Page 1

853 CO2 Suppressor

Manual

8.853.8001EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Schweiz

Telefon +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

853 CO2 Suppressor

Manual

8.853.8001EN 04.2008 / zst

Page 4

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked

with great care, errors cannot be entirely excluded. Should you notice any

mistakes please inform the author at the address given above

Page 5

Table of contents

Table of contents

1 Introduction.................................................... 1

1.1 Instrument description ............................................................. 1

1.2 Parts and controls .................................................................... 2

1.2.1 Front view 853 CO2 Suppressor....................................................2

1.2.2 Rear view 853 CO2 Suppressor ....................................................3

1.3 Information on the Instructions for Use .................................. 4

1.3.1 Organization ..................................................................................4

1.3.2 Notation and pictograms ..............................................................5

1.4 Safety information..................................................................... 6

1.4.1 Electrical safety..............................................................................6

1.4.2 General safety rules....................................................................... 6

2 Installation ..................................................... 7

2.1 Instrument setup....................................................................... 7

2.1.1 Packaging...................................................................................... 7

2.1.2 Checks........................................................................................... 7

2.1.3 Arranging the instruments ............................................................. 7

2.2 Mains connection...................................................................... 7

2.3 Connection to the 861 Advanced Compact IC ........................ 8

2.4 Connection to 830 IC Interface ................................................ 9

2.5 Connection of capillaries ....................................................... 10

2.6 Cartridges................................................................................ 10

3 Operation...................................................... 11

3.1 General information................................................................ 11

3.2 Control..................................................................................... 11

3.2.1 Control via 861 Advanced Compact IC (2.861.0040)................. 11

3.2.2 Control via 830 IC Interface.........................................................11

4 Troubleshooting - Problems......................... 12

4.1 Remedying faults and problems ............................................ 12

4.2 Chromatography problems .................................................... 12

4.3 Instrument problems .............................................................. 13

4.4 Care and maintenance............................................................ 13

4.4.1 Care .............................................................................................13

4.4.2 Maintenance by Metrohm Service ..............................................14

4.4.3 CO2 Absorber Cartridge replacement.........................................14

4.4.4 H2O Absorber Cartridge regeneration ........................................14

5 Appendix ....................................................... 15

5.1 Technical data......................................................................... 15

5.2 Standard equipment ............................................................... 17

5.2.1 2.853.0010 CO2 Suppressor .......................................................17

5.3 Optional accessories.............................................................. 18

5.4 Validation / GLP ...................................................................... 19

5.5 Warranty and Conformity ....................................................... 20

5.5.1 Warranty.......................................................................................20

5.5.2 Declaration of Conformity ...........................................................21

5.5.3 Quality Management Principles ..................................................22

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

I

Page 6

Table of contents

5.5.4 Index............................................................................................ 23

List of illustrations

Figure 1: Front view 853 CO2 Suppressor .................................................... 2

Figure 2: Rear view 853 CO2 Suppressor..................................................... 3

Figure 3: Connection between 853 CO2 Suppressor and 861 Advanced

Compact IC ...................................................................................

Figure 4: Connection between the 853 CO2 Suppressor and 830 IC

Interface.........................................................................................

8

9

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

II

Page 7

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 853 CO2 Suppressor is used to remove CO2 before detection

takes place. CO

produced by the suppressor reaction (see below, Reaction in the sup-

pressor module «MSM II»).

can enter the eluent flow from the sample itself, or is

2

If the 853 CO

dule «MSM II» and the detector block the CO

mized. The principle is based on the permeability of the Teflon AF

membrane in the degassing cell of the 853 CO

Suppressors is connected between the suppressor mo-

2

peak is effectively mini-

2

Suppressor to gases.

2

TM

The eluent (together with the injected sample) passes through a capillary with a Teflon AF

TM

membrane contained in the degassing cell, in

which a vacuum has been created by a pump. At the same time the

pump draws CO

Cartridge) through the degassing cell. The lower CO

-free air (the CO2 is removed by the CO2 Absorber

2

vapor pressure in

2

the degassing cell compared with that in the capillary results in the diffusion of CO

from the eluent flow. The pump of the 853 CO2 Suppres-

2

sors is provided with electricity from an external power supply. The 853

Suppressor is controlled by Remote commands.

CO

2

Reaction in the suppressor module «MSM II»

If a carbonate eluent is used then the following reaction (among others)

takes place in the suppressor module «MSM II»:

R-SO

-H+

+ NaHCO3/Na2CO3 → R-SO

3

-

Na+ + H2O + CO

3

2

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

1

Page 8

1 Introduction

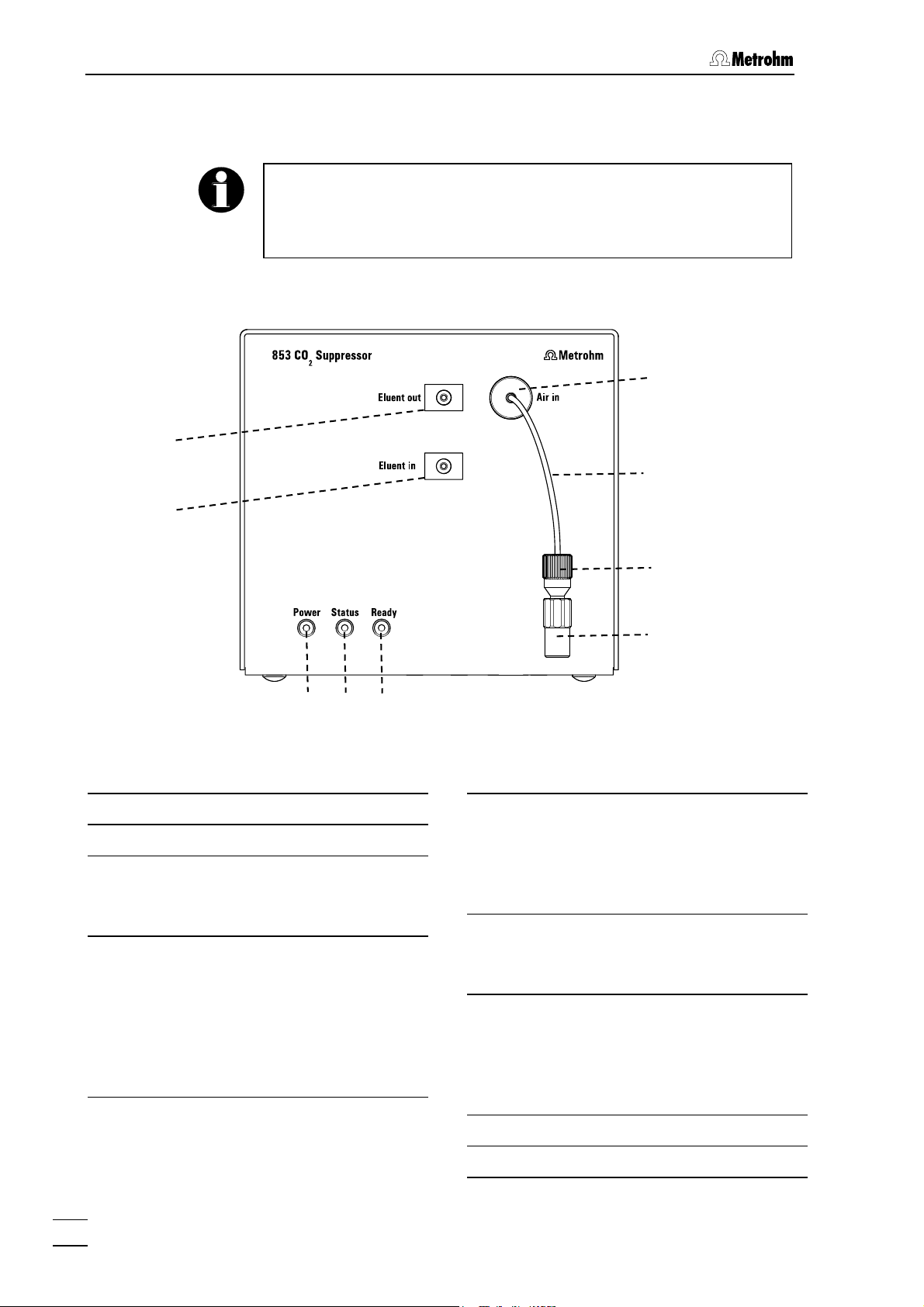

1.2 Parts and controls

In this section you will find the numbers and designations of the parts

and controls of the 853 CO

throughout the instructions for use, i.e. bold numbers in the text (e.g.

3

) refer to the parts and controls illustrated here.

1.2.1 Front view 853 CO2 Suppressor

1

Suppressor. The numbering applies

2

6

7

2

3

4

Figure 1: Front view 853 CO2 Suppressor

Eluent flow outlet "Eluent out"

1

Eluent flow inlet "Eluent in"

2

LED "Power"

3

Lights up green when the pump is running.

LED "Status"

4

Lights up orange when the pump is

running and the pressure in the vacuum chamber is too high or too low.

After the pump has been switched on it

takes a few seconds for the vacuum to

be established.

5

8

9

LED "Ready"

5

Lights up green when the pump is running and the pressure in the vacuum

chamber is within the ideal working

range.

Aspiration opening "Air in"

6

Opening for drawing in CO

(through CO

PEEK flow reduction capillary

7

Absorber Cartridge).

2

-free air

2

6.1831.130

The length of the flow reduction capillary provides an optimal flow and should

not be altered.

Pressure screw

8

Coupling

9

2

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

Page 9

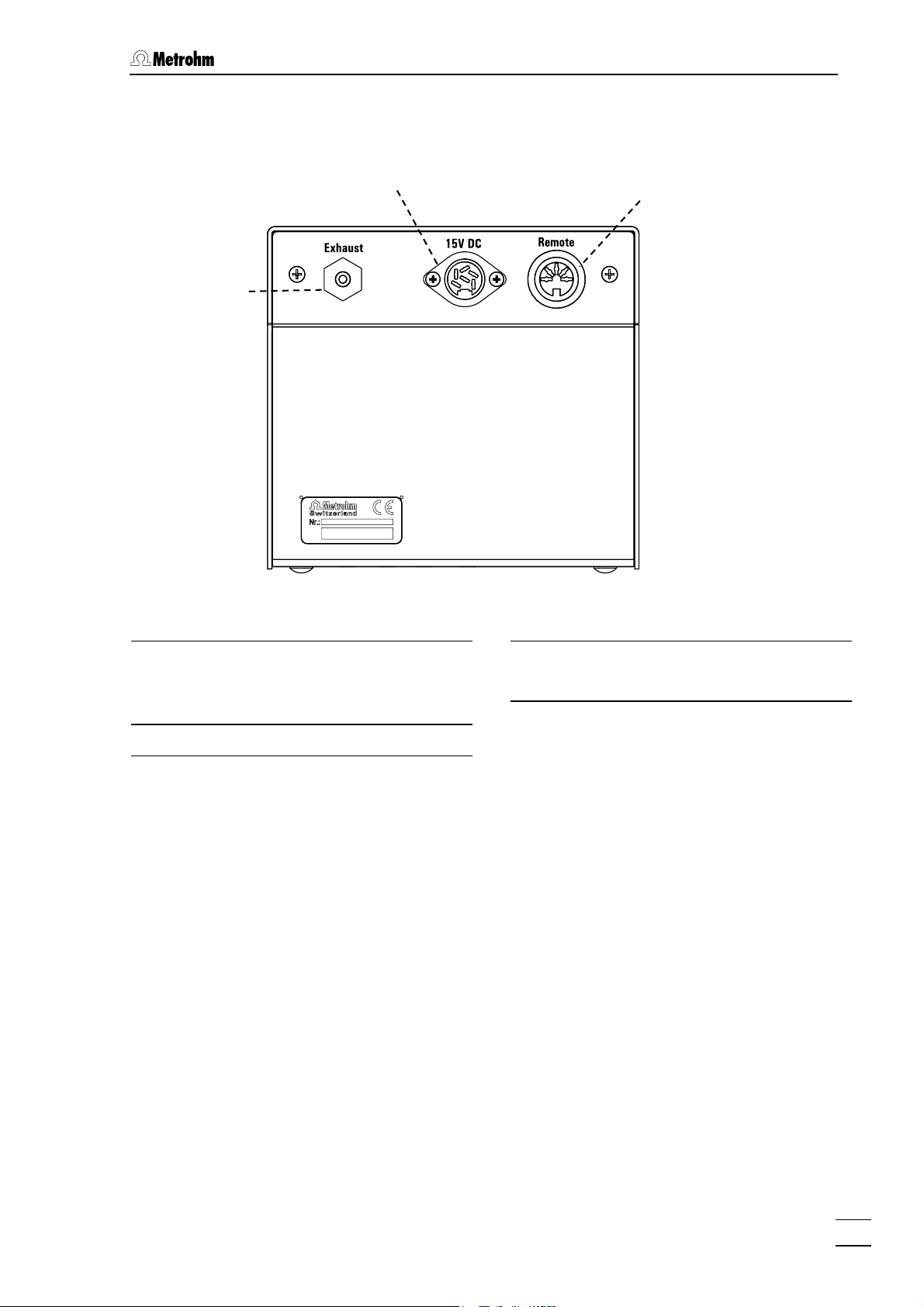

1.2 Parts and controls

1.2.2 Rear view 853 CO2 Suppressor

10

11

Figure 2: Rear view 853 CO2 Suppressor

12

Exhaust opening "Exhaust"

10

Air is pumped out of the degassing cell

through this opening.

15V Mains connection "15V DC"

11

Remote interface "Remote"

12

For remote control by external devices.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

3

Page 10

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 853 CO

tain information and warnings to which the user must pay attention in

order to assure safe operation of the instrument.

1.3.1 Organization

These Instructions for Use 8.853.8001EN for the 853 CO2 Suppressor provide a comprehensive overview of installation, startup procedure, operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organized as follows:

Suppressor into operation. The Instructions for Use con-

2

Section

1 Introduction

General description of instrument, parts and controls

and safety notes

Section

2 Installation

Installation and connection of the instrument, of the

accessories and of the software

Section

3 Operation

Introduction to the operation.

Section

4 Troubleshooting - Problems

Possible faults and their remedies.

Section

5 Appendix

Technical data, standard equipment, optional accessories, validation, warranty and declaration of conformity, index

In order to find the information you require about the 853 CO

ressor you should either use the Contents or the Index.

Supp-

2

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

4

Page 11

1.3 Information on the Instructions for Use

1.3.2 Notation and pictograms

The following notation and pictograms (symbols) are used in these Instructions:

10 Part or control

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components by

electric current.

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the instrument or its components.

Attention

This symbol indicates important information that you should read before continuing.

Information

This symbol indicates additional information and tips which may be of

particular use to you.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

5

Page 12

1 Introduction

1.4 Safety information

1.4.1 Electrical safety

Electrical safety when handling the 853 CO2 Suppressor is guaranteed

within the scope of Standard IEC 1010-1 (protection class III, protection

code IP20). The following points must be observed:

• Mains connection

The mains connection must be made in accordance with the instructions given in Section

• Opening the instrument

The housing contains no components which could be set or adjusted

by the user .

2.2.

The instrument should only be opened by specialists from Metrohm. If

the 853 CO

neither be opened nor should components be removed from it, as

Suppressor is connected to the mains supply it should

2

otherwise there is a risk of coming into contact with current-carrying

components. Before opening the instrument always make sure that

the plug has been pulled out!

• Protection against electrostatic charges

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Before you touch any electronic components of the 853 CO

tools by grasping a grounded object (e.g. the instrument housing or a

radiator) in order to eliminate any electrostatic charges that may be

present.

1.4.2 General safety rules

• Solvent handling

Check the pump tubing and inlet and outlet connections for leaks at

regular intervals. Observe the relevant regulations when handling and

disposing of flammable and/or toxic solutions.

Suppressor you should ground you and your

2

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

6

Page 13

2.1 Instrument setup

2 Installation

2.1 Instrument setup

2.1.1 Packaging

The 853 CO2 Suppressor and its separately packed accessories are

supplied in very protective special packaging. Please store all this special packaging; it is the only way in which the safe transport of the

instrument can be guaranteed.

2.1.2 Checks

Please check that the delivery is complete and undamaged immediately on receipt (compare with delivery note and list of accessories given in

Section

on given in Section

5.2). If transport damage is evident please refer to the informati-

5.5.1 "Warranty".

2.1.3 Arranging the instruments

Place the 853 CO2 Suppressor next to the detector block in the Compact IC. With a modular system, place it in the Separation Center, likewise next to the detector block.

2.2 Mains connection

The 853 CO2 Suppressor is provided with a 15 V power supply from an

external power supply (6.2152.020).

1 Connection 853 – Power supply

• Connect the external power supply (6.2152.020) to the 15V

connection "15V DC" of the 853 CO

2 Mains connection

• Plug the mains cable into the connection on the external power

supply (6.2152.020), and connect it to the mains supply (100240 V).

Mains cable

The instrument is supplied with one of the following mains cables

Suppressor.

2

• 6.2122.020 with SEV 12 plug (Switzerland, …)

• 6.2122.040 with CEE(7), VII plug (Germany, …)

• 6.2133.070 with NEMA 5-15 plug (USA, …)

which has three wires and is fitted with a plug with a grounding pin. If a

different plug has to be used then the yellow/green wire (IEC standard)

must be connected to the grounding pin (Protection class I).

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

7

Page 14

2 Installation

Make sure that the power supply is always in a dry location. Protect it

against direct contact with liquids.

2.3 Connection to the 861 Advanced Compact IC

The 853 CO2 Suppressor is part of the version 2.861.0040 of the 861

Advanced Compact IC.

The electrical connections of the system, consisting of the 861 Advanced Compact IC and 853 CO

ing diagram:

Suppressor, are shown in the follow-

2

853

861

6.2143.230

PC

Figure 3: Connection between 853 CO

6.2134.100

Suppressor and 861 Ad-

2

vanced Compact IC

The 853 CO

Suppressor can be controlled by the system driver of the

2

861 (Version 2.861.0040) in the PC program «IC Net» (from Version 2.3

SR2) (see «IC Net» Instructions for Use, Section 6.27).

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

8

Page 15

2.4 Connection to 830 IC Interface

2.4 Connection to 830 IC Interface

Connect an Event line of the 830 IC Interface to the remote interface 12

of the 853 CO

830

853

816

Suppressor using a cable 6.2128.180.

2

6.2128 .180

Figure 4: Connection between the 853 CO

Suppressor and 830

2

IC Interface

In the PC program «IC Net» the 853 CO

Suppressor does not have its

2

own device driver. It can be controlled via the 830 IC Interface. This

means that the 830 IC Interface must be included in your system and

configured for controlling the 853 CO

Suppressor:

2

1 Open «IC Net» system

• In the PC program «IC Net» open the system in which the 830

IC Interface is to be included.

2 Include the 830 IC Interface in the system

• Use Setup/New devices/Link to existing device to select

the 830 IC Interface (the 830 IC Interface must already have

previously been added to the "Workplace", see IC Net

Instructions for Use, Section 5). The device symbol for the 830

IC Interfaces is added to the system.

3 Open the "Events setup" tab

• Double-click on the device symbol of the 830 IC Interfaces to

open its configuration menu and select the Events setup tab.

4 Set the control line for the 853 CO2 Suppressor

• The value for the Event line used to control the 853 CO2

Suppressor must be set to 1. In the example shown above this

is Event Line 1, see

Figure 4.

The 853 CO

Suppressor has now been included in your system and

2

can be controlled by the PC program «IC Net». It is started together

with the other system hardware with System/Control/Startup hard-

ware and closed down with System/Control/Shutdown hardware.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

9

Page 16

2 Installation

2.5 Connection of capillaries

The 853 CO2 Suppressor is connected between the suppressor module

«MSM II» and the detector block.

1 Suppressor module «MSM II» – 853 CO2 Suppressor

• Connect the "Suppressor outlet capillary for eluent" (marked

with "Detector") to the "Eluent in" inlet (

2) of the 853 CO2

Suppressor using a 6.2744.010 Pressure screw.

2 853 CO2 Suppressor – Detector block

• Connect the "Inlet capillary to detector block" to the "Eluent

out" outlet (

1) of the 853 CO2 Suppressor using a 6.2744.010

Pressure screw.

2.6 Cartridges

Effective CO2 removal requires that the air pumped through the degassing cell should contain as little CO

by drawing the air through a 6.2837.000 CO

The CO

Absorber Cartridge can become blocked by moisture. This

2

can be prevented by connecting a 6.2837.010 H

as possible. This is achieved

2

Absorber Cartridge.

2

O Absorber Car-

2

tridge in front of it.

The cartridges are installed as follows:

1 Remove caps

• Remove the sealing caps at the inlet and outlet of each

cartridge.

2 Connect CO2 Absorber Cartridge

• Insert the CO2 Absorber Cartridge (3-layer filling, blue-brown-

gray) in the coupling

9.

3 Connect H2O Cartridge – CO2 Cartridge

• Insert the 6.1808.190 Adapter in the CO2 Absorber Cartridge.

• Attach the 6.1801.140 PVC tubing to the 6.1808.190 Adapter.

• Insert the H

O Absorber Cartridge (filled with orange drying

2

beads) into the 6.1801.140 PVC tubing.

4 Attach the cartridges

• Attach the two cartridges to the left-hand mounting support of

the 861 Advanced Compact IC or 820 IC Separation Center

using two 6.2027.070 Holders.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

10

Page 17

3.1 General information

3 Operation

3.1 General information

• The pump has two operating stages. The first stage is used to create the vacuum, the second stage to maintain it.

• The Power display lights up green when the pump is switched on.

• The Status display lights up orange when the pump is running and

the pressure in the vacuum chamber is either too low or too high.

After the pump has been switched on it takes a few seconds for the

vacuum to become established.

• The Ready display lights up green when the pump is running and

the pressure in the vacuum chamber is within the working range.

3.2 Control

The 853 CO2 Suppressor is controlled by the PC program «IC Net». It is

not included in the software as a separate device driver, but is controlled from other devices via a Remote line.

3.2.1 Control via 861 Advanced Compact IC (2.861.0040)

The 853 CO2 Suppressor is included in the device driver of Version

2.861.0040 of the 861 Advanced Compact IC. Detailed information is

provided in the «IC Net» Instructions for Use, Section 6.27.

3.2.2 Control via 830 IC Interface

If the 853 CO2 Suppressor is used together with a modular system then

it can be controlled via a Remote line of the 830 IC Interface (see Sec-

2.4).

tion

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

11

Page 18

4 Troubleshooting - Problems

4 Troubleshooting - Problems

4.1 Remedying faults and problems

If difficulties occur during analyses with your IC system then it is best to

search for their causes in the following sequence: column → pump →

eluent → IC system. In the Instructions for Use of your Modular IC

system or Compact IC you will find an overview of possible faults together with their causes and remedies.

In addition to these general problems, the following section covers

those problems which could arise from the use of the 853 CO

ressor.

4.2 Chromatography problems

Problem Cause Remedy

Supp-

2

Poor retention time

reproducibility

Noisy or unstable

baseline

High pressure in the

system

Poor peak shape

• Leak in the instrument.

• Blockage in flow path.

• Leak in the instrument.

• Blockage in flow path

• CO2 cartridge exhausted

• Vacuum pump faulty

• Pressure screws

tightened up too far.

• A liquid-transporting

component in the device

is blocked.

• Dead volume in system

• Contact Metrohm Service.

• Check the capillary connections

and replace any compressed

capillaries

• Contact Metrohm Service.

• Check the capillary connections

and replace any compressed

capillaries

• Replace CO

tion

4.4.3)

• Contact Metrohm Service.

• Loosen pressure screws slightly

or replace connection (cut new

capillary end)

• Contact Metrohm Service.

• Check capillaries

cartridge (see Sec-

2

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

12

Page 19

4.3 Instrument problems

4.3 Instrument problems

Problem Cause Remedy

LED "Power" (1) does

not light up when instrument is switched

on.

Neither LED "Status"

(2) nor LED "Ready"

3) lights up when in-

(

strument is switched on

(LED "Power" (

up).

Vacuum out of working

range. LED "Ready" (

does not light up after

instrument has been

switched on for at least

30 s.

1) lights

3)

• Power supply not con-

nected

• 6.2152.020 Power supply faulty or electronics

fault in 853 CO

sor

• LEDs faulty • Contact Metrohm Service.

• Leak in system (vacuum

too weak)

O Absorber Cartridge

• H

2

blocked (vacuum too

strong).

Suppres-

2

• Connect the 853 CO2 Suppres-

sor to the mains supply via the

external power supply (see

Section

• Contact Metrohm Service.

• Contact Metrohm Service.

• Regenerate the H2O Absorber

Cartridge (see Section 4.4.4

or 8.108.1046 Leaflet)

2.2)

4.4 Care and maintenance

4.4.1 Care

The 853 CO2 Suppressor requires adequate care. If it becomes excessively dirty then this could interfere with its functions and shorten the

working life of its robust mechanism and electronics.

Spilt chemicals and solvents must be wiped up immediately. The electrical connections on the rear panel of the instrument (the mains connection in particular) should be protected against contamination.

Although constructive measures to a large extent prevent liquid penetration, if aggressive media should nevertheless penetrate the interior

of the instrument then the mains plug of the external 6.2152.020

Power supply should be pulled out immediately to prevent serious

damage to electronic components. If such damage should occur

please contact Metrohm Service.

The instrument should only be opened by specialists from Metrohm.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

13

Page 20

4 Troubleshooting - Problems

4.4.2 Maintenance by Metrohm Service

It is advisable to carry out the maintenance of the 853 CO2 Suppressor

within the framework of an annual service visit by trained Metrohm

technicians. If aggressive and corrosive chemicals are used then it may

be necessary to reduce the service intervals.

The Metrohm Service Department will be pleased to provide you with

competent advice about the care and maintenance of all Metrohm instruments at any time.

4.4.3 CO2 Absorber Cartridge replacement

The 6.2837.000 CO2 Absorber Cartridge requires replacement at regular intervals because of blockages or exhaustion.

Blockages

Moisture will block the CO

cartridge material changing color (the blue layer turns violet). The air

flow is reduced and the vacuum becomes too low – instead of the

"Ready" LED (

Absorber Cartridge an H2O Absorber Cartridge is included up-

CO

2

3) the "Status" LED (2) lights up. In order to protect the

stream from it. Regular regeneration (see Section

sorber Cartridge increases the working life of the CO

tridge.

Absorber Cartridge. This is indicated by the

2

4.4.4) of the H2O Ab-

Absorber Car-

2

Exhaustion

The absorption capacity of the CO

Absorber Cartridge is limited. De-

2

pending on the working life and the laboratory surroundings the absorption capacity decreases with time. This is indicated by a rising

baseline (as more CO

reaches the detector).

2

4.4.4 H2O Absorber Cartridge regeneration

The purpose of the H2O Absorber Cartridge is to protect the CO2 Absorber Cartridge from moisture. The lifespan of the H

tridge depends on the humidity of the ambient air. Humidity exhausts

the H

O Absorber Cartridge. Exhaustion is indicated by a color change:

2

before the color of the whole of the filling material has changed (from

orange to colorless) the H

(see 8.108.1046 Leaflet). Regeneration consists of replacing the filling

material:

1. Heat the loose material (i.e. not in the cartridge) at 140 °C overnight and then refill it, or dispose of the old material and refill the

cartridge with new material (Fluka # 94098).

2. Cover the packed material with absorbent cotton.

O Absorber Cartridge must be regenerated

2

O Absorber Car-

2

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

14

Page 21

5.1 Technical data

5 Appendix

5.1 Technical data

Vacuum

Pressure range < 65 mm Hg

Establishment time after start < 30 s

Flow range

Recommeded flow range 0.1…1.0 mL

Degassing capillary in 853 CO

Material Teflon AF

Solvent resistance Very good resistance to most solvents (excep-

Ambient temperature

Nominal working range +5...+45 °C (at max. 85% rel. humidity)

Provided that nothing to the contrary is mentioned, the

published data represents typical values for the 853 CO

Suppressor at an ambient temperature of 25°C.

Suppressor

2

tion: PFCs)

2

Storage -40...+70 °C

Transport -40...+70 °C

Power supply

Voltage 100...240 V (± 10%)

Frequency 50 / 60 Hz

Power consumption 15 W

Fuses Overload protection

Safety specifications

Construction / Testing EN/IEC/UL 61010-1,

CSA-C22.2 No. 61010-1,

Protection code IP20,

Protection class III

Safety information These Instructions for Use contain information

and warnings that must be observed by the user

in order to ensure the safe operation of the instrument.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

15

Page 22

5 Appendix

Electromagnetic compatibility (EMC)

Emitted interference Standards met:

- EN/IEC 61326

- EN 55022

- CISPR 22

Immunity to interference Standards met:

- EN/IEC 61326

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-11

- EN/IEC 61000-4-14

Housing

Housing material Steel sheet, enameled

Width 130 mm

Height 120 mm

Depth 150 mm

Weight

Device

Power Supply

2.2 kg

280 g

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

16

Page 23

5.2 Standard equipment

5.2 Standard equipment

Subject to changes!

All dimensions are given in mm.

5.2.1 2.853.0010 CO2 Suppressor

The 2.853.0010 CO2 Suppressor includes the following accessories:

Number Order no. Description

1 1.853.0010 CO2 Suppressor

1 6.1801.140 PVC tubing

For connecting the CO2 Absorber Cartridge and H

L = 110 mm, d1 = 4 mm, d2 = 7 mm

1 6.1808.190 Adapter tubing nozzle/Luer

For connecting the CO2 Absorber Cartridge and H2O Absorber Cartridge

1 6.2027.070 Cartridge holder

Holder for the CO2/H2O Absorber Cartridges, diameter d = 25.0 mm, 2

pieces

O Absorber Cartridge.

2

4

7

d

42

1 6.2128.180 Remote connection cable

Connection cable 830 IC Interface –

853 CO2 Suppressor.

1 6.2143.230 Connection cable 861/761-853

1 6.2152.020 Power supply

External power supply for electricity supply to 853 (100-240V / 15V).

1 6.2837.000 CO2 Absorber Cartridge

2 6.2837.010 H2O Absorber Cartridge

One as spare while the other is being

regenerated.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

17

Page 24

5 Appendix

22

Number Order no. Description

1 8.853.8001

EN

Instructions for Use (English)

for 853 CO2 Suppressor

5.3 Optional accessories

Order no. Description

6.2744.014 PEEK pressure screw

Spare part. For connecting the CO2 Absorber

Cartridge.

6.2744.120 Coupling 1⁄16" – Luer

Spare part. Connection piece between

6.2744.010 PEEK pressure screw and CO

Absorber Cartridge.

6.2621.080 Capillary cutter for plastic capillaries

With 5 spare blades

26

2

55

118

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

18

Page 25

5.4 Validation / GLP

5.4 Validation / GLP

GLP (Good Laboratory Practice) requires, among other things, that the

precision and correctness of analytical instruments is checked at regular intervals by using SOPs (Standard Operating Procedures, SOP). An

example of such a standard operating procedure is available from

Metrohm under the title «Application Bulletin No. 277 – Validation of

Metrohm Ion Chromatography Systems by using Standard Operating Procedures (SOP)». This SOP can be adapted for your ion

chromatography system and used for its validation.

The 853 CO

Suppressor must be included as a part of the whole ion

2

chromatography system, whose most important components include

the pumps, separation columns, detector and evaluation system, in the

all-embracing validation of the whole system.

Please contact your local Metrohm agency in order to receive support

in validating your 853 CO

Suppressor. It can also provide you with

2

validation documentation which will help you to carry out your installation qualification (IQ) and operational qualification (OQ).

Further information about QA, GLP and validation can also be found in

the brochure «Quality management with Metrohm» which is also obtainable from your local Metrohm agency.

Checking the electronic and mechanical assemblies of Metrohm instruments can and should be undertaken within the framework of regular servicing by Metrohm technicians.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

19

Page 26

5 Appendix

5.5 Warranty and Conformity

5.5.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In this case, the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty period. For parts of

outside manufacture insofar as these constitute an appreciable part of

our instrument, the warranty stipulations of the manufacturer in question

apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the orderer has no rights or claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedment in

wood shavings or similar material, the parts must be packed in a dustproof package (for instruments, use of a plastic bag is imperative). If

open assemblies are enclosed in the scope of delivery that are sensitive to electromagnetic voltages (e.g. data interfaces etc.) these must

be returned in the associated original protective packaging (e.g. conductive protective bag). (Exception: assemblies with built-in voltage

source belong in a non-conductive protective packaging).

No warranty responsibility whatsoever will be accepted by Metrohm for

damage which arises as a result of non-compliance with these instructions.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

20

Page 27

5.5 Warranty and Conformity

5.5.2 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well

as to the standard specifications for security and to system validation issued by the manufacturing company.

CH-9101 Herisau, Switzerland

Tel. +41 71 353 85 85

Fax +41 71 353 89 01

www.metrohm.com

Name of commodity 853 CO

Name of manufacturer Metrohm Ltd., Herisau, Switzerland

Suppressor

2

Description The 853 CO2 Suppressor is a device to remove CO2. It is connected between

suppressor module «MSM II» and detector.

This instrument has been built and has undergone final type testing according to the standards:

Electromagnetic compatibility: Emission

EN/IEC 61326, EN 55022 / CISPR 22

Electromagnetic compatibility: Immunity

EN/IEC 61326, EN/IEC 61000-4-2, EN/IEC 61000-4-3, EN/IEC 61000-4-4, EN/IEC 61000-4-5,

EN/IEC 61000-4-6, EN/IEC 61000-4-8, EN/IEC 61000-4-11, EN/IEC 61000-4-14, Namur

Safety specifications

EN/IEC/UL 61010-1, EN/IEC 61010-2-081, CSA-C22.2 No. 61010-1

It has also been certified by ElectroSuisse, which is member of the International Certification

Body (CB/IEC).

The instrument meets the requirements of the CE mark as contained in the EU

directives 89/336/EEC and 73/23/EEC and fulfils the following specifications:

EN 61326 Electrical equipment for measurement, control and laboratory use – EMC re-

quirements

EN 61010-1 Safety requirements for electrical equipment for measurement, control and

laboratory use

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for quality assurance in design/development, production, installation and servicing.

The system software, stored in Read Only Memories (ROMs) has been validated in connection with standard operating procedures in respect to functionality and performance.

The technical specifications are documented in the instruction manual.

Herisau, April 1, 2005

D. Strohm Ch. Buchmann

Vice President Vice President

Head of R&D Head of Production

Responsible for Quality Assurance

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

21

Page 28

5 Appendix

5.5.3 Quality Management Principles

Metrohm Ltd., CH-9101 Herisau, Switzerland

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Metrohm Ltd. holds the ISO 9001 Certificate, registration number 10872-02, issued by

SQS (Swiss Association for Quality and Management Systems). Internal and external audits are carried out periodically to assure that the standards defined by Metrohm’s QM

Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments are fully documented and the resulting reports are archived for ten years. The development of software

for PCs and instruments is also duly documented and the documents and source codes

are archived. Both remain the possession of Metrohm. A non-disclosure agreement may

be asked to be provided by those requiring access to them.

The implementation of the ISO 9001

quality system is described in Metrohm’s

QM Manual, which comprises detailed

instructions on the following fields of

activity:

Instrument development

The organization of the instrument design, its planning and the intermediate

controls are fully documented and traceable. Laboratory testing accompanies all

phases of instrument development.

Software development

Software development occurs in terms of

the software life cycle. Tests are performed to detect programming errors

and to assess the program’s functionality in a laboratory environment.

Components

All components used in the Metrohm

instruments have to satisfy the quality

standards that are defined and implemented for our products. Suppliers of

components are audited by Metrohm as

the need arises.

Manufacture

The measures put into practice in the

production of our instruments guarantee

a constant quality standard. Production

planning and manufacturing procedures,

maintenance of production means and

testing of components, intermediate and

finished products are prescribed.

Customer support and service

Customer support involves all phases of

instrument acquisition and use by the

customer, i.e. consulting to define the

adequate equipment for the analytical

problem at hand, delivery of the equipment, user manuals, training, after-sales

service and processing of customer

complaints. The Metrohm service organization is equipped to support customers in implementing standards such

as GLP, GMP, ISO 900X, in performing

Operational Qualification and Performance Verification of the system components or in carrying out the System Validation for the quantitative determination

of a substance in a given matrix.

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

22

Page 29

5.5 Warranty and Conformity

5.5.4 Index

15V Mains connection ..................... 3

Suppressor Capillaries ... 15

853 CO

2

Adapter tubing nozzle/Luer

Ordering designation ................ 17

Ambient temperature .................... 15

Appendix ....................................... 15

Arranging the instruments............... 7

Aspiration opening .......................... 2

Attention........................................... 5

Capillary cutter 6.2621.080 ........... 18

Care ............................................... 13

Cartridge holder

Ordering designation ................ 17

CE mark......................................... 21

CE Zeichen .................................... 21

Absorber Cartridge

CO

2

Replacement ............................. 14

-Absorber Cartridge

CO

2

Ordering designation ................ 17

Connection cable 861/761-853

Ordering designation ................ 17

Connection of capillaries............... 10

Connection to 830 IC Interface ....... 9

Connection to the 861 Advanced

Compact IC ..................................... 8

Contents ........................................... I

Control ........................................... 11

Coupling 6.2744.120..................... 18

Coupling 9

Figure........................................... 2

Danger............................................. 5

Declaration of Conformity ............. 21

Dimensions.................................... 16

Electrical safety ............................... 6

Electromagnetic compatibility....... 16

Electrostatic charges....................... 6

Eluent flow inlet 2

Figure........................................... 2

Eluent flow outlet 1

Figure........................................... 2

EMC ............................................... 16

Emitted interference ...................... 16

Error remedies............................... 12

Exhaust opening ............................. 3

Front view

Fuses

Suppressor ................... 2

853 CO

2

Technical data ...........................15

General information ....................... 11

General safety rules......................... 6

GLP ..........................................19, 22

GMP ............................................... 22

Grounding.................................... 6, 7

Grounding pin.................................. 7

H

O Absorber Cartridge

2

Regeneration .............................14

O-Absorber Cartridge

H

2

Ordering designation................. 17

Housing.......................................... 16

Illustrations

List................................................ II

Immunity to interference ................ 16

Information....................................... 5

Operation ................................... 11

Information on the Instructions for

Use................................................... 4

Installation........................................ 7

Instructions for Use

Ordering designation................. 18

Instructions for Use 8.853.1001 ......4

Instrument

description ................................... 1

Instrument checks ...........................7

Instrument setup.............................. 7

Introduction...................................... 1

IQ.................................................... 19

ISO 9100 ........................................ 21

Konformitätserklärung ...................21

Leaks................................................ 6

LED ..................................................2

List

of illustrations............................... II

Mains connection ........................ 6, 7

Mains frequency ............................15

Mains voltage

Technical data ...........................15

Maintenance ..................................13

Metrohm Service............................ 14

Opening the instrument ................... 6

Operation ....................................... 11

Optional accessories..................... 18

OQ.................................................. 19

Organization of the Instructions for

Use................................................... 4

Packaging ........................................7

Parts and controls............................2

PEEK-Flow reduction capillary 7

Figure ........................................... 2

PEEK-Pressure screw 8

Figure ........................................... 2

Pictograms .......................................5

Power consumption .......................15

Power supply

Ordering designation .................17

Technical data ...........................15

Pressure range............................... 15

Problems ........................................12

Protection class ...........................6, 7

Protection code.......................... 6, 15

PVC tubing (6.1801.140)

Ordering designation .................17

QA ..................................................19

Quality assurance ..........................19

Quality Management .....................22

Rear view

853 CO

Suppressor.................... 3

Remote connection cable

Remote interface..............................3

Safety information ............................6

Safety rules ......................................6

Safety specifications ......................15

Service............................................14

Shutdown hardware.........................9

Solvent handling ..............................6

Solvent resistance..........................15

SOP ................................................ 19

Spilt chemicals ...............................13

Standard equipment ...................... 17

Standard operating procedures ....19

Startup hardware .............................9

Technical data................................15

Transport damage .....................7, 20

Troubleshooting .........................4, 12

Vacuum .......................................... 15

Validation........................................19

Warning ............................................5

Warranty .........................................20

2

853-830 ......................................17

Ordering designation .................17

Establishment time after start....15

853 CO2 Suppressor / Instructions for Use 8.853.8001EN

23

Loading...

Loading...