Fisher & Paykel RS1884FLJ1, RS1884FRJ1, RS1884FRJK1, RS2484FLJ1, RS2484FRJ1 Installation Guide

...

INTEGRATED COLUMN

REFRIGERATOR & FREEZER

RS2484S, RS2484SH, RS084S, RS084SH

RS1884F, RS2484F & RS084F

REFRIGERATOR-FREEZER

RS084W & RS084W

WINE CABINET

RS2484V

INSTALLATION GUIDE

US CA

CONTENTS

Safety and warnings 4

Integrated refrigerator & freezer 5

Integrated refrigerator-freezer 6

Integrated wine cabinet 6

Supplied parts 7

Required parts 8

Door panel kit 9

Handle kit 10

Hinge change kit 11

Wine display accessories 11

Tools 12

Product dimensions 13

Cabinetry dimensions — Single installation 14

Cabinetry dimensions — Multiple installation 15

Stainless steel Door panel dimensions — Single installation 16

Custom Door panel dimensions — Single installation 17

Custom Door panel dimensions — Multiple installation 18

Toe kick dimensions 19

Installation options 20

Door clearance 21

Drawer clearance 21

Electrical and plumbing 22

Custom door panel install dimensions 23

Before installation 28

Cavity preparation 30

Appliance preparation 31

Door panel preparation — Stainless steel panel 33

Door panel preparation — Custom panel 34

Door panel preparation — Wine cabinet only 35

Power and water supply connection 37

Install water filter 38

Single installation — Align appliance into cabinetry 39

Single installation — Secure appliance into cabinetry 41

door panel installation 42

Toe kick installation 44

Grilles installation 46

Carbon filter installation 47

Air flow divider installation 47

Cabinet trims installation 48

Top trim & hinge pocket covers installation 50

Multiple installation — Appliance preparation 51

Multiple installation — Align first appliance into cabinetry 52

Multiple installation — Secure first appliance into cabinetry 53

Multiple installation — Align second appliance into cabinetry 54

Multiple installation — Secure second appliance into cabinetry 55

Multiple installation — Install cabinet trims 56

Wine display for Wine cabinet (optional) 57

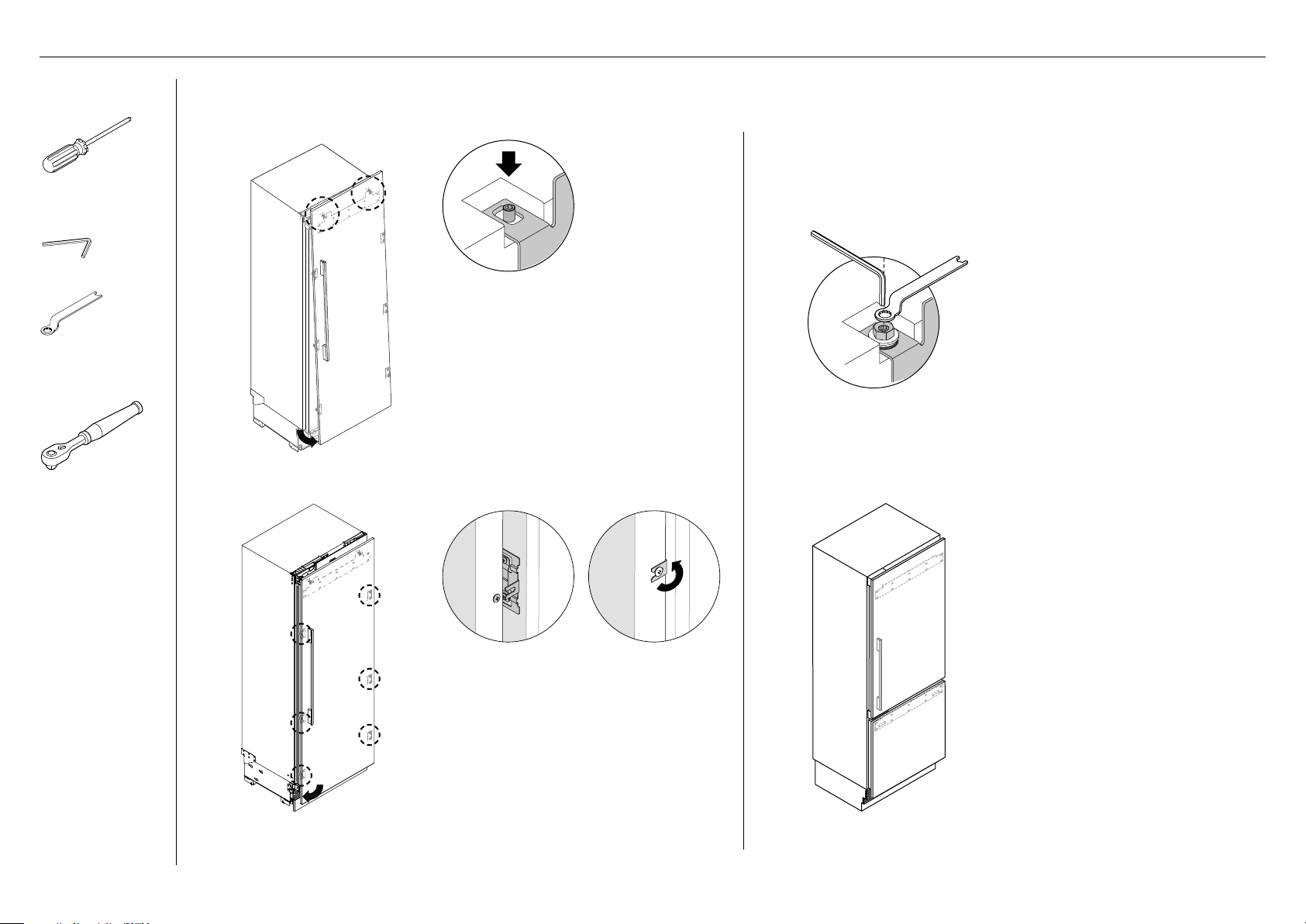

Change the door hinges (optional) 58

Final checklist 63

3

SAFETY AND WARNINGS

!

WARNING!

Electric Shock Hazard

Failure to follow this advice may result in

electrical shock or death.

• Read and follow the safety and warnings

outlined in this User guide before operating this

appliance.

!

WARNING!

Cut Hazard

Failure to use caution could result in injury.

• Take care: panel edges may be sharp.

• Do not put fingers in the drawers when closing.

!

WARNING!

Tip Hazard

• This product may tip. Keep children away and

take care. Failure to follow this advice may

result in injury.

• This appliance is top-heavy and must

be secured to prevent the possibility of

tippingforward.

To ensure that the appliance is stable under

all loading conditions:

• Theanti-tip bracket and fittings supplied

must be installed by a professional installer

according tothe installation steps in this guide.

READ AND SAVE THIS GUIDE

WARNING!

To avoid hazard, follow these instructions carefully before Installing or using thisappliance.

z

Please make this information available to the persons installing the appliance.

z

Assume all electrical parts are live.

z

Disconnect power supply before servicing and installation.

BEFORE INSTALLATION

z

The appliance has front and rear rollers to easily move forward and backward. Do not

move the appliance sideways to avoid damaging the rollers or the floor covering/surface.

z

Ensure your appliance is not exposed to any heat generating appliance eg cooktop, oven

or dishwasher.

z

The appliance must be installed by a qualified installer, or Fisher and Paykel trained and

supported service technician to avoid faulty electrical and plumbing connections.

z

All connections for electrical power and grounding must comply with local codes and

ordinances and be made by licensed personnel when required.

z

Avoid installation of the appliance/s under a ground fault circuit interrupter (GFCI).

z

Ensure the appliance is installed properly. Improper installation that results in appliance

failure is not covered under the appliance warranty.

UNPACKING

z

The appliance is heavy and requires at least twopersons to move and install.

z

Remove the installation kit (internal box) and trims kit (external box) while the product is

still on the pallet.

z

Avoid scratching the surface of your appliance when moving or installing.

z

Keep the appliance stable and door closed to prevent tipping over when moving to the

installation location.

z

Ensure the feet of the appliance are retracted before moving to the installation location.

z

If the appliance is damaged, contact your Fisher and Paykel dealer.

z

Ensure all components and accessories are complete. Refer to 'Before installation' page.

z

Record the default Wifi password, and the model and registration numbers for future

servicing or repair of your appliance.

ELECTRICAL/PLUMBING

z

We recommend to locate the electrical and water supply connections of the appliance in

an adjacent area or unit (cabinet or cupboard) that are easily accessible in case of repair

or disconnection.

z

Ensure an isolating switch is available if electrical connection is not easily accessible.

4

SAFETY AND WARNINGS

INSTALLATION

z

The anti-tip bracket and fittings supplied must be fitted tothe wall of the finished

enclosure to withstand a 220lbs (100kg) load.

z

Ensure that the anti-tip bracket is installed correctly to prevent the possibility of the

appliance tipping forward when the door is open.

z

Ensure the door of the appliance is closed when rolling into thecabinetry.

z

Ensure the power cord is not run over or damaged when rolling the product into

the cabinetry.

z

For flush installation, ensure the door panels are installed flush with cabinetry front surface.

Ensure the appliance is properly centered.

z

All four corners of the appliance must be supported firmly on the floor to eliminate any

movement. Installing the appliance on a soft, uneven, or not level floor may cause twisting

and poor door sealing.

z

Use low speed, low torque setting when using a powered driver for the screws when fixing

or aligning the product.

z

Open the appliance door to remove the alignment brackets from both sides of the

appliance, and then re-tighten the screws.

z

When removing the top door extrusion, ensure the magnet remains in place and not

damaged as this will affect the operation of the appliance.

Stainless steel panel

z

Protect the finish of the Fisher and Paykel Stainless Steel door panels from any scratch

or damage.

z

Remove the blue tape attached to inner edges of the door panels after the handles are

installed.

z

We recommend to load the shelves in the appliance door with weights to ensure an

accurate door panel gap width. Load 33lbs (15kg) for 24" models, and 44lbs (20kg) for

30" models.

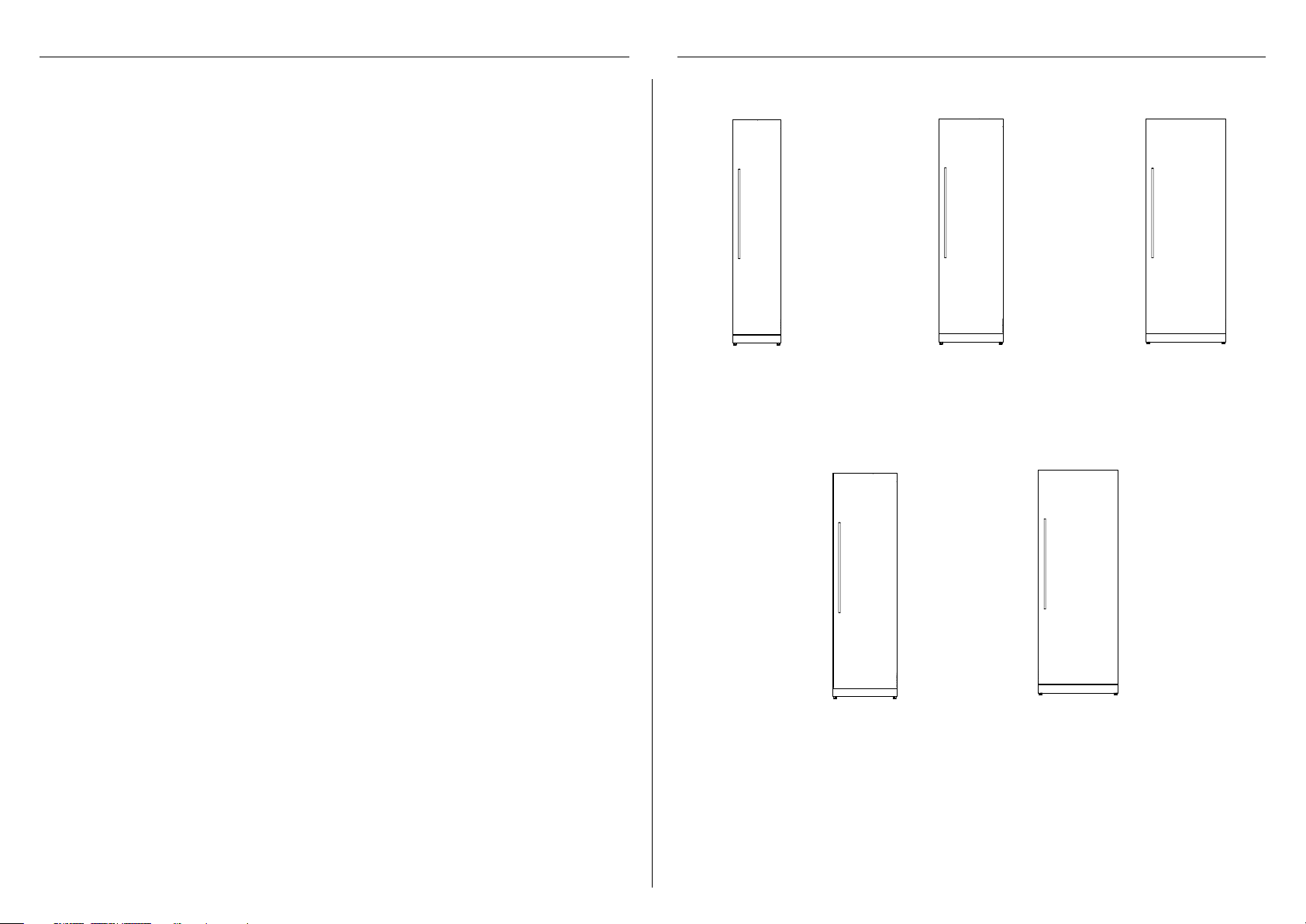

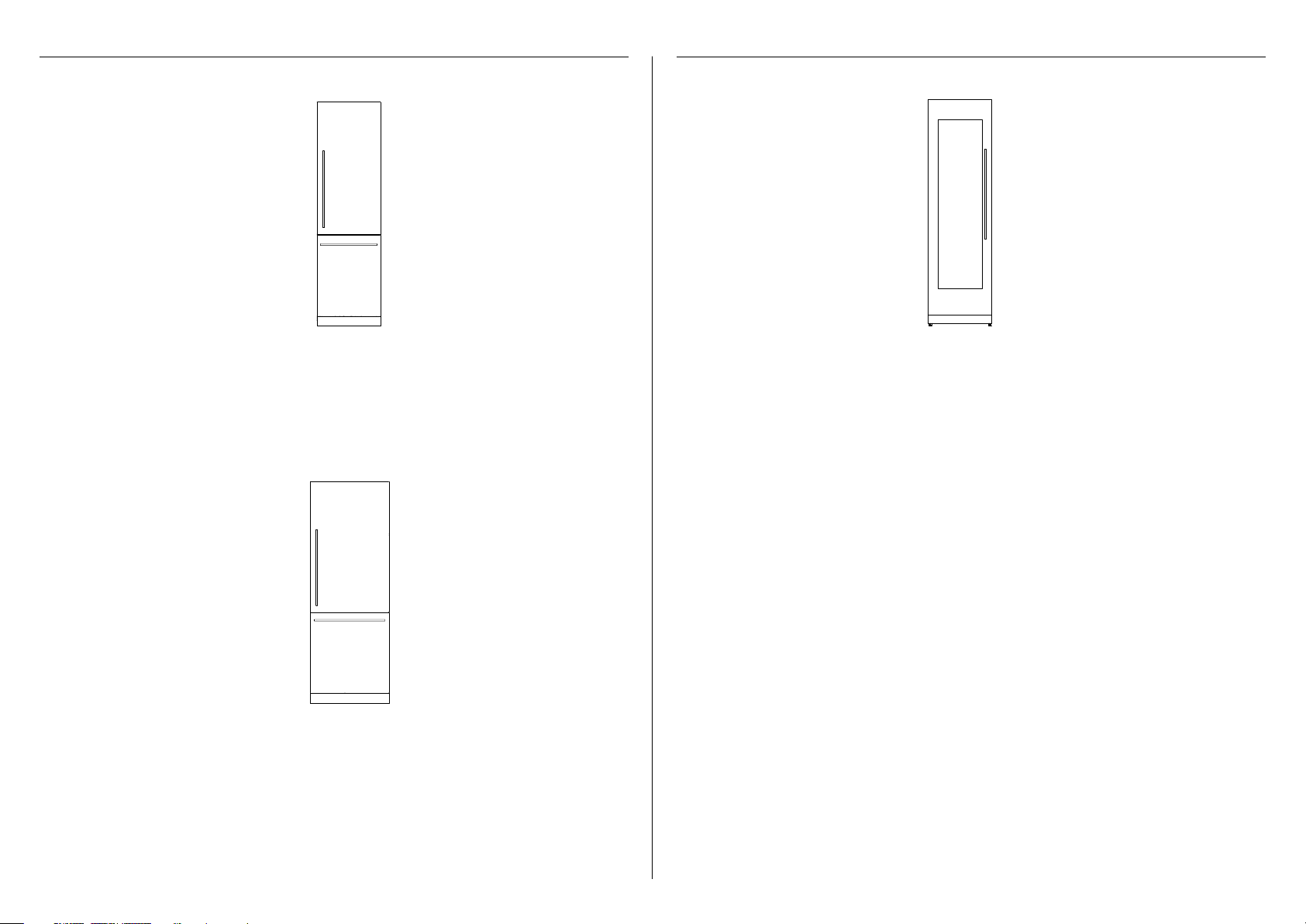

INTEGRATED REFRIGERATOR & FREEZER

18" Freezer

RS1884FLJ1, RS1884FLJK1,

RS1884FRJ1 & RS1884FRJK1

24" Freezer

RS2484FLJ1, RS2484FLJK1,

RS2484FRJ1 & RS2484FRJK1

30" Freezer

RS3084FLJ1, RS3084FLJK1,

RS3084FRJ1 & RS3084FRJK1

Custom panel

z

If using Custom door panels, ensure they are prepared as per 'Custom door panel install

dimensions' section.

z

The thickness of the custom door panel can vary as long as the screws do not penetrate

beyond the full depth of the door panel, and as long as the overall weight of door panel

does not exceed the allowable weight. Refer to 'Door panel dimensions' for maximum door

panel weight of your product.

z

Do not place the handle holes in marked areas to avoid clashing with panel

attachment brackets.

z

Minimum panel thickness where screw hole is drilled must be 5/8" (16mm).

Changing the door hinge (optional)

z

Door hinges are interchangeable for each model. A hinge change kit is available and can be

purchased separately if you prefer to change from ‘right hinge door’ to ‘left hinge door’ or

vice versa.

24" Refrigerator

RS2484SL1, RS2484SLK1,

RS2484SLHK1, RS2484SRHK1,

RS2484SR1 & RS2484SRK1

Left or Right hinged door available for each model.

30" Refrigerator

RS3084SL1, RS3084SLK1,

RS3084SLHK1, RS3084SRHK1,

RS3084SR1 & RS3084SRK1

5

INTEGRATED REFRIGERATOR-FREEZER INTEGRATED WINE CABINET

24" Refrigerator-Freezer

RS2484WLU1, RS2484WLUK1,

RS2484WRU1 & RS2484WRUK1

30" Refrigerator-Freezer

RS3084WLU1, RS3084WLUK1,

RS3084WRU1 & RS3084WRUK1

24" Wine Cabinet

RS2484VL2K1 & RS2484VR2K1

Left or Right hinged door available for each model.

6

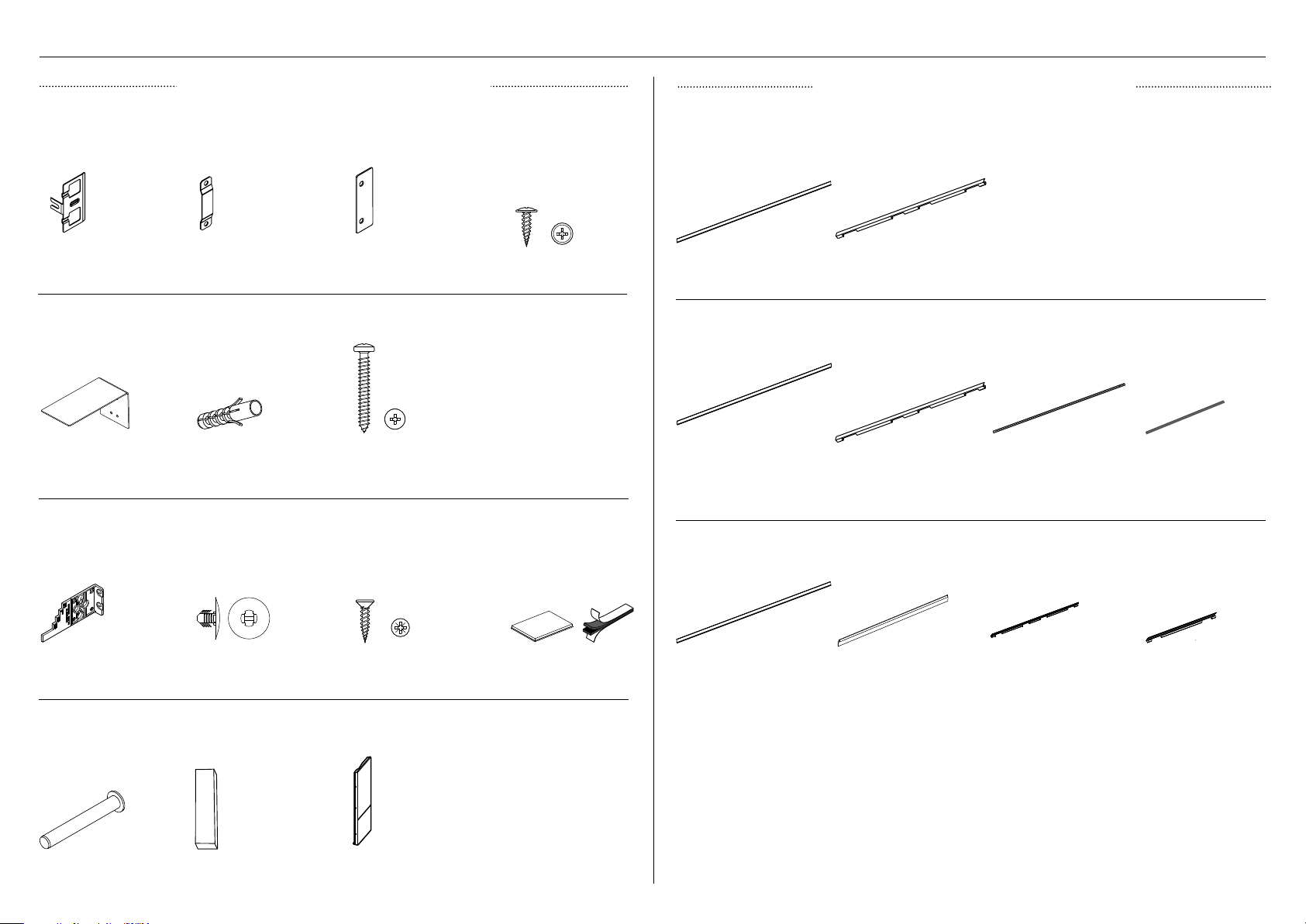

SUPPLIED PARTS

INSTALLATION KIT (INTERNAL BOX)

Door panel attachment kit Refrigerator or Freezer

Side bracket (7x)

Bracket slider (7x)

Anti-tip bracket assembly

Anti-tip bracket (1x)

Masonry plug (5x)

Install fasteners kit

Side spacer

bracket (7x)

10-12x35mm

crosshead screw (5x)

M5x12 Cross-head

screw (35x)

Wine Cabinet

Cabinet side trim (2x) Door panel side

TRIMS INSTALL KIT (EXTERNAL BOX)

Door panel side cover (2x)Cabinet side trim (2x)

Long glass trim (2x) Short glass trim (2x)

cover (2x)

Depth alignment

gauge (4x)

Miscellaneous parts

Hinge limiting pin (3x)

Barbed plug (2x)

Air toe kick seal (1x)

8Gx16 Countersunk

screw (7x)

Flow divider cap (1x)

Dual adhesive

strips (8x)

Refrigerator-Freezer

Cabinet side trim (2x) Drawer top trim (1x)

Door panel side

cover (2x) with

magnets

Drawer panel side

cover (2x) with

magnets

7

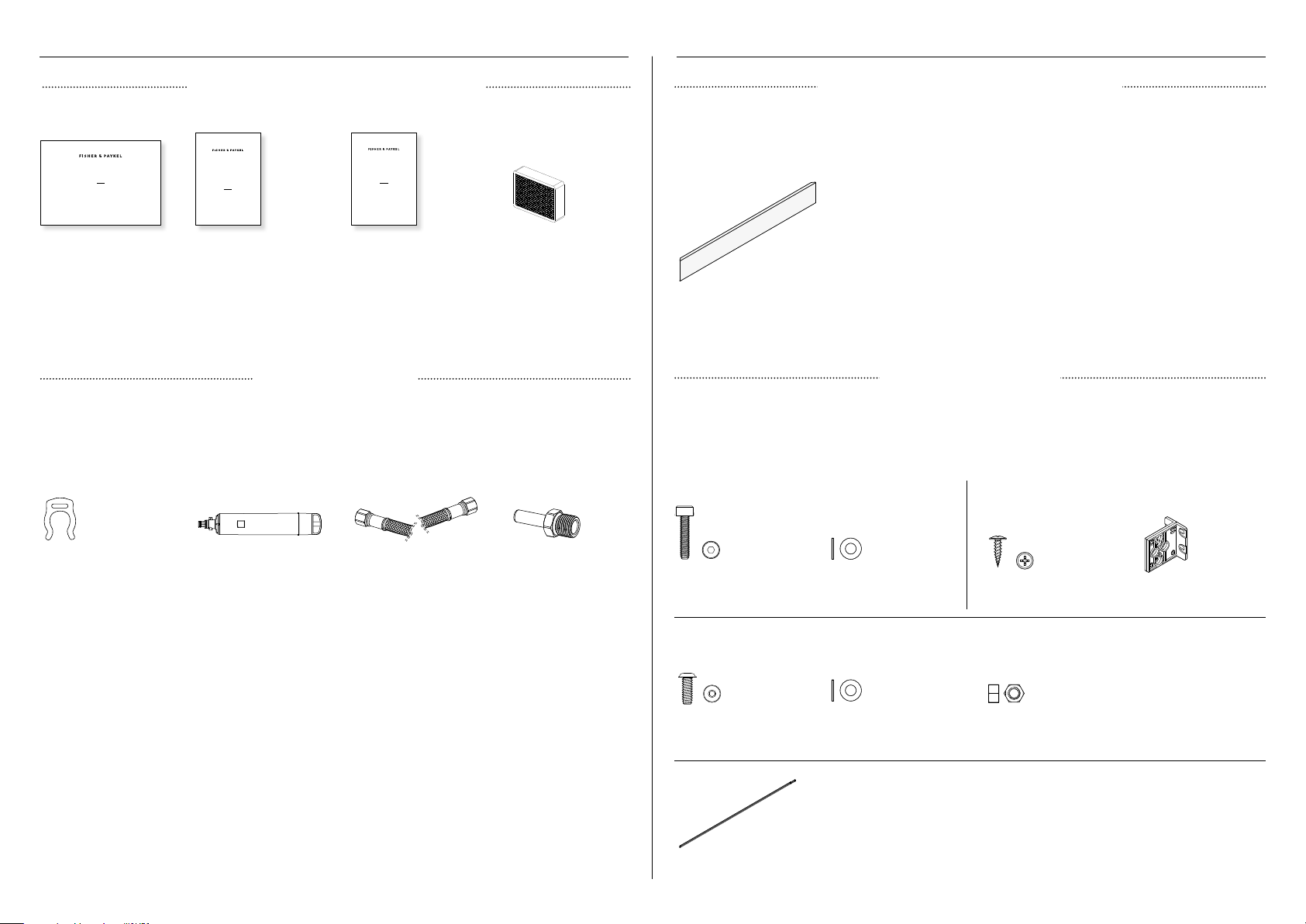

REQUIRED PARTSSUPPLIED PARTS

M6 Washer

843453

M5 Washer

M5 x20

Cap Screw

847984

M6 x 12

Cap Screw

248072

8Gx16

Mush Washer

840371

10 x 50

Dual Lock

M6 Nut

839455

M5 Nut

839107

MISCELLANEOUS ITEMS (MI) PACK

INTEGRATED COLUMN

REFRIGERATOR & FREEZER

RS2484S, RS2484SH, RS3084S, RS3084SH

RS1884F, RS2484F & RS3084F

REFRIGERATOR-FREEZER

RS3084W & RS3084W

WINE CABINET

RS2484V

INSTALLATION GUIDE

US CA

Installation guide

SERVICE & WARRANTY

SERVICE ET GARANTIE

ΣΈΡΒΙΣ ΚΑΙ ΕΓΓΎΗΣΗ

SERVIZIO E GARANZIA

SERVICE & GARANTIE

HUOLTO JA TAKUU

SERVICE OG GARANTI

保修和维修

服務和保修

Service & Warranty

INTEGRATED

REFRIGERATOR & FREEZER

INTEGRATED REFRIGERATOR

RS2484S, RS2484SH, RS3084SH & RS3084S

INTEGRATED FREEZER

RS1884F, RS2484F & RS3084F

USER GUIDE

US CA

User guide

WATER FILTER KIT

Supplied in models with Ice & Water function only

(RS2484SH, RS3084SH, RS1884F, RS2484F, RS3084F, RS2484W & RS3084W)

Air carbon filters (2x)

#862755

For Wine Cabinet only

STAINLESS STEEL TOE KICK PANEL

Not supplied and can be purchased separately through an authorised Fisher and Paykel dealer.

Visitfisherpaykel.com for more information.

Standard toe kick height is 4"(102mm) forstandard

stainless steel door panel.

For Custom door panel installation, atoe kick

2 - 6" (50 - 152mm) must be fitted andadjusted

accordingly.

An extra bottom grille is required when you

use 2" (50mm) toe kick height.

Toe kick panel (1x)

You can purchase the extra bottom grille

(#847542P) online at fisherpaykel.com.

INSTALL JOINER KIT

Used for combined installation of multiple appliances. Supplied in selected appliances only

(Freezer and Wine Cabinets). For other models, the joiner kit (AJ-RS84LR) can be purchased

separately through an authorised Fisher and Paykel dealer. Visitfisherpaykel.com for more

information.

Top joiner fastener kit

Top joiner bracket kit

Collet locking clip (1x)

8

Water filter (1x)

#847200

1/4" (6mm) Stainless

steel braided hose with

7/16-24 UNS thread (1x)

1/4” (6.35mm)

Adaptor (2x)

M5x20 Cap screw (1x)

Bottom joiner fastener kit

M6x16 Washer

screw (1x)

Aluminium center

trim (1x)

M5x16x1 Plain

washer (1x)

M6x12x3.2 Plastic

washer (1x)

8Gx16 Mush washer

screw (2x)

M6 Hex nut (1x)

Central spacer (1x)

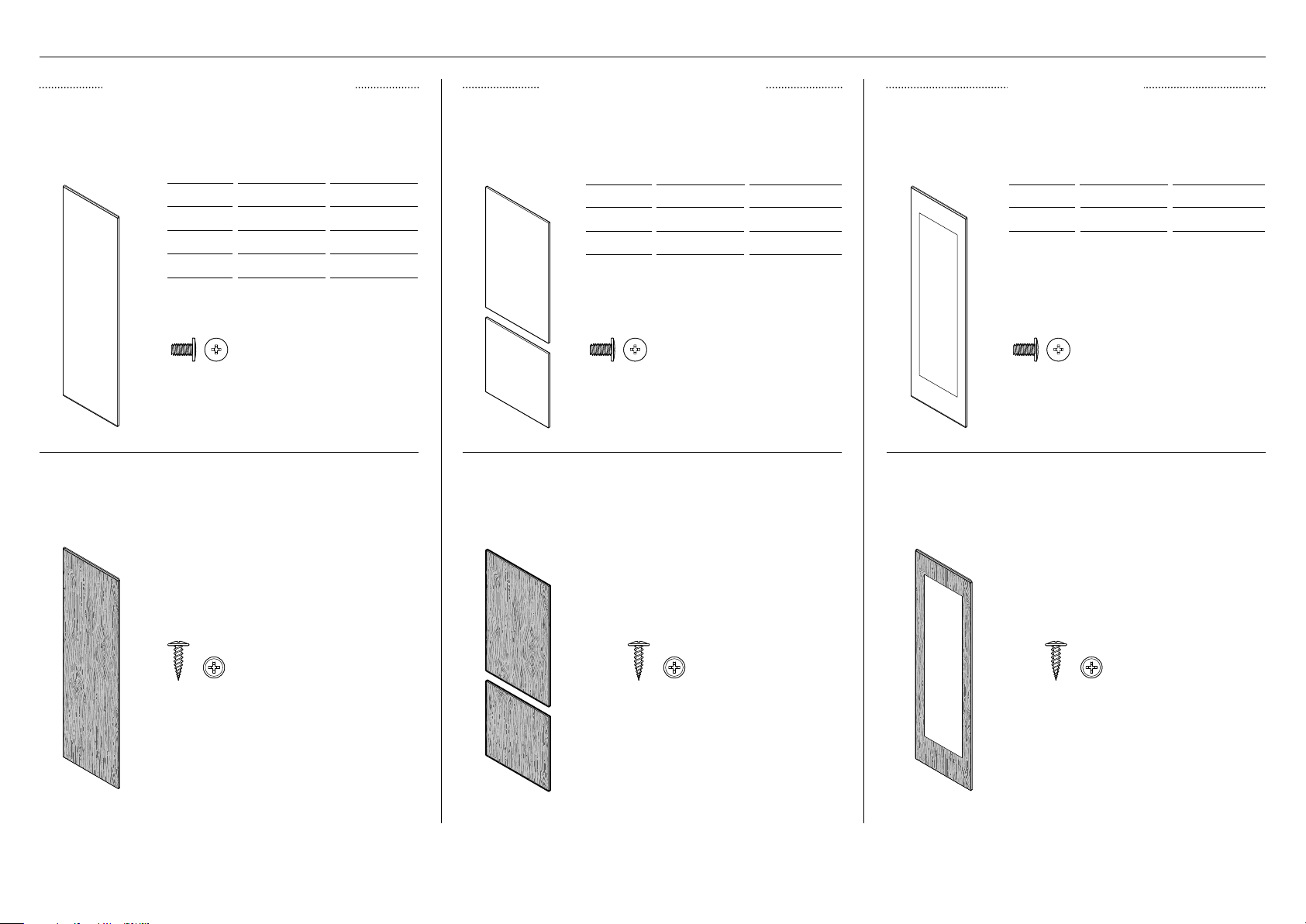

DOOR PANEL KIT

REFRIGERATOR OR FREEZER REFRIGERATOR-FREEZER WINE CABINET

Stainless steel door panel kit Stainless steel door panel kit Stainless steel door panel kit

RH LH

RS18 RD1884R4D RD1884L4D

RS24 RD2484R4D RD2484L4D

RS30 RD3084R4D RD3084L4D

8Gx16 Mush washer screw (32x)

Custom door panel Custom door panel

RH LH

RS24 RD2484WRD RD2484WLD

RS30 RD3084WRD RD3084WLD

8Gx16 Mush washer screw (32x)

RH LH

RS24 RD2484VR4 RD2484VL4

8Gx16 Mush washer screw (32x)

Custom door panel

The Custom door panel must leave the glass pane visible. A full

custom panel sheathing over the glass pane does not meet the

specifications of the Wine Cabinet.

M5x12 Cross-head screw (35x)

Included in Installation kit

M5x12 Cross-head screw (35x)

Included in Installation kit

M5x12 Cross-head screw (35x)

Included in Installation kit

Custom door panels must be supplied by the customer to match their cabinetry. Stainless steel door panels are not supplied and must be purchased separately through an authorised Fisher and Paykel dealer.

Take note of the part numbers above to ensure you are ordering the correct door panel set. Visitfisherpaykel.com for more information.

9

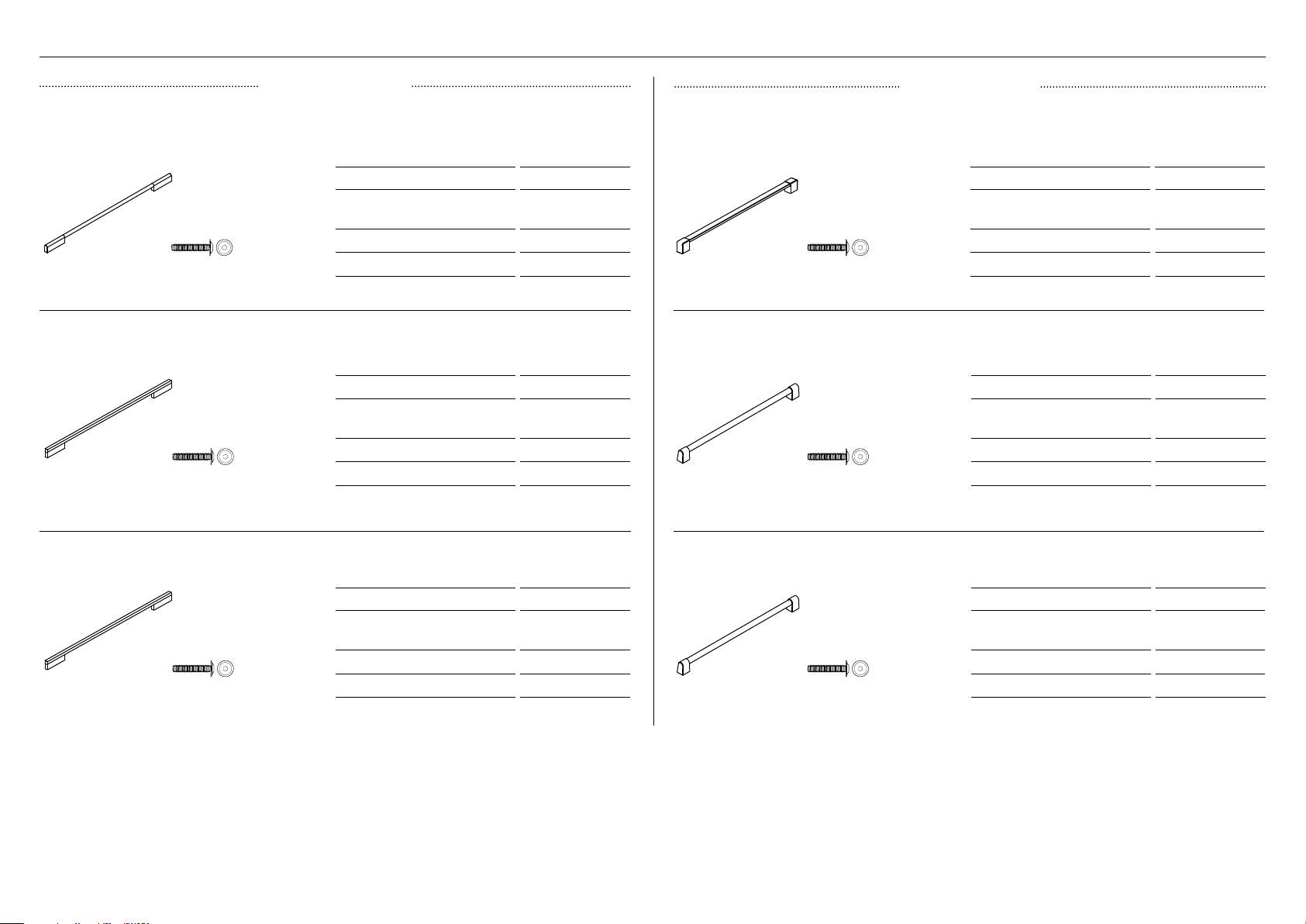

HANDLE KIT

CONTEMPORARY

Aluminium/Black square handle set Stainless steel square handle set

MODEL CODES

REFRIGERATOR/FREEZER

WINE CABINET

24" REFRIGERATOR-FREEZER AHD3-RD2484W

Square handle (1x) M5x25 Hex screw (4x)

30" REFRIGERATOR-FREEZER AHD3-RD3084W

Aluminium/Black square fine handle set Stainless steel round handle set

MODEL CODES

REFRIGERATOR/FREEZER

WINE CABINET

24" REFRIGERATOR-FREEZER AHD5RD2484W

Square fine

M5x25 Hex screw (4x)

30" REFRIGERATOR-FREEZER AHD5RD3084W

handle (1x)

AHD3-RD84

Square handle (1x) M5x25 Hex screw (4x)

AHD5-RDSF

Round handle (1x) M5x25 Hex screw (4x)

PROFESSIONAL

MODEL CODES

REFRIGERATOR/FREEZER

WINE CABINET

24" REFRIGERATOR-FREEZER AHV2-RD2484W

30" REFRIGERATOR-FREEZER AHV2-RD3084W

MODEL CODES

REFRIGERATOR/FREEZER

WINE CABINET

24" REFRIGERATOR-FREEZER AHC-RD2484W

30" REFRIGERATOR-FREEZER AHC-RD3084W

AHV2-RD84

AHC-RD84

Aluminium round handle set Stainless steel round flush handle set

MODEL CODES

Round handle (1x) M5x25 Hex screw (4x)

REFRIGERATOR/FREEZER

WINE CABINET

24" REFRIGERATOR-FREEZER AHSRD2484W

30" REFRIGERATOR-FREEZER AHSRD3084W

AHS-RD84

Round flush

M5x25 Hex screw (4x)

handle (1x)

The handle kit is not supplied and must be purchased separately through an authorised Fisher and Paykel dealer. Visitfisherpaykel.com for more information.

For Refrigerator-Freezer models, each handle kit includes two (2x) handles for door and drawer panels, and M5x25 hex screws (8x).

10

MODEL CODES

REFRIGERATOR/FREEZER

WINE CABINET

24" REFRIGERATOR-FREEZER AHP3-RD2484W

30" REFRIGERATOR-FREEZER AHP3-RD3084W

AHP3-RDSF

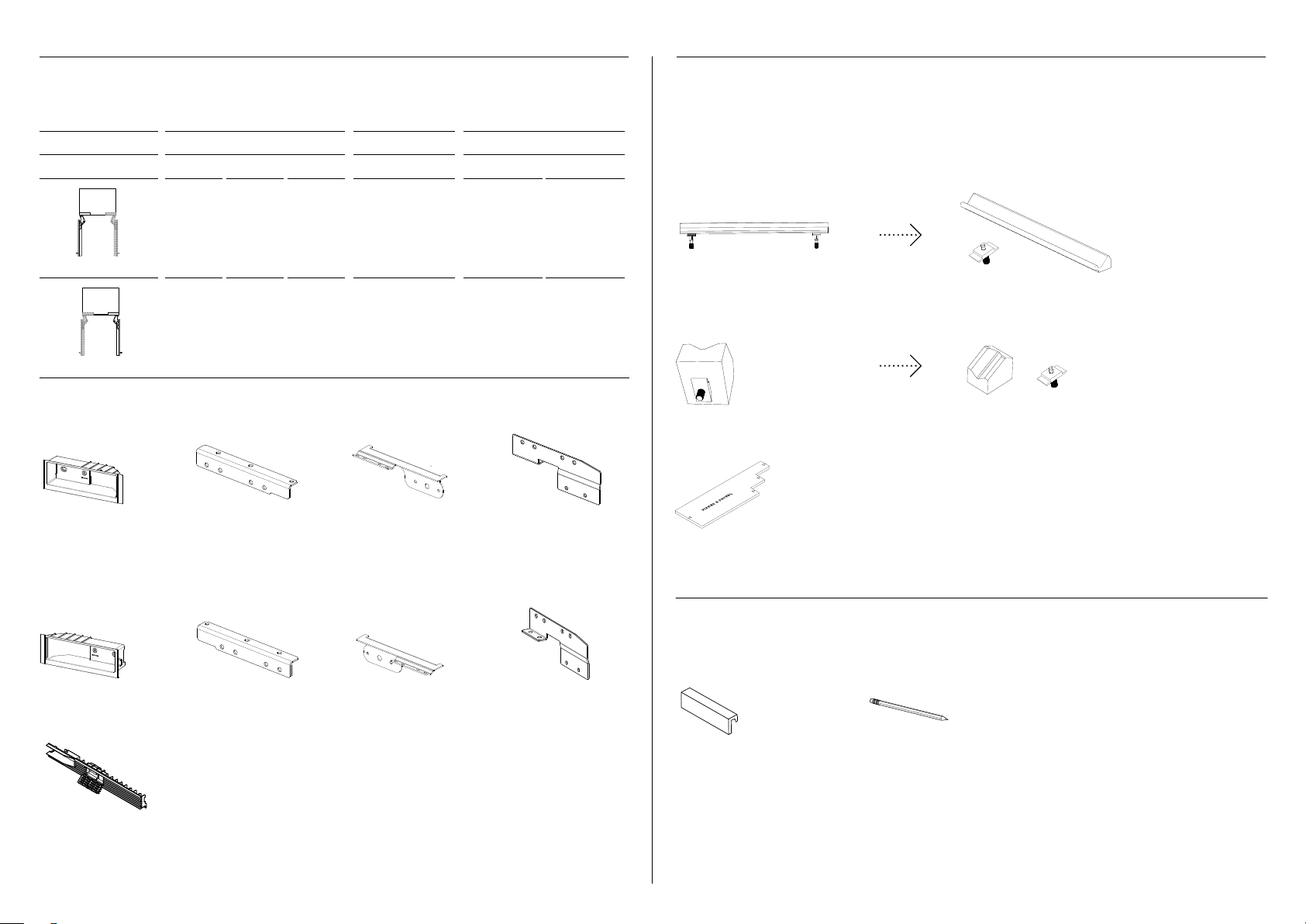

HINGE CHANGE KIT

POCKET HINGE TOP RH

BRACKET ALCOVE TOP LH

BRACKET ADAPT COL K05 RH

BRACKET ADAPT K05 BTM RH

WINE DISPLAY ACCESSORIES

Not supplied and must be purchased separately through an authorised Fisher and Paykel dealer.

Visitfisherpaykel.com for more information. Select among the hinge change kit options below:

HINGE KIT REFRIGERATOR OR FREEZER WINE CABINET REFRIGERATOR-FREEZER

18" 24" 30" 24" 24" 30"

848186 848188 848190 864757P 848184P 848184P

Left to Right hinge

848185 848187 848189 864759P 848183P 848183P

Right to Left hinge

Left to Right hinge kit

Top hinge pocket

RH (2x)

K05 bottom adaptor*

bracket RH (1x)

Top alcove bracket

RH (2x)

K05 top adaptor*

bracket RH (1x)

Accessories are not supplied with the appliance. A wine display kit and a label kit are sold

separately and can be purchased online at fisherpaykel.com.

Wine display kit

2x

1x

Handle assembly (1)

Cradle assembly (4)

Spacer (1)

Right to Left hinge kit

Top hinge pocket

LH (2x)

Top grille (1x)

Supplied in Hinge change kit

for Refrigerator & Freezer and

Wine Cabinet only.

K05 bottom adaptor*

bracket LH (1x)

* Top and bottom adaptor brackets for Wine Cabinet different from illustration.

Top alcove bracket

LH (2x)

K05 top adaptor*

bracket LH (1x)

Wine label kit

Label (14)

Pencil (1)

11

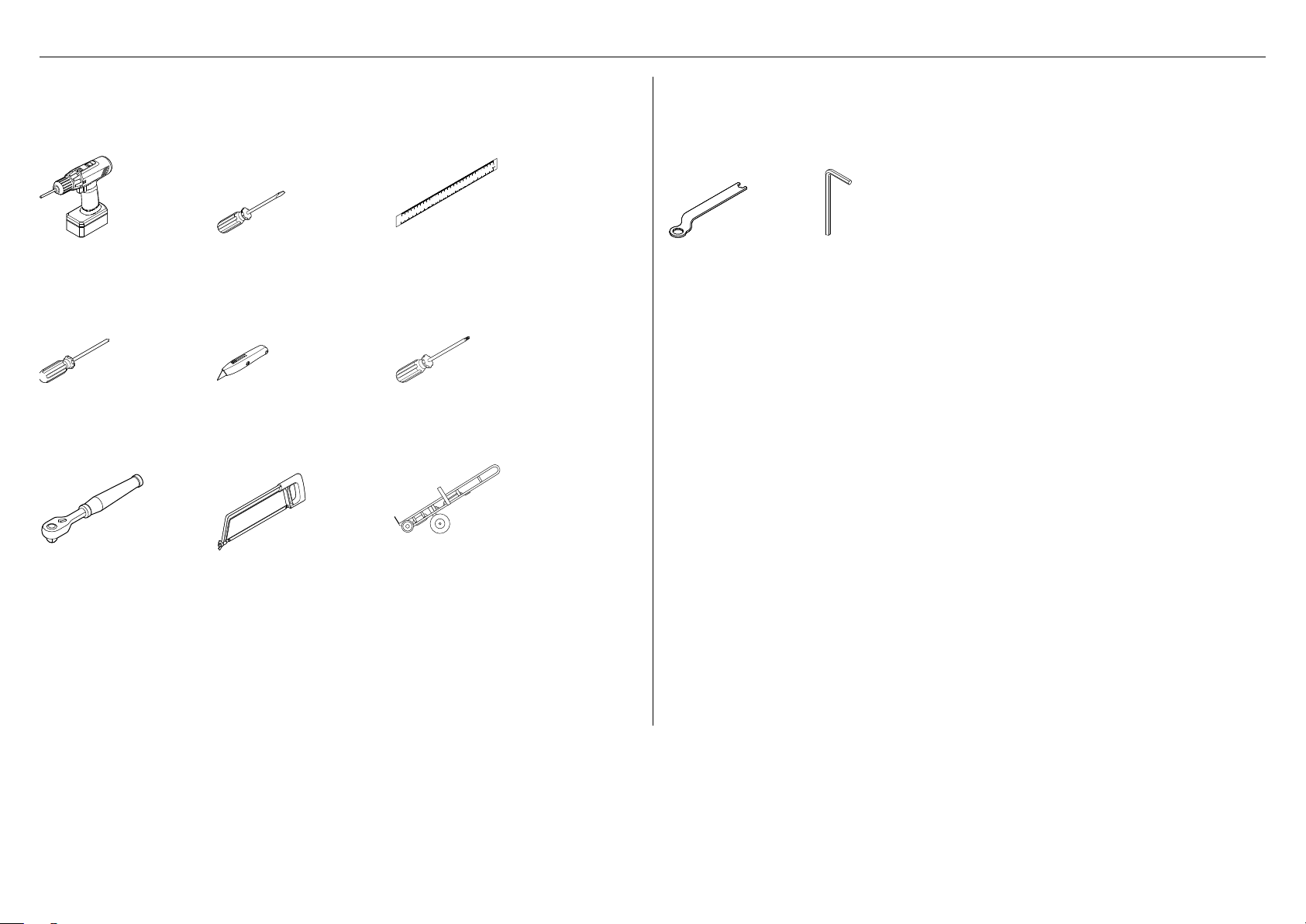

TOOLS

Required tools

Not supplied and must be provided by the installer.

Powered driver

Cross-head

Flathead screwdriver

Cutter (1)

screwdriver

Ruler

T20 star-head

screwdriver

(Used for changing hinge)

Supplied tools

Spanner

M4 hex key

1/2" (13mm) socket

wrench

(Used for drawer panel of

Refrigerator-Freezer model)

12

Hacksaw

(For cutting air flow

divider to length)

Hand truck

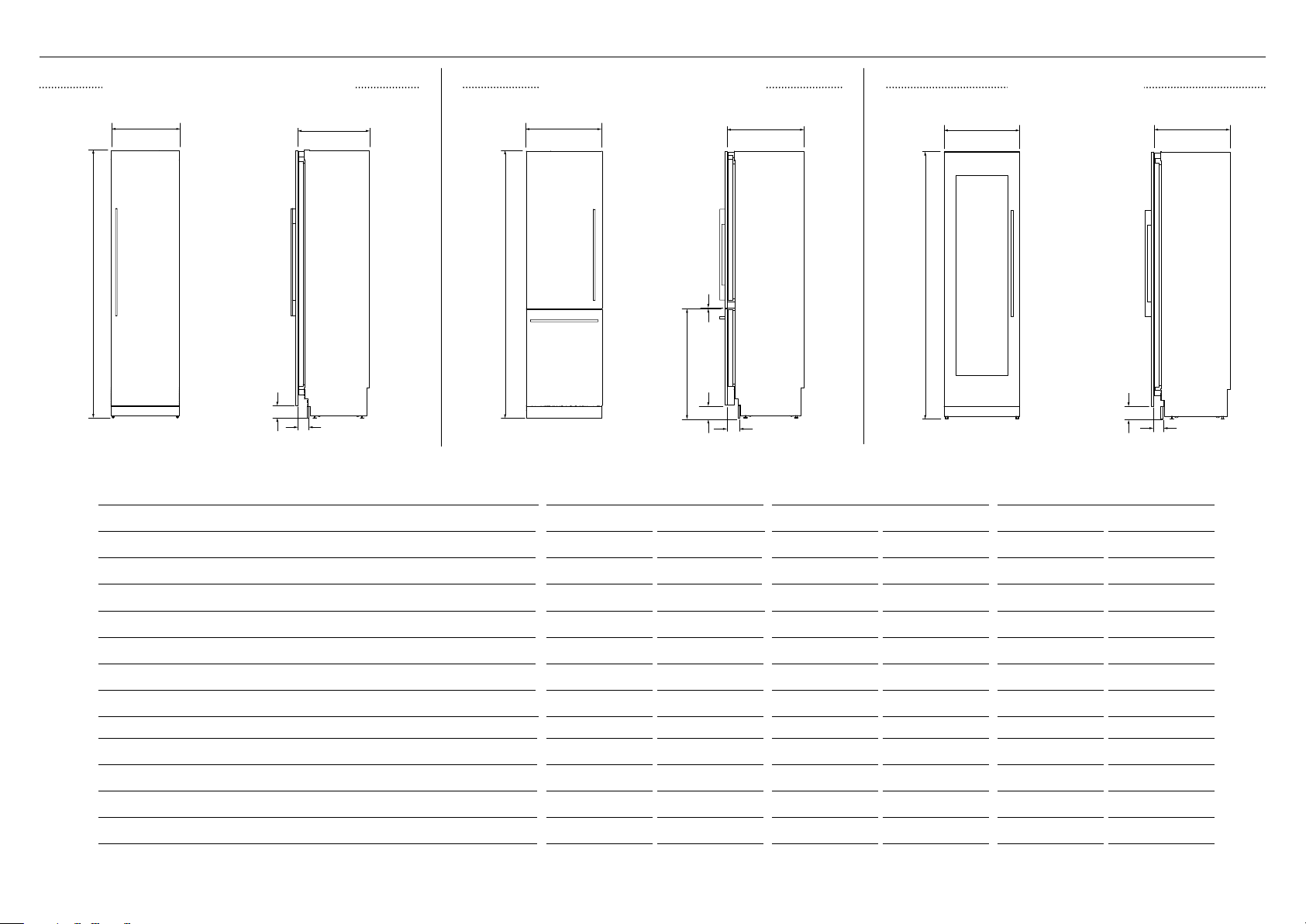

PRODUCT DIMENSIONS

REFRIGERATOR OR FREEZER REFRIGERATOR-FREEZER WINE CABINET

B

A

B

C

B

A

C

A

G

F

E

D

E

D

E

FRONT FRONT FRONTPROFILE PROFILE PROFILE

18" 24" 30"

PRODUCT DIMENSIONS IN MM IN MM IN MM

A Overall height

B Overall width

C Overall depth (excluding door panel)

D Depth of toe kick (measured from back of door panel)

E Height from floor to bottom of Stainless steel door/drawer panel

F Height from floor to top of drawer panel (Refrigerator-Freezer only)

G Gap between door and drawer panels (Refrigerator-Freezer only)

84 2134 84 2134 84 2134

17 3/4 451 23 3/4 603 29 3/4 756

24 610 24 610 24 610

27/8–4 73–102 27/8–4 73–102 27/8–4 73–102

4 102 4 102 4 102

— — 34 7/16 874 34 7/16 874

— — 1/8 3 1/8 3

C

D

PRODUCT WEIGHT (WITHOUT PACKAGING) LBS KG LBS KG LBS KG

Refrigerator or Freezer

Refrigerator-Freezer

Wine cabinet

18" model for Freezer only. Wine Cabinet available in 24" only.

Illustrations may differ from your purchased appliance.

223 101 258 117 295 134

— — 313 142 359 163

— — 335 152 — —

13

E

D

C

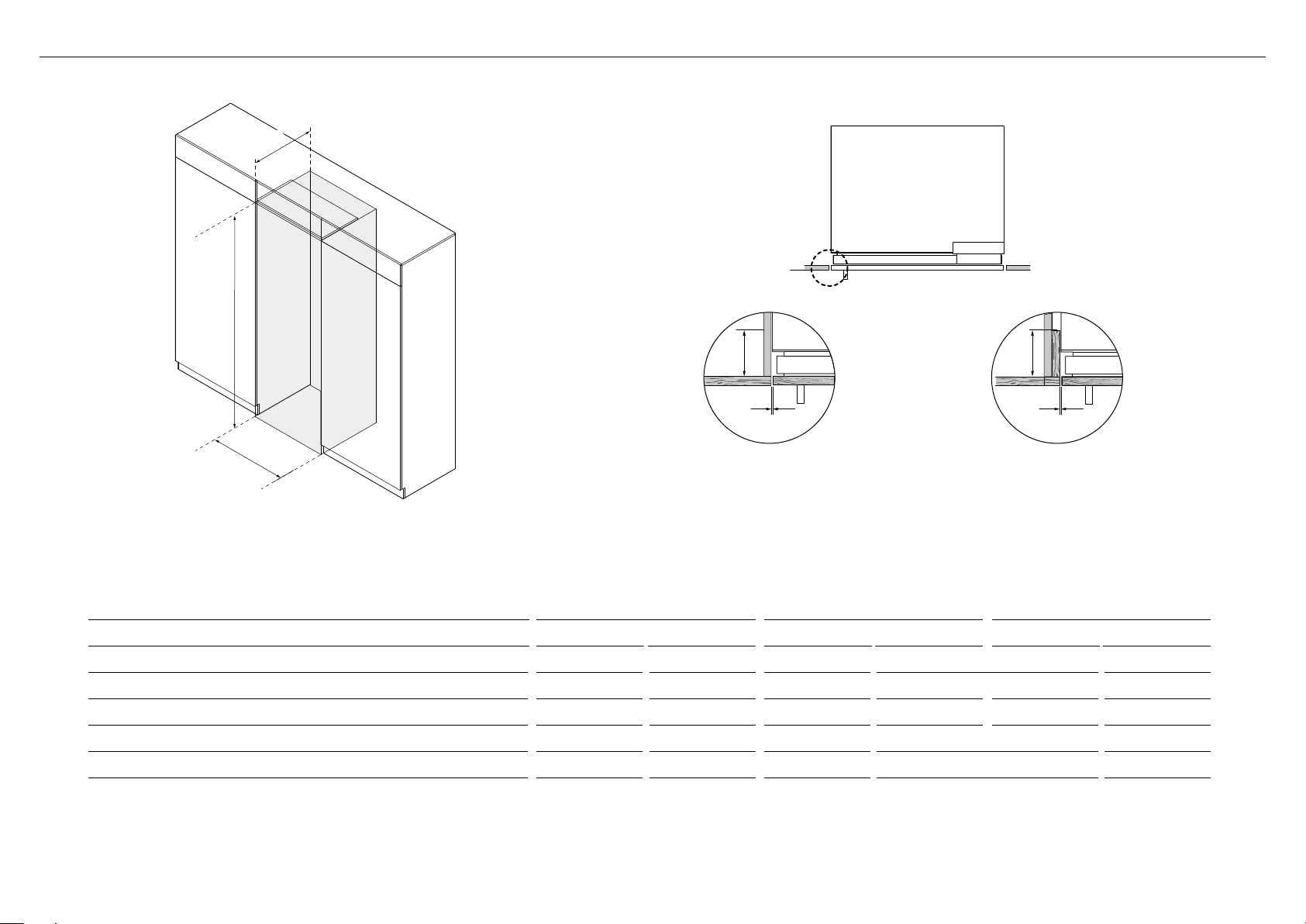

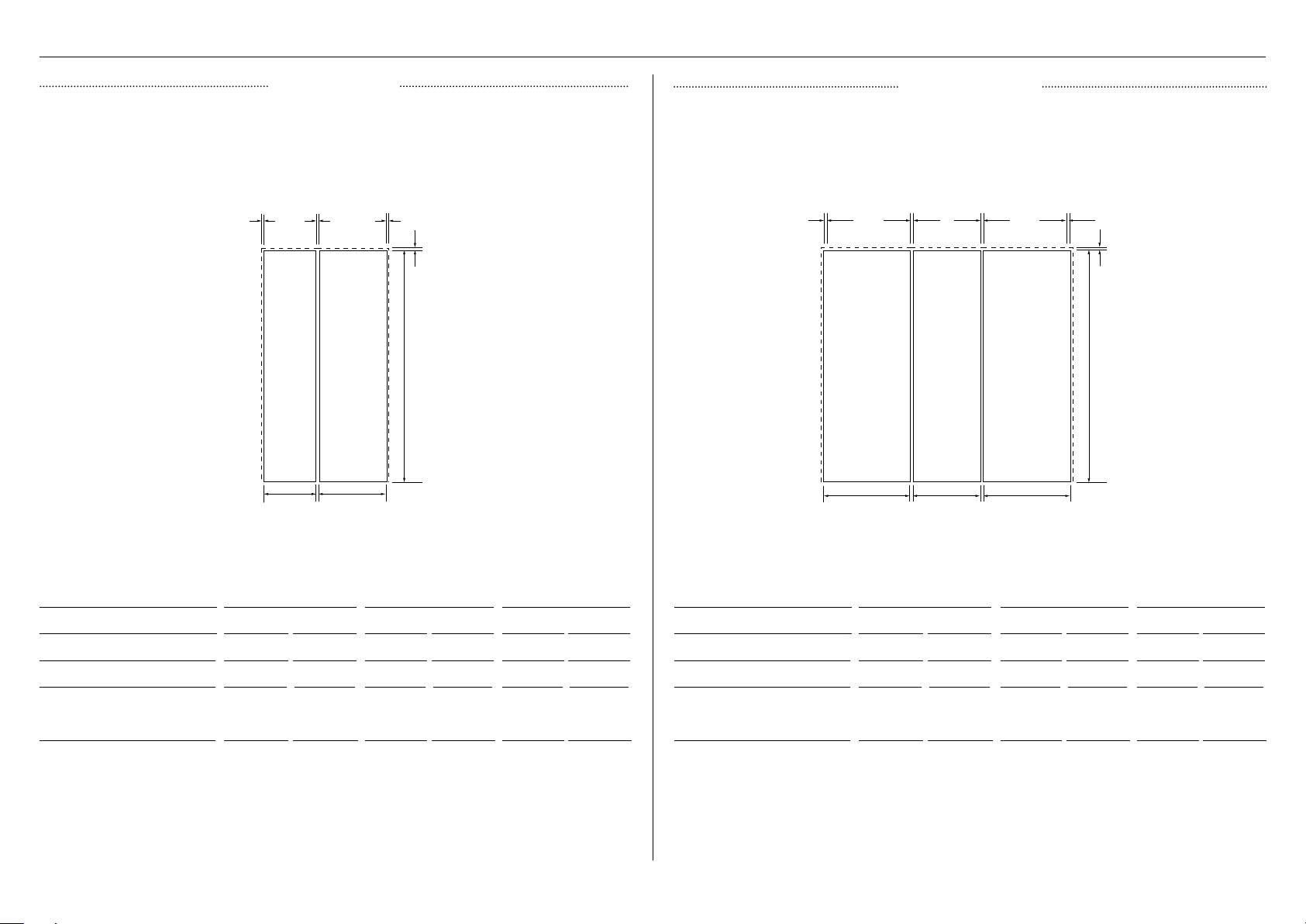

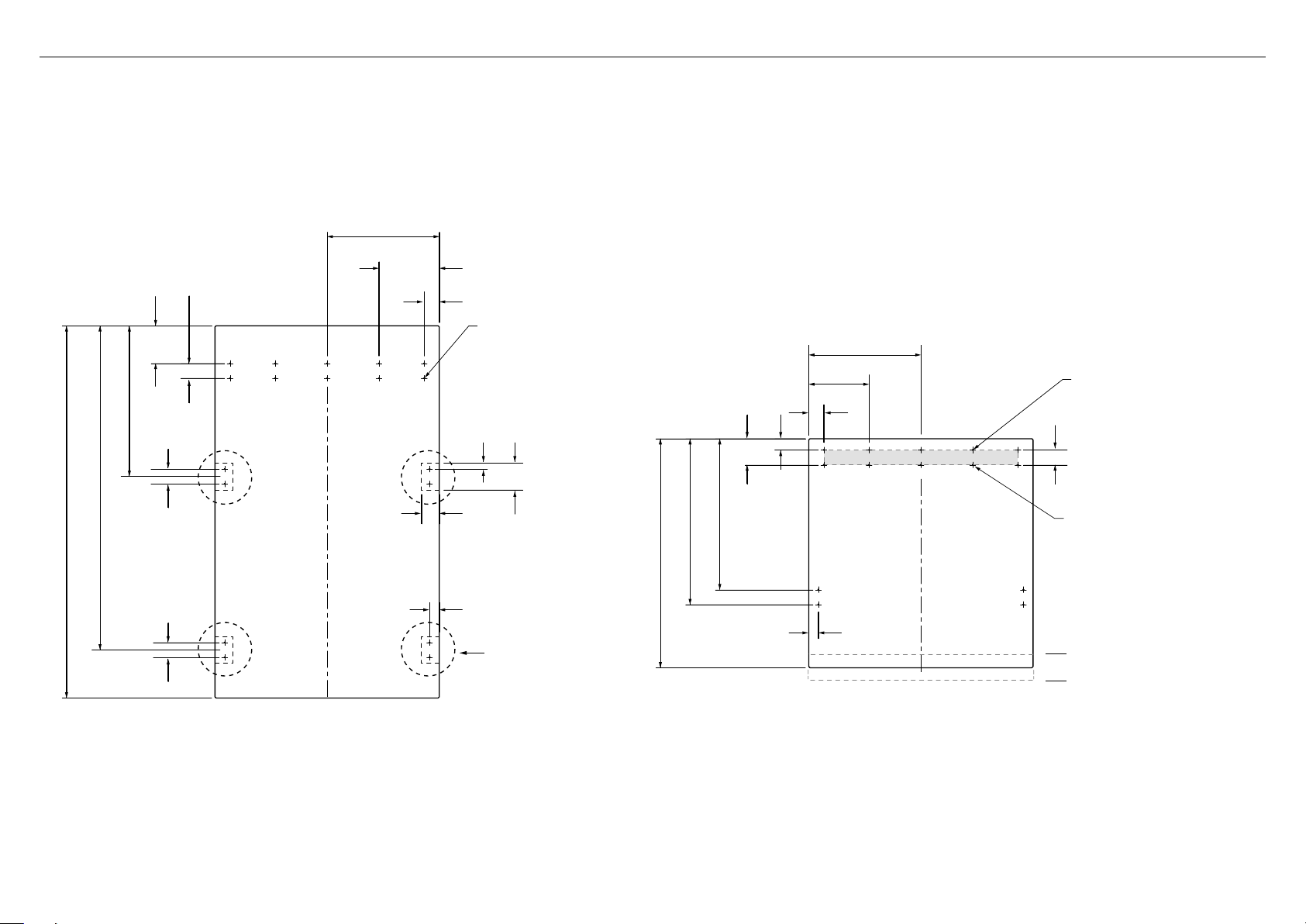

CABINETRY DIMENSIONS — SINGLE INSTALLATION

Flush with front

of cabinetry

A

B

E

D

UNFRAMED

Aligns appliance with cabinetry

PLAN

E

D

FRAMED

Aligns appliance with frame of cabinetry

ISOMETRIC

CAVITY DIMENSIONS IN MM IN MM IN MM

18" 24" 30"

A Overall height of cavity 84 2134 84 2134 84 2134

B Overall width of cavity 18 457 24 610 30 762

C Minimum overall depth of cavity* 25 635 25 635 25 635

d Minimum gap from edge of door panel to cabinetry 1/8 3 1/8 3 1/8 3

e Minimum required finished return 4 102 4 102 4 102

* Assumes a door panel thickness of 3/4" (19mm).

14

Illustrations may differ from your purchased appliance.

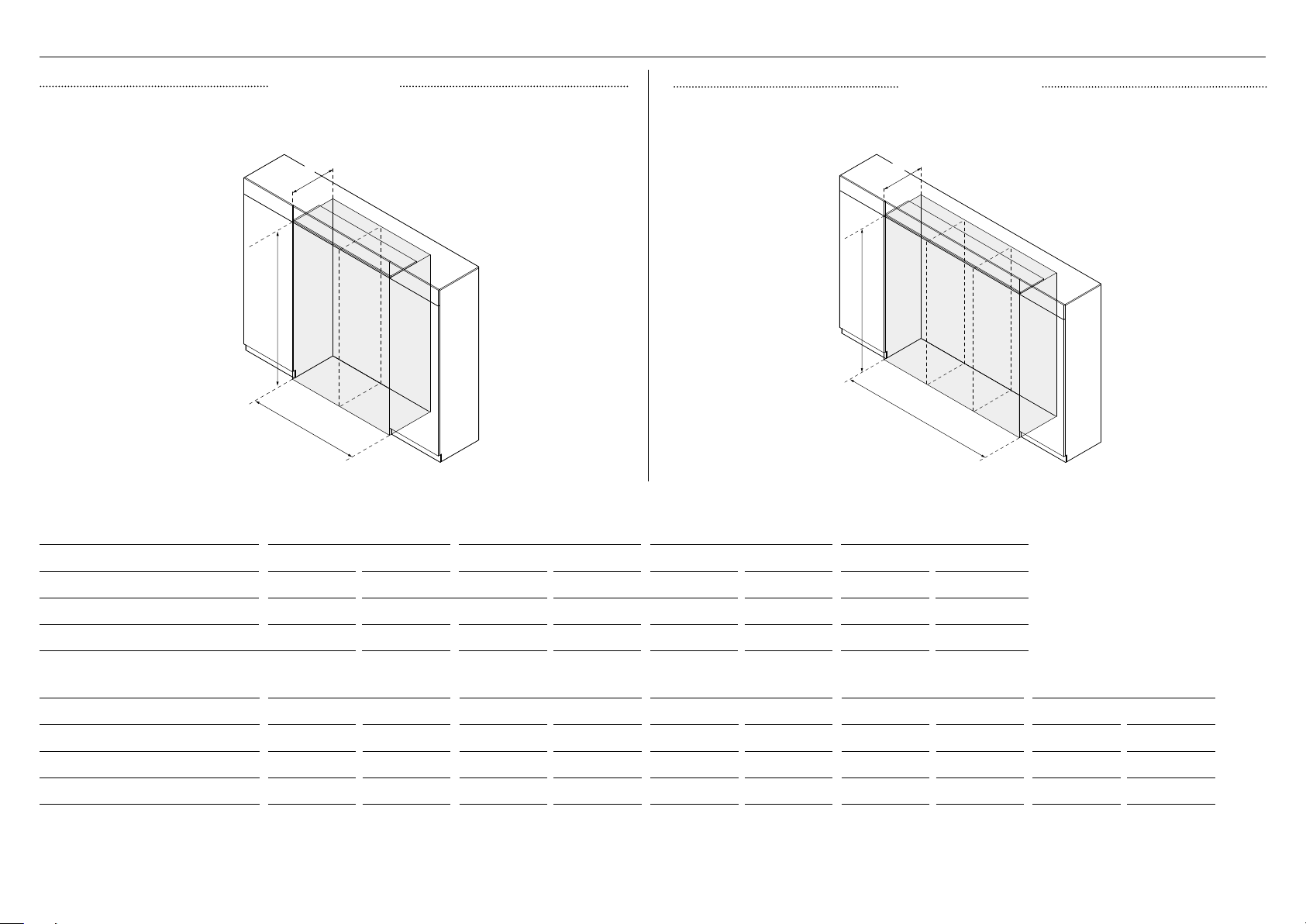

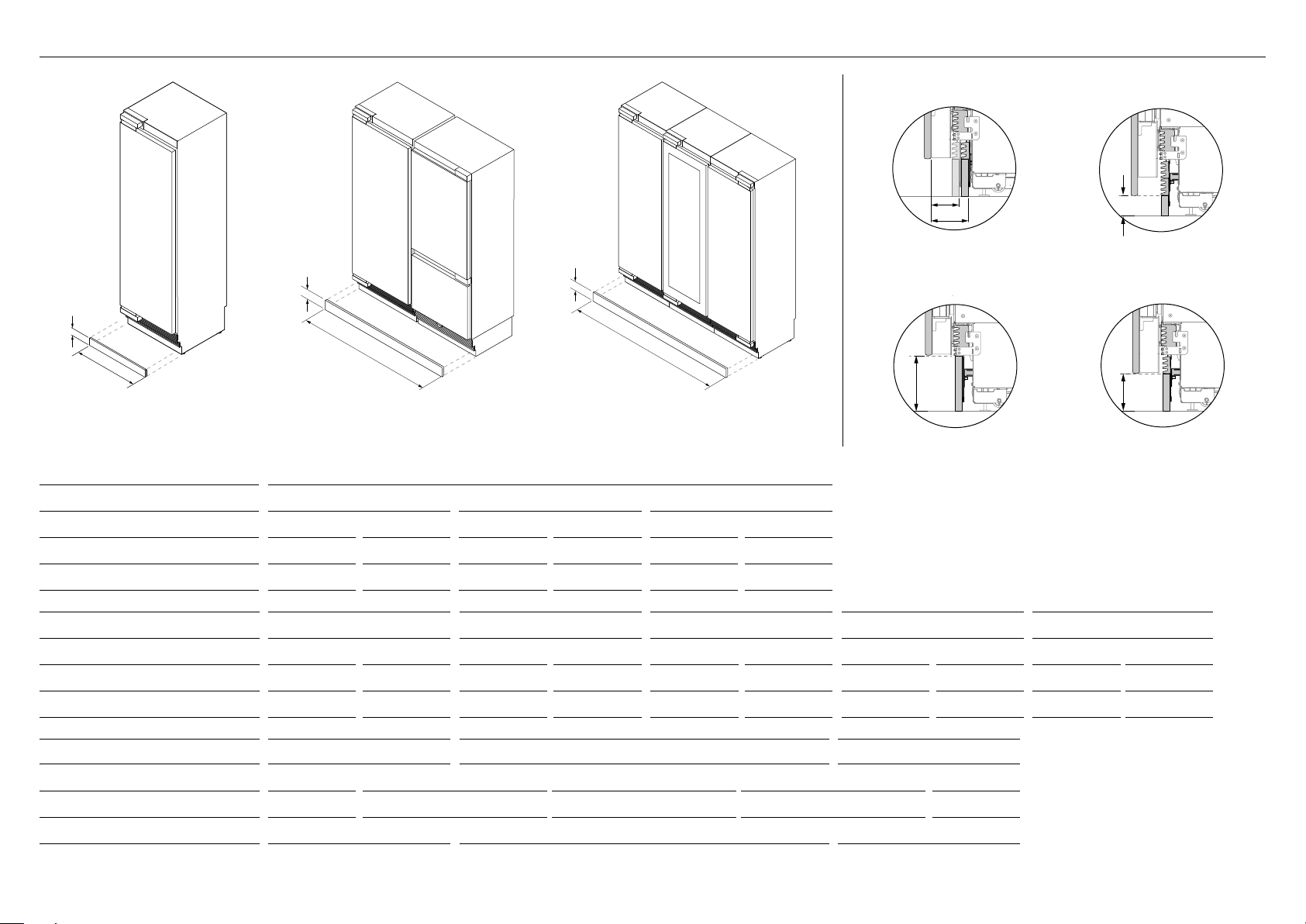

CABINETRY DIMENSIONS — MULTIPLE INSTALLATION

DUAL INSTALL

CAVITY DIMENSIONS

A Overall height of cavity

B Overall width of cavity

C Minimum overall depth of cavity*

DUAL INSTALL

C

A

B

IN MM IN MM IN MM IN MM

84 2134 84 2134 84 2134 84 2134

42 1067 48 1220 54 1372 60 1524

25 635 25 635 25 635 25 635

TRIPLE INSTALL

C

A

B

42" 48" 54" 60"

TRIPLE INSTALL

CAVITY DIMENSIONS

A Overall height of cavity

B Overall width of cavity

C Minimum overall depth of cavity*

Illustrations may differ from your purchased appliance.

IN MM IN MM IN MM IN MM IN MM

84 2134 84 2134 84 2134 84 2134 84 2134

66 1677 72 1829 78 1982 84 2134 90 2286

25 635 25 635 25 635 25 635 25 635

66" 72" 78" 84" 90"

15

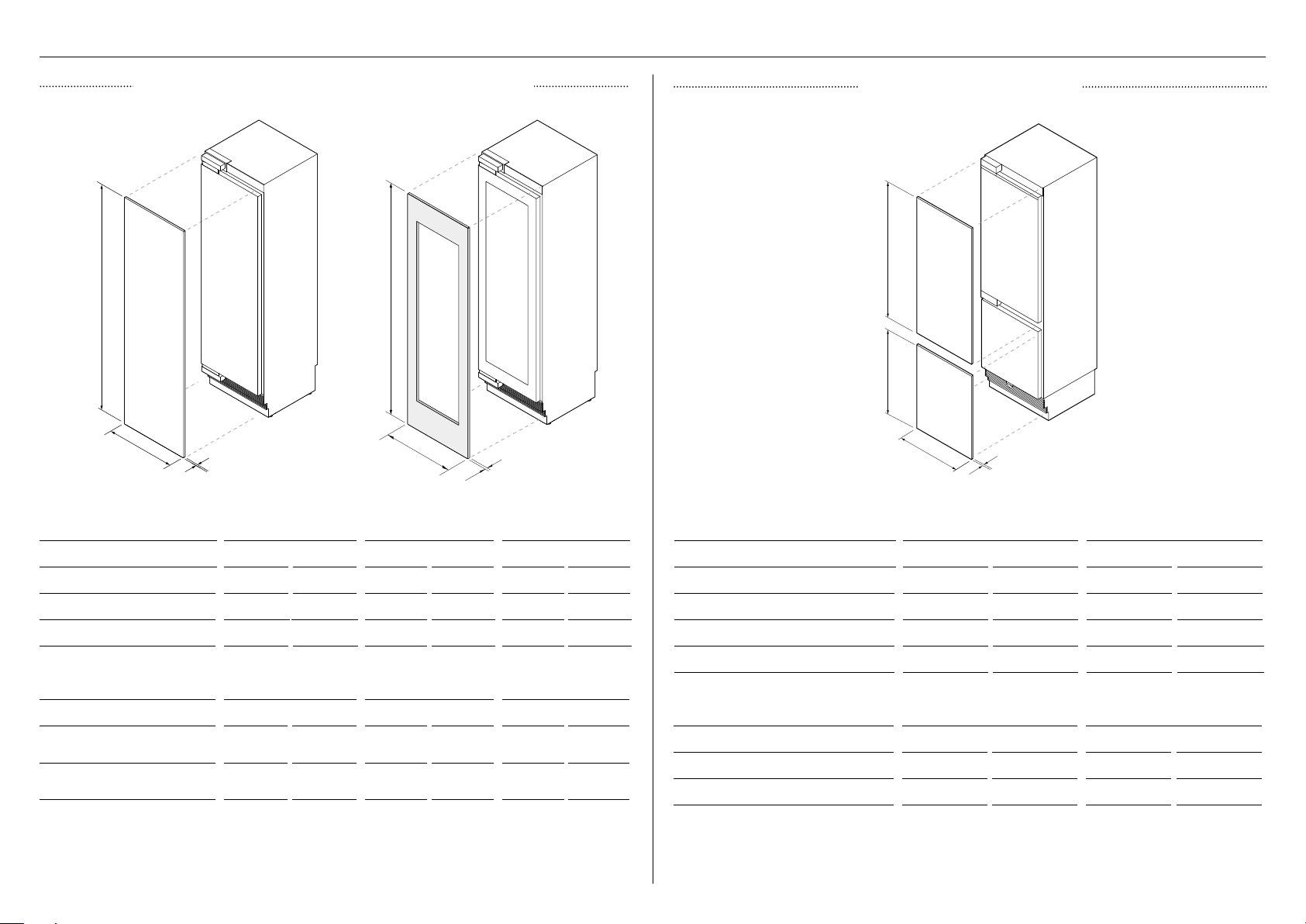

STAINLESS STEEL DOOR PANEL DIMENSIONS — SINGLE INSTALLATION

REFRIGERATOR OR FREEZER / WINE CABINET

A

B

C

18" 24" 30"

DOOR PANEL DIMENSIONS IN MM IN MM IN MM

A

B

C

REFRIGERATOR-FREEZER

A

B

C

D

24" 30"

DOOR PANEL DIMENSIONS IN MM IN MM

A Height of door panel

b Width of door panel

C Depth of door panel*

* Excluding handle

79 7/8 2029 79 7/8 2029 79 7/8 2029

17 3/4 451 23 3/4 603 29 3/4 756

3/4 19 3/4 19 3 /4 19

18" 24" 30"

DOOR PANEL WEIGHT* LBS KG LBS KG LBS KG

Weight of Refrigerator or

Freezer door panel

Weight of Wine cabinet

door panel

* Without packaging

16

44 20 55 25 66 30

— — 18 8 — —

A Height of top door panel

B Height of bottom drawer panel

C Width of door panel

D Depth of door panel*

* Excluding handle

49 3/8 1254 49 3/8 1254

30 3/8 772 30 3/8 772

23 3/4 603 29 3/4 756

3/4 19 3/4 19

24" 30"

DOOR PANEL WEIGHT* LBS KG LBS KG

Weight of top door panel 20 9 22 10

Weight of bottom drawer panel 13 6 15 7

* Without packaging

Illustrations may differ from your purchased appliance.

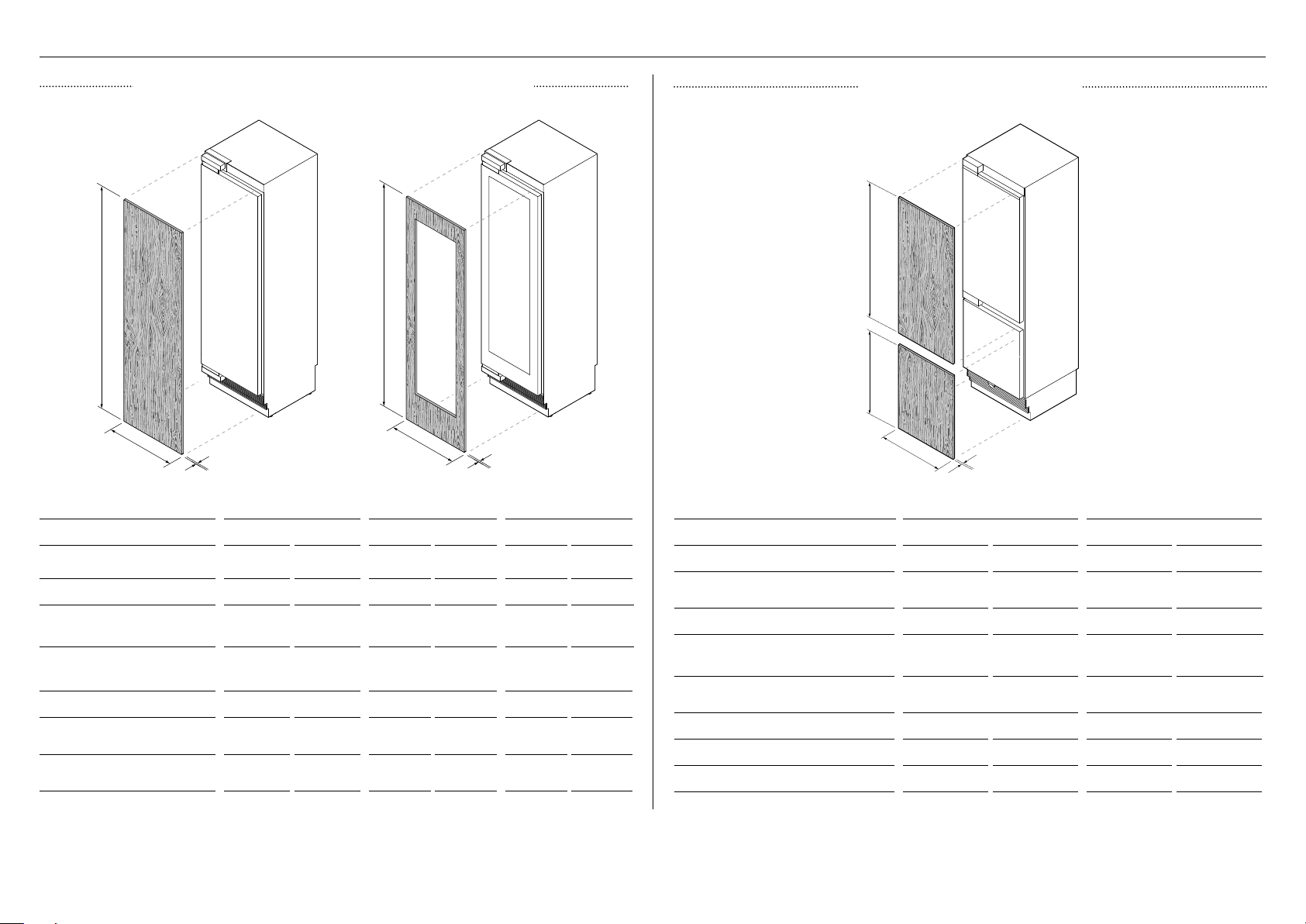

CUSTOM DOOR PANEL DIMENSIONS — SINGLE INSTALLATION

REFRIGERATOR OR FREEZER / WINE CABINET

A

B

C

DOOR PANEL DIMENSIONS

A Height of door panel

b Width of door panel

C Depth of door panel*

* Excluding handle

DOOR PANEL WEIGHT* LBS KG LBS KG LBS KG

Weight of Refrigerator or

Freezer door panel

Weight of Wine cabinet

door panel

* Without packaging

IN MM IN MM IN MM

77 7/8

- 81 7/8

17 3/4 451 23 3/4 603 29 3/4 756

min 5/8

max 1

max 44 max 20 max 55 max 25 max 66 max 30

max 25

— — max 55 max 25 — —

A

B

C

18" 24" 30"

1978

- 2080

min 16

77 7/8

- 81 7/8

min 5/8

max 1

1978

- 2080

min 16

max 25

77 7/8

- 81 7/8

min 5/8

max 1

18" 24" 30"

- 2080

min 16

max 25

1978

REFRIGERATOR-FREEZER

A

B

C

D

24" 30"

DOOR PANEL DIMENSIONS

A Height of top door panel

B Height of bottom drawer panel

C Width of door panel

D Depth of door panel*

* Excluding handle

DOOR PANEL WEIGHT* LBS KG LBS KG

Weight of top door panel max 33 max 15 max 40 max 18

Weight of drawer panel max 20 max 9 max 24 max 11

* Without packaging

IN MM IN MM

49 3/8 1254 49 3/8 1254

28 3/8

- 32 3/8

23 3/4 603 29 3/4 756

min 5/8

max 1

721 - 822

min 16

max 25

28 3/8

- 32 3/8

min 5/8

max 1

721 - 822

min 16

max 25

24" 30"

For Wine cabinet, the Custom door panel must leave the glass pane visible. A full custom panel sheathing over the glass pane does not meet the specifications of this appliance.

For all models, maximum panel weight must not be exceeded.

Illustrations may differ from your purchased appliance.

17

CUSTOM DOOR PANEL DIMENSIONS — MULTIPLE INSTALLATION

DUAL INSTALL

The illustrations below are examples of custom door panels of different combinations for dual

installation. Minimum gaps of 1/8" (3mm) must be retained between door panel side edges and

cabinetry regardless of door panel widths.

C C C

C

A

BB

TRIPLE INSTALL

The illustrations below are examples of custom door panels of different combinations for triple

installation. Minimum gaps of 1/8" (3mm) must be retained between door panel side edges and

cabinetry regardless of door panel widths.

C C C C

C

A

BBB

CUSTOM PANEL

DIMENSIONS IN MM IN MM IN MM

A Height of door panel

b Width of door panel

79 7/8 2029 79 7/8 2029 79 7/8 2029

17 13/16 452 23 13/16 605 29 13/16 757

18" 24" 30"

c Minimum clearance

between door panels and

cabinetry

* Excluding handle

18

1/8 3 1/8 3 1/8 3

CUSTOM PANEL

DIMENSIONS IN MM IN MM IN MM

A Height of door panel

b Width of door panel

79 7/8 2029 79 7/8 2029 79 7/8 2029

17 13/16 454 23 13/16 605 29 13/16 757

18" 24" 30"

c Minimum clearance

between door panels and

cabinetry

* Excluding handle

1/8 3 1/8 3 1/8 3

Illustrations may differ from your purchased appliance.

TOE KICK DIMENSIONS

Custom toe kick options

A

A

A

B

B

B

SINGLE INSTALL DUAL INSTALL TRIPLE INSTALL

SINGLE INSTALL

STAINLESS STEEL/CUSTOM PANEL

A Height of toe kick*

IN MM IN MM IN MM

2 - 6 50 - 152 2 - 6 50 - 152 2 - 6 50 - 152

18" 24" 30"

B Width of toe kick 177/8 454 23 7/8 606 29 7/8 759

DUAL INSTALL

STAINLESS STEEL/CUSTOM PANEL

A Height of toe kick*

b Width of toe kick

IN MM IN MM IN MM IN MM IN MM

2 - 6 50 - 152 2 - 6 50 - 152 2 - 6 50 - 152 2 - 6 50 - 152 2 - 6 50 - 152

3 5 7/ 8 912 41 7/8 1064 47 7/8 1216 5 3 7/ 8 1368 5 9 7/ 8 1521

36" 42" 48" 54" 60"

27/8”(73mm) –4” (102mm)

toe kick clearance measured

from rear of door panel

6” (152mm) toe kick height 4” (102mm) toe kick height

2” (51mm) toe kick height

(with extra lower grille attached)

TRIPLE INSTALL

STAINLESS STEEL/CUSTOM PANEL

A Height of toe kick*

B Width of toe kick

*Stainless steel toe kick height is 4” (102mm) for all install options.

IN MM IN MM IN MM IN MM

2 - 6 50 - 152 2 - 6 50 - 152 2 - 6 50 - 152 2 - 6 50 - 152

65 7/8 1 674 7 1 7/ 8 1826 78 1982 83 7/8 2131

Illustrations may differ from your purchased appliance.

66" 72" 78" 84"

19

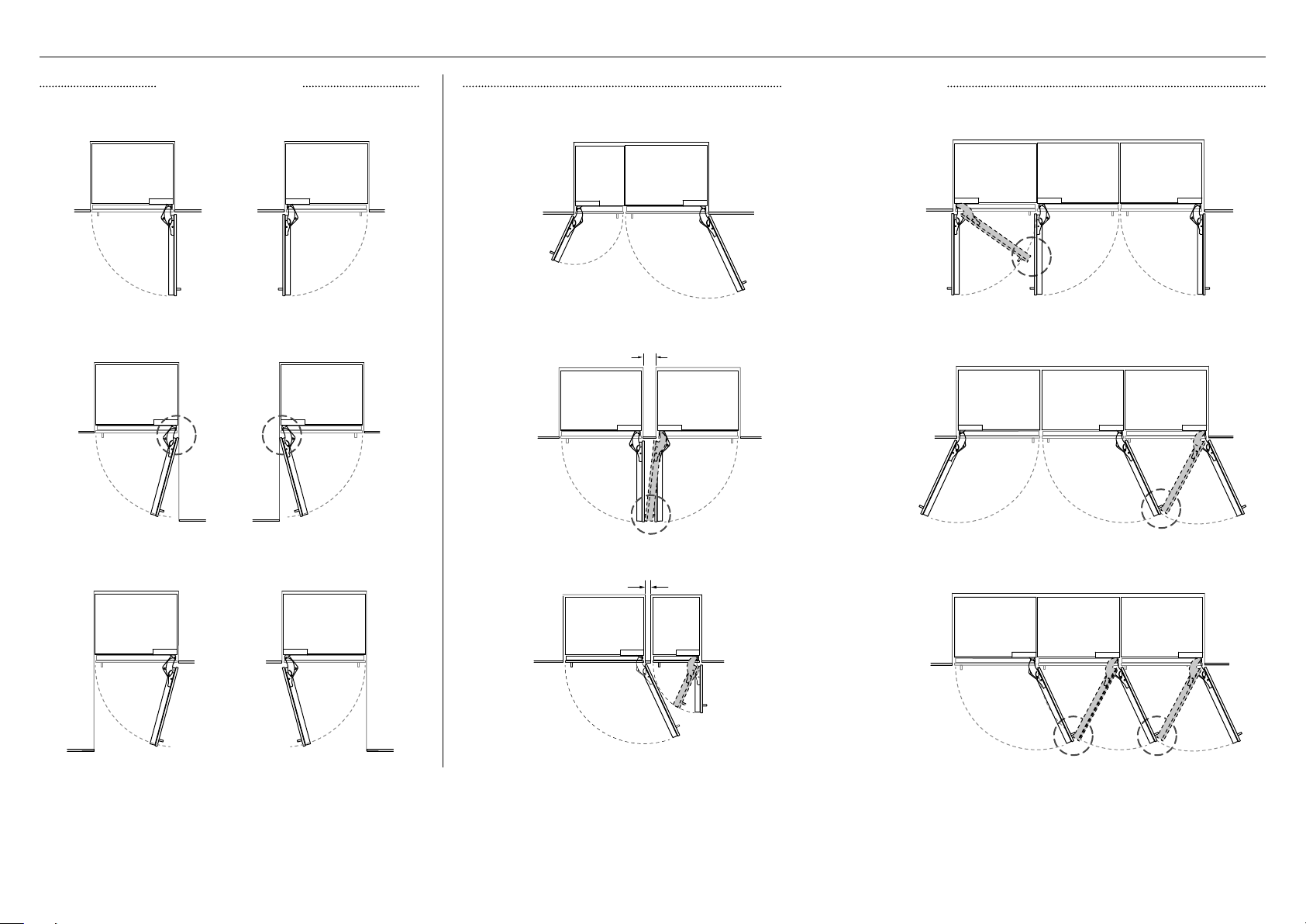

INSTALLATION OPTIONS

SINGLE INSTALL MULTIPLE INSTALL

WALL

WALL

WALL

WALL

WALL WALL

4" (100mm)

WALL

2 3/8" (60mm)

WALL WALL

WALL

WALL

WALL

WALL

WALL

WALL WALL

WALL

WALL

The illustrations above show acceptable installation options with reference to the door opening range and partition (optional). Be aware of clashing (circled) of doors or handles when opening at the same time.

If installing a partition between the appliances, ensure there is enough clearance to avoid doors/handles from interfering with each other when opening or closing.

If necessary, use a hinge limiting pin to restrict door opening rotation to 90°. Refer to ‘Door Clearance’ for more information.

20

Illustrations may differ from your purchased appliance.

DOOR CLEARANCE DRAWER CLEARANCE

These dimensions apply to Refrigerator-Freezer models only.

LIMITED INTERNAL ACCESS

C

Wall

A

B

A

FULL INTERNAL ACCESS

Insert hinge limiting pin

Before pushing the appliance into the cabinetry,

insert the supplied hinge limiting pin into the

borehole of the top and bottom/middle door

hinges. The hinge limiting pin limits door swing

to 90°.

A

B

DIMENSIONS

A Depth of door (90° open)

measured from front of door

IN MM IN MM IN MM

20 508 26 660 32 813

B Minimum door clearance to

adjacent wall*

(115°—full internal access)

11 1/2 292 14 356 16 1/2 419

C Minimum door clearance* to

adjacent wall*

(90°—reduced internal access)

4 5/16 110 4 5/16 110 4 5/16 110

Illustrations may differ from your purchased appliance.

18" 24" 30"

DIMENSIONS

A Maximum drawer extension when open

(including handle)*

B Maximum drawer extension when open

(excluding handle)

* Assumes handle depth of 1 5/8" (41mm).

24" 30"

IN MM IN MM

18 1/8 461 18 1/8 461

16 9/16 420 16 9/16 420

21

ELECTRICAL AND PLUMBING

Electrical connection must be

within this space if located

behind the appliance and must

not protrude from the back wall.

A

C

D B

Recommended locations for

connection at rear of cabinetry

SUPPLY AREA DIMENSIONS IN MM

A Overall height of supply area 9 229

B Overall depth of supply area 1 25

C Width of notch in supply area (both sides) 1/2 13

D Height of sides of supply area (both sides) 5 127

ELECTRICAL SPECIFICATIONS

Supply 115 VAC, 60 Hz

Service 10 amp circuit

Receptacle 3-prong grounding-type

PLUMBING SPECIFICATIONS

Supply 1/2” (12.7mm) BSP Stainless steel braided hose with adaptor

Pressure 22psi (min 151kPa) - 120psi (max 827kPa) @ 68°F (20°C)

A

C

POWER CORD

A Total length exiting from left side

of appliance (excluding plug)

B Total length exiting from right

side of appliance (excluding plug)

WATER HOSE

C Total length exiting from left side

of appliance

D Total length exiting from right

side of appliance

B

D

18" 24" 30"

IN MM IN MM IN MM

54 1/2 1385 71 1/4 1809 68 1/4 1733

55 9/16 1411 72 1/4 1835 69 1/4 1759

18" 24" 30"

IN MM IN MM IN MM

89 7/16 2271 86 7/16 2196 68 1/4 1733

77 1956 72 1/4 1878 69 1/4 1759

22

Illustrations may differ from your purchased appliance.

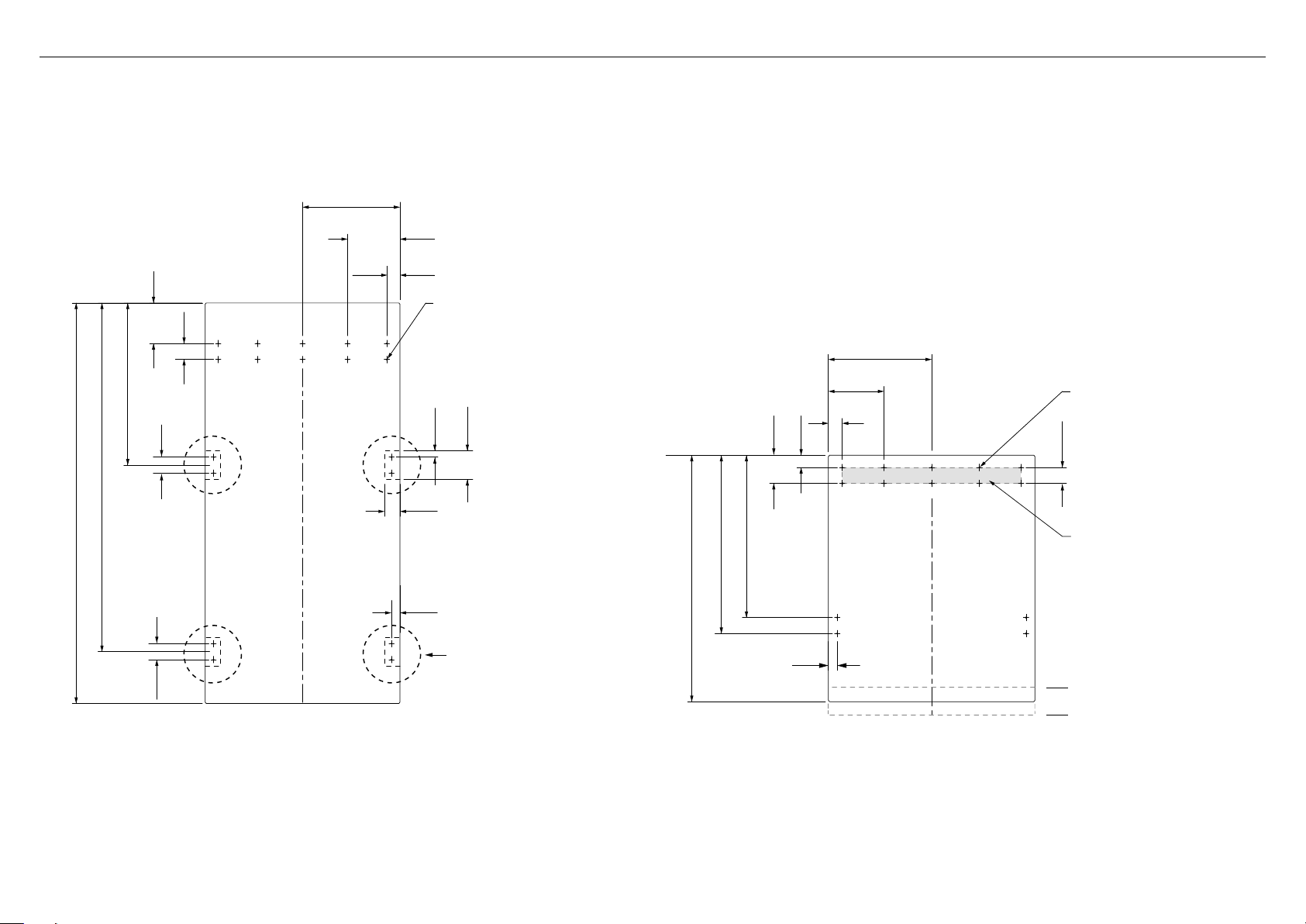

CUSTOM DOOR PANEL INSTALL DIMENSIONS

Dimensions apply for the preparation and installation of Custom door panels. For Dwg and Dxf files of the below panel preparation, download the folder from http://thekitchentools.fisherpaykel.com.

The thickness of the custom door panel can vary provided that the screws do not penetrate beyond the full depth of the door panel.

87/8” (225mm)

50” (1270mm)

70” (1778mm)

77 7/8” – 81 7/8” (1978 – 2080mm)

5” (127mm)

20” (508mm)

2” (50mm)

2” (50mm)

2” (50mm)

2” (51mm)

Ø1/16” (Ø2mm) REF

18x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

Do not place pilot holes

for handle attachment

in marked areas to avoid

clashing with panel

attachment brackets

3/4” (20mm)

31/2” (90mm)

23/8” (60mm)

2” (50mm)

18" FREEZER

1 1/4” (32mm) — For Single install

1 5/16 (33mm) — For Multiple install

For 6" (152mm) toe kick, door panel

height should be 2" (51mm) shorter

For 2" (51mm) toe kick, door panel

height should be 2" (51mm) longer

23

CUSTOM DOOR PANEL INSTALL DIMENSIONS

50” (1270mm)

70” (1778mm)

77 7/8” – 81 7/8” (1978 – 2080mm)

5” (127mm)

20” (508mm)

2” (50mm)

2” (50mm)

2” (50mm)

117/8” (302mm)

8” (203mm)

2” (51mm)

Ø1/16” (Ø2mm) REF

22x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

Do not place pilot holes

for handle attachment

in marked areas to avoid

clashing with panel

attachment brackets.

3/4” (20mm)

31/2” (90mm)

50” (1270mm)

70” (1778mm)

77 7/8” – 81 7/8” (1978 – 2080mm)

5” (127mm)

20” (508mm)

2” (50mm)

2” (50mm)

2” (50mm)

147/8” (378mm)

8” (203mm)

2” (51mm)

Ø1/16” (Ø2mm) REF

22x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

Do not place pilot holes

for handle attachment

in marked areas to avoid

clashing with panel

attachment brackets.

3/4” (20mm)

31/2” (90mm)

24

2” (50mm)

23/8” (60mm)

1 1/4” (32mm) — For Single install

1 5/16 (33mm) — For Multiple install

For 6" (152mm) toe kick, door panel

height should be 2" (51mm) shorter

For 2" (51mm) toe kick, door panel

height should be 2" (51mm) longer

2” (50mm)

23/8” (60mm)

1 1/4” (32mm) — For Single install

1 5/16 (33mm) — For Multiple install

For 6" (152mm) toe kick, door panel

height should be 2" (51mm) shorter

For 2" (51mm) toe kick, door panel

height should be 2" (51mm) longer

30" REFRIGERATOR OR FREEZER24" REFRIGERATOR OR FREEZER

CUSTOM DOOR PANEL INSTALL DIMENSIONS

For Wine cabinet, the Custom door panel must leave the glass pane visible. A full custom panel sheathing over the glass pane does not meet the specifications of this appliance.

117/8” (302mm)

8” (203mm)

5” (127mm)

2” (51mm)

50” (1270mm)

70” (1778mm)

77 7/8” – 81 7/8” (1978 – 2080mm)

20” (508mm)

2” (50mm)

2” (50mm)

2” (50mm)

2” (50mm)

Ø1/16” (Ø2mm) REF

22x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

Do not place pilot holes for

handle attachment in marked

areas to avoid clashing with

panel attachment brackets.

3/4” (20mm)

31/2” (90mm)

23/8” (60mm)

1 1/4” (32mm) — For Single install

1 5/16 (33mm) — For Multiple install

7 7/8" (200mm)

62 9/16 (1589mm)

For 6" (152mm) toe kick, door panel

height should be 2" (51mm) shorter

For 2" (51mm) toe kick, door panel

height should be 2" (51mm) longer

24" WINE CABINET

16 5/16" (415mm)

25

CUSTOM DOOR PANEL INSTALL DIMENSIONS

Dimensions apply for the preparation and installation of Custom door panels. For Dwg and Dxf files of the below panel preparation download the folder on thekitchentools.fisherpaykel.com.

z

The thickness of the custom door panel can vary provided that the screws do not penetrate beyond the full depth of the door panel.

11 7/8" (301.6mm)

8" (203.2mm)

2" (50.8mm)

5" (127mm)

2" (50mm)

Ø 1/16 (Ø2mm) REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

11 7/8" (301.6mm)

20" (507.8mm)

43" (1092mm)

49 3/8" (1254mm)

2" (50mm)

2" (50mm)

1 1/4" (32.6mm)

24" REFIGERATOR-FREEZER

TOP DOOR PANEL

3 9/16" (90mm)

13/16" (20mm)

2 3/8" (60mm)

Do not place pilot holes for

handle attachment in marked

areas to avoid clashing with

panel attachment brackets

22" (558.4mm)

30 3/8" (771.5mm)

1 1/4" (32.6mm)

1 1/2" (38.1mm)

3 1/2" (88.1mm)

20" (508.4mm)

8" (203.2mm)

2" (50.8mm)

24" REFIGERATOR-FREEZER

DRAWER PANEL

Ø 1/6" (Ø2mm) REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

2" (50mm)

Cutouts in the hanging

bracket are applicable for

Fisher and Paykel handles only.

Iflocating a custom handle in

the shaded area shown above,

ensure handle screw headsare

countersunk into the back of the

door panel to avoid interference

with the hanging bracket.

For 6" (152mm) toe kick, door panel

height should be 2" (51mm) shorter

For 2" (51mm) toe kick, door panel

height should be 2" (51mm) longer

26

CUSTOM DOOR PANEL INSTALL DIMENSIONS

Dimensions apply for the preparation and installation of Custom door panels. For Dwg and Dxf files of the below panel preparation download the folder on thekitchentools.fisherpaykel.com.

z

The thickness of the custom door panel can vary provided that the screws do not penetrate beyond the full depth of the door panel.

14 7/8" (377.8mm)

8" (203.2mm)

2" (50.8mm)

2" (50mm)

5" (127mm)

20" (507.8mm)

2" (50mm)

Ø2mm REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

13/16" (20mm)

3 1/2" (88.1mm)

14 7/8" (377.8mm)

8" (203.2mm)

2" (50.8mm)

1 1/2" (38.1mm)

1/6" (Ø2mm) REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

2" (50mm)

43" (1092mm)

49 3/8" (1254mm)

2" (50mm)

30" REFIGERATOR-FREEZER

TOP DOOR PANEL

3 9/16" (90mm)

2 3/8" (60mm)

1 1/4" (32.6mm)

Ensure handle is

mounted 65mm from

edge of panel to the

centre — this will avoid

interference with bracket.

22" (558.4mm)

30 3/8" (771.5mm)

20" (508.4mm)

1 1/4" (32.6mm)

30" REFIGERATOR-FREEZER

DRAWER PANEL

Cutouts in the hanging

bracket are applicable for

Fisher and Paykel handles only.

Iflocating a custom handle in

the shaded area shown above,

ensure handle screw headsare

countersunk into the back of the

door panel to avoid interference

with the hanging bracket.

For 6" (152mm) toe kick, door panel

height should be 2" (51mm) shorter

For 2" (51mm) toe kick, door panel

height should be 2" (51mm) longer

27

BEFORE INSTALLATION

INTEGRATED COLUMNS

RS4621F, RS6121F, RS7621F,

RS6121S & RS7621S models

INSTALLATION GUIDE

NZ AU GB EU

849164B 10.18

Checking your cabinetry

Check the dimensions of the cabinetry: height, width, depth, floor level, finished alcove returns. Refer to 'Cavity Dimensions' for the correct measurements.

Check the power supply and water connections

z

Ensure that there is a separate power socket for each appliance.

z

Avoid sharing the power point with other appliances to prevent accidental switching off

of the appliance.

z

For power requirements, refer to the information on the serial plate.

z

Ensure your appliance is properly grounded.

z

Connect your appliance to an electrical supply with the fitted plug and lead.

z

If power connection is located behind the appliance, we recommend to install

an isolating switch to a location that is easily accessible to the user for repair

or disconnection.

z

Follow local codes and ordinances when installing the appliance.

Checking your appliance

Unpack your appliance following the steps printed on the packaging box. Ensure your appliance is the correct model as your order. Ensure components and install kits are complete.

Remove the trims kit from the back of the

appliance. Refer to Supplied Parts — Trims

install kit for parts included in the box.

28

Remove the installation kit and

miscellaneous items kit from inside the

appliance.

Illustrations may differ from your purchased appliance.

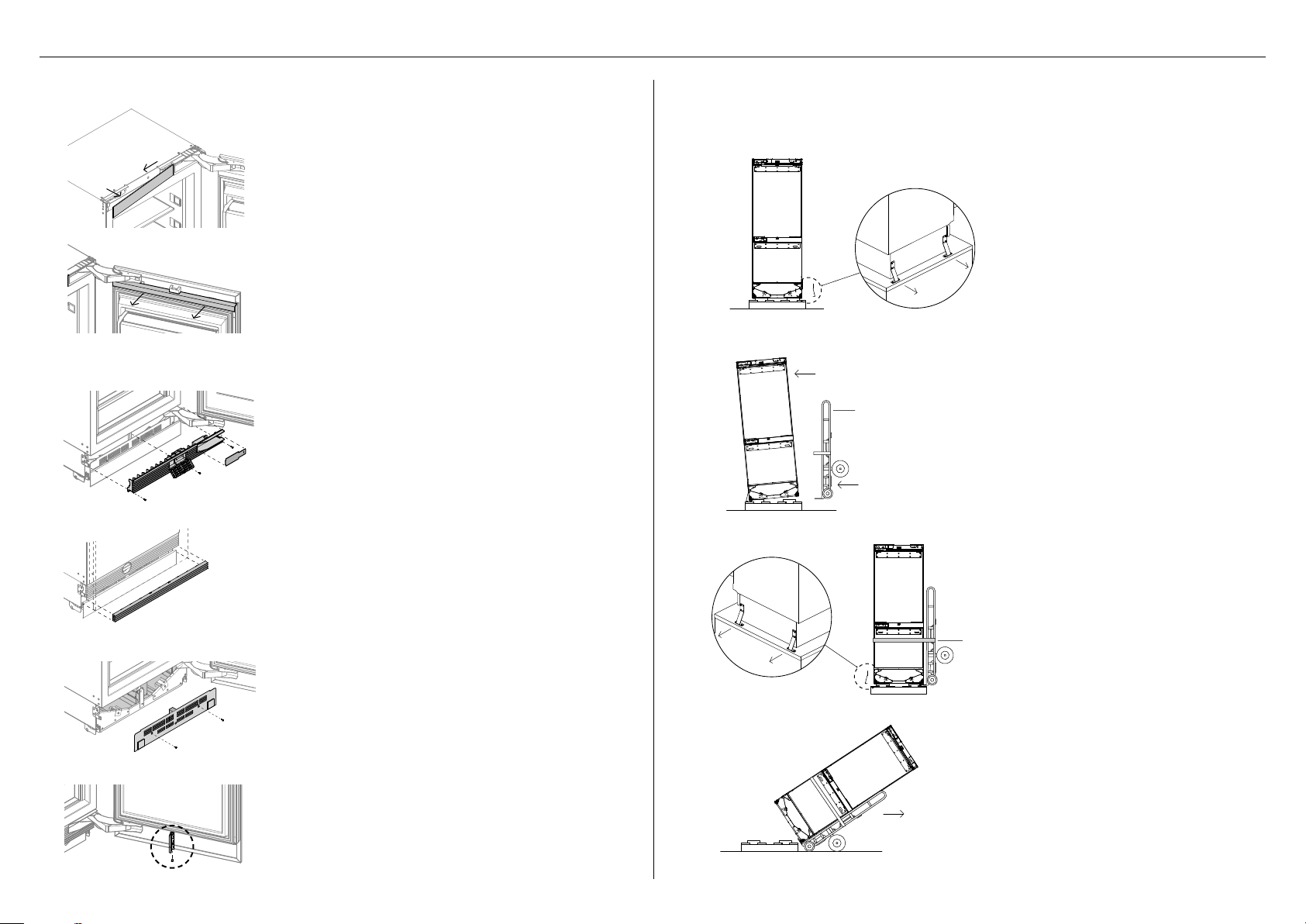

BEFORE INSTALLATION

Removing pre-installed parts Moving your appliance

Be careful when tilting the appliance forward/backward. Tape the door shut to prevent

Top trim

Disengage one end of the top trim from dual lock

strips on the non-hinge side of the appliance.

Slide the top trim out from the hinge pocket of the

appliance.

opening while moving the appliance. You need at least two persons to move this appliance.

Top door cover

Remove the trim caps of the top cover carefully from

both ends of the top of the door.

Ensure the magnet remains in place and not

damaged as this will affect the operation of the

appliance.

Top grille*

Open the door and remove hinge pocket cover using

a flat head screwdriver in theslot.

Open the water filter hatch on the bottom grille and

unscrew the #8x16 screw.

Remove the bottom grille by unscrewing the #8x16

screws from both ends of the grille.

*Top grille for Refrigerator-Freezer different from illustration.

Bottom grille

The bottom grille is detachable via magnets.

1

2

3

Hand truck

Strap

Remove the brackets from the

non-hinge side of the pallet.

Tilt the appliance slightly forward

and insert the hand truck between

pallet and appliance.

Restrain the appliance with

strap and remove the remaining

brackets.

Toe kick mounting plate

Remove the screws to detach the toe kick mounting

plate.

Air flow divider

Remove the screw to detach the air flow divider.

Set aside all the removed parts to reuse later.

Illustrations may differ from your purchased appliance.

4

Tilt backward to load the appliance

onto the hand truckandsetaside

thepallet

Pushthehandtrucktothe

installationlocation

29

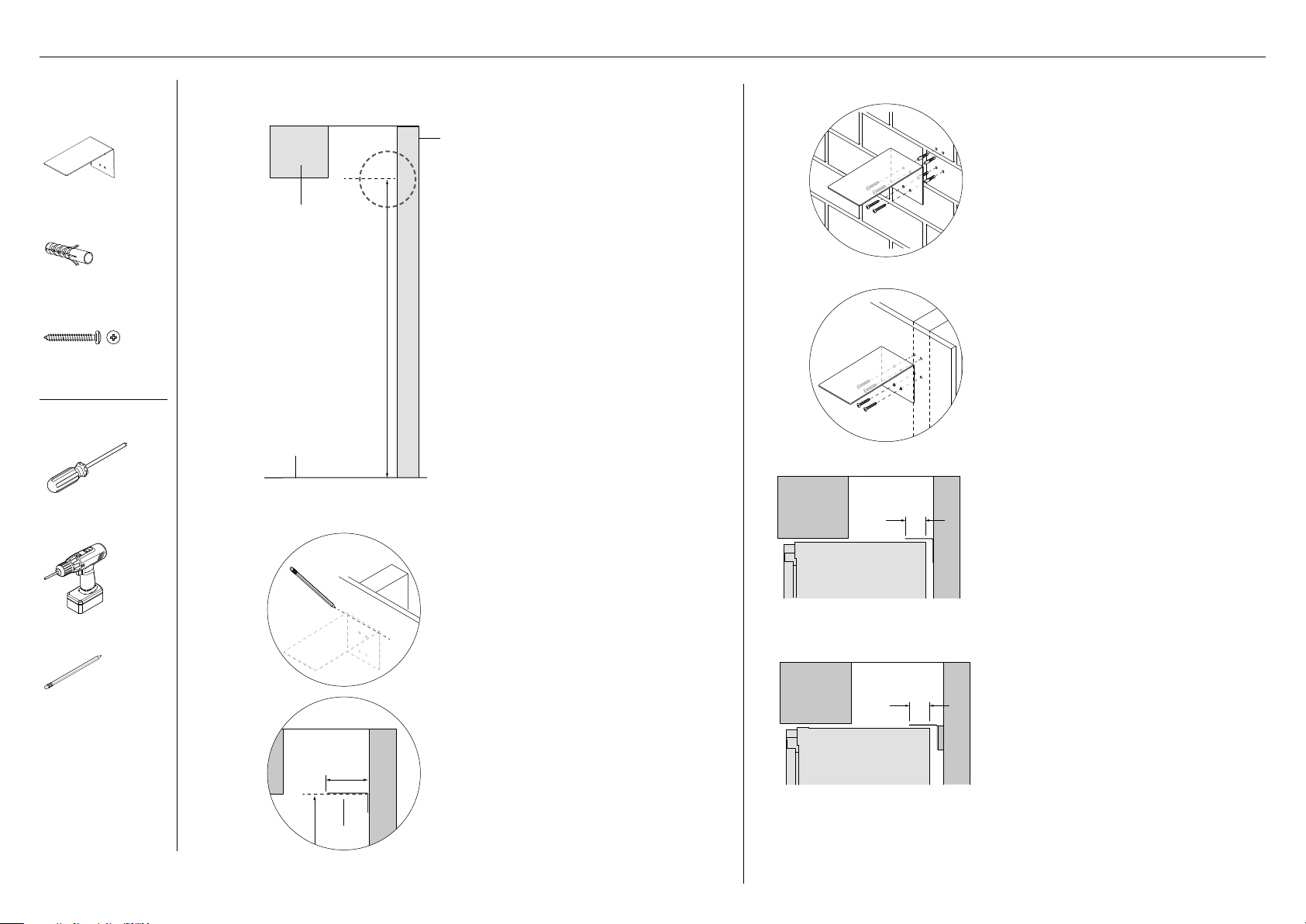

CAVITY PREPARATION

Anti-tip bracket

assembly kit

Anti-tip bracket (1x)

Masonry plug (4x)

#10x40

cross-head screw (4x)

Tools

Cross-head

screwdriver

Powered drill

Attaching the anti-tip bracket

overhead

cabinetry

1

Floor

PROFILE VIEW

A

2

B

back wall

Measure the height (A) of the attachment

location from the floor to the alcove

return.

z

The height (A) must not exceed

84 3/16" (2138mm) to ensure the

appliance does not tip over during

installation.

Mark a horizontal line (B) at the back wall.

z

Ensure there is a stud behind the wall.

4

5

For solid wall installation

Drill holes suitable to the size of the

masonry plugs.

Hammer 10x30mm masonry plugs into

wall until flush. Fix bracket to wall with

#10x40mm cross head screws, and screw

tightly.

For plaster board wall

Fix the anti-tip bracket to the wall with

#10x40mm cross head screws, and screw

tightly into the stud with a screwdriver.

When rollng the appliance into the

cabinetry, ensure the anti-tip bracket

overlaps the back edge of the appliance.

z

The bracket must overlap the appliance

by a minimum 7 1/16" (180mm) for a

secure hold.

Pencil

30

3

min 7 3/4"

(197mm)

bracket

Place the bracket to the backwall. Align

the undersurface of the bracket along the

marked line.

Mark screw hole locations, and drill screw

holes with powered drill.

If minimum 7 1/16" (180mm) overlap

cannot be achieved, install a solid spacer

to the wall stud behind the bracket.

z

Be careful not to run over the power

cord when rolling in the appliance.

Illustrations may differ from your purchased appliance.

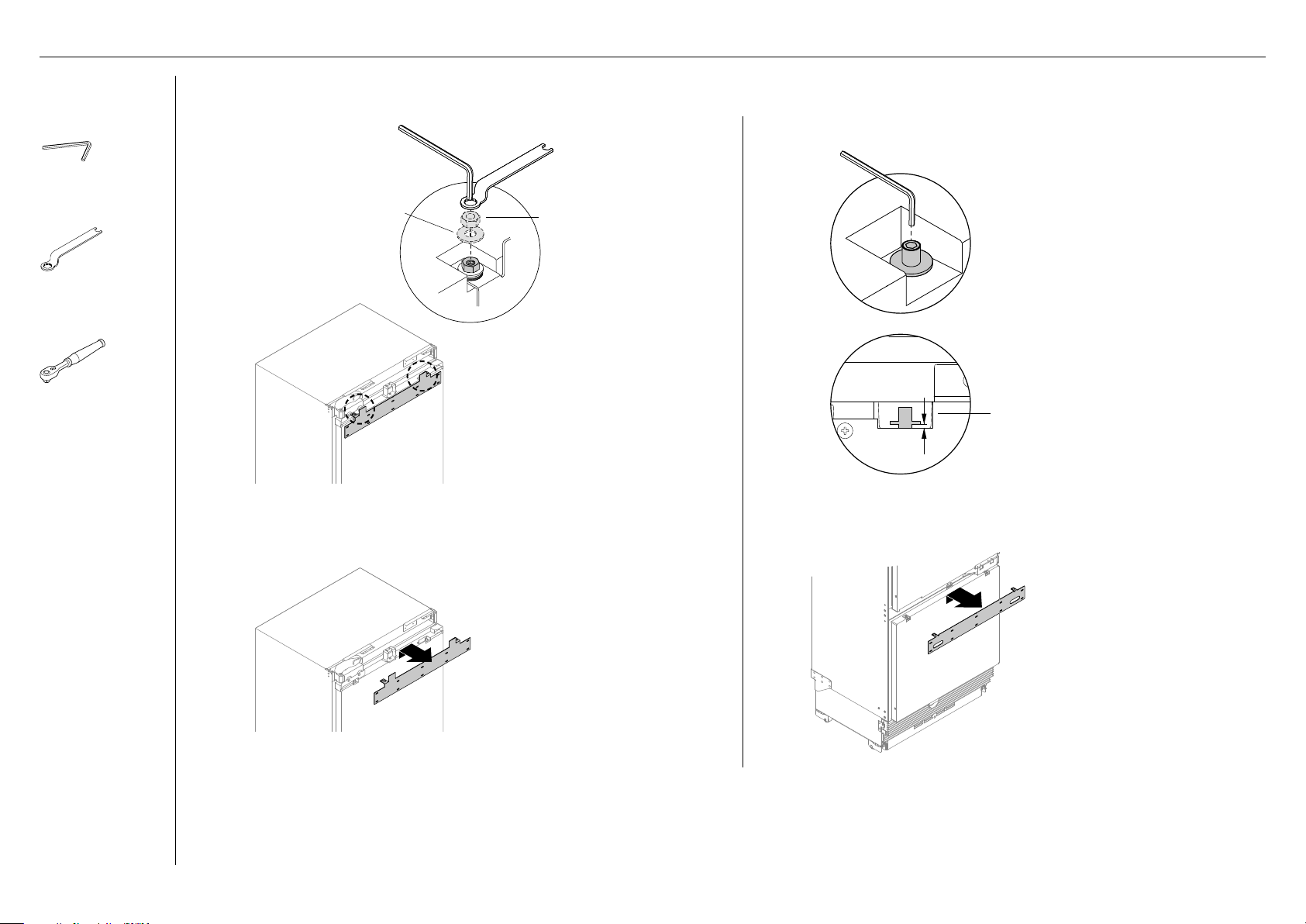

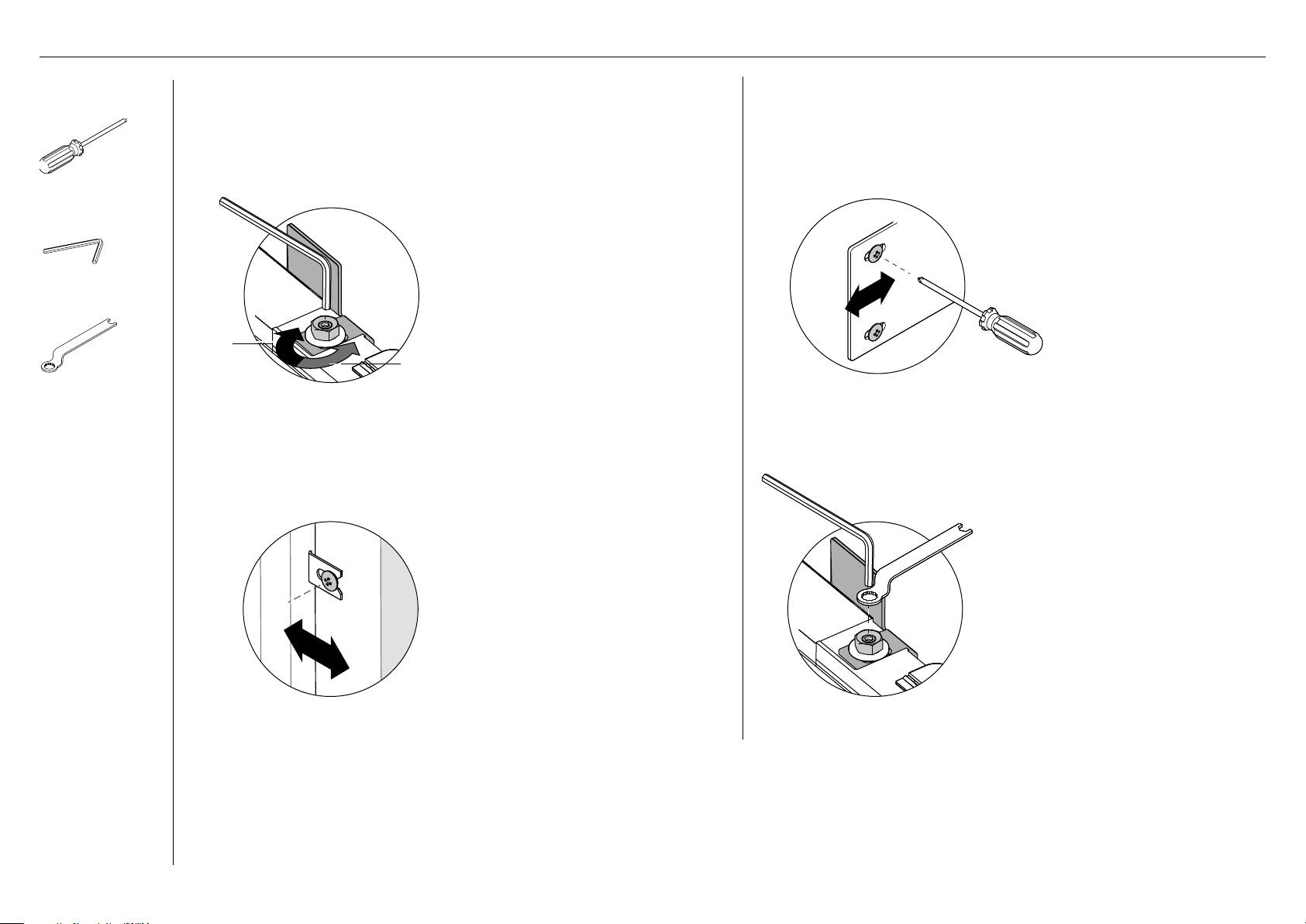

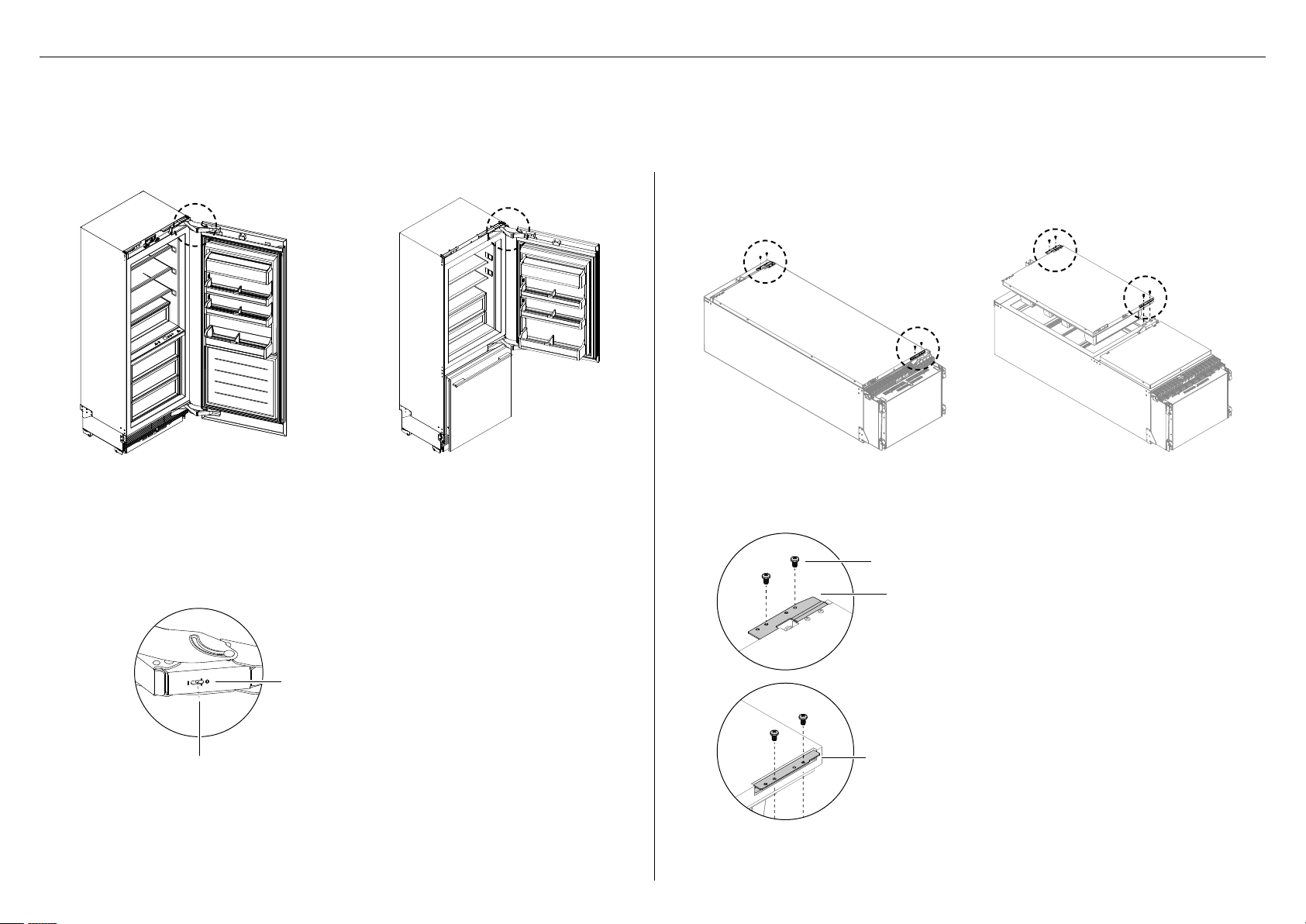

APPLIANCE PREPARATION

Tools

M8 hex key

1/2" (13mm) spanner

1/2" (13mm) socket

wrench

Removing the hanging brackets

M8 washer

1

M8 nut

Remove the M8 nut and M8

washer from the M8 screw at

the top of the door using the

supplied hex key and spanner.

3

Loosen the M8 screws by

1/8" (3mm).

M8 screw

1/8" (3mm).

2

Illustrations may differ from your purchased appliance.

Remove the hanging bracket

and set aside to use later.

4

For Refrigerator-Freezer:

Repeat steps 1 - 3 to remove

the bracket of the drawer. Use

a socket wrench to loosen the

M8 nut.

31

APPLIANCE PREPARATION

Install fasteners

kit

Barbed plugs (2x)

Cabinet depth

alignment gauge

(4x)

Tools

Cross-head

screwdriver

Attaching the barbed plugs

Before rolling into the cavity, insert a barbed plug into the

large holes at the top right and left sides of the appliance.

The plugs protect the inside surface of cabinetry from

being damaged by screws when pushing in the appliance.

Attaching the depth alignment gauges

Loosen the right and left screws at the top and bottom

sides of the door.

Locate the alignment gauges at correct orientation to the

right and left screws.

32

Left

Right

Place the alignment gauge by inserting the screw head

through the keyhole of the gauge.

Push the alignment gauge down to lock the position.

Tighten the screw just enough to firmly hold the gauge.

z

The alignment gauges are only temporary and must be

removed after installation.

Illustrations may differ from your purchased appliance.

DOOR PANEL PREPARATION — STAINLESS STEEL PANEL

Door handle kit

M5x25 Hex screw

(4x)

Door panel

attachment kit

Side bracket (6x)

Bracket slider (6x)

Bracket spacer (6x)

Door panel kit

8Gx16 Mush washer

screw (32x)

Tools

Powered driver

Attaching the handle

Remove the protective film around the handle attachment area before installing

the handle. Protect the finish of the door panel to avoid damage or scratches to

the surface.

For Refrigerator/Freezer/Wine cabinet

Remove the plastic plugs from handle

holes (4x) of the door panel.

Align the handle to the holes and secure

with M5x25 hex screws.

For Refrigerator-Freezer

Remove the plastic plugs from handle

holes (4x) of the top door panel.

Align the handle to the holes and secure

with M5x25 hex screws.

Secure the handle to the handle holes of

the drawer door panel with M5x25 hex

screws.

Attaching the brackets

hanging

bracket

side

bracket

top hanging

bracket

bottom hanging

bracket

bracket spacer

side bracket

side

bracket

For Refrigerator/Freezer/Wine cabinet

Secure the top hanging bracket to the

screw holes of the door panel with 8Gx16

Mush washer screws.

z

6x screws for 18” Column

z

10x screws for 24” or 30” Column

Secure the bracket spacer, side bracket

and bracket slider (in order as illustrated)

to the screw holes on both sides of the

door and drawer panels with 8Gx16 mush

washer screws.

bracket slider

For Refrigerator-Freezer

Secure the top hanging bracket to the

screw holes of the door panel with 8Gx16

Mush washer screws.

z

10x screws for 24” or 30” Column

Secure the bottom hanging bracket to the

screw holes of the drawer door panel with

8Gx16 Mush washer screws.

Secure the bracket spacer, side bracket

and bracket slider (in order as illustrated)

to the screw holes on both sides of the

door and drawer panels with 8Gx16 mush

washer screws.

Remove the blue tape attached to the inner edges of the door panel after the

handles are installed.

Illustrations may differ from your purchased appliance.

33

DOOR PANEL PREPARATION — CUSTOM PANEL

Door handle kit

M5x25 hex screw (4x)

Door panel

attachment kit

Side bracket (6x)

Bracket slider (6x)

Bracket spacer (6x)

M5x12 cross-head

screw (32x)

Attaching the handle

Refer to 'Custom door panel installation dimensions' page for correct screw hole

positions on the door panel.

For Refrigerator/Freezer/Wine cabinet

Secure the door handle to the handle

holes of door panel with

M5x25 hex screw.

For Refrigerator-Freezer

Secure the handle to the handle holes of

the top door panel with

M5x25 hex screw.

Attaching the brackets

Refer to 'Custom door panel installation dimensions' page for correct screw hole

positions on the door panel.

marked line

top hanging

bracket

side bracket

For all models

Mark a line across the centre of the

custom door panel.

Align the ‘V’ notch at the top of the

bracket to the centreline.

Secure the top hanging bracket to the

screw holes of the refrigerator custom

door panel with M5x12 cross-head

screws.

top hanging

bracket

side bracket

Tools

Powered driver

34

Secure the handle to the handle holes of

the drawer door panel with M5x25 hex

screw.

Ensure the door and drawer handles do not interfere when attaching the side

attachment brackets.

bottom hanging

bracket

Illustrations may differ from your purchased appliance.

For Refrigerator-Freezer

Secure the bottom hanging bracket to

the screw holes of the drawer door panel

with M5x12 cross-head screws.

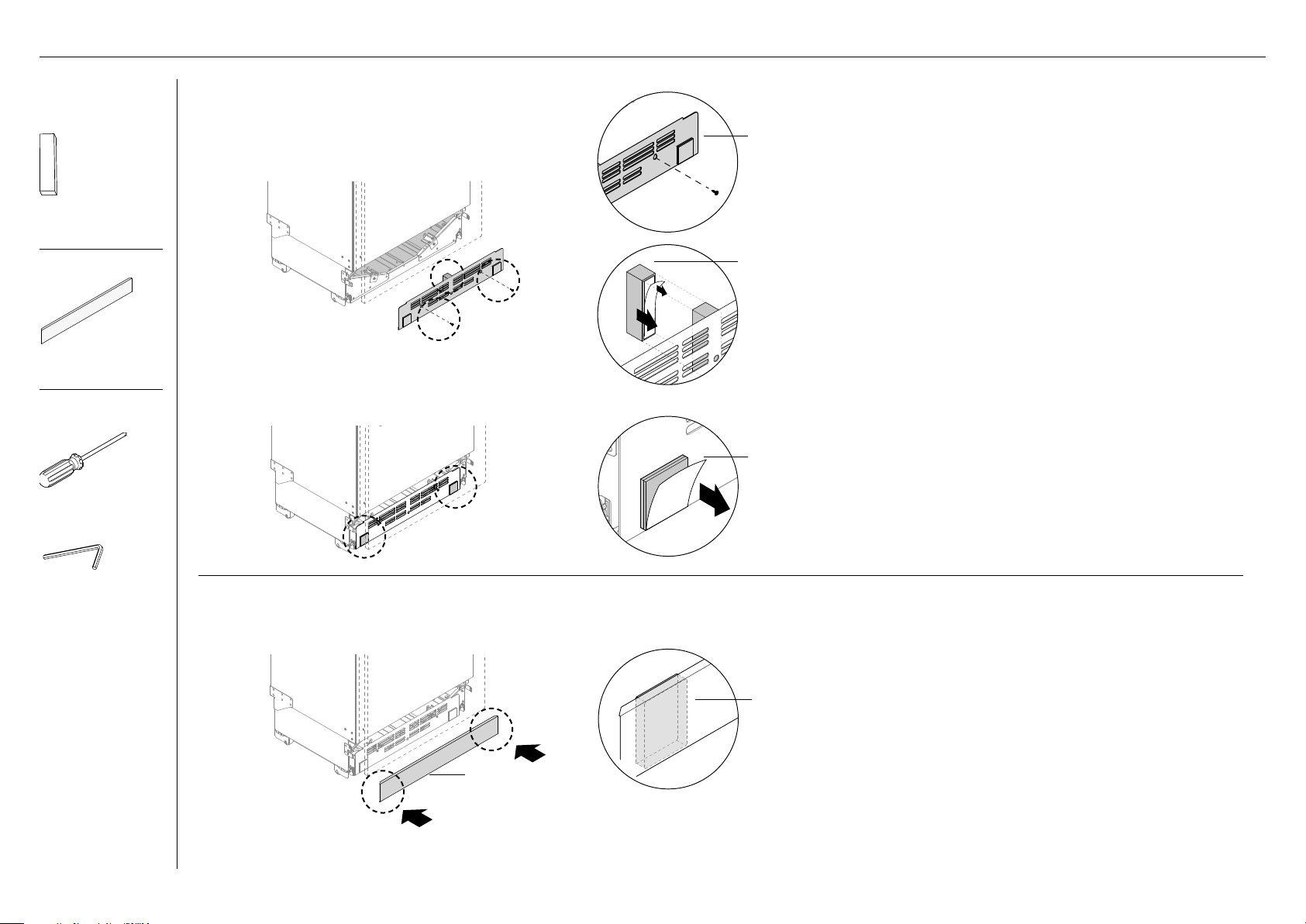

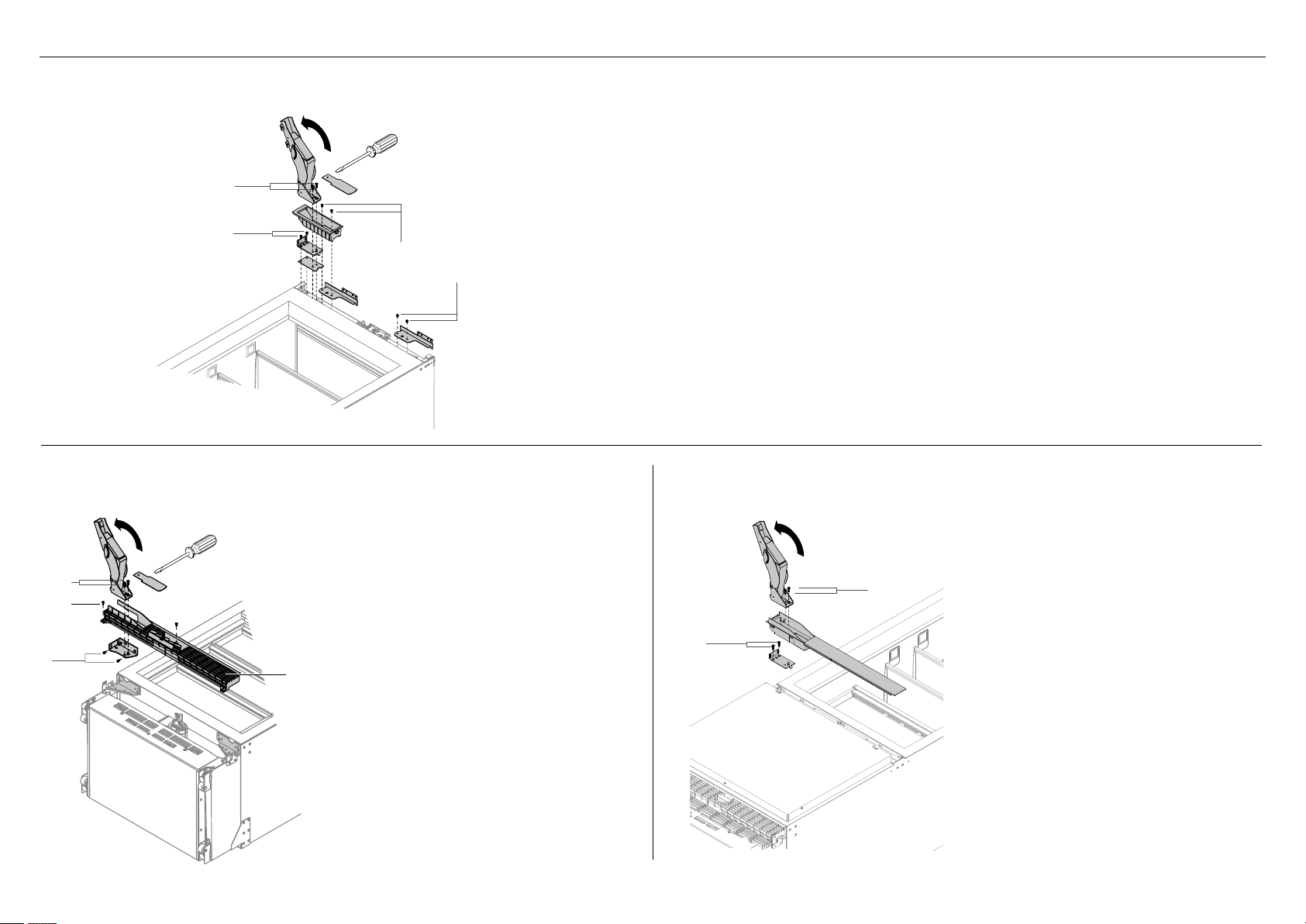

DOOR PANEL PREPARATION — WINE CABINET ONLY

Installation kit

Long trim (2x)

Tools

Cutter

Attaching the long glass trims

Glass trims are attached to cover the gap between the door panel and glass panel.

long trim

red protective film

Peel off a small portion of red

1

protective film from one end of

the long trim.

2

hanging bracket

Do not exceed

pass this line

long trim

Attach the peeled portion of the trim

starting from the top of the flange on

one side of the door panel cutout.

z

Ensure the trim does not overlap

the hanging bracket.

Align the trim flush with inside edge

of the flange.

flange

3

Cut excess length of

trim along this line

Continue attaching the long trim for

the length of the door panel cutout,

peeling off the film as you go.

Cut-off the excess length of the

bottom end of the long trim.

Repeat all steps to the other side of

door panel cutout.

35

DOOR PANEL PREPARATION — WINE CABINET ONLY

Installation kit

Short trim (2x)

Tools

Cutter

Attaching the short glass trims

1

short trim

2

short edge

long edge

Place the short trim along the

length of the top of door panel

cutout across the top ends of the

long trims.

Cut both ends of the short trim

to length.

Peel off a small portion of red

protective film from the short

edge.

3

4

long trim

short trim

long trim

short trim

Attach the peeled portion

starting from one end of flange

perpendicular to top end of

long trim.

Continue attaching the short

trim for the length of the top of

door panel cutout, peeling off

the film as you go.

Ensure the trim is aligned flush

to inside edge of flange.

Attach the remaining peeled

portion of short trim to the

flange perpendicular to top end

of the other long trim.

36

Repeat steps 1 – 5 to the

bottom of door panel cutout.

POWER AND WATER SUPPLY CONNECTION

Water fittings kit

Collet locking

clip (1x)

1/2 BSP Stainless

steel braided hose

with 7/16-24 UNS

thread (1x)

1/4” (6mm) Adaptor

(2x)

Connecting to water supply

Ensure the door of the appliance is closed before rolling into thecabinetry. Push the appliance carefully towards the front of the cabinetry close enough to allow

access at the back for power and water connection. Ensure an isolating tap is available if water supply is not easily accessible.

braided hose

1

2

3

Connect one end of a braided water

hose to the water tap.

Flush water through the hose prior to

connection to the appliance to remove

any debris in the hose.

Insert the other end of the braided

hose through a hole at the rear of the

plinth and push all the way to the front

of the appliance.

Pull the hose to the front of the

appliance.

5

6

PLV

locking clip

Insert the tube end of the adaptor

fully into the PLV at the bottom front

of the appliance.

Secure the connection with a locking

clip between the PLV and hose end of

the adaptor.

4

Connecting to power supply

Illustrations may differ from your purchased appliance.

Connect an 1/4" (6mm) adaptor to the

braided hose.

At the back of your appliance, connect

the power plug to the power outlet

(115VAC, 60Hz).

z

You will hear a chime sound when

the appliance is powered on.

When powered on for the first time,

your appliance will default to Install

mode.

Once installation is complete,

unlock the control panel and

hold Compartment

four seconds to start cooling.

z

Refer to your ‘User guide’ for more

information on activating your

appliance.

button for

37

INSTALL WATER FILTER

Freezer and Refrigerator with Ice & Water function Refrigerator-Freezer

Keep the door closed and ensure the

appliance is stable before installing the

water filter to avoid risk of appliance

tipping over.

Remove the packaging of the supplied

water filter.

Pull the filter tool gently to dislodge from

the front of the appliance.

Insert the water filter all the way into the

2

3 3

filter casing and press firmly until the filter

head is pushed further inside the casing

Using the filter tool, rotate the filter head

90° clockwise to lock in place

11

2

filter removal tool

Keep the door closed and ensure the

appliance is stable before installing the

water filter to avoid risk of appliance

tipping over.

Remove the packaging of the supplied

water filter, and the filter removal tool

from the top grille.

Align the filter head with the slot of the

filter removal tool and push until it clips

in place.

Using the filter removal tool, hold the

water filter with the handle positioned

vertically and insert into the casing until

the filter head is pushed all the way inside

the casing.

Push firmly until the water filter is all the

way into the casing.

Turn the filter removal tool clockwise to

lock the water filter in place.

38

Return the filter tool to its storage

position.

Turn on the water supply to check for

leaks.

Use the water dispenser to ensure water

is flowing freely. Refer to your User guide

for more information.

Remove the filter removal tool from the

water filter and return it to the top grille.

Turn on the water supply to check for

44

leaks.

Use the water dispenser to check if water

is flowing freely. Refer to your User guide

for more information.

Illustrations may differ from your purchased appliance.

SINGLE INSTALLATION — ALIGN APPLIANCE INTO CABINETRY

Tools

Cross-head

screwdriver

Ruler

Pencil

Pushing into the cabinetry

Aligning the depth gauges

7 1/16" (180mm)

Roll the appliance carefully into the cabinetry until the anti-tip bracket overlaps the

back edge of the appliance.

z

Ensure the bracket overlaps the appliance by a minimum 7 1/16" (180mm) for a

secure hold.

z

Be careful not to run over the water hose and power cord when rolling in

the appliance.

On the 'Cabinet depth alignment' side of the depth gauges, mark the step on both

sides of the door based on the thickness of the door panel.

z

Example illustration show the door panel thickness 1" (25.4mm) marked on the

gauges.

Illustrations may differ from your purchased appliance.

Left

Right

Check if the gaps between appliance and cabinetry side walls are

even on left and right sides.

39

SINGLE INSTALLATION — ALIGN APPLIANCE INTO CABINETRY

Tools

Cross-head

screwdriver

Powered driver

(optional)

Adjusting the alignment in the cabinetry

1

Front foot

adjustment

screw

Rear foot

adjustment

screw

Foot

Clockwise turn of the front and rear adjustment screws raise the

height of the appliance.

Counter-clockwise turn of the adjustment screws lower the height of

the appliance.

40

2

3

Front feet

Turn the front and rear adjustment screws clockwise to extend the

front feet and rear feet until they engage the floor and the top bracket

reaches the cabinetry ceiling.

Rear feet

Check the depth gauges while adjusting the screws to maintain

alignment of the appliance.

Illustrations may differ from your purchased appliance.

SINGLE INSTALLATION — SECURE APPLIANCE INTO CABINETRY

Install fasteners

kit

8Gx16 Countersunk

screw (6x)

Tools

Cross-head

screwdriver

Powered driver

(optional)

Securing the top brackets

Fix the top brackets to the ceiling surface of the

cabinetry with 8Gx16 countersunk screws.

Securing the side brackets

Illustrations may differ from your purchased appliance.

Fix the side brackets (2x) to the lower right and left sides

of the cabinetry with 8Gx16 countersunk screws.

Once the appliance is secured to the cabinetry, remove

the alignment gauges and re-tighten the side screws.

41

DOOR PANEL INSTALLATION

Tools

Cross-head

screwdriver

M4 hex key (1x)

1/2" (13mm) spanner

(1x)

1/2" (13mm) socket

wrench

Hanging the door panel

1

Hold the door panel at an angle from

the top of the door and lower the screw

holes of the hanging bracket onto the

adjustment screws. .

3

Screw the M8 washer and nut to the

adjustment screw and loosely tighten.

42

2

Align the door panel straight with the

door and slide-in the side brackets to the

side screws of the door,

Tighten the side screws loosely to

temporarily secure the door panel.

For Refrigerator-Freezer

Repeat steps 1 - 3 for the top door and

drawer panels.

Use a 1/2" (13mm) socket wrench to

tighten or loosen the M8 nut in the drawer

panel.

Illustrations may differ from your purchased appliance.

DOOR PANEL INSTALLATION

Tools

Cross-head

screwdriver

M4 hex key (1)

13mm spanner (1x)

Adjusting the height of door the panel

Ensure the side brackets are loosely screwed when adjusting the height of the

door panel. Do not adjust the door panel height when the side brackets are

screwed tight. This can generate friction which causes the hanging brackets to

bend.

Turn the adjustment screw to raise

or lower the height of the door panel

relative to the door.

Continue adjustment until gap with

cabinetry is more than 3mm.

z

Do not adjust the adjustment screw

higher than 1/4" (6.5mm) from its

Lower

Raise

fully down position.

Adjust the depth of door panel

Re-adjusing the door panel

To adjust door panel further, remove the

door panel then loosen the fixing screws

of the hanging bracket and move the

bracket sideways to suit.

Illustrations may differ from your purchased appliance.

Loosen side screws on the side

brackets, and slide door panel

forward/backward.

Re-tighten once satisfied.

To adjust door panel further, remove the

door panel then loosen the fixing screws

of the hanging bracket and move the

bracket sideways to suit.

z

Once satisfied with door panel position,

fully tighten M8 washer and nut to

adjustment screw.

43

DOOR PANEL INSTALLATION

TOE KICK INSTALLATION

Tools

Cross-head

screwdriver

Cutter

M4 hex key (1x)

13mm spanner (1x)

REFRIGERATOR OR FREEZER / WINE CABINET

1

REFRIGERATOR—FREEZER

Loosen the screw at the bottom

of the door, and slide thelocking

bracket out until it touches the panel.

Refrigerator-Freezer

The locking bracket is located at the

bottom of the top door panel.

Adjusting mounting plate bracketsInstalling locking bracket

1

cap screw

adjustment

brackets

Loosen the cap screws of the

adjustment brackets on both

sides of the plinth with a hex key.

44

2

3

B

Fix the locking bracket to the door

panel with 8Gx16 countersunk screw.

Re-tighten the screw at the bottom

of the door.

2

Adjust the brackets to the

desired depth by moving it

forward/backward.

Re-tighten the cap screws once

satisfied.

Illustrations may differ from your purchased appliance.

TOE KICK INSTALLATION

Miscellaneous

components

Air toe kick seal (1x)

Toe kick install kit

Toe kick panel (1x)

Tools

Cross-head

screwdriver

Attaching the mounting plate

1

2

mounting plate

air toe kick seal

adhesive tape

Re-attach the toe kick mounting plate to the plinth

using same screws that were set aside previously.

If toe kick depth is less than 3 5/8" (92mm), attach an

air toe kick seal to the mounting plate.

Peel off the adhesive tape of air toe kick seal and attach

to the middle of the back side of the mounting plate.

Press firmly to ensure the tape adheres to the mounting

plate.

Peel off the adhesive tape backing of the magnets

attached to the mounting plate.

z

Ensure the adhesive surface is clean and free of dust

or small particles.

M4 hex key (1x)

Attaching the toe kick panel

1

Illustrations may differ from your purchased appliance.

toe kick

spacer

Position the toe kick in front of the mounting plate.

z

The spacers on the toe kick must be aligned with the

magnets of the mounting plate.

Press the toe kick firmly onto the mounting plate to fix

the position.

z

For custom toe kick, spacers are not needed.

z

For correct dimensions of toe kick, refer to 'Toe kick

panel dimensions' for more information.

45

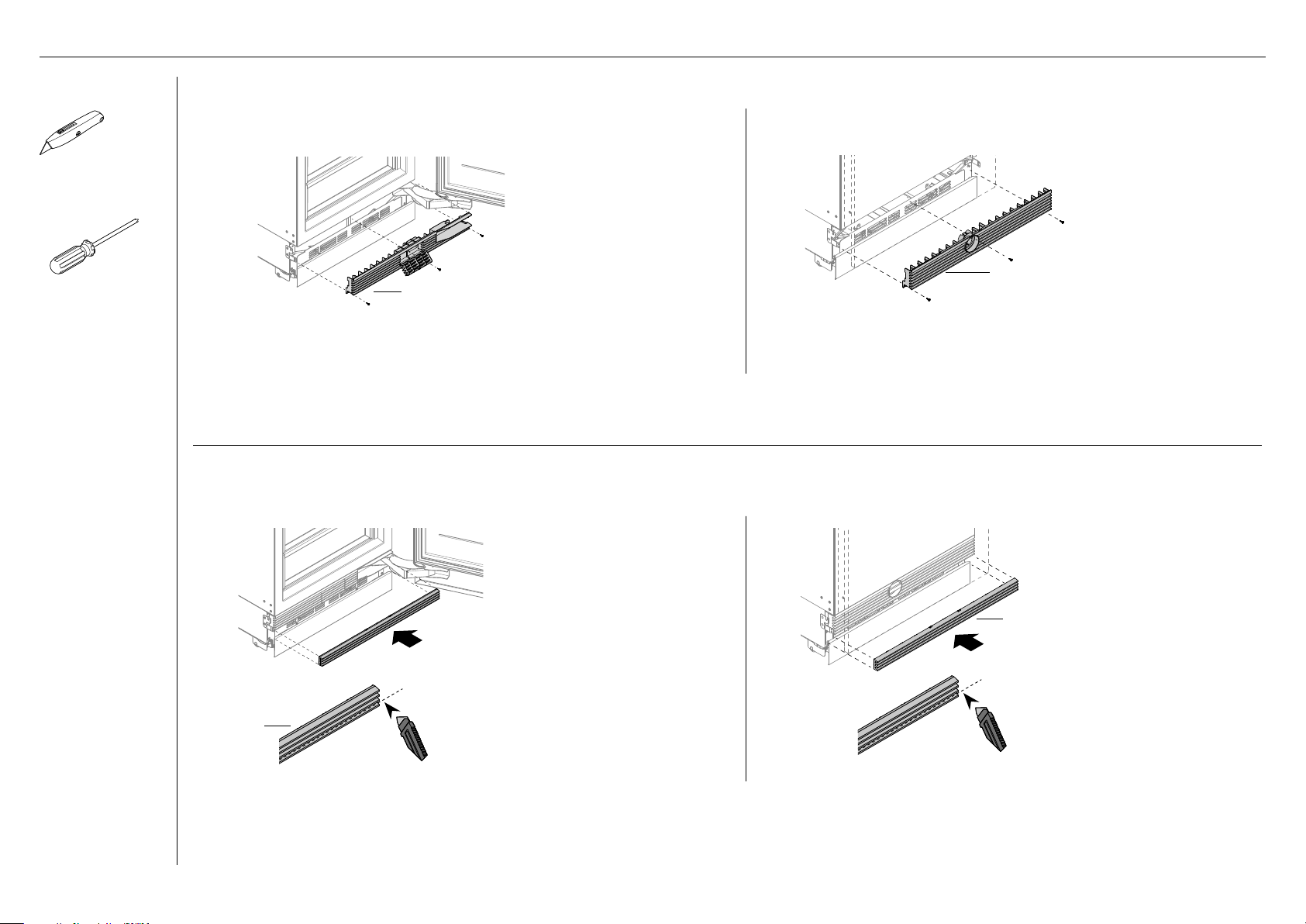

GRILLES INSTALLATION

Tools

Cutter

Cross-head

screwdriver

Attaching the top grille

Attaching the bottom grille

top grille

Refrigerator or Freezer/

Wine Cabinet

Open the door, and secure

both ends of the grille and

behind the water filter hatch

with #8x16 screws.

Refrigerator-Freezer

Reattach the top grille with

#8x16 screws.

top grille

46

Refrigerator or Freezer/

Wine Cabinet

Re-attach the bottom grille

via magnets.

bottom grille

For toe kick heights 41/2”–5” (114 – 127mm), shorten the bottom grille by cutting along the vertical ribs.

Refrigerator-Freezer

Re-attach the bottom grille

via magnets.

bottom grille

Illustrations may differ from your purchased appliance.

CARBON FILTER INSTALLATION

AIR FLOW DIVIDER INSTALLATION

The carbon filter is used for Wine Cabinet models only. Ensure the cover is completely closed

to prevent hatch or filter from being damaged. Replacement filters (862755) can be purchased

online from fisherpaykel.com or by calling Fisher & Paykel Customer Care.

1

Push-open latch

2

Housing

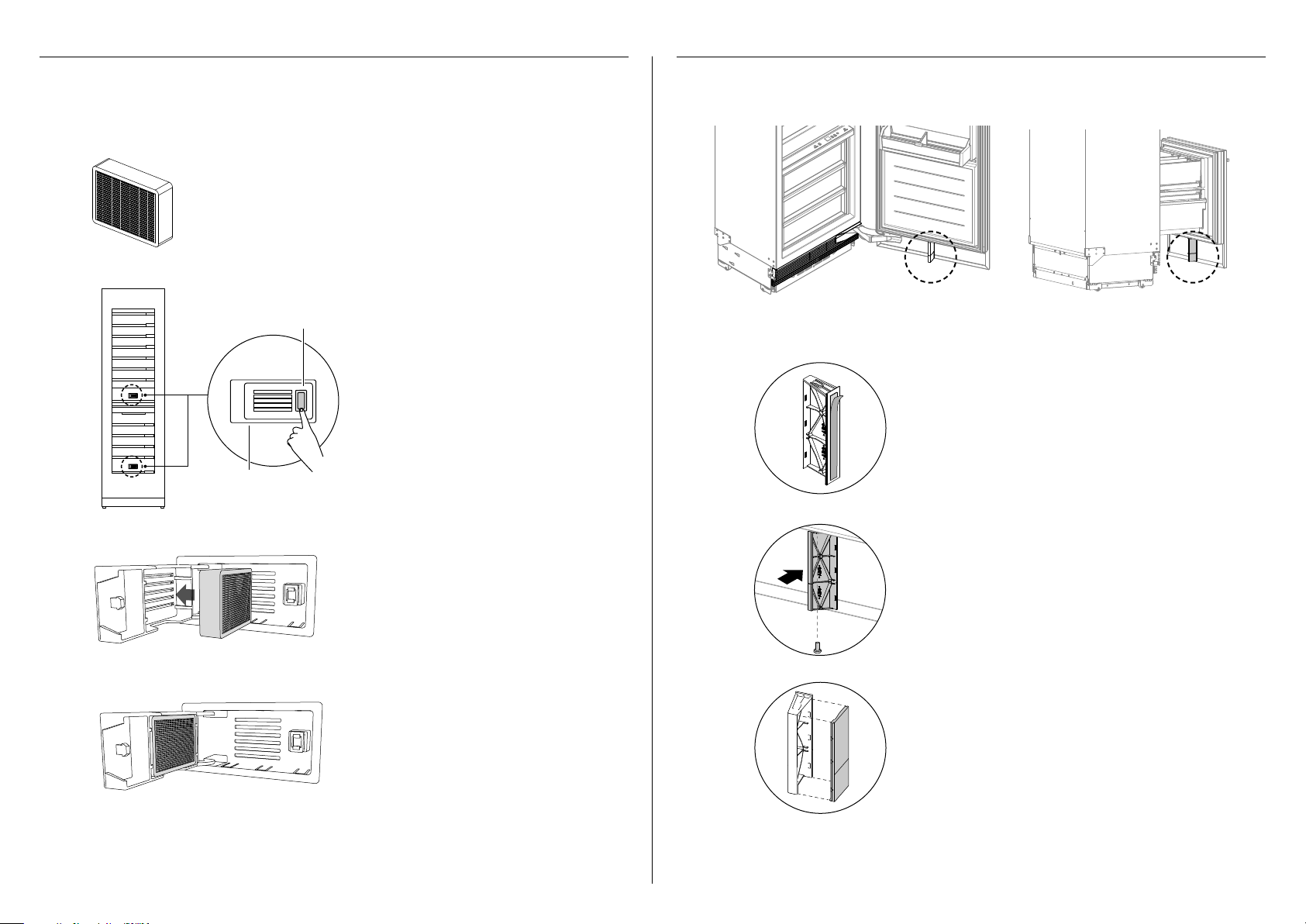

Remove the packaging of the filter.

Open the cover of filter housing by

pushing the latch.

The air flow divider blocks the air flow from bypassing the front of the bottom grille.

REFRIGERATOR—FREEZER

1

REFRIGERATOR & FREEZER / WINE CABINET

Remove the adhesive layer off the air flow

divider.

3

4

Illustrations may differ from your purchased appliance.

Insert the carbon filter in the hatch.

Push the filter gently into the hatch until

flush, and then close the cover until it

locks to the latch.

2

3

Press the flow divider firmly against the

bottom of the door/drawer panel.

Ensure the adhesive layer side of the

divider contacts the door panel.

Secure the air flow divider to the panel

with screw.

Attach a flow divider cap to the flow

divider.

47

Cabinet side trim (2x)

Dual adhesive strips

(4x)

Installing cabinet side trimsTrims install kit

1

adhesive strip

CABINET TRIMS INSTALLATION

Dual adhesive strips are pre-attached at

four locations along the side trims.

z

Ensure the adhesive strips are pressed

firmly to the cabinet side trims.

Peel off the liners from the dual adhesive

strips.

z

Ensure the adhesive surface is clean

and free of dust or small particles.

door hinge

trim

Position the trim at an angle on

the throat of the door hinge.

2

3

For Refrigerator or Freezer/Wine cabinet

Hold the same angle and slide the bottom

end of side trim behind the bottom hinge.

Slide the top end behind the top hinge.

For Refrigerator-Freezer

Hold the same angle and slide the bottom

end of side trim behind the middle hinge

down to the bottom drawer side.

Slide the top end of side trim behind the

top hinge.

Slot the side trim behind the top hinge pocket.

Press the adhesive strip to the cavity to ensure the trim is

also tight against the inner face of the appliance.

On the non-hinge side, slide in the side trim behind the

top trim.

Press firmly on the dual-lock strip locations to ensure the

side trims are securely attached.

48

REFRIGERATOR OR FREEZER

WINE CABINET

REFRIGERATOR—FREEZER

Illustrations may differ from your purchased appliance.

DOOR COVERS & TRIMS INSTALLATION

Trims install kit

Re-installing the top cover (for all models)

Remove the backing film of dual adhesive strips pre-attached to the top of the door. Ensure the magnet is in place before installing the top cover.

trim cap

Door panel side

cover (2x)

For Refrigerator or Freezer/

Wine Cabinet

1

magnet housing

Door panel side

cover (2x)

For Refrigerator-Freezer

Installing the door side covers

Ensure the door surface is free of dust or small particles. Clean the door surfaces with a cleaning liquid to improve adhesion of the adhesive strips. Dual adhesive strips

are pre-attached to the side covers and drawer top trim.

Drawer panel side

cover (2x)

For Refrigerator-Freezer

Drawer top trim (1x)

For Refrigerator-Freezer

Illustrations may differ from your purchased appliance.

notch

door panel

side cover

top cover

trim cap

Align the top cover to the top

of the door.

Clip the notch into the magnet

housing, and the trim caps on

top of the adhesive strips.

Refrigerator or Freezer/

Wine Cabinet

Peel off the liners of the dual

adhesive strips.

Slide the door panel side cover

into the gap between the door

and door panel.

Align the top of the door panel

side cover with the top door

panel extrusion.

Press firmly to ensure the

adhesive strips are fully adhered

to the door surface.

2

drawer top trim

drawer panel

side cover

Press down both ends of the top

cover to engage the trim caps on

the adhesive strips.

Ensure the magnet remains in

place and not damaged as this

will affect the operation of the

appliance.

Refrigerator-Freezer

Magnets are pre-attached to the door

and drawer side covers.

Press the door side covers into the

panel gaps on the right and left sides

of the door.

Align the top of the side covers to fit

with the right and left ends of the top

cover.

Remove the backing film of adhesive

strips on the drawer top trim.

Press down the trim firmly to engage

the back surface of drawer panel.

z

Ensure the trim is fully seated

against the drawer top surface.

Insert the drawer side covers into the

panel gaps on the right and left sides

of the drawer.

z

Ensure the cabinet is centered

to prevent the side covers from

interfering with the cabinet.

49

TOP TRIM & HINGE POCKET COVERS INSTALLATION

installing the top trim (for all models)

Slide one end of the top trim into the hinge pocket

of the appliance.

Press the other end to engage the dual lock strips

on the non-hinge side of the appliance.

top trim

installing the hinge pocket covers (for all models)

Follow the steps below to install the covers for the top, bottom or middle hinge pockets.

1

2

3

50

Place the hinge pocket cover to the hinge pocket,

matching the studs on the cover to the slots in the

hinge pocket.

Slide the cover inside the pocket.

Press the pocket cover to ensure the cover clips

into the pocket.

Your Integrated Installation is now complete!

Illustrations may differ from your purchased appliance.

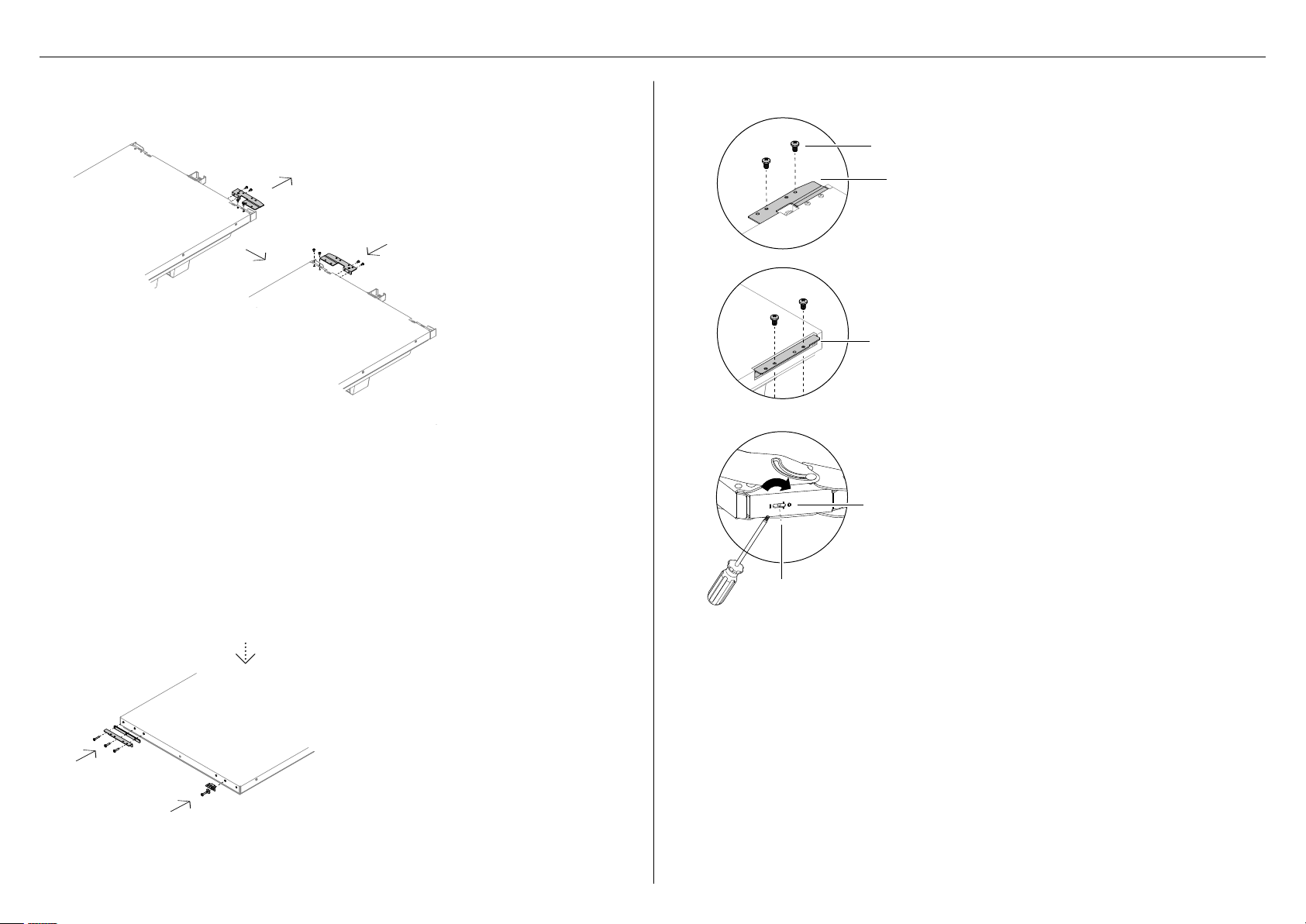

MULTIPLE INSTALLATION — APPLIANCE PREPARATION

Install fasteners

kit

Barbed plugs (2)

Cabinet depth

alignment gauges

(4)

Top joiner

bracket kit

Central spacer

(1)

8Gx16 Mush washer

screw (2)

Tools

Cross-head

screwdriver

Powered driver

(optional)

Attaching the central spacer to cabinetry Attaching barbed plugs and depth alignment gauges

barbed plugs

depth gauges locations

Before rolling into the cavity, insert

the barbed plugs into large holes on

the top right and left sides of both

appliances.

The plugs protect the inside surface

of cabinetry from being damaged by

screws when pushing in the appliance.

Loosen the right and left screws at the top

and bottom sides of the door. (A)

Locate the alignment gauges at correct

orientation to the right and left screws.

Left

Place the alignment gauge by inserting

the screw head through the keyhole of the

gauge.

Push the alignment gauge down to lock the

position.

Tighten the screw just enough to firmly

hold the gauge.

z

The alignment gauges are only

temporary and must be removed after

installation.

1

2

3

central spacer

A

b

The central spacer must be installed

to ensure correct installation of the

appliances.

Measure the widths from left (A) and

right (B) cabinetry sides towards

thecenter to determine the attachment

location of the central spacer.

Refer to "Cabinetry dimensions' page for

correct cavity width.

On the 'Top spacer depth alignment' side

of the depth gauge, mark the attachment

location of the central spacer on the

cabinetry.

The depth position of spacer depends on

the door panel thickness.

Secure the central spacer to the alcove

ceiling with two 8Gx16 countersunk

screws.

Tightenthescrews with a screwdriver or

powered driver.

1

2

3

Right

Illustrations may differ from your purchased appliance.

51

MULTIPLE INSTALLATION — ALIGN FIRST APPLIANCE INTO CABINETRY

Tools

Ruler

Pushing first appliance into the cabinetry

1

first appliance

PROFILE VIEW

Aligning the depth gauges

min 7 1/16" (180mm)

Roll the first appliance slowly into one side of the cabinetry until the

anti-tip bracket overlaps the back edge of the appliance.

Ensure the bracket overlaps the appliance by a minimum 7 1/16" (180mm)

for a secure hold. Refer to 'Attach the anti-tip bracket' for more information.

anti-tip bracket

spacer

Align the top cap of the first appliance flush with the front of the spacer.

52

1

top cap

depth gauge

Mark the step of the depth gauges on the cabinetry side of the

door based on the thickness of door panel.

Align the marked line flush with the front surface of the adjacent

cabinetry.

marked line

Illustrations may differ from your purchased appliance.

MULTIPLE INSTALLATION — SECURE FIRST APPLIANCE INTO CABINETRY

Install fasteners kit

8Gx16 Countersunk

screw (6)

Tools

Cross-head

screwdriver

Powered driver

(optional)

Adjusting alignment of first appliance in cabinetry Securing the top brackets

Turn the front and rear adjustment

screws clockwise to raise

1

Front foot

adjustment

screw

Rear foot

adjustment

screw

Foot

height of the appliance and

counter-clockwise to lower the

height.

Left top bracket

1

Turn the front and rear adjustment

Rear foot

2

screws clockwise to extend the

feet until it engages the floor, and

the top bracket reaches ceiling of

the alcove.

Securing the side brackets

Right top bracket

Fix the left and right top

brackets to the ceiling

surface of the cabinetry with

8Gx16 countersunk screws.

Ruler

3

Front foot

ruler

Check the alignment gauges while

adjusting the screws to maintain

the alignment of the appliance.

Using a ruler, check if the gaps

between appliance and cabinetry

side wall are even.

1

Fix one lower side

bracket to the cabinetry

side surface with 8Gx16

countersunk screws.

Left lower side bracket

53

MULTIPLE INSTALLATION — ALIGN SECOND APPLIANCE INTO CABINETRY

Tools

Ruler

Pushing into the cabinetry

1

first appliance

Aligning the depth gauges

min 7 1/16" (180mm)

PROFILE VIEW

anti-tip bracket

C

Push the second appliance to roll slowly into the

other side of the cabinetry side by side with the first

appliance.

Ensure the bracket overlaps the appliance by a minimum

7 1/16" (180mm) for a secure hold. Refer to 'Install antitip bracket' for more information.

Align the top cap of the second appliance flush with the

central spacer and top cap of the first appliance.

D

E

54

2

H

adjacent cabinetry

adjacent cabinetry

Mark the step of depth gauge on the cabinetry side of

the door based on the thickness of door panel.

Align the marked line flush with the front surface of the

adjacent cabinetry.

Adjust the height of the second appliance. Refer to

'Adjust height of first appliance in cabinetry' (page 51).

Using a ruler, check if the gaps between appliances and

cabinetry side walls are even.

MULTIPLE INSTALLATION — SECURE SECOND APPLIANCE INTO CABINETRY

M6 Washer

843453

M5 Washer

M5 x20

Cap Screw

847984

M6 x 12

Cap Screw

248072

8Gx16

Mush Washer

840371

10 x 50

Dual Lock

M6 Nut

839455

M5 Nut

839107

Top joiner

fastener kit

M5x20 Cap

screw (1)

M5x16x1 Plain washer

(1)

Bottom joiner

fastener kit

M6x16 Washer screw

(1)

M6x12x3.2

Plastic washer (1)

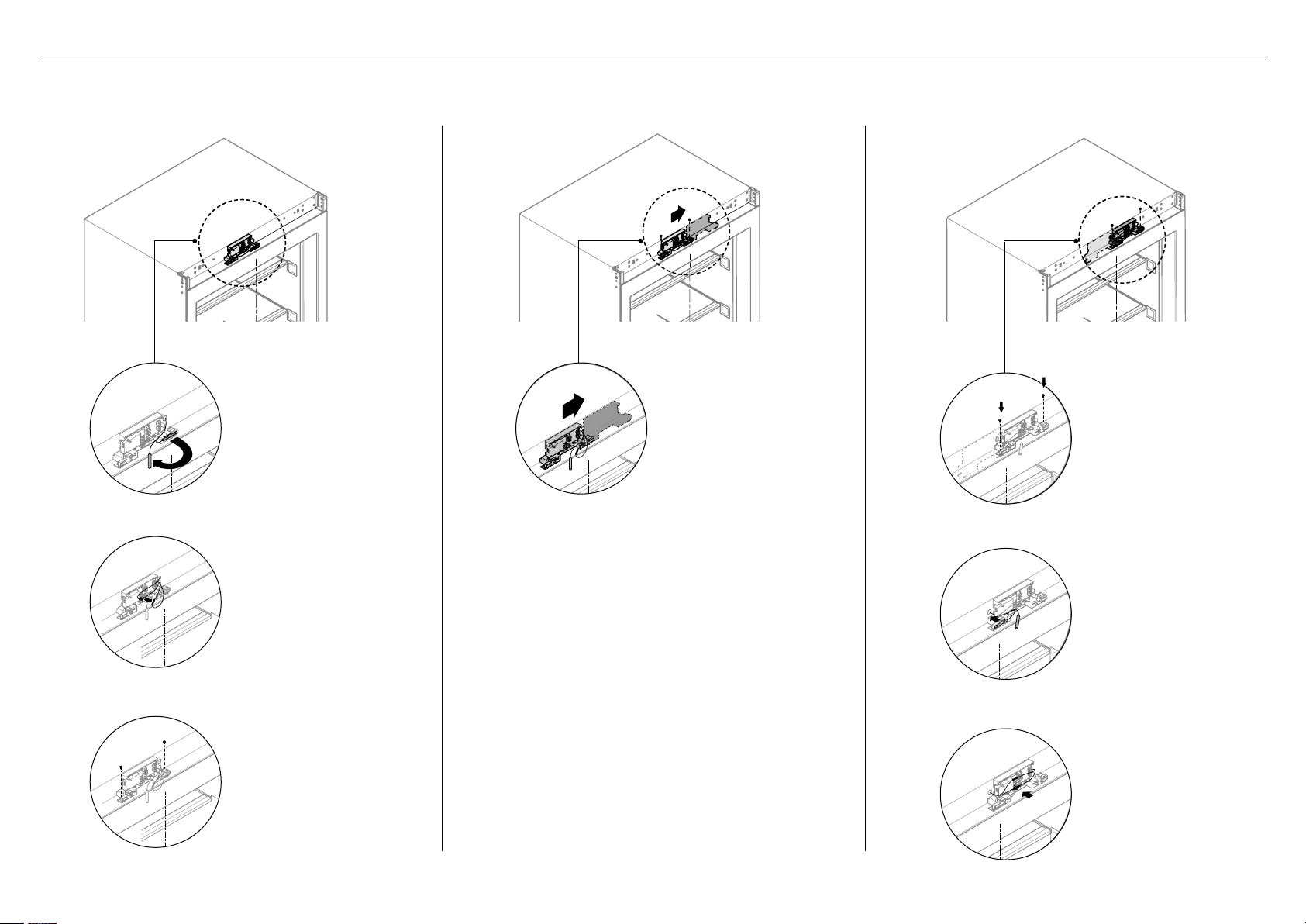

Securing the top brackets

cap screw

washer

1

Securing the joiner bracket and side brackets

Secure the top caps of both appliances to the central