Page 1

806 Exchange Unit

Manual

8.806.8003EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

806 Exchange Unit

Manual

8.806.8003EN 09.2012 ek/dm

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

Introduction 1

1

1.1 About the documentation ................................................... 1

1.1.1 Symbols and conventions ........................................................ 1

1.2 Safety instructions ................................................................ 2

1.2.1 Tubing and capillary connections ............................................. 2

1.2.2 Flammable solvents and chemicals ........................................... 2

1.2.3 Filling the dosing cylinder ........................................................ 3

1.3 Recycling and disposal ......................................................... 3

2 Construction of the 806 Exchange Unit 4

2.1 Total view .............................................................................. 4

2.2 Components of the 806 Exchange Unit .............................. 6

3 Installation 9

Table of contents

3.1 Setting up the instrument .................................................... 9

3.1.1 Packaging ................................................................................ 9

3.1.2 Checks .................................................................................... 9

3.1.3 Location .................................................................................. 9

3.2 Start-up .................................................................................. 9

3.2.1 Preparing the exchange unit .................................................... 9

3.2.2 Attaching the exchange unit .................................................. 10

3.2.3 Filling the tubings .................................................................. 12

3.2.4 Buret tips ............................................................................... 13

3.2.5 Removing the exchange unit ................................................. 14

3.3 Mounting the components ................................................ 14

3.3.1 Mounting the thermostat casing ............................................ 14

3.3.2 Mounting the flat stopcock ................................................... 16

3.3.3 Mounting the tubings on the flat stopcock ............................ 17

4 Mode of operation 19

4.1 Filling the dosing cylinder and dosing .............................. 19

5 Handling and maintenance 21

5.1 Care and upkeep ................................................................. 21

5.1.1 Disassembling the exchange unit ........................................... 21

5.1.2 Cleaning the cylinder and piston ............................................ 22

5.1.3 Assembling the exchange unit ............................................... 23

5.1.4 Flat stopcock blocked ............................................................ 24

806 Exchange Unit

5.2 Chemical resistance and materials .................................... 25

5.2.1 Solutions ............................................................................... 25

5.2.2 Body ...................................................................................... 25

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

5.2.3 Materials ............................................................................... 25

5.3

GLP - Validation .................................................................. 26

6 Troubleshooting 27

6.1 Problems ............................................................................. 27

7 Appendix 30

7.1 Buret data ........................................................................... 30

7.2 Dosing accuracy .................................................................. 30

7.2.1 Typical measurement deviation .............................................. 30

7.2.2 The ISO/EN/DIN standard 8655-3 ........................................... 31

8 Accessories 32

8.1 Scope of delivery ................................................................ 32

8.1.1 806 Exchange Unit 6.3026.xxx .............................................. 32

8.2 Optional accessories ........................................................... 34

Index 36

■■■■■■■■

IV

806 Exchange Unit

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 806 Exchange Unit ............................................................................ 4

Figure 2 806 Exchange Unit - Components ..................................................... 6

Figure 3 Thermostat casing ........................................................................... 15

Figure 4 Flat stopcock ................................................................................... 16

Figure 5 Dosing/Filling .................................................................................. 19

Table of figures

806 Exchange Unit

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

The 806 Exchange Unit is a versatile buret unit which can be operated

with various Metrohm dosing devices or titrators. The 806 Exchange Unit

is suitable for simple dosings or titrations.

Specifications concerning the exchange unit and the reagent can be

stored in the integrated data chip. This data can be read out and updated

by a suitable instrument.

1 Introduction

1.1

About the documentation

1.1.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

806 Exchange Unit

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

■■■■■■■■

1

Page 10

1.2 Safety instructions

1.2 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.2.1

Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.2.2 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

■■■■■■■■

2

806 Exchange Unit

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.2.3 Filling the dosing cylinder

CAUTION

If a buret tip is clogged, then it could happen that no liquid will be aspirated when the dosing cylinder is being filled. A vacuum can arise as a

result.

If you then remove the exchange unit from the instrument, the piston

could destroy the dosing cylinder.

Do not fail to loosen the tubing connections on the dosing cylinder

first, before you remove the exchange unit. This will eliminate the vacuum.

1 Introduction

1.3

Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

806 Exchange Unit

■■■■■■■■

3

Page 12

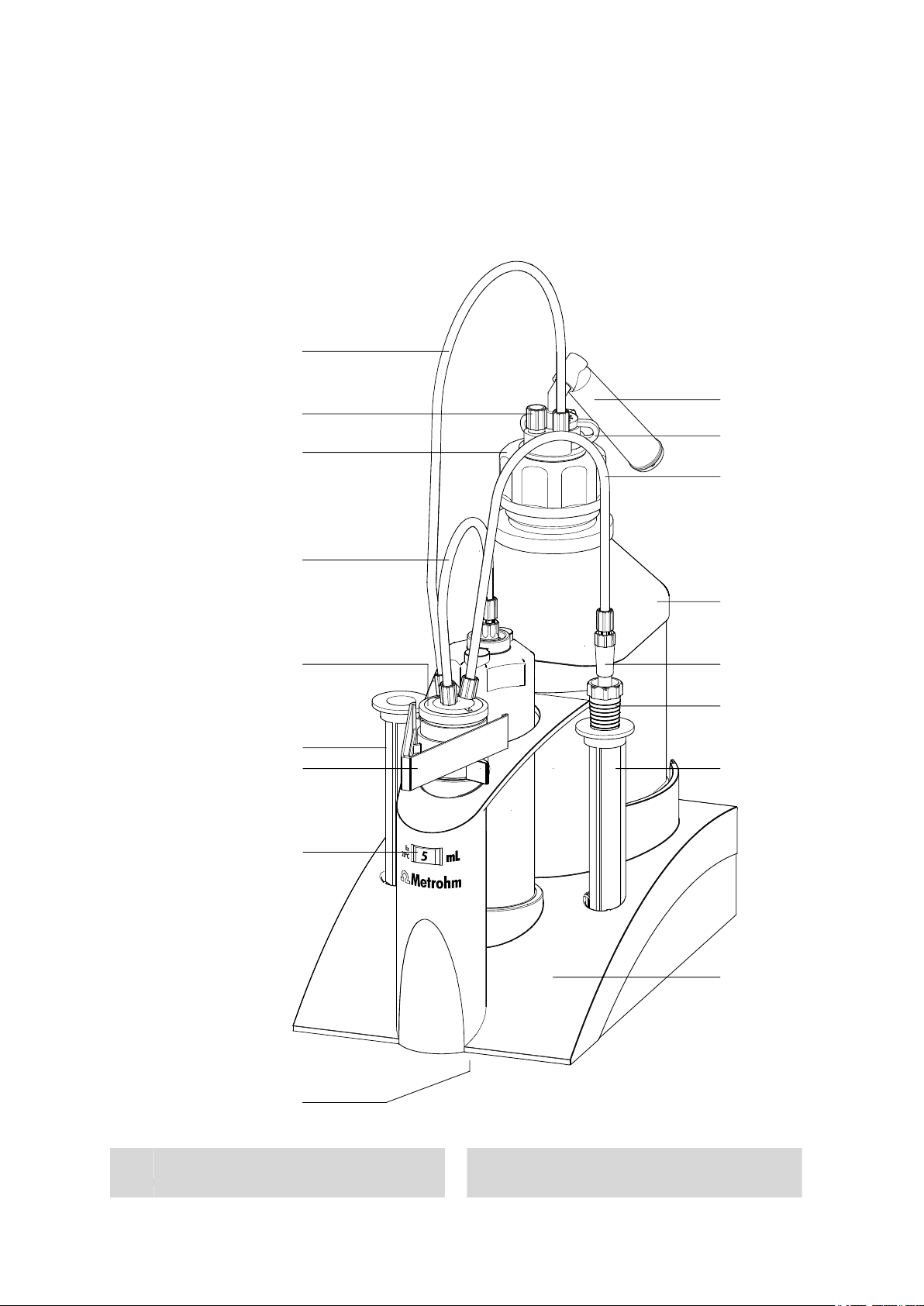

2.1 Total view

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

■■■■■■■■■■■■■■■■■■■■■■

2 Construction of the 806 Exchange Unit

2.1

Total view

Figure 1 806 Exchange Unit

1

■■■■■■■■

4

Tubing connection (6.1805.080)

Length 25 cm

Threaded stopper (6.1446.080)

2

806 Exchange Unit

Page 13

■■■■■■■■■■■■■■■■■■■■■■

2 Construction of the 806 Exchange Unit

Bottle attachment (6.1602.105)

3

Of PFA/PP, thread GL45

PCTFE/PTFE flat stopcock (6.1542.020)

5

Or ceramic stopcock 6.1542.010

Plate holder (6.2046.070)

7

For name plates

Data chip

9

On the underside of the buret

SGJ clip (6.2023.020)

11

Of POM

Bottle with thread (6.1608.23)

13

Amber glass, thread GL45

Link stopper (6.1446.030)

15

Body (6.1576.XXX)

17

.110 for 1 mL cylinder

.150 for 5 mL cylinder

.210 for 10 mL cylinder

.220 for 20 mL cylinder

.250 for 50 mL cylinder

Tubing connection (6.1805.010)

4

Length 13 cm (6.1805.050 with 1 mL cyl.)

Storage vessel (6.1228.000)

6

For buret tips or electrodes

Nominal volume

8

Adsorber tube (6.1619.010)

10

Adsorber tube 6.1619.010

Tubing connection (6.1805.100)

12

Length 40 cm

Antidiffusion tip (6.1543.200)

14

Of ETFE/FEP, for titrations

Storage vessel (6.1228.000)

16

For buret tips or electrodes

806 Exchange Unit

■■■■■■■■

5

Page 14

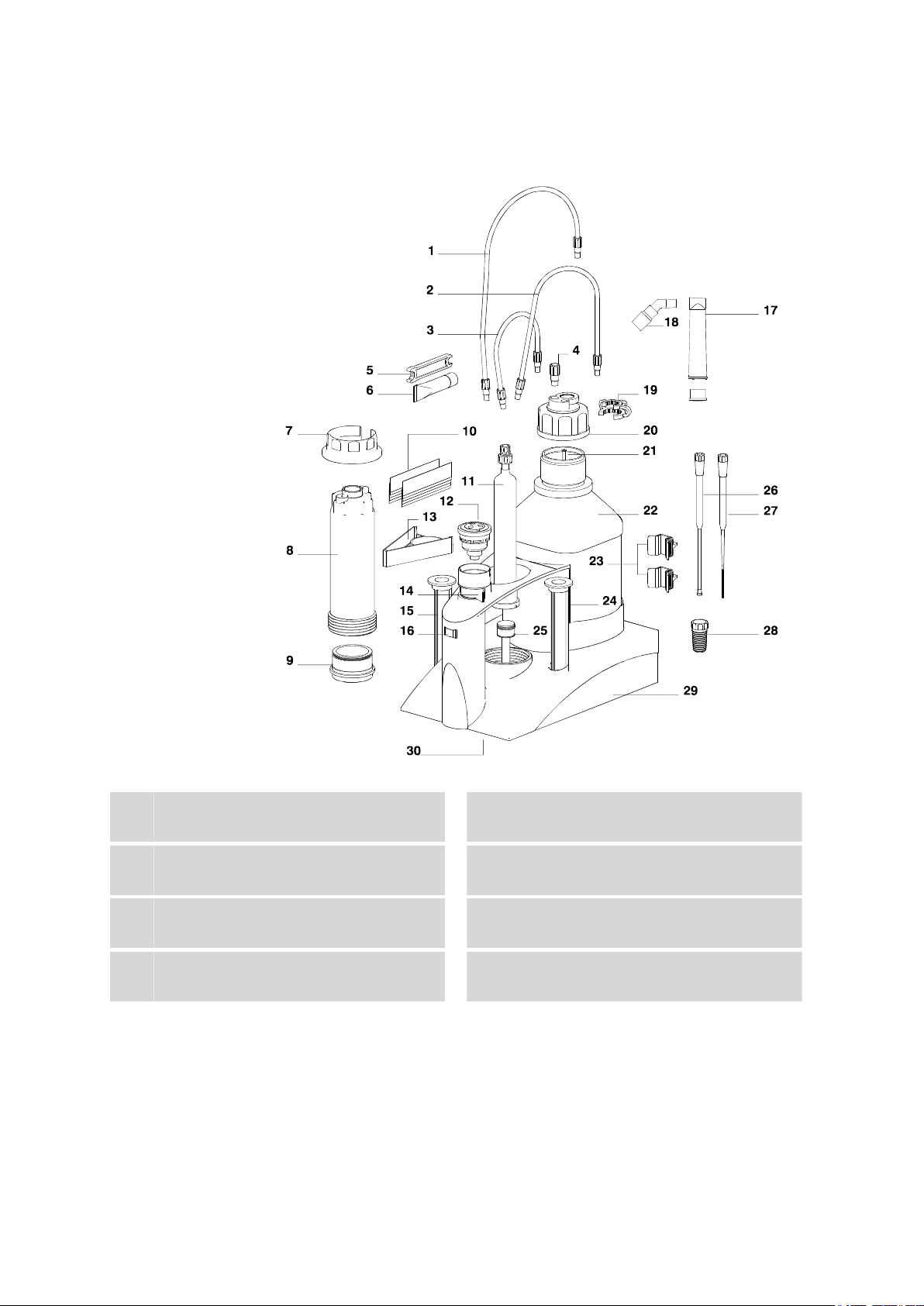

2.2 Components of the 806 Exchange Unit

2.2 Components of the 806 Exchange Unit

■■■■■■■■■■■■■■■■■■■■■■

1

3

5

7

■■■■■■■■

6

Figure 2 806 Exchange Unit - Components

Tubing connection (6.1805.080)

Length 25 cm

Tubing connection (6.1805.010)

Length 13 cm (6.1805.050 with 1 mL cyl.)

Torque key (6.2739.000)

For loosening tubing nipples

Insert for key (6.2739.030)

For loosening the light protection

Tubing connection (6.1805.100)

2

Length 40 cm

Threaded stopper (6.1446.080)

4

Paraffin fat (6.2803.010)

6

For dosing pistons, 2 g

Light protection (6.1563.030)

8

Of PETG

806 Exchange Unit

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2 Construction of the 806 Exchange Unit

Mounting ring for the cylinder

9

(6.2045.XXX)

.000 for 5, 10 mL cylinder

.010 for 20 mL cylinder

.020 for 50 mL cylinder

Dosing cylinder (6.1518.XXX)

11

Clear glass

.113 1 mL cylinder

.150 5 mL cylinder

.210 10 mL cylinder

.220 20 mL cylinder

.250 50 mL cylinder

Plate holder (6.2046.070)

13

For name plates

Storage vessel (6.1228.000)

15

For buret tips or electrodes

Adsorber tube (6.1619.010)

17

Adsorber tube 6.1619.010

Name plates (6.2244.020)

10

For labeling the reagent, 10 x

Flat stopcock

12

PCTFE/PTFE 6.1542.020

Ceramic 6.1542.010

Switching lever

14

For switching the flat stopcock

Nominal volume

16

Adapter NS14 for adsorber tube

18

Of ETFE

SGJ clip (6.2023.020)

19

Of POM

Canula (6.1819.020)

21

Of FEP, thread M6

Holding clamps (6.2043.005)

23

For reagent bottles

PTFE piston (6.1556.XXX)

25

with coupling

.110 for 1 mL cylinder

.150 for 5 mL cylinder

.210 for 10 mL cylinder

.220 for 20 mL cylinder

.250 for 50 mL cylinder

Bottle attachment (6.1602.105)

20

Of PFA/PP, thread GL45

Bottle with thread (6.1608.23)

22

Amber glass, thread GL45

Storage vessel (6.1228.000)

24

For buret tips or electrodes

Antidiffusion tip (6.1543.200)

26

Of ETFE/FEP, for titrations

806 Exchange Unit

■■■■■■■■

7

Page 16

2.2 Components of the 806 Exchange Unit

■■■■■■■■■■■■■■■■■■■■■■

Dosing tip open (6.1543.060)

27

of ETFE/FEP, for dosings

Body (6.1576.XXX)

29

.110 for 1 mL cylinder

.150 for 5 mL cylinder

.210 for 10 mL cylinder

.220 for 20 mL cylinder

.250 for 50 mL cylinder

Link stopper (6.1446.030)

28

Data chip

30

On the underside of the buret

■■■■■■■■

8

806 Exchange Unit

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3 Installation

3.1

Setting up the instrument

3.1.1 Packaging

3.1.2 Checks

3.1.3 Location

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

The instrument has been developed for operation indoors and may not be

used in explosive environments.

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Start-up

3.2.1 Preparing the exchange unit

Proceed as follows:

Mount the holding clamps in such a way that the reagent bottle rests

1

safely on the exchange unit.

Check whether the reagent bottle contains solvent.

2

Fill the adsorber tube with a suitable adsorber material.

3

CO 2 adsorption: Soda lime

KF reagent: Molecular sieve

If no special adsorber material is necessary, the adsorber tube may

also be used as dust filter when filled with cotton.

Attach the filled adsorber tube onto the reagent bottle.

4

806 Exchange Unit

■■■■■■■■

9

Page 18

3.2 Start-up

■■■■■■■■■■■■■■■■■■■■■■

Control, whether the tubing connections are fastened. Tighten the

5

tubing connection with the 6.2739.000 key if necessary.

NOTE

Do not use any other aids! The threads of the tubing nipples and

the tubing openings may not be deformed.

Write the name of the solvent in the reagent bottle on a colored

6

plate.

Slide the plate into the labeling holder.

7

Store the buret tip or the electrode in the two storage vessels.

8

Usage of original reagent bottles

You may eventually need a special bottle attachment or a thread adapter

in addition to the supplied 6.1602.105 standard bottle attachment:

Bottle attachment Order number

Bottles with GL45 thread Standard

Bottles with S40 thread 6.1602.115

Bottles with GL32 thread 6.1602.105 / 6.1618.000

Bottles with 28 mm thread 6.1602.105 / 6.1618.010

3.2.2 Attaching the exchange unit

Attach an 806 Exchange Unit as follows:

Before attaching the exchange unit, check whether the stopcock can

1

be switched manually by the switching lever.

For attaching, the switching lever must be directed to the right (stopcock in dosing position). The arrow marking must point upwards.

■■■■■■■■

10

806 Exchange Unit

Page 19

■■■■■■■■■■■■■■■■■■■■■■

Check the position of the piston rod on the underside of the

2

exchange unit.

The recess of the piston rod must be tight with the buret base and

the smooth surface with the opening must be directed to the rear.

Correct the position of the piston rod with the 6.2739.010 key if

3

necessary.

NOTE

3 Installation

In case of carelessly handling the 6.2739.010 key, the data chip of

the exchange unit may be damaged. Avoid touching the white

ceramic holder of the data chip!

Attach the exchange unit from the front onto the control device and

4

push all the way to the rear, so that it snaps in and the LED Status

flashes slowly.

It must snap in audibly.

806 Exchange Unit

■■■■■■■■

11

Page 20

3.2 Start-up

■■■■■■■■■■■■■■■■■■■■■■

If the exchange unit does not snap in, check the following:

5

3.2.3

Position of the piston rod

Stopcock position of the exchange unit

The switching lever must be directed to the right (stopcock in dosing

position). The arrow marking must point upwards (see step 1).

If the exchange unit is attached correctly, its initialization is being activated by a micro switch which is triggered by the guide bolts of the

exchange unit. It is being recognized and the data is being read automatically from the data chip.

The control device automatically rotates the stopcock and returns the

stopcock in dosing position.

After this, the LED Status on the control device lights up constantly.

Filling the tubings

The proceeding during the filling of the tubings of the exchange unit

depends on the control device and control software. Consult the corresponding manual for manual dosing and filling.

The function Preparing or PREP of the control software is used to rinse

the cylinder and tubings of the exchange unit and fill them air bubble-free.

You should carry out this function before the first determination or once

per day.

■■■■■■■■

12

806 Exchange Unit

Page 21

■■■■■■■■■■■■■■■■■■■■■■

6.1543.200

6.1543.060

3.2.4 Buret tips

3 Installation

The following buret tips are included in the standard equipment of the

dosing unit:

Open dosing tip 6.1543.060

For tasks during which the top is not immersed, e.g. dosings.

The buret tip can be stored in the same solvent as the one contained in

the reagent in order to prevent reagent crystallization.

We recommend that the storage vessel be filled with solvent and that the

buret tip be placed inside it. In the event that KF reagent is used as the

titrant, use methanol or ethanol for storing the dosing tip.

Antidiffusion tip 6.1543.200

It is used for work requiring the immersion of the tip, e.g. titrations.

This tip prevents the diffusion of liquids into the buret tip.

The pressure of the surrounding liquid and the internal stress of the membrane press on the tubing end, thus sealing off the opening.

The backpressure of the dosed liquid is overcome during the dosing process. The membrane opens up the tubing end. The tubing end is sealed off

again automatically after the dosing is completed.

CAUTION

806 Exchange Unit

Do not disassemble the antidiffusion tip.

■■■■■■■■

13

Page 22

3.3 Mounting the components

3.2.5 Removing the exchange unit

To remove the exchange unit, proceed as follows:

Carry out the 'Filling' function on the control device.

1

NOTE

Do not try to remove the exchange unit when the piston of the

exchange unit or the piston rod of the drive is in zero position.

Carefully remove the exchange unit to the front.

2

If it is not possible to remove the exchange unit, check the status of

the control device.

If the control device is still busy, press the key <STOP> and wait until

3

the device is ready.

If the control device is overloaded and a corresponding error mes-

4

sage is displayed, switch it off and on again.

If the device is displaying that it is busy with filling the cylinder but

5

apparently nothing happens, the filling rate is maybe set too low. Try

to increase the filling rate and wait until the device is ready.

■■■■■■■■■■■■■■■■■■■■■■

3.3 Mounting the components

3.3.1

■■■■■■■■

14

Mounting the thermostat casing

If a solvent with a constant temperature is necessary for a titration, the

6.1563.040 thermostat casing is used. Water with a certain temperature is

pumped through the thermostat casing and this way the temperature of

the content in the dosing cylinder is kept constant.

The thermostat casing may only be used with a thermostat equipped with

a pressure and suction pump (the feeding pressure must not be too high).

The thermostat casing may only be used in a temperature range from

15...50 °C.

806 Exchange Unit

Page 23

■■■■■■■■■■■■■■■■■■■■■■

Figure 3 Thermostat casing

Mount the thermostat casing as follows:

Loosen the tubing connection to the glass cylinder.

1

Unscrew the light protection.

2

Screw out the glass cylinder with holder.

3

Loosen the screw nipple on the glass cylinder.

4

Roll the O-ring out of the groove and upwards on the glass nozzle.

5

Do not use any hard items to remove the O-ring, otherwise the edge

of the glass nozzle may chip off!

Replace the union nut of the cylinder by the sealing ring of the ther-

6

mostat casing (threaded side upwards).

Slightly grease the O-ring and attach it on the glass nozzle.

7

Fasten the sealing ring with the screw nipple.

8

Insert the glass cylinder with holder into the thermostat casing and

9

press firmly.

Tighten the thermostat casing with the cylinder in the body.

10

Connect the thermostat tubings.

11

3 Installation

806 Exchange Unit

■■■■■■■■

15

Page 24

3.3 Mounting the components

3.3.2 Mounting the flat stopcock

Figure 4 Flat stopcock

Mount the flat stopcock as follows:

Check whether the flat stopcock can be moved. Twist the lower and

1

upper part of the flat stopcock against each other. For mounting the

stopcock, move the lower part to the right as far as the limit stop, i.e.

in clockwise direction.

Check whether the switching lever on the exchange unit is directed

2

to the right.

Insert the stopcock into the holder (see Figure 2, page 6).

3

■■■■■■■■■■■■■■■■■■■■■■

The rectangular recess of the stopcock is to be directed to the groove

on the edge (on the left side) of the holder.

Check whether the stopcock can be moved by the switching lever.

4

Rotate the switching lever to the right to the dosing position.

5

Attach the exchange unit onto the control device.

6

Types of flat stopcocks

There is a PCTFE/PTFE stopcock (6.1542..020, standard equipment) and a

6.1542.010 ceramic stopcock available, which can be ordered separately.

Generally, the ceramic stopcock is to be preferred if hard crystals can precipitate out of the solution. If only soft crystals precipitate or for reagents

only occasionally used, we recommend the PCTFE/PTFE stopcock. The

PCTFE/PTFE stopcock is subject to a certain wearing. This stopcock has to

be replaced more often than the ceramic stopcock.

We especially recommend the following type of flat stopcocks:

■■■■■■■■

16

806 Exchange Unit

Page 25

■■■■■■■■■■■■■■■■■■■■■■

6.1805.080

6.1805.010

6.1805.100

3 Installation

Solution PCTFE/PTFE

6.1542.020

Ceramic

6.1542.010

Alkaline, aqueous • •

EDTA, complexone •

HClO4 in glacial acetic acid • •

Iodine solution •

Karl Fischer reagent •

KOH in ethanol • •

Organic solvents •

Permanganate, KMnO4 •

Acids, aqueous •

Silver nitrate, AgNO3 • •

TBAOH •

Thiosulphate, Na2S2O3 • •

3.3.3 Mounting the tubings on the flat stopcock

Mounting the tubings on the flat stopcock

Fasten the 6.1805.080 tubing on the flat stopcock and on the bottle

1

attachment of the reagent bottle.

806 Exchange Unit

■■■■■■■■

17

Page 26

3.3 Mounting the components

■■■■■■■■■■■■■■■■■■■■■■

Fasten the 6.1805.010 tubing on the flat stopcock and on the dosing

2

cylinder.

Fasten the 6.1805.100 tubing on the flat stopcock.

3

Fasten the buret tip on the 6.1805.100 tubing.

4

Tighten the tubing connection by hand or with the 6.2739.000 key if

5

necessary.

NOTE

Do not use any other aids! The thread of the tubing nipple and the

tubing openings may not be deformed.

Carry out 'Filling'.

6

Fill the tubings by several dosings and fillings of the cylinder or with

7

the PREP/Prepare function.

By the several dosings and fillings, the air bubbles are driven out. It is

important that the tubing connection between the buret and the flat

stopcock is bubble-free. If necessary, knocking against the tubings

helps to remove the bubbles remained.

■■■■■■■■

18

806 Exchange Unit

Page 27

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

7

4 Mode of operation

4 Mode of operation

4.1

Filling the dosing cylinder and dosing

Figure 5 Dosing/Filling

Filling tube

1

For aspirating the solvent out of the reagent

bottle.

Dosing piston

3

For ejecting and aspirating a solution.

Dosing tubing

5

For dosing the solvent via the dosing tip.

Switching lever

7

For manually switching the flat stopcock.

806 Exchange Unit

Dosing cylinder

2

Contains the solution for dosing. Volume

1 mL , 5 mL , 10 mL , 20 mL or 50 mL .

Piston rod

4

With coupling. For moving the dosing piston

in the dosing unit.

Flat stopcock

6

For switching between filling and emptying

the dosing cylinder.

■■■■■■■■

19

Page 28

4.1 Filling the dosing cylinder and dosing

When ejecting the titrant, the piston rod of the drive moves upwards the

dosing piston in the dosing cylinder. The flat stopcock is in dosing position. The switching lever is directed to the right. The liquid in the cylinder

is pushed trough the flat stopcock into the dosing tubing.

After switching the flat stopcock, i.e. rotating the flat stopcock (switching

lever is directed to the left), liquid is aspirated out of the filling tubing as a

result of the dosing piston being pulled downwards by the piston rod of

the drive.

Because of the fact that the exchange units are interchangeable, the coupling of the piston rod exhibits a low mechanical tolerance which has an

effect on the accuracy of the dosing when the dosing piston changes its

direction of movement. This tolerance is mechanically compensated by the

drive during automated procedures.

The piston movements are controlled by the precise electronic fine

mechanics of the drive. Independent of the cylinder volume, it exhibits a

resolution of 20'000 increments across the entire piston stroke.

The rate, at which a solution is to be dosed and the rate, at which the cylinder is to be filled, depend on the cylinder volume of the exchange unit.

The maximum and minimum filling and dosing rates are:

■■■■■■■■■■■■■■■■■■■■■■

Cylinder volume (mL) 1 5 10 20 50

max. filling- dosing rate

3 15 30 60 150

(mL/min)

µ

min. filling- dosing rate (

min)

L/

10 (depending on device)

NOTE

Enter lower rates for high-viscosity liquids.

■■■■■■■■

20

806 Exchange Unit

Page 29

■■■■■■■■■■■■■■■■■■■■■■

5 Handling and maintenance

5 Handling and maintenance

5.1

5.1.1

Care and upkeep

The exchange unit needs appropriate care.

NOTE

Exchange units must be monitored regularly and cleaned from time to

time.

Monthly inspections are called for in the event that alkaline, corrosive or

high-concentration reagents are used. If non-problematic reagents are

used, then the inspection intervals can be extended to several months.

Disassembling the exchange unit

It is recommended to disassemble and clean the exchange unit when

replacing the reagent.

At the same time, the dosing piston and cylinder of the exchange unit can

be checked. When using alkaline, corrosive or high-concentration

reagents, it should be checked whether the glass cylinder has been

attacked by e.g. aggressive alkalis or whether solids have crystallized out

of the solution.

WARNING

Do not disassemble the exchange unit if it is still on the drive! Remove

the exchange unit from the control device before loosening the tubing

connections. Escaping reagents may access the inside of the device.

Proceed as follows:

Eject the reagent as far as possible without have the cylinder newly

1

filled.

Loosen the tubing connection on the reagent bottle.

2

Move the piston to zero position, i.e. carry out 'Filling'.

3

Remove the exchange unit from the drive.

4

806 Exchange Unit

■■■■■■■■

21

Page 30

5.1 Care and upkeep

Remove all tubings.

5

Unscrew and remove the cylinder unit with light protection or the

6

thermostat casing. If necessary for loosening the light protection, use

the 6.2739.010 key (standard equipment of the dosing device or

titrator) with the insert (6.2739.030).

Remove the cylinder holder with cylinder out of the light protection.

7

Press above on the screw connector.

Remove the holder of the glass cylinder upwards.

8

Thoroughly empty the cylinder with the 6.2739.010 key and carefully

9

remove the piston.

5.1.2 Cleaning the cylinder and piston

Proceed as follows:

Check the leak-tightness of the dosing piston and cylinder.

1

■■■■■■■■■■■■■■■■■■■■■■

If there is liquid under the piston, the dosing cylinder is not or not

thoroughly greased. Inspect the dosing piston for deformations or

damage to the sealing lips. The piston and the cylinder must be

replaced in the event that any changes are discovered.

Clean the dosing cylinder and piston with a liquid cleaning agent.

2

Do not use any abrasive cleaning powder which could scratch the

cylinder.

Afterwards, rinse the individual parts with plenty of deionised (or dis-

3

tilled) water.

Degreasing the piston and the glass cylinder is part of the cleaning

4

procedure. Use a suitable cleaning agent or solvent and eventually an

ultrasonic bath. Note the recommendations of the cleaning agent

manufacturer.

Slightly grease the piston with paraffin grease (6.2803.010) on the

5

sides. Wipe off the edge of the piston to avoid that the reagent will

be in contact with the grease. Wipe off excess grease with a soft,

lint-free cloth. Do not grease the piston for pipettings.

■■■■■■■■

22

806 Exchange Unit

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Check the piston and cylinder for any changes once more before

6

assembling the exchange unit. If the dosing cylinder should exhibit

scratches or rough areas, then it must be replaced.

5.1.3 Assembling the exchange unit

Mounting the cylinder

5 Handling and maintenance

Proceed as follows:

Insert the greased piston (see above) carefully into the cylinder for

1

approx. 1 cm.

Slide the cylinder holder from above over the cylinder (O-ring must

2

be on the upper side) and press firmly.

Insert the cylinder with holder into the light protection and press

3

firmly.

Attach the exchange unit onto the control device.

4

Dose manually until the piston rod of the drive protrudes just out of

5

the body of the exchange unit.

Insert the cylinder with light protection from above into the cylinder

6

holder.

806 Exchange Unit

■■■■■■■■

23

Page 32

5.1 Care and upkeep

Couple the piston rod with the push rod of the drive. The clamp of

7

the push rod must tightly fit into the opening of the piston rod, see

picture.

Carefully push the light protection downwards and tighten in the

8

thread of the body. Thereby the dosing piston is pressed into the cylinder.

Dose manually and move the piston upwards to the limit stop.

9

5.1.4 Flat stopcock blocked

Check whether the stopcock is in dosing position. The switching lever

1

must be directed to the right.

Loosen the flat stopcock out of the holder. Rotate the plate holder to

2

the left and slightly lift the clip on the side of the holder with a finger

nail or a sharp object. Then the flat stopcock can easily be removed

from the holder.

Put the stopcock into a solvent.

3

■■■■■■■■■■■■■■■■■■■■■■

with aqueous solutions – hot water

with non-aqueous solutions – suitable solvent (see chapter 8)

with KF reagent - methanol, then water, then methanol.

Eventually clean the stopcock with a suitable solvent (see above) in

4

an ultrasonic bath and let it dry afterwards.

When the stopcock can be moved again, it can be inserted back into

5

the exchange unit, see above.

■■■■■■■■

24

806 Exchange Unit

Page 33

■■■■■■■■■■■■■■■■■■■■■■

5.2 Chemical resistance and materials

Metrohm exchange units are designed for usage with aqueous solutions

and the most common solvents.

The temperature of the dosing material may not exceed 50°C. The

exchange unit and its components cannot be autoclaved. The sterility of a

germ-free dosing material cannot be guaranteed.

5 Handling and maintenance

5.2.1

Solutions

5.2.2 Body

With the 806 Exchange Unit various solutions can be dosed. The materials

of the individual components used have been selected for maximum

resistance to chemicals and functionality.

It can however not be assumed that all types of aggressive or high-concentration solutions can be conveyed without difficulty. It is the responsibility of the user to determine the resistance of the various individual components to specific, aggressive media.

Many problems involving aggressive media can be prevented by regular

cleaning and inspections.

The body is made of polybutylene terephthalate. It is only partly resistant

to chemicals.

Good resistance Acids, organic solvents

Limited resistance Alkalis (with a conc. > 1 M)

The exchange unit is not dishwater-safe. In most cases, the exchange unit

is to be cleaned with lukewarm water and dishwashing detergent.

5.2.3

806 Exchange Unit

Materials

Body PBT (polybutylene terephthalate)

Dosing piston PTFE (polytetrafluoroethylene)

Dosing cylinder Borosilicate 3.3

Flat stopcock PCTFE/PTFE or ceramic

Light protection PETG (polyethylene terephthalate, glycol-modi-

fied) or PVDF

■■■■■■■■

25

Page 34

5.3 GLP - Validation

5.3 GLP - Validation

Every drive and every dosing unit manufactured by the Metrohm Co. is

subjected to rigorous quality controls prior to shipment. Every dosing unit

is issued a quality certificate attesting conformance with the strict quality

criteria of Metrohm. GLP (Good Laboratory Practice) requires, among

other things, periodic inspection of analytical measuring devices with

respect to precision and correctness on the basis of standard operating

procedures Standard Operating Procedure, SOP). This may also include

an inspection of dosing accuracy.

Recommended literature

■ Metrohm brochure "Quality management with Metrohm", detailed

information concerning the principles and procedural methods of

Good Laboratory Practice

■ Metrohm Applications Bulletin 283/1 Validation of Metrohm burets

The validation of burets is carried out by the Metrohm service with special

software.

■■■■■■■■■■■■■■■■■■■■■■

The Metrohm agents worldwide offer the possibility of on-site inspections

and certifications of dosing units and Dosinos with respect toaccuracy. It is

recommended that an accuracy inspection be performed when the dosing

cylinders and dosing pistons of a dosing unit are replaced.

■■■■■■■■

26

806 Exchange Unit

Page 35

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

6 Troubleshooting

6.1

Problems

Problem Cause Remedy

Air bubbles in the

cylinder or in the

dosing tubing

Leaking connection ■ Check the ends of the tubing, in particular

that of the aspiration tubing.

■ Tighten all of the tubing connections with

the wrench 6.2739.000.

■ Check the locking mechanism of the hous-

ing. Suggestion: Remove the housing and

then reattach it.

The reagent degasses

excessively, e.g. released

air forms bubbles.

■ Carry out [PREP] / [Preparing]

■ Reduce the filling rate.

■ Suggestion: Degas the reagent with ultra-

sound, nitrogen or in a vacuum.

Wear Replacing piston and cylinder.

[PREP] / [Preparing] is

not carried out or false

■ Carry out [PREP] / [Preparing]

■ Correct tubing length and diameter.

parameters-

An incorrect volume

is dosed

Data of the dosing

unit cannot be read.

Exchange unit recognized either not

at all or incorrectly.

Dosing unit either mounted

or assembled incorrectly.

Data chip of the dosing

unit mechanically damaged or impaired by chemicals.

The exchange unit has not

correctly been attached.

■ Remove the dosing unit and then reattach

it.

■ Check whether the nominal volume on the

housing and the effective cylinder volume

match one another.

■ Remove the dosing drive and set it up

again.

■ Clean the data chip and the contact sur-

faces.

■ Have the data chip replaced by the

Metrohm Service Dept.

■ Remove the exchange unit and set it up

again.

■ Check the correct placing of the exchange

unit.

■ Check the piston and flat stopcock posi-

tion.

■ Switch the instrument off and on again.

806 Exchange Unit

■■■■■■■■

27

Page 36

6.1 Problems

Problem Cause Remedy

■ If necessary contact the Metrohm Service

Dept.

■■■■■■■■■■■■■■■■■■■■■■

LED "Status" is

flashing fast.

The dosing drive is overloaded because the stopcock

is blocked.

The dosing drive is overloaded because the piston is

blocked.This error is displayed by the software

(Touch Control or PC Control / tiamo).

The data of the exchange

unit cannot be read

because the data chip has

been damaged mechanically or by chemicals.

Switch off the Touch Control or exit PC Control. Check wether the exchange unit can be

removed. If it cannot be removed, check

wether the flat stopcock still can be turned.

Switch it manually to the exchange position

turning it to the right. Remove the exchange

unit and proceed as described in the manual

for the exchange unit.

Switch the control device off and then on

again. The dosing device is being initialized

during switching on. Remove the exchange

unit and clean it as described in the manual for

the exchange unit in chapter "Care and maintenance". Contact the Metrohm service if

removing the exchange unit is not possible.

Have the data chip being replaced by the

Metrohm service.Until the data chip is being

replaced you can remove the data chip yourself in order to be able to still use the

exchange unit. The cylinder volume is automatically recognized nevertheless, but no data

can be read from the exchange unit or be

saved on it anymore.

LED "Status" is not

illuminated although

an exchange unit is

attached.

No dosing takes

place at all

■■■■■■■■

28

The exchange unit has not

correctly been attached.

Tubing connections are

blocked or dosing unit is

not assembled correctly.

Remove the exchange unit and attach it again

until it snaps in. The LED flashes during data is

read from an intelligent exchange unit and

lights up constantly if the exchange unit has

correctly been recognized.

■ Check whether the dosing tip is blocked.

■ Check whether the dosing tubing is con-

nected to the correct port.

■ Check whether the dosing port is sealed off

with a stopper.

■ Check whether the VENT port is sealed off

with a stopper (vacuum in the supply bottle!). The VENT port must be open for pressure compensation.

806 Exchange Unit

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

■ Remove the dosing drive and check

whether the dosing piston is connected to

the dosing drive. The piston stopper must

be flush with the upper side of the housing.

■ Check whether the connection cable is

attached to the dosing drive.

6 Troubleshooting

The exchange unit

cannot be attached.

The exchange unit

cannot be removed

and the LED "Status" is flashing

slowly.

The flat stopcock of the

exchange unit is not in the

exchange position.

The piston rod in the

exchange unit is not in the

right position.

It is being dosed or filled

and/or the Titrando is not

in the exchange position.

Switch the flat stopcock manually to the

exchange position (lever switch directed to the

right).

Switch the piston rod to the right position.

Stop the run or carry out a "filling".

806 Exchange Unit

■■■■■■■■

29

Page 38

7.1 Buret data

7 Appendix

■■■■■■■■■■■■■■■■■■■■■■

7.1

Buret data

The 806 Exchange Unit is equipped with a data chip which contains the

specifications for the exchange unit, the tubing connections and the

reagent used.

Indications on exchange unit / tubing connections

■ Order number of the exchange unit

■ Serial number of the exchange unit

■ Serial number of the dosing cylinder

■ Length and diameter of the tubings on the dosing ports

■ Validation date

■ etc.

Indications on the reagent

■ Name of the reagent

■ Titer of the reagent

■ Concentration of the reagent

■ Production and expiry date of the reagent

■ etc

The 806 Exchange Unit makes it possible to read and overwrite data with

the aid of a suitable device (e.g. Titrando). Consult the respective manual

in order to determine whether the Metrohm device which you are using is

capable of accomplishing this.

7.2 Dosing accuracy

Every exchange unit is subjected to a strict quality inspection prior to shipment. Every exchange unit is issued a quality certificate attesting conformance with the quality criteria of Metrohm.

7.2.1 Typical measurement deviation

The accuracy of exchange units can be seen in the following table. The

values listed are to be regarded as typical values which can be achieved

with a Titrando.

■■■■■■■■

30

806 Exchange Unit

Page 39

■■■■■■■■■■■■■■■■■■■■■■

Table 1 Typical measurement deviation of Metrohm exchange units

Cylinder volume max. systematic deviation

1 mL ± 3 µL

5 mL ± 15 µL

10 mL ± 20 µL

20 mL ± 30 µL

50 mL ± 50 µL

7.2.2 The ISO/EN/DIN standard 8655-3

The Metrohm exchange units fulfil the requirements of the ISO/EN/DIN

standard 8655-3 Volume measurement instruments with pistons –

Part 3: Piston burets. Metrohm guarantees that its exchange units are

in compliance with the following limit values at the time of shipment:

Table 2 Permissible limit values as per ISO/EN/DIN 8655-3

7 Appendix

Cylinder

volume

max. systematic

measurement deviation

max. permissible

measurement deviation

1 mL ± 0.6 % ± 6 µL ± 0.1 % ± 1 µL

5 mL ± 0.3 % ± 15 µL ± 0.1 % ± 5 µL

10 mL ± 0.2 % ± 20 µL ± 0.07 % ± 7 µL

20 mL ± 0.2 % ± 40 µL ± 0.07 % ± 14 µL

50 mL ± 0.2 % ± 100 µL ± 0.05 % ± 25 µL

The Metrohm agents worldwide offer the possibility of on-site exchange

unit inspections and certifications with respect to accuracy. We recommend that an accuracy inspection be performed when the dosing cylinders and dosing pistons of an exchange unit are replaced.

806 Exchange Unit

■■■■■■■■

31

Page 40

8.1 Scope of delivery

8 Accessories

■■■■■■■■■■■■■■■■■■■■■■

8.1

Scope of delivery

Subject to change without notice.

8.1.1

806 Exchange Unit 6.3026.xxx

Qty. Order no. Description

1 6.3026.xxx 806 Exchange Unit

Exchange unit with integrated data chip with 1, 5, 10, 20 and 50 mL

glass cylinder and light protection. PCTFE/PTFE flat stopcock, FEP tubing connection, antidiffusion buret tip and standard amber glass

reagent bottle.

6.3026.110: 1 mL

6.3026.150: 5 mL

6.3026.210: 10 mL

6.3026.220: 20 mL

6.3026.250: 50 mL

NOTE

1 6.1543.060 Tip / Thread M6

Tip with M6 thread. Together with the 6.1805.160 capillary tubing

and the 6.1446.030 link stopper it provides the entire 6.1537.010

buret tip.

Material: ETFE/FEP

Length (mm): 151

■■■■■■■■

32

806 Exchange Unit

Page 41

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.1619.010 Adsorber material, complete for the

exchange unit

2 6.2043.005 Holding clamp for bottles

Holding spring for reagent bottles and exchange units.

1 6.2244.020 Labeling plates for intelligent exchange unit

8 Accessories

Set of 10 pieces, in various colors.

1 6.2739.000 Wrench

For tightening connectors

Length (mm): 68

1 6.2739.030 Insert for 6.2739.010

For exchange units (6.3026.xxx), all volumes.

806 Exchange Unit

■■■■■■■■

33

Page 42

8.2 Optional accessories

Qty. Order no. Description

1 6.2803.010 Grease (2 g)

Special quality (silicone-free). For grease-free ground joint connections, see 6.2713.XXX

1 8.806.8003ML 806 Exchange Unit Manual

8.2 Optional accessories

■■■■■■■■■■■■■■■■■■■■■■

Order no. Description

6.1563.040 Thermostat casing for 806 Exchange Units

For exchange units 6.3026.XXX

6.1576.220 Exchange unit body / 20 mL

Material: PBTE

Volume (mL): 20

■■■■■■■■

34

806 Exchange Unit

Page 43

■■■■■■■■■■■■■■■■■■■■■■

Order no. Description

6.1608.030 Round glass bottle / 1000 mL / GL 45

Material: Clear glass

Height (mm): 223

Volume (mL): 1000

6.1608.040 PE bottle / 1000 mL / GL 45

For exchange units. Bottle for auxiliary solutions

Material: PE

Width (mm): 96

Height (mm): 223

Volume (mL): 1000

8 Accessories

806 Exchange Unit

■■■■■■■■

35

Page 44

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

A

Accuracy .................................. 26

Antidiffusion tip

B

Bottle attachment .................... 10

Buret data ................................ 30

Buret tip ................................... 13

Crystallizing ........................ 13

Storage .............................. 13

C

Certification .............................. 26

Crystallizing .............................. 13

D

Data chip ..................... 11, 28, 30

Data exchange ......................... 30

Dosing accuracy ....................... 26

Dosing cylinder ......................... 19

Material

Dosing piston ........................... 19

Material .............................. 25

Dosing position .......................... 9

Dosing tip

Open .................................. 13

Dosing tubing ........................... 19

E

Exchange unit ..................... 29, 28

........................ 13

.............................. 25

F

Filling tube ............................... 19

Flat stopcock ............................ 19

of ceramic .......................... 16

of PCTFE/PTFE ..................... 16

Function

PREP ................................... 12

Preparing

G

GLP .......................................... 26

Good Laboratory Practice ......... 26

L

LED

Status ......... 11, 12, 28, 29, 28

Light protection

Material

O

Order number .......................... 30

P

PETG ........................................ 25

Piston blocked .......................... 28

Piston rod

Production date ........................ 30

Q

Quality certificate ..................... 26

............................ 12

.............................. 25

....................... 9, 11, 19

Quality control ......................... 26

R

Reagent

Concentration .................... 30

Crystallizing ........................ 13

Expiry date ......................... 30

Name ................................. 30

Production date .................. 30

Titer ................................... 30

S

Serial number ........................... 30

SOP .......................................... 26

Stopcock

Material

Stopcock blocked ..................... 28

Storage vessel .......................... 13

Switching lever ............... 9, 10, 19

T

Thread ..................................... 10

Tubing diameter ....................... 30

Tubing length ........................... 30

V

Validation ................................. 26

Validation date ......................... 30

.............................. 25

■■■■■■■■

36

806 Exchange Unit

Loading...

Loading...