Page 1

Contents: Basic course G3 and Upgrade course TNC 410

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Title

Cartesian contour movements

Holes

Square

Rounding /chamfering corners

Rounding corners

Linear movements

Circular movements

Circular arc with CC, C

Tangential contour connection

Circular arcs

Circular arc with CR

Polar contour movements

Hexagon (polar)

Circle (polar) CP

Circlualr path with tang. connection (polar) CTP

Polar coordinates (general)

PGM-No.

151

152

153

154

250

251

206

207

208

209

213

211

212

252

15

16

17

18

19

20

21

22

23

24

25

Canned cycles

Drilling cycle

Drilling with 200-series cycles

Slot plate

Bushing plate

Die I

Linear hole pattern

Hole pattern

Guide plate

Die II

Program section repeats

Hexagon

Drilled plate - slanted rows

201

260

210

262

265

220

221

261

266

268

270

HEIDENHAIN

Basic course G3/Upgrade course

D08

IH1

Page 2

Contents: Basic course G3 and Upgrade course TNC 410

No.

26

27

28

29

30

31

32

Title

Free Contour Programming

FK Cam

Maltese cross

FK Hook - type spanner wrench

Subprogramming Technique

Subprogram (Groups of holes)

Bolt hole circle segments with several tools

Milling with several settings

Contour Cycles

Contour cycles SL 1, Roughing out kidney

Coordinate Transformations

PGM-No.

288

275

295

215

280

223

174

33

34

35

36

Datum shift and mirror images

Coordinate transformations (combined)

Scaling factor - hammer

Scaling factor

229

232

284

234

HEIDENHAIN

Basic course G3/Upgrade course

D08

IH2

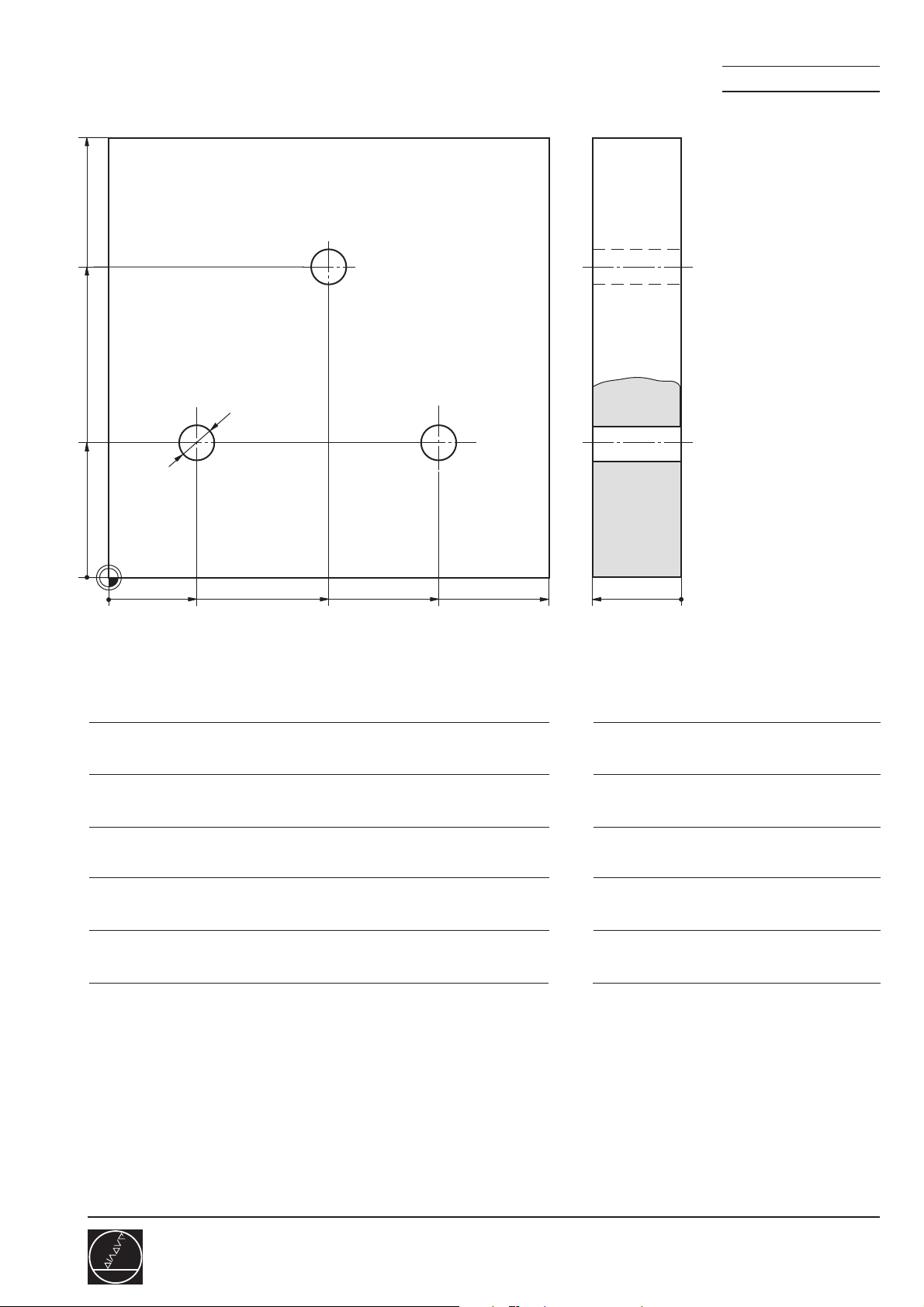

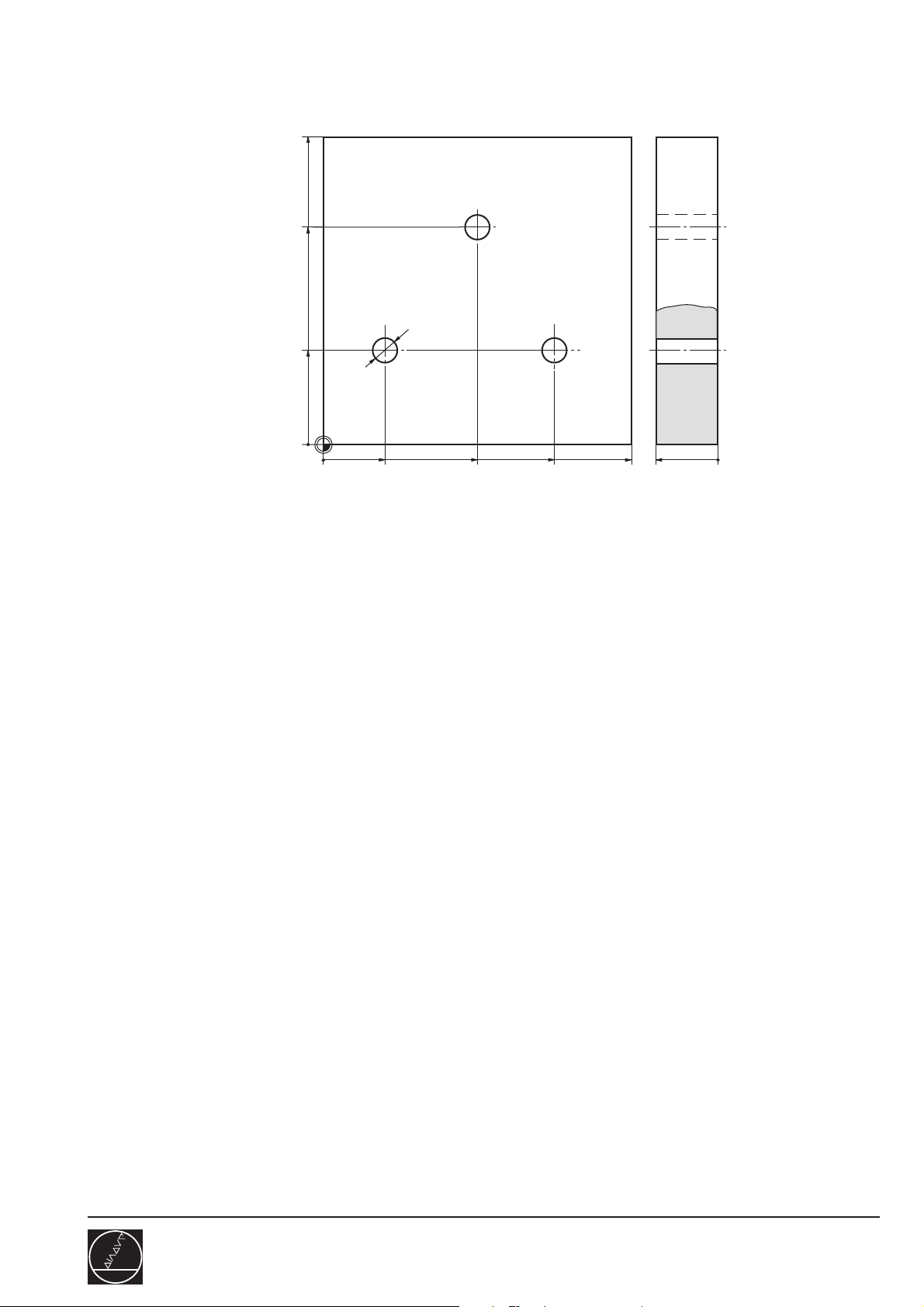

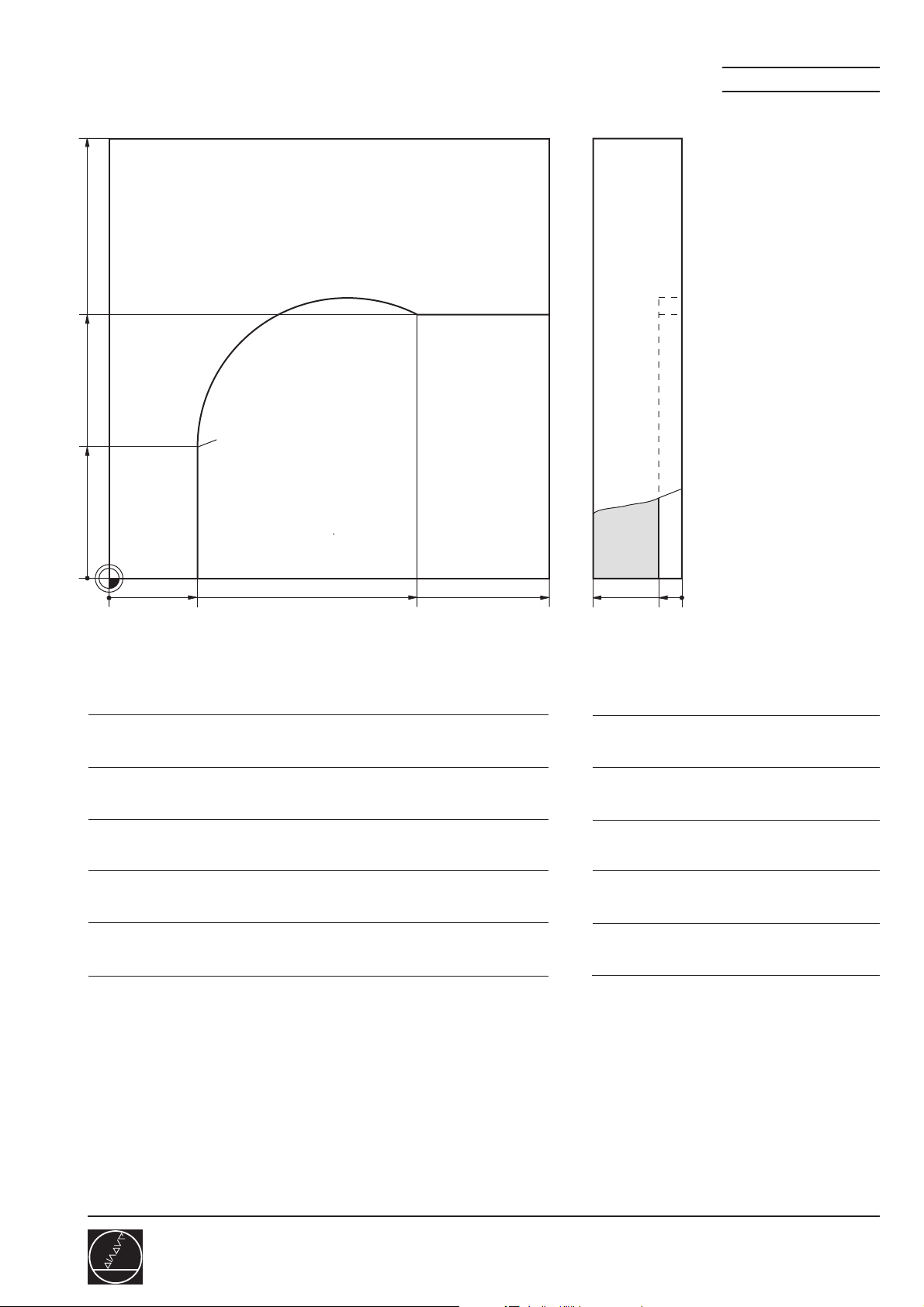

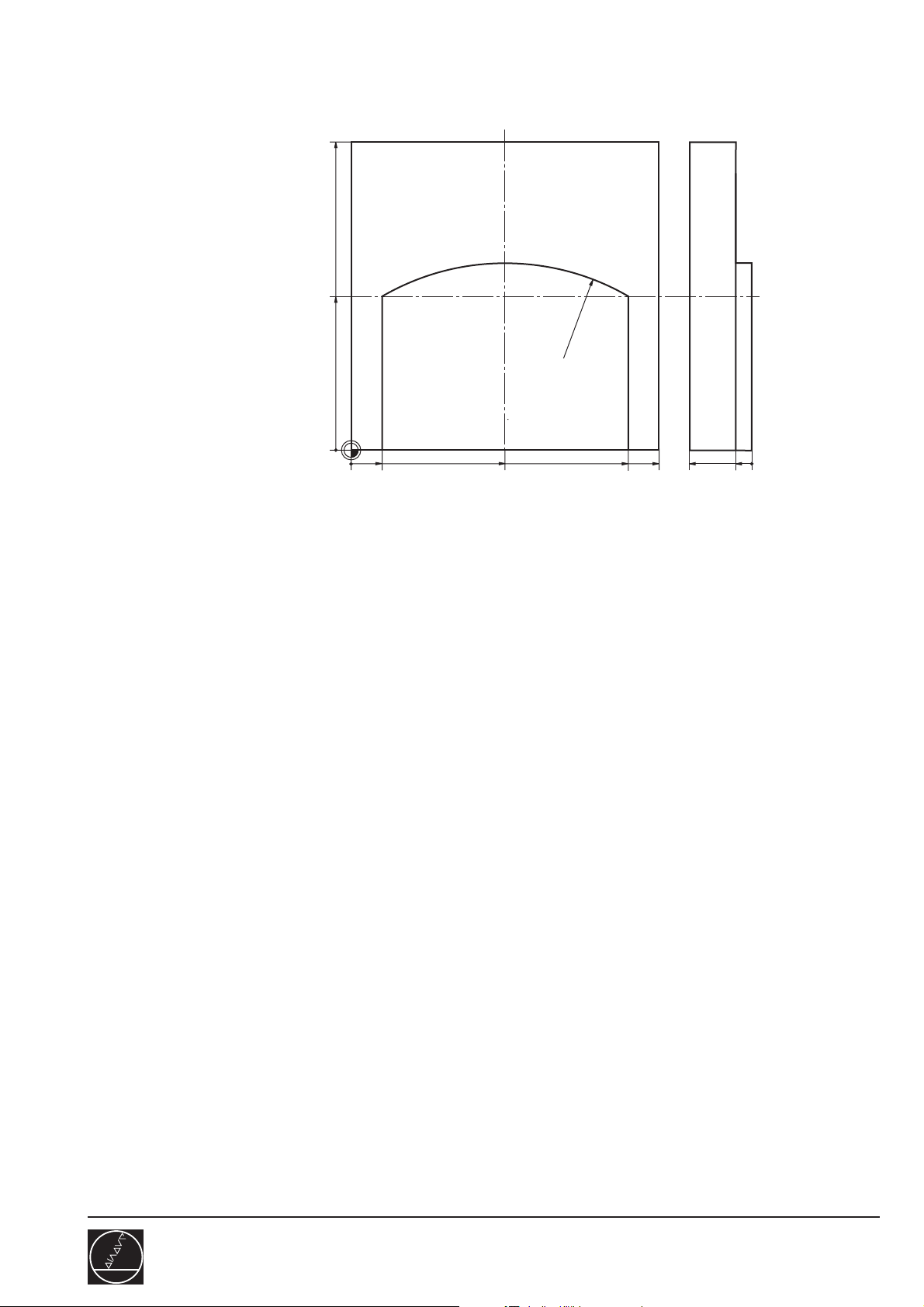

Page 3

100

70

30

Task:

Holes

8

Program(s):

0

0

20

50

75

100

20

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

151/1

Page 4

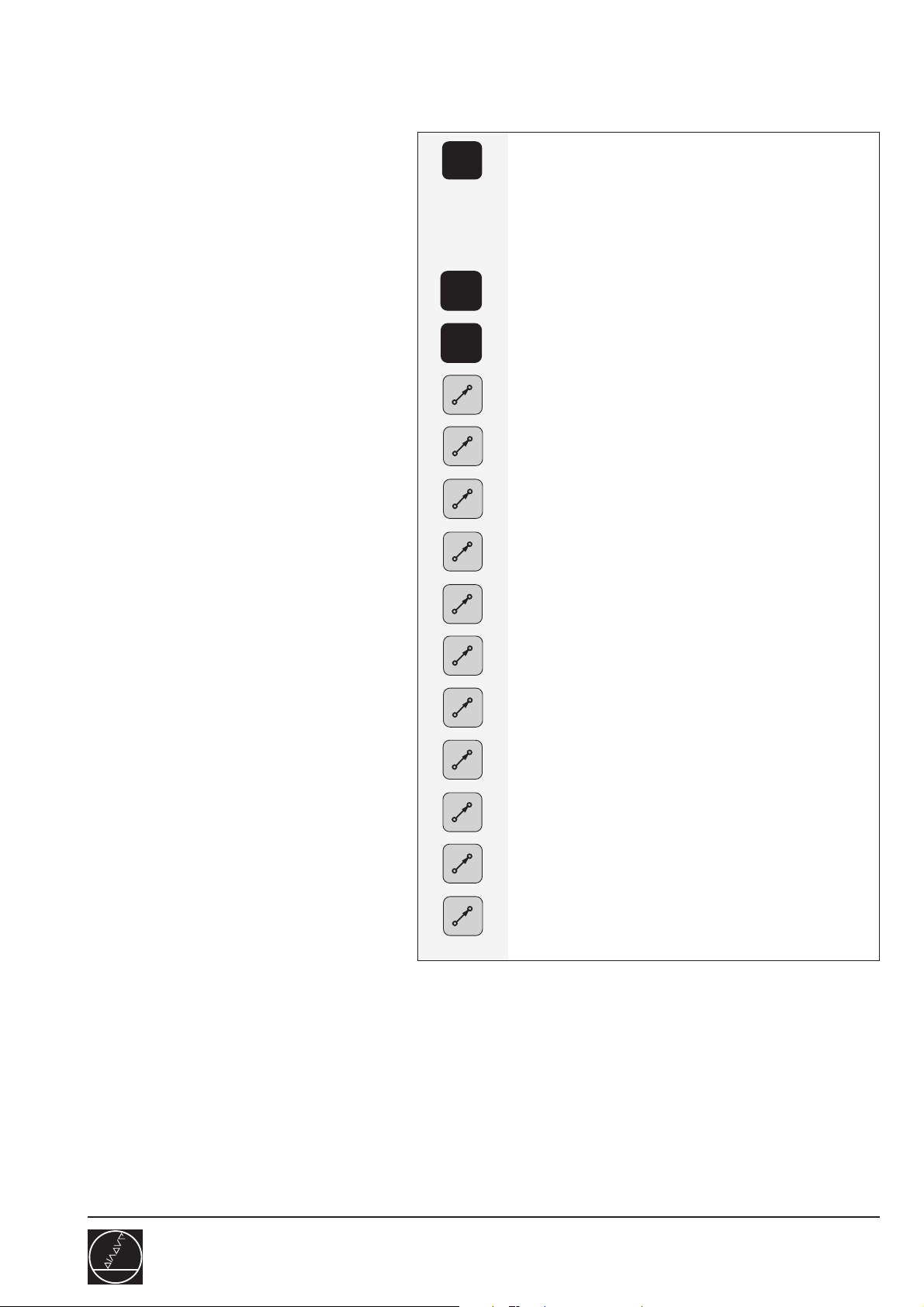

Program layout:

Holes

Begin program

Define workpiece blank

Define tool

Call tool data

Move to clearance height

Move to starting point

Move to set up clearance

Drill

Retract drill

PGM

MGT

TOOL

DEF

TOOL

CALL

L

L

L

L

L

BEGINN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL DEF . . . L . . . R . . .

TOOL CALL . . . . . . S . . .

L Z+100 R0 FMAX

L X . . . Y . . . R0 FMAX M3

L Z+ . . . R FMAX M8

L Z– . . . R F100 M

L Z+2 R0 FMAX

Move to next position

Drill

Retract drill

Next hole

Drill

Return to clearance height

End of program

L

L

L

L

L

L

L X . . . Y . . . FMAX

L Z– . . .

L Z+ . . . FMAX

L X . . . Y . . . R0 FMAX

L Z–22 R0

L Z+100 R0 FMAX M2 (M30)

HEIDENHAIN

Basic course G3/Upgrade course

D02

151/2

Page 5

Solution: Holes

100

70

30

0

0

20

8

50

75

100

20

0

Complete program

0 BEGIN PGM 151 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0............................

3 TOOL DEF 1 L+0 R+4 ...............................................

4 TOOL CALL 1 Z S4000 .............................................

5 L Z+100 R0 F MAX ...................................................

6 L X+20 Y+30 R0 F MAX M3 .....................................

7 L Z+2 R0 F MAX M8

8 L Z-22 R0 F400 .........................................................

9 L Z+2 R0 F MAX

10 L X+50 Y+70 R0 F MAX ...........................................

11 L Z-22 R0 F400

12 L Z+2 R0 F MAX

13 L X+75 Y+30 R0 F MAX ...........................................

14 L Z-22 R0 F400

15 L Z+100 R0 F MAX M2

16 END PGM 151 MM

WORKPIECE BLANK DEFINITION

DEFINE TOOL

CALL TOOL DATA

CLEARANCE HEIGHT

FIRST HOLE

DRILL

SECOND HOLE

THIRD HOLE

HEIDENHAIN

Basic course G3/Upgrade course

D02

151/3

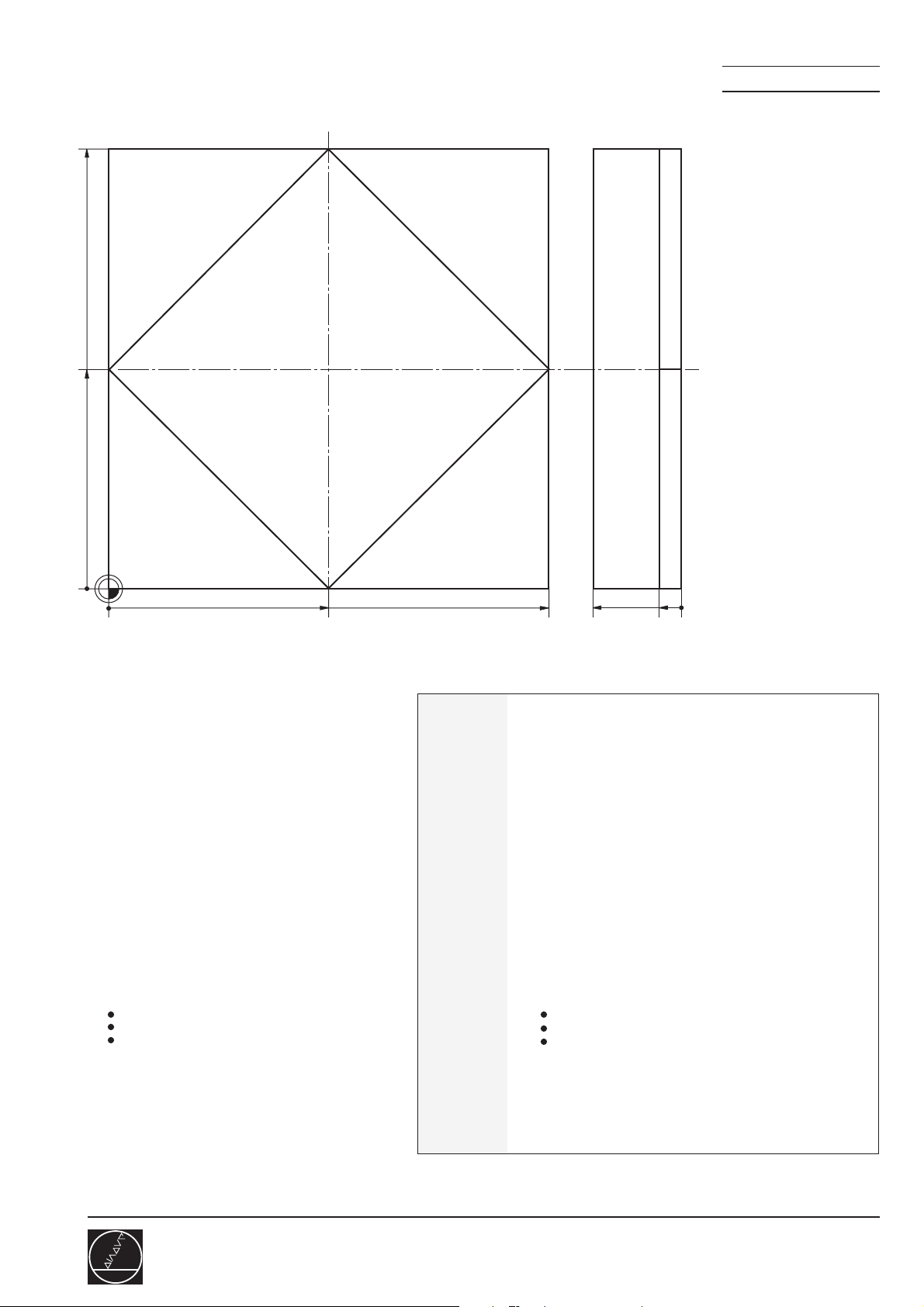

Page 6

100

50

Task:

Square

Program(s):

0

0

50

Begin program

Define workpiece blank

Define tool

Call tool data

Move to clearance height

Move to auxiliary point R0

Plunging depth

Contour starting point RL/RR

Contour coordinates RL/RR

○○○

5

0

100

20

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL DEF . . . L . . . R . . .

TOOL CALL . . . . . . S . . .

L Z+ . . . R0 F . . .

L X . . . Y . . . R . . . F . . .

L Z . . . R . . . F . . . M . . .

L X . . . Y . . . RR/RL

L X . . . Y . . . RR/RL

○○○

Last contour point RL/RR

Move to auxiliary point R0

Retract tool, PGM end

HEIDENHAIN

Basic course G3/Upgrade course

D02

L X . . . Y . . . RR/RL

L X . . . Y . . . R . . .

L Z . . . R . . . F . . . M . . .

152/1

Page 7

Solution: Square

100

50

0

0

50

100

20

5

0

Complete program

0 BEGIN PGM 152 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0............................

3 TOOL DEF 1 L+0 R+8 ...............................................

4 TOOL CALL 1 Z S4000 .............................................

5 L Z+100 R0 F MAX ...................................................

6 L X-30 Y+50 R0 F MAX ............................................

7 L Z-5 R0 F MAX M3 .................................................

8 L X+0 Y+50 RL F400 ................................................

9 L X+50 Y+100

10 L X+100 Y+50

11 L X+50 Y+0

12 L X+0 Y+50 RL .........................................................

13 L X-30 R0 F MAX M5 ...............................................

14 L Z+100 R0 F MAX M2 ............................................

15 END PGM 152 MM

WORKPIECE BLANK DEFINITION

DEFINE TOOL

CALL TOOL DATA

CLEARANCE HEIGHT

AUXILIARY POINT (R0)

PLUNGING DEPTH

CONTOUR START. POINT (RL/RR)

LAST CONTOUR POINT

AUXILIARY POINT

RETRACT TOOL/PGM END

HEIDENHAIN

Basic course G3/Upgrade course

C01

152/2

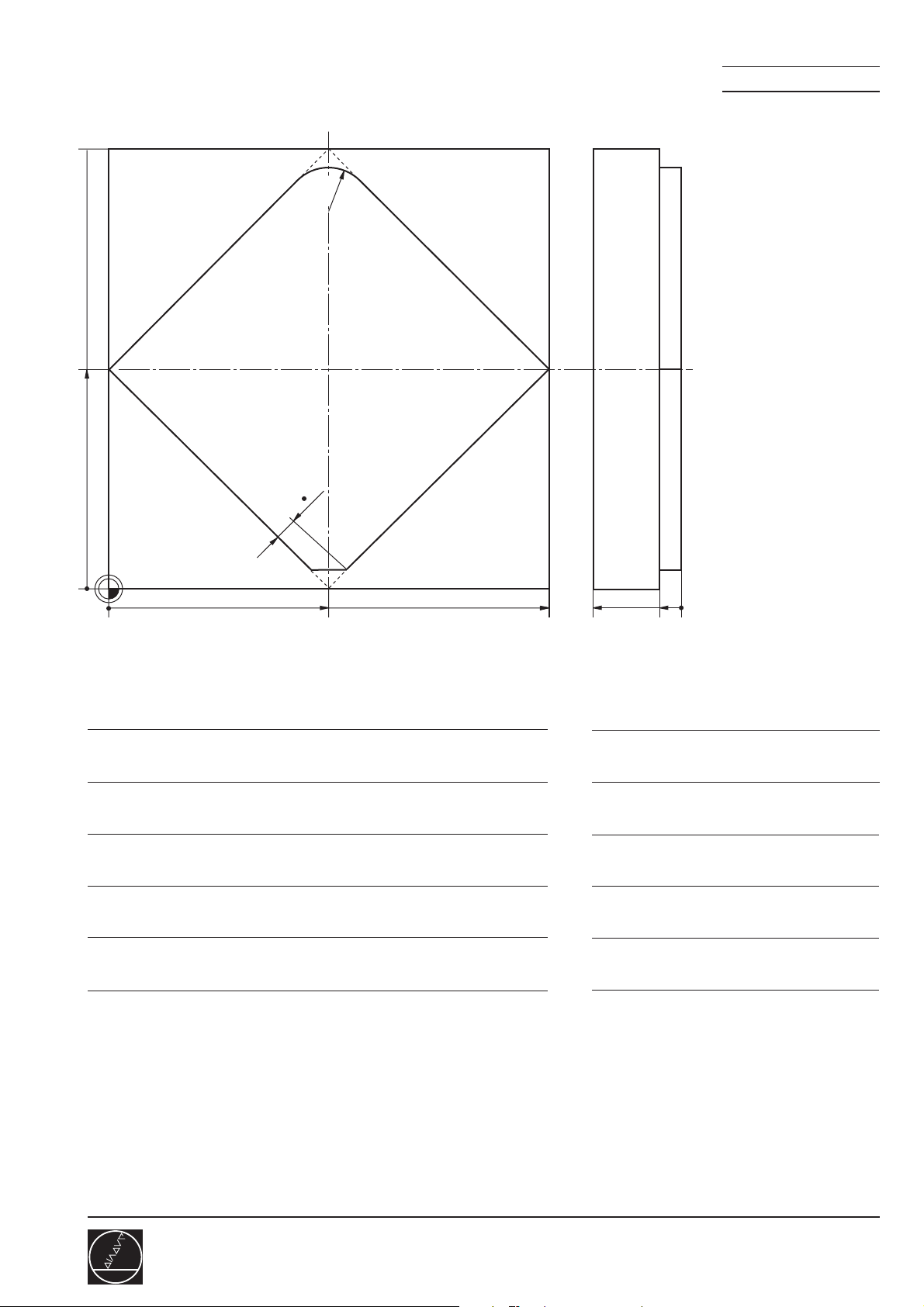

Page 8

100

50

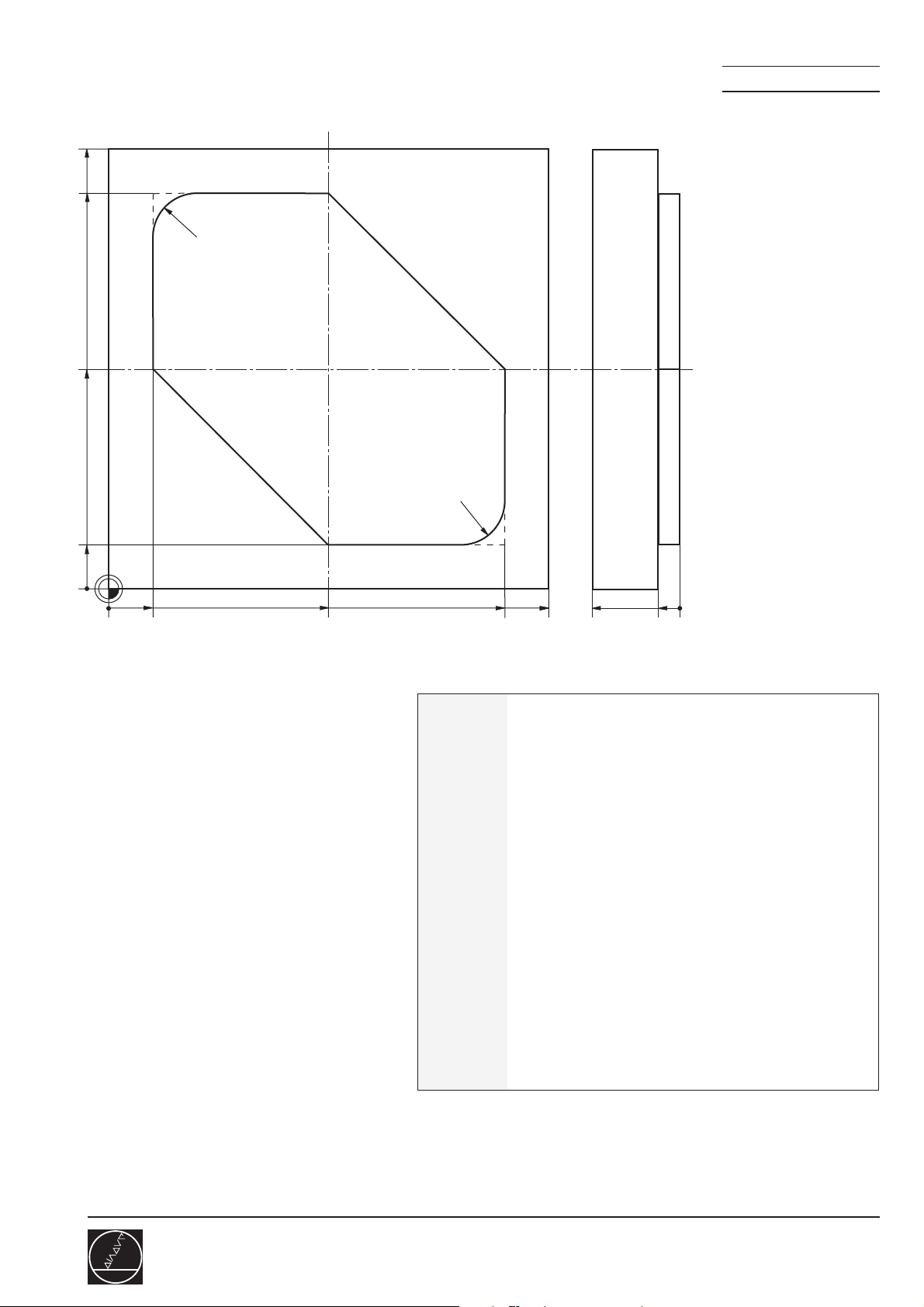

Task:

Rounding / chamfering corners

R10

Program(s):

5 45°

0

5

0

50

100

100

20

0

HEIDENHAIN

Basic course G3/Upgrade course

D02

153/1

Page 9

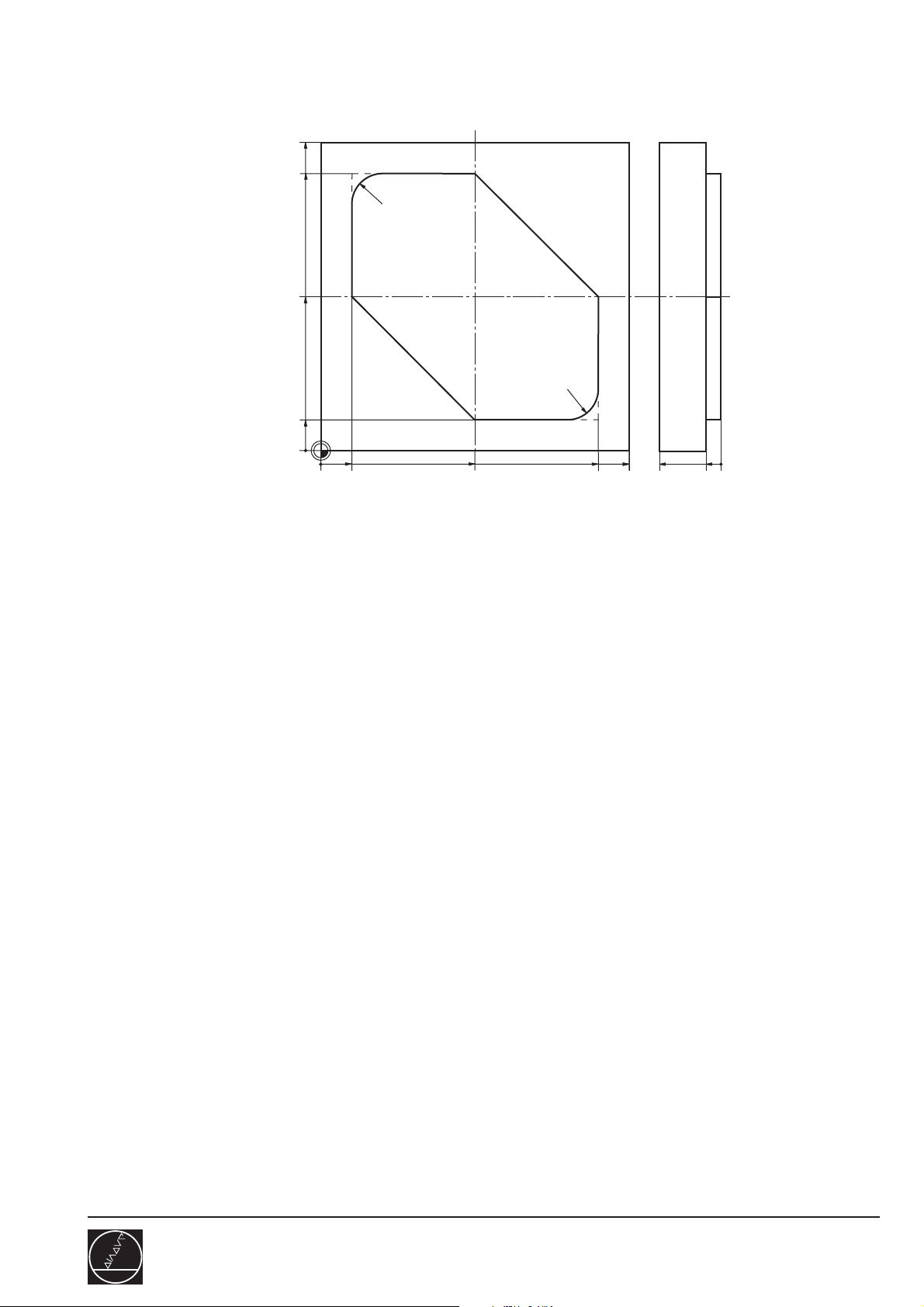

Solution: Rounding / chamfering corners

100

R10

50

5 45°

0

0

50

100

100

20

5

0

Complete program

0 BEGIN PGM 153 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0............................

3 TOOL DEF 1 L+0 R+8 ...............................................

4 TOOL CALL 1 Z S4000 .............................................

5 L Z+100 R0 F MAX ...................................................

6 L X-30 Y+50 R0 F MAX ............................................

7 L Z-5 R0 F MAX M3

8 L X+0 Y+50 RL F200 ................................................

9 L X+50 Y+100

10 RND R10 ..................................................................

11 L X+100 Y+50

12 L X+50 Y+0

13 CHF 5........................................................................

14 L X+0 Y+50 RL

15 L X-30 R0 M5 ...........................................................

16 L Z+100 R0 F MAX M2 ............................................

17 END PGM 153 MM

WORKPIECE BLANK DEFINITION

DEFINE TOOL

CALL TOOL DATA

CLEARANCE HEIGHT

AUXILIARY POINT (R0)

CONTOUT STARTING POINT RL

ROUND CORNERS

CHAMFER

AUXILIARY POINT (RO)

PGM END

HEIDENHAIN

Basic course G3/Upgrade course

D02

153/2

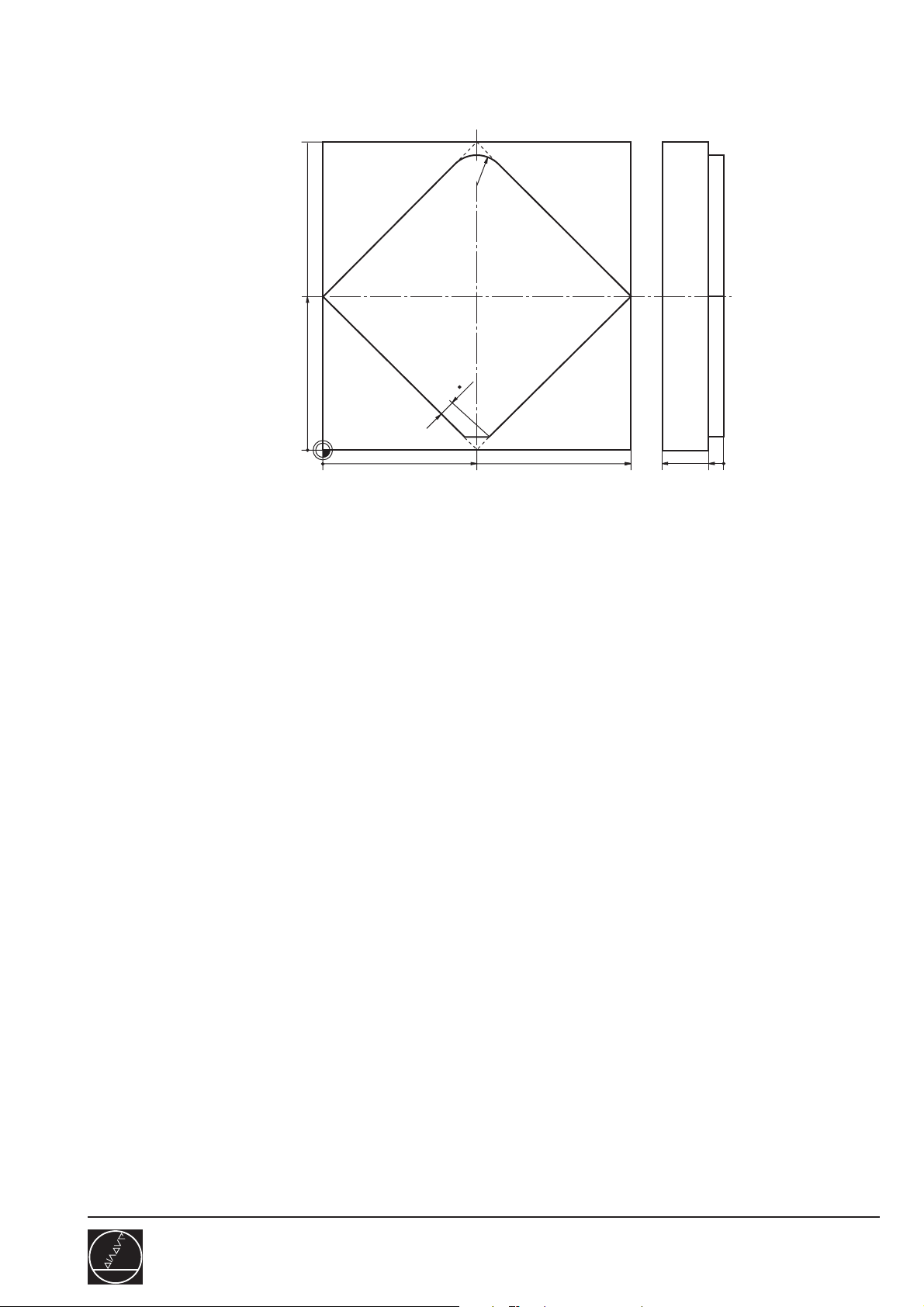

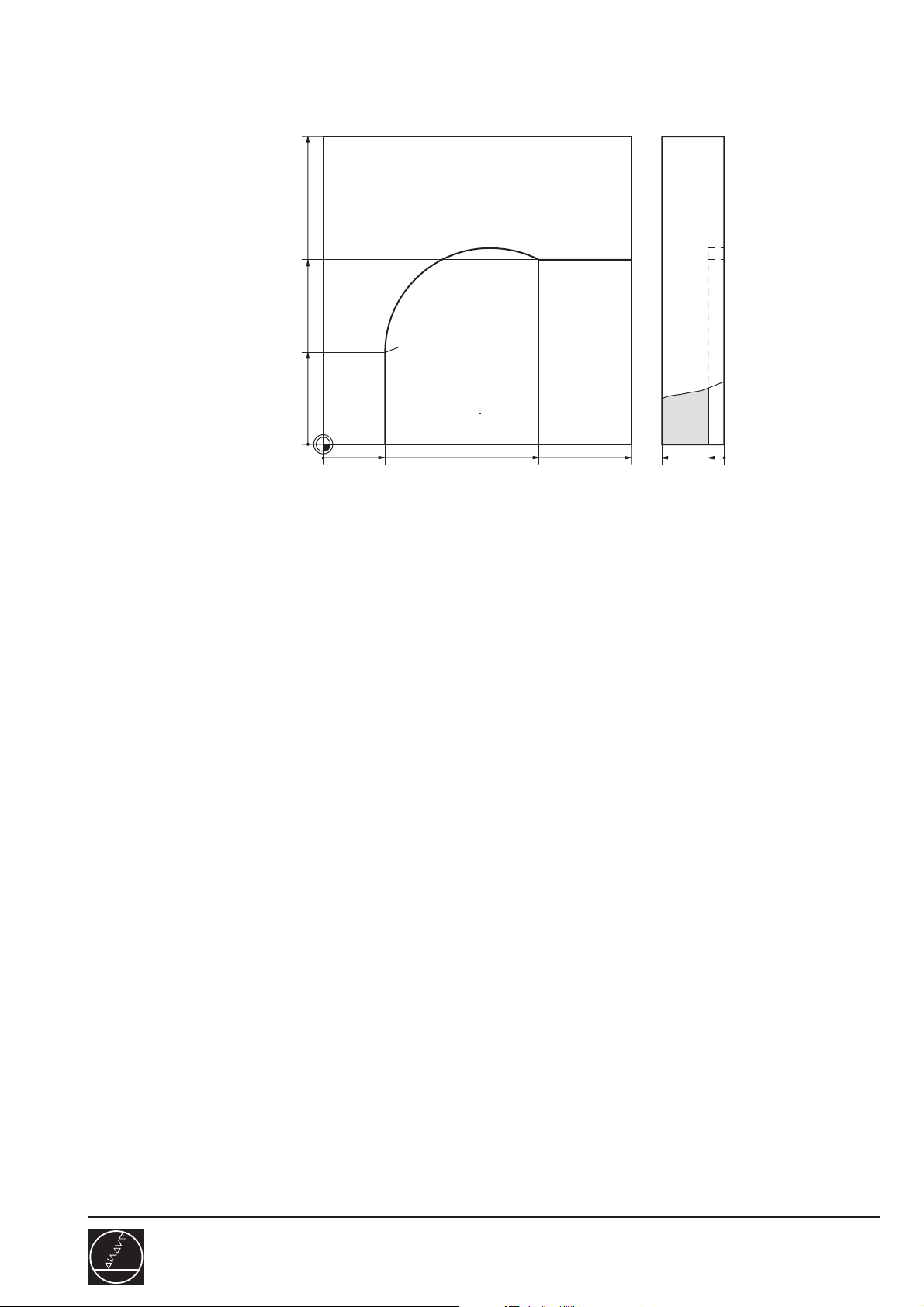

Page 10

100

Task:

Rounding corners

Program(s):

90

50

10

R10

R10

0

0

10

50

90

100

100

20

0

5

Begin program

Define workpiece blank

Define tool

Call tool data

Move to clearance height

Auxiliary point anfahren

Plunging depth

Approach tangentially

Contour

Depart tangentially

Retract tool, PGM end

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL DEF . . . L . . . R . . .

TOOL CALL . . . . . . S . . .

L Z . . .

L X . . . Y . . .

L Z . . .

APPR . . .

L . . .

DEP . . .

L Z . . .

HEIDENHAIN

Basic course G3/Upgrade course

D02

154/1

Page 11

Solution:

Rounding corners

100

Complete program

90

50

10

0

0 BEGIN PGM 154 MM

1 BLK FORM 0.1 Z X-20 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+8

4 TOOL CALL 1 Z S4000

5 L Z+100 R0 F MAX

6 L X-30 Y+70 R0 F MAX ............................................

7 L Z-5 R0 F MAX M3

8 APPR LCT X+10 Y+70 R5 RL F400 ..........................

9 L X+10 Y+90

10 RND R10

11 L X+50 Y+90

12 L Y+50 X+90

13 L X+90 Y+10

14 RND R10

15 L X+50 Y+10

16 L X+10 Y+50

17 L Y+70 ......................................................................

18 DEP LCT X-30 Y+70 R5 R0 ......................................

19 L Z+100 R0 F MAX M2

20 END PGM 154 MM

R10

R10

0

10

50

90

0

5

20

100

100

AUXILIARY POINT (R0)

APPROACH STARTING POINT

TANGENTIALLY

LAST CONTOUR POINT RL

DEPART TANGENTIALLY TO

AUXILIARY POINT

HEIDENHAIN

Basic course G3/Upgrade course

C01

154/2

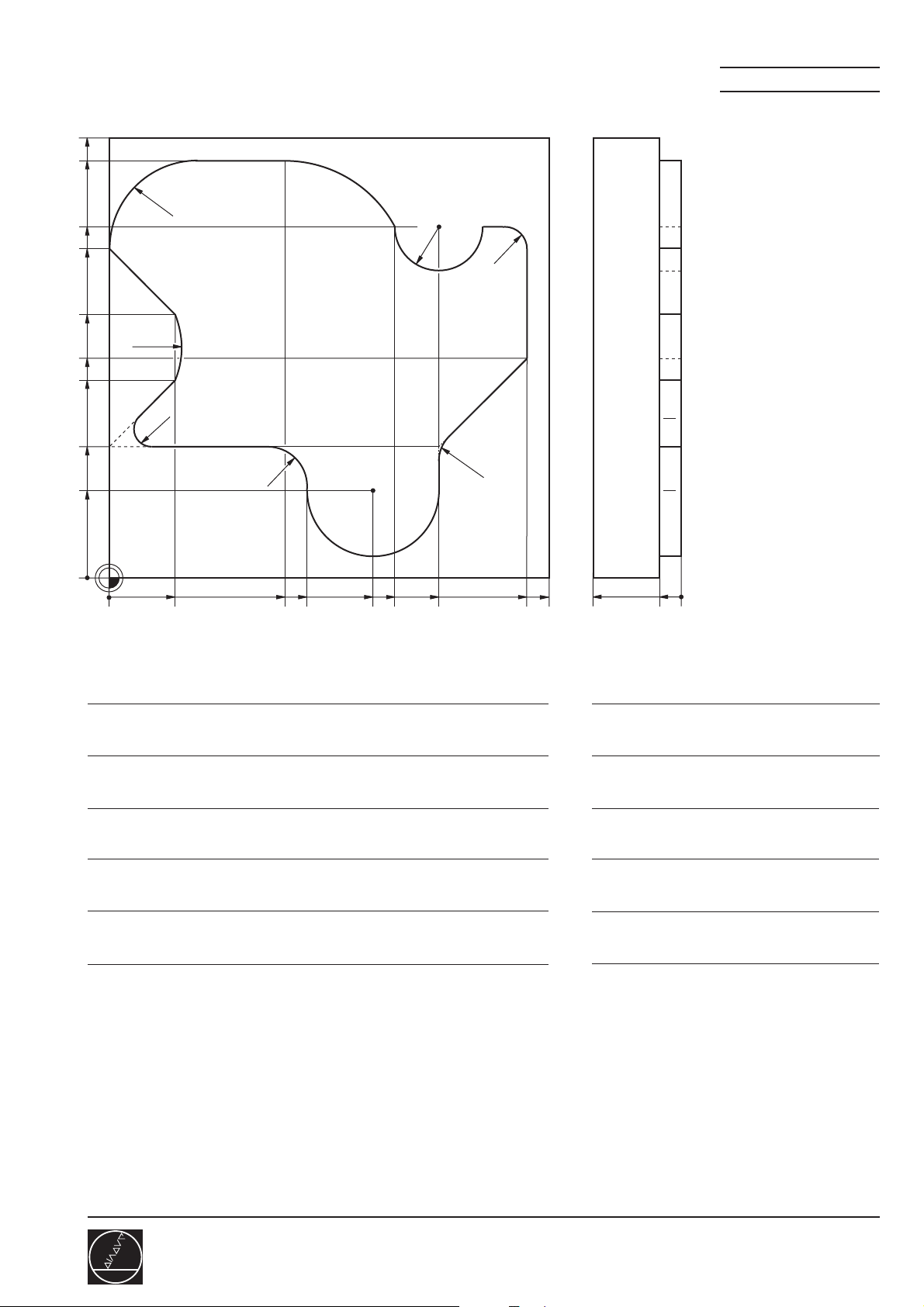

Page 12

100

90

80

70

40

Task:

Linear movements

Program(s):

10

10

10

R10

0

5

0

25

60

90

100

20

0

5

HEIDENHAIN

Basic course G3/Upgrade course

D02

250/1

Page 13

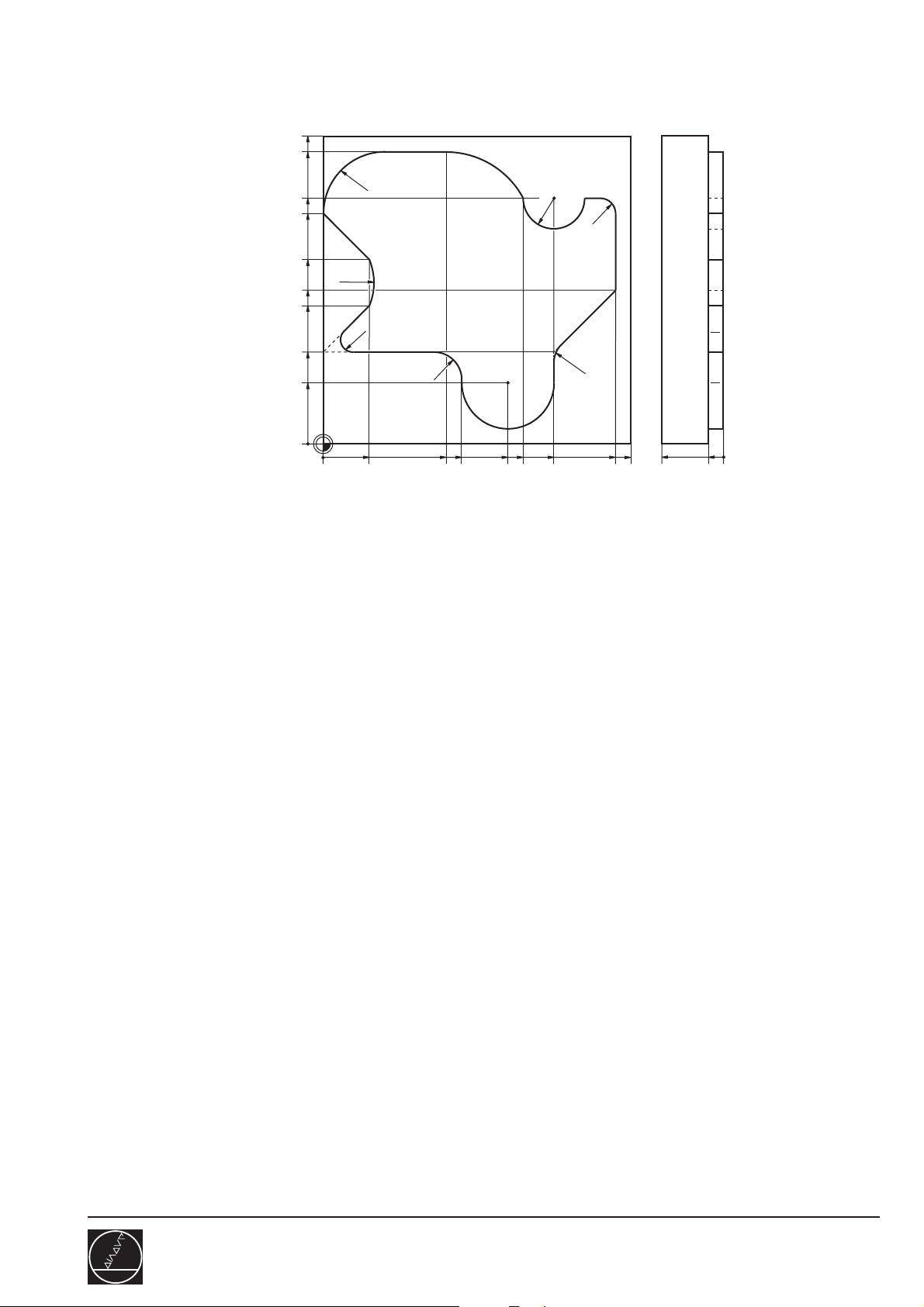

Solution: Linear movements

100

90

80

70

Complete program

40

R10

10

0

5

0

0 BEGIN PGM 250 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0 ............................

3 TOOL CALL 7 Z S2500 .............................................

4 L Z+100 R0 F9999 ....................................................

5 L X-20 Y+40 .............................................................

6 L Z+2 M3

7 L Z-5 F1000

8 APPR LCT X+5 Y+40 R3 RL F300 ............................

9 L Y+90

10 CHF 20

11 L X+60

12 L X+90 Y+80

13 L Y+40

14 CHF 10

15 L X+60 Y+10

16 L X+5

17 RND R10

18 L Y+40 ......................................................................

19 DEP LCT X-20 Y+40 R3 R0.......................................

20 L Z+100 R0 F MAX M2 ............................................

21 END PGM 250 MM

25

60

90

10

10

0

20

100

WORKPIECE BLANK DEFINITION

CALL TOOL DATA; R4

CLEARANCE HEIGHT

AUXILIARY POINT (R0)

CONTOUR STARTING POINT

(APPROACH TANGENTIALLY)

LAST CONTOUR POINT

AUXILIARY POINT (R0)

RETRACT TOOL

5

HEIDENHAIN

Basic course G3/Upgrade course

D02

250/2

Page 14

100

95

80

75

60

50

45

30

20

Task:

R20

R20

R4

Circular movements

R9

R10

Program(s):

R5

R8

0

5

0

15

40

45

60

65

75

95

100

20

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

251/1

Page 15

Solution:

100

95

Circular movements

R20

Complete program

80

75

60

50

45

30

20

R20

R4

R9

0

0

15

0 BEGIN PGM 251 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 7 Z S2500 .............................................

4 L Z+100 R0 F9999

5 L X+20 Y-20 ..............................................................

6 L Z+2 M3

7 L Z-5 F500

8 APPR LCT X+20 Y+30 R3 RL F300 ..........................

9L X+0

10 RND R4

11 L X+15 Y+45

12 CR X+15 Y+60 R+20 DR+

13 L X+0 Y+75

14 CR X+20 Y+95 R+20 DR15 L X+40

16 CT X+65 Y+80

17 CC X+75 Y+80

18 C X+85 Y+80 DR+

19 L X+95

20 RND R5

21 L Y+50

22 L X+75 Y+30

23 RND R8

24 L Y+20

25 CC X+60 Y+20

26 C X+45 Y+20 DR27 L Y+30

28 RND R9

29 L X+20 ......................................................................

30 DEP LCT X+20 Y-20 R3 R0 F500 ..............................

31 L Z+100 R0 F MAX M2

32 END PGM 251 MM

40

45

60

65

R10

R5

R8

75

5

20

95

100

R4

AUXILIARY POINT (R0)

CONTOUR STARTING POINT

(APPROACH TANGENTIALLY)

LAST CONTOUR POINT

AUXILIARY POINT (R0)

0

HEIDENHAIN

Basic course G3/Upgrade course

D02

251/2

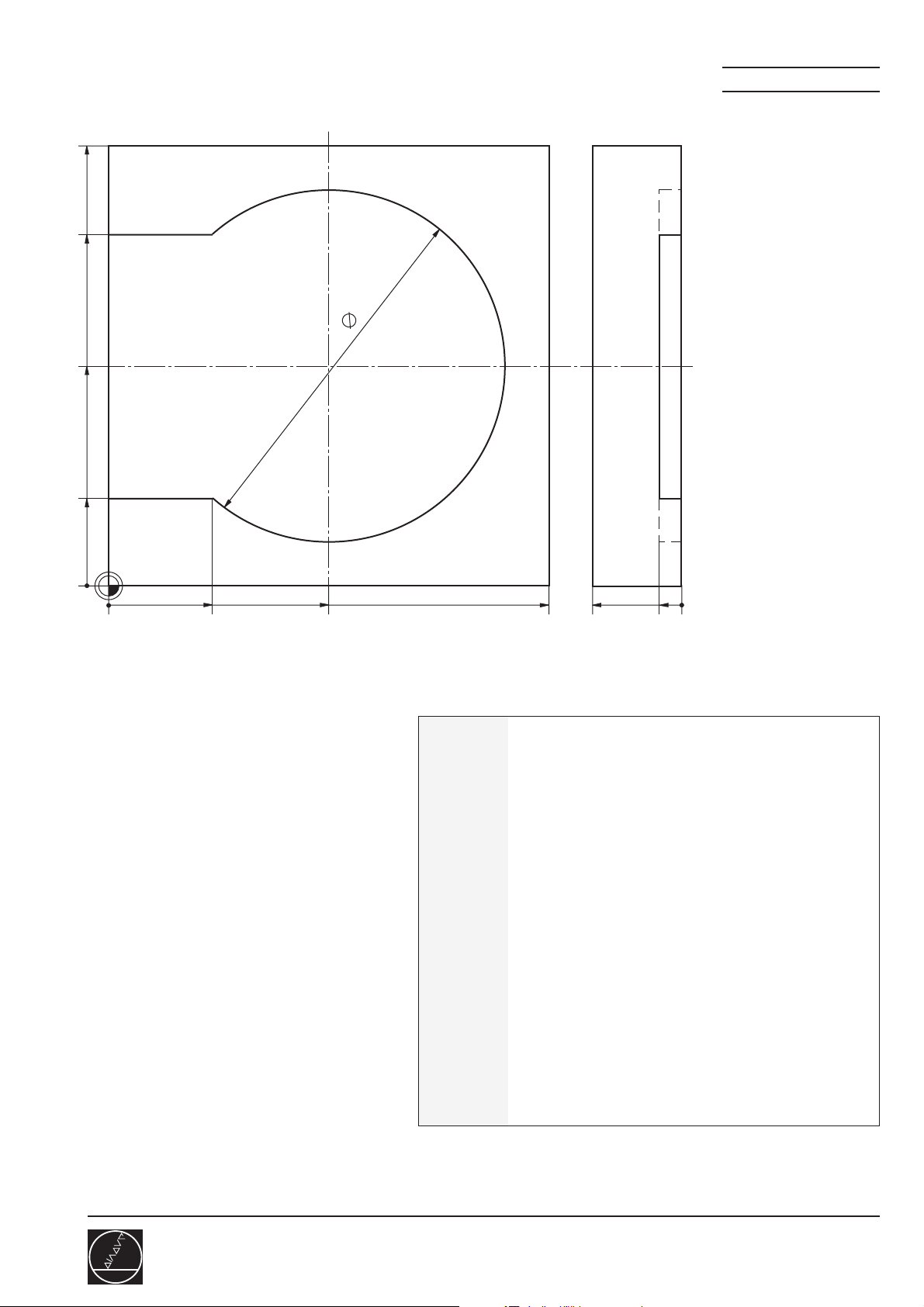

Page 16

100

80

50

20

Task:

Circular arc with CC, C

80

Program(s):

0

0

23,542

50

Begin program

Define workpiece blank

Call tool data

Move to clearance height

Move to auxiliary point R0

Plunging depth

Approach contour tangentially

Define circle center

Circular movement

5

0

100

20

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL CALL . . . . . . S . . .

L . . .

L . . . R0

L . . .

APPR . . . RL/RR

CC . . .

C . . .

Depart tangentially (aux.pt.)

Retract tool, PGM end

HEIDENHAIN

Basic course G3/Upgrade course

D02

DEP . . .

L . . .

206/1

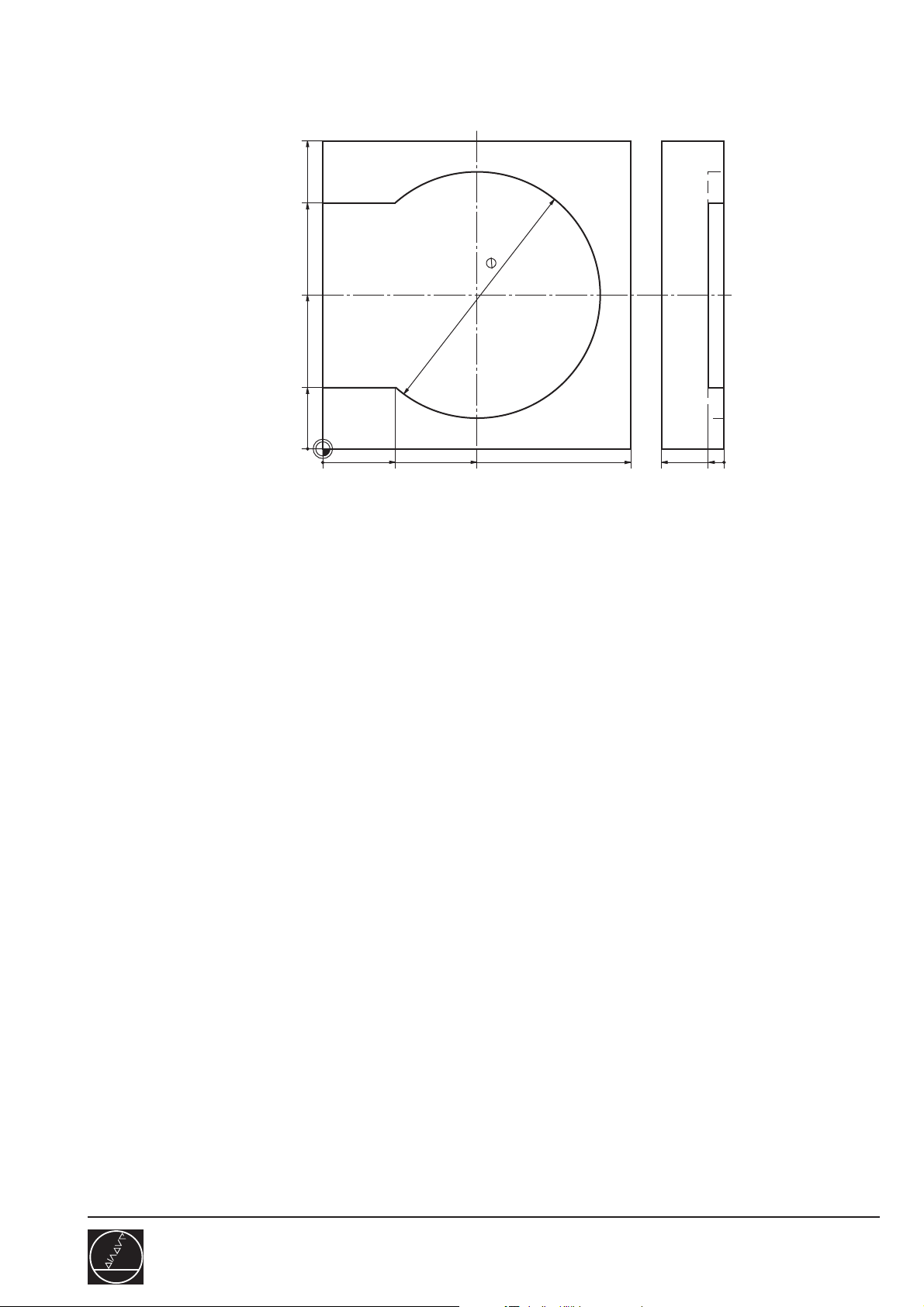

Page 17

Solution:

Circular arc with CC, C

100

80

50

20

0

0

23,542

50

80

100

20

5

0

Complete program

0 BEGIN PGM 206 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 13 Z S2500 ...........................................

4 L Z+100 R0 F MAX

5 L X-30 Y+50 R0 F MAX ............................................

6 L Z-5 R0 F MAX M3

7 APPR LT X+0 Y+20 LEN10 RL F250 M8

8 L X+23,542 RL

9 CC X+50 Y+50 ..........................................................

10 C Y+80 X+23,542 DR+ .............................................

11 L X+0 RL

12 DEP LT LEN10 R0 ....................................................

13 L Z+100 R0 F MAX M2

14 END PGM 206 MM

R20

AUXILIARY POINT

CIRCLE CENTER

CIRCULAR MOVEMENT

DEPART TANGENTIALLY (AUX.PT.)

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

206/2

Page 18

100

60

Task:

Tangential contour connection

(cartesian)

Program(s):

30

tangential

0

0

20

70

100

20

5

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

207/1

Page 19

Solution:

Tangential contour connection

(cartesian)

100

60

Complete program

30

0

0

0 BEGIN PGM 207 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 11 Z S2500 ...........................................

4 L Z+100 R0 F MAX ...................................................

5 L X+45 Y-25 R0 F MAX ............................................

6 L Z-5 F MAX M13

7 APPR LT X+20 Y+0 LEN5 RR F250 ..........................

8 L Y+30

9 CT X+70 Y+60 ..........................................................

10 L X+100

11 DEP LT LEN5 R0

12 L Z+100 R0 F MAX M2

13 END PGM 207 MM

tangential

20

70

5

20

100

R10

CLEARANCE HEIGHT

AUXILIARY POINT

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

TANGENTIAL CIRCULAR PATH

0

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

207/2

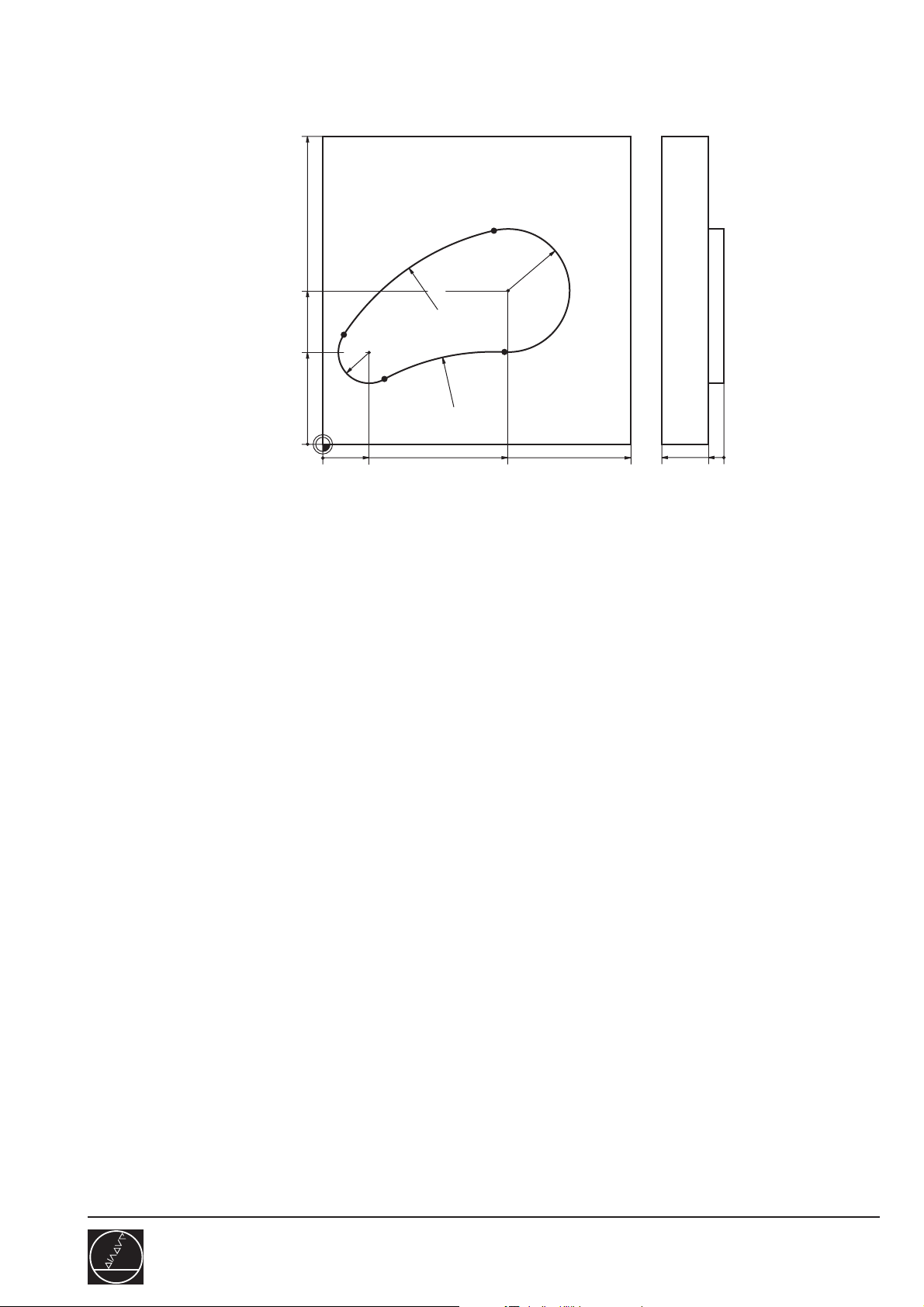

Page 20

100

Task:

Circular arcs

Program(s):

P

2

50

30

0

P

1

0

Point

P

1

R10

P

4

15

X

6,645

R80

R75

Y

35,495

R20

P

3

5

60

Point

P

3

100

X

58,995

20

0

Y

30,025

P

2

55,505

HEIDENHAIN

Basic course G3/Upgrade course

69,488

C01

P

4

19,732

21,191

208/1

Page 21

Solution:

Circular arcs

100

P

2

Complete program

50

P

1

30

0

R10

0

15

0 BEGIN PGM 208 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 13 Z S2500 ...........................................

4 L Z+100 R0 F MAX ...................................................

5 L X-30 Y+30 R0 F MAX M3 ......................................

6 L Z-5 F MAX .............................................................

7 APPR LCT X+5 Y+30 R5 RL F250 M8 ......................

8 CC X+15 Y+30 ..........................................................

9 C X+6,645 Y+35,495 DR- .........................................

10 CT X+55,505 Y+69,488 ............................................

11 CC X+60 Y+50

12 C X+58,995 Y+30,025 DR13 CT X+19,732 Y+21,191

14 CC X+15 Y+30

15 C X+5 Y+30 DR-

16 DEP LCT X-30 Y+30 R5 R0 ......................................

17 L Z+100 R0 F MAX M2

18 END PGM 208 MM

R80

P

4

R75

R20

P

3

60

5

20

100

R20

CLEARANCE HEIGHT

AUXILIARY POINT

DEPTH

APPROACH TANGENTIALLY

CIRCLE CENTER

CIRCLE

TANGENTIAL CIRCULAR PATH

DEPART TANGENTIALLY

0

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

208/2

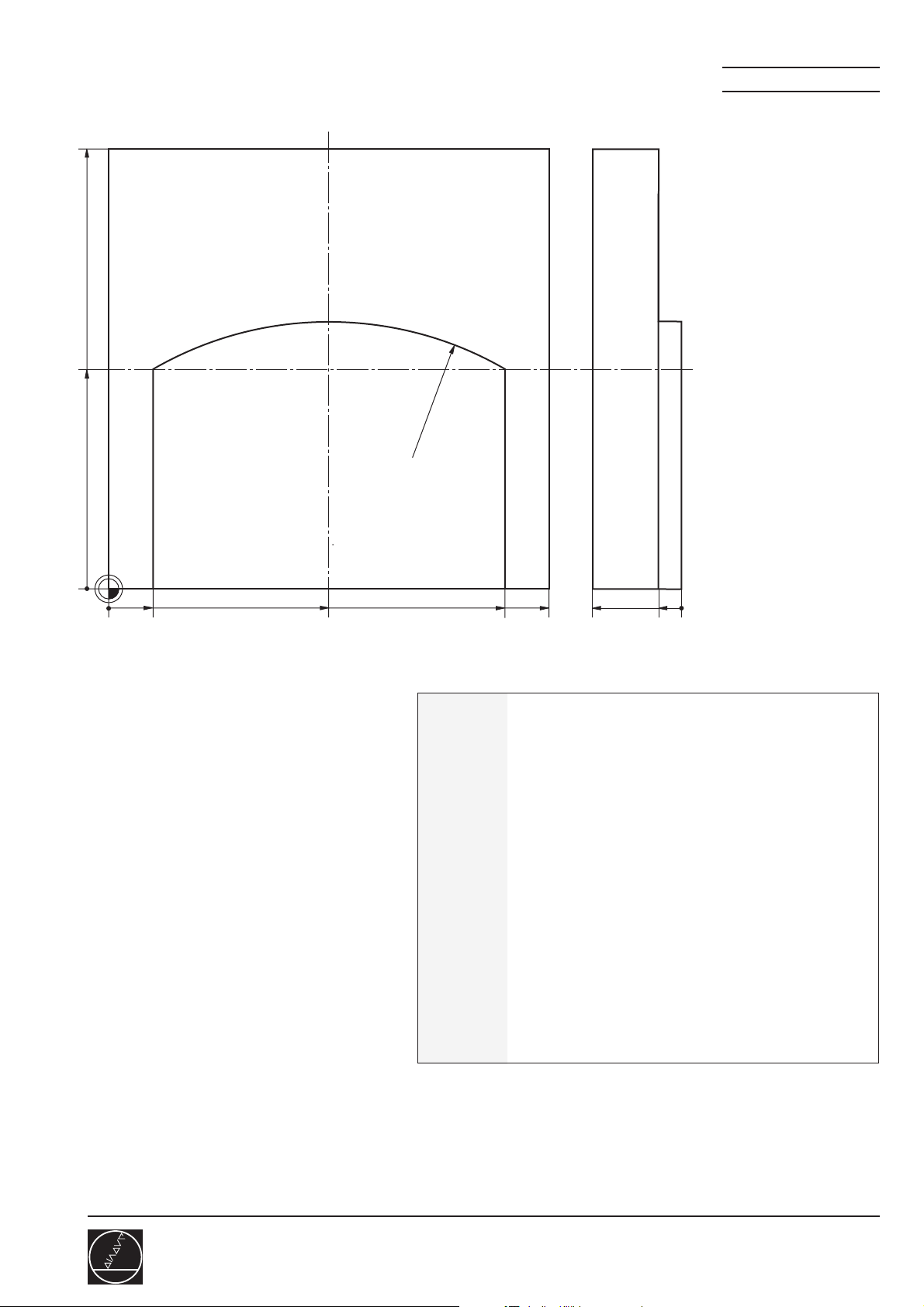

Page 22

100

50

Task:

Circular arc with CR

R80

Program(s):

0

0

10

Begin program

Define workpiece blank

Call tool data

Move to clearance height

Move to auxiliary point

Plunging depth

Approach tangentially

Contour

Depart tangentially

50

5

90

100

20

0

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL CALL . . . . . . S . . .

L . . .

. . .

. . .

. . .

. . .

. . .

Retract tool, PGM end

HEIDENHAIN

Basic course G3/Upgrade course

C01

. . .

209/1

Page 23

Solution:

Circular arc with CR

100

50

0

0

10

50

R80

90

100

20

5

0

Complete program

0 BEGIN PGM 209 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 13 Z S2500 ...........................................

4 L Z+100 R0 F MAX

5 L X-30 Y-30 R0 F MAX M13 .....................................

6 L Z-5 F MAX

7 APPR LT X+10 Y+0 LEN10 RL F250.........................

8 L Y+50

9 CR X+90 Y+50 R+80 DR- .........................................

10 L Y+0

11 DEP LT LEN10 R0 ....................................................

12 L Z+100 R0 F MAX M2

13 END PGM 209 MM

R20

AUXILIARY POINT

APPROACH STARTING POINT

TANGENTIALLY

CIRCULAR ARC

DEPART TANGENTIALLY (AUX.PT.)

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

209/2

Page 24

Task:

50

0

Hexagon (polar)

60°

R40

Program(s):

-50

-50

Begin program

Define workpiece blank

Call tool data

Move to clearance height

Define pole

Auxiliary point in polar coord.

Plunging depth

Approach tangentially

Contour

○○○

5

0

50

20

0

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL CALL . . . . . . S . . .

L Z . . .

CC X . . . Y . . .

LP PR . . . PA . . .

L Z . . .

APPR LCT X . . . Y . . . R . . .

LP PR . . . PA . . .

○○○

Depart tangentially

Retract tool, PGM end

HEIDENHAIN

Basic course G3/Upgrade course

DEP LCT X . . . Y . . . R . . .

L Z . . .

D02

213/1

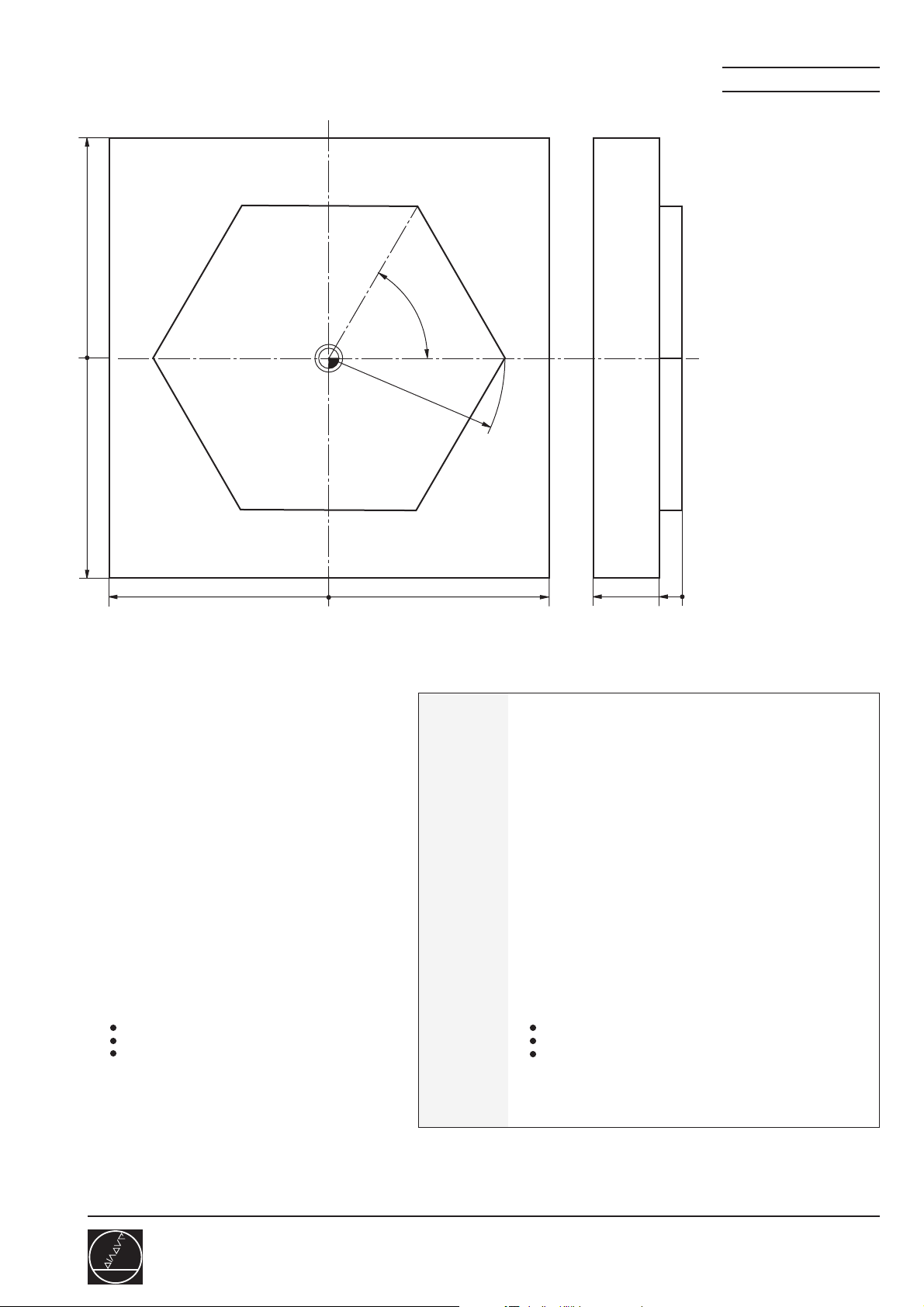

Page 25

Solution:

Hexagon (polar)

50

60°

Complete program

0

-50

-50

0 BEGIN PGM 213 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-20

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL CALL 13 Z S2500 ...........................................

4 L Z+100 R0 F MAX

5 CC X+0 Y+0 ..............................................................

6 LP PR+80 PA+0 R0 F MAX.......................................

7 L Z-5 F MAX M3

8 APPR LCT X+40 Y+0 R5 RR F250 M8 ......................

9 LP PA+60

10 LP PA+120

11 LP PA+180

12 LP PA+240

13 LP PA+300

14 LP PA+360

15 DEP LCT X+80 Y+0 R5 .............................................

16 L Z+100 R0 F MAX M2

17 END PGM 213 MM

0

R40

5

50

20

R20

POLE

AUXILIARY POINT (POLAR)

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

DEPART TANGENTIALLY

0

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

213/2

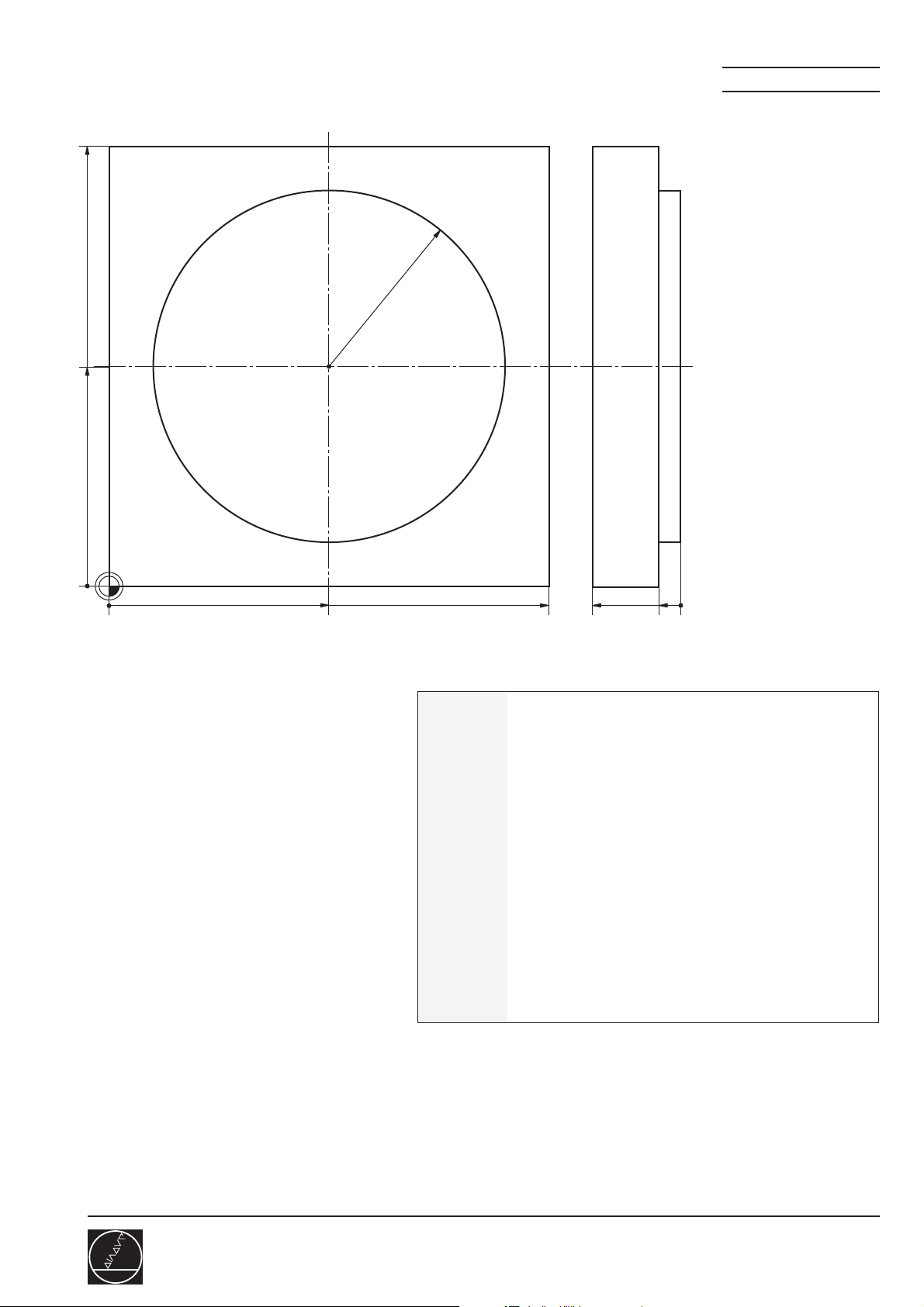

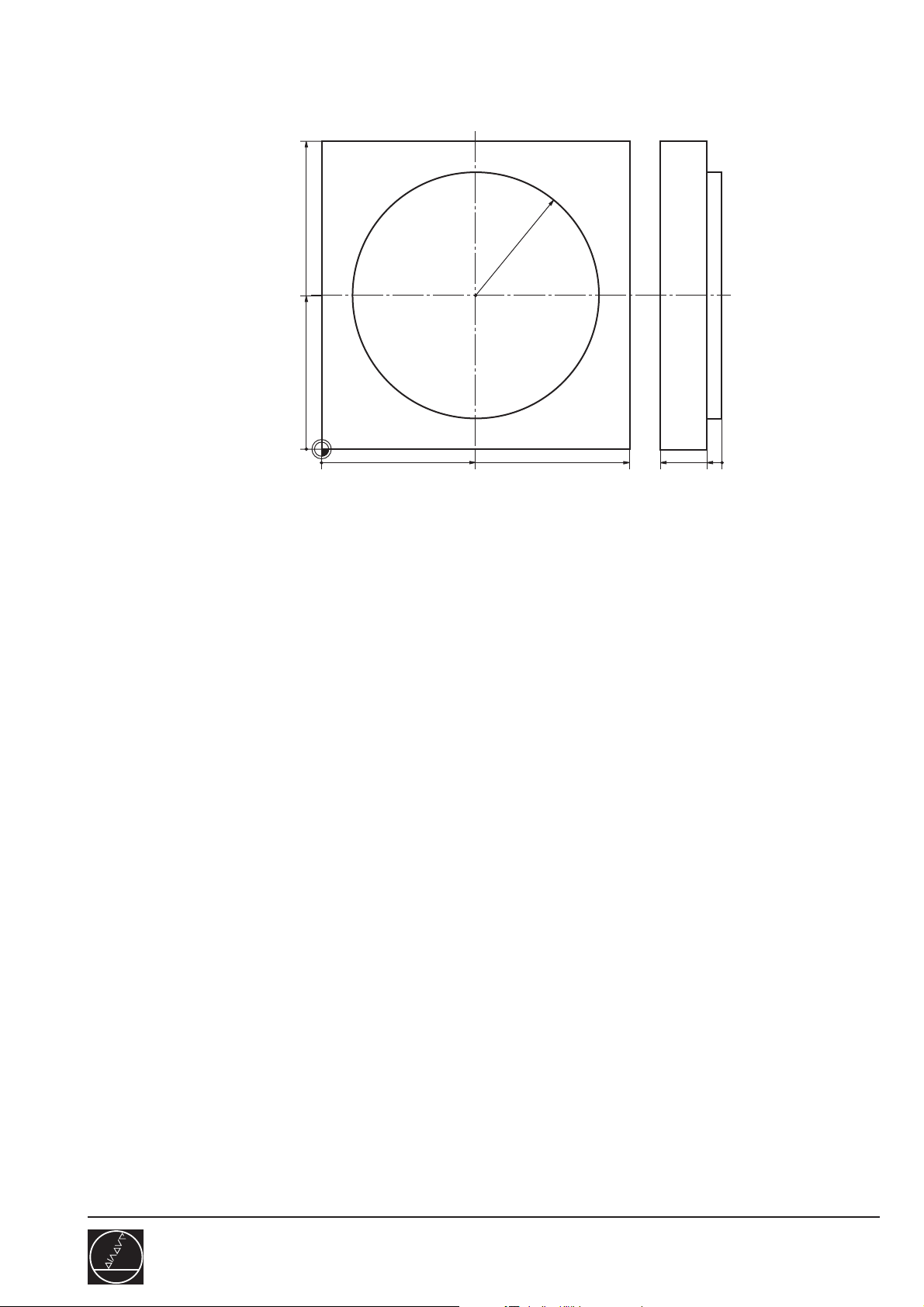

Page 26

100

Task:

Circle (polar) CP

R40

Program(s):

50

0

0

Begin program

Define workpiece blank

Call tool data

Move to clearance height

CC

50

0°

5

0

100

20

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL CALL . . . . . . S . . .

L . . .

Define pole

Auxiliary point in polar coord.

Contour

Auxiliary point

Retract tool, PGM end

HEIDENHAIN

Basic course G3/Upgrade course

C01

. . .

. . .

. . .

. . .

. . .

211/1

Page 27

Solution:

Circle (polar) CP

100

R40

Complete program

50

0

0

0 BEGIN PGM 211 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 13 Z S2500 ...........................................

4 L Z+100 R0 F MAX

5 CC X+50 Y+50 ..........................................................

6 LP PR+80 PA+180 R0 F MAX M3 ............................

7 L Z-5 F MAX

8 APPR LCT X+10 Y+50 R5 RL F250 M8 ....................

9 CP IPA+360 DR- ........................................................

10 DEP LCT X-30 Y+50 R5 R0.......................................

11 L Z+100 F MAX M2

12 END PGM 211 MM

CC

50

0°

5

20

100

R20

POLE

AUXILIARY POINT

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

CIRCLE PATH (POLAR)

DEPART TANGENTIALLY

0

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

211/2

Page 28

100

60

30

Task:

Circular path with tangential

connection (polar) CTP

76,158

Program(s):

20

0

0

20

°

40

2

3

,

1

9

9

Begin program

Define workpiece blank

Call tool data

Move to clearance height

Define pole

Auxiliary point in polar coord.

Contour

Auxiliary point

Retract tool, PGM end

5

90

100

20

0

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL CALL . . . . . . S . . .

L . . .

. . .

. . .

. . .

. . .

. . .

HEIDENHAIN

Basic course G3/Upgrade course

C01

212/1

Page 29

Solution:

Circular path with tangential connection (polar) CTP

100

76,158

60

30

Complete program

20

0

0

0 BEGIN PGM 212 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+70 Z+0

3 TOOL CALL 13 Z S4000 ...........................................

4 L Z+100 R0 F MAX

5 L X-30 Y-30 R0 F MAX M3 .......................................

6 L Z-5 F MAX

7 APPR LT X+0 Y+0 LEN5 RL F250 M8 ......................

8 L X+0 Y+30

9 L X+40 Y+60

10 CC Y+20 X+20 ..........................................................

11 CTP PR+76,158 PA+23,199 ......................................

12 L Y+0

13 DEP LT LEN5 R0.......................................................

14 L Z+100 R0 F MAX M2

15 END PGM 212 MM

20

40

2

3

,

1

9

9

°

90

5

20

100

R20

AUXILIARY POINT

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

POLE

TANGENTIAL CIRCULAR PATH

(POLAR)

DEPART TANGENTIALLY

0

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

212/2

Page 30

100

88

Task:

Polar coordinates (general)

Program(s):

30

P

5

P

6

21

50

40

30°

P

7

29

R90

32°

P

8

P

1

P

2

30°

45°

45

P

4

P

3

0

0

92

100

20

0

5

HEIDENHAIN

Basic course G3/Upgrade course

D02

252/1

Page 31

Solution:

Polar coordinates (general)

30

100

88

50

40

P

5

R90

P

21

6

30°

P

7

32°

30°

45°

45

29

P

8

P

1

P

2

Complete program

P

0

4

0

P

3

92

0 BEGIN PGM 252 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 13 Z S2500 ...........................................

4 L Z+100 R0 F MAX

5 L X+130 Y+50 F MAX M3

6 L Z-5 F MAX

7 APPR LCT X+92 Y+50 R5 RL F250 M8 ....................

8 L Y+40

9 CC X+92 Y+40 ..........................................................

10 LP PR+45 PA-135 .....................................................

11 CC X+92 Y+50

12 LP PR+90 PA-150

13 CP PA+148 DR- ........................................................

14 L IX+30 IY+0

15 CC.............................................................................

16 LP PR+21 PA-60

17 CC X+92 Y+88

18 CTP PR+29 PA-90 .....................................................

19 L Y+50

20 DEP LCT X+130 Y+50 R5 R0....................................

21 L Z+100 R0 F MAX M2

22 END PGM 252 MM

0

20

100

R20

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

POLE

STRAIGHT LINE (POLAR)

CIRCULAR PATH (POLAR)

DEFINE AS POLE POSITION

TANGENTIAL PATH (POLAR)

DEPART TANGENTIALLY

5

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

252/2

Page 32

100

70

30

Task:

Drilling cycle

8

Program(s):

0

0

20

Begin program

Define workpiece blank

Call tool data

Define cycle

Move to clearance height

Starting point first hole / call

cycle

Second hole / call cycle

Third hole / call cycle

Retract tool, PGM end

50

75

0

100

20

BEGIN PGM . . . MM

BLK-FORM 0.1 . . . X . . . Y . . . Z . . .

BLK-FORM 0.2 X . . . Y . . . Z . . .

TOOL CALL . . . . . . S . . .

CYCL DEF . . .

L Z+ . . .

L X . . . Y . . . M99

L X . . . Y . . . M99

L X . . . Y . . . M99

. . .

HEIDENHAIN

Basic course G3/Upgrade course

C01

201/1

Page 33

Solution:

Drilling cycle

100

70

30

0

0

20

8

50

75

100

20

0

Complete program

0 BEGIN PGM 201 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 7 Z S1000 .............................................

4 CYCL DEF 200 DRILLING

Q200=2 .....................................................................

Q201=-23 ..................................................................

Q206=150 .................................................................

Q202=5 .....................................................................

Q210=0 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

5 L Z+100 R0 F9999 M3

6 L X+20 Y+30 M99 ....................................................

7 L X+50 Y+70 M99 ....................................................

8 L X+75 Y+30 M99 ....................................................

9 L Z+100 R0 F MAX M2

10 END PGM 201 MM

R4

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

STARTING POSITION

2ND HOLE

3RD HOLE

HEIDENHAIN

Basic course G3/Upgrade course

D02

201/2

Page 34

50

Task:

Drilling with 200-series cycles

Program(s):

-50

0

M30 x 2

0

-50

50

Procedure: • Centering Cycle 1

• Drilling diameter 28 mm Cycle 203

• Boring Cycle 202

• Reaming Cycle 201

• Tapping Cycle 2

70

35

39,5

25

H7

40

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

260/1

Page 35

Solution:

Drilling with 200-series cycles

50

Complete program

Centering

0

-50

-50

0 BEGIN PGM 260 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-70

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL CALL 9 Z S1000 .............................................

4 L Z+100 R0 F MAX

5 CYCL DEF 1.0 PECKING

6 CYCL DEF 1.1 SET UP 2

7 CYCL DEF 1.2 DEPTH -5

8 CYCL DEF 1.3 PECKG 5

9 CYCL DEF 1.4 DWELL 0

10 CYCL DEF 1.5 F200

11 L X+0 Y+0 R0 F9999 M3

12 L Z+2 M99

13 L Z+100 M6

0

M30 x 2

50

R6

70

35

39,5

25

H7

40

0

Drilling

14 TOOL CALL 11 Z S350 .............................................

15 CYCL DEF 203 UNIVERSAL DRILLING

Q200=5 .....................................................................

Q201=-80 ..................................................................

Q206=100 .................................................................

Q202=15 ...................................................................

Q210=0 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q212=2 .....................................................................

Q213=2 .....................................................................

Q205=5 .....................................................................

Q211=0 .....................................................................

Q208=500 .................................................................

16 CYCL CALL M3

17 L Z+100 M6

R10

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

DECREMENT

NR OF BREAKS

MIN. PLUNGING DEPTH

DWELL TIME AT DEPTH

RETRACTION FEED RATE

HEIDENHAIN

Basic course G3/Upgrade course

D02

260/2

Page 36

Solution:

Drilling with 200-series cycles

Boring

Reaming

Tapping

18 TOOL CALL 13 Z S500 .............................................

19 CYCL DEF 202 BORING

Q200=2 .....................................................................

Q201=-35 ..................................................................

Q206=250 .................................................................

Q211=0 .....................................................................

Q208=500 .................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q214=0 .....................................................................

20 CYCL CALL M3

21 L Z+100 M6

22 TOOL CALL 13 Z S100 .............................................

23 CYCL DEF 201 REAMING

Q200=5 .....................................................................

Q201=-25 ..................................................................

Q206=100 .................................................................

Q211=0 .....................................................................

Q208=300 .................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

24 CYCL CALL M3

25 L Z+100 M6

26 TOOL CALL 12 Z S50 ...............................................

27 CYCL DEF 2.0 TAPPING

28 CYCL DEF 2.1 SET UP 5

29 CYCL DEF 2.2 DEPTH -45

30 CYCL DEF 2.3 DWELL 0

31 CYCL DEF 2.4 F100

32 L Z-30 M3

33 CYCL CALL

R20

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

DWELL TIME AT DEPTH

RETRACTION FEED RATE

SURFACE COORDINATE

2ND SET UP CLEARANCE

DISENGAGING DIRECTION

R20

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

DWELL TIME AT DEPTH

RETRACTION FEED RATE

SURFACE COORDINATE

2ND SET UP CLEARANCE

R15

34 L Z+100 M2

35 END PGM 260 MM

HEIDENHAIN

Basic course G3/Upgrade course

D02

260/3

Page 37

100

Task:

Slot plate

R25

Program(s):

35°

60

25

12

75

0

0

40

50

15

20°

100

20

10

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

210/1

Page 38

Solution:

Slot plate

100

Complete program

R25

60

75

25

0

0

0 BEGIN PGM 210 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 8 Z S1000 .............................................

4 L Z+100 R0 F9999 M3

5 CYCL DEF 210 SLOT RECIP. PLNG

Q200=2 .....................................................................

Q201=-10 ..................................................................

Q207=100 .................................................................

Q202=5 .....................................................................

Q215=0 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

Q216=+50 .................................................................

Q217=+25 .................................................................

Q218=75 ...................................................................

Q219=15 ...................................................................

Q224=+20 .................................................................

6 CYCL CALL

40

12

50

35°

20°

15

10

0

20

100

R5

SET UP CLEARANCE

DEPTH

FEED RATE FOR MILLNG

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

FIRST SIDE LENGTH

SECOND SIDE LENGTH

ANGLE OF ROTATION

7 CYCL DEF 211 CIRCULAR SLOT

Q200=2 .....................................................................

Q201=-10 ..................................................................

Q207=250 .................................................................

Q202=5 .....................................................................

Q215=0 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

Q216=+40 .................................................................

Q217=+60 .................................................................

Q244=50 ...................................................................

Q219=12 ...................................................................

Q245=+35 .................................................................

Q248=180 .................................................................

8 CYCL CALL

9 L Z+100 M2

10 END PGM 210 MM

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

SET UP CLEARANCE

DEPTH

FEED RATE FOR MILLNG

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

PITCH CIRCLE DIAMETER

SECOND SIDE LENGTH

STARTING ANGLE

ANGULAR LENGTH

210/2

Page 39

Task:

Bushing plate

Program(s):

0

100

85

50

15

6,5 20

+0,05

15

6,6

11

R30

60°

0

0

15

50

85

100

15

0

6,8

HEIDENHAIN

Basic course G3/Upgrade course

C01

262/1

Page 40

Program layout:

Bushing plate

Conventional

preparation:

First tool

Rough out circular

pocket

Rough out first long

slot

Rough out second

long slot

Second tool

Finish first short

slot

Finish second short

slot

BLK- FORM

TOOL CALL . . .

CYCL DEF . . .

. . . M99

CYCL DEF . . .

CYCL CALL

FN 0: Q . . .

CYCL CALL

. . . M6

TOOL CALL . . .

CYCL DEF . . .

CYCL CALL

FN 0: Q . . .

CYCL CALL

(Oversizing DR!)

Tool change

Finish first long slot

Finish second long

slot

First rounded slot

Second rounded slot

Finish circular

pocket

Retract tool, end

CYCL DEF . . .

CYCL CALL

FN 0: Q . . .

CYCL CALL

CYCL DEF . . .

CYCL CALL

FN 0: Q . . .

CYCL CALL

CYCL DEF . . .

CYCL CALL

L Z100 M2

HEIDENHAIN

Basic course G3/Upgrade course

C01

262/2

Page 41

Solution:

Bushing plate

0

Complete program

6,5 20

100

85

50

15

0

0

0 BEGIN PGM 262 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-15

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 6 Z S1500 DR+0,5 ................................

4 L Z+100 R0 F9999

5 L X+50 Y+50 M3

6 CYCL DEF 5.0 CIRCULAR POCKET

7 CYCL DEF 5.1 SET UP2

8 CYCL DEF 5.2 DEPTH -15

9 CYCL DEF 5.3 PECKG 5 F100

10 CYCL DEF 5.4 RADIUS 10

11 CYCL DEF 5.5 F200 DR+

12 L Z+2 M99

13 CYCL DEF 210 SLOT RECIP. PLNG

14 CYCL CALL

15 FN 0: Q217 = +85

16 CYCL CALL

17 L Z+100 M6

15

Q200=2 .....................................................................

Q201=-6....................................................................

Q207=200 .................................................................

Q202=6 .....................................................................

Q215=0 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+15 .................................................................

Q218=81 ...................................................................

Q219=11 ...................................................................

Q224=+0 ...................................................................

+0,05

50

R30

85

15

6,6

60°

6,8

0

15

100

R3

SET UP CLEARANCE

DEPTH

FEEDRATE FOR MILNG

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

FIRST SIDE LENGTH

SECOND SIDE LENGTH

ANGLE OF ROTATION

11

HEIDENHAIN

Basic course G3/Upgrade course

D02

262/3

Page 42

Solution:

Bushing plate

18 TOOL CALL 5 Z S2000 .............................................

19 CYCL DEF 210 SLOT RECIP. PLNG

Q200=2 .....................................................................

Q201=-9....................................................................

Q207=200 .................................................................

Q202=5 .....................................................................

Q215=0 .....................................................................

Q203=-6....................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+15 .................................................................

Q218=76,6 ................................................................

Q219=6,6 ..................................................................

Q224=+0 ...................................................................

20 CYCL CALL M3

21 FN 0: Q217 = +85

22 CYCL CALL

23 CYCL DEF 210 SLOT RECIP. PLNG

Q200=2 .....................................................................

Q201=-6,8 .................................................................

Q207=200 .................................................................

Q202=6,8 ..................................................................

Q215=0 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+15 .................................................................

Q218=81 ...................................................................

Q219=11 ...................................................................

Q224=+0 ...................................................................

24 CYCL CALL

25 FN 0: Q217 = +85

26 CYCL CALL

27 CYCL DEF 211 CIRCULAR SLOT

Q200=2 .....................................................................

Q201=-15 ..................................................................

Q207=200 .................................................................

Q202=5 .....................................................................

Q215=0 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+50 .................................................................

Q244=60 ...................................................................

Q219=6,6 ..................................................................

Q245=-30 ..................................................................

Q248=60 ...................................................................

28 CYCL CALL

29 FN 0: Q245 = +150

30 CYCL CALL

31 CYCL DEF 214 C. POCKT FINSHNG

Q200=2 .....................................................................

Q201=-15 ..................................................................

Q206=250 .................................................................

Q202=8 .....................................................................

Q207=250 .................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+50 .................................................................

Q222=19 ...................................................................

Q223=20,02 ..............................................................

32 CYCL CALL

33 L Z+100 R0 F MAX M2

34 END PGM 262 MM

R2,5

SET UP CLEARANCE

DEPTH

FEEDRATE FOR MILNG

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

FIRST SIDE LENGTH

SECOND SIDE LENGTH

ANGLE OF ROTATION

SET UP CLEARANCE

DEPTH

FEED RATE FOR MILLNG

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

FIRST SIDE LENGTH

SECOND SIDE LENGTH

ANGLE OF ROTATION

SET UP CLEARANCE

DEPTH

FEEDRATE FOR MILLING

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

PITCH CIRCLE DIAMETER

SECOND SIDE LENGTH

STARTING ANGLE

ANGULAR LENGTH

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

FEEDRATE FOR MILLING

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

WORKPIECE BLANK DIAMETER

FINISHED PART DIAMETER

.

HEIDENHAIN

Basic course G3/Upgrade course

D02

262/4

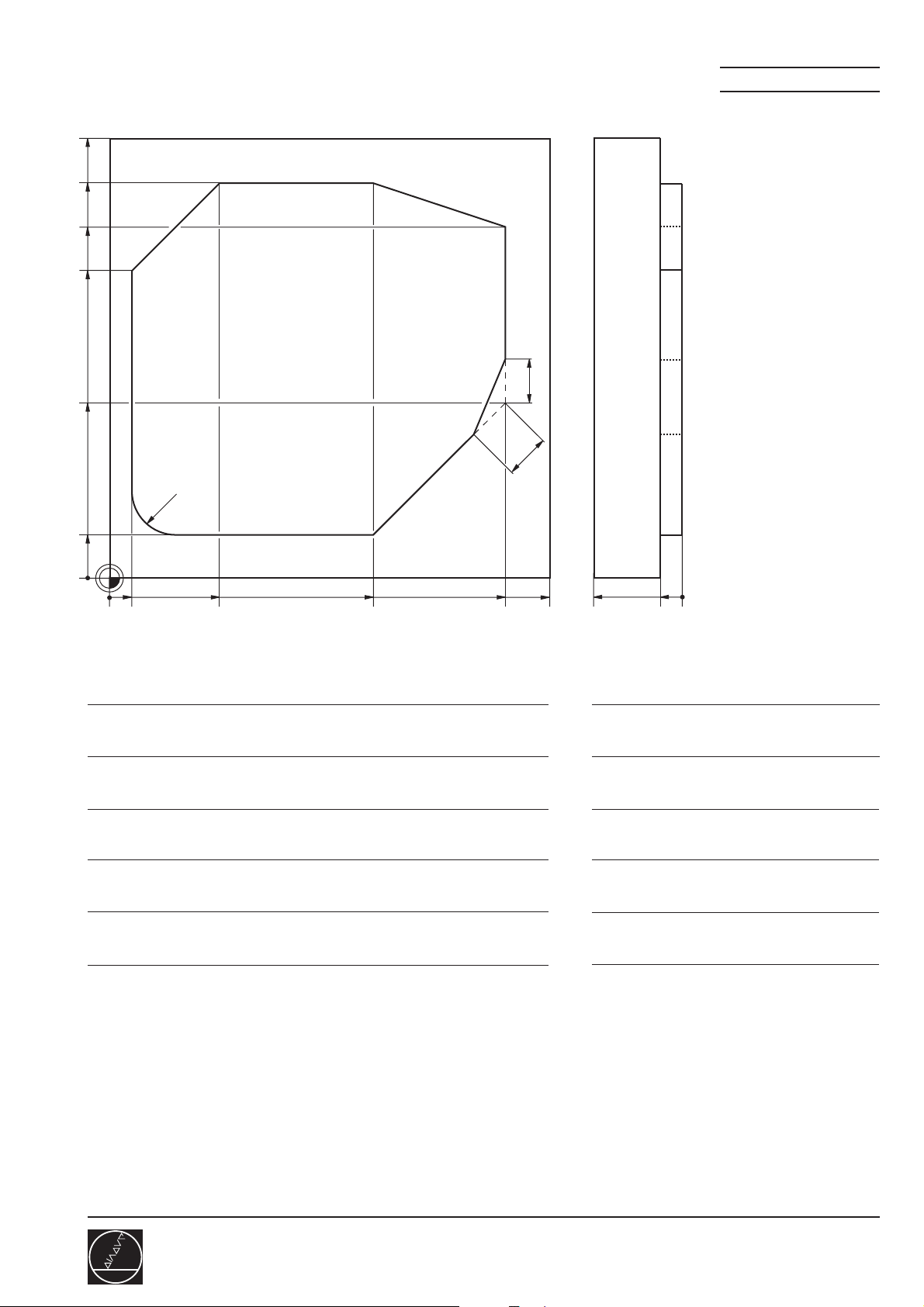

Page 43

100

Task:

Die I

Program(s):

60

50

H7

30

R5,25

0

0

50

100

90

20

10

5

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

265/1

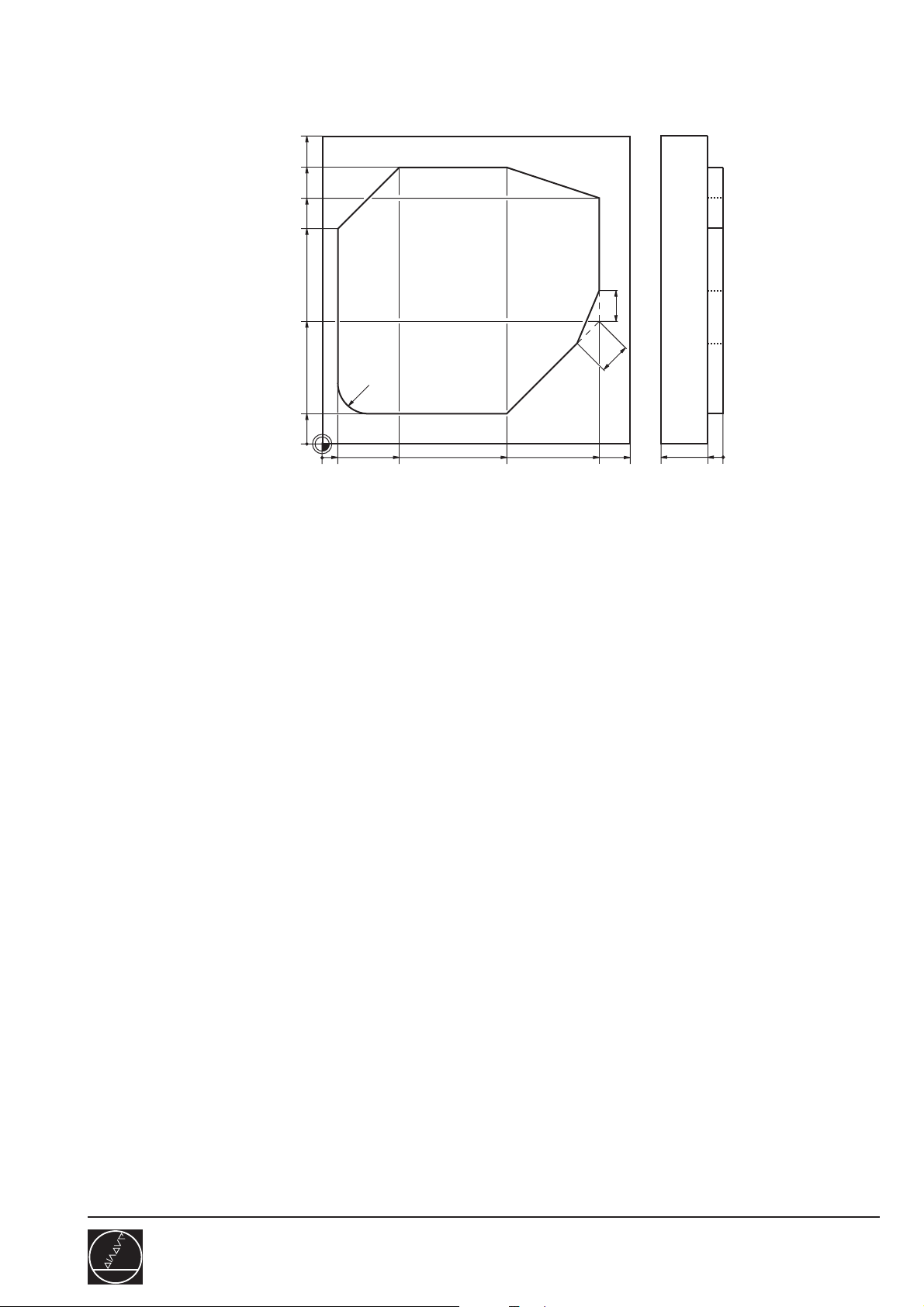

Page 44

Solution:

Die I

100

60

Complete program

50

R5,25

0

0

0 BEGIN PGM 265 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 9 Z S500 DR+1 .....................................

4 L Z+100 R0 F9999

5 CC X+50 Y+50

6 LP PR+70 PA+0

7 L Z+2 M3

8 L Z-10 F200

9 CP PA+360 DR-

10 LP PR+60

11 CP PA+360 DR12 LP PR+45 RL

13 CP PA+360 DR14 LP PR+65 PA+0 R0

15 L Z+2

16 CYCL DEF 4.0 POCKET MILLING

17 CYCL DEF 4.1 SET UP 2

18 CYCL DEF 4.2 DEPTH -5

19 CYCL DEF 4.3 PECKG 5 F100

20 CYCL DEF 4.4 X60

21 CYCL DEF 4.5 Y30

22 CYCL DEF 4.6 F250 DR- RADIUS 7

23 L X+50 Y+50 R0 F MAX M99

24 L Z+100 F MAX M6

50

30

100

H7

90

5

0

10

20

R6

HEIDENHAIN

Basic course G3/Upgrade course

D02

265/2

Page 45

Solution:

Die I

25 TOOL CALL 8 Z S1000 .............................................

26 CYCL DEF 212 POCKET FINISHING

Q200=2 .....................................................................

Q201=-5....................................................................

Q206=250 .................................................................

Q202=5 .....................................................................

Q207=250 .................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+50 .................................................................

Q218=60 ...................................................................

Q219=30 ...................................................................

Q220=5,25 ................................................................

Q221=0 .....................................................................

27 CYCL CALL M3

28 CYCL DEF 215 C. STUD FINISHNG

Q200=2 .....................................................................

Q201=-10 ..................................................................

Q206=250 .................................................................

Q202=10 ...................................................................

Q207=250 .................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

Q216=+50 .................................................................

Q217=+50 .................................................................

Q222=92 ...................................................................

Q223=90 ...................................................................

29 CYCL CALL

R5

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

FEED RATE FOR MILLNG

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

FIRST SIDE LENGTH

SECOND SIDE LENGTH

CORNER RADIUS

ALLOWANCE IN 1ST AXS

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

FEED RATE FOR MILLNG

SURFACE COORDINATE

2ND SET UP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

WORKPIECE BLANK DIAMETER

FINISHED PART DIAMETER

30 L Z+100 R0 F MAX M2

31 END PGM 265 MM

HEIDENHAIN

Basic course G3/Upgrade course

D02

265/3

Page 46

100

84

76

68

60

52

44

36

28

20

Task:

Linear hole pattern

Program(s):

6

0

0

15

25

35

45

55

65

75

85

100

40

20

0

HEIDENHAIN

Basic course G3/Upgrade course

D02

220/1

Page 47

Solution:

Linear hole pattern

100

84

76

68

60

52

44

36

28

20

0

0

15

25

35

45

55

65

75

85

100

40

20

6

0

Main program

Retract tool, end

SPGM

0 BEGIN PGM 220 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 6 Z S1500 .............................................

4 L Z+100 R0 F9999 M3

5 CYCL DEF 200 DRILLING

Q200=2 .....................................................................

Q201=-20 ..................................................................

Q206=100 .................................................................

Q202=5 .....................................................................

Q210=0 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

6 CALL LBL 1

7 L Z+100 M2

8 LBL 1

9 CYCL DEF 221 CARTESIAN PATTRN

Q225=+15 .................................................................

Q226=+20 .................................................................

Q237=+10 .................................................................

Q238=+8 ...................................................................

Q242=8 .....................................................................

Q243=9 .....................................................................

Q224=+0 ...................................................................

Q200=2 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

10 LBL 0

11 END PGM 220 MM

R3

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

STARTNG PNT 1ST AXIS

STARTNG PNT 2ST AXIS

SPACING IN 1ST AXIS

SPACING IN 2ND AXIS

NUMBER OF COLUMNS

NUMBER OF ROWS

ANGLE OF ROTATION

SET UP CLEARANCE

SURFACE COORDINATE

2ND SET UP CLEARANCE

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

D02

220/2

Page 48

Task:

Hole pattern

Program(s):

100

30

10

20

15°

80°

15

0

R50

6

0

30

90

100

20

17

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

221/1

Page 49

Solution:

Hole pattern

Main program

100

30

10

0

0

0 BEGIN PGM 221 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 6 Z S1500 .............................................

4 L Z+100 R0 F9999 M3

5 CYCL DEF 200 DRILLING

Q200=2 .....................................................................

Q201=-17 ..................................................................

Q206=150 .................................................................

Q202=6 .....................................................................

Q210=0 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

6 CALL LBL 1

7 CALL LBL 2

15

20

30

80°

15°

R50

90

6

20

17

100

R3

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

0

Retract tool, end

SPGM

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

8 L Z+100 M2

9 LBL 1

10 CYCL DEF 220 POLAR PATTERN

Q216=+90 .................................................................

Q217=+10 .................................................................

Q244=100 .................................................................

Q245=+90 .................................................................

Q246=+180 ...............................................................

Q247=15 ...................................................................

Q241=7 .....................................................................

Q200=2 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

11 LBL 0

D02

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

PITCH CIRCLE DIA.

STARTING ANGLE

STOPPING ANGLE

STEPPING ANGLE

NR OF REPETITIONS

SET UP CLEARANCE

SURFACE COORDINATE

2ND SET UP CLEARANCE

221/2

Page 50

Solution:

Hole pattern

12 LBL 2

13 CYCL DEF 221 CARTESIAN PATTRN

Q225=+30 .................................................................

Q226=+30 .................................................................

Q237=+15 .................................................................

Q238=+20 .................................................................

Q242=5 .....................................................................

Q243=2 .....................................................................

Q224=+80 .................................................................

Q200=2 .....................................................................

Q203=+0 ...................................................................

Q204=2 .....................................................................

14 LBL 0

15 END PGM 221 MM

STARTNG PNT 1ST AXIS

STARTNG PNT 2ND AXIS

SPACING IN 1ST AXIS

SPACING IN 2ND AXIS

NUMBER OF COLUMNS

NUMBER OF ROWS

ANGLE OF ROTATION

SET UP CLEARANCE

SURFACE COORDINATE

2ND SET UP CLEARANCE

HEIDENHAINHEIDENHAIN

Basic course G3/Upgrade course

C01

221/3

Page 51

-10

-22

-25

-30

100

90

70

Task:

0

Guide plate

Program(s):

M6

50

30

10

0

0

15

30

Procedure: • Shoulders

• Centering Cycle 200

• Drilling Cycle 200

• Tapping Cycle 2

70

85

100

HEIDENHAIN

Basic course G3/Upgrade course

C01

261/1

Page 52

Solution:

Guide plate

0

M6

-10

-22

-25

-30

100

90

70

50

30

Main program

10

0

0

0 BEGIN PGM 261 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-30

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 13 Z S500 .............................................

4 L Z+100 R0 F9999

5 L X-50 Y-50

6 L Z+2 M3

7 L Z-10 F200

8 APPR LCT X+30 Y+0 R2 RL

9 L Y+100

10 DEP LCT X+0 Y+150 R2 R0

11 L X+100 F MAX

12 APPR LCT X+70 Y+100 R2 RL

13 L Y+0

14 DEP LCT X+100 Y-50 R2 R0

15 L Z+100 R0 F9999 M6

16 TOOL CALL 4 Z S2000 .............................................

17 CYCL DEF 200 DRILLING

18 L Z+5 M3

19 CALL LBL 1

20 L Z+100 M6

15

30

Q200=2 .....................................................................

Q201=-3,5 .................................................................

Q206=250 .................................................................

Q202=3,5 ..................................................................

Q210=0 .....................................................................

Q203=-10 ..................................................................

Q204=20 ...................................................................

70

85

100

R20

R2,5

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

HEIDENHAIN

Basic course G3/Upgrade course

D02

261/2

Page 53

Solution:

Guide plate

Retract tool, end

SPGM

SPGM, end

21 TOOL CALL 5 Z S2000 .............................................

22 CYCL DEF 200 DRILLING

Q200=2 .....................................................................

Q201=-15 ..................................................................

Q206=250 .................................................................

Q202=5 .....................................................................

Q210=0 .....................................................................

Q203=-10 ..................................................................

Q204=20 ...................................................................

23 L Z+5 M3

24 CALL LBL 1

25 L Z+100 M6

26 TOOL CALL 6 Z S300 ...............................................

27 CYCL DEF 2.0 TAPPING

28 CYCL DEF 2.1 SET UP 2

29 CYCL DEF 2.2 DEPTH -12

30 CYCL DEF 2.3 DWELL 0

31 CYCL DEF 2.4 F300

32 L Z+5 M3

33 CALL LBL 1

34 L Z+100 R0 F MAX M2

35 LBL 1

36 CYCL DEF 221 CARTESIAN PATTRN

Q225=+15 .................................................................

Q226=+10 .................................................................

Q237=+70 .................................................................

Q238=+20 .................................................................

Q242=2 .....................................................................

Q243=5 .....................................................................

Q224=+0 ...................................................................

Q200=2 .....................................................................

Q203=-10 ..................................................................

Q204=20 ...................................................................

37 LBL 0

38 END PGM 261 MM

R2,5

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

R3

STARTNG PNT 1ST AXIS

STARTNG PNT 2ND AXIS

SPACING IN 1ST AXIS

SPACING IN 2ND AXIS

NUMBER OF COLUMNS

NUMBER OF LINES

ANGLE OF ROTATION

SET UP CLEARANCE

SURFACE COORDINATE

2ND SET UP CLEARANCE

HEIDENHAIN

Basic course G3/Upgrade course

D02

261/3

Page 54

Task:

8

8

Die II

80

Program(s):

12 x 30°

30°

5

6

M5

10

10 10 10

20

15

12

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

266/1

Page 55

Program layout: Die II

Define workpc. blank

Drilling 5 mm

Centering, pitch circle

Drilling, pitch circle

Tapping

BLK FORM

CALL PGM . . .

CYCL DEF . . .

CALL LBL . . .

L Z100 . . . M6

CYCL DEF . . .

CALL LBL . . .

L Z100 . . . M6

CYCL DEF . . .

CALL LBL . . .

L Z100 . . . M6

CYCL DEF . . .

PGM-Call

SPGM1-Call

Tool change

SPGM2-Call

Tool change

SPGM2-Call

Tool change

Retract tool, end

SPGM1

Cartesian pattern

SPGM2

Polar pattern

CALL LBL . . .

L Z . . . M2

LBL 1

CYCL DEF . . .

LBL 0

LBL 2

CYCL DEF . . .

LBL 0

Copy help program from PGM 265

SPGM2-Call

HEIDENHAIN

Basic course G3/Upgrade course

C01

266/2

Page 56

Solution:

Die II

8

8

80

10

10 10 10

12 x 30°

30°

20

15

6

12

5

M5

0

Main program

0 BEGIN PGM 266 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 CALL PGM 26501 .....................................................

4 TOOL CALL 5 Z S2000 .............................................

5 L Z+100 M3

6 CYCL DEF 200 DRILLING

Q200=2 .....................................................................

Q201=-6....................................................................

Q206=200 .................................................................

Q202=6 .....................................................................

Q210=0 .....................................................................

Q203=-5....................................................................

Q204=20 ...................................................................

7 CALL LBL 1

8 L Z+100 R0 F9999 M6

9 TOOL CALL 4 Z S2000 .............................................

10 L Z+100 M3

11 CYCL DEF 1.0 PECKING

12 CYCL DEF 1.1 SET UP 2

13 CYCL DEF 1.2 DEPTH -2,8

14 CYCL DEF 1.3 PECKG 2,8

15 CYCL DEF 1.4 DWELL 0

16 CYCL DEF 1.5 F200

17 CALL LBL 2

18 L Z+100 M6

HELP PROGRAM

R2,5

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

R2

19 TOOL CALL 5 Z S1500 .............................................

20 L Z+100 M3

21 CYCL DEF 200 DRILLING

Q200=2 .....................................................................

Q201=-15 ..................................................................

Q206=200 .................................................................

Q202=8 .....................................................................

Q210=0 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

22 CALL LBL 2

23 L Z+100 M6

HEIDENHAIN

Basic course G3/Upgrade course

D02

R2,5

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

266/3

Page 57

Solution:

Die II

SPGM

24 TOOL CALL 6 Z S300 ...............................................

25 L Z+100 M3

26 CYCL DEF 2.0 TAPPING

27 CYCL DEF 2.1 SET UP 2

28 CYCL DEF 2.2 DEPTH -12

29 CYCL DEF 2.3 DWELL 1

30 CYCL DEF 2.4 F300

31 CALL LBL 2

32 L Z+100 R0 F MAX M2

33 LBL 1

34 CYCL DEF 221 CARTESIAN PATTRN

Q225=+30 .................................................................

Q226=+42 .................................................................

Q237=+10 .................................................................

Q238=+8 ...................................................................

Q242=5 .....................................................................

Q243=3 .....................................................................

Q224=+0 ...................................................................

Q200=2 .....................................................................

Q203=-6....................................................................

Q204=20 ...................................................................

35 LBL 0

R3

STARTNG PNT 1ST AXIS

STARTNG PNT 2ND AXIS

SPACING IN 1ST AXIS

SPACING IN 2ND AXIS

NUMBER OF COLUMNS

NUMBER OF LINES

ANGLE OF ROTATION

SET UP CLEARANCE

SURFACE COORDINATE

2ND SET UP CLEARANCE

36 LBL 2

37 CYCL DEF 220 POLAR PATTERN

Q216=+50 .................................................................

Q217=+50 .................................................................

Q244=80 ...................................................................

Q245=+0 ................................................................... S

Q246=+360 ...............................................................

Q247=30 ...................................................................

Q241=12 ...................................................................

Q200=2 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

38 LBL 0

39 END PGM 266 MM

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

PITCH CIRCLE DIA.

TARTING ANGLE

STOPPING ANGLE

STEPPING ANGLE

NR OF REPETITIONS

SET UP CLEARANCE

SURFACE COORDINATE

2ND SET UP CLEARANCE

HEIDENHAIN

Basic course G3/Upgrade course

D02

266/4

Page 58

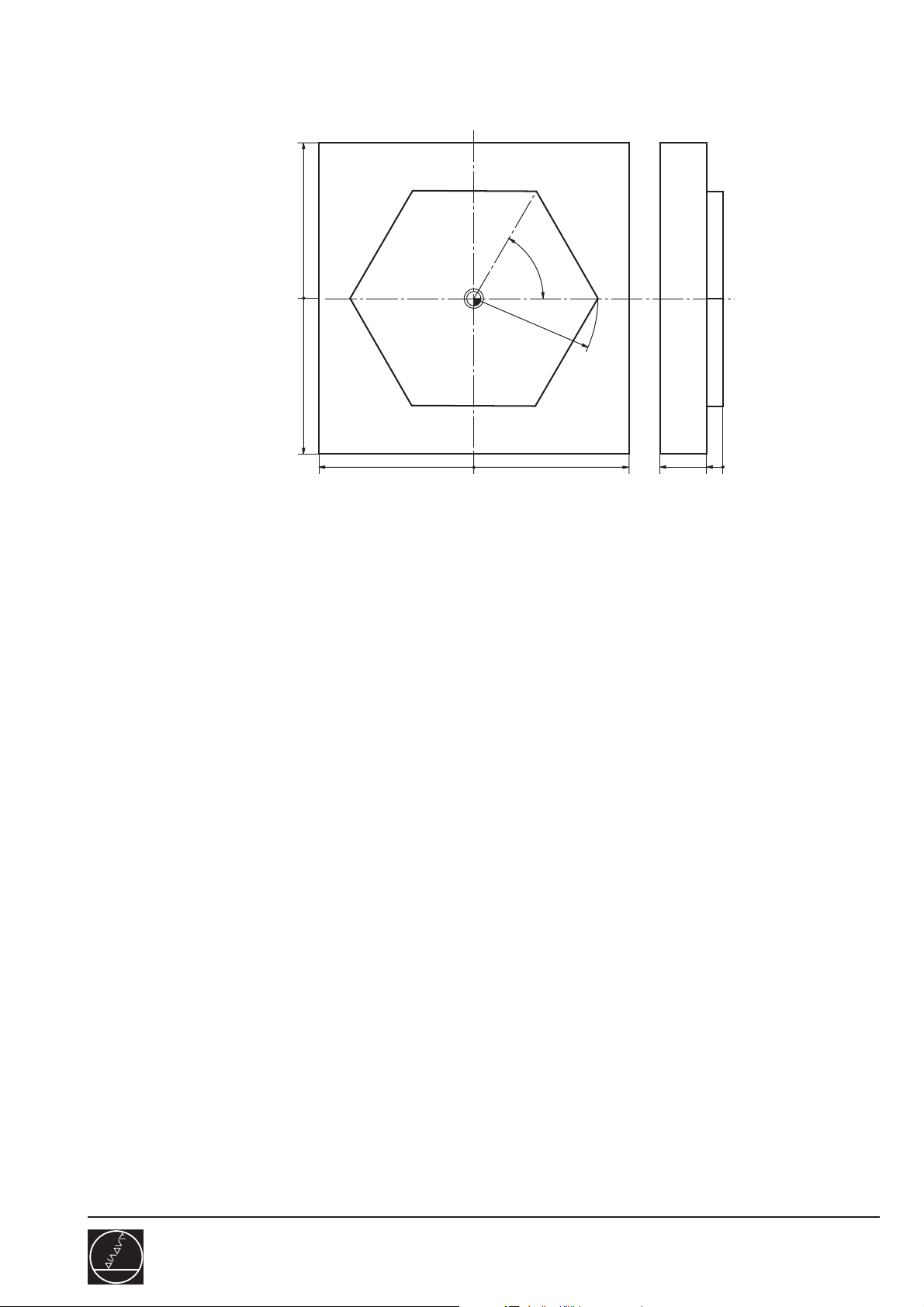

100

Task:

Hexagon

Program(s):

65

60°

50

4

R40

3

0

0

50

2

1

100

20

5

0

HEIDENHAIN

Basic course G3/Upgrade course

C01

268/1

Page 59

Solution:

Hexagon

100

65

60°

Complete program

50

4

R40

3

0

0

0 BEGIN PGM 268 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 12 Z S500 .............................................

4 L Z+100 R0 F9999

5 CC X+50 Y+50 ..........................................................

6 LP PR+80 PA+0 R0 ...................................................

7 L Z-5 M3

8 APPR LCT X+90 Y+50 R2 RL F100 ...........................

9 LBL 1 ........................................................................

10 LP PR+40 IPA-60

11 CALL LBL 1 REP 5/5 .................................................

50

2

1

5

20

100

R15

POLE

AUXILIARY POINT

STARTING POINT

DEFINE LABEL

CALL LABEL WITH REPEATS

0

12 DEP LCT X+130 Y+50 R2 R0 F200 ...........................

13 L Z+100 R0 F MAX M2

14 END PGM 268 MM

AUXILIARY POINT

HEIDENHAIN

Basic course G3/Upgrade course

D02

268/2

Page 60

100

85

70

55

40

25

Task:

Drilled plate – slanted columns

Program(s):

10

3

0

0

10

20

40

50

70

80

100

20

15

5

0

HEIDENHAIN

Basic course G3/Upgrade course

D02

270/1

Page 61

Program layout:

9

9

9

9

9

9

9

9

9

9

9

9

9

9

Drilled plate – slanted columns

Move up and

down columns

(meandering)

Pre-position

Drilling pattern

100

LBL 2

10

0

0

L X . . . Y . . .

L Z . . .

3

101520

LBL 3

40

50

70

80

5

100

20

0

Absolute pre-position

Set up clearance

LBL 1

L IX . . . M99

LBL 2

L IY . . . M99

CALL LBL 2 REP . . .

L IX . . . M99

LBL 3

L IY . . . M99

CALL LBL 3 REP . . .

CALL LBL 1 REP . . .

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

Define label 1

Cross over to first

hole

Define label 2

Move up the column

Cross over two

second column

Define label 2

Move down the

column

Remaining groups

HEIDENHAIN

Basic course G3/Upgrade course

D02

270/2

Page 62

Solution:

Drilled plate – slanted columns

100

85

70

55

40

25

Main program

10

0

0 BEGIN PGM 270 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 L Z+100 R0 F MAX

4 TOOL CALL 5 Z S4000 .............................................

5 CYCL DEF 200 DRILLING

6 L X-10 Y+10 R0 F9999 M3

7 L Z+2

8 LBL 1

9 L IX+20 M99

3

0

10

20

Q200=2 .....................................................................

Q201=-15 ..................................................................

Q206=250 .................................................................

Q202=8 .....................................................................

Q210=0 .....................................................................

Q203=+0 ...................................................................

Q204=20 ...................................................................

40

50

70

80

5

20

15

100

R2,5

SET UP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SET UP CLEARANCE

0

10 LBL 2

11 L IX+3 IY+15 M99

12 CALL LBL 2 REP 4/4

13 L IX+10 M99

14 LBL 3

15 L IX-3 IY-15 M99

16 CALL LBL 3 REP 4/4

17 CALL LBL 1 REP 2/2

18 L Z+100 R0 F MAX M2

19 END PGM 270 MM

HEIDENHAIN

Basic course G3/Upgrade course

D02

270/3

Page 63

100

75

35

Task:

FK Cam

Program(s):

R15

25

R25

R20

0

5

0

30

50

75

100

20

0

HEIDENHAIN

Basic course G3/Upgrade course

C03

288/1

Page 64

Solution:

FK Cam

100

75

35

25

0

R15

R25

0

30

50

75

R20

100

20

5

0

Complete program

0 BEGIN PGM 288 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 10 Z S4000 ...........................................

4 L Z+100 R0 F MAX

5 L X-15 Y+35 R0 F MAX M3

6 L Z-5 R0 F MAX

7 APPR LCT X+5 Y+35 R5 RL F400

8 FC DR- R25 CCX+30 CCY+35

9FLT

10 FCT DR- R15 CCX+50 CCY+75

11 FLT

12 FCT DR- R20 CCX+75 CCY+25

13 FLT

14 FCT X+5 Y+35 DR- R25 CCX+30 CCY+35

15 DEP LCT X-15 Y+35 R5

16 L Z+100 R0 F MAX M2