Page 1

96134E

Configuration Software LK-H2

for the LK-G5000 Series

LK-Navigator 2

User's Manual

Read this manual before use.

Keep this manual in a safe place for future reference.

Page 2

Introduction

This manual explains the installation, handling, operation, and precautions for <<LK-

Navigator 2>>. In order to use the functions provided in <<LK-Navigator 2>> correctly, read

and understand the contents of this manual beforehand. Store this manual where it can

easily be referenced.

When using LK-Navigator 2, also refer to the LK-G5000 series User's manual.

The following terms are used in this manual.

"Controller" refers to the LK-G5000 series controller (LK-G5000V or LK-G5000).

Symbols

The following symbols alert you to important messages concerning the prevention of

human injury and product damage.

NOTE

Provides additional information on proper operation.

Reference

Provides reference information or useful information about operation.

2

Page 3

Safety Precautions

This <<LK-Navigator 2>> manual, and the User's manual provide important information on

the safe and correct use of this product to prevent property damage of, and harm to the

user and other personnel. Read and understand the following section on notations and

symbols before reading the rest of this manual. Always obey the contents described herein.

Also read and understand the instruction manuals provided with the related devices and

equipment.

Symbols

NOTE

Provides additional information on proper operation.

Reference

Provides reference information or useful information about operation.

General precautions

• At startup and during operation, be sure to monitor the functions and performance of

this product.

• It is recommended that you take substantial safety measures to avoid any damage in

case of product failure.

• Do not modify this product or use it in any way other than as described in the

specifications. The warranty will be voided in such cases.

• When this product is used in combination with other devices, functions and

performance may be degraded depending on the operating conditions and

surrounding environment.

• The contents of this manual are subject to change without notice.

Trademarks

• Windows is a registered trademark of the Microsoft Corporation.

• Pentium is a registered trademark of the Intel Corporation.

• Acrobat Reader is a registered trademark of Adobe Systems Incorporated.

96134E

3

Page 4

End-user License Agreement

Use of <<LK-Navigator 2>> (the "software") is conditional upon the customer's acceptance

of the terms of the software end-user license agreement ("this agreement") provided

herein. Using or copying this software in part or whole constitutes the customer's

acceptance of the terms in this agreement.

1. License grant

1 The KEYENCE CORPORATION (the "owner") grants non-exclusive usage rights to the

customer provided that the customer observes the terms of this agreement.

2 The customer may install unlimited copies of this software specifically for use with the

owner's product(s) provided that it is used within the same organization.

2. Copy limitations

The customer is allowed to make one (1) copy of this software solely for purposes of retaining

a backup of said software.

3. Prohibitions

With regard to this software, the customer is prohibited from

a acts to modify, append, or otherwise alter the functionality of this software in part or

whole, unless

explicitly authorized by the owner, such as in the form of update programs or installation

of new functionality.

b any and all acts of reverse engineering, such as reverse compiling or reverse

assembling, to analyze this software.

c acts of sale, assignment, redistribution, license reuse, rent, lease, etc., unless,

the owner consents to this beforehand.

4. Copyrights

All copyrights related to this software and its manuals are the property of the owner.

5. Indemnification

The owner shall not be held liable in any way for loss or damages incurred by the customer

or a third party as a result of using this software.

4

Page 5

6. Support

In accordance with this agreement, the owner shall provide technical support for regarding

questions the customer may have regarding this software. However, the owner's technical

support is not a promise that the customer will be able to achieve its objective.

7. Termination

1 This agreement terminates automatically when the customer discontinues further use of

this software, such as by means of destroying this software and its copies.

2 The owner reserves the right to cancel this agreement unconditionally if the customer

breaches any of the clauses herein. Should this occur, the customer must return or

destroy this software and its copies to the owner immediately.

3 In the event the owner incurs loss or damage attributable to the customer's breach of

this agreement, the customer shall provide compensation to the owner for said loss or

damage.

8. Legal statutes

This agreement shall be in compliance with Japanese law.

5

Page 6

Contents

Introduction ............................................. 2

Safety Precautions .................................. 3

End-user License Agreement ................. 4

Contents .................................................. 6

Chapter 1 Before Use

Overview of LK-Navigator 2 ................. 1-2

Functions and features .................. 1-2

Operating environment .................. 1-5

Chapter 2 Preparations before

Operating

Connecting the Controller and PC ....... 2-2

USB connection............................. 2-2

Ethernet connection....................... 2-3

RS-232C connection...................... 2-5

Installing the Software .......................... 2-6

Uninstallation ................................. 2-7

Installing the USB Driver ...................... 2-8

Launching/Exiting LK-Navigator 2 ....... 2-9

Launching...................................... 2-9

Exiting .......................................... 2-11

Copying programs....................... 3-27

Initializing programs .................... 3-28

Measurement Value Display .............. 3-29

Received Light Waveform Display ..... 3-31

Data Storage Setting .......................... 3-33

Loading/Saving the Settings File ....... 3-39

Loading the settings file............... 3-39

Saving the settings file ................. 3-39

Changing "No. of used heads" and "No. of

used OUT" in the settings file

(LK-Backup) ................................. 3-40

Appendix

Error Messages and Corrective Action A-2

Index .................................................... A-5

Chapter 3 Window Functions

and Operation

Names and Functions .......................... 3-2

Flow of Operation ................................. 3-4

Basic Settings ...................................... 3-5

Head settings................................. 3-5

OUT settings .................................. 3-9

Common settings......................... 3-16

Settings list................................... 3-22

Downloading, uploading settings 3-23

Environment Settings ......................... 3-24

Communication Settings .................... 3-26

Program Settings ............................... 3-27

6

Page 7

Before Use

1

1

Overview of LK-Navigator 2....................................... 1-2

1

1-1

Page 8

1

Before Use

Overview of LK-Navigator 2

LK-Navigator 2 is software for configuring parameters and monitoring the LK-G5000 series

controller. It is used by connecting a PC and the controller to configure parameters and

monitor operating status.

1

Functions and features

This section explains the major functions and features of LK-Navigator 2.

Operation settings

• LK-Navigator 2 allows you to upload the settings in the controller to the PC for viewing

and editing. It features copy and paste functions for configuring multiple controllers and

setting programs in a short amount of time.

• The settings on the PC can be downloaded and reflected in the controller. LK-Navigator

2 communicates with the controller at the simple press of a button.

• Settings can be loaded from and saved on the PC. Settings saved on the PC can be

used to restore the settings in the controller in the event the settings are erased.

The following items can be set from the PC.

• Head settings

• OUT settings

• Common settings

• Environment settings

1-2

Page 9

1

Before Use

Monitoring functions

These two items can be monitored.

• Measurement value

• Received light waveform

The screen shown below is a display example of the "Measurement value display".

1

1-3

Page 10

1

1

Before Use

1-4

Page 11

Data storage

The controller has a data storage function for storing measurement values.

The PC can be used to control these functions:

• Start/stop/clear the data storage

• Configure the data storage method

• Upload/download settings between the controller and PC

• Upload storage data from the controller

• Read and save storage data on the PC

• Display waveform of up to 12 data series downloaded from the controller.

• Display calculations on data between user-set cursors

1

Before Use

1

1-5

Page 12

1

Before Use

Operating environment

The following environment is required to run LK-Navigator 2. Check that the PC meets the

following conditions, and that the necessary equipment is available.

1

CPU Pentium III 1 GHz or higher (1.7 GHz or higher recommended)

Supported OS

Memory capacity 256MB or more (1 GB or more recommended)

Display resolution 1024 x 768 pixels, 24-bit full color or better

Capacity required for

installation

Interface The PC must be equipped with one of these interfaces:

*

Use under an environment that exceeds the recommended environment of the your OS.

Windows 7

Windows Vista

Windows XP

Windows 2000 Professional

1GB

•

USB: Revision 2.0 HighSpeed (USB1.1 compatible full

speed)

•

LAN: 100BASE-TX, 10BASE-T

•

RS-232C (serial port)

*1

*2

*3

*4

*5

*6

*1 Compatible with each edition of Home Premium, Professional and Ultimate.

*2 Editions supported: Ultimate, Business, Home Premium, Home Basic.

*3 Supports Professional SP2 and Home Edition SP2 or later.

*4 Supports SP4 or later.

*5 Does not support connection via a USB hub.

*6 Does not support connection via private LANs or routers. Use in a 1:1 or local

connection.

1-6

Page 13

Preparations before Operating2

2

Connecting the Controller and PC........................................ 2-2

Installing the Software .......................................................... 2-6

Installing the USB Driver ...................................................... 2-8

Launching/Exiting LK-Navigator 2 ........................................ 2-9

2

2-1

Page 14

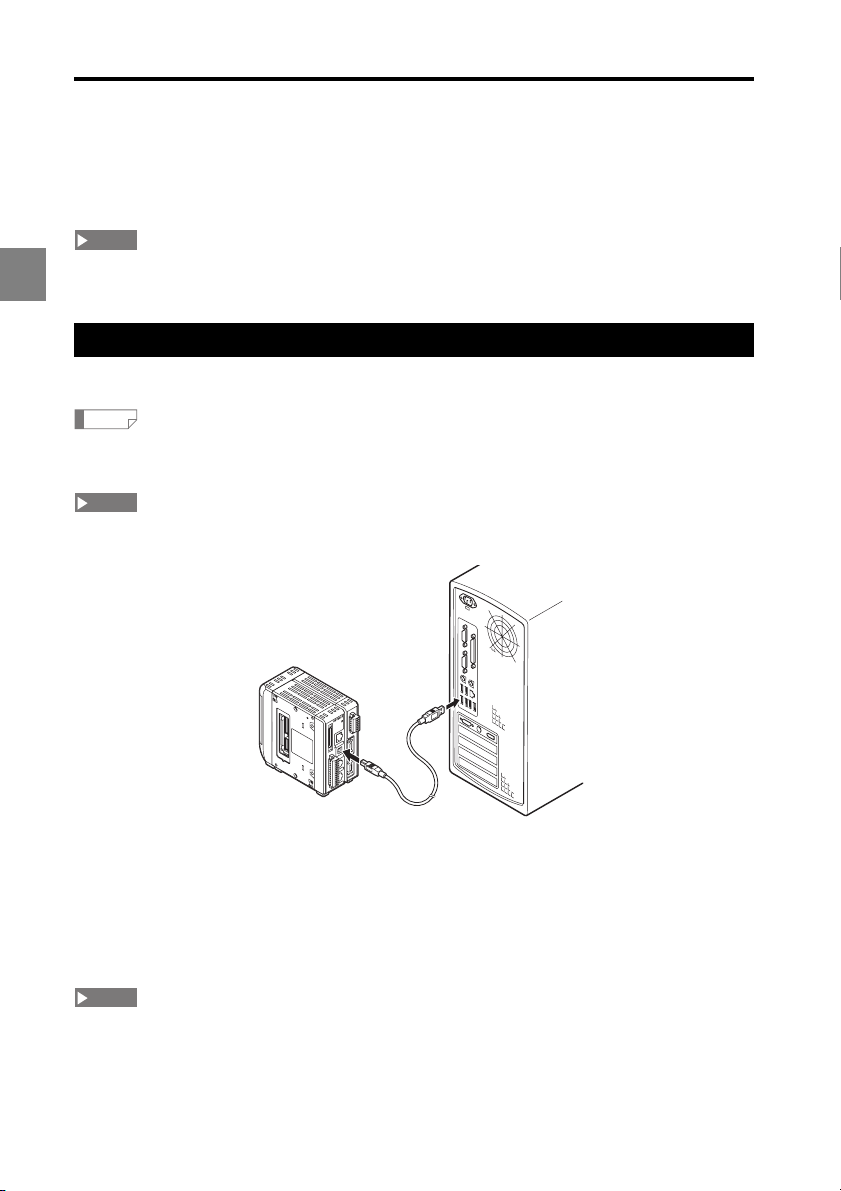

2 Preparations before Operating

Connecting the Controller and PC

This section explains how to connect the controller and the PC.

The controller provides three interfaces. Choose an interface supported by the PC.

NOTE

It is not possible to connect and communicate via the USB, Ethernet, and RS-232C interfaces

simultaneously.

2

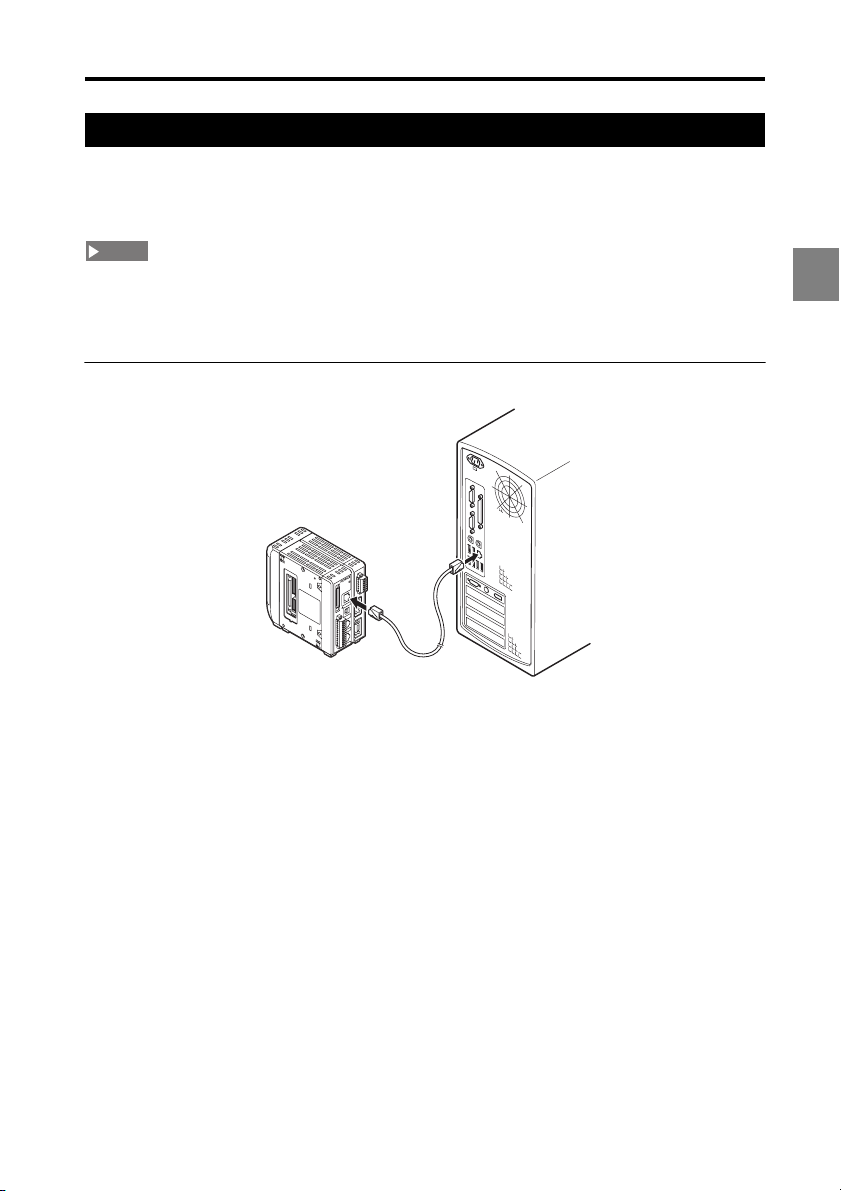

USB connection

This section explains how to connect the controller and PC with a USB cable.

Reference

The orientation and location of the USB connector on the PC differs for each PC. Refer to the

instruction manual supplied with your PC when connecting the USB cable.

NOTE

The USB connector on the controller is Type B. Use a USB cable with a Type B connector on

one end.

G5000

LK-

)

V

(

)

A

(

0V

)

V

(

)

A

(

0V

1

Connect the Type B cable to the USB connector on the controller.

1

Connect the other end of the cable to the USB connector on the PC.

2

If the PC is running, it will automatically recognize the controller.

The first time the PC and controller are connected via USB, the PC will install the

USB driver. Refer to "Installing the USB Driver" (page 2-8).

NOTE

Do not disconnect the USB cable while the controller is operating. Doing so may cause the

controller to operate erroneously. If communication stops working due to a disconnected cable,

restart LK-Navigator 2 and the controller.

2-2

Page 15

2 Preparations before Operating

Ethernet connection

This section explains how to connect the controller and PC using an Ethernet connection. An

Ethernet connection allows connection of multiple controllers to a single PC. The

communication protocol is TCP/IP, and the connection format is Peer to Peer.

NOTE

• Be sure not to use duplicated IP addresses for the controller(s) and PC.

• KEYENCE does not guarantee the operation of connections using other LAN protocols or routers.

• It is not possible to operate more than one controller simultaneously from a single PC.

• It is not possible to operate one controller simultaneously from multiple PCs.

Connection

G5000

LK-

)

V

(

)

A

(

0V

)

V

(

)

A

(

0V

1

2

Connect a commercially Ethernet cable (crossover cable, category 5) to the Ethernet

1

port on the controller.

Connect the other end of the cable to the LAN port on the PC.

2

Connecting two or more controllers

You will need a hub that supports 100BASE-TX or 10BASE-T.

For the connection between the controller and hub, or between the PC and hub, use a

commercially available straight Ethernet cable.

2-3

Page 16

2 Preparations before Operating

Change the communication settings

When connecting via Ethernet, the communication settings for connecting to the network,

such as the IP address and subnet mask must be changed.

Change the communication settings at the controller.

1

Refer to the LK-G5000 series User's Manual for details.

2

2

3

4

NOTE

To enable the new communication settings, restart the controller after changing the

settings.

Change the communication settings on the PC.

The configuration procedure differs depending on the version of Windows you are

using.

Refer to the instruction manual for the PC or LAN card you are using for details.

Launch LK-Navigator 2 (page 2-9).

From the "Communication settings" menu, select "PC communication settings".

The "PC Communication settings " dialog appears.

Select "Communicate with Ethernet". Then select the IP address of the controller.

5

Specify the controller IP address

Specify the actual IP address of the controller to connect to.

Auto search for controller

Click "Search connected controller" to specify the controller to connect to.

Click "OK".

6

2-4

Page 17

2 Preparations before Operating

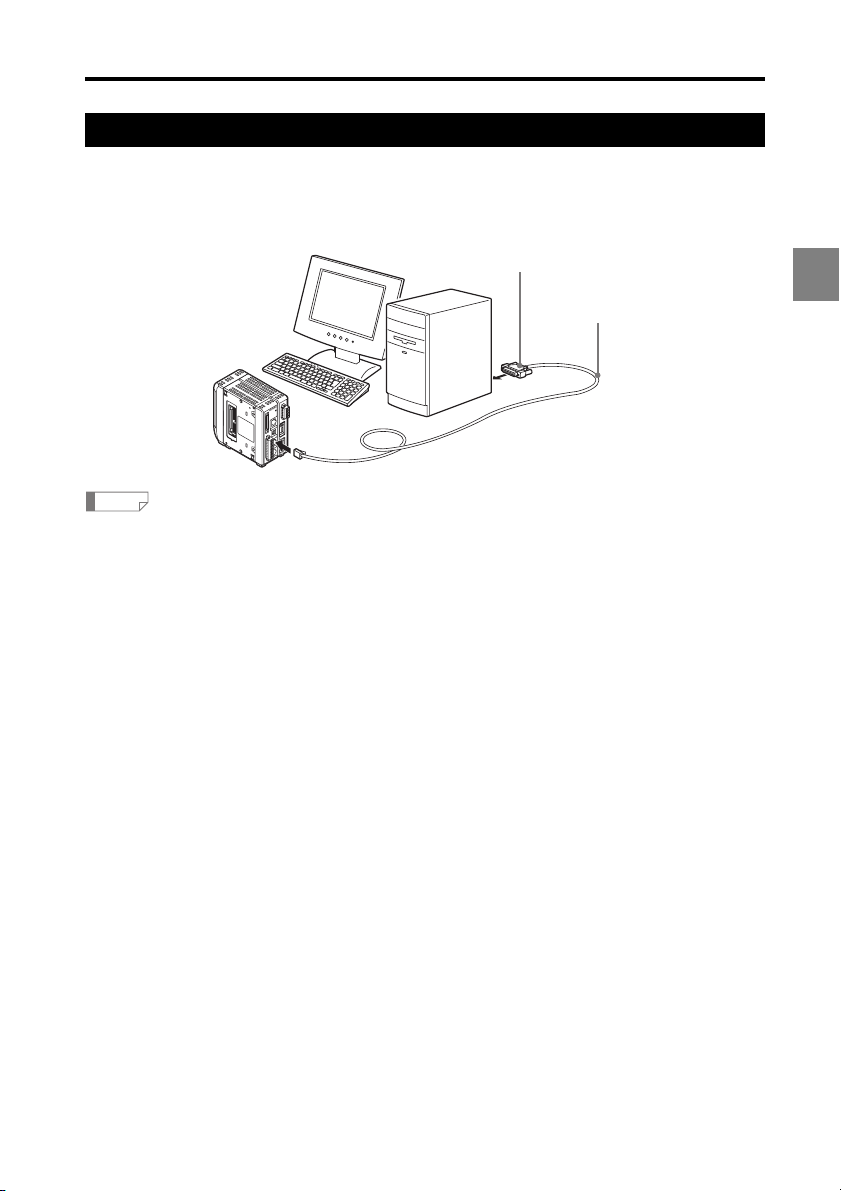

RS-232C connection

This section explains how to connect the controller and PC with an RS-232C cable.

To use the RS-232C connection, use the dedicated cable OP-96368 (straight 2.5-m cable)

with either OP-96369 (D-sub 25 pin) or OP-26401 (D-sub 9 pin).

OP-96369 or OP-26401

OP-96368

G5000

LK-

)

V

(

)

A

(

0V

)

V

(

)

A

(

0V

1

Reference

The orientation and location of the RS-232C port on the PC differs for each PC. Refer to the

instruction manual supplied with your PC when connecting the RS-232C cable.

Connect the dedicated cable OP-96368 to the RS-232C connector on the controller.

1

Connect OP-96368 and OP-96369 and connect this to the RS-232C connector on

2

the PC.

The connection in this explanation uses OP-96369 (D-sub 25 pin).

2

2-5

Page 18

2 Preparations before Operating

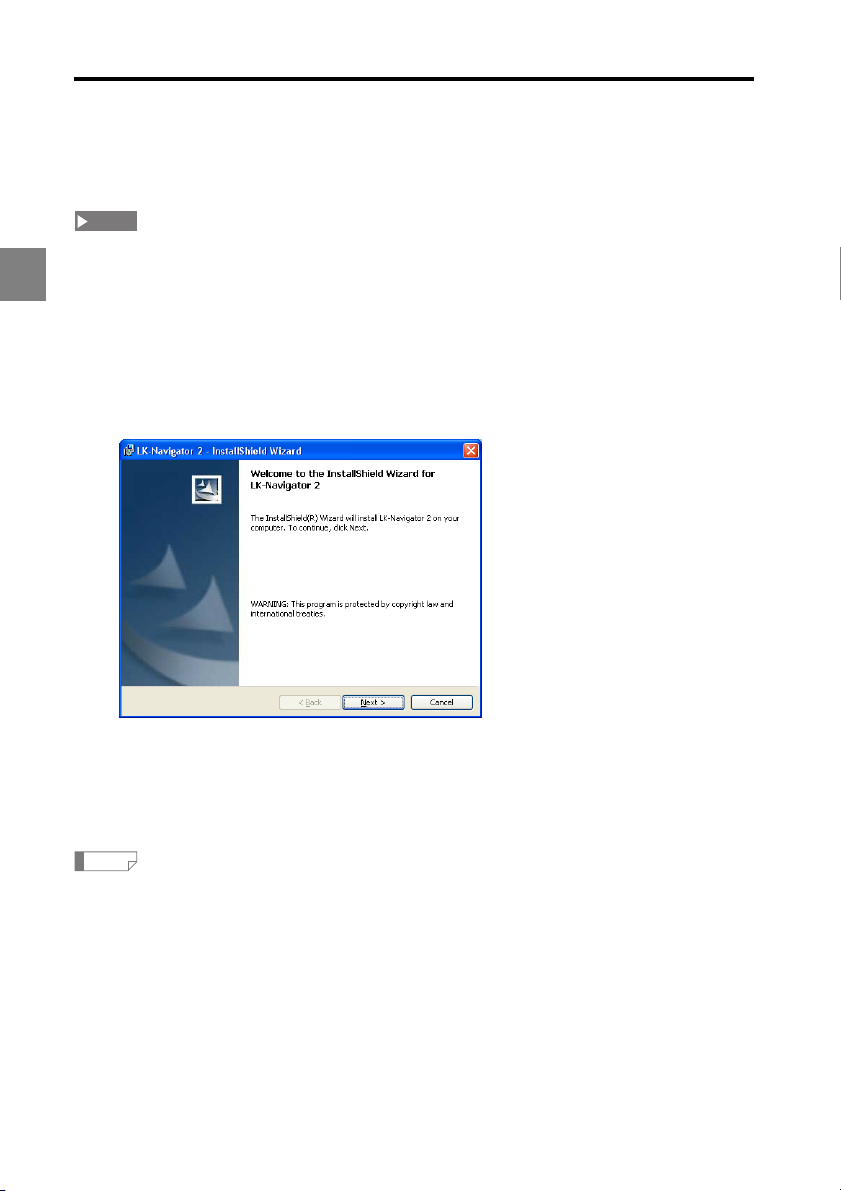

Installing the Software

This section explains the procedures for installing LK-Navigator 2 and the USB driver on

your PC.

NOTE

• This procedure explains the installation process for Windows XP.

• Before starting the installation, close any other applications currently running.

• When installing on Windows 2000 Professional, Windows XP Professional, Windows Vista, or

2

Windows 7, you must logon as a user with administrator privileges.

Insert "LK-H2" in the CD-ROM drive. Double-click "Setup.exe".

1

The "InstallShield Wizard" screen appears.

Follow the guidance on the screens.

2

When the "InstallShield Wizard Complete" screen appears, click "Finish".

3

Remove the CD-ROM.

4

This completes the installation of LK-Navigator 2.

Reference

By default, LK-Navigator 2 will be installed in "C:\Program Files\KEYENCE\LK-Navigator 2".

2-6

Page 19

2 Preparations before Operating

Uninstallation

This section explains the procedures for uninstalling LK-Navigator 2 from your PC.

NOTE

• This procedure explains the uninstallation process for Windows XP.

• Before starting the uninstallation, close any other applications currently running.

• When uninstalling on Windows 2000 Professional, Windows XP Professional, Windows Vista, or

Windows 7, you must logon as a user with administrator privileges.

Double-click "Add or remove programs" on the control panel.

1

The "Add/Remove Programs" screen appears.

Select LK-Navigator 2 and click "Remove".

2

The "Confirm Remove" dialog appears.

Click "Yes".

3

The uninstallation will start.

If the uninstallation does not complete by following steps 1 to 3,

perform steps 4 to 6 described below.

Insert "LK-H2" in the CD-ROM drive. Double-click "Setup.exe".

4

The "Confirm File Delete" dialog appears.

2

Click "OK".

5

The "Maintenance is complete" screen appears.

Click "Finish".

6

This completes the uninstallation.

2-7

Page 20

2 Preparations before Operating

Installing the USB Driver

This procedure is not required for Windows 7, Vista, XP, or 2000 because the installer

installs the USB driver when installing LK-Navigator 2.

This procedure explains how to manually install the USB driver in the event the LKNavigator 2 installer was canceled before installing the driver. When the USB driver is

installed on the PC, the PC will automatically recognize the controller.

2

NOTE

• This procedure explains the installation process for Windows XP.

• Before starting the installation, close any other applications currently running.

• When installing on Windows 2000 Professional, Windows XP Professional, Windows Vista, or

Windows 7, you must logon as a user with administrator privileges.

• The USB connector on the controller is Type B. Use a USB cable with a Type B connector on one end.

• The controller complies with the USB 2.0 High Speed standard. The USB has downward

compatibility for communicating with PCs that support USB 1.1.

Start the controller and PC.

1

Connect the controller and PC with the USB cable.

2

The "Welcome to the Found New Hardware Wizard" appears.

Insert "LK-H2" in the CD-ROM drive, and click "Next".

3

The "Please wait while the wizard installs the software..." dialog appears, indicating

installation has started.

If the installation finishes normally, the "Completing the Found New Hardware

Wizard" dialog appears.

Reference

• If the following dialog appears during the installation process, click "Continue".

• The "Welcome to the Found New Hardware Wizard" screen may appear for some

versions of Windows. In this case, select "No, not this time", and click "Next".

Click "Finish".

4

This completes the installation of the USB driver.

2-8

Page 21

2 Preparations before Operating

Launching/Exiting LK-Navigator 2

This section explains how to launch and exit LK-Navigator 2.

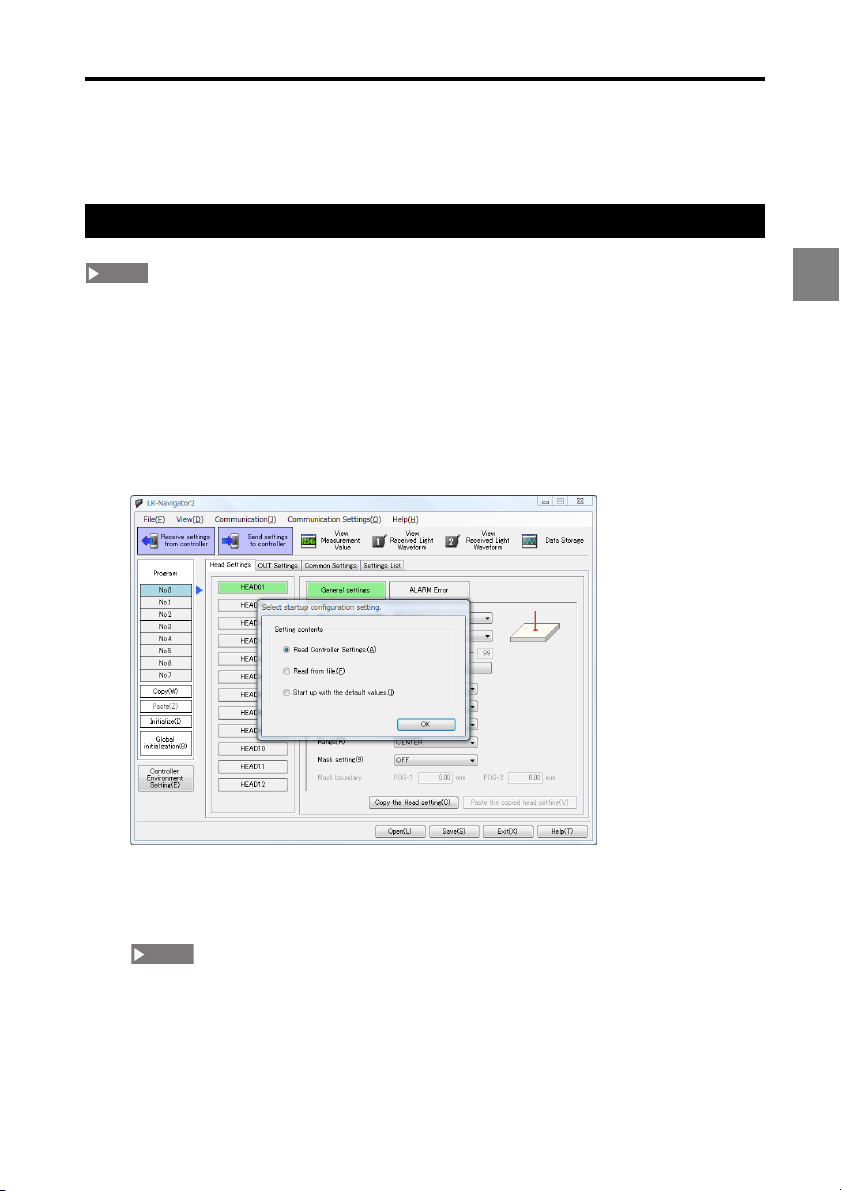

Launching

NOTE

• Multiple instances of LK-Navigator 2 cannot be run.

• The controller cannot communicate simultaneously over its USB, RS-232C, and Ethernet

interfaces.

• The controller cannot communicate when it is in "Program Setting Mode".

From the Windows Start menu, select "All Programs" - "KEYENCE Applications" - "LK-

1

Navigator 2".

LK-Navigator 2 launches. The main window and the "Select startup configuration

setting" dialog appears.

2

Select "Start up with the default values".

2

Selecting "Start up with the default values" loads the settings on the PC with the

default values.

NOTE

Selecting "Start up with the default values" does not initialize the settings in the controller.

2-9

Page 22

2 Preparations before Operating

Reference

Refer to the following explanations before selecting the other options.

• "Read from file": Refer to "Read from file" (page 2-10).

• "Read controller settings": Refer to "Read controller settings" (page 2-10).

Click "OK".

3

The program initializes.

2

Read from file

At the "Select startup configuration setting" dialog, select "Read from file".

4

Click "OK".

5

The "Open file " dialog appears.

Select the settings file to load.

6

Click "Open".

7

The settings are read.

Reference

Clicking "Cancel" results in the same operation as "Start up with the default values". (page 2-9).

Read controller settings

At the "Select startup configuration setting" dialog, select "Read controller settings".

1

Click "OK".

2

The settings are read from the controller.

Reference

This communication uses the last used settings when LK-Navigator 2 was closed before.

NOTE

• If a controller is not connected or communication fails, an error message will be displayed.

• When LK-Navigator 2 is launched for the first time, it is set to the following communication setting.

Interface: USB

• A communication failure will result in the same operation as "Start up with the default values"

2-9)

.

2-10

(page

Page 23

2 Preparations before Operating

Exiting

Click "Exit" at the bottom right of the main window.

1

If any settings were changed, a confirmation dialog appears.

Reference

Clicking the in the title bar also exits the program.

Click "Yes".

2

The "Save as" dialog appears.

NOTE

• Click "No" to exit without saving the settings.

• Click "Cancel" to return to the previous window.

Enter the file name to save the settings.

3

Reference

The extension for an LK-G series setting file ".ldtx" is automatically appended to the

specified file name.

Click "Save".

4

The settings are saved to the file and LK-Navigator 2 exits.

2

2-11

Page 24

2 Preparations before Operating

2

2-12

Page 25

Window Functions and

Operation

Names and Functions........................................................... 3-2

Flow of Operation ................................................................. 3-4

Basic Settings....................................................................... 3-5

Environment Settings ......................................................... 3-24

Communication Settings..................................................... 3-26

Program Settings................................................................ 3-27

Measurement Value Display............................................... 3-29

Received Light Waveform Display ...................................... 3-31

Data Storage Setting .......................................................... 3-33

Loading/Saving the Settings File ........................................ 3-39

Chan

ging "No. of

in the settings file (LK-Backup) ........................................... 3-40

used heads" and "No. of used OUT"

3

3

3-1

Page 26

3 Window Functions and Operation

Names and Functions

This section explains the names and functions of the LK-Navigator 2 main window.

3

(1) Menu bar

Displays the LK-Navigator 2 controls menu.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(2) Tool bar

Shows buttons for frequently used functions in the menu bar. Refer to "Measurement Value

Display" (page 3-29) to "Data Storage Setting" (page 3-33) for details.

(3) Settings pane

Used to configure each head and output.

Refer to "Basic Settings" (page 3-5) for setting procedures on each tab.

(4) Program settings

Selects, copies, and initializes program numbers. Refer to "Program Settings" (page 3-27)

for details.

(5) Controller environment setting

Configures the controller operating environment. Refer to "Environment Settings" (page 3-

24) for details.

(6) Help

Opens the LK-Navigator 2 help file.

3-2

Page 27

3 Window Functions and Operation

(7) Exit

Exits LK-Navigator 2 (page 2-9).

(8) Open/Save

Loads and saves settings made in LK-Navigator 2.

Refer to "Loading/Saving the Settings File" (page 3-39) for details on loading and saving a

settings file.

3

3-3

Page 28

3 Window Functions and Operation

Flow of Operation

This explanation will outline the procedures to set the input for HEAD01 to OUT01 after

launching LK-Navigator 2.

Connect the controller and PC with an RS-232C cable, LAN cable, or USB cable.

1

(page 2-2)

Start the controller, then start the PC.

2

3

Launch LK-Navigator 2 (page 2-9).

3

At the "Select startup configuration setting", select "Start up with the default values"

4

(page 2-9).

In the "Controller Environment Setting", specify the number of heads, OUTs, and

5

analog outputs being used. (page 3-24).

In the "Communication settings", configure the communication method to use with

6

the controller (page 3-26).

Select a program number (page 3-27).

7

Specify the "Common Settings" (page 3-16).

8

Configure "HEAD01" (page 3-5).

9

Configure "OUT01" (page 3-5).

10

Confirm the settings in the "Settings List" (page 3-22).

11

Download the settings to the controller (page 3-23).

12

Use tools to monitor operation (page 3-29 to page 3-33).

13

Save the settings file on the PC (page 3-39).

14

This completes the most typical operations.

3-4

Page 29

3 Window Functions and Operation

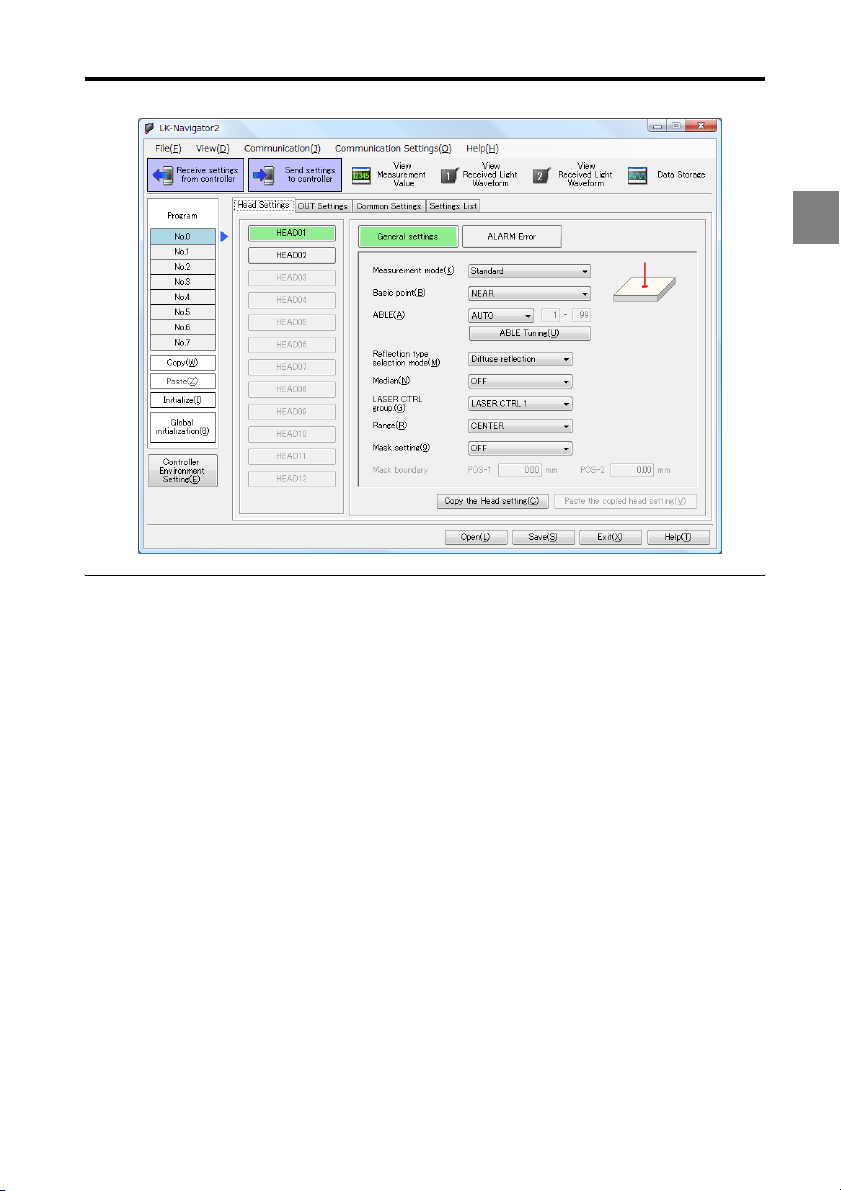

Basic Settings

This section explains the basic settings for the LK-Navigator 2.

Head settings

This section explains the items and functions on the "Head Settings" tab.

Configure the head connected to the controller to match the operating environment.

Click the "Head Settings" tab in the settings pane.

General settings

(1)

(2)

(3)

(4) (5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(1) Target head selection

Specifies the head to configure.

Reference

To use three or more heads by using the head expansion unit, change the setting in the

"Controller environment setting" dialog (page 3-24).

3

(2) Measurement mode

Selects the object to measure.

3-5

Page 30

3 Window Functions and Operation

(3) Basic point

If several peaks exist when using the transparent object mode, this control specifies

whether to use the peak that is NEAR or FAR from the sensor head as the reference.

(4) ABLE

Sets whether to use AUTO or MANUAL control of the light intensity.

• Normally set to "AUTO".

• If set to "MANUAL", set the upper and lower limits for the light intensity control range

(setting range: 1 to 99).

3

(5) ABLE tuning

This function uses "ABLE" to tune the "MANUAL" setting range according to the actual

target. Refer to "Executing ABLE tuning" (page 3-7) for details.

(6) Reflection type selection mode

Sets the installation method to diffused reflection or specular reflection.

(7) Median

Sets the number of sampling points to use for the median filter.

(8) LASER control group

Sets the LASER control group.

(9) Range

Sets the range.

(10) Mask setting

Sets whether to enable (ON) or disable (OFF) masking.

(11) Mask boundary

If the "Mask setting" is set to "ON", this control specifies the mask boundary using POS-1 or

POS-2.

• If POS-1 < POS-2: masks around POS-1 and POS-2.

• If POS-1 > POS-2: masks between POS-1 and POS-2.

• If POS-1 = POS-2: no masking is applied.

(12) Copy the head setting/Paste the copied head setting

Use this button to copy the head settings to another head (or a head in a different program

number). Refer to "Copying the head settings to another head" (page 3-7) for details.

3-6

Page 31

3 Window Functions and Operation

Executing ABLE tuning

Click "ABLE Tuning".

1

The "ABLE Tuning" dialog appears.

NOTE

• If you do not want to download the settings to the controller when tuning starts,

uncheck "Send the PC settings to the controller while executing is in progress".

• The controller enters communications mode when ABLE tuning is in progress.

Click "Start" to start tuning.

2

Click "Stop".

3

Tuning ends. The optimal settings are configured automatically.

NOTE

Clicking "Cancel" aborts the tuning process and leaves the settings unchanged.

3

Copying the head settings to another head

This example explains how to copy the settings for HEAD01 to HEAD02.

Complete all settings for HEAD01.

1

Click "Copy the Head setting".

2

The "Paste the copied head setting" button becomes active.

Click "HEAD02".

3

Reference

The settings can also be copied to the head settings in a different program number. In

this case, select the program number to copy the settings and then select the head.

Click "Paste the copied head setting".

4

The settings for HEAD01 are copied to HEAD02.

3-7

Page 32

3 Window Functions and Operation

Alarm error

(1)

3

(2)

(3)

(4)

(1) Number of Errors

Sets the number of cycles to hold the most recent valid measurement (Setting range: 0 to

9999).

Number of Errors Operation

0 Handles alarm immediately

1 to 9998 Holds most recent valid measurement

9999 No alarm handling

(2) Number of Recovery

Sets the number of cycles to measure before automatically recovering from the alarm

(Setting range: 0 to 9999).

(3) ALARM Level

Sets the alarm sensitivity level from between low (0) to high (9) (default setting: 4).

• Low (0): Weakens alarm detection sensitivity

• High (9): Strengthens alarm detection sensitivity

(4) Copy the Head setting/Paste the copied head setting

Use this button to copy the head settings to another head (or a head in a different program

number). Refer to "Copying the head settings to another head" (page 3-7) for details.

3-8

Page 33

3 Window Functions and Operation

OUT settings

This section explains the items and functions on the "OUT Settings" tab.

These settings define how the measurement data should be handled to suit the operating

environment.

To use three or more OUTs by using the head expansion unit, change the setting on

the "Controller Environment Setting" dialog (page 3-24).

Click the "OUT Settings" tab in the settings pane.

Calculation method

(1)

(2)

(3)

(1) Target OUT selection

Specifies the OUT to configure.

(2) Calculation method

Sets the calculation method according to the measurement mode and target.

Head

Sets the head number and detection target to associate with the OUT to configure.

The detection target can be set if the head measurement mode is set to transparent object

or transparent object 2.

OUT

Sets the OUT number to associate with the OUT to configure.

Calculation between OUT

Sets the calculation to apply to the OUT-to-OUT range to associate with the OUT to configure.

3

3-9

Page 34

3 Window Functions and Operation

AVE/P-P/MAX/MIN

Sets the type of output to associate with the OUT to configure.

The operation specified from the "Type" options is applied to the checked OUTs.

• AVE: Average value

• P-P: Max. to min. value

• MIN: Min. value

• MAX: Max. value

(3) Copy OUT settings/Paste OUT settings

Use this button to copy the OUT settings to another OUT (or an OUT in a different program

3

number).

Copying the OUT settings to another OUT

This example explains how to copy the settings for OUT01 to OUT02.

Complete all settings for "OUT01".

1

Click "Copy OUT settings".

2

Click "OUT02".

3

Reference

The settings can also be copied to the OUT settings in a different program number. In this

case, select the program number to copy the settings and then select the OUT.

Click "Paste OUT settings".

4

The settings for OUT01 are copied to OUT02.

3-10

Page 35

3 Window Functions and Operation

Measurement, Tolerance

(1) Measurement

Sets the measurement and tolerance comparator method.

Measurement type

Sets the measurement type.

(1)

3

(2)

(3)

Measurement mode

Sets the measurement mode.

TRIGGER

Sets a trigger for any "Measurement mode" setting other than "NORMAL".

3-11

Page 36

3 Window Functions and Operation

(2) Filter

Type

Sets the filtering process to apply to the measurement.

Averaging Times

Sets the number of averaging measurements if "Type" is set to "Moving-average".

3

Reference

Fewer average times results in faster measurement data response, while more average times

stabilizes the measurement data.

Cutoff frequency

Sets the cutoff frequency if "Type" is set to "LOW-PASS FILTER" or "HIGH-PASS FILTER".

(3) Tolerance Comparator

Upper limit value

Sets the upper tolerance limit.

Lower limit value

Sets the lower tolerance limit.

Hysteresis

Sets the hysteresis for the tolerance comparator.

3-12

Page 37

3 Window Functions and Operation

Scaling, Offset

(1) Scaling Setting

Sets the scaling.

Input1/ Display1, Input2/ Display2

Sets how to display the input value from the head using two points.

(1)

3

(2)

Set from the measurement data

Sets the scaling factor while observing the actual measurement data. Refer to "Setting

scaling from measurement data" (page 3-14) for details.

(2) Offset

Sets the offset value.

3-13

Page 38

3 Window Functions and Operation

Setting scaling from measurement data

Click "Set from the Measurement data".

1

A confirmation dialog appears.

3

Click "Yes".

2

The "Scaling Setting" dialog appears.

NOTE

The controller enters communications mode when "Scaling Setting" is in progress.

At the reference surface, click "Set" for "Input1".

3

This sets the measurement data of the reference surface into "Input1".

Insert the master work piece, then click "Set" for "Input2".

4

This sets the measurement data of the master work piece into "Input2".

Set the scaling display values in "Display1" and "Display2".

5

Click "OK".

6

3-14

Page 39

Display, Analog

3 Window Functions and Operation

(1)

(2)

(1) Display

Minimum display unit

Sets the decimal point position and number of digits to display for measured and setting

values.

Reference

Digits not displayed below the decimal point are rounded off.

NOTE

These settings are initialized when the "Minimum display unit" setting is changed:

Scaling, offset, tolerance setting, analog output scaling, auto zero reference value.

(2) Analog output scaling

Sets the scaling for the analog output with respect to the measurement data.

Reference

Analog outputs can be scaled within a range of ±10.5 V.

3

3-15

Page 40

3 Window Functions and Operation

Common settings

This section explains the items and functions on the "Common Settings" tab.

Click the "Common Settings" tab in the settings pane.

General

3

(1)

(2)

(3)

(4)

(5)

(1) Sampling cycle

Sets the sampling cycle for measuring.

(2) Tolerance comparator output format

Sets the hold behavior to apply to the tolerance comparator output when the tolerance

comparator result changes from ON to OFF.

(3) Alarm output form

Sets the alarm output operation.

(4) Strobe time

Sets the strobe time for a binary output.

3-16

Page 41

3 Window Functions and Operation

(5) Copy common settings/ Paste common settings

Use this button to copy these settings to the common settings in a different program

number. Refer to "Copying the common settings to another program" (page 3-17) for

detail.

Copying the common settings to another program

This example explains how to copy the "Common Settings" from program No. 0 to program

No. 1.

Complete all settings for the "Common Settings".

1

Click "Copy common settings" on program No. 0.

2

Select program No. 1.

3

Click "Paste common settings".

4

This copies the settings in program No. 0 to program No. 1.

3

3-17

Page 42

3 Window Functions and Operation

Synchronization setting

3

(1) Synchronization setting

Check the OUTs to synchronize.

NOTE

If the storage cycle (page 3-37) is set to "Timing input", check the OUT specified for data

storage on the "Synchronization setting" page as well. Otherwise, the data will not be stored.

(1)

3-18

Page 43

Mutual interference prevention

3 Window Functions and Operation

(1)

(1) Mutual interference prevention

Use this setting to prevent interference when multiple head units are connected.

Assign each head to a group from A to C. This setting prevents the reflection from

interfering between groups A and B, and from groups A to C.

3

3-19

Page 44

3 Window Functions and Operation

Data storage

3

(1) Amount of Data Stored

Sets the number of data points to store.

(2) Storage cycle

Sets the interval for data storage.

(1)

(2)

(3)

Reference

Data will be stored at the interval (in units of ms or μs) displayed under the value set.

(3) Selected OUT

Check the OUT to store data for.

Reference

If the storage cycle is set to "Timing input", the OUT specified for synchronization (page 3-18)

can be selected here.

3-20

Page 45

Analog output

3 Window Functions and Operation

(1)

(1) Analog output

Sets an analog channel from CH01 to CH12 to each OUT to be used as an analog output

from the controller.

3

3-21

Page 46

3 Window Functions and Operation

Settings list

This tab provides a view of the items set within a program.

Click the "Settings List" tab in the settings pane.

3

(1) Settings list

Displays a list of the settings for the selected program.

(1)

(2)

(3)

(2) Copy the settings list to the clipboard

Copies the settings list to the clipboard. This feature can be used to paste the settings to

other applications.

Reference

• The contents copied to the clipboard paste into other applications in tab-delimited format.

• Changed settings will be shown in blue if, prior to the change, you:

- launch LK-Navigator 2,

- download or upload settings with the controller, or

- open or save a settings file.

(3) Add the connected head types to the Settings List

Adds the model of the head connected to the controller to the settings list.

3-22

Page 47

3 Window Functions and Operation

Downloading, uploading settings

This section explains how to download and upload settings from the controller.

NOTE

• The controller cannot communicate when it is in "Program Setting Mode", "Program selection

mode", or "Tolerance setting mode".

• If the connection with the controller uses the RS-232C interface and you change the RS-232C

settings in the "Controller Environment Setting", LK-Navigator 2 will download the settings and then

change the "PC Communication settings".

• The controller enters "communications mode" when downloading or uploading settings.

Uploading settings

Click on the tool bar.

Reference

The settings can also be uploaded by selecting "Receive settings from controller" from the

"Communication" menu.

Downloading settings

Click on the tool bar.

Reference

• The settings can also be downloaded by selecting "Send settings to controller" from the

"Communication" menu.

• Downloading can also be started from the "View Received Light Waveform" dialog (page 3-31).

3

3-23

Page 48

3 Window Functions and Operation

Environment Settings

This section explains how to configure the operating environment of the controller.

To u se three or more heads/OUTs by using the head expansion unit, set the "No. of

used heads" and "No. of used OUT" before configuring the measurement settings.

Otherwise, changing these settings will initialize the other measurement settings.

Click the "Controller Environment Setting" in the lower left of the main window to display the

"Environment setting" dialog.

3

(1)

(2)

(3)

(1) Controller RS-232C settings

Baud rate

Sets the communication speed of the controller.

Parity

Sets the parity check method.

Automatic transmission

Sets whether to automatically download the OUT to the RS-232C interface.

NOTE

If you change the RS-232C settings in the "Controller Environment Setting" while the controller is

connected via the RS-232C interface, LK-Navigator 2 will download the settings and then

change the "PC Communication settings".

3-24

Page 49

(2) Ethernet

IP Address

Sets the controller's IP address.

Subnet mask

Sets the subnet mask for the controller.

Gateway

Sets the gateway for the controller.

3 Window Functions and Operation

(3) Basic setting

No. of used heads

Sets the number of heads the controller can use.

No. of used OUT

Sets the number of OUTs the controller can use.

No. of used analog Ch

Sets the number of analog output channels the controller can use.

Panel lock

Sets whether to lock the display panel connected to the controller.

This setting takes effect after it is downloaded to the controller.

Program change

Sets the method for selecting a program.

Reference

If program selection is set to "External terminal", LK-Navigator 2 will, after downloading or

uploading the settings, select the program number specified by the external terminal.

3

3-25

Page 50

3 Window Functions and Operation

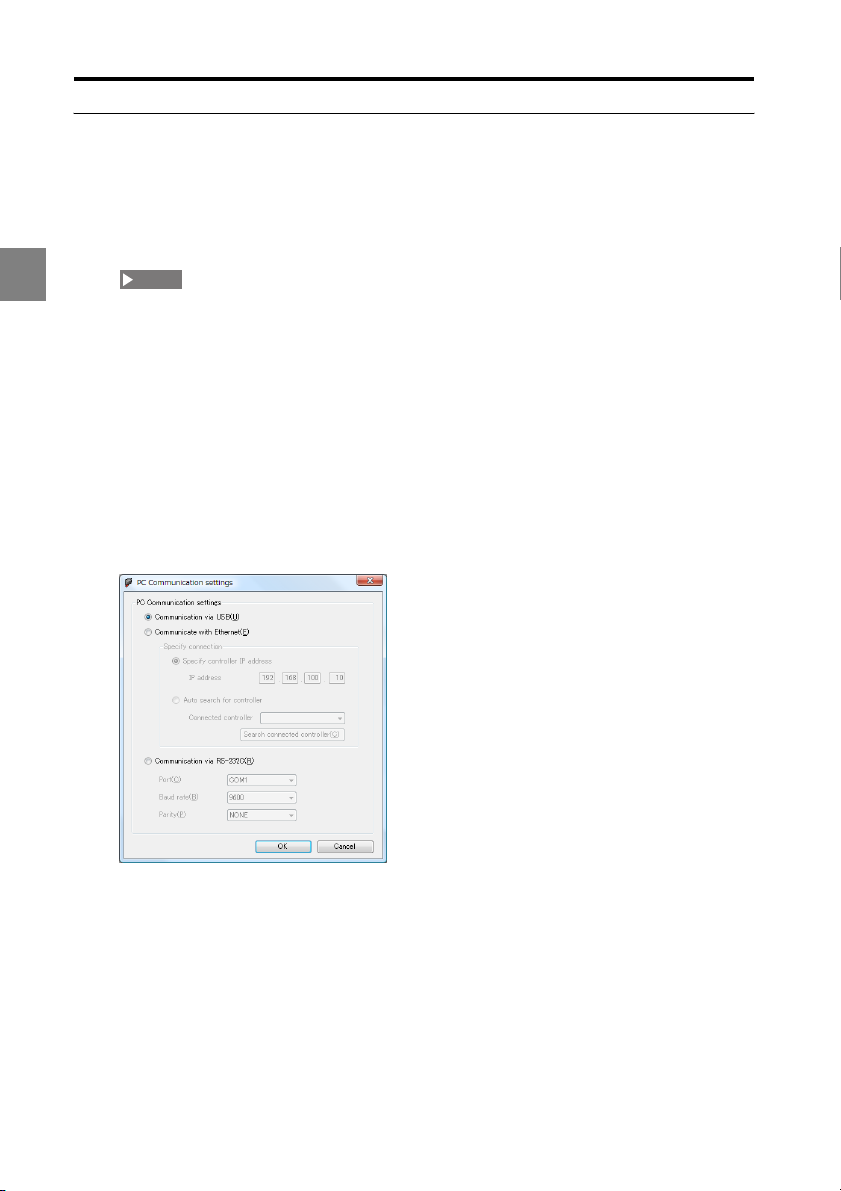

Communication Settings

This section explains how to configure the communications between the controller and PC.

From the "Communication settings" menu, select "PC Communication settings" to display

the "PC Communication settings" dialog.

(1)

3

(2)

(3)

(1) Communication via USB

Select this option when the controller and PC are connected via USB.

(2) Communicate with Ethernet

Select this option when the controller and PC are connected via Ethernet.

Specify controller IP address

Specify the actual IP address of the controller to connect to.

Auto search for controller

Click "Search connected controller" to specify the controller to connect to.

(3) Communication via RS-232C

Select this option when the controller and PC are connected via RS-232C.

Port

Specify the port to use to connect to the controller.

Baud rate

Set the baud rate to the communication speed of the controller.

Parity

Set the parity check method.

3-26

Page 51

3 Window Functions and Operation

Program Settings

This section explains the procedures for copying and initializing programs registered in the

controller.

Copying programs

Settings can be copied to other program numbers to avoid the trouble of repeating

settings.

Reference

The copied settings will overwrite any existing settings in the destination program.

1

3

2

4

From the main window, select the original program number to copy.

1

In this example, program No.0 is selected.

Click "Copy".

2

Confirm the "Paste" button is now active. Select the destination program number to paste

3

to.

In this example, program No.4 is selected.

3

Click "Paste".

4

A confirmation dialog appears.

Click "Yes".

5

The settings are copied.

3-27

Page 52

3 Window Functions and Operation

Initializing programs

The settings can be initialized to their factory default settings. Initializing erases any

existing settings.

3

1

2

Select the destination program number to initialize from the main window.

1

In this example, program No.1 is selected.

Click "Initialize".

2

A confirmation dialog appears.

Reference

To initialize the settings in all program numbers, click "Global initialization". The following

confirmation dialog appears when "Global initialization" is clicked.

Click "Yes".

3

The settings are initialized.

3-28

Page 53

3 Window Functions and Operation

Measurement Value Display

This section explains the "Measurement Value Display" function that allows viewing of

measurements on the PC.

Click "Measurement Value Display" on the tool bar to display the "Measurement Value

Display" window.

Reference

The "Measurement Value Display" window can also be displayed by selecting "Measurement

Value Display" from the "View" menu.

(1)

(2)

(3)

(4)

3

(5)

(6)

(7)

(1) Measurement value acquisition start

Starts acquiring measurement data from the controller.

Clicking "Measurement value acquisition start" causes the button label to change to

"Measurement value acquisition stop".

Reference

These buttons are disabled until "Measurement value acquisition start" is clicked: "Zero", "Reset",

"Timing", "Simultaneous Timing".

3-29

Page 54

3 Window Functions and Operation

(2) Display the measurement data after applying simultaneous auto zero, simul-

taneous reset, or simultaneous timing

Simultaneous zero

Applys auto zero simultaneous to the OUT specified for synchronization.

Simultaneous reset

Resets simultaneous to the OUT specified for synchronization.

Simultaneous timing

Inputs the timing signal simultaneous to the OUT specified for synchronization.

(3) Select display

3

Click, then check the OUTs to display.

(4) Displays the measurement data after applying auto zero, reset, and timing

processing

Zero

The current measurement data is set to the reference value (zero) and then displayed.

Refer to the LK-G5000 series User's manual, "Chapter 2 Operations during Measurement

and Their Functions" (page 2-1) for details on the auto-zero function.

Reset

The measured values are displayed after the processing in the Measurement Mode and

the Filter processing are reset to the default values.

Refer to the LK-G5000 series User's manual, "Chapter 3 Function Settings" (page 3-1) for

details on the measurement data reset function.

Timing

Toggles the timing function between on and off. Refer to the LK-G5000 series User's

manual, "Chapter 3 Function Settings" (page 3-1) for details on the timing function.

(5) Head status

Displays the head status.

Refer to the LK-G5000 series User's manual, "Chapter 2 Operations during Measurement

and Their Functions" (page 2-1) for details on the displayed information.

(6) Help

Opens the LK-Navigator 2 help file.

(7) Exit

Closes the "Measurement Value Display".

3-30

Page 55

3 Window Functions and Operation

Received Light Waveform Display

This section explains the "View Received Light Waveform" function that allows viewing of

received light measurements on the PC.

Click "View Received Light Waveform 1" or "View Received Light Waveform 2" on the tool

bar to display the "View Received Light Waveform" window. (In this example, click "View

Received Light Waveform 1").

Reference

The "View Received Lght Waveform" window can also be displayed by selecting "View Received

Light Waveform 1" or "View Received Light Waveform 2" from the "View" menu.

Reference

• The "View Received Light Waveform" window is resizable.

• The window cannot be resized smaller than the initial window size.

(1) Start acquiring the received light

Starts acquiring received light data from the controller and displays the most recent

waveform.

Clicking "Start acquiring the received light" causes the button label to change to "Stop

acquiring the received light".

3

(2) Send settings to controller

Downloads all settings to the controller, including the mask settings changed using the

mask range setting cursor.

3-31

Page 56

3 Window Functions and Operation

(3) Model display

Indicates the model of the head used to acquire the displayed waveform.

(4) Waveform display manipulating tool bar

Zoom/shrink

Zooms/shrinks the waveform vertically and horizontally.

Move display position

Moves the waveform up or down.

3

ABLE

Displays the waveform after applying ABLE processing to the displayed peak waveforms

1 to 4 if "Measurement mode" is set to "Transparent object-2". Refer to the LK-G5000 series

User's manual, "Chapter 3 Function settings" (page 3-1) for details on the ABLE function.

Hide mask range setting cursor

Hides the mask range setting cursor if the mask setting is ON.

Mask range setting cursor selection

Selects and displays the mask range setting cursor if the mask setting is ON.

Head display selection

Selects the head to display the received light from.

(5) Received light waveform display

Displays the waveform of received light data. The white vertical line superimposed on the

waveform represents the current measurement position.The waveform is read as follows.

• X axis: Position of received light waveform. The farther left the waveform, the closer the

received light waveform is to the head.

• Y axis: Intensity of received light. The higher the waveform, the stronger the light

intensity.

• Waveform display: Displays the waveform after the controller applies ABLE processing.

(6) Help

Opens the LK-Navigator 2 help file.

(7) Exit

Closes the "Received light waveform display".

(8) Overlap the waveforms

Superimposes the current waveform over the previous waveform when the mouse was

clicked.

(9) Copy the screen image

Copies the current waveform to the clipboard.

3-32

Page 57

3 Window Functions and Operation

Data Storage Setting

This section explains how to change data storage settings, and about the "Data storage"

function for displaying measurement results.

Names and functions of the data storage settings window

Click "Data Storage" on the tool bar to display the "Data Storage" window.

Reference

The "Data Storage" window can also be displayed by selecting "Data Storage" from the "View"

menu.

3

The "Data Storage" window can display up to 12 waveforms. This window can display the

following data:

• Storage data read from the controller

• Storage data saved on the PC

Reference

• The "Data Storage" window is resizable.

• The window cannot be resized smaller than the initial window size.

3-33

Page 58

3 Window Functions and Operation

(1) Start Storage

Starts storing data on the controller.

(2) Stop Storage

Stops storing data on the controller.

(3) Clear Stored Data

Clears the data stored on the controller.

NOTE

Clear storage data clears all data stored on the controller.

3

(4) Status display

Displays the status of data storage on the controller.

Reference

The following states are displayed:

Status Status displayed Number of storage data displayed

Disconnected Not connected *****

Normal mode: storage Storage in progress Currently stored number of data

Normal mode: stopped Stopping in progress Currently stored number of data

Communications error ***** *****

Other system errors System error *****

(5) Data Storage Setting

Sets the method for storing measurement data. Refer to "Data Storage Setting" (page 3-

33) for details.

(6) Storage Data Readout

Loads storage data from the controller. Refer to "Loading storage data" (page 3-38) for

details.

(7) Waveform display manipulating tool bar

Tile/cascade display

Sets whether to display measurement data waveforms tiled or cascaded.

Zoom/shrink

Zooms/shrinks the measurement data waveform vertically and horizontally.

Auto fit

Automatically adjusts the vertical scale to fit the display area.

Move display position

Moves the waveform up or down.

3-34

Page 59

3 Window Functions and Operation

Hide cursor

Hides the cursor.

Select cursor

Selects and displays the cursor.

(8) Waveform name

Sets a user-defined name to the waveform.

NOTE

• Waveform names may contain up to any 16 alphanumeric characters except the comma and

period, or 8 double-byte characters.

• Waveform names can only be set when the waveform is displayed.

(9) Waveform color

Sets the color of the waveform.

NOTE

Waveform colors can only be set when the waveform is displayed.

(10)Display position

Moves the display position of the waveform.

NOTE

The display position can only be moved when the waveform is displayed.

3

(11)Measurement data waveform display

Displays the loaded measurement data.

(12)Cursor Information

Displays the cursor information in tabular form.

Reference

Storage data is saved to a file in CSV format.

(13)Help

Opens the LK-Navigator 2 help file.

(14)Exit

Closes the "Data Storage" window.

(15)Save in File

Saves the storage data to a file.

(16)Read from File

Loads storage data from a file.

3-35

Page 60

3 Window Functions and Operation

Data storage setting flow

Click "Data Storage Setting".

1

Preset the target OUT, amount of data store, and storage cycle.

Refer to "Changing data storage settings" (page 3-37) for details.

Click "Start Storage".

2

The controller starts storing measurement data.

Storage stops automatically when number of data set in "Amount of Data Stored"

3

has been stored.

Reference

• Click "Stop Storage" to pause data storage.

• After pausing, clicking on "Start Storage" again will resume data storage from where it

was paused.

Click "Storage Data Readout".

3

The "Read accumulation data" dialog appears.

Refer to "Loading storage data" (page 3-38) for details on loading storage data.

Click "Readout".

4

The data stored in the controller is transferred to the PC.

When the transfer status bar graph reaches the right end, the data transfer is

complete.

3-36

Page 61

3 Window Functions and Operation

Changing data storage settings

At the "Data Storage" window, click "Data Storage Setting" to display the "Data Storage

Setting" dialog.

(1) Amount of Data Stored

Sets the number of data points to store.

(2) Storage cycle

Sets the interval for data storage.

3

(3) Receive from Controller

Uploads the settings from the controller.

(4) Send to Controller

Downloads settings to the controller.

NOTE

The controller enters "communications mode" when downloading or uploading data.

(5) Exit

Closes the "Data Storage Setting" dialog.

(6) Selected OUT

Check the OUT to store data for.

3-37

Page 62

3 Window Functions and Operation

Loading storage data

At the "Data Storage" window, click "Storage Data Readout" to display the "Read

accumulation data" dialog.

3

(1) Data01 to Data12

Set the target to load for each data from 01 to 12.

(2) Readout

Starts loading storage data.

NOTE

The controller enters communications mode when "Readout" is in progress.

3-38

Page 63

3 Window Functions and Operation

Loading/Saving the Settings File

This section explains how to load and sa ve settings on the PC.

Loading the settings file

Click "Open" on the main window.

1

The "Open file " dialog appears.

Reference

This dialog can also be displayed by selecting "Open settings file" from the "File" menu.

Select the settings file to load.

2

Click "Open".

3

Saving the settings file

Click "Save" on the main window.

1

The "Save as" dialog appears.

Reference

This dialog can also be displayed by selecting "Save settings file" from the "File" menu.

Open the folder to save the file, and enter a file name to save the file in the "File

2

name" field.

Reference

The extension for a controller setting file ".ldtx" is automatically appended to the specified

file name.

Click "Save".

3

3

3-39

Page 64

3 Window Functions and Operation

Changing "No. of used heads" and "No. of used OUT" in the settings file (LK-Backup)

LK-Backup allows values for "No. of used heads" and "No. of used OUT" to be changed

without initializing measurement settings.

Save the current settings file in LK-Navigator (page 3-39).

1

Launch LK-Backup by double-clicking the LK-Backup shortcut icon.

2

3

Click "Open", then select the saved settings file.

3

Change the values for "No. of used heads" and "No. of used OUT", and click "Save".

4

Enter a file name and select a directory in which to save the file, then click "Save".

5

Load the settings file with the changed "No. of used heads" and "No. of used OUT"

6

values using LK-Navigator (page 3-39).

3-40

Page 65

Appendix

A

Error Messages and Corrective Action................................. A-2

.................................................................................... A-5

Index

A-1

Page 66

A

Error Messages and Corrective Action

This section lists the error messages displayed by LK-Navigator 2 when an error occurs,

and applicable corrective action.

During operation

During data communications

Error message Cause Correction

(Communications) failed.

* Contents in () will change to

indicate the item that failed.

System error occurred. An error occurred in the

Controller is not ready for

communications.

The display panel or RS-232C is

in settings mode.

The controller is communicating

via LK-Navigator 2 with another

PC.

An active communication error

exists.

controller.

Set the controller to measurement

mode.

Terminate the other LK-Navigator

2.

Check wiring and communication

settings, then retry. If the

communications cable was

disconnected, restart the

controller and LK-Navigator 2.

Check the display on the

controller and configure it

correctly.

Refer to the "LK-G5000 series

User's manual" for operating

instructions and display

meanings for the controller.

If this error occurs frequently,

notify your nearest sales office.

When the controller is operating

Error message Cause Correction

The head unconnected error

occurred.

An error occurred in

HEAD(number).

The memory error occurred.

Do you want to initialize the

memory?

The head is not connected. Connect the head and check that

A problem occurred in the head. Check that the head is

The memory in the controller is

abnormal.

it operates correctly. Then, restart

LK-Navigator 2.

connected properly. If the

problem fails to reset, notify your

nearest sales office.

Initialize the controller.Follow the

guidance on the dialogs. This

dialog cannot be cancelled.

A-2

Page 67

During configuration

Head settings

Error message Cause Correction

ABLE tuning

Setting range is 1 to 99. The ABLE field contains a blank

Set so the lower limit < = upper

limit.

Alarm cycles to hold

Illegal input. Input a value from 0

to 9999.

or is set to 0.

The lower limit for ABLE is set to a

value greater than the upper limit.

The alarm cycles to hold field

contains a blank.

OUT settings

Error message Cause Correction

Scaling input

Illegal input.

Input a value from (-99.9999 to

99.9999)*.

Input value 1 and input value 2

cannot be set to the same value.

Scaling display

Illegal input.

Input a value from (-99.9999 to

99.9999) *.

Scaling in general

Set so that |(display value 2 display value 1) / (input value 2 input value 1) | <= 2.

Offset

Illegal input.

Input a value from (-99.9999 to

99.9999) *.

Tolerance upper/lower limit

Illegal input.

Input a value from (-99.9999 to

99.9999) *.

The scaling setting field contains

a blank, non-numeric value, or a

value outside the setting range.

The input value 1 and input value

2 fields for the scaling setting are

set to the same value.

The scaling setting for displaying

field contains a blank, nonnumeric value, or a value outside

the setting range.

The slope of the scaling setting

exceeds 2.

The offset field contains a blank,

non-numeric value, or a value

outside the setting range.

The tolerance upper/lower limit

fields contain a blank, nonnumeric value, or a value outside

the setting range.

Set the ABLE field with a value

from 1 to 99.

Set with a value so that the lower

limit < = upper limit.

Set the alarm cycles to hold field

with a value from 0 to 9999.

Set the scaling setting input value

to a value within the displayed

range.

Set the input value 1 and input

value 2 fields for the scaling

setting to a different value.

Set the scaling setting display

value to a value within the

displayed range.

Set the input and output values

so that the slope of the scaling

setting is less than or equal to 2.

Set the offset field to a value in

the displayed range.

Set the tolerance upper/lower

limit fields to a value in the

displayed range.

A

A-3

Page 68

A

Error message Cause Correction

Set so the lower limit < upper

limit.

Tolerance hysteresis

Illegal input.

Input a value from (0 to 99.9999) *.

Set so that the (upper limit - lower

limit) > hysteresis.

Analog scaling measurement data

Illegal input.

Input a value from (-99.9999 to

99.9999) *.

Measurement data 1 and

measurement data 2 cannot be

set to the same value.

Analog scaling output voltage

Illegal input.

Input a value from (-10.500 V to

10.500 V).

Analog scaling in general

Set so that |(output voltage 2 output voltage 1) / (measurement

data 2 - measurement data 1) | <

10.

* Figures between () will change depending on the value in the "Minimum display unit" setting.

The lower limit for the tolerance is

set to a value greater than the

upper limit.

The tolerance hysteresis field

contains a blank, non-numeric

value, or a value outside the

setting range.

The tolerance hysteresis field is

set to a value greater than the

tolerance measuring range

(upper limit - lower limit).

The analog scaling measurement

data field contains a blank, nonnumeric value, or a value outside

the setting range.

The measurement data 1 and

measurement data 2 fields for the

analog scaling setting are set to

the same value.

The analog scaling output

voltage field contains a blank,

non-numeric value, or a value

outside the setting range.

The slope of the analog scaling

setting exceeds the setting

range.

Set the tolerance lower limit to a

value that is less than the upper

limit.

Set the tolerance hysteresis field

to a value in the displayed range.

Set the tolerance hysteresis to a

positive value that is less than the

tolerance upper limit - lower limit.

Set the analog scaling

measurement data field to a

value in the displayed range.

Set the measurement data 1 and

measurement data 2 fields for the

analog scaling setting to a

different value.

Set the analog scaling output

voltage field to a value from -10.5

to 10.5.

Set the measurement data and

output voltage fields so that the

slope of the analog scaling

setting is less than the displayed

value.

Common settings

Error message Cause Correction

Data storage points

Illegal input.

Input a value from 1 to (1200000 /

number of storage OUTs).

The data storage points field

contains a blank, 0, or a value

greater than 65536.

Set the data storage points field

to a value from 1 to 65536.

A-4

Page 69

Index

F

Filter ..................................................3-12

Flow of operation ................................3-4

A

ABLE .................................................. 3-6

ABLE tuning ................................ 3-6, 3-7

Alarm handling.................................... 3-8

Alarm output mode ........................... 3-16

Analog output........................... 3-15, 3-21

Analog output scaling ....................... 3-15

Auto transmission.............................. 3-24

Averaging times ................................ 3-12

B

Baud rate ..................................3-24, 3-26

C

Calculation method ............................. 3-9

Common settings............................... 3-16

Communication settings.................... 3-26

Controller environment settings........ 3-24

Copying programs............................. 3-27

Cursor information ............................ 3-35

Cutoff frequency ............................... 3-12

D

Data storage.............................. 3-20, 3-36

Data storage setting .........3-33, 3-34, 3-37

Detection type ................................... 3-11

Download, upload settings ................ 3-23

Downloading, uploading settings...... 3-23

E

Environment settings......................... 3-24

Error messages and corrective

action ............................................ A-2

Ethernet .................................... 3-25, 3-26

Ethernet connection............................. 2-3

Exit .................................................... 2-11

G

Gateway............................................. 3-25

H

Head selection .....................................3-5

Head settings .......................................3-5

Hysteresis ..........................................3-12

I

Initializing programs .........................3-28

Installation........................................... 2-6

Installing.............................................. 2-6

IP address .................................3-25, 3-26

L

LASER control group.......................... 3-6

Launching/Exiting LK Navigator 2..... 2-9

Level.................................................... 3-8

LK-Backup ........................................ 3-40

Load settings file ............................... 3-39

Load storage data......................3-34, 3-38

M

Mask boundary.................................... 3-6

Mask setting ........................................3-6

Measurement data display ................. 3-29

Measurement mode ...........................3-11

Median................................................. 3-6

Menu bar.............................................. 3-2

N

Names and functions ........................... 3-2

Number of analog output

channels ....................................... 3-25

Number of heads ...............................3-25

Number of OUTs............................... 3-25

A

A-5

Page 70

A

O

Offset .................................................3-13

OUT settings........................................ 3-9

OUT to store ...................................... 3-20

P

Panel lock ..........................................3-25

Parity.........................................3-24, 3-26

PC communication settings ............... 3-26

Port ....................................................3-26

Program selection ..............................3-25

Program settings ................................3-27

R

Range...................................................3-6

Received light waveform display ......3-31

Reset ..................................................3-30

RS-232C ...................................3-24, 3-26

RS-232C connection............................ 2-5

S

Sampling frequency...........................3-16

Save settings file................................3-39

Scaling ......................................3-13, 3-14

Set from measurement data

...............................................

Settings list ........................................3-22

Simultaneous reset.............................3-30

Simultaneous timing..........................3-30

Simultaneous zero .............................3-30

Smallest display unit..........................3-15

Status display.....................................3-34

Storage interval.................................. 3-20

Storage points ....................................3-20

Strobe time.........................................3-16

Subnet mask.......................................3-25

Synchronization settings.................... 3-18

3-13, 3-14

Tolerance judgment output mode

..........................................................

3-16

U

Uninstallation.......................................2-7

USB....................................................3-26

USB connection ........................... 2-2, 2-3

USB driver installation ........................2-8

Z

Zero....................................................3-30

T

Timing ...............................................3-30

Tolerance judgment ........................... 3-12

A-6

Page 71

Page 72

Page 73

Page 74

Revision History

Date of printing Vers ion Revision details

January 2011 Official release

Page 75

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a

period of one (1) year from the date of shipment. If any models or samples were shown to

Buyer, such models or samples were used merely to illustrate the general type and quality of

the Products and not to represent that the Products would necessarily conform to said

models or samples. Any Products found to be defective must be shipped to KEYENCE with

all shipping costs paid by Buyer or offered to KEYENCE for inspection and examination.

Upon examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price

of, or repair or replace at no charge any Products found to be defective. This warranty does

not apply to any defects resulting from any action of Buyer, including but not limited to

improper installation, improper interfacing, improper repair, unauthorized modification,

misapplication and mishandling, such as exposure to excessive current, heat, coldness,

moisture, vibration or outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only

suggestions, and it is Buyer's responsibility to ascertain the fitness of the Products for

Buyer's intended use. KEYENCE will not be responsible for any damages that may result

from the use of the Products.

(3) The Products and any samples (Products/Samples) supplied to Buyer are not to be used

internally in humans, for human transportation, as safety devices or fail-safe systems, unless

their written specifications state otherwise. Should any Products/Samples be used in such a

manner or misused in any way, KEYENCE assumes no responsibility, and additionally Buyer

will indemnify KEYENCE and hold KEYENCE harmless from any liability or damage

whatsoever arising out of any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO

OTHER WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY

WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. IN NO EVENT SHALL

KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY FOR

ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL

DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS

OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF

DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF