Page 1

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

Iveco Trakker Euro 4/5 Fault Codes List

See also:

▪ Iveco Stralis Fault Codes List

▪ Iveco Workshop Manuals PDF

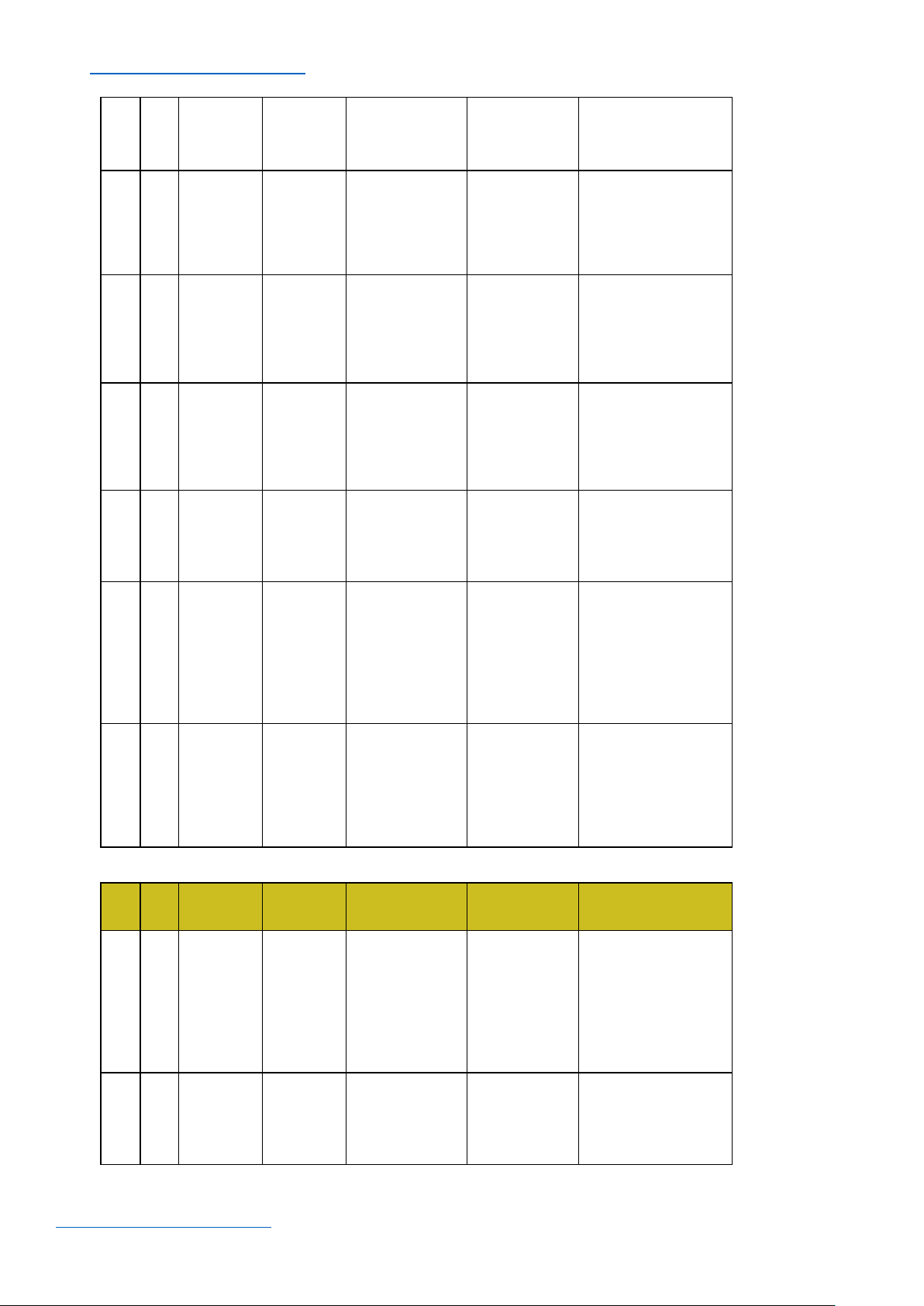

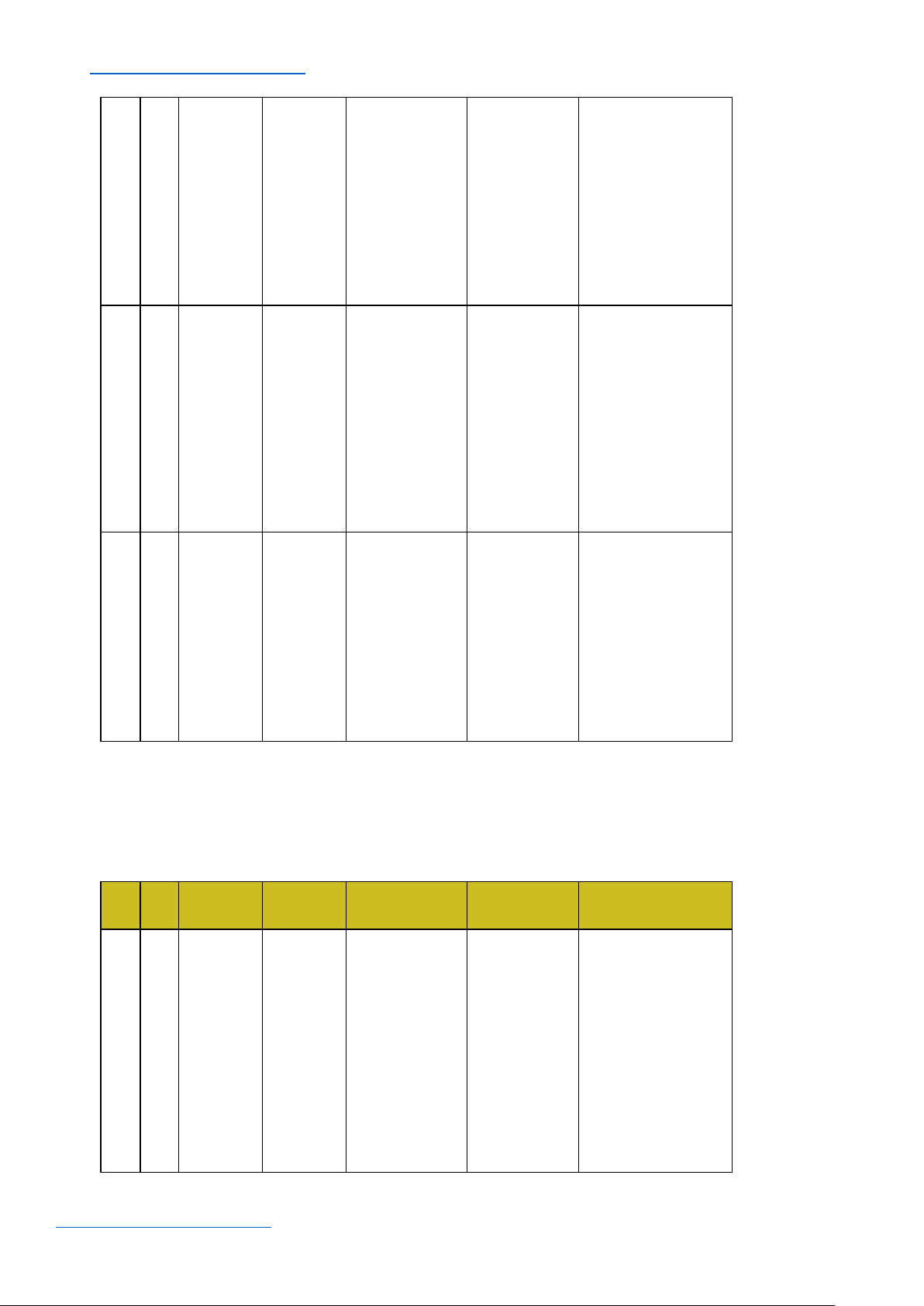

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

113

Acceler

ator

pedal/ brake

pedal suspect

Vehicle acceleration

very slow. Engine

idle speed: 500 rpm.

Accelerator pedal

and brake pressed

simultaneously (for

too long);

Accelerator pedal

blocked or faulty;

Incorrect use of

vehicle.

Check the accelerator pedal

signal and pedal mechanical

movement.

116

Clutch

signal

suspect

The parameter

reading shows that

the clutch is pressed.

Clutch switch faulty

or wiring problems in

pedal.

Check clutch pedal

switch and wiring.

117

Brake pedal

signal

error

Slight power reduction

Main and

secondary brake

switch not

synchronised. One

of the two brake

pedal switches may

be stuck.

Check the synchronisation of

both switches (signal) and

wiring.

119

Plausibil

ity +

15

Possible mechanical

problem (in pawl) or

electrical problem.

Check wiring.

121

Speed limiter w

/ light

Warning light

permanently off.

Short circuit or

defective wiring.

Check wiring.

122

Warning light

ODB

Warning light

permanently off.

Short circuit or

defective wiring.

Check wiring.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

Page 2

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

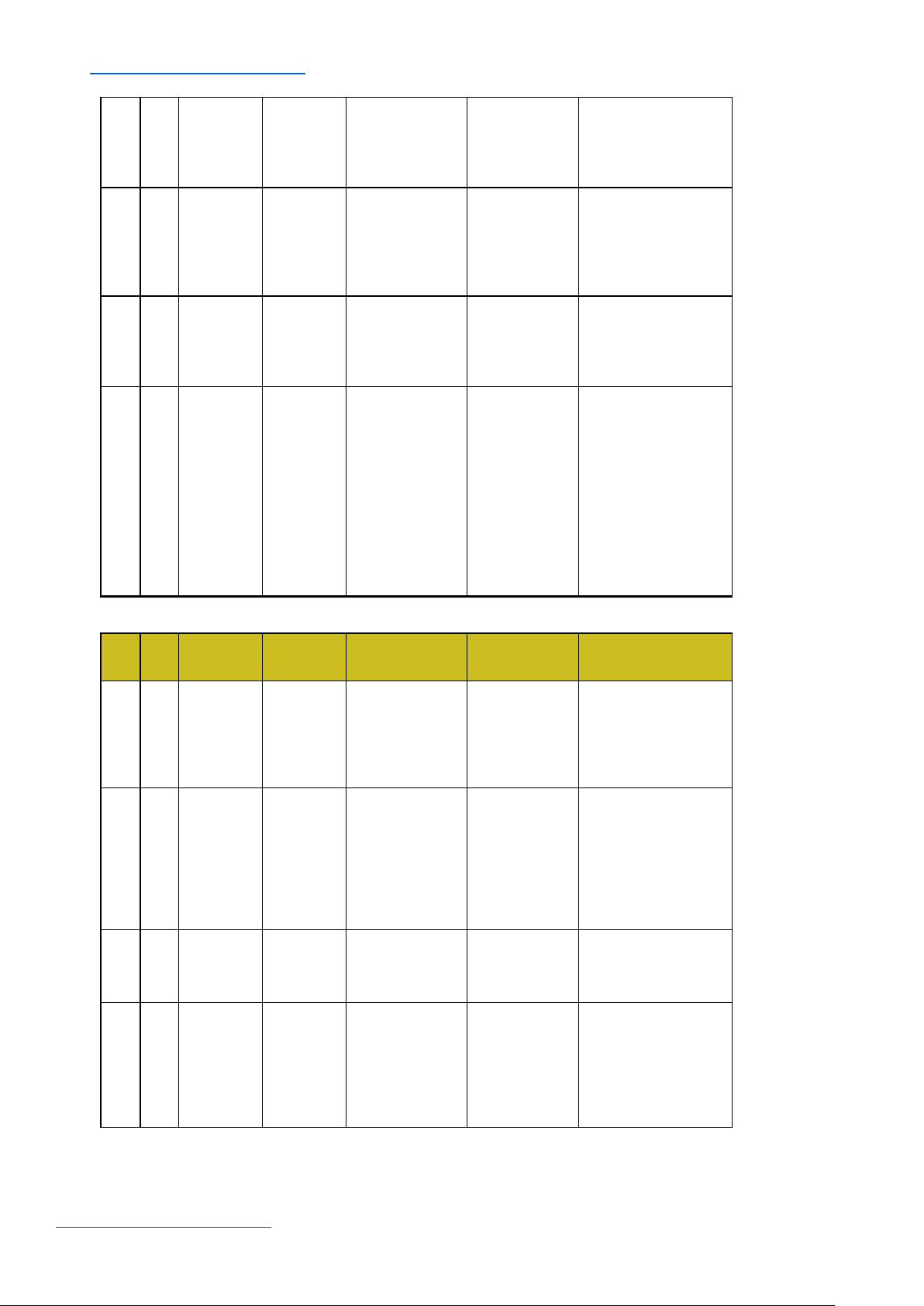

123

Edc lamp

Warning light

permanently off.

Short circuit or

defective wiring.

Check wiring.

124

Cold

start

lamp

Warning light

permanently off.

Short circuit or

defective wiring.

Check wiring.

125

Main relay

defect

Possible problems

during after-run.

Relay short circuit

to battery positive or

ground.

Check wiring between ECM

and battery.

Replace relay if necessary.

126

Battery voltage

Possible problems

during after-run.

Alternator or battery

defective. Possible

wiring problem.

Check wiring.

Replace alternator

regulator or battery

Replace the alternator if

necessary.

127

Engine brake

electro

valve

Engine brake not

operational.

Relay or wiring

short-circuited or

interrupted.

Check wiring.

Replace relay if necessary.

128

Main relay short circuit to

battery

Possible problems

during after-run.

Relay short circuit

to battery positive or

ground.

Relay may be faulty.

Check wiring between ECM

and battery.

Replace relay if necessary.

129

Air

conditioner

com

pressor

relay

Possible problems

during after run.

Relay short circuit

to battery positive or

ground.

Relay may be

faulty.

Check wiring between ECM

and battery.

Replace relay if necessary.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

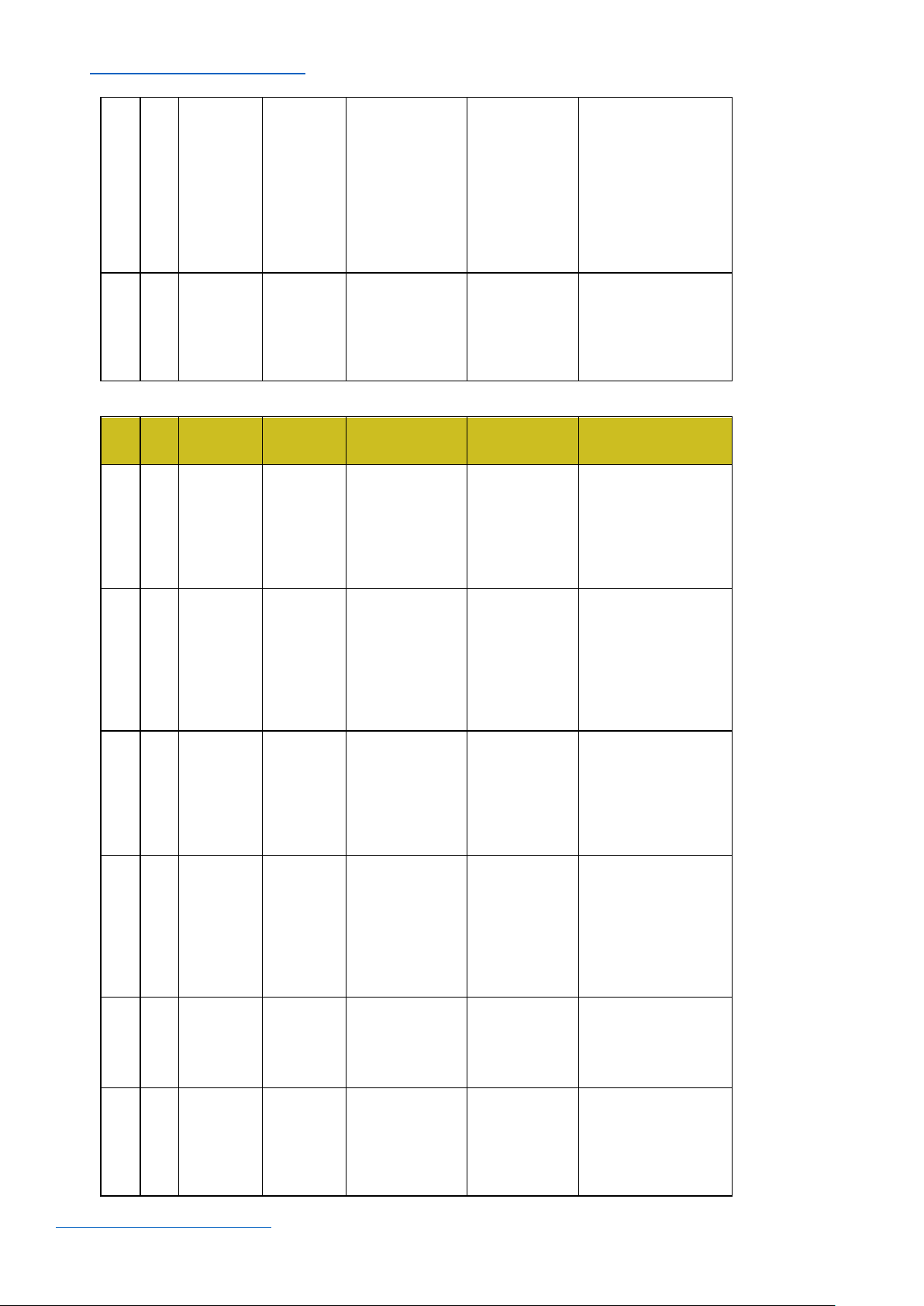

12A

Relays for

engine brake

valve

Possible problems

during after run.

Relay short circuit

to battery positive or

ground.

Relay may be faulty.

Check wiring between ECM

and battery.

Replace relay if necessary.

12B

Thermostarter

relay 1

(heater)

Heater not working.

Relay or wiring

short circuited or

interrupted.

Check wiring.

Replace relay if necessary.

Page 3

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

12C

Thermostarter

relay 2

Heater not working.

Relay or wiring

short circuited or

interrupted.

Check wiring.

Replace relay if necessary.

12E

Manageme nt

system

pre/

post heating

(active)

Grid heater

permanently

operating.

Grid heater short

circuited to ground.

Check wiring and

component.

131

Coolant

tem

perature

sensor

No reaction noticeable

on behalf of the

driver.

Sensor short circuited or value

implausible.

Check the wiring. Replace

sensor if necessary.

132

Coolant

tem

perature

sensor (test)

Slight power

reduction.

Operation in extreme

environmental

conditions or sensor

inaccurate.

Ensure the engine is not

working in extreme

environmental conditions.

Check the wiring and the

sensor accuracy.

Replace sensor if necessary.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

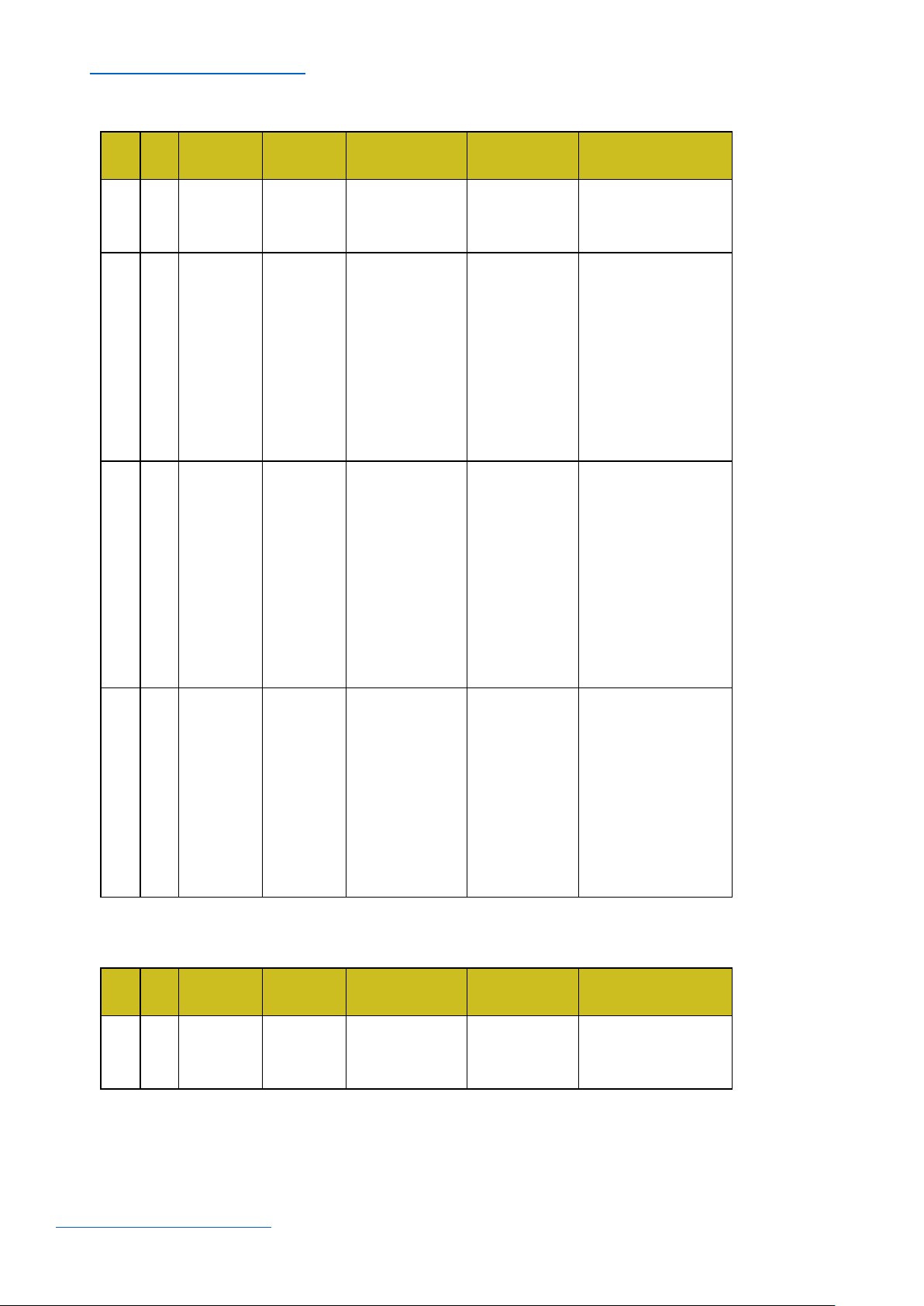

133

Air

tem

perature

sensor boost

air

Slight power reduction.

Sensor short

circuited or value

implausible.

Check the wiring. Re- place

sensor if necessary.

134

Boost

pressure

sensor

No reaction

perceivable by the

driver.

Parameter recov

ery

value: 2700 mbar.

Sensor short

circuited or

difference between

environmental

pressure and turbo

pressure

implausible.

Check the wiring. Also

check the environ- mental

pressure sensor. Replace

sensor if necessary.

135

Fuel

tem

perature

sensor

Slight power reduction.

Sensor shortcircuited or value

implausible.

Check the wiring. Re- place

sensor if necessary.

138

Oil pressure

sensor

No reaction

perceivable by the

driver.

Parameter recov

ery

value: 3000 mbar.

Sensor shortcircuited or value

implausible.

Check the wiring and oil level.

Replace sensor

if

necessary.

Page 4

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

13A

Oil tem

perature

sensor

No reaction

perceivable by the

driver.

Parameter recovery

value: coolant

temperature value

(if intact) otherwise

120 C).

Sensor shortcircuited or value

implausible.

Check the wiring. Replace

sensor if necessary.

13C

Atmospheric

temperature

sensor

(humidtiy?)

No reaction

perceivable by the

driver.

Parameter recovery

value: 40 C.

Sensor shortcircuited or value

implausible.

Check the wiring. Replace

sensor if necessary.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

141

Crank

shaft

speed

No reaction noticeable

on behalf of the

driver.

Signal interrupted or

wiring problem.

Sensor installation

may not be correct.

Check wiring and installation.

Replace sensor

if

necessary.

142

Engine

working only

With

camshaft

sensor

No reaction

perceivable by the

driver.

Signal interrupted or

wiring problem.

Sensor installation

may no t be correct.

Check wiring and installation.

Replace sensor if

necessary.

143

Camshaft

sensor

No reaction

perceivable by the

driver.

Signal interrupted or

wiring problem.

Sensor installation

may no t be correct.

Check wiring and installation.

Replace sensor

if

necessary.

144

Fault between

fly-Wheel

sensor and

camshaft

No reaction noticeable

on behalf of the

driver.

Signal interrupted or

wiring problem.

Flywheel and timing

sensor installation

may be incorrect.

Check wiring and installation

of both sensors.

145

Fan

relay

No reaction

perceivable by the

driver.

Fan off.

Short circuit or fan

actuator faulty.

Check the wiring and the

fan actuator.

Replace the actuator if

necessary.

148

Air

conditioner

com

pressor

relay

Air conditioner

permanently off.

Wiring or relay

short-circuited.

Check the wiring. Replace

relay if necessary.

Page 5

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

149

Preheating relay

fuel

Filter

Filter heater not

working.

Wiring or filter

heater shortcircuited.

Check the wiring. Re- place

the filter heater if necessary.

151

Injecto

r

cylinder

1

The engine runs on 5

cylinders.

Injector no.1

electric trouble.

Check correct tightness to

torque of the connectors on

the solenoid valve of the

injector (1.36 - 1.92 Nm).

Check

the integrity of the

injector coil and replace the

injector if defective. If the coil is

integral, check the wiring

between the solenoid valve and

EDC -con

nector.

152

Injecto

r

cylinder

2

The engine runs on 5

cylinders.

Injector no.2

electric trouble.

Check correct tightness to

torque of the connectors on

the solenoid valve of the

injector (1.36 - 1.92 Nm).

Check

the integrity of the

injector coil and replace the

injector if defective. If the

coil is integral, check the

wiring between the solenoid

valve and EDC connector.

153

Injecto

r

cylinder

3

The engine runs on 5

cylinders.

Injector no.3

electric trouble

Check correct tightness to

torque of the connectors on

the solenoid valve of the

injector (1.36 - 1.92 Nm).

Check

the integrity of the

injector coil and replace the

injector if defective. If the coil

is integral, check the wiring

between the solenoid valve

and EDC con

nector.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

149

Pre-heating

relay

fuel

Filter

Filter heater not

working.

Wiring or filter

heater shortcircuited.

Check the wiring. Replace the

filter heater if necessary.

Page 6

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

151

Injecto

r

cylinder

1

The engine runs on 5

cylinders.

Injector no.1

electric trouble.

Check correct tightness to

torque of the connectors on

the solenoid valve of the

injector (1.36 - 1.92 Nm).

Check

the integrity of the

injector coil and replace the

injector if defective. If the coil is

integral, check the wiring

between the solenoid valve and

EDC- con

nector.

152

Injecto

r

cylinder

2

The engine runs on 5

cylinders.

Injector no.2

electric trouble.

Check correct tightness to

torque of the connectors on

the solenoid valve of the

injector (1.36 - 1.92 Nm).

Check

the integrity of the

injector coil and replace the

injector if defective. If the

coil is integral, check the

wiring be- tween the

solenoid valve and EDCconnector.

153

Injecto

r

cylinder

3

The engine runs on 5

cylinders.

Injector no.3

electric trouble

Check correct tightness to

torque of the connectors on

the solenoid valve of the

injector (1.36 - 1.92 Nm).

Check

the integrity of the

injector coil and replace the

injector if defective. If the coil

is integral, check the wiring

between the solenoid valve

and EDC-con

nector.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

154

Injector

Cylinder 4

The engine runs

on 5 cylinders

Injector no.4

electric trouble

Check correct tightness to

torque of the connectors on

the solenoid

valve of the

injector

(1.36 - 1.92 Nm).

Check

the integrity of the

in

jector coil and replace

the

injector if defective. If the coil

is integral,

check the wiring

between the solenoid

valve and EDC connector.

Page 7

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

155

Injector

Cylinder 5

The engine runs on 5

cylinders

Injector no.5

electric

trouble

Check correct tightness to

torque of the connectors on

the solenoid

valve of the

injector

(1.36 - 1.92 Nm).

Check

the integrity of the

in

jector coil and replace

the

injector if defective. If the coil

is integral,

check the wiring

between the solenoid valve

and EDC connector.

156

Injector

Cylinder 6

The engine runs on 5

cylinders

Injector no.6

electric

trouble

Check correct tightness to

torque of the connectors on

the solenoid

valve of the

injector

(1.36 - 1.92 Nm).

Check

the integrity of the

in

jector coil and replace

the

injector if defective. If the coil

is integral,

check the wiring

between the solenoid valve

and EDC connector.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

161

Injector

Cylinder

1 /

short

-Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible short

-circuit

in con

nections.

Poss

ible problem in

Injector coil .

Possible

problem in control

unit.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

162

Injector

Cylinder

2 /

short

-Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible short

-circuit

in con

nections.

Poss

ible problem in

injector coil .

Possible

problem in control

unit.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

163

Injector

Cylinder

3 /

short

-Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible short

circuit

in con

nections.

Poss

ible problem in

injector coil .

Possible

problem in control

unit.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

Page 8

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

164

Injector

Cylinder

4 /

short

-Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible short

-circuit

in con

nections.

Poss

ible problem in

injector coil .

Possible

problem in control

unit.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

165

Injector

Cylinder

5 /

short

-Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible short

circuit

in con

nections.

Poss

ible problem in

injector coil .

Possible

problem in control

unit.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

166

Injector

Cylinder

6 /

short

-Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible short

-circuit

in connections.

Possible prob

lem in

injector coil.

Possible

problem in control

unit.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

167

Injector

Cylinder

1 /

open

circuit

One or more in

jectors

(bank 1 or

bank 2) not

oper

ating.

Possible injector

Connection problem

(or disconnected

inter

nally).

Possible

problem in control

unit (capacitor).

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

168

Injector

Cylinder

2 / open

Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible injector

connection problem

(or disconnected

inter

nally).

Possible

problem in control

unit (capacitor).

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

169

Injector

Cylinder

3 / open

Circuit

One or more in

jectors

(bank 1 or bank 2) not

oper

ating.

Possible injector

connection problem

(or disconnected

inter

nally).

Possible

problem in control

unit (capacitor).

Check wiring. Possible internal

problem also in ECM. Replace

the injector if

necessary.

Page 9

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

16A

Injecto

r

cylinder 4 /

open circuit

One or more injectors

(bank 1 or bank 2) not

operating.

Possible injector

connection problem

(or disconnected

internally).

Possible

problem in control

unit (capacitor).

Check wiring. Possible internal

problem also in ECM. Replace

the injector if necessary.

16B

Injecto

r

cylinder 5 /

open

Circuit

One or more injectors

(bank 1 or bank 2) not

operating.

Possible injector

connection problem

(or dis

connected

internally). Possible

problem in control

unit (capacitor).

Check wiring. Possible internal

problem also in ECM. Replace

the injector if necessary.

16C

Injecto

r

cylinder 6 /

open circuit

One or more injectors

(bank 1 or bank 2) not

operating.

Possible injector

connection problem

(or disconnected

internally). Possible

prob

lem in control

unit (capacitor).

Check wiring. Possible internal

problem also in ECM. Replace

the injector if necessary.

16D

Compression

test in progress

Compression Test

in progress.

After carrying out the

compression test, turn the

key OFF (after-run).

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

16E

The minimum

number of

injections

Was not

reached: stop

the Engine

More than 2 injectors

not operating.

See individual faults in

injectors.

Page 10

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

171

Bench 1 cc

One or more injectors

(bank 1 or bank 2) not

operating.

Possible injector

connection problem.

Injectors shortcircuited.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if necessary.

173

Bench 2 cc

One or more injectors

(bank 1 or bank 2) not

operating.

Possible injector

connection problem.

Injectors shortcircuited.

Check wiring. Possible internal

problem also in ECM. Replace

the injector if necessary.

17C

Bench 1

injectors

check (internal

ecu)

One or more injectors

(bank 1 or bank 2)

may not be operating.

Fault in control unit.

Replace the engine

control unit.

189

Egr power St.

Short To batt.

No fault perceived by

the driver.

EGR not

working.

Short circuit or EGR

actuator faulty.

Check wiring.

Replace the EGR actuator if

necessary.

191

Turbine

actuator

control

Electro-

valve

Poor

perform

ance

VGT actuator or

wiring defective.

Check VGT wiring and

actuator.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

192

TURBINE

ACTUATO

R

CON

TROL

ELECTROVALVE

SHORT

CIRCUIT

TO

POSI

TIVE

Poor performance

VGT actuator or

wiring defective.

Check VGT wiring and

actuator.

193

TURBINE

WHEEL

REVS

SENSOR

Poor performance

Air filter blocked

or turbine rpm

sensor signal

implausible.

Check the air filter and

check parameters linked

with the turbine by

performing a road test

(parameter acquisi

tion).

Page 11

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

198

FAULT ON

AT LEAST

TWO OF

THE

FOLLOWIN

G

SENSORS:

TURBINE

SPEED,

BOOT

PRESSUR

AND

EX

HAUST

GAS

PRESSURE

Poor performance

Sensor signal

implausible.

Sensor may be

faulty.

Determine which tur

bine

component caused the

problem.

199

TURBOCHARGER

CON

TRO

BOOST

PRESSURE

FAILURE

(PCR)

Poor performance

Turbo sensor or

actuator may be

faulty. Air filter

may be blocked.

Check turbine sensors

and actuator (para

meter

acquisition). Check

whether air filter

is

blocked.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

19A

TURBINE

SPEED

EXCEEDING

EVERY

PER

MITTED

RANGE

Poor

perform

ance

Turbo sensor or

actuator may be

faulty.

Air filter may

be blocked.

Check turbine sensors and

actuator (parameter

acquisition). Check whether

air filter

is blocked.

19B

TURBINE IN

OVERSPEED

(THE FAULT

IS

NOT

DISPLAYED

IF IT IS

CAUSED BY

A LOW

ATMOSPERI

C PRESSURE)

Poor

perform

ance

Air filter blocked or

turbine rpm sensor

signal implausible.

Check the air filter and

check parameters linked

with the turbine by

performing a road test

(parameter acquisition).

19F

NOx SENSOR

ERROR

No effect perceived by

the driver.

Sensor signal

implausible.

Nox

sensor may

be

faulty.

Check the Nox sensor.

1A5

TIMEOUT

OF CAN

MESSAGE

DM1DCU

No effect perceived by

the driver.

Problems in the

Denoxtronic (on the

CAN

line).

Check wiring.

Check and correct any faults

in the Denoxtronic control

unit.

Page 12

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

1A6

TIMEOUT

OF CAN

MESSAGE

SCR1

No effect perceived by

the driver.

CAN configuration

incorrect. CAN

connection

defective. Terminal

resistance not suit-

able.

Check CAN line wiring.

Check Denoxtronic control

unit wiring and operation.

1AE

HUMIDITY

SENSOR

No effect perceived

by the

driver.

Sensor shortcircuited or faulty.

Check wiring Replace sensor

if

necessary.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

1AF SERIOUSE

OBD FAULT

FROM

DE

NOX

TRON

IC (EOBD

FLASHING

LIGHT)

No effect per

ceived by

the

driver.

Problems in Ad

Blue

dosing sys

tem.

Check the faults in the

Denoxtronic and con

sult the

control unit

troubleshooting

guide.

1B1 ERROR

ON

CAN

CON

TROLLE

R A

No effect per

ceived by

the

driver.

CAN configuration

incorrect. CAN

connec

tions

defective. Terminal

resis

tance not

suit

able.

Check CAN line wiring. Check

terminal resis

tances.

1B2 ERROR

ONCAN

CON

TROLLE

R B

No effect per

ceived by

the

driver.

CAN configuration

incorrect. CAN

connec

tions

defective. Terminal

resis

tance not

suit

able.

Check CAN line wiring. Check

terminal resis

tances.

1B3 ERROR

ON

CAN

CON

TROLLE

R C

No effect per

ceived by

the

driver.

CAN configuration

incorrect. CAN

connec

tions

defective. Terminal

resis

tance not

suit

able.

Check CAN line wiring. Check

terminal resis

tances.

1B4 TIMEOUT

CAN

MESSAGE

BC2EDC1

No effect per

ceived by

the

driver.

CAN configuration

incorrect. CAN

connec

tions

defective. Terminal

resis

tance not

suit

able.

Check CAN line wiring.

Check BC wiring and

operation.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

Page 13

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

1B5

TIMEOUT

CAN

MESSAGE

VM2EDC

No effect perceived

by the driver.

CAN configuration

incorrect. CAN

connections

defective.

Terminal resistance

not suitable.

Check CAN line wiring.

Check VCM wiring and

operation.

1B7

ERROR ON

MESSAGES

CAN IN

TRANSMISSI

ON

No effect perceived

by the driver.

CAN configuration

incorrect. CAN

connections

defective.

Terminal resistance

not suitable.

Check CAN line wiring.

Check ECM wiring and

operation.

1B9

ERROR ON

THE EOBD

LIGHT

MANAGED

BY THE

CLUSTER)

No effect perceived

by the driver.

MIL/Body Controller

warning light

defective.

Consult the Body Controller

troubleshooting guide and

check the CAN line.

1BA

TIMEOUT

CAN

MESSAGE

DASH

DISPLAY

No effect perceived

by the driver.

CAN messages from

VCM inconsistent.

Consult the VCM

troubleshooting guide and

check the CAN line.

1BC

TIMEOUT

CAN

MESSAGE

AMB

COND

No effect perceived

by the driver.

CAN messages from

VCM in- consistent.

Consult the VCM

troubleshooting guide and

check the CAN line.

1BD

TIMEOUT

CAN

MESSAGE

CCVS

No effect perceived

by the driver.

CAN messages from

VCM or BC

inconsistent.

Consult the VCM /BC

troubleshooting guide and

check the CAN line.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

1C2

ERROR

MESSAGE

CAN ETC1

No effect perceived

by the driver.

CAN messages from

ETC (gearbox)

inconsistent.

Check the ETC connection

with the CAN line.

1C3

TIMEOUT IN

RECEIVING

TC01 CAN

MESSAGE

No effect perceived

by the driver.

CAN messages

from TCO inconsistent.

Check the TCO connection

with the CAN line.

1C6

ERROR

MESSAGE

CAN

TSC1PE

No effect perceived

by the driver.

CAN messages from

TCU (Transmission

Control Unit)

inconsistent.

Check the TCU connection

with the CAN line.

Page 14

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

1C8

ERROR

MESSAGE

CAN

TSC1VE

No effect perceived

by the driver.

CAN messages from

TCU (Transmission

Control Unit)

inconsistent.

Check the TCU connection

with the CAN line.

1D1

ECU

OVERRUN

MONITORIN

G ERROR

No effect perceived

by the driver.

Electrical

interference or

internal control unit

problems.

If the error persists to replace

ECU.

1D2

ECU

OVERRUN

MONITORIN

G ERROR

No effect perceived

by the driver.

Poor control

unit

programming/flash

Possible internal fault.

Reprogram the central unit. If

the error is repeated, replace

the central unit, if needed.

1D3

ECU

OVERRUN

MONITORIN

G ERROR

No effect perceived

by the driver.

Poor control

unit

programming/flash

Possible internal fault.

Reprogram the central unit. If

the error is repeated, replace

the central unit, if needed.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

1D4

ECU

OVERRUN

MONITORIN

G ERROR

No effect perceived by

the driver.

Ecu internal failure.

If the error persists to replace

ECU.

1D5

ECU

OVERRUN

MONITORING

ERROR

No effect perceived by

the driver.

Ecu internal failure.

If the error persists to replace

ECU.

1D6

ECU

INTERNAL

ERROR

(TPU)

Control unit

deactivation.

Electronic

interference or

control unit faulty.

If the error persists to replace

ECU.

1D8

ECU

OVERRUN

MONI

TORING

ERROR

No effect perceived by

the driver.

Ecu internal failure.

If the error persists to replace

ECU.

1E2

IMMOBIL

IZE

R

The engine fails to start.

Problem in CAN line

or immobiliser

control unit.

Check the Immobiliser control

unit is correctly connected.

Enter the Immobiliser PIN

code during the emergency

procedure.

Page 15

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

1E3

ERROR FOR

ECU

INTERNAL

MONI

TORING

No effect perceived by

the driver.

Ecu internal failure.

If the error persists to replace

ECU.

1E4

ERROR FOR

ECU

INTERNAL

MONITORIN

G

No effect perceived by

the driver.

Ecu internal failure.

If the error persists to replace

ECU.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible

Cause

Repair action

1E5 SENSORS

POWER

SUPPLY

FAULT

(12V)

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem.

Check battery voltage or

connections with

the ECM.

Replace the control

unit if

necessary.

1E6 SENSOR

POWER

SUPPLY 1

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem

Check battery voltage or

connections with

the ECM.

Replace the control

unit if

necessary.

1E7 SENSOR

POWER

SUPPLY 2

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem

Check battery voltage or

connections with

the ECM.

Check ECU, if required.

1E8 SENSOR

POWER

SUPPLY 3

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem

Check battery voltage or

connections with

the ECM.

Replace the control

unit if

necessary.

1E9 ECU

OVERRUN

MONITORIN

ERROR

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem

Check battery voltage or

connections with

the ECM.

Replace the control

unit if

necessary.

1EA ECU

OVERRUN

MONITORIN

ERROR

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem

Check battery voltage or

connections with

the ECM.

Replace the control

unit if

necessary.

1EB ATMOSPHERI

C PRESSURE

SENSOR

No effect per

ceived by

the driver.

Excessive/insufficient

Battery voltage or

poss

ible internal

control unit problem

Change ECU.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

Page 16

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

1FA TOO

HIGH

NUMBER OF

REGENERATI

ONS DEMAND

No reaction

per

ceivable by

the

driver.

Too many filter

regenerations carried

out.

Particulate filter

may

be blocked.

Check filter.

1FB PERMANENT

RIGENERATI

ON

ON TRAP

PARTICLE

No reaction

per

ceivable by

the

driver.

Catalytic con

verter

not installed or

dam

aged.

Check

catalytic

con

verter

visually.

1FC FIRST

SENSOR

EXAUSTED

GAS

TEMPERATUR

E

No reaction

per

ceivable by

the

driver.

Temperature sensors

damaged or

incor

rectly fitted.

Check information and

condition of sensors.

21F TOO

HIGH

EFFICIENCY

OF

CATA

LYST

SYSTEM

No reaction no

ticeable

on behalf

of the driver.

Actuator coil faulty

or not

within

specified tolerance

limits.

Check actuator condi

tion.

225

INTERRUPTE

D

AFTER

RUN

Slight power re

duction.

The control unit

is

turned off by

the

general

switch instead

of by the key (k15).

Possible prob

lem in

main relay

or

connections.

Check wiring and then

replace the main relay.

228

MAIN RELAY

–

SHORT

CIRCUIT TO

GROUND

Slight power re

duction.

Short circuit in main

relay or relay faulty.

Check wiring between

battery and ECM and then

replace the main

relay.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

232

COOLANT

TEM

PERATU

RE

SENSOR

ABSOLUTE

TEST

Slight power reduction

Extreme

envi

ronmental

conditions or

sensor incorrectly

adjusted.

Ensure the engine is working

in non-critical conditions.

Check the sensor

connections and accuracy.

Replace sensor if necessary.

238

OIL LOW

PRESSURE

Slight power reduction

Sensor incorrectly

adjusted or faults in

lubrication system.

Check the sensor

connections and accuracy.

Check the lubrication

system.

Page 17

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

23A

OIL

TEM

PERATU

RE

ABOVE

NORMAL

Slight power reduction

Sensor incorrectly

adjusted or faults in

lubrication system.

Check the sensor

connections and accuracy.

Check the lubrication

system.

27C

BENCH 2

INJECTORS

CHECK

(INTERNAL

ECU)

One or more injectors

(bank 1 or bank 2)

may not be operating

Fault in control unit.

Replace the engine

control unit.

292

TURBINE

ACTUATO

R

CONTROL

ELECTRO

VA

LVE SHORT

CIRCUIT TO

GROUND

Poor

perform

ance

VGT actuator or

wiring defective.

Check VGT wiring and

actuator.

2A6

TIMEOUT

OF CAN

MESSAGE

SCR2

No effect perceived

by the driver

Problem in the

Denoxtronic

(on the CAN line).

Check the faults in the

Denoxtronic and consult the

control unit troubleshooting

guide. Check wiring.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

2AF

SERIOUS

EOBD

FAULT

FROM

DENOXTRO

NIC (EOBD

FLASHING

LIGHT)

No effect perceived

by the driver.

Problems in AdBlue

dosing system.

Check the faults in the

Denoxtronic and consult the

control unit troubleshooting

guide.

2B4

TIMEOUT

CAN

MESSAGE

BC2EDC2

No effect perceived by

the driver.

CAN configuration

incorrect. CAN

connections

defective.

Terminal resistance

not suitable.

Check CAN line wiring.

Check BC wiring and

operation.

2C6

TIMEOUT

OF CAN

MESSAGE

TSC1-PE

PASSIVE

No effect perceived by

the driver.

CAN messages from

TCU (Transmission

Control Unit)

inconsistent.

Check the TCU connection

with the CAN line.

2C8

ERROR

MESSAGE

CAN

TSC1VR

No effect perceived by

the driver.

CAN messages from

TCU (Transmission

Control Unit)

inconsistent.

Check the TCU connection

with the CAN line.

Page 18

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

2C9

ERROR

MESSAGE

CAN

TIMEDATE

No effect perceived by

the driver.

CAN messages

from TC

(tachograph)

inconsistent.

Check the tachograph

connection with the CAN

line.

2D3

ECU

OVERRUN

MONITORIN

G ERROR

No effect perceived by

the driver.

Poor control

unit

programming/flash

Possible internal fault.

Reprogram the central unit. If

the error is repeated, replace

the central unit, if needed.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

2FF ERROR

CHECK OF

CRITICAL

TIME

FOR OIL

DILUTION

Slight power reduction

Oil overdiluted.

Change the engine oil .

392

TURBINE

ACTUATOR

CON

TROL

ELECTROVALVE

Poor performance

Connection

damaged. Battery

voltage excessive

(ECU overheating).

Check VGT connection and

actuator.

3AF SERIOUSE

OBD FAULT

FROM

DE

NOX

TRON

IC (EOBD

FLASHING

LIGHT)

No effect per

ceived

by the

driver.

Problems in Ad

Blue

dosing sys

tem.

Check the faults in the

Denoxtronic and con

sult the

control

unit troubleshooting

guide.

3C8

TIMEOUT OF

CAN

MESSAGE

TSC1-VE

PASSIVE

No effect per

ceived

by the

driver.

CAN messages from

TCU

(Transmission

Control Unit)

inconsistent.

Check the TCU con

nection

with the CAN

line.

3C9

ERROR

MESSAGE

CAN

HRDV

No effect per

ceived

by the

driver.

CAN configuration

incorrect. CAN

connec

tions

defective. Terminal

resis

tance not

suit

able.

Check CAN line wiring.

Check BC wiring and

operation.

3D3

ECU

OVERRUN

MONITORING

ERROR

No effect per

ceived

by the

driver.

Poor control unit

program

ming/flash

Possible internal

fault.

Reprogram the central

unit. If

the error is re

peated, replace

the

central unit, if needed.

DTC

FMI

Failing

component

Type of

Failure

Visible failure

Possible Cause

Repair action

Page 19

Visit https://truckmanualshub.com/ for more information’s

https://truckmanualshub.com/

3FA

REGENERAT

ION

DEMAND

NUMBER 2

No effect perceived

by the driver.

Too many

regenerations

carried out.

Check particulate filter and

faults in sensors.

4AF

SERIOUSE

OBD FAULT

FROM

DENOXTRO

NIC (EOBD

FLASHING

LIGHT)

No effect perceived by

the driver.

Problems in AdBlue

dosing system.

Check the faults in the

Denoxtronic and consult the

control unit troubleshooting

guide.

4C8

TIMEOUT

OF CAN

MESSAGE

TSC1-VR

PASSIVE

No effect perceived by

the driver.

CAN messages from

TCU (Transmission

Control Unit)

inconsistent.

Check the TCU connection

with the CAN line.

4FA

REGENERAT

ION

DEMAND

NUMBER 3

No effect perceived by

the driver.

Too many

regenerations

carried out.

Check particulate filter and

faults in sensors.

5AF

DM1DCU

SPN5

MESSAGE

No effect perceived by

the driver.

Problems in AdBlue

dosing system.

Check the faults in the

Denoxtronic and consult the

control unit troubleshooting

guide.

Loading...

Loading...