Page 1

Heavy-duty Photoelectric Sensor

Connector

pin position

w

e

q

r

PX-10(P)/10C(P)

Instruction Manual

96M1591

Warning

• This product is used to detect targets. Do not apply the product to

safety circuits for human protection.

• This product is not of explosion-proof construction. Do not use the

products in places with flammable gas, liquid, or dust.

• This product is a sensor of DC power supply type. Do not apply

AC power. Application of the AC power may lead to explosion or

fire.

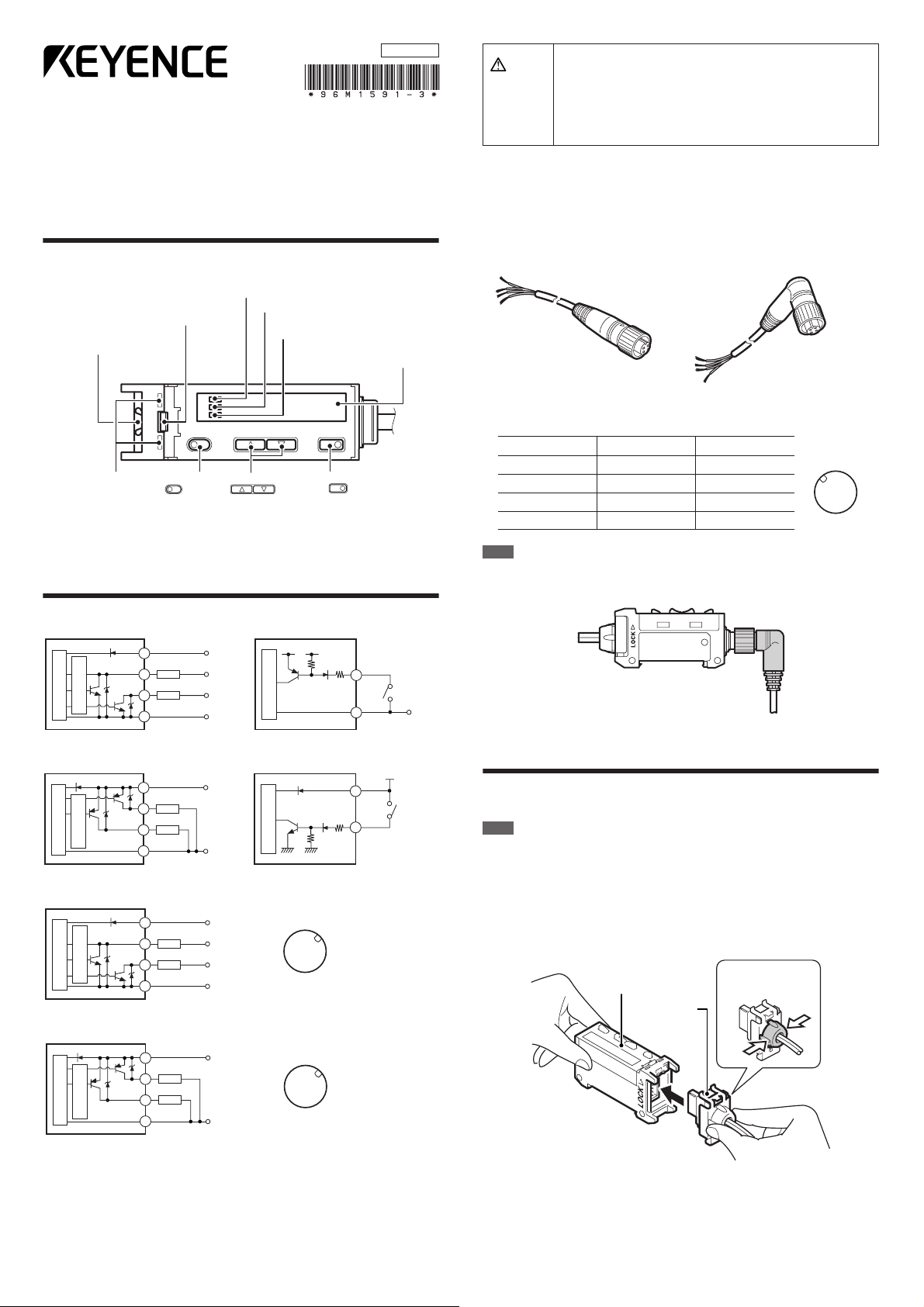

Part Names

Amplifier Unit

DSC indicator

Operation status indicator

Head release lever

Sensor head connector

receptacle

Head installation

holes

SET

SET

button

UP/DOWN

UP/DOWN

There are two types of amplifier units.

•

PX-10/10P (above): Uses a cable length of 2 m and can handle external input.

• PX-10C/10CP (connector type): Connects to the power source with a socket cable.

(detection output)

Operation status indicator

(alarm output)

Digital monitor

MODE

MODE

buttons

button

Input/Output Circuit

■PX-10 (NPN output)

Overcurrent

protection circuit

Light sensor circuit

Brown

Black (Detection output)

Load

White (Alarm output)

Load

Blue

12–24 V DC

5–40 V DC

5–40 V DC

0 V

3.3 V DC

(Short-circuit current

1 mA max.)

Main sensor circuit

Pink (input)

PLC, etc.

Blue

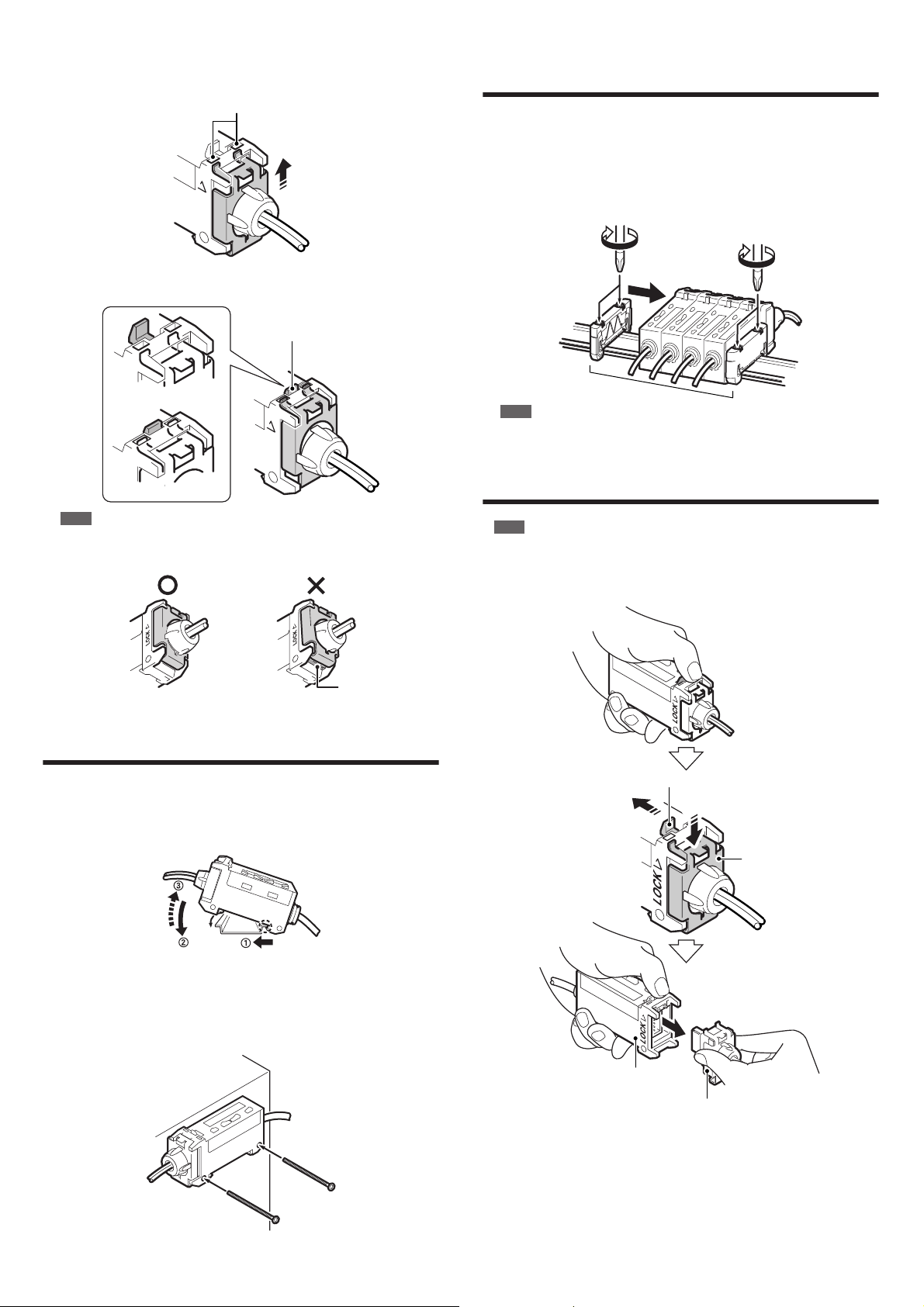

● Socket Cables for PX-10C/10CP (Optional)

■OP-75721 (cable length 2 m) ■OP-75722 (cable length 2 m)

■Relationship between connector pin numbers and cable core wires

Information in the following table is the same for OP-75721 and OP-75722.

Connector pin no. Wire casing color Connection

①

②

③

④

Note

When connecting the L-shaped cable (OP-75722) to the amplifier unit, face the

connector for the cable towards the amplifier unit in the direction shown in the following

diagram and lock it into place. Note that the connector portion cannot be reversed.

0 V

Brown 12 to 24 V DC

White Alarm output

Blue 0 V

Black

Detection output

■PX-10P (PNP output)

Overcurrent

protection circuit

Light sensor circuit

Brown

Black (Detection output)

Load

White (Alarm output)

Load

Blue

12–24 V DC

0 V

■PX-10C (connector type NPN output)

Overcurrent

protection circuit

Light sensor circuit

Pin q

Pin r (Detection output)

Load

Pin w (Alarm output)

Load

Pin e

12-24 V DC

5-40 V DC

5-40 V DC

0 V

■PX-10CP (connector type PNP output)

Overcurrent

protection circuit

Light sensor circuit

Pin q

Pin r (Detection output)

Load

Pin w (Alarm output)

Load

Pin e

12-24 V DC

0 V

Connector

pin position

w

e

q

r

Connector

pin position

w

e

q

r

(Short-circuit

current

2 mA max.)

Main sensor circuit

Brown

Pink (input)

12–24 V DC

PLC, etc.

Precautions on Installation

●

Connecting the Sensor Head to the Amplifier Unit

Note

• The sensor is not guaranteed under the conditions of the warranty if the sensor head

is not connected correctly using the procedure described above.

• The sensor is not guaranteed under the conditions of the warranty if dust or dir t

attaches to the packing for the sensor.

• If the sensor head cannot be inser ted easily, fully remove any dirt or dust from the

amplifier unit and apply silicon grease to the opening.

1 Grasp the cap for the sensor head connector and insert the connector straight

in the direction shown in the diagram.

Amplifier unit

Sensor head

connector

Hold the cap by

the sides.

1

Page 2

2

Insert the two upper tabs on the mounting fixture into the head installation hole

on the amplifier unit and pull the mounting fixture up in the direction shown in

the diagram. If the tabs do not slide into place easily, push on the bottom of the

mounting fixture.

Head installation hole

p

LOCK

Installation is complete when the head release lever locks into place as shown

in the following diagram.

Head release lever

Using Multiple Amplifier Units

(Interference Protection Function)

Installing multiple amplifier units (up to four) side by side on a DIN rail can protect

against interference.

Two end units (option item: OP-26751 (two units included)) are also required.

1

Install the sensor heads to the connected amplifier units.

Sandwich the amplifier units between the end units. Tighten the screws at the top

2

(two screws in two locations each) with a Phillips screwdriver to fix the end units.

Unlocked sensor head

LOCK

Locked sensor head

Note

Check that the lower tab on the mounting fixture for the connector fits into the

groove on the bottom of the amplifier unit. If the tab does not fit into the groove,

remove the sensor head and try connecting it again.

Tab is fitted in the groove.

Tab is not fitted in the groove.

Groove

Mounting the Amplifier Unit

Mounting on a DIN rail

■

1

Hook the tab located on the bottom of the amplifier unit to the DIN rail as

shown in the figure. While pushing the amplifier unit in the direction of arrow

, tilt it in the direction of arrow 2 .

End units

Note

End units must be used.

Removing the Sensor Head from the

Amplifier Unit

1

Note

Do not pull on the cable.

1

Grasp the amplifier unit. While pulling the head release lever in the direction of

arrow 1 , slide the mounting fixture for the connector in the direction of arrow

. Pull the connector from the amplifier unit in the direction of arrow 3 .

1

Head release lever

2

•

2

Mounting fixture

•

To dismount the sensor, raise the amplifier unit in the direction of arrow 3 while

2

pushing the amplifier unit in the direction of arrow 1 .

■

Mounting the amplifier unit sideways (Only for use with a single unit)

Mount the amplifier unit using M3 screws in the two locations as shown in the

diagram. Use a maximum torque of 0.6 N•m to tighten the screws.

3

Amplifier unit

Sensor head connector

●

Precautions for Installing the Sensor Head

Install the sensor head so that it can move at least 4 ° in any direction. This allows

beam-axis adjustment for the sensor head.

Use a mounting fixture especially made for beam-axis adjustment with an

elongated hole. Contact KEYENCE for more information about this item, which is

sold separately.

The sensor head cable in gray jacket is for the transmitter side and black jacket

for the receiver side.

2

Page 3

Setting a Sensitivity – Basic –

SET

UP/DOWN

SET

UP/DOWN

Workpiece

SET

UP/DOWN

3 seconds or longer

The set value will appear

when the settings are completed.

Workpiece

Edge

SET

UP/DOWN MODE

SET

UP/DOWN MODE

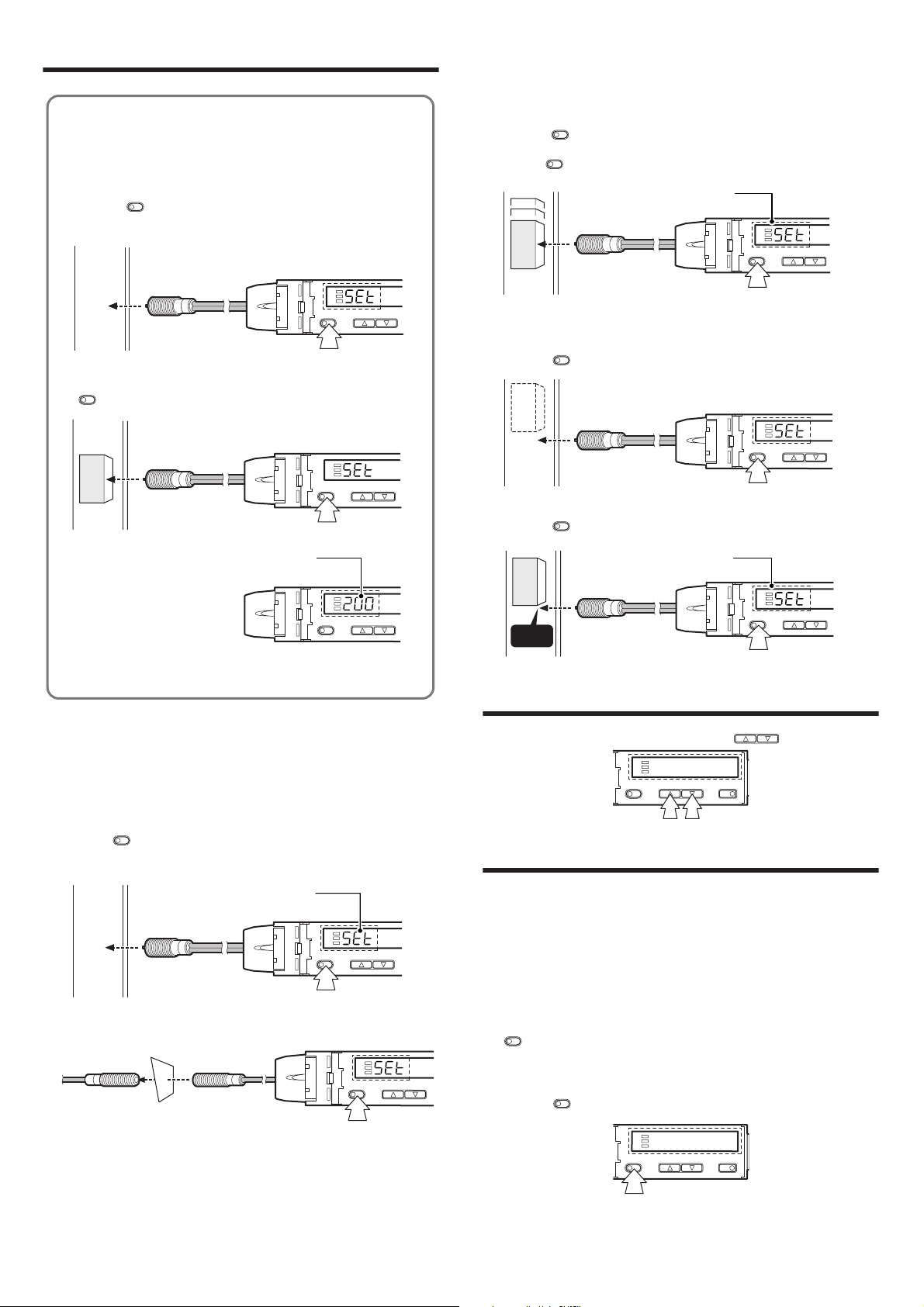

● Most Basic Sensitivity Settings

(2-point Calibration)

In this mode, the setting value used will be the mean value of two light

intensity values obtained through detection with and without a workpiece.

1 Press the button without any workpiece placed in front of the

sensor head.

SET

SET

UP/DOWN

2 Place a workpiece placed in front of the sensor head, and press the

SET

button.

SET

Workpiece

The set value will appear

when the settings are completed.

UP/DOWN

●

Detecting Moving Workpieces

(Full Auto Calibration)

In this mode, the set value will be set to the mean value of the maximum and

minimum values obtained within a certain period.

1

Press the button for at least three seconds while the target workpiece is

passing the sensing area of the sensor head.

While the button is pressed, the sensitivity of the sensor will be set

•

according to the incident values.

●

Positioning a Target (Positioning Calibration)

1

Press the button without any workpiece placed in front of the sensor

head.

Place a workpiece on the position where you want to perform positioning.

2

Press the button for at least three seconds. When the indication flashes,

release the button.

SET

SET

The set value will appear

when the settings are completed.

Workpiece

3 seconds or longer

SET

SET

SET

UP/DOWN

If the sensitivity difference is not large enough, "----" flashes for about two

seconds after the calibration is complete. The mean value of the two

detected values is still recorded.

●

Improving Performance against Dust and

Stains (Maximum Sensitivity Setting)

Set the sensitivity without a workpiece for a reflective type, and with a workpiece

for a thrubeam type. Set the sensitivity slightly higher than the amount of received

light at the setting time.

1

Press the button for at least three seconds in the state as shown in the

figure below. Release the button when "SET" flashes on the display.

Reflective

Thrubeam

SET

The set value will appear

when the settings are completed.

SET

3 seconds or longer

3 seconds or longer

UP/DOWN

SET

UP/DOWN

Fine-adjusting Sensitivity

The setting value can be changed by pressing the buttons.

UP/DOWN

Setting a Sensitivity – Advanced –

●

Setting Sensitivity with Signals from

External Devices (Page 6, No. 6)

By selecting "External calibration" in page 6, No. 6, the signal from an external

device can be used to set the sensitivity.

See "Using External Input" (page 4).

●

Percent (%) Calibration (Page 6, No. 3)

The sensitivity can be set as a percent (%) of received light intensity.

For example, when the percentage calibration target value is set to "-10P", pressing

SET

the button sets the value to 10% below the amount of received light.

When selecting the sensitivity setting method (page 6, No. 3), select percent

1

calibration, set the target value of calibration, and return to the normal display.

2

Press the button at the percentage for the desired reference for light

intensity.

SET

While percent calibration is selected, other calibrations (sensitivity setting) cannot

be used.

* External input (page 4) can still be used (PX-10/10P only).

3

Page 4

Selecting Detection Mode

Avoiding Effects of Dust and Stains

Detection mode can be set for normal detection or for one of the following two

modes.

●

Edge Detection Mode (Page 6, No. 5)

This mode detects the change in the received light intensity during a given period

of time. This mode can be set to react only to rapid changes in intensity and not

slow changes in intensity.

Select "Edge detection mode" in page 6, No. 5.

Rising edge detection

Falling edge detection

Rising/falling

(both-edge) detection

■

Sensitivity setting

Quickly press the button once to set the maximum sensitivity setting. This

completes the setting.

If the sensitivity is too low, the sensor may sense objects other than the

workpiece. In this situation, increase the value by fine-adjusting the sensitivity

(see "Fine-adjusting Sensitivity" on page 3).

SET

SET

Detects an increase (rising edge)

in the received light intensity.

Detects a decrease (falling edge)

in the received light intensity.

Detects an increase (rising edge)

and a decrease (falling edge) in

the received light intensity

UP/DOWN MODE

There are two methods for avoiding the effects of dust and stains. One uses

external input and the other does not. KEYENCE recommends using the method

with external input.

■

Using external input (PX-10/10P only)

Use the external input .to periodically correct the setting value and the display value

When using a thrubeam sensor head:

See "Percent Calibration" (page 3).

When using a reflective sensor head:

See "Zero Shift Function" (page 5).

Not using external input

■

See "Edge Detection Mode" and "Dynamic Sensitivity Correction Mode" (page 4).

●

Using External Input (PX-10/10P only)

Use the following procedure to import a signal from an external device.

1

Select an option other than OFF in the external input function selection (page 6, No. 6).

2

Short circuiting the pink wire for at least 2 ms as shown below (at least 20 ms

for OFF) accepts the signal.

PX-10 PX-10P

• External input settings (external calibration/display scaling) can be changed

up to 1 million times.

Input is not received while setting each mode.

When external calibration is selected, external input performs the same

operations as with the button.

Brown

Blue

Pink

SET

•

•

•

•

•

•

+V

OV

•

•

•

Brown

Pink

Blue

•

+V

OV

●

Dynamic Sensitivity Correction (DSC) Mode

(Page 6, No. 5)

DSC automatically corrects the setting value according to the changes in the

received light intensity when there is no workpiece (output OFF). This function is

effective when the light intensity difference is small when judging whether or not

there is a workpiece.

Select "Dynamic Sensitivity Correction" in page 6, No. 5.

■

Sensitivity setting

Sensitivity is set in the same way as for the normal detection mode

The DSC indicator illuminates when DSC mode is set.

DSC indicator

SET

UP/DOWN MODE

When L-ON is selected, the upper limit of the correctable range is twice as

much as the initial setting value.

The value is stored in memory even after the power is turned off.

The DSC indicator blinks when the L/D-ON settings are inadequate or the

amount of light changes drastically with output OFF. Verify the settings again

when the indicator blinks.

(page 4)

■

Sensitivity settings and display scaling settings

Both the sensitivity and the display scaling can be set when using the external input.

In external input function selection (page 6, No. 6), select "External calibration".

In display value correction function selection (page 7, No. 8), select "Display

scaling function".

The following shows an example of use during percent (%) calibration and

display scaling.

Input ON

.

Input OFF

Input ON

Input OFF

% calibration Display scaling

3 seconds

or less

3 seconds

or longer

% calibration% calibration

Activating Key Lock

The key lock function disables the operation of all keys.

1

Press and hold the button or the button for at least 3 seconds

while holding down the button.

Use the same procedure to deactivate keylock.

During the operations shown above where the display shows "Loc", pressing

and holding the button for at least 3 seconds activates key lock mode

with PIN number.

Press the buttons to enter a PIN number between 0 and 9999,

then press the button to activate the key lock. Use the same procedure

to deactivate the function.

Note

Write down the PIN number and store it some place safe so that you do not forget it.

The lock cannot be released if an incorrect PIN number is entered.

UP

MODE

SET

MODE

UP/DOWN

MODE

DOWN

UP/DOWN MODE

3 seconds or longer

4

Page 5

Display Selection when Running Detection

MODE

Correcting Display Values

● Display Selection (Page 7, No. 10)

The display selection can be changed in the following manner during detection

when "FuLL" is selected in page 7, No. 10. The factory default value is "1" only.

Current

received

Setting

light intensity

value

①

MODE

Press

Extension display

(received light intensity)

②

MODE

Press

Bar

Excess

③

display

*2

gain (%)

*3

* 1 When ULTRA or MEGA modes are selected, the current received light intensity

can be displayed up to five digits.

The setting value flashes when the button or the button is

pressed once.

The setting can be changed by pressing the button or the

button again while the display is flashing.

* 2 The excess gain is displayed in 5% increments from 85 to 115%.

* 3 The current light intensity for the setting value is displayed as a percentage.

* 4 Holds and displays the peak value and the bottom value.

* 5 This value is only displayed when "Limit detection function" is selected for the

alarm output settings (page 7, No. 9). The setting value for the alarm output

can be changed.

■Resetting peak and bottom values (displays 4 and 5)

• Press and hold the button and the button at the same time for at

least 3 seconds.

• Turn off the power.

SET

■Useful functions during hold display (4)

During hold display, press and hold the button for three or more seconds

to set the following advanced settings.

DOWN

Press the

button for 3

seconds or longer

MODE

Press

■Useful functions during power mode display (6)

Press and hold the button for at least 3 seconds to switch easily between

power mode and light emission power.

DOWN

MODE

Press

*1

Output

selection

⑥

*5

⑤

Setting value for

alarm output

Power

mode

Press

Peak/bottom values

for alarm output

Press

④

MODE

Press

Light intensity

peak value

UP

MODE

DOWN

Hold display selection

Select the setting by pressing the buttons.

Updates every time the current light

.

intensity is less than the specified peak

value and more than the specified

bottom value.

.

Displays the maximum and minimum

peak values since the power is turned on

(total number).

Displays the maximum and minimum

.

bottom values since the power is turned

on (total number).

.

Displays the minimum peak value and

the maximum bottom value since the

power is turned on (total number).

.

Displays the maximum peak value and

the minimum bottom value since the

power is turned on (total number).

*4

UP

Light intensity

bottom value

DOWN

MODE

MODE

*4

DOWN

UP/DOWN

● Shifting Current Light Intensity and Setting

Value by a Specific Value

(Display Shift Function: Page 7, No. 8)

This function shifts (increases or decreases) the current light intensity and the

setting value by a specific value.

•

Select "Display Shift Function" on page 7, No. 8 and set a shift value.

•

This function cannot be used during Dynamic Sensitivity Correction (DSC) mode.

●

Forcibly Setting the Current Light Intensity to 0

(PX-10/10P only)

(Zero-Shift Function: Page 6, No. 6)

The zero-shift function is used to forcibly set the current light intensity to zero by

inputting a signal from the PLC or other external device.

•

Select "Zero-shift function" at page 6, No. 6.

•

For how to input a signal, see page 4.

•

The function is reset when the power is turned off.

•

Negative values are displayed as 0.

● Changing Current Light Intensity to a

Specific Value

(Display Scaling Function: Page 7, No. 8)

This function reduces or enlarges the current received light intensity to the

"scaling target value".

(The intensity is enlarged or reduced by the same ratio as set in the parameter.)

•

It can be used when "Display Scaling Function" is selected on page 7, No. 8.

•

No value can be set when the Edge detection mode is selected.

•

The value is stored in memory even after the power is turned off.

1 When selecting a display value correction function (page 7, No. 8), select

“Display Scaling Function”, and set the target value. (The explanation here

deals with the case where the target value is set to 2000.)

2 During the normal display, press the button while pressing the

button.

(Scaling is performed for the current light intensity at this time.)

SET

The display changes as follows, and the target value (which is 2000) for

scaling is displayed.

SET

The scaled value is displayed.

SET

SET

UP/DOWN MODE

UP/DOWN MODE

UP/DOWN MODE

DOWN

Press the button for 3 seconds or longer

Power mode selection

UP/DOWN

Press buttons to select

(see page 6, No. 2)

MODE

Press

Emission power

UP/DOWN

Press buttons to select

(see page 6, No. 7)

MODE

Press

The current light intensity can be adjusted in the following range.

Power mode Minimum value Maximum value

TURBO Approx. 1/20 times Approx. 16 times

SUPER Approx. 1/40 times Approx. 8 times

ULTRA Approx. 1/160 times Approx. 2 times

MEGA Approx. 1/320 times Approx. 1 time

If the value exceeds the range, Err

is displayed and a range that can be adjusted

(minimum value or maximum value) is set.

* External input (see page 4) can be used. (PX-10/10P only)

5

Page 6

Setting Each Type of Function

Normally, only standard settings can be used.

Detection Settings Menu

From the Basic Settings Menu

Display each type of menu and change the settings as required.

Press and hold for at least three seconds to return to the basic menu.

•

•

Select a function with the

MODE

UP/DOWN

buttons and press the button to set the

MODE

value.

•

Select END for each menu and press the button to set the value.

Basic

Settings Menu

Detection

Settings Menu

System

Settings Menu

1 Detection output selection

2 Power mode selection

3 Sensitivity setting method selection

4 Timer mode selection

5 Detection mode selection

6 External input function selection (PX-10/10P only)

7 Light emission power selection

8 Display value correction function selection

9 Alarm output setting

10 Display selection during detection

11 Display reverse selection

12 Power save mode setting

MODE

Basic Settings Menu

MODE

Press for 3 seconds or longer

MODE

Press

MODE

Press

MODE

Press

When Std

is selected

A

MODE

Press

When

StG-Func

is selected

When

StG-SYS

is selected

To Detection

Settings Menu

To System

Settings Menu

When End

is selected

End of basic menu display

1 Detection output selection

Select the setting by pressing the buttons.

. ON during emission

. ON during reception

The following values are the initial settings

when the power is turned on.

Thrubeam: Reflective:

Perform this setting again after changing the

sensor head.

2 Power mode (response time) selection

Select the setting by pressing the buttons.

. TURBO : 500μs

. SUPER : 1ms

. ULTRA : 4ms

. MEGA : 16ms

3

Sensitivity setting method selection (See page 3.)

Select the setting by pressing the buttons.

. Normal sensitivity setting method

. Percent (%) calibration

When SEtP

is selected

Setting target value for percent calibration

Select the setting by pressing the buttons.

MODE

Press

Can be set between -99 and +99%.

Menu end/continue selection

Select the setting by pressing the buttons.

. The menu ends.

.

.

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

Configures detection settings

(timer, external input, etc).

Configures system settings

(display, power save, etc).

When

Timer OFF

is selected

Press

When other

than dSc

is selected

When

PX-10C/

PX-10CP

are used

Press

When other

than SCAL

is selected

Press

Return to section A

on the basic menu

MODE

Press

MODE

Press

other than

Timer OFF

is selected

a

or

MODE

selected

When PX-10/PX-10P

are used

MODE

SCAL is

selected

MODE

4Timer mode selection

Select the setting by pressing the buttons.

. Timer OFF

. OFF-delay

. One-shot

When

. One-shot

.

.

Timer setting

Select the setting by pressing the buttons.

Can be set between 1 and 9999 ms.

MODE

Press

For Timer mode selection,

* 1 is not selected → a

* 1 is selected → b

b

Press

* When 1 is selected, ON-delay timer

is set.

Timer setting 2

Sets the time of OFF-delay (One-shot).

Select the setting by pressing

the buttons.

Can be set between 1 and 9999 ms.

MODE

ON-delay + OFF-delay *1

ON-delay + One-shot *1

UP/DOWN

5Detection mode selection (See page 4)

Select the setting by pressing the buttons.

When

dSc is

Press

Press

.

.

.

.

.

MODE

MODE

Normal (light intensity) detection mode

Dynamic Sensitivity Correction mode

Detects the rising edge of the received

light intensity (Edge Detection mode)

Detects the falling edge of the received

light intensity (Edge Detection mode)

Detects both the rising and falling edges of

the received light intensity (Edge Detection mode)

Detection operation selection

Select the setting by pressing the buttons.

.

Mainly reflective

[Light intensity with workpiece >

Light intensity without workpiece]

(The output is ON when the light enters.)

.

Mainly thrubeam

[Light intensity with workpiece <

Light intensity without workpiece]

(The output is ON when the

light is blocked.)

Correction speed selection

Select the setting by pressing

UP/DOWN

the buttons.

1 to 3 The correction becomes faster as the

number becomes larger.(Select 1 in normal cases.)

6External input function selection

Select the setting by pressing the buttons.

.

Not using external input

.

External calibration

.

When

Press

MODE

Display scaling function

.

Zero-shift function

.

Light mission stop

Display scaling target value setting

Select the setting by pressing the buttons.

The value can be set between 100

and 9900 in units of 100.

displays for the maximum

possible value.

7Light emission power selection

Select the setting by pressing the buttons.

.

Normal light emission power

.

Approx. 20% of the normal time

.

Approx. 15% of the normal time

.

Approx. 3% of the normal time

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

6

Page 7

System Settings Menu

MODE

MODE

MODE

MODE

MODE

MODE

From the Basic Settings Menu

MODE

Press

MODE

Press

When oFF

is selected

Press

When oFF

or dobL is

selected

Press

Press

Press

Return to section A

on the basic menu

MODE

MODE

MODE

MODE

When

SCAL is

selected

Press

When ShFt

is selected

Press

When

LiMt is

selected

Press

Press

Press

8 Display value correction function selection

Select the setting by pressing the buttons.

. Not to be used

. Uses the display scaling function

. Uses the display shift function

Display scaling target value setting

Select the setting by pressing the buttons

MODE

The value can be set between 100

and 9900 in units of 100.

displays for the maximum

possible value.

Setting the shift value

Adjust the setting by pressing the buttons.

Negative values are displayed as 0.

Current value after shiftingShift value

MODE

9 Alarm output setting

Select the setting by pressing the buttons.

. Not to be used

. Limit setting function

. Reverse output

(Reverses the detection output)

Limit setting function selection

Select the setting by pressing the buttons.

MODE

. Peak value setting

. Bottom value setting

Alarm output selection

Select the setting by pressing the buttons.

. OFF during normal operations,

MODE

MODE

10

Display selection during detection (Se e page 5)

Select the setting by pressing the buttons.

. Only displays the setting value and

the current value

. Display can be switched

ON during alarm

. ON during normal operations,

OFF during alarm

.

ON during normal operations, switches

between ON and OFF during alarm

Alarm output value setting

Select the setting by pressing the buttons.

Select the setting value.

11 Display reverse selection

Select the setting by pressing the buttons.

. Normal display

. Reverses the display.

Even when the display is reversed,

the setting value is displayed in green and

the received light intensity is displayed in red.

12 Power save mode setting

Select the setting by pressing the buttons.

. Saves power (Turns off the display).

During power save mode, only one segment in the

digital display lights up at a time and the lit

areamoves from one segment to the next in order.

(The display returns to normal display for one

minute when the keys are pressed.)

. Normal display

To turn off all of the lights (both digital and operation display lights)

Press and hold the button for at least three

seconds to select

To revert to the normal method from ALL mode,

press the buttons at the same time

and hold them down for at least three seconds.

ALL.

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

.

● Initializing, Saving, and Loading Settings

■Initializing settings (returns the parameters to the factory default state)

1 While pressing the button, press the button or the button

MODE

UP

five times.

2

With the button or the button, select "r S t" and press the button.

3 With the button or the button, select ":n:t" and press the

UP

UP

DOWN

DOWN

button to perform initialization.

DOWN

■Saving settings (you can make changes but still return to the saved

settings)

1 While pressing the button, press the button or the button

MODE

UP

five times.

2

With the button or the button, select "SAvE" and press the button.

3 With the button or the button, select "YES" and press the

UP

UP

DOWN

DOWN

button to save the settings.

* Saved settings are not cleared even when initialization is performed.

DOWN

■Loading saved settings

1 While pressing the button, press the button or the button

MODE

UP

five times.

2

With the button or the button, select "rSt" and press the button.

3 With the button or the button, select "[vSt" and press the

UP

UP

DOWN

DOWN

button to load the saved settings.

DOWN

Outputting Alarms

● Limit Setting Function (Page 7, No. 9)

Limit settings output a warning when the difference in light intensity becomes too

small for detecting whether a workpiece is present.

•

It can be used when "Limit Setting Function" is selected on page 7, No. 9.

There are two types of limit setting functions.

Peak value

This function samples the peak value when the light intensity rises above the set

value for detection output. The warning outputs when the minimum hold value

drops below the setting value for alarm output.

Bottom value

This function samples the bottom value when the light intensity falls below the set

value for detection output. The warning outputs when the maximum hold value

rises above the setting value for alarm output.

Peak hold minimum value

Parameter for PEAk selection

Setting value for detection output

Parameter for botm selection

Bottom hold maximum value

Detection

output

Alarm output (PEAk parameter)

Alarm output (botm parameter)

Resetting peak value and bottom value

Press and hold the button and the button for at least 3 seconds to

SET

MODE

reset the values.

The function is reset when the power is turned off.

Error Displays and Corrective Actions

Error indication Cause Remedy

Sensor head is not connected.

ErH

ErC

ErE

Err The amplifier unit is broken. Replace it with a new amplifier unit.

There is a short circuit in the head

cable, or strong extraneous light has

entered the top of the short head.

Overcurrent is flowing through the

output wire.

Data write/read error Perform initialization.

Data has been written in the

EEPROM over 1 million times.

Check whether there is a short

circuit in the head cable and

whether the amplifier is inserted

correctly.

Shield the sensor from the

extraneous light.

Check the load and reduce the

current to be within the rated range.

If you need to write more data,

replace the amplifier unit.

7

Page 8

Shortening the Sensor Head Cable

Be sure to follow the steps carefully in order to waterproof the cable.

■Sensor head connector

3 Hold the IDC connector so that the back side (side where the wires can be

seen) is facing forwards. Push the upper tab in the direction of arrow 1 and

then open the back side in the direction of arrow 2.

1

Upper tab

Disassembled diagram (configuration diagram)

The connector for the sensor head can be disassembled into the following parts.

Upper tab

Lower

tab

IDC connector Cap B Packing*

* 1 Made up of two parts

Note

Do not remove parts other than the IDC connector from the cables.

Mounting fixture

1

Removing the Connector and Cutting the Cables

1

Turn Cap A counterclockwise and remove both Cap A and the mounting fixture.

Cap A

Cap A

4 Remove the cables.

5 Cut the cable to the required length.

Back

(Wires are visible)

2

Mounting fixture

2 Pull the IDC connector gently in the direction of the arrow to remove it from

Cap B. Remove the packing from Cap B.

Cap B

IDC connector

Note

If all of the parts are accidentally removed, insert the cable through all of the parts as

shown below before starting the procedure under "Connecting the Cables and the IDC

Connector" (page 9).

• Thread the gray cable through the hole near the raised portion of Cap

Cap B

Packing

Mounting fixture

Cap A

Cap B

Black (Receiver side)

Gray

(Transmitter side)

Raised portion

B.

Packing

8

Page 9

Connecting the Cables and the IDC Connector

Note

When the cable length of the sensor head is changed, be sure to connect the amplifier

to check that it operates correctly.

1 Manipulate the end of the cables as shown in the following figure.

•

Peel back the insulation 10 mm from the end. (Do not strip the wires in the core.)

•

Twist the base of the shielded wire at least five times so it does not unravel,

and bend it 90° to the side.

12

Core wires

90°

90°

Note

Do not install the connectors more than two times. If the installation exceeds twice,

purchase OP-77758 (two connectors) separately.

If "ErH" appears on the amplifier even when using pliers to crimp the connector,

press the cable (part A) between the metallic contacts with a thin tool such as a

flathead screwdriver to crimp the cable more firmly.

Metallic

contact

Cable

Part A

Metallic

contact

Shielded wire

* Be careful not to twist the core wires along with the shielded wire.

If the wires become twisted, untwist them slightly and pull the core wires apart

from the shielded wires.

2 Align the core wires with the same color as indicated by the sticker on the IDC

connector and insert the wires as shown below.

• Insert the two wires (one black and one white) for the black cable (receiver

side) into the connector completely.

• The red wire for the gray cable (transmitter side) cannot be inserted

completely, but insert it as far as it can go.

• Twist the shielded wires in the direction of the arrow while pulling them into

the ditches.

Black

Red

White

*

Shielded wire

Mounting the Connector

1 Install the IDC connector tight with Cap B.

IDC connector

Cap B

2 Slide the packing and the mounting fixture in the direction of the arrow to

combine them.

Cap B

Packing

Mounting fixture

Insert the packing into the hole in Cap B and combine the parts so that the

raised portion on Cap B lines up with the notch on the mounting fixture.

3 Close the IDC connector, crimp it tight with pliers or a similar tool, and push

down on the top to lock it shut.

Note

Be careful not to crush the raised portion shown in the diagram when using pliers.

Back Front

Raised portion

4 Use wire cutters or a similar tool to trim off the wires sticking out of the IDC

connector.

Raised portion

Raised

portion

Cutout

Packing

3 Push Cap A in the direction of the arrow and turn it clockwise to lock it into

place. Tighten Cap A while pushing on the IDC connector as shown in the

diagram below.

Cap A

Tighten the parts until there

is no gap between them.

9

Page 10

Specifications

■Sensor head

Ty pe

Cable Normal Spiral Normal Normal Spiral Normal Spiral

Model PX-H71 PX-H71G

Enclosure rating IEC: IP68, JEM: IP68g, NEMA: 4X,6P,13, DIN: IP69K

Light source

TURBO 4 m 10 m 400 mm

SUPER 6 m 15 m 600 mm

Detection

distance

ULTRA 12 m 30 m 1200 mm

MEGA 20 m 40 m 2000 mm

Standard

detecting object

Operating

ambient

light

Operating

ambient

Environ-

temperature

ment

resistance

Operating

ambient

humidity

Vibration

resistance

Housing SUS303 (plastic portions: PMP, POM)

Lens Glass

Material

Cable PVC

Connector

portion

Cable length 2 m

Accessory

The connector is

connected to the

cable.

Weigh t

* Note that when using the sensor underwater, the detection distance becomes

extremely short.

M8 straight M8 nut M12 straight M12 straight

4 element red LED

(Wavelength: 635 nm)

φ 4 mm opaque object

Incandescent lamp: 20,000 lx max., Sunlight: 30,000 lx max.

10 to 55 Hz, Compound amplitude 1.5 mm, 2 hours for each of XYZ axes

M8 nut x4

Metal

washer x2

Approx.

80 g

■Amplifier

Type Cable type Connector type

Model

Control

output

Number of units required to

Environment

al resistance

* 1

* 2 When using several units in close proximity.

NPN output PX-10 PX-10C

PNP output PX-10P PX-10CP

Response time

NPN output

PNP output

External input Input time, ON: 2 ms, OFF: 20 ms max.

prevent interference

Powe r voltage

Current consumption

Case material

Accessory Instruction Manual

*1

Enclosure

rating

Operating

ambient

*2

temperature

Operating

ambient

humidity

Vibration

resistance

Weight Approx. 100g Approx. 50 g

When the sensor head cable is 3 m or longer, use a power supply voltage of 24 V DC.

2 to 4 units : 55°C

5+ units : 45°C

Thrubeam Reflective

PX-H71TZ

35 to 85% RH (No condensation)

M8 nut x4

M8 nut x2

Metal

washer x2

washer x2

Approx.

250 g

NPN open collector, 40 V, 100 mA max. per output

2 outputs for total 100 mA max., residual voltage 1 V max.

PNP open collector, 30 V, 100 mA max. per output

2 outputs for total 100 mA max., residual voltage 1 V max.

12-24 VDC, Ripple (P-P): 10% max, Class2

Normal: 50 mA max. at 24 V, 55 mA max. at 12 V

Powe r saving: 40 mA max. at 24 V, 45 mA max at 12 V

10 to 55 Hz Compound amplitude 1.5 mm,

Main unit: PBT, display portion: PSU, display cover and connector

cover: SUS304, heat sink: SUS304, gasket: NBR

PX-H72 PX-H72G PX-H61 PX-H61G

Infrared LED

(

Wavelength: 870 nm

φ 7.5 mm opaque

object

-10 to +55°C (No freezing)

PBT, NBR, POM, SUS304

M12 nut x4

Metal

washer x2

Approx.

88 g

500 µs (TURBO)/1 ms (SUPER)/

4 ms (ULTRA)/16 ms (MEGA)

4 (when all are in power mode)

IEC: IP67 JEM: IP67 NEMA: 4X

-10 to +55°C (No freezing)

35 to 85% RH (No condensation)

2 hours for each of XYZ axes

Metal

Approx.

90 g

M12 nut x4

Metal

washer x2

Approx.

260 g

4 element red LED

)

(

Wavelength: 635 nm

Spot size

Detection distance

15 mm at 100 mm

65 mm at 500 mm

M13 nut x2

Metal

washer x1

Approx.

80 g

M13 nut x2

Metal

washer x1

Approx.

220 g

Hints On Correct Use

•

Do not wire the amplifier line along with power lines or high-tension lines,

•

otherwise the sensor may malfunction or receive damage due to noise.

•

When using a commercially available switching regulator, ground the frame

ground terminal and ground terminal.

•

Do not use the PX series outdoors, or in a place where extraneous light can enter

the light receiving surface directly.

•

Due to the individual dispersion of characteristics and the difference in sensor

head model, the maximum sensing distance or displayed value of all the units are

not the same.

•

)

Changing the cable layout can change the light intensity slightly. Reset the

sensitivity when changing the layout.

•

Even when using the interference prevention function, devices installed and

connected to the sensor may have a slight effect on detection. In these cases,

fine-adjust the sensitivity (raise the value).

•

Infrared light used for communicating with the amplifier unit emits from the back

of the amplifier unit. Make sure that the receiving head is not used too close to the

amplifier unit.

•

Do not use the sensor while it is submerged in oil.

•

Performance may be lowered depending on the type of oil.

Precautions on UL Certificate

The PX series complies with the following UL and CSA standards. The PX series

has obtained UL and C-UL certificate.

•

Applicable standard UL508 Industrial Control Equipment

CAN/CSA C22.2 No.14-M05 Industrial Control Equipment

•

UL File No. E301717

•

UL category: NRKH, NRKH7

•

Enclosure Type 1 (according to UL50)

■Precautions

• The PX series must be supplied from the power source defined as Class 2

according to NFPA70 (NEC: National Electrical Code).

• The UL certificate for the PX series is for the sensor head unit and the amplifier

unit used in combination. The PX-H series (the sensor head unit) must be used

together with the PX-10 series (amplifier unit) exclusively.

Warranties and Disclaimers

KEYENCE, at its sole option, will refund, repair or replace at no charge any

defective Products within 1 year from the date of shipment. Unless stated

otherwise herein, the Products should not be used internally in humans, for human

transportation, as safety devices or fail-safe systems. EXCEPT FOR THE

FOREGOING, ALL EXPRESS, IMPLIED AND STATUTORY WARRANTIES,

INCLUDING WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE AND NONINFRINGEMENT OF PROPRIETARY RIGHTS,

ARE EXPRESSLY DISCLAIMED. KEYENCE SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, INCIDENTAL, CONSEQUENTIAL OR OTHER DAMAGES,

EVEN IF DAMAGES RESULT FROM THE USE OF THE PRODUCTS IN

ACCORDANCE WITH ANY SUGGESTIONS OR INFORMATION PROVIDED BY

KEYENCE. In some jurisdictions, some of the foregoing warranty disclaimers or

damage limitations may not apply.

E 1101-3

10

Copyright (c) 2007 KEYENCE CORPORATION. All rights reserved.

1591E 1062-3a 96M1591 Printed in Japan

Loading...

Loading...