Frymaster GF14-SD Owner’s Manual

Fryers Gas Series GF40 and GF14

Manual Operation & Installation

Frymaster, a member of the Commercial Food Equipment Service Association, recommends using CFESA Certified Technicians.

24-Hour Service Hotline |

OCT 11 |

1-800-551-8633 |

*8195887A* |

|

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A Frymaster DEAN Factory Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country and/or region in which the appliance is installed. See NATIONAL CODE REQUIREMENTS in Chapter 2 of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: 1) This device may not cause harmful interference, and 2) This device must accept any interference received, including interference that may cause undesired operation. While this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can cause property damage, injury, or death. Read the installation, operating, and service instructions thoroughly before installing or servicing this equipment. Only qualified service personnel may convert this appliance to use a gas other than that for which it was originally configured.

DANGER

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

DANGER

DANGER

Adequate means must be provided to limit the movement of this appliance without depending upon the gas line connection. Single fryers equipped with legs must be stabilized by installing anchor straps. All fryers equipped with casters must be stabilized by installing restraining chains. If a flexible gas line is used, an additional restraining cable must be connected at all times when the fryer is in use.

DANGER

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result from slips or contact with the hot oil.

DANGER

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance.

DANGER

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak must be posted in a prominent location. This information can be obtained from the local gas company or gas supplier.

DANGER

DANGER

This product contains chemicals known to the state of California to cause cancer and/or birth defects or other reproductive harm.

Operation, installation, and servicing of this product could expose you to airborne particles of glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne particles of glasswool or ceramic fibers is known to the State of California to cause cancer. Inhalation of carbon monoxide is known to the State of California to cause birth defects or other reproductive harm.

NOTICE

The Commonwealth of Massachusetts requires any and all gas products to be installed by a licensed plumber or pipe fitter.

GF14 and GF40 SERIES GAS FRYERS

TABLE OF CONTENTS

CHAPTER 1: General Information |

|

|

1.1 |

Parts Ordering and Service Information .............................................................. |

1-1 |

1.2 |

Safety Information ............................................................................................... |

1-2 |

1.3 |

Equipment Description ........................................................................................ |

1-2 |

1.4 |

Installation, Operating, and Service Personnel.................................................... |

1-3 |

1.5 |

Definitions............................................................................................................ |

1-3 |

1.6 |

Shipping Damage Claim Procedure..................................................................... |

1-4 |

CHAPTER 2: Installation Instructions |

|

|

2.1 |

General Installation Requirements....................................................................... |

2-1 |

2.2 |

Caster/Leg Installation......................................................................................... |

2-2 |

2.3 |

Pre-Connection Preparations ............................................................................... |

2-2 |

2.4 |

Connection to Gas Line ....................................................................................... |

2-3 |

2.5 |

Converting to Another Gas Type......................................................................... |

2-4 |

CHAPTER 3: Operating Instructions |

|

|

3.1 |

Start-Up Procedures............................................................................................. |

3-1 |

3.2 |

Boiling Out the Frypot......................................................................................... |

3-2 |

3.3 |

Filling with Cooking Oil or Shortening ............................................................... |

3-3 |

3.4 |

Shutting the Fryer Down...................................................................................... |

3-3 |

3.5 |

Thermostat Operation .......................................................................................... |

3-3 |

3.6 |

Draining and Filtering.......................................................................................... |

3-4 |

CHAPTER 4: Preventive Maintenance and Operator Troubleshooting |

|

|

4.1 |

Daily Checks and Services................................................................................... |

4-1 |

4.2 |

Quarterly Checks and Services ............................................................................ |

4-1 |

4.3 |

Semi-Annual Checks and Services ...................................................................... |

4-2 |

4.4 |

Operator Troubleshooting.................................................................................... |

4-4 |

i

GF14 and GF40 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1.1Parts Ordering and Service Information

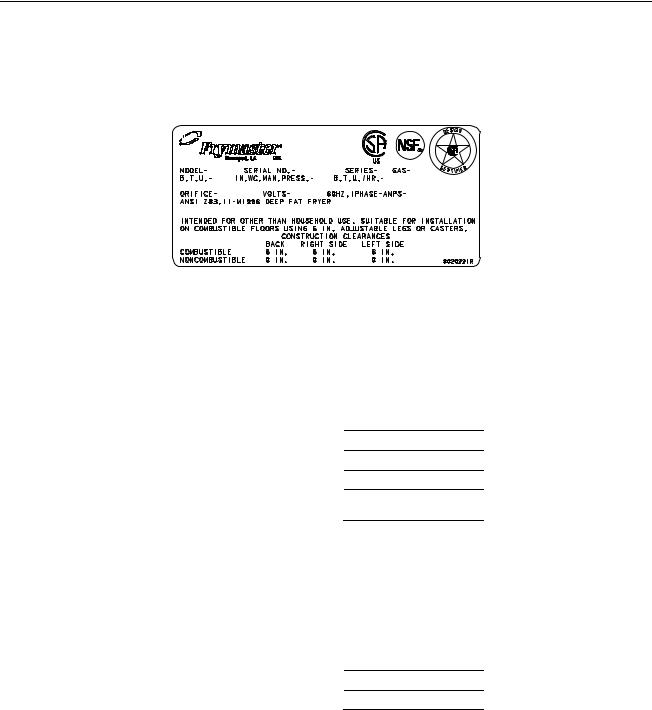

In order to assist you, the Frymaster Factory Authorized Servicer (FAS) or Service Department representative requires certain information about your equipment. Most of this information is printed on a data plate inside the fryer door. A typical data plate is illustrated below.

GF14SD |

0201FM0208 |

AF |

NAT |

1050 |

4.00 |

10000 |

|

1.65 |

000 |

|

.00 |

Parts orders must be placed with your local FAS or distributor. A list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster website at www.frymaster.com. If you do not have access to this list, contact the Frymaster Technical Service Department at 1-800-551-8633 or 1- 318-865-1711.

When ordering parts, the following information is required:

Model Number:

Serial Number:

Type of Gas:

Item Part Number:

Quantity Needed:

Service information may be obtained by contacting your local FAS. Information may also be obtained by calling the Frymaster Technical Service Department at 1-800-551-8633 or 1-318-865- 1711.

When requesting service, please have the following information ready:

Model Number:

Serial Number:

Type of Gas:

In addition to the model number, serial number, and type of gas, please be prepared to describe the nature of the problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-1

1.2Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the ones below.

CAUTION

CAUTION

Caution boxes contain information about actions or conditions that may cause or result in a malfunction of your system.

WARNING

WARNING

Warning boxes contain information about actions or conditions that may cause or result in damage to your system, and which may cause your system to malfunction.

DANGER boxes contain information about actions or conditions that may cause or result in injury to personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER

DANGER

Danger boxes contain information about actions or conditions that may cause or result in injury to personnel, and which may cause damage to your system and/or cause your system to malfunction.

1.3Equipment Description

The GF14 and GF40 Series gas fryers are designed for all-purpose frying. Other than the capacity of the frypot, both fryers are virtually identical. The GF14 model holds up to 40 lbs. (20 liters) of cooking oil or shortening. GF40 fryers hold up to 50 lbs. (25 liters). Both models must be manually filtered or filtered with a portable filtration unit such as the Frymaster PF50 portable filter.

These fryers use a millivolt temperature control circuit, which requires no external power.

Both models use an open-pot design and have a hand-sized opening into the deep cold zone, which makes cleaning the frypot quick and easy.

The fryers require installation of legs or optional casters. All fryers are shipped with a package of standard accessories. Each fryer is adjusted, tested, and inspected at the factory before crating for shipment.

Frypots are constructed of welded, heavy-gauge stainless steel. Heat is supplied by a burner assembly with multiple gas jets, which are focused on deflectors located around the lower side of the frypot. The deflectors concentrate the burners’ heat on the bottom of the frypot.

1-2

The burner assembly can be configured for natural gas, propane, or manufactured gas, as required by the customer. A drain is tapped into the center of the frypot, with a front-controlled manual ball valve.

Each fryer is equipped with a thermostat for temperature control. The thermostat is located near the centerline of the frypot for responsiveness and accurate temperature measurement.

A high temperature thermostat (hi-limit) shuts off gas to the burner assembly if the controlling thermostat fails.

1.4Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or authorized personnel only, as defined in Section 1.5.

All installation and service on Frymaster equipment must be performed by qualified, certified, licensed, and or/authorized installation or service personnel, as defined in Section 1.5.

1.5Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this manual and have familiarized themselves with the equipment functions, or who have had previous experience with the operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, or firms, corporations, or companies which, either in person or through a representative, are engaged in and are responsible for the installation of gasfired appliances. Qualified personnel must be experienced in such work, be familiar with all gas precautions involved, and have complied with all requirements of applicable national and local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those familiar with Frymaster equipment and authorized by Frymaster to perform service on Frymaster equipment. All authorized service personnel are required to be equipped with a complete set of service and parts manuals and stock a prescribed minimum amount of Frymaster equipment parts.

A list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster website at www.frymaster.com. Failure to use qualified service personnel will void the Frymaster Warranty on your equipment.

1-3

1.6Shipping Damage Claim Procedure

Your Frymaster equipment was inspected and packed before leaving the factory. The transportation company assumes full responsibility for safe delivery upon acceptance of the equipment for transport.

What to do if your equipment arrives damaged:

1.File a claim for damages immediately, regardless of the extent of damages.

2.Inspect for and record all visible loss or damage, and ensure that this information is noted on the freight bill or express receipt and is signed by the person making the delivery.

3.Concealed loss or damage that was unnoticed until the equipment was unpacked should be recorded and reported to the freight company or carrier immediately upon discovery. A concealed damage claim must be submitted within 15 days of the date of delivery. Ensure that the shipping container is retained for inspection.

Frymaster DOES NOT ASSUME

RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1-4

Loading...

Loading...