Page 1

96M12004

Surface Scanning

Laser Confocal Displacement Meter

LT-9001 Series

User’s Manual

Page 2

Introduction

This instruction manual describes the operation and functions of the Surface

Scanning Laser Confocal Displacment Meter LT-9001 Series. To ensure safety,

performance and the function of the LT-9001 Series, please read this manual

carefully.

Keep this manual in a safe place for future reference. Be sure that this manual

eventually goes to the person who operates this product.

Symbols

These symbols alert you the matters that should be followed to prevent human

injury and/or product damage.

DANGER

Failure to follow instructions may lead to death or serious injury.

WARNING

Failure to follow instructions may lead to injury.

CAUTION

Failure to follow instructions may lead to product damage.

Note

Provides additional information on proper operation.

Reference

Provides advanced and useful information for operation.

The contents of this manual pertain to operating the LT-9501/9010M or LT9501SO (5652)/LT-9030M.

If you are using the LT-9001/LT-9010 or LT-9001SO (5653)/LT-9030, skip the

articles on the microscope function.

The profile mode cannot be used in the LT-9501SO (5652)/LT-9030 or LT9001SO (5653)LT-9030M.

Page 3

Safety Precautions

General Precautions

• At startup and during operation, be sure to monitor the functions and

performance of the LT-9001 Series.

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the LT-9001 Series or use it in any way other than

described in the specifications.

• When the LT-9001 Series is used in combination with other devices, functions

and performance may be degraded, depending on operating conditions and

the surrounding environment.

• Do not use the LT-Series for the purpose of protecting the human body and

lives.

• Do not change the temperature around the LT-Series including peripheral

devices. Condensation may lead to malfunction.

Follow the safety precautions below to ensure operator safety.

• Apply the voltage correctly. Failure to do so may cause fire, electric shock or

malfunction.

• Be sure to connect the earth ground terminal on the adaptor inlet of the

controller. Failure to do so may cause electric shock and malfunction.

• Do not open or modify the unit. It may cause a fire or electric shock.

Handling the abnormalities

Turn off the power immediately in the following cases. Using the unit in an

abnormal condition could cause fire, electric shock, or accident. Contact your

nearest KEYENCE office for repair.

• If liquid including water, chemicals or debris enters the unit

• If the unit drops or the case is damaged.

• If abnormal smoke or smell occurs.

Follow the safety precautions below to ensure operator safety.

• Be sure to turn the power off when you plug/unplug the cable which connects

the unit and the devices connected to the unit. Otherwise damage could result.

• Do not turn the power off while setting up the unit. Part or all of setting data may

be lost.

• Do not block the vent holes on the unit and peripheral devices. Otherwise,

excessive heat can build up and cause failure.

Installation environment

To use the LT-9001 Series correctly and safely, avoid installing it in the following

locations:

• Locations that are humid, dusty or poorly ventilated.

• Locations with a high temperature such as a place exposed to direct sunlight

• Locations where there are flammable or corrosive gases.

• Locations where the unit may be directly subjected to vibration or impact.

• Location where water, oil or chemicals may splash onto the unit.

• Locations where the static electricity is easily generated.

96M12004E LT-9001-IM

1

Page 4

Safety Precautions

Corrective action for noise

Do not install the LT-9001 Series near power sources or high tension cables,

otherwise noise may cause the LT-9001 Series to malfunction. Take corrective

action for noise by using noise filters, by separating these cables, by installing

insulations to the controller and to the measuring unit.

Laser safety precautions

The LT-9001 is classified as a class1 laser product by IEC60825-1. (FDA class

IIa)

• Caution - use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposure.

• Do not stare into the laser beam directly for a long time.

• Do not disassemble the LT-9001 Series.

The Influence of ambient temperature

A change in ambient temperature may cause measurement fluctuations. Be sure

to keep the temperature stabilized. When the ambient temperature changes 10

°C, it takes 60 minutes to equalize the distribution of the inside temperature.

Warming up

Before using the LT-9001 Series, wait approximately 60 minutes after the power is

turned on. Otherwise, the measured value may gradually fluctuate because the

circuit is not stable immediately after the power is turned on.

The Influence of dust or dirt

The measurement may fluctuate due to dirt, dust or fluid such as water or oil in

the following cases:

• On the LT-9001 optics: Blow the dirt off with clean air. If dirt persists, wipe the

glass surface gently using soft cloth soaked with alcohol.

•On the target surface: Blow the dirt off with clean air or wipe it off.

• Airborne: Build a protective enclosure with an air purge system around the

measurement area.

Note

Influence of vibration

When the measurement target is vibrating, the measured value may fluctuate. In

this case, increase the number or times the measurement value is averaged to

achieve more accurate measurements.

2

E LT-9001-IM

Page 5

Measurement target

The measured value may fluctuate when the shapes or surfaces of targets vary. In

this case, use a known target and perform appropriate correction with the

calibration function.

Scan straightness

The scan orbit of the LT-9001 Series makes a slight arc. Therefore, the measured

value may fluctuate when the target is slanted.

Handling

Do not wipe with a wet cloth, benzene, or thinner. Doing so could change the

color or shape of the lens. If the lens has a lot of dirt on it, wipe it off with a cloth

moistened with a mild detergent, then wipe with a soft dry cloth.

Effect of atmospheric motions

Slow atmospheric motions may affect the measurement resulting in the measured

value fluctuation.

In such a case, take the following countermeasures.

• Enclose the measurement portion with the appropriate enclosure.

• Agitate the air between the measurement point and the workpiece strongly with

the fan.

Best Management Practice for Perchlorate Materials - California only

When you sell, manufacture and/or waste the products containing perchlorate

material in California, the following statement must appear on the exterior of all

outer shipping packages and on consumer packages, based on California Code

of Regulations.

E LT-9001-IM

"Perchlorate Material – special handling may apply, See

www.dtsc.ca.gov/hazardouswaste/perchlorate."

Note: Alternative option is to indicate this statement on your MSDS or manual

accompanying with each product.

This product includes a CR coin type cell containing perchlorate material. If you

ship this product (or your product including this product) to California, you must

ensure to comply with this regulation.

3

Page 6

Precaution on CE Marking

It is confirmed that the LT-9001 Series satisfies the requirement of the EU

Directives when the following conditions are fulfilled. Therefore, users must fulfill

the following conditions when the LT-9001 Series is going to be used in EU

Member States.

Precautions

Precautions on EMC Directive

• Applicable standard (EMI) EN61326-1, Class A

• Applicable standard (EMS) EN61326-1

• Wind the following ferrite core twice on the cable at the position within 50 mm

from the analog output that is on the rear panel of the controller.

Model: ZCAT3035-1330 (Product of TDK)

• Wind the following ferrite core twice on the cable at the position within 200 mm

from the VIDEO output that is on the rear panel of the controller.

Model: ZCAT2035-0930 (Product of TDK)

Precautions on Low Voltage Directive

• Applicable standard EN61010-1

• Overvoltage category II

• Pollution degree 2

• The LT-9001 Series is classified as a class 1 laser product.

• When the LT-9001 Series is used in EU Member States, the power supply cable

conforming to the relevant EU standards and obtaining the certification by a

third-party certification organization, and its plug shape fitting to outlets of

respective countries must be used.

• Because the LT-9001 Series is designed as class I equipment, be sure to

connect the protective earthing terminal located in the inlet to the protective

earthing conductor in the building when installing it.

• When replacing the fuse, be sure to use the fuse that satisfies the following

rating and is approved by certification organization based on the appropriate

EU standard.

Fuse rating 250 V, 3.15 A, Time lag fuse

EN60825-1 Laser Class 1

4

E LT-9001-IM

Page 7

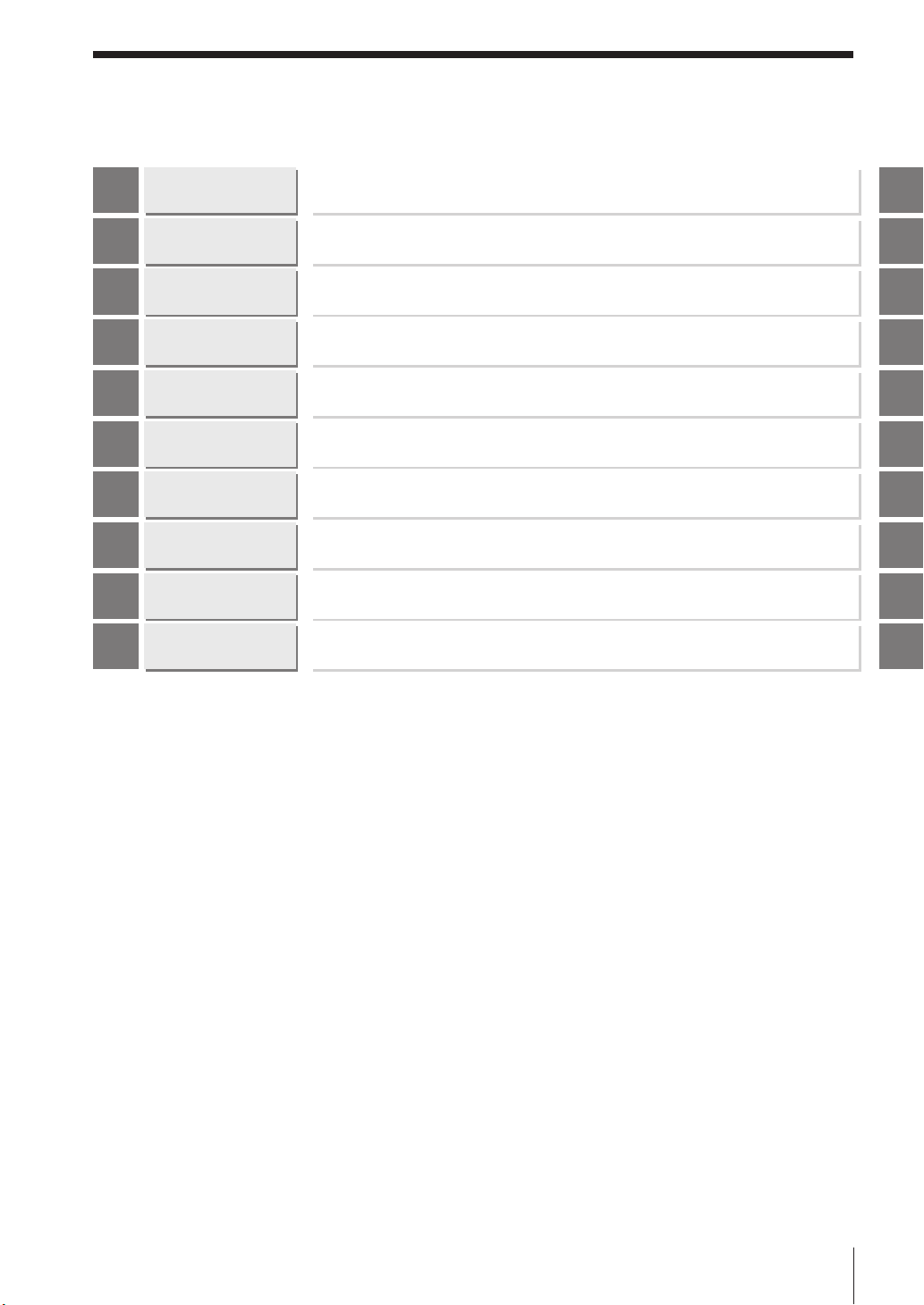

Organization of this Manual

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Appendices

Before Use

Basic Operations

Operations and

Function Settings in

the Displacement Mode

Operations and

Function Settings

in the Profile Mode

Common

Operations and

Function Settings

Environment

Settings

I/O Terminal

RS-232C

Specifications

Index

Describes the cautions for use and the required preparation before use.

Describes how to use the remote control console and the basic operations of

the LT-9001 Series.

Describes the operations and functions in the displacement mode.

Describes the operations and functions in the profile mode.

Describes operations and functions common to the displacement mode and

the profile mode.

Describes the items for the basic settings and the setting procedures related to

the overall unit that are required for operation.

Describes the specifications and timing chart of each I/O terminal.

Describes each function and setting method of the RS-232C interface.

Provides specifications, characteristics, and outer dimensions.

Describes the troubleshooting methods, contents of the error messages and

optional products.

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Appendices

E LT-9001-IM

5

Page 8

Table of Contents

Safety Precautions......................................................1

General Precautions............................................1

WARNING............................................................1

CAUTION.............................................................1

Note .....................................................................3

Precaution on CE Marking..........................................4

Precautions..........................................................4

Organization of this Manual........................................5

Chapter 1 Before Use

Outline of the LT-9001 Series ..................................1-1

System Configuration ..............................................1-2

Checking the Package Contents.............................1-3

LT-9501 ............................................................1-3

LT-9010M .........................................................1-3

LT-C2/C10 ........................................................1-3

Identifying Part Names and Functions ...................1-4

Controller..........................................................1-4

Measuring Unit .................................................1-5

Remote Control Console ..................................1-6

Mounting and Connecting Parts..............................1-7

Mounting the Measuring Unit ...........................1-7

Installation of the Controller..............................1-8

Connection .......................................................1-8

Chapter 2 Basic Operations

Outline of Basic Operations ....................................2-1

Displacement Mode and Profile Mode....................2-2

Displacement Mode .........................................2-2

Profile Mode .....................................................2-2

Outline of Measurement and Settings ....................2-3

Run Mode.........................................................2-4

Program Mode .................................................2-5

Program Function.............................................2-8

Flow of Measurement .......................................2-9

Operations.............................................................2-10

How to Use the [ENTER] Button.....................2-10

Selecting an Item ...........................................2-11

Entering a Value .............................................2-11

Selection Method of the Run Mode .......................2-12

Operational Flow ............................................2-12

Using the Displacement Mode..............................2-13

Selecting the Displacement Mode ................2-13

Adjusting the Distance Between the Measuring

Unit and the Measurement Target .................2-14

Setting the Scanning Width/interval ..............2-14

Setting the Light Intensity Level ....................2-15

Measuring the Displacement ........................2-15

Using the Profile Mode ..........................................2-16

Selecting the Profile Mode ............................2-16

Adjusting the Distance Between the Measuring

Unit and the Measurement Target .................2-17

Setting the Scanning Width/interval ..............2-17

Setting the Upper and Lower Limits Display..2-18

Setting the Area..............................................2-18

Measuring the Level Differences ...................2-19

Basic Operations that Stabilize Measurement .....2-20

Changing the Scanning Width and the

FINE Mode .....................................................2-20

Changing the Light Intensity Level.................2-20

Resetting the Device to the Factory Settings ........2-22

Default Values and Settings Range (LT-9010 (M))....

Displacement Mode .......................................2-23

Profile Mode ...................................................2-24

Default Values and Setting Range ................2-25

Default Values and Settings Range (LT-9030 (M))

Displacement Mode .......................................2-26

Default Values and Setting Range ................2-27

2-23

....2-26

Chapter 3 Operations and Function

Settings in the Displacement

Mode

Outline of Displacement Mode................................3-1

What is displacement mode?...........................3-1

Display Screens ......................................................3-2

Identifying Part Names and Functions of Screens ..3-3

Measurement Screen .......................................3-3

Light Intensity Screen.......................................3-4

Measurement Screen ..............................................3-5

Display of Measured Value ..............................3-5

6

E LT-9001-IM

Page 9

Display of the Trend Graph..............................3-5

Light Intensity Screen..............................................3-7

Display of Measured Values ............................3-7

Display of Received Light Intensity Graph.......3-7

Setting the Light Intensity Level .......................3-8

Setting the Measurement Target Surface ........3-8

Pause Screen ..........................................................3-9

Setting the Pause Screen ................................3-9

OUTPUT Settings ..................................................3-10

Functions of the OUTPUT Settings.................3-10

Basic Settings........................................................3-15

SCAN..............................................................3-15

DARK ALARM ................................................3-17

MASK .............................................................3-18

OPTIONAL Settings...............................................3-19

CORRECT (Auto slant correction) .............3-19

Chapter 4 Operations and Function

Settings in the Profile Mode

Outline of Profile Mode ............................................4-1

What is profile mode?.......................................4-1

Types of Screens.....................................................4-2

Identifying Part Names and Functions of Screens ..4-3

Measurement Screen .......................................4-3

Light Intensity Screen.......................................4-4

Measurement Screen ..............................................4-5

Display of Measured Value ..............................4-5

Display of Profile Waveform .............................4-6

Light Intensity Screen..............................................4-8

Display of Measured Value ..............................4-8

Display of Received Light Intensity Graph.......4-8

Setting the Light Intensity Level .......................4-8

Changing the Ranges of the Areas..................4-9

Pause Screen ........................................................4-10

Setting the Pause Screen...............................4-10

OUTPUT Settings ..................................................4-12

Functions of the OUTPUT Settings.................4-12

Basic Settings........................................................4-13

AREA ..............................................................4-13

SCAN..............................................................4-14

DARK ALARM ................................................4-16

SMOOTH (Smoothing) ...................................4-17

OPTIONAL Settings...............................................4-18

CORRECT (Auto Slant Correction) ............4-18

PROFILE OUT (Profile Output) .......................4-19

Chapter 5 Common Operations and

Function Settings

Outline of Common Operations and

Function Settings.....................................................5-1

Outline of Operations and Functions.......................5-2

Microscope Function...............................................5-2

Hold Function ..........................................................5-3

Auto-zero Function ..................................................5-4

Keylock Function .....................................................5-5

Program Change .....................................................5-6

OUTPUT Settings ....................................................5-7

LIMITS (Tolerance)...........................................5-7

OUTPUT (Output).............................................5-8

CALIB (Calibration) ........................................5-16

OPTIONAL Settings...............................................5-18

DISPLAY.........................................................5-18

I/O...................................................................5-20

GAIN (Sensitivity) ...........................................5-20

Chapter 6 Environment Settings

Setting up the Basic Settings for the Overall Unit ...6-1

Items to be Set in the Environment Setting .............6-2

Environment Setting Items ...............................6-2

List of Default Values........................................6-2

How to Set up Environment Settings .......................6-4

How to Set up Environment Settings ...............6-4

RS-232C Interface............................................6-5

Program............................................................6-6

Beep Sound .....................................................6-7

Interface Language..........................................6-7

Coefficient ........................................................6-7

Chapter 7 I/O Terminal

Controlling and Outputting from the I/O Terminal ...7-1

E LT-9001-IM

7

Page 10

Table of Contents

Identifying Names and Functions of

the I/O Terminal .......................................................7-2

Terminal Block..................................................7-2

Control I/O ........................................................7-3

VIDEO Output ..................................................7-5

Functions of the I/O Signals .............................7-5

Electrical Specifications ..................................7-8

Timing Chart ............................................................7-9

Normal Measurement

(When Profile Output is OFF) ...........................7-9

When Profile Output is ON (LT-9010 (M) only)

Timing Details (LT-9010 (M))..........................7-13

Timing Details (LT-9030 (M))..........................7-14

Timing Details

(Common to the LT-9001 Series) ...................7-15

....7-11

Chapter 8 RS-232C

Connecting to External Devices via RS-232C .........8-1

Specifications ..........................................................8-2

Pin Layout ........................................................8-2

Communication Specifications.........................8-2

Connecting to External Devices.......................8-2

Outputting Measured Values and

Changing Settings by Using Commands ...............8-3

Environment Settings Parameters ....................8-3

Outline of Command Format ............................8-3

Measurement Control Command and

Measurement Operation Command Formats...8-4

Command Details.............................................8-5

Change Parameter Command Format .............8-8

Command Details.............................................8-9

Check Parameter Command Format .............8-15

Timing Chart...................................................8-16

ASCII Code Table (Reference) ......................8-16

Outputting Measured Values by Using External

Synchronization .....................................................8-17

Environment Settings Parameters ..................8-17

Output Method ...............................................8-17

Timing Chart...................................................8-18

Output format .................................................8-18

Chapter 9 Specifications

Specifications of the LT-9001 Series.......................9-1

Specifications ..........................................................9-2

Specifications of the Controller ........................9-2

Specifications of the Measuring Unit ...............9-3

Status Table .....................................................9-4

Specifications of the cable between

measuring unit and controller ..........................9-5

Response Delay Time ....................................9-6

Display Update Cycle ......................................9-6

Outside Dimensions .........................................9-7

Appendices

Troubleshooting ......................................................A-2

Error Messages.......................................................A-4

Optional Product List ..............................................A-5

Parameter Memo.....................................................A-6

Displacement mode.........................................A-6

Profile mode.....................................................A-8

Environment Setting Parameter Memo .................A-10

Index .....................................................................A-11

8

E LT-9001-IM

Page 11

Outline of the LT-9001

Chapter

1

Before Use

Series

The LT-9001 Series is a double scan high-

accuracy sensor that employs a lens drive and a

tuning fork in the confocal displacement principle.

The LT-9001 Series can measure not only a highly

accurate displacement, but also the slanting

degree, the thickness of transparent object and

the shape.

This chapter describes the configuration of the

LT-9001 Series, cautions and the required

preparation before use.

System Configuration ..............................................1-2

Checking the Package Contents .............................1-3

Identifying Part Names and Functions.....................1-4

Mounting and Connecting Parts ..............................1-7

Chapter

1

Before Use

E LT-9001-IM

1-1

Page 12

System Configuration

control output and the measured

Chapter

1

The LT-9001 Series can be used for various purposes in combination with commercially available devices.

Before Use

PC

Enables control and import of

the measured value from the RS232C or the parallel I/O board.

Programmable controller

Enables timing control of the

measurement and the switching

of program No. as well as the

value import.

Recorder

Records the measurement

result.

Indicator light/Buzzer

Produces an alarm sound by

an output of the judgement.

Photoelectric/Proximity

sensor

Transmits a signal to the

TIMING input when the sensor

detects a target.

LT-9001 Series

Monitor

CA-MN80

Controller

LT-9501

Measuring unit

LT-9010M

Stage system

The 2D shape or the 3D shape

can be detected in combination

with a manual or auto stage

system.

1-2

Video printer

Prints the image of an LCD

monitor.

E LT-9001-IM

Page 13

Checking the Package Contents

This

product

is subje ct to th e e xport

regulations in

Japan. When you need to e xport this pr odu ct

from

your country, be sure to c

heck if thi

s pr

oduct is

su

b

-

ject to the e xport regulations w

ithin your c

ountry

or

not upon your own re sponsibility. If r

equired, please

take appropriate action for g aining app

roval f

or exp

ort

by the government or responsib le organization within

your country.

The LT-9001 Series consists of the following models. Check if the parts and equipment listed below are

included in the package of the models you purchased before using the unit.

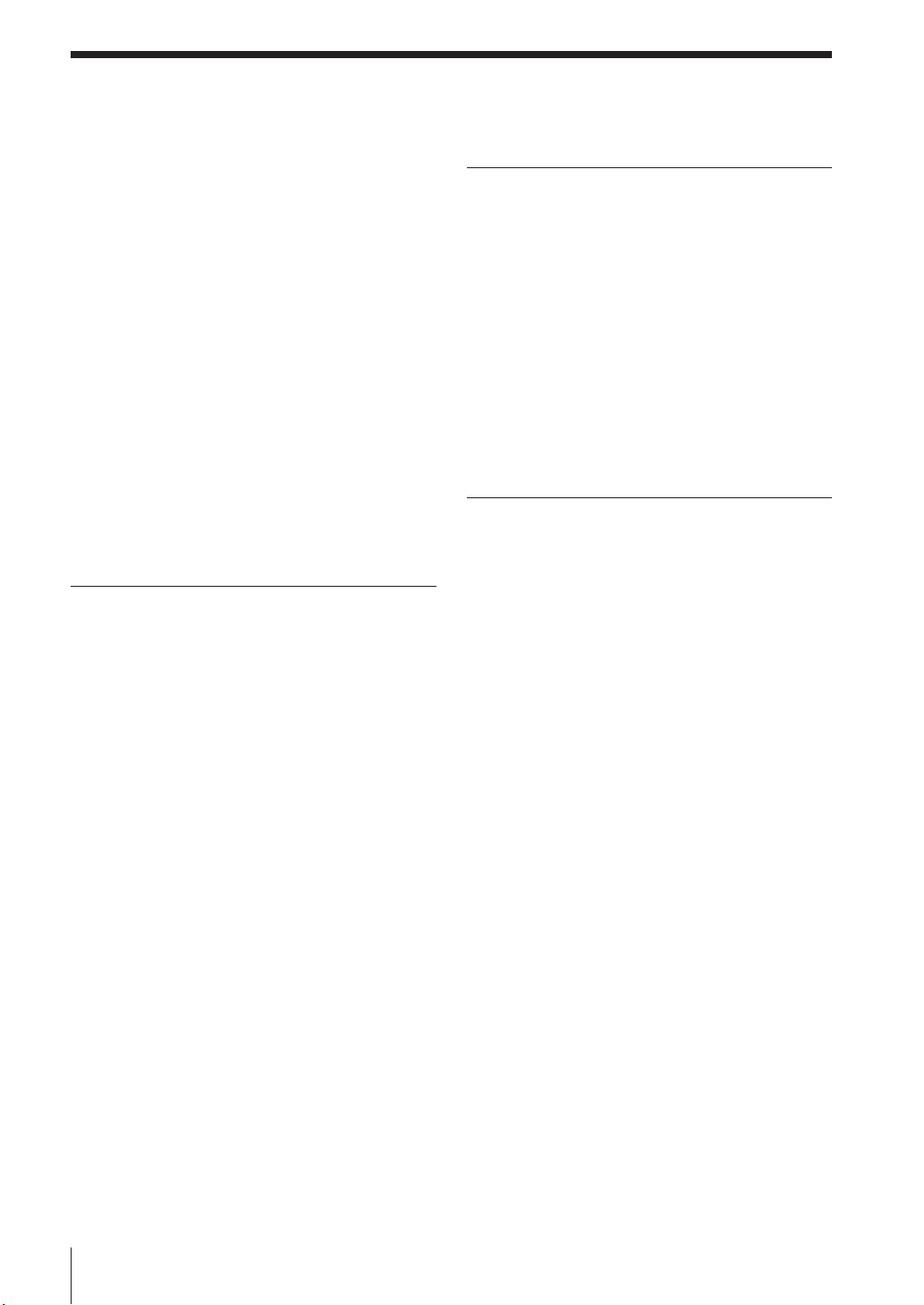

LT-9501

Controller Remote control console Monitor connecting cable

(LT-9501) ×1 (Cable length 3 m) ×1 (PIN-to-PIN cable: 2 m) ×1 (2 m) ×1

User's Manual (This manual) ×1

96M1086

Doub

le Scan

High-Accuracy Laser Sensor

LT-9001 Serie

User’s Manual

Read this manual before using the system in order to

achieve maximum performance.

Keep this manual in a safe place for future reference.

Monitor power supply cable

LT-9010M

Chapter

1

Before Use

Measuring Unit Hexagon socket head bolt Cautions for export

(LT-9010M) ×1 (M4 × 40 washer faced) ×3 (A6) ×1

LT-C2/C10

Cable between the controller and the measuring unit ×1

LT-C2: 2 m cable

LT-C10: 10 m cable

Up to three cables below the total length of 20 m can be connected.

* We have thoroughly inspected the package contents before shipment. However, in the event of defective or

broken items, contact your nearest KEYENCE office (Address listed in the end of this manual).

* The contents included in the LT-9001/LT-9010 are the same as the ones in the LT-9501/LT-9010M

respectively.

* The sensor head contained in the LT-9030M and LT-9030 is the LT-9030 and LT-9030, respectively. All of the

other contents included in the LT-9030M or LT-9030 are the same as those included in the LT-9010M.

E LT-9001-IM

1-3

Page 14

Identifying Part Names and Functions

Chapter

1

Before Use

This section describes the names and functions of the controller, measuring

unit, and remote control console.

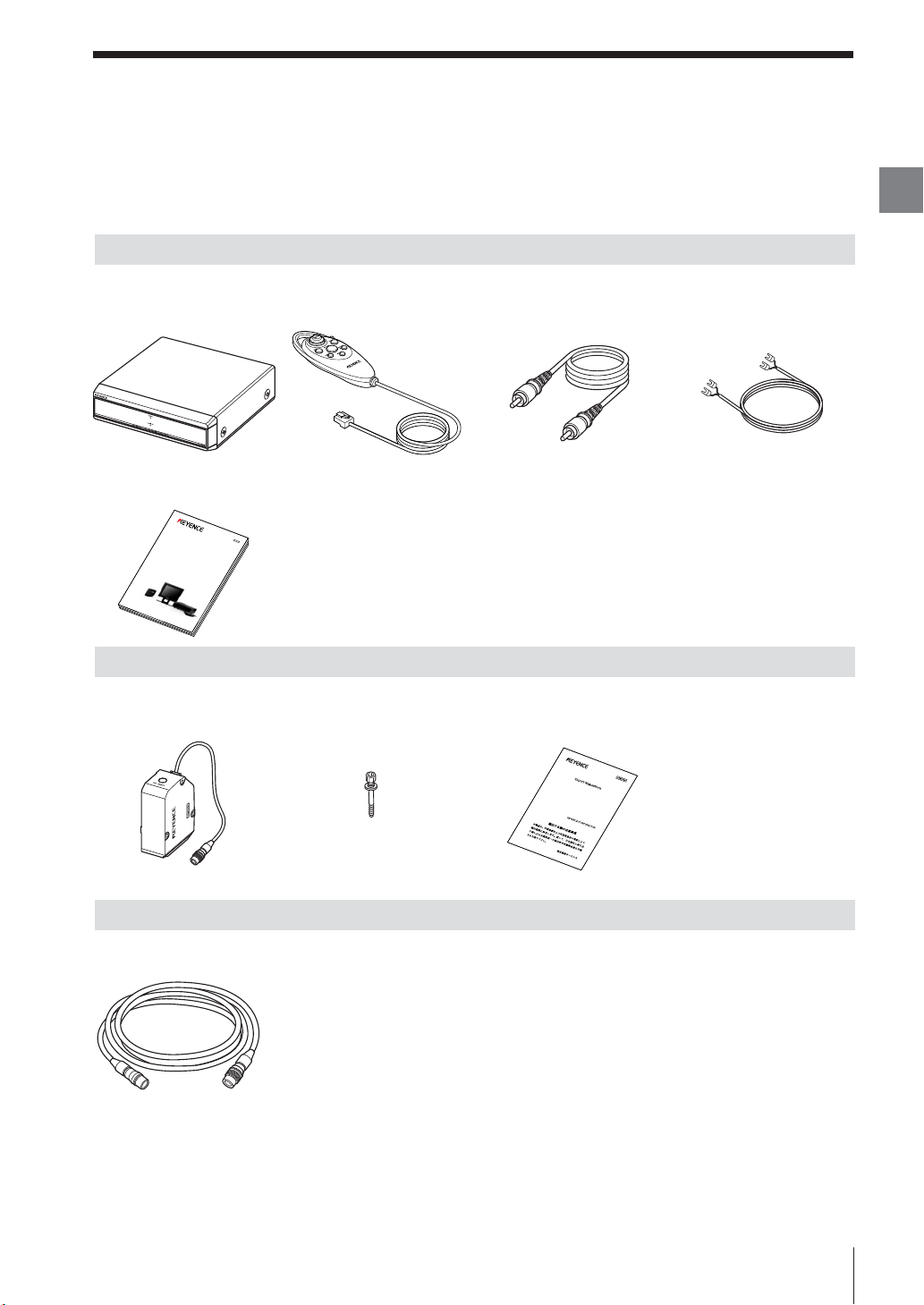

Controller

Front

1

2

Power LED

1

Lights up when the power is ON.

Laser LED

2

Lights up during laser emission.

Back

2

1

5

3

4

6

8

7

1-4

Measuring unit connector

1

The cable between the controller and the measuring unit is connected here.

Connector terminals (Control I/O)

2

Outputs binary data and tolerance judgment value, and switches the

program No.

Remote control console connector

3

The supplied remote control console is connected here.

RS-232C connector

4

The RS-232C communication cable is connected here.

Video composite output terminal

5

The external monitor is connected here.

Terminal block

6

Used for power supply, analog output, and input of control signal to the

monitor (CA-MN80).

E LT-9001-IM

Page 15

AC power inlet

7

Supplies power to the LT-9001 Series.

Power switch

8

Turns on/off the power.

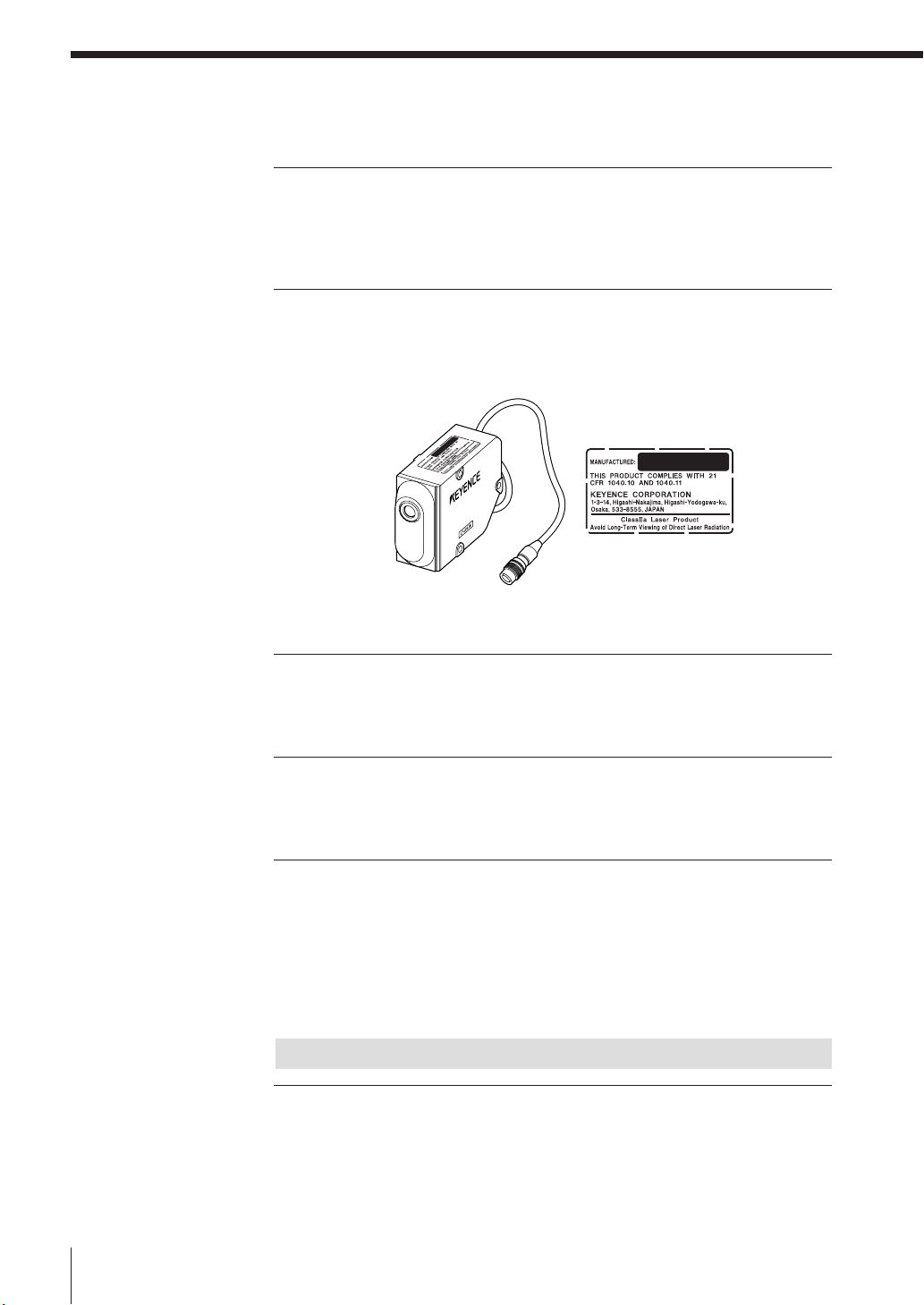

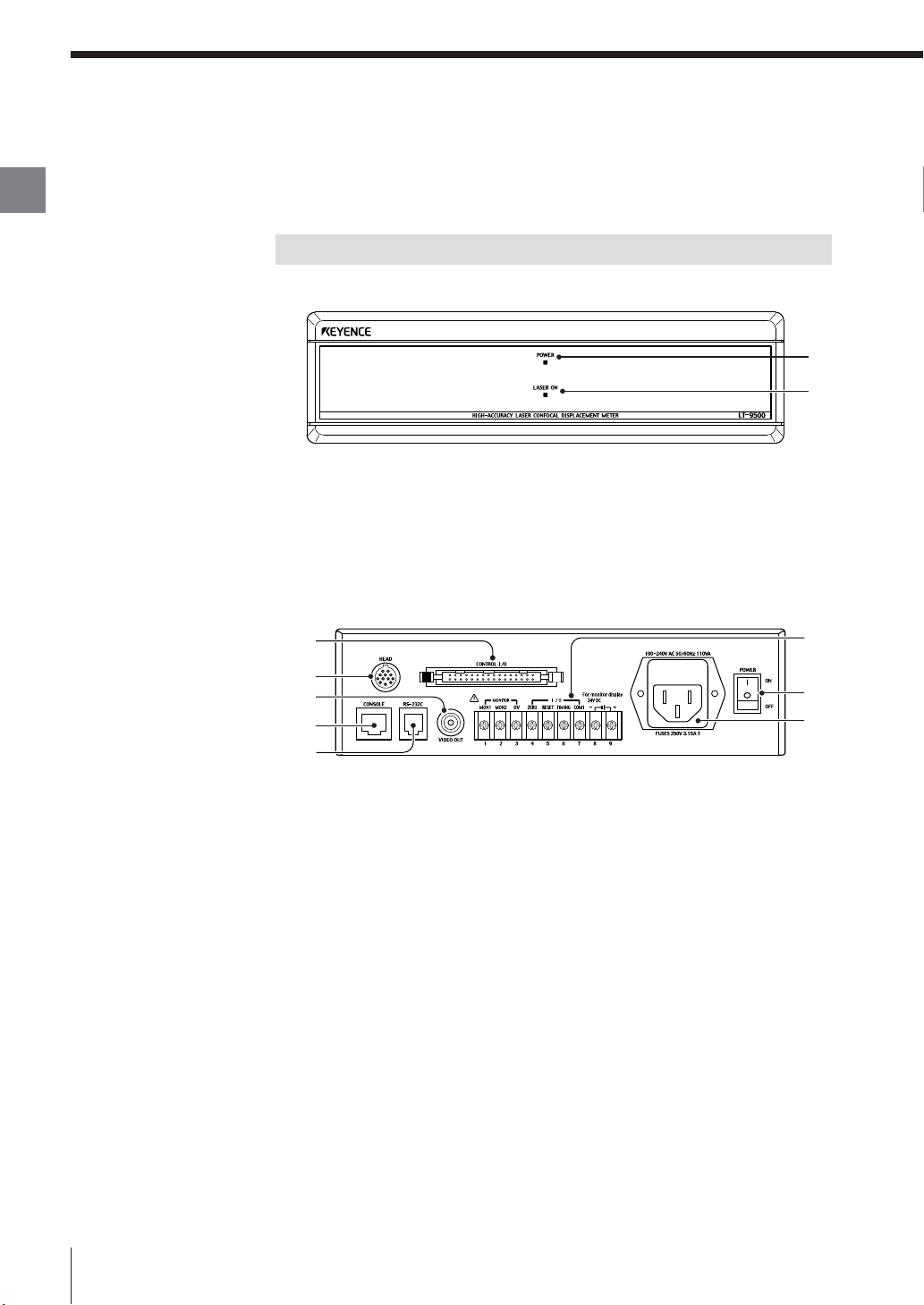

Measuring Unit

4

2

1

3

Sensor unit (Emitter/Receiver)

1

Emits and receives a laser beam for measurement. It is protected with a

cover glass.

Mounting holes

2

The measuring unit is mounted with the supplied hexagon socket head bolt.

Chapter

1

Before Use

E LT-9001-IM

Connecting cable

3

The cable between the controller and the measuring unit can be connected

to this cable, or the controller can be connected directly.

Laser emission LED

4

Lights up during laser emission.

1-5

Page 16

Identifying Part Names and Functions

Chapter

1

Before Use

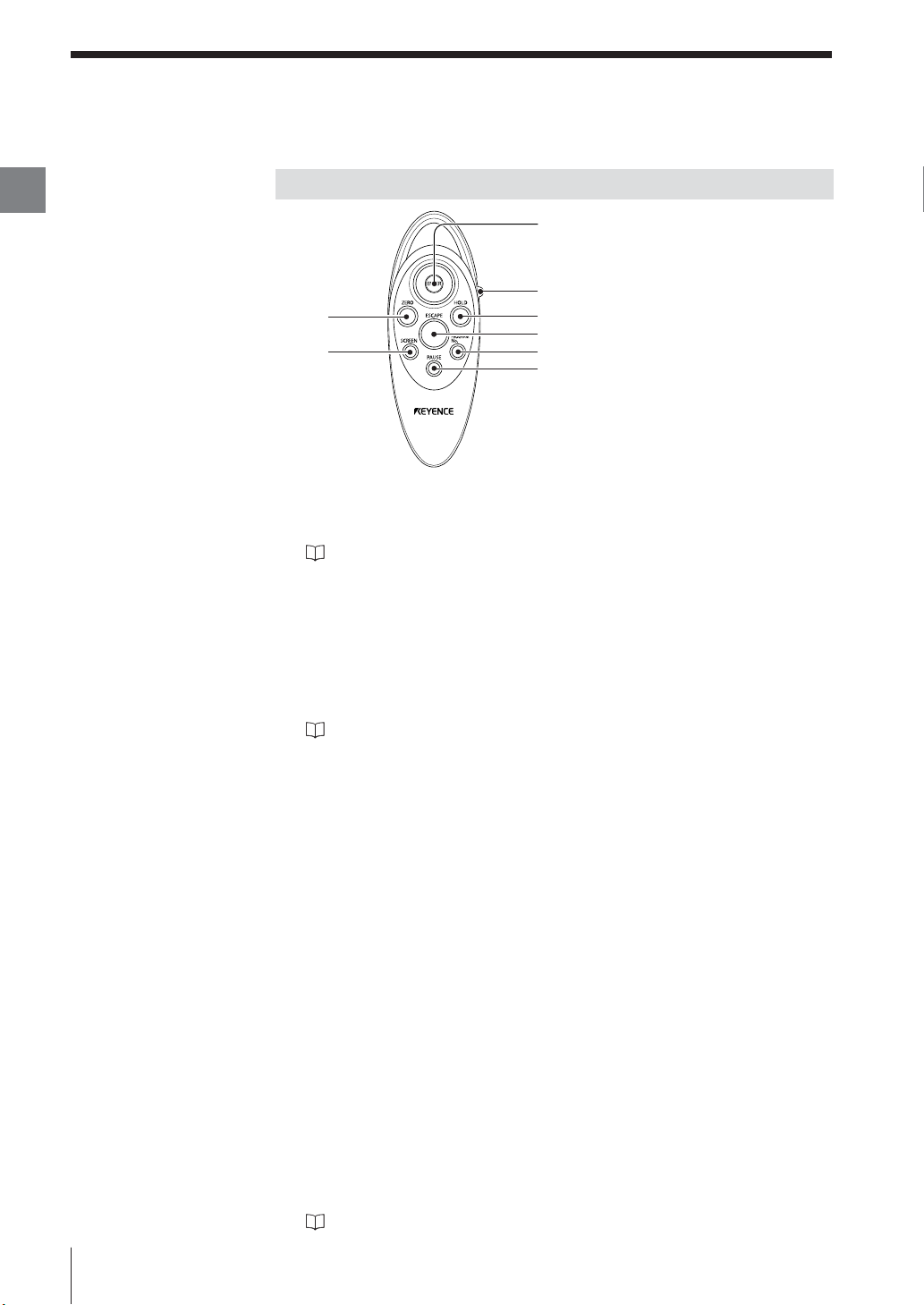

Remote Control Console

1

2

8

7

[ENTER] button

1

Select the items by tilting the [ENTER] button up, down, right or left.

Fix the selected item by pressing the button straight down.

Refer to "How to Use the [ENTER] button" (page 2-10).

[PROG/RUN] switch

2

Switch the run/program modes by sliding down the switch. Each sliding

movement switches the modes.

[HOLD] button

3

Press the [HOLD] button to retain the measured value. This button has the

same function with the TIMING input terminal on the back of the controller.

Refer to "Hold Function" (page 5-3).

3

4

5

6

1-6

[ESCAPE] button

4

Press the [ESCAPE]

settings.

Press this button to exit or abort the setting item. This button has the same

function with the RESET input terminal on the back of the controller in the run

mode.

[PROGRAM No.] button

5

Press the [PROGRAM No.] button to switch the display to the program No.

selection screen.

[PAUSE] button

6

Press the [PAUSE] button to stop updating the graph display while in the

measurement screen, and to switch to the pause screen.

[SCREEN] button

7

During measurement: Press the [SCREEN] button to switch the measurement

screen to the light intensity screen.

During setting: Press the [SCREEN] button to switch the selection status.

[ZERO] button

8

Press the [ZERO] button to use the Auto-zero function. This button has the

same function with the ZERO input terminal on the back of the controller.

Refer to "Auto-zero Function" (page 5-4).

button

to return to the previous display or operation during

E LT-9001-IM

Page 17

Mounting and Connecting Parts

This section describes how to mount the controller and the measuring unit.

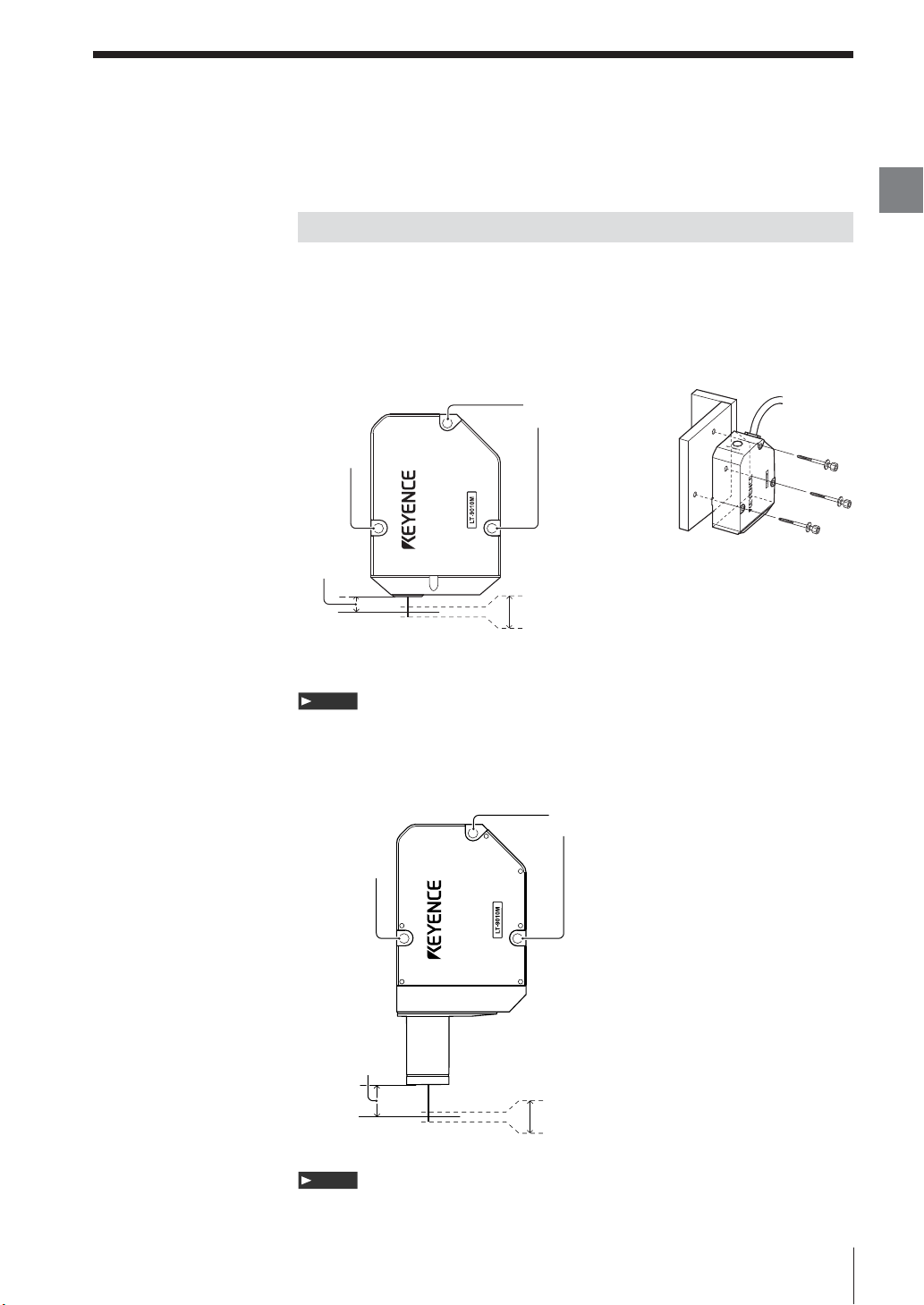

Mounting the Measuring Unit

Adjust the distance between the measuring unit and the measurement target and

fix the measuring unit with screws in the three installation holes.

The measurement range is shown in the figure below.

• Measurement range • How to mount the unit

■ LT-9010 (M)

Installation

hole

Installation

hole

Reference

distance

6mm

+

0.3mm

Reference

position

0mm

Measurement range

-

0.3mm

Chapter

1

Before Use

Note

The reference distance may vary within the range of 0.5 mm according to the

manufacturing variation of individual measuring units.

■ LT-9030 (M)

Installation

hole

Installation

hole

Reference

distance

30mm

+

Reference

position

0mm

Note

1.0mm

Measurement range

-

1.0mm

The reference distance may vary within the range of 2.0 mm according to the

manufacturing variation of individual measuring units.

E LT-9001-IM

1-7

Page 18

Mounting and Connecting Parts

Chapter

1

Before Use

Installation of the Controller

Use the controller on a level place.

Note

• Keep enough room around the controller for ventilation.

• When the temperature in the controlling system unit rise over 35 °C, decrease

the ambient temperature no more than 35 °C by cooling it down with cool air or by

make room around the system.

• Do not use the controller on other devices.

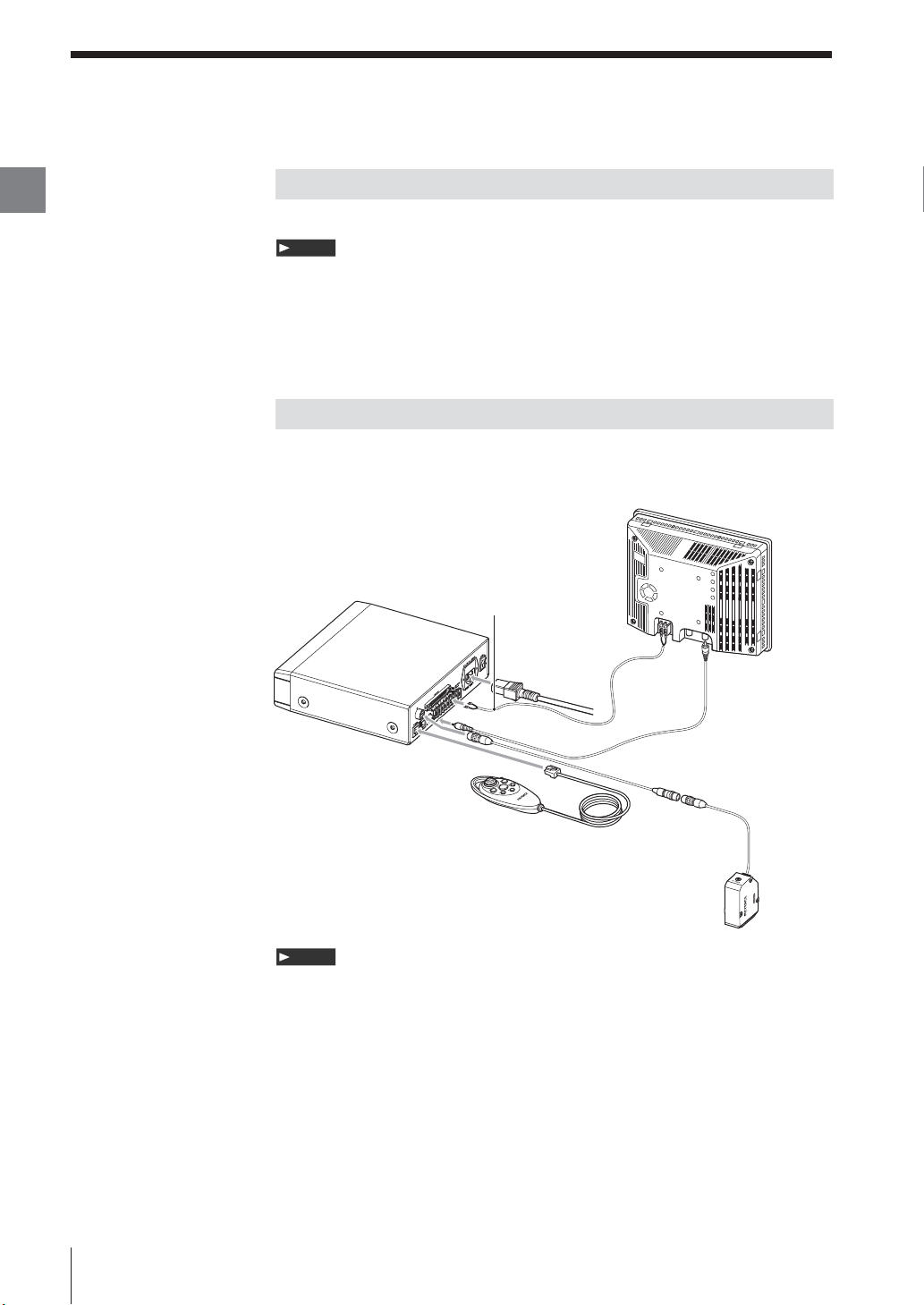

Connection

Connect the measuring unit, the controller, the remote control console, the

monitor and the power supply with cables.

Connecting to

LT-9501

24 V DC terminal

AC cable

Power supply

cable for the monitor

Monitor

CA-MN80

Monitor connecting

cable

1-8

Cable between the controller

and the measuring unit

Remote control

console

LT-9010M

Note

• Turn off the power supply of the controller before connecting/disconnecting

cables. Failure to do so may cause malfunction.

• Eusure correct orientation of all connectors. Otherwise the pins may break and

may lead to system breakdown.

• Before connecting the monitor power cable, ensure the correct polarity of the

monitor power terminals. Failure to do so may cause malfunction.

• The 24 V DC terminal on the terminal block is a dedicated power supply unit to

the monitor specified by KEYENCE only. This supply may not be used to power

any additonal hardware.

E LT-9001-IM

Page 19

Outline of Basic

Chapter

2

Basic Operations

Operations

The LT-9001 Series performs settings concerning

the measurement method or displayed

information while in the program mode, and

displays the measurement result value or graph

while in the measurement mode.

You can also switch between displacement mode

and profile mode depending on the target.

This chapter describes the outlines of program

mode and run mode, and the procedures to

operate the LT-9001 Series in displacement mode

and profile mode using the remote control

console.

Displacement Mode and Profile Mode.....................2-2

Outline of Measurement and Settings .....................2-3

Operations .............................................................2-10

Selection Method of the Run Mode .......................2-12

Using the Displacement Mode...............................2-13

Using the Profile Mode ..........................................2-16

Basic Operations that Stabilize Measurement.......2-20

Resetting the Devices to the Factory Settings.......2-22

Default Value and Settings Range ........................2-23

Chapter

2

Basic Operations

* All the measurement screens used in this User's

Manual are those for the LT-9010(M).

Some screens are different when you are using

the LT-9030(M).

E LT-9001-IM

2-1

Page 20

Chapter

2

Basic Operations

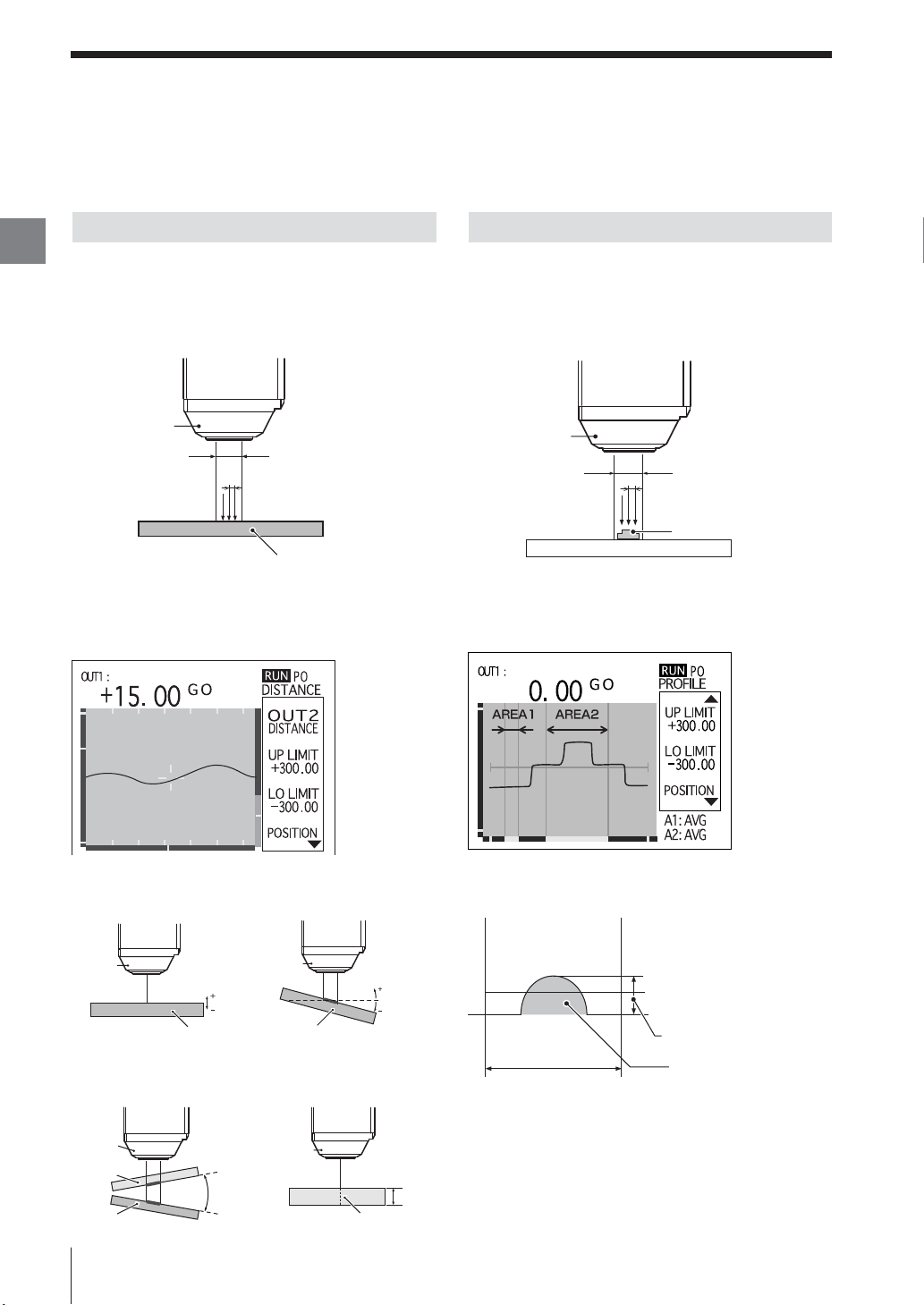

Displacement Mode and Profile Mode

You can select either displacement mode or profile mode in the LT-9010(M).

(Only displacement mode is available in the LT-9030(M).

Displacement Mode

The displacement mode enables you to measure a

targed in four ways such as displacement,

transparent object thickness, slant, and Δslant of the

target by measuring the changes in the distance from

the reference point.

Profile Mode

The profile mode enables you to measure the target shape

by using the measured value of each scanned point.

You can also measure the average value, maximum value,

minimum value, differential between the maximum and the

minimum value, and area by specifying two different areas

on the target.

Mesuring

unit

Scanning width

Scanning interval

Measurement Target

Example of the measurement screen in the

displacement mode

A change in the distance from the reference point

can be measured.

DISTANCE

The distance change from the

reference distance on the

measurement target is measured.

SLANT (LT-9010 (M) only)

The degree between the

reference surface and the

target surface is measured.

Measuring

unit

Scanning

width

Scanning interval

Measurement Target

Example of the measurement screen in the profile

mode

The profile of a target can be displayed in a

waveform.

Example of setting areas

The following features can be selected and

measured within the specified Area 1 and Area 2.

Distance

Measuring

unit

Δ

SLANT (LT-9010 (M) only)

The relative degree between

the target and a transparent

target is measured.

Measuring

unit

Transparent

object

Measurement

Target

change from

the reference

point

Measurement Target

Relative

slant

2-2

Measuring

unit

Measurement Target

THICK

(Transparent object thickness)

The thickness of a transparent

object is measured.

Measuring

unit

Measurement Target

(transparent object)

Degree in relation

to the reference

surface.

Thickness of the

transparent object

Area setting range

MAX (maximum value)

AVG (average value)

MIN (minimum value)

DIFF (differential value)

AREA (amount of space)

E LT-9001-IM

Page 21

Outline of Measurement and Settings

The LT-9001 Series has a run mode that performs a measurement, and a program mode that sets the

measurement conditions. Measuring various targets is possible by combining several measurement

conditions.

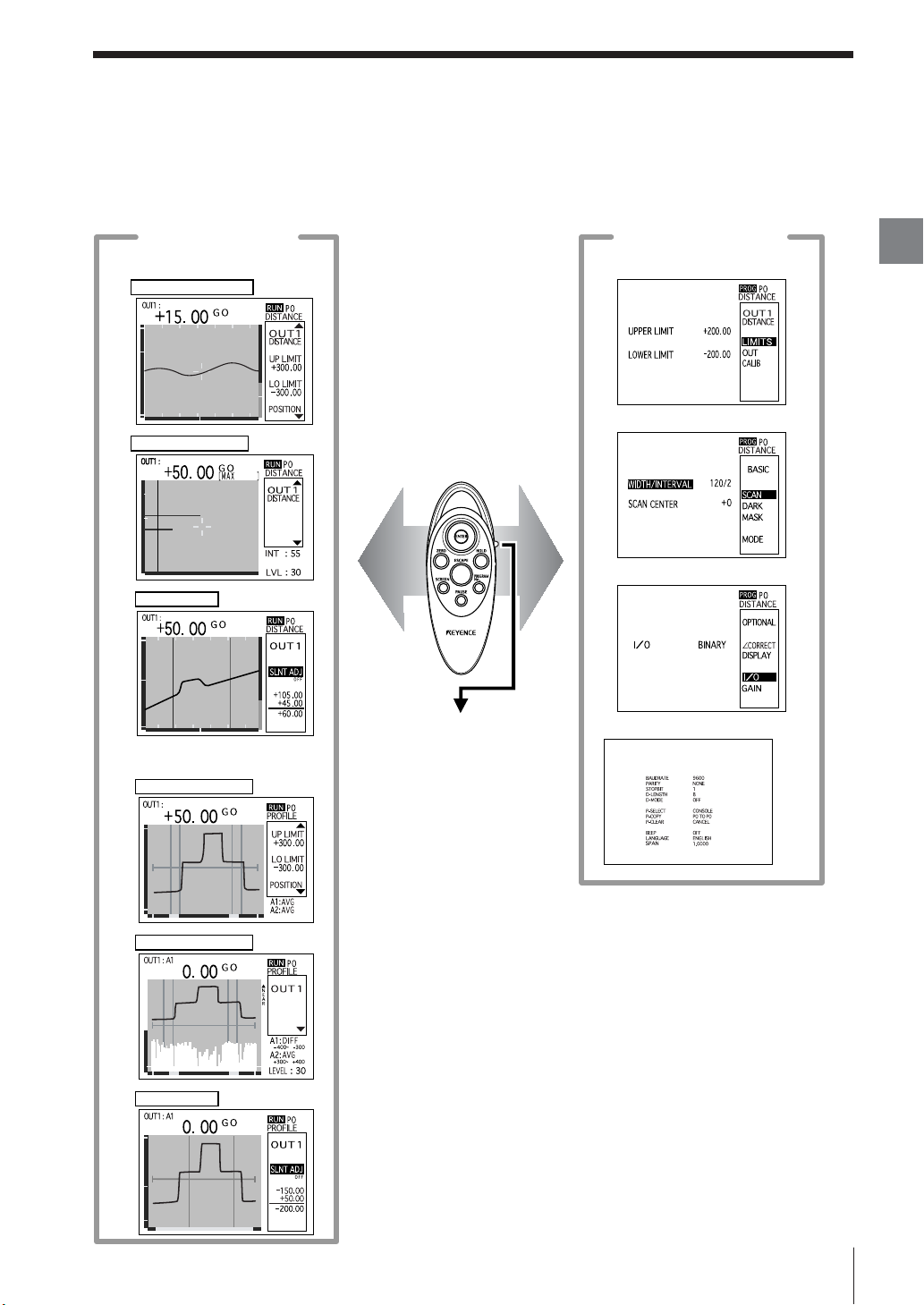

Run mode screen

DISTANCE (Displacement mode)

Measurement screen

Light intensity screen

Pause screen

Program mode screen

<OUTPUT settings>

<BASIC settings>

<OPTIONAL settings>

Chapter

2

Basic Operations

PROFILE (Profile mode)

Measurement screen

Light intensity screen

Pause screen

The run mode and the

<Environment settings>

program mode are

switched every time the

[PROG/RUN] switch is

pushed down.

E LT-9001-IM

2-3

Page 22

Outline of Measurement and Settings

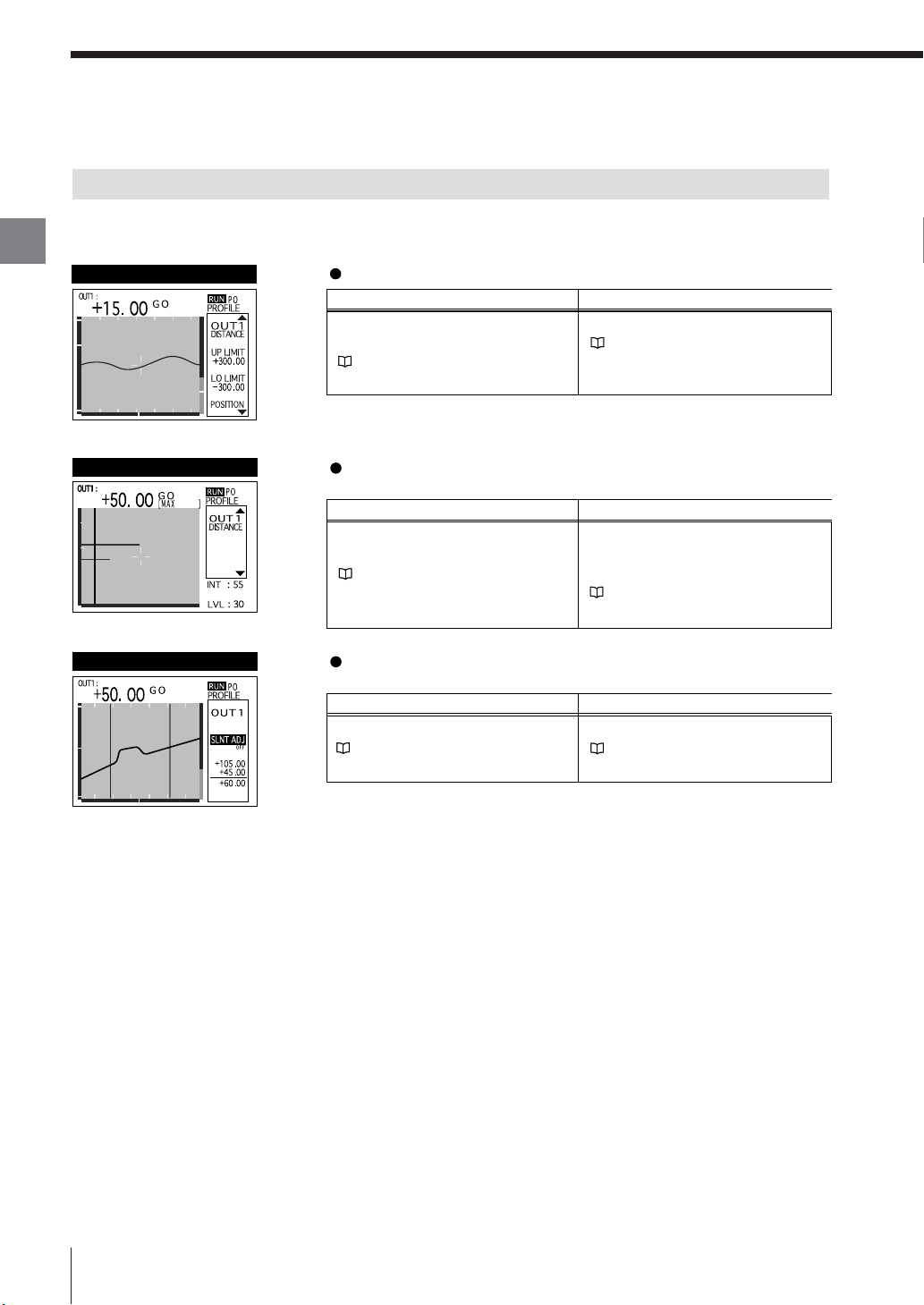

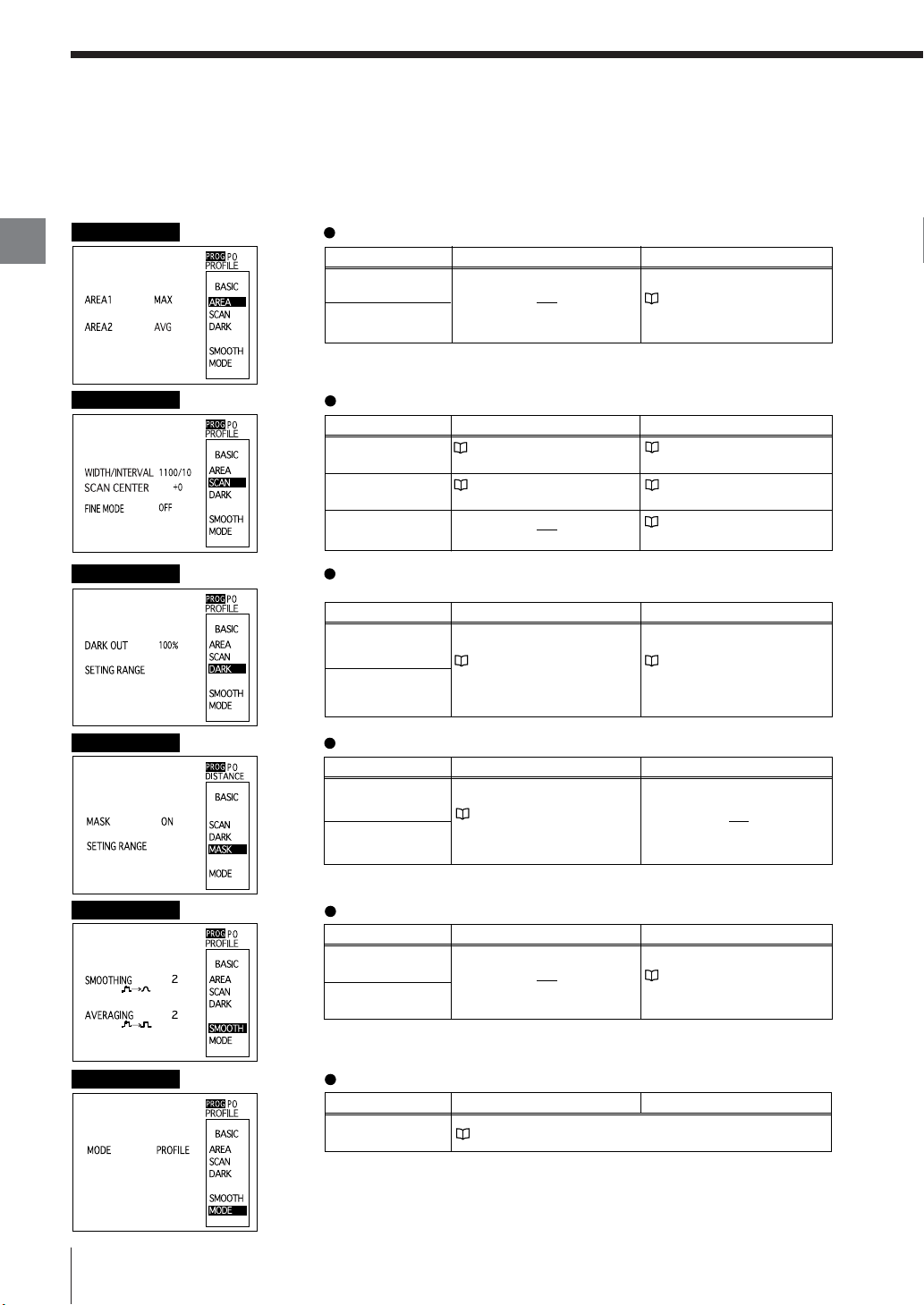

Run Mode

Chapter

2

Basic Operations

The run mode displays the measurement screen, the light intensity screen, and the pause screen

interchangeably.

MEASUREMENT

INT (Light intensity)

The measured value and the graph can be displayed.

Displacement mode Profile mode

Displays the temporal change of the

measured value.

Chapter 3 "Measurement Screen"

(page 3-5)

Displays the profile of the target.

Chapter 4 "Measurement Screen"

(page 4-5)

The measured value and the graph of the amount of light the

measurement surface receives can be displayed.

Displacement mode Profile mode

Pause

Displays up to four peaks of light intensity.

Changes the light intensity level.

Chapter 3 "Light Intensity Screen"

(page 3-7)

Performs correction or measurement while suspending the update of

Displays the distribution of light intensity

in reference with the scanning width.

Changes the light intensity level.

Chapter 4 "Light Intensity Screen"

(page 4-8)

the displayed graph.

Displacement mode Profile mode

Chapter 3 "Pause Screen" (page 3-9) Chapter 4 "Pause Screen" (page 4-10)

2-4

E LT-9001-IM

Page 23

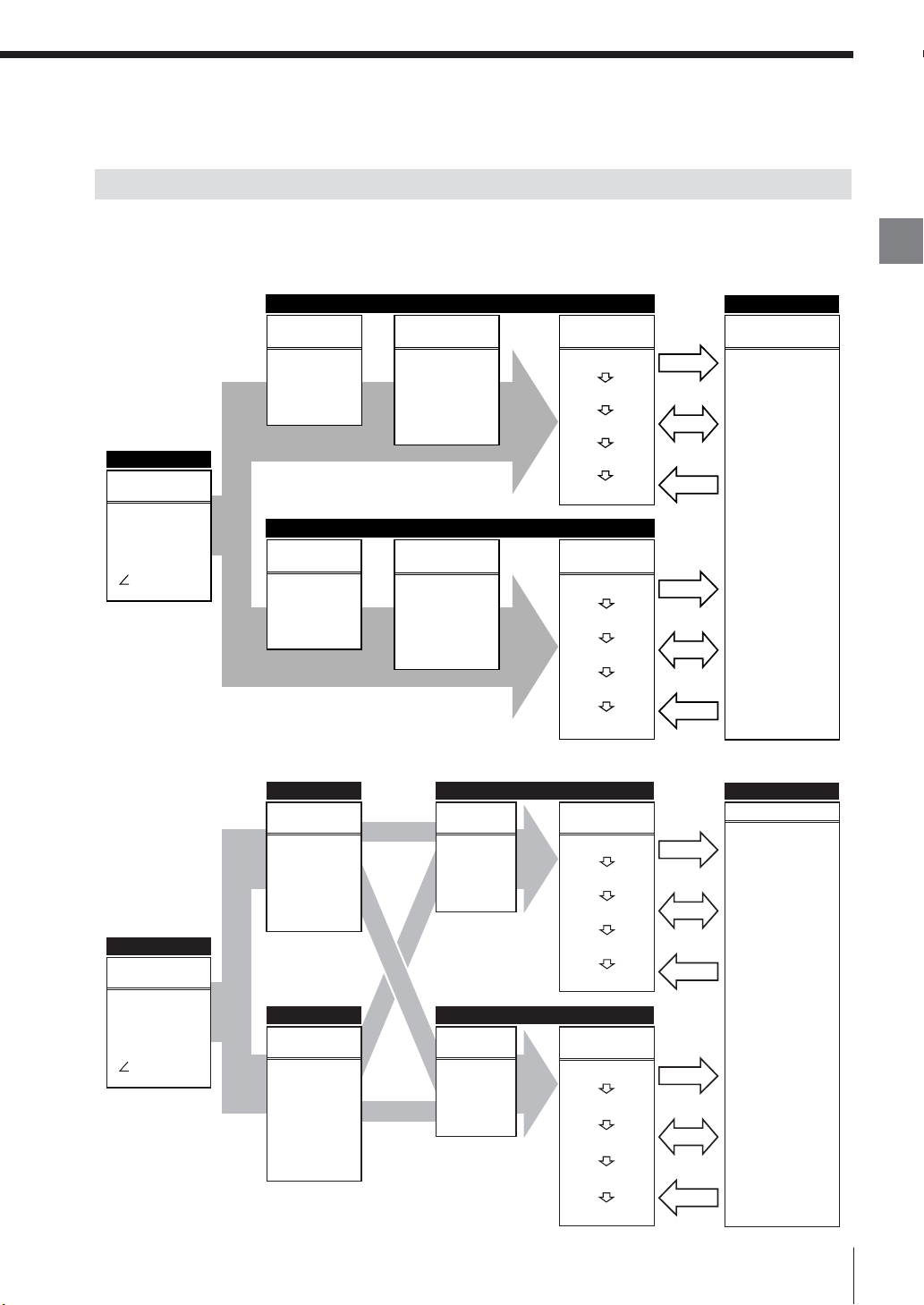

Program Mode

Four types of settings (OUTPUT settings, BASIC settings, OPTIONAL settings, and Environment settings) can

be performed in the program mode according to the target to measure.

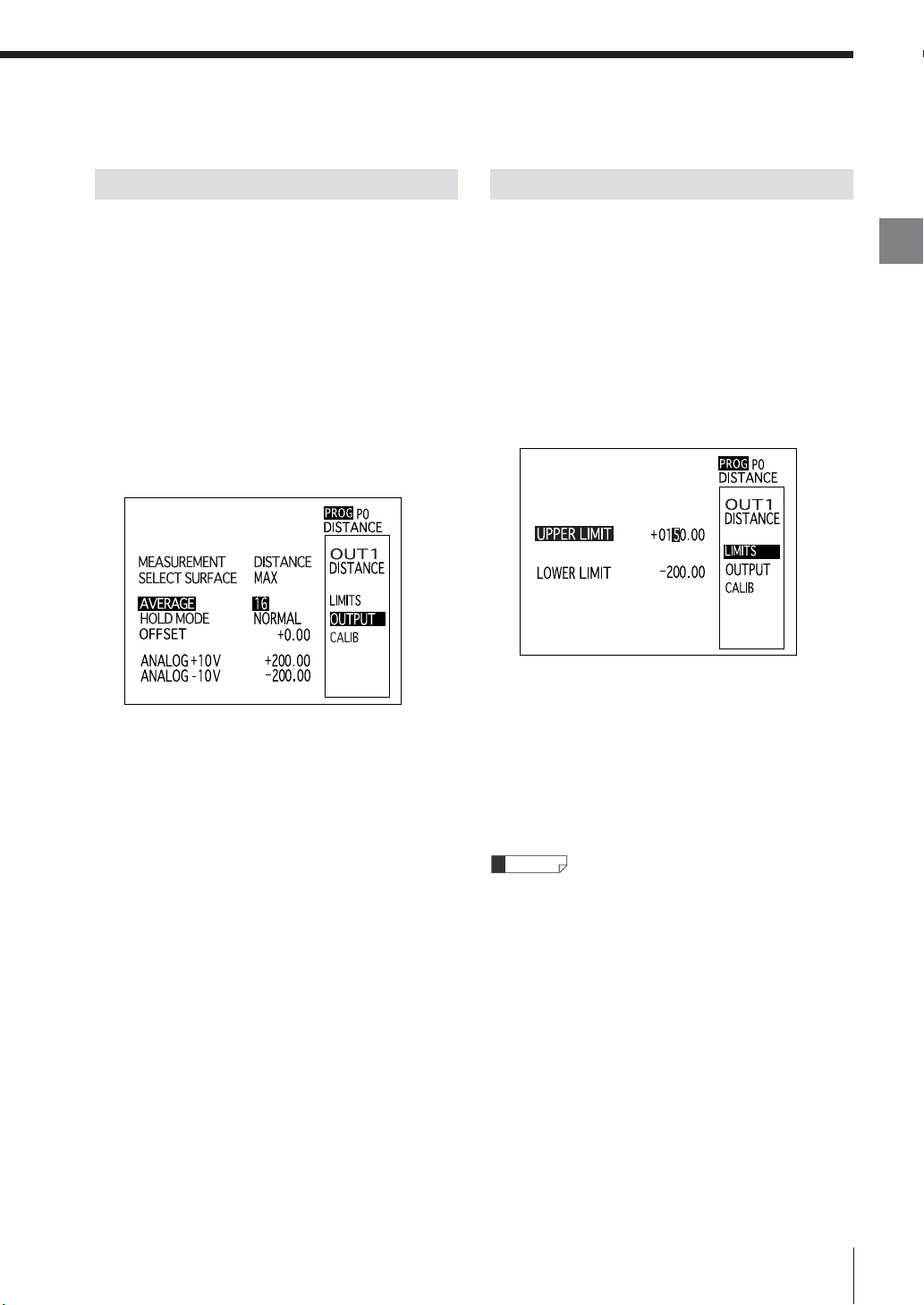

OUTPUT settings

Performs settings for OUT1 and OUT2 respectively.

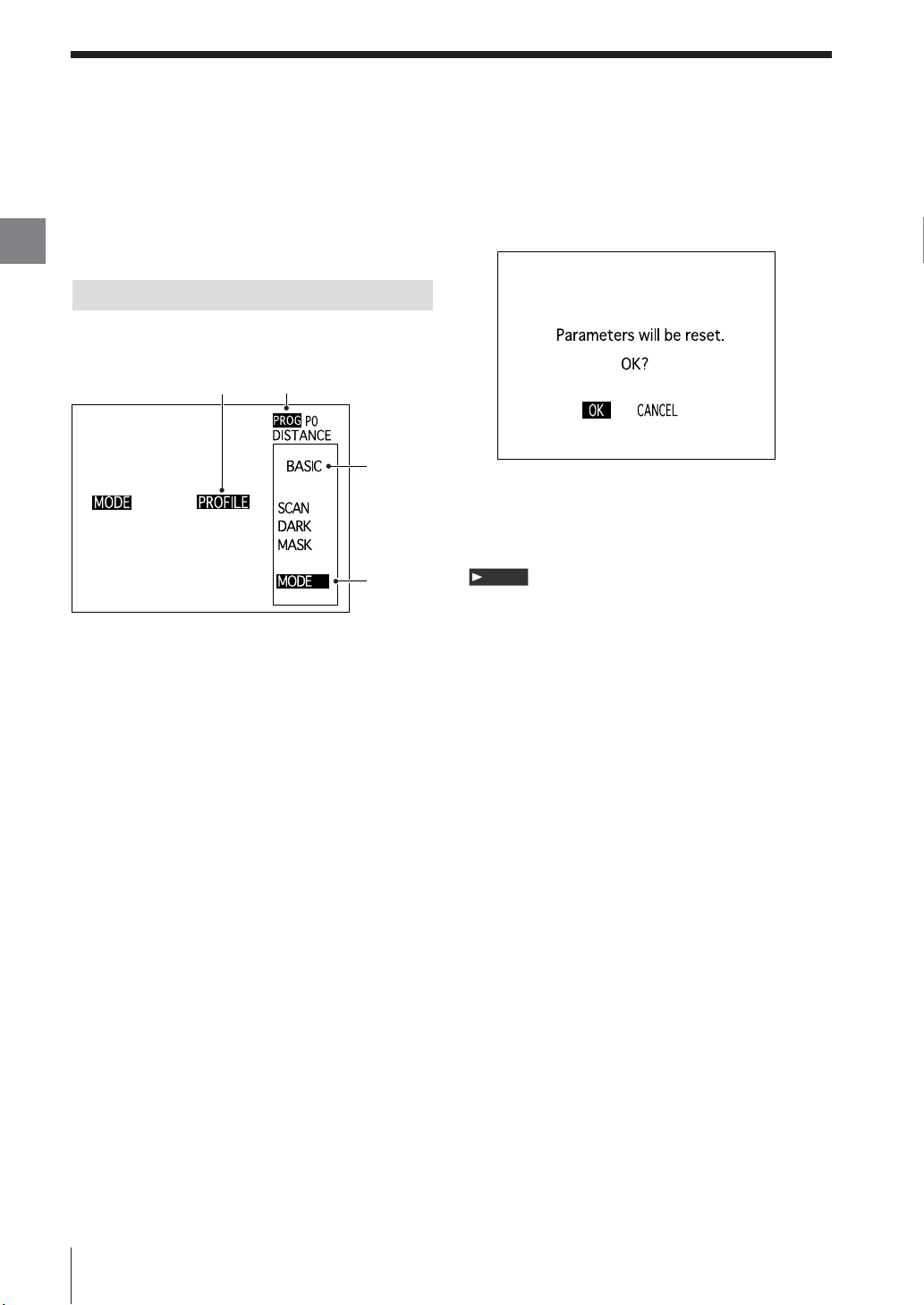

LIMITS (Tolerance)

OUTPUT

Sets the upper and lower limits of the tolerance.

Displacement mode Profile modeSetting item

UPPER LIMIT

LOWER LIMIT

Chapter 5 "OUT Settings" - "LIMITS" (page 5-7)

Sets the measurement method and the processing of the measured data.

Displacement mode Profile modeSetting item

MEASURMENT

SELECT SURFACE

AVERAGE

HOLD MODE

OFFSET

ANALOG output

Chapter 3 "OUT Settings" "Measurement" (page 3-10)

Chapter 3 "OUT Settings" "SELECT SURFACE" (page 3-12)

Chapter 5 "OUT Settings" - "AVERAGE" (page 5-8)

Chapter 5 "OUT Settings" - "HOLD MODE" (page 5-9)

Chapter 5 "OUT Settings" - "OFFSET" (page 5-14)

Chapter 5 "OUT Settings" - "ANALOG output" (page 5-15)

Chapter 4 "OUT Settings" "Measurement" (page 4-12)

Chapter

2

Basic Operations

CALIB (Calibration)

Calibrates the error caused by slant or refractive.

Displacement mode Profile modeSetting item

Measured value

and

calibrated value

Chapter 5 "OUTPUT Settings" - "CALIB" (page 5-16)

E LT-9001-IM

2-5

Page 24

Chapter

2

Basic Operations

Outline of Measurement and Settings

BASIC settings

Performs settings for the preprocessing common to both OUT1 and OUT2.

AREA

Performs settings for the profile measurement method.

Displacement mode Profile modeSetting item

AREA1

AREA2

Chapter 4 "BASIC Settings" "AREA" (page 4-13)

SCAN

DARK

MASK

SMOOTH

Performs settings for the swing width of a spot.

Setting item

SCAN WIDTH

SCAN CENTER

(LT-9010 only)

FINE MODE

Displacement mode Profile mode

Chapter 3 "BASIC Settings" "Scan width/interval" (page 3-15)

Chapter 3 "BASIC Settings" "Scan center" (page 3-16)

Chapter 4 "BASIC Settings" "Scan width/interval" (page 4-14)

Chapter 4 "BASIC Settings" "Scan center" (page 4-15)

Chapter 4 "BASIC Settings" "FINE mode" (page 4-15)

Performs settings for the processing for the case that the light intensity

is lower than the setting range.

Displacement mode Profile modeSetting item

DARKOUT

SETTING RANGE

Chapter 3 "BASIC Settings" "DARK ALARM" (page 3-17)

Chapter 4 "BASIC Settings" "DARK ALARM" (page 4-16)

Performs settings for the range to be excluded from the measurement.

Displacement mode Profile modeSetting item

MASK

SETTING RANGE

Chapter 3 "BASIC Settings" "MASK" (page 3-18)

Performs settings for the functions that stabilize the profile waveform.

Displacement mode Profile modeSetting item

SMOOTHING

AVERAGING

Chapter 4 "BASIC Settings" "SMOOTH" (page 4-17)

2-6

MODE

Toggles between the displacement mode and the profile mode.

Profile modeSetting item

MODE

Displacement mode

Chapter 2 "Selection Method of the Run Mode" (page 2-12)

E LT-9001-IM

Page 25

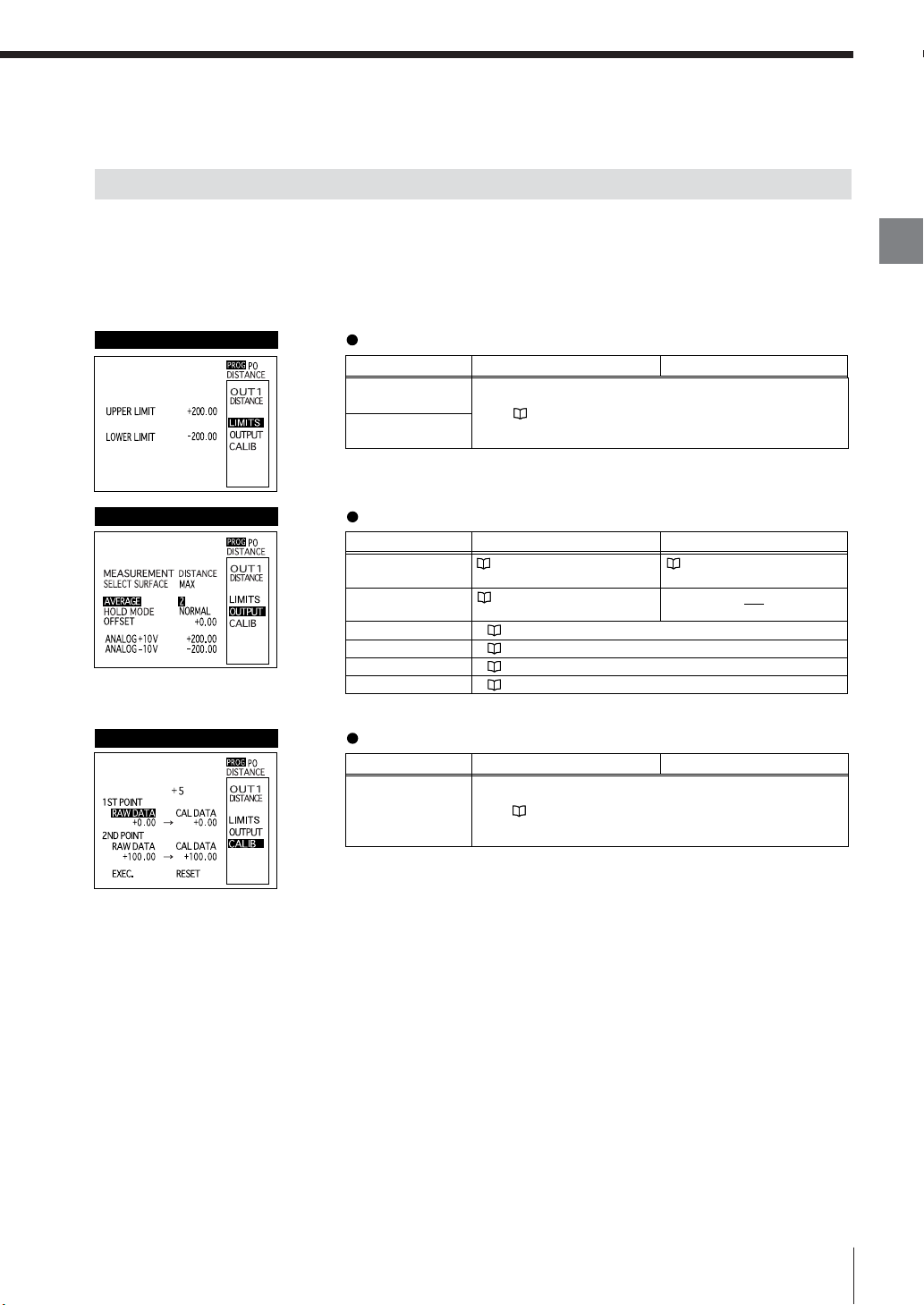

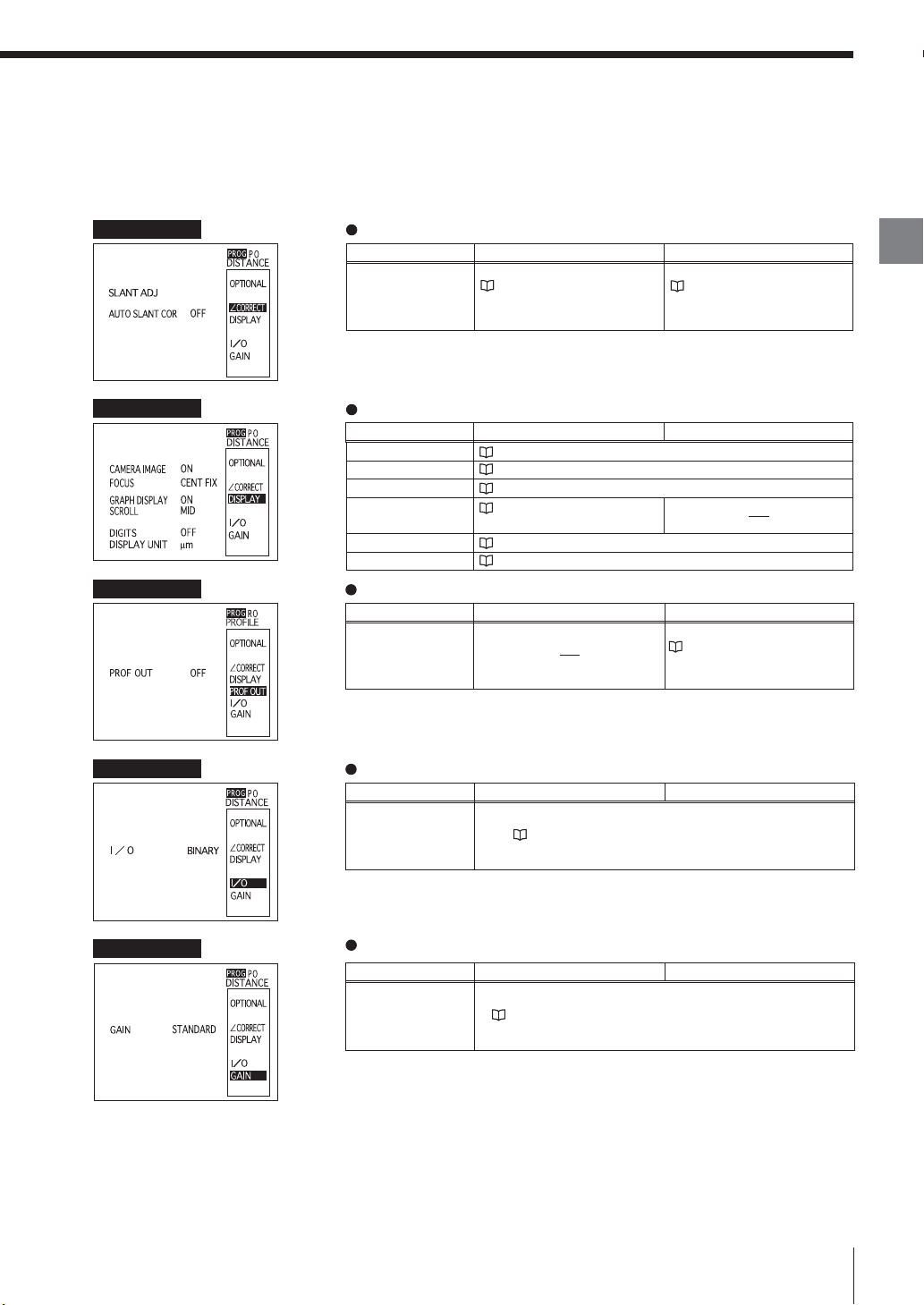

OPTIONAL settings

Perform settings for the additional functions common to both OUT1 and OUT2.

SLANT

Performs settings for the automatic slant correction on the target. (LT-9010 only)

Setting item

SLANT ADJ

AUTO SLANT COR

Displacement mode Profile mode

Chapter 3 "OPTIONAL Settings"

- "SLANT" (page 3-19)

Chapter 4 "OPTIONAL Settings"

- "SLANT" (page 4-18)

Chapter

2

Basic Operations

DISPLAY

PROF OUT

I/O

Performs settings for the measured value display.

Setting item

CAMERA IMAGE

FOCUS

GRAPH DISPLAY

SCROLL

DIGITS

DISPLAY UNIT

Displacement mode Profile mode

Chapter 5 "OPTIONAL Settings" - "CAMERA IMAGE" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "FOCUS" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "GRAPH DISPLAY" (page 5-18)

Chapter 5 "OPTIONAL Settings"

- "SCROLL" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "DIGITS" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "DISPLAY UNIT" (page 5-19)

Performs settings to output the waveform data of the target shape.

Setting item

PROF OUT

Displacement mode Profile mode

Chapter 4 "OPTIONAL Settings"

- "PROFILE" (page 4-19)

Performs settings for the control I/O.

Setting item

I/O

Displacement mode Profile mode

Chapter 5 "OPTIONAL Settings" - "I/O" (page 5-20)

GAIN

E LT-9001-IM

Performs settings for the sensitivity toward light intensity to be received.

Displacement mode Profile modeSetting item

GAIN

Chapter 5 "OPTIONAL Settings" - "GAIN" (page 5-20)

2-7

Page 26

Outline of Measurement and Settings

Chapter

2

Basic Operations

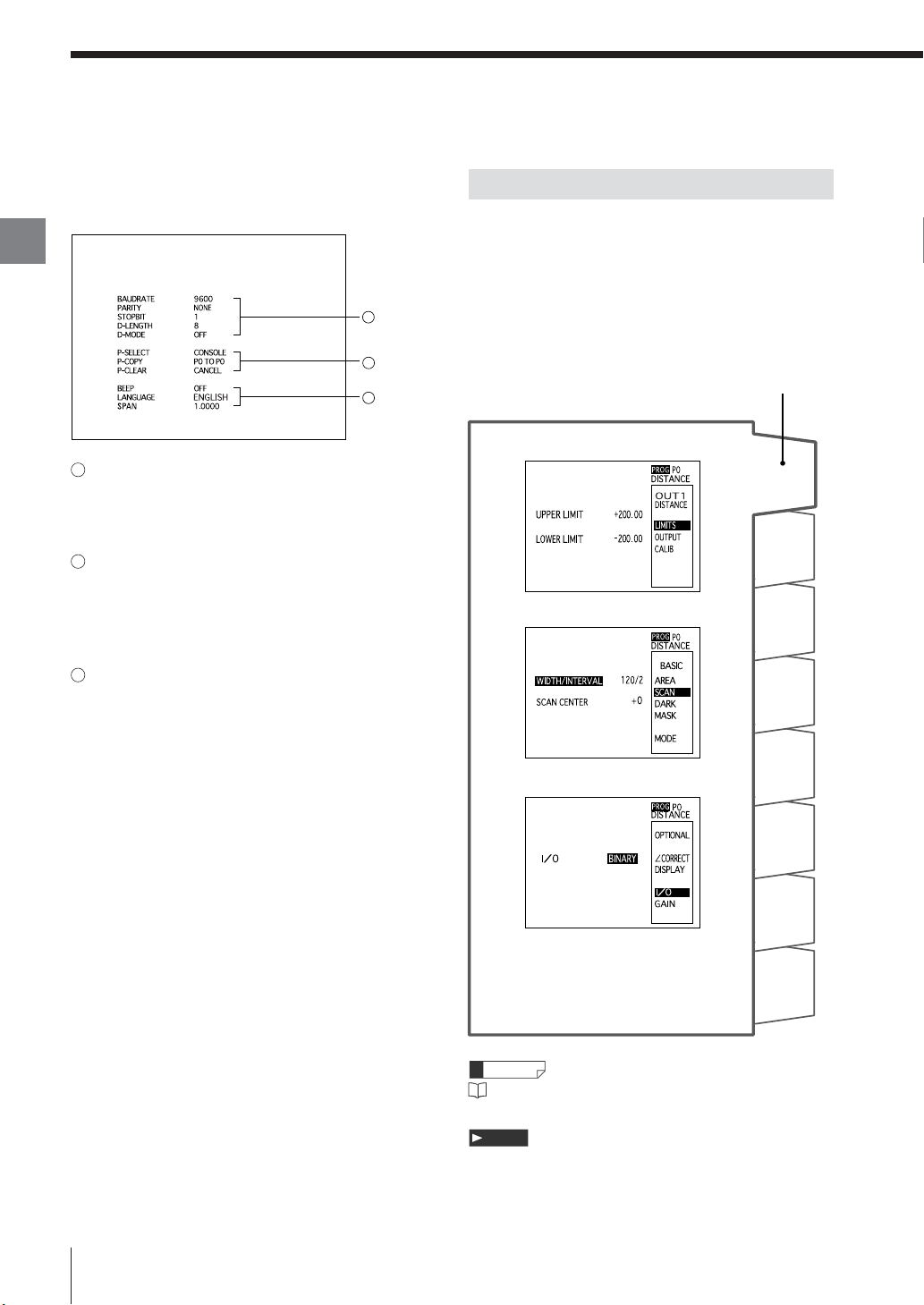

Environment settings

Performs basic settings that are necessary in

operating the LT-9001 Series.

1

2

3

1 RS-232C

Performs settings for the communication

specifications of the RS-232C interface.

2 Program operations

Performs settings for the program number switching

method, copying program settings, and resetting the

program to default.

3 Others

Performs settings for the beep sound, user interface

language, and span of the measuring unit.

Program Function

Eight programs can be toggled among program

numbers 0 to 7 in the LT-9001 Series.

You can register a set of parameters as a program

according to the run mode or the measurement

target.

The set parameters can easily be changed if

calling up the desired program as needed.

Program No.

<OUT settings>

P0

P1

<BASIC settings>

P2

P3

2-8

P4

<OPTIONAL settings>

P5

P6

<AUTO-ZERO parameter>

P7

Reference

Refer to "Program Change" (page 5-6) for a

program switching method.

Note

Environment settings are not saved.

E LT-9001-IM

Page 27

Flow of Measurement

The LT-9001 Series can display and output the measured value of OUT1 and OUT2.

Displacement mode

OUT1

Measured value

processing

CALIB

AVERAGE

HOLD MODE

AUTO-ZERO

OFFSET

Measured value

processing

CALIB

AVERAGE

HOLD MODE

AUTO-ZERO

OFFSET

Output

I/O

Input

Output

I/O

Input

Basic/Optional

Measurement

condition

• INT parameter

• SCAN

• DARK

• SMOOTH

CORRECT

•

Profile mode

Measurement

• DISTANCE

• SLANT

• ΔSLANT

• THICKNESS

Measurement

• DISTANCE

• SLANT

• THICKNESS

Select Surface

• MAX

• M1

• M2

• +4P to +1P

• –1P to –4P

OUT2

Select Surface

• MAX

• M1

• M2

• +4P to +1P

• –1P to –4P

I/O

Measured value

Judgment

output

(LIMITS)

Analog output

Binary output

RS-232C

TIMING

RESET

ZERO

Chapter

2

Basic Operations

Basic/Optional

Measurement

condition

• INT parameter

• SCAN

• DARK

• SMOOTH

CORRECT

•

E LT-9001-IM

AREA1 (A1)

AREA

condition

• AREA range

• AVG

• MAX

• MIN

• DIFF

AREA2 (A2)

AREA

condition

• AREA range

• AVG

• MAX

• MIN

• DIFF

• AREA

OUT1

Select

measurement

• A1

• A2

• A1–A2

• A1+A2

OUT2

Select

measurement

• A1

• A2

• A1–A2

• A1+A2

Measured value

processing

CALIB

AVERAGE

HOLD MODE

AUTO-ZERO

OFFSET

Measured value

processing

CALIB

AVERAGE

HOLD MODE

AUTO-ZERO

OFFSET

Output

I/O

Input

Output

I/O

Input

I/O

Measured value

Judgment

output

(LIMITS)

Analog output

Binary output

RS-232C

TIMING

RESET

ZERO

2-9

Page 28

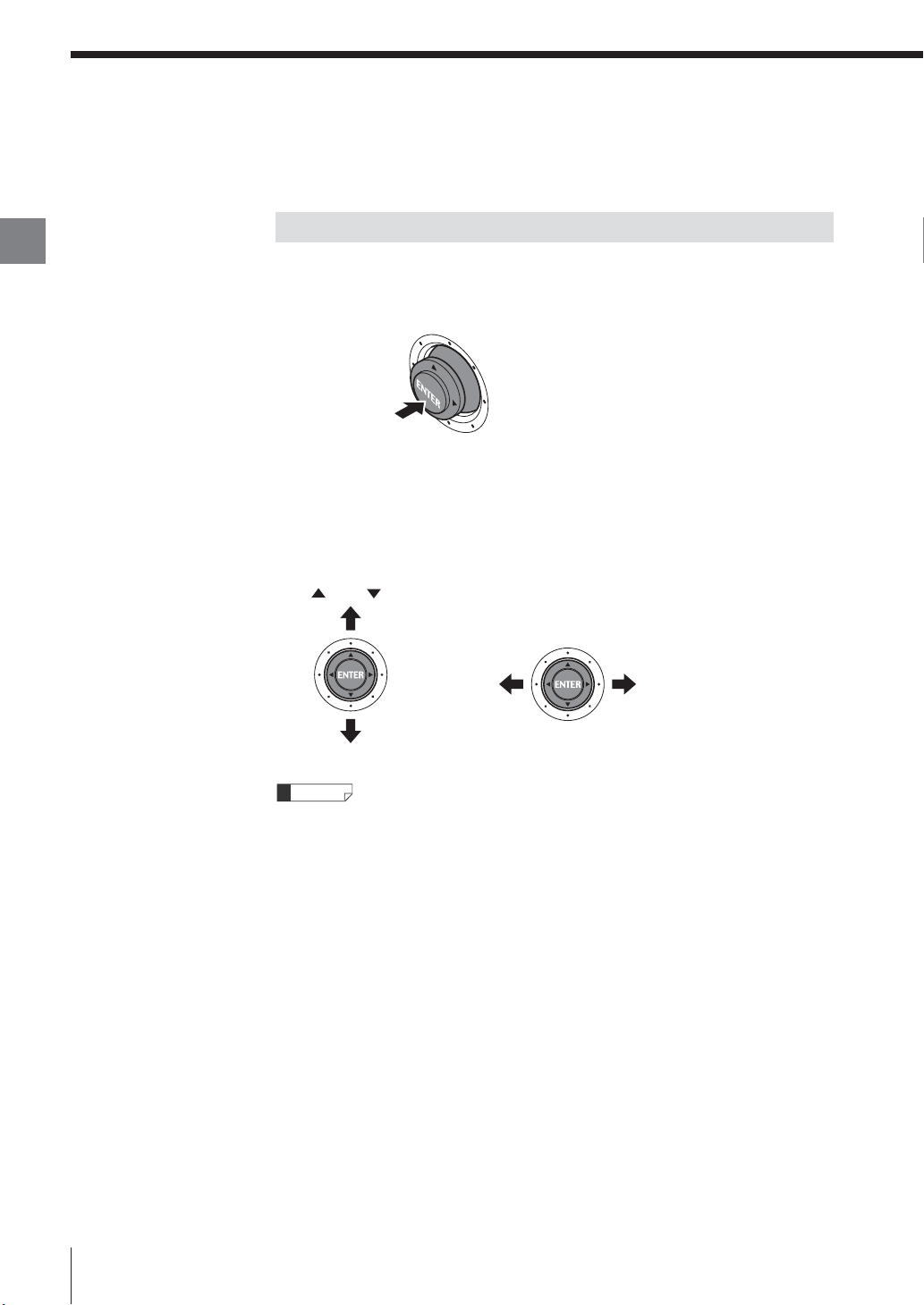

Operations

The LT-9001 Series is operated using the remote control console.

Chapter

2

Basic Operations

How to Use the [ENTER] Button

Pressing the button straight down

• For selecting a menu item

• For fixing a setting

Press

Tilting the button up, down, left or right

The button moves up, down, left and right. This is used to perform the following

operations.

• Moving to another item

• Entering a value such as a tolerance

[ ] and [ ] buttons

Moves upward

Moves downward

[t] and [s] buttons

Moves to

the left

Moves to

the right

2-10

Reference

The operation to tilt the [ENTER] button up or down is described as [▲] or [▼]

button in this manual.

The operation to tilt the [ENTER] button left or right is described as [t] or [s]

button.

E LT-9001-IM

Page 29

Selecting an Item

Entering a Value

The procedure used to select or to enter items/values

such as parameters is explained as follows.

Place the cursor on the item you want to set

1

by using the [▲], [▼], [t] and [s] buttons.

Press the [ENTER] button.

2

The item on which the cursor was placed at step

1 is selected.

Repeat step 1 and 2 to change the selected

3

item or the parameter.

When you want to cancel the operation

If you press the [ESCAPE] button on the remote

control console, the cursor moves to the item

selected immediately before.

The procedure used to enter a value such as the

tolerance is explained as follows.

Select the item whose value is to be entered.

1

Specify the digit of the entering value with the

2

[t] and [s] buttons.

Specify the value that you want to enter with

3

the [▲] and [▼] buttons.

Press the [ENTER] button after changing the

4

value.

The specified value is fixed.

When you want to cancel the changed value

Press the [ESCAPE] button before pressing the

[ENTER] button in step 3 above.

Chapter

2

Basic Operations

E LT-9001-IM

Reference

If the [ZERO] button is pressed while changing the

value, the value can be set to zero.

2-11

Page 30

Selection Method of the Run Mode

Chapter

2

Basic Operations

Select either the displacement mode or the profile

mode according to the measurement required.

(Only displacement mode is available in the LT-

9030 (M).

Operational Flow

The operational flow in selecting the displacement

mode or the profile mode is as follows.

5, 6 2

3

4

Turn on the power of the controller.

1

Select [OK] with the [▲] and [▼] buttons and

7

press the [ENTER] button.

The mode is switched to the selected run mode.

Slide down the [PROG/RUN] switch on the

8

remote control console to display the run

mode screen.

Note

All parameters are reset to the default value if

displacement mode/profile mode is changed.

Slide the [PROG/RUN] switch downward on

2

the remote control console to display the

program mode screen.

Select [BASIC] with the [▲] and [▼] buttons

3

and press the [ENTER] button.

The basic setting screen is displayed.

Place the cursor on [MODE] with the [▲] and

4

[▼] buttons and press the [ENTER] button.

The cursor moves to [MODE] on the mode

setting screen.

Press the [ENTER] button and move the

5

cursor to the mode currently selected.

When the setting is performed for the first time,

[DISTANCE] is displayed.

Select [PROFILE] or [DISTANCE] with the [▲]

6

and [▼ ] buttons and press the [ENTER]

button.

The confirmation screen is displayed.

2-12

E LT-9001-IM

Page 31

Using the Displacement Mode

This section describes how to measure the level

differences on the measurement target in the

displacement mode.

The operational flow is as follows.

Selecting the Displacement Mode

Set the suitable mode for the measurement required.

↓

Adjusting the Distance Between the

Measuring Unit and the Measurement Target

Adjust the position and height of the measuring unit

according to the measurement target.

↓

Setting the Scan Width/Interval

Set the scan width and the pitch of the laser emission

for stable measurement.

↓

Setting the Light Intensity Level

Selecting the Displacement Mode

Turn on the power of the controller.

1

Slide the [PROG/RUN] switch downward on

2

the remote control console to display the

program mode screen.

Select [BASIC] by using the [▲] and [▼ ]

3

buttons and press the [ENTER] button.

The basic settings screen appears.

Chapter

2

Basic Operations

Set the threshold level value for the amount of light

intensity to be measured.

↓

Measuring the Displacement

The operational procedure is explained for the

respective steps.

Place the cursor on [MODE] by using the [▲]

4

and [▼ ] buttons and press the [ENTER]

button.

The cursor moves to [MODE] on the mode

setting screen.

Press the [ENTER] button and move the

5

cursor to the mode currently selected.

When this setting is performed for the first time,

[DISTANCE] is displayed.

Select [DISTANCE] by using the [▲] and [▼]

6

buttons and press the [ENTER] button.

The run mode is changed.

Slide the [PROG/RUN] switch downward on

7

the remote control console to display the run

mode screen.

Selecting the displacement mode is completed.

Adjusting the distance between the measuring unit

and the measurement target is described next.

E LT-9001-IM

2-13

Page 32

Using the Displacement Mode

Chapter

2

Basic Operations

Adjusting the Distance Between the Measuring Unit and the Measurement Target

Adjust the height and position of the

1

measuring unit and fix the distance and

position relating to the measurement target.

Setting the Scanning Width/interval

Slide the [PROG/RUN] switch downward on

1

the remote control console to display the

program mode.

Select [BASIC] by using the [▲] and [▼ ]

2

buttons and press the [Enter] button.

Place the cursor on [SCAN] by using the [▲]

3

and [▼ ] buttons and press the [ENTER]

button.

Reference

How to adjust the distance between a

measurement target and the measuring unit.

It will be easier to adjust by combining the three

methods shown below.

1 Adjust the distance to obtain the smallest possible

red laser spot.

2 Adjust the distance to get the measurement target

into focus.

3 Adjust the distance while reading the light intensity

peaks graph on the light intensity screen.

Setting the scanning width/interval is described

next.

2-14

Place the cursor on [SCAN WIDTH] by using

4

the [▲] and [▼ ] buttons and press the

[ENTER] button

Select [120/2] by using the [▲] and [▼ ]

5

buttons and press the [ENTER] button.

Slide the [PROG/RUN] switch downward on

6

the remote control console to display the run

mode screen.

Setting the scanning width/interval is completed.

Setting the light intensity level is described next.

E LT-9001-IM

Page 33

Setting the Light Intensity Level

Measuring the Displacement

LOW HIGH

Press the [SCREEN] button on the

1

measurement screen to display the light

intensity screen.

Move the cursor by using the [t] or [s]

2

button to change the light intensity level.

Set the light intensity level to a higher level of

light intensity, but less than the peak.

Press the [SCREEN] button to return to the

3

measurement screen.

When the measurement target moves,

the measured value and the trend

graph changes according to the target.

Press the [ENTER] button twice on the

1

measurement screen and place the cursor on

the value of [UP LIMIT].

Specify the value by using the [t], [s], [▲]

2

and [▼] buttons and press the [ENTER] button.

The value +100.00 is specified in this example.

Place the cursor on [LO LIMIT] by using the

3

[▲] and [▼] buttons.

Chapter

2

Basic Operations

Setting the light intensity level is completed.

How to measure the displacement is described next.

E LT-9001-IM

Place the cursor on the value by pressing the

4

[ENTER] button.

Specify the value by using the [t], [s], [▲]

5

and [▼] buttons and press the [ENTER] button.

The value –100.00 is specified in this example.

Press the [ESCAPE] button to return to the

6

measurement screen.

Set the current position as a reference point

7

by pressing the [ZERO] button.

The displacement based on this reference point

is displayed on the screen after this setting.

Reference

The value based on the current position as the

reference point is displayed on the measurement

screen. When the measurement target moves, the value

of the measured value display changes to the value of

the level difference between the former reference point

and the current reference point. Responding to the

change of value, the trend graph changes.

2-15

Page 34

Using the Profile Mode

Chapter

2

Basic Operations

This section describes how to measure the level

differences on the measurement target in the

profile mode.

The operational flow is as follows.

Selecting the Profile Mode

Set the suitable mode for the measurement content.

↓

Adjusting the Distance Between the

Measuring Unit and the Measurement Target

Adjust the position and height of the sensor head

according to the measurement target.

↓

Setting the Scan Width/interval

Set the range to be measured in the profile as the

scanning width [WIDTH/INTERVAL] and the pitch

between measurement points. Set the pitch in

balance with the shape of the measurement target.

↓

Setting the Upper and Lower

Limits Display

Set the upper and lower limits display according to

the shape of the measurement target in the profile

waveform graph.

↓

Selecting the Profile Mode

Turn on the power of the controller.

1

Slide the [PROG/RUN] switch downward on

2

the remote control console, and select the

program mode screen.

Select [BASIC] by using the [▲] and [▼ ]

3

buttons and press the [ENTER] button.

The basic settings screen appears.

Place the cursor on [MODE] by using the [▲]

4

and [▼ ] buttons and press the [ENTER]

button.

The cursor moves to [MODE] on the mode

setting screen.

Setting the Area

Change the two areas (Area1 and Area2) to any

range, respectively, on the graph display.

↓

Measuring the Level Differences

The operational procedure is explained for the

respective items.

2-16

Press the [ENTER] button and move the

5

cursor to the mode currently selected.

When this setting is performed for the first time,

[DISTANCE] is displayed.

Select [PROFILE] by using the [▲] and [▼]

6

buttons and press the [ENTER] button.

The run mode is changed.

Slide the [PROG/RUN] switch downward on

7

the remote console to display the run mode

screen.

Selecting the profile mode is completed.

Adjusting the distance between the measuring unit

and the measurement target is described next.

E LT-9001-IM

Page 35

Adjusting the Distance Between the Measuring Unit and the Measurement Target

Adjust the height and position of the

1

measuring unit and fix the distance and

position relating to the measurement target.

Setting the Scanning Width/interval

Slide the [PROG/RUN] switch downward on

1

the remote control console to display the

program mode screen.

Select [BASIC] by using the [▲] and [▼ ]

2

buttons and press the [Enter] button.

Place the cursor on [SCAN] by using the [▲]

3

and [▼ ] buttons and press the [ENTER]

button.

Chapter

2

Basic Operations

Reference

How to adjust the distance between a

measurement target and the measuring unit.

It will be easier to adjust by combining the three

methods shown below.

1 Adjust the distance to obtain the smallest possible

red laser spot.

2 Adjust the distance to get the measurement target

into focus.

3 Adjust the distance while reading the profile

waveform graph on the measurement screen.

Setting the scanning width/interval is described

next.

Place the cursor on [WIDTH/INTERVAL] by

4

using the [▲] and [▼] buttons and press the

[ENTER] button.

Select [1100/10] by using the [▲] and [▼]

5

buttons and press the [ENTER] button.

Slide the [PROG/RUN] switch downward on

6

the remote control console to display the run

mode screen.

The profile waveform appears.

Setting the scan width/interval is completed.

Setting the upper and lower limits display is

described next.

E LT-9001-IM

2-17

Page 36

Using the Profile Mode

Chapter

2

Basic Operations

Setting the Upper and Lower Limits Display

Press the [ENTER] button twice on the

1

measurement screen and place the cursor on

the value of [UP LIMIT].

Specify the value by using the [t], [s], [▲]

2

and [▼ ] buttons and press the [ENTER]

button.

The value +100.00 is specified in this example.

Place the cursor on [LO LIMIT] by using the

3

[▲] and [▼] buttons.

Place the cursor on the value by pressing the

4

[ENTER] button.

Specify the value by using the [t], [s], [▲]

5

and [▼ ] buttons and press the [ENTER]

button.

The value –100.00 is specified in this example.

Press the [ESCAPE] button to return to the

6

measurement screen.

Setting the upper and lower limits display is

completed.

Setting the area is described next.

Setting the Area

Press the [SCREEN] button on the

1

measurement screen to display the light

intensity screen.

Set the area range on the light intensity screen.

Place the cursor on [A1] by pressing the

2

[ENTER] button.

Place the cursor on the value by pressing the

3

[ENTER] button.

Press the [SCREEN] button to select the

4

cursor on the left or the right.

Change the position of the cursor by using

5

the [▲] and [▼] buttons.

Set [A1] (Area1) for the range including the

protruded part in this example.

Fix the setting value by pressing the [ENTER]

6

button.

Exit the setting by pressing the [ESCAPE]

7

button.

Press the [SCREEN] button to return to the

8

measurement screen.

2-18

Setting the area is completed.

How to measure the level differences is described

next.

E LT-9001-IM

Page 37

Measuring Height Differences

Slide the [PROG/RUN] switch downward on

1

the remote control console to switch to the

program mode screen.

Select [BASIC] by using the [▲] and [▼ ]

2

buttons and press the [Enter] button.

Place the cursor on [AREA] by using the [▲]

3

and [▼ ] buttons and press the [ENTER]

button.

Place the cursor on [AREA 1] by using the [▲]

4

and [▼ ] buttons and press the [ENTER]

button.

Chapter

2

Basic Operations

Select [DIFF] by using the [▲] and [▼] buttons

5

and press the [ENTER] button.

The [DIFF] measures the differential between the

maximum and minimum values within a userdefined area.

Slide the [PROG/RUN] switch downward on

6

the remote control console to display the

measure mode screen.

The measured value displayed is that of the

7

level differences (the differential between the

maximum and minimum values) set within

[AREA 1].

Reference

The value can be measured without moving the

measurement target in the profile mode (maximum

value, minimum value, differential between the

maximum and minimum values and area).

E LT-9001-IM

2-19

Page 38

Chapter

2

Basic Operations

Basic Operations that Stabilize Measurement

The LT-9001 has functions to stabilize measurement and prevent errors.

• Changing the scanning width and the FINE mode

• Changing the light intensity level

High-accuracy measurement can be obtained by using these functions properly.

The LT-9001 measures the value based on the amount of reflection from the laser

(the received light intensity) on the measurement target surface.

The received light intensity is at the maximum when the measurement target is in

focus, but the reflective light is not necessarily stabilized.

Depending on the shape of the material of the measurement target, the receiver

might not receive light or might receive excess light from other than the focal

point.

If the target is measured under such circumstances, an error could occur.

Changing the Scanning Width and the FINE Mode

The LT-9001 scans the laser spot using a built-in oscillating function.

Measurement can be stabilized by a scanning process that measures multiple

points and cancels any points reflecting insufficient light.

The scanning width can be changed in the displacement mode. FINE mode is

used in the profile mode for stabilizing the measurement.

Refer to "SCAN" (page 3-15) for details on setting FINE mode in the displacement

mode. Refer to "SCAN" (page 4-14) for setting FINE mode in the profile mode.

Reference

Use the proper procedure for changing the setting for the light intensity level,

even when the function for changing the scanning width is in use.

2-20

Changing the Light Intensity Level

The light intensity level is a threshold value defining an adequate amount of light

for measurement.

When the received light intensity is higher than the level, the target is measured. If

it is lower, measurement is canceled.

In such a case, the measured value remains as it was beforehand.

Light intensity level

Measuring

Make the settings so as to ignore undesirable light that affects the measurement

results and to cancel any point with insufficient light for measurement.

E LT-9001-IM

Page 39

Measuring the surface shape or displacement

Set the longest peak bar (the first peak), which shows that the measurement

target is in the focus, so that it extends to the right side of the vertical cursor.

Light intensity level

(vertical cursor)

Measuring the thickness or backside of a transparent object

When there is more than one light intensity peak, set the light intensity level bar so

that at least two surface peaks extends to the right.

Chapter

2

Basic Operations

Light intensity level

(vertical cursor)

Reference

Accuracy of the measurement differs depending on whether or not the light

intensity level is set properly. For more accurate measurement, set the light

intensity as high as possible within the range so as not to exceed adequate light

for measurement. Be sure not to set it too high or the measured value will be

retained and measurement will be disabled.

The displacement mode is used in this example. Stabilized measurement can be

obtained in the profile mode by making the same settings.

Refer to "Setting the Light Intensity Level" (page 3-8) for setting of the

displacement mode.

Refer to "Setting the Light Intensity Level" (page 4-8) for setting of the profile

mode.

E LT-9001-IM

2-21

Page 40

Chapter

2

Basic Operations

Resetting the Device to the Factory Settings

It is possible to delete all setting contents and

change to the LT-9001 default values set at the

factory.

To reset the device to the factory settings, follow

the procedure below.

Turn off the power switch of the controller.

1

Turn on the power switch of the controller

2

while holding down the [ZERO] button on the

console.

Select [OK] by using the [t] and [s] buttons

3

and press the [ENTER] button.

Initialization is executed.

Reference

The interface language and the coefficients set in the

environment settings are not initialized.

2-22

E LT-9001-IM

Page 41

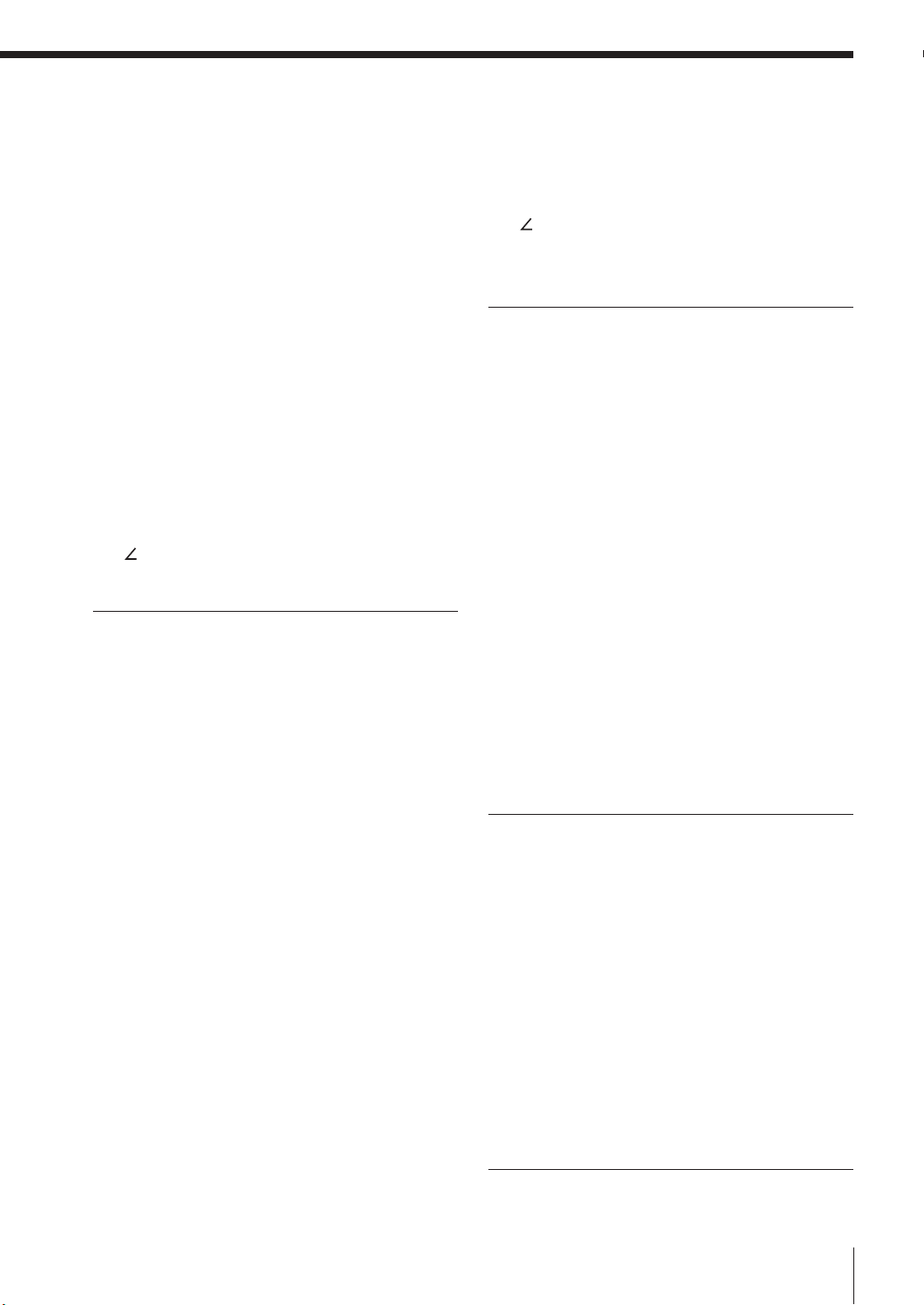

Default Values and Settings Range (LT-9010 (M))

Displacement Mode

The default values and the setting range of the setting contents of the displacement mode are shown below.

Displacement mode

Program

Programs

OUT settings

(OUT1/OUT2)

Run

GRAPH DISPLAY

Tolerance

Output

Calibration

Setting contents

Light intensity level

OUT1 Upper limit

OUT1 Lower limit

OUT2 Upper limit

OUT2 Lower limit

Upper limit

Lower limit

Select

mesurement

Measurement surface

(One surface)

Measurement surface

(Two surfaces)

Number of measurement

times for averaging

Measurement mode

Offset

Analog +10V

Analog –10V

1st point/measured value

1st point/calibrated value

2nd point/measured value

2nd point/calibrated value

Default

value

0~255

30

+300.00

–300.00

–9999.99 ~ +9999.99*

+300.00

–300.00

+200.00

–9999.99 ~ +9999.99*

–200.00

Displacement, Transparent object thickness,

Displacement

Slant ΔSlant

Maximum

[MAX]

MAX, M1, M2, +1P, +2P, +3P

+4P, –1P, –2P, –3P, –4P

Maximum

[MAX]

2 ~ 128 (256 ~ 4096)

2

Normal [NORMAL], Auto peak hold [A.PEAK H],

Auto bottom hold [A BOTM H], Auto P-P hold

Normal

[A P-P H], Average hold [AVER. H],Peak hold

[NORMAL]

[PEAK HLD], Bottom hold [BOTTOM H], P-P

hold [P-P HOLD], Sample hold [SAMPLE H]

0.00

–9999.99 ~ +9999.99*

+200.00

–9999.99 ~ +9999.99*

–200.00

0.00

0.00

–9999.99 ~ +9999.99*

+100.00

+100.00

Reference pagesSetting range

Chapter 3 “Light Intensity Screen” – “Setting the

Light Intensity Level (page 3-8)

Chapter 3 “Measurement Screen” – “Setting the

upper and lower limits of the trend graph display”

(page 3-6)

Chapter 5 "OUT Settings" - "LIMITS" (page 5-7)

Chapter 3 "OUT Settings" - "MEASUREMENT" (page 3-10)

Chapter 3 "OUT Settings" - "SELECT SURFACE"

(page 3-12)

Chapter 5 "OUT Settings" - "AVERAGE " (page 5-8)

Chapter 5 "OUT Settings" - "HOLD MODE"

(page 5-9)

Chapter 5 "OUT Settings" - "OFFSET" (page 5-14)

Chapter 5 "OUT Settings" - "ANALOG output"

(page 5-15)

Chapter 5 "OUT Settings" - "CALIB" (page 5-16)

Chapter

2

Basic Operations

OFF, 120/2, 120/5,

Basic

settings

Optional

settings

Scan

Dark

Mask

CORRECT

Display

I/O

GAIN

Scan Width

Scan center

Darkout

Darkout range (HI)

Darkout range (LO)

Mask

Mask range (HI)

Mask range (LO)

AUTO SLANT COR

Camera Image

Focus

Graph display

Scroll

Minimum number of

non-displayed digits

Display unit

I/O

GAIN

120/10, 250/2, 250/5,

120/5

250/10, 500/2, 500/5,

500/10, 1100/2, 1100/5,

1100/10, 4/1

0

–550 ~ +550

OFF, ON

OFF

100

1 ~ 255

20

0 ~ 254

OFF

OFF, ON

+100

–400 ~ +400

–100

OFF

ON, OFF

ON

ON, OFF

Center fix, Maximum displacement,

Minimum displacement,

Center fix

Average displacement

ON

ON, OFF

Medium

Low, Medium, High

OFF, 1-Digit, 2-Digit

OFF

μm μm,mil

Binary

Binary, Judgment output

[BINARY]

Normal, High sensitivity

Standard

Chapter 3 "BASIC Settings" - "Scan Width"

(page 3-15)

Chapter 3 "BASIC Settings" - "Scan center" (page 3-16)

Chapter 3 "BASIC Settings" - "DARK" (page 3-17)

Chapter 3 "BASIC Settings" - "DARK" (page 3-17)

Chapter 3 "BASIC Settings" - "DARK" (page 3-17)

Chapter 3 "BASIC Settings" - "MASK" (page 3-18)

Chapter 3 "BASIC Settings" - "MASK" (page 3-18)

Chapter 3 "OPTIONAL Settings" - "AUTO SLANT COR" (page 3-19)

Chapter 5 "OPTIONAL Settings" - "CAMERA IMAGE" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "FOCUS" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "GRAPH DISPLAY" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "SCROLL" (page 5-18)

Chapter 5 "OPTIONAL Settings" - "DIGITS"

(page 5-18)

Chapter 5 "OPTIONAL Settings" - "DISPLAY UNIT"

(page 5-19)

Chapter 5 "OPTIONAL Settings" - "I/O" (page 5-20)

Chapter 5 "OPTIONAL Settings" - "GAIN" (page 5-20)

*The values differ according to the setting for the minimum number of non-displayed units and of the area.

E LT-9001-IM

2-23

Page 42

Default Values and Settings Range

Profile Mode

Chapter

2

Basic Operations