Page 1

< > !

R-30+B/ R-30+B Mate CONTROLLER

Optional Function

OPERATOR'S MANUAL

B-83284EN-2/05

Page 2

• Original Instructions

Thank you very much for purchasing FANUC Robot.

Before using the Robot, be sure to read the "FANUC Robot SAFETY HANDBOOK (B-80687EN)"

and understand the content.

• No part of this manual may be reproduced in any form.

• The appearance and specifications of this product are subject to change without notice.

The products in this manual are controlled based on Japan's “Foreign Exchange and

Foreign Trade Law". The export from Japan may be subject to an export license by the

government of Japan. Further, re-export to another country may be subject to the license

of the government of the country from where the product is re-exported. Furthermore, the

product may also be controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual, we endeavor to include all pertinent matters. There are, however, a very

large number of operations that must not or cannot be performed, and if the manual

contained them all, it would be enormous in volume. It is, therefore, requested to assume

that any operations that are not explicitly described as being possible are "not possible".

Page 3

B-83284EN-2/05 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This chapter describes the precautions which must be observed to ensure the safe use of the robot.

Before attempting to use the robot, be sure to read this chapter thoroughly.

Before using the functions related to robot operation, read the relevant operator's manual to become

familiar with those functions.

For the safety of the operator and the system, follow all safety precautions when operating a robot and its

peripheral devices installed in a work cell.

In addition, refer to the “FANUC Robot SAFETY HANDBOOK (B-80687EN)”.

1 DEFINITON OF USER

The user can be classified as follows.

Operator

Turns the robot controller power ON/OFF

•

Starts the robot program with operator’s panel

•

Programmer

Operates the robot

•

Teaches the robot inside the safety fence

•

Maintenance engineer

Operates the robot

•

Teaches the robot inside the safety fence

•

Maintenance (repair, adjustment, replacement)

•

- “An operator” cannot

- “Programmer”, “Teaching operator”, and “Maintenance engineer” can

The working activities inside the safety fence include lifting, setting, teaching, adjusting,

maintenance, etc.

- To work inside the safety fence, the person must be trained on proper robot operation.

During the operation, programming, and maintenance of your robotic system, programmer, teaching

operator and maintenance engineer must operate with circumspection by using following safety

precautions.

- Adequate clothes for the operation

- Safety shoes

- A helmet

:

:

:

work inside the safety fence

work inside the safety fence.

s-1

Page 4

SAFETY PRECAUTIONS B-83284EN-2/05

2 DEFINITION OF SAFETY NOTATIONS

To ensure the safety of users and prevent damage to the machine, this manual indicates each precaution on

safety with or "WARNING" or "CAUTION" according to its severity. Supplementary information is

indicated by "NOTE". Please read each "WARNING", "CAUTION" and "NOTE" before using the robots.

Symbol Definitions

WARNING

CAUTION

NOTE

• Check this manual thoroughly, and keep it handy for the future reference.

Used if hazard resulting in the death or serious injury of the user will be expected to

occur if he or she fails to follow the approved procedure.

Used if a hazard resulting in the minor or moderate injury of the user, or equipment

damage may be expected to occur if he or she fails to follow the approved procedure.

Used if a supplementary explanation not related to any of WARNING, and CAUTION

is to be indicated.

3 USER SAFETY

User safety is the primary safety consideration. As it is very dangerous to enter the operating area of the

robot during its automatic operation, adequate safety precautions must be observed.

The following lists the general safety precautions. Careful consideration must be made to ensure user

safety.

(1) We obligate the User to take a FANUC training courses.

FANUC provides various training courses. Contact your local FANUC representative for

details.

(2) Even when the robot is stationary, it is possible that the robot is still in a ready to move state, and is

waiting for a signal. In this state, the robot is regarded as still in motion. To ensure user safety,

provide the system with an alarm to indicate visually or aurally that the robot is in motion.

(3) Install a safety fence with a gate so that no user can enter the safety fence inside without passing

through the gate. Install an interlocking device, a safety plug, and so forth in the safety gate so that

the robot is stopped as the safety gate is opened.

The controller is designed to receive this interlocking signal of the door switch. When the

safety fence is opened and this signal received, the controller stops the robot (Please refer to

"STOP TYPE OF ROBOT" in SAFETY PRECAUTIONS for detail of stop type). For

connection, refer to below Fig.3 (b).

(4) Provide the peripheral devices with appropriate grounding (Class A, Class B, Class C, and Class D).

(5) Recommend to install the peripheral device outside of the operating space.

(6) Draw an outline on the floor, clearly indicating the range of the robot motion, including the tools

such as a hand.

(7) Install a mat switch or photoelectric switch on the floor with an interlock to a visual or aural alarm

that stops the robot when a user enters the operating space.

(8) If necessary, install a safety lock so that no one except the user in charge can turn the power on the

robot.

s-2

Page 5

B-83284EN-2/05 SAFETY PRECAUTIONS

The circuit breaker installed in the controller is designed to disable anyone from turning it on

when it is locked with a padlock.

(9) When adjusting each peripheral device independently, make sure to turn the power off the robot.

(10) Operators must take the gloves off while manipulating the operator’s panel or teach pendant.

Operation with gloved fingers may cause an operation error.

(11) Programs, system variables, and other information can be saved on memory card or USB memories.

Be sure to save the data periodically in case the data is lost in an accident.

(12) The robot must be transported and installed by accurate procedure recommended by FANUC.

Wrong transportation or installation may cause the robot to fall, resulting in severe injury to

workers.

(13) In the first operation of the robot after installation, the operation should be restricted to low speeds.

Then, the speed should be gradually increased to check the operation of the robot.

(14) Before the robot is started, it should be checked that no one is in the area of the safety fence. At the

same time, a check must be made to ensure that there is no risk of hazardous situations. If detected,

such a situation should be eliminated before the operation.

(15) Do not operate the robot under the following conditions. Otherwise, the robot and peripheral

equipment can be adversely affected, or workers can be severely injured.

- Flammable

- Explosive

- Massive dose of Radiation

- Under water, high (heavy) Humidity

- Transport human or animals

- Stepladder (climb or hang down)

- Outdoor

(16) When connecting the peripheral devices related to stop(safety fence etc.) and each signal (external

emergency , fence etc.) of robot, be sure to confirm the stop movement and do not take the wrong

connection.

(17) In preparing the trestle, please secure the maintenance engineer safety at high place in reference to

Fig. 3 (c). Design with the Scaffolding and Safety-belt with circumspection.

s-3

Page 6

SAFETY PRECAUTIONS B-83284EN-2/05

RP1

Pulsecoder

RI/RO,XHBK,XROT

RM1

Motor power/brake

EARTH

Safety fence

Interlocking device and safety plug that are activated if the

gate is opened.

Fig. 3 (a) Safety fence and safety gate

WARNING

When you close a fence, please confirm that there is not a person from all

directions of the robot.

Dual chain

Single chain

Emergency sto p board

Panel board

or Panel board

EAS1

EAS11

EAS2

EAS21

Panel board

F ENC E 1

(Note)

(Note)

In case of R-30iA

For the R-30iB, the R-30iB Mate

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

Terminals EAS1,EAS11 ,EAS2,EAS21 ar e p rovided on t he

are provided on the operation box or on the terminal block

emergency stop board.

of the printed circuit board.

Refer to th e ELECTRICAL CONNCETIONS Ch apte r of

In case of R-30iA Mate

CONNECTION of

Terminals EAS1,EAS11,EAS2,EAS21 are provided

R-30iB cont rol ler mainte nan ce manual (B-83 195EN) or

on the emergency stop board or connector panel.

(in case of Open air type)

R-30iB Mate controller maintenance manual (B-83525EN)

for details.

Termianls FENCE1,FENCE2 are provided

on the emergency stop board.

Refer to controller maintenance manual for details.

F ENC E 2

Fig. 3 (b) Connection diagram for the signal of safety fence

s-4

Page 7

B-83284EN-2/05 SAFETY PRECAUTIONS

Hook for safety belt

Fence

Steps

Trestle

Pedestal

for maintenance

Fig. 3 (c) Pedestal for maintenance

3.1 OPERATOR SAFETY

The operator is a person who operates the robot system. In this sense, a worker who operates the teach

pendant is also an operator. Operator cannot work inside the safety fence.

(1) If you don’t need to operate the robot, turn the power off the robot controller, or press the

“EMERGENCY STOP” button, and then proceed your work.

(2) Operate the robot system outside of the robot operating space.

(3) Install a safety fence with a safety gate to prevent any worker other than the operator from entering

the dangerous area unexpectedly and the worker from entering a hazardous area.

(4) Install one or more necessary quantity of EMERGENCY STOP button(s) within the operator’s reach

in appropriate location(s) based on the system layout.

The robot controller is designed to be connected to an external EMERGENCY STOP button.

With this connection, the controller stops the robot operation (Please refer to "STOP TYPE

OF ROBOT" in SAFETY PRECAUTIONS for detail of stop type), when the external

EMERGENCY STOP button is pressed. See the diagram below for connection.

Dual cha in

External s top button

Single chain

External stop button

Emerg ency stop board

Panel board

or Panel board

EE S1

EE S11

EES2

EES21

Panel board

EMGIN1

EMGIN2

Fig. 3.1 Connection diagram for external emergency stop button

(Note)

Connect EES1 and EES11, EES2 and EES21

(No te)

For th e R-30iB, the R-30iB Mate

Connect EE S1an d EES 11,EES2 and EE S21or EMG IN 1and E MGIN2.

EES1,EES11,EES2,EES21 are on the emergency stop board

In c ase of R-30i A

EES 1,E ES11, EES2,E ES21 or EMGI N1,EMG IN2 are on the panel board.

Refer to the ELECTRICAL CONNCET IONS Chapter of

CONNECTION of

In c ase of R-30i A Mate

EES 1,E ES11, EES2,EES2 1 are on the em ergen cy stop b oa rd

R-30i B controller maintenance manu al (B-83195EN) or

or connector p anel ( in case of Open air type ).

R-30i B Mate controller maintenance manual (B-83525EN)

EMGIN1,EMGIN2 are on the emergency stop board.

for de tails.

Refer to the mainten ance manual of the controller for details.

s-5

Page 8

SAFETY PRECAUTIONS B-83284EN-2/05

3.2 SAFETY OF THE PROGRAMMER

While teaching the robot, the operator must enter the operating space of the robot. Please ensure the

safety of programmer.

(1) Unless it is specifically necessary to enter the robot operating space, carry out all tasks outside the

area.

(2) Before teaching the robot, check that the robot and its peripheral devices are all in the normal

condition.

(3) If it is inevitable to enter the robot operating space to teach the robot, check the locations, settings,

and other conditions of the safety devices (such as the EMERGENCY STOP button, the

DEADMAN switch on the teach pendant) before entering the area.

(4) The programmer must be extremely careful not to let anyone else enter the robot operating space.

(5) Programming must be done outside of the safety fence as far as possible. If programming needs to be

done in the area of the safety fence, the programmer must take the following precautions:

- Before entering the safety fence area, ensure that there is no risk of hazardous situation in the

area.

- Be ready to press the emergency stop button whenever it is necessary.

- Operate the Robot at low speed.

- Before starting programming, check the entire system status to ensure that no remote instruction

to the peripheral equipment or motion would harm user .

Our operator panel is provided with an emergency stop button and a key switch (mode switch) for selecting the

automatic operation mode (AUTO) and the teach modes (T1 and T2). Before entering the inside of the safety

fence for the purpose of teaching, set the switch to a teach mode, remove the key from the mode switch to prevent

other people from changing the operation mode carelessly, then open the safety gate. If the safety gate is opened

with the automatic operation mode set, the robot stops (Please refer to "STOP TYPE OF ROBOT" in SAFETY

PRECAUTIONS for detail of stop type). After the switch is set to a teach mode, the safety gate is disabled. The

programmer should understand that the safety gate is disabled and is responsible for keeping other people from

entering the inside of the safety fence.

Teach pendant is provided with a switch to enable/disable robot operation from teach pendant and DEADMAN

switch as well as emergency stop button. These button and switch function as follows:

(1) Emergency stop button: Causes the stop of the robot (Please refer to "STOP TYPE OF ROBOT" in SAFETY

PRECAUTIONS for detail of stop type) when pressed.

(2) DEADMAN switch: Functions are different depending on the teach pendant enable/disable switch setting

status.

(a) Enable: Servo power is turned off and robot stops when the operator releases the DEADMAN switch

or when the operator presses the switch strongly.

(b) Disable: The DEADMAN switch is disabled.

(Note) The DEADMAN switch is provided to stop the robot when the operator releases the teach pendant or

presses the pendant strongly in case of emergency. The R-30iB/R-30iB Mate employs a 3-position

DEADMAN switch, which allows the robot to operate when the 3-position DEADMAN switch is pressed

to its intermediate point. When the operator releases the DEADMAN switch or presses the switch

strongly, the robot stops immediately.

The operator’s intention of starting teaching is determined by the controller through the dual operation of setting the

teach pendant enable/disable switch to the enable position and pressing the DEADMAN switch. The operator

should make sure that the robot could operate in such conditions and be responsible in carrying out tasks safely.

Based on the risk assessment by FANUC, number of operation of DEADMAN switch should not exceed about

10000 times per year.

s-6

Page 9

B-83284EN-2/05 SAFETY PRECAUTIONS

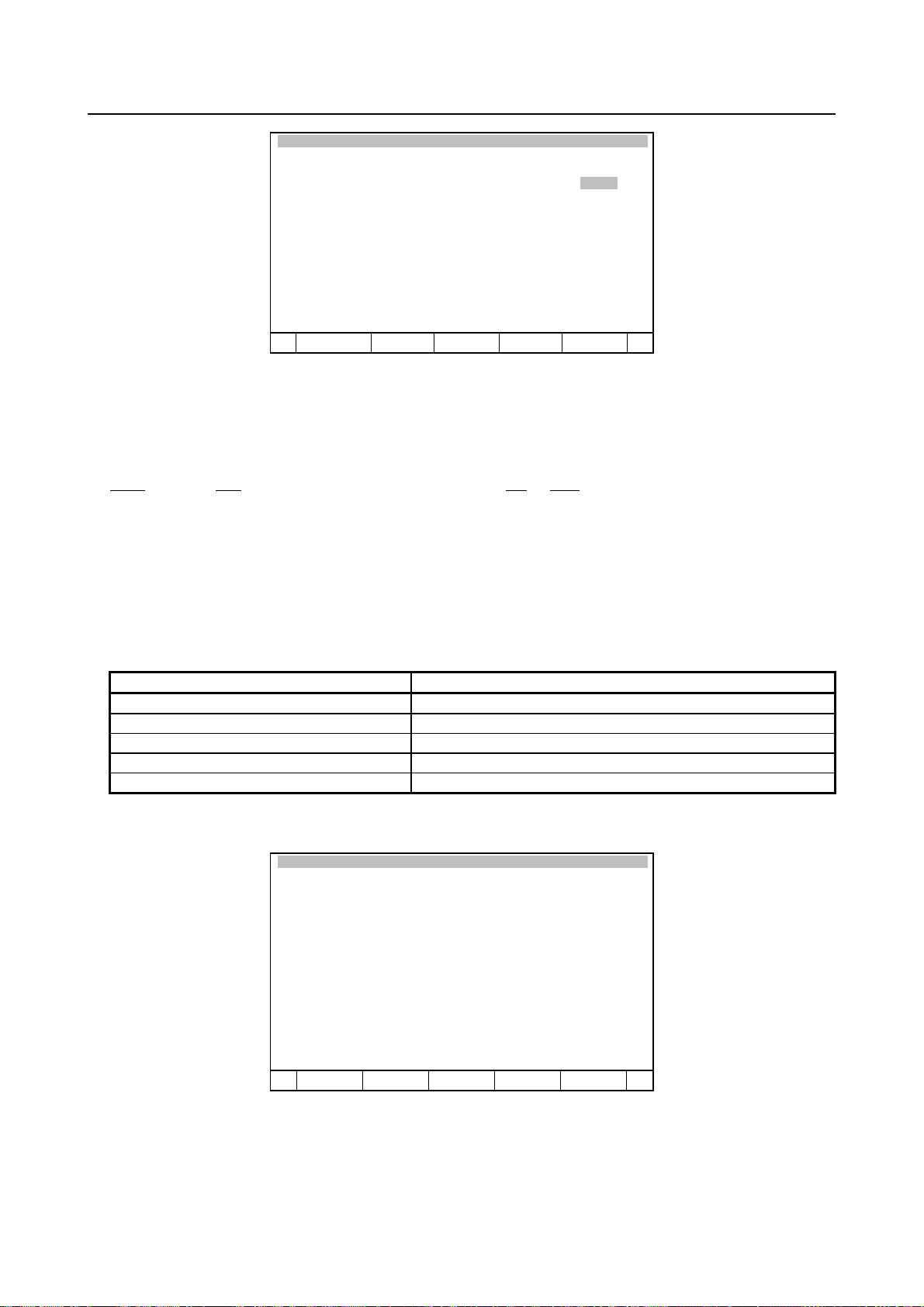

The teach pendant, operator panel, and peripheral device interface send each robot start signal. However the

validity of each signal changes as follows depending on the mode switch and the DEADMAN switch of the operator

panel, the teach pendant enable switch and the remote condition on the software.

Mode

AUTO

mode

T1, T2

mode

T1,T2 mode: DEADMAN switch is effective.

Teach pendant

enable switch

On

Off

On

Off

Software

remote

condition

Local Not allowed Not allowed Not allowed

Remote Not allowed Not allowed Not allowed

Local Not allowed Allowed to start Not allowed

Remote Not allowed Not allowed Allowed to start

Local Allowed to start Not allowed Not allowed

Remote Allowed to start Not allowed Not allowed

Local Not allowed Not allowed Not allowed

Remote Not allowed Not allowed Not allowed

Teach pendant Operator panel Peripheral device

(6) To start the system using the operator’s panel, make certain that nobody is in the robot operating

space and that there are no abnormal conditions in the robot operating space.

(7) When a program is completed, be sure to carry out the test operation according to the following

procedure.

(a) Run the program for at least one operation cycle in the single step mode at low speed.

(b) Run the program for at least one operation cycle in the continuous operation mode at low

speed.

(c) Run the program for one operation cycle in the continuous operation mode at the intermediate

speed and check that no abnormalities occur due to a delay in timing.

(d) Run the program for one operation cycle in the continuous operation mode at the normal

operating speed, and check that the system operates automatically without trouble.

(e) After checking the completeness of the program through the test operation above, execute it in

the automatic operation mode.

(8) While operating the sy stem in the automatic operation mode, the teach pendant operator must leave

the safety fence.

3.3 SAFETY OF THE MAINTENANCE ENGINEER

For the safety of maintenance engineer personnel, pay utmost attention to the following.

(1) Must never be in the area during its operation.

(2) A hazardous situation may occur when the robot or the system, are kept with their power-on during

maintenance operations. Therefore, for any maintenance operation, the robot and the system must be

put into the power-off state. If necessary, a lock should be in place in order to prevent any other

person from turning on the robot and/or the system. In case maintenance needs to be executed in the

power-on state, the emergency stop button must be pressed.

(3) If it becomes necessary to enter the robot operation area while the power is on, press the emergency

stop button on the operator panel, or the teach pendant before entering the area. The maintenance

personnel must indicate that maintenance work is in progress and be careful not to allow other

people to operate the robot carelessly.

(4) When entering the area enclosed by the safety fence, the maintenance engineer must check the entire

system in order to make sure that there is no dangerous situation around. In case the worker needs to

enter the safety area whilst a dangerous situation exists, extreme care must be taken, and entire

system status must be carefully monitored.

(5) Before the maintenance of the pneumatic system is started, the supply pressure should be shut off

and the pressure in the piping should be reduced to zero.

s-7

Page 10

SAFETY PRECAUTIONS B-83284EN-2/05

(6) Before the start of maintenance, check the robot and its peripheral devices are all in the normal

condition.

(7) Do not operate the robot in the automatic mode while anybody is in the robot operating space.

(8) In maintaining the robot parallel to a wall or instrument, or when multiple workers are working

nearby, make certain that their escape path is not obstructed.

(9) When a tool is mounted on the robot, or any moving device other than the robot is installed,

such as belt conveyor, careful attention required for those motion.

(10) Assign an expert near the operator panel who can press the EMERGENCY STOP button whenever

he sees the potential danger.

(11) In case of replacing a part, please contact your local FANUC representative. Wrong procedure may

cause the serious damage to the robot and the worker.

(12) Make sure that no impurity into the system in while (in) replacing or reinstalling components.

(13) Turn off the circuit breaker to protect again electric shock in handling each unit or printed circuit

board in the controller during inspection. If there are two cabinets, turn off the both circuit breaker.

(14) A part should be replaced with a part recommended by FANUC. If other parts are used, malfunction

or damage would occur. Especially, a fuse that is not recommended by FANUC should not be used.

Such a fuse may cause not only a damage to the internal parts of the controller but also a fire.

(15) When restarting the robot system after completing maintenance work, make sure in advance that

there is no person in the operating space and that the robot and the peripheral devices are not

abnormal.

(16) In case of remove the motor or brake, suspend the arm by crane or other equipment beforehand to

avoid falling.

(17) Whenever grease is spilled on the floor, remove them as soon as possible to prevent from falling.

(18) The following parts are heated. If a maintenance engineer needs to touch such a part in the heated

state, the worker should wear heat-resistant gloves or use other protective tools.

• Servo motor

• Inside of the controller

• Reducer

• Gearbox

• Wrist unit

(19) Maintenance must be done with appropriate lightning. Be careful that those lightning will not cause

any further danger.

(20) When a motor, reducer, or other heavy load is handled, a crane or other equipment should be used to

protect maintenance engineers from excessive load. Otherwise, the maintenance engineers would be

severely injured.

(21) Must never climb or step on the robot even in the maintenance. If it is attempted, the robot would be

adversely affected. In addition, a misstep can cause injury to the worker.

(22) Secure a pedestal and wear the safety belt in performing the maintenance work in high place.

(23) Remove all the spilled oil or water and metal chips around the robot in the safety fence after

completing the maintenance.

(24) All the related bolts and components must return to the original place in replacing the parts. If some

parts are missing or left (remained), repeat the replacement work until complete the installation.

(25) In case robot motion is required during maintenance, the following precautions should be taken :

• Secure an escape route. And during the maintenance motion itself, monitor continuously the

whole system so that your escape route will not become blocked by the robot, or by peripheral

equipment.

• Keep vigilant attention for the potential danger. and to press the emergency stop button

whenever it is necessary.

(26) Periodic inspection required. (Refer to the robot mechanical manual and controller maintenance

manual.) A failure to do the periodical inspection can may adversely affect the performance or

service life of the robot and may cause an accident

(27) After replacing some parts, a test run required by the predetermined method. (See TESTING section

of “Controller operator’s manual”. During the test run, the maintenance staff must work outside the

safety fence.

s-8

Page 11

B-83284EN-2/05 SAFETY PRECAUTIONS

4 SAFETY OF THE TOOLS AND

PERIPHERAL DEVICES

4.1 PRECAUTIONS IN PROGRAMMING

(1) Adopt a limit switch or other sensor to detect a dangerous state and, if necessary, design the program

to stop the robot when the sensor signal is received.

(2) Design the program to stop the robot when an abnormal condition occurs in any other robots or

peripheral devices, even though the robot itself is normal.

(3) For a system in which the robot and its peripheral devices are in synchronous motion, particular care

must be taken in programming in order not to interfere with each other.

(4) Provide a suitable interface between the robot and its peripheral devices so that the robot can detect

the states of all devices in the system, and can be stopped according to the states.

4.2 PRECAUTIONS FOR MECHANISM

(1) Keep the component cells of the robot system clean, operate the robot where insulated from the

influence of grease, water, and dust.

(2) Don’t use unconfirmed liquid for cutting fluid and cleaning fluid.

(3) Adopt limit switches or mechanical stoppers to limit the robot motion, and avoid the robot from

collisions against peripheral devices or tools.

(4) Observe the following precautions about the mechanical unit cables. Failure to follow precautions

may cause mechanical troubles.

• Use mechanical unit cable that have required user interface.

• Do not add user cable or hose to inside of mechanical unit.

• Please do not obstruct the movement of the mechanical unit when cables are added to outside

of mechanical unit.

• In the case of the model that a cable is exposed, please do not perform remodeling (Adding a

protective cover and fix an outside cable more) obstructing the behavior of the outcrop of the

cable.

• When installing user peripheral equipment on the robot mechanical unit, please pay attention

that equipment does not interfere with the robot itself.

(5) The frequent power-off stop for the robot during operation causes the trouble of the robot. Please

avoid the system construction that power-off stop would be operated routinely. (Refer to bad case

example.) Please perform power-off stop after reducing the speed of the robot and stopping it by

hold stop or cycle stop when it is not urgent. (Please refer to "STOP TYPE OF ROBOT" in

SAFETY PRECAUTIONS for detail of stop type.)

(Bad case example)

• Whenever poor product is generated, a line stops by emergency stop and power-off of the robot

is incurred.

• When alteration is necessary, safety switch is operated by opening safety fence and power-off

stop is incurred for the robot during operation.

• An operator pushes the emergency stop button frequently, and a line stops.

• An area sensor or a mat switch connected to safety signal operates routinely and power-off stop

is incurred for the robot.

• Power-off stop is regularly incurred due to an inappropriate setting for Dual Check Safety

(DCS).

(6) Power-off stop of Robot is executed when collision detection alarm (SRVO-050) etc. occurs. Please

try to avoid unnecessary power-off stops. It may cause the trouble of the robot, too. So remove the

causes of the alarm.

s-9

Page 12

SAFETY PRECAUTIONS B-83284EN-2/05

5 SAFETY OF THE ROBOT MECHANICAL

UNIT

5.1 PRECAUTIONS IN OPERATION

(1) Operating the robot in the jog mode, set it at an appropriate speed so that the operator can manage

the robot in any eventuality.

(2) Before pressing the jog key, be sure to comprehend the robot movement by the key in advance.

5.2 PRECAUTIONS IN PROGRAMMING

(1) Design to arrange avoiding mutual interfere when various robot’s operation area crossover

significantly.

(2) Be sure to specify the predetermined work origin in a motion program so that the robot starts from

the origin and terminates at the origin. Make it possible for the operator to distinguish easily that the

robot motion has terminated at a glance.

5.3 PRECAUTIONS FOR MECHANISMS

Keep the operating space areas of the robot clean, and operate the robot in an environment free of grease,

water, and dust.

5.4 PROCEDURE TO MOVE ARM WITHOUT DRIVE POWER

IN EMERGENCY OR ABNORMAL SITUATIONS

For emergency or abnormal situations (e.g. persons trapped in or pinched by the robot), brake release unit

can be used to move the robot axes without drive power.

Please refer to controller maintenance manual and mechanical unit operator’s manual for using method of

brake release unit and method of supporting robot.

6 SAFETY OF THE END EFFECTOR

6.1 PRECAUTIONS IN PROGRAMMING

(1) Circumspect program with sufficient delay required for the program after executing some control

command in adopting actuators (pneumatic, hydraulic, and electric)

(2) Adopt limit switches for the end effector, and control the robot system by monitoring the state.

7 STOP TYPE OF ROBOT

There are following three types of Stopping Robot.

s-10

Page 13

B-83284EN-2/05 SAFETY PRECAUTIONS

Power-Off Stop (Category 0 following IEC 60204-1)

Servo power is turned off, and the robot stops immediately. Servo power is turned off when the robot is

moving, and the motion path of the deceleration is uncontrolled.

“Power-Off stop” performs following processing.

• An alarm is generated, and then the servo power turns off. Instantly the robot stops.

• Execution of the program is paused.

Frequent Power-Off stop of the robot during operation can cause mechanical problems of the robot.

Avoid system designs that require routine or frequent Power-Off stop conditions.

Controlled stop (Category 1 following IEC 60204-1)

The robot is decelerated until it stops, and servo power is turned off.

“Controlled stop” performs following processing.

• The alarm "SRVO-199 Controlled stop" occurs along with a decelerated stop. The program

execution is paused.

• An alarm is generated, and then the servo power turns off.

Hold (Category 2 following IEC 60204-1)

The robot is decelerated until it stops, and servo power remains on.

“Hold” performs following processing.

• The robot operation is decelerated until it stops. Execution of the program is paused.

WARNING

The stopping distance and time of Controlled stop are longer than those of

Power-Off stop. A risk assessment for the whole robot system which takes into

consideration the increased stopping distance and stopping time, is necessary

when Controlled stop is used.

When the emergency stop button is pressed or the FENCE is open, the stop type of robot is Power-Off

stop or Controlled stop. The configuration of stop type for each situation is called stop pattern. The stop

pattern is different according to the controller type or option configuration.

There are the following 3 Stop patterns.

Stop

pattern

AUTO P-Stop P-Stop C-Stop C-Stop P-Stop

A T1 P-Stop P-Stop - C-Stop P-Stop

T2 P-Stop P-Stop - C-Stop P-Stop

AUTO P-Stop P-Stop P-Stop P-Stop P-Stop

B T1 P-Stop P-Stop - P-Stop P-Stop

T2 P-Stop P-Stop - P-Stop P-Stop

AUTO C-Stop C-Stop C-Stop C-Stop C-Stop

C T1 P-Stop P-Stop - C-Stop P-Stop

T2 P-Stop P-Stop - C-Stop P-Stop

Mode

Emergency

stop

button

P-Stop: Power-Off stop

C-Stop: Controlled stop

-: Disable

The following table indicates the Stop pattern according to the controller type or option configuration.

Option

Standard A (*)

Controlled stop by E-Stop (A05B-2600-J570) C (*)

External

Emergency

stop

FENCE open SVOFF input

R-30iB/ R-30iB Mate

Servo

disconnect

s-11

Page 14

SAFETY PRECAUTIONS B-83284EN-2/05

(*) R-30iB / R-30iB Mate does not have servo disconnect. R-30iB Mate does not have SVOFF input.

The stop pattern of the controller is displayed in "Stop pattern" line in software version screen. Please

refer to "Software version" in operator's manual of controller for the detail of software version screen.

"Controlled stop by E-Stop" option

When "Controlled stop by E-Stop" (A05B-2600-J570) option is specified, the stop type of the following

alarms becomes Controlled stop but only in AUTO mode. In T1 or T2 mode, the stop type is Power-Off

stop which is the normal operation of the system.

Alarm Condition

SRVO-001 Operator panel E-stop Operator panel emergency stop is pressed.

SRVO-002 Teach pendant E-stop Teach pendant emergency stop is pressed.

SRVO-007 External emergency stops External emergency stop input (EES1-EES11, EES2-EES21) is open.

SRVO-408 DCS SSO Ext Emergency Stop In DCS Safe I/O connect function, SSO[3] is OFF.

SRVO-409 DCS SSO Servo Disconnect In DCS Safe I/O connect function, SSO[4] is OFF.

Controlled stop is different from Power-Off stop as follows:

• In Controlled stop, the robot is stopped on the program path. This function is effective for a system

where the robot can interfere with other devices if it deviates from the program path.

• In Controlled stop, physical impact is less than Power-Off stop. This function is effective for

systems where the physical impact to the mechanical unit or EOAT (End Of Arm Tool) should be

minimized.

• The stopping distance and time of Controlled stop is longer than the those of Power-Off stop,

depending on the robot model and axis. Please refer to the operator's manual of a particular robot

model for the data of stopping distance and time.

When this option is loaded, this function cannot be disabled.

The stop type of DCS Position and Speed Check functions is not affected by the loading of this option.

WARNING

The stopping distance and time of Controlled stop are longer than those of

Power-Off stop. A risk assessment for the whole robot system which takes into

consideration the increased stopping distance and stopping time, is necessary

when this option is loaded.

150916

s-12

Page 15

B-83284EN-2/05 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

1 PREFACE................................................................................................ 1

1.1 ABOUT MANUAL ..........................................................................................1

2 OVERVIEW .............................................................................................3

3 SOFTFLOAT FUNCTION........................................................................ 5

3.1 JOINT / CARTESIAN SOFTFLOAT............................................................... 5

3.2 PUSHOUT SOFTFLOAT ............................................................................... 9

3.3 KNOWHOW OF SOFTFLOAT..................................................................... 11

3.4 KNOWHOW OF CARTESIAN SOFTFLOAT ...............................................12

3.5 CAUTIONS / RESTRICTIONS..................................................................... 13

4 CONTINUOUS ROTATION FUNCTION ............................................... 15

5 OPERATION GROUP DO OUTPUT FUNCTION..................................20

6 AUTOMATIC ERROR RECOVERY FUNCTION...................................22

6.1 AUTOMATIC ERROR RECOVERY FUNCTION ......................................... 22

6.2 RESUME PROGRAM FUNCTION ..............................................................22

6.3 FAST EXIT/ENTRY FEATURE....................................................................23

6.4 RESUME_PROG INSTRUCTION ...............................................................23

6.5 RETURN_PATH_DSBL INSTRUCTION...................................................... 26

6.6 MAINT_PROG INSTRUCTION.................................................................... 27

6.7 SETTING OF THE AUTOMATIC ERROR RECOVERY FUNCTION........... 30

6.8 MANUAL OPERATION SCREEN OF THE RESUME PROGRAM FUNCTION

..................................................................................................................... 40

6.9 EXECUTION OF THE RESUME PROGRAM FROM THE TEACH PENDANT

AND TEST MODE ....................................................................................... 43

6.10 CHANGING CONDITIONS FOR EXECUTING THE RESUME PROGRAM 43

6.11 OTHER SPECIFICATIONS AND RESTRICTIONS ..................................... 44

6.12 WARNINGS (Be sure to read this section for safety.).................................. 45

7 REMOTE TCP FUNCTION....................................................................46

7.1 SETUP......................................................................................................... 48

8 HIGH SENSITIVITY COLLISION DETECTION..................................... 51

8.1 SPECIFICATION ......................................................................................... 51

8.2 SETTINGS................................................................................................... 51

8.3 COLLISION GUARD SETUP SCREEN....................................................... 52

8.4 PROGRAM INSTRUCTIONS ...................................................................... 53

8.4.1 COL DETECT ON / COL DETECT OFF .............................................................53

8.4.2 COL GUARD ADJUST .........................................................................................54

8.5 CAUTIONS .................................................................................................. 56

9 LOAD ESTIMATION ............................................................................. 57

c - 1

Page 16

TABLE OF CONTENTS B-83284EN-2/05

9.1 OPERATING PROCEDURE........................................................................57

9.2 LOAD ESTIMATION PROCEDURE (for 6-Axis Robots) ............................. 57

9.3 CALIBRATION PROCEDURE (for 6-Axis Robots) ...................................... 61

9.4 OTHER RELATED MATTERS..................................................................... 64

10 PAYLOAD OVER AND PAYLOAD SETTING CONFIRM FUNCTION . 65

10.1 LIMITATIONS .............................................................................................. 66

10.2 PROCEDURE..............................................................................................66

10.2.1 Procedure to Show Payload Over and Payload Setting Confirm Screen ...............66

10.2.2 Procedure to Use Payload Setting Confirm (When Payload is Changed) ..............66

10.2.3 Procedure to Use Payload Over Confirm (When The Program or Payload is

Changed) ................................................................................................................67

11 GRAVITY COMPENSATION.................................................................69

11.1 SYSTEM VARIABLES ................................................................................. 69

11.2 MOTION SCREEN ...................................................................................... 69

11.3 MASTERING ...............................................................................................70

11.3.1 “Normal Mastering” and “GC Mastering” .............................................................70

11.3.2 How to Choose Mastering Method.........................................................................71

11.3.3 Mastering Procedure...............................................................................................71

11.3.4 Guidance of GC Mastering.....................................................................................72

12 OPERATION LOG BOOK..................................................................... 73

12.1 RECORDED EVENTS................................................................................. 75

12.2 SETTING UP BOOK.................................................................................... 78

12.3 OPERATIONS ............................................................................................. 79

12.4 EXTENDED ALARM LOG ...........................................................................83

12.4.1 Setup.......................................................................................................................83

12.4.2 How to Display Alarm Log ....................................................................................84

13 PROGRAM TOOLBOX ......................................................................... 86

13.1 SOFT LIMIT SETTING ................................................................................ 86

14 ADVANCED CONSTANT PATH...........................................................89

14.1 LINEAR DISTANCE.....................................................................................89

14.1.1 How to Use.............................................................................................................90

14.1.2 Limitations..............................................................................................................91

14.1.3 Procedure to Use ....................................................................................................92

14.2 CORNER REGION ...................................................................................... 92

14.2.1 Limitation of the Specifiable CR Value .................................................................93

14.2.2 Limitations..............................................................................................................94

14.3 PROCESS SPEED ...................................................................................... 95

14.3.1 Limitations..............................................................................................................97

14.4 MAX SPEED................................................................................................97

14.4.1 Limitations..............................................................................................................98

15 SINGULARITY AVOIDANCE FUNCTION ............................................99

15.1 HOW TO USE SINGULARITY AVOIDANCE............................................... 99

15.1.1 How to Use Singularity Avoidance in Jogging ......................................................99

15.1.2 How to Use Singularity Avoidance in TPE Program .............................................99

15.2 LIMITATIONS ............................................................................................ 100

15.3 CAUTIONS ................................................................................................ 100

c - 2

Page 17

B-83284EN-2/05 TABLE OF CONTENTS

16 PATH SWITCHING FUNCTION.......................................................... 101

17 AUXILIARY AXIS SERVO OFF (LOCAL STOP) FUNCTION ............107

17.1 SPECIFICATION ....................................................................................... 107

17.2 CONSTRAINTS ......................................................................................... 109

17.3 SETTINGS................................................................................................. 109

17.4 ATTENTION .............................................................................................. 112

17.5 PROGRAMMING.......................................................................................113

18 DUAL MOTOR DRIVE ........................................................................117

18.1 SETUP....................................................................................................... 117

19 MULTI UOP INTERFACE FUNCTION ................................................119

19.1 PERIPHERAL I/O ...................................................................................... 120

19.1.1 Setting of the Number of UOP Set .......................................................................121

19.1.2 Modification and Addition of Signal....................................................................122

19.1.3 HOLD#1 to #N.....................................................................................................123

19.1.4 CSTOPI#1 to #N ..................................................................................................123

19.1.5 START#1 to #N ...................................................................................................124

19.1.6 RSR ......................................................................................................................124

19.1.7 PNSTROBE#1 to #N,PROD_START#1 to #N ...................................................125

19.1.8 CMDENBL#1 to #N ............................................................................................125

19.1.9 SYSRDY#1 to #N ................................................................................................125

19.1.10 PROGRUN#1 to #N,PAUSED#1 to #N ..............................................................125

19.1.11 HELD#1 to #N .....................................................................................................126

19.1.12 FAULT#1 to #N...................................................................................................126

19.1.13 ATPERCH............................................................................................................126

19.2 SELECT PROGRAM .................................................................................126

19.2.1 Setting of Motion Groups Intended by Each UOP Set.........................................128

19.2.2 Select Program at Running or Paused ..................................................................129

19.2.3 Program Edit Screen Display When Operating Motion Group is Changed .........129

19.3 RUN PROGRAM ....................................................................................... 130

19.3.1 Robot Service Request (RSR) ..............................................................................130

19.3.2 Program Number Select (PNS) ............................................................................130

19.4 STOP PROGRAM .....................................................................................130

19.4.1 Pause Program by UOP ........................................................................................130

19.4.2 Abort Program by UOP........................................................................................130

19.4.3 Other.....................................................................................................................131

19.5 SYSYTEM VARIABLES............................................................................. 131

20 ERROR CODE OUTPUT FUNCTION .................................................134

20.1 SPECIFICATION ....................................................................................... 134

20.1.1 Types of Alarms ...................................................................................................134

20.1.2 Input and Output Signals......................................................................................134

20.2 MEANING OF ALARM CODE ................................................................... 135

20.2.1 Severity of Alarm .................................................................................................136

20.2.2 Alarm ID...............................................................................................................137

20.2.3 Alarm Number......................................................................................................138

21 DATA MONITOR FUNCTION .............................................................139

21.1 DATA MONITOR SETUP ..........................................................................140

21.2 DATA MONITOR SCHEDULE................................................................... 146

c - 3

Page 18

TABLE OF CONTENTS B-83284EN-2/05

21.3 PROGRAMMING.......................................................................................149

21.4 DATA MONITOR CHART .......................................................................... 150

22 BRAKE CHECK FUNCTION...............................................................152

22.1 INITIAL SETTING BEFORE USE .............................................................. 152

22.2 START BRAKE CHECK ............................................................................153

22.3 RESULTS OF BRAKE CHECK.................................................................. 154

22.4 LIMITATIONS ............................................................................................ 154

22.5 CAUTION .................................................................................................. 154

23 PANEL WIZARD .................................................................................155

23.1 SETTING UP ............................................................................................. 155

23.1.1 Overview ..............................................................................................................155

23.1.2 Available iPendant Controls.................................................................................158

23.1.3 Setting up Fast Label............................................................................................159

23.1.4 Setting up Fast Lamp............................................................................................160

23.1.5 Setting up Fast Switch..........................................................................................162

23.1.6 Addition of Button Change Control .....................................................................163

23.1.7 Addition of Command Button Control.................................................................166

23.1.8 Addition of Edit Box Control...............................................................................167

23.1.9 Addition of Label Control ....................................................................................168

23.1.10 Addition of Toggle Button Control......................................................................168

23.1.11 Addition of Toggle Lamp Control........................................................................170

23.1.12 Modification of Panel...........................................................................................171

23.1.13 Modification of Control........................................................................................173

23.1.14 Delete of Control..................................................................................................173

23.1.15 Cut/Copy Paste of Control ...................................................................................174

23.1.16 Modification of Page............................................................................................175

23.1.17 Re-creation of Panel .............................................................................................176

23.2 RUN KAREL PROGRAM BY PANEL ........................................................177

23.2.1 Caution for Creation of KAREL Program............................................................177

23.2.2 Creation of Run Button ........................................................................................177

23.3 USAGE ...................................................................................................... 178

23.3.1 Display of Panel ...................................................................................................178

23.3.2 Backup/Restore ....................................................................................................180

24 ENHANCED MIRROR IMAGE ............................................................ 181

24.1 PARALLEL MIRROR IMAGE..................................................................... 182

24.2 ROTATIONAL MIRROR IMAGE................................................................ 184

24.3 MIRROR IMAGE USING EXISTING FRAMES AND MIRROR PLANES, WITH

CONTROLLED ORIENTATION.................................................................185

24.4 MIRROR IMAGE OF EXTENDED AXES................................................... 186

25 CUSTOMIZE SUPPORT FUNCTION..................................................195

25.1 KAREL CONFIG ........................................................................................ 195

25.1.1 KAREL Config Screen.........................................................................................195

25.1.2 Use KAREL Config Screen..................................................................................195

25.1.3 Run KAREL Program ..........................................................................................196

25.1.4 Abort KAREL Program........................................................................................197

25.1.5 Start Mode Config of KAREL program...............................................................198

25.1.6 Detail Screen of KAREL Config..........................................................................199

25.1.7 Limitation and Caution of KAREL Config ..........................................................200

c - 4

Page 19

B-83284EN-2/05 TABLE OF CONTENTS

25.1.8 Cycle Power (R-30iB Controller).........................................................................201

25.2 CUSTOM MENU........................................................................................ 201

25.2.1 Overview ..............................................................................................................201

25.2.2 Starting Custom Menu..........................................................................................201

25.2.3 Set Custom Menu .................................................................................................202

25.2.4 Delete Set .............................................................................................................204

26 KAREL PROGRAM EXECUTION HISTORY RECORD .....................205

26.1 HARDWARE AND SOFTWARE................................................................ 205

26.1.1 Hardware and Software Requirements .................................................................205

26.1.2 Hardware ..............................................................................................................205

26.1.3 Software................................................................................................................205

26.1.4 Performance..........................................................................................................206

26.2 SETUP AND OPERATIONS...................................................................... 206

26.2.1 Setting Up the KAREL Program Execution History Record ...............................206

26.2.2 Dump Selections Screen.......................................................................................207

26.2.3 Task Selection Screen ..........................................................................................208

26.2.4 Stop Logging Tasks Screen ..................................................................................209

26.2.5 List Selected Tasks Screen ...................................................................................211

26.2.6 Event Class Selection Screen ...............................................................................212

26.2.7 Event Detail Selection Screen ..............................................................................214

26.2.8 Enable or Disable All Event Logging ..................................................................214

26.3 LOGGING EVENTS................................................................................... 215

26.3.1 Setting up Events..................................................................................................215

26.3.2 Logging Events to an ASCII File .........................................................................216

26.3.3 ASCII File General Event Information ................................................................216

26.3.4 ASCII File Specific Event Information................................................................217

26.4 EXAMPLES ............................................................................................... 220

26.4.1 Overview ..............................................................................................................220

26.4.2 KAREL Program Example...................................................................................221

26.4.3 Teach Pendant Program Example ........................................................................221

26.4.4 ASCII File Example .............................................................................................222

27 TORQUE LIMIT FUNCTION................................................................223

27.1 TORQUE LIMIT FUNCTION FEATURE .................................................... 224

27.2 TORQUE LIMIT MULTI-AXIS SETUP FUNCTION.................................... 225

27.2.1 Torque Limit Multi-Axis Setup Function.............................................................225

27.3 LIMITATIONS ............................................................................................ 226

27.4 CAUTION .................................................................................................. 226

28 TCP SPEED OUTPUT.........................................................................227

28.1 LIMITATIONS ............................................................................................ 227

28.2 SETTING UP TCP SPEED OUTPUT ........................................................ 228

28.3 TCP SPEED OUTPUT INSTRUCTION ..................................................... 230

29 TP DRAM/FILE STORAGE FUNCTION .............................................232

29.1 STORAGES...............................................................................................232

29.1.1 CMOS Programs ..................................................................................................232

29.1.2 SHADOW Programs ............................................................................................232

29.1.3 SHADOW ONDEMAND Programs ....................................................................233

29.1.4 FILE Programs .....................................................................................................233

29.2 STORAGE CONFIGURATION .................................................................. 233

c - 5

Page 20

TABLE OF CONTENTS B-83284EN-2/05

29.3 SAVE / LOAD PROGRAMS ...................................................................... 238

29.3.1 Save / Load TP Files ............................................................................................238

29.3.2 Copy Programs.....................................................................................................239

29.3.3 Save / Load LS Files ............................................................................................239

29.3.4 Make Backup of Programs ...................................................................................239

29.4 LOADING PROCESS IN PROGRAM EXECUTION .................................. 239

29.5 PROGRAM EXCHANGE FUNCTION WITHOUT ENOUGH MEMORY SPACE

................................................................................................................... 240

29.6 PRECAUTION ........................................................................................... 240

29.6.1 Cause and Remedy for Alarm Occurrence ...........................................................240

30 CYCLE TIME LOGGING ..................................................................... 242

30.1 DISPLAY MODES OF CYCLE TIME ......................................................... 243

30.1.1 Cycle Mode ..........................................................................................................243

30.1.2 Hourly Mode ........................................................................................................244

30.1.3 Line-by-Line Mode ..............................................................................................244

30.2 LOGGING CYCLE TIME ........................................................................... 245

30.2.1 Change Display Format of Cycle Time Data .......................................................245

30.2.2 Save Cycle Time Data ..........................................................................................246

30.2.3 Update Cycle Time Data ......................................................................................246

30.2.4 Display Target Cycle Time Line ..........................................................................246

30.2.5 Display Reference Cycle Time Line ....................................................................247

30.3 EXECUTION EXAMPLE OF SPOT PROGRAM........................................ 248

31 MATH FUNCTION INSTRUCTION .....................................................250

31.1 TYPE OF MATH FUNCTIONS ..................................................................250

31.2 INSTRUCTION FORMAT OF MATH FUNCTION......................................250

31.2.1 Instruction Format of Assignment Statements .....................................................250

31.2.2 Instruction Format of Relational Statements ........................................................251

31.2.3 Instruction Format of Wait Command Statements ...............................................252

31.3 FUNCTION SPECIFICATION OF MATH FUNCTIONS ............................. 252

31.3.1 Square Root(SQRT)........................................................................................252

31.3.2 Trigonometric Function(SIN) .........................................................................252

31.3.3 Trigonometric Function(COS) ........................................................................253

31.3.4 Trigonometric Function(TAN)........................................................................253

31.3.5 Inverse Trigonometric Function(ASIN)..........................................................253

31.3.6 Inverse Trigonometric Function(ACOS) ........................................................254

31.3.7 Inverse Trigonometric Function(ATAN2) ......................................................254

31.3.8 Inverse Trigonometric Function(ATAN) ........................................................255

31.3.9 Exponent...............................................................................................................255

31.3.10 Natural Logarithm ................................................................................................255

31.3.11 Absolute(ABS)................................................................................................256

31.3.12 Truncate(TRUNC) ..........................................................................................256

31.3.13 Round Off(ROUND).......................................................................................256

31.4 BACKGROUND OPERATION OF MATH FUNCTION .............................. 257

31.5 TEACH MATH FUNCTION INSTRUCTION............................................... 257

31.6 RESTRICTION OF TEACHING MATH FUNCTION ..................................259

31.7 EXCEPTIONS AND RESTRICTION.......................................................... 259

32 SERVO TOOL CHANGE FUNCTION .................................................261

32.1 OUTLINE ................................................................................................... 261

c - 6

Page 21

B-83284EN-2/05 TABLE OF CONTENTS

32.1.1 Feature of Function ..............................................................................................261

32.1.2 Basic Specification ...............................................................................................261

32.1.3 Restrictions...........................................................................................................261

32.1.4 System Configuration...........................................................................................263

32.1.5 Outline of Installation...........................................................................................264

32.2 INITIAL SETUP.......................................................................................... 264

32.3 PRELIMINARY TOOL ATTACH OPERATION .......................................... 265

32.4 TOOL CHANGE SETUP............................................................................ 267

32.5 SETTING THE REFERENCE POSITION.................................................. 272

32.5.1 Battery-less Type Tools........................................................................................272

32.5.2 Battery-Mounted Type Tools ...............................................................................272

32.6 TOOL CHANGE INSTRUCTION ............................................................... 273

32.6.1 TOOL DETACH Instruction................................................................................273

32.6.2 TOOL ATTACH Instruction................................................................................273

32.6.3 Sample Program ...................................................................................................273

32.6.4 Forward Execution ...............................................................................................274

32.6.5 Backward Execution.............................................................................................274

32.7 TOOL CHANGE SEQUENCE.................................................................... 275

32.8 TOOL CHANGE STATUS ......................................................................... 275

32.9 TEACHING ................................................................................................ 276

32.9.1 Notice for Teaching..............................................................................................276

32.9.2 Sample Program ...................................................................................................277

32.10 CONSTRUCTION OF SERVO TOOL CHANGE SCREEN........................ 277

32.11 TOOL CHANGE INITIAL SETUP............................................................... 278

32.11.1 Setting Motion Parameters for Servo Tool Axes..................................................278

32.11.2 Assigning Tool Numbers to Servo Tool Axes .....................................................278

32.11.3 Setting System Variables......................................................................................279

32.12 TOOL CHANGE REFERENCE POSITION SETUP METHOD

(BATTERY-LESS TYPE) ........................................................................... 280

32.12.1 Reference Position Setup for Calibration Types 3 and 4 .....................................280

32.12.2 Reference Position Setup for Calibration Types 5 and 6 .....................................282

32.12.3 Quick Mastering Reference Position Setup..........................................................283

32.13 TROUBLESHOOTING............................................................................... 284

32.13.1 The Attach Instruction is Executed when the Tool is not Attached. ....................284

32.13.2 The Robot Stopped during Calibration. ...............................................................285

32.13.3 Calibration Motion Failed. ...................................................................................285

32.13.4 A Different Tool from that Specified by the Attach Instruction is Attached. ......286

32.13.5 The Attached Tool has been Detached by Mistake (without Using the Detach

Instruction). ..........................................................................................................286

32.13.6 The Tool Axis of a Detached Tool has Moved. ...................................................286

32.13.7 The Battery Voltage has Fallen............................................................................287

32.13.8 The Battery Ran Low while the Tool was Detached............................................287

33 OPERATION WITHOUT SHIFT FUNCTION....................................... 288

33.1 JOG OPERATION WITHOUT SHIFT ........................................................ 288

33.2 TEST EXECUTION OPERATION WITHOUT SHIFT................................. 289

34 HIGH SPEED SHIFT KEY FUNCTION ...............................................291

34.1 SETUP FOR HIGH SPEED SHIFT KEY FUNCTION ................................ 291

34.2 HIGH SPEED SHIFT JOG OPERATION................................................... 291

34.3 HIGH SPEED SHIFT TEST EXECUTION OPERATION ........................... 292

c - 7

Page 22

TABLE OF CONTENTS B-83284EN-2/05

35 iRDIAGNOSTICS ................................................................................ 294

35.1 ROBOT CONDTION DETECTION ............................................................ 294

35.1.1 Setup.....................................................................................................................294

35.1.2 Execute Program ..................................................................................................296

35.1.3 Robot Condition Detection Status ........................................................................296

35.1.4 After Replacement................................................................................................297

35.2 SERVO DIAGNOSIS ................................................................................. 297

35.3 MOTION PROFILER ................................................................................. 299

35.3.1 Setup.....................................................................................................................299

35.3.2 Results ..................................................................................................................300

35.3.2.1 Detail ............................................................................................................... 301

36 MENU UTILITY FUNCTION ................................................................ 305

36.1 SETUP ABOUT MENU UTILITY................................................................ 305

36.1.1 Prompt Box Msg ..................................................................................................306

36.1.2 Prompt Box Yes/No Menu ...................................................................................308

36.1.3 List Menu .............................................................................................................310

36.1.4 Status Menu..........................................................................................................313

36.1.5 Operator Entry Menu............................................................................................316

37 4D GRAPHICS FUNCTION.................................................................320

37.1 OVERVIEW ............................................................................................... 321

37.1.1 Graphic Models ....................................................................................................321

37.1.2 Operation Procedure.............................................................................................321

37.2 4D GRAPHICS SCENE ............................................................................. 324

37.2.1 4D GRAPHICS Display .......................................................................................324

37.2.1.1 Visual jog......................................................................................................... 324

37.2.1.2 Jog preview...................................................................................................... 325

37.2.1.3 Set visibility: 4D GRAPHICS display............................................................. 326

37.2.2 4D GRAPHICS Node Map ..................................................................................327

37.2.2.1 4D GRAPHICS edit node map ........................................................................ 327

37.2.2.2 4D GRAPHICS select node map ..................................................................... 328

37.2.2.3 Set Visibility: node map position number ....................................................... 329

37.2.2.4 Data supported by node map ........................................................................... 329

37.2.3 4D GRAPHICS Frame Display............................................................................329

37.2.4 4D GRAPHICS TCP Trace ..................................................................................330

37.2.5 4D GRAPHICS Position Register ........................................................................330

37.2.5.1 Set Visibility: position register number ........................................................... 331

37.2.6 4D GRAPHICS DCS............................................................................................332

37.3 4D EDITOR FUNCTION ............................................................................ 332

37.3.1 OVERVIEW.........................................................................................................332

37.4 FULL SCREEN 4D DISPLAY .................................................................... 333

37.4.1 OVERVIEW.........................................................................................................333

37.4.2 Setup.....................................................................................................................334

37.4.2.1 Requirements ................................................................................................... 334

37.4.2.2 Configuring Microsoft® Internet Explorer...................................................... 334

37.4.3 Operation..............................................................................................................334

37.4.3.1 Accessing The Full Screen 4D Display ........................................................... 334

37.4.3.2 View Adjustment Mode................................................................................... 336

37.4.3.3 Scene Visibility................................................................................................ 337

38 DATA TRANSFER BETWEEN ROBOTS FUNCTION........................ 339

38.1 TERMINOLOGY ........................................................................................ 339

38.2 SETUP....................................................................................................... 340

c - 8

Page 23

B-83284EN-2/05 TABLE OF CONTENTS

38.3 TCP/IP SETUP FOR ROBOGUIDE........................................................... 340

38.4 STANDARD DATA TRANSFER PROGRAM............................................. 341

38.4.1 Program to Get Numeric Register ........................................................................342

38.4.2 Program to Set Numeric Register.........................................................................342

38.4.3 Program to Get Position Register .........................................................................343

38.4.4 Program to Set Position Register..........................................................................344

38.5 RECOVERY FROM ERROR ..................................................................... 345

38.6 KAREL BUILT-IN ....................................................................................... 346

38.6.1 RGET_PORTCMT Built-in ROUTINE...............................................................347

38.6.2 RGET_PORTSIM Built-in ROUTINE ................................................................347

38.6.3 RGET_PORTVAL Built-in ROUTINE ...............................................................348