GE GXSHC40N Installation Manual

WATER SOFTENING SYSTEM

Safety Information . . . . . . . . . . . . . 2

Specifications

and Performance Claims . . . . . . . . 3

About the Softener . . . . . . . . . . . . 4

Before you Start . . . . . . . . . . . . . . . 7 Installation Requirements . . . . . . . 8 Installation Instructions . . . . . . . . . 11 Programming the Softener . . . . . .18 Care and Cleaning . . . . . . . . . . . . 25 Routine Maintenance . . . . . . . . . . 27 Before you call for Service . . . . . 28 Exploded View/Parts List . . . . . . 34 Warranty (U.S.). . . . . . . . . . . . . . . 38 Warranty (Canada) . . . . . . . . . . . 39 Consumer Support . . . . . . . . . . . . 42

OWNER’S MANUAL AND INSTALLATION INSTRUCTIONS

Model GXSHC40N

Write the model and serial numbers here:

Model #_____________

Serial # _____________

To find these numbers, lift the cover and look on the rim below the control panel.

Systems tested and certified by NSF International against NSF/ANSI Standard 44 for the chemical reduction claims specified on page 3, and certified to NSF/ANSI 372.

Systems Tested and Certified by the Water Quality

Association against CSA B483.1.

If you have any questions or concerns when installing or maintaining your water softener, call our toll free number at 800-952-5039 (US) or 866-777-7627 (Canada), or visit geappliances.com. When you call, please be prepared to provide the model and serial number of your product. This information can be found on the rating decal located on the rim under the salt cover.

GE is a trademark of the General Electric Company. Manufactured under trademark license.

7375781 49-6000221 Rev. 0 04-19 GEA

IMPORTANT SAFETY INFORMATION. READ ALL INSTRUCTIONS BEFORE USING

SAFETY PRECAUTIONS

WARNING |

For your safety, the information in this manual must be followed to |

minimize the risk of electric shock, property damage or personal injury. |

|

|

|

WARNING

A copper or galvanized cold water pipe may be used to ground electrical outlets in the home. Failure to maintain this ground path may result in an electric shock hazard. If the cold water pipe is used to ground electric outlets, please refer to Installing the Ground Wire section before cutting the pipe.

Check and comply with your state and local codes. You must follow these guidelines.

Use care when handling the water softening system. Do not turn upside down, drop, drag or set on sharp protrusions.

Water softening systems using sodium chloride (salt) for recharge add sodium to the water.

Persons on sodium restricted diets should consider the added sodium as part of their overall intake. Potassium chloride can be used as an alternative to sodium chloride in your softener.

Use only lead-free solder and flux for all sweat-solder connections, as required by state and federal codes.

This water softening system must be properly installed and located in accordance with the installation instructions before it is used.

Keep the salt hole cover in place on the softener unless servicing the unit or refilling with salt.

In the state of California: You must turn the Salt Efficiency Feature setting to ON. This may initiate more frequent recharges. However it will operate at 4,000 grains per pound of salt or higher. To turn on the Salt Efficiency Feature, follow the instructions in the “Salt Saver” section of this manual

WARNING

Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

WARNING

Discard all unused parts and packaging material after installation. Small parts remaining after the installation could be a choke hazard.

The water softening system works on 24 volt60 Hz electrical power only. Be sure to use the included external power supply.

External power supply must be plugged into an indoor 120 volt, grounded outlet only.

Use clean water softening salts only, at least 99.5% pure. NUGGET, PELLET or coarse SOLAR salts are recommended. Do not use rock, block, granulated or ice cream making salts. These types of salts may contain dirt and sediments that might mush or cake, creating maintenance issues for the water softener.

Avoid installing in direct sunlight. Excessive heat may cause distortion or other damage to non-metallic parts.

If installing the water softener outdoors, do not locate where it will be exposed to wet weather, direct sunlight, extreme hot or cold temperatures, or other forms of abuse.

In the Commonwealth of Massachusetts, Plumbing Code 248 CMR shall be adhered to. Consult with your licensed plumber.

READ AND SAVE THESE INSTRUCTIONS

2

Specifications and Performance Claims

This model is efficiency rated. The efficiency rating is valid only at the minimum stated salt dose. The softener has a demand initiated regeneration (D.I.R) feature that complies with specific performance specifications intended to minimize the amount of regenerant brine and water used in its operation.

The softener has a rated salt efficiency of not less than 4,000 grains of total hardness exchange per pound of salt (based on sodium chloride), and shall not deliver more salt than its listed rating or be operated at a sustained maximum service flow rate greater than its listed rating. This softener has been proven to deliver soft water for at least ten continuous minutes at the rated service flow rate. The rated salt efficiency is measured by laboratory test described in NSF/ANSI Standard 44. These tests represent the maximum possible efficiency that the system can

achieve. Operational efficiency is the actual efficiency after the system has been installed. It is typically less than the efficiency, due to individual application factors including water hardness, water usage, and other contaminants that reduce the softener’s capacity.

|

Specifications |

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

GXSHC40N |

|

Rated Capacity* (Grains@ Salt Dose) |

|

|

|

|

11,700 @ 2.3 lbs |

|

||

|

|

|

|

|

|

31,500 @ 8.7 lbs. |

|

|

|

|

|

|

|

40,000 @ 15.1 lbs. |

|

||

Rated Efficiency** (Grains/Pound of Salt @ Minimum Salt Dose) |

|

|

5,090 @ 2.3 lbs. |

|

||||

|

|

|

|

|

|

|

|

|

Water used during Regeneration (gallons/grains) |

|

|

|

|

2.7 /1000 |

|

||

|

|

|

|

|

|

|

||

Total Water Used per Regeneration @ Maximum Salt Dose |

|

|

|

37.0 gallons |

|

|||

|

|

|

|

|

|

|

|

|

Amount of High Capacity Ion Exchange Resin (lb/cu.ft.) |

|

|

|

57.56/1.11 |

|

|||

Resin Tank Nominal Size (in., dia. x height) |

|

|

|

|

|

9 x 40 |

|

|

Service Flow Rate (gpm) |

|

|

|

|

9.5 |

|

||

Pressure Drop at Rated Service Flow (psig) |

|

|

|

|

12.7 |

|

||

Water Supply Maximum Hardness (gpg) |

|

|

|

|

110 |

|

||

Water Supply Maximum Clear Water Iron (ppm)*** |

|

|

|

|

8 |

|

||

Water Pressure Limits (minimum-maximum psi)**** |

|

|

|

|

20-125 |

|

||

Water Temperature Limits (minimum-max. °F) |

|

|

|

|

40-120 |

|

||

Maximum Flow Rate to Drain (gpm) |

|

|

|

|

2.3 |

|

||

These systems conform to NSF/ANSI 44 for |

|

|

|

|

|

|

|

|

the specific capacity claims as verified and |

|

|

|

Performance Claims |

||||

substantiated by test data. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Influent |

Maximum |

||

* |

Testing was performed using pellet grade |

|

|

|

|

|

||

|

Contaminant |

|

|

Challenge |

Allowable Product |

|||

|

sodium chloride as |

|

|

|

||||

|

|

|

|

|

|

Level |

Water Level |

|

the regenerant salt. |

|

|

|

|

|

|||

** |

Efficiency rating is valid only at the lowest |

|

Barium |

|

|

10 ±10% mg/L |

2.0 mg/L |

|

|

stated salt dosage. These softeners were |

|

|

|

|

|

|

|

|

Radium 226/228 |

|

25 pCi/L |

5pCi/L |

||||

|

efficiency rated according to NSF/ANSI 44. |

|

||||||

*** Extent of iron removal may vary with |

Test parameters include: pH = 7.5±0.5, flow rate = 7.5 gpm |

|||||||

|

conditions. The capacity to reduce clear |

|||||||

|

|

|

|

|

|

and dynamic pressure = 35±5 psig |

||

|

water iron is substantiated by WQA test data. |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

State of Wisconsin requires additional treatment if water supply contains greater than 5 ppm clear water iron. |

|||||||

|

Refer to Cleaning Iron Out of the Water Softening System section. |

|

||||||

**** |

Canada working pressure limits: 1.4–7.0 kg/cm2. |

|

|

|

|

|

|

|

3

About the water softener system

SERVICE

When the water softening system is providing soft water, it is called “Service.” During service, hard water flows from the house main water pipe into the water softening system. Inside the water softening system resin tank is a bed made up of thousands of tiny, plastic resin beads. As hard water passes through the bed, each bead attracts and holds the hard minerals. This is called ion-exchanging. It is much like a magnet attracting and holding metals. Water without hard minerals (soft water) flows from the water softening system and to the house pipes.

After a period of time, the resin beads become coated with hard minerals and they have to be cleaned. This cleaning is called recharge. Recharge is started at 2:00 AM (factory setting) by the water softening system control, and consists of five stages or cycles. These are

FILL, BRINING, BRINE RINSE, BACKWASH and FAST RINSE.

AUTOMATIC HARD WATER BYPASS DURING RECHARGE

During recharge the water softener is automatically put in bypass mode allowing hard water to be available to the home. Once the softener is recharged water is directed back through the softener to be conditioned.

However, you should avoid using HOT water because the water heater will fill with the hard water.

FILL

Salt dissolved in water is called brine. Brine is needed to clean the hard minerals from resin beads. To make the brine, water flows into the salt storage area during the fill stage.

BRINING

During brining, brine travels from the salt storage area into the resin tank. Brine is the cleaning agent needed to remove hard minerals from the resin beads. The hard minerals and brine are discharged to the drain.

The nozzle and venturi create a suction to move the brine, maintaining a very slow rate to get the best resin cleaning with the least salt.

BRINE RINSE

After a pre-measured amount of brine is used, the brine valve closes. Water continues to flow in the same path as during brining, except for the discontinued brine flow. Hard minerals and brine flush from the resin tank to the drain.

BACKWASH

During backwash, water travels up through the resin tank at a fast flow rate, flushing accumulated iron, dirt and sediments from the resin bed and to the drain.

FAST RINSE

Backwash is followed by a fast flow of water down through the resin tank. The fast flow flushes brine from the bottom of the tank, and packs the resin bed.

After fast rinse, the water softening system returns to soft water service.

4

About the water softener system

NORMAL OPERATION, CONTROL DISPLAYS

During normal operation, the present time of day and AM or PM and DAYS TO EMPTY show in the control display area.

The system will automatically recharge at the preset recharge time as needed.

FEATURE: OPTIONAL RECHARGE CONTROLS

Sometimes, a manually started recharge may be desired or needed. Two examples:

You have used more water than usual (house guests, extra washing, etc.) and you may run out of soft water before the next recharge.

The system ran out of salt.

Use one of the following features to start a recharge immediately, or at the next preset recharge start time.

RECHARGE TONIGHT

Touch (do not hold) the RECHARGE button. RECHARGE TONIGHT flashes in the control display area. A recharge will occur at the next preset recharge start time. If you decide to cancel this recharge, touch the same button once more.

RECHARGE NOW

Press and hold the RECHARGE button until RECHARGE NOW starts to flash in the control display area. The water softening system begins an immediate recharge and, when over in about two hours, you will have a new supply of soft water. Once started, you cannot cancel this recharge.

FEATURE: MEMORY

If electrical power to the water softening system is interrupted, the control display is blank, and the blue indicator light is off, but the control keeps correct time for 6 hours. When power

is restored, you have to reset the present time only if the display and blue indicator light are flashing. All other settings are maintained and never require resetting unless a change is desired.

If the time is flashing after a long power outage, the water softening system continues to work as it should to provide you with soft water. However, recharge may occur at the wrong time of day until you reset the control to the correct time of day.

FEATURE/SERVICE: AUTOMATIC ELECTRONIC DIAGNOSIS

The control computer has a self-diagnostic function for the electrical system (except input power and water meter). The computer

monitors the electronic components and circuits for correct operation. If a malfunction occurs, an error code appears in the control display.

5

About the water softener system

WATER CONDITION INFORMATION IRON

Iron in water can cause stains on clothing and plumbing fixtures. It can negatively affect the taste of food,drinking water, and other beverages. Iron in water is measured in parts per million (ppm). The total* ppm of iron, and type or types*, is determined by chemical analysis. Four different types of iron in water are:

Ferrous (clear water) iron

Ferric (red water) iron

Bacterial and organically bound iron

Colloidal and inorganically bound iron (ferrous or ferric)

Ferrous (clear water) iron is soluble and dissolves in water. This water softener will reduce moderate amounts of this type of iron (see specifications).**Ferrous (clear water) iron is usually detected by taking a sample of water in a clear bottle or glass. Immediately after taking, the sample is clear. As the water sample stands, it gradually clouds and turns slightly yellow or brown as air oxidizes the iron. This usually occurs in 15 to 30 minutes.

When using the softener to reduce Ferrous (clear water) iron, add 5 grains to the hardness setting fore very 1 ppm of Ferrous (clear water) iron. See “Set Water Hardness Number” section.

Ferric (red water), and bacterial and organically bound irons are insoluble. This water softener will not remove ferric or bacterial iron. This iron is visible immediately when drawn from a faucet because it has oxidized before reaching the home. It appears as small cloudy yellow, orange, or reddish suspended particles. After the water stands for a period of time,the particles settle to the bottom of the container. Generally these irons are removed from water by filtration. Chlorination is also recommended for bacterial iron.

Colloidal and inorganically bound iron is of ferric or ferrous form that will not filter or exchange out of water. This water softener will not remove colloidal iron. In some instances, treatment may improve colloidal iron water. Colloidal iron water usually has a yellow appearance when drawn. After standing for several hours, the color persists and the iron does not settle,but remains suspended in the water.

SEDIMENT FILTER (BUILT IN)

Sediment is fine, foreign material particles suspended in water. This material is most often clay or silt. Extreme amounts of sediment may give the water a cloudy appearance. The built in sediment filter keeps larger particles

of sediment from entering the home plumbing system. As water passes through the softener, the larger sediment particles are collected in the integrated basket and then rinsed to the drain before each regeneration. The sediment filter feature provides added protection for water using appliances by reducing the chance of larger particles entering the various products valves and screens.

IMPORTANT: The sediment filter is not intended to replace pretreatment filtration. For problem water applications, additional sediment filtration is recommended.

CHLORINE

Softener resins may degrade in the presence of chlorine above 2 ppm. If you have chlorine in excess of this amount, you may experience reduced life of the resin. In these conditions, you may wish to consider purchasing a GE point-of-entry household filtration system with a chlorine reducing filter.

* Water may contain one or more of the four types of iron and any combination of these. Total iron is the sum of the contents.

** Capacity to reduce clear water iron is substantiated by WQA test data.

6

Before you start

BEFORE YOU START

The water softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum allowable inlet water pressure is 125 psi. If daytime pressure is over 80 psi, nighttime pressure may exceed the maximum. Use a pressure reducing valve if necessary (Adding a pressure reducing valve may reduce the flow). If your home is equipped with a back flow preventer, an expansion tank must be installed in accordance with local codes and laws.

The water softener uses a direct plug-in external power supply (included). Be sure to use the included power supply and plug it into a nominal 120V, 60 cycle household outlet that is in a dry location only, grounded and properly protected by an over current device such as a circuit breaker or fuse.

WiFi communication requires WiFi connectivity and electrical power at the location of the softener. App connectivity will not function should either fail. (Check for both before the system is fully installed.)

Do not use this system to treat water that is microbiologically unsafe or of unknown quality without adequate disinfection upstream or downstream of the system.

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

Pliers

Screwdriver

Razor knife

Two adjustable wrenches

Teflon tape

INSPECT SHIPMENT

2 fittings to connect household plumbing to 1” NPT threads on softening adaptors.

Additional installation parts may be required:

•UL-approved grounding clamps and 6-gauge copper grounding wire.

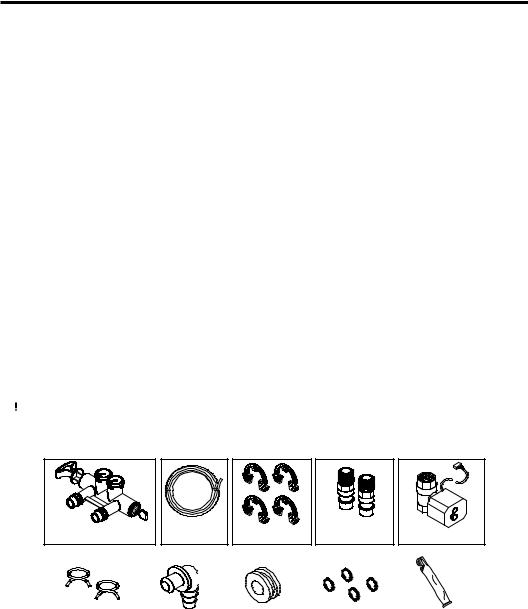

Make sure all the parts shown below are present. Additional parts must be purchased to complete the installation. Thoroughly check the water softener for possible shipping damage and parts loss. Also inspect and note any damage to the shipping carton.

Remove and discard (or recycle) all packing materials. To avoid loss of small parts, we suggest you keep the small parts in the parts bag until you are ready to use them.

WARNING |

Discard all unused parts and packaging material after installation. |

Small parts remaining after the installation could be a choke hazard. |

NOTE: Failure to comply with these installation instructions will void the product warranty, and the installer will be responsible for any service, repair or damages caused thereby.

Bypass Valve |

Drain Hose |

Clips |

Installation |

Shutoff Valve |

Adaptors |

Hose Clamps |

|

|

|

|

|

|

|

|

Silicone |

|

|

|

|

|

|

|

|

||

|

Overflow |

|

Grommet |

|

O-rings |

|

|||

|

|

Adapter |

|

|

|

|

|

Grease |

|

7

Installation Requirements

LOCATION REQUIREMENTS

Consider all of the following when selecting an installation location for the water softener.

Do not locate the water softener where freezing temperatures occur. Do not attempt to treat water over 120ºF. Freezing temperatures or hot water damage voids the warranty.

To condition all water in the home, install the water softener close to the water supply inlet, and upstream of all other plumbing connections, except outside water pipes. Outside faucets should remain on hard water to avoid wasting conditioned water and salt.

A nearby drain is needed to carry away regeneration discharge (drain) water. Use a floor drain,laundry tub, sump, standpipe, or other options(check your local codes). See “Air Gap Requirements” and “Valve Drain Requirements”sections.

The water softener uses a direct plug-in external power supply (included). Be sure to use the included power supply and plug it into a nominal 120V, 60 cycle household outlet that is in a dry location only, grounded and properly protected by an over current device such as a circuit breaker or fuse.

Always install the water softener between the water inlet and water heater. Any other installed water conditioning equipment should be installed between the water inlet and water softener (See Figure below).

If installing the water softener outdoors, do not locate where it will be exposed to wet weather, direct sunlight, extreme hot or cold temperatures, or other forms of abuse.

DO NOT RUN HOT WATER THROUGH THE SOFTENER. Temperature of water passing through the softener must be less than 120° F.

Avoid installing in direct sunlight. Excessive sun heat may cause distortion or other damage to non-metallic parts.

When installing in an outside location you must take steps necessary to assure the softener, installation plumbing and wiring, are protected from the elements, direct sunlight, contamination, vandalism, insects, vermin, etc.

Do not install the softener where it would block access to the water heater or access to the main water shutoff.

DIMENSIONS

22-7/16"

22-7/16"

|

IN |

3-3/4" |

14-7/16" |

OUT

OUT

TOP VIEW

IN - OUT

47-5/8"

41-1/2"

SIDE VIEW |

FRONT VIEW |

PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

Untreated Water to |

City Water Supply |

||

Cold Water to House Outside Faucets |

Shut off |

|

|

|

|

valve |

|

Hot Water to House |

Optional |

Pressure |

OR |

|

Tank |

||

|

Sediment |

|

|

|

Filter |

|

|

Water |

Water |

Well Water Supply |

|

Heater |

Softener |

Well |

|

|

|

|

|

|

|

Pump |

|

8

Installation Requirements

PLUMBING CODES

All plumbing must be completed in accordance with national, state and local plumbing codes.

In the state of Massachusetts: The Commonwealth of Massachusetts plumbing code 248-CMR shall be adhered to. A licensed plumber shall be used for this installation.

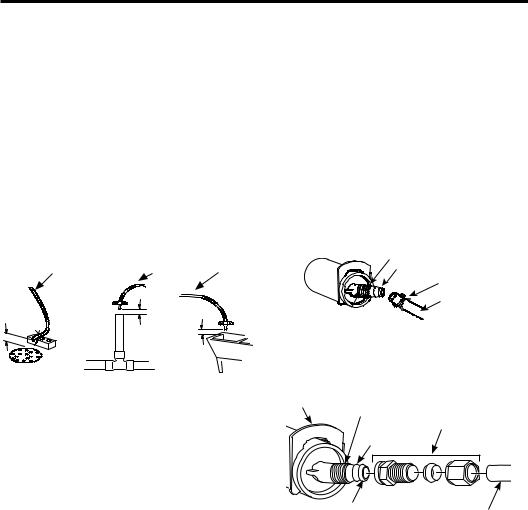

AIR GAP REQUIREMENTS

A drain is needed for regeneration water (See Figure 1). A floor drain, close to the water softener, is preferred. A laundry tub, standpipe, etc. are other drain options. Secure valve drain hose in place. Leave an air gap of 1-1/2”

between the end of the hose and the drain. This gap is needed to prevent back flow of sewer water into the water softener. Do not put the end of the drain hose into the drain.

Drain |

|

Drain |

Drain |

Hose |

|

Hose |

Hose |

1-1/2” |

|

|

|

air gap |

1-1/2” |

|

|

|

|

|

|

|

air gap |

|

|

|

|

1-1/2” |

|

|

|

air gap |

|

FLOOR |

STANDPIPE |

LAUNDRY |

|

DRAIN |

|

TUB |

|

Figure 1

VALVE DRAIN REQUIREMENTS

Using the flexible drain hose (included) (See Figure 2), measure and cut to the length needed. Flexible drain hose is not allowed in all localities (check your plumbing codes). If local codes do not allow use of a flexible drain hose, a rigid valve drain run must be used. Purchase a compression fitting (1/4 NPT x 1/2 in. minimum tube) and 1/2” tubing from your local hardware store. Plumb a rigid drain as needed (See Figure 3).

NOTE: Avoid drain hose runs longer than 30 feet. Avoid elevating the hose more than 8 feet above the floor. Make the valve drain line as short and direct as possible.

FLEXIBLE DRAIN LINE

1/4” NPT Thread

Barbs for 3/8Ǝ I.D. tubing

Hose clamp

Drain hose

Drain hose adapter

Figure 2

RIGID DRAIN LINE

|

|

Compression fitting |

|

Clip |

|

137 [ Ǝ 2 ' |

|

1/4Ǝ NPT thread |

tube (not provided) |

||

|

|||

|

Barbs |

|

Cut barbs from valve drain

elbow (pull clip and remove Ǝ RXWVLGH drain valve elbow from valve) diameter

copper tube (not provided)

Figure 3

9

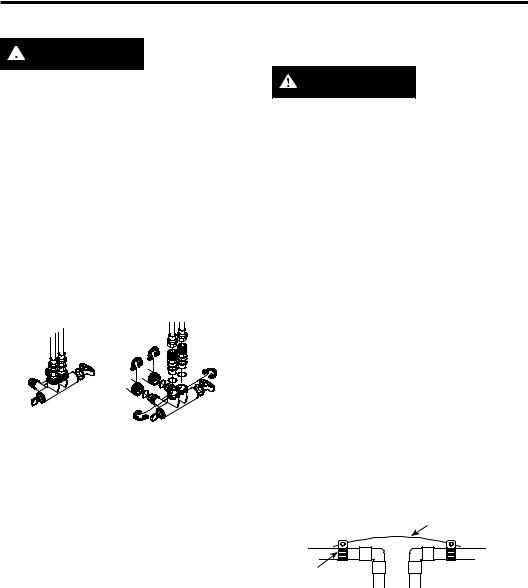

Installation Requirements

INLET/OUTLET PLUMBING REQUIREMENTS

Always install either a single bypass valve (provided),as shown in Figure 4, or, if desired, parts for a 3 valve bypass system (not included) can be purchased and assembled, as shown in Figure 5. Bypass valves allow you to turn off water to the softener for maintenance if needed, but still have water in house pipes.

Pipe fittings must be 1/2” minimum. Use:

Copper pipe

Threaded pipe

PEX (Crosslinked Polyethylene) pipe

CPVC plastic pipe

Other pipe approved for use with potable water

IMPORTANT: Do not solder with plumbing attached to installation adaptors and single bypass valve. Soldering heat will damage the adaptors and valve.

SINGLE BYPASS VALVE

Pull out for “Service” (Soft water)

Push in for “Bypass”

Installation

Installation

adaptors

Figure 4

WARNING

WARNING

A copper or galvanized cold water pipe may be used to ground electrical outlets in the home. Failure to maintain this ground path may result in an electric shock hazard. If the cold water pipe is used to ground electric outlets, please refer to Installing the Ground Wire section before cutting the pipe.

3-VALVE BYPASS SYSTEM

For soft water service: Open the inlet and outlet valves and close the bypass valve.

For bypass hard water: Close the inlet and outlet valves and open the bypass valve.

3 VALVE BYPASS

Bypass

Valve

Outlet |

Inlet |

Valve |

Valve |

From Water |

To Water |

Softener |

Softener |

Figure 5

10

Installation Instructions

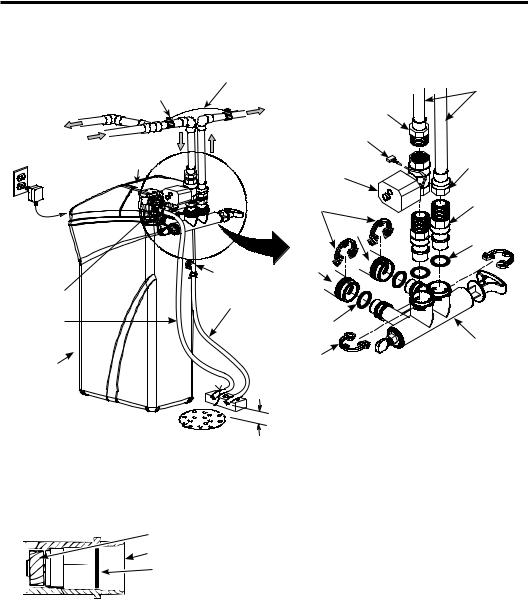

TYPICAL INSTALLATION

|

Clamp |

Ground Wire |

1” NPTM |

|

(not included) |

||

Hard Water |

(not included) |

Conditioned |

Threaded |

|

Adaptor (not |

||

to Outside |

|

Water |

included) |

Faucets |

|

Main Water Pipe |

|

Incoming |

|

Plug into |

|

Hard Water |

Top |

controller |

|

Plug-in |

Cover |

Motorized Water |

|

|

Shutoff valve |

||

Transformer |

|

||

|

|

|

|

|

|

Clips |

|

To |

|

|

Outlet |

Controller |

|

|

|

|

|

|

|

|

Overflow |

Inlet |

|

Drain Hose |

Adapter |

|

|

Brine Tank |

|||

Adapter |

|||

|

Overflow Hose* |

||

Valve Drain |

|

Lubricated |

|

Hose* |

|

O-ring |

|

Brine Tank |

|

Clips |

|

|

Secure Valve Drain |

||

(Salt Storage) |

|

||

|

|

Hose in place over Floor |

|

|

|

Drain |

|

Pipe

1” NPTF

Sweat

Adaptor (not included)

1” NPTM Threaded Adaptor

O-ring

Single Bypass

Valve

Figure 7

*Do not connect the water |

1-1/2” |

NOTE: See “Air Gap Requirements” section. |

air gap |

||

softener valve drain hose to |

Floor Drain |

|

the brine tank overflow |

|

|

|

|

Figure 6

• Remove plastic shipping plug and wire from valve outlet.

Turbine

Valve outlet

Plastic shipping plug

Turbine shaft and support

Turbine shaft and support

Figure 8

NOTE: Be sure the turbine and support are firmly in place in the valve outlet. Blow into the valve port and observe the turbine for free rotation.

11

Installation Instructions

TURN OFF WATER SUPPLY

1.Close the main water supply valve, located near the well pump or water meter.

2.Open all faucets to drain all water from house pipes.

NOTE: Be sure not to drain water from the water heater, as damage to the water heater elements could result.

INSTALL BRINE TANK OVERFLOW ADAPTER

Install the brine tank overflow grommet and adapter in the 13/16” diameter hole in the back of the salt storage tank sidewall, (see Figure 9).

NOTE: The brine tank overflow adapter accepts either 1/2” or 3/8” I.D. hose.

INSTALL THE BYPASS VALVE

NOTE: For easier installation, remove the top cover. Release 2 clips at rear of cover. Rotate cover forward and lift up.

1.Remove two clips from the water softener valve inlet and outlet ports and visually check and remove any debris, (see Figure 7).

2.Make sure the turbine assembly spins freely in the”out” port of the valve, (see Figure 8).

3.If not already done, put a light coating of silicone grease (provided) on the single bypass valve o-rings, (see Figure 7).

4.Push the single bypass valve into the softener valve as far as it will go. Snap the two large holding clips into place, from the top down, (see Figure 7 and 10).

IMPORTANT: Be sure the clips snap firmly into place so the single bypass valve will not pull out.

MOVE WATER SOFTENER INTO PLACE

WARNING Excessive Weight Hazard

WARNING Excessive Weight Hazard

Use two or more people to move and install water Softener Failure to do so can result in back or other injury.

1.Move the water softener into the desired location. Set it on a solid, level surface.

IMPORTANT: Do not place shims directly under the salt storage tank to level the softener. The weight of the tank, when full of water and salt, may cause the tank to fracture at the shim.

Salt |

|

Cover |

Nozzle Venturi |

|

Assembly |

Brinewell |

Nut - Ferrule |

Cover |

Hole |

|

|

|

Grommet |

Brine |

|

Tank |

Brine Tank |

|

Overflow |

|

Adapter |

Stand |

Brine |

Tube |

Tubing |

Brine |

Brinewell |

|

|

Valve |

|

Assembly |

Float Stem |

|

Figure 9

NOTE: Unit is shown with top cover removed.

SINGLE BYPASS VALVE

If connecting to floor level plumbing, install the bypass valve turned downward, as shown.

CORRECT ASSEMBLY

Clip

Outside diameter of water softener valve inlet & outlet

Outside diameter of clip channel on single bypass valve

Outside diameter of clip channel on single bypass valve

Figure 10

NOTE: Be sure all 3 tabs of the clip go through the matching holes on the water softener valve inlet or outlet, and fully into the channel on the single bypass valve. Make sure that the tabs are fully seated.

12

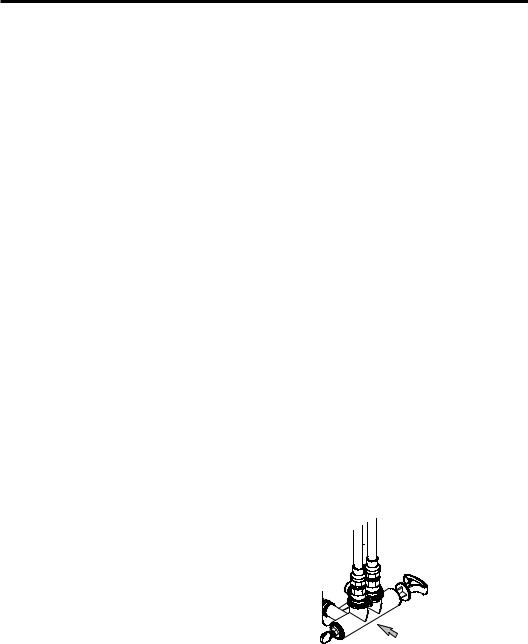

Installation Instructions

GETTING ACCESS TO MAIN CONTROL BOARD

(TO PLUG IN WATER SHUTOFF VALVE)

INSTALL MOTORIZED WATER SHUTOFF VALVE

Install the included water shutoff valve on the threaded installation adapter leading to the water softener’s INLET. Optionally, it may be installed elsewhere in the plumbing upstream of the water softener inlet, making sure that the 10 foot long cable will reach the water softener’s main control board (see illustration). The shutoff valve’s inlet and outlet are female 1” NPT. Support the weight of the shutoff valve.

After completing plumbing, make sure that the water softener is not powered up, and plug the cable from the shutoff valve into the corresponding connector on the main control board (see illustration at right).

NOTE: The shutoff valve may be operated manually by pulling out and turning the knob on the shutoff valve body, although there is no need to do this when installing.

CAUTION |

Do not place fingers into |

|

the motorized shutoff valve |

|

when it is plugged into the electronic controller.

1. Pull out both tabs on back of the top cover to unlock cover.

2.Tilt top cover upward and lift off.

3.Open salt lid and tilt back until is rests.

4.Pull both tabs toward center to unlock faceplate.

Salt Lid |

Top Cover |

Faceplate

5.Tilt faceplate forward to expose back of the control board.

Faceplate

13

Installation Instructions

6.With power off, plug the shutoff valve’s cable into this connector.

Main |

Control Board |

Back of Faceplate Assembly

MOTORIZED WATER SHUTOFF VALVE

To manually operate the motorized water shutoff valve, pull out the round knob on the valve and turn it until the red line in the sight glass matches the desired (open or closed) position. See illustration below.

Motorized Water Shutoff Valve

OPEN

Sight glass

Knob – Pull out to turn

14

Installation Instructions

COMPLETE INLET AND OUTLET PLUMBING

WARNING

WARNING

A copper or galvanized cold water pipe may be used to ground electrical outlets in the home. Failure to maintain this ground path may result in an electric shock hazard. If the cold water pipe is used to ground electric outlets, please refer to Installing the Ground Wire section before cutting the pipe.

IMPORTANT: This water softener has a nonmetallic valve system. Installing it on metal plumbing will break electrical continuity, which may interrupt grounding for the home. You must restore electrical continuity in your metal plumbing system.

If you install a 3-valve bypass system (Figure 5), electrical continuity will be maintained. If you install the non-metallic bypass valve (Figure 11), please refer to the Installing the Ground Wire section before cutting the pipe.

Figure 11

Measure, cut, and loosely assemble pipe and fittings from the main water pipe to the inlet and outlet ports of the water softener valve. Be sure to keep fittings fully together, and pipes squared and straight.

BE SURE INCOMING HARD WATER SUPPLY IS DIRECTED TO THE SOFTENER VALVE

INLET PORT.

NOTE: Inlet and outlet are marked on the water softener valve. Trace the water flow direction to be sure hard water is to inlet.

IMPORTANT: Be sure to fit, align and support all plumbing to prevent putting stress on the water softener valve inlet and outlet. Stress from misaligned or unsupported plumbing may cause damage to the valve.

•If making a soldered copper installation, do all sweat soldering before connecting pipes to the NPT adapters and bypass valve. Torch heat will damage plastic parts.

WARNING

If solder is used to make pipe connection use only lead free solder and flux to prevent lead poisoning.

•When turning threaded pipe fittings onto plastic fittings, use care not to cross-thread.

•Use Teflon Tape on all external pipe threads.

Complete the inlet and outlet plumbing for the type of pipe you will be using. Secure ground clamp to metal pipes.

INSTALLING THE GROUND WIRE

NOTE: If your house plumbing is plastic, it would not be used as a grounding path, and this step should be skipped.

IMPORTANT: A copper or galvanized cold water pipe is often used to ground electrical outlets in the home. Grounding protects you from electrical shock. The water softener may have broken this ground path. To restore connection, install a 12”-long, 6-gauge copper wire across and tightly clamp using UL-approved 1/2”–1” bronze grounding clamps

at both ends as shown (Figure 12). Zinc clamps should not be used on copper plumbing. Wire and clamps may be purchased separately from your local hardware store.

1.Clean copper pipe and ends of wire with emery paper. Bare wire is recommended. If insulated wire is used, is should be stripped 3/4” at each end before cleaning with emery paper.

2.Attach bronze clamps to pipe. Tighten screws.

3.Attach to clamps as shown. Tighten screws.

Ground Wire

Clamp (2)

Figure 12

NOTE: If you are installing a sediment filter or other item(s) into the plumbing system, along with the water softener, be sure to restore electrical continuity across all removed metal pipe sections.

15

Installation Instructions

INSTALL VALVE DRAIN HOSE

1.Measure and connect the 3/8”drain line (provided) to the water softener valve drain fitting. Use a hose clamp to hold the hose in place.

NOTE: Avoid drain hose runs longer than 30 feet. Avoid elevating the hose more than 8 feet above the floor. Make the valve drain line as short and direct as possible.

IMPORTANT: If codes require a rigid drain line see “Valve Drain requirements” section.

2.Route the drain hose or copper tubing to the floor drain or other suitable drain

point. Secure drain hose. This will prevent “whipping’’ during regenerations. See “Air Gap Requirements” section (Figure 1).

3.Cut and secure the hose.

NOTE: The softener will not work if the water cannot exit the drain hose during recharge.

INSTALL BRINE TANK (SALT STORAGE) OVERFlOW HOSE

1.Measure, cut to needed length and connect the 3/8”drain line (provided) to the salt storage tank overflow elbow and secure in place with a hose clamp.

2.Route the hose to the floor drain, or other suitable drain point no higher than the drain fitting on the salt storage tank (This is a gravity drain). If the tank overfills with water, the excess water flows to the drain point. Cut the drain line to the desired length and route it neatly out of the way.

IMPORTANT: For proper operation of the water softener, do not connect the water softener valve drain tubing to the salt storage tank overflow hose.

RINSE OUT CARBON FINES

Small particles of carbon filtration material are generated during manufacturing and shipping. These particles will exit the media tank with the first water that flows through the softener. These carbon “fines” are not harmful, but give the water a gray color and should be rinsed down the drain before any water from the softener is directed to the home’s faucets or water heater.

TEST FOR LEAKS

To prevent air pressure in the water softener and plumbing system, complete the following steps in order:

1.Fully open two or more softened cold water faucets close to the water softener, located down stream from the water softener.

2.Place the bypass valve (single or 3 valve) into the”bypass” position (see Figures 4 or 5).

3.Slowly open the main water supply valve. Run water until there is a steady flow from the opened faucets, with no air bubbles.

4.Place bypass valve(s) in “service” or soft water position as follows:

•Single bypass valve (Figure 4): Slowly move the valve stem toward “service,” pausing several times to allow the water softener to fill with water.

•3 valve bypass (Figure 5): Fully close the bypass valve and open the outlet valve. Slowly open the inlet valve, pausing several times to allow the water softener to fill with water.

5.After about three minutes, open a hot water faucet until there is a steady flow and there are no air bubbles, then close this faucet.

6.Close all cold water faucets and check for leaks at the plumbing connections that you made.

7.Check for leaks around clips at softener’s inlet and outlet. If a leak occurs at a clip, depressurize the plumbing (turn off the water supply and open faucets) before removing clip. When removing clips at the softener’s inlet or outlet, push the single bypass valve body toward the softener (See Figure 14). Improper removal may damage clips. Do not reinstall damaged clips.

If removing

clips.....

|

....depressurize the |

|

plumbing, then push |

Figure 14 |

Bypass Valve body |

toward softener |

16

Installation Instructions

ADD WATER AND SALT TO THE SALT STORAGE TANK

WARNING

WARNING

EXCESSIVE WEIGHT HAZARD:

Use two or more people to move and lift salt bags. Failure to do so can result in back or other injuries.

1.Using a container, add about three gallons of clean water into the salt storage tank.

2.Add salt to the storage tank. Use nugget, pellet or coarse solar salts with less than 1% impurities.

PLUG IN THE WATER SOFTENER

1.Plug the water softener into an electrical outlet that is not controlled by a switch.

2.Replace the top cover.

3.Replace the salt hole cover.

NOTE: The water heater is filled with hard water and,as hot water is used, it will refill with conditioned water. In a few days, the hot water will be fully conditioned. To have fully conditioned hot water immediately, wait until the initial recharge is over. Then, drain the water heater(following instructions for water heater) until water runs cold.

WARNING

WARNING

Discard all unused parts and packaging material after installation. Small parts remaining after the installation could be a choke hazard.

SANITIZE THE WATER SOFTENER / SANITIZE AFTER SERVICE

1.Open salt hole cover, remove the brinewell cover and pour about 3 oz. (6 tablespoons) of household bleach into the softener brinewell. Replace the brinewell cover.

2.Make sure the bypass valve(s) is in the “service”(open) position.

3.Start a recharge (regeneration). See “Start a Recharge”on Page 17.

4.After the recharge has completed, fully open a cold water faucet, downstream from the softener, and allow 50 gallons of water to pass through the system. This should take at least 20 minutes. Close the faucet.

17

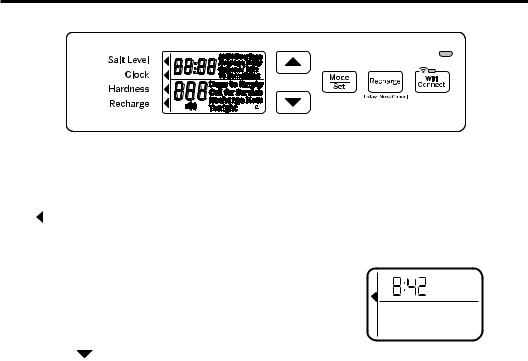

Programming the Water Softener

When the transformer is plugged into the electrical outlet, a model code and test number (example: y4.1 & H40) are shown in the display. Then, “12:00 PM” begins to flash. An arrow is displayed next to CLOCK on the face plate decal.

CONTROL OPERATION:

• CONTROL SETTINGS REQUIRED upon initial installation and after an extended power outage.

•Use the MODE/SET button to scroll arrow to desired control function set.

•After the mode is selected use the UP

and DOWN buttons to change the settings of the control.

•Press the MODE/SET button to accept changes.

•A “beep” sounds while pressing buttons for control programming. One beep signals a change in the control display. Repeated beeps mean the control will not accept a change from the button you have pressed, and you should select another button.

SET TIME OF DAY

1.Press MODE/SET button until the arrow points to CLOCK.

points to CLOCK.

2.Press the UP or DOWN

or DOWN buttons to set the present time. UP

buttons to set the present time. UP moves the display ahead; DOWN

moves the display ahead; DOWN sets the time back. Be sure AM and PM is correct.

sets the time back. Be sure AM and PM is correct.

PM

Salt Level

Clock

Hardness

Recharge

NOTE: Press buttons and quickly release to slowly advance the display one number at a time. Hold the buttons down for fast advance.

3.When the correct time is shown in the display, press MODE/SET to accept.

18

Programming the Water Softener

SET WATER HARDNESS NUMBER

1. Press the MODE/SET button until the arrow  points to HARDNESS. A flashing 25 will

points to HARDNESS. A flashing 25 will

appear in the display.

Salt Level

Clock

Hardness

Recharge

2.Press the UP or DOWN

or DOWN buttons to set your water hardness number.

buttons to set your water hardness number.

NOTE: If your water supply contains iron, compensate for it by adding to the water hardness number. For example, assume your water is 20 gpg hard and contains 2 ppm iron. Add 5 to the hardness number for each 1 ppm or iron. In this example, you would use 30 for your hardness number.

|

20 gpg hardness |

|

2 ppm iron x 5 = 10 +10 |

||

|

|

|

(times) |

30 HARDNESS NUMBER |

|

3.When the display shows your water hardness (in grains per gallon), press MODE/SET to accept.

You can get the grains per gallon (gpg) hardness of your water supply from a water analysis laboratory. If you are on a municipal supply, call your local water department. Or call Legend Technical Services, an independent laboratory, to request a water hardness test kit at 1.800.949.8220, Option 4. If your report

shows hardness in parts per million (ppm) or milligrams per liter (mg/l), simply divide by 17.1 to get the equivalent number of grains per gallon.

SET RECHARGE (STARTING) TIME

1. Press the MODE/SET button until the arrow  points to RECHARGE.

points to RECHARGE.

Salt Level |

AM |

|

Clock

Hardness

Recharge

NOTE: A flashing 2:00 AM (factory default) should show in the display. This is a good time for recharge to start (takes about 2 hours) in most households because water is not in use. HARD WATER is bypassed to house faucets during recharge.

If no change is needed, go to step 3. To Change the recharge starting time, follow step 2.

2.Press UP or DOWN

or DOWN button to set the desired recharge start time. Be sure to observe the AM or PM as you did when setting the time of day.

button to set the desired recharge start time. Be sure to observe the AM or PM as you did when setting the time of day.

3.Press the MODE/SET button to accept.

19

Programming the Water Softener

SET SALT LEVEL

1.Press the MODE/SET button until the arrow

points to SALT LEVEL.

points to SALT LEVEL.

Salt Level

Clock

Hardness

Recharge

2.Determine level of salt in brine tank using the numbered scale on side of brine well, inside brine tank (see Figure 15).

3.Press UP  or DOWN

or DOWN  button to set the SALT LEVEL to correspond to level on the numbered scale in brine tank.

button to set the SALT LEVEL to correspond to level on the numbered scale in brine tank.

Salt Level

Clock

Hardness

Recharge

NOTE: Each press of a button changes the level by increments of 0.5 up to 8.0. Lowering the salt level below zero turns the SALT LEVEL indicator OFF.

4.Press the MODE/SET button to accept. The display shows the present time of day and

DAYS TO EMPTY.

PM

Days to Empty

Days to Empty

8

7

6

5

4

3

2

1

Figure 15

DAYS TO EMPTY

The words DAYS TO EMPTY and a number are shown in the lower half of the display. This information is shown in the normal run display. This is to inform the user of the number of days before the salt level in the brine tank reaches Level 0. There will be salt left in the salt tank, but it may not be sufficient to fully recharge the system. Salt should be added at this time to avoid hard water. The value is updated daily and whenever the SALT LEVEL value is changed.

AM

Days to Empty

Days to Empty

NOTE: For the first several weeks of operation, the DAYS TO EMPTY may provide erratic operation. For example, the blue indicator light may flash, showing that more salt is required when the actual salt level in the tank is well above the Level 0. In some cases, the DAYS TO EMPTY may even increase over a several week period.

It takes a couple of months for the water softener to learn your water usage pattern. Once it does this, it will accurately determine actual salt usage pattern. During this first period, check salt level when blue indicator light flashes. If the salt level in the tank is at Level 1 or above, allow system to run. Be sure to reset your salt level indicator each time you add salt to the system.

START A RECHARGE

Press the RECHARGE button and hold for three seconds, until “RECHARGE NOW” begins to flash in the display, starting a recharge. This recharge draws the sanitizing bleach or brine into and through the water softener. Any air remaining in the water softener is purged to the drain. During this time periodically check for leaks.

NOTE: As with all other water system applications, leaks may occur. Leaks may not be immediately apparent. Recheck 24 hours after first recharge cycle is complete.

20

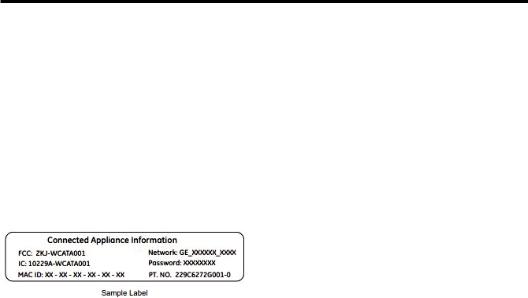

Appliance Communication: WiFi Connect

(For customers in the United States, its Territories, and Canada)

• WiFi communication requires WiFi connectivity and electrical power at the location of the softener. App connectivity will not function should either fail. (Check for both before the system is fully installed.)

• App requires smart phone with service to receive notifications.

• App provides alert, but requires user to respond to turn off water.

• The system is not able to detect all small leaks, and cannot shut off leaks between the system and shut off valve.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1.This device may not cause harmful interference, and

2.This device must accept any interference received, including interference that may cause undesired operation. This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/television technician for help.

Labelling: Changes or modifications to this unit not expressly approved by the manufacturer could void the user’s authority to operate the equipment.

21

Programming the Water Softener

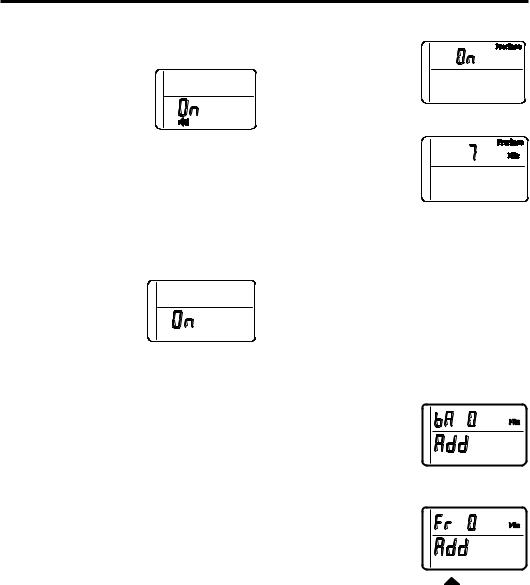

OPTIONAL CONTROL SETTINGS

The controller display has several options and features.

LOW SALT ALARM

The LOW SALT ALARM,

when enabled, will sound the beeper when the DAYS TO EMPTY value is 15 days or less. To change this

setting, press and hold the MODE/SET button for 3 seconds or hear a beep. ON (factory default) or OFF will flash in the display. Press the UP  or DOWN

or DOWN  buttons to toggle this feature ON or OFF. Press the MODE/SET button to accept, and the display will move to the SALT EFFICIENCY screen.

buttons to toggle this feature ON or OFF. Press the MODE/SET button to accept, and the display will move to the SALT EFFICIENCY screen.

SALT EFFICIENCY

When the SALT EFFICIENCY feature is ON, the unit will operate

at a salt efficiency of

4000 grains of hardness removed per pound of salt.

This mode of operation  is the most efficient setting for salt usage, because the system will tend to recharge more often with less salt usage. Turning the feature OFF will tend to lengthen the time between recharge cycles, which will provide the most efficient usage of water, but may use more salt. The degree of difference between these two cycles is highly dependent on the water usage and hardness at particular installation.

is the most efficient setting for salt usage, because the system will tend to recharge more often with less salt usage. Turning the feature OFF will tend to lengthen the time between recharge cycles, which will provide the most efficient usage of water, but may use more salt. The degree of difference between these two cycles is highly dependent on the water usage and hardness at particular installation.

NOTE: California Regulations require this feature to be ON for installations in California.

To change the setting, press the UP  or DOWN

or DOWN  buttons to toggle this feature ON or OFF. Press the MODE/SET button to accept, and the display will move to the PRERINSE ON/OFF screen.

buttons to toggle this feature ON or OFF. Press the MODE/SET button to accept, and the display will move to the PRERINSE ON/OFF screen.

PRERINSE

If your water contains sediment, the prerinse feature will remove

sediment from the resin bed prior to regeneration. Press the UP  or DOWN

or DOWN  buttons to turn

buttons to turn

prerinse ON or OFF.

Press the MODE/SET button to accept, and the

display will move to SET PRERINSE TIME screen.

In this screen, you can adjust the duration of the prerinse, in minutes, by pressing the UP  or DOWN

or DOWN  buttons. Press the MODE/ SET button to accept, and the display will move to the ADD BACKWASH TIME screen.

buttons. Press the MODE/ SET button to accept, and the display will move to the ADD BACKWASH TIME screen.

BACKWASH AND FAST RINSE

If you experience salty tasting water after regeneration, you may need to increase the backwash and fast rinse times. The cycle times during regenerations are determined by the softener’s electronic controller. However, you may Increase the backwash and fast rinse times. You may add up to 10 minutes.

For Backwash, you can

add up to 10 minutes in 1 minute increments,

by pressing the UP  button, or subtract time by pressing the DOWN

button, or subtract time by pressing the DOWN

button.

For Fast Rinse, press |

|

MODE/SET and the |

|

display moves to the |

|

ADD FAST RINSE TIME |

|

screen. You can add up |

|

to 10 minutes in 1 minute |

|

increments, by pressing the UP |

button, |

or subtract time by pressing the DOWN  button. Press the MODE/SET button to accept, and the display will move to the Run Display screen.

button. Press the MODE/SET button to accept, and the display will move to the Run Display screen.

22

Programming the Water Softener

FEATURE: OTHER DATA DISPLAY

These models have an option to have the run display indicate different information. The information displayed on the top half of the display can be changed to one of the following by pressing UP  or DOWN

or DOWN  buttons:

buttons:

• CAPACITY REMAINING

– This is the percentage of water softening capacity remaining. Immediately after a regeneration, 100%

shows. As water is used,

the percentage will decrease until the next regeneration. During regenerations, the percentage increments upward.

When present time is displayed, press the DOWN  button; % Remaining will appear in the display. The value shown is between 0 and 100 percent. This value is based on current operating capacity. Pressing the UP

button; % Remaining will appear in the display. The value shown is between 0 and 100 percent. This value is based on current operating capacity. Pressing the UP  button will return the screen to the previous display.

button will return the screen to the previous display.

RESETTING TO FACTORY DEFAULT

To reset the electronic controller to its factory default for all settings (time, hardness, etc.):

1.Press the MODE/SET button and hold until the display changes twice to show the flashing mode code.

2.Press the UP  button to display a flashing “SoS”.

button to display a flashing “SoS”.

3.Press the MODE/SET button and the electronic controller will restart.

4.Set the present time, hardness, etc, as described in the Programming the Water Softener section

• AVERAGE DAILY GALLONS – The figure displayed is the average gallons of water used by the household each day over the past seven-day period.

Average Daily

Gallons

Gallons

Days to Empty

Days to Empty

Recharge

Recharge

Tonight

Press the DOWN  button again to display the Average Daily Gallons. Average Daily Gallons will appear in the display. This value is updated every night at midnight. Pressing the UP

button again to display the Average Daily Gallons. Average Daily Gallons will appear in the display. This value is updated every night at midnight. Pressing the UP  button will return the screen to the previous display.

button will return the screen to the previous display.

• FLOW RATE, GPM |

|

|

– When using soft water, |

|

Gallons/Min |

this display shows the flow |

|

|

|

Days to Empty |

|

rate passing through the |

|

|

softener (in gallons per |

|

|

minute). Zero shows if water |

|

|

is not passing through the softener. |

|

|

Press the DOWN  button again to display the flow rate. Gallons/Min will appear in the display. This value is updated every 1»2 second. Pressing the UP

button again to display the flow rate. Gallons/Min will appear in the display. This value is updated every 1»2 second. Pressing the UP  button will return the screen to the previous display. Pressing the DOWN

button will return the screen to the previous display. Pressing the DOWN  button will return the screen to the

button will return the screen to the

present time display.

23

Programming the Water Softener

POWER OUTAGE MEMORY

If electrical power to the water softener is lost, “memory’’ built into the timer circuitry will keep all settings for up to 6 hours. While the power is out, the display is blank and the water softener will not regenerate. When electrical power is restored, the following will occur:

Reset the present time only if the display is flashing. The HARDNESS and RECHARGE TIME never require resetting unless a change is desired. Even if the clock is incorrect after a long power outage, the softener operates as it should to keep your water soft. However, regenerations may occur at the wrong time of day until you reset the clock to the correct time of day.

NOTE: If the water softener was regenerating when power was lost, it will now finish the cycle.

BLUE INDICATOR LIGHT

Steady blue light indicates that the unit is working correctly. The light flashes when the unit needs attention from the user.

•Light will also flash when power to the unit has been interrupted. Check the PRESENT TIME setting.

•Light flashes and DAYS TO EMPTY flashes - check salt level and add salt as required.

•Light flashes and Err is in the display - electrical problem with system.

LOW SALT SIGNAL

When the DAYS TO EMPTY drops to 15, the blue indicator light and DAYS TO EMPTY in the display will flash every second and the alarm will beep every 30 seconds (from 8:00 AM to 8:00 PM), to notify the user that the unit is running low on salt. As soon as any button is pressed, the alarm will stop beeping. The blue indicator light and DAYS TO EMPTY will continue to flash. Once salt is added to the brine tank and the SALT LEVEL is reset, the DAYS TO EMPTY will be reset.

ERROR SIGNALS

If there is an error code detected, the blue indicator light will flash

4 times every second,

the display will flash Err and the alarm will beep

every 30 seconds (from 8:00 AM to 8:00 PM) to signal that the softener requires service. The alarm can be turned off by pressing any button, but the blue indicator light and display will continue to flash.

Disconnect the transformer from the wall outlet momentarily, and plug it back in. The normal display will appear. The motor may run for several minutes, as the unit resets. If the problem is not corrected, the error code will reappear in 8 minutes. If Err 6, 7, or 8 appears, it can be cleared by pressing recharge for 5 seconds.

See the Before you Call for Service section to assist in troubleshooting the water softener.

24

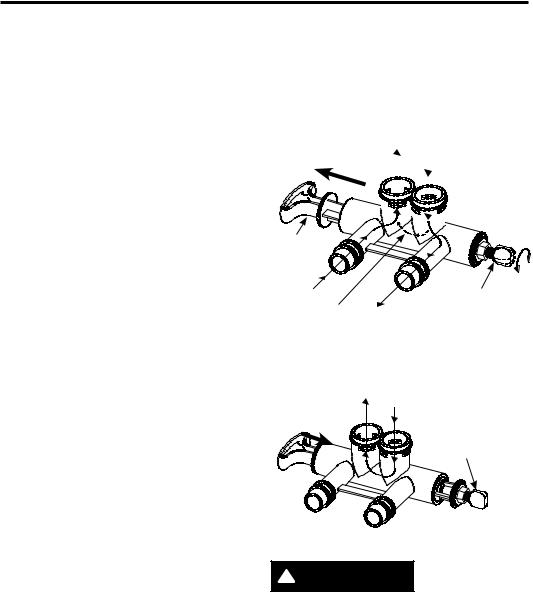

Care and cleaning

ADJUSTING YOUR WATER HARDNESS

The blend adjusting knob (Figure 16) gives the ability to finely adjust hardness of the treated water leaving the water softener. If slightly harder water is desired than is normally delivered by the water softener, the blend adjusting knob can divert a small stream of hard water and blend it with the soft water entering the home. The amount

of water diverted is controlled by turning a blend adjusting knob on the end cap of the valve stem.

NOTE: To get full performance from your water softener leave blending valve in the factory closed position.

To make adjustments to water hardness:

1.Hold bypass handle to keep the valve stem from rotating (see Figure 16). Loosen hex nut on blend adjustment knob by turning the hex nut counterclockwise (see Figure 17).

2.TO INCREASE HARDNESS: With the bypass in the service position (see Figure 16) hold the handle to keep the valve stem from rotating and turn the blend adjusting knob counterclockwise up to 2 turns from the closed position. It is recommended that adjustments be made in quarter turn increments over several weeks until the desired hardness is achieved. NOTE: Once an adjustment is made to the blend valve knob the change in water hardness at the homes faucets or shower heads may take several days to be noticed. This delay is due to the large amounts of already conditioned water in the pipes and water heater that must be exchanged before a change in hardness can be noticed. Have the water tested to determine the actual water hardness.

3.TO DECREASE HARDNESS: With the bypass in the service position (see Figure 16) hold the handle to keep the valve stem from rotating and turn the blend adjusting knob clockwise. When the knob will not turn anymore, hard water is no longer being blended into the soft water.

4.Once the desired hardness is achieved tighten the hex nut (see Figure 17) clockwise until it comes in contact with the bypass stem.

NOTE: To meet the water softener performance specifications and reduction of barium and radium claims the adjustable hardness must be kept in the “OFF” position. The off position is achieved when the blend adjusting knob is fully rotated clockwise until it stops.

SERVICE POSITION

(Normal Softener Operation)

Pull |

|

Soft Water Out |

||||||||||

|

|

|

|

|

|

|

Hard Water In |

|||||

Handle |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stem |

|

|

|

Softener |

|

|

|

Valve Outlet |

|

Blend Adjusting |

|

Diverted Hard |

Softener |

Knob |

|

Water (Controlled |

Turn counterclockwise |

||

Valve Inlet |

to increase hardness |

||

by blend adjusting |

|

of treated water |

|

knob) |

|

||

|

(clockwise to decrease |

||

Figure 16 |

|||

hardness) |

|||

BYPASS POSITION |

|||

Hard Water Out |

|

||

Push |

Hard Water In Hex Nut |

||

Handle |

|

Turn clockwise to lock |

|

|

|

blend adjusting knob |

|

|

|

(counterclockwise to |

|

|

|

unlock). |

|

|

Blend Adjusting Knob |

||

|

If servicing water softener, |

||

Figure 17 |

turn clockwise as far as it |

||

|

will go. |

||

CAUTION

CAUTION

If the water softener is to be serviced or disconnected from the bypass valve, the blend adjusting knob must be turned all the way clockwise to close the diversion path and prevent water leaking from the softener valve inlet of the bypass.

25

Care and Cleaning

CHECKING THE SALT STORAGE LEVEL and REFILL

Brine (salt dissolved in water) is needed for each and every recharge. The water for making brine is metered into the salt storage area by the water softening system valve and control.

However, you must keep the tank supplied with salt.

ADDING SALT

Lift the salt hole cover and check the salt storage level frequently. If the water softener uses all the salt before you refill it, you

will experience hard water. Until you have established a refilling routine, check the salt every two or three weeks. Always add if less than 1/4 full. Be sure the brinewell cover is on.

NOTE: if using potassium chloride (KCI), do not fill above level 4 on the brinewell decal.

NOTE: In humid areas, it is best to keep the salt storage level lower, and to refill more often to avoid salt “bridging”.

Recommended Salt: Nugget, pellet or coarse solar salts with less than 1% impurities.

Salt Not Recommended: Rock salt, high in impurities, block, granulated table, ice melting, ice cream making salts, etc.

CAUTION

CAUTION

Water softening salt with iron removing additives:

Some salts may have an additive to help the water softening system handle iron in the water supply. Although this additive may help to keep the water softening system resin clean, it may also release corrosive fumes that weaken and shorten the life of some water softening system parts.

CLEANING IRON OUT OF THE WATER SOFTENING SYSTEM

Your water softening system takes hardness minerals (calcium and magnesium) out of the water. Also, it can control some (see the Specification Guidelines section) “clear water”

iron. With clear water iron, water from a faucet is clear when first put into a glass. After 15 to 30 minutes, the water begins to cloud or turn rust colored. A water softening system will not remove any iron that makes the water cloudy or rusty as it comes from the faucet (called red water iron). To take red water iron out of water, or over the maximum of clear water iron,

an iron filter or other equipment is needed.

GE Appliances recommends using Super Iron Out® to clean your resin bed if your iron content is high. Use Super Iron Out® with every 40lb. bag of salt as preventative maintenance against rust build up. Clean the bed at least every six months, or more often if iron appears in the soft water between cleanings.

IMPORTANT: It is important to mix the resin bed cleaner with water (following the manufacturer’s instructions), pour it into the brinewell (see Figure 9) and recharge the softener immediately. Do not pour the resin bed cleaner in with the salt, as it will not be as effective in cleaning the resin, and can

cause damage to the softener if it is left in the brine tank for an extended period due to the corrosive gases that are formed.

26

Loading...

Loading...