Page 1

Service and Maintenance Manual

Model(s)

AM Series

20AM

25AM

30AM

36AM

41AM

3120752

June 29, 2018 - Rev N

Page 2

Page 3

FOREWORD

The purpose of this manual is to provide users with the operating procedures essential for the promotion of

proper machine operation for its intended purpose. It is important to over-stress proper machine usage. All

information in this manual should be READ and UNDERSTOOD before any attempt is made to operate the

machine. YOUR OPERATING MANUAL IS YOUR MOST IMPORTANT TOOL - Keep it with the machine.

REMEMBER ANY EQUIPMENT IS ONLY AS SAFE AS THE OPERATOR.

BECAUSE THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND

OPERATION, PROPER SAFETY PRACTICES ARE THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

ALL INSTRUCTIONS IN THIS MANUAL ARE BASED ON THE USE OF THE MACHINE UNDER PROPER

OPERATING CONDITIONS, WITH NO DEVIATIONS FROM THE ORIGINAL DESIGN. ALTERATION AND/

OR MODIFICATION OF THE MACHINE IS STRICTLY FORBIDDEN, WITHOUT WRITTEN APPROVAL

FROM JLG INDUSTRIES, PER OSHA REGULATIONS.

THIS "SAFETY ALERT SYMBOL" IS USED TO CALL ATTENTION TO POTENTIAL HAZARDS

WHICH MAY LEAD TO SERIOUS INJURY OR DEATH IF IGNORED.

Safety of personnel and proper use of the machine are of primary concern, DANGER, WARNING, CAUTION,

NOTICE, INSTRUCTIONS and NOTE are inserted throughout this manual to emphasize these areas. They

are defined as follows:

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED WILL RESULT IN SERIOUS

INJURY OR DEATH.

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR

MODERATE INJURY. IT MAY ALSO BE USED TO ALERT

AGAINST UNSAFE PRACTICES.

Also in this Manual "Notes:" are used to provide information of special interest.

JLG INDUSTRIES, INC. MAY HAVE ISSUED SAFETY RELATED BULLETINS FOR YOUR JLG PRODUCT. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG DISTRIBUTOR FOR INFORMATION CONCERNING SAFETY RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR YOUR JLG PRODUCT. ALL ITEMS REQUIRED BY THE SAFETY RELATED

BULLETINS MUST BE COMPLETED ON THE AFFECTED JLG PRODUCT.

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED COULD RESULT IN SERIOUS INJURY OR DEATH.

IMPORTANT OR INSTRUCTIONS PROCEDURES ESSENTIAL

FOR SAFE OPERATION AND WHICH, IF NOT FOLLOWED

MAY RESULT IN A MALFUNCTION OR DAMAGE TO THE

MACHINE.

Due to the continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without

prior notification. Contact JLG Industries, Inc. for updated information.

Page 4

NOTES:

Page 5

INTRODUCTION - OPERATION/SAFETY PRECAUTIONS

INTRODUCTION - OPERATION/SAFETY PRECAUTIONS

All procedures herein are based on the use of the

machine under proper operating conditions, with no deviations from original design intent ... as per OSHA regulations.

READ & HEED!

The ownership, use, service, and/or maintenance of this

machine is subject to various federal, state and local laws

and regulations. It is the responsibility of the owner/user to

be knowledgeable of these laws and regulations and to

comply with them. The most prevalent regulations of this

type are the Federal OSHA Safety Regulations*. Listed

below, in abbreviated form are some of the requirements

of Federal OSHA regulations in effect as of the date of

publication of this handbook.

The listing of these requirements shall not relieve the

owner/user of the responsibility and obligation to determine all applicable laws and regulations and their exact

wording and requirements, and to comply with the

requirements. Nor shall the listing of these requirements

constitute an assumption of responsibility of liability on the

part of JLG Industries, Inc.

1. Only trained and authorized operators shall be permitted to operate the aerial lift.

2. A malfunctioning lift shall be shut down until

repaired.

3. The controls shall be plainly marked as to their function.

4. The controls shall be tested each day prior to use to

determine that they are in safe operating condition.

5. Load limits specified by the manufacturer shall not

be exceeded.

6. Instruction and warning placards must be legible.

7. Aerial lifts may be "field modified" for uses other than

those intended by the manufacturer only if certified

in writing by the manufacturer or an equivalent

entity, such as a nationally recognized testing lab, to

be in conformity to applicable OSHA safety regulations and to be at least as safe as it was prior to

modification.

8. Aerial lifts shall not be used near electric power lines

unless the lines have been deenergized or adequate

clearance is maintained (see OSHA 29 CFR 1910.67

and 1926.400).

9. Employees using aerial lifts shall be instructed how

to recognize and avoid unsafe conditions and hazards.

10. Ground controls shall not be operated unless permission has been obtained from personnel in the

platform, except in case of an emergency.

11. Regular inspection of the job site and aerial lift shall

be performed by competent persons.

12. Personnel shall always stand on the floor of the platform, not on boxes, planks, railing or other devices

for a work position.

*Applicable Federal OSHA regulations, as of the date of

publication of this manual include, but are not limited to,

29 CFR 1910.67, 29 CFR 1926.20, 29 CFR 1926.21, 29

CFR 1926.28, 29 CFR 1926.400 and 29 CFR 1926.453.

Consult the current regulations for the exact wording and

full text of the requirements and contact the closest Federal OSHA office for specific interpretations.

3120752 – JLG Lift – a

Page 6

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

General

This section contains the general safety precautions

which must be observed during maintenance of the aerial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others or

damage to the equipment. A maintenance program must

be established by a qualified person and must be followed

to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED IS A SAFETY VIOLATION.

The specific precautions to be observed during machine

maintenance are inserted at the appropriate point in the

manual. These precautions are, for the most part, those

that apply when servicing hydraulic and larger machine

component parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of component weight and never attempt to

move heavy parts without the aid of a mechanical device.

Do not allow heavy objects to rest in an unstable position.

When raising a portion of the equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA IS THE RESPONSIBILITY OF THE OWNER/

OPERATOR.

Maintenance Safety

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY VIOLATION.

• REMOVE ALL RINGS, WATCHES, AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL DANGER, WARNING, CAUTION AND OTHER INSTRUCTIONS ON MACHINE AND

IN SERVICE MANUAL.

• KEEP STANDING SURFACES AND HAND HOLDS

FREE OF OIL, GREASE, WATER, ETC.

• NEVER WORK UNDER AN ELEVATED PLATFORM

UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED

FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

•BATTERY SHOULD ALWAYS BE DISCONNECTED

DURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

Hydraulic System Safety

1. It should be particularly noted that the machines

hydraulic systems operate at extremely high and

potentially dangerous pressures. Every effort should

be made to relieve any system pressure prior to disconnecting or removing any portion of the system.

2. Relieve system pressure by activating the lift DOWN

control with the platform completely lowered to

direct any line pressure back into the return line to

the reservoir. Pressure feed lines to system components can then be disconnected with minimal fluid

loss.

b – JLG Lift – 3120752

Page 7

EFFECTIVITY CHANGES

June 1, 1998 - A - Original Issue of Manual

December 2, 1998 - B - Manual Revised

July 26, 2000 - C - Manual Revised

September 22, 2000 - D - Manual Revised

November 16, 2000 - E - Revised - Pages Affected:Section 2 - Pages 2-11, 2-18 thru 2-22.

June 14, 2001 - F - Revised - Pages Affected:Section 2 - Pages 2-4 thru 2-9.

Section 3 - Pages 3-3 thru 3-6.

October 17, 2001 - G - Manual Revised – Pages Affected:Section 1 - Page 1-1.

Section 2 - Pages 2-1 thru 2-4.

October 31, 2003 - H - Manual Revised – Pages Affected:Section 1 - Pages 1-1, 1-2 and 1-5

Section 3 - Pages 3-8 thru 3-15

March 23, 2005 - I - Manual Revised

July 11, 2006 - J - Manual Revised

January 30, 2008 - K - Manual Revised

August 29, 2012 - L -Manual Revised

EFFECTIVITY PAGE

April 2, 2013 - M - Manual Revised

June 29, 2018 - N - Revised Covers

3120752 – JLG Lift – c

Page 8

EFFECTIVITY PAGE

NOTES:

d – JLG Lift – 3120752

Page 9

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE NO.

INTRODUCTION -- OPERATION/SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

INTRODUCTION -- MAINTENANCE SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

EFFECTIVITY CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

SECTION 1 - SPECIFICATIONS

1.1 CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Hydraulic Oil Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 COMPONENT DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hydraulic Pump/Electric Motor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Batteries (1) – DC Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Battery Charger – DC Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Platform Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Platform Cycle Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Machine Weight (with Standard Platform). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Machine Height (Platform Stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Maximum Platform Height (Mast Extended) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Maximum Working Height (Average Person) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Machine Overall Width and Length (Base) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Outrigger Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Outrigger Machine Leveling Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.4 TORQUE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Hydraulic Oil (HO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6 HYDRAULIC PRESSURE ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 CYLINDER SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.8 SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

SECTION 2 - SERVICE PROCEDURES

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Pre-Delivery Inspection and Frequent Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Annual Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 PREVENTIVE MAINTENANCE AND INSPECTION SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 SERVICING AND MAINTENANCE GUIDELINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Safety and Workmanship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Components Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Component Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Pressure-Fit Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3120752 – JLG Lift – i

Page 10

TABLE OF CONTENTS

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Bolt Usage and Torque Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Hydraulic Lines and Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Lubrication and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Mast Chain Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Mast Cable Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 LUBRICATION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.5 BATTERY CHARGER - ASSEMBLY AND DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Battery Charger Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transformer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Printed Circuit Board Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

DC Circuit Breaker Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

AC Circuit Breaker and Voltage Selection Switch Replacement . . . . . . . . . . . . . . . . . . . . . 2-11

Shunt Assembly, Varistor, and SCR Rectifier Replacement (See Illustration) . . . . . . . . . . . 2-11

2.6 HYDRAULIC LIFT PUMP - SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

FENNER BRAND PUMP - Brush Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Motor Cap/Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Motor Brush Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Brush Housing Final Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

MONARCH BRAND PUMP - Brush Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Motor Assembly - Remove/Install - Reference Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Motor/Brush Cover - Remove/Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Brush Carrier Assembly - Remove/Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Brush Assembly - Remove/Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

TANK AND PUMP REMOVAL - (All Pumps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Tank Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Filter Screen Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Pressure Adjust Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Pressure Check Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2.7 HYDRAULIC LIFT CYLINDER - REMOVAL, INSPECTION AND REBUILD . . . . . . . . . . . . . . . . . .2-18

Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Cylinder Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Lift Cylinder Component Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Cylinder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.8 MAST ASSEMBLY AND DISASSEMBLY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Mast Disassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Platform Section Removal (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Mast Section 6 Removal (7 Section Mast) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Mast Section 5 Removal (6 & 7 Section Mast). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Mast Section 4 Removal (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Mast Section 3 Removal (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Mast Section 2 Removal (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Mast Section 1 Disassembly (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2.9 MAST ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Mast Section 1 - Assembly (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Mast Section 2 - Assembly (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

ii – JLG Lift – 3120752

Page 11

Mast Section 3 - Assembly (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Mast Section 4 - Assembly (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Mast Section 5 - Assembly (25/30/36/41 ft. Masts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Mast Section 6 - Assembly (30/41 ft. Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Platform Mounting Section - Assy. (All Masts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

2.10 MAST TO BASE FRAME INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.11 MAST CHAINS/CABLES AND SEQUENCING CABLES ADJUSTMENT . . . . . . . . . . . . . . . . . . . .2-35

Mast Chain/Cable Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Sequencing Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2.12 SEQUENCE CABLE REPLACEMENT KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Remove Old Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Replacement Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Clamp Installation (Drum/Socket Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

SECTION 3 - TROUBLESHOOTING

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 TROUBLESHOOTING INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 HYDRAULIC CIRCUIT CHECKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.4 ELECTRICAL SYSTEM - MULTIMETER BASICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Backprobing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Min/Max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Continuity Measurement Over Long Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Requirements: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.5 ELECTRICAL SWITCH TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Basic Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Automatic Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Switch Wiring - Low Side, High Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.6 OUTRIGGER INTERLOCK CONTACTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Outrigger Socket and Outrigger Beam - Interlock Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Outrigger Socket - Contactor Screw Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Outrigger Beam - Interlock Contactor Plate Mounting Instructions . . . . . . . . . . . . . . . . . . . .3-8

Detent Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

TABLE OF CONTENTS

3120752 – JLG Lift – iii

Page 12

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Hydraulic Pressure Setting - Adjustment Screw Located at Base of Pump Motor . . . . . . . . . . . .1-3

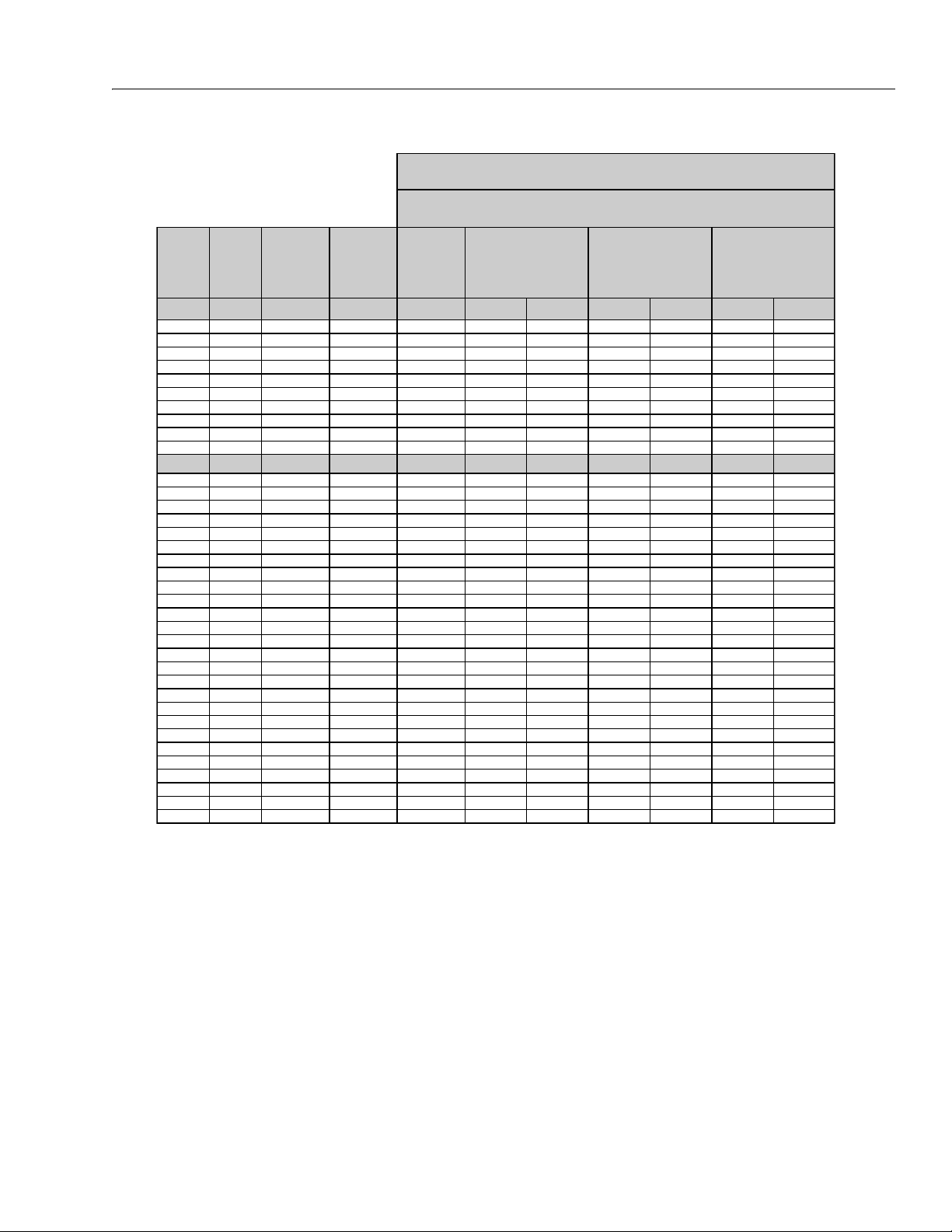

1-2. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2-1. Lift Cylinder Internal Component Assembly Cross-Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2-2. Mast Section - Assembly/Disassembly Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2-3. 20AM Mast Assembly Components. (5 - Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2-4. 25AM & 36AM Mast Assembly Components. (6 - Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2-5. 30AM & 41AM Mast Assembly Components. (7 - Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2-6. Mast Chain/Cable Routing Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2-7. Mast Chain/Cable/Sequence Cable Adjustment Components. (Typical) . . . . . . . . . . . . . . . . . . .2-36

3-1. Voltage Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2. Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-3. Continuity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-4. Current Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-5. Outrigger Socket Contactor Heads and Outrigger Beam -

Contactor Plate Mounting Hardware (ORIGINAL AND 5/2001 - DESIGN) . . . . . . . . . . . . . . . . . . .3-9

3-6. Hydraulic Schematic. (AM Series) (2792491_A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-7. Electrical Diagram. (AM Series - 12V-DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-8. Electrical Diagram. (AM Series - 120V-AC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3-9. Electrical Diagram. (AM Series - 240V-AC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3-10. Electrical Diagram. (AM Series - 100V-AC - JAPAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Hydraulic Oil Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4 Model AM - Lubrication Intervals for Various Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2-1 Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 AM Model - Preventive Maintenance & Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 Chain Stretch Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-4 AM Series Mast Component Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

3-1 AC Unit - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-2 DC Unit - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

iv – JLG Lift – 3120752

Page 13

SECTION 1. SPECIFICATIONS

SECTION 1 - SPECIFICATIONS

1.1 CAPACITIES

Hydraulic Oil Reservoir

AC Models – 5 qts. U.S. (4.7L)

DC Models – 5 qts. U.S. (4.7L)

1.2 COMPONENT DATA

Hydraulic Pump/Electric Motor Assembly

DC Models - 12 Volt DC Motor/Pump

Motor - 12v - DC Standard Duty

Pump Displacement – .049 cu. in./rev.(AFC 0.8 cc/rev.)

Pump Output – 0.43 GPM @ 3500 PSI @ 11.7v-DC @

150 AMPS @ 45 Centistrokes

Pressure Relief – Adjustable Range 1500 to 5000 PSI,

Set to 2800 PSI (193 bar) at factory

AC Models - 100 Volt AC Motor/Pump

Motor - 100v-AC, 2HP, 2850/3450 RPM, 50/60Hz

Pump Displacement – .049 in./rev. (0.8 cc/rev.)

Pump Output – 0.43 GPM @ 3500 PSI @ 16 AMPS @

100v-AC @ 45 Centistrokes

Pressure Relief – Adjustable Range 1500 to 5000 PSI,

Set to 2800 PSI (193 bar) at factory

AC Models - 120 Volt AC Motor/Pump

Motor – 100/230v-AC, 1HP, 2850/3450 RPM, 50/60Hz

Pump Displacement – .049 in./rev. (0.8 cc/rev.)

Pump Output – 0.43 GPM @ 3500 PSI @ 16 AMPS @

115v-AC @ 45 Centistrokes

Pressure Relief – Adjustable Range 1500 to 5000 PSI,

Set to 2800 PSI (193 bar) at factory

AC Models - 240 Volt AC Motor/Pump

Motor – 100/230v-AC, 1HP, 2850/3450 RPM, 50/60Hz

Pump Displacement – .049 in./rev. (0.8 cc/rev.)

Pump Output – 0.43 GPM @ 3500 PSI @ 8 AMPS @

230v-AC @ 45 Centistrokes

Pressure Relief – Adjustable Range 1500 to 5000 PSI,

Set to 2800 PSI (193 bar) at factory

Batteries (1) – DC Models

12 Volt – 165 Amp (min.) – Deep Cycle Marine - RV

Battery Charger – DC Models

Input - 120/240 Volts AC – 50/60 Hz - Voltage Selectable

Output - 12 volt, 10 Amp - DC - w/Auto Charge Sensing

Circuit.

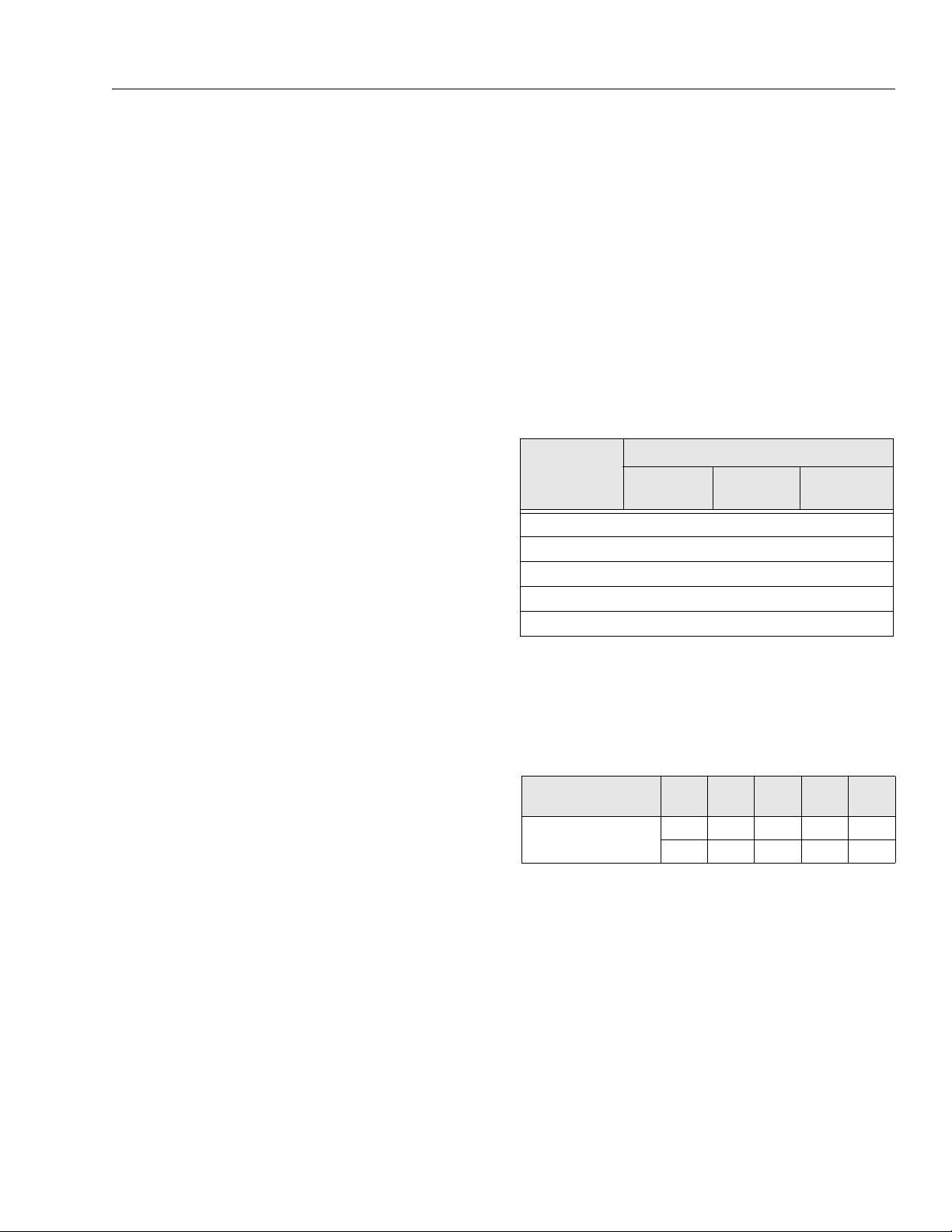

1.3 PERFORMANCE DATA

Platform Capacity

PLATFORM CAPACITY

MODEL

20AM - AC & DC 350 lb. (160kg) 350 lb. (160kg) 160kg (350 lb.)

25AM- AC & DC 350 lb. (160kg) 350 lb. (160kg) 160kg (350 lb.)

30AM - AC & DC 350 lb. (160kg) 350 lb. (160kg) 135kg (300 lb.)

36AM - AC & DC 300 lb. (135kg) 300 lb. (135kg) 135kg (300 lb.)

41AM - AC & DC 300 lb. (135kg) 300 lb. (135kg) 135kg (300 lb.)

ANSI

(U.S.A.)

C.S.A.

(Canada)

Brazil/

Japan

Platform Cycle Performance

Lift Up cycle time - from stowed to maximum platform

height with maximum rated load.

Lift Down cycle time - from maximum platform height to

stowed position with maximum rated load.

MAXIMUM PLATFORM

SPEEDS: (IN SECONDS)

Lift Up: 50 62 72 128 120

Lift Down: 32-42 32-42 32-42 47-57 45-55

20AM 25AM 30AM 36AM 41AM

Machine Weight (with Standard Platform)

20AM-AC - 740 lbs. (336kg)

20AM-DC - 860 lbs. (390kg)

25AM-AC - 825 lbs. (374kg)

25AM-DC - 905 lbs. (411kg)

30AM-AC - 890 lbs. (404kg)

30AM-DC - 940 lbs. (427kg)

36AM-AC - 1,060 lbs. (481kg)

36AM-DC - 1,160 lbs. (526kg)

41AM-AC - 1,100 lbs. (499kg)

41AM-DC - 1,230 lbs. (558kg)

3120752 – JLG Lift – 1-1

Page 14

SECTION 1 - SPECIFICATIONS

Machine Height (Platform Stowed)

20AM-AC & DC - 78 in. (2.0m)

25AM-AC & DC - 78 in. (2.0m)

30AM-AC & DC - 78 in. (2.0m)

36AM-AC & DC - 104.5 in. (2.64m) *75.5 in. (1.9m)

41AM-AC & DC - 104.5 in. (2.64m) *77.5 in. (2.0m)

* In tilt-back mode.

Maximum Platform Height (Mast Extended)

20AM-AC & DC - 20 ft. (6.09m)

25AM-AC & DC - 25 ft. (7.62m)

30AM-AC & DC - 30 ft. (9.14m)

36AM-AC & DC - 36 ft. (11m)

41AM-AC & DC - 41 in. (12.42m)

Maximum Working Height (Average Person)

20AM-AC & DC - 26 ft. (7.92m)

25AM-AC & DC - 31 ft. (9.45m)

30AM-AC & DC - 36 ft. (11m)

36AM-AC & DC - 42 ft. (12.80m)

41AM-AC & DC - 47 ft. (14.33m)

Machine Overall Width and Length (Base)

20AM Models - 29 in.(W) x 47 in.(L) (74cm x 1.19m)

25AM Models - 29 in.(W) x 49 in.(L) (74cm x 1.24m)

30AM Models - 29 in.(W) x 52 in.(L) (74cm x 1.32m)

36AM Models - 29 in.(W) x 54.5 in.(L) (74cm x 1.38m)

41AM Models - 29 in.(W) x 57.5 in.(L) (74cm x 1.46m)

Outrigger Footprint

20/25AM Models - 62 in. x 54 in. (1.57m x 1.37m)

30AM Models - 68 in. x 62 in. (1.72m x 1.57m)

36AM Models - 79 in. x 79 in. (2.0m x 2.0m)

41AM Models - 79 in. x 79 in. (2.0m x 2.0m)

Outrigger Machine Leveling Capability

MAXIMUM GRADE

MODEL

20AM 10° 11.5°

25AM 10° 11.5°

30AM 9° 8.5°

36AM 8.3° 7.2°

41AM 8° 7.1°

(OUTRIGGERS CAN LEVEL MACHINE ON)

FRONT TO BACK SIDE TO SIDE

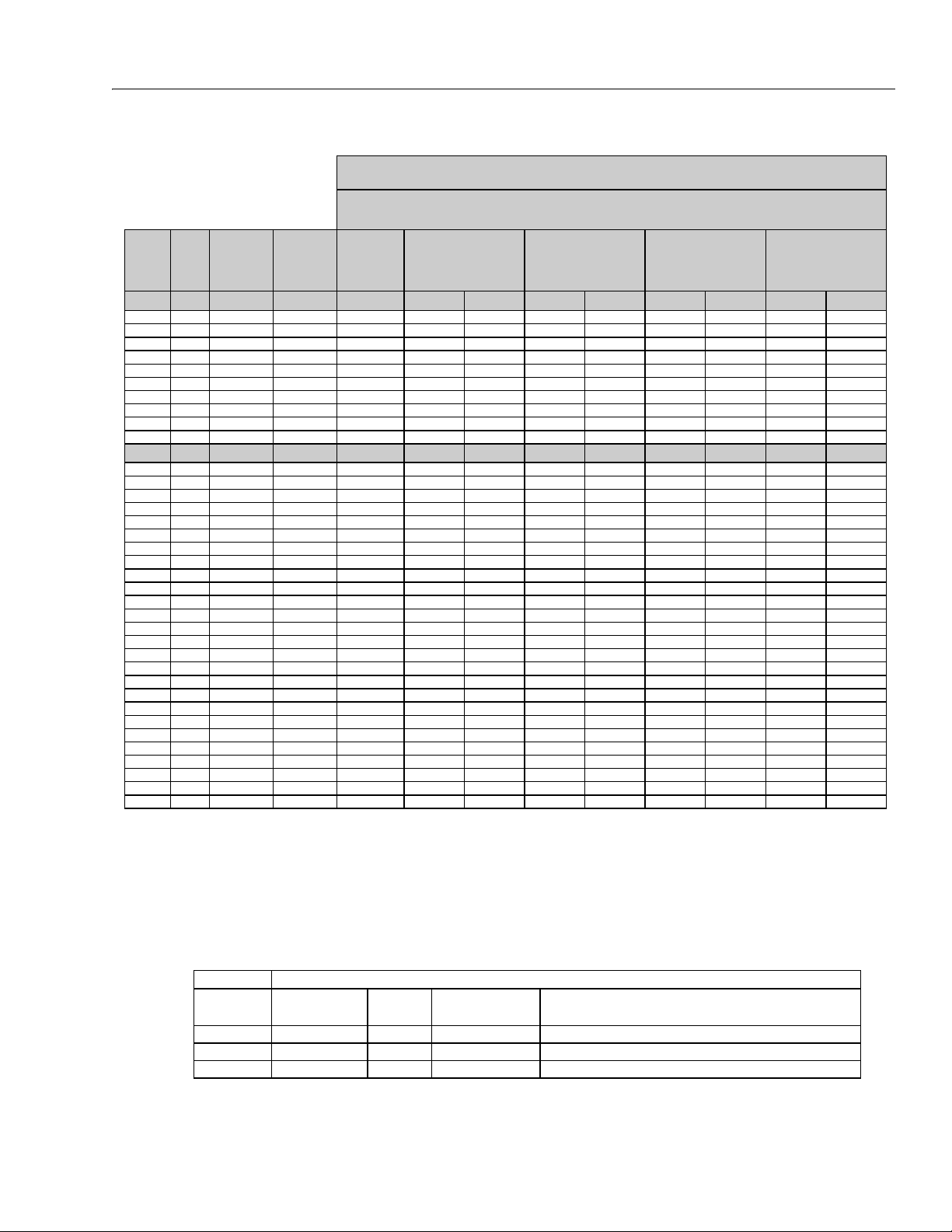

1.4 TORQUE REQUIREMENTS

When maintenance becomes necessary or a fastener has

loosened, refer to the Torque Chart, Figure 1-2. on page 15 to determine proper torque value.

1.5 LUBRICATION

Hydraulic Oil (HO)

Hydraulic oils must have anti-wear qualities at least to API

Service Classification GL-3, and sufficient chemical stability for mobile hydraulic system service. JLG Industries,

recommends Mobilfluid 424 hydraulic oil, which has an

SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. when temperatures

remain consistently below +20°F (–7°C) JLG recommends using Mobil DTE 13 hydraulic oil.

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not contain the same required additives or be of comparable viscosities. If use of hydraulic oil other than Mobilfluid 424 is

desired, contact JLG Industries for proper recommendations.

Table 1-1. Hydraulic Oil Operating Range

HYDRAULIC SYSTEM OPERATING

TEMPERATURE RANGE

+0 F to +180 F

(-18 C to +83 C)

+0 F to +210 F

(-18 C to +99 C)

+ 50 F t o + 2 10 F

(+10 C to +99 C)

Table 1-2. Lubrication Specifications

KEY SPECIFICATIONS

MPG - Multipurpose Grease having a minimum dripping point

of 350° F. Excellent water resistance and adhesive qualities, and being of extreme pressure type. (Timken OK

40 pounds minimum.)

EPGL - Extreme Pressure Gear Lube (oil) meeting API service

c la ss if i ca ti on GL- 5 or MI L-S pe c MI L-L- 21 0 5.

HO - Hydraulic Oil. ISO-Vg grade 32, 46.

CL - Chain Lube. Use a good quality chain lubricant

SAE VISCOSITY

GRADE

10W

10W-20, 10W-30

20W-20

1-2 – JLG Lift – 3120752

Page 15

SECTION 1 - SPECIFICATIONS

PRESSURE

ADJUSTMENT

SCREW

HYDRAULI C

OIL TANK

GROUND

CONTROL

STATION

COVER

ADJUSTMENT

SCREW CAP

(SHOWNREMOVED)

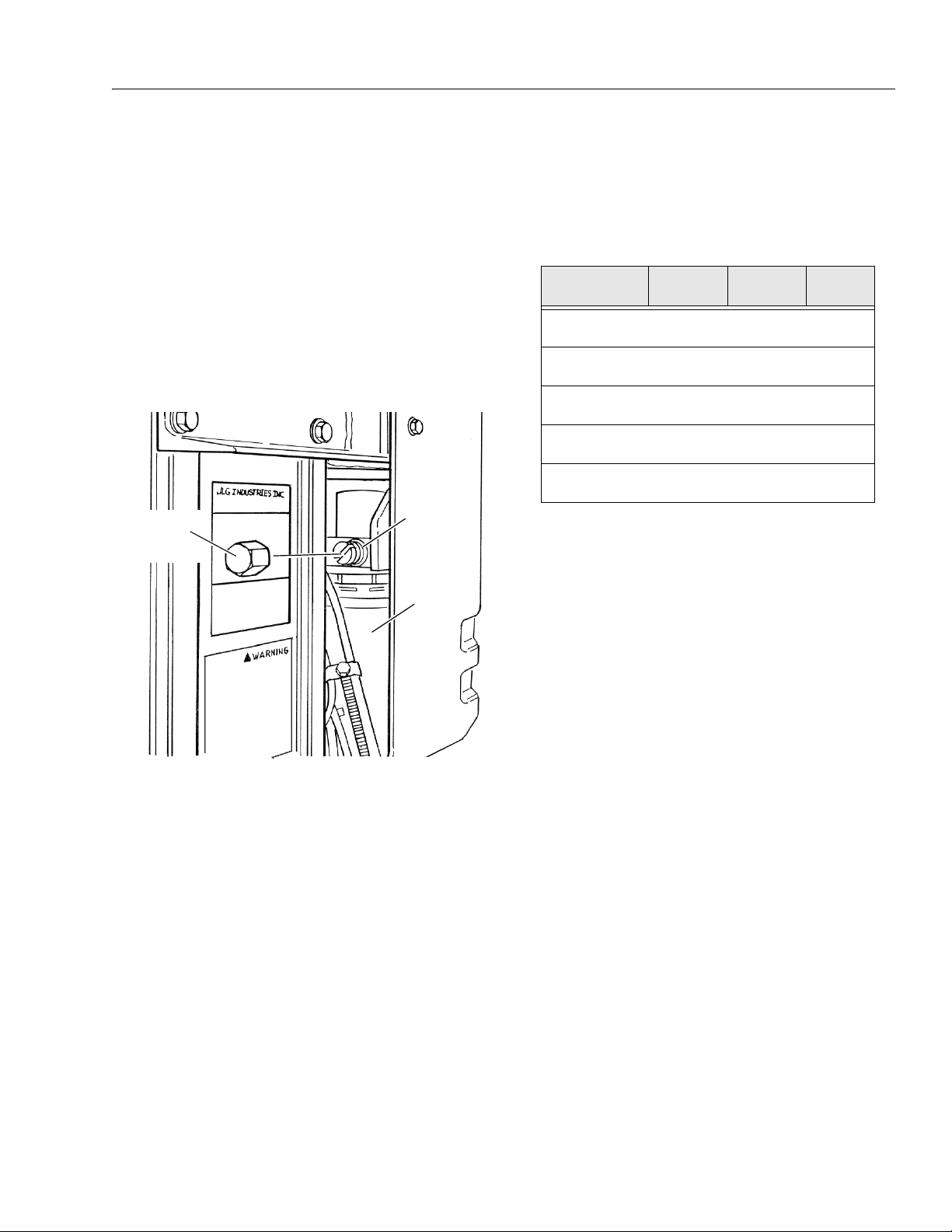

1.6 HYDRAULIC PRESSURE ADJUSTMENT

(See Figure 1-1.)

Adjust system pressure so that platform will raise with

rated capacity in platform.

Turning adjustment screw clockwise, increases system

pressure, turning screw counterclockwise, decreases

system pressure.

Do not adjust system pressure higher than required to

raise the load. Make pressure adjustment with oil at normal operating temperature. If pressure is set when oil is

cold, platform may not raise rated load after oil has

warmed.

1.7 CYLINDER SPECIFICATIONS

NOTE: All dimensions are given in inches (in), with the met-

ric equivalent, centimeters (cm), given in parentheses.

Table 1-3. Cylinder Specifications

DESCRIPTION

Lift Cylinder 20AM-AC & DC

Lift Cylinder 25AM-AC & DC

Lift Cylinder 30AM-AC & DC

Lift Cylinder 36AM-AC & DC

Lift Cylinder 41AM-AC & DC

BORE

in./(cm)

1.63

(4.14)

1.63

(4.14)

1.63

(4.14)

1.63

(4.14)

1.63

(4.14)

STROKE

in./(cm)

56.50

(143.50)

56.50

(143.50)

56.50

(143.50)

83.25

(211.40)

78.25

(198.75)

ROD DIA.

in./(cm)

1.38

(3.50)

1.38

(3.50)

1.38

(3.50)

1.38

(3.50)

1.38

(3.50)

1.8 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed

to the machine. The plate is located on the back of the

mast, just above the mast support bracket.

Figure 1-1. Hydraulic Pressure Setting - Adjustment

Screw Located at Base of Pump Motor

(Remove Hex Head Cap as Shown)

3120752 – JLG Lift – 1-3

Page 16

SECTION 1 - SPECIFICATIONS

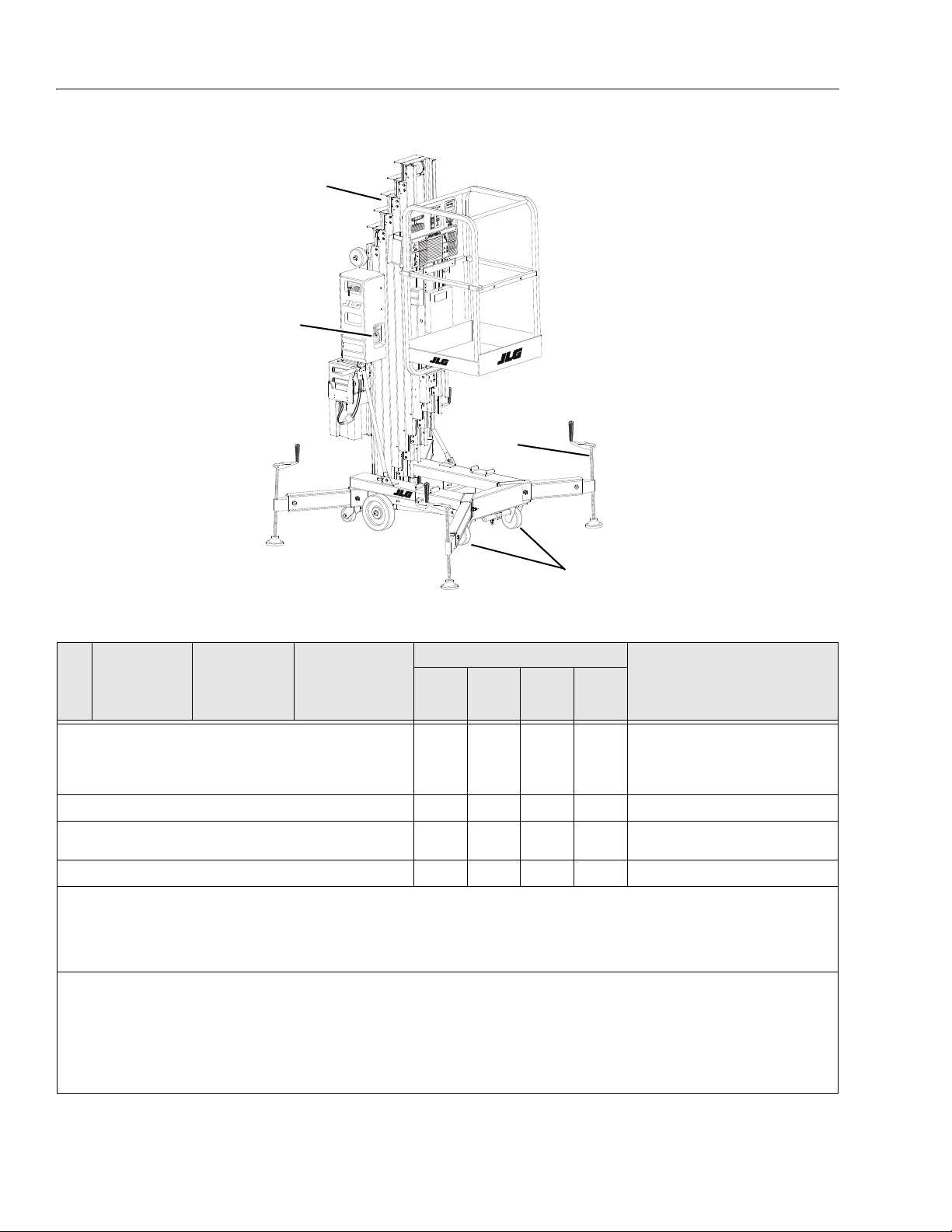

1

4

2

3

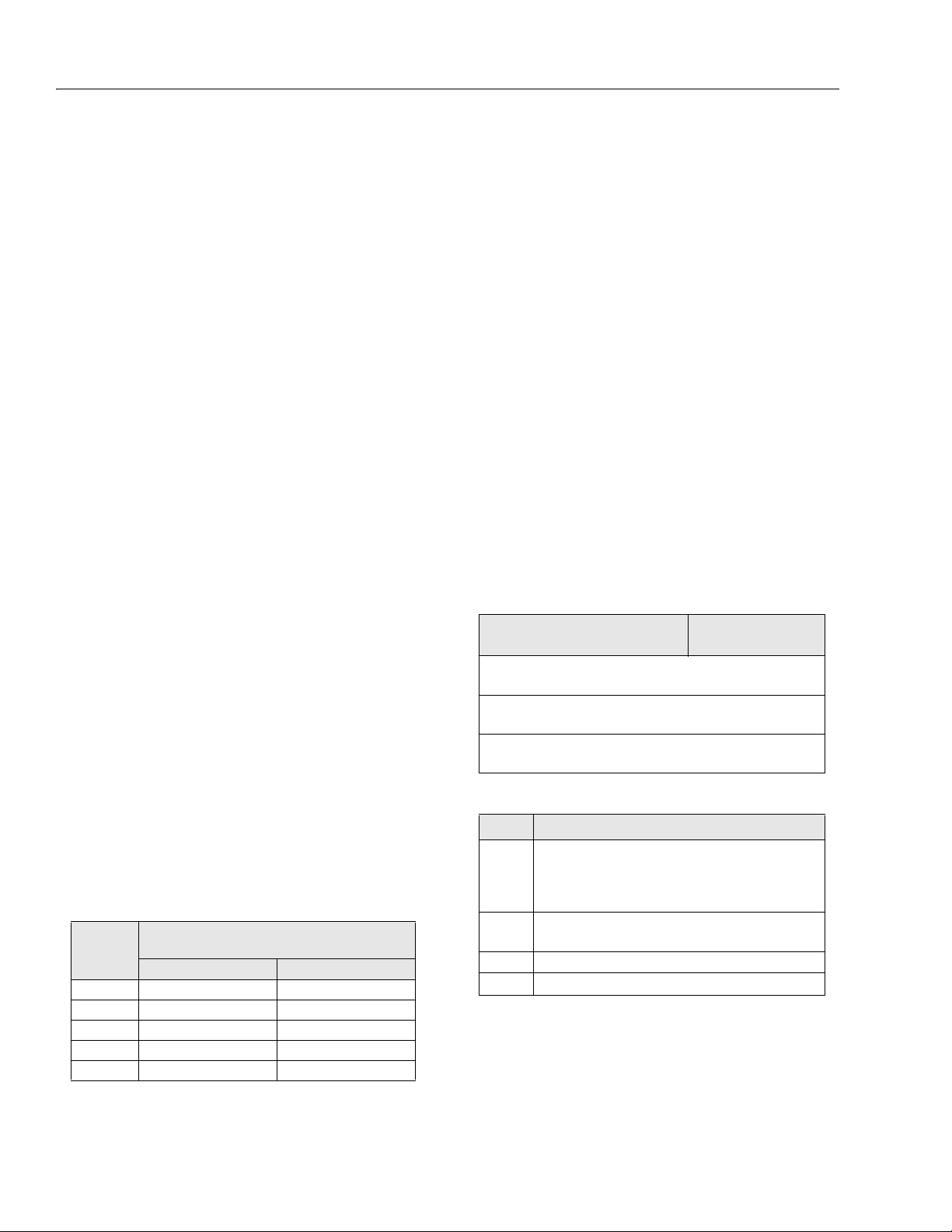

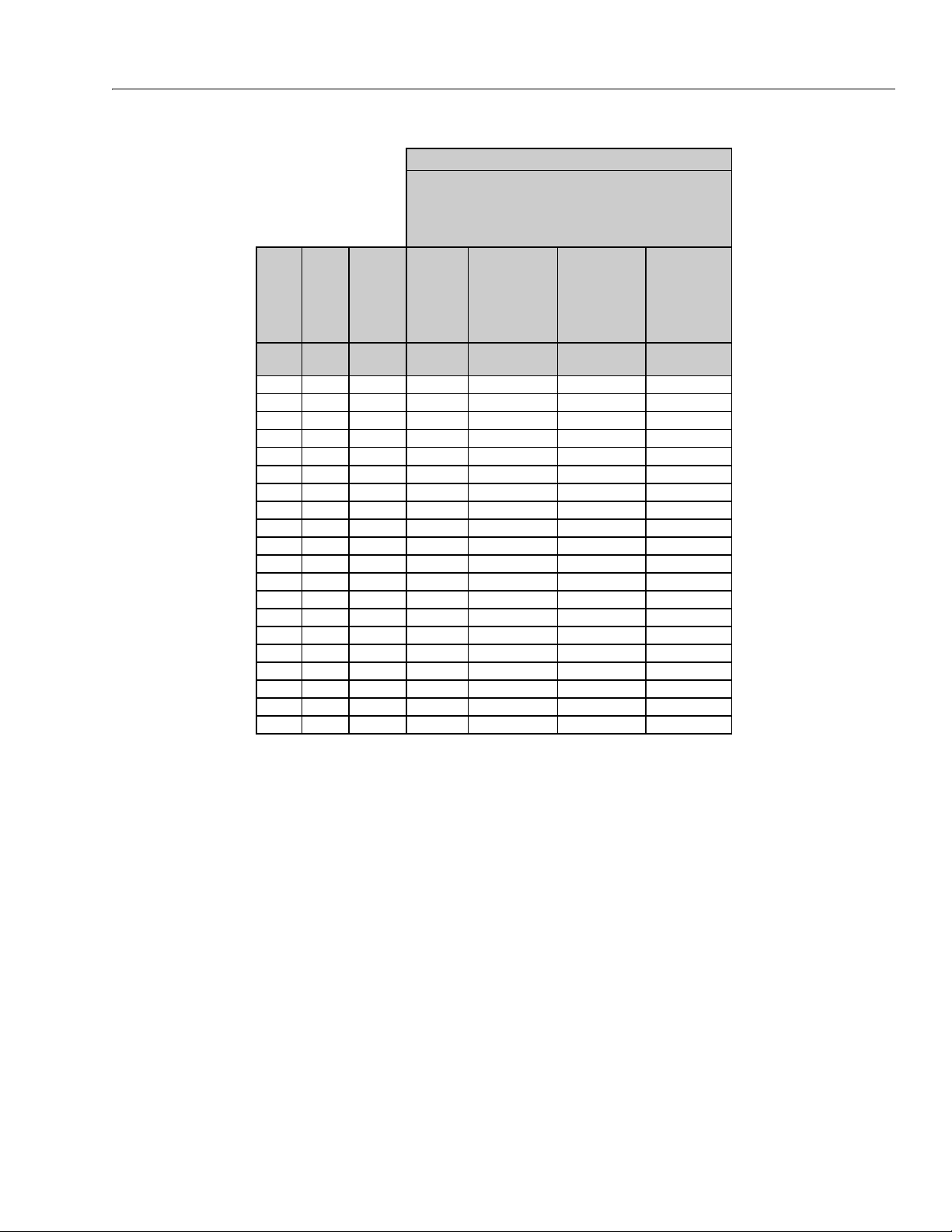

Table 1-4. Model AM - Lubrication Intervals for Various Components

INTERVAL HOURS

ITEM COMPONENT

Hydraulic Oil Fill To Line

1

Swivel Raceways 2 - Front Casters MPG - Pressure Gun

2

Leveling Jack

3

Screws

Mast Chains * 2 - Per Section CL - Brush or Spray

4

* Ap p l ie s On l y t o M as t Se c ti o n s w i th C ha i ns .

Key to Lu bricants: MPG - Multipurpose Grease

HO - Hydraulic Oil - ISO-Vg grade 32, 46

CL - Chain Lube. Use a good quality chain lubricant

Notes: 1. Be cer tain to lubricate like items on each side of the machine.

2. Recommended lubricating intervals are based on normal use. If machine is subjected to severe operating conditions,

such as a high number of cycles, location, corrosive/dir ty environment, etc., user must adjust lubricating requirements accordingly.

3. Lubricating intervals are calculated on 50 hours of machine operation a week.

4. Prior to checking hydraulic oil level, operate machine through one complete cycle of lift function (full up and down). Failure to do so will

result in incorrect oil level reading on the hydraulic reservoir.

NO/TYPE

LUBE POINTS

on Reservoir

5 Qt. (4.3 L)

Reservoir

4 - Jack Threads MPG - Br ush

LUBE/METHOD

HO - Check

H y d. O il L e ve l

HO - Change

H y d. O il

3

MONTHS

150 Hrs.

6

MONTHS

300 Hrs.

✔

✔

✔

1

YEAR

600 Hrs.

2

YEARS

1200 Hrs.

✔

COMMENTS

Check oil level every day.

Change hydraulic oil every 2 years.

Inspect, lubricate if drying or rusting.

<--- START HERE - COPY AND PASTE

1-4 – JLG Lift – 3120752

Page 17

SECTION 1 - SPECIFICATIONS

REFERENCE JLG ANEROBIC THREAD LOCKING COMPOUND

JLG P/N Loctite® P/N ND Industries P/N

Description

0100011

242

TM

Vibra-TITE

TM

121

Medium Strength (Blue)

0100019

271

TM

Vibra-TITE

TM

140

High Strength (Red)

0100071

262

TM

Vibra-TITE

TM

131

Medium - High Strength (Red)

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0.1120 0.00604 380 8 0.9 6 0.7

48 0.1120 0.00661 420 9 1.0 7 0.8

6 32 0.1380 0.00909 580 16 1.8 12 1.4

40 0.1380 0.01015 610 18 2.0 13 1.5

8 32 0.1640 0.01400 900 30 3.4 22 2.5

36 0.1640 0.01474 940 31 3.5 23 2.6

10 24 0.1900 0.01750 1120 43 4.8 32 3.5

32 0.1900 0.02000 1285 49 5.5 36 4

1/4 20 0.2500 0.0318 2020 96 10.8 75 9 105 12

28 0.2500 0.0364 2320 120 13.5 86 10 135 15

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0.3125 0.0524 3340 17 23 13 18 19 26 16 22

24 0.3125 0.0580 3700 19 26 14 19 21 29 17 23

3/8 16 0.3750 0.0775 4940 30 41 23 31 35 48 28 38

24 0.3750 0.0878 5600 35 47 25 34 40 54 32 43

7/16 14 0.4375 0.1063 6800 50 68 35 47 55 75 45 61

20 0.4375 0.1187 7550 55 75 40 54 60 82 50 68

1/2 13 0.5000 0.1419 9050 75 102 55 75 85 116 68 92

20 0.5000 0.1599 10700 90 122 65 88 100 136 80 108

9/16 12 0.5625 0.1820 11600 110 149 80 108 120 163 98 133

18 0.5625 0.2030 12950 120 163 90 122 135 184 109 148

5/8 11 0.6250 0.2260 14400 150 203 110 149 165 224 135 183

18 0.6250 0.2560 16300 170 230 130 176 190 258 153 207

3/4 10 0.7500 0.3340 21300 260 353 200 271 285 388 240 325

16 0.7500 0.3730 23800 300 407 220 298 330 449 268 363

7/8 9 0.8750 0.4620 29400 430 583 320 434 475 646 386 523

14 0.8750 0.5090 32400 470 637 350 475 520 707 425 576

1 8 1.0000 0.6060 38600 640 868 480 651 675 918 579 785

12 1.0000 0.6630 42200 700 949 530 719 735 1000 633 858

1 1/8 7 1.1250 0.7630 42300 800 1085 600 813 840 1142 714 968

12 1.1250 0.8560 47500 880 1193 660 895 925 1258 802 1087

1 1/4 7 1.2500 0.9690 53800 1120 1518 840 1139 1175 1598 1009 1368

12 1.2500 1.0730 59600 1240 1681 920 1247 1300 1768 1118 1516

1 3/8 6 1.3750 1.1550 64100 1460 1979 1100 1491 1525 2074 1322 1792

12 1.3750 1.3150 73000 1680 2278 1260 1708 1750 2380 1506 2042

1 1/2 6 1.5000 1.4050 78000 1940 2630 1460 1979 2025 2754 1755 2379

12 1.5000 1.5800 87700 2200 2983 1640 2224 2300 3128 1974 2676

NO. 5000059 REV. J

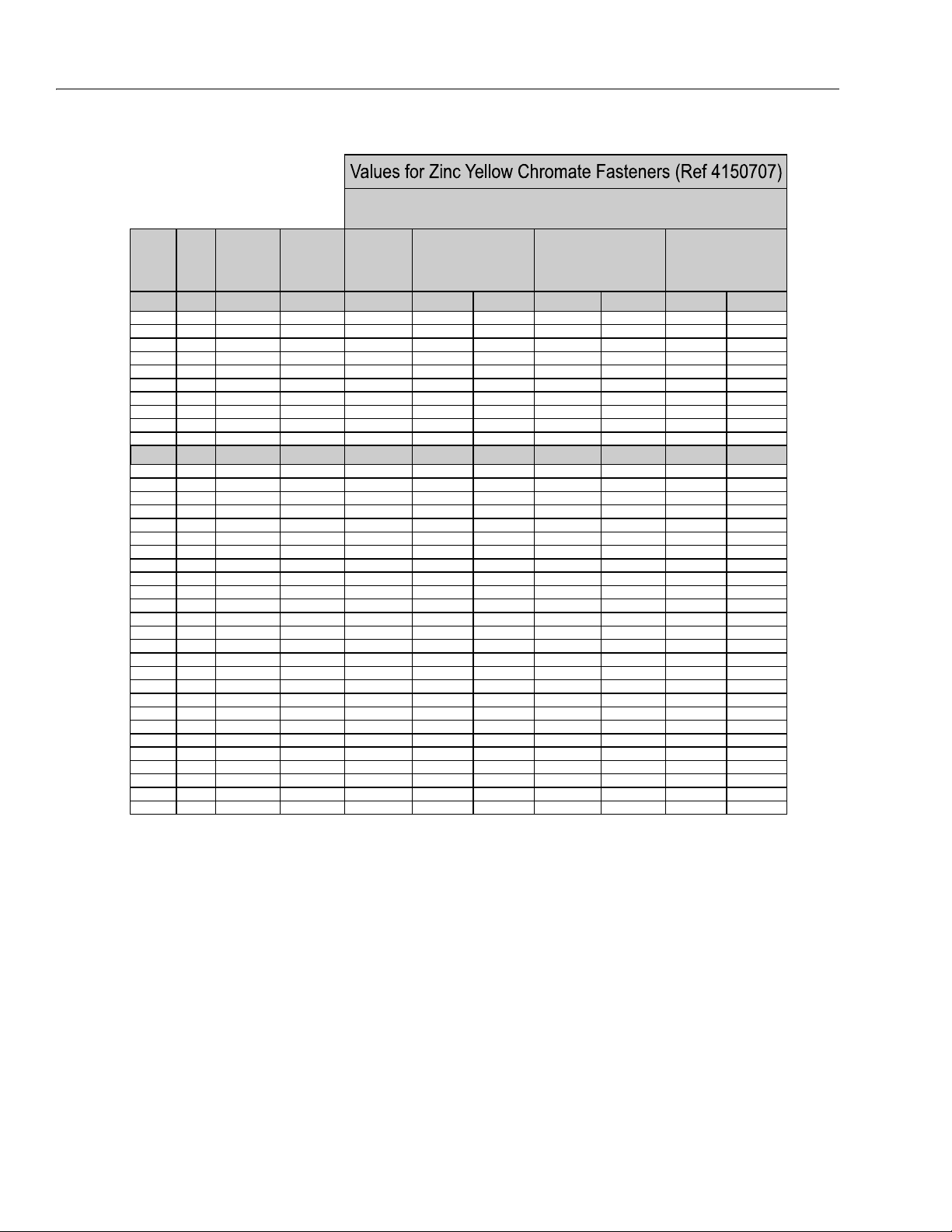

Values for Zinc Yellow Chromate Fasteners (Ref 4150707)

SAE GRADE 5 BOLTS & GRADE 2 NUTS

Torque

(Dry)

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

Torque

Lubricated

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TIT E

TM

111 or

140)

3. * ASSEMBLY USES HARDENED WASHER

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

Figure 1-2. Torque Chart (SAE Fasteners - Sheet 1 of 7)

3120752 – JLG Lift – 1-5

Page 18

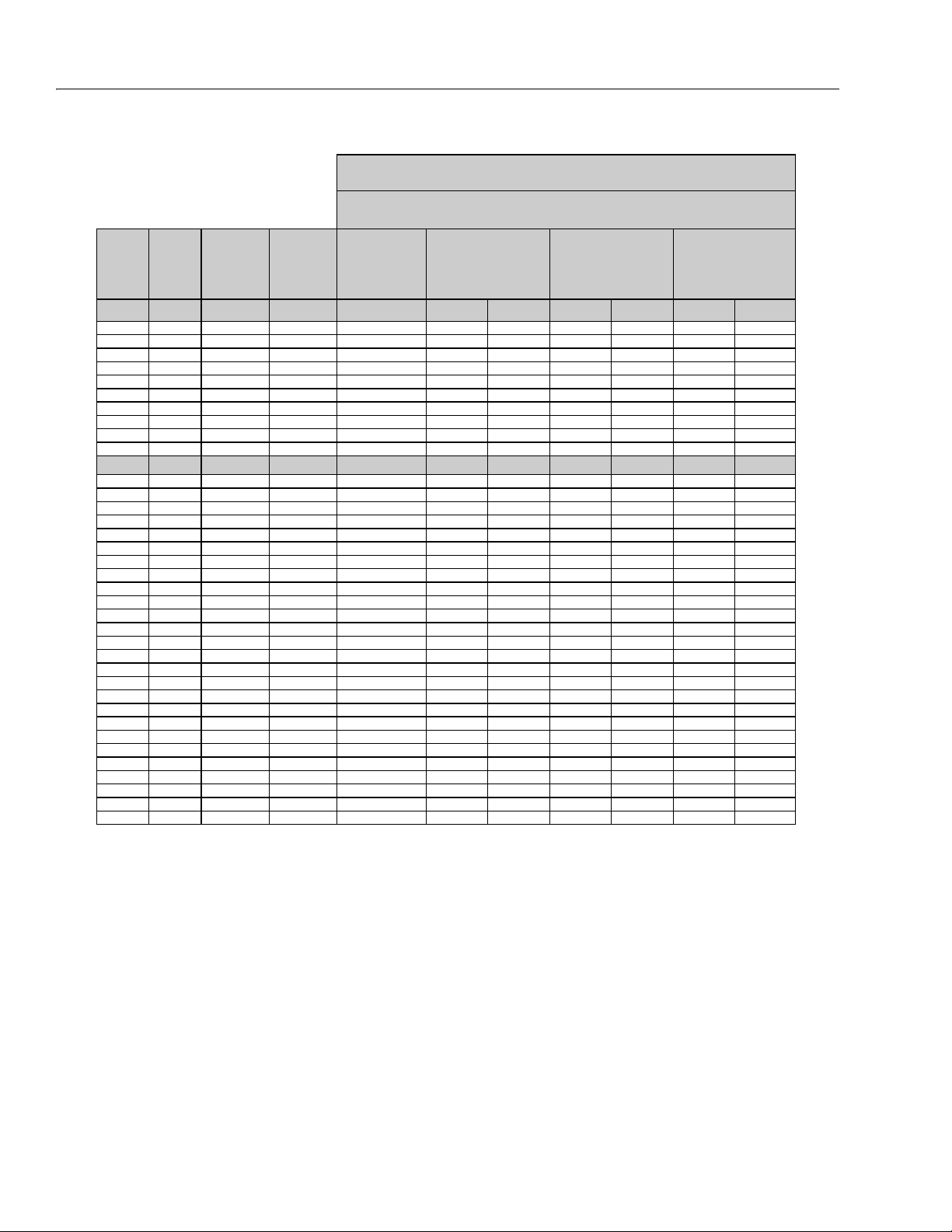

SECTION 1 - SPECIFICATIONS

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

In Sq In

4 40 0.1120 0.00604

48 0.1120 0.00661

6 32 0.1380 0.00909

40 0.1380 0.01015

8 32 0.1640 0.01400

36 0.1640 0.01474

10 24 0.1900 0.01750

32 0.1900 0.02000

1/4 20 0.2500 0.0318

28 0.2500 0.0364

In Sq In

5/16 18 0.3125 0.0524

24 0.3125 0.0580

3/8 16 0.3750 0.0775

24 0.3750 0.0878

7/16 14 0.4375 0.1063

20 0.4375 0.1187

1/2 13 0.5000 0.1419

20 0.5000 0.1599

9/16 12 0.5625 0.1820

18 0.5625 0.2030

5/8 11 0.6250 0.2260

18 0.6250 0.2560

3/4 10 0.7500 0.3340

16 0.7500 0.3730

7/8 9 0.8750 0.4620

14 0.8750 0.5090

1 8 1.0000 0.6060

12 1.0000 0.6630

1 1/8 7 1.1250 0.7630

12 1.1250 0.8560

1 1/4 7 1.2500 0.9690

12 1.2500 1.0730

1 3/8 6 1.3750 1.1550

12 1.3750 1.3150

1 1/2 6 1.5000 1.4050

12 1.5000 1.5800

NO. 5000059 REV. J

3. * ASSEMB LY USES HARDENED WASHER

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VA LUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

1320 43 5

1580 60 7

1800 68 8

2860 143 16 129 15

3280 164 19 148 17

LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m

4720 25 35 20 25 20 25

5220 25 35 25 35 20 25

7000456040 553550

7900 50 70 45 60 35 50

9550 70 95 65 90 50 70

10700 80 110 70 95 60 80

12750 105 145 95 130 80 110

14400 120 165 110 150 90 120

16400 155 210 140 190 115 155

18250 170 230 155 210 130 175

20350 210 285 190 260 160 220

23000 240 325 215 290 180 245

30100 375 510 340 460 280 380

33600 420 570 380 515 315 430

41600 605 825 545 740 455 620

45800 670 910 600 815 500 680

51500 860 1170 770 1045 645 875

59700 995 1355 895 1215 745 1015

68700 1290 1755 1160 1580 965 1310

77000 1445 1965 1300 1770 1085 1475

87200 1815 2470 1635 2225 1365 1855

96600 2015 2740 1810 2460 1510 2055

104000 2385 3245 2145 2915 1785 2430

118100 2705 3680 2435 3310 2030 2760

126500 3165 4305 2845 3870 2370 3225

142200 3555 4835 3200 4350 2665 3625

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140) K=.18

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

SAE GRADE 8 (HEX HD) BOLTS & GRADE 8 NUTS*

Torque

(Dry or Loctite® 263)

K= 0.20

1-6 – JLG Lift – 3120752

Figure 1-3. Torque Chart (SAE Fasteners - Sheet 2 of 7))

Page 19

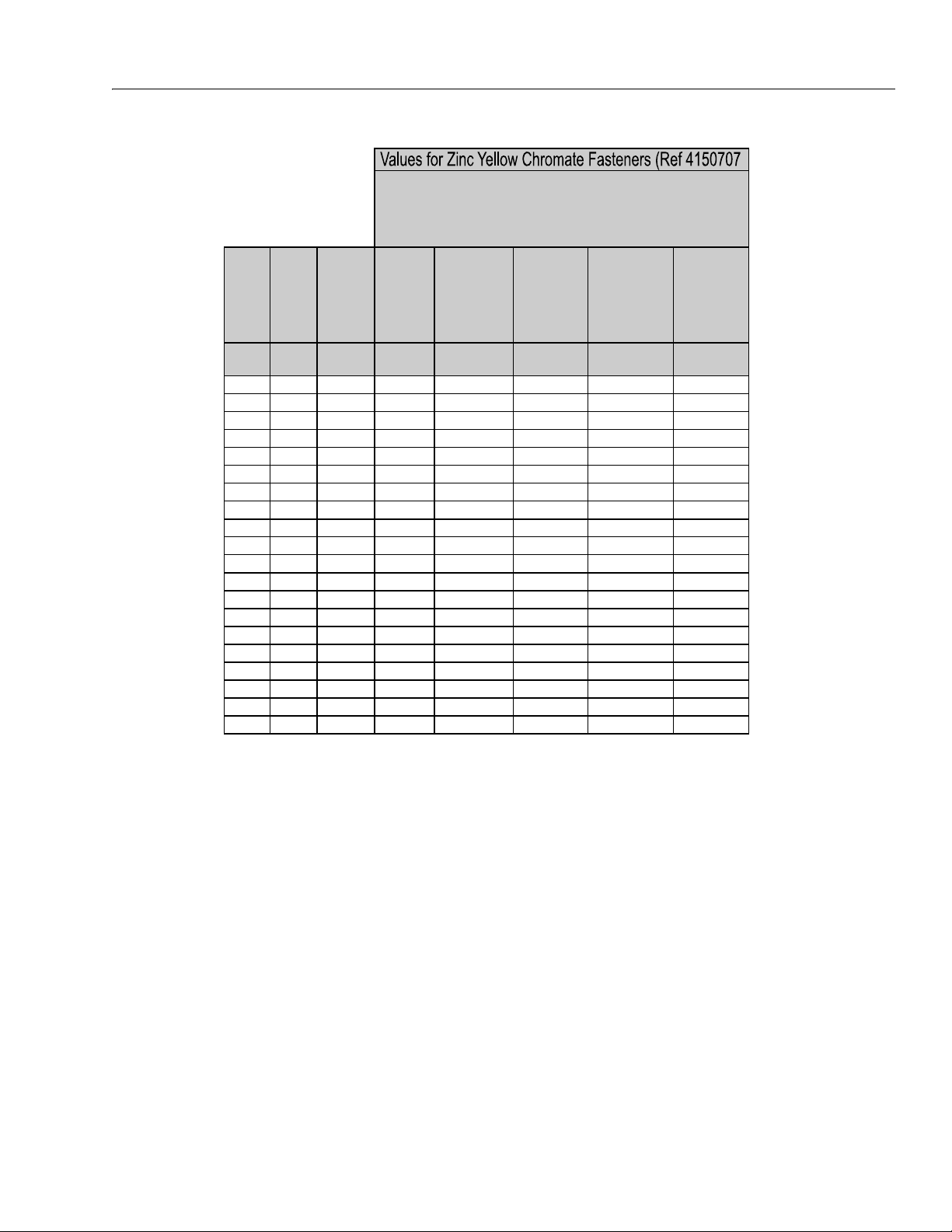

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

See Note 4

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0.1120 0.00604

48 0.1120 0.00661

6 32 0.1380 0.00909

40 0.1380 0.01015

8 32 0.1640 0.01400

36 0.1640 0.01474

10 24 0.1900 0.01750

32 0.1900 0.02000

1/4 20 0.2500 0.0318 2860 122 14 114 13

28 0.2500 0.0364 3280 139 16 131 15

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0.3125 0.0524 4720 20 25 20 25 20 25

24 0.3125 0.0580 5220 25 35 20 25 20 25

3/8 16 0.3750 0.0775 7000 35 50 35 50 35 50

24 0.3750 0.0878 7900 40 55 40 55 35 50

7/16 14 0.4375 0.1063 9550 60 80 55 75 50 70

20 0.4375 0.1187 10700 65 90 60 80 60 80

1/2 13 0.5000 0.1419 12750 90 120 85 115 80 110

20 0.5000 0.1599 14400 100 135 95 130 90 120

9/16 12 0.5625 0.1820 16400 130 175 125 170 115 155

18 0.5625 0.2030 18250 145 195 135 185 130 175

5/8 11 0.6250 0.2260 20350 180 245 170 230 160 220

18 0.6250 0.2560 23000 205 280 190 260 180 245

3/4 10 0.7500 0.3340 30100 320 435 300 410 280 380

16 0.7500 0.3730 33600 355 485 335 455 315 430

7/8 9 0.8750 0.4620 41600 515 700 485 660 455 620

14 0.8750 0.5090 45800 570 775 535 730 500 680

1 8 1.0000 0.6060 51500 730 995 685 930 645 875

12 1.0000 0.6630 59700 845 1150 795 1080 745 1015

1 1/8 7 1.1250 0.7630 68700 1095 1490 1030 1400 965 1310

12 1.1250 0.8560 77000 1225 1665 1155 1570 1085 1475

1 1/4 7 1.2500 0.9690 87200 1545 2100 1455 1980 1365 1855

12 1.2500 1.0730 96600 1710 2325 1610 2190 1510 2055

1 3/8 6 1.3750 1.1550 104000 2025 2755 1905 2590 1785 2430

12 1.3750 1.3150 118100 2300 3130 2165 2945 2030 2760

1 1/2 6 1.5000 1.4050 126500 2690 3660 2530 3440 2370 3225

12 1.5000 1.5800 142200 3020 4105 2845 3870 2665 3625

NO. 5000059 REV. J

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH

CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

SOCKET HEAD CAP SCREWS

Magni Coating (Ref 4150701)*

Torque

(Dry) K = .17

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140 OR Precoat 85®

K=0.16

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED STEEL OR RAW ALUMINUM

SECTION 1 - SPECIFICATIONS

3120752 – JLG Lift – 1-7

Figure 1-4. Torque Chart (SAE Fasteners - Sheet 3 of 7)

Page 20

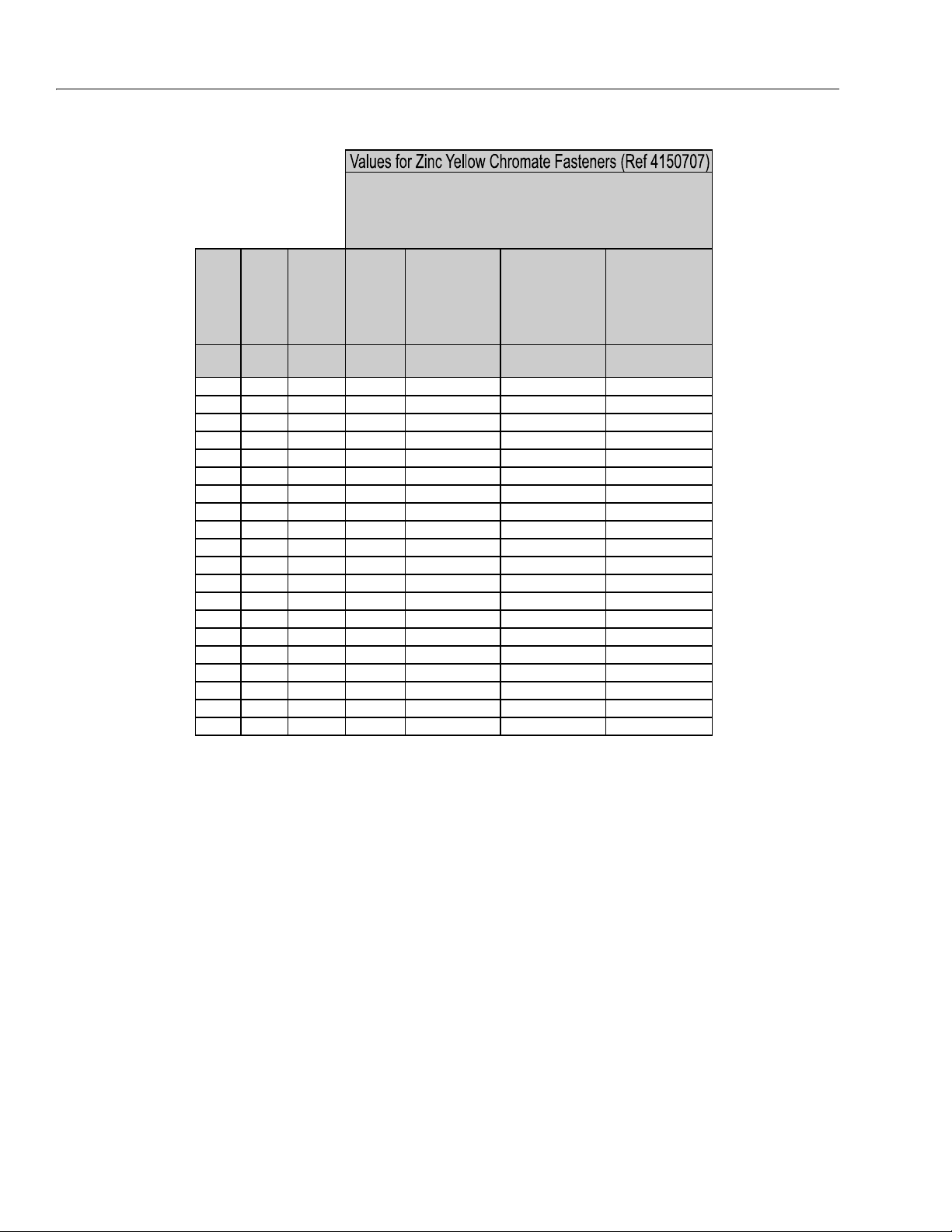

SECTION 1 - SPECIFICATIONS

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

See Note 4

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0.1120 0.00604

48 0.1120 0.00661

6 32 0.1380 0.00909

40 0.1380 0.01015

8 32 0.1640 0.01400

36 0.1640 0.01474

10 24 0.1900 0.01750

32 0.1900 0.02000

1/4 20 0.2500 0.0318 2860 143 16 129 15

28 0.2500 0.0364 3280 164 19 148 17

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0.3125 0.0524 4720 25 35 20 25 20 25

24 0.3125 0.0580 5220 25 35 25 35 20 25

3/8 16 0.3750 0.0775 7000 45 60 40 55 35 50

24 0.3750 0.0878 7900 50 70 45 60 35 50

7/16 14 0.4375 0.1063 9550 70 95 65 90 50 70

20 0.4375 0.1187 10700 80 110 70 95 60 80

1/2 13 0.5000 0.1419 12750 105 145 95 130 80 110

20 0.5000 0.1599 14400 120 165 110 150 90 120

9/16 12 0.5625 0.1820 16400 155 210 140 190 115 155

18 0.5625 0.2030 18250 170 230 155 210 130 175

5/8 11 0.6250 0.2260 20350 210 285 190 260 160 220

18 0.6250 0.2560 23000 240 325 215 290 180 245

3/4 10 0.7500 0.3340 30100 375 510 340 460 280 380

16 0.7500 0.3730 33600 420 570 380 515 315 430

7/8 9 0.8750 0.4620 41600 605 825 545 740 455 620

14 0.8750 0.5090 45800 670 910 600 815 500 680

1 8 1.0000 0.6060 51500 860 1170 775 1055 645 875

12 1.0000 0.6630 59700 995 1355 895 1215 745 1015

1 1/8 7 1.1250 0.7630 68700 1290 1755 1160 1580 965 1310

12 1.1250 0.8560 77000 1445 1965 1300 1770 1085 1475

1 1/4 7 1.2500 0.9690 87200 1815 2470 1635 2225 1365 1855

12 1.2500 1.0730 96600 2015 2740 1810 2460 1510 2055

1 3/8 6 1.3750 1.1550 104000 2385 3245 2145 2915 1785 2430

12 1.3750 1.3150 118100 2705 3680 2435 3310 2030 2760

1 1/2 6 1.5000 1.4050 126500 3165 4305 2845 3870 2370 3225

12 1.5000 1.5800 142200 3555 4835 3200 4350 2665 3625

NO. 5000059 REV. J

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH

CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

SOCKET HEAD CAP SCREWS

Torque

(Dry)

K = .20

Torque

(Loctite® 242TM or 271

TM

OR Vibra-TITE

TM

111 or

140 OR Precoat 85®

K=0.18

Zinc Yellow Chromate Fasteners (Ref 4150707)*

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED STEEL OR RAW ALUMINUM

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

1-8 – JLG Lift – 3120752

Figure 1-5. Torque Chart (SAE Fasteners - Sheet 4 of 7)

Page 21

SECTION 1 - SPECIFICATIONS

Size PITCH

Tensile

Stress

Area

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

Torque

(Lub)

Torque

(Loctite® 262

TM

OR Vibra-

TITE

TM

131)

Torque

(Loctite®

242

TM

or 271

TM

OR Vibra-

TITE

TM

111 or

140)

Sq mm KN [N.m ] [N.m] [N.m] [N.m]

3 0.5 5.03 2.19 1.3 1.0 1.2 1.4

3.5 0.6 6.78 2.95 2.1 1.6 1.9 2.3

4 0.7 8.78 3.82 3.1 2.3 2.8 3.4

5 0.8 14.20 6.18 6.2 4.6 5.6 6.8

6 1 20.10 8.74 11 7.9 9.4 12

7 1 28.90 12.6 18 13 16 19

8 1.25 36.60 15.9 26 19 23 28

10 1.5 58.00 25.2 50 38 45 55

12 1.75 84.30 36.7 88 66 79 97

14 2 115 50.0 140 105 126 154

16 2 157 68.3

219 164 197 241

18 2.5 192 83.5 301 226 271 331

20 2.5 245 106.5 426 320 383 469

22 2.5 303 132.0 581 436 523 639

24 3 353 153.5 737 553 663 811

27 3 459 199.5 1080 810 970 1130

30 3.5 561 244.0 1460 1100 1320 1530

33 3.5 694 302.0 1990 1490 1790 2090

36 4 817 355.5 2560 1920 2300 2690

42 4.5 1120 487.0 4090 3070 3680 4290

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT

REPRESENT FULL STRENGTH CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED,

ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED

STEEL OR RAW ALUMINUM

CLASS 8.8 METRIC BOLTS

CLASS 8 METRIC NUTS

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT

METHODS TOLERANCE = ±10%

NO. 5000059 REV. J

Figure 1-6. Torque Chart (METRIC Fasteners - Sheet 5 of 7))

3120752 – JLG Lift – 1-9

Page 22

SECTION 1 - SPECIFICATIONS

Size PITCH

Tensile

Stress

Area

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

K = 0.20

Torque

(Lub OR Loctite®

242

TM

or 271TM OR

Vibra-TITE

TM

111 or

140)

K= 0.18

Torque

(Loctite® 262

TM

OR

Vibra-TITE

TM

131)

K=0.15

Sq mm KN [N.m] [N.m] [N.m]

3 0.5 5.03 3.13

3.5 0.6 6.78 4.22

4 0.7 8.78 5.47

5 0.8 14.20 8.85

6 1 20.10 12.5

7 1 28.90 18.0 25.2 22.7 18.9

8 1.25 36.60 22.8 36.5 32.8 27.4

10 1.5 58.00 36.1 70 65 55

12 1.75 84.30 52.5 125 115 95

14 2 115 71.6 200 180 150

16 2 157 97.8

315 280 235

18 2.5 192 119.5 430 385 325

20 2.5 245 152.5 610 550 460

22 2.5 303 189.0 830 750 625

24 3 353 222.0 1065 960 800

27 3 459 286.0 1545 1390 1160

30 3.5 561 349.5 2095 1885 1575

33 3.5 694 432.5 2855 2570 2140

36 4 817 509.0 3665 3300 2750

42 4.5 1120 698.0 5865 5275 4395

CLASS 10.9 METRIC BOLTS

CLASS 10 METRIC NUTS

CLASS 12.9 SOCKET HEAD CAP SCREWS M3 - M5*

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT

REPRESENT FULL STRENGTH CAPABILI TY OF SHCS. IF HIGHER LOAD IS REQUIRED,

ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED

STEEL OR RAW ALUMINUM

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT

METHODS TOLERANCE = ±10%

NO. 5000059 REV. J

Figure 1-7. Torque Chart (METRIC Fasteners - Sheet 6 of 7)

1-10 – JLG Lift – 3120752

Page 23

SECTION 1 - SPECIFICATIONS

Size PITCH

Tensile

Stress

Area

Clamp Load

See Note 4

Torque

(Dry or Loctite®

263

TM

)

K = .17

Torque

(Lub OR Loctite®

242

TM

or 271

TM

OR Vibra-TITE

TM

111 or 140)

K = .16

Torque

(Loctite® 262

TM

OR Vibra-TITE

TM

131)

K = .15

Sq mm kN [N.m] [N.m] [N.m]

30.55.03

3.5 0.6 6.78

40.78.78

50.814.20

6120.1012.5 13 12 11

7128.9018.0 21 20 19

8 1.25 36.60 22.8 31 29 27

10 1.5 58.00 36.1 61 58 54

12 1.75 84.30 52.5 105 100 95

14 2 115 71.6 170 160 150

16 2 157

97.8 265 250 235

18 2.5 192 119.5 365 345 325

20 2.5 245 152.5 520 490 460

22 2.5 303 189.0 705 665 625

24 3 353 220.0 900 845 790

27 3 459 286.0 1315 1235 1160

30 3.5 561 349.5 1780 1680 1575

33 3.5 694 432.5 2425 2285 2140

36 4 817 509.0 3115 2930 2750

42 4.5 1120 698.0 4985 4690 4395

CLASS 12.9 SOCKET HEAD CAP SCREWS

M6 AND ABOVE*

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT

REPRESENT FULL STRENG TH CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED,

ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATE D

STEEL OR RAW ALUMINUM

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT

METHODS TOLERANCE = ±10%

NO. 5000059 REV. J

Magni Coating (Ref 4150701)*

3120752 – JLG Lift – 1-11

Figure 1-8. Torque Chart (METRIC Fasteners - Sheet 7 of 7)

Page 24

SECTION 1 - SPECIFICATIONS

NOTES:

1-12 – JLG Lift – 3120752

Page 25

SECTION 2 - SERVICE PROCEDURES

SECTION 2. SERVICE PROCEDURES

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE

General

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness and maintain its safe

operating condition. For maximum service life and safe

operation, ensure that all the necessary inspections and

maintenance have been completed before placing the

machine into service.

Preparation, Inspection, and Maintenance

It is important to establish and conform to a comprehensive inspection and preventive maintenance program.

The following table outlines the periodic machine inspections and maintenance recommended by JLG Industries,

Inc. Consult your national, regional, or local regulations

for further requirements for aerial work platforms. The frequency of inspections and maintenance must be

increased as environment, severity and frequency of

usage requires.

Pre-Start Inspection

It is the User’s or Operator’s primary responsibility to perform a Pre-Start Inspection of the machine prior to use

daily or at each change of operator. Reference the Operator’s and Safety Manual for completion procedures for the

Pre-Start Inspection. The Operator and Safety Manual

must be read in its entirety and understood prior to performing the Pre-Start Inspection.

Pre-Delivery Inspection and Frequent Inspection

The Pre-Delivery Inspection and Frequent Inspection shall

be performed by a qualified JLG equipment mechanic.

JLG Industries, Inc. recognizes a qualified JLG equipment

mechanic as a person who, by possession of a recognized degree, certificate, extensive knowledge, training, or

experience, has successfully demonstrated the ability and

proficiency to service, repair, and maintain the subject

JLG product model.

The Pre-Delivery Inspection and Frequent Inspection procedures are performed in the same manner, but at different times. The Pre-Delivery Inspection shall be performed

prior to each sale, lease, or rental delivery. The Frequent

Inspection shall be accomplished for each machine in service for 3 months or 150 hours (whichever comes first);

out of service for a period of more than 3 months; or when

purchased used. The frequency of this inspection must be

increased as environment, severity and frequency of

usage requires.

Reference the JLG Pre-Delivery and Frequent Inspection

Form and the Inspection and Preventative Maintenance

Schedule for items requiring inspection during the performance of these inspections. Reference the appropriate

areas of this manual for servicing and maintenance procedures.

Annual Machine Inspection

The Annual Machine Inspection must be performed by a

qualified JLG equipment mechanic on an annual basis, no

later than thirteen (13) months from the date of the prior

Annual Machine Inspection. JLG Industries, Inc. recognizes a qualified JLG equipment mechanic as a person

who has successfully completed the JLG Service Training

School for the subject JLG product model. Reference the

machine Service and Maintenance Manual and appropriate JLG inspection form for performance of this inspection.

Reference the JLG Annual Machine Inspection Form and

the Inspection and Preventative Maintenance Schedule for

items requiring inspection during the performance of this

inspection. Reference the appropriate areas of this manual for servicing and maintenance procedures.

For the purpose of receiving safety-related bulletins, it is

important that JLG Industries, Inc. has updated ownership

information for each machine. When performing each

Annual Machine Inspection, notify JLG Industries, Inc. of

the current machine ownership.

Preventative Maintenance

In conjunction with the specified inspections, maintenance shall be performed by a qualified JLG equipment

mechanic. JLG Industries, Inc. recognizes a qualified JLG

equipment mechanic as a person who, by possession of a

recognized degree, certificate, extensive knowledge, training, or experience, has successfully demonstrated the

ability and proficiency to service, repair, and maintain the

subject JLG product model.

Reference Table 2-2, AM Model - Preventive Maintenance

& Inspection Schedule., and the appropriate areas of this

manual for servicing and maintenance procedures. The

frequency of service and maintenance must be increased

as environment, severity and frequency of usage requires.

3120752 – JLG Lift – 2-1

Page 26

SECTION 2 - SERVICE PROCEDURES

Table 2-1. Inspection and Maintenance

TYPE FREQUENCY

Pre-Start

Inspection

Pre-Delivery

Inspection

Frequent

Inspection

Annual

Machine

Inspection

Preventative

Maintenance

Prior to use each day; or

At each Operator change.

Prior to each sale, lease, or

rental delivery.

In service for 3 months or 150 hours,

whichever comes first; or Out of service

for a period of more than 3 months; or Purchased used.

Annually, no later than 13 months from the

date of the prior inspection.

At intervals as specified in the Ser vice and

Maintenance Manual.

PRIMARY

RESPONSIBILITY

User or Operator User or Operator Operator and Safety M anual

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Qualified JLG

SERVICE

QUALIFICATION

Mechanic

Mechanic

Mechanic

Mechanic

REFERENCE

Service and Maintenance Manual and applicable JLG inspection form.

Service and Maintenance Manual and applicable JLG inspection form.

Service and Maintenance Manual and applicable JLG inspection form.

Service and Maintenance Manual

2.2 PREVENTIVE MAINTENANCE AND INSPECTION SCHEDULE

(See Table 2-2.)

The preventive maintenance and inspection checks are

listed and defined in the following table. This table is

divided into two basic parts, the “AREA” to be inspected

and the “INTERVAL” at which the inspection is to take

place. Under the “AREA” portion of the table, the various

systems along with the components that make up that

system are listed. The “INTERVAL” portion of the table is

divided into five columns representing the various inspection time periods. The numbers listed within the interval

column represent the applicable inspection code for

which that component is to be checked.

The checks and services listed in this schedule are not

intended to replace any local or regional regulations that

may pertain to this type of equipment nor should the lists

be considered as all inclusive. Variances in interval times

may occur due to climate and/or conditions and depending on the location and use of the machine.

2-2 – JLG Lift – 3120752

Page 27

SECTION 2 - SERVICE PROCEDURES

Table 2-2. AM Model - Preventive Maintenance & Inspection Schedule.

INTERVAL

AREA ON MACHINE

PRE-START (1)

INSPECTION

WEEKLY

PREVENTATIVE

MAINTENANCE

MAST ASSEMBLY 1

Mast Sections 2, 5

Chain Systems 14 3, 14 14, 25

Sequence Cable Systems 31, 2, 3

Support Bars 1, 2

Covers or Shields 1

Sheave Systems 1, 2 1, 2

Bearings 1, 2

Slide Pads 1, 2

PLATFORM ASSEMBLY 1

Platform 11

Guard Rails 1, 2 2

Gate 1, 5 5

Floor 2

Extension Deck Assembly 1, 5

Lanyard Anchorage Point 1

CHASSIS ASSEMBLY 1

Outrigger Beams, Sockets, and Locking Pins 1, 2, 5, 7 1, 2, 5, 7

Outrigger Screw Jacks 51, 2, 5

Tires/Wheels/Caster Systems 1, 2 1, 2

Bubble Level 1, 2, 7 1, 2, 7

Cable Reel (LiftMaster Only) 55

Winch and Winch Brake (LiftMaster Onl y) 1, 2, 5

FUNCTIONS/CONTROLS 1

Platform Controls 55, 6, 7

Ground Controls 5 5, 6, 24

Function Control Locks, Guards, or Detents 55

Function Enable System 5

Emergency Stop Switches (Ground & Platform) 55

Function Limit or Cutout Switch Systems

Manual Descent or Auxiliary Power 55

POWER SYSTEM

Batteries 19 9

Battery Fluid 11 11

Battery Charger 5

HYDRAULIC/ELECTRIC SYSTEM 1

Hydraulic Pump 9 1, 2, 9 2, 5

Hydraulic Pump Cover 1

Hydraulic Cylinder 7, 9 2, 9 2, 9

Cylinder Attachment Pi ns and Pin Retainers 1, 2

Hydraulic Hoses, Lines, and Fittings 91, 9

Hydraulic Reservoir, Cap, and Breather 5, 7 5, 7 5, 7

Hydraulic Filter

3 MONTH

PREVENTATIVE

MAINTENANCE

PRE-DELIVERY (2)

OR FREQUENT (3)

INSPECTION

ANNUAL (4)

(YEARLY)

INSPECTION

3120752 – JLG Lift – 2-3

Page 28

SECTION 2 - SERVICE PROCEDURES

Table 2-2. AM Model - Preventive Maintenance & Inspection Schedule.

INTERVAL

AREA ON MACHINE

PRE-START (1)

INSPECTION

WEEKLY

PREVENTATIVE

MAINTENANCE

Hydraulic Fluid * 11 11 11 11 11

Electrical Connections 20 20

Outrigger Interlock Systems 1, 2, 5 5

GENERAL

Operator and Safety Manuals in Storage Box 21 21 21

ANSI and EMI Manuals/Handbooks Installed 21 21 21

Capacity Decals Installed, Secure, Legible 21 21 21

All Decals/Placards Installed, Secure, Legible 21 21 21

"Walk-Around" Inspection Perfor med 22

Annual Machine Inspection Due 21

No Unauthorized Modifications or Additions 21 21

All Relevant Safety Publications Incorporated 21 21, 22

General Structural Condition and Welds 2, 4 2, 4

All Fasteners, Pins, Shields, and Covers 1, 2

Grease and Lubricate to Specifications 22 22

Function Test of All Systems 22

Paint and Appearance 77

S ta mp I n sp ec t io n D a te o n F ra me 22

Notify JLG of Machine Ownership 22

3 MONTH

PREVENTATIVE

MAINTENANCE

PRE-DELIVERY (2)

OR FREQUENT (3)

INSPECTION

ANNUAL (4)

(YEARLY)

INSPECTION

* Change per Lubrication Chart in Section-1 of this Service Manual.

Footnotes:

(1) Prior to use each day; or at each Operator change

(2) Prior to each sale, lease, or delivery

(3) In service for 3 months or 150 hours; or Out of service

for 3 months or more; or Purchased used

(4) Annually, no later than 13 months from the date of the

prior inspection

Inspection and Maintenance Codes:

1. Check for proper and secure installation.

2. Visual inspection for damage, cracks, distortion, or

excessive wear.

3. Check for proper adjustment.

4. Check for cracked or broken welds.

5. Operates properly.

6. Returns to neutral or "off" position when released.

7. Clean and free of debris.

8. Interlocks function properly.

9. Check for signs of leakage.

10. Decals installed and legible.

11. Check for proper fluid level.

12. Check for chafing and proper routing.

13. Check for proper tolerances.

14. Properly lubricated.

15. Torqued to proper specification.

16. No gouges, excessive wear, or cords showing.

17. Properly inflated and seated around rim.

18. Proper and authorized components.

19. Fully charged.

20. No loose connections, corrosion, or abrasions.

21. Verify.

22. Perform.

23. Sealed properly.

24. Overrides Platform controls.

25. Inspected per Service and Maintenance Manual.

2-4 – JLG Lift – 3120752

Page 29

SECTION 2 - SERVICE PROCEDURES

2.3 SERVICING AND MAINTENANCE GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this chapter.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of component weight. Never attempt to

move heavy parts without the aid of a mechanical device.

Do not allow heavy objects to rest in an unstable position.

When raising a portion of the equipment, ensure that adequate support is provided.

NEVER WORK UNDER AN ELEVATED PLATFORM UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED FROM ANY MOVEMENT

BY BLOCKING OR OVERHEAD SLING.

Cleanliness

The most important single item in preserving the long service life of a machine is to keep dirt and foreign materials

out of the vital components. Precautions have been taken

to safeguard against this. Shields, covers, seals, and filters are provided to keep the wheel bearings, mast sections and oil supply clean; however, these items must be

maintained on a scheduled basis in order to function

properly.

At any time when oil lines are disconnected, clear adjacent areas as well as the openings and fittings themselves. As soon as a line or component is disconnected,

cap or cover all openings to prevent entry of foreign matter.

Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings are

unobstructed. Cover all parts to keep them clean. Be sure

all parts are clean before they are installed. New parts

should remain in their containers until they are ready to be

used.

Components Removal and Installation

Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as near

perpendicular as possible to top of part being lifted.

Should it be necessary to remove a component on an

angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between the supporting

structure and the component becomes less than 90

degrees.

If a part resists removal, check to see whether all nuts,

bolts, cables, brackets, wiring, etc., have been removed

and that no adjacent parts are interfering.

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an “anti-seize” or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings

When a bearing is removed, cover it to keep out dirt and

abrasives. Clean bearings in nonflammable cleaning solvent and allow to drip dry. Compressed air can be used

but do not spin the bearing.

Discard bearings if the races and balls (or rollers) are pitted, scored, or burned.

If bearing is found to be serviceable, apply a light coat of

oil and wrap it in clean (waxed) paper. Do not unwrap

reusable or new bearings until they are ready to install.

Lubricate new or used serviceable bearings before installation. When pressing a bearing into a retainer or bore,

apply pressure to the outer race. If the bearing is to be

installed on a shaft, apply pressure to the inner race.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

3120752 – JLG Lift – 2-5

Page 30

SECTION 2 - SERVICE PROCEDURES

Bolt Usage and Torque Application

Use bolts of proper length. A bolt which is too long will

bottom before the head is tight against its related part. If a

bolt is too short, there will not be enough thread area to

engage and hold the part properly. When replacing bolts,

use only those having the same specifications of the original, or one which is equivalent.

Unless specific torque requirements are given within the

text, standard torque values should be used on heattreated bolts, studs, and steel nuts, in accordance with

recommended shop practices. (See Figure 1-2.)

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System