Omron ACCURAX G5 SERVO DRIVE, ACCURAX G5 SERVO DRIVES DATASHEET

R88D-KN@@@-ML2, R88D-KT@

Accurax G5 servo drive

Accurate motion control in a compact size servo drive family. MECHATROLINK-II motion bus and safety built-in.

•MECHATROLINK-II and Analog/ Pulse servo drive models

•Safety conforming ISO13849-1 Performance Level D

•High-response frequency of 2 kHz

•High resolution serial encoder for greater accuracy provided by 20 bits encoder

•External encoder input for full close loop

•Real time auto-tuning

•Advanced tuning algorithms (Anti-vibration function, torque feedforward, disturbance observer)

Ratings

•230 VAC Single-phase 100 W to 1.5 kW (8.59 Nm)

•400 VAC three-phase 600 W to 5 kW (28.7 Nm)

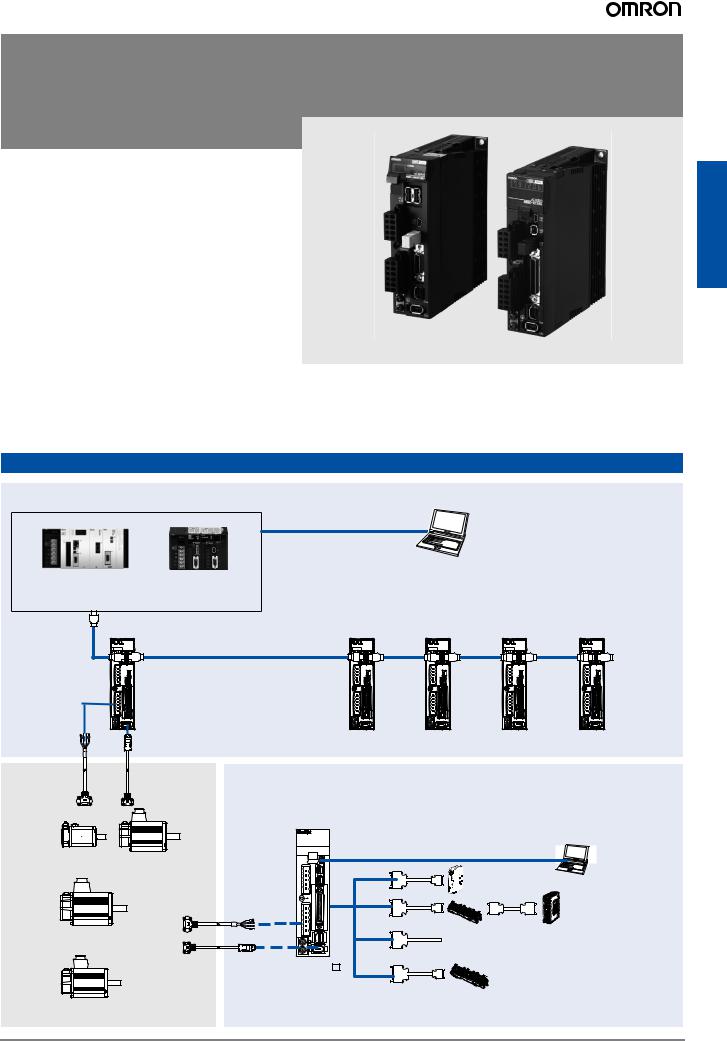

System configuration

MECHATROLINK-II control

Personal computer software: CX-One

TJ1-MC04/16 CJ1W-MCH72

CJ1W-NCF71

Accurax G5 ML-II Servo Drives

Terminator

MECHATROLINK-II

R88D-KN -ML2

-ML2

R88D-KN -ML2

-ML2

Power cable |

Encoder cable |

Open Analog/pulse control |

|

Accurax G5 Analog/pulse |

|

Servo Drive |

Servo Motor |

Personal computer: |

3000 rpm (50 W-5 kW) |

Software CX-One |

|

Motion control unit |

Power cable |

Position control unit |

Servo Motor |

General purpose cable |

|

2000 rpm (400 W-5 kW) |

||

|

|

Encoder cable |

|

|

R88D-KT |

Terminal block |

|

|

|

|

|

for Servo drive I/O |

|

|

general purpose |

Servo Motor |

|

signals |

|

Unit |

|

1000 rpm (900 W-3 kW) |

|

|

|

|

AC Servo systems

Accurax G5 servo drive |

61 |

Servo motor supported

|

|

|

Accurax G5 rotary servo motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Accurax G5 servodrive |

|

|

||||||||

|

Voltage |

Speed |

Rated torque |

Capacity |

Model |

MECHATROLINK-II model |

|

|

Analog/Pulse model |

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230V |

|

400V |

230V |

400V |

|

|||||

|

230 V |

3000 min-1 |

0.16 Nm |

50 W |

R88M-K05030(H/T)-@ |

R88D-KN01H-ML2 |

- |

|

|

R88D-KT01H |

- |

|

|||||||||||||||||

|

|

|

|

0.32 |

Nm |

100 W |

R88M-K10030(H/T)-@ |

R88D-KN01H-ML2 |

- |

|

|

R88D-KT01H |

- |

|

|||||||||||||||

|

|

|

|

0.64 |

Nm |

200 W |

R88M-K20030(H/T)-@ |

R88D-KN02H-ML2 |

- |

|

|

R88D-KT02H |

- |

|

|||||||||||||||

|

|

|

|

1.3 Nm |

400 W |

R88M-K40030(H/T)-@ |

R88D-KN04H-ML2 |

- |

|

|

R88D-KT04H |

- |

|

||||||||||||||||

|

|

|

|

2.4 Nm |

750 W |

R88M-K75030(H/T)-@ |

R88D-KN08H-ML2 |

- |

|

|

R88D-KT08H |

- |

|

||||||||||||||||

|

|

|

|

3.18 |

Nm |

1000 W |

R88M-K1K030(H/T)-@ |

R88D-KN15H-ML2 |

- |

|

|

R88D-KT15H |

- |

|

|||||||||||||||

|

|

|

|

4.77 |

Nm |

1500 W |

R88M-K1K530(H/T)-@ |

R88D-KN15H-ML2 |

- |

|

|

R88D-KT15H |

- |

|

|||||||||||||||

|

400 V |

|

|

2.39 Nm |

750 W |

R88M-K75030(F/C)-@ |

- |

|

|

|

|

|

R88D-KN10F-ML2 |

- |

R88D-KT10F |

|

|||||||||||||

|

|

|

|

3.18 |

Nm |

1000 W |

R88M-K1K030(F/C)-@ |

- |

|

|

|

|

|

R88D-KN15F-ML2 |

- |

R88D-KT15F |

|

||||||||||||

|

|

|

|

4.77 |

Nm |

1500 W |

R88M-K1K530(F/C)-@ |

- |

|

|

|

|

|

R88D-KN15F-ML2 |

- |

R88D-KT15F |

|

||||||||||||

|

|

|

|

6.37 |

Nm |

2000 W |

R88M-K2K030(F/C)-@ |

- |

|

|

|

|

|

R88D-KN20F-ML2 |

- |

R88D-KT20F |

|

||||||||||||

|

|

|

|

9.55 |

Nm |

3000 W |

R88M-K3K030(F/C)-@ |

- |

|

|

|

|

|

R88D-KN30F-ML2 |

- |

R88D-KT30F |

|

||||||||||||

|

|

|

|

12.7 |

Nm |

4000 W |

R88M-K4K030(F/C)-@ |

- |

|

|

|

|

|

R88D-KN50F-ML2 |

- |

R88D-KT50F |

|

||||||||||||

|

|

|

|

15.9 |

Nm |

5000 W |

R88M-K5K030(F/C)-@ |

- |

|

|

|

|

|

R88D-KN50F-ML2 |

- |

R88D-KT50F |

|

||||||||||||

|

230 V |

2000 min-1 |

4.77 Nm |

1000 W |

R88M-K1K020(H/T)-@ |

R88D-KN10H-ML2 |

- |

|

|

R88D-KT10H |

- |

|

|||||||||||||||||

|

|

|

|

7.16 |

Nm |

1500 W |

R88M-K1K520(H/T)-@ |

R88D-KN15H-ML2 |

- |

|

|

R88D-KT15H |

- |

|

|||||||||||||||

|

400 V |

|

|

1.91 Nm |

400 W |

R88M-K40020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN06F-ML2 |

- |

R88D-KT06F |

|

|||||||||||||

|

|

|

|

2.86 |

Nm |

600 W |

R88M-K60020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN06F-ML2 |

- |

R88D-KT06F |

|

||||||||||||

|

|

|

|

4.77 |

Nm |

1000 W |

R88M-K1K020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN10F-ML2 |

- |

R88D-KT10F |

|

||||||||||||

|

|

|

|

7.16 |

Nm |

1500 W |

R88M-K1K520(F/C)-@ |

- |

|

|

|

|

|

R88D-KN15F-ML2 |

- |

R88D-KT15F |

|

||||||||||||

|

|

|

|

9.55 |

Nm |

2000 W |

R88M-K2K020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN20F-ML2 |

- |

R88D-KT20F |

|

||||||||||||

|

|

|

|

14.3 |

Nm |

3000 W |

R88M-K3K020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN30F-ML2 |

- |

R88D-KT30F |

|

||||||||||||

|

|

|

|

19.1 |

Nm |

4000 W |

R88M-K4K020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN50F-ML2 |

- |

R88D-KT50F |

|

||||||||||||

|

|

|

|

23.9 |

Nm |

5000 W |

R88M-K5K020(F/C)-@ |

- |

|

|

|

|

|

R88D-KN50F-ML2 |

- |

R88D-KT50F |

|

||||||||||||

|

230 V |

1000 min-1 |

8.59 Nm |

900 W |

R88M-K90010(H/T)-@ |

R88D-KN15H-ML2 |

- |

|

|

R88D-KT15H |

- |

|

|||||||||||||||||

|

400 V |

|

|

8.59 Nm |

900 W |

R88M-K90010(F/C)-@ |

|

|

|

|

|

|

R88D-KN15F-ML2 |

- |

R88D-KT15F |

|

|||||||||||||

|

|

|

|

19.1 Nm |

2000 W |

R88M-K2K010(F/C)-@ |

|

|

|

|

|

|

R88D-KN30F-ML2 |

- |

R88D-KT30F |

|

|||||||||||||

|

|

|

|

28.7 Nm |

3000 W |

R88M-K3K010(F/C)-@ |

|

|

|

|

|

|

R88D-KN50F-ML2 |

- |

R88D-KT50F |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type designation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Servo drive |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R88D-KN01H-ML2 |

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

Accurax G5 Series servo drive |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Blank: Analog/pulse type |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ML2: MECHATROLINK-II comms |

|

|

|

|||

Drive Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity and Voltage |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

T: Analog/pulse type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Voltage |

Code |

Output |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

N: Network type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

01H |

100 W |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

02H |

200 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230 V |

04H |

400 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

08H |

750 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10H |

1 kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15H |

1.5 kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

06F |

600 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10F |

1.0 kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 V |

15F |

1.5 kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20F |

2.0 kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30F |

3.0 kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50F |

5.0 kW |

|

|

|

|

62 |

AC servo systems |

Servo drive specifications

Single-phase, 230 V

Servo drive type |

|

R88D-K@ |

01H@ |

|

02H@ |

|

04H@ |

08H@ |

10H@ |

|

15H@ |

|

|||

Applicable |

R88M-K@ |

05030(H/T)@ |

|

20030(H/T)@ |

40030(H/T)@ |

75030(H/T)@ |

1K020(H/T)@ |

|

1K030(H/T)@ |

|

|

||||

servo motor |

|

|

10030(H/T)@ |

|

- |

|

- |

- |

- |

|

1K530(H/T)@ |

|

|

||

|

|

|

|

|

- |

|

- |

|

- |

- |

- |

|

1K520(H/T)@ |

|

|

|

|

|

|

|

- |

|

- |

|

- |

- |

- |

|

90010(H/T)@ |

|

|

|

Max. applicable motor capacity |

W |

100 |

|

200 |

|

400 |

750 |

1000 |

|

1500 |

|

|

||

|

Continuous output current |

|

Arms |

1.2 |

|

1.6 |

|

2.6 |

4.1 |

5.9 |

|

9.4 |

|

ServoAC systems |

|

specificationsBasic |

|

|

|

|

|

|

|

|

|

|

|||||

Conditions Vibration/shock resistance |

(max.) |

5.88 m/s2 10-60 Hz (Continuous operation at resonance point is not allowed) / 19.6 m/s2 |

|

|

|

||||||||||

|

Input power |

Main circuit |

Single-phase/3-phase, 200 to 240 VAC + 10 to -15% (50/60 Hz) |

|

|

|

|

|

|||||||

|

Supply |

Control circuit |

Single-phase, 200 to 240 VAC + 10 to -15% |

(50/60 Hz) |

|

|

|

|

|

|

|||||

|

Control method |

|

|

IGBT-driven PWM method, sinusoidal drive |

|

|

|

|

|

|

|

||||

|

Feedback |

|

|

Serial encoder (incremental/absolute value) |

|

|

|

|

|

|

|

||||

|

|

Usage/storage temperature |

|

0 to +55°C / -20 to 65°C |

|

|

|

|

|

|

|

|

|||

|

|

Usage/storage humidity |

|

90% RH or less (non-condensing) |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Altitude |

|

|

1000m or less above sea level |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Configuration |

|

|

Base mounted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Approx. weight |

|

Kg |

|

0.8 |

|

1.1 |

1.6 |

|

1.8 |

|

|

|||

Three-phase, 400 V

Servo drive type |

R88D-K@ |

06F-@ |

|

10F-@ |

15F-@ |

20F-@ |

30F-@ |

|

50F-@ |

|||

Applicable |

R88M-K@ |

40020(F/C)-@ |

|

75030(F/C)-@ |

1K030(F/C)-@ |

2K030(F/C)-@ |

3K030(F/C)-@ |

|

4K030(F/C)-@ |

|||

servo motor |

|

|

60020(F/C)-@ |

|

1K020(F/C)-@ |

1K530(F/C)-@ |

2K020(F/C)-@ |

3K020(F/C)-@ |

|

5K030(F/C)-@ |

||

|

|

|

|

|

- |

|

- |

1K520(F/C)-@ |

- |

2K010(F/C)-@ |

|

4K020(F/C)-@ |

|

|

|

|

|

- |

|

- |

90010(F/C)-@ |

- |

- |

|

5K020(F/C)-@ |

|

|

|

|

|

- |

|

- |

- |

- |

- |

|

3K010(F/C)-@ |

|

Max. applicable motor capacity |

kW |

0.6 |

|

1.0 |

1.5 |

2.0 |

3.0 |

|

5.0 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous output current |

|

Arms |

|

2.9 |

4.7 |

6.7 |

9.4 |

|

16.5 |

||

specificationsBasic |

Input power |

Main circuit |

3-phase, 380 to 480 VAC + 10 to -15% (50/60Hz) |

|

|

|

|

|||||

Conditions Vibration/shock resistance |

|

5.88 m/s2 10-60 Hz (Continuous operation at resonance point is not allowed) / 19.6 m/s2 |

|

|

||||||||

|

Supply |

Control circuit |

24 VDC ±15% |

|

|

|

|

|

|

|

||

|

Control method |

|

|

IGBT-driven PWM method, sinusoidal drive |

|

|

|

|

||||

|

Feedback |

|

|

Serial encoder (incremental/absolute value) |

|

|

|

|

||||

|

|

Usage/storage temperature |

|

0 to +55°C / -20 to +65°C |

|

|

|

|

|

|||

|

|

Usage/storage humidity |

|

|

90% RH or less (non-condensing) |

|

|

|

|

|

||

|

|

Altitude |

|

|

1000 m or less above sea level |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Configuration |

|

|

Base mounted |

|

|

|

|

|

|

|

|

|

Approx. weight |

|

Kg |

|

1.9 |

|

2.7 |

|

4.7 |

|||

Accurax G5 servo drive |

63 |

General specifications (for MECHATROLINK-II servo drives)

Control mode |

|

Position control, velocity control, torque control, full-closed control. |

|

Performance |

Frequency characteristics |

2 kHz |

|

|

|

Speed zero clamp |

Preset velocity command can be clamped to zero by the speed zero clamp input. |

|

|

|

|

|

|

soft start time setting |

0 to 10 s (acceleration, deceleration can be set separately). |

Command input |

MECHATROLINK-II |

MECHATROLINK-II commands (for sequence, motion, data setting/reference, monitor, adjustment and other |

|

|

|

communication |

commands) |

|

|

|

|

signal |

Sequence input signal |

- Multi-function input x 8 by parameter setting (forward/reverse drive prohibition, emergency stop, external latch, |

|

Sequence output signal |

It is possible to output three types of signal form incl.: brake release, servo ready, servo alarm, positioning com- |

||

|

|

|

origin proximity, forward/reverse torque limit, general purpose monitor input). |

I/O |

|

|

plete, motor rotation speed detection, torque limit detection, zero speed detection, speed coincidence detection, |

|

|

warning, position command status, speed limit detection, alarm ouput, speed command status. |

|

|

|

|

|

|

USB |

Interface |

Personal computer/ Connector mini-USB |

|

communications |

|

|

|

Communications standard |

Compliant with USB 2.0 standard |

|

|

|

Function |

Parameter setting and status monitoring |

|

MECHATROLINK- |

Communications protocol |

MECHATROLINK-II |

|

II communications |

|

|

|

Station address |

41H to 51 FH (max. number of slaves: 30) |

|

|

|

Tranmission speed |

10 Mbps |

|

|

Transmission cycle |

1, 2 & 4 ms |

|

|

|

|

|

|

Data length |

32 bytes |

functions |

Automatic load inertia detection |

Automatic motor parameter setting. One parameter rigidity setting. |

|

Dynamic brake (DB) |

|

Built-in. Operates during main power OFF, servo alarm, servo OFF or overtravel. |

|

|

|

||

|

|

|

|

|

Regenerative processing |

Internal resistor included in models from 600 W to 5 kW. Regenerative resistor externally mounted (option). |

|

|

Overtravel (OT) prevention function |

DB stop, deceleration stop or coast to stop during P-OT, N-OT operation |

|

Integrated |

Encoder divider function |

Optional division possible |

|

|

|

|

|

Protective functions |

|

Overcurrent, overvoltage, undervoltage, overspeed, overload, encoder error, overheat... |

|

|

|

||

|

Analog monitor functions for supervision |

Analog monitor of motor speed, speed reference, torque reference, command following error, analog input... |

|

|

|

|

The monitoring signals to output and their scaling can be specified with parameters. |

|

|

|

Number of channels: 2 (Output voltage: ±10V DC) |

|

Panel operator |

Display functions |

2-digit 7-segment LED display shows the drive status, alarm codes, parameters... |

|

|

|

MECHATROLINK-II communications status LED indicator (COM) |

|

|

|

|

|

|

Switches |

2 x rotary switches for setting the MECHATROLINK-II node address |

|

CHARGE lamp |

|

Lits when the main circuit power supply is turned ON. |

|

Safety terminal |

Functions |

Safety Torque OFF function to cut off the motor current and stop the motor. Output signal for failure monitoring |

|

|

|

function. |

|

|

Conformed standards |

EN ISO13849-1:2008 (PL- d, Performance Level d), IEC61800-5 -2:2007 (function STO, Safe Torque OFF), |

|

|

|

EN61508:2001 (Safety Integrity Level 2, SIL2), EN954-1:1996 (CAT3). |

|

|

|

|

|

External encoder feedback |

Serial signal and line-driver A-B-Z encoder for full-close control |

|

General specifications (for analog/pulse servo drives)

Control mode |

|

7 modes selectables by parameter: (1) position control, (2) velocity control, (3) torque control, (4) position/velocity |

|||

|

|

|

|

|

control, (5) position/torque control, (6) velocity/torque control and (7) full-closed control. |

control |

Performance |

Frequency characteristics |

2 kHz |

||

|

|

|

Speed zero clamp |

Preset velocity command can be clamped to zero by the speed zero clamp input. |

|

|

|

|

|

|

|

|

|

|

Soft start time setting |

0 to 10 s (acceleration, deceleration can be set separately). S-curve acceleration/deceleration is also available. |

|

Speed/torque |

signalInput |

Speed control |

Speed reference voltage |

6 VDC at rated speed: set at delivery (the scale and polarity can be set by parameters) |

|

|

|

||||

|

|

|

|

Torque limit |

3 VDC at rated torque (torque can be limited separately in positive/negative direction). |

|

|

|

|

|

|

|

|

|

|

Preset speed control |

Preset speed is selectable from 8 internal settings by digital inputs. |

|

|

Torque control |

Torque reference voltage |

3 VDC at rated torque: set at delivery (the scale and polarity can be set by parameters). |

|

|

|

|

|

Speed limit |

Speed limit can be set by parameter. |

|

|

|

|

|

|

controlPosition |

signalInput |

Command |

Input pulse type |

Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train |

|

|

|

||||

|

|

pulse |

Input pulse frequency |

4 Mpps max. (200 Kpps max. at open collector). |

|

|

|

|

|

Command pulse scaling |

Applicable scaling ratio: 1/1000 - 1000 |

|

|

|

|

(Electronic Gear) |

Any value of 1-230 can be set for numerator (encoder resolution) and denominator (command pulse resolution |

|

|

|

|

|

per motor revolution). The combination has to be within the range shown above. |

|

|

|

|

|

|

|

|

Command |

Input pulse type |

Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train |

|

closedcontrol |

ExternalInputsignal |

encoder |

|

|

|

scaling |

Applicable scaling ratio: 1/20 - 160 |

||||

|

|

pulse |

Input pulse frequency |

4 Mpps max. (200 Kpps max. at open collector). |

|

|

|

|

|

Command pulse scaling |

Applicable scaling ratio: 1/1000 - 1000 |

|

|

|

|

(Electronic Gear) |

Any value of 1-230 can be set for numerator (encoder resolution) and denominator (command pulse resolution). |

|

|

|

|

|

The combination has to be within the range shown above. |

Full- |

|

|

|

|

|

|

|

|

|

Any value of 1-230 can be set for numerator (encoder resolution) and denominator (external encoder resolution |

|

|

|

|

|

|

|

|

|

|

|

|

per motor revolution). The combination has to be within the range shown above. |

|

|

|

|||

|

Position signal output |

A-phase, B.phase, Z-phase line driver output and Z-phase open-collector output. |

|||

|

Sequence input signal |

- Multi-function input x 10 by parameter setting (servo ON, control mode switching, forward/reverse drive prohi- |

|||

signalI/O |

|

|

|

|

bition, vibration filter switching, gain switching, electronic gear switching, error counter reset, pulse prohibition, |

|

|

|

|

- Dedicated input x 1 (SEN: sensor ON, ABS data request). |

|

|

|

|

|

|

alarm reset, internal speed selection, torque limit switching, zero speed, emergency stop, inertia ratio switching, |

|

|

|

|

|

velocity/torque command sign). |

|

|

|

|||

|

Sequence output signal |

It is possible to output four types of signal form incl.: brake release, servo ready, servo alarm, positioning com- |

|||

|

|

|

|

|

plete, motor rotation speed detection, torque limit detection, zero speed detection, speed coincidence detection, |

|

|

|

|

|

warning, position command status, speed limit detection, speed command status. |

64 |

AC servo systems |

|

USB |

Interface |

Personal computer/ Connector mini-USB |

|

|

|

Communications |

Communications standard |

Compliant with USB 2.0 standard |

|

|

|

|

|

|

|

|

|

|

Function |

Parameter setting and status monitoring |

|

|

|

Automatic load inertia detection |

Automatic motor parameter setting. One parameter rigidity setting. |

|

|

|

|

Dynamic brake (DB) |

Built-in. Operates during main power OFF, servo alarm, servo OFF or overtravel. |

|

|

|

|

|

|

|

|

|

|

Regenerative processing |

Internal resistor included in models from 600 W to 5 kW. Regenerative resistor externally mounted (option). |

|

|

|

|

Overtravel (OT) prevention function |

DB stop, deceleration stop or coast to stop during P-OT, N-OT operation |

|

|

|

Integratedfunctions |

Encoder divider function |

Optional division possible |

|

|

|

|

|

|

|

systemsServo |

|

|

Panel operator keys |

Used to set/monitor parameters and drive condition (5 key switches). |

|

||

|

Electronic gearing (Numerator/Denominator) |

Up to 4 electronic gear numerators by combining with inputs. |

|

|

|

|

Internal speed setting function |

8 speeds may be set internally |

|

|

|

|

Protective functions |

Overcurrent, overvoltage, undervoltage, overspeed, overload, encoder error, overheat... |

|

|

|

|

Analog monitor functions for supervision |

Analog monitor of motor speed, speed reference, torque reference, command following error, analog input... |

|

|

|

|

|

|

The monitoring signals to output and their scaling can be specified by parameters. |

|

|

|

|

|

Number of channels: 2 (Output voltage: ±10V DC) |

|

|

|

|

|

|

|

|

|

Panel operator |

Display functions |

6-digit 7-segment LED display shows the drive status, alarm codes, parameters... |

|

|

|

|

|

|

|

AC |

|

CHARGE lamp |

|

Lits when the main circuit power supply is turned ON. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Safety terminal |

Functions |

Safety torque OFF function to cut off the motor current and stop the motor. Output signal for failure monitoring |

|

|

|

|

|

function. |

|

|

|

|

Conformed standards |

EN ISO13849-1:2008 (PL- d, Performance Level d), IEC61800-5 -2:2007 (function STO, Safe Torque OFF), |

|

|

|

|

|

EN61508:2001 (Safety Integrity Level 2, SIL2), EN954-1:1996 (CAT3). |

|

|

|

External encoder feedback |

Serial signal and line-driver A-B-Z encoder for full-close control |

|

|

|

|

Expansion connector |

Serial bus for option board |

|

|

|

|

|

|

|

|

|

Servo drive part names

Monitor connector (CN5)

Main circuit power supply terminals (L1, L2, and L3)

Control circuit power supply terminals (L1C and L2C)

Charge lamp

External Regeneration Resistor connection terminals (B1, B2 and B3)

Motor connection terminals (U, V and W)

Protective ground terminals

Display area

Address number switches

Address number switches

MECHATROLINK-II connector (CN6)

MECHATROLINK-II connector (CN6)

USB connector (CN7)

USB connector (CN7)

Safety connector (CN8)

Safety connector (CN8)

Control I/O connector (CN1) - 26 pins-

External encoder connector (CN4)

External encoder connector (CN4)

Encoder connector (CN2)

Encoder connector (CN2)

Monitor connector (CN5)

Main circuit power supply terminals (L1, L2, and L3)

Control circuit power supply terminals (L1C and L2C)

Charge lamp

External Regeneration Resistor connection

terminals (B1, B2 and B3)

Motor connection terminals (U, V and W)

Protective ground terminals

Display area |

Operation area

Operation area

USB connector (CN7)

USB connector (CN7)

Expansion connector (CN3)

Expansion connector (CN3)

Safety connector (CN8)

Safety connector (CN8)

Control I/O connector (CN1) - 50 pins -

External encoder connector (CN4)

External encoder connector (CN4)

Encoder connector (CN2)

Encoder connector (CN2)

MECHATROLINK-II servo drives |

Analog/pulse servo drives |

Note: the above pictures show 230 V servo drives models only. The 400 V servo drives have 24 VDC power input terminals for control circuit instead of L1C and L2C terminals.

Accurax G5 servo drive |

65 |

I/O specifications

Terminals specifications (for all drives)

Symbol |

Name |

Function |

L1 |

Main power supply input terminal |

AC power input terminals for the main circuit |

L2 |

|

Note: for single-phase servo drives connect the power supply input to L1 and L3. |

|

|

|

L3 |

|

|

|

|

|

L1C |

Control power supply input terminal |

AC power input terminals for the control circuit |

L2C |

|

(for 200V single/three-phase servo drives only). |

|

|

|

24 V |

|

DC power input terminals for the control circuit |

0 V |

|

(for 400V three-phase servo drives only). |

B1 |

External regeneration resistor connection terminals |

Servo drives below 750W: no internal resistor is connected. Leave B2 and B3 open. |

|

|

Connect an external regenerative resistor between B1 and B2. |

B2 |

|

|

B3 |

|

Servo drives from 750W to 5 kW: short-circuit in B2 and B3 for internal regenerative resistor. If the |

|

|

|

|

|

internal regenerative resistor is insufficient, connect an external regenerative resistor between B1 and |

|

|

B2 and remove the wire between B2 and B3. |

U |

Servo motor connection terminals |

Terminals for outputs to the servomotor. |

|

|

|

V |

|

|

W |

|

|

I/O signals (CN1) - Input signals (for MECHATROLINK-II servo drives)

Pin No. |

Signal name |

Function |

|

|

6 |

I-COM |

± pole of external DC power. The power must use 12V-24V (±5%) |

||

5 |

E-STOP |

Emergency stop |

|

The signal name shows the factory setting. The function can be |

|

|

|

|

changed by parameter setting. |

7 |

P-OT |

Forward run prohibited |

|

|

8 |

N-OT |

Reverse run prohibited |

|

|

9 |

DEC |

Origin proximity |

|

|

|

|

|

|

|

10 |

EXT3 |

External latch input 3 |

|

|

11 |

EXT2 |

External latch input 2 |

|

|

12 |

EXT1 |

External latch input 1 |

|

|

|

|

|

|

|

13 |

SI-MON0 |

General purpose monitor input 0 |

|

|

14 |

BTP-I |

Connecting pin for the absolute encoder backup battery. Do not connect when a battery is connected to the encoder cable (CN2 |

||

15 |

BTN-I |

connector). |

|

|

17 |

- |

Terminals not used. Do not connect. |

||

18 |

- |

|

|

|

19 |

- |

|

|

|

|

|

|

|

|

20 |

- |

|

|

|

21 |

- |

|

|

|

22 |

- |

|

|

|

|

|

|

|

|

23 |

- |

|

|

|

24 |

- |

|

|

|

- |

PCL |

Forward torque limit |

The function of input signals allocated to pins 5 and 7 to 13 can be changed with these options by |

|

|

|

|

parameters settings. |

|

|

NCL |

Reverse torque limit |

||

|

SI-MON1 |

General-purpose monitor input 1 |

|

|

|

SI-MON2 |

General-purpose monitor input 2 |

|

|

|

|

|

|

|

Shell |

FG |

Shield ground. Connected to frame ground if the shield wire of the I/O signal cable is connected to the connector shell. |

||

16 |

GND |

Signal ground. It is insulated with power supply (I-COM) for the control signal in the servo drive. |

||

I/O signals (CN1) - output signals (for MECHATROLINK-II servo drives)

Pin No. |

Signal name |

Function |

|

|

1 |

BRK-OFF+ |

External brake release signal |

||

2 |

BRK-OFF |

|

|

|

|

|

|

||

25 |

S-RDY+ |

Servo ready: ON when there is no servo alarm and control/main circuit power supply is ON |

||

26 |

S-RDY- |

|

|

|

3 |

ALM+ |

Servo alarm: Turns OFF when an error is detected |

||

|

|

|

|

|

4 |

ALM- |

|

|

|

- |

INP1 |

Position complete output |

1 |

The function of output signals allocated to pins 1,2, 25 and 26 can be changed with these options by |

|

AT-SPEED |

Speed complete |

|

parameters settings |

|

|

|

|

|

|

T_LIM |

Torque limit |

|

|

|

ZSP |

Zero speed |

|

|

|

V-COIN |

Speed coincidence |

|

|

|

|

|

|

|

|

INP2 |

Position complete output |

2 |

|

|

WARN1 |

Warning 1 |

|

|

|

WARN2 |

Warning 2 |

|

|

|

|

|

|

|

|

DEN |

Origin proximity |

|

|

|

V_LIM |

Speed limit |

|

|

66 |

AC servo systems |

Loading...

Loading...