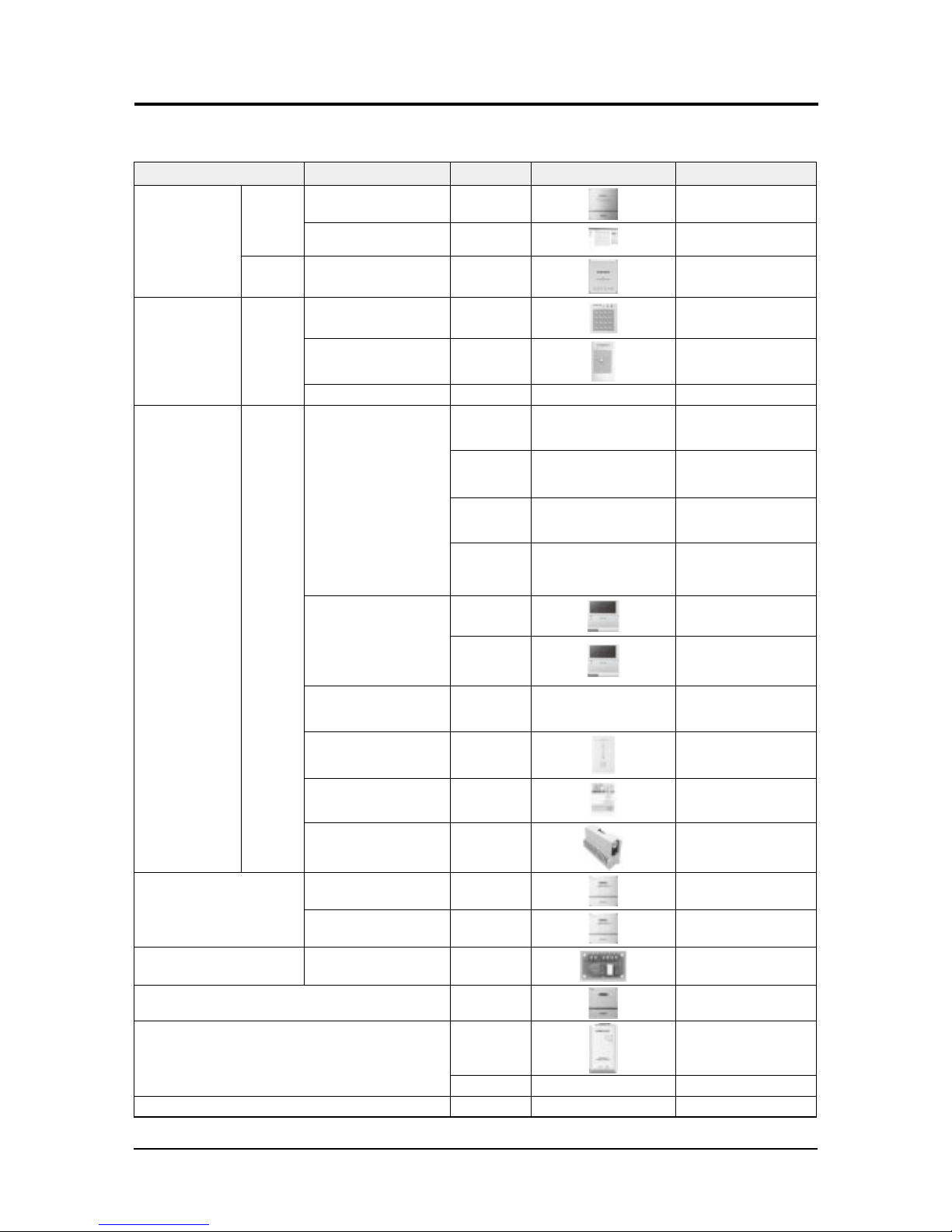

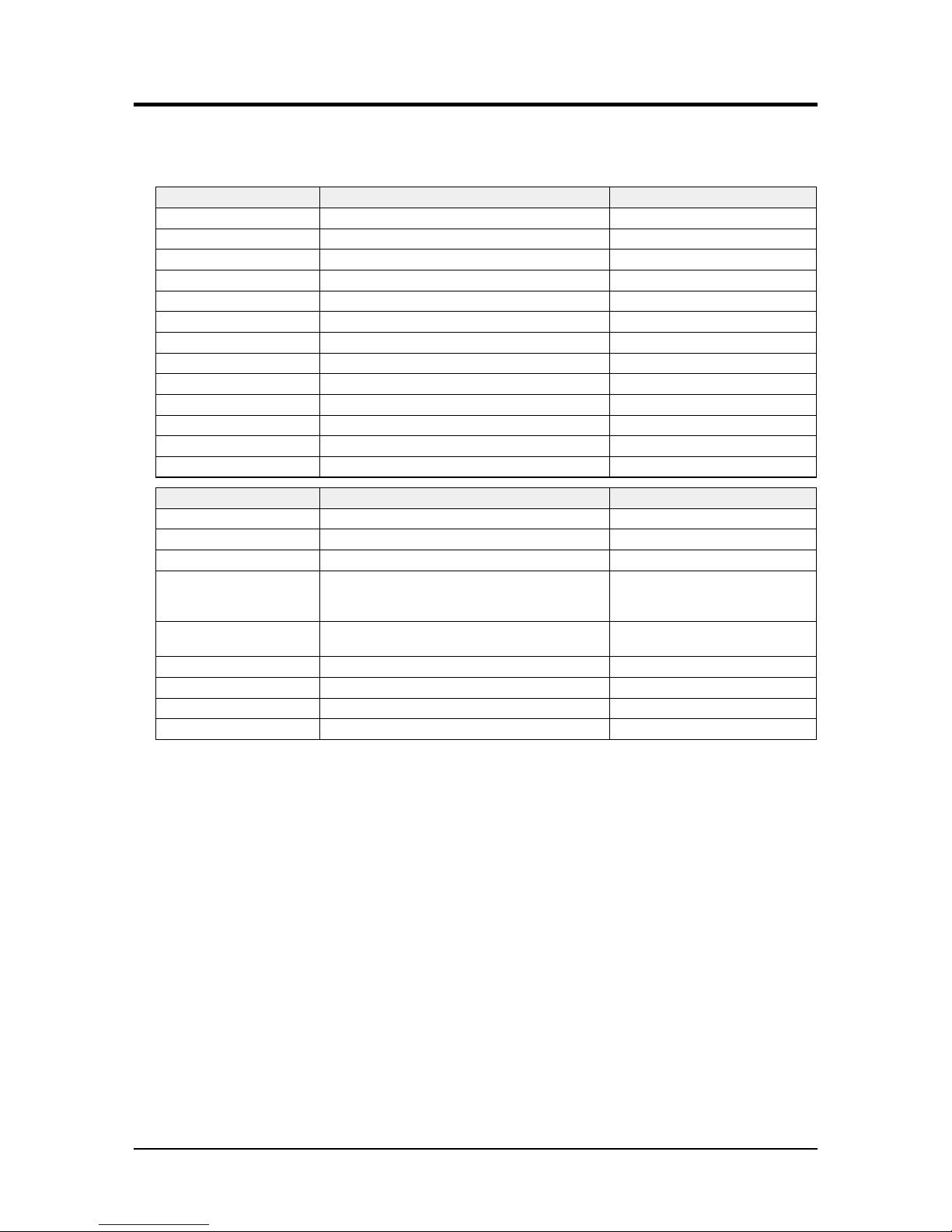

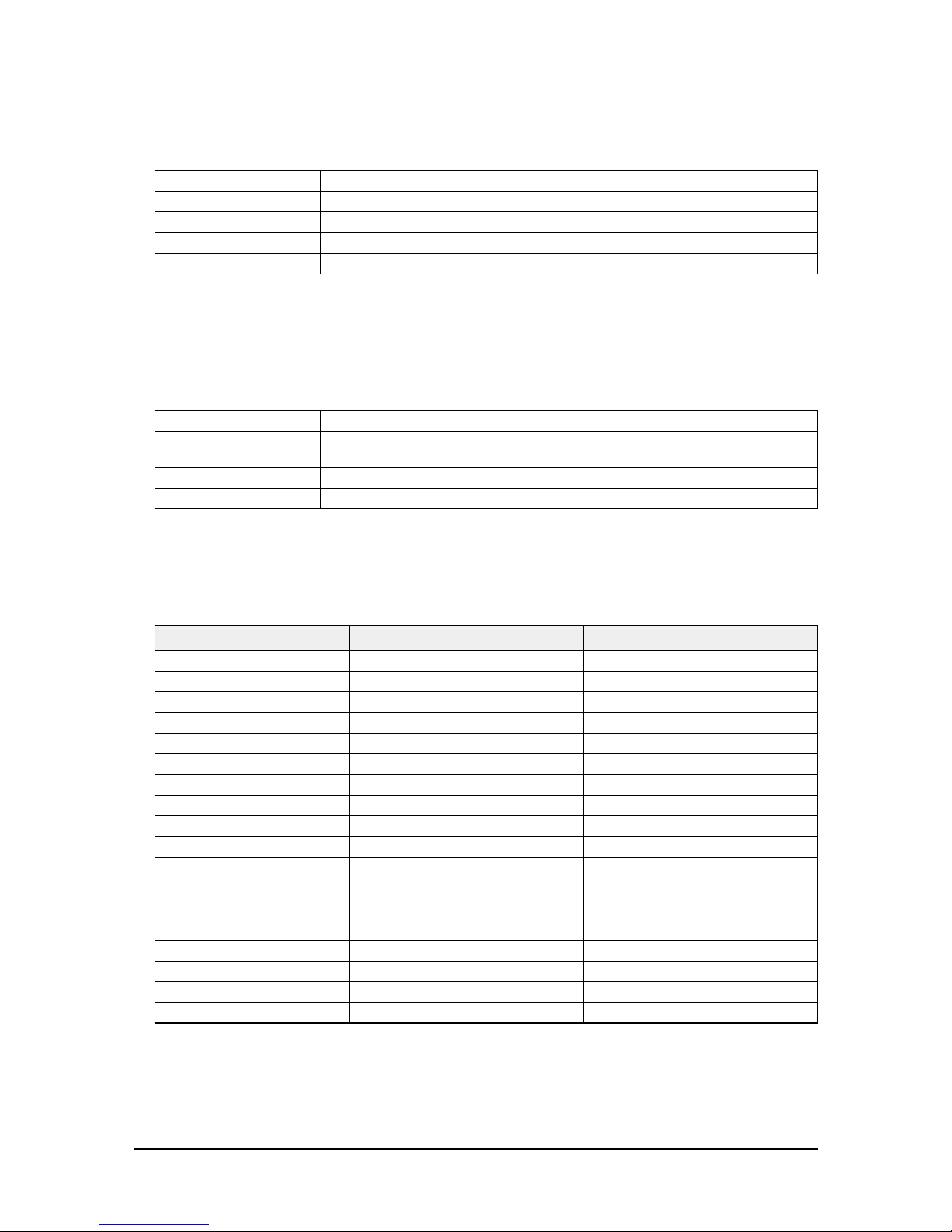

2-2 Accessory and Option Specifications

2-2-1 Accessories

Classification Product Model Image Application model

Integrated manage

-

ment system

Controller

DMS 2 MIM-D00AN

DVM Series, FJM, CAC, ERV

Hydro unit, Hydro unit HT

S-NET 3 MST-P3P

DVM Series, FJM, CAC, ERV

Hydro unit, Hydro unit HT

Interface

Module

SIM MIM- MIM-B12N

DVM Series, FJM

Centralized control

system

Controller

Centralized controller MCM-A202DN

DVM Series, FJM, CAC, ERV

Hydro unit, Hydro unit HT

Operation mode

selection switch

MCM-C200

DVM Series

(Except HR models)

New touch CONTROLLER MCM-A300N

Individual

control system

ControllerController

Controller

Wireless remote controller

MR-DH00

Cassette, Duct

(Receiver needed)

MR-EH00

Cassette, Duct

(Receiver needed)

MR-KH00

360 cassette

AR-EH03E

All model

Wired remote controller

(Multi function)

MWR-WE10N

Cassette, Wall-mounted,

Ceiling, Duct, Console, ERV

MWR-WE13N

All model

Wired remote controller

(Multi function)

MWR-WW00N Hydro unit / Hydro unit HT

Wireless signal receiver MRK-A10

Duct (For wireless remote

controller)

Remote sensor MRW-TA

Cassette, Wall-mounted,

Ceiling, Duct, Console

ERV CO2 Sensor MOS-C1

ERV, ERV PLUS

Building management system

Lonworks interface module MIM-B18N

DVM Series, FJM, CAC, ERV

DMS-Bnet (BACnet) MIM-B17N

DVM Series, FJM

Hydro unit, Hydro unit HT

Guest room management system

External contact

interface module

MIM-B14

Mini DVM(R-410A), DVM

PLUS III, FJM

Power distribution MIM-B16N

DVM Series, FJM

Converter

MIM-C02N

DVM Series, FJM, CAC

MIM-N00

Multi Tenant Function Controller MCM-C210

※ DVM Series : DVM mini, DVM PLUS III, DVM PLUS III HR, DVM PLUS IV, DVM PLUS IV HR

Product Specifications

14

Samsung Electronics

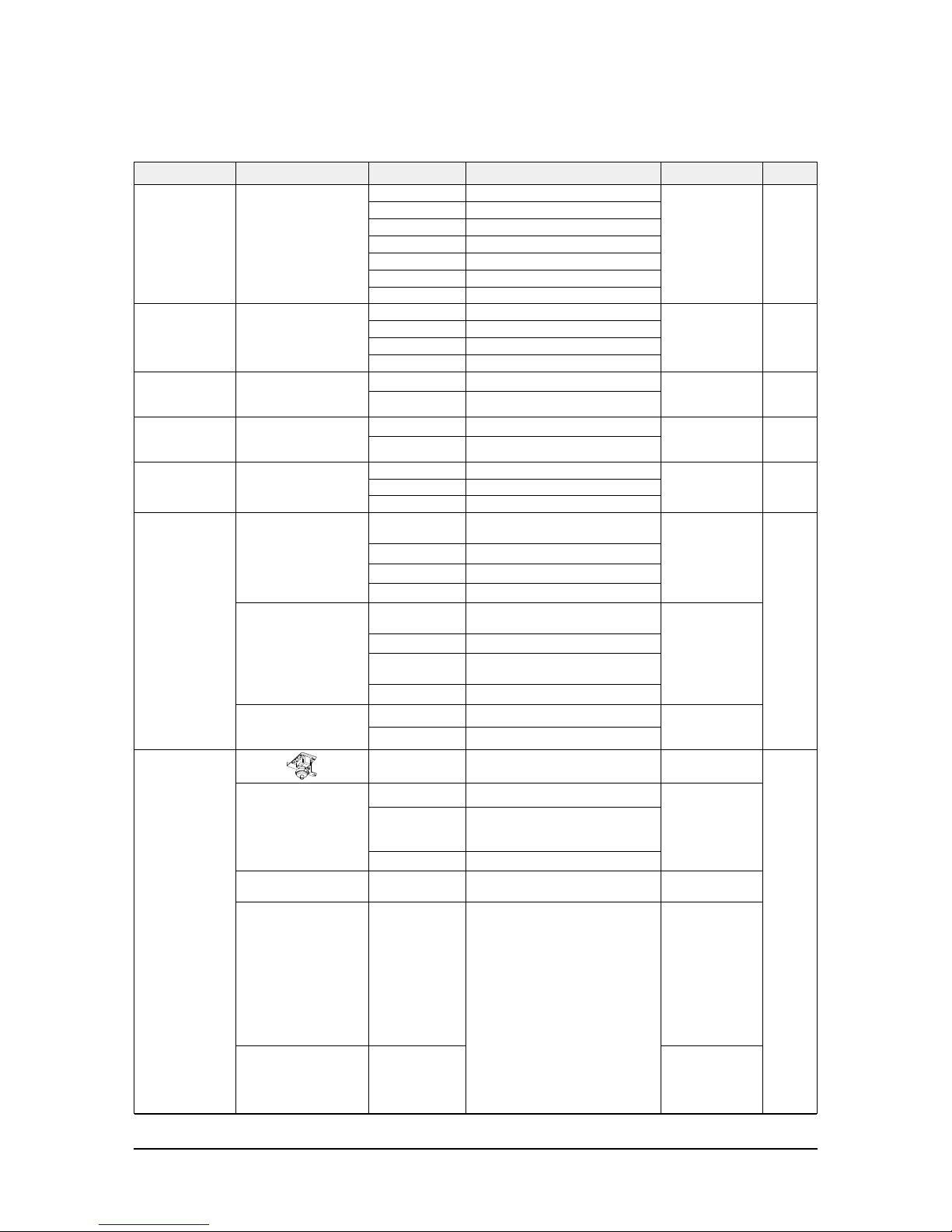

Classification Feature

Model Description Relevant unit Remark

Y-JOINT

MXJ-YA1509M

15.0 kW and below

DVMS HP / HR Requisite

MXJ-YA2512M

Over 15.0 ~ 40.6 kW and below

MXJ-YA2812M

Over 40.6 ~ 46.4 kW and below

MXJ-YA2815M

Over 46.4 ~ 69.6 kW and below

MXJ-YA3419M

Over 69.6 ~ 98.6 kW and below

MXJ-YA4119M

Over 98.6 ~ 139.2 kW and below

MXJ-YA4422M

Over 139.2 kW

Y-joint(High

Pressure Gas)

for DVM S HR

MXJ-YA1500M

23.2 kW and below

DVMS HR Requisite

MXJ-YA2500M

Over 23.2 ~ 69.6 kW and below

MXJ-YA3100M

Over 69.6 ~ 139.2 kW and below

MXJ-YA3800M

Over 139.2 kW

Outdoor joint

(Outdoor

Connection)

MXJ-TA3819M

Below 48 HP

DV

MS HP / HR Requisite

MXJ-TA4422M

Over 50 HP

Outdoor joint

(High Pressure

Gas) for DVM S HR

MXJ-TA3100M

Below 48 HP

DVMS HR Requisite

MXJ-TA3800M

Over 50 HP

Header joint

MXJ-HA2512M

Below 46.4 kW

DVMS HP / HR Requisite

MXJ-HA3115M

Below 69.6 kW

MXJ-HA3819M

Over 69.7 kW

EEV kits

MXD-E13K116A

Below 3.6 kW (1 Room) +

5.6 kW ~9.0 kW (1Room)

Wall-mounted &

Ceiling indoor unit

(For 2 indoor units)

Option

MXD-E13K200A

Below 3.6 kW (2 Rooms)

MXD-E16K200A

5.6 kW~9.0 kW (2Rooms)

MXD-E22K200A

Over 9.0 kW (2Rooms)

MXD-E13K216A

Below 3.6 kW (2 Rooms) +

5.6 kW ~9.0 kW (1Room)

Wall-mounted &

Ceiling indoor unit

(For 3 indoor units)

MXD-E13K300A

Below 3.6 kW (3 Rooms)

MXD-E16K213A

Below 3.6 kW (1 Room) +

5.6 kW ~9.0 kW (2Rooms)

MXD-E16K300A

5.6 kW ~ 9.0 kW (3Rooms)

MEV-E13SA

Below 3.6 kW (1 Room)

Wall-mounted &

Ceiling indoor unit

(for single unit)

MEV-E16SA

5.6 kW ~ 9.0 kW (1Room)

Drain Pump

MDP-N047SNC1D

HSP Duct 22.0/28.0kW -

Option

MDP-M075SGU1D

MSP Duct (9.0/11.2) kW

-

MDP-M075SGU2D

MSP

HSP Duct (11.2/12.8/14.0) kW

Duct (12.8/14.0) kW

MDP-M075SGU3D

MSP Duct (5.6/7.1) kW

MDP-E075SEE3D

MDP-G075SQ

(Internal installation)

Global Duct

GD-S Big Duct

SlimDuct (1.7~14.0) kW -

-

MDP-G075SP

(External installation)

-

Product Specifications

Samsung Electronics

15

Classification Feature

Model Description Relevant unit Remark

PDM KIT

MXD-A38K2A

8~12HP

DVMS Option

MXD-A58K2A

14~22HP

Humidifier

MVO-VA050100

500CMH

- Option

MVO-VA100100

1000CMH

S-Plasma Ion KIT

MSD-CAN1

4way Cassette

- Option

MSD-EAN1

ERV-Plus

Motion detect

sensor

MCR-SMA

4way Cassette - Option

Front panel

PC1NUSMAN

Slim

PC1BWSMAN

PC1MWFMAN

PC1NWFMAN

PC1BWFMAN

Slim 1way cassette

Wind-free 1way cassette

PC1NWSMAN

Slim 1way cassette

PC1MWSKAN

Slim 1way cassette

1way cassette

- Requisite

PC1NUPMAN

Slim 1way cassette

PC2NUSMEN

2 way cassette

PC4SUSMAN

Mini 4way cassette

PC4SYSMEN

Mini 4way cassette

PC4NUSKAN

4 way cassette

PC4NUSKEN

4 way cassette

PC4NBSKAN

PC4NUDMAN

PC4NUNMAN

4 way

360 cassette

360 cassette

cassette

MCU

MCU-S4NEE1N

Below 4 indoor units

DVMS HR

Requisite

(HR Only)

MCU-S6NEE1N

Below 2 large capacity ducts

MCU-S4NEE2N

Below 6 indoor units

AHU KIT

MXD-K025AN

7.0kW~8.75kW

- Option

MXD-K050AN

14.0kW~17.5kW

MXD-K075AN

21.0kW~26.25kW

MXD-K100AN

28.0kW~35.0kW

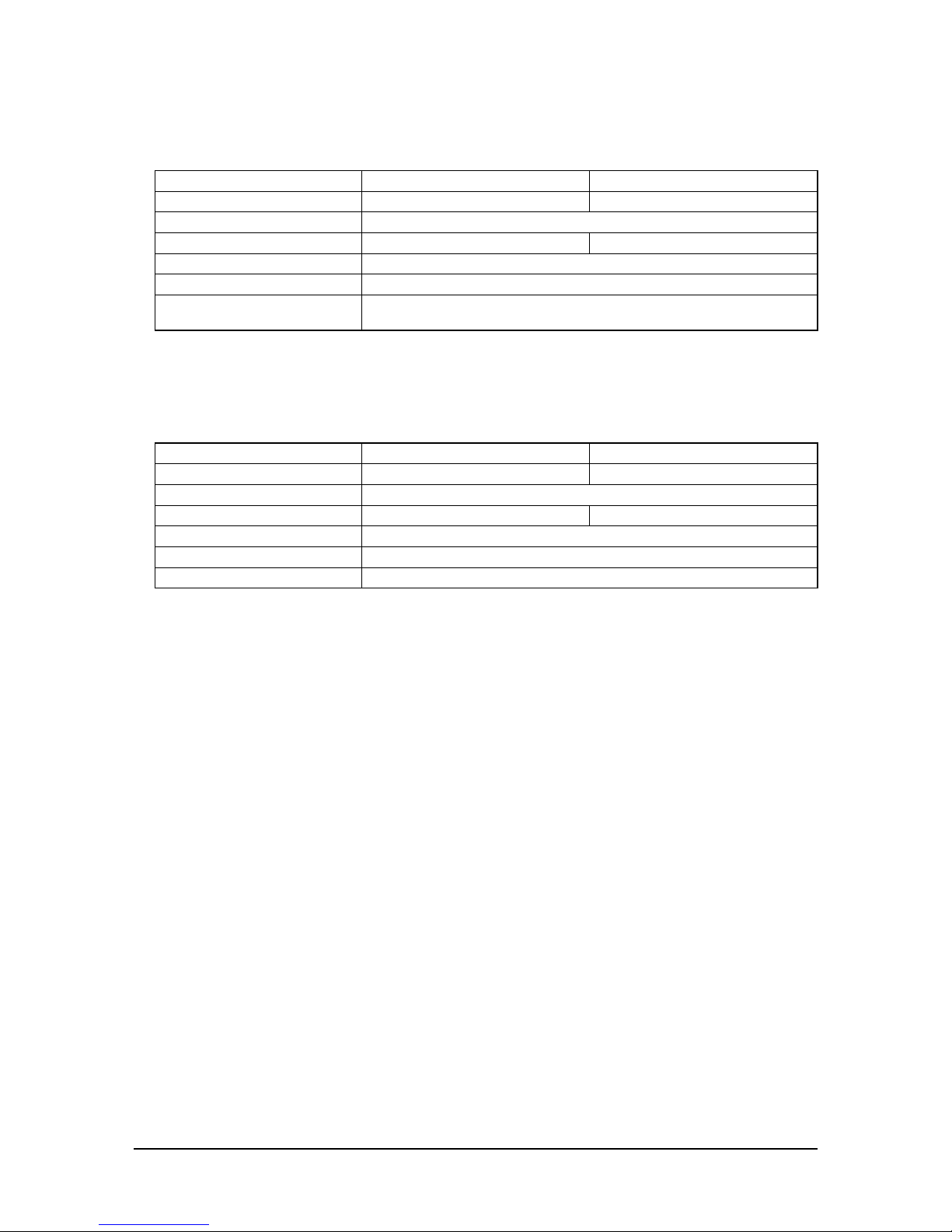

16

Samsung Electronics

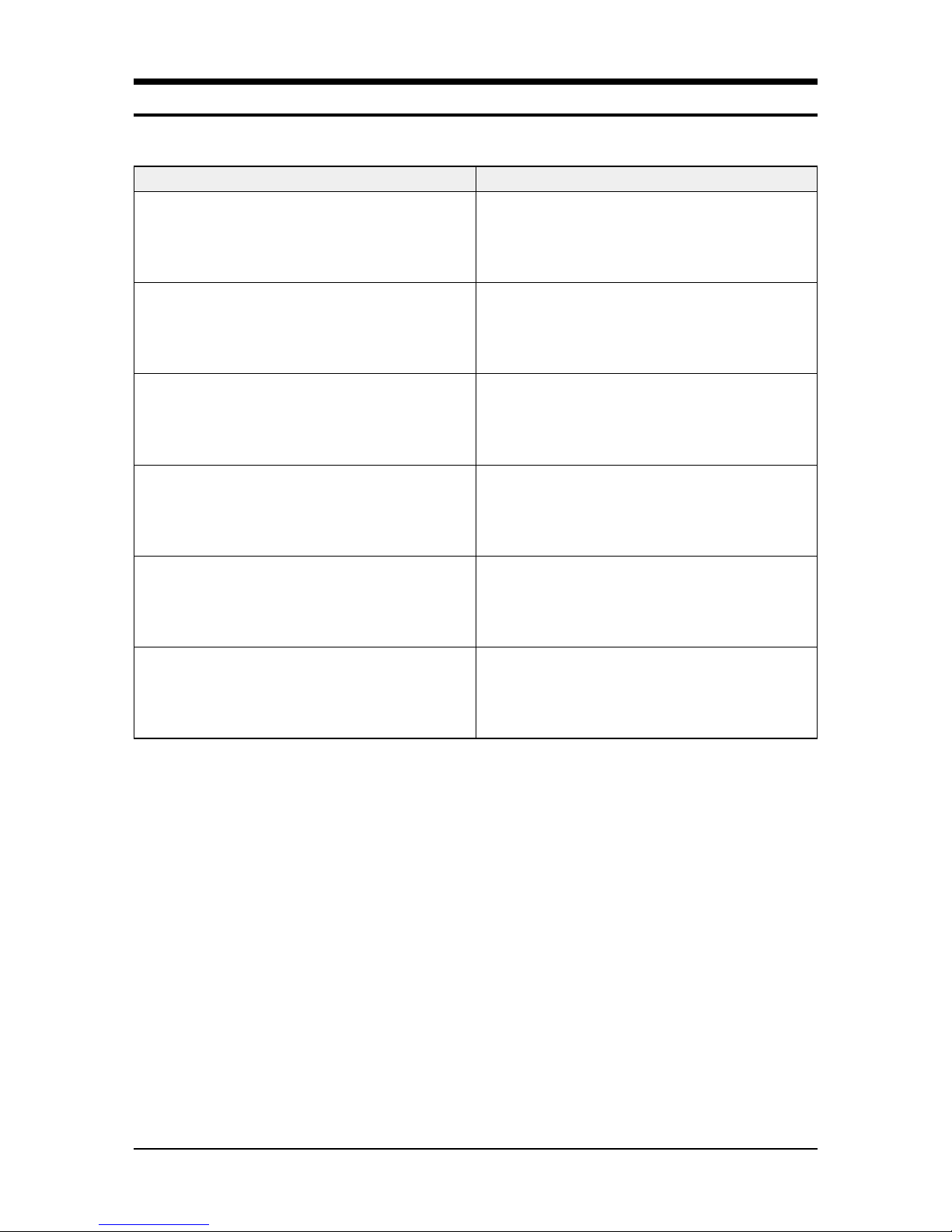

■ Necessary Tools

3. Disassembly and Reassembly

Item Remark

+Screw Driver

Monkey Spanner

–Screw Driver

Nipper

Electric Motion Driver

L-Wrench

Disassembly and Reassembly

Samsung Electronics

17

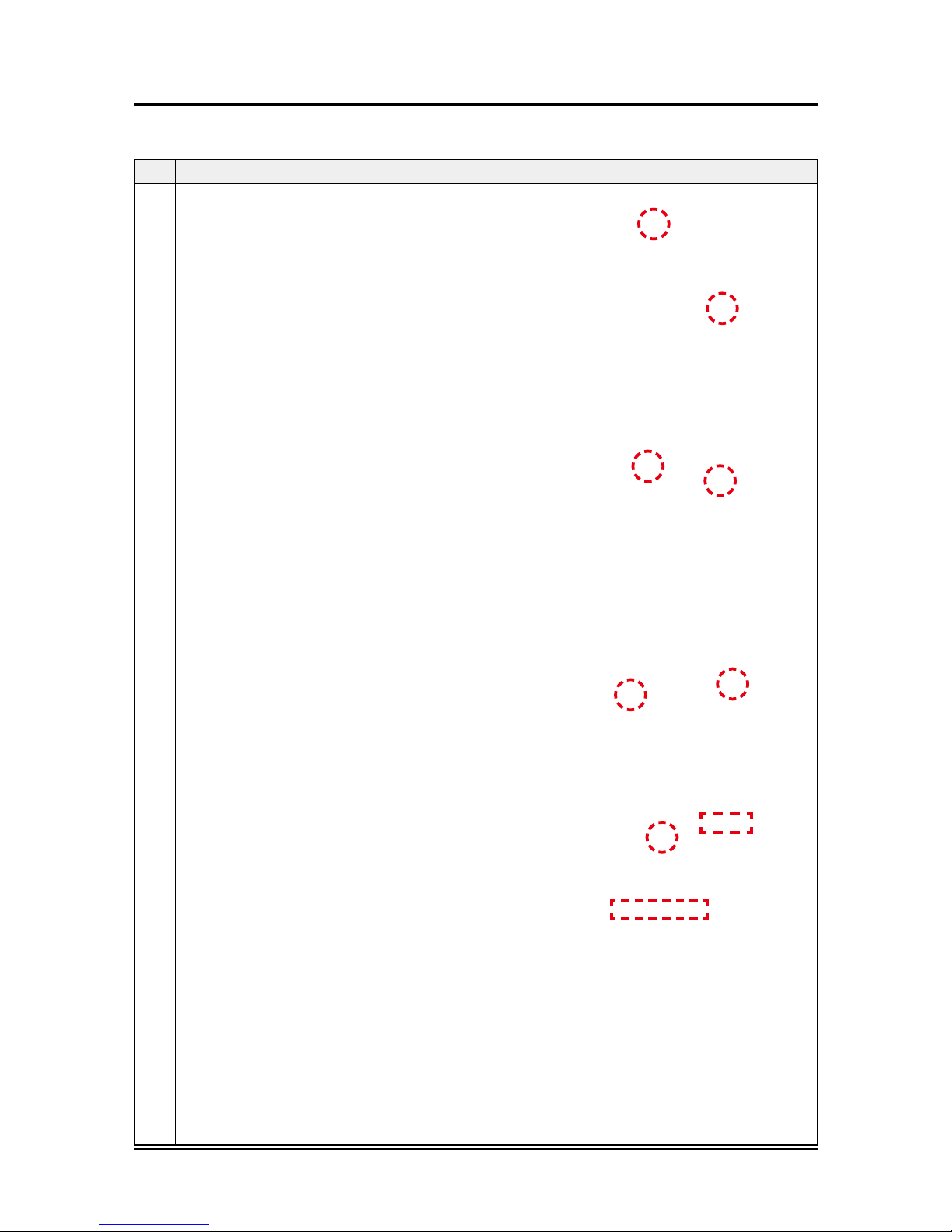

No Parts

Procedure Remark

1 Panel

1)

Pull two levers below Samsung logo to open

the grille.

2) Detach the safety clip and white link from the

panel.

3) Remove the 2 fixed screws to remove the

Control-Box Cover.(Use +Screw Driver)

4)

Remove the 4 connector wires from the PBA.

(Remocon-Receiver, Blade motor and Humidity

sensor.)

5)

Detach the 4 corners of the panel using both

hands.

3-1 Indoor Unit

■ AM045/056/071/090/112/128/140NN4DEH/**

AM009/012/018/024/036/048NN4DCH/**

Disassembly and Reassembly

18

Samsung Electronics

No Parts

Procedure Remark

6) RDisassemble the bolts that are assembled

with the indoor unit at the 4 panel corners.

7) PPress the Steel Hangers at both sides of the

panel inwards, and rotate them 90 degrees

to remove it from the indoor unit’s Hock.

Remove the panel from the indoor unit.

2 Control-Box 1) Disconnect the Connector Wire that is con-

nected to the indoor unit’s PBA from the PBA.

2) Unscrew the 2 fixed screws on both sides of

the Control Box, and disassemble the Control

Box from the indoor unit. (Use +Screw Driver)

Disassembly and Reassembly

Samsung Electronics

19

No Parts

Procedure Remark

3 Bell-Mouth 1) Unscrew the screw fixed on the Bell-Mouth.

(Use +Screw Driver)

2) Push the Bell-Mouth in the direction opposite

to where it’s installed on the Control-Box to

remove it.

4 Drain Pan 1) Unscrew the screws on the 4 corners of the

indoor unit. (Use +Screw Driver)

2) Remove the Drain Pan from the indoor unit.

Disassembly and Reassembly

20

Samsung Electronics

No Parts

Procedure Remark

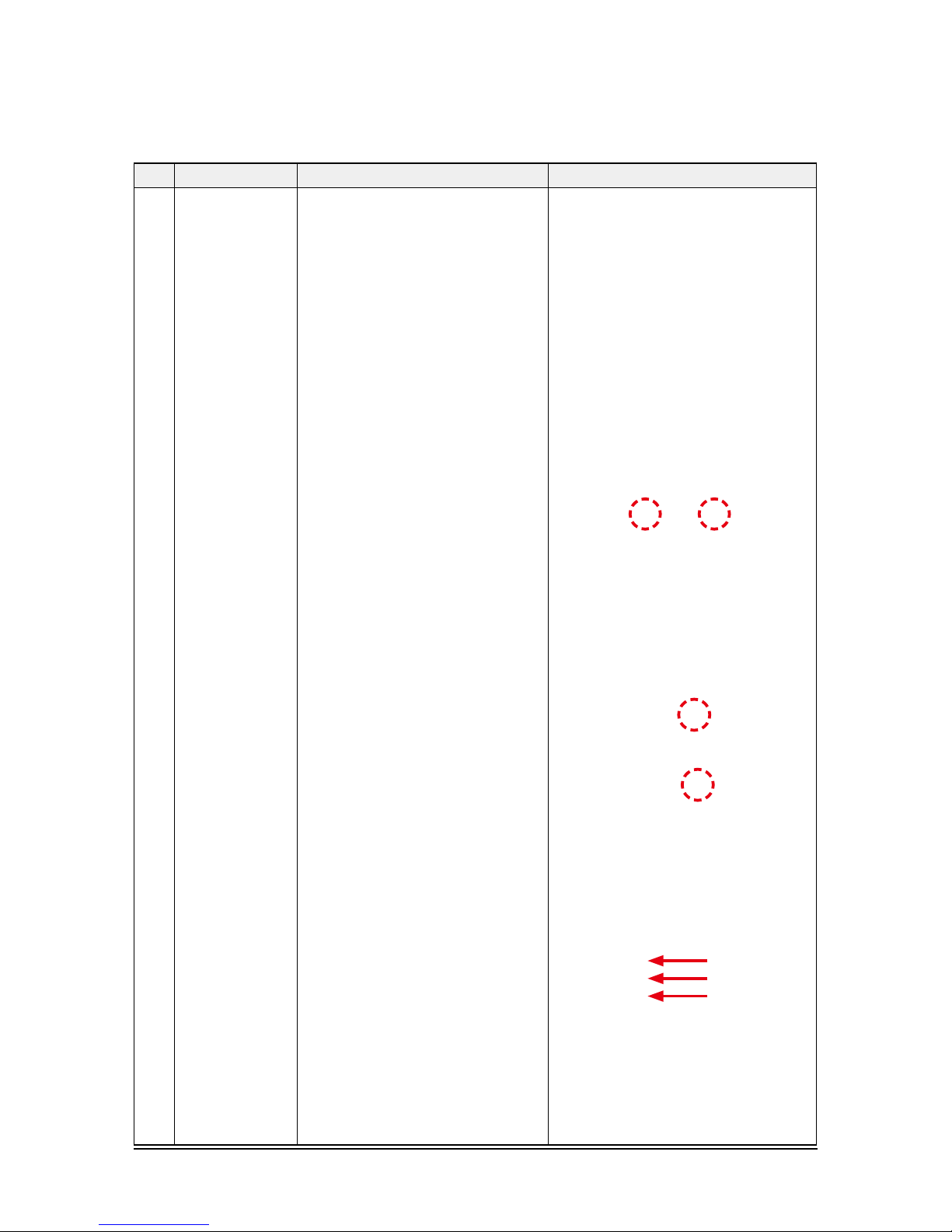

1 Panel

1)

Pull both hooks and take the grille downward.

Two safety clips are mounted to the front grille

to prevent it from dropping.

2) Detach the safity clip and take up the grille.

3) Remove the 2 fixed screws to remove the

Control-Box Cover. (Use +Screw Driver)

4)

Remove the Remocon-Receiver and Blade

Connector Wire from the PBA. (3EA)

■ AM015/022/028/036/045/056/060NNNDEH/**

AM005/007/009/012/018/020NNNDCH/**

Disassembly and Reassembly

Samsung Electronics

21

No Parts

Procedure Remark

1 Panel

5)

Push the 4 panel corners and cover downwards

to remove it.

6) Disassemble the bolts that are assembled with

the indoor unit at the 4 panel corners.

7) Press the Hangers at both sides of the panel

inwards, to remove it from the indoor unit’s

hook. Remove the panel from the indoor unit.

2

Control-Box

1) Disconnect the Connector Wire that is

connected to the indoor unit’s PBA.

Disassembly and Reassembly

22

Samsung Electronics

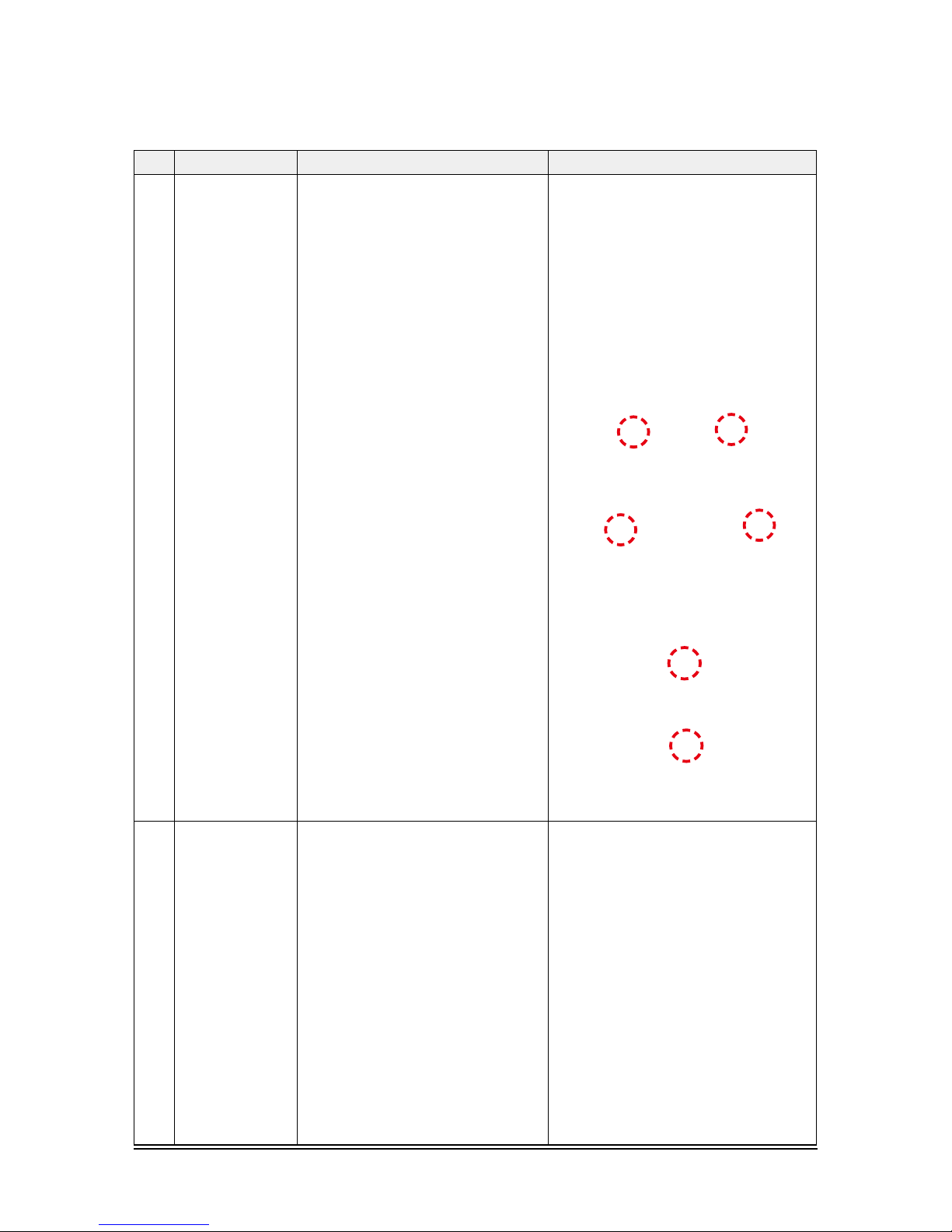

No Parts

Procedure Remark

2

Control-Box

2)

Unscrew the 2 fixed screws on both sides of

the Control Box, and disassemble the Control

Box from the indoor unit. (Use +Screw Driver)

3

Bell-Mouth

1) Unscrew the screw fixed on the Bell-Mouth.

(Use +Screw Driver)

1) Push the Bell-Mouth in the direction opposite

to where it’s installed on the Control-Box to

remove it.

4

Drain Pan

1) Unscrew the screws on the 4 corners of the

indoor unit. (Use +Screw Driver)

Disassembly and Reassembly

Samsung Electronics

23

No Parts

Procedure Remark

4

Drain Pan

1) Remove the Drain Pan from the indoor unit.

24

Samsung Electronics

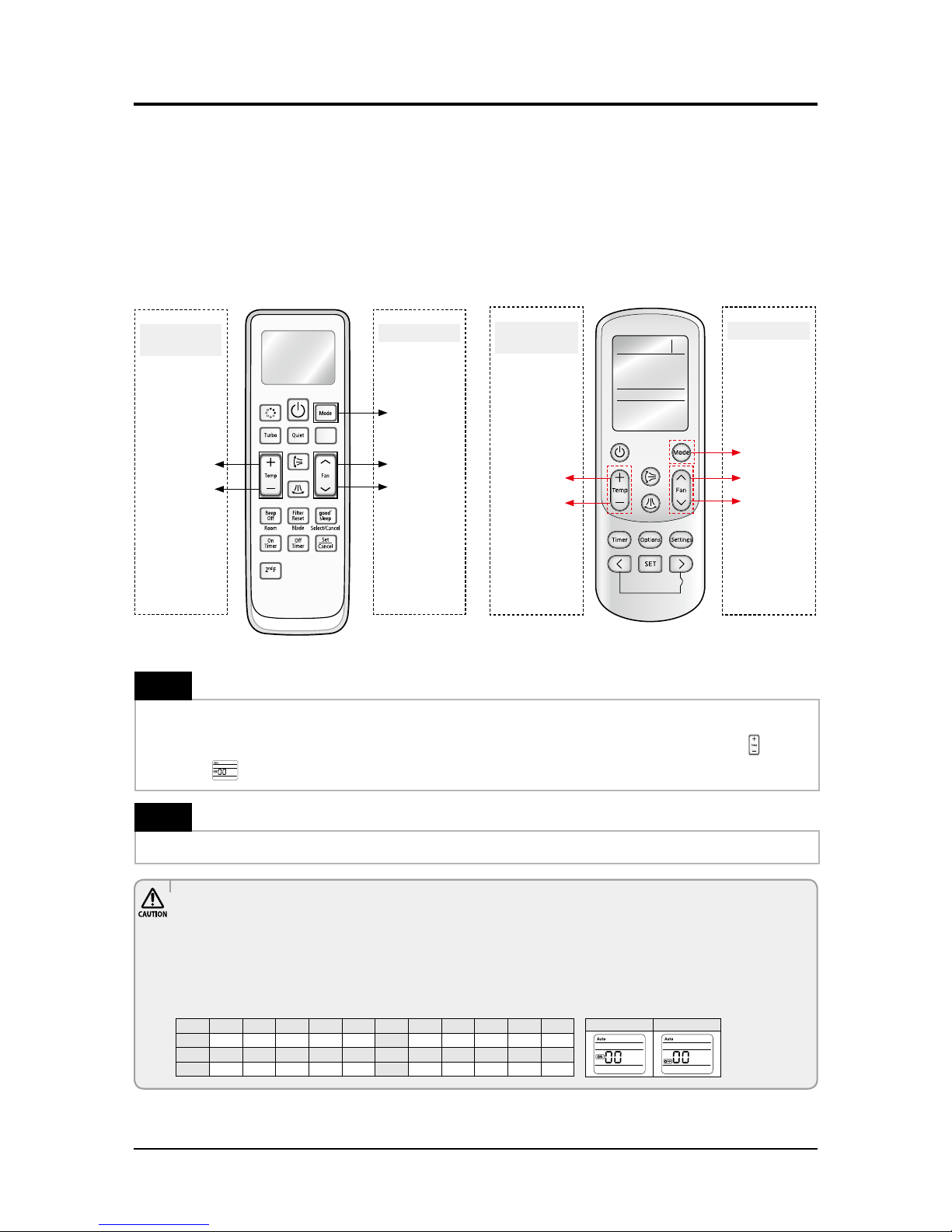

4. Troubleshooting

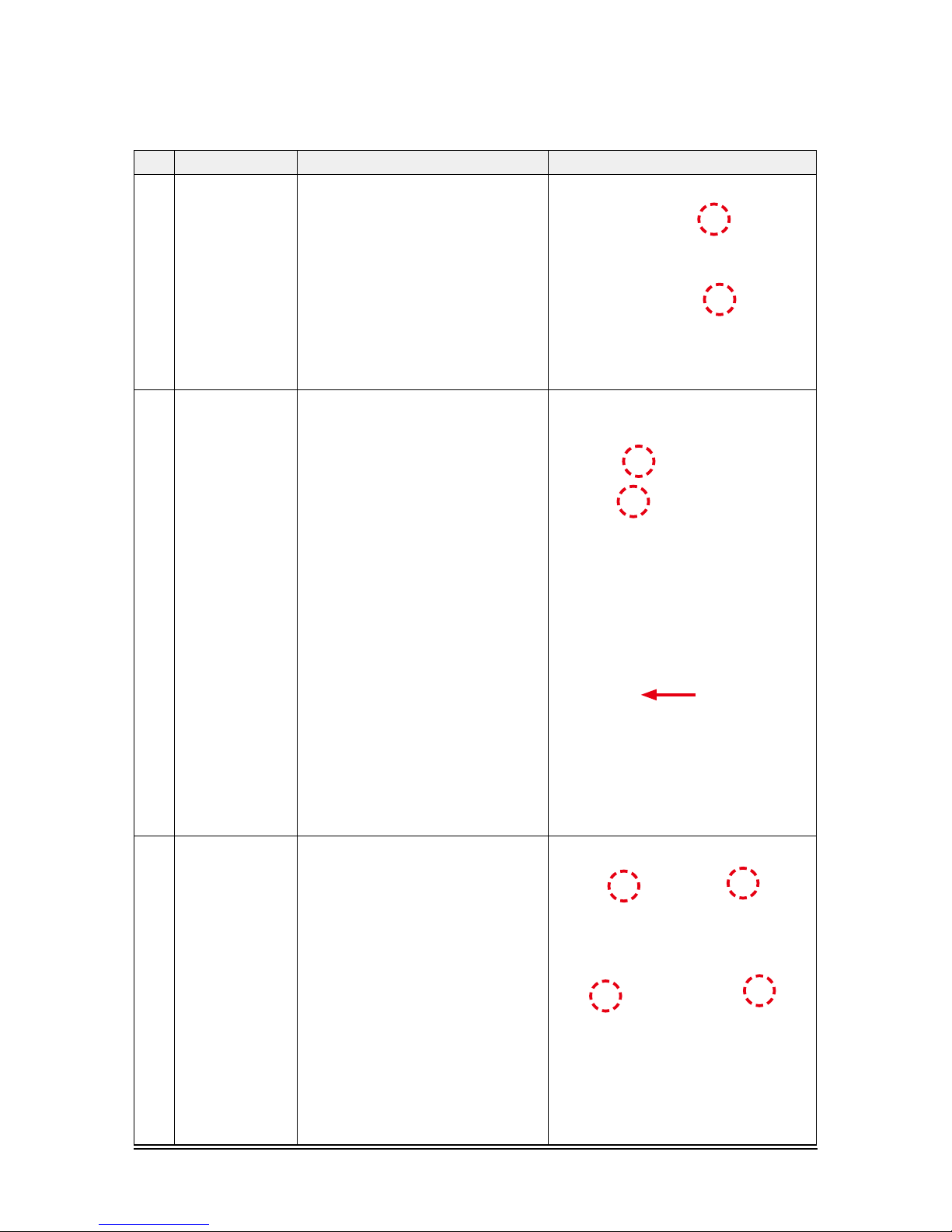

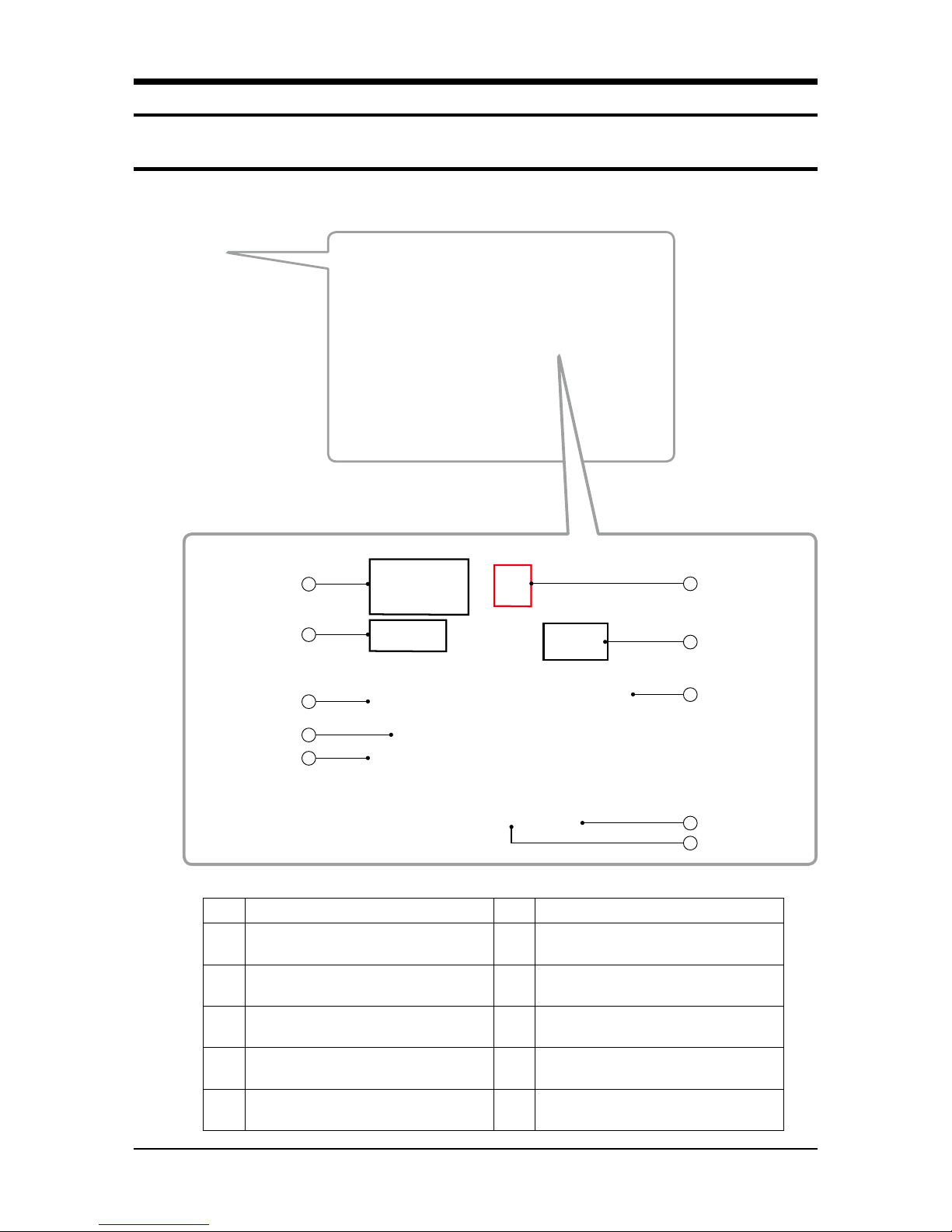

4-1 Check-up Window Description

No. Function No. Function

1

CN22 download (PC)

(SMW200-10 black)

6 Set up the number of connected outdoor units

2

MICOM. download (AS-PRO)

(SMW200-07P white)

7

For checking indoor unit communication

(YW396-02P red)

3 ERROR DISPLAY

8

Transmitter 12V

(YW396-02P blue)

4

State Check

(SMW250-04P red)

9 Outdoor Unit Tact Switch

5 EEPROM SOCKET 10 Outdoor Unit Dip Switch

3

6

8

7

4

9

1

5

2

10

Troubleshooting

Samsung Electronics

25

4-2 Service Operation

4-2-1 Special Operation

► Key input of the outdoor unit when the service enters the operation mode.

K1 (Number of press) Key operation Display on segment

1 time Refrigerant charging in Heating mode K, 1, BLANK, BLANK

2 times Trial operation in Heating mode K, 2, BLANK, BLANK

3 times Pump out in Heating mode (Outdoor unit address 1) K, 3, BLANK, 1

4 times Pump out in Heating mode (Outdoor unit address 2) K, 3, BLANK, 2

5 times Pump out in Heating mode (Outdoor unit address 3) K, 3, BLANK, 3

6 times Pump out in Heating mode (Outdoor unit address 4) K, 3, BLANK, 4

7 times Vacuumig (Outdoor unit address 1) K, 4, BLANK, 1

8 times Vacuumig (Outdoor unit address 2) K, 4, BLANK, 2

9 times Vacuumig (Outdoor unit address 3) K, 4, BLANK, 3

10 times Vacuumig (Outdoor unit address 4) K, 4, BLANK, 4

11 times Vacuuming (All outdoor units) K, 4, BLANK, A

12 times End Key operation

-

Press and hold 1 time Auto trial operation

K, K, BLANK, BLANK

K2 (Number of press) Key operation Display on segment

1 time Refrigerant charging in Cooling mode K, 5, BLANK, BLANK

2 times Trial operation in Cooling mode K, 6, BLANK, BLANK

3 times Pump down all units in Cooling mode K, 7, BLANK, BLANK

4 times

H/R: Checking the pipe connection

H/P: Automatic setting of operation mode (Cooling/Heating)

for trail operation

K, 8, BLANK, BLANK

5 times Checking the amount of refrigerant

K 9 X X (Display of last two digits may differ

depending on the progress)

6 times Discharge mode of DC link voltage K, A, BLANK, BLANK

7 times Forced defrost operation K, B, BLANK, BLANK

8 times Forced oil collection K, C, BLANK, BLANK

9 times End Key operation -

※ Inv1 & Inv2 voltage during discharge mode are displayed alternately.

※ Outdoor Power Off even when the Inverter PCB, Fan PCB is a high DC voltage charging contacts at danger.

※ When you run the repair and replacement of the PCB should work after the power is turned off, the DC voltage discharge.

(Natural discharge until Please wait for at least 15 minutes.)

※ If an error occurs, the discharge mode may not work properly.

In particular, E464 & E364 is power devices can be damaged.

Therefore, the discharge mode, do not use.

Troubleshooting

26

Samsung Electronics

■

Commissioning

► After initial installation, stable operation for a certain period of time limited to operation conditions.

Cooling Heating

Method of Entry K2 Tac t Switch twice K2 Tact Switch twice

Compressor Normal operation, but the maximum frequency limit (differ by model)

Indoor Unit Whole operation (The set temperature=3°C) Whole operation ( The set temperature=40°C)

Outdoor fan and valves Normally control conduct

Operation time Min : 60 minutes, Max : 10 hours

Etc. Exceed the maximum operating time at stops and waits.

Protection and control, self-diagnosis is performed.

■

Refrigerant lling operation

► Operation to filling the refrigerant compressor was fixed at a certain frequency.

Cooling Heating

Method of Entry K2 Tact Switch one time K1 Tac t Switch one time

Compressor Starting frequency (Mild Start frequency) operation

Indoor Unit Whole operation (The set temperature=3°C) Whole operation ( The set temperature=40°C)

Outdoor fan and valves Normally control conduct

Operation time 60 minutes

Etc. During the filling operation does not enter the special operation, such as oil recovery, defrost.

Troubleshooting

Samsung Electronics

27

■

Heating Pump Out

► Operation for the repair of the Individual outdoor unit, the outdoor unit refrigerant emissions to the indoor part.

► Liquid pipe service valve and the gas pipe service valve operation, the operator manually need to close.

► Observe low pressure using View Mode of K4 button if compressor operate.

If low pressure goes down below about 0.2 MPa.g : Immediately lock the gas side service valve, Pump Out operation is shut down.

(Pump out operation shut down : K1 button once more press or K3 button one time press)

► If operation of low pressure goes down below 0.1 MPa.g : Will be stopped automatically for the protection of the compressor.

How to Initiate K1 Tac t Switch 3 times~6 times

Compressor 60Hz

Indoor Unit Whole Operation (The set temperature=40°C)

4Way Valve ON (Heating Mode)

Outdoor Fan Maximum air flow

Main EEV Operation side : 700 Step (Stop side : 0 step)

Maximum Operation Time 10 minutes

Protection Control Conduct the discharge temperature, high pressure control. (Low pressure protection control is not carried out)

※ Low pressure is outside normal limits : Operation is shut down after gas pipe manually closed.

Etc. Entry after safety start. (Only the corresponding Outdoor Unit operation.)

To pump out more than 2 : Except communication between Outdoor Unit of relevant set after working for one,

remainder set makes Pump Out add.

■

Cooling Pump Down

► Recover the refrigerant of Indoor Unit and Piping to outdoor side.

► Liquid pipe service valve and the gas pipe service valve operation, the operator manually need to close.

► If the installation of the long pipe : Any refrigerant into the outdoor unit can not be recovered, therefore should use a separate container.

► Observe low pressure using View Mode of K4 button if compressor operate.

If low pressure goes down below about 0.2 MPa.g : Immediately lock the gas side service valve, Pump Out operation is shut down.

(Pump out operation shut down : K1 button once more press or K3 button one time press)

► If operation of low pressure goes down below 0.1 MPa.g : Will be stopped automatically for the protection of the compressor.

How to Initiate K2 Tact Switch 3 times

Compressor Address No.1 Outdoor Unit - 60Hz (Other Outdoor Unit COMP OFF)

Indoor Unit Whole Operation (The set temperature=3°C)

4Way Valve OFF (Cooling Mode)

Outdoor Fan Maximum air flow

Main EEV Operation side : 2000 Step , Stop side : 2000 step

Maximum Operation Time 30 minutes

Etc. Does not conduct the operation of the special operation, and protection control.

Pressure and temperature is outside normal limits : Operation is shut down after gas pipe manually

closed.

Troubleshooting

28

Samsung Electronics

■

Vacuum Operation

► Operation to facilitate vacuum to open the valve after the Outdoor Unit repair.

■

Piping Inspection Operation

► Operation mode to check the status of the piping between the MCU and the indoor unit.

► Heat Pump Model : Outdoor temperature is more than 15°C / Cooling commissioning start

Outdoor temperature is less than 15°C / Heating commissioning start

■

Discharge Mode Operation

► Outdoor power is turned off, the Inverter PCB and Fan PCB charging a high DC voltage, so dangerous to touch.

- To replace the PCB, first turn off the power and the begin if DC voltage is discharged.

- If not use the discharge mode, the discharge time of about 15 minutes takes.

- If an error occurs, the discharge mode may not properly run. (Wait until natural discharge.)

- In particular, E 464, E364, power devices may be damaged, therefore do not use the discharge mode.

► Block the Inverter PCB 3-phase relay after connected the power, and through compressor, DC voltage is discharging.

- INV1 and INV2 DC voltage during discharge mode are displayed alternately.

-Discharge mode Display (Rotate the three page display, as shown below.)

'K' 'A' '' ' ‘

→

DC Link Volt1 ( For example, 120[V] 0 1 2 0 display)

→ DCLinkVolt2 ( For example, 120[V] 0 1 2 0 display) 'K' 'A' '' ' ‘ DC Link Volt1 …

► Discharge is complete, the power of the Inverter PCB and Fan PCB is being blocked, communication function is blocked,

E206 will occur.

► If want operation again after complete discharge mode : Restart after K3 key to Reset or Power Reset.

How to Initiate K1 Tact Switch 7 times~11 times

Compressor OFF

Indoor Unit/Outdoor Fan OFF

4Way Valve OFF

Valves Open all valves maximum

Etc. If not turn off the vacuum mode, the start of normal operation is prohibited.

Troubleshooting

Samsung Electronics

29

■

Forced defrost operation

► Forced defrost operation : Is operation when Frost Formation occurs in the outdoor. (When carried out the service)

■

Forced oil recovery operation

► Forced oil recovery operation : Oil recovery in the outdoor unit for the purpose of moving, installation if necessary.

Method of Entry K2 Tac t Switch 6 times

Start pattern Heating commissioning pattern

Defrost start Defrost start : It is after 10 minutes which Safety Start finishes.

Defrost off General defrost operation conditions are the same as.

Etc. Defrost shut down and stop the normal pattern of the outdoor unit stop.

Method of Entry K2 Tac t Switch 7 times

Start pattern Outdoor temperature is more than 10°C : Cooling commissioning

Outdoor temperature is less than 10°C : Heating commissioning

Oil recovery start Oil recovery star t : It is after 10 minutes which Safety Start finishes.

Etc. Oil recovery shut down and stop the normal pattern of the outdoor unit stop.

4-2-2 DVM S Models EEPROM Code Table

No. Model Name EEP Code

1 AM080FXVAGH/EU DB82-01358A

2 AM100FXVAGH/EU DB82-01359A

3 AM120FXVAGH/EU DB82-01360A

4 AM140FXVAGH/EU DB82-01361A

5 AM160FXVAGH/EU DB82-01362A

6 AM180FXVAGH/EU DB82-01363A

7 AM200FXVAGH/EU DB82-01364A

8 AM220FXVAGH/EU DB82-01365A

9 AM080FXVAGR/EU DB82-01330A

10 AM100FXVAGR/EU DB82-01331A

11 AM120FXVAGR/EU DB82-01332A

12 AM140FXVAGR/EU DB82-01333A

13 AM160FXVAGR/EU DB82-01334A

14 AM180FXVAGR/EU DB82-01335A

15 AM200FXVAGR/EU DB82-01336A

16 AM220FXVAGR/EU DB82-01337A

17 AM080FXMDGH/EU DB82-01774A

18 AM090FXMDGH/EU DB82-01776A

Troubleshooting

30

Samsung Electronics

4-3 Troubleshooting

4-3-1 Setting Option Setup Method

4-3-1-1 PCB option code input method

▶

Set the indoor unit address and installation option with remote controller option.

Set the each option separately since you cannot set the ADDRESS setting and indoor unit installation setting option at the

same time.You need to set twice when setting indoor unit address and installation option.

■ The procedure of setting option

High Temp Button

High Fan Button

Mode change

Low Temp Button

Low Fan Button

Entering mode for

setting option

Option setting mode

Step 1

Entering mode to set option

1. Remove batteries from the remote controller.

2. Insert batteries and enter the option setting mode while pressing High Temp button and Low Temp button

.

3.

Check if you have entered the option setting status.

Step 2

The procedure of option setting

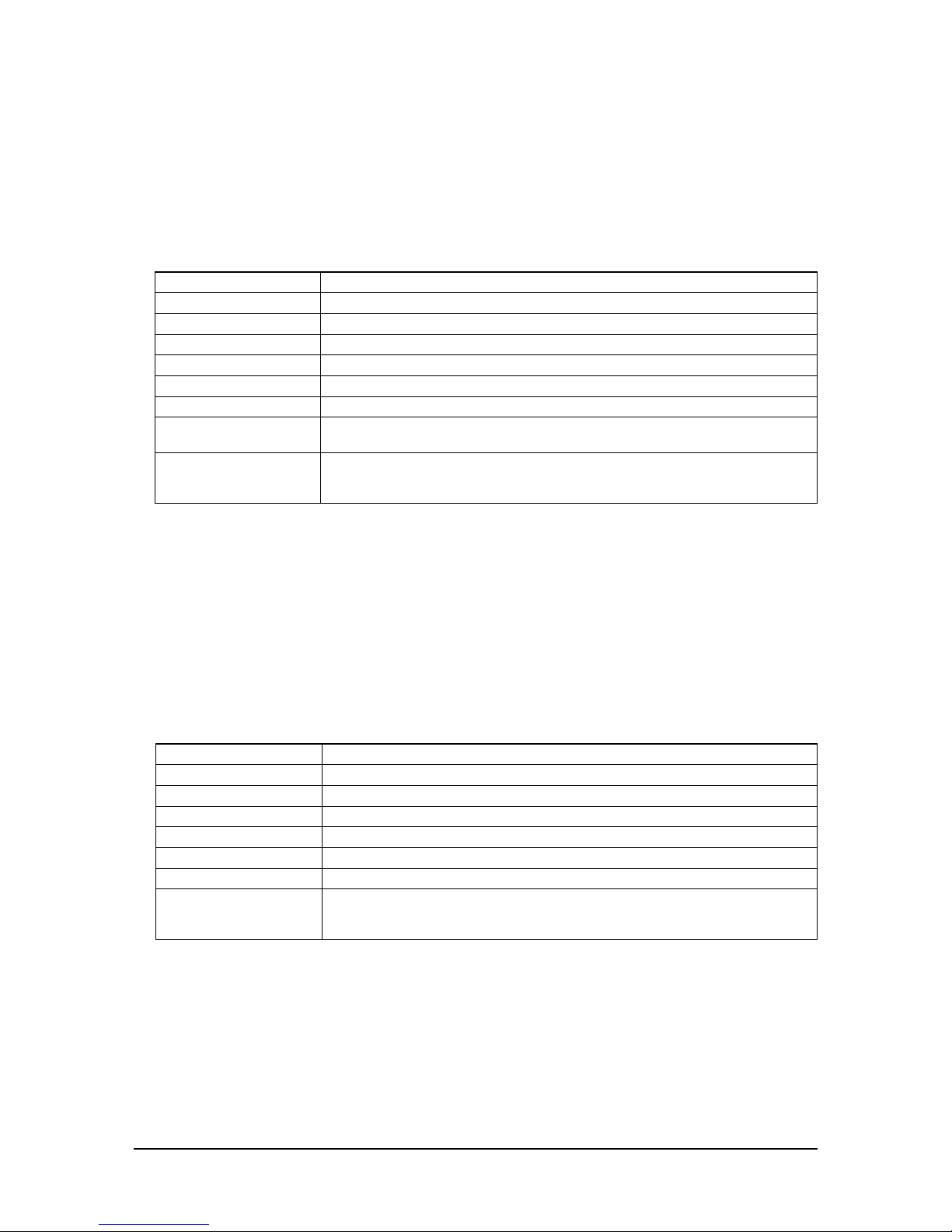

After entering the option setting status, select the option as listed below.

• The total number of available options are 24: SEG1 to SEG24.

• Because SEG1, SEG7, SEG13, and SEG19 are the page options used by the previous remote control models, the modes to set values

for these options are skipped automatically.

• Set a 2-digit value for each option pair in the followinig order: SEG2 and SEG3

→