Page 1

Operators and Safety Manual

ANSI

MODEL

15ELI

3120778

August 5, 2002

Page 2

CALIFORNIAN PROPOSITION 65

BATTERY WARNING

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemical known to the

State of Califormia

to cause cancer and

reproductive harm.

WASH HANDS

AFTER HANDLING!

Page 3

FOREWORD

The purpose of this manual is to provide users with the operating procedures essential for the promotion of

proper machine operation for its intended purpose. It is important to over-stress proper machine usage. All

information in this manual should be READ and UNDERSTOOD before any attempt is made to operate the

machine. YOUR OPERATING MANUAL IS YOUR MOST IMPORTANT TOOL - Keep it with the machine.

REMEMBER ANY EQUIPMENT IS ONLY AS SAFE AS THE OPERATOR.

BECAUSE THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND

OPERATION, PROPER SAFETY PRACTICES ARE THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

ALL INSTRUCTIONS IN THIS MANUAL ARE BASED ON THE USE OF THE MACHINE UNDER PROPER

OPERATING CONDITIONS, WITH NO DEVIATIONS FROM THE ORIGINAL DESIGN. ALTERATION AND/

OR MODIFICATION OF THE MACHINE IS STRICTLY FORBIDDEN, WITHOUT WRITTEN APPROVAL

FROM JLG INDUSTRIES, PER OSHA REGULATIONS.

THIS "SAFETY ALERT SYMBOL" IS USED TO CALL ATTENTION TO POTENTIAL HAZARDS

WHICH MAY LEAD TO SERIOUS INJURY OR DEATH IF IGNORED.

Safety of personnel and proper use of the machine are of primary concern, DANGER, WARNING, CAUTION,

IMPORTANT, INSTRUCTIONS and NOTE are inserted throughout this manual to emphasize these areas.

They are defined as follows:

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED WILL RESULT IN SERIOUS

INJURY OR DEATH.

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR

MODERATE INJURY. IT MAY ALSO BE USED TO ALERT

AGAINST UNSAFE PRACTICES.

Also in this Manual "Notes:" are used to provide information of special interest.

JLG INDUSTRIES, INC. MAY HAVE ISSUED SAFETY RELATED BULLETINS FOR YOUR JLG PRODUCT. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG DISTRIBUTOR FOR INFORMATION CONCERNING SAFETY RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR YOUR JLG PRODUCT. ALL ITEMS REQUIRED BY THE SAFETY RELATED

BULLETINS MUST BE COMPLETED ON THE AFFECTED JLG PRODUCT.

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED COULD RESULT IN SERIOUS INJURY OR DEATH.

IMPORTANT OR INSTRUCTIONS PROCEDURES ESSENTIAL

FOR SAFE OPERATION AND WHICH, IF NOT FOLLOWED

MAY RESULT IN A MALFUNCTION OR DAMAGE TO THE

MACHINE.

Due to the continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without

prior notification. Contact JLG Industries, Inc. for updated information.

Page 4

This page left intentionally blank.

Page 5

INTRODUCTION - OPERATION/SAFETY PRECAUTIONS

INTRODUCTION - OPERATION/SAFETY PRECAUTIONS

All procedures herein are based on the use of the

machine under proper operating conditions, with no deviations from original design intent ... as per OSHA regulations.

READ & HEED!

The ownership, use, service, and/or maintenance of this

machine is subject to various federal, state and local laws

and regulations. It is the responsibility of the owner/user to

be knowledgeable of these laws and regulations and to

comply with them. The most prevalent regulations of this

type are the Federal OSHA Safety Regulations*. Listed

below, in abbreviated form are some of the requirements

of Federal OSHA regulations in effect as of the date of

publication of this handbook.

The listing of these requirements shall not relieve the

owner/user of the responsibility and obligation to determine all applicable laws and regulations and their exact

wording and requirements, and to comply with the

requirements. Nor shall the listing of these requirements

constitute an assumption of responsibility of liability on the

part of JLG Industries, Inc.

1. Only trained and authorized operators shall be permitted to operate the aerial lift.

2. A malfunctioning lift shall be shut down until

repaired.

3. The controls shall be plainly marked as to their function.

4. The controls shall be tested each day prior to use to

determine that they are in safe operating condition.

5. Load limits specified by the manufacturer shall not

be exceeded.

6. Instruction and warning placards must be legible.

7. Aerial lifts may be "field modified" for uses other than

those intended by the manufacturer only if certified

in writing by the manufacturer or an equivalent

entity, such as a nationally recognized testing lab, to

be in conformity to applicable OSHA safety regulations and to be at least as safe as it was prior to

modification.

8. Aerial lifts shall not be used near electric power lines

unless the lines have been deenergized or adequate

clearance is maintained (see OSHA 29 CFR 1910.67

and 1926.400).

9. Employees using aerial lifts shall be instructed how

to recognize and avoid unsafe conditions and hazards.

10. Ground controls shall not be operated unless permission has been obtained from personnel in the

platform, except in case of an emergency.

11. Regular inspection of the job site and aerial lift shall

be performed by competent persons.

12. Personnel shall always stand on the floor of the platform, not on boxes, planks, railing or other devices

for work positioning.

*Applicable Federal OSHA regulations, as of the date of

publication of this manual include, but are not limited to,

29 CFR 1910.67, 29 CFR 1926.20, 29 CFR 1926.21, 29

CFR 1926.28, 29 CFR 1926.400 and 29 CFR 1926.453.

Consult the current regulations for the exact wording and

full text of the requirements and contact the closest Federal OSHA office for specific interpretations.

3120778 – JLG Lift – a

Page 6

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A. GENERAL

This section contains the general safety precautions

which must be observed during maintenance of the aerial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others or

damage to the equipment. A maintenance program must

be established by a qualified person and must be followed

to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED IS A SAFETY VIOLATION.

The specific precautions to be observed during machine

maintenance are inserted at the appropriate point in the

manual. These precautions are, for the most part, those

that apply when servicing hydraulic and larger machine

component parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of component weight and never attempt to

move heavy parts without the aid of a mechanical device.

Do not allow heavy objects to rest in an unstable position.

When raising a portion of the equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA IS THE RESPONSIBILITY OF THE OWNER/

OPERATOR.

C. MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY VIOLATION.

• REMOVE ALL RINGS, WATCHES, AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL DANGER, WARNING, CAUTION AND OTHER INSTRUCTIONS ON MACHINE

AND IN SERVICE MANUAL.

• KEEP STANDING SURFACES AND HAND HOLDS

FREE OF OIL, GREASE, WATER, ETC.

• NEVER WORK UNDER AN ELEVATED PLATFORM

UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED

FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

•BATTERY SHOULD ALWAYS BE DISCONNECTED

DURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

B. HYDRAULIC SYSTEM SAFETY

1. It should be particularly noted that the machines

hydraulic systems operate at extremely high and

potentially dangerous pressures. Every effort should

be made to relieve any system pressure prior to disconnecting or removing any portion of the system.

2. Relieve system pressure by activating the lift DOWN

control with the platform completely lowered to

direct any line pressure back into the return line to

the reservoir. Pressure feed lines to system components can then be disconnected with minimal fluid

loss.

b – JLG Lift – 3120778

Page 7

EFFECTIVITY CHANGES

February 1, 1999 - Original Issue of Manual

April 20, 2000 – Revised – Added Proposition 65 to front of manual.

August 5, 2002 – Manual Revised

EFFECTIVITY PAGE

3120778 – JLG Lift – c

Page 8

EFFECTIVITY PAGE

This page left intentionally blank

d – JLG Lift – 3120778

Page 9

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

INTRODUCTION -- OPERATION/SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

INTRODUCTION -- MAINTENANCE SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

A GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

B HYDRAULIC SYSTEM SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

C MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

EFFECTIVITY CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 ELECTROCUTION HAZARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 TRANSPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 TRANSPORT SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 PRE-OPERATIONAL SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.6 OPERATING SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SECTION 2 - PREPARATION AND INSPECTION

2.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 PREPARATION FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 DELIVERY AND FREQUENT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Platform Guard Rail Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Platform Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mast Chains & Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Control/(Power) Cable(s) for Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Lift Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Wheels and Casters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Hydraulic Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Machine Controls - (Platform and Ground). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Batteries - (DC Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Power Cord - (AC Models). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electric Motor/Hydraulic Pump and Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Placards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 DAILY WALK-AROUND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Batteries Charged (DC Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Overall Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Placards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Operators & Safety and ANSI Responsibilities Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 DAILY FUNCTIONAL CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.6 TORQUE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7 BATTERY CHARGING & MAINTENANCE (ELI-DC MODELS ONLY) . . . . . . . . . . . . . . . . . . . . . . . 2-4

Battery Maintenance and Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Battery Charger Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Abnormal Cycle Indicator LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3120778 – JLG Lift – i

Page 10

TABLE OF CONTENTS

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 PERSONNEL TRAINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Operator Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 OPERATING CHARACTERISTICS AND LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Placards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Ground Control Station (See Figure 3-1.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Platform Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

SECTION 4 - MACHINE OPERATION

4.1 MACHINE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 MACHINE SET-UP AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Floor Brake Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Platform Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Platform Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 QUICK-CHANGE PLATFORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Platform Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Platform Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 STOWING MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.6 TRANSPORTING, LIFTING AND TIE DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Transporting by Pushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Transport Vehicle Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

SECTION 5 - OPTIONAL EQUIPMENT

5.1 OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

22" x 25" Quick-Change Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

26" x 26" Quick-Change Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

28" x 26" Quick-Change Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

25" x 26" Step-in Molded Platform w/Swing-up Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

26" x 50" Quick-Change - ExtendiblePlatform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Tool Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Fluorescent Tube Caddy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Extra Power Pack (DC Battery, Charger & Case) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Lifting Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Platform Auxiliary Power Lowering Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Laser Positioning Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

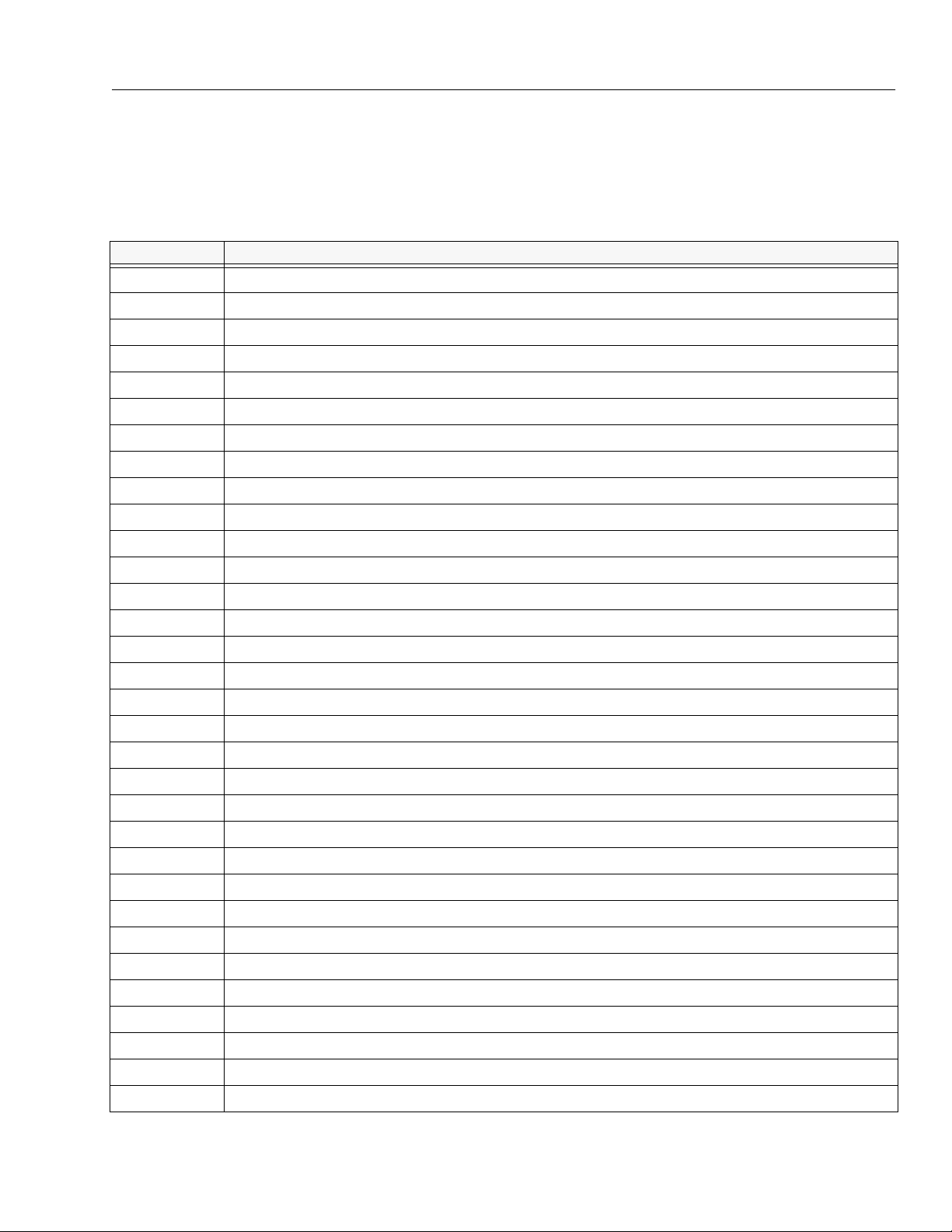

5.2 EXTENDIBLE PLATFORM OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Mounting to Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Entering/Exiting Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Extending Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Retracting Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

SECTION 6 - EMERGENCY PROCEDURES

6.1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

ii – JLG Lift – 3120778

Page 11

6.2 EMERGENCY CONTROLS AND THEIR LOCATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Platform Emergency Stop Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Ground Emergency Stop Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Manual Descent Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.3 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Use of Ground Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Operator Unable to Control Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Platform Caught Overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Righting of Tipped Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Post-Incident Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

SECTION 7 - INSPECTION AND REPAIR LOG

LIST OF FIGURES

1-1. Electrocution Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2. Use Handles Provided On Mast Crossbar To Move Machine.. . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-3. Do Not Move Unit on Soft or Uneven Surfaces or Over Obstructions, Bumps, Debris, Etc. . . . . .1-2

1-4. Two People May Be Required on Slopes Up To Five Degrees. Also Always Travel

With Platform End On The Low Side of Slope.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-5. Read Your Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-6. Always Look in the Direction of Movement. Watch for Overhead and Other Obstructions. . . . . .1-4

1-7. Death or Serious Injury Could Occur from a Tip Over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-8. All Personnel Must Stand Clear When Platform Is Being Raised Or Lowered. . . . . . . . . . . . . . . .1-5

1-9. Falling from Platform could cause Death or Serious Injury.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2-1. Daily Walk-Around Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2-2. Battery Fluid Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-3. Battery Box and Charger Assembly. (D.C. Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-4. Dual Voltage Battery Charger - Front Panel.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-5. Lubrication Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-6. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

3-1. Ground Control Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2. Manual Descent Control Valve Location - Machines Since S/N-0900019526 . . . . . . . . . . . . . . . .3-3

3-3. Platform Control Station.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-4. Decal Locations (Front View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-5. Decal Locations (3124221 decal from Front View). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-6. Decal Locations (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-7. Decal Locations (Top View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-8. Decal Locations (Right/Left View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

4-1. Setting & Releasing Floor Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-2. Quick Change Platform Mount.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-3. 15ELI Tie Down Pockets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

5-1. Extendible Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

TABLE OF CONTENTS

LIST OF TABLES

1-1 Minimum Safe Approach Distance (to energized power lines or parts) . . . . . . . . . . . . . . . . . . . .1-1

2-1 Lubrication Intervals for Various Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

4-1 Maximum Platform Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4-2 ELI Machine Gross Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

7-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

3120778 – JLG Lift – iii

Page 12

TABLE OF CONTENTS

This page intentionally left blank.

iv – JLG Lift – 3120778

Page 13

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section prescribes the proper and safe practices for

major areas of machine usage which have been divided

into three basic categories: Transporting, Pre-Operation

and Operation. In order to promote proper usage of the

machine, it is mandatory that a daily routine be established based on instruction given in this section. A maintenance program must also be established by a qualified

person and must be followed to ensure that the machine

is safe to operate.

The user/operator of the machine should not accept operating responsibility until this manual has been READ and

UNDERSTOOD, and operating instructions of the machine

under the supervision of an experienced and qualified

operator, has been completed. If there is a question on

application and/or operation, JLG Industries Product

Safety and Reliability Department should be consulted.

MODIFICATION OF THE MACHINE WITHOUT APPROVAL OF JLG

INDUSTRIES INC., OR CERTIFICATION BY A NATIONALLY RECOGNIZED TESTING LAB TO BE IN CONFORMITY WITH APPLICABLE OSHA REGULATIONS, AND TO BE AT LEAST AS SAFE AS

BEFORE MODIFICATION, IS PROHIBITED AND IS A VIOLATION

OF OSHA RULES.

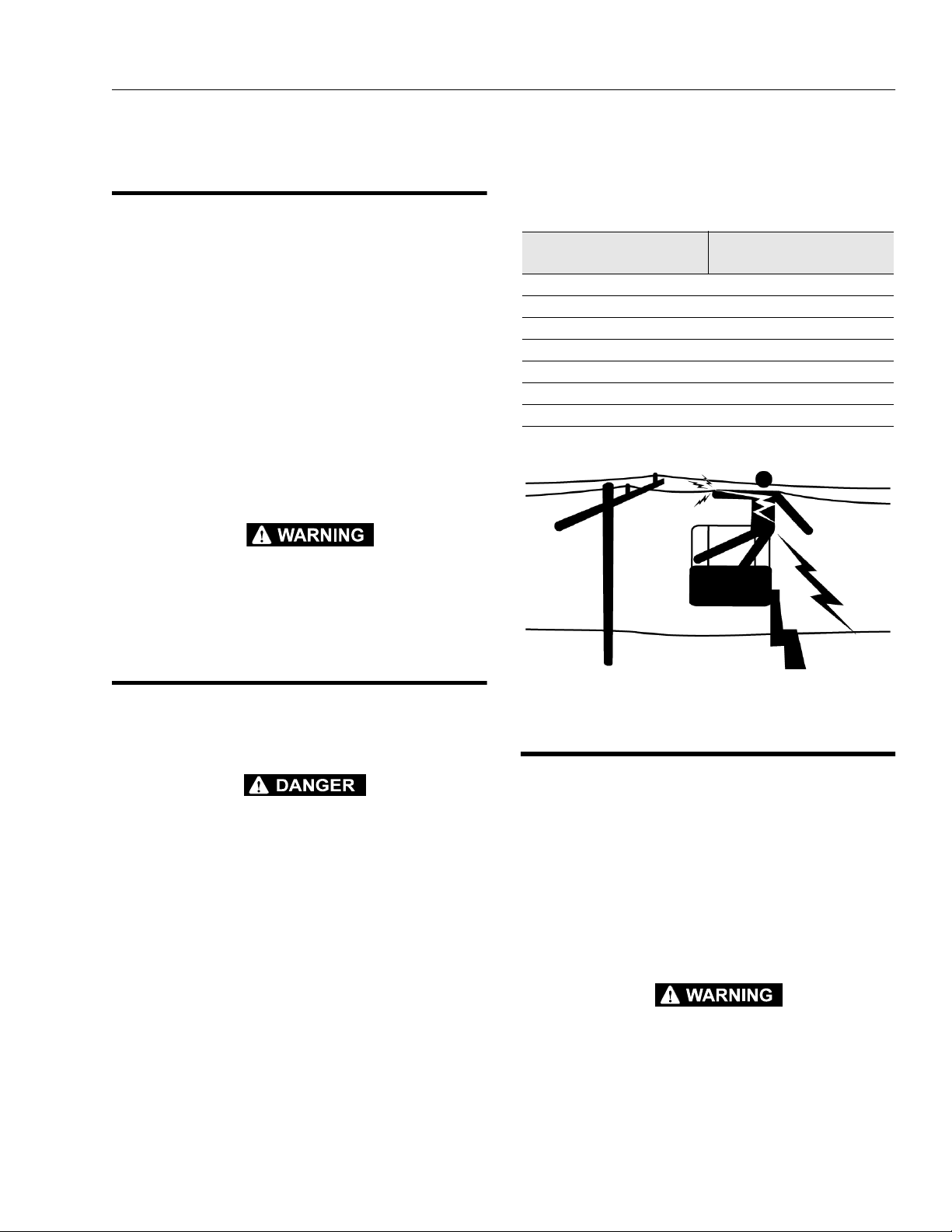

Table 1-1. Minimum Safe Approach Distance

(to energized power lines or parts)

VOLTAGE RANGE

(PHASE TO PHASE)

0-300V – Avoid Contact

Over 300V to 50KV – 10 f t. [3 m]

Over 50KV to 200KV – 15 f t. [4.6 m]

Over 200KV to 350KV – 20 f t. [6 m]

Over 350KV to 500KV – 25 f t. [7.6 m]

Over 500KV to 750KV – 35 ft. [10.6 m]

Over 750KV to 1000KV – 45 ft. [13.7 m]

MINIMUM SAFE DISTANCE -

Feet [m]

1.2 ELECTROCUTION HAZARD

Minimum safe approach distances (M.S.A.D.) to energized (exposed or insulated) power lines and parts.

DO NOT MANEUVER MACHINE OR PERSONNEL TO DISTANCE

LESS THAN M.S.A.D (SEE TABLE 1-1.). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE ENERGIZED UNLESS KNOWN

OTHERWISE.

THIS MACHINE DOES NOT PROVIDE PROTECTION FROM CONTACT WITH OR PROXIMITY TO AN ELECTRICALLY CHARGED

CONDUCTOR. MAINTAIN A CLEARANCE OF AT LEAST 10 FT.

(3M) BETWEEN ANY PART OF THE MACHINE AND ANY ELECTRICAL LINE OR APPARATUS CARRYING UP TO 50,000 VOLTS. 1

FT. (0.3M) ADDITIONAL CLEARANCE IS REQUIRED FOR EVERY

ADDITIONAL 30,000 VOLTS OR LESS. ALLOW FOR PLATFORM

SWAY, ROCK OR SAG AND ELECTRICAL LINE SWAYING, (SEE

FOLLOWING TABLE).

Figure 1-1. Electrocution Hazard.

1.3 TRANSPORTING

Before transporting the machine the user/operator must

be familiar with the proper procedures for transporting the

machine, as well as the weight and size of the machine.

The user/operator should be familiar with the surrounding

work area and surface before transporting the machine.

The work area must be a smooth, firm surface on which

machine is capable of being leveled.

NOTE: Remember that the key to safe and proper usage is

common sense and its careful application.

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION AND ON MACHINE MAY RESULT IN MACHINE

DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY

VIOLATION.

3120778 – JLG Lift – 1-1

Page 14

SECTION 1 - SAFETY PRECAUTIONS

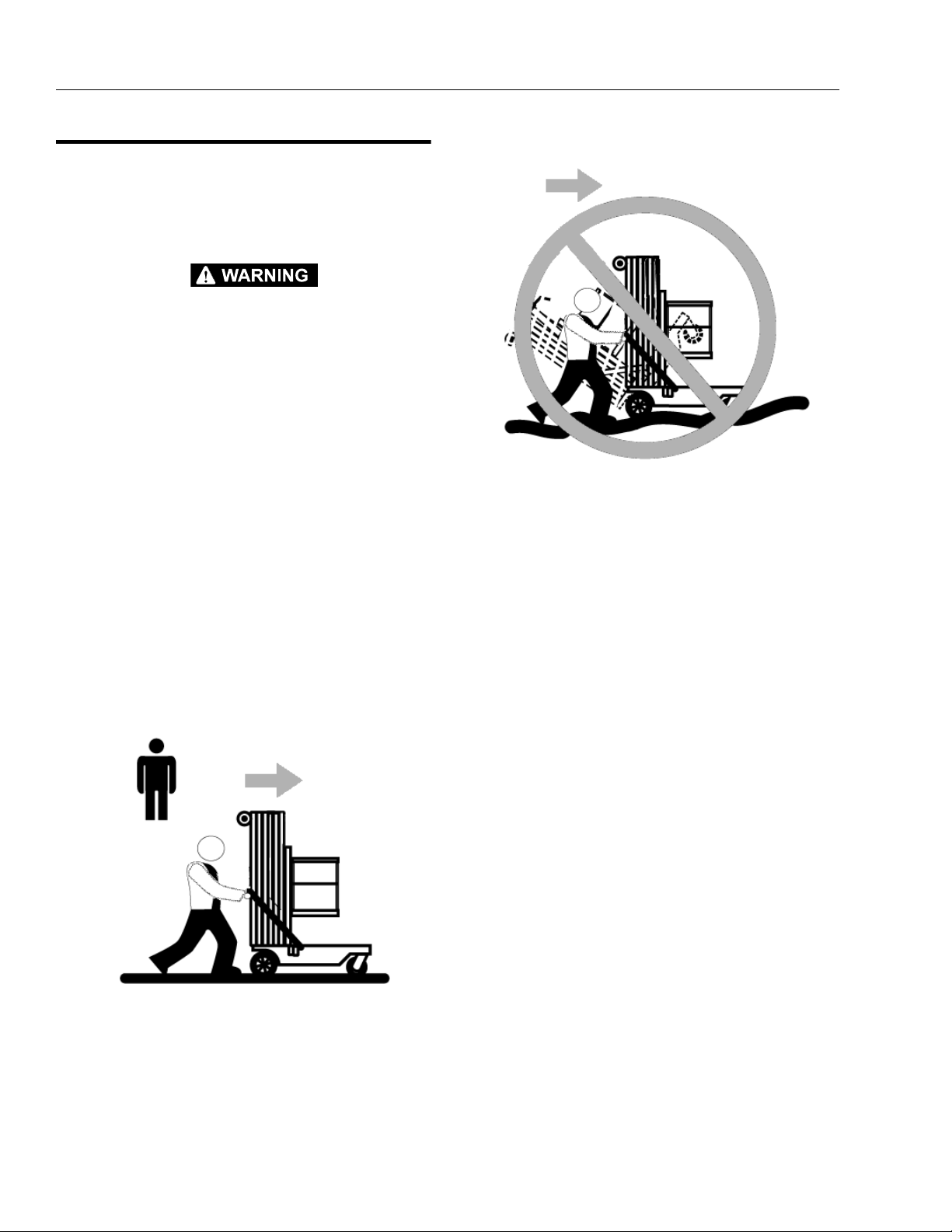

1.4 TRANSPORT SAFETY

• FULLY LOWER AND COMPLETELY EMPTY PLATFORM

OF TOOLS AND DEBRIS BEFORE MOVING MACHINE.

• NEVER ALLOW PERSONNEL IN PLATFORM WHILE

MOVING MACHINE.

FAILURE TO OBSERVE THE FOLLOWING TIPPING HAZARD

INSTRUCTIONS COULD CAUSE THE UNIT TO TIP OVER OR BE

HARD TO CONTROL WHEN BEING MOVED, WHICH COULD

RESULT IN SERIOUS INJURY OR DEATH DUE TO BEING PINNED

OR CRUSHED BY THE UNIT.

• ON A LEVEL SURFACE, ALWAYS TRAVEL WITH THE

PLATFORM END LEADING THE WAY.

• WATCH FOR OBSTRUCTIONS AROUND MACHINE

AND OVERHEAD WHEN MOVING.

• CHECK TRAVEL PATH FOR PERSONS, HOLES,

BUMPS, DROP-OFFS, OBSTRUCTIONS, DEBRIS, AND

COVERINGS WHICH MAY CONCEAL HOLES AND

OTHER HAZARDS, AS TIPPING COULD OCCUR.

• BEFORE MOVING MACHINE ON FLOORS, TRUCKS

AND OTHER SURFACES, CHECK ALLOWABLE

CAPACITY OF SURFACES.

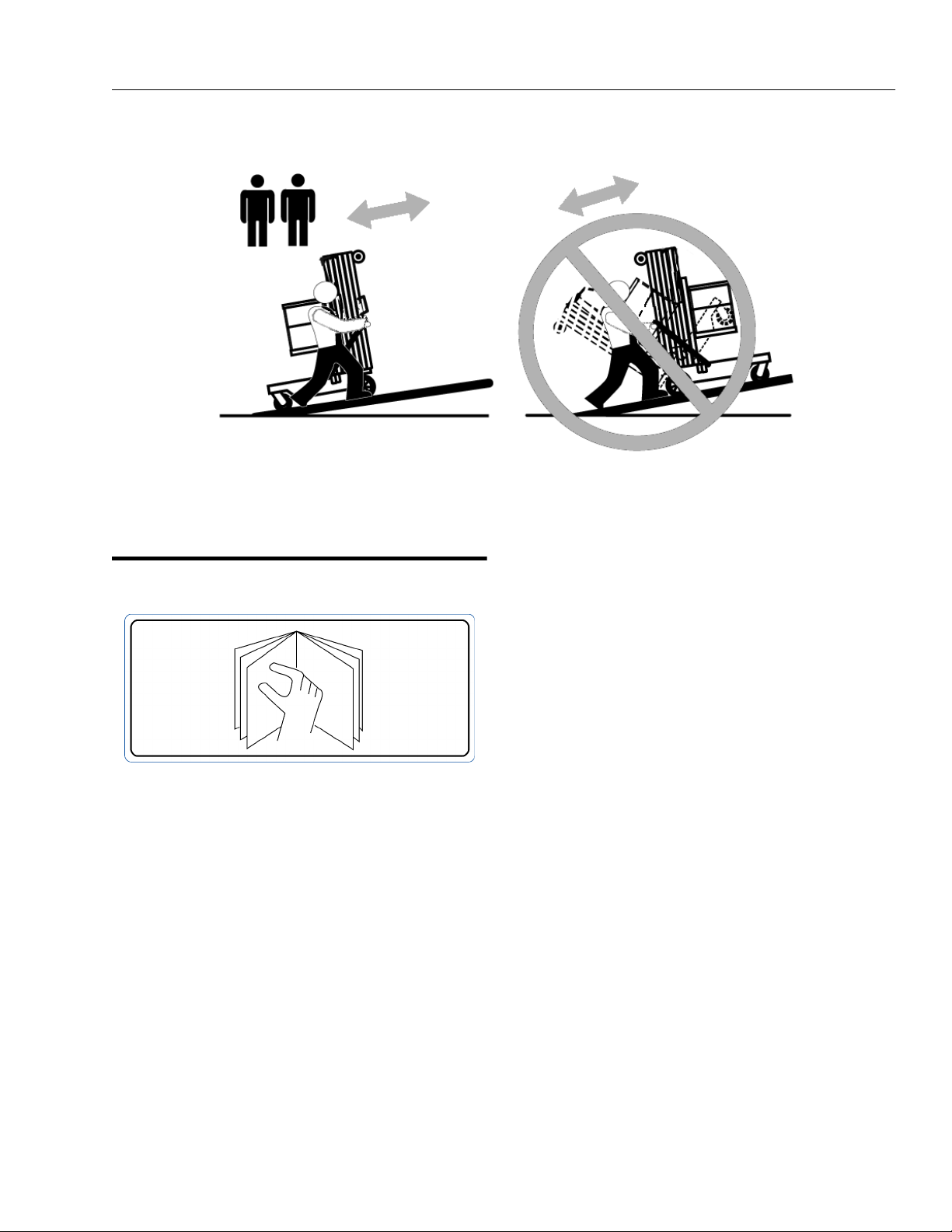

• TWO PEOPLE ARE REQUIRED ON SLOPES UP TO 5

DEGREES. A FORKLIFT MUST BE USED WHEN MOVING UNITS ON SLOPES GREATER THAN 5 DEGREES.

Figure 1-3. Do Not Move Unit on Soft or Uneven Sur-

faces or Over Obstructions, Bumps, Debris, Etc.

• ALWAYS TRAVEL UP OR DOWN A SLOPE WITH THE

PLATFORM END OF THE MACHINE POSITIONED

TOWARDS THE LOW SIDE OF THE SLOPE. THE

OPERATOR AND ASSISTANT MUST WALK BESIDE

AND GUIDE THE MACHINE WITH THE HANDLES ON

THE MAST CROSSBAR.

• NEVER POSITION THE UNIT SIDEWAYS ON A SLOPE.

• USE CAUTION AND CHECK CLEARANCES WHEN

MOVING MACHINE IN RESTRICTED OR CLOSE QUARTERS.

• ALWAYS USE AN ASSISTANT WHEN MOVING

MACHINE IN AREAS WHERE VISION IS

OBSTRUCTED.

• KEEP NON-OPERATING PERSONNEL AT LEAST 6

FEET (1.8 M) AWAY FROM MACHINE DURING TRANSPORTING OPERATIONS.

Figure 1-2. Use Handles Provided On Mast Crossbar

To Move Machine.

•

1-2 – JLG Lift – 3120778

Page 15

SECTION 1 - SAFETY PRECAUTIONS

Figure 1-4. Two People May Be Required on Slopes Up To Five Degrees.

Also Always Travel With Platform End On The Low Side of Slope.

1.5 PRE-OPERATIONAL SAFETY

Figure 1-5. Read Your Manual.

• READ YOUR MANUAL. UNDERSTAND WHAT YOU’VE

READ - THEN BEGIN OPERATIONS.

• ALLOW ONLY THOSE AUTHORIZED AND QUALIFIED

PERSONNEL TO OPERATE MACHINE WHO HAVE

DEMONSTRATED THAT THEY UNDERSTAND SAFE

AND PROPER OPERATION AND MAINTENANCE OF

THE UNIT.

• AN OPERATOR MUST NOT ACCEPT OPERATING

RESPONSIBILITIES UNTIL ADEQUATE TRAINING HAS

BEEN GIVEN BY COMPETENT AND AUTHORIZED

PERSONS.

• BEFORE OPERATION CHECK WORK AREA FOR

OVERHEAD ELECTRIC LINES. (SEE ELECTROCUTION

HAZARD, SECTION 1-2.)

• BEFORE OPERATION CHECK WORK AREA FOR

MACHINE TRAFFIC SUCH AS FORKLIFTS, CRANES,

AND OTHER CONSTRUCTION EQUIPMENT.

• SET-UP MACHINE FOR OPERATION ONLY ON A

SMOOTH, FIRM LEVEL SURFACE.

• ENSURE THAT OPERATORS OF OTHER OVERHEAD

AND FLOOR LEVEL MACHINES ARE AWARE OF THE

AERIAL PLATFORMS PRESENCE. DISCONNECT

POWER TO OVERHEAD CRANES. BARRICADE FLOOR

AREA IF NECESSARY.

• PRECAUTIONS TO AVOID ALL KNOWN HAZARDS IN

THE WORK AREA MUST BE TAKEN BY THE OPERATOR AND HIS SUPERVISOR BEFORE STARTING THE

WORK.

• DO NOT OPERATE THIS MACHINE UNLESS IT HAS

BEEN SERVICED AND MAINTAINED ACCORDING TO

THE MANUFACTURERS SPECIFICATIONS AND

SCHEDULE.

• ENSURE DAILY INSPECTION AND FUNCTION CHECK

IS PERFORMED PRIOR TO PLACING MACHINE INTO

OPERATION. HAVE AUTHORIZED PERSONNEL TAKE

ANY NECESSARY CORRECTIVE ACTION BEFORE

PLACING MACHINE INTO OPERATION.

• NEVER DISABLE OR MODIFY ANY SAFETY DEVICE.

ANY MODIFICATION OF THE MACHINE IS A SAFETY

VIOLATION AND IS A VIOLATION OF OSHA AND ANSI

RULES.

• DO NOT OPERATE MACHINE WHEN EXPOSED TO

HIGH WIND, RAIN OR SNOW.

3120778 – JLG Lift – 1-3

Page 16

SECTION 1 - SAFETY PRECAUTIONS

• NEVER OPERATE OR RAISE PLATFORM WHEN

MACHINE IS ON A TRUCK OR OTHER VEHICLE.

• APPROVED HEAD GEAR (I.E. HARD HAT, ETC.) MUST

BE WORN WHEN REQUIRED BY ALL OPERATING AND

GROUND PERSONNEL.

• READ AND OBEY ALL DANGER, WARNINGS, CAUTIONS AND OPERATING INSTRUCTIONS ON

MACHINE AND IN THIS MANUAL.

• BE FAMILIAR WITH LOCATION AND OPERATION OF

GROUND STATION AND EMERGENCY CONTROLS.

1.6 OPERATING SAFETY

• DO NOT OPERATE ANY MACHINE ON WHICH DANGER, WARNING, CAUTION OR INSTRUCTION PLACARDS OR DECALS ARE MISSING OR ILLEGIBLE.

• NEVER EXCEED MANUFACTURERS RATED PLATFORM CAPACITY - REFER TO CAPACITY DECAL ON

MACHINE.

• OPERATE AC UNITS WITH AN EXTENSION CORD

WIRE RATED AT A MINIMUM OF 15 AMPS.

Figure 1-7. Death or Serious Injury Could Occur from a

Tip Over

MACHINE, REMOVE IT FROM SERVICE, AND NOTIFY

PROPER AUTHORITIES.

• WHEN APPLICABLE BY REASON OF LOCAL REGULATIONS OR JOBSITE/EMPLOYER SAFETY RULES,

PERSONNEL IN THE PLATFORM SHALL AT ALL TIMES

Figure 1-6. Always Look in the Direction of Movement.

Watch for Overhead and Other Obstructions.

• DO NOT ENTER PLATFORM UNTIL THE FLOOR

BRAKE HAS BEEN PROPERLY ADJUSTED AND THE

UNIT’S BASE FRAME IS LEVEL ACCORDING TO THE

BUBBLE LEVEL INDICATOR ON BASE FRAME.

• DO NOT OPERATE MACHINE ON SOFT FOOTING

THAT WILL ALLOW THE FLOOR BRAKE TO SETTLE

INTO OR BREAK THROUGH SURFACE.

• NEVER OPERATE A MALFUNCTIONING MACHINE. IF

A MALFUNCTION OCCURS, SHUT DOWN THE

WEAR APPROVED FALL PROTECTION DEVICES AND

OTHER SAFETY GEAR AS REQUIRED. A LANYARD

ATTACHMENT IS SUPPLIED ON THE SIDE OF THE

MACHINE’S MAST.

• CHECK CLEARANCES ABOVE, ON SIDES AND BOTTOM OF PLATFORM WHEN RAISING AND LOWERING

PLATFORM.

• NEVER USE THE MAST TO GAIN ACCESS TO OR

LEAVE PLATFORM.

• DO NOT ATTACH OVERHANGING LOADS TO THE

PLATFORM OR INCREASE THE PLATFORM SIZE WITH

1-4 – JLG Lift – 3120778

Page 17

SECTION 1 - SAFETY PRECAUTIONS

Figure 1-8. All Personnel Must Stand Clear When Plat-

form Is Being Raised Or Lowered.

UNAUTHORIZED DECK EXTENSIONS OR ATTACHMENTS.

• DO NOT TIE OFF MACHINE TO ANY ADJACENT

STRUCTURE. NEVER ATTACH WIRE, CABLE OR ANY

SIMILAR ITEMS TO PLATFORM.

• TRANSFERS BETWEEN A STRUCTURE AND THE

PLATFORM EXPOSE OPERATORS TO FALL POTENTIALS. THIS PRACTICE SHOULD BE DISCOURAGED

WHEREVER POSSIBLE. WHERE TRANSFER MUST BE

ACCOMPLISHED TO PERFORM THE JOB, TWO LANYARDS WILL BE USED AND THE PLATFORM MUST BE

WITHIN 1 FOOT (0.3 M) OF THE ADJACENT - SAFE

AND SECURE - STRUCTURE. ONE LANYARD SHOULD

BE ATTACHED TO THE PLATFORM, THE OTHER TO

THE STRUCTURE. THE SAFETY LANYARD THAT IS

ATTACHED TO THE PLATFORM SHOULD NOT BE DISCONNECTED UNTIL SUCH TIME AS THE TRANSFER

TO THE STRUCTURE IS COMPLETE.

• NO HORSEPLAY IS PERMITTED IN PLATFORM.

• DO NOT ALLOW PERSONNEL TO TAMPER WITH,

SERVICE, OR OPERATE THIS MACHINE FROM THE

GROUND WITH PERSONNEL IN PLATFORM EXCEPT

IN AN EMERGENCY.

• DURING PLATFORM OPERATION KEEP ALL BODY

PARTS INSIDE PLATFORM RAILINGS.

Figure 1-9. Falling from Platform could cause

Death or Serious Injury.

• NEVER POSITION LADDERS, STEPS, OR SIMILAR

ITEMS ON UNIT TO PROVIDE ADDITIONAL REACH

FOR ANY PURPOSE.

• WHEN WORKING FROM PLATFORM BOTH FEET

MUST BE FIRMLY POSITIONED ON DECK.

• DO NOT EXTEND REACH LIMITS OF THIS MACHINE

WITH ADDITIONAL EQUIPMENT SUCH AS PLANKS,

BOXES, ETC.

• DO NOT USE LADDERS ON OR AGAINST MACHINE.

DO NOT PERFORM WORK THAT WILL SUBJECT UNIT

TO A HORIZONTAL FORCE OR CREATE A ROCKING

MOTION OF THE PLATFORM.

• DO NOT OPERATE MACHINE FROM PLATFORM

WITHOUT THE PLATFORM GATE IN PLACE AND

PROPERLY CLOSED. THIS IS A SAFETY VIOLATION.

• ALWAYS ENSURE THAT POWER TOOLS ARE PROPERLY STOWED AND NEVER LEFT HANGING BY THEIR

CORD FROM THE PLATFORM WORK AREA.

• AVOID ACCUMULATION OF DEBRIS ON PLATFORM

WORK AREA. KEEP MUD, OIL, GREASE AND OTHER

SLIPPERY SUBSTANCES FROM FOOTWEAR AND

PLATFORM DECK.

3120778 – JLG Lift – 1-5

Page 18

SECTION 1 - SAFETY PRECAUTIONS

This page intentionally left blank.

1-6 – JLG Lift – 3120778

Page 19

SECTION 2 - PREPARATION AND INSPECTION

SECTION 2. PREPARATION AND INSPECTION

2.1 GENERAL

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness, and lists checks that are

performed prior to use of the machine. It is important that

the information contained in this section be read and

understood before any attempt is made to operate the

machine. Ensure that all the necessary inspections have

been completed successfully before placing the machine

into service. These procedures will aid in obtaining maximum service life and safe operation.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE, THIS

IS THE RESPONSIBILITY OF THE OWNER/OPERATOR.

2.2 PREPARATION FOR USE

Before a new machine is put into operation it must be

carefully inspected for any evidence of damage resulting

from shipment and inspected periodically thereafter, as

outlined in Section 2-3, Delivery and Periodic Inspection.

The unit should be thoroughly checked for hydraulic leaks

during initial start-up and run. A check of all components

should be made to assure their security.

All preparation necessary to place the machine in operation readiness status are the responsibility of management personnel. Preparation requires good common

sense, (i.e. lift works smoothly) coupled with a series of

visual inspections. The mandatory requirements are given

in Section 2-4, Daily Walk Around Inspection.

It should be assured that the items appearing in the Delivery and Frequent Inspection and Functional Check are

complied with prior to putting the machine into service.

2.3 DELIVERY AND FREQUENT INSPECTION

The following check list provides a systematic inspection

to assist in detecting defective, damaged, or improperly

installed parts. The check list denotes the items to be

inspected and conditions to examine. Frequent inspection

shall be performed every three (3) months or more often

when required by environment, severity, and frequency of

usage.

Platform Guard Rail Assemblies

Properly installed; no loose or missing parts; no visible

damage.

Platform Assembly

No visible damage; free of dirt and debris. Platform gate

or slide bar functions properly on machines so equipped.

Mast

No visible damage, abrasions and/or distortions; no binding; mast sections free of dirt or other foreign material.

Sequencing cables properly secured; no visible damage;

proper cable tension.

Mast Chains & Cables

No visible damage; proper chain/cable tension; evidence

of proper lubrication. Chain/cable sheaves and sheave

pins properly secured; no visible damage.

Control/(Power) Cable(s) for Platform

No visible damage; cable properly tensioned and seated

in control cable sheaves; control cable sheaves not damaged and rotating freely.

Lift Cylinder

No rust, nicks, scratches or foreign material on piston rod.

No leakage. Manual Descent Valve secure; no visible

damage.

NOTE: This machine requires periodic safety and mainte-

nance inspections by an authorized JLG Dealer. An

annual inspection shall be performed on the aerial

platform no later than thirteen (13) months from the

date of the new machine inspection or prior annual

inspection. The inspection shall be performed by

person(s) qualified as a mechanic on the specific

make and model of the aerial platform.

Frame

No visible damage; loose or missing hardware (top and

underside); floor brake assembly working properly,

secured and undamaged.

Wheels and Casters

Free rolling; no loose or missing parts; no visible damage.

Hydraulic Oil Supply

Check the hydraulic oil level at the hydraulic fluid reservoir

through the access hole on the side of the ground control

panel. Maintain an oil level to the "Fill to Line" indicator on

the side of the reservoir. If fluid level is low, add a hydraulic

oil with a minimum Service Classification of GL-3, and has

3120778 – JLG Lift – 2-1

Page 20

SECTION 2 - PREPARATION AND INSPECTION

an SAE viscocity of 10W-30 or 10W-20 and a viscosity

index of 152. See Section 1 of the Service Manual for

more details about hydraulic oil for this machine.

Machine Controls - (Platform and Ground)

Switches operable; no visible damage; placards secure

and legible.

Batteries - (DC Models)

Proper electrolyte level; cable connections tight; no visible

damage; no corrosion at battery cable connections.

Power Cord - (AC Models)

No visible damage; connector and cable properly

secured.

Electric Motor/Hydraulic Pump and Valve

No leakage; unit secure.

Placards

No visible damage; placards secure and legible.

2.4 DAILY WALK-AROUND INSPECTION

It is the user/operator’s responsibility to inspect the

machine before the start of each workday. It is recommended that each user/operator inspect the machine

before operation, even if the machine has already been

put into service under another user/operator. This Daily

Walk-Around Inspection is the preferred method of inspection.

General

Begin the “Walk-Around Inspection” (See Figure 2-1.) at

item 1 listed following. Continue around machine checking each item in sequence for the conditions listed in the

“Walk-Around Inspection Check list”.

TO AVOID INJURY DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNCTIONING MACHINE IS A SAFETY VIOLATION.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS

“OFF” DURING “WALK-AROUND INSPECTION”.

NOTE: Do not overlook visual inspection of chassis under-

side. Checking this area often results in discovery of

conditions which could cause extensive machine

damage.

1. Wheels and Casters - Properly secured, wheels

and casters turn freely and are properly lubricated.

Check for any visible damage.

2. Floor Brake - Properly secured to frame, no visible

damage (cracks, distortion, etc.) and is functioning

properly.

3. Base Frame - No visible damage; components

properly secured, no loose wires dangling below

base; bubble level in place and functioning properly.

4. Battery/Battery Charger Installation - (DC

Machines)

secure, no damage or corrosion.

5. Motor/Pump/Reservoir Unit - All properly secured,

no visible damage, no evidence of hydraulic leaks.

Check that hydraulic reservoir fluid level is filled to

the "Fill to Line" mark on the side of the reservoir.

6. Manual Descent Control Valve - Properly secured,

no loose or missing parts, no visible damage.

7. Ground Controls - Key switch operable, no visible

damage; placards secure and legible; emergency

stop switch, no visible damage and properly set for

operation.

8. Mast Installation - Mast sections properly secured,

no visible damage to mast sections, no loose or

missing parts, slide pads properly secured. Mast

chains and cables properly secured, lubricated and

undamaged. Sequencing cables properly secured

and undamaged. Sheaves and pins are properly

secured, have no visible damage, no loose or missing parts and are lubricated.

9. Platform Controls - Up/Down and Function Enable

buttons properly secured, no loose or missing parts,

no visible damage. Placards secure and legible,

emergency shut-off button set for operation. Control

markings legible; Operators manual enclosed in

manual storage tube.

10. Guard Rail Installation - All railings securely

attached, no visible damage, no missing parts; sliding entry bar in proper working order. Platform gate/

slide bar working properly, no visible sign of damage (if so equipped).

11. Platform Assembly - Secure to mast; no loose or

missing parts, no visible damage. Control and

power cables, no visible damage; cables properly

tensioned and seated in control cable sheaves; control cable sheaves not damaged and rotate freely.

In addition to the Daily Walk-Around Inspection, be sure to

include the following as part of the daily inspection:

Proper battery electrolyte level, cables

Batteries Charged (DC Models)

Start each day with fully charged batteries. (See Section

2.7 “Battery Charging and Maintenance.”)

2-2 – JLG Lift – 3120778

Page 21

SECTION 2 - PREPARATION AND INSPECTION

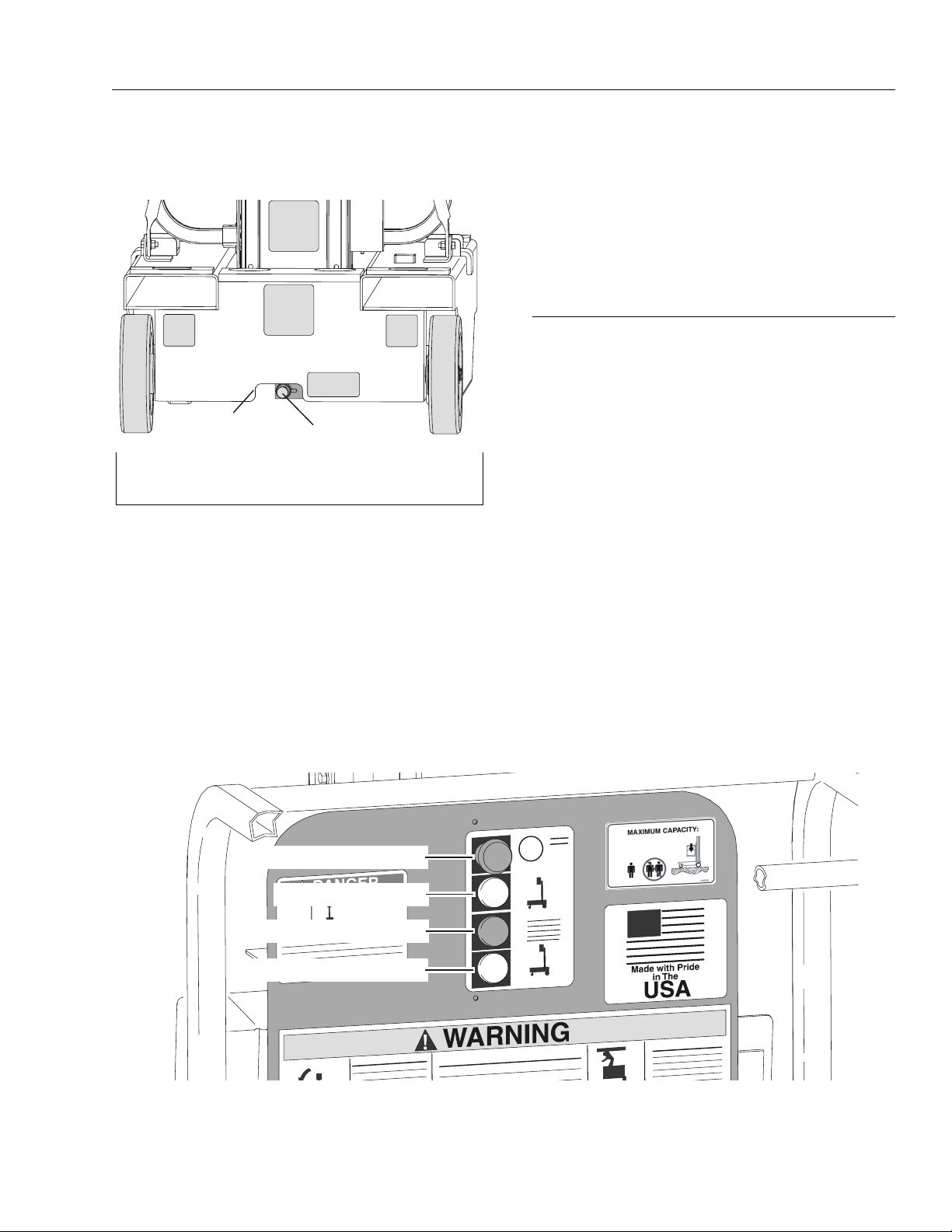

Daily Walk-Around

Inspection Items

1. Wheels & Casters

2. Floor Brake

3. Base Frame

4. Battery Box/Charger

5. Motor/Pump/Reservoir Unit

Manual Descent Con trol

Valve Location

6a.

Prior to S/N- 090001952 6

6b.

Since S/N- 0900019526

7. Ground Controls

8. Mast Installation

9. Platform Control s

10. Guard Rail Installation

11. Plat form Assembly

6a

8

9

0

1

7

1

1

5

4

6b

1

Figure 2-1. Daily Walk-Around Inspection.

Overall Cleanliness

Keep oil, grease, water, etc. wiped from standing surfaces

and hand holds.

Placards

Keep all information and operating placards clean and

unobstructed. Cover areas where placards are present

when using the machine for spraying paint or any material

which could cover these surfaces and reduce legibility.

3

2

1

Operators & Safety and ANSI Responsibilities Manual

Ensure a copy of the Operators and Safety and ANSI

Responsibilities manual is enclosed in the manual storage

box.

Lubrication

For those parts pointed out in the Walk-Around Inspection

requiring lubrication, (refer to the Lubrication Chart, Table

2-1., this Section), for specific time interval requirements.

3120778 – JLG Lift – 2-3

Page 22

SECTION 2 - PREPARATION AND INSPECTION

2.5 DAILY FUNCTIONAL CHECK

TO AVOID INJURY DO NOT OPERATE A MACHINE UNTIL ALL

MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNCTIONING MACHINE IS A SAFETY VIOLATION.

Once the walk-around inspection is complete, a functional

check of all systems should be performed in an area free

of overhead and ground level obstructions. Perform a

functional check in accordance with the following procedures:

1. Set-up machine for operation according to instructions in Section 4-3, “Machine Set-Up & Operation”,

(i.e.. smooth, firm level surface, set floor brake and

make sure castor wheels are off ground, etc.)

2. Enter platform, raise and lower platform 2 ft. to 3 ft.

(.61m to .92m) several times. Check for smooth elevation and lowering of platform.

3. With platform completely lowered, check hydraulic

oil level in reservoir at ground control station. Maintain an oil level to the "Fill to Line" indicator on the

side of the reservoir. NEVER USE HYDRAULIC

BRAKE FLUID.

NOTE: If oil level is low, add hydraulic oil with a minimum

Service Classification of GL-3, and an SAE viscocity

of 10W-30 or 10W-20 and a viscosity index of 152.

See Section 1 of the Service Manual for more details

about hydraulic oil for this machine.

2.7 BATTERY CHARGING & MAINTENANCE

(ELI-DC MODELS ONLY)

ELI-DC Models are equipped with 12 volt, 10 amp output

battery chargers (U.S.A. - 120V-AC/60Hz input). The bat-

tery charger has a microprocessor controlled automatic

charge sensing circuit which can determine cell voltage

and regulate charger output as required. The charger

automatically terminates charging when a full battery

charge is acheived.

Battery Maintenance and Safety Practices

(See Figure 2-2.)

ENSURE THAT BATTERY ACID DOES NOT COME INTO CONTACT

WITH SKIN OR CLOTHING. WEAR PROTECTIVE CLOTHING AND

EYEWEAR WHEN WORKING WITH BATTERIES. NEUTRALIZE ANY

BATTERY ACID SPILLS WITH BAKING SODA AND WATER.

BATTERY ACID RELEASES AN EXPLOSIVE GAS WHILE CHARGING, ALLOW NO OPEN FLAMES, SPARKS OR LIGHTED TOBACCO

PRODUCTS IN THE AREA WHILE CHARGING BATTERIES.

CHARGE BATTERIES ONLY IN A WELL VENTILATED AREA.

ADD ONLY DISTILLED WATER TO BATTERIES. WHEN ADDING

DISTILLED WATER TO THE BATTERIES, A NON-METALLIC CONTAINER AND/OR FUNNEL MUST BE USED.

Check the electrolyte level of the batteries often, adding

only distilled water when required. When fully charged,

battery fluid level should be 1/8" below vent tubes. (See

Figure 2-2.).

2.6 TORQUE REQUIREMENTS

The Torque Chart, Figure 2-6., consists of standard torque

values based on bolt diameter and grade, it also specifies

dry and wet torque values in accordance with recommended shop practices. This chart is provided as an aid

to the user/operator in the event the user/operator notices

a condition that requires prompt attention during the walkaround inspection or during operation until the proper service personnel can be notified. Utilizing this Torque Chart

in conjunction with the Preventive Maintenance table in

Section 2 of the Service and Maintenance Manual, will

enhance the safety, reliability and performance of this

machine.

• DO NOT fill to bottom of vent tubes.

• DO NOT allow fluid level to go below the top of the

plates when charging or operating.

Battery Charger Operation

(See Figure 2-3. & 2-4.)

Position machine in well ventilated area near an AC electrical outlet and set the Ground Control-PLAT/OFF/GRND

key switch to the OFF position.

ALWAYS CHECK THE VOLTAGE SELECT SWITCH ON THE FACE

OF THE BATTERY CHARGER BEFORE OPERATION. IF NOT SET

TO THE PROPER AC POWER INPUT VOLTAGE DAMAGE WILL

OCCUR TO THE CHARGER.

1. Set the AC voltage switch on the face of the charger

for the local AC line voltage.

2. Remove the battery charger AC power cable stowed

inside the battery/charger carrier (beside charger).

2-4 – JLG Lift – 3120778

Page 23

Figure 2-2. Battery Fluid Level.

SECTION 2 - PREPARATION AND INSPECTION

a. First all five (5) LED’s on the face of the charger

flash three (3) times.

b. Then each LED lights in sequence.

c. Then all five (5) LED’s flash three (3) times

again.

4. When ready to charge, the CHARGER ON LED and

the INCOMPLETE CHARGE (25%) LED on the front

panel of the charger will light up, the charger will

then begin to charge the batteries.

NOTE: If the ABNORMAL CYCLE LED comes on and stays

on at any time during the charge cycle, see sub-section following about the ABNORMAL CYCLE indicator LED.

5. When the battery cell voltage reaches 2.37 V/cell the

80% CHARGE LED on the front panel of the charger

will light up. The charger then continues to monitor

the increase in charge until it sees no increase, and

then terminates the charging process.

6. The CHARGE COMPLETE (100%) LED will come on

when the charging process is finished.

7. Unplug the charger AC power cord and stow the

cord in the opening in the battery/charger carrier

(beside charger).

DC BATTERY

CHARGER

AC POWER

CORD

(Shown Stowed)

BATTERY BOX &

CHARGER ASSY.

DC MAIN

POWER

CONNECTOR

(from battery to machine)

Figure 2-3. Battery Box and Charger Assembly.

(D.C. Model Only)

Connect the battery charger AC power cable to a

properly grounded receptacle, use a suitable extension cord, if necessary.

3. When plugged in, the charger runs through a selfdiagnostic check. The LED’s on the front panel of

the battery charger flash in the sequence noted following;

Abnormal Cycle Indicator LED

If the ABNORMAL CYCLE indicator LED should come on

during the normal charging cycle of the batteries, it could

indicate any of the following conditions;

• The AC input to the charger was interrupted, i.e. local

power failure or charger cable was unplugged or

bumped and power was interrupted intermittently.

• A dead cell or cells in the battery would prevent the

charger from sensing enough voltage to complete the

battery charge.

• One or more of the battery terminal connections loose

or corroded resulting in an intermittent incomplete circuit.

3120778 – JLG Lift – 2-5

Page 24

SECTION 2 - PREPARATION AND INSPECTION

%OFCHARGE

IN PROGRESS

(GREEN LED’S)

CHARGER ON

(GREEN LED)

ABNORMAL CYCLE

(YELLOW LED)

CIRCUIT

BREAKERS

A/C VOLTAGE

SELECT SWITCH

Figure 2-4. Dual Voltage Battery Charger - Front Panel.

2-6 – JLG Lift – 3120778

Page 25

SECTION 2 - PREPARATION AND INSPECTION

3

1

2

Figure 2-5. Lubrication Locations (See Table below).

Table 2-1. Lubrication Intervals for Various Components

INTERVAL HOURS

ITEM COMPONENT

1 Hydraul ic Oil Fill To Line

NO/TYPE

LUBE POINTS

on Reservoir

5 Qt. Reservoir

LUBE/METHOD

HO - Check Hyd.

Oil Level

HO - Change

Hyd. Oil

2 Swivel Raceways 2 - Front Casters MPG - Pressure Gun

3 Mast Chains * 2 - Per Section Chain Lube - Brush

or Spray

3

MONTHS

150 Hrs.

✔

6

MONTHS

300 Hrs.

✔

1

YEAR

600 Hrs.

2

YEARS

1200 Hrs.

✔

COMMENTS

Check Hydraulic Oil

every 10 hrs.

Change Hydrauli c Oil

every 1200 hrs.

* Applies Only to Mas t Sections with Chains.

Key to Lubricants: MPG - Multipurpose Grease

HO - Hydraulic Oil - See Table 1-1 in Service Manual. (JLG recommen ds Mobil 424 hydraulic oil.)

Notes: 1. Lubricate like items on each side of the ma chine.

2. Recommended lubric ating intervals are based on nor mal use. If machine is subjected to severe operating conditions,

such as a high numbe r of cycles, location, corrosive/d irty environment, etc., user must ad just lubricating requirements accordingly.

3. Lubricating interv als are calculated on 50 hours of machine operation a week.

4. Prior to checking hydraulic oil level, operate m achine through one complete cycl e of lift function (full up and down). Failure to do so will

result in incorr ect oil level reading on the hydraulic reservoir.

3120778 – JLG Lift – 2-7

Page 26

SECTION 2 - PREPARATION AND INSPECTION

Figure 2-6. Torque Chart.

2-8 – JLG Lift – 3120778

Page 27

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

SECTION 3. USER RESPONSIBILITIES & MACHINE CONTROLS

3.1 GENERAL

SINCE THE MANUFACTURER HAS NO DIRECT CONTROL OVER

MACHINE APPLICATION AND OPERATION, CONFORMANCE WITH

GOOD SAFETY PRACTICES IN THESE AREAS IS THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

This section provides the necessary information needed

to understand control functions. Included in this section

are the operating characteristics and limitations, and functions and purposes of controls and indicators. It is important that the user/operator read and understand the

proper procedures before operating the machine. These

procedures will aid in optimizing service life and safe

operation.

3.2 PERSONNEL TRAINING

The aerial lift is a personnel handling device; therefore, it

is essential that it be operated and maintained only by

authorized personnel who have demonstrated that they

understand the proper operation and maintenance of the

machine. It is important that all personnel who are

assigned to and responsible for the operation and maintenance of the machine undergo a thorough training program and check out period in order to become familiar

with the characteristics prior to operating the machine.

In addition, personnel operating the machine should be

familiar with the ANSI A92.3-1990 Manual of Responsibilities supplied with this machine. This standard contains

sections outlining the responsibilities of the owners, users,

operators, lessors and lessees concerning safety, training,

inspection, maintenance, application and operation.

Persons under the influence of drugs or alcohol or who

are subject to seizures, dizziness or loss of physical control must not be permitted to operate the machine.

Statutes, including training in the recognition and

avoidance of potential hazards in the work place;

with particular attention to the work to be performed.

4. Proper use of all required personnel safety equipment.

5. Sufficient knowledge of the mechanical operation of

the machine to recognize a malfunction or potential

malfunction.

6. The safest means to operate near overhead obstructions, other moving equipment, obstacles, depressions, holes, drop-offs, etc. on the supporting

surface.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Any other requirements of a specific job or machine

application.

The operator of a JLG manually propelled aerial work platform must not accept operating responsibility until

instructed by a qualified person, the Operators and Safety

Manual has been read and understood, as well as having

operated the JLG manually propelled aerial work platform

under the supervision of a qualified person. A qualified

operator must have reviewed and understood the video,

the Operators and Safety Manual, and all warning placards and operating instructions on the machine, and contacted JLG with any questions regarding safe operation of

the manually propelled aerial work platform. In addition,

the operator and employer are responsible for complying

with federal, state, local or provincial rules and regulations

covering the proper use and operation of this product. If

there is a question on application and/or operation, or to

inquire about operator training, contact the Product Safety

and Reliability Department at JLG Industries, Inc. at (877)

JLG-SAFE (877-554-7233).

Operator Training

Operator training must include instruction in the following:

1. Use and limitations of the platform controls, ground

controls and emergency controls.

2. Knowledge and understanding of this manual, the

control markings, instructions and warnings on the

machine itself and the "JLG Manually Propelled

Aerial Work Platform Safety" video supplied with this

machine.

3. Knowledge and understanding of all safety work

rules of the employer and Federal, State and Local

Operator Responsibility

The operator must be instructed that he has the responsibility and authority to shut down the machine in case of a

malfunction or other unsafe condition of either the

machine or the job site and to request further information

from his supervisor or JLG Industries, Inc.

NOTE: If you require further operator and service training, in

addition to the information supplied with your aerial

work platform, please contact JLG Industries, Inc., 1

JLG Drive, McConnellsburg, PA. 17233 or telephone

toll free at (877) 554-7233.

3120778 – JLG Lift – 3-1

Page 28

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

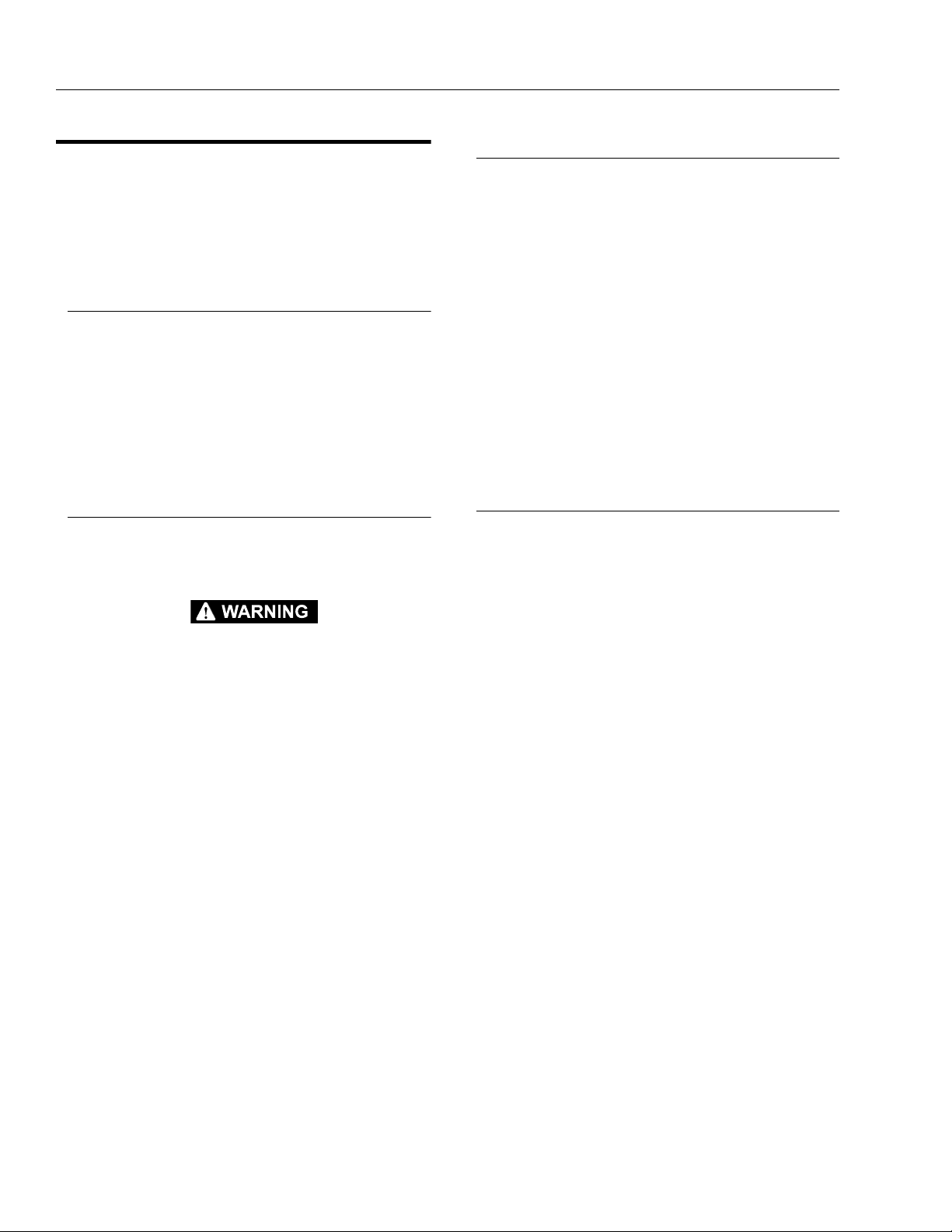

EMERGENCY

STOP BUTTON

3.3 OPERATING CHARACTERISTICS AND LIMITATIONS

General

A thorough knowledge of the operating characteristics

and limitations of the machine is always the first requirement for any user, regardless of user’s experience with

similar types of equipment.

Placards

(See Figures 3-4., 3-5., 3-6., 3-7. & 3-8.)

Important points to remember during operation are provided at the control stations by DANGER, WARNING,

CAUTION, IMPORTANT and INSTRUCTION placards. This

information is placed at various locations on the machine

for the express purpose of alerting personnel of potential

hazards constituted by the operating characteristics and

load limitations of the machine. See Foreword at the start

of this manual for a definition of the seriousness of each of

the above placard types. See Decal Location Figures in

this section for decals which apply to this machine.

Capacities

Raising the platform above the stowed position is based

on the following criteria:

• The machine is positioned on a smooth, firm level surface.

• The load is within manufacturer’s rated capacity.

• All machine systems are functioning properly.

• The machine floor brake on the base frame is properly

set and locked in place.

tion. When left unattended removing key will prevent

unauthorized machine use.

2. EMERGENCY STOP Button

An emergency stop (RED button) is mounted on

both the ground control station and the platform

control panel. When the button is depressed, all

machine functions will stop. To re-activate power to

the machine, turn emergency stop button clockwise

until button is reset.

POWER ON/OFF

KEY SWITCH

MANUAL

DESCENT

CONTROL

VALVE

(MACHINES PRIOR

TO S/N- 0900019526)

HYDRAULIC

OIL

RESERVOIR

Stability

This machine, as originally manufactured by JLG and

operated within its rated capacity on a smooth, firm and

level supporting surface, provides a stable aerial platform

for all platform positions.

3.4 CONTROLS AND INDICATORS

Ground Control Station (See Figure 3-1.)

NOTE: When the machine is shut down for overnight park-

ing or battery charging, be sure the POWER ON/

OFF KEY SWITCH is positioned to OFF to prevent

draining the batteries.

1. POWER ON/OFF Key Switch

A key operated power on/off switch located on the

ground control station panel controls power to all

functions on the unit. The machine will not operate

without the key inserted and turned to the ON posi-

Figure 3-1. Ground Control Station.

3. MANUAL DESCENT CONTROL VALVE

Machines Built Prior to S/N - 0900019526 -

(See Figure 3-1.)

This (RED knurled) knob, located on the electric/

hydraulic pump-motor unit on the ground control

station panel provides for lowering of the platform in

the event of an emergency or power failure. Turning

the valve knob to the left (counterclockwise) opens

the valve, turning the valve back to the right (clock-

wise) closes the valve.

Machines Built Since S/N- 0900019526 -

(See Figure 3-2.)

The control knob is located in the recess under the

base frame at the rear of the machine. To open the

valve (lower the platform) pull the (RED) knob on the

3-2 – JLG Lift – 3120778

Page 29

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

control, to close the valve (stop platform lowering)

release the valve knob (spring loaded).

2

1. Manual Descent Control Valve

2. Cut-Out at Rear of Base Frame

Figure 3-2. Manual Descent Control Valve Location -

Machines Built Since S/N- 0900019526.

1. HYDRAULIC RESERVOIR / CIRCUIT BREAKER /

FUSE (located inside ground control station housing)

The hydraulic reservoir is housed inside the ground

control station, the hydraulic oil level can be

checked through an access hole in the side of the

cover. Maintain an oil level to the "Fill to Line" indicator on the side of the reservoir.

1

NOTE: Check hydraulic oil only when platform is completely

lowered and after cycling platform up/down a few

times.

A 20 amp reset type circuit breaker is located on the

cover of the electrical box on ELI-AC Models.

On ELI-DC Models, a 5 Amp fuse is located inside

the ground control station.

Platform Control Station

(See Figure 3-3.)

1. EMERGENCY STOP/SHUT-OFF Button.

An EMERGENCY STOP (RED) button is provided in

order to turn machine power on and off in the platform and also to turn off machine power in the event

of an emergency. Power is on when the switch is in

the reset position (turned completely clockwise out). Power is off and all machine functions will stop,

when button is depressed.

2. FUNCTION ENABLE Button.

This (GREEN) button must be depressed simultaneously with either the UP or DOWN platform function buttons in order to operate the platform.

3. PLATFORM UP Button.

When depressed simultaneously with ENABLE button raises the platform to a higher level.

4. PLATFORM DOWN Button.

When depressed simultaneously with ENABLE button lowers the platform to a lower level.

EMERGENCY STOP BUTTON

PLATFORM UP BUTTON

FUNCTION ENABLE BUTTON

PLATFORM DOWN BUTTON

Figure 3-3. Platform Control Station.

3120778 – JLG Lift – 3-3

Page 30

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

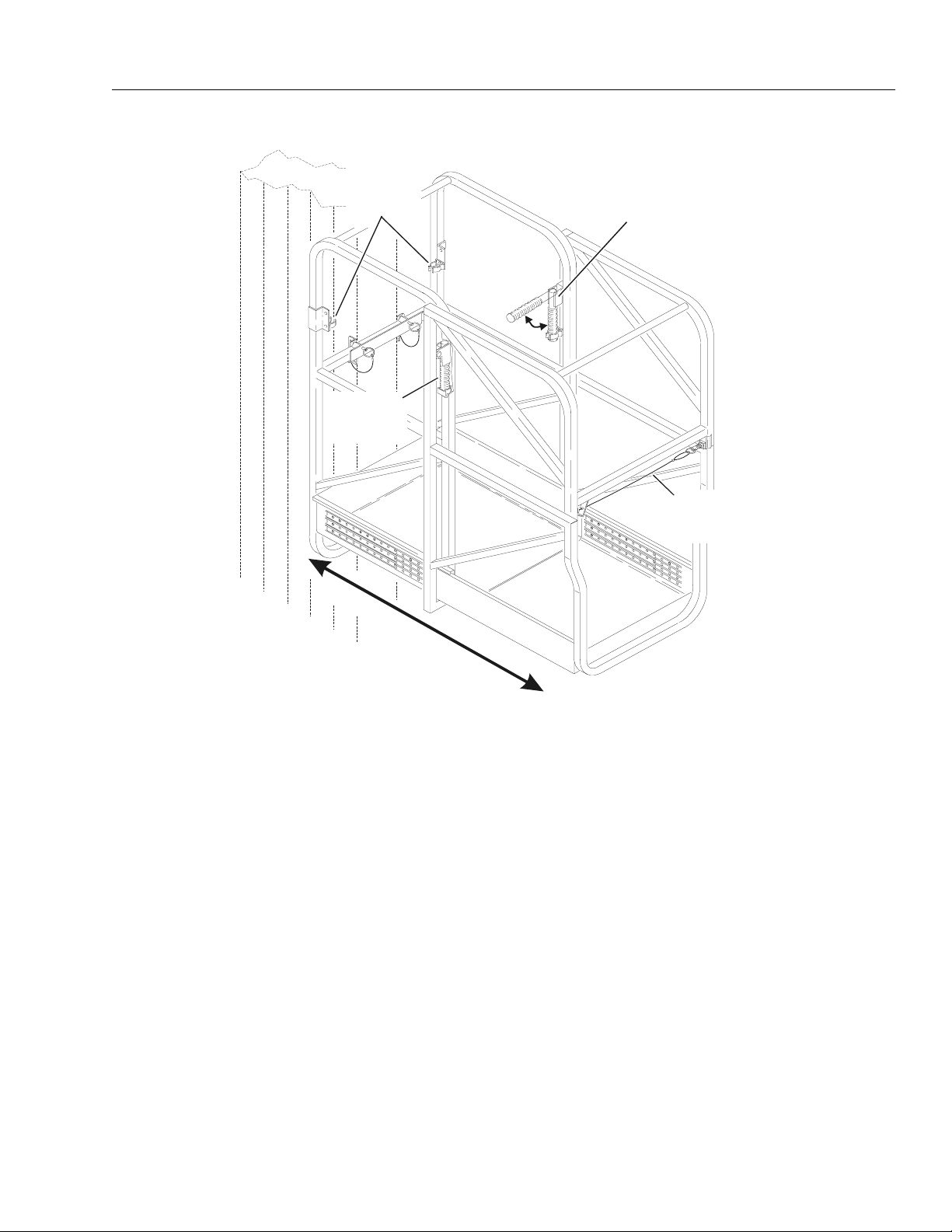

Figure 3-4. Decal Locations (Front View)

3-4 – JLG Lift – 3120778

Page 31

Always look in the direction of

CRUSHING HAZARD

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

o

Keep clear of obstructions.

movement.

Keep all body parts inside

platform during operation.

.

o

.

platform end leading way.

Use handles provided to move unit.

platform end on low side of slope.

On a level surface, always travel with

On a slope, always travel with

CRUSHING/TIPPING

Failure to follow instructions

could result in death or

HAZARD

serious injury.

Two people may be required on

Never turn unit sideways on a

surfaces, or over obstructions,

slopes up to 5

Do not move unit on soft or uneven

A forklift must be used when moving

units on slopes greater than 5

slope.

bumps, debris, etc.

Failure to follow these instructions

could result in death or serious

1704221 A

injury.

WARNING

THIS MACHINE MUST NOT BE USED

UNTIL IT IS INSPECTED AND OPERATING

Keep both feet on platform floor.

FALLING HAZARD

PROPERLY:

Do not climb, sit or stand on

properly trained as described in the JLG Operation and

Safety Manual by a qualified person and authorized to

operate this machine. Your training includes reading

and understanding the safety, operating and

Do not operate this machine unless you have been

Ensure entrance area is properly

platform guard rails.

maintenance instructions in manufacturerÕs manuals,

Do not use planks, ladders or

closed.

similar items in platform to get

added reach.

Sections 6, 7, and 8 of ANSI A92.3-1990 Manually

knowing your employers work rules and applicable

governmental regulations.

Propelled Elevating Aerial Platforms for daily, frequent,

and annual inspections. These may be obtained from

your authorized JLG Industries, Inc. equipment dealer

or JLG Industries, Inc.

floor stop has been set.

Follow the instructions in the Operating Manual and

All guard rails must be properly

installed during operation.

Falling from platform could

cause death or serious injury.

TIP-OVER HAZARD

capacity or rated number of

Do not exceed platform rated

Check that unit is properly set up, level, and that the

people.

Do not expose platform to high

winds or horizontal forces.

counterweight, etc.) with items of different weight or

Do not replace items (i.e., batteries, wheels,

Figure 3-5. Decal Locations (3124221 decal from Front View)

specification because this will affect stability of

machine.

and level surface before elevating

Machine must be on smooth, firm

platform. Set floor stop. Check

approval from manufacturer.

operation if malfunction occurs.

Do not modify or change machine without written

Operate this machine with extreme caution. STOP all

Improper use of this machine could cause death

or serious injury.

bubble level provided on machine

to ensure base is level before

elevating platform.

Death or serious injury could

occur from a tip-over.

3120778 – JLG Lift – 3-5

Page 32

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

Figure 3-6. Decal Locations (Rear View)

3-6 – JLG Lift – 3120778

Page 33

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

Figure 3-7. Decal Locations (Top View)

3120778 – JLG Lift – 3-7

Page 34

SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

ATTACH LANYARD HERE

P/N - 1703815

P/N - 1703681

1703815A

Figure 3-8. Decal Locations (Right/Left View)

3-8 – JLG Lift – 3120778

Page 35

SECTION 4 - MACHINE OPERATION

SECTION 4. MACHINE OPERATION

4.1 MACHINE DESCRIPTION

ELI machines are manually propelled machines, with a

platform mounted to an elevating aluminum mast mechanism. The mast is raised and lowered by a hydraulic cylinder extending between mast section-1 and -2, the

remaining mast sections are proportionally extended and

retracted using steel chains and cables. Hydraulic pressure is supplied to the lift cylinder by an electrically powered hydraulic pump. The platform may be raised only

when lift is positioned on smooth, firm, level surface with

the floor brake set. The ELI personnel lift’s intended purpose is to provide personnel (with their tools and supplies)

access to areas above ground level.

The ELI personnel lift has a primary operator control station in the platform. From this control station the operator

can raise and lower the platform. A ground control station

is also provided. This station contains a keyed power on/

off switch, an emergency stop button and an emergency/

manual decent valve which enables the platform to be

lowered to the ground in an emergency, if the operator in

the platform is unable to do so, or if a power failure should

occur.

Instructions and warnings are posted adjacent to both

operator control stations and at other places on the

machine. It is extremely important that the user/operator

know what instructions and warnings are placed on the

machine and in the manual. And that these instructions

and warning’s be reviewed periodically. The JLG personnel lift is designed to provide efficient and safe operation

when maintained and operated in accordance with

instructions and warnings on the machine, in the Operating, Safety and Maintenance Manual and all jobsite and

government rules and regulations.

As with any type of machinery, the operator is very

important to efficient and safe operation. It is absolutely

necessary that the JLG lift be regularly maintained in

accordance with this manual.

Any evidence of lack of maintenance, malfunction, excessive wear, damage or modification to the machine must be

reported immediately to the machine owner, the jobsite

supervisor or safety manager and the machine must be

taken out of service until all discrepancies are corrected.

The JLG personnel lift is not intended to be used to lift

material other than supplies which personnel in the platform require to do their job. Supplies or tools which

extend outside the platform are prohibited except for JLG

approved recepticals. The personnel lift must not be used

as a forklift, crane, or support for overhead structure.

The total platform capacity is to be uniformly distributed in

the center of the platform. This means that the total combined weight of personnel, tools and supplies loaded into

the platform must not exceed the total platform capacity.

4.2 GENERAL

This section provides the necessary information needed

to operate the machine. Included in this section are the

procedures for set-up, raising, lowering, platform loading

and transporting. It is important that the user read and

understand the proper procedures before operating the

machine. Although some of the more important operating

safety precautions will be listed in the following paragraph

sections, it is extremely important all safety precautions in

Section 1 - Safety Precautions be read and understood

before operating machine. If a “Daily Walk-Around Inspection”, (see Section 2-4.) has not been completed, perform

this inspection before starting set-up and operation. The

operator must also be familiar with all machine controls as

described in Section 3 - User/Operator Responsibilities

and Machine Controls.

3120778 – JLG Lift – 4-1

Page 36

SECTION 4 - MACHINE OPERATION

4.3 MACHINE SET-UP AND OPERATION