Frymaster BIELA14 Service Manual

BIELA14 Series

Gen II LOV™ Electric Fryer

Service Manual

This manual is updated as new information and models are released. Visit our website for the latest manual. This equipment chapter is to be installed in the Fryer Section of the Equipment Manual.

FOR YOUR SAFETY

Do Not Store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

*8196446*

Part Number: FRY_SM_8196446 05/2015

Original Instructions

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS FACTORY AUTHORIZED SERVICERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A Frymaster Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country and/or region in which the appliance is installed. See NATIONAL CODE REQUIREMENTS in Chapter 2 of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug Administration.

NOTICE

This appliance is intended to be used for commercial applications, for example in kitchens of restaurants, canteens, hospitals and in commercial enterprises such as bakeries, butcheries, etc., but not for continuous mass production of food.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: 1) This device may not cause harmful interference, and 2) This device must accept any interference received, including interference that may cause undesired operation. While this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the ICES 003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B prescrites dans la norme NMB 003 edictee par le Ministre des Communcations du Canada.

DANGER

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can cause property damage, injury, or death. Read the installation, operating, and service instructions thoroughly before installing or servicing this equipment.

NOTICE

The appliance must be installed and used in such a way that any water cannot contact the fat or oil.

DANGER

DANGER

The front ledge of this appliance is not a step! Do not stand on the appliance. Serious injury can result from slips or contact with the hot oil.

DANGER

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance.

DANGER

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container at the end of frying operations each day. Some food particles can spontaneously combust if left soaking in certain shortening material.

WARNING

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal the joint between the fry vessels. Banging fry baskets on the strip to dislodge shortening will distort the strip, adversely affecting its fit. It is designed for a tight fit and should only be removed for cleaning.

DANGER

DANGER

Adequate means must be provided to limit the movement of this appliance without depending on or transmitting stress to the electrical conduit. A restraint kit is provided with the fryer. If the restraint kit is missing contact your local KES.

DANGER

DANGER

This fryer has a power cord (three phase) for each frypot and a single five wire cord for the entire system. Prior to movement, testing, maintenance and any repair on your Frymaster fryer; disconnect ALL electrical power cords from the electrical power supply.

DANGER

DANGER

Keep all items out of drains. Closing actuators may cause damage or injury.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are for an RTI system. These instructions may not be applicable to other bulk oil systems.

LOV™ ELECTRIC WARRANTY STATEMENT

Frymaster, L.L.C. makes the following limited warranties to the original purchaser only for this equipment and replacement parts:

A.WARRANTY PROVISIONS - FRYERS

1.Frymaster L.L.C. warrants all components against defects in material and workmanship for a period of two years.

2.All parts, with the exception of the frypot, O-rings and fuses, are warranted for two years after installation date of fryer.

3.If any parts, except fuses and filter O-rings, become defective during the first two years after installation date, Frymaster will also pay straight-time labor costs up to two hours to replace the part, plus up to 100 miles/160 km of travel (50 miles/80 km each way).

B.WARRANTY PROVISIONS - FRYPOTS

The frypot has a lifetime parts and labor warranty. If a frypot develops a leak after installation, Frymaster will replace the frypot, allowing up to the maximum time per the Frymaster time allowance chart hours of straight-time labor. Components attached to the frypot, such as the high-limit, probe, gaskets, seals, and related fasteners, are also covered by the lifetime warranty if replacement is necessitated by the frypot replacement. Leaks due to abuse or from threaded fittings such as probes, sensors, high-limits, drain valves or return piping are not included.

C.PARTS RETURN

All defective in-warranty parts must be returned to a Frymaster Authorized Factory Service Center within 60 days for credit. After 60 days, no credit will be allowed.

D.WARRANTY EXCLUSIONS

This warranty does not cover equipment that has been damaged due to misuse, abuse, alteration, or accident such as:

improper or unauthorized repair (including any frypot which is welded in the field);

failure to follow proper installation instructions and/or scheduled maintenance procedures as prescribed in your MRC cards. Proof of scheduled maintenance is required to maintain the warranty;

improper maintenance;

damage in shipment;

abnormal use;

removal, alteration, or obliteration of either the rating plate or the date code on the heating elements;

operating the frypot without shortening or other liquid in the frypot;

ii

no fryer will be warranted under the ten-year program for which a proper start-up form has not been received.

This warranty also does not cover:

transportation or travel over 100 miles/160 km (50 miles/80 km each way), or travel over two hours;

overtime or holiday charges;

consequential damages (the cost of repairing or replacing other property which is damaged), loss of time, profits, use or any other incidental damages of any kind.

There are no implied warranties of merchantability or fitness for any particular use or purpose.

This warranty is applicable at the time of this printing and is subject to change.

ELECTRICAL POWER SPECIFICATIONS

|

|

WIRE |

MIN. |

AWG |

|

AMPS PER LEG |

|

||

VOLTAGE |

PHASE |

SERVICE |

SIZE |

(mm2) |

L1 |

|

L2 |

|

L3 |

208 |

3 |

3 |

6 |

(16) |

39 |

|

39 |

|

39 |

240 |

3 |

3 |

6 |

(16) |

34 |

|

34 |

|

34 |

480 |

3 |

3 |

8 |

(10) |

17 |

|

17 |

|

17 |

220/380 |

3 |

4 |

6 |

(16) |

21 |

|

21 |

|

21 |

240/415 |

3 |

4 |

6 |

(16) |

20 |

|

20 |

|

21 |

230/400 |

3 |

4 |

6 |

(16) |

21 |

|

21 |

|

21 |

iii

BIELA14 SERIES GEN II LOV™ ELECTRIC FRYERS

SERVICE

TABLE OF CONTENTS

CAUTIONARY STATEMENTS........................................................................................................................................ |

i |

||

WARRANTY STATEMENT ............................................................................................................................................ |

ii |

||

ELECTRICAL POWER SPECIFICATIONS ............................................................................................................... |

iii |

||

CHAPTER 1: Service Procedures |

|

||

1.1 |

General |

........................................................................................................................................................... |

1-1 |

1.2 |

Replacing ....................................................................................................................................a Computer |

1-1 |

|

1.3 |

Replacing .......................................................................................................Component Box Components |

1-1 |

|

1.4 |

Replacing ..............................................................................................................a High-Limit Thermostat |

1-3 |

|

1.5 |

Replacing .....................................................................................................................a Temperature Probe |

1-3 |

|

1.6 |

Replacing .........................................................................................................................a Heating Element |

1-5 |

|

1.7 |

Replacing ..........................................................................................................Contactor Box Components |

1-7 |

|

1.8 |

Replacing .........................................................................................................................................a Frypot |

1-8 |

|

1.9 |

Built-In .............................................................................................Filtration System Service Procedures |

1-10 |

|

|

1.9.1 ........................................................................................ |

Filtration System Problem Resolution |

1-10 |

|

1.9.2 ........................................... |

Replacing the Filter Motor, Filter Pump and Related Components |

1-11 |

|

1.9.3 ....................................................................... |

Replacing the Filter Transformer or Filter Relay |

1-13 |

1.10 |

ATO (Automatic ...........................................................................................Top-Off) Service Procedures |

1-13 |

|

|

1.10.1 ................................................................................................................ |

ATO Troubleshooting |

1-14 |

|

1.10.2 ................................................................................... |

ATO Board Pin Positions and Harnesses |

1-15 |

|

1.10.3 ........................... |

Replacing the ATO board, LON Gateway, ATO pump relay or Transformer |

1-16 |

|

1.10.4 .......................................................................................................... |

Replacing the ATO Pump |

1-16 |

1.11 |

MIB (Manual .....................................................................................Interface Board) Service Procedures |

1-16 |

|

|

1.11.1 ................................................. |

Manually Draining, Refilling or Filtering with the MIB Board |

1-17 |

|

1.11.2 ................................................................................................................. |

MIB Troubleshooting |

1-18 |

|

1.11.3 .............................................................................................. |

MIB Pin Positions and Harnesses |

1-20 |

|

1.11.4 ........................................................................................................... |

MIB Display Diagnostics |

1-21 |

|

1.11.5 ............................................................................................................. |

MIB Display Characters |

1-22 |

|

1.11.6 ........................................................................................................... |

Replacing the MIB board |

1-22 |

|

1.11.7 ....................................................................................................... |

Control Power Reset Switch |

1-22 |

1.12 |

RTI Service .......................................................................................................................................Issues |

1-23 |

|

|

1.12.1 ........................................................................................................................... |

RTI MIB Tests |

1-23 |

|

1.12.2 ........................................................................................................................ |

RTI LOV Wiring |

1-24 |

|

1.12.3 ........................................................................................................... |

RTI Plumbing Schematic |

1-24 |

|

1.12.4 ........................................................................................................ |

RTI LOV Quick Reference |

1-25 |

1.13 |

AIF (Automatic ........................................................................Intermittent Filtration) Service Procedures |

1-27 |

|

|

1.13.1 .................................................................................................................. |

AIF Troubleshooting |

1-27 |

|

1.13.2 ...................................................................... |

AIF Actuator Board Pin Positions and Harnesses |

1-28 |

|

1.13.3 ............................................................................................................. |

Replacing an AIF Board |

1-29 |

|

1.13.4 ................................................................................................................ |

Replacing an Actuator |

1-29 |

1.14 |

M3000 Computer ..........................................................................................................Service Procedures |

1-30 |

|

|

1.14.1 ............................................................................................ |

M3000 Computer Troubleshooting |

1-30 |

|

1.14.2 ......................................................................................... |

M3000 Useful Codes and Passwords |

1-33 |

|

1.14.3 ............................................................................................................. |

Service Required Errors |

1-34 |

|

1.14.4 ......................................................................................................................... |

Error Log Codes |

1-35 |

|

1.14.5 ................................................................................................................................. |

Tech Mode |

1-36 |

|

1.14.6 .................................................................................................... |

M3000 Filter Error Flowchart |

1-37 |

|

1.14.7 ..................................................................................................... |

M3000 Menu Summary Tree |

1-38 |

|

1.14.8 ................................................................................ |

M3000 Board Pin Positions and Harnesses |

1-39 |

1.15 |

Loading ................................................................................................and Updating Software Procedures |

1-40 |

|

1.16 |

Data Network ..............................................................................................................................Flowchart |

1-41 |

|

1.17 |

Interface .................................................................................................................Board Diagnostic Chart |

1-42 |

|

1.18 |

Probe Resistance ................................................................................................................................Chart |

1-43 |

|

1.19 |

Wiring Diagrams.......................................................................................................................................... |

1-43 |

|

iv

BIELA14 SERIES GEN II LOV™ ELECTRIC FRYERS CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Frymaster fryer, disconnect the fryer from the electrical power supply.

WARNING

WARNING

To ensure the safe and efficient operation of the fryer and hood, the electrical plug for the 120-volt line, which powers the hood, must be fully engaged and locked in its pin and sleeve socket.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to facilitate re-assembly.

1.2 Replacing a Computer

1.Disconnect the fryer from the electrical power supply.

2.The computer bezel is held in place by tabs at the top and bottom. Slide the metal bezel up to disengage the lower tabs. Then slide the bezel down to disengage the upper tabs.

3.Remove the two screws from the upper corners of the control panel. The control panel is hinged at the bottom and will swing open from the top.

4.Unplug the wiring harnesses from the connectors on the back of the computer, marking their position for reassembly, and disconnect the grounding wires from the terminals. Remove the computer panel assembly by lifting it from the hinged slots in the control panel frame.

Ground Wire Terminal

Ground Wire Terminal

Ground Wire Terminal

20-Pin Connector

20-Pin Connector

Communication |

Locator Wire |

Harnesses |

5.Install the replacement computer. Reinstall the control panel assembly by reversing steps 1 thru 4.

6.Setup the computer following the instructions on page 4-9 in the Installation and Operation manual. Setup MUST be performed after replacement.

7.Once setup is complete on all replaced computers, reset all control power following the instructions in section 1.11.7 on page 1-22 to readdress the new M3000 computer. Check software version and if necessary update the software. If a software update was necessary, follow the instructions to update the software in section 1.15

1.3 Replacing Component Box Components

1.Disconnect the fryer from the electrical power supply.

2.The computer bezel is held in place by tabs at the top and bottom. Slide the metal bezel up to disengage the lower tabs. Then slide the bezel down to disengage the upper tabs.

1-1

3.Remove the two screws from the upper corners of the computer and allow the computer to swing down.

4.Unplug the wiring harnesses and disconnect the grounding wires from the terminals on the back of the computer. Remove the computer assembly by lifting it from the hinge slots in the control panel frame.

5.Disconnect the wiring from the component to be replaced, being sure to make a note of where each wire was connected.

6.Dismount the component to be replaced and install the new component, being sure that any required spacers, insulation, washers, etc. are in place.

NOTE: If more room to work is required, the control panel frame assembly may be removed by removing the hex-head screws which secure it to the fryer cabinet (see illustration below). If this option is chosen, all computer assemblies must be removed per steps 1 thru 4 above. The cover plate, on the lower front of the component box, may also be removed to allow additional access if desired.

Remove these three |

screws at each end. |

Remove these two screws |

from the center supports. |

Removing the Control Panel Frame and Top Cap Assembly |

7.Reconnect the wiring disconnected in step 5, referring to your notes and the wiring diagrams on the fryer door to ensure that the connections are properly made. Also, verify that no other wiring was disconnected accidentally during the replacement process.

8.Reverse steps 1 through 4 to complete the replacement and return the fryer to service.

1-2

1.4 Replacing a High-Limit Thermostat

1.Remove the filter pan and lid from the unit. Drain the frypots into an McDonald’s Shortening Disposal Unit (MSDU) or other appropriate METAL container using the computer “drain to pan option” or using the MIB board in manual mode.

DANGER

DANGER

DO NOT drain more than one full frypot or two split frypots into the MSDU at one time.

2.Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear of the fryer.

3.Remove the four screws from both the left and right sides of the lower back panel.

4.Locate the high-limit that is being replaced and follow the two-black wires to the 12-pin connector C-6. Note where the leads are connected prior to removing them from the connector. Unplug the 12-pin connector C-6 and using a pin-pusher push the pins of the high-limit out of the connector.

5.Carefully unscrew the high-limit thermostat to be replaced.

6.Apply Loctite™ PST 567 or equivalent sealant to the threads of the replacement and screw it securely into the frypot.

7.Insert the leads into the 12-pin connector C-6 (see illustration below). For full-vat units or the left half of a dual-vat unit (as viewed from the rear of the fryer) the leads go into positions 1 and 2 of the connector. For the right half of a dual-vat unit (as viewed from the rear of the fryer), the leads go into positions 7 and 8. In either case, polarity does not matter.

8.Reconnect the 12-pin connecting plug C-6. Use wire ties to secure any loose wires.

9.Reinstall the back panels, contactor plug guards, reposition the fryer under the exhaust hood, and reconnect it to the electrical power supply to return the fryer to service.

1.5 Replacing a Temperature Probe

1.Lift the element out of the oil.

2.Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear of the fryer.

3.Remove the four screws from both sides of the lower back panel. Then remove the two screws on both the left and right sides of the back of the tilt housing. Lift the tilt housing straight up to remove from the fryer.

1-3

4.Locate the red (or yellow) and white wires of the temperature probe to be replaced. Note where the leads are connected prior to removing them from the connector. Unplug the 12-pin connector C-6 and using a pin-pusher push the pins of the temperature probe out of the connector.

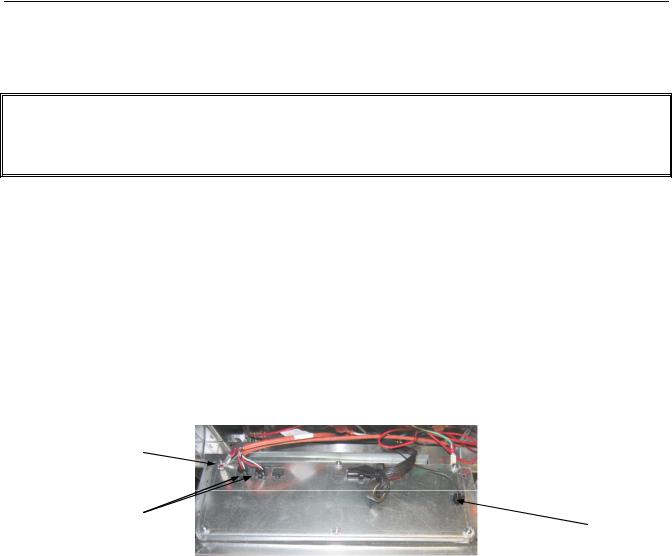

5.Remove the securing probe bracket and metal tie wraps that secure the probe to the element (see illustration below). Remove the ground clip on the probe shield.

Probe

Leads

|

Probe |

Metal Wire Tie |

Bracket |

|

6.Gently pull on the temperature probe and grommet, pulling the wires up the rear of the fryer and through the element tube assembly.

7.Insert the replacement temperature probe (wires first) into the tube assembly ensuring that the grommet is in place. Secure the probe to the elements using the bracket which was removed in Step 5 and the metal tie wraps which were included in the replacement kit.

8.Route the probe wires out of the tube assembly following the element wires down the back of the fryer through the Heyco bushings to the 12-pin connector C-6. Secure the wires to the sheathing with wire ties. Attach the ground clip.

9.Insert the temperature probe leads into the 12-pin connector C-6 (see illustration below). For fullvat units or the right half of a dual-vat unit (as viewed from the rear of the fryer) the red (or yellow) lead goes into position 3 and the white lead into position 4 of the connector. For the left half of a dual-vat unit (as viewed from the rear of the fryer), the red (or yellow) lead goes into position 9 and the white lead into position 10. NOTE: Right and left refer to the fryer as viewed from the rear.

10.Secure any loose wires with wire ties, making sure there is no interference with the movement of the springs. Rotate the elements up and down, making sure that movement is not restricted and that the wires are not pinched.

11.Reinstall the tilt housing, back panels and contactor plug guards. Reposition the fryer under the exhaust hood and reconnect it to the electrical power supply to return the fryer to service.

1-4

1.6Replacing a Heating Element

1.Perform steps 1-5 of section 1.5, Replacing a Temperature Probe.

2.Disconnect the wire harness containing the probe wiring, where the temperature probe is attached to the element being replaced. Using a pin pusher, disconnect the probe wires from the 12-pin connector.

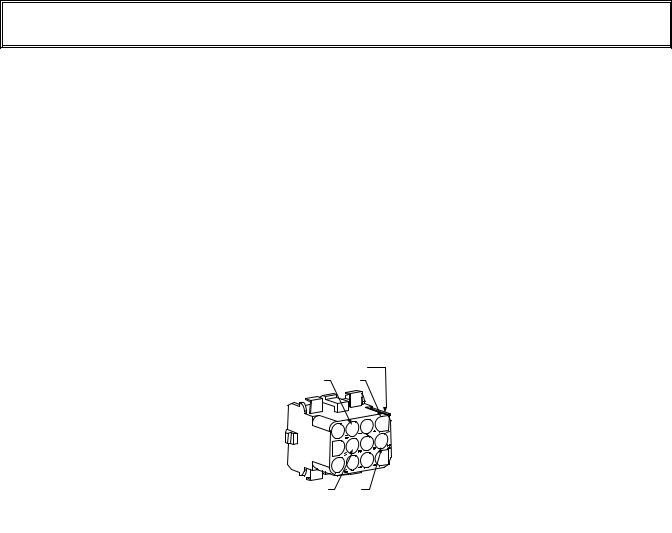

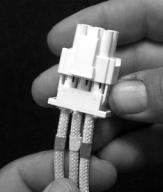

3.In the rear of the fryer disconnect the 6-pin connector for the left element (as viewed from the front of the fryer) or the 9-pin connector for the right element from the contactor box. Press in on the tabs on each side of the connector while pulling outward on the free end to extend the connector and release the element leads (see photo below). Pull the leads out of the connector and out of the wire sleeving.

4.Raise the element to the full up position and support the elements.

5.Remove the hex head screws and nuts that secure the element to the tube assembly and pull the element out of the frypot. NOTE: The nuts inside the tube can be held and removed using the RE element tube nut spanner, PN# 2304028. Full-vat elements consist of two dual-vat elements clamped together. For full-vat units, remove the element clamps before removing the nuts and screws that secure the element to the tube assembly.

6.If applicable, recover the probe bracket and probe from the element being replaced and install them on the replacement element. Install the replacement element in the frypot, securing it with the nuts and screws removed in Step 5 to the tube assembly. Ensure the gasket is between the tube and element assembly.

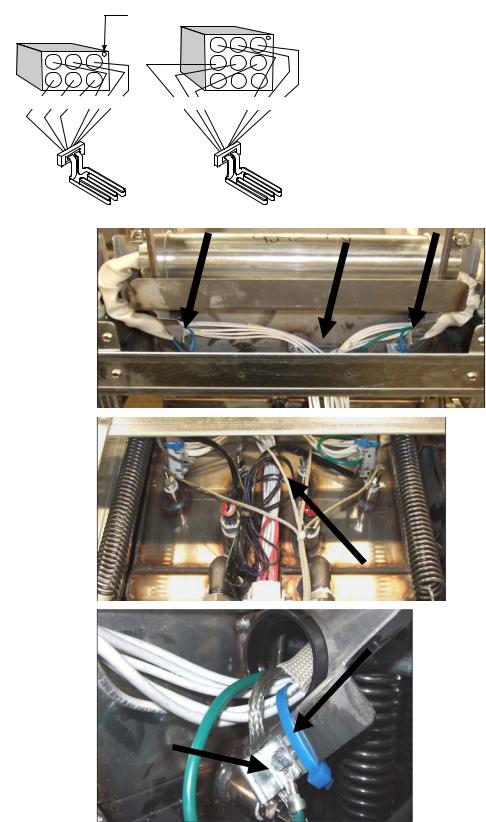

7.Route the element leads through the element tube assembly and into the wire sleeving to prevent chafing. Ensure that the wire sleeving is routed back through the Heyco bushing, keeping it clear from the lift springs (see photos next page). Also ensure that the wire sleeving extends into the tube assembly to protect the edge of the tube assembly from chafing the wires. Press the pins into the connector in accordance with the diagram on the following page, and then close the connector to lock the leads in place. NOTE: It is critical that the wires be routed through the sleeving to prevent chafing.

1-5

|

|

|

|

|

Index Marker marks |

|

|

|

||

|

|

|

|

|

Position 1 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

2 |

1 |

|

|

3 |

2 |

1 |

|

|

|

6 |

5 |

4 |

|

|

6 |

5 |

4 |

|

|

|

9 |

8 |

7 |

|

6L |

5L |

4L |

3L 2L |

1L |

6 |

5 |

4R |

3R |

2 |

1R |

|

|

|

|

|

R |

R |

|

|

R |

|

Full vat element wire routing

Pull the element wires through the bushings on either side of the frypot and down the back. Element wires should be routed to the right of the ATO temperature probe on the back wall of the frypot.

Dual vat element wire routing

Pull the element wires through the bushings on either side of the frypot and down the back. Element wires should be routed to the center of the frypot between the ATO temperature probes.

Element grounding and wire routing

To ground the element wires, use the hole in the frypot frame located under the bushing that the element wires pass through. Using a screw through the ground wires ring terminal, connect it to the frypot using the probe ground clip. Use a tie wrap to tie up half of the element wires after the wires are pulled through the bushing. Do not pull tie wrap tight, leave it slack at about one inch

1-6

8.Reconnect the element connector ensuring that the latches lock.

9.Insert the temperature probe leads into the 12-pin wiring harness connector (see illustration below). For full-vat units or the right half of a dual-vat unit, the red lead goes into position 3 and the white into position 4. For the left half of a dual-vat unit, the red lead goes into position 9 and the white into position 10. NOTE: Right and left refer to the fryer as viewed from the rear.

10.Reconnect the 12-pin connector of the wiring harness disconnected in Step 2.

11.Lower the element to the full down position.

12.Reinstall the tilt housing, back panels and contactor plug guard. Reposition the fryer under the exhaust hood, and reconnect it to the electrical power supply.

1.7Replacing Contactor Box Components

1.If replacing a contactor box component in boxes above the filter pan, first remove the filter pan and lid from the unit. If replacing components in fryers tht have ATO boxes, the ATO box may require removal.

2.Disconnect the fryer from the electrical power supply.

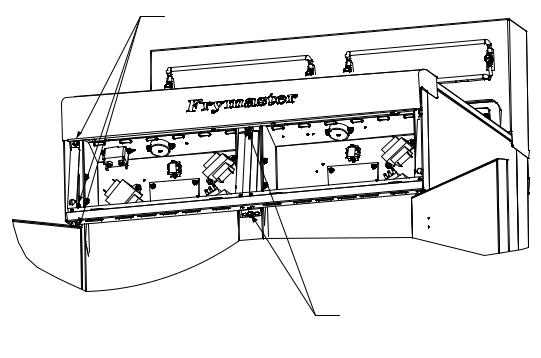

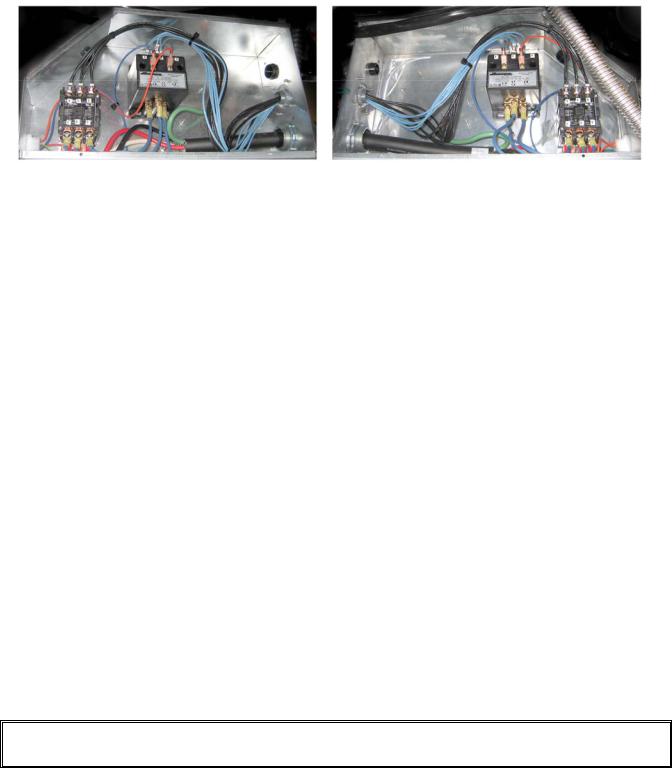

3.Remove the two screws securing the cover of the contactor box. The contactor boxes above the filter pan are accessed by sliding under the fryer. They are located to the left and right above the guide rails (see photo below). The contactor boxes for frypots not over the filter pan are accessed by opening the fryer door directly under the affected frypot.

Remove two screws to access contactor box components above the filter pan.

1-7

4.The contactors and relays are held on by threaded pin studs so that only removal of the nut is required to replace the component.

5.After performing necessary service, reverse steps 1-4 to return the fryer to operation.

Left and right views of mechanical contactor box components.

Sometimes it is necessary to remove the entire contactor box to repair. Below are the instructions for removing the far left contactor box.

1.Remove fryers from hood and remove all power to fryers.

2.Remove lower back panel.

3.Remove filter pan, lid and downspout splash shield.

4.Remove clevis clip from dispose handle at rear of fryer and let handle drop out of waste valve bracket.

5.Remove two screws holding waste valve handle at front of fryer and remove bracket and handle from fryer.

6.Remove AIF board and tuck wires out of the way of the contactor box for box removal.

7.Remove shipping brace that supports filter pump shelf brace to top of contactor box.

8.Remove contactor box cover.

9.Unplug all wiring from front and rear of contactor box.

10.Remove two screws that hold element wire shield to rear of contactor box and remove wire shield.

11.Remove two screws that support contactor box at rear of box.

12.Remove two screws that support contactor box at front of box.

13.Lift contactor box up to clear left frame rail and slide to the right far enough that the left rear corner of the pump and motor shelf protrude inside of the contactor box slightly.

14.Tip front of contactor box down and to the right slightly and then pull out from opening where filter pan lid would rest.

15.Reverse above steps for reinstallation.

1.8 Replacing a Frypot

1.Drain the frypot into the filter pan or, if replacing a frypot over the filter system, into a McDonald’s Shortening Disposal Unit (MSDU) or other appropriate METAL container. If replacing a frypot over the filter system, remove the filter pan and lid from the unit.

DANGER

DANGER

DO NOT drain more than one full frypot or two split frypots into the MSDU at one time.

2.Disconnect the fryer from the electrical power supply and reposition it to gain access to both the front and rear.

1-8

3.Slide the metal bezel up to release the bottom tabs, then slide the bezel down to disengage the upper tabs.

4.Remove the two screws from the upper corners of the computers and allow them to swing down (see illustration and photo on page 1-1).

5.Unplug the wiring harnesses and ground wires from the backs of the computers. Remove the computers by lifting them from the hinge slots in the control panel frame.

6.Remove the tilt housing and back panels from the fryer. The tilt housing must be removed first in order to remove the upper back panel.

7.To remove the tilt housing, remove the hex-head screws from the rear edge of the housing. The housing can be lifted straight up and off the fryer.

8.Remove the control panel by removing the screw in the center and the nuts on both sides.

9.Loosen the component boxes by removing the screws, which secure them in the cabinet.

10.Dismount the top cap by removing the nuts at each end that secure it to the cabinetry.

11.Remove the hex head screw that secures the front of the frypot to the cabinet cross brace.

12.Remove the top-connecting strip that covers the joint with the adjacent frypot.

13.Unscrew the nut located on the front of each section of drain tube, and remove the tube assembly from the fryer.

14.Remove the actuators from the drain and return valves and disconnect the wiring.

15.Disconnect any auto filtration probes and auto top off sensors and wiring.

16.At the rear of the fryer, unplug the 12-pin connector C-6 and, using a pin pusher, disconnect the high-limit thermostat leads. Disconnect any other probe wiring.

17.Disconnect the oil return flexline(s).

18.Raise the elements to the “up” position and disconnect the element springs.

19.Remove the machine screws and nuts that secure the element tube assembly to the frypot. Carefully lift the element assembly from the frypot and secure it to the cross brace on the rear of the fryer with wire ties or tape.

20.Carefully lift the frypot from the fryer and place it upside down on a stable work surface.

21.Recover the drain valve(s), oil return flexline connection fitting(s), actuators, AIF boards and highlimit thermostat(s) from the frypot. Clean the threads and apply Loctite™ PST 567 or equivalent sealant to the threads of the recovered parts and install them in the replacement frypot.

22.Carefully lower the replacement frypot into the fryer. Reinstall the hex head screw removed in step 11 to attach the frypot to the fryer.

1-9

Loading...

Loading...