Samsung AM096FXVAFH series, AM120FXVAFR series, AM120FXVAFH series, AM096FXVAFR series, AM072FXVAFR series Service Manual

...

AIR CONDITIONER CONTENTS

SYSTEM AIR CONDITIONER

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram and Parts List

6. Wiring Diagram

7. Cycle Diagram

8. Key Options

9. Test Operation

10. Reference Sheet

OUTDOOR UNIT

AM072/096/120/144FXVAFH

6

AM072/096/120/144FXVAFR

6

AM072/096/120/144FXVAJH

6

AM072/096/120/144FXVAJR

6

AM072/096/120/192HXWAFR

AM072/096/120/192HXWAJR

AM168/192HXVAFH

6

AM168/192HXVAFR

6

AM168/192HXVAJH

6

AM168/192HXVAJR

6

AM072/096KXVTF

6

AM072/096KXVTJ

6

AM216KXVGJH

AM038/048/055KXWDCH

Section 0

Samsung Electronics 3

Contents

1. Precautions .......................................................................................................... 1-1

1-1 Precautions for the Service ......................................................................................................................................1-1

1-2 Precautions for the Static Electricity and PL .....................................................................................................1-1

1-3 Precautions for the Safety ........................................................................................................................................1-1

1-4 Precautions for Handling Refrigerant for Air Conditioner ..........................................................................1-2

1-5 Precautions for Welding the Air Conditioner Pipe .........................................................................................1-2

1-6 Precautions for Additional Supplement of Air Conditioner Refrigerant ...............................................1-2

1-7 Other Precautions ........................................................................................................................................................1-2

2. Product Specifications ....................................................................................... 2-1

2-1 The Feature of Product ..............................................................................................................................................2-1

2-1-1 Feature ...............................................................................................................................................................2-1

2-1-2 Changes in comparison to basic mode ................................................................................................2-3

2-1-3 Structure of product .................................................................................................................................. 2-10

2-2 Product Specifications ........................................................................................................................................... 2-15

2-2-1 Outdoor Unit ................................................................................................................................................2-15

2-3 Accessory and Option Specifications ............................................................................................................... 2-24

2-3-1 Accessories ....................................................................................................................................................2-24

3. Disassembly and Reassembly ........................................................................... 3-1

3-1 Necessary Tools .............................................................................................................................................................3-1

3-2 Disassembly and Reassembly .................................................................................................................................3-2

3-2-1 AM072FXVA66 ..............................................................................................................................................3-2

3-2-2 AM096FXVAJ6/AM120FXVAJ6/AM168HXVA66/AM192HXVA66/096KXVA66

...... 3-12

3-2-3 AM096FXVAF6/AM120FXVAF6/AM144FXVA66/072KXVA 66 ........................................... 3-22

3-2-4 AM216KXVGJ✳ ............................................................................................................................................ 3-33

3-2-5 AM072/096/120HXWA66 ...................................................................................................................... 3-47

3-2-6 AM192HXWA66.........................................................................................................................................3-55

3-3 Caution at compressor exchange ...................................................................................................................... 3-62

3-4 MCU ................................................................................................................................................................................ 3-68

3-5 EEV KIT ........................................................................................................................................................................... 3-69

4. Troubleshooting .................................................................................................. 4-1

4-1 Check-up Window Description ..............................................................................................................................4-1

4-2 PCB Description ............................................................................................................................................................4-2

4-3 Service Operation ........................................................................................................................................................4-3

4-3-1 Special Operation ..........................................................................................................................................4-2

4-3-2 DVM S Models EEPROM Code Table ...................................................................................................4-13

4-3-3 Number Display Method ........................................................................................................................ 4-13

4-4 Appropriate Measures for Different Symptom ............................................................................................. 4-18

4-4-1 Outdoor Unit Operation Flow ............................................................................................................... 4-18

4-4-2 Main PCB has no power phenomenon ............................................................................................. 4-23

4-4-3 Communication Error between Indoor and Outdoor Units during Tracking.................... 4-26

4-4-4 Communication Error between Indoor and Outdoor Units after Tracking ........................ 4-30

4-4-5

Communication error between main and sub Unit of outdoor unit or between outdoor units

.. 4-32

4-4-6 Internal Communication error of the Outdoor Unit C-Box ....................................................... 4-34

4-4-7 Internal PCB Communication error of the Outdoor Unit C-Box..............................................4-36

4-4-8

MCU branch part setup error – inconsecutive connection with the use of 2 branch parts

..... 4-39

4-4-9 MCU branch part setup error-Repeated setup for the same address over 3 times ........ 4-40

4-4-10 MCU branch part setup error-non-installed address setup ................................................... 4-41

4-4-11 Setup Error for MCU Branch part – Setup Error for MCU Quantity Used ..........................4-42

4-4-12 MCUMCU branch part setup error – Overlapping Indoor unit Address setup .............. 4-43

4-4-13

MCU branch part setup error – Set as being used without connection to an Indoor unit

.. 4-44

Section 0

4 Samsung Electronics

Contents

4-4-14

MCU branch part setup error – Connect an Indoor unit to a branch part not being used

...... 4-45

4-4-15 MCU branch part setup error – Connect more Indoor units than what is actually set up in MCU .. . 4-46

4-4-16 MCU/MCU subcooler entrance/exit sensor error (Open/Short) ........................................... 4-47

4-4-17 Outdoor Temperature Sensor Error .................................................................................................. 4-48

4-4-18 Cond Out Temperature Sensor Error (Open/Short) ...................................................................4-49

4-4-19 Outdoor Cond Out sensor breakaway error ................................................................................. 4-51

4-4-20 Compressor Discharge or Top 1/2 Temperature sensor error ...............................................4-53

4-4-21 Compressor Discharge or Top temperature sensor breakaway error ................................ 4-55

4-4-22 E269 : Suction Temperature sensor breakaway error ............................................................... 4-57

4-4-23 High Pressure sensor error (Open/Short) .......................................................................................4-59

4-4-24 Low Pressure sensor error (Open/Short) ........................................................................................ 4-61

4-4-25 Suction Temperature sensor error (Open/Short) ........................................................................ 4-63

4-4-26 Liquid Pipe Temperature sensor error (Open/Short) ................................................................. 4-65

4-4-27 EVI In Temperature sensor error (Open/Short) ............................................................................ 4-67

4-3-28 EVI Out Temperature sensor error (Open/Short) ........................................................................ 4-68

4-4-29 Suction-2 Temperature Sensor Error (OPEN/SHORT) ................................................................ 4-69

4-4-30 Measures of other outdoor unit error ............................................................................................. 4-70

4-4-31 E407 : Comp. Down due to High Pressure Protection Control .............................................4-72

4-4-32 E410 : Comp. Down due to Low Pressure Protection Control ...............................................4-75

4-4-33 E416 :

Suspension of starting due to Compressor discharge temperature sensor

/ Top temperature sensor

........................................................................................................ 4-77

4-3-34 3-phase Input Wiring error ...................................................................................................................4-79

4-3-35 E428 : Suspension of starting by abnormal compression ratio ............................................ 4-80

4-3-36 EVI EEV Open error ..................................................................................................................................4-81

4-3-37 Refrigerant leakage error ...................................................................................................................... 4-83

4-3-38 Prevention of heating / cooling operation due to outdoor temperature ........................ 4-85

4-3-39 Prevention of heating refrigerant charge due to outdoor temperature ..........................4-86

4-3-40 CH wire breaking error........................................................................................................................... 4-87

4-3-41 Fan starting error ......................................................................................................................................4-90

4-3-42 Fan lock error ............................................................................................................................................. 4-91

4-3-43 Momentary Blackout error .........................................................................................................................4-92

4-3-44 Outdoor Fan Motor overheating ....................................................................................................... 4-93

4-3-45 Fan IPM Overheat error .......................................................................................................................... 4-94

4-3-46 Compressor starting error ....................................................................................................................4-95

4-3-47 COMP Overcurrent error ....................................................................................................................... 4-98

4-3-48 Overvoltage / Low voltage error .....................................................................................................4-103

4-3-49 DC Link voltage sensor error .............................................................................................................4-105

4-3-50 Fan Motor Overcurrent error .............................................................................................................4-107

4-3-51 Input / Output Current sensor error ...............................................................................................4-109

4-3-52 Outdoor Fan PCB Overvoltage / Low voltage error .................................................................4-111

4-3-53 Hall IC(Fan) error .....................................................................................................................................4-112

4-3-54 Inverter Overheat error ........................................................................................................................4-113

4-3-55 Option setting error of outdoor unit .............................................................................................4-114

4-3-56 Model mismatching of Indoor unit. ...............................................................................................4-116

4-3-57 Error due to using single type outdoor unit in a module installation .............................4-117

5. PCB Diagram and Parts List ............................................................................... 5-1

5-1 ASS'Y PCB MAIN ...........................................................................................................................................................5-1

5-2 ASS'Y PCB MAIN-HUB ................................................................................................................................................5-6

5-3 ASS’Y PCB INVERTER ............................................................................................................................................... 5-10

5-4 OUT DOOR UNIT PCB ............................................................................................................................................. 5-14

5-5 ASS’Y PCB FAN ........................................................................................................................................................... 5-16

5-6 ASS’Y PCB EMI .......................................................................................................................................................... 5-20

5-7 OUT DOOR UNIT PCB ............................................................................................................................................ 5-21

5-8 SUB-COMM ................................................................................................................................................................ 5-22

5-9 ASSY PCB WATER-HUB ............................................................................................................................................ 5-23

Section 0

Samsung Electronics 5

Contents

6. Wiring Diagram ................................................................................................... 6-1

6-1 AM072/096/120/144FXVA66 ................................................................................................................................6-1

6-2 AM072/096/120/192HXWA66 ..............................................................................................................................6-3

6-3 AM168/192HXVAJ6A .................................................................................................................................................6-5

6-4 AM168/192HXVAF6 ...................................................................................................................................................6-7

6-5 AM072/097KXVAJ6 ....................................................................................................................................................6-9

6-6 AM072KXVAF6 ..........................................................................................................................................................6-11

6-7 AM096KXVAF6 ..........................................................................................................................................................6-13

6-8 AM216KXVGJ6 .......................................................................................................................................................... 6-15

6-9 AM038/048/055KXWD6 ........................................................................................................................................ 6-17

7. Cycle Diagram ...................................................................................................................7-1

7-1 AM072FXVAFH6/AM072FXVAJH6......................................................................................................................7-1

7-2 AM096FXVAJH/AM120FXVAJH

6

..........................................................................................................................7-1

7-3 AM096FXVAFH

6

/AM120FXVAFH6/AM144FXVAFH6/AM144FXVAJH/AM168HXVAJH6/

AM168HXVAFH

6

/AM192HXVAJH6/AM192HXVAFH6 ..............................................................................7-2

7-4 AM072FXVAFR

6

/AM072FXVAJR6 .......................................................................................................................7-2

7-5 AM096FXVAJR

6

/AM120FXVAJR6 .......................................................................................................................7-3

7-6 AM096FXVAFR

6

/AM120FXVAFR6/AM144FXVAFR6/AM144FXVAJR6/AM168HXVAJR6/

AM168HXVAFR

6

/AM192HXVAJR6/AM192HXVAFR6 ................................................................................7-3

7-7 AM216KXVGJH ..............................................................................................................................................................7-4

7-8 AM192HXWA66 ..........................................................................................................................................................7-4

7-9 Cooling operation (H/R) ............................................................................................................................................7-5

7-10 Main cooling operation (H/R) ...............................................................................................................................7-6

7-11 Heating operation (H/R) .........................................................................................................................................7-7

7-12 Main heating operation (H/R) ..............................................................................................................................7-8

7-13 Cooling operation (H/P) ..........................................................................................................................................7-9

7-14 Heating operation (H/P) ......................................................................................................................................7-10

7-15 Cooling operation(H/R) ........................................................................................................................................7-11

7-16 Main cooling operation(H/R) ............................................................................................................................. 7-12

7-17 Heating operation(H/R) .......................................................................................................................................7-13

7-18 Main heating operation(H/R) ............................................................................................................................7-14

7-19 AM038KXWD66 .................................................................................................................................................... 7-15

7-20 AM048/055KXWD66 ........................................................................................................................................... 7-15

7-21 Cycle Component Function Explanation ....................................................................................................7-16

8. Key Options .........................................................................................................8-1

8-1 Outdoor unit option switch settings ...................................................................................................................8-1

8-2 How to set the key function of the outdoor unit ...........................................................................................8-4

8-3 How to check the view mode using a tact switch ...................................................................................... 8-13

9. Test Operation .....................................................................................................9-1

9-1 Auto Trial Operation ....................................................................................................................................................9-1

9-1-1 Auto Trial Operation Synopsis ..................................................................................................................9-1

9-1-2 Auto Trial Operation functions .................................................................................................................9-3

9-1-3 How to troubleshoot of the "Undetermined"....................................................................................9-4

9-1-4 Auto Trial Operation Error Code ........................................................................................................... 9-13

9-2 Amount of refrigerant automatically checking ............................................................................................ 9-14

10. Reference Sheet .............................................................................................. 10-1

10-1 Nomenclature ..........................................................................................................................................................10-1

Samsung Electronics 1-1

1. Precautions

1-1 Precautions for the Service

OUse the correct parts when changing the electric parts.

– Please check the labels and notices for the model name, proper voltage, and proper current for the electric parts.

OFully repair the connection for the types of harness when repairing the product after breakdown.

– A faulty connection can cause irregular noise and problems.

OWhen disassembling or assembling, make sure that the product is laid down on a work cloth.

– Doing so will prevent scratching to the exterior of the rear side of the product.

OCompletely remove dust or foreign substances on the housing, connection, and inspection parts when performing repairs.

– This can prevent fire hazards for tracking, short, etc.

OPlease tighten the service valve of the outdoor unit and the valve cap of the charging valve as securely as possible by using

a monkey spanner.

OCheck whether the parts are properly and securely assembled after performing repairs.

– These parts should be in the same condition as before the repair.

1-2 Precautions for the Static Electricity and PL

OPlease carefully handle the PCB power terminal during repair and measurement when it is turned on since it is vulnerable

to static electricity.

– Please wear insulation gloves before performing PCB repair and measurement.

OCheck if the place of installation is at least 2m away from electronic appliances such as TV, video players, and stereos.

– This can cause irregular noise or degrade the picture quality.

OPlease make sure the customer does not directly repair the product.

– Arbitrary dismantling may result in electric shock or fire.

1-3 Precautions for the Safety

ODo not pull or touch the power plug or the subsidiary power switch with wet hands.

– This may result in electric shock or fire.

OIf the power line or the power plug is damaged, then it must be changed since this is a hazard.

ODo not bend the wire too much or position it so that it can be damaged by a heavy object on top.

– This may result in electric shock or fire.

OThe use of multiple electric outlets should be prohibited.

– This may result in electric shock or fire.

OGround the connection if it is necessary.

– The connection must be grounded if there is any risk of electrical short due to water or moisture.

OUnplug the power or turn off the subsidiary power switch when changing or repairing electrical parts.

– Doing so will prevent electric shock.

OExplain to workers that the battery for the remote control needs to be separated for storage purposes when the product

will not be used for a long time.

– This can cause a problem for the remote control since battery fluid may trickle out.

1-2 Samsung Electronics

1-4 Precautions for Handling Refrigerant for Air Conditioner

Environmental Cautions: Air pollution due to gas release

OSafety Cautions

If liquid gas is released, then body parts that come into contact with it may experience frostbite/blister/numbness.

If a large amount of gas is released, then suffocation may occur due to lack of oxygen. If the released gas is heated, then noxious

gas may be produced by combustion.

OContainer Handling Cautions

Do not subject container to physical shock or overheating. (Flowage is possible while moving within the regulated pressure.)

1-5 Precautions for Welding the Air Conditioner Pipe

ODangerous or flammable objects around the pipe must be removed before the welding.

OIf the refrigerant is kept inside the product or the pipe, then remove the refrigerant prior to welding.

If the welding is carried out while the refrigerant is kept inside, the welding cannot be properly performed. This will also produce

noxious gas that is a health hazard. This leakage will also explode with the refrigerant and oil due to an increase in the refrigerant

pressure, posing a danger to workers.

OPlease remove the oxide produced inside the pipe during the welding with nitrogen gas.

Using another gas may cause harm to the product or others.

1-6 Precautions for Additional Supplement of Air Conditioner Refrigerant

OPrecisely calculate the refrigerant by using a scale and S-net, and proceed with the test operation.

Excessive supplement can cause harm to the product since it can cause an inflow of the liquid refrigerant into the compressor.

ODo not heat the refrigerant container for a forced injection.

This may cause harm to the product or others since the refrigerant container may burst.

ODo not operate the product after removing the product safety pressure switch and sensor.

If the product is blocked inside, then this may cause harm to the product or others due to the excess pressure increase of the

refrigerant gas.

1-7 Other Precautions

OThere should be no leakage of the pipes after installation. When withdrawing the refrigerant, the compressor should be

stopped before removing the connecting pipe.

If the compressor is operating while the refrigerant pipe is not correctly connected and the service valve is opened, then

air and other substances can enter the pipe. The interior of the refrigerant cycle may then build up excessive high pressure

resulting in explosion and damage.

Samsung Electronics 2-1

2. Product Specifications

2-1 The Feature of Product

2-1-1 Feature

Q Dual SSC System Technology

When load changes, capacity amendment that is soft by continuous operation of Dual Inverter is available.

Q Dual Smart Inverter System

DSC System

Digital base Inverter base

. DVI variable + DVI constant speed

. AC Motor

. 2 generation, Vapor Injection

. Dual Smart Inverter : SSC + SSC

. BLDC Inverter Motor (14~160Hz driving)

. 3 generation, Vapor Injection

(Performance maximization of low temperature heating)

DSI System

High Pressure Refrigerant Outlet

Medium Pressure

Refrigerant Injection

Low Pressure

Refrigerant Inlet

Low Pressure

Refrigerant Inlet

3 generation,

Vapor Injection

3 generation,

Vapor Injection

Low Pressure

Refrigerant Inlet

High Pressure Refrigerant Outlet High Pressure Refrigerant Outlet

Medium Pressure

Refrigerant Inlet

Capacity

Variable

Ŷ Compressor driving : When load changes, is variable by fast inverter frequency.

Ŷ Amenities elevation : ᇹ0.5°C

Step 1

ON OFF

Step 2

Step 3 Step 4

ON OFF

ON ON ON ON

Product Specications

2-2 Samsung Electronics

Feature

(cont.)

QInverter circuit refrigerant cooling technology

- Applied high eciency refrigerant cooling circuit. Secured stable Inverter PCB cooling performance.

- Air cooling method : When natural convection / electric heat performance is low and is high load, eciency is fallen.

- Refrigerant cooling system : Forced circulation / electric heat performance is high and control of (thermal conductivity is

10 times higher than air) load is available.

Cooling of

inverter circuit

Refrigerant cooling system :

It is cooling technology of inverter circuit that use

refrigerating cycle technology.

Cooling of

inverter circuit

Product Specications

Samsung Electronics 2-3

2-1-2 Changes in comparison to basic mode

Changed

part

Changed item

and feature

Basic After changed

Control Box

structure

Monolayer structure ࣖ Double Layer Structure

- Inverter technology integration

(Inverter control circuit composition)

- C/Box volume maximum use

Built-in type Controller embodiment

- Integrated power supply

+ control unit

- Piping service easiness

Q Control Box & PCB

Changed

part

Changed item

and feature

Basic After changed

CABINET

Change the color :

TOUCH GRAY

ࣖ EARTH BROWN

Wire Harness installation part

change

LOGO change

Product Specications

2-4 Samsung Electronics

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

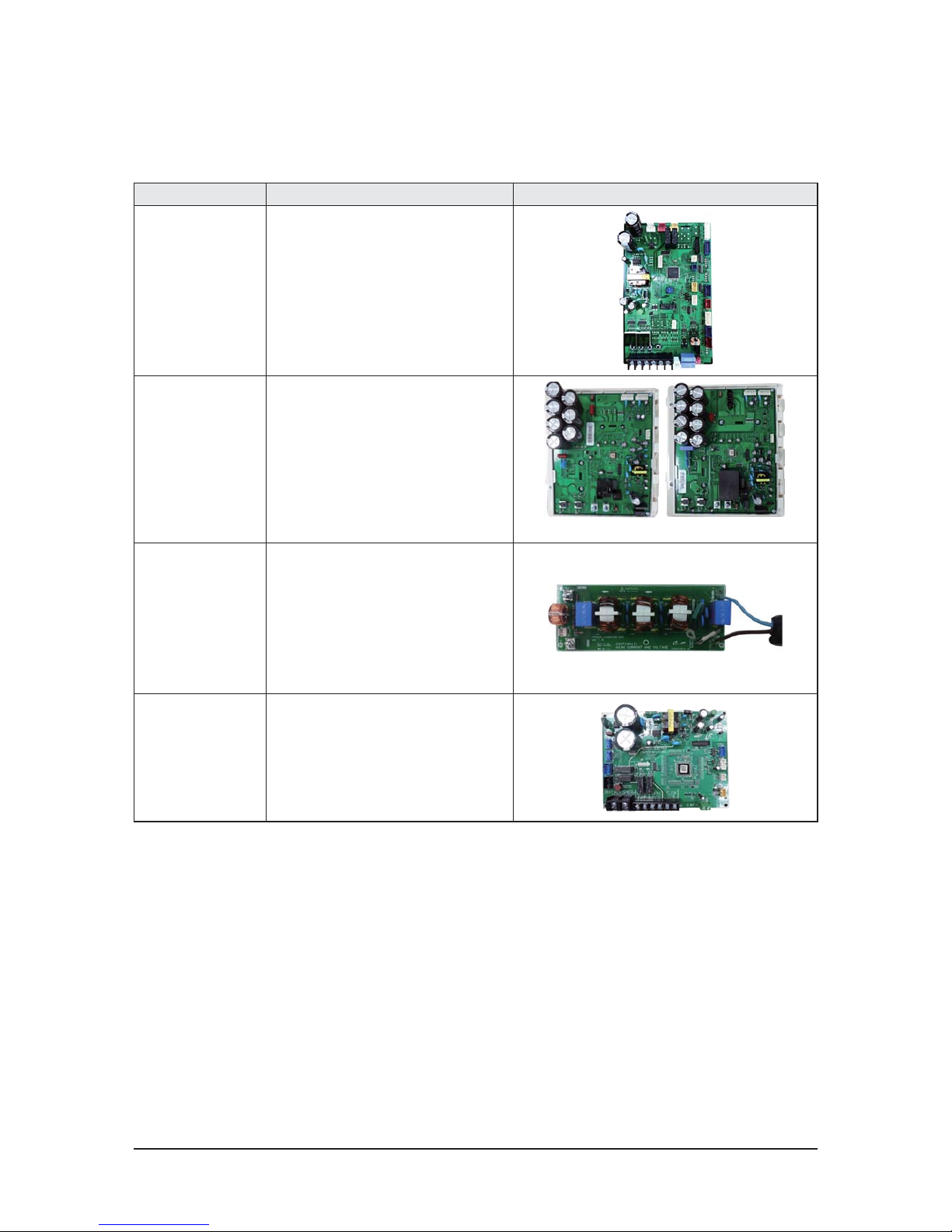

Main PCB

Change Main PCB

- Separation for load / control.

- Option resistance delete by model.

(standardization)

- When do PCB replace, need option

download.

Hub PCB

Hub PCB newly application

- Separation for load / control.

- Enhanced fixing of load / sensor

wire.

FAN PCB

Use controller of 3 phase power

- Prevented phase unbalance.

- Temperature protection of IPM.

Inverter PCB

(Compressor

Control PCB)

Applied inverter Compressor

- Refrigerant cooling method

- Magnet S/W

ױ Did Power Relay mount to PCB.

EMI PCB

3 phase power EMI PCB

- Fuse mount

-

Communication

Terminal block

Did Communication Terminal block

mount to PCB.

QAM072/096/120/144FXVA66/168HXVAJ6/192HXVAJ6/072KXVA66/096KXVAJ

6

Product Specications

Samsung Electronics 2-5

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

Main PCB

Change Main PCB

- Separation for load / control.

- Option resistance delete by model.

(standardization)

- When do PCB replace, need option

download.

Hub PCB

Hub PCB newly application

- Separation for load / control.

- Enhanced fixing of load / sensor wire.

FAN PCB

Use controller of 3 phase power

- Prevented phase unbalance.

- Temperature protection of IPM.

Inverter PCB

(Compressor

Control PCB)

Inverter PCB newly application

- Capacitor size increased

- EMI Coil applied

EMI PCB

EMI PCB newly application

- Coil size increased

- Fuse capacity changed

- Capacitor changed

Reactor

Reactor newly application.

- Terminal block for screw applied

-

PCB Cooling

Tube

Capacity of heat sink increased.

Tube size increased.

Communication

Terminal block

Did Communication Terminal block

mount to PCB.

Q AM168/1926XVAF6/AM096KXVAF

6

Product Specications

2-6 Samsung Electronics

Changes in comparison to basic mode (cont.)

Item Feture PBA

Main PCB

Main PCB

- Separation for load / control.

- Option resistance delete by model. (standardization)

- When replace the PCB, must download option.

- Enhanced fixing of load / control wire.

Inverter PCB

(Compressor control PCB)

Compressor control

Inverter PCB

3/4HP:PF#4 5/6HP : PF#5

EMI PCB

Single-phase power supply EMI PCB

- FUSE mount

Water Hub PCB

Water Hub PCB

-The external contact point of the water-cooled.

Q

AM038/048/055KXWD

66

Product Specications

Samsung Electronics 2-7

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

Main PCB

Change Main PCB

- Separation for load / control.

- Option resistance delete by model.

(standardization)

- When do PCB replace, need option

download.

←

Hub PCB

Hub PCB newly application

- Separation for load / control.

- Enhanced fixing of load / sensor

wire.

←

Inverter PCB

(Compressor

Control PCB)

Applied inverter Compressor

- Refrigerant cooling method

- Magnet S/W

ױ Did Power Relay mount to PCB.

←

EMI PCB

3 phase power EMI PCB

- Fuse mount

←

Communication

Terminal block

Did Communication Terminal block

mount to PCB.

←

Water Hub PCB

Water Hub PCB

- External contact for DVM S WATER

-

Q

AM072/096/120/192HXWA

66

Product Specications

2-8 Samsung Electronics

Changed

part

Changed item

and feature

Basic After changed

Main PCB

Change Main PCB

- Increase MICOM capability

FAN PCB

Applies 600V IPM by LC

resonance buck-converter

Inverter PCB

(Compressor

Control

PCB)

- Increases current due to

high capacity compressor

- Increases capacitor's capacity

- Applies EMI coil on board

(Deletes core in wire)

EMI PCB

- Develops 50A EMI PBA

ױIncreases coil size and

fuse capacity

- Improves EMI characteristic.

REACTOR

- Increases current due to

high capacity compressor

- Improved wire connection terminal

Refrigerant

cooling

- Increases heat cooling capacity

- Increases pipe size and heat

exchange area

Changes in comparison to basic mode (cont.)

Q

AM216KXVGJH

Product Specications

Samsung Electronics 2-9

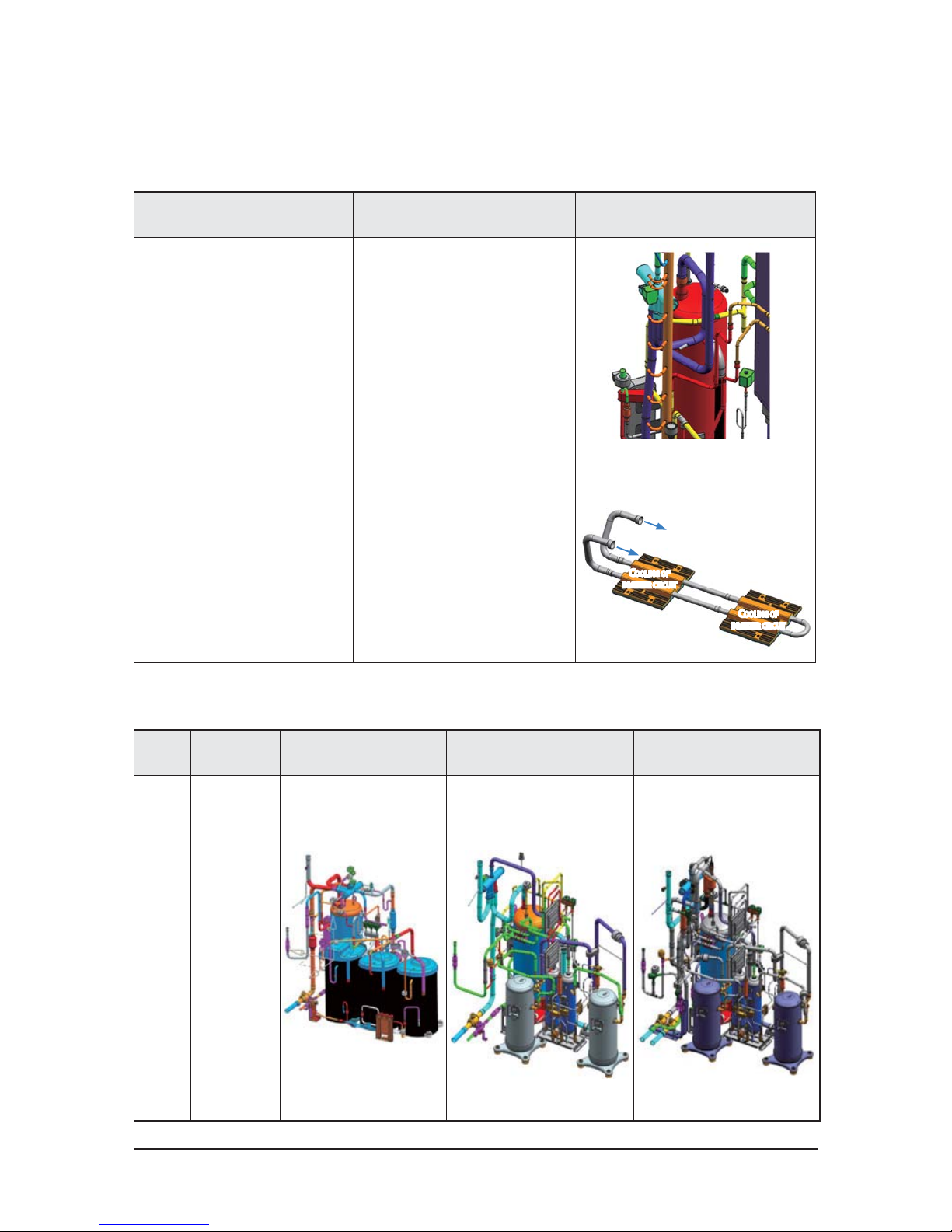

Changes in comparison to basic mode (cont.)

Changed

part

Changed item

and feature

Basic After changed

Pipe

Cooling

New Pipe Cooling for cooling

of inverter PCB.

Unapplied

C

OOLING OF

INVERTER CIRCUIT

REFRIGERANT COOLING SYSTEM :

I

T IS COOLING TECHNOLOGY OF INVERTER CIRCUIT THAT USE

REFRIGERATING CYCLE TECHNOLOGY.

C

OOLING OF

INVERTER CIRCUIT

Changed

part

Changed item

and feature

Basic After changed [HP] After changed [HR]

Tube

structure

New inverter

cycle technology

application

New piping

Q

Pipe Cooling

Q

Tube

Product Specications

2-10 Samsung Electronics

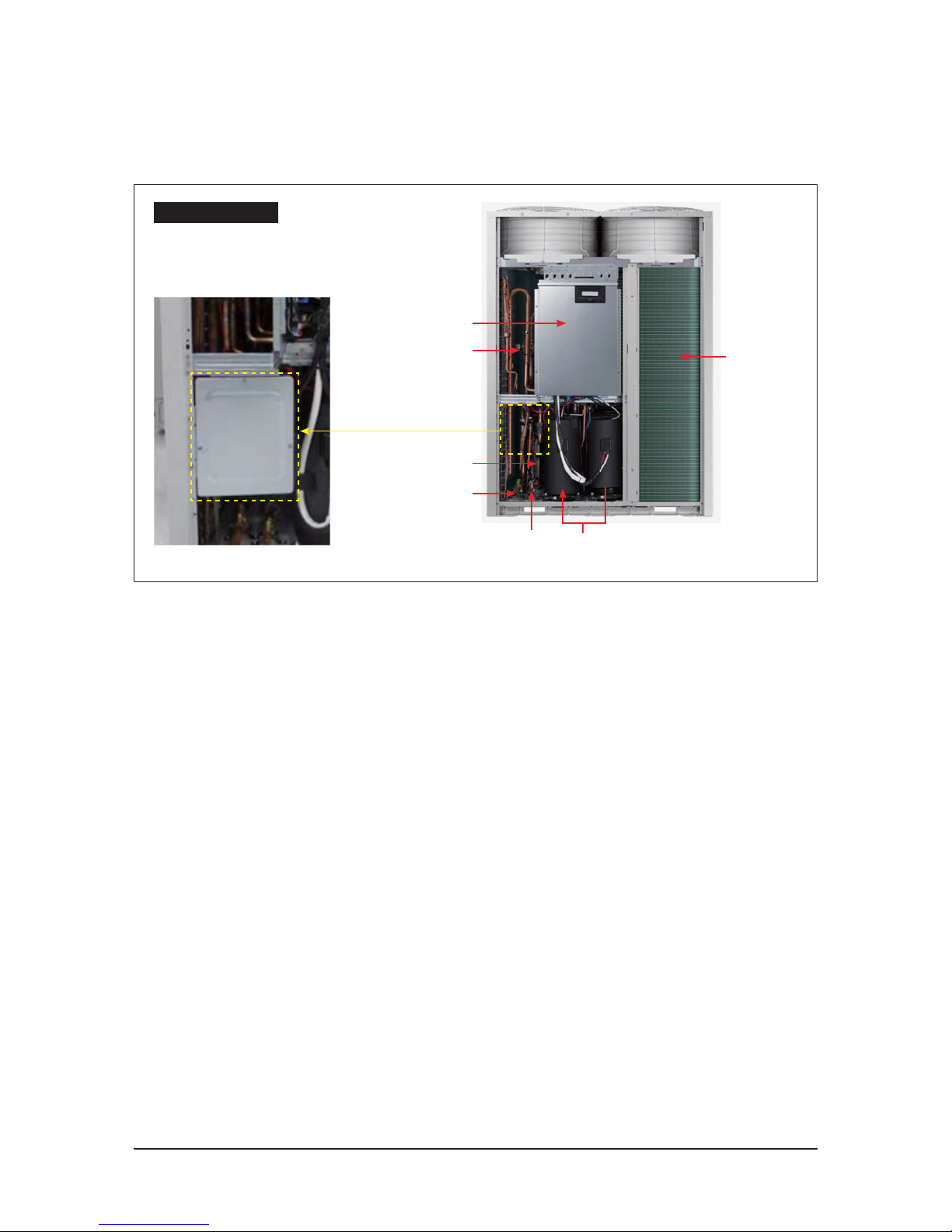

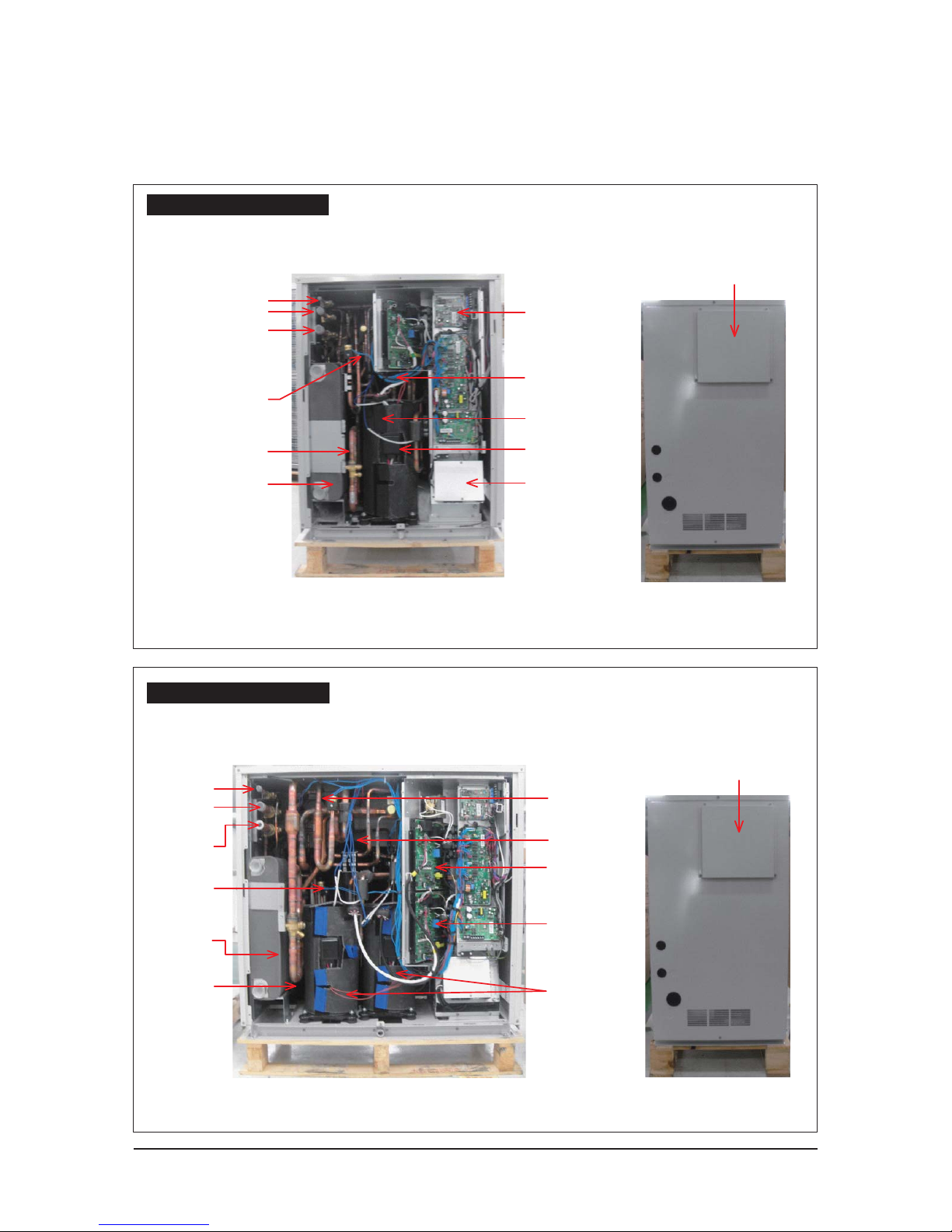

2-1-3 Structure of product

AM072FXVAF

6

AM072FXVAJ

6

AM096FXVAF

6

AM120FXVAF

6

AM144FXVAF6

AM168HXVAF

6

AM192HXVAF

6

AM072KXVAF

6

AM096KXVAF

6

AM096FXVAJ

6

AM120FXVAJ

6

AM144FXVAJ

6

AM168HXVAJ

6

AM192HXVAJ

6

AM072KXVAJ

6

AM096KXVAJ

6

TRANS BOX

TRANS BOX

Product Specications

Samsung Electronics 2-11

Heat Exchanger

Compressor

CONTROL BOX

4-WAY V/V

Subcooler

Gas Pipe

Liquid Pipe

AM216KXVGJ

6

2-12 Samsung Electronics

ACCUMULATOR

4WAY V/V

SUBCOOLER

EEV

Liquid Pipe

Gas Pipe

Plate Heat Exchanger

Compressor

CONTROL BOX

AM038/048/055KXWD

6

Product Specications

Samsung Electronics 2-13

AM072/096/120HXWAF

6

AM192HXWAF

6

CONTROL BOX

Liquid Pipe

High pressure Gas Pipe

Low pressure Gas Pipe

4 WAY V/V

Receiver

Plate Heat Exchanger

Accumulator

Sub Cooler

Compressor

Oil separator

Liquid Pipe

4 WAY V/V

Accumulator

CONTROL BOX

Oil separator

Compressor

High pressure

Gas Pipe

Low pressure

Gas Pipe

Sub Cooler

Plate Heat

Exchanger

Receiver

Product Specications

2-14 Samsung Electronics

AM072/096/120HXWAJ

6

AM192HXWAJ

6

CONTROL BOX

Liquid Pipe

High pressure Gas Pipe

Low pressure Gas Pipe

4 WAY V/V

Receiver

Plate Heat Exchanger

Accumulator

Sub Cooler

Compressor

Oil separator

TRANS BOX

TRANS BOX

Liquid Pipe

4 WAY V/V

Accumulator

CONTROL BOX

Oil separator

Compressor

High pressure

Gas Pipe

Low pressure

Gas Pipe

Sub Cooler

Plate Heat

Exchanger

Receiver

Product Specications

2-15 Samsung Electronics

Product Specications

Samsung Electronics 2-16

2-2 Product Specifications

2-2-1 Outdoor Unit

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 80.6 ሥ DB/66.2 ሥ WB, outdoor 95 ሥ DB, length 50m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 68 ሥ DB, outdoor 44.6 ሥ DB, length 50m of piping, fall 0ft standard.

2. If proper form heating capacity is outdoor temperature 44.6 ሥ standard and outdoor temperature goes down by below zero,

heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 656ft (Equivalent length 722ft).

5. If the indoor unit is below, height length allows up to 361ft (If over 164ft, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 131ft.

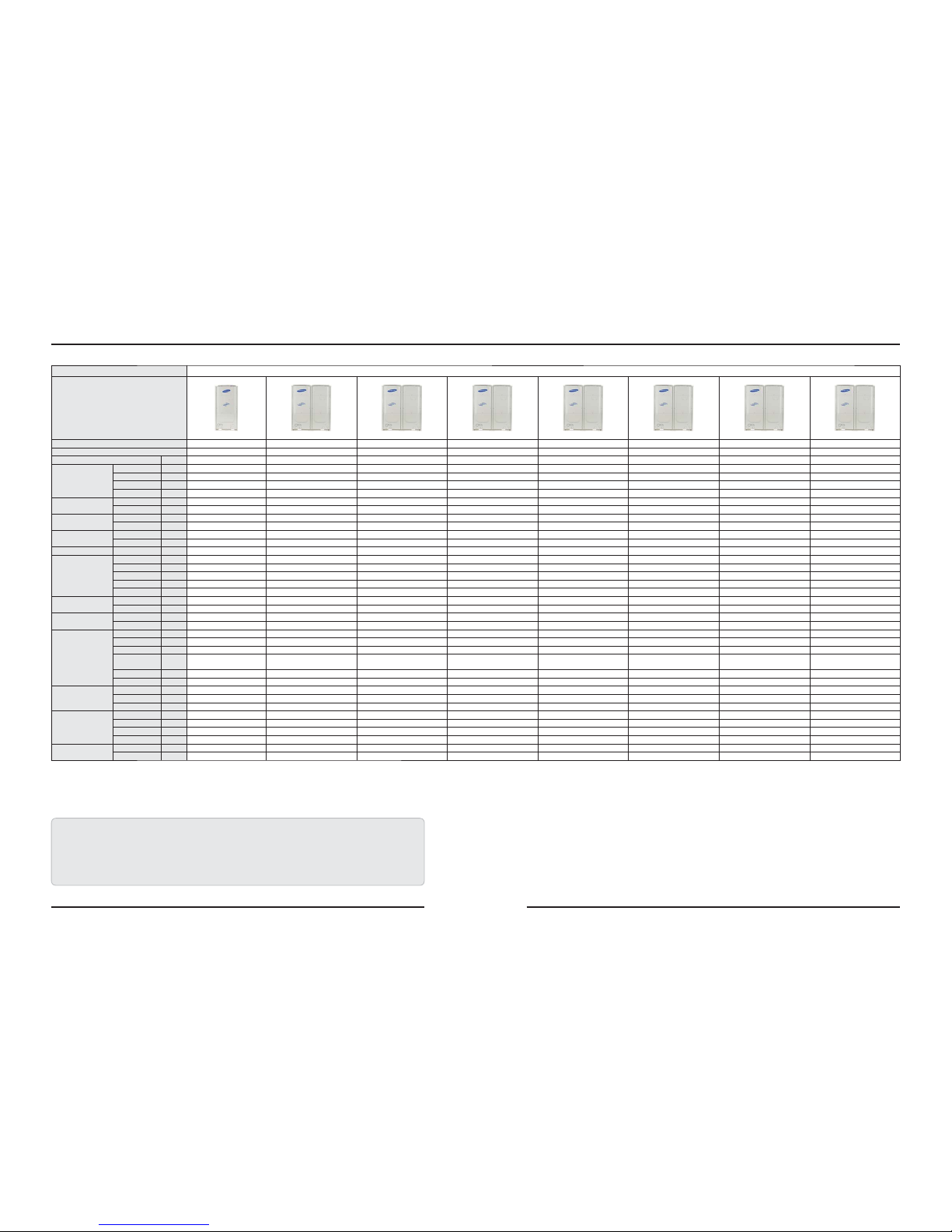

TYPE DVM S HP - 208-230V

Model

AM072FXVAFH

6

AM096FXVAFH

6

AM120FXVAFH

6

AM144FXVAFH

6

AM168HXVAFH

6

AM192HXVAFH

6

AM072KXVTF

6

AM096KXVTF

6

Mode HP HP HP HP HP HP HP HP

Power Ø,V,Hz 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60

Capacity

Cooling (Nominal) Btu/h 72,000 96,000 120,000 144,000 168,000 192,000 72,000 96,000

Cooling (Rated) Btu/h 69,000 92,000 114,000 138,000 160,000 184,000 69,000 92,000

Heating (Nominal) Btu/h 81,000 108,000 135,000 162,000 189,000 216,000 81,000 108,000

Heating (Rated) Btu/h 77,000 103,000 129,000 154,000 180,000 206,000 77,000 103,000

Power Consumption

(Nonducted, AHRI)

Cooling W 5,350 6,680 9,140 12,340 14,680 17,360 4,450 5,940

Heating W 5,430 7,130 9,520 12,400 14,460 17,250 5,010 6,490

current consumption

(Nonducted, AHRI)

Cooling A 14.6 18.2 24.9 33.7 40.05 47.37 12.1 16.2

Heating A 14.8 19.5 26.0 33.8 39.45 47.07 13.7 17.7

EER

(Nonducted, AHRI)

Cooling Btu/Wh 12.9 13.8 12.5 11.2 11.4 11.1 15.5 15.5

Heating W/W 4.15 4.23 3.97 3.64 3.83 3.67 4.50 4.65

IEER(AHRI) Cooling W/W 23.0 26.0 24.2 22.7 24.5 23.0 40.0 37.0

Compressor

Model - DS-GB052FBVASG DS-GB052FBVASG DS-GB052FBVASG DS-GB052FBVASG DS-GB052FBVASG DS4GJ5066EVASG DS-GB052FBVASG DS4GJ5066EVASG

Output kW 5.18 5.18 5.18 5.18 5.18 6.45 5.18 6.45

Excluded Volume cc/rev 52.0 52.0 52.0 52.0 52.0 66.0 52.0 66.0

Capacity Btu/h 58,500 58,500 58,500 58,500 58,500 73,500 58,500 73,500

Quantity EA 1 2 2 2 2 2 2 2

Lubricant oil

Type Liter FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) PV68D(PVE) PV68D(PVE)

Factory Charging Liter 3.9 6.2 6.2 6.2 6.2 6.2 6.2 6.2

Refrigerant

Type - R410A R410A R410A R410A R410A R410A R410A R410A

Factory Charging lb 12.13 16.31 16.31 19.18 24.30 24.30 18.5 18.5

FAN

Ø mm 700 575 575 575 575 575 575 575

MAX STEP - 19 29 29 31 35 35 28 29

CODE - DB31-00298A DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B

MAX RPM

STEP

(RPM)

800 1050 1050 1100 1200 1200 1000 1050

QuantityEA12222222

Airow CMM 205 260 260 270 310 310 240 260

Piping

Connections

Gas Inch 3/4"(19.05) 7/8"(22.22) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58)

Dis. Gas Inch - - - - - - - -

Liquid Inch 3/8"(9.52) 3/8"(9.52) 1/2"(12.7) 1/2"(12.7) 5/8"(15.88) 5/8"(15.88) 1/2"(12.7) 1/2"(12.7)

DIMENSION

NET mm 880x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765

GROSS mm 948x1887x832 1363x1887x832 1363x1887x832 1363x 1887 x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832

NET kg 190 278 278 293 325 333 298 333

GROSS kg 206 300 300 312 342 350 317 350

Operating Temp.

Range

Cooling

ሥ

23~118 23~118 23~118 23~118 23~118 23~118 23~118 23~118

Heating

ሥ

-13~75 -13~75 -13~75 -13~75 -13~75 -13~75 -13~75 -13~75

2-17 Samsung Electronics

Outdoor Unit(Continue)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 80.6 ሥ DB/66.2 ሥ WB, outdoor 95 ሥ DB, length 50m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 68 ሥ DB, outdoor 44.6 ሥ DB, length 50m of piping, fall 0ft standard.

2. If proper form heating capacity is outdoor temperature 44.6 ሥ standard and outdoor temperature goes down by below zero,

heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 656ft (Equivalent length 722ft).

5. If the indoor unit is below, height length allows up to 361ft (If over 164ft, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 131ft.

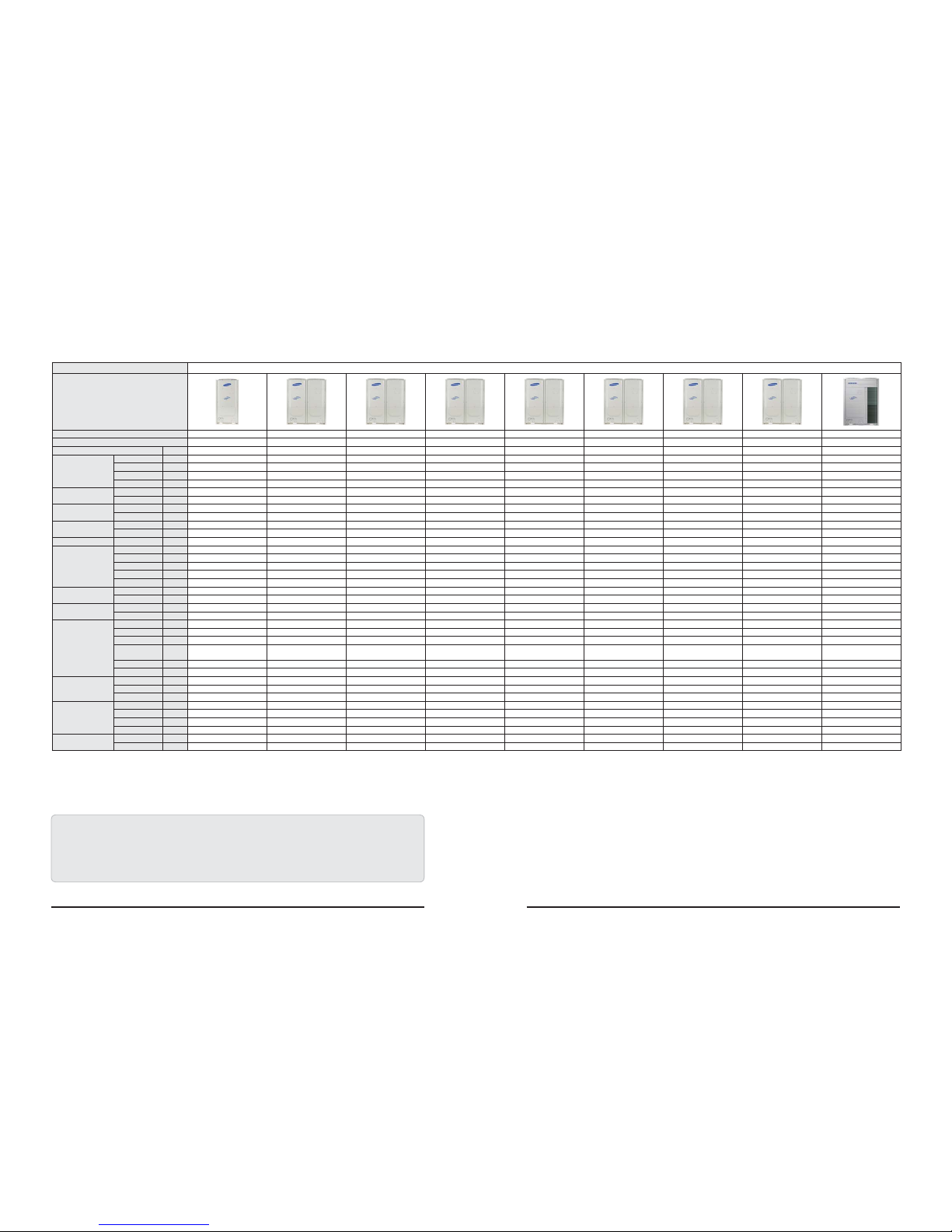

TYPE DVM S HR - 208-230V

Model

AM072FXVAFR6AM096FXVAFR6AM120FXVAFR6AM144FXVAFR6AM168HXVAFR6AM192HXVAFR

6

Mode

HR HR HR HR HR HR

Power Ø,V,Hz

3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60 3/208-230/60

Capacity

Cooling (Nominal) Btu/h

72,000 96,000 120,000 144,000 168,000 192,000

Cooling (Rated) Btu/h

69,000 92,000 114,000 138,000 160,000 184,000

Heating (Nominal) Btu/h

81,000 108,000 135,000 162,000 189,000 216,000

Heating (Rated) Btu/h

77,000 103,000 129,000 154,000 180,000 206,000

Power Con-

sumption

(Nonducted,

AHRI)

Cooling W

5,350 6,680 9,140 12,340 14,680 17,360

Heating W

5,430 7,130 9,520 12,400 14,460 17,250

current con-

sumption

(Nonducted,

AHRI)

Cooling A

14.6 18.2 24.9 33.7 40.05 47.37

Heating A

14.8 19.5 26.0 33.8 39.45 47.07

EER

(Nonducted,

AHRI)

Cooling Btu/Wh

12.9 13.8 12.5 11.2 11.4 11.1

Heating W/W

4.15 4.23 3.97 3.64 3.83 3.67

IEER(AHRI) Cooling W/W

23.0 26.0 24.2 22.7 24.5 23.0

Compressor

Model -

DS-GB052FBVASG DS-GB052FBVASG DS- GB052FBVASG DS-GB052FBVASG DS-GB052FBVASG DS4GJ5066E VASG

Output kW

5.18 5.18 5.18 5.18 5.18 6.45

Excluded Volume cc/rev

52.0 52.0 52.0 52.0 52.0 66.0

Capacity Btu/h

58,500 58,500 58,500 58,500 58,500 73,500

Quantity EA

1 2 2 2 2 2

Lubricant oil

Type Liter

FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE)

Factory Charging Liter

3.9 6.2 6.2 6.2 6.2 6.2

Refrigerant

Type -

R410A R410A R410A R410A R410A R410A

Factory Charging lb

12.13 16.31 16.31 19.18 24.30 24.30

FAN

Ømm

700 575 575 575 575 575

MAX STEP -

19 29 29 31 35 35

CODE -

DB31-00298A DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B

MAX RPM

STEP

(RPM)

800 1050 1050 1100 1200 1200

Quantity EA

122222

Airow CMM

205 260 260 270 310 310

Piping

Connections

Gas Inch

3/4"(19.05) 7/8"(22.22) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58)

Dis. Gas Inch

5/8"(15.88) 3/4"(19.05) 7/8"(22.22) 7/8"(22.22) 1+1/8"(28.58) 1+1/8"(28.58)

Liquid Inch

3/8"(9.52) 3/8"(9.52) 1/2"(12.7) 1/2"(12.7) 5/8"(15.88) 5/8"(15.88)

DIMENSION

NET mm

880x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765

GROSS mm

948x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832

NET kg

195 284 284 299 332 340

GROSS kg

211 303 303 318 349 357

Operating Temp.

Range

Cooling

ሥ

23~118 23~118 23~118 23~118 23~118 23~118

Heating

ሥ

-13~75 -13~75 -13~75 -13~75 -13~75 -13~75

Product Specications

2-18 Samsung Electronics

Product Specications

Samsung Electronics 2-19

Outdoor Unit(Continue)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 80.6 ሥ DB/66.2 ሥ WB, outdoor 95 ሥ DB, length 50m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 68 ሥ DB, outdoor 44.6 ሥ DB, length 50m of piping, fall 0ft standard.

2. If proper form heating capacity is outdoor temperature 44.6 ሥ standard and outdoor temperature goes down by below zero,

heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 656ft (Equivalent length 722ft).

5. If the indoor unit is below, height length allows up to 361ft (If over 164ft, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 131ft.

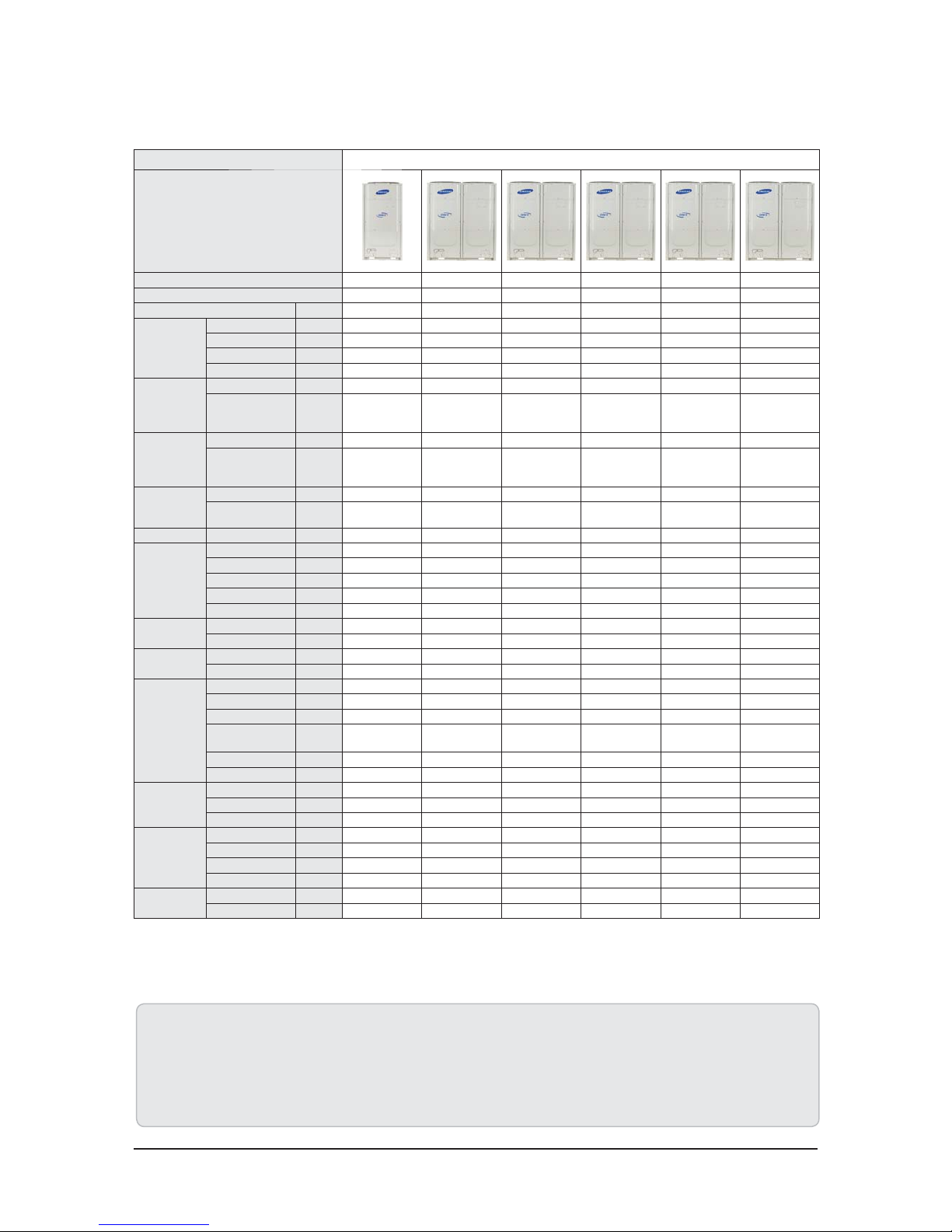

TYPE DVM S HP - 460V

Model

AM072FXVAJH

6

AM096FXVAJH

6

AM120FXVAJH

6

AM144FXVAJH

6

AM168HXVAJH

6

AM192HXVAJH

6

AM072KXVTJ

6

AM096KXVTJ

6 AM216KX VGJH/AA

Mode HP HP HP HP HP HP HP HP HP

Power Ø,V,Hz 3/460/60 3/460/60 3/460/60 3/460/60 3/460/60 3/460/60 3/460/60 3/460/60 3/460/60

Capacity

Cooling (Nominal) Btu/h 72,000 96,000 120,000 144,000 168,000 192,000 72,000 96,000 216,000

Cooling (Rated) Btu/h 69,000 92,000 114,000 138,000 160,000 184,000 69,000 92,000 206,000

Heating (Nominal) Btu/h 81,000 108,000 135,000 162,000 189,000 216,000 81,000 108,000 243,000

Heating (Rated) Btu/h 77,000 103,000 129,000 154,000 180,000 206,000 77,000 103,000 230,000

Power Consumption

(Nonducted, AHRI)

Cooling W 5,350 6,600 9,190 12,340 14,680 17,360 4,450 5,940 18,400

Heating W 5,430 7,130 9,520 12,400 14,460 17,250 5,010 6,490 16,440

current consumption

(Nonducted, AHRI)

Cooling A 7.3 9.0 12.5 16.8 20.03 23.68 6.1 8.1 25.1

Heating A 7.4 9.7 13.0 16.9 19.73 23.53 6.8 8.9 22.4

EER

(Nonducted, AHRI)

Cooling Btu/Wh 12.9 13.9 12.4 11.2 11.4 11.1 15.5 15.5 11.2

Heating W/W 4.15 4.23 3.97 3.64 3.83 3.67 4.50 4.65 4.1

IEER(AHRI) Cooling W/W 23.0 24.2 23.0 22.7 24.5 23.0 40.0 37.0 25.5

Compressor

Model - DS-GB052FAVBSG DS-GB052FAVBSG DS-GB052FAVBSG DS-GB052FAVBSG DS-GB052FAVBSG DS-GB066FAVBSG DS-GB052FAVBSG DS- GB066FAVBSG DS-GB066FAVB

Output kW 5.18 5.18 5.18 5.18 5.18 6.39 5.18 6.39 6.39

Excluded Volume cc/rev 52.0 65.8 65.8 52.0 52.0 66.0 52.0 66.0 66.0

Capacity Btu/h 58,500 58,500 58,500 58,500 58,500 73,500 58,500 73,500 73,500

Quantity EA 1 2 2 2 2 2 2 2 2

Lubricant oil

Type Liter FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) PV68D(PVE) PV68D(PVE) PV68D(PVE)

Factory Charging Liter 3.9 6.2 6.2 6.2 6.2 6.2 6.2 6.2 6.2

Refrigerant

Type - R410A R410A R410A R410A R410A R410A R410A R410A R410A

Factory Charging lb 12.13 16.31 16.31 19.18 24.30 24.30 18.5 18.5 27.6

FAN

Ø mm 700 575 575 575 575 575 575 575 575

MAX STEP - 19 29 29 31 35 35 28 29 35

CODE - DB31-00298A DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285A

MAX RPM

STEP

(RPM)

800 1050 1050 1100 1200 1200 1000 1050 1200

Quantity EA 1 2 2 2 2 2 2 2 2

Airow CMM 205 260 260 270 310 310 240 260 340

Piping

Connections

Gas Inch 3/4"(19.05) 7/8"(22.22) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58)

Dis. Gas Inch - - - - - - - - -

Liquid Inch 3/8"(9.52) 3/8"(9.52) 1/2"(12.7) 1/2"(12.7) 5/8"(15.88) 5/8"(15.88) 1/2"(12.7) 1/2"(12.7) 5/8"(15.88)

DIMENSION

NET mm 880x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1795x765

GROSS mm 948x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1987x832

NET kg 190 278 278 293 326 334 305 334 340

GROSS kg 206 300 300 312 343 351 324 351 362

Operating Temp.

Range

Cooling

ሥ

23~118 23~118 23~118 23~118 23~118 23~118 23~118 23~118 23~118

Heating

ሥ

-13~75 -13~75 -13~75 -13~75 -13~75 -13~75 -13~75 -13~75 -13~75

Product Specications

Samsung Electronics 2-20

Outdoor Unit(Continue)

TYPE DVM S HR - 460V

Model

AM072FXVAJR6AM096FXVAJR6AM120FXVAJR6AM144FXVAJR6AM168HXVAJR6AM192HXVAJR

6

Mode

HR HR HR HR HR HR

Power Ø,V,Hz

3/460/60 3/460/60 3/460/60 3/460/60 3/460/60 3/460/60

Capacity

Cooling (Nominal) Btu/h

72,000 96,000 120,000 144,000 168,000 192,000

Cooling (Rated) Btu/h

69,000 92,000 114,000 138,000 160,000 184,000

Heating (Nominal) Btu/h

81,000 108,000 135,000 162,000 189,000 216,000

Heating (Rated) Btu/h

77,000 103,000 129,000 154,000 180,000 206,000

Power Con-

sumption

(Nonducted,

AHRI)

Cooling W

5,350 6,600 9,190 12,340 14,680 17,360

Heating W

5,430 7,130 9,520 12,400 14,460 17,250

current con-

sumption

(Nonducted,

AHRI)

Cooling A

7.3 9.0 12.5 16.8 20.03 23.68

Heating A

7.4 9.7 13.0 16.9 19.73 23.53

EER

(Nonducted,

AHRI)

Cooling Btu/Wh

12.9 13.9 12.4 11.2 11.4 11.1

Heating W/W

4.15 4.23 3.97 3.64 3.83 3.67

IEER(AHRI) Cooling W/W

23.0 24.2 23.0 22.7 24.5 23.0

Compressor

Model -

DS-GB052FAVBSG DS-GB052FAVBSG DS-GB052FAVBSG DS- GB052FAVBSG DS-GB052FAVBSG DS-GB066FAVBSG

Output kW

5.18 5.18 5.18 5.18 5.18 6.39

Excluded Volume cc/rev

52.0 65.8 65.8 52.0 52.0 66.0

Capacity Btu/h

58,500 58,500 58,500 58,500 58,500 73,500

Quantity EA

1 2 2 2 2 2

Lubricant oil

Type Liter

FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE) FV68D(PVE)

Factory Charging Liter

3.9 6.2 6.2 6.2 6.2 6.2

Refrigerant

Type -

R410A R410A R410A R410A R410A R410A

Factory Charging lb

12.13 16.31 16.31 19.18 24.30 24.30

FAN

Ømm

700 575 575 575 575 575

MAX STEP -

19 29 29 31 35 35

CODE -

DB31-00298A DB94-03285B DB94-03285B DB94-03285B DB94-03285B DB94-03285B

MAX RPM

STEP

(RPM)

800 1050 1050 1100 1200 1200

Quantity EA

122222

Airow CMM

205 260 260 270 310 310

Piping

Connections

Gas Inch

3/4"(19.05) 7/8"(22.22) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58) 1+1/8"(28.58)

Dis. Gas Inch

5/8"(15.88) 3/4"(19.05) 7/8"(22.22) 7/8"(22.22) 1+1/8"(28.58) 1+1/8"(28.58)

Liquid Inch

3/8"(9.52) 3/8"(9.52) 1/2"(12.7) 1/2"(12.7) 5/8"(15.88) 5/8"(15.88)

DIMENSION

NET mm

880x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765 1295x1695x765

GROSS mm

948x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832 1363x1887x832

NET kg

195 284 284 299 333 341

GROSS kg

211 303 303 318 350 358

Operating Temp.

Range

Cooling

ሥ

23~118 23~118 23~118 23~118 23~118 23~118

Heating

ሥ

-13~75 -13~75 -13~75 -13~75 -13~75 -13~75

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 80.6 ሥ DB/66.2 ሥ WB, outdoor 95 ሥ DB, length 50m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 68 ሥ DB, outdoor 44.6 ሥ DB, length 50m of piping, fall 0ft standard.

2. If proper form heating capacity is outdoor temperature 44.6 ሥ standard and outdoor temperature goes down by below zero,

heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 656ft (Equivalent length 722ft).

5. If the indoor unit is below, height length allows up to 361ft (If over 164ft, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 131ft.

Product Specications

2-21 Samsung Electronics

Product Specications

Samsung Electronics 2-22

TYPE DVM S Water 208-230V

Model Name(Samsung Model)

AM038KXWDCH/AA AM048KXWDCH/AA AM055KXWDCH/AA AM072HXWAFR/AA AM096HXWAFR/AA AM120HXWAFR/AA AM192HXWAFR/AA

Mode-HPHPHPHRHRHRHR

Power Supply Φ, V, Hz 1Φ,208~230V,60Hz 3Φ,208~230V,60Hz

Performance

TonTon345681016

Capacity

(Nominal)

Cooling Btu/h 38200 47800 54600 72,000 96,000 120,000 192,000

Heating 42600 54600 61400 81,000 108,000 135,000 216,000

Capacity

(Rated)

Cooling Btu/h 38000 48000 54500 69,000 92,000 114,000 184,000

Heating 42000 54000 61000 77,000 103,000 129,000 206,000

Eciency

Ratings

EER Btu/W*h 15 16.2 14.7 20.20 19.90 12.80 11.60

IEER Btu/W*h 28 28 26 30.10 28.60 22.20 18.30

COP W/W 5.7 5.6 5.4 6.00 5.90 4.40 4.30

SCHE Btu/W*h - - - 26.50 27.40 17.80 20.20

Power

MCA A 20 24 26 16.0 23.0 30.0 39.6

MOP 35 40 45 25 40 50 50

Compressor

Type - Rotary Inverter Rotary Inverter Rotary I nverter SSC Scroll x 1 SSC Scroll x 1 SSC Scroll x 1 SSC Scroll x 2

Output kW × n 2.82 4.11 4.11 4.96 4.96 4.96 4.96 x 2

Oil

Type - PVE PVE PVE PVE PVE PVE PVE

Initial Charge Liter 1.2 1.7 1.7 3.9 3.9 3.9 6.2

Condenser

Type - Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger

Pipe Size(Female Thread) Φ, inch 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT

Lost Head kPa (ftAq) 25(8.4) 20(6.7) 28(9.4) 22(7.3) 30(10.0) 43(14.4) 54(18.1)

Water Flow Rate LPM(GPM) 40(10.5) 50(13.2) 60(15.8) 80(21.1) 96(25.4) 114(30.1) 190(50.2)

Water Max. Pressure Mpa(Psi) 1.96(285) 1.96(285) 1.96(285) 1.96(285) 1.96(285) 1.96(285) 1.96(285)

Piping

Connections

Liquid Pipe

Φ, mm------Φ, inch 3/8 3/8 3/8 3/8 3/8 1/2 5/8

Gas Pipe

Φ, mm------Φ, inch 5/8 3/4 3/4 3/4 7/8 1-1/8 1-1/8

Discharge Gas Pipe

Φ, mm------Φ, inch - - - 5/8 3/4 3/4 1-1/8

Installation

Limitation

Max. Length m (ft) 75(246) 75(246) 75(246) 170(558) 170(558) 170(558) 170(558)

Max. Height m (ft) 30(98) 30(98) 30(98) 50(164) 50(164) 50(164) 50(164)

Refrigerant

Type - R410A R410A R410A R410A R410A R410A R410A

Factory Charging kg (lbs) 1.1(2.4) 1.6(3.5) 1.6(3.5) 5.5(12.1) 5.8(12.8) 6(13.2) 9.8(21.6)

Sound

Sound Pressure dB(A) 47 48 49 48 48 50 51

Sound Power 70 70 70 73

External

Dimension

Net Weight kg (lbs) 73(161) 87(191) 87(191) 160(353) 160(353) 160(353) 240(529)

Shipping Weight kg (lbs) 80(176) 94(207) 94(207) 167(368) 167(368) 167(368) 250(551)

Net Dimensions (WxHxD)

mm 750x800x330 750x800x330 750x800x330 770x1000x545 770x1000x545 770x1000x545 1100x1000x545

Inch 29.5x31.5x13.0 29.5x31.5x13.0 29.5x31.5x13.0 30.3x39.4x21.5 30.3x39.4x21.5 30.3x39.4x21.5 43.3x39.4x21.5

Shipping Dimensions (Wx-

HxD)

mm 812x950x392 812x950x392 812x950x392 840x1200x620 840x1200x620 840x1200x620 1170x1200x620

Inch 31.9x37.4x15.4 31.9x37.4x15.4 31.9x37.4x15.4 33.1x47.2x24.4 33.1x47.2x24.4 33.1x47.2x24.4 46.1x47.2x24.4

Operating

Temp. Range(Water)

Cooling

ఁሥ

10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113)

Heating

ఁሥ

10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113)

Product Specications

2-23 Samsung Electronics

Outdoor Unit(Continue)

TYPE DVM S Water 460V

Model Name(Samsung Model) AM072HXWAJR/AA AM096HXWAJR/AA AM120HXWAJR/AA AM192HXWAJR/AA

Mode -HRHRHRHR

Power Supply Φ, V, Hz 3Φ,460V,60Hz

Performance

Ton Ton 6 8 10 16

Capacity

(Nominal)

Cooling Btu/h 72,000 96,000 120,000 192,000

Heating 81,000 108,000 135,000 216,000

Capacity

(Rated)

Cooling Btu/h 69,000 92,000 114,000 184,000

Heating 77,000 103,000 129,000 206,000

Eciency

Ratings

EER Btu/W*h 20.20 19.90 15.40 11.60

IEER Btu/W*h 30.10 28.60 25.30 18.30

COP W/W 6.00 5.90 4.80 4.30

SCHE Btu/W*h 26.50 27.40 20.30 20.20

Power

MCA A 10.0 11.0 15.6 26.2

MOP

15 15 25 35

Compressor

Type - SSC Scroll x 1 SSC Scroll x 1 SSC Scroll x 1 SSC Scroll x 2

Output kW × n 4.96 4.96 6.13 4.96 x 2

Oil

Type - PVE PVE PVE PVE

Initial Charge Liter 3.9 3.9 3 .9 6.2

Condenser

Type - Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger

Pipe Size(Female Thread) Φ, inch 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT 1-1/4 FPT

Lost Head kPa (ftAq) 22(7.3) 30(10.0) 43(14.4) 54(18.1)

Water Flow Rate LPM(GPM) 80(21.1) 96(25.4) 114(30.1) 190(50.2)

Water Max. Pressure M pa(Psi) 1.96(285) 1.96(285) 1.96(285) 1.96(285)

Piping

Connections

Liquid Pipe

Φ, mm---Φ, inch 3 /8 3/8 1/2 5/8

Gas Pipe

Φ, mm---Φ, inch 3 /4 7/8 1-1/8 1-1/8

Discharge Gas Pipe

Φ, mm---Φ, inch 5 /8 3/4 3/4 1-1/8

Installation

Limitation

Max. Length m (ft) 170(558) 170(558) 170(558) 170(558)

Max. Height m (ft) 50(164) 50(164) 50(164) 50(164)

Refrigerant

Type - R410A R410A R410A R410A

Factory Charging kg (lbs) 5.5(12.1) 5.8(12.8) 6(13.2) 9.8(21.6)

Sound

Sound Pressure dB(A) 48 48 50 5 1

Sound Power 70 7 0 70 73

External

Dimension

Net Weight kg (lbs) 167(368) 167(368) 167(368) 247(545)

Shipping Weight kg (lbs) 174(384) 174(384) 174(384) 257(567)

Net Dimensions (WxHxD)

mm 790x1000x545 790x1000x545 790x1000x545 1120x1000x545

Inch 31.1x39.4x21.5 31.1x39.4x21.5 31.1x39.4x21.5 44.1x39.4x21.5

Shipping Dimensions (Wx-

HxD)

mm 840x1200x620 840x1200x620 840x1200x620 1170x1200x620

Inch 33.1x47.2x24.4 33.1x47.2x24.4 33.1x47.2x24.4 46.1x47.2x24.4

Operating

Temp. Range(Water)

Cooling

ఁሥ

10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113)

Heating

ఁሥ

10~45(50~113) 10~45(50~113) 10~45(50~113) 10~45(50~113)

1. Proper form capacity standard of air conditioning

- Cooling capacity : It is figures that appear in indoor 80.6 ሥ DB/66.2 ሥ WB, outdoor 95 ሥ DB, length 50m of piping, fall 0m standard.

- Heating capacity : It is figures that appear in indoor 68 ሥ DB, outdoor 44.6 ሥ DB, length 50m of piping, fall 0ft standard.

2. If proper form heating capacity is outdoor temperature 44.6 ሥ standard and outdoor temperature goes down by below zero,

heating capacity can drop according to temperature condition.

3. Need special load calculation in case of use by main heating in the winter, and please buy product for low temperature that heating effect excels at low temperature.

4. Maximum length between outdoor and indoor units allows up to 656ft (Equivalent length 722ft).

5. If the indoor unit is below, height length allows up to 361ft (If over 164ft, decide whether to install the PDM kit). If the outdoor unit is below, allowable height length is 131ft.

Product Specications

Samsung Electronics 2-24

2-3 Accessory and Option Specifications

2-3-1 Accessories

Picture Classification Model Name Remark

Y-Joint

MXJ-YA1509M

15.0 kW and below

MXJ-YA2512M

Over 15.0 kW~40.6 kW and below

MXJ-YA2812M

Over 40.6 kW~46.4 kW and below

MXJ-YA2815M

Over 46.4 kW~69.6 kW and below

MXJ-YA3419M

Over 69.6 kW~98.6 kW and below

MXJ-YA4119M

Over 98.6 kW~139.2 kW and below

MXJ-YA4422M

Over 139.2 kW

Y-Joint

(Only H/R)

MXJ-YA1500M

23.2 kW and below

MXJ-YA2500M

Over 23.2 kW~69.6 kW and below

MXJ-YA3100M

Over 69.6 kW~139.2 kW and below

MXJ-YA3800M

139.2 kW and below

Distribution header

MXJ-HA2512M

46.4 kW and below (for 4 rooms)

MXJ-HA3115M

69.6 kW and below (for 8 rooms)

MXJ-HA3819M

Over 69.6 kW (for 8 rooms)

Y-Joint -Outdoor Unit

MXJ-TA3819M

139.2 kW and below

MXJ-TA4422M

145 kW and below

Y-Joint

(Only H/R)-Outdoor Unit

MXJ-TA3100M

139.2 kW and below

MXJ-TA3800M

145 kW and Over

MCU

(Mode Control Unit)

MCU-S6NEE1N

6 ROOM

MCU-S4NEE1N

4 ROOM

MCU-S4NEE2N

2 ROOM

MCU-S2NEK1N

2 ROOM

EEV KIT (1 Room)

MEV-E24SA

Applty to products without EEV

(Wall mount & Ceiling)

MEV-E32SA

EEV KIT (2 Room)

MXD-E24K132A

MXD-E24K200A

MXD-E32K200A

MXD-E24K232A

EEV KIT (3 Room)

MXD-E24K132A

MXD-E24K300A

MXD-E32K224A

MXD-E32K300A

Samsung Electronics 3-1

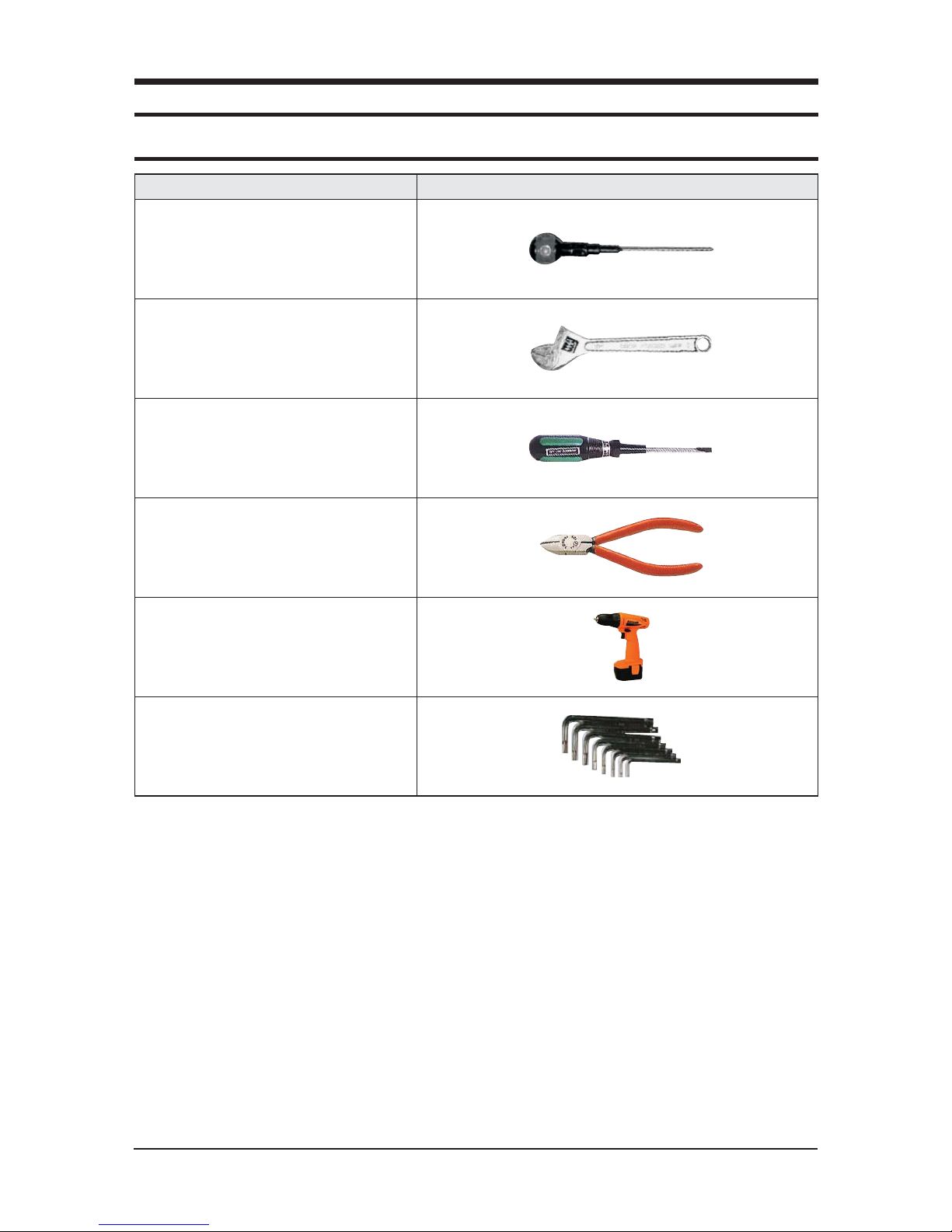

3-1 Necessary Tools

3. Disassembly and Reassembly

OFor “disassembly and assembly” DVM PLUS ዟ indoor unit, please refer to the products with the same structures.

Only those products that are not specified elsewhere are described here.

Item Remark

+SCREW DRIVER

MONKEY SPANNER

-SCREW DRIVER

NIPPER

ELECTRIC MOTION DRIVER

L-WRENCH

3-2 Samsung Electronics

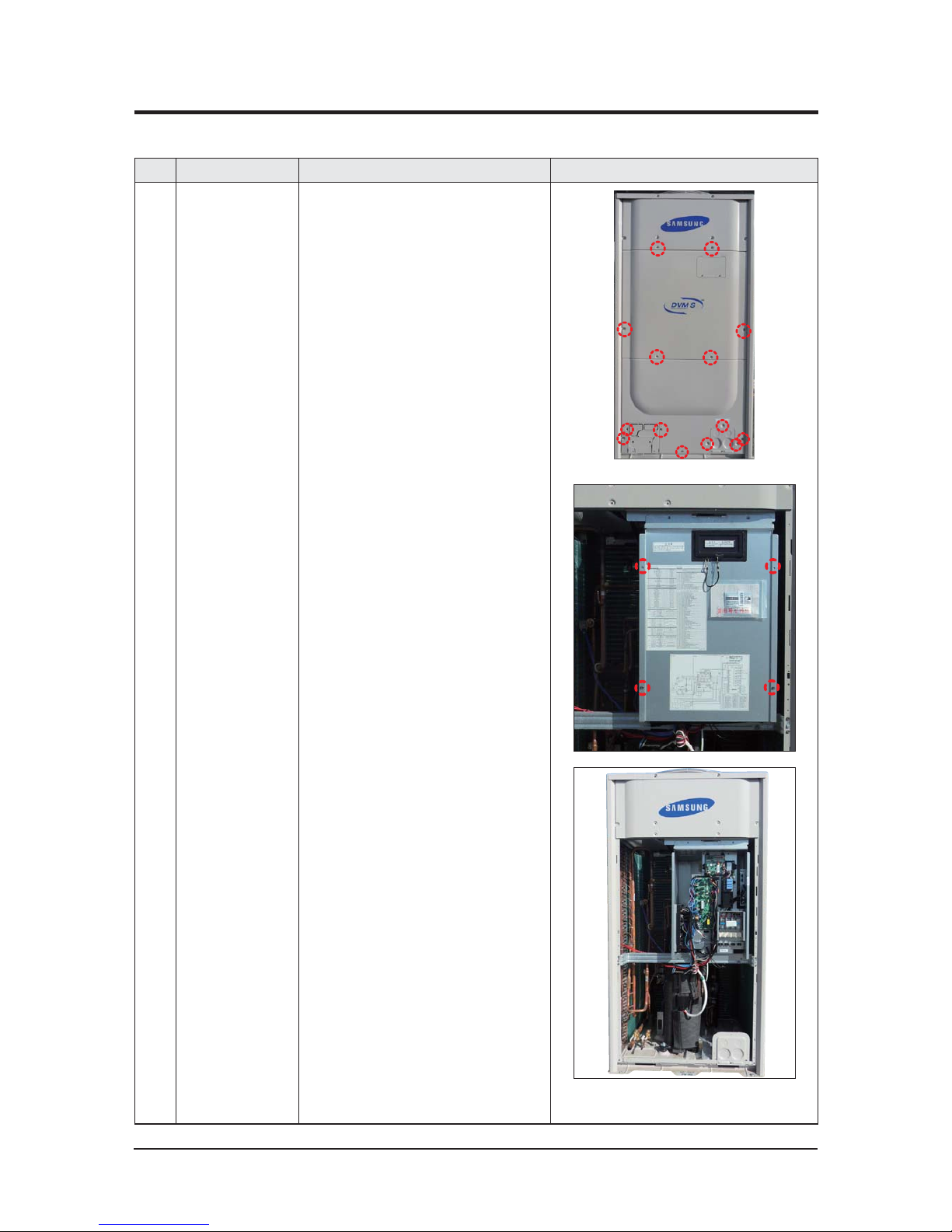

No. Parts Procedure Remark

1 Electrical

equipment Part

1) Remove 14 screws from the cabinet

(Use + screw driver)

2) Remove 4 screws that is fixing and

separate Cover Control Box.

(Use + Screw driver)

3) Power, Compressor, Valve, Motor, Sensor

connector connected to ASSY PCB

remove.

3-2 Disassembly and Reassembly

3-2-1 AM072FXVA66

Disassembly and Reassembly

Samsung Electronics 3-3

No. Parts Procedure Remark

4) 2 screws had fixed in terminal block cover

when change power terminal block, com-

munication terminal block remove.

5) 2 screws had fixed in terminal block after

remove 4 screws had fixed to Cabinet for

terminal block protection remove.

6) 5 screws had fixed to Front part remove.

Loading...

Loading...