Page 1

Ultra High-Speed/High-Accuracy

Laser Displacement Sensor

SETUPGUIDE

This guide explains basic setting methods for the LK-G5000.

For more detailed information, refer to the User’s Manual.

LK-G5000

INDEX

Introduction

1

• Core component layout

• Mounting the Sensor Head

Setup using LK-Navigator 2 (LK-H2)

2

• What is LK-Navigator 2?

• Launching LK-Navigator 2

• Sending settings

• Receiving settings

• Displaying measurement values

Sensor head-related settings

3

• Head settings

• Measurement mode

• Mounting mode

OUT settings

4

• OUT settings

• Calculation method

• Measurement/Tolerance-Measurement type

• Measurement/Tolerance-Filter

• Measurement /Tolerance - Tolerance Evaluation

Measurement setup examples

5

• Eccentricity/ Vibration Measurement Setting Methods

• Thickness Measurement Setting Methods

• Setting methods for measuring the thickness of transparent objects

• Data storage function setting methods

FAQ's

6

• Common questions

• Connecting a PC/PLC link unit

• Wiring guide

• Optional parts

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

➔

P. 2

P. 2

P. 4

P. 4

P. 5

P. 5

P. 5

P. 6

P. 6

P. 7

P. 8

P. 8

P. 9

P. 9

P. 9

P. 10

P. 12

P. 15

P. 17

P. 20

P. 21

P. 22

P. 23

Page 2

1

Introduction

This section contains information related to the component layout and installation of this device.

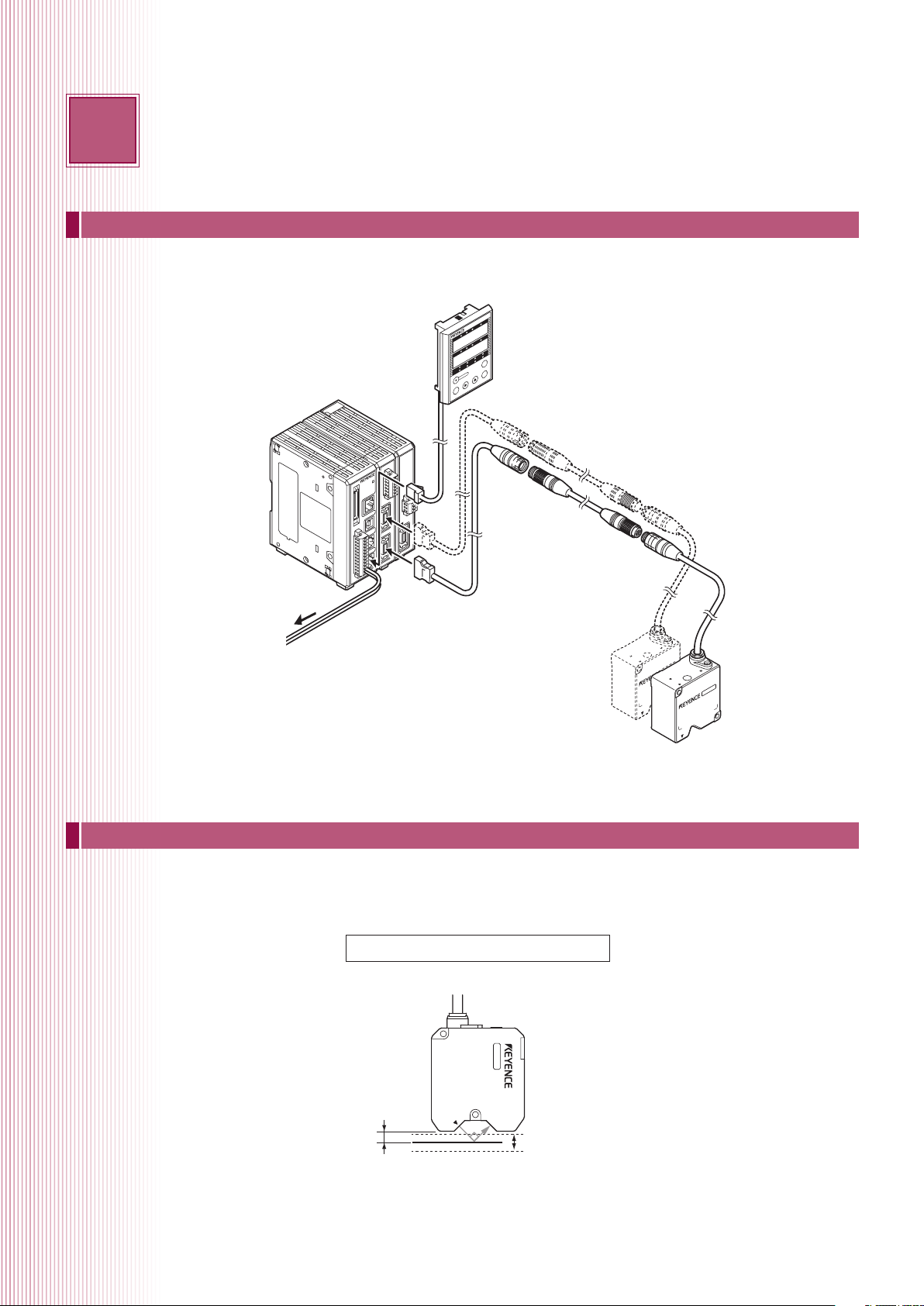

Core Component Layout

Displ ay pan el cable

(0.33 m /3 m/10 m)

LK-HD500

Displ ay pan el

GO LO TIM

HI

OUT1

OUT2

HEAD1

HEAD2

SET

(When usin g a sepa rat e cont roll er)

GO LO TIM

HI

ARK

ARK

STABILITY BRIGHT D

STABILITY BRIGHT D

ZERO

LASER ON

LASER ON

ENT

ROGRAM

P

Sensor head-to-con trol ler ex tension ca ble op tion al

LK-HA100

POWER

STABILITY

BRIGHT

)

V

(

)

A

(

ARK

D

0V

)

V

(

)

A

(

0V

1

)

V

(

)

A

(

)

A

(

HEAD

Sensor head-to-con trol ler ca ble

(0.7 m/2 m/5 m /10 m/ 20 m/ 30 m)

24 VDC po wer sup ply

Head 0 2

Head 01

Mounting the Sensor Head

In order to accurately measure a target, mount the sensor head so that the top surface of the target enters the measurement range.

LK-H008

Diffused target/specular reflection target

Refer ence posit ion

8 mm

0 mm

Meas urement ra nge

+0.5 mm

-0.5 mm

2

Page 3

DIFFUSE TARGET SPECULAR TARGET

LK-H02x

Refer ence posit ion Refer ence posit ion

20 mm

0 mm

Meas urement ra nge

+3 mm

-3 mm

LK-H05x

Refer ence posit ion

50 mm

Meas urement ra nge

0 mm

+10 mm

-10 mm

LK-H08x

LK-H02xK

LK-H05xK

Refer ence posit ion

LK-H08x+LK-F3

16.1 mm

0 mm

46.3 mm

0 mm

Meas urement ra nge

+2.8 mm

-2.8 mm

Meas urement ra nge

+5.2 mm

-5.2 mm

Refer ence posit ion

80 mm

0 mm

Meas urement ra nge

+18 mm

-18 mm

76.7 mm

Refer ence posit ion

0 mm

Meas urement ra nge

+17.6 mm

-17.6 mm

LK-H15x LK-H15x+LK-F2

Refer ence posit ion

150 mm

0 mm

Meas urement ra nge

+40 mm

-40 mm

MEASURING A SPECULAR TARGET

When measuring specular targets like glass or mirrors, mount the sensor head at an angle so that reflected laser light returns to the

receiver. When using the LK-H08x or the LK-H15x, use the LK-F3 or LK-F2 neutral density filter.

147.5 mm

Refer ence posit ion

0 mm

Meas urement ra nge

+39.5 mm

-39.5 m m

3

Page 4

2

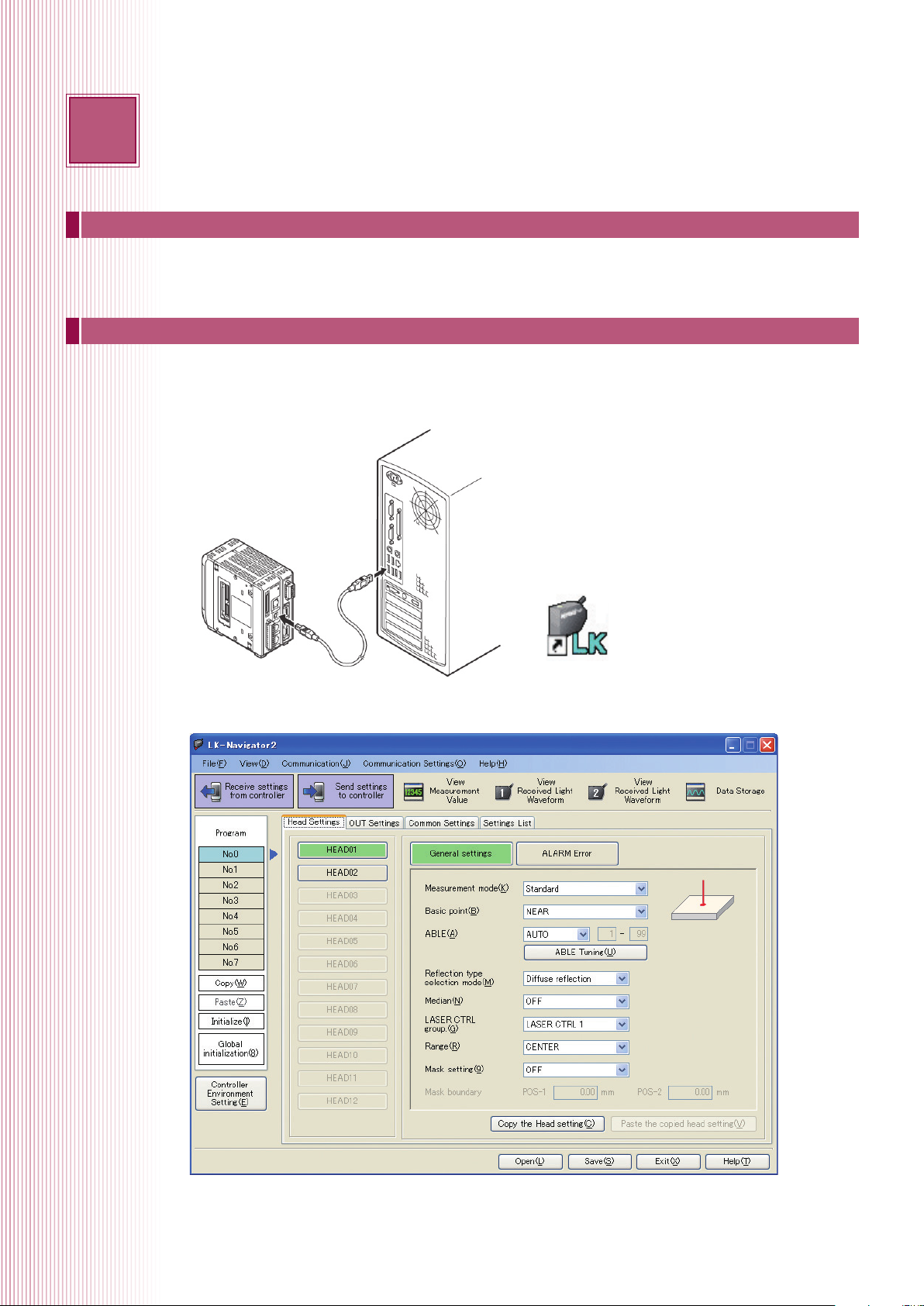

What is LK-Navigator 2?

LK-Navigator 2 is a software package that can be used to set up the LK-G5000 and acquire measurement values.

Launching LK-Navigator 2

Connect the sensor head to the controller and turn on the power. Prepare the PC that has had LK-Navigator (LK-H2) installed on it

and then connect the controller to the PC via USB cable.

Double click the LK-Navigator 2 icon to launch LK-Navigator 2.

Setup using LK-Navigator 2 (LK-H2)

This section will cover basic setup using LK-Navigator 2.

Connecting the PC and the controller

LK-Navigator 2 settings screen

4

Page 5

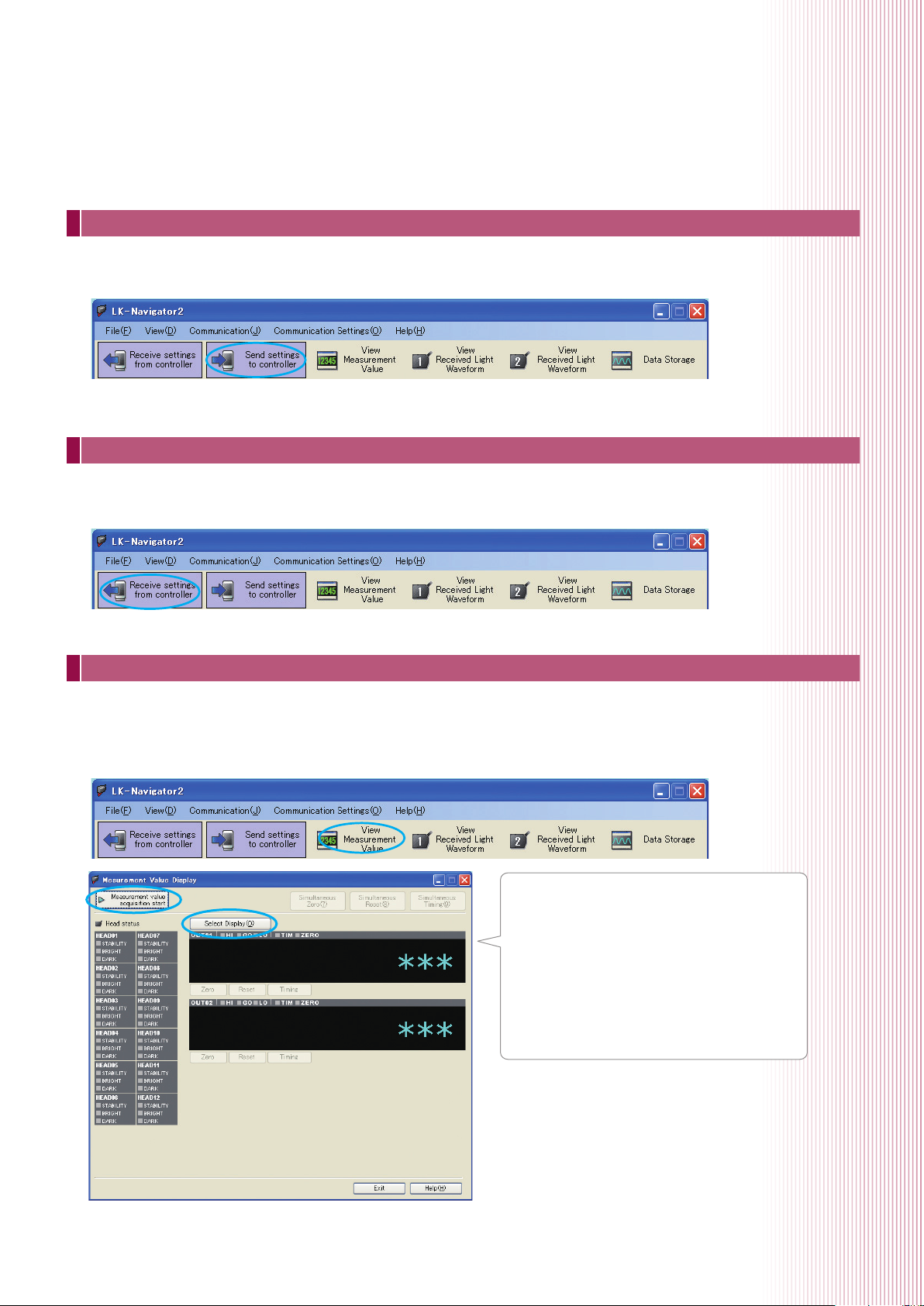

Sending settings

Once the button for “Send settings to controller” is clicked, the settings that have been created in LK-Navigator 2 will be applied

to the controller.

Receiving settings

Once the button for “Receive settings from controller” is clicked, the controller settings will be downloaded to LK-Navigator 2.

This is useful when checking the settings that are currently being used.

Displaying measurement values

Using LK-Navigator 2, it is possible to check the current measurement values. Once the “View Measurement Value” button has

been clicked, the Measurement Value Display window will appear.

Once the button for “Measurement value acquisition start” in this window is clicked, it will be possible to check the measurement

values.

Once the window is opened, the "Measurement

Value Display" screen will be on standby. By

clicking the "Measurement value acquisition start”

button, it will be possible to acquire measurement

values from the controller. By clicking the "Select

Display" button, it will be possible to select the OUT

number that will be displayed in the Measurement

Value Display window.

5

Page 6

3

Sensor head-related settings

This section covers basic head level processing settings.

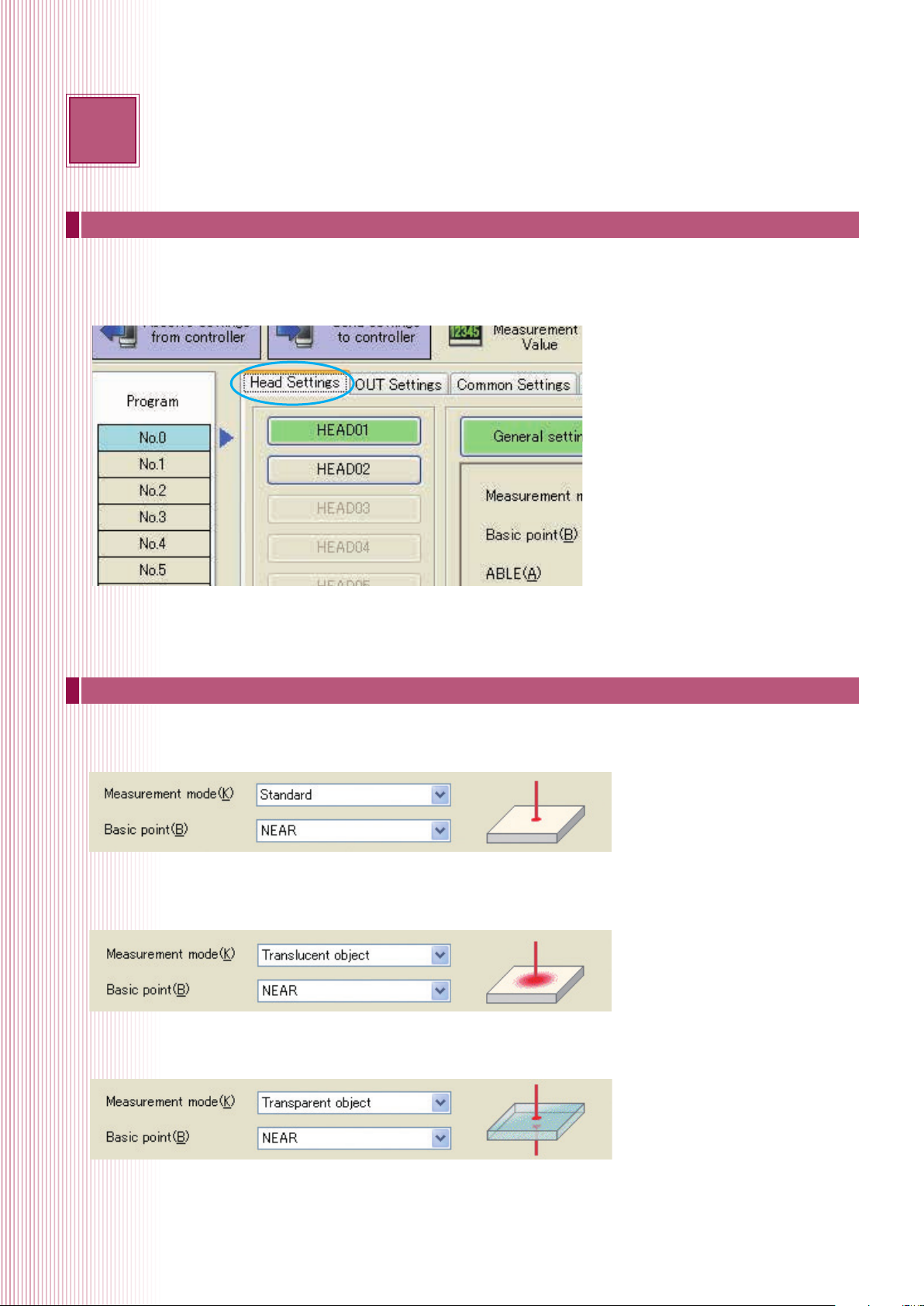

Head settings

This section controls head level target optimisation processes. This makes it possible to select measurement modes that are

optimised for specific target surface conditions and materials, and allows for corrections to compensate for sensor head mounting.

Measurement mode

Selects settings that have been optimised for various target surfaces.

Standard mode

The measurement mode that has been set as default and is optimal for the vast majority of diffuse targets. Measurement is normally

performed in this mode.

Translucent object mode

Used when measuring target that scatter light such as translucent resin.

Transparent object mode

Used when performing displacement or thickness measurement for transparent objects like glass or transparent films.

Used when the reflectivity of the different surfaces of a transparent object are the same.

6

Page 7

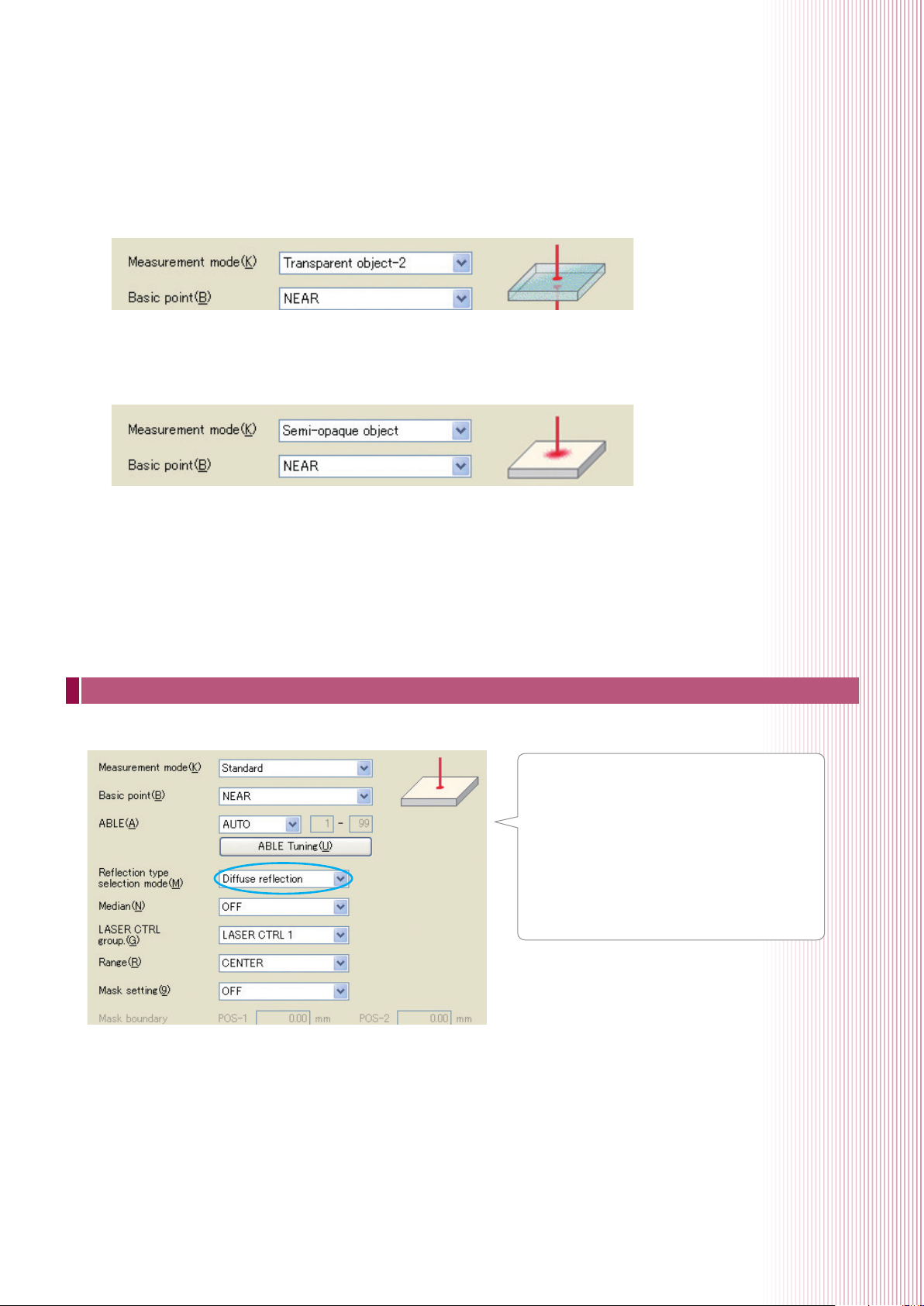

Transparent object 2 mode

Used when measuring transparent object target that have multiple surfaces that differ in

reflectivity such as when measuring metal-deposited glass.

Semi-opaque object mode

Used when measuring diffuse targets with strong surface luster.

Mounting mode

Selects settings in response to the mounting method for the sensor head.

“Diffuse reflection”

As listed in P.2 of this guide, this setting is used when

the sensor head is mounted perpendicular to the target.

“Specular reflection mounting”

A method where the sensor head is mounted at an

angle to the target. By performing specular reflection

mounting, measurement is possible after correcting

physical errors caused by the angle.

7

Page 8

4

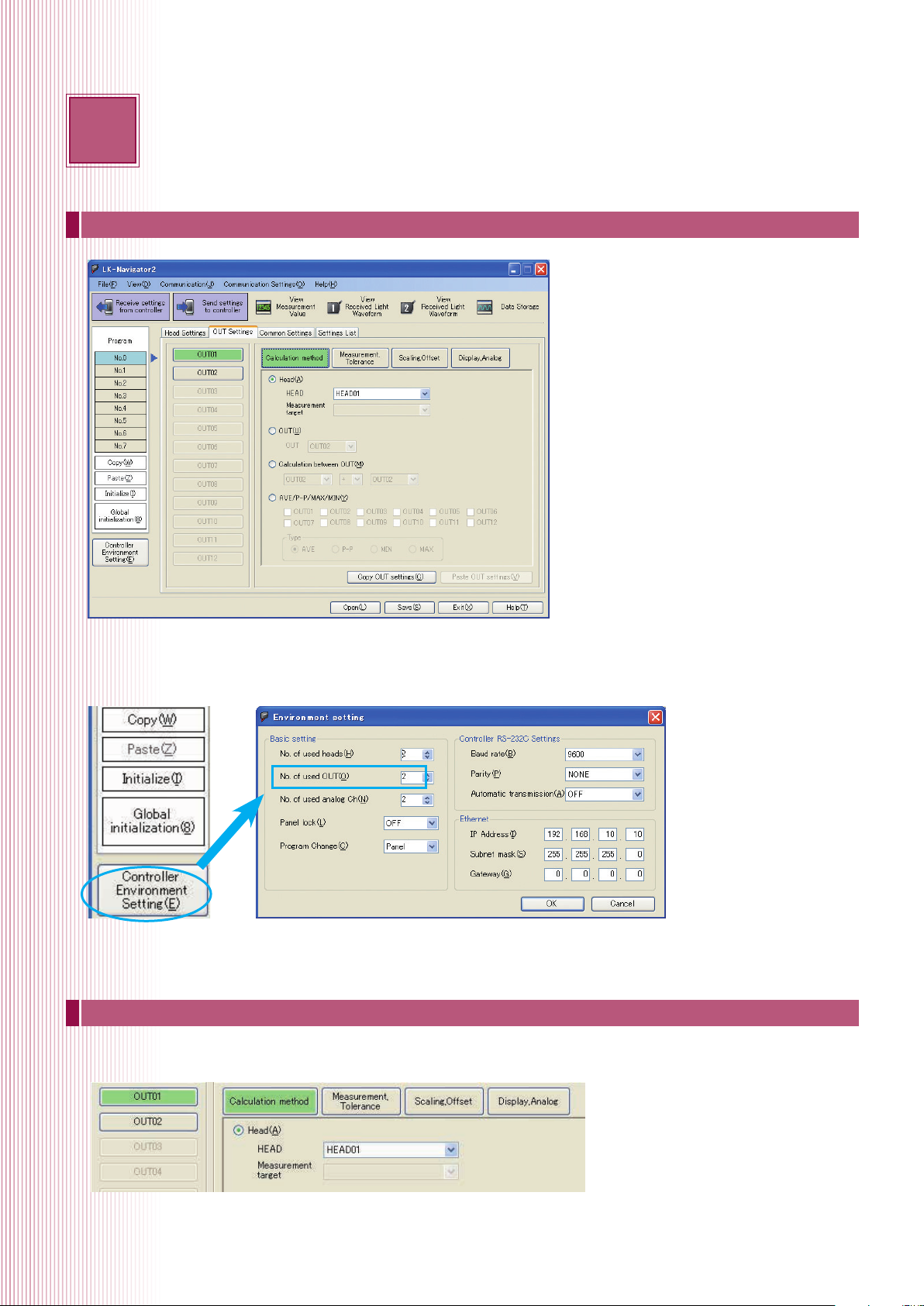

OUT settings

OUT settings

These settings related to measurement value processing.

With the LK-G5000, measurement values can be calculated and displayed for each OUT. At default, the number of used OUTs is 2,

and up to 12 can be set. The number of used OUTs can be set in the environment settings.

*Once the “No. of used OUT” is changed, all programs will be initialised. The number of used OUTs must be the first thing to be set.

Calculation method

Sets which sensor head will display measurement values to which OUT and performs calculations between these measurement

values.

With the settings listed above, measurement values that have been measured with head 01 will be displayed at OUT1.

8

Page 9

Measurement/Tolerance-Measurement type

Selects which of the following targets will be measured in “Measurement type”.

Displacement/Speed/Acceleration

Measurement/Tolerance-Filter

Settings related to measurement value processing are performed in Filter. By setting the moving average, it is possible to stabilise

measurement values.

The measurement values are set with a moving average in the range of 1 to 262144 times.

When an average of 4x has been set, the following process will occur.

Sampling cycle

Internal data

Average

measuring time

Average

measuring time

Average

measuring time

Outputs the average of Data 1 to 4 as Data A.

Outputs the average of Data 2 to 5 as Data B.

Outputs the average of Data 3 to 6 as Data C.

Measurement/Tolerance - Tolerance Evaluation

Can set the evaluation values for the allowable measurement value range. The upper/lower limit values are set so that a signal is

output from the controller when the measurement values exceed these values.

9

Page 10

5

Measurement setup examples

This section provides application setup examples.

Eccentricity/Vibration Measurement Setting Methods

Setting methods when performing eccentricity/vibration measurements are as follows.

Preparation and Overview

LK-G5000 Series controller 1

LK-G5000 Series sensor head 1

LK-G5000 Series head cable 1

LK-Navigator 2 configuration software 1

24 V power source 1

Required Components No. of units

When measuring eccentricity/vibration for flat or

cylindrical workpieces, the “Peak-to-peak function” of

the LK-G Series is used.

1. Peak-to-peak function

The peak-to-peak function automatically calculates the difference between MAX and MIN value for a custom sampling

cycle. The custom sampling cycle can be controlled using the timing input or by RS-232C commands.

Controller

0.031

Display of

vibration

amount

Timing signal

Comparator output

2. Timing input

The target is rotated, time input is turned ON, and sampling is started. When the timing input is turned ON once

again, sampling ends and the maximum variation in the measurement value is displayed, making it possible to obtain

comparator output.

10

(V)

Start of measurement

Timing signal

Sampling time

ON

OFF (t)

End of measurement

Comparator output

MAX value

Output value

MIN value

Page 11

Settings and Procedures

The following settings should be used as a default.

1. Measurement mode and average frequency settings

(1) Change the measurement mode for OUT1 to “PEAK-TO-PEAK HOLD” and change the average frequency to 1 time or as

needed.

(2) In “General” under “Common Settings”, set the “Sampling cycle” to 20 μs or as needed.

(3) Click “Send settings to controller”. (Pg. 5 of this guide).

2. Measuring the amount of eccentricity and vibration

(1) Click “View Measurement Value”.

(2) Click “Timing” on the input terminal or in the included software to display the amount of eccentricity/vibration whenever

the timing input is ON.

11

Page 12

Thickness Measurement Setting Methods

When two sensor heads are connected to measure thickness between the two sensor heads, the setting method is as follows.

With measurement between two sensor heads, it is possible to minimise the influence of vertical vibration.

Preparation and Overview

LK-G5000 Series controller 1

Required Components No. of units

LK-G5000 Series sensor head 2

LK-G5000 Series head cable 2

LK-Navigator 2 configuration software 1

24 V power source 1

1. Sensor head mounting bracket

In order to perform measurement between two sensor heads, mount

the sensor heads as seen in the figure on the right. Once the target

has been inserted, mount the sensor head so that the surface of the

target comes to the standard distance for each head.

USEFUL TIP

As seen in the image on the right, a reverse-C-shaped single body jig can

reduce the influence of vibration in the mounting bracket.

2. Adjusting the optical axis.

OK

Reverse-C-shaped single-body jig

The optical axis for two sensor heads is adjusted to form a single

straight line. Adjust the optical axis so that the relative spot position

NG

does not deviate even if the target is moved up and down.

USEFUL TIP

Use a thin, white coloured plastic or piece of paper as a setup tool. These

types of materials will allow the user to see both the top and bottom spot

simultaneously. Sensor head position should be adjusted so that the beam

spots appear to overlap at all points in the measurement range.

Note

12

Check that the top and bottom spots are properly overlapped even if the target is moved up and down.

The laser spots are

overlapping

The laser spots are slightly misaligned Modify target installation so that the centres of

the laser spots overlap to form a single

Page 13

Settings and Procedures

The following settings should be used as a default.

1. Setting the number of used OUTs

(1) Click “Environment Setting”.

(2) Set the number of used OUTs

according to the number of

thickness areas that will be

measured.

Measurement area X 3 = Number

of used OUTs

Ex.) If one thickness area is

measured, then the number of

OUTs that will be used is 3

(3) Click [OK].

1. Changing OUT settings

(1) Click the “OUT settings” tab.

(2) Configure each of the following

settings.

OUT01: HEAD 01 (Head)

OUT02: HEAD 02 (Head)

OUT03: OUT1 + OUT2

(Calculation between OUT)

* When measuring the thickness of multiple

areas, perform settings as listed below.

OUT04: HEAD 03 (Head)

OUT05: HEAD 04 (Head)

OUT06: OUT4 + OUT5 (Calculation between

OUT)

13

Page 14

3. Scaling settings

This will explain the individual setting methods for the following two patterns.

A: Calibrating with 2 master targets that have different dimensions

B: Calibrating with 1 master workpiece

* When measuring workpieces that have different thicknesses, accurate calibration can be performed with method A.

A: Calibrating with 2 master workpieces that have different dimensions

Ex.) Setting scaling for OUT3 with 1 mm and 1.5 mm gauge blocks

(1) Click “Set from measurement data” in the scaling/offset settings for

OUT3.

(2) Insert the 1 mm gauge, click “Set” for input value 1 and then enter

1mm for display value 1.

(3) Insert the 1.5 mm gauge, click “Set” for input value 2 and then enter

1.5 mm for display value 2.

(4) Click [OK] and then click “Send settings to controller”.

B: Calibrating with 1 master workpiece

Ex.) Setting scaling for OUT3 with a 1 mm gauge

(1) Enter 1 mm for the scaling setting offset for OUT3.

(2) Click “Send settings to controller”.

(3) Measure the 1 mm master workpiece.

(4) Click “View Measurement value” and then click “Measurement value acquisition start”.

(5) Once “Zero” is clicked for OUT3, the thickness of the master workpiece will be displayed as the measurement value.

With the current settings “1.000” will be displayed.

4. Click the button for “Send settings to controller”. (pg. 5 of this guide)

Once the “Measurement value acquisition start” button has been clicked, Measurement Value Acquisition/Display will appear.

14

Page 15

Setting methods for measuring the thickness of transparent objects

The setting methods that are used when measuring the thickness of transparent objects with the LK-G5000 are as follows. With

the LK-G5000, position data for the top and bottom surface are obtained as the detection surface, so it is possible to measure the

thickness of transparent objects from one side.

Preparation and Overview

LK-G5000 Series controller 1

LK-G5000 Series sensor head 1

LK-G5000 Series head cable 1

LK-Navigator 2 configuration software 1

24 V power source 1

An neutral density filter must be mounted with the following models.

Required Components No. of units

Models that require an neutral density filter

LK-H080/082/085/087 ➔ Mount the LK-F3

LK-H150/152/155/157 ➔ Mount the LK-F2

Mount the sensor head at an angle that is half of angle a, which is listed in the schematics for the LK-G5000.

* Mounting at an angle is not required for the LK-H008/LK-H008W.

Neutral density

Filter

LK-F3

LK-F2

a

Angle

a

2

Settings and Procedures

The following settings should be used as a default.

1. Set the measurement mode for head 01 to “Transparent object-2” and set the installation

mode to “Specular reflection”.

Once the measurement mode

is set to Transparent object-2,

ABLE adjustment will take effect

individually for the top and bottom

surfaces of transparent objects.

This will allow stable position

measurement for both surfaces.

* ABLE adjustment: A function that senses

the top surface of the measurement target

to adjust to the optimal amount of laser

light.

15

Page 16

2. For the calculation method for OUT1, set the measurement target to “[1st peak] – [2nd peak]”.

Displaying received light waveforms Received light waveform when measuring transparent glass

Sensor head

Light-receiving

element

(CMOS)

Light-receiving

lens

Top surface (1st peak)

Bottom surface

reflected light

Top surface

reflected light

Transparent glass

Waveform for received light

from the top surface

Waveform for received light

from the bottom surface

Bottom surface (2nd peak)

3. Measurement value scaling

(1) Click “OUT1 Scaling, Offset”.

(2) Click “Set from measured data” in scaling settings.

(3) Measure the master workpiece.

(4) Click “Set” for input value 2.

(5) Enter the thickness of the master workpiece for

Display2. For example, if the thickness of the master

workpiece is 1.0mm, enter “1.000” for Display2.

(6) Click [OK] and then click “Send settings to controller”.

Master workpiece

(For example, a thickness of

0.1 mm)

4. Click the button for “Send settings to controller”. (pg. 3 of this guide)

Click the “Measurement value acquisition start” button and Measurement Value Acquisition/Display will appear.

16

Page 17

Data storage function setting methods

If the data storage function is used, it will be possible to save up to 1.2 million points of LK-G measurement data to the controller.

If the LK-Navigator 2 is used, this measurement data can be checked on a PC and saved as a CSV file as well.

Overview

Up to 1.2 million individual measurement values for OUT1 through OUT12 can be accumulated to the internal memory for each

external timing input or set storage cycle.

The data storage interval can be controlled via the LK-Navigator 2 software (LK-H2) or from RS-232C commands.

When stored data is loaded in LK-Navigator 2, the waveform display or cursor can be used to display recorded values such as

maximum and minimum measurements. Also, stored data can be saved in CSV format, allowing the data to be loaded into Excel

or other data analysis systems.

17

Page 18

Settings and Procedures

1. Data storage function settings

Controls the settings for the selected OUT, storage cycle, and amount of data stored.

(1) Click “Data Storage”.

(2) Click “Data Storage Setting” in the window that has appeared.

* Once each setting has been configured, click “Send settings to controller”.

❶

2. Selected OUT settings

Check the selected OUTs that you wish to store.

3. Storage cycle settings

The storage cycle is the cycle at which measurement data is stored in the internal memory. Storage is performed in specified

multiples or with the timing input that has been specified in the “sampling cycle” in the common settings.

For example, with a sampling cycle setting of “200 μs”, if the storage cycle is set to “20x”, the storage cycle will be every

4 ms (= 200 μs x 20). The storage cycle is set in “Storage cycle” in the data storage settings.

❹

❸

❷

18

Page 19

4. Setting the amount of data stored

The amount of data stored equals the number of data points that you wish to store. The storage time is equal to the amount

of data stored x the storage cycle.

* Once data storage settings have been completed, click “Send settings to controller”.

For example, when setting the amount of data stored to 10,000 points and the storage cycle to 200 μs, the storage time will equal

2 seconds (= 10,000 points x 200 μs). The amount of data stored is configured in the settings for “Amount of Data Stored” in data storage settings.

5. Starting and stopping data storage

To start data storage, click “Start Storage” in data storage. After starting

data storage, storage will automatically finish once it has recorded the

amount of data specified in the data storage settings.

If you wish to stop during the storage process, click “Stop Storage”.

When you wish to restart collection from storage that was stopped

mid-process, click “Start storage” once again. Also, when starting data

storage from the beginning, click “Clear Stored Data” and then

“Start storage”.

Accumulation data

It is possible to load up to a maximum of 12 sets of accumulated data on the same screen.

(1) Select the data set that you wish to load from “Data01 to Data12”.

(2) Once the “Read out” button is clicked, the data will be loaded.

With the data storage function, the following is possible.

• Viewing accumulation data waveforms (the horizontal and vertical axis can also be adjusted)

• Using the cursor to view number values for current value, maximum value, minimum value, and average value

• Saving accumulation data in CSV format

• Loading accumulation data that has been previously saved*

* Click “Read from File”.

Data storage waveform data

Data storage numerical data

Data storage numerical data

19

Page 20

6

FAQ's

Common Questions

Q: Where can I find more details on the RS-232C commands for the LK-G5000 controller?

A:

The commands are described completely in chapter 5 of the user’s manual. All of the operations described in the user's

manual can be performed using a combination of direct RS-232C commands.

Q: What parts do I need to connect LK-G5000 to 9-Pin RS-232C port?

A:

While it is possible to crimp a custom cable, Keyence recommends the following components.

OP-96368

OP-26401

Q: How do I switch my unit so that it displays in English rather than metric units?

A:

There are two methods available.

When using a LK-HD500 or LK-G5001(P)V

- Hold down SET for 3 seconds to enter settings screen.

- Hold down ZERO and Program for 5 seconds.

- Change to “unit-1 inch” using up arrow and press ENT.

- LK-G will now display in thousandth’s of an inch, to display inches adjust decimal point setting.

When using the LK-Navigator 2 software

- Make sure the Num. Lock and Scroll Lock on the keyboard are set to ON

- While holding down the Shift and Ctrl keys, click on the “Controller Environment Settings” button on the left hand side of the

LK-Navigator screen.

- When the Environment setting screen appears, it will have an option for Unit.

- Change Unit to “inch (mil)” and click “OK”.

Q: Does Keyence provide any assistance for communicating with the USB or Ethernet port

without using LK-Navigator 2?

Please contact your local Keyence representative for assistance.

A:

Q: I am trying to read my output values via the binary output and am not getting a valid value.

A:

Please take the following corrective actions. If they do not resolve the issue, contact your local Keyence representative for

further assistance.

- Verify that the output status is read only when the strobe output (pin 19 on the expansion connector) is on.

- Verify that the correct output is being selected for the binary channel using pins 5-8 on the expansion connector. (For more

information refer to page 4-10 of the user’s manual.)

20

Page 21

Connecting a PC/PLC link unit

The connection requires the OP-96368 dedicated cable (2.5 m straight cable) and either

the OP-26401 (D-sub 9-pin) or OP-96369 (D-sub 25-pin) conversion adapter.

* Also refer to user's manual for the PC or PLC link unit before starting connection.

NOTE

Be sure to read “Precautions on wiring”(pg.7) of the user's manual before starting wiring.

Connection diagram

PC

0

0

50

-G

K

L

)

V

(

)

A

(

V

0

)

V

(

)

A

(

V

0

1

LK-G side

RD (RXD) (5)

SG (GND) (4)

SD (TXD) (3)

OP-96369 OP-26401 Signal name

(3) (2) RD (RXD)

(7) (5) SG (GND)

(2) (3) SD (TXD)

(4) (7) RS (RTS)

(5) (8) CS (CTS)

(6) (6) DR (DSR)

(8) (1) CD (DCD)

(20) (4) ER (DTR)

PC side

0

0

0

5

G

K

L

)

V

(

)

A

(

V

0

)

V

(

)

A

(

V

0

1

PLC link unit

Environment settings parameters

Change the following parameters on the PC or PLC link unit to be connected.

Item Setting value Remark

Baud rate 9600/19200/38400/57600/115200

Parity check None/even/odd

Set the appropriate parameter according to the external

device to be connected.

21

Page 22

Wiring Guide

Electrical specications for the NPN type models

CAUTION

NOTE

■ Non-voltage input

Input

COM

for input

Be sure to read “Precautions on wiring”(pg.7) of the user's manual before starting wiring.

■ Non-voltage input 2 (TIMING/TIMING1) ■ NPN open-collector output

+5 V

2.2 kΩ

1 kΩ

+5 V

Internal circuit

TIMING

COM

for input

+14 V

330 kΩ

1.6 kΩ

Internal circuit

Internal circuit

+5 V

1 kΩ

4.7 kΩ

Output

10 kΩ

COM

for input

ON voltage 1 V max.

OFF current 0.6 mA max.

Short-circuit current (Typical) 2 mA

Input

COM

or

Input

COM

ON voltage 5 V max.

OFF current 1 mA max.

Short-circuit current (Typical) 8 mA

Input

COM

or

Input

COM

Maximum applied voltage 40 V

Maximum sink current 50 mA

Residual voltage 0.5 V max.

Leakage current 0.1 mA max.

Compatible with the DC 2-wire model

of the KEYENCE EV Series proximity sensor.

Electrical specications for the PNP type models

CAUTION

NOTE

■ Voltage input ■ Voltage input 2 (TIMING/TIMING1) ■ PNP open - collector output

Input

COM

for input

Be sure to read “Precautions on wiring”(pg.7) of the user's manual before starting wiring.

4.7 kΩ

1.5 kΩ

+5 V

TIMING

COM

for input

Internal circuit

3.9 kΩ

680 kΩ

Internal circuit

+5 V

10 kΩ

10 kΩ

Internal circuit

COM

for input

Output

22

Maximum input voltage rating 26.4 V

ON voltage 10.8 V min.

OFF current 0.6 mA max.

Short-circuit current (Typical) 2 mA

Input Input

COM COM

Maximum input voltage rating 26.4 V

ON voltage 10.8 V min.

ON current (Typical) 3 mA

OFF voltage 5 V max.

OFF current 1 mA max.

Maximum applied voltage 30 V

Maximum source current 50 mA

Residual voltage 0.5 V max.

Leakage current 0.1 mA max.

Page 23

Optional Parts

O

P

-26401

O

P

-26401

OP

-96369

O

P

-26401

OP

-96369

O

P

-26401

OP

-96369

Name Model Appearance Description

LK-F2

(LK-H150/155/152/157)

Neutral density filters

LK-F3

(LK-H80/85/82/87)

Display panel housing OP-84426

Used when the mirror surface is measured at a mirror

reflection setup. (M1.6 x 3 countersink-head screw x 2)

Used to combine the display panel (LK-HD500) and

controller (LK-G5001/LK-G5001P).

33 cm OP-84427

Display panel

cable

3 m OP-51655

A cable used to connect the display panel (LK-HD500/

LKHD1001) and controller (LKG5001/LK-G5001P).

10 m OP-51656

I/O Expansion connector cable

(3 m)

OP-51657 I/O cable for the expansion connector (3 m).

RS-232C cable OP-96368 A communication cable for RS-232C (2.5 m).

-26401

P

RS-232C conversion adapter OP-26401

O

A conversion adapter for a D-sub 9-pin connector. This

connector is used in combination with the OP-96368.

RS-233C conversion adapter OP-96369

OP

A conversion adapter for a D-sub 25-pin connector. This

connector is used in combination with the OP-96368.

-96369

USB cable OP-66844 A cable for USB connection (2 m).

Key-operated switch OP-86982 Key-operated switch for laser emission control

Ethernet cable OP-66843 Cross cable (3m) for Ethernet communication

23

Page 24

Copyright (c) 2012 KEYENCE CORPORATION. All rights reserved. LKG5Setup-WW-TG-GB 1022-1 600A80 Printed in Japan

* 6 0 0 A 8 0 *

Loading...

Loading...