GE IC3645SR4U404N2, IC3645SP4U400N3 User Manual

INSTALLATION AND OPERATION

SX TRANSISTOR CONTROL Page 1

SEPARATELY EXCITED (SX) TRANSISTORIZED DUAL MOTOR TRACTION CONTROL

AND SERIES PUMP CONTROL

INSTALLATION AND OPERATION MANUAL

(IC3645SR4U404N2 and IC3645SP4U400N3)

Note: The information contained herein is intended to assist OEM's, Dealers and Users of electric vehicles in the application, installation and service of GE solid-state controllers. This manual does not purport to cover all variations in OEM vehicle types. Nor does it provide for every possible contingency to be met involving vehicle installation, operation or maintenance. For additional information and/or problem resolution, please refer the matter to the OEM vehicle manufacturer through his normal field service channels. Do not contact GE directly for this assistance.

Table of Contents

|

|

Copyright by General Electric Company January 2000 |

|

Section 1.0 |

INTRODUCTION ........................................................................................................................................................ |

4 |

|

|

1.1 |

Motor Characteristics .............................................................................................................. |

4 |

|

1.2 |

Solid-State Reversing............................................................................................................... |

5 |

|

1.3 |

Flexible System Application..................................................................................................... |

5 |

|

1.4 |

More Features with Fewer Components ................................................................................ |

5 |

Section 2.0 |

FEATURES OF SX FAMILY OF MOTOR CONTROLLERS .................................................................................... |

6 |

|

|

2.1 |

Performance.............................................................................................................................. |

6 |

|

2.1.1 |

Oscillator Card Features .................................................................................................. |

6 |

|

2.1.1.a |

Standard Operation .................................................................................................. |

6 |

|

2.1.1.b |

Creep Speed............................................................................................................... |

6 |

|

2.1.1.c |

Controlled Acceleration .......................................................................................... |

6 |

|

2.1.2 |

Current Limit ...................................................................................................................... |

6 |

|

2.1.3 |

Braking ............................................................................................................................... |

6 |

|

2.1.3.a |

Plug Braking .............................................................................................................. |

6 |

|

2.1.3.b |

Regenerative Braking to Zero Speed...................................................................... |

6 |

|

2.1.3.c |

Pedal Position Plug Braking .................................................................................... |

6 |

January 2000

INSTALLATION AND OPERATION

|

SX TRANSISTOR CONTROL |

|

Page 2 |

|

|

|

|

|

|

|

|

|

Table of Contents ( Continued ) |

|

|

|

2.1.3.d |

Auto Braking.............................................................................................................. |

6 |

|

|

2.1.4 |

Auxiliary Speed Control.................................................................................................... |

6 |

|

|

2.1.4.a |

Field Weakening................................................................................................................ |

6 |

|

|

2.1.4.b |

Speed Limits ...................................................................................................................... |

7 |

|

|

2.1.4.c |

Proportional Operation for Dual Motor Vehicles .......................................................... |

7 |

|

|

2.1.5 |

Ramp Operation ................................................................................................................ |

7 |

|

|

2.1.5.a |

Ramp Start ................................................................................................................. |

7 |

|

|

2.1.5.b |

Anti-Rollback ............................................................................................................. |

7 |

|

|

2.1.6 |

Steer Pump Contactor Time Delay ................................................................................. |

7 |

|

|

2.1.7 |

On-Board Coil Drivers and Internal Coil Suppression ................................................. |

8 |

|

|

2.2 |

System Protective Override ..................................................................................................... |

8 |

|

|

2.2.1 |

Static Return to Off (SRO) ............................................................................................... |

8 |

|

|

2.2.2 |

Accelerator Volts Hold Off............................................................................................... |

8 |

|

|

2.2.3 |

Pulse Monitor Trip (PMT)................................................................................................. |

8 |

|

|

2.2.4 |

Thermal Protector (TP)..................................................................................................... |

8 |

|

|

2.2.5 |

Low Voltage .................................... .................................................................................. |

8 |

|

|

2.3 |

Diagnostics................................................................................................................................ |

8 |

|

|

2.3.1 |

Systems Diagnostics...................................... .................................................................. |

8 |

|

|

2.3.2 |

Status Codes...................................................................................................................... |

8 |

|

|

2.3.2.a |

Standard Status Codes............................................................................................. |

8 |

|

|

2.3.2.b |

Stored Status Codes ......................................... ....................................................... |

8 |

|

|

2.3.3 |

Hourmeter Readings ........................................................................................................ |

9 |

|

|

2.3.3.a |

Maintenance Alert and Speed Limit .................... .................................................. |

9 |

|

|

2.3.4 |

Battery Discharge Indication (BDI)....................... ......................................................... |

9 |

|

|

2.3.4.a |

Internal Resistance Compensation ................................................................................ |

9 |

|

|

2.3.5 |

Handset ................................................. ............................................................................ |

9 |

|

|

2.3.6 |

RS-232 Communication Port ........................................................................................... |

9 |

|

|

2.3.6.a |

Dash Display Interaction Modes ................... ............................................................... |

9 |

|

|

2.3.7 |

Circuit Board Coil Driver Modules........................ .......................................................... |

9 |

|

|

2.3.8 |

Truck Management Module (TMM) ............................................................................... |

9 |

|

|

2.4 |

Hydraulic Pump Control........................................................................................................... |

9 |

|

Section 3.0 |

ORDERING INFORMATION, ELEMENTARY AND OUTLINE DRAWINGS...................................................... |

11 |

|

|

|

3.1 |

Ordering Information for Separately Excited Controls................................................................. |

11 |

|

|

3.2 |

Outline: SX-3 and SR-3 Package Size............................................................................................. |

12 |

|

|

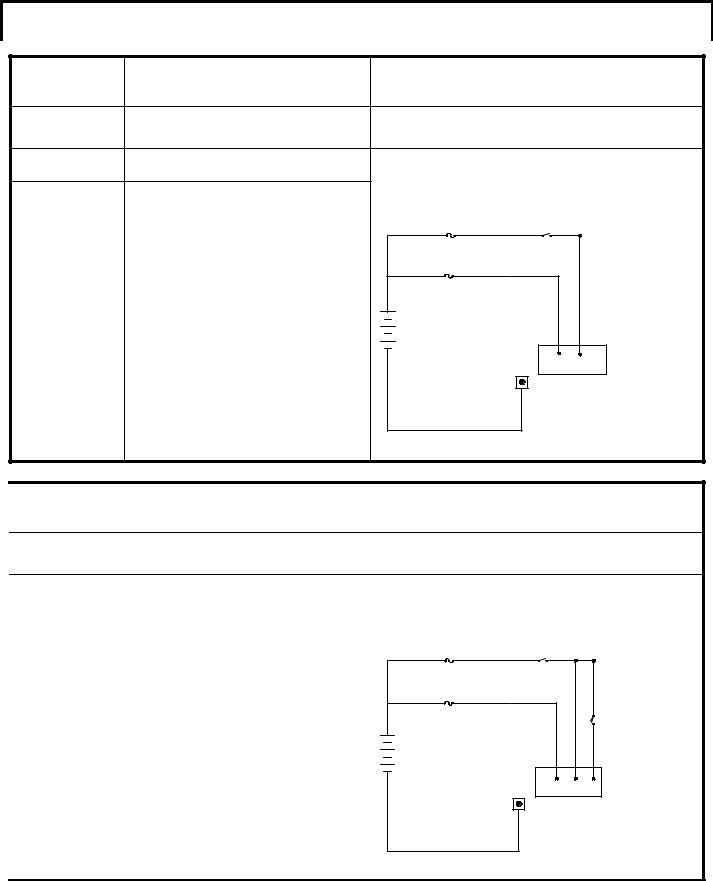

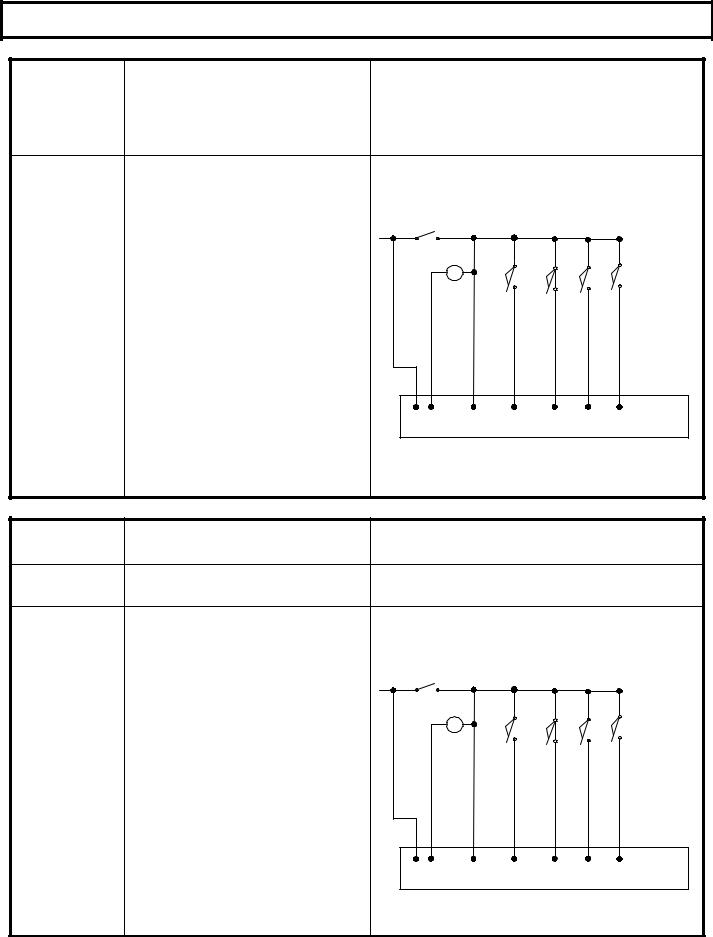

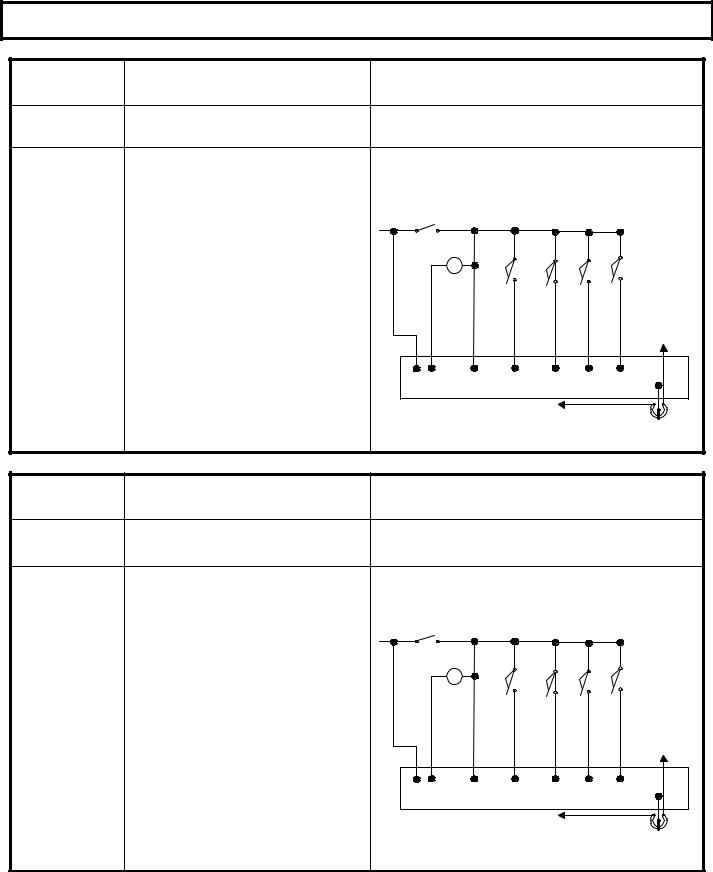

3.3 |

Traction Elementary ......................................................................................................................... |

13 |

|

|

3.4 |

Pump Elementary.............................................................................................................................. |

14 |

|

|

3.5 |

Traction and Pump Control Input / Output List ............................................................................. |

15 |

|

Section 4.0 |

TROUBLESHOOTING AND DIAGNOSTIC STATUS CODES.............................................................................. |

16 |

|

|

|

4.1 |

General Maintenance Instructions................................................................................................. |

16 |

|

|

4.2 |

Cable Routing and Separation ............................................................................................... |

16 |

|

|

4.2.1 |

Application Responsibility ............................................................................................... |

16 |

|

|

4.2.2 |

Signal/Power Level Definitions ............................................................................................... |

16 |

|

|

4.2.2.a |

Low Level Signals (Level L) .............................................................................................. |

16 |

|

|

4.2.2.b |

High Level Signals (Level H)............................................................................................. |

17 |

|

|

4.2.2.c |

Medium-Power Signals (Level MP) ................................................................................ |

17 |

|

|

4.2.2.d |

High-Power Signals (Level HP) ....................................................................................... |

17 |

|

|

4.2.3 |

Cable Spacing Guidelines ........................................................................................................ |

17 |

|

|

4.2.3.a |

General Cable Spacing..................................................................................................... |

17 |

|

|

4.2.4 |

Cabling for Vehicle Retrofits.................................................................................................... |

17 |

January 2000

INSTALLATION AND OPERATION

|

SX TRANSISTOR CONTROL |

|

Page 3 |

||

|

|

|

|

|

|

|

|

|

Table of Contents ( Continued ) |

|

|

|

|

|

|

|

|

|

|

4.2.5 |

RF Interference.......................................................................................................................... |

17 |

|

|

|

4.2.6 |

Suppression............................................................................................................................... |

17 |

|

|

|

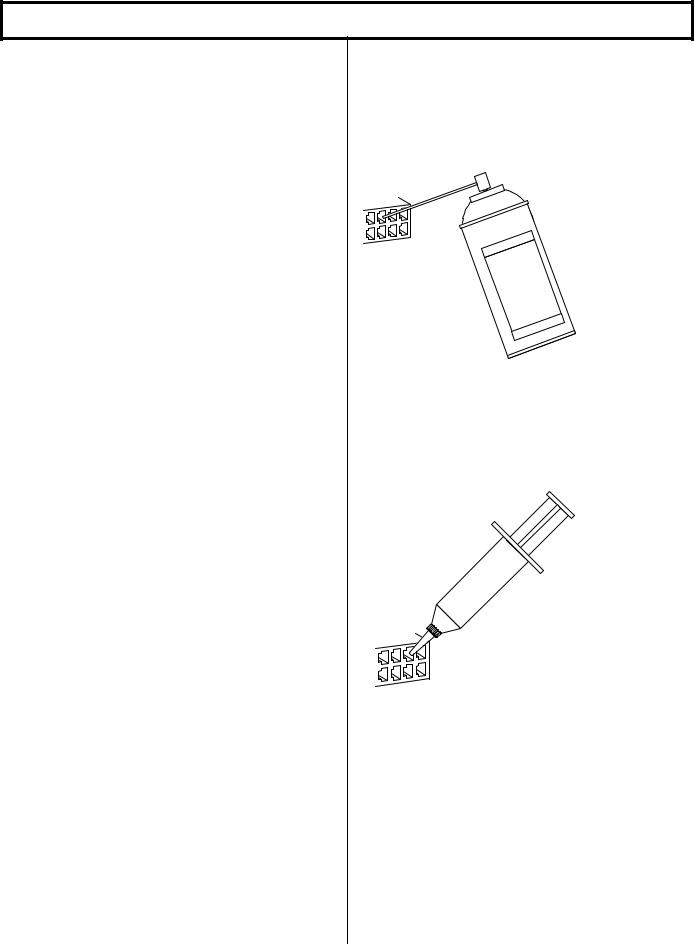

4.3 |

Recommended Lubrication of Pins and Sockets Prior to Installation........................................ |

18 |

|

|

|

4.4 |

General Troubleshooting Instructions ........................................................................................... |

19 |

|

|

|

4.5 |

Traction Controller Status Codes ................................................................................................... |

20-40 |

|

|

|

4.6 |

TMM Status Codes........................................................................................................................... |

41-45 |

|

|

|

4.7 |

Pump Control Status Codes............................................................................................................. |

46-52 |

|

|

Section 5.0 |

TRUCK MANAGEMENT MODULE (TMM)............................................................................................................ |

53 |

|

|

|

|

5.1 |

General Features .............................................................................................................................. |

53 |

|

|

|

5.2 |

Operation ...................................................... .................................................................................... |

53 |

|

|

|

5.3 |

Installation......................................................................................................................................... |

53 |

|

|

|

5.4 |

Connection Diagrams....................................................................................................................... |

53 |

|

|

|

5.4.1 |

TMM7A Card Connections ...................................................................................................... |

53 |

|

|

|

5.4.2 |

TMM7A Typical Brush Wear Sensor Connections ............ ................................................. |

53 |

|

|

|

5.4.3 |

TMM Pump Control Connections ........................................................................................... |

54 |

|

|

|

5.5 |

TMM7A Outline Drawings ............................................................................................................... |

54 |

|

|

Section 6.0 |

SX FAMILY - GE HANDSET INSTRUCTIONS ...................................................................................................... |

55 |

|

|

|

|

6.1 |

General Features .............................................................................................................................. |

55 |

|

|

|

6.2 |

Purpose/Setup Functions ............................................................................................................... |

55 |

|

|

|

6.3 |

Setup Function Procedures ............................................................................................................ |

56 |

|

|

|

6.3.1 |

Setup Mode ............................................ .................................................................................. |

56 |

|

|

|

6.3.2 |

Status Code Scrolling............................................................................................................... |

56 |

|

|

|

6.3.3 |

SX Handset Plug Connections & Outline Drawing.... ........................................................... |

56 |

|

|

|

6.4 |

Setup Functions for Traction Controller .. ..................................................................................... |

57-62 |

|

|

|

6.5 |

Summary of Current Limit Adjustments ......................................................................................... |

62 |

|

|

|

6.6 |

Setup Functions for Hydraulic Pump Controller . ......................................................................... |

64-66 |

|

|

Section 7.0 |

DASH DISPLAYS....................................................................................................................................................... |

67 |

|

|

|

|

7.1 |

Application ............................................. ............................................................................................. |

67 |

|

|

|

7.2 |

Standard Dash Displays .................................. .................................................................................. |

67 |

|

|

|

7.3 |

Interactive Dash Displays................................................................................................................... |

67 |

|

|

|

7.4 |

Start-up Display Sequence ................................................................................................................ |

68 |

|

|

|

7.5 |

Outline Drawings ........................................ ........................................................................................ |

68 |

|

|

Section 8.0 |

TURN ANGLE POTENTIOMETER INSTALLATION.............................................................................................. |

69 |

|

|

|

|

8.1 |

General................................................................................................................................................. |

69 |

|

|

|

8.2 |

320 Degree Potentiometer Input........................................................................................................ |

70 |

|

|

|

8.3 |

Turn Angle Input Volts vs. Steer Wheel Degrees vs. Handset Readings..................................... |

71 |

|

|

Section 9.0 |

MEMORY MAPS........................................................................................................................................................ |

72 |

|

|

|

|

9.1 |

Typical Memory Map for Traction Control.................................................................................... |

72-74 |

|

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 4

Section 1. INTRODUCTION

Section 1.1 Motor Characteristics

The level of sophistication in the controllability of traction motors has changed greatly over the past several years. Vehicle manufacturers and users are continuing to expect more value and flexibility in electric vehicle motor and control systems as they are applied today. In order to respond to these market demands, traction system designers have been forced to develop new approaches to reduce cost and improve functions and features of the overall system. Development is being done in a multigenerational format that allows the market to take advantage of today’s technology, while looking forward to new advances on the horizon. GE has introduced a second generation system using separately excited DC shunt wound motors. The separately excited DC motor system offers many of the features that are generally found on the advanced AC systems. Historically, most electric vehicles have relied have on series motor designs because of their ability to produce very high levels of torque at low speeds. But, as the demand for high efficiency systems increases, i.e., systems that are more closely applied to customers’ specific torque requirements, shunt motors are now often being considered over series motors. In most applications, by independently controlling the field and armature currents in the separately excited motor, the best attributes of both the series and the shunt wound motors can be combined.

|

SPEED |

|

|

NO LOAD CURRENT |

FULL |

LOAD CURRENT |

STARTING CURRENT |

|

TORQUE |

|

|

|

ARMATURE CURRENT |

|

|

|

Figure 1 |

|

|

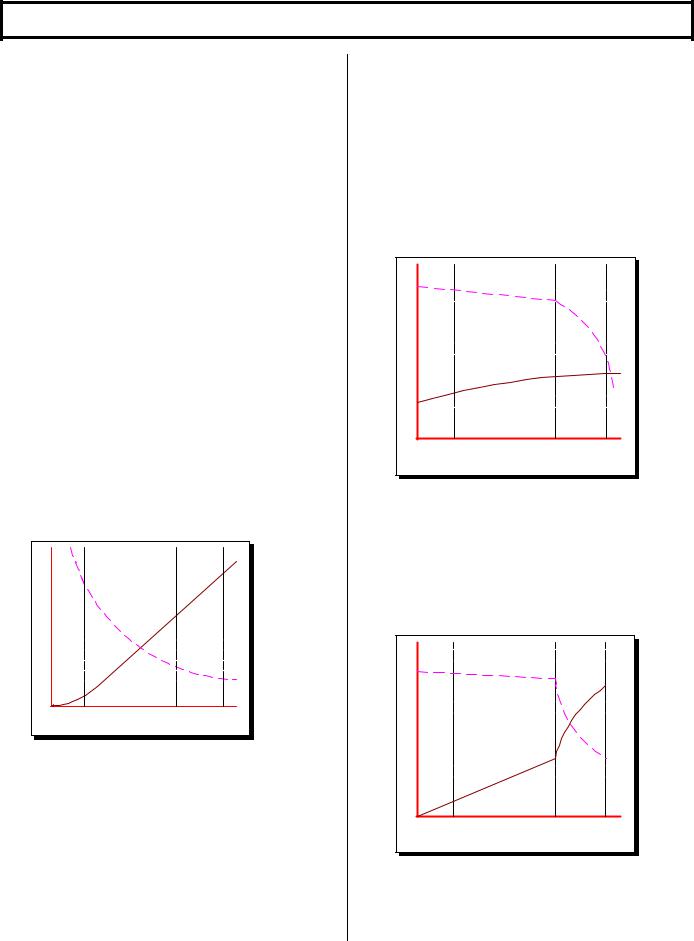

As shown in from the typical performance curves of Figure 1, the high torque at low speed characteristic of the series motor is evident.

In a shunt motor, the field is connected directly across the voltage source and is therefore independent of variations in load and armature current. If field strength is held constant, the torque developed will vary directly with the armature current. If the mechanical load on the motor increases, the motor slows down, reducing the back EMF (which depends on the speed, as well as the constant field strength). The reduced back EMF allows the armature

current to increase, providing the greater torque needed to drive the increased mechanical load. If the mechanical load is decreased, the process reverses. The motor speed and the back EMF increase, while the armature current and the torque developed decrease. Thus, whenever the load changes, the speed changes also, until the motor is again in electrical balance.

In a shunt motor, the variation of speed from no load to normal full load on level ground is less than 10%. For this reason, shunt motors are considered to be constant speed motors (Figure 2).

|

SPEED |

|

|

LOADCURRENT |

FULL |

LOAD CURRENT |

STARTING CURRENT |

NO |

|

|

|

|

TORQUE |

|

|

ARMATURE CURRENT

Figure 2

In the separately excited motor, the motor is operated as a fixed field shunt motor in the normal running range. However, when additional torque is required, for example, to climb non-level terrain, such as ramps and the like, the field current is increased to provide the higher level of torque. In most cases, the armature to field ampere turn ratio can be very similar to that of a comparable size series motor (Figure 3.)

|

SPEED |

|

|

NO LOAD CURRENT |

FULL |

LOAD CURRENT |

STARTING CURRENT |

|

TORQUE |

|

|

ARMATURE CURRENT

Figure 3

Aside from the constant horsepower characteristics described above, there are many other features that provide increased performance and lower cost. The

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 5

following description provides a brief introduction to examples of some of these features.

Section 1. 2 Solid-State Reversing

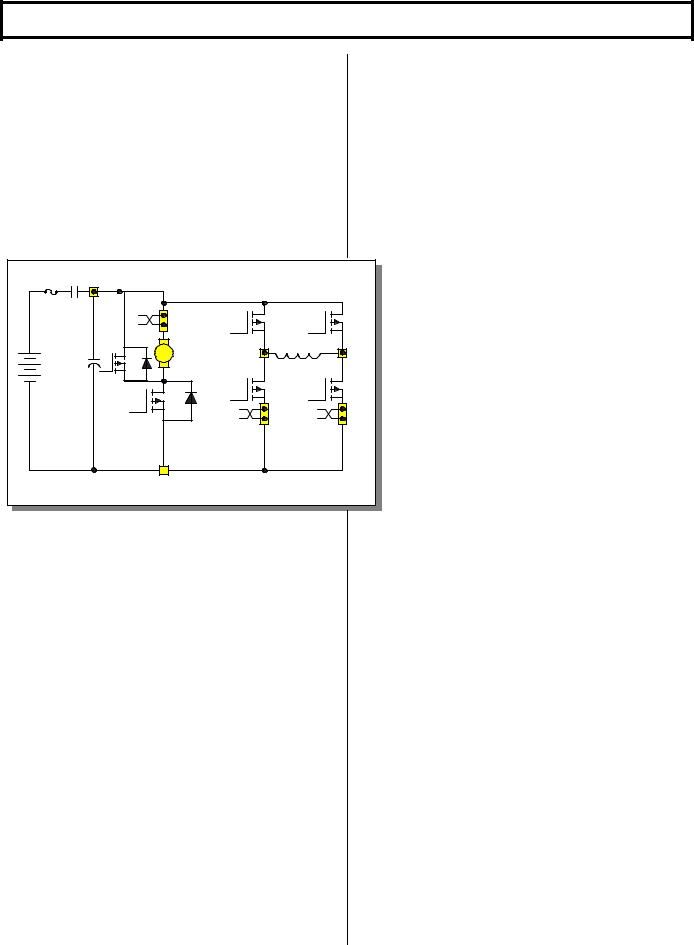

The direction of armature rotation on a shunt motor is determined by the direction in which current flows through the field windings. Because of the of the shunt motor field only typically requires about 10% of the armature current at full torque, it is normally cost effective to replace the double-pole, double-throw reversing contactor with a low power transistor H-Bridge circuit (Figure 4).

LINE |

POS |

|

|

|

|

FUSE |

|

|

|

|

|

|

|

|

|

Q3 |

Q5 |

|

|

A1 + |

|

|

|

CAP |

Q2 |

ARM |

F1 |

F2 |

|

A2 |

- |

|

|

||

|

|

|

|

||

|

|

|

|

Q4 |

Q6 |

|

|

Q1 |

|

|

|

NEG

Figure 4

By energizing the transistors in pairs, current can be made to flow in either direction in the field. The armature control circuit typically operates at 12KHZ to 15KHZ, a frequency range normally above human hearing. This high frequency coupled with the elimination of directional contactors, provides very quiet vehicle operation. The field control circuits typically operate at 2 KHZ.

The line contactor is normally the only contactor required for the shunt motor traction circuit. This contactor is used for both pre-charge of the line capacitors and for emergency shut down of the motor circuit, in case of problems that would cause a full motor torque condition. The line can be energized and de-energized by the various logic combinations of the vehicle, i.e. activate on key, seat or start switch closure, and de-energize on time out of idle vehicle. Again, these options add to the quiet operation of the vehicle.

Section 1. 3 Flexible System Application

Because the shunt motor controller has the ability to control both the armature and field circuits independently, the system can normally be adjusted for maximum system efficiencies at certain operating parameters. Generally speaking, with the ability of independent field and

armature, the motor performance curve can be maximized through proper control application.

Section 1. 4 More Features with Fewer Components

Field weakening with a series wound motor is accomplished by placing a resistor in parallel with the field winding of the motor. Bypassing some of the current flowing in the field into the resistor causes the field current to be less, or weakened. With the field weakened, the motor speed will increase, giving the effect of “overdrive”. To change the “overdrive speed”, it is necessary to change

the resistor value. In a separately excited motor, independent control of the field current provides for infinite adjustments of “overdrive” levels, between motor base speed and maximum weak field. The desirability of this feature is enhanced by the elimination of the contactor and resistor required for field weakening with a series motor.

With a separately excited motor, overhauling speed limit, or downhill speed, will also be more constant. By its nature, the shunt motor will try to maintain a constant speed downhill. This characteristic can be enhanced by increasing the field strength with the control. Overhauling load control works in just the opposite way of field weakening, armature rotation slows with the increase of current in the field.

Regenerative braking (braking energy returned to the battery) may be accomplished completely with solid-state technology. The main advantage of regenerative braking is increased motor life. Motor current is reduced by 50% or more during braking while maintaining the same braking torque as electrical braking with a diode clamp around the armature. The lower current translates into longer brush life and reduced motor heating. Solid state regenerative braking also eliminates a power diode, current sensor and contactor from the circuit.

For GE, the future is now as we make available a new generation of electric traction motor systems for electric vehicles having separately excited DC shunt motors and controls. Features that were once thought to be only available on future AC or brushless DC technology vehicles systems are now achievable and affordable.

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 6

Section 2. FEATURES OF SX FAMILY OF TRANSISTOR

MOTOR CONTROLLERS

Section 2.1 Performance

Section 2.1.1 Oscillator Card Features

Section 2.1.1.a Standard Operation

With the accelerator at maximum ohms or volts, the creep speed can be adjusted by Function 2 of the Handset or a trimpot. The field control section allows the adjustment of the field weakening level in order to set the top speed of the motor. This top speed function (Minimum Field Current) is enabled when the armature current is less than the value set by Function 24 and the accelerator input voltage is less than 1 volt. Top Speed can be adjusted by Function 7 of the Handset or a trimpot.

The percent on-time has a range of approximately 0 to 100 percent. The SX controllers operate at a constant frequency and the percent on-time is controlled by the pulse width of the voltage / current applied to the motor circuits.

Section 2.1.1.b Creep Speed

With the accelerator at maximum ohms or volts (approximately 3.7 to 3.5 VDC), the creep speed can be adjusted by Function 2 of the Handset. At creep speed, the ON time can decrease to approximately 5%, with the OFF time at approximately 95%. At full transistor operation, this condition will be reversed (short OFF time, long ON time). This variation of ON and OFF time of the oscillator varies the voltage applied to the motor, thereby varying the speed of the motor for a given load.

Section 2.1.1.c Control Acceleration

This feature allows for adjustment of the rate of time it takes for the control to accelerate to 100% applied battery voltage to the motor on hard acceleration. Armature C/A is adjusted by Function 3 from 0.1 to 22 seconds.

Section 2.1.2 Current Limit

This circuit monitors motor current by utilizing sensors in series with the armature and field windings. The information detected by the sensor is fed back to the card so that current may be limited to a pre-set value. If heavy load currents are detected, this circuit overrides the oscillator and limits the average current to a value set by Function 4 and Function 8 of the Handset. The C/L setting is based on the maximum thermal rating of the control. Because of the flyback current through 3REC, the motor current is usually greater than battery current, except at 100% ON time.

Section 2.1.3 Braking

Section 2.1.3.a Plug Braking

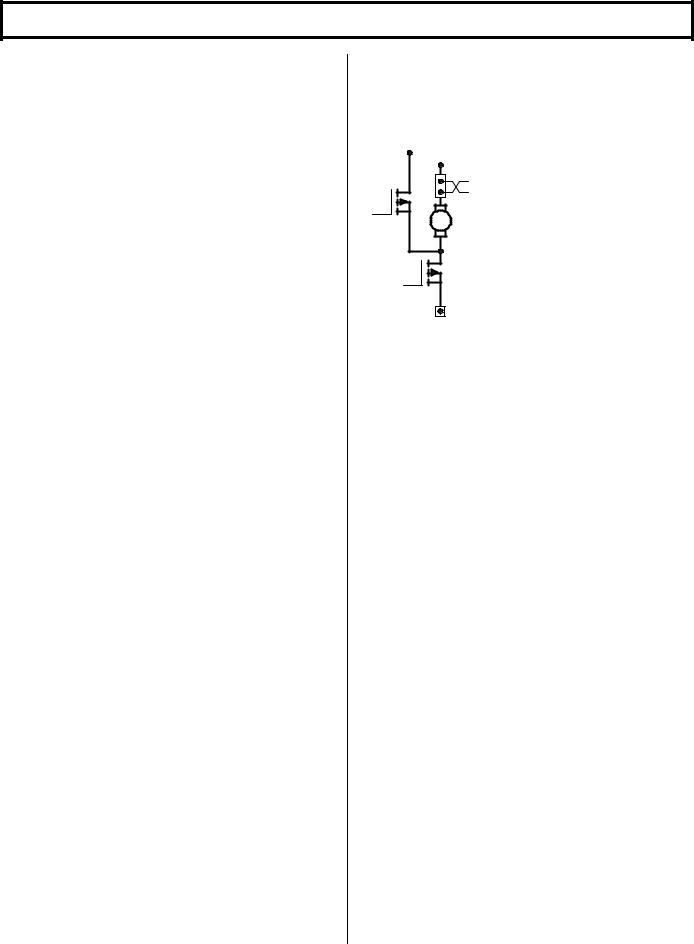

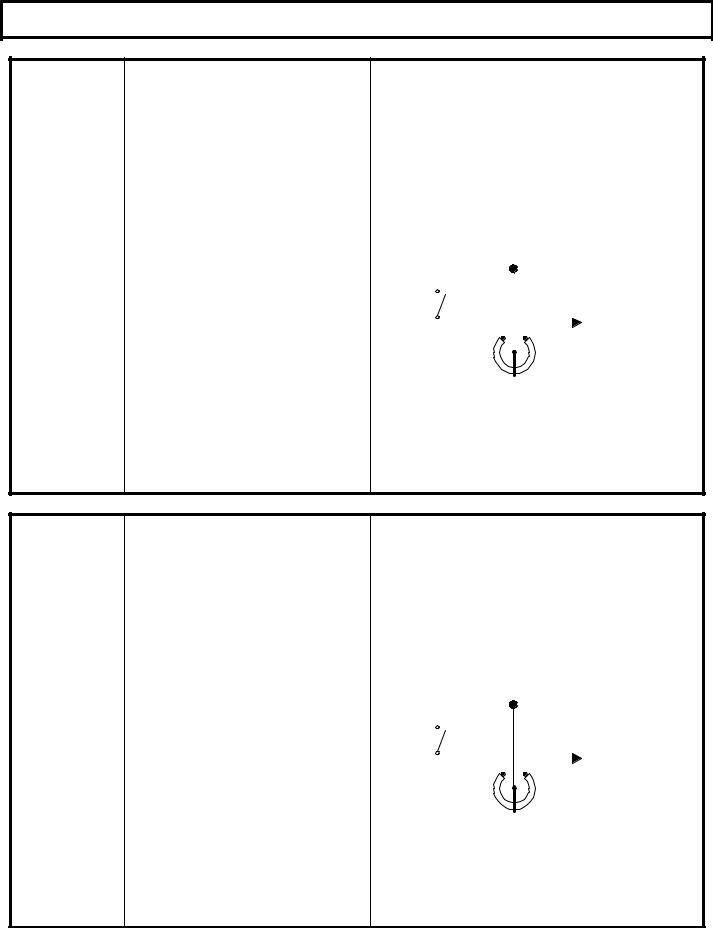

Section 2.1.3.b Regenerative Braking to Zero Speed

|

|

Slow down is accomplished when |

|

|

reversing direction by providing a |

|

|

small amount of retarding torque for |

Q2 |

|

deceleration. If the vehicle is |

|

ARM moving, and the directional lever is |

|

|

|

moved from one direction to the |

|

|

other, the regen signal is initiated. |

|

Q1 |

Once the regen signal has been |

|

initiated, the field current is |

|

|

|

|

Figure 5 |

|

increased (armature circuit shown in |

|

|

Figure 5). Armature current is |

regulated to the regen current limit as set by Function 9. As the vehicle slows down, the field current continues to increase, and transistor Q2 begins to chop. The field current will increase until it reaches a preset value set by Function 10, and transistor Q2 on-time will increase until it reaches 100% on-time. Once both of the above conditions have been met, and regen current limit can no longer be maintained, the braking function is canceled. The fields will then reverse, and the control reverts back to motoring. Part of the energy produced by the motor during regen is returned to the battery, and part is dumped in the motor as heat.

Section 2.1.3.c Pedal Position Plug Braking

This feature allows control of the plugging distance based on pedal position when there has been a “directional switch" change. Pedal position will reduce the regenerative current to the "value set by this function" as the accelerator is returned to the creep speed position. Maximum regen current is obtained with the accelerator in the top speed position.

Section 2.1.3.d Auto Braking

This feature is enabled by initiating a "neutral position" using either the directional switch or the accelerator switch. Once activated, Auto Braking operates similar to Pedal Position Plug Braking and is adjusted by using Function 21 of the Handset.

Section 2.1.4 Auxiliary Speed Control

Section 2.1.4.a Field Weakening

This function allows the adjustment of the field weakening level in order to set the top speed of the motor. The function is enabled when the armature current is less than the value set by Function 24 and the accelerator input voltage is less than 1 volt. It is important to note that this function is used

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 7

to optimize motor and control performance, and this setting will be determined by GE and OEM engineers at the time of vehicle development. This setting must not be changed by field personnel, without the permission of the OEM.

Section 2.1.4.b Speed Limits

This feature provides a means to control speed by limiting motor volts utilizing three "adjustable speed limits. This motor volt limit regulates top speed of the transistor controller, but actual truck speed will vary at any set point depending on the loading of the vehicle. Each speed limit can be adjustable with the Handset using Functions 11, 12, and 13.

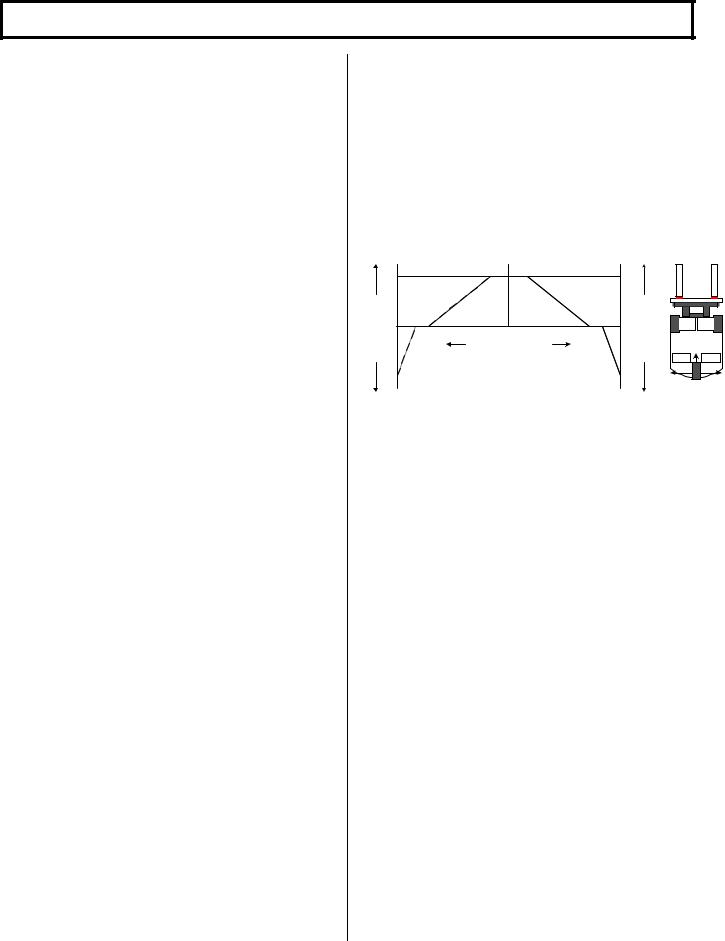

Section 2.1.4.c Proportional Operation for Dual Motor Vehicles

A key performance advantage of this control is the ability to achieve actual "proportioning" of motor speed. In a non-proportioning, or single control, system when the vehicle starts to turn, the outside drive wheel turns in a larger circle than the inside wheel. Depending on the geometry of the vehicle, at some degree of turn angle, the inside wheel must slow down to prevent scrubbing of the wheel. This is accomplished on single control system by disconnecting the inside motor and letting the wheel "free wheel" or "float" at whatever speed is dictated by the outside wheel that is still under power. The main disadvantage of this system is that no torque is available on that motor when the inside wheel is in the "free-wheel" mode, and performance in a turn is reduced. When the steer wheel nears to the 90° turn angle, the inside motor is re-connected in the opposite direction of the outside. At this point, torque is returned to the inside wheel and the speed is the same on both motors.

With two controls, the speed of each motor can be regulated independently. The driver controls the speed of the outside wheel with the accelerator input signal. The inside wheel speed is controlled by the turn angle of the steer wheel . A potentiometer is attached to the steer wheel in order to communicate the steer angle to the controllers. During vehicle manufacture, software selection identifies each control for its application as a right or left control. The controls are physically identical, and it is only software that separates a right from a left control or differentiates a control for a dual motor application from one intended for a single motor vehicle. As the steer reaches some pre-selected turn angle, approximately 20o, the speed of the inside wheel decrease proportionally to the speed of the outside wheel. This proportional decline will continue on a linear path until the steer angle reaches another predetermine angle of, approximately 65o.

At this point, the inside wheel will stop, as the steer angle is increased toward the 90° point, the inside wheel will reverse direction and start to accelerate proportionally in speed. As the steer angle reaches the 90° point, the inside wheel speed will be the same as that of the outside wheel. During this entire turn, except for several degrees when the motor was stopped to change direction, torque was always present on the inside wheel, providing a smoother ride throughout the turning radius of the vehicle.

Details for adjustment of the steer angle potentiometer can be found in Appendix A of this manual.

|

100% |

RIGHT |

|

LEFT |

100% |

|

|

|

|

|

|

|

|

|

|

||

- FWD |

50% |

MOTOR |

|

MOTOR |

50% |

- FWD |

|

|

|

|

|

|

|

||||

|

LEFT |

|

|

|

|

|

||

SPEED- |

90O |

|

|

90O |

SPEED- |

LEFT |

RIGHT |

|

|

80O 70O 60O 50O 40O 30O 20O 10O 0O 10O 20O 30O 40O 50O 60O 70O 80O |

|

MOTOR |

MOTOR |

||||

|

|

|

|

|

|

|||

REV |

50% |

TURN |

STEERING ANGLE |

RIGHT |

50% |

REV |

|

0O |

|

LEFT |

|||||||

|

|

|

|

TURN |

|

|

RIGHT |

|

|

|

|

|

|

|

CONTROL |

CONTROL |

|

|

100% |

|

|

|

100% |

|

90O |

90O |

Section 2.1.5 Ramp Operation

Section 2.1.5a Ramp Start

This feature provides maximum control torque to restart a vehicle on an incline. The memory for this function is the directional switch. When stopping on an incline, the directional switch must be left in its original or neutral position to allow the control to initiate full power when restarted. The accelerator potentiometer input will modulate ramp start current.

Section 2.1.5b Anti-Rollback

This feature provides retarding torque to limit rollback speed in the non-travel direction when the ACC pedal is released when stopping on a grade, or when the brake pedal is released when starting on a grade. This feature forces the vehicle to roll very slowly down the grade when accelerator or brake is released. Because the vehicle can gain significant speed during roll-back, the torque needed to re-start on the ramp is lower than an unrestricted rollback speed.

Section 2.1.6 Steer Pump Contactor Time Delay

This feature provides two options for SP time delay. Option 1 provides a 0.5 to 63 second time delayed drop out of the steer pump contactor when the Forward or Reverse directional switch is opened. This Option 1 is overridden by a 1.5 second time delayed drop out whenever the seat switch is opened. Option 2 provides a 0.5 to 63 second time delayed drop out of the SP contactor when the seat switch is opened.

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 8

Section 2.1.7 On-Board Coil Drivers & Internal Coil

Suppression

Coil drivers for the LINE and SP contactors

are on-board the control card. These contactors must have coils rated for the vehicle battery volts.

Section 2.2 System Protective Override

Section 2.2.1 Static Return to Off (SRO)

This inherent feature of the control is designed to require the driver to return the directional lever to the neutral position anytime he leaves the vehicle and returns. Additionally, if the seat switch or key switch is opened, the control shuts off and cannot be restarted until the directional lever is returned to neutral. A time delay of approximately 2 seconds is built into the seat switch input to allow momentary opening of the seat switch, if a bump is encountered.

Section 2.2.2 Accelerator Volts Hold Off

This feature checks the voltage level at the accelerator input whenever the key switch or seat switch is activated. If, at start up, the voltage is less than 3.0 volts, the control will not operate. This feature assures that the control is calling for low speed operation at start up.

Section 2.2.3 Pulse Monitor Trip (PMT)

The PMT design contains three features which shut down, or lock out, control operation if a fault conditions occurs that would cause a disruption of normal vehicle operation:

•Look ahead

•Look again

•Automatic look again and reset

The PMT circuit will not allow the control to start under the following conditions:

•The control monitors both armature and field FET's at start-up and during running.

•The control will not allow the line contactor to close at start-up, or will drop it out during running, if either the armature or field FET's are defective, so as to cause uncontrolled truck movement.

Section 2.2.4 Thermal Protector (TP)

This temperature sensitive device is internal to the power transistor (Q1) module. If the transistor's temperature begins to exceed the design limits, the thermal protector will lower the maximum current limit, and maintain the transistors within their temperature limits. Even at a reduced current limit, the vehicle will normally be able to

reach sufficient speed. As the control cools, the thermal protector will automatically reset, returning the control to full power.

Section 2.2.5 Low Voltage

Batteries under load, particularly if undersized or more than 80 percent discharged, will produce low voltages at the control terminals. The SX control is designed for use down to 50 percent of a nominal battery voltage of 36-84 volts, and 75 percent of a nominal battery voltage of 24 volts. Lower battery voltage may cause the control to operate improperly, however, the resulting PMT should open the Line contactor, in the event of a failure.

Section 2.3 Diagnostics

Section 2.3.1 Systems Diagnostics

The control detects the system's present operating status and can be displayed to either the Dash Display or the Handset. There are currently over 70 status codes that are available with SX systems using Traction and Pump controls and Truck Management Module (TMM). Along with the status code display from the TMM, the SX control is capable of reducing the current to the motor, alerting the operator of a critical fault condition.

Section 2.3.2 Status Codes

Section 2.3.2a Standard Status Codes

The SX traction control has over 30 Status Codes that assist the service technician and operator in trouble shooting the vehicle. If mis-operation of the vehicle occurs, a status code will be displayed on the Dash Display for vehicles so equipped, or be available by plugging the Handset into the “y” plug of the logic card.

With the status code number, follow the procedures outlined in DIAGNOSTIC STATUS CODES to determine the problem and a solution.

Note: The Status Code Instruction Sheets do not claim to cover all possible causes of a display of a "status code ". They do provide instructions for checking the most direct inputs that can cause status codes to appear.

Section 2.3.2.b Stored Status Codes

This feature records the last 16 "Stored Status Codes" that have caused a PMT controller shut down and/or disrupted normal vehicle operation. (PMT type faults are reset by cycling the key switch). These status codes, along with the corresponding BDI and hourmeter readings, can be accessed with the Handset, or by using the RS 232 communications port and dumping the information to a Personal Computer terminal.

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 9

Section 2.3.3 Hourmeter Readings

This feature will display the recorded hours of use of the traction and pump control to the Dash Display each time the key switch is turned off.

Section 2.3.3.a Maintenance Alert & Speed Limit

This feature is used to display Status Code 99 and/or activate a speed limit when the vehicle operating hours match the hours set into the maintenance alert register. This feature is set with the Handset using Functions 19 and 20. The operator is alerted that maintenance on the vehicle is required.

Section 2.3.4 Battery Discharge Indication (BDI)

The latest in microprocessor technology is used to provide accurate battery state of charge information and to supply passive and active warning signals to the vehicle operator. Features and functions:

•Displays 100 to 0 percent charge.

•Display blinks with 20% charge. Disables pump circuit with 10% charge. Auto ranging for 36/48 volt operation. Adjustable for use on 24 to 80 volts.

Section 2.3.4.a Internal Resistance Compensation

This feature is used when the Battery Discharge Indicator is present. Adjustment of this function will improve the accuracy of the BDI.

Section 2.3.5 Handset

This is a multi-functional tool used with the LX, ZX, and SX Series GE solid state controls. The Handset consists of a Light Emitting Diode (LED) display and a keyboard for data entry. Note, for ordering purposes, a separate Handset part is required for SX controls.

Features and functions:

•Monitor existing system status codes for both traction and pump controls. Monitor intermittent random status codes.

•Monitor battery state of charge, if available.

•Monitor hourmeter reading on traction and pump controls. Monitor or adjust the control functions.

Section 2.3.6 RS 232 Communication Port

This serial communication port can be used with Interactive Custom Dash Displays to allow changes to vehicle operating parameters by the operator. Or, it can be used by service personnel to dump control operating information and settings into a personal computer program.

Section 2.3.6.a Interactive Dash Display

Modes

The Interactive Custom Dash Display allows the operator to select the best vehicle performance for changing factory (task) conditions. There are four (4) "operator interaction modes" that can be selected by depressing a push button on the dash display.

From the Dash Display, the operator may select any of four pre-set interactive modes consisting of (4) Controlled Acceleration levels, (4) Field Weakening levels and (4) Speed Limits.

These interactive modes are "pre-set" using the Handset (Functions 48-62) or a personal computer (Functions 97112). This feature allows the operator to select the best vehicle performance for changing factory (task) conditions.

Section 2.3.7 Circuit Board Coil Driver Modules

Coil drivers are internal to the control card, and are the power devices that operate the Line and SP contactor coils. On command from the control card, these drivers initiate opening and closing the contactor coils. All driver modules are equipped with reverse battery protection, such that, if the battery is connected incorrectly, the contactors can not be closed electrically.

Section 2.3.8 Truck Management Module (TMM)

The Truck Management Module is a multifunction accessory card, or an integral function of the GE Pump controls when used with the SX Traction control. The Module provides the OEM the ability to initiate status codes or operator warning codes to be displayed on the Dash Display, whenever a normally open switch or sensor wire provides a signal to the Module.

The TMM Module can be used to display a separate status code indicating over-temperature of traction motors, hydraulic motors, or any other device or system that can activate a switch that closes.

The TMM Module can also be used as a Brush Wear Indicator (BWI). The Brush Wear Indicator is designed to detect a "worn out brush" and display a fault code on the Dash Display to warn maintenance personnel that the motor brushes need to be replaced before they wear to the point of causing destructive damage to the motor commutator surface.

Section 2.4 Hydraulic Pump Control

This hydraulic motor controller consists of the following features:

January 2000

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 10

•Three speeds, adjustable from O to 100% motor volts. Fixed speeds actuated by switch closure to negative.

•Current limit and controlled acceleration adjustable.

•Battery Discharge Indicator interrupt compatible.

Operation of voltage regulator card: This card provides the basic functions required for controlling the pump control, optional contactors, and PMT functions. Battery positive is applied through a main control fuse to the key switch, energizing the control card power supply input to P1.

When a pump contactor is used, PMT operation is the same as outlined for the traction controllers.

The three speed (motor volts) reference points P12, P19, and P20 are selected by connecting these points independently to battery negative.

The first speed is obtained by closing Speed Limit I (P12) to control negative. SLl is adjustable by Function 11 using the Handset to adjust motor voltage from O to 100%. The specified motor volts will be regulated, however, the magnitude of motor current will vary depending on the loading of the vehicle.

The second speed is obtained by closing SL2 (P19) to control negative. SL2 is adjusted using the Handset and Function 12 similar to SL1.

The third speed is obtained by closing SL3 (P20) to control negative. SL3 is adjusted using the Handset and Function 13 similar to SL1.

If more than one Speed Limit is activated, the selected speed with the highest motor volts will override the low motor volt speed. The current limit circuit is adjustable and operates the same as the traction current limit.

The controlled acceleration circuit is adjustable and operates the same as the traction circuit. Adjustment range is from 0.1 to 5.5 seconds.

The Battery Discharge Indicator (BDI) interrupt will disable the hydraulic controller if the connection at P10 loses the 12 volt signal from the traction control. BDI interrupt can be disabled by Function 17 using the Handset. Select card type with or without BDI function.

January 2000

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL |

|

|

|

|

|

|

|

|

Page 11 |

Section 3.0 ORDERING INFORMATION, ELEMENTARY AND OUTLINE DRAWINGS |

|

||||||||

Section 3.1 Ordering Information for Separately Excited Controls |

|

|

|

|

|

|

|||

Example: |

|

|

|

|

|

|

|

|

|

Part Number: |

IC3645 |

|

SE |

|

4 |

D |

33 |

2 |

C3 |

Argument Number: |

01 |

|

02 |

|

03 |

04 |

05 |

06 |

07 |

Argument 01: |

Basic Electric Vehicle Control Number |

|

|

|

|||||

Argument 02: |

Control Type: |

|

|

|

|

|

|

|

|

|

SP |

= |

Series Control (Pump) |

|

|

|

|

||

|

SH |

= |

Separately Excited Control ( Plugging ) |

|

|||||

|

SR |

= |

Separately Excited Control ( Regen to Zero ) |

|

|||||

Argument 03: |

Operating Voltage: |

|

|

|

|

|

|

||

|

1 |

= |

120 volts |

|

4 |

= |

48 volts |

|

|

|

2 |

= |

24 volts |

|

|

5 |

= |

36/48 volts |

|

|

3 |

= |

36 volts |

|

|

6 |

= |

24/36 volts |

|

|

7 |

= |

72/80 volts |

|

|

|

|

|

|

Argument 04: |

Package Size: |

|

|

|

|

|

|

||

|

D |

= |

6.86” |

X |

6.67” |

|

|

|

|

|

R |

= |

6.86” |

X |

8.15” |

|

|

|

|

|

U |

= |

8.66” |

X |

8.13” |

|

|

|

|

|

W |

= |

8.66” |

X |

10.83” |

|

|

|

|

Argument 05: |

Armature Current |

|

|

|

|

|

|

||

|

( 2 characters ) |

|

|

|

|

|

|

||

|

22 |

= |

220 Amps |

|

|

|

|

|

|

|

33 |

= |

330 Amps |

|

|

|

|

|

|

|

40 |

= |

400 Amps |

|

|

|

|

|

|

|

etc. |

|

|

|

|

|

|

|

|

Argument 06: |

Field Current |

|

|

|

|

|

|

|

|

|

( 1 character ) |

|

|

|

|

|

|

||

|

2 |

= |

20 Amps |

|

|

|

|

|

|

|

3 |

= |

30 Amps |

|

|

|

|

|

|

|

4 |

= |

40 Amps |

|

|

|

|

|

|

|

etc. |

|

|

|

|

|

|

|

|

Argument 07: |

Customer / Revision |

|

|

|

|

|

|

||

|

A1 |

= |

Customer A / Revision 1 |

|

|

|

|||

|

B1 |

= |

Customer B / Revision 1 |

|

|

|

|||

|

etc. |

|

|

|

|

|

|

|

|

January 2000

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

|

|

|

SX TRANSISTOR CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 12 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

Section 3.2 Outline: SX-3 and SR-3 Package Size |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

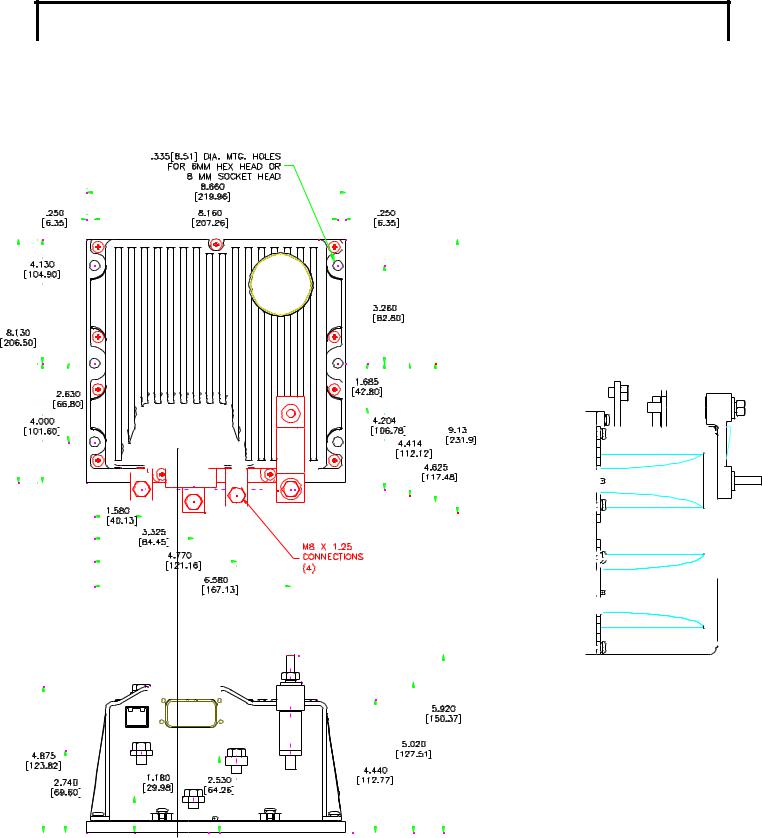

|

|

|

|

|

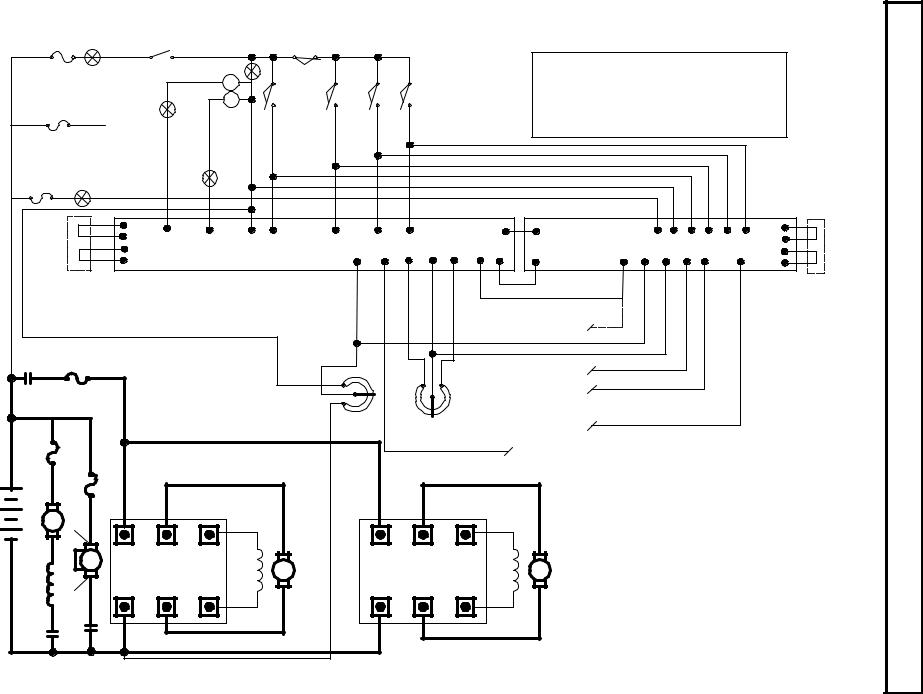

|

|

|

|

|

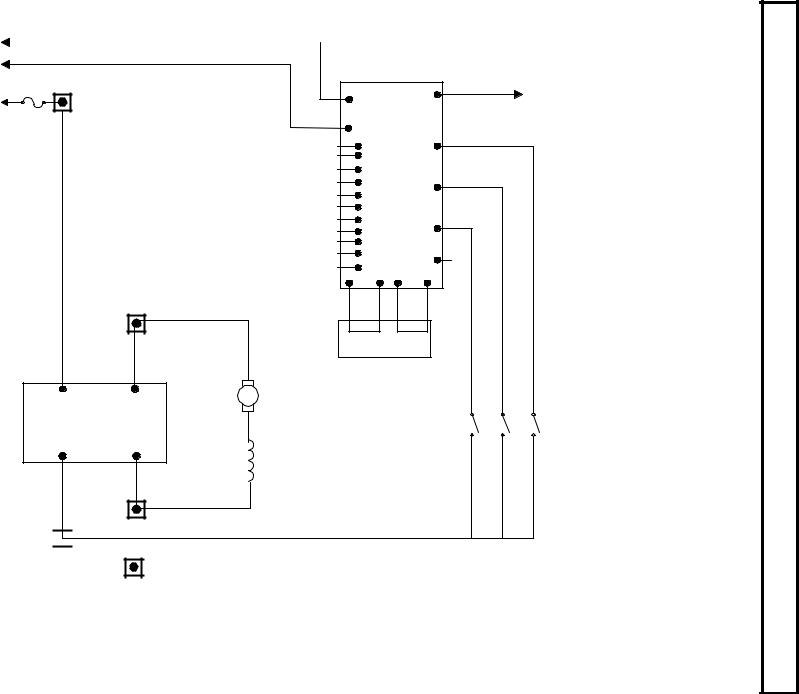

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|