Page 1

858 Professional Sample Processor

Manual

8.858.8002EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

858 Professional Sample Processor

Manual

8.858.8002EN 06.2011 dm

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Field of application ............................................................... 1

1.2 Instrument description ......................................................... 1

1.3 Model versions ...................................................................... 2

1.4 Intended use ......................................................................... 3

1.5 About the documentation ................................................... 3

1.5.1 Symbols and conventions ........................................................ 3

1.6 Safety instructions ................................................................ 4

1.6.1 General notes on safety ........................................................... 4

1.6.2 Electrical safety ........................................................................ 4

1.6.3 Personnel safety ...................................................................... 5

1.7 Recycling and disposal ......................................................... 7

Table of contents

2 Overview of the instrument 8

2.1 Front ...................................................................................... 8

2.2 Rear ........................................................................................ 9

2.3 Connector strip ................................................................... 10

2.4 Sample racks ....................................................................... 10

2.5 The Swing Head .................................................................. 12

2.6 Peristaltic pump .................................................................. 14

2.7 Injection valve ..................................................................... 15

3 Installation 16

3.1 Setting up the instrument .................................................. 16

3.1.1 Packaging .............................................................................. 16

3.1.2 Checks .................................................................................. 16

3.1.3 Location ................................................................................ 16

3.2 Connecting the Swing Head .............................................. 16

3.3 Connecting the mains cable .............................................. 17

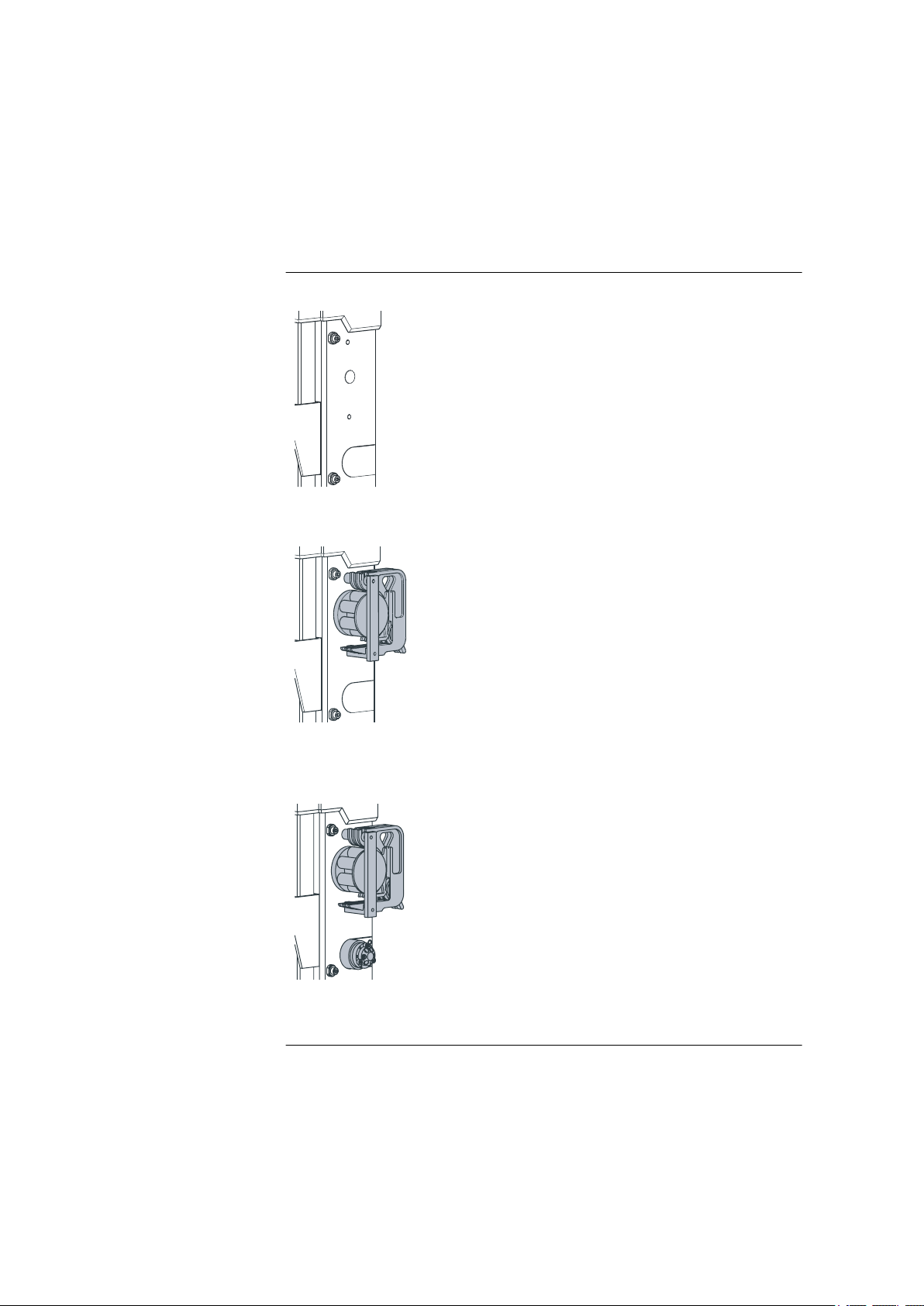

3.4 Mounting the retaining plate ............................................ 17

858 Professional Sample Processor

3.5 Mounting a filtration cell holder or Dosino holder ......... 18

3.6 Mounting the stand plate .................................................. 20

3.7 Guide chain for cables and tubing .................................... 23

3.8 Mounting the sample tube ................................................ 25

3.9 Mounting the safety shield ................................................ 27

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

3.10 Connecting the tower stirrer ............................................. 28

3.11 Connecting pumps ............................................................. 29

3.12 Installing the peristaltic pump .......................................... 30

3.13 Connecting a computer ...................................................... 33

3.14 Connecting MSB devices ................................................... 35

3.14.1 Connecting dosing devices .................................................... 36

3.14.2 Connecting a stirrer or titration stand .................................... 37

3.14.3 Connecting a remote box ...................................................... 38

3.15 Connecting USB devices ..................................................... 39

3.15.1 Connecting a barcode reader ................................................. 39

4 Handling and maintenance 41

4.1 General ................................................................................ 41

4.2 Injection valve ..................................................................... 41

4.3 Filter ..................................................................................... 41

4.4 Peristaltic pump .................................................................. 42

4.5 Pump tubing ....................................................................... 42

4.6 Quality Management and validation with Metrohm ....... 44

5 Troubleshooting 45

5.1 Problems and their solutions ............................................. 45

6 Appendix 46

6.1 Remote interface ................................................................ 46

6.1.1 Pin assignment of the remote interface .................................. 46

7 Technical data 48

7.1 Lift and turntable ............................................................... 48

7.2 786 Swing Head ................................................................. 48

7.3 Two-channel peristaltic pump ........................................... 48

7.4 Injection valve ..................................................................... 49

7.5 Interfaces and connectors ................................................. 49

7.6 Mains connection ............................................................... 49

7.7 Safety specifications ........................................................... 50

■■■■■■■■

IV

7.8 Electromagnetic compatibility (EMC) ................................ 50

7.9 Ambient temperature ......................................................... 50

7.10 Reference conditions .......................................................... 51

7.11 Dimensions .......................................................................... 51

858 Professional Sample Processor

Page 7

■■■■■■■■■■■■■■■■■■■■■■

8 Conformity and warranty 52

9 Accessories 55

Index 96

Table of contents

8.1 Declaration of Conformity ................................................. 52

8.2 Quality Management Principles ........................................ 53

8.3 Warranty (guarantee) ......................................................... 54

9.1 Scope of delivery ................................................................ 55

9.1.1 858 Professional Sample Processor 2.858.0010 ..................... 55

9.1.2 858 Professional Sample Processor 2.858.0020 ..................... 58

9.1.3 858 Professional Sample Processor 2.858.0030 ..................... 62

9.2 Optional accessories 2.858.0010 ...................................... 68

9.3 Optional accessories 2.858.0020 ...................................... 76

9.4 Optional accessories 2.858.0030 ...................................... 86

858 Professional Sample Processor

■■■■■■■■

V

Page 8

Table of figures

Table of figures

Figure 1 Front 858 Professional Sample Processor ........................................... 8

Figure 2 Rear 858 Professional Sample Processor ............................................ 9

Figure 3 Connector strip 858 Professional Sample Processor ......................... 10

Figure 4 Sample rack with sample vessels ...................................................... 10

Figure 5 Attaching a sample rack .................................................................. 11

Figure 6 Swing Head - Configuration data .................................................... 13

Figure 7 Peristaltic pump ............................................................................... 14

Figure 8 Injection valve ................................................................................. 15

Figure 9 Fill / Inject ........................................................................................ 15

Figure 10 Connecting the Swing Head ............................................................ 16

Figure 11 Connecting the mains cable ............................................................ 17

Figure 12 Mounting the retaining plate ........................................................... 18

Figure 13 Mounting filtration cell holder or Dosino holder .............................. 18

Figure 14 Mounting the Dosino ...................................................................... 19

Figure 15 6.1618.020 Thread adapter ............................................................. 19

Figure 16 6.2001.070 stand plate ................................................................... 20

Figure 17 Mounting the support rod ............................................................... 20

Figure 18 Mounting the stand plate ................................................................ 21

Figure 19 Mounting the stirrer and the dilution vessel ..................................... 22

Figure 20 Mounting the cross strut ................................................................. 22

Figure 21 Fixing the support rod ..................................................................... 23

Figure 22 Guide chain - Opening chain links ................................................... 24

Figure 23 Mounting the needle ....................................................................... 25

Figure 24 Mounting the safety shield .............................................................. 27

Figure 25 Rod stirrer 802 Stirrer ...................................................................... 28

Figure 26 Magnetic stirrer 741 Stirrer .............................................................. 28

Figure 27 Connecting the tower stirrer ............................................................ 28

Figure 28 772 Pump Unit ............................................................................... 29

Figure 29 823 Membrane Pump Unit .............................................................. 29

Figure 30 Connecting pumps .......................................................................... 29

Figure 31 Installing the pump tubing .............................................................. 30

Figure 32 Inserting the tubing cartridge .......................................................... 32

Figure 33 Connecting the computer ............................................................... 34

Figure 34 MSB connections ............................................................................ 35

Figure 35 Connecting a dosing device ............................................................. 37

Figure 36 Connecting MSB stirrer .................................................................... 38

Figure 37 Rod stirrer and titration stand .......................................................... 38

Figure 38 Connecting a remote box ................................................................ 39

Figure 39 USB connectors ............................................................................... 40

Figure 40 Pump tubing connection – Changing the filter ................................. 41

Figure 41 Connectors of the remote box ......................................................... 46

Figure 42 Pin assignment of the remote socket and plug ................................ 46

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

VI

858 Professional Sample Processor

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Field of application

The 858 Professional Sample Processor is an instrument with many applications that was conceived for preparing samples for ion chromatography.

Inline filtration, dialysis, preparing dilutions, sample preconcentration,

inline calibration, partial loopfill, etc. are techniques that can be used with

the 858 Professional Sample Processor without any problem. The entire

array of sample preparation techniques can be automated in time-saving

manner.

Thanks to its proven USB interface, the 858 Professional Sample Processor

can be flexibly linked into the Metrohm instrument systems. The control of

the instrument is always accomplished thereby by means of a high-performance PC software, e.g. MagIC Net from Metrohm.

1 Introduction

The equipment with a Swing Head with a robotic arm makes it possible to

approach any given point on a sample rack. As a result, the number (maximum 999 rack positions) and sequencing of the samples on the sample

rack is almost completely unlimited. Customer-specific special racks for

individual requirements can be fabricated upon request.

1.2 Instrument description

The 858 Professional Sample Processor has the following characteristics:

■ Turntable with interchangeable sample rack. The prefabricated sample

racks can hold various numbers of different vessel types and sizes. Any

number of reserved special positions can be defined on the rack.

■ Tower with load-bearing lift. The lift contains a precision drive with

robotic arm as a receptacle for a needle holder or other working

heads.

■ Three MSB connectors (Metrohm Serial Bus), each for controlling one

800 Dosino, one 801 Magnetic Stirrer, one Remote Box, etc.

■ Two USB connectors, through which e. g. printers, keyboards, barcode

readers or additional devices such as Dosing Interfaces, etc., can

directly be connected

■ Two connectors for a peristaltic or a membrane pump

■ Stirrer connector on the tower, for rod stirrer or magnetic stirrer

858 Professional Sample Processor

Depending on the model:

■ Two-channel peristaltic pump

■ Returnable injection valve

■■■■■■■■

1

Page 10

1.3 Model versions

1.3 Model versions

The 858 Professional Sample Processor is available in various models with

a number of different accessories.

Table 1 Model versions of the 858 Professional Sample Processor

Model 2.858.0010

Model 2.858.0020 with peristaltic pump

■■■■■■■■■■■■■■■■■■■■■■

■ Tower with 786 Swing Head and

robotic arm

■ 2 pump connectors

■ 1 stirrer connector

■ 3 connectors for dosing devices and/or

stirrers

■ 2 USB connectors

■ Controller connection for connection

to PC

■ Tower with 786 Swing Head and

robotic arm

■ Peristaltic pump

■ 2 pump connectors

■ 1 stirrer connector

■ 3 connectors for dosing devices and/or

stirrers

■ 2 USB connectors

■ Controller connection for connection

to PC

Model 2.858.0030 with peristaltic pump and injection valve

■ Tower with 786 Swing Head and

robotic arm

■ Injection valve

■ Peristaltic pump

■ 2 pump connectors

■ 1 stirrer connector

■ 3 MSB connectors for dosing devices

and/or stirrers

■ 2 USB connectors

■ Controller connection for connection

to PC

■■■■■■■■

2

858 Professional Sample Processor

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.4 Intended use

The 858 Professional Sample Processor is designed for usage as an automation system in analytical laboratories. It is not suitable for usage in biochemical, biological or medical environments in its basic equipment version.

This instrument is suitable for processing chemicals and flammable samples. The usage of the 858 Professional Sample Processor therefore

requires that the user has basic knowledge and experience in the handling

of toxic and caustic substances. Knowledge with respect to the application of the fire prevention measures prescribed for laboratories is also

mandatory.

1.5 About the documentation

Caution

1 Introduction

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.5.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

858 Professional Sample Processor

■■■■■■■■

3

Page 12

1.6 Safety instructions

1.6 Safety instructions

1.6.1 General notes on safety

■■■■■■■■■■■■■■■■■■■■■■

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.6.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Warning

Warning

■■■■■■■■

4

858 Professional Sample Processor

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

1.6.3 Personnel safety

Wear protective goggles and working clothes suitable for laboratory

work while operating the 858 Professional Sample Processor. It is also

advisable to wear gloves when caustic liquids are used or in situations

where glass vessels could break.

Warning

Warning

858 Professional Sample Processor

■■■■■■■■

5

Page 14

1.6 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Warning

Always install the safety shield supplied with the equipment before

using the instrument for the first time. Pre-installed safety shields are

not allowed to be removed.

The 858 Professional Sample Processor may not be operated without a

safety shield!

Warning

Personnel are not permitted to reach into the working area of the

instrument while operations are running!

A considerable risk of injury exists for the user.

Warning

In the event of a possible blockage of a drive, the mains plug must be

pulled out of the socket immediately. Do not attempt to free jammed

sample vessels or other parts while the device is switched on. Blockages

can only be cleared when the instrument is in a voltage-free status; this

action generally involves a considerable risk of injury.

Warning

The 858 Professional Sample Processor is not suitable for utilization in

biochemical, biological or medical environments in its basic equipment

version.

Appropriate protective measures must be implemented in the event

that potentially infectious samples or reagents are being processed.

■■■■■■■■

6

858 Professional Sample Processor

Page 15

■■■■■■■■■■■■■■■■■■■■■■

1.7 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

1 Introduction

858 Professional Sample Processor

■■■■■■■■

7

Page 16

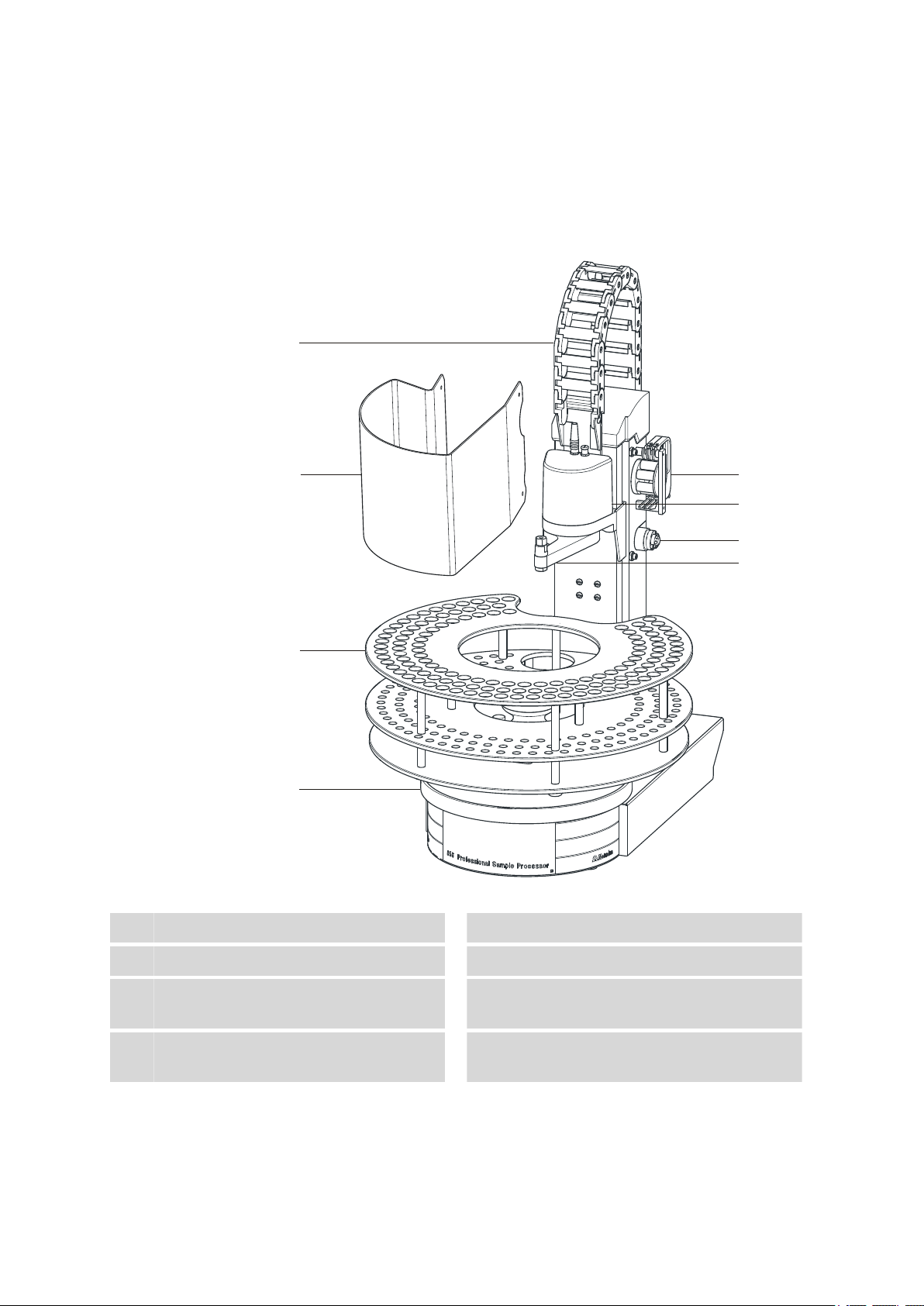

2.1 Front

s

w

i

s

s m

a

d

e

1

2

3

4

5

6

7

8

2 Overview of the instrument

2.1 Front

■■■■■■■■■■■■■■■■■■■■■■

Guide chain

1

Sample rack

3

Peristaltic pump

5

Figure 1 Front 858 Professional Sample Processor

Safety shield

2

Assembly rail

4

Swing Head

6

Depending on the model version

Injection valve

7

8

Depending on the model version

■■■■■■■■

Robotic arm with needle adapter

8

(6.1462.030)

858 Professional Sample Processor

Page 17

■■■■■■■■■■■■■■■■■■■■■■

USB 2

USB 1

Contr.

MSB 1

MSB 2

MSB 3

Made by Metrohm

Herisau Switzerland

P: 115W U: 100 - 240 V f: 50 - 60 Hz

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

Swing

Head

Ext.

Pump 1

Ext.

Pump 2

Nr.

1

2

4

5

3

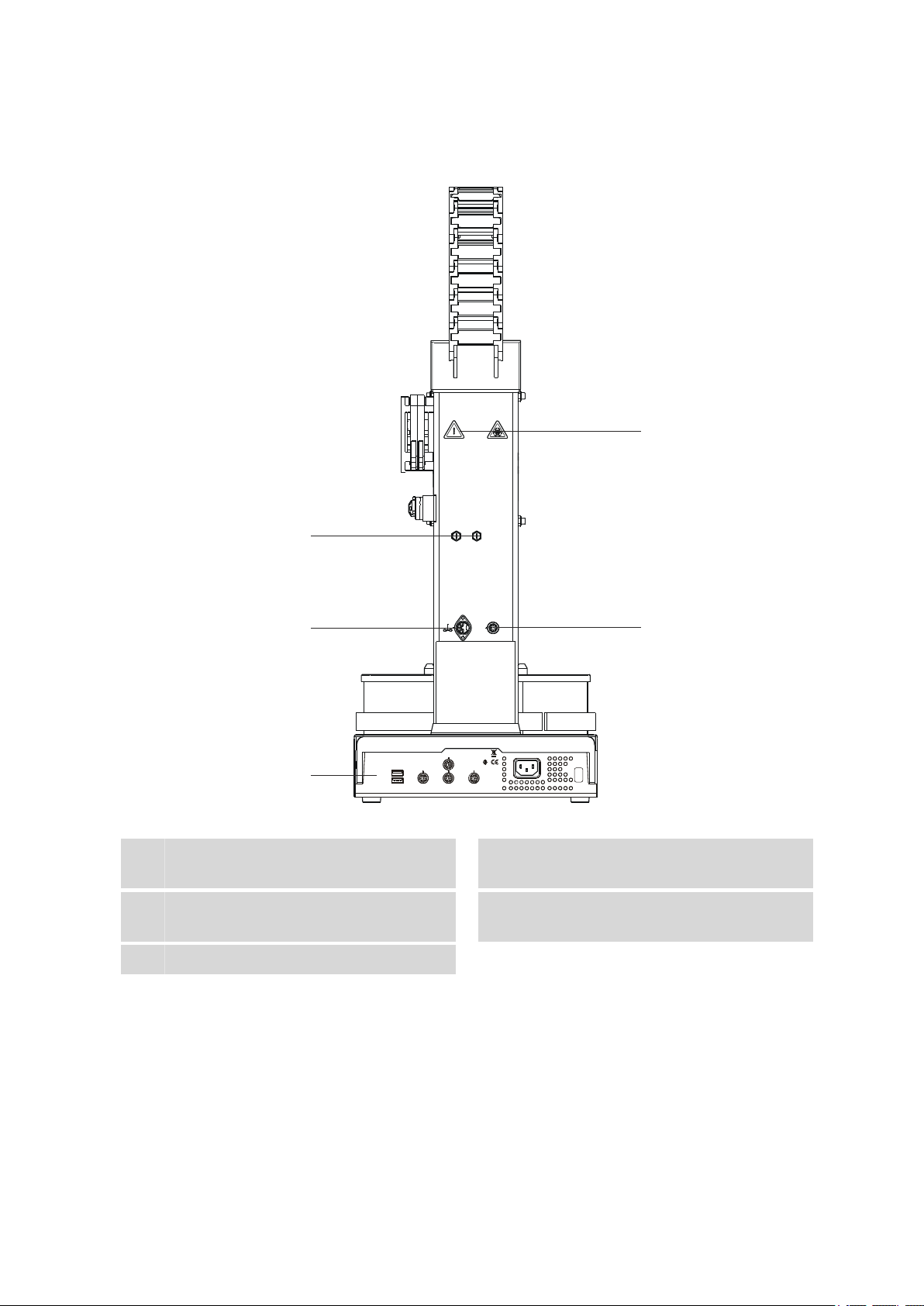

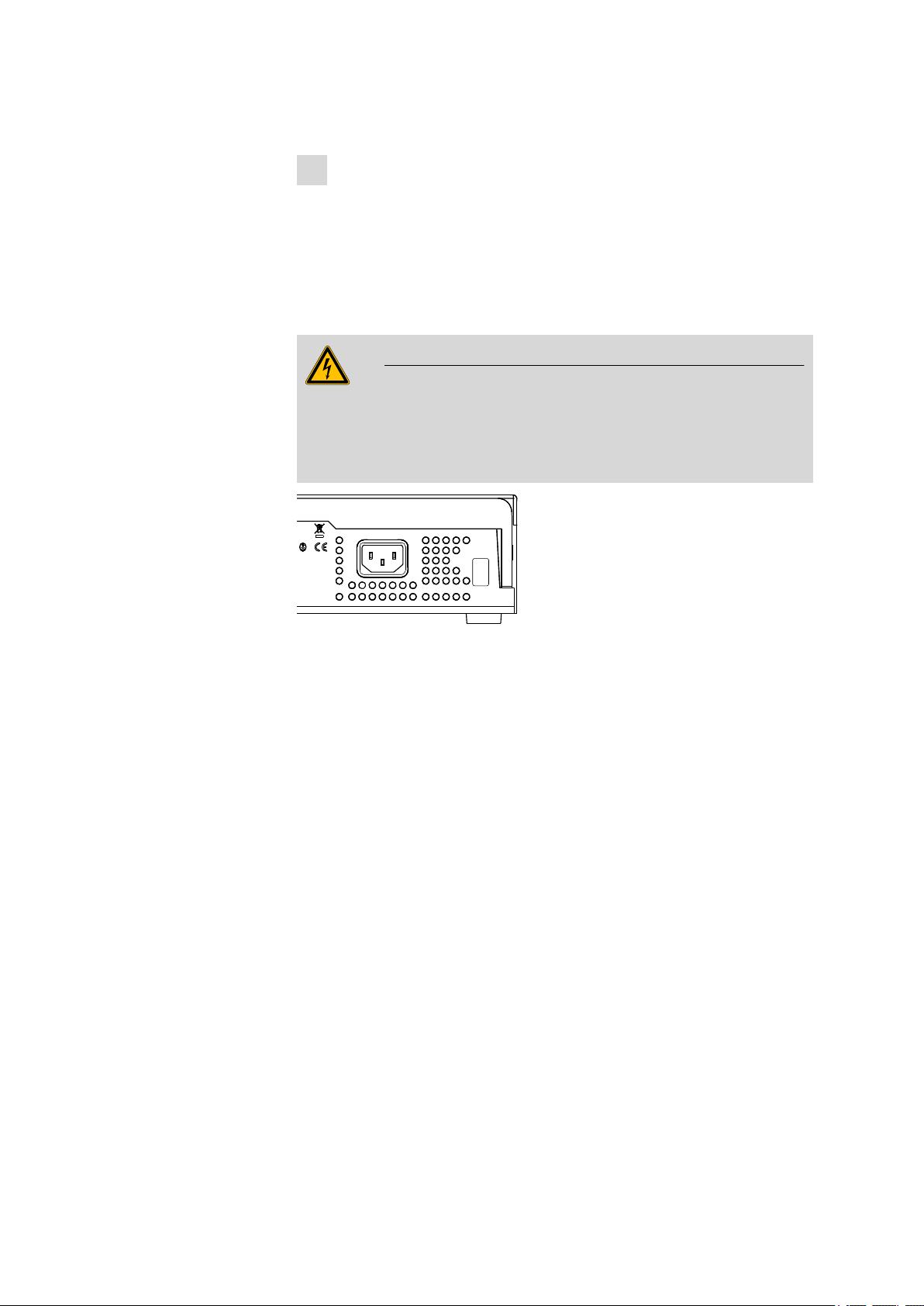

2.2 Rear

2 Overview of the instrument

Figure 2 Rear 858 Professional Sample Processor

Pump connectors

1

M8 connector for external pumps

Connector strip

3

Details (see Chapter 2.3, page 10)

786 Swing Head connector

5

858 Professional Sample Processor

Stirrer connector

2

For rod stirrer and 741 Magnetic Stirrer

Warning symbols

4

(see Chapter 1.6.3, page 5)

■■■■■■■■

9

Page 18

2.3 Connector strip

USB 2

USB 1

Contr.

MSB 1

MSB 2

MSB 3

Made by Metrohm

Herisau Switzerland

P: 115W U: 100 - 240 V f: 50 - 60 Hz

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

Nr.

1 2 3 4 5

2.3 Connector strip

Figure 3 Connector strip 858 Professional Sample Processor

■■■■■■■■■■■■■■■■■■■■■■

USB connectors

1

MSB connectors

3

For dosing devices, stirrers, etc.

Type plate

5

2.4 Sample racks

Controller connector

2

For the connection to the PC

Mains connection

4

10

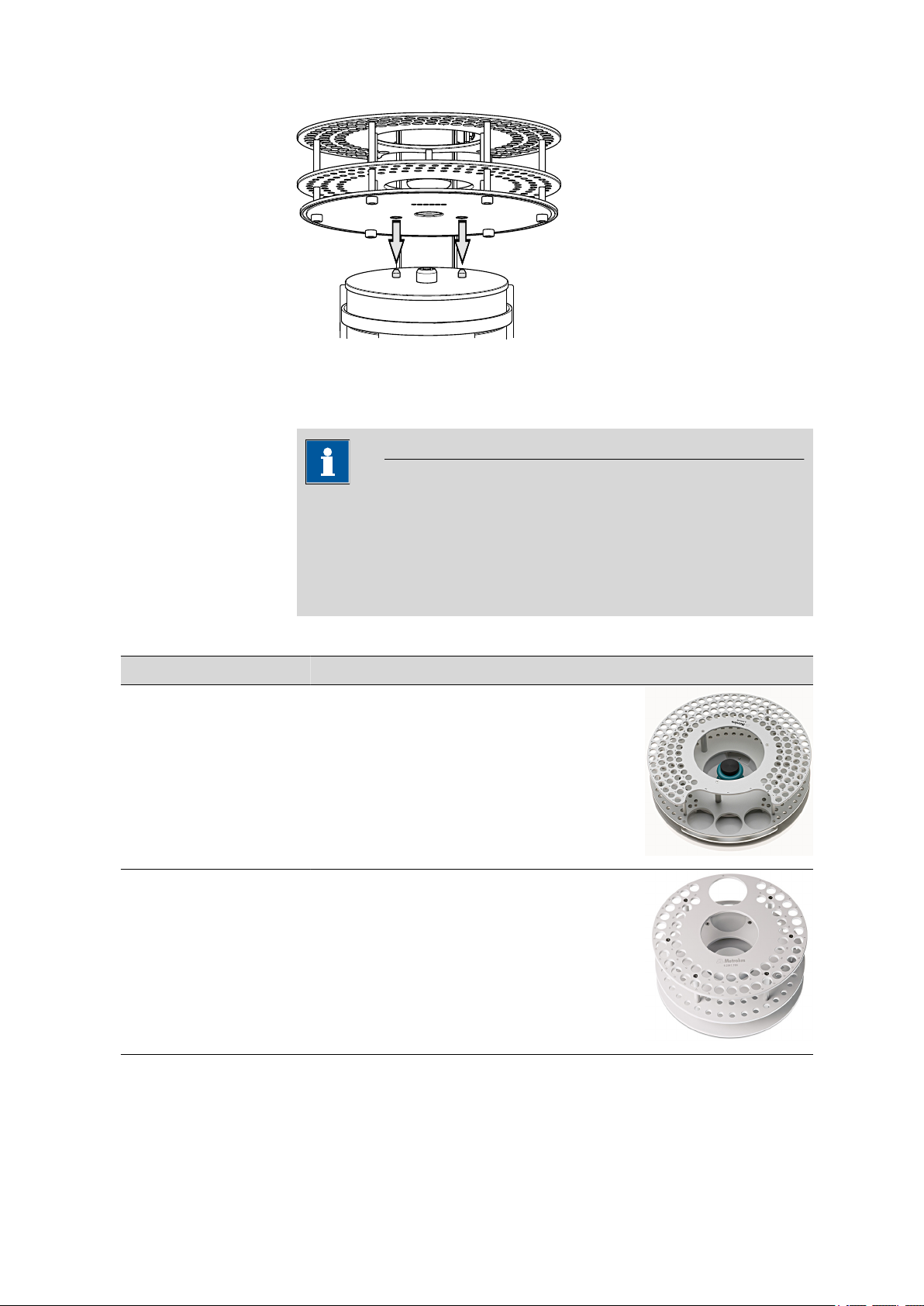

Figure 4 Sample rack with sample vessels

A sample rack is a turntable that acts as a receptacle for sample vessels.

Various types of sample racks are available for different numbers and

types of sample vessels. The 858 Professional Sample Processor requires

sample racks with up to a maximum of 42 cm in diameter or smaller.

Attaching a rack

Attach the sample racks in such a way that the guide pins of the turntable

engage through the guide openings in the base of the rack.

■■■■■■■■

858 Professional Sample Processor

Page 19

■■■■■■■■■■■■■■■■■■■■■■

2 Overview of the instrument

Figure 5 Attaching a sample rack

Certain sample racks have a handle with a fixing screw. With this, the rack

can be fixed on the turntable by rotating in clockwise direction.

Note

After the sample rack has been attached, the rack must be initialized

with the Rack initialization function in the control software ("Manual

Operation"), so that the magnet code of the rack can be recognized.

Automatic recognition of the rack type is only possible when the rack is

rotated into the starting position.

Recommended sample racks for the 858 Professional Sample Processor:

Qty. Order no. Description

6.2041.440 Sample rack 148 x 11 mL

Sample rack for 148 samples at 11 mL with 3 rinsing beakers

Outer diameter (mm): 420

Hole diameter (mm): 17 / 68

6.2041.760 Sample rack for IC Sample Processor, 54 x

11 mL + 1 x 300 mL

Sample rack with small diameter for 54 x 11 mL sample vessels in

two rows and additionally 1 x 300 ml bottle

Outer diameter (mm): 270

Hole diameter (mm): 17 / 68

858 Professional Sample Processor

■■■■■■■■

11

Page 20

2.5 The Swing Head

■■■■■■■■■■■■■■■■■■■■■■

Other user-defined racks can be supplied upon request and the required

rack data can be defined in the control software. Any arrangement of rack

positions is possible. The magnet code for user-defined racks is 110000.

Magnet codes

Every single sample rack can be unambiguously identified by means of a

magnet code. Magnetic pins in a holder attached on the underside of the

rack can be combined to make a binary, six-digit code. The Sample Processor can thus recognize automatically which rack is in place.

When replacing a rack, this should first be returned to starting position

using the Rack initialization function (see "Manual Operation" in the

control software). This will enable an unambiguous recognition of the rack

and thus the correct positioning of the beaker. A positioning table is

assigned to each rack type in which for each rack position the rotation

angle and the distance to the middle of the rack is defined.

The standard racks supplied by Metrohm are already provided with a predefined magnet code for each type.

Format of the magnet code (example):

000001 only one magnet is inserted, Bit 0

000101 two magnets are inserted, Bit 0 and 2

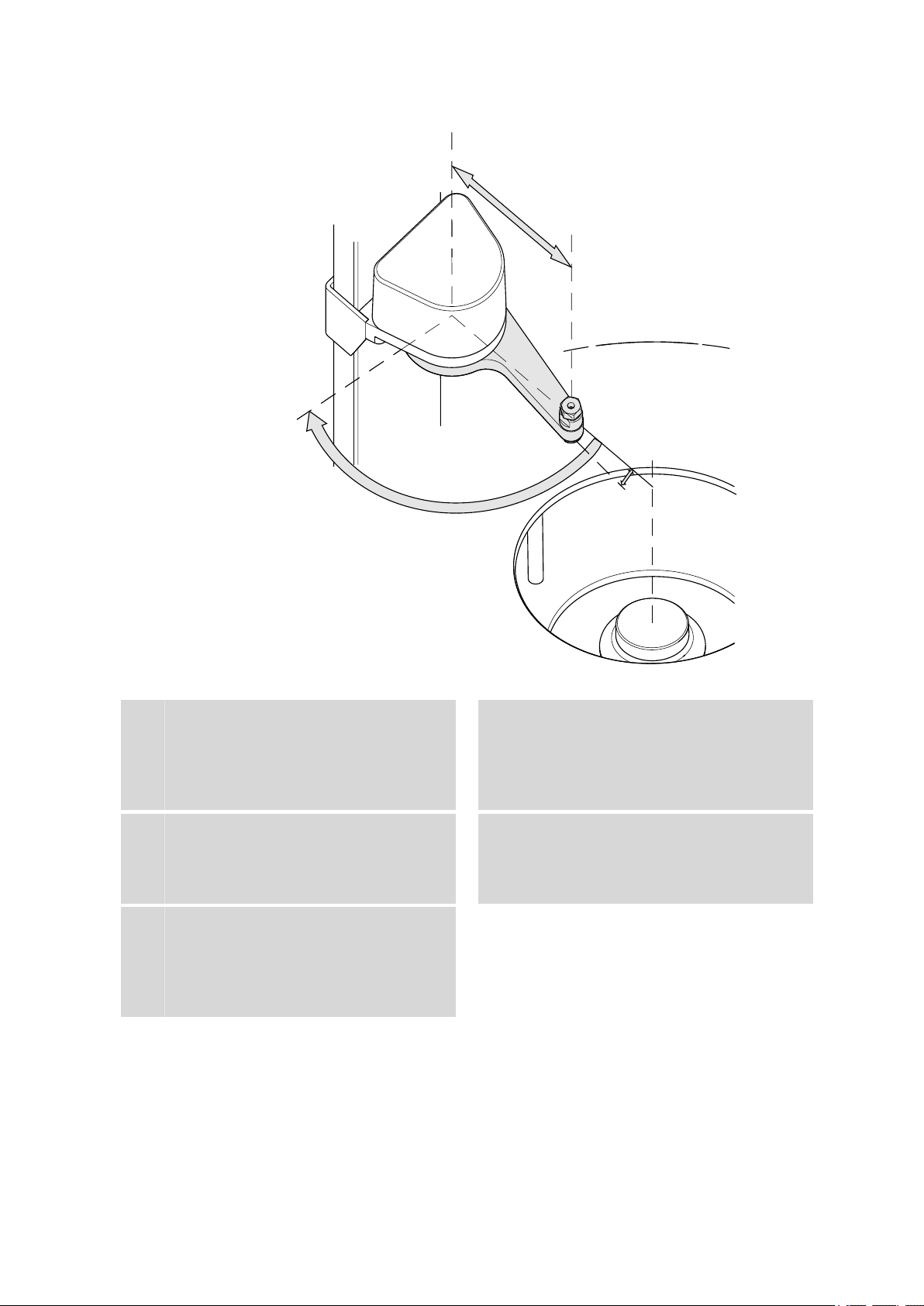

2.5 The Swing Head

The 786 Swing Head is an auxiliary drive for the Metrohm Sample Processor series, e.g. the 858 Professional Sample Processor. It is a high-precision motor drive that makes it possible to move to any point position on a

sample rack. Even positions outside of the sample rack are reachable

when a suitable robotic arm is used.

Left-swinging or right-swinging models are available as different types of

robotic arms. "Left-swinging" means swinging from the initial position

(pointing towards the middle of the rack) outwards to the left.

The following diagram illustrates the most important configuration data

that needs to be set in the control software to ensure correct usage of a

robotic arm (left-swinging, here).

■■■■■■■■

12

858 Professional Sample Processor

Page 21

■■■■■■■■■■■■■■■■■■■■■■

2

3

4

5

1

2 Overview of the instrument

Figure 6 Swing Head - Configuration data

Swing axis

1

This runs through the middle of the Swing

Head drive.

Source axis

3

This runs from the swing axis to the midpoint of the sample rack and marks the initial position of the robotic arm.

Max. swing angle

5

This stands for the swing range that the

robotic arm can reach. The range runs from

the source axis to the maximum possible

robotic arm position.

The configuration data of a robotic arm can be read on its underside or

can be found on an accompanying sheet. Before mounting a robotic arm,

the configuration data must be set in the control software.

Swing radius

2

This is determined by the length of the

robotic arm. The radius runs from the axis of

rotation to the midpoint of the tip of the

robotic arm.

Swing offset

4

This determines the 0° position of the

robotic arm.

858 Professional Sample Processor

■■■■■■■■

13

Page 22

2.6 Peristaltic pump

1

2

3

4

5

6

If a Swing Head drive is mounted with a 6.2058.020 adapter in order to

use racks smaller than intended, then the axial distance must be modified in the configuration of the control software. The corresponding data

can be found on the accompanying sheet of the 6.2058.020. The axial

distance refers to the distance of the swing axis (see figure) and of the axis

of rotation (middle point) of the sample rack.

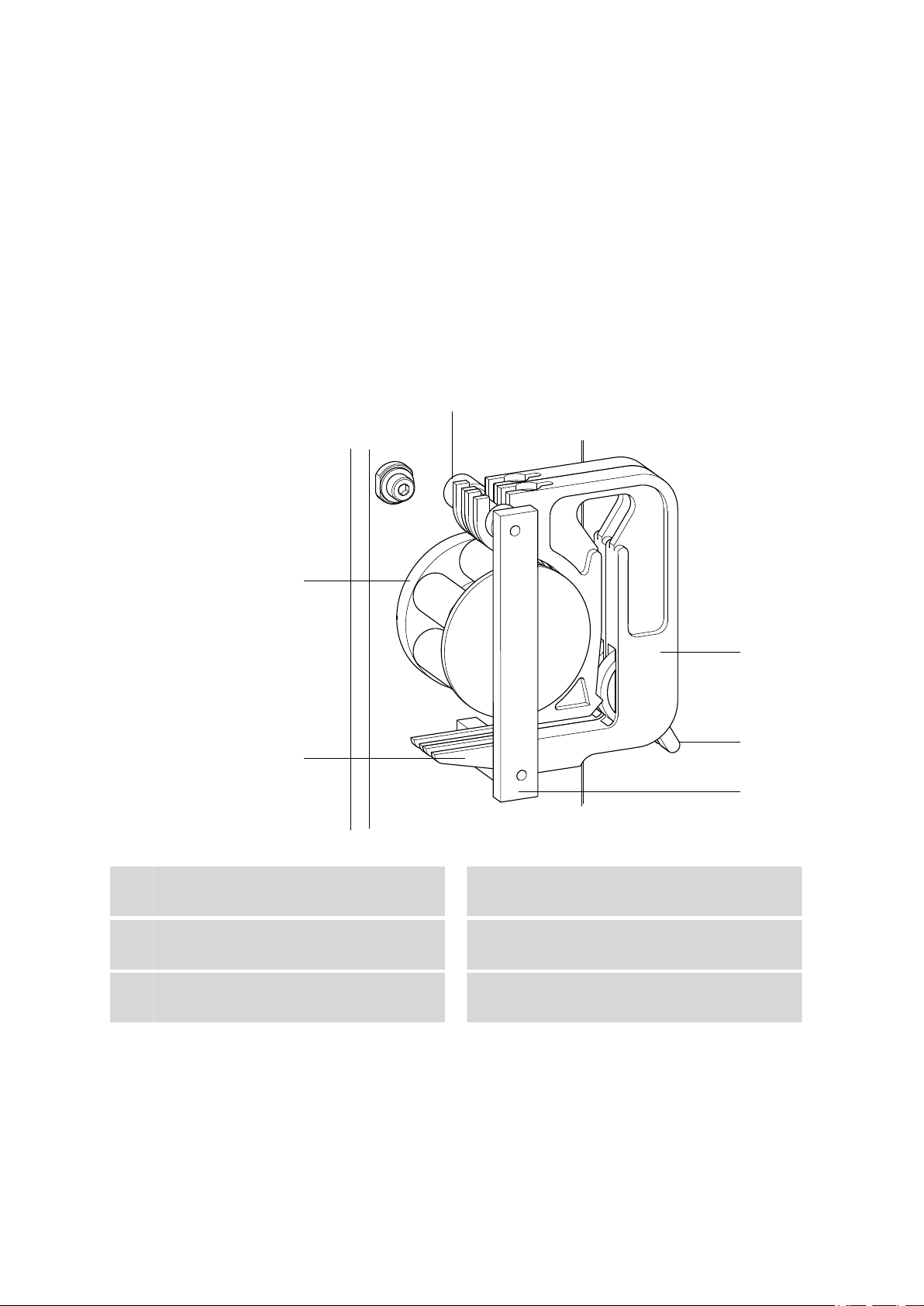

2.6 Peristaltic pump

The peristaltic pump (for the model versions 2.858.0020 and 2.858.0030)

can be used as a 1-channel or 2-channel pump. One or two 6.2755.000

tubing cartridges can be mounted.

■■■■■■■■■■■■■■■■■■■■■■

Figure 7 Peristaltic pump

Mounting bolt

1

For engaging the tubing cartridge

Contact pressure lever

3

For regulating the contact pressure

Snap-action lever

5

For loosening the tubing cartridge

■■■■■■■■

14

Tubing cartridge 6.2755.000

2

For 6.1826.0X0 pump tubings

Retaining bracket

4

Pump drive

6

Roller head with contact pressure rollers

858 Professional Sample Processor

Page 23

■■■■■■■■■■■■■■■■■■■■■■

2.7 Injection valve

The injection valve (for the model version 2.858.0030) can be used with

its connectors 1 to 6 (see figure) for complex sample preparation steps.

Figure 8 Injection valve

The connections of the connectors in the switching positions FILL and

INJECT can be found in the schematics shown below.

2 Overview of the instrument

Figure 9 Fill / Inject

The injection valve must be covered with the red protective cap to protect

it against dust contamination when not in use.

858 Professional Sample Processor

■■■■■■■■

15

Page 24

3.1 Setting up the instrument

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

■■■■■■■■■■■■■■■■■■■■■■

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Connecting the Swing Head

Take care to ensure that the Swing Head is connected before the instrument is set to work. Check the connection cable.

The connection socket (Mini DIN) for the Swing Head drive is located on

the rear of the tower next to the stirrer connector.

Figure 10 Connecting the Swing Head

■■■■■■■■

16

858 Professional Sample Processor

Page 25

■■■■■■■■■■■■■■■■■■■■■■

P: 115W U: 100 - 240 V f: 50 - 60 Hz

Nr.

If the Swing Head is not connected, connect it as follows:

1

Plug in the cable

Guide the Swing Head connection cable through the guide chain of

the tower (see Chapter 3.7, page 23) and plug the Mini DIN plug

into the 'Swing Head' socket.

3.3 Connecting the mains cable

Warning

This instrument may only be used with the mains voltage specified (see

rear of the instrument).

Protect the connection sockets against moisture.

3 Installation

Figure 11 Connecting the mains cable

3.4 Mounting the retaining plate

When removing samples from sealed vessels with the needle, the

6.2064.000 retaining plate is used for stripping vials while the lift is moving upward.

858 Professional Sample Processor

■■■■■■■■

17

Page 26

3.5 Mounting a filtration cell holder or Dosino holder

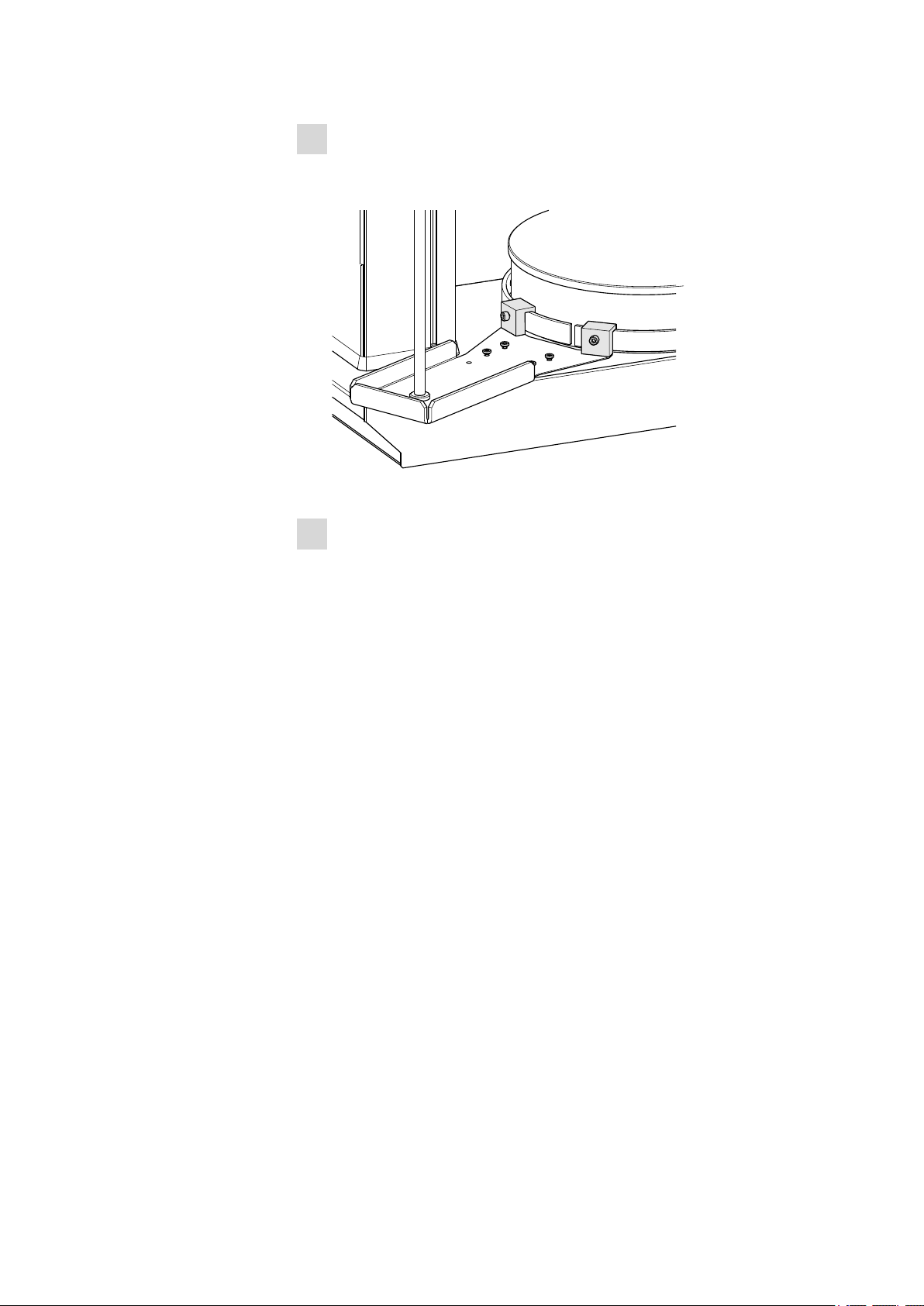

Figure 12 Mounting the retaining plate

1

Mount the retaining plate

Fix the plate to the front of the tower with the four hexagon screws

provided. The hexagon key required is part of the accessories.

■■■■■■■■■■■■■■■■■■■■■■

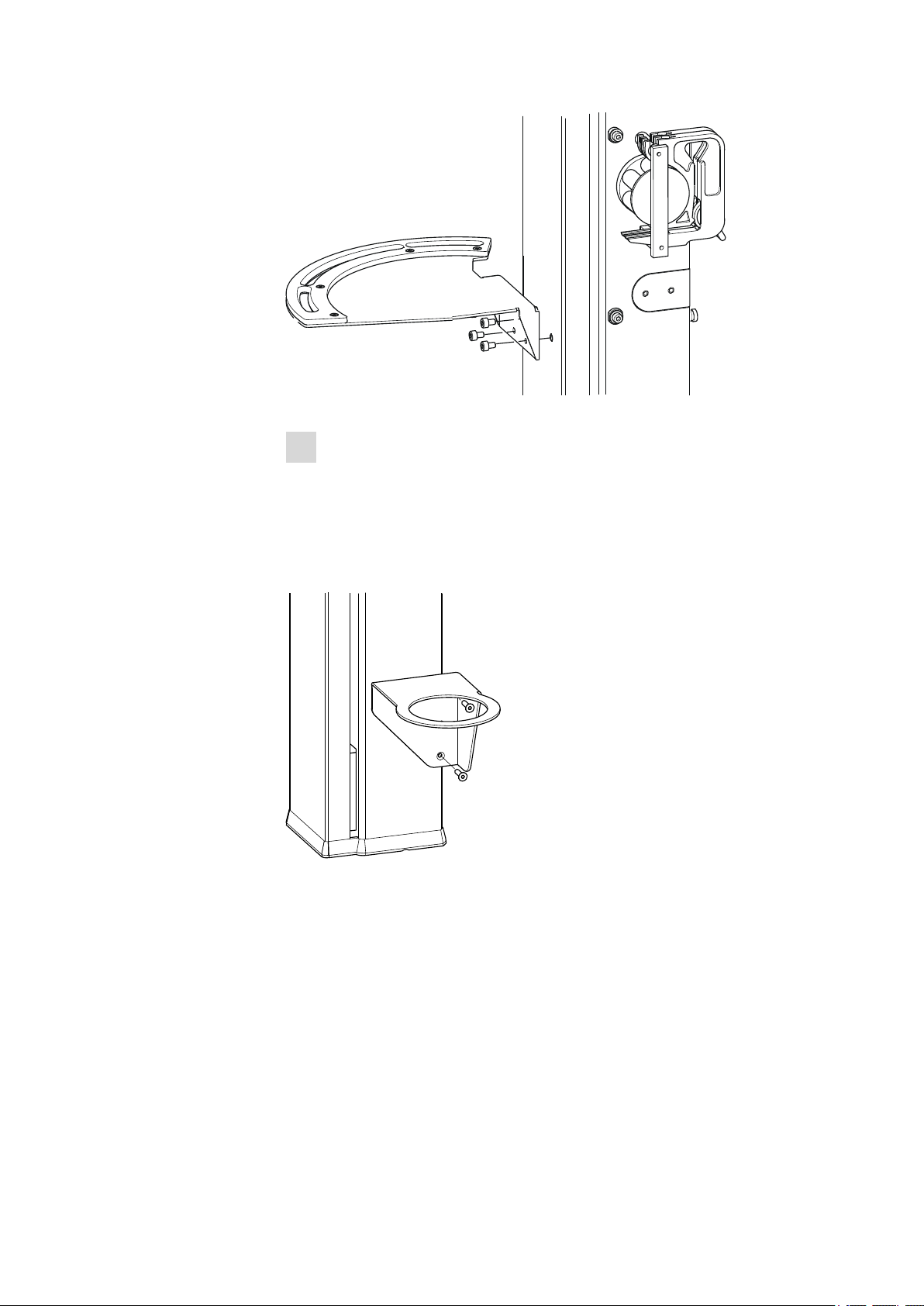

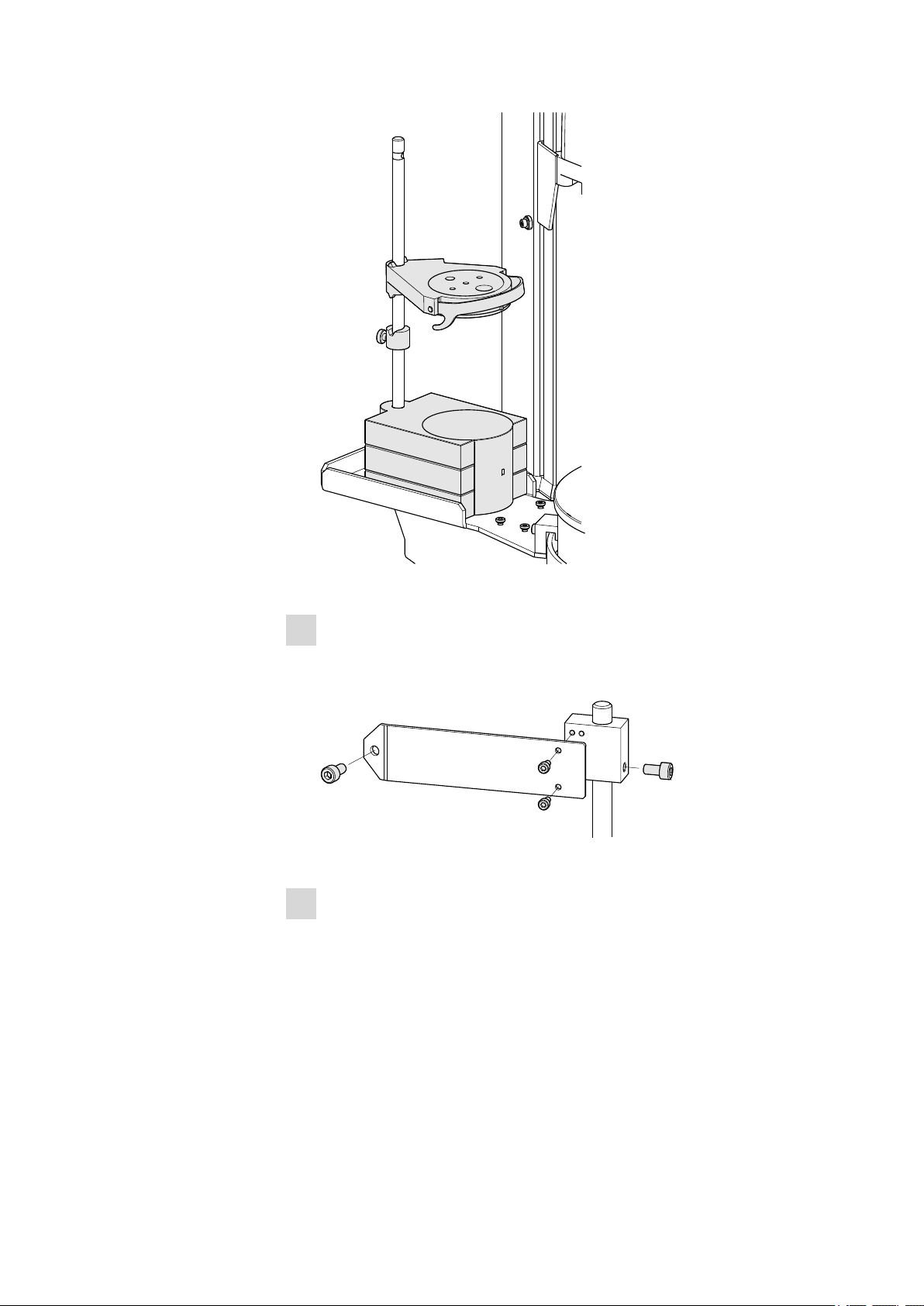

3.5 Mounting a filtration cell holder or Dosino holder

Figure 13 Mounting filtration cell holder or Dosino holder

The filtration cell holder (6.2057.030) or the Dosino holder (6.2057.040)

can be mounted on the side wall of the tower, see above.

First remove the second and third screws from the bottom on the side

wall. Then fix the filtration cell holder or Dosino holder in place with the

two screws supplied.

■■■■■■■■

18

Mounting the Dosino

If a Dosino is required, then it can be installed in the 6.2057.040 Dosino

holder.

858 Professional Sample Processor

Page 27

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Figure 14 Mounting the Dosino

Mount the Dosino as follows:

1

Fix the Dosino

■ Guide the thread adapter GL 45 (6.1618.020) from below into the

Dosino holder.

■ Attach the dosing unit on the Dosino holder and screw the thread

adapter tight.

■ Connect the tubings.

Figure 15 6.1618.020 Thread adapter

858 Professional Sample Processor

■■■■■■■■

19

Page 28

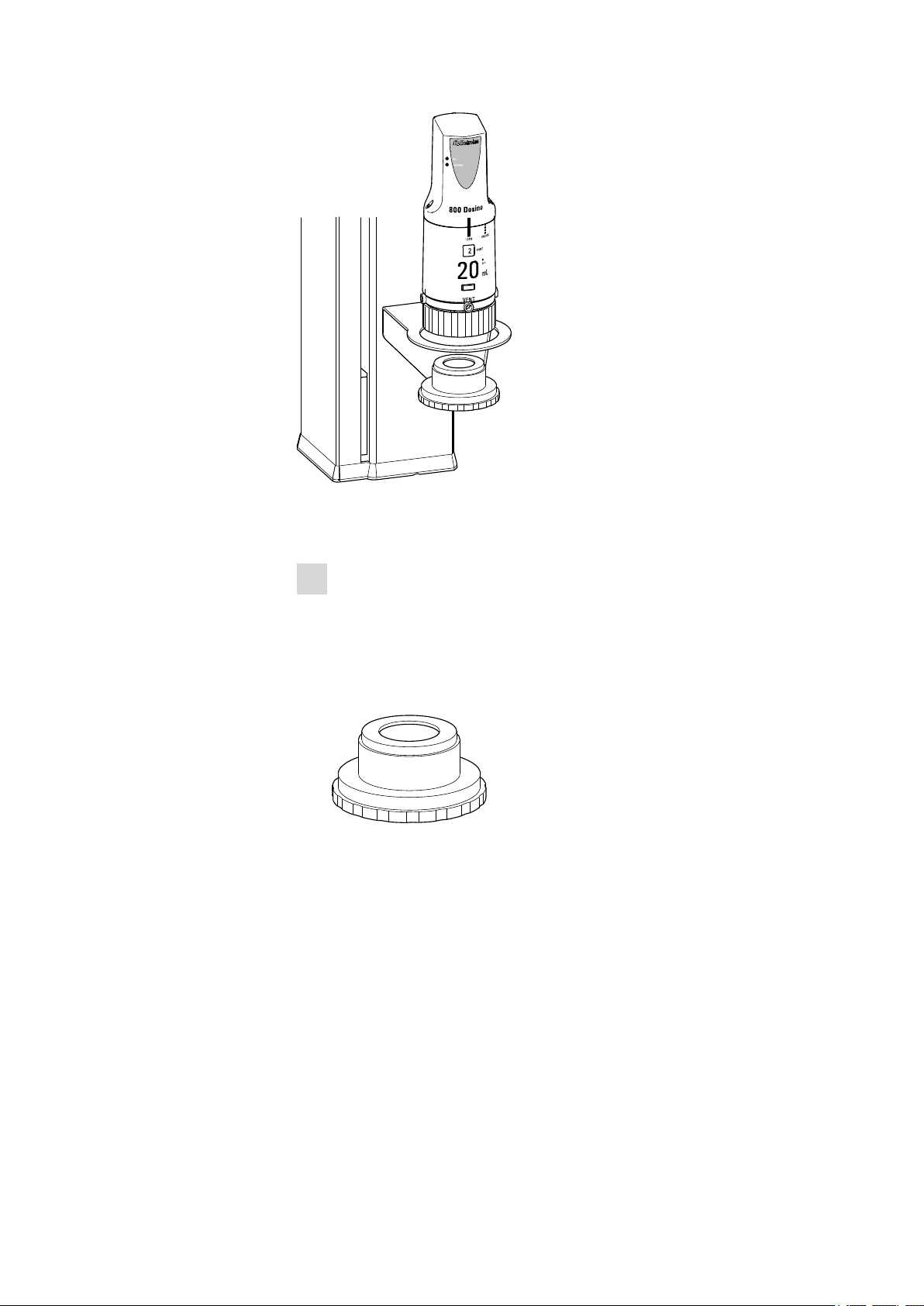

3.6 Mounting the stand plate

3.6 Mounting the stand plate

An external dilution or measuring cell can be mounted to the 858 Professional Sample Processor with the aid of a 6.2001.070 stand plate.

Figure 16 6.2001.070 stand plate

Mount the stand plate as follows:

1

Mount the support rod

■ Plug together the cutting ring and the hexagon screw with the

base plate (see below) and place on a flat support surface.

■ Place the support rod on the screw and screw tightly.

■ Tighten the hexagon screw with a hexagon key of the proper size.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

20

Figure 17 Mounting the support rod

858 Professional Sample Processor

Page 29

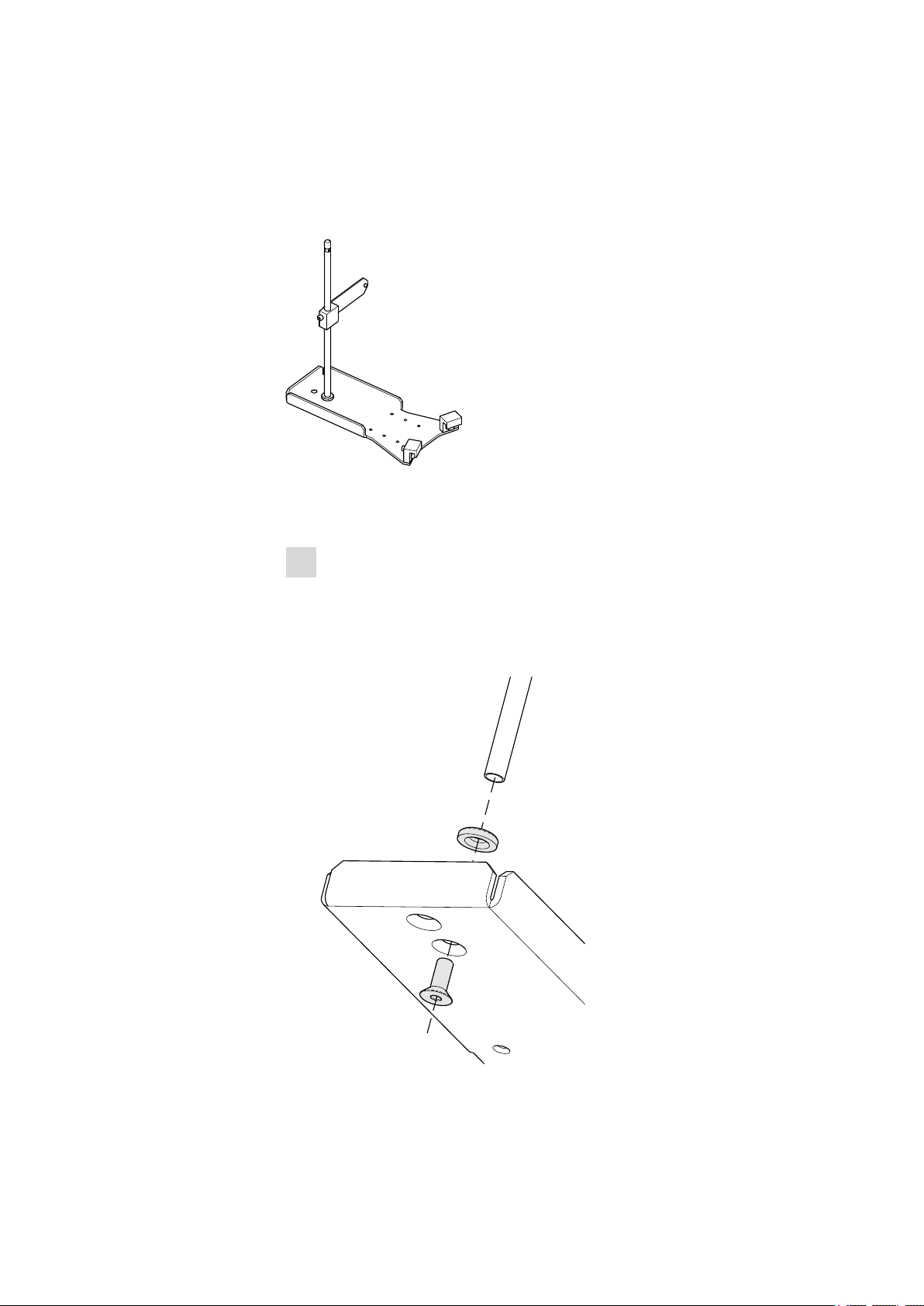

■■■■■■■■■■■■■■■■■■■■■■

2

Fasten the stand plate

■ Hook the fixing clamps on the stirrer rail.

■ Tighten the hexagon screws of the fixing clamps.

Figure 18 Mounting the stand plate

3

Mount the stirrer and dilution vessel

■ Hang the magnetic stirrer (801 Stirrer) on the support rod and

align it.

■ Fix the orientation of the stirrer using the red knurled screw on

the rear.

■ Fasten the 6.2013.010 clamping ring, see the following figure.

■ Fasten dilution vessel lid to the support rod.

3 Installation

858 Professional Sample Processor

■■■■■■■■

21

Page 30

3.6 Mounting the stand plate

■■■■■■■■■■■■■■■■■■■■■■

Figure 19 Mounting the stirrer and the dilution vessel

4

Mount the cross strut

■ Assemble the cross strut according to the drawing shown below.

■ Fasten the cross strut provisionally to the support rod.

Figure 20 Mounting the cross strut

5

Fix the support rod

■ Screw the cross strut to the rear of the tower with the hexagon

screw provided as shown below.

■ Tighten all hexagon screws.

■■■■■■■■

22

858 Professional Sample Processor

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Figure 21 Fixing the support rod

The accessories for the dilution vessel and the necessary tubings and

capillaries can then be attached. You will find information about the

corresponding accessories set in the documentation.

3.7 Guide chain for cables and tubing

Tubing, capillaries and cables can be placed in the guide chain.

You can open the individual chain links with a screwdriver as follows.

1

Open the guide chain

■ Insert a screwdriver into the groove located on the side of a chain

link.

■ Loosen the clip with a forceful leverage movement.

■ Pull the clip out of the chain by hand.

■ Repeat the above actions for each chain link.

3 Installation

858 Professional Sample Processor

■■■■■■■■

23

Page 32

3.7 Guide chain for cables and tubing

■■■■■■■■■■■■■■■■■■■■■■

Figure 22 Guide chain - Opening chain links

2

Insert into the guide chain

■ Place the required tubing, capillaries or cables into the guide

chain.

3

Close the guide chain

■ Close the clip for each chain link again by hand and apply forceful

pressure to snap them into place.

The clip of one chain link can be removed entirely if required by releasing

it on both sides.

■■■■■■■■

24

858 Professional Sample Processor

Page 33

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

3.8 Mounting the sample tube

Needles made of zirconium oxide or PEEK can be used for removing samples.

Warning

When a sample tube 6.1835.050 or a blunt PEEK needle is used, no

stopper is permitted to be used on the sample vessels. These stoppers

cannot be penetrated by such needles. The needle could become damaged if this is attempted! Perforated stoppers can be used with double-bevel needles.

3 Installation

Figure 23 Mounting the needle

PTFE capillary

1

6.1803.070 or 6.1831.050 / 6.1831.060 /

6.1831.080

858 Professional Sample Processor

PEEK pressure screw

2

6.2744.010

■■■■■■■■

25

Page 34

3.8 Mounting the sample tube

■■■■■■■■■■■■■■■■■■■■■■

Nut

3

4.766.4320 (or 6.2833.020 + 6.2744.080)

Needle holder

5

This is how you mount needle and capillary:

1

Remove the PEEK pressure screw

Loosen and remove the nut (23-3) screwed onto the needle holder.

2

Insert the needle

■ Insert the needle from above part way into the opening of the

■ Pull the PEEK ring wedge (23-4) down over the needle from

3

Fasten the needle

■ Screw the nut (23-3) into the needle holder. Slight pressure will

■ Use your hand to screw the nut in the needle holder tight (do not

4

Connect the capillary

Ring wedge

4

Sample tube

6

6.2846.000 (zirconium oxide) or

6.1835.020 / 6.1835.040 / 6.1835.050

(made of PEEK)

needle holder (23-5).

above. The narrow side of the seal must face upwards.

be required from below to push the needle upward while doing

this.

use any tools!).

■■■■■■■■

26

■ Pull the 6.2744.010 PEEK pressure screw (23-2) over the end of

the capillary.

■ Manually screw tight the PEEK pressure screw with the capillary in

the nut of the needle holder. The capillary must be pressed tight

while doing so.

858 Professional Sample Processor

Page 35

■■■■■■■■■■■■■■■■■■■■■■

3.9 Mounting the safety shield

For safety reasons, it is imperative that you mount the accompanying

safety shield (splash protection 6.2751.110). A serious risk of injury exists

if anyone reaches into the working area of the instrument.

Caution

The 858 Professional Sample Processor may not be operated without a

safety shield.

Use the accompanying hexagon screws and the hexagon key to mount

the safety shield according to the following figure.

3 Installation

858 Professional Sample Processor

Figure 24 Mounting the safety shield

If a different robotic arm is used, then a different, suitable safety shield

can be ordered from Metrohm.

■■■■■■■■

27

Page 36

3.10 Connecting the tower stirrer

3.10 Connecting the tower stirrer

A DIN socket for connecting a rod stirrer (802 Stirrer) or a magnetic stirrer (741 Stirrer) is located on the rear of the tower.

Figure 25 Rod stirrer 802 Stirrer

Figure 26 Magnetic stirrer 741 Stirrer

Take care to observe correct orientation of the contact pins when plugging in the stirrer connection cable. The rib on the outside of the plug

must match the reference mark (on the left) on the socket.

■■■■■■■■■■■■■■■■■■■■■■

Figure 27 Connecting the tower stirrer

Note

If an MSB stirrer is connected to the MSB1 socket, then the stirrer connector at tower 1 cannot be used, because both sockets are controlled

internally via MSB1.

■■■■■■■■

28

858 Professional Sample Processor

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Ext.

Pump 1

Ext.

Pump 2

3.11 Connecting pumps

The 858 Professional Sample Processor is equipped with two connectors

for external pumps which, for example, can be used for rinsing or applying suction to vessels. The appropriate pump models are:

Figure 28 772 Pump Unit

3 Installation

The peristaltic pump 772 Pump Unit is suitable for organic solvents and

aqueous solutions containing precipitates.

Figure 29 823 Membrane Pump Unit

The 823 Membrane Pump Unit is suitable for aqueous media without

precipitates.

858 Professional Sample Processor

Figure 30 Connecting pumps

■■■■■■■■

29

Page 38

3.12 Installing the peristaltic pump

1 2 3 4 5 6 7 8 1

9 10 3

6.2744.160

The two pump connectors are located on the rear side of the tower. Connect a pump as follows:

1

Connecting the connection cable

■ Plug the M8 plug of the pump connection cable into one of the

"Ext. Pump" connector sockets. Correct orientation of the 3 contact pins must be observed.

■ Tighten the knurled screw at the front end of the plug by hand in

clockwise direction. This will secure the plug.

The pump connectors (3-pole M8 plugs) supply 16 Volt feed voltage and

may not be loaded with more than a maximum of 600 mA.

3.12 Installing the peristaltic pump

■■■■■■■■■■■■■■■■■■■■■■

Figure 31 Installing the pump tubing

PEEK pressure screws, short

1

(6.2744.070)

Stopper

3

The colors of the stopper indicate the inner

diameter of the pump tubing.

Contact pressure lever

■■■■■■■■

30

5

Adapter

7

Pump tubing

9

Tubing olive (6.2744.030)

2

Tubing cartridge (6.2755.000)

4

Union nut

6

Tubing olive

8

Snap-action lever

10

858 Professional Sample Processor

Page 39

■■■■■■■■■■■■■■■■■■■■■■

Mount the pump tubing as follows:

1

Remove the tubing cartridge

Release the tubing cartridge from the cartridge holder by pressing

the snap-action lever and unhooking from the mounting bolts (see

Figure 7, page 14).

2

Insert the pump tubing

■ Press the contact pressure lever all the way down.

■ Place the pump tubing in the tubing cartridge. The stoppers

(31-3) must snap into the corresponding holder of the tubing cartridge.

3

Connect the aspiration side

Place a 6.2744.030 tubing olive (31-2) on the aspiration side of the

pump tubing.

4

Connect the pressure side

3 Installation

■ Slide the union nut (31-6) of the 6.2744.160 pump tubing con-

nection (without filter) onto the pump tubing.

■ Select a suitable adapter (31-7) (depends on the outer diameter

of the pump tubing) and slide it onto the pump tubing.

■ Place the tubing olive (31-8) onto the pump tubing.

■ Screw the union nut (31-6) tight on the tubing olive (31-8).

5

Insert the tubing cartridge

■ Hang the tubing cartridge in the mounting bolt and press it

underneath in the cartridge holder until the snap-action lever

snaps in.

858 Professional Sample Processor

■■■■■■■■

31

Page 40

3.12 Installing the peristaltic pump

■■■■■■■■■■■■■■■■■■■■■■

Figure 32 Inserting the tubing cartridge

6

Connect the capillaries

■ Screw the respective capillaries tightly to the two tubing olives

with PEEK pressure screws (31-1).

Setting the flow rate

The contact pressure of the tubing cartridge must be adjusted in order to

regulate the flow rate. Proceed as follows:

1

Set the contact pressure

■ Press the contact pressure lever (31-5) all the way forward.

■ Switch on the drive of the peristaltic pump.

■ Then release the contact pressure lever gradually until the liquid is

suctioned for the first time.

■ Now release the contact pressure lever by two latch positions.

The contact pressure is now set optimally.

■■■■■■■■

32

858 Professional Sample Processor

Page 41

■■■■■■■■■■■■■■■■■■■■■■

The flow rate depends not only on the correct contact pressure but

also on the inner diameter of the pump tubing and the rotational

speed of the drive.

Note

Pump tubings are consumables. The lifetime of the pump tubings

depends on the contact pressure, among other factors.

3.13 Connecting a computer

The 858 Professional Sample Processor requires a USB connection to a

computer in order to be able to be controlled by a PC software. Using a

6.2151.000 controller cable, the instrument can be connected directly,

either to a USB socket on a computer, to a connected USB hub or to a

different Metrohm control device.

You need administrator rights for the installation of the driver and software on your PC.

3 Installation

Cable connection and driver installation

A driver installation is required in order to ensure that the 858 Professional

Sample Processor is recognized by the PC software. To accomplish this,

you must comply with the procedures specified. The following steps are

necessary:

1

Install the software

■ Insert the PC software installation CD and carry out the installa-

tion program directions.

■ Exit the program if you have started it after the installation.

2

Establish the cable connections

■ Connect all peripheral devices to the instrument (see Chapter

3.14, page 35).

■ Connect the 858 Professional Sample Processor to the mains sup-

ply if you have not already done this.

■ Connect the instrument to a USB connector (Type A) of your com-

puter (see manual of your computer). The 6.2151.000 cable is

used for this purpose.

858 Professional Sample Processor

■■■■■■■■

33

Page 42

3.13 Connecting a computer

6.2151.000

USB 2

USB 1

Contr.

MSB 2

■■■■■■■■■■■■■■■■■■■■■■

Figure 33 Connecting the computer

The instrument is recognized. The driver installation is carried out differently, depending on the version of the Windows operating system

used.

■ Either the required driver is installed automatically, or an installa-

tion wizard is started.

Follow the instructions of the installation wizard.

3

If problems should occur during installation, contact your company's IT

supporter.

Note

The plug on the instrument end of the 6.2151.000 controller cable is

protected against accidental disconnection by means of a pull-out protection feature. If you wish to pull out the plug, you will first need to

pull back the outer plug sleeve marked with arrows.

Registering and configuring the instrument in the PC software

The instrument must be registered in the configuration of your PC software. Once that has been done, you can then configure it according to

your requirements. Proceed as follows:

1

Set up the instrument

■ Start the PC software.

The instrument is automatically recognized. The configuration dialog for the instrument is displayed.

■ Make configuration settings for the instrument and its connec-

tors.

■■■■■■■■

34

858 Professional Sample Processor

Page 43

■■■■■■■■■■■■■■■■■■■■■■

MSB

Stirrer / Ti Stand

Dosino

Remote Box

Dosino

Dosino

Relay Box

Ti Stand / Stirrer

More detailed information concerning the configuration of the

instrument can be found in the documentation for the respective PC

software.

3.14 Connecting MSB devices

In order to connect MSB devices, e.g.stirrers or dosing devices, Metrohm

instruments are equipped with up a maximum of four connectors at what

is referred to as the Metrohm Serial Bus (MSB). Various kinds of peripheral

devices can be connected in sequence (in series, as a "daisy chain") at a

single MSB connector (8-pin Mini DIN socket) and controlled simultaneously by the respective control instrument. In addition to the connection

cable, stirrers and the remote box are each equipped with their own MSB

socket for this purpose.

The following illustration provides an overview of the devices that can be

connected to an MSB socket, along with a number of different cabling

variations.

3 Installation

858 Professional Sample Processor

Figure 34 MSB connections

The question of which peripheral devices are supported depends on the

control instrument.

■■■■■■■■

35

Page 44

3.14 Connecting MSB devices

■■■■■■■■■■■■■■■■■■■■■■

Note

When connecting MSB devices together, the following must be

observed:

■ Only one device of the same type can be used at a single MSB con-

nector at one time.

■ Type 700 Dosino and 685 Dosimat dosing devices cannot be con-

nected together with other MSB instruments on a shared connector.

These dosing devices must be connected separately.

■ Only one device of the same type can be used at a single MSB con-

nector at one time.

■ MagIC Net software supports only dosing devices of the 800 Dosino

type.

Caution

Exit the control software before you plug MSB instruments in. The control instrument recognizes when it is switched on which instrument is

connected at which MSB connector. The operating unit or the control

software enters the connected MSB devices into the system configuration (Device manager).

MSB connections can be extended with the 6.2151.010 cable. The length

of the connection must not exceed a maximum of 15 m.

3.14.1 Connecting dosing devices

Three dosing devices can be connected to the instrument.

MagIC Net software supports only the 800 Dosino as a dosing device.

The types of dosing devices that are supported are:

■ 800 Dosino

■ 700 Dosino

■ 805 Dosimat

■ 685 Dosimat

■■■■■■■■

36

858 Professional Sample Processor

Page 45

■■■■■■■■■■■■■■■■■■■■■■

USB 1

Contr.

MSB 2

MSB 3

T.2400.102

3 Installation

Warning

If a Dosino is connected to the 858 Professional Sample Processor then

the connection cable must be equipped with a T.2400.102 ferrite core.

The ferrite core reduces any interference voltages that may occur and

thus ensures compliance with strict EMC standards pursuant to applicable technical norms, see Chapter "Technical Data".

Proceed as follows:

1

Mounting ferrite core

Fasten a T.2400.102 ferrite core to the Dosino connection cable near

to the plug.

2

Connect a dosing device

■ Exit the control software.

■ Connect the connection cable to one of the sockets marked with

MSB on the rear of the control instrument.

■ Start the control software.

Figure 35 Connecting a dosing device

3.14.2 Connecting a stirrer or titration stand

You can use a magnetic stirrer 801 Stirrer or 803 Ti Stand (stirring "from

below") or the 804 Ti Stand with a rod stirrer 802 Stirrer (stirring "from

above").

Connect a stirrer or a titration stand as follows:

1

Connect a stirrer or titration stand

■ Exit the control software.

858 Professional Sample Processor

■■■■■■■■

37

Page 46

3.14 Connecting MSB devices

USB 1

Contr.

MSB 2

MSB 3

■■■■■■■■■■■■■■■■■■■■■■

■ Connect the connection cable of the magnetic stirrer or of the

titration stand to one of the sockets marked with MSB on the

rear of the control instrument.

■ If desired, connect the rod stirrer to the stirrer socket (with stirrer

symbol) of the titration stand.

■ Start the control software.

Figure 36 Connecting MSB stirrer

Figure 37 Rod stirrer and titration stand

3.14.3 Connecting a remote box

Instruments that are controlled via remote lines and/or which send control

signals via remote lines can be connected using the 6.2148.010 remote

box. In addition to Metrohm, other instrument manufacturers also use

similar connectors that make it possible to connect different instruments

together. These interfaces are also frequently given the designations "TTL

Logic", "I/O Control" or "Relay Control" and generally have a signal level

of 5 volts.

Control signals are understood to be electrical line statuses or brief

(> 200 ms) electrical pulses which display the operational state of an

instrument or which trigger or report an event. Sequences on a variety of

instruments can thus be coordinated in a single complex automation system. No exchange of data is possible, however.

■■■■■■■■

38

858 Professional Sample Processor

Page 47

■■■■■■■■■■■■■■■■■■■■■■

USB 1

Contr.

MSB 2

MSB 3

3 Installation

Proceed as follows:

1

Connect a remote box

■ Exit the control software.

■ Connect the remote box connection cable to one of the sockets

marked with MSB on the rear of the control instrument.

■ Start the control software.

Figure 38 Connecting a remote box

You can, for example, connect an 849 Level Control Box (fill level monitor

in a waste canister) or a 731 Relay Box (switch box for 230/110 volt alternating current sockets and low-voltage direct current outlets). The remote

box also has an MSB socket at which a further MSB instrument, e.g. a

dosing device or a stirrer, can be connected.

You will find precise information concerning the pin assignment of the

interface on the remote box in the appendix (see Chapter 6.1, page 46).

3.15 Connecting USB devices

Two USB connectors (Type A sockets) are available for connecting devices

with USB interfaces. The 858 Professional Sample Processor functions then

as a USB hub (distributor). If you wish to connect more than two USB

devices, you can also use an additional commercially available USB hub.

Note

When a USB device is connected, the control instrument recognizes

which device is connected. The control software automatically enters a

connected USB device into the system configuration (Device manager).

3.15.1 Connecting a barcode reader

A barcode reader is used as an input aid for entering text and numbers.

You can connect a barcode reader to a USB interface.

858 Professional Sample Processor

■■■■■■■■

39

Page 48

3.15 Connecting USB devices

USB 2

USB 1

■■■■■■■■■■■■■■■■■■■■■■

Connect a barcode reader as follows:

1

Connecting the cable

■ Plug the USB plug (Type A) of the barcode reader into one of the

USB sockets on the rear side of the instrument.

Figure 39 USB connectors

2

Configuring the barcode reader in the control software

■ Configure the barcode reader in the configuration part of the

control software as described in the online Software Help.

Settings of the barcode reader

The barcode reader requires certain basic settings. You will find directions

in the Instructions for Use as to how you can program the barcode reader.

Switch the barcode reader to programming mode and make the following

settings:

■ Select the keyboard layout for the desired country (USA, Ger-

1

many, France, Spain, Switzerland (German)). This setting must

match the setting in the control software.

■ Make sure that the Ctrl characters (ASCII 00 to 31) are allowed to

be sent.

■ Adjust the settings so that the ASCII character 02 (STX or Ctrl B) is

sent as the first character as "Preamble" or "Prefix Code".

■ Adjust the settings so that the ASCII character 04 (EOT or Ctrl D) is

sent as the last character as "Postamble" or "Record Suffix" or

"Postfix Code".

■ Exit programming mode.

■■■■■■■■

40

858 Professional Sample Processor

Page 49

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4 Handling and maintenance

4.1 General

It is not only highly sensitive measuring instruments but also sample processors that require proper care. Excess contamination of the instrument

may result in functional disruptions and a reduction in the service life of

the sturdy mechanics and electronics of the instrument.

Severe contamination can also have an influence on the measured results.

Regular cleaning of exposed parts can prevent this to a large extent.

Spilled chemicals and solvents must be removed immediately. In particular,

the connector strip (especially the mains plug) should be protected from

contamination.

4.2 Injection valve

4 Handling and maintenance

4.3 Filter

Tubing olive

1

Filter screw

3

If the injection valve is blocked, then the channels of the valves can be

rinsed with water in the opposite direction. If this is not successful, then

the injection valve must be cleaned by a Metrohm service technician.

The 6.2821.130 filters (40-2) should be changed every 3 months, more

frequently at higher backpressure.

Figure 40 Pump tubing connection – Changing the filter

Filter (6.2821.130)

2

Packaging contains 10 items.

Changing the filter

858 Professional Sample Processor

1

Unscrew the filter screw

■ Unscrew the filter screw out of the tubing olive.

■■■■■■■■

41

Page 50

4.4 Peristaltic pump

2

Insert the filter

■ Place the filter in the tubing olive and press flat.

3

Mount the filter screw

■ Screw the filter screw back into the tubing olive.

4.4 Peristaltic pump

The flow rate of the peristaltic pump depends on the drive speed, the contact pressure and, above all, the inner diameter of the pump tubing.

Depending on the application, different pump tubings are used.

The lifetime of the pump tubings also depends on the contact pressure.

Therefore lift the tubing cartridges by loosening the snap-action lever if

the peristaltic pump is to be switched off for a longer period. This

ensures that the contact pressure, once it has been set, will be maintained.

■■■■■■■■■■■■■■■■■■■■■■

Caution

The 6.1826.xxx pump tubings consist of PVC or PP and therefore must

not be used for rinsing with solutions containing acetone. In this case,

use other pump tubings or use another pump for rinsing.

4.5 Pump tubing

The pump tubing used in the peristaltic pump is a consumable whose

service life is restricted.

The LFL pump tubing with 3 stoppers is stretched in the tubing cartridge

in such a way that it comes to rest between two stoppers. This results in

two possible positions for the tubing cartridge. If the pump tubing should

exhibit clear signs of wear, then this can be stretched a second time, in

the respective alternate position.

Therefore replace the pump tubing periodically, or when used permanently approx. every 4 weeks .

Caution

■■■■■■■■

42

858 Professional Sample Processor

Page 51

■■■■■■■■■■■■■■■■■■■■■■

Table 2 Pump tubing

4 Handling and maintenance

Selecting the pump tubing

The pump tubing differs in material, diameter and hence also pumping

capacity. Depending on the application, different pump tubings are used.

The following table provides information on the properties and use of the

pump tubing:

Order

Name Material Inner

number

6.1826.020 Pump tubing (blue/

blue), 2-stopper

6.1826.310 Pump tubing LFL

(orange/green), 3stopper

6.1826.320 Pump tubing LFL

(orange/yellow), 3stopper

6.1826.330 Pump tubing LFL

(orange/white), 3stopper

6.1826.340 Pump tubing LFL

(black/black), 3-stopper

Use

diameter

PVC (Tygon

ST)

1.65 mm Pump tubing for online IC

instruments and automation in voltammetry

PVC (Tygon) 0.38 mm Pump tubing for bromate

determination using the

triiodide method.

PVC (Tygon) 0.48 mm For suppressor solutions,

acceptor solutions for

inline dialysis and for inline

ultrafiltration.

PVC (Tygon) 0.64 mm No special applications.

PVC (Tygon) 0.76 mm For the sample solution in

inline dialysis.

6.1826.360 Pump tubing LFL

(white/white), 3-stopper

6.1826.380 Pump tubing LFL

(gray/gray), 3-stopper

6.1826.390 Pump tubing LFL (yellow/yellow), 3-stopper

858 Professional Sample Processor

PVC (Tygon) 1.02 mm For sample transfer.

PVC (Tygon) 1.25 mm For inline sample dilution.

PVC (Tygon) 1.37 mm For the sample solution in

inline ultrafiltration.

■■■■■■■■

43

Page 52

4.6 Quality Management and validation with Metrohm

■■■■■■■■■■■■■■■■■■■■■■

4.6 Quality Management and validation with Metrohm

Quality Management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure «Quality Management with

Metrohm» available from your local Metrohm agent.

Validation

Please contact your local Metrohm agent for support in validating instruments and software. Here you can also obtain validation documentation

to provide help for carrying out the Installation Qualification (IQ) and

the Operational Qualification (OQ). IQ and OQ are also offered as a

service by the Metrohm agents. In addition, various application bulletins

are also available on the subject, which also contain Standard Operat-

ing Procedures (SOP) for testing analytical measuring instruments for

reproducibility and correctness.

Maintenance

Electronic and mechanical functional groups in Metrohm instruments can

and should be checked as part of regular maintenance by specialist personnel from Metrohm. Please ask your local Metrohm agent regarding the

precise terms and conditions involved in concluding a corresponding

maintenance agreement.

Note

You can find information on the subjects of quality management, validation and maintenance as well as an overview of the documents currently available at www.metrohm.com/com/ under Support.

■■■■■■■■

44

858 Professional Sample Processor

Page 53

■■■■■■■■■■■■■■■■■■■■■■

5 Troubleshooting

5.1 Problems and their solutions

Problem Cause Remedy

5 Troubleshooting

Marked rise in pressure

The Swing Head

either misses the

rack positions

totally or is inaccurate

Peristaltic pump –

insufficient or no

delivery rate

Injection valve – valve

blocked.

Sample Processor – The

Swing Head is not correctly

configured.

Sample Processor – The

axial distance is not correctly configured.

Sample Processor – The

wrong rack table is being

used.

Peristaltic pump – contact

pressure too weak.

Peristaltic pump – filter

blocked.

Peristaltic pump – pump

tubing defective.

Rinse the valve with water in the opposite

direction or have it cleaned (by Metrohm service technician).

Enter the correct values for Swing radius,

Swing offset etc. in the control software

under "Configuration".

Enter the correct value for Axial distance in

the control software under "Configuration".

Initialize the rack using the function Initialize

rack in the "Manual Control" of the control

software.

Correctly set the contact pressure .

Replace the filter .

Replace the pump tubing .

Precision problems significant scattering of the measured

values

858 Professional Sample Processor

Injection valve – sample

loop.

Injection valve – defective.

Check the installation of the sample loop.

Contact the Metrohm Service.

■■■■■■■■

45

Page 54

6.1 Remote interface

1

2

3

13

1

14

25

1

13

14

25

6 Appendix

6.1 Remote interface

The 6.2148.010 remote box allows devices to be controlled which cannot

be connected directly to the MSB interface of the Sample Processor.

■■■■■■■■■■■■■■■■■■■■■■

Figure 41 Connectors of the remote box

Cable

1

For connecting the Sample Processor.

Remote connector

3

For connecting devices with a remote interface.

MSB connector

2

Metrohm Serial Bus. For connecting external

dosing devices or stirrers.

6.1.1 Pin assignment of the remote interface

Figure 42 Pin assignment of the remote socket and plug

The above presentation of the pin assignment of a Metrohm remote interface applies not only for the remote box, but also for all Metrohm devices

with 25-pin D-Sub remote connection.

■■■■■■■■

46

858 Professional Sample Processor

Page 55

■■■■■■■■■■■■■■■■■■■■■■

+5 V

t

p

t

p

6 Appendix

Inputs

approx. 50 kΩ Pull-up

tp >20 ms

active = low, inactive = high

The input lines can be scanned with the SCAN command.

Outputs

Open Collector

tp >200 ms

active = low, inactive = high

IC = 20 mA, V

CEO

= 40 V

+5 V: maximum load = 20 mA

The output lines can be set with the CONTROL command.

Table 3 Inputs and outputs of the remote interface

Assigment Pin No. Assigment Pin No.

Input 0 21 Output 0 5

Input 1 9 Output 1 18

Input 2 22 Output 2 4

Input 3 10 Output 3 17

Input 4 23 Output 4 3

Input 5 11 Output 5 16

Input 6 24 Output 6 1

Input 7 12 Output 7 2

0 volts / GND 14 Output 8 6

+5 volts 15 Output 9 7

0 volts / GND 25 Output 10 8

Output 11 13

Output 12 19

Output 13 20

858 Professional Sample Processor

■■■■■■■■

47

Page 56

7.1 Lift and turntable

7 Technical data

7.1 Lift and turntable

■■■■■■■■■■■■■■■■■■■■■■

Stroke path

Maximum lift load

Lift rate

Shift rate

235 mm

Approx. 30 N

Adjustable, 5…25 mm/s

Adjustable, 3...20 angle degrees/sec

7.2 786 Swing Head

Maximum load

Swing rate

Beaker sensor

connector

Approx. 15 N

10...55 angle degrees/sec

M8 socket

7.3 Two-channel peristaltic pump

Pump rate

Typical flow rate

6…90 rpm, adjustable in 15 steps each in both directions of rotation

0.3 mL/min at 18 rpm; with standard pump tubing 6.1826.320

The effective flow rate is dependent on contact pressure and type of

tubing.

Maximum pressure

Conveyable fluids

Tubing materials

■■■■■■■■

48

4 bar (0.4 MPa)

Clear fluids without solids

PVC (Tygon® ST), PVC (Tygon® LFL), PP

858 Professional Sample Processor

Page 57

■■■■■■■■■■■■■■■■■■■■■■

7.4 Injection valve

7 Technical data

Positions

Fill…Inject

7.5 Interfaces and connectors

Controller connection

MSB connectors

MSB1…MSB3

USB connectors

1/2

Stirrer connector

Stirring rate

Pump connectors

Swing Head connector

USB Upstream Port (9-pin Mini DIN socket) for connecting a computer

to the control system of the device.

Three 9-pin Mini DIN sockets for connecting dosing devices, stirrers,

etc.

Two USB Downstream Ports (Type A sockets), each 500 mA, for connecting Metrohm instruments or USB peripheral devices of other manufacturers.

DIN socket

Rod Stirrer 722/802: 180…3000 rpm

Magnetic Stirrer 741: 180…2600 rpm

Adjustable in 15 steps each in both directions of rotation

Two M8 sockets for 772 Pump Unit or 823 Membrane Pump Unit

U= 16 ± 1 V, I= ≤ 0.8 A

9-pin Mini DIN socket

7.6 Mains connection

Voltage

Frequency

Power consumption

Fuse

100…240 V (±10%)

50…60 Hz

115 W

2.0 ATH

858 Professional Sample Processor

■■■■■■■■

49

Page 58

7.7 Safety specifications

7.7 Safety specifications

■■■■■■■■■■■■■■■■■■■■■■

Design and testing

According to EN/IEC/UL 61010-1, EN/IEC 61010-2-081, CSA-C22.2 No.

61010-1, Protection Class Ⅰ

Safety instructions

This document contains safety instructions which have to be followed

by the user in order to ensure safe operation of the instrument.

7.8 Electromagnetic compatibility (EMC)

Emission

Standards fulfilled

Immunity

Standards fulfilled

■ EN/IEC 61326

■ EN 55022 / CISPR 22

■ EN/IEC 61000-3-2

■ EN/IEC 61326

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-8

■ EN/IEC 61000-4-11

■ EN/IEC 61000-4-14

■ NAMUR

7.9 Ambient temperature

Nominal working

range

Storage

Transport

■■■■■■■■

50

5…45 °C

Relative humidity <80% (below 30 °C)

Relative humidity <50% (below 45 °C)

–20…60 °C

Relative humidity <95% (below 40 °C)

Relative humidity <85% (below 50 °C)

Relative humidity <50% (below 60 °C)

–40…60°C

Relative humidity <95% (below 40 °C)

Relative humidity <85% (below 50 °C)

Relative humidity <50% (below 60 °C)

858 Professional Sample Processor

Page 59

■■■■■■■■■■■■■■■■■■■■■■

7.10 Reference conditions

7 Technical data

Ambient temperature

Relative humidity

25°C (±3°C)

≤60%

7.11 Dimensions

Width

Height

Depth

Weight (without

accessories)

Material

Housing

0.28 m

0.73 m

0.50 m

1.858.0010: 15.50 kg

1.858.0020: 15.55 kg

1.858.0030: 15.85 kg

Metal housing, surface-treated

858 Professional Sample Processor

■■■■■■■■

51

Page 60

8.1 Declaration of Conformity

8 Conformity and warranty

8.1 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical

appliances and accessories, as well as to the standard specifications for

security and to system validation issued by the manufacturing company.

■■■■■■■■■■■■■■■■■■■■■■

Name of commodity

Electromagnetic

compatibility

Safety specifications

858 Professional Sample Processor

Sample changer with advanced Liquid Handling abilities for the automation of sample preparation in analytical laboratories.

This instrument has been built and has undergone final type testing

according to the standards:

Emission: EN/IEC 61326-1, EN 55022 / CISPR 22,

EN/IEC 61000-3-2

Immunity: EN/IEC 61326-1, EN/IEC 61000-4-2,

EN/IEC 61000-4-3, EN/IEC 61000-4-4,

EN/IEC 61000-4-5, EN/IEC 61000-4-6,

EN/IEC 61000-4-8, EN/IEC 61000-4-11,

EN/IEC 61000-4-14, NAMUR

EN/IEC/UL 61010-1, CSA-C22.2 No. 61010-1, , EN/IEC 61010-2-081, protection class I

It has also been certified by ElectroSuisse, a member of the International

Certification Body (CB/IEC).

■■■■■■■■

52

The system software, stored in Read Only Memories (ROMs) has been validated in connection with standard operating procedures in respect to

functionality and performance. The technical specifications are documented in the instruction manual.

This instrument meets the requirements of the CE mark as contained in

the EU directives 73/23/EEC (LVD), 89/336/EEC (EMC) and their amendment 93/68/EEC. It fulfils the following specifications:

EN 61326-1 Electrical equipment for measurement, control

and laboratory use – EMC requirements

EN 61010-1 Safety requirements for electrical equipment for

measurement, control and laboratory use

858 Professional Sample Processor

Page 61

■■■■■■■■■■■■■■■■■■■■■■

8 Conformity and warranty

EN 61010-2-081 Particular requirements for automatic and semi-

automatic laboratory equipment for analysis and

other purposes

Manufacturer

Metrohm Ltd., CH-9101 Herisau/Switzerland

Metrohm Ltd. is holder of the SQS-certificate ISO 9001:2000 Quality management system for development, production and sales of instruments

and accessories for ion analysis.

Herisau, January 27, 2006

D. Strohm

Vice President, Head of R&D

8.2 Quality Management Principles

Metrohm Ltd. holds the ISO 9001:2000 Certificate, registration number

10872-02, issued by SQS (Swiss Association for Quality and Management

Systems). Internal and external audits are carried out periodically to assure

that the standards defined by Metrohm’s QM Manual are maintained.

Ch. Buchmann

Vice President, Head of Production

Responsible for Quality Assurance

The steps involved in the design, manufacture and servicing of instruments

are fully documented and the resulting reports are archived for ten years.

The development of software for PCs and instruments is also duly documented and the documents and source codes are archived. Both remain

the possession of Metrohm. A non-disclosure agreement may be asked to

be provided by those requiring access to them.

The implementation of the ISO 9001:2000 quality management system is

described in Metrohm’s QM Manual, which comprises detailed instructions on the following fields of activity:

Instrument development

The organization of the instrument design, its planning and the intermediate controls are fully documented and traceable. Laboratory testing

accompanies all phases of instrument development.

Software development

Software development occurs in terms of the software life cycle. Tests are

performed to detect programming errors and to assess the program’s

functionality in a laboratory environment.

858 Professional Sample Processor

■■■■■■■■

53

Page 62

8.3 Warranty (guarantee)

■■■■■■■■■■■■■■■■■■■■■■

Components

All components used in the Metrohm instruments have to satisfy the quality standards that are defined and implemented for our products. Suppliers of components are audited by Metrohm as the need arises.

Manufacture

The measures put into practice in the production of our instruments guarantee a constant quality standard. Production planning and manufacturing

procedures, maintenance of production means and testing of components, intermediate and finished products are prescribed.

Customer support and service

Customer support involves all phases of instrument acquisition and use by

the customer, i.e. consulting to define the adequate equipment for the

analytical problem at hand, delivery of the equipment, user manuals, training, after-sales service and processing of customer complaints. The