Page 1

819 IC Detector

820 IC Separation Center

5.819.0010 Program

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Instructions for Use

8.819.1013

Page 2

Page 3

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

819 IC Detector

820 IC Separation Center

5.819.0010 Program

Instructions for Use

8.819.1013 05.2004 / pkl

Page 4

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

2nd Edition 2004

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 5

Table of contents

Table of contents

1 Introduction.................................................... 1

1.1 Instrument description ............................................................. 1

1.1.1 819 IC Detector .............................................................................1

1.1.2 820 IC Separation Center..............................................................2

1.1.3 Schematic arrangement of the IC systems...................................3

1.2 Parts and controls .................................................................... 4

1.2.1 819 IC Detector .............................................................................4

1.2.2 820 IC Separation Center..............................................................6

1.3 Information on the Instructions for Use ................................ 10

1.3.1 Organization ................................................................................10

1.3.2 Notation and pictograms ............................................................11

1.4 Safety notes ............................................................................12

1.4.1 General precautionary rules ........................................................ 12

2 Installation ................................................... 13

2.1 Setting up the instrument ....................................................... 13

2.1.1 Packaging.................................................................................... 13

2.1.2 Check...........................................................................................13

2.1.3 Location ....................................................................................... 13

2.1.4 Arrangement of the instruments..................................................13

2.2 Installation of accessories .....................................................15

2.2.1 Insert detector block.................................................................... 15

2.2.2 Connection of column heating....................................................18

2.2.3 Connection of syringe and aspirating tubing..............................19

2.2.4 Connection of the drain tube.......................................................19

2.2.5 Connection of the 6.5324.000 Bottle rack (option).....................19

2.3 Electrical connection .............................................................. 20

2.3.1 Connection to 830 IC Interface ...................................................20

2.3.2 Connection to PC ........................................................................23

2.4 Mains connection.................................................................... 25

2.4.1 819 IC Detector ...........................................................................25

2.4.2 820 IC Separation Center............................................................27

2.4.3 Column heating ...........................................................................27

2.5 Software-installation............................................................... 27

2.6 Capillary connections............................................................. 28

2.7 Connection of 818 IC Pump ................................................... 29

2.7.1 Electrical connection ...................................................................29

2.7.2 Pulsation dampener ....................................................................29

2.7.3 Filter unit PEEK............................................................................30

2.7.4 Connection to injection valve ......................................................31

2.8 Precolumns ............................................................................. 33

2.9 Separating columns and suppressor module ....................... 34

2.9.1 General information on separating columns ..............................34

2.9.2 Installing a separating column in the column heating ................35

2.9.3 Selection of the sample loop ......................................................37

2.9.4 General information on suppressor module ............................... 37

2.9.5 One-channel system without suppressor module......................39

2.9.6 Two-channel system without suppressor module ...................... 41

2.9.7 One-channel system with suppressor module ........................... 42

2.9.8 Two-channel system with suppressor module ...........................47

2.9.9 Leak testing and conditioning.....................................................48

819 IC Detector / 820 IC Separation Center

I

Page 6

Table of contents

3 Operation ...................................................... 50

3.1 819 IC Detector .......................................................................50

3.1.1 819 IC Detector icon ...................................................................50

3.1.2 Settings in the "819 IC Detector" window.................................... 50

3.2 820 IC Separation Center ....................................................... 60

3.2.1 820 IC Separation Center icon.................................................... 60

3.2.2 "820 IC Separation Center" window ............................................ 60

4 Notes – Maintenance – Faults ...................... 66

4.1 Practical notes on ion chromatography ................................66

4.1.1 Separating columns .................................................................... 66

4.1.2 Pumps ......................................................................................... 67

4.1.3 Eluents......................................................................................... 68

4.1.4 Suppressor module..................................................................... 69

4.1.5 Connections ................................................................................ 69

4.2 Maintenance and servicing ....................................................69

4.2.1 General information..................................................................... 69

4.2.2 Passivation .................................................................................. 70

4.2.3 Recycling..................................................................................... 70

4.2.4 Shutdown ....................................................................................70

4.2.5 Changing separating columns ................................................... 71

4.2.6 Regeneration of suppressor .......................................................72

4.2.7 Cleaning the suppressor............................................................. 73

4.2.8 Replacement of suppressor module .......................................... 75

4.3 Faults and malfunctions ......................................................... 77

4.3.1 Malfunctions and their rectification ............................................. 77

5 Interfaces ..................................................... 79

5.1 RS 232 interface...................................................................... 79

5.1.1 Data transmission protocol......................................................... 79

5.1.2 Pin assignment............................................................................ 80

5.2 Remote interfaces................................................................... 81

5.2.1 "Remote" interface ....................................................................... 81

5.2.2 "IC Separation Center" interface.................................................. 83

5.3 Analog output.......................................................................... 85

5.4 External power supply for 820 IC Separation Center .......... 85

5.5 Valve interfaces....................................................................... 86

6 Appendix ....................................................... 87

6.1 Technical data......................................................................... 87

6.1.1 819 IC Detector ........................................................................... 87

6.1.2 820 IC Separation Center............................................................ 90

6.2 Scope of delivery .................................................................... 92

6.2.1 819 IC Detector ........................................................................... 92

6.2.2 820 IC Separation Center............................................................ 94

6.3 Optional accessories ............................................................ 103

6.3.1 Accessories for 820 IC Separation Center ...............................103

6.3.2 Column heating......................................................................... 104

6.3.3 Cable ......................................................................................... 105

6.3.4 Literature.................................................................................... 105

6.4 Validation / GLP ....................................................................106

819 IC Detector / 820 IC Separation Center

II

Page 7

Table of contents

6.5 Warranty and Conformity ..................................................... 107

6.5.1 Warranty.....................................................................................107

6.5.2 Declaration of Conformity .........................................................108

6.5.3 Declaration of Conformity .........................................................109

6.5.4 Quality Management Principles ................................................110

6.6 Index ...................................................................................... 111

819 IC Detector / 820 IC Separation Center

III

Page 8

Table of contents

List of figures

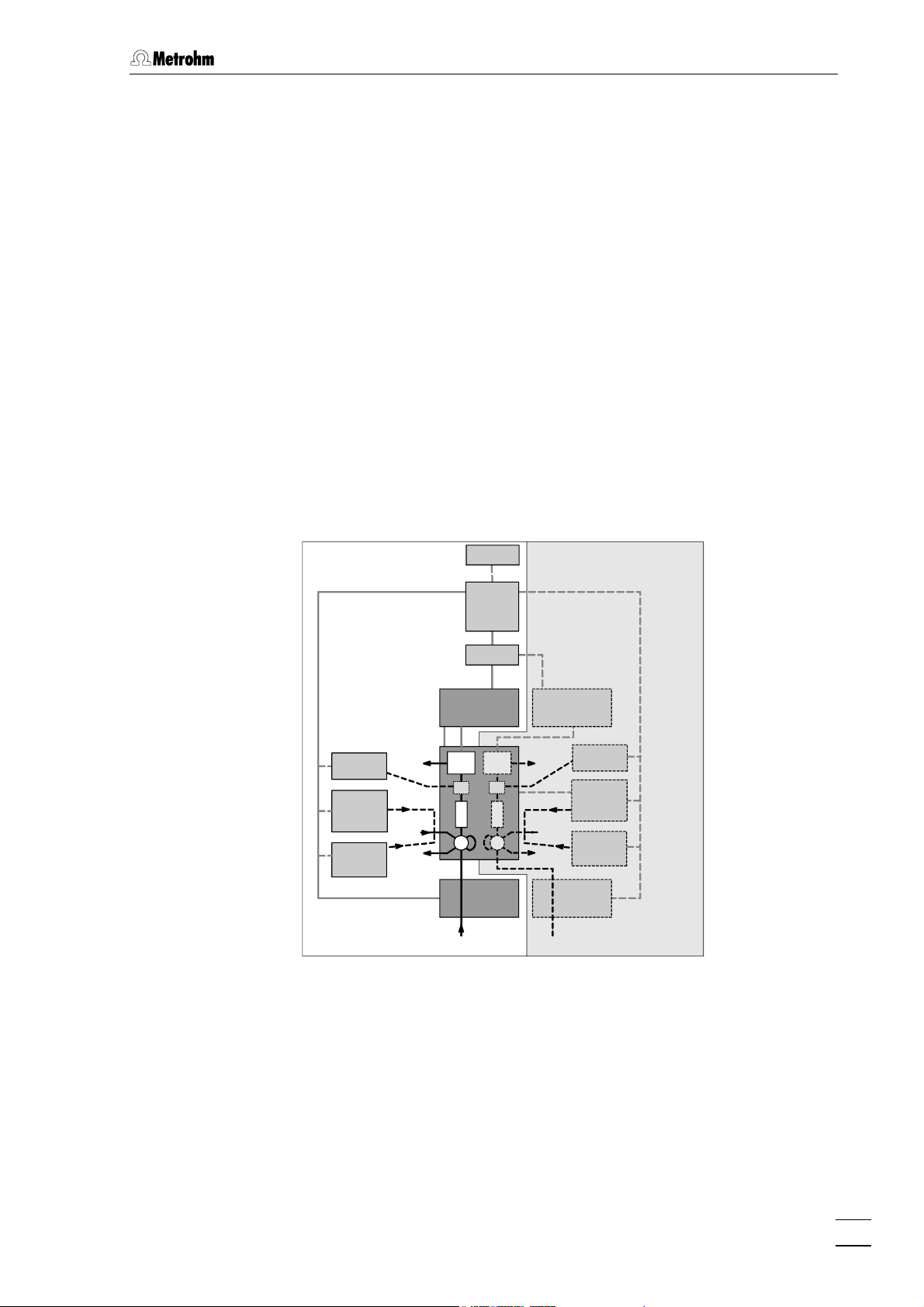

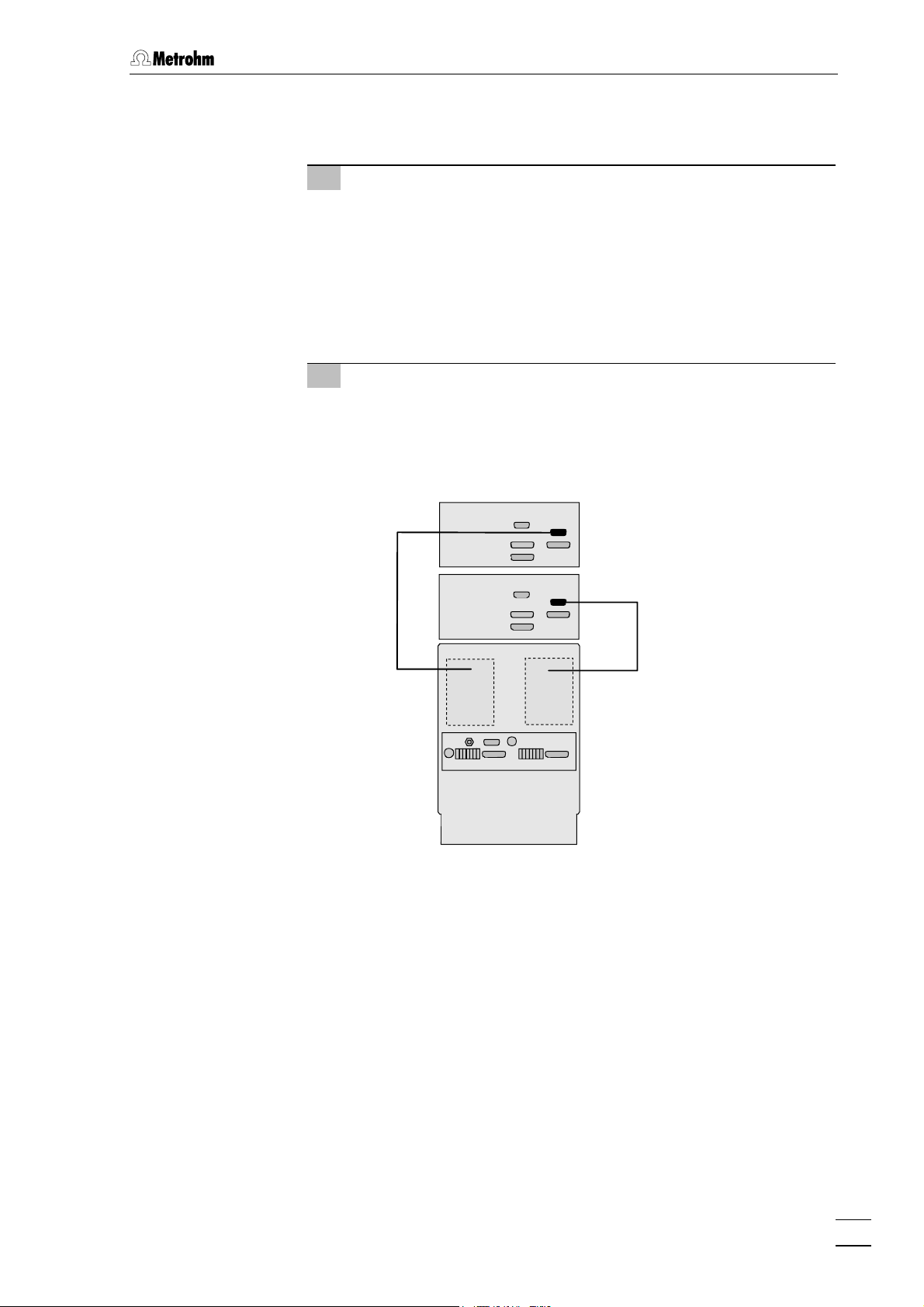

Fig. 1: Block diagram of the ion chromatography systems ................................. 3

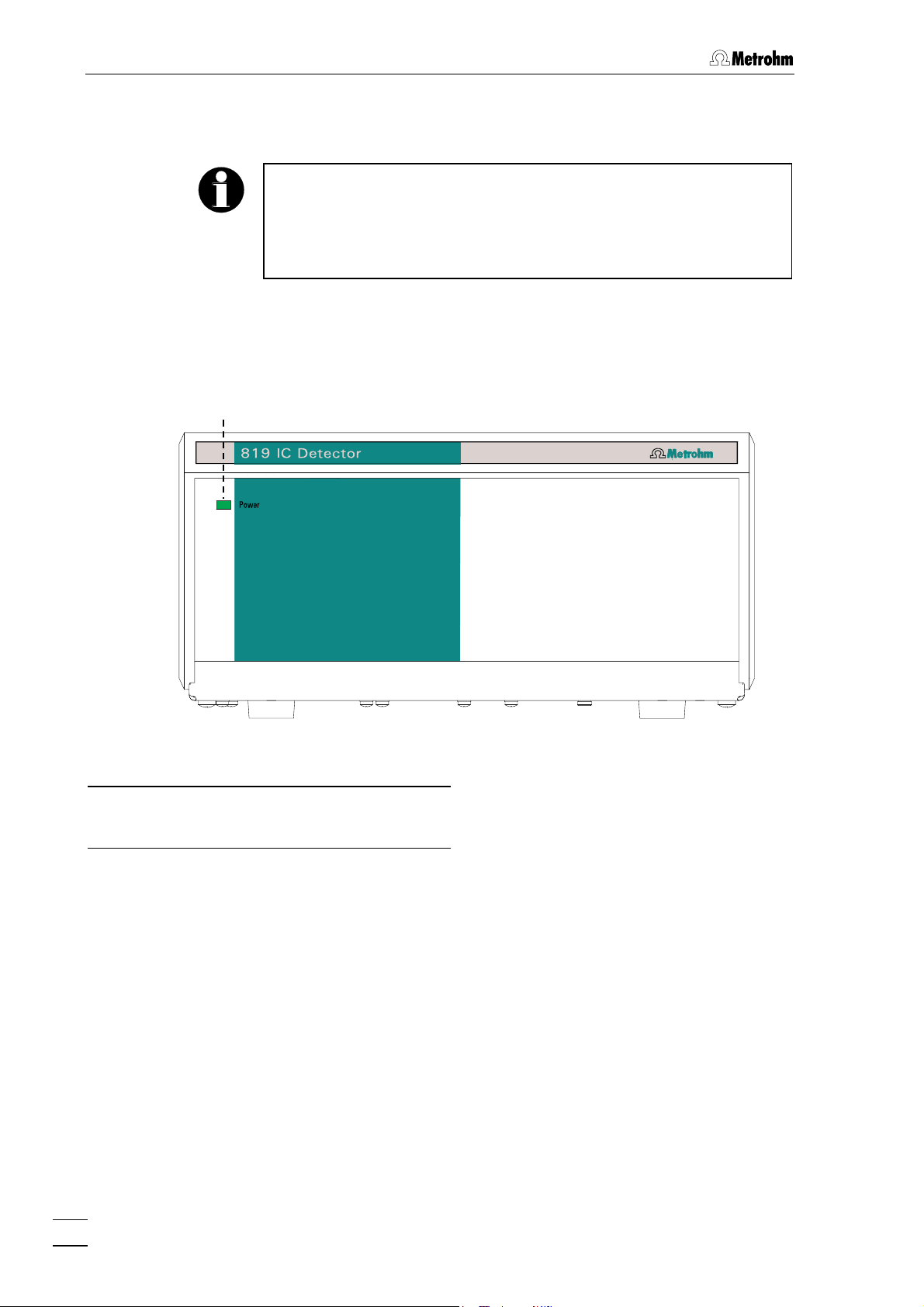

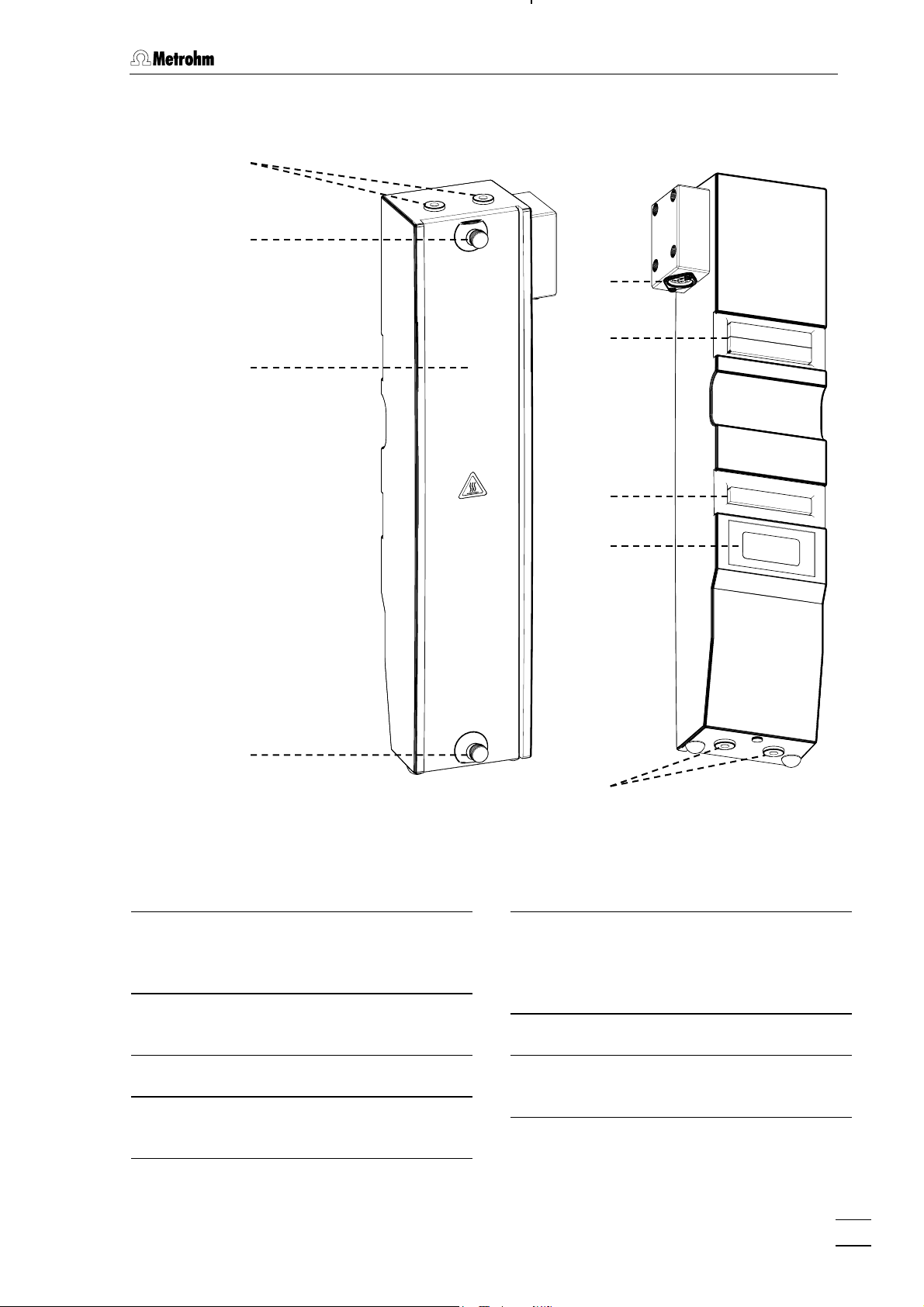

Fig. 2: Front of the 819 IC Detector ...................................................................... 4

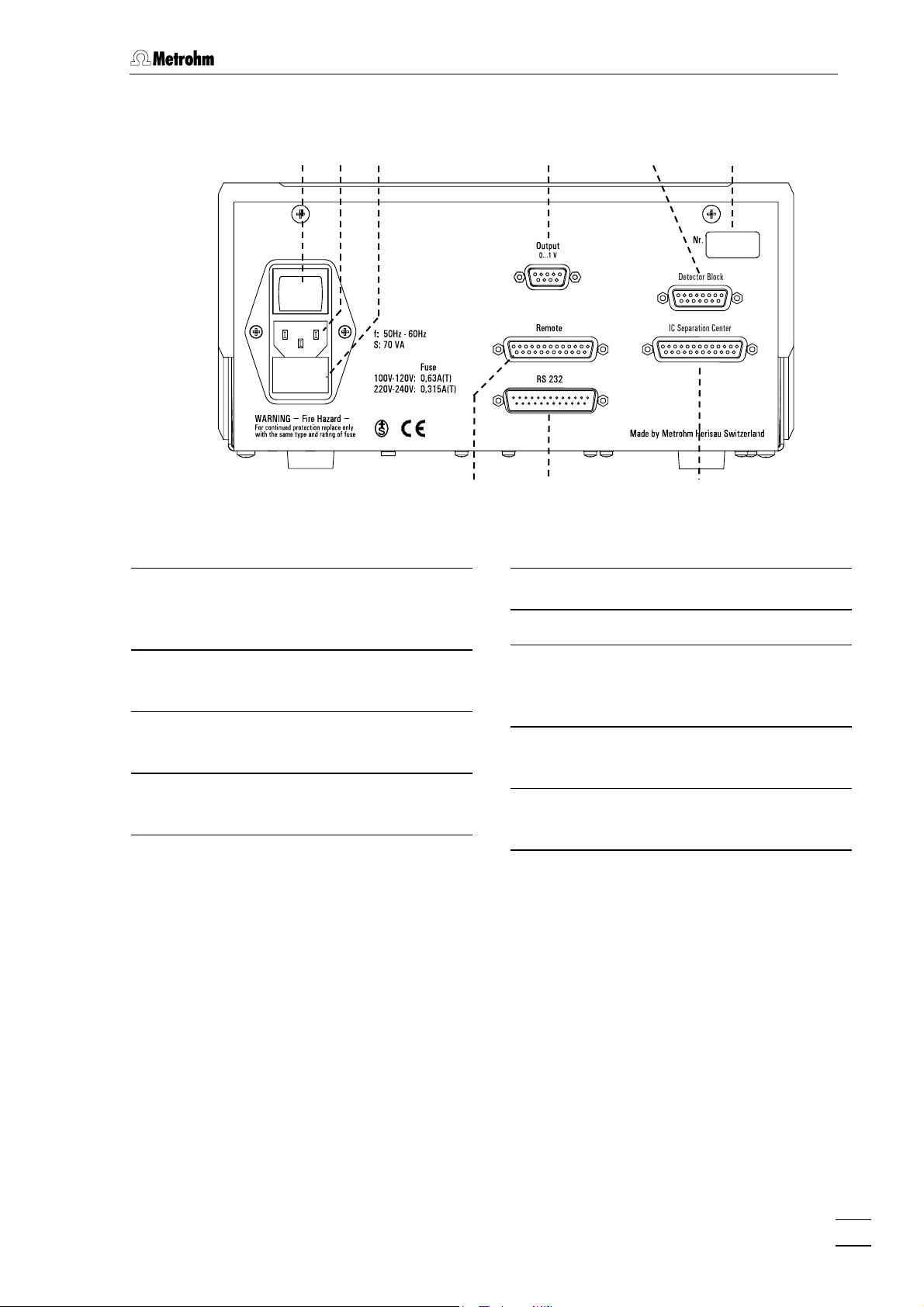

Fig. 3: Rear of the 819 IC Detector....................................................................... 5

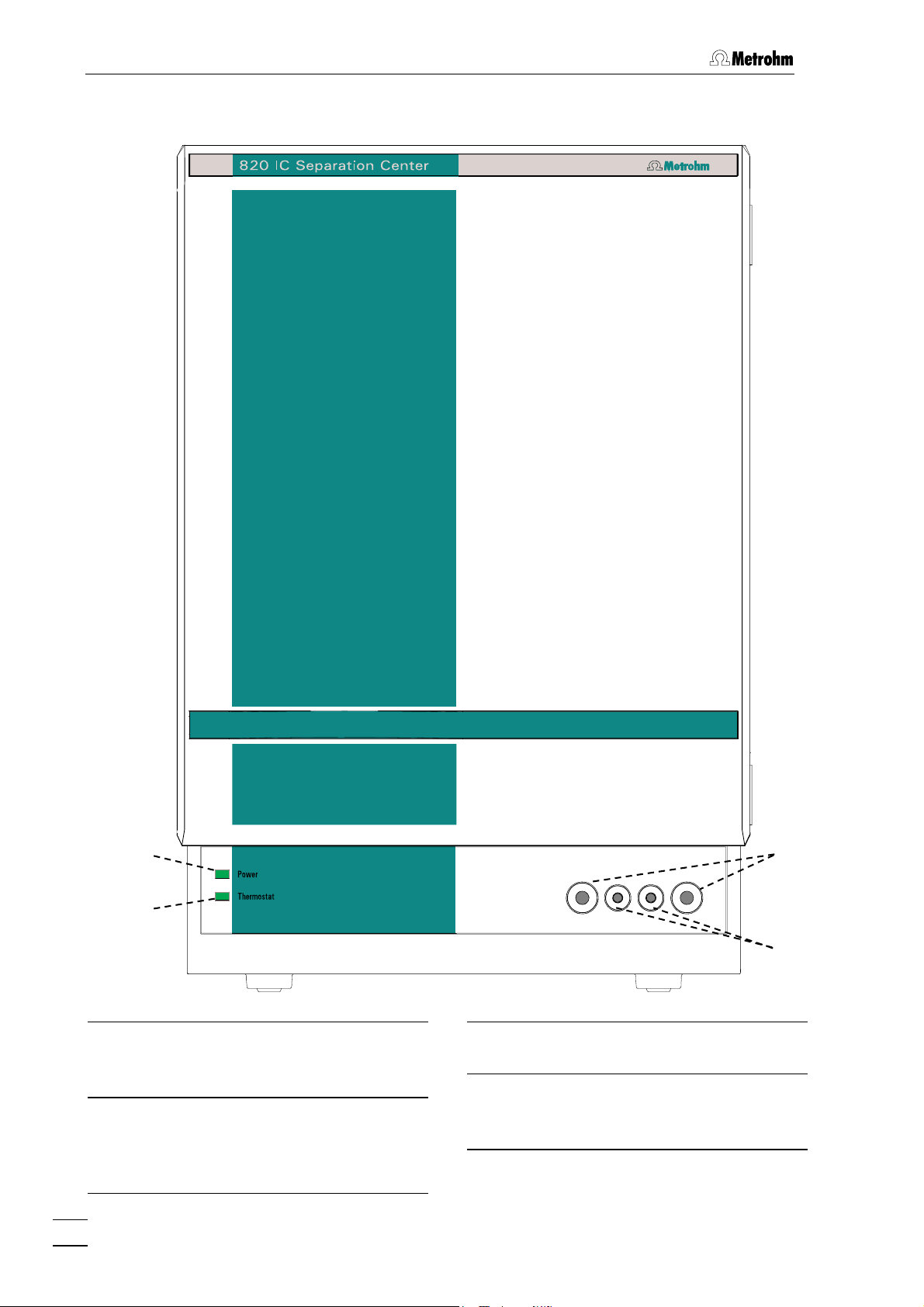

Fig. 4: Front of the 820 IC Separation Center....................................................... 6

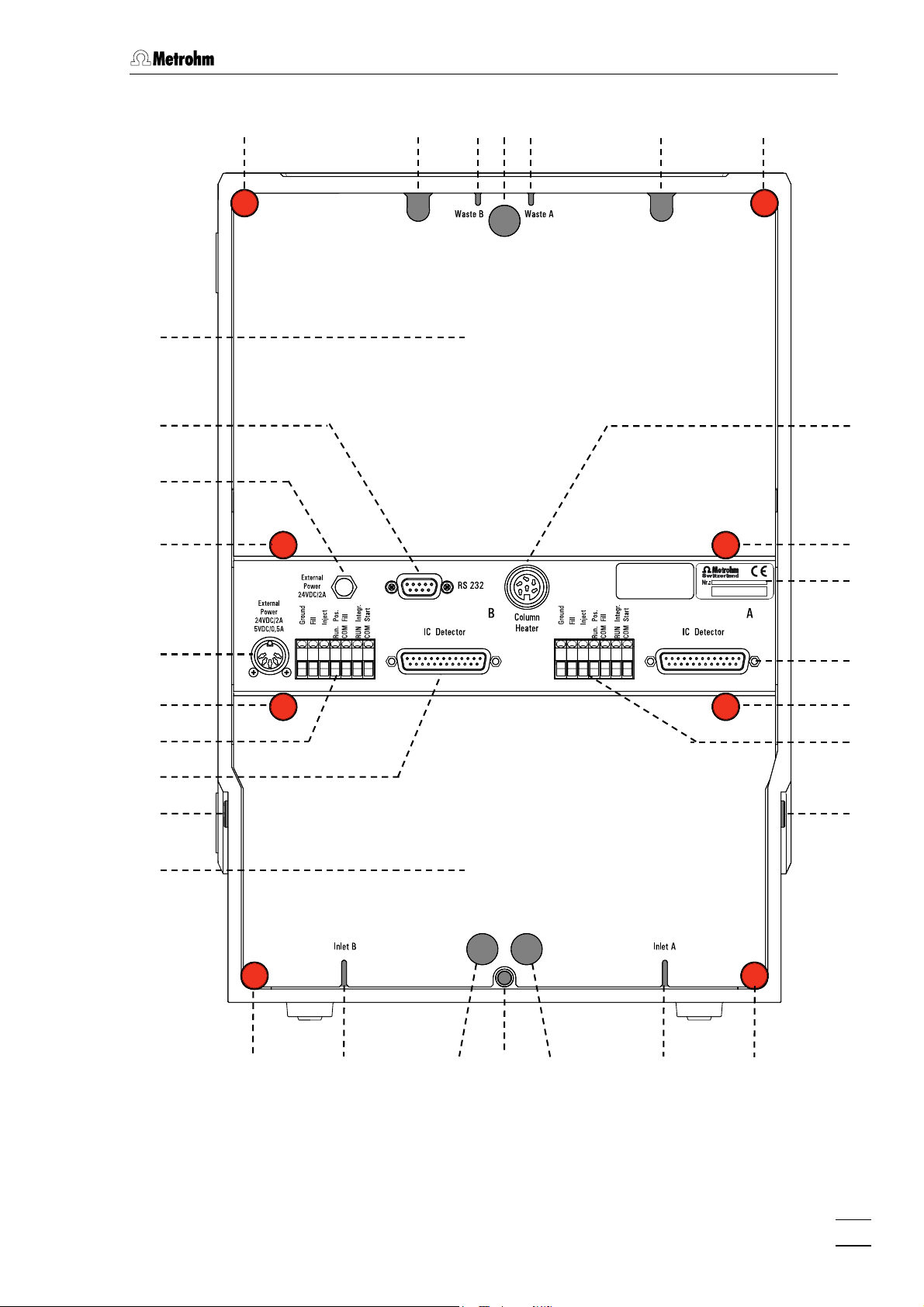

Fig. 5: Rear of the 820 IC Separation Center ....................................................... 7

Fig. 6: Column heating closed ............................................................................. 9

Fig. 7: Insert detector block in the Separation Center........................................ 15

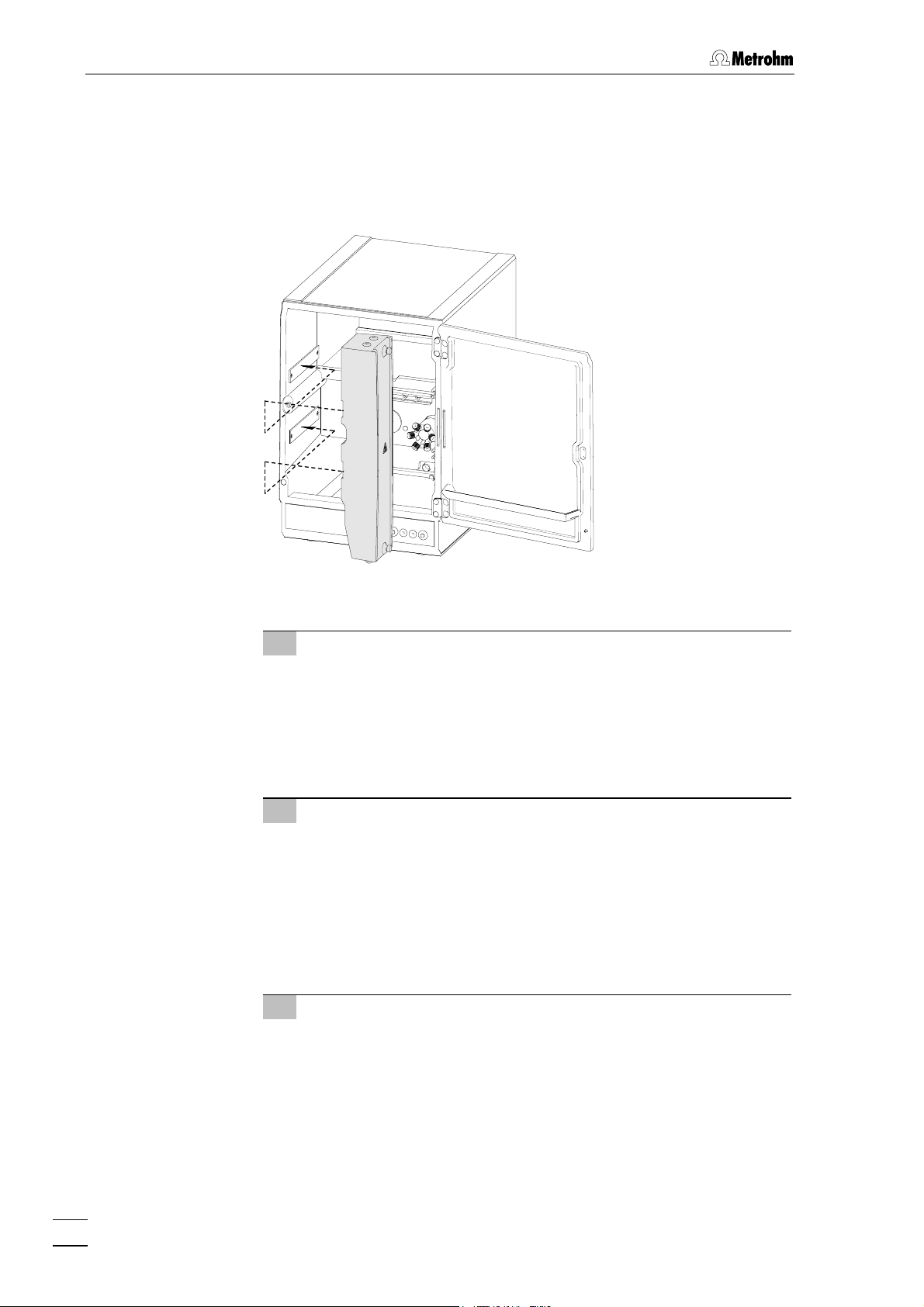

Fig. 8: Connection Detector 819 – 2.820.0X10/2.820.0X30 ............................... 16

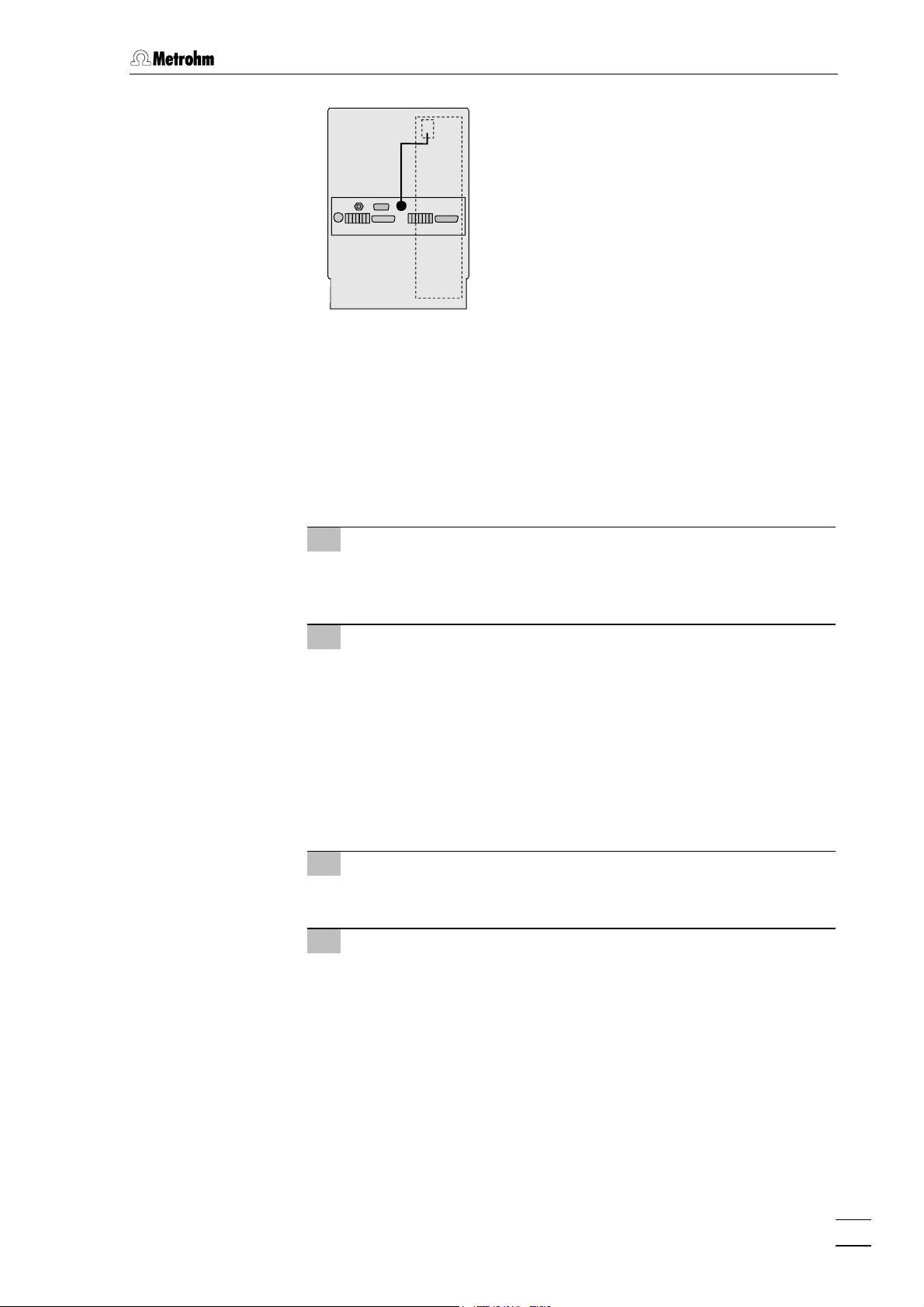

Fig. 9: Connection 2 x 819 Detector – 2.820.0X20............................................. 17

Fig. 10: Install column heating in Separation Center ........................................... 18

Fig. 11: Connection 820 – column heating .......................................................... 19

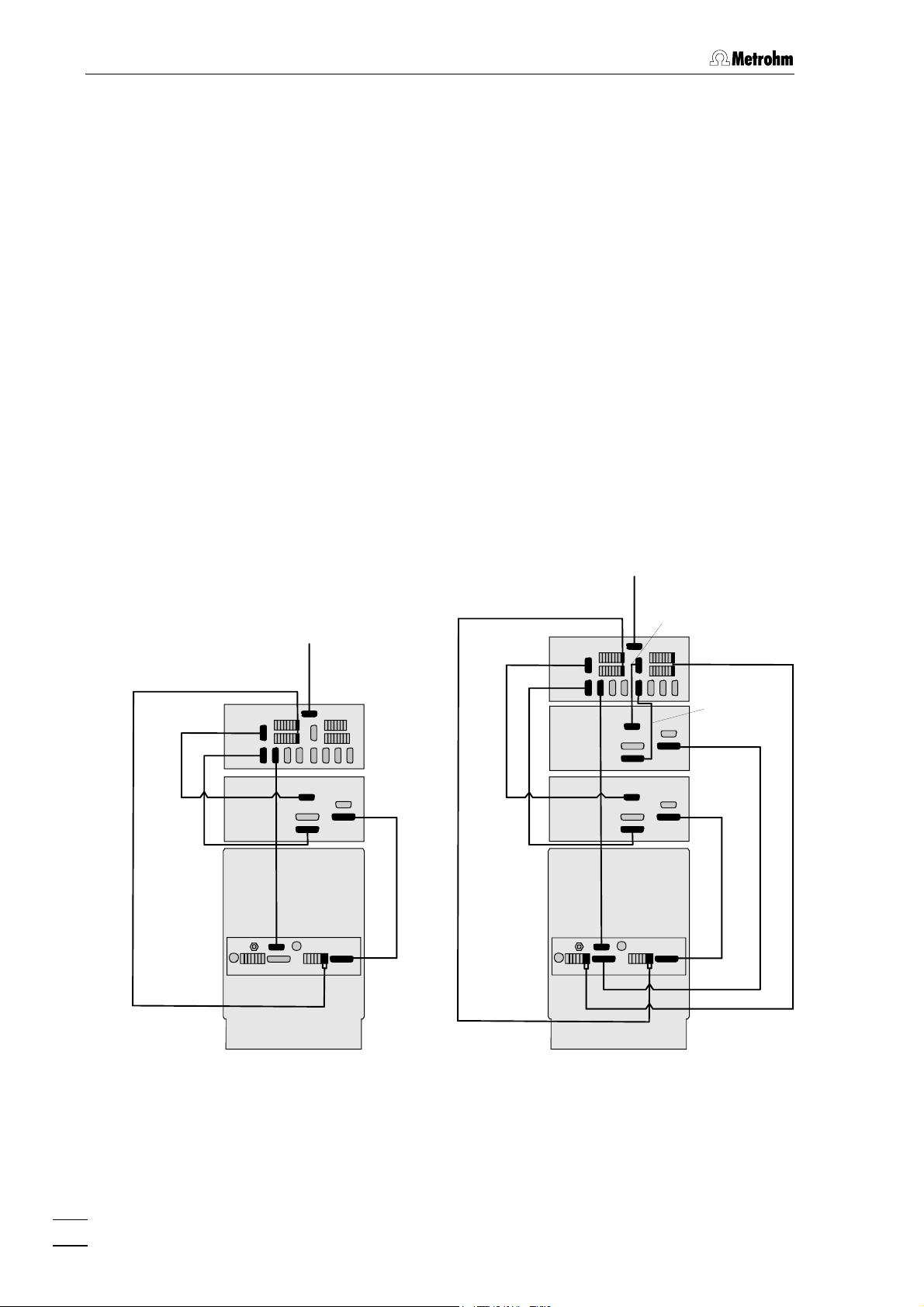

Fig. 12: Connection of 820 via 819 to 830............................................................ 20

Fig. 13: Connection of 819 and 820 to 830 .......................................................... 22

Fig. 14: Connection of 819 and 820 to a PC ........................................................ 24

Fig. 15: Setting the mains voltage........................................................................ 26

Fig. 16: Connect capillaries.................................................................................. 28

Fig. 17: Connection of 818 IC Pump to 830 IC Interface...................................... 29

Fig. 18: Filter unit PEEK (6.2821.120)................................................................... 30

Fig. 19: Connection to injection valve .................................................................. 31

Fig. 20: Insert column in column heating ............................................................. 35

Fig. 21: Interior of the 2.820.0310 Separation Center .......................................... 39

Fig. 22: Interior of the2.820.0320 Separation Center ........................................... 41

Fig. 23: Interior of 2.820.0330 Separation Center ................................................ 42

Fig. 24: Suppressor module connections ............................................................ 44

Fig. 25: Interior of 2.820.0320 Separation Center with suppressor module........ 47

Fig. 26: Operating principle of Auto-zero ............................................................. 52

Fig. 27: Diagram of measuring and full-scale range............................................ 54

Fig. 28: Flow path of the injection valve ............................................................... 62

Fig. 29: Assembling the suppressor .................................................................... 74

819 IC Detector / 820 IC Separation Center

IV

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

1.1.1 819 IC Detector

The 819 IC Detector is a conductivity detector especially designed for

ion chromatography with an extensive operating range and high sensitivity for the recording of chromatograms with and without chemical

suppression. The associated thermostattable detector block is normally

installed in the 819 IC Separation Center, but can also be used as a

separate detector. The two following versions are available:

• 2.819.0010 IC Detector with metal detector block

• 2.819.0110 IC Detector with metal-free detector block

The 819 IC Detector can be fully remotely controlled via the Metrohm

«IC Net» software. All functions can be quickly and easily accessed by

the software and can be clearly shown on the screen. Apart from setting

the measuring parameters, it is possible to draw up any time programs

required. These can be used to control a large number of instrument

functions and freely programmable events.

The 819 IC Detector is connected via the 830 IC Interface or directly to

a PC. The control of the instrument and the recording and evaluation of

the chromatograms take place under «IC Net». It is also possible to

control external devices or start functions in the IC system from these

devices via a “Remote” interface using programmable signals.

819 IC Detector / 820 IC Separation Center

1

Page 10

1 Introduction

1.1.2 820 IC Separation Center

The 820 IC Separation Center is a thermally and electronically insulated wet-chemistry component that accommodates injectors, columns,

column heating, detector blocks, suppressor module, pulsation dampeners and various optional sample preparation modules. The 820 IC

Separation Center is also remotely controlled via the Metrohm «IC Net»

software; it can either be connected to the 819 IC Detector and controlled through it, or connected directly to the 830 IC Interface and controlled directly from «IC Net».

The following versions are available:

• 2.820.0210 IC Separation Center with 1 injector for a one-channel

system with column heating, metal-free

• 2.820.0220 IC Separation Center with 2 injectors for a

two-channel system with column heating, metal-free

• 2.820.0230 IC Separation Center with 1 injector and 1 Metrohm

Suppressor Module MSM for a one-channel system

with column heating, metal-free

• 2.820.0310 IC Separation Center with 1 injector for a one-channel

system, metal-free

• 2.820.0320 IC Separation Center with 2 injectors for a

two-channel system, metal-free

• 2.820.0330 IC Separation Center with 1 injector and 1 Metrohm

Suppressor Module MSM for a one-channel system;

metal-free

2

819 IC Detector / 820 IC Separation Center

Page 11

1.1 Instrument description

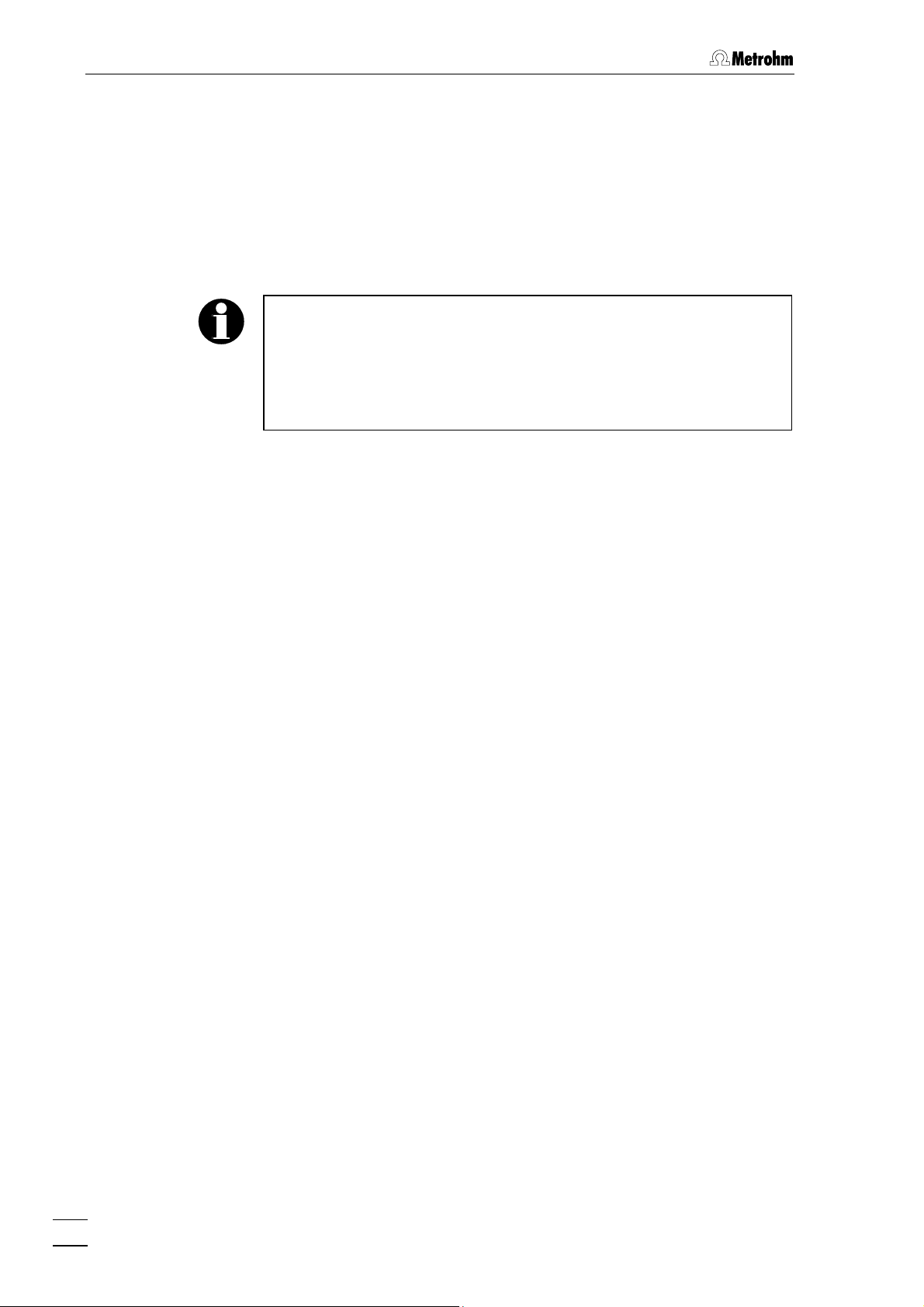

1.1.3 Schematic arrangement of the IC systems

The 819 IC Detector and 820 IC Separation Center are the main components of a modular ion chromatography system that can be expanded to meet the wishes of the individual user (see Fig. 1). The

minimum configuration of the one-channel system also includes a 818

IC Pump, a separating column, a 830 IC Interface and an PC. The twochannel system requires at least a second 819 IC Detector and a second 818 IC Pump. Both systems can be extended virtually without any

limits by further modular Metrohm IC devices such as sample changers

for automation, sample preparation devices, components for postcolumn derivation and other detectors. Further, practically all HPLC peripherals and parts available on the market such as precolumns, additional separating columns, additional detectors and other injection systems can be seamlessly integrated in the system.

However, the individual IC units can also be freely combined with

common HPLC instruments. This offers the possibility of expanding

your system to a stand-alone ion chromatograph.

Suppressor

Sample

changer

Sample

preparation

Two-channel systemOne-channel system

PR

PC

830

819

D

D

M

M

820

C

C

S

W

I

I

818 818

WW

S

W

EE

819

Suppressor

Sample

changer

Sample

preparation

Fig. 1: Block diagram of the ion chromatography systems

C Separating Column M

D Detector PC PC 819 IC Detector

E Eluent PR Printer 820 IC Separation Center

I Injector S Probe

IF Interface W Waste

819 IC Detector / 820 IC Separation Center

Suppressor module

818 IC Pump

3

Page 12

1 Introduction

1.2 Parts and controls

In this Section you will find the numbers and designations of the parts

and controls of the 819 IC Detector and 820 IC Separation Center.

The numbering applies throughout the instructions for use, i.e. bold

numbers in the text (e.g.

here.

1.2.1 819 IC Detector

1

3

) refer to the parts and controls illustrated

Fig. 2: Front of the 819 IC Detector

Mains pilot lamp

1

Lights up when instrument is switched on

4

819 IC Detector / 820 IC Separation Center

Page 13

1.2 Parts and controls

2 3 5 4

Fig. 3: Rear of the 819 IC Detector

Mains switch

2

For switching instrument on/off:

I = ON 0 = OFF

6

7

8 9 10

Connection for detector block

6

Model plate with serial number

7

Mains connection plug

3

Mains connection see Section 2.4.1

Fuse holder

4

Changing the fuses, see Section 2.4.1

Analog output

5

0...1 V

Remote interface

8

remote I/O lines for connection of external devices

RS 232 interface for connection of

9

IC Interface 830 or PC

Connection for 820 IC Separation

10

Center

819 IC Detector / 820 IC Separation Center

5

Page 14

1 Introduction

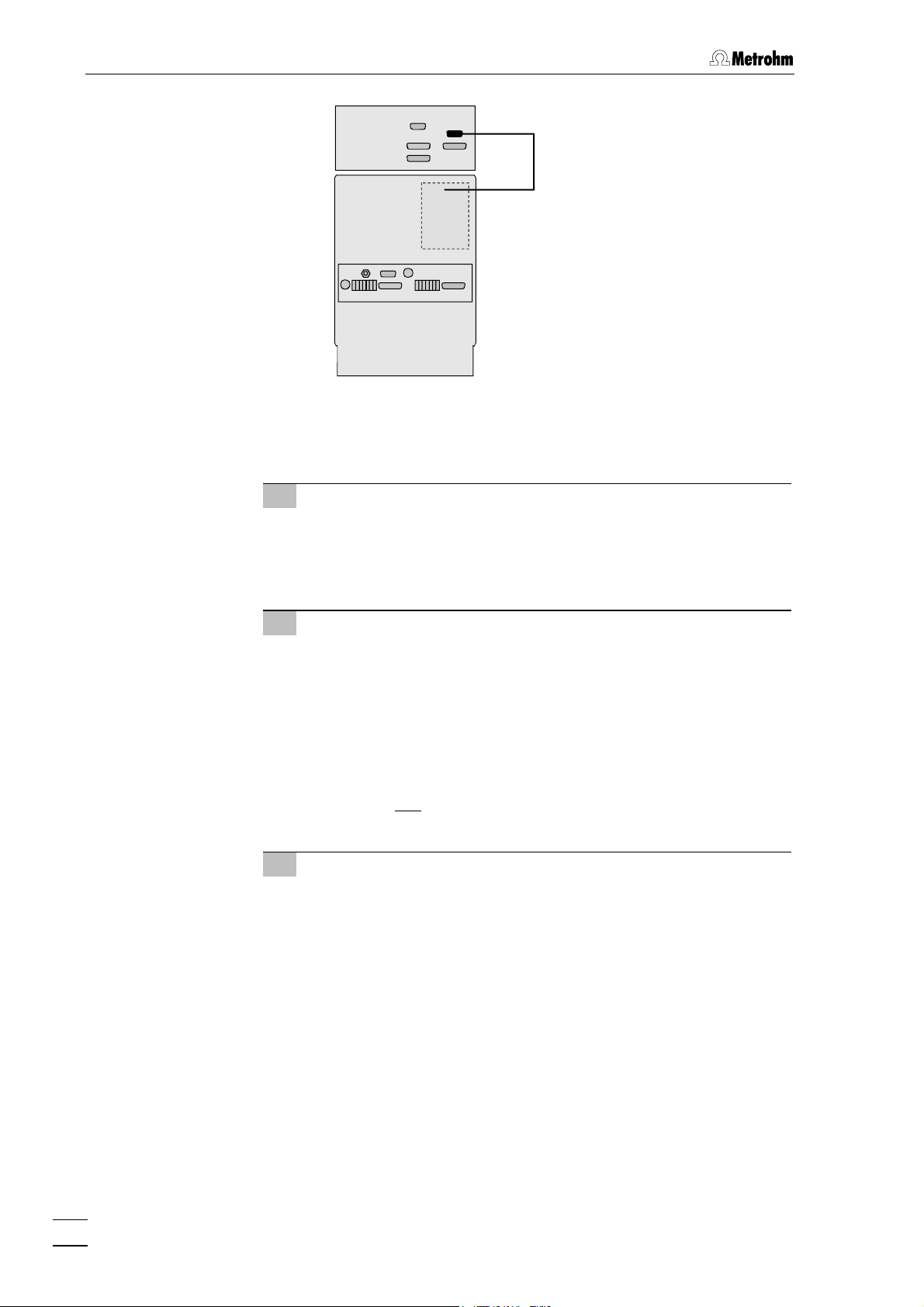

1.2.2 820 IC Separation Center

1

12

Fig. 4: Front of the 820 IC Separation Center

Mains pilot lamp

11

Lights up when instrument is switched

on

Thermostat lamp

12

Lights up when column heating is

Connection for syringe 6.2816.020

13

Feedthrough

14

for sample, eluent, suppressor reagent,…

connected, see Section 2.2.2 and Sec-

tion 2.4.3

6

819 IC Detector / 820 IC Separation Center

13

14

Page 15

1.2 Parts and controls

21

22

24

15

15 16 18 20

17 19

15

23

15

25

15

26

27

14

28

29

30

15

31

14

15

Fig. 5: Rear of the 820 IC Separation Center

819 IC Detector / 820 IC Separation Center

32 18

33 34

18

15

7

Page 16

1 Introduction

Feedthrough

14

for sample, eluent, suppressor reagent,…

Knurled screw

15

for fastening rear panel 21, resp. 28.

Opening for detector cable B

16

opening for connecting cable:

detector block B – 819

Opening for outlet capillary B

17

discharge of the eluent of column B to

waste

Rear panel opening

18

(closed with plastic stopper) for additional supply and discharge lines to

and from the inner compartment

Opening for outlet capillary A

19

discharge of the eluent of column A to

waste

Opening for detector cable A and

20

for connecting cable to the column

heating

opening for connecting cable:

detector block B – 819

column heating – 820 (6.2108.120)

Detachable rear panel

21

access to top part of the inner compartment

RS 232 interface for column heat-

22

ing

to connect to 830 IC Interface or PC

with cable 6.2134.040

Connection for external power

25

supply of the Separation Center

connection of power supply unit

6.2152.000

(5 V, 0.5 A / 24 V, 2 A) in operation

without 819 IC Detector

Terminal block for valve B

26

Ground, Fill, Inject:

inputs for control of the valve

RUN Pos. / COM Fill:

output signal on switching of the

valve to position "FILL"

RUN Integr. / COM Start:

output signal on switching of the

valve to position "INJECT"

Connection for 819 IC Detector

27

Detachable rear panel

28

access to bottom part of the inner

compartment

Model plate with serial number

29

Connection for 819 IC Detector A

30

Terminal block for Valve A

31

Ground, Fill, Inject:

inputs for control of the valve

RUN Pos. / COM Fill:

output signal on switching of the

valve to position "FILL"

RUN Integr. / COM Start:

Output signal on switching of the

valve to position "INJECT"

Opening for inlet capillary B

32

supply of the eluent for column B

Connection for column heating

23

with cable 6.2108.120

Connection for drain tube

33

for discharge of spilled liquid from the

inner compartment

Connection for external power

24

supply of column heating

with power supply unit 6.2152010

Opening for inlet capillary A

34

supply of the eluent for column A

8

819 IC Detector / 820 IC Separation Center

Page 17

1.2 Parts and controls

Column heating

35

36

38

39

37

39

36

Fig. 6: Column heating closed

Feedthrough

35

for the capillary from the separating

column to detector

Knurled screw

36

for fastening the heater cover 37

40

41

Front Rear

Magnetic holder

39

for fastening the column heater in the

inner compartment of the Separation

Center

Model plate with serial number

40

Cover of column heating

37

Connection for Separation Center

38

with cable 6.2108.120

819 IC Detector / 820 IC Separation Center

Feedthrough

41

for column connection capillary 50

9

Page 18

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 819 IC Detector and 820 IC Separation Center into operation. The

Instructions for Use contain information and warnings which must be

heeded the user to assure safe operation of the instruments.

1.3.1 Organization

These 8.819.1013 Instructions for Use for the 819 IC Detector and

820 IC Separation Center provide a comprehensive overview of the installation, startup procedure, operation, fault rectification and technical

specifications of these instruments. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instruments, parts and controls

and safety notes

Section 2 Installation

Installation of 819 IC Detector / 820 IC Separation

Center, electrical connections, tubing connections,

mains connection

Section 3 Operation

Operation via «IC Net»

Section 4 Notes - Maintenance - Faults

Practical notes, maintenance, fault rectification

Section 5 Interfaces

Description of the interfaces

Section 6 Appendix

Technical data, standard equipment, options, validation, warranty, declaration of conformity, index

To find the information you require about the instrument please use either the Table of contents or the Index at the back.

As an addition to the Instructions for Use the Metrohm Monographs

listed in Section 6.3.4 can be requested on the Internet under

http://www.metrohm.com

your local Metrohm agency. Detailed information about separating columns available from Metrohm can be found in the Metrohm IC Col-

umn Catalog or on the Internet under http://www.metrohm.com

ion chromatography range of products. Information about special IC

applications is given in the relevant "Application Bulletins" or "Appli-

cation Notes"; these can be found on the Internet under

http://www.metrohm.com

quested free of charge from your local Metrohm agency.

in the literature section, or free of charge from

in the

in the applications section or can be re-

10

819 IC Detector / 820 IC Separation Center

Page 19

1.3 Information on the Instructions for Use

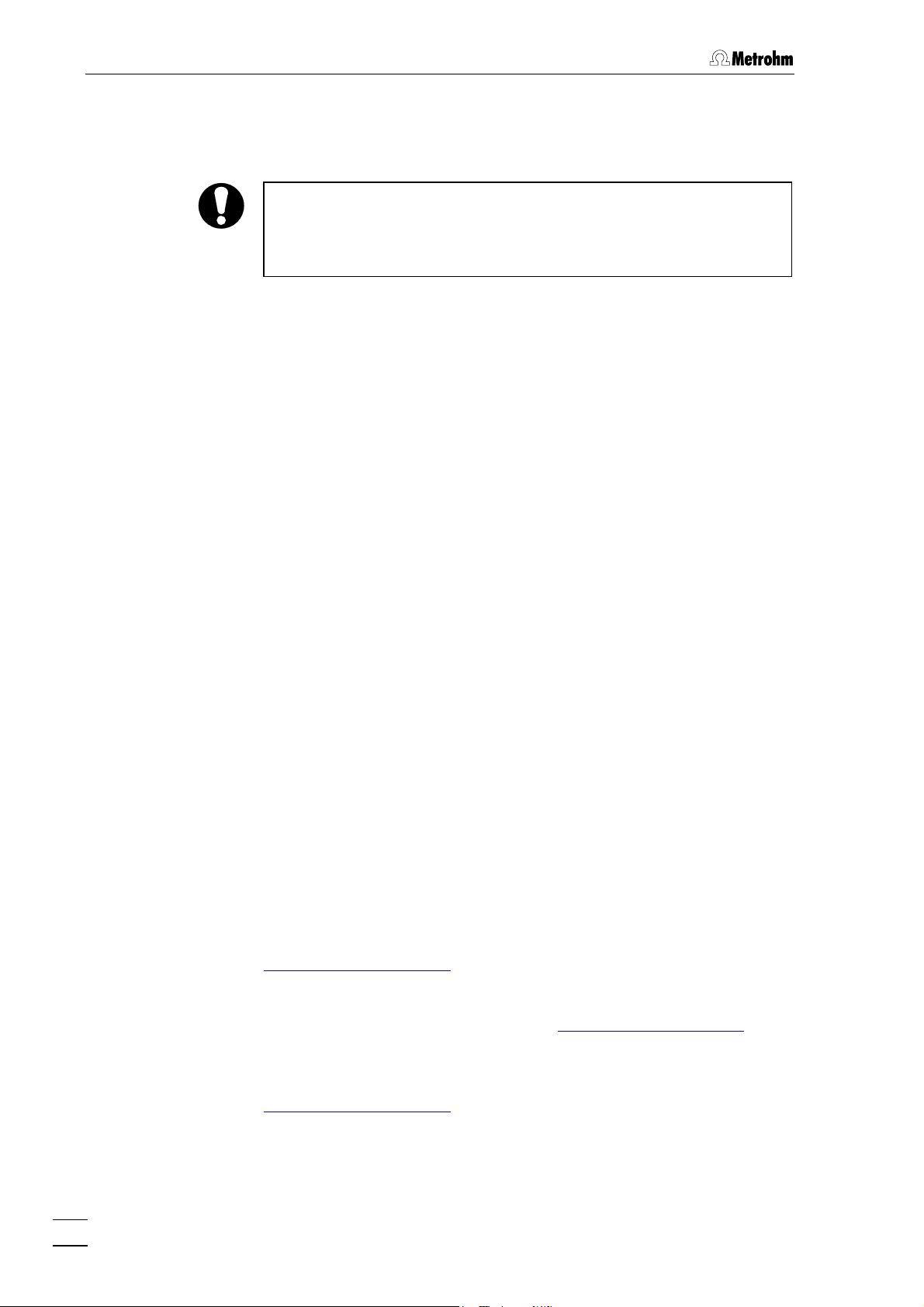

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

Range Menu item, parameter or entry

value

in «IC Net» program

SYSTEM STATE Program window

in «IC Net» program

<OK> Button

in «IC Net» program

7 Part or control of 819 / 820

3 Part or control of 818

21 Part or control of 833

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components by

electricity.

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the instrument or its components.

Attention

This symbol indicates important information that you should read before continuing.

Information

This symbol indicates additional information and tips which may be of

particular use to you.

819 IC Detector / 820 IC Separation Center

11

Page 20

1 Introduction

1.4 Safety notes

While electrical safety in the handling of the 819 IC Detector and 820 IC

Separation Center is assured in the context of the specifications EN/IEC

61010-1 / UL 3101-1 (protection class I), the following points should be

noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in Section 2.4.

• Opening the 819 IC Detector

Inside the instrument there are no parts which must be set or adjusted

by the user.

If the 819 IC Detector is connected to the mains then the instrument

must not be opened, nor should any components be removed from it

as otherwise you run the risk of coming into contact with currentcarrying components. For this reason you should always separate the

instrument from sources of electricity before opening it and also en-

3

sure that the mains plug is removed from mains connector

!

• Opening the 820 IC Separation Center

The instrument contains no components that can be set or adjusted by

the user.

Disconnect all connecting cables on the rear of the 820 IC

Separation Center before you remove the middle housing panel

with connectors.

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 819 IC Detector or 820 IC Separation Center, you should

earth yourself and any tools you are using by touching an earthed object (e.g. housing of the instrument or a radiator) to eliminate any

static charges which exist.

1.4.1 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

12

819 IC Detector / 820 IC Separation Center

Page 21

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

819 IC Detector and 820 IC Separation Center are supplied together

with the separately packed accessories in special packagings

containing shock-absorbing foam linings designed to provide excellent

protection. The actual instrument is packed in an evacuated

polyethylene bag to prevent the ingress of dust. Please store all these

special packagings as only they assure transport of the instruments

free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in Section 6.2). In the case of transport damage, see

instructions in Section 6.5.1 "Warranty".

2.1.3 Location

Position the instrument the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

To avoid disturbing temperature influences on the insulated column

compartment, the pump and eluent reservoir must be protected

against direct sunlight.

2.1.4 Arrangement of the instruments

Modular IC instruments can be stacked on top of each other in any sequence.

In a modular system any instruments containing liquid-transporting

assemblies should always be located as low down in the stack as

possible, so that any leaks which may occur in tubing or connections

will cause no damage to the other instruments by escaping liquids

such as acids.

819 IC Detector / 820 IC Separation Center

13

Page 22

2 Installation

In one-channel operation, the 818 IC Pump, 820 IC Separation Center

and 819 IC Detector are best stacked on top of one another in this order.

In two-channel operation (2.820.0X20 IC Separation Center), the optimum arrangement (1, 2 or 3 towers) depends on the laboratory space

available. However, the 818 IC Pumps should be set up at the very bottom and the 819 IC Detectors at the very top.

To ensure that the arrangement of pumps and detectors for the two

channels A and B is clearly apparent in two-channel operation, it is

advantageous to mark the instruments. The 6.2248.000 Magnetic

plate is enclosed with the 819 IC Detector for this purpose. It can be

cut to the desired size, labeled (e.g. with "A" or "B") and affixed to the

appropriate instrument.

14

819 IC Detector / 820 IC Separation Center

Page 23

2.2 Installation of accessories

2.2 Installation of accessories

2.2.1 Insert detector block

In order to operate an 820 IC Separation Center with an 819 IC Detector

the detector block contained in the standard equipment of the detector

(1.732.0110 Detector block metal-free or 1.732.0100 Metal) must

be inserted in the upper part of the Separation Center.

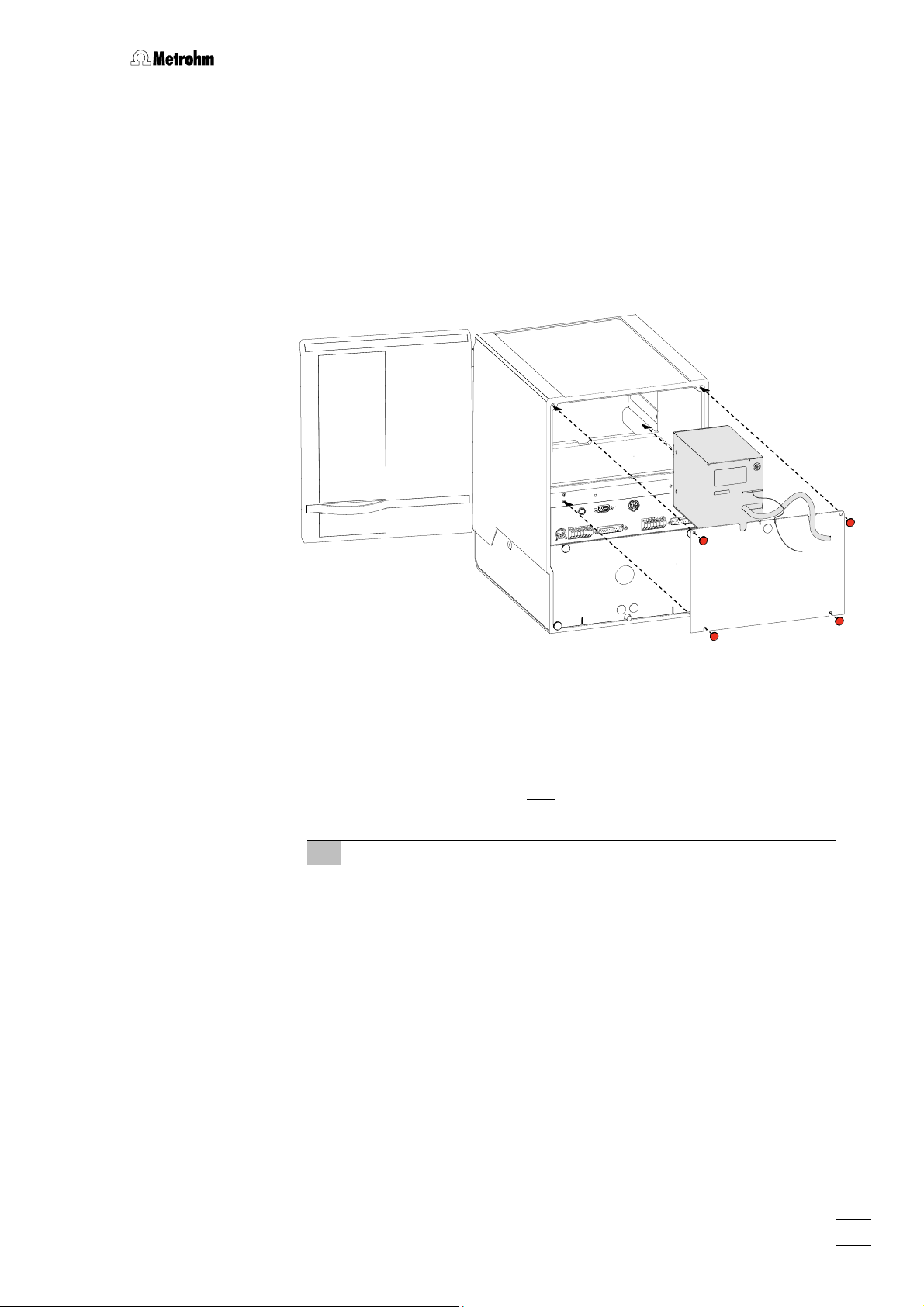

Fig. 7: Insert detector block in the Separation Center

2.820.0X10/2.820.0X30 IC Separation Center

The instrument versions 2.820.0X10 and 2.820.0X30 of the IC Separation Center are operated with one

as follows when connecting the two instruments and the detector block:

1 Install detector block

• Unscrew the four knurled screws 15 from the top rear panel

21 of the 820 IC Separation Center and remove rear panel

(see Fig. 5).

• Position detector block from the back in the space provided

in the 820 IC Separation Center on the right and push fully to

the front (see Fig. 7, resp. Fig. 21 and Fig. 23).

• Insert the cable permanently attached to the detector block in

opening 20 and the outlet capillary in opening 19 "Waste A"

of the rear panel 21.

• Replace rear panel 21 and screw to the 820 IC Separation

Center using the four knurled screws 15.

819 IC Detector. It is best to proceed

819 IC Detector / 820 IC Separation Center

15

Page 24

2 Installation

819

Cable from

detector block

820

Fig. 8: Connection Detector 819 – 2.820.0X10/2.820.0X30

2 Connect detector block

• Plug the gray connecting cable permanently attached to the

detector block into connection 6 „Detector Block“ of the 819

IC Detector and fasten to the instrument by tightening the

screws in the cable connector (see Fig. 8).

3 Connect waste container

• Lead the outlet capillary of the detector block to a sufficiently

large waste container and fix in place.

2.820.0X20 IC Separation Center

The two-channel versions 2.820.0X20 of the IC Separation Center can

be operated with two

819 IC Detectors. It is best to proceed as follows

when connecting the instruments and the two detector blocks:

1 Install detector blocks

• Unscrew the four knurled screws 15 from the top rear panel

21 of the 820 IC Separation Center and remove rear panel

(see Fig. 5).

• Position first detector block from the back in the space pro-

vided in the 820 IC Separation Center on the right and push

fully to the front (see Fig. 7, resp. Fig. 22 and Fig. 25).

• Position second detector block from the back in the space

provided in the 820 IC Separation Center on the left and push

fully to the front (see Fig. 7, resp. Fig. 22 and Fig. 25).

• Insert the cable permanently attached to the detector block A

in opening 20 and the outlet capillary in opening 19 "Waste A"

of the rear panel 21.

• Insert the cable permanently attached to the detector block B

in opening 16 and the outlet capillary in opening 17 "Waste B"

of the rear panel 21.

16

819 IC Detector / 820 IC Separation Center

Page 25

2.2 Installation of accessories

• Replace rear panel 21 and screw to the 820 IC Separation

Center using the four knurled screws 15.

2 Connect detector blocks

• Plug the gray connecting cable permanently attached to the

detector block A into connection 6 „Detector Block“ of the

first 819 IC Detector and fasten to the instrument by

tightening the screws in the cable connector (see Fig. 9).

• Plug the gray connecting cable permanently attached to the

detector block B into connection 6 „Detector Block“ of the

second 819 IC Detector and fasten to the instrument by

tightening the screws in the cable connector (see Fig. 9).

3 Connect waste container

• Lead the outlet capillary of both detector blocks to a suffi-

ciently large waste container and fix in place.

819

819

Cable from

detector block B

820

Fig. 9: Connection 2 x 819 Detector – 2.820.0X20

Cable from

detector block A

819 IC Detector / 820 IC Separation Center

17

Page 26

2 Installation

2.2.2 Connection of column heating

The instrument versions 2.820.02X0 of the IC Separation Center contain

a column heating for thermostatting the separating column as an option. If you wish to use this column heating then it should be installed as

follows:

Fig. 10: Install column heating in Separation Center

1 Laying the connection cable

• Screw off the 4 knurled screws 15 from upper rear panel 21

of the 820 IC Separation Center and remove the rear panel

(see Fig. 5).

• Lead 6.2108.120 Cable through opening 20.

• Replace rear panel 21 and screw it onto 820 IC Separation

Center using the 4 knurled screws 15.

2 Insert column heating

• Carefully place the column heating inside the Separation

Center. If the column has already been inserted in the heating

then be careful with the capillaries at feedthroughs 35 and 41

(see Section 2.9.2).

• Use magnetic holder 39 and the corresponding counter-

pieces to attach the column heating to the left-hand inside

wall of the Separation Center.

3 Connect column heating

• Insert 6.2108.120 Cable at connection 38 of the column heat-

ing (see Fig. 6) and at connection 23 on the rear panel of the

Separation Center (see Fig. 5).

18

819 IC Detector / 820 IC Separation Center

Page 27

2.2 Installation of accessories

820

6.2108.120

Fig. 11: Connection 820 – column heating

2.2.3 Connection of syringe and aspirating tubing

For manual filling of the sample loops mounted on the injection valves,

the 6.2816.020 Syringe and the PTFE aspirating tubing already screwed

to the valve are needed. These accessories are mounted or adjusted as

follows:

1 Connect syringe

• Push 6.2816.020 Syringe (without needle) as far as it will go

into connection socket 13 (left for valve A, right for valve B)

(see Fig. 4).

2 Lead aspirating tubing to the outside

• Lead the PTFE aspirating tubing 63 (see Fig. 21, Fig. 22 resp.

Fig. 23) through one of the feedthroughs 14 at the front or

side of the separation center (see Fig. 4 and Fig. 5) to the

outside.

2.2.4 Connection of the drain tube

The 820 IC Separation Center has a connection at the rear to which a

drain tube for discharged liquids can be attached. Proceed as follows:

1 Connect drain tube

• Mount 6.1816.00 Silicone tubing on connection nipple 33

(see Fig. 5).

2 Lead drain tube to collecting vessel

• Lead the other end of the drain tube to a suitable collecting

vessel and fix in place.

2.2.5 Connection of the 6.5324.000 Bottle rack (option)

The optional available 6.5324.000 Bottle rack for supply vessels can be

placed on top of the IC system tower. The accessories include the supply vessels for eluent (2 L), regeneration solution (1 L) and rinsing solution (1 L). For the connection of the supply capillaries leading to the 818

IC Pump and the suppressor module, see the instructions given on the

enclosed leaflet.

819 IC Detector / 820 IC Separation Center

19

Page 28

2 Installation

2.3 Electrical connection

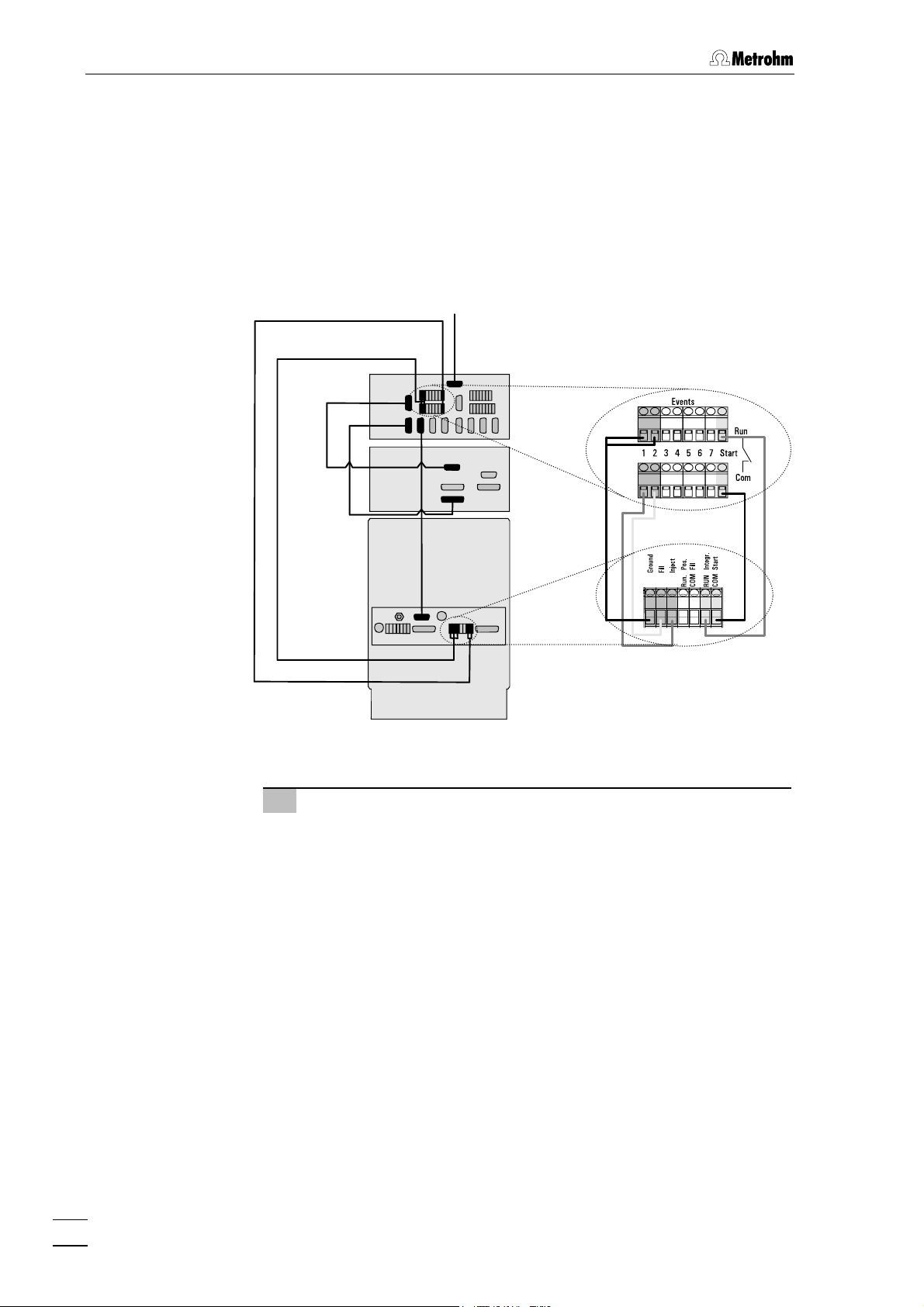

2.3.1 Connection to 830 IC Interface

The instruments are controlled via the Metrohm «IC Net» software. They

are normally connected to a PC via an 830 IC Interface.

The 820 IC Separation Center can be operated in two different ways.

It can operated via the 819 IC Detector, or included as an independent

instrument in the «IC Net» via the 830 IC Interface. Both the cable

connections and the installation under «IC Net» depend on the type of

control.

Control of the Separation Center via 819

Normally the Separation Center is controlled with «IC Net» via the time

program of the detector. When a system is being set up either

to IC Detector

or 820.03X0 to IC Detector must be selected for the Separa-

tion Center in «IC Net».

In a 2-channel system each channel of the Separation Center is controlled via the time program of the assigned detector.

820.02X0

6.2115.070

6.2134.130

6.2134.090

830

819

820

PC

6.2134.100

6.2134.040

6.2125.090

PC

6.2134.100

6.2115.070

6.2134.130 6.2115.070

6.2134.090

830

819 B

819 A

820

6.2134.040

6.2134.130

6.2134.090

6.2125.090

6.2125.090

One-channel system Two-channel system

Fig. 12: Connection of 820 via 819 to 830

20

819 IC Detector / 820 IC Separation Center

Page 29

2.3 Electrical connection

1 Connect 819 to 820

• Use 6.2125.090 Cable to connect Connection 10 “IC Separa-

tion Center” of the 819 IC Detector to Connection 30 “IC Detector” of the 820 IC Separation Center (see Fig. 12).

For the 2-channel versions 820.0X20 additionally:

• Use a further 6.2125.090 Cable to connect Connection 10 “IC

Separation Center” of the second 819 IC Detector to Connection 27 “IC Detector” of the 820 IC Separation Center

(see Fig. 12).

2 Connect 819 to 830

• Use 6.2134.090 Cable (830 accessory) to connect Connec-

tion 9 “RS 232” of the 819 IC Detector to a free RS 232 interface of System 1 of the 830 IC Interface (see Fig. 12).

• Use 6.2134.130 Cable to connect Connection 5 “Output” of

the 819 IC Detector to analog connection “Channels 1/2” of

System 1 of the 830 IC Interface (see Fig. 12).

For 2-channel versions 820.0X20 additionally:

• Use a further 6.2134.090 Cable (830 accessory) to connect

Connection 9 “RS 232” of the second 819 IC Detector to a

free RS 232 interface of System 2 of the 830 IC Interface

(see Fig. 12).

• Use 6.2134.130 Cable to connect Connection 5 “Output” of

the 819 IC Detector to analog connection “Channels 3/4” of

System 2 of the 830 IC Interface (see Fig. 12).

3 Connect 820 to 830

This cable connection starts data recording (chromatogram

window turns blue) when the valve in the 820 is switched to

INJECT via a program command; not necessary if valve is operated manually:

• Use 6.2115.070 Cable to connect the positions Integr. and

Start of terminal block 31 of the 820 IC Separation Center

to the event line Start of System 1 of the 830 IC Interface

(see Fig. 12).

For 2-channel versions 820.0X20 additionally:

• Use a further 6.2115.070 cable to connect the positions In-

tegr. and Start of terminal block 26 of the 820 IC Separation Centers to the event line Start of System 2 of the 830

IC Interface (see Fig. 12).

Take care that each of the RUN connections at 830 and 820 and the

COM connections at 830 and 820 are connected to each other.

4 Connect column heating to 830

For 820.02X0 only:

• Use 6.2134.040 Cable to connect RS 232 interface 22 of the

820 IC Separation Center to a free RS 232 interface of the

830 IC Interface (see Fig. 12).

819 IC Detector / 820 IC Separation Center

21

Page 30

2 Installation

Separate control of the Separation Center

Alternatively you have the possibility of controlling the Separation Center with its own time program from «IC Net». This requires you to select

the appropriate

terface, 820.0310 to Interface, 820.0320 to Interface or 820.0330 to Interface for

820.0210 to Interface, 820.0220 to Interface, 820.0230 to In-

the Separation Center when setting up the systems in «IC Net».

6.2115.070

6.2128.100

6.2134.130

6.2134.090

830

819

820

PC

6.2134.100

6.2134.040

Fig. 13: Connection of 819 and 820 to 830

1 Connect 819 to 830

• Use 6.2134.090 Cable (830 accessory) to connect Connec-

tion 9 “RS 232” of the 819 IC Detector to a free RS 232 interface of System 1 of the 830 IC Interface (see Fig. 13).

• Use 6.2134.130 Cable to connect Connection 5 “Output” of

the 819 IC Detector to the analog connection “Channels

1/2” of System 1 of the 830 IC Interface (see Fig. 13).

22

819 IC Detector / 820 IC Separation Center

Page 31

2.3 Electrical connection

2 Connect 820 to 830

Control lines to switch the valve to FILL or INJECT:

• Use 6.2128.100 Cable to connect positions Ground, Fill and

Inject of terminal block 31 of the 820 IC Separation Center

to two free event lines of System 1 of the 830 IC Interface

(see Fig. 13).

Start data recording:

• Use 6.2115.070 Cable to connect positions Integr. and Start

of terminal block 31 of the 820 IC Separation Center to the

event line Start of System 1 of the 830 IC Interface (see

Fig. 13).

This cable connection starts data recording (chromatogram

window turns blue) when the valve in the 820 is switched to

INJECT via a program command; not necessary if valve is operated manually.

3 Connect column heating to 830

For 820.02X0 only:

• Use 6.2134.040 Cable to connect RS 232 interface 22 of the

820 IC Separation Center to a free RS 232 interface of the

830 IC Interface (see Fig. 13).

If a 2-channel system is used then the cable connections for the second detector and the second valve are made in a similar way.

2.3.2 Connection to PC

The 819 IC Detector can also be connected directly to a PC. In this

case the 820 IC Separation Center must then be connected to the detector and controlled via its time program. In addition a 771 IC Compact

Interface is required; this is included between the analog output of the

detector and the RS 232 interface of the PC and carries out the A/Dconversion of the detector signal. If present, the column heating is also

connected directly to an RS 232 interface of the PC.

This means that three free RS 232 interfaces are required at the PC for

controlling the detector and Separation Center. If a complete IC system

is to be operated directly from a PC then at least four free RS 232 interfaces are required (2 for detector, 1 for column heating and 1 for the

high-pressure pump) at the PC.

Always switch off the 819 IC Detector, column heating and PC before

connecting up the instruments with cables.

1 Connect 819 to 820

• Use 6.2125.090 Cable to connect Connection 10 “IC Separa-

tion Center” of the 819 IC Detector to Connection 30 “IC Detector” of the 820 IC Separation Center (see Fig. 14).

819 IC Detector / 820 IC Separation Center

23

Page 32

2 Installation

2 Connect 819 to PC

• Use 6.2125.110 Cable to connect Connection 9 “RS 232” of

the 819 IC Detector to a free RS 232 interface at the PC

(see Fig. 14).

3 Connect 819 and 820 to 771

• Use 6.2134.140 Cable to connect Connection 5 “Output” of

the 819 IC Detector to Connection “Channel 1” of the 771

IC Compact Interface (see Fig. 14). The cable end with the

marking “Analog” is inserted into the detector.

• Attach the two cable ends “RUN” and “COM” of 6.2134.140

Cable to the positions Integr. and Start of terminal block 27

of the 820 IC Separation Center (see Fig. 14).

3 Connect 771 to PC

• Use 6.2134.100 Cable to connect Connection “RS 232, PC”

of the 771 IC Compact Interface to a free RS 232 interface

at the PC (see Fig. 14).

4 Connect column heating to PC

For 820.02X0 only:

• Use 6.2134.040 Cable to connect RS 232 interface 22 of the

820 IC Separation Center to a free RS 232 interface at the

PC (see Fig. 14).

6.2134.100

6.2125.110

6.2134.040

Fig. 14: Connection of 819 and 820 to a PC

6.2134.140

771

819

6.2125.090

820

If a 2-channel system is used then the cable connections for the second detector and second valve are made in a similar way.

24

819 IC Detector / 820 IC Separation Center

Page 33

2.4 Mains connection

2.4 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

2.4.1 819 IC Detector

Setting the mains voltage

Before switching on the 819 IC Detector for the first time, check whether

the mains voltage set on the instrument (see Fig. 15) matches the local

mains voltage. If this is not

on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 3 of the

819 IC Detector.

the case, you must reset the mains voltage

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 4 below the mains connection plug 3 and take out completely.

3 Change and check fuse if necessary

Carefully take the fuse installed for the desired mains voltage out

of fuse holder 4 and check its specifications (the position of the

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100…120 V 0.63 A (slow blow) Metrohm-No. U.600.0014

220…240 V 0.315 A (slow blow) Metrohm-No. U.600.0011

4 Insert fuse

Change fuse if necessary and reinsert in fuse holder 4.

5 Install fuse holder

Depending on the desired mains voltage, insert fuse holder 4 in

the 819 IC Detector so that the corresponding mains voltage

range can be read normally and the adjacent white arrow points

to the white bar imprinted below the fuse holder (see Fig. 15).

819 IC Detector / 820 IC Separation Center

25

Page 34

2 Installation

V

V

220 – 240

2

3

100

120 V

-

4

220 - 240 V

Fig. 15: Setting the mains voltage

Fuses

One of the two fuses 0.63 A/slow-blow for 100…120 V or 0.315 A/slowblow for 220…240 V is installed in fuse holder 4 of the 819 IC Detector

as standard.

Ensure that the instrument is never put into operation with fuses of another type, otherwise there is danger of fire!

100 –120

240 V

-

100 - 120 V

2 Mains switch

3 Mains connec-

tion plug

4 Fuse holder

220

For checking or changing fuses, process as described above.

Mains cable

The instrument is supplied with one of three mains cables

6.2122.020 with plug SEV 12 (Switzerland, …)

6.2122.040 with plug CEE(7), VII (Germany, …)

6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Plug the mains cable into mains connection plug 3 of the 819 IC Detector (see Fig. 3).

On/off switching of the instrument

The 819 IC Detector is switched on and off using mains switch 2 (see

Fig. 3). When the instrument is switched on the mains pilot lamp 1 lights

up.

26

819 IC Detector / 820 IC Separation Center

Page 35

2.5 Software-installation

2.4.2 820 IC Separation Center

If an 820 IC Separation Center is included in a modular IC system via an

819 IC Detector then the power supply for the Separation Center is provided by the 6.2125.090 Cable (see Fig. 12 and Fig. 14).

If the 820 IC Separation Center is controlled separately (see Fig. 13)

then the optionally available 6.2152.000 Power Supply must be used

and inserted in Connection 25 (see Fig. 5).

2.4.3 Column heating

The column heating contained in the 2.820.02X0 versions has its own

power supply. You must connect the 6.2152.010 Power Supply contained in the standard equipment to Connection 24 on the rear panel of

the Separation Center (see Fig. 5).

2.5 Software-installation

The PC program «IC Net 2.3» is required for the operation of 819 IC

Detector and 820 IC Separation Center. This program runs under Windows 2000 and Windows XP operating systems and is installed according to Section 1.5.2 of the Instructions for Use 8.110.8283 from the

Metrodata software «IC Net 2.3».

The installation of the instruments is described in Section 6.1.1 / Section

6.1.2 of the Instructions for Use 8.110.8283 from the Metrodata soft-

ware «IC Net 2.3». For the settings of the 819 IC Detector see Section

6.4, for the settings of 820 Separation Center see Section 6.8.

If the Separation Center is to be controlled via the time program of the

detector (see Fig. 12 and Fig. 14) then during installation the Separation

Center must be installed appropriately as

820.03X0 to IC Detector. If the 820 IC Separation Center is to be controlled

separately (see Fig. 13), then it must be installed as

820.0220 to Interface, 820.0230 to Interface, 820.0310 to Interface, 820.0320 to

Interface

or 820.0330 to Interface.

820.02X0 to IC Detector or

820.0210 to Interface,

819 IC Detector / 820 IC Separation Center

27

Page 36

2 Installation

2.6 Capillary connections

Some of the connections under high pressure between the feed pump

and the detector block must be set up by the user. For that the

6.1831.010 PEEK capillary (i.d. = 0.25 mm, o.d. =

length = 3 m) and the 6.2744.010 Compression fittings supplied in

the accessories of the 820 IC Separation Center can be used. These

capillaries can be used in the pressure range from 0…30 MPa

(0…300 bar).

Capillaries fitted with new connectors must have a perfectly flat cut

surface. For PEEK capillaries it is best to use the 6.2621.080 Capil-

lary tubing cutter

1

/16",

Fig. 16: Connect capillaries

PEEK capillary6.1831.010

42

43 42

Compression fitting 6.2744.010

43

For the connection of 6.1831.010 PEEK capillaries or of the 6.1834.000

PTFE aspirating tubing, the supplied 6.2744.010 PEEK Compression

fittings are used. It is best to proceed as follows:

1 Mount compression fitting

Slide a compression fitting 43 (6.2744.010) over the end of the

capillary 42 to be fastened as shown in Fig. 16.

2 Insert capillary in connection

Push capillary end in the corresponding connection as far as it

will go (to avoid dead volume).

3 Tighten compression fitting

Tighten compression fitting 43 by hand (never use tools).

28

819 IC Detector / 820 IC Separation Center

Page 37

2.7 Connection of 818 IC Pump

2.7 Connection of 818 IC Pump

2.7.1 Electrical connection

For operation of the 819 IC Detector and 820 IC Separation Center you

can use any commercial HPLC pump. However, as the attainable sensitivity depends to a large extent on the quality of the pump, Metrohm

advises use of the 818 IC Pump, which has been specially developed

for the demands of ion chromatography and has minimal pump pulsation and an outstanding flow constancy.

Startup and operation of the 818 IC Pump are described in the 818

Instructions for Use. The eluent, which must be degassed and filtered

(cf. Section 4.1.3), is selected on the basis of the separating column installed in the 820 IC Separation Center and the current separation problem.

The 818 IC Pump is normally integrated into the modular IC system via

830 IC Interface. Connect the RS 232 interface 17

with a free RS 232 interface at the 830 IC Interface using the 6.2134.080

or 6.2134.090 cable according to the figure below. To ensure proper

functioning of the communication between the 830 IC Interface and 818

IC Pump, the sliding switch 16

on the IC pump must be set to "RS 232".

of the 818 IC Pump

830

818

Fig. 17: Connection of 818 IC Pump to 830 IC Interface

2.7.2 Pulsation dampener

PC

6.2134.100

6.2134.080/6.2134.090

CURRENT

LOOP

RS 232

To protect the column material against pressure drops caused by the

injector, the use of a pulsation dampener connected between the pump

and the injection valve of the 820 IC Separation Center is recommended. The optional 6.2620.150 Pulsation dampener (see Section

6.3) is very well suited to this purpose.

The metal-free 6.2620.150 Pulsation Dampener is supplied fully assembled and has two connections for capillaries, for which either the con-

819 IC Detector / 820 IC Separation Center

29

Page 38

2 Installation

nectors supplied or two 6.2744.010 PEEK compression fittings can be

used. The flow direction is arbitrary. The pulsation dampener is positioned in the interior of the 820 IC Separation Center on the base below

the injection valve (see Fig. 21, Fig. 22, Fig. 23, resp. Fig. 25).

The pulsation dampener is filled with isopropanol when new. Rinse

your IC system carefully after the first installation of a new pulsation

dampener.

2.7.3 Filter unit PEEK

The 6.2821.120 Filter unit PEEK 47 supplied (see Fig. 18) serves to

avoid contamination of the piston seals by abrasive particles and can

be used in the pressure range 0…30 MPa (0…300 bar). The filter unit

consists of the housing 44, the filter 45 and the connector 46 to be

screwed into the housing 44. For the connection of capillaries 42, PEEK

compression fittings 43 (6.2744.010) must be used.

New filter 45 are available as an option with the ordering number

6.2821.110 (10 pieces).

For the connection of the filter unit, please note the flow direction arrow printed on the housing.

The filter unit is filled with isopropanol when new. Rinse your IC system

carefully after the first installation of a new filter unit.

43 42 43 464544 42

Fig. 18: Filter unit PEEK (6.2821.120)

PEEK capillary (6.1831.010)

42

Compression fitting (6.2744.010)

43

Filter housing

44

Filter

45

6.2821.130

Filter connector

46

30

819 IC Detector / 820 IC Separation Center

Page 39

2.7 Connection of 818 IC Pump

2.7.4 Connection to injection valve

It is recommended to use 6.1831.010 PEEK capillaries, a 6.2620.150

Pulsation dampener (see Section 2.7.2) and a 6.2821.120 Filter unit

PEEK (see Section 2.7.3) to connect the 818 IC Pump to the injection

valve of the 820 IC Separation Center. Proceed as follows:

818

Fig. 19: Connection to injection valve

Connection capillary

3

to 818 IC Pump

PEEK capillary (6.1831.010)

Filter unit PEEK (6.2821.120)

47

PEEK capillary (6.1831.010)

48

Pulsation dampener 6.2620.150

49

1 Connection to 818 IC Pump

• Cut connection capillary 3 (6.1831.010 PEEK capillary) to the

48

50

49 47 3

50 51

820

Column connection capillary

48

PEEK capillary (6.1831.010)

Injection valve

51

required length and equip it with compression fittings.

• Attach connection capillary 3

to the upper connection of the

purge valve (see Fig. 1 818 Instructions for Use).

2 Connection of filter unit PEEK

• Attach the other end of connection capillary 3 at the filter

housing 44 of the filter unit 47 (see Fig. 18).

• Connect a PEEK capillary 6.1831.010 cut to the required

length and equipped with connectors to the filter connector

46 of the filter unit 47.

819 IC Detector / 820 IC Separation Center

31

Page 40

2 Installation

3 Installation of the capillary in the IC Separation

Center

• Unscrew the four knurled screws 15 of the bottom rear panel

28 of the 820 IC Separation Center and remove rear panel

(see Fig. 5).

• Insert PEEK capillary 48 from the back into the inner com-

partment of the IC Separation Center.

• Install rear panel 28 so that the capillary is positioned in

opening 34 „Inlet A“ or 32 „Inlet B“ and screw on with the four

knurled screws 15.

4 Connection of the pulsation dampener

• Procedure see section 2.7.2.

5 Connection to the injection valve

• Connect PEEK capillary 48 to pulsation dampener 49 (see

Section 2.7.2). Using another PEEK capillary 48, connect pul-

sation dampener to connection „5“ (see Fig. 28) of injection

valve 51.

6 Mount column connection capillary

This step is only necessary, if no column heating is used.

• Connect column connection capillary50 (ca. 20 cm of

6.1831.010 PEEK capillary) to connection „4“ (see Fig. 28) of

injection valve 51.

32

819 IC Detector / 820 IC Separation Center

Page 41

2.8 Precolumns

2.8 Precolumns

The use of easily exchangeable precolumns protects the separating

columns and prolongs their lifetime. The precolumns available from

Metrohm are either real precolumns or precolumn cartridges, which are

used together with a cartridge holder. For the installation of a precolumn cartridge into the accompanying cartridge holder see the attached

leaflet.

The precolumn that is suitable for your separating column can be

found in the Metrohm IC Column Catalog which can be obtained

from your local Metrohm agency, the data sheet accompanying your

separating column, the product information about separating columns

that can be found under http://www.metrohm.com

phy products, or let your agency advise you directly.

New IC precolumns are normally filled with solution and sealed at

both ends. Before the precolumn is installed in the system, it must be

ensured that this solution is freely miscible with the eluent used

(check manufacturer's specifications).

, ion chromatogra-

1 Connect precolumn

• Remove end caps from the precolumn.

• Fit compression fitting to the connection capillary 50

mounted to the injection valve (see Section 2.6).

• Screw column connection capillary 50 to precolumn.

• Cut off a small piece, ca. 5 cm, from the PEEK capillary

6.1831.010 and fit compression fittings to both ends (see

Section 2.6).

• Mount the prepared capillary to the outlet of the precolumn.

When you install the column, always ensure that this is inserted correctly in accordance with the flow direction (if existent) shown.

2 Rinse the precolumn

• Place a beaker beneath outlet capillary.

• Switch on 818 IC Pump in «IC Net» and rinse precolumn for

ca. 10 min with eluent.

• Switch off 818 IC Pump.

819 IC Detector / 820 IC Separation Center

33

Page 42

2 Installation

2.9 Separating columns and suppressor module

2.9.1 General information on separating columns

The precolumn that is suitable for your separating column can be

found in the Metrohm IC Column Catalog, the product information

about separating columns that can be found under

http://www.metrohm.com

agency advise you directly.

New IC separating columns are normally filled with solution and

sealed at both ends. Before the column is installed in the system, it

must be ensured that this solution is freely miscible with the eluent

used (check manufacturer's specifications).

The separating columns currently available from Metrohm and precolumns can be found in the Metrohm IC Column Catalog, or on the

Internet under http://www.metrohm.com

product section. Each column is supplied with a test chromatogram

and a data sheet. More detailed information about special IC applications can be found in the relevant "Application Bulletins" or "Applica-

tion Notes"; these are available on the Internet under

http://www.metrohm.com

quested free of charge from your local Metrohm agency.

, ion chromatography products, or let your

in the ion chromatography

in the applications sector, or can be re-

When you install the column, always ensure that this is inserted correctly in accordance with the flow direction shown.

34

819 IC Detector / 820 IC Separation Center

Page 43

2.9 Separating columns and suppressor module

2.9.2 Installing a separating column in the column heating

35

52

55

53

36

37

36

Fig. 20: Insert column in column heating

Feedthrough

35

for the capillary from separating column to detector

Knurled screw

36

for fastening the heater cover 37

Cover of the column heating

37

50

41

54

Capillary to detector block

52

PEEK capillary 6.1831.010

Separating column

53

Holder plate

54

for separating column

Feedthrough

41

for column connection capillary 50.

Column connection capillary

50

PEEK capillary 6.1831.010

819 IC Detector / 820 IC Separation Center

Capillary prewarming

55

for column connection capillary 50.

35

Page 44

2 Installation

1 Open column heating

• Open the two knurled screws 36 and remove cover 37 of the

column heating.

2 Prepare column heating

• Unscrew the six screws of holder plate 54 and remove the

holder plate from the column heating.

• Lead column connection capillary 50 (approx. 1 m PEEK-

Capillary 6.1831.010) through feedthrough 41 in the column

heating and place in the recesses in capillary prewarmer 55

as shown in Fig. 20.

• Then screw down holder plate 54 again with the six screws.

• Cut off a further piece of 6.1831.010 PEEK Capillary, lead this

Capillary 52 out through feedthrough 35 and provide its inner

end with a 6.2744.010 Compression fitting 43.

If not much space is available then the 6.2744.070 PEEK compression fitting short contained in the standard equipment can also be

used for attaching the PEEK capillary.

3 Insert separating column

• Press separating column 53 into the holding clips and fasten

the column connection capillary 50 to the separating column

inlet (bottom) with a 6.2744.010 Compression fitting 43.

• Fasten capillary 52 from the detector to the outlet of the

separating column (top) with a 6.2744.010 Compression fitting 43.

4 Close column heating

• Screw down cover 37 on to the column heating again with

the two knurled screws 36.

36

819 IC Detector / 820 IC Separation Center

Page 45

2.9 Separating columns and suppressor module

2.9.3 Selection of the sample loop

Selection of the sample loop depends on the separating column used.

Normally, the following sample loops are used:

Anion columns 100 µL

Cation columns 10 µL

Columns for suppressor technique 20 µL

Depending on the instrument version, the following sample loops are

installed in the 820 IC Separation Center:

Version Valve Sample loop Volume

2.820.0X10 A 6.1825.210 (PEEK) 20 µL

2.820.0X20 A 6.1825.220 (PEEK) 100 µL

B 6.1825.210 (PEEK) 20 µL

2.820.0X30 A 6.1825.210 (PEEK) 20 µL

If desired, the built-in sample loop can be replaced by one of the sample loops available as an option (see Section 6.3.1).

2.9.4 General information on suppressor module

The Metrohm Suppressor Module MSM for chemical suppression

installed in the 2.820.0X30 IC Separation Center comprises a total of 3

suppressor units which are in turn used for suppression, regenerated

with sulfuric acid and rinsed with water. To record every new chromatogram under comparable conditions, work is normally carried out with

freshly regenerated suppressor. Switching is either automatic together

with the valve switching or manual.

The suppressor units must never be regenerated with H

same flow direction used for the eluent. You should thus always install

2SO4

in the

the inlet and outlet capillaries as described in Section 2.9.7 according

to the scheme shown in Fig. 23.

For operation of the suppressor module, a two-channel peristaltic

pump is needed which conveys the regeneration solution (normally

50 mmol/L H

) and the rinsing solution (normally dist. H2O) to the

2SO4

suppressor units. We advise working with a flow rate of 0.5 mL/min.

The 2.833.0010 IC Liquid Handling Pump Unit is available from

Metrohm as an option. Two lengths of pump tubing (6.1826.050) are

enclosed with this pump (flow rate 0.5 mL/min). Startup and operation

of the 833 Pump Unit is described in the Instructions for Use enclosed

with the pump.

The three inlets and outlets numbered 1...3 on the suppressor module

each have 2 permanently mounted PTFE capillaries, which must be

connected as described in Section 2.9.7 (see Fig. 23 und Fig. 24).

819 IC Detector / 820 IC Separation Center

37

Page 46

2 Installation

To avoid contamination of the suppressor module by foreign particles

or bacterial growth, it is advantageous to install an in-line filter between the 833 IC Liquid Handling Pump Unit and the suppressor module. For this the two 6.2821.120 Filter units PEEK (mounting see Fig.

18 Section 2.7.3) supplied with the 2.833.0010 IC Liquid Handling

Pump Unit should be used.

The suppressor module must never

be switched in the dry state as

there is a danger of blocking. Before every switching operation of the

suppressor module, the three suppressor units must have been

rinsed for at least ½ h with eluent, regeneration and rinsing solution.

38

819 IC Detector / 820 IC Separation Center

Page 47

2.9 Separating columns and suppressor module

2.9.5 One-channel system without suppressor module

56

57

58

53

Make sure that the connection separating column outlet – detector

inlet is as short as possible in order to prevent unnecessary peak widening after the separation.

58

58

60

51

58

59

48

50

Fig. 21: Interior of the 2.820.0310 Separation Center

PEEK capillary (6.1831.010)

48

to 818 IC Pump

Column connection capillary

50

PEEK capillary 6.1831.010

58

61

62

63

49

Pulsation dampener (6.2620.150)

49

819 IC Detector / 820 IC Separation Center

Injection valve

51

39

Page 48

2 Installation

Separating column

53

Detector block

56

Inlet capillary for detector block

57

fixed mounting

Mounting rail

58

Column holder (6.2027.0X0)

59

With the one-channel system without suppressor module, the IC separating column is installed in the 2.820.0X10 IC Separation Center as follows (see Fig. 21):

1 Connect column to injector

Capillary for syringe 13

60

PEEK capillary, fixed mounting

Sample loop (6.1825.210)

61

20 µL, PEEK, fixed mounting

Inlet capillary for injector

62

PEEK-Capillary 6.1831.010

PTFE aspirating tube

63

fixed mounting

• Remove end caps from column 53.

• without column heating:

Screw inlet end of separating column 53 (note flow direction)

to column connection capillary 50 mounted on the injector.

• with column heating:

Prepare column heating according to Section 2.9.2 and

screw column connection capillary 50 (see Fig. 20) with a

compression fitting to injection valve 51.

• With precolumn:

Install precolumn according to the supplied leaflet between

inlet of the separating column and the injection valve.

2 Rinse column

• Place a beaker beneath the column outlet.

• Start 818 IC in «IC Net» with suitable flow (see leaflet of the

column) and rinse column for ca. 10 min with eluent.

• Stop 818 IC Pump.

3 Connect column to detector block

• without column heating

Screw outlet end of separating column 53 to the inlet capillary

57 permanently mounted on the detector block 56.

• with column heating

Connect outlet end of separating column 52 (see Fig. 20) with

coupling (6.2744.040) to the inlet capillary 57 permanently

mounted on the detector block 56.

4 Fix column

• without column heating

Insert one or two column holders 59 (6.2027.030, 6.2027.040

or 6.2027.050) in the mounting rails 58 and fasten separating

column in the column holder.

• with column heating

Insert column heating according to Fig. 10 into the Separation

Center.

40

819 IC Detector / 820 IC Separation Center

Page 49

2.9 Separating columns and suppressor module

2.9.6 Two-channel system without suppressor module

Make sure that the connection separating column outlet – detector

inlet is as short as possible in order to prevent unnecessary peak widening after the separation.

With the two-channel system without suppressor module (2.820.0X20

IC Separation Center), the first IC separating column is connected on

the left side to injection valve A and detector block A as with the onechannel system (see Section 2.9.5 und Fig. 21). The second column is

connected on the right side to injection valve B and detector block B in

an analogous manner.

Fig. 22: Interior of the2.820.0320 Separation Center

819 IC Detector / 820 IC Separation Center

41

Page 50

2 Installation

2.9.7 One-channel system with suppressor module

56

64

Make sure that the connection separating column outlet – detector

inlet is as short as possible in order to prevent unnecessary peak widening after the separation.

In the case of the one-channel system with suppressor module, first the

IC separating column is installed in the 2.820.0X30 IC Separation Center (see Fig. 23) and then the suppressor module is connected to the

833 IC Liquid Handling Pump Unit needed for operation (see Fig. 24).

Proceed as follows:

56

57

58

58

53

58

59

61

50

48

49

60

58

71

51

70

58

69

68

67

66

65

63

62

Fig. 23: Interior of 2.820.0330 Separation Center

42

819 IC Detector / 820 IC Separation Center

Page 51

2.9 Separating columns and suppressor module

PEEK capillary (6.1831.010)

48

to 818 IC Pump

Pulsation dampener (6.2620.150)

49

Column connection capillary

50

PEEK capillary 6.1831.010

Injection valve

51

Separating column

53

Detector block

56

Inlet capillary for detector block

57

fixed mounting

Mounting rail

58

Column holder (6.2027.0X0)

59

Capillary for syringe 13

60

PEEK capillary, fixed mounting

Inlet capillary for injector

62

PEEK-Capillary 6.1831.010

PTFE aspirating tube

63

fixed mounting

Suppressor inlet capillary for elu-

64

ent

Suppressor inlet capillary for

65

2SO4

2SO4

H

Suppressor outlet capillary for

66

H

Suppressor outlet capillary for H

67

Suppressor inlet capillary for H

68

Suppressor outlet capillary for elu-

69

ent

Suppressor module

70

2

2

O

O

Sample loop (6.1825.210)

61

20 µL, PEEK, fixed mounting

Coupling (6.2744.040; PEEK)

71

1 Connect column to injector

• Remove end caps from column 53

• without column heating:

Screw inlet end of separating column 53 (note flow direction)

to column connection capillary 50 mounted on the injector.

• with column heating:

Prepare column heating according to Section 2.9.2 and

screw column connection capillary 50 (see Fig. 20) with a

compression fitting to injection valve 51.

• With precolumn:

Install precolumn according to the supplied leaflet between

inlet of the separating column and the injection valve.

2 Rinse column

• Place a beaker beneath the column outlet.