Computer Numerical Controls

GE Fanuc Aut omation Eu r ope

Laser C Series

Operator‘s Manual

B

4

/

0

N

E

4

1

1

0

7

-

TECHNOLOGY AND MORE

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

B–70114EN/04

PREFACE

PREFACE

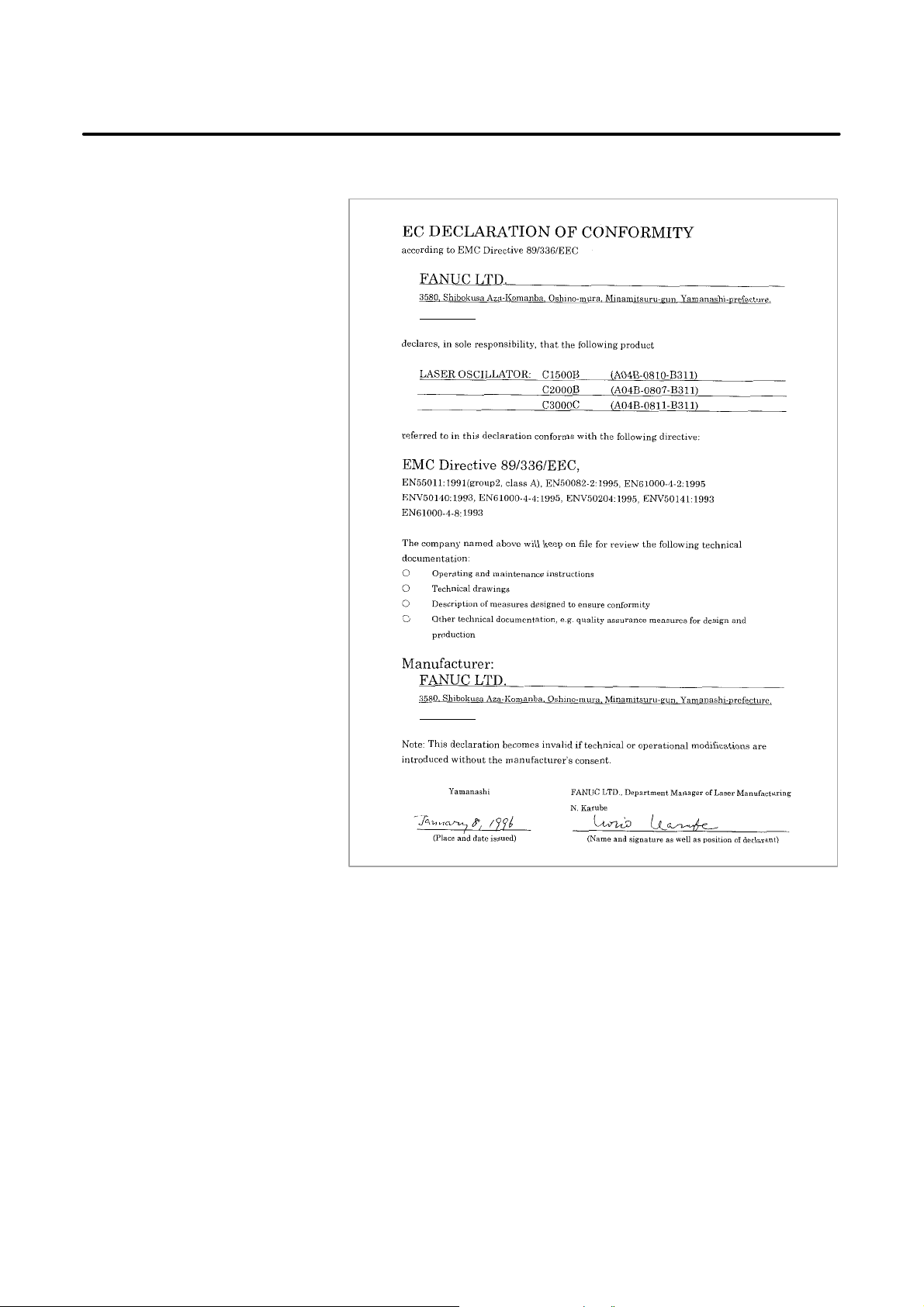

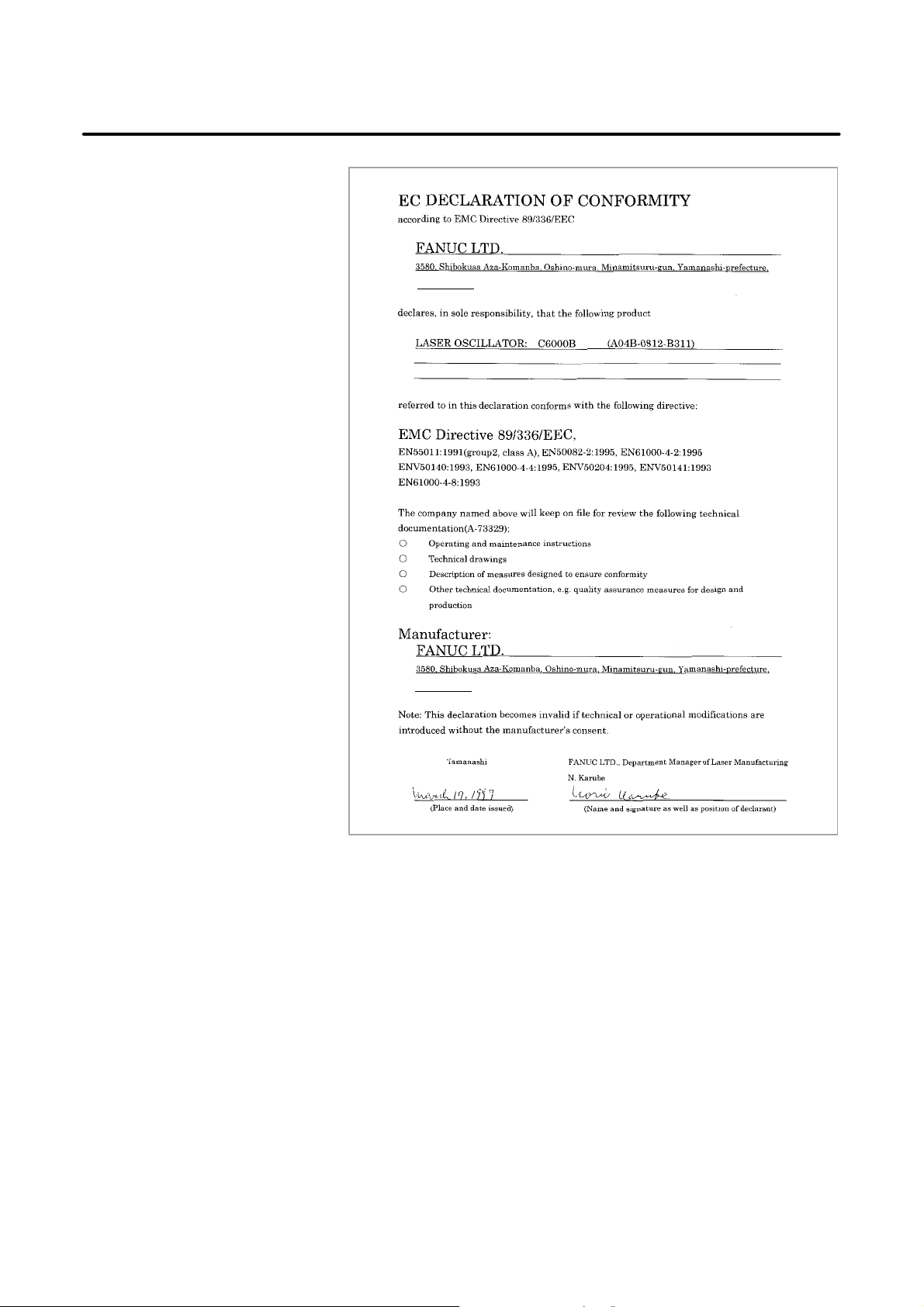

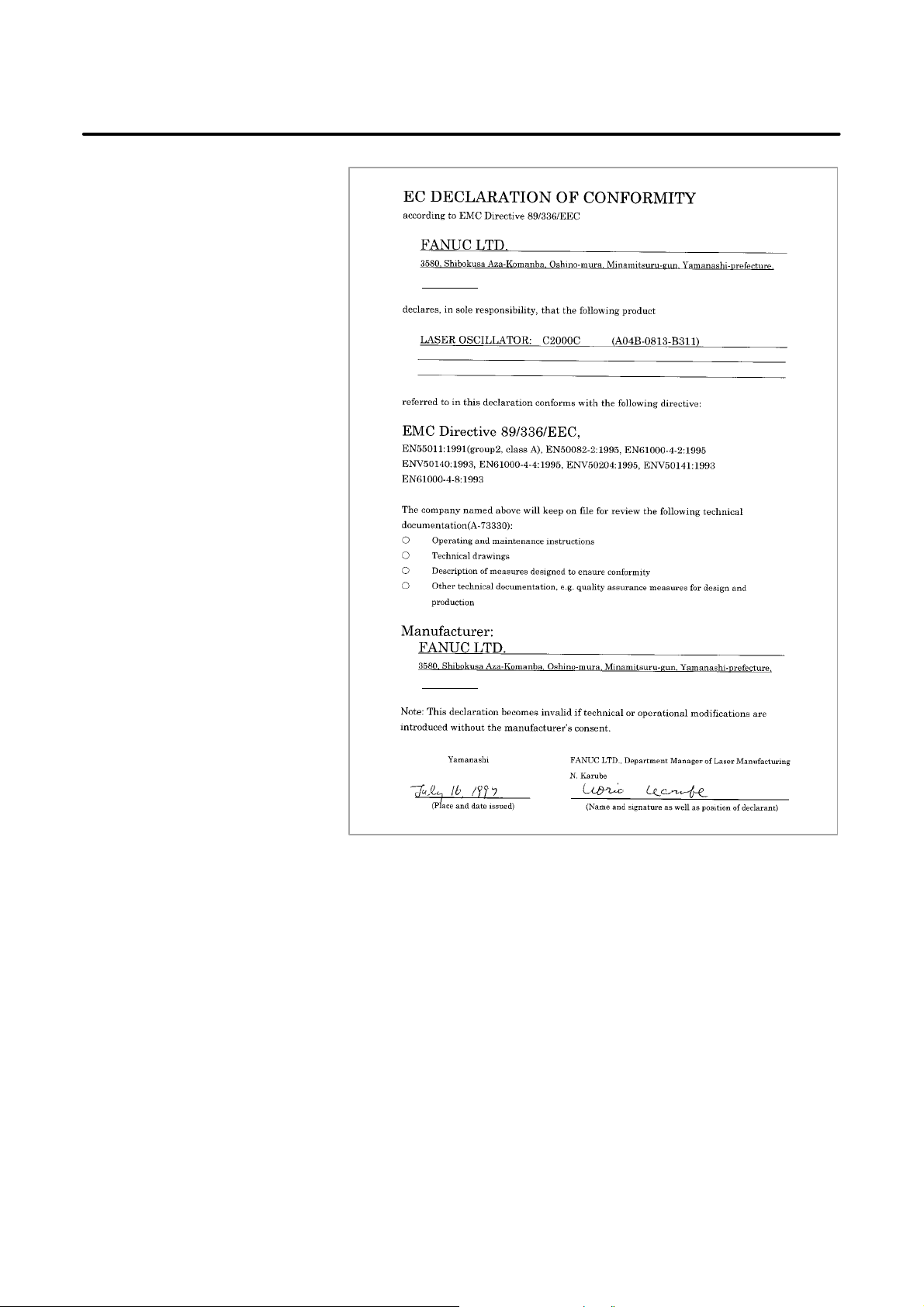

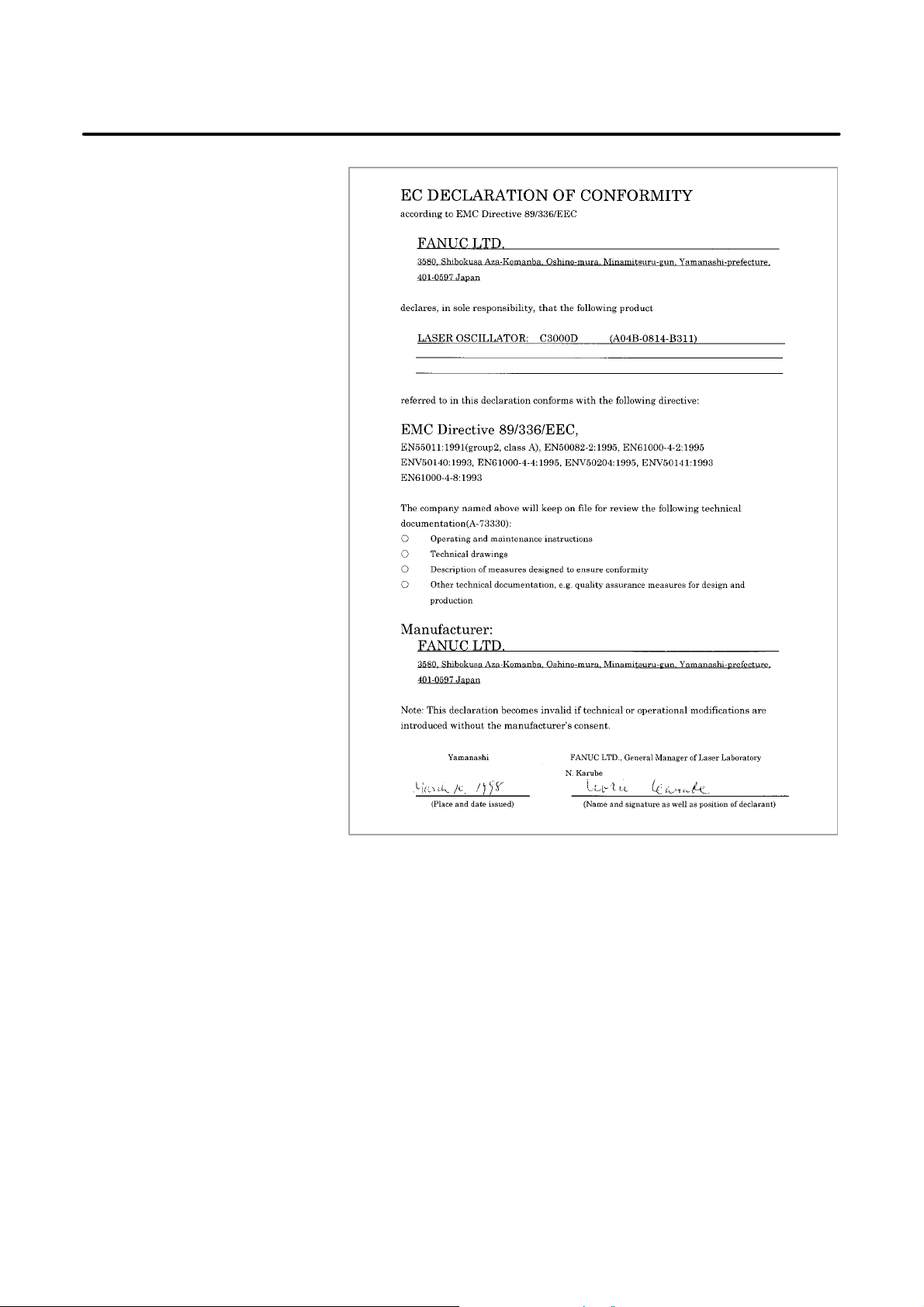

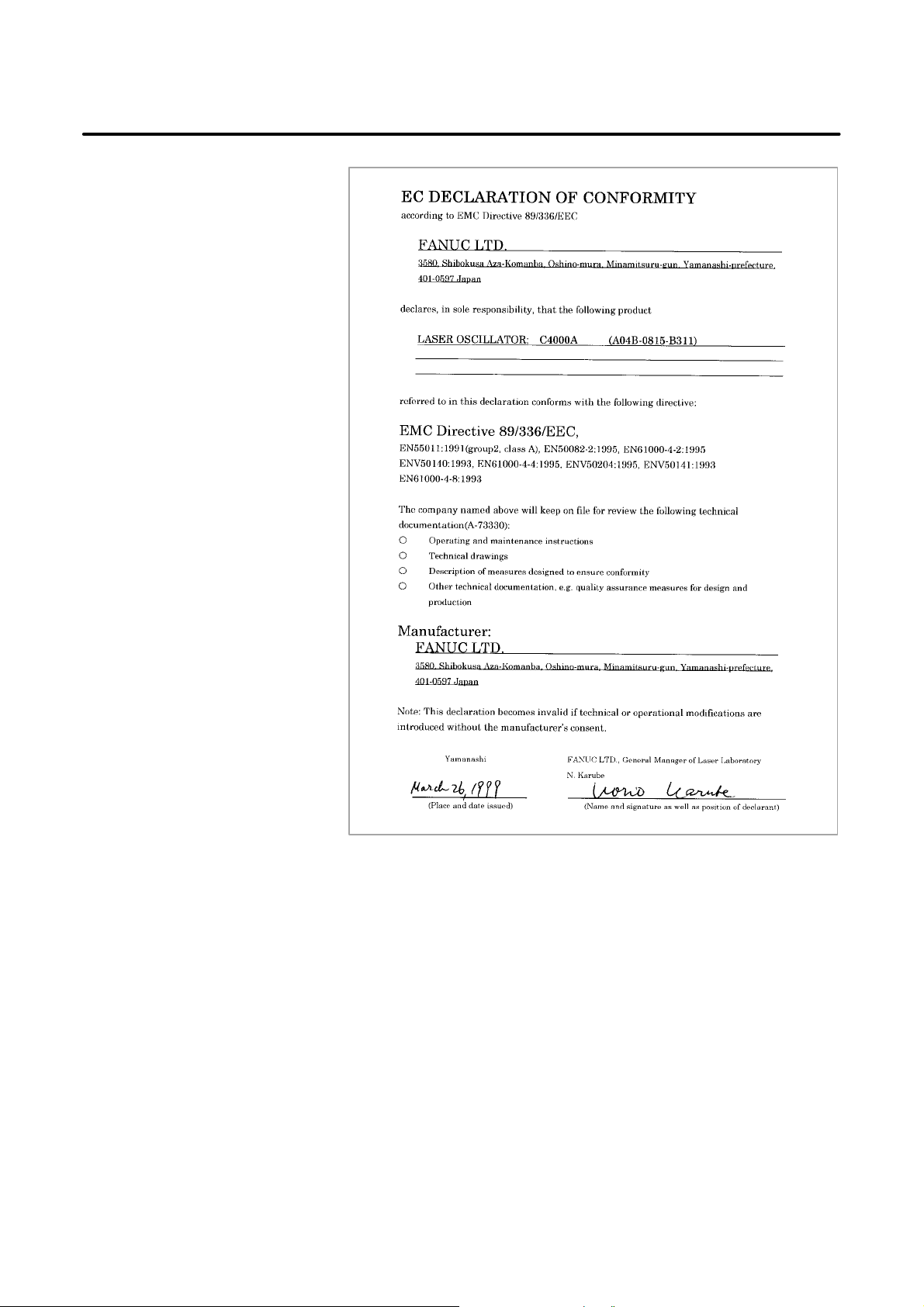

This document describes the following models.

Model Abbreviation

FANUC LASER–MODEL C1500B C1500B

FANUC LASER–MODEL C2000B C2000B

FANUC LASER–MODEL C2000C C2000C

FANUC LASER–MODEL C3000C C3000C

FANUC LASER–MODEL C3000D C3000D

FANUC LASER–MODEL C4000A C4000A

FANUC LASER–MODEL C6000B C6000B

p–1

PREFACE

B–70114EN/04

And, these models conform with EMC Directive 89/336/EEC.

401-0597 Japan

401-0597 Japan

p–2

B–70114EN/04

PREFACE

401-0597 Japan

401-0597 Japan

p–3

PREFACE

B–70114EN/04

401-0597 Japan

401-0597 Japan

p–4

B–70114EN/04

PREFACE

p–5

PREFACE

B–70114EN/04

p–6

B–70114EN/04

Table of Contents

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. OVERVIEW 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 MANUAL CONTENTS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 APPLICABLE MODELS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 RELATED MANUALS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 FOR SAFE OPERATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 NOTES ON READING THIS MANUAL 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SAFETY 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 LASER BEAM 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 HIGH VOLTAGE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 SAFETY ENCLOSURE (AT YOUR WORK STATION) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 FIRE 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 TOXIC FUME 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 HIGH TEMPERATURE 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 WARNING LABELS 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 KEY CONTROL 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 SHUTTER LOCK 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 EMERGENCY STOP BUTTON 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 WARNING LIGHT (OPTIONAL) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 INAPPOSITE USE OF LASER OSCILLATOR 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 CONDITION 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Environmental Conditions 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Power Source 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Laser Gas 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Cooling Water 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 TRANSPORTATION 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Lifting Laser Oscillator 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Packing 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Environmental Condition 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 STORAGE 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Environmental Condition 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 BASE OF OSCILLATOR 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 MAINTENANCE AREA 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 WATER CONNECTION 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Chiller 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Cooling Water Temperature 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 Cooling Water Flow Rate 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.4 Plumbing 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 LASER GAS 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 Gas Bottle 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 Laser Gas Tubing 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.3 Gas Pipe 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

TABLE OF CONTENTS

3.8 LASER BEAM 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.1 Position and Tolerance of Laser Beam Exit 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.2 Beam Divergence 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.3 Tolerance of Beam Direction 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.4 Beam Guide 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 ELECTRIC CONNECTION 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Power Cable (L1, L2, L3) 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 Ground Cable 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.3 I/O Signal Cable 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.4 Other Signal Cables to the IF PCB 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.5 XT20 Terminal 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.6 EMC Countermeasure 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–70114EN/04

4. FUNCTIONS 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

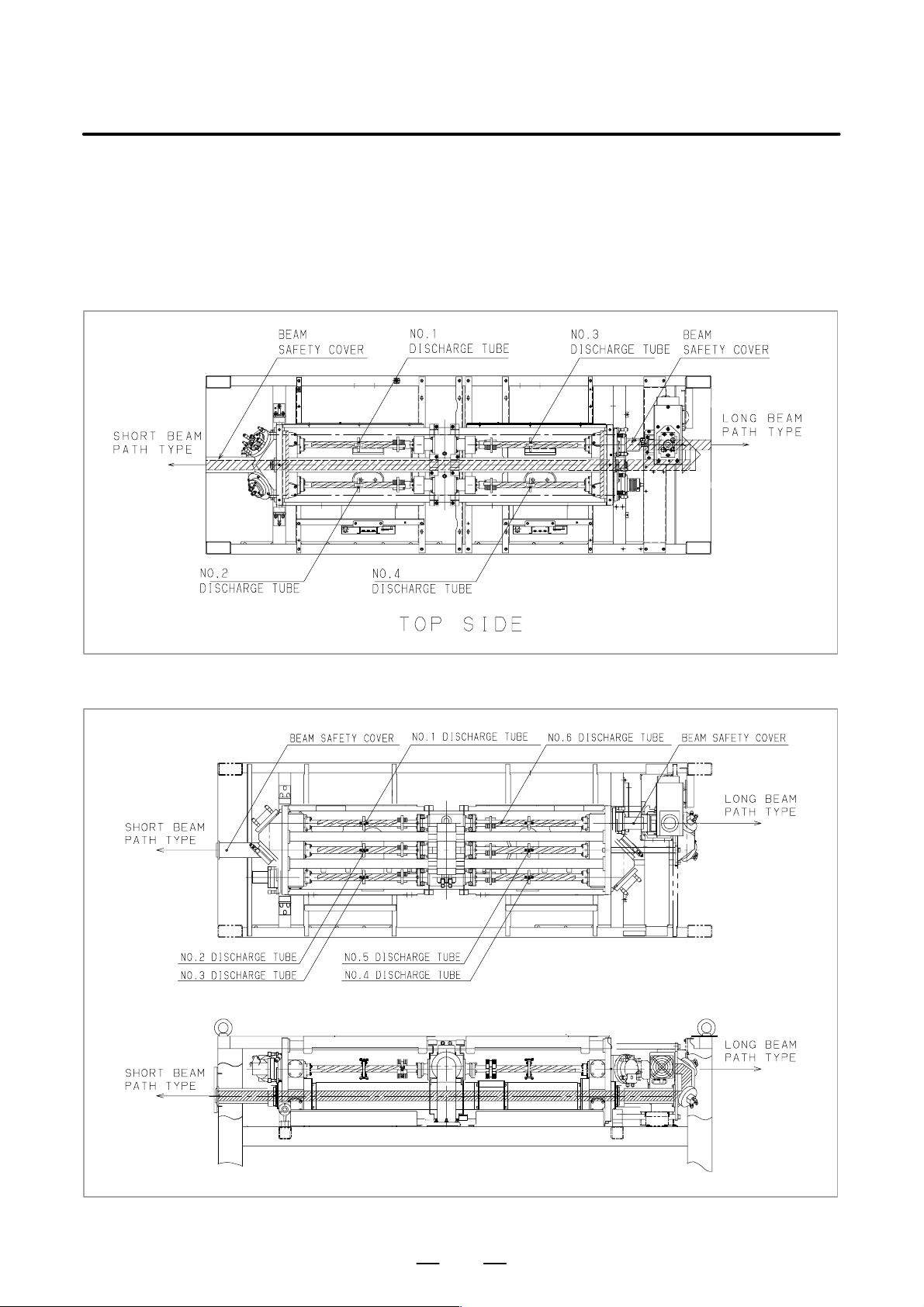

4.1 INTERNAL STRUCTURE 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Outline 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 COMPONENT DETAILS 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 OPERATION SEQUENCE 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 LASER PROCESSING MACHINE SYSTEM 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. MAINTENANCE 1 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 DAILY INSPECTION 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 PERIODIC MAINTENANCE 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 DETAILS OF MAINTENANCE 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Maintenance Panels and Oil Gauge Position 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Turbo Blower Oil 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Exhaust Pump Oil 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Exhaust Pump Filter 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Exhaust System Filter 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 AGING 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Leak Check Method 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Aging Method 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 MAINTENANCE PARTS 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Spare Parts 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Maintenance Tools 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TROUBLESHOOTING 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 CHECKING ON FAULTS 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 RESPONDING TO ALARM MESSAGES ON THE SCREEN 142. . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. EXTERNAL VIEW 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. FANUC LASER C SERIES SPECIFICATIONS 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. ERROR CODE LIST 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. FANUC SERVICE NETWORK 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. GLOSSARY 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–70114EN/04

1

1. OVERVIEW

OVERVIEW

In this manual, we have tried as for as possible to address all issues.

However, space restrictions prevent us from describing everything that

must not be done, or which cannot be done, because there are so many

possibilities.

Therefore, all matters which are not specifically described as being

possible should be regarded as being “impossible”.

Contents of this chapter

1.1 MANUAL CONTENTS 2. . . . . . . . . . . . . . . . . . . . . . . . .

1.2 APPLICABLE MODELS 3. . . . . . . . . . . . . . . . . . . . . . .

1.3 RELATED MANUALS 3. . . . . . . . . . . . . . . . . . . . . . . . .

1.4 FOR SAFE OPERATION 4. . . . . . . . . . . . . . . . . . . . . . .

1.5 NOTES ON READING THIS MANUAL 4. . . . . . . . . . .

1

1. OVERVIEW

B–70114EN/04

1.1

MANUAL CONTENTS

This manual consists of the following chapters and appendixes:

1. OVERVIEW

Chapter 1 covers the configuration of the manual, applicable models,

related manuals, and provides notes on reading the manual.

2. SAFETY

Chapter 2 covers the warnings and precautions related to laser beams,

high voltages, high temperatures, and a toxic substances.

To ensure safe operation, read this chapter first.

3. INSTALLATION

Chapter 3 describes the condition for installation and connection of

electrical cables, water tubes, gas tubes.

4. FUNCTIONS

Chapter 4 describes the structure and operation of the laser oscillator .

5. MAINTENANCE

Chapter 5 describes the periodic maintenance of the laser oscillator.

6. TROUBLESHOOTING

Chapter 6 describes the actions to be taken if the oscillator

malfunctions.

APPENDIX

A. EXTERNAL VIEW

B. FANUC LASER C SERIES SPECIFICATIONS

C. ERROR CODE LIST

D. FANUC SERVICE NETWORK

E. GLOSSARY

2

B–70114EN/04

1. OVERVIEW

1.2

APPLICABLE MODELS

1.3

RELATED MANUALS

This manual covers the following models:

Model Abbreviation

FANUC LASER–MODEL C1500B C1500B

FANUC LASER–MODEL C2000B C2000B

FANUC LASER–MODEL C2000C C2000C

FANUC LASER–MODEL C3000C C3000C

FANUC LASER–MODEL C3000D C3000D

FANUC LASER–MODEL C4000A C4000A

FANUC LASER–MODEL C6000B C6000B

The following manuals are available for the FANUC LASER C series:

FANUC Series 0–L DESCRIPTIONS B–61572E

CONNECTION MANUAL B–61573E

OPERATOR’S MANUAL B–61574E

MAINTENANCE MANUAL B–61575E

FANUC Series 16–LA DESCRIPTIONS B–61852E

CONNECTION MANUAL B–61854E

OPERATOR’S MANUAL B–61853E

MAINTENANCE MANUAL B–61855E

P ARAMETER MANUAL B–61810E

FANUC Series 16–LB DESCRIPTIONS B–62442E

CONNECTION MANUAL

(HARDWARE)

CONNECTION MANUAL

(FUNCTION)

OPERATOR’S MANUAL B–62594EN

MAINTENANCE MANUAL B–62445E

P ARAMETER MANUAL B–62600EN

FANUC Series 16i–LA DESCRIPTIONS B–63192EN

CONNECTION MANUAL B–63193EN

B–62443E

B–62443E–1

OPERATOR’S MANUAL B–63194EN

MAINTENANCE MANUAL B–63195EN

FANUC LASER C series OPERA TOR’S MANUAL B–70114EN

MAINTENANCE MANUAL B–70115EN

3

1. OVERVIEW

B–70114EN/04

1.4

FOR SAFE OPERATION

Warning

Caution

Note

1.5

NOTES ON READING THIS MANUAL

This manual contains precautions which must be observed during

operation of the laser oscillator, to ensure the operator’s safety and prevent

damage to the oscillator. Each precaution is indicated by “Warning” or

“Caution” according to its severity.

Supplementary information is indicated by “Note”.

Read the contents of each “Warning”, “Caution”, and “Note” before

attempting to use the oscillator.

Precautions to be applied in those situations where there is a danger of the

operator being killed or seriously injured

Precautions to be applied in those situations where there is a danger of the

operator being slightly injured or the oscillator being damaged

Supplementary information other than precautions

The functions of a laser machining system depend not only on the laser

oscillator, but also on the machine, power magnetics cabinet, servo

system, CNC, and operator’s panel. This manual describes only the laser

oscillator. For a description of the other components, refer to the

corresponding manuals, supplied by the machine tool builder.

Read this manual thoroughly and store it in a safe place.

4

B–70114EN/04

2

SAFETY

2. SAFETY

C1500B, C2000C (C2000B), C3000D (C3000C), C4000A, C6000B

produce the rated laser output power of 1500W , 2000W, 3000W , 4000W,

6000W. The CO

and is invisible to human eyes. The adequate care must be taken,

therefore, in dealing with it. When removing the panel, always turn the

power source off and confirm no power is applied to the laser machine.

This oscillator fulfills the requirements of the relevant product safety

standard of EN60825–1:1994.

laser beam is the wavelength of 10.6 mm, far infrared,

2

5

2. SAFETY

B–70114EN/04

2.1

LASER BEAM

1) Potential hazards

Laser oscillator emits CO

laser beam(10.6 mm), which is high power

2

and invisible.

D Being directly exposed to the CO

D The CO

beam could bource off your workpiece and burn your eyes

2

beam could severely burn you.

2

or skin.

FANUC LASER C series have a diode laser. The diode laser beam

is visible (red color) and low power . It is used to ensure that the CO

beam is correctly positioned on your workpiece.

D The diode laser beam is not considered harmful to your skin. But

if you stared head on into the laser diode beam, it could harm your

eyes.

2) Safety recommendations

Never expose the eyes and skin to the laser beam. Be careful of the

laser beam when performing the inspection and maintenance.

Do not turn on the power supply to the oscillator when the panel open

and do not drive. It is bleached to radiation of the laser beam and high

voltage.

Do the countermeasure (For instance, installs safety glasses and the

protection gloves) to danger in case of stopped no finish and nor

opening the panel while it energizes the oscillator.

Install beam safety cover after mirror cleaning or replacement. And if

not beam safety cover installation, do not operation and alignment.

Confirm when it does alignment, the protection pipe (Safety cover) is

installed. If it dose not install the protection pipe, it will put the finger

in the laser beam and there is possibility to do the burn.

When entering the area exposed to the scattered beam, wear the safety

glasses. Mount the stand made of acrylic resin or any material which

can absorb the CO

laser beam to protect the personnel from the

2

scattered beam.

Avoid exposure of any part of your body to the CO

laser beam.

2

When testing the beam output, any personnel other than the

maintenance personnel should be out of the working environment.

In designing a material processing machine utilizing F ANUC LASER

C series, be sure that the CO

laser beam goes from laser to the

2

workpiece only through the enclosed beam delivery system. This

prevents the exposure to laser beam by the operator switch could

otherwise take place. It is absolutely necessary to include the

instructions given here in the manuals of the laser material–processing

machine as a whole, which are to be read.

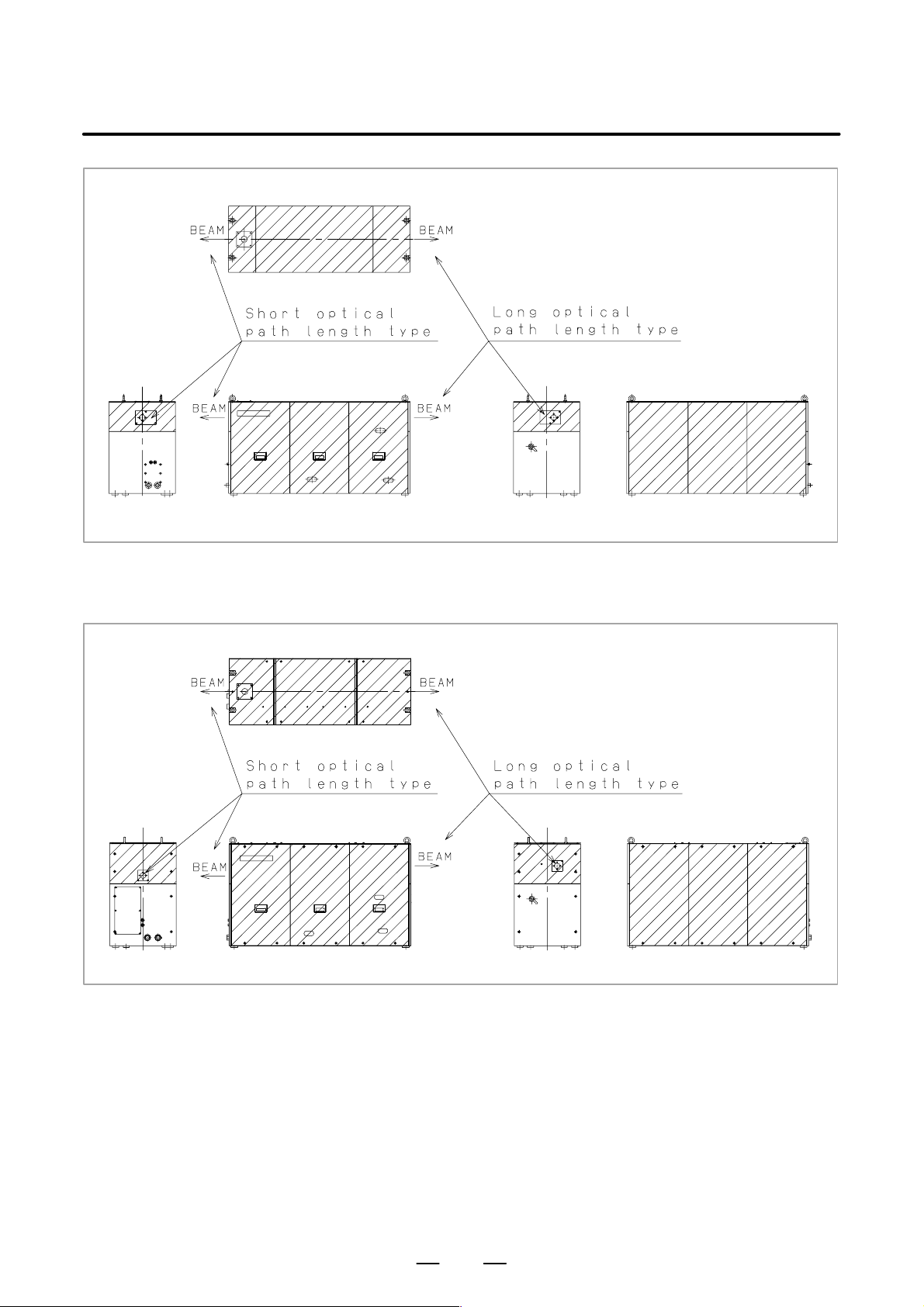

3) Position of laser beam emission

Fig. 2.1 (a) is the position of laser beam delivery in C1500B,

C2000B, C2000C.

Fig. 2.1 (b) is the position of laser beam delivery in C3000C,

C3000D.

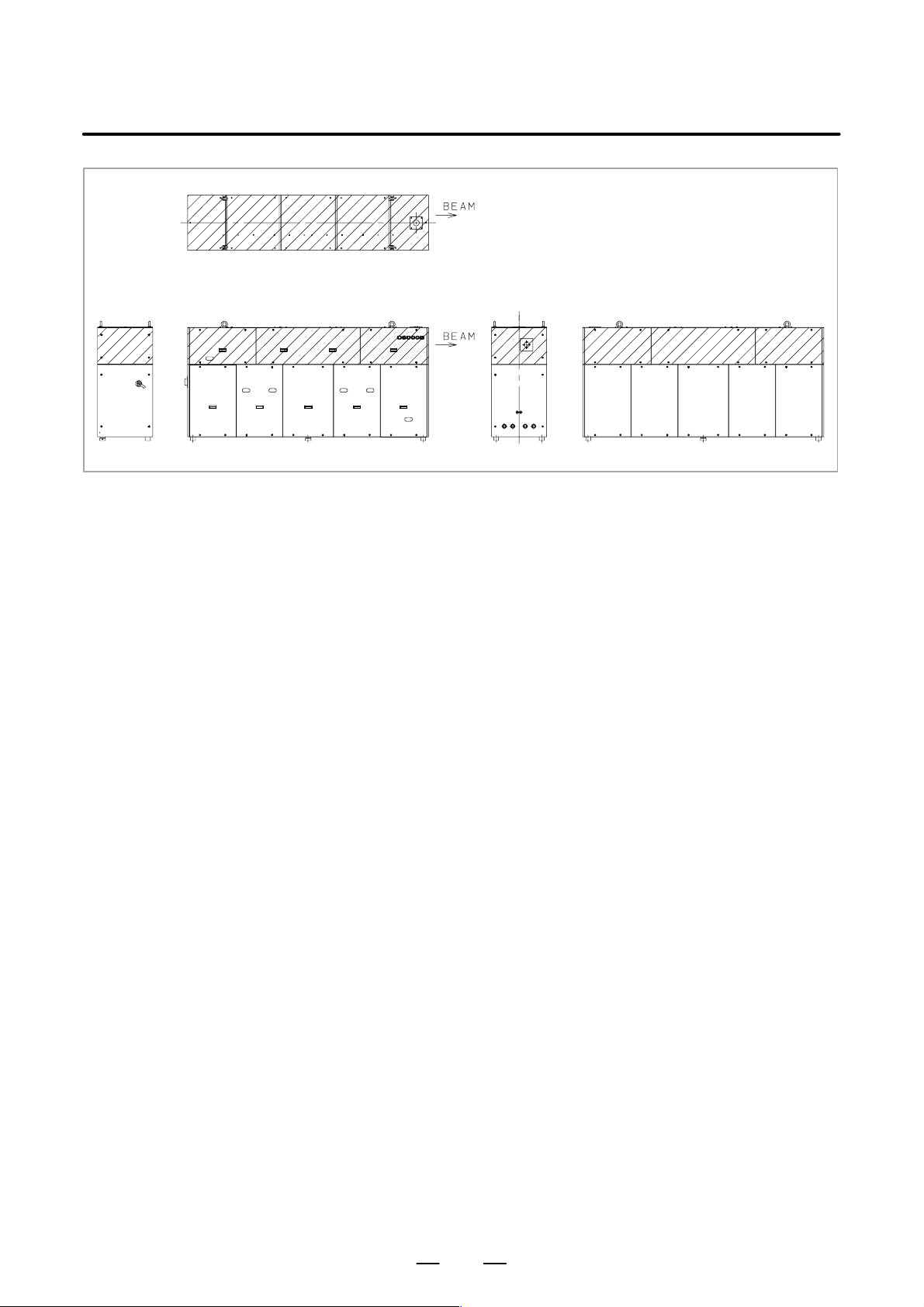

Fig. 2.1 (c) is the position of laser beam delivery in C4000A.

Fig. 2.1 (d) is the position of laser beam delivery in C6000B.

Fig. 2.1 (e) is the position of panel that laser beam exposure is

occurred without panel in C1500B, C2000B, C2000C,

C3000C, C3000D, when your maintenance.

2

6

B–70114EN/04

2. SAFETY

Fig. 2.1 (f) is the position of panel that laser beam exposure is

occurred without panel in C4000A, when your

maintenance.

Fig. 2.1 (g) is the position of panel that laser beam exposure is

occurred without panel in C6000B, when your

maintenance.

Fig. 2.1 (a) The position of laser beam delivery (C1500B, C2000B, C2000C)

Fig. 2.1 (b) The position of laser beam delivery (C3000C, C3000D)

7

2. SAFETY

B–70114EN/04

Fig. 2.1 (c) The position of laser beam delivery (C4000A)

Fig. 2.1 (d) The position of laser beam delivery (C6000B)

8

B–70114EN/04

2. SAFETY

Fig. 2.1 (e) Laser beam exposure position without panel as operating

(C1500B, C2000B, C2000C, C3000C, C3000D)

Fig. 2.1 (f) Laser beam exposure position without panel as operating (C4000A)

9

2. SAFETY

B–70114EN/04

Fig. 2.1 (g) Laser beam exposure position without panel as operating (C6000B)

10

B–70114EN/04

2. SAFETY

2.2

HIGH VOLTAGE

1) Potential hazards

There is RF voltage of 3 to 4kV

in the cabinet of the laser oscillator .

o–p

There is 200 VAC power in the relay panel, be careful not to touch the

high voltage.

2) Safety recommendations

When it checks the oscillator and exchange the unit, intercept a main

breaker of the oscillator and the power supply. Lock the breaker to

prevent misconnection and display the sign while working.

Install safety cover after unit replacement or cable connection. Unless

safety cover is installed, never perform operation.

Follow standard industrial safety practices for working with high

voltage.

EXAMPLES

D Do not work on the laser oscillator if you are tired or have taken

medicine.

D Use the buddy system.

D Do not wear anything metal, like a ring, bracelet, watch, belt

buckle, earrings, or keys.

D They might contact high voltage.

D Never stand on a wet surface.

D Do not touch electrical components in the cabinets with both hands

at once. Keep one hand in a pocket.

3) Position of high voltage

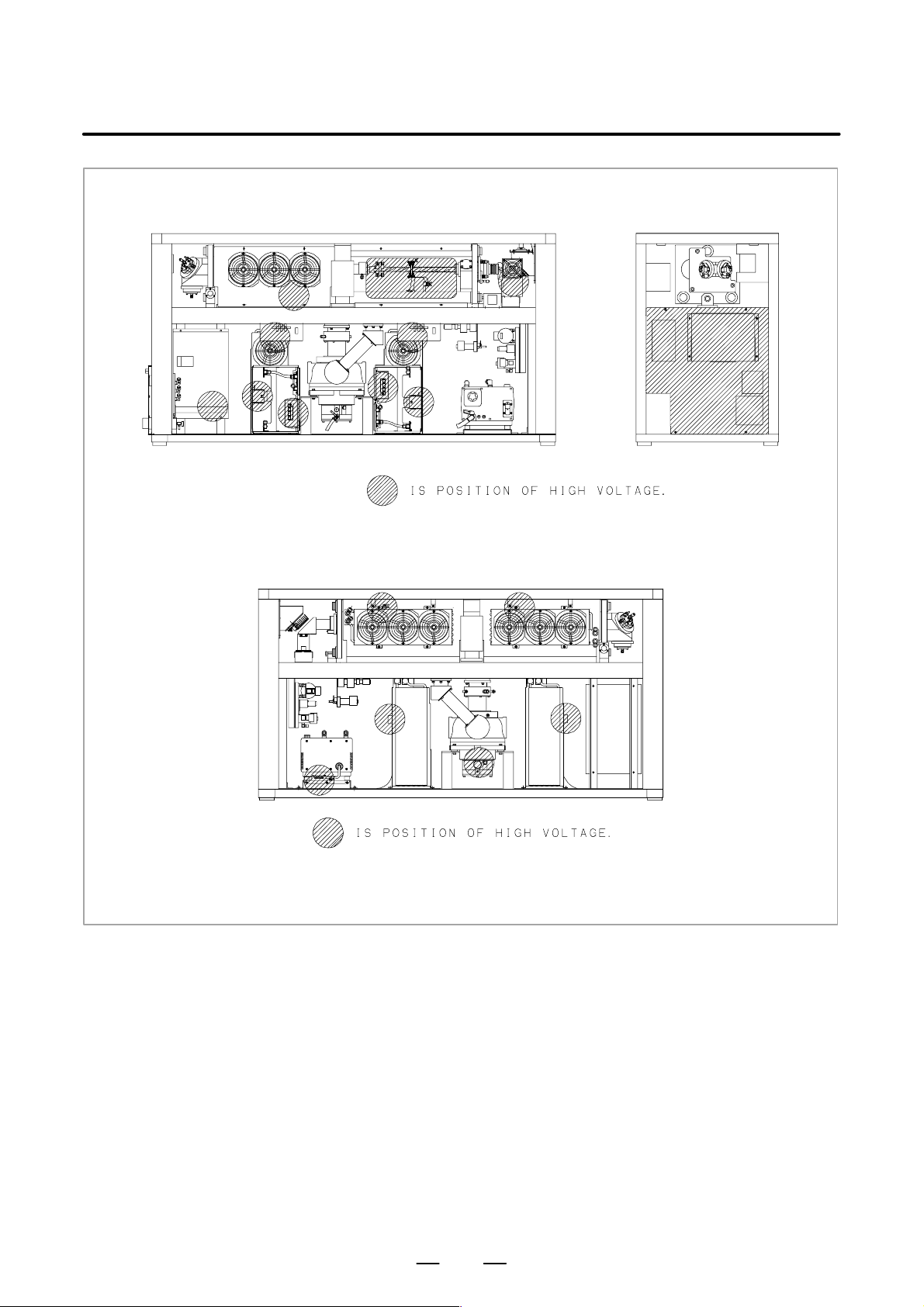

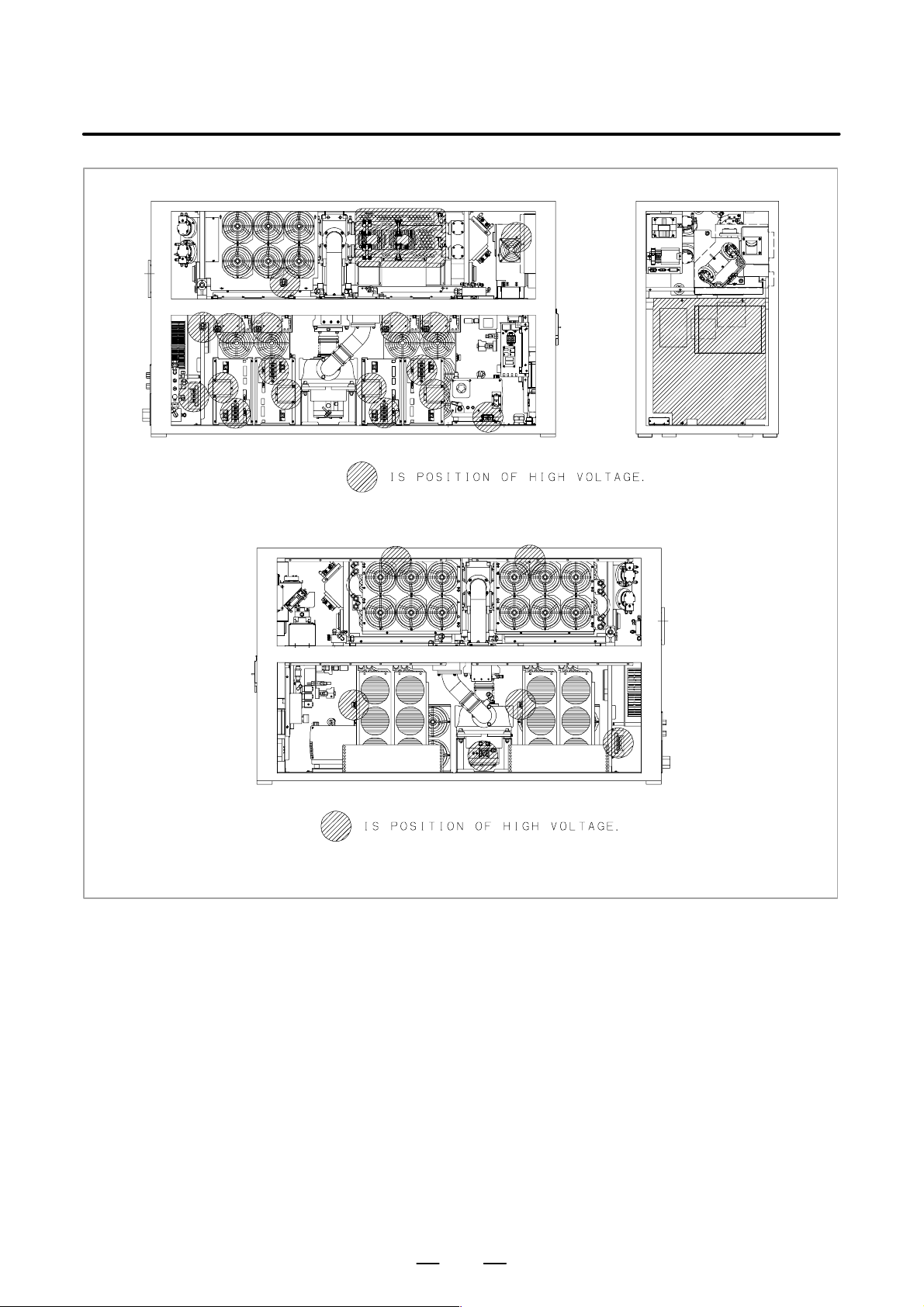

Fig. 2.2 (a) is the position of high voltage in C1500B (Front side,

Back side).

Fig. 2.2 (b) is the position of high voltage in C2000B (Front side,

Back side).

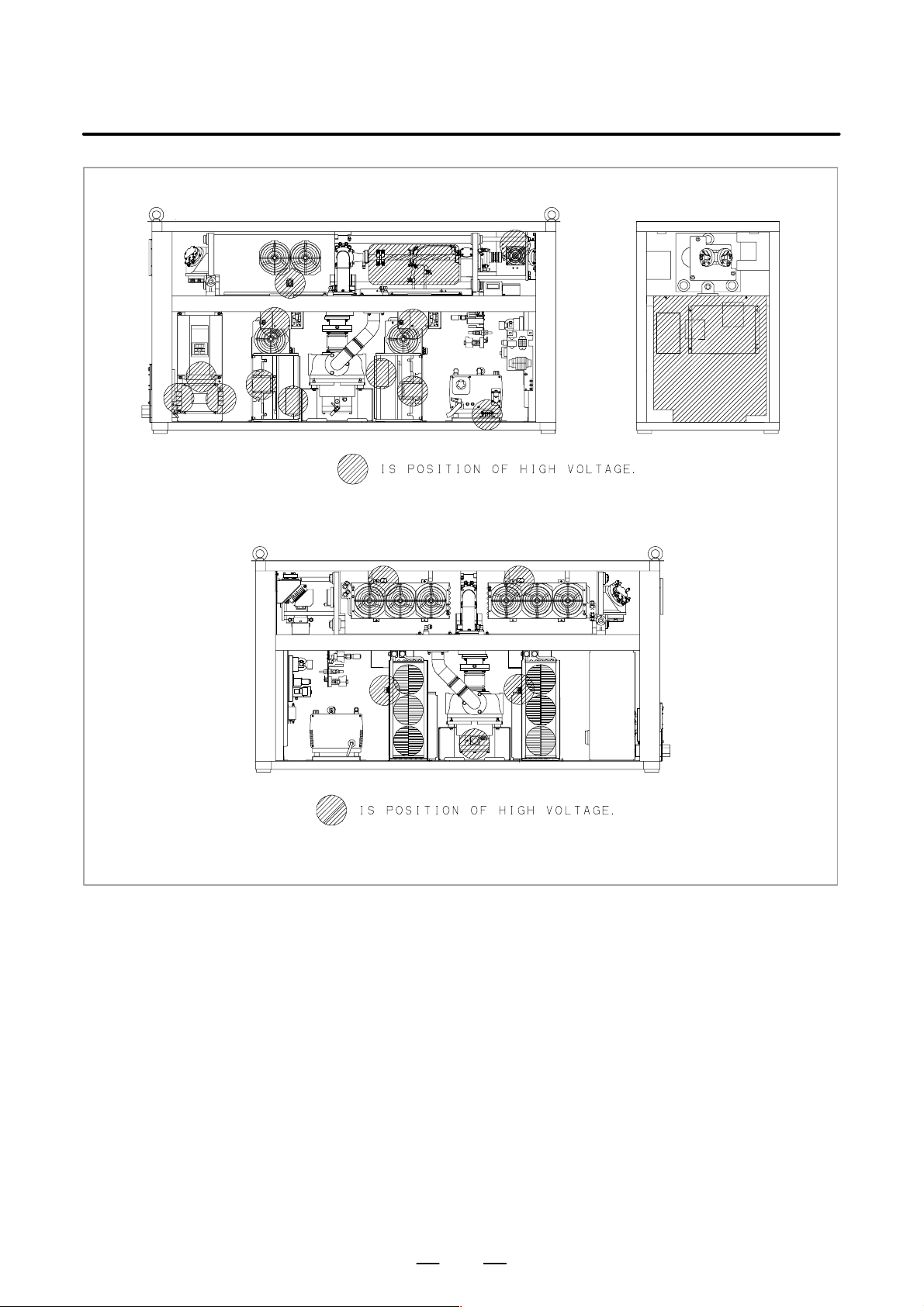

Fig. 2.2 (c) is the position of high voltage in C2000C (Front side,

Back side).

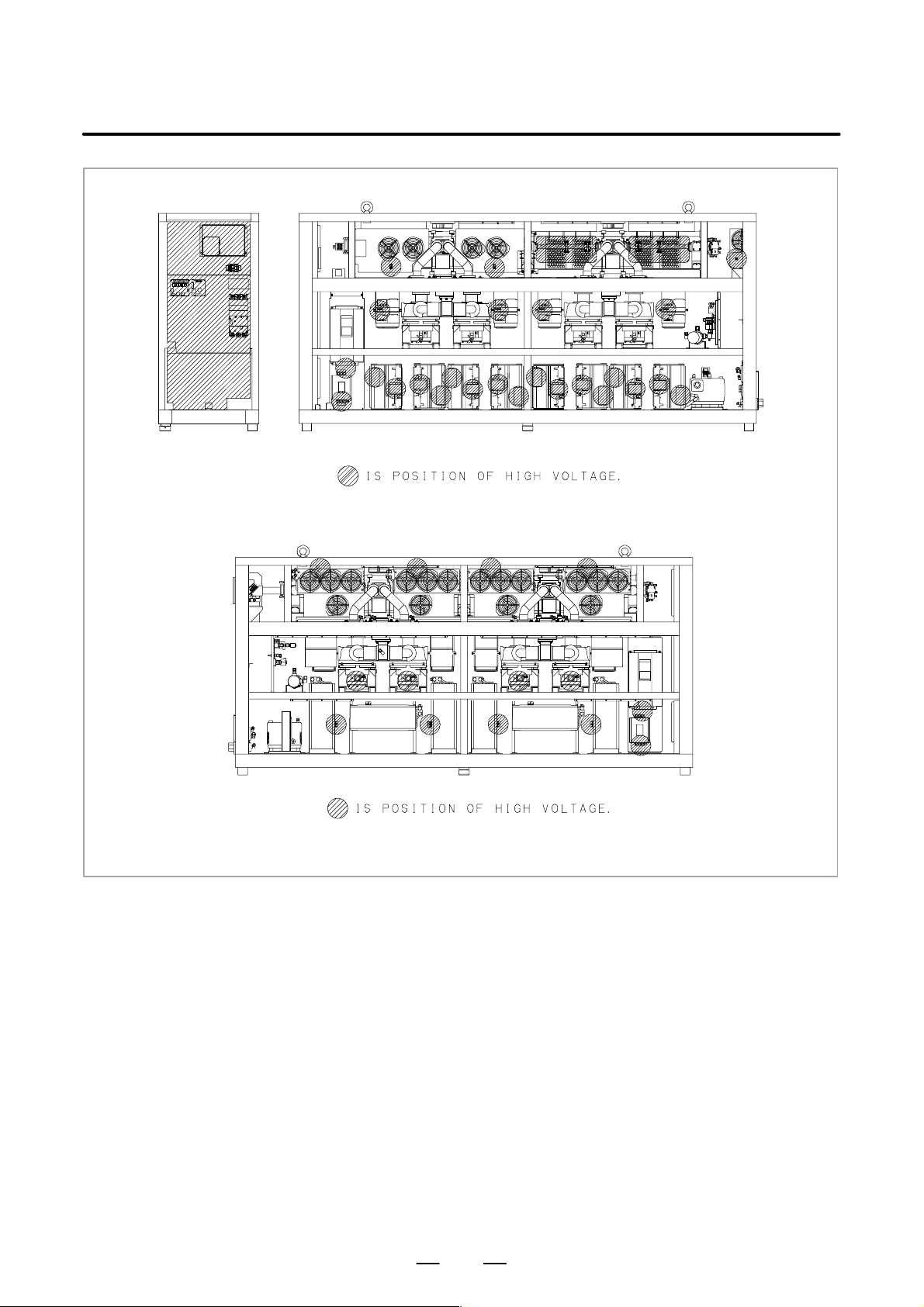

Fig. 2.2 (d) is the position of high voltage in C3000C (Front side,

Back side, AUX).

Fig. 2.2 (e) is the position of high voltage in C3000D (Front side,

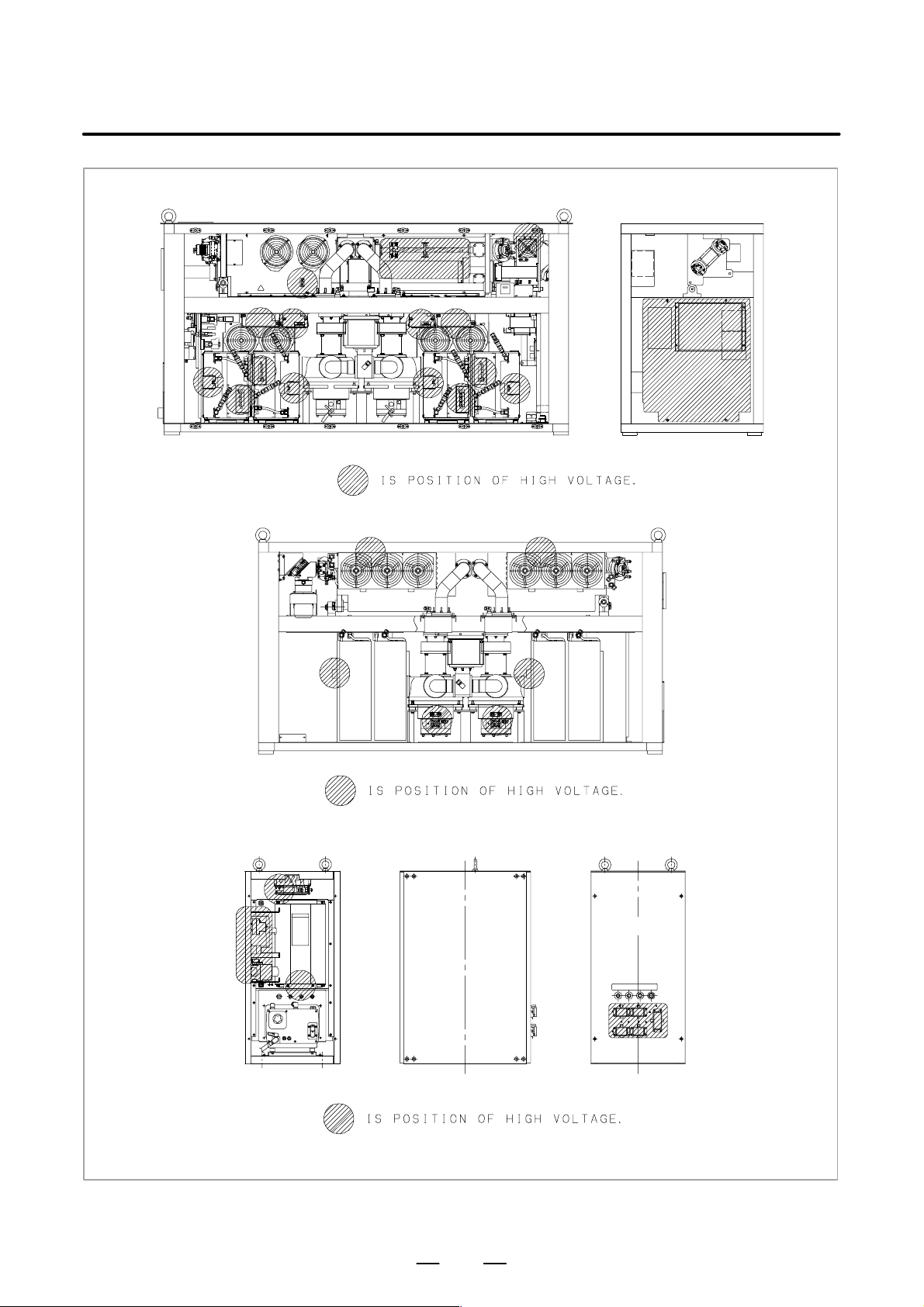

Back side).

Fig. 2.2 (f) is the position of high voltage in C4000A (Front side,

Back side).

Fig. 2.2 (g) is the position of high voltage in C6000B (Front side,

Back side).

11

2. SAFETY

B–70114EN/04

Front side

Back side

Fig. 2.2 (a) The position of high voltage in C1500B (Front side, Back side)

12

B–70114EN/04

2. SAFETY

Front side

Back side

Fig. 2.2 (b) The position of high voltage in C2000B (Front side, Back side)

13

2. SAFETY

B–70114EN/04

Front side

Back side

Fig. 2.2 (c) The position of high voltage in C2000C (Front side, Back side)

14

B–70114EN/04

2. SAFETY

Front side

Back side

Auxiliary unit

Fig. 2.2 (d) The position of high voltage in C3000C (Front, Back, AUX)

15

2. SAFETY

B–70114EN/04

Front side

Back side

Fig. 2.2 (e) The position of high voltage in C3000D (Front side, Back side)

16

B–70114EN/04

2. SAFETY

Front side

Back side

Fig. 2.2 (f) The position of high voltage in C4000A (Front side, Back side)

17

2. SAFETY

B–70114EN/04

Front side

Back side

Fig. 2.2 (g) The position of high voltage in C6000B (Front side, Back side)

18

B–70114EN/04

2. SAFETY

2.3

SAFETY ENCLOSURE (AT YOUR WORK STATION)

2.4

FIRE

1) Potential hazards

beam is delivery from oscillator. Direct or scattered beam is

CO

2

exposed.

2) Safety recommendations

Mount the safety enclosure made of acrylic resin which can absorb the

laser beam around the working environment.

Mount the interlock switch on the safety enclosure door which

extinguishes the laser beam output when the door is open. Never

perform operation without safety cover of laser machine.

1) Potential hazards

When you work with the laser oscillator or machine, hot fragments or

slag can scatter from your workpiece. The CO

of it could ignite flammable material.

2) Safety recommendations

The direct or scattered laser beam can ignite flammable materials such

as paper, cloth, and wood. Provide a beam absorber behind the

workpiece and around it during maintenance. The absorber can be

anodized aluminum, graphite or brick.

Put a shield between yourself and the workpiece when the CO

is on. Even diffuse reflections can harm eyes and skin and may ignite

flammable material.

beam or a reflection

2

beam

2

2.5

TOXIC FUME

1) Potential hazards

Some materials such as certain plastics can emit toxic fume when they

burn under the laser beam.

2) Safety recommendations

Install the exhaust system to remove toxic fume from the work

environment.

Consult the manufacturer of the material you are processing to learn

if it creates any fumes when heated or burned.

19

2. SAFETY

B–70114EN/04

2.6

HIGH TEMPERATURE

1) Potential hazards

When you touch a part of high temperature, your skin burn.

2) Safety recommendations

The pipes of the gas circular system are very a high temperature. Do

not touch pipes, heat exchanger and turbo blower because it does not

do the burn. It is hot immediately after having stopped driving. After

getting cold enough in case of removing, dismount it.

3) Position of high temperature

Fig. 2.6 (a) is the position of high temperature in C1500B (Front side,

Back side).

Fig. 2.6 (b) is the position of high temperature in C2000B (Front side,

Back side).

Fig. 2.6 (c) is the position of high temperature in C2000C (Front side,

Back side).

Fig. 2.6 (d) is the position of high temperature in C3000C (Front side,

Back side, Aux).

Fig. 2.6 (e) is the position of high temperature in C3000D (Front side,

Back side).

Fig. 2.6 (f) is the position of high temperature in C4000A (Front side,

Back side).

Fig. 2.6 (g) is the position of high temperature in C6000B (Front side,

Back side).

20

B–70114EN/04

2. SAFETY

Front side

Back side

Fig. 2.6 (a) The position of high temperature in C1500B (Front side, Back side)

21

2. SAFETY

B–70114EN/04

Front side

Back side

Fig. 2.6 (b) The position of high temperature in C2000B (Front side, Back side)

22

B–70114EN/04

2. SAFETY

Front side

Back side

Fig. 2.6 (c) The position of high temperature in C2000C (Front side, Back side)

23

2. SAFETY

B–70114EN/04

Front side

Back side

Auxiliary unit

Fig. 2.6 (d) The position of high temperature in C3000C (Front , Back, Aux)

24

B–70114EN/04

2. SAFETY

Front side

Back side

Fig. 2.6 (e) The position of high temperature in C3000D (Front side, Back side)

25

2. SAFETY

B–70114EN/04

Front side

Back side

Fig. 2.6 (f) The position of high temperature in C4000A (Front side, Back side)

26

B–70114EN/04

2. SAFETY

Front side

Back side

Fig. 2.6 (g) The position of high temperature in C6000B (Front side, Back side)

27

2. SAFETY

B–70114EN/04

2.7

W ARNING LABELS

Fig. 2.7 (a)–(g) show the location of the warning labels indicating the high

voltage and laser beam path.

Fig. 2.7 (a) is the location of the warning sticker at front side. (C1500B,

C2000B, C2000C, C3000C, C3000D)

Fig. 2.7 (b) is the location of the warning sticker at back side. (C1500B,

C2000B, C2000C, C3000C, C3000D)

Fig. 2.7 (c) is the location of the warning sticker (Auxiliary unit of

C3000C)

Fig. 2.7 (d) is the location of the warning sticker at front side. (C4000A)

Fig. 2.7 (e) is the location of the warning sticker at back side. (C4000A)

Fig. 2.7 (f) is the location of the warning sticker at front side. (C6000B)

Fig. 2.7 (g) is the location of the warning sticker at back side. (C6000B)

Fig. 2.7 (a) The location of warning sticker at front side (C1500B, C2000B, C2000C, C3000C, C3000D)

28

B–70114EN/04

2. SAFETY

Fig. 2.7 (b) The location of warning sticker at back side (C1500B, C2000B, C2000C, C3000C, C3000D)

Fig. 2.7 (c) The location of the warning sticker (Auxiliary unit of C3000C)

29

2. SAFETY

B–70114EN/04

Fig. 2.7 (d) The location of warning sticker at front side. (C4000A)

Fig. 2.7 (e) The location of warning sticker at back side. (C4000A)

30

B–70114EN/04

2. SAFETY

Fig. 2.7 (f) The location of warning sticker at front side. (C6000B)

Fig. 2.7 (g) The location of the warning sticker at back side. (C6000B)

31

2. SAFETY

D Detail of warning sticker

B–70114EN/04

Warning logotype

32

7000W

B–70114EN/04

2. SAFETY

Warning logotype

Label for defeasible non–interlocked protective housing

Label for defeasible non–interlocked protective housing

33

2. SAFETY

Caution label for lifting

B–70114EN/04

Aperture label

Label of non–interlocked protective panel

34

B–70114EN/04

Identification label

2. SAFETY

80

110

110

150

Address label

High voltage warning label

150

190

300

35

2. SAFETY

B–70114EN/04

Supply voltage label

Label of over–current protective

36

B–70114EN/04

2. SAFETY

Label of motor and transformer (C1500B,C2000B,C2000C)

Label of motor and transformer (C3000C)

37

2. SAFETY

B–70114EN/04

Label of motor and transformer (C3000D)

Label of motor and transformer (C4000A)

38

B–70114EN/04

2. SAFETY

Label of motor and transformer (C6000B)

Label of warning light

Maintenance label

39

2. SAFETY

B–70114EN/04

Certification label

Short–circuit interrupting capacity of main breaker

Caution label for lifting

40

B–70114EN/04

2. SAFETY

2.8

KEY CONTROL

2.9

SHUTTER LOCK

All the laser products have to comply with the various kinds of laser safety

regulations, which include the use of key control. For instance, FDA

PART 1040 PERFORMANCE STANDARDS FOR

LIGHT–EMITTING PRODUCTS, Sec 1040. 10 (f), (4) states: “Each

laser system classified as a Class IIIb or IV laser product shall incorporate

a key–actuated master control. The key shall be removable and the laser

shall not be operable when the key is removed” and EN60825–1:1994, 4.5

Key control state “Any laser system belonging to one of the following

classes shall incorporate a key operation master control: Class 4 and Class

3B, except for Class 3B with not more than five times the AEL of Class

2 in the wavelength range from 400 nm to 700 nm. The key shall be

removable and the laser radiation shall not be accessible when the key is

removed.”

Because the laser package products offered by FANUC cannot produce

the laser beam as they are in the state of shipment, the system integrator

who incorporates FANUC products into the system, which generates the

laser beam, is obliged to incorporate the master key as defined by the

relevant regulation.

The shutter lock is prepared because it dose not put out the laser beam by

mistake. If you do not put out the beam, lock the shutter.

Use the mechanical switch at shutter lock switch, not electrical

component (Relay)or switching circuit (Transistor, FET).

Use the one with the compulsion dissociation mechanism for the switch

used for the shutter lock circuit and the switch for welding prevention.

To designer of laser processing machine

1. Use a mechanical switch for the switch used to lock the

shutter. Do not use an electric switch (For instance,

transistor circuit, etc.). Moreover, use the one with the

contact dissociation mechanism to prevent welding for a

mechanical switch.

2. Put it in the series of the contact of the emergency stop

button in the shutter lock circuit. When the emergency stop

switch is pushed, it is necessary to intercept the power

supply to the shutter.

41

2. SAFETY

B–70114EN/04

2.10

EMERGENCY STOP BUTTON

2.11

W ARNING LIGHT (OPTIONAL)

Press the emergency stop button when it is dangerous and breaks down.

The oscillator is stopped discharging, gas pressure control and stand by

purge state.

Use the one with the compulsion dissociation mechanism for the relay

used for the emer gency stop circuit and the switch for welding prevention.

FANUC LASER C series are equipped with the warning light optionally.

The light is flashed during discharging and ready of laser beam emission.

Be careful of laser beam and high voltage.

To designer of laser processing machine

In EN60825–1, it needs the design with the fail safe or

redundant for warning equipment. The redundant warning

light is needed near the work–point of processing machine.

The warning light is prepared for the oscillator. Select this as

a warning light more than the second for the fail safe.

42

B–70114EN/04

2. SAFETY

2.12

INAPPOSITE USE OF LASER OSCILLA T OR

Inapposite use and the result are described in each explanation place.

Inapposite major use are described in the following.

(1)The gas with different composition and purity from the specification

is connected with the oscillator.

The oscillator does not work normally and do the protection

movement. In the worst case, the oscillator breaks down.

(2)The gas piping with different material and structure from the

specification is used.

A leakage of the laser gas and a defective composition are occurred.

In the worst case, the oscillator breaks down.

(3)The water piping of the material, which corrodes to water, is used.

Water is blocked by the generation of rust. If cooling water does not

flow in a regulated amount, the oscillator will not work normally.

(4)Cooling water is not regularly exchanged.

W ater is blocked by the generation of rust. Moreover , it is easy for the

water fittings in the oscillator to corrode. In the worst case, the fittings

are damaged and the water leak happens.

(5)The oil of turbo blower and the exhaust pump is not regularly

exchanged.

Turbo blower is damaged and the oscillator does not work. The

exhaust pump is damaged similarly.

(6)The filter of the exhaust pump is not regularly exchanged.

The exhaust ability of the exhaust pump decreases. Moreover, white

smoke comes out from the pump exit and the oil leak happens. In the

worst case, the oscillator does not work.

(7)You will touch an unrelated place when usually maintaining.

In the oscillator there are adjustment place. The adjustment place is the

best value when shipping. When the adjustment shifts, the oscillator

will not work normally. It is necessary to adjust it by service man that

was trained.

(8)You open the panel immediately after the oscillator was stopped and

oil is exchanged.

(9)There is a place of the high temperature immediately after the

oscillator stopped. When you touches there, you will do the burn. After

getting cold of the oscillator, open the panel. Refer to safety in Chapter

2 for the place of the high temperature.

43

3. INSTALLATION

INSTALLATION

3

B–70114EN/04

44

B–70114EN/04

3.1

CONDITION

3. INSTALLATION

3.1.1

Environmental Conditions

3.1.2

Power Source

(1)Ambient temperature

+5 to 30°C

(2)Temperature drift

Max 1.1°C/min

(3)Humidity

<75% (relative)

(4)Vibration

Acceleration <0.05G

Amplitude <5µm

(5)Atmosphere

Free from dust and volatile vapor

(1)Input power and maximum current

Model Power Maximum current

C1500B 23 KVA 80 A

C2000B, C2000C 33 KVA 1 10 A

C3000C, C3000D 44 KVA 150 A

C4000A 55 KVA 190 A

3.1.3

Laser Gas

C6000B 90 KVA 300 A

(2)Voltage

200VAC+10%, –15%, 50/60Hz"1Hz, 3f

or 220VAC+10%, –15%, 60Hz"1Hz, 3f

(3)Earth–ground

S Ground (<10 ohm)

S Protective earth (PE)

For the laser gas, the following specifications are required.

(1)Composition and its accuracy

:5"0.25% Purity >99.99%

CO

2

He: 40"2.00% >99.99%

;55"2.75% (Balance) >99.99%

N

2

(2)Water vapor (H

(3)Hydrocarbon (CmHn) <1ppm

O) <5ppm

2

45

3. INSTALLATION

B–70114EN/04

3.1.4

Cooling Water

(1)Cooling water specification

The quality of cooling water is specified in the table below . If tap water

is used, it should be treated in an ion exchanger.

Refrigerator/air–conditioner cooling water quality standard

(JRA–9001–1980)

pH (25°C) 6.0 to 8.0

Conductivity (25°C)(m s/cm) 200 or less

Chlorine ion Cl* (ppm) 20 or less

*

Standard item

Reference item

Sulfate ion SO

M alkalinity CaCO3 (ppm) 50 or less

Total hardness CaCO3 (ppm) 50 or less

Iron Fe (ppm) 0.3 or less

Sulfur ion S

Ammonia ion NH

Ionic silica SiO2 (ppm) 30 or less

2

(ppm) 50 or less

4

*

2

(ppm) Not to be detected

+

(ppm) 0.2 or less

4

(2)Anticorrosive

T o avoid cooling water trouble and minimize the frequency of cooling

water exchange, the following anticorrosive should be added to the

cooling water. Consult the chiller manufacturer for use of the

anticorrosive.

Product name: CONTLIME K–6000

Manufacturer: MITSUBISHI GAS CHEMICAL. ISC

Use: Refer to the description indicated on the product.

Replace the cooling water every year , even if an anticorrosive has been

added to it.

(3)Cleaning agent

The following cleaning agent should be used. Consult the chiller

manufacturer for use of the cleaning agent.

Product name: DESLIME

Manufacturer: MITSUBISHI GAS CHEMICAL ISC

Use: Refer to the description indicated on the product.

(4)Antifreezing solution

If the chiller is used in a cold district, it should be provided with an

antifreezing function. When it is extremely cold, the chiller should be

kept running. If it is necessary to use an antifreezing solution for lack

of an alternative, the following antifreezing solution should be used.

Its concentration should be 30% (usually) or 40% (in an extremely

cold district). Use of an antifreezing solution should be restricted

within four months in winter. Do not use antifreezing solution

together with an anticorrosive. The following antifreezing solution is

already added with an anticorrosive.

Product name: AURORA BRINE

Manufacturer: TOKYO FINE CHEMICAL Co.

Use: Refer to the description indicated on the product.

46

B–70114EN/04

3. INSTALLATION

Caution

In winter or in a cold district, when the oscillator is at a rest and

the ambient temperature gets to or below the freezing point,

the cooling water in the oscillator freezes, possibly breaking

the water pipe or damaging the chilling unit. When the

oscillator is not in use, drain cooling water from it. To drain

water, keep blowing compressed air at 5 kgf/cm2 or less into

the oscillator through the cooling water inlet for 15 minutes.

47

3. INSTALLATION

3.2

TRANSPORTATION

B–70114EN/04

3.2.1

Lifting Laser Oscillator

In lifting the FANUC LASER C series, be sure to use the four eyebolts

screwed into the top surface of the cabinet as shown in the figure. Never

lift using only the two bolts. The weight is shown following tables. The

permissible impact value of the oscillator is 2G. When the impact which

exceeds the permissible impact value is given, the resonator will warp and

the shape of the beam mode worsens.

Fig. 3.2.1 Method of lifiting

48

B–70114EN/04

3. INSTALLATION

3.2.2

Packing

1) Clamp

When shipped from FANUC, the two components of the laser listed

below are in the clamped position. Because this is for shipment only,

remove the clamp during the installation. Be sure to use the clamp,

when the machine is shipped again. (1) Optical resonator (2)

Mechanical shutter.

Fig.3.2.2(a)–(d) are clamp layout.

Fig. 3.2.2 (a) Clamp layout (C1500B, C2000B, C2000C, C3000C, C3000D)

49

3. INSTALLATION

B–70114EN/04

Fig. 3.2.2 (b) Clamp layout (C4000A)

50

B–70114EN/04

3. INSTALLATION

Fig. 3.2.2 (c) Clamp layout (C6000B)

51

3. INSTALLATION

B–70114EN/04

Fig. 3.2.2 (d) Clamp layout (C6000B)

CAUTION

If the machine is not clamped during transportation, the

optical resonator may cause distortion or may be damaged.

52

B–70114EN/04

3. INSTALLATION

2) Water

Be sure to drain water in the oscillator at shipment.

Refer to the maintenance manual for draining.

CAUTION

If water remains in the oscillator, internal water pipes may

be damaged in cold climates.

3.2.3

Environmental Condition

3.3

STORAGE

(1)Temperature

–20 to 50°C

CAUTION

Must be completed to drain in the oscillator. If water remain

in the oscillator, water freeze during the transportation at

cold district. Therefore oscillator is damaged.

(2)Humidity <75% (relative)

(3)Vibration

Acceleration < 0.05G

Amplitude < 5µm

(4)Atmosphere

Free from the dust and the volatile vapor

The various kinds of clamps should be used only during the

transportation. Especially the clamps used for resonator should be

loosened during the storage. Storing the resonator as fixed with the

clamps for a long time will cause its distortion. The clamps are provided

for cavity, shutter unit.

Do not keep the oscillator in the place of the high temperature humidity.

Otherwise, it generates rust in the resonator.

3.3.1

Environmental Condition

(1)Temperature

–20 to 50°C

CAUTION

Must be completed to drain in the oscillator. If water remain

in the oscillator, water freeze during the transportation at

cold district. Therefore oscillator is damaged.

(2)Humidity < 75% (relative)

(3)Vibration

Acceleration <0.05G

Amplitude <5µm

(4)Atmosphere

Free from the dust and the volatile vapor

(5)Location

Plain, no slope

53

3. INSTALLATION

B–70114EN/04

3.4

BASE OF OSCILLATOR

In F ANUC LASER C series, the two type of that is the four taps and hole

are prepared in the base as shown in the figure for fixing the laser cabinet

against the machine base.

Fig. 3.4 (a) Mounting (A)

54

Fig. 3.4 (b) Mounting (B)

B–70114EN/04

3. INSTALLATION

Fig. 3.4 (c) Cabinet base (C1500B, C2000B, C2000C, C3000C, C3000D, C4000A)

Fig. 3.4 (d) Cabinet base (C6000B)

55

3. INSTALLATION

B–70114EN/04

3.5

MAINTENANCE AREA

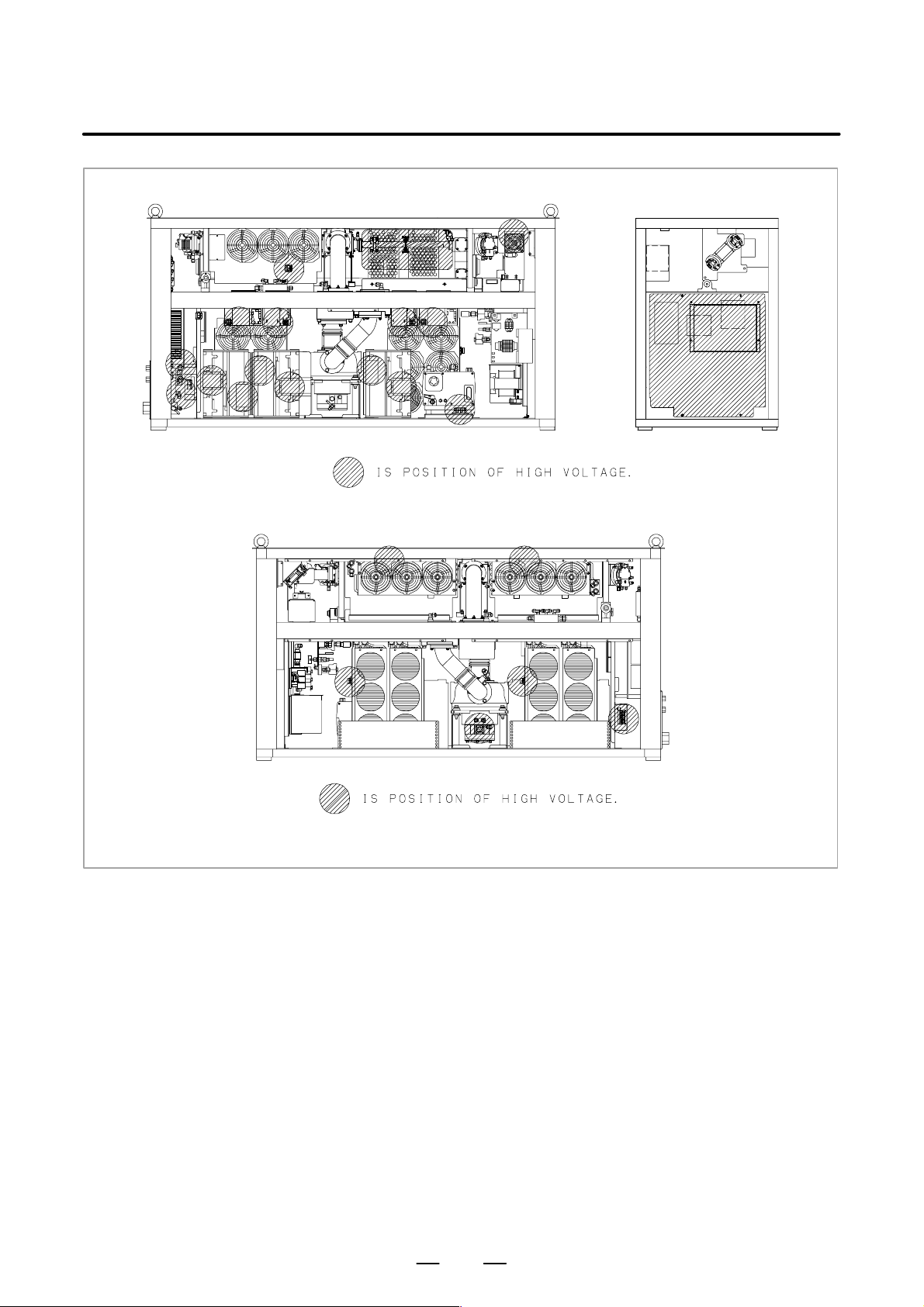

The maintenance areas of FANUC LASER C series are shown in the

figures below. The customer is requested to prepare adequate space

around the laser even for the sides, which are not requested in the figures.

Fig. 3.5 (a) Maintenace area (C1500B: Short type)

56

B–70114EN/04

3. INSTALLATION

Fig. 3.5 (b) Maintenace area (C1500B: Long type)

57

3. INSTALLATION

B–70114EN/04

Fig. 3.5 (c) Maintenace area (C2000B, C3000C, C3000D: Short type)

58

B–70114EN/04

3. INSTALLATION

Fig. 3.5 (d) Maintenace area (C2000B, C3000C, C3000D: Long type)

59

3. INSTALLATION

B–70114EN/04

Fig. 3.5 (e) Maintenance area (Auxiliary unit)

60

B–70114EN/04

3. INSTALLATION

Fig. 3.5 (f) Maintenace area (C2000C: Short type)

61

3. INSTALLATION

B–70114EN/04

Fig. 3.5 (g) Maintenace area (C2000C: Long type)

62

B–70114EN/04

3. INSTALLATION

Fig. 3.5 (h) Maintenace area (C4000A: Short type)

63

3. INSTALLATION

B–70114EN/04

Fig. 3.5 (i) Maintenace area (C4000A: Long type)

64

B–70114EN/04

3. INSTALLATION

Fig. 3.5 (j) Maintenace area (C6000B)

65

3. INSTALLATION

3.6

WATER CONNECTION

B–70114EN/04

3.6.1

Chiller

Make the cooling water re–circulate in the closed loop using a chiller unit.

The cooling requirements of the chiller are as below.

(1)Chiller capacity

Type Capacity

C1500B >15.7kW

C2000B, C2000C >22kW

C3000C, C3000D >33.7kW

C4000A >44.2kW

C6000B >67.5kW

(2)Temperature control range 20 to 30°C

(3)Temperature accuracy "1°C

(4)Water pressure 5.0 bar or less

(5)Heat exhaust Water cooling or air cooling

(6)Attachment

f Water filter

f Water valve

f Flow switch

f Interface to externally switch of chiller

f Contact interface to send signal of normal operation of

chiller(CLRDY).

3.6.2

Cooling Water Temperature

Note

Output the signal of “contact on” when everything is normal

with cooling water flow rate, temperature, water level,

overheat switch of chiller, high and low pressure switch,

over–current relay, etc.

Throughout the year, set the chiller water temperature to 27°C in general

regions and 30°C in humid regions.

66

B–70114EN/04

3. INSTALLATION

3.6.3

Cooling Water Flow Rate

3.6.4

Plumbing

The flow rate should be chosen so that the temperature difference between

the inlet and outlet of the chiller becomes less than 3°C. The customer can

refer to the following table.

Type Flow rate

C1500B 50 liter/min

C2000B, C2000C 75 liter/min

C3000C, C3000D 120 liter/min

C4000A 160 liter/min

C6000B 250 liter/min

The cooling water from chiller is temperature–regulated.

D Choose the tubing material which can withstand corrosion, which will

choke the water flow.

D Make the hose length between the laser and chiller as short as possible.

Along hose makes the pressure 1oss high and becomes a burden to the

chiller pump.

D Place a strainer at the water inlet of laser. It will prevent the f1owing

in of the dust into the laser.

D Place flow meters both at the inlet and outlet of the laser. Daily

checking of the water f1ow contributes to the prevention of abrupt stop

of laser operation.

The water fittings of the inlet and outlet of lasers are shown below.

67

3. INSTALLATION

B–70114EN/04

Fig. 3.6.4 (a) W ater connection and gas connection (C1500B, C2000B)

68

B–70114EN/04

3. INSTALLATION

Fig. 3.6.4 (b) W ater connection and gas connection (C2000C)

69

3. INSTALLATION

B–70114EN/04

Fig. 3.6.4 (c) W ater connection and gas connection (C3000C)

70

B–70114EN/04

3. INSTALLATION

Fig. 3.6.4 (d) W ater connection and gas connection (C3000C)

71

3. INSTALLATION

B–70114EN/04

Fig. 3.6.4 (e) W ater connection and gas connection (C3000D)

72

B–70114EN/04

3. INSTALLATION

Fig. 3.6.4 (f) Water connection and gas connection (C4000A)

73

3. INSTALLATION

B–70114EN/04

Fig. 3.6.4 (g) W ater connection and gas connection (C6000B)

74

B–70114EN/04

3.7

LASER GAS

3. INSTALLATION

3.7.1

Gas Bottle

3.7.2

Laser Gas Tubing

3.7.3

Gas Pipe

Use the gas bottle of the volume of 7m3. Store the necessary number of

bottles according to the operation of the laser.

Drawing of last chapter 1 shown laser gas connection of inlet and outlet.

Inlet and outlet fittings on laser are female PT 3/8”.

(1)Gas inlet of oscillator

D Use the tube designated. (FANUC recommends the use of AS1

tube manufactured by Jyunkosha.)

Do not use a tube possessing high permeability to He. (In the worst

case, the laser will be damaged by improper gas composition.)

D Use the gas of the correct composition.

(2)Gas outlet of oscillator

The oil mist and the dissociated gas come out from the exit of the gas.

Tie the piping of 3/8 inches or more to the gas exit and put it out to

outdoor. It will load the exhaust pump when thin piping or extremely

1ong and the exhaust ability decreases occasionally.

Observe the following cautions for piping between the laser gas cylinder

and laser oscillator.

D Use nylon tube having an inside diameter of 8 mm or larger (Junlon

AS1 manufactured by Junkousha, or equivalent). Do not use a rubber

or urethane tube.

D Use a swage–lock vacuum joint (Fujikin’s product or equivalent). Do

not use a one–touch coupler, quick coupler, or hose–band joint.

D Minimize the length of tubing. It should be kept within 5 m. Never

exceed 15 m. For a length of 15 m or greater, use stainless pipe.

D If it is necessary to use metal pipe for lack of an alternative, use

stainless bright annealed pipe. Minimize the number of joints used.

Connect pipes, if necessary, using a swage–lock vacuum joint or by

TIG welding. Do NOT use silver soldering or copper piping. Piping

should be installed by a vacuum piping specialist. Do not extend metal

piping over 30 m.

D Always keep the piping materials clean. Do not allow foreign matter

to get in the pipe.

D Use a pressure reducer that is free from gas leakage.

D After installing the pipe, check it for gas leakage, using a liquid leak

checker (Gyupoflex: A98L–0001–0856, detecting bubbles caused by

leaking gas) or a clamp test

1)

.

Note

1. Open the valve of the gas cylinder to pressurize the inside

of the pipe, then close the valve. Check to see if the

pressure in the pipe becomes low with time. Monitor the

primary pressure of the gas reducer for over 8 hours. If the

gas pressure becomes lower by 10% within 8 hours, gas is

likely to be leaking. Take an appropriate measure.

75

3. INSTALLATION

B–70114EN/04

3.8

LASER BEAM

3.8.1

Position and Tolerance of Laser Beam Exit

Here explanation are given for the convenience of designing machines.

The following figures and attached tables show the positions and

tolerances of beam.

Fig. 3.8.1 (a) Beam exit (C1500B, C2000B, C2000C, C3000C,

C3000D, C4000A)

Fig. 3.8.1 (b) Beam exit (C6000B)

76

B–70114EN/04

3. INSTALLATION

Fig. Position of laser beam exit

Model W1 W2 W3 H

C1500B, C2000B, C2000C

Short path length type

C1500B, C2000B, C2000C

Long path length type

C3000C, C3000D, C4000A

Short path length type

C3000C, C3000D, C4000A

Long path length type

C6000B 435"5 70 505 1375"5

3.8.2

310"5 65 375 876"5

390"5 65 455 876"5

310"5 65 375 811"5

420"5 65 485 921"5

The beam divergence for FANUC LASER C series is less than 2 mrad.

Beam Divergence

3.8.3

Tolerance of Beam Direction

The tolerance of beam direction is "0.3 degrees. The customer is

requested to prepare adjusting mechanism on the machine side to

compensate for the beam direction error.

3.8.4

Beam Guide

The laser had better be isolated mechanically from the machine for

preventing the coupling between them. The vibration might enter the

opponent from each side. It is, however, absolutely necessary to provide

the beam guide between them so that the operator is protected from the

exposure to the laser beam all the time. The structure of the beam guide

must permit the mechanical de–coupling required as shown in the figure.

77

3. INSTALLATION

B–70114EN/04

3.9

ELECTRIC CONNECTION

The following cables should be connected to the laser. Refer to the

Connecting Manual of the controller (CNC).

Cable connection point and clamp of cable refer to Fig. 3.9 (a) to (h). All

cable must be used the cable inlet.

Fig. 3.9 (a) Cable connection (C1500B)

Fig. 3.9 (b) Cable connection (C2000B)

78

B–70114EN/04

3. INSTALLATION

Fig. 3.9 (c) Cable connection (C2000C)

Fig. 3.9 (d) Cable connection (C3000C)

79

3. INSTALLATION

B–70114EN/04

Fig. 3.9 (e) Cable connection (C3000C)

Fig. 3.9 (f) Cable connection (C3000D)

80

B–70114EN/04

3. INSTALLATION

Fig. 3.9 (g) Cable connection (C4000A)

Fig. 3.9 (h) Cable connection (C6000B)

81

3. INSTALLATION

B–70114EN/04

3.9.1

Power Cable (L1, L2, L3)

3.9.2

Ground Cable

3.9.3

I/O Signal Cable

Use the cable with 4 cores. (C1500B, C2000B, C2000C, C3000C,

C3000D, C4000A)

Conductor cross section must be more than 22mm

(C2000B, C2000C, C3000C, C3000D, C4000A).

Outer diameter of cable must be between f 22mm to f 32mm (C1500B),

f 28mm to f 38mm (C2000B, C2000C, C3000C, C3000D, C4000A).

Use the 4 cable (C6000B)

Conductor cross section of one cable must be more than 100 mm

The one of earth cable should be connected to the Cu plate upon which

the laser power supply units are mounted. (Earth [<10 ohm], Protective

earth). The other of earth cable is protective earth and should be connected

to the laser at left upper of input unit. This point is marked “PE”.

D For 16–L, 16–iL (one cable)

Optical fiber cable should be connected to COPIB of IF PCB.

(Connect Jumper pins SP5 and SP6 of IF to the 2–3 side.)

D For 0–L (two cables)

Metal cables should be connected to CN1 and CN2 of IF PCB.

2

(C1500B), 35mm

2

.

2

3.9.4

Other Signal Cables to the IF PCB

D For 16–L, 16i–L

1) Emergency stop signal input (ESP1, ESP2)

This terminal is shorted usually.

2) OFF prohibition signal (OFI1,OFI2) – (EOF, COM) CNC side

A contact

Closing the contact to inhibit the OFF switch operation.

Connection parallel with the OFF switch. Contact capacity

250VAC, 3A or 30 VDC, 5A.

3) Laser power unit ON/OFF signal (ON, OFF) – (EXR, EXS) CNC

side

When a door interlock is used. Connect 200VAC whose ON/OFF

is controlled by CNC Capacity 200VAC, 10mA

4) Door interlock contact signal (DIL1, DIL2)

B contact (AC200V applied to laser and CNC is shut in OPEN

state.)

When the door of the oscillator is open, the contact opens. When

the contact are open, the ON – OFF signal of 200 VAC, 3A or 30

VDC, 5A.

82

B–70114EN/04

3. INSTALLATION

Fig. 3.9.4 (a) Detail of IF PCB 16–L

Fig. 3.9.4 (b) Detail of 16i–L

83

3. INSTALLATION

B–70114EN/04

D For 0–L

1) Fuse alarm signal (FAL1, FAL2)

The warning signals contact of the thermal switch and circuit

protector. When the contact is closed, turn off either the CNC

power supply or the laser power supply ON/OFF signal. Contact

capacity 220 VAC, 6A or 24VDC, 10A.

2) OFF prohibition signal (OFS1, OFS2)

Closing the contact to inhibit the OFF switch operation. Connect

in parallel with the OFF switch. Contact capacity 250VAC, 3A or

30 VDC, 5A.

3) Laser power unit ON/OFF signal (ON, OFF)

When the door interlock is used.

Connect 200VAC whose ON/OFF is controlled by CNC

Capacity 200 VAC, 10mA

4) Door interlock contact signal (ND11, ND12)

B contact (AC200V applied to laser and CNC is shut in OPEN

state.)

Use the key switch with the compulsion dissociation mechanism

for the key switch used for welding prevention. When the door of

the oscillator is open, the contact opens. When the contact is open,

the ON–OFF signal of 200 VAC, 3A or 30 VDC, 5A.

Fig. 3.9.4 (c) Detail of IF PCB 0–L

84

B–70114EN/04

3. INSTALLATION

3.9.5

XT20 Terminal

The diagram of safety interlock circuit is shown in Fig. (a) to (g). T erminal

layout is shown in Fig. (h).

Fig. 3.9.5 (a) Safety interlock circuit (C1500B)

85

3. INSTALLATION

B–70114EN/04

Fig. 3.9.5 (b) Safety interlock circuit (C2000B)

86

B–70114EN/04

3. INSTALLATION

Fig. 3.9.5 (c) Safety interlock circuit (C2000C)

87

3. INSTALLATION

B–70114EN/04

Fig. 3.9.5 (d) Safety interlock circuit (C3000C)

88

B–70114EN/04

3. INSTALLATION

Fig. 3.9.5 (e) Safety interlock circuit (C3000D)

89

Loading...

Loading...