Page 1

797 VA Computrace

Software Version 1.3.x

Manual

8.797.8002EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

797 VA Computrace

Software Version 1.3.x

Manual

8.797.8002EN 08.2009 zst

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on http://prod-

ucts.metrohm.com under Literature/Technical documentation.

Page 5

Table of contents

Table of contents

1 Introduction ......................................................... 1

1.1 Purpose of program................................................................ 1

1.2 General information................................................................ 2

Hardware requirements for the PC................................................. 2

Demo version................................................................................. 2

Registration ................................................................................... 2

1.3 Installation.............................................................................. 2

Installation of the hardware........................................................... 2

Installation of Dosing Devices ........................................................ 3

Installation of 863 Compact VA Autosampler ................................ 4

Installation of 838 Advanced Sample Processor ............................. 5

Deinstallation................................................................................. 6

1.4 Overview of program windows .............................................. 6

1.5 Overview of file types ............................................................. 7

1.6 Context sensitive menus ......................................................... 8

2 Main window ....................................................... 9

2.1 Main window overview .......................................................... 9

Main window elements ................................................................. 9

Main window menus ..................................................................... 9

Main window icons ..................................................................... 10

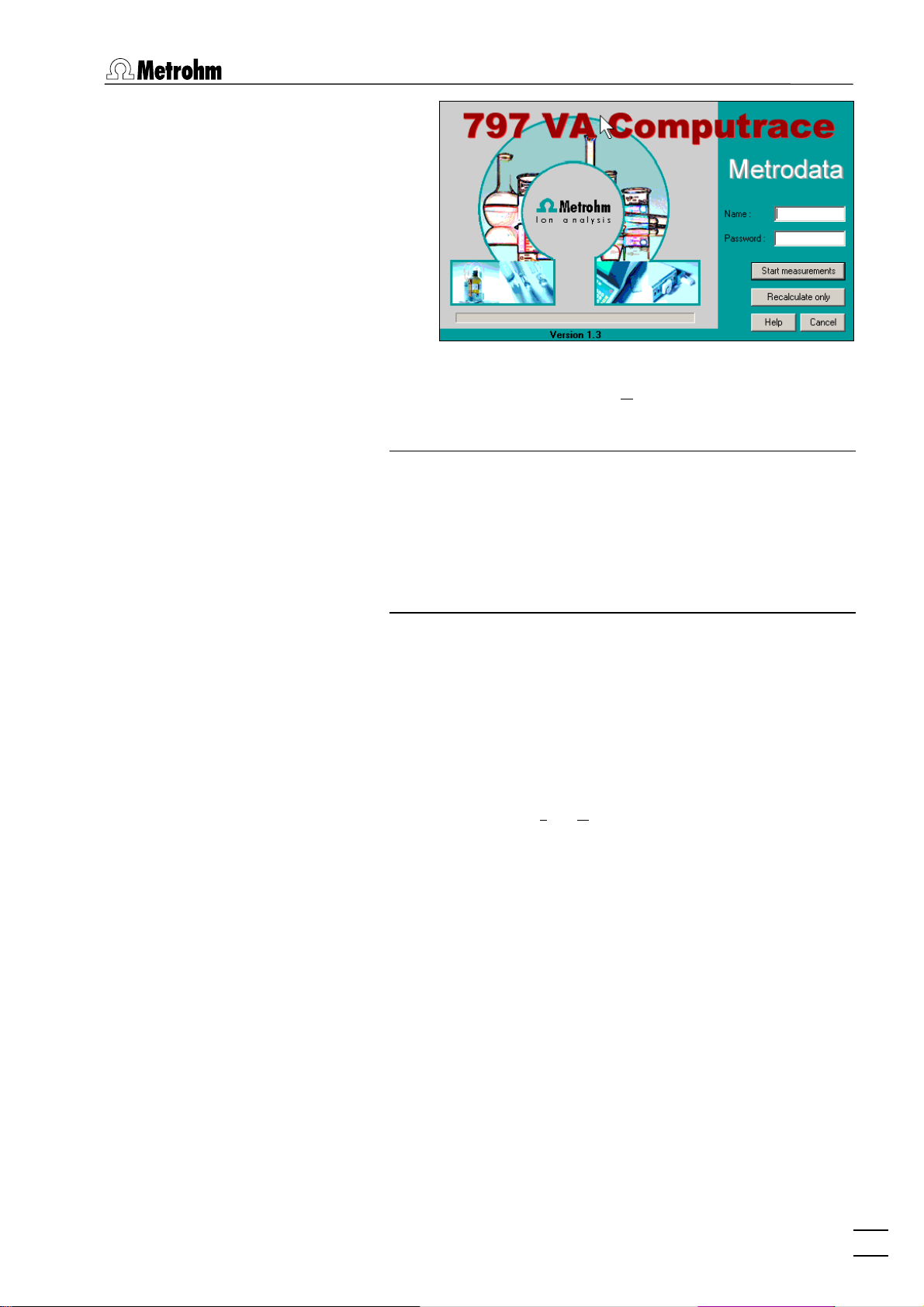

2.2 Starting/closing the program................................................ 11

Starting the VA Computrace program.......................................... 11

Closing the VA Computrace program........................................... 11

2.3 File menu .............................................................................. 12

Method files ................................................................................ 12

Determination files ...................................................................... 12

Export/Import of Data with Autodatabase ................................... 13

Signal files ................................................................................... 14

Printing of reports and curves ...................................................... 15

Program exit ................................................................................ 15

2.4 Mode menu ........................................................................... 15

2.5 Utility menu .......................................................................... 16

797 VA Computrace – Software

Exploratory mode selection.......................................................... 15

Determination mode selection ..................................................... 15

Computrace control selection ...................................................... 16

Dosing Device control selection ................................................... 16

Pump control selection ............................................................... 16

I

Page 6

Table of contents

Film deposition selection.............................................................. 16

Cleaning procedure selection....................................................... 16

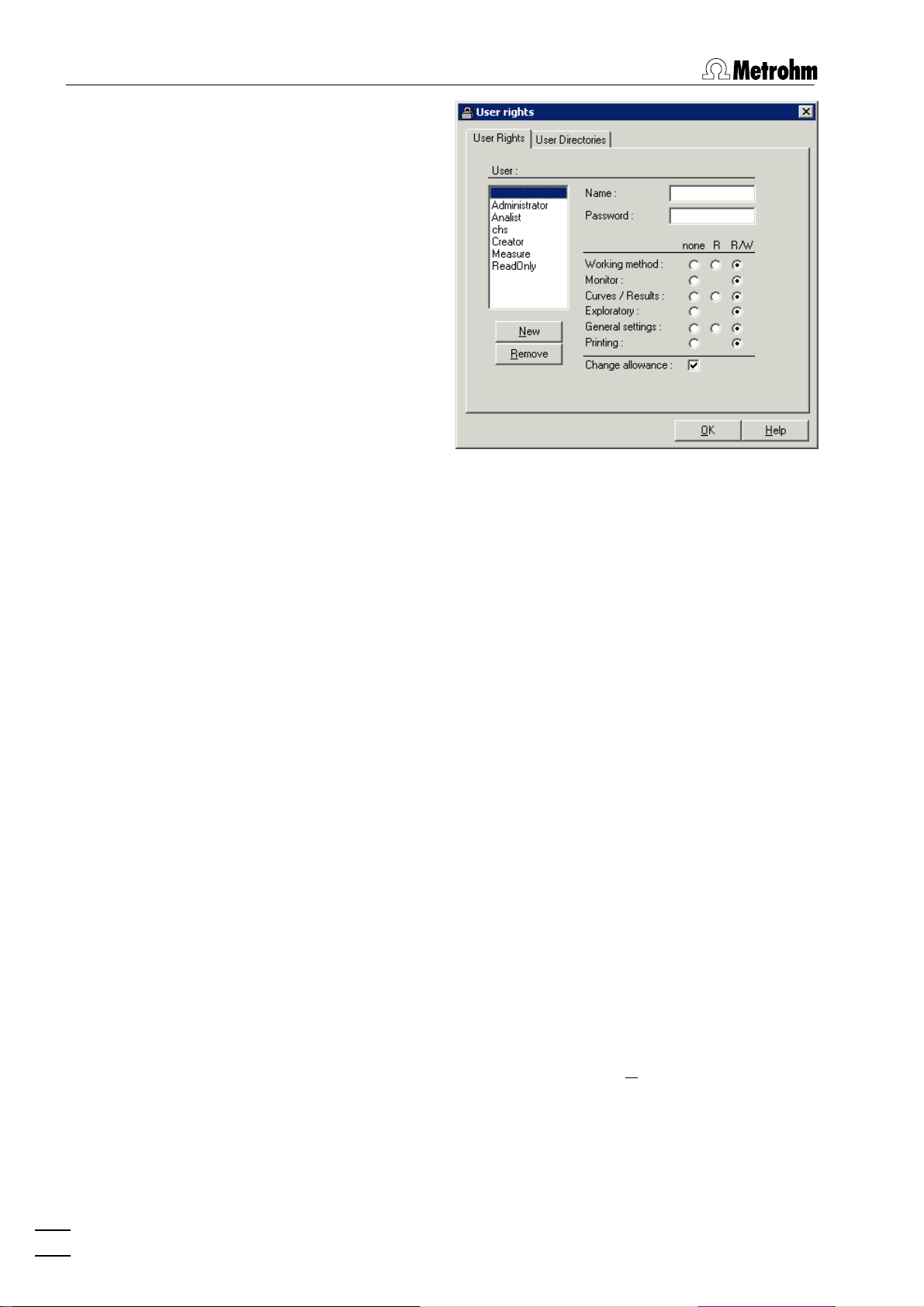

2.6 User menu ............................................................................. 16

Login ........................................................................................... 16

User rights ................................................................................... 17

User rights overview .................................................................... 20

2.7 Settings menu ....................................................................... 20

General settings........................................................................... 20

Dosing settings ............................................................................ 23

Automation ................................................................................. 25

GLP.............................................................................................. 29

Database settings ........................................................................ 33

Save settings................................................................................ 34

2.8 Window menu....................................................................... 34

Tiling of windows ........................................................................ 34

Opening and closing of program windows .................................. 34

Display settings for Main window................................................ 35

3 General settings for exploratory and

determination mode ..........................................

3.1 Electrodes ............................................................................. 36

MME............................................................................................ 36

DME ............................................................................................ 36

SMDE........................................................................................... 37

HMDE.......................................................................................... 38

RDE/SSE ....................................................................................... 39

3.2 VA measurement modes ....................................................... 40

DP – Differential Pulse.................................................................. 40

SqW – Square Wave .................................................................... 42

DC – Sampled Direct Current ....................................................... 44

NP – Normal Pulse (for "Exploratory" only)................................... 46

CV – Cyclic Voltammetry.............................................................. 48

PSA – Potentiometric Stripping Analysis....................................... 50

CCPSA – Constant Current Potentiometric Stripping Analysis....... 51

AC – Alternating Current Voltammetry ........................................ 53

CVS - Cyclic Voltammetric Stripping............................................. 55

CPVS - Cyclic Pulse Voltammetric Stripping .................................. 57

3.3 Potentiostat .......................................................................... 59

36

3.4 General operation sequence.................................................. 60

Overview of operation sequence.................................................. 60

Stirring......................................................................................... 61

Purging........................................................................................ 61

Conditioning of solid state electrodes .......................................... 62

Pretreatment ............................................................................... 62

Stand-by potential ....................................................................... 63

3.5 Graphical settings ................................................................. 64

Curve window elements .............................................................. 64

Page properties............................................................................ 64

II

797 VA Computrace – Software

Page 7

Table of contents

Axis properties............................................................................. 65

Curve properties .......................................................................... 67

Line properties............................................................................. 68

4 Exploratory mode .............................................. 70

4.1 Exploratory mode overview.................................................. 70

Exploratory mode features........................................................... 70

Exploratory mode selection.......................................................... 70

Exploratory mode windows ......................................................... 70

4.2 Exploratory specification window ........................................ 71

Exploratory specification settings ................................................. 71

Load/save signals ......................................................................... 72

Transfer parameters and data ...................................................... 73

Performing exploratory measurements ........................................ 73

4.3 Exploratory curves ................................................................ 74

Exploratory curves window.......................................................... 74

Load signal curves........................................................................ 75

Select signal curves ...................................................................... 75

Zooming ...................................................................................... 76

Auto scaling................................................................................. 76

Swap axes ................................................................................... 76

Graphical properties for exploratory curves.................................. 76

Copy to clipboard ........................................................................ 77

Save as enhanced metafile........................................................... 77

Change labels .............................................................................. 77

Clear signal curves ....................................................................... 77

Signal cursor................................................................................ 77

Peak search ................................................................................. 78

Edit baseline ................................................................................ 82

Wave evaluation .......................................................................... 83

4.4 Printing in exploratory mode................................................ 84

5 Determination mode .......................................... 86

5.1 Determination mode overview.............................................. 86

Determination mode features ...................................................... 86

Determination mode selection ..................................................... 86

Determination mode windows..................................................... 86

5.2 Working method specifications ............................................ 87

Load/save methods...................................................................... 87

Working method specifications window ...................................... 88

Determination.............................................................................. 90

Voltammetric............................................................................... 93

Substances................................................................................... 94

Baseline ....................................................................................... 98

Calculations ................................................................................. 99

Calculation Window .................................................................. 100

Variable addition ....................................................................... 102

Concentrations of calibration solutions ...................................... 103

Documentation.......................................................................... 104

797 VA Computrace – Software

III

Page 8

Table of contents

Export........................................................................................ 105

Dosing Devices .......................................................................... 107

5.3 Monitor ............................................................................... 108

Start determination.................................................................... 108

Stop/Hold determination ........................................................... 109

Monitor determination .............................................................. 110

Message windows during determination ................................... 111

Graphical properties for monitoring curves ................................ 117

Copy to clipboard ...................................................................... 118

5.4 Determination curves.......................................................... 118

Load/save determinations .......................................................... 118

Copy parameters to working method ........................................ 120

Determination curves window ................................................... 120

Edit determination method parameters...................................... 121

Specifications............................................................................. 121

Determination............................................................................ 123

Voltammetric............................................................................. 123

Substances................................................................................. 123

Calculations ............................................................................... 123

Export........................................................................................ 123

Edit addition parameters............................................................ 124

Edit baseline .............................................................................. 124

Zooming .................................................................................... 125

Auto scaling............................................................................... 126

Swap axis .................................................................................. 126

Show baselines .......................................................................... 126

Show unknown peaks................................................................ 126

Show spikes............................................................................... 126

Graphical properties for determination curves ........................... 126

Graphical properties for calibration curves ................................. 127

Copy/export graphics................................................................. 127

5.5 Results ................................................................................ 129

Results window overview........................................................... 129

Header....................................................................................... 130

Determination data.................................................................... 130

Method data.............................................................................. 130

Sample data............................................................................... 130

Substance evaluation ................................................................. 131

Peak evaluation ......................................................................... 131

Calibration data ......................................................................... 132

Solutions.................................................................................... 132

Final results................................................................................ 133

Copy text to clipboard ............................................................... 133

5.6 Sample table ....................................................................... 134

Load/save sample table.............................................................. 135

Edit sample table ....................................................................... 136

5.7 Printing in determination mode.......................................... 137

5.8 Data processing and evaluation.......................................... 138

Data transfer.............................................................................. 138

IV

797 VA Computrace – Software

Page 9

Table of contents

Data acquisition......................................................................... 138

Background compensation ........................................................ 139

Smoothing and differentiation ................................................... 139

Peak recognition........................................................................ 139

Baseline calculation.................................................................... 140

Evaluation quantity calculation .................................................. 141

Content calculation.................................................................... 142

Dilution calculation .................................................................... 143

Standard addition calculation .................................................... 143

Rules for standard addition........................................................ 145

Calibration curve calculation ...................................................... 145

Rules for calibration curves ........................................................ 148

Formula calculation.................................................................... 149

6 Electroplating Bath VA .................................... 150

6.1 Electroplating Bath VA – Introduction ................................ 150

6.2 Calibration techniques with CVS and CPVS......................... 150

Standard addition plating bath .................................................. 150

LAT Record intercept value ........................................................ 154

LAT Standard addition for brighteners ....................................... 158

MLAT Standard addition for brighteners .................................... 164

DT Suppressors with calibration curve........................................ 168

DT Record calibration curve ....................................................... 174

RC Sample with response curve ................................................. 179

RC Record response curve.......................................................... 183

6.3 Different settings and options with CVS and CPVS ............ 188

Pretreatment with CVS and CPVS .............................................. 189

Initial mixing time with CVS and CPVS ....................................... 189

Conditioning cycles with CVS and CPVS..................................... 190

Initial electrode conditioning ..................................................... 190

Result details with CVS and CPVS .............................................. 191

6.4 Some Definitions used with CVS and CPVS......................... 192

VMS (Virgin Make-up Solution).................................................. 193

Intercept solution....................................................................... 193

Intercept value........................................................................... 193

Production bath solution ........................................................... 194

Addition ratio ............................................................................ 194

Evaluation ratio.......................................................................... 194

Begin of evaluation.................................................................... 194

Contamination potential ............................................................ 195

Chloride potential ...................................................................... 195

Calibration factor Z .................................................................... 195

Suppressor................................................................................. 195

Brightener.................................................................................. 195

Electrolyte solution .................................................................... 196

7 Manual control................................................. 197

7.1 Computrace control ............................................................ 197

797 VA Computrace – Software

Computrace control selection .................................................... 197

V

Page 10

Table of contents

8 How to ...? ....................................................... 205

Computrace control window ..................................................... 197

7.2 Dosing Device control ......................................................... 199

Dosing Device control selection ................................................. 199

Dosino control window ............................................................. 199

7.3 Pump control ...................................................................... 200

Pump control selection .............................................................. 200

Pump control window ............................................................... 200

7.4 Film deposition ................................................................... 201

Film deposition selection............................................................ 201

Film deposition window............................................................. 201

7.5 Cleaning procedure ............................................................. 203

Cleaning procedure selection..................................................... 203

Cleaning procedure window...................................................... 203

8.1 Installation and program start............................................ 205

Install Dosing Devices for automatic addition............................. 205

Switch on the instruments and start program ............................ 205

8.2 User rights .......................................................................... 206

Define a new user...................................................................... 206

Change user rights..................................................................... 206

8.3 Signals in exploratory mode ............................................... 206

Load a signal curve .................................................................... 206

Save a signal curve..................................................................... 207

Save signal curves automatically ................................................ 207

Record a signal curve................................................................. 207

Evaluate signal peaks automatically ........................................... 208

Evaluate signal peaks manually .................................................. 208

Evaluate signal waves ................................................................ 209

Print signal curves and/or voltammetric parameters ................... 209

8.4 Methods in determination mode......................................... 209

Load a method .......................................................................... 209

Copy parameters from determination methods.......................... 210

Copy parameters from signal files .............................................. 210

Save the working method.......................................................... 210

Edit the working method ........................................................... 210

Modify methods for automatic background compensation........ 211

8.5 Determinations with voltammetric trace analysis............... 211

Load a determination................................................................. 211

Save a determination ................................................................. 212

Automatically save determinations............................................. 212

Perform a determination............................................................ 212

Perform a test determination with the Pb test method .............. 213

Perform determinations using the 863 Compact VA Autosampler214

Perform VA determinations using the 838 Advanced Sample

Processor ................................................................................... 215

838 method for trace analysis.................................................... 216

Recalculate an existing determination........................................ 217

VI

797 VA Computrace – Software

Page 11

Table of contents

Print determination results and curves ....................................... 218

8.6 Analyze Electroplating Bath Solutions................................ 218

Introduction............................................................................... 218

Choose the mode in Electroplating Bath VA............................... 219

Choose the Calibration technique in Electroplating Bath VA ...... 219

Operate a sequence in Electroplating Bath VA ........................... 223

Brightener Analysis with 838 Advanced Sample Processor and

"MLAT"...................................................................................... 224

Brightener Analysis with 838 Advanced Sample Processor and

"LAT"......................................................................................... 228

Suppressor Analysis with 838 Advanced Sample Processor and DT234

Suppressor Analysis with 838 Advanced Sample Processor and RC239

8.7 Standard addition technique .............................................. 245

Use manual standard addition without solution exchange ......... 245

Use manual standard addition with solution exchange .............. 246

Use automatic standard addition ............................................... 247

8.8 Calibration curve technique ................................................ 248

Record calibration curve manually by adding standard solution . 248

Record calibration curve manually with solution exchange ........ 249

Record calibration curve automatically....................................... 250

Measure a sample using a calibration curve ............................... 252

8.9 Work with film electrodes .................................................. 252

Deposit a mercury film............................................................... 252

Remove a mercury film .............................................................. 253

8.10 Diagnostic procedures ........................................................ 253

Check the purging ..................................................................... 253

Check the stirring....................................................................... 254

Check the MME ......................................................................... 254

Check theRDE ............................................................................ 254

Perform a linearity test with the dummy cell .............................. 254

Perform a peak test with the dummy cell................................... 255

Perform a GLP Validation........................................................... 256

9 Troubleshooting............................................... 257

9.1 General procedure for error messages................................ 257

9.2 Connection problems .......................................................... 257

Error message "Could not start the embedded system" ............. 257

9.3 Software problems ............................................................. 257

Error message "Name or password incorrect"............................ 257

Error message "The file 'ecousb.sys' is needed" ......................... 257

Wrong language in Help............................................................ 257

Error message "Please select a new database file" ..................... 258

9.4 Dosing Device problems...................................................... 258

Dosing Device does not work .................................................... 258

Irreproducible standard additions with a Dosing Device............. 258

9.5 General rules for VA trace analysis ..................................... 259

Chemicals and equipment.......................................................... 259

797 VA Computrace – Software

VII

Page 12

Table of contents

Electrolytes ................................................................................ 259

Standard solutions ..................................................................... 259

Samples ..................................................................................... 260

Blank values, contamination ...................................................... 260

Selection of VA Measurement mode.......................................... 260

9.6 Voltammetric problems....................................................... 262

Low background current or unstable baseline............................ 262

Curves with high noise............................................................... 263

SqW Problems ........................................................................... 263

Standard addition curves are not reproducible........................... 264

Peak displacement ..................................................................... 265

No peak found........................................................................... 265

Peak is in the highest μA range.................................................. 266

Double peak .............................................................................. 266

Standard addition peaks displaced............................................. 267

No addition ............................................................................... 267

Spikes / signal jump in voltammogram....................................... 268

Oxygen interference .................................................................. 268

Unsuitable bridging electrolyte in the reference electrode.......... 269

Overloading of the working electrode........................................ 269

Disturbances at the HMDE through gas formation..................... 271

Complex formation.................................................................... 272

Peak on highly curved baseline .................................................. 273

Peak overlapping ....................................................................... 273

Calibration with chemically non-isoformal standards ................. 274

Results not reproducible ............................................................ 274

Software license.................................................... 276

Declaration of conformity – Software validation .. 278

Index ..................................................................... 279

VIII

797 VA Computrace – Software

Page 13

1.1 Purpose of program

1 Introduction

1.1 Purpose of program

«797 VA Computrace Software 1.3.x» is the name of the control

software for the PC-controlled 797 VA Computrace System for

voltammetric analysis. This system consists of the following parts:

1.797.0010 VA Computrace Stand with accessories

6.2151.020 USB Cable

6.6053.030 797 VA Computrace Software 1.3.x

For a detailed description of the hardware components of the 797

VA Computrace System, see the 797 Hardware Manual.

This 797 Software Manual describes the features and operation

procedures of the 797 VA Computrace Software 1.3.x, which comprises the clearly arranged user interface with a task bar that can

be clicked for control of the instrument, method development and

the recording and evaluation of the voltammograms.

Depending on the objective, the 797 VA Computrace Software

1.3.x can be used in two different operating modes:

• The exploratory mode for qualitative analysis is suitable

for practice-oriented voltammetry training at universities, technical colleges and in plants. It allows the user to apply ten different VA measurement techniques and to compare their results.

• The determination mode is used for quantitative analy-

sis of inorganic or organic substances. Calibration can be done

via standard addition or calibration curves. Additionally, a multitude of electroplating bath calibration techniques are available. Signal evaluation and concentration calculation are automatic. On completion of the measurement, a report can be

compiled to suit individual requirements and printed out. The

most important methods for the determination of metals or

other substances can be called up directly. All curves appearing

on the screen, i.e. voltammograms and calibration curves plus

the results can be transferred to other Windows applications

via the Windows Clipboard. Data export in ASCII format is also

possible.

797 VA Computrace – Software

1

Page 14

1 Introduction

1.2 General information

Hardware requirements for the PC

Computer Pentium III with 1 GHz or higher

Operating system Windows™ 2000, Windows™ XP Pro-

Free space on hard disk 40 MB for program files

Working memory RAM 256 MB

Graphics resolution 1024×768 or more

Interface 1 free USB connection

Printer Any printer supported by operating

Note: Set the screen saver to "None" and deactivate any energy

saving features. Additionally, do not use several other programs

together with VA Computrace.

fessional, Windows™ Vista Professional

system

Demo version

If the 797 VA Computrace Software 1.3.x (6.6053.030) is installed

on a PC without installation of VA Computrace stand, this software

can be used as a demo version, which is restricted to the recalculation of determination or signal files.

Registration

Please send us your 8.797.8027 Registration card as soon as

possible. Only registered users will get updated program versions at

a special price.

1.3 Installation

Installation of the hardware

1. Switch on PC and start operating system (Windows™ 2000,

Windows™ XP Professional, Windows™ Vista Professional)

without connection of the VA Computrace via USB cable.

2. Insert installation CD into CD drive.

3. If the autorun option for the CD drive is disabled, select <Start>

and Run. Browse for the Setup.exe file on the installation CD

and click on

4. Click on "

program.

<OK>.

797" and follow the instructions given in the setup

5. The software package will be installed in the desired directory

(the default directory is Program Files/Metrohm/797 VA Compu-

trace

). In addition to the program files, the following folders

are installed:

2

797 VA Computrace – Software

Page 15

1.3 Installation

Data

Folder for storage of new signal (*.sig) and deter-

mination files (*.dth). In Windows Vista, this folder

is stored in ProgramData/Metrohm/797 VA Com-

putrace

Demo data

.

Folder containing signal and determination file ex-

amples. The subfolder CVS contains examples for

the electroplating bath analysis, the subfolder

Practical Voltammetry all examples of the

8.757.5003 Metrohm Monograph "Practical Voltammetry", which is available from

Metrohm on request. In Windows Vista, this folder

is stored in ProgramData/Metrohm/797 VA Com-

putrace.

Note: The signal and determination file examples are

installed as read-only.

Firmware

Folder for storage of new files (*.exe) for a firmware update.

Hardware

Folder for storage of firmware files (*.x).

Method

Folder for storage of method files (*.mth). You find

some basic examples in the Method folder and

more examples in the subfolders Application Bulle-

tin

, Application Notes and CVS. In Windows Vista,

this folder is stored in ProgramData/Metrohm/797

VA Computrace.

XML

Folder for storage of files which are needed for

viewing XML files in a browser.

6. Connect VA Computrace to the PC using the 6.2151.020

USB cable. The PC detects a new USB device and starts the

setup wizard. Insert installation CD into CD drive and follow the

wizard instructions always selecting the recommended default

options.

7. Start the 797 VA Computrace software.

8. In the login-window click Start measurements without entering

anything for Name and Password.

Installation of Dosing Devices

797 VA Computrace – Software

Up to seven Dosing Devices (possible: 700/800 Dosino, 685/805

Dosimat) can be connected to the MSB ports of the 797 VA Com-

putrace stand or (in case you installed one) the 846 Dosing Interface.

Connection of Dosing Devices:

1. Switch off the 797 VA Computrace stand.

3

Page 16

1 Introduction

2. If required, connect the 846 Dosing Interface to one of the USB

ports of the 797 VA Computrace or the PC. Connect the 846

Dosing Interface to the mains supply.

3. Connect the Dosing Device via MSB connection to the 797 VA

Computrace stand or the 846 Dosing Interface.

4. Switch on the 797 VA Computrace stand.

5. Open 797 VA Computrace Software 1.3.x and log in.

6. Open the

tings

GENERAL SETTINGS window in MAIN WINDOW / Set-

, activate the Dosinos (or Dosing Interface) tab and click

the button.

7. Choose for menu item Prep/Empty via port the port which is

used for the functions "Prep" and "Empty". Recommended is

Port 3 (doesn't lead to the measuring cell but to a waste container). Using Port 3 you can reduce contamination of the

measuring cell and the electrode. Moreover the dosing unit can

be rinsed and emptied faster.

Note: If you choose Port 3 for menu item Prep/Empty via

port, you must install an FEP Tubing Connection

6.1805.530 from Port 3 to a waste container.

8. Choose the number for No. of Prep cycles. It defines the num-

ber of "Prep-Cycles" conducted before starting the measurement or before starting the sample table.

Installation of 863 Compact VA Autosampler

For automated voltammetric trace analysis it is possible to connect

an 863 Compact VA Autosampler, a 843 Pump Station and

up to three Dosing Devices (four more with a 846 Dosing Interface) to the 797 VA Computrace stand. Proceed as follows:

1. Switch on the PC

2. Connect the 797 VA Computrace stand and the 843

Pump Station (Remote 1) using the cable 6.2141.280 (see

797 Hardware Manual).

3. Connect 863 Compact VA Autosampler and the 843

Pump Station (Remote 2) using cable 6.2141.230.

4. Install the accessories on the 863 Compact VA Autosam-

pler (see 797 Hardware Manual).

5. Connect the Dosing Devices to the 797 VA Computrace or the

846 Dosing Interface (via MSB).

6. Connect the 797 VA Computrace stand to the PC (via

USB).

7. Switch on the 797 VA Computrace stand, the 863 Com-

pact VA Autosampler and the 843 Pump Station.

8. Set Method 2 at the 863 Compact VA Autosampler (see

863 Instructions for Use).

4

797 VA Computrace – Software

Page 17

1.3 Installation

9. Start the 797 VA Computrace Software 1.3.x.

10. Set hardware settings for the 863 Compact VA Autosam-

pler.

11. Check the checkbox for

mation

tab of the GENERAL SETTINGS window, and define

Relay box / Pump Station on the Auto-

the default settings for the pumps.

12. Set hardware settings for Dosing Devices.

13. Define the addition or predose solution in the DOSINOS win-

dow.

Installation of 838 Advanced Sample Processor

To automate Electroplating bath analysis with CVS it is possible to

connect an 838 Advanced Sample Processor, a 843 Pump

Station and up to three Dosing Devices (four more with a 846

Dosing Interface) to the 797 VA Computrace stand. Additionally,

up to three Dosing Devices can be connected to the 838 Ad-

vanced Sample Processor via MSB (but they can't be controlled

by the 797 Software in that case). Proceed as follows

1. Switch on the PC.

2. Connect the 797 VA Computrace stand and the 843

Pump Station (Remote 1) using cable 6.2141.290 (see 797

Hardware Manual).

3. Connect the 838 Advanced Sample Processor and the

843 Pump Station (Remote 2) using cable 6.2141.290.

4. Install the accessories on the 838 Advanced Sample Proc-

essor (see 797 Hardware Manual).

5. Connect the Dosing Devices to the 797 VA Computrace or to

the 846 Dosing Interface (or the 838 Advanced Sample Processor) (via MSB).

6. Connect the 797 VA Computrace stand to the PC (via

USB).

7. Switch on the 797 VA Computrace stand, the 838 Ad-

vanced Sample Processor and the 843 Pump Station.

8. Specify a suitable method at the 838 Advanced Sample Proces-

sor and adjust it if necessary (see 838 Manual).

9. Start the 797 VA Computrace Software 1.3.x.

10. Choose the 838 Advanced Sample Processor for menu

item Sample Processor on the Automation tab of the GEN-

ERAL SETTINGS window, and check the field Relay box /

Pump Station

on the Automation tab of the GENERAL SET-

TINGS window.

797 VA Computrace – Software

11. Make hardware settings for the 838 Advanced Sample

Processor, and define the default settings for the 843 Pump

Station.

5

Page 18

1 Introduction

12. Make hardware settings for Dosing Devices.

13. Define the addition or predose solution in the DOSINOS window.

Deinstallation

1. Select <Start> / Settings / Control panel.

2. Double-click the Software icon.

3. Select 797 VA Computrace in the list and click on

<Add/remove>. Select the Remove option and click on <Next>.

All program files and icons should be removed.

1.4 Overview of program windows

797 VA Computrace consists of different windows whose functionality is linked together. The different windows are:

MAIN WINDOW File administration, printing, mode se-

lection, opening of other program windows, utilities, login and user rights,

settings, window handling

EXPLORATORY SPECIFICATIONS

Method definition for exploratory

mode

EXPLORATORY CURVES Display of exploratory mode curves and

curve evaluation

WORKING METHOD SPECIFICATIONS

Definition of the working method for

determination mode

MONITOR Start of determinations, live display

DETERMINATION CURVES Display of determination and calibra-

tion curves, modification and recalculation of determinations

RESULTS Display of determination reports

SAMPLE TABLE Display of sample table (only available

if "863 Compact VA Autosampler", or

"838 advanced Sample Processor" and

Use sample table is selected for Working method source

on the Automation

tab of the GENERAL SETTINGS window)

COMPUTRACE CONTROL Manual control of 797 VA Computrace

stand

DOSINO CONTROL Manual control of Dosing Devices

(Possible: 700/800 Dosino, 685/805

Dosimat)

6

797 VA Computrace – Software

Page 19

1.5 Overview of file types

PUMP CONTROL Manual control of siphoning and rins-

ing pump

FILM DEPOSITION Program for Hg film deposition on

solid state electrodes

CLEANING PROCEDURE Program for cleaning procedures for

solid state electrodes

1.5 Overview of file types

The following file types are produced by the 797 VA Computrace

Software 1.3.x:

*.csv Text file in .csv-format (ASCII file) for data ex-

port

Results can be stored as .csv-file. CSV stands for

comma separated values, i.e. the entries of a file

are separated by a comma.

Text files in .csv-format suit perfectly for the import in spreadsheets like Microsoft Excel.

The .csv-files are also used for data import into a

LIMS (Labor Information Management System).

*.dth Determination file (binary file)

Contains determination data and method.

The *.dth file is stored automatically in the Data

folder if the autosave option is enabled in the

GENERAL SETTINGS window.

*.mth Method file (binary file)

Contains the method.

*.sig Signal file (binary file)

Contains exploratory data and exploratory method. The *.sig file is stored automatically in the

Data folder if the autosave option is enabled in the

GENERAL SETTINGS window.

*.spt Sample table file (binary file)

Contains sample table data.

*.txt Text file (ASCII file) for data export

A *.txt file is produced if methods, results, measurement points of determination files or measurement points of signal files are exported.

In the case of methods, this data file contains a

block of working method and sample data followed by the voltammetric parameters block and a

peak evaluation block. On the bottom, it has a

block substance evaluation, a block baseline, a

block solutions and a block export options.

In the case of results, this data file contains a

block of determination data followed by a method

and a sample data block. On the bottom are a

substance evaluation, a solutions and a final re-

797 VA Computrace – Software

7

Page 20

1 Introduction

sults block.

In the case of determination point export,

this data file contains a block of the used method

parameters followed by the sweep blocks of X and

Y values each preceded by VR number and number of measurement points.

In the case of extended determination point

export, this data file contains a block of the used

method parameters followed by the voltammetric

parameters, a block peak evaluation, a block baseline, a block solutions, a block export options and

the sweep blocks of X and Y values each preceded

by VR number and number of measurement

points.

In the case of signal points, this data file contains a block of the used method parameters followed by the sweep block of X and Y values preceded by the number of measurement points.

The

*.txt files can be imported into spreadsheet

programs like Microsoft Excel.

*.xml Text file in .xml-format (ASCII file) for data

export

Results can be stored as .xml-file. The three files

CT797.css, CT797.xsd and CT797.xsl will be exported along. They are needed for viewing the results in a web browser.

The .xml-files are also used for data import into a

LIMS (Labor Information Management System).

1.6 Context sensitive menus

Most of the menu functions of the program windows are also accessible by clicking on the desired window or item and pressing the

right mouse button. The pop up windows have different contents and functions depending on the selected active window or

item type.

8

797 VA Computrace – Software

Page 21

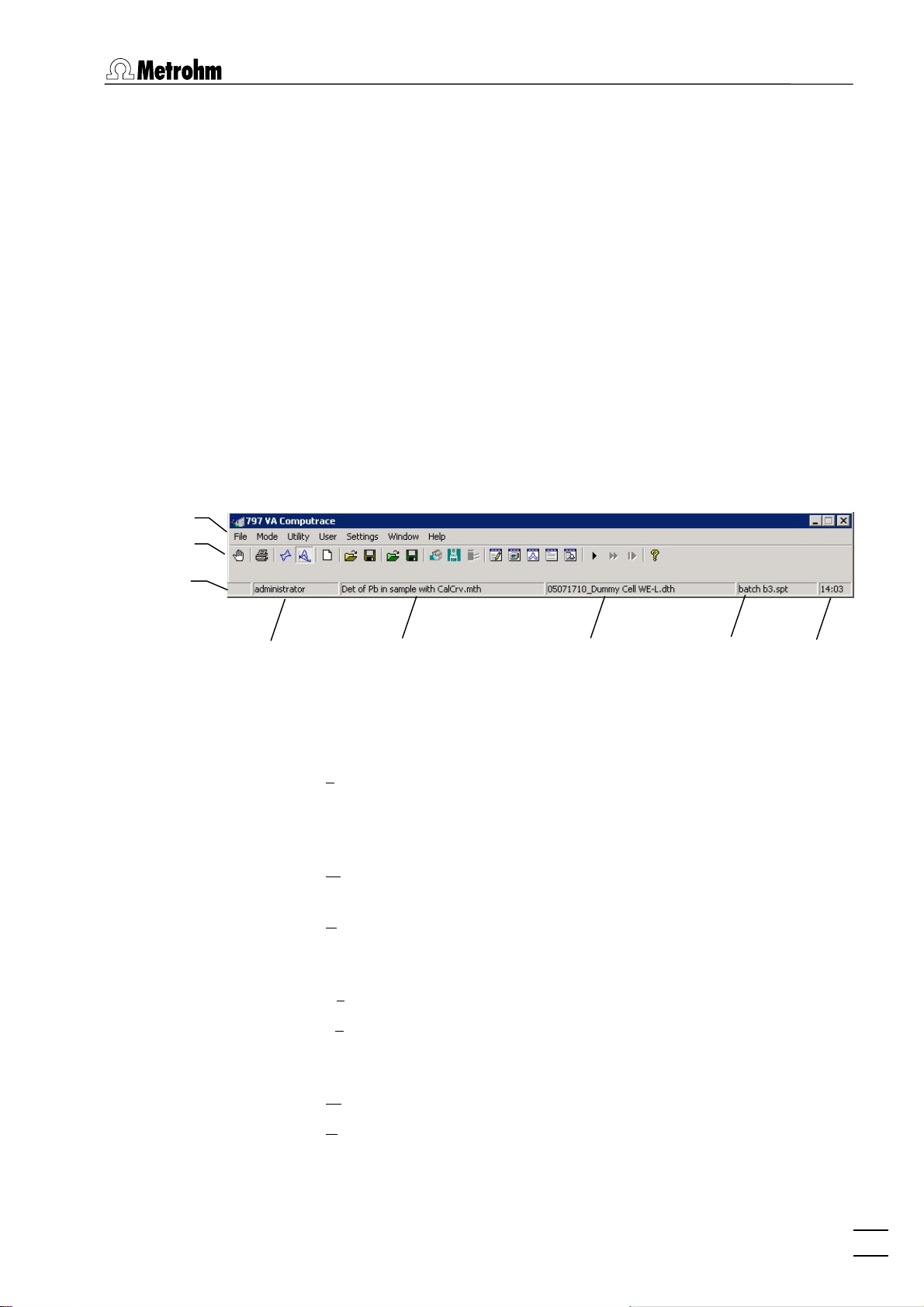

2.1 Main window overview

2 Main window

2.1 Main window overview

Main window elements

The MAIN WINDOW is the center of the 797 VA Computrace Soft-

ware 1.3.x. Its elements are the menu bar, the tool bar and the sta-

tus bar indicating user, method and determination.

Menu bar

Tool bar

Status bar

Logged-in

user

Main window menus

Method in

working memory

Determination in

working memory

Sample table in

working memory

Time

File Loading, saving and export of method, determina-

tion and signal files; printing of reports and

curves, loading and saving of determinations with

the Autodatabase

Mode Switching between exploratory and determination

mode

Utility VA Computrace stand control; Dosino control;

pump control; film deposition and cleaning procedure for solid state electrodes

User Login, user rights entry and overview

Settings General settings for saving, Autodatabase, au-

tomation, Dosing Devices, relay box, remote control, GLP

Window Tiling, opening and closing of program windows

Help Call context-sensitive Help and Help contents

797 VA Computrace – Software

9

Page 22

2 Main window

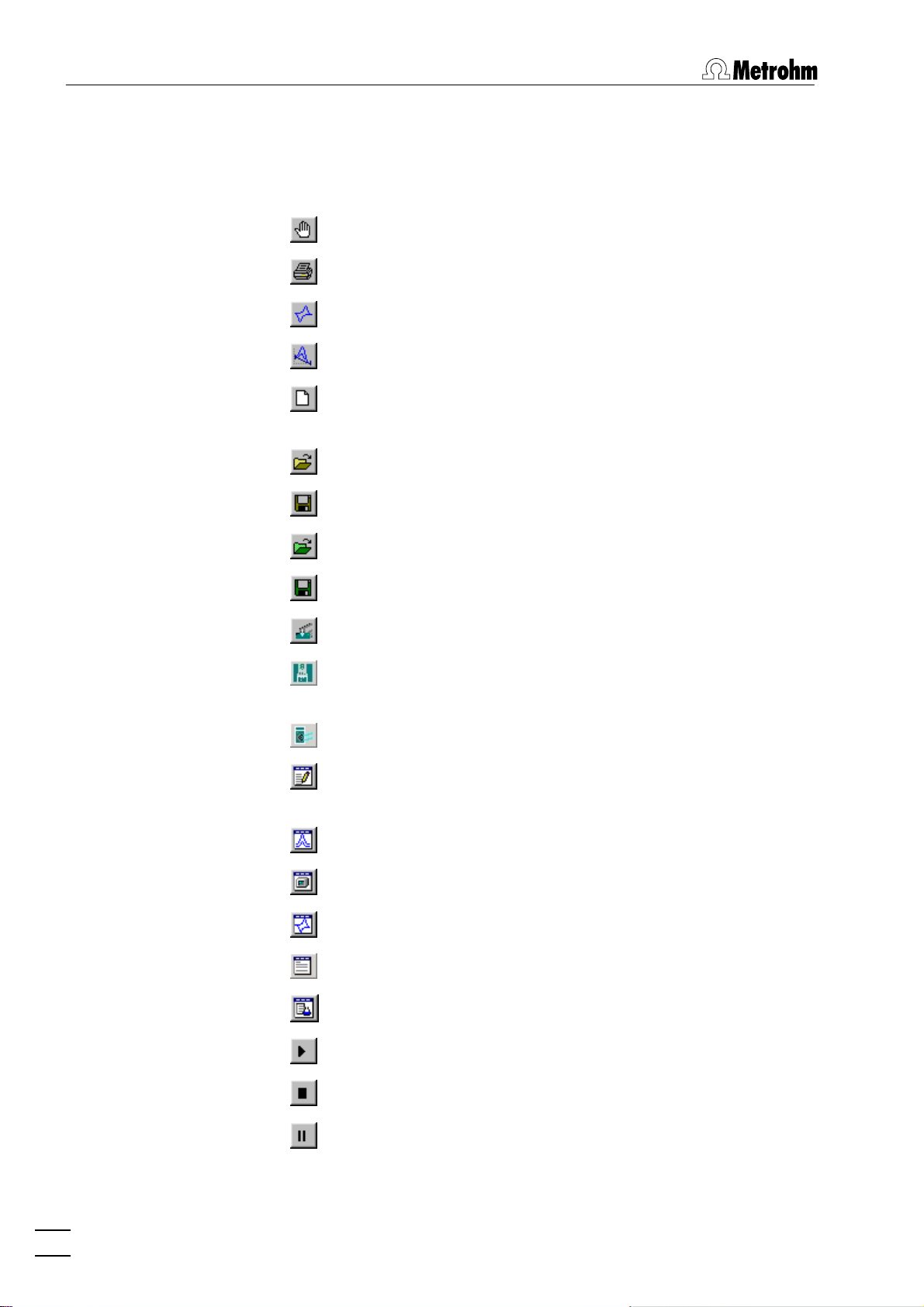

Main window icons

It depends on the selected mode (exploratory or determination)

whether the following icons are displayed in the MAIN WINDOW or

not.

Exit the VA Computrace program.

Print reports and curves.

Switch to exploratory mode.

Switch to determination mode.

Load default parameters for exploratory or determination

mode.

Load existing method or signal file.

Save method or signal file.

Load existing determination file.

Save determination file.

Manual control of 797 VA Computrace stand.

Manual control of Dosing Devices connected to the 797

VA Computrace stand.

Manual control of pumps.

Open or close WORKING METHOD SPECIFICATIONS or EX-

PLORATORY SPECIFICATION

window.

Open or close DETERMINATION CURVES window.

Open or close MONITOR window for determinations.

Open or close EXPLORATORY CURVES window.

Open or close RESULTS window for determinations.

Open or close SAMPLE TABLE window.

Start measurement.

Stop measurement.

Hold measurement.

10

797 VA Computrace – Software

Page 23

2.2 Starting/closing the program

Continue measurement.

Go to next step in operation sequence.

Help.

2.2 Starting/closing the program

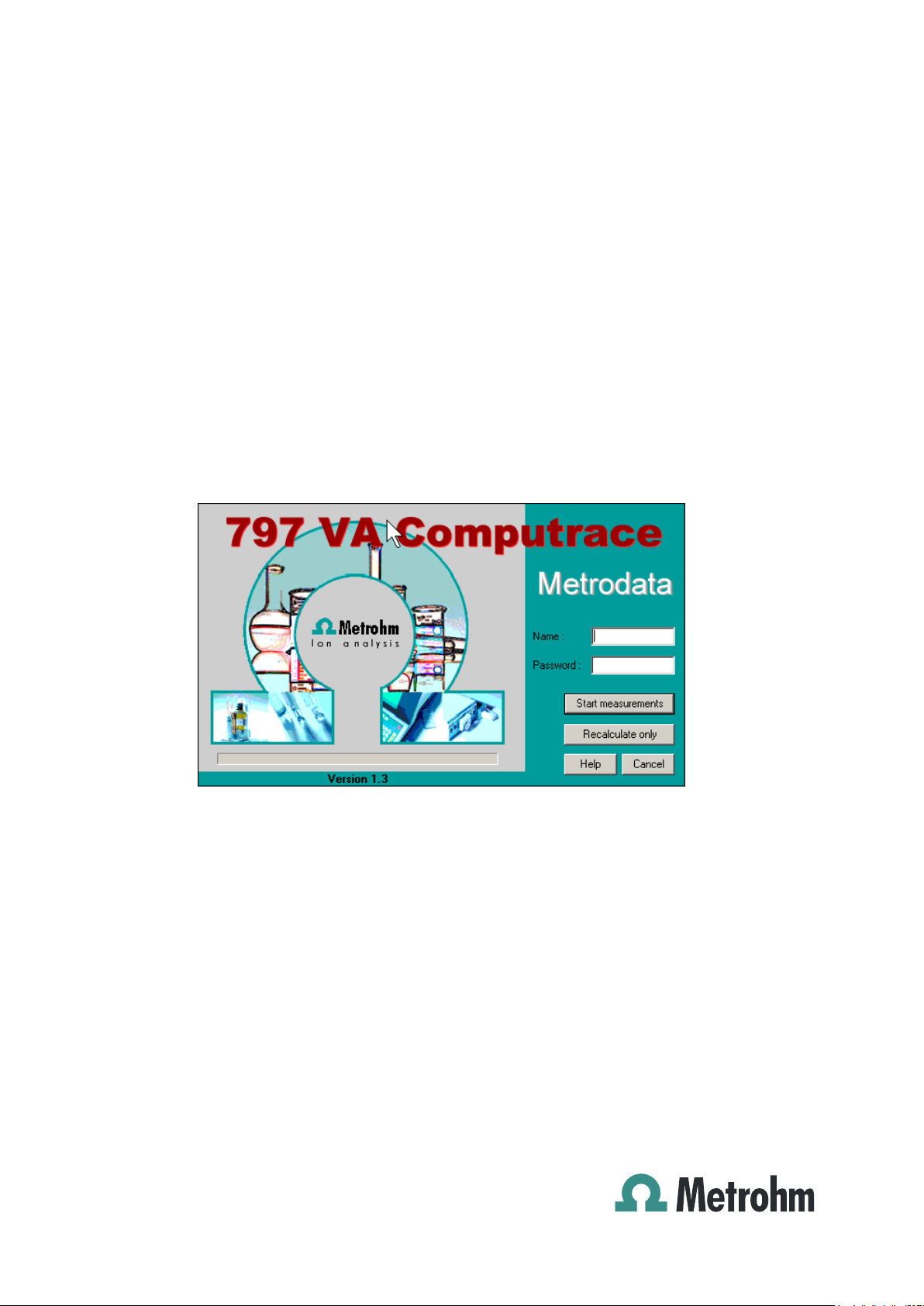

Starting the VA Computrace program

Start the Program

Double-click the 797 VA Computrace icon or the

Ct797.exe file to start the 797 VA Computrace

program. The 797 VA COMPUTRACE LOGIN window appears.

Enter

Note: After software installation, the program can be started without entering Name and Password. For the definition of users, see

section 2.6 User rights.

Closing the VA Computrace program

MAIN WINDOW / File / Exit

The program is also quit by clicking on

797 VA Computrace – Software

Name and Password and select the desired

option

ments or

Start measurements for starting measure-

Recalculate only for recalculation.

Exit the VA Computrace program.

upper right part of the

MAIN WINDOW.

in the

11

Page 24

2 Main window

2.3 File menu

Method files

Method files (*.mth) contain all the specifications and parameters

for running a determination. They can only be loaded or saved in

the determination mode.

MAIN WINDOW / File / New method (Ctrl+N)

Load a standard template with the selected mode

for creating a new method.

MAIN WINDOW / File / Load method (Ctrl+O)

Load an existing method file. Normally, method

files are stored in the Method folder.

MAIN WINDOW / File / Save method (Ctrl+S)

Save the current method loaded in the working

memory. The old file will be overwritten.

Determination files

MAIN WINDOW / File / Save method as ...

Save the current method loaded in the working

memory in a new file. Enter name and directory

for storage of the method file.

797 VA COMPUTRACE / File / Export method ...

Save the current method loaded in the working

memory into an ASCII file (extension *.txt). This file

contains all method parameters.

Determination files (*.dth) contain the measurement data and the

specifications of the method used for the determination. They can

only be loaded or saved in the determination mode.

MAIN WINDOW / File / Load determination

Load an existing determination file. Normally, determination files are stored in the Data folder.

MAIN WINDOW / File / Save determination

Save the current determination loaded in the working memory. The old file will be overwritten.

MAIN WINDOW / File / Save determination as ...

Save the current determination loaded in the

working memory in a new file. Enter name and directory for storage of the determination file.

MAIN WINDOW / File / Export determination points

Save the measurement points of all sweeps of the

current determination loaded in the working

12

797 VA Computrace – Software

Page 25

2.3 File menu

memory into a data file (extension *.txt). This data

file contains a block of the used method parameters followed by the sweep blocks of X and Y values each preceded by VR number and number of

measurement points. The data files can be imported into spreadsheet programs like Microsoft

Excel.

MAIN WINDOW / FILE / EXPORT EXTENDED DETERMINA-

TION POINTS...

In the case of extended determination point

export, this data file contains a block of the used

method parameters followed by the voltammetric

parameters, a block peak evaluation, a block baseline, a block solutions, a block export options and

the sweep blocks of X and Y values each preceded

by VR number and number of measurement

points.

MAIN WINDOW / FILE / EXPORT RESULTS / CURRENT DE-

TERMINATION...

Save the results report of the current determination loaded in the working memory into an ASCII

file with extension *.txt, *.csv, or *.xml. This file

can be imported into spreadsheet programs like

Microsoft Excel (*.txt und *.csv) or in a LIMS (*.csv

and *.xml).

MAIN WINDOW / FILE / EXPORT RESULTS / DETERMINA-

TIONS...

Save the results report of the selected determination into an ASCII file with extension *.txt, *.csv,

or *.xml. This file can be imported into spread-

sheet programs like Microsoft Excel (*.txt und

*.csv) or in a LIMS (*.csv and *.xml).

Export/Import of Data with Autodatabase

MAIN WINDOW / File / Export To Database / Current De-

termination

Export the data from the current determination to

the database.

Procedure after starting Export To Database / Cur-

rent Determination

If Ask for database file.. is activated for Manual

Transfer Mode

ERAL SETTINGS

NATION DATABASE FILE

choose the database file where the current determination is stored.

If Use default database file.. is activated, the current determination is stored automatically in the

Default database file.

MAIN WINDOW / File / Export To Database / Determination

Files..

797 VA Computrace – Software

:

on the Database tab in the GEN-

window, the SELECT DETERMI-

window opens, and you

13

Page 26

2 Main window

Export previously saved determination data to the

database.

Procedure after starting

termination Files..

The Select Determination Files window opens,

choose the determination(s) you want to export

and click <Open>.

If Ask for database file.. is activated for Manual

Transfer Mode

ERAL SETTINGS

NATION DATABASE FILE

on the Database tab in the GEN-

window, the SELECT DETERMI-

choose the database file where the selected determination(s) is(are) stored.

If Use default database file.. is activated, the selected determination(s) is(are) stored automatically

in the Default database file.

Note: If you work with the new program version «797 VA

Computrace Software 1.3.x» and try to export to a database created with an old program version «797 VA Computrace Software 1.X», an error message appears (see

Error message "Please select a new database file"). If you

work with the «797 VA Computrace Software 1.3.x», export only to databases created with «797 VA Computrace

Software 1.3.x».

Export To Database / De-

window opens, and you

Signal files

MAIN WINDOW / File / Import from Database..

Import a determination from the database.

Note: Before importing: In your Autodatabase

software, open database file from which you want

to export a determination. Open next a report

template in the report window of your Autodatabase software. Select then the determination in

EXPLORER window first, before clicking on the

the

REPORT window to activate it (highlighted).

Signal files (*.sig) contain the measurement data and specifications

of a signal recorded in the exploratory mode. They can only be

loaded or saved in this mode.

MAIN WINDOW / File / New parameters

Load default parameters for selected electrode

and measurement mode.

MAIN WINDOW / File / Load signal

Load an existing signal file. Normally, signal files

are stored in the

14

797 VA Computrace – Software

Data folder.

Page 27

2.4 Mode menu

MAIN WINDOW / File / Save signal as ...

Save the current signal loaded in the working

memory in a new file. Enter name and directory

for storage of the signal file.

MAIN WINDOW / File / Export signal points

Save the measurement points of the sweep of the

current signal loaded in the working memory into

a data file (extension *.txt). This data file contains

a block of the used method parameters followed

by the sweep block of X and Y values preceded by

the number of measurement points. The data files

can be imported into spreadsheet programs like

Microsoft Excel.

Printing of reports and curves

MAIN WINDOW / File / Print (Ctrl+P)

Print reports and/or curves. Depending on the

mode selection, a window appears for selection of

the items to be printed (see section 4.4 Printing in

exploratory mode for exploratory mode, and section 5.7 Printing in determination mode for de-

termination mode).

MAIN WINDOW / File / Printer setup

MAIN WINDOW / File / Print GLP report

Program exit

MAIN WINDOW / File / Exit

The program is also quit by clicking on in the

2.4 Mode menu

Exploratory mode selection

MAIN WINDOW / Mode / Exploratory

Selection of a printer and definition of paper size

and format.

Print a GLP report created with the GLP Wizard.

Quit the VA Computrace program.

upper right part of the

MAIN WINDOW.

Switching to the exploratory mode for recording

and displaying of signals (see section 4).

Determination mode selection

MAIN WINDOW / Mode / Determination

Switching to the determination mode for recor-

797 VA Computrace – Software

15

Page 28

2 Main window

2.5 Utility menu

Computrace control selection

MAIN WINDOW / Utility / Computrace control

Dosing Device control selection

MAIN WINDOW / Utility / Dosino control

ding and displaying of determinations (see section

5).

Start manual control of 797 VA Computrace stand

(details see section 7.1).

Control of Dosing Devices (Possible: 700/800 Dosinos; 685/805 Dosimats) connected to the 797 VA

Computrace stand or to the 846 Dosing Interface

(details see section

7.2).

Pump control selection

MAIN WINDOW / Utility / Pump control

Film deposition selection

MAIN WINDOW / Utility / Film deposition

Cleaning procedure selection

MAIN WINDOW / Utility / Cleaning procedure

Start manual control of Pumps connected to the

797 VA Computrace stand. (details see section

7.3).

Start Hg film deposition for solid state electrodes

in the 797 VA Computrace stand (details see sec-

tion 7.4).

Start cleaning procedure for solid state electrodes

in the 797 VA Computrace stand (details see sec-

tion 7.5).

2.6 User menu

Login

MAIN WINDOW / User / Login

797 VA COMPUTRACE LOGIN window ap-

The

16

797 VA Computrace – Software

pears.

Page 29

2.6 User menu

Enter the desired Name and Password to login as

a new user and click

OK.

Note: In case that the firmware of your 797 VA Compu-

trace stand is version 3.01 or older, the firmware update

dialog starts automatically after login. To update the firmware, confirm each step with <OK> or <Next>. The information about the version of the firmware can be gathered

from the window Info (this window can be opened via

MAIN WINDOW / Help / About 797 VA Computrace ... ).

User rights

The «VA Computrace» program has a security system based on a

list of user rights. For every user or user category, a password and

different access levels can be defined. We recommend to make a

new user list and enter passwords as a first action after system installation.

MAIN WINDOW / User / User rights

The

USER RIGHTS window appears. It contains the

two tabs User Rights and User Directories.

797 VA Computrace – Software

17

Page 30

2 Main window

User

List of all users. The user rights are displayed for

the selected and highlighted user. The following

users with blank passwords are defined as default

examples:

Administrator

Access to all program parts and allowance to change the user rights.

Analist

Read only access to working method,

curves/results and general settings.

Creator

Only access to Working method and Exploratory mode.

Measure

Read only access to working method,

curves/results, no access to general settings and printing.

ReadOnly

Read only access to working method,

curves/results and general settings.

" " (empty)

Blank user. Access to all program parts

and allowance to change the user rights.

Name

Display of user name (read only). For addition of a

new user name click the <New> button.

Password [ max. 21 characters ]

Change password for user. A " * " is displayed for

each character entered.

18

797 VA Computrace – Software

Page 31

2.6 User menu

User rights

The different user rights options can be changed

for the selected user:

none No access to this program part.

R Permission to read in this program part.

R/W Permission to read/write in this program

part.

Change allowance

Permission to edit the user rights.

Add a new user to the users list. The ADD NEW

USER

window appears.

Name [ max. 13 characters; ]

User name. This name is inserted in the User field

of all reports and results windows.

Password [ max. 21 characters ]

Enter password for user. A " * " is displayed for

each character entered.

Remove a user from the users list.

Note: GLP can only be started if there is no blank user. Blank user

has to be removed to apply GLP.

797 VA Computrace – Software

19

Page 32

2 Main window

User rights overview

Use default locations

Set default directories for Data folder and Method

folder

.

Data folder

User specific folder for determination and signal

files. Use <Browse> to change the folder.

Method folder

User specific folder for method files. Use

<Browse> to change the folder.

MAIN WINDOW / User / Overview

The OVERVIEW window displaying the list of all

users appears.

Detailed user list with all user rights.

User list without user rights.

User list with small icons.

Help.

2.7 Settings menu

General settings

MAIN WINDOW / Settings / General Settings

User list with large icons.

On the General tab of the GENERAL SETTINGS

window general settings can be defined, e.g. for

automatic storage or for conducting electrode

tests.

20

797 VA Computrace – Software

Page 33

2.7 Settings menu

Auto save options

Auto save determination and signal

If this option is enabled, every signal or determination file is stored automatically in the data folder

(defined in the User Directories tab of the USER

RIGHTS

window) after the end of the measure-

ment.

Save calibration curves additionally without date and time

If this option is enabled, every determination will

be saved twice, once with date/time and the defined Sample ID (e.g. "07181430_CalibrationLead.dth"), and once only with the Sample ID (e.g.

"CalibrationLead.dth"). That enables automatically

overwriting of files.

Activation of this option enables automatic (re)calibration of methods during an automated sample

run with a sample changer. It also enables automatic re-determination of the "Intercept value"

with the LAT technique for analyzing electroplating baths.

This possibilities apply for the VA-Calibration

technique "Record calibration curve"; and the

electroplating bath Calibration techniques "DT Record calibration curve", "LAT Record intercept

value" and "RC Record response curve".

Options for CSV export

797 VA Computrace – Software

21

Page 34

2 Main window

Basic settings for the csv export.

Record delimiter

Selection of the characters which will separate the

determinations resp. results:

CR/LF

Carriage Return and Line Feed (standard)

CR

Only Carriage Return

LF

Only Line Feed

Field delimiter

Selection of the characters which will separate the

data fields:

Semicolon

Semicolon (standard)

Comma

Comma

Tab

Tabulator

Text qualifier

Selection of the character which defines a string

as text:

“

Double quote (standard)

‘

Single quote

none

no character

Electrode test

Selection of the electrode test settings.

Perform electrode test

If this option is activated, an electrode test is conducted automatically before each determination:

When test fails

Wahl was bei missglücktem Test geschehen soll:

stop measurement

Stop determination.

continue measurement

Continue determination.

Audio files

Selection of the sound which should remind a user

of taking an action.

22

797 VA Computrace – Software

Page 35

2.7 Settings menu

Dosing settings

MAIN WINDOW / Settings / General Settings

On the Dosinos tab of the GENERAL SETTINGS

windows, the default settings for Dosing Devices

which are connected to the 797 VA Computrace

can be defined.

On the Dosing Interface tab of the GENERAL SET-

TINGS

windows, the default settings for Dosing

Devices which are connected to the 846 Dosing

Interface can be defined. This tab is only displayed

if a 846 Dosing Interface is connected.

Dosinos / Dosing Interface

Settings for the Dosing Devices (possible: 700/800

Dosino, 685/805 Dosimat) connected to the 797

VA Computrace stand or the 846 Dosing Interface

(details see section 1.3 Installation of Dosing De-

vices).

Dosino no.

Defined by the number of the used MSB-port.

Dosino Device MSB

1 797 VA Computrace MSB1

2 797 VA Computrace MSB2

3 797 VA Computrace MSB3

797 VA Computrace – Software

23

Page 36

2 Main window

Dosino Device MSB

4 846 Dosing Interface MSB1

5 846 Dosing Interface MSB2

6 846 Dosing Interface MSB3

7 846 Dosing Interface MSB4

Volume Burette (mL) [read only]

Volume of the exchange unit of the Dosing Device.

Type [read only]

Which Dosing Device is connected (possible:

700/800 Dosino, 685/805 Dosimat).

Dose rate (mL/min) [ 0.01 ... 166 mL/min (depending on

dosing/exchange unit); 2 mL/min ]

Dosing rate of the Dosing Device. The dose rate is

limited by the 3.333 fold volume of the burette

per minute.

Note: If the diameter of Tube out is smaller than

1 mm, the maximum Dose rate is generally limited

to 4 mL/min.

Fill rate (mL/min) [ 0.01 ... 166 mL/min (depending on dos-

ing/exchange unit); 3 * Volume Burette / min ]

Filling rate of Dosing Device.

Tube in

φ (mm)

Diameter of the tube going in the Dosing Device

(Dosino: Port 2).

length (cm)

Length of the tube going in the Dosing Device

(Dosino: Port 2).

Tube out

φ (mm)

Diameter of the tube going out the Dosing Device

(Dosino: Port 1).

length (cm)

Length of the tube going out the Dosing Device

(Dosino: Port 1).

Note: If a tube is removed and replaced by a tube

with a different diameter, change first the parameter Tube (in/out) φ (mm), and afterwards the

parameter Dose rate (mL/min).

Prep / Empty via port [ 1, 3 ; 1 ]

Choose the port which is used for the functions

"Prep" and "Empty". Recommended is Port 3

(does not lead to the measuring cell but to a

24

797 VA Computrace – Software

Page 37

2.7 Settings menu

waste container). Using Port 3 you can reduce

contamination of the measuring cell and the electrode. Moreover the emptying can be conducted

faster.

Note: If you choose Port 3 for menu item

Prep/Empty via port, you must install an FEP

Tubing Connection 6.1805.530 from Port 3

to a waste container.

No. of Prep cycles [ 0, 1, ... ,5 ; 0 ]

Define the number of "Prep-Cycles" for the respective Dosino.

If you work with a sample table, the defined

number of "Prep Cycles" is conducted at the beginning of the sample table. Exception: With the

two DT Calibration techniques "DT Record calibration curve" and "DT Suppressors with calibration

curve", Dosino 3 is "preped" at the beginning of

every determination (with or without sample table).

If you work without sample changer, the defined number of "Prep Cycles" is conducted at the

beginning of each determination. If you work

without sample changer it is recommended to set

this parameter on 0, and conduct "Preps" manually.

Automation

Refresh

Update of the Dosing Device connections.

Default

Set the Dosing Device parameters back to their

default values.

MAIN WINDOW / Settings / General Settings

In the GENERAL SETTINGS window default settings for the operation of a 863 Compact VA

Autosampler / 838 Advanced Sample Processor and the 731 Relay Box to control two

772 Pump Units / 823 Membrane Pump

Units or the 843 Pump Station can be defined

with the Automation tab.

797 VA Computrace – Software

25

Page 38

2 Main window

With 843:

With 838:

26

797 VA Computrace – Software

Page 39

2.7 Settings menu

Sample handling

Define the default settings of a connected used

automation unit.

Sample processor [ read only ]

Select the connected sample processor.

Time to change sample [ > 25 s ; 30 s ] (only with the 863

Compact VA Autosampler)

During that time, the rack is changed to the next

position and the needle is immersed into the sample solution. It is the time between first and second remote signal that are sent from 797 Computrace to the Autosampler (see 863 Manual).

Sample transfer time (s) [ > 20 s ; 300 s (with 863) / 9999 s

(with 838) ]

With 863: Time to transfer the sample solution

from the sample vessel to the measurement vessel

using the peristaltic pump of the 863 Compact VA

Autosampler.

With 838: During that time the 797 Computrace

waits for an incoming signal (Handshake) from the

838 Advanced Sample Processor. That signal indicates that the sample has been changed and

transferred to the measuring vessel.

Working method source [ use sample table, repeat current

method ]

Define the sample sequence. With use sample ta-

ble

, the working method can be defined individually for each sample. With repeat current method

the current working method is taken for all samples.

Delay next sample

Define the waiting period between measuring two

samples.

Repeat sample table, delay (h)

sample table

)

(only applicable with use

Check the checkbox if you want to repeat the

sample sequence, and define the waiting period.

Number of samples (-1 for infinity) (only with repeat cur-

rent method

)

Define the number of samples you want to measure.

Purge and stir during sample transfer

Check the checkbox if you want to purge the

sample during transfer to the measurement vessel.

Dose auxiliary solution via sample processor

If you want to add solutions via Dosinos connected to the 838 Advanced Sample Processor,

this box must be checked to ensure the operation

797 VA Computrace – Software

27

Page 40

2 Main window

of the program at the 838 Advanced Sample Processor.

Rinsing

Define the default settings of a possibly used

pump unit.

Relay box / Pump Station

Check the checkbox if a 843 Pump Station or a

731 Relay Box with 772 Pump Units or 823 Membrane Pump Units is connected.

Automatic rinsing

Check the checkbox to rinse automatically.

Note: If Automatic rinsing is activated, the measuring cell is siphoned off at the beginning of

every determination. If you work with manual

sample addition, the sample should not be added

until the siphoning process has finished and the

message window PLACE SAMPLE appears.

No. of rinsing cycles

Number of rinsing cycles.

Default: 3

Siphoning time (s)

For each rinsing cycle, the measuring vessel is siphoned off during that time, using a 843 Pump

Station (or 823 Membrane Pump Unit).

Default: 25 s

Rinsing time (s)

For each rinsing cycle, the measuring vessel is

rinsed during that time, using a 772 Pump Unit (or

823 Membrane Pump Unit).

Default: 8 s

Remote control (not accessible with 863 Compact VA Autosampler)

Define the communication with connected devices.

Remote start

797 VA Computrace waits for an incoming signal

to start the measurement.

End of sample

Send a signal after measuring the sample.

End of sample table

Send a signal at the end of the sample table (only

accessible if use sample table is activated for

Working method source) (the signal stops the 838

Advanced Sample Processor).

Test the 863 Compact VA Autosampler, or

838 Advanced Sample Processor with the set

automation parameters.

28

797 VA Computrace – Software

Page 41

2.7 Settings menu

Note: Before starting the test, switch on either 863 Compact VA

Autosampler(set Method 2) or the 838 Advanced Sample Processor

(set method VA, and enter the position of the first sample vessel

for the 838 parameter "SAMPLE" with the 838 keypad), and

place two sample vessels filled with water on the sample rack.