Page 1

96M12875

LK-G5000 Series

Dedicated Touch Panel

Read this manual before use.

Keep this manual in a safe place for future reference.

User's Manual

LK-HD1001

Page 2

NOTE

Reference

Introduction

This manual contains hardware information and basic operating procedures for the

dedicated touch panel display unit LK-HD1001 for use with the LK-G5000 series. In order

to take advantage of the functionality of the LK-G5000 series dedicated touch panel display

unit LK-HD1001, read and understand the contents of this manual thoroughly.

Keep this manual in a safe place for future reference.

Please deliver this manual to the end users of this product.

Symbols

The following symbols alert you to important messages concerning the prevention of

human injury and product damage.

DANGER

Failure to follow the instructions may lead to death or severe injury.

WARNING

Failure to follow the instructions may lead to injury (such as electric shock or burn).

CAUTION

Failure to follow the instructions may lead to property damage or product breakdown.

Provides additional information on proper operation.

Provides reference information or useful information about operation.

2

Page 3

Safety Precautions

General Cautions

•At startup and during operation, be sure to monitor the functions and performance of this

product.

• It is recommended that you take substantial safety measures to avoid any damage in

case of product failure.

• Do not modify this product or use it in any way other than as described in the

specifications. The warranty will be voided in such cases.

• When this product is used in combination with other devices, functions and performance

may be degraded depending on the operating conditions and surrounding environment.

•Do not subject this device or any peripheral equipment to sudden temperature changes.

Doing so can cause condensation and damage the equipment.

• To prevent noise-induced operation or failures, route all cabling away from high voltage

and power lines.

• The LCD panel may have black or bright specks or uneven brightness, and may exhibit

crosstalk (lines or patterns non-existent in the actual image).

Image retention may become noticeable if the same image is displayed over a prolonged

period. This is a feature of LCD screens.

CAUTION

• Do not press the touch panel (touch switch) with a sharp object such as a pen or

screwdriver. Doing so can scratch or damage the touch panel (touch switch).

• Do not apply shock or press the touch panel (touch switch) stronger than necessary.

Doing so may damage the touch panel (touch switch).

• Do not wipe the LCD with paint thinner or organic solvents as doing so may damage it.

Wipe with a mild detergent diluted with water.

96M12875

3

Page 4

Installation environment

To use this product properly and safely, avoid installing it in the following locations. Doing so

may lead to product breakdown.

• Location that is humid, dusty or poorly ventilated

• Location where the temperature becomes high, such as a place exposed to direct

sunlight

• Location where there are flammable or corrosive gases

• Location where the product may be directly subjected to vibration or impact

• Location where water, oil or chemicals may splash onto the product

Considerations for improving noise immunity

• Do not install in enclosures where high voltage devices are installed.

• Locate as far away as possible from power lines.

• Locate as far away as possible from devices that generate intense electric or magnetic

fields such as solenoids and chopper circuits.

• Use separate conduit for I/O lines, power lines, and high voltage lines to prevent noiseinduced erroneous operation.

•Ground protective earth terminals and shield wires to a ground resistance of 100 ohms

or less.

Precautions on CE Marking

This device conforms to CE marking directives when the following conditions are met:

Make sure these conditions are met if using this device within the EU nations.

The applicable standards (EMC Directive) are listed below:

EMI:EN61326-1, Class A

EMS:EN61326-1

Limit the length of the power supply cable and all input/output cables that are connected to

the terminal panel of the controller to 30 m or less.

4

Page 5

Contents

Introduction .............................................. 2

Safety Precautions .................................. 3

General Cautions ...............................3

CAUTION .......................................... 3

Precautions on CE Marking ............... 4

Contents ............................................ 5

Chapter 1 Before Use

Checking the Package Contents ..........1-2

Overview ...............................................1-3

LK-G5000 series system

configuration ...............................1-3

Functions and features ...................1-4

Part Names and Functions ...................1-6

Mounting the Touch Panel ....................1-7

Mounting Precautions .....................1-7

Mounting .........................................1-8

Using the Stand ............................1-10

Connecting the Units ..........................1-12

Chapter 2 Screen Functions and

Operation

Names and Functions on the Main

Screen ............................................2-2

Flow of Operation .................................2-3

Basic Settings .......................................2-4

Head Settings .................................2-4

OUT Settings ..................................2-9

Common Settings .........................2-16

Environment Settings .........................2-21

Program Settings ................................2-23

Copying Programs ........................2-23

Initializing Programs .....................2-25

Measurement Value Display ...............2-26

Received Light Waveform Display ......2-28

Chapter 3 Specifications

Specifications .......................................3-2

LK-HD1001 .....................................3-2

Dimensions ...........................................3-3

Appendices

Troubleshooting ................................... A-2

Error Codes ......................................... A-4

List of Optional Accessories ................ A-6

Maintenance ........................................ A-7

Replacing the Protection Sheet ..... A-7

Index .................................................... A-8

5

Page 6

6

Page 7

Before Use1

Before Use1

This chapter provides an overview of the LK-HD1001 and explains

the names and functions of each part. Read this chapter before

using this product.

Checking the Package Contents ....................................... 1-2

Overview.............................................................................. 1-3

Part Names and Functions ................................................ 1-6

Mounting the Touch Panel................................................. 1-7

Connecting the Units ....................................................... 1-12

1

1-1

Page 8

1 Before Use

Checking the Package Contents

Check to make sure your package contains these parts.

1

LK-HD1001 touch panel: 1 Mounting bracket: 4 User's Manual: 1

The package contents have been carefully inspected; however, if any component is

defective or damaged, contact your nearest KEYENCE office (address listed at the end of

this manual).

Refer to "List of Optional Accessories" (A-6) for details on optional parts.

1-2

Page 9

1 Before Use

LK-HD500

OUT1

HIGO

LO TIM

OUT2

HIGOLO

TIM

HEA

D1

LASER ON

S

TABILITY

BRIGHT

DARK

HEA

D2

LASER ON

S

TABILITY

BRIGHT

DARK

ZERO

ENT

SET

P

RO

G

R

A

M

Indicator, buzzer

Issues an alarm depending

on the comparator result

output.

Photoelectric sensors,

proximity sensors

Use to send timing input

signals when the measurement

object is detected.

Dedicated touch panel

*3

LK-HD1001

Heads

(maximum connection 12 heads)

LK-G5000 Series

Programmable logic

controller (PLC)

Enables synchronization

control of the measurement

and program number

switching as well as reading

of control output and

measured values.

Enables control and

measured value reading

through RS-232C

communication or the parallel

I/O board of the PC.

LK Navigator2

Recorder

Records the measurement

result.

Head expansion unit

LK-HA100

Controller

*1

LK-G5001V/

LK-G5001PV

CC-Link

communication unit

*1

LK-CC100

DeviceNet

communication unit

*4

LK-DN100

USB/RS-232C/

Ethernet

Setup support software (LK-H2)

*2

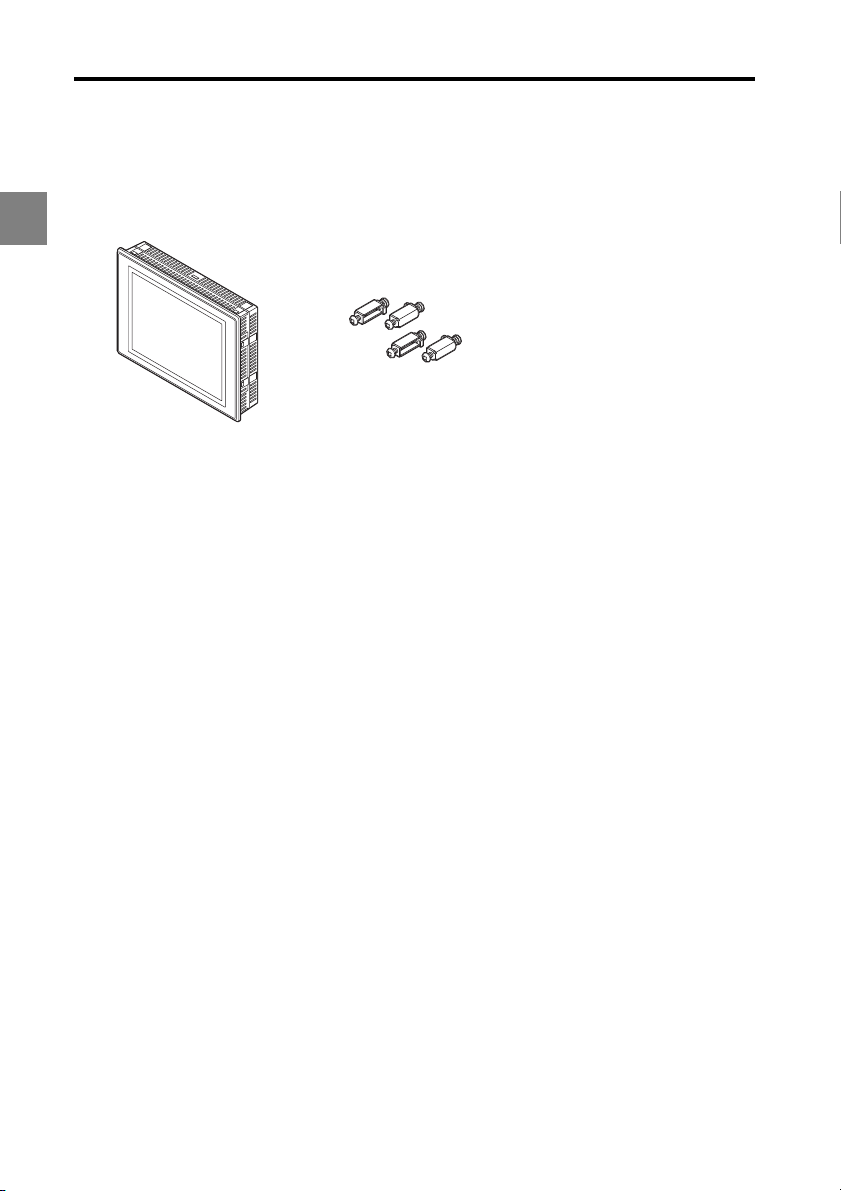

Overview

This touch panel display unit is exclusively designed for visually configuring parameters

and monitoring the LK-G5000 series controller. It is used by connecting it to the controller

to configure parameters and monitor operating status.

LK-G5000 series system configuration

1

*1: Refer to the LK-G5000 series User's Manual for further details on the controller LK-G5000 series.

*2: Refer to the LK-Navigator 2 User's Manual (the PDF file is on the CD-ROM) for further details on the setup

support software (LK-H2) LK-Navigator 2.

*3: Refer to the LK-HD1001 User's Manual (this document) for further details on the dedicated touch panel LK-

HD1001.

*4: Refer to the LK-CC100/DN100 User's Manual for further details on the CC-Link communication unit LK-

CC100 and the DeviceNet LK-DN100 communication unit.

1-3

Page 10

1 Before Use

Functions and features

This section explains the major functions and features of this touch panel.

Operation settings

1

•This touch panel allows you to display the settings in the controller for viewing and

editing. It features copy and paste functions for configuring multiple outputs and setting

programs in a short amount of time.

• The software settings made on the touch panel will be downloaded into the controller.

This touch panel communicates with the controller at the simple press of a button.

The following items can be set from this touch panel.

• Head settings

• OUT settings

• Common settings

• Environment settings

1-4

Page 11

1 Before Use

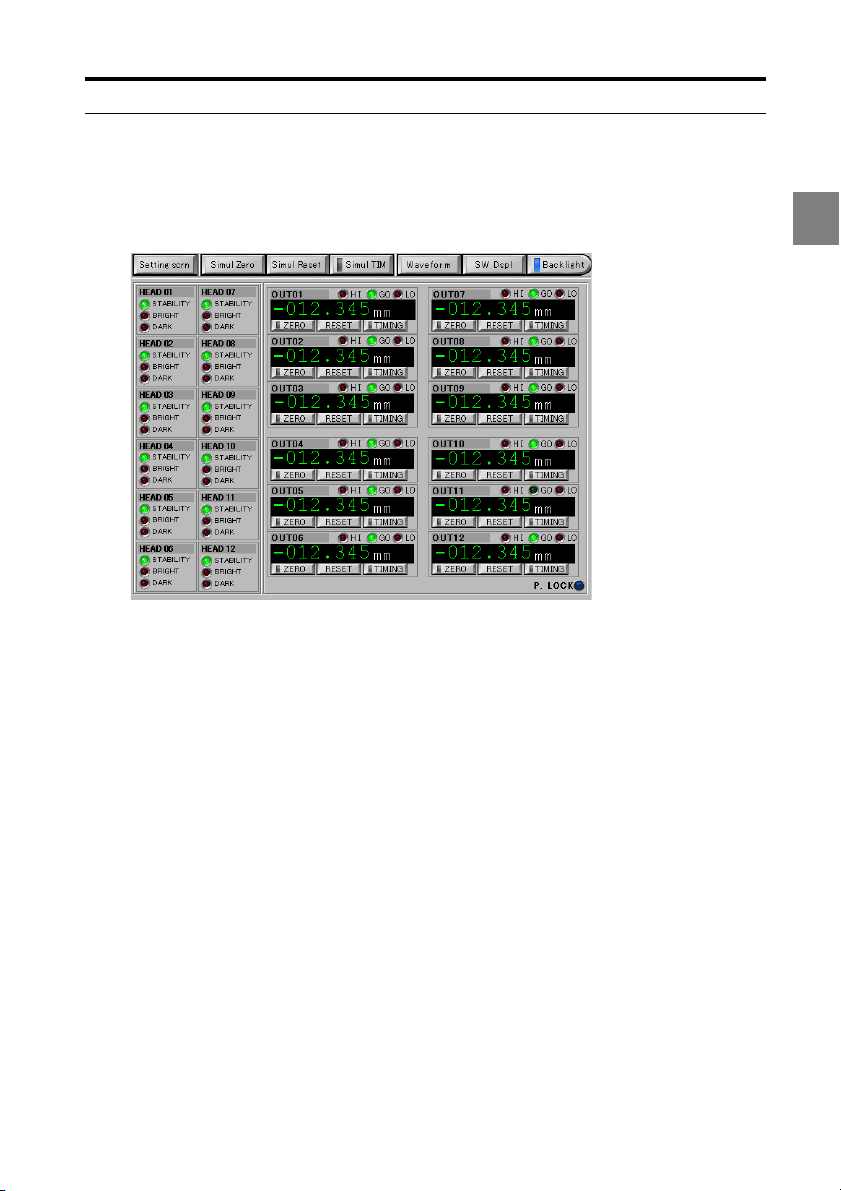

Monitoring functions

These two items can be monitored.

• Measurement values

• Received light waveform

The screen shown below is a display example of the "Measurement value display".

1

1-5

Page 12

1 Before Use

TO

C

O

N

T

R

O

LLE

R

2

4

V

D

C

N

.C

.

TO

C

O

N

T

R

O

LLE

R

(1) (2)

(3)

(4) (5)

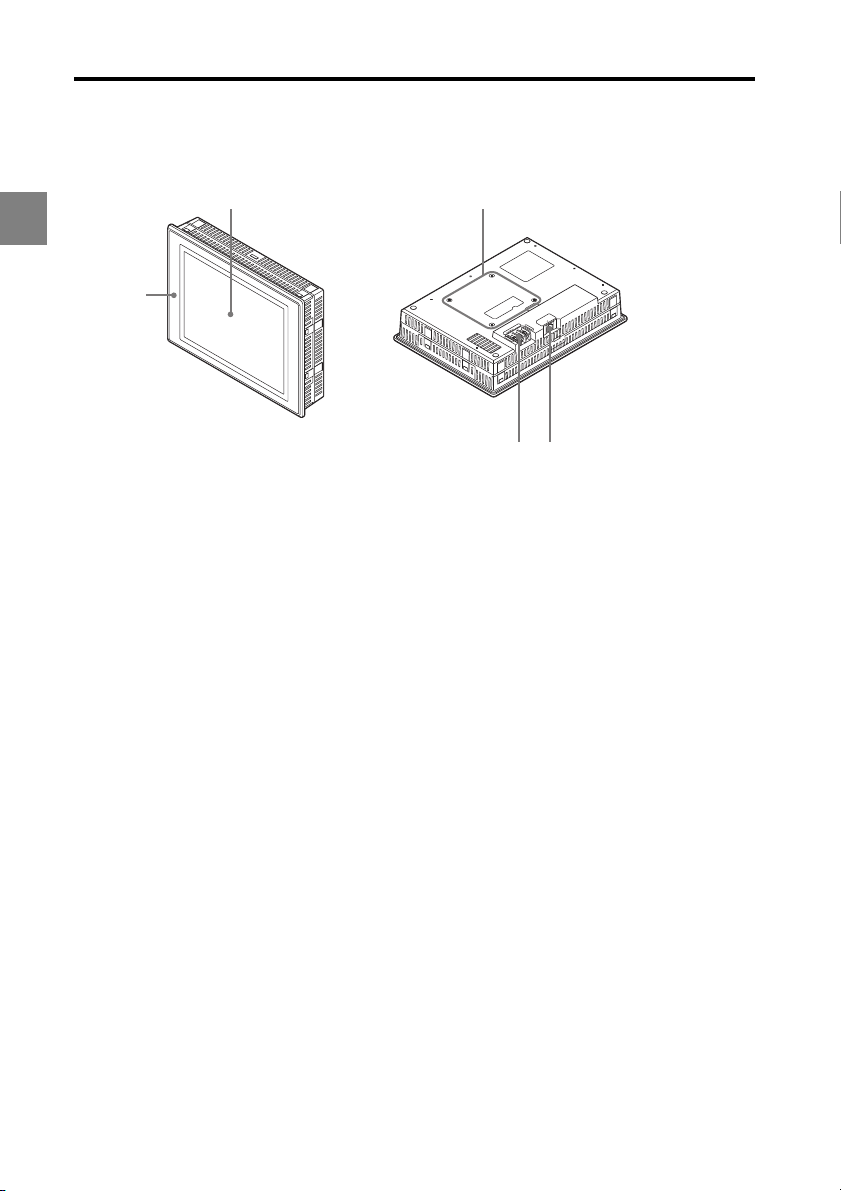

Part Names and Functions

This section describes the name and functions of each component.

1

(1) Display area/touch panel

Displays the measurement screen, settings screen, and messages.

Displays buttons used to change the screen and settings.

(2) Stand mount

Mount for the optional stand.

(3) Power indicator

Lit when power is supplied.

(4) Power supply terminals

Connect the power supply (24 VDC ±10%) to these terminals.

(5) TO CONTROLLER port

Connect the connection cable from the controller.

1-6

Page 13

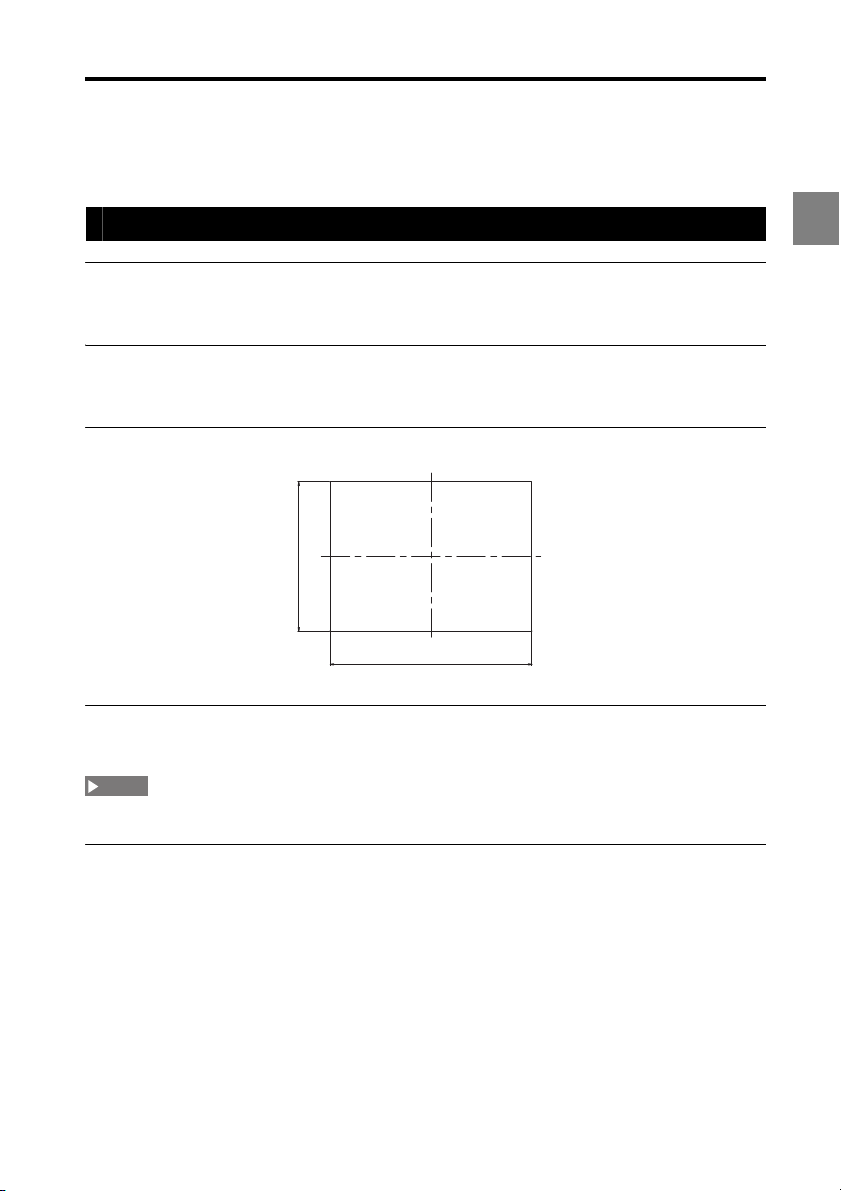

Mounting the Touch Panel

Mount the touch panel using the supplied mounting brackets.

1 Before Use

Mounting Precautions

Mounting direction/angle

Mount the touch panel so that the right and left sides are level.

Panel thickness

1.6 to 4.0 mm

Panel cutout

0

+1

167.5

+1

0

226.5

Mounting bracket tightening torque

Tighten to 0.3 to 0.5 Nm.

NOTE

Tightening improperly can cause the panel or case to deform, or damage to the mounting brackets.

1

Notes to fulfill the protective construction (IP65f) of the panel surface

•Be sure the seal is free from dirt and debris.

•Mount in the center of the cutout in the panel.

• Tighten the mounting brackets to the appropriate torque.

1-7

Page 14

1

TO CONT

R

OLLER

24V

D

C

N

.C

.

Mounting hole

Ta b

1 Before Use

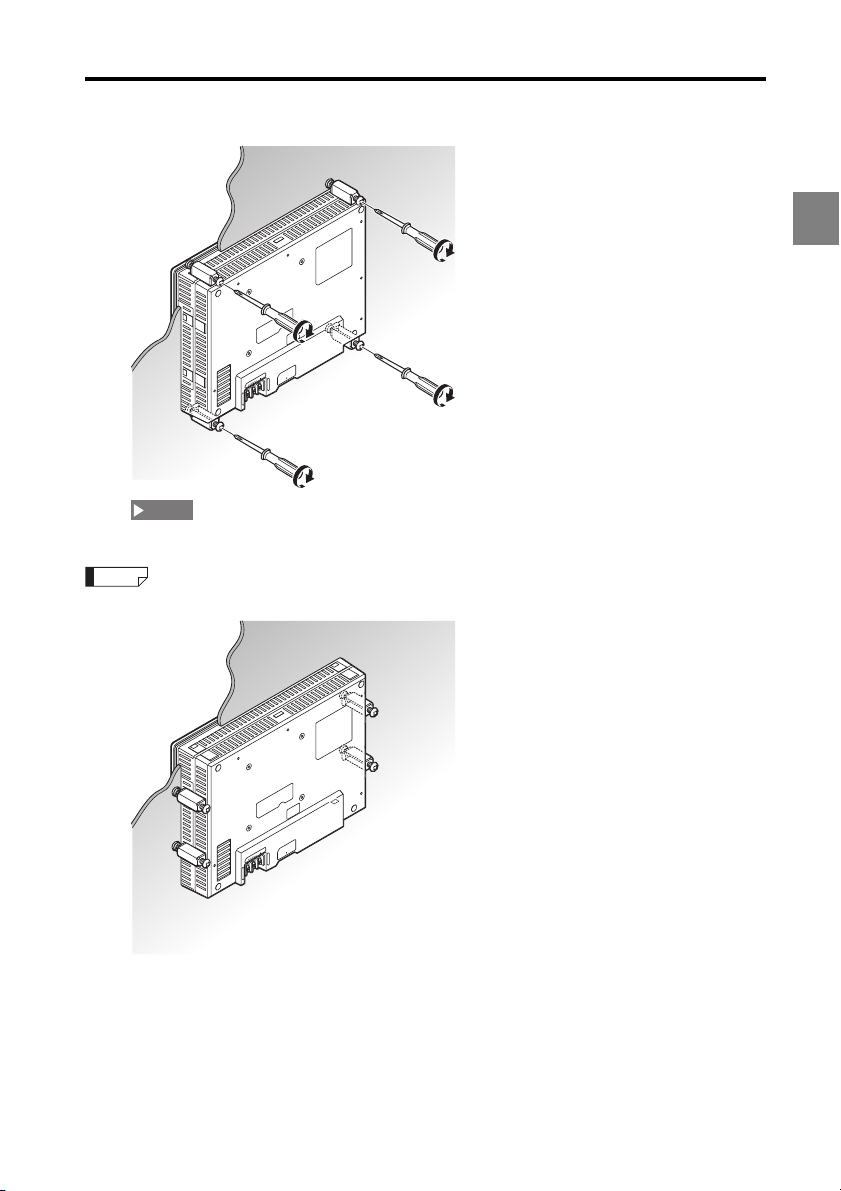

Mounting

Insert into the cutout from the front of the panel.

1

Secure the touch panel using the mounting brackets from the rear side of the

2

panel.

Turn the screws in the mounting bracket counterclockwise until the tabs at the back of

the mounting brackets enter the mounting holes in the touch panel.

1-8

Page 15

1 Before Use

Tighten the screws in the mounting brackets by turning clockwise.

3

OLLER

R

.

N.C

TO CONT

24V DC

NOTE

The tightening torque for the mounting bracket screws is 0.3 to 0.5 Nm.

Reference

The mounting brackets can also be attached to the left and right sides of the touch panel.

1

OLLER

R

.

N.C

TO CONT

24V DC

1-9

Page 16

1 Before Use

TO CONT

R

OLLER

24V DC

N.C

.

TO CONT

R

OLLER

24V DC

N.C

.

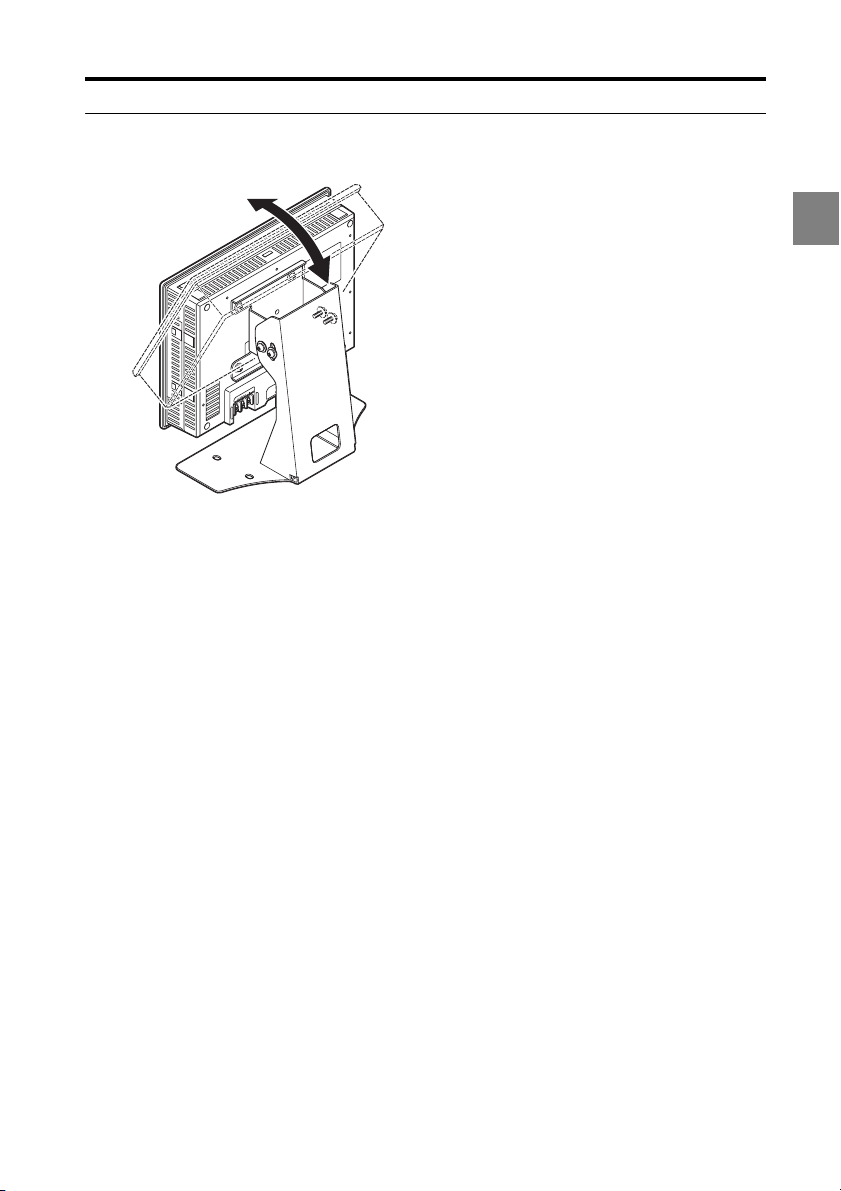

Reference

Using the Stand

The separately sold stand (OP-84428) mounts to the rear side of the touch panel with

screws.

1

Attach the stand mounting panel to the rear side of the touch panel using the

1

four M4 screws.

Attach the stand using the four M6 screws.

2

• The stand mounting holes supports the VESA mou nting standard for 75 x 75 mm.

• The stand mounting holes can be used to secure the touch panel to a desk or control cabinet.

1-10

Page 17

Stand tilt angle adjustment

The title angle of the stand can be adjusted according to the location.

OLLER

R

N.C.

TO CONT

24V DC

1 Before Use

1

1-11

Page 18

1 Before Use

TO

C

O

N

TROLLE

R

2

4

V

DC

N.C

.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

2

1

22

23

24

2

5

2

6

27

28

29

30

3

1

3

2

33

34

35

3

6

3

7

38

39

40

LA

S

ER O

N

ETHERNE

T

USB

DI

SPL

A

Y

RS-2

32C

HEAD

1

OUT

(

V

)

O

UT

(

A

)

OUT 0V

OUT

(

V

)

O

U

T

(

A

)

OUT 0V

COM INZERO 1TIMING 1GO

LASER 1

DC 24V

1

HEAD

LK-

G5000

2

TO CON

T

R

OLLE

R

24V DC

N.C

.

TO CON

T

24V

DC

N.C

.

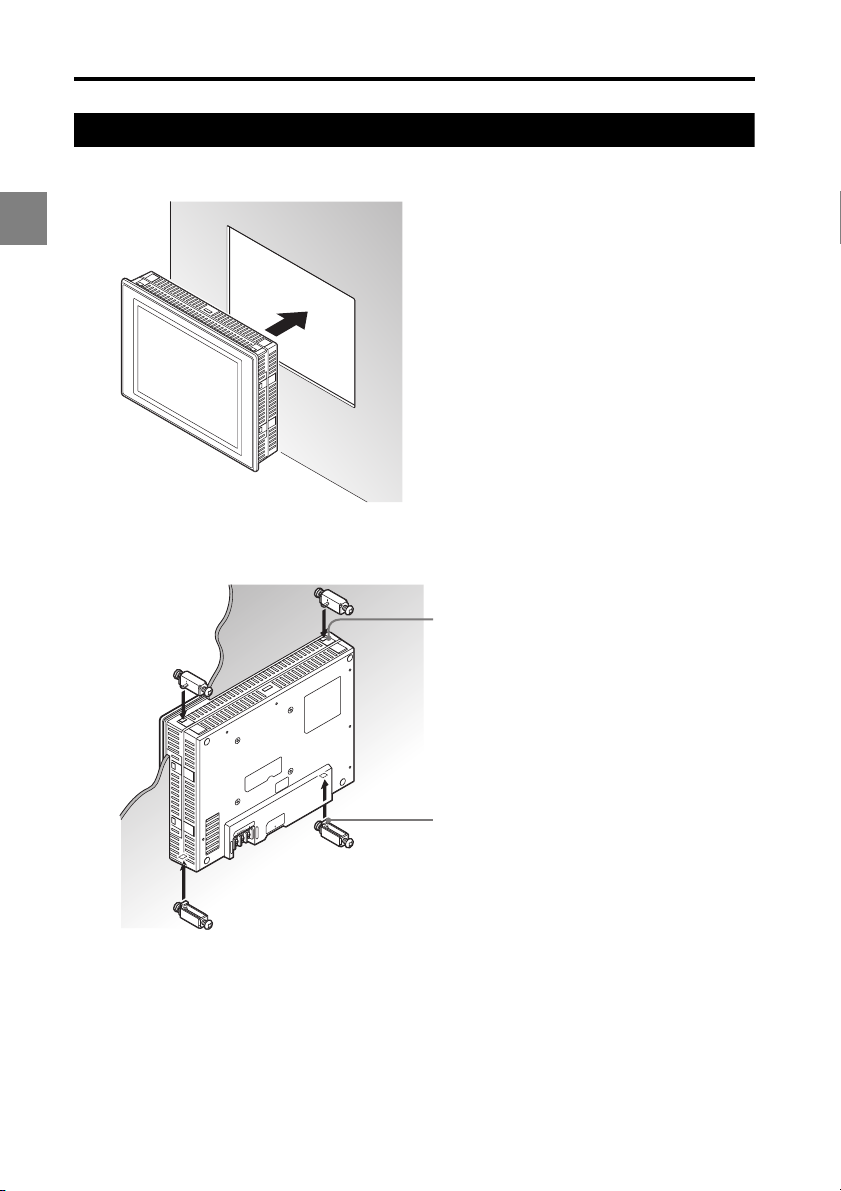

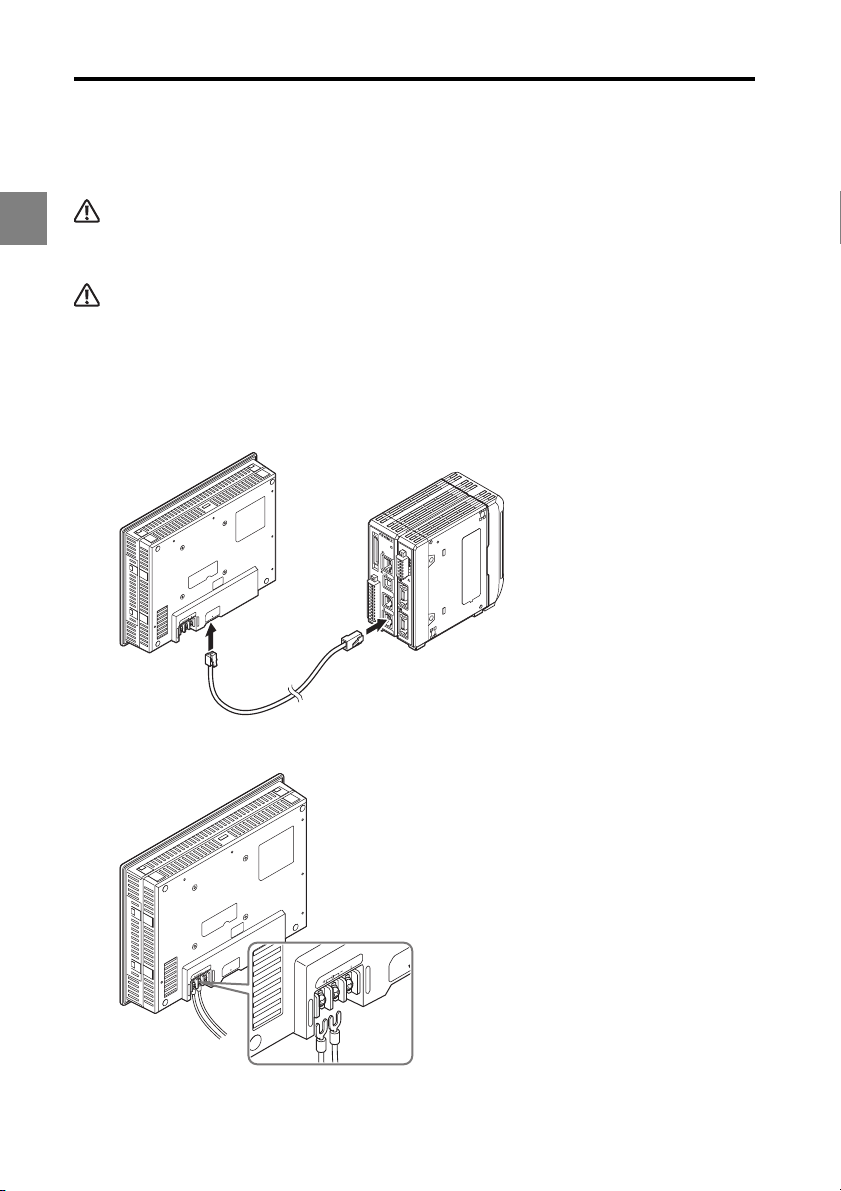

Connecting the Units

Connect the touch panel to the controller, then connect the power supply.

1

Always shut power off to the touch panel before making connections. Failure to obey this warning may

lead to electrical shock.

CAUTION

WARNING

Verify the wiring is correct before turning the power on. Failure to obey this precaution may damage the

touch panel and the peripheral devices.

Use the separately sold display panel cable (OP-84427: 0.33 m, OP-51655: 3 m,

1

or OP-51656: 10 m) for the connection between the TO CONTROLLER port on

the touch panel and the DISPLAY port on the controller.

Connect the power supply (24 VDC ±10%) to the power supply terminals.

2

1-12

Page 19

Screen Functions and Operation2

2

Names and Functions on the Main Screen ...................... 2-2

Flow of Operation ............................................................... 2-3

Basic Settings..................................................................... 2-4

Environment Settings....................................................... 2-21

Program Settings.............................................................. 2-23

Measurement Value Display ............................................ 2-26

Received Light Waveform Display .................................. 2-28

2

2-1

Page 20

2 Screen Functions and Operation

(1)

(2)

(3)

(4)

Names and Functions on the Main Screen

This section explains the names and functions of the main screen.

2

(1) Cancel

Displays the measurement screen without saving any of the settings.

(2) Meas screen

Displays the measurement screen (Page 2-26).

(3) Settings screen

Changes settings on the touch panel.

(4) Program settings

Selects, copies, and initializes program numbers. Refer to "Program Settings" (Page 2-23)

for details.

2-2

Page 21

2 Screen Functions and Operation

Flow of Operation

This explanation will show how to assign the input at HEAD01 to the output at OUT01 when

turning the touch panel on for the first time.

Connect the controller and touch panel (Page 1-12).

1

Start the controller, then turn on the touch panel.

2

On the "Environment settings" screen, specify the number of heads, OUTs,

3

and analog outputs being used (Page 2-21).

Select a program number (Page 2-23).

4

Specify the "Common settings" (Page 2-16).

5

Configure "HEAD01" (Page 2-4).

6

Configure "OUT01" (Page 2-9).

7

This completes the procedure.

2

2-3

Page 22

2 Screen Functions and Operation

(3)

(4)

(1)

(2)

(5)

(6)

(7)

Reference

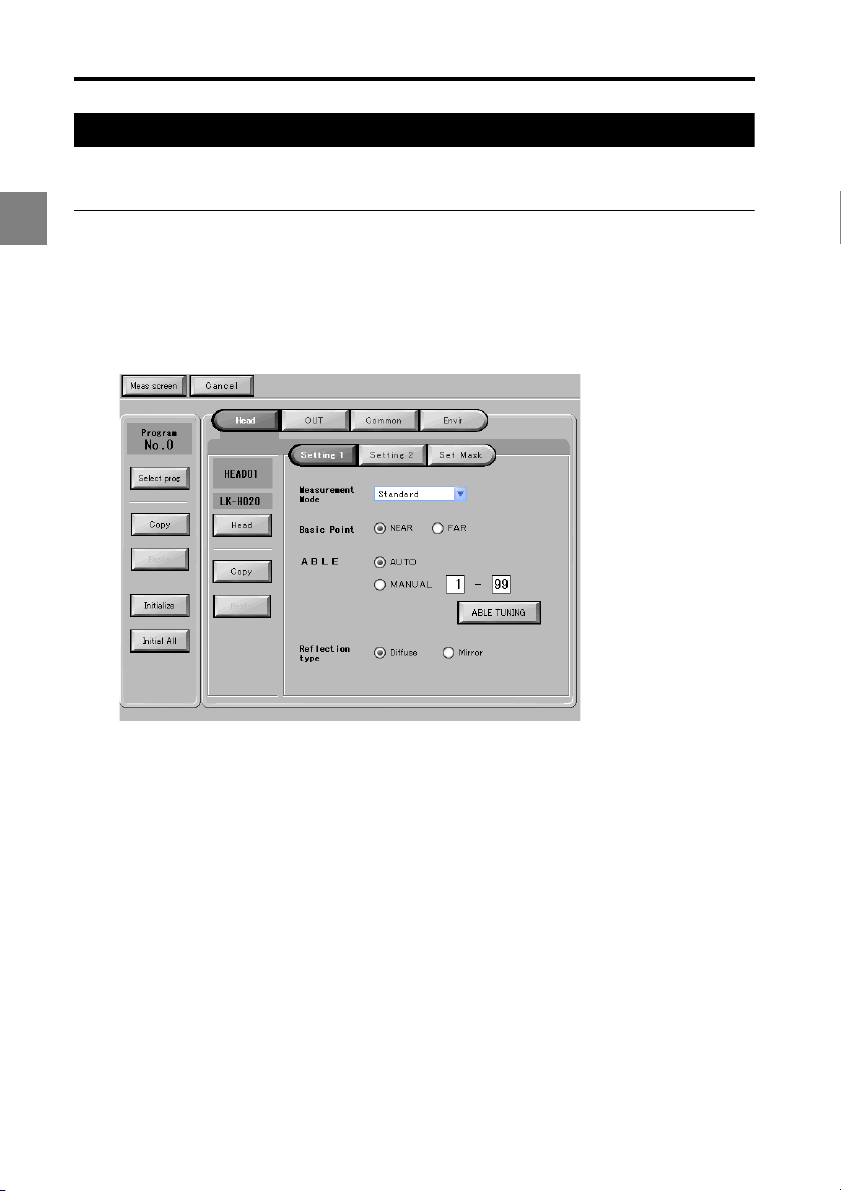

Basic Settings

This section explains the basic settings available on the touch panel.

Head Settings

This section explains the functions on the "Head settings" screen.

2

Configure the head(s) connected to the controller to match the operating environment.

To uch "Head" on the settings screen.

Setting 1

(1) Head

Specifies the head to configure.

To use three or more heads by using the head expansion unit, change the settings on the "Environment

settings" screen (Page 2-21).

(2) Measurement Mode

Selects the object to measure.

2-4

Page 23

2 Screen Functions and Operation

(3) Basic Point

If several peaks exist when using the transparent object mode, this control specifies

whether to use the peak that is NEAR or FAR from the sensor head as the reference.

(4) ABLE

ABLE sets whether to use AUTO or MANUAL control of the light intensity.

• Normally set to "AUTO".

• If set to "MANUAL", set the upper and lower limits for the light intensity control range

(setting range: 1 to 99).

(5) ABLE TUNING

This function uses "ABLE" to calibrate the "MANUAL" setting range according to the actual

object. Refer to "Performing the ABLE calibration" (Page 2-6) for details.

(6) Reflection type

Sets the reflection type to diffuse or mirror.

(7) Copy/Paste

Use these buttons to copy head settings to another head (or a head in a different program

number). Refer to "Copying the head settings to another head" (Page 2-5) for details.

Copying the head settings to another head

This example shows how to copy the settings for HEAD01 to HEAD02.

2

Complete all settings for HEAD01.

1

Touch "Copy".

2

"Paste" becomes active.

Touch "Head".

3

The "Select head" dialog box appears.

Touch "HEAD02".

4

Touch "Paste".

5

The settings for HEAD01 are copied to HEAD02.

2-5

Page 24

2 Screen Functions and Operation

NOTE

Performing the ABLE calibration

Touch "ABLE TUNING".

1

The "ABLE TUNING" dialog box appears.

2

Touch "Start" to start the ABLE calibration.

2

A confirmation dialog box appears to confirm whether to reflect the settings.

Touch "YES".

3

Touch "Stop".

4

The ABLE calibration ends. The optimal settings are configured automatically.

To uching "Cancel" aborts the ABLE calibration and leaves the settings unchanged.

2-6

Page 25

Setting 2

2 Screen Functions and Operation

(1)

(2)

(3)

(4)

(5)

(6)

(1) Median

Sets the number of sampling points to use for the median filter.

(2) LASER CTRL group

Sets the LASER control group.

(3) Range

Sets the range.

(4) No. of alarm processing

Sets the number of cycles to hold the most recent valid measurement (Setting range: 0 to

9999).

Process count Operation

0 Handles alarm immediately

1 to 9998 Holds most recent valid measurement

9999 Alarms off

(5) No. of alarm recovery

Sets the number of cycles to measure before automatically recovering from the alarm state

(Setting range: 0 to 9999).

2

(6) Alarm level

Sets the alarm sensitivity level from between low (0) to high (9) (default setting: 4).

• Low (0): Weakens alarm detection sensitivity

• High (9): Increases alarm detection sensitivity

2-7

Page 26

2 Screen Functions and Operation

(2)

(1)

Mask setting

2

(1) Mask setting

Sets whether to enable (ON) or disable (OFF) masking.

(2) Mask boundary

If the "Mask setting" is set to "ON", this control specifies the mask boundary using POS-1

or POS-2.

• If POS-1 < POS-2: masks around POS-1 and POS-2.

• If POS-1 > POS-2: masks between POS-1 and POS-2.

• If POS-1 = POS-2: masking is not applied.

2-8

Page 27

2 Screen Functions and Operation

OUT Settings

This section explains the functions on the "OUT settings" screen.

These settings define how the measurement data should be handled according to the

operating environment.

To use three or more OUTs by using additional head expansion units

Change the setting on the "Environment settings" screen (Page 2-21).

To uch "OUT" on the settings screen.

Calculation method

(1)

(2)

2

(3)

(1) OUT

Specifies the OUT to configure.

(2) Calculation

Sets the calculation method according to the measurement mode and target.

Select head

Sets the head number and measurement target to associate with the OUT.

The measurement target can be set if the head measurement mode is set to Transparent or

Transparent2.

Select OUT

Sets the OUT number to associate with the OUT.

2-9

Page 28

2 Screen Functions and Operation

Add bet. OUT/Sub bet. OUT/AVE bet. OUT/P-P bet. OUT/MAX bet. OUT/MIN bet. OUT

Sets the type of output value to associate with the OUT.

The operation specified from the "Type" options is applied to the checked OUTs.

• Add bet. OUT: Sum of the checked OUTs

•Sub bet. OUT: Difference of the checked OUTs

•AVE bet. OUT: Average of the checked OUTs

•P-P bet. OUT: Maximum to minimum value of the checked OUTs

2

•MIN bet. OUT: Minimum of the checked OUTs

•MAX bet. OUT: Maximum of the checked OUTs

(3) Copy/Paste

Use this button to copy the OUT settings to another OUT (or an OUT in a different program

number).

Copying the OUT settings to another OUT

This example explains how to copy the settings for OUT01 to OUT02

Complete all settings for "OUT01".

1

Touch "Copy".

2

Touch "OUT".

3

The "Out Settings" dialog box appears.

Touch "OUT02".

4

Touch "Paste".

5

The settings for OUT01 are copied to OUT02.

2-10

Page 29

Measurement/Filter

(1) Measurement

Sets the measurement mode and filter type.

Measurement type

Sets the measurement type.

2 Screen Functions and Operation

(1)

2

(2)

(3)

Measurement mode

Sets the measurement mode.

TRIGGER

Sets a trigger for any "Measurement mode" setting other than "NORMAL".

2-11

Page 30

2 Screen Functions and Operation

Reference

(2) Filter

Type

Sets the filtering process to apply to the measurement.

Averaging Times

Sets the number of averaging measurements if "Type" is set to "Moving-avg".

2

Fewer average times result in faster measurement data response, while more average times stabilizes

the measurement data.

Cutoff frequency

Sets the cutoff frequency if "Type" is set to "LPF" or "HPF".

2-12

Page 31

Tolerance/Scaling

2 Screen Functions and Operation

(1)

(2)

(3)

(1) Tolerance setting

Upper limit value

Displays the upper tolerance limit.

Lower limit value

Displays the lower tolerance limit.

Hysteresis

Displays the hysteresis for the tolerance comparator.

Change

To uch to change the upper limit, lower limit, and hysteresis values for the tolerance

comparator.

The "Tolerance Comparator" dialog box appears. Enter the desired values and touch "OK".

Scaling Setting

Sets the scaling.

2

Input1/ Display1, Input2/ Display2

Sets how to display the OUT value.

Change

To uch to change the scaling reference values.

The "Scaling Setting" dialog box appears. Enter the desired values and touch "OK".

(2) Offset

Sets the offset value.

2-13

Page 32

2 Screen Functions and Operation

Setting scaling from measurement data.

Touch "Change" in the "Scaling Setting" area on the "Tolerance/Scaling"

1

screen.

The "Scaling Setting" dialog box appears.

2

Touch "Set from Meas data".

2

A confirmation dialog box appears.

Touch "YES".

3

The "Set measured value" dialog box appears.

At the reference surface, touch "Set" for "Input1".

4

This sets the measurement data of the reference surface into "Input1".

Insert the master work piece, then touch "Set" for "Input2".

5

This sets the measurement data of the master work piece into "Input2".

Set the scaling display values in "Display1" and "Display2".

6

Touch "OK".

7

2-14

Page 33

Display/Analog

2 Screen Functions and Operation

(1)

(2)

(1) Minimum display unit

Sets the decimal point position and number of digits to display for measured and setting

values.

Reference

Digits not displayed below the decimal point are rounded off.

NOTE

These settings are initialized when the "Minimum display unit" setting is changed:

Scaling, offset, tolerance setting, analog output scaling, auto zero reference value.

(2) Analog output scaling

Displays the scaling for the analog output with respect to the measurement data.

Change

To uch to change the scaling reference values for the analog output.

The "Analog output scaling" dialog box appears. Enter the desired values and touch "OK".

2

Reference

Analog outputs can be scaled within a range of ±10.0 V.

2-15

Page 34

2 Screen Functions and Operation

(1)

(2)

(3)

(4)

Common Settings

This section explains the functions on the "Common settings" screen.

To uch "Common" on the settings screen.

Common

2

(1) Sampling cycle

Sets the sampling cycle for measuring.

(2) Tolerance comparator output format

Sets the hold behavior to apply to the tolerance comparator output when the tolerance

comparator result changes.

(3) Alarm output form

Sets the alarm output operation.

(4) Strobe time

Sets the strobe time for the binary output when the measurement mode is set to a setting

other than Normal.

2-16

Page 35

2 Screen Functions and Operation

Synchronization settings

(1)

(1) Sync

Check the OUTs to synchronize.

NOTE

If the storage cycle (Page 2-19) is set to "Timing input", check the OUT specified for data storage on the

"Synchronization settings" screen as well. Otherwise, the data will not be stored.

2

2-17

Page 36

2 Screen Functions and Operation

(1)

Mutual interference prevention

2

(1) Mutual interference prevention

Use this setting to prevent mutual interference when multiple head units are connected.

Assign each head to a group from A to C. This setting prevents the reflection from

interfering between groups A and B, and from groups A to C.

2-18

Page 37

Data storage

2 Screen Functions and Operation

(1)

(2)

(3)

(4)

(1) Amount of Data Stored

Displays the number of data points to store.

(2) Storage cycle

Displays the interval for data storage.

(3) Change

To uch to change the data storage settings.

The "Data Storage Setting" dialog box appears. Enter the desired values and touch "OK".

(4) Selected OUT

Displays the OUTs for which data will be stored.

Reference

If the storage cycle is set to "Timing input", the OUT specified for synchronization (Page 2-17) can be

selected here.

2

2-19

Page 38

2 Screen Functions and Operation

(1)

Analog output

2

(1) CH01 to CH12

Assigns each analog OUT from the controller to an analog channel from CH01 to CH12.

2-20

Page 39

2 Screen Functions and Operation

Environment Settings

This section explains how to configure the operating environment of the controller.

To use three or more OUTs by using the head expansion unit

Before taking any measurements, set the "No. of used heads", "No. of used OUT", and

"No. of used analog Ch". Changing the setting for the "No. of used heads" and "No. of

used OUT" initializes the other measurement settings.

To uching "Envir" on the settings screen displays the "Environment settings" screen.

(1)

(2)

(3)

2

(1) Basic setting

No. of used heads

Sets the number of heads the controller can use.

No. of used OUT

Sets the number of OUTs the controller can use.

No. of used analog Ch

Sets the number of analog output channels the controller can use.

Panel lock

Sets whether to lock the display panel connected to the controller.

This setting takes effect after touching "Yes" and returning to the measurement screen.

Program Change

Specifies where programs will be changed from.

2-21

Page 40

2 Screen Functions and Operation

Reference

NOTE

If set to "Terminal", the touch panel will change to the program number specified at the terminals after

returning to the measurement screen.

(2) Controller RS-232C Settings

Baud rate

Sets the communication speed of the controller.

2

Parity

Sets the parity check method.

Auto trans

Sets whether to automatically download the OUT to the RS-232C interface.

If you change the RS-232C settings in the "Environment settings" while the controller is connected via

the RS-232C interface, the touch panel will download the settings and then change the "PC

communication settings".

(3) Ethernet

IP Address

Sets the controller's IP address.

Subnet mask

Sets the subnet mask for the controller.

Gateway

Sets the gateway for the controller.

2-22

Page 41

2 Screen Functions and Operation

Program Settings

This section explains the procedures for copying and initializing programs registered in the

controller.

Copying Programs

Settings can be copied to other program numbers to avoid the trouble of repeating settings.

Reference

The copied settings will overwrite any existing settings in the destination program.

1

3

6

This example shows how to copy program No. 0 to program No. 1.

Touch "Select prog".

1

The "Select Program No." dialog box appears.

Touch "No. 0".

2

Touch "Copy".

3

2

2-23

Page 42

2 Screen Functions and Operation

Touch "Select prog".

4

The "Select Program No." dialog box appears.

2

Touch "No. 1".

5

Touch "Paste".

6

This copies the settings in program No. 0 to program No. 1.

2-24

Page 43

2 Screen Functions and Operation

Initializing Programs

The settings can be initialized to their factory default settings. Initializing erases any

existing settings.

Select the program number to initialize.

1

In this example, program No.1 is selected.

Touch "Initialize".

2

A confirmation dialog box appears.

Reference

To initialize the settings in all program numbers, touch "Initial All". The following confirmation

dialog box appears when "Initial All" is touched.

2

Touch "YES".

3

The settings are initialized.

2-25

Page 44

2 Screen Functions and Operation

(6)

(1)

(2)

(3)

(4)

(5)

(7)

(8)

Measurement Value Display

This section explains the "Measurement value display" function available on the touch

panel.

To uching "Meas screen" on the settings screen displays the measurement screen.

2

(1) Setting scrn

Displays the settings screen (Page 2-2).

(2) Display the measurement data after applying simultaneous auto zero,

simultaneous reset, or simultaneous timing

Simul Zero

Applies auto zero simultaneously to the OUT with the OUTs set to synchronize.

Simul Reset

Resets the OUT simultaneously with the OUTs set to synchronize.

Simul TIM

Inputs the timing signal to the OUT simultaneously with the OUTs set to synchronize.

(3) Backlight

Turns off the touch panel backlight.

When the backlight is unlit, touching anywhere on the screen turns it on again.

(4) SW Dspl

Each touch switches the number of OUTs displayed.

2-26

Page 45

2 Screen Functions and Operation

(5) Waveform

Displays the received waveform display screen (Page 2-28).

(6) Displays the measurement data after applying auto zero, reset, and timing

processing

ZERO

The current measurement data is set to the reference value (zero) and then displayed.

Refer to the LK-G5000 series User's Manual, "Chapter 2 Operations during Measurement

and Their Functions" (page 2-1) for details on the auto-zero function.

RESET

The measured values are displayed after the processing in the measurement mode and the

filter processing are reset to the default values.

Refer to the LK-G5000 series User's Manual, "Chapter 3 Function Settings" (page 3-1) for

details on the measurement data reset function.

TIMING

Toggles the timing function between on and off. Refer to the LK-G5000 series User's

Manual, "Chapter 3 Function Settings" (page 3-1) for details on the timing function.

(7) P.LOCK

Illuminates when the panel lock is set to ON.

(8) Head status

Displays the head status.

Refer to the LK-G5000 series User's Manual, "Chapter 2 Operations during Measurement

and Their Functions" (page 2-1) for details on the displayed information.

2

2-27

Page 46

2 Screen Functions and Operation

(5)

(4)

(1)

(6)

(2)

(3)

Received Light Waveform Display

This section explains the "Received light waveform display" function available on the touch panel.

To uching "Waveform" on the measurement screen displays the waveform display screen.

2

(1) Return

Returns to the measurement screen.

(2) Change head

Displays the "Select head" dialog box. Select which head to display the received light

waveform for.

(3) Start/Stop

Starts acquiring received light data from the controller and displays the most recent waveform.

Clicking "Start acquisition" causes the button label to change to "Stop".

(4) 1st peak to 4th peak

If "Measurement mode" is set to "Transparent2", these buttons will apply ABLE processing

to the displayed peak waveforms from 1 to 4, and display the resulting waveform. Refer to

the LK-G5000 series User's Manual, "Chapter 3 Function Settings" (page 3-1) for details on

the ABLE function.

(5) Received light waveform display

Displays the waveform after the controller applies ABLE processing. The waveform is read

as follows.

• X axis: Position of received light waveform. The farther left the waveform, the closer the

received light waveform is to the head.

• Y axis: Intensity of received light. The higher the waveform, the stronger the light intensity.

(6) Zoom in/Zoom out

Zooms in or out the waveform display.

2-28

Page 47

Specifications3

This chapter explains the specifications for the touch panel.

Specifications ..................................................................... 3-2

Dimensions ......................................................................... 3-3

3

3-1

Page 48

3 Specifications

Specifications

LK-HD1001

Model LK-HD1001

Model name LK-G5000 series dedicated touch panel display unit

Element TFT color LCD

3

Display

panel

Backlight

To uch

switch

Communications function Dedicated support for the LK-G5000 series

Construction

Operating atmosphere Must be reasonably free of dust and corrosive gases

Ambient temperature 0 to +50°C

Relative humidity

Storage temperature -10 to +60°C (no freezing)

Storage humidity

Vibration resistance

Weight Approximately 1,150 g

Rated voltage 24 VDC ± 10%

Current consumption 1 A or less

Colors 32768 colors

Pixels (W x H) 640 x 480

Effective display area

(W x H) (mm)

Life (room temperature

and humidity)

Method White LED (replacement impossible)

Life Approximtely 50,000 hours

Activating force 0.98 N or less

Life 1,000,000 times or more

170.9 x 128. 2

Approximtely 50,000 hours

Panel mounted,

limited to front panel operation: IP65f -equivalent

protection against dust and water droplet intrusion.

35 to 85% RH (no condensation)

Use under an absolute humidity of 85% or less at

40°C if ambient temperature exceeds 40°C.

35 to 85% RH (no condensation)

Store under an absolute humi

40°C if ambient temperature e

10 to 57 Hz 0.3 mm p-p

57 to 500 Hz 2G x,y, and z 3 hours in each direction

dity of 85% or less at

xceeds 40°C.

3-2

Page 49

Dimensions

170.9

237

128.2

178

643

167

51

167.5

226.5

0

+1

+1

0

99

99

190

1.6 to 4.0 mm

(50)

With mounting brackets attached

Panel cutout

Effective display area

Effective display area

Size with mounting brackets attached

Panel thickness

Mounting bracket

(For panel thickness of 4 mm)

Mounting screw

Unit: mm

3 Specifications

3

3-3

Page 50

3 Specifications

3

With stand mount

237

5

2xR2.5

8

130

230

(139)

21.5

45

(228)

110.2

(203)

(160)

(143)

(122)

30°

(251.2)

18°

Unit: mm

3-4

Page 51

AppendicesA

A

This chapter provides other related information.

Troubleshooting.................................................................. A-2

Error Codes.........................................................................A-4

List of Optional Accessories.............................................A-6

Maintenance........................................................................ A-7

Index .................................................................................... A-8

A-1

Page 52

Appendices

Troubleshooting

This section describes the countermeasures against errors or problems that may occur

during the operation of this touch panel.

Problem Possible Cause Countermeasure

Is the display panel cable

A

Nothing is displayed

on the display panel.

An error code is

displayed.

A measured value is

not displayed.

properly connected to the

controller?

Is the power supply cable

properly connected?

-

Is the measurement target

placed within the

measurement range?

Are the head settings

properly set?

Is the glass cover dirty? Remove the dust and dirt.

Does the glass cover have

any flaws or cracks?

Is the synchronization control

properly set according to the

measurement mode?

Does condensation occur in

the unit?

Connect the power supply cable and

display panel cable properly.

(Page 1-12)

Address the problem by following the

instruction provided for the displayed

error code.

(Page A-4)

Place the measurement target

properly within the measurement

range.

Adjust to the proper settings.

The glass cover must be replaced.

Because this replacement requires

KEYENCE repair service, contact

your nearest KEYENCE office.

Set the synchronization control

according to the measurement

mode.

Check the installation environment.

A-2

Page 53

Problem Possible Cause Countermeasure

The measured value

display fluctuates.

he measured value

T

display de

Program No. cannot

be changed.

The operation key

does not work.

viates.

Is the number of averaging

measurements properly set?

Is the glass cover dirty? Remove the dust and dirt.

Does the glass cover have

any flaws or cracks?

Are there any water or oil

splashes in the operating

atmosphere?

Does mutual interference

occur?

Is there strong ambient light? Block the ambient light.

Does the measurement

target or sensor head

vibrate?

Are the head settings

properly set?

Is the measurement target

slanted or displaced?

Is the LK-G5000 Series

calibrated properly?

Does the temperature in the

operating environment

change greatly?

Is the setting selection

properly set?

Is the key lock set to ON? Change the key lock setting to OFF.

Is the LK-G5000 Series in

either the setting mode or the

communication mode?

Is the display panel properly

connected?

Is the panel lock set to ON? Set the panel lock to OFF.

Set the number of averaging

measurements properly.

The glass cover must be replaced.

Because this replacement requires

KEYENCE repair service, contact

your nearest KEYENCE office.

Use air purge or another method to

remove the splashes.

Use the mutual interference

prevention function or the laser OFF

function.

Change the mounting position of the

sensor head.

Take appropriate countermeasures

such as vibration isolation.

st to the proper settings.

Adju

Place the measurement target

properly within the measurement

range.

Calibrate the unit again.

Keep the ambient temperature

constant.

Set the setting selection according to

the method to be used.

Change the mode to the measuring

mode.

Connect the display panel properly.

Appendices

A

A-3

Page 54

Appendices

Error Codes

This section lists the error codes displayed by the LK-G5000 Series and the

countermeasures.

A

Display

Err-00 Head connection error Check the sensor head connection.

Err-01 to

12

Err-13 Controller error

Err-15

Err-16

Err-17

Err-19 Expansion unit error

Err-30 to

39

Err-50 Command error

Err-51 Status error

Err-60 Command length error

Err-61 Parameter count error

System

error

Error description Countermeasure

Head 01 to 12

error

Controller

SRAM error

USB communication

error

Ethernet

communication error

Head expansion unit

r

erro

If there are errors with two or more sensor heads,

the smallest error number among Err-01 to 12 is

displayed.

Turn off the power and turn it on again.

If the error continues, contact your nearest

KEYENCE office.

Turn off the power and turn it on again, or initialize

the settings.

If the error continues, contact your nearest

KEYENCE office.

Turn off the power and turn it on again.

If the error continues, contact your nearest

KEYENCE office.

Turn off the power and turn it on again.

If the error continues, contact your nearest

KEYENCE office.

Turn off the power, disconnect the expansion unit

and connect it again, and then turn on the power

again.

If the error continues, contact your nearest

KEYENCE office.

Turn off the power, disconnect the head expansion

nit and connect it again, and then turn on the

u

power again.

If the error continues, contact your nearest

KEYENCE office.

The received command is not defined for the RS232C communication.

Check the command you sent.

Operation through the RS-232C communication is

not available (e.g., a measurement control

command was received in the communication

mode).

Check the mode and the command you sent.

The command or parameter received through the

RS- 232C communication has an insufficient

number of characters. Check the command you

sent.

The command received through the RS-232C

communication has insufficient parameters. Check

the command you sent.

A-4

Page 55

Appendices

Display

Err-62 Parameter range error

Err-63

Err-64

Err-65

Err-66

Err-67

Err-68

Err-69

Err-70

Err-71

Err-88 Timeout error

Err-99 Other error Contact your nearest KEYENCE office.

* If you cannot resume the LK-G5000 Series after taking the above countermeasures or if you

encounter an error which is not listed in the table, contact your nearest KEYENCE office.

System

error

Error description Countermeasure

The setting value received through the RS-232C

communication is out of the possible setting range.

Check the command you sent.

Parameter range error

OUT calculation count

limitation)

Parameter range error

(OUT/Head No.)

Parameter range error

(Velocity/acceleration

calculation method)

Parameter range error

(OUT specification)

Parameter range error

(Sampling cycle)

P

arameter range error

(Scaling)

Parameter range error

(Analog output scaling)

Parameter range error

(Number of data to be

stored)

Parameter range error

(OUT specified for

data storage)

The repeated use of an OUT value in OUT

calculation exceeds the limit. Check the command

you sent.

The number of sensor heads or OUT being used

exceeds the active head/OUT count.

Check the setting.

The OUT set to the measurement type of

"Velocity" or "Acceleration" was set to OUT for

another measurement type or to AVE/P-P/MAX or

other calculation between OUT.

Check the setting.

The calculation range set for a certain OUT

includes the OUT itself, or no target OUT has been

set for the AVE/PP/MIN/MAX calculation.

The specified sampling cycle is faster than the

fastest sampling cycle available based on the

active OUT count, active head count,

measurement mode, and calculation method.

elect a slower sampling cycle or change other

S

parameters.

The specified scaling parameters do not satisfy

the following conditions:

•Input value 1 - Input value 2 0

• |(Displayed value 2 - Displayed value 1) / (Input

value 2 - Input value 1) | 2.

The specified analog output scaling parameters do

not satisfy the following conditions:

•Input value 1 - Input value 2 0

•|(Output voltage value 2 - Output voltage value 1)

/ (Displayed value 2 - Displayed value 1) |

The specified number of data to be stored exceeds

the possible setting range.

The number of OUT for which data is stored

exceeds the active OUT count.

The delimiting CR expected after receiving a

command via RS-232C communication was not

received for 30 or more seconds.

Check the command you sent and the

communication program.

2.

A

A-5

Page 56

Appendices

List of Optional Accessories

The following table lists the optional accessories compatible with this touch panel.

Name Model Appearance Description

A

Stand OP-84428

33 cm OP-84427

Display panel

cable

Protection sheet OP-42257

3 m OP-51655

10 m OP-51656

Used to secure the touch panel

on a stand.

A cable used to connect the

display panel (LK-HD500/LKHD1001) and controller (LKG5001/LK-G5001P).

Replacement protection sheets

(set of 5 sheets).

A-6

Page 57

Maintenance

Replacing the Protection Sheet

Follow these procedures to replace the protection sheet.

NOTE

Use the dedicated protection sheet, OP-42257 for this touch panel.

Peel off the protection sheet currently on the touch panel.

1

Partially peel back the backing paper from the new protection sheet and align it

2

to the corners of the touch panel.

Appendices

A

Continue peeling the backing paper and apply it to the touch panel while

3

removing any air bubbles that get trapped inside.

A-7

Page 58

Index

A

ABLE..................................................... 2-5

ABLE TUNING ...................................... 2-5

ABLE tuning .......................................... 2-6

Add bet. OUT ...................................... 2-10

Alarm level ............................................ 2-7

Alarm output form ............................... 2-16

Amount of Data Stored .............. 2-19, 2-20

Analog output............................. 2-15, 2-20

Analog output scaling.......................... 2-15

A

Auto zero............................................. 2-26

Automatic transmission....................... 2-22

AVE bet. OUT ..................................... 2-10

Averaging Times ................................. 2-12

B

Backlight ............................................. 2-26

Basic point ............................................ 2-5

Baud rate ............................................ 2-22

C

Calculation method ............................... 2-9

Caution..................................................... 3

CE marking .............................................. 4

Common ............................................. 2-16

Common settings ................................ 2-16

Connections........................................ 1-12

Controller specifications ........................ 3-2

Copying a program ............................. 2-23

Copying programs............................... 2-23

Cutoff frequency.................................. 2-12

D

Data storage ....................................... 2-19

Display area .......................................... 1-6

Display/Analog .................................... 2-15

E

Environment settings .......................... 2-21

Error Codes...........................................A-4

Ethernet settings ................................. 2-22

Dimensions ........................................... 3-3

F

Features................................................ 1-4

Filter .................................................... 2-12

Flow of Operation.................................. 2-3

G

Gateway.............................................. 2-22

H

HEAD A/HEAD B .................................. 2-4

Head selection ...................................... 2-4

Head settings ........................................ 2-4

Hysteresis ........................................... 2-13

I

Initializing all........................................ 2-25

Initializing programs ............................ 2-25

Installation environment ........................... 4

IP Address .......................................... 2-22

IP65f...................................................... 1-7

L

LASER control group ............................ 2-7

List of Optional Accessories..................A-6

M

Main screen .......................................... 2-2

Mask boundary ..................................... 2-8

Mask setting.......................................... 2-8

MAX bet. OUT..................................... 2-10

Measurement ...................................... 2-11

Measurement data display selector ...... 1-7

Measurement mode ..................... 2-4, 2-11

Measurement type .............................. 2-11

Measurement Value Display ............... 2-26

Measurement/Filter ............................. 2-11

A-8

Page 59

Median...................................................2-7

MIN bet. OUT ...................................... 2-10

Minimum display unit...........................2-15

Mounting................................................1-7

Mutual interference prevention............2-18

N

Names and functions on the main screen

.........................................................2-2

No. of used heads ...............................2-21

No. of alarm processing.........................2-7

No. of alarm recovery ............................2-7

No. of used OUTs................................ 2-21

No. of used analog Ch.........................2-21

O

Offset ...................................................2-13

OP-84428 ............................................1-10

OUT selection........................................2-9

OUT settings..........................................2-9

OUT1/OUT2 ..........................................2-9

P

P.LOCK ...............................................2-27

Package contents..................................1-2

Panel cutout...........................................1-7

Panel lock ............................................2-21

Parity ...................................................2-22

Parts and functions................................ 1-6

P-P bet. OUT.......................................2-10

Program change .................................. 2-21

Program settings .................................2-23

R

Range ....................................................2-7

Received Light Waveform Display.......2-28

Reflection type.......................................2-5

Reset ...................................................2-27

RS-232C..............................................2-22

S

Sampling cycle ....................................2-16

Scaling Setting.....................................2-13

Select head............................................2-9

Selected OUT ...................................... 2-19

Set from the measurement data ..........2-14

Setting 1 ................................................2-4

Setting 2 ................................................2-7

Setting scaling from measurement data

.......................................................2-14

Simultaneous auto zero.......................2-26

Simultaneous reset..............................2-26

Simultaneous timing ............................2-26

Specifications ........................................3-2

Stand ...................................................1-10

Storage cycle.......................................2-19

Strobe time ..........................................2-16

Sub bet. OUT.......................................2-10

Subnet mask........................................2-22

Synchronization settings......................2-17

T

Timing..................................................2-27

TO CONTROLLER port .........................1-6

Tolerance Comparator.........................2-13

Tolerance comparator output format ...2-16

Tolerance Comparator.........................2-13

Tolerance/Scaling................................2-13

Touch panel...........................................1-6

TRIGGER ............................................2-11

Troubleshooting.................................... A-2

Type (filter) ..........................................2-12

W

Waveform display ...................... 2-27, 2-28

Z

Zero .....................................................2-27

AA

A-9

Page 60

Revision History

Date of printing Version Revision details

December 2013 Official release

Page 61

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any models or samples were shown to Buyer, such models or samples

were used merely to illustrate the general type and quality of the Products and not to represent that the

Products would necessarily conform to said models or samples. Any Products found to be defective must

be shipped to KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE for inspection and

examination. Upon examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price

of, or repair or replace at no charge any Products found to be defective. This warranty does not apply to any

defects resulting from any action of Buyer, including but not limited to improper installation, improper

interfacing, improper repair, unauthorized modification, misapplication and mishandling, such as exposure

to excessive current, heat, coldness, moisture, vibration or outdoors air. Components which wear are not

warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only suggestions,

and it is Buyer's responsibility to ascertain the fitness of the Products for Buyer’s intended use. KEYENCE

will not be responsible for any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not to be used internally in

humans, for human transportation, as safety devices or fail-safe systems, unless their written specifications

state otherwise. Should any Products/Samples be used in such a manner or misused in any way,

KEYENCE assumes no responsibility, and additionally Buyer will indemnify KEYENCE and hold KEYENCE

harmless from any liability or damage whatsoever arising out of any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO OTHER

WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY WARRANTIES,

INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE EXPRESSLY

DISCLAIMED. IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY

PERSON OR ENTITY FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING

FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR

INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF

SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF

OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE

OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM FOR

DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In some jurisdictions, some of the foregoing

warranty disclaimers or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer must

provide such third party with a copy of this document, all specifications, manuals, catalogs, leaflets and

written information provided to Buyer pertaining to the Products/Samples.

E 1101-3

Page 62

2013

12874E 1123-1 96M12875

Loading...

Loading...