Page 1

EURO RANGE

BODYBUILDERS INSTRUCTIONS

EURO RANGE

EDITION 2002

Page 2

FOLLOW THESE INSTRUCTIONS CAREFULLY IN ORDER TO PRESERVE THE EFFICIENCY AND

RELIABILITY OF ALL VEHICLE COMPONENTS.

OUR PRODUCTS ARE SUBJECT TO CONSTANT DEVELOPMENT; AS A RESULT CERTAIN PARTS

OF THIS PUBLICATION MAY NOT BE FULLY UP TO DATE.

PRODUCED BY

SATIZ S.P.A.

EDITORIA TECNICA

PUBBLICAZIONI TECNICHE C/O IVECO

LUNGO STURA LAZIO 49

10156

TORINO ITALY

PUBLICATION EDITED BY

IVECO ENGINEERING

PUBLICATION NR. 603.42.371 -7THED.

PRINTED IN ITALY - 02.2002

Page 3

Foreword

For the technical information concerning modification of the vehicle, application of bodies and re-

quests for technical documentation, please contact the relevant IVECO Commercial Sector.

These instructions refer to the vehiclesof the EuroCargo, EuroTech, EuroStar and EuroTrakker ranges

that are currently in production; for vehicles in these ranges that have gone out of production, please

refer to the instructions given in previous editions.

For other current models and ones no longer manufactured by IVECO, refer to the instructions contained in the booklet N

R. 603. 42.141.

Warning

The following symbols are widely used in this manual and the indications to which they refer should

be carefully followed.

Danger to people: failure to fully observe these precautions can involve serious danger

for personal safety.

Warning/Precautions: failure to fully observe these precautions involves the risk of serious damage to the vehicle (with resulting loss of warranty conditions) and/or persons.

Foreword

Page 4

Contents

SECTION

GENERAL SPECIFICATIONS 1

CHASSIS MODIFICATIONS 2

BUILDING AND MOUNTING THE STRUCTURES 3

POWER TAKE-OFFS 4

SPECIFIC INFORMATION AND INSTRUCTIONS 5

Contents

Page 5

Alphabetical index to subjects

ABS system, precautions 2-10;2-68;2-75;2-96; 2 -105

ABS system, service operations 2-68

ABS, precautions 2-10; 2-75; 2-96; 2-105

ABS, service operations 2-68

Access to components for maintenance, instructions 1-18

Accident prevention 1-19

Additional alternator, installation 2-75

Additional batteries 2-75

Air conditioning system, installation 2-60; 2-75

Air draw from system 2-69

Alternator, p recautions 2-6; 2-10

Aluminium subframe 3-5

Anti-rust protection 2-7

Antitheft device installation 5-12

Antitheft device, precautions 2-75

Assessment of superstructure centre of gravity and payload 1-9

Authorizations, necessity 2-5; 2-15

Authorizations, request 1-5

Automatic transmissions, precautions 2-75

Ball hooks 2-24

Batteries, precautions 1-21; 2-6; 2-10;2-72

Bolts 2-5; 2-9

Box-body installations 3-19

Brake corrector, installation/adjustment 2-69

Brake piping, precautions 2-6; 2-11; 2-65; 2-67; 2-68

Brake piping, tightening torque 2-65; 2-67

Brakes, precautions / prescriptions 2-6; 2-11; 2-49; 2-65; 2-67; 2-68

Braking system, precautions 2-6; 2-11; 2-49; 2-65; 2-67; 2-68

Braking system, service operations 2-65

C.B., mobile phone, transmitting and receiving systems 2-74

Cab , modification 2-61

CAN line 2-72

Cement mixers, installation 3-28

Alphabetical index to subjects

I

Page 6

Centre of gravity, transverse stability 1-16

Centre-axle trailer hooks 2-44

Centre-axle trailers 2-28; 5-18

Chassis crossmembers 2-15

Chassis sidemember extension sizes available from IVECO Spare Part Office 5-83

Chassis modifications, general rules 2-5

Chassis reinforcements 2-46

Chassis, specific precautions 2-6

Chassis stress, checks and limits 2-14; 2-46

Chassis weighing 1-9

Chocks, position 2-10

Choice of chassis 1-8

Choice of the material to be used: Ecology — Recycling 1-20

CNG gas-fuelled vehicles, service operations / precautions 5-20

Connection (chassis / subframe), elastic type 3-14

Connection (chassis / subframe), type and features 3-12

Connection (chassis / subframe), with brackets 3-13

Connection (chassis / subframe), with U-bolts 3-15

Connection (chassis / subframe), with shear-resistant plates 3-17

Conversion of a truck into a s emitrailer tractor 3-44

Crane, behind cab 3-49

Crane, installation 3-48

Crane, on rear overhang 3-54

Current draws 2-75; 2-78

Current master switch 2-97

Demountable bodies 3-22

Dimensions and weights 1-9

Distance between holes 2-9

Drilling, closing of existing holes 2-12

Drilling, execution 2-9

Drilling, prohibitions 2-5; 2-9

Drive shafts, modifications 2-17

Earthing, execution and precautions 2-6

ECAS, rear axle air suspension power supply check 5-17

Ecology 1-20

II

Alphabetical index to subjects

Page 7

EDC, engine speed isochronous check 2-10; 2 -75; 2-105

Electric / electronic on-board systems, interface with Cursor engine version 5-23

Electric / electronic parts, precautions 2-6; 2-10; 2-72; 2-74; 2-75; 2-96

Electric circuits, precautions 2-7; 2-72; 2-96

Electric system, precautions 2-6;2-7; 2-10; 2-72; 2-74; 2-75; 2-96

Electric system, service operations 2-72

Electromagnetic compatibility 2-73; 2-96

Electronic control units, positioning on vehicles 5-6

Electronic control units, precautions 2-6; 2-10; 2-72

Engine air intake system, modifications 2-56

Engine cooling system, modifications 2-58

Engine exhaust, modifications 2-56

Engine speed adjustment 4-27

Engine speed isochronous check (EDC) 2-10; 2-75; 2-105

Fifth wheel mounting 3-33

Fifth wheel supporting structure 3-33; 3-41; 3-42

Fifth wheels, fastening 3-31; 3-33

Forces applied to steering-wheel 2-13

Fuel tank, position 2-102

Gas, electric / electronic arrangements 5-22

Gas, service operations / precautions for gas-fuelled vehicles 5-20

Gas-fuelled vehicles, service operations / precautions 5-20

General specifications 1-5

Grinding, precautions 2-6

Hazard goods transport 2-104

Interchangeable parts, outfits 3-22

Interface with electric / electronic on-board systems with Cursor engine version 5-26

Interface with electric / electronic on-board systems with EuroMover engine version 5-54

Interface with electric / electronic on-board systems with TECTOR engine version 5-67

IVECO approval, necessity 2-5; 2-15

IVECO approval, request 1-5

Alphabetical index to subjects

III

Page 8

IVECO offices to be contacted 1-5

Legal requirements 1-19

Limits on modifications 1-7

Load permitted variations 2-75; 2-78

Material, chassis 2-10

Minimum load on front axle, limits 1-15

Mudguard flap 2-108

Optimized drive 5-17

Painting 2-7

Plastic brake piping 2-66

Positioning of electronic control units on vehicles 5-6

Power takeoffs from engine 4-16

Power takeoffs from gearbox 4-7

Power takeoffs from torque restorer 4-15

Power takeoffs from transmission 4-15

Power takeoffs 4-5

Quality system management 1-20

Rear axle air suspension load check with ECAS electronic device 5-17

Rear crossmember, lowered position 2-26

Rear crossmember, reinforcements 2-42

Rear mudguards and wheelboxes 2-107

Rear overhang modification 2-22

Recycling 1-20

Repositioning equipment 2-102

Retarder installation 2-75; 2-105

Self-supporting superstructures 3-11

Semitrailer tractors 3-31, 3-32

Side guards 2-108

Side marker lamps, arrangement 2-97

Side member cutting, precautions and procedure 2-6; 2-11; 2-16

Slide-and-dump containers 3-27

Snowplough 3-68

Special / fire-fighting / municipal vehicles 3-68

Speed limiter, precautions 2-75

IV

Alphabetical index to subjects

Page 9

Spoiler, fitting 2-61; 2-62

Stabilizer bars, use 1-14

Steering, influence following wheelbase modifications 2-13

Subframe material 3-5

Subframe sections, cement mixers 3-29

Subframe sections, centre-axle trailers 2-30

Subframe sections, crane 3-50; 3-52; 3 -55

Subframe sections, tippers 3 -25; 3 -26; 3-27

Subframe sections, fifth wheels 3-43

Subframe sections, b ox-bodies 3-19

Subframe sections, tail lifts 3-62

Subframe sections, tanks 3-45

Subframe, connection to chassis 3-12

Subframe, , crossmembers 3-10

Subframe, construction 3-5

Subframe, material 3-5

Subframe, profile 3-7

Subframe, stiffening 3-10

Superstructure centre of gravity and positioning payload 1-9; 1-13

Superstructures 3-5

Supplementary axles, installation 2-45

Supplementary heater system 2-59; 2-75

Suspensions, modifications 2-55

Tail lifts, installation 3-58

Tanks, installation 3-44

Tipper installation 3-23

Top-sleeper, assembling 2-62

Towable weight increase 2-25

Towing hook, application 2-24

Towing device installation 2-24

Tractor and semitrailer combination 3-32

Tradenames and logos 1-7

Transmission modifications 2-17

Transmission, drive line modifications 2-17

Transport of indivisible material 3-44

Tyres, replacement 2-64

Under run-bar, modifications 2-106

Alphabetical index to subjects

V

Page 10

Vans, manufacture 3-23

Vehicle component functions and maintenance 1-6; 1-18

Vehicle delivery 1-21

Vehicle maintenance, accessibility 1-18

Vehicle identification 1-8

Vertical engine exhaust 2-57

Warranty, issue 1-21

Warranty, undertaking 1-6; 2-75

Weight variations 1-15

Weights, compliance with permitted values 1-9; 1-15

Weights, permitted variations 1-15

Welding, execution 2-10

Welding, precautions 2-6; 2-10

Welding, prohibitions 2-5

Wheelbase modification 2-13

Wheelbase, permitted increase 2-13

Winches, installation 3-69

VI

Alphabetical index to subjects

Page 11

I. GENERAL

SPECIFICATIONS

General specifications

1-1

Page 12

1-2

General specifications

Page 13

Index

1. General Specifications

1.1 General Specifications 1-5

1.2 Dimensions and Weights 1-9

1.2.1 General Specifications 1-9

1.2.2 Determining the Centre of Gravity of the Body and Payload 1-9

1.2.3 Observing the Permitted Weights 1-15

1.3 Instructions for the Correct Functioning of the Parts of the Vehicle

and Accessibility for Maintenance 1-18

1.4 Legal Provisions and Prevention of Accidents 1-19

1.5 Choice of material to use:

Ecology - Recycling 1-20

1.6 Quality System management 1-20

1.7 Vehicle delivery 1-21

General specifications

1-3

Page 14

1-4

General specifications

Page 15

1.1 General Specifications

Purpose

The purpose of these instructions is to permit modifications and/or fitting genuine IVECO parts while

safeguarding the operation, safet y and reliabilit y of the vehicle and its components.

The modifications and fittings made in compliance with the following instructions, except for the contents of

point 2.1.1, require no specific IVECO approval.

All modifications and fittings not covered in these instructions are to be approved beforehand by IVECO.

IVECO shall not be held liable for any modifications or fittings where approval has not been requested or, if

it has, where approval has been rejected or not given.

Departments to be Contacted and Documentation to be Submitted

Whenever equipment has to be constructed and this is not taken into consideration by the specifications

contained in this manual, the responsible Departments, which can be contacted through the Sales Management

of the Company, will provide the pertinent information. In these cases contact the IVECO Office in your

zone.

When contacting these bodies two copies of the following documentation must be submitted:

a) Drawing of the vehicle including dimensions of the body or of the modified components or of the new

equipment.

b) A break down of the weights, with indications regarding the centre of gravity where necessary.

c) Description of the auxiliary frame, dimensions, fastenings to the chassis of the vehicle.

d) Distribution of the forces and moments acting on the vehicle as a result of the equipment (cranes, cement

mixers, hoists, concrete pumps etc.).

Reference must be made on the drawings themselves to all the points which differ from these specifications.

Furthermore, the use of the vehicle and the conditions under which it is to be used must be briefly described.

IVECO Technical Documentation Available on Computer

The specific IVECO - THB web site contains technical documentation on the product concerning:

- Instructions for bodybuilders;

- Technical descriptions;

- Bodybuilder drawings

- Chassis, transmission, p.t.o. diagrams;

- Type-approval data.

Access information can be requested directly from the above-mentioned IVECO office.

This same office will be able to provide you with CD-ROMs with the collection of chassis cab diagrams for the

various product ranges in CAD - IGS and/or DXF format.

General specifications

1-5

Page 16

Authorization and Liabilities

The authorizations issued by IVECO concern solely the technical feasibility of the modification

and/or fitting to be made on a genuine IVECO vehicle.

The bodybuilder is responsible for the:

- project of the modification or fitting;

- choice and features of the products used;

- workmanship of the modification or fitting;

- compliance of the project and its implementation with all the instructions provided by

IVECO;

- compliance of the project and its implementation with all the current regulations in the

country where the vehicle is registered;

- operation, safety, reliability and generally the good handling of the vehicle as well as the

effects the modifications and fitting may have on the performance and specifications of the

vehicle.

Guarantees

The bodybuilder/chassis converter who has built the body or who has modified the chassis must guarantee

that the work was undertaken in a professional manner in full compliance with the specifications contained in

this manual. IVECO reserves the right to declare void its own warranties for the vehicles where:

- These specifications have not been adhered to or where unauthorised equipment was installed, or

unauthorised modifications were carried out.

- The chassis was used in a way which is not suitable for the equipment or for the intended purpose of the

vehicle.

- The specifications, standards or instructions issued by the Manufacturer for the flawless execution of the

operations have not be heeded.

- Original spare parts or components which the Manufacturer has made available for specific interventions

were not used.

Maintaining Proper Operation of Parts and Vehicle

It is clearly understood that for all authorised modification and applications, the proper

functioning of the various parts of the vehicle, the safety of operation and use of the various

elements of the vehicle, in compliance with the national and international regulations (EEC

Standards) and to the norms pertaining to the prevention of accidents must be guaranteed.

1-6

General specifications

Page 17

Limits on Modifications

To ensure driving safety and good vehicle operation, the following assemblies in general must not be

modified:

-Axles

- Steering system

- Brakes

- Suspension (springs, brackets, anchor bar)

- Chassis

- Power unit

- Coupling devices (hooks, fifth wheels)

- Cab supports, locking and tilting devices

- Electrical system.

Modifications to the above assemblies, where included in these directives, may only be carried out after

approval has been received from IVECO.

Trademarks and Logos

Trademarks, nameplates and denominations must not be modified or displaced in relation to the original

design. The appearance of the vehicle must not be changed or modified.

The application of trademarks tied to the transformation or trim levels must be authorised by IVECO. They

must not be applied near to the IVECO tradenames or logos.

IVECO reserves the right to withdraw the tradenames and logos if the fitting or conversion fails to conform

with requirements. The bodybuilder accepts all responsibility for the entire vehicle.

Instructions for Additional Units

The bodybuilder shall, upon delivering the vehicle, supply the necessary service and maintenance

instructions for additional installed units.

General specifications

1-7

Page 18

Choosing the Chassis

The correct choice of chassis, in the appropriate version, is very important if the o utcome of the

modification is to be successful.

Before proceeding with the modifications, ensure that the vehicle supplied corresponds to the one requested

by checking information given on the order, and in the technical documentation provided by the Manufacturer.

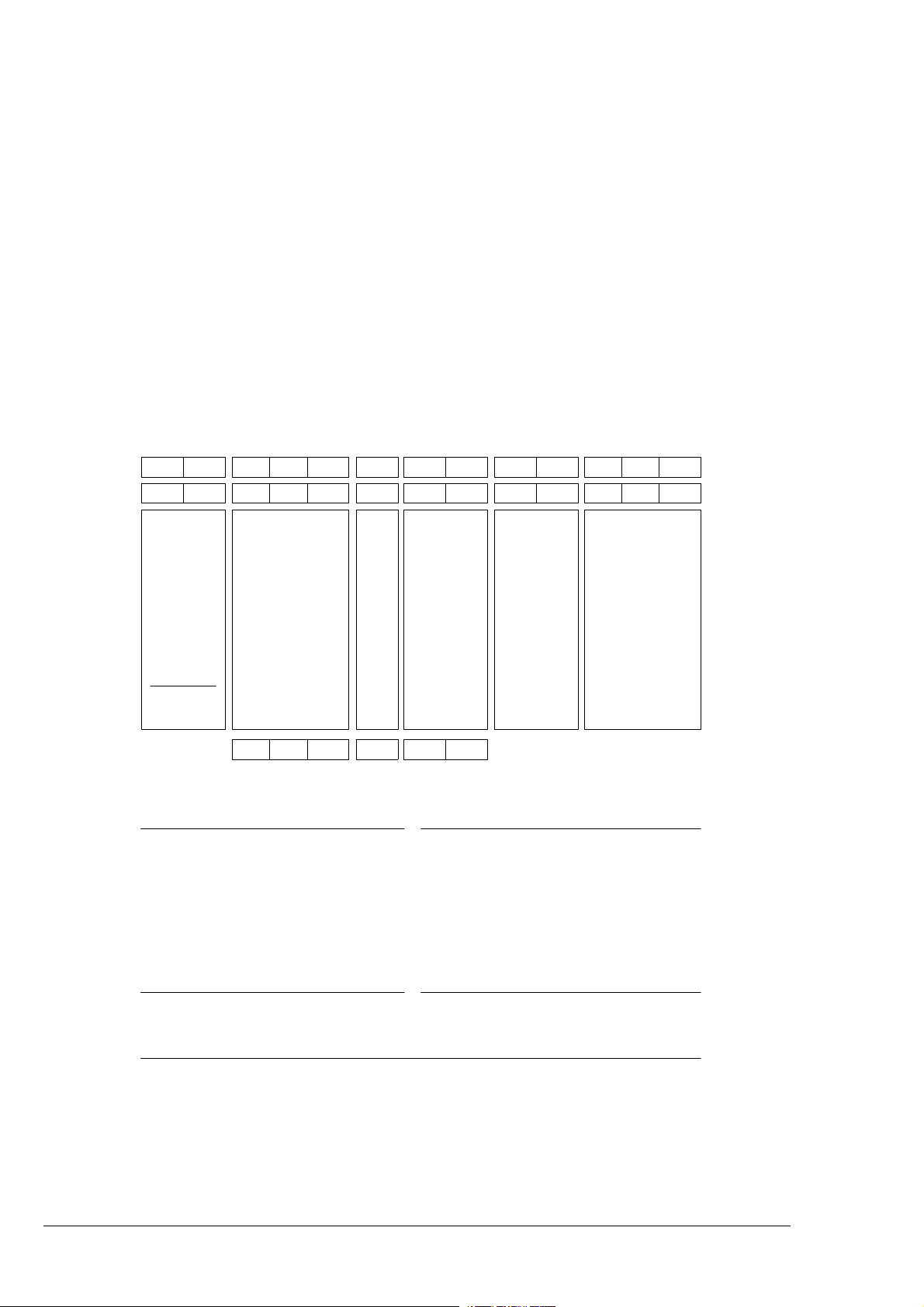

Vehicles Identification

Two examples concerning the identification of the Euro Range of vehicles are given below together with

the meaning of the relevant initials:

Cab Range Model Power Version

CHASSIS

CAB VEHICLES

TRACTOR

EXTERNAL NAMEPLATE ON VEHICLE

LD190 /FPE25

MP 400 /PE83XT

ML

MH

MP

LD

FF

M

CC

CAB RANGE

ML = Medium light

MH= Medium Heavy

MP = Multipurpose

LD = Long distance

FF = Fire fighting

M = Military

CC = Chassis cowl

GVW-Vehicles with cab

GVC - Tractors for

semitrailers (:10 in ton)

EURO Engine power

190 E 25

Configuration

C

D

H

K

T

R

V

X

(x 10 in HP)

VERSION

C=Combi

D = Double cab

H = Heavy duty

HM = Heavy mission

K = Kipper

T = Tractor for semitrailers

R = Drawbar

V=Van

X = 6x2COnlytractors

Y = 6x2PRoad

Z = 6x4

W = All wheel drive

Y

Z

W

Gearbox

Suspension

/TN

/P

/PT

/PS

/FP

/FT

/FS

/E

1-8

SUSPENSION

/TN = Only for 6 x 2P vehicles, mechanical rear suspension with fixed 3rd axle (twin wheels)

/P = 4x2, 6x4, 6x2P vehicles, rear air suspension. 6x2P with fi xed 3rd axle, single wheels

/PT = Only for 6x2P rear air suspension with fixed 3rd axle, controlled steering

/PS = Only for 6x2P, rear air suspension with fixed 3rd axle (twin wheels)

/FP = 4x2, 6x4, 6x2P, 6x2C, full air suspension

/FT = Only 6x2P, full air suspension with fixed 3rd axle (twin wheels)

/FS = Only 6x2P full air suspension with 3rd single wheel axle, controlled steering

/E = Rubber rear suspension (6x4, U.K. market)

General specifications

Page 19

1.2 Dimensions and weights

1.2.1 General Specifications

The dimensions and maximum permissible mass on the axles are indicated on drawings, on technical

specifications and, in greater details, on the official documentation issued by the Company.

The kerb weights refer to vehicles with standard equipment. Special equipment may involve considerable

modification to the mass and its distribution on the axles.

Lights and rear-view mirrors positioning on our vehicles is designed for widths of 2,500 mm. This dimension

may also be applied to special body versions with a width of 2,600 mm (e.g. refrigerator vans).

Weighing the Chassis

As a result of production factors there may be a variation in mass of approx. 5%.

It is, therefore, advisable to determine the mass of the vehicle with its cab before fitting the body and equipment

and establishing their distribution on the axles.

1.2.2 Determining the Centre of Gravity of the Body and Payload

Positioning on longitudinal plane

To establish the location of the centre of gravity of the body and payload the following examples below may

be used as guidelines.

The technical documentation specific to each model (chassis cab drawing) give the positions permitted with

the vehicle in its standard form. The masses and positioning of the single components of the vehicle are given

in the chassis and weight distribution diagram.

General specifications

1-9

Page 20

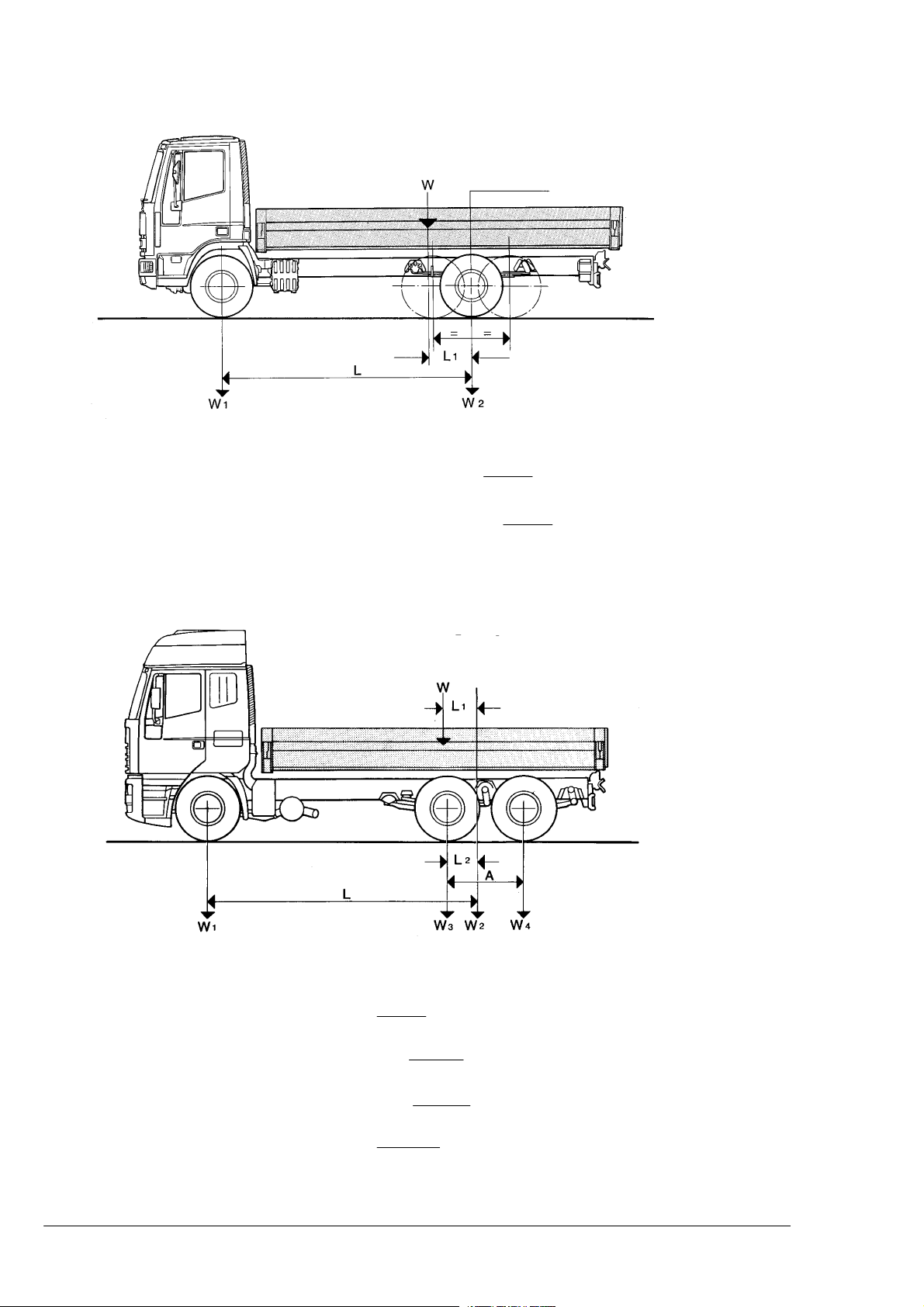

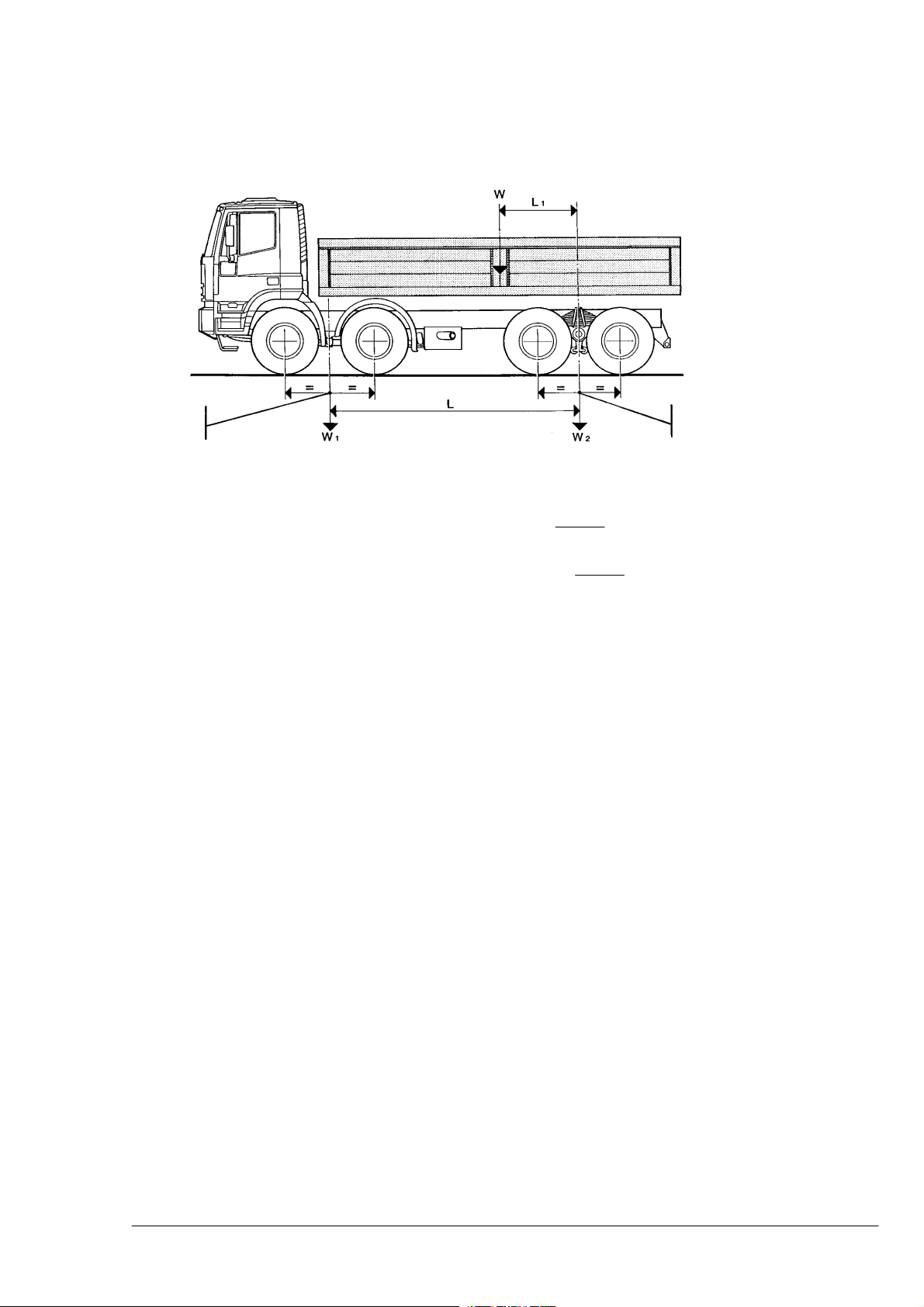

Figure 1.1

Vehicles with 2 axles; vehicles with 3 axles with an

equal load on the two rear axles

Rear wheel axle or

tandem centre line

Example to determine the position of the centre of gravity of the payload plus body

W = Payload + body

= Share of payload on front axle

W

1

= Share of payload on rear axle (or tandem)

W

2

= Distance of centre of gravity from centre-line

L

1

of rear axle (or tandem centre-line)

L = Actual wheelbase

Figure 1.2

W1xL

=

L

1

W

respectively L

1

=L-

W2xL

W

Vehicles with 3 or more axles with a constant mass

distribution ratio on the two rear axles. For these

vehicles the ”ideal” values of the wheelbase and

centreline between the axles, resulting from mass

distribution, is determined by the Manufacturer.

Example to verify compliance of admitted masses on the axles

W = Payload + body

= Share of payload on front axle

W

1

= Share of payload on rear axles

W

2

= Share of payload on first rear axle

W

3

= Share of payloa d on second rear axle

W

4

= Distance of centre of gravity relative

L

1

calculated centreline

L = Calculated wheelbase (ideal)

= Calculated centreline (ideal)

L

2

A = Distance between rear axles

1-10

W

1

W

2

W

3=W2

W

4

WxL

=

=Wx

W2xL

=

x

L

A

1

(L - L1)

L

(A - L2)

A

2

Attention:

On vehicles with three or more axles, with

a variable mass distribution ratio on the two

rear axles depending on the load, the ”ideal”

values of wheelbase and centreline between

the axles will have to be calculated on the basis of the information given in the chassis cab

diagram, or in the specific documentation

specially prepared by IVECO. In this way, for

special versions (e.g. cranes on rear overhang) it will be possible to determine the correct positioning of the centre of gravity of the

equipment and payload on the basis of the actual load (see point 5.4 in section 5).

General specifications

Page 21

Figure 1.3

4 axle vehicles with the same loading on both the

front and rear axles

Front axle

centreline

Example to determine the position of the centre of gravity of the payload plus body

W = Payload + body

= Share of payload on front axles

W

1

= Share of payload on rear axles (tandem)

W

2

= Distance of centre of gravity from centreline

L

1

of rear bogie

L = Actual wheelbase

respectively L

1

L

1

=L-

=

Rear axle (tandem)

centre line

W1xL

W

W2xL

W

General specifications

1-11

Page 22

In order to apportion the payload on the axles, it must be uniformly distributed except when the shape of the

loading surface itself entails a different distribution of the load.

As for equipment, the actual location of the centre of gravity is considered.

When building bodies or containers, loading and unloading systems for the transported goods must be devised

which preclude excessive variations in the distribution of the load and/or excessive loads on the axles, also giving

the relevant instructions to the users.

The bodybuilder will also need to install suitable payload securing systems on the body so that transport can

be made with the utmost safety.

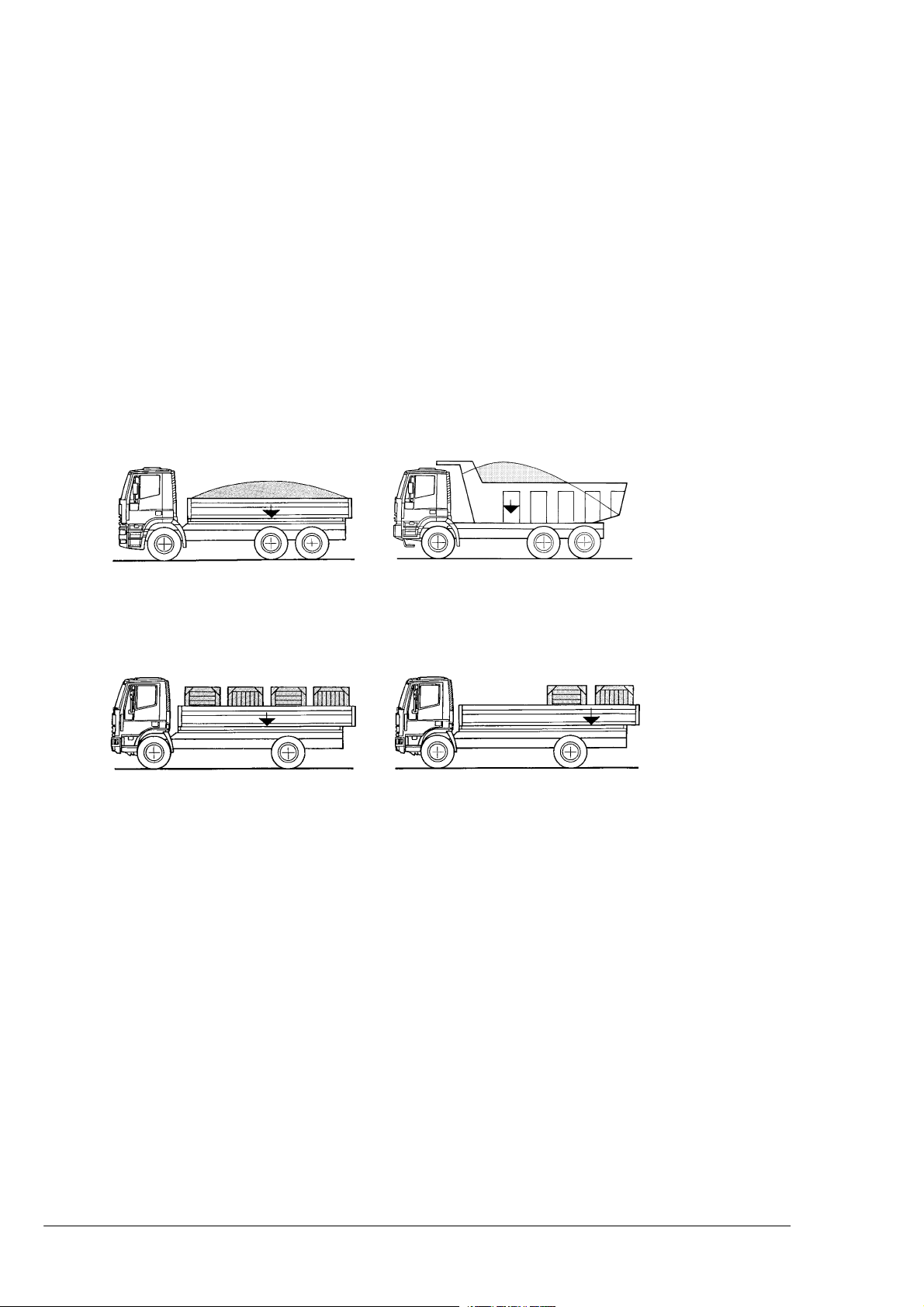

Figure 1.4

Uniform distribution of the load Non-uniform distribution of the load due to the

Uniform distribution of the load Non-uniform distribution of the load (beware of

lack of a rear overhang

load on axles and of minimum ratio)

1-12

General specifications

Page 23

HeightoftheCentreofGravity

The height of the centre of gravity of the chassis cab is given in the technical documentation specific to each

model (chassis drawing).

For testing the vehicle complete with superstructure, the bodybuilder must check that the height of the centre

of gravity of the equipment including the payload, or of the entire vehicle when fully loaded, falls within the

maximum permitted values.

These limits are defined in compliance with the national or international regulations (e.g. EC Directive 71/320

as amended by the current braking directive regarding breaking) or requested by the Manufacturer to ensure

good handling of the vehicle (e.g. transverse stability of the moving vehicle).

In order to comply with the current EC Directive, IVECO provides information for the various models

(wheelbase and specific body) on computer, regarding:

- Height of centre of gravity of chassis cab (e.g. chassis cab diagram, braking data);

- Maximum height of centre of gravity of complete vehicle at full load

(e.g. national type-approval document);

- Braking capacity of each single axle (e.g. braking data).

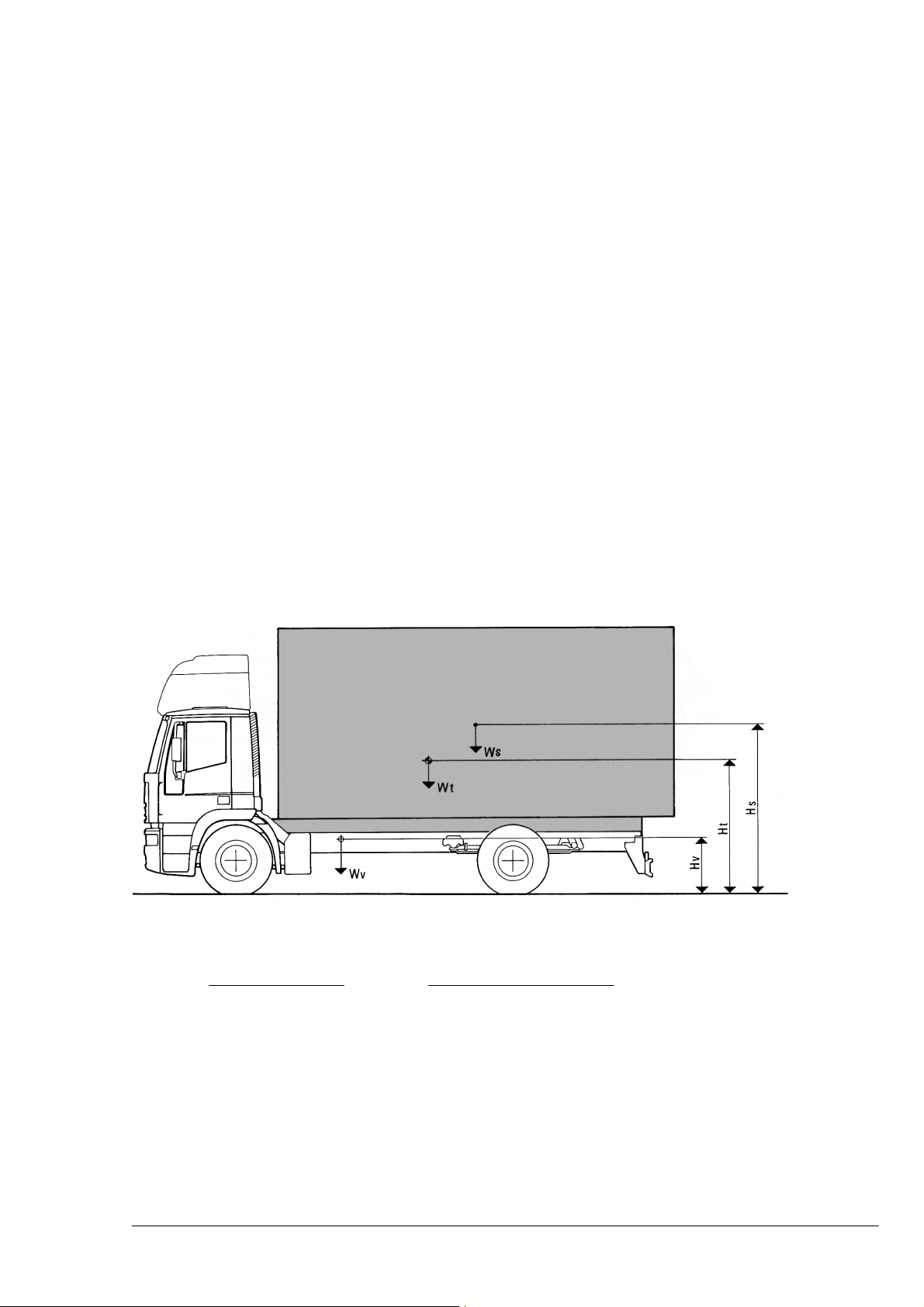

Figure 1.5

Verification with full load:

(Wv . Hv) + (Ws . Hs)

Ht =

Wv = Chassis cab vehicle tare weight

Hv = Height of centre of gravity of chassis cab vehicle (laden condition)

Ws = Payload plus superstructure tare

Hs = Height of centre of gravity of body and payload in relation to ground

Wt = Vehicle mass when fully loaded

Ht = Height of centre of gravity of vehicle with full load

Wv + Ws

[(Wv + Ws) . Ht] − (Wv . Hv)

Hs =

Ws

To check the vehicle with its body but no payload, use above formula but for Ws use only the body tare weight

(The position for Hv will depend on the load and deflection of the suspension).

General specifications

1-13

Page 24

The height of the centre of gravity indicated in table 1.1 represents values which are not to be exceeded for

each given equipment level. These values have been calculated only in terms of the transverse stability of the

vehicle and are applicable to a mid wheelbase. Any other possible restrictive specification, e.g. braking

regulation, should be taken into consideration.

The values given in table 1.1 refer to the superstructure with fixed payload. In versions where the payload tends

to move on side (e.g. suspended loads, fluid loads etc.) especially when turning, higher dynamic stress is

generated which makes the vehicle less stable. This must be taken into consideration when providing vehicle

operating instructions or for possible reduction in the height of the centre of gravity.

Using Stabiliser Bars

Supplementary stabilising or anti-roll bars, where available, spring reinforcements or the application of

rubber components (incompliance with point 2.7) may increase the height of the centre of gravity of the payload

which must be defined as each occasion arises. The modification must be carried out after careful consideration

has been given to the specifications of the version, to the wheelbase and to the distribution of the cross-stresses

acting on the suspension both at the front and at the rear of the vehicle. It must be borne in mind that it is often

advisable to modify the rear axle only since a modified front axle would give the driver a false sense of stability

making it more difficult to perceive the safety limits. Modification to the front axle may be made where the load

is positioned behind the cab (e.g. crane) or where the superstructures are very rigid (e.g. van conversion).

Exceeding the Limits

When transporting goods with an exceptionally high centre of gravity (e.g. machinery, indivisible cargo etc.)

from a technical point of view it is possible to exceed the values indicated in the table provided that the steering

system of the vehicle is suitably adapted to this condition (e.g. reduced speed, running path gradual variations,

etc.).

Modifications may only be carried out after approval has been received from IVECO.

1-14

General specifications

Page 25

1.2.3 Observing the Permitted Weights

All limits indicated in our documentation must be adhered to. The mass of the front axle is of particular

importance under varying load conditions, in order to ensure the correct steering characteristics on road

surfaces of all types.

Particular attention must therefore be paid to vehicles with a weight which is concentrated on the rear overhang

(e.g. cranes, tail-lifts, centre axle trailers) and to vehicles with a short wheelbase and a high centre of gravity

(e.g. silo vehicles, cement mixers).

When positioning the body and equipment, the loads must be correctly distributed transversally. For each

wheel a variation in the rated load (1/2 of the axial load) of 4% is permitted (e.g. admitted load on axle: 10,000

kg load admitted on each wheel: 4, 800 to 5,200 kg) provided that the tyres permit it, without impairing braking

or driving stability.

For vehicles with an added rear lift axle it must be remembered that, with the axle in the raised position, the

effective wheelbase is reduced, whereas the rear overhang is increased. It is therefore advisable that the centre

of gravity of the body and payload is located in front of the centre line of the driving axle. In addition to this

it is not advisable to equip a vehicle which has its load concentrated at the rear, with a lifting device. Apart from

different specifications for specific individual vehicles, the following may be taken to be the minimum values for

the front axle:

- 20% of the total vehicle mass with uniformly distributed loads

- 25% of the total vehicle mass for loads that are concentrated on the rear overhang.

The rear overhang of the body must be built in strict observance of the permitted axle loads, the limitations

in length, the positioning of the tow hook and of the underride guard stipulated by the relevant laws and

regulations.

Variations in the Permissible Mass

Special exceptions to the maximum permissible mass may be granted for particular applications for which,

however, precise limitations regarding the use will be imposed in addition to possible vehicle reinforcements.

Such exemptions, if they exceed the limits imposed by law, must be authorised by the Administrative Authority.

A reduction in admissable vehicle load (downrating) may require interventions on some parts, such as the

suspension. In these circumstances, the necessary indications may be supplied.

The request for authorisation must include:

- Vehicle type, wheelbase, identification number, designated use.

- Tare distribution on the axles (e.g. vehicles equipped with crane and body) including positions of the centre

of gravity of the payload.

- Proposals concerning the reinforcement of the vehicle components where necessary.

General specifications

1-15

Page 26

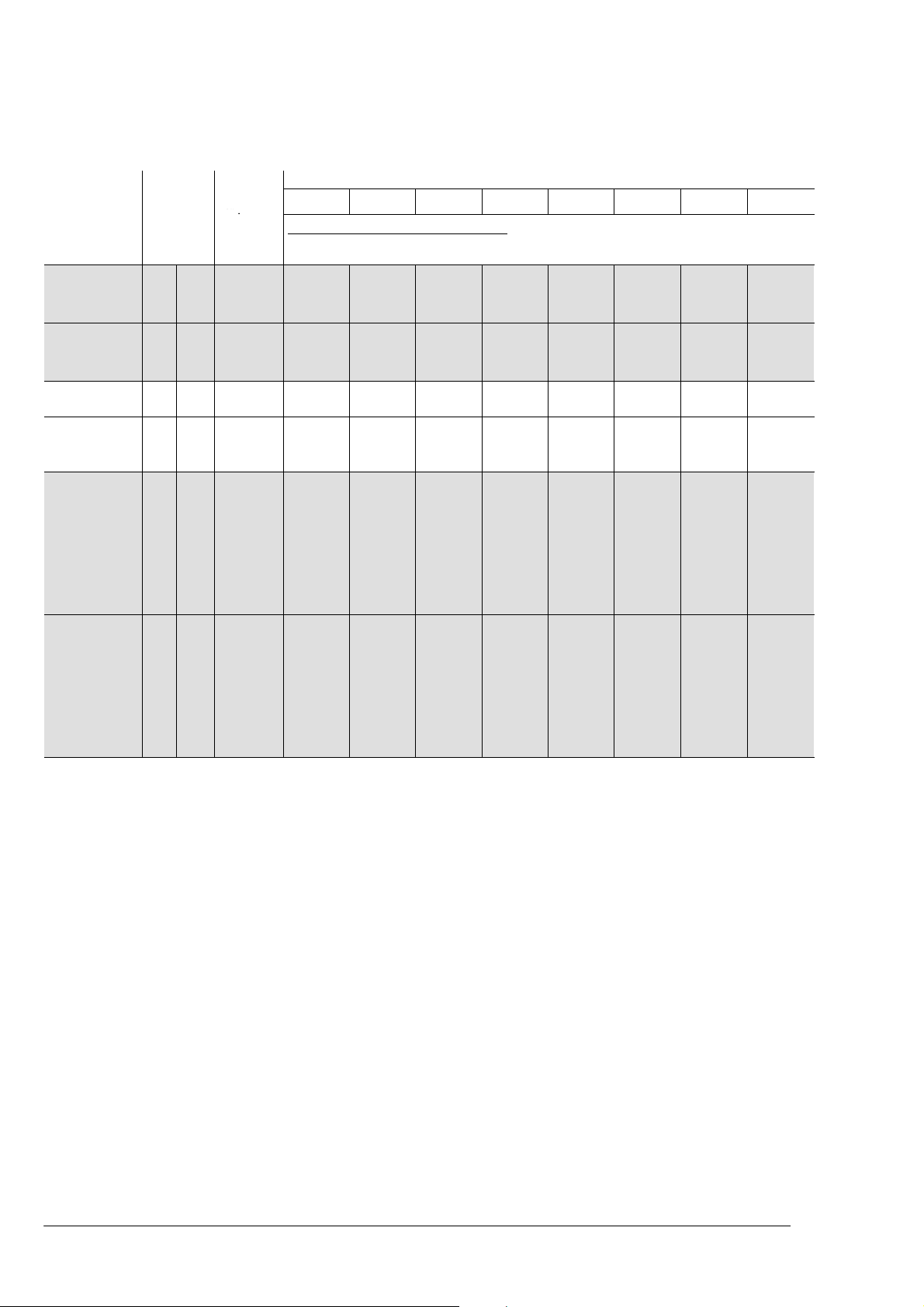

Table 1.1

gypy(

MP260

Maximum heights in relation to the centre

1)

of gravity

of the payload and cornering stability

MODELS BASIC EQUIPMENT

ML 60; 60P x x 2450

ML 60K x x 2400

ML 65; 75; 80; 65P; 75P; 80P x x 2300

ML 65K; 75K x x 2250

ML 65H x x 2400

ML 80K x x 2350

ML 85H x x 2400

ML 95W x x 2750

ML 100; 100P x x 2200

ML 100K x x 2250

ML 100W x x 2470

ML 120; 120P x x 2400

ML 110EL ; /P x x 2200

ML 120K x x 2550

ML 120H x x 2550

ML 130 x x 2300

ML 130P; 130FP x x 2400

ML 130K; 150K x x 2500

ML 135W x x 2750

ML 140W x x 2500

ML 150 x x 2350

ML 150P; 150FP x x 2400

ML 150H x x 2600

ML 170; ML 180 x x 2550 ; 2400

ML 170P; ML 180; /P x x 2650 ; 2500

ML 170K x x 2600

ML 260KE x - - 2650

MP 180; 180P x x 2650

MP 180FP x x 2590

MH / MP 190 x x 2720

MH / MP 190P x x 2750

MP 190FP x x 2700

MP 190H x x 2720

MP 190W x x 2800

MP 240; 240TN; MH 260; TN x x - 2740

MP 240P; PS; MH 260P; PS x x x 2720

MP 240FP; FS x x x 2690

MP 240PT; MH 260PT x x x 2830

MP 240FT x x x 2850

MP 260

with anti-roll bars

Front Rear

1212

x - - 2650

x SW - 2650

Max. height (approx.) of centre

of gravity of payload (includ.

body or equipment) in relation

to the ground (mm)

1-16

General specifications

Page 27

Table 1.1 (continued)

gypy(

Maximum heights in relation to the centre

1)

of gravity

of the payload and cornering stability

MODELS BASIC EQUIPMENT

with anti-roll bars

Front Rear

1212

MP 260P x x x 2720

MP 260FP x x x 2680

MP 260H x x - 2780

MP 260W x x - 2890

MP 330H x x - 2600

MP 330W x x - 2620

MP 380H x x - 2510

MP 380W x x - 2520

MP 340H x - x - 2290

MP 410H/HB x - x - 2510

Max. height (approx.) of centre

of gravity of payload (includ.

body or equipment) in relation

to the ground (mm)

Note:

1) = values referred to the transversal stability of the vehicle comply with further possible restrictions imposed b y the

regulations in force (e.g. braking system).

x = with standard anti-roll bar

- = without anti-roll bar

SW = anti-roll bar on request

General specifications

1-17

Page 28

1.3 Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

As a rule, when modifying or installing any type of equipment, nothing must be altered which prevents the

correct functioning of assemblies and parts of the vehicle under all operational conditions.

For example:

- Ready access to all parts requiring inspection or maintenance and periodic servicing must be provided. In

the case of closed body types suitable opening doors must be provided.

- For tilting cabs, adequate space permitting tilting must be assured. In the case of structures which involve

the space above the driver’s cab, adequate space for the passage of intake air must be guaranteed (see fig1.6).

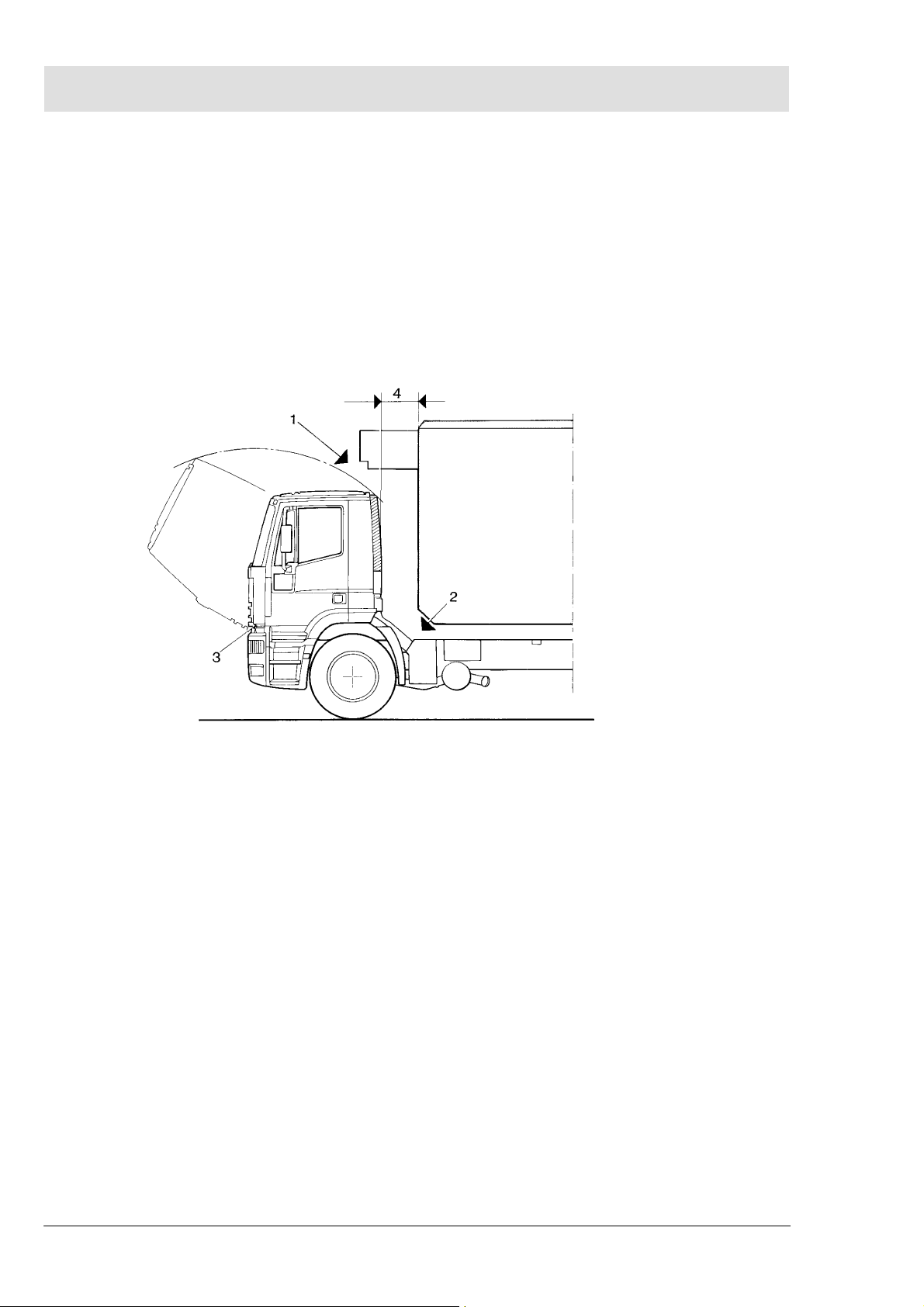

Figure 1.6

1 Retain adequate room for tilting the driver’s cab

2 Retain the free space above the gearbox (for tractors with semitrailers consider the movement between tractor and semitrailer)

3 Cab rotational centre

4 Observe the minimum distance required by the specific documentation

- Service access to chassis/driveline components must be retained. For instance repairing the gearbox or

clutch must be possible without necessitating the removal of major components of the added structure.

- The cooling system (radiator cowling, radiator, air passages, cooling circuit etc.), fuel supply (pump position,

filters, pipe diameter, etc.) and the engine air intake must not be altered.

- The anti-noise panels must not be altered or moved in order to prevent changes in the approved noise levels

of the vehicle. Should it be necessary to make openings (e.g. for the longitudinal runner of the body to pass

through) these must be properly closed off using material with inflammability and soundproofing

characteristics equivalent to those used originally.

1-18

General specifications

Page 29

- Adequate ventilation of the brakes and battery case (especially in the case of vans) must be guaranteed.

- The positioning of the mud-guards and wheel-arches must allow free movement of the rear wheels even

when chains are being used. Sufficient space must also be ensured with lifting axles. Some of our models have

3rd axle steering which also steers in the raised position; and it is necessary to leave space for this function

(see point 2.20).

- When vehicle body building has been completed the adjustment of the headlights must be checked for safety

and re-adjusted where necessary. In these circumstances it may be necessary to adjust the screw on the

headlights or to check the adjustment range of theadjusting device when the vehicle is laden. The adjustment

must be carried out in compliance with the instructions given in the Owner’s Manual in which the new values,

if any, will be included.

- In the case of parts which are supplied loose (e.g. spare wheel, chocks) it will be the responsibility of the

bodybuilder to position and secure them in an accessible and safe manner in compliance with possible

national laws.

1.4 Legal Provisions and Prevention of Accidents

On completing the vehicle the bodybuilder/chassis converter must check the work (modifications, body +

equipment etc.) to ensure that the legal provisions required in the country of registration are observed (e.g.

weights, dimensions, braking, noise, emissions etc.). Information regarding these matters may be obtained from

the competent Authorities or the IVECO Area Network.

The vehicles manufactured at our plant (except some versions for extra-European countries) comply with the

EEC directives. Converted vehicles must also comply with these directives. The only permissible exception is

granted where local type approval differs from EEC homologation.

Prevention of Accidents

The structures and devices fitted to the vehicles must comply with the current regulations concerning the

prevention of accidents and safety regulations in force in the countries where the vehicle is to be used. All the

precautions dictated by technical awareness must be adopted to prevent malfunction and functional defects.

Compliance with these regulations will be the responsibility of the manufacturers of the structures and devices.

Warning

Components such as seats, upholstery, seals, protective panels etc, may constitute a potential fire risk if

exposed to sources of intense heat.

Remove these components before undertaking welding or flame-cutting work.

General specifications

1-19

Page 30

1.5 Choice of material to use: Ecology - Recycling

Increasingly greater attention should be p aid, at the study and design stage, to the choice of materials to

be used. T his is especially the case as regards the aspects connected with ecology and recycling in the light

of domestic and international regulations that are constantly being developed in the sector.

In this connection:

- Everyone must be aware of the prohibitions on using harmful or potentially hazardous materials, such as

ones containing asbestos, lead, halogen additives, fluorocarbons, etc.

- Use materials whose processing produces limited waste and that permit easy recycling after their first use.

- With composite synthetic materials, use components that are compatible with each other, envisaging also

their possible utilization with the addition of other salvaged components. Affix the markings required in

compliance with the current regulations.

1.6 Quality System management

For some time IVECO has been promoting Quality System development and training for bodybuilders.

This is a requirement due not only to compliance with domestic and international regulations on product

liability, but also the growing demand for increasingly higher quality levels. The creation of new forms of

organization in the various sectors and the quest for increasingly more advanced levels of efficiency.

IVECO believes it expedient for bodybuilders to be equipped with an organization where the following are

defined and available:

- Organization charts for functions and responsibilities

- Quality system

- Quality goals

- Technical design documentation

- Process and control phases with relevant resources

- Product improvement plan, obtained also with corrective actions

- After sales service

- Staff training

- Manufacturer liability documentation.

1-20

General specifications

Page 31

1.7 Vehicle delivery

Before delivering the vehicle to the Customer check that:

- The equipment requested has been correctly fitted.

- The vehicle and equipment is completely ready for service and fully operational.

- The functionality and safety of the vehicle and/or equipment has been respected.

- Information/documentation concerning the equipment has been included.

- New data have been entered on the appropriate plates (where applicable)

Concerning the periodical checks on the vehicle, please remember the instructions for correct battery

maintenance referred to on the specific information sheets on the vehicle before delivery to the customer.

The bodybuilder will moreover need to confirm that the operations carried out are in compliance with the

latest bodybuilder instructions manual/documentation provided by IVECO and with the requirements of the

law.

Guarantee

A guarantee is provided for all our vehicles, under the terms and conditions set out in the relevant

documentation. An equivalent guarantee must be provided by the bodybuilder/chassis converter covering the

work carried out, by them.

General specifications

1-21

Page 32

1-22

General specifications

Page 33

2. CHASSIS MODIFICATIONS

Chassis modifications

2-1

Page 34

2-2

Chassis modifications

Page 35

Index

2. Chassis Modifications

2.1 General 2-5

2.1.1 General Specifications and Approval of the Company concerning Modifications

of the Chassis 2-5

2.1.2 Specific Precautions 2-6

2.1.3 Protection against Rust and Painting 2-7

2.2 Specific Instructions 2-9

2.2.1 Drilling the Chassis 2-9

2.2.2 Bolts and Rivets 2-9

2.2.3 Characteristics of the Materials to be Used when Modifying the Original Chassis 2-10

2.2.4 Welding the Chassis 2-10

2.3 Modifying the Wheelbase 2-13

2.3.1 General Specifications 2-13

2.3.2 Modifying the Drive Line 2-17

2.4 Modifying the Rear Overhang 2-22

2.4.1 Reducing the Overhang 2-22

2.4.2 Increasing the Overhang 2-22

2.5 Installing a Towing Device 2-24

2.5.1 General Specifications 2-24

2.5.2 Increasing the Towable Mass 2-25

2.5.3 Lowered Rear Cross-Member 2-26

2.5.4 Centre Axle Trailers (Rigid Towbar) 2-28

2.6 Installing a Supplementary Axle 2-45

2.7 Work on the Suspension 2-55

2.7.1 Changing a Mechanical Suspension into a Pneumatic o r Mixed Suspension 2-55

2.8 Modification of the Engine Air Intake and Exhaust Systems 2-56

2.8.1 Vertical Exhaust 2-57

2.9 Modifications of the Engine Cooling System 2-58

2.10 Installation of a Supplementary Heating System 2-59

2.11 Installing an Air Conditioning System 2-60

2.12 Cab Modifications 2-61

2.12.1 General Specifications 2-61

2.12.2 Roof Panel Modifications 2-61

2.12.3 Installation of a Spoiler or Top-sleeper 2-62

2.12.4 Crew Cabs 2-62

Chassis modifications

2-3

Page 36

2.13 Changing the Size of the Tyres 2-64

2.14 Modifications to the Braking System 2-65

2.14.1 General Specifications 2-65

2.14.2 Brake Pipes 2-65

2.14.3 Vehicles with ABS Devices 2-68

2.14.4 Taking air from the System 2-69

2.14.5 Instructions for Adjusting the Load Apportioning Valve 2-69

2.14.6 Installing a Load Apportioning Valve on Vehicles not so Equipped 2-71

2.15 Electrical system: Modifications and Drawing-off Power 2-72

2.15.1 General Information 2-72

2.15.2 Additional equipment 2-75

2.15.3 Power Draw-off 2-78

2.15.3.1 EuroCargo Range;

EuroTech, Star, Trakker Range (Production until June 98) 2-78

2.15.3.2 EuroCargo T

ECTOR range 2-82

2.15.3.2.1 Connection for Engine switching off when a Person is standing on the Footboard

and the Reverse gear is engaged 2-91

2.15.3.3 EuroTrakker and EuroTech MH range with Cursor engine

EuroTech, Star, Trakker range (production started as of July 1998) 2-92

2.15.4 Additional Circuits 2-96

2.15.5 Harness Modifications due to Changes to Wheelbase or Overhang 2-97

2.15.6 Power Draw-off at a Voltage Different from that of the System 2-97

2.15.7 Battery Main Switch 2-97

2.15.8 Installing Side Marker Lamps 2-97

2.16 Repositioning Parts and Mounting Auxiliary Assemblies and Equipment 2-102

2.17 Transporting Dangerous Goods 2-104

2.18 Retarder Installation 2-105

2.19 Modifications to the Rear Underrun 2-106

2.20 Rear Mudguards and Wheel Boxes 2-107

2.21 Mudflaps 2-108

2.22 Side Guards 2-108

2.23 Chocks 2-109

2-4

Chassis modifications

Page 37

2.1 General

2.1.1 General Specifications and Approval of the Company concerning

Modifications of the Chassis

Any modifications must be carried out according to the criteria detailed in the following paragraphs.

Particular attention must be given to the following points:

- Welding to the bearing structures of the chassis is explicitly prohibited (with the exception of

the items described at points 2.2.4, 2.3, 2.4 and 2.6).

- Holes in the flanges of the side members are not permitted (except for the items described at point

3.1.2).

- Where riveted connections exist and can be modified as explained below, these can be replaced by

flanged-head screws and nuts of min. class 8.8 or by hex screws of the next greater diameter and self locking

nuts. Screws greater than M14 must not be used (max. diameter of hole 15 mm) unless otherwise specified.

- In cases where the original joints were detached and rejoined with bolts or where rivets are replaced with

bolts, the bolt torque must be checked after the vehicle has been driven approximately 500 to 1.000 kms.

IVECO Approval

The following modifications may only be performed following IVECO approval:

a) Modifications to the wheelbase following instructions given at points 2.2.3, 2.2.4, and 2.3.

b) Modifications to the rear overhang within the limitations imposed by weight and national legislation,

following instructions given at points 2.2.3, 2.2.4 and 2.4.

c) Work on the braking system (see point 2.14) and on the steering system (after appropriate checks).

d) Modification to the characteristics of the suspension (see point 2.7).

e) Changing mechanical suspension into a pneumatic or mixed suspension (see point 2.7.1.).

f) Modifications to the driver’s cab (see point 2.12).

g) Modifications to the exhaust system and to the engine air intake (see point 2.8).

h) Modifications to the engine cooling system (see point 2.9).

i) Modifications to the engine assembly and driving gear (see point 2.3.2).

k) Modifications to the front and rear axles

l) Installation of supplementary axles following the instructions given at point 2.6.

m) Installation of retarder brakes (see point 2.18).

n) Installation of power take-offs (in cases where authorisation is required, see paragraph 4).

o) Changing the dimensions of the tyres (see point 2.13).

As a general rule, to obtain official approval, the request must contain full documentation illustrating the intended

project which must reflect the general and specific specifications contained therein.

It is the responsibility of the bodybuilder to present the intended modification to the proper authorities and

to seek their approval whenever called upon to do so by national laws.

Chassis modifications

2-5

Page 38

2.1.2 Specific Precautions

During the welding, drilling, grinding and cutting operations when working in the proximity of brake lines

and particularly if these are of plastic material or electric wiring, care must be taken to ensure their

protection. Where necessary they should be removed (follow the instructions given in paragraphs 2.2.3 and

2.15).

Figura 2.1

Regarding the electrical equipment remember to:

a) Take precautions concerning the alternator and the electrical/electronic components. In order to avoid

damaging the diode rectifier, never disconnect the batteries (or open the isolator) when the engine is

running.

If the vehicle has to be tow started make certain that the batteries are connected. Should it be necessary

to quick charge the batteries, disconnect them from the vehicle circuit.

In order to run the engine with external means and in order to avoid current peaks which might damage

the electric/electronic components, do not use the ”start” function in conjunction with external charge

devices if such devices are equipped with this function. Starting will have to be carried out only with the

external battery trolley ensuring correct polarity.

b) Checking the earth connections.

As a general rule the original earth connections of the vehicle must not be changed. If it is necessary to move

these connections or to implement further earth points use the existing holes on the chassis as far as

possible and:

- Remove, mechanically, and/or with an appropriate chemical product, the paint on the chassis side and

ontheterminalsidecreatingarestingplanefreefromindentationsorridges.

- Apply appropriate high conductivity paint between the cable terminal and the metal surface (e.g.

galvanizing paint IVECO Part number 459622 by PPG).

- Connect the earth cables within 5 minutes from the application of the paint.

Do not use the IVECO standardised M1 (battery earth connection) M2, M 8 (earth connection for starter

motor depending onthe driving position) points for the earth connectionsfor control switches (e.g. sensors

or low absorption devices): See IVECO Workshop manuals.

With regard to the electronic devices, avoid linking earth connections between the devices; only use single

wire earths with optimised lengths (as short as possible).

2-6

Chassis modifications

Page 39

c) Electric wiring.

The wires of the electrical equipment must be connected by waterproof connections of the same type as

the original. The additional section of wire must be protected inside an appropriate sheath and suitably

attached by clips. The new wiring must not be positioned on the side of the electronic circuits already

existing on the vehicle.

For further information regarding the braking and electronic system, refer to chapter 2.14 and 2.15.

2.1.3 Protection against Rust and Painting

All parts of the vehicle (chassis, driver’s cab, body etc.) which have been subject to modification must be

protected against oxidation and corrosion.

Protection and painting operations must be carried out with due care on all the parts concerned.

In particular the frame, cab and various parts exposed to atmospheric agents and sunlight must be treated with

a cycle which includes:

Ironphosphor - degreasing, anti-corrosion, sealing, primer coat and final coat (the enamel type

primer can be replaced with powdered paint, the cab body excluded).

Miscellaneous parts (boxes, protective grills etc.) with complex forms (with boxed parts, joints, overlaps and

areas not accessible using the traditional spray application) which are attached to the frame must be treated

with a cycle which includes:

Ironphosphor - degreasing, electrophoresis or immersion anti-corrosion, enamel or powdered

paint.

When joining surfaces by welding and when the electrophoretic stage is not used, it is extremely important

to protect the contact surfaces with the electrically weldable paints.

For those parts which are not directly in contact with atmospheric agents (e.g. inside the cab) reduced cycles

are acceptable.

Ironphosphor - degreasing, powdered paints or phosphor - degreasing, electrophoresis or

phosphor - degreasing, anti-corrosion.

The phosphor - degreasing process may be replaced by degreasingwith solvents and wash primer

(5 to 10 µm).

Other important operations included are: protection of the open or semi-open boxed parts using oil-wax

products by injection using suitable probes, sealing of the joints and overlaps of the areas subject to abrasive

action (wheel arches, under body, etc.) using specific product (elastomers, acrylics, etc.) after the anti-corrosion

protection.

Parts mounted on the outside of the cab (brackets and bolts in general) must be of stainless steel or protected

with ”Dacromet”. The coupling elements (hinges, handles etc.) used on the frame and/or body (floor panels,

tanks etc) must be protected with ”Dacromet” or with 12 µm min. galvanising. The same quality of the parts

used on the cab must in all cases be guaranteed.

Chassis modifications

2-7

Page 40

Precautions

Suitable precautions must be taken to protect those parts whose conversion and operation could be

damaged by paints such as:

- Rubber or plastic hoses for the air and hydraulic installations.

- Gaskets, parts in rubber or plastic.

- Flanges of the transmission shafts or power take-offs.

-Radiators.

- Shock absorber and hydraulic or air cylinder rods.

- Drainage and bleeder valves (mechanical components, air tanks, cold starting heater plug pre-heating tanks etc.).

- Fuel sediment filter.

- Nameplates and logos.

Engines with electric and electronic components

- On all the engine and vehicle wiring harness, including earth contacts.

- On all connectors on the sensor/actuator side and wiring harness side.

- On all sensors/actuators, on flywheel, on flywheel revs sensor support bracket.

- On the pipes (plastic and metal) of all the diesel fuel circuit.

- On the complete diesel fuel filter base.

- On the control unit and its respective base.

- On the area inside the sound-proof cover (injectors, rail, pipes).

- On the common rail pump complete with regulator.

- On the vehicle’s electric pump.

- On the tank.

- On the front belts and relevant pulleys

- On the power-steering pump and its respective piping.

If the wheels are removed protect the contact surfaces on the drums and hubs, avoid increasing the thickness

and especially avoid the build-up of paint on the connecting flanges of the wheel disks and resting points of the

fixing nuts. Ensure that the disc brakes are adequately protected.

The electronic components and modules must be removed.

When the painting operation is to be completed by oven drying (max. temp. 80ºC), all parts which may be

damaged by exposure to heat must be removed.

When modifing the cab the application of noise deadening and insulating materials must be included inside the

cab and under the floor to eliminate vibrations, contain noise levels and to restore the original heat insulation

levels.

2-8

Chassis modifications

Page 41

2.2 Specific Instructions

2.2.1 Drilling the Chassis

When it is necessary to mount assemblies or auxiliary units on the chassis, as a general rule, the existing

holes made at the factory should be used.

Under no circumstances should the flanges of the sidemember of the vehicle be drilled unless in

compliance with the indications given in point 3.1.2.

In those cases (installation of shelves, brackets etc.) where it is necessary to drill new holes, they must be drilled

in the vertical web of the side member and must be carefully deburred and reamed.

Position and Size

The new holes must not be made in areas of high stress (such as supports for springs) and at variance with

the cross-section of the side member.

The diameter of the holes must be proportional to the thickness of the steel. Under no circumstances must

this exceed 15 mm unless otherwise specified. The distance from the centre of the hole to the edges of the

side member must not be below 40 mm. The centres of the holes must never be located at a distance of less

than 45 mm from each other or in relation to the existing holes. The holes must be staggered as shown in figure

2.2. When relocating spring supports or cross members, the same drilling arrangements must be preserved.

Figure 2.2

2.2.2. Bolts and Rivets

In general, fixings of the same type and class designed for similar fixings of the original vehicle should be used.

Use class 10.9 bolts for high-stress fixings (e.g. spring supports, bar connections, shock absorbers etc.). When

space permits it use flanged head screws and nuts.

Chassis modifications

2-9

Page 42

2.2.3 Characteristics of the Materials to be Used when Modifying

the Original Chassis

For the modification of the vehicle’s chassis and for the reinforcements applied directly to the side members,

the material used must correspond both in quality and thickness to that of the original chassis. If material of

the specified thickness is not available standard material of the next greater thickness (e.g. 7 mm instead of 6.7

mm)canbeused.Thematerialtobeusedmustmeettheseminimumstandards.

Vehicles with a weight rating equal to or lower than ML 180, including ML 260 KE (EuroCargo):

Chassis made of high yield steel FeE420 (QSt E 420 TM-BS1499 part I grade 46/40)

Tensile strength R

Yield point R 0.2

Stretching A 5

≥ 530 N/mm

≥ 420 N/mm

≥ 21%

2

(53 kg/mm2)

2

(42 kg/mm2)

Vehicles with a weight rating equal to or greater than MP 180 (EuroTech/EuroStar/EuroTrakker):

Chassis made of high yield steel FeE490 (QSt E 500TM-BS1449 HS 50/45)

Tensile strength R

Yield point R 0,2

≥ 610 N/mm

≥ 490 N/mm

2

(61 kg/mm2)

2

(49 kg/mm2)

Stretching A 5 ≥ 19%

As an alternative, only for extending of the rear overhang, Fe510D (QSt 52-3-BS4360, grade 50C) with the

following characteristics may be used:

Tensile strength R

≥ 520 N/mm

2

(52 kg/mm2)

Yield point R 0,2 ≥ 360 N/mm2(36 kg/mm2)

Stretching A 5

≥ 22%

For the dimensions and thicknesses, see the information given in the relevant documentation.

2.2.4 Welding the Chassis

The welding operations may be carried out only by specialist, trained personnel using

equipment that is suitable to ensure high quality workmanship (see specifications EN

287).

Welding is permitted:

- for joining of the side members if they are lengthened or shortened.

- for the application of reinforcing L section flitch on a side member that is to be modified as detailed below

(see Fig. 2.5).

For vehicles equipped with electronic devices (e.g. ABS, EDC, ECAS, etc.) disconnect the connectors of the

control units (see wiring diagram in the relevant documentation); see their positioning on the vehicle in section

5 (point 5.2). Should close welding be required, remove the control unit from its position.

During welding earth the welding machine directly to the piece that is to be welded in order to protect the

electrical equipment (alternator, batteries). Ensure that the negative pole of the battery has been disconnected.

2-10

Chassis modifications

Page 43

Plastic pipes must be protected from heat sources and splashes of material during welding. If necessary these

parts should be removed.

The surfaces of the leaf springs and air springs must be protected against weld splashes during welding. Do

not allow the electrodes or conductors to come into contact with the spring.

As part of the procedure it will be necessary to remove the paint and deoxidise the parts of the chassis that

are affected by the welding operation as well as those parts which may have to be covered by possible

reinforcements. When work has been completed the modified part must be protected with adequate

rustproofing (see point 2.1.3.).

The instructions given below should be followed to ensure that welding is carried out correctly.

a) Cut the side members with a diagonal or vertical cut. (We recommend that the diagonal cut be used

particularly for the section between the wheelbase) Cuts are not permitted in areas in which the profile

ofthesidememberaswellasthechassiswidthchangeor in those where there is a high concentration of

stresses (e.g. spring brackets). The cuts must not be made through the holes present in the side member

(see Fig. 2.3.).

Figure 2.3

NO

NO

YES

YES

b) on the inner side of the side member give the parts that are to be joined a V-shaped chamfer of 60° along

theentirelengthtobewelded(seeFig.2.4).

c) archweld in stretches using carefully dried basic electrodes. The recommended electrodes are:

for FeE420 (BS 1449 HS 46/40): DIN 1913 - E 51 B 1023

FeE490 (BS 1449 HS 50/45): DIN 8529 - EY 4687 Mn 1 Ni B H5

Diameter of the electrode is 2.5 mm, current intensity approx. 90A (max. 40A for each millimetre of

diameter of the electrode).

Using MIG-MAG welding use a welding rod with the same characteristics as the material to be welded

(diameter 1 to 1.2 mm).

Recommended welding rod: DIN 8559 - SG3 M2 5243

gas DIN 32526-M21 or DIN EN 439

For the FeE490 (BS 1449 HS 50/45) material when used with low temperatures, the following are

recommended:

PrEN 440 G7 AWS A 5.28 - ER 80S - Ni 1

gas DIN EN439-M21

Avoid current overloading. Welding must be free from marginal cuts and waste material.

d) Repeat the operation on the reverse side by welding as detailed in point c).

e) Allow the side members to cool slowly and uniformly. Cooling by air, water or other means is not

permitted.

f) Remove excess material resulting from the welding operations by grinding.

Chassis modifications

2-11

Page 44

Figure 2.4

g) On the inner side reinforcing L-section flitches should be applied. These should be made of steel and have

the same characteristics as the steel used for the chassis. The minimum dimensions are given in Fig. 2.5.

The reinforcements may only be fixed to the vertical web of the side member using welding beads, plug

welds, bolts or rivets (Huck rivets may also be used).

The cross-section and the length of the weld bead, the number and distribution of the plug welds, bolts or

rivets must be adequate to transmit the bending and shearing moment of the section.

Figure 2.5

a ~= 0.3 H

b ~= H (min 175 mm)

S ~= (0.8 to 1) S1

Closing of existing holes

If, when making new holes, the existing holes are found to be too close (see Fig. 2.2) these may be closed

up by welding. To ensure the success of this operation the outer edge of the hole should be chamfered and

copper plate used for the inner part.

For holes with a diameter of over 20 mm, chamfered plugs may be used, welded on both sides.

2-12

Chassis modifications

Page 45

2.3 Modifying the Wheelbase

MT180

t

p

t

S:1-1

3

8000110A:

2,4,6-1

2

2.3.1 General Specifications

As a rule, for each vehicle, modification to the wheelbase must be carried out on the standard wheelbase

above or closer to the new wheelbase required.

The measurements given in the written authorisations will apply in all cases particularly for extensions made

to the longest standard wheelbase.

On vehicles with a parallel chassis and constant-section side members, the wheelbase should be modified by

repositioning the rear axle (or axles) when the internal reinforcements and their connections to the chassis

permit it. The suspensions supports must also be repositioned ensuring that they are positioned where there

are crossbars in compliance with the points detailed in 2.2.1.

In other cases the chassis may be cut following the instructions given in point 2.2.4.

Whenever permitted by the body size, wheelbases should be made equal to those planned in our production.

This enables the original transmission shafts and previously defined crossmember positions to be used. When

extending a wheelbase beyond the production longest planned, the vehicle used must have the longest

production wheelbase to ensure the correct thickness side members are used. Particular care must be taken

to comply with the limits set by national regulations particularly with regard to the limits for overall dimensions

(where specified).

Consequences for steering

The lengthening of the wheelbase, depending on its extent, can affect the steering characteristics. Whenever

national regulations require it, the limits on the overall dimensions must be observed as well as the limits

concerning the effort applied on the steering wheel and the relevant operation times (e.g. ECE - R 79/01

standard). Table 2.1 shows the permitted wheelbase lengthening values for a standard steering system, the

maximum permitted load on the front axle and the specified tyre type.

Should longer wheelbase dimensions be needed, for special versions, it will be necessary to envisage various

devices aimed at improving the steering characteristics such as a reduction in the maximum permitted load on

the front axle or the installation of wheels and tyres with shorter kingpin offset values. The adoption of an

additional pump and a dual circuit power steering unit, if not immediately available, will require authorisation

and must only be installed by an authorised workshop.

Table 2.1.

Maximum permitted wheelbase lengthening depending on the load on the front axle and tyre

dimensions (ECE - R79/01 regulation or EC Directive 96/2)

Models Max. load on front axle

ML 60-100 Standard - Standard and optional 500 6300

ML 120-150-170 Standard - Standard and optional 500 6700

ML 60-180 Tector Range - Standard and optional 465 6570

MT 180

MT 190

MH 190

MP 180

MP 190

ML 260 KE 7100 - Standard and optional 500 4190

MH 260/PS 8000

MH 260/P; PT; TN 8000

MP 240/P; FP

MP 240/FT; PT

MP 240; 240/TN

MP 260

MP 240/FS; PS 8000 110

1)

For tyre type see page 2-14.

(observe tyre carrying

capacity) (kg)

7500 - S

7500 100

8000 119

8000 110

8000 110

Kingpin

offset

(mm)

120

89

72 S: 1

120

Permitted tyres

S: 1-13

A: 2, 4, 6-9

Sp:2,4,6-11

S: 6-15

A: 2, 4, 6-12

Sp:2,4,6-12

S: 1-13

A: 2, 4, 6-12

Sp:2,4,6-12

S: 1-15

A: 2, 4, 6-12

Sp:2,4,6-12

S: 1-11

A: 2, 4

Sp:2,4

S: 1-15

A: 2, 4, 6-12

Sp:2,4,6-12

S: 1-15

A: 2, 4, 6-12

Sp:2,4,6-12

S: 1-13

A: 2, 4, 6-12

Sp:2,4,6-12

andard and o

1)

ional 500/530 6700

Steering wheel

dia. (mm)

465 6210

465

530

500

530 6300

530 5100

500 5100

500

530

500

530

500

530

Max wheelbase value

between 1st steering axle

and 1st driving axle

(mm)

5100

6300

5100

6100

4800

5100

4200

5100

Chassis modifications

2-13

Page 46

Tyre type

Tyrecarryin

g

Type Size Kingpin offset (mm)

Rim

Front dead axle Front driving axle

S A Sp S A Sp

1 12.00 R 24 24-8.5 72 - - 105 - - 8000

2 13 R 22.5 22.5x9.00 76 84 86 108 116 118 7500/8000

3 12.00 R 20 20x8.5 77 - - 109 - - 7500/8250

4 315/80 R 22.5 22.5x9.00 78 86 88 110 118 120 7500/8000

5 11.00 R 20 20-8.5 80 - - 111 - - 6500/6700

6 12 R 22.5 22.5x8.25 82 91 93 113 122 124 6700/7100

7 315/70 R 22.5 22.5x9.00 83 91 93 114 122 124 7100/7500

8 295/80 R 22.5 22.5x8.25 84 93 95 115 124 126 6700/7100

9 305/70 R 22.5 22.5x8.25 88 97 99 118 127 129 6700/7100

10 11 R 22.5 22.5x7.50 88 103 99 119 134 130 6300

11 275/80 R 22.5 22.5x7.50 89 104 100 120 135 131 6300

12 275/70 R 22.5 22.5x7.50 93 108 105 124 139 135 6000/6300

13 10.00 R 20 20-7.5 93 - - 113 - - 6000

14 14.00 R 20 20-10.0W 109 - - 142 - - 9000/10000

15 385/65 R 22.5 22.5x11.75 110 - - 141 - - 8250/9000

16 18 R 22.5 22.5x14.00 130 - - 162 - - 11200

17 425/65 R 22.5 22.5x13.00 132 - - 164 - - 10300

Tyre carrying

capacity

S = Steel wheels

A = Alcoa aluminium wheels

Sp = Speedline aluminium wheels

Chassis Stress Level

When lengthening a wheelbase, in addition to local reinforcement on the side member joint, the bodybuilder

must provide sufficient reinforcements to achieve the section moduli of the side member section no lower than

that designed by IVECO for the same wheelbase or for next size up. Alternatively, when permitted by local

regulations, larger subframe sections can be used.

When prescribed by national regulations the bodybuilder must check that the stress limits are not exceeded.

In any event such stress must be no greater than that of a chassis with the original wheelbase assuming that

the load is evenly distributed and taking the chassis to be a beam resting on the spring hanger brackets.

When extending out from the longest original wheelbase the reinforcements must depend on the length of the

extension, the type of body built and the use to which the vehicle is to be put.

2-14

Chassis modifications

Page 47

Approval

The alteration of the wheelbase for the 4x2 versions is permitted without specific approval by IVECO in

the following cases:

- if the wheelbase is to be lengthened and the new value is still within the standard range of length with the

same side member section. These dimensions can be found in the relevant technical documentation or in

the table from 3.9 to 3.10.

- if the wheelbase is to be shortened without falling below the standard minimum values established for each

model.

Provided the chassis converter gives sufficient guarantees from the technological and control point of view

(qualified personnel, adequate operating processes, etc.).

For the 6x2, 6x4 and 8x4 versions the wheelbase may only be modified following specific approval by IVECO.

This also applies to the 4x4 and 6x6 versions (all wheel drive) in which the position of the transfer box must

be maintained in relation to the front axle.

The conversion must be carried out in compliance with these instructions and the appropriate adjustments (e.g.

LAV adjustment) or adaptations made (e.g. change in the layout of the exhaust pipe) and taking those

precautions (e.g. adherence to the minimum rear axle load with unladen vehicle) which are normally taken by

IVECO for the corresponding original wheelbases.

Cross Members

The necessity of applying one or more cross members depends on the extent of extension, the location of

the transmission shaft support, the welding area, the introduction points of the forces produced by the body

and the condition under which the vehicle is to be used.

Any supplementary cross members must have the same features as those already existing (flexural strength,

torsional strength, quality of the material, connection to the side members, etc). Fig. 2.6 shows an example of

the application on the models of class 80 or higher of the On-Road Range. A cross member is mandatory for

any extension over 600 mm.

As a general rule the distance between the two cross members must not be greater than 1,000 to 1,200 mm.

The minimum distance between the two cross members particularly for off-road vehicles must not be less than

600 mm. The light cross member supporting the transmission is excluded from this limitation.

Figure 2.6

Chassis modifications

2-15

Page 48

Recommended Procedure

To ensure the success of the operations proceed as follows:

- Arrange the vehicle so that the chassis is perfectly level, using the appropriate stands.

- Remove the transmission shafts, brake lines, electrical wires and any devices that may prevent the work from

being carried out efficiently.

- Identify the reference points on the chassis (e.g. pilot holes, suspension supports).

- Mark the reference points with a light line of punch marks on the top flange on both side members after

ensuring that their joining line is perfectly at right-angles to the longitudinal axis of the vehicle.

- When re-positioning the spring hanger brackets, identify the new position using the reference marks made

previously.

Check that the new measurements are identical between the left and right sides. Differences no greater than

2 mm should emerge from diagonal checking of the lengths less than 1,500 mm.

Unless another tool is available, make new holes by using the supports and gussets of the cross members

as a template.

Fix the supports and cross members with rivets or bolts. If using bolts, fix the supports by reaming the holes

and using class 10.9 calibratedbolts with nuts equipped with a device that prevents them from working loose.

When space permits it use flanged-head screws and nuts.

- If cutting the chassis, make a second line of reference points so that the area affected by the modification

is included between these and the previous points (in any event ensure a distance of not less than 1500 mm.

measured when the work has been completed). Inside these two reference lines make points to mark out

the area of the cut then proceed as indicated in point 2.2.4.

Before welding, ensure that the side members, including any added portion, are perfectly aligned and take

measurements on both sides and diagonally to check, as previously described. Fit the reinforcements as

instructed at Point 2.2.4.

Further indications

- Protect the surfaces from oxidation as described in point 2.1.3.

- Restore the electrical and braking systems as described in points 2.14 and 2.15.

For vehicles with anti-lock brake systems (ABS) follow the instructions given in point 2.14.3.

- For work on the drive line follow the instructions given in point 2.3.2.

2-16

Chassis modifications

Page 49

2.3.2 Modifying the Drive Line

Following the modification of the wheelbase, work on the transmission as a general rule, is carried out on

the basis of the transmission of a similar vehicle with approximately the same wheelbase. The maximum value

of the inclinations of the propeller shafts used for standard production vehicles is to be retained. This rule must

also be applied when any modifications to the suspension and rear drive axles are made.

In cases of particular difficulty, the assistance of the company may be sought. A diagram giving the length and

inclination of the proposed new transmission must accompany the request.

The purpose of the specifications contained in this manual is to ensure the proper functioning of the

transmission, to limit its noise and to avoid the build-up of stress transmitted from the engine assembly. In no

way does this diminish the responsibility of the bodybuilder for the work he has completed.

Permitted lengths

The maximum operating lengths obtainable for both the intermediate shaft sections and the sliding shafts

”LG” or ”LZ” (see fig.2.7) can be determined according to the external diameter of the tube existing on the

vehicle and the maximum operating rotational speed (see formula). These are specified in table 2.2.

For the propeller shaft length specified in Table 2.2. when the tube diameter is not sufficient, a new shaft section

with the same characteristics as the existing shafts must be used. As an alternative, in some cases the

transmission shaft with a larger diameter tube can be used. The tube diameter required can be determined

in compliance with the required length and the maximum rotational speed, directly from table 2.2.

Figure 2.7

Intermediate