Page 1

CH-9101 Herisau/Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

E-Mail info@metrohm.ch

http://www.metrohm.com

813 Compact Autosampler

Program version 5.813.0010

Instructions for use

8.813.1003 06.2001 / dm

Page 2

D. Möckli

Teachware

Metrohm Ltd.

Oberdorfstr. 68

CH-9100 Herisau

st

1

Edition 2001

Copyright © 2001 by Metrohm Ltd. All rights reserved.

This manual was carefully produced. Nevertheless the author does not warrant the

information contained herein to be free of errors. The author appreciates your

comments and feedback.

© Metrohm Ltd. 2001

Printed in Switzerland

Page 3

Table of content

1

2

Introduction ......................................................1

1.1 Instrument description .................................................................................1

1.2 Parts and controls.........................................................................................2

1.3 Rear view........................................................................................................4

1.4 The keyboard .................................................................................................5

Installation........................................................6

2.1 Setting up the instrument.............................................................................6

2.1.1 Packaging ..................................................................................................6

2.1.2 Delivery check ............................................................................................6

2.1.3 Location......................................................................................................6

2.2 Mains connection ..........................................................................................7

2.2.1 Setting the mains voltage...........................................................................7

2.2.2 Fuses..........................................................................................................8

2.2.3 Mains cable and mains connection...........................................................8

2.2.4 Switching the instrument on/off..................................................................9

2.3 Attaching the accessories............................................................................9

2.3.1 Connecting the keyboard...........................................................................9

2.3.2 Installing the plug cover .............................................................................9

2.3.3 Installing the needle .................................................................................10

2.3.4 Installing the splash protection ................................................................11

2.3.5 Placing the sample rack...........................................................................12

2.3.6 Adjusting the sample rack .......................................................................12

2.3.7 Tubing connections..................................................................................14

2.3.8 Tubing connection to Metrohm 761 / 790 IC–Systems ...........................15

2.3.9 Tubing connection to a Metrohm 747 VA Stand......................................16

2.3.10 Tubing connection to a Metrohm Computrace 757.................................16

2.4 Instrument connections..............................................................................17

2.4.1 Remote interface ......................................................................................17

2.4.2 Interconnection with Metrohm IC systems...............................................17

2.4.3 Interconnection with a Metrohm 746 VA Trace Analyzer .........................18

2.4.4 Interconnection with a Metrohm 757 VA Computrace .............................19

2.4.5 Interconnection with other instruments ....................................................19

Page 4

3

4

Operation ........................................................20

3.1 Keyboard functions.................................................................................... 20

3.2 Configuration .............................................................................................. 21

3.2.1 Course of configuration ...........................................................................23

3.3 RAM initialization........................................................................................ 24

3.4 The methods ............................................................................................... 25

3.5 The Metrohm IC control software ............................................................. 27

3.5.1 Operational conditions............................................................................. 27

3.6 Modular Metrohm IC System 732/733 ....................................................... 28

3.7 Metrohm 746 VA Trace Analyzer ............................................................... 28

3.7.1 Monitoring ................................................................................................28

3.7.2 Command sequence ............................................................................... 28

3.7.3 Conditions to be met ...............................................................................29

Appendix..........................................................30

4.1 Error Messages........................................................................................... 30

4.2 Sequences................................................................................................... 31

4.3 Technical specifications ............................................................................ 35

4.4 Maintenance and servicing........................................................................ 37

4.4.1 Maintenance by Metrohm service ...........................................................37

4.4.2 Care of the unit.........................................................................................37

4.4.3 Replacing the pump tubing .....................................................................37

4.5 Warranty and conformity ........................................................................... 39

4.5.1 Warranty ................................................................................................... 39

4.5.2 Certificate of Conformity and System Validation .....................................40

4.6 Standard equipment................................................................................... 42

4.7 Optional accessories.................................................................................. 46

5

Index................................................................48

Page 5

Table of Figures

Fig. 1 Side view ........................................................................................................ 2

Fig. 2 Rear view........................................................................................................ 4

Fig. 3 Keyboard ........................................................................................................ 5

Fig. 4 Setting the mains voltage .............................................................................. 8

Fig. 5 Keyboard connection..................................................................................... 9

Fig. 7 Installing the splash protection.................................................................... 11

Fig. 8 Sample rack placing .................................................................................... 12

Fig. 9 Installing the pump tubing ........................................................................... 15

Fig. 10 Connection of a 747 VA Stand ..................................................................... 16

Fig. 11 Measuring head of the747 VA Stand ........................................................... 16

Fig. 12 Interconnection with 761 or 790 IC System ................................................ 17

Fig. 13 Interconnection with a modular Metrohm IC System .................................. 18

Fig. 14 Interconnection with a Metrohm 746 VA Trace Analyzer............................. 18

Fig. 15 Interconnection with 757 VA Computrace................................................... 19

Fig. 16 Configuration................................................................................................ 23

Fig. 17 Time program of the IC control software ..................................................... 27

Page 6

Page 7

1 Introduction

1 Introduction

1.1 Instrument description

The 813 Compact Autosampler can be used for automating different tasks, e.g. ion chromatographic determinations with

the Metrohm IC system instruments or voltammetric determinations with the Metrohm 746 Trace Analyzer or 757 VA Computrace . The sample rack provided may hold up to 36 vials of 2.5

or 11 mL volume respectively. Sample tubes made of polypropylene are standard. To protect the samples from external contamination, the tubes can be hermetically sealed.

Sample introduction from the 813 Compact Autosampler is

achieved by means of its integrated peristaltic pump. The sample

is conveyed by the pump through the capillary into e. g. the sample loop of the injector located within an ion chromatograph. A

PEEK needle for sealed or a PEEK tube for open sample tubes

can be used alternatively.

Preprogrammed methods for the most common modes of operation allow to use the 813 Compact Autosampler directly, without

programming effort.

813 Compact Autosampler

1

Page 8

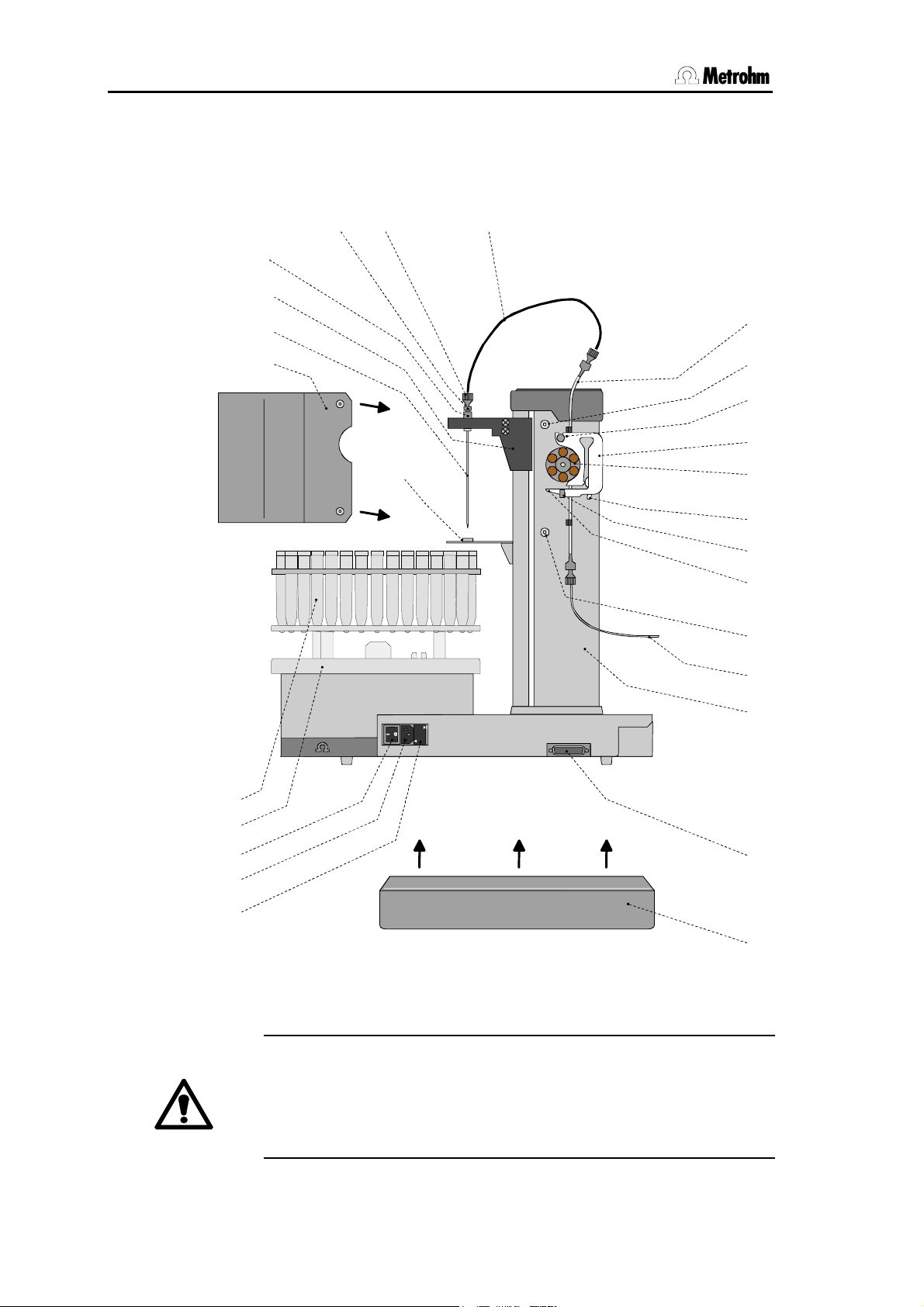

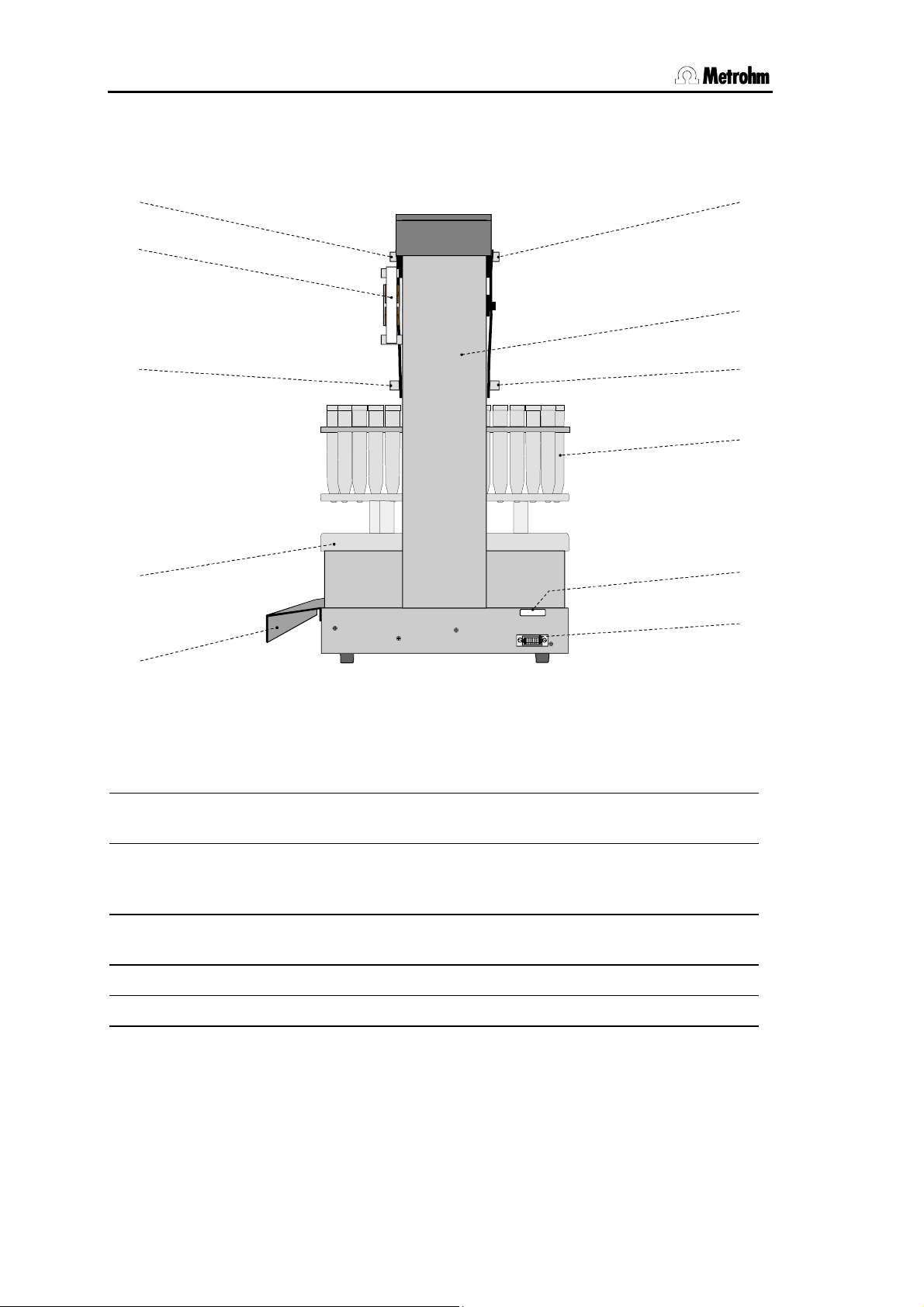

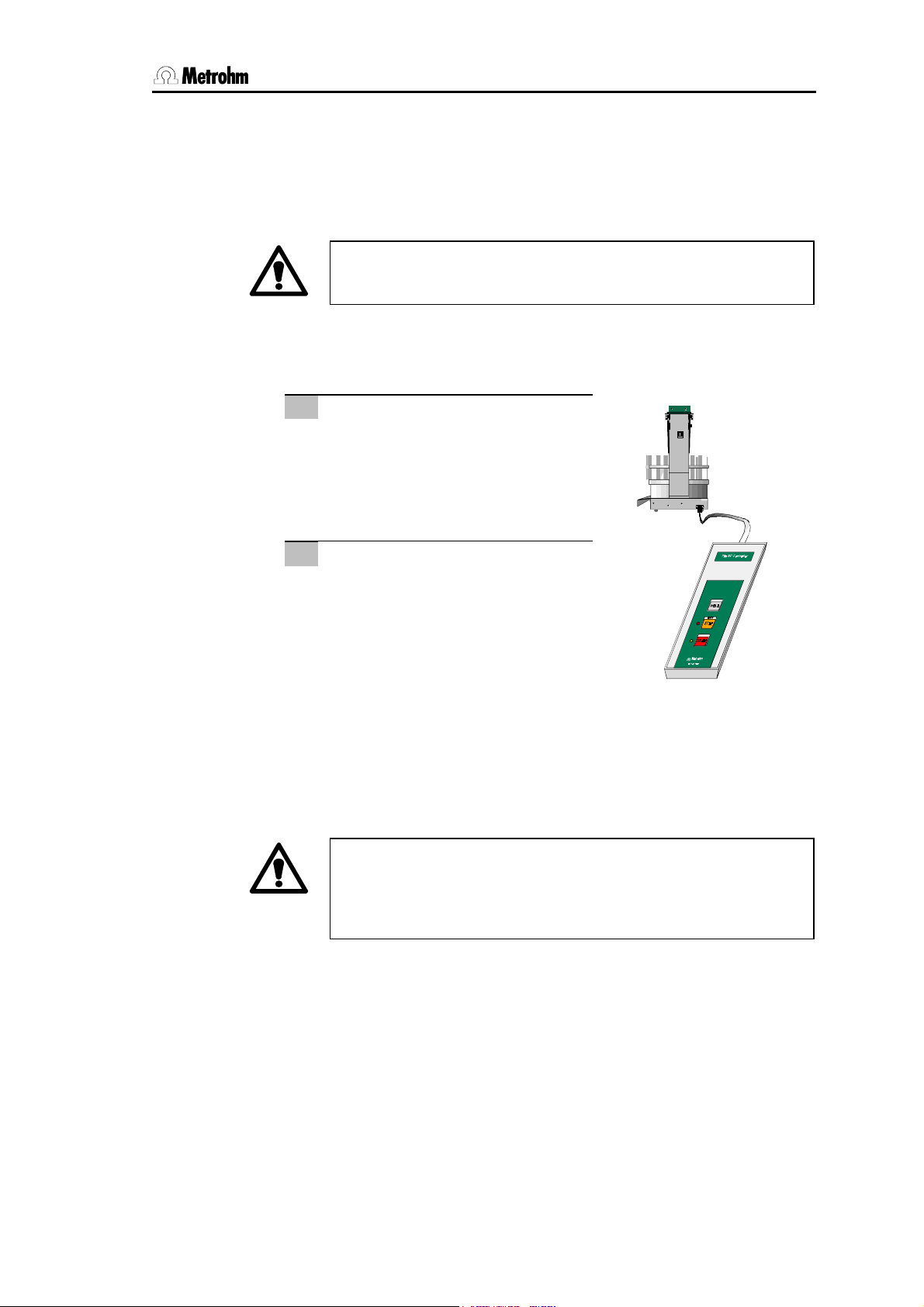

1.2 Parts and controls

0

3

4

5

7

8

9

012

6

1.2 Parts and controls

56 7

4

3

2

8

25

1

9

1

11

26

1

1

1

1

1

1

Metrohm

DES FU SIB L ES DE 2 50V

100-120V

USE ONLY WITH 250V

UNIQUEMENT AVEC

FUSES/EMPLOYER

220-240V

2

24

23

1

22

21

2

Fig. 1 Side view

Safety note:

Never operate the instrument without splash protection and plug

cover being mounted.

The plug cover prevents any contamination of the connectors,

caused by spilled solvents or chemicals.

813 Compact Autosampler

Page 9

1 Introduction

1

Splash protection 6.2751.040

Must be installed always in operation!

14

Holding clamp

For locking the tubing cartridge into

place

2

Needle

PEEK needle 6.1835.020 or PEEK

tube 6.1835.010 or 6.1835.030

3

Lift

4

Steel holder 4.766.4330

attached (part of 6.2833.000 Needle

holder)

5

PEEK compression fitting

4.766.4320

for connection of PEEK capillary

(part of 6.2833.000 Needle holder)

6

PEEK compression fitting

6.2744.010

7

PEEK capillary 6.1831.050

(40 cm)

connection needle – pump tubing

7

15

Snap-action lever

For releasing the tubing cartridge

16

Screw thread for splash

protection

17

PEEK capillary 6.1831.060 or

6.1822.410 (1 m or 1.2 m)

For conveying the sample to e.g. an

injection valve

18

Tower

19

Remote connection

20

Plug cover 6.2752.010

8

Pump tubing 6.1826.040

For conveying the sample

9

Screw thread for splash

protection

10

Mounting pin

For attaching the tubing

cartridge

11

Tubing cartridge 6.2755.000

For 6.1826.0X0 pump tubing

6.1826.0X0

12

Pump drive

Roller head with contact rollers

13

Contact pressure lever

For adjusting the contact pressure

21

Fuse holder

Changing the fuses, see section 2.2.2

22

Mains connection plug

Mains connection, see section 2.2.3

23

Mains switch

For switching the instrument on/off:

I = ON 0 = OFF

24

Sample rack 6.2041.7500

25

PP sample tube 6.2743.050

(can be sealed with 6.2743.060 PE

caps)

26

Needle guide

813 Compact Autosampler

3

Page 10

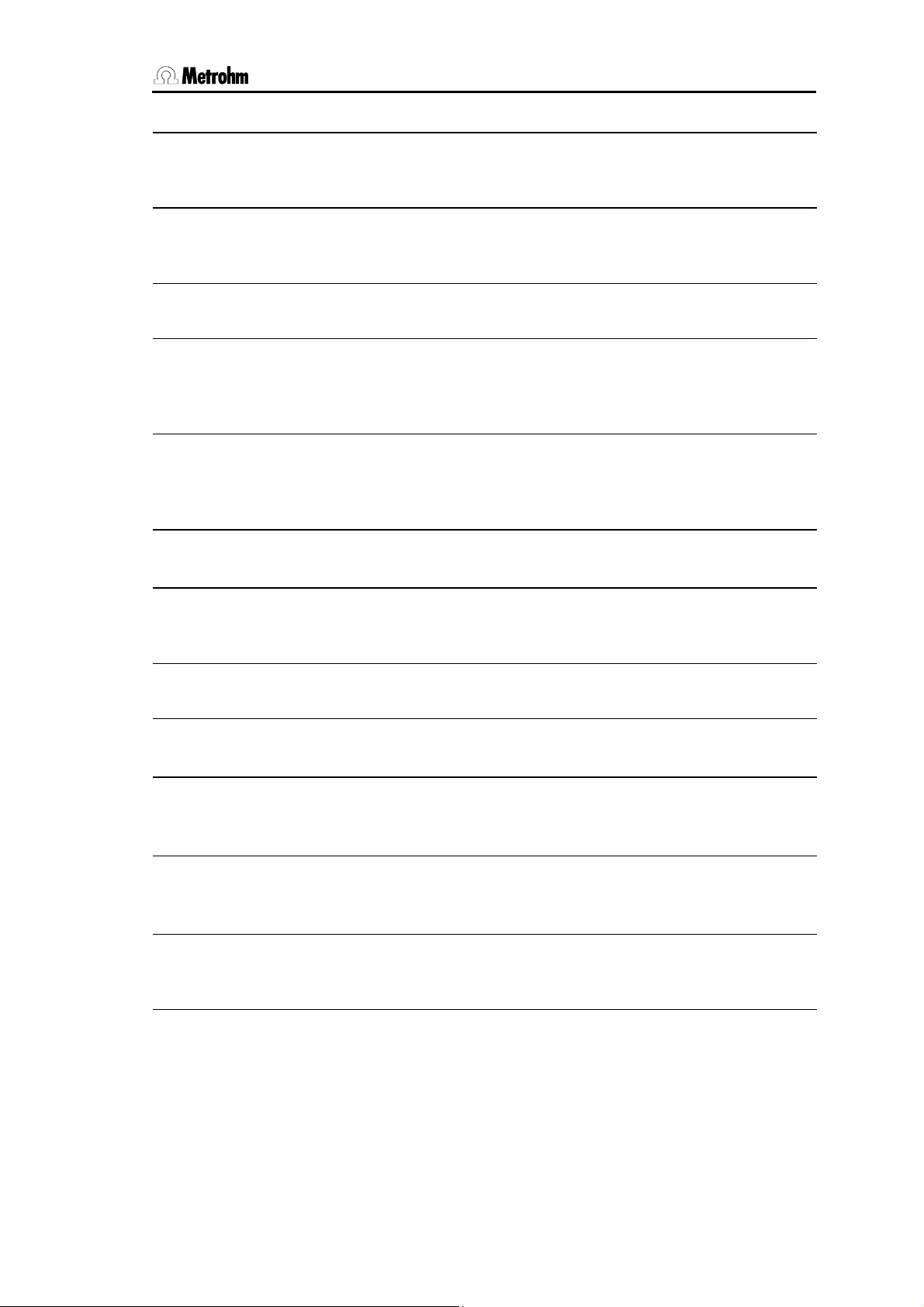

1.3 Rear view

1.3 Rear view

9

11

9

18

16

24

20

9

Mounting screws for

splash protection

Type 1.813.

Made by Metrohm Herisau Switzerl and

Fig. 2 Rear view

24

Sample rack 6.2041.750

Keyboard

16

25

27

28

4

11

Tubing cartridge

6.2755.000

For 6.1826.0X0 pump tubing

16

Mounting screws for

splash protection

18

Tower

20

Plug cover 6.2752.010

25

PP sample tubes 6.2743.050

(can be sealed with 6.2743.060 PE

caps)

27

Serial number

28

Keyboard connection

813 Compact Autosampler

Page 11

1 Introduction

1.4 The keyboard

813 Compact Aut osampl er

• The <START> key starts a sample series or

continues an interrupted series.

• The <STOP> key terminates a sample series

or resets (if pressed twice) the 813 Compact

Autosampler (RESET).

• The <HOLD> key interrupts the course of a

sample series and establishes the 'HOLD'

state. The green LED blinks. With the

<START> key the interrupted sample series

can be continued.

HOLD

RESE T

STOP

START

Met r ohm

6.2142. 110

Fig. 3 Keyboard

• The green LED indicates the status of the

Autosampler.

The LED is lit in the 'ready' state.

-

It blinks steady during the course of a

-

method.

It blinks in fast frequency when a series is

-

interrupted ('HOLD' state).

• The red LED indicates error states or parameter settings.

If an error occured the type of error is indi-

-

cated by the number of blinks, see Ap-

pendix, Error messages.

813 Compact Autosampler

5

Page 12

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 813 Compact Autosampler is supplied together with the

separately packed accessories in special packagings containing

shock-absorbing foam linings designed to provide excellent protection. The actual instrument is packed in an evacuated polyethylene bag to prevent the ingress of dust. Please store all these

special packagings as only they can assure damage-free transport of the instrument.

2.1.2 Delivery check

After receipt, immediately check whether the shipment is complete and undamaged (compare with delivery note and list of accessories in section 4.6). In the case of transport damage, see instructions in section 4.5.1 "Warranty".

2.1.3 Location

Position the instrument in the laboratory at a location convenient

for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

Do not operate the 813 Compact Autosampler without splash

protection

Take precautions to ensure that any leaks from pump tubings or

connections cannot cause more damage.

Take precautions to ensure that any leaks from pump tubings or

connections cannot cause more damage.

1

and plug cover 20 being installed!

6

813 Compact Autosampler

Page 13

2 Installation

2.2 Mains connection

Follow the instructions below for connecting to the power

supply. If the instrument is operated with the mains voltage set

wrongly and/or wrong mains fuse there is a danger of fire!

2.2.1 Setting the mains voltage

Before switching on the 813 Compact Autosampler for the first

time, check that the mains voltage set on the instrument (see Fig.

4) matches the local mains voltage. If not

on the instrument as follows:

Disconnect mains cable

1

Disconnect mains cable from mains connection plug 22 of the

813 Compact Autosampler.

, reset the mains voltage

Remove fuse holder

2

Using a screwdriver, loosen fuse holder 21 beside the mains

connection

Check fuse

3

Carefully take the fuse installed for the desired mains voltage out

of fuse holder

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100…120 V 0.5 A (slow-blow)

Metrohm-Nr. U.600.0013

220…240 V 0.25 A (slow-blow)

Metrohm-Nr. U.600.0010

Insert fuse

4

Change fuse if necessary and reinsert in fuse holder 21.

Install fuse holder

5

Depending on the desired mains voltage, insert fuse holder 21

in the 813 Compact Autosampler so that the corresponding

mains voltage range can be read normally and the adjacent

white arrow points to the white bar imprinted on the right side of

the fuse holder (see Fig. 4).

22

and take out completely.

21

and check its specifications (the position of the

813 Compact Autosampler

7

Page 14

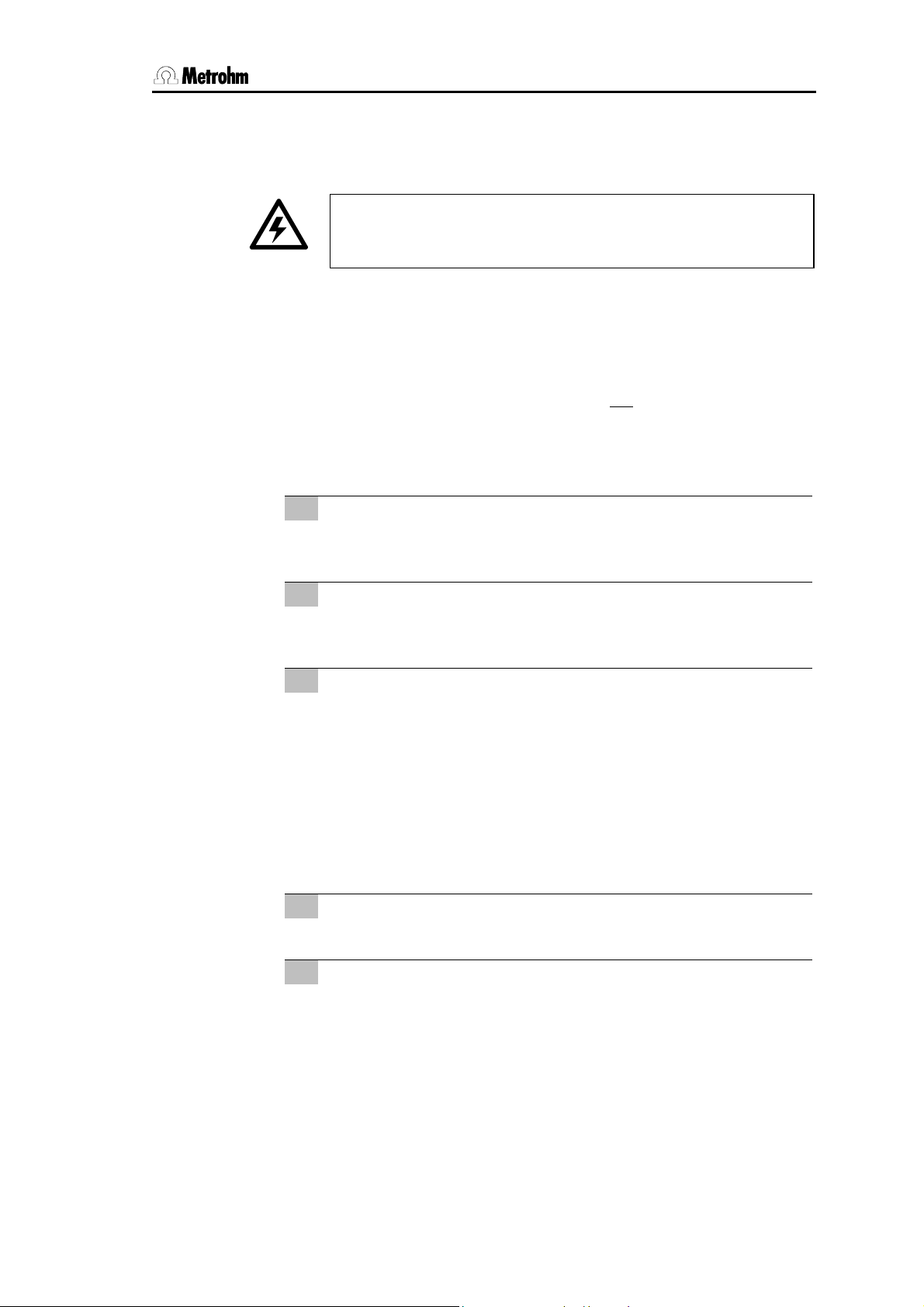

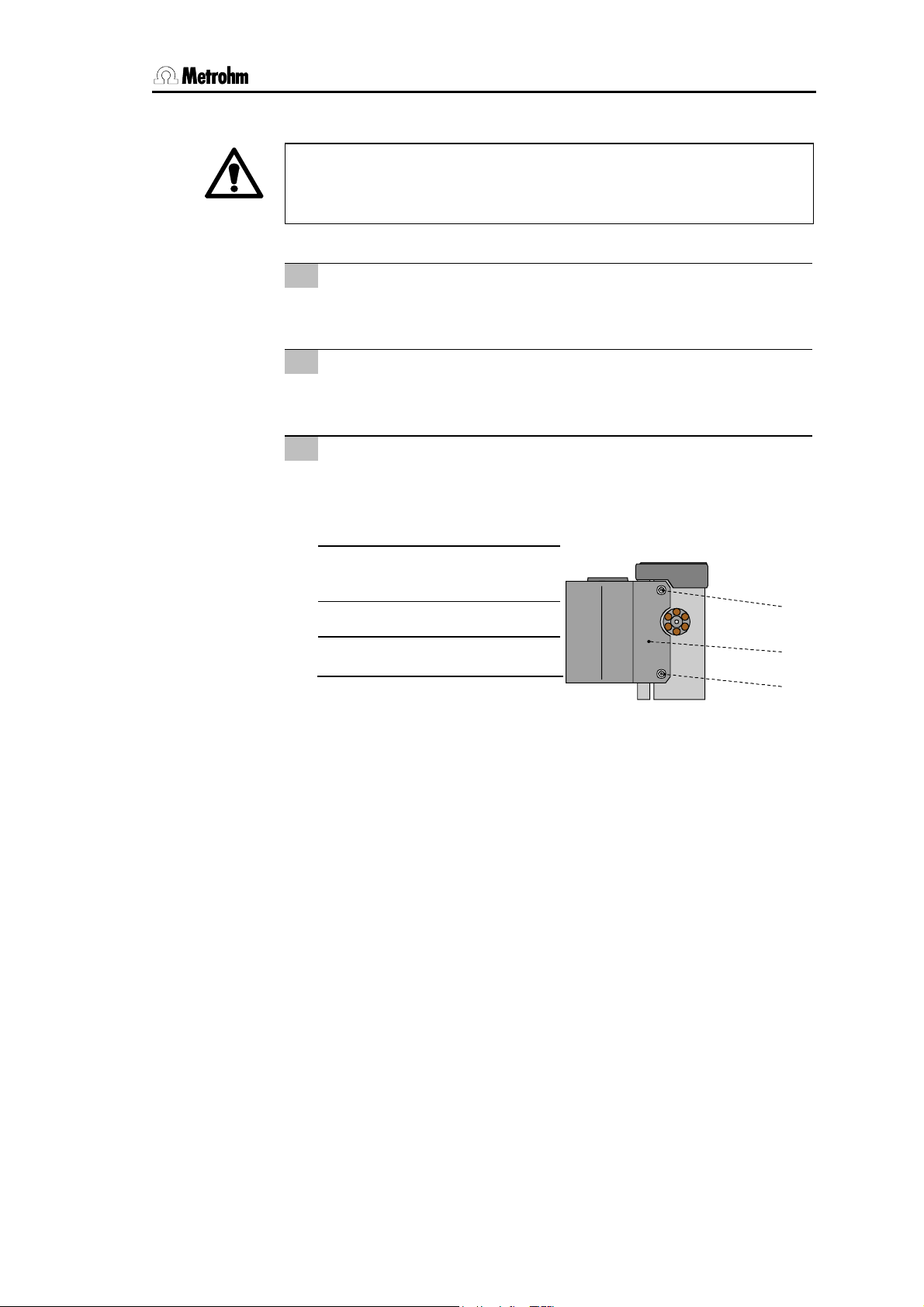

2.2 Mains connection

23

22

21

2.2.2 Fuses

100 – 120 V

220 - 240 V

One of the two fuses 0.5 A/slow-blow for 100…120 V or 0.25

A/slow-blow for 220…240 V is installed in fuse holder

813 Compact Autosampler as standard

Ensure that the instrument is never put into operation with fuses

of another type, otherwise there is danger of fire!

220 – 240 V

100

-

120 V

100 - 120 V

220 - 240 V

Fig. 4 Setting the mains voltage

21 Fuse holder

22

Mains connection plug

23

Mains switch

21

of the

For checking or changing fuses, proceed as described in section

2.2.2.

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin.

If a different plug has to be fitted, the yellow/green lead (IEC

standard) must be connected to protective earth (protection class

1).

Any break in the earthing inside or outside the instrument can

make it a hazard!

Mains connection

Plug the mains cable into mains connection plug 22 of the 813

Compact Autosampler (see Fig. 4).

8

813 Compact Autosampler

Page 15

2 Installation

2.2.4 Switching the instrument on/off

The 813 Compact Autosampler is switched on and off using the

mains switch

23

.

2.3 Attaching the accessories

For attaching the accessories at the 813 Compact Autosampler,

proceed in the order described below.

2.3.1 Connecting the keyboard

Connecting the keyboard

1

Connect the 6.2142.110 keyboard

to the keyboard connection

"Keyboard". For disconnection,

press the plug together slightly on

both sides.

Switch on the instrument

2

Switch on the 813 Compact

Autosampler with mains switch

The instrument is initialized and

the lift is raised completely. The

green LED lights up.

2.3.2 Installing the plug cover

28

Type 1.760.001 0 Nr.

0010/01104

Keyboard

Made by Metrohm Herisau Switzerland

23

.

Fig. 5 Keyboard connection

813 Compact Autosampler

To prevent any contamination of the mains and remote connection by spilled solvents or chemicals, the 6.2752.010 plug cover

must always be installed when operating the 813 Compact

Autosampler!

Install the plug cover

above mains connection plug

20

in the corresponding guide groove

22

and remote connection 19 (see

Fig. 1 and Fig. 2).

9

Page 16

2.3 Attaching the accessories

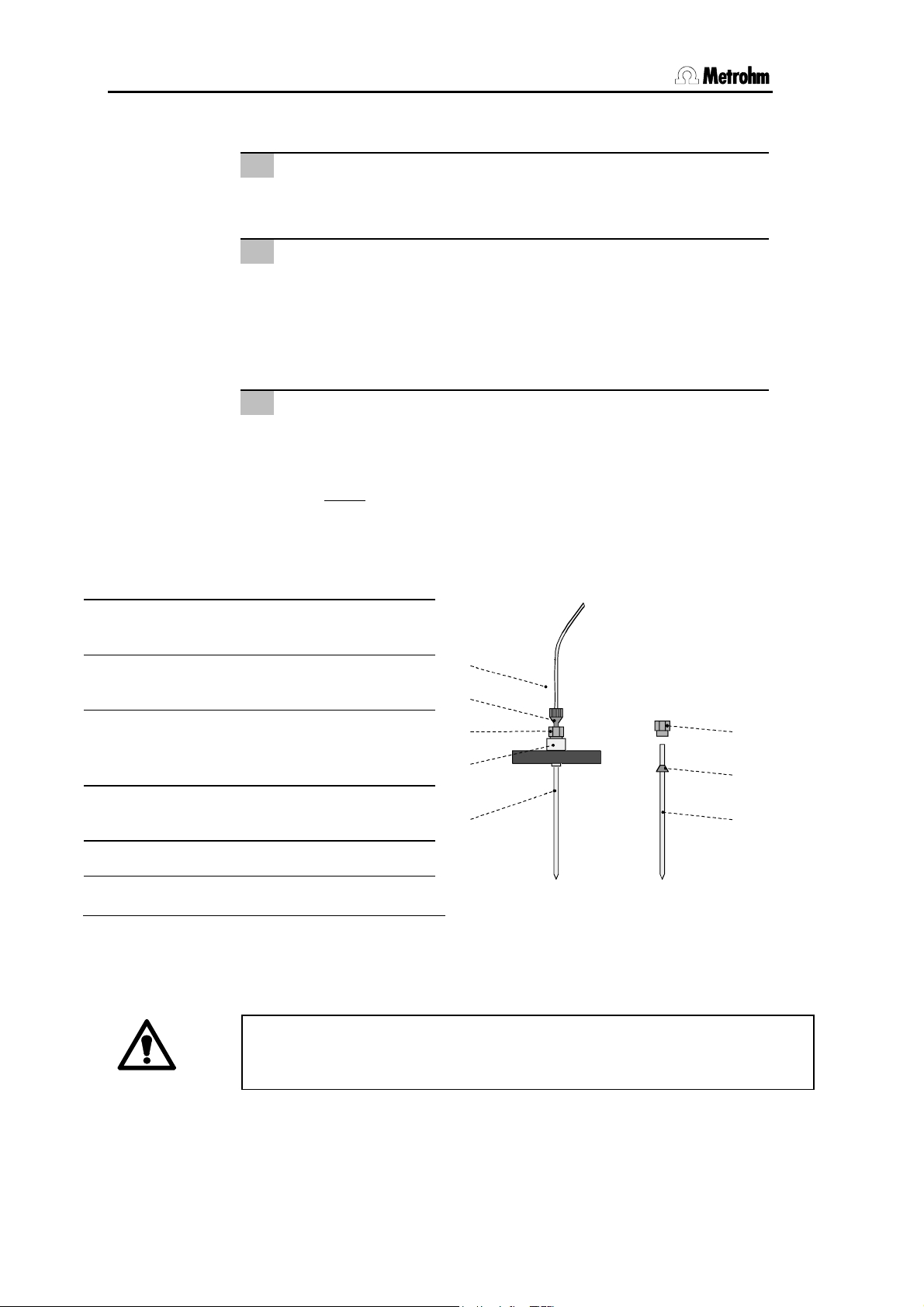

2.3.3 Installing the needle

Remove PEEK compression fitting 5

1

Remove PEEK compression fitting 5 screwed onto the needle

holder

Insert needle

2

Fix needle

3

4

.

• Needle

6.1835.010 PEEK tube) is inserted a short distance into the

opening of steel holder

• Push PEEK round seal

smaller end of the seal must face upwards.

• Screw PEEK compression fitting

pressing needle

• Tighten compression fitting

(never

2

(6.1835.010 PEEK needle or 6.1835.020 or

4

.

29

over needle 2 from above. The

5

into steel holder 4 while

2

gently upwards from below.

5

in steel holder 4 by hand

use tools!).

2 PEEK needle (6.1835.010) or PEEK

tube (6.1835.020 or 6.1835.030)

4 Steel holder (4.766.4330)

(part of 6.2833.000 Needle holder)

5 PEEK compression fitting

(4.766.4320)

(part of 6.2833.000 Needle holder)

6 PEEK compression fitting

(6.2744.010)

7 PEEK capillary (6.1831.050)

29 PEEK ferrule

If you are using the 6.1835.020 or 6.1835.030 PEEK tube as needle, the

sample tubes must not be sealed with caps because they cannot be

pierced by the PEEK tube and this could damage the tube!

7

6

5

4

2

Fig. 6 Needle installation

5

29

2

10

813 Compact Autosampler

Page 17

2 Installation

2.3.4 Installing the splash protection

To avoid any danger of injury by the needle, the 6.2751.070 splash

protection must always be installed when operating the 813 Compact

Autosampler!

Remove holding screws

1

Remove the holding screws 16 and the washer mounted on the

screw threads

Remove protective film from splash protection

2

Remove the plastic film glued on both sides of the splash

protection

Install splash protection

3

Attach splash protection 1 onto the screw threads 9 and 16 at

the tower

using the 6.2621.100 Allen key.

9

at tower 18 using the 6.2621.100 Allen key.

1

.

18

and fix it with the holding screws 9 and the washer

1 Splash protection

6.2751.040

9 Holding screw

16 Holding screw

9

1

16

Fig. 7 Installing the splash protection

813 Compact Autosampler

11

Page 18

2.3 Attaching the accessories

2.3.5 Placing the sample rack

Place sample rack

1

Place sample rack 24 on the

turntable of the 813 Compact

Autosampler acc. to Fig. 8.

Initialize rack

2

Press <RESET> to move the

rack to the home position, in

which the magnetic code can

be read (coding magnet 30).

30

2.3.6 Adjusting the sample rack

If a new sample rack is placed on the 813 Compact Autosampler

for the first time, it must be adjusted. Make sure you have

mounted a steel needle or a PEEK needle before. Proceed as follows:

Place sample rack

1

Place empty sample rack 24 on the turntable of the 813 Compact Autosampler and switch off the instrument.

Switch on the instrument

2

Keep the <HOLD> key pressed and simultaneously press the

mains switch on the right hand side of the 813 Compact Autosampler. The instrument is initialized and the needle is placed

above rack position 1. Press the <START> key. The green LED

is now blinking twice.

Fig. 8 Sample rack placing

12

813 Compact Autosampler

Page 19

2 Installation

Check needle position

3

• Press <HOLD

upper level of the sample rack

> until the needle 2 is about 1 cm above the

24

.

• Check needle position: If the needle 2 cannot be lowered

unhindered through the upper hole of the rack position 1,

continue directly with point 4.

• Press <HOLD> once and continue lowering the needle by

pressing <

• Check needle position: If the needle

HOLD

> again until the needle 2 stops.

2

points to the middle of

lower hole of the rack position 1, the sample rack must not be

adjusted (continue directly with point 5).

Adjusting the sample rack

4

• Loosen the four adjusting screws

33

on the lower level of the

sample rack using the 6.2621.100 Allen key .

• Carefully turn the two upper levels of the sample rack

hand until the lowered needle

2

is exactly in the middle of the

27

by

lower hole at the rack position 1.

• Tighten the adjusting screws

Move to rest position

5

33

.

Press <STOP> twice to move the sample rack to the initial

position.

813 Compact Autosampler

13

Page 20

2.3 Attaching the accessories

2.3.7 Tubing connections

Pump tubings are consumable material with a lifetime which

depends on the contact pressure (see section 4.4 Maintenance

and servicing). This is why the tubing cartridges should be

raised completely by loosening snap-action lever 15 on the

right-hand side if the pump is to remain switched off for a

considerable length of time (the set contact pressure remains

unchanged).

The 6.1826.0X0 pump tubing is made of PVC and must not be

used for rinsing with solutions which contain acetone. In such

cases, rinse with different pump tubing or a different pump.

For transferring the sample from the 813 Compact Autosampler

to an injection valve the following tubing connections must be

made:

Install pump tubing

1

• Release tubing cartridge

pressing down snap-action lever

mounting pin

9).

• Press contact pressure lever

as far as it will go.

• Insert pump tubing

Fig. 9. The black stopper

ing holder on the left-hand side of the tubing cartridge.

• Place the tubing cartridge

down on the right-hand side until snap-action lever

into position on holding clamp

formed in the pump tubing.

Connection needle – pump tubing

2

• Mount a PEEK compression fitting

PEEK capillary

• Screw the PEEK capillary

6

on to the PEEK compression fitting 5 already mounted on

needle holder

• Screw a coupling

the other end of PEEK capillary

• Push coupling

(see Fig. 9).

10

on the 813 Compact Autosampler (see Fig.

7

.

4

(see Fig. 9).

31

31

on to the inlet end of the pump tubing 8

11

from holding clamp

13

8

in the tubing cartridge 11 as shown in

32

must click into the correspond-

11

on mounting pin 10 and press

7

with the PEEK compression fitting

on to the PEEK compression fitting at

14

by

15

and remove it from

on the tubing cartridge down

15

clicks

14

. Take care that no kinks are

6

on both ends of the

7

.

14

813 Compact Autosampler

Page 21

7 31 8 32 11 13 32 31 1715 66

2 Installation

Fig. 9 Installing the pump tubing

6

PEEK compression fitting

6.2744.010

7

PEEK capillary 6.1831.050

8

Pump tubing 6.1826.040

11

Tubing cartridge 6.2755.000

13

Contact pressure lever

15

Snap-action lever

17

PEEK capillary 6.1831.060

or 6.1822.410

31

Coupling 6.2744.030

32

Stopper (black)

2.3.8 Tubing connection to Metrohm 761 / 790 IC–Systems

Connection pump tubing – injection valve

3

• Use a 6.2744.010 PEEK compression fitting and a 6.2744.030

coupling to tighten the 6.1831.060 PEEK capillary

pump tubing

• Loosen the screw thread of the outer connector of the suction

tubing inside the Ion chromatograph (see the Ion chromatograph's user manual).

• Replace the suction tubing of the Ion chromatograph with

PEEK capillary

front side of the housing.

• Use a 6.2744.010 PEEK compression fitting to tighten the

capillary to the connector "1" of the injection valve.

8

.

17

. Pass it through the outer connector of the

17

to the

813 Compact Autosampler

Tubing connection injection valve – waste

4

• Remove the coupling and the 6.2744.010 compression fitting

from syringe tubing.

• Lead the free end of the syringe tubing to the waste container and fix in place.

15

Page 22

2.3 Attaching the accessories

p

2.3.9 Tubing connection to a Metrohm 747 VA Stand

Connection Pumpschlauch – VA Stand 747

3

• Use a 6.2744.010 PEEK compression fitting and a 6.2744.030

coupling to tighten the 6.1831.060 PEEK capillary

pump tubing

8

.

To keep the dead volume as small as possible shorten the

pump tubing to a suitable length.

Measuring head of the 747 VA Standes

4

• Insert the other end of the PEEK capillary

17

opening of the Measuring head of the VA Stand and fix it

with a 4.420.2580 fitting screw.

17

to the

into a threaded

illary

Metrohm

6.1822.410 PEEK ca

747

Fig. 10 Connection of a 747 VA Stand

waste elektrolyte

rinsing

sample

gassing /

4-way-micro tip

vent

Fig. 11 Measuring head of the747 VA Stand

2.3.10 Tubing connection to a Metrohm Computrace 757

Install tubing connections 813 Compact Autosampler – 757 VA

Computrace as shown above for the 747 VA Stand. See the 757

VA Computrace user manual for more details.

16

813 Compact Autosampler

Page 23

2 Installation

2.4 Instrument connections

2.4.1 Remote interface

External devices can be connected to the 25 pin remote connection (see Fig. 1). The remote line Input 2 (pin 22, see section 4.3

Technical description) allows the 813 Compact Autosampler to

get synchronized with an other instrument.

Connecting instruments to the 813 Compact Autosampler requires Metrohm cables. Otherwise a safe signal transmission

may not be guaranteed.

Before an external device is connected to remote connection

22

the 813 Compact Autosampler must always be switched off

using mains switch

26

!

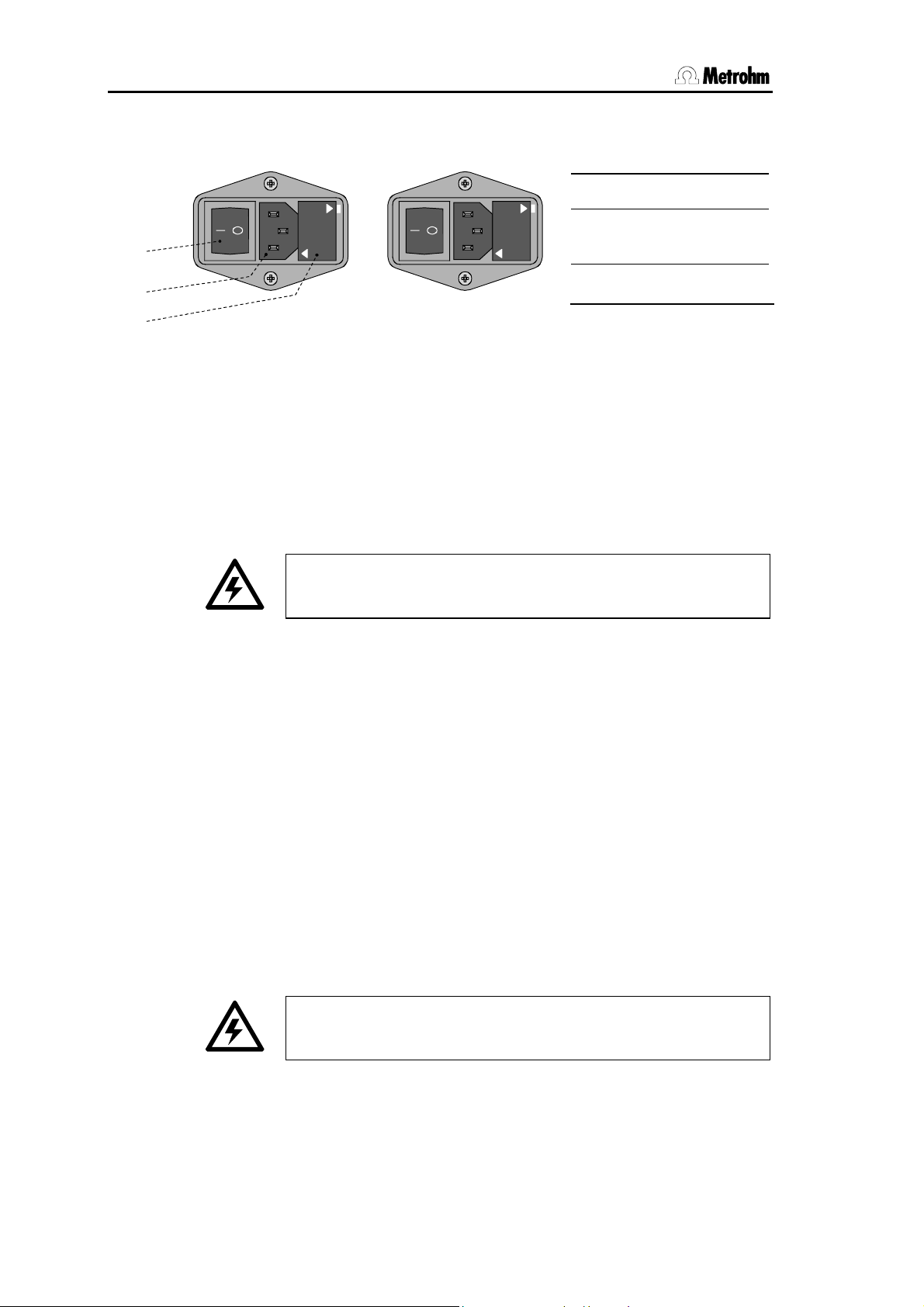

2.4.2 Interconnection with Metrohm IC systems

The 813 Compact Autosampler is connected to a Metrohm IC

system (761 Compact IC or 790 Personal IC) using the 25 pin

6.2141.130 Remote cable.

761 / 790

813

Fig. 12 Interconnection with 761 or 790 IC System

The interconnection of a 813 Compact Autosampler with a modular Metrohm IC System (IC Detector 732, IC Separation Center

733 …) can be done in different ways. Depending on the individual instrument combinations you need a 6.2141.130 or

6.2125.090 Remote cable to connect the 813 Compact Autosampler to a 732 IC Detector. A 6.2125.120 Remote adapter may

be required as well. See the user manual of your IC System or

contact your Metrohm distributor for more details.

6.2141.130 cable

813 Compact Autosampler

17

Page 24

2.4 Instrument connections

Example for the interconnection of a modular Metrohm IC System:

732

733

6.2125.090 cable

6.2125.090 cable

6.2125.060 cable

752

709

753

813

6.2143.210 cable

6.2141.110 cable

6.2125.120 adapter

6.2143.200 cable

Fig. 13 Interconnection with a modular Metrohm IC System

2.4.3 Interconnection with a Metrohm 746 VA Trace Analyzer

The 813 Compact Autosampler is connected to a Metrohm 746

VA Trace Analyzer with 747 VA Stand using the 25 pin 6.2141.020

Remote cable. Connect the Remote cable to the 'Control lines'

socket of the Trace analyzer.

813

Made by Metrohm Herisau Switzerland

Type 1.747

External Bus Address

Kabel 6.2141.020

746

Control Lines

Dos. 1

External Bus

Dos. 3

Dos. 2

Dos. 4

RS 232 Interface 1

RS 232 Interface 2

Printer

Reset

Fig. 14 Interconnection with a Metrohm 746 VA Trace Analyzer

230V

2A(TH)

0

I

115V

230V

18

813 Compact Autosampler

Page 25

2 Installation

2.4.4 Interconnection with a Metrohm 757 VA Computrace

You need a 6.2141.150 Remote cable to interconnect a 813

Compact Autosampler with a Metrohm VA Computrace 757, see

below.

6.2141.080 cable

765

813

757

6.2141.150 cable

Fig. 15 Interconnection with 757 VA Computrace

2.4.5 Interconnection with other instruments

The Metrohm 813 Compact Autosampler can be connected to

other Metrohm instruments or instruments of other equipment

manufacturers. It is strongly recommended to use a parallel

Metrohm 25-pin Remote cable (6.2141.130 or 6.2141.020) for the

interconnection to function properly. The parallel interface of the

other instruments has to fulfill the electrical requirements of the

Metrohm Remote interface, see 4.3 Technical specifications.

The method sequences of the Metrohm 813 Compact Autosampler require trigger signals (pulses) via the Remote connection. A

trigger signal will be accepted, whenever a negative slope (TTL

voltage) or a negative pulse (min. duration 200 ms) on Remote

input line 2 (pin 22) is recognized, see section 4.3 Technical

specifications.

731

772

772

813 Compact Autosampler

19

Page 26

3.1 Keyboard functions

3 Operation

3.1 Keyboard functions

The 813 Compact Autosampler provides three keys and two

LEDs, which may offer different functions depending on the current instrument status.

After switching on the instrument the readyness of the 813

Compact Autosampler is displayed by lighting up of the green

LED.

Function of the keys

START

RESET

STOP

HOLD

Starts processing of a sample series.

Stops processing of a sample series or initializes the 813

Compact Autosampler (by pressing twice).

Interrupts processing of a sample series, green LED blinks.

An interrupted process can be continued with <START>.

If using different proceedings (single injections, double or triple

injections), you have to select the appropriate method before

starting a sample series.

Depending on the size of the sample tubes and the desired lift height

for the suction of the sample solution the work position for the

needle has to be set before starting a sample series.

20

Read the following pages to learn how to configure the 813 Compact Autosampler.

813 Compact Autosampler

Page 27

3 Operation

3.2 Configuration

To select a method or to define the work position switch on the

813 Compact Autosampler while holding down the <HOLD>

key. The green LED blinks once a second while you can enter the

desired settings.

Keyboard functions for configuration:

(after Power on while <HOLD> depressed, green LED

blinks)

START

HOLD

RESET

STOP

Accepts the setting of a value and moves on to the next value.

Selection of method or manual lift movement for the definition of

the work position.

Cancels a setting or closes the configuration mode after a

settings is accepted with <START>.

Four different Autosampler methods are available. They

apply to the following tasks:

Single injection with air gap in after each determination, the

needle will be drawn out of the sample.

Single injection without air gap, the needle rests in the sam-

ple during the determination.

Double injection of each sample, no air gap, the needle re-

mains in the sample during the determination.

Triple injection of each sample, no air gap, the needle re-

mains in the sample during the determination.

Before running the 813 Compact Autosampler for the first time,

the work position of the lift has to be set correctly. The work

position defines the position of the suction needle while aspirating the sample. It depends mainly from the size of the sample

tubes.

813 Compact Autosampler

21

Page 28

3.2 Configuration

For setting the work position place a filled sample tube on the

sample rack of the Autosampler on rack position 1.

The needle should remain dipped in the sample solution during

the aspiration interval or reach the bottom of the sample vial, depending on the application.

Press <START> to accept a setting. To cancel a setting press

<STOP>. Press <STOP> twice to abort the configuration procedure.

The configuration procedure

Key LEDs Explanation

HOLD

+

"Power ON"

HOLD

START

HOLD

START

green 1*

red 1-4*

green 1*

green 2*

red blinks

green 2*

blinks

In order to start the configuration procedure the

<HOLD> key must be pressed while the Autosampler is

switched on.

The green LED lights up once to show that the configuration procedure is active. The method can now be

selected.

When the <HOLD> key is pressed the red LED blinks

once for the first method. Each time <HOLD> is

pressed again the next method is selected up to method

4, then method 1 again..

<START> accepts the setting. The green LED blinks

twice. The working position of the lift can now be

set.

When the <HOLD> key is pressed the lift can be

moved manually. Each further time the <HOLD> key is

pressed the direction in which the lift moves is altered. In

this way the working position can be set accurately.

<START> accepts the setting. The working position is

stored. The configuration procedure is now complete. It

can be restarted by pressing <HOLD> in order to select

the method.

RESET

STOP

lights up

The configuration procedure is terminated with

<STOP>. When the green LED is illuminated the 813

Compact Autosampler is in the basic state and is ready

to process a series of samples.

See next page for a figure of the whole configuration process.

22

813 Compact Autosampler

Page 29

3 Operation

3.2.1 Course of configuration

Power on + <HOLD>

Init

<STOP>

Select method 1...4

<HOLD>

<HOLD>

<START>

<STOP>

<HOLD>

<HOLD> <HOLD>

<START>

Set work position

<START>

<STOP>

(move lift)

<HOLD>

<HOLD>

<STOP>

Init

813 Compact Autosampler

Ready

Ready

Fig. 16 Configuration

If you just want to select a method:

1. Switch off Autosampler.

2. Press <HOLD> and simultaneously switch on Autosampler.

The green LED blinks.

3. Press <HOLD> again, to select method 1. The red LED

blinks slowly. To select method 2 press <HOLD> again. The

red LED blinks double times.

To select method 3 or 4 press <HOLD> again. The red LED

will display the selected method by the blinking frequency.

23

Page 30

3.3 RAM initialization

4. Accept the selected method with <START>.

5. To return to the basic state, press the <STOP> key.

If you just want to define the work position:

1. Switch off Autosampler .

2. Press <HOLD> and simultaneously switch on Autosampler.

The green LED blinks.

3. Press <START>. The green LED blinks twice.

4. Press <HOLD> to run the lift downward. The red LED

slowly. Press <HOLD> again and again to set the work position exactly. Each time the <HOLD> key is pressed, the direction of the lift movement is reversed. The PEEK needle

should be immersed deep enough to assure a trouble-free

aspiration of the sample or. Depending on your application

you may want to aspirate tho whole sample. In the latter case

drive the lift down until the needle reaches the bottom of the

sample vial.

5. The lift position set can be accepted with the <START> key.

6. Reestablish basic state of the 813 Compact Autosampler by

pressing the <STOP> key.

3.3 RAM initialization

The internal software of the 813 Compact Autosampler may be

initialized to reset all instrument settings after serious malfunctions, which should be very scarce of course. All settings (including the not accesible ones) will be reset to factory defaults.

Initialization can be done by pressing all keys simultaneously

while switching on the instrument.

It may be appropriate to initialize the 813 Compact Autosampler

before using it the first time.

START HOLD STOP

Method selection and the definition of the working position has to

be redone after RAM initialization.

RESET

and "Power on"

24

813 Compact Autosampler

Page 31

3 Operation

3.4 The methods

All methods of the 813 Compact Autosampler make use of the

built-in peristaltic pump to aspirate the sample and to fill the

sample loop of the Ion chromatograph connected. The pump duration is controlled by the time program of the Ion chromatograph's PC software by sending Remote signals to the Autosampler.

The number of samples to be processed is to be set in the sample queue of the control software. The Autosampler should be

stopped manually after processing the last sample.

Method 1 (detailed command sequence, see section 4.2 Se-

quences)

Single determination with air gap after each run, needle lifted after

sample transfer.

Sequence:

1. Await first Remote signal of the instrument.

2. Get sample tube and immerse needle.

3. On receiving second Remote signal, switch on the peristaltic

pump. Sample is transferred.

4. Await third Remote signal. The instrument starts its determination.

5. Peristaltic pump is switched off after 12 s.

6. Raise needle out of sample and aspirate air for 6 s.

Method 2

quences)

Single determination, no air gap, needle remains in sample after

sample transfer.

Sequence:

1. Await first Remote signal of the instrument.

2. Get sample tube and immerse needle.

3. On receiving second Remote signal, switch on the peristaltic

pump. Sample is transferred.

4. Await third Remote signal. The instrument starts its determination.

5. Peristaltic pump is switched off after 12 s.

(detailed command sequence, see section 4.2 Se-

813 Compact Autosampler

25

Page 32

3.4 The methods

Method 3

Double determination of each sample, no air gap, needle remains

in sample after sample transfer.

Sequence:

1. Await first Remote signal of the instrument.

2. Get sample tube and immerse needle.

3. On receiving second Remote signal, switch on the peristaltic

pump. Sample is transferred.

4. Await third Remote signal. The instrument starts its determination.

5. Peristaltic pump is switched off after 12 s.

6. Await first Remote signal of the instrument again.

7. On receiving second Remote signal, switch on the peristaltic

pump. Sample is transferred.

8. Await third Remote signal. The starts the second determination.

9. Peristaltic pump is switched off after 12 s.

(detailed command sequence, see 4.2 Sequences)

Method 4

Triple determination of each sample, no air gap, needle remains in

sample after sample transfer.

Sequence:

1. Await first Remote signal of the instrument.

2. Get sample tube and immerse needle.

3. On receiving second Remote signal, switch on the peristaltic

pump. Sample loop is transferred.

4. Await third Remote signal. The instrument starts its determination.

5. Peristaltic pump is switched off after 12 s.

6. Await first Remote signal of the instrument again.

7. On receiving second Remote signal, switch on the peristaltic

pump. Sample is transferred.

8. Await third Remote signal. The instrument starts the second

determination.

9. Peristaltic pump is switched off after 12 s.

10. Await first Remote signal of the IC again.

11. On receiving second Remote signal, switch on the peristal-

tic pump. Sample is transferred.

12. Await third Remote signal. The instrument starts the third

determination.

13. Peristaltic pump is switched off after 12 s.

(detailed command sequence, see 4.2 Sequences)

26

813 Compact Autosampler

Page 33

3 Operation

3.5 The Metrohm IC control software

To use the 813 Compact Autosampler with a 761 Compact IC or

a 790 Personal IC one has to create a time program. First of all the

IC has to send a Remote signal (Remote line 3) to synchronize

the command sequence (first Remote signal) of the 813 Compact

Autosampler. After that the injection valve is switched to 'Fill' position. Then a second Remote signal starts the filling of the sample

loop. The pump duration for filling the sample loop is defined by

the third Remote signal. After sending this Remote signal the injection valve is switched to 'Inject' position immediately which

starts the data aquisition. During sample injection the peristaltic

pump of the 813 Compact Autosampler is still running. 12 s after

receiving the Remote signal the Autosampler will stop the pump.

Fig. 17 Time program of the IC control software

3.5.1 Operational conditions

To ensure a correct interconnection (Autosampler – Ion chromatograph), the following conditions must be met:

• When the Ion chromatograph is operational the 813 Compact Autosampler hast to be started before the 'Sample

Queue' of the IC.

• When using the 761 Compact IC the initial state of the Remote line 3 has always to be set to 0 (set

ues: Remote line 3 = 0

813 Compact Autosampler

).

System startup val-

27

Page 34

3.6 Modular Metrohm IC System 732/733

3.6 Modular Metrohm IC System 732/733

The 813 Compact Autosampler can be controlled directly by a

Metrohm 732 IC Detector or by a PC control software, such as the

Metrohm IC Net 2.0 using the remote control lines of the 732 IC

Detector. See the 732 IC Detector user manual for details or read

the IC Net 2.0 documentation.

3.7 Metrohm 746 VA Trace Analyzer

Using a 813 Compact Autosamplers with a 746 VA Trace Analyzer require modified command sequences and monitoring settings.

Between each sample determination a rinsing procedure for the

tubings has to be executed. For this purpose place a sample

tube containing rinsing solution on each second (even) rack position. The samples to be determined have to be placed between

those rinsing tubes. This reduces the amount of a sample series

to 18 samples max.

3.7.1 Monitoring

The number of samples of a series is defined on the monitoring

page of the 746 VA Trace Analyzer, see below.

Auto.samples on 18 of 160

Auto.batch on 0 of 18

Start interval 0.0 h

3.7.2 Command sequence

A command sequence of the 746 VA Trace Analyzer has to contain explicit trigger signals for the 813 Compact Autosampler that

are to be sent via the Remote output line 2. Use the 'SETCTRL'

command to send the required pulses, see line 4 and 5 of the example method on the next page.

28

813 Compact Autosampler

Page 35

3 Operation

Sample method for the 746 VA Trace Analyzer:

Instructions t/s Main parameters Auxiliary parameters

------------- ----- ------------------------- ----------------------- 1 STIR Rot.speed 2000 /min

2 PURGE

3 SMPL/M V.fraction mL V.total L

4 SETCTRL 1.0 Code *****1** Message

5 SETCTRL Code *****0** Message

6 REM 30.0 move to sample

7 SETCTRL 1.0 Code *****1** Message

8 SETCTRL Code *****0** Message

9 REM 300.0 transfer sample

10 SETCTRL 1.0 Code *****1** Message

11 SETCTRL Code *****0** Message

12 REM stop pump

13 DOS>M Soln.name Buffer V.add 2.000 mL

14 PURGE 90.0

15 (ADD

16 STIR Rot.speed 2000 /min

17 PURGE 30.0

18 (REP

19 SEGMENT Segm.name NiCoAdSV

20 REP)1

21 ADD>M Soln.name Standard V.add 0.010 mL

22 ADD)2

23 RINSE Cycles 1 V.rinse 20.000 mL

24 SETCTRL 1.0 Code *****1** Message

25 SETCTRL Code *****0** Message

26 REM 20.0 move to rinsing position

27 SETCTRL 1.0 Code *****1** Message

28 SETCTRL Code *****0** Message

29 REM 300.0 rinse tubes

30 SETCTRL 1.0 Code *****1** Message

31 SETCTRL Code *****0** Message

32 REM stop pump

33 RINSE Cycles 1 V.rinse 40.000 mL

34 RINSE Cycles 2 V.rinse 15.000 mL

35 END

3.7.3 Conditions to be met

For the correct intercommunication of the 813 Compact Autosampler and the 746 VA Trace Analyzer the following conditions

must be met:

• Method 2 of the 813 Compact Autosampler has to be selected.

• Always start the method of the 813 Compact Autosampler

first, then you can start the 746 VA Trace Analyzer.

• Ensure that the control line 2 (Remote output 2) of the 746

VA Trace Analyzer is reset (inactive state) before you start the

sample series.

813 Compact Autosampler

29

Page 36

4.1 Error Messages

4 Appendix

4.1 Error Messages

An error occurring during a sample series is displayed by a blinking red LED. The number of flashes indicates the error number. If

an error occurs during processing of a sample series, the

changer will then be switched into the 'HOLD' state. The current

method has to be halted by pressing <STOP>.

The list of possible error messages and their causes:

1* RAM defect

3* battery low

6* changer low power

7* rack data missing

8* invalid rack code

10* raise lift first

12* changer overload

Call Metrohm-Service.

The battery for the permanent storage of the settings

must be replaced.

The power supply cannot deliver enough power for the

simultaneous operation of all components currently in

use (pump and lift).

No sample rack is in position or no rack data can be

found for the sample rack that is in place.

The rack code read by the changer could not be found

in the internal position tables.

Turning of a rack could not be carried out because the

lift was below the rest (shift) position.

Load or resistance too large to turn the rack.

30

813 Compact Autosampler

Page 37

4 Appendix

4.2 Sequences

The available Autosampler methods are described briefly in section 3.4 The following listings explain the sequences in detail.

Method 1

Single determination with air gap after each run, needle lifted after

sample transfer.

813 Compact Autosampler 813.0010

parameters

method 813_1

number of samples: *

>start sequence

1 SAMPLE: = 1

>sample sequence

1 SCN:Rm: *****1**

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 SCN:Rm: *****1**

5 PUMP 1.1 : on

6 WAIT 5 s

7 SCN:Rm : *****1**

8 WAIT 12 s

9 PUMP 1.1 : off

10 LIFT: 1 : 0 mm

11 PUMP 1.1 : 6 s

>final sequence

>changer settings

rack number 0

lift rate 12 mm/s

shift rate 20

shift direction: auto.

>manual stop

------------

¬ Program version

¬ Method name

¬ Number of samples unlimited

¬ First rack position

¬ Await 1st Remote signal

¬ Move next sample to tower

¬ Lift to work position / immerse needle

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for sample transfer

¬ Switch off pump

¬ Lift to rest position / raise needle

¬ Switch on pump for 6 seconds

------ Settings for changer functions --------------

813 Compact Autosampler

31

Page 38

4.2 Sequences

Method 2

Single determination, no air gap, needle remains in sample after

sample transfer.

813 Compact Autosampler 813.0010

parameters

method 813_2

number of samples: *

>start sequence

1 SAMPLE: = 1

>sample sequence

1 SCN:Rm: *****1**

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 SCN:Rm: *****1**

5 PUMP 1.1 : on

6 WAIT 5 s

7 SCN:Rm : *****1**

8 WAIT 12 s

9 PUMP 1.1 : off

>final sequence

>changer settings

rack number 0

lift rate 12 mm/s

shift rate 20

shift direction: auto.

>manual stop

------------

¬ Program version

¬ Method name

¬ Number of samples unlimited

¬ First rack position

¬ Await 1st Remote signal

¬ Move next sample to tower

¬ Lift to work position / immerse needle

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for sample transfer

¬ Switch off pump

------ Settings for changer functions --------------

32

813 Compact Autosampler

Page 39

4 Appendix

Method 3

Double determination of each sample, no air gap, needle remains

in sample after sample transfer.

813 Compact Autosampler 813.0010

parameters

method 813_3

number of samples: *

>start sequence

1 SAMPLE: = 1

>sample sequence

1 SCN:Rm: *****1**

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 SCN:Rm: *****1**

5 PUMP 1.1 : on

6 WAIT 5 s

7 SCN:Rm : *****1**

8 WAIT 12 s

9 PUMP 1.1 : off

10 SCN:Rm: *****1**

11 WAIT 5 s

12 SCN:Rm: *****1**

13 PUMP 1.1 : on

14 WAIT 5 s

15 SCN:Rm : *****1**

16 WAIT 12 s

17 PUMP 1.1 : off

>final sequence

>changer settings

rack number 0

lift rate 12 mm/s

shift rate 20

shift direction: auto.

>manual stop

------------

¬ Program version

¬ Method name

¬ Number of samples unlimited

¬ First rack position

¬ Await 1st Remote signal

¬ Move next sample to tower

¬ Lift to work position / immerse needle

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for 1st sample transfer

¬ Switch off pump

¬ Await 1st Remote signal again

¬ Waiting time

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for 2nd sample transfer

¬ Switch off pump

------ Settings for changer functions --------------

813 Compact Autosampler

33

Page 40

4.2 Sequences

Method 4

Triple determination of each sample, no air gap, needle remains in

sample after sample transfer.

813 Compact Autosampler 813.0010

parameters

method 813_4

number of samples: *

>start sequence

1 SAMPLE: = 1

>sample sequence

1 SCN:Rm: *****1**

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 SCN:Rm: *****1**

5 PUMP 1.1 : on

6 WAIT 5 s

7 SCN:Rm : *****1**

8 WAIT 12 s

9 PUMP 1.1 : off

10 SCN:Rm: *****1**

11 WAIT 5 s

12 SCN:Rm: *****1**

13 PUMP 1.1 : on

14 WAIT 5 s

15 SCN:Rm : *****1**

16 WAIT 12 s

17 PUMP 1.1 : off

18 SCN:Rm: *****1**

19 WAIT 5 s

20 SCN:Rm: *****1**

21 PUMP 1.1 : on

22 WAIT 5 s

23 SCN:Rm : *****1**

24 WAIT 12 s

25 PUMP 1.1 : off

>final sequence

>changer settings

rack number 0

lift rate 12 mm/s

shift rate 20

shift direction: auto.

>manual stop

------------

¬ Program version

¬ Method name

¬ Number of samples unlimited

¬ First rack position

¬ Await 1st Remote signal

¬ Move next sample to tower

¬ Lift to work position / immerse needle

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for 1st sample transfer

¬ Switch off pump

¬ Await 1st Remote signal again

¬ Waiting time

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for 2nd sample transfer

¬ Switch off pump

¬ Await 1st Remote signal again

¬ Waiting time

¬ Await 2nd Remote signal

¬ Switch on pump

¬ Waiting time

¬ Await 3rd Remote signal

¬ Waiting time for 3rd sample transfer

¬ Switch off pump

------ Settings for changer functions --------------

34

813 Compact Autosampler

Page 41

4 Appendix

4.3 Technical specifications

Dimensions Height: 0.50 m, Width: 0.28 m, Depth: 0.49 m

Weight 12.3 kg (incl. sample rack)

Material Housing: Metal case, multiple enameling

Splash protection: Polymethylmethacrylate (PMMA)

Sample rack: Polypropylene (PP)

Lift path ca. 125 mm

Lift Load: ca. 30 N

Stroke speed: 12 mm/s

Turntable Rotational speed: 20 angular degrees/s

Pump Pump type 1-channel peristaltic pump with

rotational speed of 20 /min

Pump capacity (with water, without counterpressure)

with 6.1826.040 pump tubing:

typ. 0.9…1.1 mL/min

(depends on contact pressure)

Pressure max. 1.5 bar (0.15 MPa)

Pump tubing material PVC (Tygon

Remote- Parallel interface for remote control by external devices

RS232 interface

t

p

Input:

t

>20 ms

p

t

Output:

I

p

t

V

= 40 V

CEO

= 20 mA

C

>200 ms

p

The +5 V supply line may by charged with 20 mA maximally.

)

+5V

active = low

inactive = high

active = low

inactive = high

813 Compact Autosampler

0 Vo lt

+5 Volt

Output 5

Output 3

Output 1

Output 12

Output 13

Input 0

Input 2

Input 4

Input 6

0 Vo lt

14 1

1325

Outp ut 6

Outp ut 7

Outp ut 4

Outp ut 2

Outp ut 0

Outp ut 8

Outp ut 9

Outp ut 1 0

Inp ut 1

Inp ut 3

Inp ut 5

Inp ut 7

Outp ut 1 1

35

Page 42

4.3 Technical specifications

Temperatures Nominal operating range 5...40 °C

at 20...80 % atmospheric humidity

Storage, transport –20...+60 °C

60 °C at atmospheric humidity <50%

50 °C " " <85%

40 °C " " <95%

Mains connection Voltage 100...120 V, 220...240 V

Frequency 50...60 Hz

Power consumption 40 VA

Fuse 0.5 AT (110 V), 0.25 AT (220 V)

Safety specifications

Construction / Testing According to IEC 1010 / EN 61010 /

UL 3101-1, protection class 1

Degree of protection IP 22

The Instructions for Use include information and warnings which

must be heeded by the user to assure safe operation of the instrument.

Electromagnetic compatibility (EMC)

Emitted interference

Standards met:

EN55011 (class B), EN55022 (class B), EN50081-1 01.92

Immunity to interference

Standards met:

IEC801-2/IEC1000-4-2 (class 4), IEC801-3/ IEC1000-4-3 (class 2),

IEC801-4/IEC1000-4-4 (class 3), IEC801-5/IEC1000-4-5 (class 2/3),

IEC801-6/IEC1000-4-6 (class 2), EN55011 (class B), EN55022 (class

B), EN50081-1/2 01.92, EN50082-1 01.92, EN61000-3, EN61316-1

03.97

36

813 Compact Autosampler

Page 43

4 Appendix

4.4 Maintenance and servicing

4.4.1 Maintenance by Metrohm service

is best done as part of an annual service performed by specialists

from the Metrohm company. If work is frequently performed with

caustic and corrosive chemicals, it may be necessary to shorten

the interval between servicing.

The Metrohm service department is always willing to offer expert

advice on the maintenance and servicing of all Metrohm instruments

4.4.2 Care of the unit

The 813 Compact Autosampler requires proper care and attention. Ex-cessive contamination of the instrument could possibly

lead to malfunctions and a shorter service life of the inherently

rugged mechanical and electronic parts.

Wipe up spilled chemicals and solvents immediately. The connectors (in particular the power supply) should be protected from

contamina-tion. The 813 Compact Autosampler should never be

operated without plug cover

The unit has been constructed in such a way as to virtually eliminate

the possibility of penetration of corrosive media into the interior of the

instruments. If such a situation does occur, disconnect the mains

plug of the 766 Compact Autosampler immediately to prevent extensive damage to the instrument electronics. Inform Metrohm service if

your instrument has been damaged in such a way.

The instrument must not be opened by untrained personnel. Please

comply with the safety notes in section 2.2.

4.4.3 Replacing the pump tubing

Pump tubings are consumable material with a limited lifetime and

should be replaced at regular intervals (approx. every 2 weeks

under continuous use).

813 Compact Autosampler

The working life of pump tubing depends to a considerable extent

on the contact pressure. This is why the contact pressure must

be correctly set as described in section 2.3.7. If the pump is to

remain switched off for a lengthy period of time the tubing cartridges should be raised completely by loosening snap-action

lever

15

on the right-hand side (the pre-set contact pressure re-

mains unchanged).

37

Page 44

4.4 Maintenance and servicing

To replace a pump tubing proceed as follows:

Remove old pump tubing

1

• Press contact pressure lever 11 on the tubing cartridge down

as far as it will go.

• Release tubing cartridge

ing down snap-action lever

10

pin

• Remove old pump tubing.

Insert new pump tubing

2

• Insert the new pump tubing

cartridge as shown in Fig. 9. The Stopper

the corresponding holder on the left-hand side of the tubing

cartridge.

• Place the tubing cartridge on mounting pin

down on the right-hand side until snap-action lever

into position on holding clamp

formed in the pump tubing.

at the 813 Compact Autosampler (see Fig. 1).

11

from holding clamp 14 by press-

15

and remove from mounting

8

(6.1826.040) in the tubing

32

must click into

10

and press

15

clicks

14

. Take care that no kinks are

Set contact pressure

3

• Press contact pressure lever

just starts to be drawn in. Then press contact pressure lever

upwards until it clicks once more to obtain optimal contact

pressure.

The 6.1826.0X0 pump tubing is made of PVC and must not be

used for rinsing with solutions which contain acetone. In such

cases, rinse with different pump tubing or a different pump.

13

upwards until the solution

38

813 Compact Autosampler

Page 45

4 Appendix

4.5 Warranty and conformity

4.5.1 Warranty

The warranty on our products is limited to defects that are traceable to material, construction or manufacturing error which occur

within 12 months from the day of delivery. In this case, the defects will be rectified in our workshops free of charge. Transport

costs are to be paid by the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not

covered by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty

period. For parts of outside manufacture insofar as these constitute an appreciable part of our instrument, the warranty stipulations of the manufacturer in question apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as

the absence of guaranteed features, the orderer has no rights or

claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if the goods show signs of transport damage after unpacking, the carrier must be informed immediately and a written

damage report demanded. lack of an official damage report releases Metrohm from any liability to pay compensation.

If any instruments and parts have to be returned, the original

packaging should be used if at all possible. This applies above all

to instruments, electrodes, burette cylinders and PTFE pistons.

Before embedment in wood shavings or similar material, the parts

must be packed in a dustproof package (for instruments, use of a

plastic bag is imperative). If open assemblies are enclosed in the

scope of delivery that are sensitive to electromagnetic voltages

(e.g. data interfaces etc.) these must be returned in the associated original protective packaging (e.g. conductive protective

bag). (Exception: assemblies with built-in voltage source belong

in a non-conductive protective packaging).

No warranty responsibility whatsoever will be accepted by

Metrohm for damage which arises as a result of non-compliance

with these instructions.

813 Compact Autosampler

39

Page 46

4.5 Warranty and conformity

4.5.2 Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well as to the standard specifications for security and

to system validation issued by the manufacturing company.

Name of commodity: 813 Compact Autosampler

System software: stored in ROMs

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

Technical information: Voltages:

100…120, 220…240 V

Frequency: 50…60 Hz

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

Electromagnetic compatibility

IEC 801-2 / level 3, IEC 801-3 / level 2, IEC 801-4 / level 3,

EN 55011 / class B, EN 55022 / class B, EN 50081-1/2 1992,

EN 50082-1 1997

Security specifications

IEC 1010, EN 61010, UL 3101-1

It has also been certified by the Swiss Electrotechnical Association (SEV), which

is member of the International Certification Body (CB/IEC).

The technical specifications are documented in the instruction manual.

The system software, stored in Read Only Memories (ROMs) has been validated

in connection with standard operating procedures in respect to functionality and

performance. The features of the system software are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for

quality assurance in design/development, production, installation and servicing.

Herisau, March 5, 2001

40

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

813 Compact Autosampler

Page 47

4 Appendix

Ionenanalytik • Analyse des ions • Ion analysis • Análisis iónico

813 Compact Autosampler

EU Declaration of conformity

The METROHM AG company, Herisau, Switzerland hereby certifies that the in-strument:

813 Compact Autosampler

meets the requirements of EC Directives 89/336/EWG and 73/23/EWG.

Source of the specifications:

EN 50081 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control

equipment

Description of the instrument:

Sample changer for automatic processing of sample series with ion chromatographic

methods

Herisau, March 5, 2001

813 Compact Autosampler

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

41

Page 48

4.6 Standard equipment

4.6 Standard equipment

Subject to changes! All dimensions

The following parts are included:

2.813.0010 Compact Autosampler (for IC applications)

Quant. Order No. Description

are given in mm.

2 6.1826.040 Pump tubing

made of PVC (Tygon

attached black-black stoppers;

i.d. = 0.76 mm, e.d. = 2.27 mm

1 6.1831.050 PEEK Capillary

Length = 40 cm

2 6.1831.060 PEEK Capillary

Length = 100 cm

1 6.2041.750 Sample rack

for 36 sample tubes 6.2743.050 (11 mL)

or 6.2743.040 (2,5 mL)

1 6.2122.0X0 Mains cable

to customers specifications:

Cable socket

Type IEC 320/C 13 Type SEV 12 (CH…)............................... 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…) .......................... 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) ...................... 6.2122.070

); with 2 firmly

Cable plug

150

0.5

400

1.59

1.59

0.5

42

1 6.2141.130 Connection cable (Remote)

Connection cable 813 Compact Autosampler – Compact IC 761,

Personal IC 790 or 732 IC Detector

1 6.2142.110 Keyboard

for 813 Compact Autosampler

1 6.2621.060 Open-end spanner

2 6.2621.090 Open-end spanner

5

⁄16"

1

⁄2"

94

147

813 Compact Autosampler

Page 49

4 Appendix

Quant. Order No. Description

1 6.2621.100 Allen key 3 mm

For Allen screws on sample rack

and for splash protection

1 6.1835.010 PEEK needle

For aspiration of solutions from

sealed sample tubes

SW3

63

20

1 6.2743.057 PP Sample tubes (11 mL)

For 6.2041.750 sample rack

set of 200

1 6.2743.077 PE Caps

For sealing the 6.2743.057 sample tubes

set of 200

1 6.2744.010 PEEK Compression fitting

For the connection of 6.1831.0X0 PEEK

capillaries or 6.1803.0X0 PTFE capillaries;

set of 5

1 6.2744.030 PEEK Coupling

Connection between 6.2744.010 PEEK compression fitting and 6.1826.0X0 pump tubing

set of 4

1 6.2751.070 Splash protection

Must be installed at the tower of the 813 Compact Autosampler.

1 6.2752.010 Plug cover

Must be installed at the 813 Compact Autosampler.

26

25

1 6.2755.000 Tubing cartridge

For peristaltic pump at 813 Compact Autosampler

1 8.813.1003 Instructions for Use (English)

for 813 Compact Autosampler

813 Compact Autosampler

43

Page 50

4.6 Standard equipment

2.813.0020 Compact Autosampler (for VA applications)

Quant. Order No. Description

2 6.1826.020 Pump tubing

made of PVC (Tygon

attached black-black stoppers;

i.d. = 0.76 mm, e.d. = 2.27 mm

1 6.1831.050 PEEK Capillary

Length = 40 cm

1 6.1822.410 PEEK Capillary 1x M6

Length = 120 cm

1 6.2041.750 Sample rack

for 36 sample tubes 6.2743.050 (11 mL)

or 6.2743.040 (2,5 mL)

1 6.2122.0X0 Mains cable

to customers specifications:

Cable socket

Type IEC 320/C 13 Type SEV 12 (CH…)............................... 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…) .......................... 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) ...................... 6.2122.070

); with 2 firmly

Cable plug

150

0.5

400

1.59

1.59

0.5

1 6.2142.110 Keyboard

for 813 Compact Autosampler

1 6.2621.060 Open-end spanner

2 6.2621.090 Open-end spanner

1 6.2621.100 Allen key 3 mm

For Allen screws on sample rack

and for splash protection

1 6.1835.030 PEEK tube

For aspiration of solutions from

open sample tubes

5

⁄16"

1

⁄2"

SW3

94

147

63

20

44

813 Compact Autosampler

Page 51

4 Appendix

Quant. Order No. Description

1 6.2743.057 PP Sample tubes (11 mL)

For 6.2041.750 sample rack

set of 200

1 6.2744.010 PEEK Compression fitting

For the connection of 6.1831.0X0 PEEK

capillaries or 6.1803.0X0 PTFE capillaries;

set of 5

1 6.2744.030 PEEK Coupling

Connection between 6.2744.010 PEEK compression fitting and 6.1826.0X0 pump tubing

set of 4

1 6.2751.070 Splash protection

Must be installed at the tower of the 813 Compact Autosampler.

1 6.2752.010 Plug cover

Must be installed at the 813 Compact Autosampler.

1 6.2755.000 Tubing cartridge

For peristaltic pump at 813 Compact Autosampler

26

25

1 8.813.1003 Instructions for Use (English)

for 813 Compact Autosampler

813 Compact Autosampler 45

Page 52

4.7 Optional accessories

4.7 Optional accessories

Order No. Description

6.1835.020 PEEK needle

For aspiration of solutions from open sample

tubes

1.5

1.5

6.1835.000 PEEK needle

For aspiration of solutions from open sample

tubes

6.2624.000 Steel needle

For aspiration of solutions from sealed sample

tubes

150

150

6.1831.040 PEEK capillary

Length = 15 cm

6.2833.000 Needle holder (1/8")

for PEEK needle 6.1835.010 and 6.1835.020

6.2833.010 Needle holder (1/16")

For steel needle 6.2624.000 and PEEK

needle 6.1835.000

6.2743.040 PP Sample tubes (2,5 mL)

For sample rack 6.2041.750

set of 2000

0.5

1.59

46

6.2743.047 PP Sample tube (2,5 mL)

For sample rack 6.2041.750

set of 200

813 Compact Autosampler

Page 53

4 Appendix

6.2743.050 PP Sample tube (11 mL)

For sample rack 6.2041.750

set of 2000

6.2743.077 PE Caps

For sealing the 6.2743.057 sample tubes

set of 200

6.2743.060 PE Caps

For sealing the 6.2743.0x0 sample tubes

set of 1000

6.2125.120 Adaptor for remote connection

with 5 connections for remote cables

6.2141.150 Connection cable (Remote)

Connection cable 813 Compact Autosampler – 757 Computrace/ 731

Relay Box/Dosimat

6.1826.020 Pump tubing

made of PVC (Tygon®); with two firmly attached

blue-blue stoppers;i.d. = 1.6 mm, e.d. = 2.27 mm.

For use with preconcentration columns.

150

400

813 Compact Autosampler 47

Page 54

4.7 Optional accessories

5 Index

<HOLD> key ..................... 5

<START> key .................... 5

<STOP> key.................... 5

6.1835.010 PEEK needle

Insertion ......................... 10

6.1835.020 PEEK tube

Insertion ......................... 10

6.2141.020 Remote cable

Connection..................... 18

6.2141.130 Remote cable

Connection..................... 17

746 VA Trace Analyzer

Interconnection .............. 18

A

Abort the configuration

procedure..................... 22

Accept setting................... 22

Accessories

Attaching.......................... 9

Adapter 6.2125.120

Ordering designation..... 47

Adjusting screws .............. 13

Adjusting the sample rack 13

Allen key 6.2621.100

Installing the splash

protection.................... 11

Ordering designation43, 44

Appendix........................... 30

Attaching the accessories .. 9

B

Battery............................... 30

C

Cable 6.2141.130

Ordering designation42, 44

Cable 6.2141.020

Interconnection .............. 19

Changer overload............. 30

Coding magnet................. 12

Configuration .................... 21

Connecting