Page 1

797 VA Computrace

Hardware Manual

8.797.8001EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

797 VA Computrace

Hardware Manual

8.797.8001EN 08.2009 zst

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

Inhaltsverzeichnis

Table of contents

1 Introduction ..........................................................1

1.1 Instrument description.................................................................. 1

1.2 Parts and controls......................................................................... 2

1.3 Information about the Instructions for Use................................... 7

1.3.1 Organization............................................................................ 7

1.3.2 Notation and pictograms......................................................... 8

1.4 Support documentation................................................................ 9

1.4.1 Application-Bulletins................................................................ 9

1.4.2 Application Notes .................................................................. 10

1.4.3 Monographs.......................................................................... 11

1.4.4 Reprints................................................................................. 11

2 Installation..........................................................12

2.1 Setting up the instrument ........................................................... 12

2.1.1 Packaging.............................................................................. 12

2.1.2 Check .................................................................................... 12

2.1.3 Location ................................................................................ 12

2.2 Installation of the 797 VA Computrace Stand............................. 12

2.2.1 Mains cable and mains connection ........................................ 12

2.2.2 Switching the instrument on/off ............................................ 13

2.2.3 Connection to the PC............................................................. 13

2.2.4 Equipping the measuring head .............................................. 14

2.2.5 Inert gas connection.............................................................. 17

2.3 Multi-Mode Electrode (MME)...................................................... 20

2.3.1 Construction and operating characteristics of the MME......... 20

2.3.2 Filling the MME with mercury................................................ 22

2.3.3 Mounting the capillary........................................................... 23

2.3.4 Filling capillary without vacuum............................................. 23

2.3.5 Filling the capillary using vacuum .......................................... 25

2.3.6 Storing the MME ................................................................... 29

2.3.7 Replenishing the mercury (without changing capillary) .......... 29

2.3.8 Changing capillary ................................................................. 29

2.3.9 Cleaning the MME................................................................. 31

2.4 Rotating disk electrode (RDE) ..................................................... 34

2.4.1 Construction and startup of the RDE...................................... 34

2.4.2 Regeneration of RDE ............................................................. 34

2.5 Reference electrode .................................................................... 36

2.5.1 Construction.......................................................................... 36

2.5.2 Startup procedure.................................................................. 37

2.6 Auxiliary electrode ...................................................................... 38

2.6.1 Construction.......................................................................... 38

2.6.2 Startup procedure.................................................................. 38

2.7 Stirrer ......................................................................................... 39

2.8 Connection of Dosing devices..................................................... 40

2.8.1 Electrical Connection ............................................................. 40

2.8.2 Tubing connection................................................................. 40

2.8.3 Change Dosing-/Exchange unit .............................................. 44

2.9 Connection of 863 Compact Autosampler .................................. 46

2.9.1 Electrical connection.............................................................. 47

2.9.2 Tubing connections ............................................................... 48

2.9.3 Software settings................................................................... 51

2.9.4 Operation of the 863 Compact Autosampler ......................... 52

2.10 Connection of 838 Advanced Sample Processor ......................... 53

797 VA Computrace / Hardware-Manual 8.797.8001EN

I

Page 6

Inhaltsverzeichnis

2.10.1 General composition.............................................................. 55

2.10.2 System description for a combined system for Brightener and

Suppressor.............................................................................

2.10.3 System description for Suppressor determination .................. 59

2.10.4 System description for Brightener determination with MLAT. 61

2.10.5 System description for Brightener determination with LAT .... 65

56

2.11 Control lines................................................................................ 67

2.12 Connection of peripherals ........................................................... 67

2.13 Communication diagrams for automation .................................. 68

2.13.1 Communication diagram VA.................................................. 69

2.13.2 Communication diagram LAT................................................. 70

2.13.3 Communication diagram MLAT ............................................. 71

2.13.4 Communication diagram DT .................................................. 72

2.13.5 Communication diagram "RC Record response curve" ........... 73

2.13.6 Communication diagram "RC Sample with response curve"... 74

3 Safety ................................................................. 75

3.1 Electrical safety ...........................................................................75

3.2 Change fuses .............................................................................. 76

3.3 Cabinet temperature ................................................................... 76

3.4 Safety considerations concerning mercury ..................................77

3.4.1 Properties of mercury ............................................................ 77

3.4.2 Toxicity of mercury and its compounds.................................. 78

3.4.3 Handling of mercury .............................................................. 78

3.4.4 References dealing with mercury ........................................... 80

4 Appendix ............................................................ 82

4.1 Technical data............................................................................. 82

4.2 Scope of delivery.........................................................................88

4.2.1 VA Computrace 2.797.0010 .................................................. 88

4.2.2 VA Computrace 2.797.0020 .................................................. 93

4.2.3 VA Computrace 2.797.0030 .................................................. 95

4.3 Options .......................................................................................99

4.3.1 General options ..................................................................... 99

4.3.2 6.5327.000 MVA-Hg: Equipment for Hg-determination....... 102

4.3.3 6.5327.010 MVA-As: Equipment for As-determination ........ 104

4.3.4 6.5327.020 MVA-CVS: Equipment for CVS/CPVS ................. 106

4.3.5 Accessories for the automated addition of auxiliary solutions108

4.3.6 Automation for trace analysis .............................................. 109

4.3.7 Automation for electroplating bath analysis ........................ 110

4.4 Validation / GLP.................................................................. 112

4.5 Warranty and certificates.......................................................... 113

4.5.1 Warranty ............................................................................. 113

4.5.2 Declaration of Conformity ................................................... 114

4.5.3 Quality Management Principles ........................................... 115

4.6 Index......................................................................................... 115

797 VA Computrace / Hardware-Manual 8.797.8001EN

II

Page 7

Inhaltsverzeichnis

List of figures

Fig. 1: Front of the 797 VA Computrace Stand ..................................... 2

Fig. 2: Rear of the 797 VA Computrace Stand ......................................3

Fig. 3: Right side view of the 797 VA Computrace Stand (fully

equipped)..................................................................................

Fig. 4: Left side view of the 797 VA Computrace Stand (fully

equipped)..................................................................................

Fig. 5: Connection to PC ....................................................................14

Fig. 6: Measuring head arm................................................................15

Fig. 7: Scheme showing the inert gas connections at the 797 VA

Computrace Stand...................................................................

Fig. 8: Multi-Mode-Electrode.............................................................. 21

Fig. 9: Adding the mercury.................................................................22

4

4

19

Fig. 10: Setting up the filling station.....................................................26

Fig. 11: Filling the capillary...................................................................26

Fig. 12: Measuring head arm with rotating disk electrode (RDE) ...........35

Fig. 13: Construction of the reference electrode...................................36

Fig. 14: Construction of the auxiliary electrode.....................................39

Fig. 15: Electrical connection of the 863 Compact Autosampler ...........47

Fig. 16: Tubing connections for operation of the 863 Compact

Autosampler............................................................................

Fig. 17: Installation of accessories for rinsing and siphoning off............48

Fig. 18: Adjusting the pipetting needle.................................................49

Fig. 19: Complete system for automation with the 838 Advanced

Sample Processor ....................................................................

Fig. 20: Tubing connections for the rinsing equipment with the 838

Advanced Sample Processor ....................................................

Fig. 21: Electrical connection for a combined system with the 838

Advanced Sample Processor ....................................................

Fig. 22: Tubing connections for Suppressor determination with the

838 Advanced Sample Processor (and DT) with a combined

system.....................................................................................

47

55

55

56

57

Fig. 23: Tubing connections for Brightener determination with the

838 Advanced Sample Processor with a combined system .......

Fig. 24: Measuring head for a combined system with the 838

Advanced Sample Processor ....................................................

Fig. 25: Electrical connection for Suppressor determination with the

838 Advanced Sample Processor .............................................

797 VA Computrace / Hardware-Manual 8.797.8001EN

57

58

59

III

Page 8

Inhaltsverzeichnis

Fig. 26: Tubing connections for Suppressor determination (with DT)

with the 838 Advanced Sample Processor ...............................

60

Fig. 27: Tubing connections for Suppressor determination (with RC)

with the 838 Advanced Sample Processor ...............................

60

Fig. 28: Measuring head for Suppressor determination with the 838

Advanced Sample Processor....................................................

61

Fig. 29: Electrical connection for Brightener determination with the

838 Advanced Sample Processor and MLAT ............................

62

Fig. 30: Tubing connections for Brightener determination for

samples>10mL with the 838 Advanced Sample Processor

and MLAT...............................................................................

63

Fig. 31: Tubing connections for Brightener determination for

samples<10mL with the 838 Advanced Sample Processor

and MLAT...............................................................................

63

Fig. 32: Measuring head for Brightener determination for

samples>10mL with the 838 Advanced Sample Processor

and MLAT...............................................................................

64

Fig. 33: Measuring head for Brightener determination for

samples>10mL with the 838 Advanced Sample Processor

and MLAT...............................................................................

64

Fig. 34: Electrical connection for Brightener determination with the

838 Advanced Sample Processor and LAT ...............................

65

Fig. 35: Tubing connections for Brightener determination with the

838 Advanced Sample Processor and LAT ...............................

66

Fig. 36: Tubing connections for Brightener determination with the

838 Advanced Sample Processor and LAT ...............................

66

Fig. 37: Communication diagram for VA.............................................. 69

Fig. 38: Communication diagram for LAT............................................. 70

Fig. 39: Communication diagram for MLAT ......................................... 71

Fig. 40: Communication diagram for DT .............................................. 72

Fig. 41: Communication diagram for "RC Record response curve"........ 73

Fig. 42: Communication diagram for "RC Sample with response

curve".....................................................................................

74

797 VA Computrace / Hardware-Manual 8.797.8001EN

IV

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

797 VA Computrace is a PC controlled system for voltammetry, which consists of the

following parts:

1.797.0010 VA Computrace Stand with accessories

6.2151.020 Connecting Cable

6.6053.030 797 VA Computrace Software (current version)

For a detailed description of the PC software «797 VA Computrace Software» see the

797 Software Manual.

This 797 Hardware Manual describes the installation and maintenance of the 797

VA Computrace Stand and its accessories. The central element of this Stand is the

Multi-Mode Electrode (MME), which combines the dropping mercury electrode

(DME/SMDE) and the stationary hanging mercury drop electrode (HMDE) in a single

construction. The rotating disk electrode (RDE) can also be used in the stand.

The 797 VA Computrace Stand is controlled with the PC-Software «797 VA Computrace Software», parameters necessary for the VA measurement are sent from the PC

to the VA Computrace via USB connection. The data acquisition at the 797 VA Computrace Stand is started and controlled by the PC-Software «797 VA Computrace

Software», which receives and stores the measurement data. At the end of the determination, the recorded data are sent back to the PC where they are evaluated and

saved in a determination file.

Operation of the 797 VA Computrace Stand follows the potentiostatic 3-electrode

principle in which the voltage of the working electrode is controlled by means of a virtually currentless reference electrode to the preset desired value and the current flows

across a separate auxiliary electrode.

797 VA Computrace / Hardware-Manual 8.797.8001EN

1

Page 10

1 Introduction

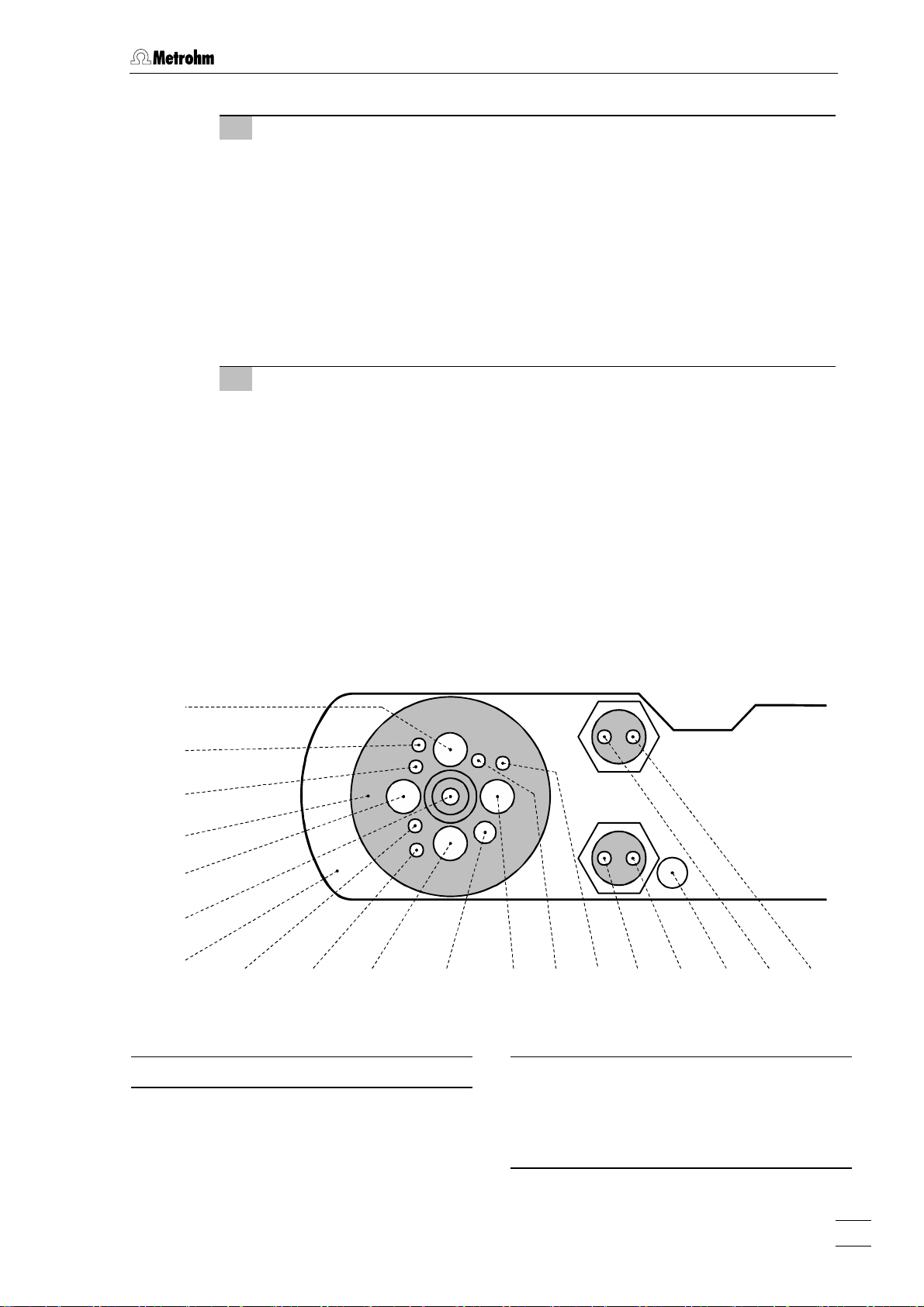

1.2 Parts and controls

In this section you will find the numbers and designations of the parts

and controls of the 797 VA Computrace Stand. The numbering applies

throughout the instructions for use, i.e. bold numbers in the text (e.g.

7 ) refer to the parts and controls illustrated here.

2

3

4

1

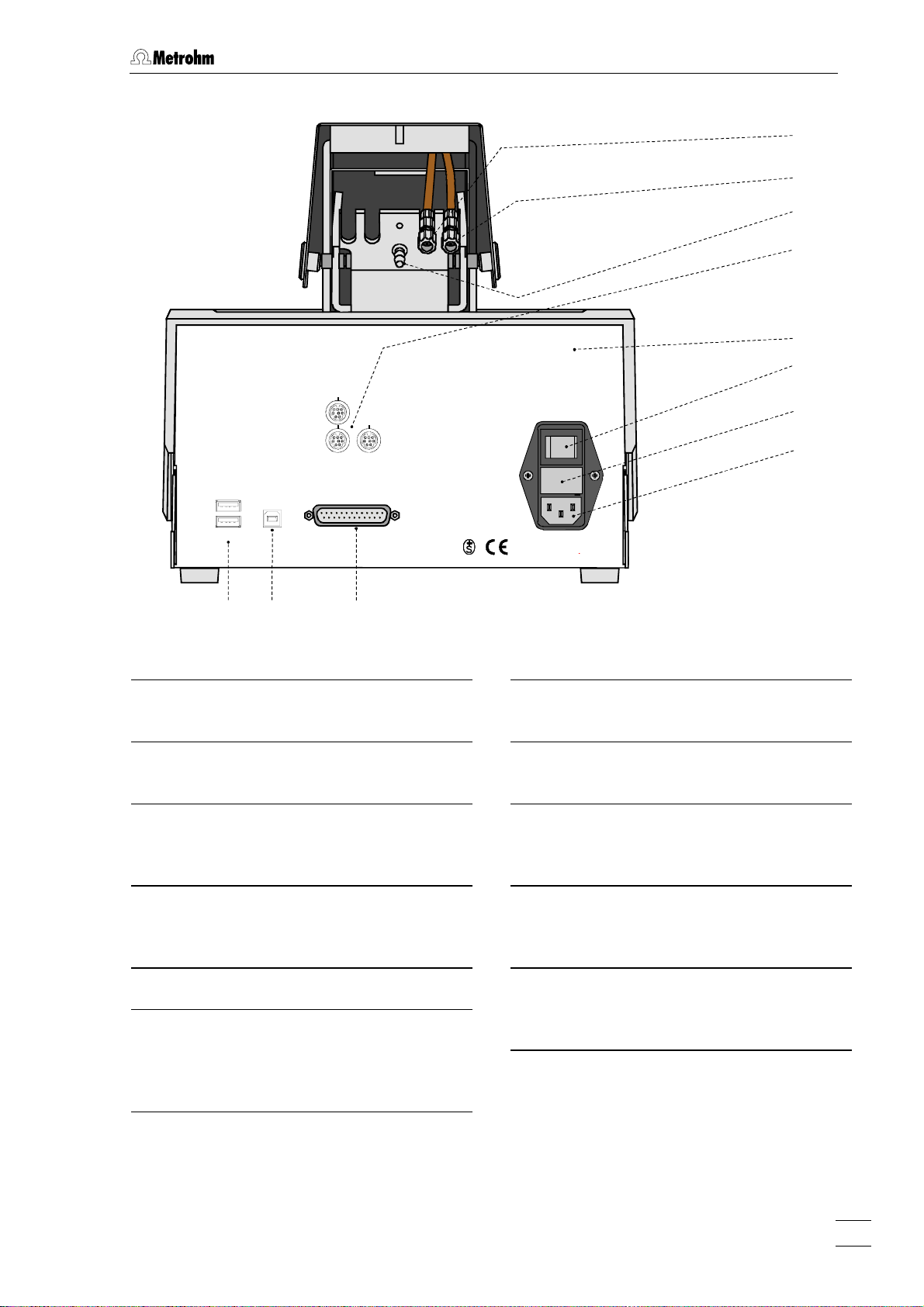

Fig. 1: Front of the 797 VA Computrace Stand

Mains pilot lamp

1

lit up when instrument switched on

Cover of measuring head arm

2

hinged

Release slide

3

to release fixture of the lifted measuring

head arm

Stopper (6.2709.080)

4

to close the pipetting opening

Gas wash bottle (6.2405.030)

6

for inert gas supply (filling with dist.

water, see section

Measuring vessel

7

when measuring head arm is fully raised, the measuring vessel can be pulled

forward out of the holder

Drip pan (6.2711.040)

8

2.2.5)

5

5

6

7

8

Holder for measuring vessel

5

2

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 11

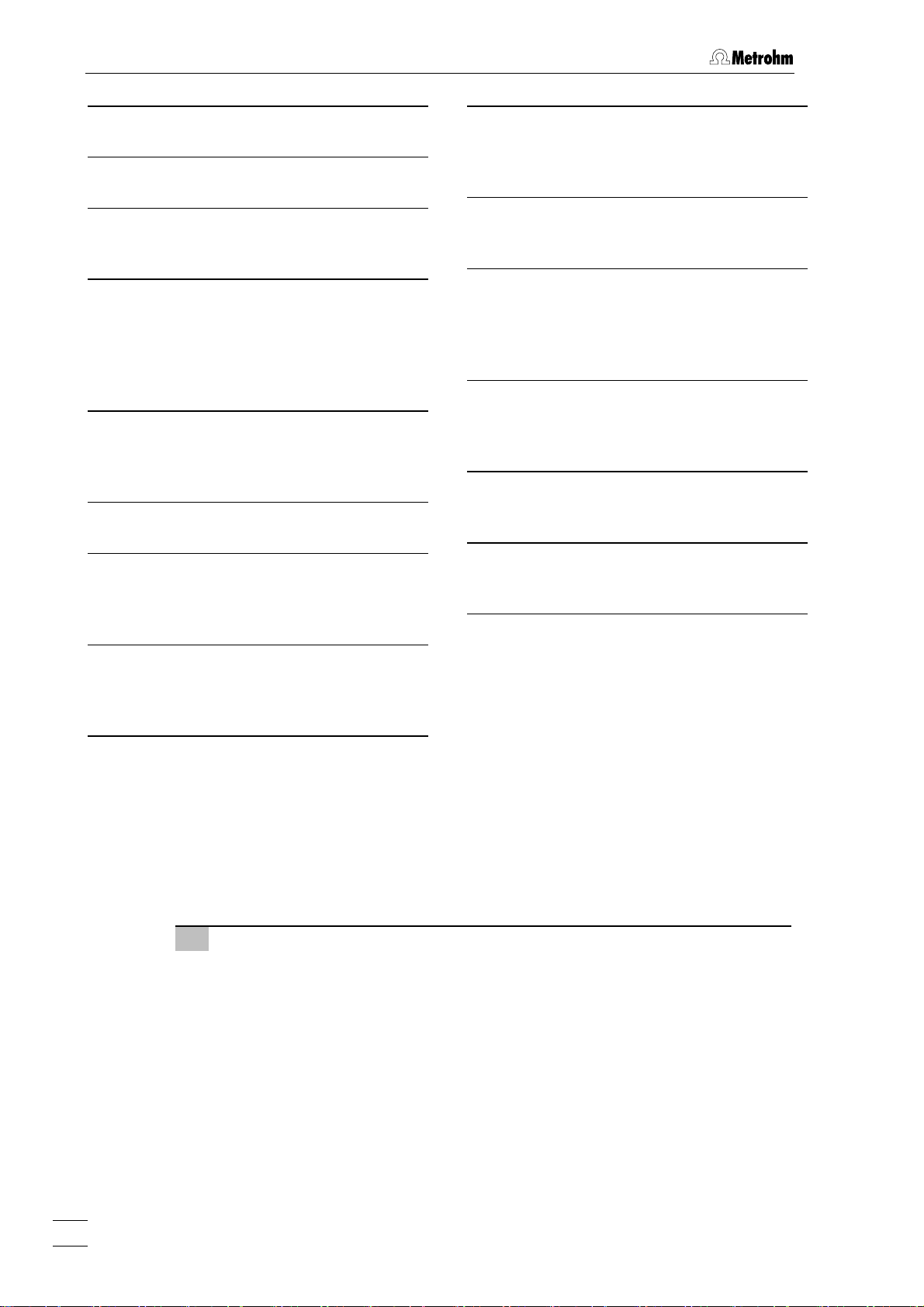

1.2 Parts and controls

12 9 13

16 10 11

Type: 1.797.0010

Nr.:___________

MSB 1

14

15

MSB 2 MSB 3

USB 2

USB 1

19

PC

Made by Metrohm Herisau Switzerland

18

Fig. 2: Rear of the 797 VA Computrace Stand

Connection for inert

9

gas lead-off

Connection for optional waste

10

solution lead-off

Connection for inert gas supply

11

required pressure:

p = 1 ± 0.2 bar

MSB1 – MSB3

12

(Metrohm Serial Bus)

Connections for Dosing devices

Remote

17

Fuse

100 - 240 V: 1.6 A(TH)

f = 50-60 Hz

S= 120 VA

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

Fuse cover

15

Changing the fuses, see section

Mains connection plug

16

mains connection, see section

Remote

17

Connection for Sample Changer and

Rinsing Equipment

PC

18

Connection socket for connection cable

6.2151.020 to PC, see section

3.2

2.1.1

2.2.3

Serial number

13

USB1 and USB2

19

Connections for peripherals like

Mains switch (on/off)

14

printer, ..., see section

2.12

on/off switching of instrument (the pilot

1 is lit up when the instrument is

lamp

on)

797 VA Computrace / Hardware-Manual 8.797.8001EN

3

Page 12

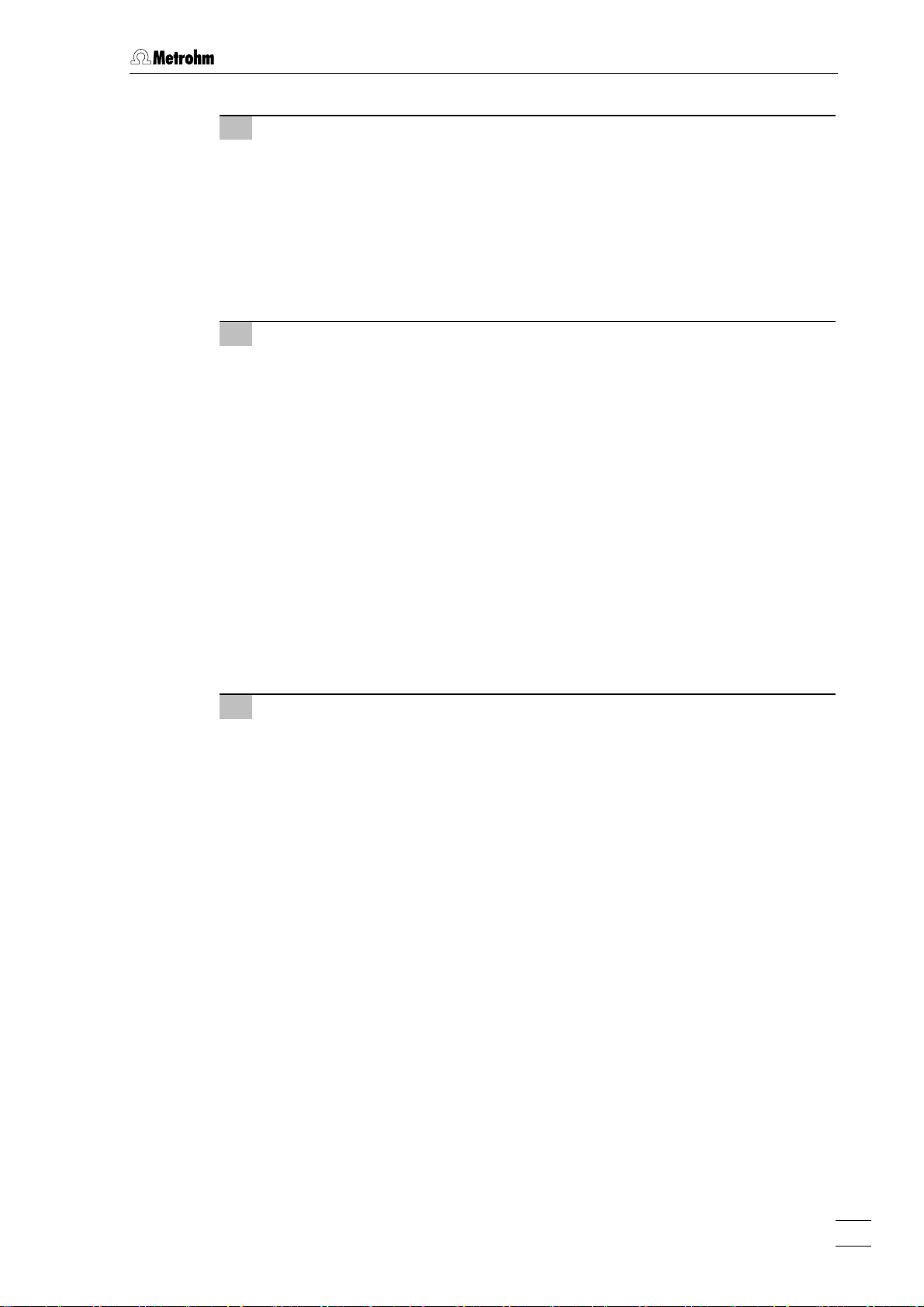

1 Introduction

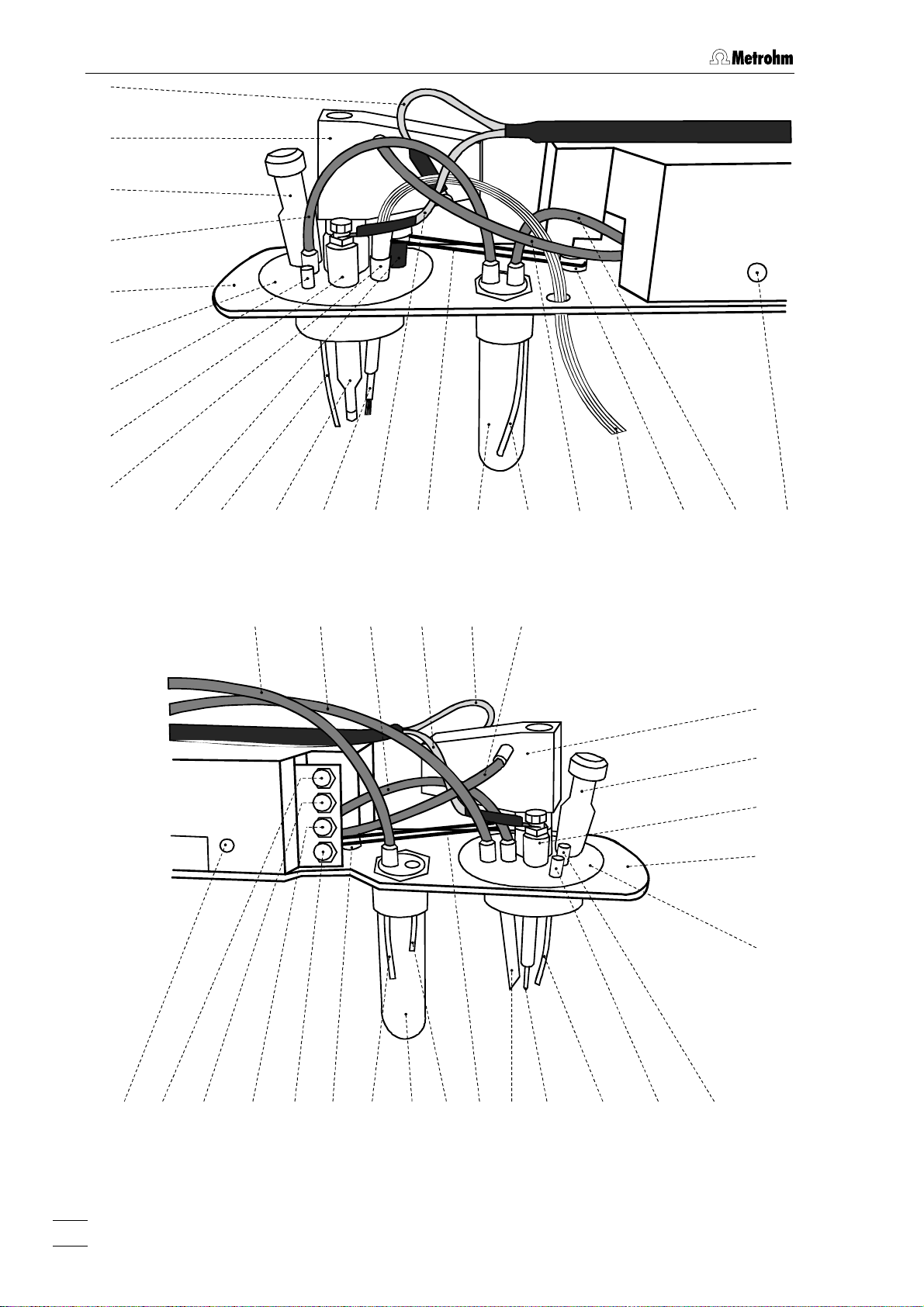

22 23 24 25

26 27

42

20

21

4

28 29 26 30 31

Fig. 3: Right side view of the 797 VA Computrace Stand (fully equipped)

38 39 40 41 20

32 6 33 34 30 35 36 37

21

4

43

23

24

53 52 51 50 49 35

47 32 43

4648

29 45 44

Fig. 4: Left side view of the 797 VA Computrace Stand (fully equipped)

4

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 13

1.2 Parts and controls

4

Stopper (6.2709.080)

to close the pipetting opening

6

Gas wash bottle (6.2405.030)

for inert gas supply

(must be filled halfway with dist. H

see section

Electrode cable ”WE”

20

2.2.5)

connection for working electrode

2

O,

Electrode cable ”RE”

31

connection for reference electrode

Drive belt (6.1244.020)

32

connection between drive wheel

stirrer 28

PTFE tube (6.1819.000)

33

for inert gas delivery to gas wash bottle

6 (attached)

26

35 and

(MME or RDE)

FEP tubing (6.1805.180)

34

Multi-Mode Electrode (MME)

21

for inert gas supply to MME

21

(6.1246.020)

details, see section

FEP tubing (6.1805.180)

22

for inert gas supply to measuring vessel

(attached)

2.3

Drive wheel of drive motor

35

FEP tubing (6.1805.040)

36

for inert gas delivery to gas wash bottle

6 attached.

Measuring head arm

23

carrier plate with permanently attached

measuring head, raisable

Measuring head

24

measuring vessel upper half made of

PTFE; with openings for electrodes,

stirrer, gas and liquid supply lines

Dummy stopper (6.1446.040)

25

Reference electrode

26

comprising 6.0728.020 Ag/AgCl Reference system and 6.1245.010 Electrolyte

vessel (details, see section

Nipple (6.2730.030)

27

2.5)

for mounting the 4-way microtip

dummy stopper

Stirrer (6.1204.200)

28

30 or a

Slotted screw for controlling the

37

inert gas flow

: The factory setting of ca. 20 L/h

Note

should not be changed without good

reason!

FEP tubing (6.1805.020)

38

for inert gas lead-off (attached)

FEP tubing (6.1805.090)

39

for inert gas lead-off (attached)

FEP tubing (6.1805.180)

40

for inert gas supply to tapping mechanism (attached)

Electrode cable ”AE”

41

connection for auxiliary electrode

FEP tubing (6.1805.180)

42

for inert gas supply to MME

43

21

PTFE tube (6.1819.000)

29

(attached)

4-way microtip (6.1824.000)

30

Auxiliary electrode

43

for details see section

Dummy stopper (6.1446.040)

44

2.6

for delivery of solutions; with 4 lengths

of PTFE tubing with connecting nipples

for Dosing devices

797 VA Computrace / Hardware-Manual 8.797.8001EN

Dummy stopper (6.1446.040)

45

5

Page 14

1 Introduction

PTFE tube (6.1819.010)

46

for optional supply of the waste solution

to gas wash bottle

Gas wash bottle (6.2405.030)

47

47 (attached)

for separating mercury from the waste

solution (attached)

PTFE tube (6.1819.010)

48

for optional siphoning off the waste

solution from gas wash bottle

47

(attached)

Dummy cell connection ”WE-D”

49

differential mode simulation (peak/wave)

Dummy cell connection ”WE-L”

50

linear mode simulation (RC element)

Dummy cell connection ”RE”

51

Dummy cell connection ”AE”

52

Slotted screw for controlling the

53

tapping power in the DME or SMDE

case

: The factory setting should not be

Note

changed without good reason!

6

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 15

1.3 Information about the Instructions for Use

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 797 VA Computrace Stand into operation. The Instructions for Use

contain information and warnings to which the user must pay attention in order to assure safe operation of the instrument.

1.3.1 Organization

This 8.797.8001EN Hardware Manual for the 797 VA Computrace Stand provides a

comprehensive overview of the installation, operation, and technical specifications of

these instruments. The Instructions for Use are divided into the following 4 sections:

Section

Section

1 Introduction

2 Installation

General instrument description

Numbers and designations of the parts and controls

Safety instructions

Installation of 797 VA Computrace Stand

Installation of working, reference and auxiliary electrodes

Attachment of 700 and 800 Dosinos

Attachment of 685 and 805 Dosimats

Attachment of the 863 Compact Autosampler

Attachment of the 838 Advanced Sample Processor

Section

Section

To find the required information on the instrument please use either the Table of

contents or the Index at the back.

3 Safety

Electrical safety

Safety considerations in the handling of mercury

4 Appendix

Scope of delivery, options, validation, warranty, certification, index

797 VA Computrace / Hardware-Manual 8.797.8001EN

7

Page 16

1 Introduction

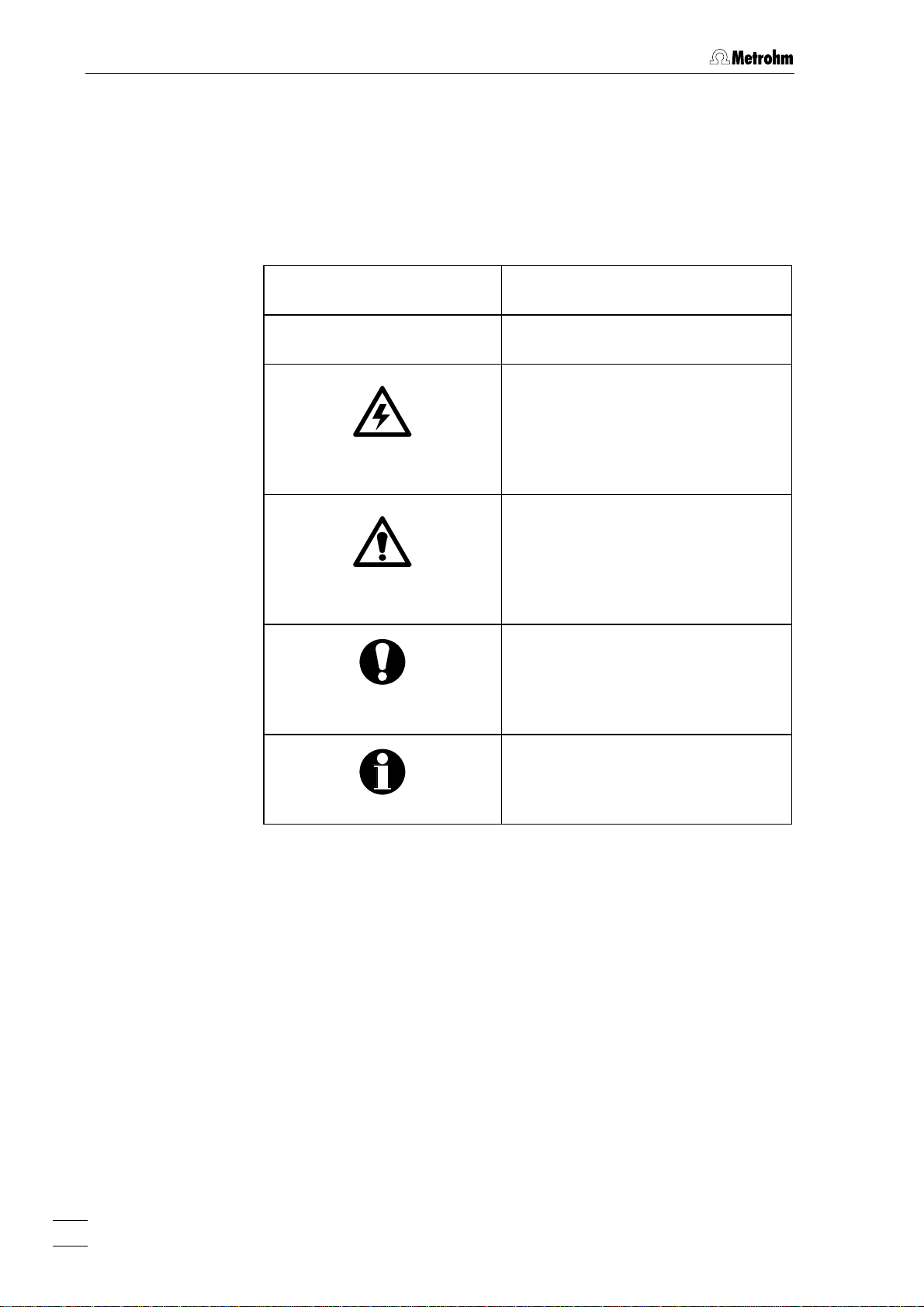

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for

Use:

Mode Parameter or entry value

15 Part or control

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. First read the associated

directions before you continue.

Comment

This symbol marks additional

information and tips.

8

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 17

1.4 Support documentation

1.4 Support documentation

1.4.1 Application-Bulletins

The «Application Bulletins» is a collection of analytical methods, application examples

and literature references. Of Metrohm's approximately 200 Application Bulletins, ca.

60 refer to Polarography and Voltammetry. All these Application Bulletins are available

on request free of charge from your Metrohm supplier.

The examples listed here substantiate the versatility of the polarographic and voltammetric methods for a range of applications including both inorganic and organic substances. At any time you will find an updated list of the Application Bulletins with the

option for download in the Internet under «

Most of the methods required to run the applications described in the Application Bulletins are installed when the 797 VA Computrace software is installed.

No. Title

36 Polarographic analysis – Half-wave potentials of inorganic substances

50 Polarographic determination of lead in petrochemical products

57 Polarographic determination of nicotine

www.metrohm.com ».

60 Polarographic determination of fructose

70 Polarographic nitrate determination in water samples, soil and plant extracts,

vegetable juices, meat and sausage products, fertilizers, liquid manure etc.

73 Polarographic analysis – Half-wave potentials of organic substances

74 Polarographic and stripping voltammetric analysis methods for thallium, antimony,

bismuth and iron (copper, vanadium)

76 Polarographic determination of nitrilotriacetic acid (NTA) and ethylenediamine-

tetraacetic acid (EDTA)

96 Stripping voltammetric analysis of mercury

97 Voltammetric determination of tocopherols (vitamin E) in edible oils and fats

98 Determination of ascorbic acid (vitamin C) and its compounds

105 Determination of permissible lead and cadmium levels in crockery and glassware

110 Polarographic determination of free cyanide

113 Determination of lead, cadmium and copper in foodstuffs, waste water and

sewage sludge by anodic stripping voltammetry after digestion

114 Polarographic determination of five metal ions (copper, cobalt, nickel, zinc and

iron) in a single operation

116 Polarographic determination of chromium in small quantities

117 Determination of selenium by stripping voltammetry

123 Voltammetric determination of iron and manganese in water samples

126 Polarographic determination of quinine

127 Polarographic determination of nitrite in water samples, meat and sausages

131 Voltammetric determination of aluminum

132 Polarographic determination of molybdenum in strongly ferruginous substances

and ferrous metals

136 Polarographic determination of styrene in polystyrenes and copolymers

141 Analysis of edible fats and oils

797 VA Computrace / Hardware-Manual 8.797.8001EN

9

Page 18

1 Introduction

No. Title

146 Direct polarographic determination of trace amounts of molybdenum in water

147 Simultaneous trace determination of seven metal ions (Zn, Cd, Pb, Cu, Ni, Co, Fe) in

«electronic grade» materials with the aid of stripping voltammetry

176 Simultaneous determination of lead and tin by anodic stripping voltammetry

179 Polarographic determination of maleic and fumaric acid alone or in mixtures

186 Determination of aluminum in water samples by adsorptive stripping voltammetry

190 Polarographic determination of 4-carboxybenzaldehyde in terephthalic acid

191 Polarographic determination of cystine and cysteine simultaneously

192 Determination of thiourea in the lower ppm and ppb range by polarography and

stripping voltammetry

196 Polarographic determination of formaldehyde

199 Polarographic determination of sulphide and sulphite

207 Stripping voltammetric analysis of silver

213 Polarographic determination of nicotinamide

215 Polarographic determination of folic acid (vitamin B9, vitamin BC)

218 Polarographic determination of thiamine (vitamin B1)

219 Polarographic determination of riboflavin (vitamin B2)

220 Voltammetric determination of platinum and rhodium in the ultratrace range

221 Standard methods in water analysis – use of Metrohm instruments

224 Polarographic determination of pyridoxine (vitamin B6)

226 Determination of arsenic by anodic stripping voltammetry at the rotating gold

electrode

231 Voltammetric determination of zinc, cadmium, lead, copper, thallium, nickel and

cobalt in water samples according to DIN 38406 E 16

241 Determination of cadmium and lead at the «Ultra Trace» graphite electrode by

anodic stripping voltammetry

242 Determination of tungsten at the «Ultra Trace» graphite electrode by anodic

stripping voltammetry

243 Determination of chromium at the «Ultra Trace» graphite electrode by cathodic

stripping voltammetry

250 Polarographic determination of diazepam in body fluids and pharmaceutical

preparations

251 Polarographic determination of cinchocaine (dibucaine) in pharmaceutical prepara-

tions

254 Determination of zinc, cadmium, lead and copper by anodic stripping voltammetry

using carbon electrodes

266 Voltammetric determination of titanium and uranium

276 Validation of Metrohm VA instruments using Standard Operating Procedures

1.4.2 Application Notes

The «Application Notes» present application information in concentrated form. In the

field of voltammetry, there are at present approximately 120 Application Notes (in

English), which can be viewed in the Internet under «

10

797 VA Computrace / Hardware-Manual 8.797.8001EN

www.metrohm.com » and cop-

Page 19

1.4 Support documentation

ied from there. All these Application Notes are printed in the 8.757.2003 VA Applications Collection supplied with the instrument. All methods required to run the ap-

plications described in the Application Notes are installed when the 797 VA Computrace software is installed.

1.4.3 Monographs

The «Metrohm Monographs» listed below impart theoretical fundamentals and general information on measurement techniques and sample preparation of polarography

and voltammetry. All these monographs are available on request free of charge from

your Metrohm supplier.

Title

First aid for polarography and voltammetry (8.693.1071)

Sample preparation techniques in voltammetric trace analysis

Inorganic Adsorptive Stripping Analysis

Organic Stripping Analysis

Stripping Voltammetry

Electrode Reaction Kinetics determined by Cyclic Voltammetry

The Application of VA Techniques to the Galvanic/Plating Industry

Practical voltammetry (8.757.5003)

Introduction to Polarography and Voltammetry (8.027.5003)

Voltammetric analysis methods in electroplating (8.108.5002EN)

1.4.4 Reprints

The following reprints reporting on practical applications are available on request free

of charge from your Metrohm supplier.

Title

Investigations of oxidative UV photolysis:

I. Sample preparation for the voltammetric determination of Zn, Cd, Pb, Cu, Ni and Co in

waters

Investigations of oxidative UV photolysis:

II. Sample preparation for the voltammetric determination of mercury in water samples

Determination of Zn, Cd, Pb, and Cu in soils and sewage sludges by microprocessorcontrolled voltammetry in comparison with AAS

Voltammetric instrument for training and trace analysis

797 VA Computrace / Hardware-Manual 8.797.8001EN

11

Page 20

2 Installation

2 Installation

This section offers a full description of the 797 VA Computrace Stand

and provides detailed information on the various electrodes and the

stirrer. Reliable operation of the instrument is assured only if you

follow the instructions in this section exactly.

2.1 Setting up the instrument

2.1.1 Packaging

The 797 VA Computrace Stand is supplied together with the separately packed accessories in special packages designed to ensure excellent protection. These contain

shock-absorbing foam linings. The instrument itself is packed in an evacuated polyethylene bag. As only these special packaging guarantees indemnified transport of the

instrument, it is essential you store it in a safe place.

2.1.2 Check

After recipt, immediately check whether the shipment is complete and has arrived

without damage (compare with delivery note and list of accessories in sections

the case of transport damage, see instructions in section

4.5.1 "Warranty".

2.1.3 Location

Place the 797 VA Computrace on a laboratory bench in a position suitable for operation and which is free from vibrations, protected against corrosive atmospheres and

contamination by chemicals. The drip pan

front side of the 797 VA Computrace Stand to catch drops (see

8 (6.2711.040) has to be placed at the

Fig. 1).

2.2 Installation of the 797 VA Computrace Stand

If the 797 VA Computrace Stand is connected to the power supply,

the instrument may not be opened or parts removed, as there is a

danger of contact with live components. Before you open the 797 VA

Computrace Stand to change components or for maintenance or

repair work, always switch off the instrument by setting the mains

switch

from the mains connection plug

14 to the OFF position and then disconnect the mains cable

16 of the 797 VA Computrace Stand.

4.2). In

2.2.1 Mains cable and mains connection

The instrument is supplied with one of three mains cables:

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with a grounding pin. If a different plug

has to be fitted, the yellow/green lead (IEC standard) must be connected to protective

earth (protection class 1).

12

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 21

2.2 Installation of the 797 VA Computrace Stand

Any break in the grounding inside or outside the instrument can make

it a hazard!

Plug the mains cable into mains connection plug

(see

16 of the 797 VA Computrace Stand

Fig. 2).

2.2.2 Switching the instrument on/off

The 797 VA Computrace Stand is switched on and off using mains switch 14. When

the instrument is switched on, the pilot lamp

1 lights up.

2.2.3 Connection to the PC

The 797 VA Computrace Stand is connected to the PC via USB Cable 6.2151.020.

Proceed as follows:

The 797 VA Computrace Stand must not be connected until the Software is installed.

1 Software installation

• Switch on PC and start operating system (Windows™ 2000, XP Professional

or Vista Professional)) without connection of the 797 VA Computrace via

USB cable.

• Insert installation CD into CD drive.

• If the autorun option for the CD drive is disabled, select

Browse for the

• Click on "

Setup.exe file on the installation CD and click on <OK>.

797" and follow the instructions given in the setup program. The

software package will be installed in the desired directory (the default directory is

Program Files/Metrohm/797 VA Computrace).

2 Connection of the 797 VA Computrace

• Connect 797 VA Computrace to the PC using the 6.2151.020 USB cable

and switch on the 797 VA Computrace. The PC detects a new USB device

and starts the setup wizard. Insert installation CD into CD drive and follow

the wizard instructions always selecting the recommended default options.

• Start the 797 VA Computrace Software.

<Start> and Run.

The setup wizard is started three times when installing the instrument

driver. All three installation steps must be conducted to ensure proper

operation.

797 VA Computrace / Hardware-Manual 8.797.8001EN

13

Page 22

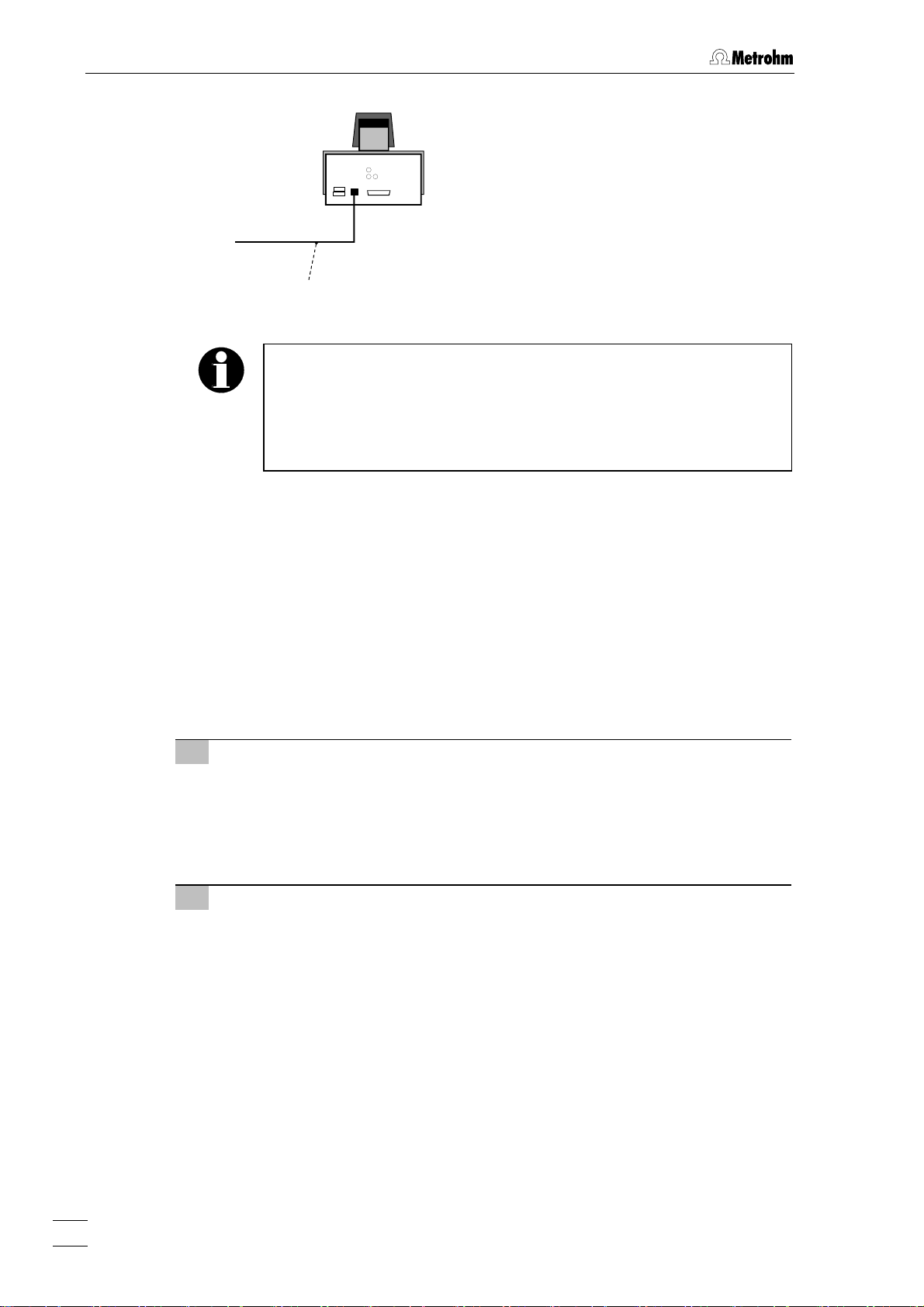

2 Installation

797

PC

6.2151.020 USB Cable

Fig. 5: Connection to PC

In case your computer does not start if the 797 VA Computrace stand

is switched on, it might is due to an older version of the BIOS. These

BIOS versions are not able to handle USB Hubs in a correct way.

In that case, start the computer first, and switch on 797 VA Computrace stand as soon as Windows booting is finished.

2.2.4 Equipping the measuring head

The fixtures inserted in the openings and connections of the measuring head 24 in

the 797 VA Computrace Stand depend on the working electrode selected (MME or

RDE) (see

Electrode is illustrated in section

tating disk electrode in section

When equipping the measuring head for the first time, the best procedure is as follows:

1 Preparations

2 Insert dummy stoppers

Fig. 6). The fully equipped measuring head for operation with a Multi-Mode

1.2 (Fig. 3 und Fig. 4), that for operation with a ro-

2.4 (Fig. 12).

• Prepare Multi-Mode Electrode MME 21 (details, see section 2.3) or rotating

disk electrode RDE (details, see section

• Prepare reference electrode

• Tilt back cover

2 of measuring head arm.

• Screw dummy stopper 45 (6.1446.040) into opening 55.

• Screw dummy stopper

44 (6.1446.040) into opening 56.

2.4) for operation.

26 (details, see section 2.5.2) for operation.

14

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 23

2.2 Installation of the 797 VA Computrace Stand

3 Insertion of 4-way microtip (option)

For automatic solution addition with Dosinos or Dosimats, the 6.1824.000 4way microtip has to be installed. Proceed as follows:

• Remove stopper from nipple

27 and insert 4-way microtip 30 into nipple as

far as it will go.

• Tighten nipple using a 6.2739.010 Wrench until the 4-way microtip can no

longer move.

• Pull the 4 lengths of PTFE tubing of the 4-way microtip in succession from

above through the opening

2.8).

tion

68 (connection of Dosinos or Dosimats see sec-

4 Install stirrer or RDE

in operation with MME:

• Insert stirrer (6.1204.200) in opening

• Stretch drive belt

of the stirrer

32 (6.1244.020) between drive wheel 35 and drive shaft

.

63 as far as it will go.

in operation with RDE:

• Screw electrode tip

also section

2.4).

• Insert RDE in opening

• Stretch drive belt

98 (6.1204.XXX) to drive shaft 99 (6.1204.210) (see

63 as far as it will go.

32 (6.1244.020) between drive wheel 35 and drive shaft

99 of the RDE.

• Attach electrode cable

20 (WE) to the RDE: push cable lug under the screw

and then tighten screw firmly.

54

55

56

24

57

58

23

59 60 61 62 65 66 67 68 69 70

Fig. 6: Measuring head arm

23

Measuring head arm

24

Measuring head

6463

Opening

54

for auxiliary electrode

43 (6.0343.000 Pt

- auxiliary electr. or optional GC electr.

comprising 6.1241.020 Electrode holder

and 6.1247.000 GC tip)

797 VA Computrace / Hardware-Manual 8.797.8001EN

15

Page 24

2 Installation

Threaded opening

55

for dummy stopper

Threaded opening

56

for dummy stopper

Pipetting opening

57

45 (6.1446.040)

44 (6.1446.040)

for the manual addition of solutions,

closed with stopper

Opening

58

4 (6.2709.080)

in operation with MME:

for Multi-Mode Electrode

21

(6.1246.020)

in operation with RDE:

for 6.2709.040 Stopper

Threaded opening

59

for FEP tubing

22 (6.1805.180, already

permanently attached); inert gas supply

to measuring vessel

Threaded opening

60

for dummy stopper

Opening

61

for reference electrode

7

25 (6.1446.040)

26 (Ag/AgCl

reference system and 6.1245.010

Electrolyte vessel)

Threaded opening

62

for nipple

stopper or 4-way microtip

27 (6.2730.030) with dummy

30

(6.1824.000)

Threaded opening

64

for FEP tubing

40 ((6.1805.180, already

permanently attached); inert gas supply

for tapping mechanism

Threaded opening

65

for FEP tubing

39 (6.1805.090, already

perm. attached); inert gas lead-off

Threaded opening

66

for FEP tubing

22 (6.1805.180, already

permanently attached); inert gas supply

from gas wash bottle

vessel

67

7

Threaded opening

for FEP tubing

36 (6.1805.040, already

6 to measuring

permanently attached); inert gas supply

to gas wash bottle

Opening

68

6

for feed-through of tubing connections

of 4-way microtip

Threaded opening

69

30 (6.1824.000)

for FEP tubing (6.1805.180); optional

waste solution lead-off

Threaded opening

70

for FEP tubing

38 (6.1805.090, already

permanently attached); optional waste

solution supply from gas wash bottle to

waste

Opening

63

in operation with MME:

for stirrer

28 (6.1204.200)

in operation with RDE:

for rotating disk electrode, comprising

drive shaft

trode tip

99 (6.1204.210) and elec-

98 (6.1204.XXX)

5 Install reference electrode

• Insert reference electrode 26 in opening 61.

• Attach electrode cable

under the screw and then tighten screw firmly.

• Turn reference electrode so that the electrode cable points to the rear and

not to the side (in the latter position it may become kinked and damaged

when cover

31 (RE) to reference electrode: push cable lug

2 is closed).

16

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 25

2.2 Installation of the 797 VA Computrace Stand

6 Install auxiliary electrode

• Insert auxiliary electrode 43 (6.0343.000 Pt auxiliary electrode or GC auxil-

iary electrode, see section

• Attach electrode cable

2.6) in opening 54.

41 (AE) to auxiliary electrode: push cable lug under

the screw and then tighten screw firmly.

• Turn auxiliary electrode 39 so that the electrode cable 37 points to the rear

and not to the side (in the latter position it may become kinked and damaged when cover

2 is closed).

7 Install MME or dummy stopper

in operation with MME:

• Carefully insert Multi-Mode Electrode

21 (6.1246.020) in opening 58 (the

underside of the capillary must not touch the measuring head during insertion) and push in as far as it will go.

• Screw FEP tubing

34 (6.1805.180) for inert gas supply into connection 71

of the MME.

• Screw FEP tubing

42 (6.1805.180) for inert gas supply into connection 72

of the MME.

• Attach electrode cable

20 (WE) to screw connection 88 of the MME: push

cable lug under the screw and then tighten screw firmly.

in operation with RDE:

• Insert stopper

97 (6.2709.040, option) into opening 58 as far as it will go

so that the two blind holes point to the rear of the stand.

• Screw FEP tubing

• Screw FEP tubing

34 (6.1805.180) into upper hole of stopper 97.

42 (6.1805.180) into lower hole of stopper 97.

8 Install measuring vessel

• Tilt back measuring head arm 23.

• Slide measuring vessel

solution or dist. H

the reference electrode are immersed in the liquid.

• Lower measuring head arm

2.2.5 Inert gas connection

Nitrogen (N2) is generally used as the inert gas to de-aerate the analyte solution and

for operation of the MME. The nitrogen must be of sufficient purity.

w(N

) ≥ 0.99996 (= 99.996%)

2

for general polarography/voltammetry

w(N

) ≥ 0.99999 (= 99.999% = "5 × 9")

2

for analyses in organic solvents; for determinations involving very high

current amplification (e.g. in the determination of very low concentrations without preceding enrichment)

For electroplating bath applications, using CVS or CPVS, no inert gas connection is required.

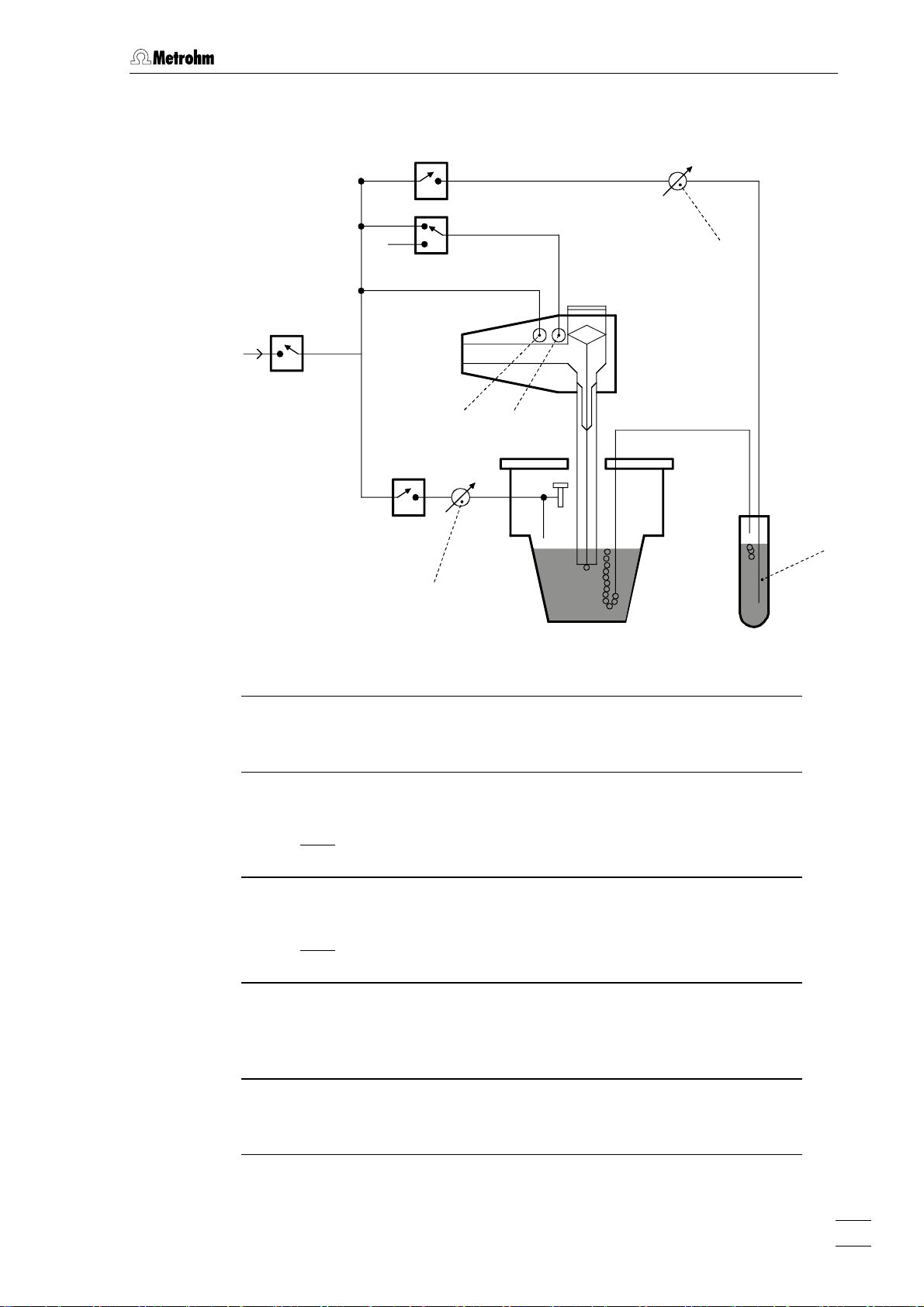

The scheme for de-aeration of the analyte solution and the inert gas connections at

the 797 VA Computrace Stand needed for operation of the MME is shown in

The inert gas connections are established as follows:

7 into holder 5 from the front and fill with analyte

O (storage solution) until the tips of the MME or RDE and

2

23 and cover 2.

Fig. 7.

797 VA Computrace / Hardware-Manual 8.797.8001EN

17

Page 26

2 Installation

1 Fill gas wash bottle

• Unscrew gas wash bottle 6 from measuring head arm 23.

• Fill gas wash bottle half full with dist. H

O (for long-term measurements

2

with supporting electrolytes such as Acetic acid / Acetate buffer or Ammonia / Ammonium chloride buffer, fill with supporting electrolyte; for measurements in organic solvents fill with the used solvent).

• Screw gas wash bottle back on measuring head arm.

2 Connect inert gas supply

• Attach one end of 6.1801.080 PVC tubing to connection 11 of the 797 VA

Computrace Stand.

• Attach the other end of the 6.1801.080 PVC tubing to connection of the

inert gas bottle.

• Set inert gas pressure at gas bottle using the reducing valve to

p = 1 ± 0.2 bar.

• Open gas supply line at gas bottle.

3 Connect inert gas lead-off (option)

• Attach a length of suitable tubing (e.g. Metrohm 6.1805.030, length

150 cm) to connection

9 for inert gas lead-off.

• Route the other end of the lead-off tubing to a fume cupboard.

18

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 27

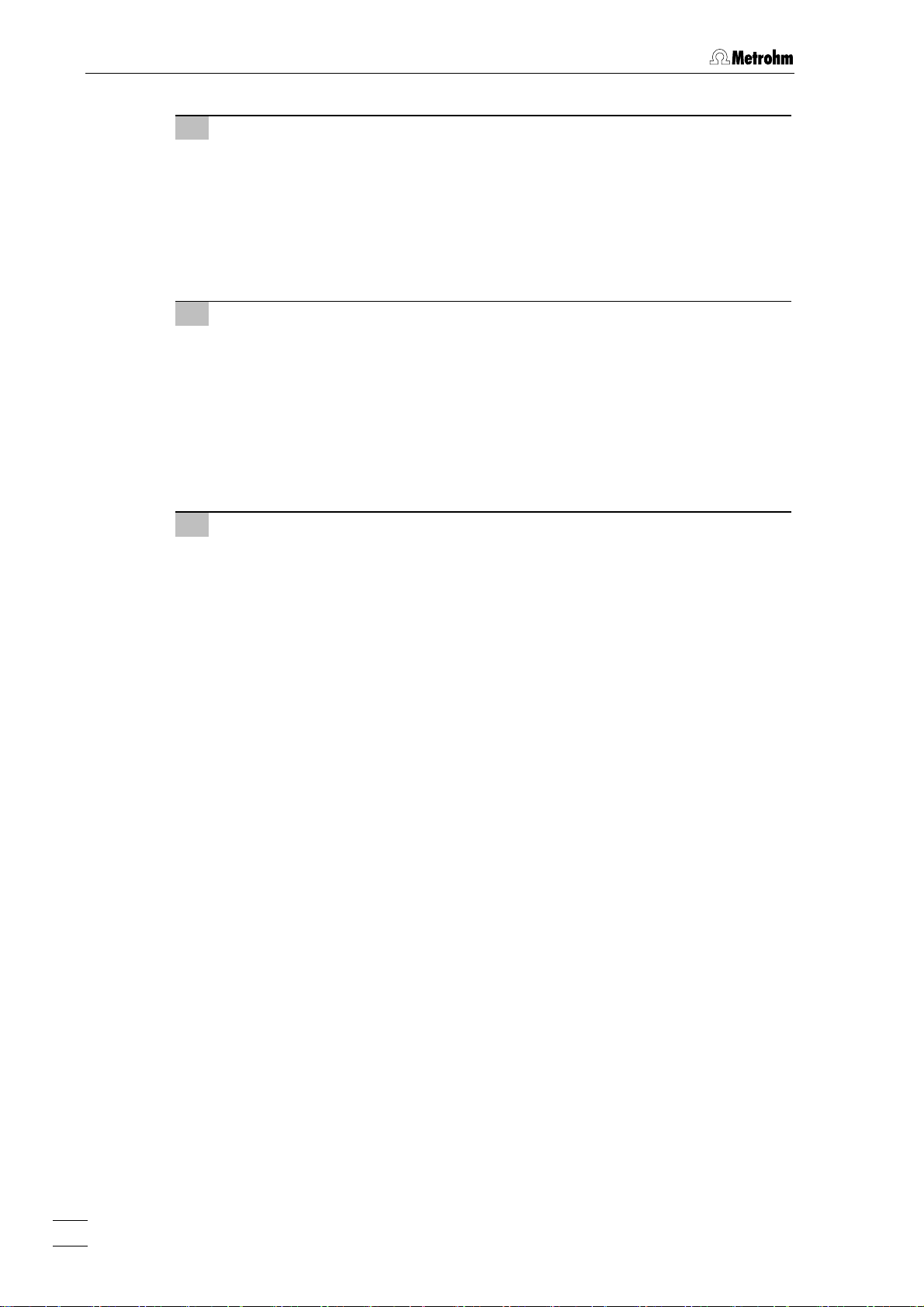

2.2 Installation of the 797 VA Computrace Stand

V

2

V

3

N

2

V

1

71

V

4

72

6

53

Fig. 7: Scheme showing the inert gas connections at the 797 VA Com-

putrace Stand

37

6 Gas wash bottle (6.2405.030)

for inert gas supply (must be filled only halfway with dist. H

O or

2

supporting electrolyte, see also Fig. 3)

37 Slotted screw for controlling the inert gas flow for de-aeration

(see also Fig. 3)

Note

: The factory setting of ca. 20 L/h should not be changed

without good reason!

53 Slotted screw for controlling the tapping power in the DME

case (see also

Note

: The factory setting should not be changed without good

Fig. 4)

reason!

Connection for inert gas supply

71

of the MME

for raising and lowering the sealing needle in the MME (see also

section

Connection for inert gas supply

72

2.3.1 and Fig. 8)

of the MME

for pressurizing the mercury (see also section

2.3.1 and Fig. 8)

V1, V2, V3, V4 Valves

797 VA Computrace / Hardware-Manual 8.797.8001EN

19

Page 28

2 Installation

2.3 Multi-Mode Electrode (MME)

The Multi-Mode Electrode combines the most important polarographic and voltammetric mercury electrodes in a single construction:

• HMDE Hanging mercury drop electrode

Mercury is forced through a glass capillary until a drop

forms at the capillary tip and the entire voltage sweep

performed on this single stationary drop; in general with

preceding enrichment (stripping voltammetry).

• DME Dropping mercury electrode

The classical electrode, the mercury drops fall from the

glass capillary at a controlled rate.

• SMDE Static mercury drop electrode

The latest electrode, it combines the features of the

DME and the HMDE: during the measurement, the drop

surface is constant and stationary (as with the HMDE);

however, for the complete voltage sweep several drops

are needed (renewal as with the DME).

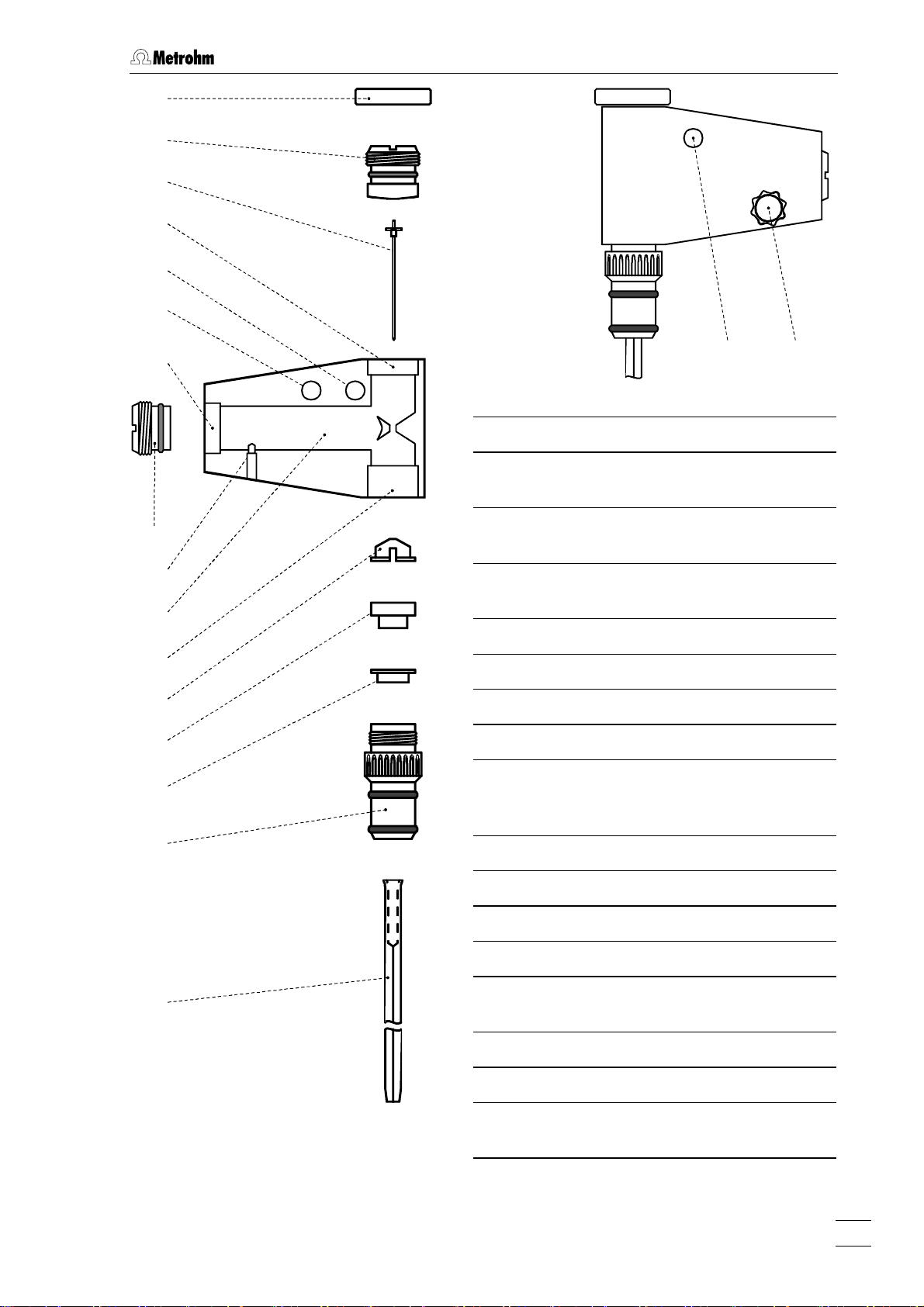

2.3.1 Construction and operating characteristics of the MME

The construction of the 6.1246.020 Multi-Mode Electrode is shown in Fig. 8. The

mercury in the reservoir

end. The mercury flow is controlled by the sealing needle

lowered pneumatically. The different types of electrodes (HMDE, DME, SMDE) are implemented by timed opening or closing of the mercury flow using this sealing needle.

The operating characteristics of the MME are illustrated by

V1 (inert gas supply) is opened, the mercury in the reservoir 81 is pressurized. In

valve

the standby mode, a back pressure is built up in the interior of the slotted screw

which causes the built-in spring to press the sealing needle

opening of the glass capillary

the valve

gas pressure in the mercury reservoir

PTFE membrane of the slotted screw

The tapping mechanism of the DME and SMDE is triggered by brief opening and closing of valve

The mercury drops formed at the end of the capillary are very small and stable and

thus afford a very good signal/noise ratio. The mercury hermetically sealed in the reservoir comes into contact only with inert gas and other inert materials and suffices

for around 200'000 drops.

V3 allows the inert gas to escape thus releasing the back pressure. The inert

V4.

81 flows through the glass capillary 87 forming a drop at its

75 which can be raised or

Fig. 7 and Fig. 8. After

75 onto the capillary

87 thus preventing the outflow of mercury. Switching

81 presses the sealing needle 74 fixed to the

75 upwards and the mercury can now flow out.

74

20

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 29

2.3 Multi-Mode Electrode (MME)

73

74

75

76

72

77

78

79

80

81

82

83

84

85

71 88

71 Connection for inert gas supply

72 Connection for inert gas supply

(for all MME operating modes)

Locking ring (4.420.2920)

73

for slotted screw

Slotted screw (6.1247.040)

74

with PTFE membrane and built-in spring

Sealing needle (6.1247.020)

75

Screw thread for slotted screw 74

76

Unused connection

77

Screw thread for slotted screw 79

78

Slotted screw (4.420.2960)

79

74

for replenishing the mercury with capillary fitted

86

87

Fig. 8: Multi-Mode-Electrode

797 VA Computrace / Hardware-Manual 8.797.8001EN

Electrical contact pin for mercury

80

Mercury reservoir

81

Screw thread for retaining nut 86

82

Insert ring (4.420.3011)

83

Sealing ring (4.420.2800)

84

made of silicone rubber

Locking ring (4.420.2870)

85

Retaining nut (4.420.2850)

86

Glass capillary (6.1226.030 or

87

6.1226.050)

Screw connection

88

electrical contact for "WE" electrode

cable

21

Page 30

2 Installation

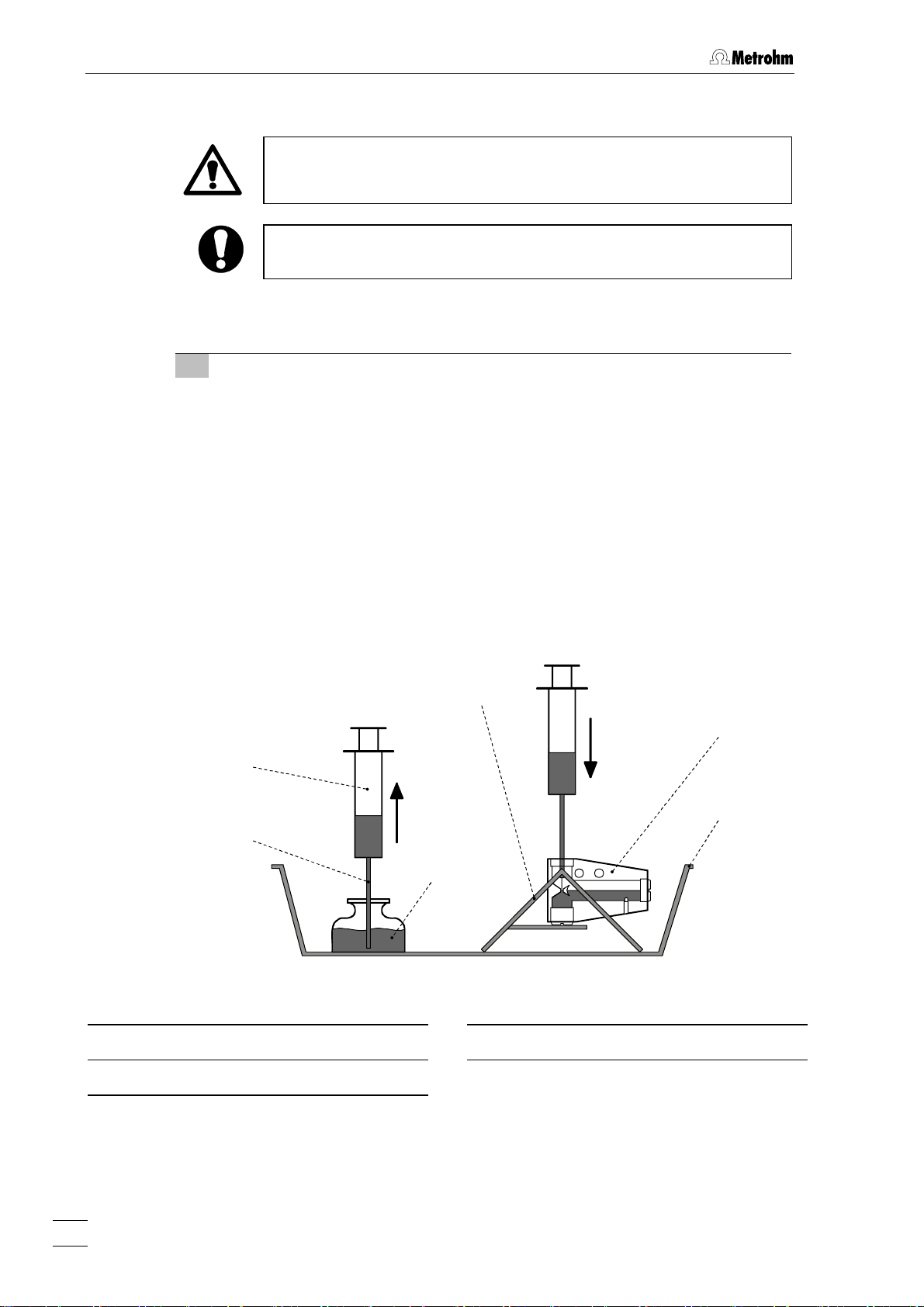

2.3.2 Filling the MME with mercury

When handling mercury, it is necessary to take special precautionary

measures. These are described in detail in section

All actions involving the electrode and mercury vessels must be performed in or over the drip pan

91 supplied (see Fig. 9 - Fig. 11).

The Hg reservoir

81 of the Multi-Mode Electrode 21 is filled with mercury of the hig-

hest degree of purity (mass fraction w ≥ 0.99999) as follows:

1 Prepare Multi-Mode Electrode

• Unscrew locking ring 73 from slotted screw 74 (this gray PVC ring is nee-

ded only to remove the slotted screws

2.3.9).

tion

• Turn slotted screw

74 in or out of the screw thread 76 using a suitable

74 or 79, see section 2.3.7 and sec-

coin until the contact surface of the black O-ring at the Plexiglas wall (thin,

black stripe) is just visible below the metal thread

• Remove the plastic cap used as a transport safeguard from the retaining

86.

nut

• Undo retaining nut

• Place Multi-Mode Electrode

in the electrode holder

86 fully and remove from screw thread 82.

21 with the capillary opening facing upwards

92 (see Fig. 9).

3.4.

76.

89

90

Fig. 9: Adding the mercury

21

Multi-Mode Electrode (6.1246.0020)

Syringe (6.2816.020)

89

Needle (6.2816.030)

90

Hg

92

Drip pan (6.2711.030)

91

Electrode holder (6.2615.030)

92

21

91

22

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 31

2.3 Multi-Mode Electrode (MME)

2 Draw up mercury

• Attach needle 90 to syringe 89.

• Draw up 6 mL ultra pure mercury slowly and carefully using syringe

3 Add mercury to MME

• Lower syringe needle 90 into the top opening of the MME 21 between

sealing ring

• Expel mercury slowly and carefully from the syringe to allow it to flow into

the Hg reservoir

The Hg reservoir

ry.

84 and sealing needle 75.

81.

81 must never be filled more than 2/3 full with mercu-

.

2.3.3 Mounting the capillary

The glass capillaries 87 for the Multi-Mode Electrode 21 are supplied separately in a

protective plastic package. After they have been unpacked, avoid any contact whatsoever with the sensitive capillary tip. The capillary is mounted in the MME filled with

mercury (as described in section

2.3.2) as follows:

1 Insert retaining nut

• Screw retaining nut 86 into screw thread 82 until a slight resistance is noti-

ceable (on no account screw in retaining nut fully!).

2 Insert capillary

• Cut open plastic package containing the glass capillary 87 on the side of

the large capillary opening using scissors (do not tear open), leave capillary

in the package.

• Insert glass capillary directly from its protective plastic package through the

retaining nut

3 Tighten retaining nut

• Firmly tighten retaining nut 86 by hand (do not use a tool). The glass

capillary should then be centered in the opening of the retaining nut.

• If this is not the case, undo retaining nut by one full turn and then retighten

by hand. When tightening, move glass capillary in a circle so that it is centered in the feed-through of the retaining nut.

86 into the sealing ring 84 and push in as far as it will go.

2.3.4 Filling capillary without vacuum

The glass capillary 87 can normally be filled with mercury by the method described

here without vacuum. However, if difficulties regarding stability or reproducibility arise

with a capillary filled in this manner, try to fill the capillaries by the alternative method

with vacuum (section

without vacuum, proceed as follows:

2.3.5). To fill the mounted glass capillary (section 2.3.3) with Hg

797 VA Computrace / Hardware-Manual 8.797.8001EN

23

Page 32

2 Installation

1 Install Multi-Mode Electrode in 797 VA Computrace Stand

• With the measuring head arm 23 tilted back, slide the empty measuring

7 into the holder 5 of the 797 VA Computrace Stand and then lower

vessel

the measuring head arm.

• Carefully insert Multi-Mode Electrode

24 (during insertion, the tip of the capillary 87 must not touch the

head

21 in opening 58 of the measuring

measuring head) and push in carefully as far as it will go. Avoid water drops

touch the tip of the capillary.

2 Connect Multi-Mode Electrode

• Screw FEP tubing 34 for the inert gas supply into connection 71 of the

Multi-Mode Electrode

• Screw FEP tubing

21.

42 for the inert gas supply into connection 72 of the

Multi-Mode Electrode.

• Attach electrode cable

20 (WE) to screw connection 88 of the Multi-Mode

Electrode: push cable lug under the screw and then tighten screw firmly.

3 Fill capillary with mercury

• Switch on 797 VA Computrace Stand with mains switch 14 (the 797 VA

Computrace Stand must first be installed properly as described in section

2.2).

• Start the VA Computrace program and click on

/ Computrace control

to open the COMPUTRACE CONTROL window. Then switch

or MAIN WINDOW / Utility

on the inert gas supply to the 797 VA Computrace Stand by clicking on

This pressurizes the Multi-Mode Electrode 21 and the mercury begins to

flow slowly out of the capillary.

• Gently tap the MME with your finger (to remove any air bubbles) and allow

the mercury to flow out of the capillary into the empty measuring vessel for

approx. 2 min.

• Fill measuring vessel

7 with 10 mL ultra pure water and add 1 drop KCl

solution (in pure water, mercury drops from the capillary only with difficulty).

• Allow mercury to flow out of the capillary for ca. 2 min while checking the

drop formation: The drop time should be ca. 3 s.

4 Adjusting the sealing needle 75

• Turn slotted screw 74 using a suitable coin slowly in a clockwise direction

until the mercury flow stops.

• Open slotted screw slightly in an anticlockwise direction until the mercury

flow restarts.

• Gently tap the MME with your finger and turn the slotted screw very slowly

clockwise until the mercury flow just stops. (The tapping action is used to

knock off the mercury drops so that it is easier to see whether mercury continues to flow).

• Finally, turn slotted screw a quarter of a turn clockwise.

DME.

5 Checking the MME for leaks

• Switch on the dropping mercury electrode by selecting DME in the COM-

24

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 33

2.3 Multi-Mode Electrode (MME)

PUTRACE CONTROL window and clicking on . The mercury drops

freely out of the capillary.

• Select

HMDE and click on . A single mercury drop is formed.

Knock this off by gently tapping the MME

that the mercury flow has really stopped. Repeat this operation several

times.

• If mercury continues to flow, turn slotted screw

wise direction and repeat check.

• If it is not possible to stop the mercury flow, both the glass capillary

the sealing needle 75 have to be replaced (see section 2.3.9).

2.3.5 Filling the capillary using vacuum

Filling of the glass capillary 87 with vacuum is advisable in all cases where difficulties

have been found with the method without vacuum described in section

with vacuum is especially recommended when no ultra pure Hg is available.

To fill the mounted glass capillary (section

follows:

1 Set up filling station

• All actions involving the electrode and the mercury vessels must be performed in or over the drip pan

• The MME

21 is placed in the electrode holder 92 for filling.

91 supplied (see Fig. 10).

21 with your finger and check

74 still further in a clock-

87 and

2.3.4 Filling

2.3.3) with Hg with vacuum, proceed as

2 Connection for vacuum pump

• For filling the capillary 87, the filling tubing 93 is required. At one end it is

fitted with a filling cone

end with the tubing coupling

94 for mounting on the capillary, and at the other

96 for attachment to the line for the vacuum

pump.

• To avoid possible mercury losses, two gas wash bottles

95 are attached to

the filling tubing

3 Vacuum pump

• To draw up mercury a suitable vacuum pump is required (e.g. water jet

Δ

pump). The partial vacuum

p should be around 25 mbar.

• A vacuum release tap must be installed at the vacuum pump or in the line

between the gas wash bottle and the pump for slowly releasing the vacuum.

4 Mount filling tubing

• Mount filling tubing 93 with filling cone 94 on glass capillary 87.

• Connect filling tubing with tubing coupling

96 to the two gas wash bottles

95 and the vacuum pump (see Fig. 10).

797 VA Computrace / Hardware-Manual 8.797.8001EN

25

Page 34

2 Installation

V

93

94

87

21

91

92

Fig. 10: Setting up the filling station

96

Pump

acuum release

tap

95

95

Vacuum

93

94

87

91 92 21

Fig. 11: Filling the capillary

21

Multi-Mode Electrode (6.1246.0020)

87

Glass capillary (6.1226.030)

91

Drip pan (6.2711.030)

Vacuum

1 2

3

92

Electrode holder (6.2615.030)

Filling tubing (6.1817.000)

93

26

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 35

2.3 Multi-Mode Electrode (MME)

Filling cone (4.420.2860)

94

(part of the filling tubing

Gas wash bottle

95

5 Evacuating in vertical position

• Place Multi-Mode Electrode 21 vertically in the electrode holder 92 (see

• Evacuate for ca. 2 min in this position.

6 Evacuating in inclined position

• Carefully tilt Multi-Mode Electrode 21 in the electrode holder 92 to an in-

7 Release vacuum

• As soon as mercury issues from the tip of the glass capillary 87 into the

Tubing coupling (6.1809.000)

96

93)

(part of the filling tubing

Fig. 11-1).

clined position and continue evacuating (see

filling tubing

93, carefully release the vacuum by opening the vacuum re-

lease tap.

93)

Fig. 11-2).

The filling tubing

87 when under vacuum, otherwise the mercury which has issued

ry

from the capillary would be sprayed onto the tubing wall and can no

93 must not be disconnected from the glass capilla-

longer be disposed of in drop form!

• Tap the glass capillary

tip are knocked into the filling tubing

• Disconnect filling tubing

• Place Multi-Mode Electrode

holder

92 (see Fig. 11-3).

87 gently by hand so that any mercury drops at its

93.

94 with filling cone from glass capillary.

21 in a horizontal position in the electrode

From now on, the MME must be left in this position until it is installed

in the stand!

8 Install Multi-Mode Electrode in 797 VA Computrace Stand

• With measuring head arm 23 tilted back, push empty measuring vessel 7

into the holder

ing head arm

• Carefully insert Multi-Mode Electrode

24 (during insertion, the tip of the capillary 87 must not touch the

head

5 of the 797 VA Computrace Stand and then lower measur-

23.

21 in opening 58 of the measuring

measuring head) and push in as far as it will go.

797 VA Computrace / Hardware-Manual 8.797.8001EN

27

Page 36

2 Installation

9 Connect Multi-Mode Electrode

• Screw FEP tubing 34 for the inert gas supply into connection 71 of the

Multi-Mode Electrode

• Screw FEP tubing

21.

42 for the inert gas supply into connection 72 of the

Multi-Mode Electrode.

• Attach electrode cable

20 (WE) to screw connection 88 of the Multi-Mode

Electrode push cable lug under the screw and then tighten screw firmly.

10 Pressurize the MME

• Switch on 797 VA Computrace Stand with mains switch 14 (the 797 VA

Computrace Stand must first be installed properly as described in section

2.2).

• Start the VA Computrace program and click on

/ Computrace control

to open the COMPUTRACE CONTROL window. Then switch

or MAIN WINDOW / Utility

on the inert gas supply to the 797 VA Computrace Stand by clicking on

DME. This pressurizes the Multi-Mode Electrode 21 and the mercury begins

to flow slowly out of the capillary.

• Gently tap the MME with your finger (to remove any air bubbles) and allow

mercury to flow out of the capillary into the empty measuring vessel for

approx. 2 min.

• Fill measuring vessel

7 with 10 mL ultra pure water and add 1 drop KCl

solution (in pure water, mercury drops from the capillary only with difficulty).

• Allow mercury to flow out of the capillary for ca. 2 min while checking the

drop formation: The drop time should be ca. 3 s.

11 Adjusting the sealing needle 75

• Turn slotted screw 74 using a suitable coin slowly in a clockwise direction

until the mercury flow stops.

• Open slotted screw slightly in an anticlockwise direction until the mercury

flow restarts.

• Gently tap the MME with your finger and turn the slotted screw very slowly

clockwise until the mercury flow just stops. (The tapping action is used to

knock off the mercury drop so that it is easier to see whether mercury continues to flow).

• Finally, turn slotted screw a quarter of a turn clockwise.

12 Checking the MME for leaks

• Switch on the dropping mercury electrode by selecting DME in the COM-

PUTRACE CONTROL

window and clicking on . The mercury drops

freely out of the capillary.

• Select

HMDE and click on . A single mercury drop is formed.

Knock this off by gently tapping the MME

21 with your finger and check

that the mercury flow has really stopped. Repeat this operation several

times.

• If mercury continues to flow, turn slotted screw

74 still further in a clock-

wise direction and repeat check.

• If it is not possible to stop the mercury flow, both the glass capillary

87 and

the sealing needle 75 have to be replaced (see section 2.3.9).

28

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 37

2.3 Multi-Mode Electrode (MME)

2.3.6 Storing the MME

On completion of the measurements, the MME is stored in the 797 VA Computrace

Stand so that the tip of the glass capillary

vent used). This prevents blockage of the capillary by crystallized salts.

An electrode treated in this manner can be taken out of the 797 VA Computrace

Stand after a few hours and stored in air for a lengthy period without suffering any

damage. Always store the MME so that the glass capillary is horizontal (see

87 is immersed in pure water (or in the sol-

Fig. 11-3).

2.3.7 Replenishing the mercury (without changing capillary)

The Multi-Mode Electrode 21 can also be refilled with mercury without having to remove the glass capillary

1 Dismantle Multi-Mode Electrode

• Unscrew FEP tubing 34 and 42 from the MME. Disconnect electrode cable

20 from the MME.

• Take Multi-Mode Electrode

MME gently to knock off any mercury drops on the glass capillary into the

measuring vessel.

• Place Multi-Mode Electrode horizontally in the electrode holder

11-3). The slotted screw 79 is now at the top.

87.

21 out of the measuring head 24 and tap the

92 (see Fig.

2 Replenish mercury

• Unscrew slotted screw 79 using a suitable coin. If the slotted screw can not

be loosened by hand, screw on locking ring 73 and pull out of the MME.

• Draw up mercury using the syringe

into the Hg reservoir

• Reinsert slotted screw into screw thread

The Hg reservoir must never be filled more than

using a suitable coin (this action may expel a few drops of mercury from

glass capillary).

Do not turn so tightly that the cemented-in steel threaded ring

comes loose and hence jeopardizes the tightness and safety of the

MME!

2.3.8 Changing capillary

The capillary has a limited life time due to mechanical wearout of and chemical contamination of the capillary tip. This results in irreproducible drop fall in DME mode,

fall-off of the drop in stripping voltammetry using HMDE or increased noise or high

background currents. If the MME is stored for a longer period of time, it is possible

that the capillary is blocked by mercury salts. In such cases, exchange the capillary.

81.

89 with attached needle 90 and expel

2

/3 full with mercury.

78 and screw flush to surface

78 be-

We also recommend exchanging the sealing needle regularly. After a longer period of

use the surface can be covered with mercury oxides and/or glass particles from the

capillary. Both produce high noise during the measurement. Damaged sealing needles

797 VA Computrace / Hardware-Manual 8.797.8001EN

29

Page 38

2 Installation

can also lead to leakage of the MME, i.e. the mercury flow cannot be stopped any

more.

Proceed as follows:

1 Remove Multi-Mode Electrode from 797 VA Computrace Stand

• Unscrew FEP tubing 34 and 42 from the MME, disconnect electrode cable

20 from MME.

• Take Multi-Mode Electrode

21 out of measuring head 24 while gently tapping the MME to knock off any mercury drops on the glass capillary into

the measuring vessel.

• Place Multi-Mode Electrode in a horizontal position in the electrode holder

92 (see Fig. 11-3).

2 Unscrew slotted screw 74

• Using a suitable coin, unscrew slotted screw 74 out of screw thread 76 un-

til the contact surface of the black O-ring at the Plexiglas wall (thin, black

stripe) is just visible below the metal thread.

3 Replace sealing needle 75

If problems with leaks arise owing to a worn, deformed or damaged sealing

needle, it must be replaced. Three spare needles are supplied separately in a

protective plastic package. After unpacking a needle, please avoid any contact

whatsoever with the needle tip. The spare needle

75 is installed as follows:

• Carefully pull old sealing needle out of PTFE membrane of the slotted screw

74.

• Carefully insert new sealing needle without tilting into the hole in the PTFE

membrane of the slotted screw.

NOTE: Do not touch the needle with bare fingers but use the plastic package

4 Dismantle old capillary

• Position Multi-Mode Electrode vertically in the electrode holder (see Fig. 11-

1).

• Undo retaining nut

the lower part of the glass capillary

86 completely by turning anticlockwise and lift up until

87 with the wide opening is visible.

• Gently tap the glass capillary to knock off any residual mercury in the wide

opening into the MME.

• Press the retaining nut downward with one hand and with your other hand

take glass capillary completely out of the mount.

5 Dispose of old capillary

• Connect filling tubing 93 with the tubing coupling 96 to the two gas wash

bottles

• Insert glass capillary

95 and the vacuum pump (see Fig. 10).

87 (capillary end) in the filling cone 94 of the filling

tubing.

• Remove mercury from capillary with the vacuum pump.

6 Replenish mercury if necessary

Proceed as described in section 2.3.2.

30

797 VA Computrace / Hardware-Manual 8.797.8001EN

Page 39

2.3 Multi-Mode Electrode (MME)

7 Mount new capillary

Proceed as described in section 2.3.3.

8 Fill capillary

Proceed as described in section 2.3.4 or section 2.3.5.

2.3.9 Cleaning the MME

If the mercury in the Multi-Mode Electrode is contaminated and this leads to disturbances, the MME must be cleaned and refilled with ultra pure mercury. Proceed as

follows:

1 Remove Multi-Mode Electrode from 797 VA Computrace Stand

• Unscrew FEP tubing 34 and 42 from the MME, disconnect electrode cable

20 from MME.

• Take Multi-Mode Electrode

ping the MME to knock off any mercury drops on the glass capillary into

the measuring vessel.

21 out of measuring head 24 while gently tap-

2 Remove old mercury

• Place Multi-Mode Electrode 21 in a horizontal position in the electrode hol-

92 (see Fig. 11-3). The slotted screw 79 is now at the top.

der

• Unscrew slotted screw using a suitable coin.

• Carefully turn MME and empty mercury through the threaded opening

into a waste container placed in the drip pan

tap the glass capillary

of the MME.

3 Dismantle MME

• Unscrew retaining nut 86.

• Take glass capillary

locking ring

from the glass capillary.

• Remove insert ring

• Unscrew slotted screw

from screw thread

• Screw locking ring

4 Dispose of old capillary

• Connect filling tubing 93 with the tubing coupling 96 to the two gas wash

bottles

• Insert glass capillary

tubing.

• Remove mercury from the capillary with the vacuum pump.

85 are removed at the same time. Remove these two parts

95 and the vacuum pump (see Fig. 10).

87 and the MME to ensure that all mercury flows out

87 out of opening 82, the sealing ring 84 and the

83 from the MME.

74 with a suitable coin in an anticlockwise direction

76.

73 onto slotted screw and pull out of the MME.

87 (capillary end) in the filling cone 94 of the filling

91. While doing so, gently

78

797 VA Computrace / Hardware-Manual 8.797.8001EN

31

Page 40

2 Installation

5 Clean MME

• Clean inner compartments of the MME, contact pin 80 and the screw

threads

76, 78 and 82 with a lint-free cloth.

• If required, rinse all inner compartments of the MME and the unscrewed

individual parts with dist. water and then dry with N

.

2

Do not use any organic solvents.

If you used water to clean the MME, make sure that the inside of the

electrode has dried entirely. Residual moistness can cause problems

during subsequent measurements.

6 Replace sealing needle 75 if needed

If problems with leaks arise owing to a worn, deformed or damaged sealing

needle this must be replaced. Three spare needles are supplied separately in a

protective plastic package. After unpacking a needle, please avoid any contact

whatsoever with the needle tip. The spare needle

75 is installed as follows:

• Carefully pull old sealing needle out of PTFE membrane of the slotted screw

74.

• Carefully insert new sealing needle without tilting into the hole in the PTFE

membrane of the slotted screw.