Honda BF25, BF30 Owner's Manual

The engine exhaust from this product

contains chemicals known to the State

of California tlo cause cancer, birth

defects or other reproductive harm.

Keep this owner’s manual handy, so you can refer to it at any time. This owner’s manual is

considered a permanent part of the outboxd motor and should remain with the outboard

motor if resold.

The information and specifications included in this publication were in effect at the time of

approval for printing. Honda Motor Co., Ltd. reserves the right, however, to discontinue or

change specifications or design at any time without notice and without incurring any

obligation whatever. No part of this publication may be reproduced without written permis-

sion.

INTRODUCTION

Congratulations on your selection of a

Honda outboard motor. We are certain

you will be pleased with your purchase

of one of the finest outboard motors on

the market.

We want to help you get the best results

from your new outboard motor and to

operate it safely. This manual contains

the information on how to do that;

please read it carefully.

As you read this manual, you will find

information preceded by a -1

symbol. That information is intended to

help you avoid damage to your outboard

motor, other property, or the environ-

ment.

We suggest you read the warranty policy

to fully understand its coverage and your

responsibilities of ownership. The

warranty policy is a separate document

that should have been given to you by

your dealer.

When your outboard motor needs

scheduled maintenance, keep in mind

that your Honda marine dealer is

specially trained in servicing Honda

outboard motors. Your Honda marine

dealer is dedicated to your satisfaction

and will be pleased to answer your

questions and concerns.

0 1999 Honda Motor Co., Ltd.

All Right Reserved

1

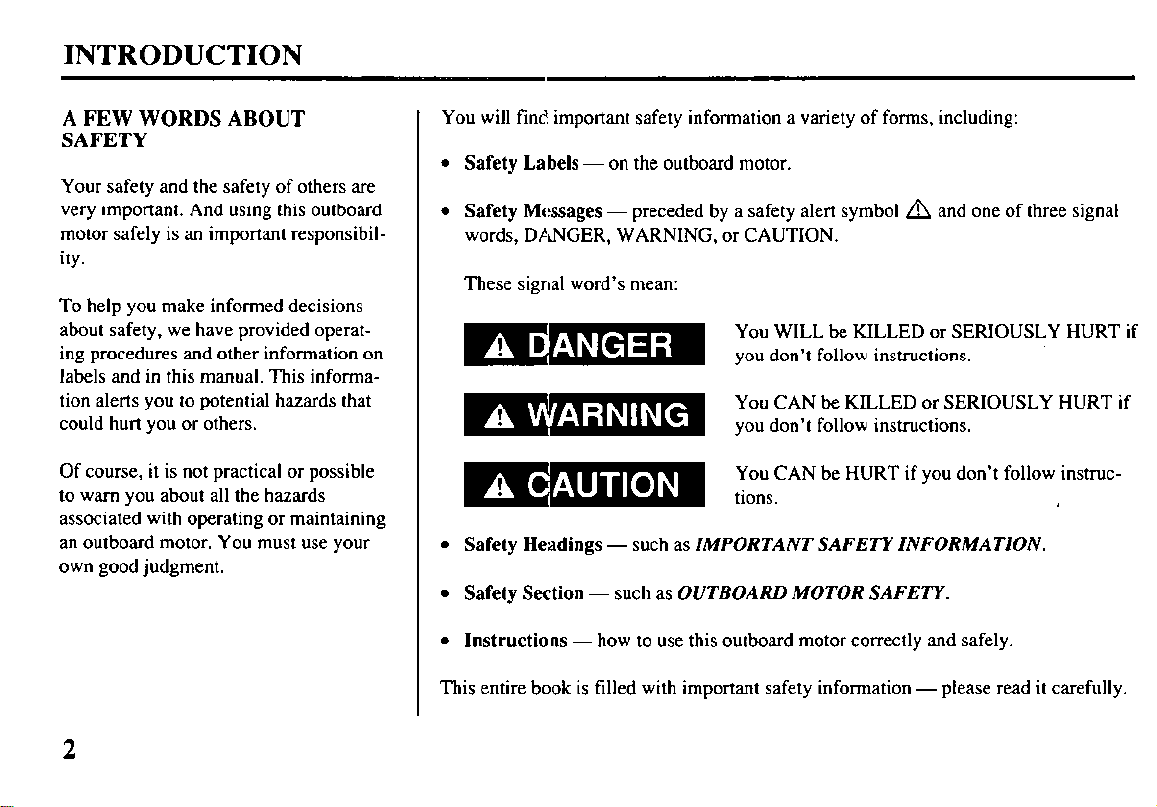

INTRODUCTION

A FEW WORDS ABOUT

SAFETY

Your safety and the safety of others are

very important. And using this outboard

motor safely is an important responsibil-

ity.

To help you make informed decisions

about safety, we have provided operat-

ing procedures and other information on

labels and in this manual. This informa-

tion alerts you to potential hazards that

could hurt you or others.

Of course, it is not practical or possible

to warn you about all the hazards

associated with operating or maintaining

an outboard motor. You must use your

own good judgment.

You will find important safety information a variety of forms, including:

l Safety Labels - on the outboard motor.

.

Safety Messages - preceded by a safety alert symbol A and one of three signal

words, DANGER, WARNING, or CAUTION.

These signal word’s mean:

You WILL be KILLED or SERIOUSLY HURT

you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT i

you don’t follow instructions.

l Safety Headings - such as IMPORTANT SAFETY INFORMATION.

l Safety Section - such as OUTBOARD MOTOR SAFETY.

l Instructions - how to use this outboard motor correctly and safely.

This entire book is filled with important safety information - please read it carefully.

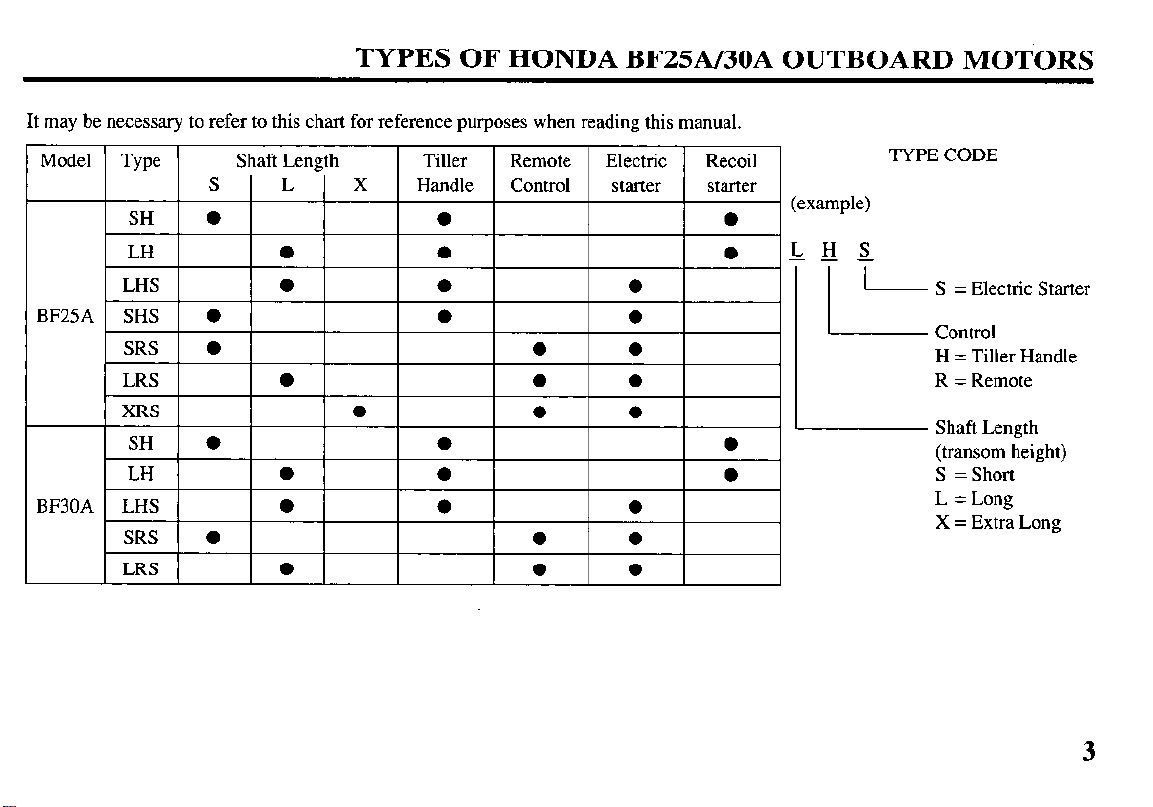

TYPES OF HONDA BF25A/30A OUTBOARD MOTORS

It may be necessary to refer to this chart for reference purposes when reading this manual.

TYPE CODE

(example)

LHS

-

I S = Electric Starter

Control

H = Tiller Handle

R = Remote

Shaft Length

(transom height)

S = Short

L = Long

X = Extra Long

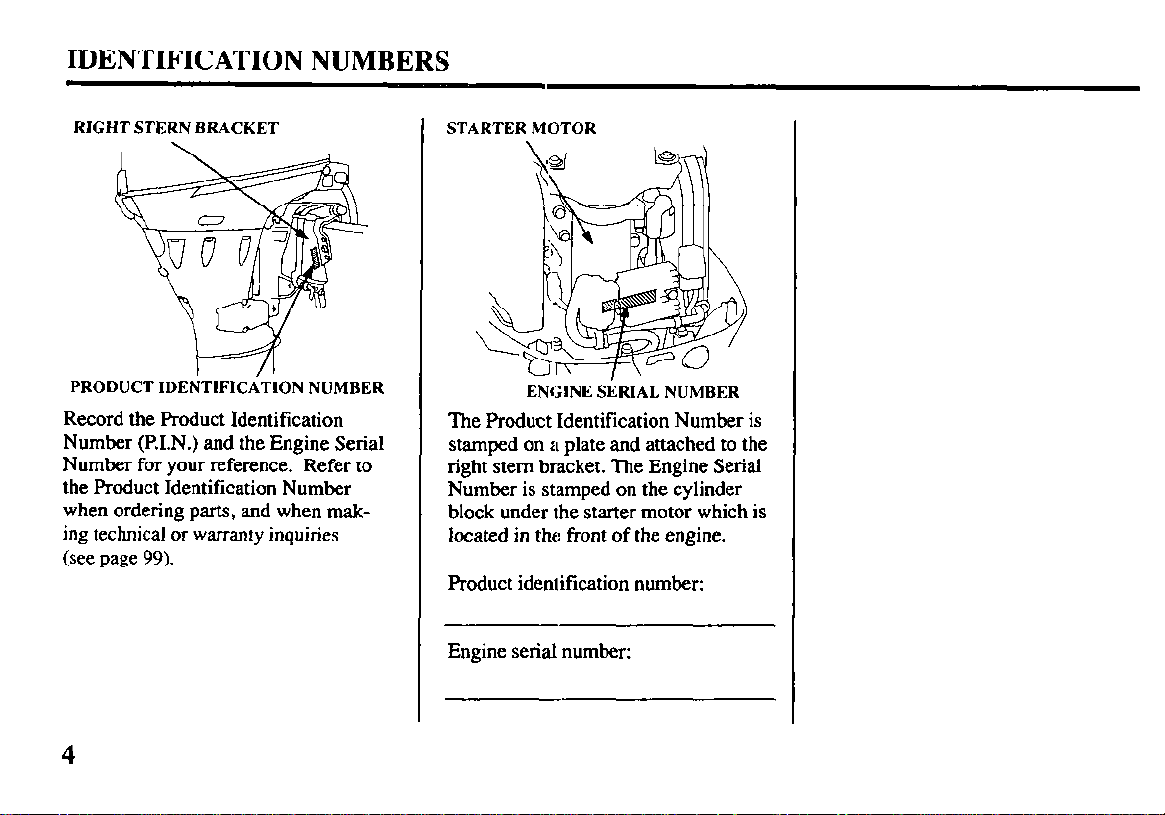

IDENTIFICATION NUMBERS

RIGHT STERN BRACKET

PRODUCT IDENTIFICiTION

NUMBER

Record the Product Identification

Number (P.I.N.) and the Engine Serial

Number for your reference. Refer to

the Product Identification Number

when ordering parts, and when mak-

ing technical or warranty inquiries

(see page 99).

1 STARTER MOTOR

ENGINE SERIAL NUMBER

The Product Identification Number is

stamped on a plate and attached to the

right stem bracket. The Engine Serial

Number is stamped on the cylinder

block under the starter motor which is

located in the front of the engine.

Product identification number:

Engine serial number:

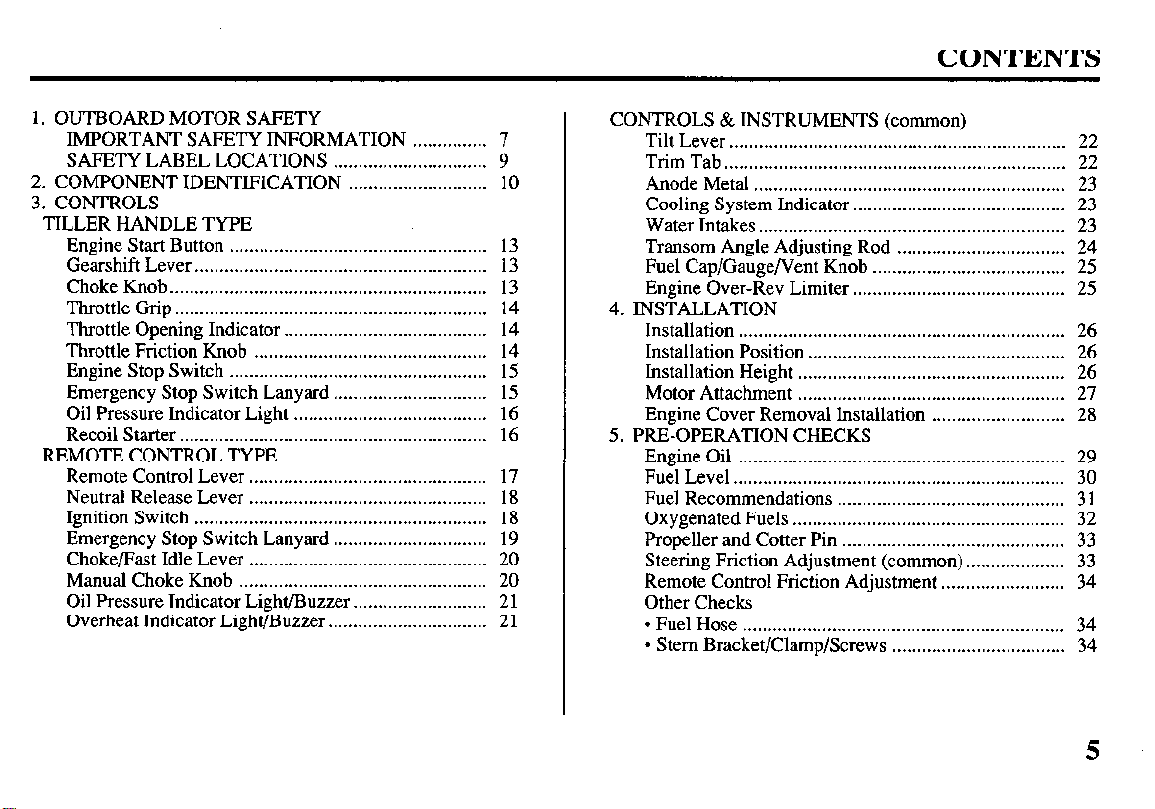

CONTENTS

1. OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY INFORMATION

............... 7

SAFETY LABEL LOCATIONS ...............................

9

2.

COMPONENT IDENTIFICATION ............................

10

3. CONTROLS

TILLER HANDLE TYPE

Engine Start Button ....................................................

13

Gearshift Lever

...........................................................

13

Choke Knob.. ..............................................................

13

Throttle Grip ...............................................................

14

Throttle Opening Indicator

.........................................

14

Throttle Friction Knob

...............................................

14

Engine Stop Switch ....................................................

15

Emergency Stop Switch Lanyard ...............................

15

Oil Pressure Indicator Light .......................................

16

Recoil Starter ..............................................................

16

REMOTE CONTROL TYPE

Remote Control

Lever

................................................

17

Neutral Release

Lever ................................................

18

Ignition Switch

...........................................................

18

Emergency Stop Switch Lanyard

...............................

19

Choke/Fast Idle

Lever ................................................

20

Manual Choke Knob

..................................................

20

Oil Pressure Indicator Light/Buzzer

........................... 21

Overheat Indicator Light/Buzzer

................................

2 1

CONTROLS & INSTRUMENTS (common)

Tilt

Lever.. ..................................................................

22

Trim

Tab.. ...................................................................

22

Anode

Metal ...............................................................

23

Cooling

System Indicator..

.........................................

23

Water

Intakes.. ............................................................

23

Transom

Angle Adjusting Rod

..................................

24

Fuel Cap/Gauge/Vent Knob

.......................................

25

Engine Over-Rev

Limiter

...........................................

25

4. INSTALLATION

Installation

..................................................................

26

Installation

Position ....................................................

26

Installation

Height ......................................................

26

Motor Attachment

......................................................

27

Engine Cover Removal Installation

...........................

28

5. PRE-OPERATION CHECKS

Engine

Oil ..................................................................

29

Fuel

Level ...................................................................

30

Fuel

Recommendations ..............................................

3 1

Oxygenated

Fuels .......................................................

32

Propeller and Cotter Pin

.............................................

33

Steering Friction Adjustment (common).

...................

33

Remote Control Friction Adjustment

.........................

34

Other Checks

l

Fuel

Hose .................................................................

34

l

Stern Bracket/Clamp/Screws

...................................

34

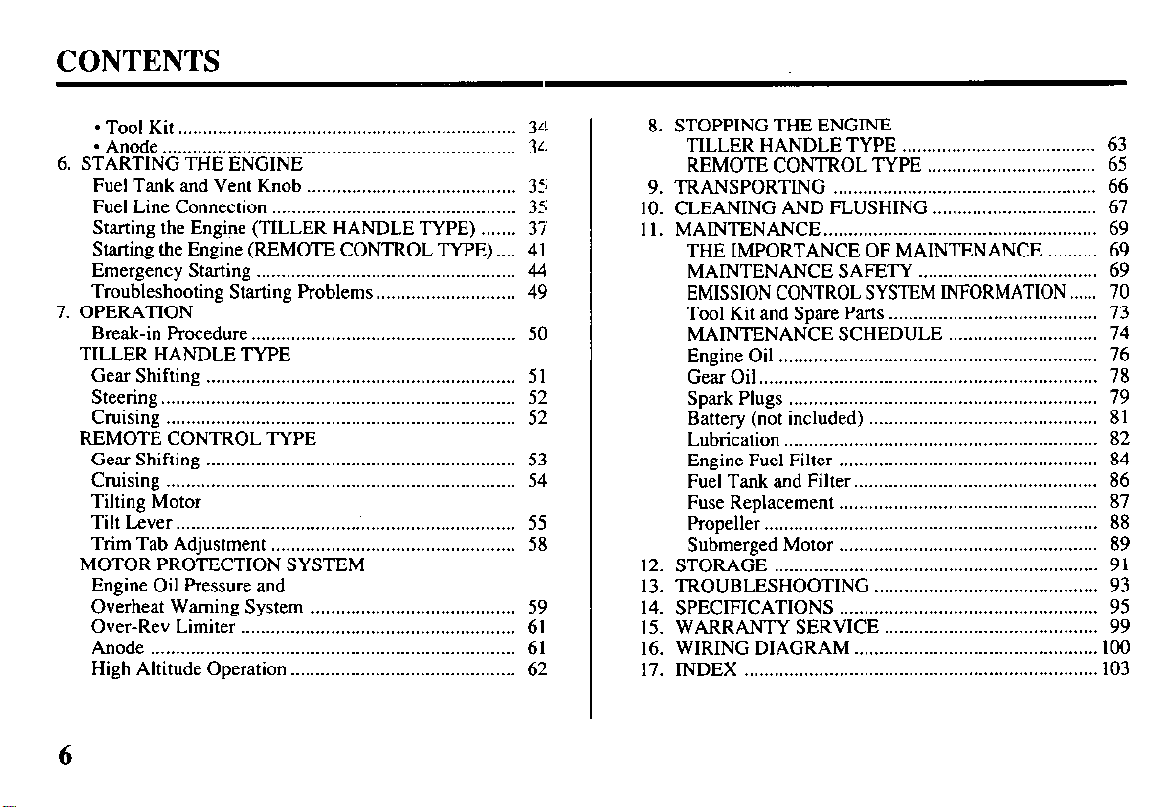

5

CONTENTS

l

Tool Kit.. ..................................................................

34

l

Anode

.......................................................................

3L.

6. STARTING THE ENGINE

Fuel Tank and

Vent Knob .......................................... 3:~

Fuel Line Connection .................................................

35

Starting the Engine (TILLER HANDLE TYPE)

....... 35

Starting the Engine (REMOTE CONTROL TYPE).

...

41

Emergency Starting

.................................................... 44

Troubleshooting

Starting Problems

............................

49

7. OPERATION

Break-in Procedure

..................................................... 50

TILLER HANDLE TYPE

Gear Shifting

.............................................................. 5 1

Steering..

.....................................................................

52

Cruising

......................................................................

52

REMOTE CONTROL TYPE

Gear Shifting

..............................................................

53

Cruising ......................................................................

54

Tilting Motor

Tilt Lever

....................................................................

Trim Tab Adjustment

.................................................

:‘8

MOTOR PROTECTION SYSTEM

Engine Oil Pressure and

Overheat Warning

System

.........................................

59

Over-Rev Limiter .......................................................

61

Anode .........................................................................

61

High Altitude

Operation ............................................. 62

8. STOPPING THE ENGINE

TILLER HANDLE TYPE ....................................... 63

REMOTE CONTROL TYPE .................................. 65

9. TRANSPORTING

..................................................... 66

10. CLEANING AND FLUSHING

................................. 67

11. MAINTENANCE

....................................................... 69

THE IMPORTANCE OF MAINTENANCE .......... 69

MAINTENANCE SAFETY .................................... 69

EMISSION CONTROL SYSTEM INFORMATION.. .... 70

Tool Kit and Spare Parts .......................................... 73

MAINTENANCE SCHEDULE .............................. 74

Engine Oil ................................................................ 76

Gear Oil

....................................................................

78

Spark Plugs

..............................................................

79

Battery (not included) .............................................. 81

Lubrication

...............................................................

82

Engine Fuel Filter .................................................... 84

Fuel Tank and Filter..

...............................................

86

Fuse Replacement .................................................... 87

Propeller ................................................................... 88

Submerged Motor .................................................... 89

12. STORAGE

................................................................. 91

13. TROUBLESHOOTING

............................................. 93

14.

SPECIFICATIONS .................................................... 95

15.

WARRANTY SERVICE ........................................... 99

16.

WIRING DIAGRAM ................................................. 100

17. INDEX

.......................................................................

103

6

1. OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY

INFORMATION

Honda BF25A and BF30A outboard

motors are designed for use with boats

that have a suitable manufacturer’s

power recommendation, and other uses

can result in injury to the operator or

damage to the outboard motor and other

property.

Most accidents can be prevented if you

follow all instructions in this manual and

on the outboard motor. The most

common hazards are discussed below,

along with the best way to protect

yourself and others.

Operator Responsibility

It is the operator’s responsibility to

provide the necessary safeguards to

protect people and property. Know

how to stop the engine quickly in

case of emergency. Understand the

use of all controls.

Stop the engine immediately if

anyone falls overboard, and do not

run the engine while the boat is near

anyone in the water.

Always stop the engine if you must

leave the controls for any reason.

Attach the emergency stop switch

lanyard securely to the operator.

l

Always wear a PFD (Personal

Flotation Device) while on the boat.

l

Familiarize yourself with all laws and

regulations relating to boating and the

use of outboard motors.

l

Be sure that anyone who operates the

outboard motor receives proper

instruction.

l

Be sure the outboard motor is

properly mounted on the boat.

l

Do not remove the engine cover

while the engine is running.

l

Do not attempt to modify the out-

board motor.

l

Do not remove any labels, covers, or

safety devices; they are installed for

your safety.

1. OUTBOARD MOTOR SAFETY

Refuel With Care

l

Gasoline is extremely flammable, and

gasoline vapor can explode. Refuel

outdoors, in a well-ventilated area,

with the engine stopped. Never

smoke near gasoline, and keep other

flames and sparks away.

l

Remove any portable fuel tank from

the boat for refueling. Keep the

portable fuel tank away from the

battery or other potential spark

sources.

l

Refuel carefully to avoid spilling

fuel. Avoid overfilling the fuel tank.

l

After refueling, tighten the filler cap

securely. If any fuel is spilled, make

sure the area is dry before starting the

engine.

Carbon Monoxide Hazard

Exhaust gas contains poisonous carbon

monoxide. Avoid inhalation of exhaust

gas. Never run the engine in a closed

garage or confined area.

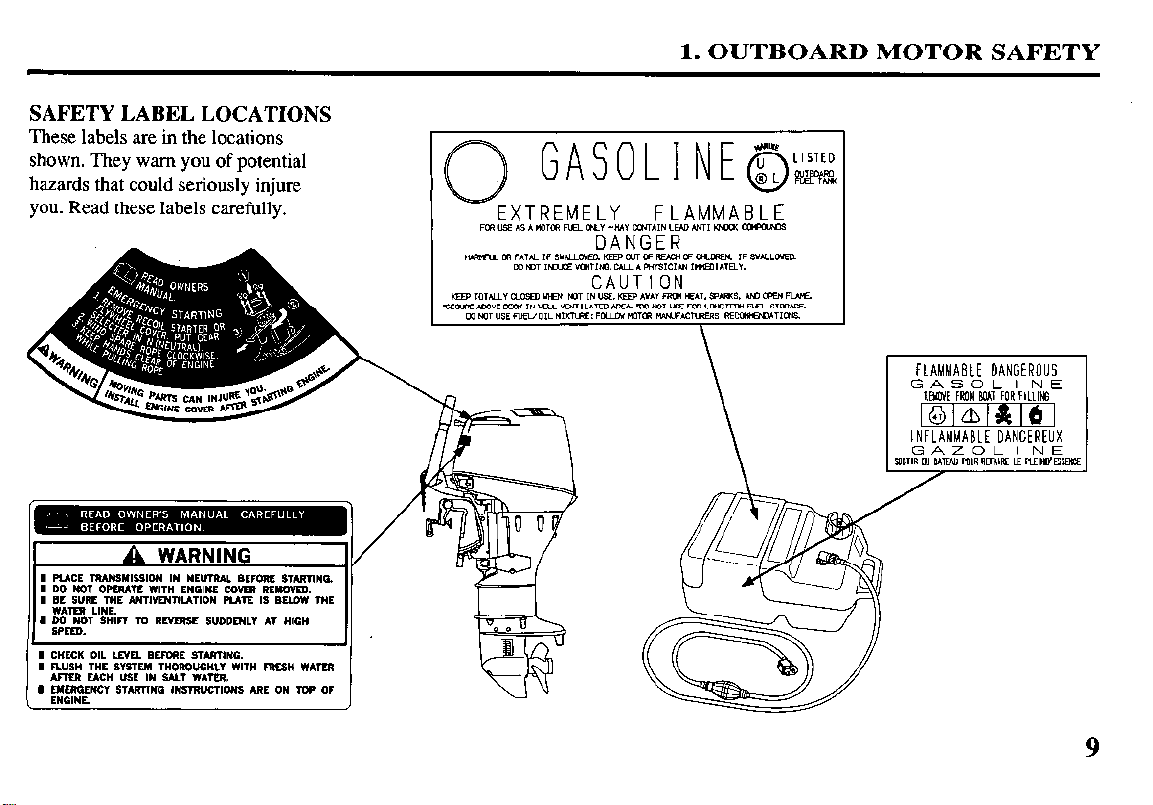

1. OUTBOARD MOTOR SAFETY

SAFETY LABEL LOCATIONS

These labels are in the locations

shown. They warn you of potential

hazards that could seriously injure

you. Read these labels carefully.

FLAMMABLE

*KlTcRRa(N”-n**m*r*LEmurrlw?ax-

DANGER

ITH FRESH WATEN

s ME ON mP OF

FLAMMABLE DANGEROUS

GASOL I NE

REWE FROM BOAT FOR FIttIM

INFLAMMABLE DANGEREUX

GAZOI- I NE

WIA UJ MWJI PDUR REFAIRE II PLEINUTSSENCE

9

2. COMPONENT IDENTIFICATION

(TILLER HANDLE TYPE)

FUEL LINE

OIL LEVEL DIPSTICK

STARTER GRIP

THROTTLE GRIP CONNECTOR

\- I

\

(Recoil starter

OIL FILLER CAP type)

ENGINE COVER

I /

--- - _--

OIL PRESSURE INDICATOR LIGHT

I

ENGINE

ETfi”

.AW

GEARSHIm LEVER

THRdI-TLE

FRICTION KNOB

ANTICAVITATION

PLATE

I

ENGINE START

(Electric starter type)

LEVEL PLUG

TRIM TAB

(ANODE METAL)

WASH PLUC

(Flush plug)

EXHAUST PORT

\

WATER INTAKE

’ I

EMERGENCY

STOP SWITCH

EMERGENCY

LANYARD

STOP SWITCH

CLIP

I

I

I

SPARE EMERGENCY

PROPELLER

STOP SWITCH CLIP

GEAR OIL DRAIN PLUG

10

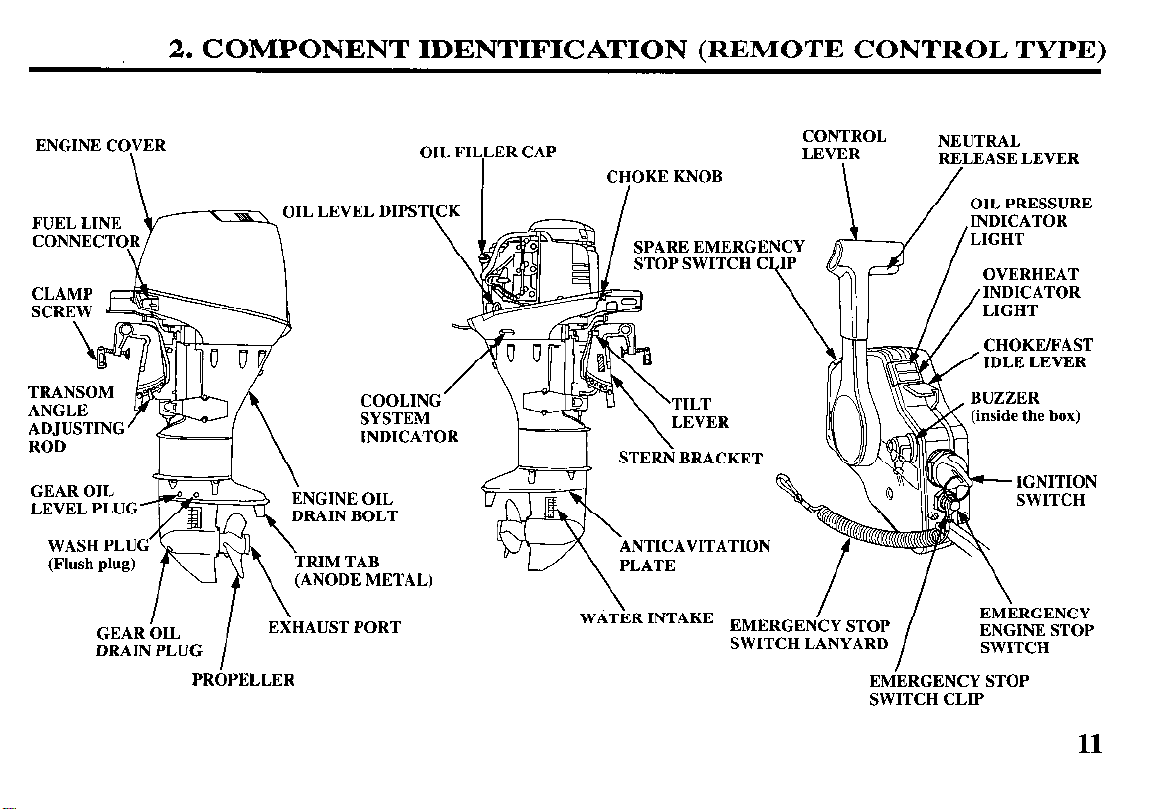

2. COMPONENT IDENTIFICATION

(REMOTE CONTROL TYPE)

ENGINE COVER

\

OIL FILLER CAP

CONTROL

NEUTRAL

LEVER

I

RELEASE LEVER

CHOKE KNOB

/

FUEL LINE

CONNECTO$--+ u’~ LEVEL

\

DIpsT~

TRANSOM

Mllik x

COOLING

TILT

SYSTEM

LEVER

1.1-r”. m-r.

OIL PRESSURE

OVERHEAT

CHOKE/FAST

IDLE LEVER

ANGLE

AD.HJSTINGYI vf

GEAR OIL

LEVEL PLUG

ENGINE OIL

DRAIN BOLT

WASH PLU

(Flush plug)

M TAB

ODE METAL)

I

I

\

GEAR OIL

EXHAUST PORT

DRAIN PLUG

\

/

WATER INTAKE EMERGENCY STOP

SWITCH LANYARD

EMERGENCY

ENGINE STOP

SWITCH

PRbPELLER

EMERGENCY STOP

SWITCH CLIP

11

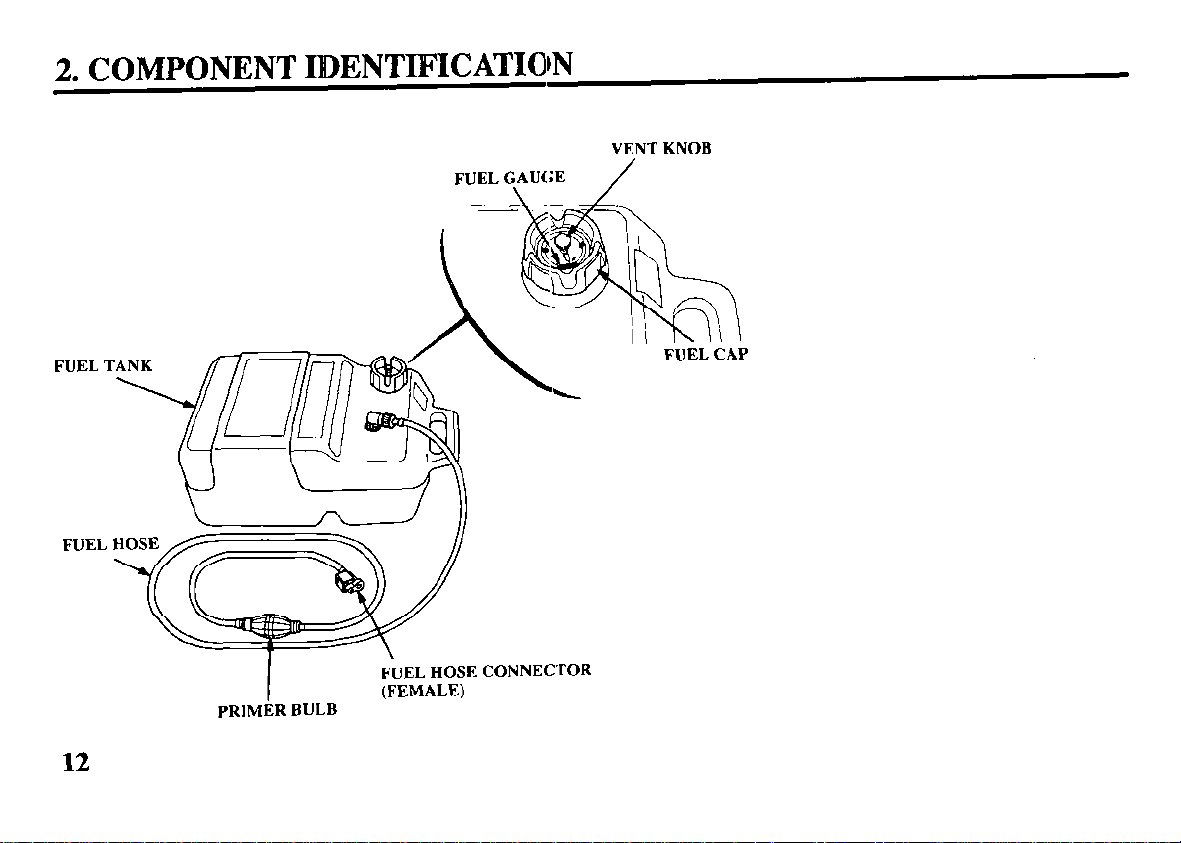

2. COMPONENT IDENTIFICATION

VENT KNOB

FUEL GAUGE

/

FUEL

FUEL CAP

FUEL

I

FUEL HOSE CONNECTOR

(FEMALE)

PRIMER BULB

12

3. CONTROLS (TILLER HANDLE TYPE)

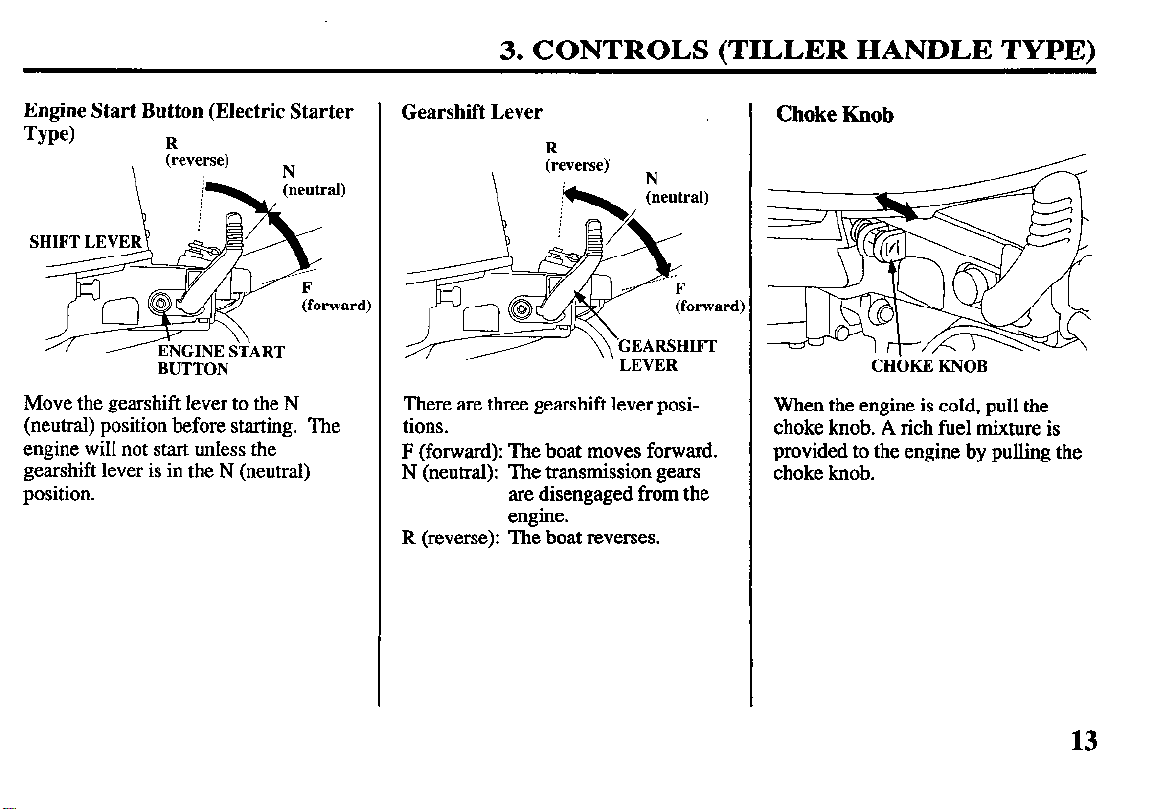

Engine Start Button (Electric Starter

BUTTON

Move the gearshift lever to the N

(neutral) position before starting. The

engine will not start unless the

gearshift lever is in the N (neutral)

position.

Gearshift Lever

There are three gearshift lever posi-

tions.

F (forward): The boat moves forward.

N (neutral): The transmission gears

are disengaged from the

engine.

R (reverse): The boat reverses.

Choke Knob

CHbKE KNOB

When the engine is cold, pull the

choke knob. A rich fuel mixture is

provided to the engine by pulling the

choke knob.

13

3. CONTROLS (TILLER IHANDLE TYPE)

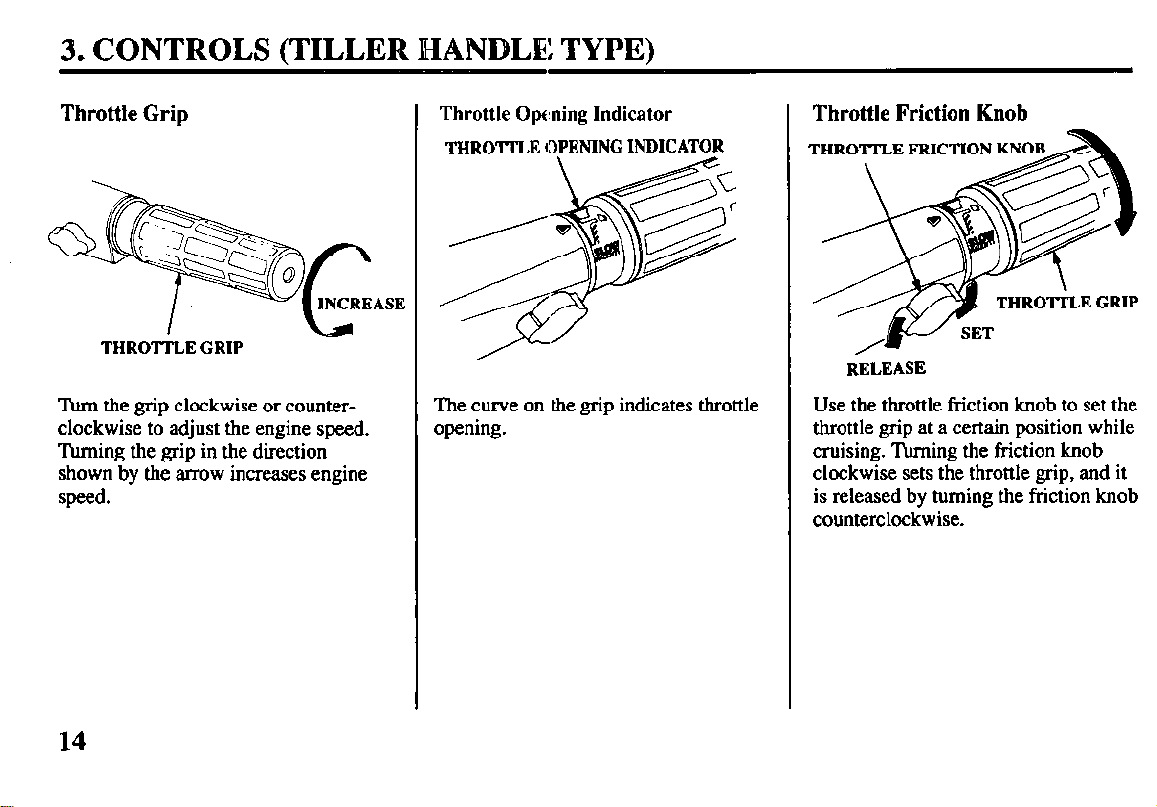

Throttle Grip

THROTTLE GRIP

Turn the grip clockwise or counter-

clockwise to adjust the engine speed.

Turning the grip in the direction

shown by the arrow increases engine

speed.

Throttle Opening Indicator

THROTI’LE OPENING INDICATOR

The curve on the grip indicates throttle

opening.

Throttle Friction Knob

RELEASE

Use

the throttle friction knob to set the

throttle grip at a certain position while

cruising. Turning the friction knob

clockwise sets the throttle grip, and it

is released by turning the friction knob

counterclockwise.

14

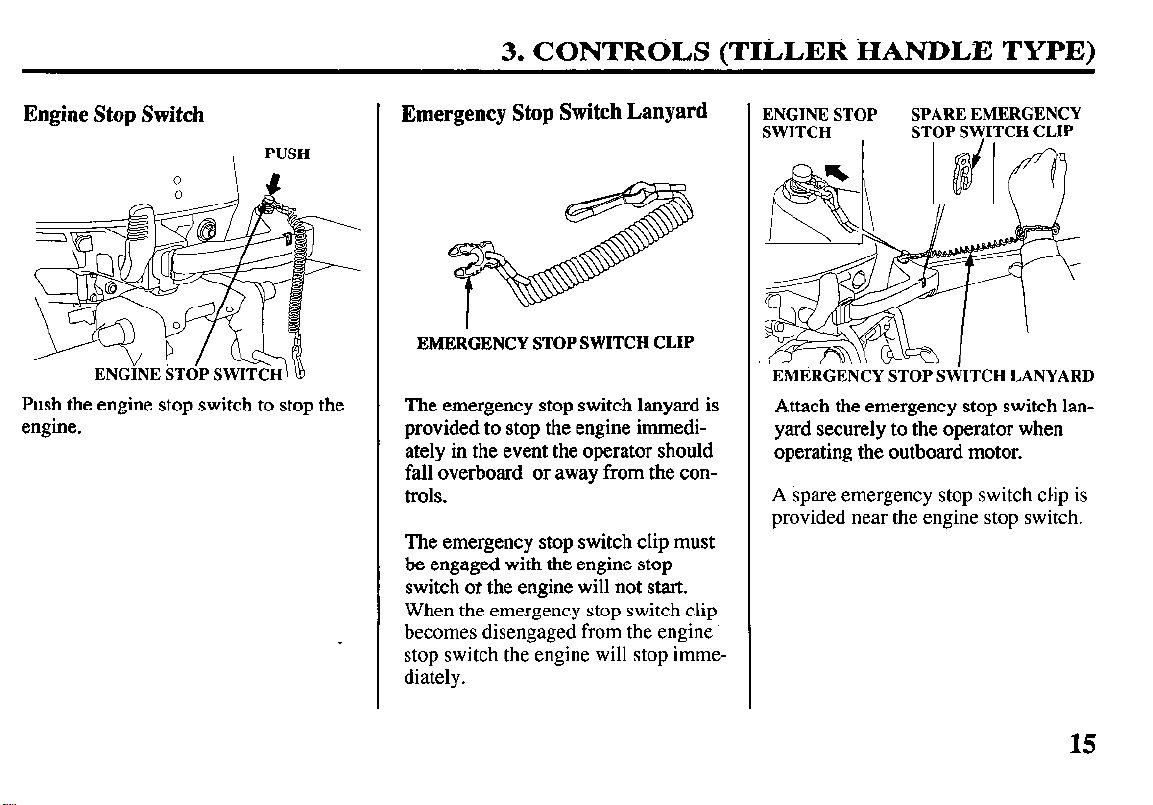

Engine Stop Switch

\ PUSH

Push the engine stop switch to stop the

engine.

Emergency Stop Switch Lanyard

EMERGENCY STOP SWITCH CLIP

The emergency stop switch lanyard is

provided to stop the engine immedi-

ately in the event the operator should

fall overboard or away from the con-

trols.

The emergency stop switch clip must

be engaged with the engine stop

switch or the engine will not start.

When the emergency stop switch clip

becomes disengaged from the engine

stop switch the engine will stop imme-

diately.

ENGINE STOP

SPARE EMERGENCY

SWITCH

STOP SWITCH CLIP

EMERGENCY STOP SWITCH LANYARD

Attach the emergency stop switch lan-

yard securely to the operator when

operating the outboard motor.

A spare emergency stop switch clip is

provided near the engine stop switch.

15

3. CONTROLS (TILLER IHANDLP~ TYPE)

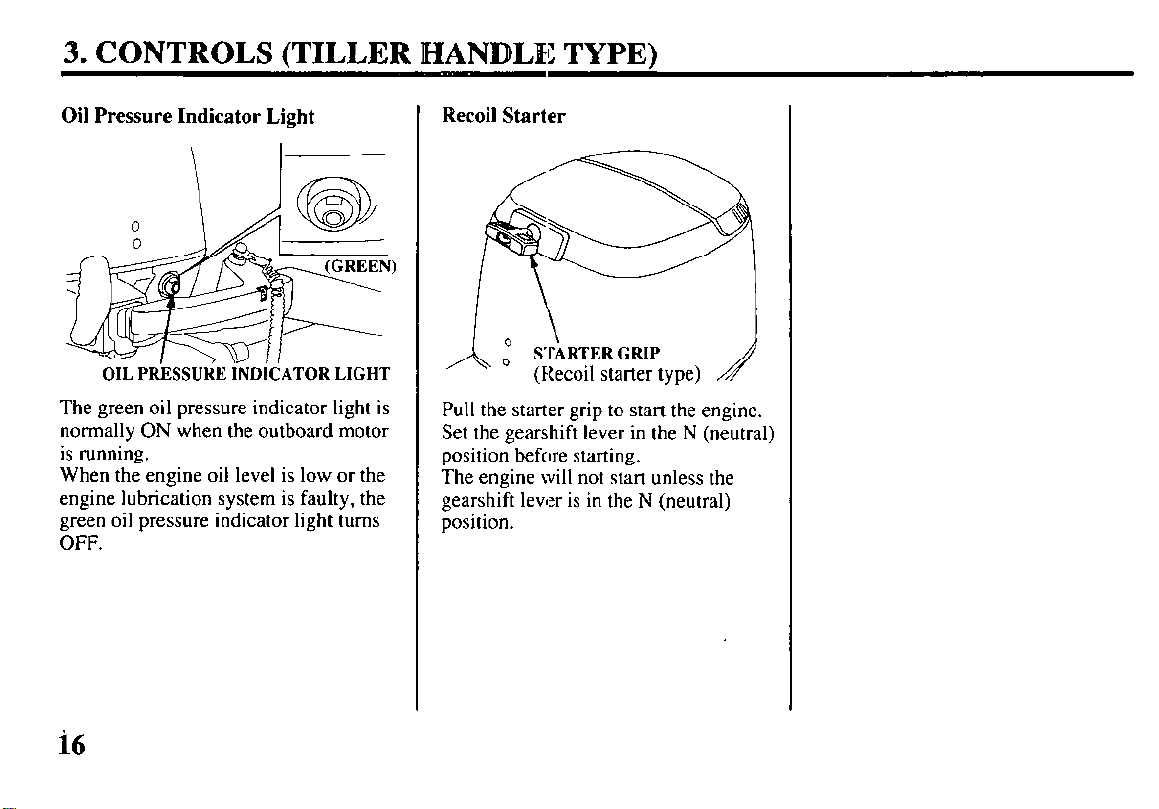

Oil Pressure Indicator Light

\ I

OIL PRESSURE INDICATOR LIGHT

The green oil pressure indicator light is

normally ON when the outboard motor

is running.

When the engine oil level is low or the

engine lubrication system is faulty, the

green oil pressure indicator light turns

OFF.

Recoil Starter

,” S’l’iRTER GRIP

(Recoil starter type)

Pull the starter grip to start the engine.

Set the gearshift lever in the N (neutral)

position before starting.

The engine will not start unless the

gearshift lever is in the N (neutral)

position.

i6

3. CONTROLS (REMOTE CONTROL TYPE:)

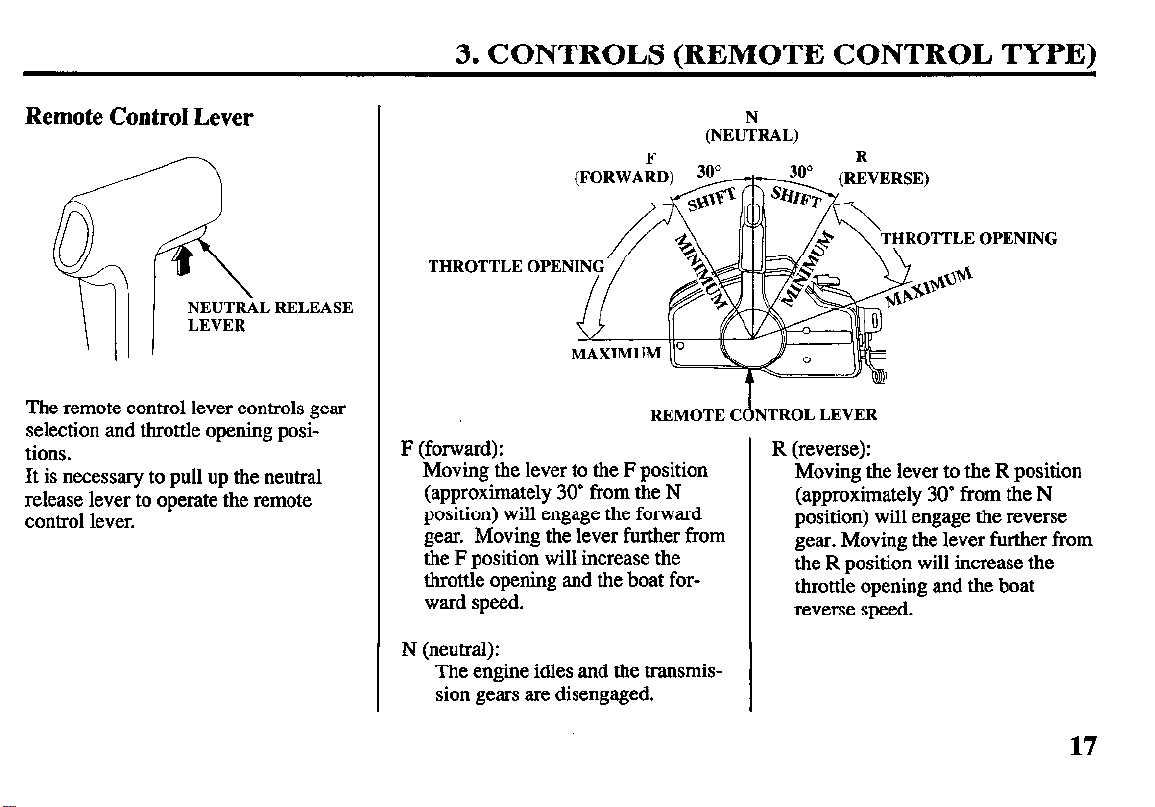

Remote Control Lever

1 II 1

LEVER

The remote control lever controls gear

selection and throttle opening posi-

tions.

It is necessary to pull up the neutral

release lever to operate the remote

control lever.

THROTTLE

(NE&&AL)

P

R

REMOTE CdNTROL LEVER

F (forward):

Moving the lever to the F position

(approximately 30’ from the N

position) will engage the forward

gear. Moving the lever further from

the F position will increase the

throttle opening and the boat for-

ward speed.

N (neutral):

The engine idles and the transmis-

sion gears am disengaged.

OPENING

R (reverse):

Moving the lever to the R position

(approximately 30’ from the N

position) will engage the reverse

gear. Moving the lever further from

the R position will increase the

throttle opening and the boat

reverse speed.

17

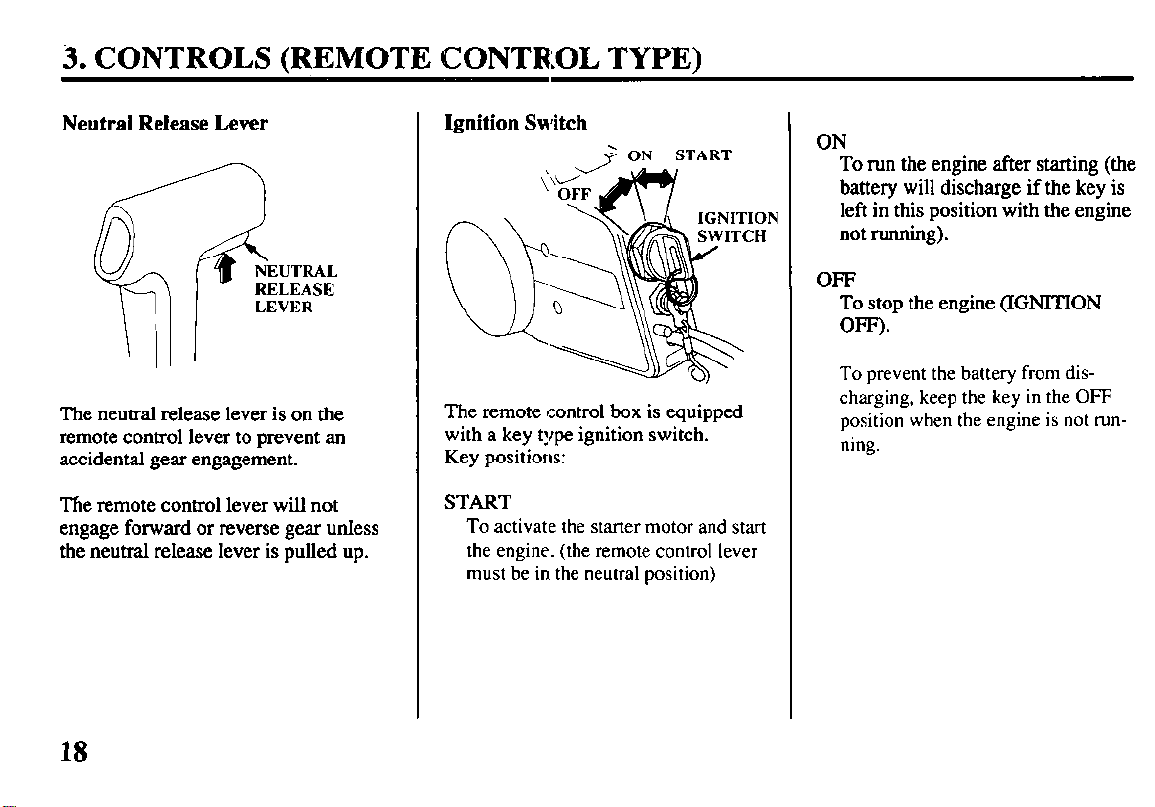

3. CONTROLS (REMOTE CONTROL TYPE)

Neutral Release Lever

1 il 1

The neutral release lever is on the

remote control lever to prevent an

accidental gear engagement.

The remote control lever will not

engage forward or reverse gear unless

the neutral release lever is pulled up.

Ignition Switch

START

The remote control box is equipped

with a key type ignition switch.

Key positions:

START

To activate the starter motor and start

the engine. (the remote control lever

must be in the neutral position)

ON

To run the engine after starting (the

battery will discharge if the key is

left in this position with the engine

not running).

OFF

To stop the engine (IGNITION

OFF).

To

prevent the battery from dis-

charging, keep the key in the OFF

position when the engine is not run-

ning.

18

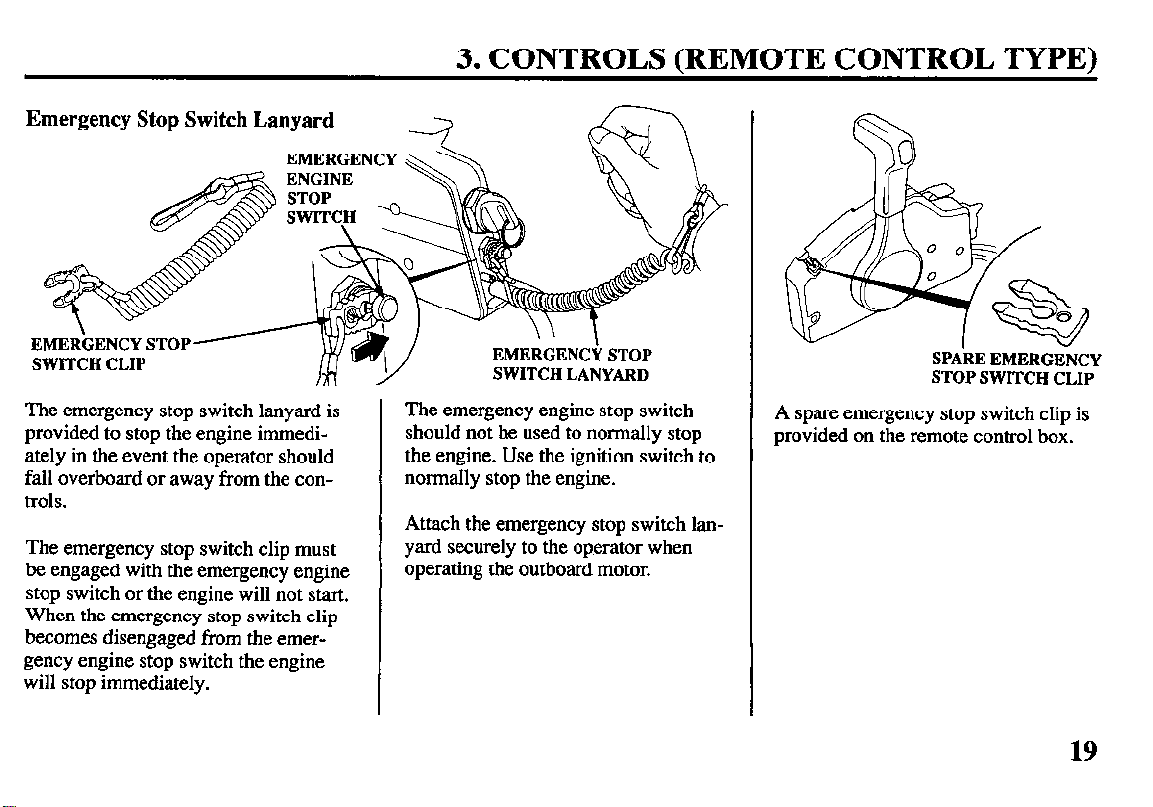

3. CONTROLS (REMOTE CONTROL TYPE)

Emergency Stop Switch Lanyard

4

EMERGENCY STOP

EMER\GENCY STOP’

SWITCH CLIP

The emergency stop switch lanyard is

provided to stop the engine immedi-

ately in the event the operator should

fall overboard or away from the con-

trols.

The emergency stop switch clip must

be engaged with the emergency engine

stop switch or the engine will not start.

When the emergency stop switch clip

becomes disengaged from the emer-

gency engine stop switch the engine

will stop immediately.

SWITCH LANYARD

The emergency engine stop switch

should not be used to normally stop

the engine. Use the ignition switch to

normally stop the engine.

Attach the emergency stop switch lan-

yard securely to the operator when

operating the outboard motor.

SPAkE EMERGENCY

STOP SWITCH CLIP

A spare emergency stop switch clip is

provided on the remote control box.

19

3. CONTROLS (REMOTE CONTRlOL TYPE)

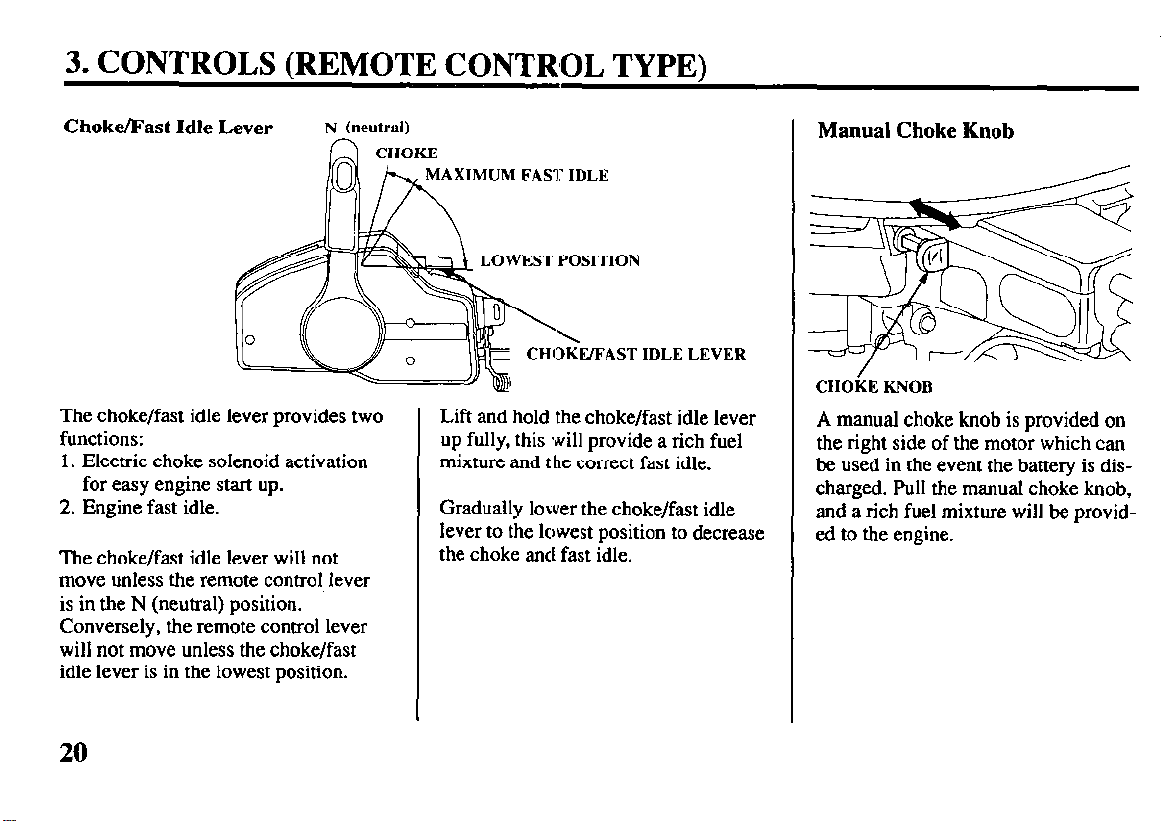

Choke/Fast

Idle

Lever

N (neutrd)

MAXIMUM FAST IDLE

LOWEST POSITION

-.d o ]& CHOKE/FAST IDLE

The choke/fast idle lever provides two

functions:

1. Electric choke solenoid activation

for easy engine start up.

2. Engine fast idle.

The choke/fast idle lever will not

move unless the remote control lever

is in the N (neutral) position.

Conversely, the remote control lever

will not move unless the choke/fast

idle lever is in the lowest position.

LEVER

Lift and hold the choke/fast idle lever

up fully, this will provide a rich fuel

mixture and the correct fast idle.

Gradually lower the choke/fast idle

lever to the lowest position to decrease

the choke and fast idle.

Manual Choke Knob

CHOKE KNOB

A manual choke knob is provided on

the right side of the motor which can

be used in the event the battery is dis-

charged. Pull the manual choke knob,

and a rich fuel mixture will be provid-

ed to the engine.

20

3. CONTROLS (REMOTE CONTROL TYPE)

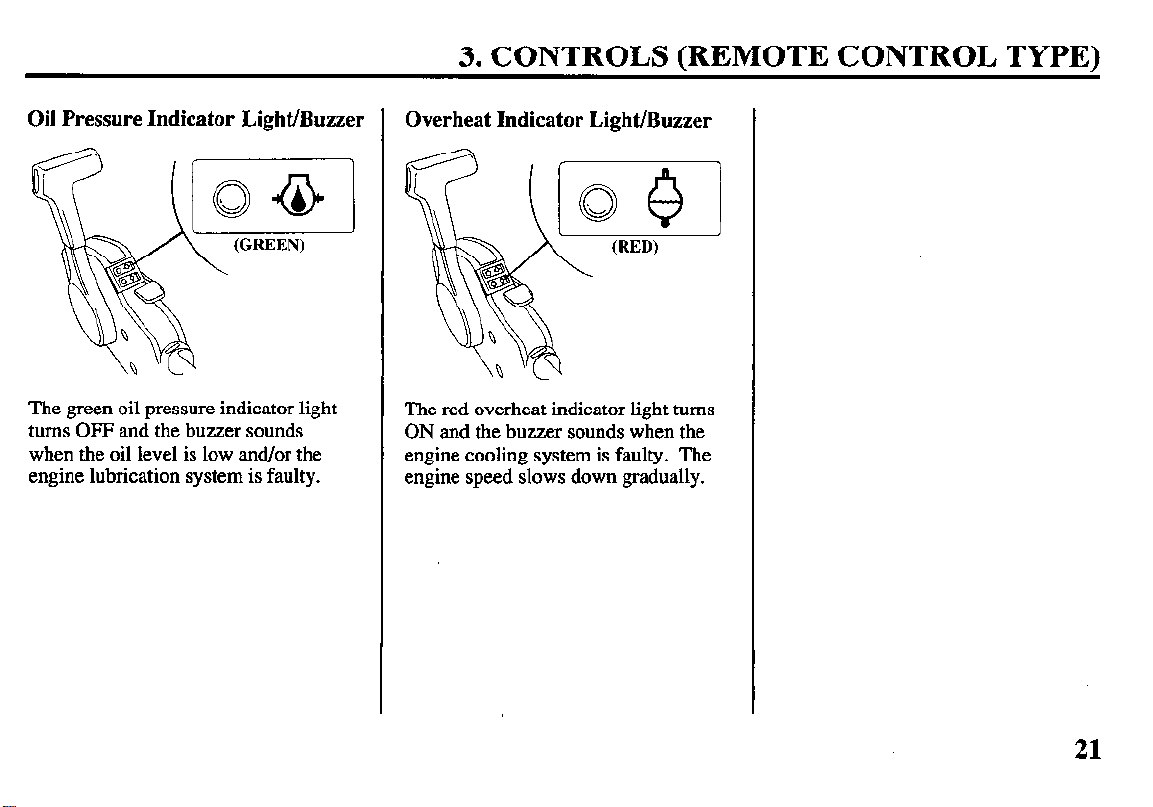

Oil Pressure Indicator Light/Buzzer

I

Overheat Indicator Light/Buzzer

The green oil pressure indicator light

The red overheat indicator light turns

turns OFF and the buzzer sounds

ON and the buzzer sounds when the

when the oil level is low and/or the

engine cooling system is faulty. The

engine lubrication system is faulty.

engine speed slows down gradually.

21

3. CONTROLS & INSTRUMENTS

(common)

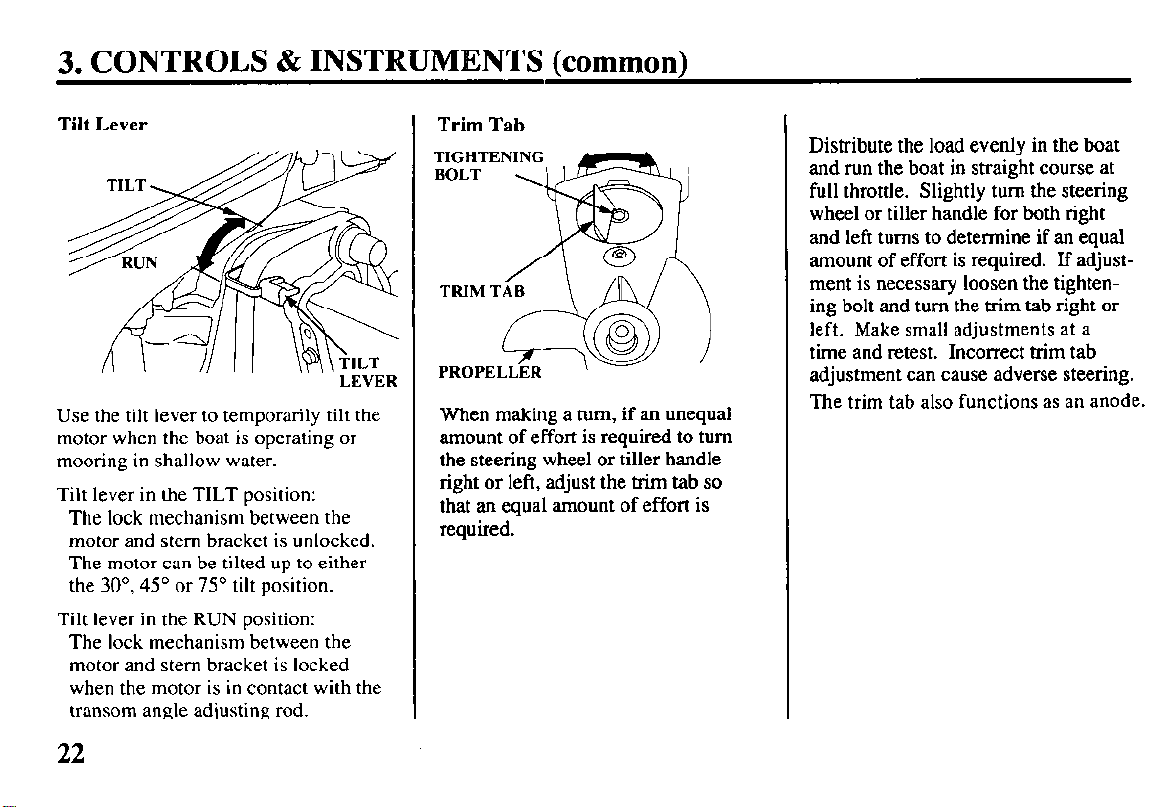

Tilt Lever

LEVER

Use the tilt lever to temporarily tilt the

motor when the boat is operating or

mooring in shallow water.

Tilt lever in the TILT position:

The lock mechanism between the

motor and stem bracket is unlocked.

The motor can be tilted up to either

the 30”, 45” or 75” tilt position.

Tilt lever in the RUN position:

The lock mechanism between the

motor and stem bracket is locked

when the motor is in contact with the

transom angle adjusting rod.

22

Trim Tab

TIGHTENING

BOLT \

/

TRIM TAB

6

PROPELLER

When making a turn, if an unequal

amount of effort is required to turn

the steering wheel or tiller handle

right or left, adjust the trim tab so

that an equal amount of effort is

required.

Distribute the load evenly in the boat

and run the boat in straight course at

full throttle. Slightly turn the steering

wheel or tiller handle for both right

and left turns to determine if an equal

amount of effort is required. If adjust-

ment is necessary loosen the tighten-

ing bolt and turn the trim tab right or

left. Make small adjustments at a

time and retest. Incorrect trim tab

adjustment can cause adverse steering.

The trim tab also functions as an anode.

3. CONTROLS & INSTRUMENTS (common)

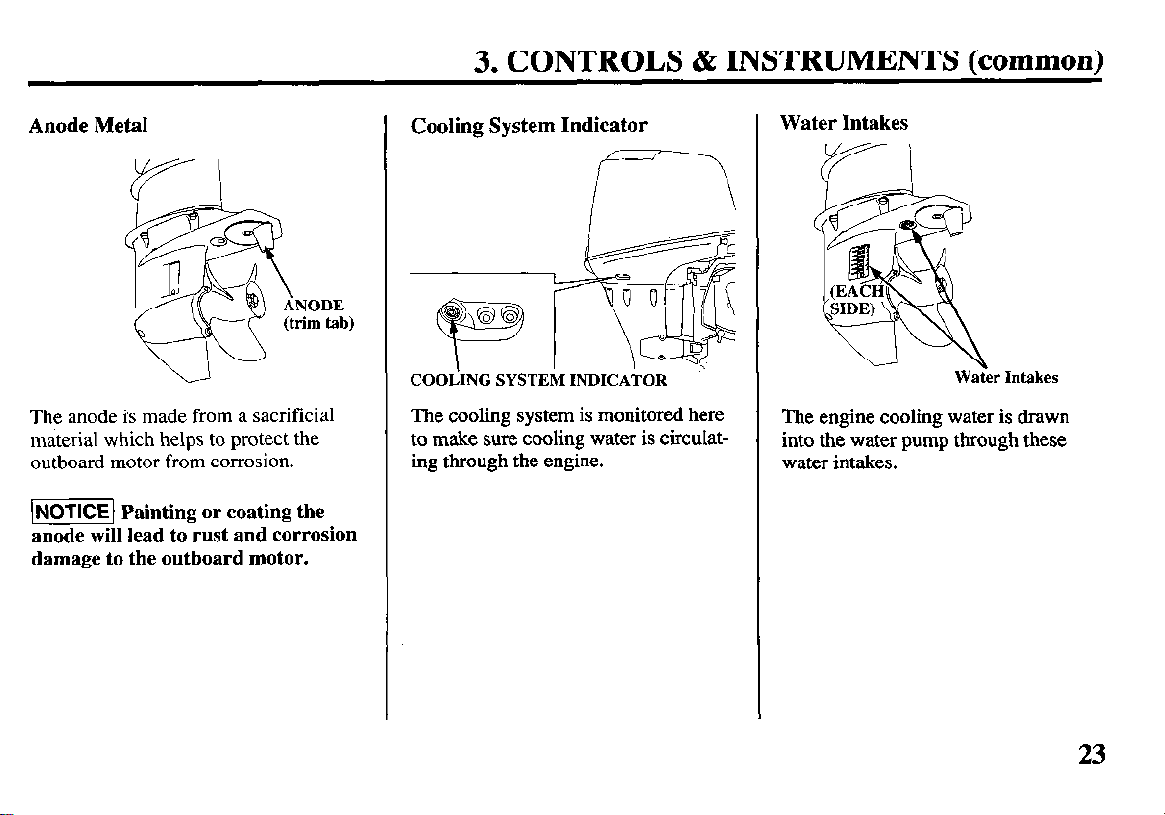

Anode Metal

NODE

rim tab)

The anode i’s made from a sacrificial

material which helps to protect the

outboard motor from corrosion.

-1 Painting or coating the

anode will lead to rust and corrosion

damage to the outboard motor.

Cooling System Indicator

COOLING SYSTEM INDICATOR

The cooling system is monitored here

to make sure cooling water is circulat-

ing through the engine.

Water Intakes

Water Intakes

The engine cooling water is drawn

into the water pump through these

water intakes.

23

3. CONTROLS & INSTRUMENTS

(common)

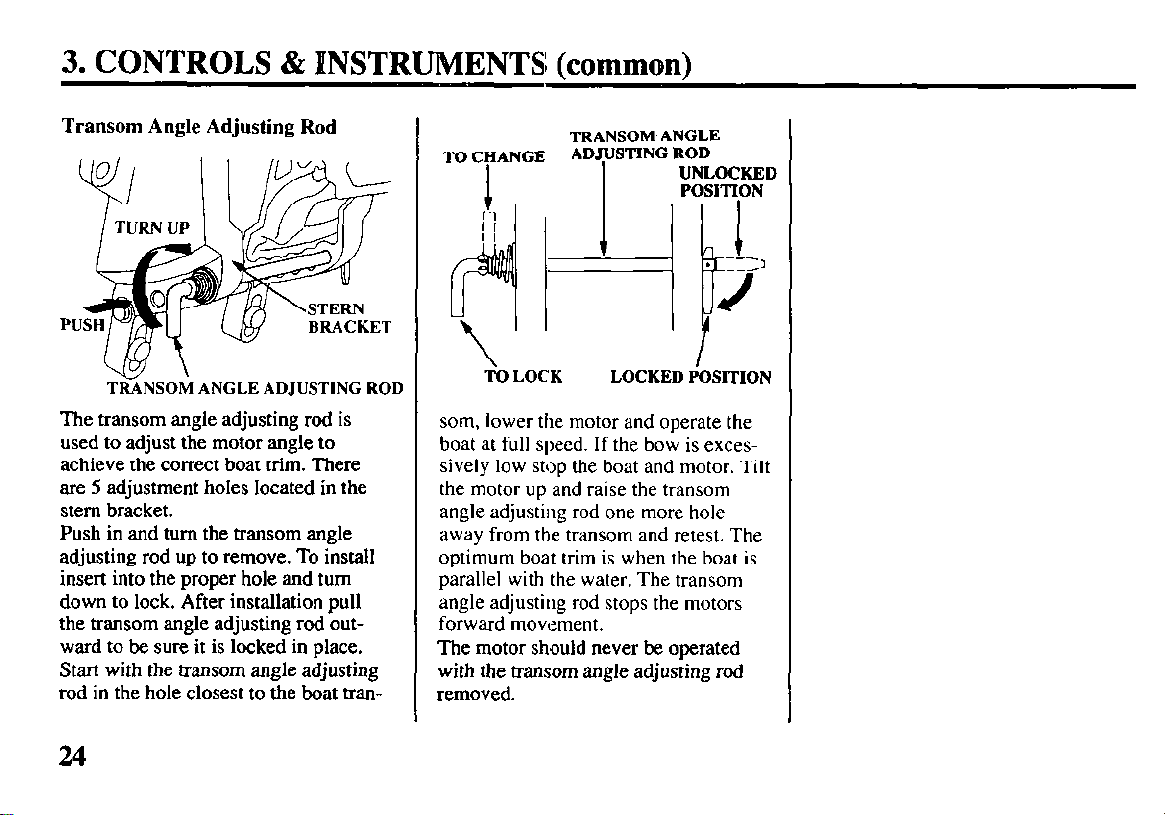

Transom Angle Adjusting Rod

TRANSOM ANGLE ADJUSTING ROD

The transom angle adjusting rod is

used to adjust the motor angle to

achieve the correct boat trim. There

are 5 adjustment holes located in the

stem bracket.

Push in and turn the transom angle

adjusting rod up to remove. To install

insert

into the proper hole and turn

down to lock. After installation pull

the transom angle adjusting rod out-

ward to be sure it is locked in place.

Start with the transom angle adjusting

rod in the hole closest to the boat tran-

24

TRANSOM ANGLE

TO CHANCE

ADJUSTING ROD

I

UNJXKXJZD

POSJTJON

+I

1

---

.

--/I

J

TO LOCK

LOCKED POSITION

som, lower the motor and operate the

boat at full speed. If the bow is exces-

sively low stop the boat and motor. Tilt

the motor up and raise the transom

angle adjusting rod one more hole

away from the transom and retest. The

optimum boat trim is when the boat is

parallel with the water. The transom

angle adjusting rod stops the motors

forward movement.

The motor should never

be operated

with the transom angle adjusting rod

removed.

3, CONTROLS & INSTRUMENTS

(common)

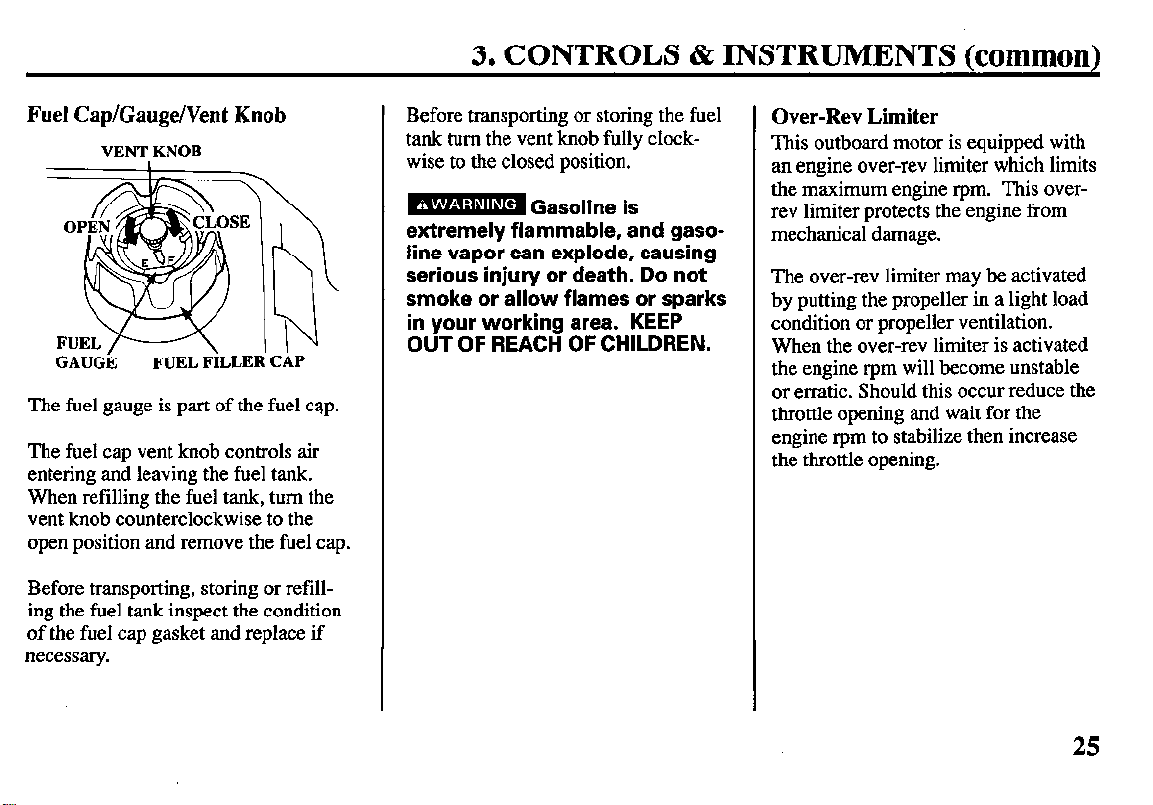

Fuel Cap/Gauge/Vent Knob

VENTKNOB

GAUGE FUELFiLLER'CkP

The fuel gauge is part of the fuel cap.

The fuel cap vent knob controls air

entering and leaving the fuel tank.

When refilling the fuel tank, turn the

vent knob counterclockwise to the

open position and remove the fuel cap.

Before transporting, storing or refill-

ing the fuel tank inspect the condition

of the fuel cap gasket and replace if

necessary.

Before transporting or storing the fuel

tank turn the vent knob fully clock-

wise to the closed position.

m Gasoline is

A l

extremely flammable, and gaso-

line vapor can explode, causing

serious injury or death. Do not

smoke or allow flames or sparks

in your working area. KEEP

OUT OF REACH OF CHILDREN.

Over-Rev Limiter

This outboard motor is equipped with

an engine over-rev limiter which limits

the maximum engine ‘pm. This over-

rev limiter protects the engine from

mechanical damage.

The over-rev limiter may be activated

by putting the propeller in a light load

condition or propeller ventilation.

When the over-rev limiter is activated

the engine rpm will become unstable

or erratic. Should this occur reduce the

throttle opening and wait for the

engine rpm to stabilize then increase

the throttle opening.

25

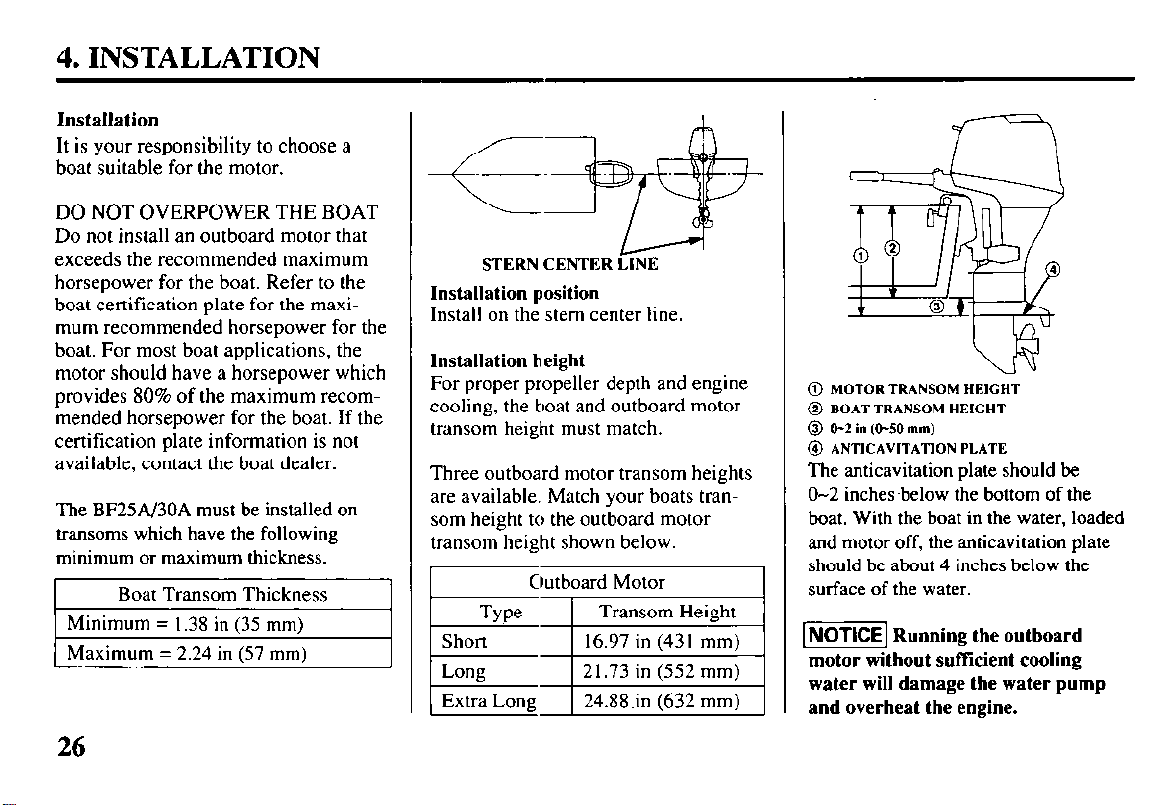

4. INSTALLATION

Installation

It is your responsibility to choose a

boat suitable for the motor.

DO NOT OVERPOWER THE BOAT

Do not install an outboard motor that

exceeds the recommended maximum

horsepower for the boat. Refer to the

boat certification plate for the maxi-

mum recommended horsepower for the

boat. For most boat applications, the

motor should have a horsepower which

provides 80% of the maximum recom-

mended horsepower for the boat. If the

certification plate information is not

available, contact the boat dealer.

The BF25A/30A must be installed on

transoms which have the following

minimum or maximum thickness.

Boat Transom Thickness

Minimum = 1.38 in (35 mm)

1 Maximum = 2.24 in (57 mm)

STERN CENTER LINE

Installation position

Install on the stem center line.

Installation height

For proper propeller depth and engine

cooling, the boat and outboard motor

transom height must match.

Three outboard motor transom heights

are available. Match your boats tran-

som height to the outboard motor

transom height shown below.

I

Outboard Motor

1 Type !

Transom Height

1 Extra Long 1 24.88.in (632 mm) 1

@ MOTOH TRANSOM HEIGHT

@ BOAT TRANSOM HEIGHT

@I O-2 in (O-50 mm)

@ ANTICAVITATION PLATE

The anticavitation plate should be

O-2 inches.below the bottom of the

boat. With the boat in the water, loaded

and motor off, the anticavitation plate

should be about 4 inches below the

surface of the water.

[MI Running the outboard

motor without suffkient cooling

water will damage the water pump

and overheat the engine.

26

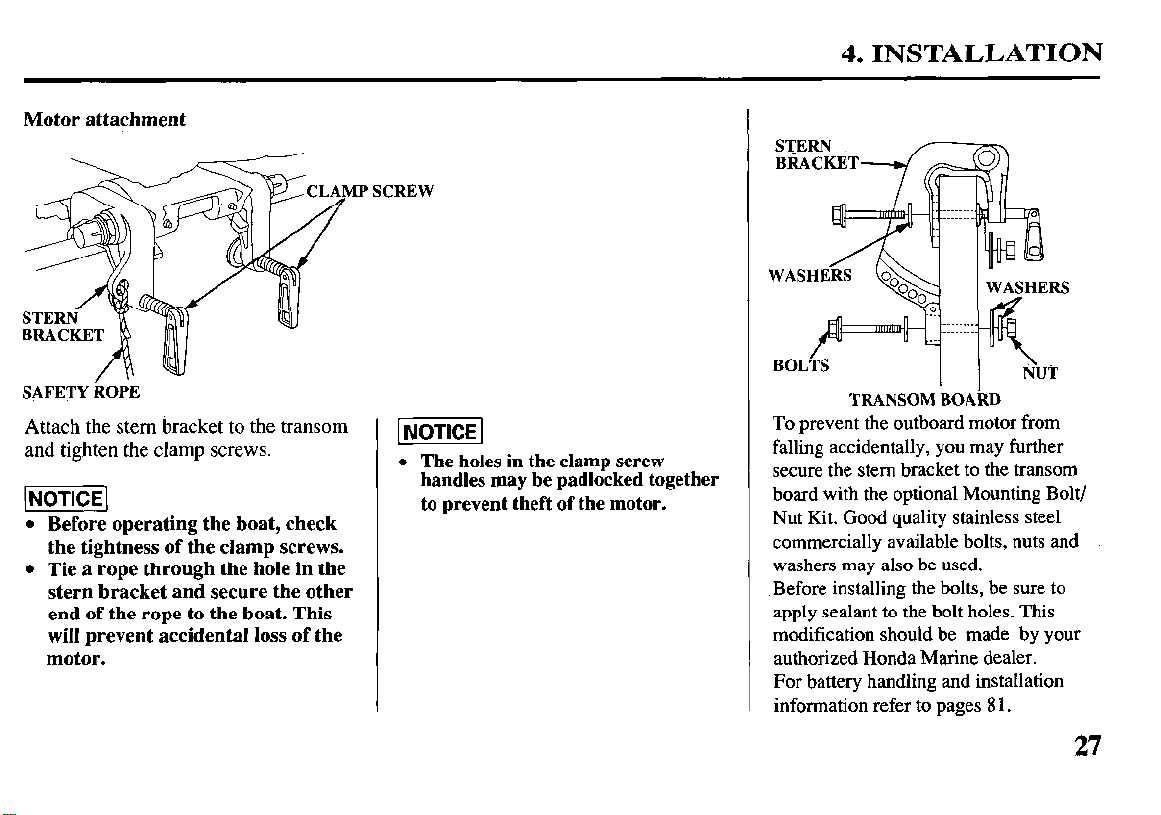

4. INSTALLATION

Motor attachment

P SCREW

SAFETY kOPE

Attach the stem bracket to the transom

and tighten the clamp screws.

l Before operating the boat, check

the tightness of the clamp screws.

l Tie a rope through the hole in the

stern bracket and secure the other

end of the rope to the boat. This

will prevent accidental loss of the

motor.

l The holes in the clamp screw

handles may be padlocked together

to prevent theft of the motor.

BOLb

I I

TRANSOM BOAkD

To prevent the outboard motor from

falling accidentally, you may further

secure the stem bracket to the transom

board with the optional Mounting Bolt/

Nut Kit. Good quality stainless steel

commercially available bolts, nuts and

washers may also be used.

Before installing the bolts, be sure to

apply sealant to the bolt holes. This

modification should be made by your

authorized Honda Marine dealer.

For battery handling and installation

information refer to pages 8 1.

27

4. INSTALLATION

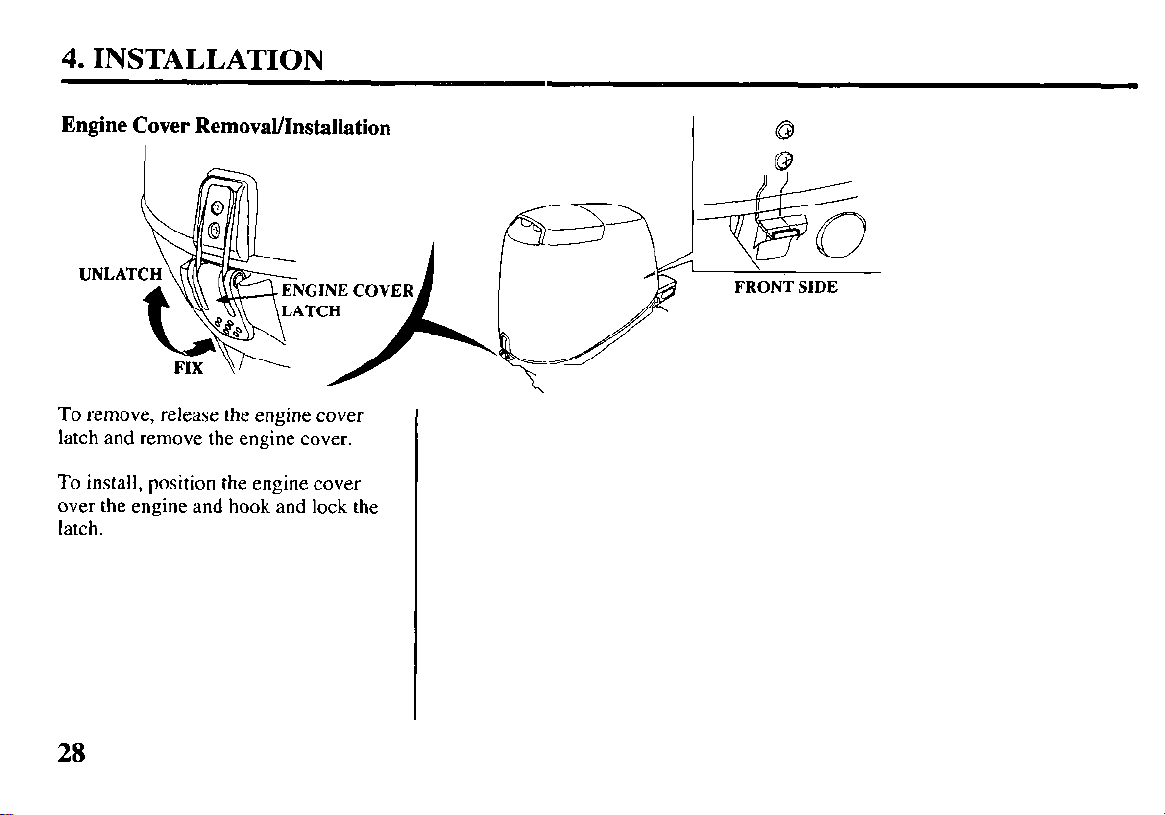

Engine Cover Removal/Installation

UNLAT

GINE COVER

To remove, release the engine cover

latch and remove the engine cover.

To install, position the engine cover

over the engine and hook and lock the

latch.

FRONT SIDE

28

Loading...

Loading...