HP 8903B Operation Manual

Agilent Technologies. Inc

24001

E

Mission

Liberty

take, WA

99019

www

agilent

corn

..

,

.':tis:.

.

Ag

i

I

en

t

Technologies

:

.

:

.

Innovating

the

HP

Way

.**e..

June

8,2000

Dear Customer,

As

of

November

1,1999,

four of Hewlett-Packard's businesses, test and measurement,

semiconductor products, health care solutions, and chemical analysis became a new company,

Agilent Technologies. Now, many of your Hewlett-Packard products and services are in the care

of

Agilent Technologies.

At Agilent Technologies, we are working diligently to make this transition as smooth as possible for

you. However, as a result of this transition, the products and related documentation contained in this

shipment may be labeled with either the Hewlett-Packard name and logo, the Agilent Technologies

name and logo, or a combination

of

both. Information in this package may refer to Hewlett-Packard

(HP), but applies to your Agilent Technologies product. Hewlett-Packard and Agiient branded

products with the same model number are interchangeable.

Whatever logo you see, the information, products, and services come from the same reliable source.

If

you have questions about Agilent Technologies products and services, please visit our website at

http://www. anilent.com.

Sincerely,

Rebranding

Team

HP

8903B

AUDIO

ANALYZER

(Including Option

001)

Operation and Calibration Manual

Operation and Calibration Manual HP Part 08903-90079

Other Documents Available:

Service Manual (Volume

1,

2)

HP Part 08903-90062

Microfiche Operation and Service Manual HP Part 08903-90080

Printed in U.S.A.

:

November 1989

SERIAL

NUMBERS

This

manual applies directly to instruments with

serial numbers prefixed

2450A

to

2922A

and all

Mqior

changes that apply

to

your

instrument.

rev.ZOJUN91

For

additional important information about serial

numbers, refer

to

“INSTRUMENTS COVERED

BY

THIS

MANUAL’’

in Section

1.

Fourth Edition

This

material may be reproduced by

or

for the

US.

Government pursuant

to

the Copyright License

un-

der the clause at

DFARS

52.227-7013

(AF’R

1988).

Copyright

GHEWLETT-PACKARD COMPANY 1985

EAST 24001

MISSION

AVENUE, TAF C-34, SPOKANE, WASHINGTON, U.S.A. 99220

HEW

LETT@

PACKARD

1

Regulatory Information

(Updated

March

1999)

1

Regulatory

Information

(Updated

March

1999)

Safety Considerations

GENEFtAL

This product and related documentation must be reviewed for familiarization with safety

markings and instructions before operation.

This product has been designed and tested in accordance with

IEC

Publication

1010,

"Safety Requirements for Electronic Measuring Apparatus," and has been supplied in

a

safe condition. This instruction documentation contains information and warnings which

must be followed by the user

to

ensure safe operation and

to

maintain the product in a safe

condition.

SAFETY EARTH GROUND

A

uninterruptible safety earth ground must be provided from the main power source

to

the

product input wiring terminals, power cord,

or

supplied power cord set.

SAFETY

SYMBOLS

A

Indicates instrument damage can occur

if

indicated operating limits are exceeded.

A

Indicates hazardous voltages.

&

-

Indicates earth (ground) terminal

~~~~ ~

~ ~

WARNING

A

WARNING

note denotes a hazard. It calls attention to a procedure,

practice, or the like, which,

if

not correctly performed or adhered to,

could result in personal injury.

Do

not proceed beyond a

WARNING

sign until the indicated conditions are fully understood and met.

~

CAUTION

A

CAUTION note denotes a hazard. It calls attention

to

an operation

procedure, practice,

or

the like, which, if not correctly performed

or

adhered

to,

could result in damage

to

or

destruction

of

part

or

all of the product.

Do

not proceed beyond an CAUTION note until the indicated conditions are hlly

understood and met.

2

Chapter

1

Regulatory

Information

(Updated

March

1999)

Safety Considerations for this Instrument

WARNING

This product is

a

Safety Class

I

instrument (provided with

a

protective earthing ground incorporated in the power cord). The

mains plug shall only be inserted in

a

socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor inside or outside of the product is likely

to

make the

product dangerous. Intentional interruption

is

prohibited.

Whenever it

is

likely that the protection has been impaired, the

instrument must be made inoperative and be secured against any

unintended operation.

If

this instrument

is

to be energized

via

an auto transformer (for

voltage reduction), make sure the common terminal

is

connected

to

the earth terminal of the power source.

If

this product

is

not used as specified, the protection provided by

the equipment could be impaired. This product must be used in

a

normal condition (in which

all

means for protection are intact) only.

No

operator serviceable parts in this product. Refer servicing to

qualified personnel. To prevent electrical shock, do not remove

covers.

Servicing instructions are for use by qualified personnel only. To

avoid electrical

shock,

do not perform any servicing unless you are

qualified to do

so.

The opening

of

covers

or

removal of parts

is

likely to expose

dangerous voltages. Disconnect the product from

all

voltage sources

while it

is

being opened.

The power cord

is

connected to internal capacitors that

my

remain

live for

5

seconds after disconnecting the plug

from

its

power supply.

For Continued protection against fire hazard, replace the line fuse(s)

only with

250

V

fuse(s) or the same current rating and type (for

example, normal blow

or

time delay). Do not use repaired fuses or

short circuited fuseholders.

Always use the three-prong ac power cord supplied with this

product. Failure

to

ensure adequate earth grounding by not using

this cord may cause product damage.

This product

is

designed for use in Installation Category

I1

and

Pollution Degree

2

per

IEC

1010

and

IEC

664

respectively. FOR

INDOOR

USE

ONLY.

This product has autoranging line voltage input, be sure the supply

voltage is within the specified range.

~~~~

Chapter

1

3

Regulatory Information (Updated

March

1999)

To

prevent electrical shock, disconnect instrument from mains (line)

before cleaning. Use a dry cloth or one slightly dampened with water

to clean the external case parts.

Do

not attempt to clean internally.

Ventilation Requirements: When installing the product in a cabinet,

the convection into and out of the product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by

4"

C

for every

100

watts dissipated in the cabinet.

If

the total power dissipated in the

cabinet

is

greater than

800

watts, then forced convection must be

used.

Product

Markings

CE

-

the CE mark

is

a registered trademark

of

the European Community.

A

CE mark

accompanied by

a

year indicated the year the design was proven.

CSA

-

the

CSA

mark

is

a registered trademark

of

the Canadian Standards Association.

4

Chapter

1

CERTIFICATION

Hewlett-Packard Company certifies

that

this

product met

its

published specifications at

the

time of shipment

from

the factom. Hewlett-Packard further certifies that its calibration measurements are traceable to the

United States National Bureau of Standards, to the extent allowed

by

the

Bureau's calibration facility, and

to the calibration facilities of other International Standards Organization members.

WARRANTY

This Hewlett-Packard instrument product is warranted against defects

in

material and workmanship for a

period of one year from

date

of shipment. During the warranty period, Hewlett-Packard Company will at

its

option, either repair

or

replace products which prove

to

be defective.

For

warranty senrice

or

repair, this product must be returned

to

a service facility designated by HP. Buyer

shall prepay shipping charges to

HP

and HP shall pay shipping charges to return the product

to

the Buyer.

However, Buyer shall pay all shipping charges, duties, and taxes for products returned

to

HP from another

country.

HP warrants that its software and firmware designated by HP for use with an instrument will execute

its programming instructions when properly installed on that instrument. HP does not warrant that the

operation of the instrument,

or

sohare,

or

firmware will be uninterrupted

or

error free.

LIMITATION

OF

WARRANTY

The foregoing warranty shall not apply to defects resulting from improper

or

inadequate maintenance by

Buyer, Buyer-supplied software

or

interfacing, unauthorized modification

or

misuse, operation outside of the

environmental specifications

for

the product,

or

improper site preparation

or

maintenance.

NO OTHER WARRANTY

IS

EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES

OF

MERCHANTABILITY AND FITNESS FOR

A

PAWICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYERS SOLE AND EXCLUSIVE REMEDIES.

HP

SHALL NOT BE LIABLE FOR

ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TOFU', OR

ANY

OTHER

LEGAL THEORY.

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are available for Hewlett-

Packard products.

For

any assistance, contact your nearest Hewlett-Packard Sales and Service Office. Addresses are provided

at the back

of

this manual.

Model

8903B

Safety Considerations

SAFETY

CONSIDERATIONS

GENERAL

This product and related documentation must be re-

viewed for familiarization with safety markings and

instructions before operation.

This product

is

a Safety Class

I

instrument (provided

with a protective earth terminal).

BEFORE

APPLYING

POWER

Verify that the product is set to match the available

line voltage and the correct fuse

is

installed.

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be pro-

vided from the main power source to the product input

wiring terminals, power cord,

or

supplied power cord

set.

SAFETY SYMBOLS

Instruction manual symbol: the product will

/I\

be marked with this symbol when

it

is

necessary for the user to refer to the instruction

manual (refer to Table of Contents).

Indicates hazardous voltages.

Indicates earth (ground) terminal.

The WARNING sign denotes a

hazard. It calls attention to a

procedure, practice,

or

the like, which,

if

not correctly

performed

or

adhered to, could result in personal in-

jury.

Do

not proceed beyond a WARNING sign until

the indicated conditions are fully understood and met.

The

CAUTION

sign denotes a haz-

ard. It calls attention to an

operating procedure, practice,

or

the like, which, if not

correctly performed

or

adhered to, could result in dam-

age to

or

destruction of part

or

all of the product.

Do

not proceed beyond a CAUTION sign until the indi-

cated conditions are fully understood and met.

(WARNING

I

Any interruption of the protective (ground-

ing) conductor (inside

or

outside

the

instru-

ment)

or

disconnecting the protective earth

terminal will cause a potential shock hazard

that could result

in

personal injury. (Ground-

ing one conductor of a two conductor outlet

is not sufficient protection).

Whenever it

is

likely that the protection has

been impaired, the instrument

must

be made

inoperative and be secured against any unin-

tended operation.

If this instrument is to be energized via an

autotransformer (for voltage reduction) make

sure the common terminal

is

connected to the

earth terminal

of

the power source.

Servicing instructions are

for

use by service-

trained personnel only.

To

avoid dangerous

electric shock, do not perform any servicing

unless qualified to do

so.

Adjustments described

in

the manual are per-

formed with power supplied to the instrument

while protective covers are removed. Energy

available at manypoints may,

if

contacted, re-

sult in personal injury.

Capacitors inside the instrument may still be

charged even

if

the instrument

has

been dis-

connected from its source of supply.

For

continued protection against fire hazard,

replace the line fuse(s) only with

250V

fuse(s)

of the same current rating and type (for exam-

ple, normal blow, time delay, etc.).

Do

not use

rep a ired fuses

o

r

s

ho

r

t

c irc

u

i

t ed

fuseholders.

Model

8903B

Safety Considerations

ATTENTION

Static Sensitive

Devices

This instrument was constructed in an ESD (electro-static dis-

charge) protected environment. This is because most of the semi-

conductor devices used

in

this

instrument are susceptible to damage

by static discharge.

Depending on the magnitude of the charge, device substrates can

be punctured

or

destroyed by contact

or

mere proximity of a static

charge. The results can cause degradation of device performance,

early failure,

or

immediate destruction.

These charges are generated

in

numerous ways such

as

simple con-

tact, separation of materials, and normal motions of persons

working with static sensitive devices.

When handling

or

servicing equipment containing static sensitive

devices, adequate precautions must be taken to prevent device dam-

age

or

destruction.

Only those who are thoroughly familiar with industry accepted

techniques for handling static sensitive devices should attempt to

service circuitry with these devices.

In all instances, measures must be taken to prevent static charge

build-up on work surfaces and persons handling the devices.

For

further information on ESD precautions, refer to “SPECIAL

HANDLING CONSIDERATIONS

FOR

STATIC SENSITIVE

DEVICES,’

in

Section VIII Service Section.

HP 8903B

TABLE

OF

CONTENTS

Section +General Information

Table

of

Contents

Introduction

1.1

Specifications

.....................................................

1-1

Safety Considerations

................................................

1.2

Instruments Covered By Manual

..........................................

1.2

Manualchanges

...................................................

1-2

Description

......................................................

1-3

General

......................................................

1-3

Audio Testing

..................................................

1-3

Transceiver Testing

...............................................

1-4

Systems

......................................................

1-5

Options

........................................................

1-6

Electrical Options

................................................

1-6

Mechanical Options

...............................................

1-6

Hewlett-Packard Interface Bus

...........................................

1-8

Compatibility

...................................................

1-8

Selecting the HP-IB Address

..........................................

1-8

Accessories Supplied

.................................................

1-8

Electrical Equipment Available

...........................................

1-8

HP-IB Controllers

................................................

1-8

Front-to-Rear-Panel Connectors Retrofit Kit

.................................

1-8

Rear-to-Front-Panel Connectors Retrofit Kit

.................................

1-8

Mechanical Equipment Available

..........................................

1-9

Chassis Slide Mount Kit

............................................

1-9

Chassis Tilt Slide Mount Kit

..........................................

1-9

Recommended Test Equipment

...........................................

1-9

Principles

of

Operation

for

Simplified Block Diagram

..............................

1-9

Voltmeter and Notch Filter

..........................................

1-10

Counter

.....................................................

1-11

Source

.....................................................

1-11

Controller

....................................................

1-12

Basics

of

Audio Measurements

..........................................

1-12

ACLevel

....................................................

1-12

Frequency

....................................................

1-13

DCLevel

....................................................

1-13

Signal Impurities

................................................

1-13

Distortion

...................................................

1-13

Signal-to-Noise Ratio

.............................................

1-15

Internal Source

.................................................

1-16

Plotting

.....................................................

1-16

.....................................................

SINAD

.....................................................

1-15

HP

8903B

Table

of

Contents

Section 2-Installation

Introduction

.....................................................

2.1

Initial Inspection

...................................................

2.1

Preparation

for

Use

.................................................

2.1

Power Requirements

...............................................

2.1

Line Voltage and Fuse Selection

........................................

2-2

Power Cables

...................................................

2.2

HP-IB Address Selection

............................................

2.3

Interconnections

.................................................

2.5

Mating Connectors

...............................................

2.5

Operating Environment

...............................................

2.6

Bench Operation

.................................................

2.6

Rack Mounting

..................................................

2.6

Storage and Shipment

................................................

2.8

Packaging

.....................................................

2.8

Environment

...................................................

2.8

Section %Operation

....................................................

Introduction

-3-1

General

......................................................

3-1

"urn-On Procedure

3-1

Local Operation

3-2

Remote Operation

3-3

Operating Characteristics

............................................

3-1

...............................................

..................................................

................................................

Operator's Checks

..................................................

3-3

Operator's Maintenance

.............................................

3-4

Front-Panel Features

.................................................

3-6

Basic Functional Checks

3-12

Simplified Operation

.................................................

3-8

Rear-Panel Features

3-11

Description

3-12

Equipment

3-12

Procedure

3-12

Preliminary Check

3-12

Filter Check

3-13

Distortion Check

3-15

SINAD Check

3-15

..............................................

................................................

...................................................

...................................................

....................................................

...............................................

AC Level and Output Level Check

......................................

3-12

..................................................

................................................

.................................................

Signal-to-Noise Ratio Check

.........................................

3-15

Sweep,

X

Axis,

Y

Axis, Pen Lift, and DC Level Check

...........................

3-15

.............................................

...................................................

..................................................

...................................................

HP-IB Functional Checks

3-16

Description

3-16

Initial Setup

3-16

Equipment

3-16

Address Recognition

..............................................

3-16

Remote and Local Messages and the LCL Key

...............................

3-17

Receiving the Data Message

.........................................

3-18

Local Lockout and Clear Lockout/Set Local Messages

...........................

3-18

..........................................

Sending the Data Message

3-17

HP 8903B

Table

of

Contents

ClearMessage

.................................................

3-18

AbortMessage

.................................................

3-19

Status Byte Message

..............................................

3-20

Require Service Message

...........................................

3-21

Trigger Message and Clear Key Triggering

..................................

3-22

Remote Operation. Hewlett-Packard Interface Bus

...............................

3-22

HP-IB Compatibility

.............................................

3-23

Remote Mode

.................................................

3-23

LocalMode

...................................................

3-23

Addressing

...................................................

3-23

Data Messages

.................................................

3-26

Receiving the Data Message

.........................................

3-26

Sending the Data Message

..........................................

3-30

Receiving the Clear Message

.........................................

3-31

Receiving the Trigger Message

........................................

3-32

Receiving the

Remote

Message

........................................

3-32

Receiving the Local Message

.........................................

3-33

Receiving the Local Lockout Message

....................................

3-33

Receiving the Clear Lockout/Set Local Message

..............................

3-33

Receiving the Pass Control Message

.....................................

3-33

Sending the Require Service Message

....................................

3-33

Selecting the Service Request Condition

...................................

3-34

Sending the Status Byte Message

......................................

3-34

Sending the Status Bit Message

.......................................

3-35

Receiving the Abort Message

.........................................

3-35

HP-IB

Syntax

and Characteristics Summary

..................................

3-35

Amplitude

.......................................................

3-44

Automatic Operation

................................................

3-46

ACLevel

......................................................

3-42

CommonMode

...................................................

3-47

DCLevel

......................................................

3-50

Default Conditions and Power-up Sequence

...................................

3-52

Detector Selection

.................................................

3-53

Display Level in Watts

...............................................

3-55

Display Source Settings

..............................................

3-57

Distortion

......................................................

3-58

Distortion Level

..................................................

3-60

Error Disable

....................................................

3-62

Error Message Summary

..............................................

3-64

Filters

........................................................

3-68

Float

.........................................................

3-72

Frequency

......................................................

3-74

Hold Decimal Point

................................................

3-76

Hold Settings

....................................................

3-78

HP-IB Address 3-79

Increment

......................................................

3-82

Input Level Range (DC Level)

..........................................

3-84

Input Level Range (Except DC Level)

......................................

3-86

Monitor

.......................................................

3-88

Notch~ne

.....................................................

3-91

Output Impedance

.................................................

3-93

Plot Limit 3-96

Post-Notch Detector Filtering (Except SINAD)

.................................

3-98

...................................................

......................................................

Table of Contents HP 8903B

Post-Notch Gain

.................................................

Rapid Frequency Count

.............................................

Rapidsource

...................................................

RATIO and LOG/LIN

..............................................

Read Display

to

HP-IB

.............................................

Service Request Condition

............................................

Signal-to-Noise

..................................................

Special Functions

.................................................

Sweep

.......................................................

Sweep Resolution

.................................................

Time Between Measurements

..........................................

X-YRecording

..................................................

3-100

3-102

3-105

3-109

3-112

3-114

3-116

3-121

3-128

3-131

3-134

3-135

Section 4-Performance

Introduction

.....................................................

4.1

Equipment Required

.................................................

4.1

TestRecord

......................................................

4-1

Calibration Cycle

...................................................

4.1

Abbreviated Performance Testing

..........................................

4.1

Performance Test

1

AC

Level Accuracy and Output Level Accuracy and Flatness

...............

4-2

Performance Test

2

DC Level Accuracy

.....................................

4-12

Performance Test 3 Distortion and Noise

....................................

4-14

Performance Test 4 Distortion, SINAD, and Signal-to-Noise Accuracy

....................

4-16

Performance Test 5 Frequency Accuracy and Sensitivity

............................

4-19

Performance Test 6 Audio Filters

.........................................

4-21

Performance Test

7

Input and Output Impedance

................................

4-28

Performance Test

8

Common-Mode Rejection Ratio

..............................

4-29

Section 5-Adjustments

Introduction

.....................................................

5.1

Safety Considerations

................................................

5.1

Equipment Required

.................................................

5.1

Factory-Selected Components

............................................

5.1

Post-Repair Tests, Adjustments, and Checks

....................................

5.2

Related Adjustments

.................................................

5.2

Adjustment

1

Internal Reference Frequency

....................................

5.4

Adjustment

2

Input Flatness

............................................

5.5

Adjustment 3 Common Mode Rejection

......................................

5.8

Adjustment 4 Input DC

Offset

...........................................

5.9

Adjustment 5 400 Hz High-Pass and Weighting Bandpass Filters

.......................

5-10

Adjustment 6 Notch Filter Tune and Balance

..................................

5-12

Adjustment

7

Voltmeter

..............................................

5-13

Adjustment

8

SINAD Meter

............................................

5-15

Adjustment 9 Oscillator and Output Attenuator

.................................

5-16

Model

8903B

General Information

Section

1

GENERAL INFORMATION

1-1.

INTRODUCTION

This manual contains information required to install, operate, test, adjust, and service the Hewlett-

Packard Model 8903B Audio Analyzer. This manual documents options installed in the Audio Analyzer

such

as

rear-panel connections and internal plug-in filters.

This section of the manual describes the instruments documented by the manual and covers

instrument description, options, accessories, specifications, and other basic information. This section

also contains principles of operation on a simplified block diagram level and basic information on audio

measurements. The other sections contain the following information:

Section

2,

Installation:

provides information about initial inspection, preparation for use (including

address selection for remote operation), and storage and shipment.

Section

3,

Operation:

provides information about panel features, and includes operating checks,

operating instructions for both local and remote operation, and maintenance information.

Section

4,

Performance Tests:

provides the information required

to

check performance of the

instrument against the critical specifications in Table

1-1.

Section

5,

Adjustments:

provides the information required to properly adjust the instrument.

Section

6,

Replaceable Parts:

provides ordering information for all replaceable parts and assemblies.

Section

7,

Instrument Changes:

provides instrument modification recommendations and procedures.

Section

8,

Service:

provides the information required

to

repair the instrument.

Sections

1

through

5

are bound in this volume, the Operation and Calibration Manual. One copy of the

Operation and Calibration Manual is supplied with the instrument. Sections 6 through

8

are bound

in

two

separate volumes, the Service Manual. Copies of the Service Manual are not supplied with the

instrument unless specifically requested (as Option 915) at time of instrument order. Copies of all

volumes can be ordered separately through your nearest Hewlett-Packard office. The part numbers are

listed on the title page of this manual.

Also listed on the title page of this manual, below the manual part number, is

a

microfiche part number.

This number may be used to order 100

x

150

mm

(4

x

6 inch) microfilm transparencies of this manual.

Each microfiche contains up to 96 photo-duplicates of the manual’s pages. The microfiche package also

includes the latest MANUAL UPDATES packet, as well as all pertinent Service Notes.

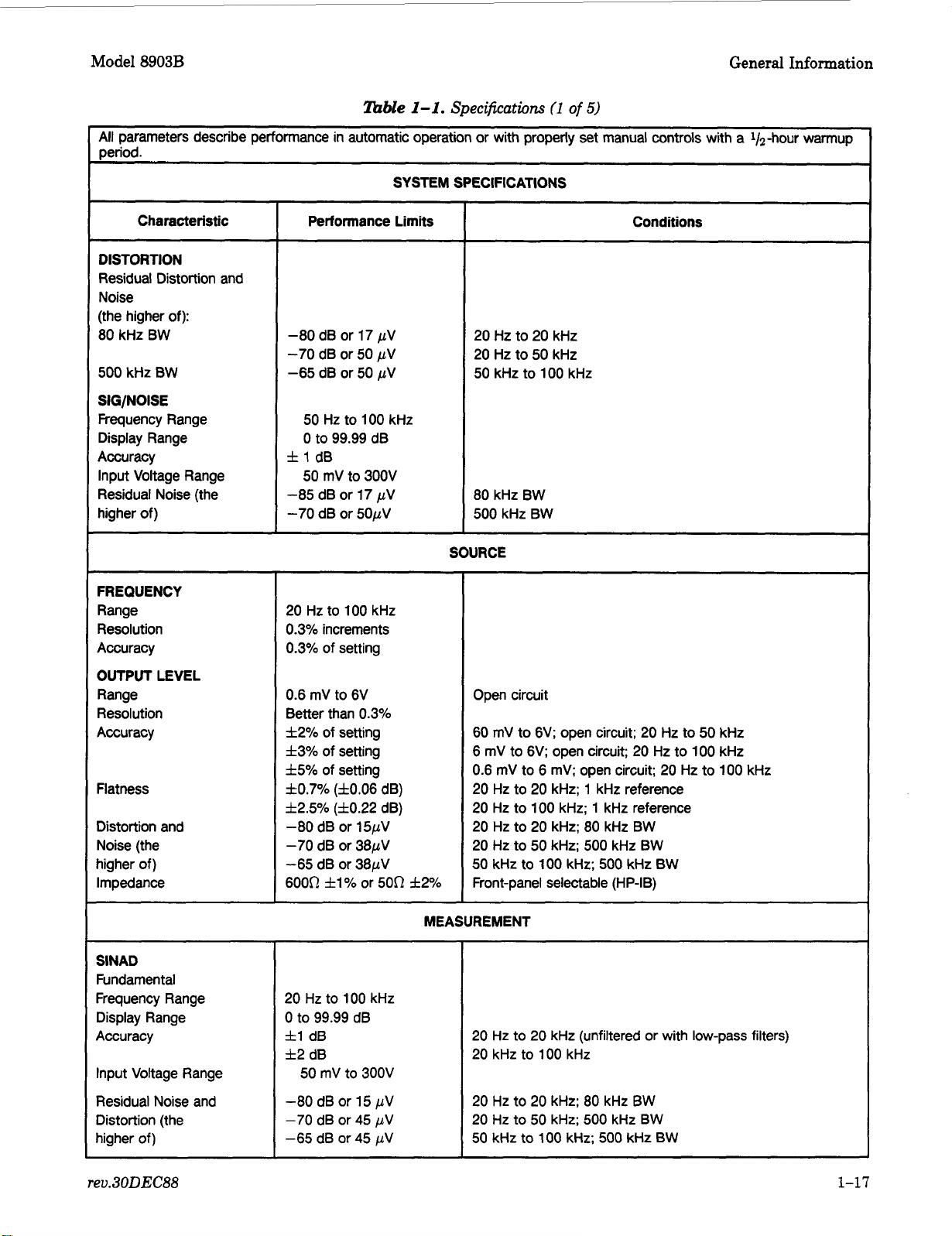

1-2.

SPECIFICATIONS

Instrument specifications are listed in Table

1-1.

These are the performance standards, or limits against

which the instrument may be tested. Characteristics listed under Supplemental Information, Table

1-2,

are not warranted specifications but are typical characteristics included as additional information for

the user.

1-1

General Information Model

8903B

1-3.

SAFETY CONSIDERATIONS

This product is a Safety

Class

I instrument (that is, provided with a protective earth terminal). The

Audio Analyzer and all related documentation must be reviewed for familiarization with safety markings

and instructions before operation. Refer to the Safety Considerations page found at the beginning of

this manual

for

a summary of the safety information. Safety information pertinent to the task at hand

(installation, performance testing, adjustment,

or

service) is found throughout the manual.

1-4.

INSTRUMENTS COVERED

BY

MANUAL

Serial

Numbers.

This instrument has a two-part serial number in the form

OOOOAOOOOO

which is

stamped on the serial number plate attached to the rear

of

the instrument. The first four digits and the

letter constitute the serial number prefix, and the last five digits form the suffix. The prefix is the same

for all identical instruments.

It

changes only when a change

is

made to the instrument. The suffix,

however,

is

assigned sequentially and is different for each instrument. The contents of this manual

apply directly to instruments having the same serial prefix(es) as listed under SERIAL NUMBERS

on the title page.

Options.

Electrical Option

001,

internal plug-in filter options, and various mechanical options are

documented in this manual. The differences are noted under the appropriate paragraph such

as

Options

in Section

1,

the Replaceable Parts List, and the schematic diagrams.

1-5.

MANUAL UPDATES

An instrument manufactured after the printing of this manual

may

have

a

serial prefix that

is

not

listed on the title page. Having a serial number prefix that

is

greater than that shown on the title page

indicates that the instrument is slightly different from those documented in the manual. In this case,

your manual

is

provided with updating information to make it as current

as

possible. This updating

information includes any hardware

or

software changes that have occurred as well as corrections to the

manual.

A Description

of

the Manual Update Packet

A

“MANUAL UPDATES” packet is shipped with the Operation and Calibration Manual when

necessary to provide you with the most current information available at the time

of

shipment. These

packets consist of replacement and addition pages which should be incorporated into the manual to

bring it up to date.

Signing Up

for

the Documentation Update Service

Hewlett-Packard offers a Documentation Update Service that will provide you with further updates

and changes as they become available. If you have not received update information that matches the

serial number of your instrument, you can receive this information through the Update Service.

If

you

operate

or

service instruments with different serial prefixes, we strongly recommend that you

join this service immediately to ensure that your manual is kept current. For more information, refer

to the Documentation Update Service reply card included in this manual

or

contact:

Hewlett-Packard Company

Technical Writing Department

24001

E.

Mission-TAF C-34

Spokane, WA. 99220

(509) 922-4001

1-2

Model 8903B

General Information

1-6.

DESCRIPTION

General

The HP Model 8903B Audio Analyzer is a complete audio measurement system covering the frequency

range of

20

Hz

to

100 kHz.

It

combines a low-distortion signal source with a signal analyzer. The

source has a maximum open-circuit output of 6 Vrms and a selectable output impedance of either

50

or

6000. The analyzer can perform distortion analysis, frequency count, and ac level, dc level, SINAD, and

signal-to-noise ratio measurements. The Audio Analyzer reduces the number of instruments required

in many applications involving audio signal characterization.

The Audio Analyzer is easy

to

use. All measurements are selected by one

or

two keystrokes. For

distortion measurements, the Audio Analyzer automatically tunes to and levels the input signal.

Measurement and output ranges are automatically selected for maximum resolution and accuracy.

firthermore, tuning is independent of the source. Thus, the source can be set to one frequency while

the analyzer

is

measuring the distortion on a signal

at

another frequency (that is, there

is

no need to

tune the analyzer

to

the source).

The combined capabilities of the instrument are enhanced by microprocessor control, resulting

in

more

capability than would be available from separate instruments. For example, when making signal-to-noise

ratio measurements, the Audio Analyzer monitors the ac level while turning the source on and

off.

The

microprocessor then computes and displays the ratio of the on and

off

levels. The ratio can be displayed

in either

5%

or

dB.

In addition, the source can be swept. This makes measurements such as frequency response

or

complete

distortion characterization simple

to

perform. Microprocessor control allows flexible entry of source

parameters and versatile display formats. For example, ac level can be displayed in V, mV, dBm into

6000, watts,

or

as a ratio (in

%

or

dB)

referenced to an entered

or

measured value.

Virtually all functions are remotely programmable through the Hewlett-Packard Interface Bus

(HP-IB'). Programming is easy

and

straightforward; all measurements are made through a single

input. This eliminates the need to switch between multiple inputs under remote control and reduces

software development time and hardware costs. The Audio Analyzer measures the true rms level

on all ac measurements. True rms measurements assure greater accuracy when measuring complex

waveforms and noise. For those applications where average detection

is

required, the analyzer can

be switched to average-responding

(rms

calibrated) detection through special functions. Accurate

distortion measurements typically can be made to less than

0.003%

(-90

dB)

between

20

Hz and

20

kHz

at

a 1.5V level. For those applications where quasi-peak detection

is

required, the analyzer

(Serial Prefix 2730A and above) can be switched

to

this type of detection through special functions.

This detector is designed

to

meet the requirements specified by CCIR 468-3.

Audio Testing

The Audio Analyzer has numerous features which make audio testing simple and convenient.

These features include flexible data entry and display formats, convenient source control, and swept

measurements capability.

For

example, distortion results can be displayed in

%

or

dB.

AC level

measurements can be displayed in volts, dBm into 600R,

or

watts. Measurement results can be displayed

in

%

or

dB

relative to a measured

or

entered value. Finding the

3

dB

points of filters and amplifiers

is simplified by using the source frequency increment and decrement keys together with the relative

display feature.

A

major contribution of the Audio Analyzer is its ability to make swept measurements.

When sweeping, the Audio Analyzer tuning steps

its

source frequency in logarithmic increments. With

an x-y recorder, hard copy measurement results can be obtained. X-axis scaling

is

determined by the

entered start and stop frequencies. Y-axis scaling

is

determined by the measurement units selected and

the plot limits entered through the keyboard. Any valid display units (except mV) are allowed when

plotting. To change the scaling from frequency response to swept distortion plots, simply key in new

HP-IB: Not just IEEE-488, but the hardware, documentation and support that delivers the shortest path to a

measurement system.

1-3

General Information Model

8903B

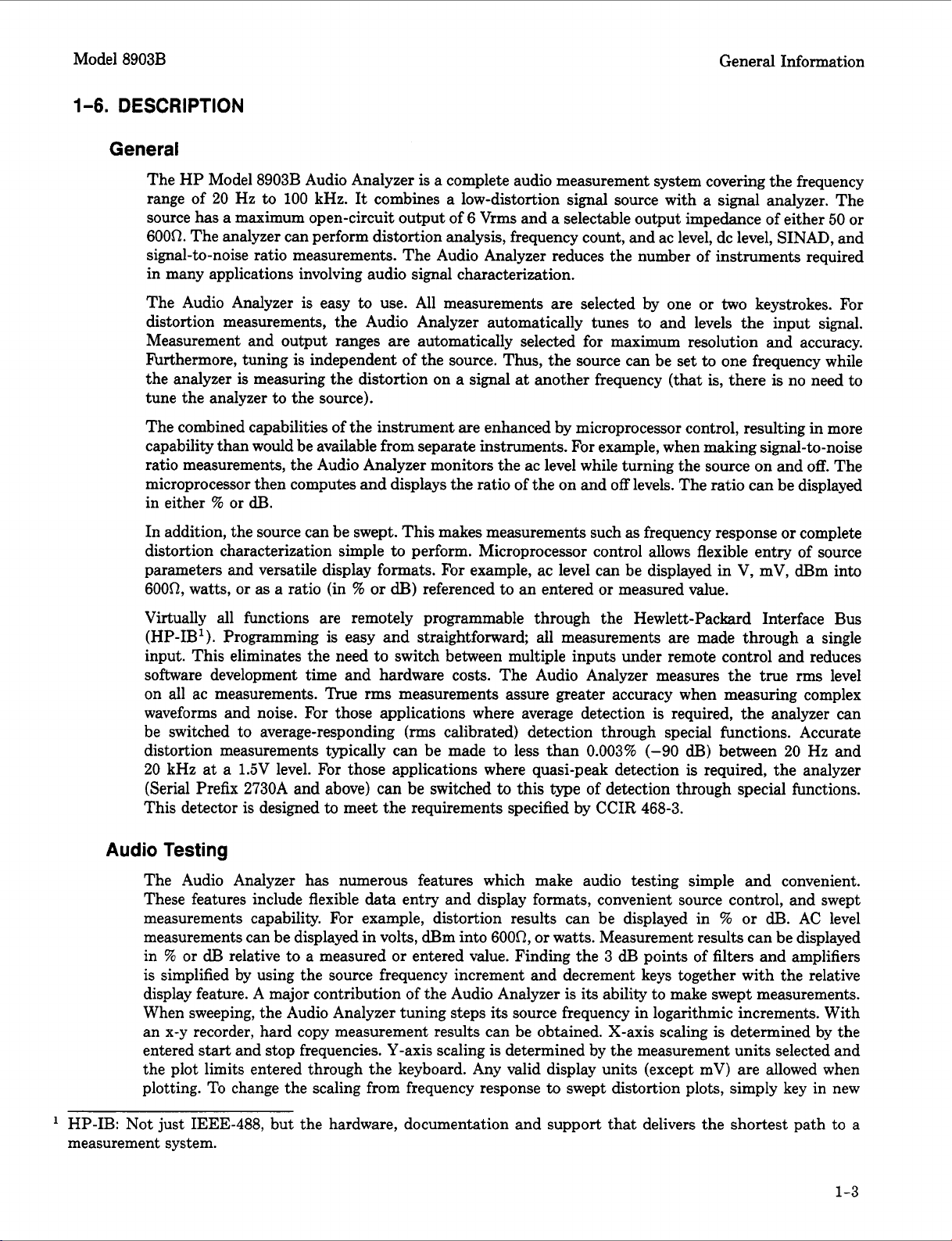

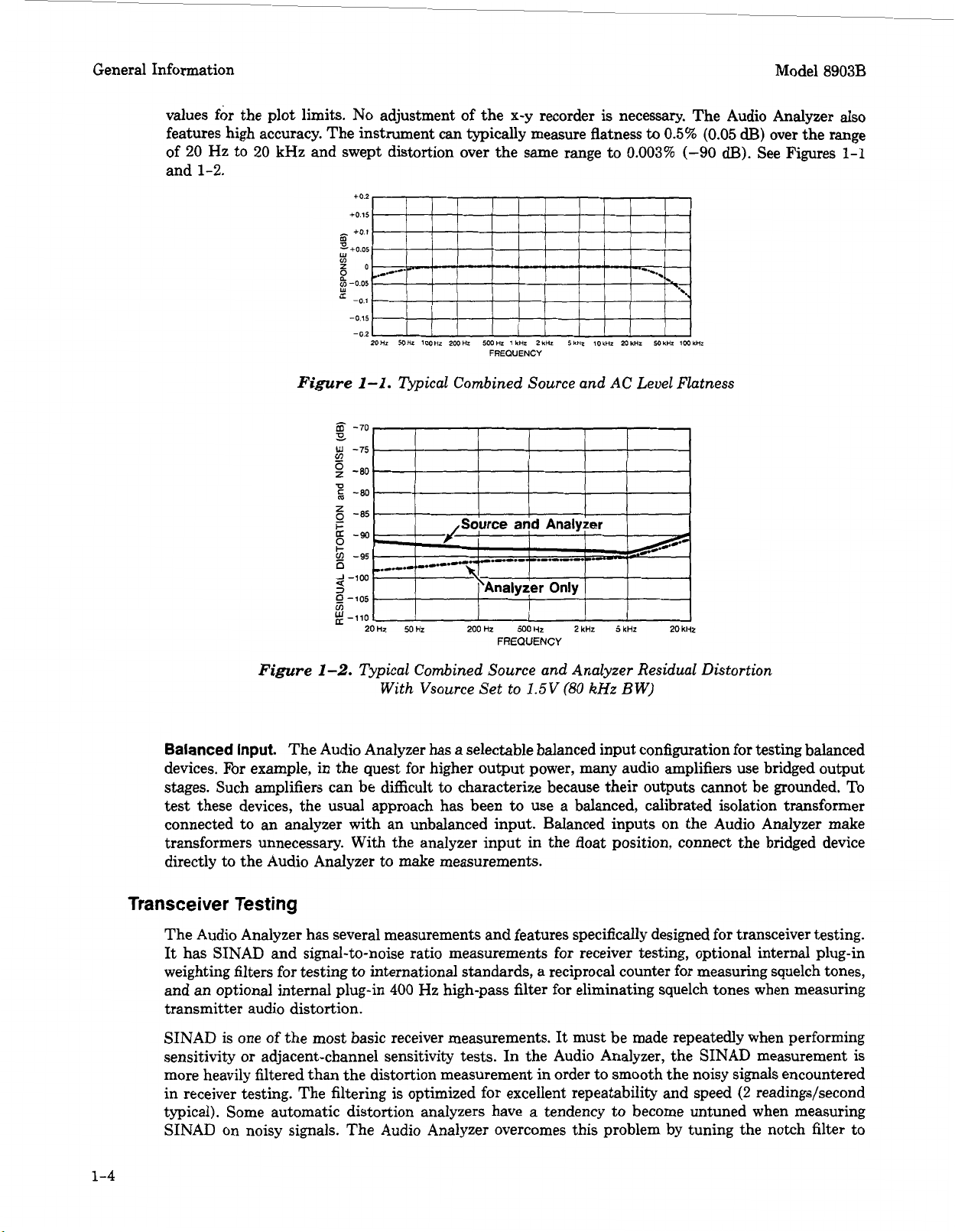

values for the plot limits.

No

adjustment of the x-y recorder

is

necessary. The Audio Analyzer also

features high accuracy. The instrument can typically measure flatness

to

0.5%

(0.05

dE3)

over the range

of

20

Hz to

20

kHz and swept distortion over the same range to

0.003%

(-90

dB).

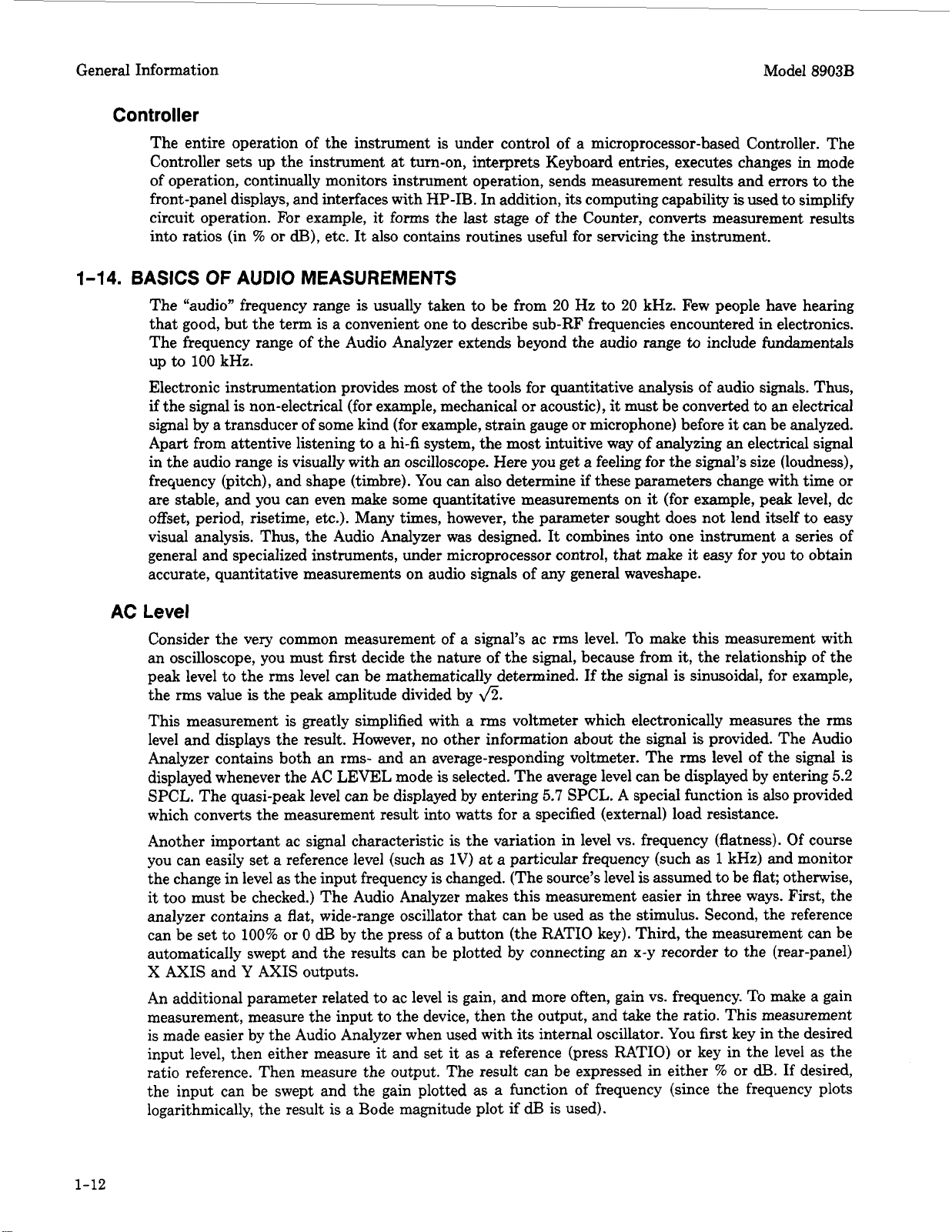

See Figures

1-1

and

1-2.

+0.2,

I,,

I1

Figure

1-1.

npical Combined Source and

AC

Level Flatness

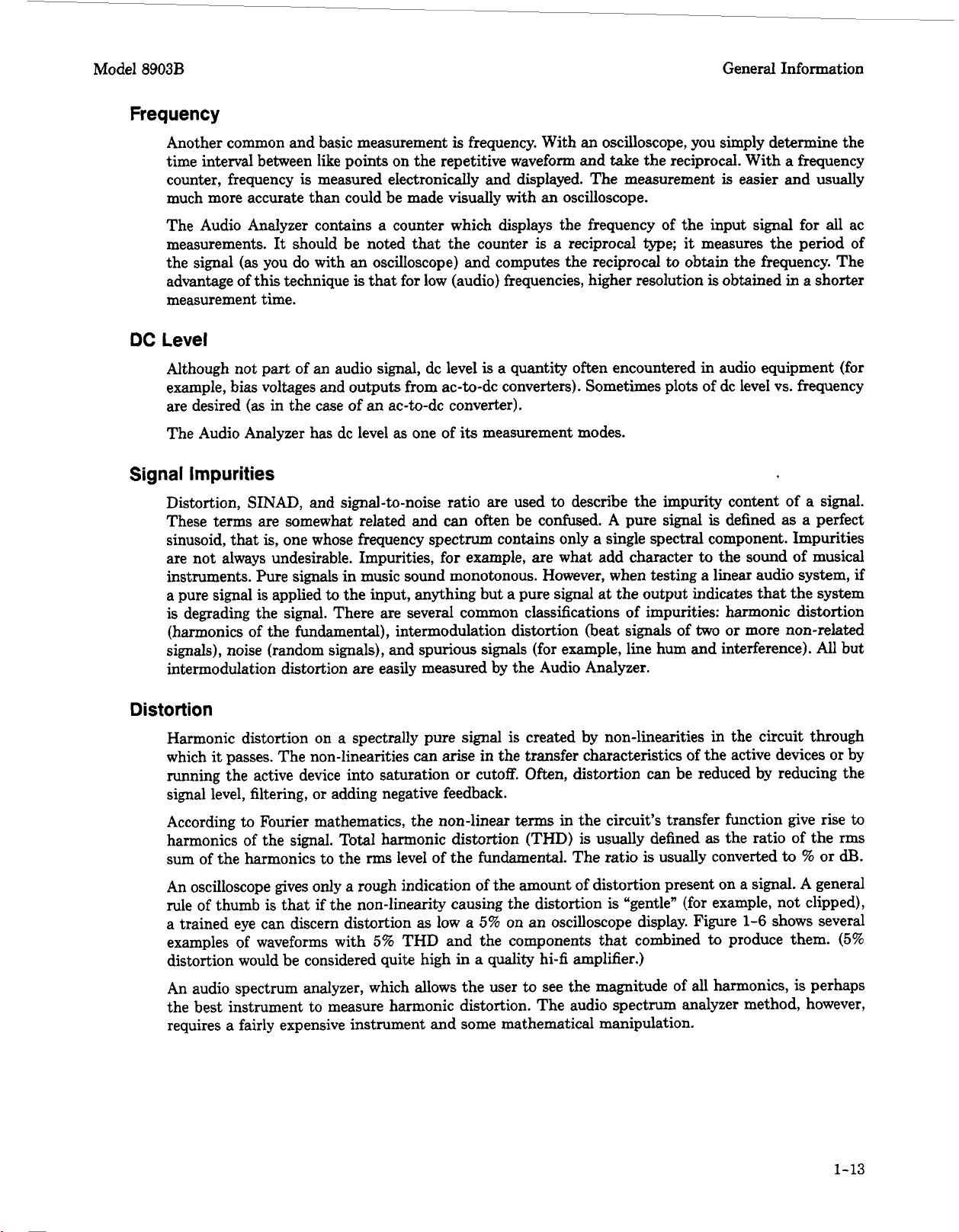

-70

9

w

-75

v,

g

-80

p

-80

'?o

-85

'0

-

I-

!

9

-95

D

3

0

-105

v)

-110

2

-100

20Hz

5OHz

2OOHz

500Hz

PkHr

5kHz

20kHz

FREQUENCY

Figure

1-2.

Typical Combined Source and Analyzer Residual Distortion

With Vsource Set to 1.5V

(80

kHz

BW)

Balanced

Input.

The Audio Analyzer has

a

selectable balanced input configuration for testing balanced

devices. For example, in the quest for higher output power, many audio amplifiers use bridged output

stages. Such amplifiers can be difficult to characterize because their outputs cannot be grounded. To

test these devices, the usual approach has been

to

use a balanced, calibrated isolation transformer

connected to an analyzer with an unbalanced input. Balanced inputs on the Audio Analyzer make

transformers unnecessary. With the analyzer input in the float position, connect the bridged device

directly to the Audio Analyzer to make measurements.

Transceiver Testing

The Audio Analyzer has several measurements and features specifically designed for transceiver testing.

It

has SINAD and signal-to-noise ratio measurements for receiver testing, optional internal plug-in

weighting filters for testing to international standards, a reciprocal counter for measuring squelch tones,

and an optional internal plug-in

400

Hz high-pass

filter

for eliminating squelch tones when measuring

transmitter audio distortion.

SINAD is one

of

the most basic receiver measurements. It must be made repeatedly when performing

sensitivity

or

adjacent-channel sensitivity tests. In the Audio Analyzer, the SIN AD measurement is

more heavily filtered than the distortion measurement in order to smooth the noisy signals encountered

in receiver testing. The filtering is optimized for excellent repeatability and speed

(2

readings/second

typical). Some automatic distortion analyzers have

a

tendency to become untuned when measuring

SINAD on noisy signals. The Audio Analyzer overcomes this problem by tuning the notch filter to

1-4

Model

8903B

General Information

the source frequency when measuring SINAD. SINAD measurement results are indicated both by the

digital display and a front-panel analog meter. The meter is specifically marked for

EIA

and CEPT

sensitivity and selectivity. For SINAD ratios less than

25

dB,

the digital display

is

automatically

rounded to the nearest

0.5

dB

to reduce digit flicker.

Signal-to-noise ratio measurements are also filtered for improved repeatability and speed

(1

read-

ing/second typical), and automatic display rounding

is

provided. For accurate noise measurements, the

Audio Analyzer uses true

rms

detection for both SINAD and signal-to-noise measurements. Most older

instruments employ average detection which reads low for noise. The discrepancy can be

1.5

dB

or

greater and varies with the ratio being measured. For correlating results with past test data, the Audio

Analyzer’s detector can be switched via special functions

to

an average responding configuration.

For those applications where quasi-peak detection is required, the analyzer (Serial Prefix

2730A

and

above) can be switched

to

this type of detection through special functions. This detector is designed

to

meet the requirements specified by CCIR

468-3.

For transceivers, the Audio Analyzer has an optional, internal plug-in seven-pole 400 Hz high-pass filter

for rejecting squelch tones. Rejection of squelch tones up to

250

Hz

is

greater than

40

dB.

Therefore,

audio distortion measurements

to

1%

residual distortion can be made without disabling the transmitter

squelch tones.

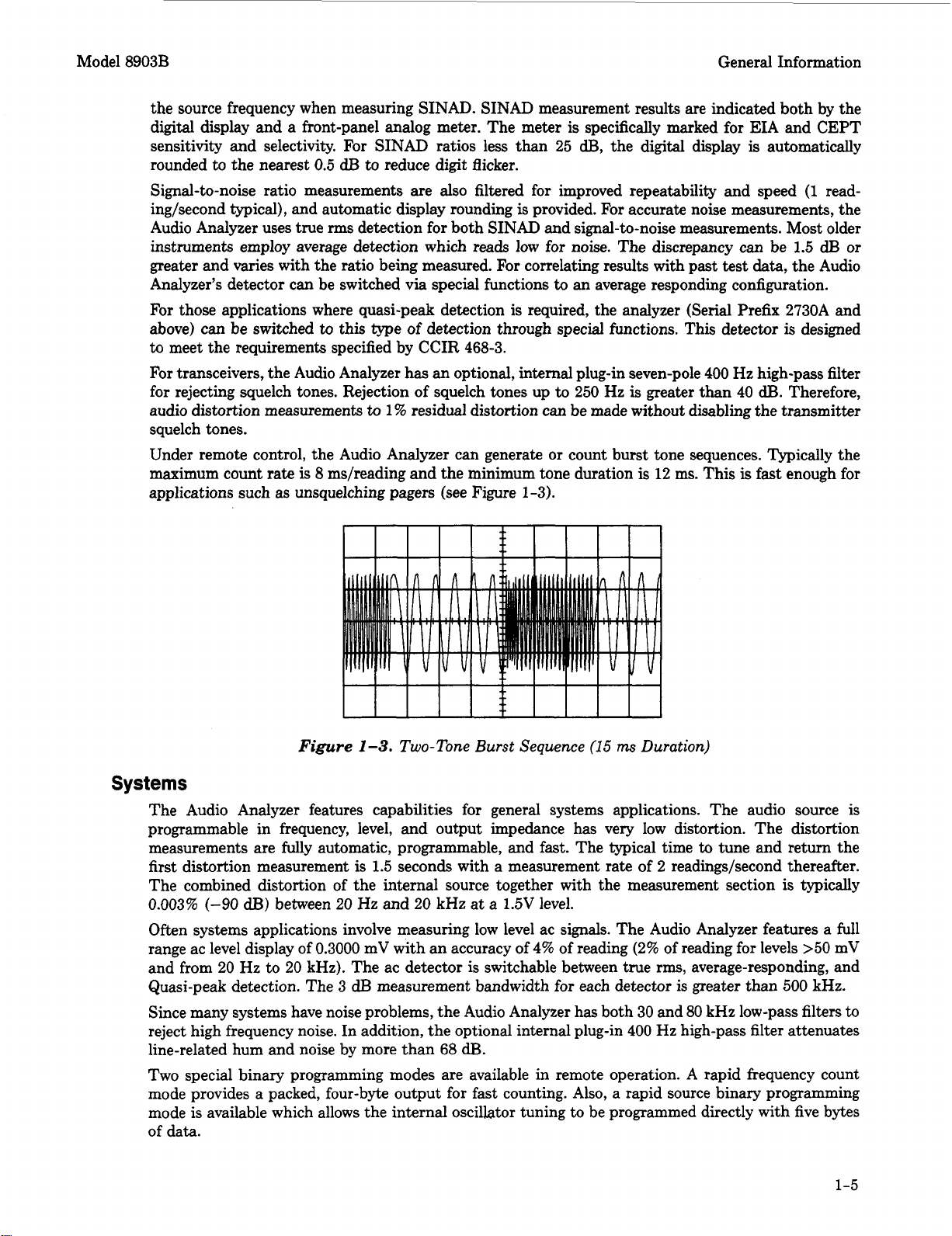

Under remote control, the Audio Analyzer can generate

or

count burst tone sequences. Typically the

maximum count rate

is

8

ms/reading and the minimum tone duration

is

12

ms. This

is

fast

enough for

applications such as unsquelching pagers (see Figure

1-3).

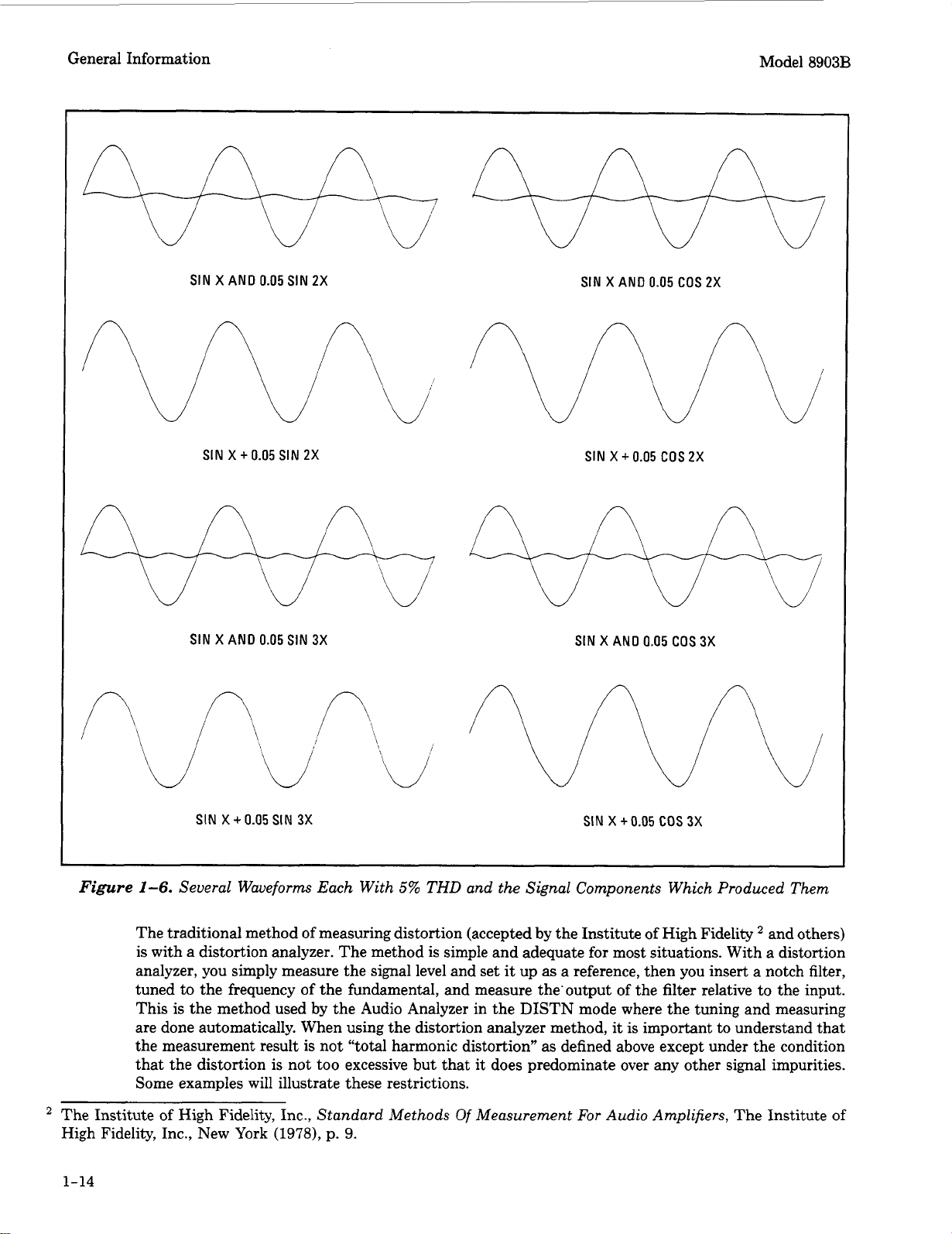

Figure

1-3.

Two-Tone

Burst

Sequence

(15

ms

Duration)

Systems

The Audio Analyzer features capabilities for general systems applications. The audio source

is

programmable in frequency, level, and output impedance has very low distortion. The distortion

measurements are fully automatic, programmable, and

fast.

The typical time

to

tune and return the

first distortion measurement

is

1.5

seconds with a measurement rate of

2

readings/second thereafter.

The combined distortion of the internal source together with the measurement section is typically

0.003%

(-90

dB)

between

20

Hz

and

20

kHz at a

1.5V

level.

Often systems applications involve measuring low level ac signals. The Audio Analyzer features a full

range ac level display of

0.3000

mV with an accuracy of

4%

of reading

(2%

of reading for levels

>50

mV

and from

20

Hz

to

20

kHz). The ac detector is switchable between true rms, average-responding, and

Quasi-peak detection. The

3

dB

measurement bandwidth for each detector is greater than

500

kHz.

Since many systems have noise problems, the Audio Analyzer has both

30

and

80

kHz low-pass filters

to

reject high frequency noise. In addition, the optional internal plug-in

400

Hz

high-pass filter attenuates

line-related hum and noise by more than

68

dB.

Two special binary programming modes are available in remote operation.

A

rapid frequency count

mode provides a packed, four-byte output for fast counting. Also, a rapid source binary programming

mode

is

available which allows the internal oscillator tuning to be programmed directly with five bytes

of data.

1-5

Model 8903B

General Information

1-7.

OPTIONS

Electrical Options

Electrical Option

001.

This option provides rear-panel (instead of front-panel) connections for both

the INPUT and OUTPUT HIGH and LOW BNC connectors.

Internal Plug-in Filter Options.

The Audio Analyzer has

two

plug-in filter positions; each position

can be loaded with any one of six optional filters. Each filter is referenced to its corresponding filter

position by one

of

two

option numbers. For example, the 400 Hz high-pass filter option can be ordered

as Option 010 which corresponds to the left-most filter position,

or

as

Option

050

which corresponds

to the right-most filter position. These optional plug-in filters can be configured in any combination

desired.

(If

there is no filter ordered for a position, a jumper

is

loaded and a label marked

“No

Filter”

is placed above the filter key on the front panel.) The following list includes the name and option

numbers for each available filter.

0

400 Hz High-Pass Filter (Option 010,050)

0

CCITT Weighting Filter (Option 011, 051)

0

CCIR Weighting Filter (Option 012, 052)

0

C-MESSAGE Weighting Filter (Option 013, 053)

0

CCIR/ARM Weighting Filter (Option 014,

054)

0

“A”

Weighting Filter (Option 015,

055)

Specific information on each plug-in filter option can be found in the Detailed Operating Instructions

in Section 3 under “Filters”.

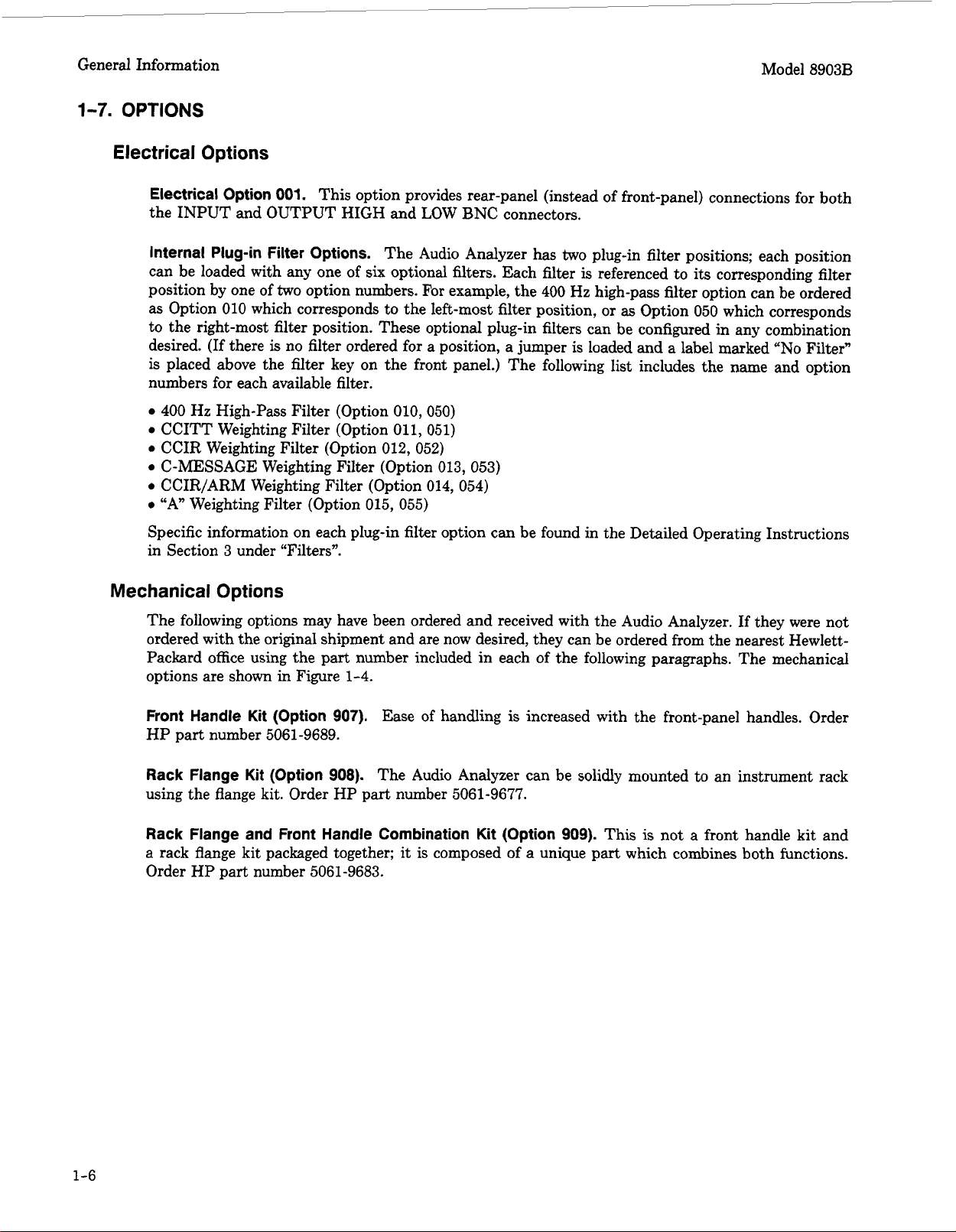

Mechanical Options

The following options may have been ordered and received with the Audio Analyzer.

If

they were not

ordered with the original shipment and are now desired, they can be ordered from the nearest Hewlett-

Packard office using the part number included in each of the following paragraphs. The mechanical

options are shown in Figure 1-4.

Front Handle Kit (Option

907).

Ease of handling

is

increased with the front-panel handles. Order

HP

part number 5061-9689.

Rack Flange

Kit

(Option

908).

The Audio Analyzer can be solidly mounted to an instrument rack

using the flange kit. Order HP part number 5061-9677.

Rack Flange and Front Handle Combination Kit (Option 909).

This

is

not a front handle kit and

a rack flange kit packaged together; it is composed of

a

unique part which combines both functions.

Order

HP

part number 5061-9683.

1-6

General Information

Model

8903B

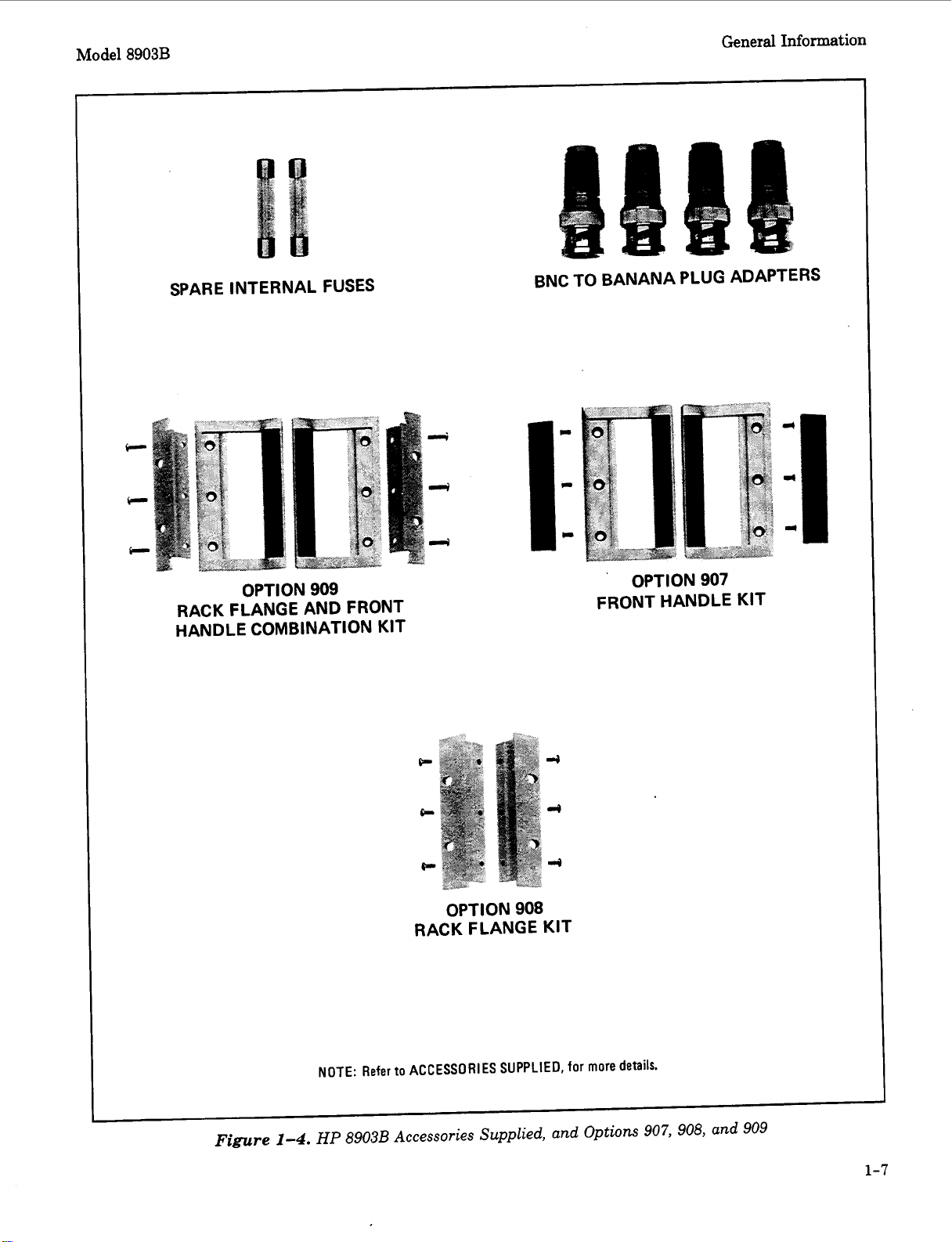

SPARE INTERNAL FUSES

BNC TO BANANA PLUG ADAPTERS

OPTION

909

RACK FLANGE AND FRONT

HANDLE COMBINATION KIT

’

OPTION907

FRONT HANDLE KIT

OPTION

908

RACK FLANGE KIT

NOTE:

Refer

to

ACCESSORIES

SUPPLIED,

for

more

details.

Figure

1-4.

HP

8903B Accessories Supplied, and Options

907,

908, and 909

1-7

General Information Model 8903B

1-8.

HEWLETT-PACKARD INTERFACE BUS

Compatibility

The Audio Analyzer is compatible with HP-IB to the extent indicated by the following code: SH1,

AH1,

T5,

TEO, L3, LEO,

SR1,

RL1, PPO, DC1, DT1,

CO,

El.

The Audio Analyzer interfaces with the

bus via open collector TTL circuitry. An explanation of the compatibility code can be found in IEEE

Standard 488,

IEEE Standard Digital Interface for Programmable Instrumentation

or the identical

ANSI Standard MC1.l.

For

more detailed information relating to programmable control of the Audio

Analyzer, refer to

Remote Operation, Hewlett-Packard Interface

Bw

in Section 3 of this manual.

Selecting the HP-IB Address

The HP-IB address switches are located within the Audio Analyzer. The switches represent a five-

bit binary number. This number represents the talk and listen address characters which an HP-IB

controller is capable of generating. In addition,

two

more switches allow the Audio Analyzer to be set

to talk only

or

listen only.

A

table in Section 2 shows all HP-IB talk and listen addresses. Refer to

HP-IB

Address Selection

in Section 2

of

this manual.

1-9.

ACCESSORIES SUPPLIED

The accessories supplied with the Audio Analyzer are shown in Figure

1-4.

Fast

blow fuses with

a

1.5A rating for 100/120 Vac operation (HP 2110-0043) and a

1.OA

rating for

220/240 Vac operation (HP 2110-0001) are supplied. One fuse is installed in the instrument at the

time of shipment. The rating of the installed fuse is selected according to the line voltage specified by

the customer.

If

the voltage

is

not specified, the rating of the installed fuse will be selected according

to the country of destination.

Four type BNC-to-banana-plug adapters (HP 1250-2164) are also supplied for use when double-ended

inputs

or

outputs are desired. The conductor of the banana connector is connected to the center

conductor of the BNC connector adapted to. These adapters are used when the front-panel INPUT

or

OUTPUT FLOAT switches are set to FLOAT.

1-1

0.

ELECTRICAL EQUIPMENT AVAILABLE

(Also refer to Service Accessories, Table

1-4.)

HP-I6

Controllers

The Audio Analyzer has

an

HP-IB interface and can be used with any HP-IB compatible computing

controller

or

computer for automatic systems applications.

Front-to-Rear-Panel Connectors Retrofit Kit

This kit contains all the necessary components and full instructions for converting instruments with

front-panel connections for INPUT and OUTPUT HIGH and LOW to rear-panel connections.

For

serial prefixes 2730A and below, order

HP

part number 08903-60171. For serial prefix 2742A and

above, order HP part number 08903-60199. After installation and calibration, performance will be

identical to the

HP

8903B Option 001.

Rear-to-Front-Panel Connectors Retrofit Kit

This kit contains all the necessary components and full instructions for converting instruments with

rear-panel connections for INPUT and OUTPUT HIGH and

LOW

to front-panel connections. For

serial prefix 2730A and below order HP part number 08903-60172.

For

serial prefix 2742A and above,

order HP part number 08903-60200. After installation and calibration, performance will be identical

to the standard HP 8903B.

1-8

rev.26JU.9

Model

8903B

1-1

1.

MECHANICAL EQUIPMENT AVAILABLE

General Information

Chassis

Slide

Mount Kit

This kit

is

extremely useful when the Audio Analyzer

is

rack mounted. Access

to

internal circuits and

components

or

the rear-panel

is

possible without removing the instrument from the rack. Order HP

part number

1494-0060

for

431.8

mm

(17

in.) fixed slides and part number

1494-0061

for the correct

adapters for non-HP rack enclosures.

Chassis Tilt

Slide

Mount Kit

This kit

is

the same as the Chassis Slide Mount Kit above except

it

also allows the tilting of the

instrument up

or

down

90".

Order HP part number

1494-0062

for

431.8

mm

(17

in.) tilting slides and

part

number

1494-0061

for

the correct adapters for non-HP rack enclosures.

OIFFERENTIAL-

OVER- TO-SINGLE- PROGRAMMABLE

AC/OC

INPUT

VOLTAGE ENOEO- GAIN

ATTFTOR

PROTECTION

AMPLICIER AMPLIFIER

IN^

c>-

HIGH

I" I

-

-

OVFII-

I

I

%?

ACfOC

VOLTAGE

PROTECTION

INTERNAL

PLUG-IN

HP/BP

PROGRAMMABLE PROGRAMMABLE

MONITOR

FILTER

!t

1I

VOLTAGE-

TO-TIME

CONVERTER

SINAO METER

-0

RB8giE;o

..--

0

KEYBOARO AN0 OISPLAY

2

rn

a8

ooDD

D

w..

-P

Figure

1-5.

Simplified

HP

8903B

Audio Analyzer

Block

Diagram

1-12.

RECOMMENDED TEST EQUIPMENT

Table

1-3

lists the test equipment recommended for use in testing, adjusting, and servicing the Audio

Analyzer.

If

any of the recommended equipment

is

unavailable, instruments with equivalent minimum

specifications may be substituted. Table

1-3

also includes some alternate equipment listings.

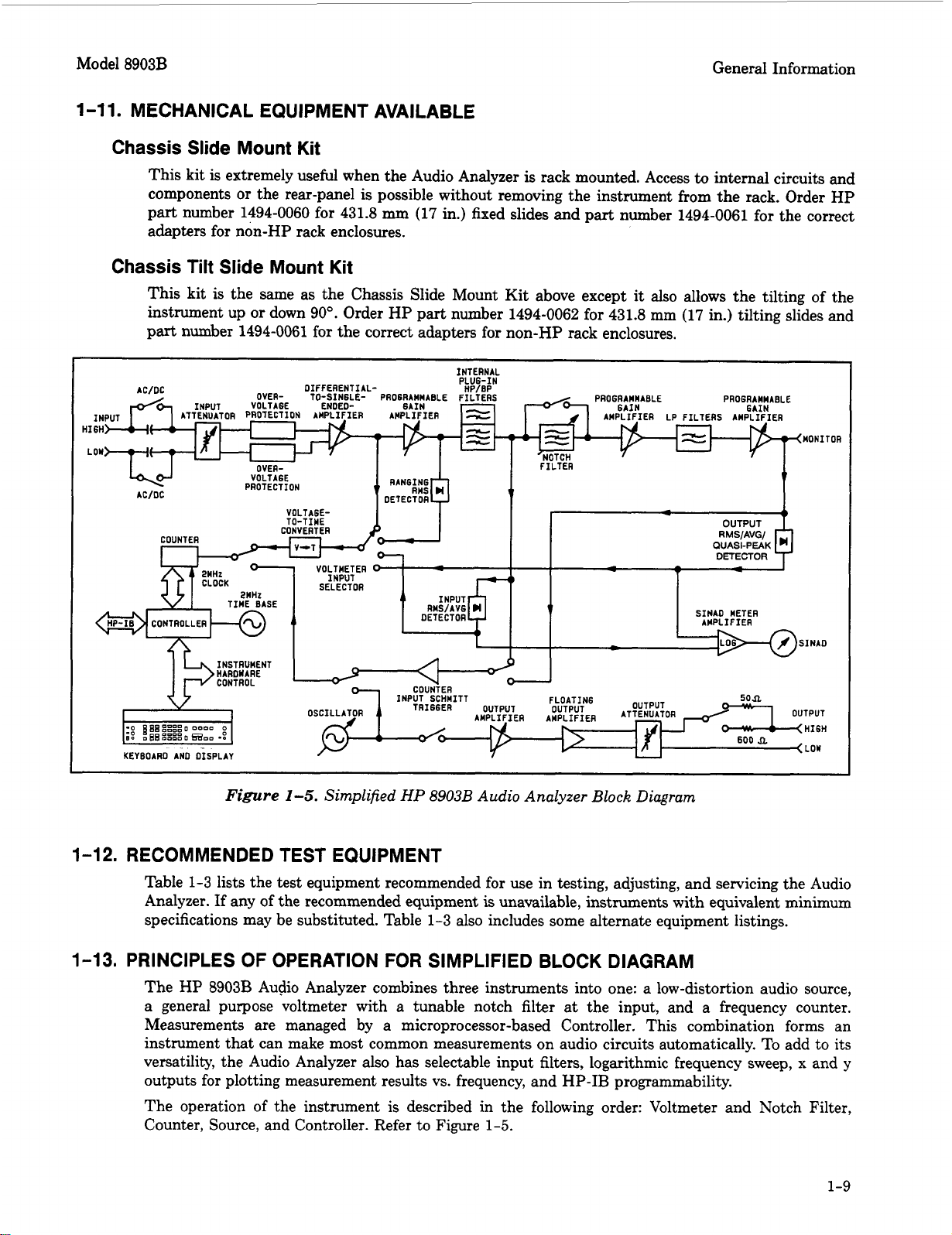

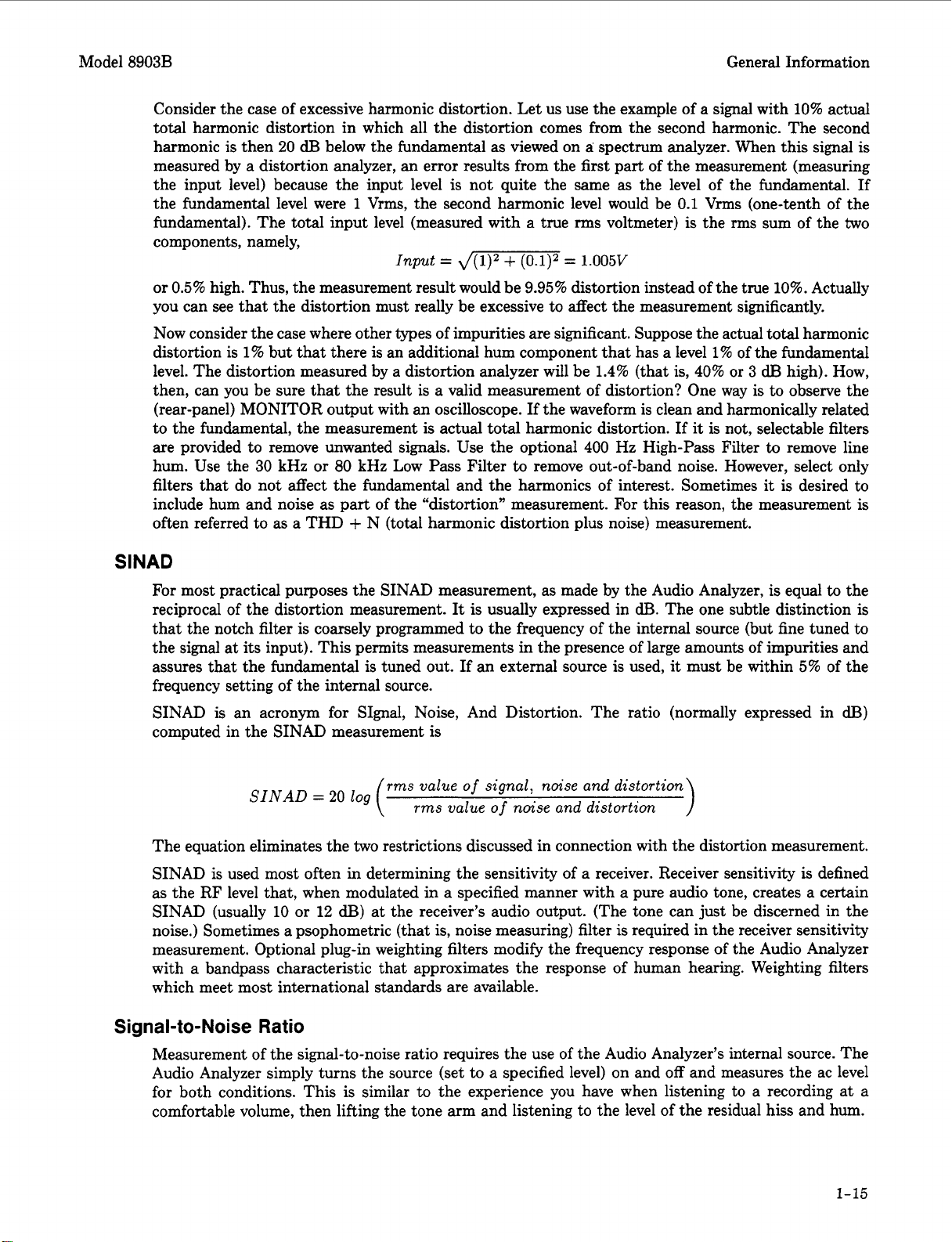

1-13.

PRINCIPLES OF OPERATION FOR SIMPLIFIED BLOCK DIAGRAM

The HP

8903B

Audio Analyzer combines three instruments into one: a low-distortion audio source,

a general purpose voltmeter with

a

tunable notch filter at the input, and a frequency counter.

Measurements are managed by a microprocessor-based Controller. This combination forms an

instrument that can make most common measurements on audio circuits automatically. To add to its

versatility, the Audio Analyzer also has selectable input filters, logarithmic frequency sweep,

x

and

y

outputs

for

plotting measurement results vs. frequency, and HP-IB programmability.

The operation

of

the instrument

is

described in the following order: Voltmeter and Notch Filter,

Counter, Source, and Controller. Refer to Figure

1-5.

1-9

General Information Model

8903B

Voltmeter

and

Notch

Filter

The amplitude measurement path flows from the INPUT connectors (HIGH and LOW) to the MONI-

TOR output (on the rear panel) and includes the Input RM$/Average and Output RMS/Average/Quasi-

Peak Detectors, dc voltmeter (the Voltage-to-Time Converter and Counter), and SINAD meter circuitry.

Measurements are made on the difference between the signals at the HIGH INPUT connector and the

LOW INPUT connector

(or

ground). Differential and common-mode levels can be as high as 300V.

Signals that are common to both the HIGH and LOW connectors are balanced out.

The input signal

is

ac coupled for all measurement modes except dc level. The signal

is

scaled by the

Input Attenuator to

a

level of 3V

or

less. To protect the active circuits that follow, the Over-Voltage

Protection circuit opens whenever its input exceeds 15V. The differential signal

is

converted

to

a

single-ended signal (that is, a signal referenced to ground) and amplified. In the dc level mode, the dc

voltage

is

measured at this point by the dc voltmeter. The signal

is

further amplified by a Programmable

Gain Amplifier which

is

ac coupled. The gain

of

this amplifier and the Differential-to-Single-Ended

Amplifier are programmed to keep the signal level into the Input Detector and Notch Filter between

1.7

and

3

Vrms

to

optimize their effectiveness and accuracy, particularly in the distortion and SINAD

modes.

The output from the first Programmable Gain Amplifier is converted to dc by the Ranging RMS

Detector and measured by the dc voltmeter. The output of this detector is used to set the gain of

the input circuits. The signal then passes through the

HP/BP

filters to the Input RMS/Average

Detector and becomes the numerator of the SINAD measurement and the denominator of the distortion

measurement (refer to

Basics

of

Audio Measurements).

The Input RMS/Average Detector

is

not used

to make the ac level measurement; the Output RMS/Average/Quasi-peak Detector is used for this

measurement. For dc level measurements, the Ranging RMS Detector also monitors the ac component

(if there

is

one) and lowers the gain of the input path

if

the signal will overload the input amplifiers;

otherwise, the gain of the input path is determined by measuring the dc level.

At

this point, one of the

two internal plug-in filters can be inserted into the signal path. The

400

Hz high-pass filter

is

usually

used to suppress line hum

or

the low frequency squelch tone used on some mobile transceivers. The

weighting filters have bandpass frequency responses that simulate the “average” response of human

hearing. In the SINAD, distortion, and distortion level modes, the frequency of the input signal is

counted at the output of the internal plug-in HP/BP Filters.

When measuring SINAD, distortion,

or

distortion level, the fundamental of the signal is removed by

the Notch Filter. The output from the filter

is

the distortion and noise of the signal. In the ac level

and signal-to-noise ratio modes the Notch Filter

is

bypassed. After amplifying and low-pass filtering,

the output from the Notch Filter is converted to dc by the Output RMS/Average/Quasi-peak Detector

and measured by the dc voltmeter.

When measuring distortion

or

distortion level, the Notch Filter

is

automatically tuned to the frequency

counted at the input to the filter. Coarse tuning

is

via the Controller. Fine tuning and balance are via

circuitry internal to the Notch Filter. When measuring SINAD, the Notch Filter

is

coarse tuned by

the Controller to the same frequency as the internal source. Thus, a SINAD measurement

is

normally

only made with the internal source as the stimulus and permits measurements in the presence

of

large amounts of noise (where the Controller would be unable to determine the input frequency).

If

an

external source

is

used in the SINAD measurement mode, the source frequency must be within

5%

of

the frequency of the internal source. The

two

Programmable Gain Amplifiers, following the Notch

Filter, amplify the low-level noise and distortion signals from the Notch Filter. The overall gain of the

two amplifiers is normally set to maintain a signal level of

0.3

to 3V at the MONITOR output.

The 30 kHz and

80

kHz LP Filters are selected from the Keyboard. With no low-pass filtering,

the

3

dB

bandwidth of the measurement system is approximately

750

kHz. The filters are most

often used to remove the high-frequency noise components in low-frequency SINAD and distortion

measurements. The output from the second Programmable Gain Amplifier drives the rear-panel

MONITOR output connector. The frequency of this signal

is

also measured by the Counter in the

ac

level

and signal-to-noise ratio measurement modes because of the increased sensitivity at this point.

The Output Detector is read by the dc voltmeter in the ac level, SINAD (the denominator), distortion

(the numerator), distortion level, and signal-to-noise ratio measurement modes.

It

is also used to set the

1-10

Model

8903B

General Information

gain

of

the

two

Programmable Gain Amplifiers. Both the input and output detectors can be configured

via special functions to respond to the absolute average of the signal instead

of

the true

rms

value.

In the SIN AD mode the outputs from the Input RMS/Average and Output RMS/Average/Quasi-peak

Detectors are converted to a current representing the log of the ratio

of

the

two

signals by the SINAD

Meter Amplifier

to

drive the SINAD panel meter. Since SINAD measurements are often made under

very noisy conditions, the panel meter makes

it

easier

to

average the reading and to discern trends.

The Voltage-to-Time Converter converts the dc inputs into a time interval which

is

measured by the

Counter. The Output Detector can also be configured via special functions to respond

to

the quasi-peak

of the signal. This type of detector

is

designed

to

respond to impulse type signals better than other

types. The Quasi-peak Detector has a fast rise time coupled with a slow decay time constant which

“captures” impulses

or

other

signals

with a high crest factor (noise

or

repetitive signal bursts).

Counter

The Counter

is

a reciprocal counter. To measure frequency, it counts the period of one

or

more cycles

of the signal at

its

input, then the Controller divides the number of periods by the accumulated count.

The reference

for

the Counter is the

2

MHz Time Base which also is the clock for the Controller. The

Counter has four inputs and three modes of operation:

Voltage Measurement.

The time interval from the Voltage-to-Time Converter

is

counted. The

accumulated count is proportional

to

the dc voltage.

For

direct measurements (ac level, dc level,

and distortion level), the count

is

processed directly by the Controller and displayed on the right

display. For ratio measurements (SIN

AD,

distortion, and signal-to-noise), the counts

of

two

successive

measurements are processed and displayed. For SINAD and distortion, the ratio of the output of the

Input RMS/Average Detector and Output RMSIAveragejQuasi-Peak Detector

is

computed. For signal-

to-noise, the ratio of

two

consecutive outputs from the Output RMS/Average/Quasi-peak Detector is

computed. One output is with the Oscillator on, the other is with the Oscillator

off.

Input Frequency Measurement.

The signal from the last Programmable Gain Amplifier or the HP/BP

Filters is conditioned by the Counter Input Schmitt Trigger to make it compatible with the Counter’s

input. The period of the signal is then counted, the count

is

processed by the Controller, and the

frequency is displayed on the left display.

Source Frequency Measurement.

The Counter measures the frequency

of

the internal source only

when the Oscillator

is

being tuned. The frequency is normally not displayed. To make a measurement

of the source frequency, the output

of

the Oscillator is fed

into

the Counter, the period measured,

and

the result processed by the Controller.

Source

The source covers the frequency range from

20

Hz

to

100

kHz.

It is tuned to the frequency entered

from Keyboard by the Controller using a tune-and-count routine. (Note that the frequency is not

obtained by frequency synthesis.) The switch following the Oscillator is normally closed except in the

signal-to-noise ratio measurement mode

or

when an amplitude of OV

is

entered from the Keyboard.

The output from the Oscillator

is

approximately

3V.

The Output Amplifier sets the source output level in fine steps. The Floating Output Amplifier converts

the single-ended input into a floating signal (either output can be grounded

or

floated up to

1OV

peak).

The Output Attenuator sets the output level in coarse steps. The maximum signal to the OUTPUT

connectors is 6V into an open circuit

or

3V into the matching termination. The output impedance of

the source is

HP-IB

programmable to either

50

or

600R. (The keyboard-selected level

is

the open-circuit

level.)

1-11

General Information Model

8903B

Controller

The entire operation of the instrument is under control of a microprocessor-based Controller. The

Controller sets up the instrument at turn-on, interprets Keyboard entries, executes changes

in

mode

of operation, continually monitors instrument operation, sends measurement results and errors to the

front-panel displays, and interfaces with HP-IB. In addition, its computing capability

is

used

to

simplify

circuit operation.

For

example, it forms the last stage of the Counter, converts measurement results

into ratios (in

’3%

or

dB),

etc. It also contains routines useful for servicing the instrument.

1-14.

BASICS

OF

AUDIO MEASUREMENTS

The “audion frequency range is usually taken to be from

20

Hz to

20

kHz. Few people have hearing

that good, but the term is a convenient one to describe sub-RF frequencies encountered in electronics.

The frequency range of the Audio Analyzer extends beyond the audio range

to

include fundamentals

up

to

100

kHz.

Electronic instrumentation provides most of the tools for quantitative analysis of audio signals. Thus,

if

the signal is non-electrical (for example, mechanical

or

acoustic),

it

must be converted

to

an electrical

signal by a transducer of some kind (for example, strain gauge or microphone) before

it

can be analyzed.

Apart

from attentive listening

to

a hi-fi system, the most intuitive way of analyzing an electrical signal

in the audio range

is

visually with an oscilloscope. Here you get a feeling for the signal’s size (loudness),

frequency (pitch), and shape (timbre). You can also determine

if

these parameters change with time

or

are stable, and you can even make some quantitative measurements on it (for example, peak level, dc

offset, period, risetime, etc.). Many times, however, the parameter sought does not lend itself

to

easy

visual analysis. Thus, the Audio Analyzer was designed.

It

combines into one instrument a series of

general and specialized instruments, under microprocessor control, that make it easy for you to obtain

accurate, quantitative measurements on audio signals of any general waveshape.

AC

Level

Consider the very common measurement of a signal’s ac rms level. To make this measurement with

an oscilloscope, you must first decide the nature of the signal, because from it, the relationship of the

peak level to the

rms

level can be mathematically determined. If the signal is sinusoidal, for example,

the rms value

is

the peak amplitude divided by

a.

This measurement is greatly simplified with a rms voltmeter which electronically measures the rms

level and displays the result. However, no other information about the signal is provided. The Audio

Analyzer contains both an rms- and an average-responding voltmeter. The

rms

level of the signal

is

displayed whenever the AC

LEVEL

mode is selected. The average level can be displayed by entering

5.2

SPCL. The quasi-peak level can be displayed by entering

5.7

SPCL.

A

special function

is

also provided