Pilot

TNC 426

NC-Software

280 462 xx

280 463 xx

1/97

The Pilot

Contents

... is your concise programming guide for the HEIDENHAIN

TNC 426 CA and TNC 426 PA contouring controls. For more

comprehensive information on programming and operating,

refer to the TNC User's Manual. There you will find complete information on:

the SL cycle group I (Cycles 6, 14, 15, 16)

Q-parameter programming

the central tool file

3D tool compensation

tool measurement

Certain symbols are used in the Pilot to denote specific types

of information:

Important note

Warning: danger for the user or the machine!

The TNC and the machine tool must be prepared by

the machine tool builder to perform these functions!

Chapter in User's Manual where you will find more

detailed information on the current topic.

The information in this Pilot applies to TNCs with the following

software numbers:

Control NC Software Number

Fundamentals ................................................................... 4

Contour Approach and Departure..................................... 13

Path Functions .................................................................. 18

FK Free Contour Programming ......................................... 25

Subprograms and Program Section Repeats ................... 33

Working with Cycles......................................................... 36

Drilling Cycles ................................................................... 39

Pockets, Studs, and Slots ................................................. 46

Point Patterns ................................................................... 55

SL Cycles .......................................................................... 57

Multipass Milling ............................................................... 64

Coordinate Transformation Cycles ................................... 67

Special Cycles ................................................................... 73

Digitizing 3D Surfaces....................................................... 75

Graphics and Status Displays ........................................... 81

ISO Programming ............................................................. 84

Miscellaneous Functions M.............................................. 88

Contents

TNC 426 CA, TNC 426 PA 280 462 01

TNC 426 CE*, TNC 426 PE* 280 463 01

*) Export version

3

Fundamentals

Files in the TNC

File type

Programs/Files

See Introduction, File Management

The TNC keeps its programs, tables and texts in files.

A file designation consists of two components:

THREAD2.H

Fundamentals

File name File type

Maximum length: see table at right

8 characters

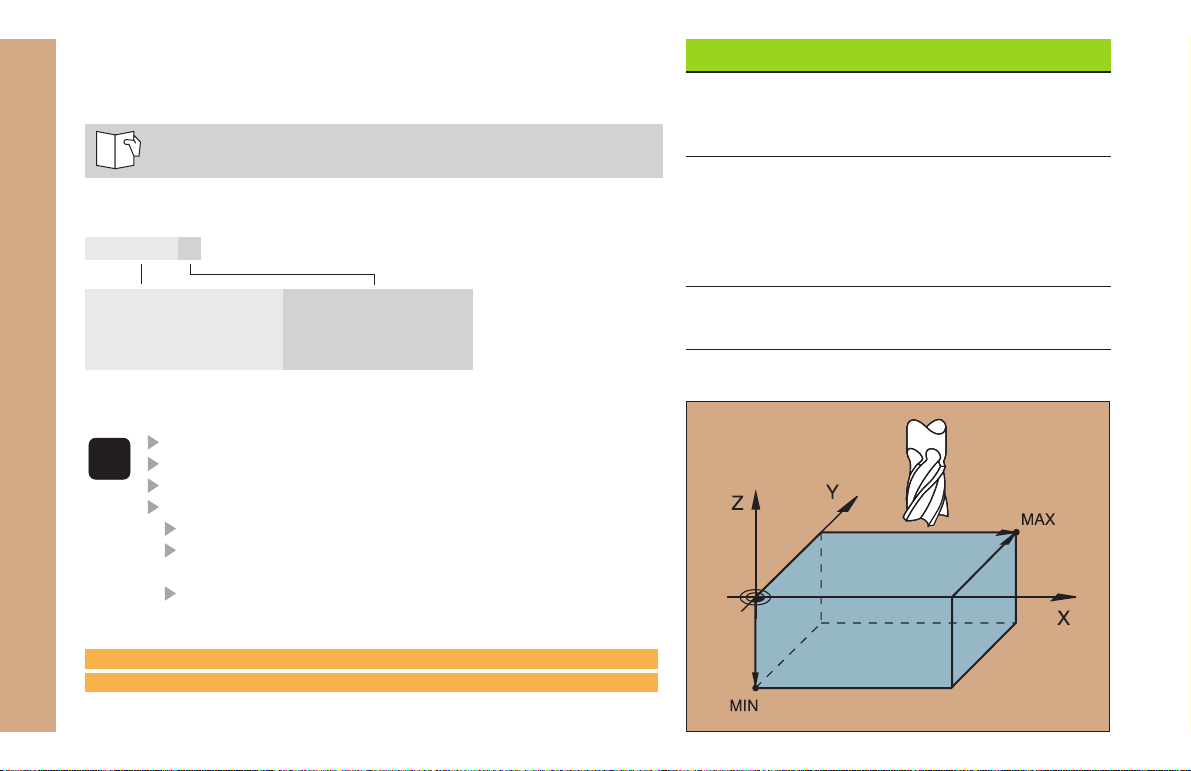

Creating a New Part Program

PGM

MGT

1 BLK FORM 0.1 Z X+0 Y+0 Z-50

2 BLK FORM 0.2 X+100 Y+100 Z+0

Select the directory in which the program is stored

Enter a new file name with file type

Select unit of measure for dimensions (mm or inches)

Define the blank form (BLK) for graphics:

Enter the spindle axis

Enter coordinates of the MIN point:

the smallest X, Y and Z coordinates

Enter coordinates of the MAX point:

the greatest X, Y and Z coordinates

4

Programs

in HEIDENHAIN format

in ISO format

Tables for

Tools

Datums

Pallets

Points

Texts as

ASCII files

.H

.I

.T

.D

.P

.PNT

.A

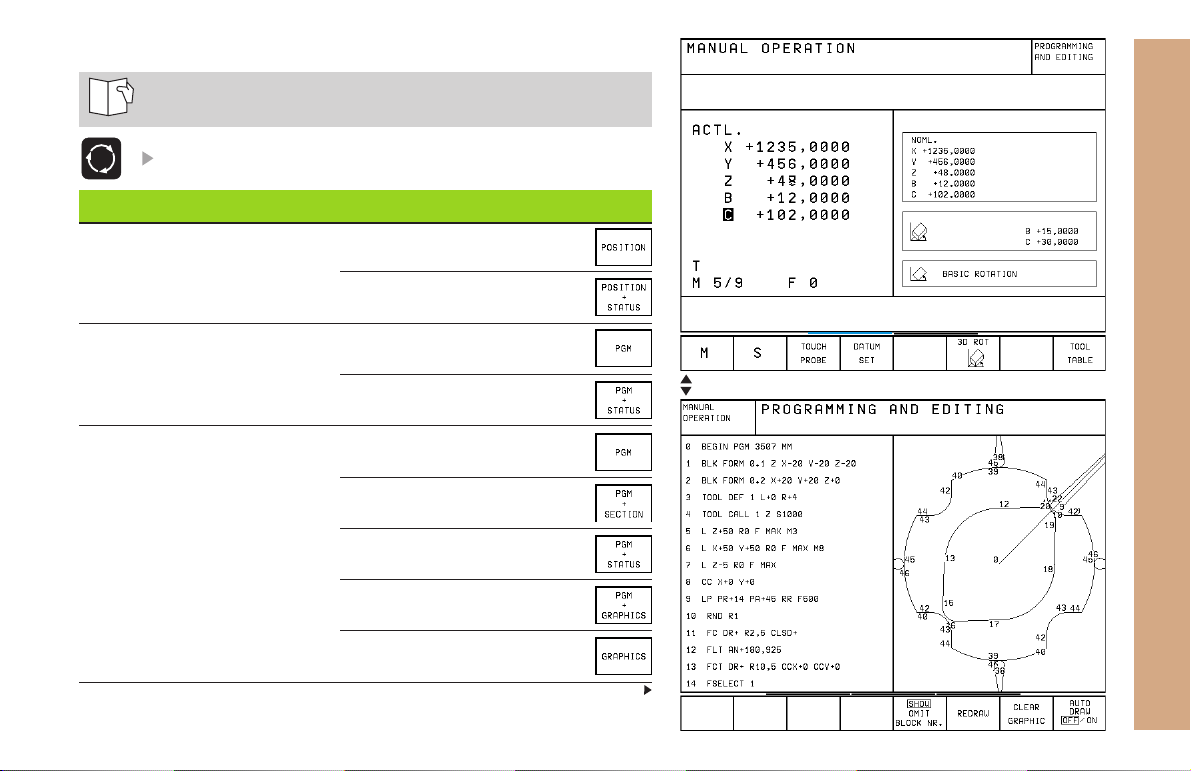

Choosing the Screen Layout

See Introduction, the TNC 426

Show soft keys for setting the screen layout

Mode of operation Screen contents

MANUAL OPERATION

ELECTRONIC HANDWHEEL

POSITIONING WITH

MANUAL DATA INPUT

PROGRAM RUN,

FULL SEQUENCE

PROGRAM RUN,

SINGLE BLOCK TEST RUN

Positions

Positions at left

Status at right

Program

Program at left

Status at right

Program

Program at left

Program structure at right

Program at left

Status at right

Program at left

Graphics at right

Graphics

Positions at left, status at right

Program at left, graphics at right

Fundamentals

Continued

5

Mode of operation Screen contents

PROGRAMMING AND EDITING

Program

Program at left

Program structure at right

Program at left

Programming graphics at right

Fundamentals

Program at left, program structure at right

6

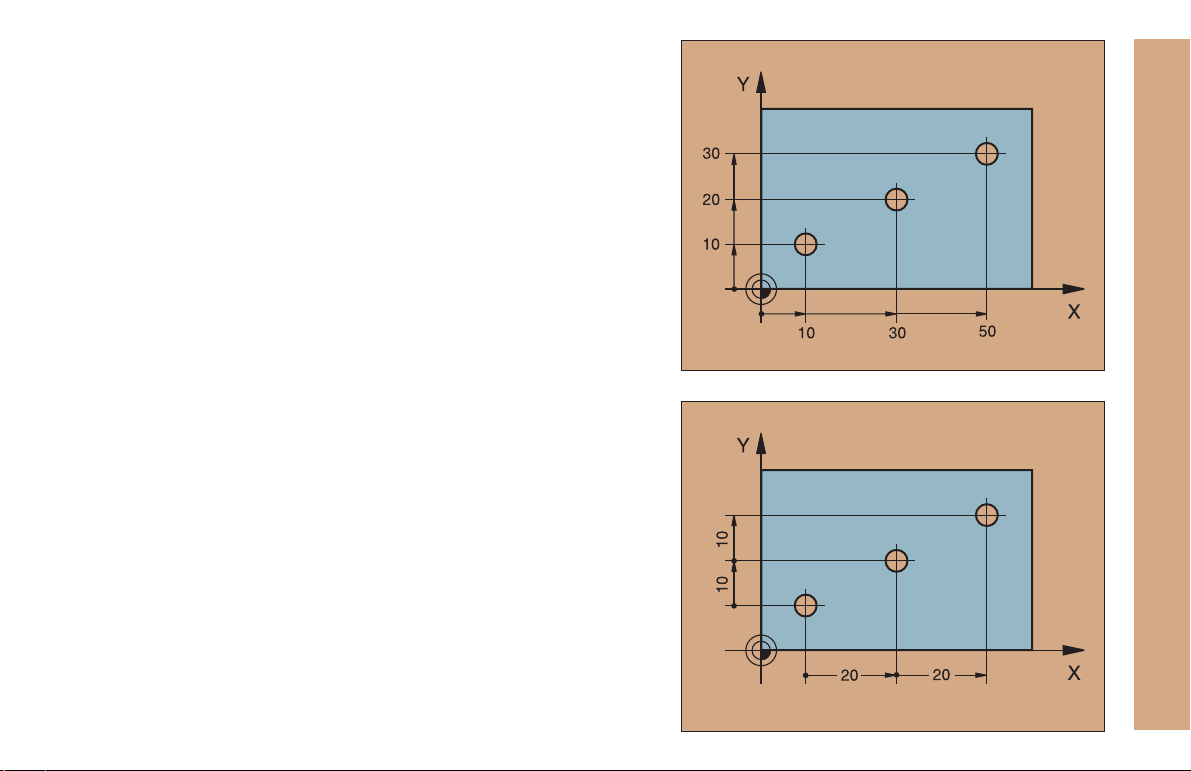

Absolute Cartesian Coordinates

The dimensions are measured from the current datum.

The tool moves to the absolute coordinates.

Programmable axes in an NC block

Linear motion: 3 or 5 axes (depending on machine or control)

Circular motion: 2 linear axes in a plane or

3 linear axes with cycle 19

WORKING PLANE

Incremental Cartesian Coordinates

The dimensions are measured from the last programmed position of

the tool.

The tool moves by the incremental coordinates.

Fundamentals

7

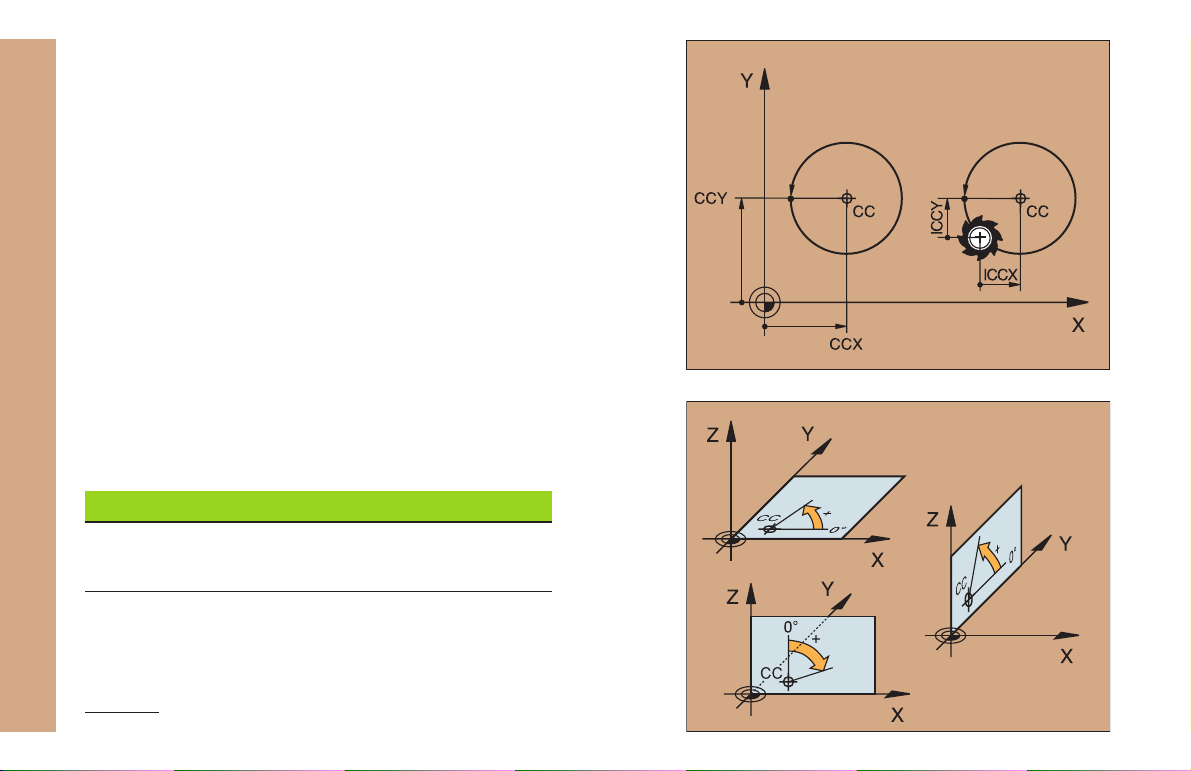

Circle Center and Pole: CC

The circle center (CC) must be entered to program circular tool

movements with the path function C (see page 21). CC is also needed

to define the pole for polar coordinates.

CC is entered in Cartesian coordinates*.

An absolutely defined circle center or pole is always measured from

the workpiece datum.

Fundamentals

An incrementally defined circle center or pole is always measured

from the last programmed position of the workpiece.

Angle Reference Axis

Angles such as a polar coordinate angle PA or an angle of rotation

ROT are measured from the angle reference axis.

Working plane Ref. axis and 0° direction

X/Y X

Y/Z Y

Z/X Z

8

*Circle center in polar coordinates: See FK programming

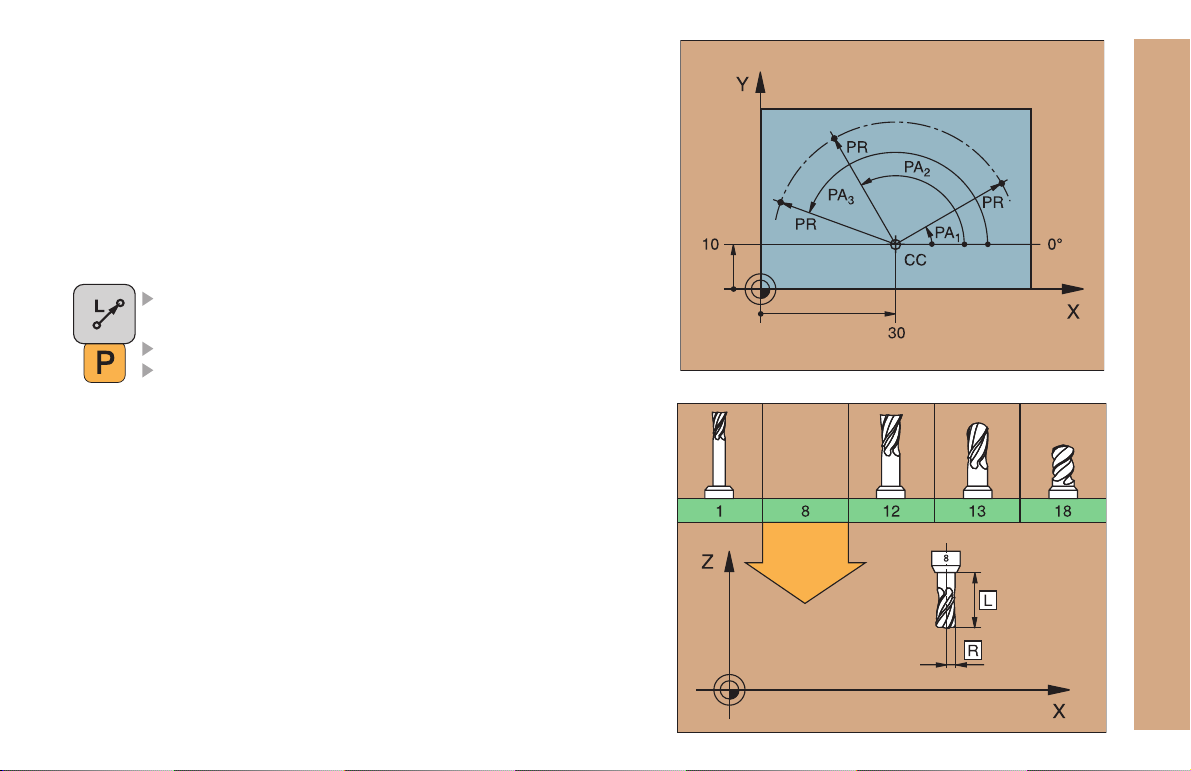

Polar Coordinates

Dimensions in polar coordinates are referenced to the pole (CC).

A position in the working plane is defined by

Polar coordinate radius PR = Distance of the position from the pole

Polar coordinate angle PA = Angle from the angle reference axis to

the straight line CC PR

Incremental dimensions

Incremental dimensions in polar coordinates are measured from the

last programmed position.

Programming polar coordinates

Select the path function

Press the P key

Answer the dialog prompts

Defining Tools

Tool data

Every tool is designated by a tool number between 1 and 254 or, if

you are using tool tables, by a tool name.

Entering tool data

You can enter the tool data (length L and radius R)

in a tool table (centrally, Program TOOL.T)

or

within the part program in TOOL DEF blocks (locally)

Fundamentals

9

TOOL NUMBER

TOOL LENGTH L

TOOL RADIUS R

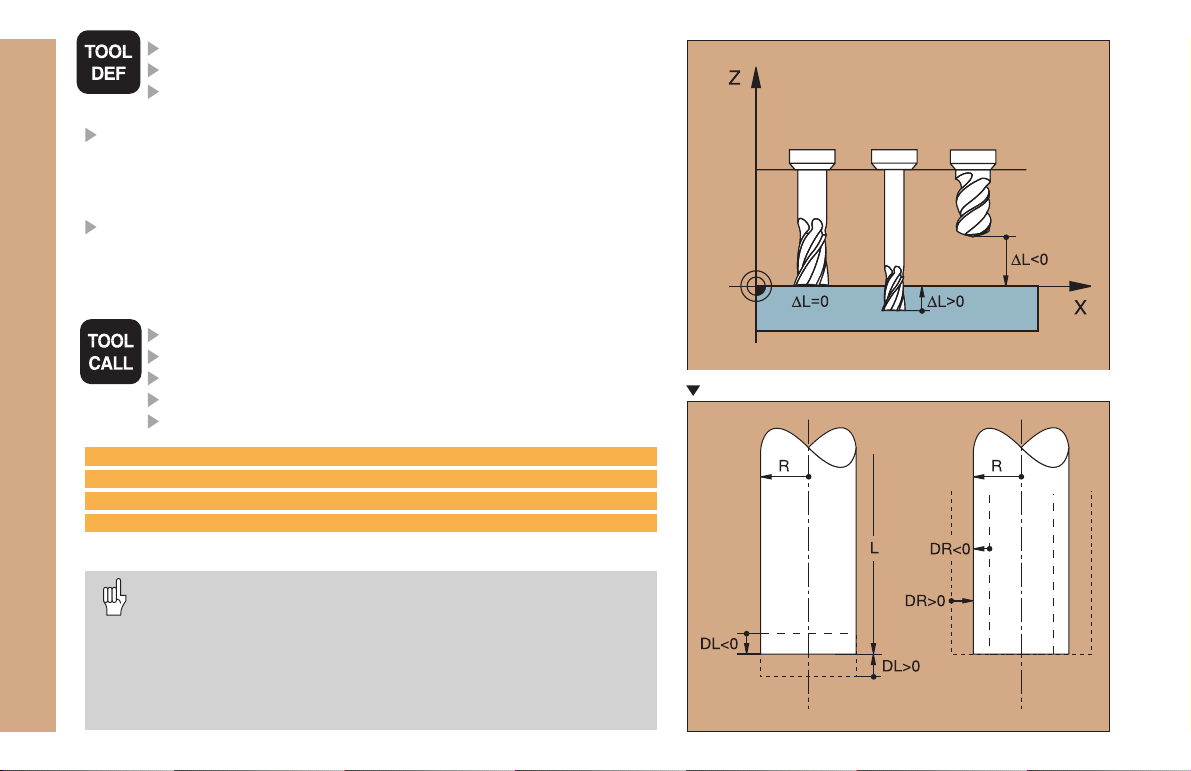

Program the tool length as its difference ∆L to the zero tool:

∆L>0: The tool is longer than the zero tool

∆L<0: The tool is shorter than the zero tool

With a tool presetter you can measure the actual tool length, then

Fundamentals

program that length.

Calling the tool data

TOOL NUMBER or name

WORKING SPINDLE AXIS: tool axis

SPINDLE SPEED S

TOOL LENGTH OVERSIZE DL (e.g. to compensate wear)

TOOL RADIUS OVERSIZE DR (e.g. to compensate wear)

3 TOOL DEF 6 L+7.5 R+3

4 TOOL CALL 6 Z S2000 DL+1 DR+0.5

5 L Z+100 R0 FMAX

6 L X-10 Y-10 R0 FMAX M6

Tool change

Beware of tool collision when moving to the tool change

position!

The direction of spindle rotation is defined by M function:

The maximum permissible oversize for tool radius or length

10

is ±99.999mm!

Oversizes on an end mill

M3: Clockwise

M4: Counterclockwise

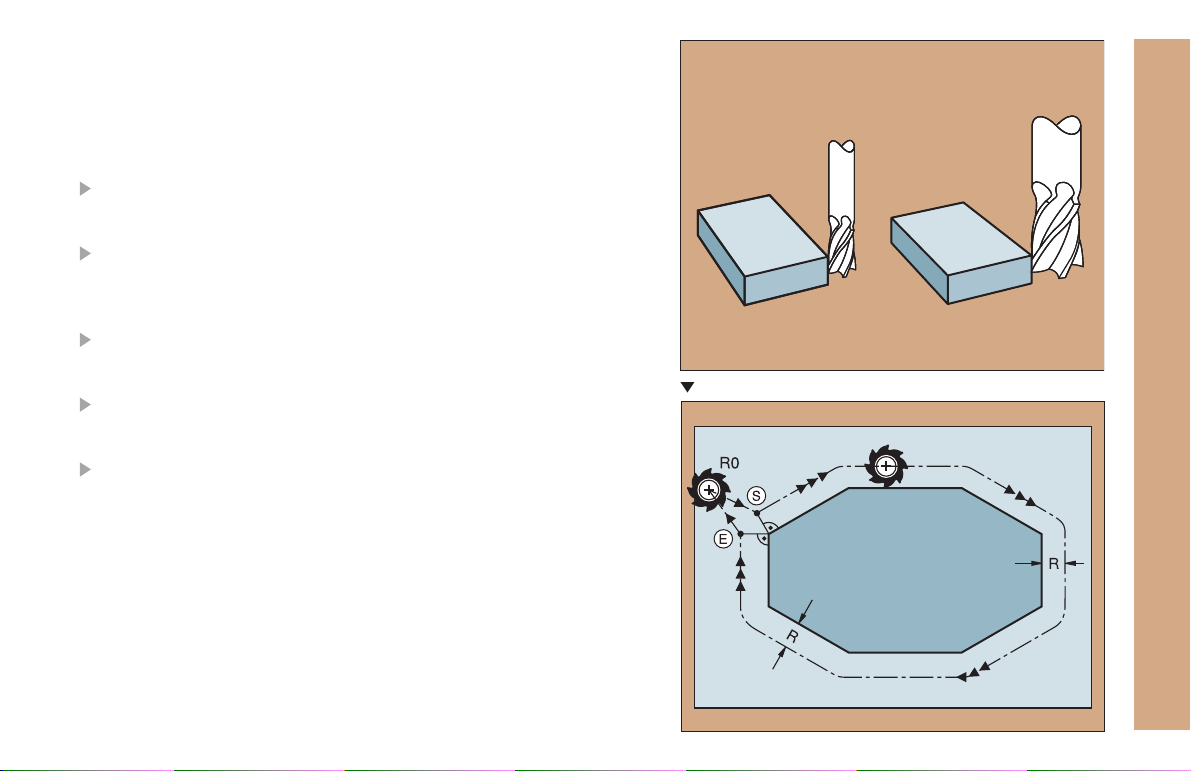

Tool Compensation

The TNC compensates the length L and radius R of the tool during

machining.

Length compensation

Beginning of effect:

Tool movement in the spindle axis

End of effect:

Tool exchange or tool with the length L=0

Radius compensation

Beginning of effect:

Tool movement in the working plane with RR or RL

Fundamentals

End of effect:

Execution of a positioning block with R0

Working without radius compensation (e.g. drilling):

Tool movement with R0

S = Start; E = End

11

Datum Setting Without a 3D Touch Probe

During datum setting you set the TNC display to the coordinates of a

known position on the workpiece:

Insert a zero tool with known radius

Select the MANUAL OPERATION or

ELECTRONIC HANDWHEEL mode

Touch the reference surface in the tool axis with the tool and enter

its length

Fundamentals

Touch the reference surface in the working plane with the tool and

enter the position of the tool center

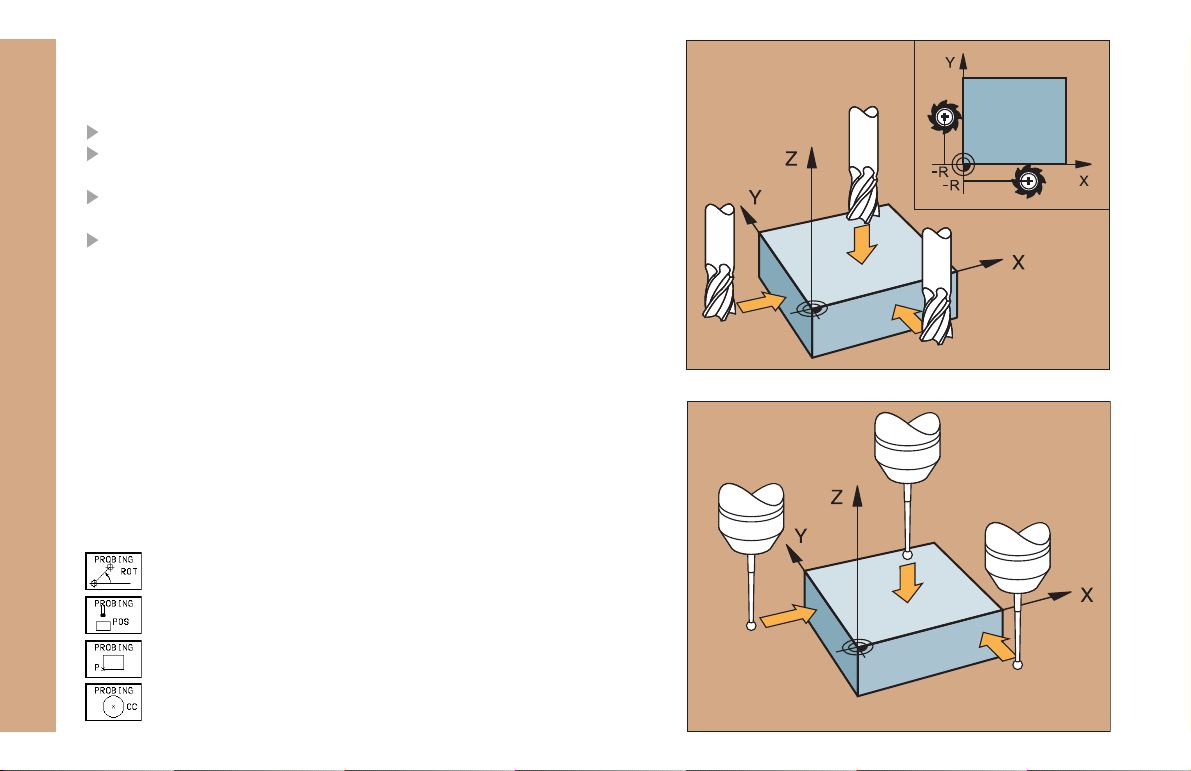

Datum Setting with a 3D Touch Probe

The fastest, simplest and most accurate way to set a datum is to use

a HEIDENHAIN 3D touch probe.

The following probe functions are provided by the MANUAL OPERATION and ELECTRONIC HANDWHEEL modes of operation:

Basic rotation

Datum setting in one axis

12

Datum setting at a corner

Datum setting at a circle center

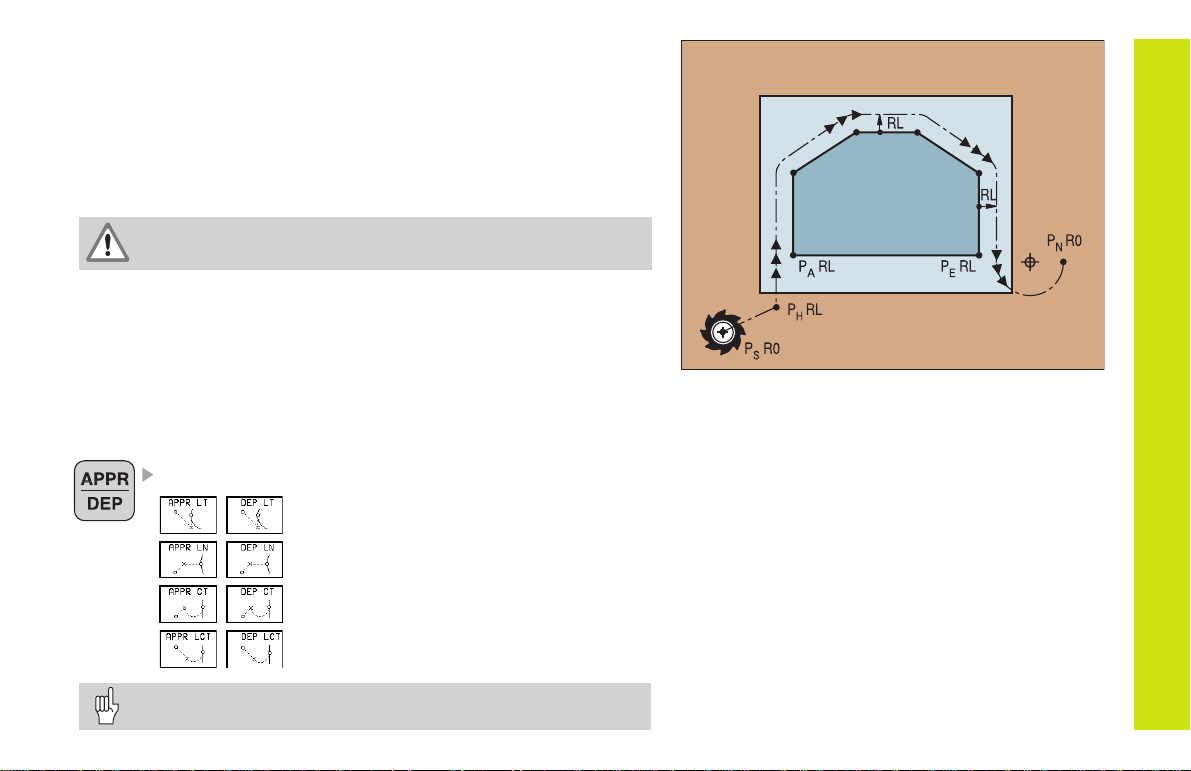

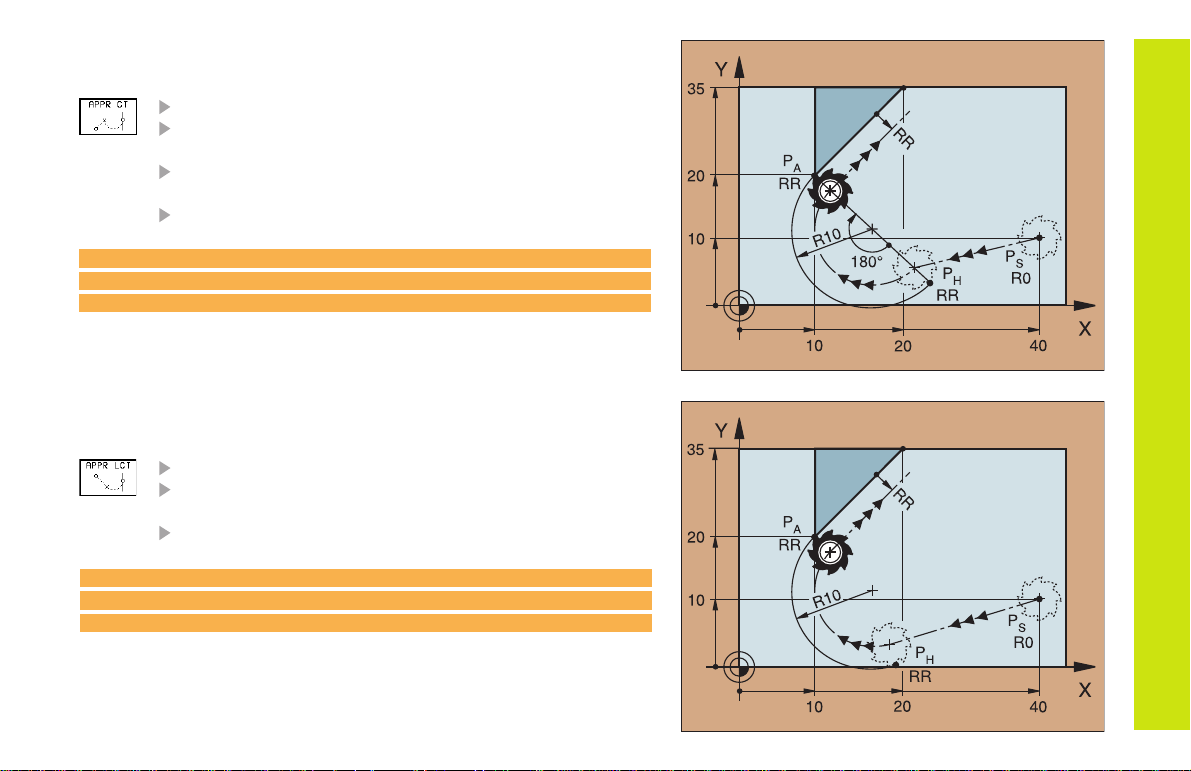

Contour Approach and Departure

Starting point P

PS lies outside of the contour and must be approached without radius

S

compensation.

Auxiliary point P

PH lies outside of the contour and is calculated by the TNC.

The tool moves from the starting point P

P

at the feed rate last programmed feed rate!

H

First contour point P

The first contour point PA is programmed in the APPR (approach) block.

H

and last contour point P

A

to the auxiliary point

S

E

The last contour point is programmed as usual.

End point P

PN lies outside of the contour and results from the DEP (departure)

block. P

N

is automatically approached with R0.

N

Path Functions for Approach and Departure

Press the soft key with the desired path function:

Straight line with tangential connection

Straight line perpendicular to the

contour point

Circular arc with tangential connection

Straight line segment tangentially connected

to the contour through an arc

Contour Approach and Departure

Program a radius compensation in the APPR block!

DEP blocks set the radius compensation to 0!

13

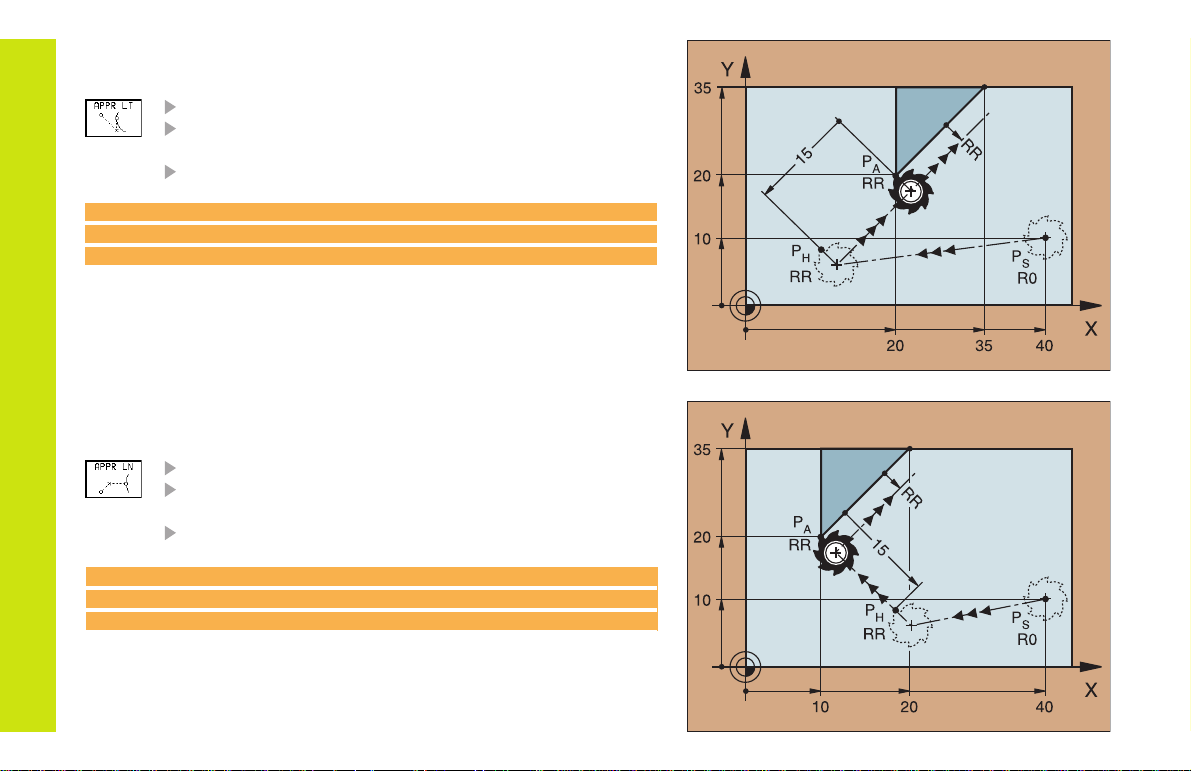

Approaching on a Straight Line with

Tangential Connection

COORDINATES for the first contour point P

Distance LEN (length) from PH to P

Enter a length LEN > 0

TOOL RADIUS COMPENSATION RR/RL

A

7 L X+40 Y+10 R0 FMAX M3

8 APPR LT X+20 Y+20 LEN 15 RR F100

9 L X+35 Y+35

A

Approaching on a Straight Line Perpendicular to

the First Contour Element

COORDINATES for the first contour point P

Distance LEN (length) from PH to P

Enter a length LEN > 0

Contour Approach and Departure

RADIUS COMPENSATION RR/RL

A

7 L X+40 Y+10 R0 FMAX M3

8 APPR LN X+10 Y+20 LEN 15 RR F100

9 L X+20 Y+35

A

14

Approaching Tangentially on an Arc

COORDINATES for the first contour point P

RADIUS R

Enter a radius R > 0

CIRCLE CENTER ANGLE (CCA)

Enter a CCA > 0

TOOL RADIUS COMPENSATION RR/RL

7 L X+40 Y+10 R0 FMAX M3

8 APPR CT X+10 Y+20 CCA 180 R10 RR F100

9 L X+20 Y+35

Approaching Tangentially on an Arc

and a Straight Line

COORDINATES for the first contour point P

RADIUS R

Enter a radius R > 0

TOOL RADIUS COMPENSATION RR/RL

7 L X+40 Y+10 R0 FMAX M3

8 APPR LCT X+10 Y+20 R10 RR F100

9 L X+20 Y+35

A

A

Contour Approach and Departure

15

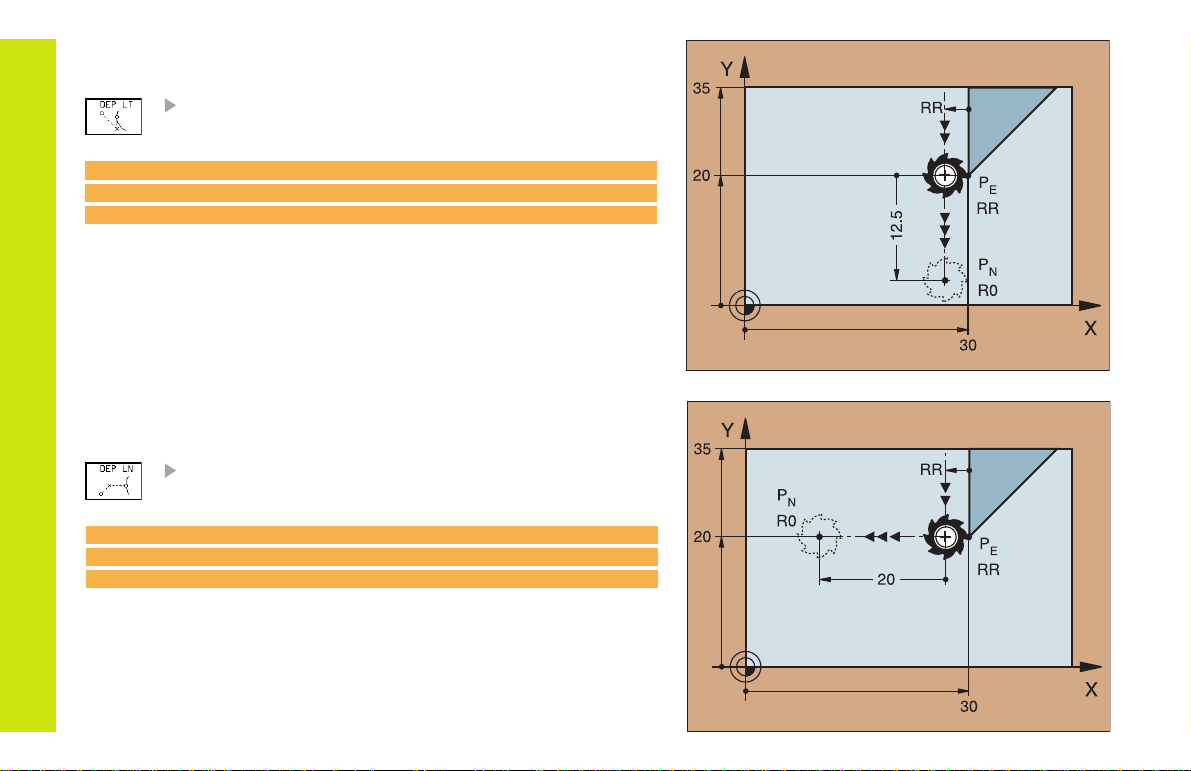

Departing Tangentially on a Straight Line

Distance LEN (length) from PE to P

Enter a length LEN > 0

N

23 L X+30 Y+35 RR F100

24 L Y+20 RR F100

25 DEP LT LEN 12.5 F100 M2

Departing on a Straight Line

Perpendicular to the Last Contour Element

Distance LEN (length) from PE to P

Enter a length LEN > 0

Contour Approach and Departure

23 L X+30 Y+35 RR F100

24 L Y+20 RR F100

25 DEP LN LEN+20 F100 M2

N

16

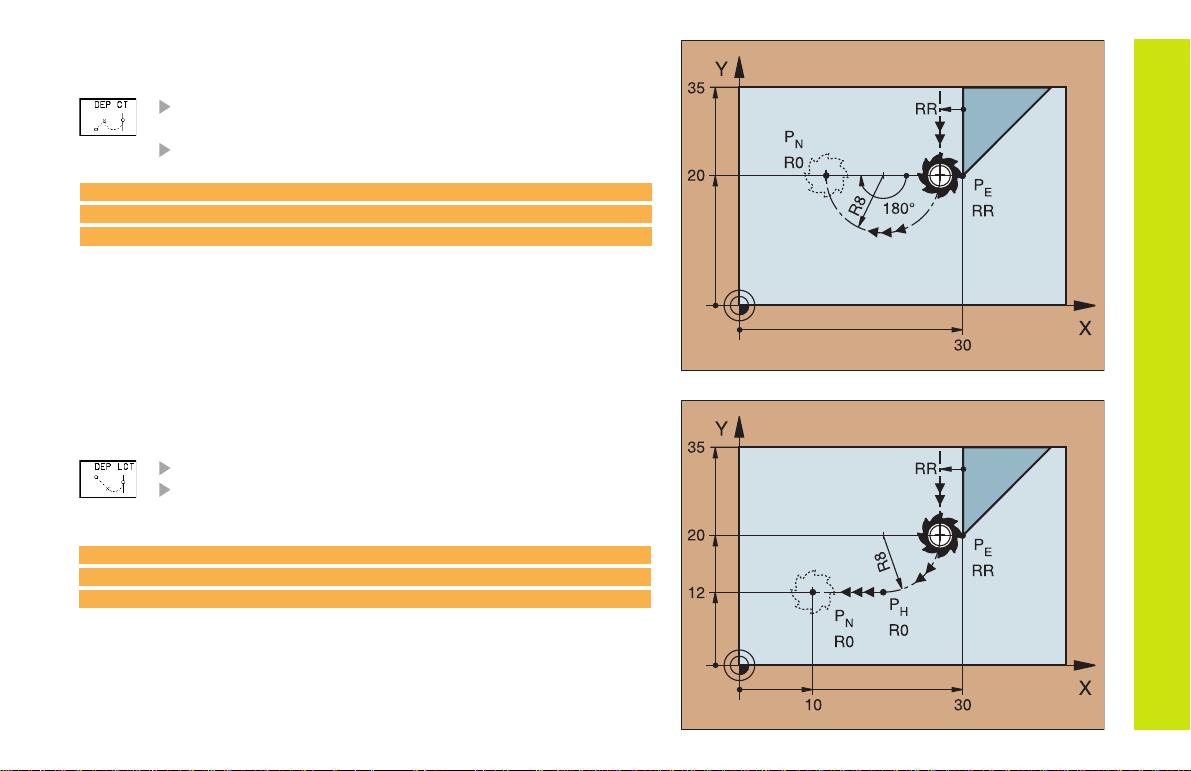

Departing Tangentially on an Arc

RADIUS R

Enter a radius R > 0

CIRCLE CENTER ANGLE (CCA)

23 L X+30 Y+35 RR F100

24 L Y+20 RR F10

25 DEP CT CCA 180 R+8 F100 M2

Departing on an Arc Tangentially Connecting

the Contour and a Straight Line

COORDINATES of the end point P

RADIUS R

Enter a radius R > 0

N

23 L X+30 Y+35 RR F100

24 L Y+20 RR F100

25 DEP LCT X+10 Y+12 R8 F100 M2

Contour Approach and Departure

17

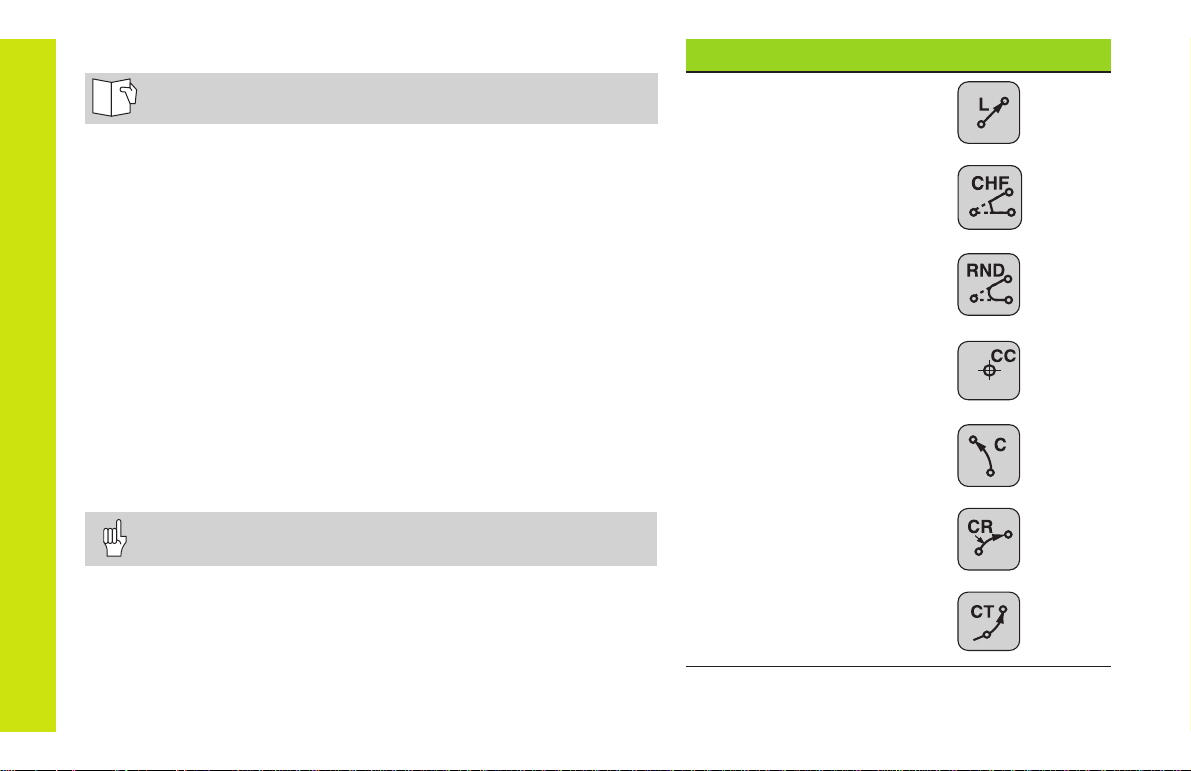

Path Functions for Positioning Blocks

Path functions

See Programming Tool Movements.

Programming the Direction of Traverse

Regardless of whether the tool or the workpiece is actually moving,

you always program as if the tool is moving and the workpiece is

stationary.

Entering the Target Positions

Target positions can be entered in Cartesian or polar coordinates

Path Functions

either as absolute or incremental values, or with both absolute and

incremental values in the same block.

Entries in the Positioning Block

A complete positioning block contains the following data:

Path function

Coordinates of the contour element end points (target position)

Radius compensation RR/RL/R0

Feed rate F

Miscellaneous function M

Before you execute a part program, always pre-position the tool

to prevent the possibility of damaging the tool or workpiece!

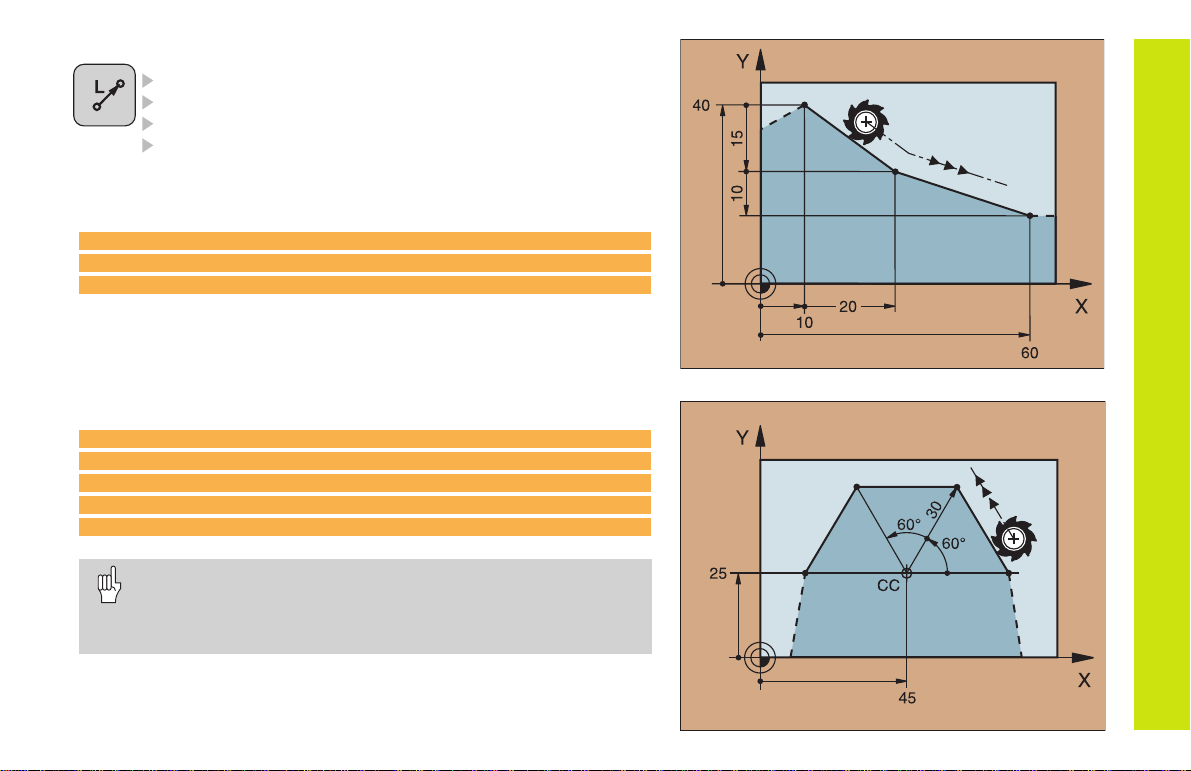

Straight line

Chamfer between two

straight lines

Corner rounding

Circle center or pole for

polar coordinates

Circular path aroundthe

circle center CC

Circular path with

known radius

Circular path with

tangential connection to

previous contour

Page 19

Page 20

Page 20

Page 21

Page 21

Page 22

Page 23

18

Straight Line

COORDINATES of the straight line end point

TOOL RADIUS COMPENSATION RR/RL/R0

FEED RATE F

MISCELLANEOUS FUNCTION M

With Cartesian coordinates:

7 L X+10 Y+40 RL F200 M3

8 L IX+20 IY-15

9 L X+60 IY-10

With polar coordinates:

12 CC X+45 Y+25

13 LP PR+30 PA+0 RR F300 M3

14 LP PA+60

15 LP IPA+60

16 LP PA+180

You must first define the pole CC before you can program

polar coordinates!

Program the pole CC only in Cartesian coordinates!

The pole CC remains effective until you define a new one!

Path Functions

19

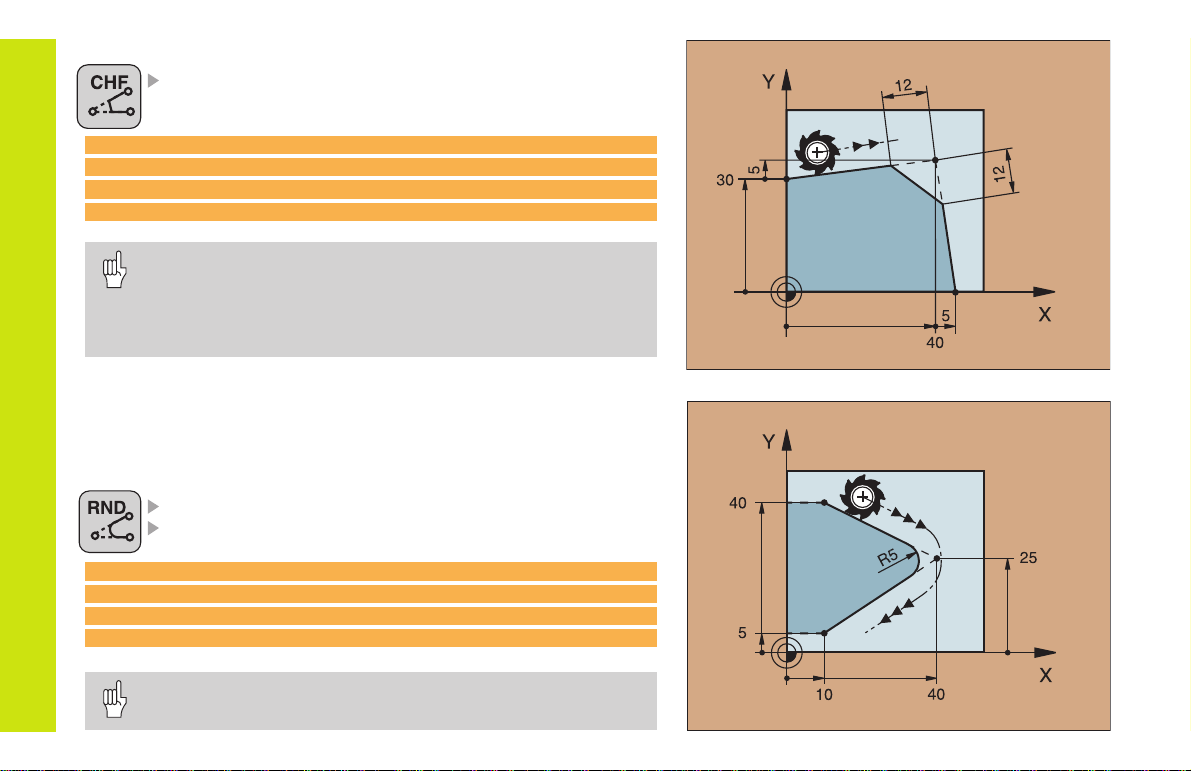

Inserting a Chamfer Between Two Straight Lines

CHAMFER SIDE LENGTH

7 L X+0 Y+30 RL F300 M3

8 L X+40 IY+5

9 CHF 12

10 L IX+5 Y+0

Path Functions

You cannot start a contour with a CHF block!

The radius compensation before and after the CHF block

must be the same!

An inside chamfer must be large enough to accommodate

the current tool!

Corner Rounding

The beginning and end of the arc extend tangentially from the previous and subsequent contour elements.

RADIUS R of the circular arc

FEED RATE F for corner rounding

5 L X+10 Y+40 RL F300 M3

6 L X+40 Y+25

7 RND R5 F100

8 L X+10 Y+5

An inside arc must be large enough to accommodate the

20

current tool!

Circular Path Around the Circle Center CC

COORDINATES of the circle center CC

COORDINATES of the arc end point

DIRECTION OF ROTATION DR

C and CP enable you to program a complete circle in one block.

With Cartesian coordinates:

5 CC X+25 Y+25

6 L X+45 Y+25 RR F200 M3

7 C X+45 Y+25 DR+

With polar coordinates:

18 CC X+25 Y+25

19 LP PR+20 PA+0 RR F250 M3

20 CP PA+180 DR+

Define the pole CC before programming polar coordinates!

Program the pole CC only in Cartesian coordinates!

The pole CC remains effective until you define a new one!

The arc end point can be defined only with the polar

coordinate angle (PA)!

Path Functions

21

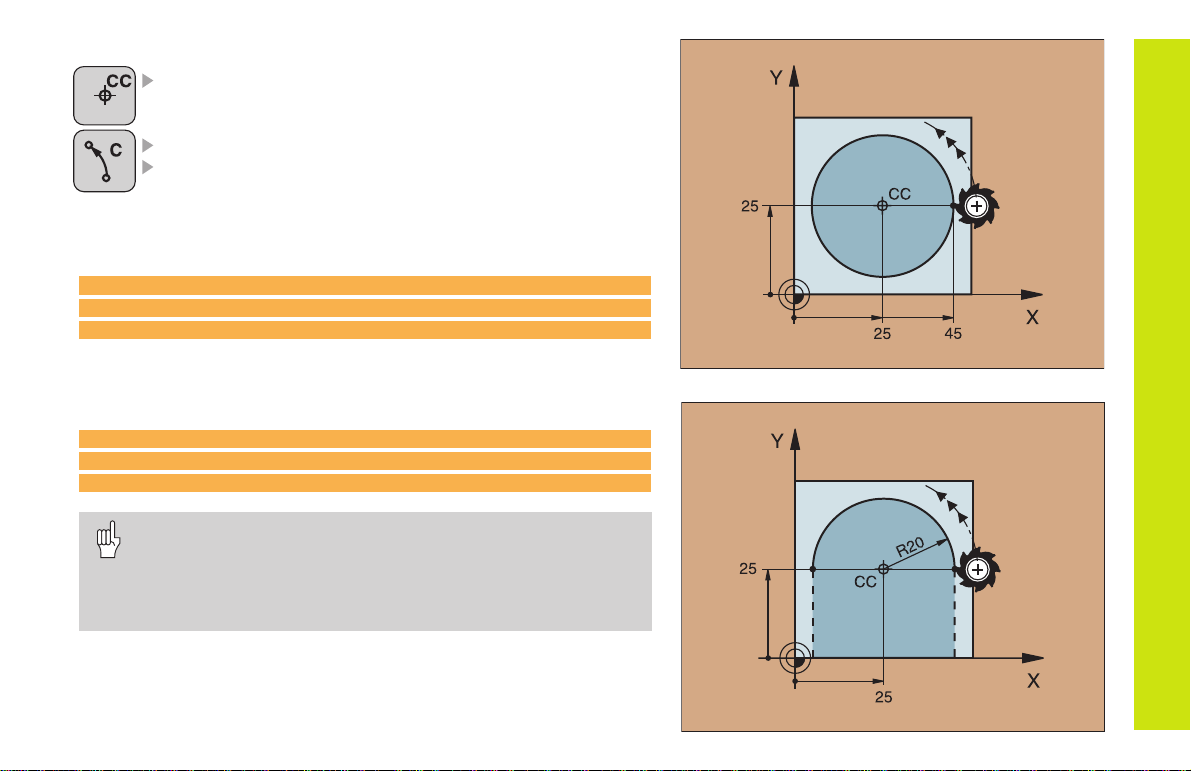

Circular Path with Known Radius (CR)

COORDINATES of the arc end point

RADIUS R

If the central angle ZW > 180, R is negative.

If the central angle ZW < 180, R is positive.

DIRECTION OF ROTATION DR

10 L X+40 Y+40 RL F200 M3 Arc starting point

11 CR X+70 Y+40 R+20 DR- Arc

11 CR X+70 Y+40 R+20 DR+ Arc

Path Functions

10 L X+40 Y+40 RL F200 M3 Arc starting point

11 CR X+70 Y+40 R-20 DR- Arc

11 CR X+70 Y+40 R-20 DR+ Arc

or

1

2

Arcs

and

1

2

or

3

Arcs 3 and

4

4

22

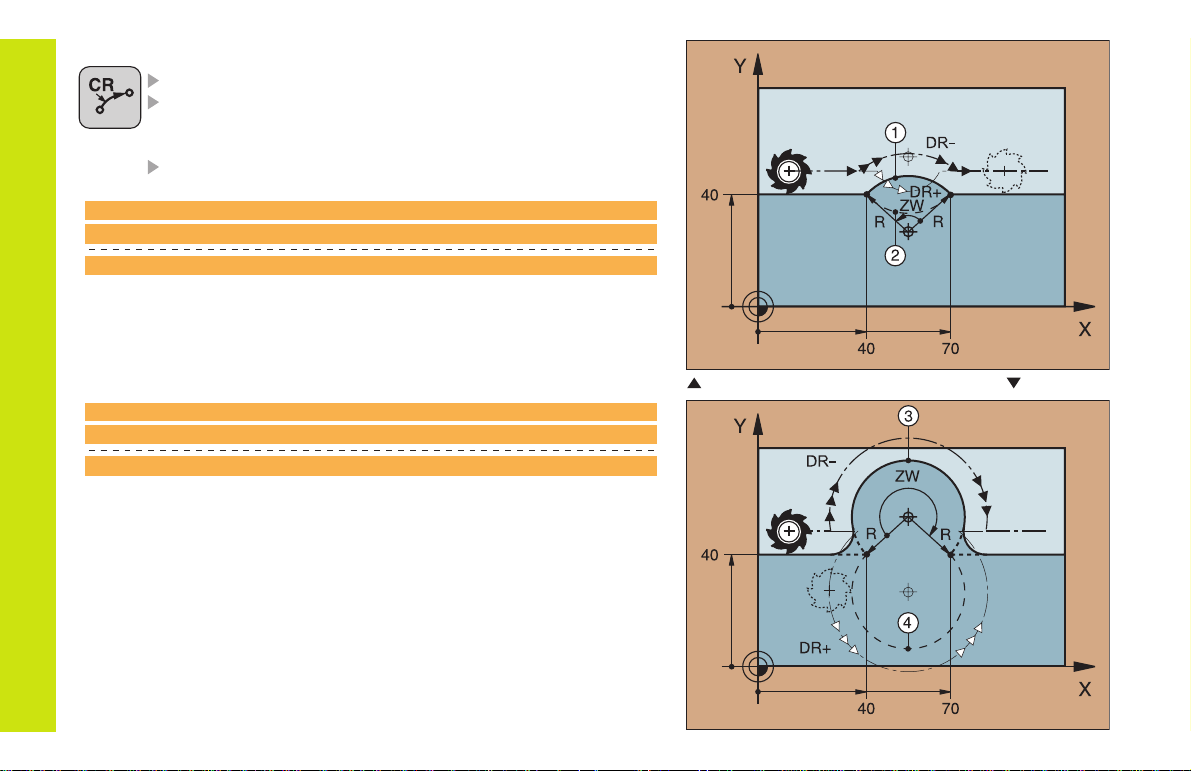

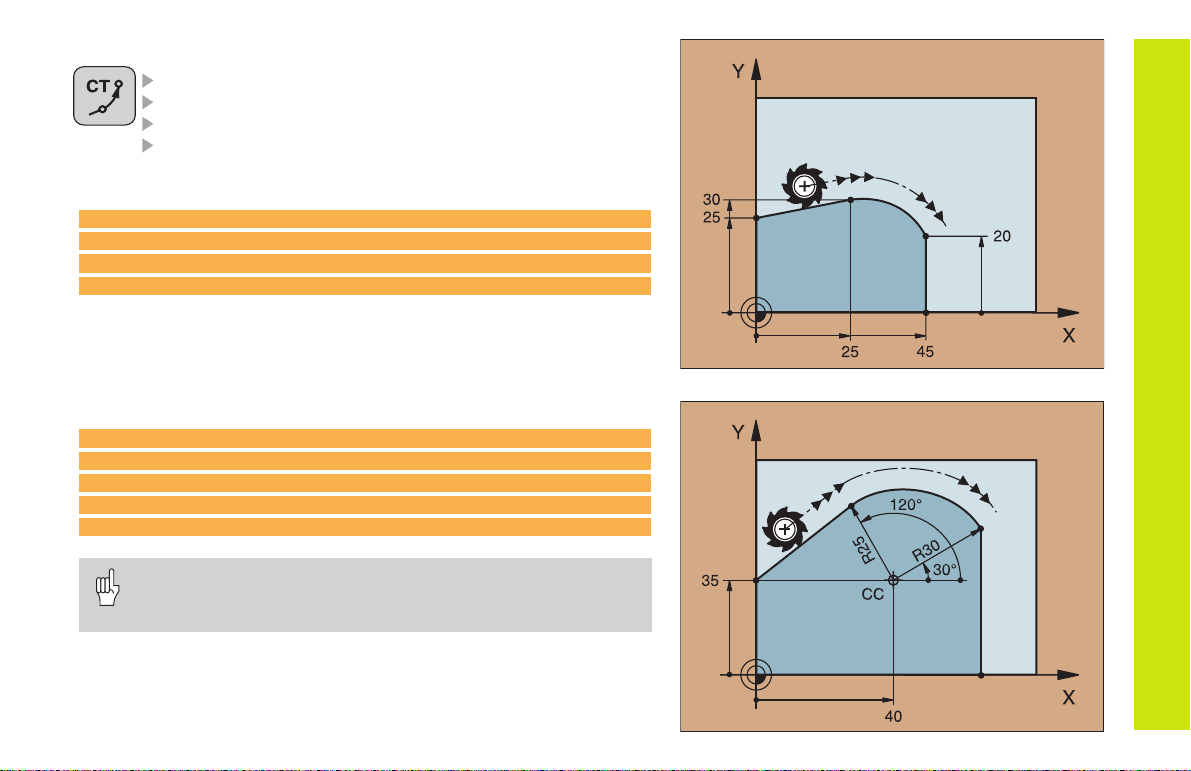

Circular Path CT with Tangential Connection

COORDINATES of the arc end point

RADIUS COMPENSATION RR/RL/R0

FEED RATE F

MISCELLANEOUS FUNCTION M

With Cartesian coordinates:

5 L X+0 Y+25 RL F250 M3

6 L X+25 Y+30

7 CT X+45 Y+20

8 L Y+0

With polar coordinates:

12 CC X+40 Y+35

13 L X+0 Y+35 RL F250 M3

14 LP PR+25 PA+120

15 CTP PR+30 PA+30

16 L Y+0

Define the pole CC before programming polar coordinates!

Program the pole CC only in Cartesian coordinates!

The pole CC remains effective until you define a new one!

Path Functions

23

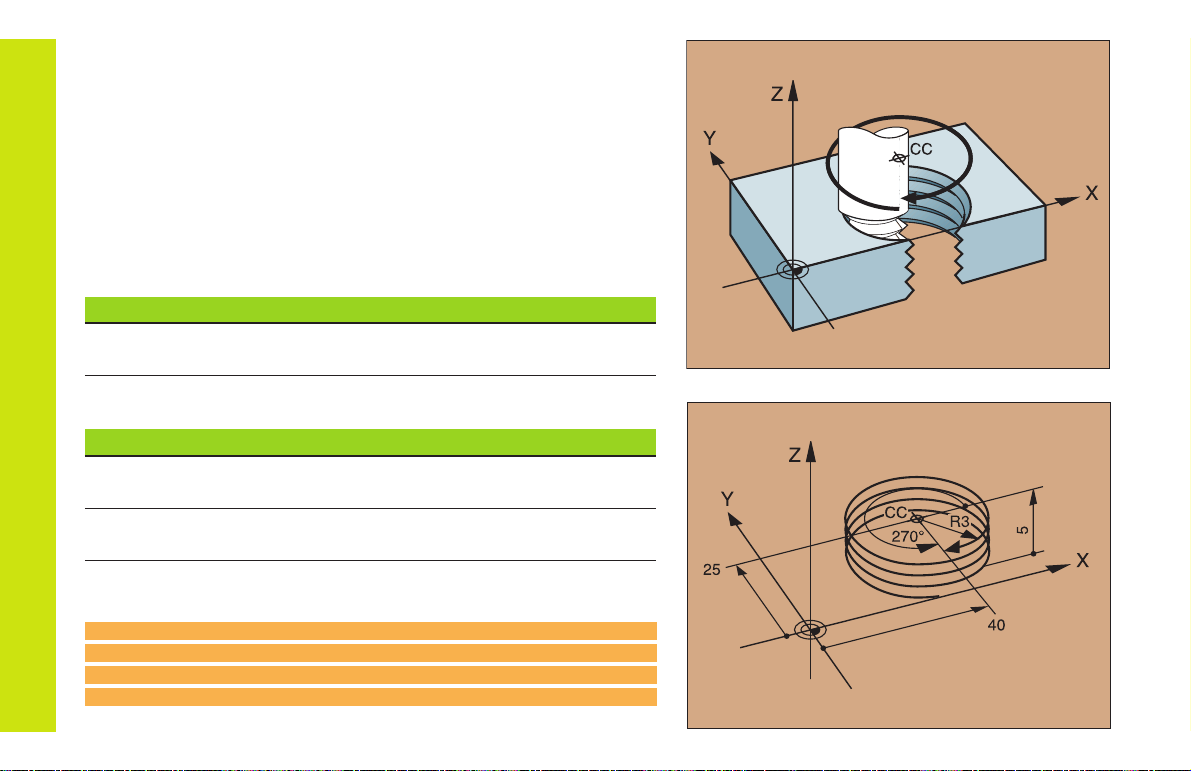

Helix (Only in Polar Coordinates)

Calculations (upward milling direction)

Path revolutions: n = Thread revolutions + overrun at start and

end of thread

Total height: h = Pitch P x path revolutions n

Incr. coord. angle: IPA = Path revolutions n x 360°

Start angle: PA = Angle at start of thread + angle for

overrun

Start coordinate: Z = Pitch P x (thread revolutions + thread

overrun at start of thread)

Path Functions

Shape of helix

Internal thread Work direction Direction Radius comp.

Right-hand Z+ DR+ RL

Left-hand Z+ DR RR

Right-hand Z DR RR

Left-hand Z DR+ RL

External thread

Right-hand Z+ DR+ RR

Left-hand Z+ DR RL

Right-hand Z DR RL

Left-hand Z DR+ RR

24

M6 x 1 mm thread with 5 revolutions

12 CC X+40 Y+25

13 L Z+0 F100 M3

14 LP PR+3 PA+270 RL

15 CP IPA-1800 IZ+5 DR- RL F50

:

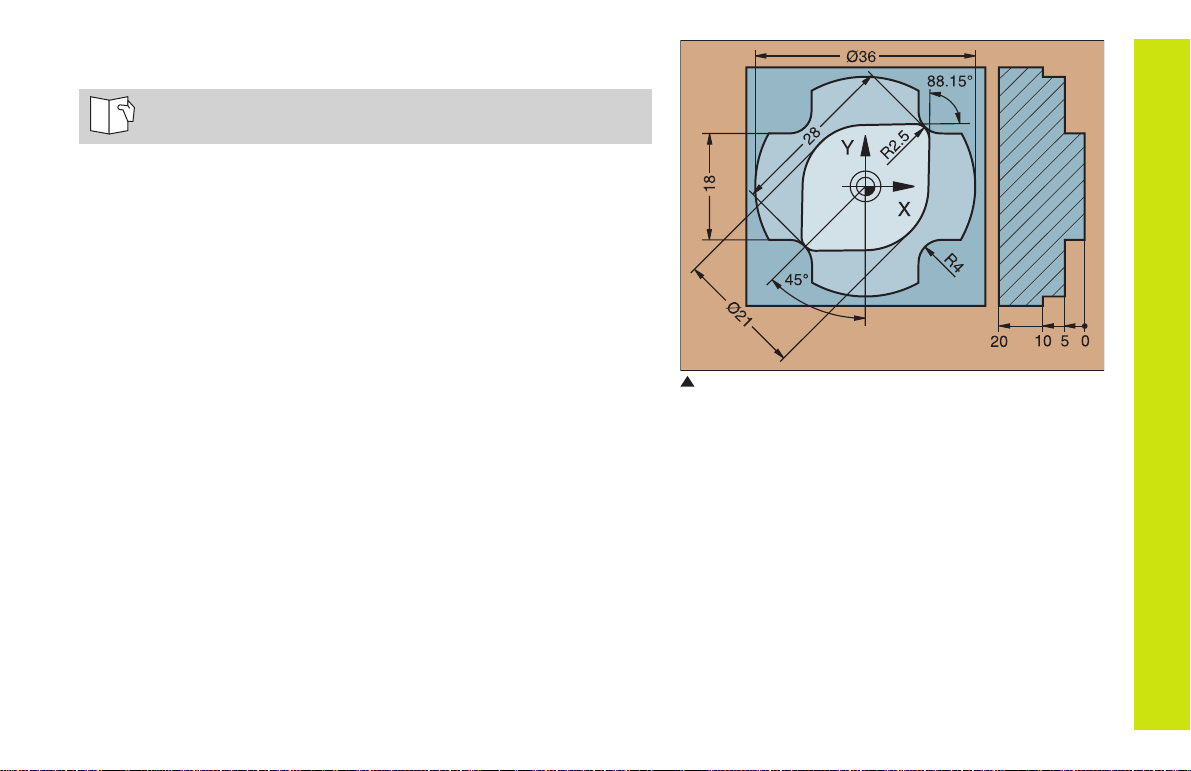

FK Free Contour Programming

See Programming Tool Movements FK Free Contour

Programming

If the end point coordinates are not given in the workpiece drawing

or if the drawing gives dimensions that cannot be entered with the

gray path function keys, you can still program the part by using the

FK Free Contour Programming.

Possible data on a contour element:

Known coordinates of the end point

Auxiliary points on the contour element

Auxiliary points near the contour element

A reference to another contour element

Directional data (angle) / position data

Data regarding the course of the contour

To use FK programming properly:

All contour elements must lie in the working plane.

Enter all available data on each contour element.

If a program contains both FK and conventional blocks, the FK

contour must be fully defined before you can return to conventional

programming.

These dimensions can be programmed with FK

FK Free Contour Programming

25

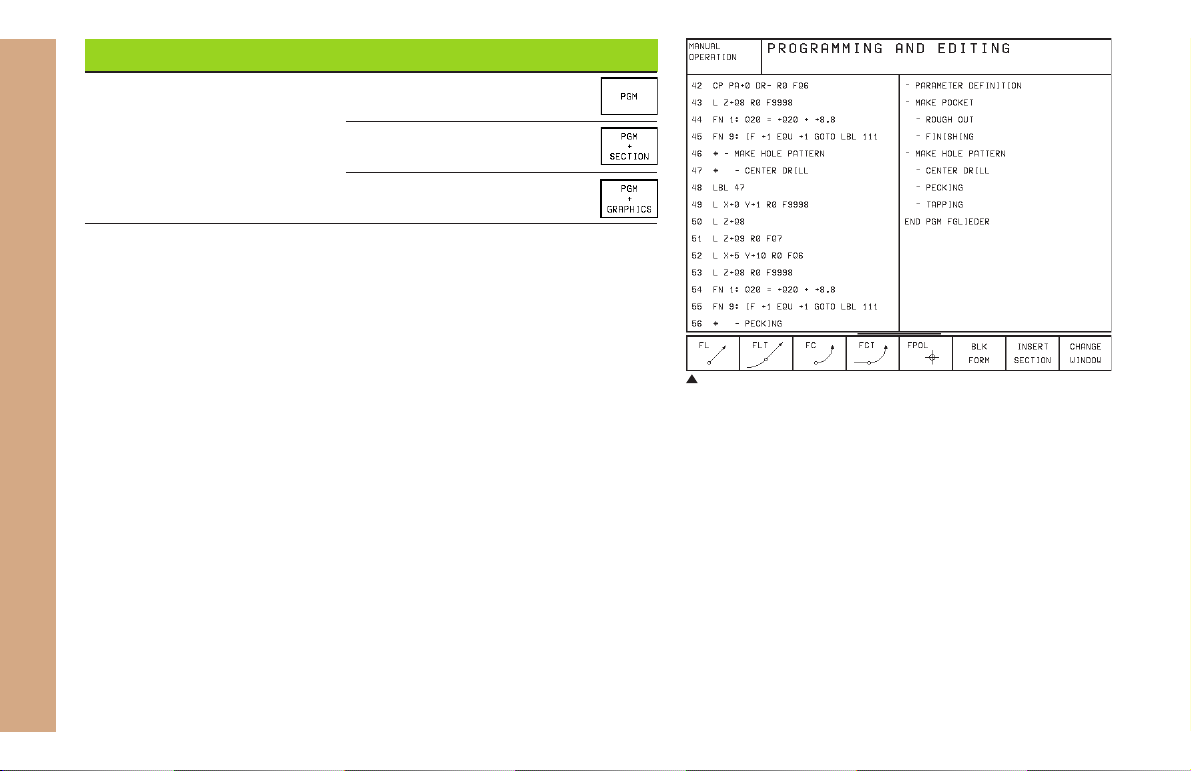

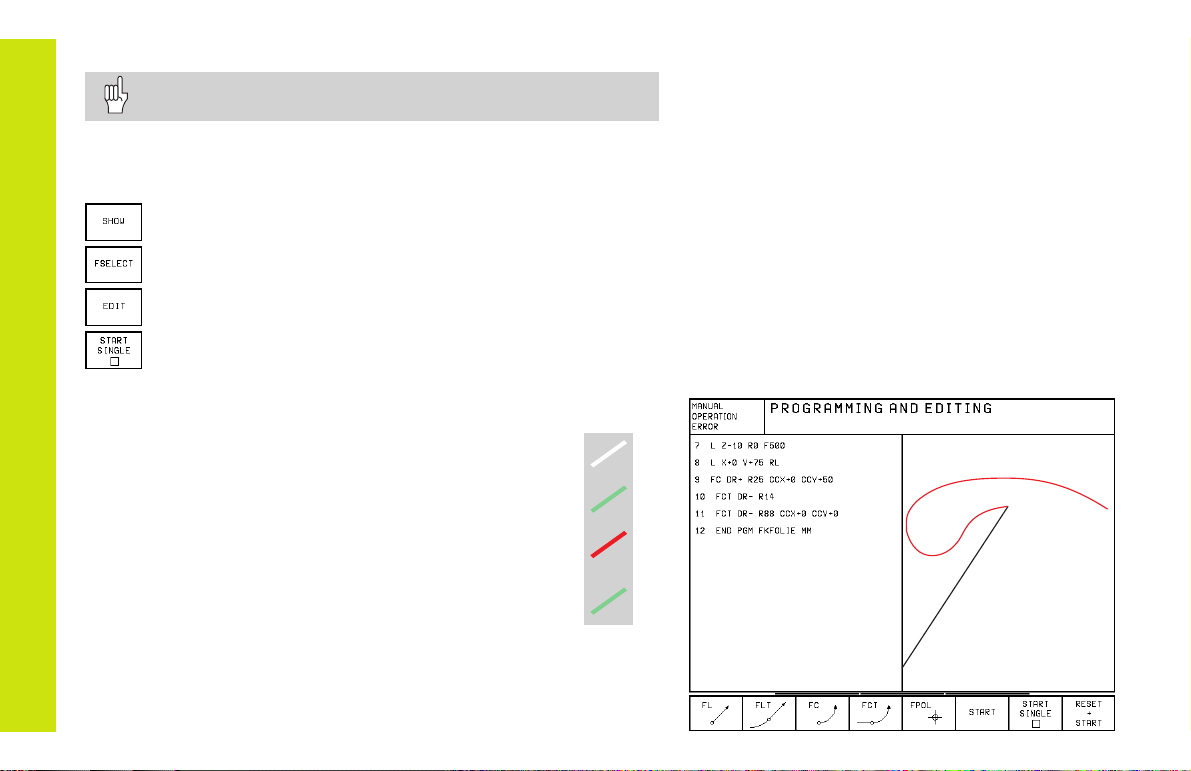

Working with the Interactive Graphics

Select the PGM+GRAPHICS screen layout!

The interactive graphics show the contour as you are programming it.

If the data you enter can apply to more than one solution, the following soft keys will appear:

To show the possible solutions

To enter the displayed solution in the part program

To enter data for subsequent contour elements

To graphically display the next programmed block

Standard colors of the interactive graphics

Fully defined contour element

The displayed element is one of a limited number of

FK Free Contour Programming

possible solutions

The element is one of an infinite number of solutions

Contour element from a subprogram

26

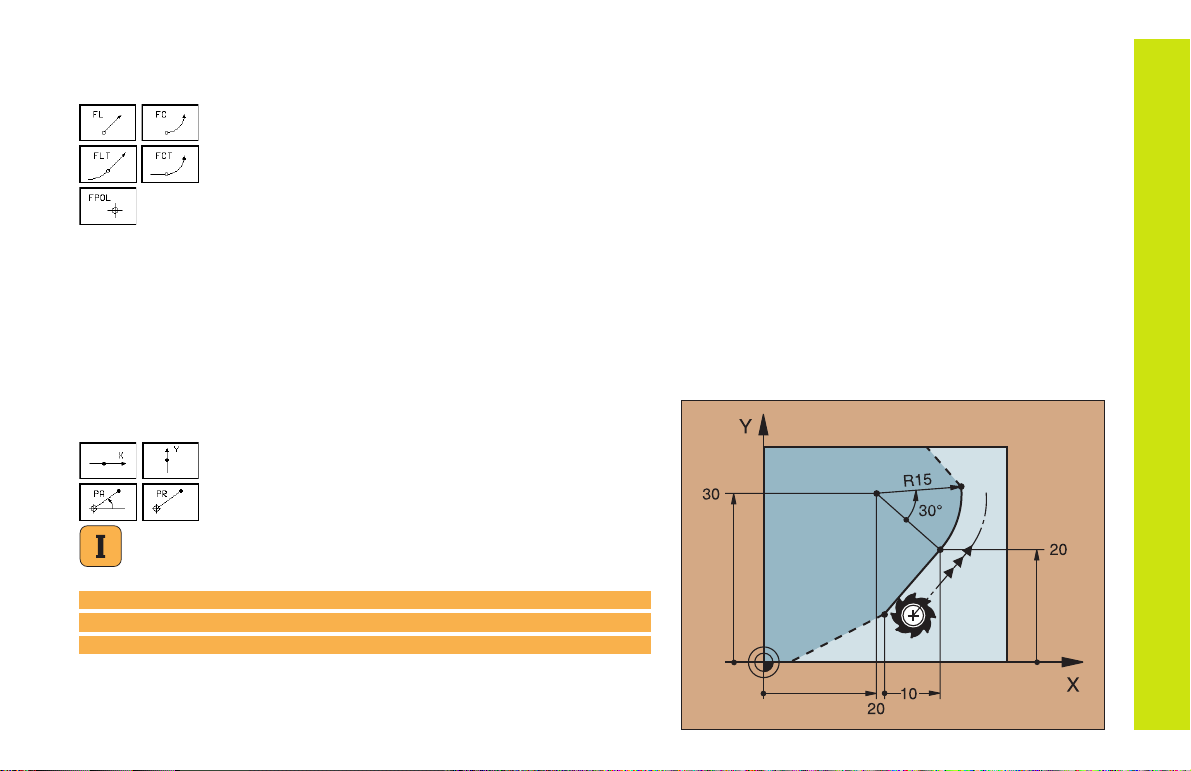

Initiating the FK Dialog

Straight Circular

Contour element without tangential connection

Contour element with tangential connection

Pole for FK programming

End Point Coordinates X, Y or PA, PR

Cartesian coordinates X and Y

Polar coordinates referenced to FPOL

Incremental input

7 FPOL X+20 Y+30

8 FL IX+10 Y+20 RR F100

9 FCT PR+15 IPA+30 DR+ R15

FK Free Contour Programming

27

Loading...

Loading...