Page 1

Quick Setup

.D$"//"7BMWFT.D$"//"7BMWFT

.D$"//"7BMWFT

-JNJUPSRVF"DUVBUJPO4ZTUFNT-JNJUPSRVF"DUVBUJPO4ZTUFNT

-JNJUPSRVF"DUVBUJPO4ZTUFNT

for Accutronix

MX Actuators

Page 2

Experience In Motion

USER INSTRUCTIONS

Installation

Operation

Maintenance

MX Electronic Actuator

FCD LMENIM2306-00 – 08/05

Before You Begin

The MX actuator’s 32-character LCD display provides easy-to-read

actuator status, diagnostics, and setup information—in the language you

choose. Once you have set the actuator’s position limits, the unit will be

ready for normal operation. The screen message will indicate the valve

position as a percentage of the valve opening. Full open is expressed as

100% OPEN and full close is expressed as 0% OPEN.

Factory Settings

The MX actuator can be configured with the parameters that you require in

the field. The calibration of position limits are addressed in this document.

If full valve data was not provided when ordering, or if changes to the

default settings are needed, see Bulletin LMENIM2306, Installation and

Operation for MX-05 through MX-140, for complete instructions.

Page 3

Checking the Open/Closed Settings

•

Valve Closed As you close the valve using the actuator, make

sure that the close light (green) illuminates just as the travel limit is

reached. The display should read 0% OPEN.

•

Valve Open As you open the valve using the actuator, make sure that

the open light (red) illuminates just as the travel limit is reached. The

display should read 100% OPEN.

0% OPEN

Before You Begin

Setting the Password

At the ENtEr PasswOrd? prompt, use the black knob and toggle

to select the correct password. Another option in the Change Settings

menu is chaNgE PasswOrd? You may disable the actuator’s

password function by setting the password to 000. The password

function can be re-enabled by resetting the password to any other

three-digit code.

100% OPEN

100

FactOry dEFaULt

PasswOrd

Page 4

Setup

1

Connect Power to the Unit.

Refer to the nameplate on the

actuator for the correct voltage

for the main power supply. Or

connect an auxiliary 24 VDC

supply to terminal points 6 (-)

and 7 (+).

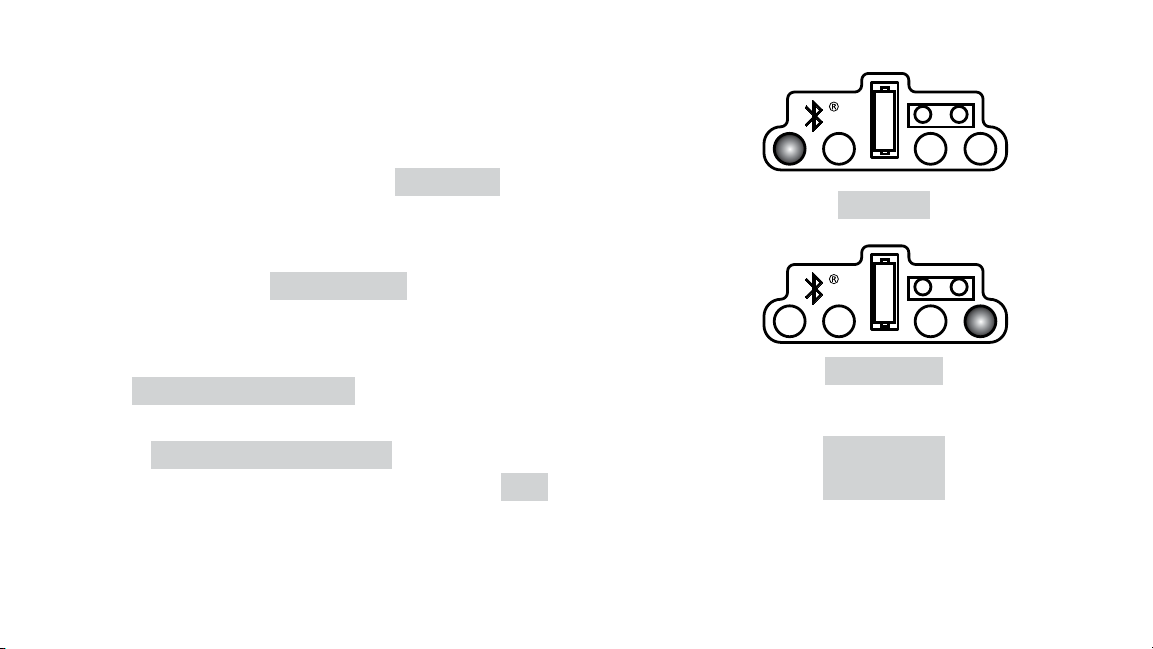

2

Begin Setup.

Move the red selector knob to

. Within 10 seconds,

toggle the black control knob

to the , , and

positions. This will trigger the

prompt sEtUP? to appear

on the screen. Answer

within 10 seconds.

Page 5

Use the black control knob to answer

the following prompts:

sEtUP?

chaNgE sEttINgs? . . .

ENtEr PasswOrd . . . . . .

Toggle through numbers using the

three-digit password by toggling

you are having trouble.

. . . . . . . . . . . . . . . .

knob and select the correct

. See “Setting the Password” if

Change Settings Menu.

After successfully entering

the password, answer

to the Change Settings

menu prompts until you

3

choosing either electrical or handwheel operation …

reach the prompt chaNgE

POsItION sEtUP?

Answer .

Next, follow steps 4–6 to set Position Limits,

Setup

Page 6

Set Position Limits for Electrical Operation

Set closed valve position. At the cLOsE VaLVE-OK? prompt, move the red control knob

4

to . Hold the black control knob in the position until the valve has reached the

desired position. Move the red control knob to .

Set the open valve position. At the OPEN VaLVE-OK? prompt, move the red control knob

5

to . Hold the black control knob in the position until the valve has reached the

desired position. Move the red control knob to .

Inspect for correct operation. The position calibration is now complete. The actuator will

6

function as ordered. Inspect for correct operation by running actuator electrically.

Note: For torque seated valves, ensure that the Position limit is not set at torque seat. It is

recommended that the Position limit be set approximately one handwheel turn (360°) in the opposite

direction from the torque seat.

Page 7

Set Position Limits for Manual Operation

Set close position. At sEt cLOsE POsItION LIMIt? answer . At cLOsE

VaLVE-OK?

4

Release declutch lever; the clutch will stay in handwheel mode. If the valve is fully closed, move

the handwheel one turn in the open direction to allow for coasting of the motor. When valve is

in the desired location, select . At saVE cLOsE LIMIt-OK? select to set the

close position or to adjust the setting.

Set open position. At sEt OPEN POsItION LIMIt? select to get OPEN

VaLVE-OK?

5

one turn toward the closed position to allow for coasting of the motor. When valve is in the

desired location, select again to set the open position or to adjust the setting.

Checking the settings. Turn the handwheel and verify that the open and close LEDs function

6

correctly (see Checking the Settings). If adjustments are necessary, select to return to

chaNgE POsItION sEtUP?

depress declutch lever and slowly rotate handwheel until clutch is fully engaged.

Engage the clutch (see step 1). Valve should be fully opened. Move the handwheel

and repeat from step 1.

If your actuator has DDC, Modutronic, or APT options,

continue to the nex t page for steps 7 and 8 …

Set Position Limits

Page 8

Set Actuator Options

Networks

Change Networks menu. At the chaNgE sEttINgs? prompt, select and enter

7

your password. Toggle through the change settings menu items until you reach chaNgE

NEtwOrKs

prompts until you reach chaNgE NEtwOrKs.)

Set DDC address. Select at each prompt in the Networks menu until you reach

NEtwOrK addrEss OK?

8

the black control knob until the correct number is displayed (1-250). Set the address by

selecting .

Caution: The network address of the valve must be entered in accordance with the user address

assignment sheet. The address should correspond to the contract specifications and should not be

used elsewhere in the same network.

. Select . (If you are already in the Change Settings menu, select to the

Select . Change the address by selecting with

Page 9

Modutronic & Analog Position Transmitter (APT)

If you have these options, setting the open and close limits will automatically calibrate zero and span

of the Modutronic and APT (Analog Position Transmitter) actuators. The 4-20 mA signal will default

to 4 mA at close and 20 mA at open. To change from the default setting, see Bulletin LMENIM2306,

Installation and Operation for MX-05 through MX-140.

Set Options

Page 10

For More Information

Experience In Motion

USER INSTRUCTIONS

Installation

Operation

Maintenance

MX Electronic Actuator

FCD LMENIM2306-00 – 08/05

For in-depth instructions for setup and operation of your MX actuator, see Bulletin LMENIM2306,

Installation and Operation for MX-05 through MX-140. This document is supplied with each actuator.

Page 11

Page 12

FLOWSERVE CORPORATION

FLOWSERVE FLOW CONTROL

Limitorque Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434 528 4400

Facsimile: 434 845 9736

www.limitorque.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When

properly selected, this Flowser ve product is designed to perform its intended function safely during its useful life.

However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in

numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and often does)

provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/

user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and

maintenance of Flowserve products. The purchaser/user should read and understand the Installation and Maintenance

(I & M) instructions included with the product, and train its employees and contractors in the safe use of Flowserve

products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for

informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance

thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design,

the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of

its worldwide operations or offices.

For more information about Flowserve Corporation, visit www.flowserve.com or call USA 1-800-225-6989.

USA

Flowserve Limitorque

5114 Woodall Road

Lynchburg, VA 24506

Phone: 43 4-528- 4400

Fax: 434-84 5-9736

China

Limitor que Asia - Beijing

Room B803

Han Wei Plaz a

No. 7 Guang Hua Road, Chao

Yang Distri ct

Beijing 100 004, P.R. China

Phone: 8610 6561 2701

FAX: 8610 6561 2702

Singapo re

Limitor que Asia PTD

12, Tuas Avenue 20

Singapore 638824

Phone: 06 5 6862 3332

Fax: 065 6862 494 0

Canada

Flowserve Flow Control 120

Vinyl Cour t

Woodbrid ge, Ontario L4L

4A3

Canada

Phone: 905 856 8568

Fax: 905 856 7905

EMA

Limitor que EMA

Abex Road

Newbur y, Berkshire RG14

5EY

United Kingdom

Phone: 44 1635 46999

Fax: 4 4 1635 36034

Japan

Nippon Gea r Co., Ltd

Asahi Seimei Building

9th Floo r

1-11-11 Kita-Sai wai

Nishi-Ku

Yokohama-Shi,

Japan 220-0004

Phone: 81 45 326 20 65

Fax: 81 45 32 0 5962

FCD LMENIM2310-00 Printed in USA . © 2006 Flowserve Corporation, Irving, Texas, USA. Flowserve and Limitorque are registered trademarks of Flowserve Corporation.

Loading...

Loading...