Fisher & Paykel WA37T26EW, WA42T26GW, WA42T26GW1 Service Manual

479602

Service Manual

ECOSMART

Electronic Washer

Model:

WA37T26EW

WA42T26GW

Product codes:

96186 US

96193 US

96194 CA

479602 April 2010

Fisher & Paykel Appliances Ltd

78 Springs Road,

East Tamaki,

Manukau 2013

PO Box 58-732, Botany

Manukau 2163

New Zealand

Telephone: 09 273 0600

Facsimile: 09 273 0656

Fisher & Paykel Appliances Inc

5900 Skylab Road

Huntington Beach

CA 92647

USA

Phone: 1 888 936 7872

2

The specifications and servicing procedures outlined in this manual are subject to change without

notice.

The latest version is indicated by the reprint date and replaces any earlier editions.

479602

3

FISHER & PAYKEL

ELECTRONIC WASHING MACHINES

Covering the following model:

WA37T26EW

WA42T26GW

Product codes: 96186 US, 96193 US & 96194 CA

COPYRIGHT FISHER & PAYKEL LTD 2010 - ALL RIGHTS RESERVED

479602

4

CONTENTS

1

HEALTH & SAFETY ................................................................................................................6

2 SPECIFICATIONS ................................................................................................................... 7

2.1 Dimensions .................................................................................................................... 7

2.2 Maximum Capacity (Full Load) ...................................................................................... 7

2.3 Water Consumption ....................................................................................................... 7

2.4 Water Fill Temperature (Approximate Factory Settings)................................................ 7

2.5 Wash Motor....................................................................................................................7

2.6 Pump Motor ...................................................................................................................7

2.7 Water Valves..................................................................................................................8

2.8 Recirculating Valve ........................................................................................................ 8

2.9 Thermistor...................................................................................................................... 8

2.10 Cabinet...........................................................................................................................8

2.11 Lid .................................................................................................................................. 8

2.12 Top Deck........................................................................................................................8

2.13 Inner Basket...................................................................................................................8

2.14 Outer Tub.......................................................................................................................9

2.15 Console..........................................................................................................................9

2.16 Agitator...........................................................................................................................9

2.17 Fabric Softener Dispenser .............................................................................................9

2.18 Electric Supply ............................................................................................................... 9

2.19 User Information ............................................................................................................9

2.20 Lid Lock..........................................................................................................................9

2.21 Control Panel – (EcoSmart) ........................................................................................9

3 TECHNICAL OVERVIEW ......................................................................................................10

3.1 Electronics ...................................................................................................................10

3.2 Stand By Mode ............................................................................................................11

3.3 Out of Balance Detection – ‘Bump Detect’...................................................................11

3.4 Water Temperature Sensing........................................................................................11

3.5 Water Valves................................................................................................................12

3.6 Recirculating Valve ...................................................................................................... 12

3.7 Water Level Measurement...........................................................................................13

3.8 Motor............................................................................................................................ 14

3.9 Pump............................................................................................................................16

3.10 Lid Lock........................................................................................................................16

3.11 Inner Basket and Outer Tub......................................................................................... 16

3.12 Agitator.........................................................................................................................18

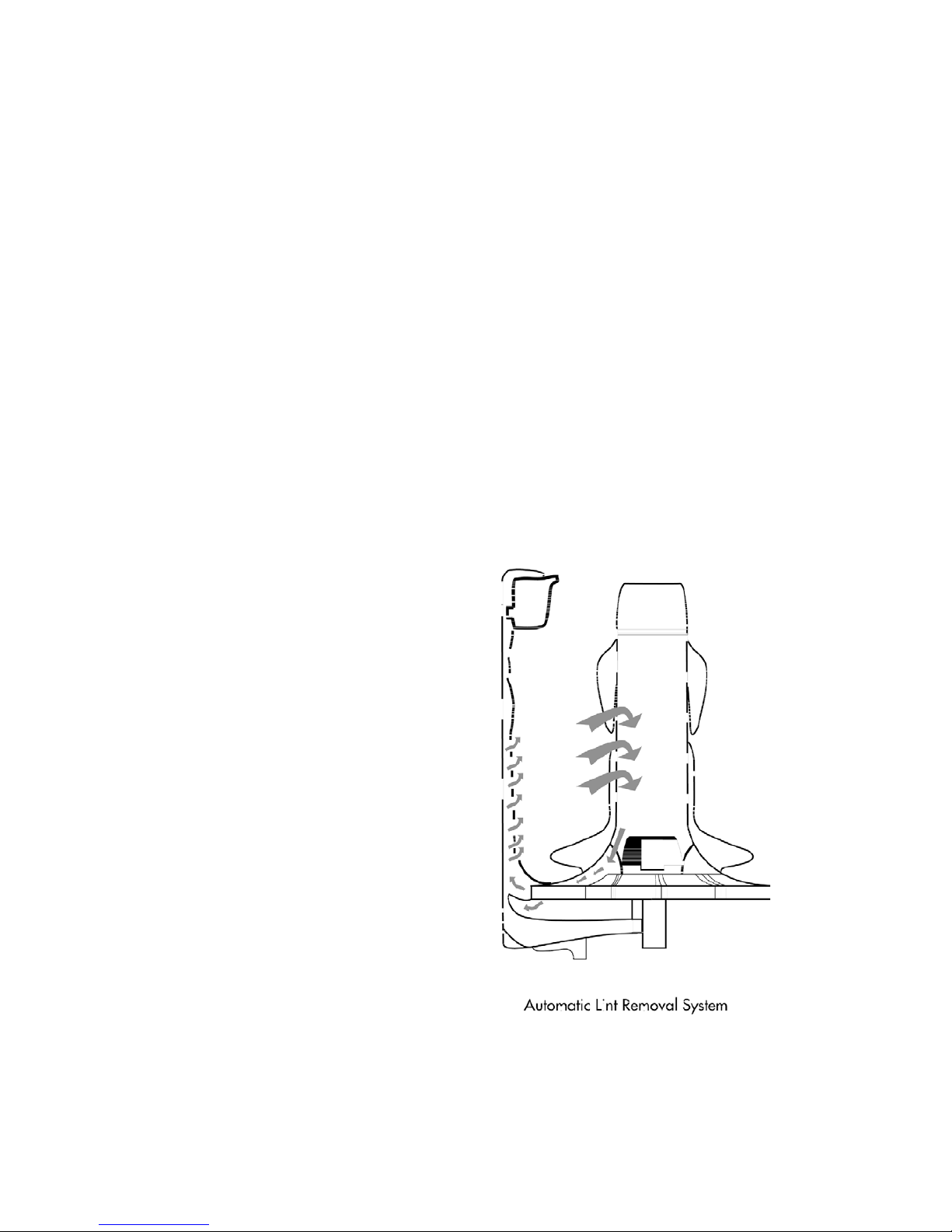

3.13 Lint Removal System ...................................................................................................18

3.14 Fabric Softener Dispensing.......................................................................................... 19

4 SIZE SETTING MODE ...........................................................................................................20

5 DIAGNOSTIC MODE .............................................................................................................20

5.1 Last Fault Data.............................................................................................................20

5.2 Drain Pump Test .......................................................................................................... 21

5.3 Water Valve Test .........................................................................................................21

5.4 Recirculation Valve Test .............................................................................................. 21

5.5 Restart Feature............................................................................................................ 21

5.6 Recycle Feature........................................................................................................... 22

5.7 Hot Basket Flag ...........................................................................................................22

5.8 Data Download ............................................................................................................22

5.9 User Warnings ............................................................................................................. 23

5.10 Diagnostic Table .......................................................................................................... 25

5.11 Voltage Readings from the Controller.......................................................................... 27

5.12 Resistance Readings from the Controller ....................................................................28

5.13 Binary Decoding Chart – 8 Bits (0-255) .......................................................................29

6 WIRING DIAGRAM................................................................................................................30

7 DETAILED FAULT CODES...................................................................................................31

7.1 Fault Descriptions ........................................................................................................ 31

479602

5

8

SERVICE PROCEDURES ..................................................................................................... 42

8.1 Removal of Lid............................................................................................................. 42

8.2 Components in Console Area...................................................................................... 42

8.3 Removal of Display Module......................................................................................... 42

8.4 Removal of Water Valves ............................................................................................ 43

8.5 Removal of Recirculating Valve................................................................................... 43

8.6 Removal of Thermistor ................................................................................................43

8.7 Removal of Motor Control Module............................................................................... 44

8.8 Removal of Cord Set ...................................................................................................44

8.9 Removal of Lid Lock .................................................................................................... 45

8.10 Removal of Top Deck .................................................................................................. 45

8.11 Removal of Neck Ring ................................................................................................. 46

8.12 Removal of Agitator ..................................................................................................... 46

8.13 Removal of Inner Basket ............................................................................................. 46

8.14 Removal of Clutch Mechanism (Spline Drive / Spline Driven)..................................... 46

8.15 Removal of Pump Hood............................................................................................... 47

8.16 Removal of Outer Tub from the Cabinet...................................................................... 47

8.17 Removal of Rotor......................................................................................................... 48

8.18 Removal of Stator ........................................................................................................ 48

8.19 Removal of Pump ........................................................................................................ 48

9 SPECIALISED SERVICE PROCEDURES ............................................................................ 50

9.1 Blocked Pump Procedure............................................................................................ 50

9.2 Shaft & Bearing Replacement .....................................................................................51

9.3 Shaft & Bearing Assembly........................................................................................... 53

10 WASH PERFORMANCE INFORMATION............................................................................. 55

10.1 Creasing ......................................................................................................................55

10.2 Soiling.......................................................................................................................... 55

10.3 Linting .......................................................................................................................... 55

10.4 Detergent Residue....................................................................................................... 55

10.5 Black Marks on Clothes ............................................................................................... 55

10.6 Grey Marks on Clothes ................................................................................................ 55

10.7 Dye Transfer ................................................................................................................ 55

10.8 Tangling....................................................................................................................... 55

11 OPERATING PROBLEMS .................................................................................................... 56

11.1 No Power ..................................................................................................................... 56

11.2 Flooding / Leaking .......................................................................................................56

11.3 Noisy............................................................................................................................ 56

11.4 Continuous or Slow Spinning....................................................................................... 57

11.5 Siphoning..................................................................................................................... 57

479602

6

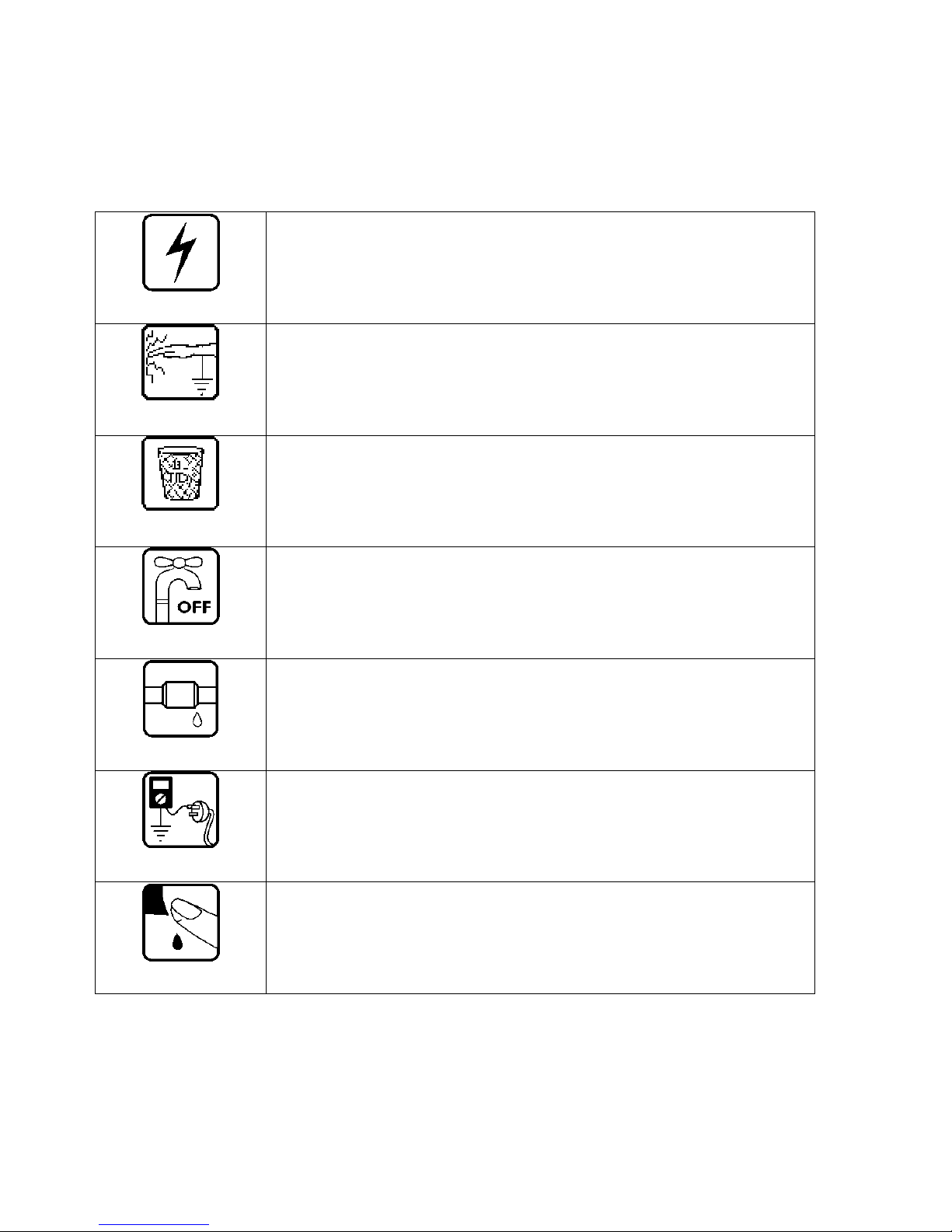

1 HEALTH & SAFETY

When servicing the Designer series Range Hood, health & Safety issues must be considered at all

times. Specific safety issues are listed below with the appropriate icon.

Electrical Safety

Ensure the mains power has been disconnected before servicing the

washer.

If the mains supply is required to be on to service the washer, make sure it

is turned off when removing any electrical component or connection to

avoid electric shock.

Electrostatic Discharge

An anti-static strap is to be used as electrical static discharge (ESD)

protection when servicing electronic components.

Good Working practices

Ensure the work area is in a tidy and orderly condition at all times so as

not to cause a hazard while service work is being completed. Always clean

and tidy the washer and work area after service is completed.

Isolate Water Supply

Turn off the water connection taps before servicing

Water Leak Check

Check for water leaks as part of the testing after the service has been

completed.

Insulation test

Megger test to check insulation

Warning: short together the phase and neutral pins on the plug so not to

damage any electronic circuitry.

Sharp Metal Edges

When working around cut sheet metal edges, use appropriate gloves or

protection to eliminate the change of receiving a laceration.

479602

7

2 SPECIFICATIONS

2.1 Dimensions

Height to lid

Open 55.5in – 56.6in / 1410mm – 1440mm

Closed 37.4in – 38.5 / 950mm – 980mm

Height to console 39.7in – 41.3in / 1010mm – 1050mm

Width 25.5in / 650mm

Depth 25.5in / 650mm

Inlet hose length 47.24in / 1200mm

Packed weight 143.3lb / 60.5kg

Unpacked weight 114.64lb / 52.0kg

Note: Exact height of the machine is dependent on how far the feet are inserted into the

base of the machine.

2.2 Maximum Capacity (Full Load)

Dry Weight 17.6lb / 8kg

2.3 Water Consumption

*Note: Approximate consumption for a high water level load for each rinse option offered.

Fill (High) 23.7 gal / 90 liters

Spray & Deep Rinse 34.3 gal / 175 liters

Water Save 39.6 gal / 150 liters

1 Deep Rinse 43.5 gal / 165 liters

2 Deep Rinse 56.79 gal / 215 liters

2.4 Water Fill Temperature (Approximate Factory Settings)

Supply Water Fill Temp

Hot 130

o

F / 60 oC

Hot / Warm 115

o

F / 50 oC

Warm 105

o

F / 40 oC

Warm / Cold 95

o

F / 35 oC

Cold Plus 60

o

F / 20 oC

Cold Supply temperature

Recommended hot water inlet temperature 149

o

F / 65 oC (Max)

2.5 Wash Motor

Electronically commutated 36 pole direct drive 3 phase brushless DC motor.

Motor Resistance @68

o

F (20oC): 19.5Ω +/- 10% (39Ω +/- 3.95Ω across any two phases)

2.6 Pump Motor

Part Number Voltage Frequency Resistance

420325P 110V AC 60Hz 7Ω +/- 8% @ 68

o

F / 20oC

Note: Thermal cut-out fitted

479602

8

2.7 Water Valves

Supply Mode of Operation Voltage Resistance Flow Rate

Cold Digitally Operated 24V DC 64Ω @ 68

o

F / 20oC 4.2 Gallons per minute

Hot Digitally Operated 24VDC 64Ω @ 68

o

F / 20oC 3 Gallons per minute

Note: Flow rate will vary slightly depending on pressure.

Operating pressures: Maximum 150psi / 1034 kPa - Minimum 5psi / 34 kPa

Note: Pressures below 5psi / 34kPa can create seating problems with the internal

diaphragm of the valve, and may cause water to drip into the inner basket when the

machine is not in use.

2.8 Recirculating Valve

Supply Mode of Operation Voltage Resistance

Recirculates Wax Solenoid 160V DC 1.7KΩ @ 68

o

F / 20oC

2.9 Thermistor

NTC-type temperature sensor (Thermistor) Resistance 10KΩ @ 77oF / 25oC

2.10 Cabinet

Pre-painted steel

2.11 Lid

ABS plastic

2.12 Top Deck

Polypropylene

2.13 Inner Basket

Stainless steel: Grade 430T

Basket base and balance ring: Polypropylene

The inner basket on the large machine has a

series of small bumps around the base of the

inner basket. These bumps are designed to

improve wash performance by increasing load

turnover and movement.

Note: The inner basket is backwardly

compatible with all earlier large machines.

479602

9

Inner Basket Weight

Large 23.10lb +/- 9.7oz / 10.480kg +/- 275g

Inner Basket Speed Heavy Duty Regular Delicate Allergy Permanent Press

Fast Spin 1,000 RPM 1,000 RPM N/A 1,000 RPM 1,000 RPM

Medium Spin 670 RPM 670 RPM N/A 670 RPM 670 RPM

Slow Spin 300 RPM 300 RPM 300 RPM 300 RPM 300 RPM

Stir Speed 25 RPM 25 RPM 25 RPM 25 RPM 25 RPM

2.14 Outer Tub

Aluminium insert over-moulded with polypropylene

2.15 Console

ABS plastic with ABS plastic insert for display module.

2.16 Agitator

Polypropylene

2.17 Fabric Softener Dispenser

Dosage 75cc

2.18 Electric Supply

Operating Voltage 110/120V AC 60Hz

Maximum Current 7.0 amps

2.19 User Information

User Guide 478183

2.20 Lid Lock

Resistance 63Ω +/- 10% @ 68oF / 20oC

Note: Normally low voltage, potentially 110V if harness is grounded on the cabinet!

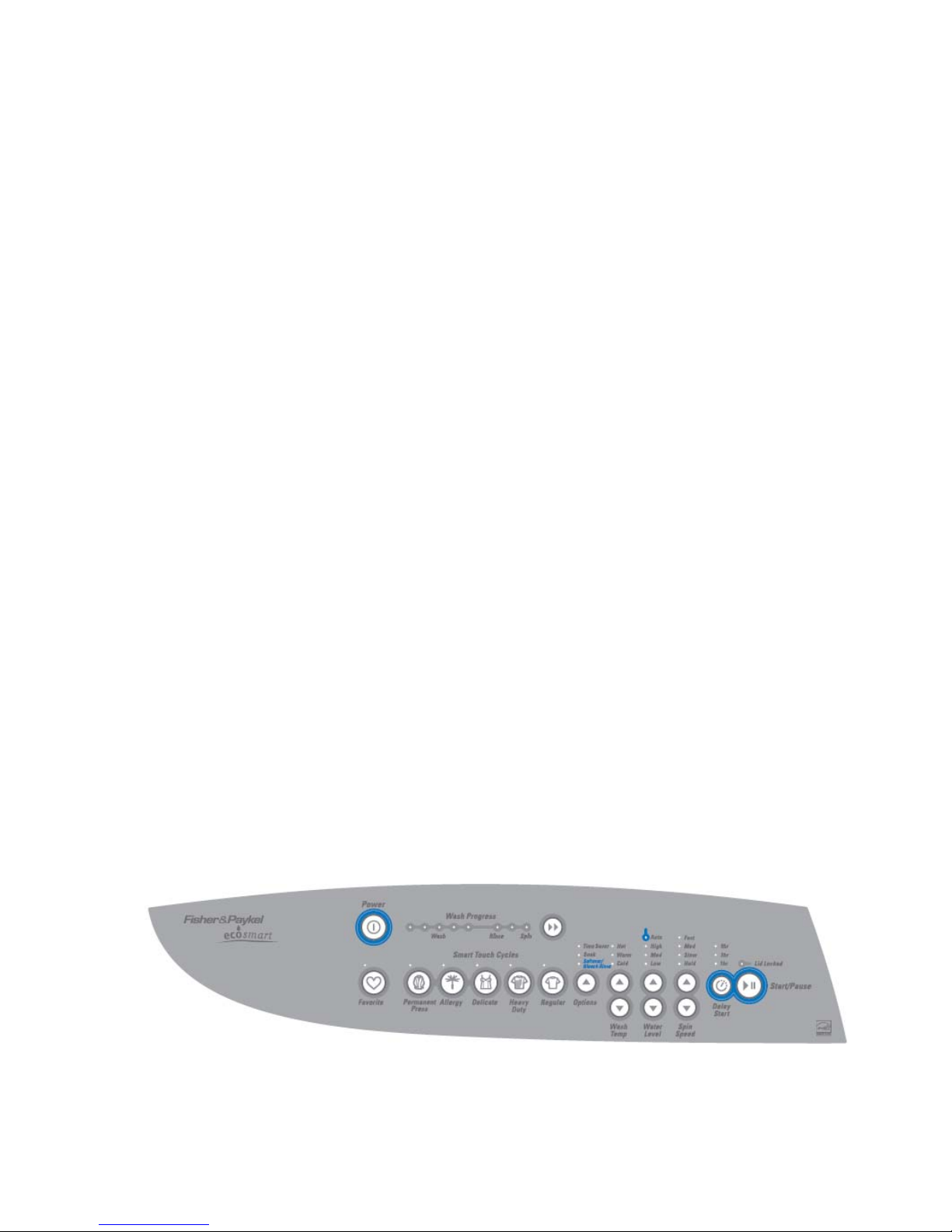

2.21 Control Panel – (EcoSmart)

479602

10

3 TECHNICAL OVERVIEW

This Service Manual contains information on the Product Specifications, Diagnostic Mode, Detailed

Fault Codes and the complete disassembly and assembly instructions for the washing machine.

3.1 Electronics

3.1.1 Motor Control Module

The Motor Control microprocessor performs a wide variety of tasks. Primarily it controls the

electronic switching hardware to control the three phase currents in the Smart Drive DC motor.

The micro can accurately control not only the velocity of the motor but also the acceleration. This

accurate control is required to perform all the different agitator profiles, or wash actions, that are

used for caring for clothes. The Motor Control module performs the functions of fill, wash, drain

spray rinse and spin, when commanded to by the Display.

The Motor Control module microprocessor has a wide range of control with great accuracy over

water level, fill temperature, agitate action and spin speed. Having such control insures the wash

cycle selected provides the optimum soil removal combined with appropriate gentleness for the

washing and care of the clothes load.

The Motor Control Module for this Washer is air-cooled.

This Motor Control Module is not inter-changeable with other any other Series of machine.

Identification

The Motor Control module also has a white label attached to the top of the housing stating P9ECO

(Phase 9, Conventional Pump Eco).

Motor Control Module

Note: When replacing a Motor Control Module ensure that the pressure tube is clear of any

water droplets before operating the machine on a fill cycle. If the basket is full of water

drain the water then blow down the tube before reconnecting the pressure tube.

Ensure you have checked the resistance of all components going to the controller such as

pump, water valves, etc. otherwise controller will short and fail.

3.1.2 Display Module

The Display Module provides the link between

the washing machine electronics and the user.

Input on wash type, water level, spin speed,

start/stop and wash cycle time is given by the

user via the display push buttons.

Feedback on selection is given to the user by

Light Emitting Diodes (LEDs). Sound effects

accompany button presses.

479602

11

3.2 Stand By Mode

If the machine has not received any instructions for 10 minutes after being switched on at the

power point, or after completing the cycle, it will automatically go into a low power “Stand By”

mode. The control panel will be blank as if it was powered off at the wall.

Before entering the Diagnostic or Option Adjustment modes, the machine must be taken out of the

Stand By mode. To do this, the POWER button will have to be pressed, or the machine turned off

and back on at the mains supply point.

3.3 Out of Balance Detection – ‘Bump Detect’

On this machine the Out of Balance detection, is undertaken with electronic sensing, known as

‘Bump Detect’. ‘Bump Detect’ is software written into the Motor Control Module, which looks at

specific feedback from the Motor.

No fault codes are associated with ‘Bump Detect’, and there are no hard and fast tests that can be

carried out.

If a machine continually goes into an out of balance condition then the following needs to be

checked in the order given.

1. Even distribution of the wash load.

2. Ensure that the corner cabs are clear of the floor & machine is sitting on its feet.

3. Ensure that the machine is both level and stable on the floor with feet inserts fitted.

4. Check the weight of the inner basket (23.10 +/- 9.7oz / 10.480kg +/- 275g).

Note: If the OOB problem persists after checking the above, we would then recommend

replacing both the suspension rods and the rotor. It is highly unlikely that the Motor

Control Module will be the cause.

3.4 Water Temperature Sensing

The thermistor for sensing water temperature is

located in the back of the outlet elbow on the

valve assembly, and is connected directly to the

Motor Control Module.

For details on the wash temperature adjustment

Refer to the Use & Care manual.

Specifications

NTC-type temperature sensor (Thermistor)

Resistance 10KΩ @ 77

o

F / 25oC.

3.4.1 Controlled Cold

CONTROLLED COLD OPTIONS

Light color

Green = controlled cold

Amber = uncontrolled cold

This machine is designed for installations that

have both hot and cold water. To ensure

optimum performance even in very cold

weather, the cold-water temperature is

controlled to 60

o

F (20 oC). However if for some

reason you do not have hot water available you

may need to change to uncontrolled cold in very

cold weather.

The machine leaves the factory with the Controlled Cold Option set. To change this settings enter

the Option Adjustment mode and press the ADVANCE button once. Refer to the Use & Care

manual for the various options adjustments available.

479602

12

To enter the option adjustment mode:

1. Plug the machine in but do not press POWER.

2. Press and hold the Start / Pause button, then press the Power button

3. Three quick beeps will be heard and the machine will show an unusual pattern of lights.

4. Carry out any option adjustments necessary.

Refer to the Use & Care manual for the various options adjustments available

5. Press POWER to return to normal mode.

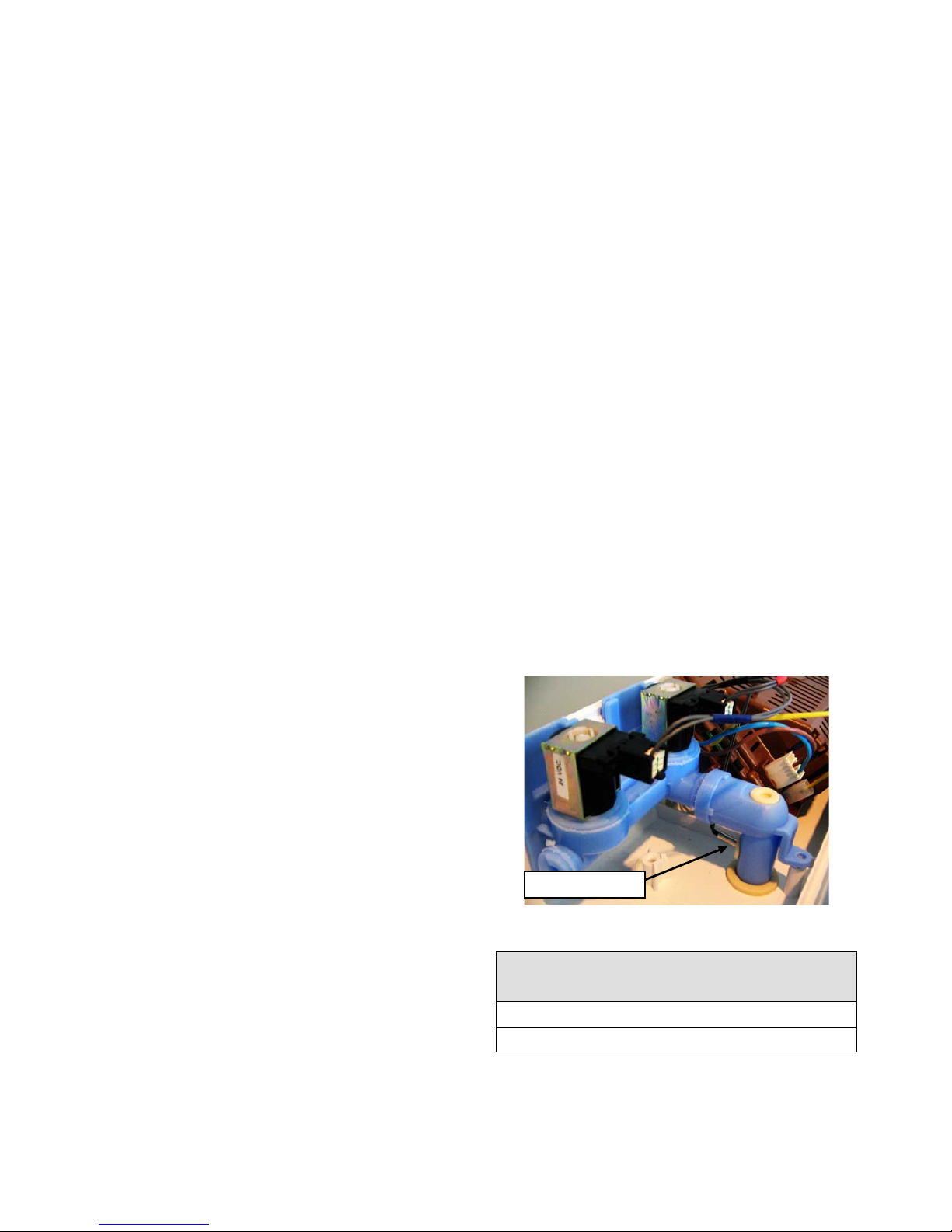

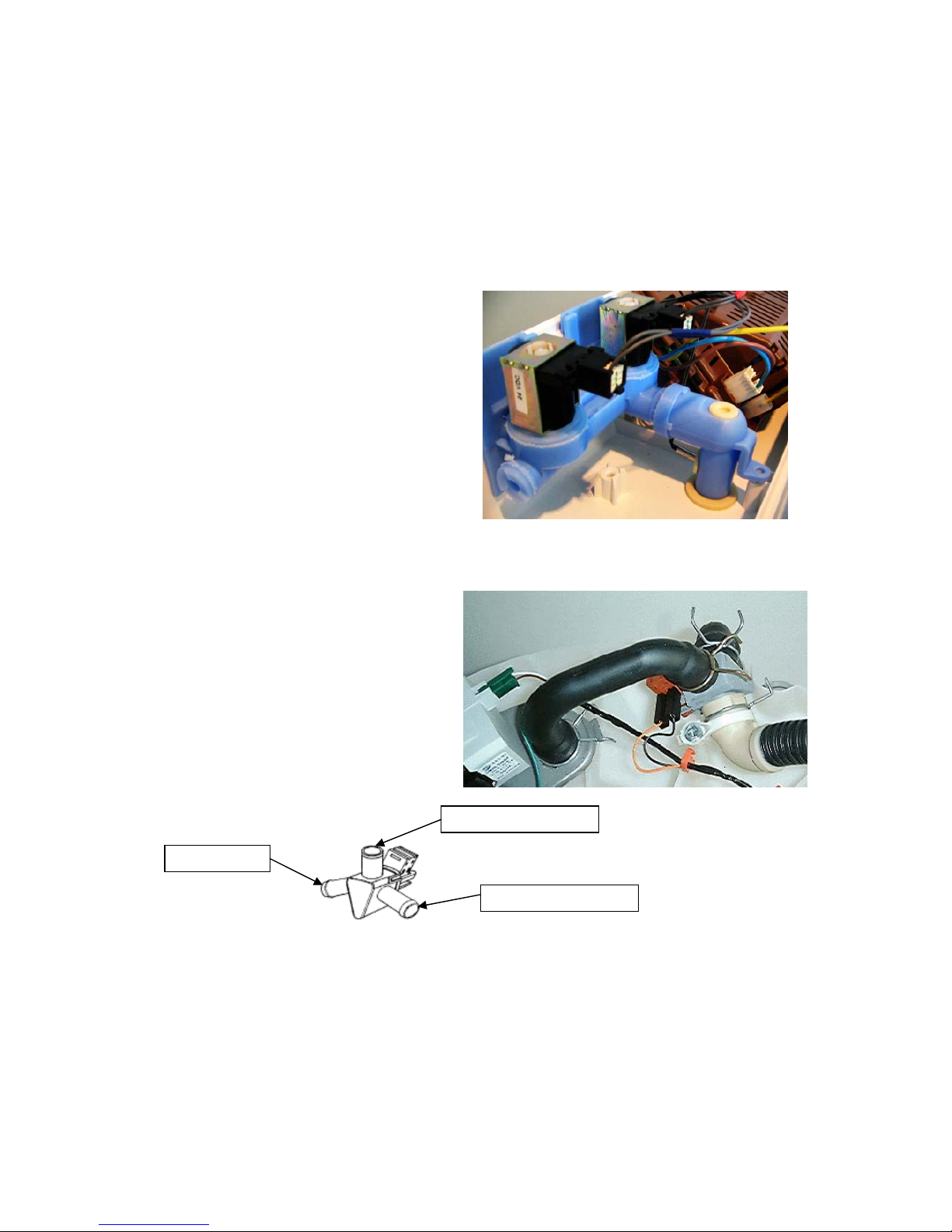

3.5 Water Valves

The machine uses a dual valve block assembly.

Independent coils control the hot and cold water

supply, which feeds the water through a

common outlet.

The valve block has a location feature for the

thermistor.

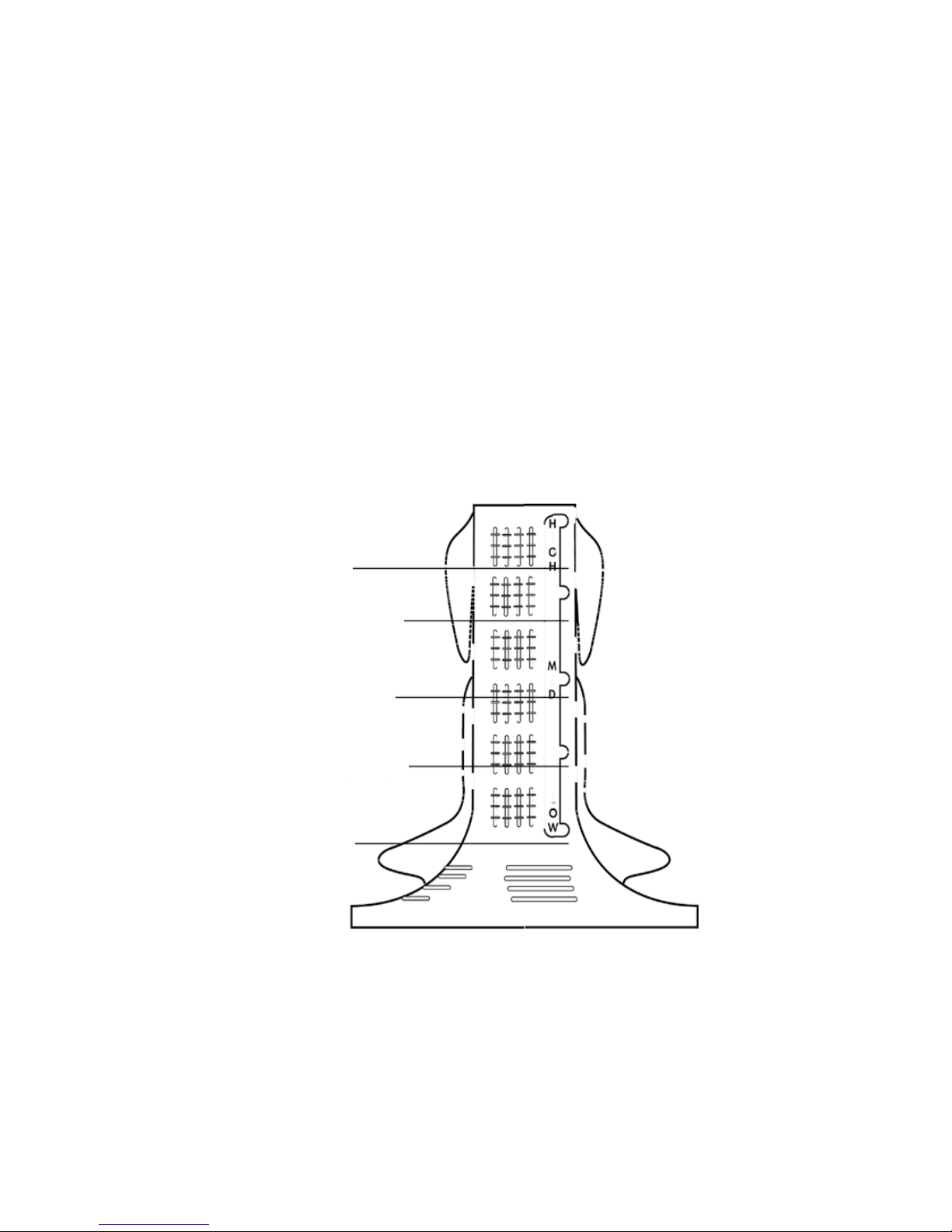

3.6 Recirculating Valve

The Recirculating Valve is situated at the

bottom of the Tub beside the Pump. It consist of

a wax solenoid which heats up and moves a

flapper to close off the drain enabling the water

to be recirculated back into the inner basket,

with the pump running. When powered on there

is 160 volts DC across the terminals.

NB: The Valve takes approximately 1 minute

to activate and 3 minutes to cool down and

return to its normal position.

479602

13

3.7 Water Level Measurement

The machine is fitted with a pressure sensor, which can control the fill to any water level. The

pressure sensor is incorporated within the Motor Control Module and cannot be removed. The

pressure tube connects from the Motor Control Module to the air bell at the bottom of the outer tub,

and is part of the harness assembly. Care must be taken when removing or refitting the pressure

tube to the pressure sensor as too much force can damage the device.

3.7.1 Manual Water Level

The agitator has 5 levels marked on its stem that can be used to help the user select the correct

water level. Select the correct water level by using the mark nearest to the top of the clothes.

The levels marked on the agitator are a guide for the clothes and do not correspond exactly to the

water level.

Occasionally water may be added during agitation. This is to maintain the water level due to the

release of air trapped in the garments.

For example: If the garments sat between the medium and high marks on the agitator, choosing a

medium water level would be better than choosing a high water level. Alternatively additional

garments could be added so that the garments were brought closer to the high mark.

Water Level Settings

Tolerance for each water level = +/- .59in / 15mm

High 2.12in / 54mm

Medium High 4.13in / 105mm

Medium 6.69in / 170mm

Medium Low 9.64in / 245mm

Low 11.81in / 300mm

479602

14

3.7.2 Auto Water Level

The machine automatically selects the appropriate water level for the load when AUTO Water

Level is selected, and will choose one of the pre-existing 5 water levels (low, medium low, medium,

medium high and high). During fill the machine pauses occasionally to sense the water level. The

machine checks if the water level is correct by using a series of 2 different agitate strokes. A slow

stroke to sense the load and an agitate stroke to mix the load. If the machine detects that the

water level is too low it will fill with more water and check the level again.

When washing an unusual load eg. large bulky garments, pillows, it is recommend that the

water level is manually selected.

Manually select the water level if there is already water in the basket.

If the machine does not fill to the correct level, the auto water level can be adjusted in the Option

Adjustment Mode. Refer to the Use & Care manual for the various options adjustments available.

To enter the option adjustment mode:

1. Plug the machine in but do not press POWER.

2. Press and hold the Start / Pause button, then press Power

3. Three quick beeps will be heard and the machine will show an unusual pattern of lights.

4. Carry out any option adjustments necessary.

5. Press POWER to return to normal mode.

3.8 Motor

3.8.1 Stator

The stator used on this machine is unique to this series only and therefore it is not

interchangeable with any previous phase or series of machines. The stator has 36 poles with the

windings being Aluminium and is Identified by the printed marking AL 60 190T it looks the same as

the copper Stator but is 19.5 per winding.

Stator (36 Poles) Curved pole tips

Testing the Stator

If the stator needs to be tested we would first recommend testing the resistance of the windings at

the harness that is connected to the Motor Control Module. (Refer to Section

5.12).

Note: Ensure that the Rotor and basket are stationary when measurements are made.

Testing the stator from the console

The resistance of each individual winding is approximately 19.5, however when testing the stator

from the console we are testing across two windings therefore the resistance should be

approximately. 39 +/- 10%.

479602

15

To test all windings you will need to measure across:

Red & Blue

Red & Yellow

Blue & Yellow

If the meter shows an incorrect reading we would then recommend testing the stator from

underneath the machine as there could be a fault in the wiring harness. To test the stator, remove

the rotor and stator. Refer to Sections

8.17 and 8.18.

Note: Two clamp plates are used to secure the Stator, one on each side. The four bolts are

tightened to a torque of 5Nm. The plastic bolt for securing the Rotor requires a 16mm

socket and should be tightened to 8Nm.

Testing the Stator

After removing the Stator, it can now be tested.

Test points are:

R (Red) / B (Blue)

B (Blue) / Y (Yellow)

Y (Yellow) / R (Red)

The value should be approx. 39 +/- 10%

across any of the two windings.

3.8.2 Rotor

The rotor is also unique to this machine. It has 48 blocks of individual magnets in a black

moulding.

The rotor is not interchangeable with any previous phase or series of machine.

The rotor can physically be interchanged, however electrically they are incompatible.

The photograph below shows the Rotor used.

Black

39.0

Ω

479602

16

3.9 Pump

The pump is coupled directly to the outer tub.

This eliminates tub to pump hoses and the

accompanying seals, clips etc. The pump

housing is an integral part of the outer tub.

When removing the pump up to a 1/3 of a

Gallon of water may leak from the pump cavity.

When refitting the pump; lubricate the seal face

with liquid soap or detergent (do not use

grease).

Blocked Pump Detection

This is achieved by monitoring the water level

during drain. If the water level has not dropped

by approximately 1/8” within a predetermined

time period (approximately 9-10 minutes), then

the product will report a blocked pump fault.

Note: The Resistance of the pump should

read 7Ω +/- 8%. (Refer to section

2.6)

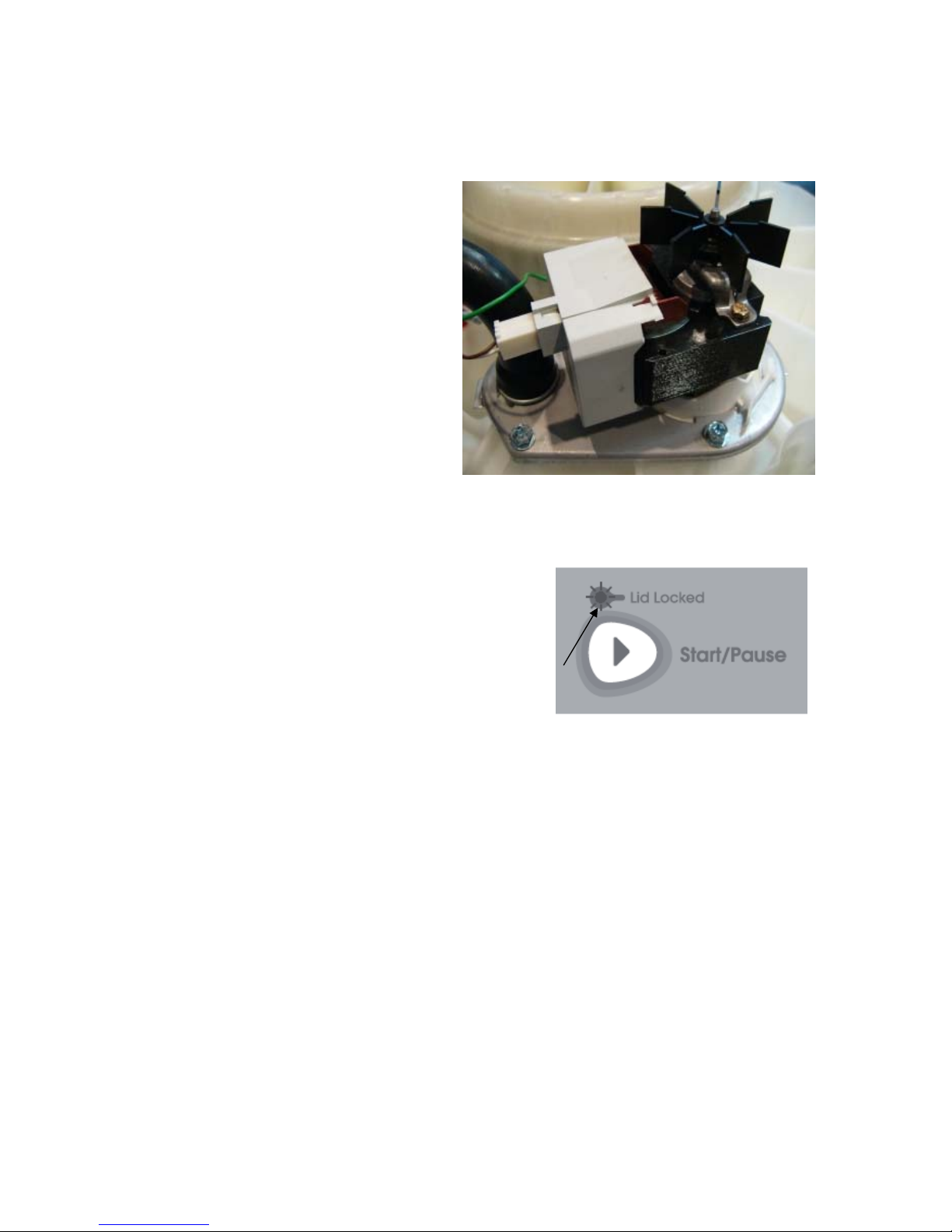

3.10 Lid Lock

The Washer uses a lid lock to secure the lid closed, which is

locked for the entire cycle. When locked the Lid Locked LED

will illuminate. Once the spin has completed, the lock will

release and the lid can be opened. To open the lid during

the cycle the START/PAUSE button must be pressed, the

machine will come to a halt, and the lid locked LED will

extinguish.

If the lid is left open, the machine will be unable to lock the lid

and the cycle will be halted. The machine will play a tune

and the lid lock will flash until the lid is closed and the

START/PAUSE button is pressed.

If the lid-lock fails in the closed position, the locked lid can be forced upwards and out of the

lock. Note: This is the only time in which we would recommend doing this as this action

will DAMAGE the lid lock which will need replacing and the lid tang will need to be

inspected for damage.

If the harness is damaged, the complete lid lock assembly will need to be replaced.

If the power supply is cut during the spin cycle, the machine will keep the lid locked until the rotor

has ceased to turn (3 to 10 secs). Only then will it release the lock. The motor is acting like a

generator and allows the lock to stay energized under the baskets inertia.

In a brown out situation, the machine will restart at the beginning of the section of the cycle it was

on and continue the wash. The lid lock would then be reactivated.

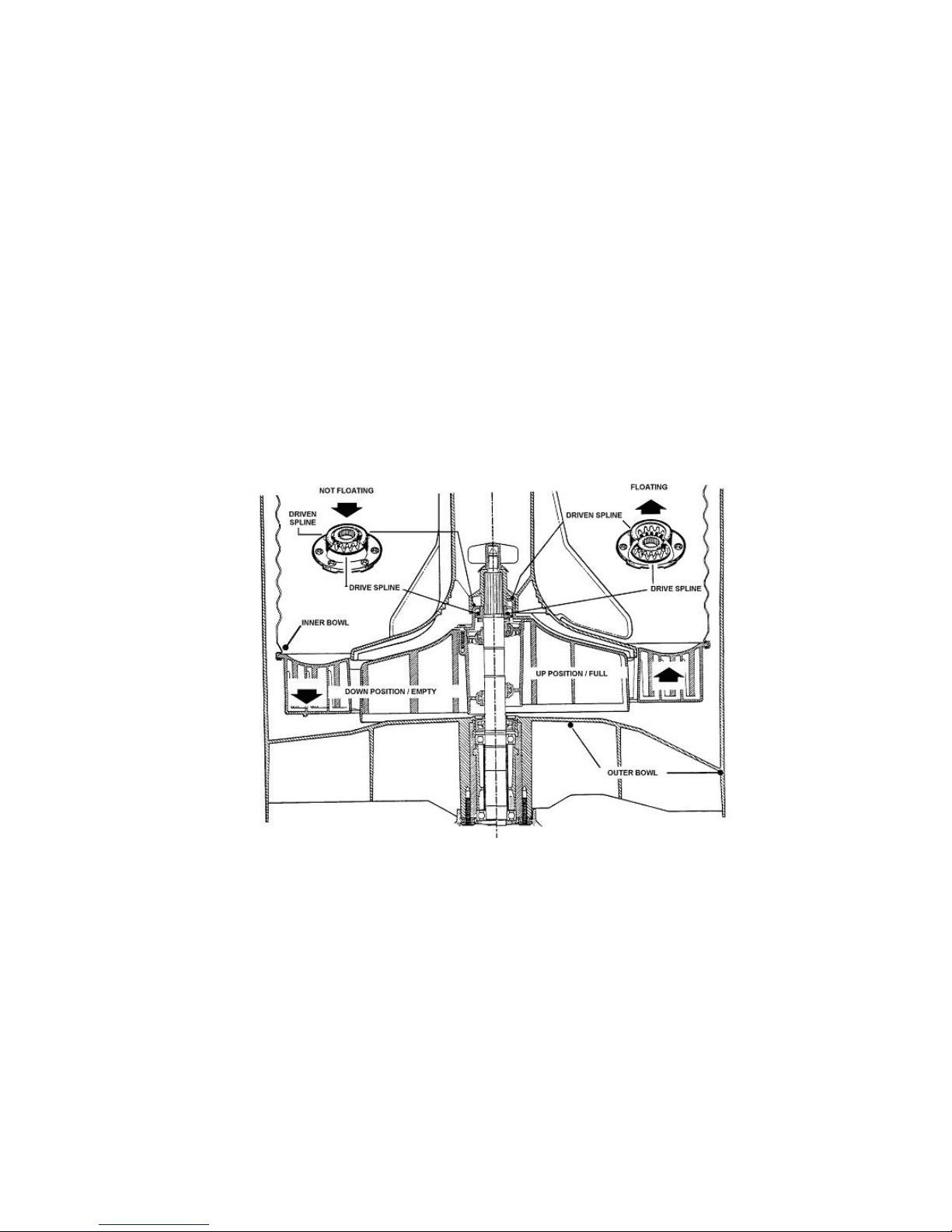

3.11 Inner Basket and Outer Tub

The outer tub is the assembly to which all the motor, pump system, suspension rods, etc are

mounted. Within the outer tub is the inner basket and the agitator. During spin, the agitator and

inner basket have to be coupled together and turn as a single unit. In agitate; the agitator and

inner basket are free to rotate independently.

479602

17

The inner basket is free to move in a vertical direction. The position of the inner basket is

determined by the water level. At the base of the inner basket is a flotation chamber consisting of

a number of individual cells. When the machine is filling with water, the pressure on the air in

these cells increases as the water level rises until eventually the inner basket floats upwards and

disengages the driven spline from the drive spline. This action frees the agitator from the inner

basket and allows it to move freely in both directions.

When the water is draining, the pressure on the air trapped in the cells of the flotation chamber

decreases allowing the inner basket to settle back down onto the drive spline and re-engage the

driven spline, thus allowing the agitator and inner basket to turn as one unit. The floating basket is

also used to detect if the user has selected the correct water level for the size of the clothes load.

The point at which the basket starts to float is determined by the water level and the size of the

load. The greater the load, the more water is needed before the inner basket will float. By

detecting the point at which the basket floats, the machine can determine whether the correct

water level for the particular clothes load has been chosen by the operator. If the operator has

chosen a level that is too low for the load, the machine will override that choice and fill to the

correct level. This is to ensure optimum wash performance and minimal clothes wear. If the user

has selected a level that is higher than necessary, the machine will still fill to the users selected

level.

3.11.1 Detection of Inner Basket Float off Point – Basket Check

During fill the inner basket will rotate to ensure that the clothes are evenly saturated with water.

When the chosen water level is reached, and before the agitate cycle is started, the machine will

carry out inner basket float checks (basket check). The inner basket will stop and commence a

number of small agitate type actions. During this action the machine determines if the inner basket

has floated. If it has the machine will determine the required water level and check if the operator

has selected the correct level. If the inner basket has not floated, the machine will continue filling

and check again later. The water level at which the inner basket floats is not necessarily the same

as the final water level.

3.11.2 Detection of Inner Basket Re-Engagement – Basket Check

After the water has drained, the inner basket will sink down and re-engage onto the drive spline.

To ensure the inner basket has re-engaged correctly, the machine will carry out a basket reengage test sequence (basket check). Basket check consists of a series of short agitate type

actions before the spin cycle starts. A sound may be heard as the inner basket re-engages.

479602

18

3.11.3 Balance Rings

The inner basket has 2 balance rings, one at the top, and one at the bottom. These are sealed

compartments half full of water. This water allows the basket to balance. If one or both of these

rings have lost water then the inner basket must be replaced. The easiest way to determine a loss

of water is to weigh the baskets on an accurate set of scales.

Inner Basket Weight: 23.10lb +/- 9.7oz / 10.480kg +/- 275g

3.12 Agitator

The agitator design differs from conventional designs in that it is made of very flexible plastic that

bends and flexes as the clothes are moved around the basket. The agitator action is similar to that

of a fish moving through the water, so the side-wards motion is translated to forward thrust. This

is not only more forgiving on the clothes but helps to slowly move the clothes around the basket in

a toroidal motion, i.e. a vertical circular motion. The fins at the top of the agitator pull the clothes

on the surface of the water inwards and then push them downwards. The bottom fins then push

the clothes towards the outside of the basket again and back up to the surface.

The agitator also features guides on the side to help the user choose the correct water level for

each load size. The guides relate to the level that the dry clothes come up to, which relates back

to the correct water level. The agitator also gives the user information when measuring detergent,

to ensure that they dose correctly for the load size.

3.13 Lint Removal System

The machines self cleaning lint removal system

works by continuous water circulation, resulting

in the separation of lint from the wash water. As

the agitator moves, the specially designed

vanes on the bottom create turbulence. The

agitator acts as a centrifugal pump, circulating

the wash water.

As a result of the agitator action, lint and wash

water are sucked into the agitator stem and

down to the base where they are directed into

the cavity between the inner basket and outer

tub. The extruded holes of the inner basket are

shaped to allow the wash water to flow back into

the basket, but prevent the lint from following.

The lint then floats to the surface of the water

between the inner and outer basket and

remains there until it is flushed out the drain at

the end of the wash cycle.

Loading...

Loading...